Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Reinforced concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced concrete (RC) (also called reinforced cement concrete or RCC) is a composite material in which concrete's relatively low tensile strength and ductility are counteracted by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel reinforcing bars and is usually embedded passively in the concrete before the ...

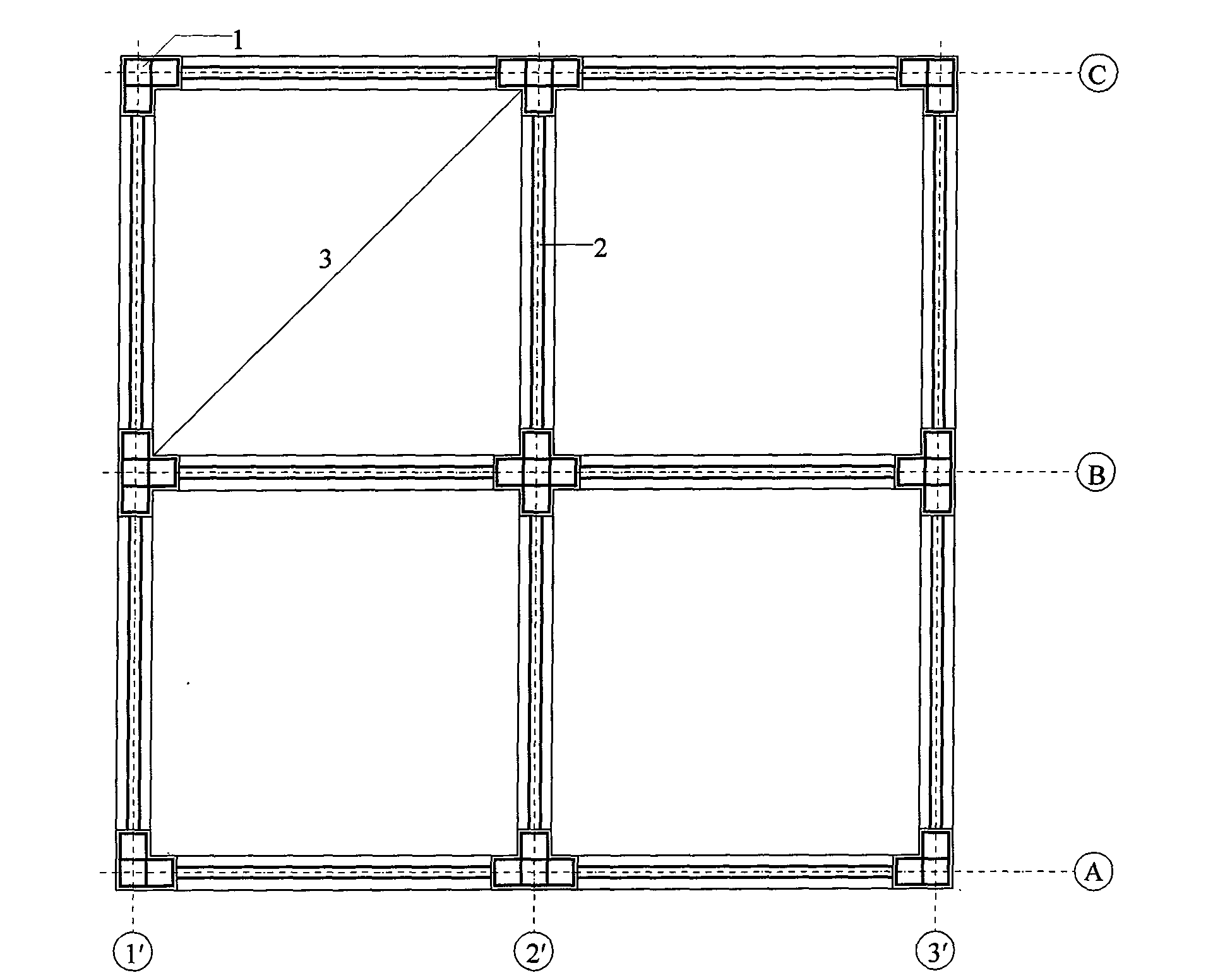

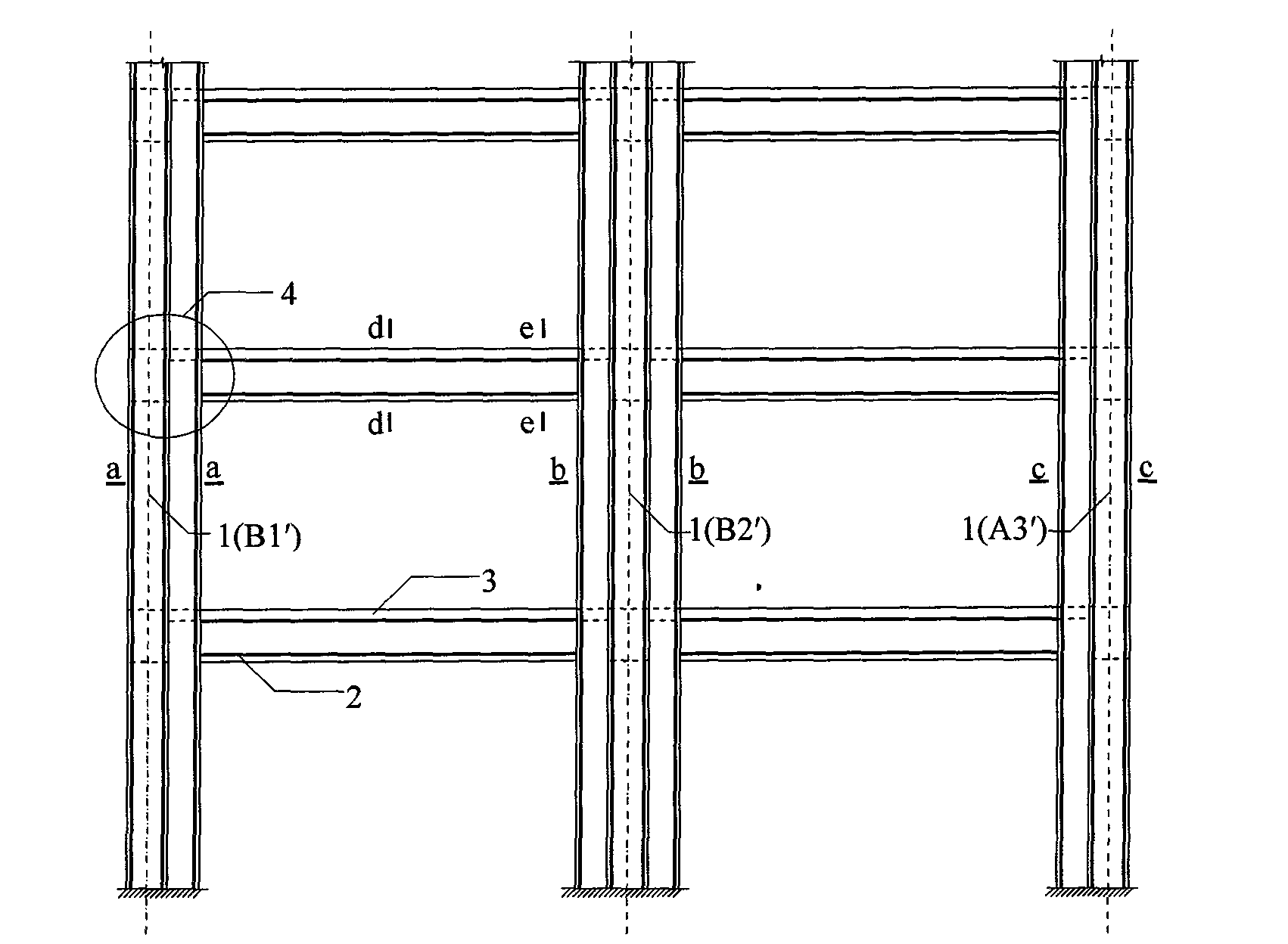

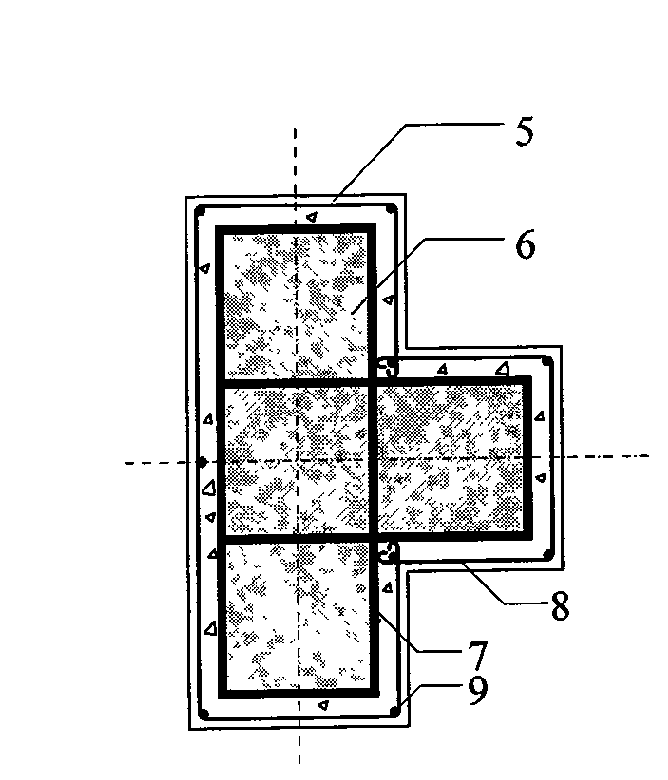

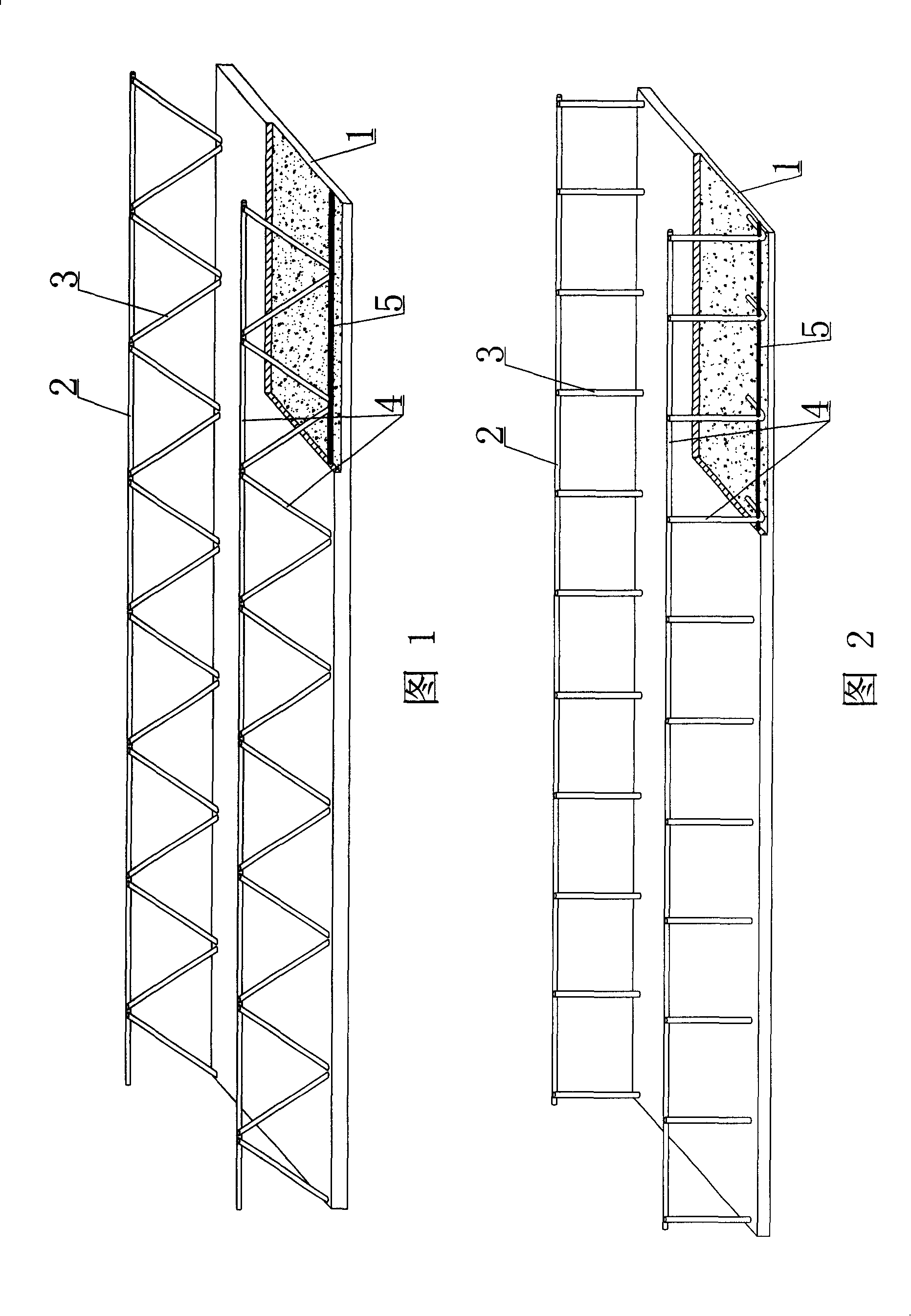

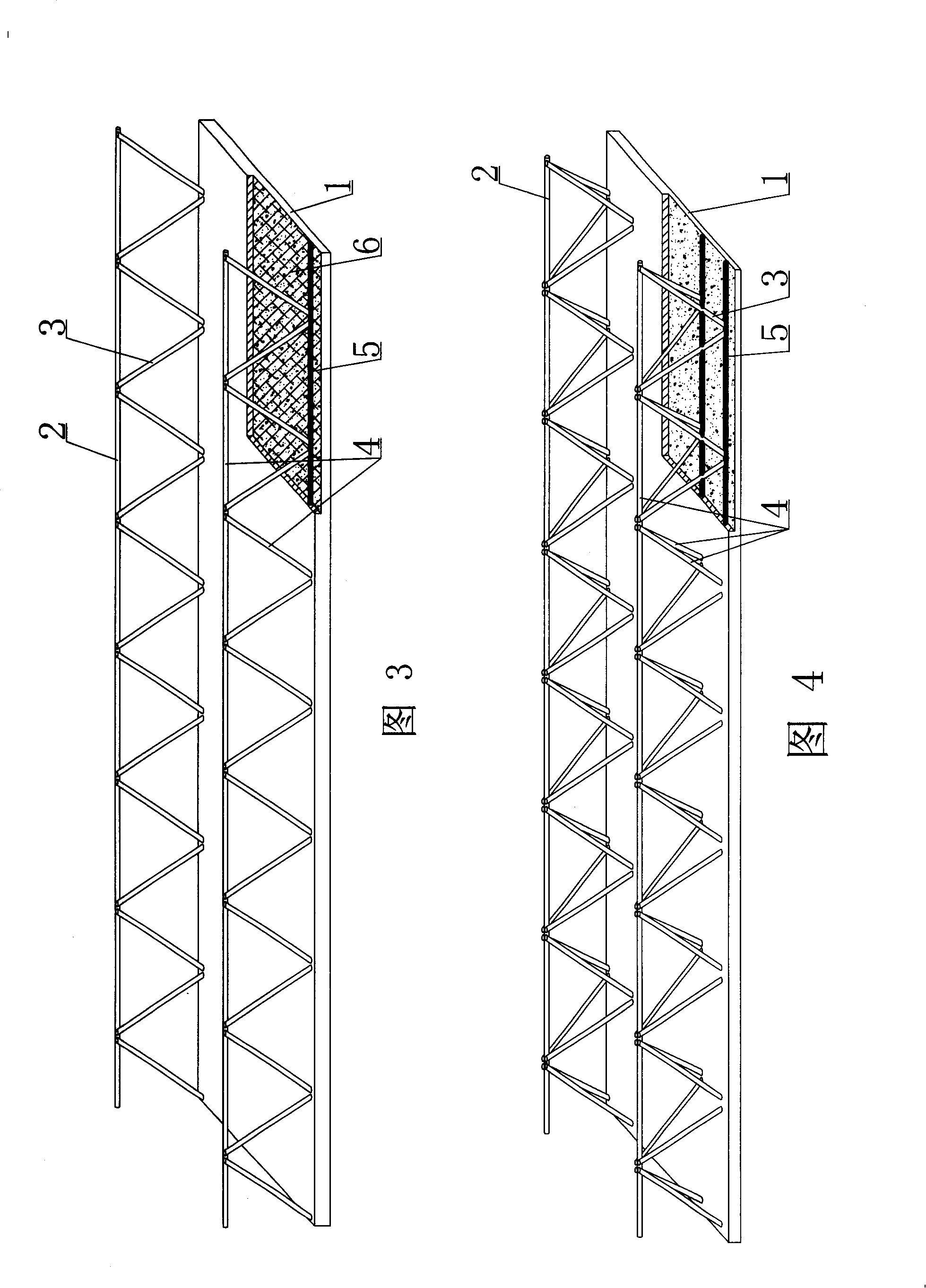

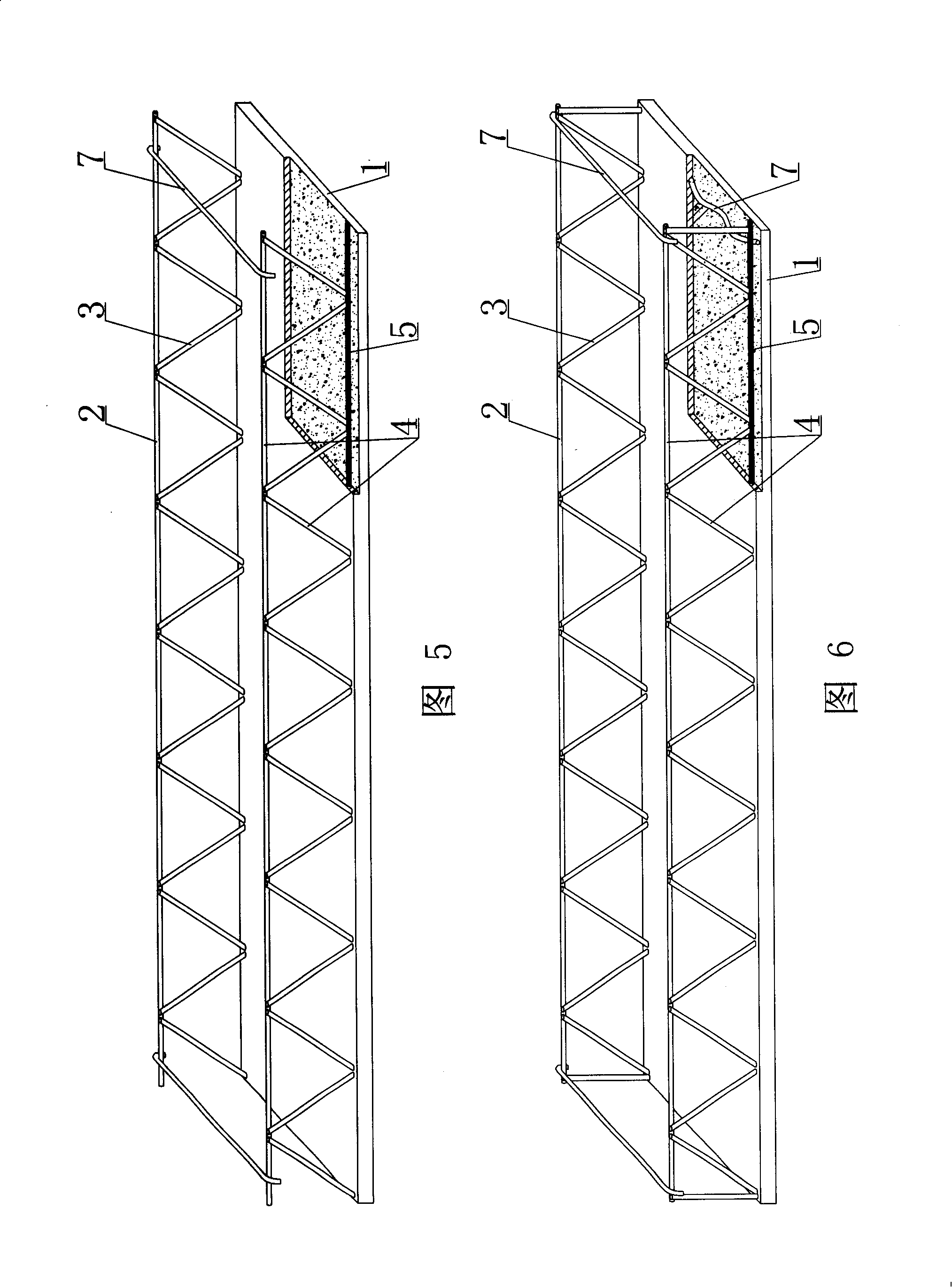

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

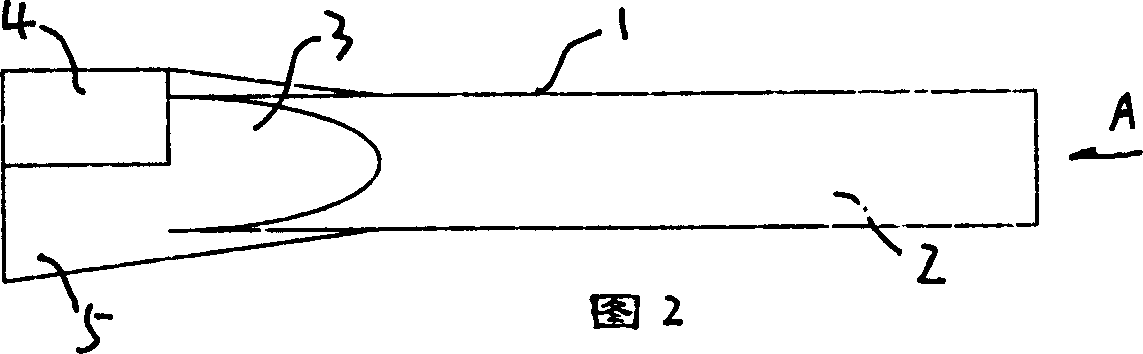

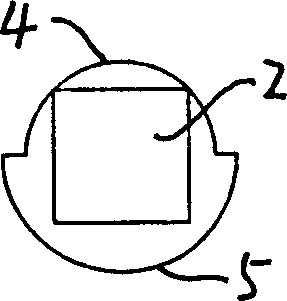

Openable skirt type steel reinforcement cage of reamed pile

The invention discloses an openable skirt type steel reinforcement cage of a reamed pile and belongs to piling building materials. According to the openable skirt type steel reinforcement cage, a reaming section of a pedestal pile has a horizontal expansion function, the reinforced concrete structure forms of the existing rotary expanding piles are changed, and the load capacity of the rotary expanding piles is increased; the steel reinforcement cage is unfolded at the bottom of a hole through a plurality of link mechanisms, the appearance of the unfolded steel reinforcement cage is basically similar to the contour of the reamed hole, the link mechanisms are simultaneously opened and are connected with an existing steel reinforcement cage through steel stranded wires, then, concrete is cast, the link mechanisms serve as steel reinforcement members, and thus, the strength of concrete members of rotary expanding pile bodies is enhanced.

Owner:XUZHOU LEHMAN MASCH TECH CO LTD

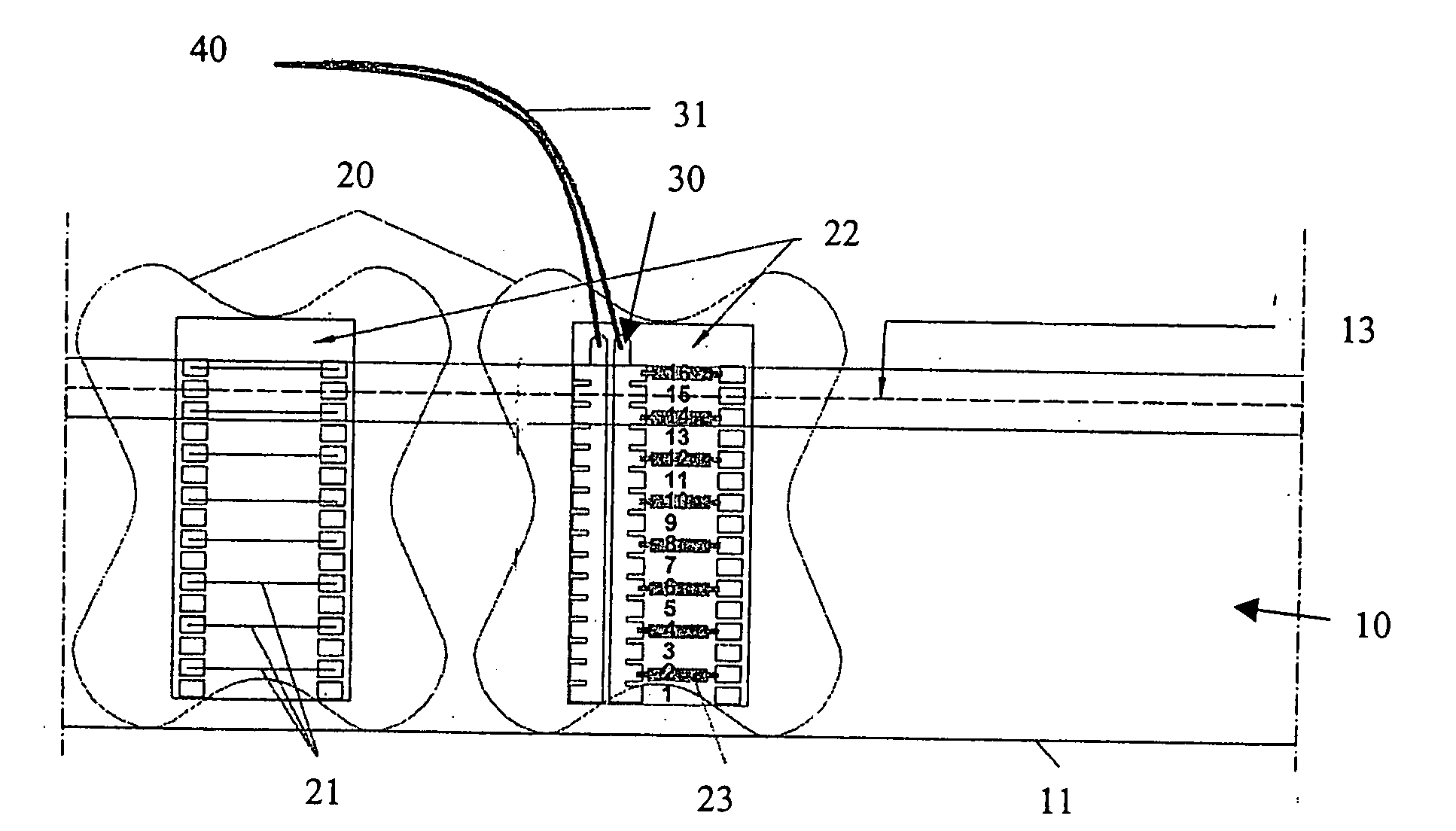

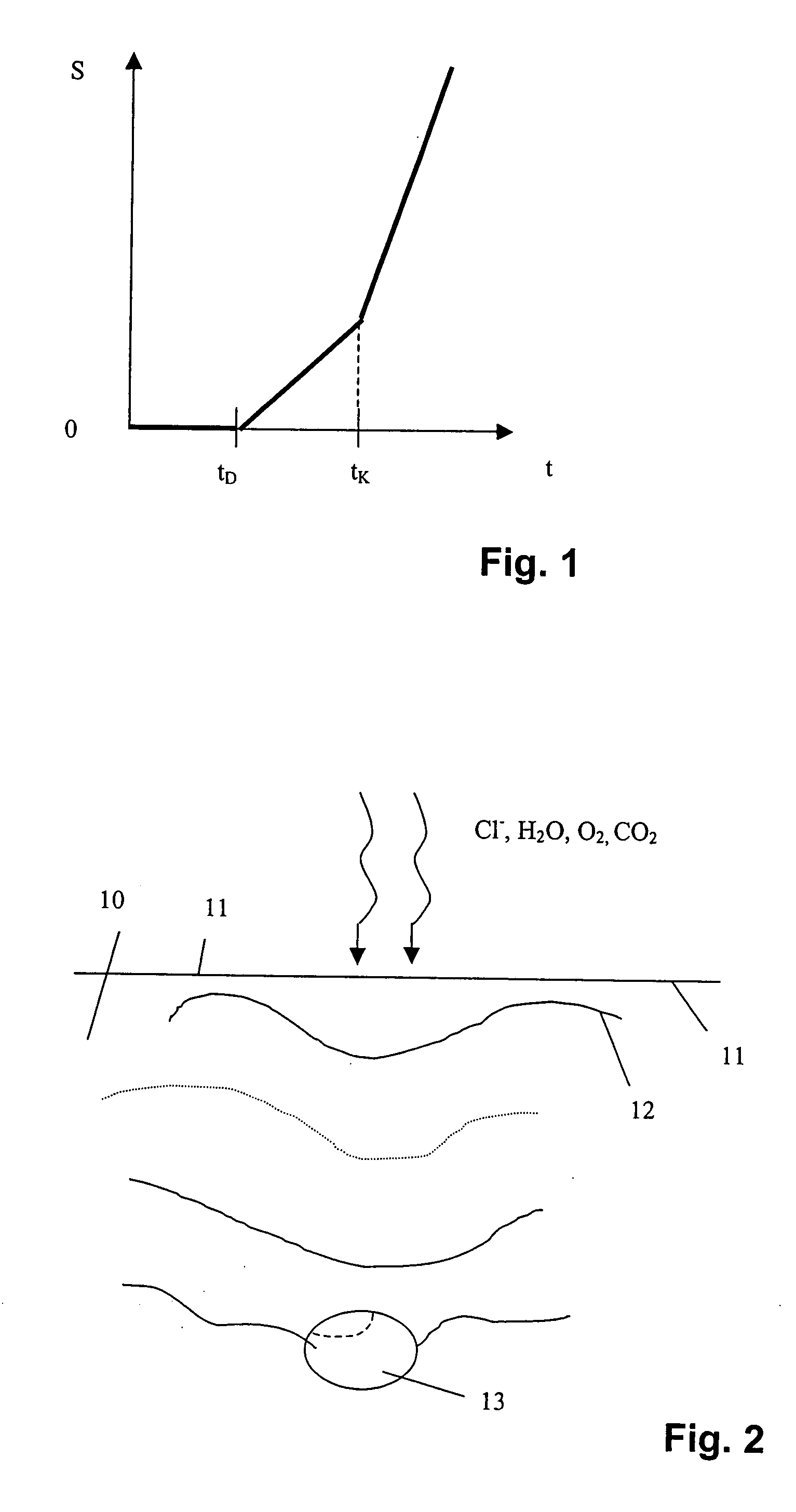

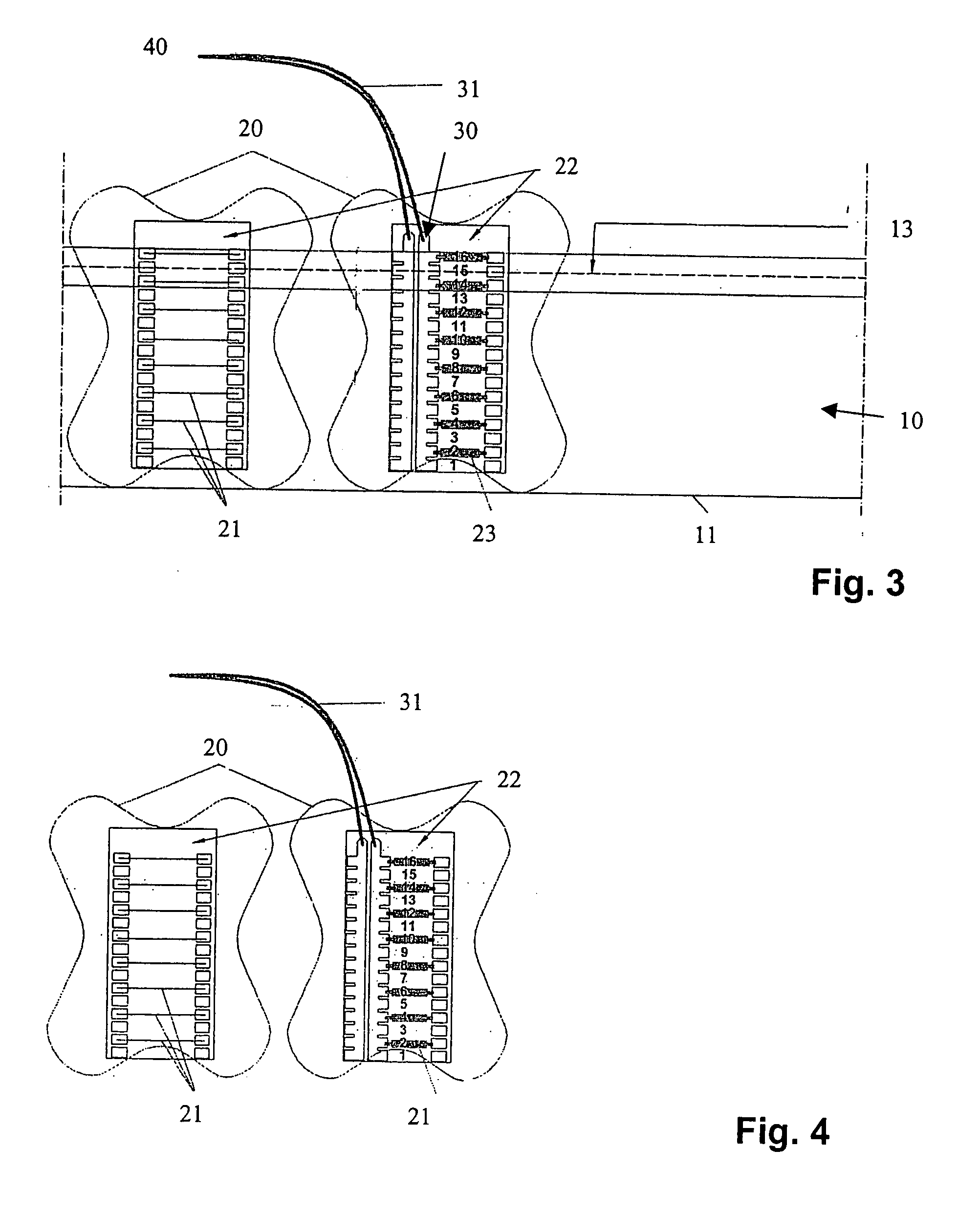

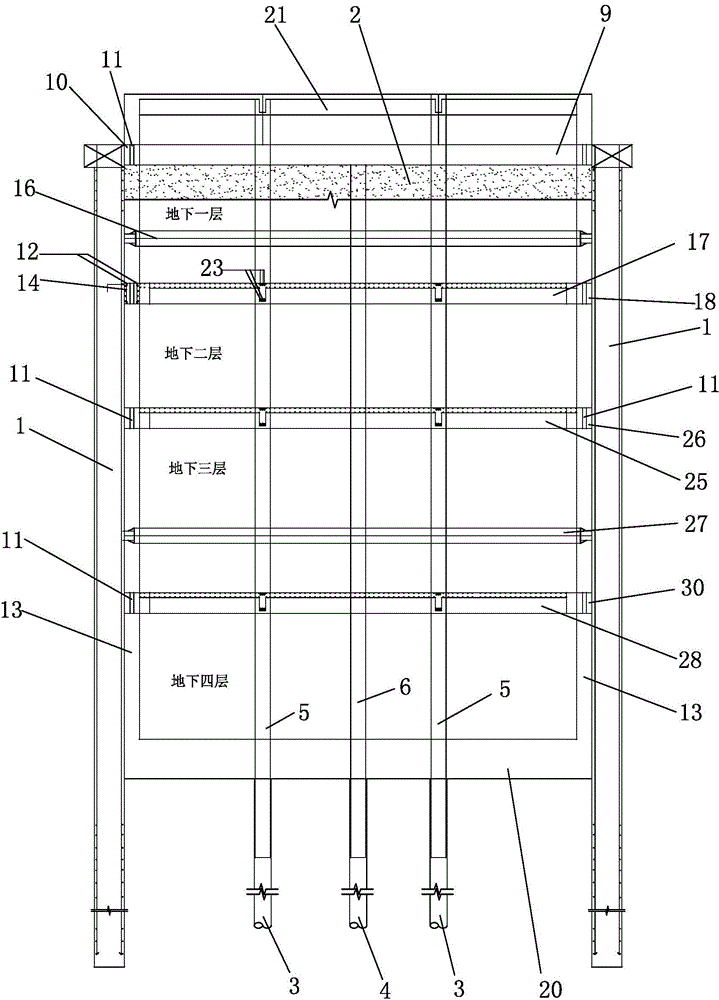

Device for detecting the state of steel-reinforced concrete construction parts

InactiveUS20080136425A1Small constructionPrecise positioningWeather/light/corrosion resistanceResistance/reactance/impedenceRebarReinforced concrete

Owner:BRAUNSCHWEIG UNIVERSITY OF TECHNOLOGY

Piezomagnetic turbine loss type reinforced concrete strain sensor and piezomagnetic stain meter thereof

InactiveCN101806577AHigh sensitivityImprove stabilityForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsObservational errorCantilevered beam

The invention discloses a piezomagnetic turbine loss type reinforced concrete strain sensor, and is characterized in that a piezomagnetic turbine loss effect is used as a sensing mechanism to manufacture a piezomagnetic turbine loss type reinforced concrete strain sensor and a piezomagnetic stain meter thereof for measuring surface strain, inner strain and steel bar strain. The sensor is designed with a mechanics model and a deformation structure of a combined cantilever beam or a cantilever curved beam with two elastic free ends. The invention uses a seamless connection technology of whole manufacturing and conical hole connection and a component separation signal processing method. Compared with the prior art, the invention has the characteristics of high sensitivity, good stability, small measuring error, strong reliability, simple structure, low cost and convenient use; and the invention has wide application prospect.

Owner:何思龙

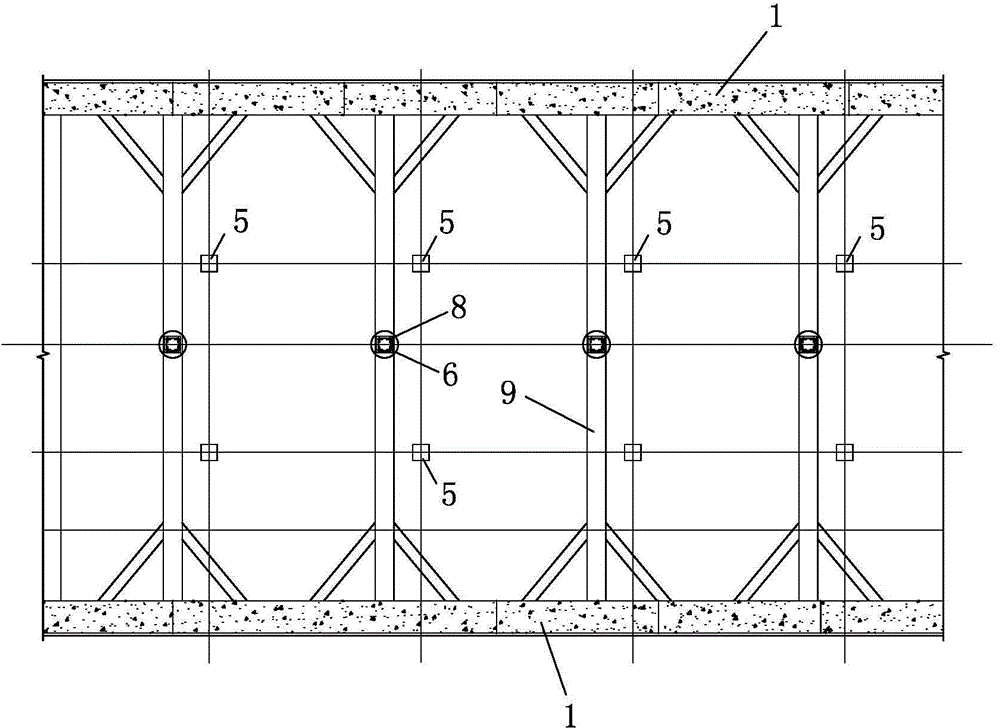

Construction method of structural system with structural floors as horizontal braces

InactiveCN104631466AControl and reduce distortionImprove securityExcavationsPurlinReinforced concrete

Owner:TIANSONG CONSTR GRP

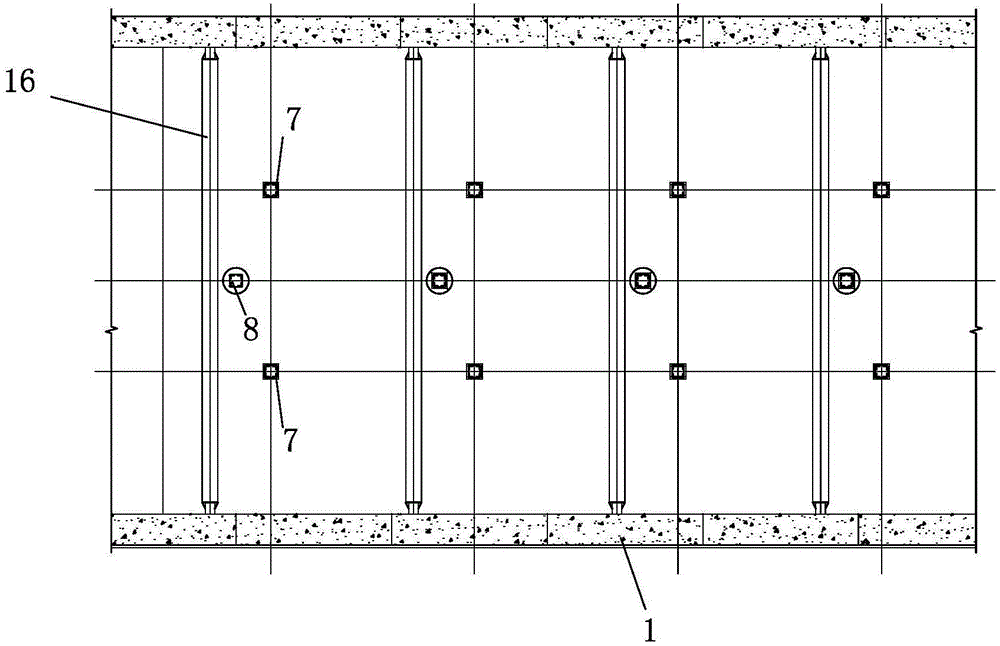

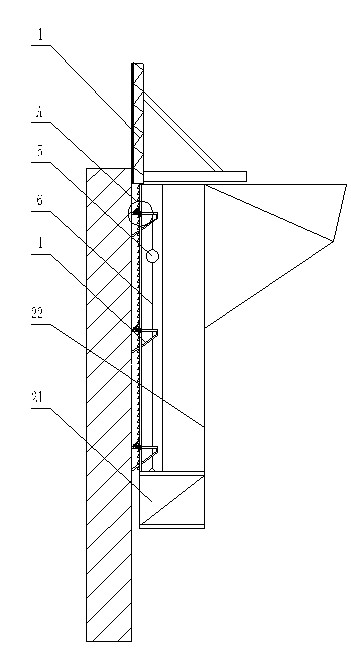

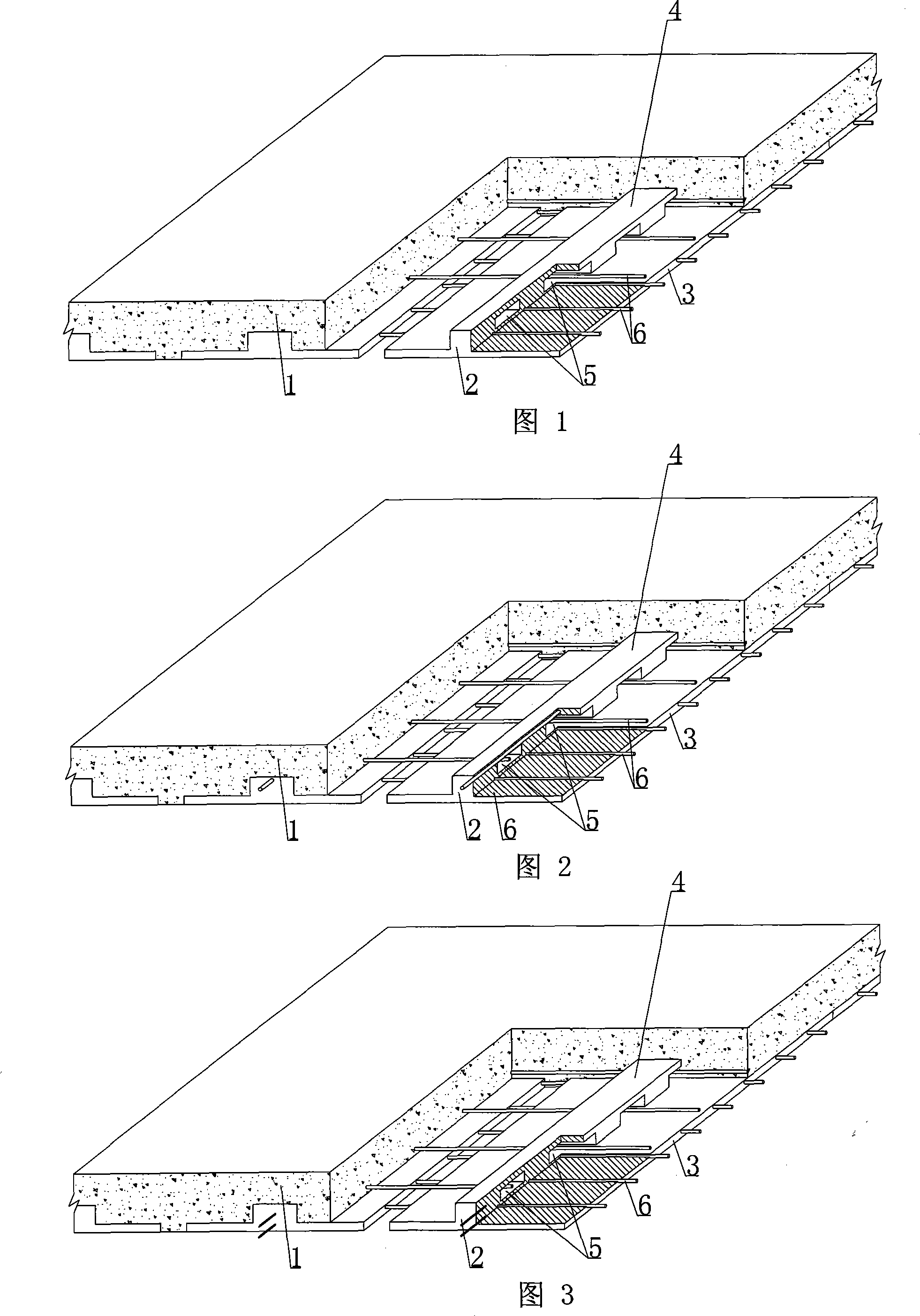

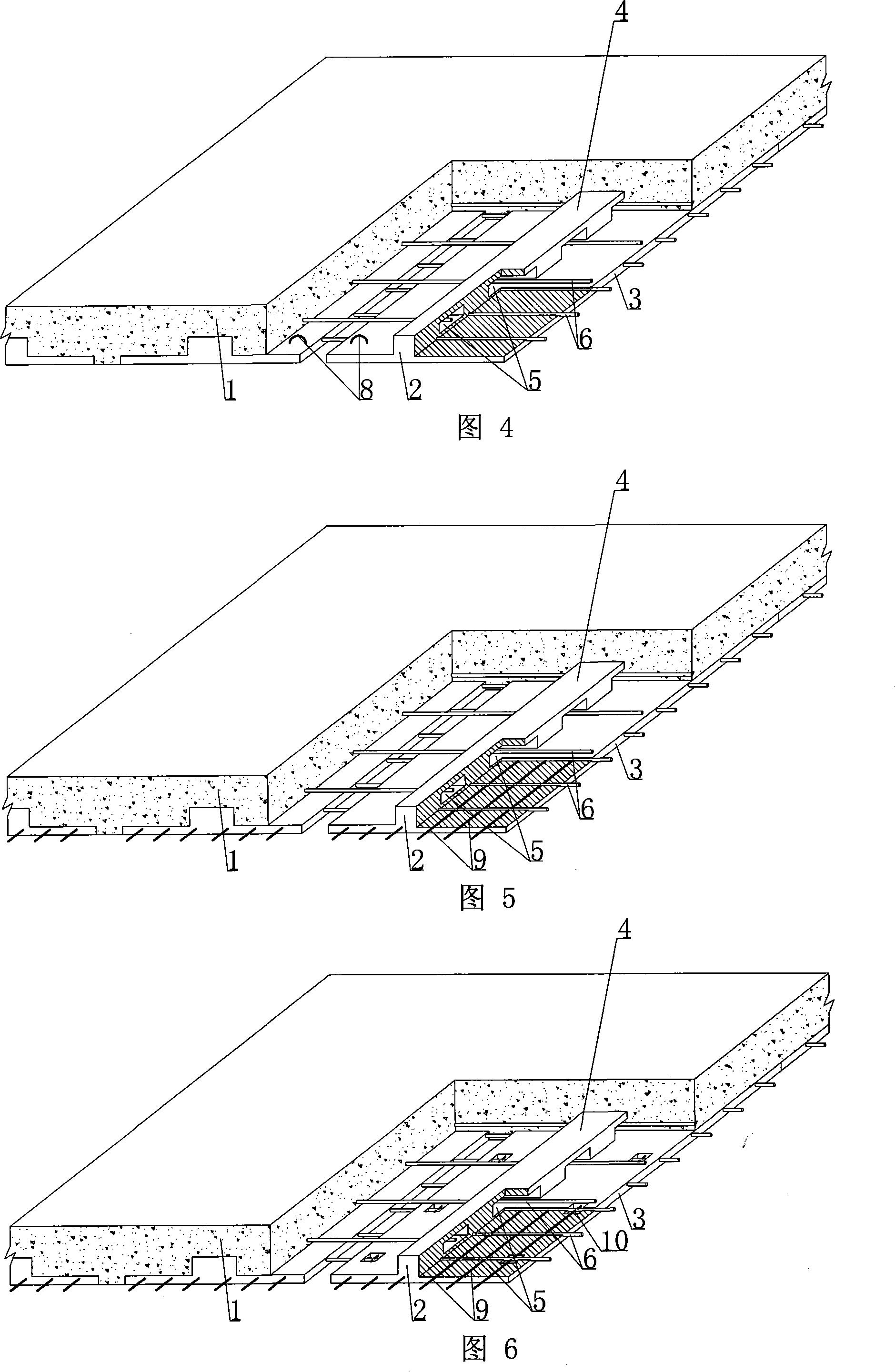

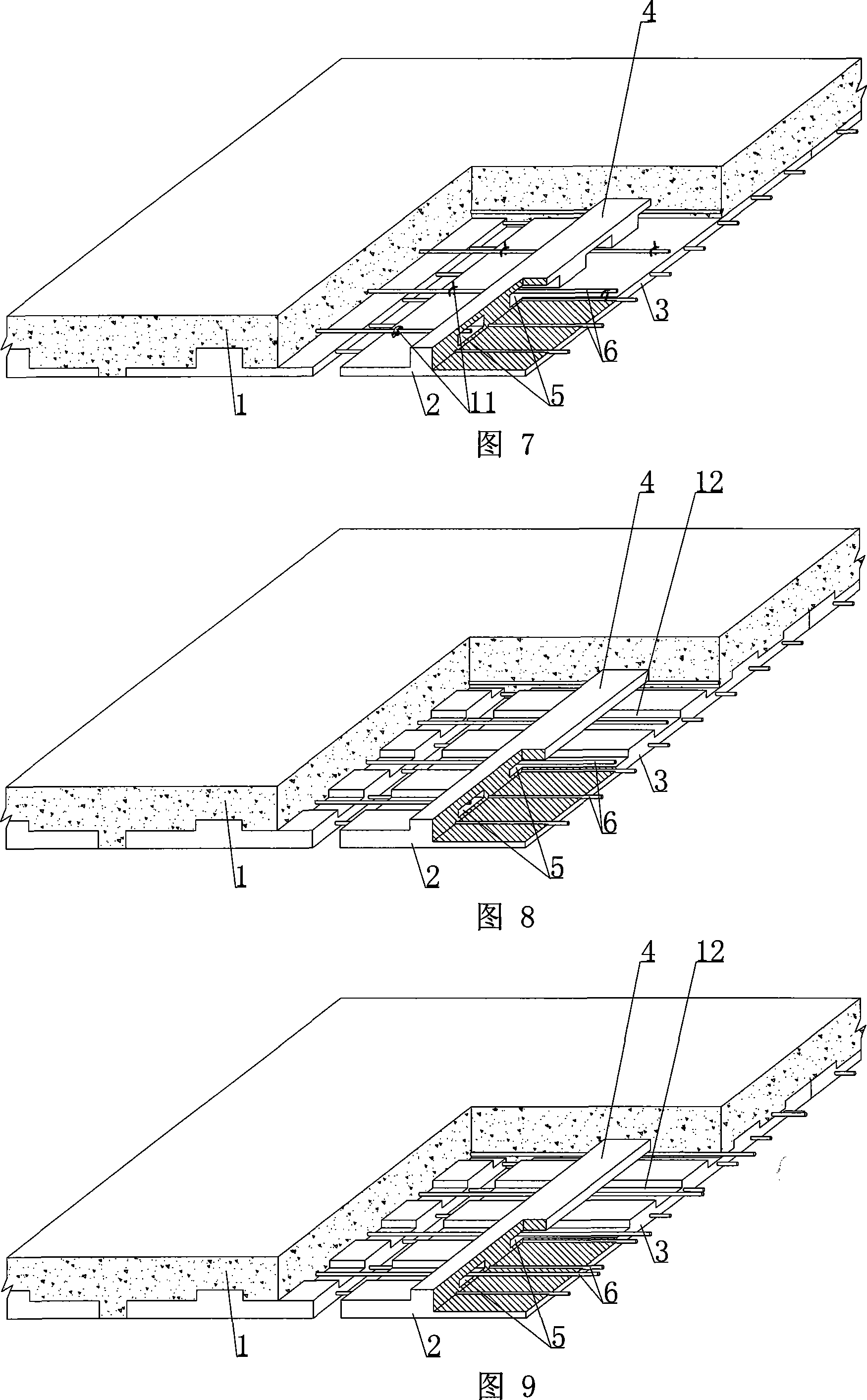

Hollow composite floor slab and construction method thereof

InactiveCN104612300AImprove construction efficiencyEasy to transportFloorsReinforced concreteCrack resistance

The invention discloses a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab comprises a prefabricated hollow bottom plate and an upper cast-in-place slab, continuous fully-closed preformed holes and semi-closed preformed holes are distributed in the prefabricated hollow bottom plate at intervals, or the continuous fully-closed preformed holes and plate ribs are distributed on the prefabricated hollow bottom plate at intervals, bottom plate rebars are distributed on the prefabricated hollow bottom plate at intervals in the longitudinal direction and the transverse direction, prestress rebars or prestress rebars and non-prestress rebars distributed at intervals are adopted as the bottom plate rebars, and the rebars penetrate through the semi-closed preformed holes or plate rib preformed holes. Concrete is poured on the prefabricated hollow bottom plate to form the upper cast-in-place slab, multiple sets of top rebars are distributed on the cast-in-place slab in the longitudinal and the transverse directions parallel to the bottom plate at intervals, and reinforced concrete is integrally poured on the bottom plate to form the hollow composite floor slab. Only the prefabricated bottom plate needs to be produced and transported, transportation and installation are convenient and fast, formworks are not needed, the crack resistance and the integrity are good, and the construction efficiency is high.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Creeping formwork platform

InactiveCN102155091AReduce weightImprove reliabilityForms/shuttering/falseworksRebarReinforced concrete

The invention relates to a cast-in-place reinforced concrete template, in particular to a creeping formwork platform. The platform comprises a template body, a creeping formwork, a guide rail and an anti-falling and anti-inclining supporting seat, wherein the template body is arranged at the upper part of the creeping formwork, the guide rail is vertically fixed on the creeping formwork, and the anti-falling and an-inclining supporting seat is arranged on a building and is matched with the guide rail; the creeping formwork platform is characterized in that an electric block is arranged below the anti-falling and anti-inclining supporting seat and is connected with the bottom of the creeping frame through a chain; the framework body of the creeping formwork platform adopting the technical scheme is light and has high reliability; moreover, the cost is relatively lower.

Owner:NORNOVA GRP

Reinforced concrete windowsill coping adverse construction method

The invention relates to a reinforced concrete windowsill coping adverse construction method comprising the following steps: (1) making pre-cast reinforced concrete building blocks; (2) removing a form; (3) maintaining the pre-cast reinforced concrete building blocks; (4) laying a masonry; (5) burying the pre-cast reinforced concrete building blocks; (6) welding windowsill coping reinforcing steel bars with reinforcing steel bars reserved for the reinforced concrete building blocks; (7) making a template; and (8) processing the joint of the template and the wall. The reinforced concrete windowsill coping adverse construction method can ensure that the reinforced concrete windowsill coping construction is not restricted by the length of the windowsill coping, guarantee the compact construction joint and greatly improve the windowsill coping construction progress and the windowsill coping construction quality. In addition, the reinforced concrete windowsill coping adverse construction method is simple and is convenient to operate. Moreover, the reinforced concrete windowsill coping adverse construction method uses the filed concrete construction residual material to make the pre-cast reinforced concrete building blocks, thereby causing no pollution to the environment and saving the energy and the windowsill coping construction cost.

Owner:WENZHOU ZHONGCHENG CONSTR GRP CO LTD

Steel plate externally-rived stengthening method for reinforced concrete structure and its special-purpose rivet

InactiveCN1460763AImprove bearing capacityImprove reinforcementBuilding repairsBridge erection/assemblyReinforced concreteSheet steel

Owner:郑州长建工程技术开发有限公司

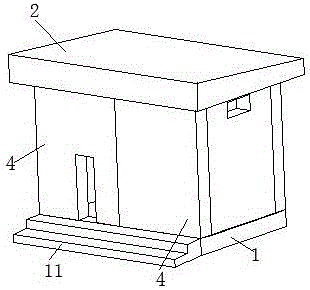

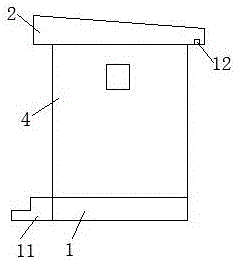

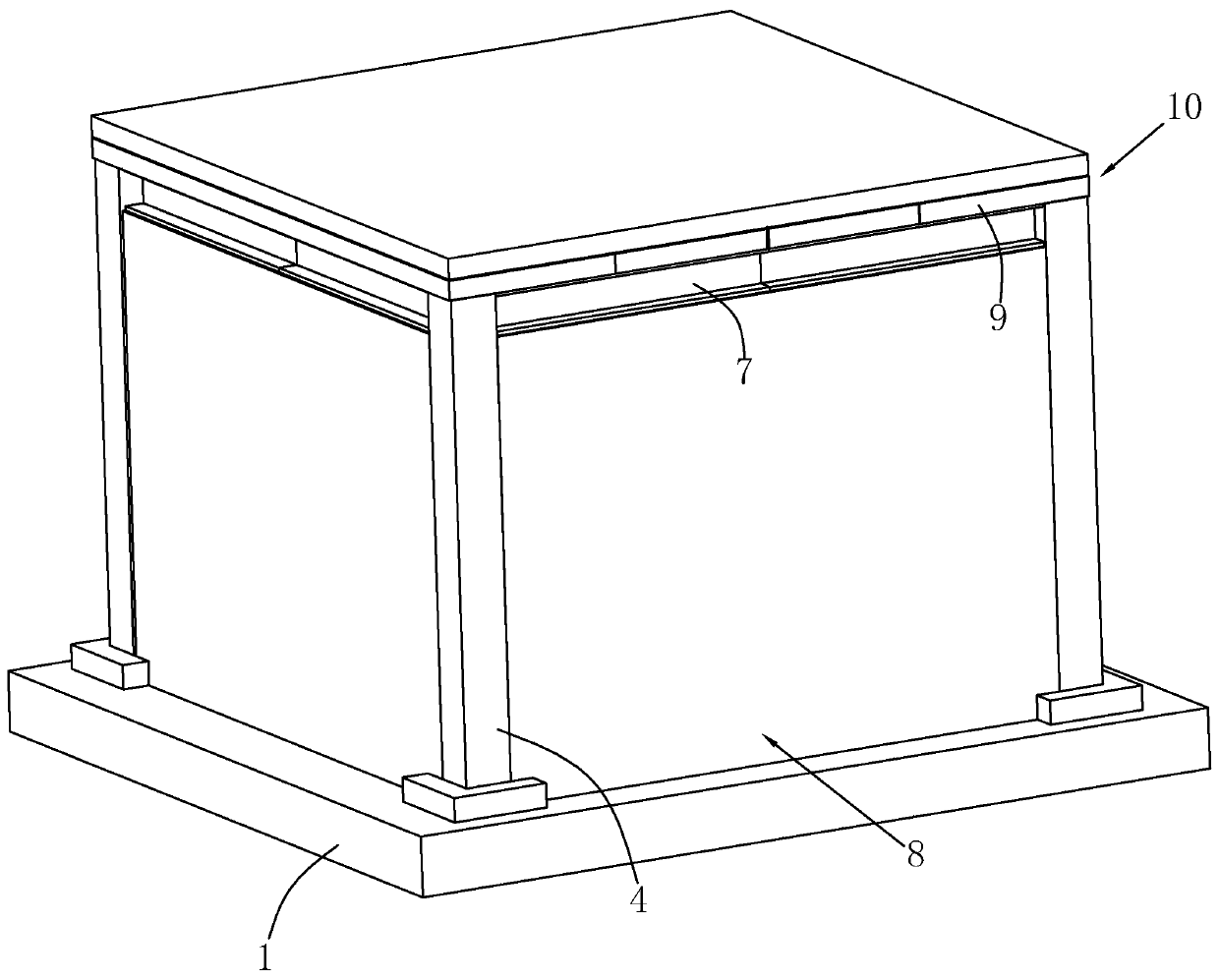

Pitched roof assembly type communication machine room

Owner:人天通信集团有限公司

Reinforcement method for broken damage of power transmission and transformation reinforced concrete pole

InactiveCN107989392AMeet the fixLimit hoop tensile strainBuilding repairsElectric power transmissionTensile strain

The invention discloses a reinforcement method for broken damage of a power transmission and transformation reinforced concrete pole. After clearing away loose concrete at a broken place of the concrete pole, the broken power transmission and transformation reinforced concrete pole can be reinforced by electrification through the application of forming of a repairing concrete layer, installation of a pre-stressed steel pipe on the outer layer, crack sealing of the concrete pole, overall appearance corrosion protection, and the installation of a pre-stressed steel hoop; and the axial bearing capacity and the bending resistance of the concrete pole can be effectively reinforced, the repair of the large-area damaged cement pole can be fulfilled, and the tensile strain in the circumferential direction of a pre-stressed electric pole after bearing the axial load can be effectively limited, thereby limiting the expansion and formation of longitudinal cracks.

Owner:SHANDONG ELECTRIC POWER IND BOILER & PRESSURE VESSEL INSPECTION CENT CO LTD +2

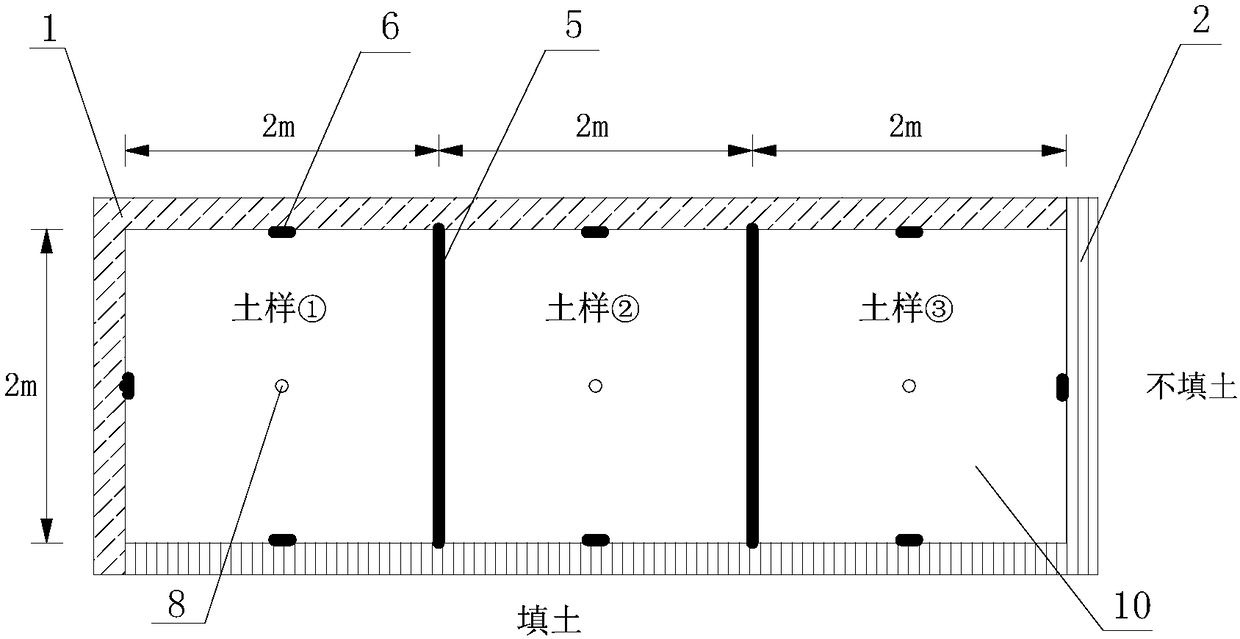

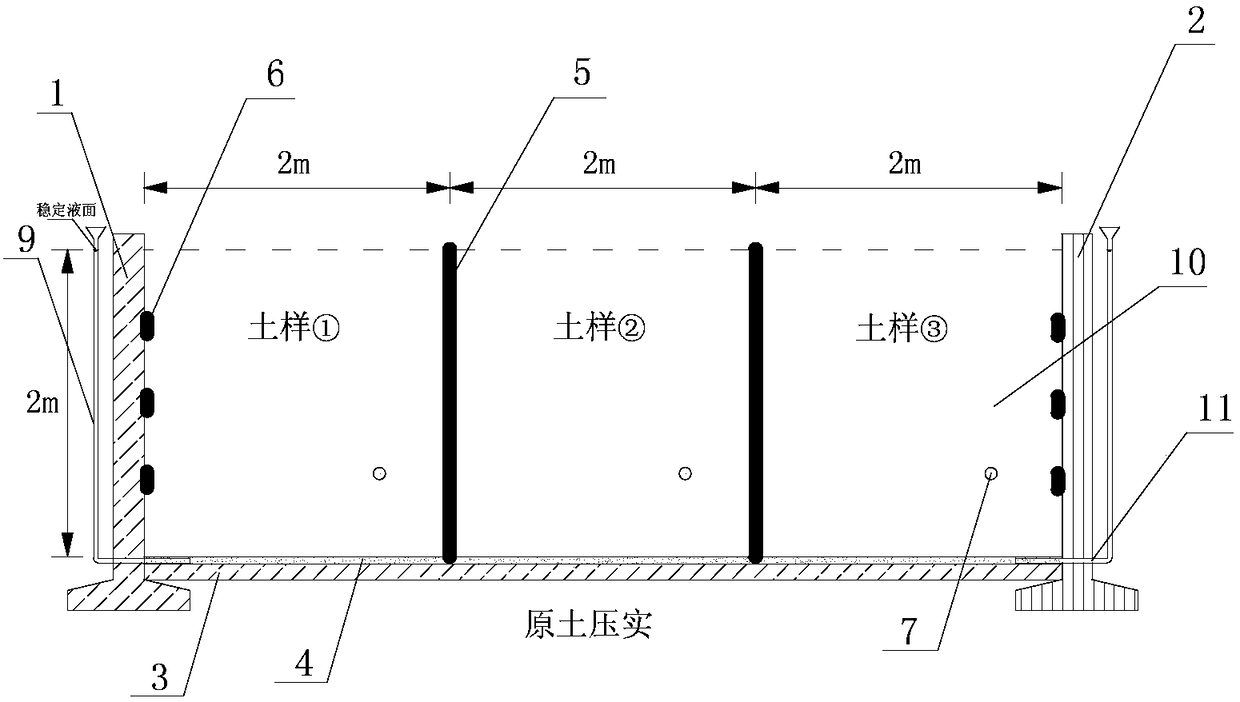

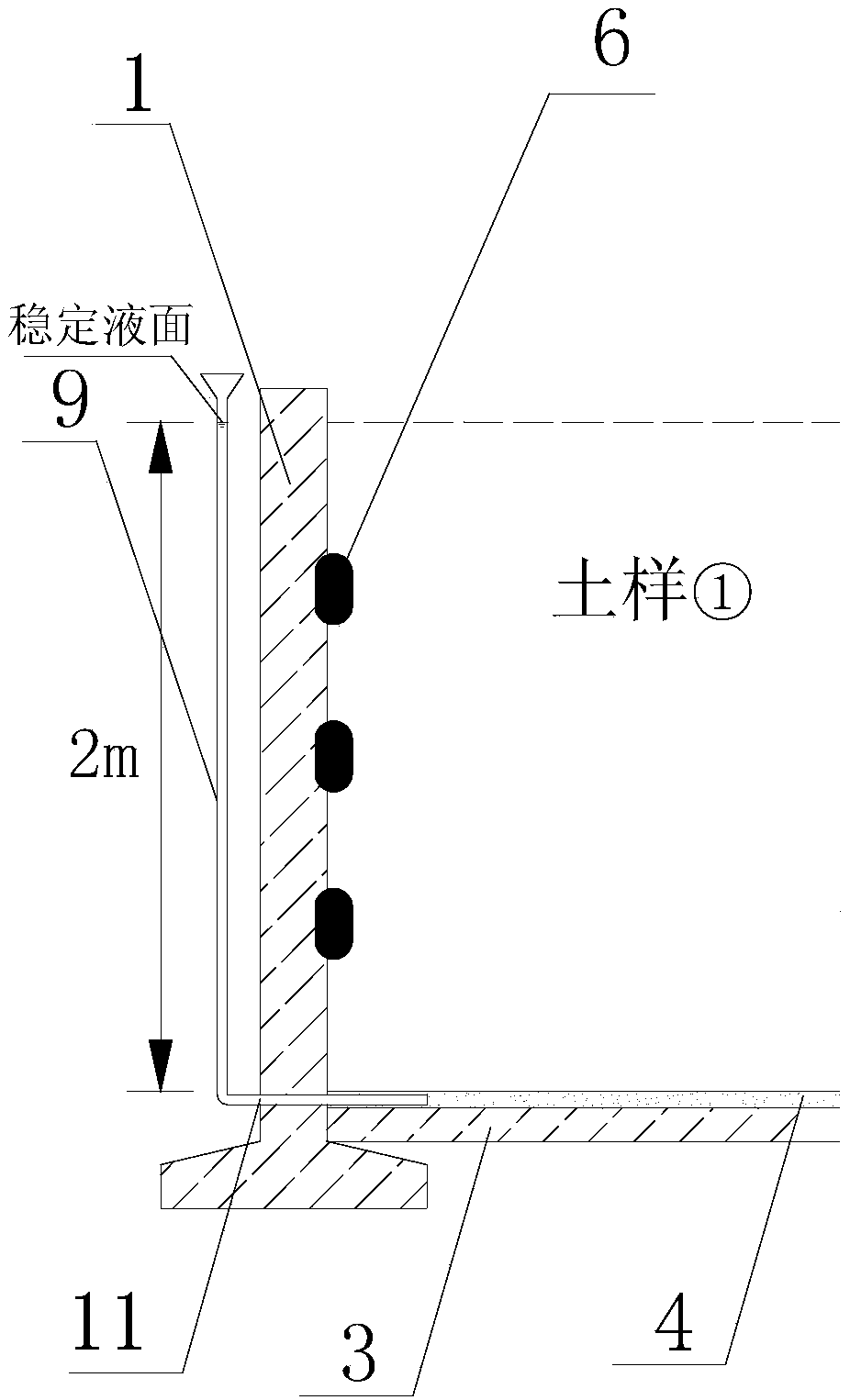

Multifunctional testing apparatus for on-site determination of expansion of sulfuric acid salinized soil saline

ActiveCN108333329AMeasured expansion rateMeasured expansion forceEarth material testingSoil scienceReinforced concrete

Owner:ANHUI GOLDENLAND ARCHITECTURAL DESIGN

Laminated slab

Owner:邱则有

Anticorrosive coating material for reinforced concrete, preparation method and applications thereof

ActiveCN108300166AAvoid corrosionReduce film thicknessAnti-corrosive paintsEpoxy resin coatingsRebarPhenol

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

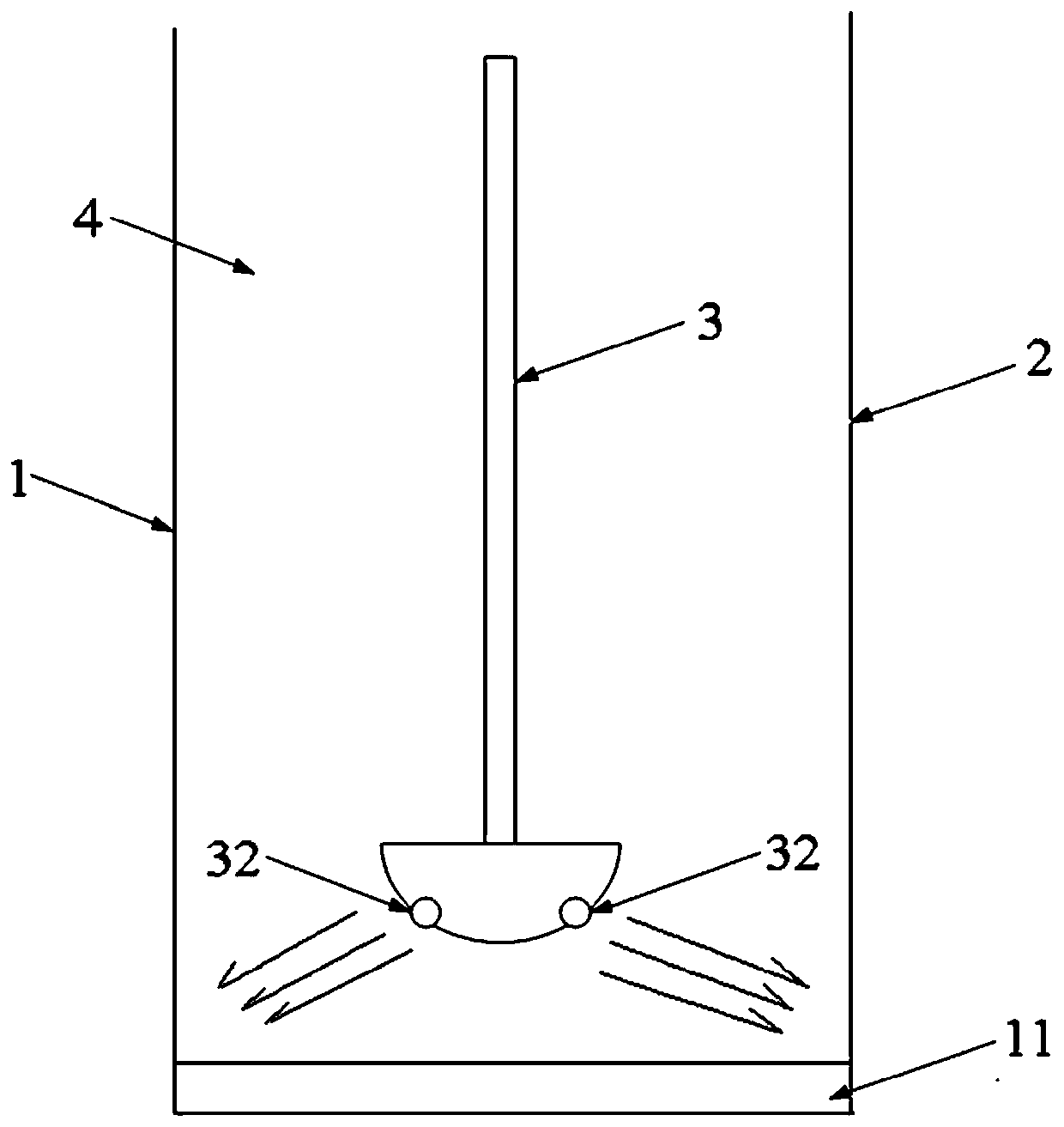

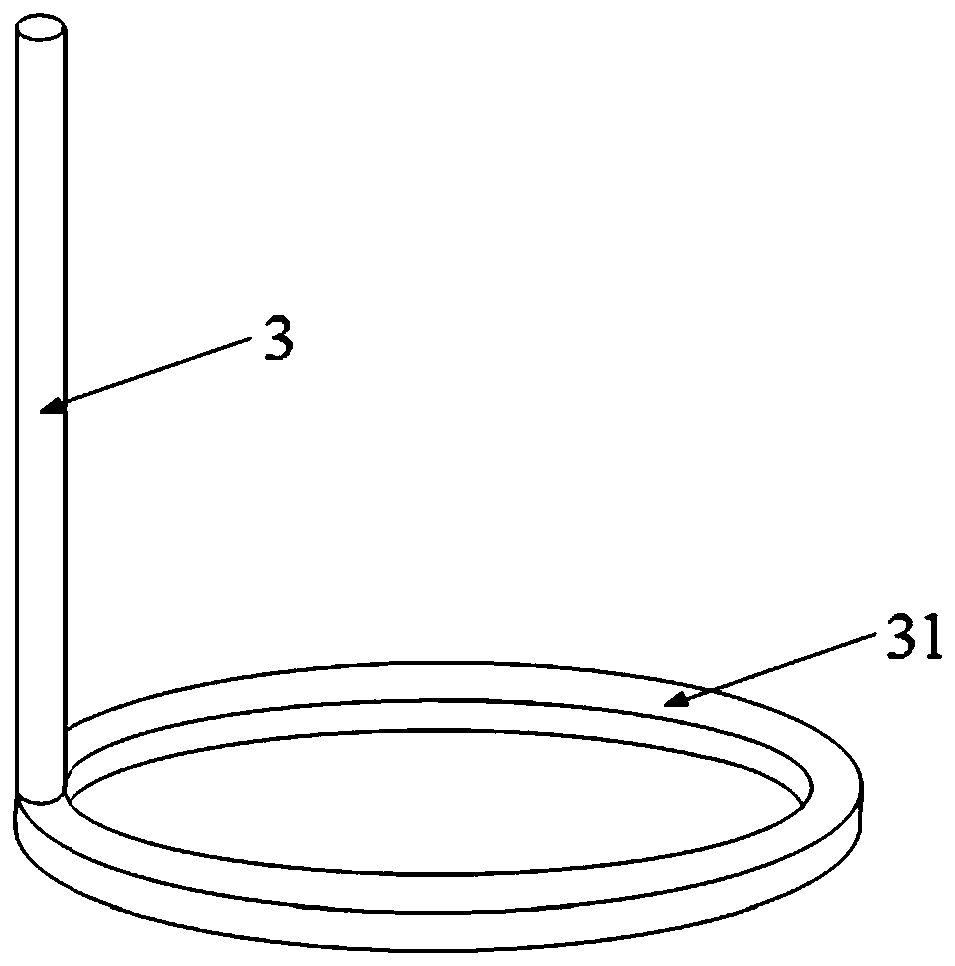

Reinforced concrete intelligent stirring device

InactiveCN111300641AQuality improvementAvoid pollutionMixing operation control apparatusIngredients proportioning apparatusReinforced concreteElectric machine

The invention provides a reinforced concrete intelligent stirring device. The reinforced concrete intelligent stirring device comprises a stirring device, a stirring motor mounted on one side of the stirring device, a first hopper, a second hopper, two discharging barrels, weighing assemblies, a cement feeding assembly, a sand feeding assembly, a cement stock bin and a sand stock bin, wherein thefirst hopper and the second hopper are located above the stirring device; the two discharge barrels are installed on the bottom side of the first hopper and the bottom side of the second hopper respectively, the weighing assemblies are installed at the bottom sides of the discharge barrels; the cement feeding assembly is connected with the top side of the first hopper, and the sand feeding assembly is connected with the top side of the second hopper; and the cement stock bin is connected with the cement feeding assembly, and the sand stock bin is connected with the sand feeding assembly. The reinforced concrete intelligent stirring device has the advantages of being high in intelligence degree and high in precision.

Owner:CHANGDE XIAOPING BUILDING MATERIALS CO LTD

Precast pre-stressed truss type steel-reinforced concrete box

InactiveCN107100063APrecise positioningImprove connection strengthBridgesReinforced concretePre stress

Owner:YANGZHOU POLYTECHNIC INST

Reinforced concrete prefabricated part with reinforced plasticity

Owner:徐州金盟新型建材有限公司

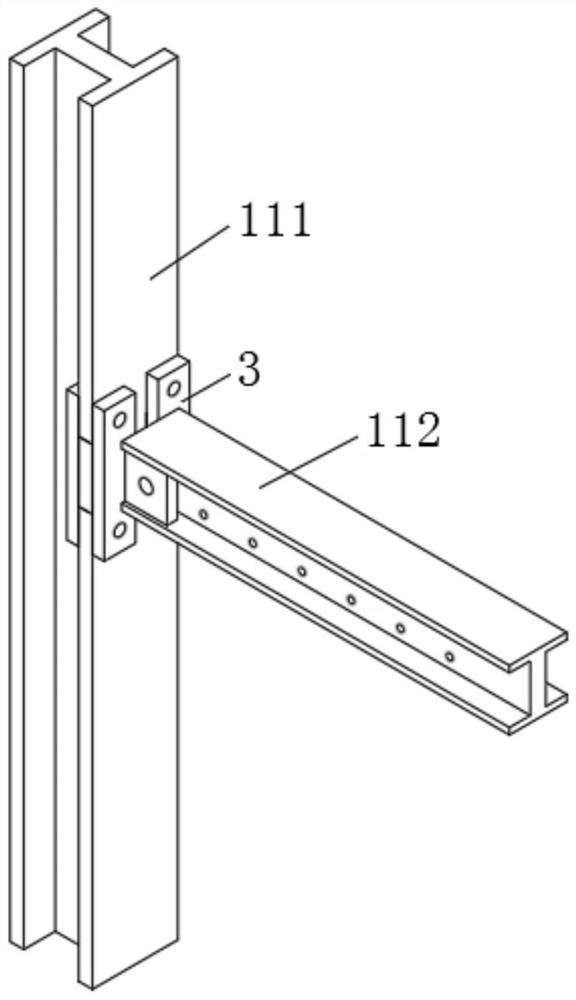

Frame beam steel bar connecting system of profile steel column and concrete and pouring construction method

InactiveCN113062448AAccurate and quick installationReduce labor intensityBuilding reinforcementsBuilding material handlingReinforced concreteClassical mechanics

Owner:潮峰钢构集团有限公司

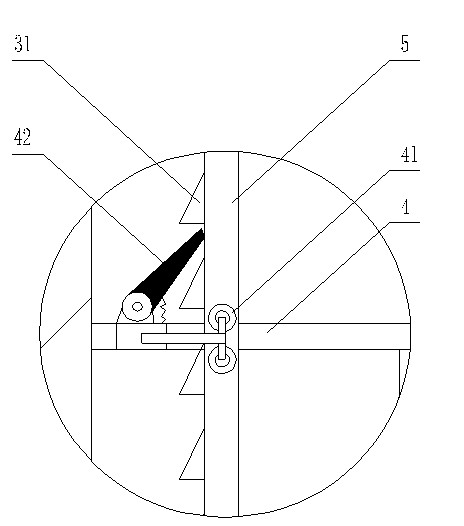

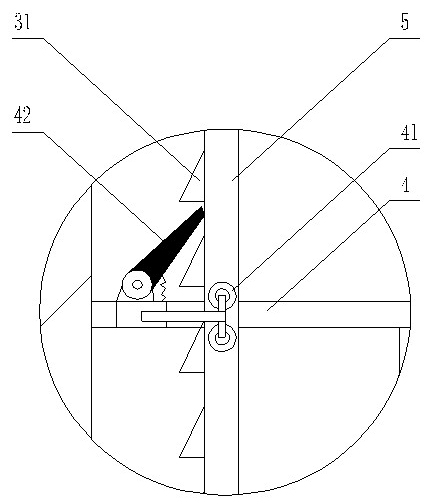

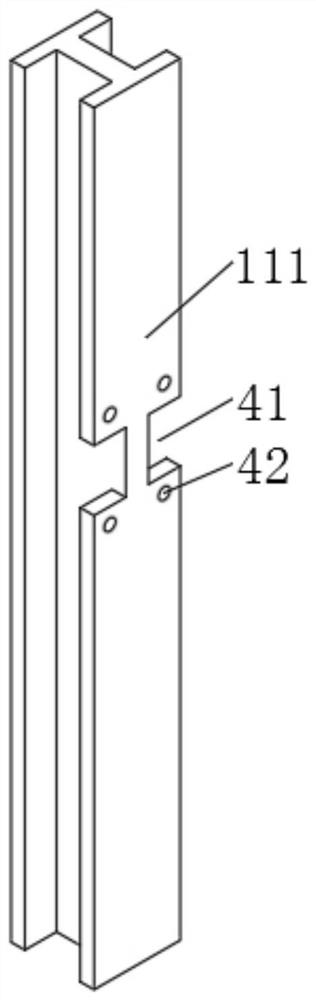

Simple claw type wall connecting part

ActiveCN106437149ADoes not affect the functionSimple structureAuxillary members of forms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a simple claw type wall connecting part. The simple claw type wall connecting part comprises a bearing grabber and a connecting piece in matched connection with the bearing grabber. The bearing grabber is formed by combining three identical single limb grabber bodies in a matched mode. Each single limb grabber body is composed of a hollow screw component obtained after a hollow screw is trisected, and a hook, wherein the hook comprises a straight section and a grabber section, the included angle of the straight section and the grabber section is 45 degrees, and the straight section of the hook is welded to the lower end of the hollow screw component. After combined, the hollow screw components of the three single limb grabber bodies form a complete hollow screw. The simple claw type wall connecting part further comprises embedded sleeves matched with the grabber sections of the hooks. When the claw type wall connecting part is installed, the embedded sleeves are arranged outside the grabber sections and embedded in concrete structures. The claw type wall connecting part has the advantages of being simple in structure, capable of being used circularly after machined and formed, convenient to install and dismantle, low in cost, high in applicability, free of influence on the usage function of reinforced concrete and easy to repair after demolition.

Owner:NO 4 CONSTR ENG CO LTD OF GUANGXI CONSTR ENG GRP

Unbonded prestressed steel reinforced concrete wall and construction method thereof

PendingCN108517985ASolve the problem that the bonding force cannot be guaranteedSimple processWallsBuilding reinforcementsReinforced concretePre stress

The invention discloses an unbonded prestressed steel reinforced concrete wall and a construction method thereof. The concrete wall comprises a concrete wall body, non-prestressed rib meshes, unbondedprestressed rib strands, I-shaped steel and a prestressed rib strand anchoring device. The method comprises the steps of 1, deepening a design drawing; 2, processing and manufacturing the horizontalunbonded prestressed rib strands and the vertical unbonded prestressed rib strands; 3, fixing the I-shaped steel; 4, fixing positioning bracket reinforcing steel bars; 5, binding the unbonded prestressed rib strands; 6, binding the non-prestressed rib meshes; 7, supporting a lateral formwork; 8, pouring and maintaining concrete, and tensioning prestressed ribs; 9, conducting sealed anchoring. Theunbonded prestressed steel reinforced concrete wall solves the problems that in an existing prestressed steel reinforced concrete structure, grouting of bonded prestressed ribs is difficult, and the corrosion prevention of the vertical prestressed ribs and the whole bonding force of the vertical prestressed ribs and concrete cannot be ensured, and the steps of the construction method are simple and convenient.

Owner:CHONGQING CONSTR ENG GRP +1

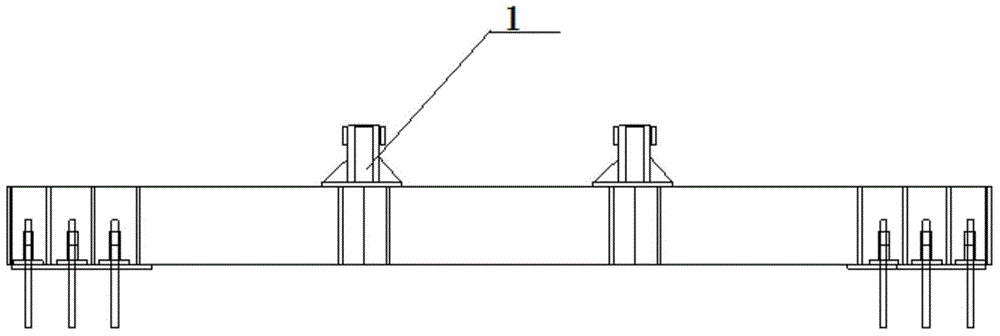

Method for mounting tower crane on top surface of shaped bridge

InactiveCN106149571ALow costReduce standard section usageBridge erection/assemblyReinforced concreteRebar

Owner:WUJIANG CITY MINGGANG ROAD & BRIDGE

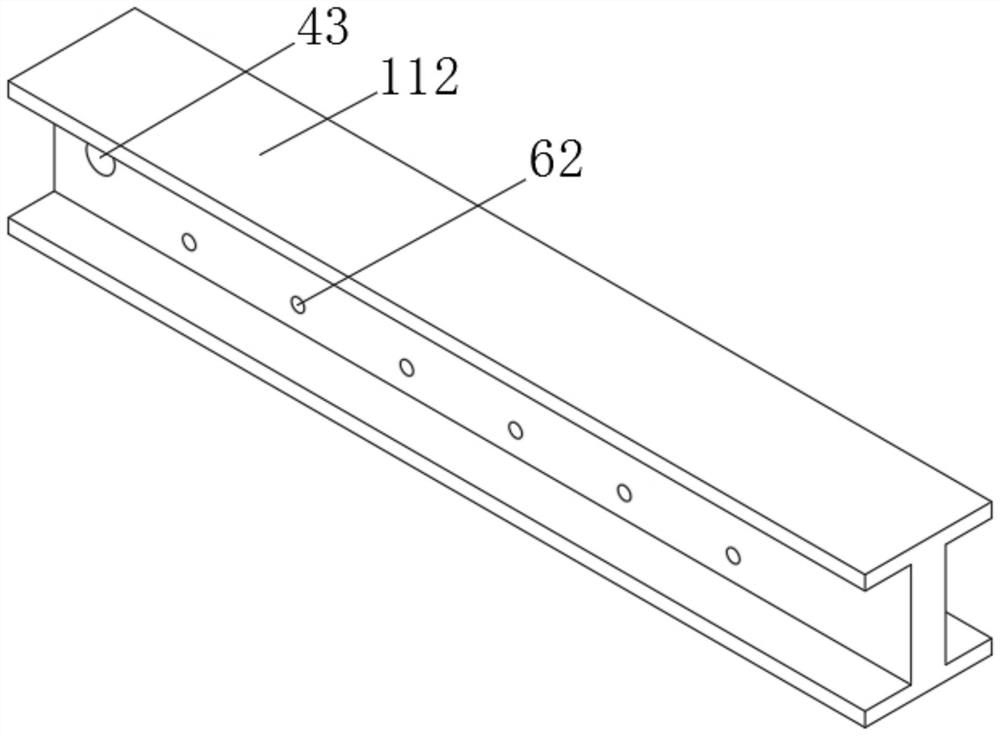

Novel dry type welded joint of fabricated concrete continuous beams

The invention discloses a connecting joint of a prefabricated concrete continuous beams and the connecting joint can be used for connecting the joints of a prefabricated frame structure, and belongs to the technical field of fabricated concrete structure in structural engineering. The connecting joint is characterized by comprising a steel covering plate, a pre-buried steel plate, epoxy resin adhesive and reinforced concrete continuous beams, wherein a testing beam is prefabricated in a factory, two prefabricated beam sections are bonded by the epoxy resin adhesive, and after intensity is achieved, the pre-buried steel plate is spliced with the steel covering plate in a welding mode. The welded joint is suitable for prefabricating the concrete fabricated continuous beams structure, and hasthe advantages of being convenient to construct and environment-friendly and saves energy; and the requirement of sustainable development is met.

Owner:NORTHEAST FORESTRY UNIV

Road-rail layered bridge pier and beam combination structure suitable for multi-span long coupling and large expansion and contraction quantity beams on both sides

PendingCN108797319AReduce the number of basesImprove economyBridge structural detailsReinforced concreteCoupling

The invention relate to the technical field of bridge structures, in particular to a road-rail layered bridge pier and beam combination structure suitable for multi-span long coupling and large expansion and contraction quantity beams on both sides. The road-rail layered bridge pier and beam combination structure suitable for the multi-span long coupling and large expansion and contraction quantity beams on both sides comprises a bearing platform and a bridge pier positioned on the bearing platform, and further comprises a pier-beam combination section and a beam part. The pier-beam combination section is of a reinforced concrete structure cast and fixed at the upper end of the bridge pier, and comprises beam section supporting parts for supporting the multi-span long coupling and large expansion and contraction quantity beams on both sides at two ends in the bridge direction and a beam part supporting part for bearing the beam part in the middle. The beam part is fixed to the beam part supporting part for connecting the multi-span long coupling and large expansion and contraction quantity beams on both sides, an expansion and contraction joint is reserved between the two ends of the beam part in the bridge direction and the multi-span long coupling and large expansion and contraction quantity beams on both sides, and the beam part comprises an upper deck and a lower deck. Thepier and beam combination structure skillfully solves a series of difficult problems caused by the continuous arrangement of multi-span long coupling and long-span bridges through a series of measures, effectively improves the overall arrangement of the bridge hole span, and has reasonable and safe structural stress and good economic benefits.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP CO LTD

Assembly type concrete component mounting method

InactiveCN111456453ASimplify the production and construction processEasy to installWallsFloorsReinforced concreteShaped beam

Owner:豫通工程管理有限公司

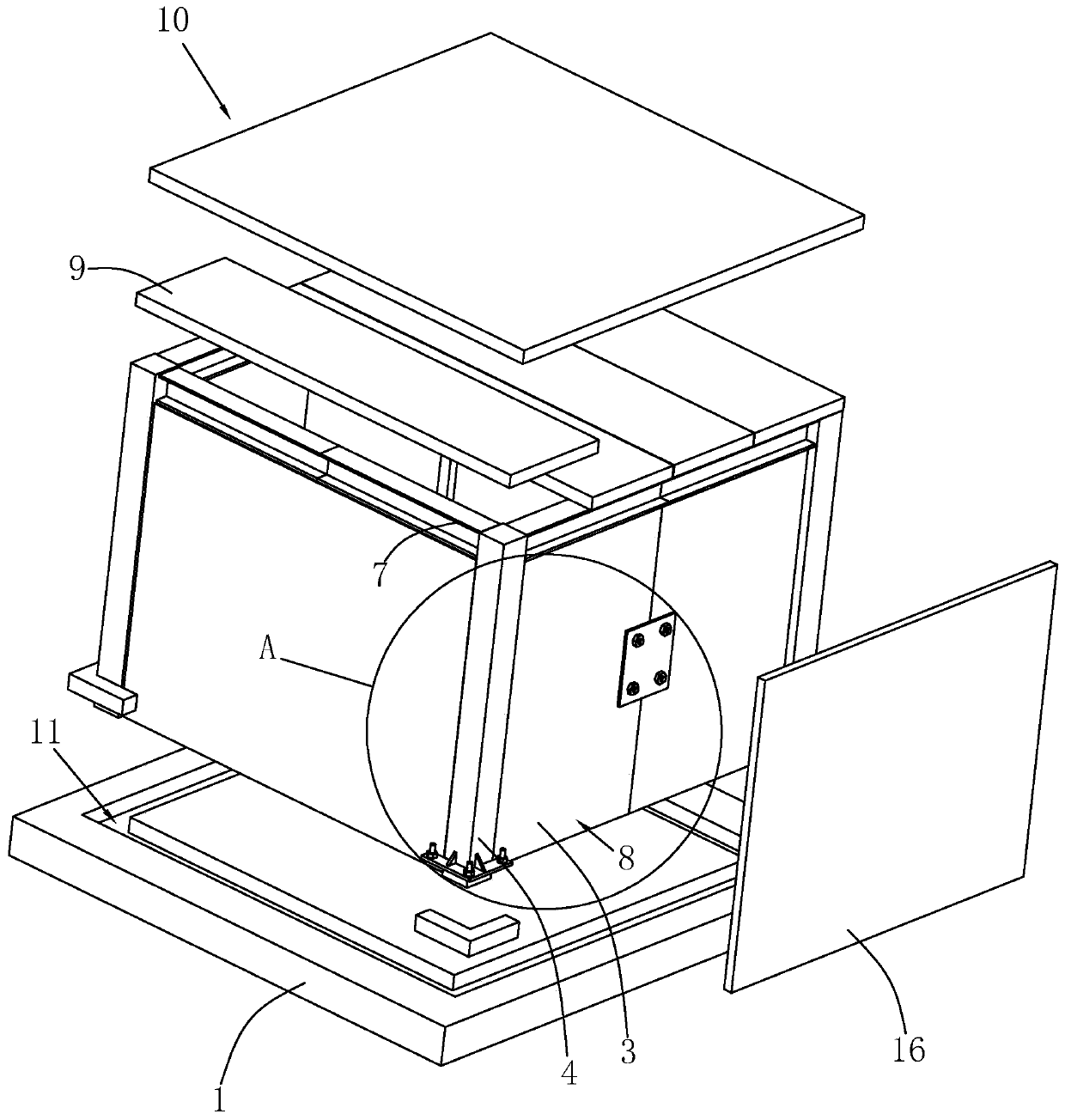

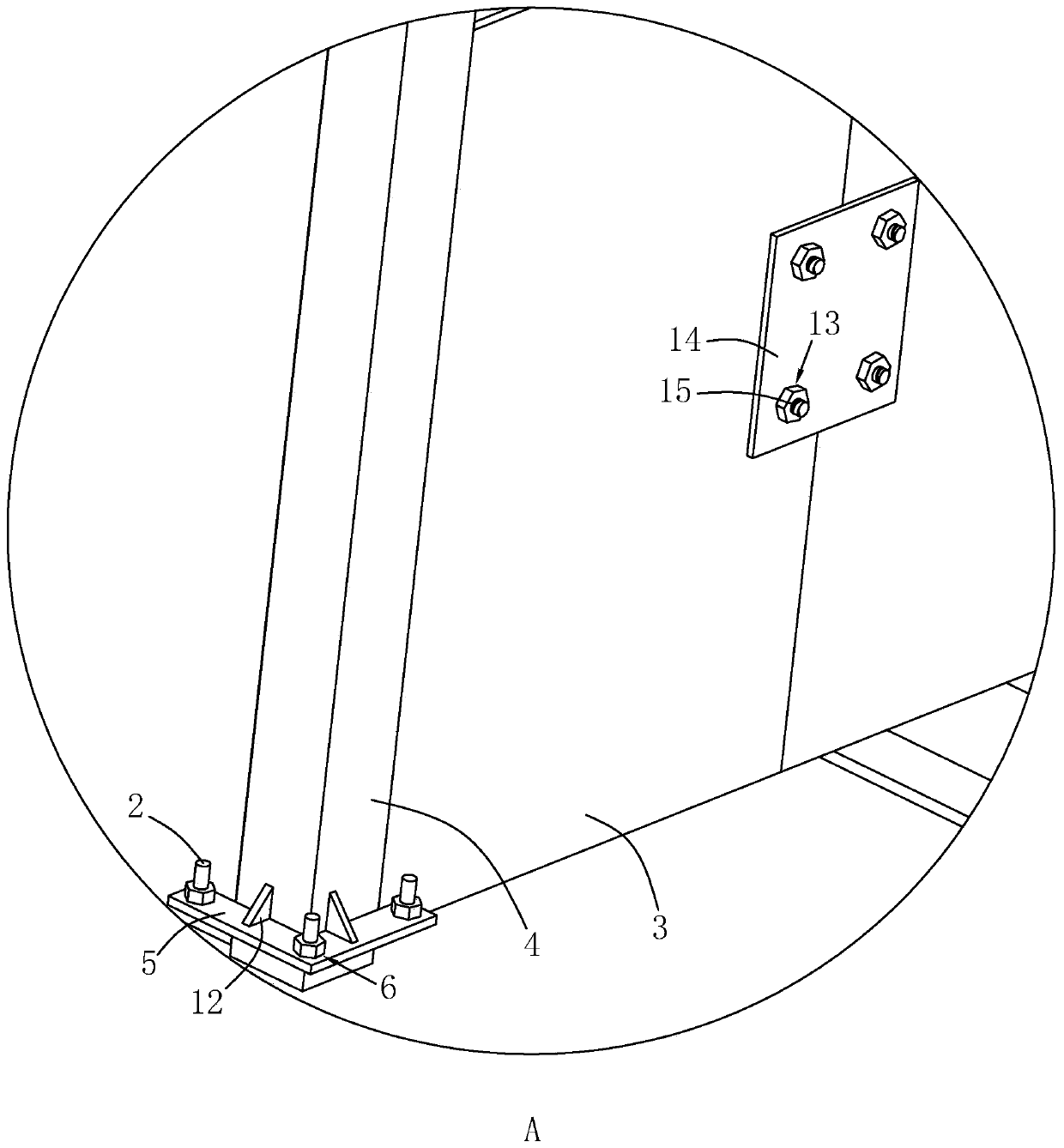

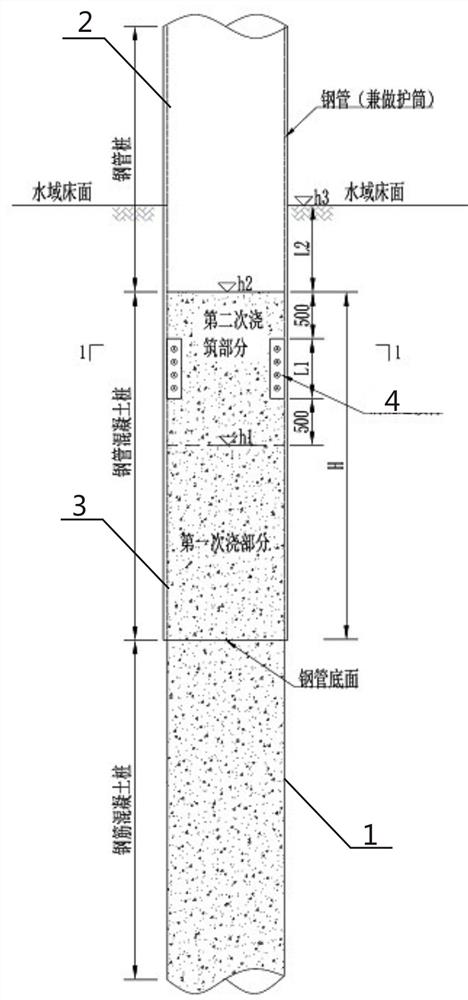

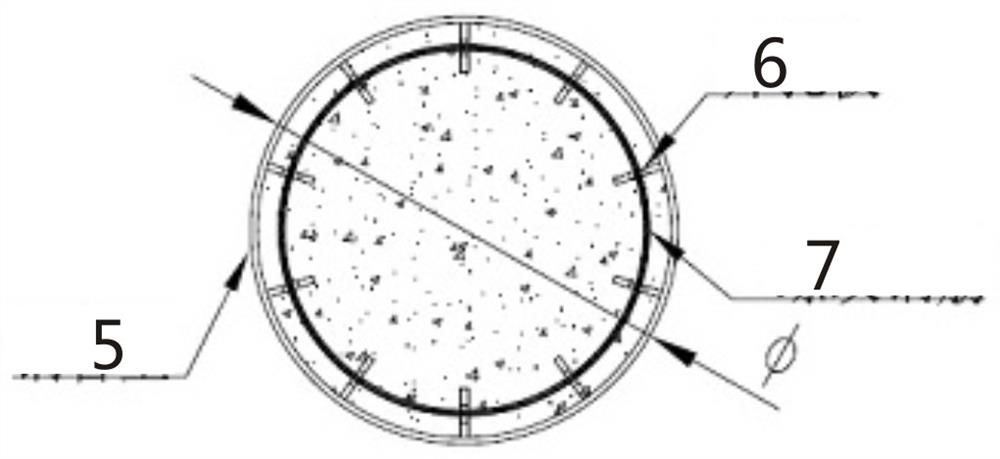

Steel pipe-reinforced concrete combined pile

PendingCN113882361AReduce the impactImprove horizontal bearing capacityBulkheads/pilesReinforced concreteRebar

Owner:四川路桥华东建设有限责任公司 +1

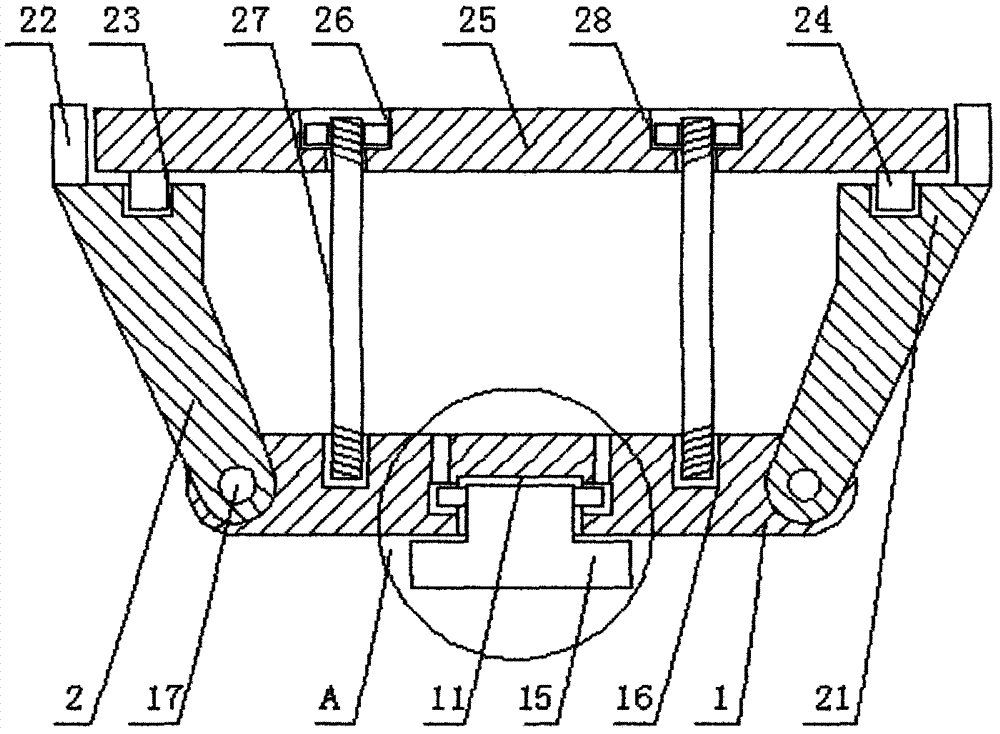

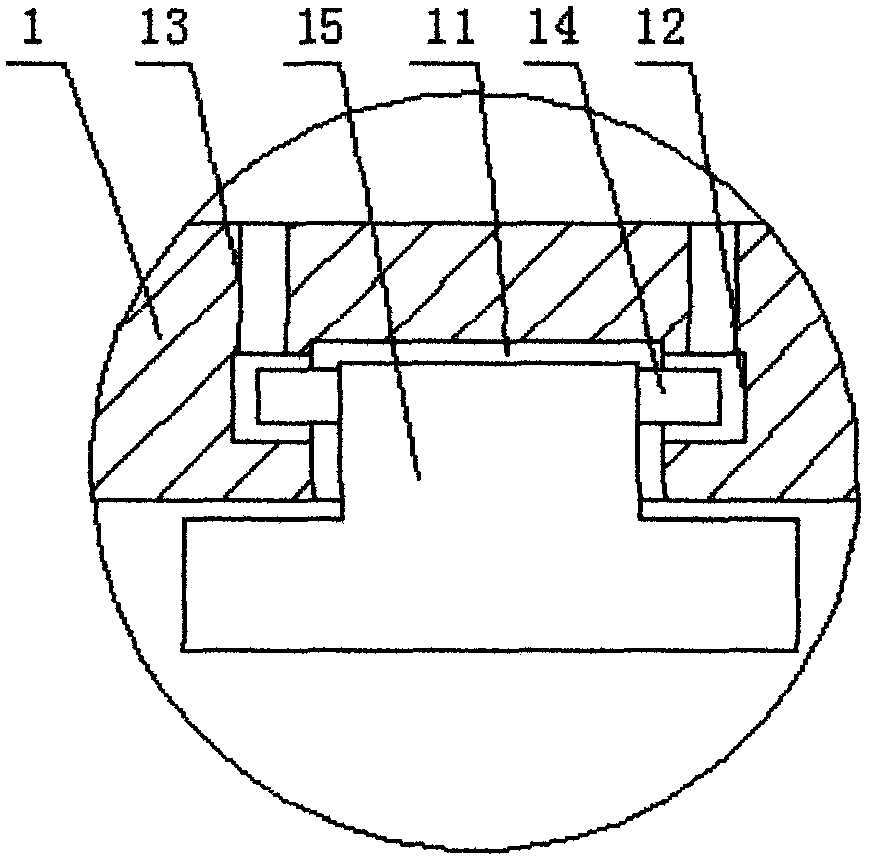

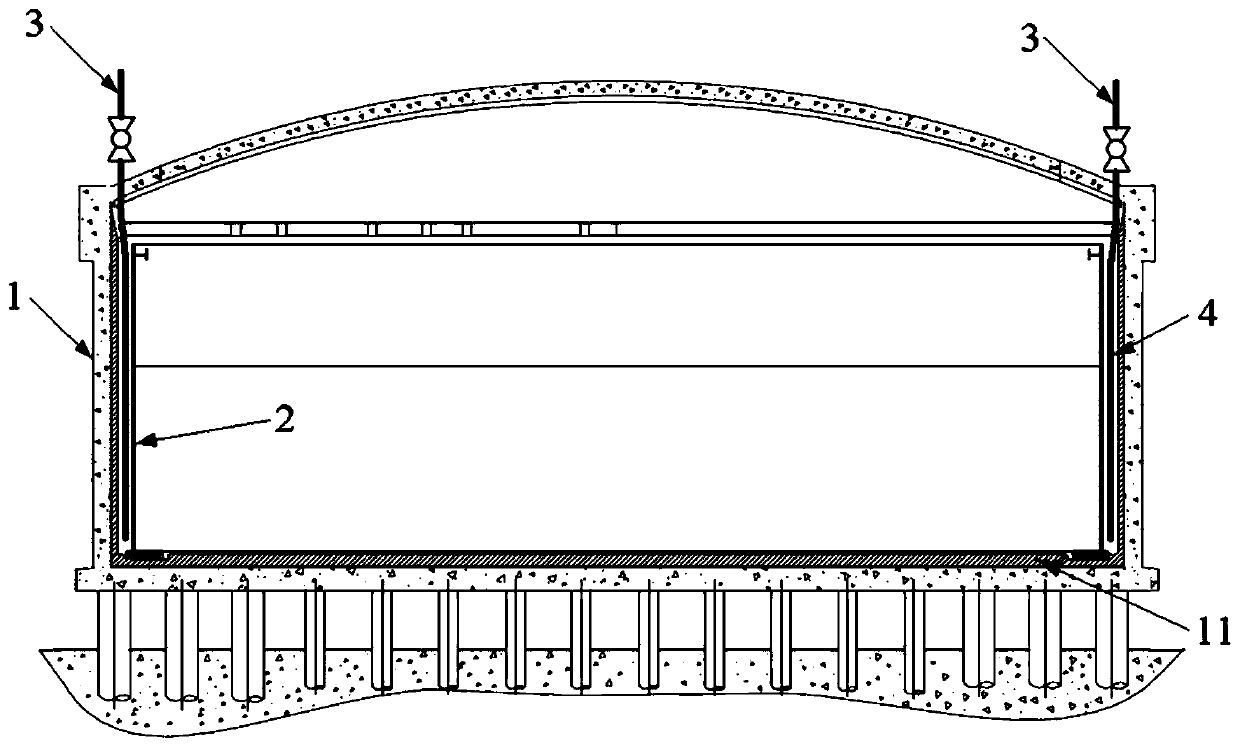

Hydraulic test device with peeping window

InactiveCN109632465ARealize high simulation testEasy to observeMaterial strength using tensile/compressive forcesAgricultural engineeringRebar

The invention discloses a hydraulic test device with a peeping window. The device comprises a water tank, a water pressure control system, a water pipe joint, an oil pressure control system and a hydraulic cylinder, and is characterized in that the water tank comprises a tank body and a tank cover, wherein a mounting hole is formed in the middle of the tank cover, a hydraulic cylinder piston rod penetrates through the upper portion of the tank cover and penetrates through the mounting hole to enter the tank body, and fixes the hydraulic cylinder on the tank cover in a sealing mode, a valve isfurther arranged on the tank cover, the hydraulic cylinder is arranged at the right end of the tank body, a water inlet pipe joint is arranged at the left end of the tank box, the water pipe joint communicates with a water pressure control system, the front end of the tank body is provided with a closed glass peeping window, a window hole is formed in the center of a bottom plate of the tank body,a boss and a rubber sealing gasket are arranged on the window hole, the oil pressure control system controls the movement and the pressure intensity of the piston in the hydraulic cylinder, and the left end of the piston rod is movably connected with a pressing plate. The device is used for carrying out durability tests on reinforced concrete components under the saline-alkali erosion and press-load multi-coupling action

Owner:JIANGSU UNIV OF SCI & TECH

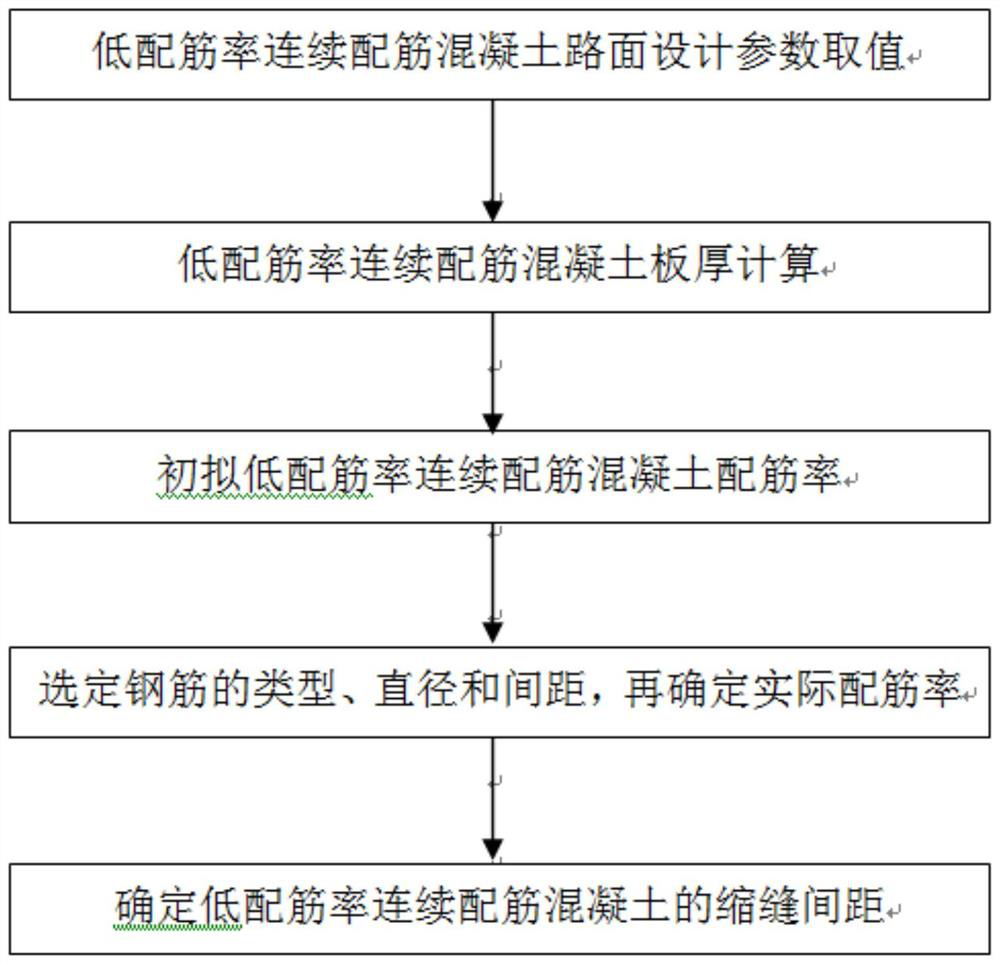

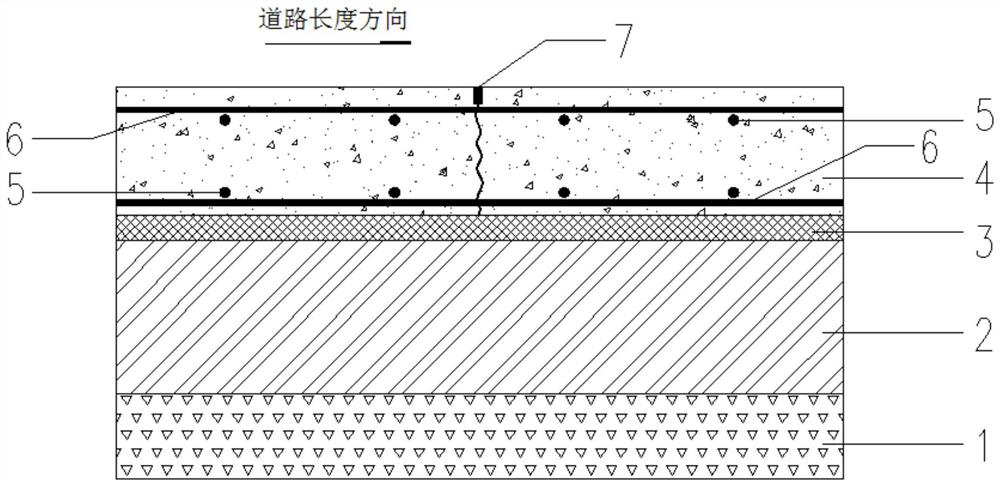

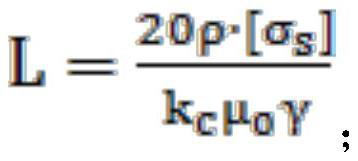

Method for determining shrinkage gap distance of low-reinforcement-rate continuous reinforced concrete pavement

Owner:中冶南方城市建设工程技术有限公司 +1

Preparation method of concrete square pile mould

InactiveCN104416123AUnified specificationsImprove reliabilityMouldsFoundry mouldsRebarReinforced concrete

The invention discloses a preparation method of a concrete square pile mould. The preparation method comprises the following steps: pre-arranging a plurality of separating rods in a steel mould, pouring molten iron into the steel mould, cooling and molding the molten iron in the steel mould to obtain a mould framework; drawing out the plurality of separating rods from the steel mould, forming a plurality of accommodating cavities for accommodating the concrete square piles in the mould framework; and opening the side mould in the steel mould, blocking each accommodating cavity, punching compressed air into the steel mould, and separating the steel mould from the mould framework to obtain the concrete square pile mould. According to the preparation method of the concrete square pile mould disclosed by the invention, the concrete square piles are produced by adopting a technical mode of prefabricating a mould, so that the concrete square piles are unified in specification, the construction cost is lowered, the condition that a filling core of reinforced concrete is pulled out is avoided, and the reliability of the concrete square piles is improved.

Owner:QINGDAO XINGHE BUILDING MATERIAL

Low-temperature ethylene storage tank and condensate treatment method thereof

ActiveCN110645472AAvoid destructionImprove efficiencyWaterborne vesselsVessel geometry/arrangement/sizeReinforced concreteNitrogen gas

Owner:青岛海湾化学股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap