Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Exhaust gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline, petrol, biodiesel blends, diesel fuel, fuel oil, or coal. According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle. It often disperses downwind in a pattern called an exhaust plume.

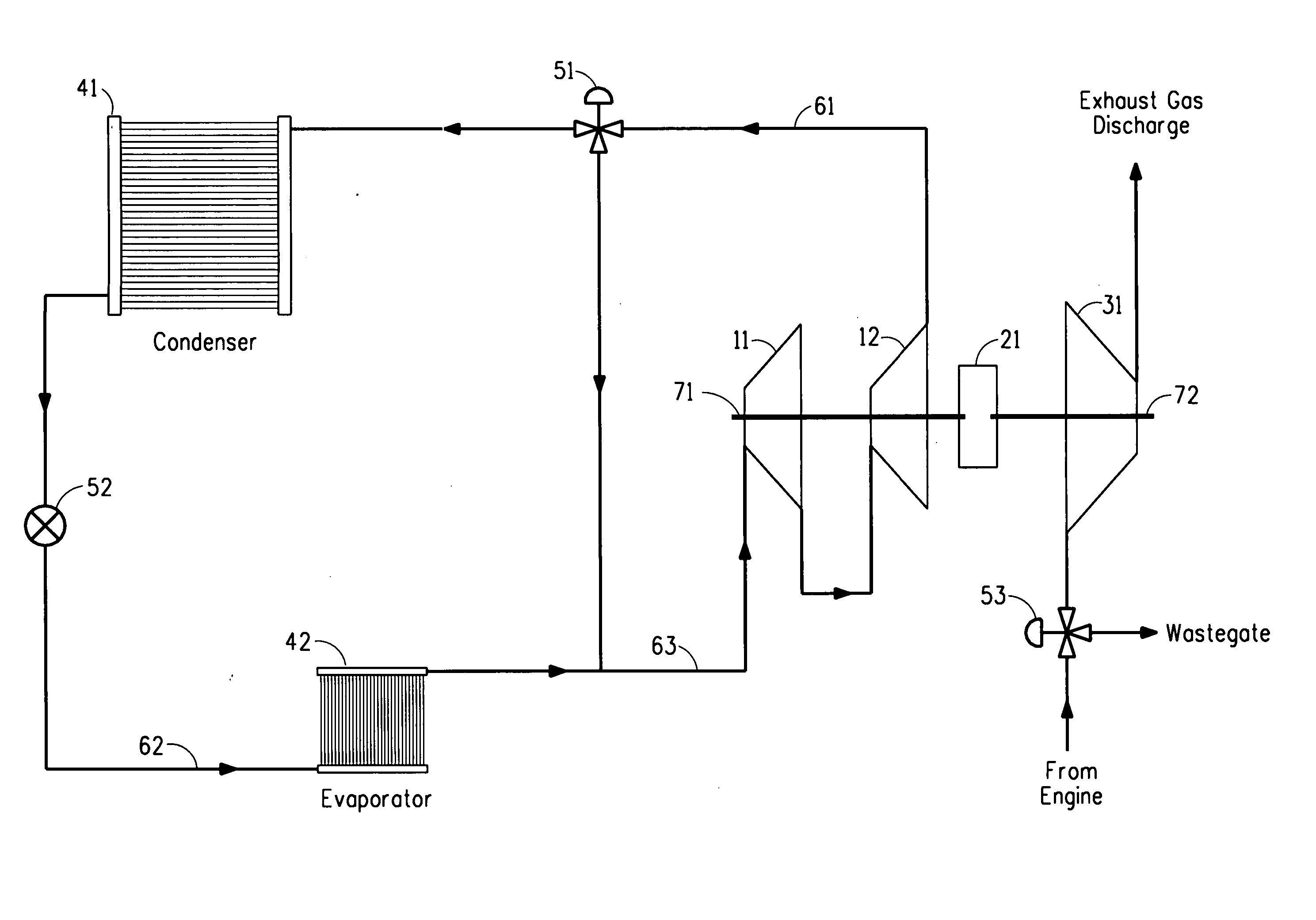

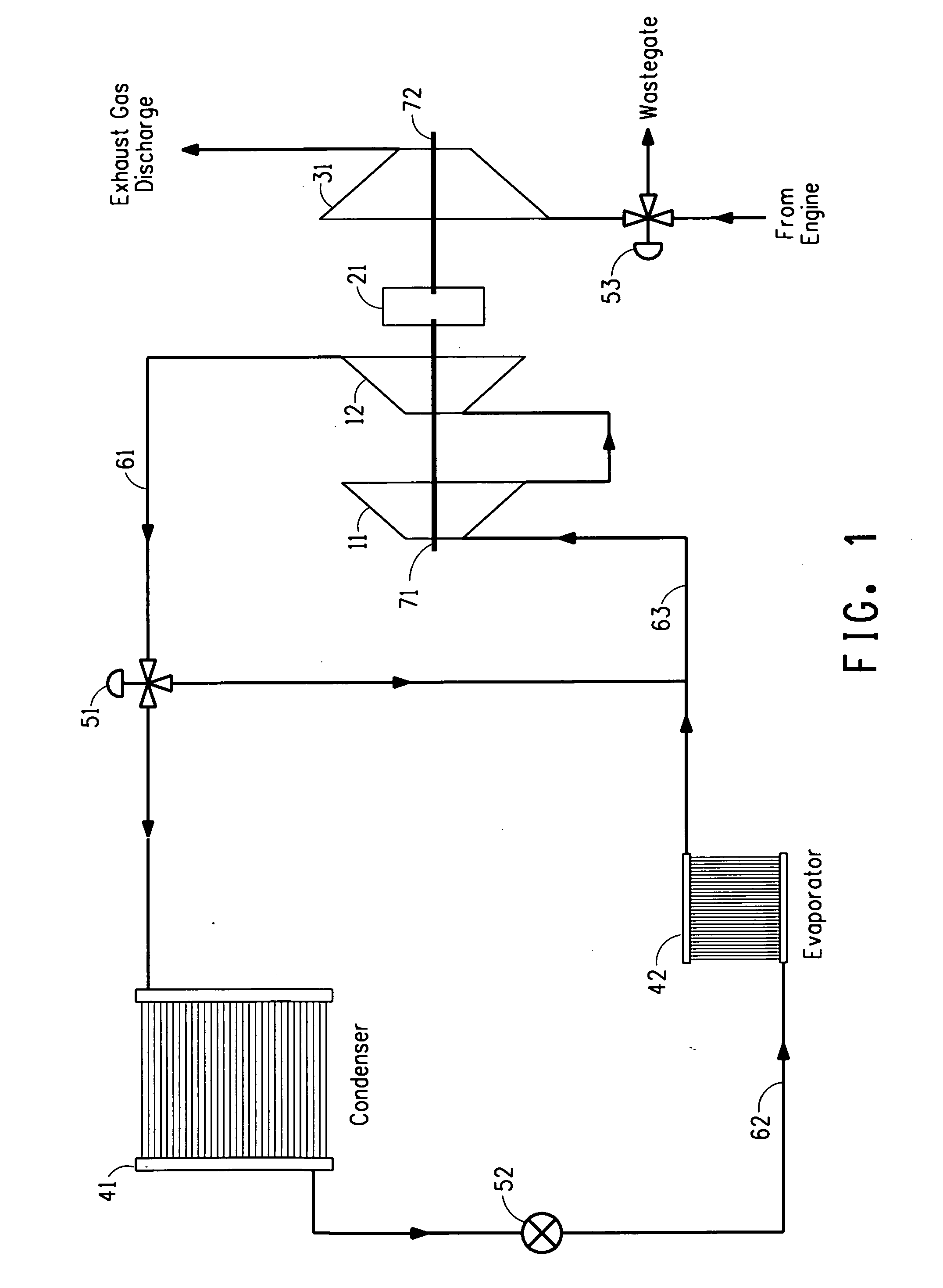

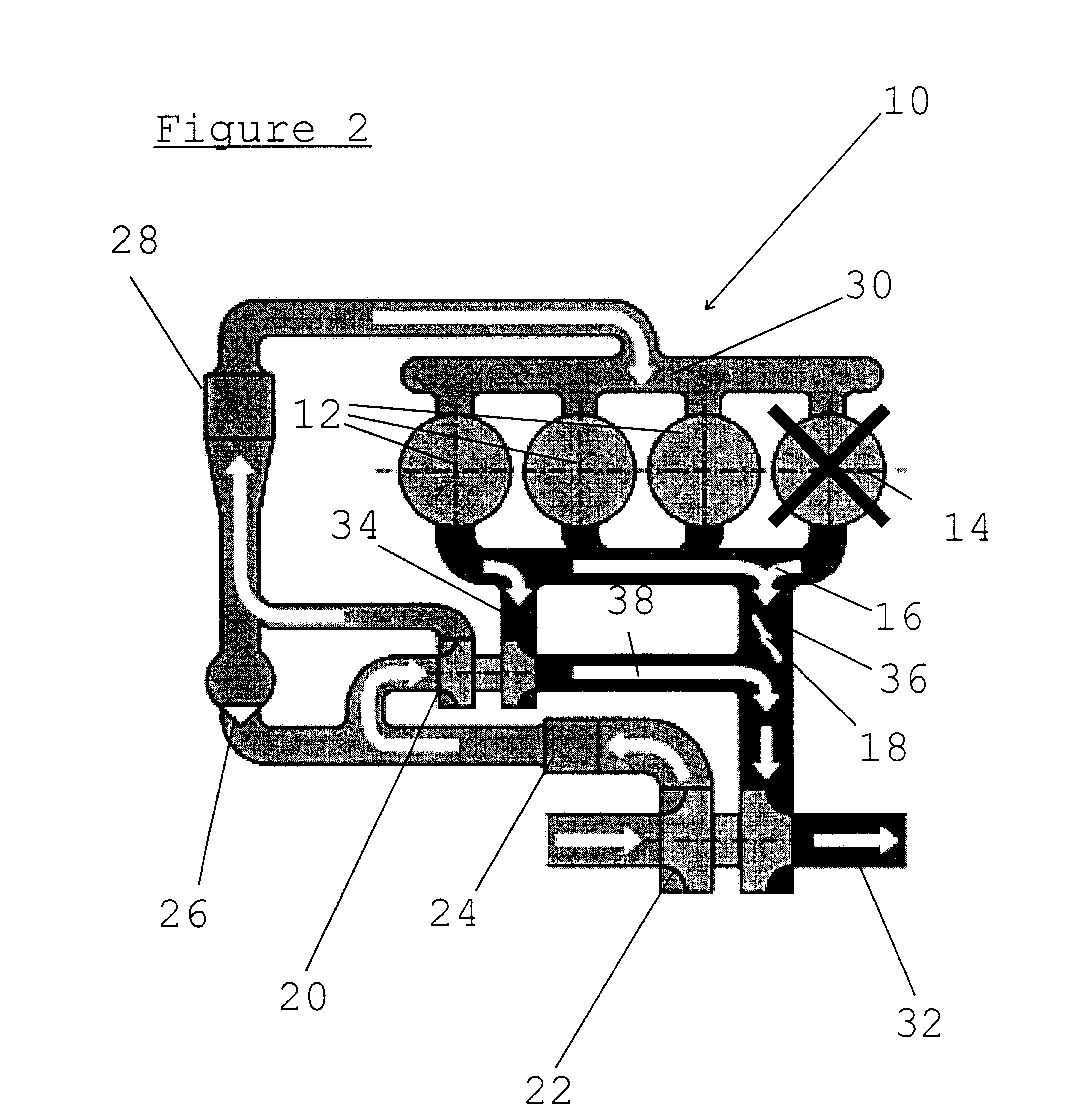

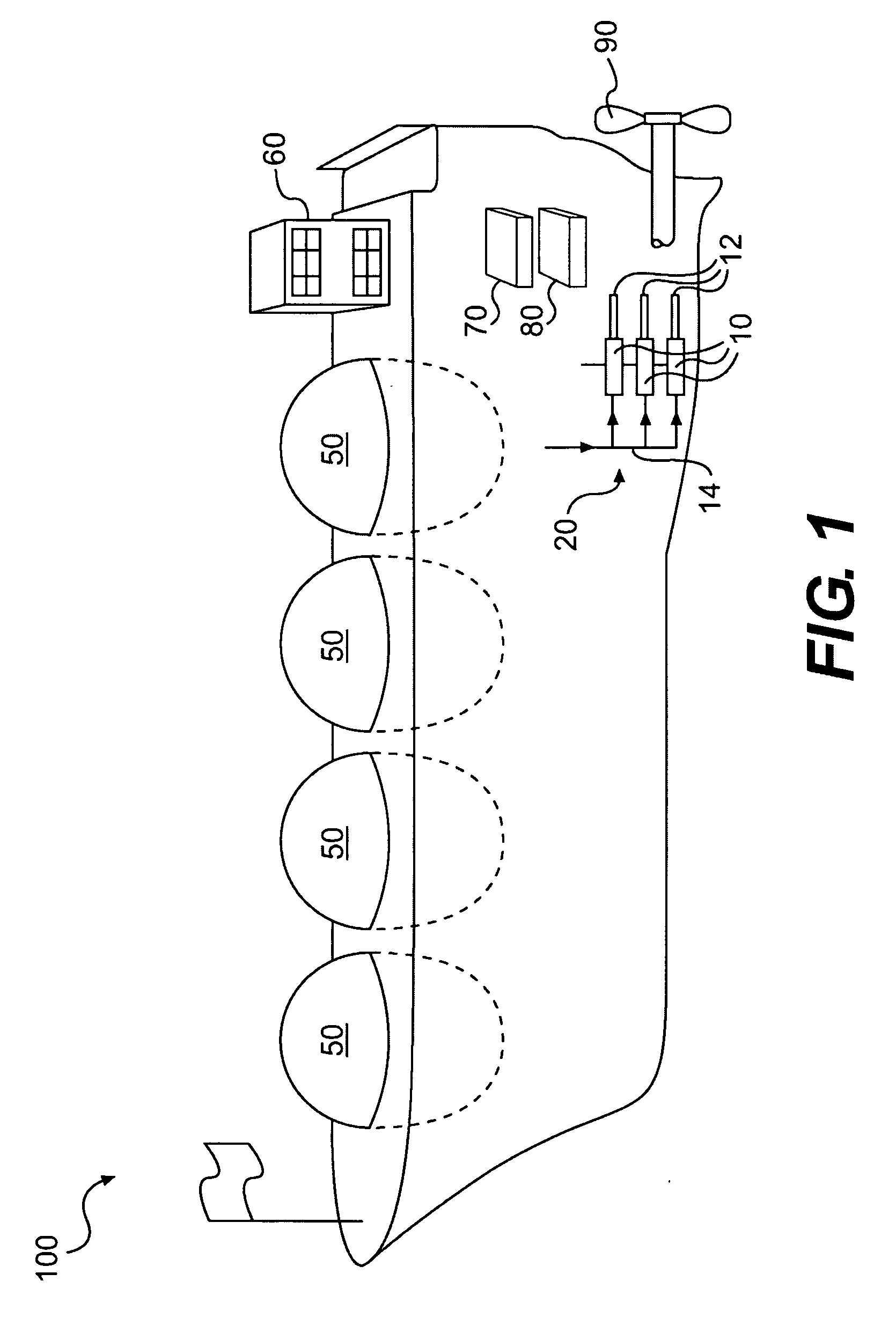

Refrigeration/air-conditioning apparatus powered by an engine exhaust gas driven turbine

InactiveUS20060242985A1Vary amountCompression machines with non-reversible cycleClimate change adaptationAir conditioningRefrigeration

Owner:EI DU PONT DE NEMOURS & CO

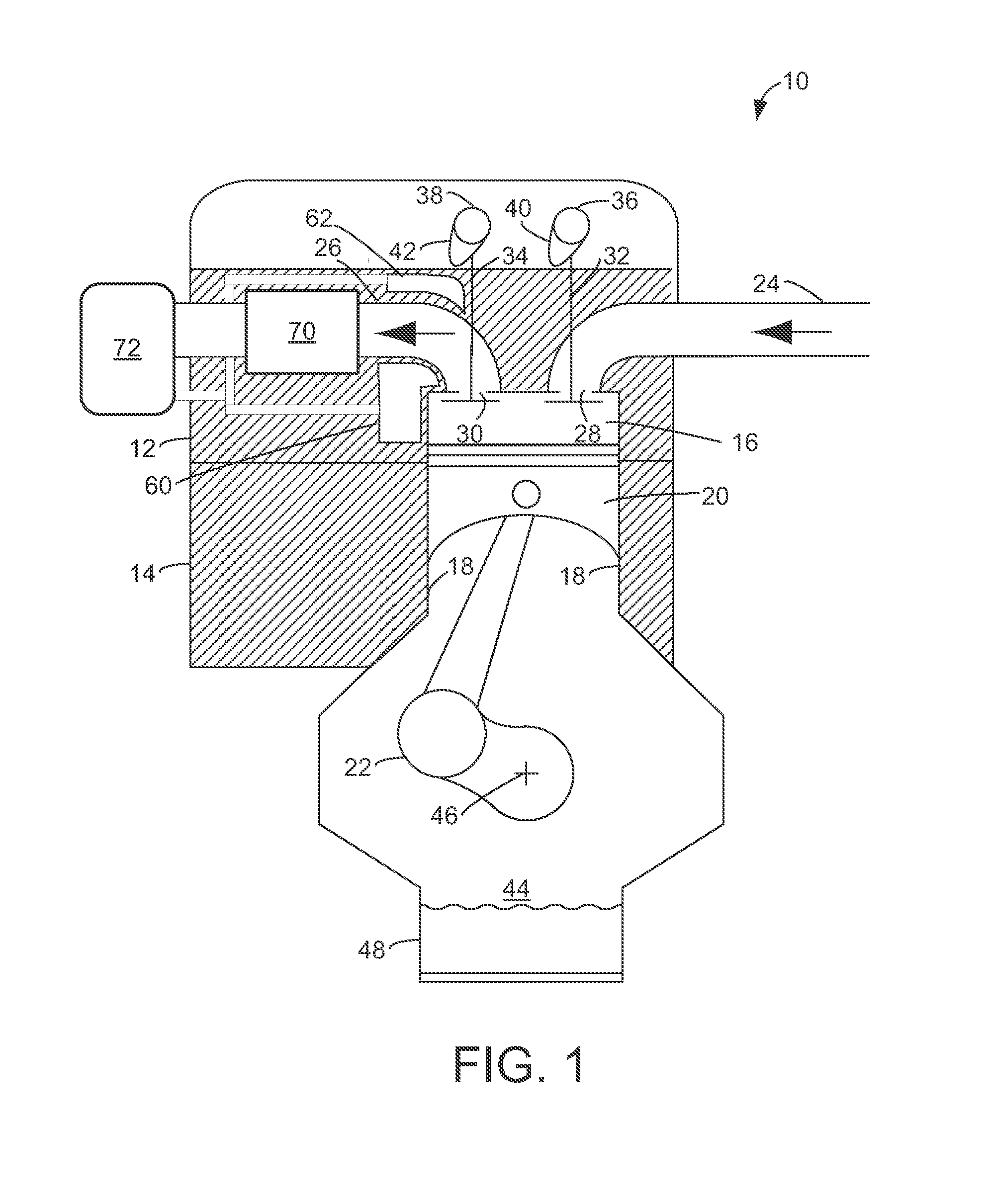

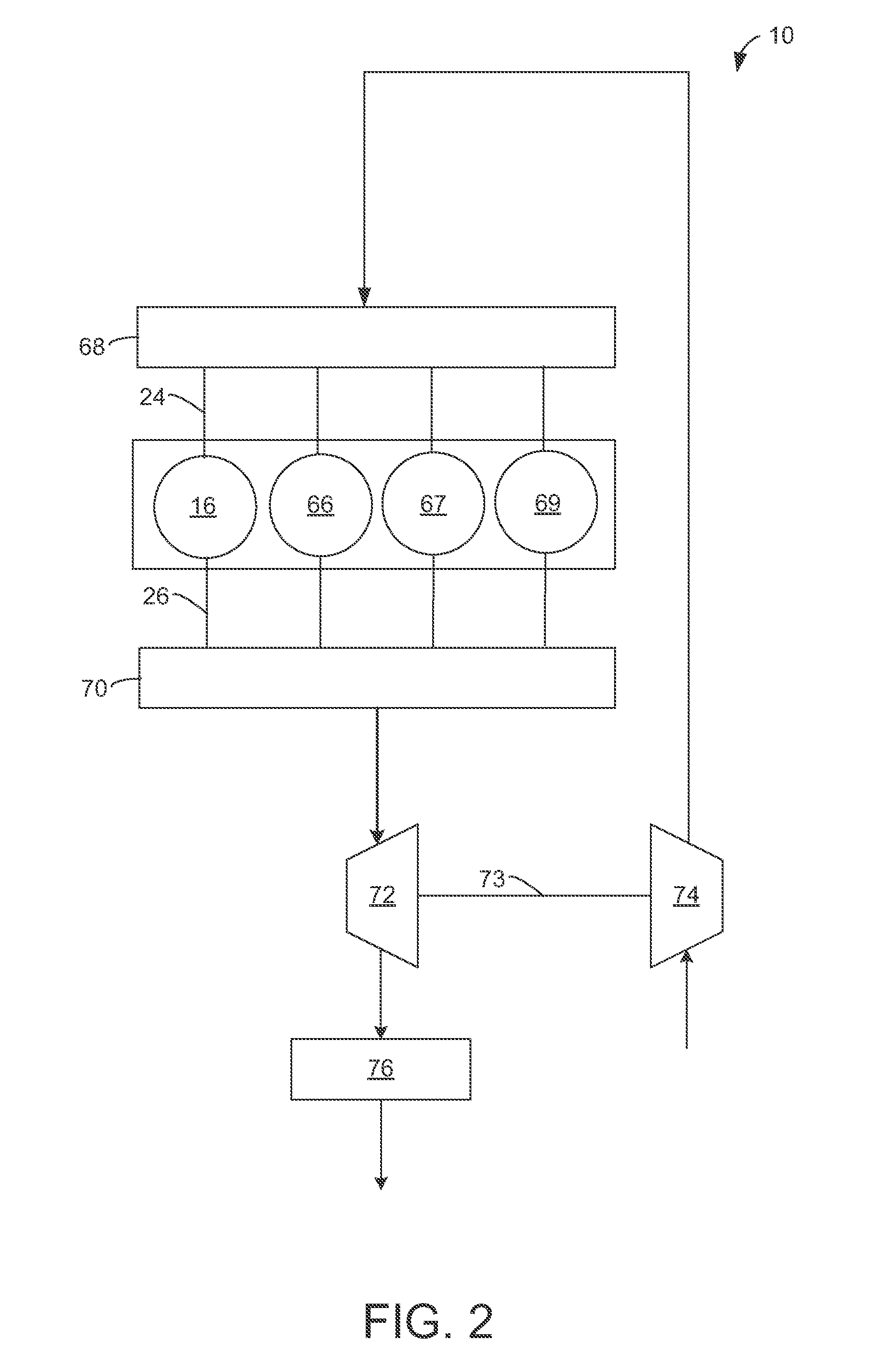

Turbo charging in a variable displacement engine

Owner:FORD GLOBAL TECH LLC

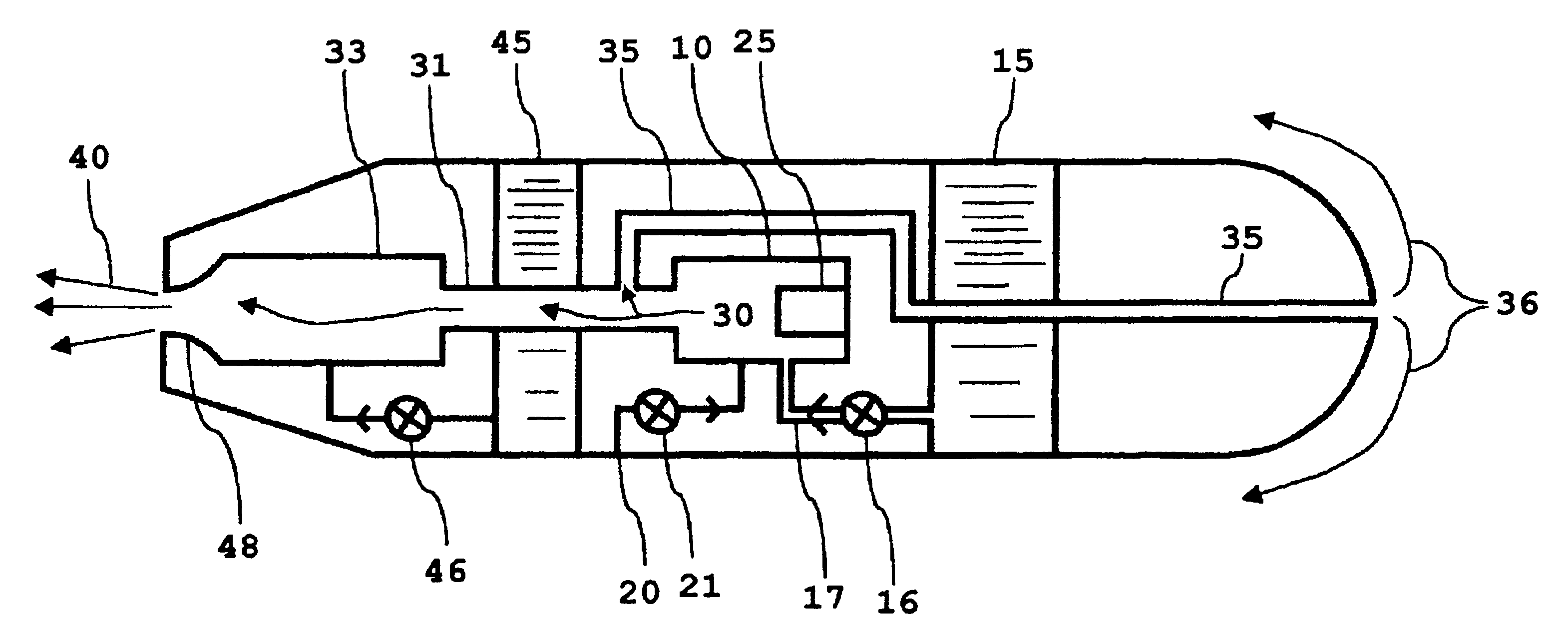

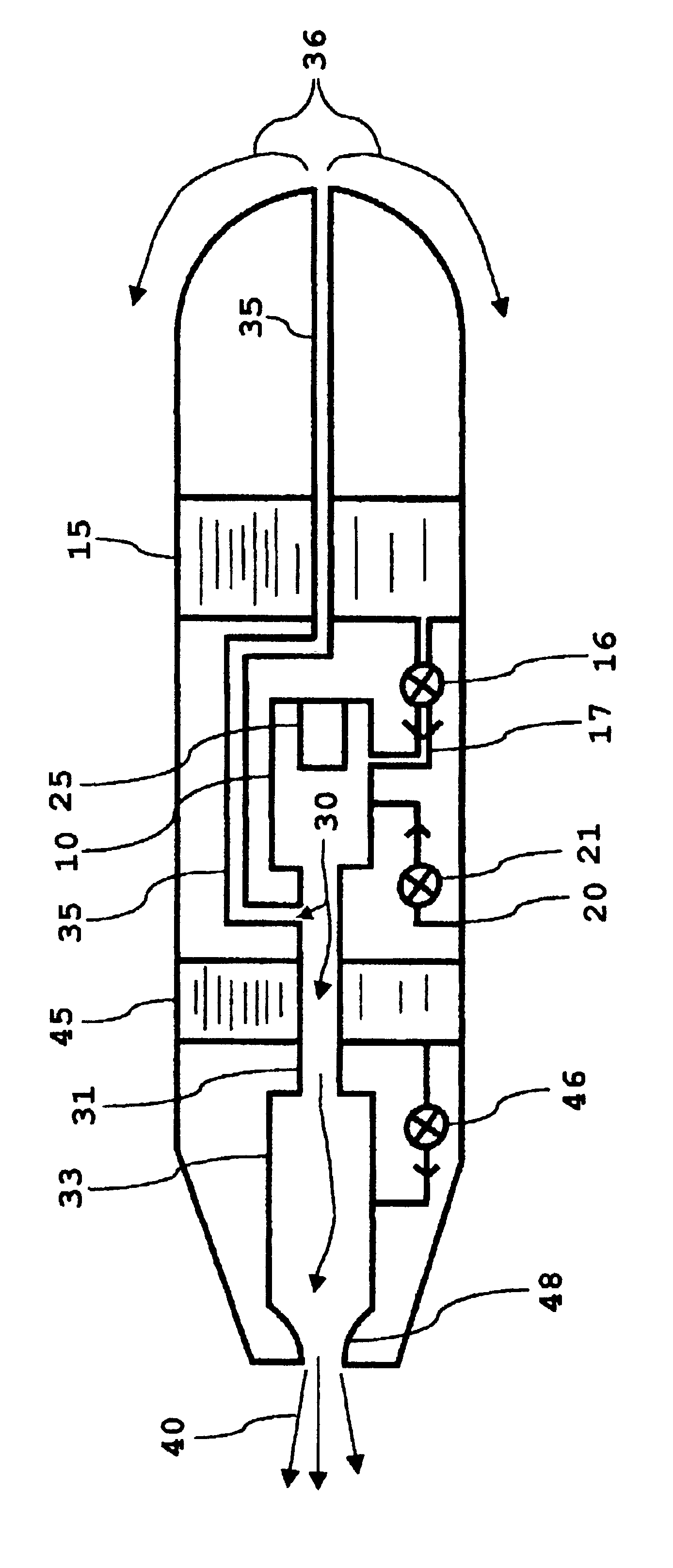

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

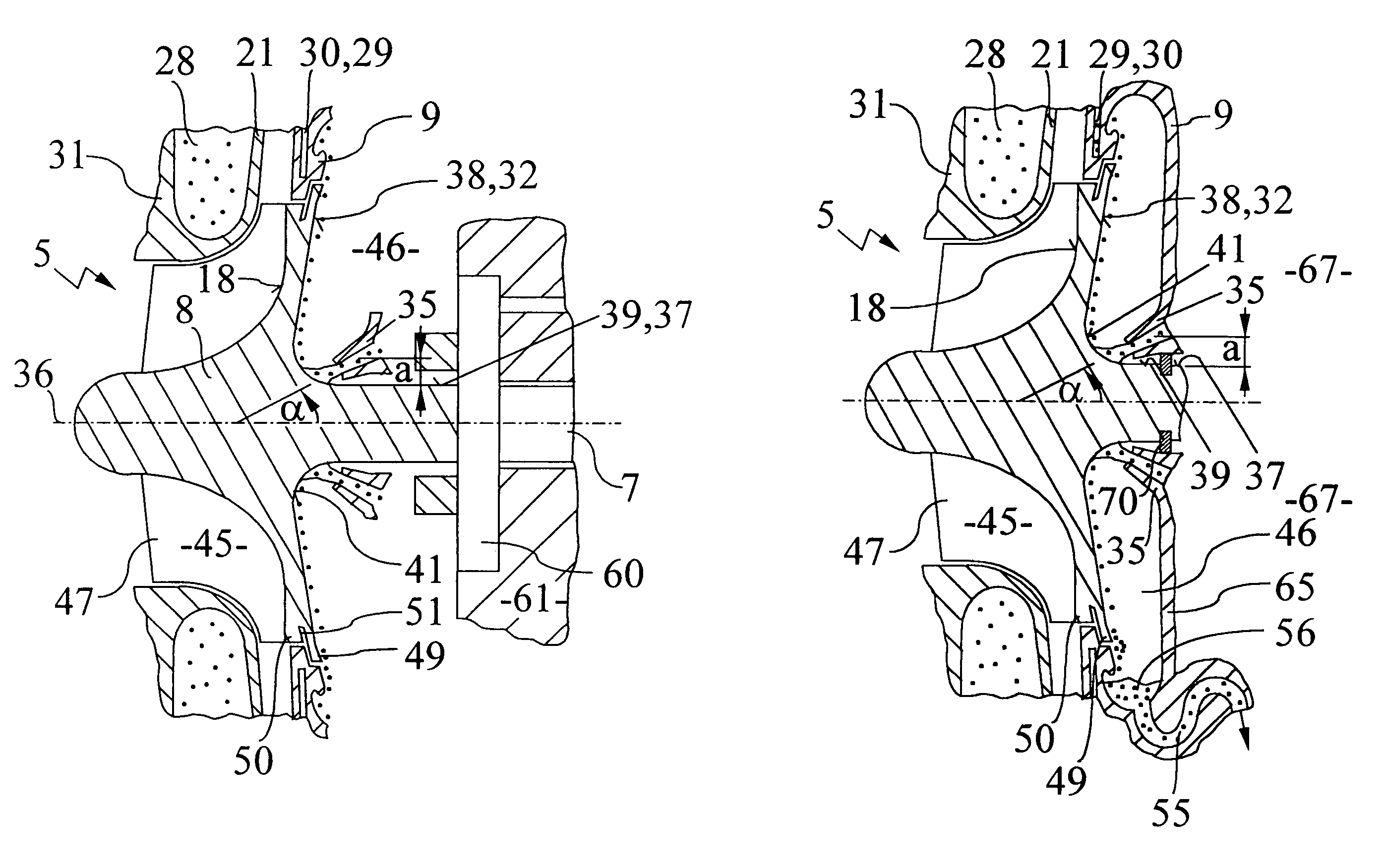

Engine air brake device for a 4-stroke reciprocating piston internal combustion engine

ActiveUS20050087170A1Low costHigh engine braking outputValve arrangementsExhaust apparatusExhaust valveEngineering

Owner:MAN NUTZFAHRZEUGE AG

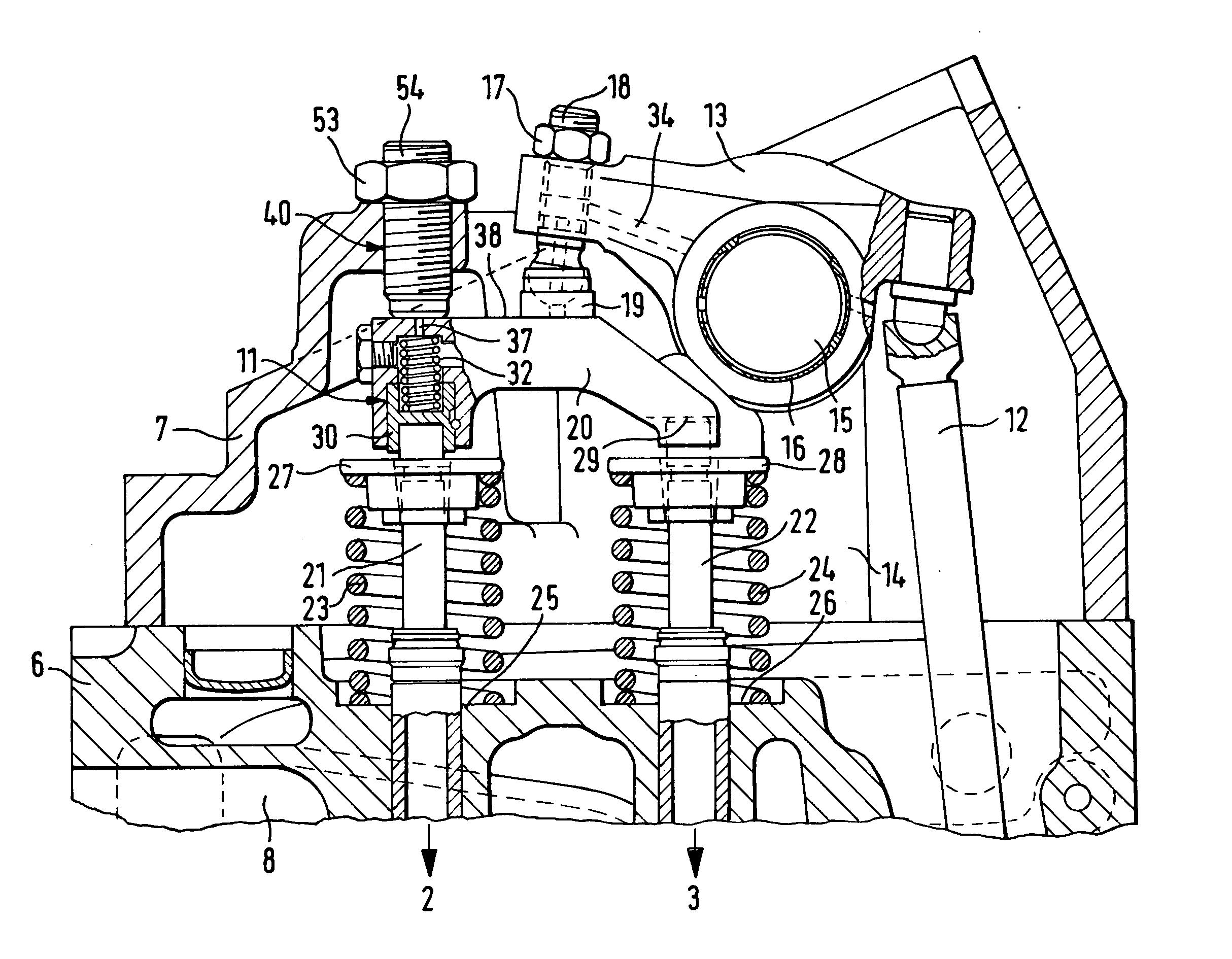

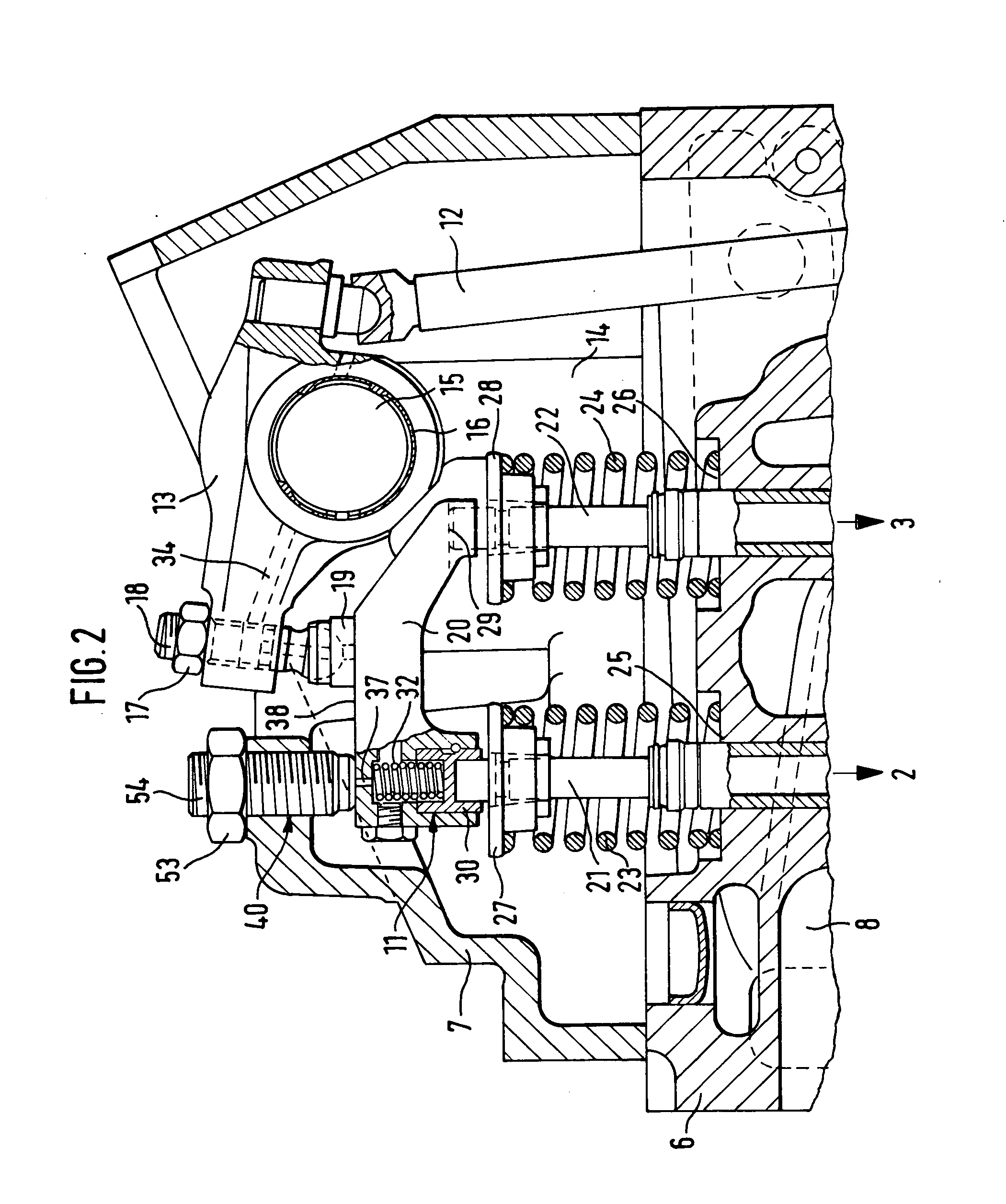

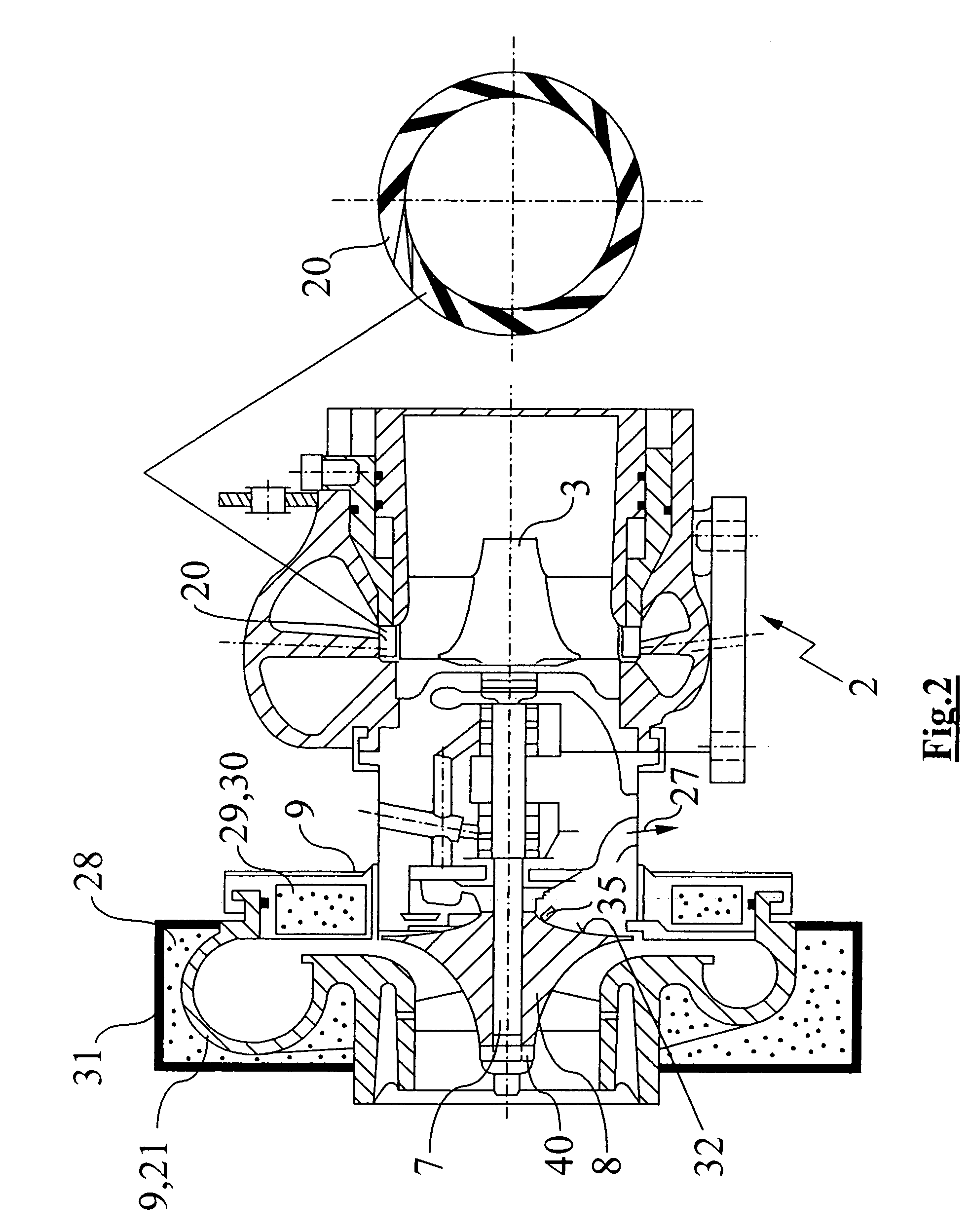

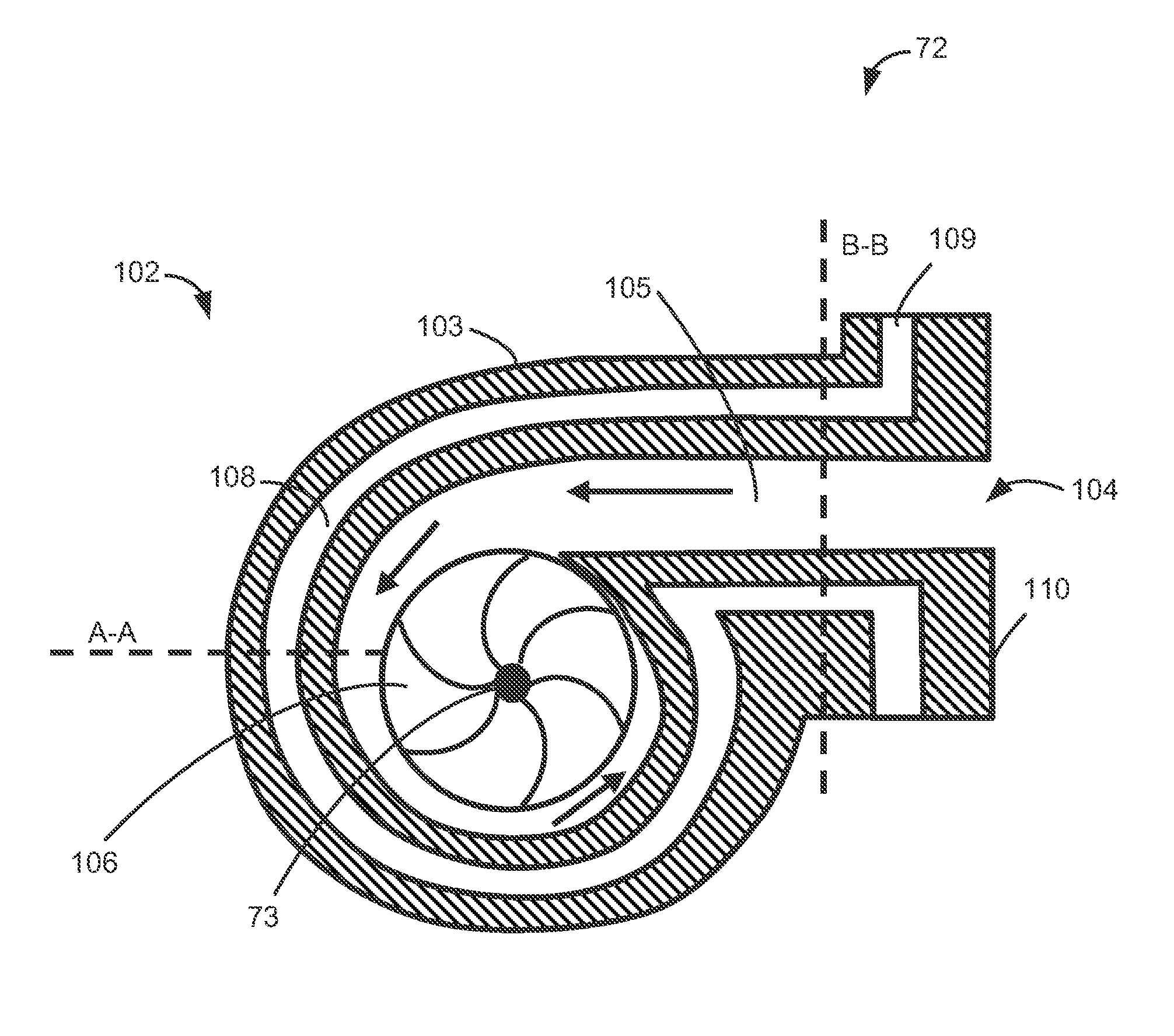

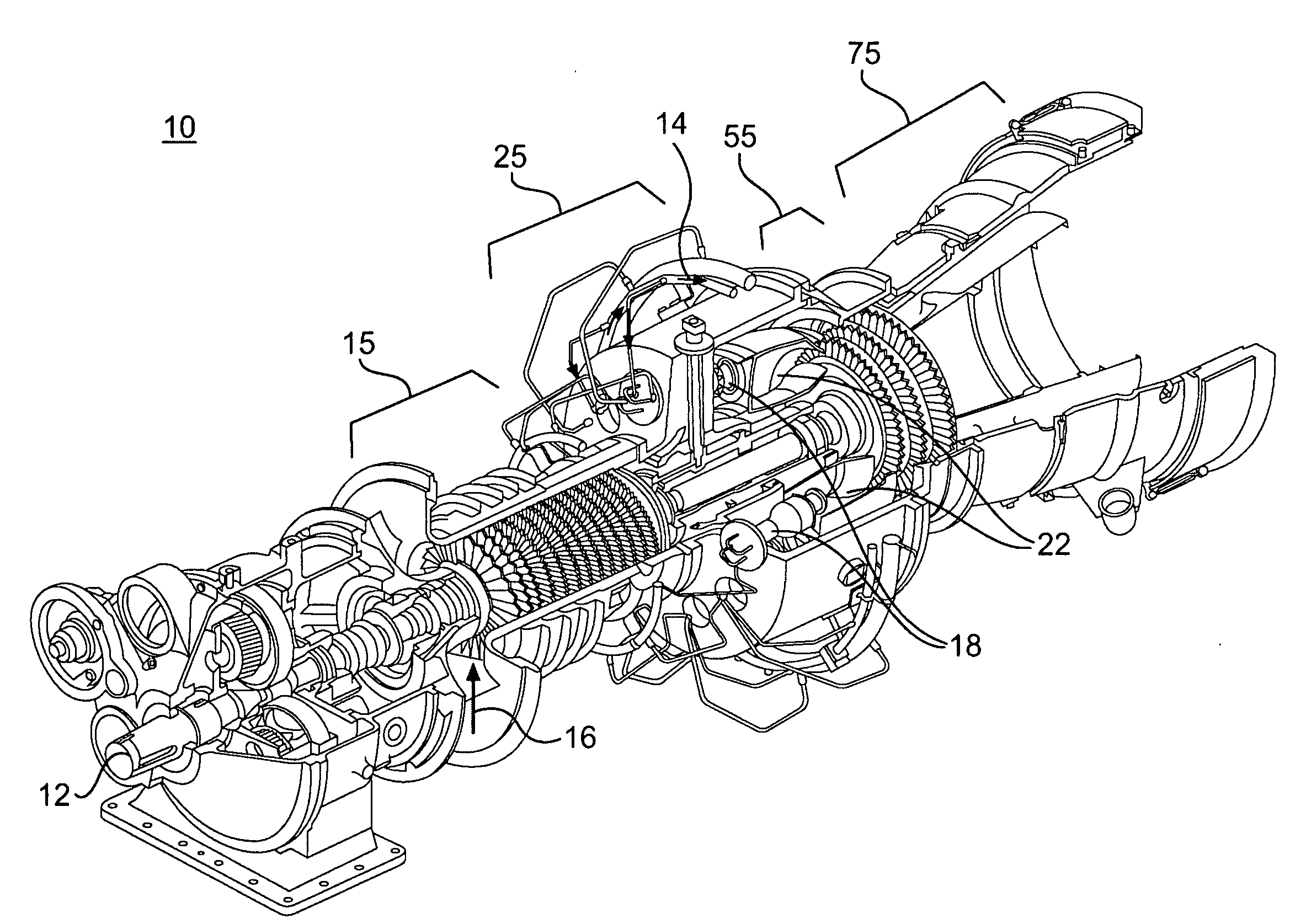

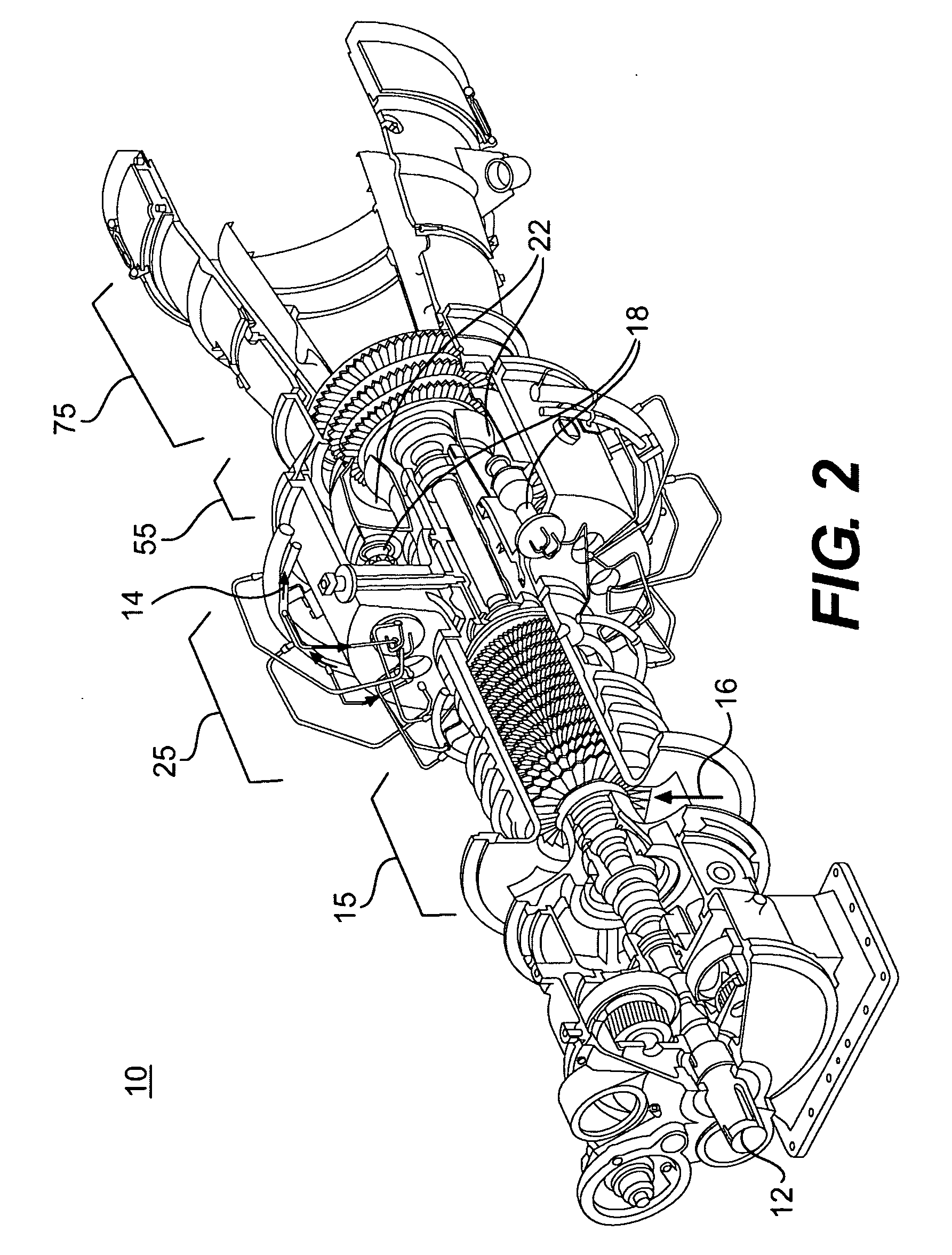

Exhaust-gas turbocharger

InactiveUS7010916B2Cooling of the backside of the compressor wheel is improvedImprove cooling effectPump componentsEngine fuctionsExhaust gasExhaust fumes

In an exhaust gas turbocharger including a compressor wheel, the compressor wheel is cooled by at least one nozzle which is arranged in close axial proximity to the axis of rotation of the compressor wheel for spraying the backside of the compressor wheel near the center thereof with coolant whereby the coolant, utilizing the centrifugal forces of the rotating compressor wheel, is completely distributed over the entire wheel back surfaces.

Owner:DAIMLER AG

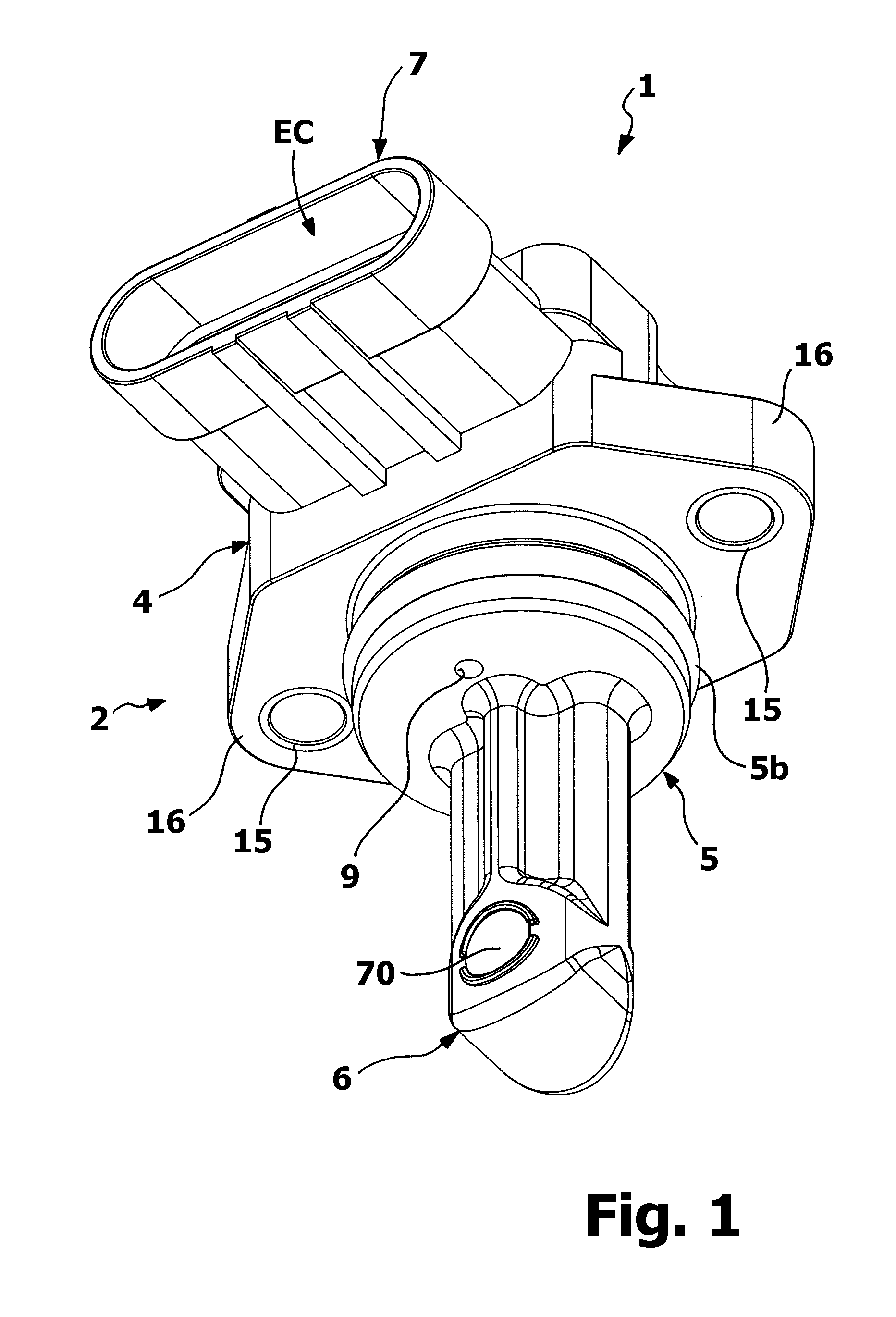

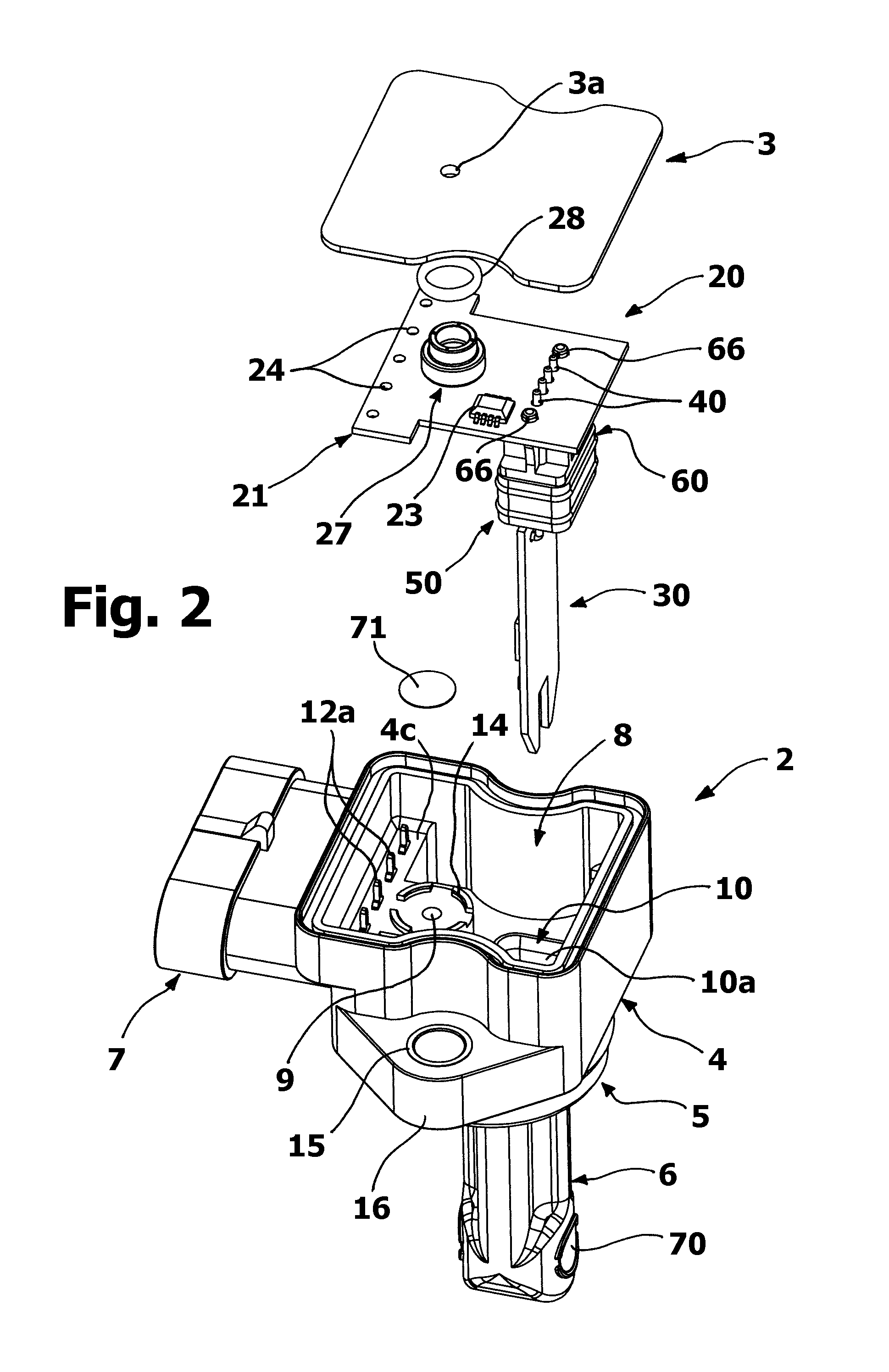

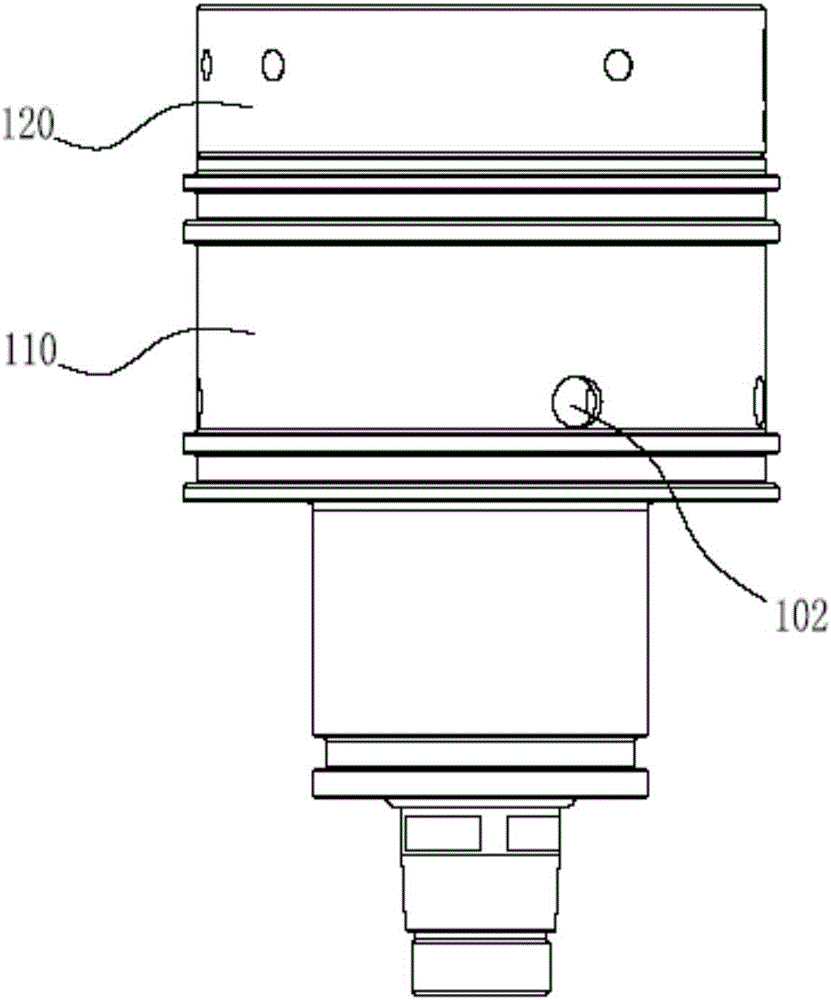

Detection device

InactiveUS20120237402A1Improve accuracyImprove operational reliabilityInternal-combustion engine testingThermometer detailsCombustionEngineering

Owner:ELTEK

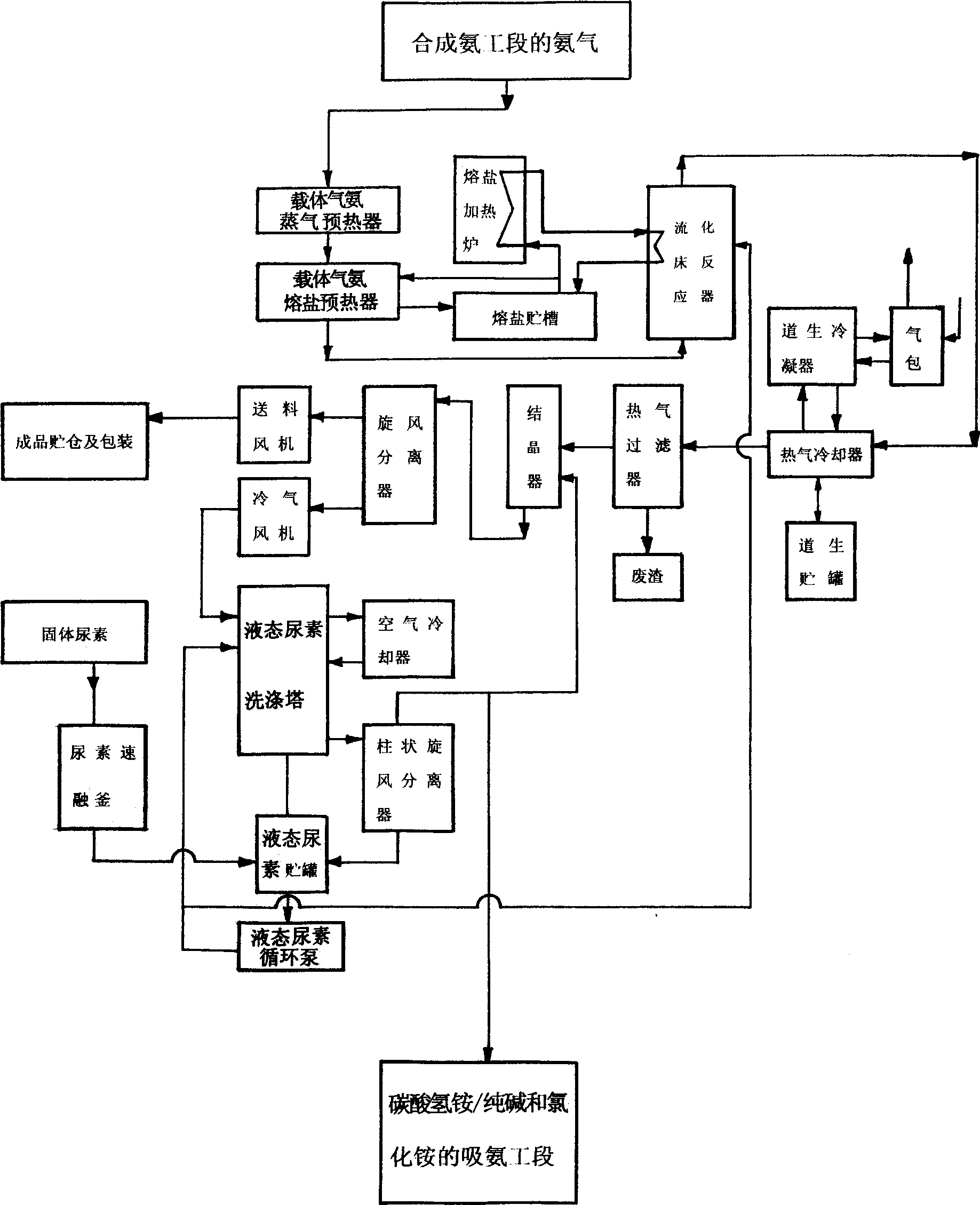

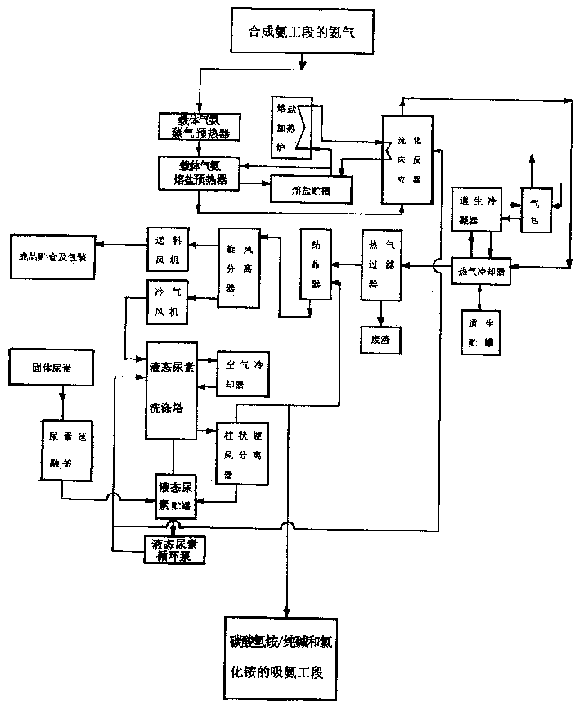

Trimeric cyanamide joint production method using one step method

InactiveCN1493565AImprove product qualityReduce labor intensityOrganic chemistryChemistryAmmonium chloride mixture

Owner:河南金山化工有限责任公司

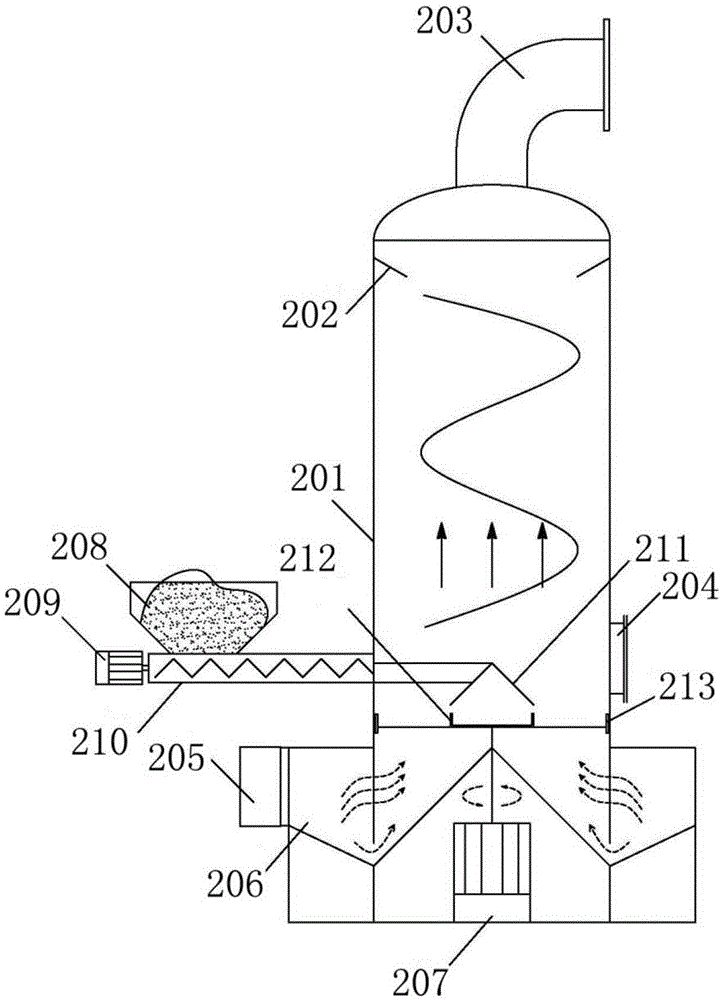

Stereoscopic deodorization system

InactiveCN102002972AGood deodorizing effectSuppresses odor formationLavatory sanitoryExhaust gasAgricultural engineering

The invention relates to an air deodorization system, in particular to a stereoscopic deodorization system for public restrooms. The stereoscopic deodorization system comprises a lower tuyere exhaust system and an upper tuyere intake system. The invention is characterized in that the lower tuyere exhaust system comprises an exhaust pipe, an exhaust fan, a slanted pipe and a deodorizing device; a downcomer, which communicates a toilet stool and a main soil pipe, is provided with the slanted pipe; the exhaust pipe is connected with the slanted pipe, a settling basin and a fertilizer storage pool; the exhaust pipe is provided with the exhaust fan and the deodorizing device; the outlet of the exhaust pipe is arranged at the leeward position of the public restroom; the upper tuyere intake system comprises an intake pipe, a deodorizing device, a blower and air valves; the inlet of the intake pipe is arranged at the weather position of the public restroom; the blower is arranged at the inlet of the intake pipe; one air valve is arranged beside each toilet stool; the intake pipe is connected with the air valve; and the deodorizing device is arranged on the intake pipe between the blower and the air valve. The stereoscopic deodorization system can be widely used in foam restrooms or common restrooms, and has obvious deodorization effect, so that people entering the public restroom can feel comfortable.

Owner:昆明惠云夜光工程有限责任公司

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

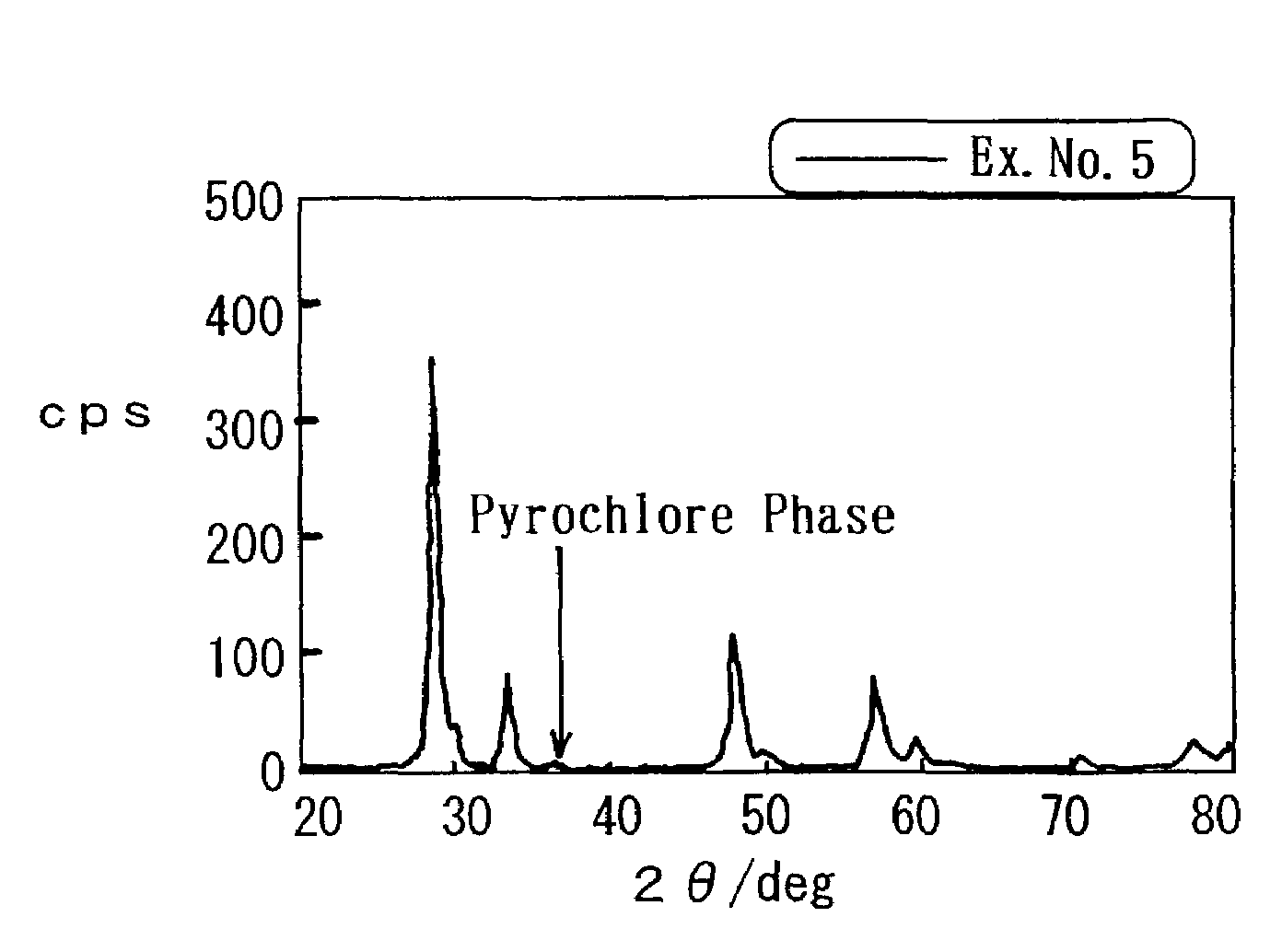

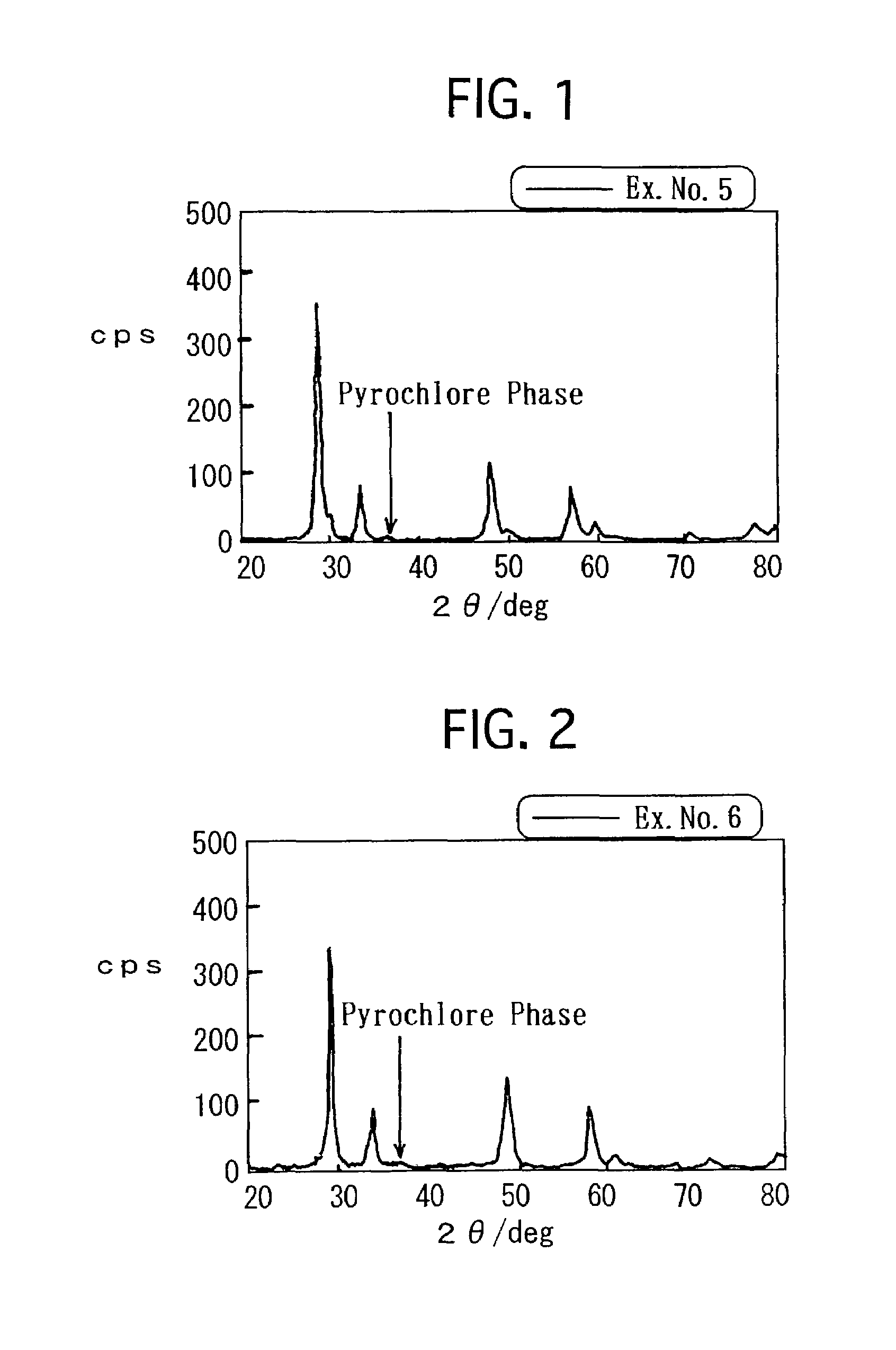

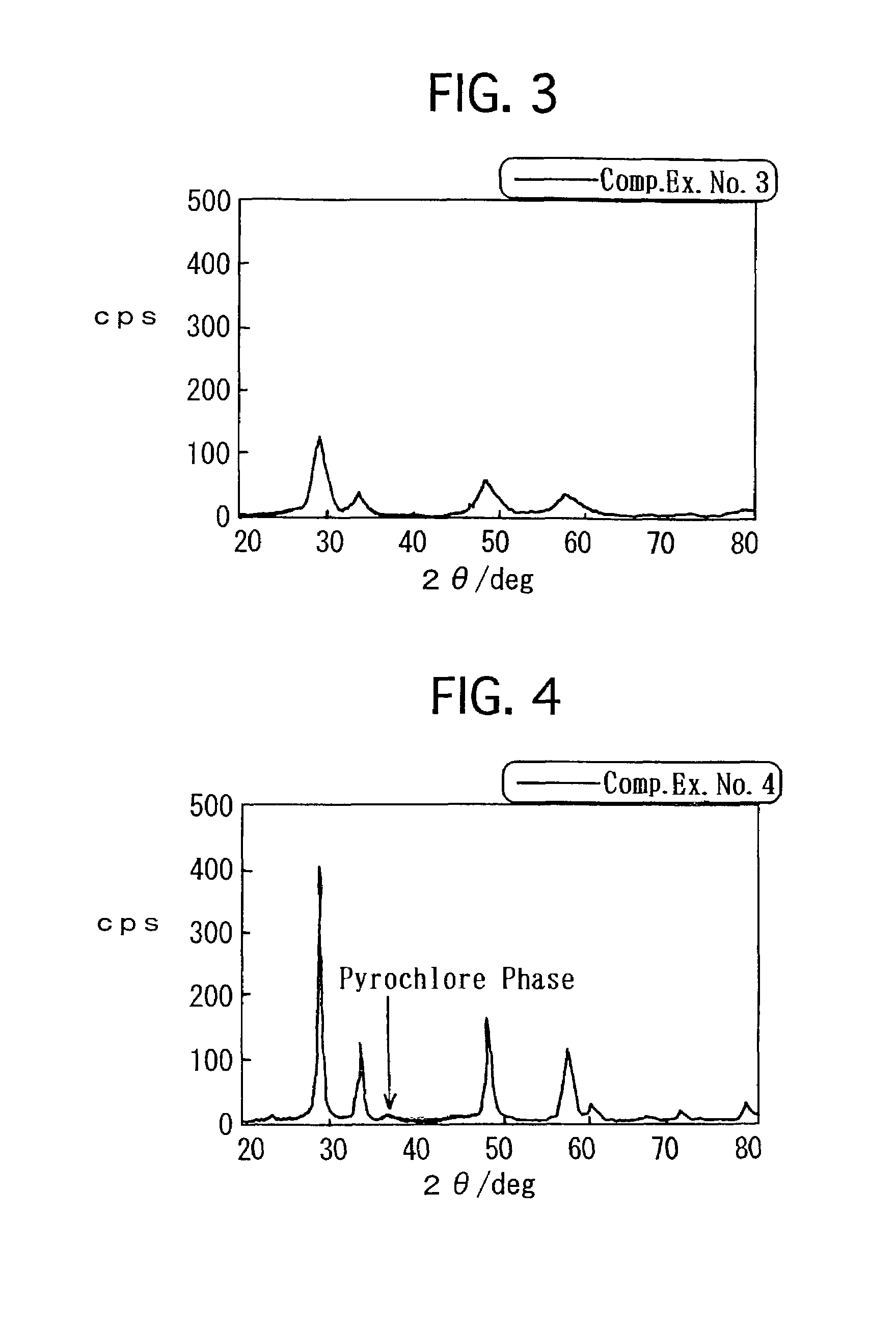

Composite oxide, process for producing the same, and exhaust gas reducing co-catalyst

ActiveUS7247597B2Lack of durabilityUpgrade heat resistanceDispersed particle separationCatalyst activation/preparationExhaust gasComposite oxide

Owner:TOYOTA CENT RES & DEV LAB INC

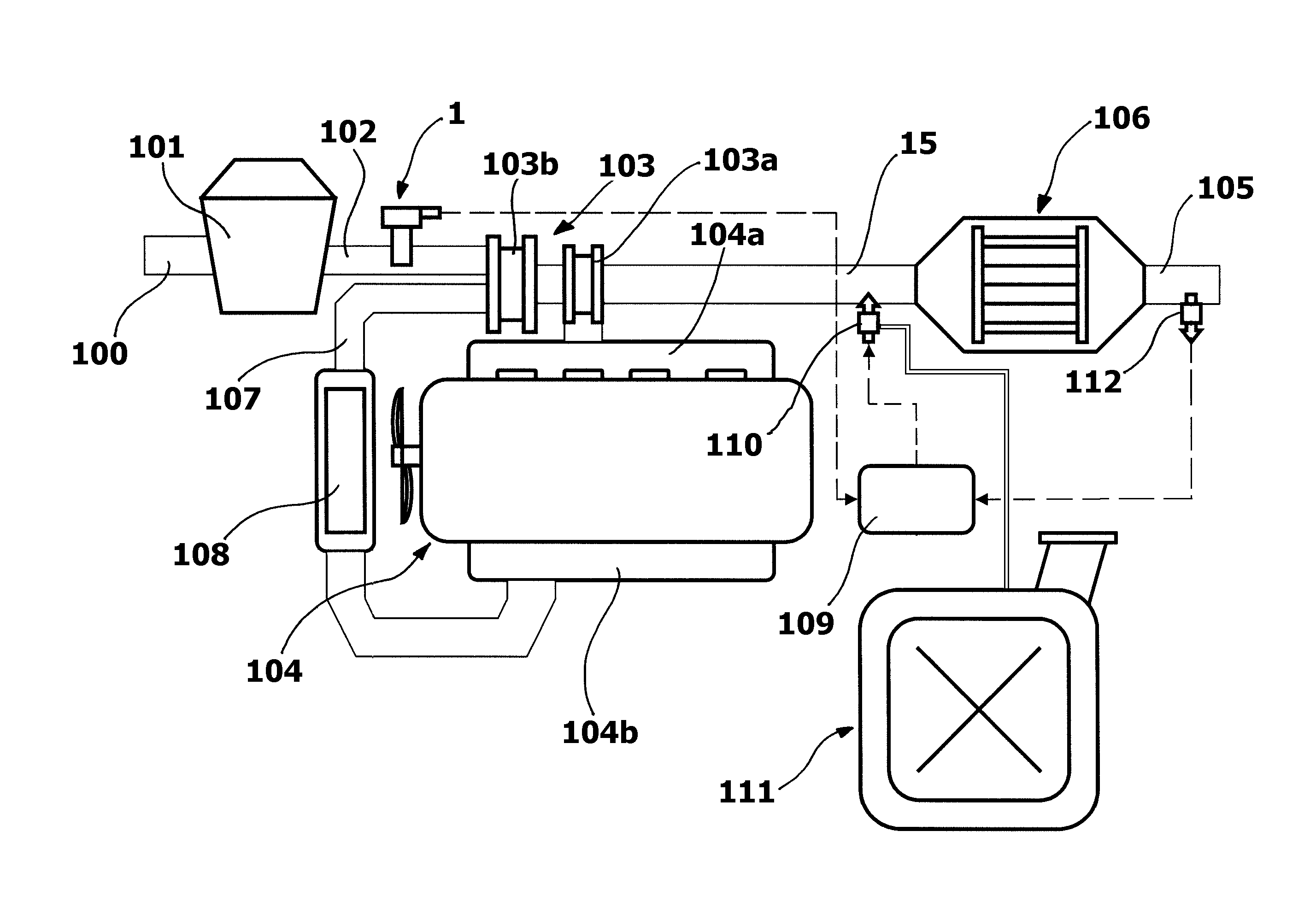

Aftertreatment system and control strategy for internal combustion engine

ActiveUS20120260633A1Shorten speedBreakage of the DPFElectrical controlNon-fuel substance addition to fuelExternal combustion engineLow load

In an exhaust gas treatment device in which a diesel oxidation catalyst and a DPF are provided in an exhaust pipe of an internal combustion engine, abnormal combustion in the DPF, occurring when the internal combustion engine varies from a high load condition to a low load condition, poses a problem. To solve this problem, in the present invention, a DPF abnormal combustion causing operation is determined to have occurred when the internal combustion engine shifts from a high rotation or high load operation region α to a low rotation, low load operation region β within a set time T1. When it is determined that a DPF abnormal combustion causing operation has occurred, abnormal combustion of PM collected in the DPF is suppressed by fully opening an intake throttle valve 44 in order to increase an exhaust gas flow so that heat is removed by sensible heat of the exhaust gas, thereby cooling a DPF device 52, and continuing a late post-injection in order to reduce an oxygen concentration of the DPF. As a result, an abnormal temperature increase in the DPF device 52 can be suppressed early.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

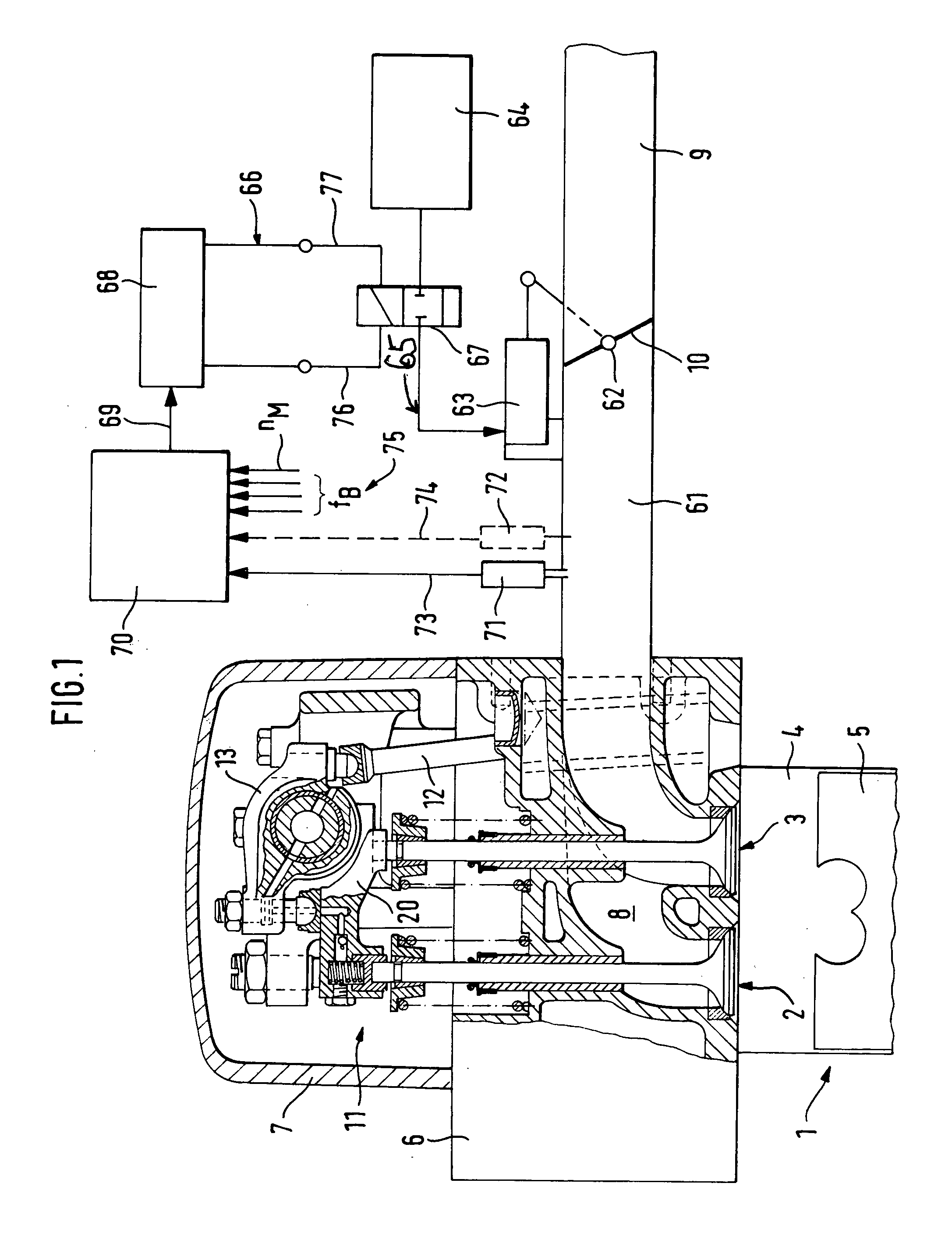

Exhaust gas turbocharger for an internal combustion engine and method of operating an exhaust gas turbocharger

InactiveUS20070101714A1Improve responseImprove power densityInternal combustion piston enginesExhaust apparatusTurbochargerElectric machine

In an exhaust gas turbocharger for an internal combustion engine comprising a compressor and a turbine interconnected by a shaft in a rotationally fixed manner, and an electric machine which can be connected to the exhaust gas turbocharger via a clutch, the exhaust gas turbocharger can be driven at least temporarily by a disk-shaped flywheel rotatably supported on the shaft and being operable selectively by the turbine and by an electro-dynamic structure for improving the response behavior of the exhaust gas turbocharger.

Owner:DAIMLER AG

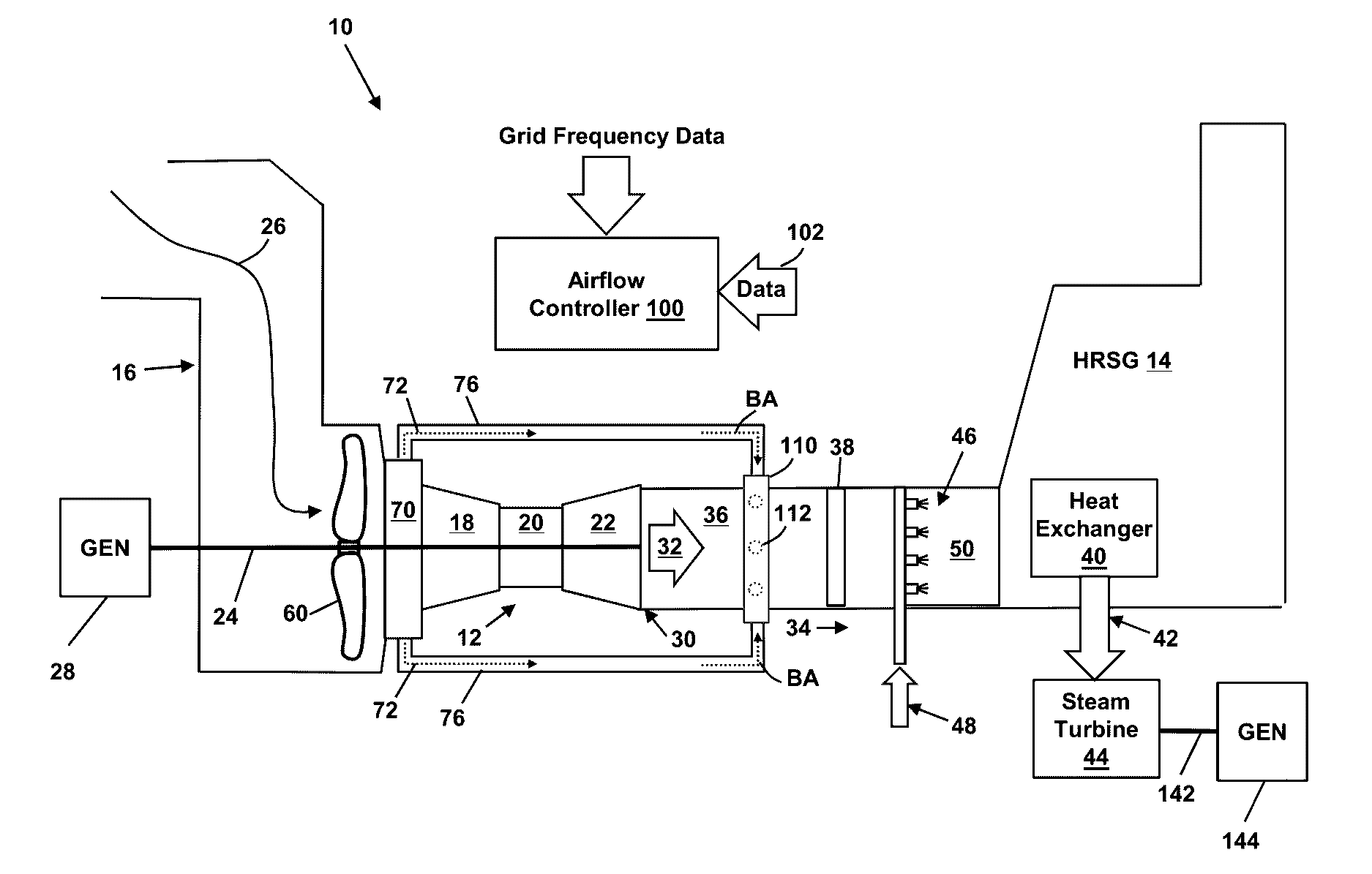

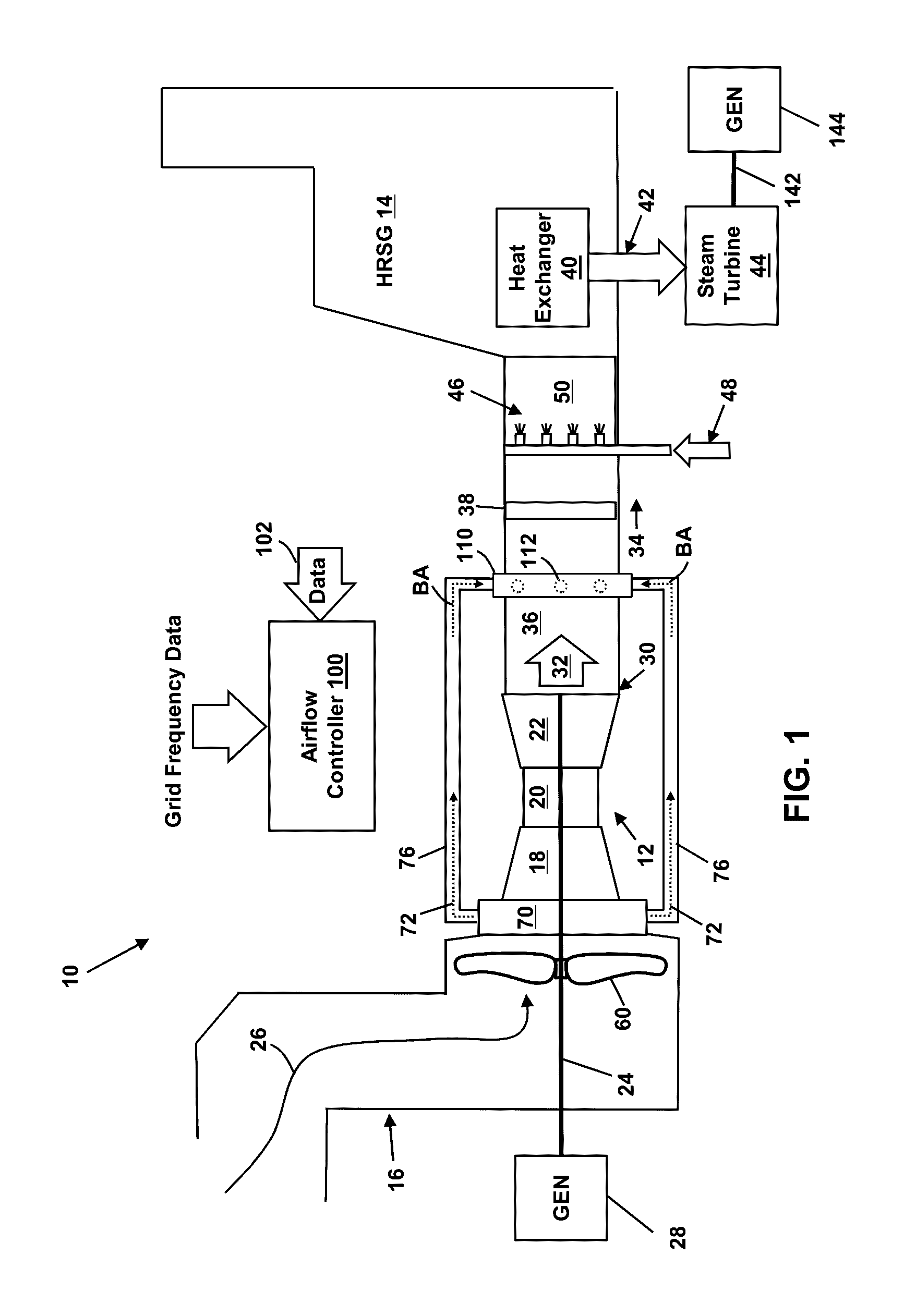

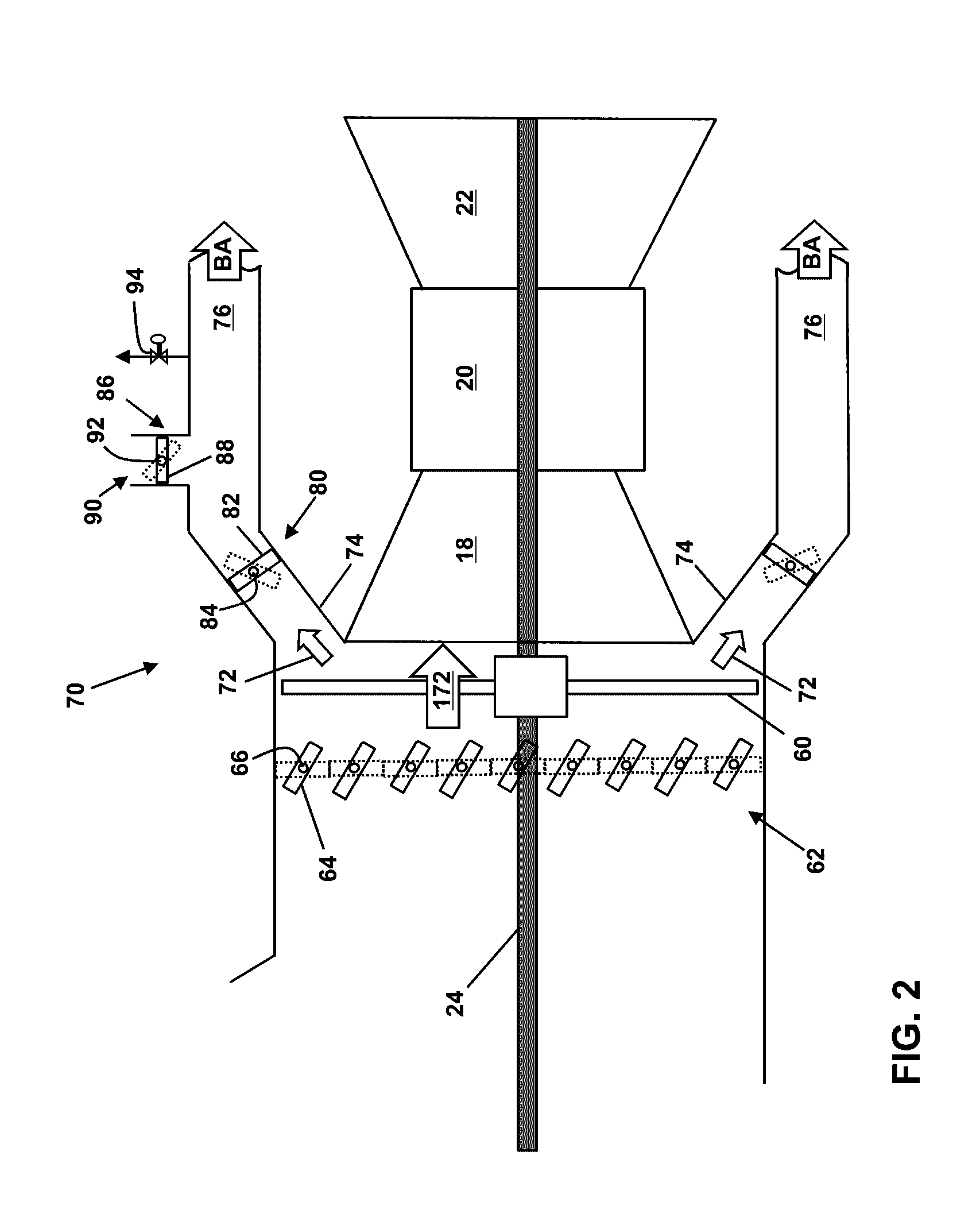

Power generation system exhaust cooling

ActiveUS20160376960A1Reduce the temperatureEngine fuctionsExhaust apparatusExhaust gasAutomotive engineering

Owner:GENERAL ELECTRIC CO

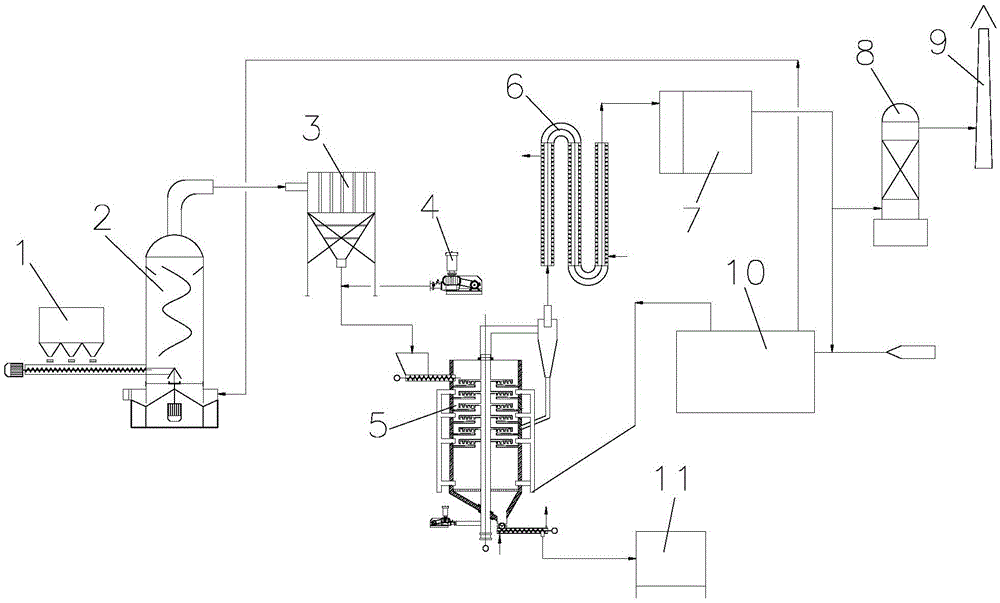

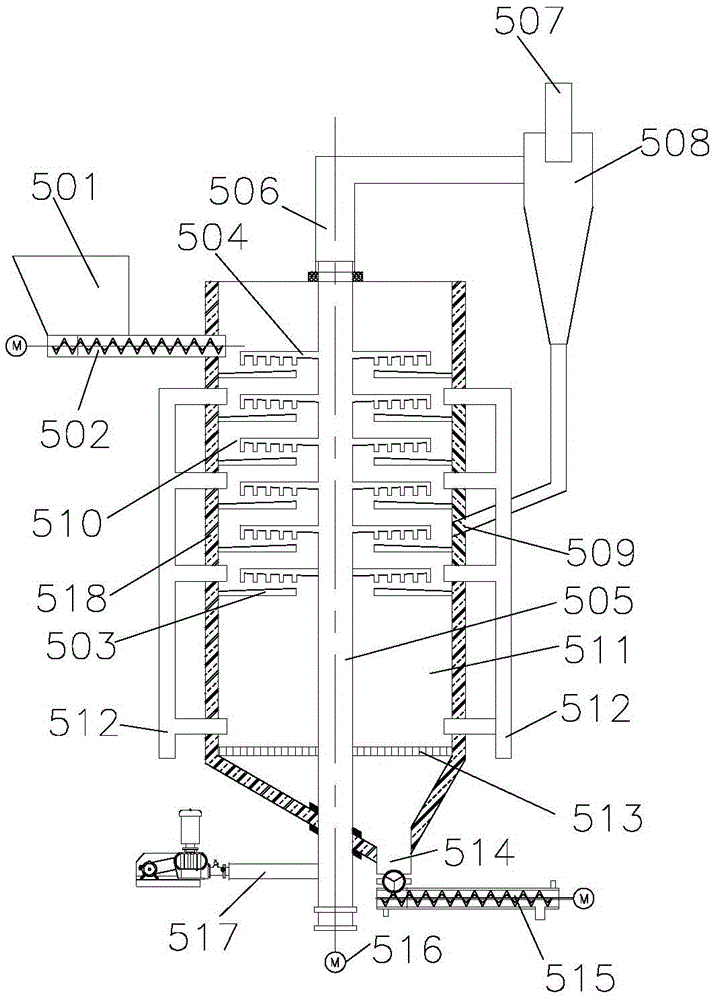

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

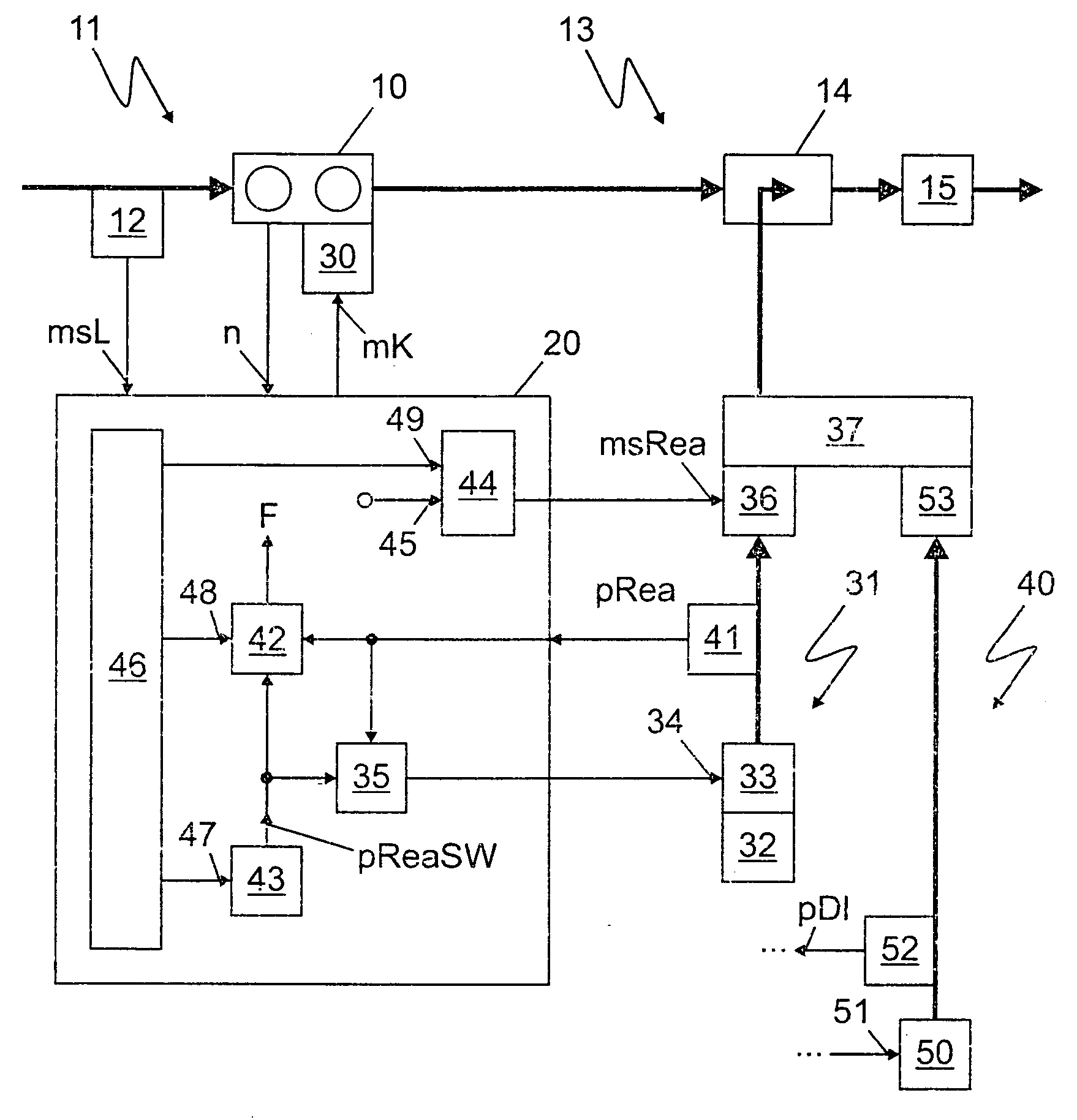

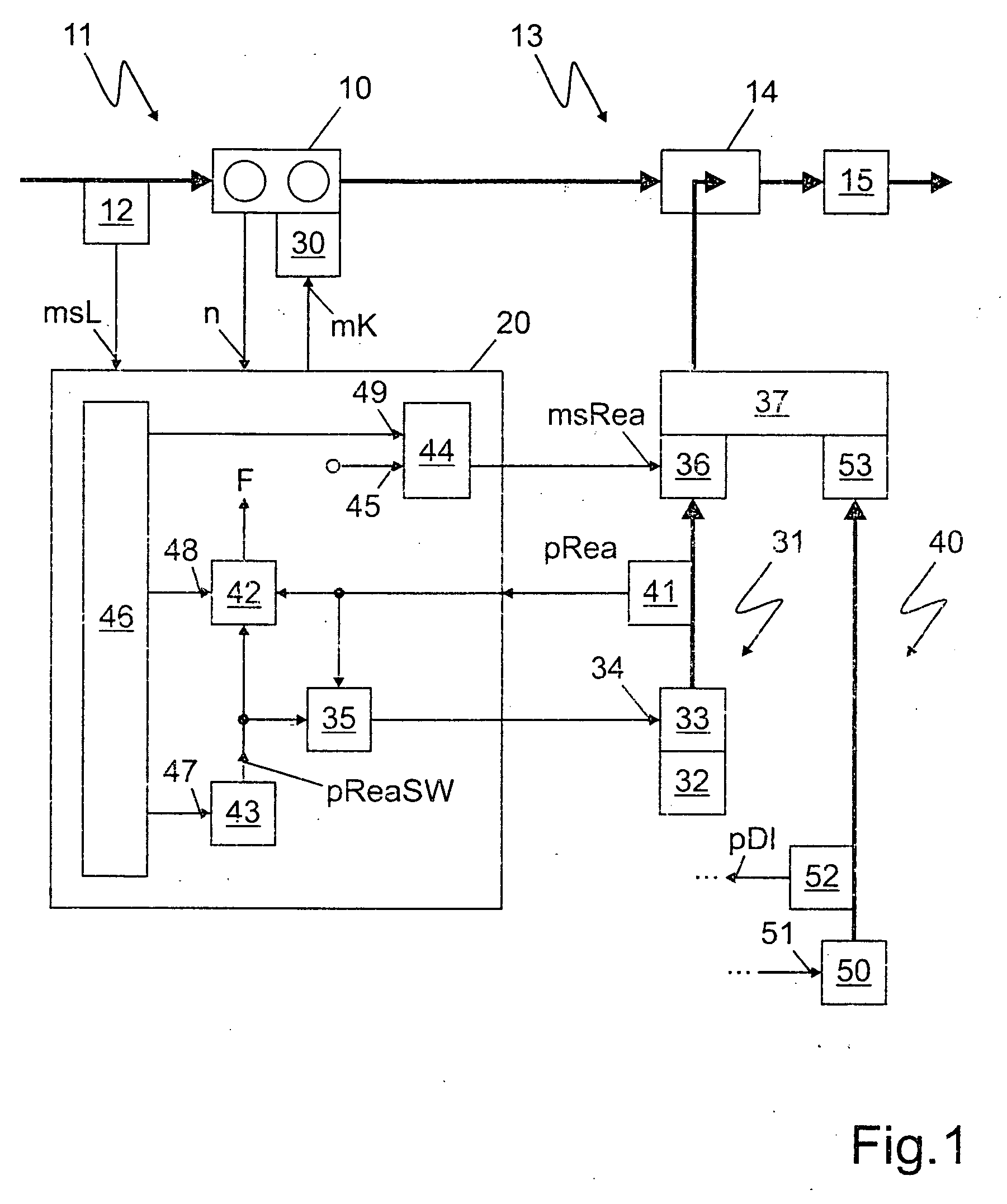

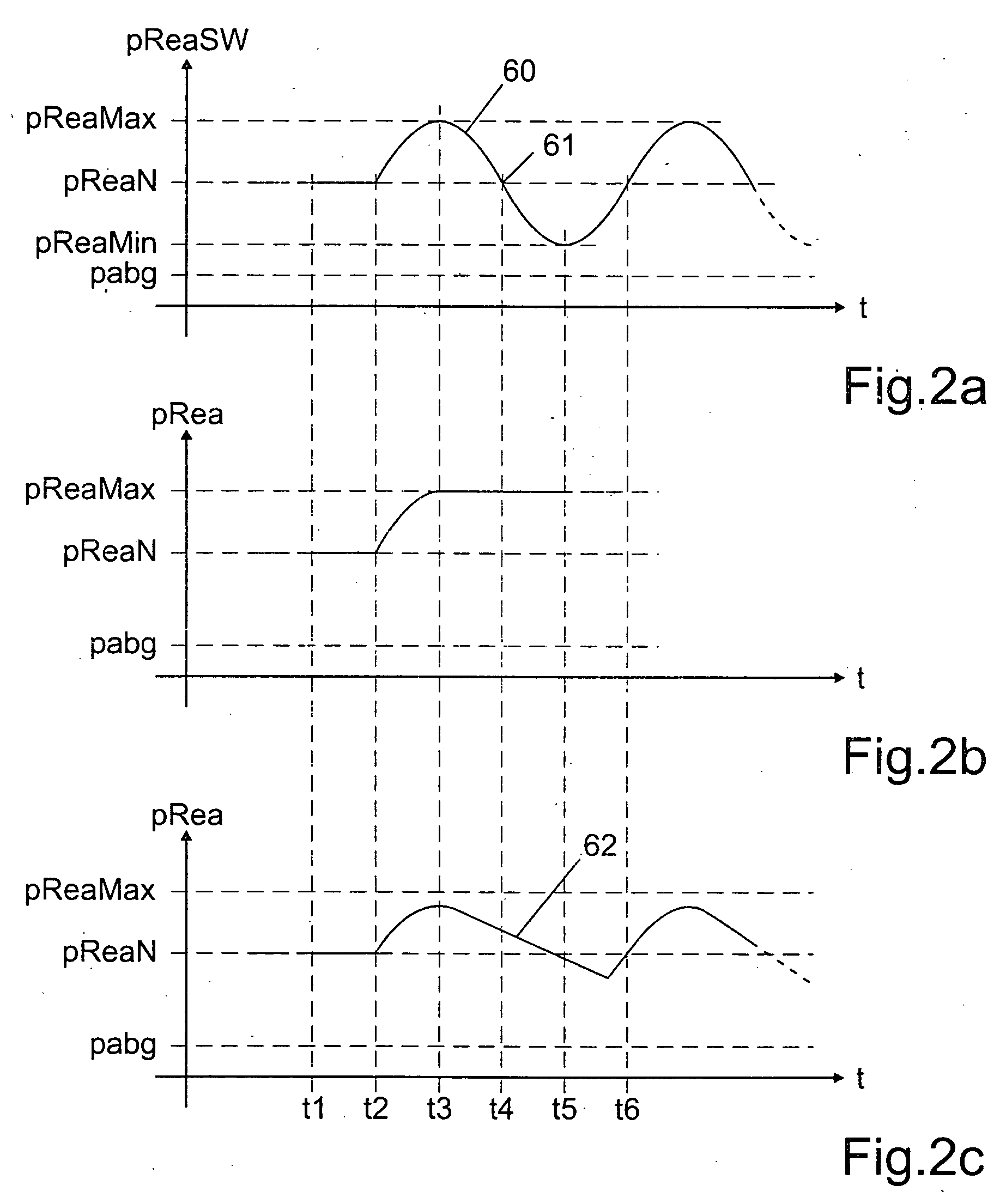

Method for operating an internal combustion engine and device for executing the method

InactiveUS20060196170A1Improve reliabilityEasily flammableInternal combustion piston enginesLighting and heating apparatusEngineeringInternal combustion engine

Owner:ROBERT BOSCH GMBH

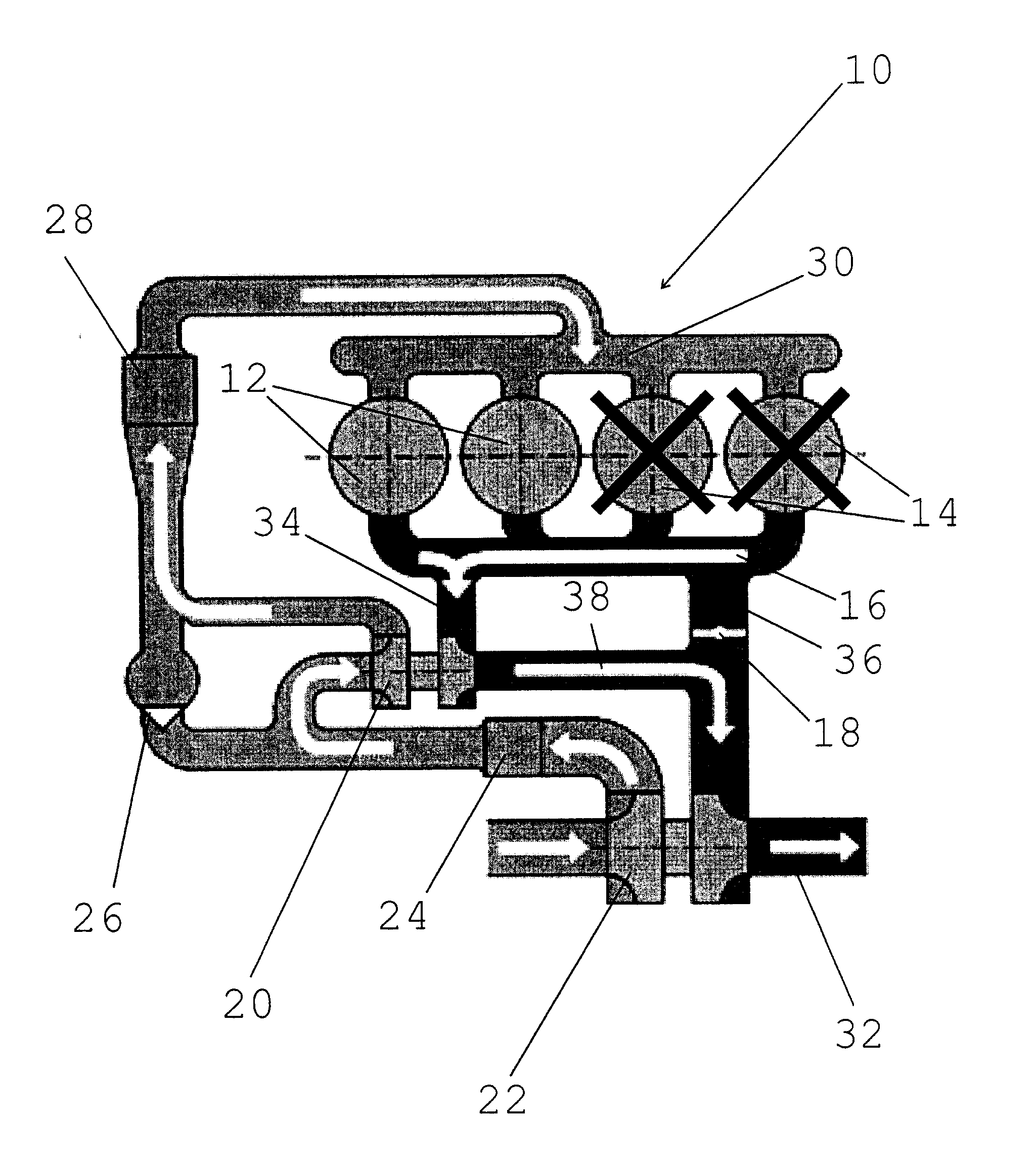

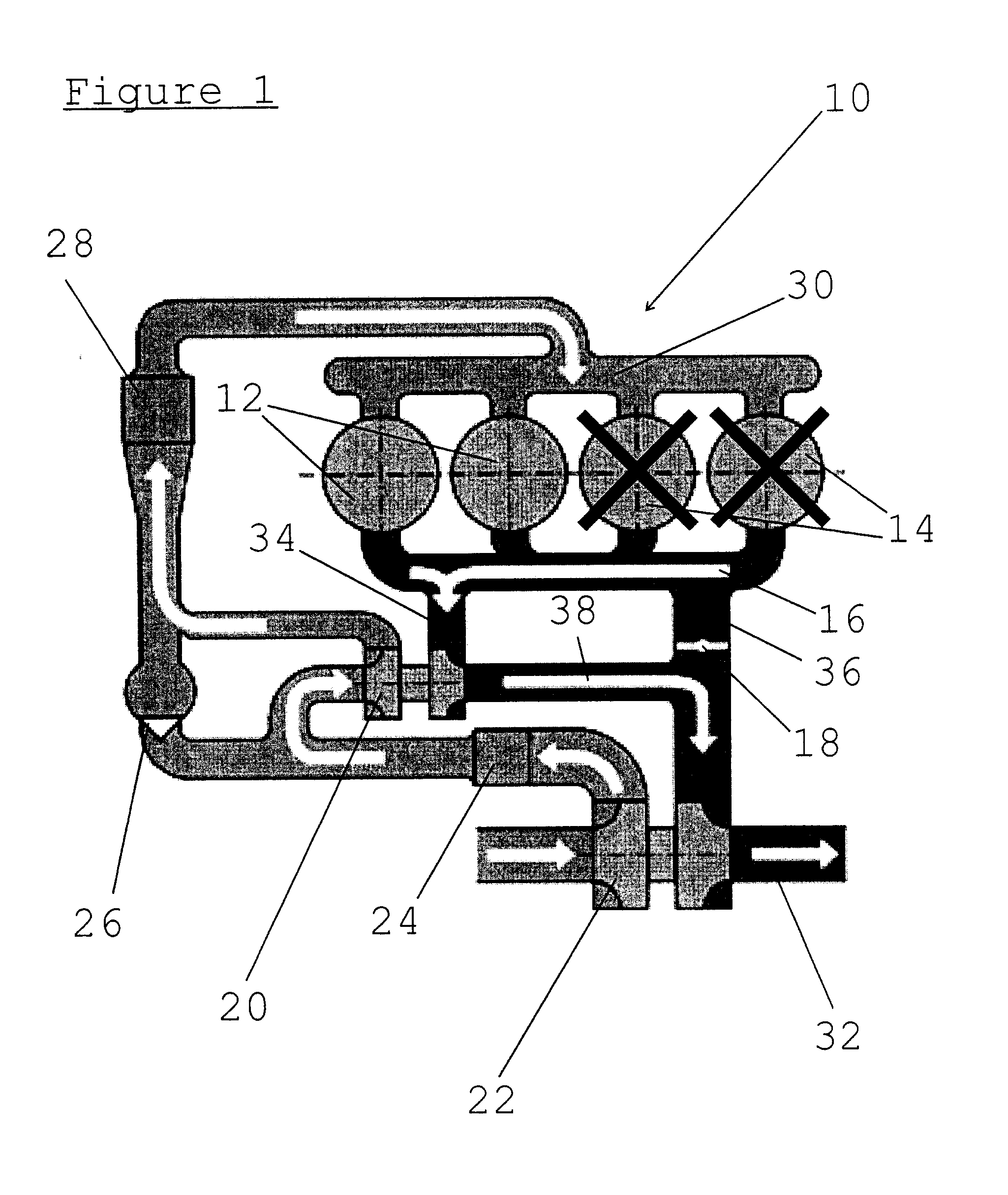

Cylinder head with turbine

InactiveUS20120055424A1Large amount of heatA large amountPump componentsEngine fuctionsCylinder headRadial turbine

Owner:FORD GLOBAL TECH LLC

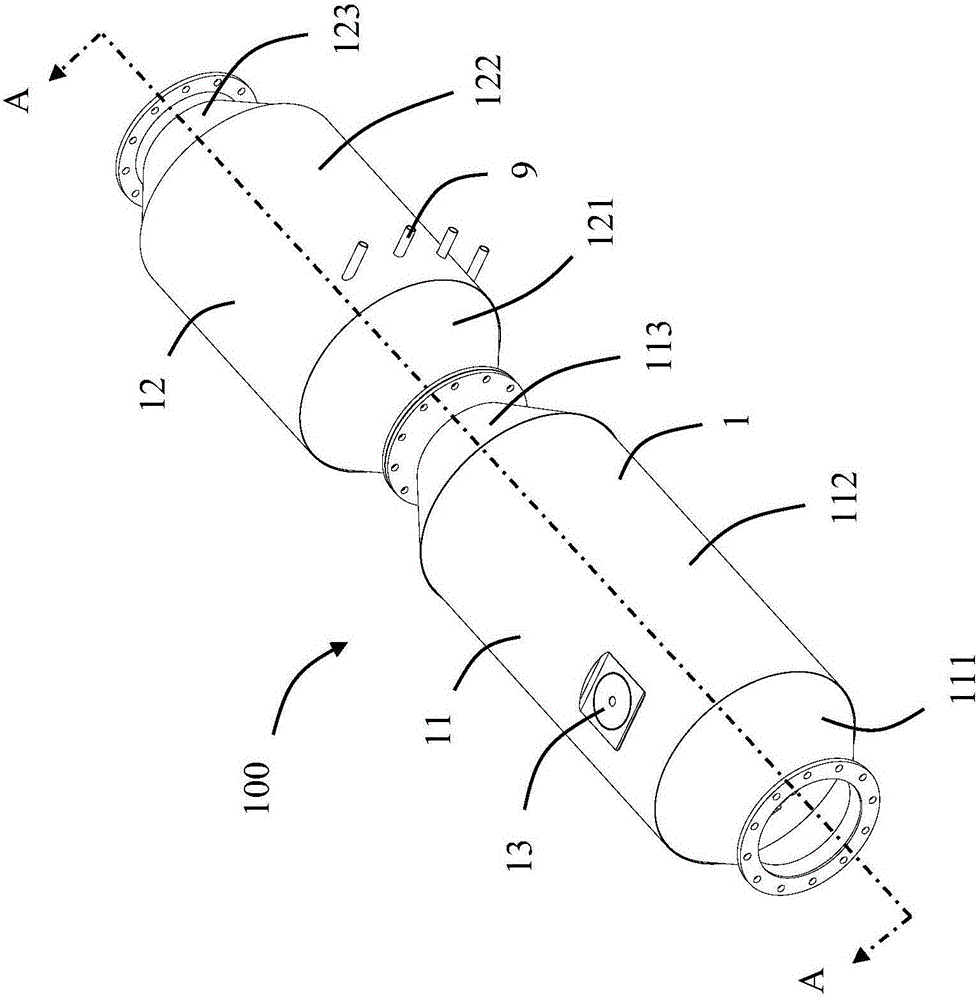

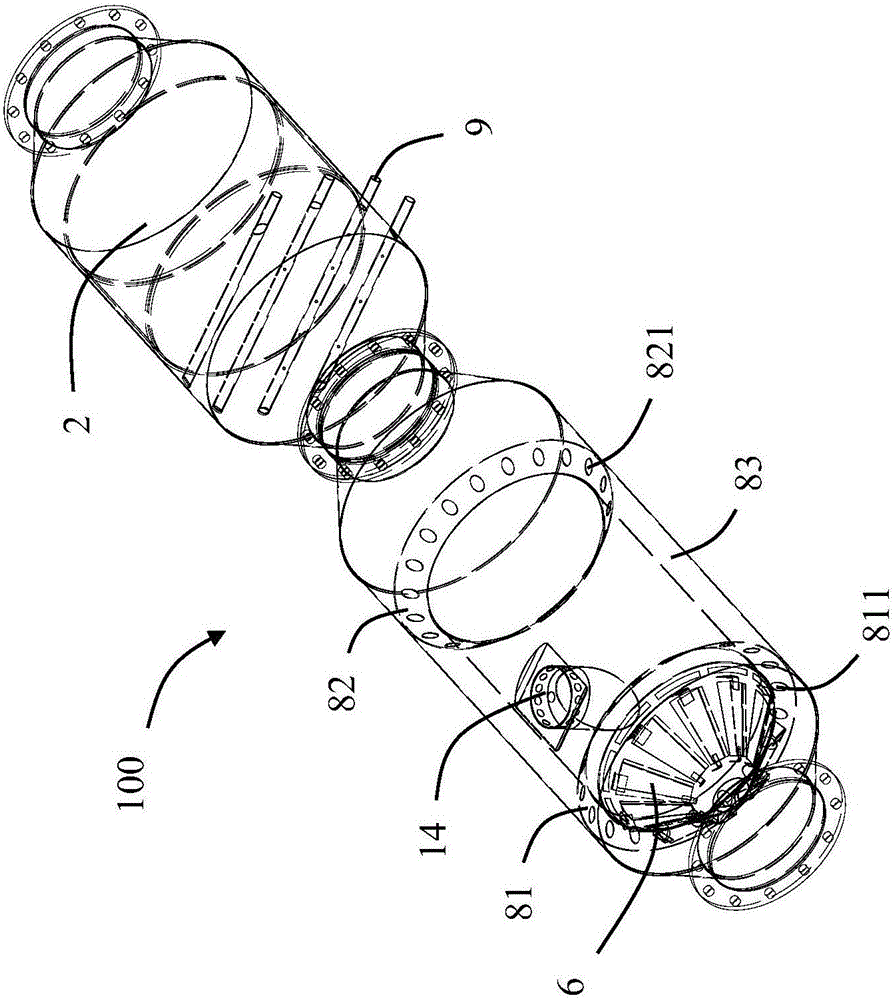

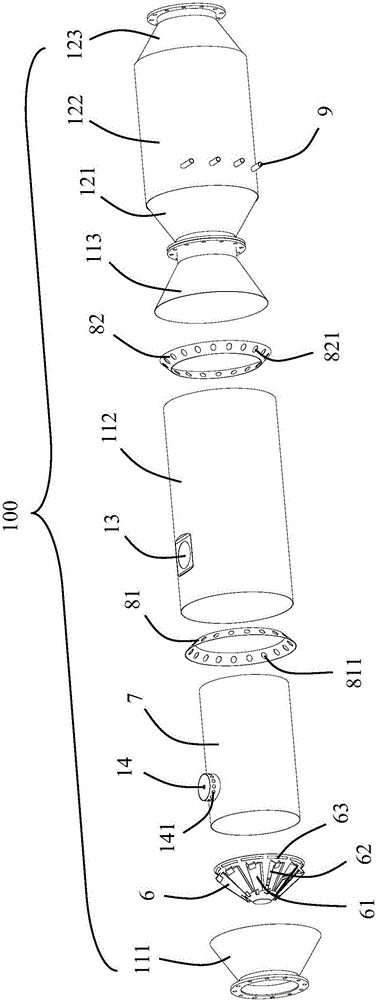

Exhaust gas treatment device

ActiveCN105804840AIncrease evaporation areaExtended stayExhaust apparatusSilencing apparatusEvaporationEngineering

Owner:TENNECO SUZHOU EMISSION SYST

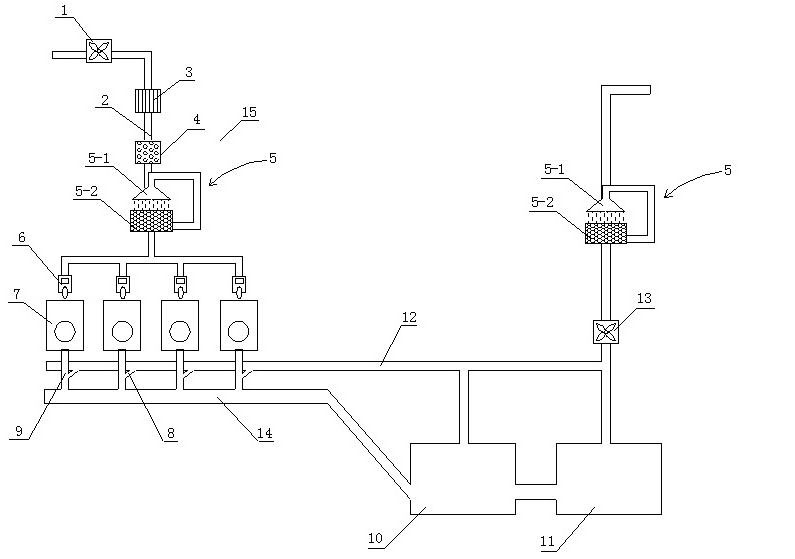

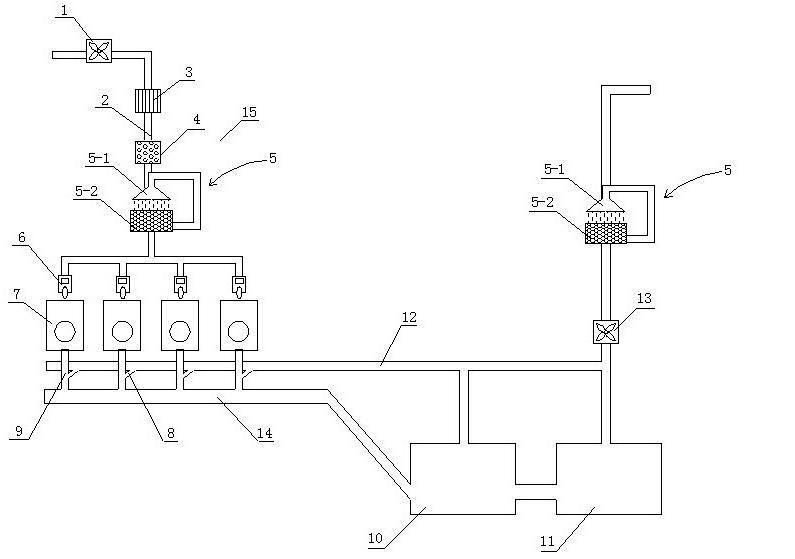

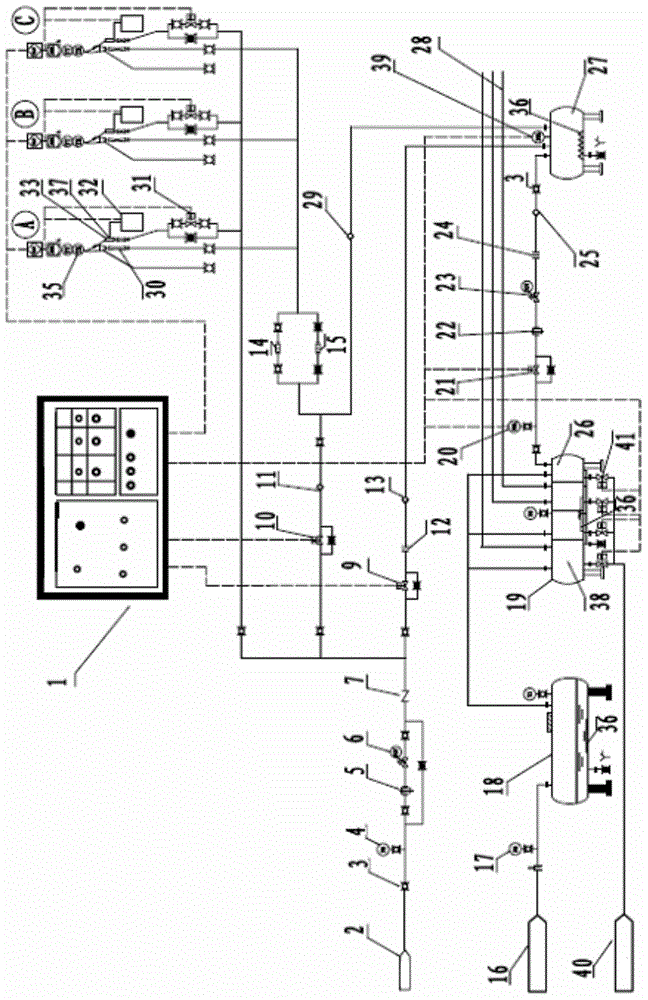

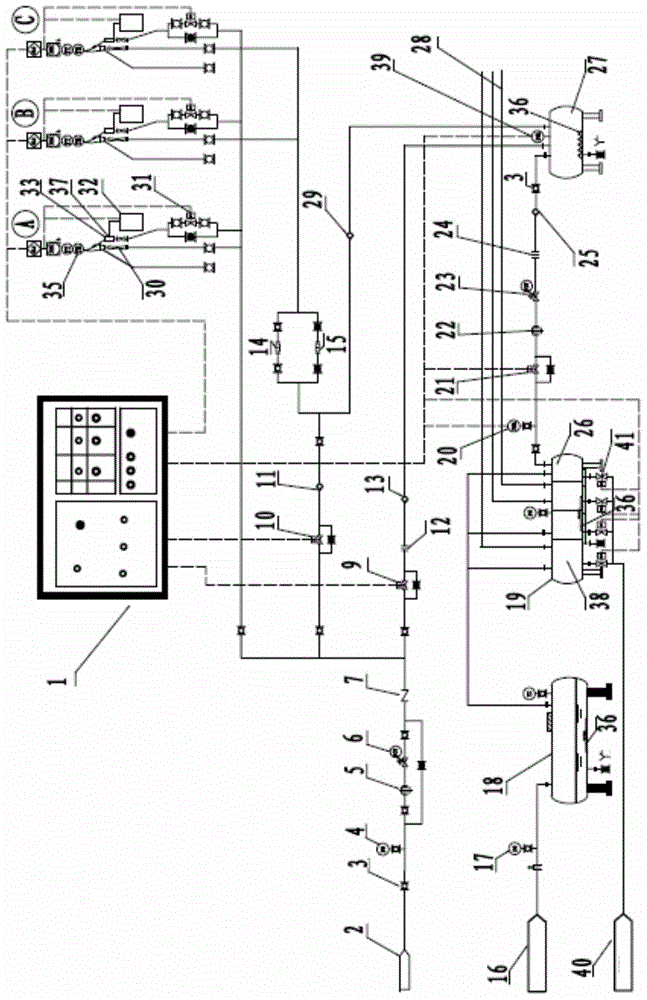

Automatic control system and method for emission monitoring of radioactive airborne effluents

InactiveCN103076816AReduce labor intensityImprove work efficiencyFlow control using electric meansProgramme control in sequence/logic controllersAutomatic controlProgrammable logic controller

The invention discloses an automatic control system and an automatic control method for mission monitoring of radioactive airborne effluents. According to the automatic control system, an emission flow monitoring sensor is connected with a flow monitoring PLC (Programmable Logic Controller) through a cable; the flow monitoring PLC is connected with an automatic control unit through a signal line; the automatic control unit is connected with a flow adjusting valve, an electromagnetic valve, sampling monitoring equipment, a mass flow meter, a pressure gauge and a pump respectively through a signal control line; and an airborne substance sampling head is connected with a tail gas emission pipe after being connected with the flow adjusting valve, the electromagnetic valve, the sampling monitoring equipment, the mass flow meter, the pressure gauge and the pump respectively in sequence through a sampling pipe. Due to the adoption of the automatic control system and the automatic control method disclosed by the invention, the sample representativeness of effluent monitoring under the conditions of separate or simultaneous emission, large differences among airborne substance source items and scattered emission in a plurality of radioactive operating places can be enhanced, the labor intensity of effluent monitoring can be relieved, and the working efficiency is increased; and the system and the method have the characteristics of stability, reliability, intelligent regulation and control, and unattended operation.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

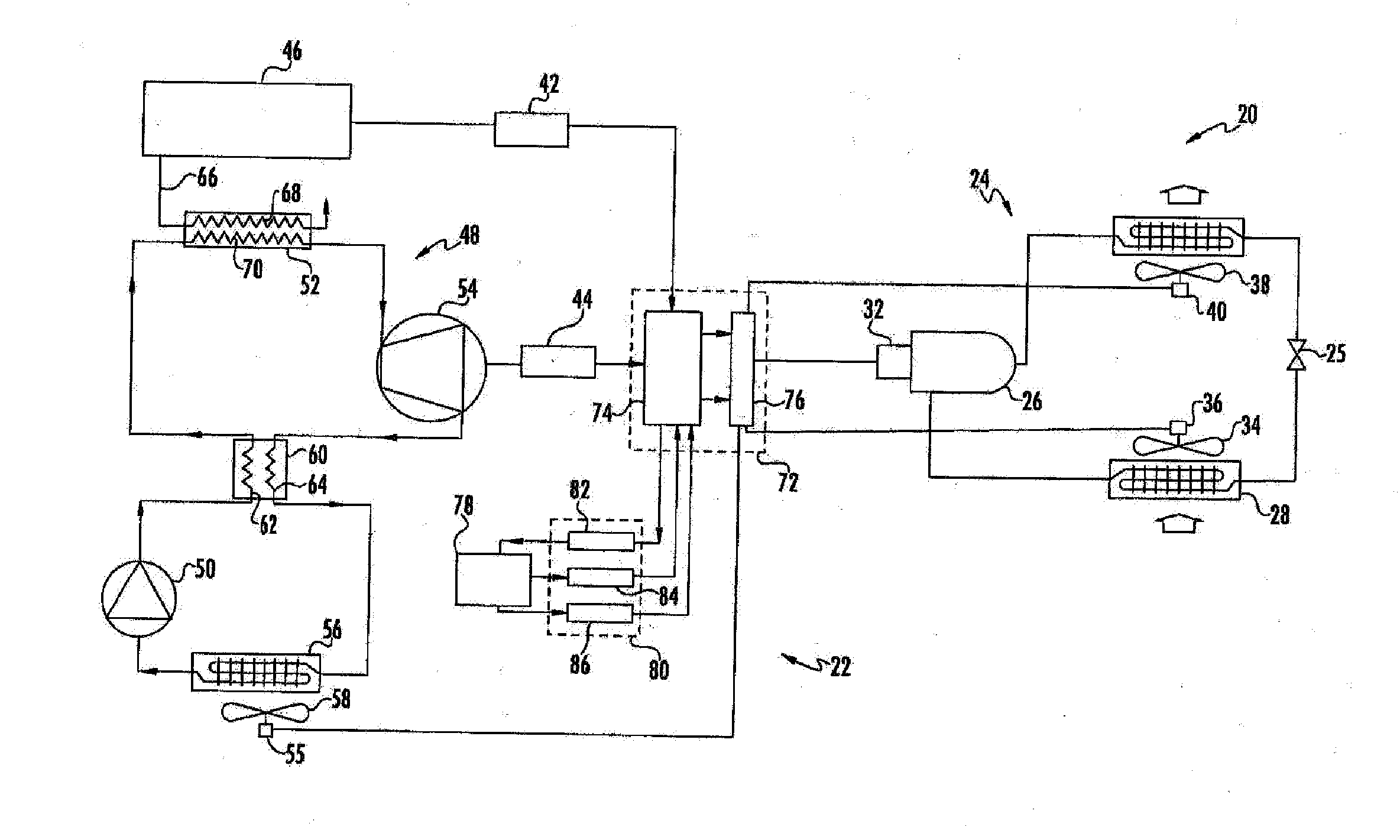

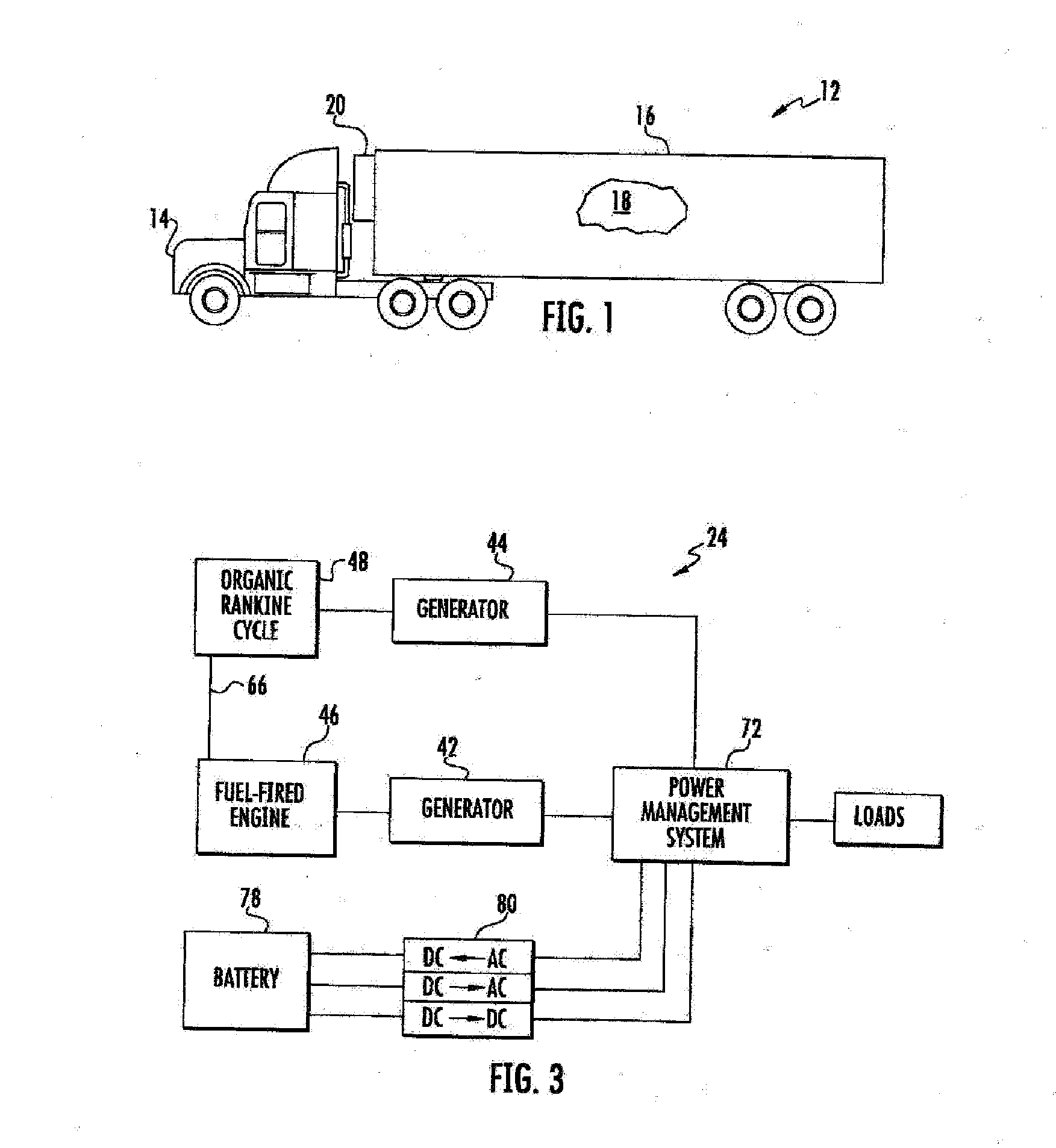

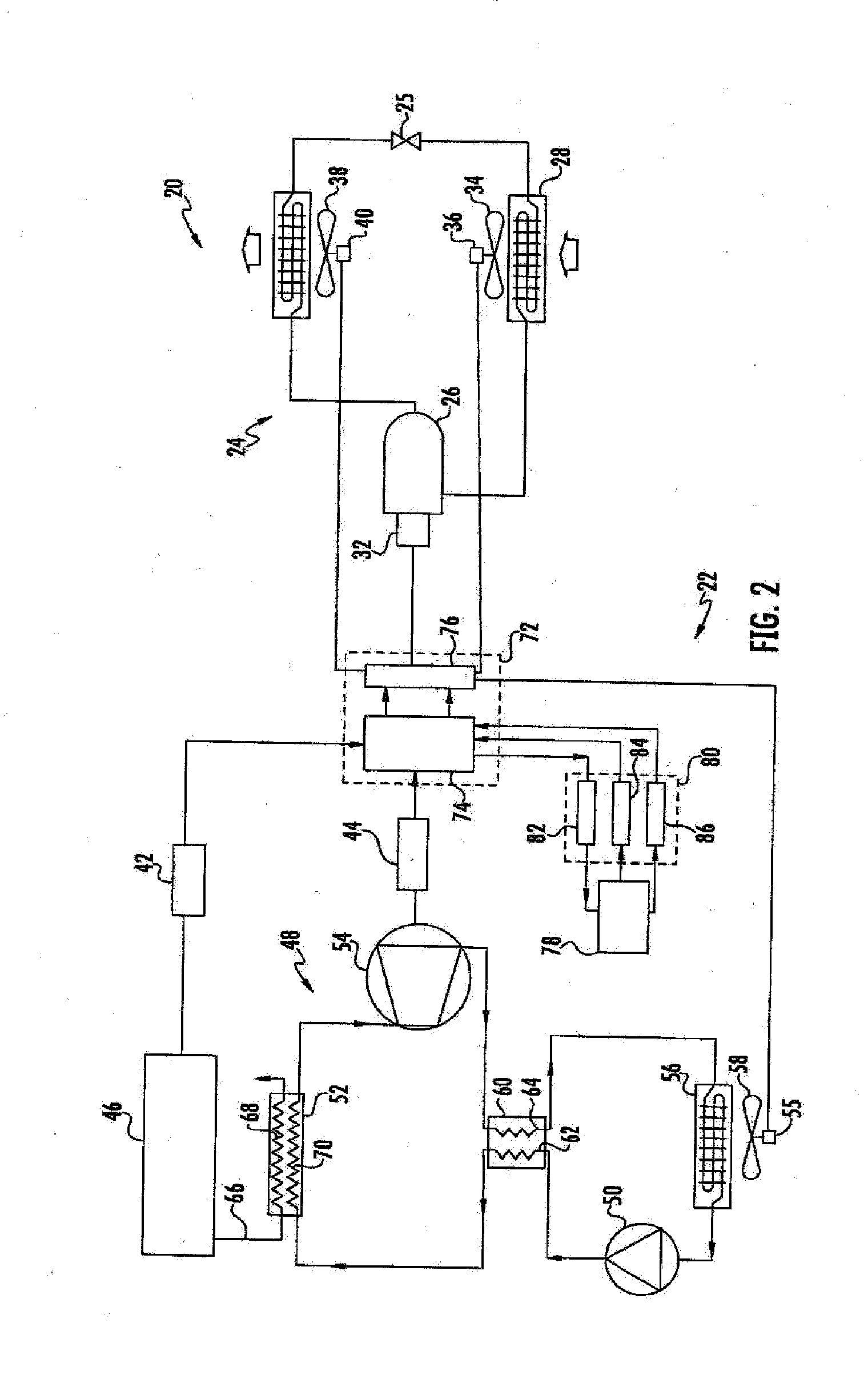

Organic rankine cycle augmented power supply system for mobile refrigeration units

Owner:CARRIER CORP

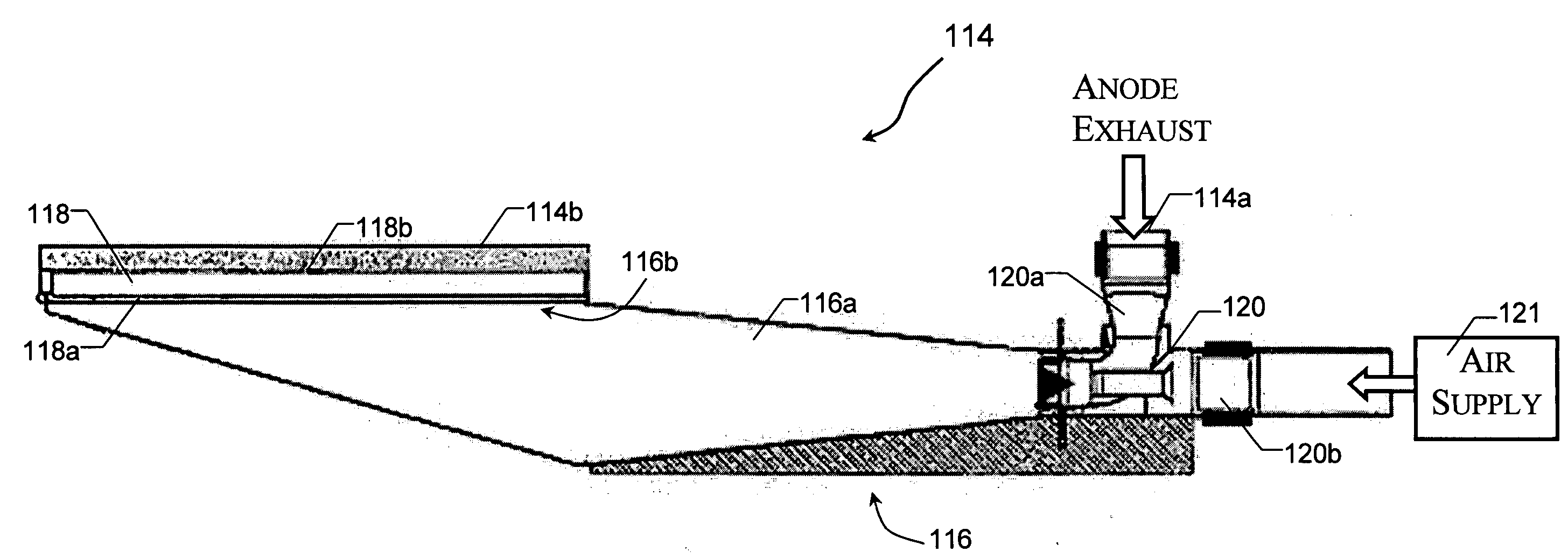

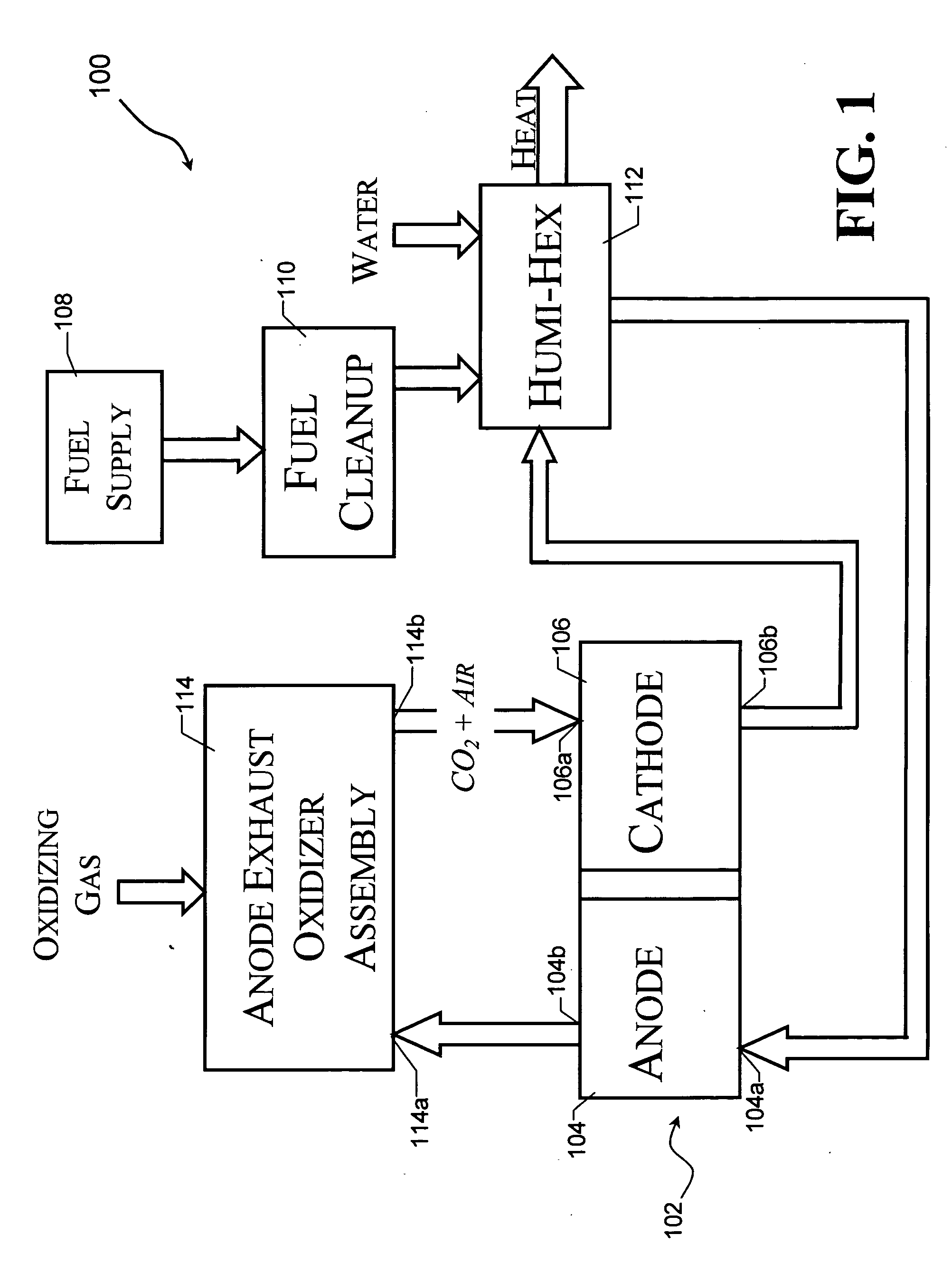

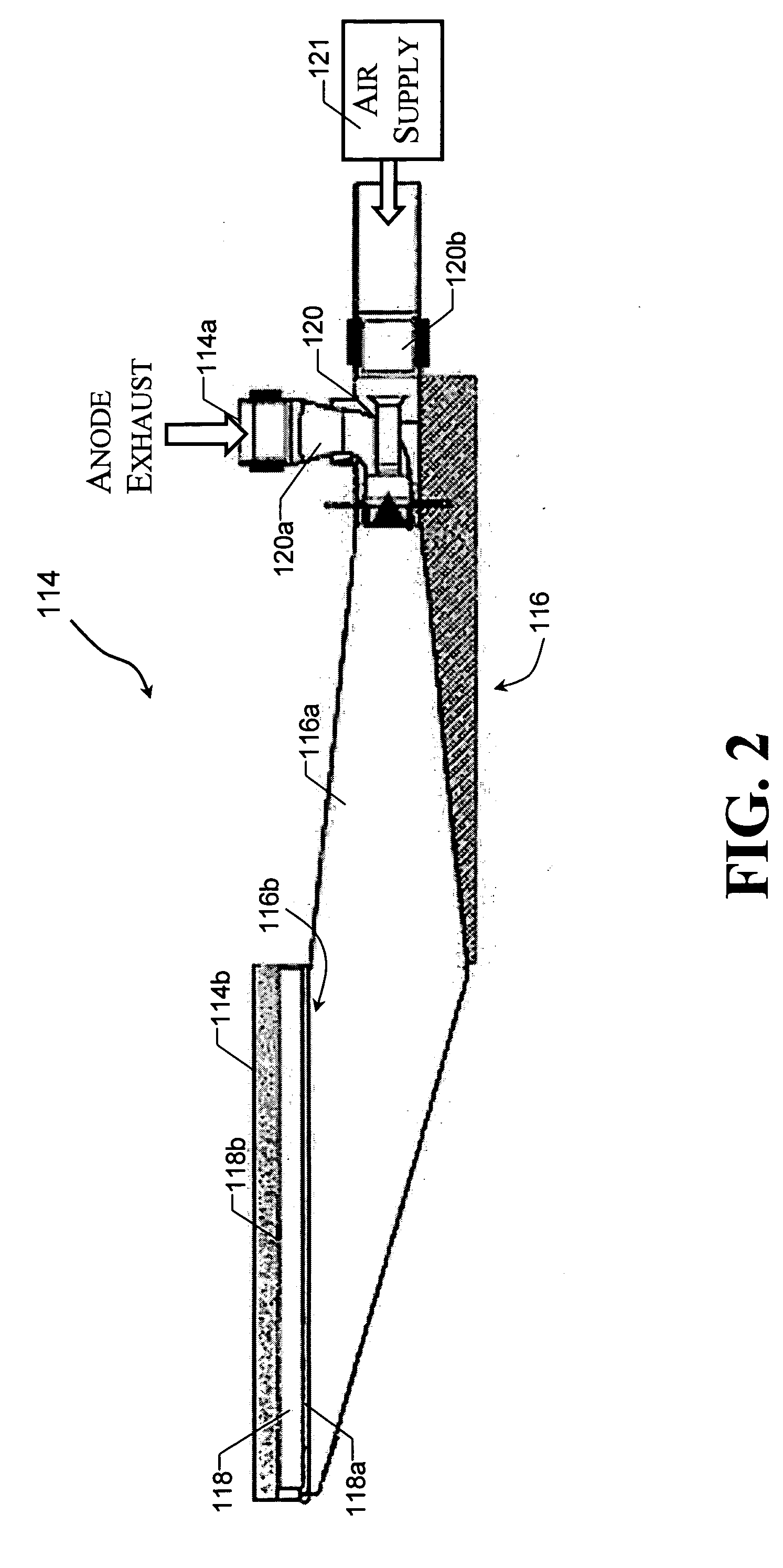

In-situ removal of electrolyte from gas oxidizer

Owner:FUELCELL ENERGY INC

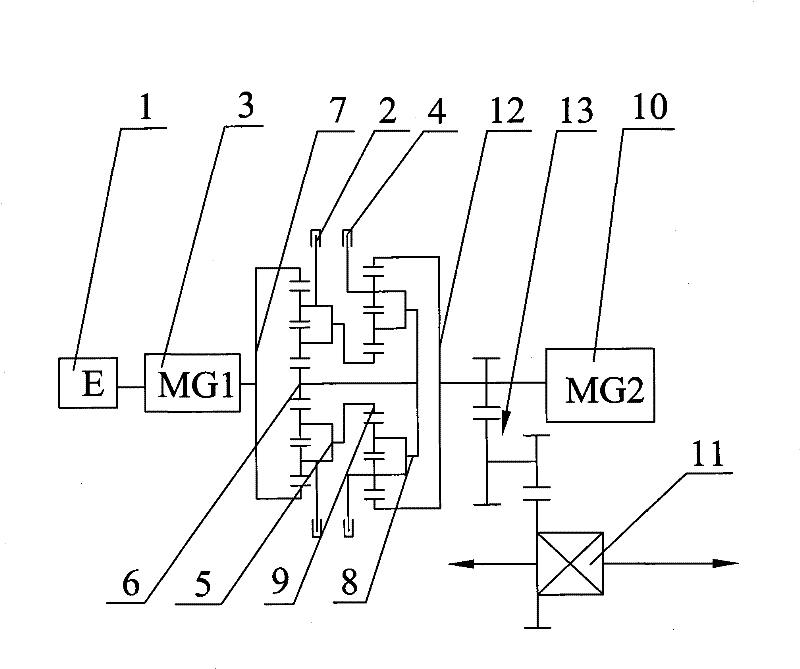

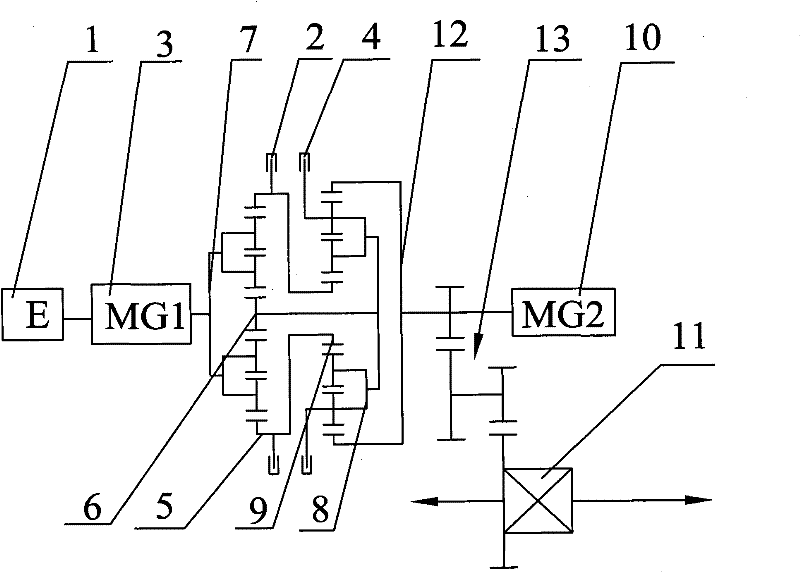

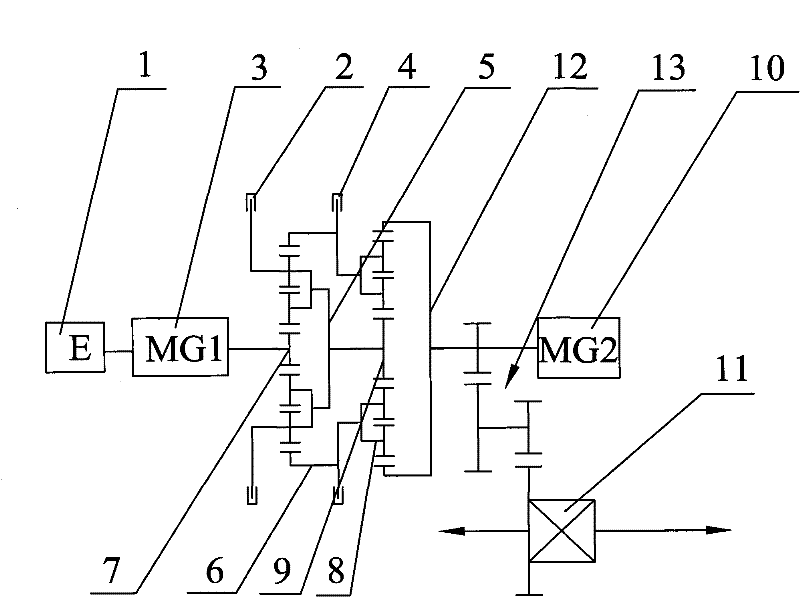

Hybrid driving system and vehicle including same

ActiveCN102343796AMeet the driving needs under different working conditionsEasy dischargeGas pressure propulsion mountingToothed gearingsLow speedInternal combustion engine

Owner:BYD CO LTD

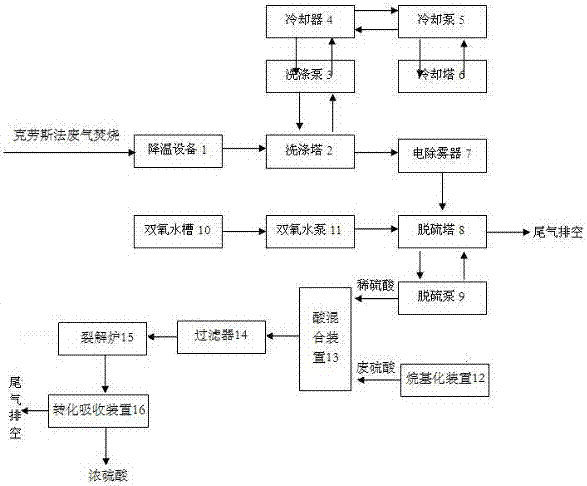

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

Clean production process and device for sulfur recycling and alkylated waste acid combined treatment

Owner:HULUDAO DESIGN INST PETROCHINA NORTHEAST REFINING & CHEM ENG +1

Engine with intake air temperature control system

Owner:SOLAR TURBINES

Internal combustion engine exhaust cooling and removal apparatus

An internal combustion engine exhaust cooling and removal apparatus includes a heat exchange assembly connected to an exhaust pipe of an internal combustion engine. A flexible hose is connected to the heat exchange assembly, and an exhaust fan assembly is connected to the flexible hose. Use of the internal combustion engine exhaust cooling and removal apparatus of the invention provides a clean air environment in an indoor confined space by removing the engine exhaust gases which are hazardous to one's health. The apparatus of the invention is especially useful with non-electric powered tools and machines, such as for indoor excavations with diesel-powered excavators or other construction equipment. The apparatus of the invention can also be used with diesel-powered saws.

Owner:PATRY IVAN J

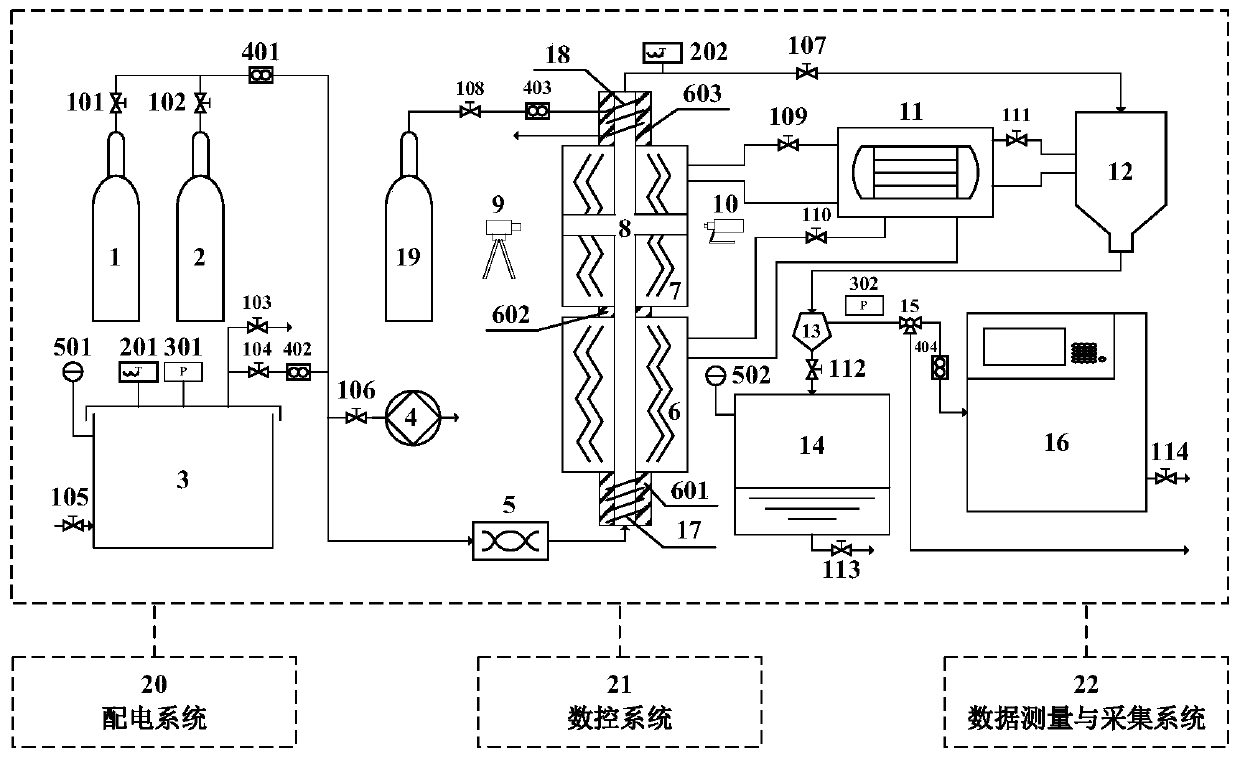

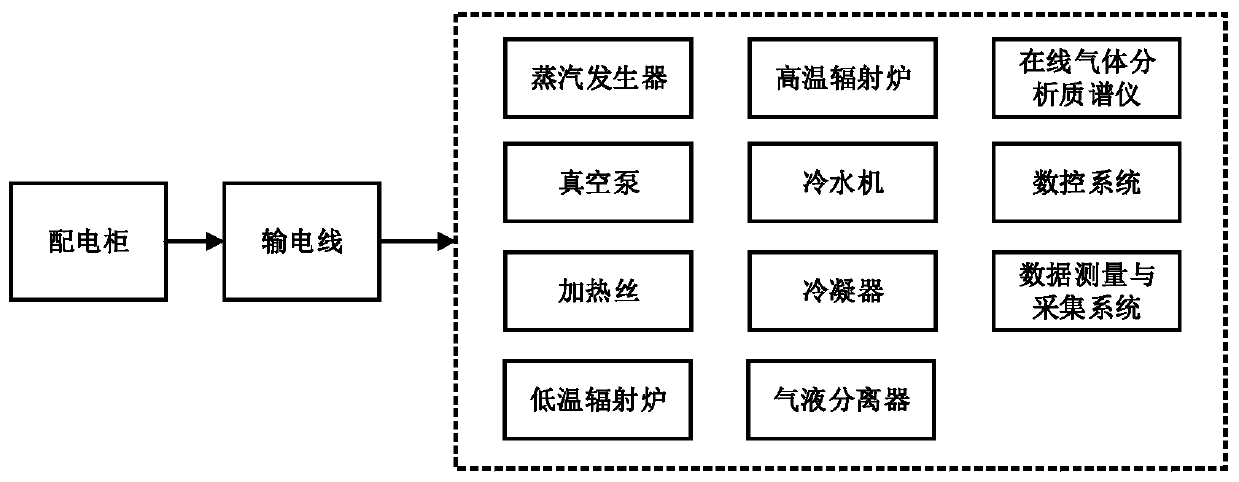

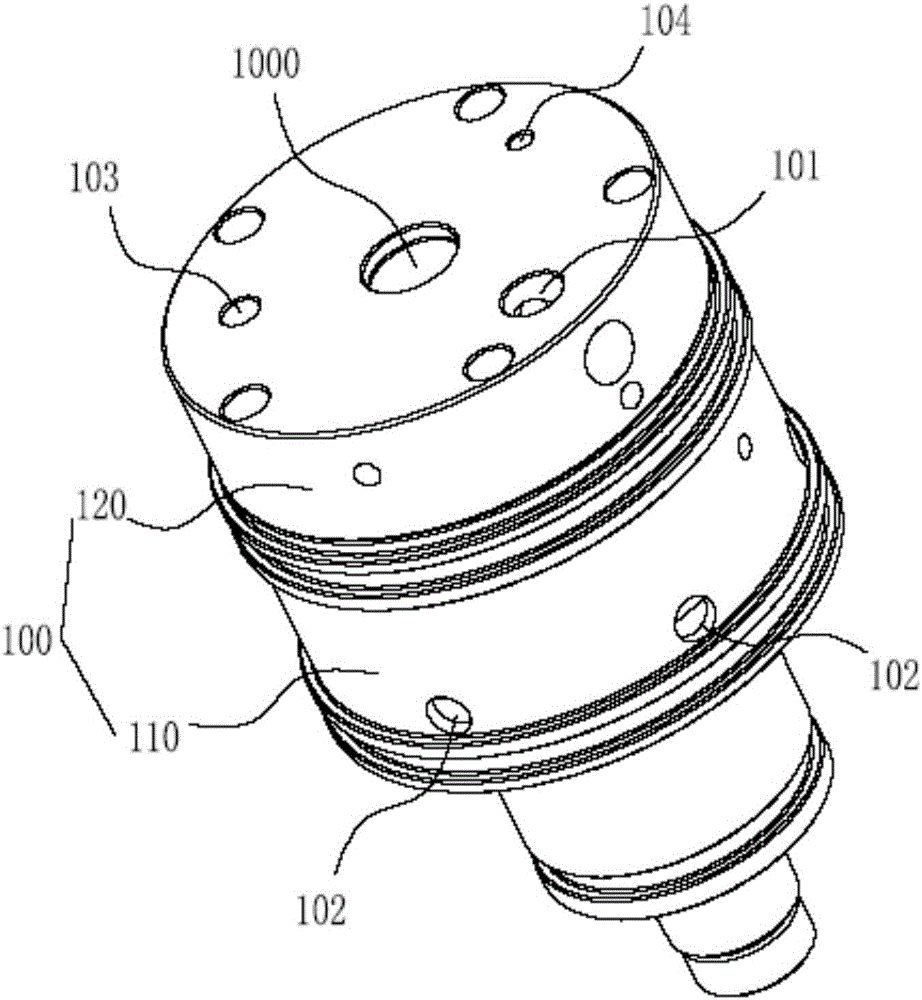

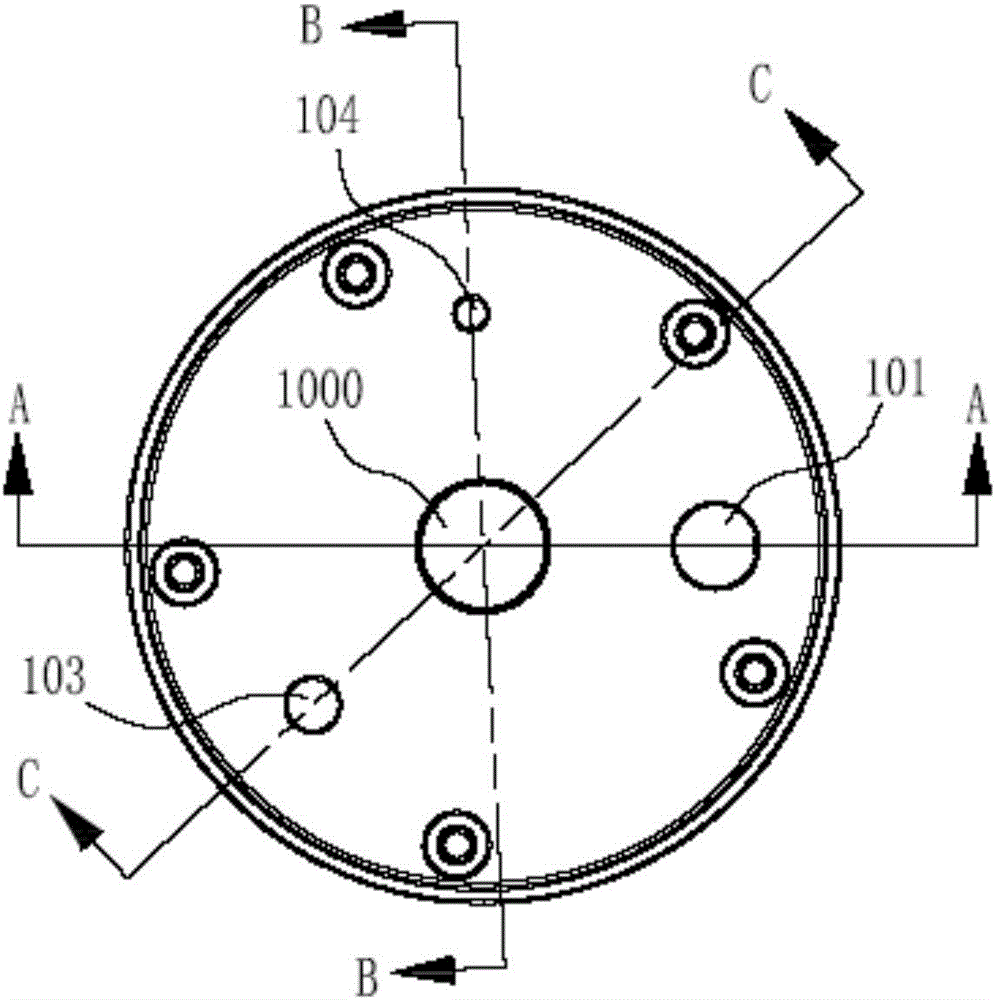

Structural material ultra-high temperature corrosion experiment system and method under serious accident of nuclear reactor

ActiveCN110553974AReduce space consumptionGuaranteed tightnessWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansContinuous measurementCorrosion reaction

Owner:XI AN JIAOTONG UNIV

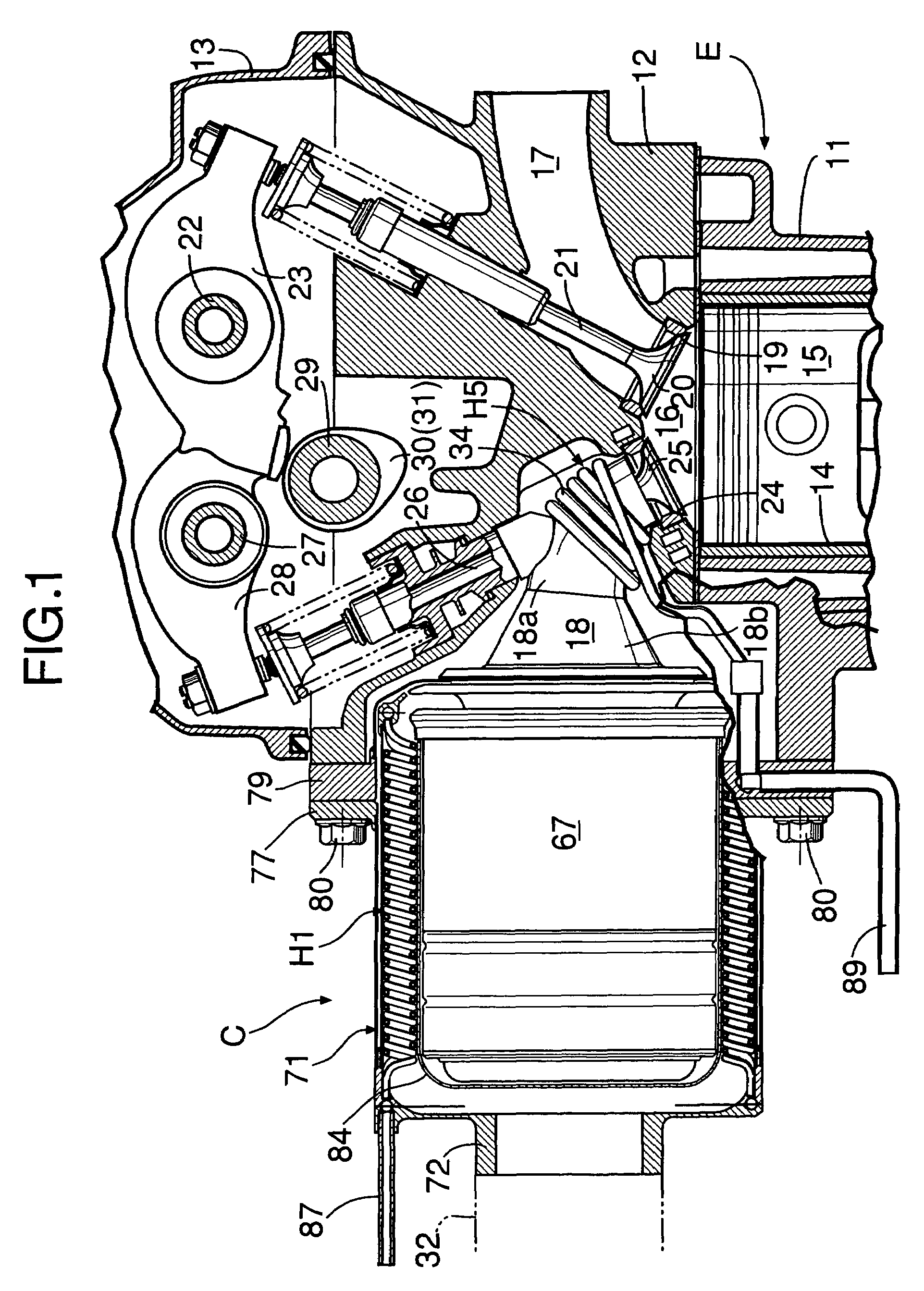

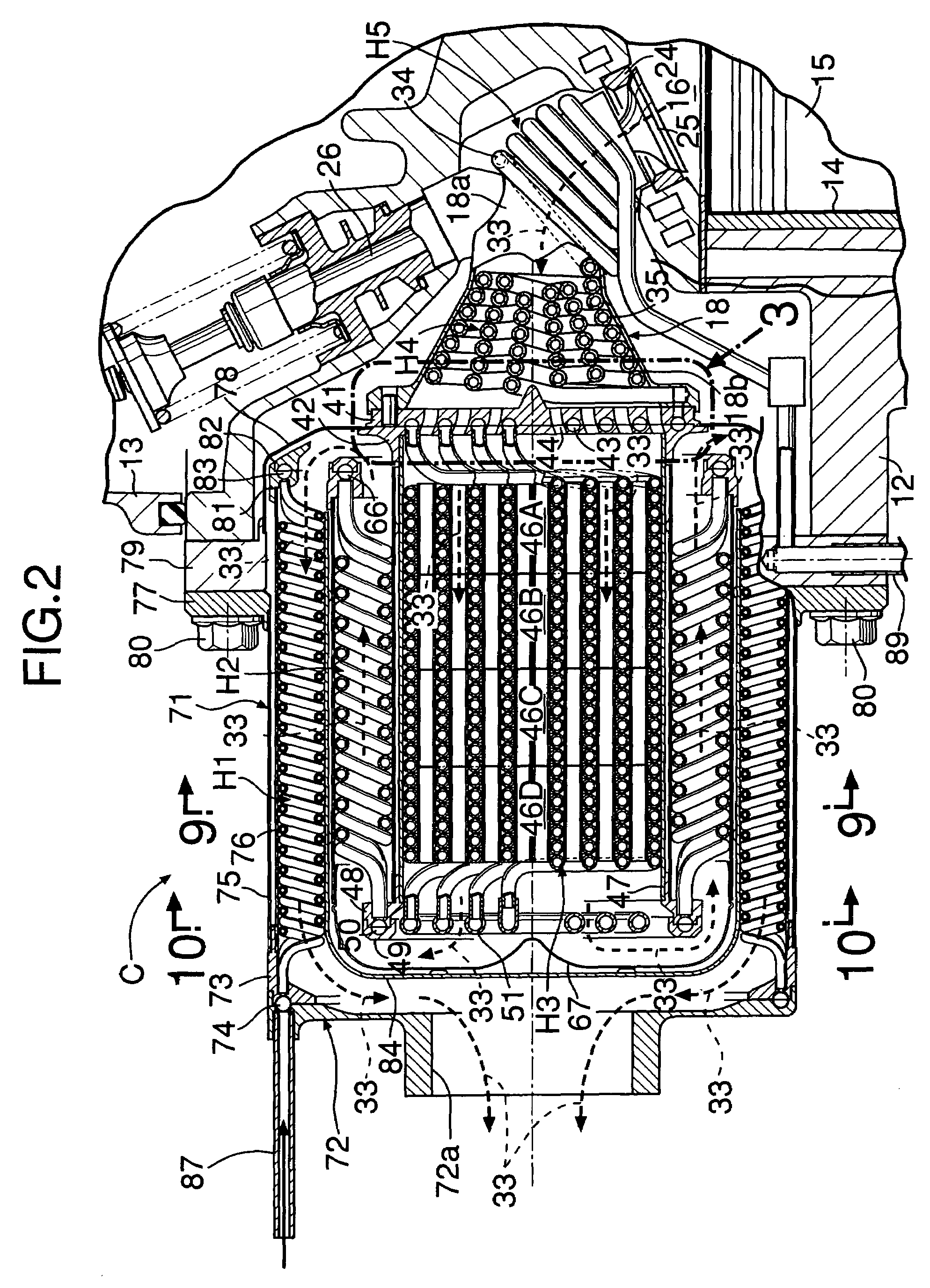

Internal combustion engine

InactiveUS7096664B2Improve exhaust gas purification performanceEfficient use ofInternal combustion piston enginesExhaust apparatusEngineeringTemperature difference

Owner:HONDA MOTOR CO LTD

Hydrocarbon adsorbent state determining apparatus

Owner:HONDA MOTOR CO LTD

Ignition system and ignition method of energy-saving eternal lamp utilizing exhaust gas

ActiveCN104421960AReduce energy consumptionReduce pollutionElectric spark ignitersIncinerator apparatusEngineeringNatural gas

Owner:北京融茂福元科技有限公司

Pneumatic motor

Owner:SICHUAN SHENGXIANGSHENG INTELLIGENT TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap