Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms parts with an excellent surface finish.

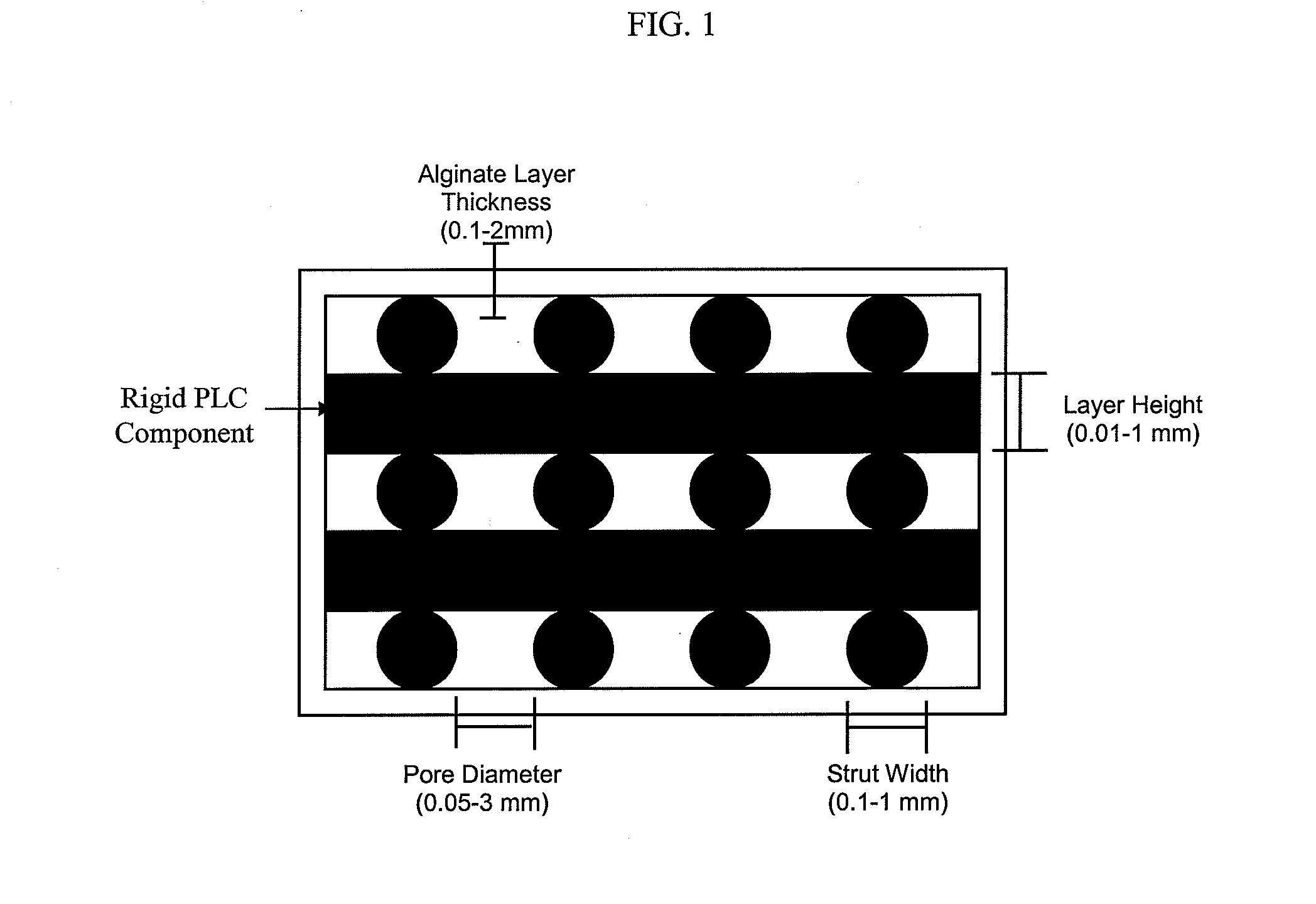

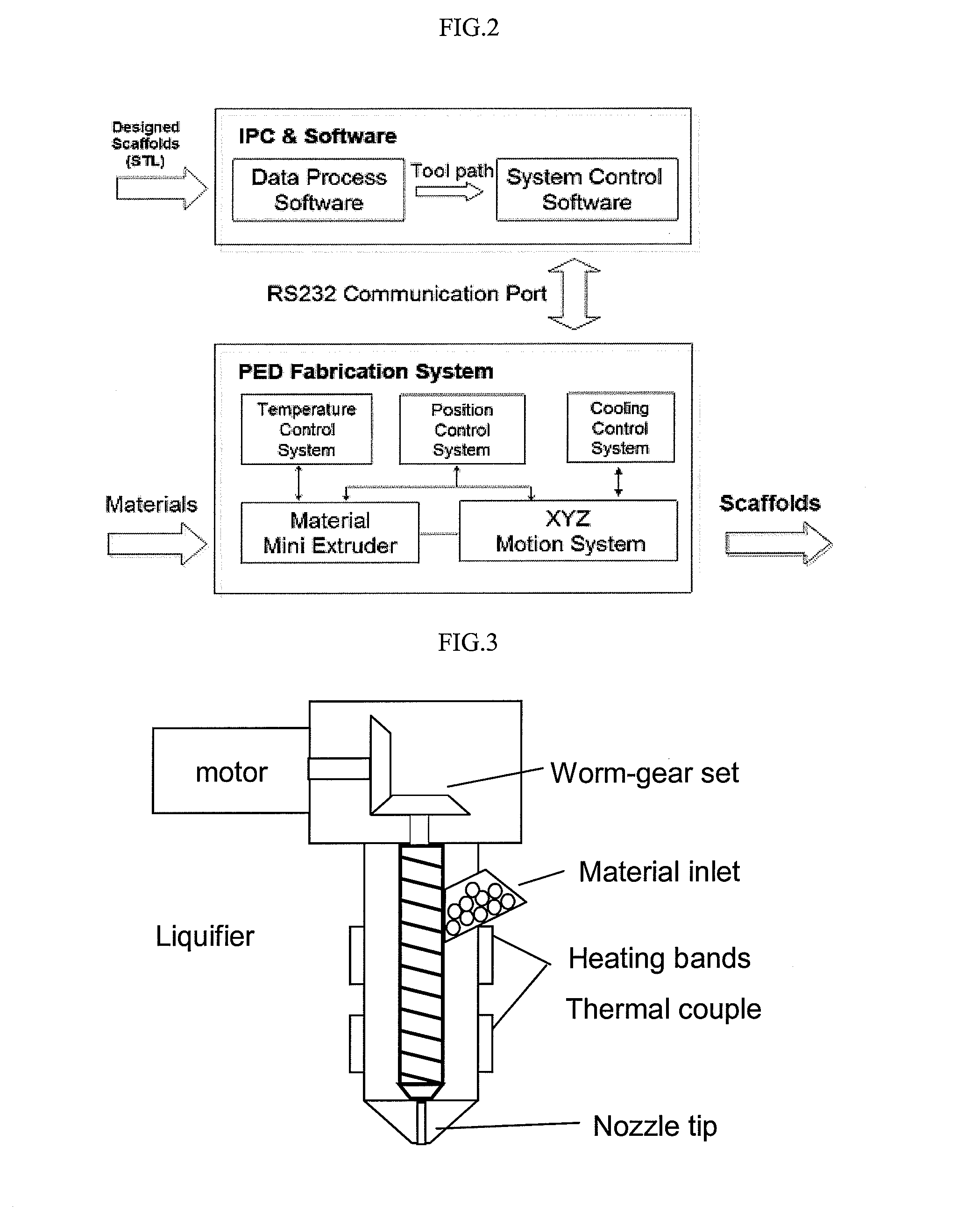

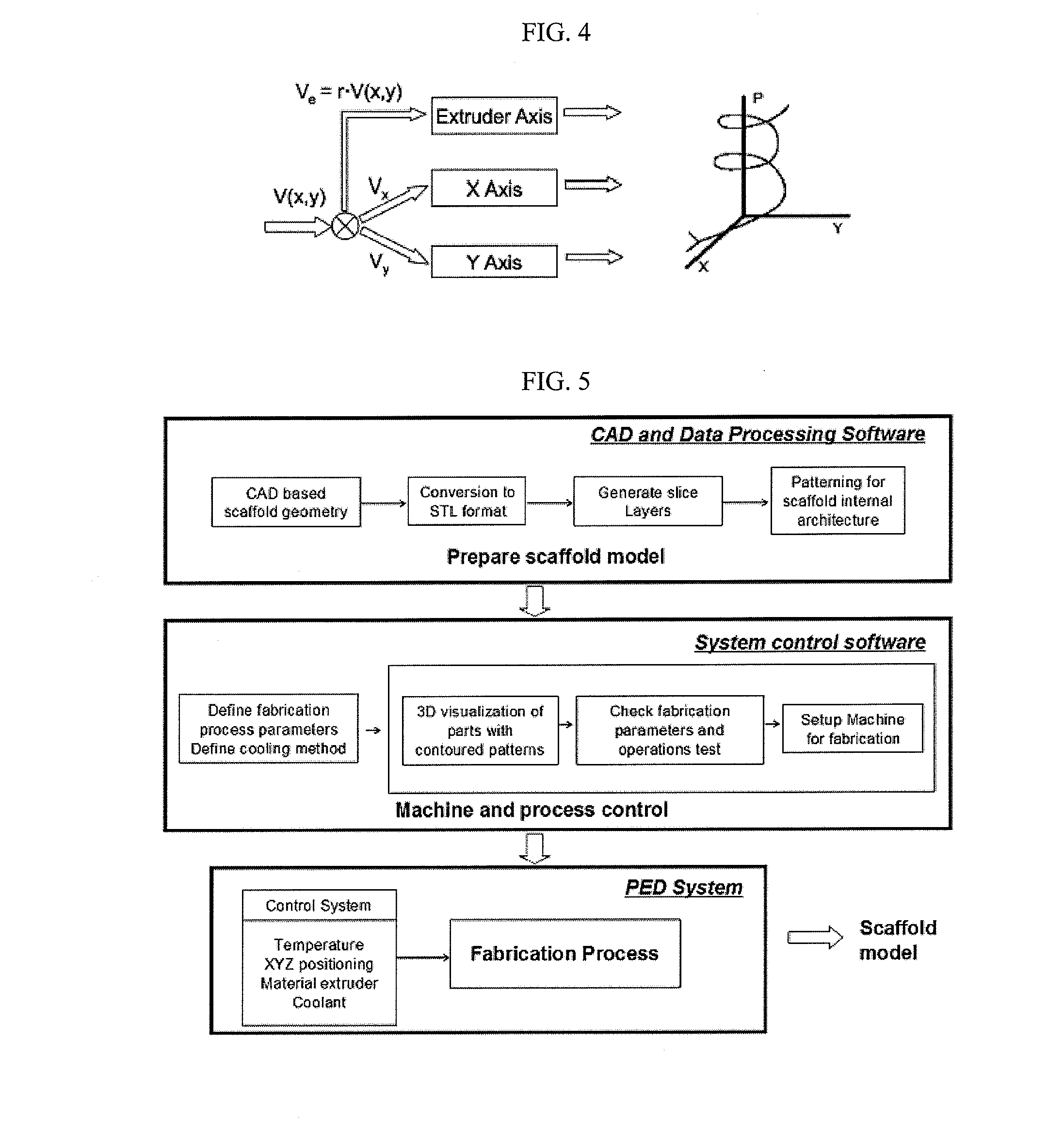

Super-sparger microcarrier beads and precision extrusion deposited poly-epsilon-caprolactone structures for biological applications

Owner:DARLING ANDREW +3

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Preparation method of sheepskin collagen casing

The invention discloses a preparation method of a sheepskin collagen casing. The preparation method comprises raw sheepskin immersion in water and washing, liming hair removal, hydrogen peroxide treatment, primary pickling, mincing and beating, compounding, secondary pickling, homogenization and filtration, extrusion and curing, water washing and plastification, UV crosslinking, drying and humidification. The preparation method realizes the comprehensive utilization of bur sheepskin, prevents the waste of resources and the pollution of the environment and can produce huge economic and social benefits.

Owner:INNER MONGOLIA QIUSHI BIOLOGICAL CO LTD

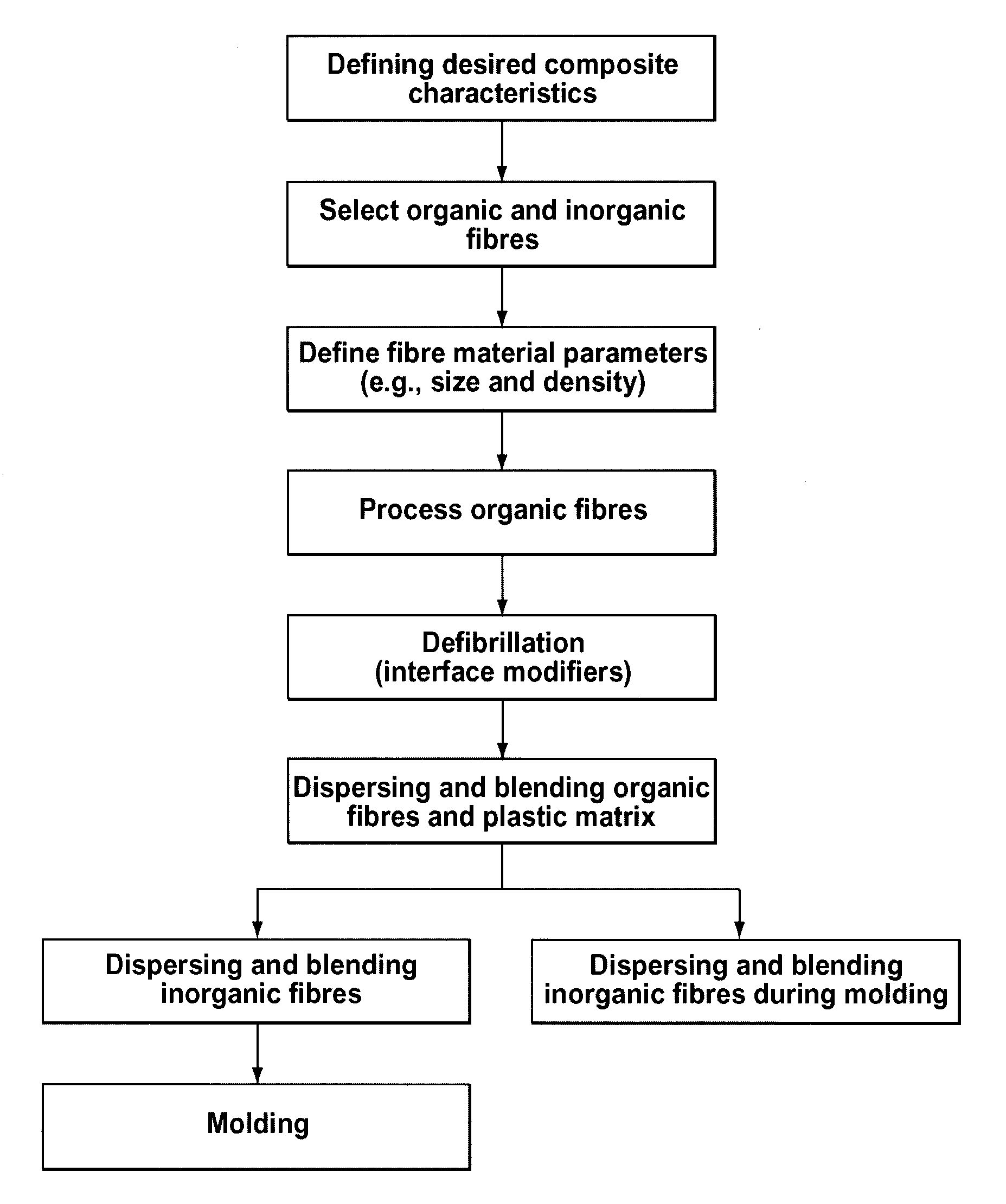

Manufacturing process for hybrid organic and inorganic fibre-filled composite materials

Owner:SAIN MOHINI M +2

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

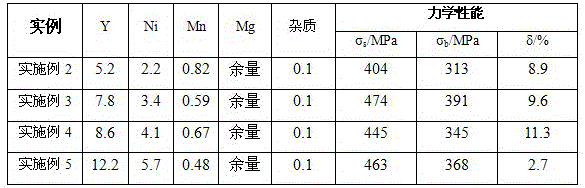

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

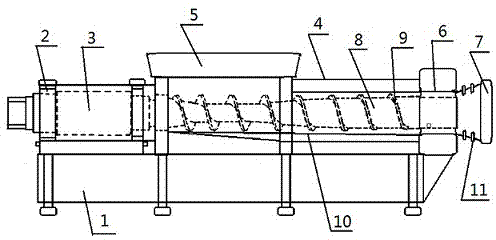

Single-screw extruder

Owner:NANNING SUGAR INDUSTRY CO LTD

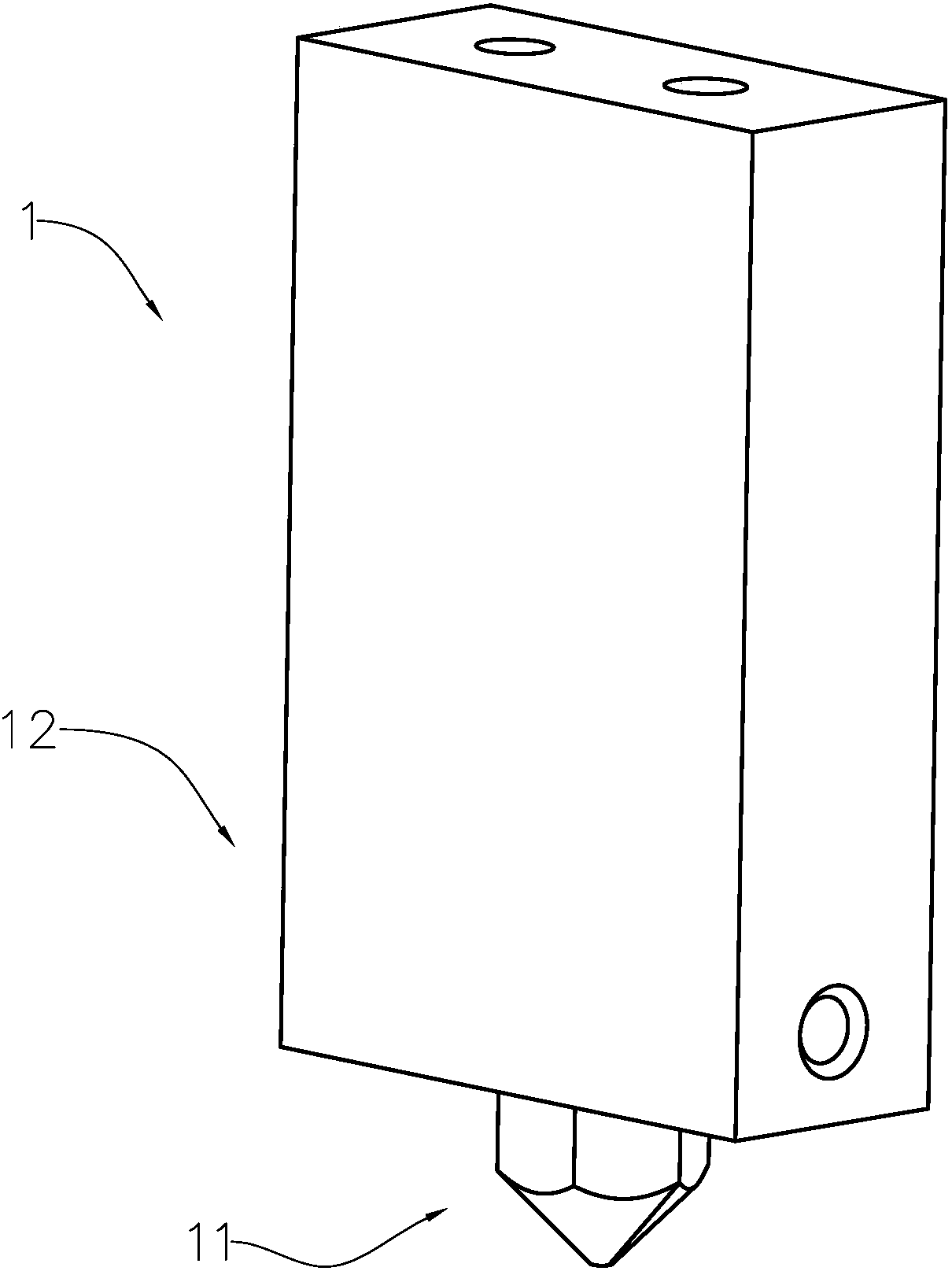

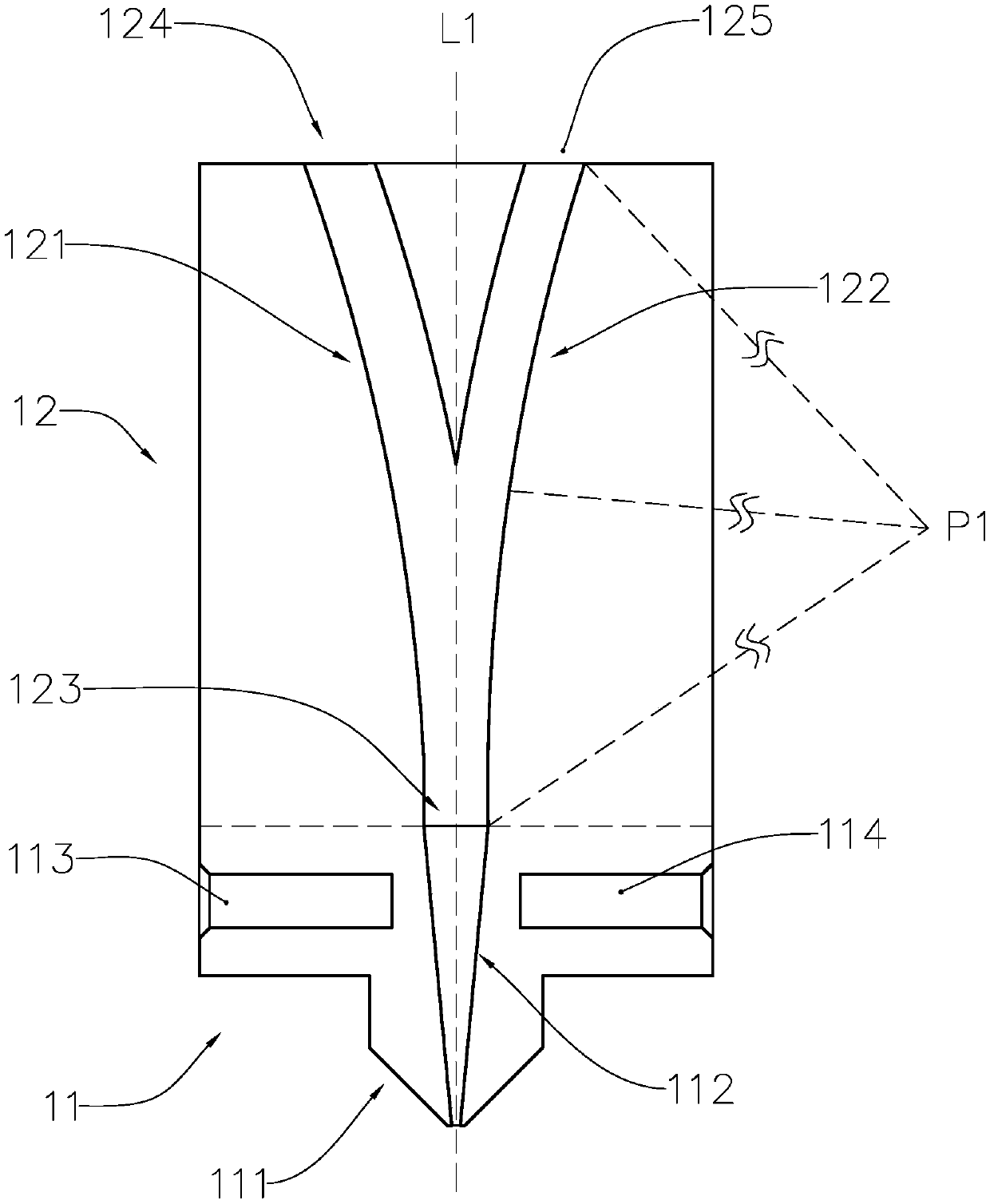

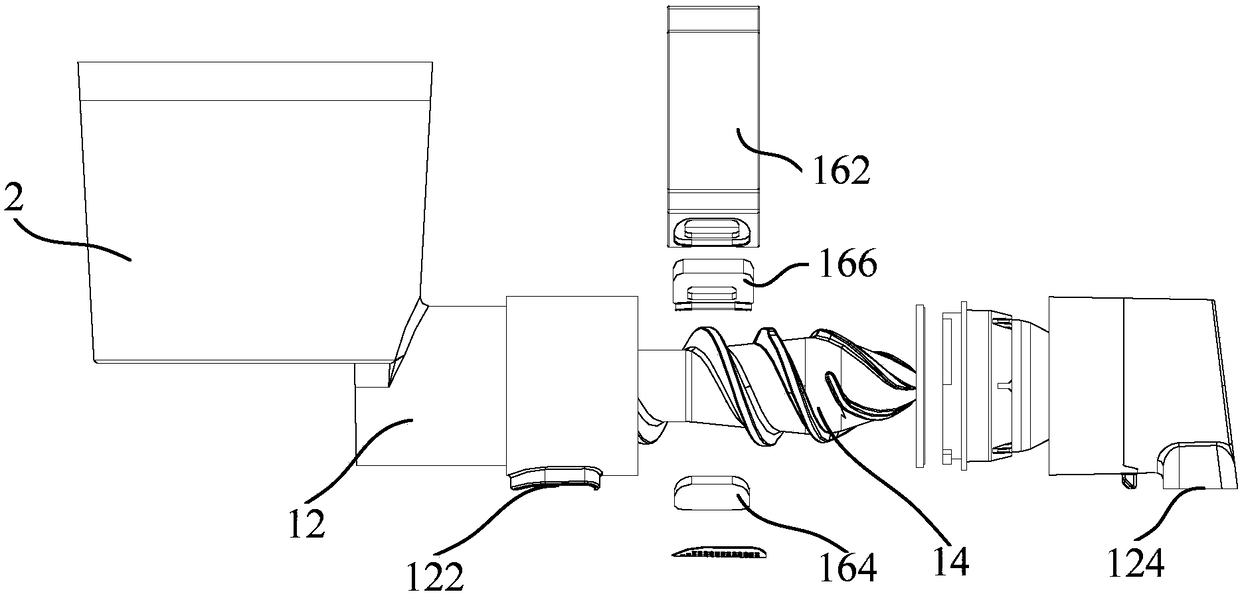

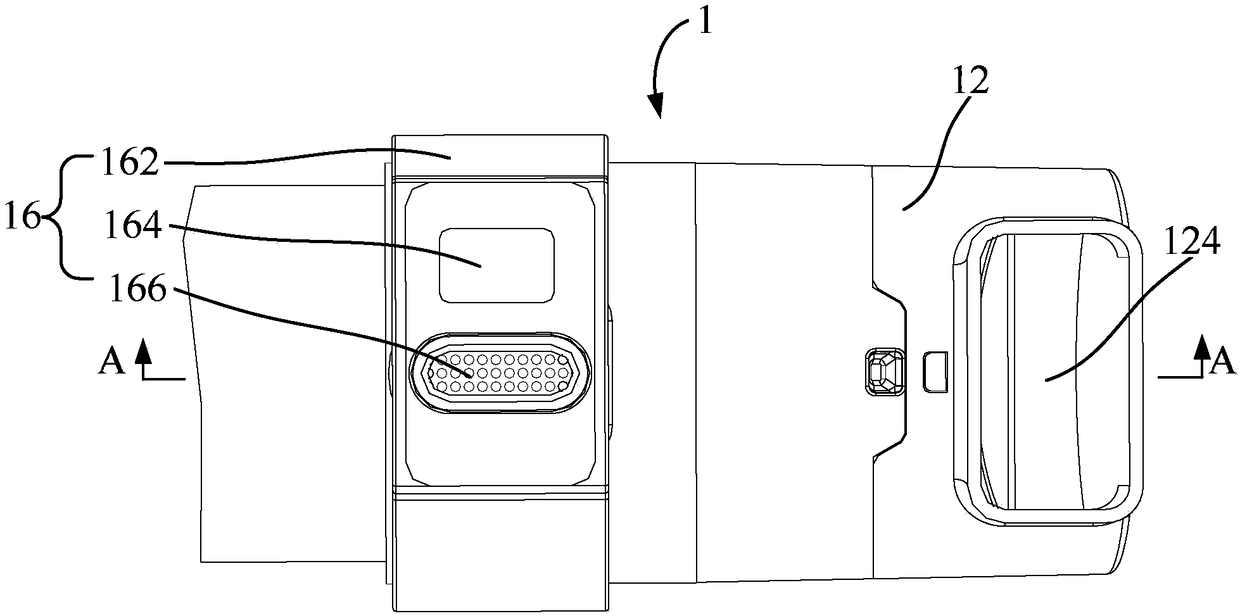

3D (three-dimensional) printing extruder, 3D printer and manufacturing method of 3D printing extruder

PendingCN107855530ASmooth and easy feedingNo cloggingAdditive manufacturing apparatusIncreasing energy efficiencyEngineering3d printer

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

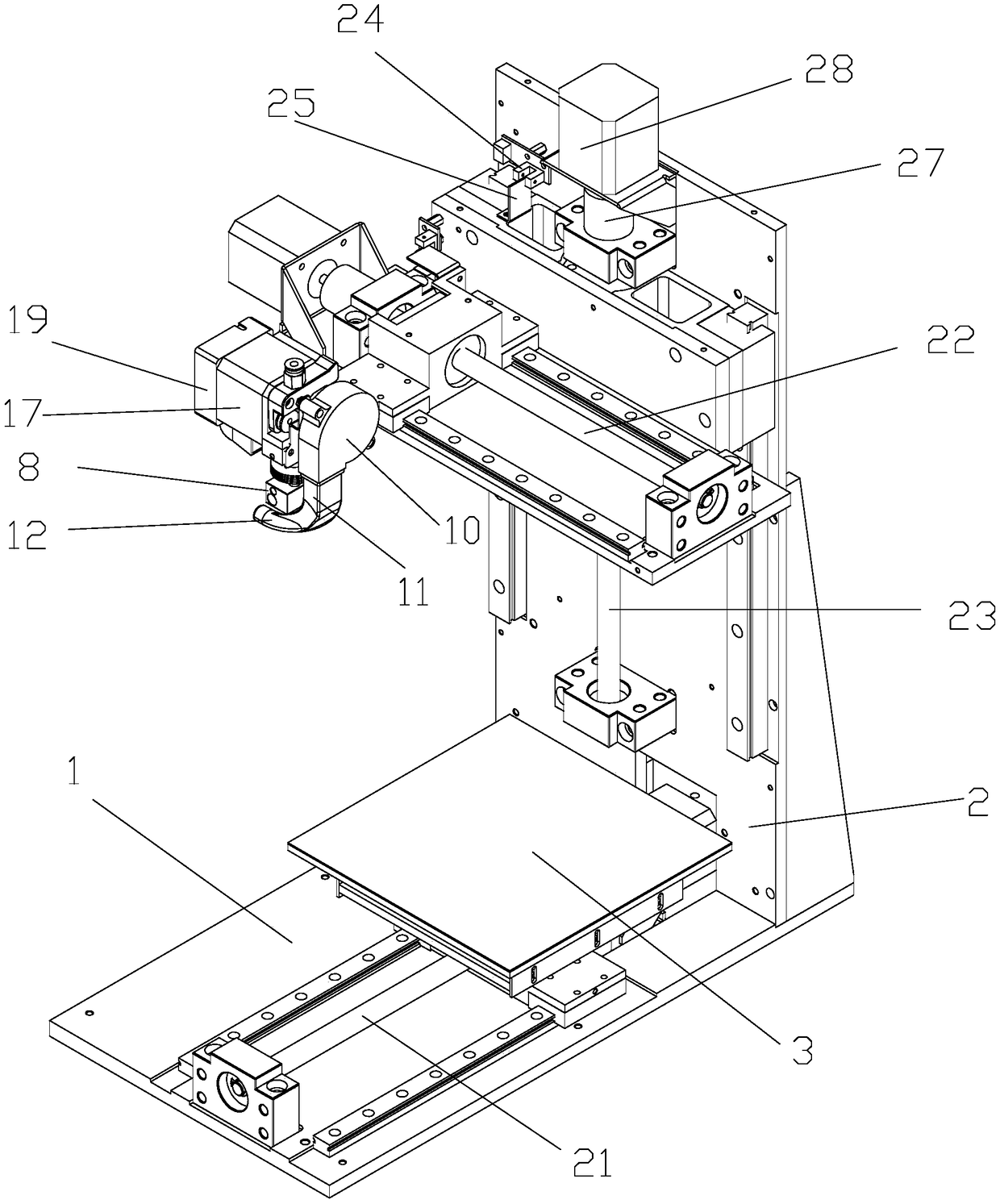

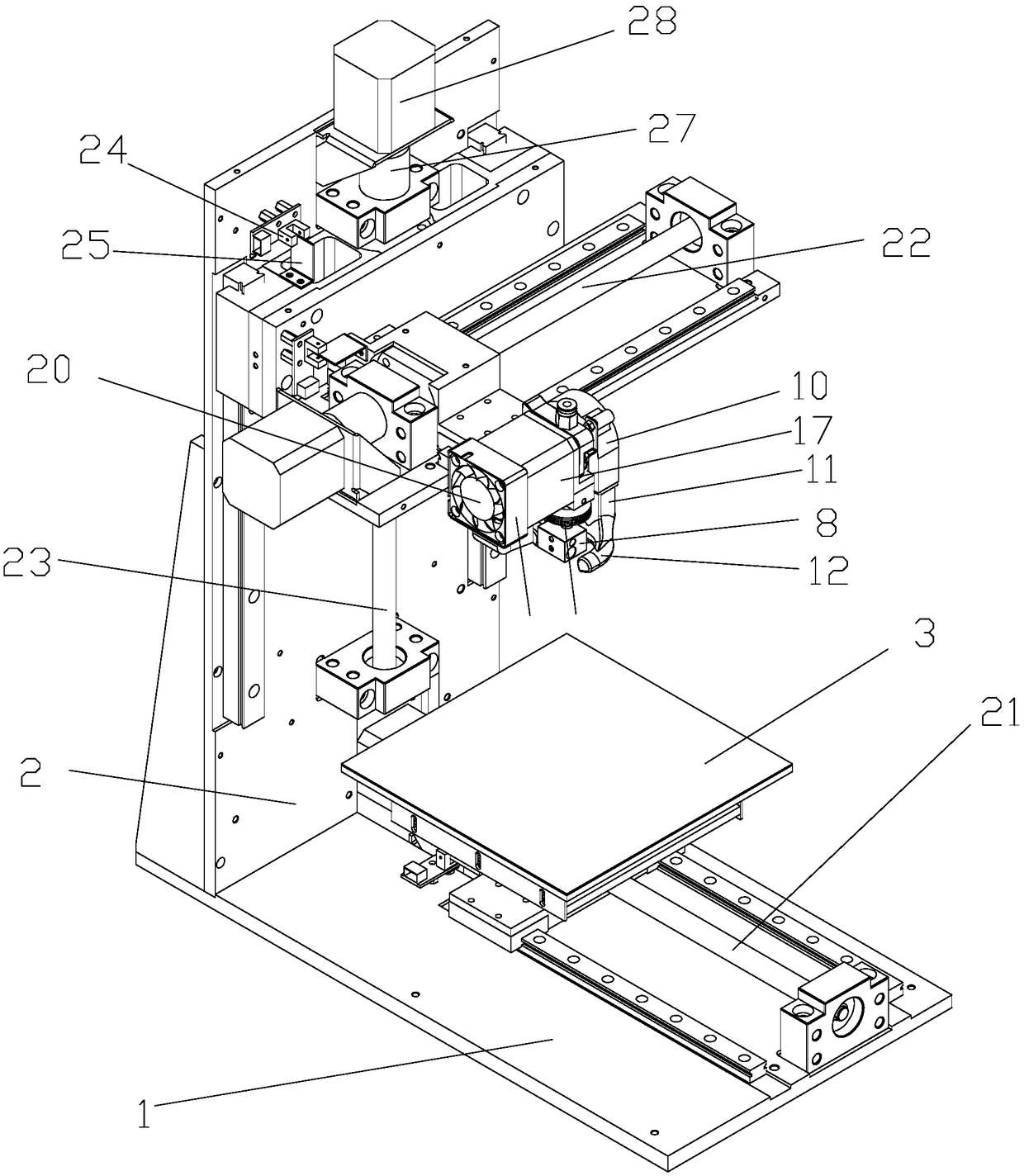

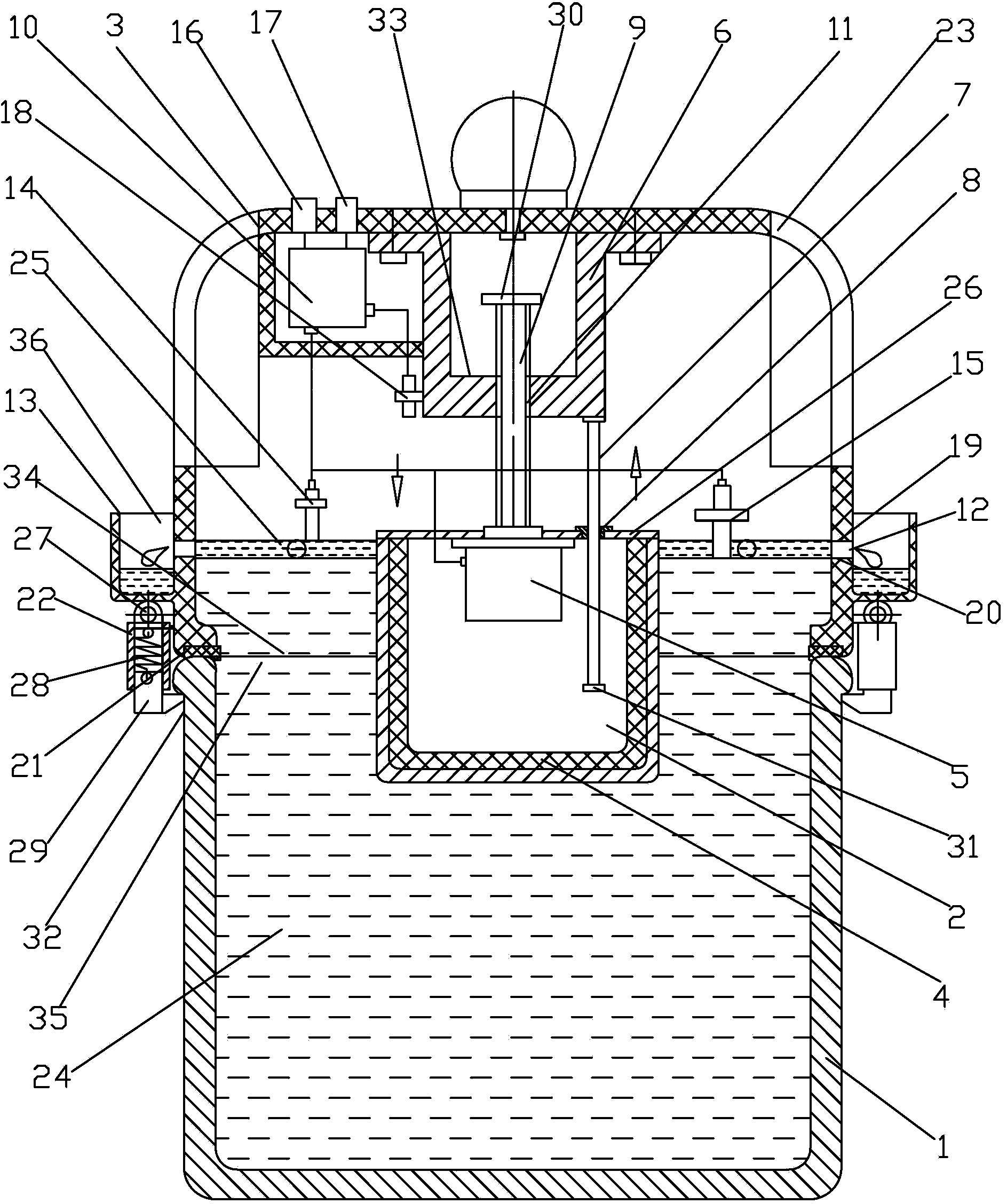

High-precision 3D printer

PendingCN109228324AAchieve high precision controlReasonable structureManufacturing platforms/substratesManufacturing driving meansControl systemEngineering

Owner:HANGZHOU HIMALAYA INFORMATION TECH

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Preparation method for Nb-Zr alloy/Cu multi-core composite wire

ActiveCN105855316AOrganizational structure is stableHigh strengthCable/conductor manufactureOxidation resistantHigh intensity

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

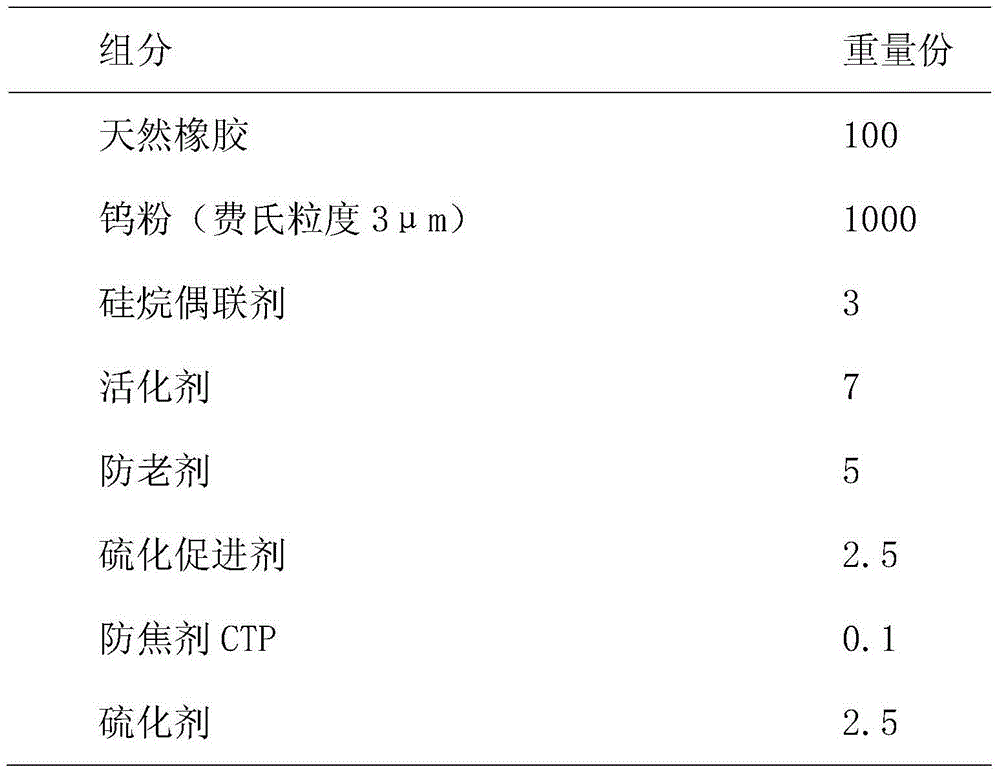

Tungsten-base composite material applied to ray shielding and preparation method thereof

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

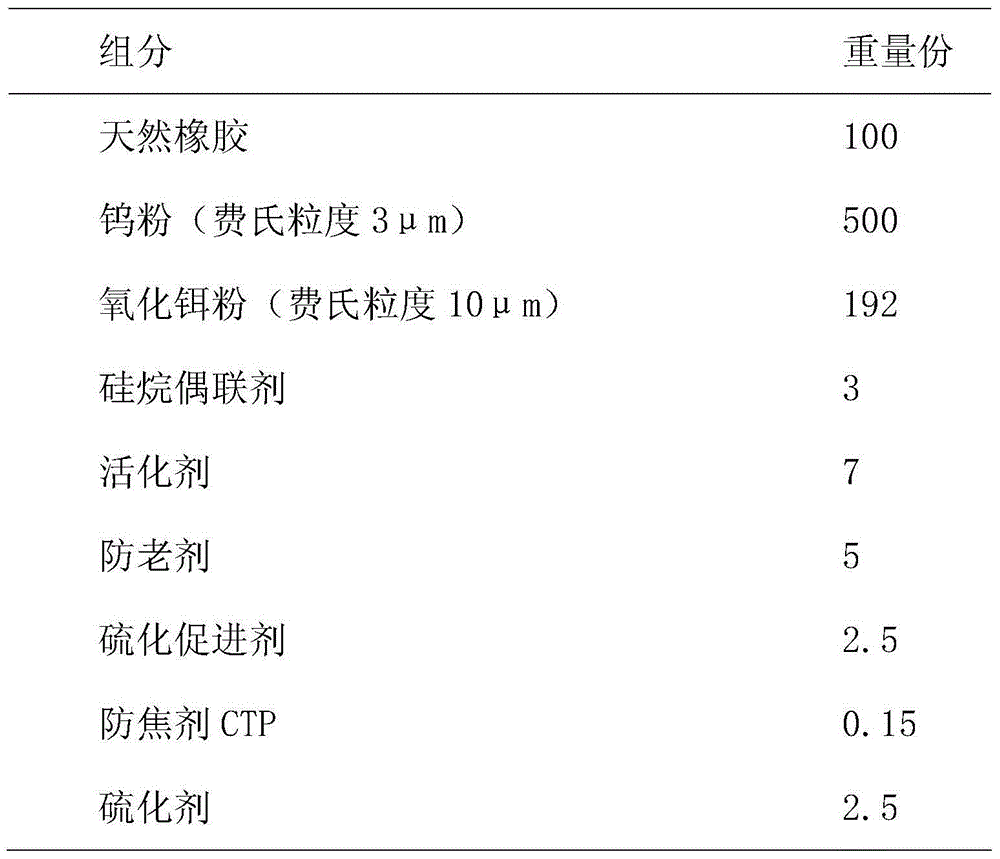

Screw rod of EPE/EPS single-screw rod foam extrusion machine with constant temperature oil for cooling forepart inner wall

InactiveCN101480841AIncrease elasticitySatisfy the processing technology requirements of subsection coolingFoaming agentReturn channel

Owner:罗承绪

Antibacterial and hydrolysis-resistant thermoplastic polyurethane elastomer

Owner:中天科盛(上海)企业发展股份有限公司

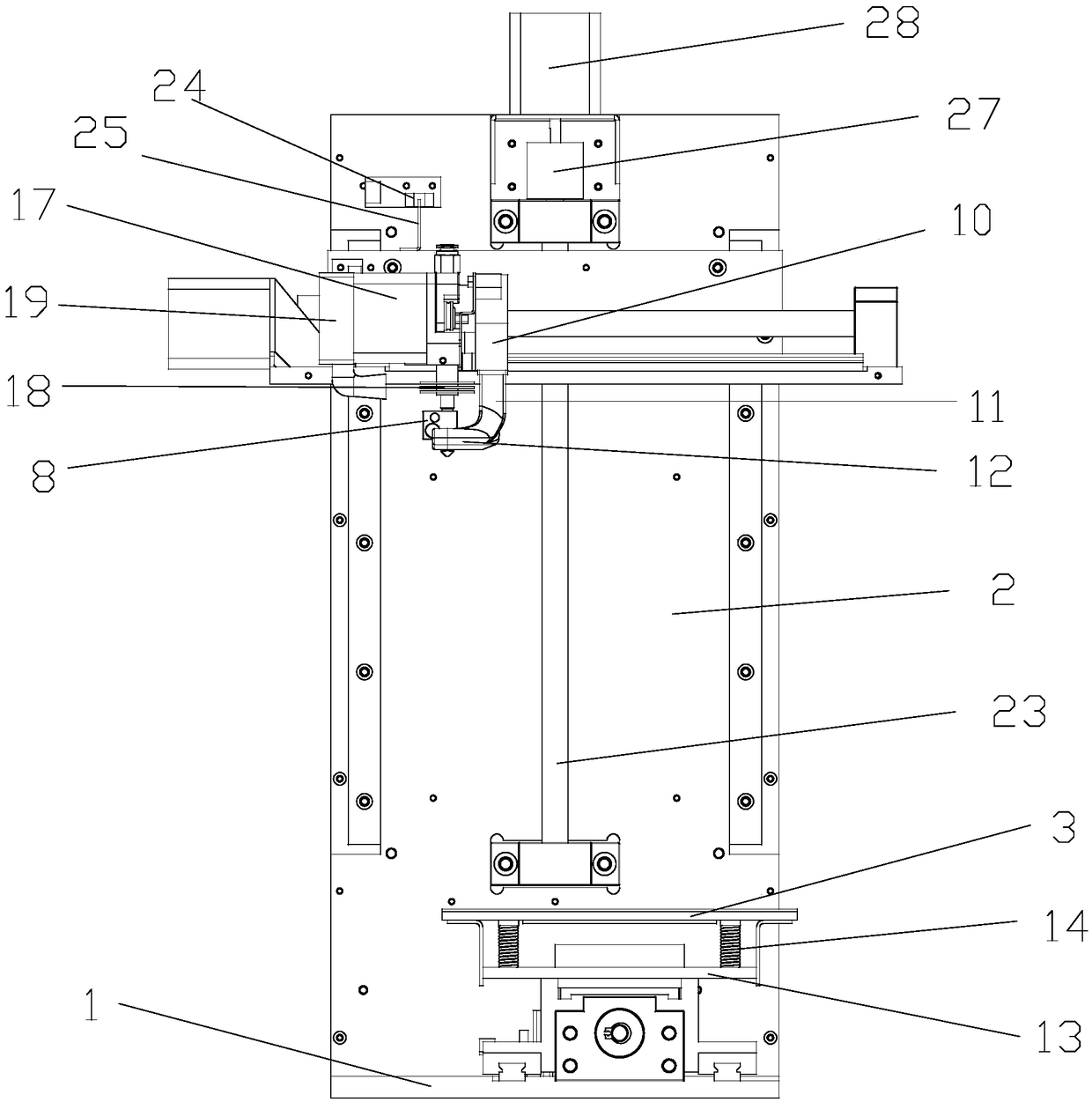

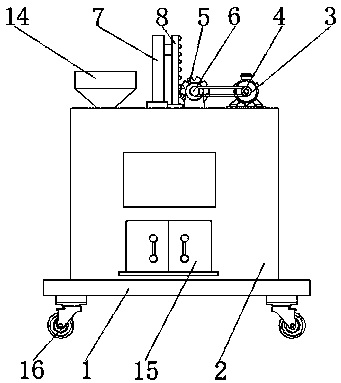

Full-automatic material distribution device and production process used for producing micro powder polished tiles

The invention discloses a full-automatic material distribution device and production process used for producing micro powder polished tiles. The full-automatic material distribution device comprises a main conveying belt for conveying micro powder, a line micro powder distribution mechanism, a material distribution mechanism, a material supplement mechanism, a grid feeding mechanism and an extrusion machine are sequentially arranged above the main conveying belt in the conveying direction, the line micro powder distribution mechanism, the material distribution mechanism and the material supplement mechanism sequentially distribute different types of powdery materials on the main conveying belt and then overlap the powdery materials step by step, and the grid feeding mechanism cuts the mixed powdery materials on the main conveying belt according to the specification of polished tiles and then feeds the materials into the extrusion machine for extrusion formation. The full-automatic material distribution device is ingenious and practical in structure. Ceramic micro power polished tiles produced through the full-automatic material distribution device are fine in texture, natural and vivid, the patterns of finished tiles are natural in transition, novel and irregular, and the decoration effect of ceramic micro powder polished tiles is greatly improved.

Owner:GUANGDONG HUIYA CERAMICS CO LTD

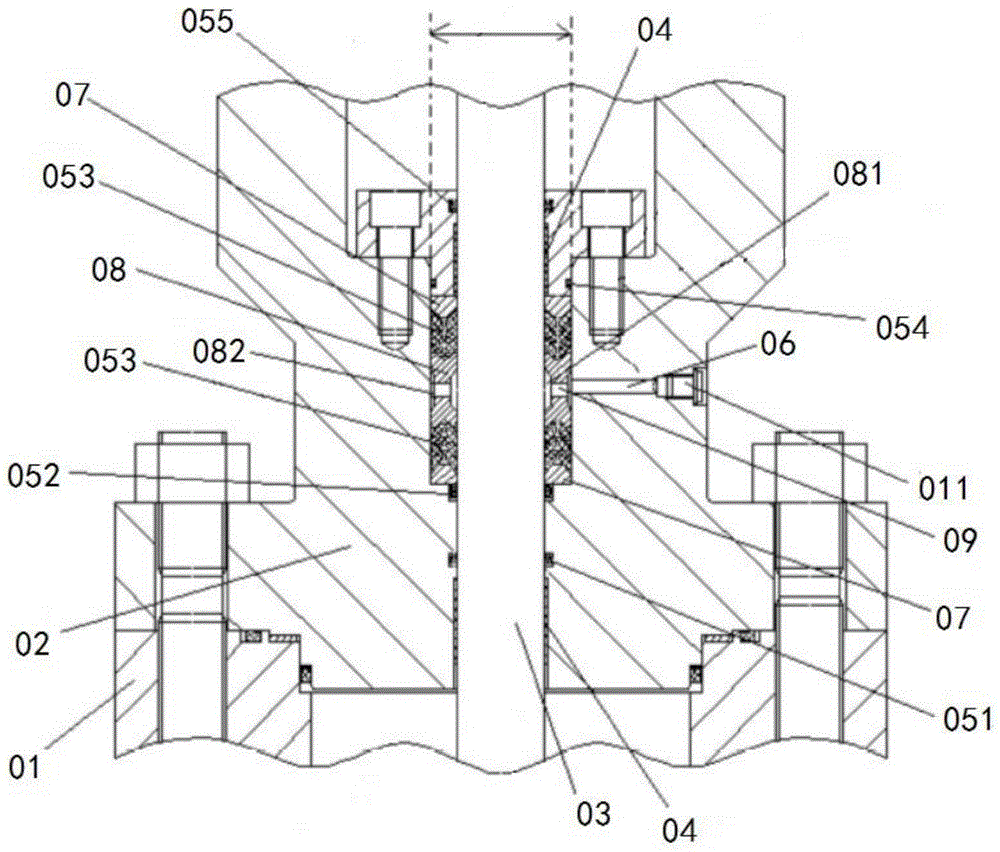

Superconducting niobium pipe and preparation method thereof

ActiveCN103219459ALow residual resistivity dropSuperconductor device manufacture/treatmentHydrogenIngot

The invention relates to the technical field of metal materials and provides a superconducting niobium pipe and a preparation method thereof. The preparation method comprises the specific steps of: forging superconducting niobium ingots, wherein the temperature during a forging process is lower than or equal to 60 DEG C; carrying out first thermal treatment on the forged superconducting niobium ingots; coating a lubricating agent on the surfaces of the superconducting niobium ingots after the first thermal treatment, and carrying out reverse extrusion; and carrying out secondary thermal treatment on the superconducting niobium ingots after the reverse extrusion, so as to obtain the superconducting niobium pipe. According to the superconducting niobium pipe and the preparation method thereof, the forging temperature is controlled in a forging process, and the lubricating agent is coated on the surfaces of the niobium ingots in an extrusion process, so that the carbon absorption, the hydrogen absorption and the oxygen absorption of the niobium ingots in a machining process are effectively avoided, and the decreasing amplitude of the residual resistivity of the prepared superconducting niobium pipe is relatively small.

Owner:NINGXIA ORIENT TANTALUM IND

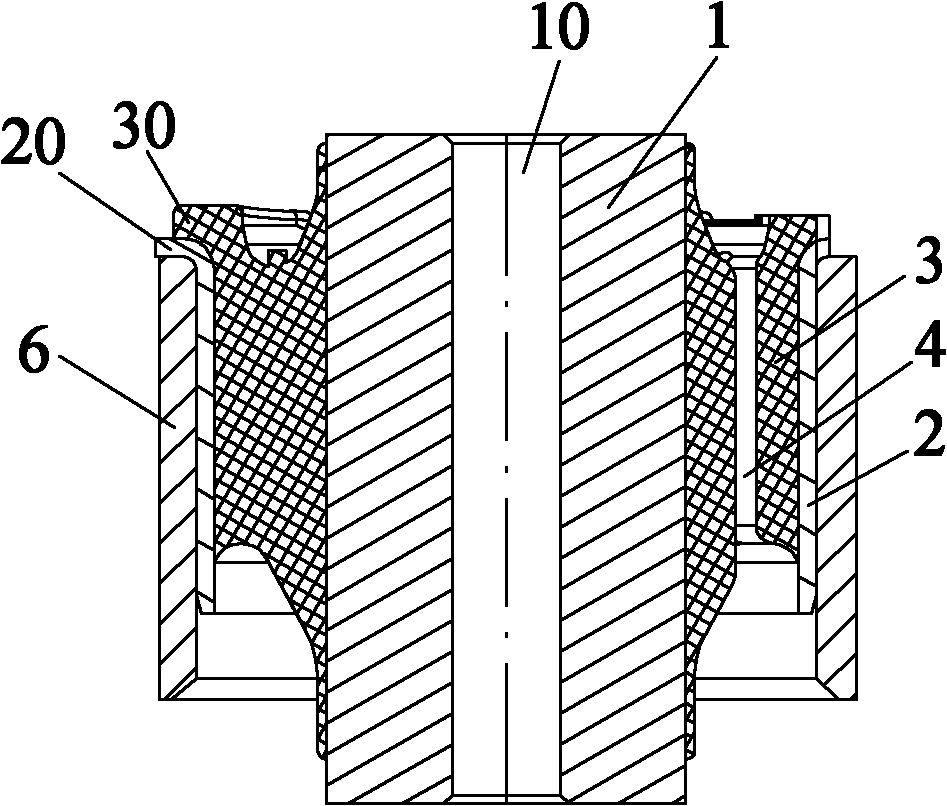

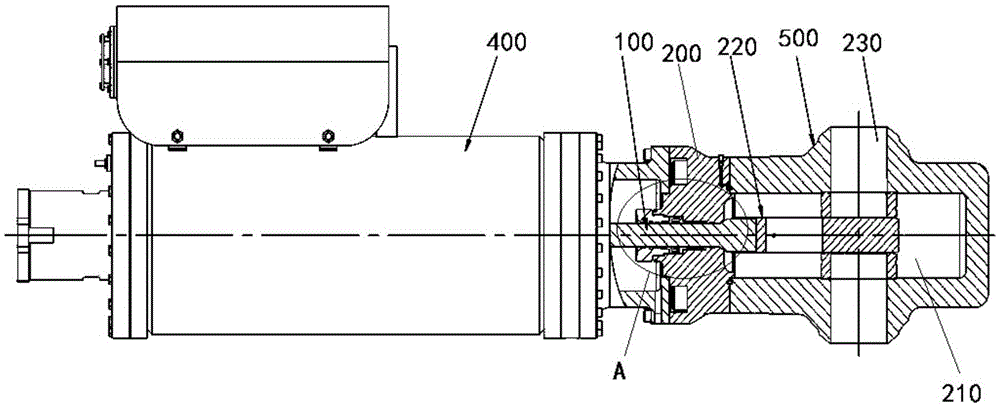

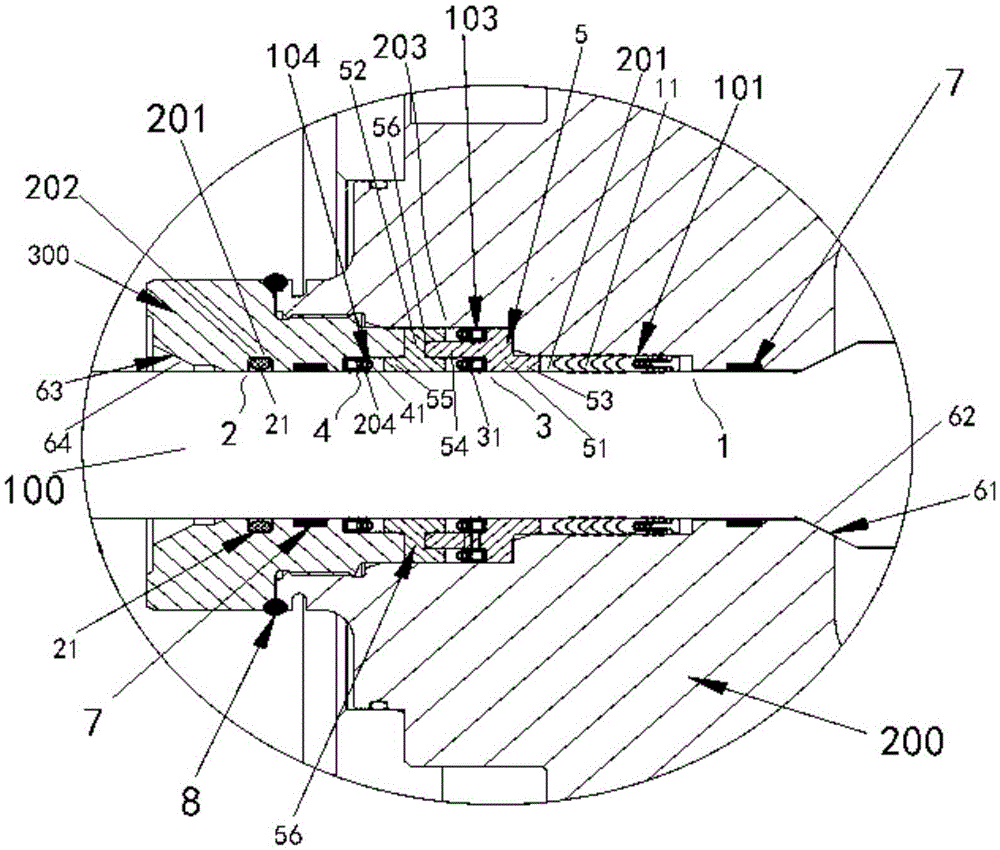

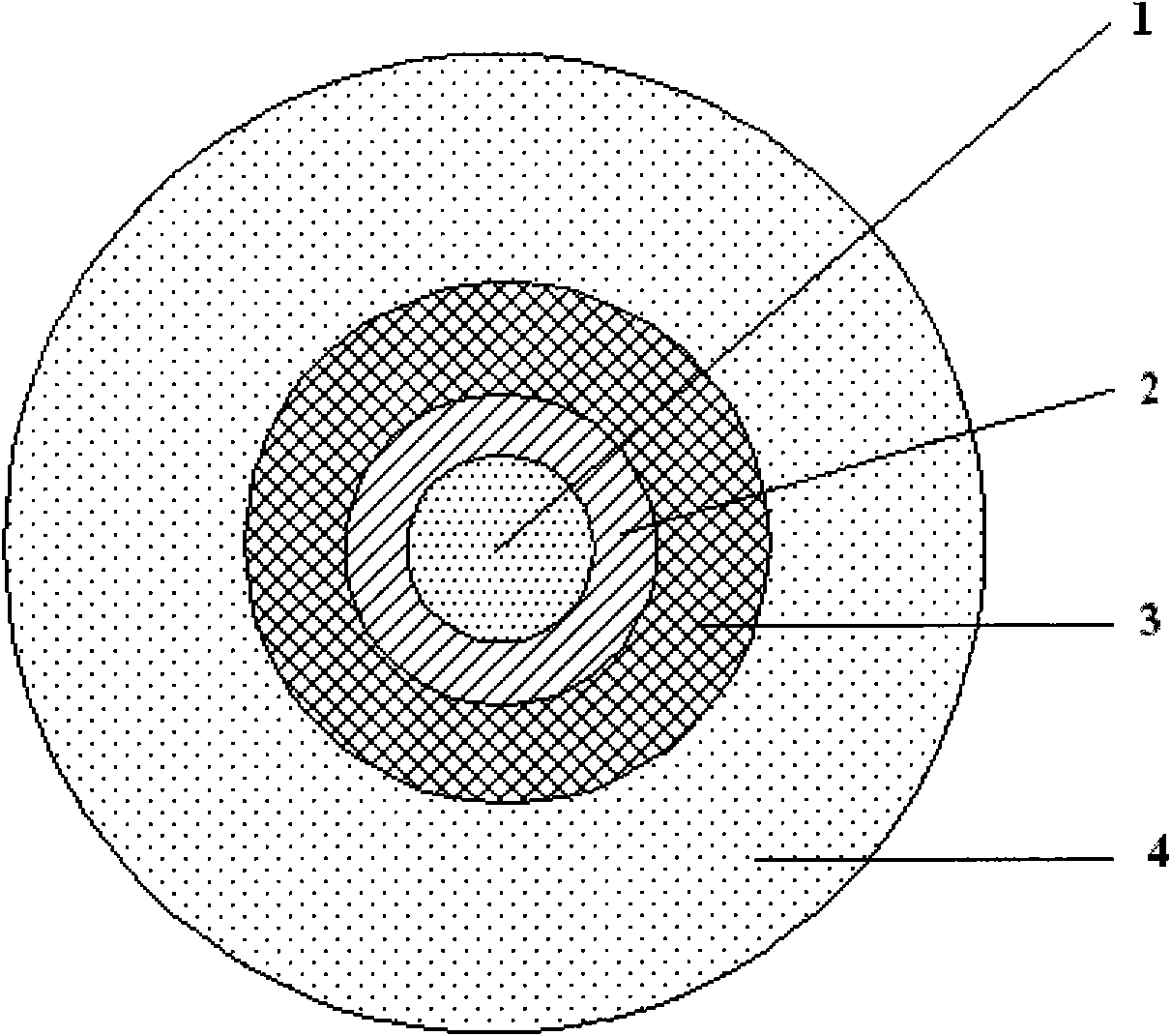

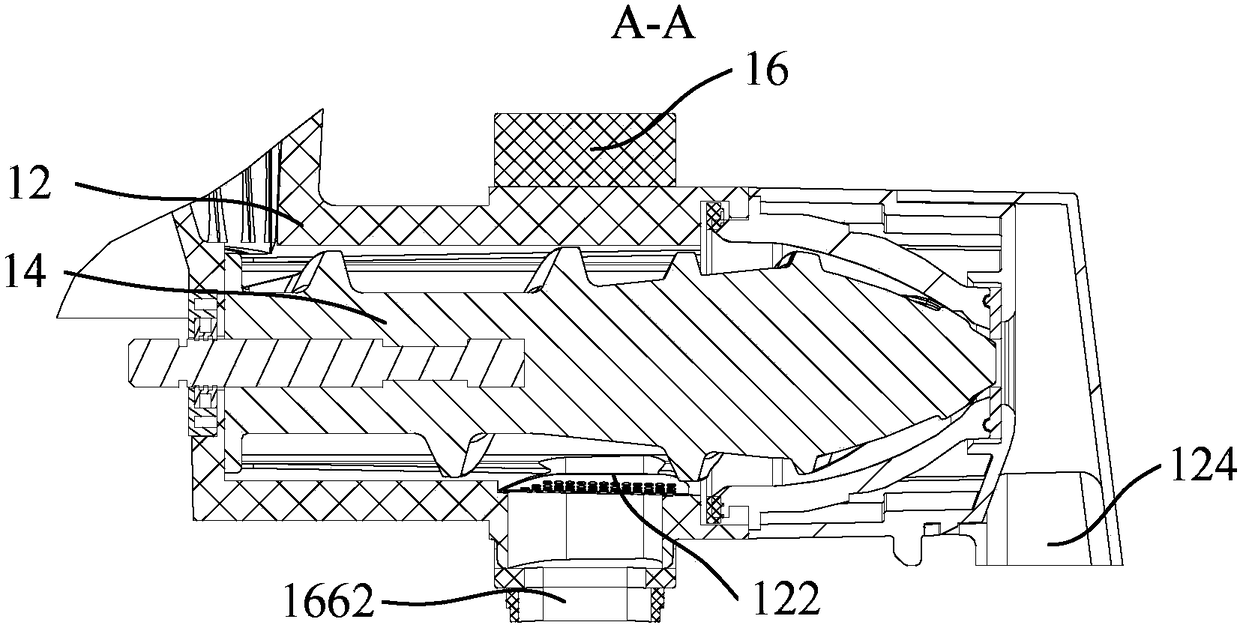

Extrusion type rubber bushing structure

Owner:CHERY AUTOMOBILE CO LTD

Novel environment-friendly and energy-saving vermicelli manufacturing device

Owner:佛山市天宇鸿图创新科技有限公司

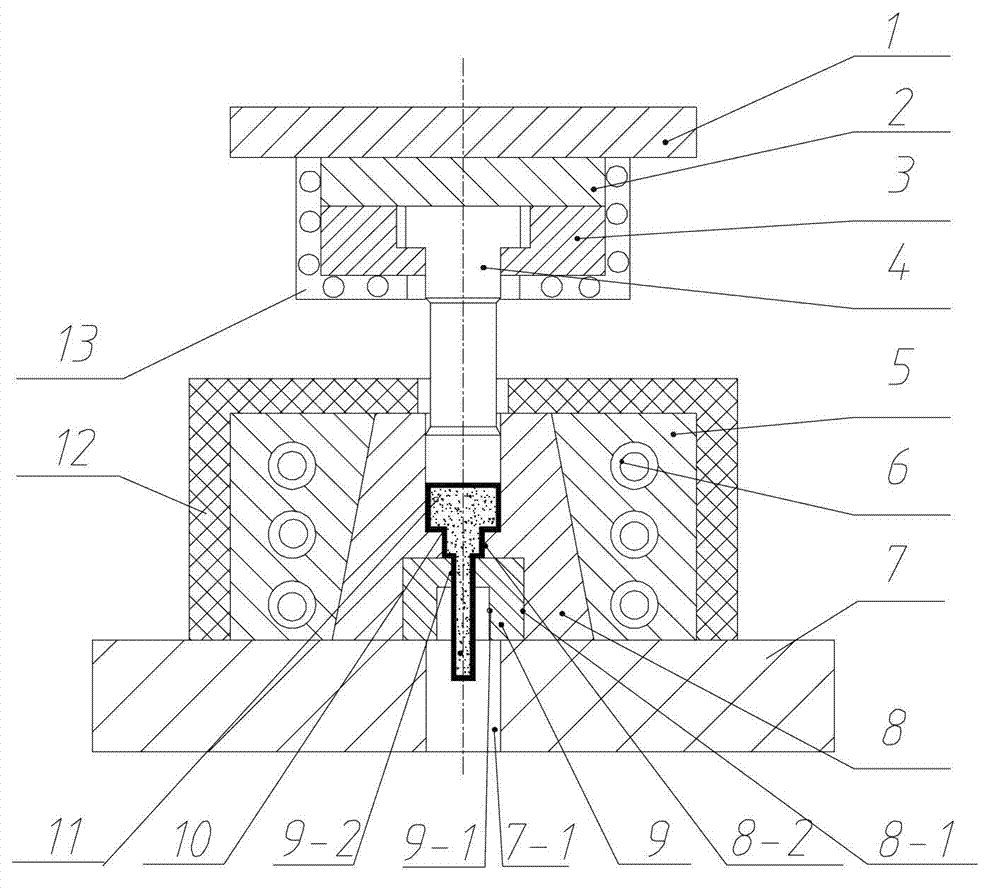

Device and method for step type hot extrusion preparation of Nd-phase-rich Nd2Fe14B/alpha-Fe permanent magnet

ActiveCN103084577AGrain size growthEnhanced couplingInorganic material magnetismInductances/transformers/magnets manufactureNanometreBall mill

Owner:HARBIN INST OF TECH

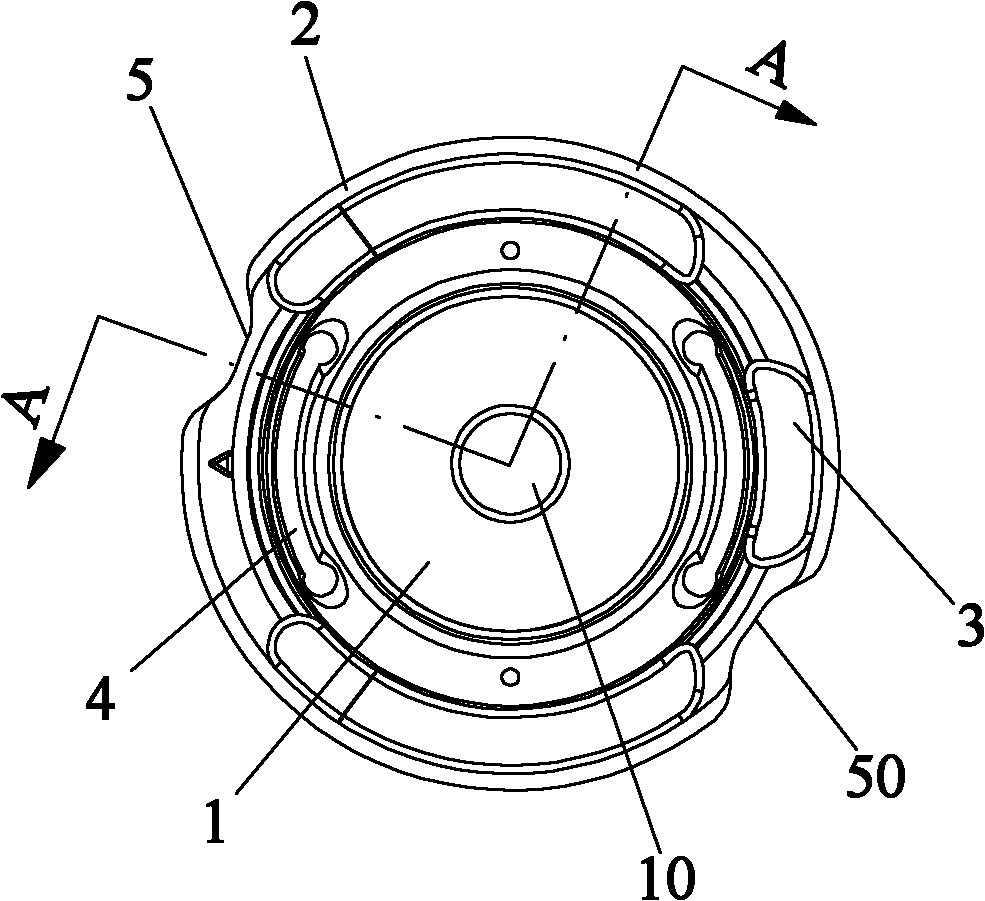

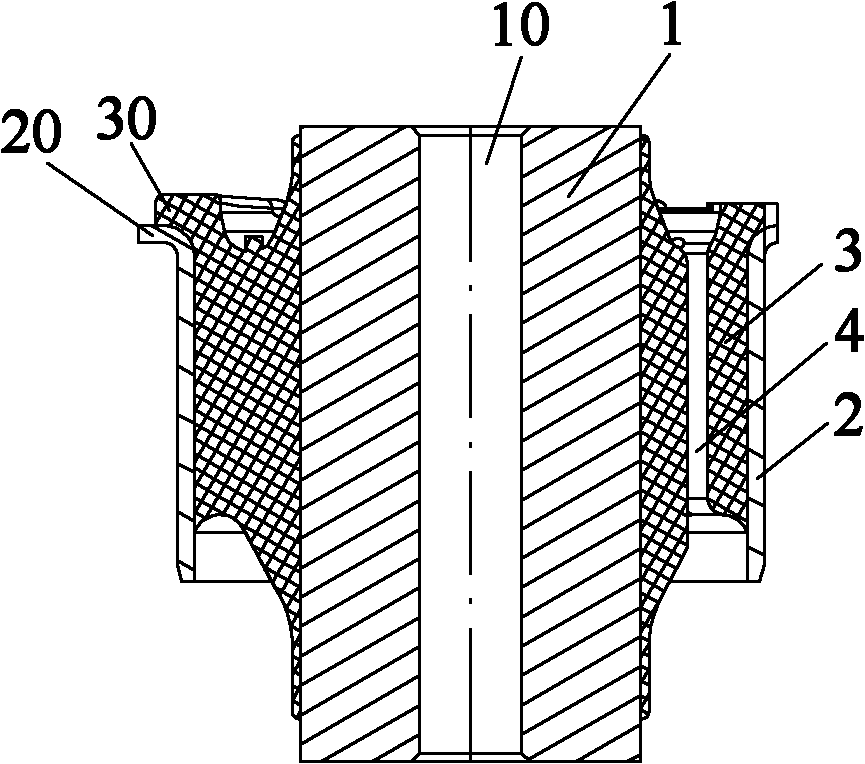

Sealing structure and gate valve with sealing structure

InactiveCN105626869AImprove sealingSmall amount of deformationSpindle sealingsEngine sealsEngineeringAND gate

Owner:NEWAY VALVE SUZHOU

Preparation method of special coating resin composition for polyethylene

ActiveCN102863670AImprove melt strengthLow shrinkageNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethylenePeroxide

Owner:PETROCHINA CO LTD

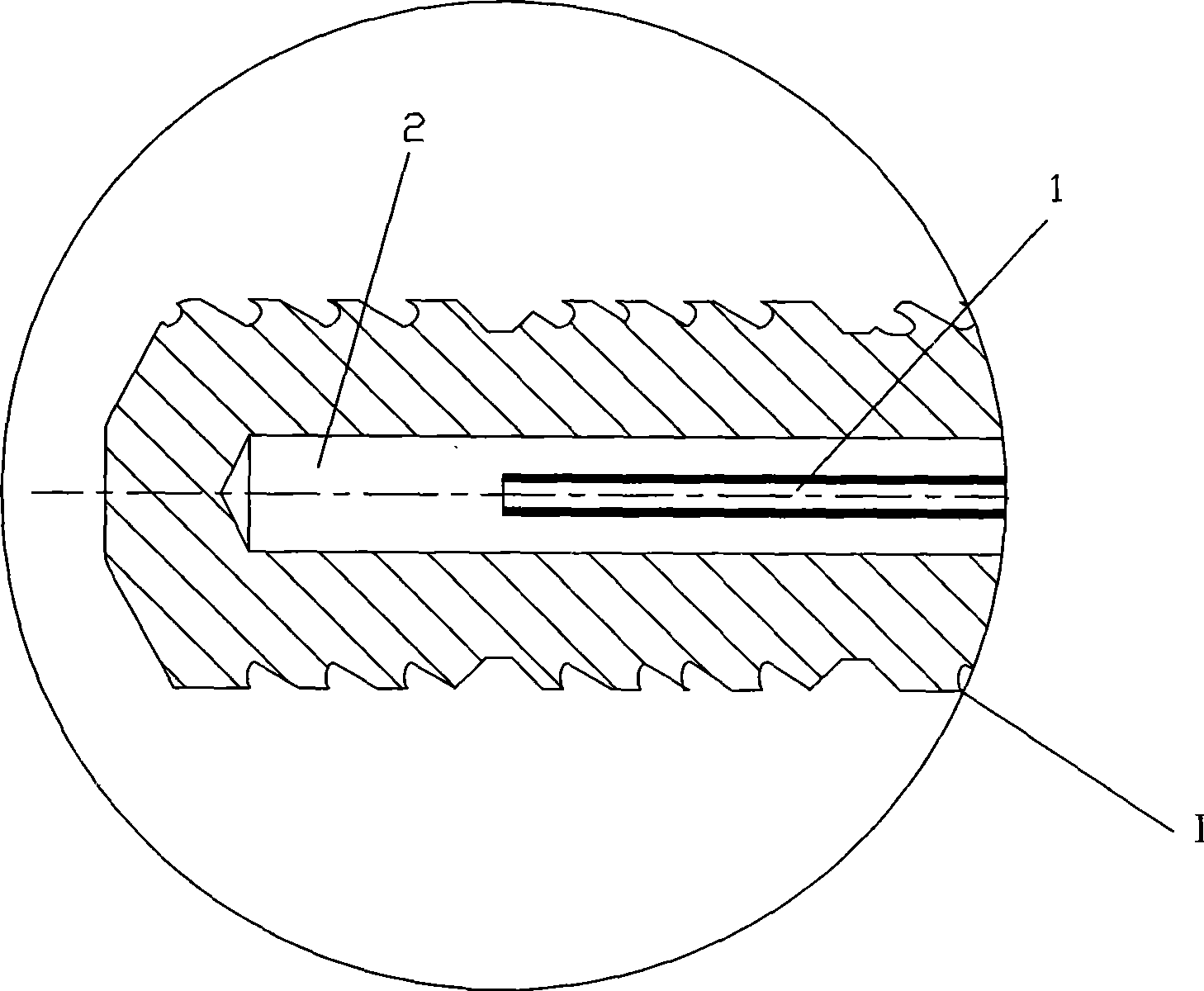

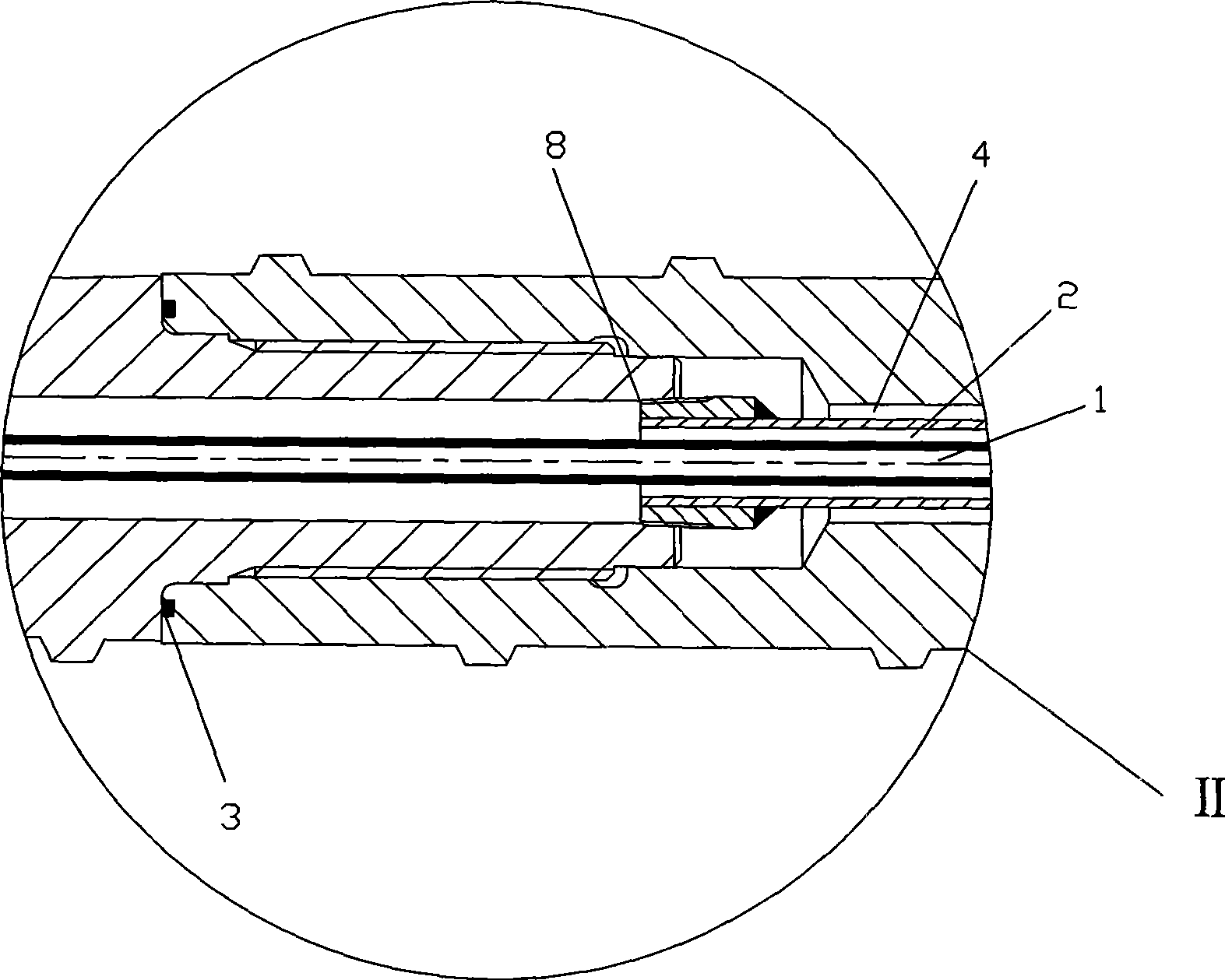

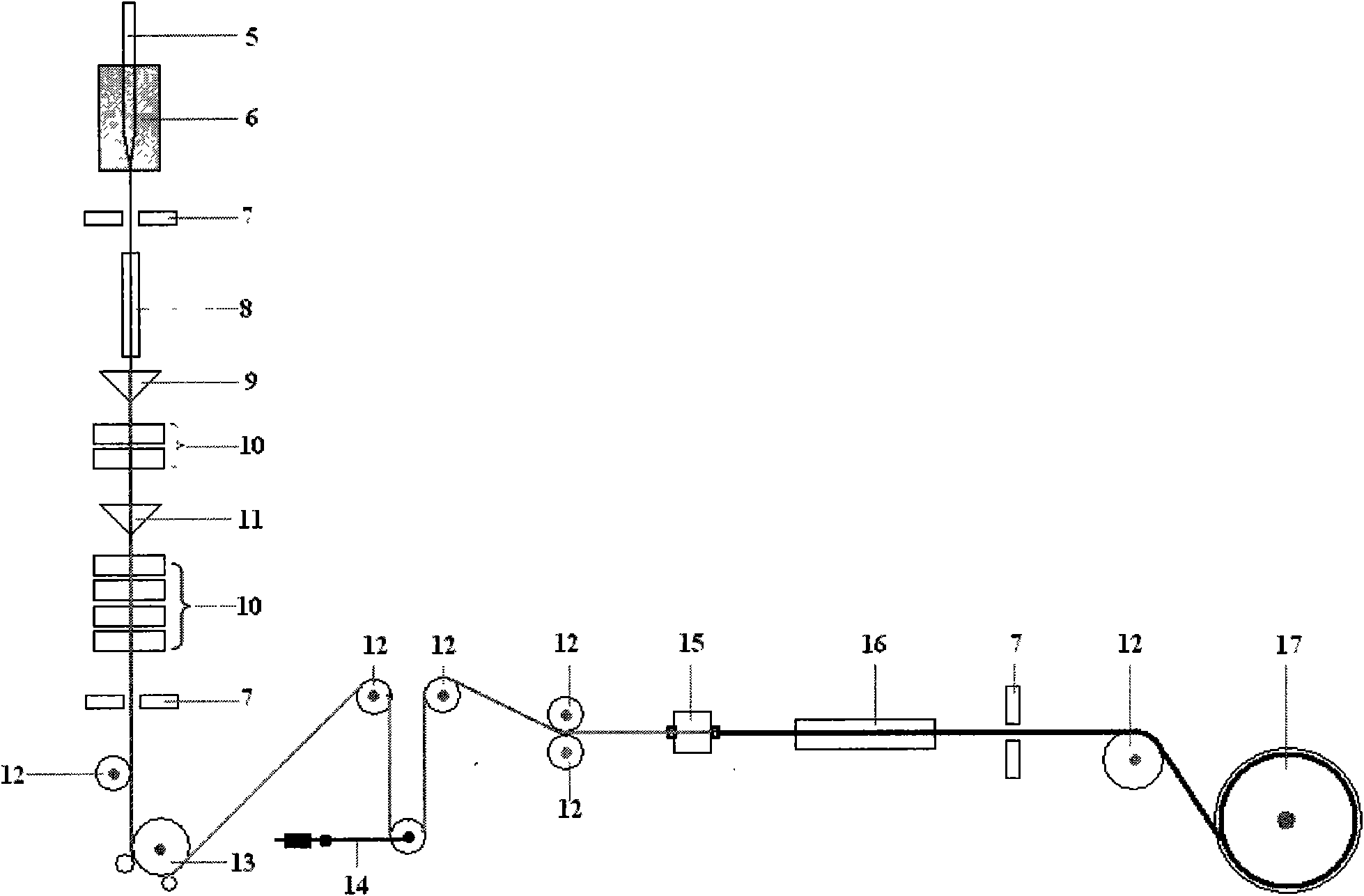

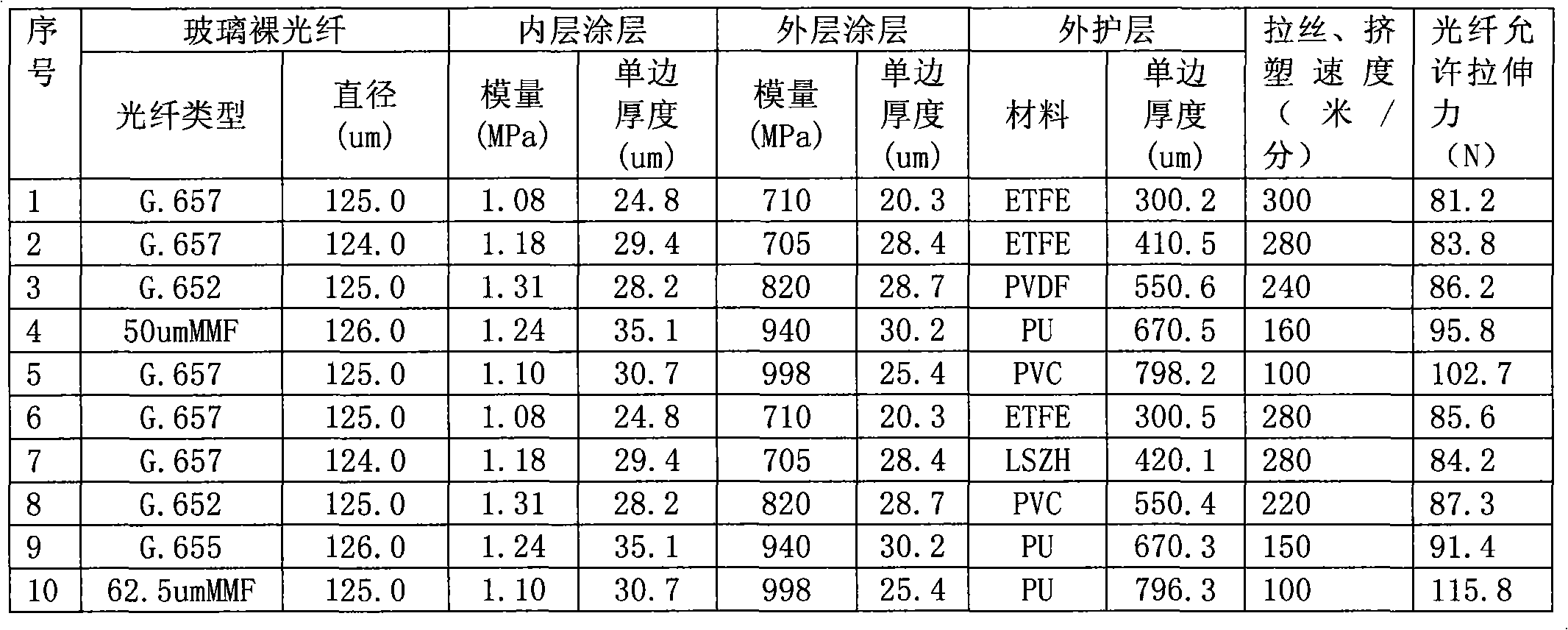

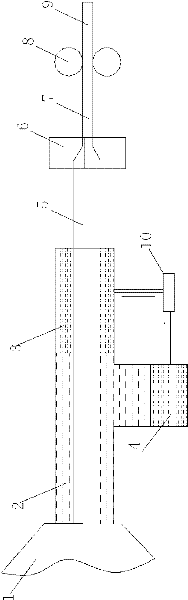

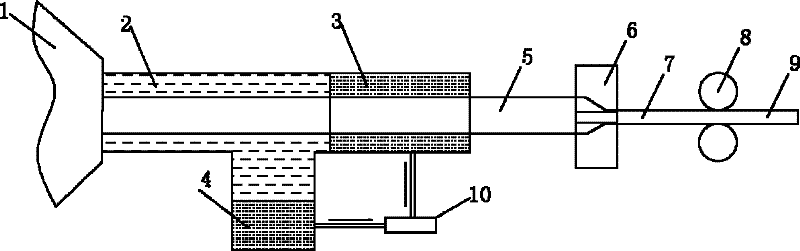

Indoor-laying optical fiber and manufacture method thereof

ActiveCN101614842AQuality improvementIncrease internal stressGlass making apparatusCladded optical fibreProduction lineProtection layer

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

High-precision plate strip production method

Owner:常州艾邦机械科技有限公司

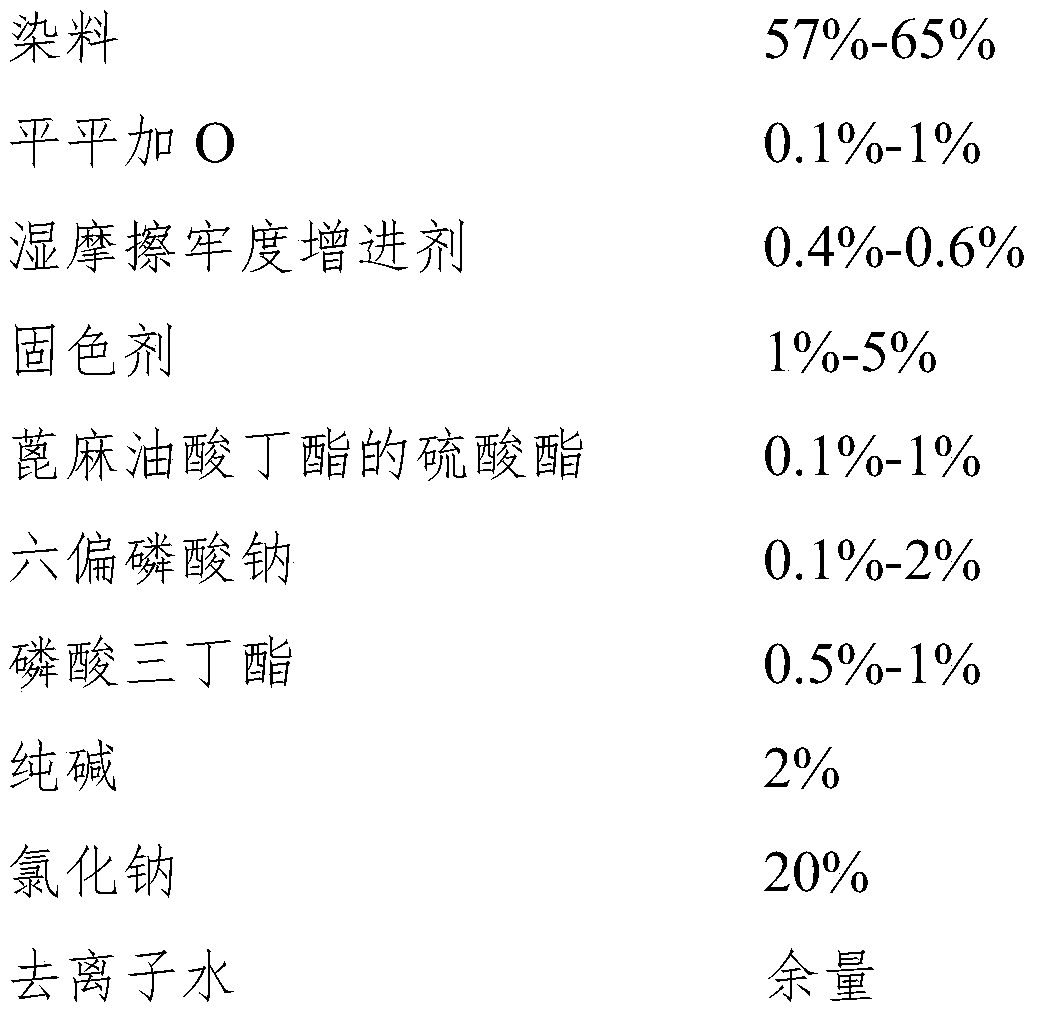

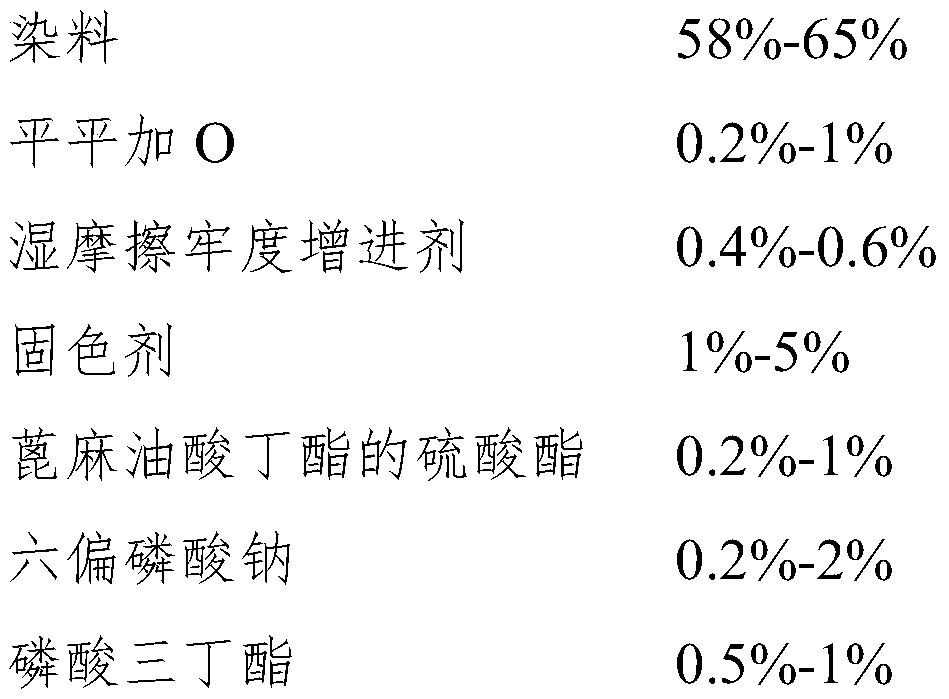

Reactive dye formula for cotton/linen blending and preparing method thereof

InactiveCN105507027AImprove wet rubbing fastnessHigh color fixing rateDyeing processRubbingRicinoleic acid

Owner:XIAO COUNTY TAI DA DRESS PROD

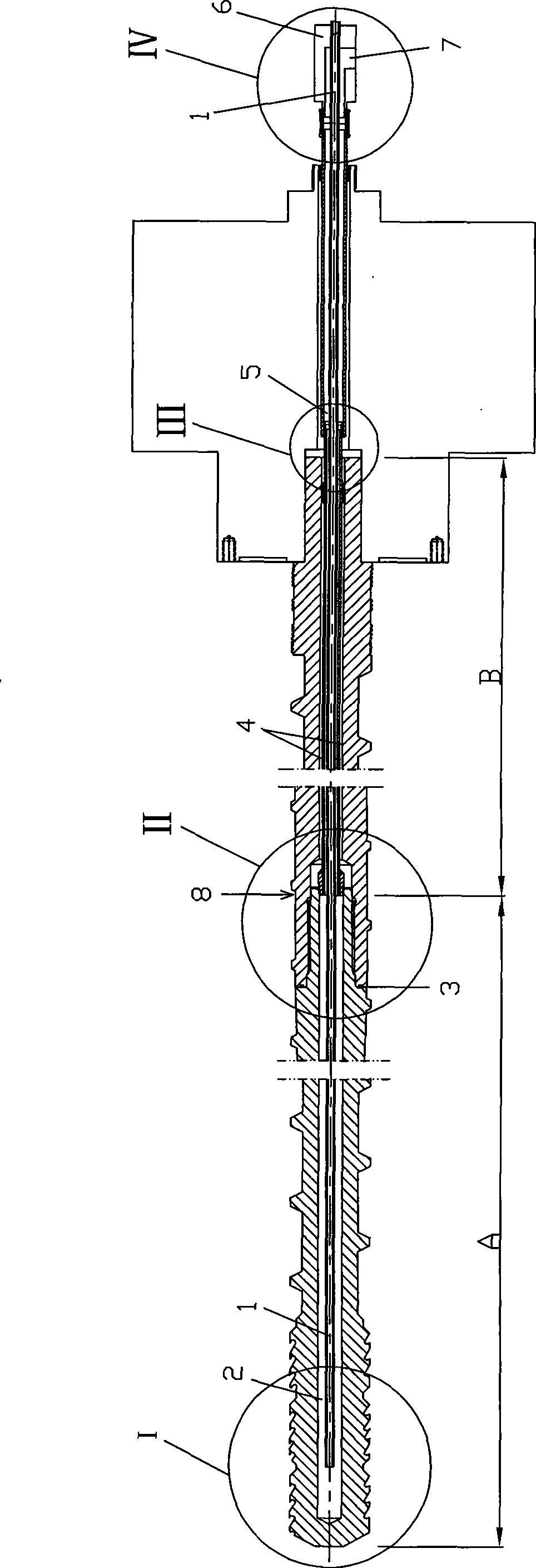

Continuous food 3D printer

The invention relates to the technical field of agricultural product processing equipment, and provides a continuous food 3D printer, which comprises a rotating platform, a clamping extrusion mechanism, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism and a plurality of raw material extrusion heads; the plurality of raw material extrusion heads are detachably connected to the rotating platform; the Z-axis motion mechanism drives the Y-axis motion mechanism to move in the Z-axis direction, the Y-axis motion mechanism drives the X-axis motion mechanism to move inthe Y-axis direction, and the X-axis motion mechanism drives the clamping extrusion mechanism to move in the X-axis direction; the clamping extrusion mechanism is used for clamping the raw material extrusion heads and extruding the raw material from the raw material extrusion heads. The continuous food 3D printer is provided with the plurality of raw material extrusion heads, so that raw materialswith various tastes can be added to the printed food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Use method of oil removal device

Owner:湖南海霸食品有限公司

Extrusion barrel and food processor

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Steamed total millet flour cone-shaped bread and producing method thereof

Owner:CHINA AGRI UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap