Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Optical fiber cable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fiber-optic cable, also known as an optical-fiber cable, is an assembly similar to an electrical cable, but containing one or more optical fibers that are used to carry light. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable will be deployed. Different types of cable are used for different applications, for example, long distance telecommunication, or providing a high-speed data connection between different parts of a building.

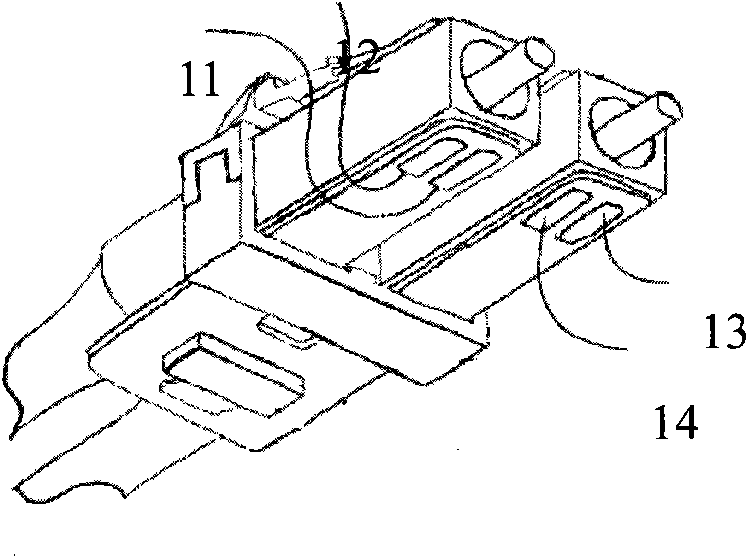

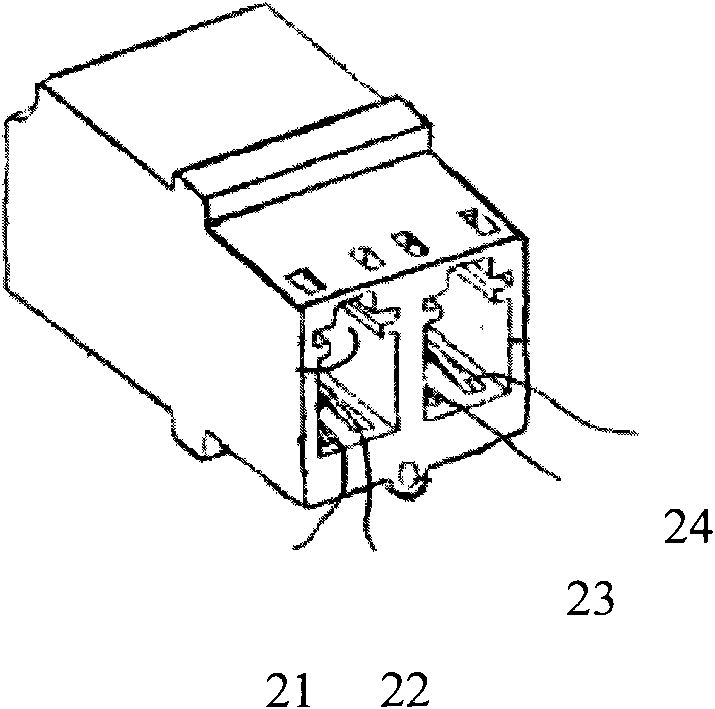

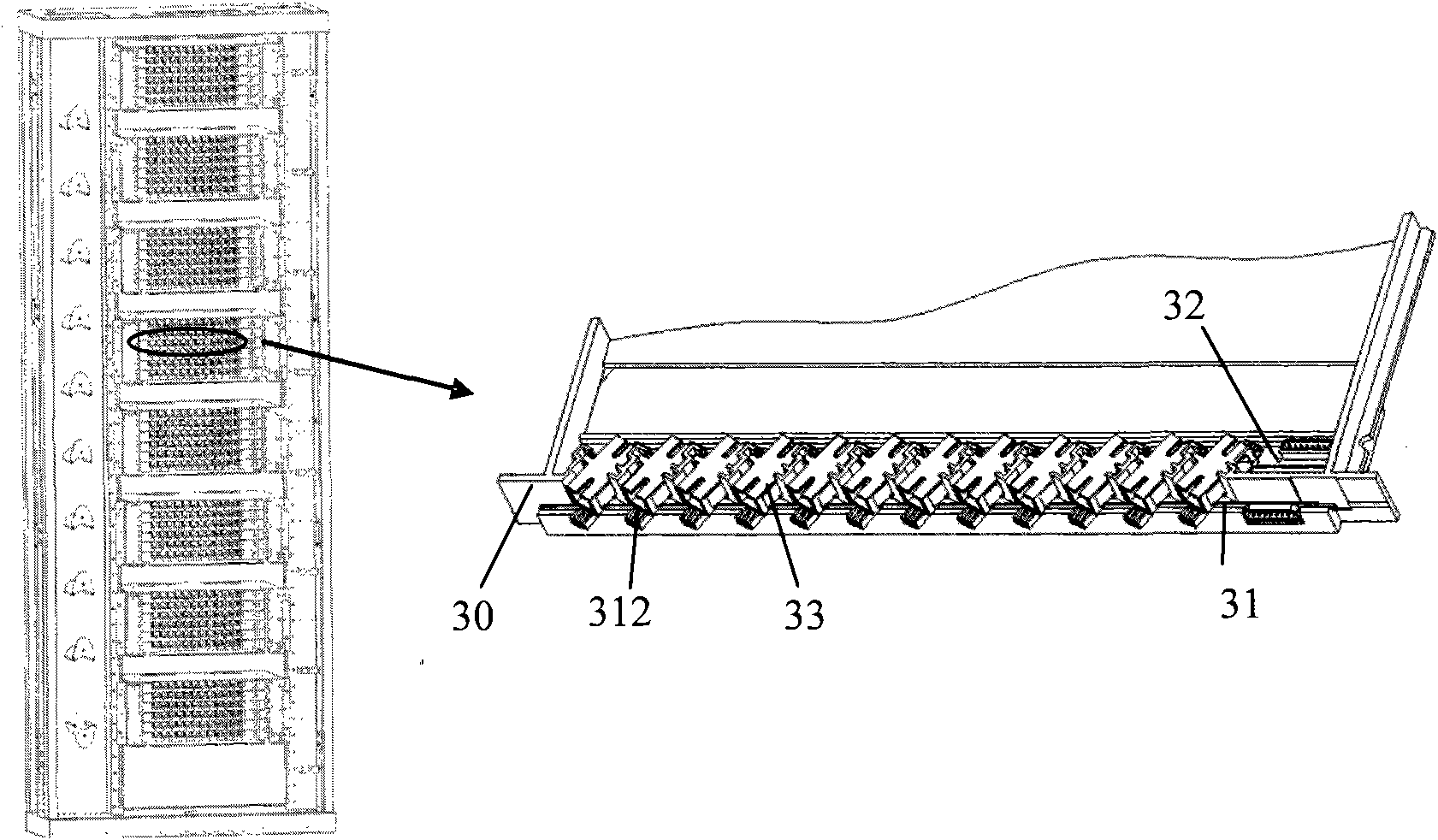

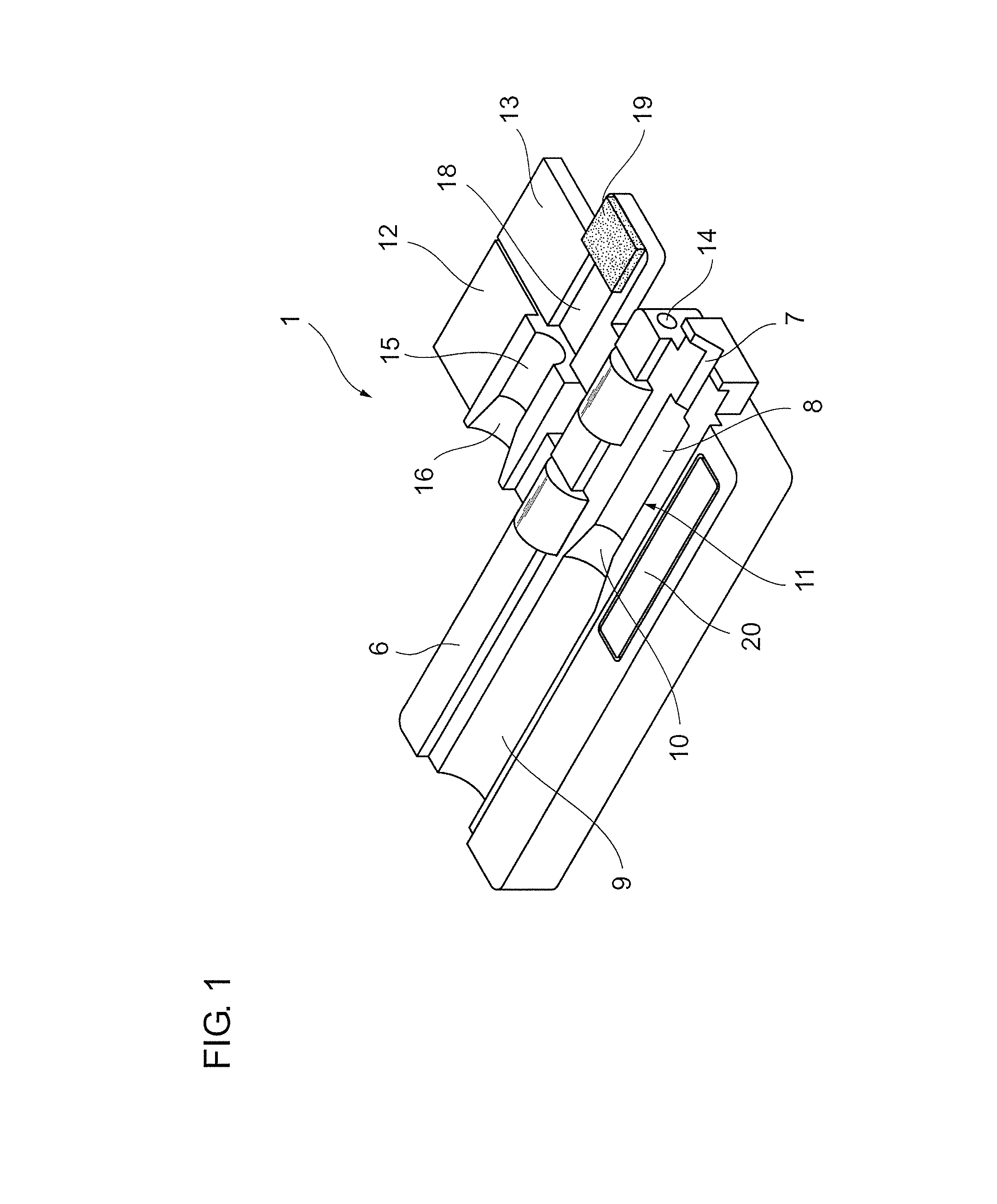

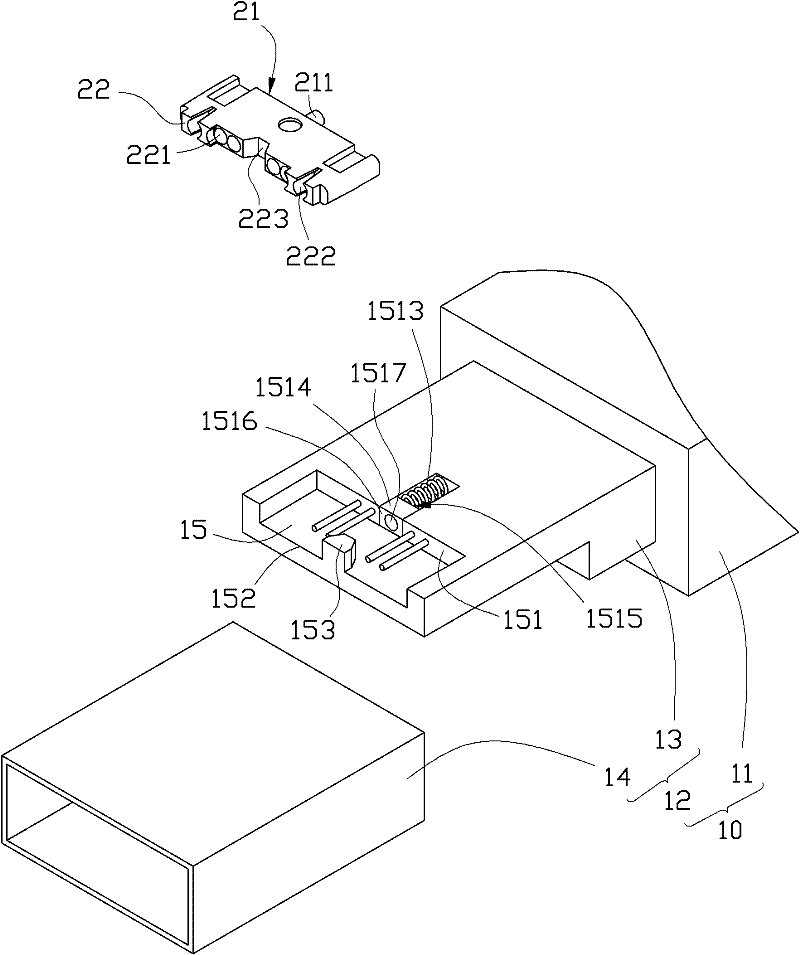

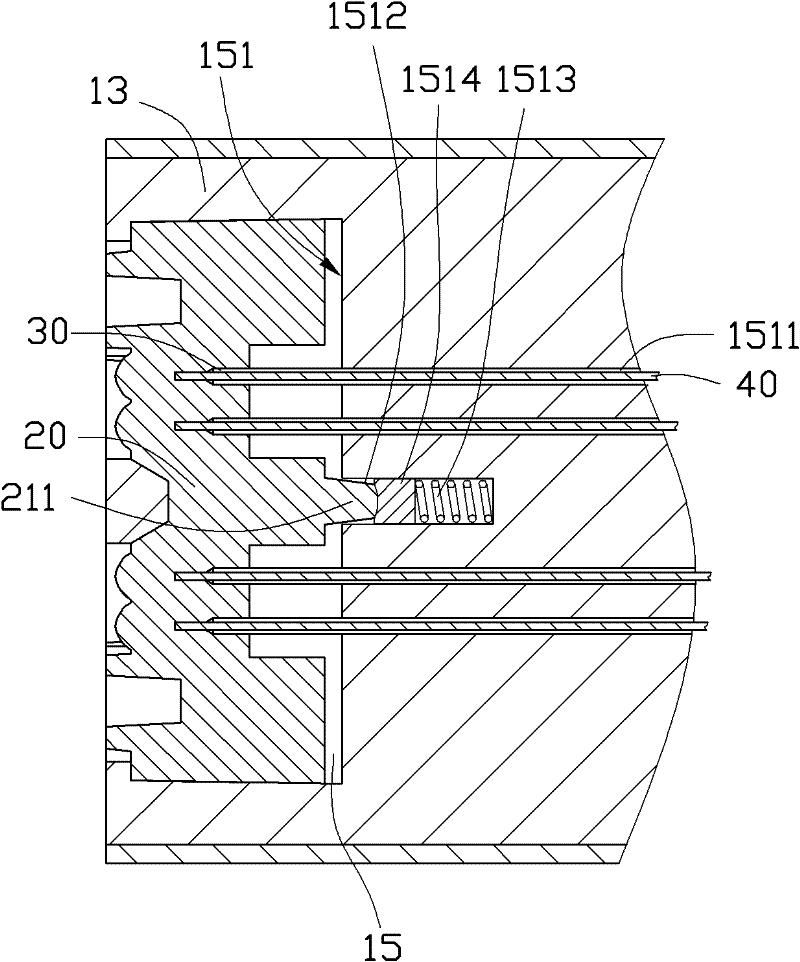

Optical fiber distribution module, optical fiber plug and optical fiber distribution frame

Owner:HUAWEI TECH CO LTD

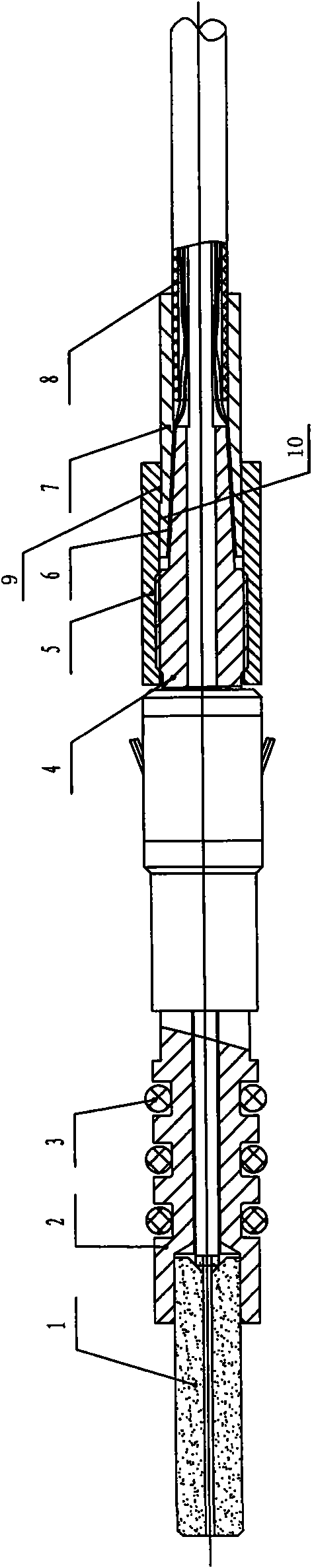

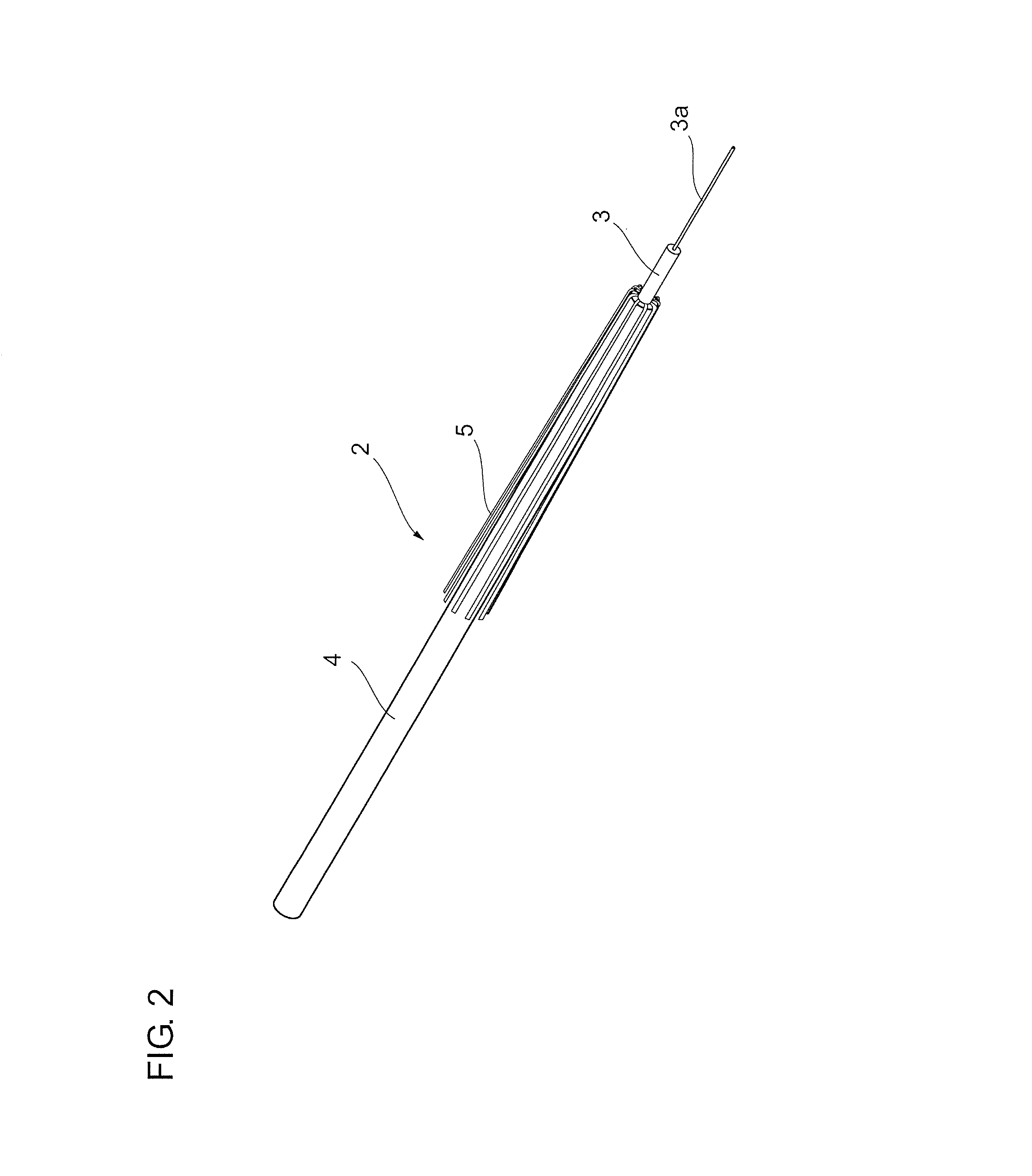

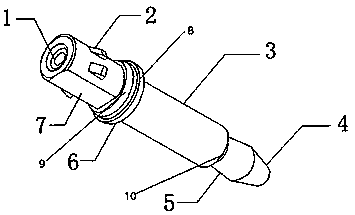

Rapid hot melt type optical fiber connector

ActiveCN102928922AImprove the shortcomings of poor performanceTroubleshoot communication outagesCoupling light guidesHot meltEngineering

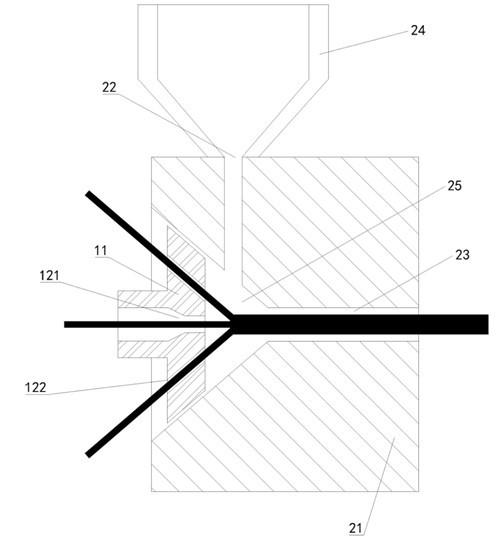

The invention relates to a rapid hot melt type optical fiber connector which is characterized by comprising a core inserting component, a connector shell, a prefabricated optical fiber, a connecting lining, a cable end optical fiber, a thermal shrinkage protecting tube, a tail part shell and a tightening screw cap. The connector has the following advantages: 1), as the problem of thrusting needle return is solved by utilizing a surplus optical fiber section, and an optical fiber cable is tightly clamped with a connector shell, a front end inserting core is not driven to move together when the tail optical fiber cable of the connector is stressed, so that the problem that the communication is interrupted as the tail part optical fiber cable of a conventional connector is stressed when being used is solved; 2), the problem that too many components are assembled in the construction process is solved; 3), the problem that most conventional hot melt type optical fiber connectors are low in success rate and cannot be used repeatedly is solved; and 4), the rapid hot melt type optical fiber connector is applicable to various rapid hot melt type optical fiber connectors such as an SC (straight connector), an LC (lucent connector) and an FC (fixed connector) with coating layer optical fibers, 0.9 optical fiber cables, 2.0 circular optical fiber cables, 3.0 circular optical fiber cables and butterfly optical fiber cables.

Owner:NANJING PUTIAN TELEGE INTELLIGENT BUILDING

Inserting pin component of optical cable connector and tensile connecting structure of inserting pin component and optical cable

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Longitudinal seal underwater optical cable and manufacturing method thereof

ActiveCN102540370ASimple structureImprove sealingFibre mechanical structuresWater leakageEngineering

Owner:JIANGSU HONGTU HIGH TECHNOLOGY STOCK CO LTD

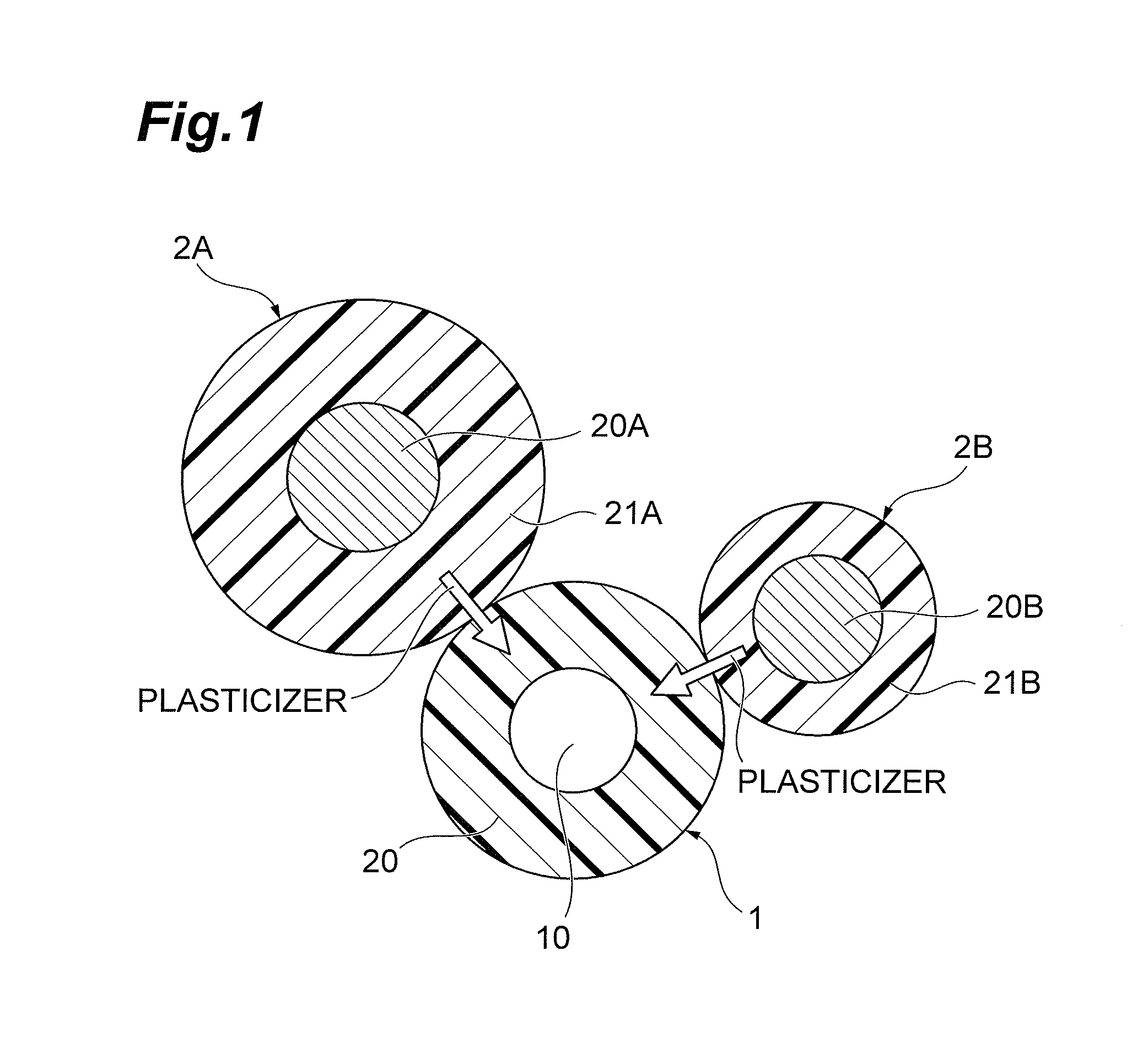

Optical fiber holder and method for holding coated optical fiber

ActiveUS20120251068A1No loss of splicing qualityHigh strengthPositioning apparatusOptical light guidesFiberEngineering

Owner:SUMITOMO ELECTRIC IND LTD

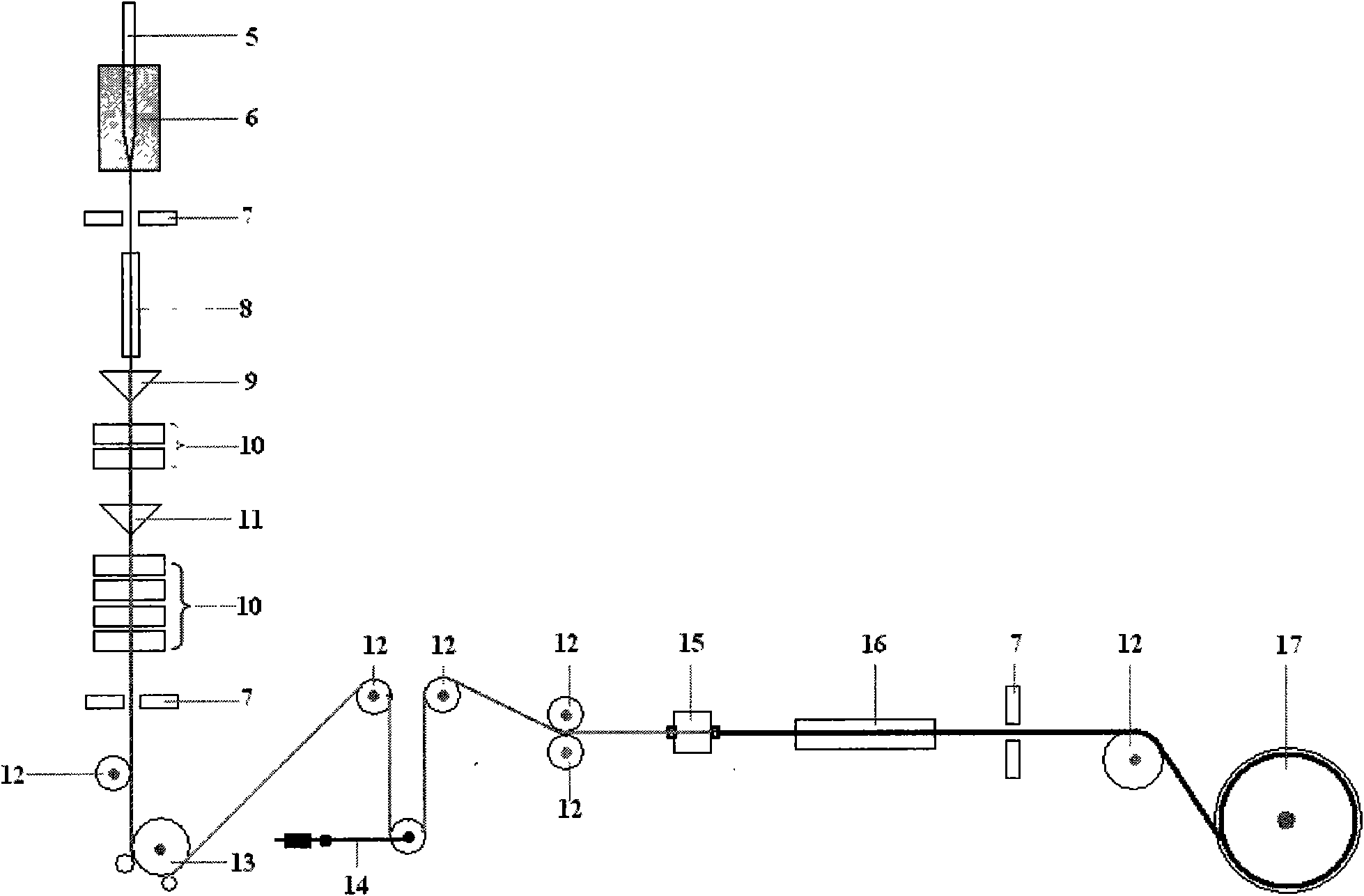

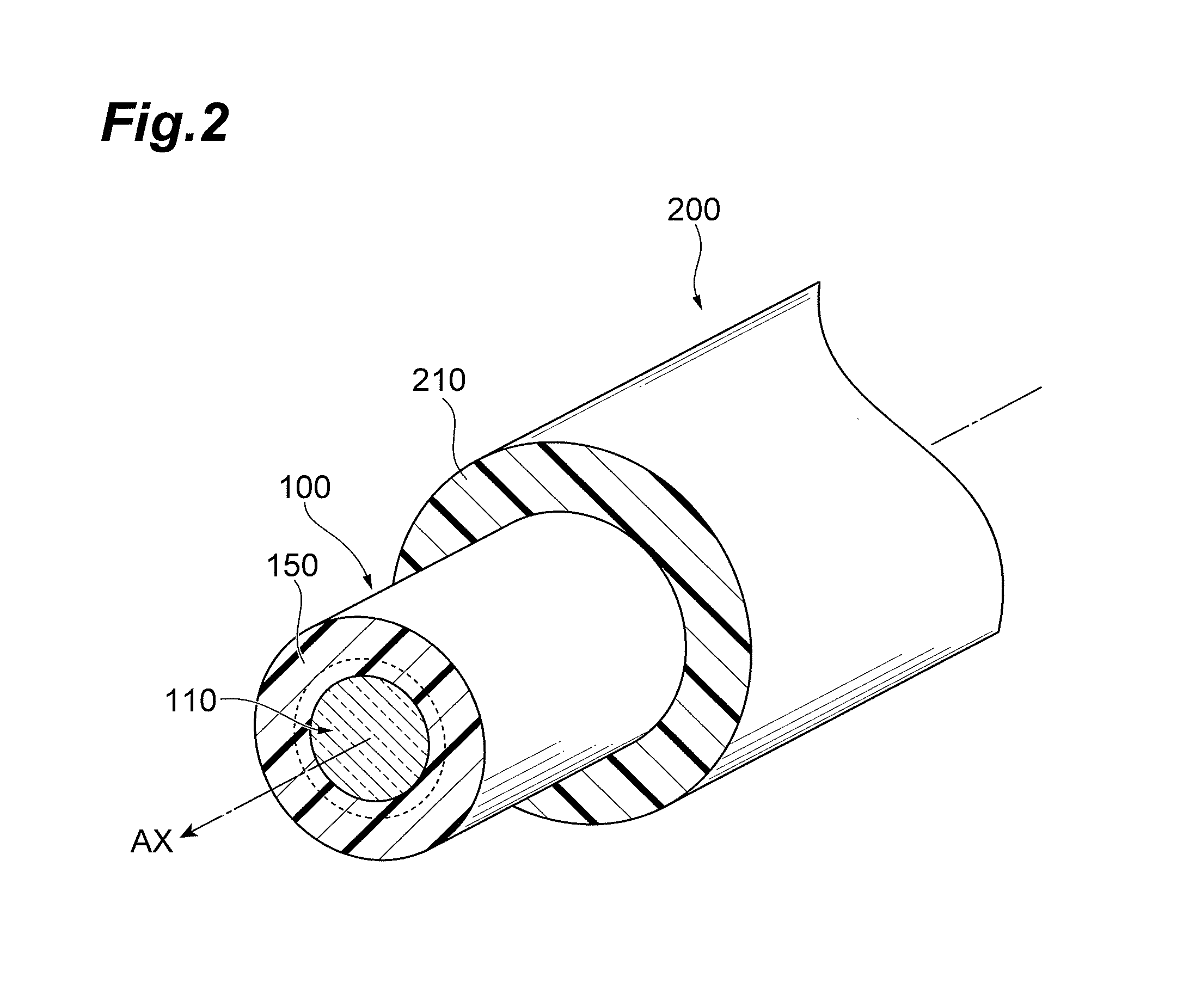

Indoor-laying optical fiber and manufacture method thereof

ActiveCN101614842AQuality improvementIncrease internal stressGlass making apparatusCladded optical fibreProduction lineProtection layer

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

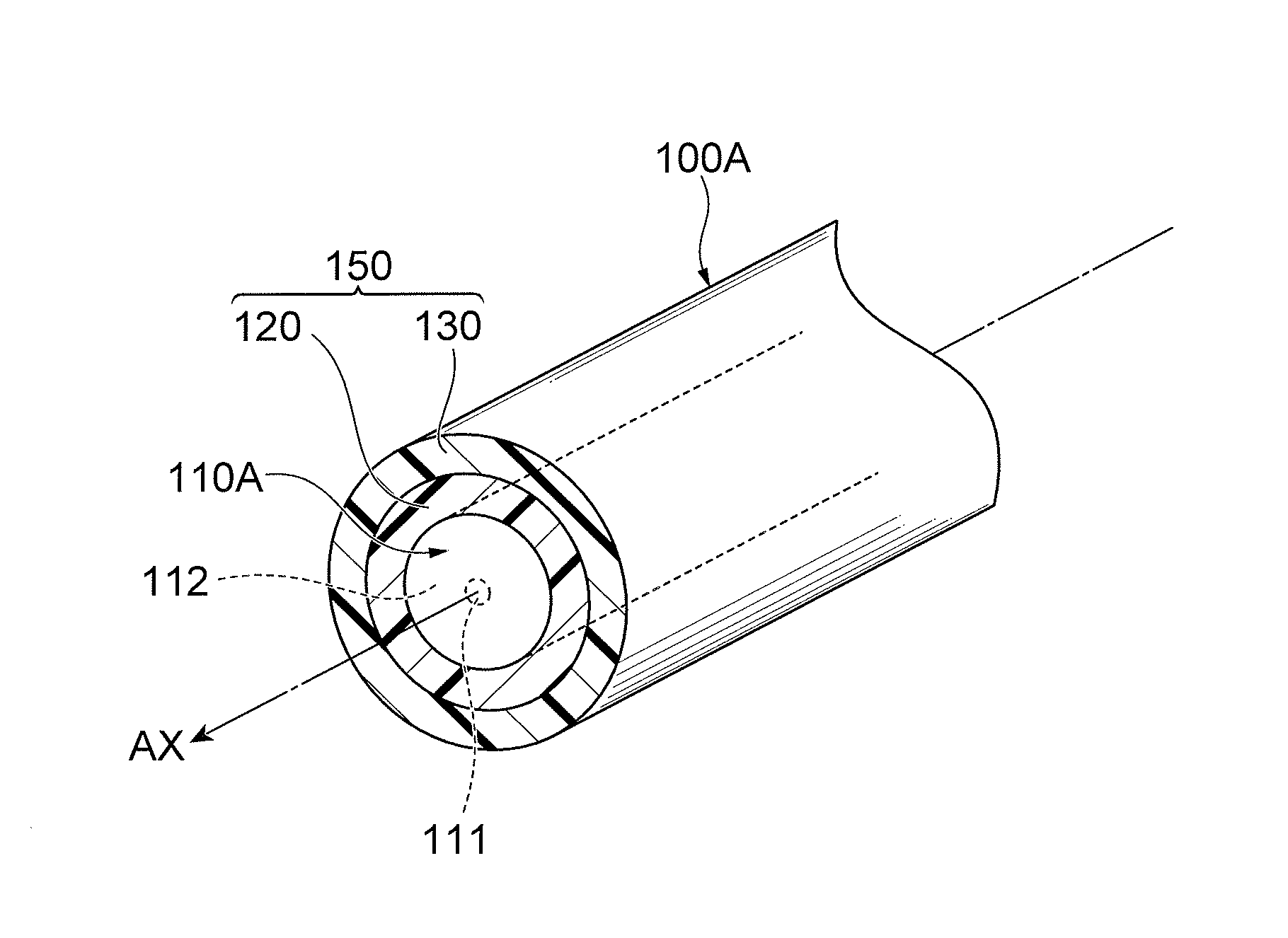

Optical fiber and optical cable

ActiveUS8923674B1Easy to crackInhibit migrationGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberUV curing

Owner:SUMITOMO ELECTRIC IND LTD

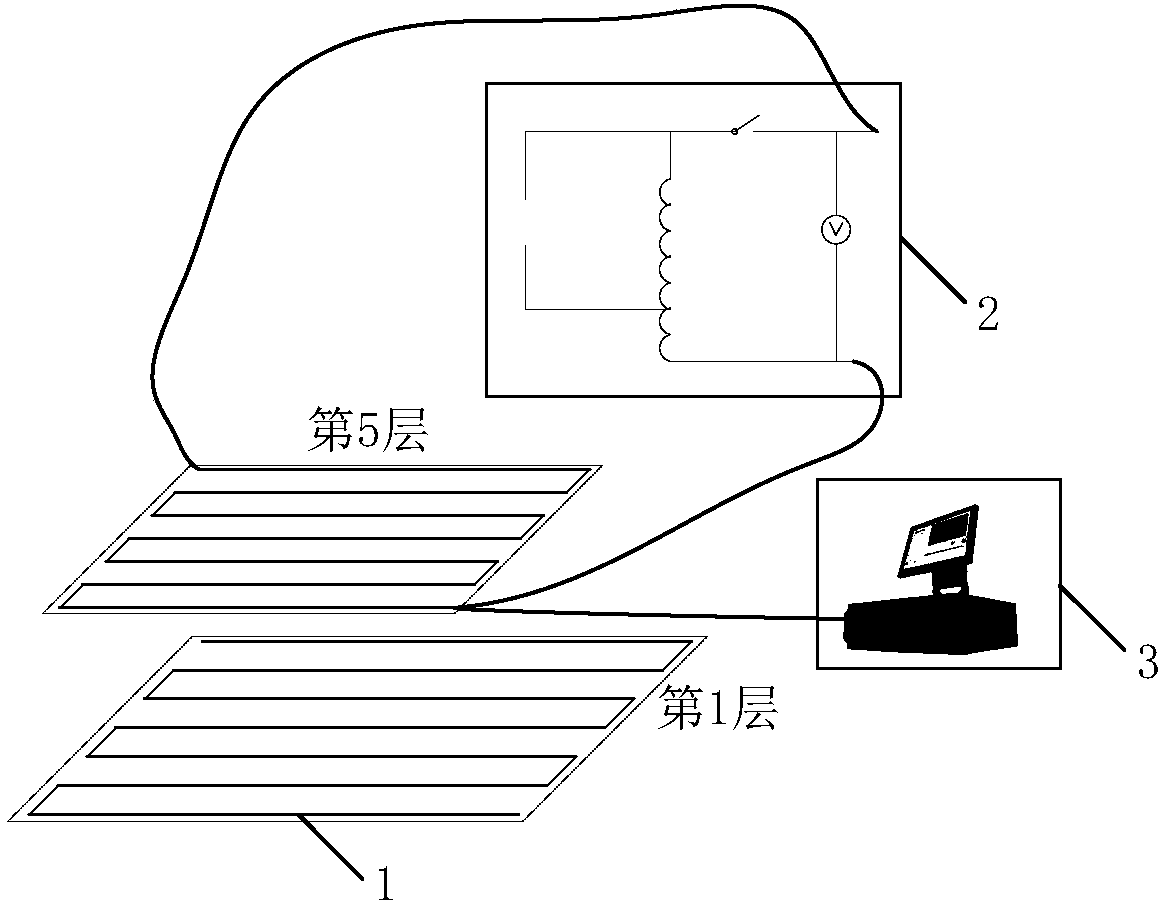

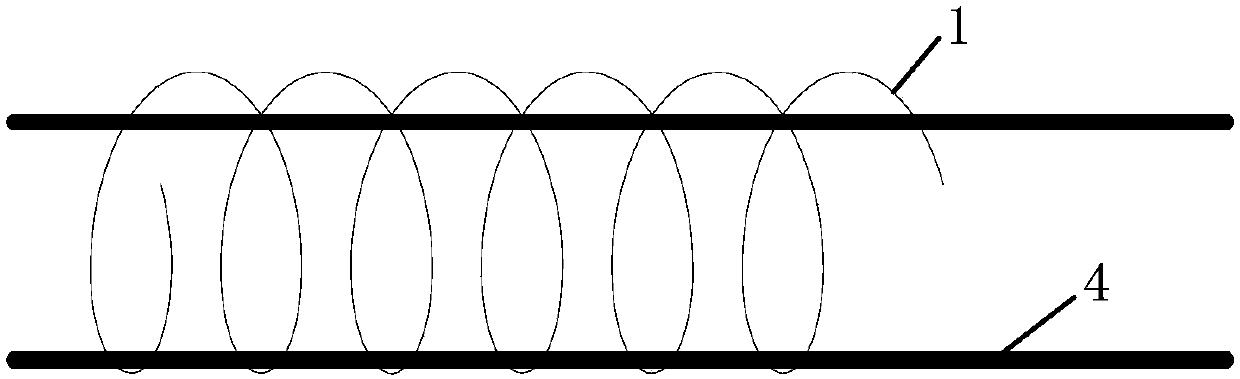

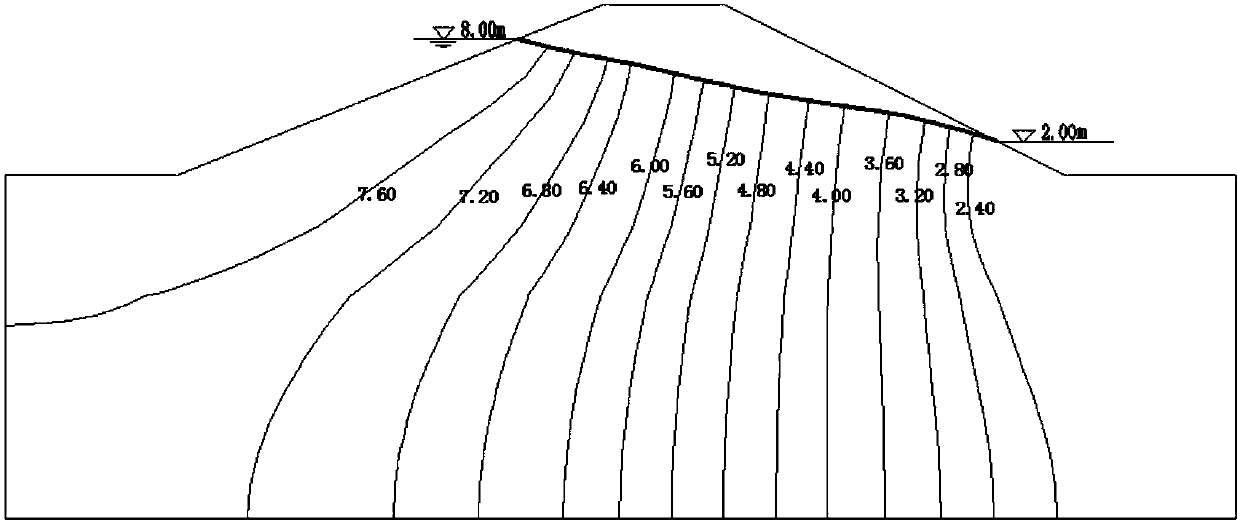

Optical fiber laying and imaging device and method for sensing phreatic surface of dam

Owner:HOHAI UNIV

Controlled variable length and illumination pattern light diffusing optical fiber

InactiveUS20160278622A1Exposure was also limitedLow costMechanical apparatusDiffusing elementsFiberMedicine

An illuming device for use in medically illuminating tissue of interest within a patient generally includes a light diffusing optical fiber and an at least partially optically opaque sheath that is mounted over the fiber for selective, sliding movement along the length thereof. By sliding the sheath relative to the optical fiber after it has been inserted into a patient to illuminate a particular area of tissue, the length, size, and / or shape of the light that is exposed to the tissue can be selectively controlled. Such in situ variation of the properties of the exposed light permit use of a single instrument and a single procedure regardless of variation in the size and shape of the diseased tissue being medically treated.

Owner:CORNING INC

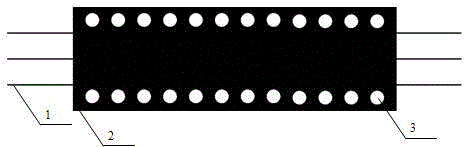

Novel optical cable sensing system for pipeline leakage detection

InactiveCN109424859AAccurately detect the location of leaksAlarm in timePipeline systemsEconomic benefitsComputerized system

Owner:苏州攀星光电科技有限公司

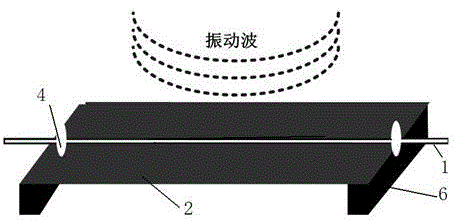

High-sensitivity metal baseband armored vibration sensing optical cable

PendingCN106405771AExtended service lifeEasy to processSubsonic/sonic/ultrasonic wave measurementFibre mechanical structuresAdhesiveAcoustic wave

Owner:SOUTH CHINA UNIV OF TECH

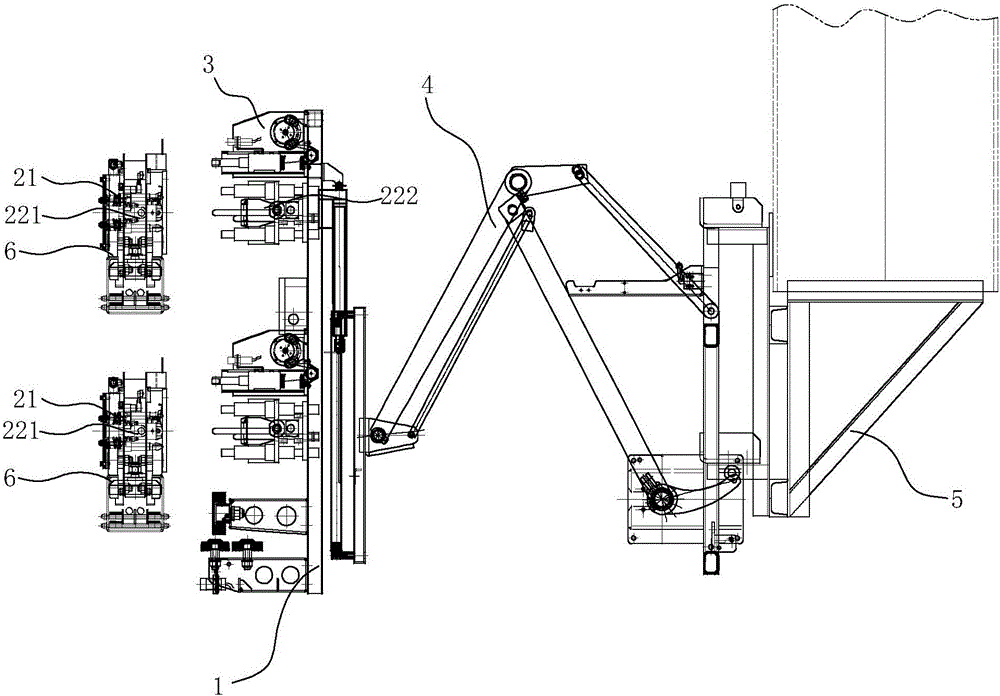

Remote control system for tyre gantry crane

ActiveCN105776025ASatisfy the operation mode of remote controlEasy to controlLoad-engaging elementsControl systemRemote control

Owner:NINGBO WEILONG PORT MASCH CO LTD

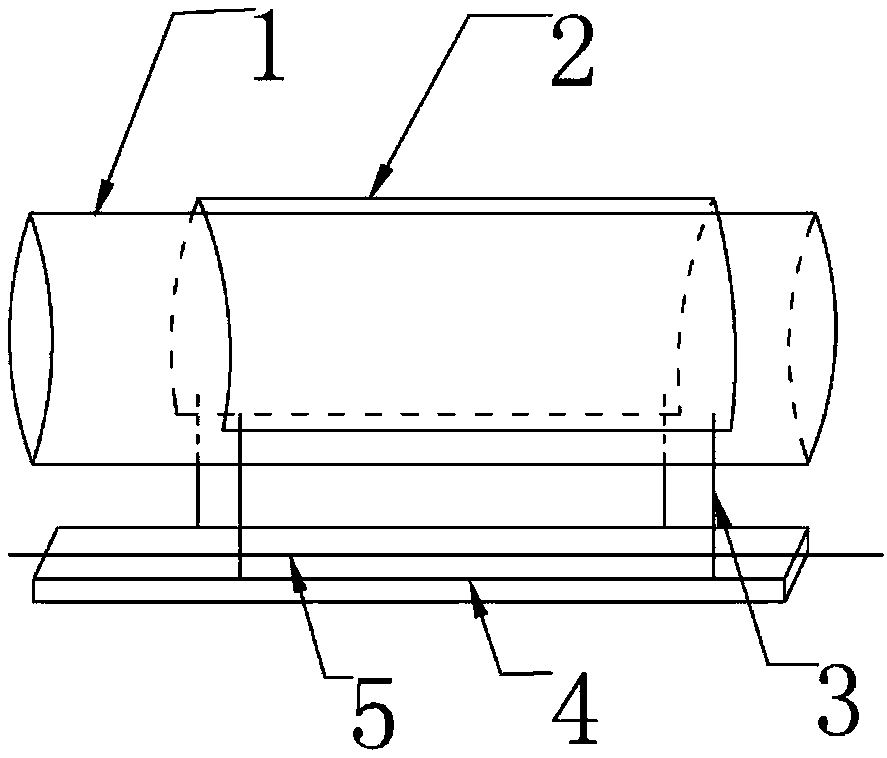

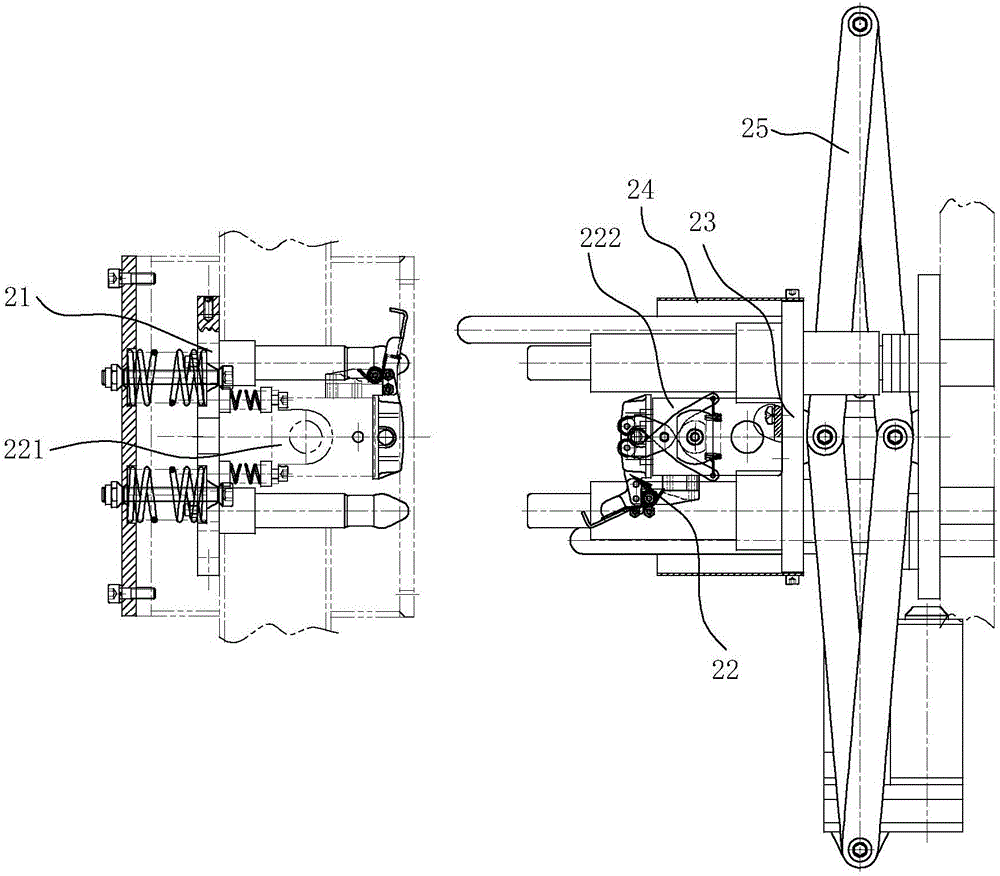

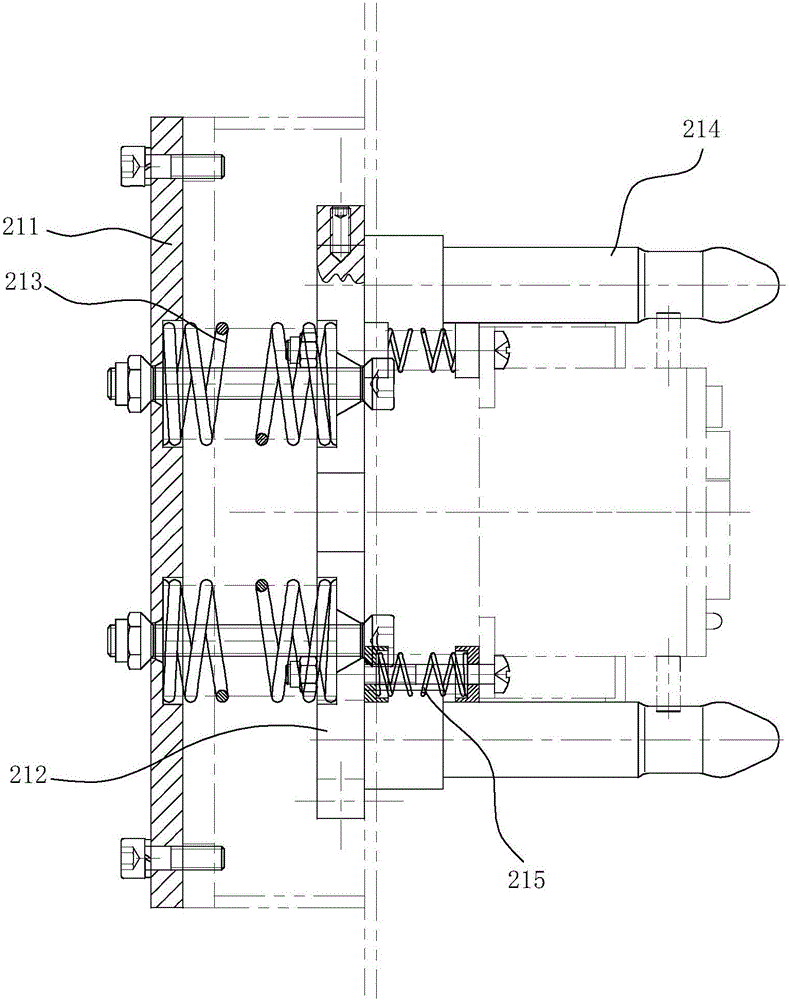

Fatigue test device based on optical fiber sensing technology

InactiveCN109374451ASave raw materialsReduce testing costsMaterial strength using repeated/pulsating forcesTension compressionBiochemical engineering

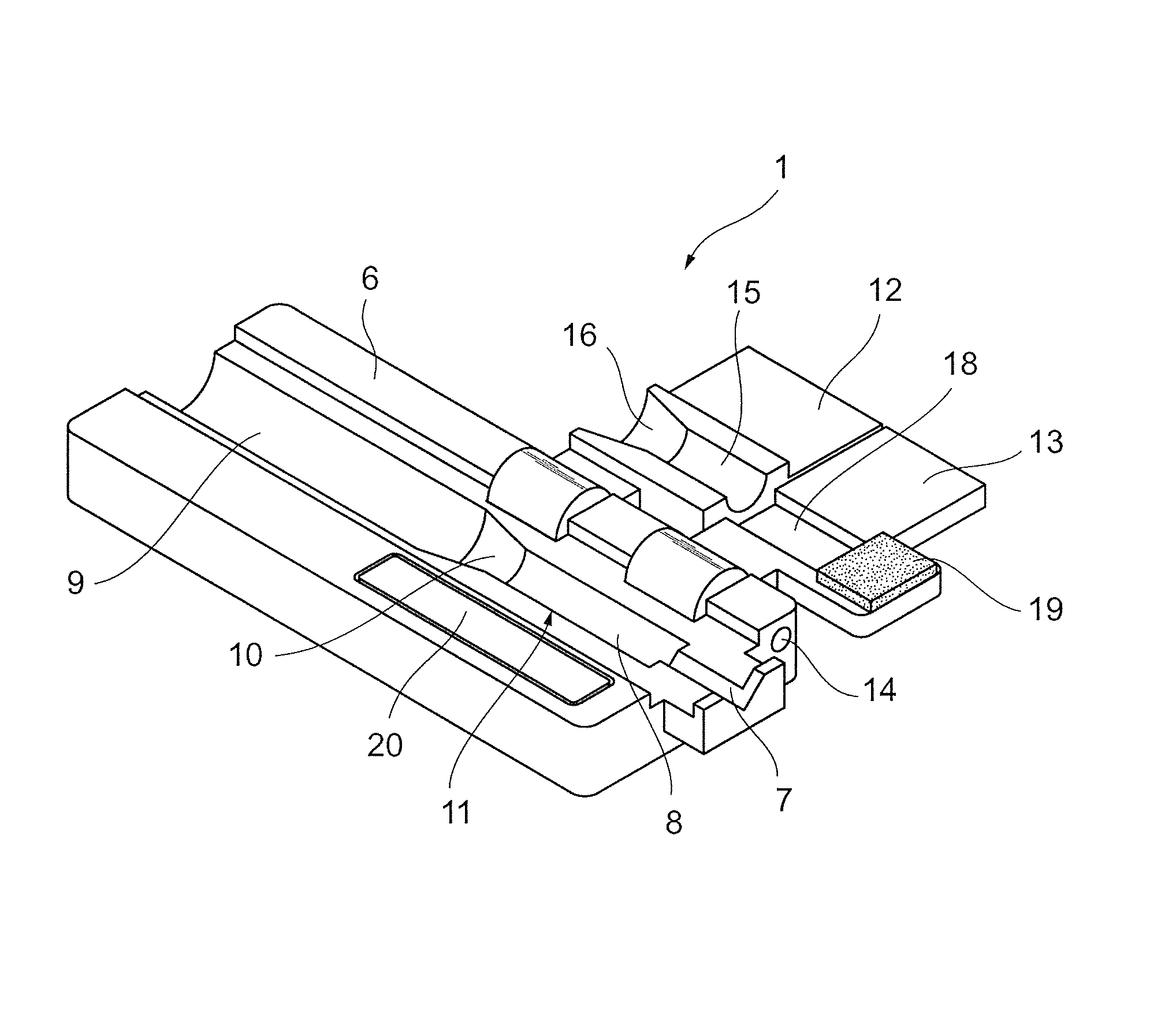

The invention provides a fatigue test device based on an optical fiber sensing technology. The fatigue test device comprises a loading mechanism, a fixing mechanism and an optical fiber sensor. The loading mechanism comprises a first loading piece and a second loading piece which are arranged oppositely and can move reversely in the tension-compression direction. The fixing mechanism is arranged between the first loading piece and the second loading piece and comprises a first fixing assembly and a second fixing assembly which are arranged oppositely, the first fixing assembly is connected with the first loading piece and can be connected with the first end of a test piece, and the second fixing assembly is connected with the second loading piece and can be connected with the second end ofthe test piece. The optical fiber sensor is detachably mounted on the test piece and used for detecting deformation of the test piece in the tension-compression direction. The fatigue test device canbe used for conducting tension-compression testing on the rod-shaped test piece, raw materials of the test piece can be saved, meanwhile, the deformation amount of the test piece can be precisely measured by adopting the optical fiber sensor, and the calculation precision of the fatigue life is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

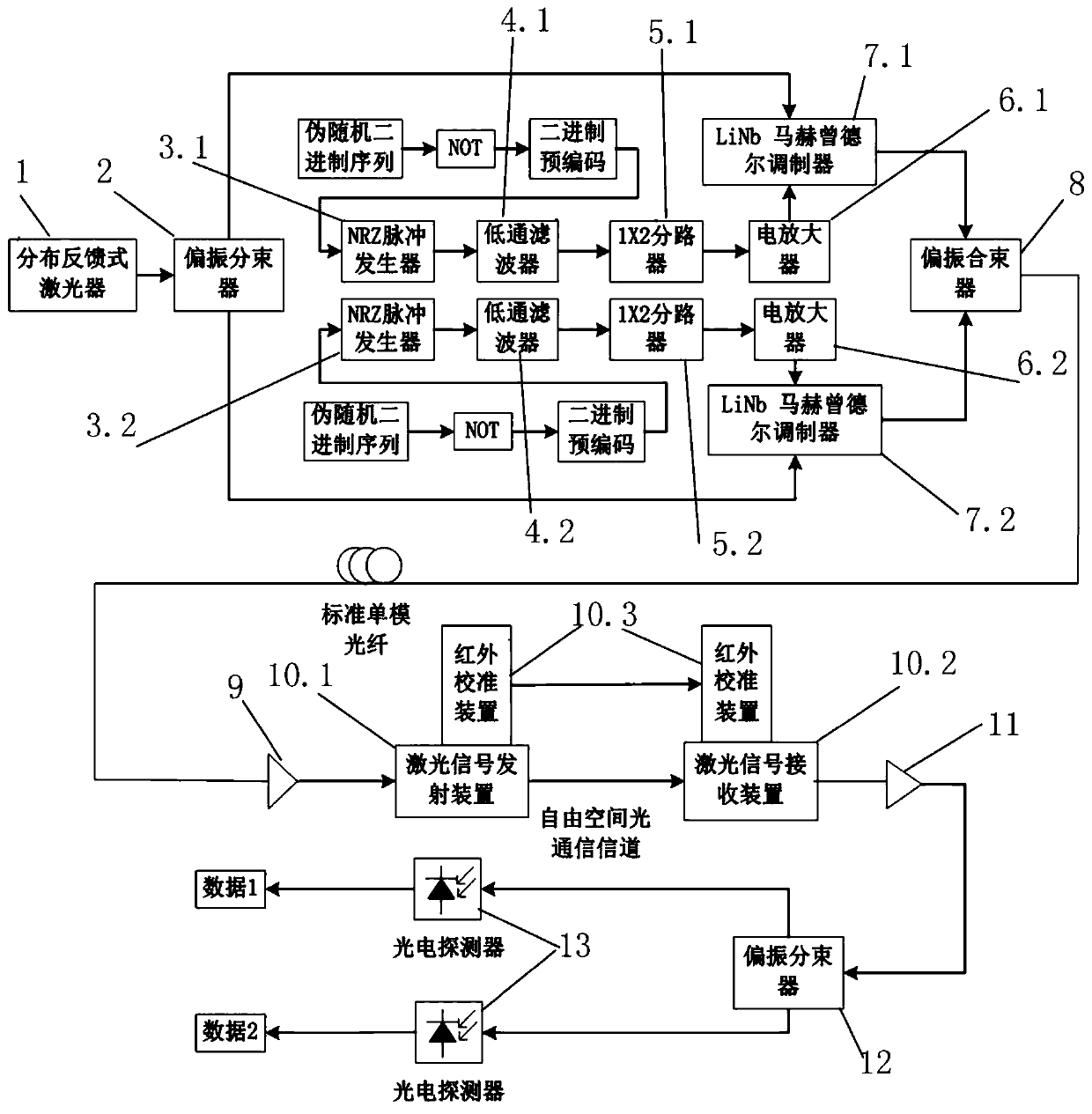

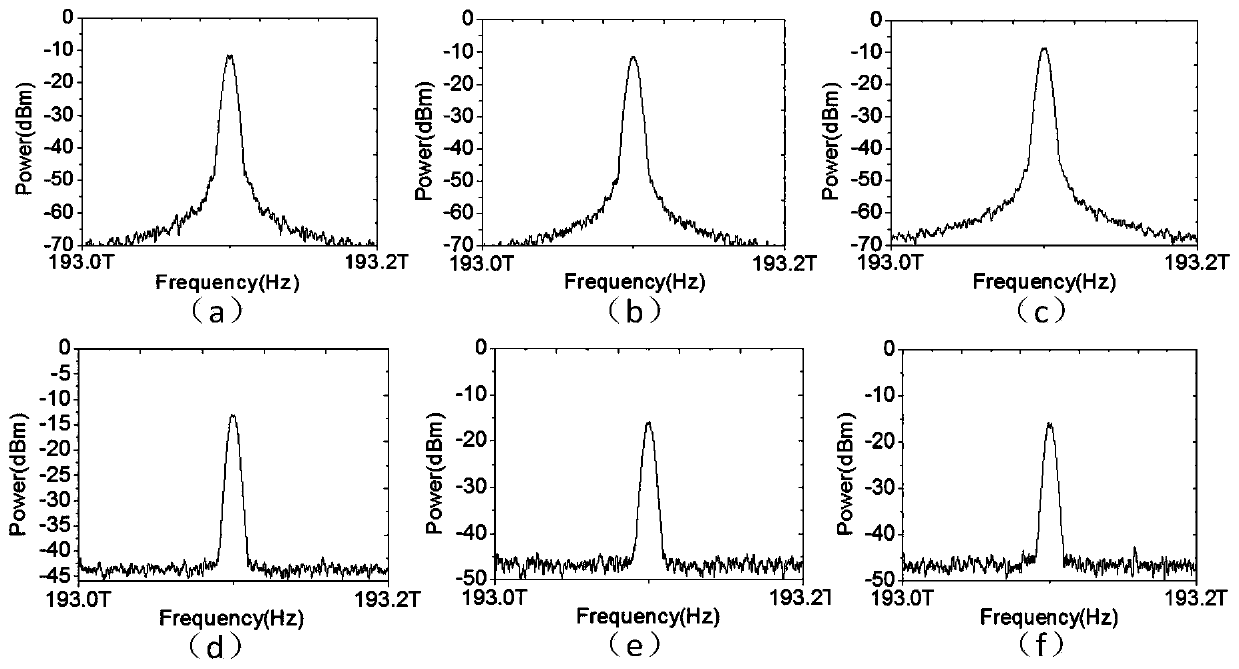

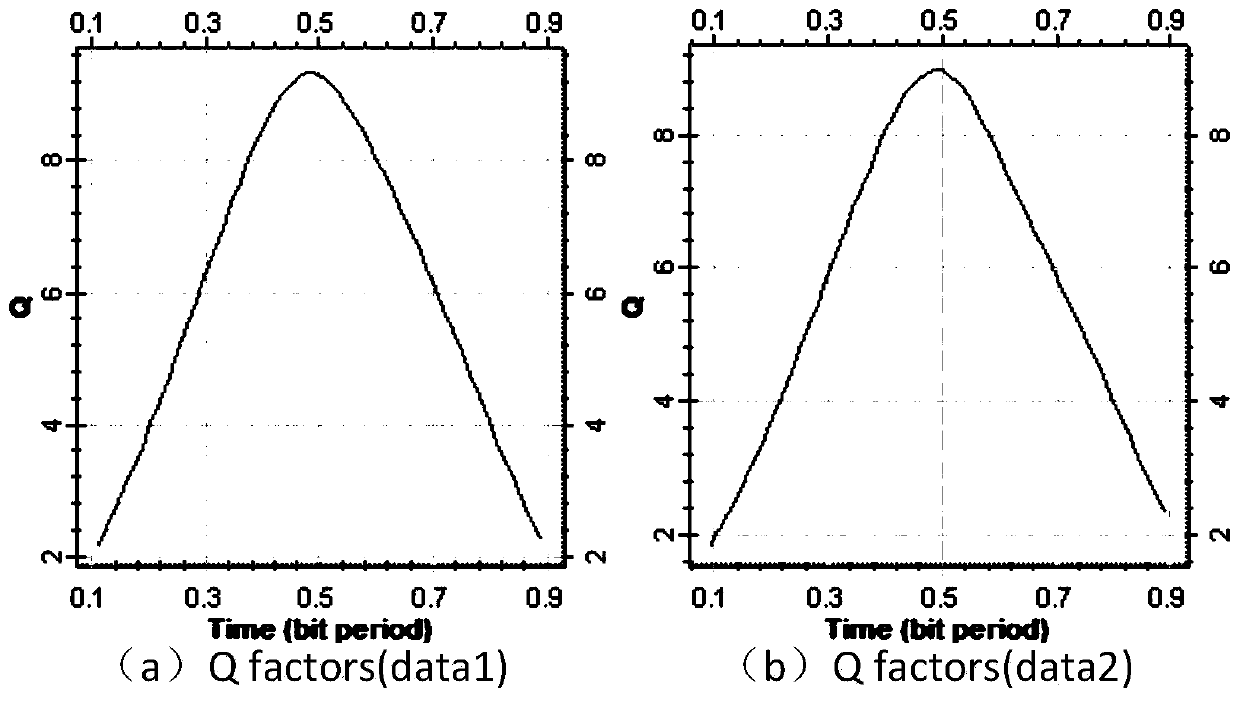

Dual-polarization-state dual-binary optical access system fusing optical fiber link and free space optical communication channel

ActiveCN110138454ANo added complexityPolarisation multiplex systemsFibre transmissionHigh bandwidthEngineering

Owner:CHONGQING THREE GORGES UNIV

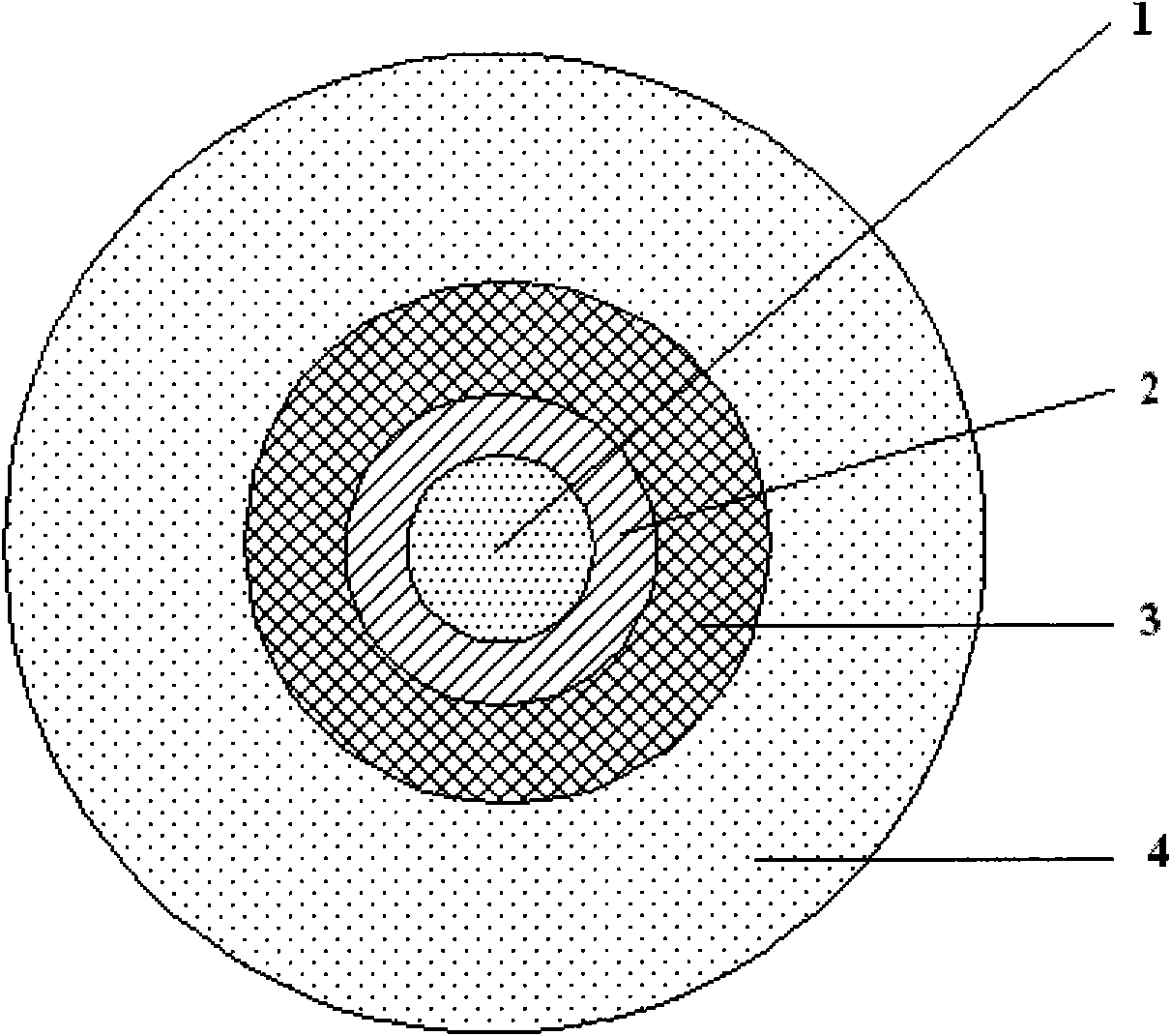

Purified quartz powder modified for cladding optic fiber cable

A highly purified quartz powder having a low level of naturally occurring lithium modified for cladding a fiber optic cable, said modified quartz powder having an increased total amount of lithium in solid solution in said powder, said increased total amount being in the range of more than 0.50 ppm and less than 1.00 ppm and a method of modifying an highly purified quartz powder to make the same.

Owner:SIBELCO NORTH AMERICA INC

Audio/video communication guide rope for fire control

InactiveCN104575827AAccurate transmissionImprove shielding effectPower cables with screens/conductive layersInsulated cablesElectrical conductorFire control

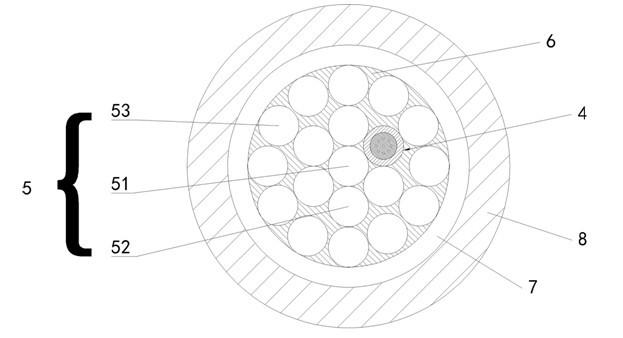

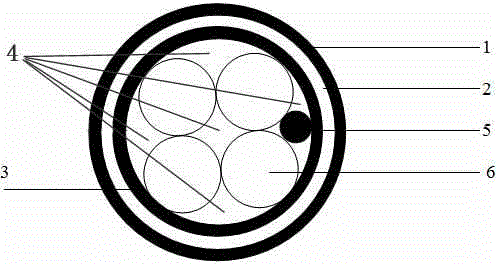

The invention discloses an audio / video communication guide rope for fire control. The audio / video communication guide rope comprises an optical cable core. The optical cable core comprises a center stiffener located at the center, and cables and optical cables distributed in the peripheral direction of the center stiffener in a staggered mode. The cables are used for transmitting electric energy, and each cable core comprises a conductor and an insulating layer covering the conductor. The optical fibers are used for transmitting video signals and audio signals. Each optical cable core comprises a PBT loose tube and an optical fiber unit attached to the inner side of the PBT loose tube. The cable cores and the optical cable cores are stranded integrally in the circumferential direction of the center stiffener. The audio / video communication guide rope further comprises a metal shielding layer covering the optical fiber cores and a tensile high-strength protection layer covering the metal shielding layer. The tensile high-strength protection layer is made of nylon, and waterproof fillings are arranged between the cable cores and optical fiber cores and the metal shielding layer and between the PBT loose tubes and the optical fiber units.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

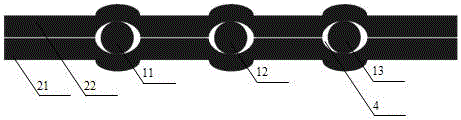

Novel FTTH optical fiber cable and production process thereof

PendingCN109725397AImprove bindingStable structureFibre mechanical structuresCrack resistanceEngineering

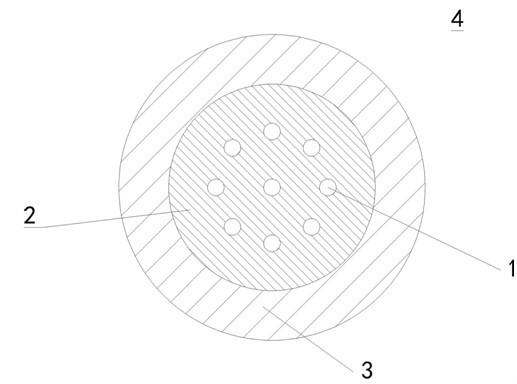

The invention discloses a novel FTTH optical fiber cable and a production process thereof. The novel FTTH optical fiber cable has the advantages of high adhesion between a reinforcing element and a sheath, torsion resistance, crack resistance, sheath tension resistance and stable structure, and is suitable for optical fiber cables in various complicated installation environments. The novel FTTH optical fiber cable of the invention is composed of a sheath layer, an optical fiber and a reinforcing element; the novel FTTH optical fiber cable comprises an indoor FTTH optical cable and an indoor and outdoor dual-purpose FTTH optical cable. The indoor FTTH optical cable only comprises a main component, and the indoor and outdoor dual-purpose FTTH optical cable comprises a main component and an auxiliary component integrally with the main component. The main component comprises a reinforcing element, a reinforcing element coating layer, a sheath layer and an optical fiber coated with the sheath layer, which are sequentially arranged from the inside to the outside; and the auxiliary component comprises a reinforcing element, a reinforcing element coating layer and a sheath layer arranged sequentially from the inside to the outside.

Owner:HEFEI XINGLIAN COMM

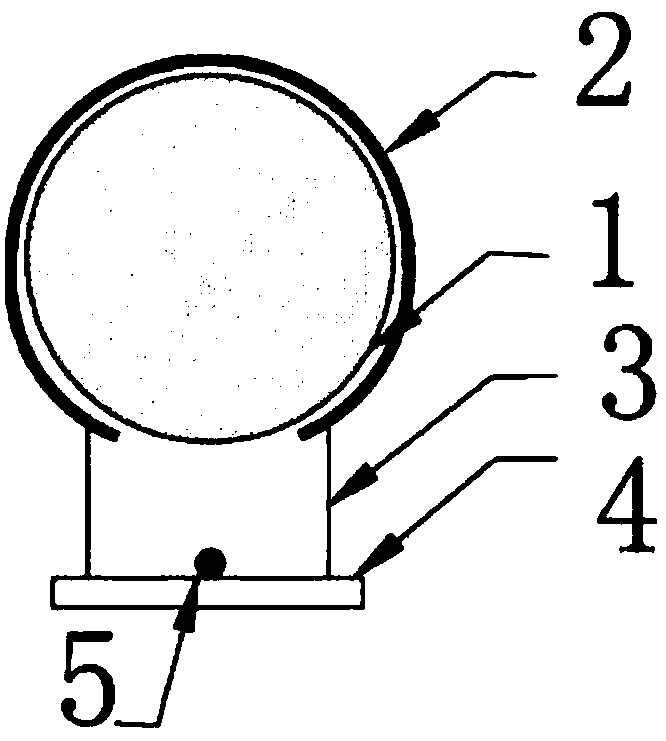

Near-infrared light electrode cap with optical fiber prompt

PendingCN107551409ALarge spread angleWider and more uniform diffusion angleLight therapyElectricityTreatment effect

Owner:WUHAN ZNION TECH CO LTD

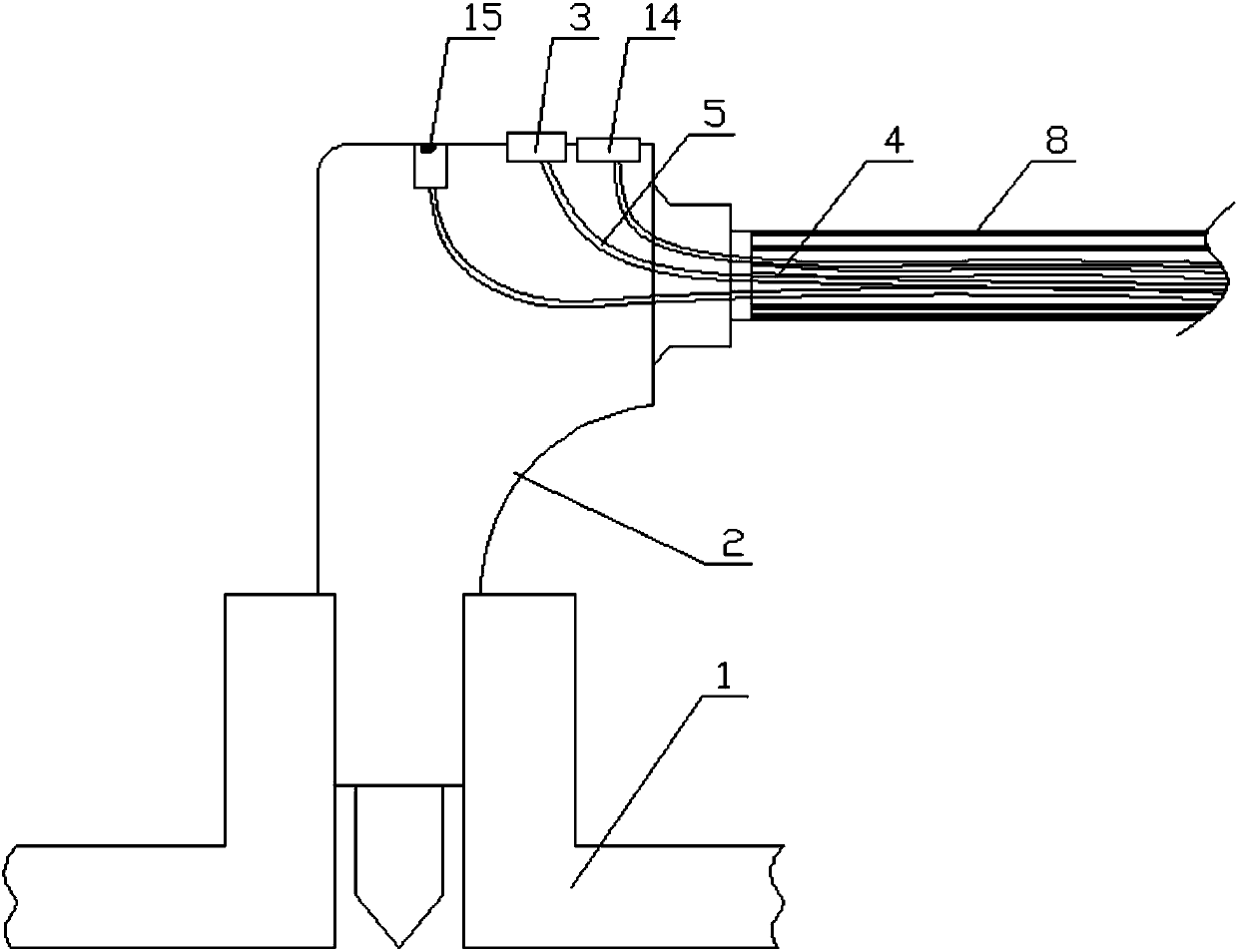

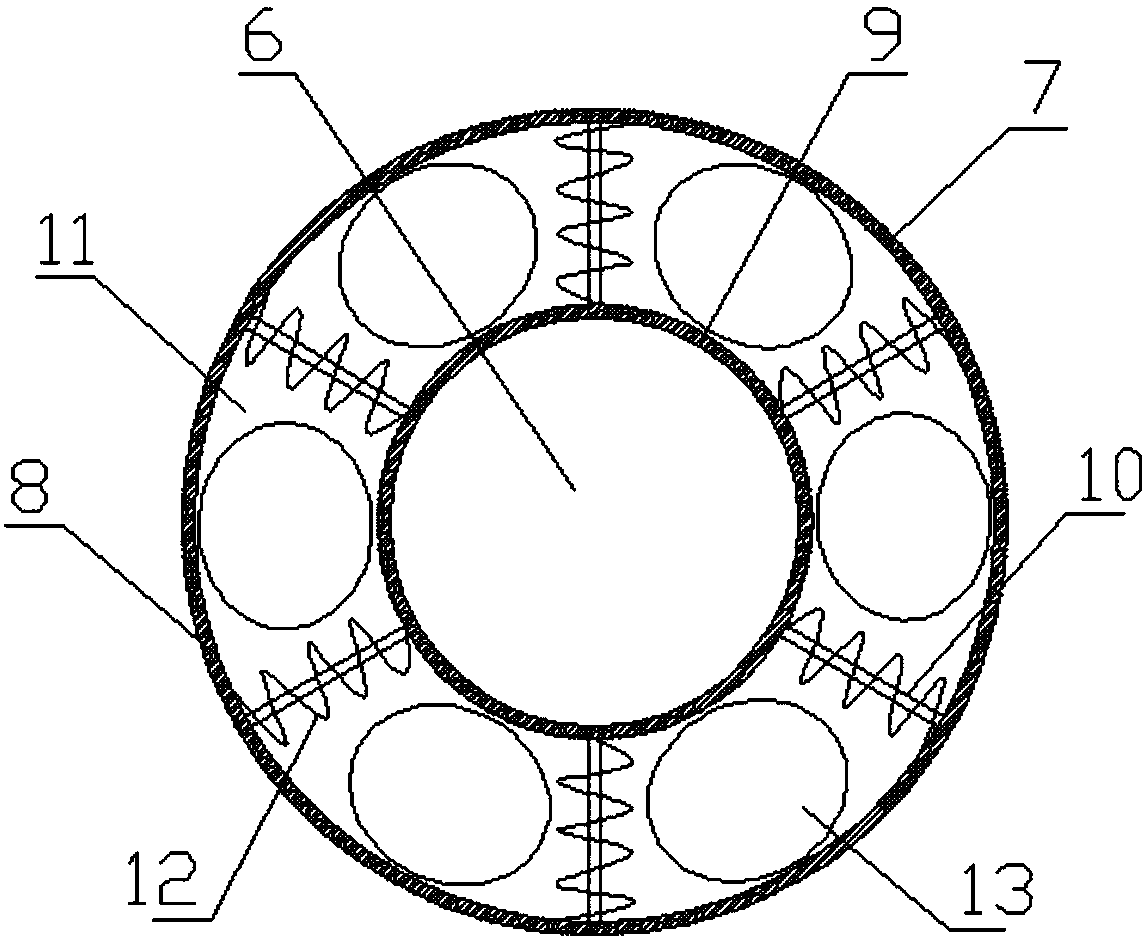

Novel optical fiber composite low-voltage cable

InactiveCN104952540ASave resourcesPrevent easy breakageInsulated cablesPower cablesElectric power transmissionLow voltage

Owner:WUXI SHUGUANG CABLE

Novel optical fiber adapter tube

InactiveCN109782395ABarrier damageReduce vibrationCoupling light guidesRubber ringBiochemical engineering

Owner:丹阳亿仁通信设备有限公司

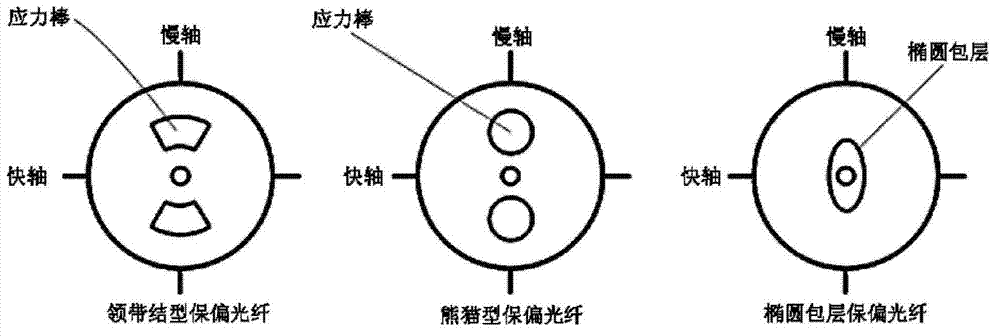

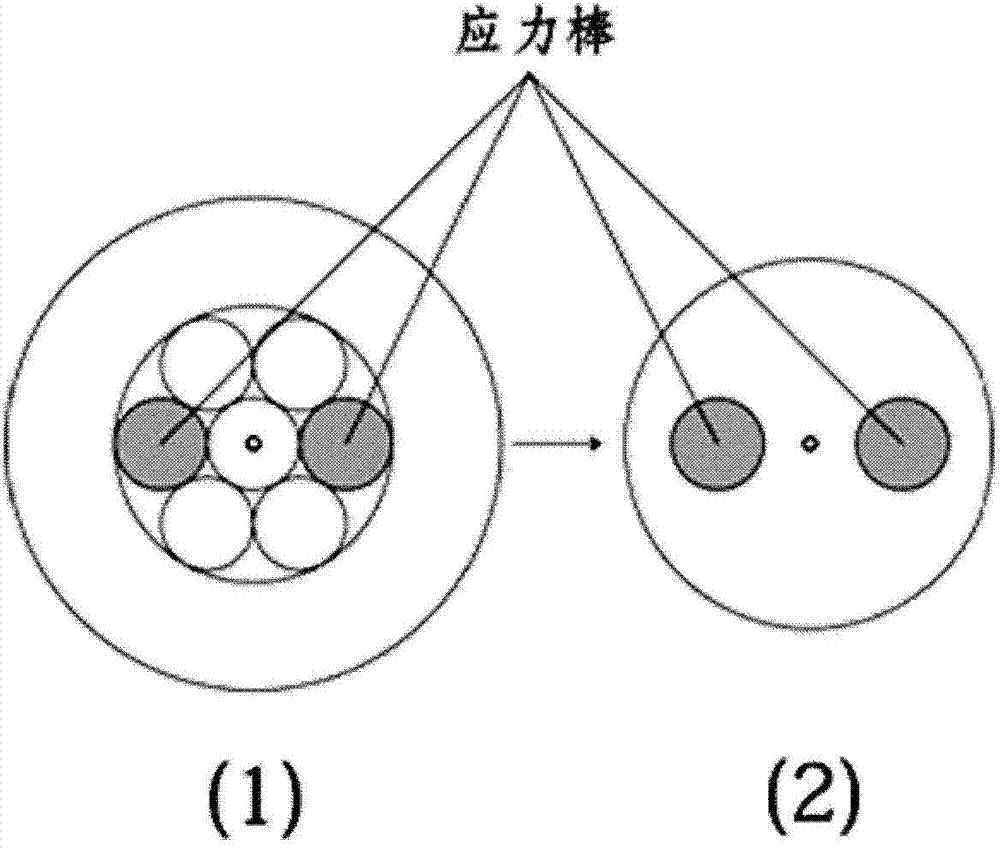

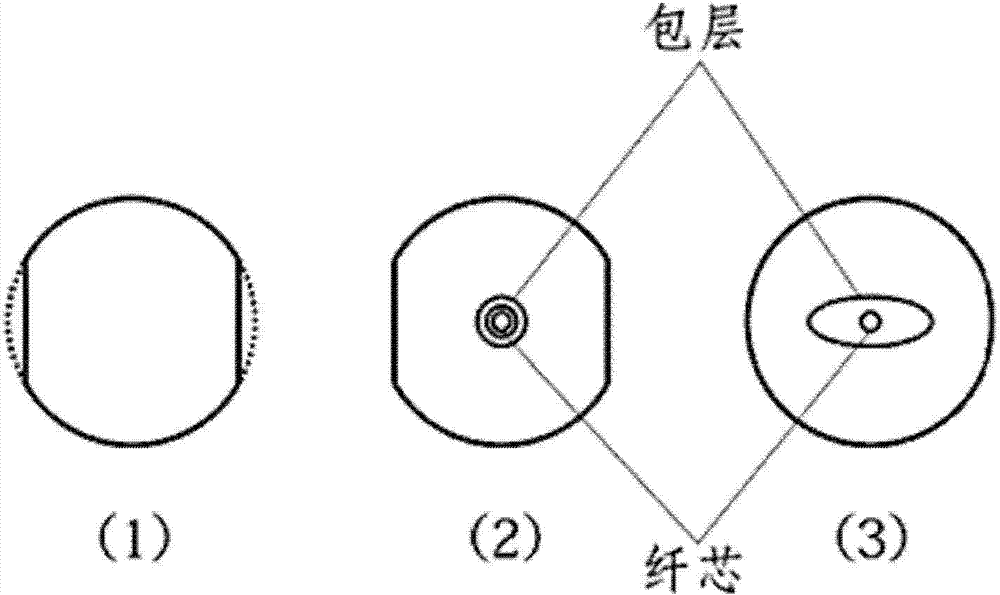

Novel high-birefringence polarization maintaining optical fiber capable of maintaining random polarization and manufacturing method thereof

InactiveCN103048731AGlass making apparatusOptical fibre with polarisationRefractive indexPolarization-maintaining optical fiber

Owner:UNIV OF SCI & TECH OF CHINA

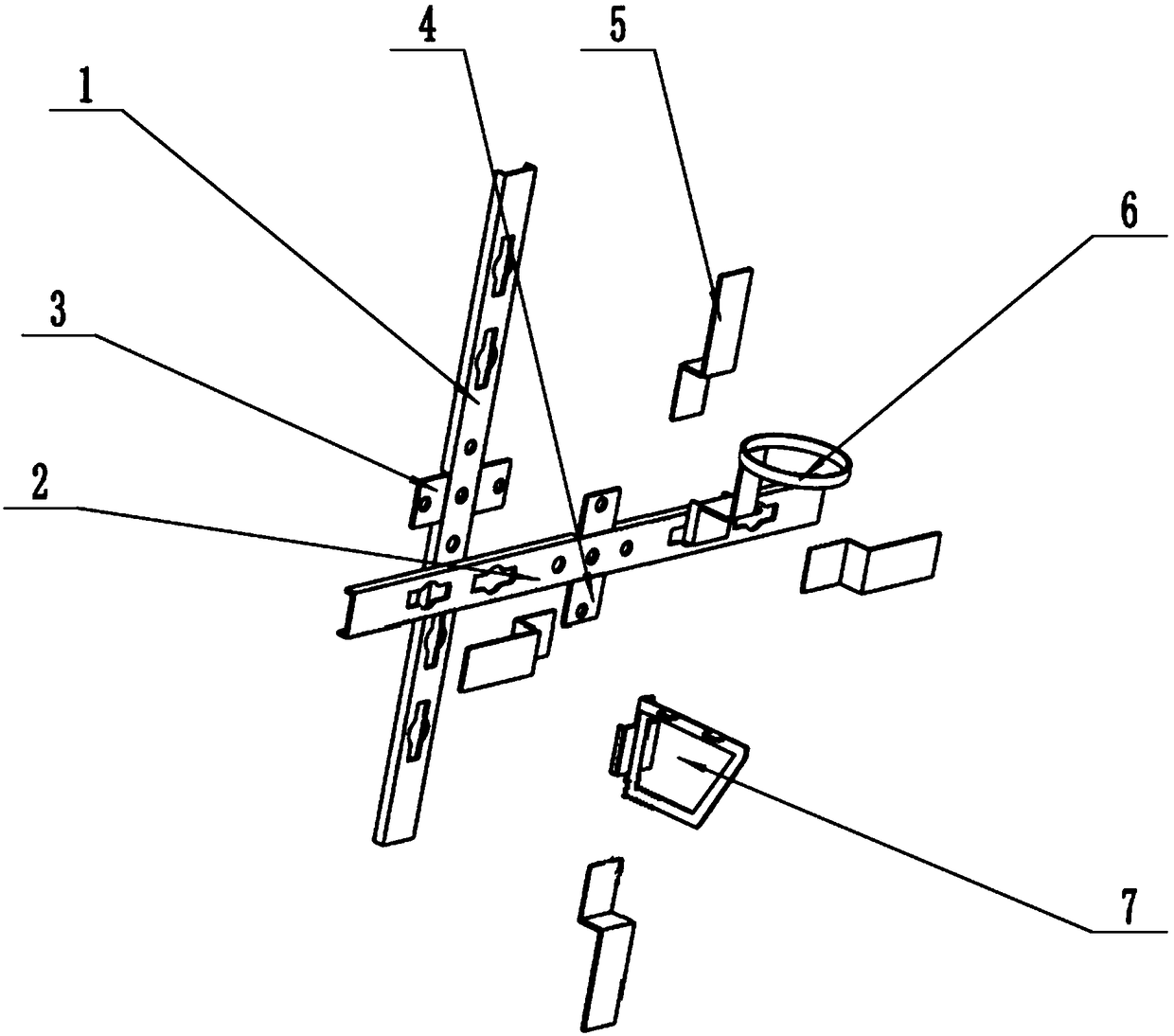

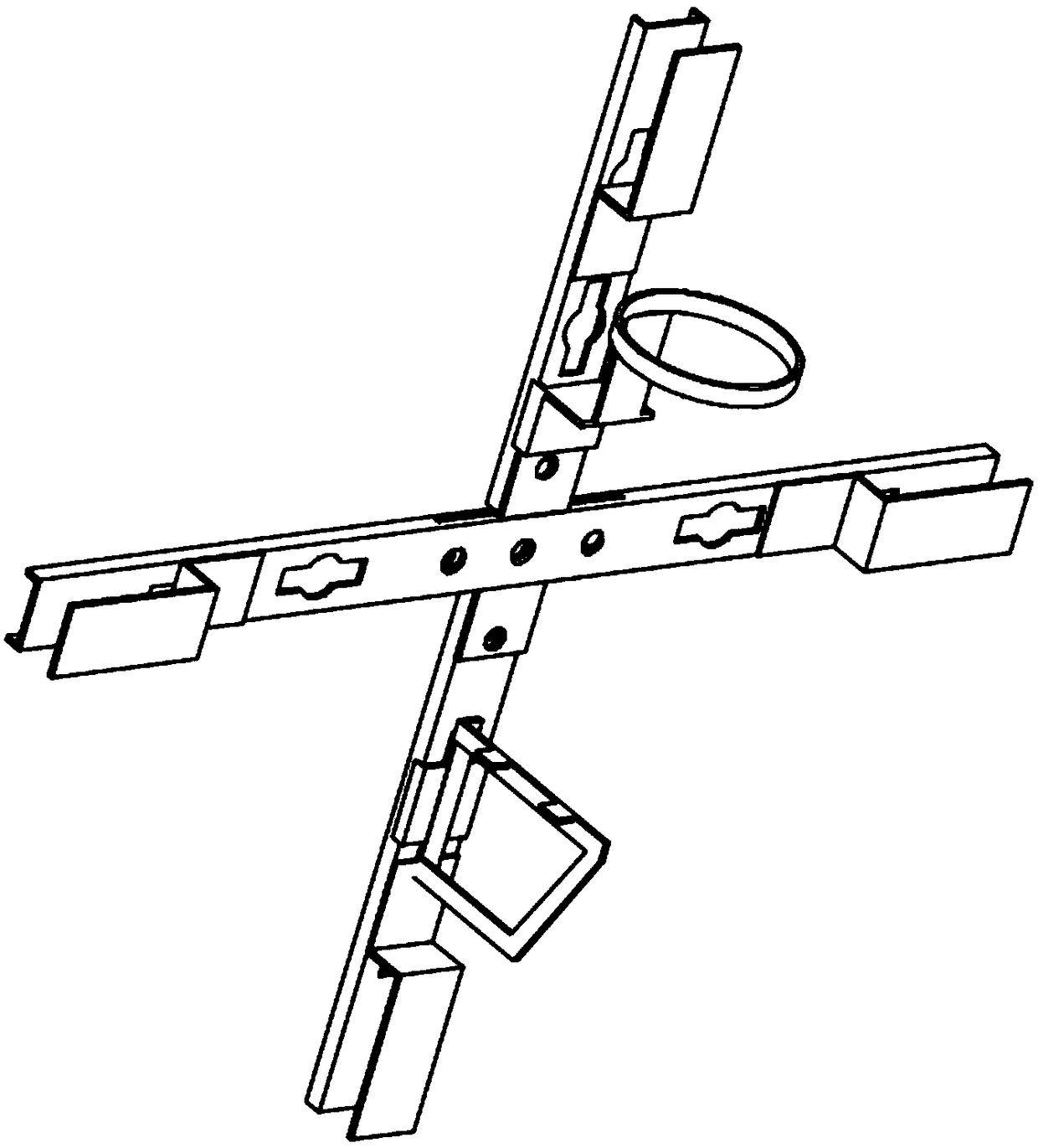

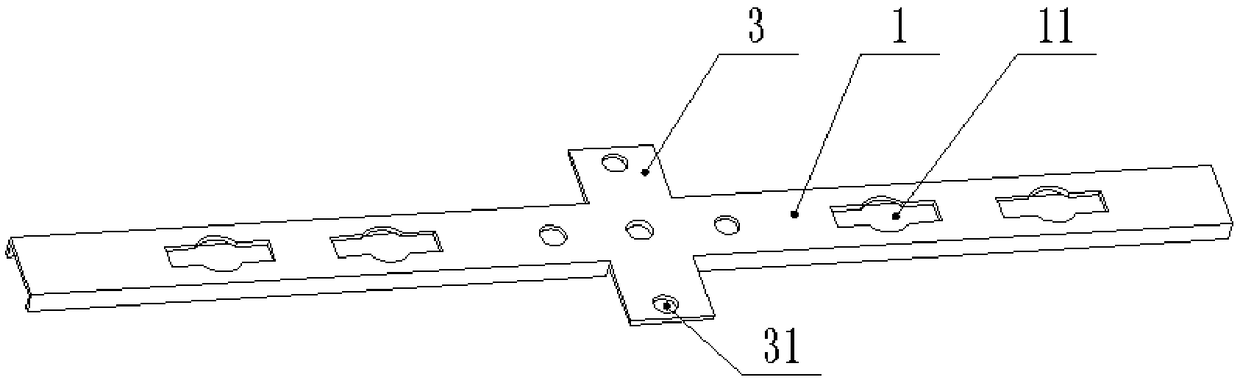

Combined residual cable coiling storage device suitable for ADSS (All Dielectric Self-Supporting) optical fiber cable

PendingCN109307914ASave manpower and material resourcesSave moneyFibre mechanical structuresEngineeringOptical fiber cable

Owner:INFORMATION COMM COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

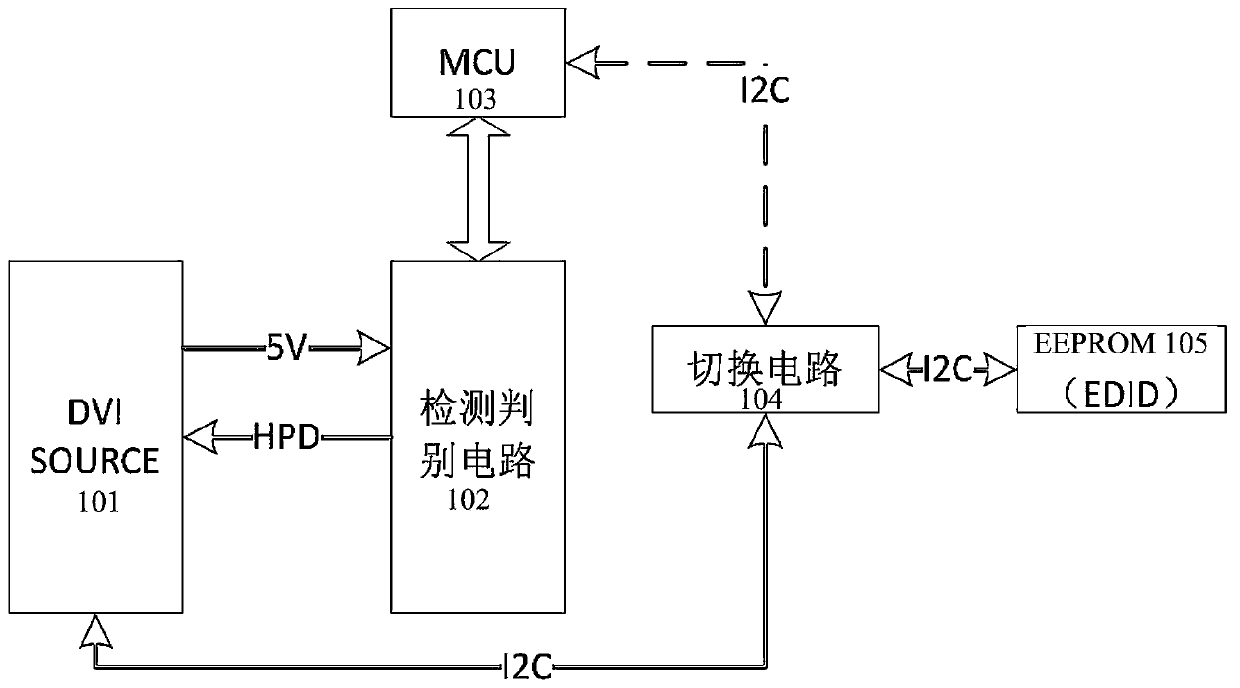

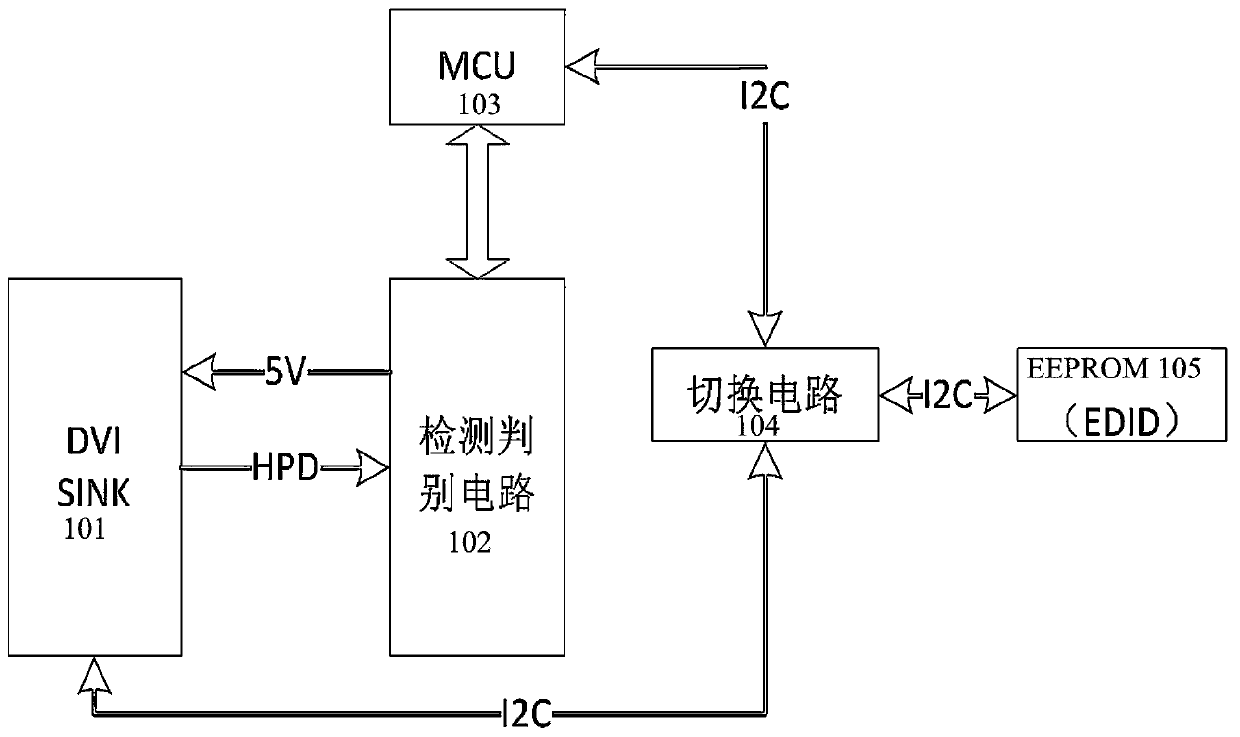

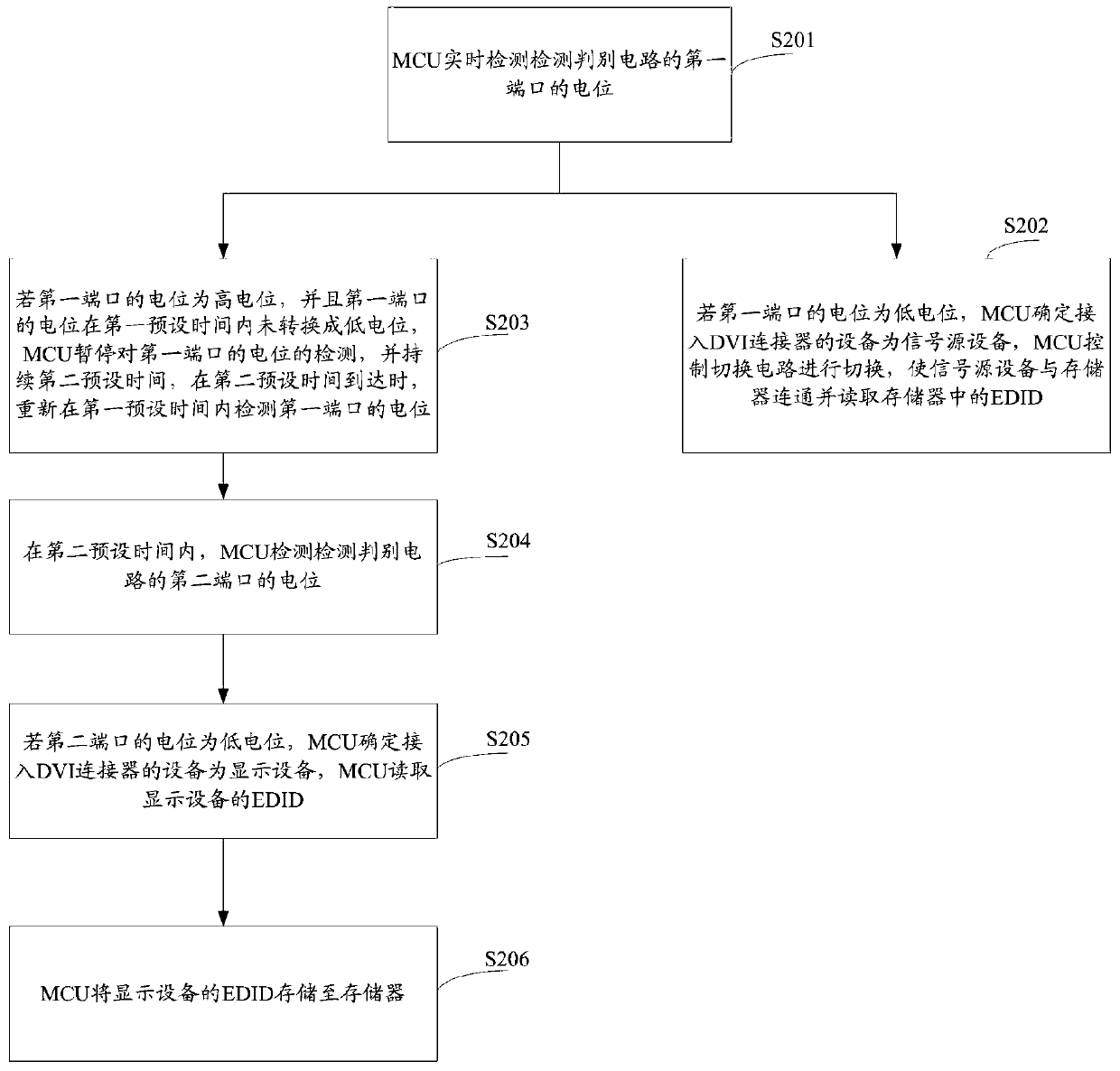

EDID processing method, micro-control unit and optical fiber sending box

Owner:GUANGDONG VTRON TECH CO LTD

Optical fiber coupling connector

InactiveCN102445734AGuaranteed Optical AlignmentImprove the efficiency of optical signal transmissionCoupling light guidesMechanical engineeringOptical fiber cable

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap