Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ductility is a measure of a material's ability to undergo significant plastic deformation before rupture, which may be expressed as percent elongation or percent area reduction from a tensile test. According to Shigley's Mechanical Engineering Design (10th Ed.) significant denotes about 5.0 percent elongation (Section 5.3, p. 233). See also Eq. 2–12, p. 50 for definitions of percent elongation and percent area reduction. Ductility is often characterized by a material's ability to be stretched into a wire.

Safety component moulded in a1-si alloy

Owner:ALUMINUM PECHINEY

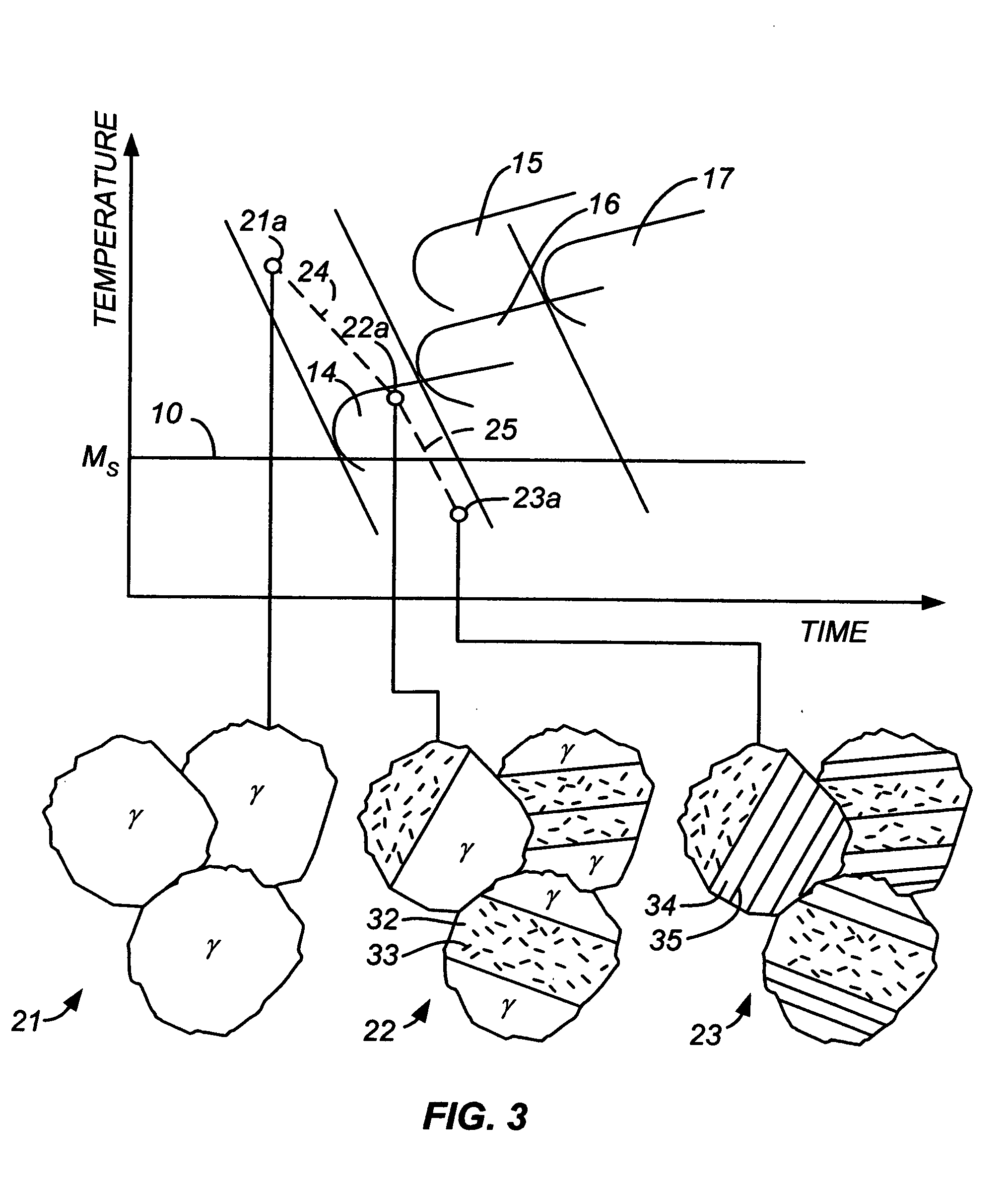

High-strength four-phase steel alloys

Owner:CMC STEEL FABTORS

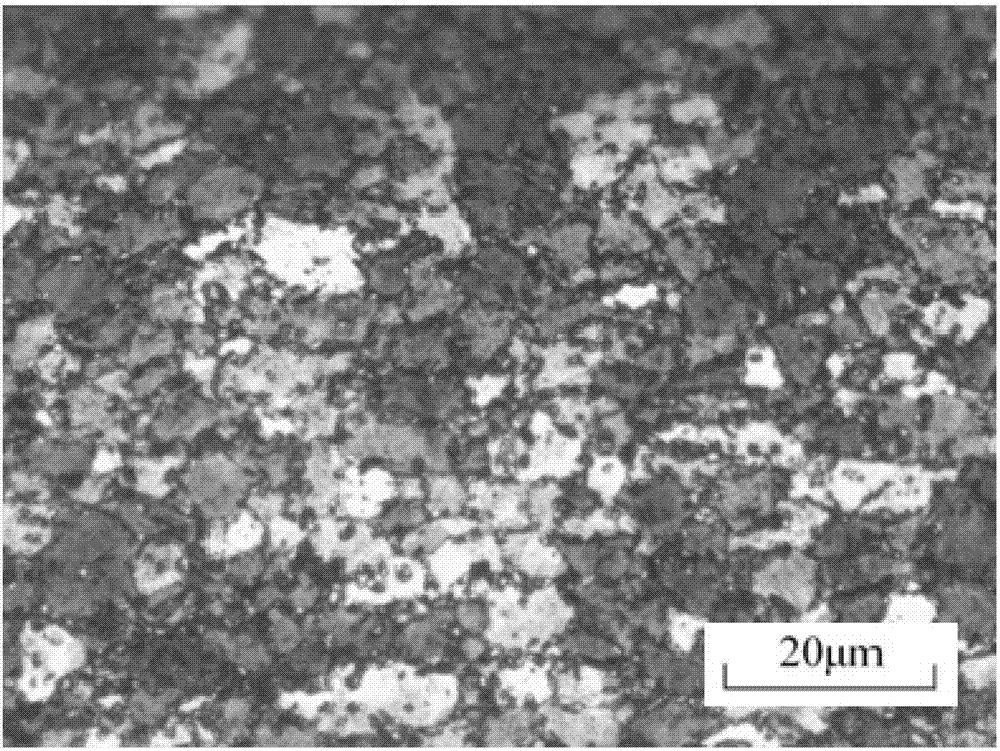

Production process of high-ductility cold-rolled ribbed steel bars

Owner:ANYANG HELI CHUANGKE METALLURGY NEW TECH RES & DEV

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

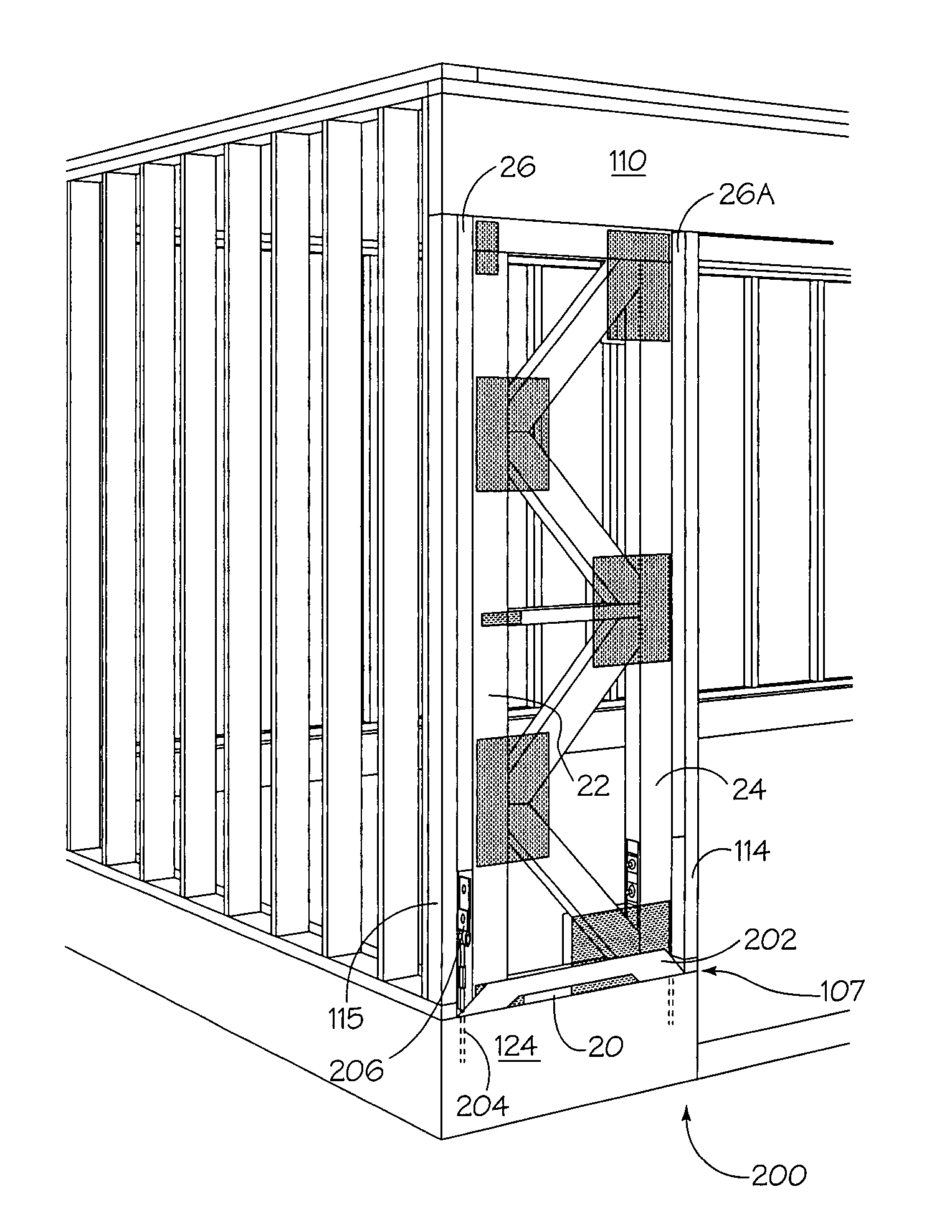

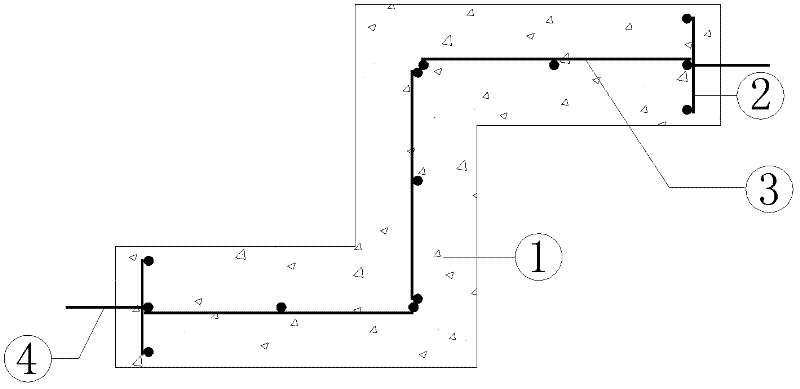

Truss type steel-reinforced concrete framework side node with energy dissipation device

InactiveCN102628296AImprove energy consumptionImprove seismic performanceShock proofingViscous dampingConcrete beams

The invention relates to a truss type steel-reinforced concrete framework side node with an energy dissipation device. The steel skeleton in a beam is a truss type steel skeleton, which comprises vertical members, chord members and diagonal members. T-shaped profile steels are arranged on the upper and the lower parts of the beam to serve as the chord members, and are connected through angle irons, so that a truss type steel skeleton concrete beam member is formed. The vertical members and the chord members on the ends of the beam and in the core area of the node form a rectangular structure, the diagonal members are crossed, and are welded between the upper chord members and the lower chord members, the truss type steel skeleton extends into a column, and the length of the extending end is 0.9 times as the width of the section of the column in the direction. The ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of the truss type steel-reinforced concrete framework side node with the energy dissipation device disclosed by the invention are remarkably increased in comparison with the ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of reinforced concrete nodes. The truss type steel-reinforced concrete framework side node with the energy dissipation device has good structural seismic resistance and energy-dissipating capability.

Owner:GUANGXI UNIV

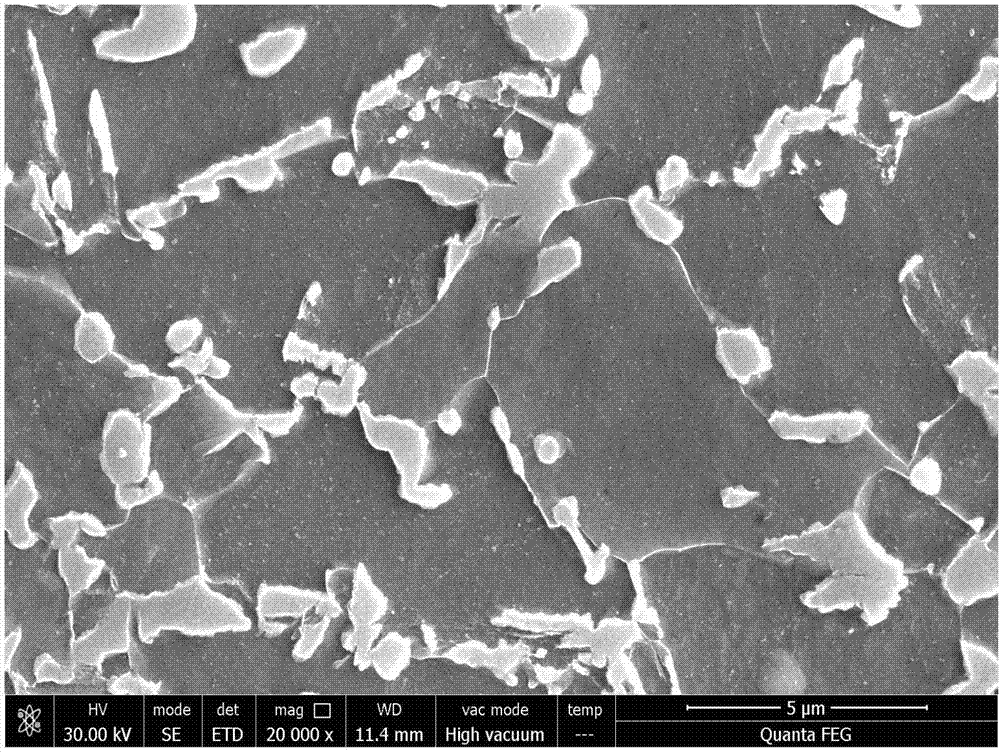

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Cold rolling production method of medium-chromium ferrite stainless steel for vehicle exhaust system

InactiveCN106140813AGood formabilityUniform shear strainRoll mill control devicesMetal rolling arrangementsReduction rateChromium

The invention discloses a cold rolling production method of medium-chromium ferrite stainless steel for a vehicle exhaust system. Cold rolling steps adopt five passes of continuous cold rolling by a five-stand tandem rolling unit; the reduction rate in the first pass is 19-21%; the reduction rate in the second pass is 34-36%; the reduction rate ratio in the third, fourth and fifth passes is 6-7: 4-5: 3; the total reduction rate is not lower than 70%; and the plate thickness after cold rolling is within 0.8-1.5 mm. The steel has the r value of 1.5-1.8, the yield strength of not less than 240 MPa, the tensile strength of not less than 415 MPa, the ductility of not less than 36% and the roughness of not more than 0.7 microns; the molding strain ratio of the steel is increased; the forming performance is enhanced; the roughness satisfies the use conditions of the vehicle exhaust system; and a new technology is provided for industrial production of the medium-chromium ferrite stainless steel for the vehicle exhaust system.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

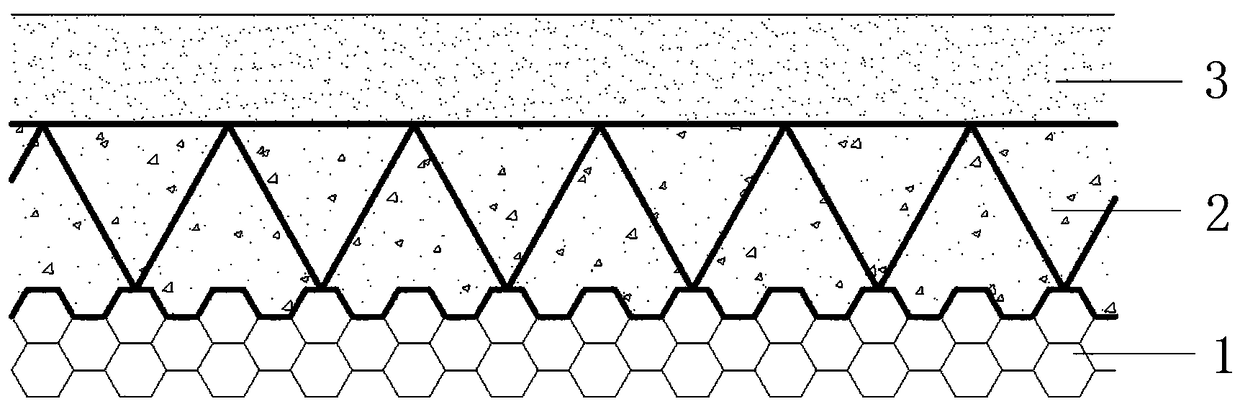

Composite protective structure resistant to blast shock

ActiveCN108487490AIncrease resistance levelDecentralized ConstraintsProtective buildings/sheltersShock proofingEnergy absorbingDuctility

The invention discloses a composite protective structure resistant to blast shock which is mainly a point truss honeycomb integral protective structure formed by a honeycomb tensile layer and a lattice truss-type compression resistance layer through welding spots and connecting keys, and a foam energy absorbing layer is added on the outer layer. According to the composite protective structure, theforce transmission path of a concrete protective structure under the action of blast is innovatively optimized, the resistance level of the protective structure can be greatly improved, and the structure ductility is improved; and the dispersion of concrete fragments in the structure can be restrained, and the phenomenon of blast and explosion-induced collapse of similar traditional concrete protective structures is eliminated.

Owner:TAIYUAN UNIV OF TECH

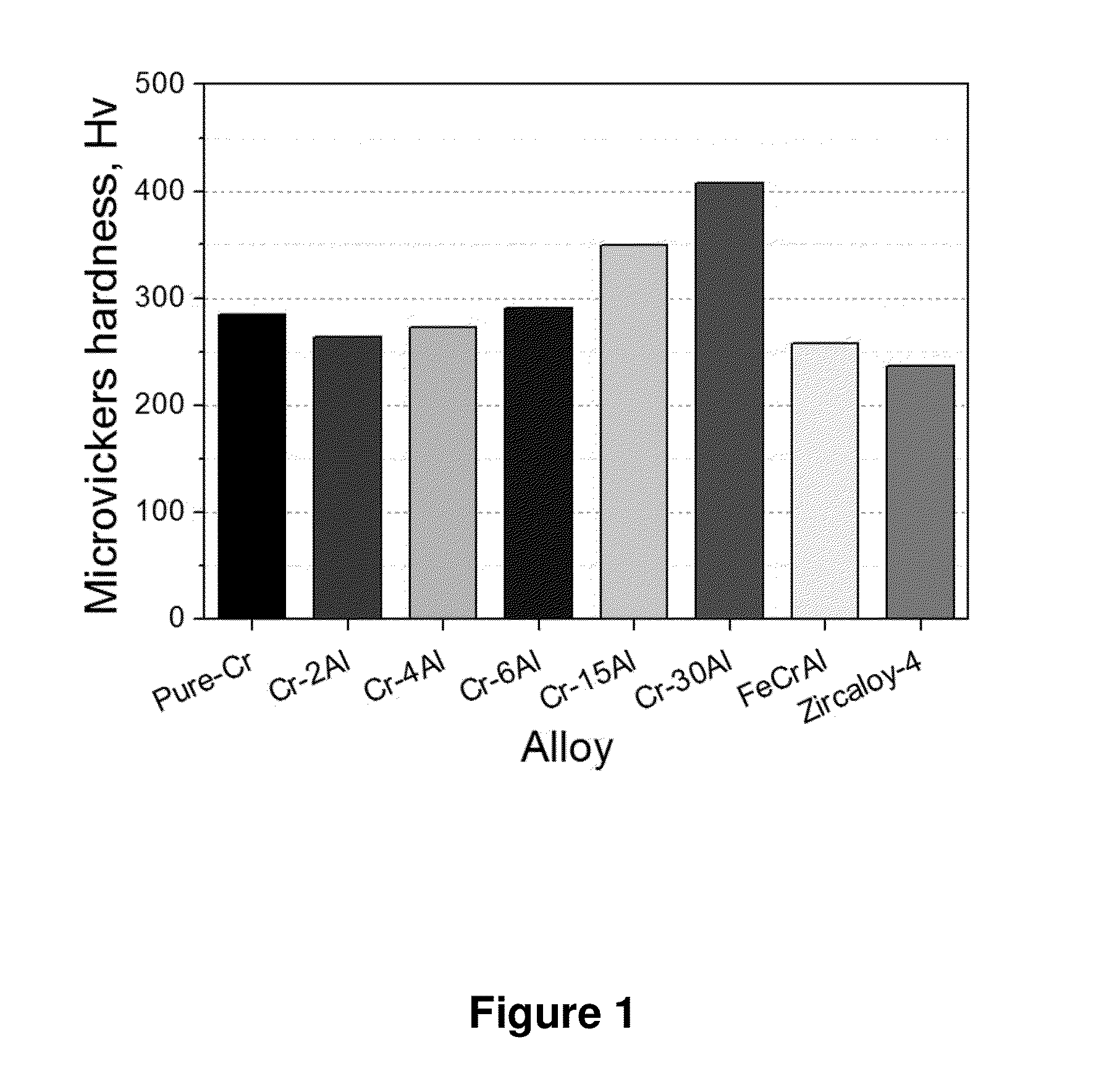

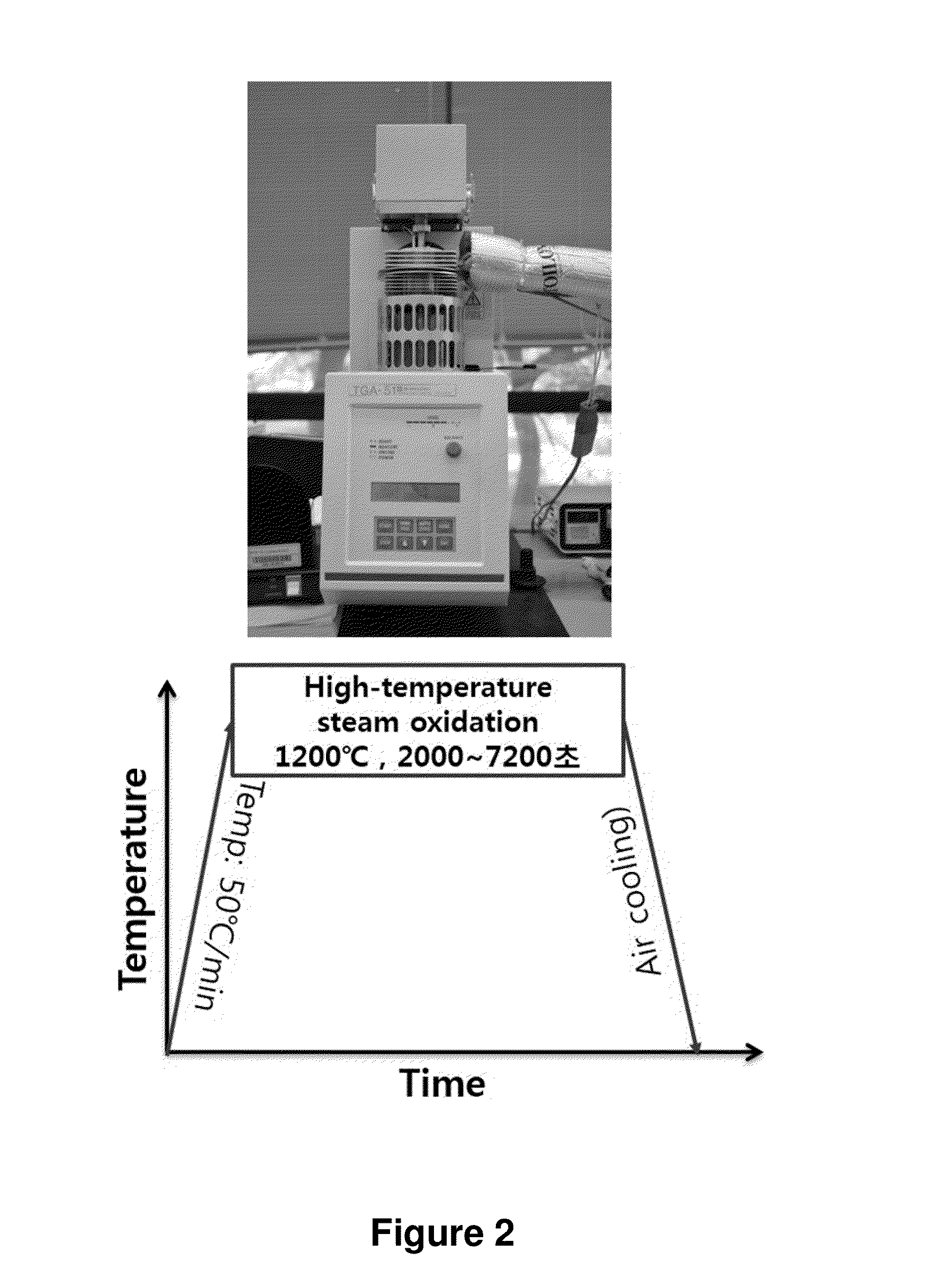

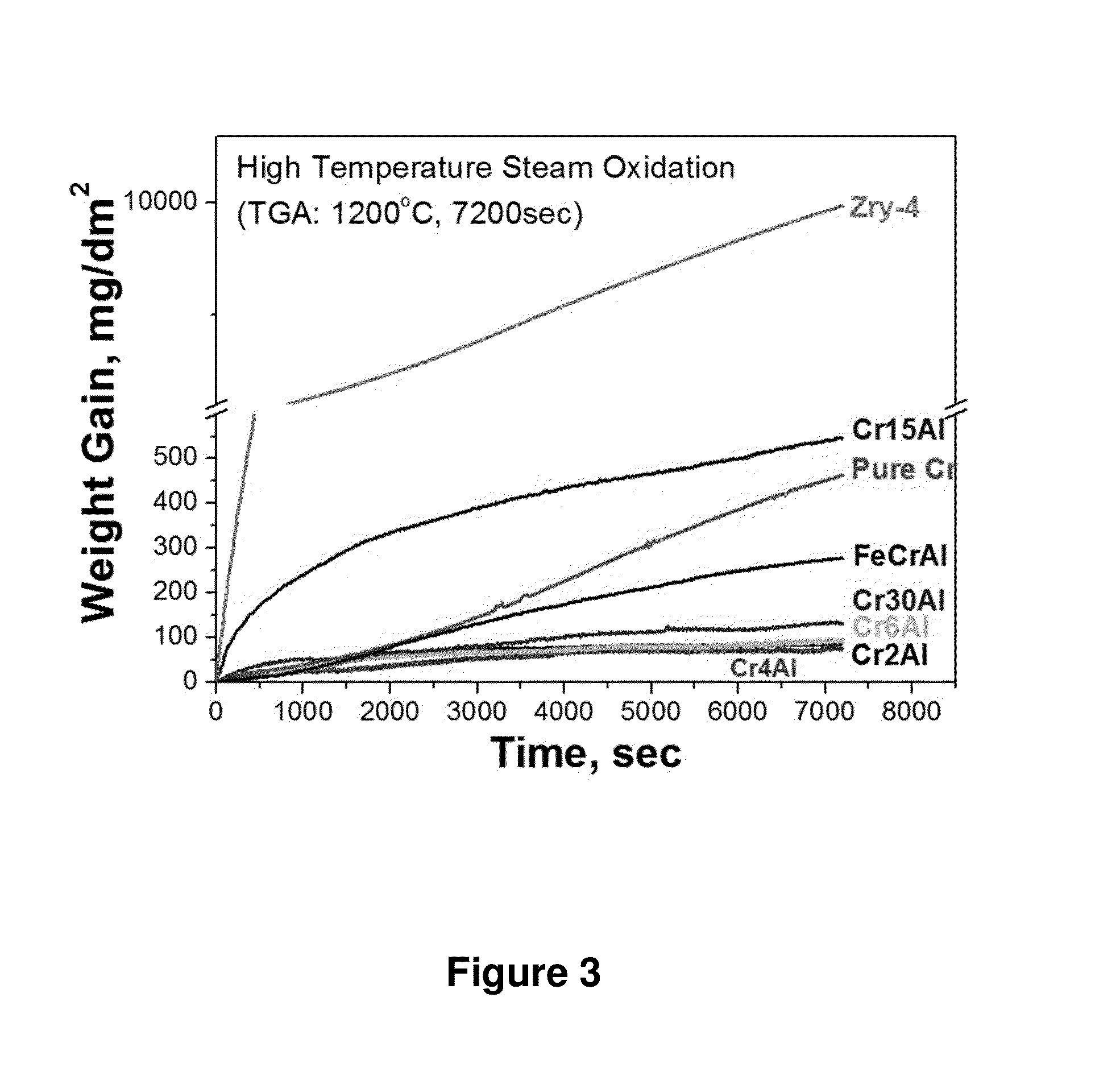

Chromium-Aluminum Binary Alloy Having Excellent Corrosion Resistance and Method of Manufacturing Thereof

Owner:KOREA ATOMIC ENERGY RES INST

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Titanium-iron-carbon alloy with low cost and high strength

Disclosed is titanium-iron-carbon alloy with low cost and high strength. The titanium-iron-carbon alloy is characterized by comprising, by mass, 11%-12% of Fe, 0.03%-0.07% of C, the balance Ti and inevitable impurities. According to the titanium-iron-carbon alloy, a titanium alloy system serves as an object; the two elements of titanium and iron serve as a main alloy body; the titanium alloy with high strength and ductility is obtained by adding trace carbon element. The titanium alloy adopting the matching ratio is not only easy to smelt, but also low in cost.

Owner:YANSHAN UNIV

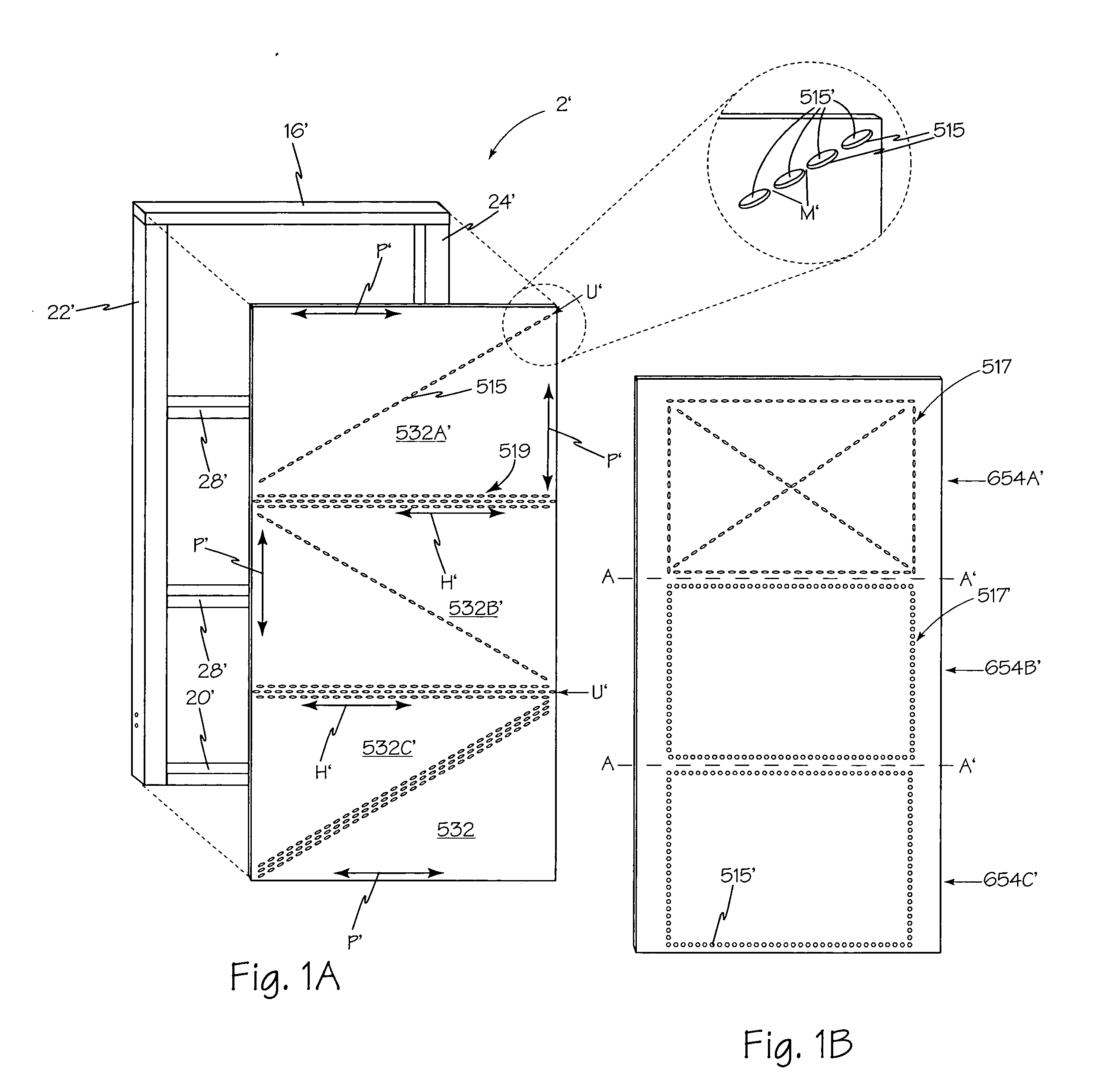

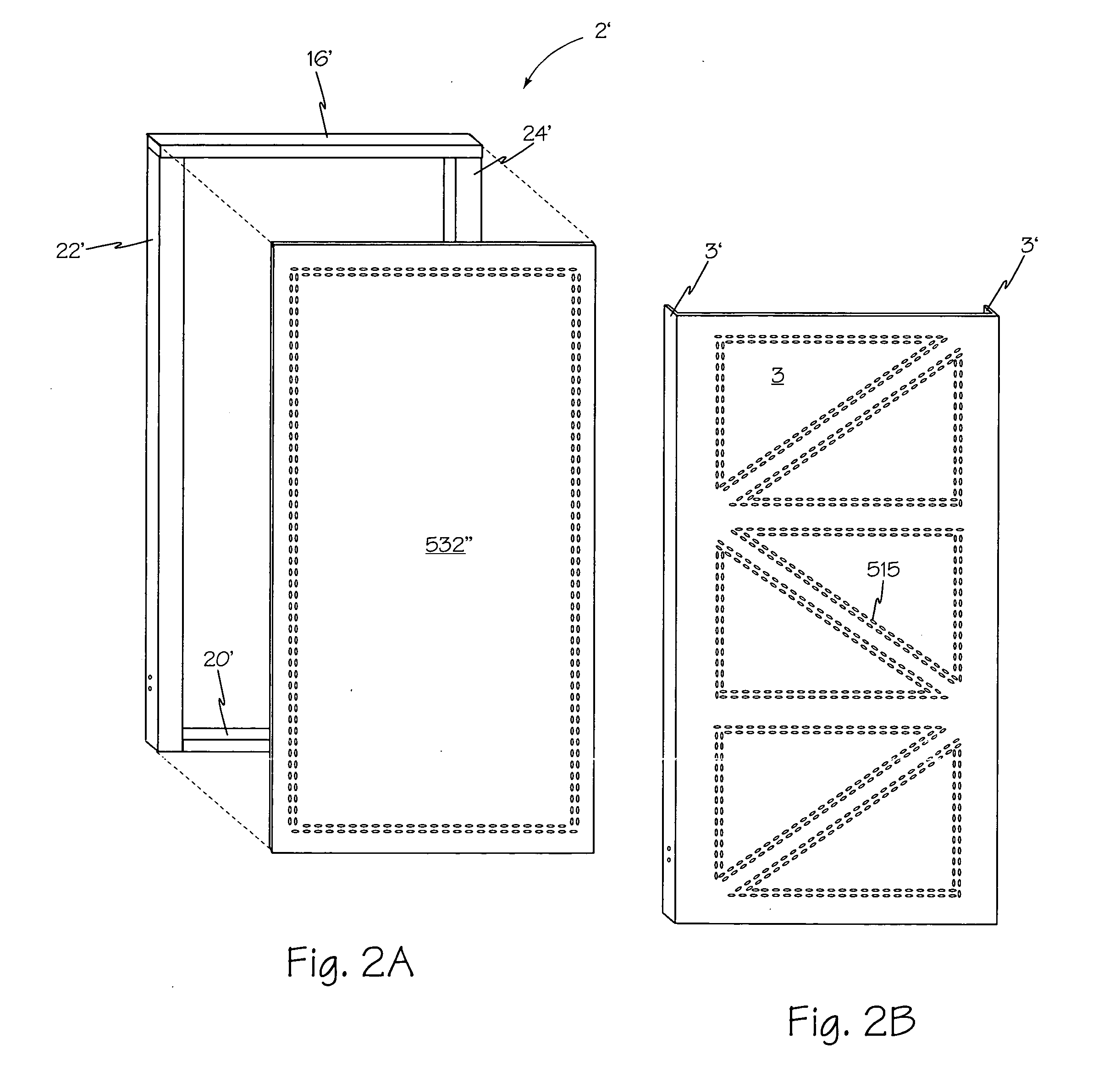

Lateral force resisting system

Owner:TIMMERMAN TIMOTHY L +1

Aluminum foil material for air conditioner and preparation method for aluminum foil material

Owner:成都毅诚机电工程有限公司

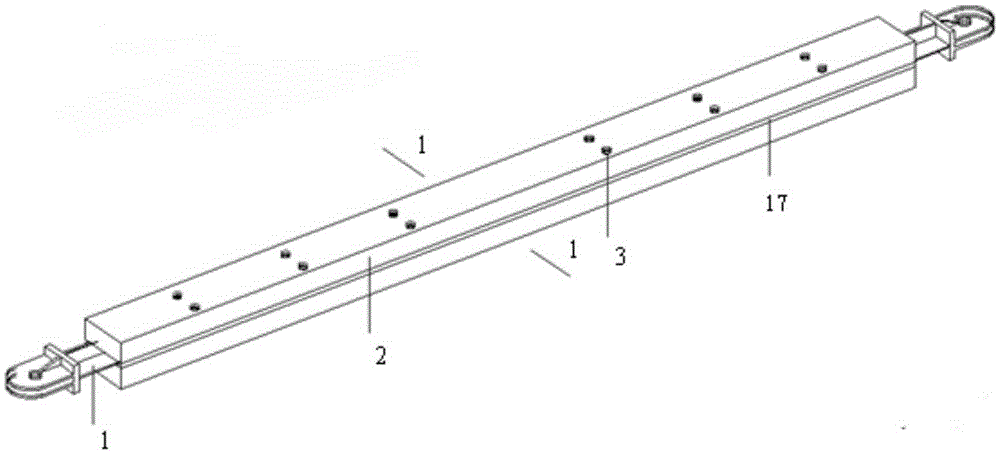

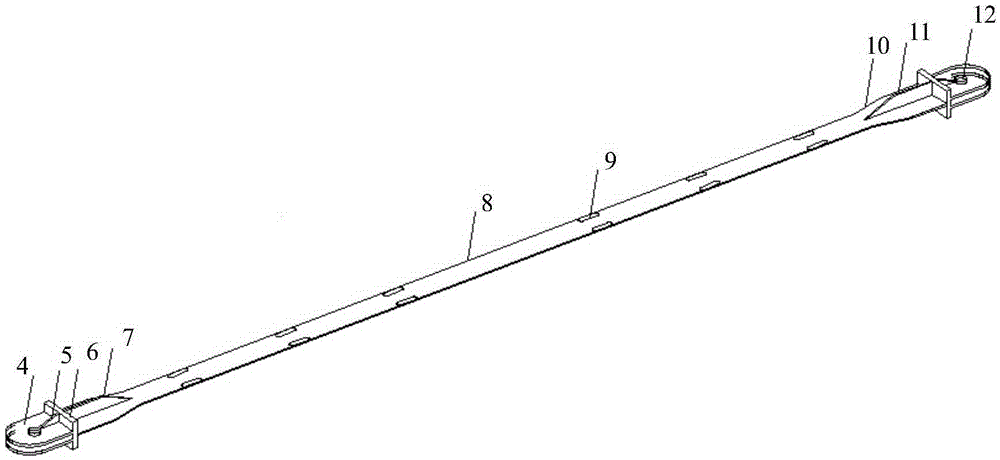

Assembly type bolted connection reinforced wood constraint buckling-restrained brace

ActiveCN105386534AImprove ductilityImprove energy consumptionShock proofingBuckling-restrained braceBolt connection

Owner:NANJING UNIV OF TECH

Barrier structure

InactiveUS20150360447A1Synthetic resin layered productsCellulosic plastic layered productsDuctilityEngineering

Owner:LIU TAJO +1

Novel environment-friendly insulating paint and preparation method thereof

InactiveCN108822625AHigh glossImprove antistatic performanceFireproof paintsStarch dervative coatingsEpoxyPhenyl Ethers

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Latticed single-row reinforced Z-shaped sectional concrete column and making method

InactiveCN102561594AReduce dosageImprove shear resistanceStrutsBuilding reinforcementsBrickSteel bar

Owner:BEIJING UNIV OF TECH

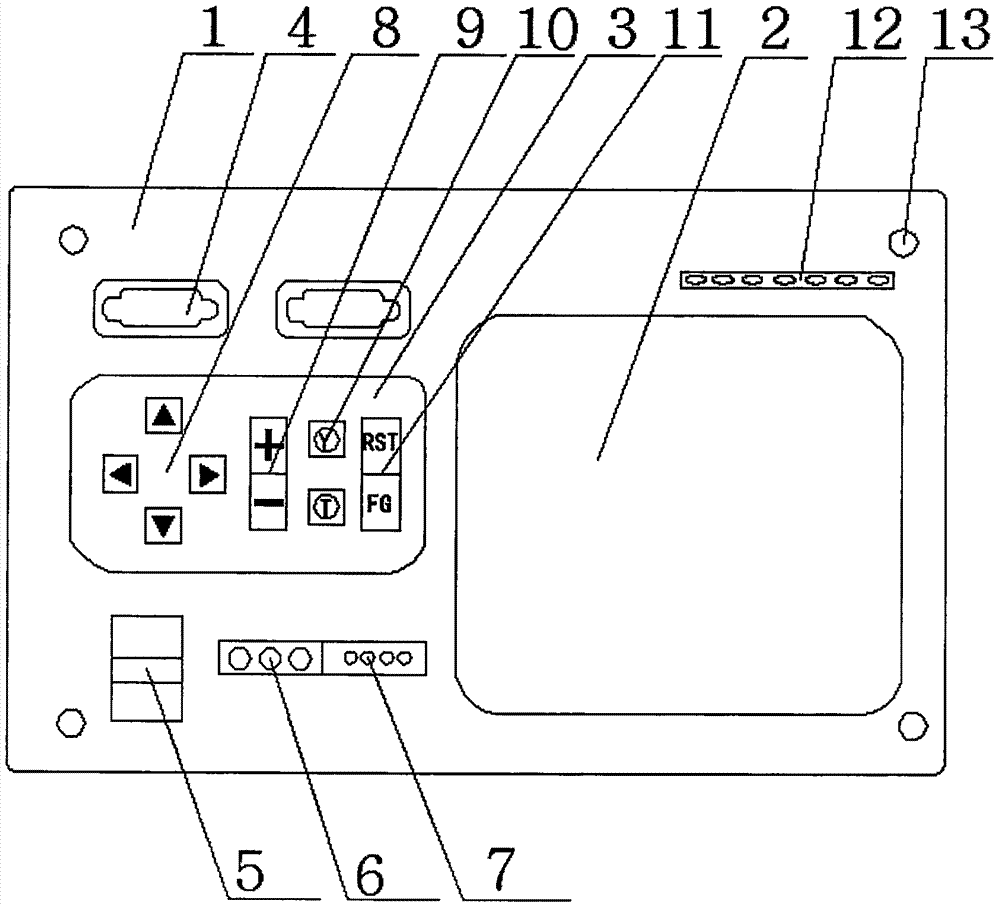

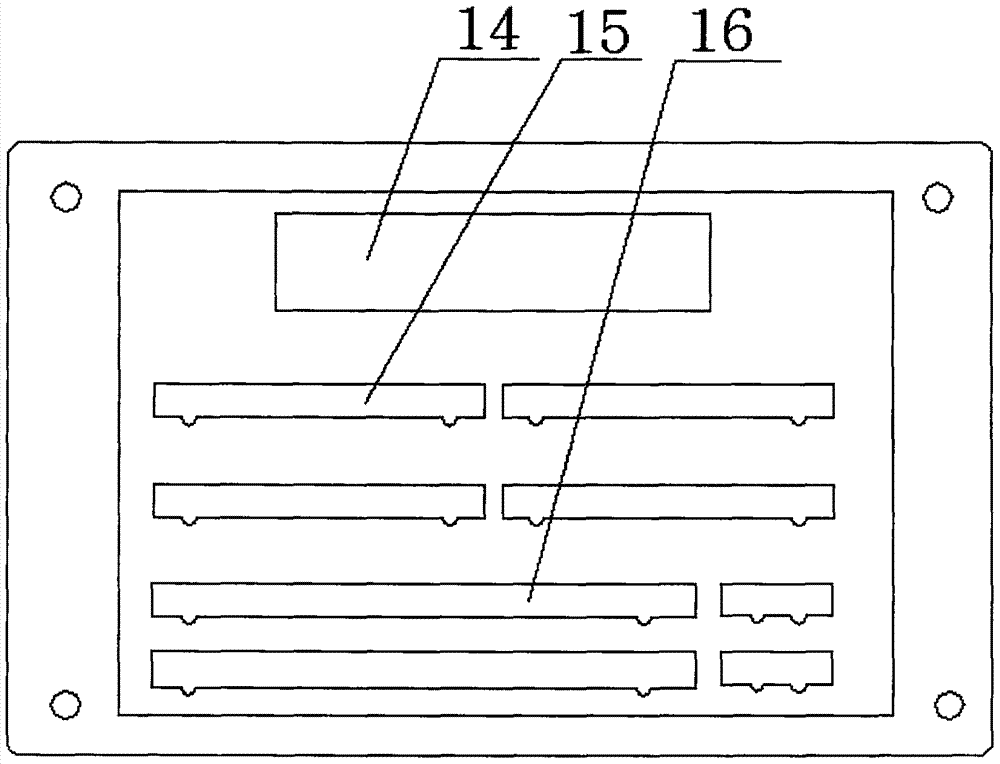

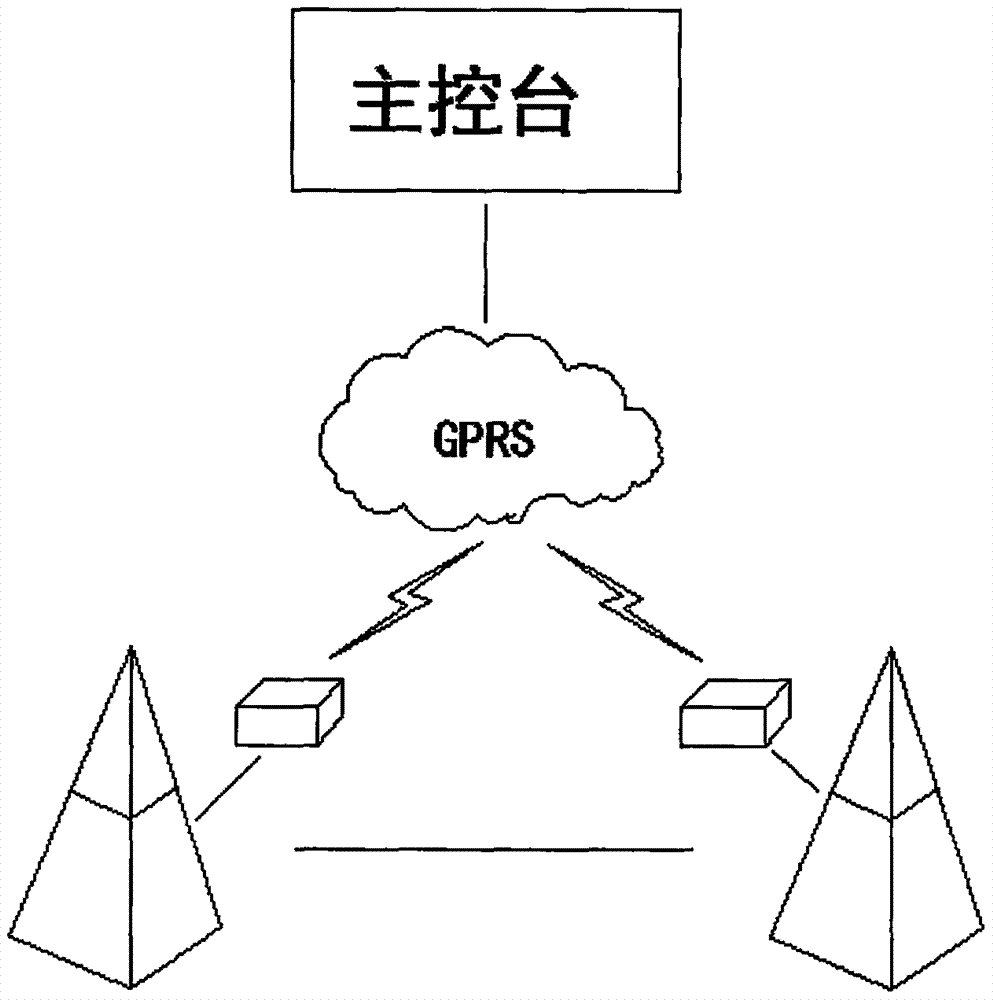

Relay protection device in transmission line

InactiveCN106877294AMeet protection needsProtection securityEmergency protective circuit arrangementsElectrical testingTransmission towerLED display

Owner:赵志国

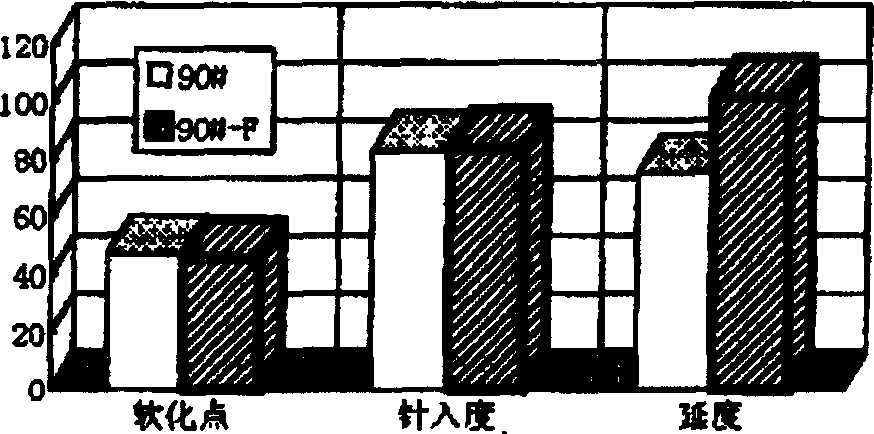

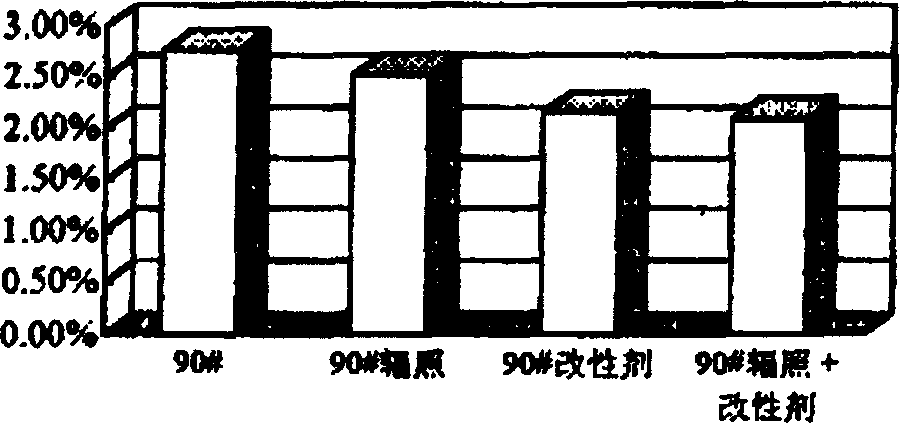

High molecular radiation crosslinking modified asphalt and preparation process

Owner:NORTHWEST NORMAL UNIVERSITY

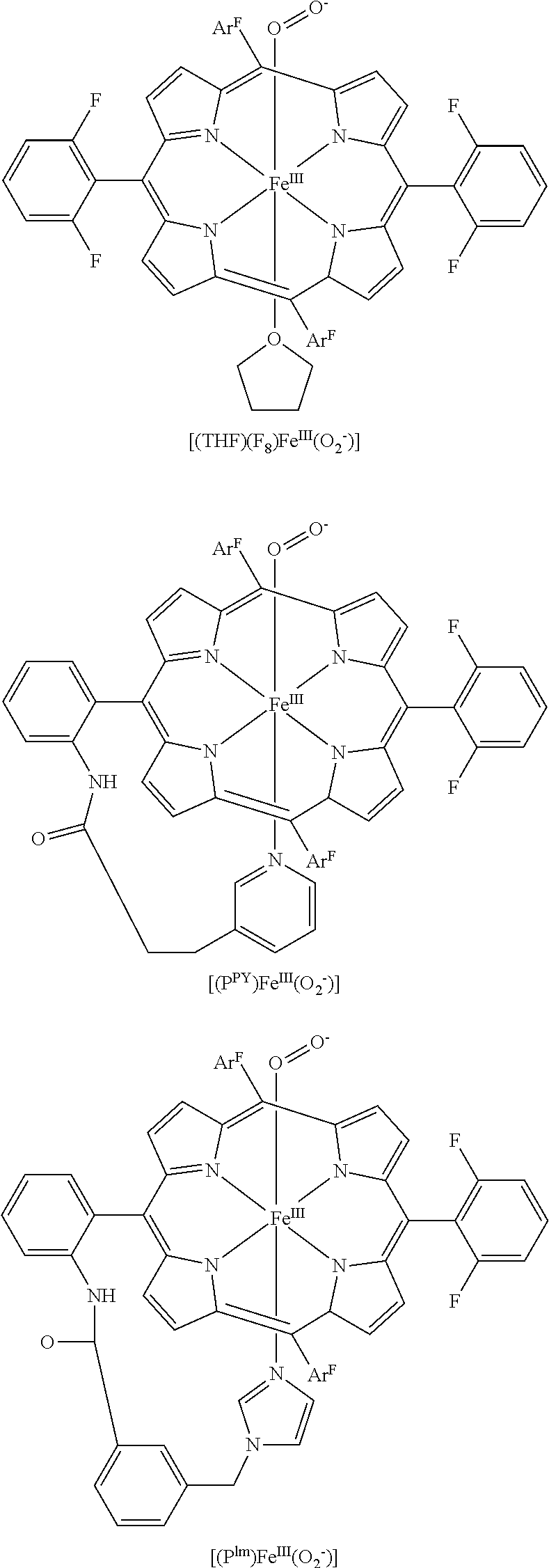

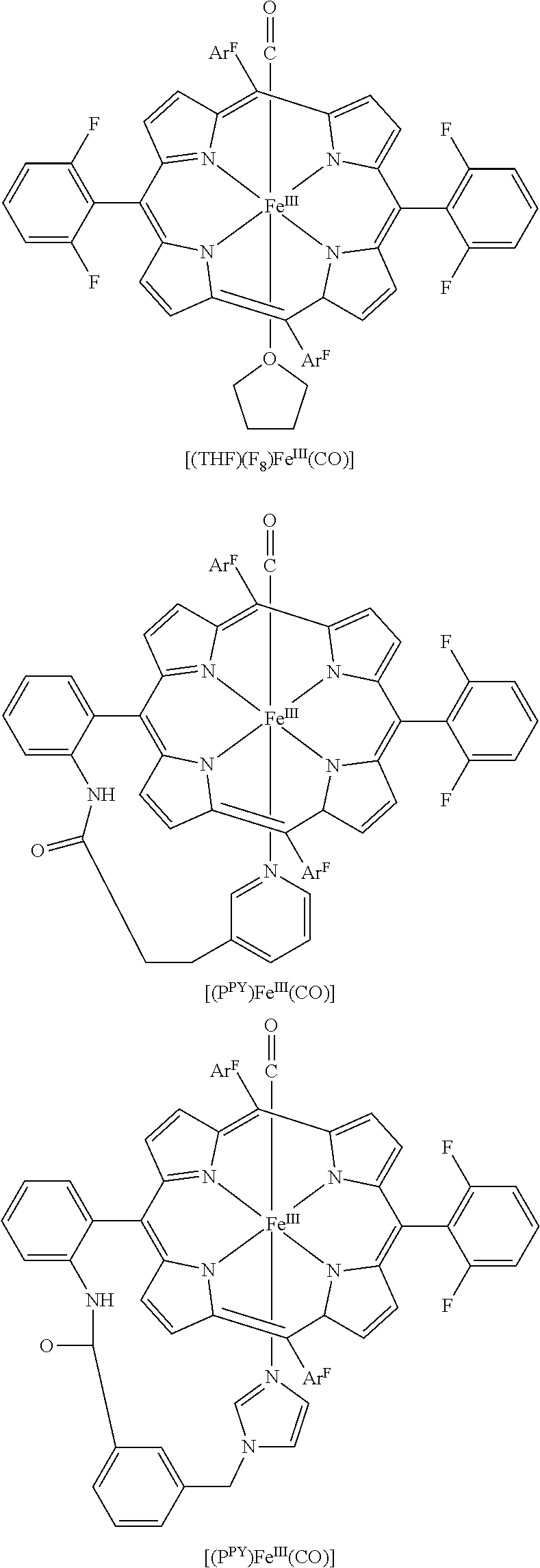

Artificial fracture imaging method and system for physical simulation gas fracturing experiment

InactiveCN110243690AAvoid interferenceMaterial strength using tensile/compressive forcesThin layerRock sample

The invention provides an artificial fracture imaging method and system for a physical simulation gas fracturing experiment and belongs to the field of petroleum and natural gas exploration and development. The artificial fracture imaging method for the physical simulation gas fracturing experiment comprises the steps that 1, a rope saw is used to cut off a rock sample, obtained after the gas fracturing experiment, along a section of the rock sample; 2, a writing thin layer with ductility is tightly combined with the section of the rock sample; and 3, the surface, where a coloring block is attached, is used to uniformly color the writing thin layer. Through the artificial fracture imaging method and system, the problems that the rock sample obtained after the gas fracturing experiment cannot be directly transplanted, and dyeing of a rock sample fracture is performed by adding a coloring material in the prior art are solved, and a new artificial fracture imaging method is proposed; and through the method, no aqueous medium is added, a rock block and a fracture surface maintain a waterless dry state all the time, and experiment result disturbance caused by an aqueous medium is avoided.

Owner:CHINA NAT PETROLEUM CORP +1

Asphaltum composite modified by particles / polymers, and preparation method

InactiveCN100526388CFully dispersedEase of industrial productionBuilding insulationsBenzeneZno nanoparticles

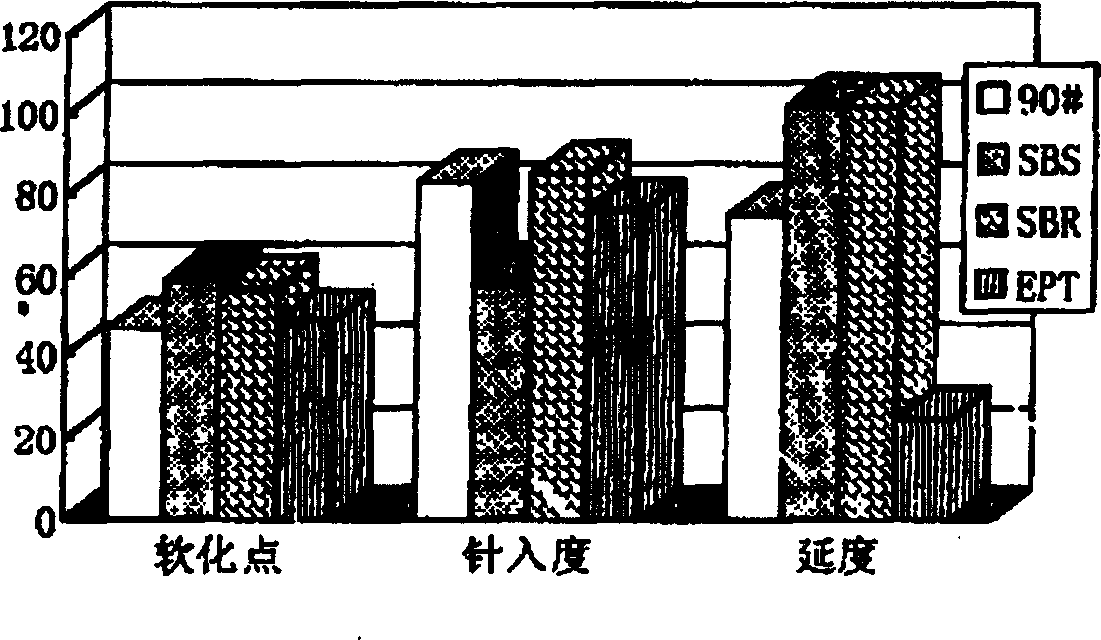

This invention discloses a method for preparing nanoparticles / polymer composite-modified asphalt. The method comprises: mixing ZnO nanoparticles, SBS, matrix asphalt and solvent benzene at a certain ratio, stirring uniformly to obtain asphalt mother liquor, recovering solvent benzene at 70-100 deg.C to obtain a solid, mixing with matrix asphalt at a weight ratio of 1:5, stirring uniformly at 160-175 deg.C, and developing at 120 plus and minus 5 deg.C for 2 plus and minus 0.1 h to obtain nanoparticles / polymer composite-modified asphalt. The nanoparticles / polymer composite-modified asphalt has such advantages as easy preparation, good properties and high ductility at 5 deg.C.

Owner:YANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap