Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Plastic/resin/waxes insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

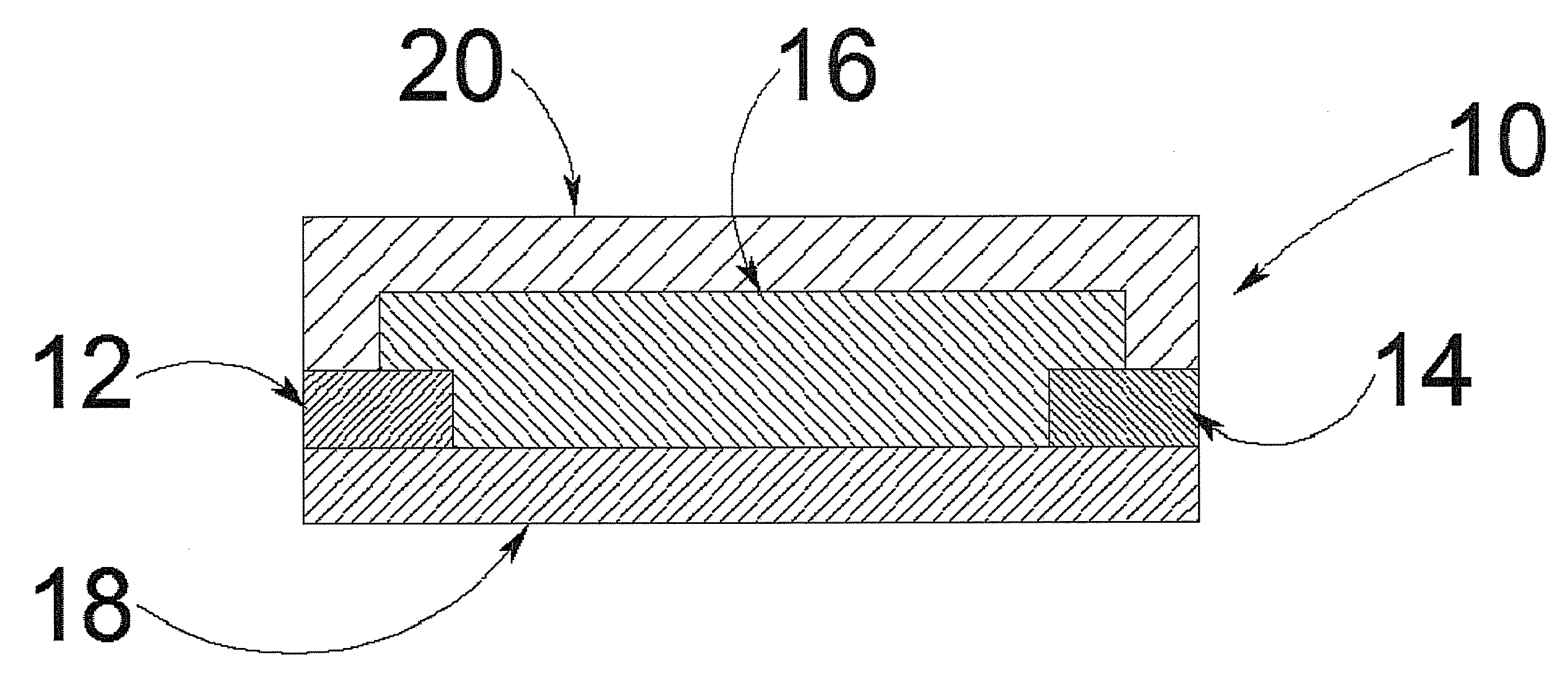

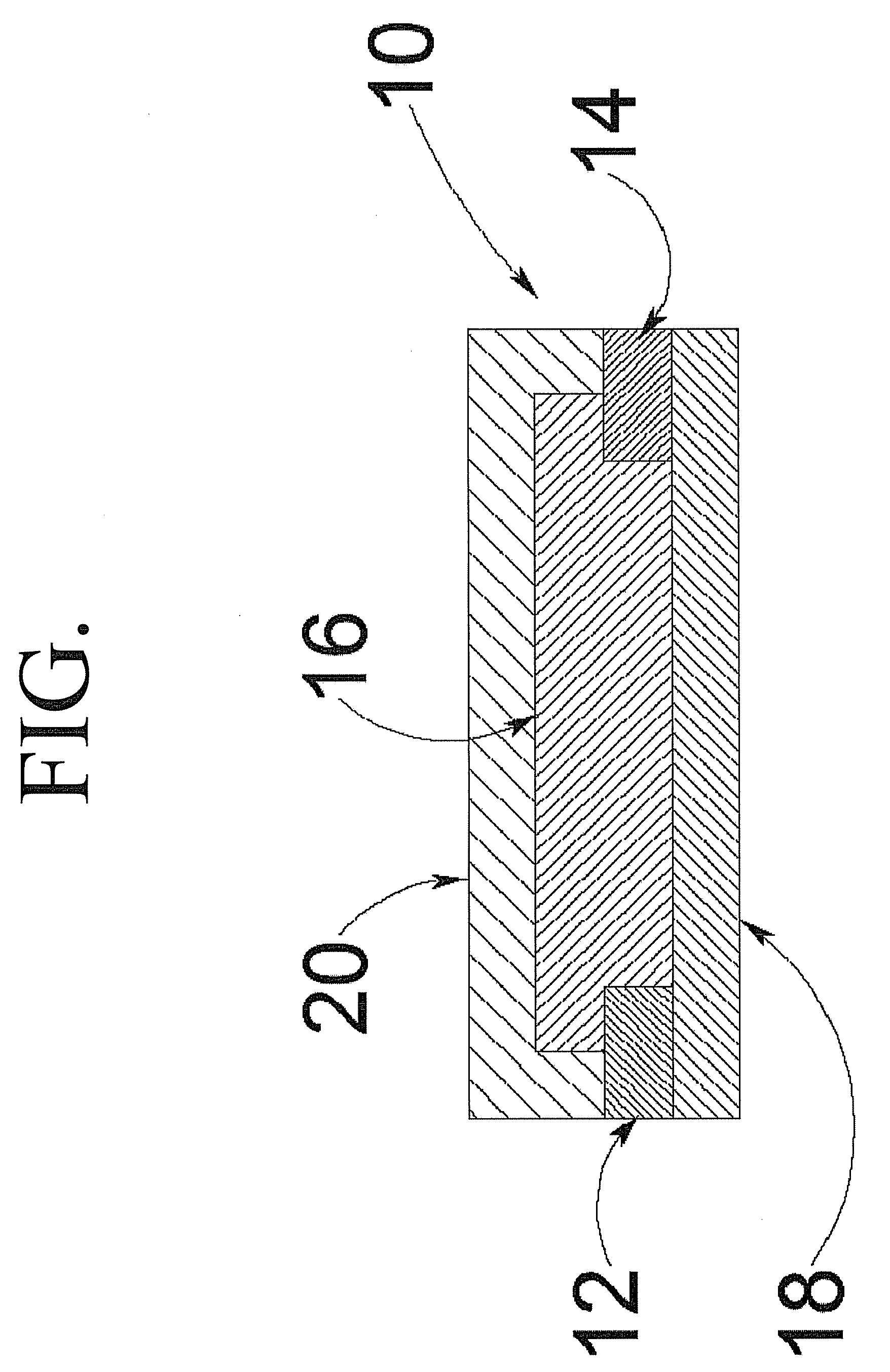

Downhole Well Communications Cable

ActiveUS20120031607A1High service temperaturePlastic/resin/waxes insulatorsCommunication cablesVinyl etherTetrafluoroethylene

Owner:THE CHEMOURS CO FC LLC

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsGas phaseAging resistance

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:JIAXING JUNHONG OPTICAL CO LTD

Electric cable and manufacturing process thereof

InactiveUS7105749B2Increase flexibilityImprove peeling-off propertyPlastic/resin/waxes insulatorsInsulated cablesEngineeringLow stress

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

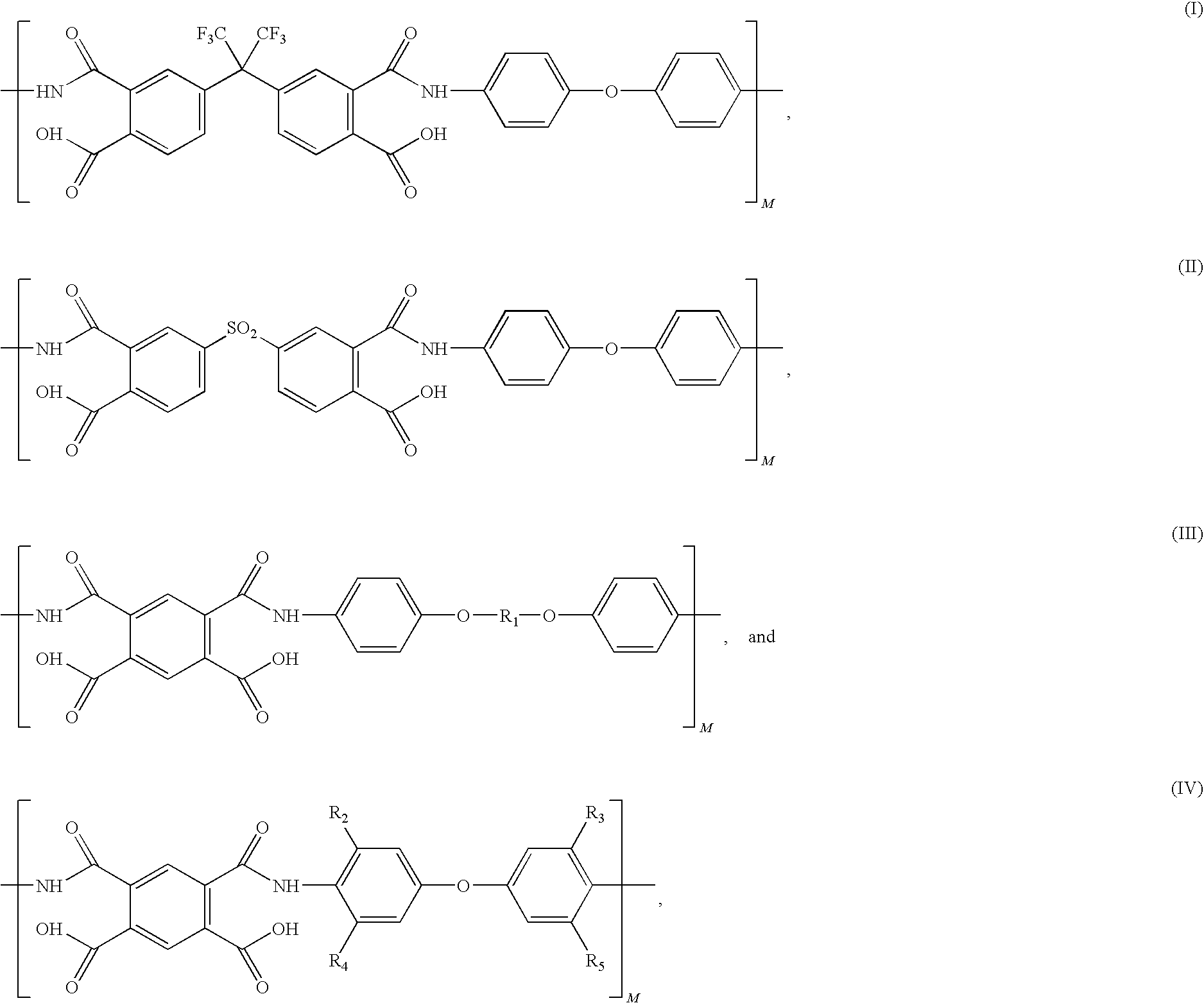

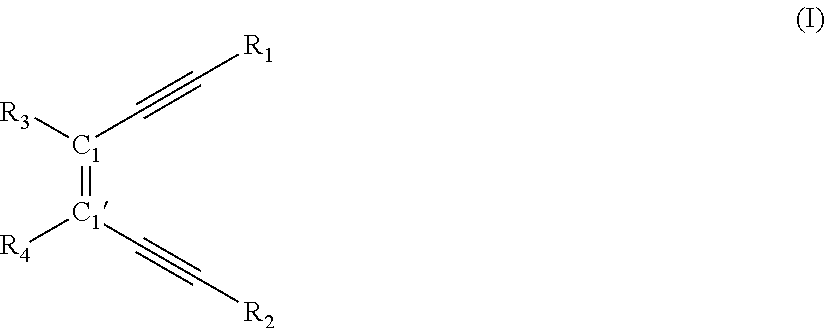

Gas layer formation materials

InactiveCN1735945APlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsAcenaphthyleneMethacrylate

The present invention provides gas layer formation material selected from the group consisting of acenaphthylene homopolymers; acenaphthylene copolymers; poly(arylene ether); polyamide; B-staged multifunctional acrylate / methacrylate; crosslinked styrene divinyl benzene polymers; and copolymers of styrene and divinyl benzene with maleimide or bis-maleimides. The formed gas layers are used in microchips and multichip modules.

Owner:HONEYWELL INT INC

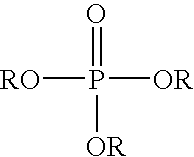

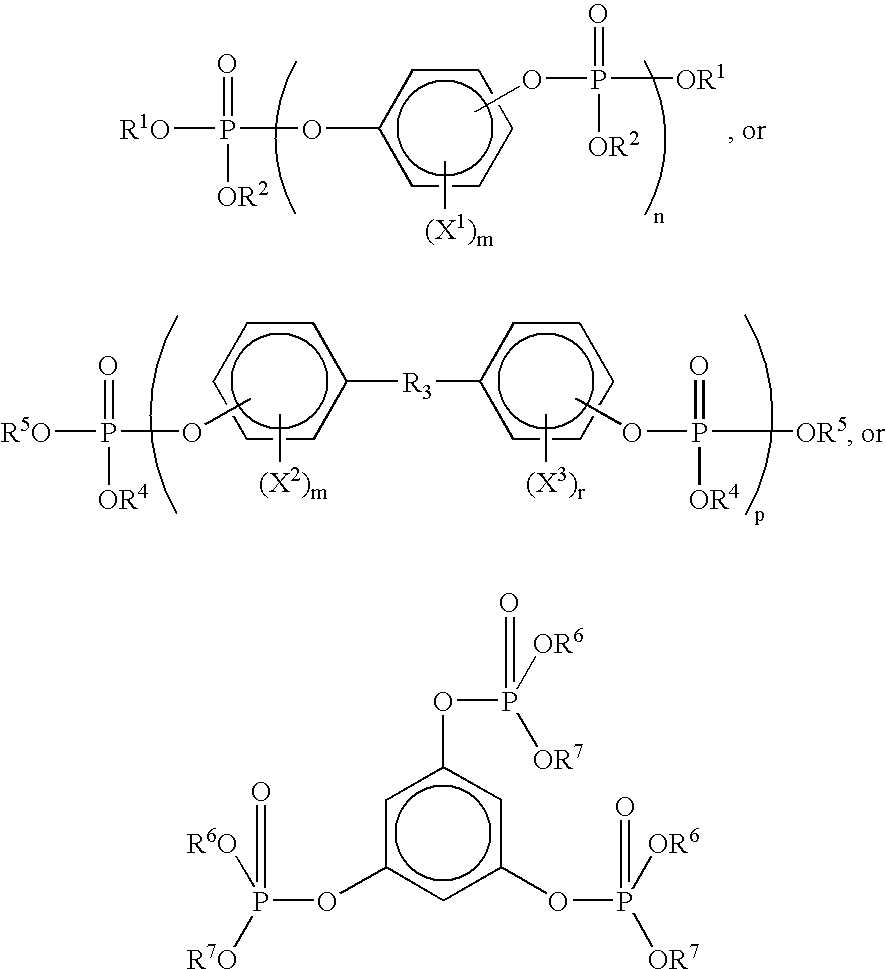

Additive for thermoplastic resins and flame retardant resin compositions

InactiveUS6689825B1Increase the number of repetitionsImproved phase morphology stabilizationPlastic/resin/waxes insulatorsAntifouling/underwater paintsHeat deflection temperatureChemistry

Owner:SABIC INNOVATIVE PLASTICS IP BV

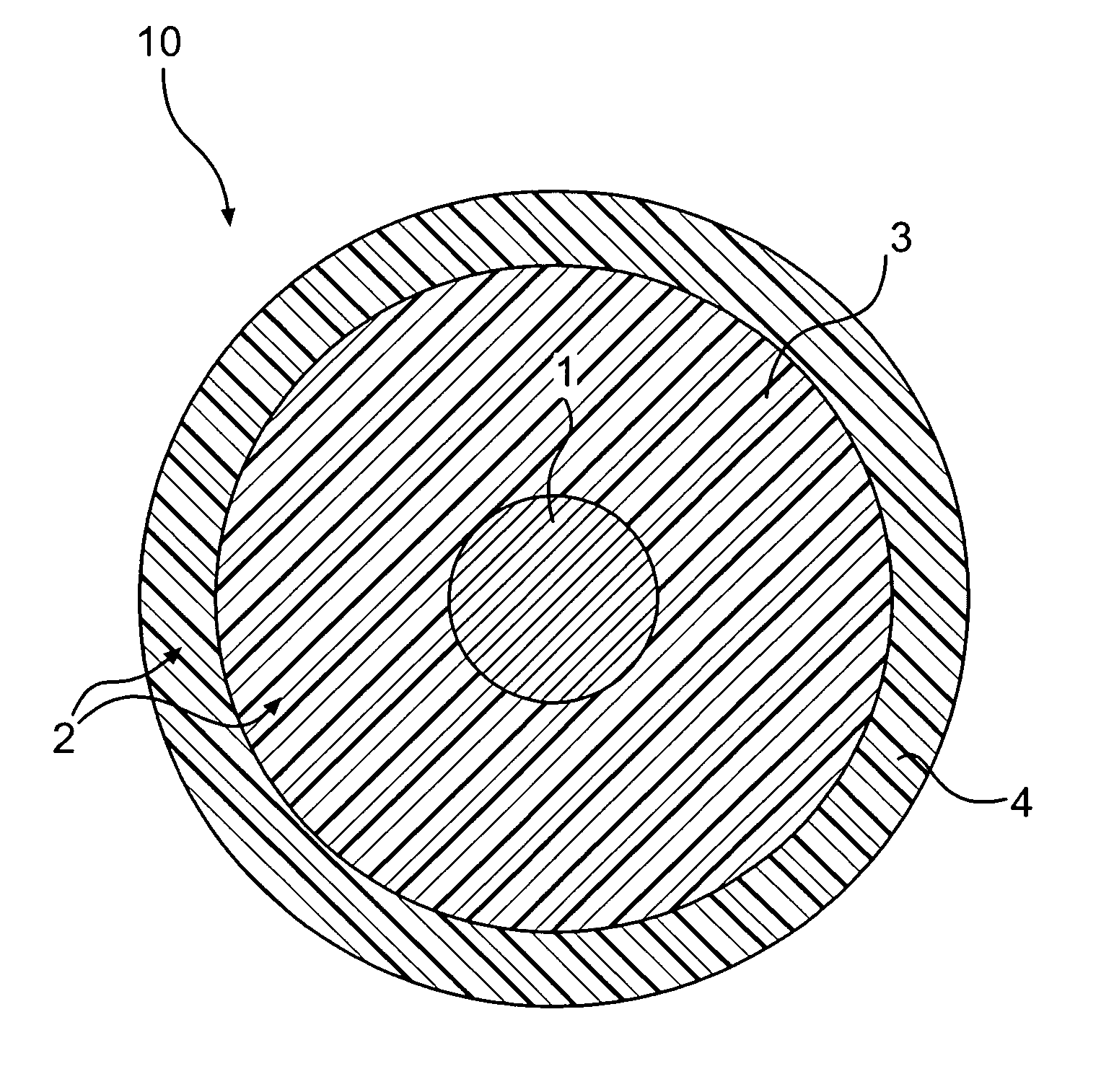

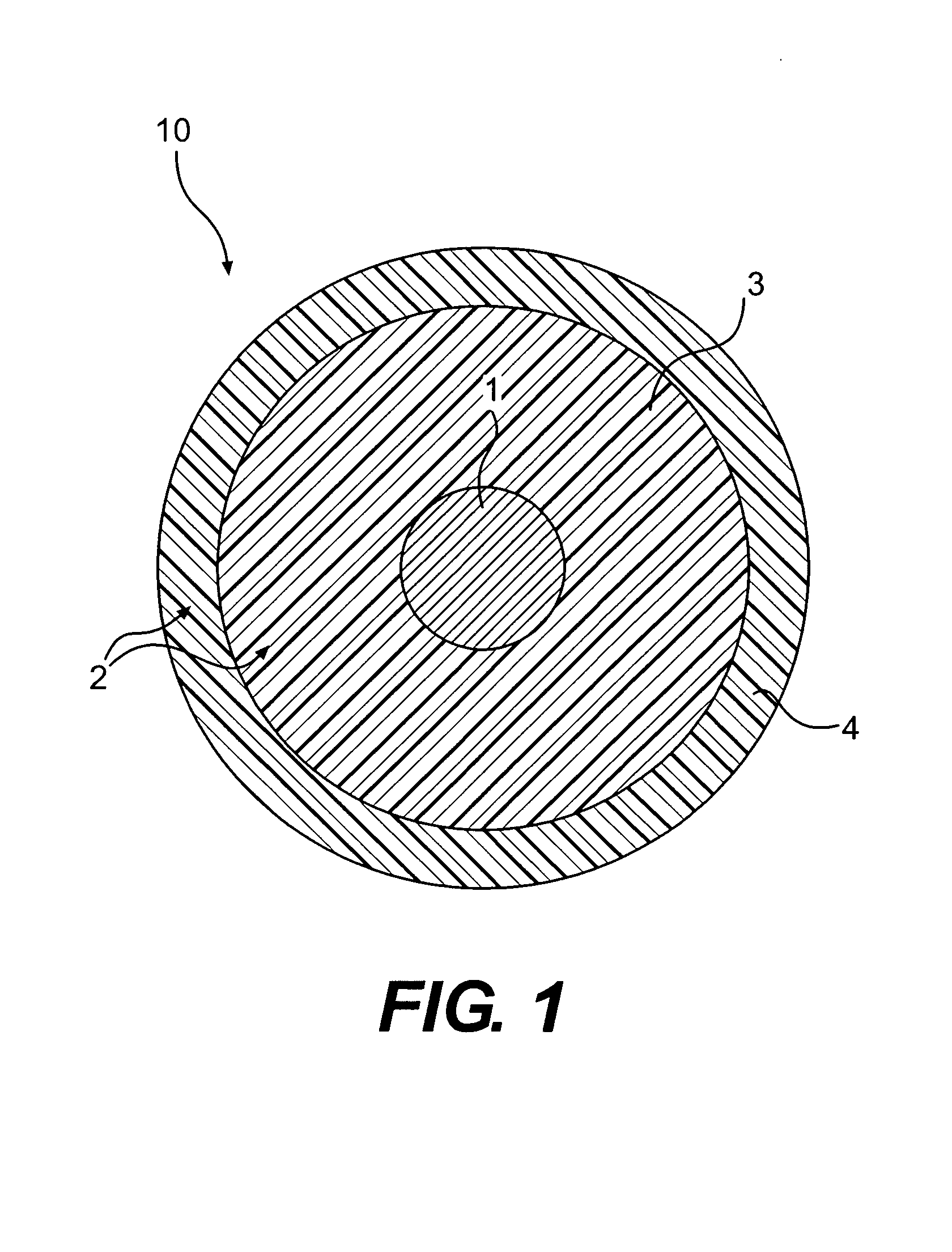

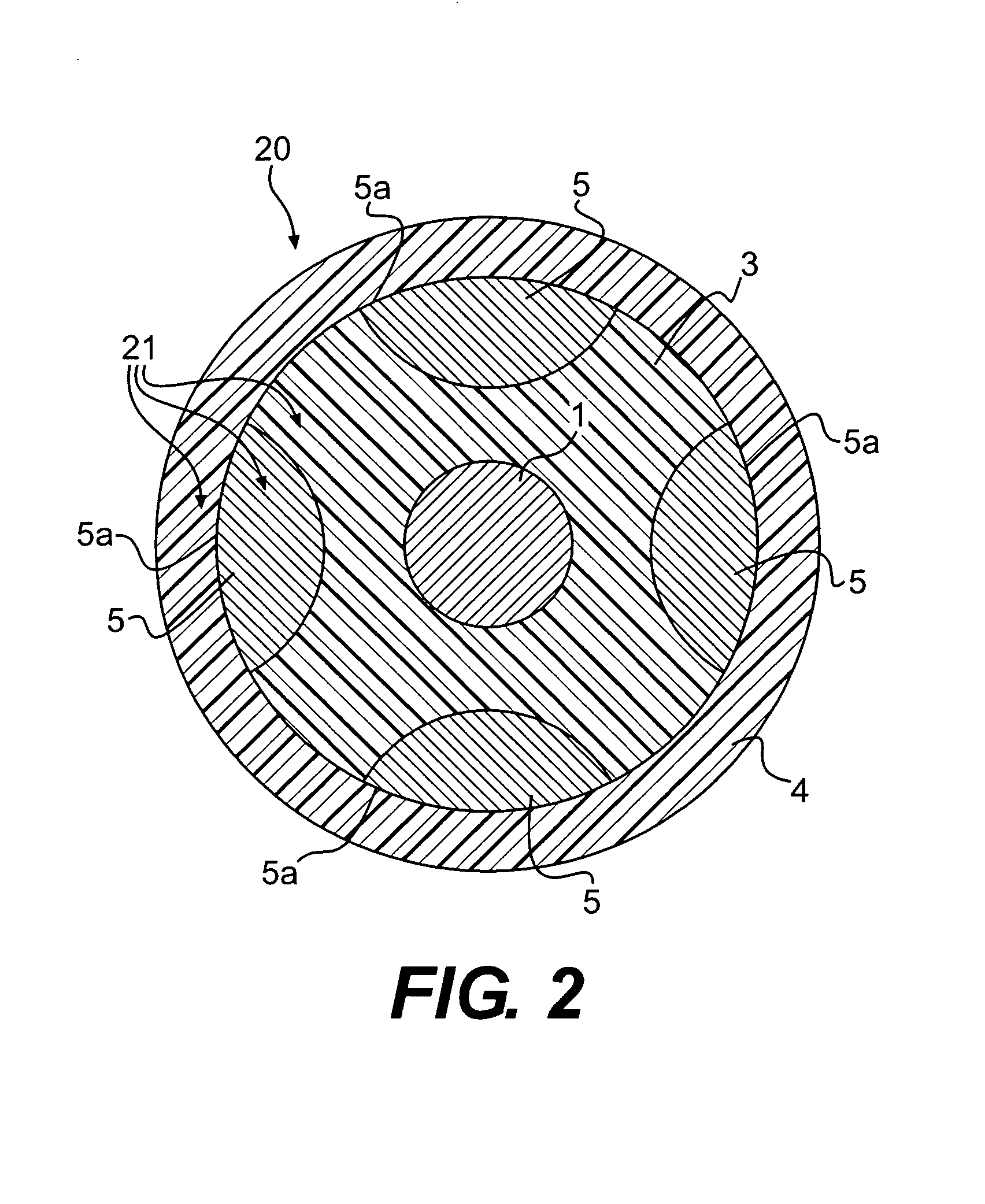

Low Dielectric Loss Power Cable Sheaths Comprising High Pressure Polyolefins Free of Silane Functionality

Power cables that comprise a sheath layer, e.g., an insulation layer, are produced from a mixture of a high pressure polyolefin free of silane functionality, e.g., high pressure low density polyethylene, and a polyether polyol of which at least 50 percent of its molecules comprise no more than a single hydroxyl functionality. Preferably, the power cable is a medium or high voltage power cable, and the polyolefin is crosslinked as the sheath layer is fabricated and / or subsequent to the fabrication of the sheath layer.

Owner:DOW GLOBAL TECH LLC

Foaming Resin Composition, Foam Using the Same and Coaxial Insulated Cable

ActiveUS20080087454A1Improve fidelityCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsElectrical conductorWhiskers

Owner:JUNKOSHA

Irradiation-crosslinked halogen-free flame-retardant photovoltaic cable, and preparation method and application thereof

InactiveCN106432895AImprove flame retardant performanceImproved color stabilityPlastic/resin/waxes insulatorsInsulated cablesChemistryWeather resistance

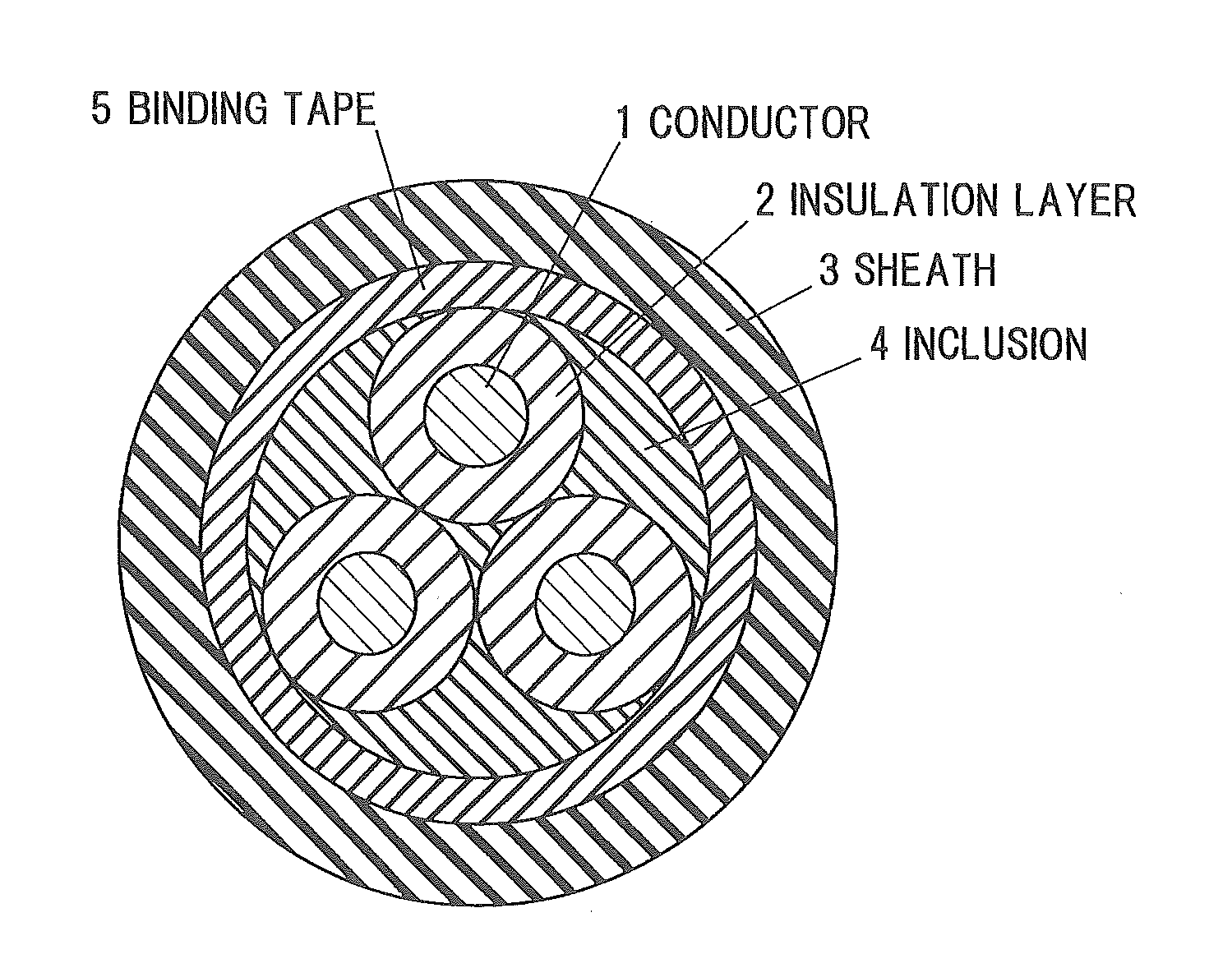

The invention discloses an irradiation-crosslinked halogen-free flame-retardant photovoltaic cable, and a preparation method and application thereof. The photovoltaic cable comprises a conductive core wire, an insulation layer and a sheath layer. The insulation layer and sheath layer are respectively prepared from the following raw materials: 100 parts of polyolefin resin, 5-15 parts of compatilizer, 40-100 parts of compound flame retardant, 1-3 parts of lubricant, 0.5-2.5 parts of antioxidant, 1-2.5 parts of sensitizer, 0.5-2 parts of modified silicone and 3-5 parts of titanium white. The preparation method comprises the following steps: 1) preparing the insulation layer cable material; 2) preparing the sheath layer cable material; and 3) carrying out coextrusion on the conductive core wire, insulation layer cable material and sheath layer cable material, and carrying out irradiation crosslinking. The photovoltaic cable product has the advantages of excellent flame retardancy, no halogen, environment friendliness, high / low temperature resistance, ultraviolet resistance, mold resistance, damp heat resistance, salt spray resistance, high color stability, excellent mechanical properties, excellent weather resistance, long service life, simple production technique and low production cost, and can be widely used for photovoltaic industry.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Flame-retardant polyethylene insulated cable material

InactiveCN104861271ANot easy to smoke and dustNot easy to producePlastic/resin/waxes insulatorsHalogenMagnesium

The invention discloses a flame-retardant polyethylene insulated cable material, and relates to the technical field of cables. The flame-retardant polyethylene insulated cable material is prepared from the following raw materials in parts by weight: 80 parts of polyethylene, 5 parts of aluminum oxide, 20-35 parts of magnesium hydroxide and 1-5 parts of an anti-aging agent. According to the invention, the flame-retardant polyethylene insulated cable material is unlikely to combust and can prevent combustion, has a flame retardant rating of V-0, is not liable to produce halogen-containing toxic substances or smoke dust when the cable material is combusted, and is applicable to high and low voltage power cables.

Owner:ANHUI MEITENG SPECIAL ELECTRIC CABLE MATERIALS

Fluorine-including elastomer composition, and insulated wire and insulated cable using the same

InactiveUS20140377557A1Good toughnessGood appearanceRubber insulatorsPlastic/resin/waxes insulatorsTetrafluoroethylenePolyethylene

A fluorine-including elastomer composition includes a fluororesin component including a first fluorine-including copolymer including a tetrafluoroethylene and an α-olefin having a carbon number of 2 to 4 and a second fluorine-including copolymer including an ethylene-tetrafluoroethylene copolymer, a polyethylene resin mixed in an amount of 10 to 50 parts by mass per 100 parts by mass of the fluororesin component, and a crosslinking aid. A mass ratio of the first fluorine-including copolymer to the second fluorine-including copolymer is 90:10 to 10:90.

Owner:HITACHI METALS LTD

Fluorine-free plasma curing process for porous low-k materials

InactiveUS7011868B2Improving elastic modulusImproving material hardnessSilicaPlastic/resin/waxes insulatorsFluorine freeElastic modulus

Low dielectric constant porous materials with improved elastic modulus and material hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material with a fluorine-free plasma gas to produce a fluorine-free plasma cured porous dielectric material. Fluorine-free plasma curing of the porous dielectric material yields a material with improved modulus and material hardness, and with comparable dielectric constant. The improvement in elastic modulus is typically greater than or about 50%, and more typically greater than or about 100%. The improvement in material hardness is typically greater than or about 50%. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims 37 CFR §1.72(b).

Owner:JSR CORPORATIOON +1

Thermoplastic Elastomer Compositions Comprising Intumescent Flame Retardants and Non-Phosphorous-Based Flame Retardant Synergists

ActiveUS20120125657A1Plastic/resin/waxes insulatorsInsulated cablesThermoplastic elastomerPolyphosphate

Owner:UNION CARBIDE CORP

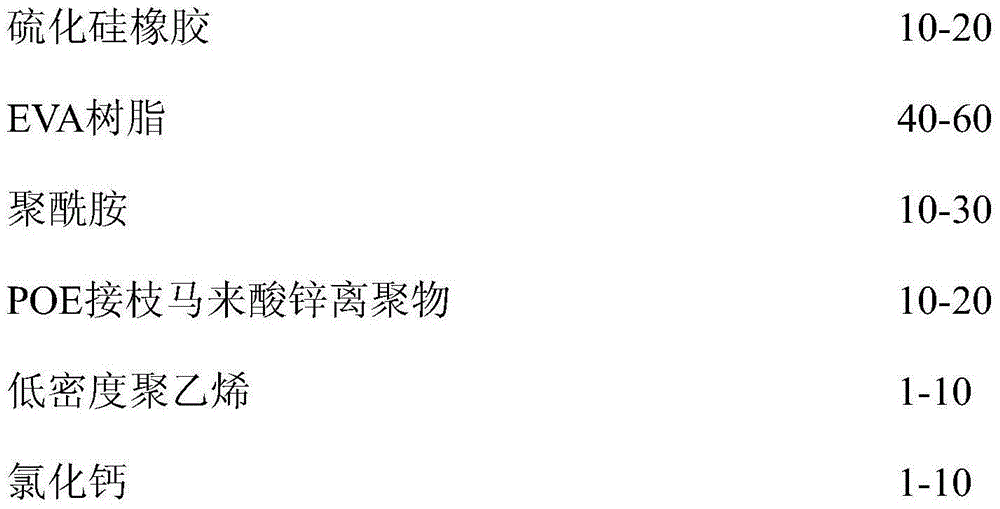

Grafted blending electric cable insulation material and preparation method thereof

InactiveCN105175877AHarmonized halogen-free effectGood oil resistancePlastic/resin/waxes insulatorsLow-density polyethyleneAntioxidant

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Polyvinyl Chloride Resin Composition for Automotive Electric Wire, and Ultrathin-Wall Low-Voltage Electric Wire for Automobile

ActiveUS20150240104A1High hardnessPlastic/resin/waxes insulatorsInsulated cablesChemistryPlasticizer

Owner:YAZAKI CORP

Low viscosity polymeric printing solutions and electronic components bearing polyimide based upon the low viscosity polymeric printing solutions

Owner:INFINEON TECH AG

Polymer composition

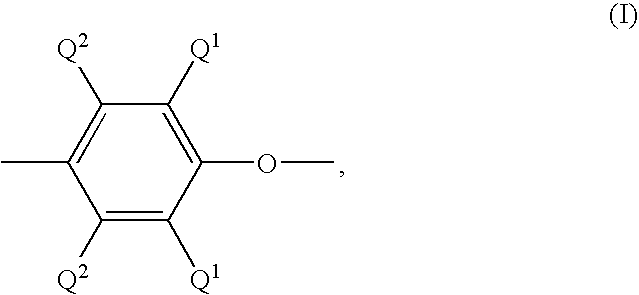

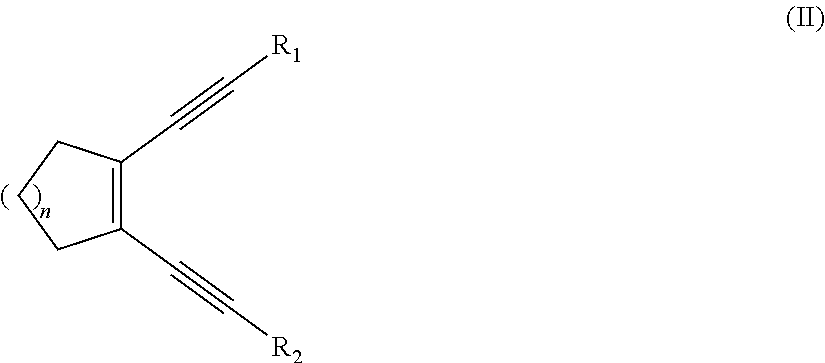

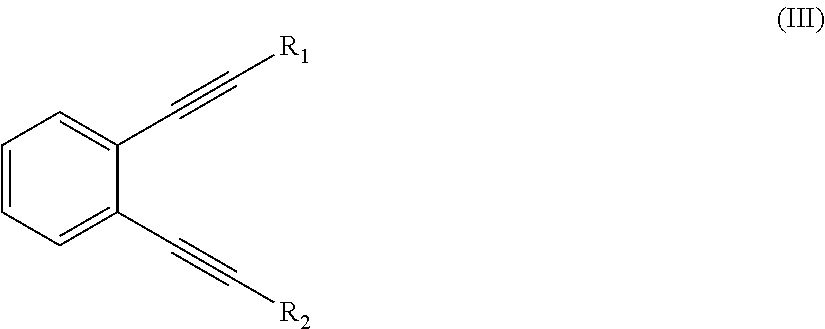

ActiveUS20110315424A1Inhibition formationReduced and no formation of undesirablePlastic/resin/waxes insulatorsSpecial surfacesPolymer chemistryPolymer composition

The invention relates to a method for modifying a polymer composition, to modified polymer compositions, to an article, preferably wire or cable, comprising said modified polymer composition, to a process for preparing an article, preferably a wire or cable, to the use of said modified polymer in one or more layers of a wire or cable, as well as to a compound for use as a radical generating compound for modifying a polymer composition.

Owner:BOREALIS AG

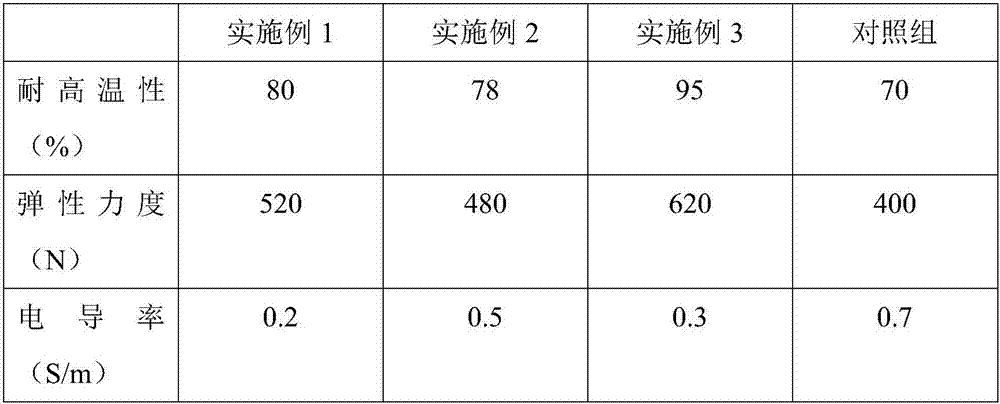

High-temperature-resistant insulation material applied to power equipment and preparation method of high-temperature-resistant insulation material

InactiveCN107189167AGood mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsEpoxyAlkali free

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

High-wear-resistant transformer insulation paper

InactiveCN105350383APlastic/resin/waxes insulatorsWater-repelling agents additionChemistrySodium carboxymethylcellulose

Owner:TONGLING SANJIA TRANSFORMER

Fluorine-containing highly branched polymer and epoxy resin composition containing the same

ActiveUS20150158959A1Increased modificationLess tanglePlastic/resin/waxes insulatorsEpoxy resin coatingsPolymer scienceOxetane

A fluorine-containing highly branched polymer obtained by polymerizing a polyfunctional monomer A that has two or more radically polymerizable double bonds and all or a portion of which has a bisphenol structure, a monomer B having a fluoroalkyl group and at least one radically polymerizable double bond, within a molecule, and a monomer C having at least one ring-opening polymerizable group selected from the group including an epoxy group and an oxetanyl group, and having at least one radically polymerizable double bond, within a molecule, under the presence of a polymerization initiator D with an amount of 5% by mole to 200% by mole to the number of moles of the polyfunctional monomer A; an epoxy resin composition including the polymer; and an epoxy resin cured product obtained from the resin composition.

Owner:NISSAN CHEM CORP

Modified PVC (Polyvinyl Chloride) composite material and preparation method thereof

InactiveCN107474428AImprove creep resistanceImprove low temperature impact performancePlastic/resin/waxes insulatorsActive agentPolyvinyl chloride

The invention discloses a PVC (Polyvinyl Chloride) composite modified material and a preparation method thereof, relates to a PVC modified material and a preparation method thereof, and aims to solve the problems that a product surface is rough and lusterless as a conventional PVC modified material has a certain amount of unsaturated double bonds on a molecular chain, an active center can be formed and thus the ductility is low and a melt is easily crushed. The PVC composite modified material is prepared from the following components in parts by weight: a PVC resin, a low-temperature flexibilizer, an impact modifier, processing aids, a surfactant, a composite stabilizer, a covering agent, an initiator and a cross-linking agent. The preparation method comprises the following steps: I, weighing; II, premixing so as to obtain a premix; III, mixing at different steps so as to obtain mixtures of different steps; IV, performing final mixing so as to obtain a final mixture; and V, performing extrusion pelletizing, thereby obtaining the PVC composite modified material. The invention aims to prepare the PVC composite modified material.

Owner:WUHU PILOT NEW MATERIAL TECH CO LTD

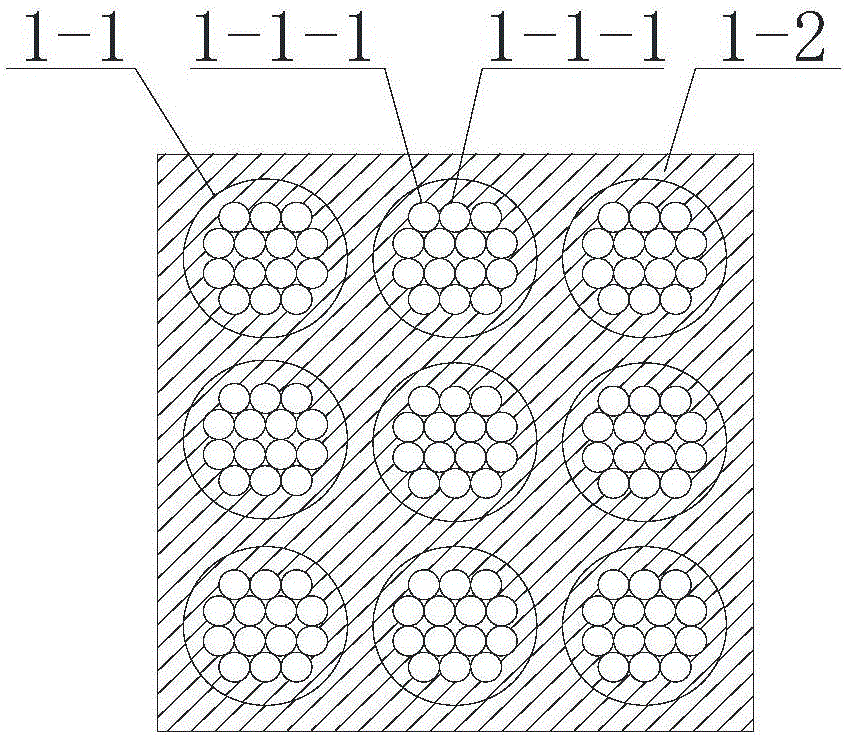

Flexible data line

PendingCN110289130APlastic/resin/waxes insulatorsDetails of conductive coresCopper wireElectrical conductor

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

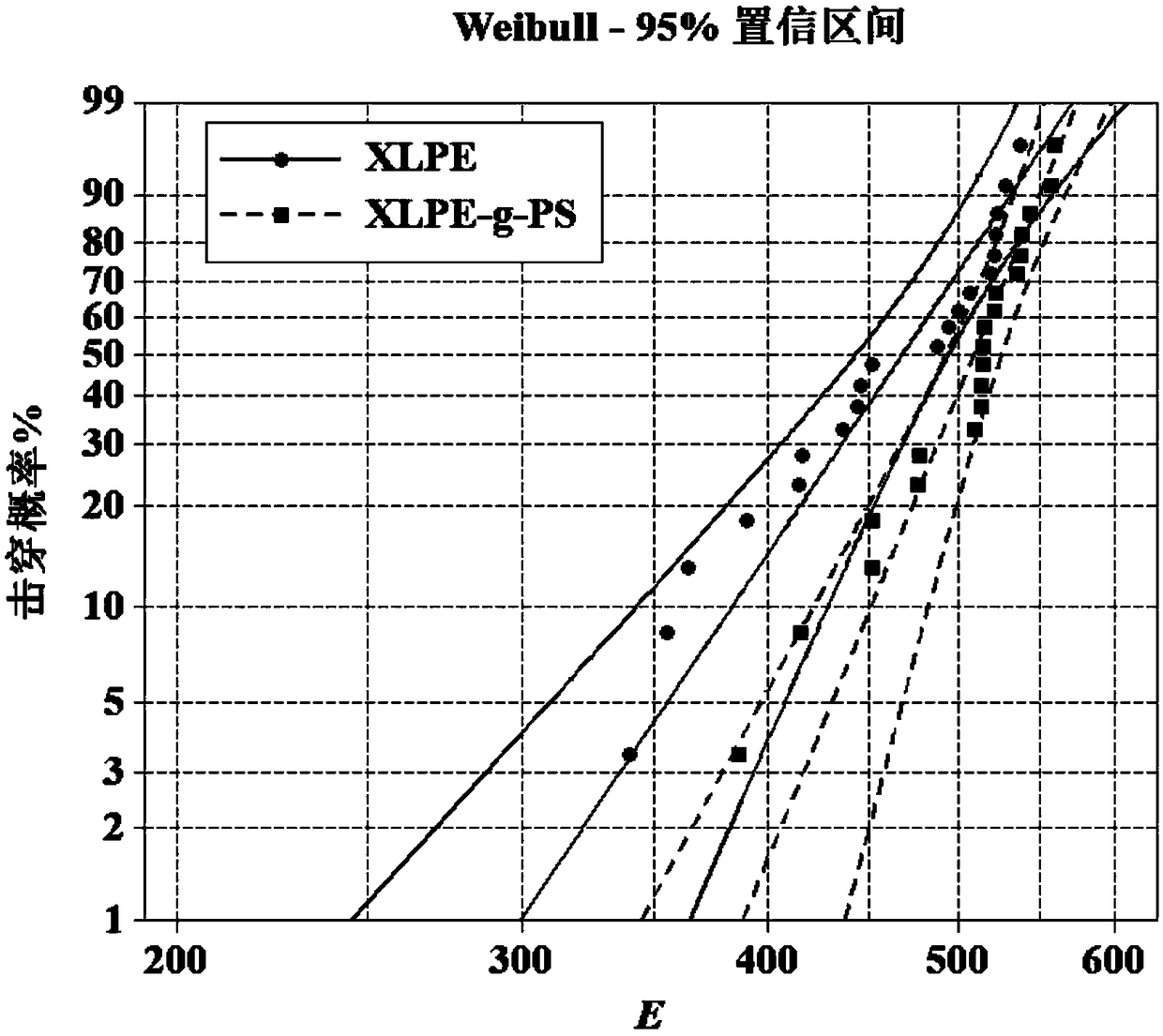

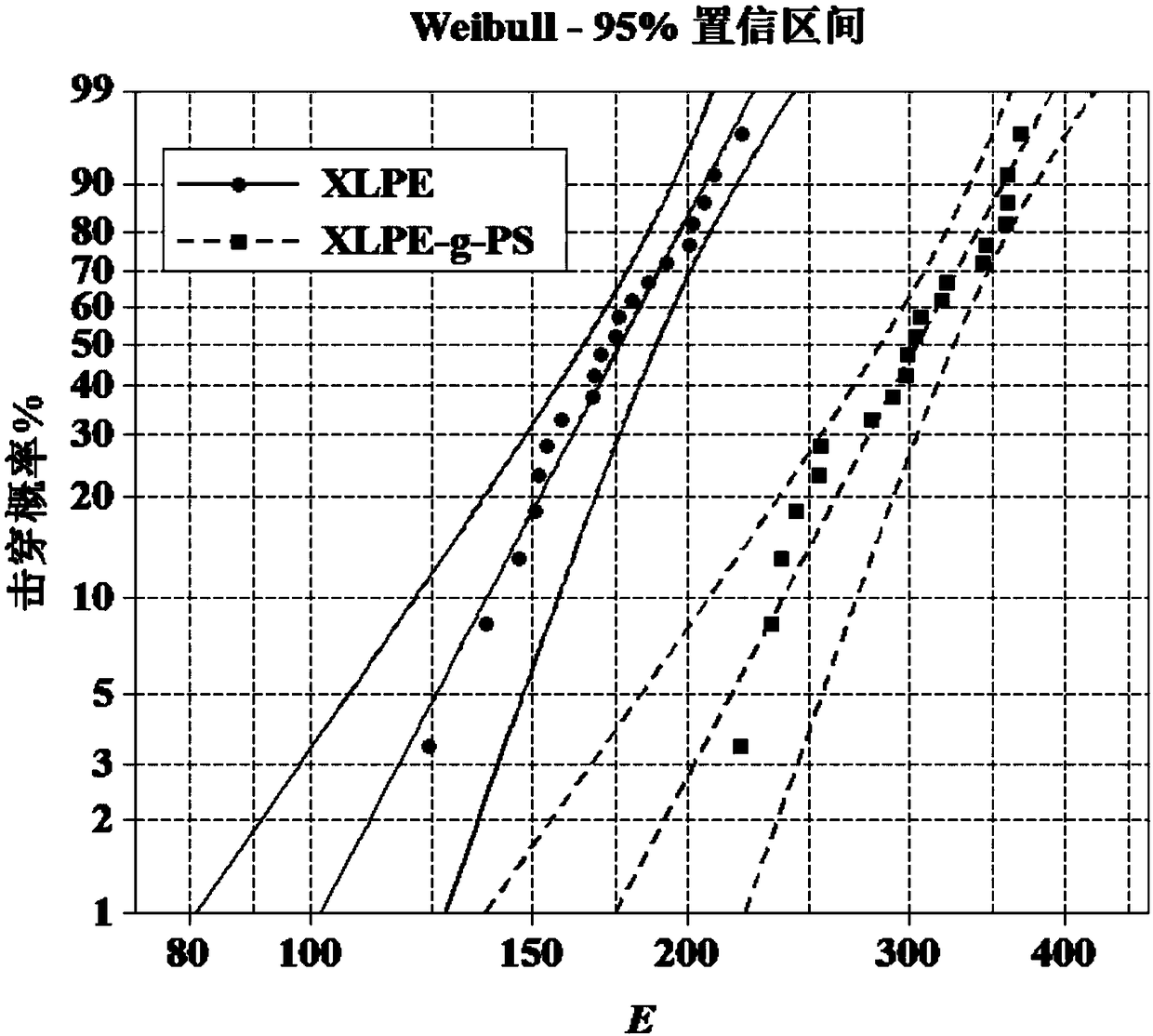

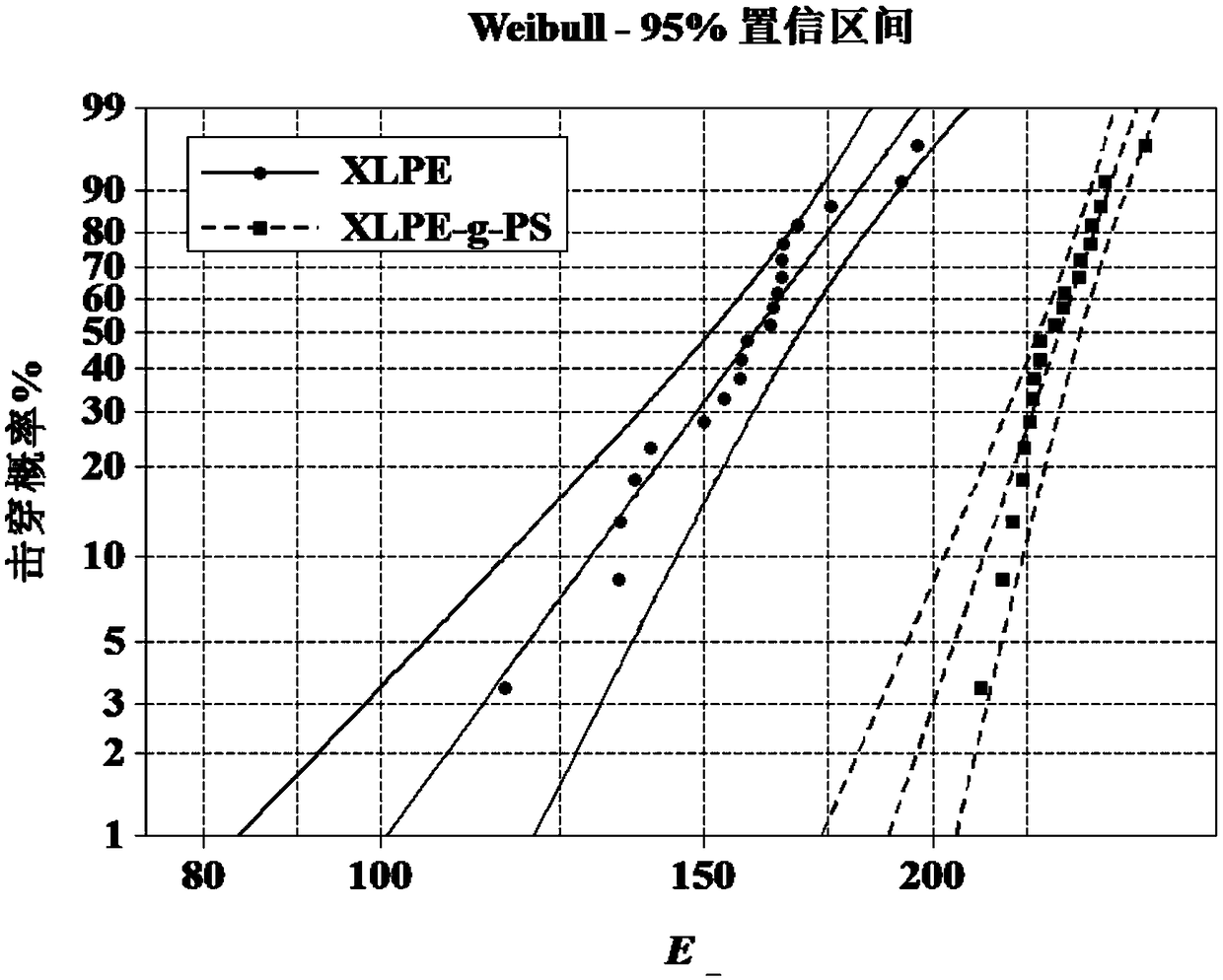

High voltage direct current cable insulating material and preparation method thereof

ActiveCN109265791AHigh DC breakdown field strengthIncreased DC breakdown field strengthPlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

Owner:XI AN JIAOTONG UNIV +1

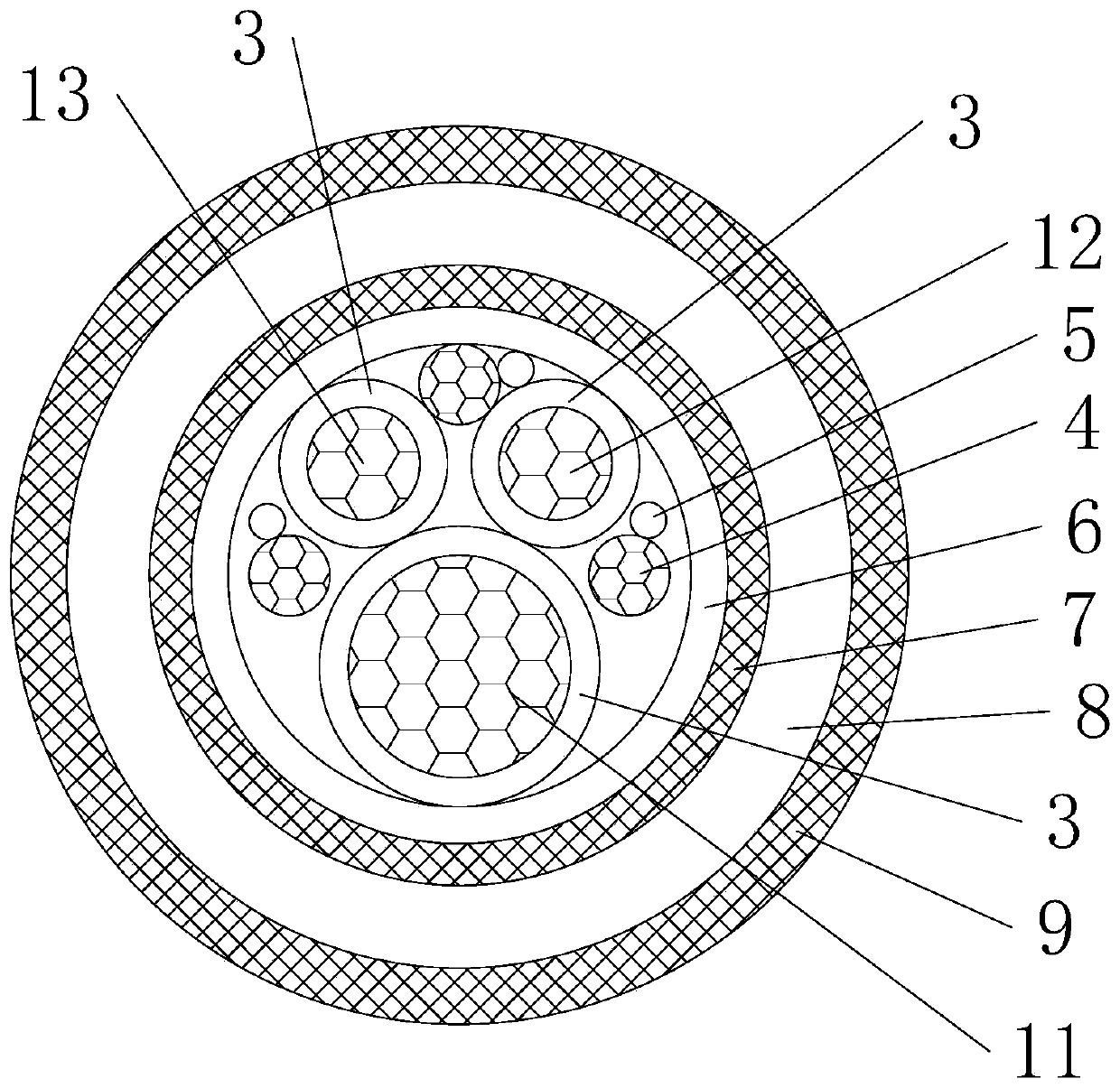

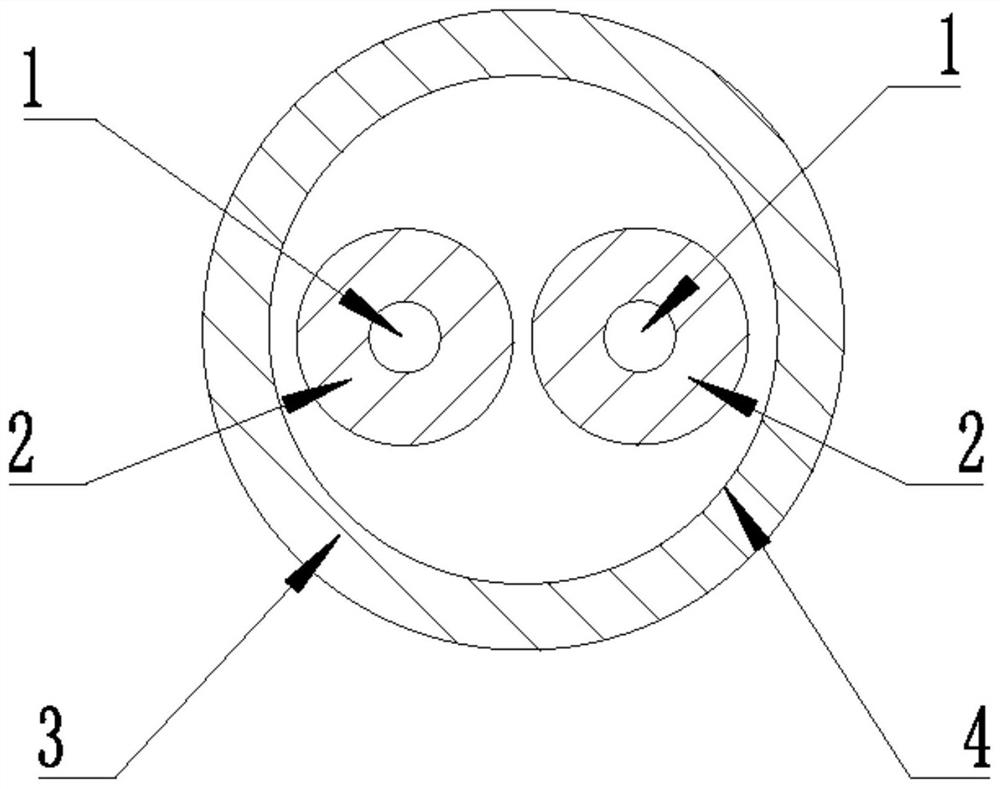

Temperature measurement cable

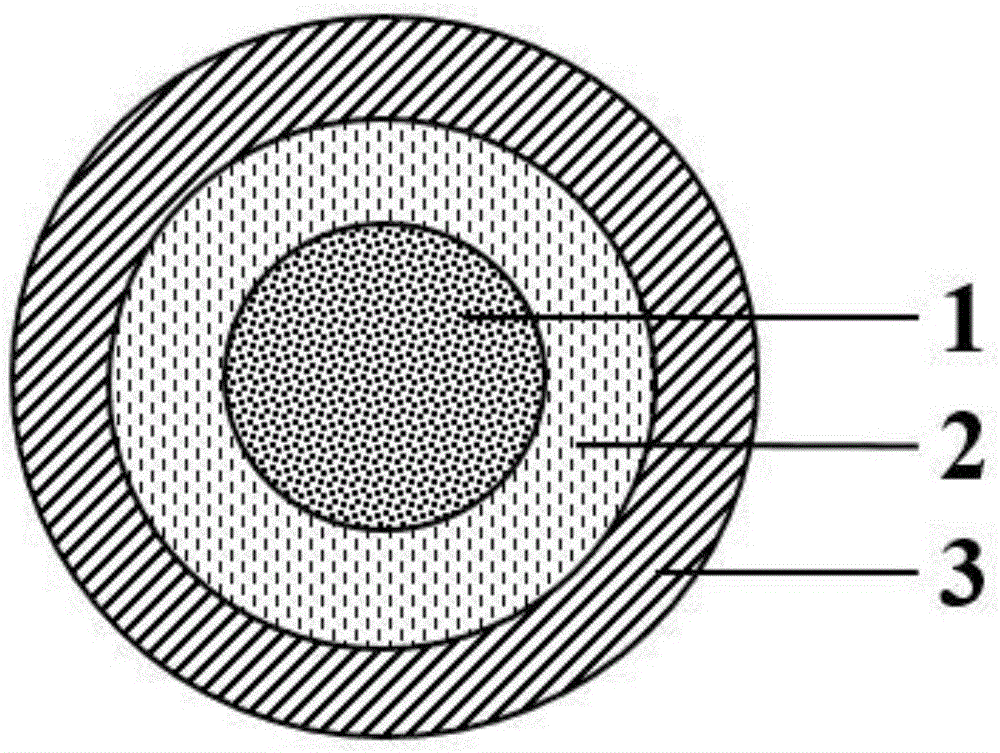

PendingCN111667945APlastic/resin/waxes insulatorsPower cables with screens/conductive layersTemperature measurementElectromagnetic interference

The invention discloses a temperature measurement cable which comprises a temperature measurement wire, an insulation protection sleeve and a shielding protection sleeve, the insulation protection sleeve sleeves the outer side of the temperature measurement wire, and the shielding protection sleeve sleeves the outer side of the temperature measurement wire. According to the temperature measurementcable provided by the invention, the outer side of the temperature measurement wire is sleeved with the insulating protection sleeve, so that the temperature measurement wire is protected. The shielding protection sleeve is arranged on the outer side of the temperature measurement wire, the measurement deviation generated by electromagnetic interference is reduced, the temperature measurement wire is more suitable for measurement in high-voltage, high-magnetic-field and greasy-dirt environments, measurement accuracy and the durability of the temperature measurement cable are improved, and therefore, the temperature measurement accuracy is improved while the service life of the temperature measurement wire is prolonged.

Owner:XIAN XIDIAN TRANSFORMER +1

Low-smoke halogen-free cable material

InactiveCN105906922ANot easy to producePlastic/resin/waxes insulatorsInsulated cablesLow voltageToxic material

The invention discloses a low-smoke halogen-free cable material, and relates to the technical field of cables. The low-smoke halogen-free cable material is prepared from the following raw materials in parts by weight: 100 parts of polyethylene, 5 parts of silicon carbide, 10-20 parts of aluminum hydroxide, 5-20 parts of magnesium hydroxide and 2-4 parts of an anti-ageing agent. The cable material has the performance of stopping combustion while being difficult to combust, and has flame retardant rating being V-0 level; during combustion, toxic substances containing halogen are not easily generated, and smoke is not easily generated, and therefore, the low-smoke halogen-free cable material can be suitable for a high-low-voltage power cable.

Owner:HEFEI OUBANG RUBBER TECH CO LTD

High-flexibility and flame-retardant halogen-free cable material and preparation method thereof

InactiveCN110283391AGood flexibilityImprove flame retardant performancePlastic/resin/waxes insulatorsAntioxidantEPDM rubber

The invention discloses a high-flexible and flame-retardant halogen-free cable material, which is prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 1-3 parts of an anti-aging agent, 45-55 parts of a halogen-free flame retardant, 0.5-1 part of an antioxidant, 3-8 parts of nanocomposite, 5-8 parts of paraffin oil, 1-2 parts of a crosslinking agent and 0.5-1 part of a coupling agent, and also provides a preparation method of the above high-flexibility and flame-retardant halogen-free cable material: mixing the EPDM rubber, the anti-aging agent and (1-3) / 4 formulated amount of the nanocomposite, adding the halogen-free flame retardant, antioxidant, paraffin oil and coupling agent and performing mixing, thinning, filtering and calendaring for sheeting without slitting, and adding the crosslinking agent and (1-3) / 4 formulated amount of the nanocomposite and mixing to obtain the high-flexibility and flame-retardant halogen-free cable. The cable material prepared by the invention has good softness and the material oxygen index reaches OI is more than or equal to 38, offering good flame retardant performance.

Owner:WUXI INST OF ARTS & TECH

Halogen-free low-smoke cable material for ship and ocean engineering cables

The invention belongs to the technical field of compositions of high-molecular compounds, and discloses a halogen-free low-smoke cable material for a ship and ocean engineering cable. The flame-retardant EVA rubber material is prepared from 35-45 parts of ethylene-vinyl acetate resin, 20-25 parts of EVA rubber material, 15-18 parts of carbon fiber, 7-8 parts of filler, 7-8 parts of ceramic powder, 4-6 parts of halogen-free flame retardant, 3-6 parts of lubricating oil, 2-4 parts of processing aid, 2-4 parts of antioxidant and 1-3 parts of compatilizer. The cable material solves the problem that the existing cable material is light in weight, so that the mechanical strength of the cable material is complemented due to the proportion of the raw materials, and the service life of the prepared cable is short.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

Anti-UV wear-resistant mildewproof cable material and preparation process thereof

InactiveCN108570199AStrong UV resistanceSolve the problem of easy yellowing and discolorationPlastic/resin/waxes insulatorsEmulsionWear resistant

The invention discloses an anti-UV wear-resistant mildewproof cable sheath material, which is prepared from the following raw materials by weight percentage: 34%-50% of PVC powder, 25%-35% of plasticizer, 15%-22% of composite wear-resistant emulsion, 5%-6.5% of nanoparticles, 5%-8% of natural extracting type mildewproof agent, 1%-5% of stabilizer, and 0.1%-0.6% of antioxidant. The anti-UV wear-resistant mildewproof cable sheath material has good UV resistance, has long-lasting high-efficiency antibacterial and mildewproof performance and good processability, is environmentally friendly, is harmless to human body, and is simple to prepare.

Owner:GUANGDONG BAOMING IND TECH CO LTD

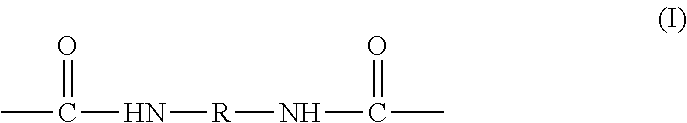

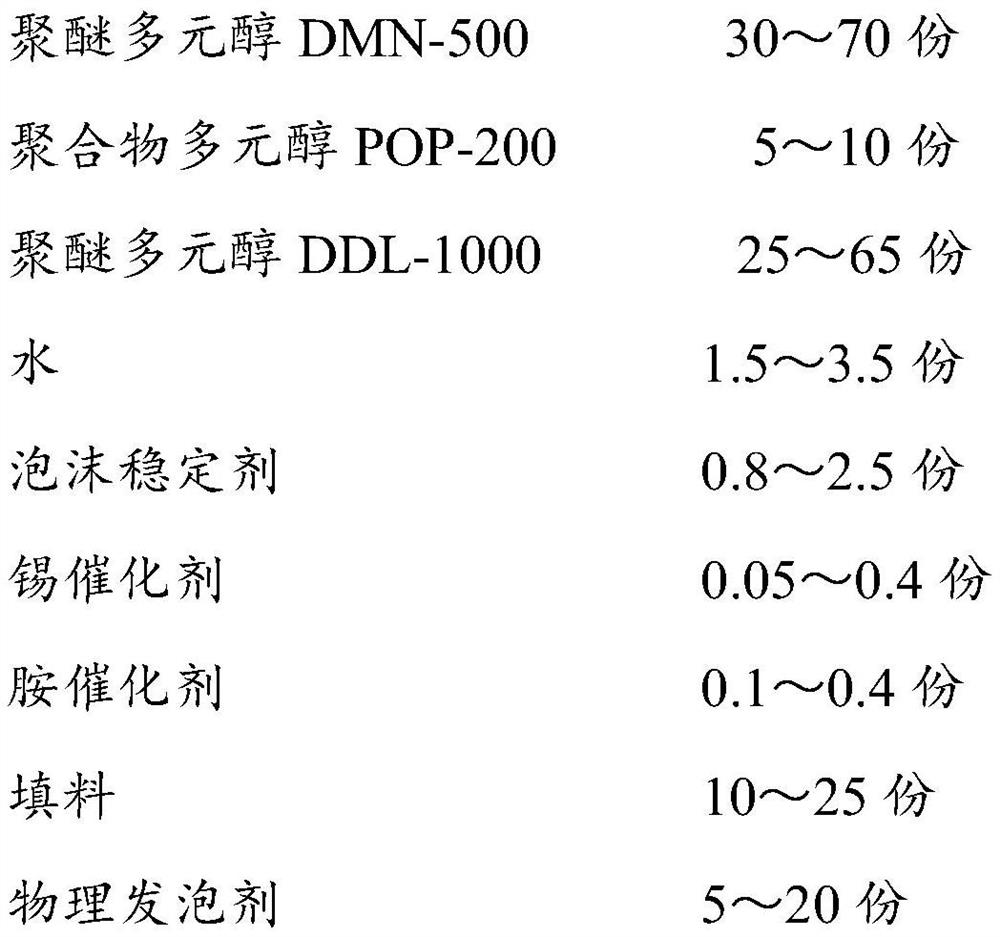

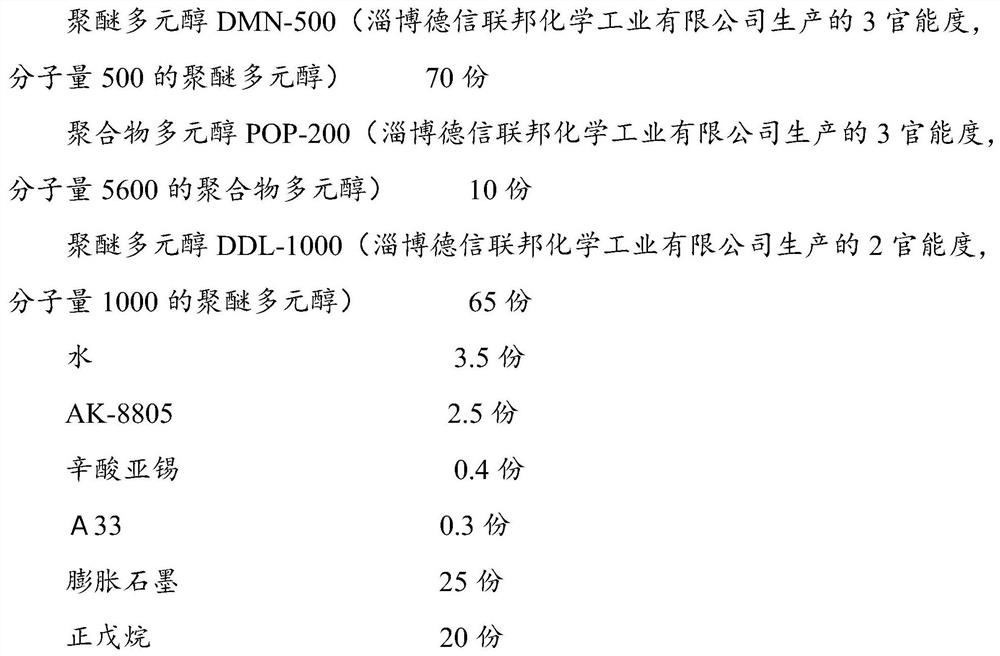

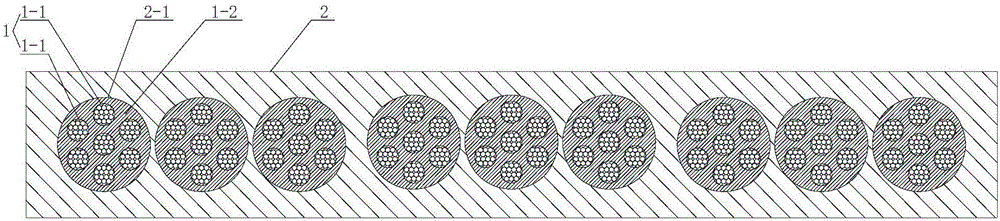

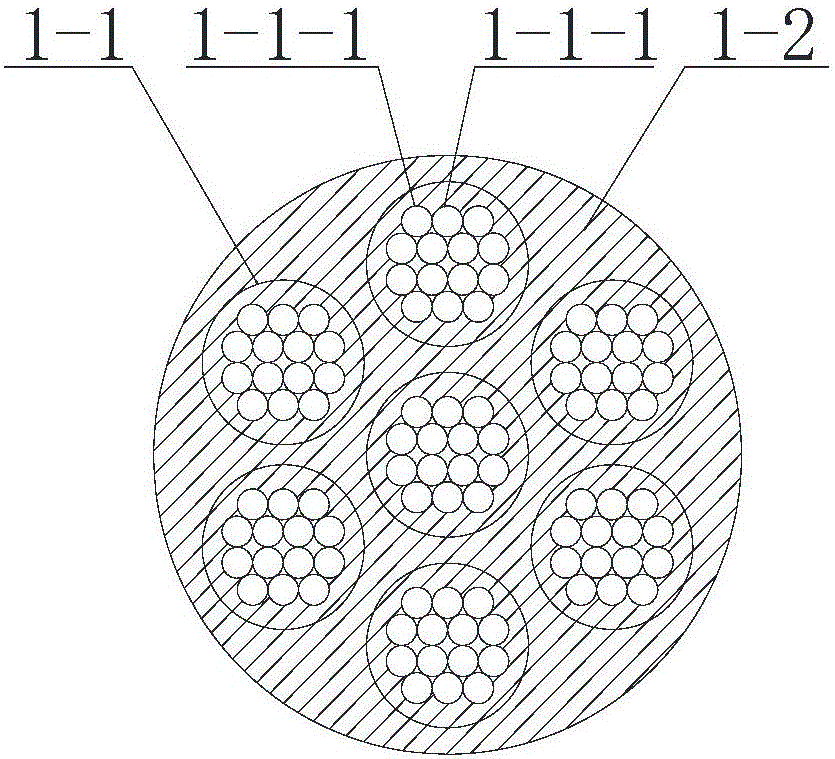

Polyurethane cable insulating material and preparation method thereof

InactiveCN111892691ASimple processing technologyIncrease productivityPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

Owner:荆晓东

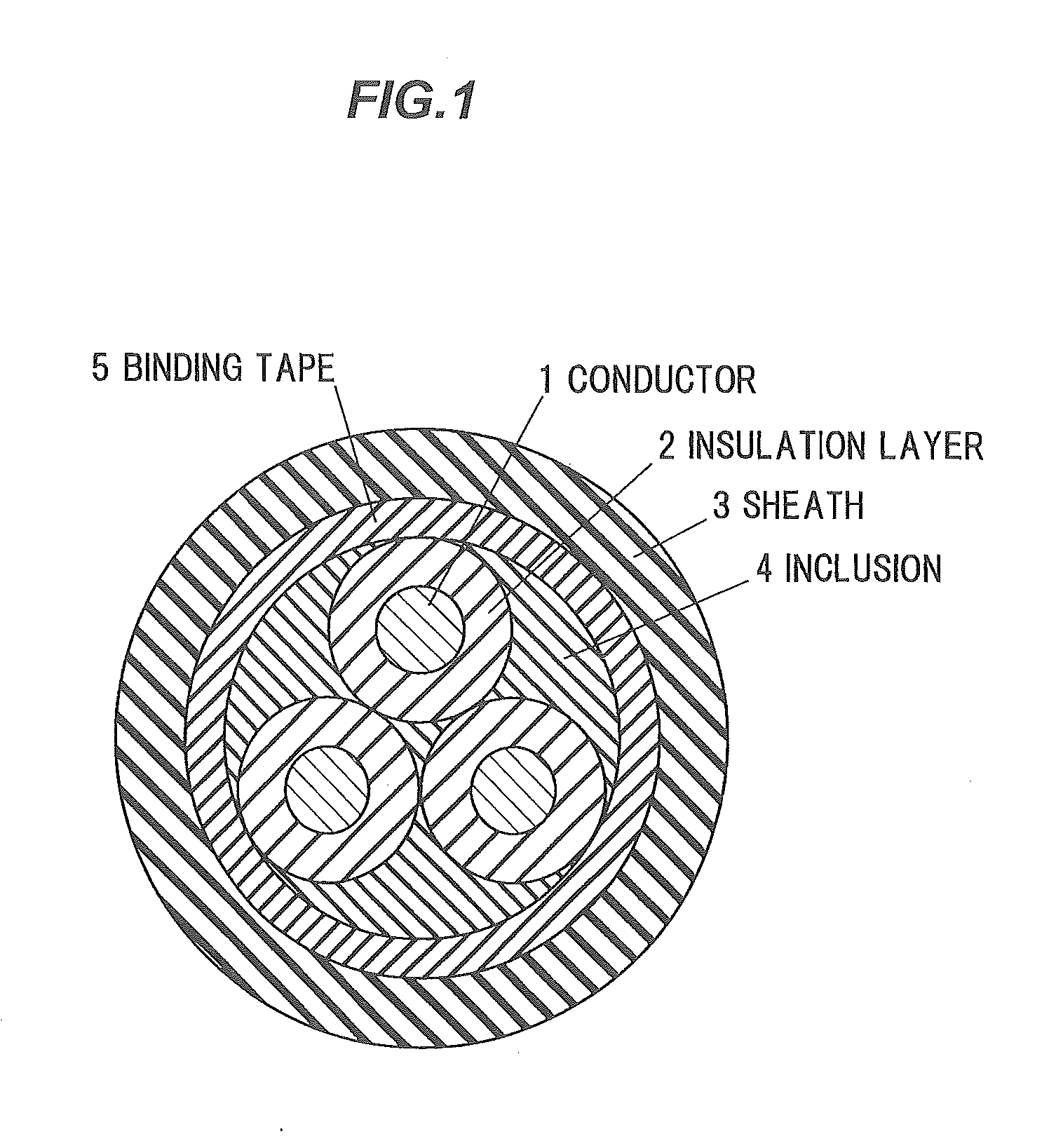

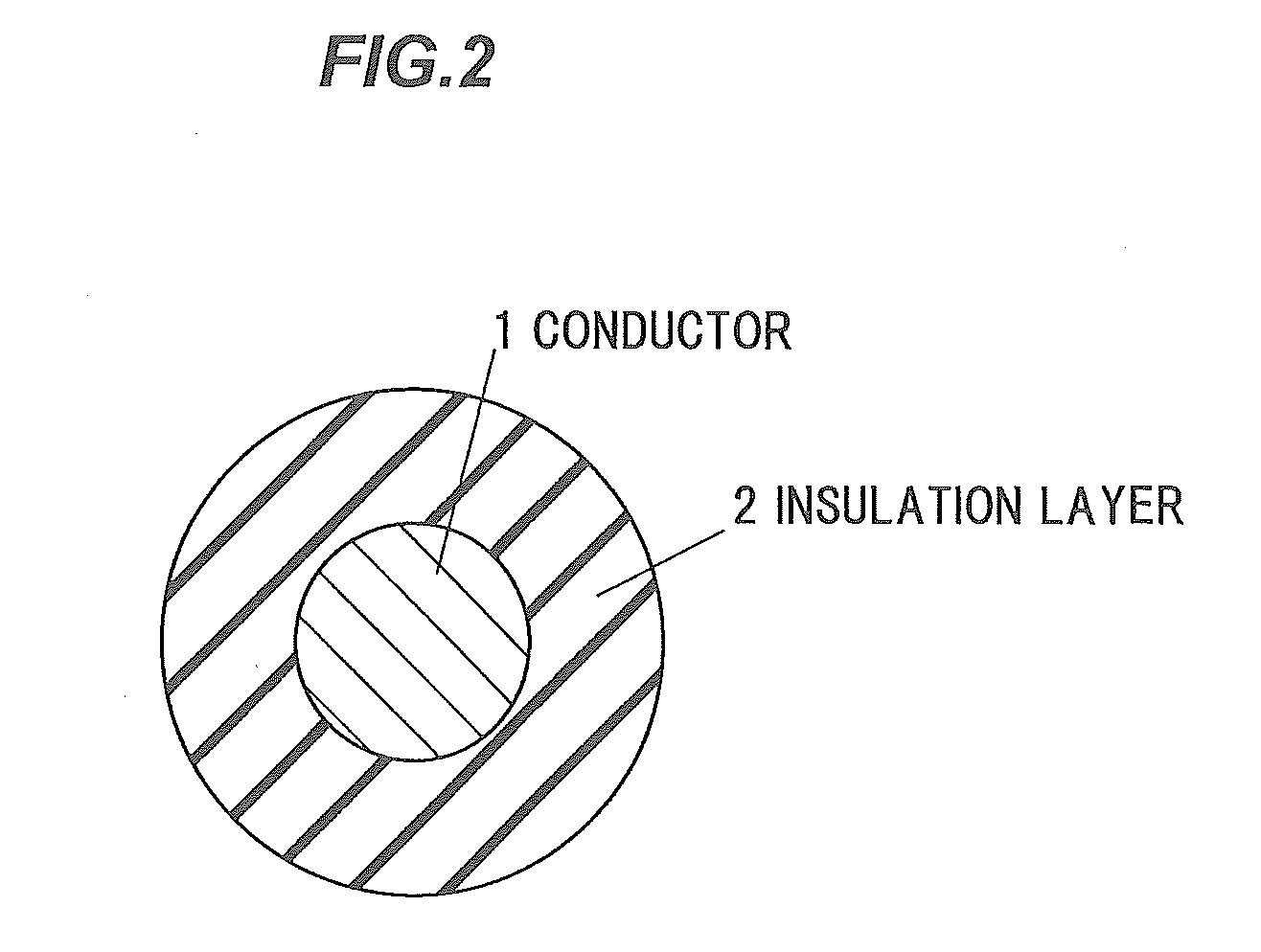

Elevator cable

Owner:上海新时达线缆科技有限公司 +2

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap