Indoor-laying optical fiber and manufacture method thereof

A manufacturing method and optical fiber technology, applied in cladding optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as difficulty in adapting to wiring space, poor bending performance, and large diameter of optical cable, and achieve flexible and convenient wiring connection and low manufacturing cost. Low, good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings.

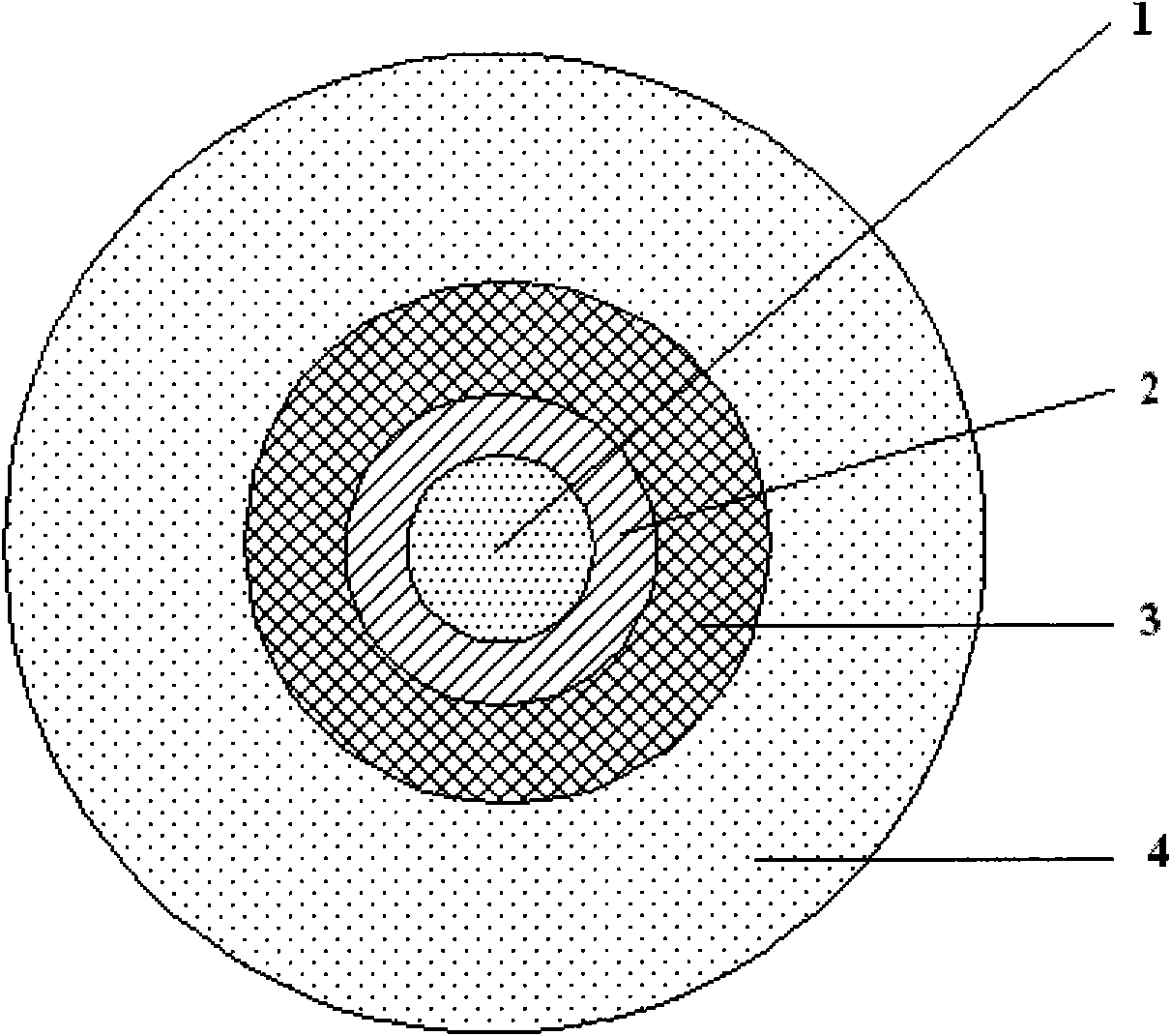

[0020] It includes a bare glass optical fiber 1, a buffer layer 2 and a transition layer 3 are sequentially coated on the outer periphery of the bare glass optical fiber, and an outer protective layer 4 is coated on the transition layer.

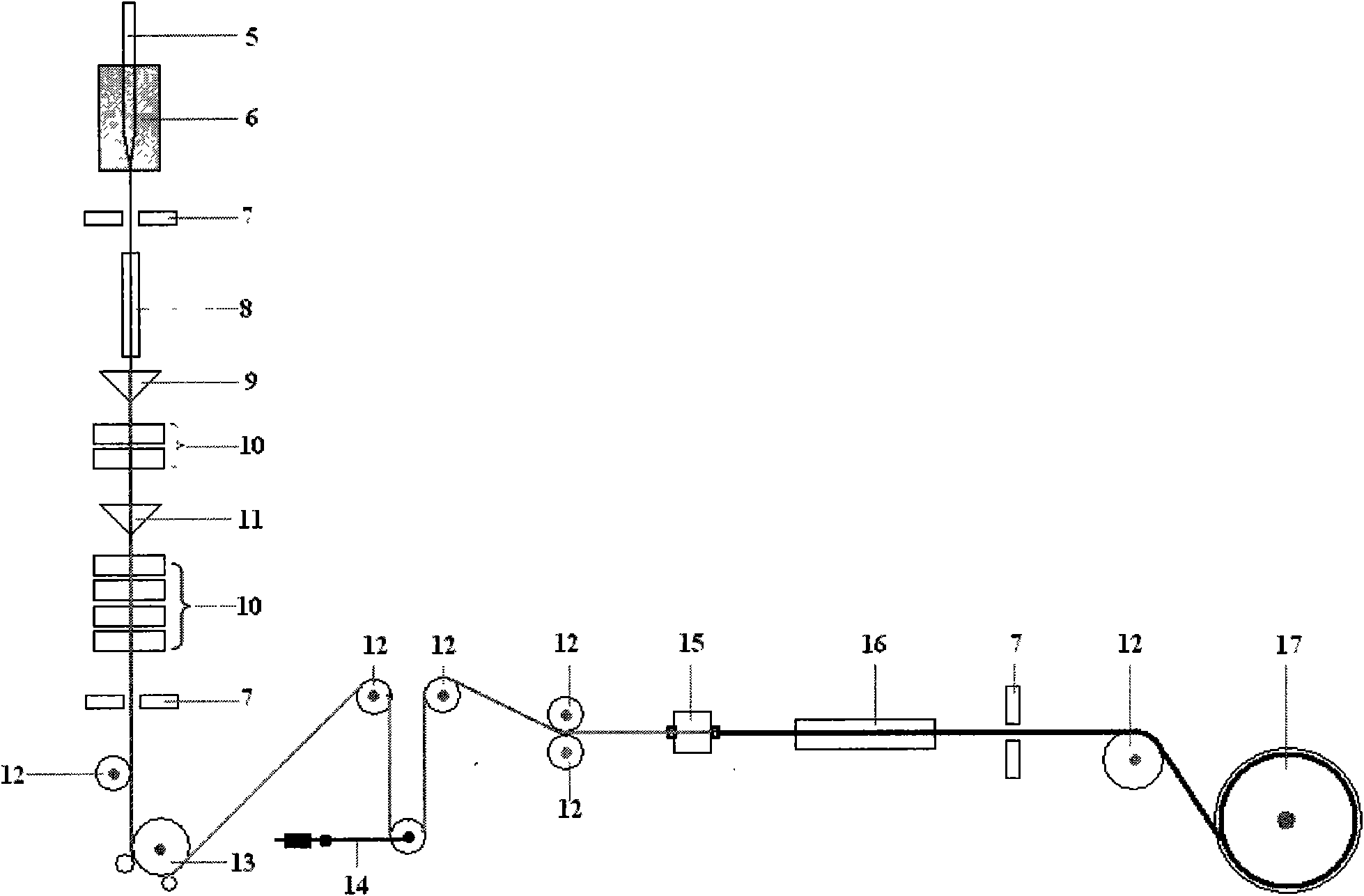

[0021] The manufacturing process of the optical fiber is as follows: put the optical fiber preform 5 into the drawing furnace 6, heat and pull out the optical fiber, after the optical fiber is cooled by the outer diameter measuring instrument 7 and the cooling pipe 8, it is successively passed through two surface coating devices 9, 11 and 8. The ultraviolet curing device 10 is used to coat and cure the buffer layer and the coating and curing of the transition layer. After the optical fiber coated with the buffer layer and the transition layer is drawn out, it passes through the outer diameter measuring instrument

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap