Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hollow floor system filled with an air-filling bag and construction method thereof

InactiveCN101793070ALight shock and vibration resistanceGood shock and vibration resistanceFloorsEarthquake resistanceCrack resistance

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

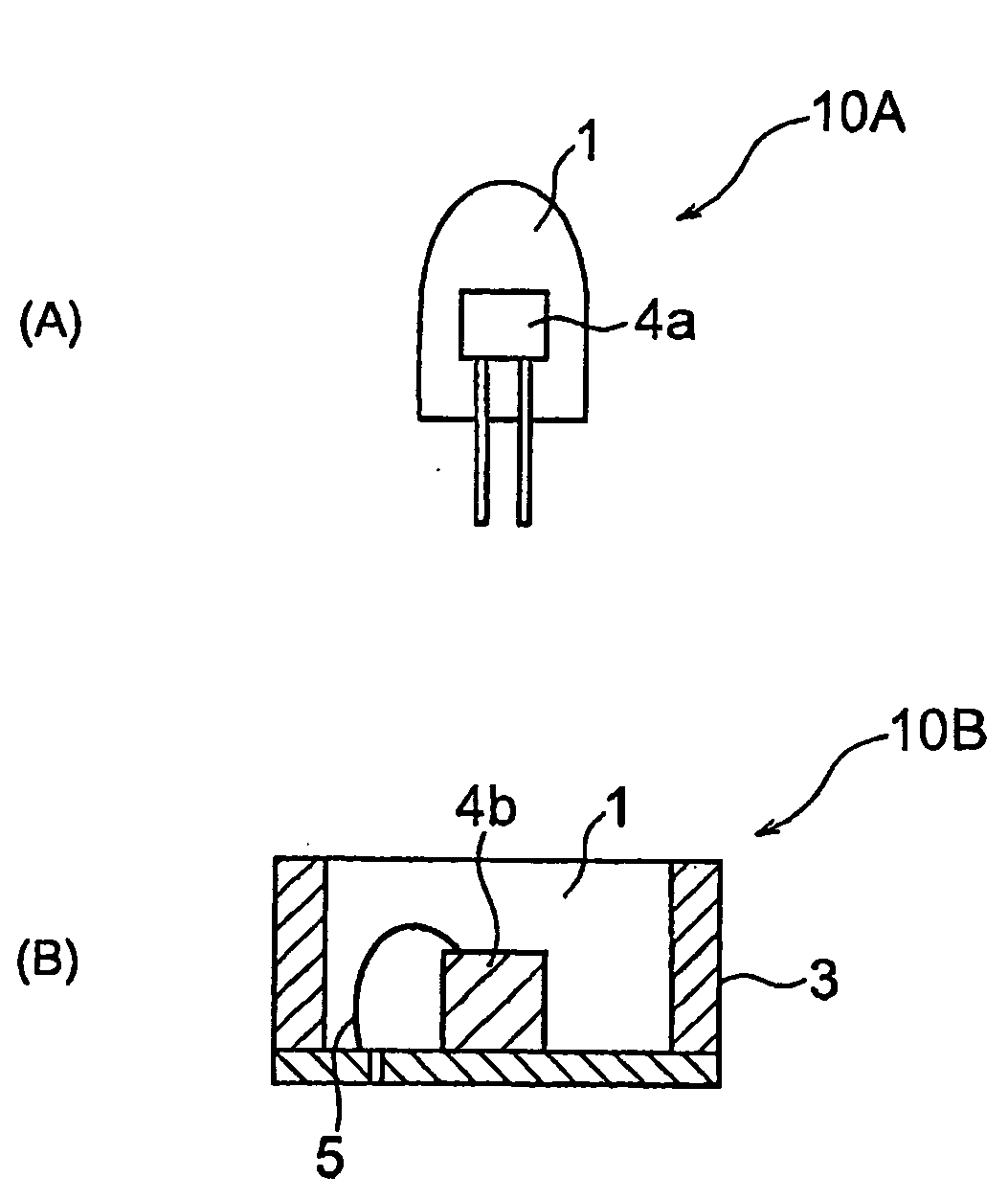

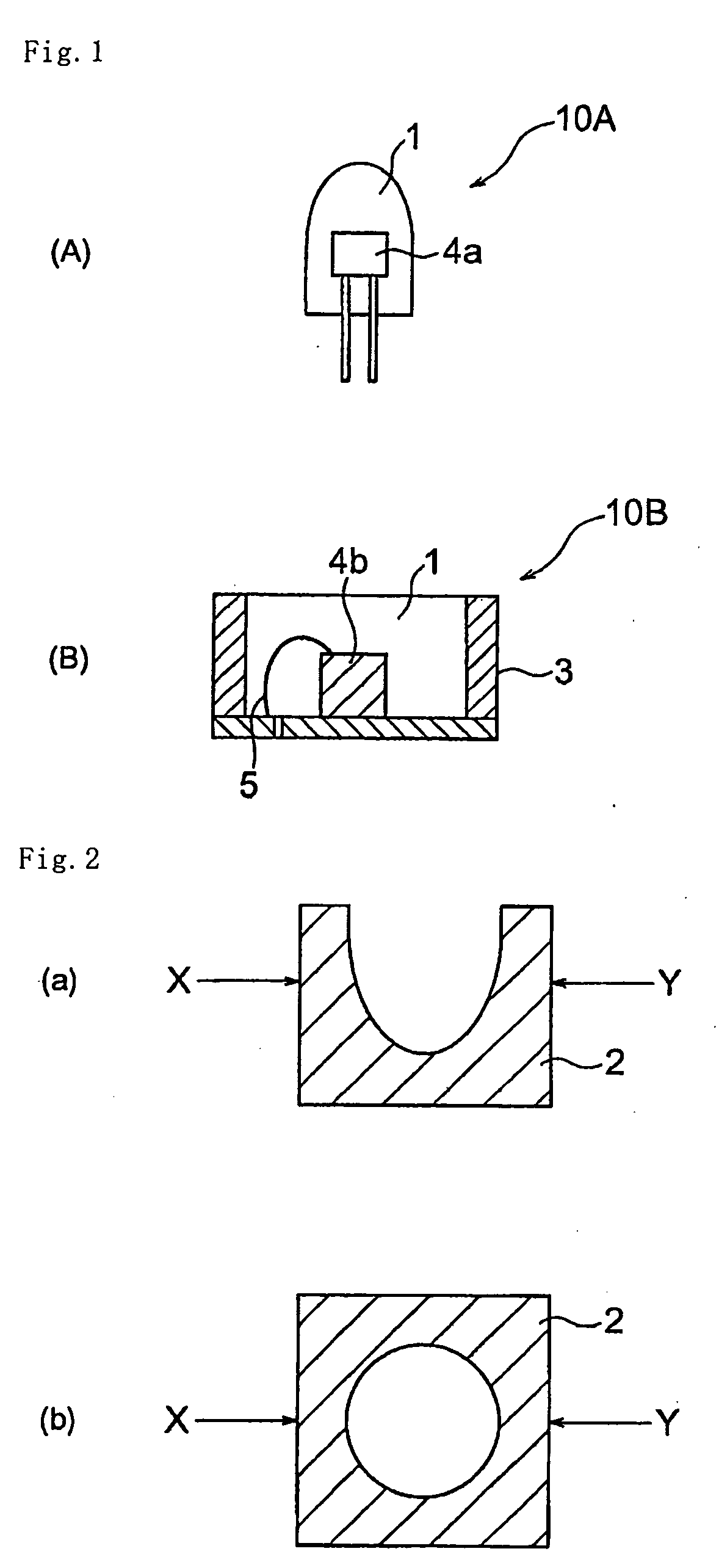

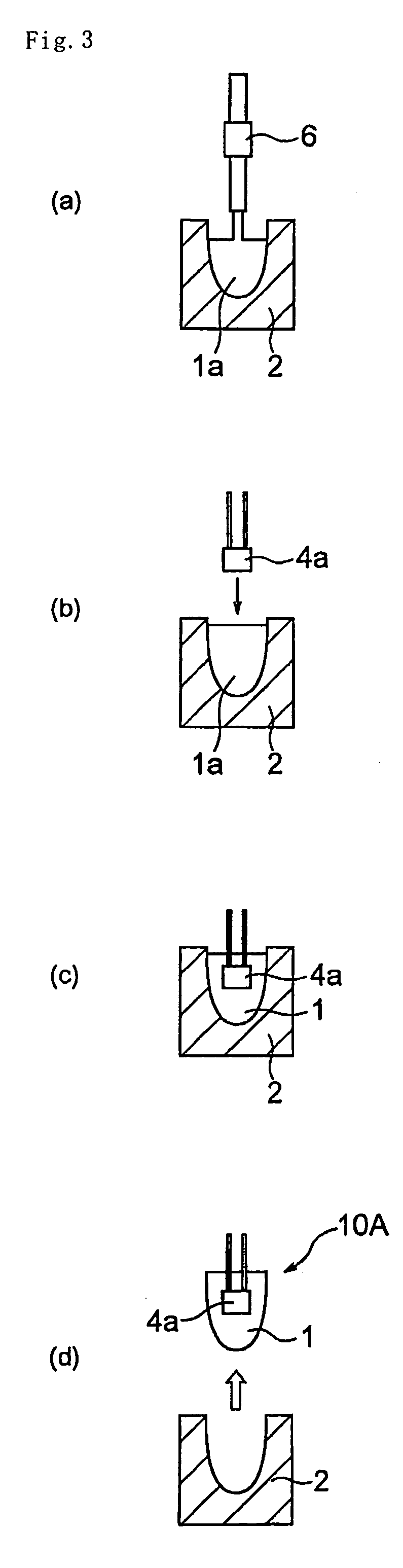

Sealing material for optical element and sealed optical element

InactiveUS20080249278A1Outstanding transparencyOutstanding crack resistanceOther chemical processesSolid-state devicesCrack resistanceHalogen

Owner:LINTEC CORP

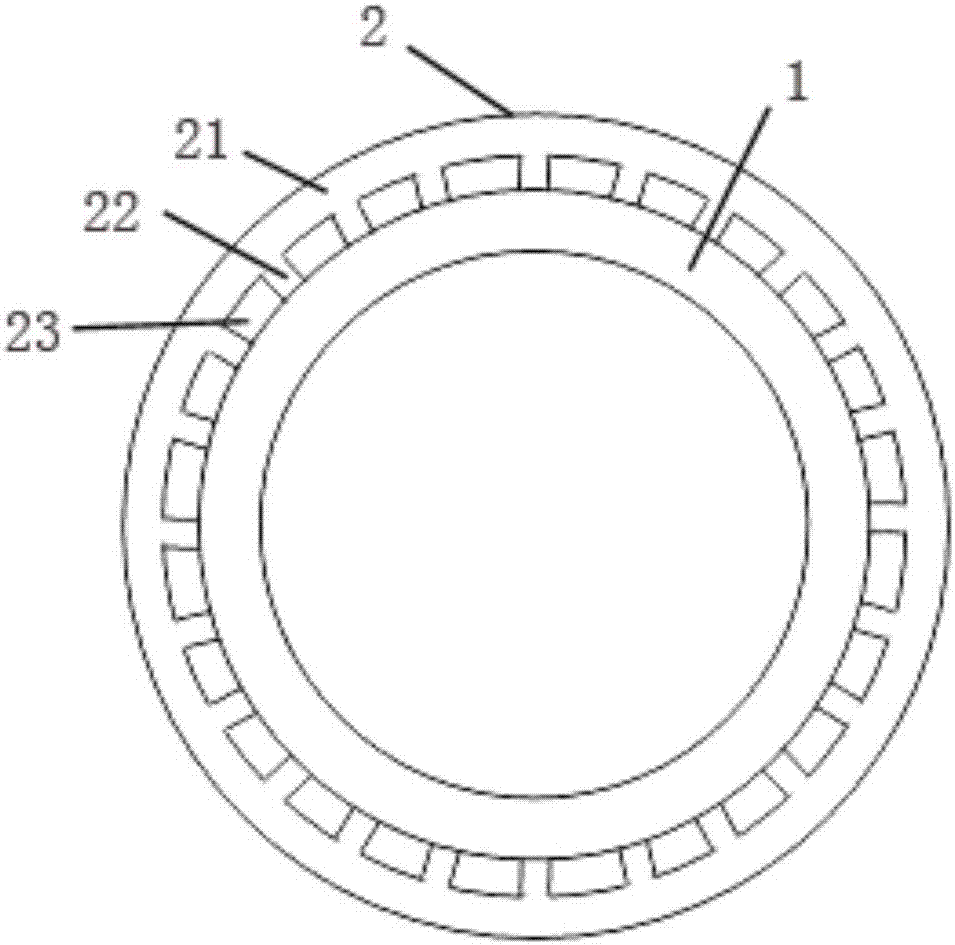

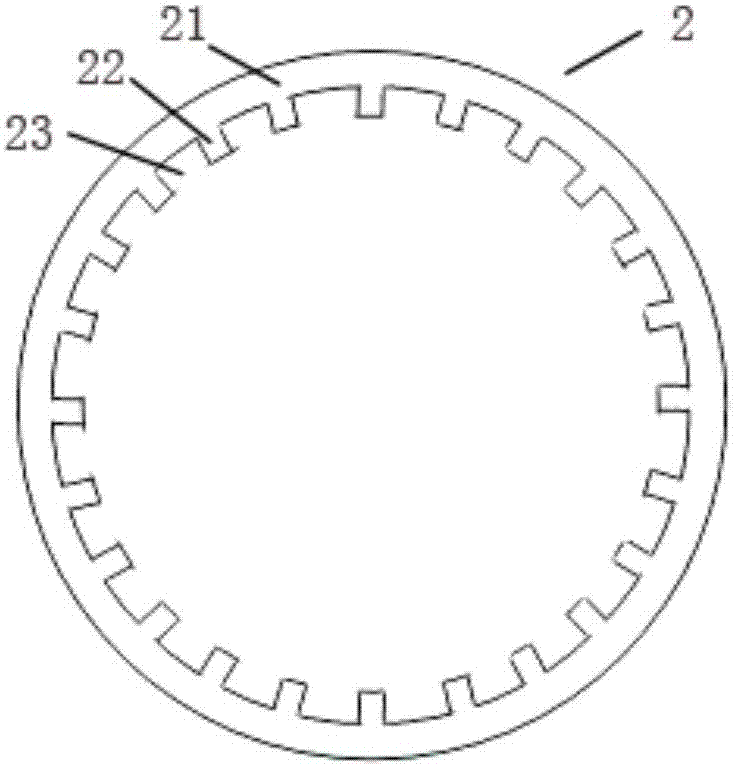

Hollow composite floor slab and construction method thereof

InactiveCN104612300AImprove construction efficiencyEasy to transportFloorsReinforced concreteCrack resistance

The invention discloses a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab comprises a prefabricated hollow bottom plate and an upper cast-in-place slab, continuous fully-closed preformed holes and semi-closed preformed holes are distributed in the prefabricated hollow bottom plate at intervals, or the continuous fully-closed preformed holes and plate ribs are distributed on the prefabricated hollow bottom plate at intervals, bottom plate rebars are distributed on the prefabricated hollow bottom plate at intervals in the longitudinal direction and the transverse direction, prestress rebars or prestress rebars and non-prestress rebars distributed at intervals are adopted as the bottom plate rebars, and the rebars penetrate through the semi-closed preformed holes or plate rib preformed holes. Concrete is poured on the prefabricated hollow bottom plate to form the upper cast-in-place slab, multiple sets of top rebars are distributed on the cast-in-place slab in the longitudinal and the transverse directions parallel to the bottom plate at intervals, and reinforced concrete is integrally poured on the bottom plate to form the hollow composite floor slab. Only the prefabricated bottom plate needs to be produced and transported, transportation and installation are convenient and fast, formworks are not needed, the crack resistance and the integrity are good, and the construction efficiency is high.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AFast shapingEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesCalcium silicateFiber

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

Improved nodular cast iron rail finishing roll and production method thereof

PendingCN110273100AStrong impact toughnessExtended service lifeRollsMetal rolling arrangementsCrack resistanceDuctile iron

The invention relates to the technical field of finishing rolls, in particular to an improved nodular cast iron rail finishing roll and a production method of the improved nodular cast iron rail finishing roll. The improved nodular cast iron rail finishing roll is provided with a stepped roll body. An upper roll neck is fixed to the upper end of the roll body. A lower roll neck is fixed to the lower end of the roll body. A transmission end is fixed to the lower end of the lower roll neck. According to the improved nodular cast iron rail finishing roll and the production method of the improved nodular cast iron rail finishing roll, the density and red hardness of the roll are greatly improved, the impact toughness and the thermal crack resistance are high, the hardness drop is reduced, and the service life of the roll is prolonged. The production method is simple, the process is reasonable, and wide popularization and use can be conveniently realized.

Owner:CHANGZHOU ZHONGYU FERROALLOY FACTORY

Nuclear power plant containment concrete

ActiveCN108059405AIncreased durabilityReduce porosityNuclear energy generationContainmentFiberCrack resistance

The invention relates to nuclear power plant containment concrete. The concrete consists of the following components in parts by mass: 130-200 parts of cement with strength of 52.5 or 42.5, 60-120 parts of slag, 50-100 parts of metakaolin, 50-150 parts of boron glass sand, 600-800 parts of nickel slag, 600-800 parts of barite, 200-400 parts of limonite, 100-300 parts of ceramsite, 20-50 parts of lead fibers, 130-160 parts of water, 4-6 parts of a water reducing agent and 4-6 parts of an early strength agent. After 28 days of curing of the concrete, the inner surface of the concrete is coated with a layer of anti-radiation coating. The nuclear power plant containment concrete provided by the invention has a good anti-radiation property, can well shield alpha, beta and gamma rays and neutronrays, and has good crack resistance, high-temperature resistance and durability, and simultaneously solid wastes such as nickel slag, glass powder and the like are utilized, so that the problems of resource waste and environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

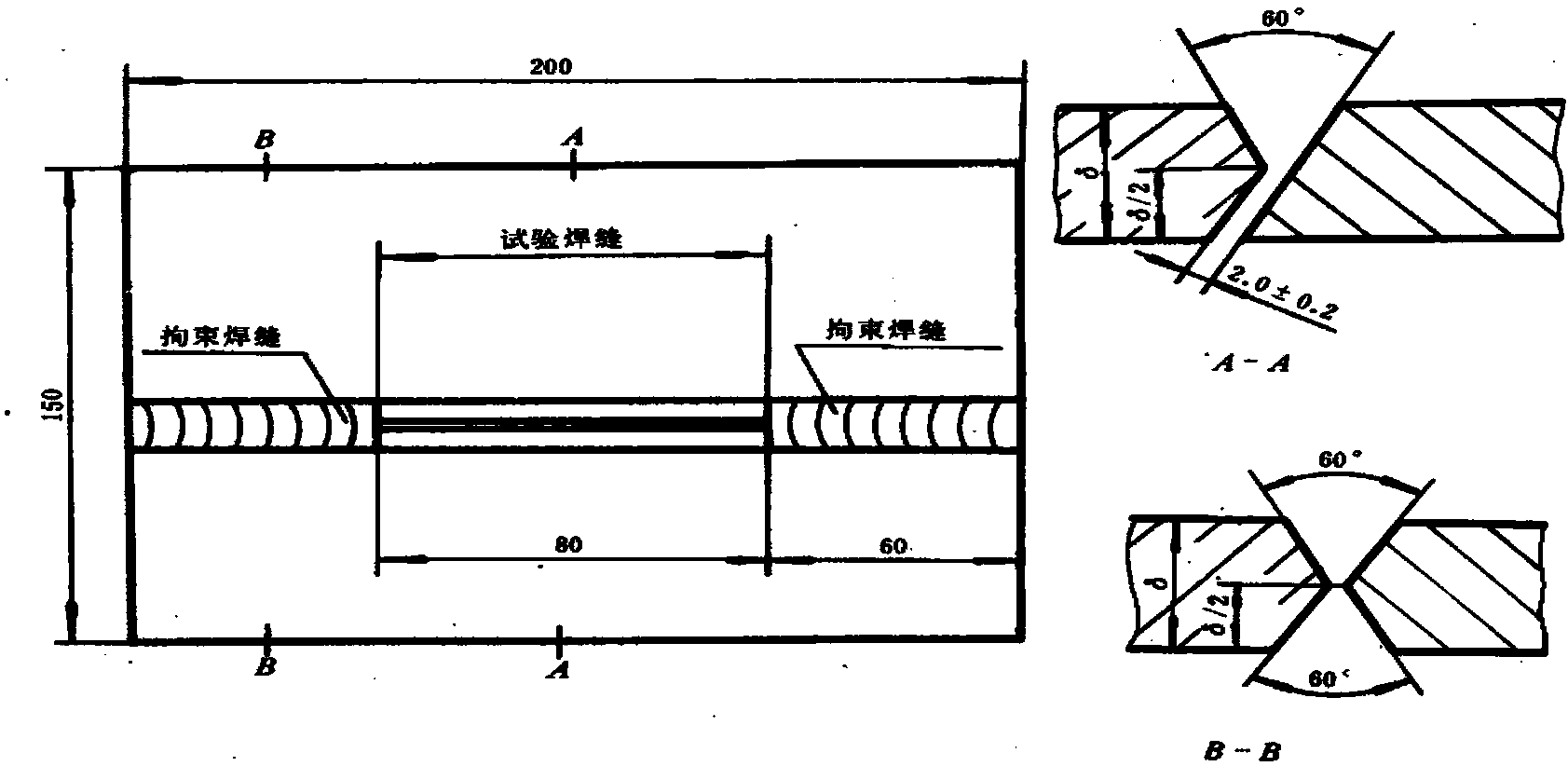

Titanium type gas-shielded flux-cored wire

ActiveCN103521949AGood workmanshipImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceManganese

Owner:TIANJIN YONGCHANG WELDING WIRES

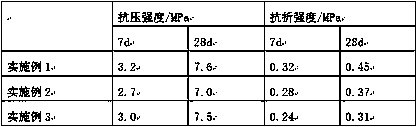

Preparation method of modified pitchstone-based thermal insulation mortar

InactiveCN110282929AImprove insulation effectImprove crack resistanceCrack resistanceThermal insulation

Owner:含山县领创新材料科技有限公司

Halogen-free metal insulating tube and preparation method thereof

InactiveCN107573573AAchieve low smokeNot easy to catch fireThermal insulationCorrosion preventionCrack resistancePolyolefin

Owner:佛山市恒合信管业有限公司

Caulking gypsum with high crack resistance

The invention provides caulking gypsum with high crack resistance. The caulking gypsum is prepared from the following components: 39 to 55 parts of gypsum powder, 10 to 15 parts of desulfurized gypsum, 12 to 18 parts of cement, 0.4 to 0.6 part of a water-retaining agent, 10 to 14 parts of glass beads, 2 to 3 parts of redispersible latex powder and 100 parts of water, the caulking gypsum has the beneficial effects that the tensile strength and the crack resistance of the caulking gypsum are improved by adding the cement and the redispersible latex powder into the caulking gypsum, so that the caulking gypsum with high crack resistance is obtained, and the high crack resistance requirement of the caulking gypsum is met.

Owner:ANHUI SHENGCHENG NEW MATERIALS CO LTD

Novel FTTH optical fiber cable and production process thereof

PendingCN109725397AImprove bindingStable structureFibre mechanical structuresCrack resistanceEngineering

The invention discloses a novel FTTH optical fiber cable and a production process thereof. The novel FTTH optical fiber cable has the advantages of high adhesion between a reinforcing element and a sheath, torsion resistance, crack resistance, sheath tension resistance and stable structure, and is suitable for optical fiber cables in various complicated installation environments. The novel FTTH optical fiber cable of the invention is composed of a sheath layer, an optical fiber and a reinforcing element; the novel FTTH optical fiber cable comprises an indoor FTTH optical cable and an indoor and outdoor dual-purpose FTTH optical cable. The indoor FTTH optical cable only comprises a main component, and the indoor and outdoor dual-purpose FTTH optical cable comprises a main component and an auxiliary component integrally with the main component. The main component comprises a reinforcing element, a reinforcing element coating layer, a sheath layer and an optical fiber coated with the sheath layer, which are sequentially arranged from the inside to the outside; and the auxiliary component comprises a reinforcing element, a reinforcing element coating layer and a sheath layer arranged sequentially from the inside to the outside.

Owner:HEFEI XINGLIAN COMM

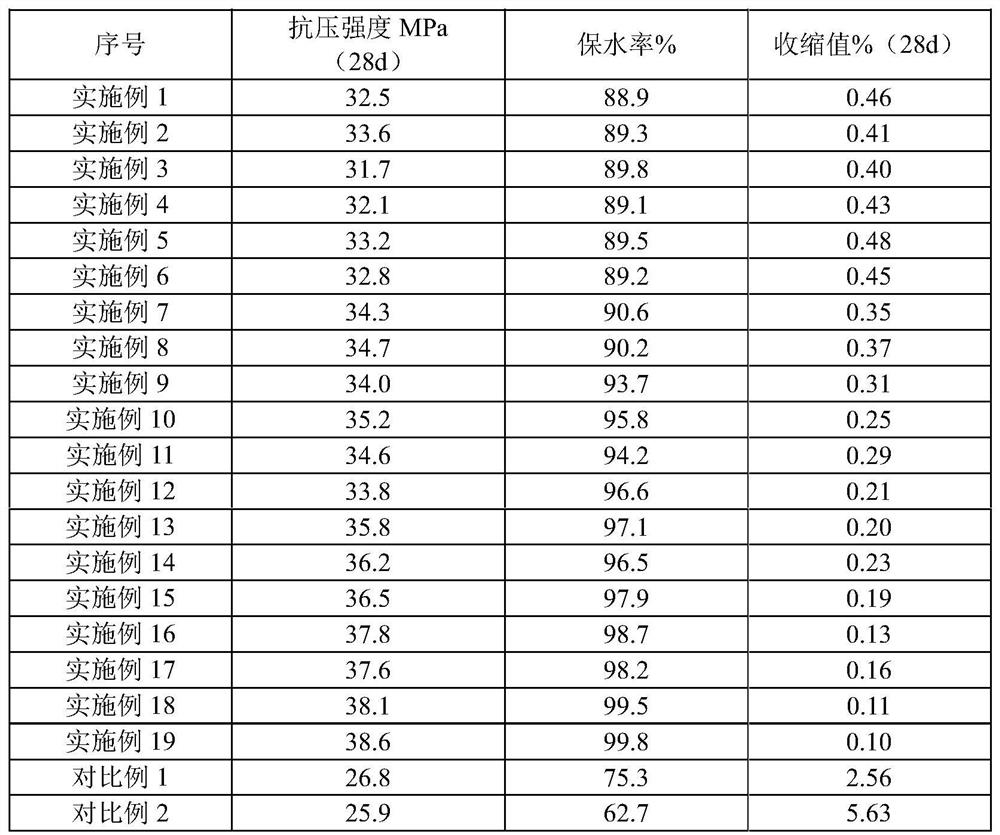

High-strength anti-crack masonry dry-mixed mortar and production process thereof

ActiveCN113387657AReduce autogenous shrinkageGood structural strengthSolid waste managementCelluloseCrack resistance

Owner:河南融之科建材有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap