Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Programmable logic controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A programmable logic controller (PLC) or programmable controller is an industrial digital computer which has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, or robotic devices, or any activity that requires high reliability control and ease of programming and process fault diagnosis.

Multi-axle vehicle as well as electro-hydraulic servo steering system and steering control method thereof

ActiveCN102372022AOptimize structure layoutMeet traffic requirementsSteering linkagesFluid steeringControl systemElectronic control system

The invention discloses an electro-hydraulic servo steering system and a steering control method of a multi-axle vehicle and the multi-axle vehicle with the steering system. The electro-hydraulic servo steering system comprises a hydraulic steering system and an electric control system, wherein the hydraulic steering system comprises a variable pump, power-assisted steering oil cylinders and a servo proportional valve; the power-assisted steering oil cylinders are at least arranged on various rear steering axles; the servo proportional valve is used for controlling the trend of an oil path and the flow adjustment; the electronic control system comprises a lower controller and an upper controller; the lower controller is in signal connection with the servo proportional valve on each steering axle and forms closed loop control; and the upper controller is used for calculating a target corner of each steering axle according to a first axle corner and a steering mode. According to the invention, the electronic control systems of a two-stage controller is optimized, so that the servo proportional valve and the lower controller form a small closed loop; the lower controller with high frequency response is matched with the servo proportional valve to ensure the precision; and a programmable logic controller is used for main calculation work and transmitting a corner instruction to the each lower controller. The invention has the advantages of simple structural arrangement, safety, reliability and favorable control stability.

Owner:ZOOMLION HEAVY IND CO LTD

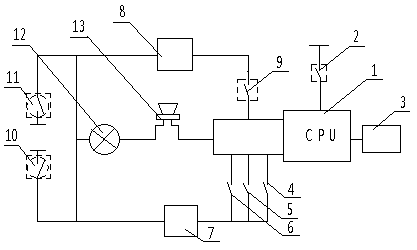

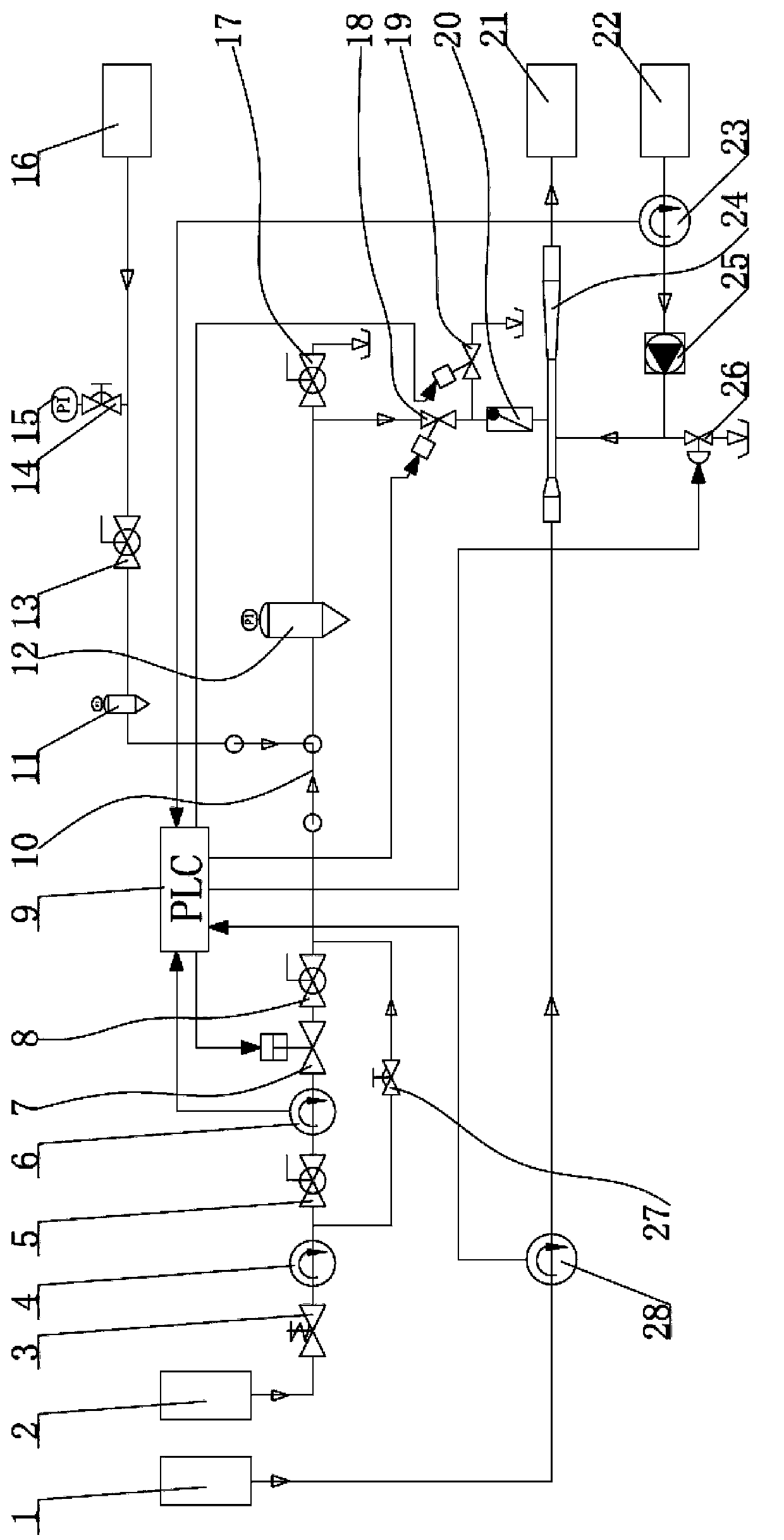

Automatic control system and method for emission monitoring of radioactive airborne effluents

InactiveCN103076816AReduce labor intensityImprove work efficiencyFlow control using electric meansProgramme control in sequence/logic controllersAutomatic controlProgrammable logic controller

The invention discloses an automatic control system and an automatic control method for mission monitoring of radioactive airborne effluents. According to the automatic control system, an emission flow monitoring sensor is connected with a flow monitoring PLC (Programmable Logic Controller) through a cable; the flow monitoring PLC is connected with an automatic control unit through a signal line; the automatic control unit is connected with a flow adjusting valve, an electromagnetic valve, sampling monitoring equipment, a mass flow meter, a pressure gauge and a pump respectively through a signal control line; and an airborne substance sampling head is connected with a tail gas emission pipe after being connected with the flow adjusting valve, the electromagnetic valve, the sampling monitoring equipment, the mass flow meter, the pressure gauge and the pump respectively in sequence through a sampling pipe. Due to the adoption of the automatic control system and the automatic control method disclosed by the invention, the sample representativeness of effluent monitoring under the conditions of separate or simultaneous emission, large differences among airborne substance source items and scattered emission in a plurality of radioactive operating places can be enhanced, the labor intensity of effluent monitoring can be relieved, and the working efficiency is increased; and the system and the method have the characteristics of stability, reliability, intelligent regulation and control, and unattended operation.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Statistical principle and PLC technology-based method for measuring and calculating discharge amount of tobacco shred storage cabinet

ActiveCN102183280AVolume measurement apparatus/methodsProgramme control in sequence/logic controllersRegression analysisProgrammable logic controller

Owner:CHINA TOBACCO SHANDONG IND

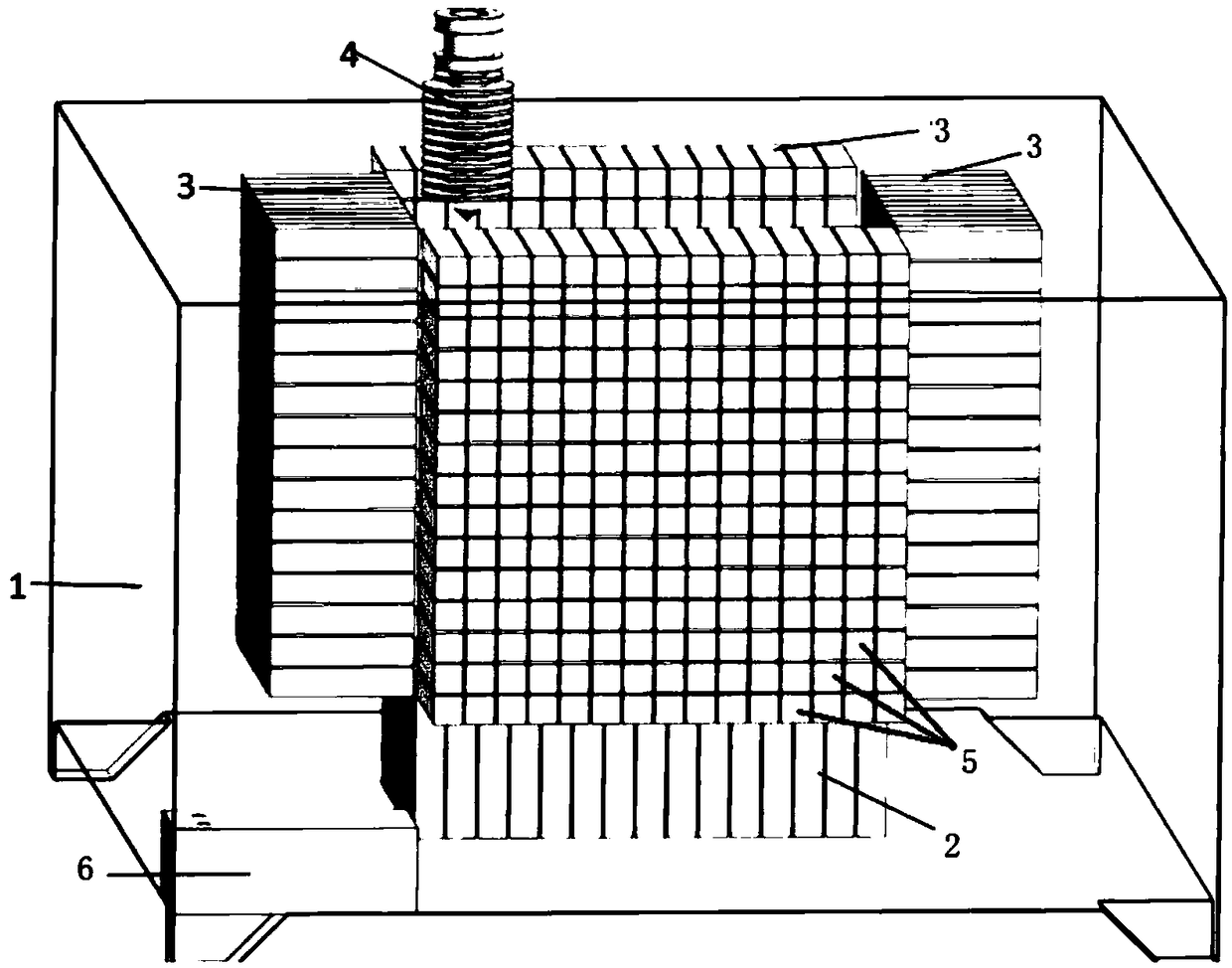

Cast pipe conveying device

PendingCN108557401AAvoid collision problemsGuaranteed appearance qualityControl devices for conveyorsMechanical conveyorsProgrammable logic controllerEngineering

Owner:河北新兴铸管有限公司

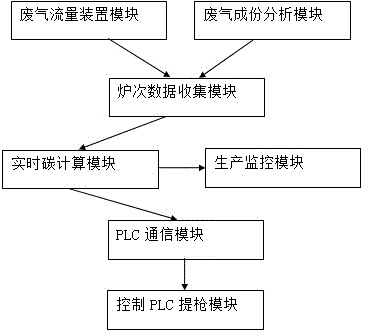

Mass spectrometer based RH dynamic decarbonization method and device

InactiveCN104131137ARealize automatic controlRealize stop blowingAutomatic controlRelevant information

Owner:NANJING MEISHAN METALLURGY DEV +2

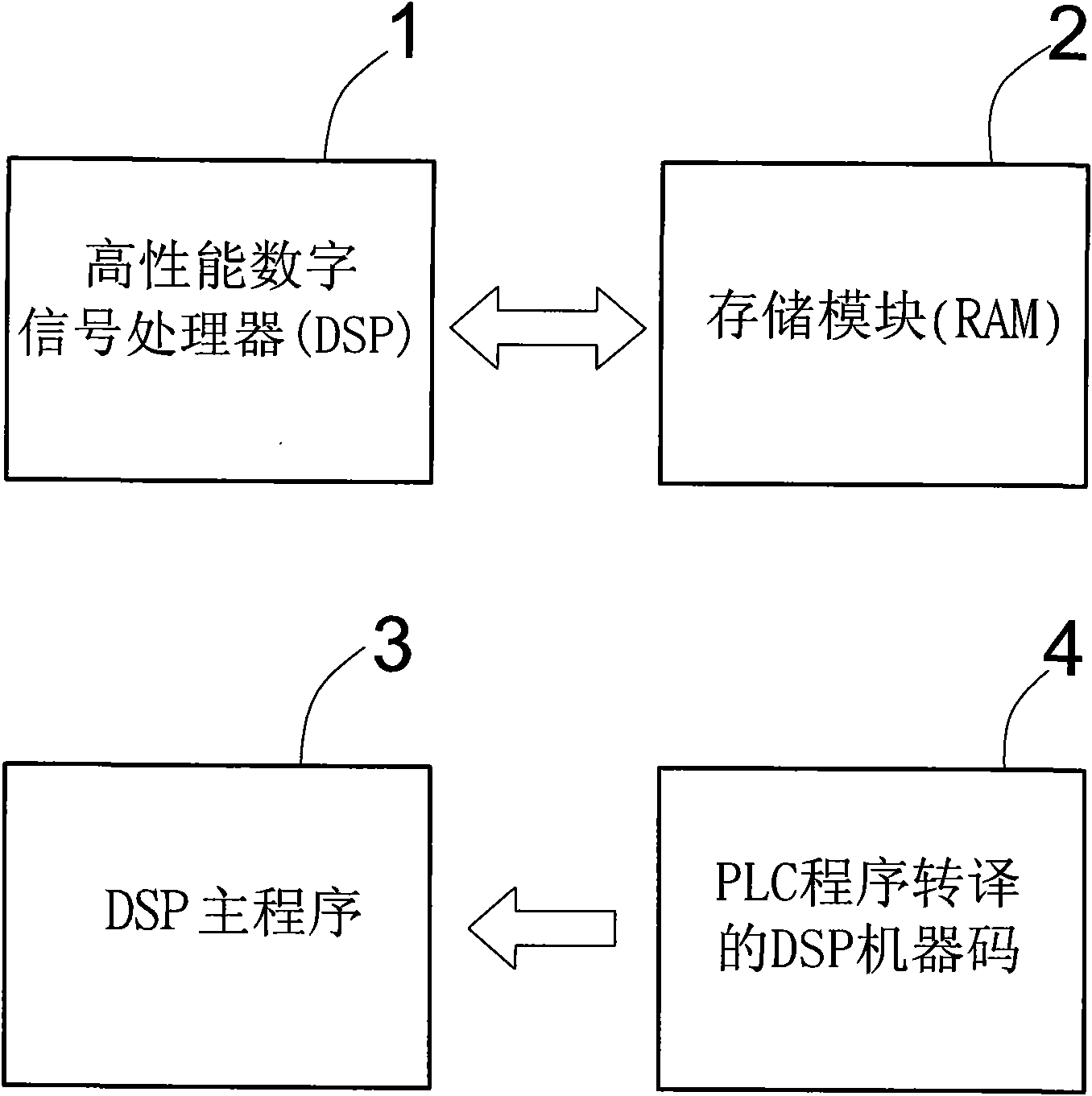

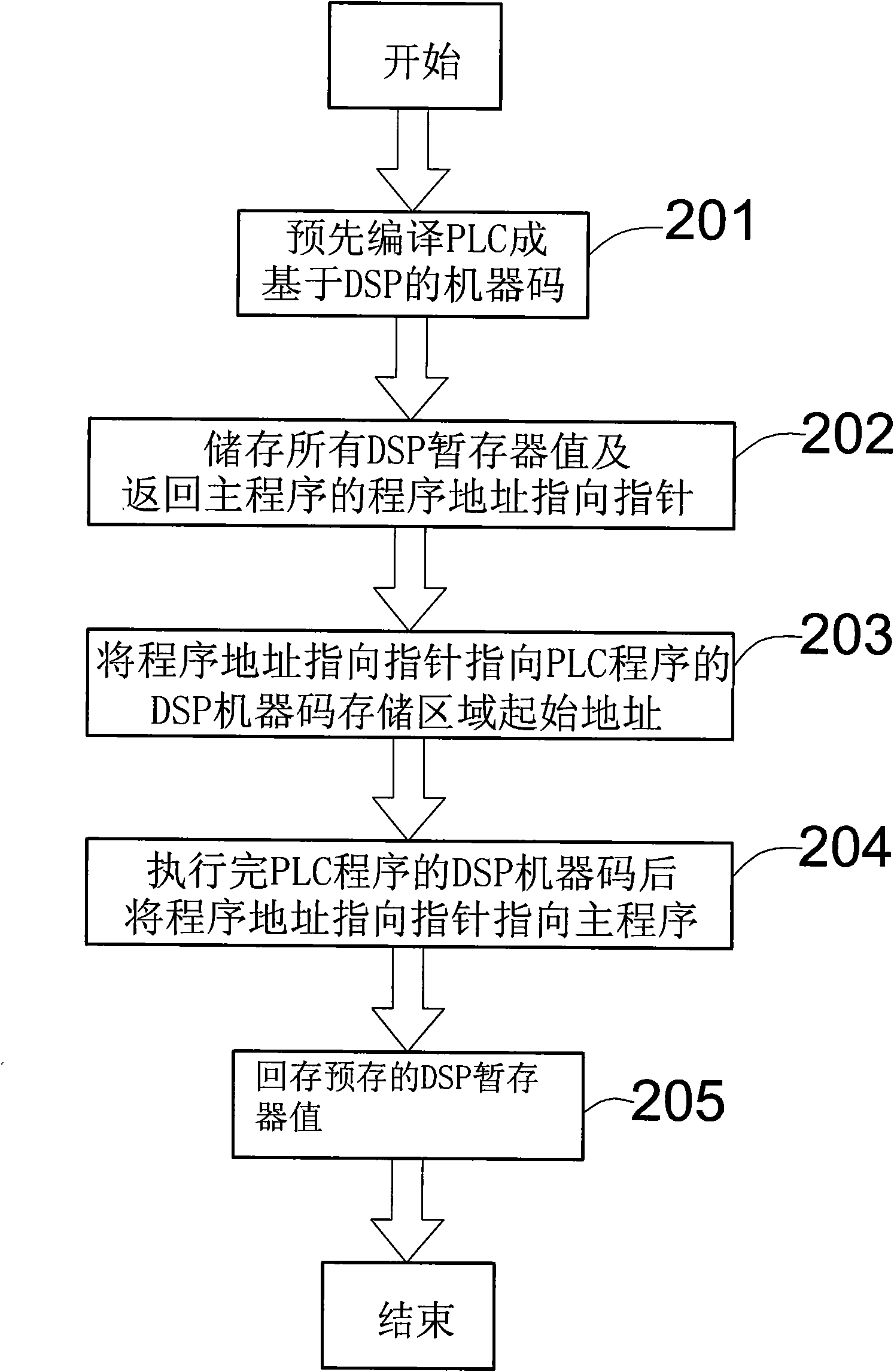

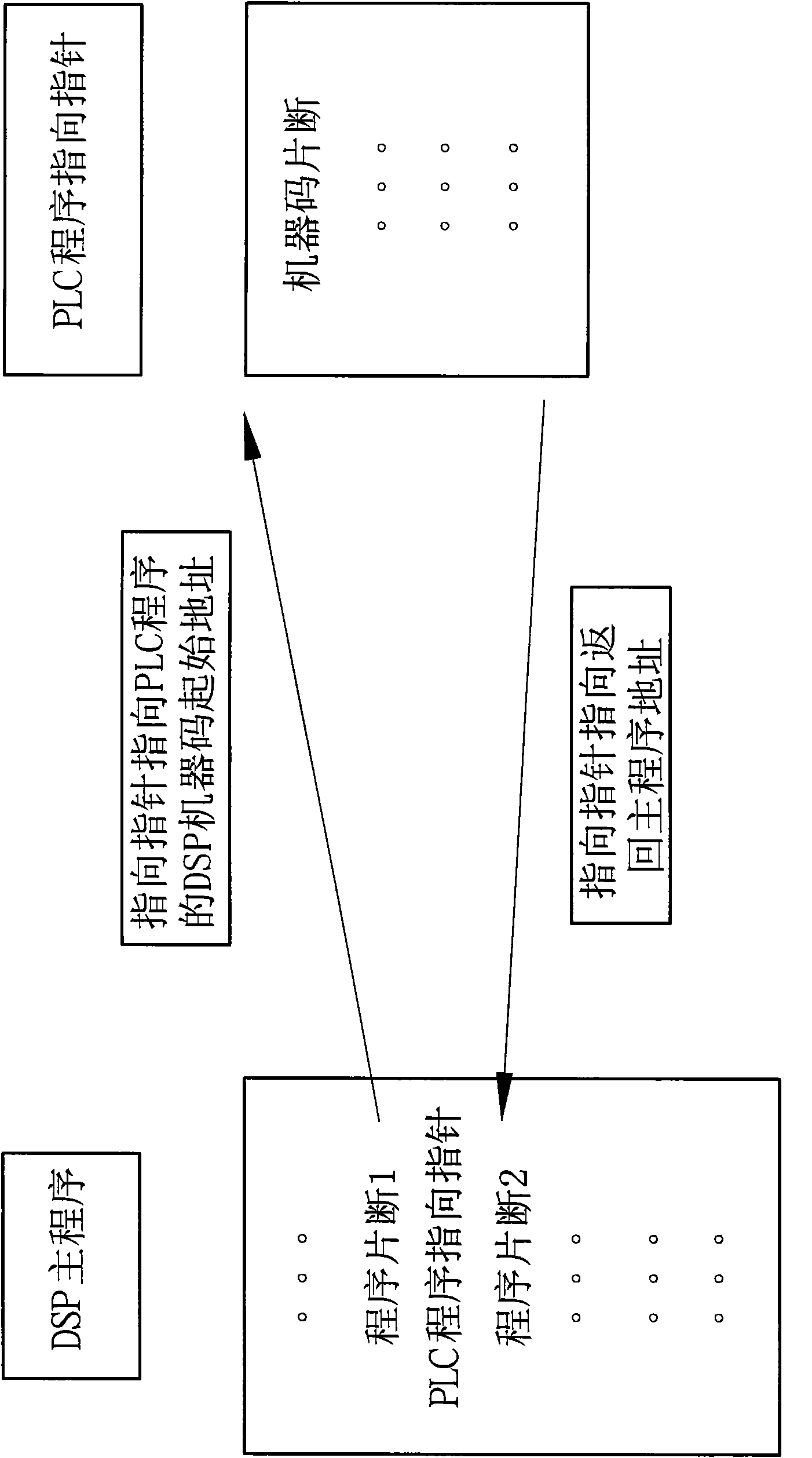

Method for executing programmable logic controller (PLC) code

InactiveCN101576744ACycle scan time will not be limitedImprove responsivenessProgramme control in sequence/logic controllersCommunication interfaceDigital signal processing

Owner:LNC TECH CO LTD

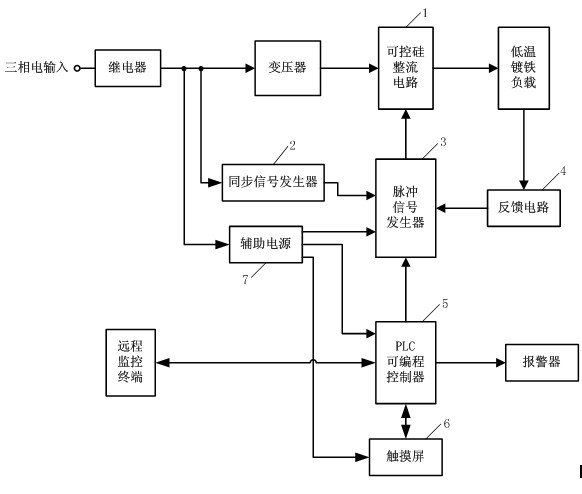

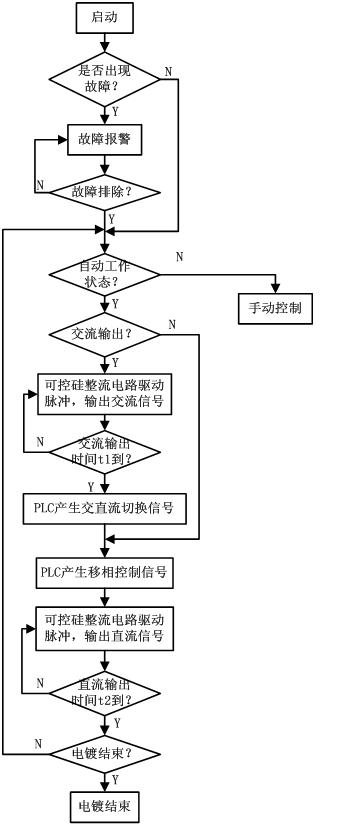

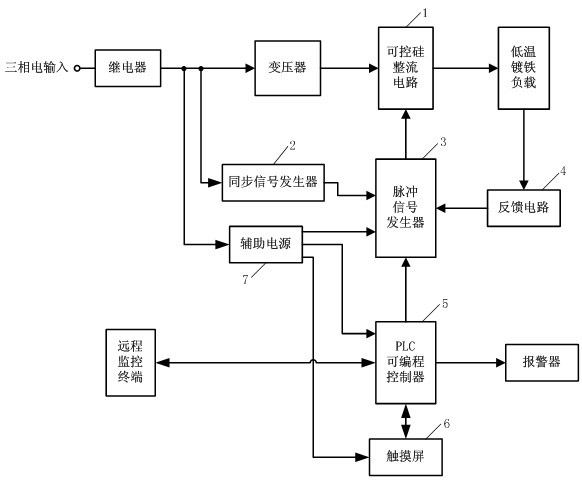

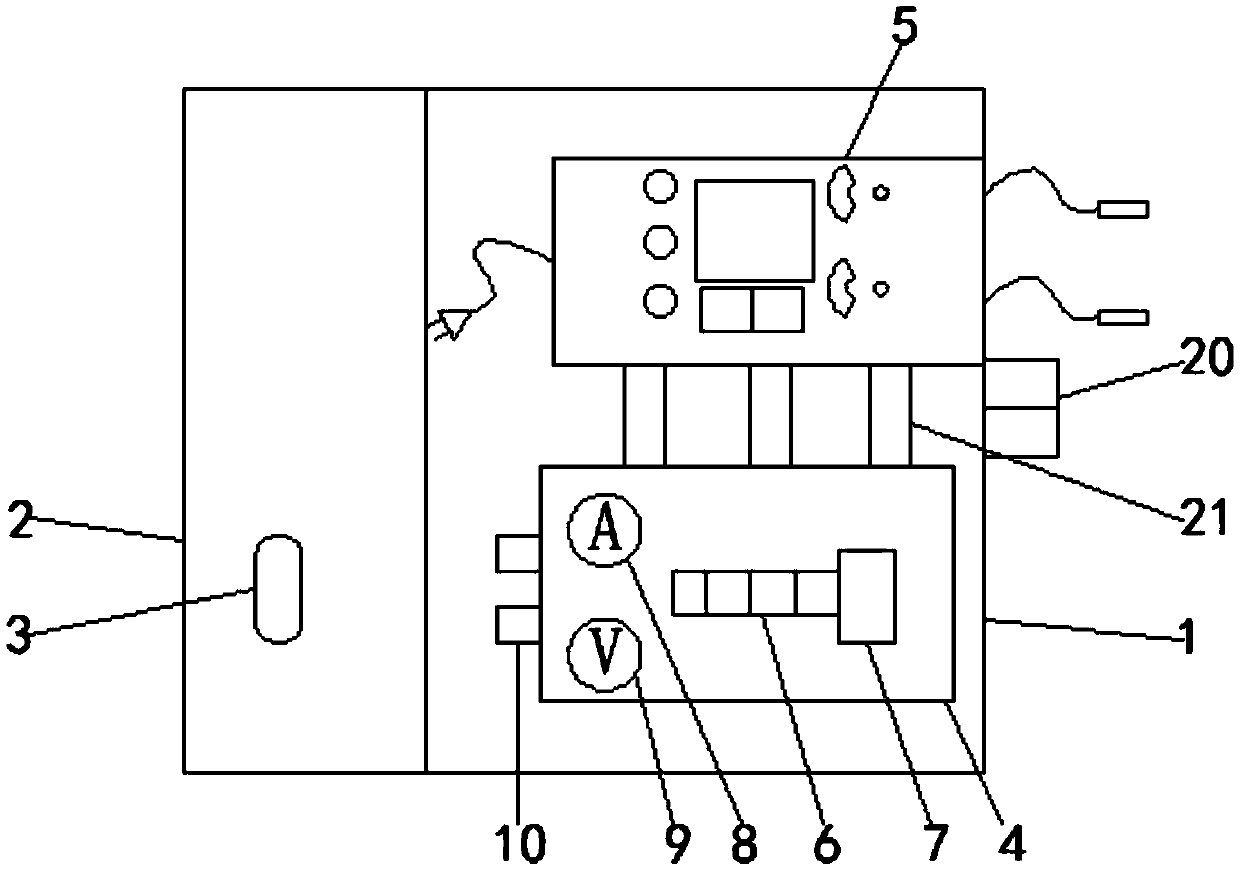

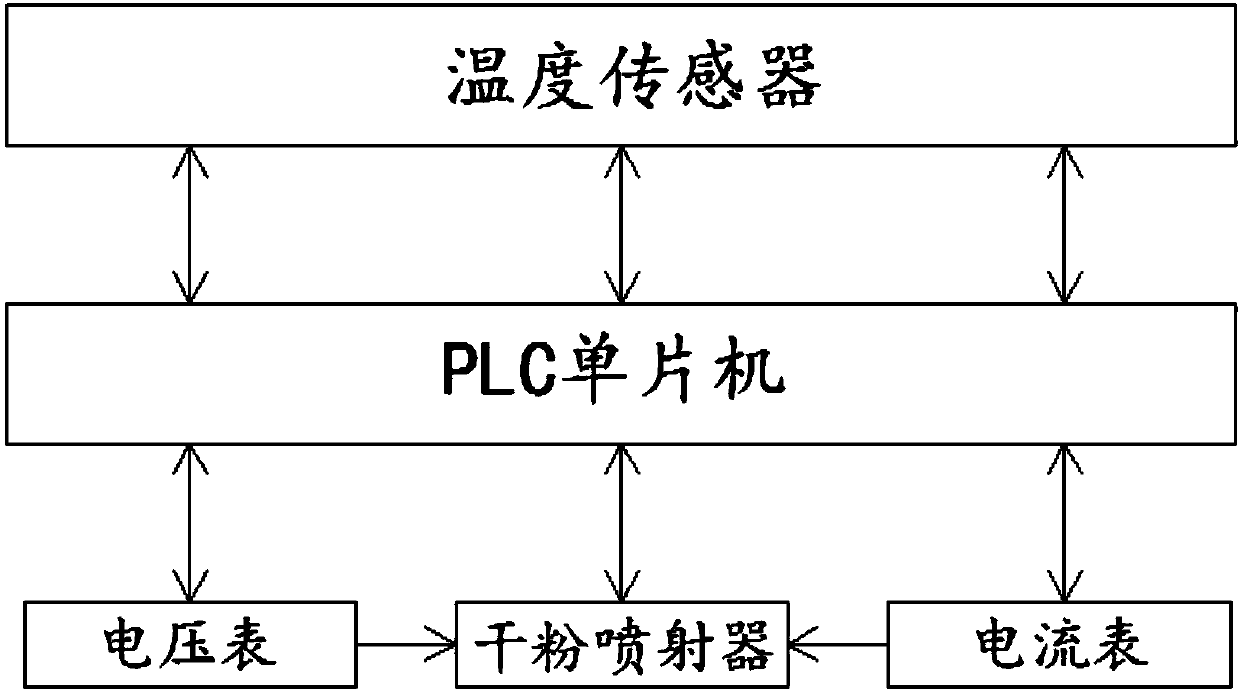

Intelligent power supply device for low-temperature etching-free iron plating process and power supply method thereof

InactiveCN102185498AAC and DC amplitude adjustmentStrong reliabilityAc-dc conversionSilicon-controlled rectifierEtching

Owner:HUANGSHAN JINYI POWER SUPPLY

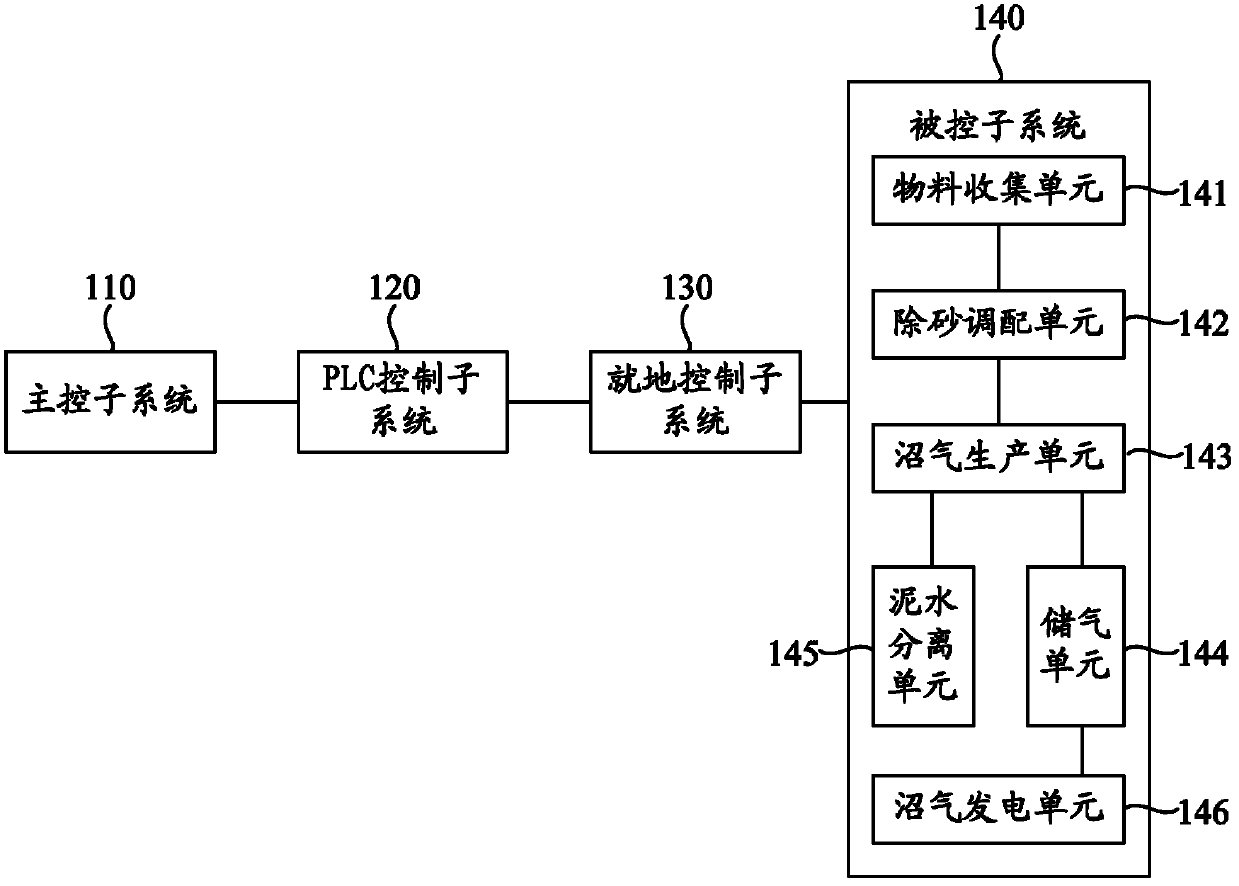

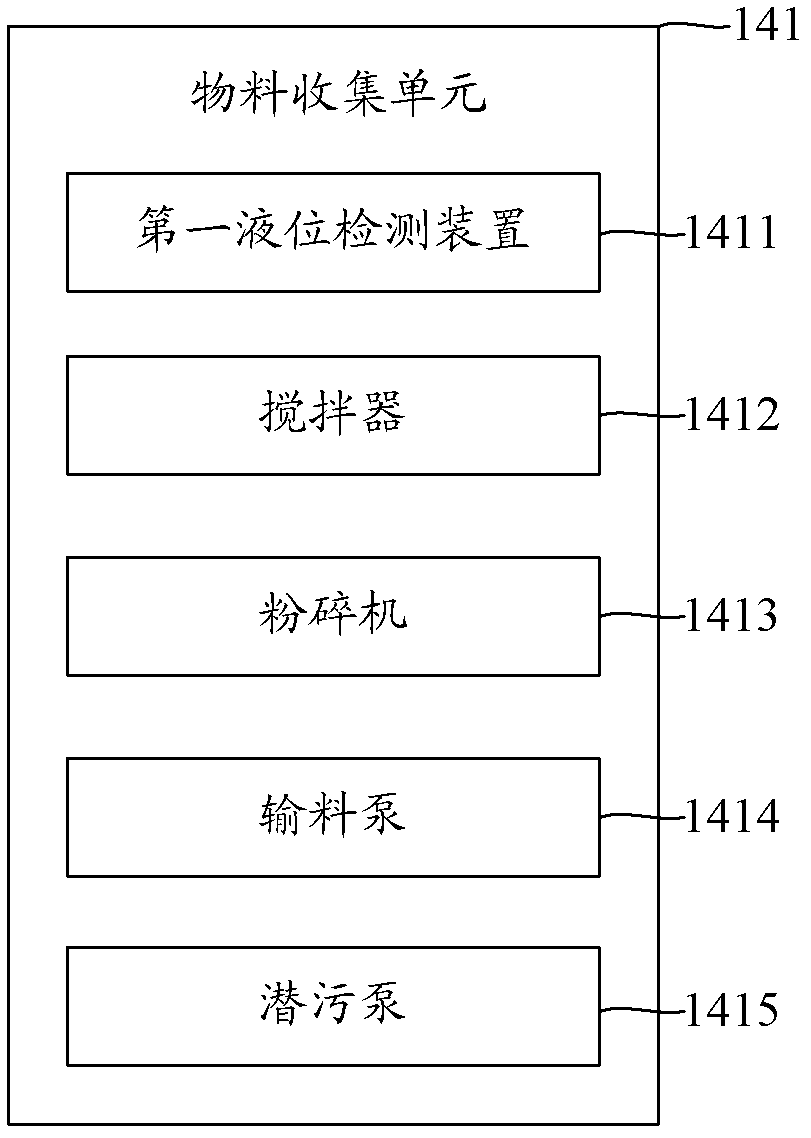

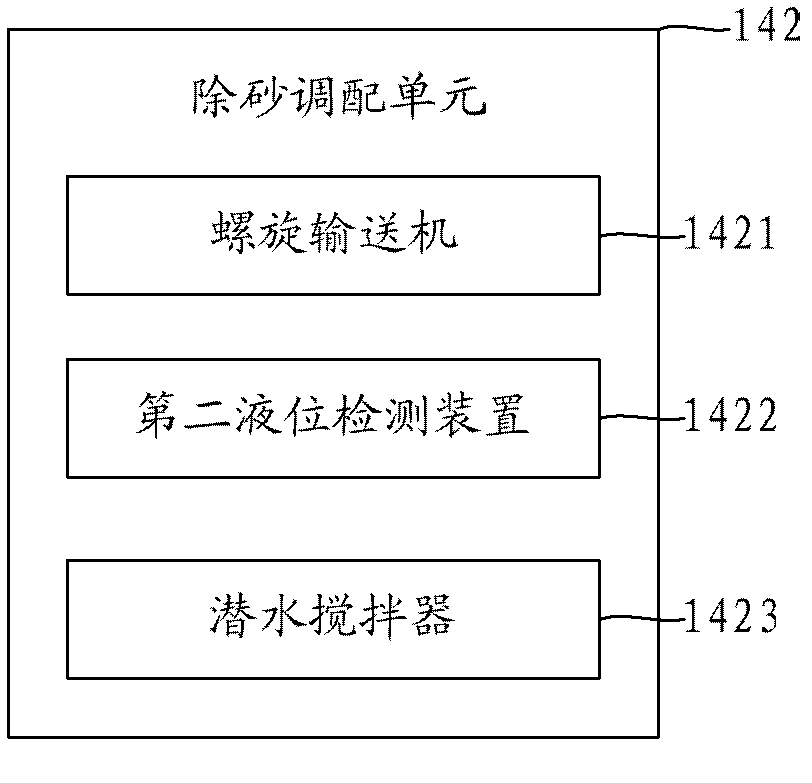

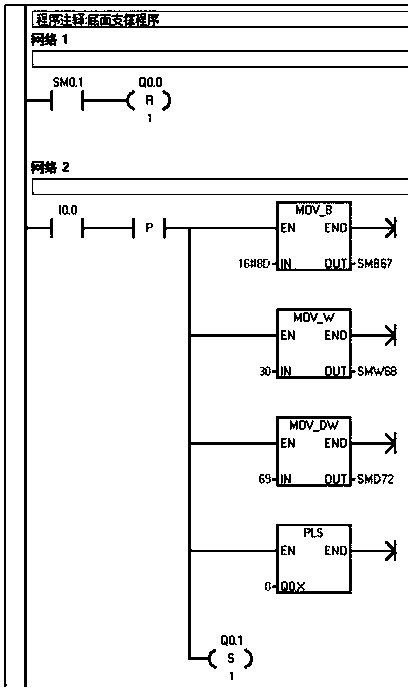

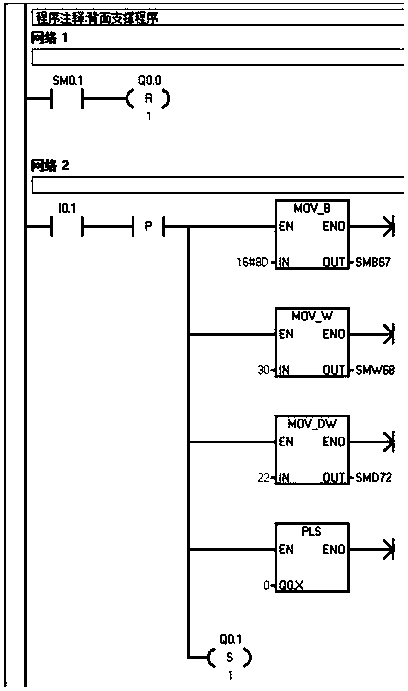

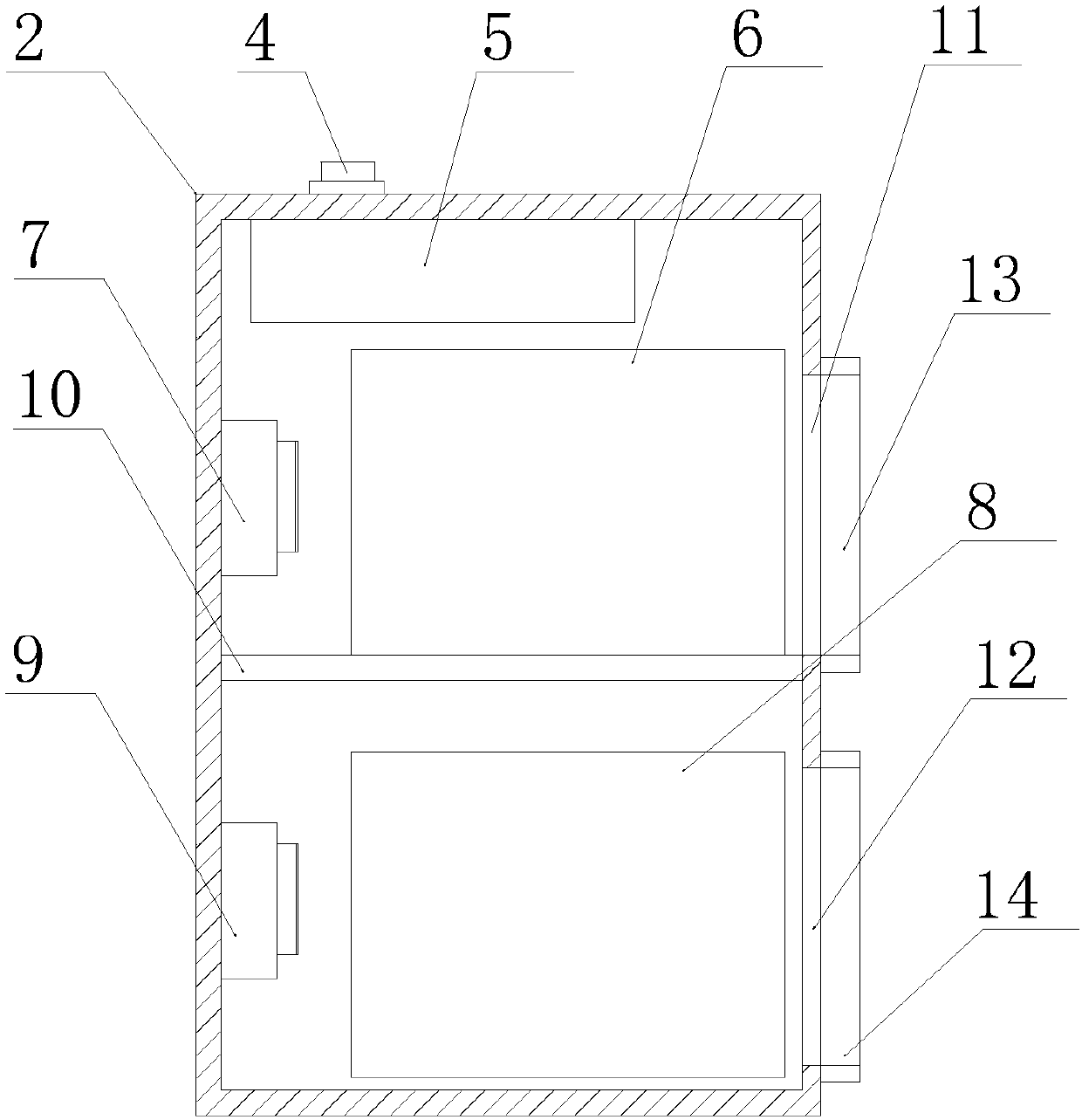

Biogas fermentation gas supply engineering control system

InactiveCN103305413AImprove real-time performanceImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlEngineering controls

Owner:北京愿景宏能源环保科技发展有限公司

Three-dimensional printing table and multi-sided support printing method thereof

Owner:JIANGSU UNIV OF SCI & TECH

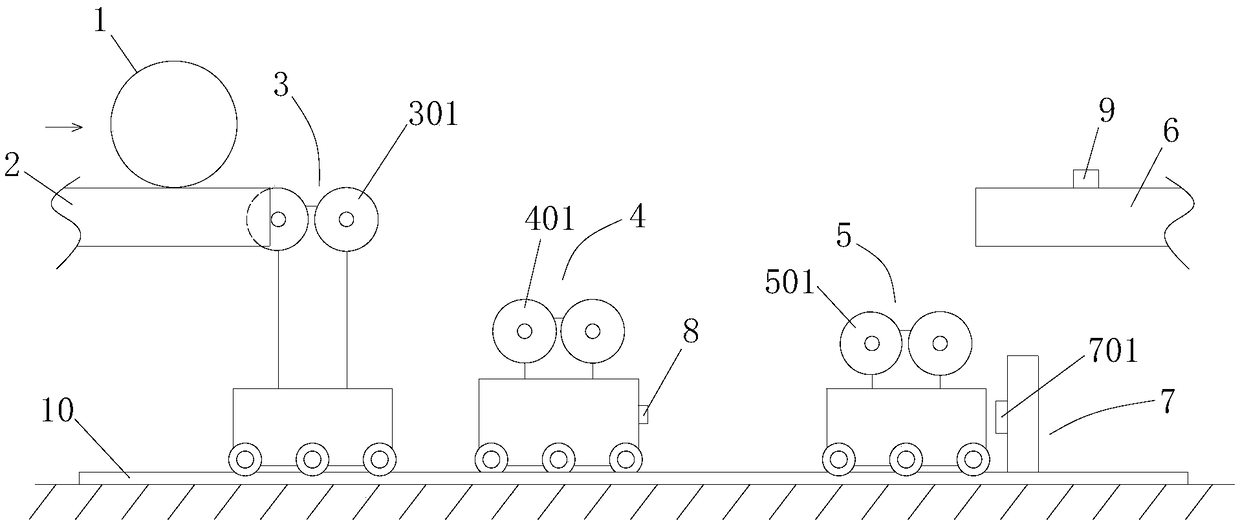

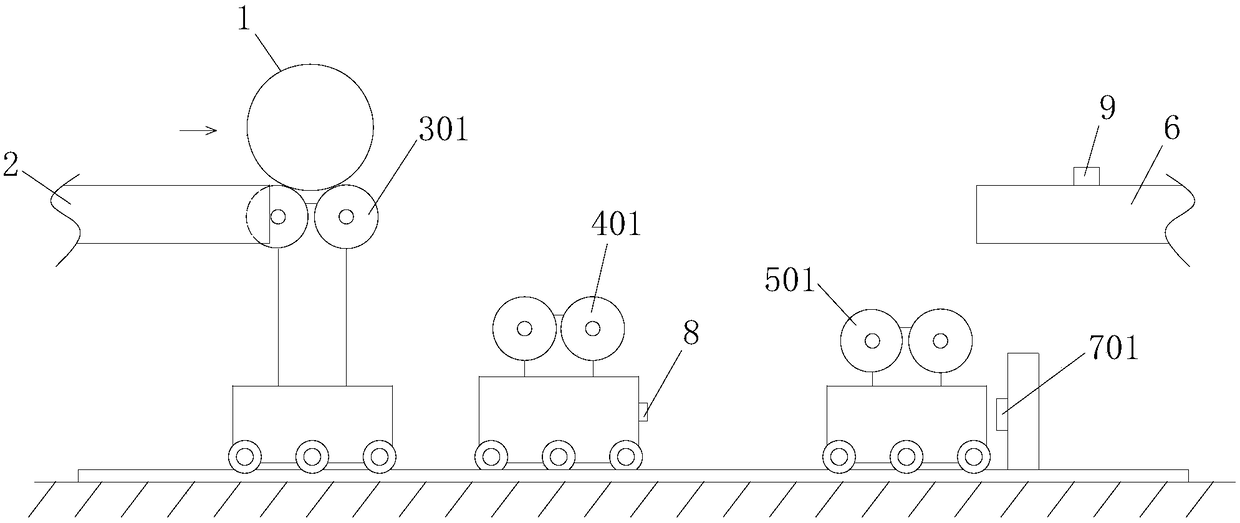

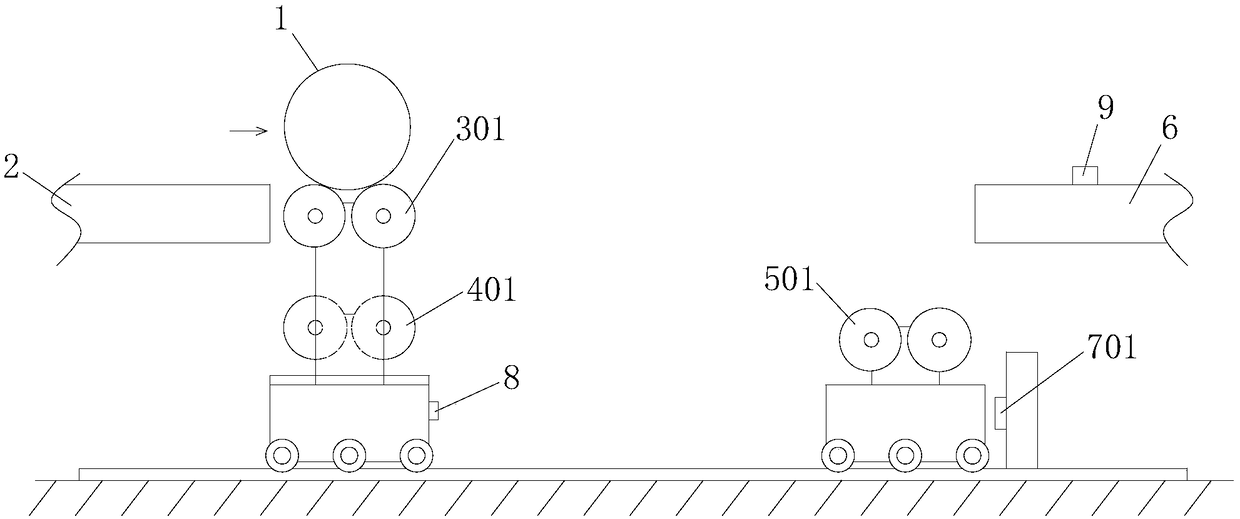

Fixed-size production equipment of steel rope

InactiveCN102002874AHigh tensile strengthImprove efficiencyRope making machinesProgrammable logic controllerEngineering

Owner:JIANGSU JULI WIRE ROPE

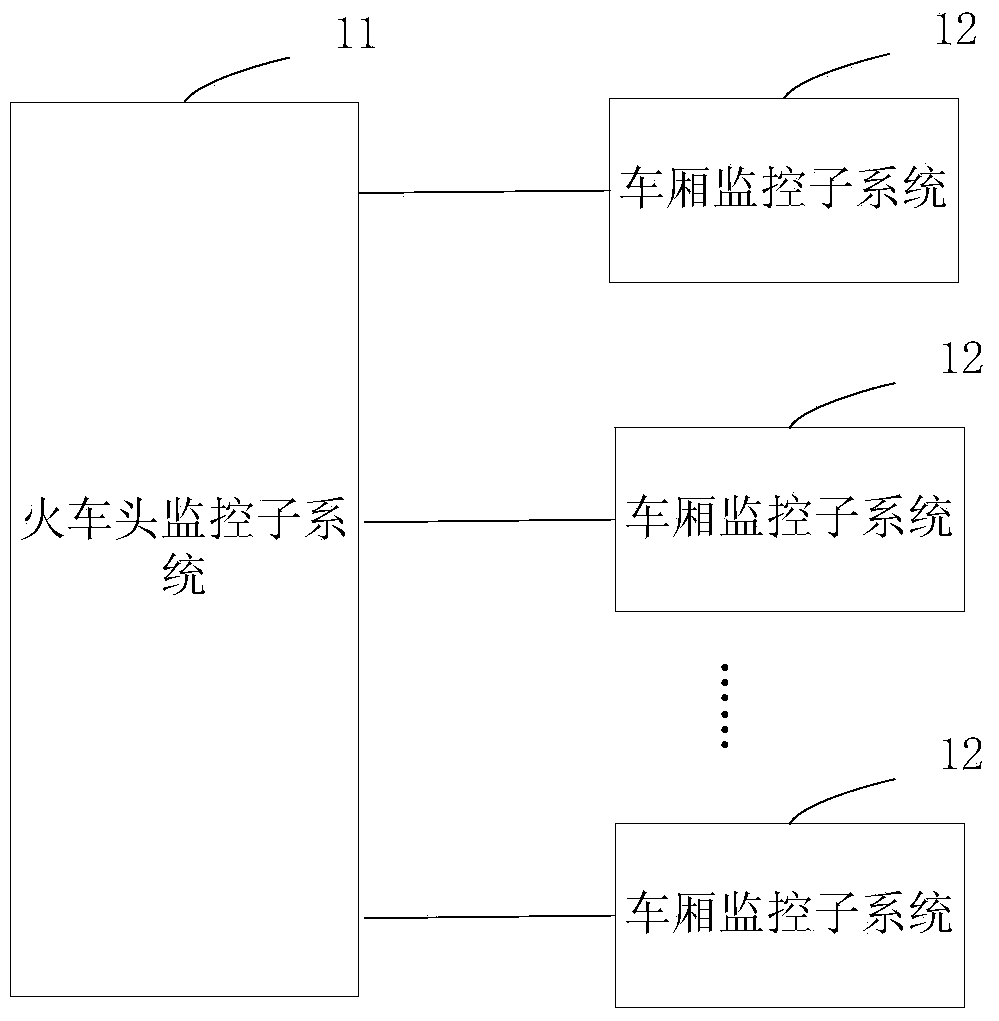

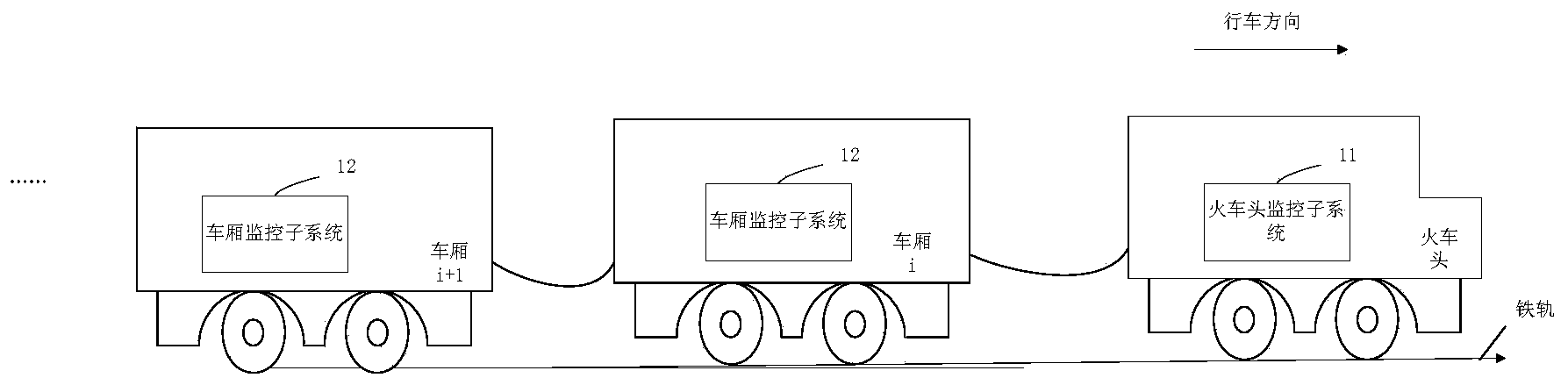

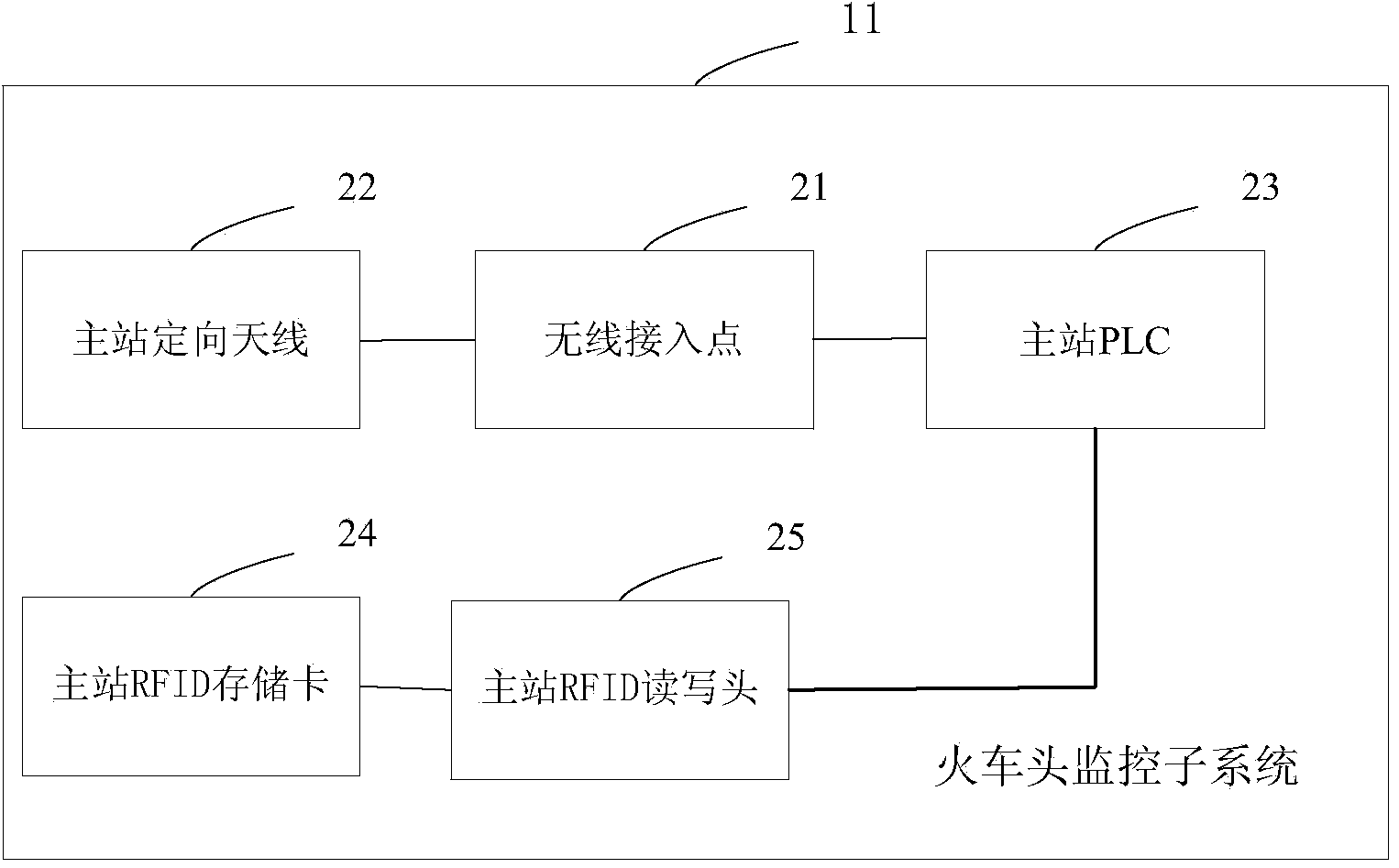

Material state monitoring system for freight train

InactiveCN104238518ATo achieve the purpose of real-time monitoringReal-time monitoring of status changesProgramme total factory controlState variationFreight trains

Owner:何安

One-click gear shifting system and method of drilling winch

ActiveCN106395661AEasy to operate and controlHumanized control operationWinding mechanismsAutomatic controlProgrammable logic controller

The invention discloses a one-click gear shifting system of a drilling winch. The one-click gear shifting system comprises a PLC (Programmable Logic Controller), wherein the PLC is respectively in control connection with five electromagnetic valves in an electromagnetic valve island box, the five electromagnetic valves are electrically controlled air two-position reversing valves, the input ends of the five electromagnetic valves are respectively connected with an air source, and the output end of the electromagnetic valve Y1 is connected with an air cavity of a gear locking cylinder; the output end of the electromagnetic valve Y2 is connected with a rod cavity of the gear locking cylinder; the output end of the electromagnetic valve Y3 communicates with a right cavity of a gear shifting cylinder; the output end of the electromagnetic valve Y4 communicates with a middle cavity of the gear shifting cylinder; the output end of the electromagnetic valve Y5 communicates with a left cavity of the gear shifting cylinder; and the end of a piston rod of the gear locking cylinder is vertically hinged to a piston rod of the gear shifting cylinder, the piston rod of the gear shifting cylinder is fixedly connected with a gear shifting mechanism, and the gear shifting mechanism is arranged between a reduction gearbox and a drum shaft of a winch drum. The invention further discloses a one-click gear shifting method of the drilling winch, and the drilling efficiency and the automatic control level of the winch are increased.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Squeezing safety and automatic alarm device of diaphragm filter press

PendingCN111298490AImprove the safety requirements of automatic control operationEasy to useAlarmsElectric transmission signalling systemsText displayAutomatic control

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

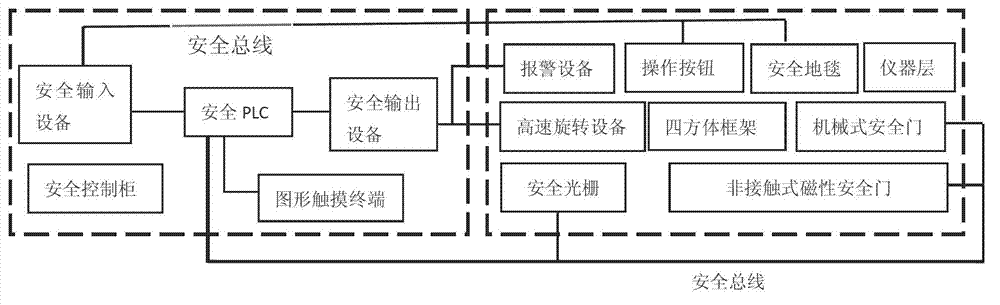

Function safety monitoring development and demonstration system for major hazard source equipment

ActiveCN102890483AAvoid enteringRealize emergency stopTotal factory controlProgramme total factory controlGratingProgrammable logic controller

Owner:CHINA ACAD OF SAFETY SCI & TECH +1

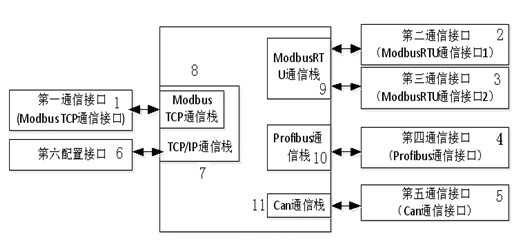

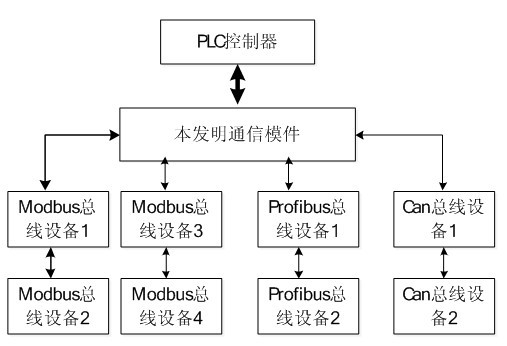

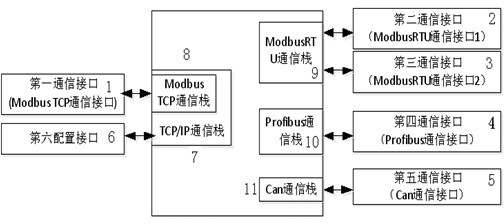

Universal programmable logic controller (PLC) communication module for field bus

InactiveCN102323788AProgramme control in sequence/logic controllersCommunication interfaceProgrammable logic controller

Owner:NANJING SCIYON AUTOMATION GRP

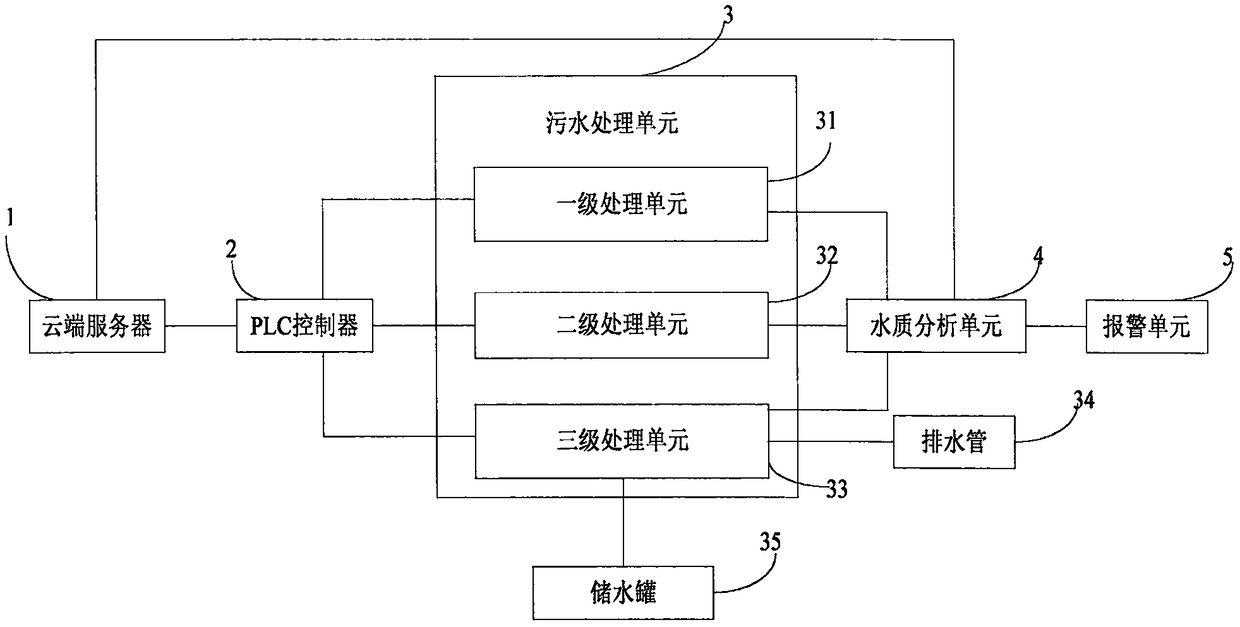

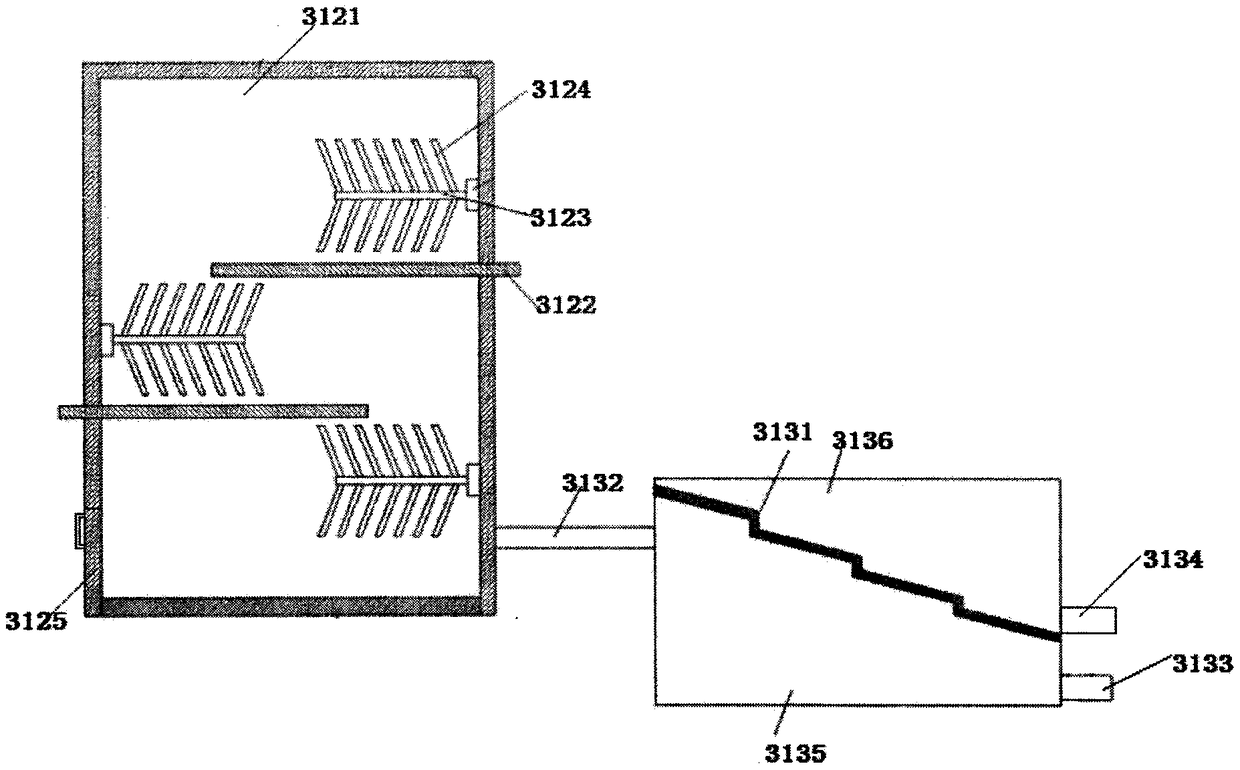

Sewage treatment system

InactiveCN109502889AGood processing effectHarm reductionWater treatment parameter controlFatty/oily/floating substances removal devicesProgrammable logic controllerWater quality

Owner:HENAN INST OF SCI & TECH

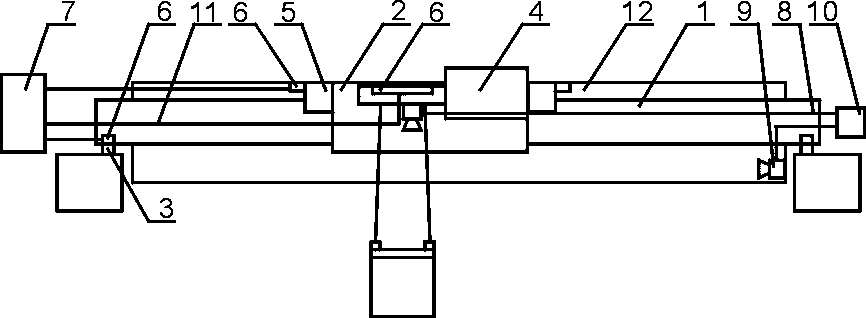

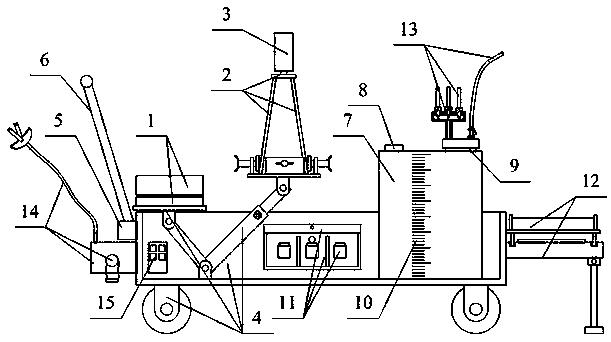

Mechanical swinging light-supplementing device for fruits and vegetables in greenhouse

InactiveCN104566022ASimple structureStable structureLighting support devicesGlobesSocial benefitsControl manner

The invention relates to a mechanical swinging light-supplementing device for fruits and vegetables in a greenhouse. The mechanical swinging light-supplementing device comprises a swinging rod, a big gear, a lampshade swinging shaft, a small gear, a connecting rod, a crank, a stepping motor, a control box, a rack, a lampshade, a light source, a lamp base and the like. A crank swinging rod mechanism is combined with the stepping motor and a programmable logic controller is used for controlling, so that the demand on mechanical swinging light-supplementing for the fruits and vegetables in the greenhouse is met and the illumination for the fruits and vegetables in the greenhouse is maintained at an optimal state for a long time. Under the control mode, the structure is simple and reliable and the cost is saved. The mechanical swinging light-supplementing device has the characteristics of simple and useful property, convenience in mounting and adjusting, huge market potential, obvious economic benefit and social benefit, wide application prospect, and the like.

Owner:CHANGCHUN AGRI MASCH RES INST (CHANGCHUN MECHANIZED CONSERVATION TILLAGE RES & PROMOTION CENT CHANGCHUN URBAN AGRI MECHANIZATION TECH PROMOTION STATION CHANGCHUN AGRI MASCH PROD QUALITY SUPERVISION & INSPECTION STATION)

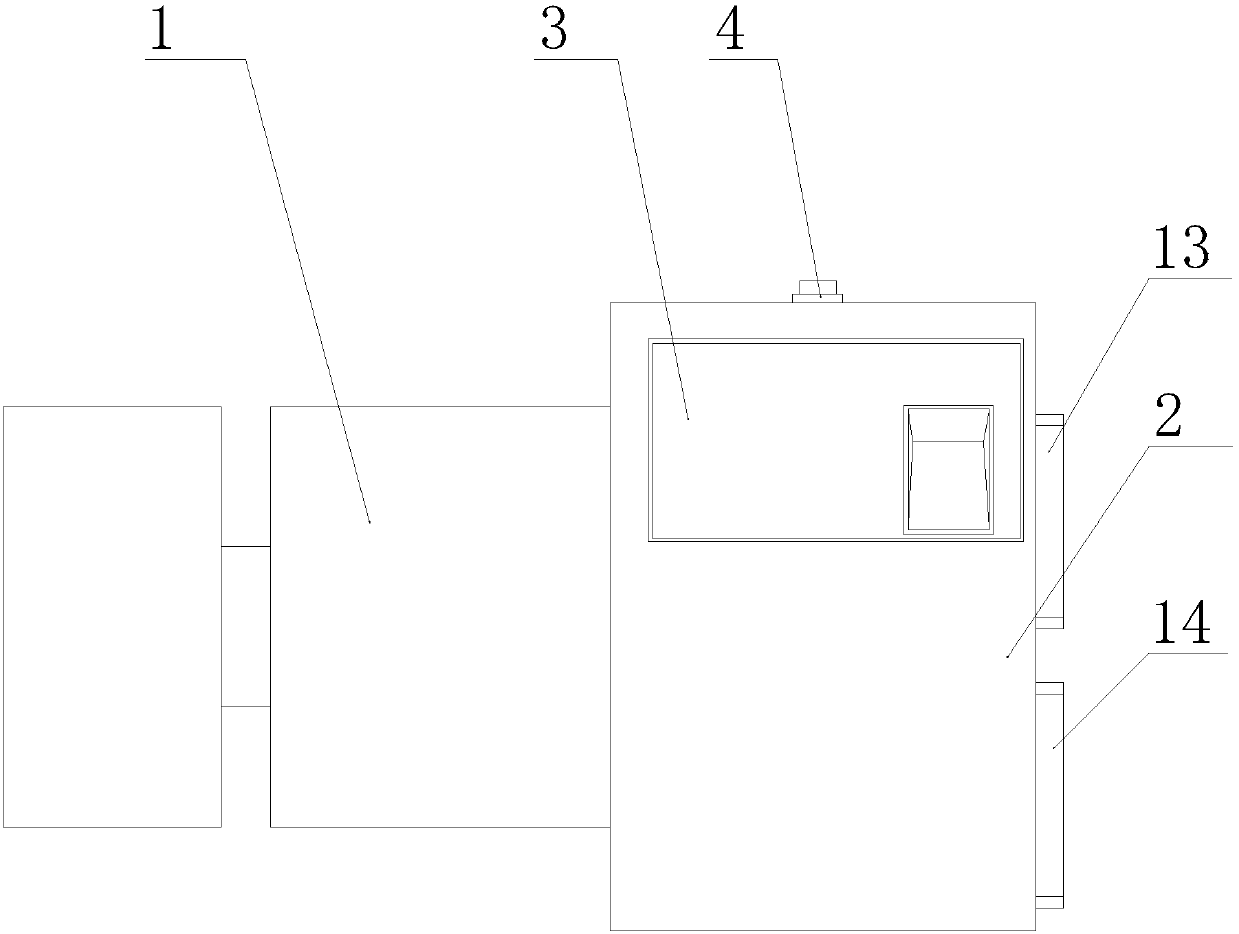

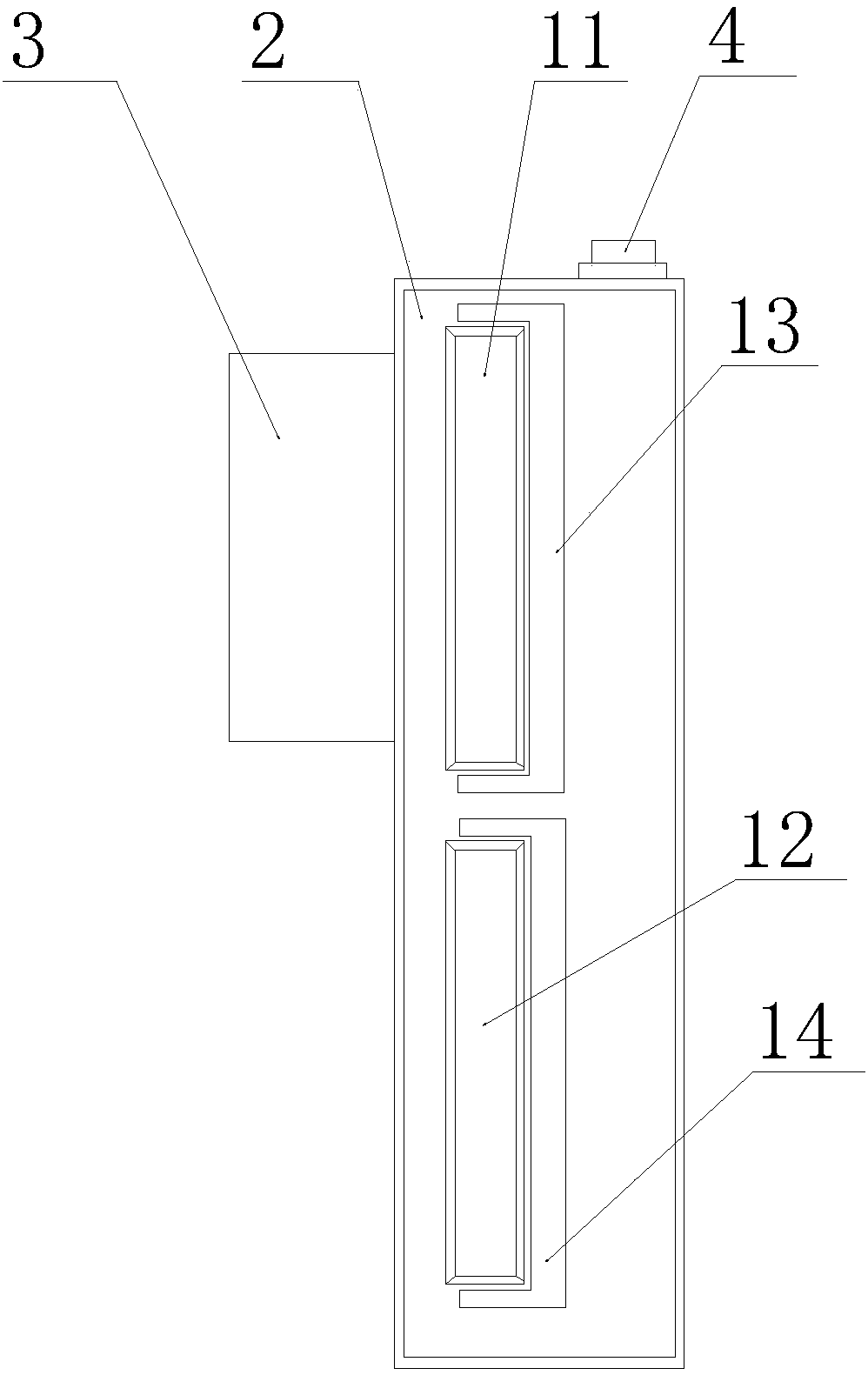

Intelligent lock compatible with second generation identity cards

PendingCN107622553AImprove convenienceOpen quicklyIndividual entry/exit registersCommunication interfaceInformation transmission

Owner:成都易住信息技术有限公司

Pulp-viscosity detecting system for circulation of production line of corrugated boards and detecting method

PendingCN108489862AStable pressureAvoiding Effects on Viscosity MeasurementsProgramme control in sequence/logic controllersDirect flow property measurementProduction lineProgrammable logic controller

Owner:东莞市禾雅实业有限公司

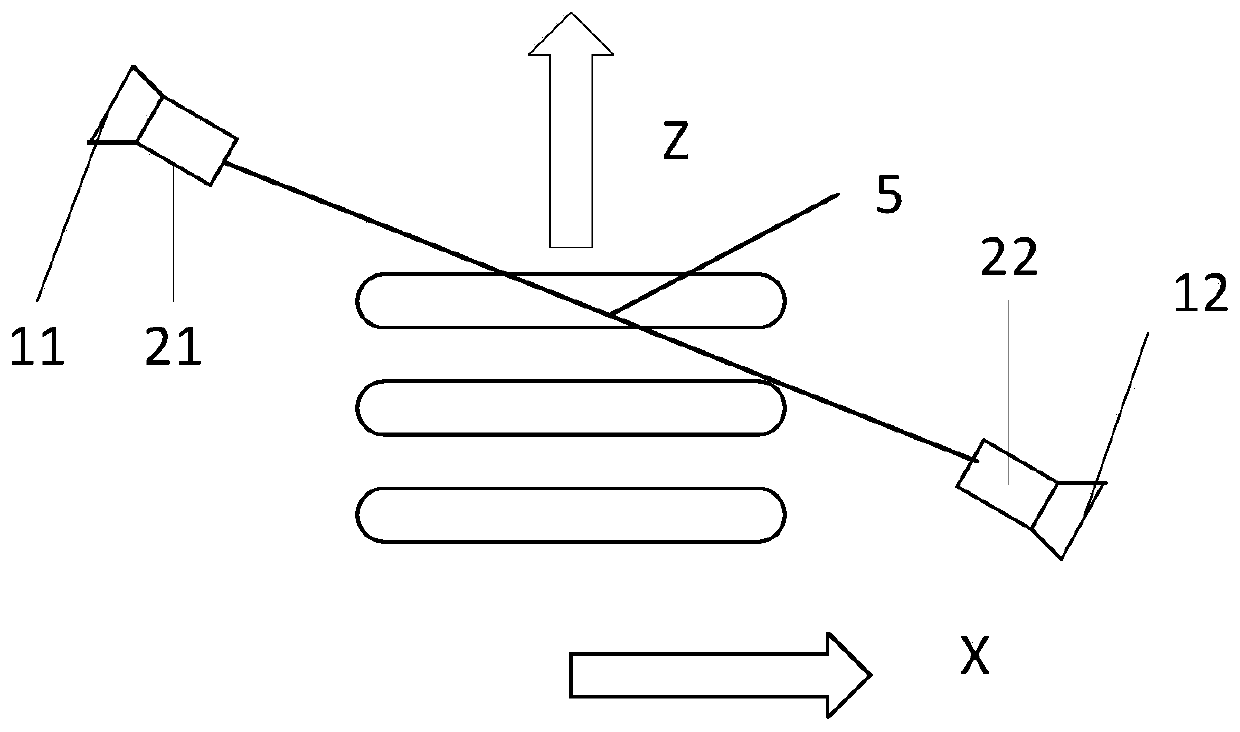

Distance measurement method and distance measurement system

InactiveCN106896368AHigh precisionSimple structureProgramme control in sequence/logic controllersElectromagnetic wave reradiationProgrammable logic controllerLevel measurement

The invention discloses a distance measurement method and distance measurement system, wherein the method includes the following steps: a pulse laser emits a laser signal; a photodiode APD array receives a return signal which is returned after the laser signal encounters a measured target, and transmits the received return signal to a timing chip; the timing chip determines the flight time of a rail train to the measured target according to the laser signal and the return signal, and transmits the determined flight time to a Programmable Logic Controller (PLC), and the timing chip reaches ns-level measurement accuracy; and the PLC determines distance between the rail train and the measured target according to the received flight time. The distance measurement method provided by the invention solves the technical problems of complicated measurement structure and low accuracy brought by adoption of a direct counting mode in related technologies, improves measurement accuracy, and simplifies the structure.

Owner:CRRC QINGDAO SIFANG CO LTD

Crane for automatically positioning and aligning at position to search object in corresponding position in nuclear radiation environment

InactiveCN104176644APrecise positioning operationRealize automatic crawlingTravelling cranesLoad-engaging elementsNuclear radiationProgrammable logic controller

Owner:SICHUAN TUOJIANG CRANE EQUIP

Security and protection system pressure regulating device no-load pressure regulating electron outage method

InactiveCN103105835ATotal factory controlProgramme total factory controlProgrammable logic controllerClosure operation

Owner:XIAN ALL SAFE SCI & TECH

Safety protection device for laser automatic unpacking machine

InactiveCN102152873ASimple structureLow costPackaging automatic controlProgrammable logic controllerNatural state

Owner:CHONGQING LANGZHENG TECH

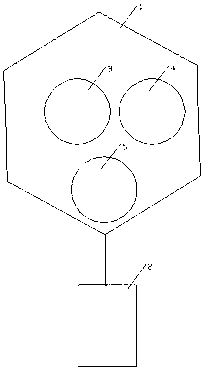

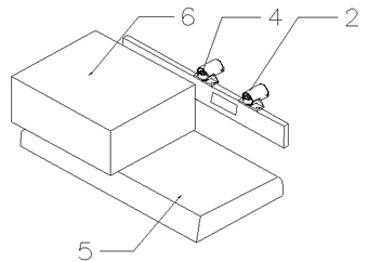

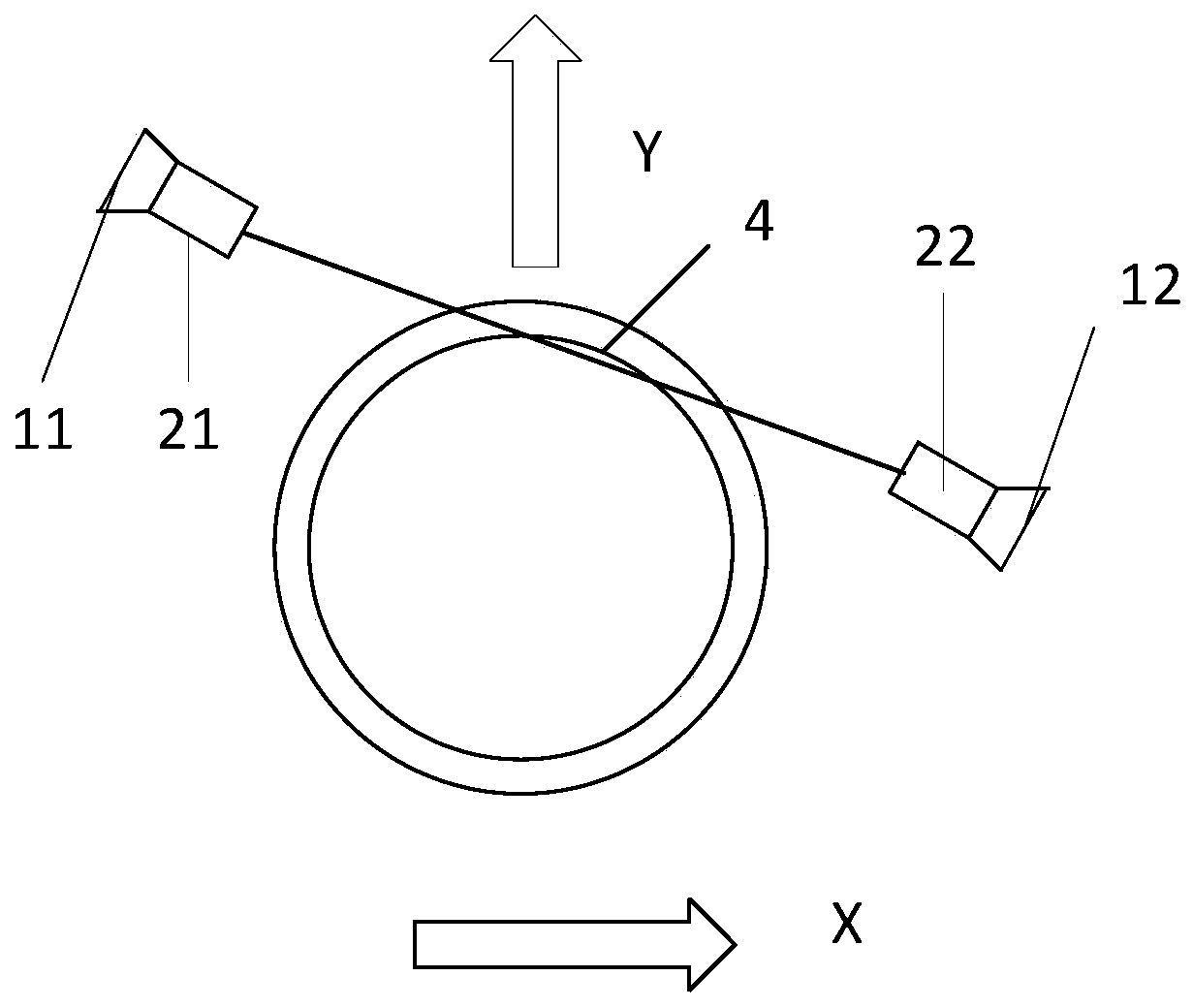

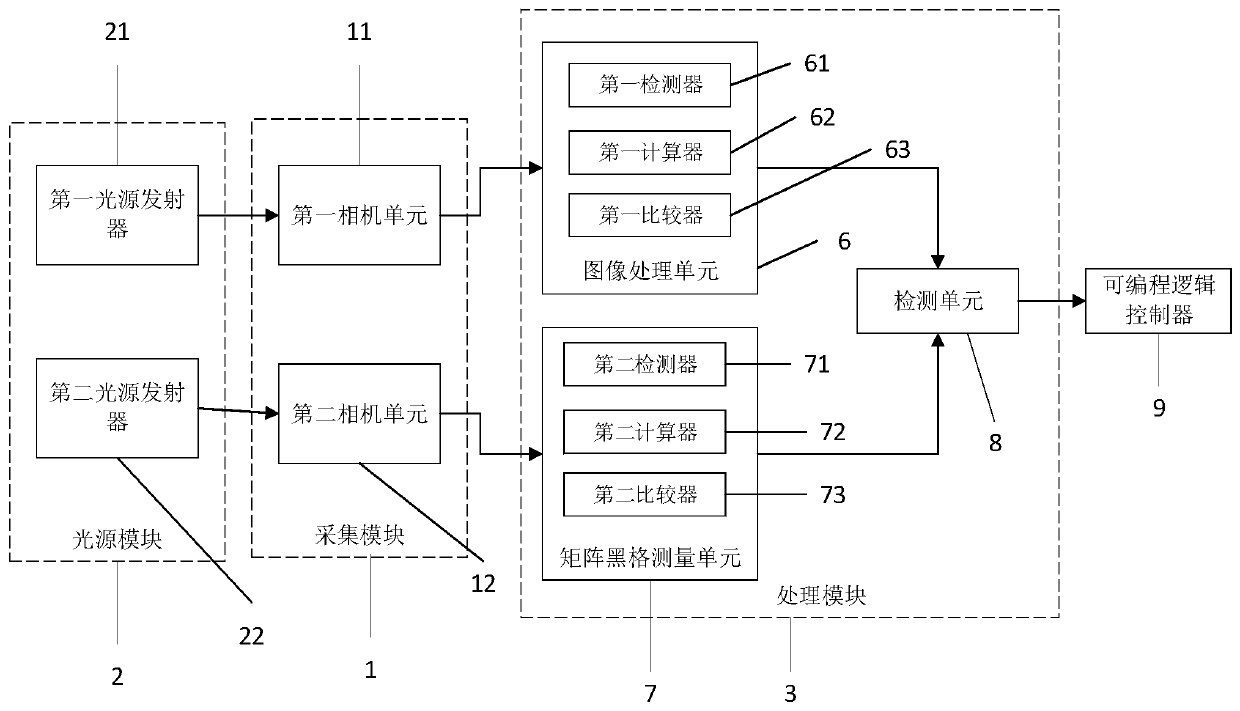

Device for rapidly detecting bunching head defects of steel wires

Owner:GUILIN UNIV OF ELECTRONIC TECH

Convenient-to-charge photovoltaic power supply assembly

InactiveCN107707005ABatteries circuit arrangementsElectric powerCharge voltageProgrammable logic controller

Owner:曹政

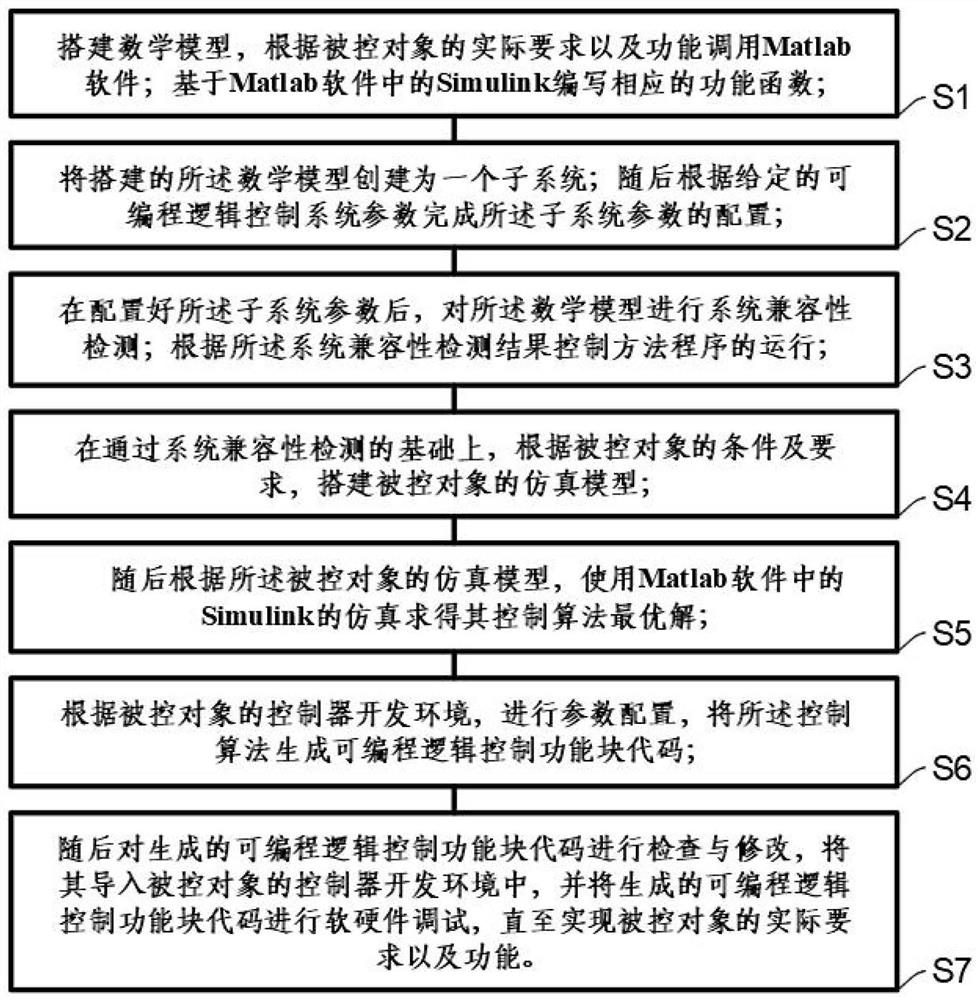

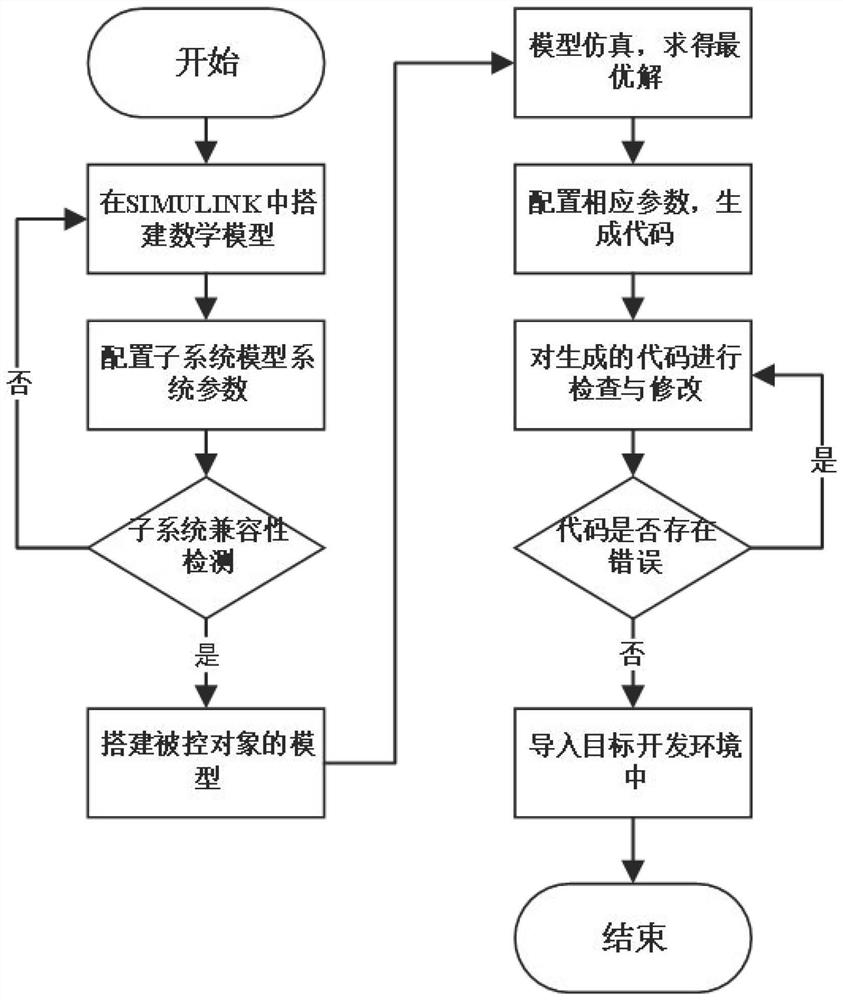

Method for rapidly generating programmable logic control function block codes

PendingCN114879590ATotal factory controlProgramme control in sequence/logic controllersPerformance functionSystems design

Owner:XIANGTAN UNIV

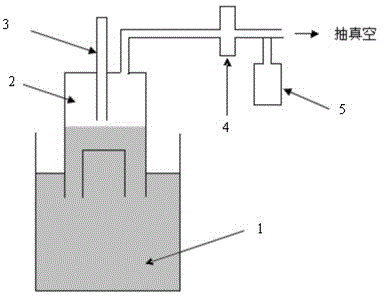

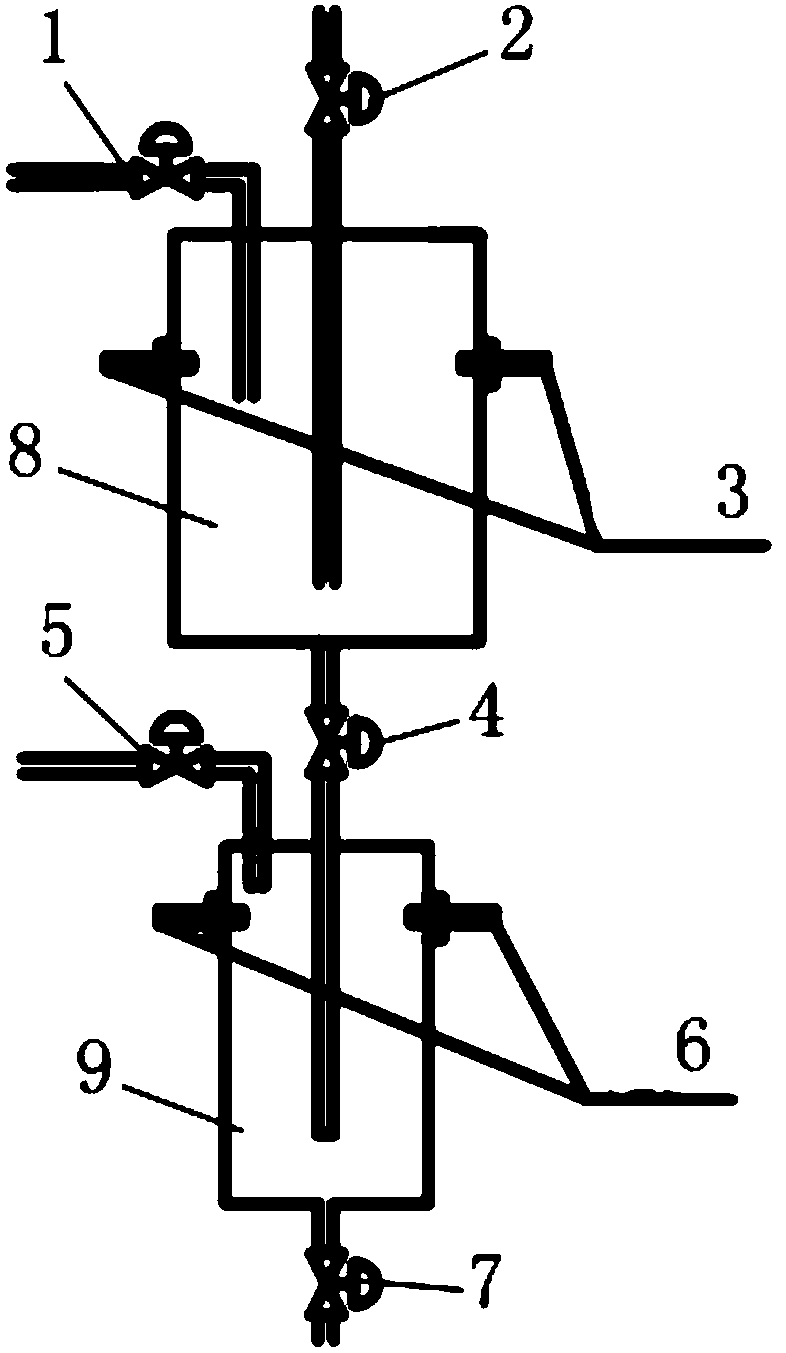

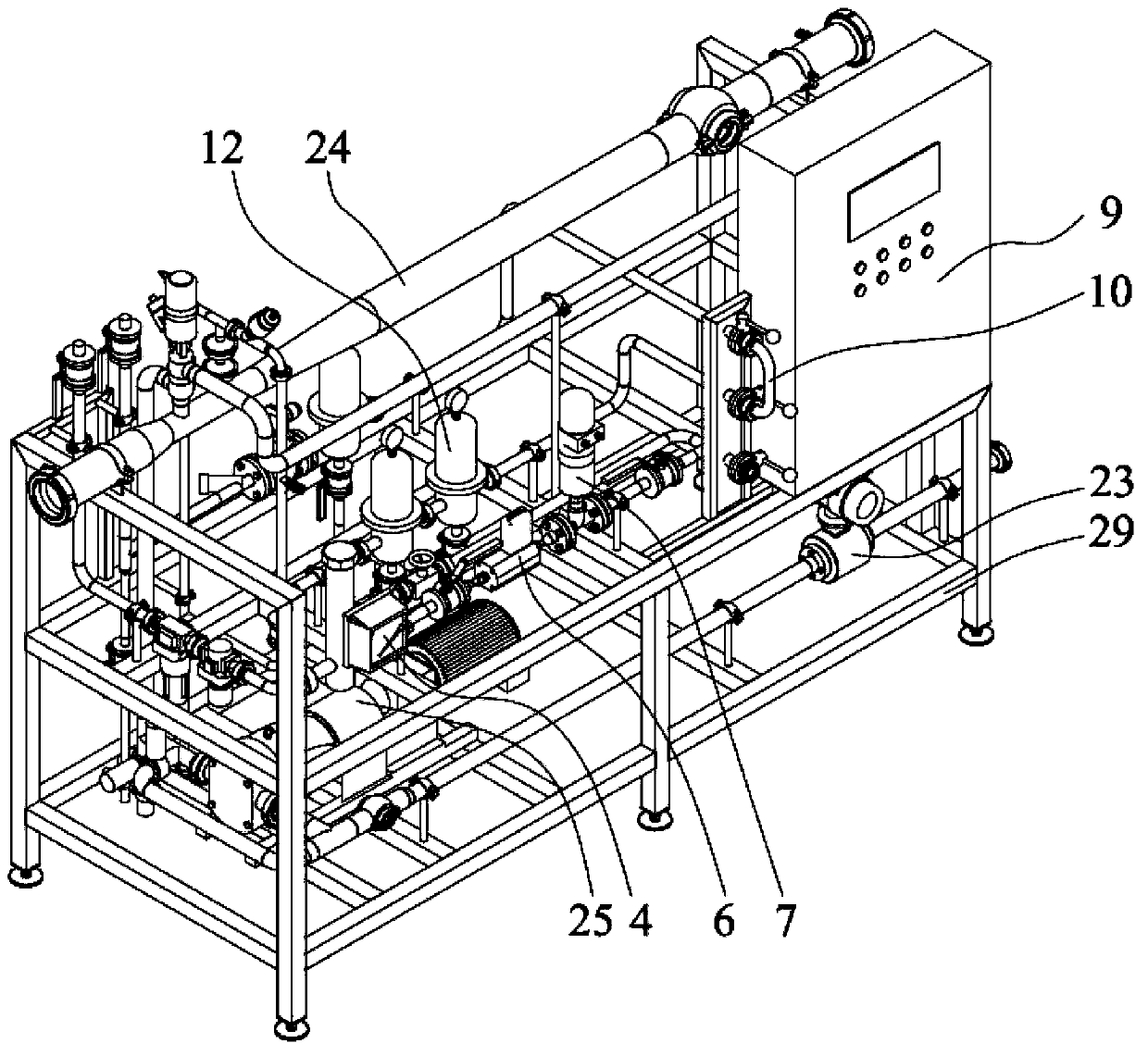

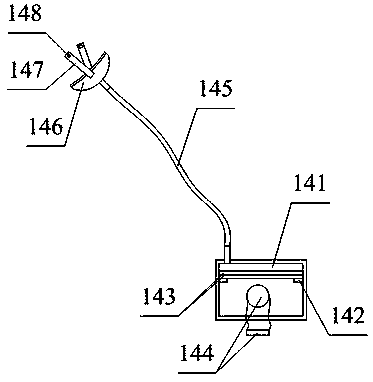

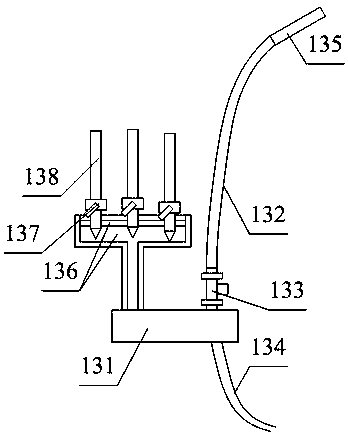

Full-automatic wort oxygenated yeast adding machine and wort oxygenated yeast adding method

InactiveCN102816662BAvoiding problems with feedback regulation hysteresisMethod is feasibleWort preparationHuman error probabilityLoop control

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

Comprehensive environment protection detection and treatment equipment

InactiveCN108362841AImprove filtering effectIncrease inhalationDispersed particle filtrationTransportation and packagingWater storageEnvironmental resistance

Owner:杨晓丽

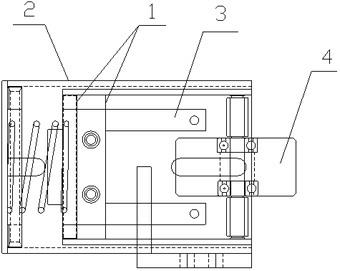

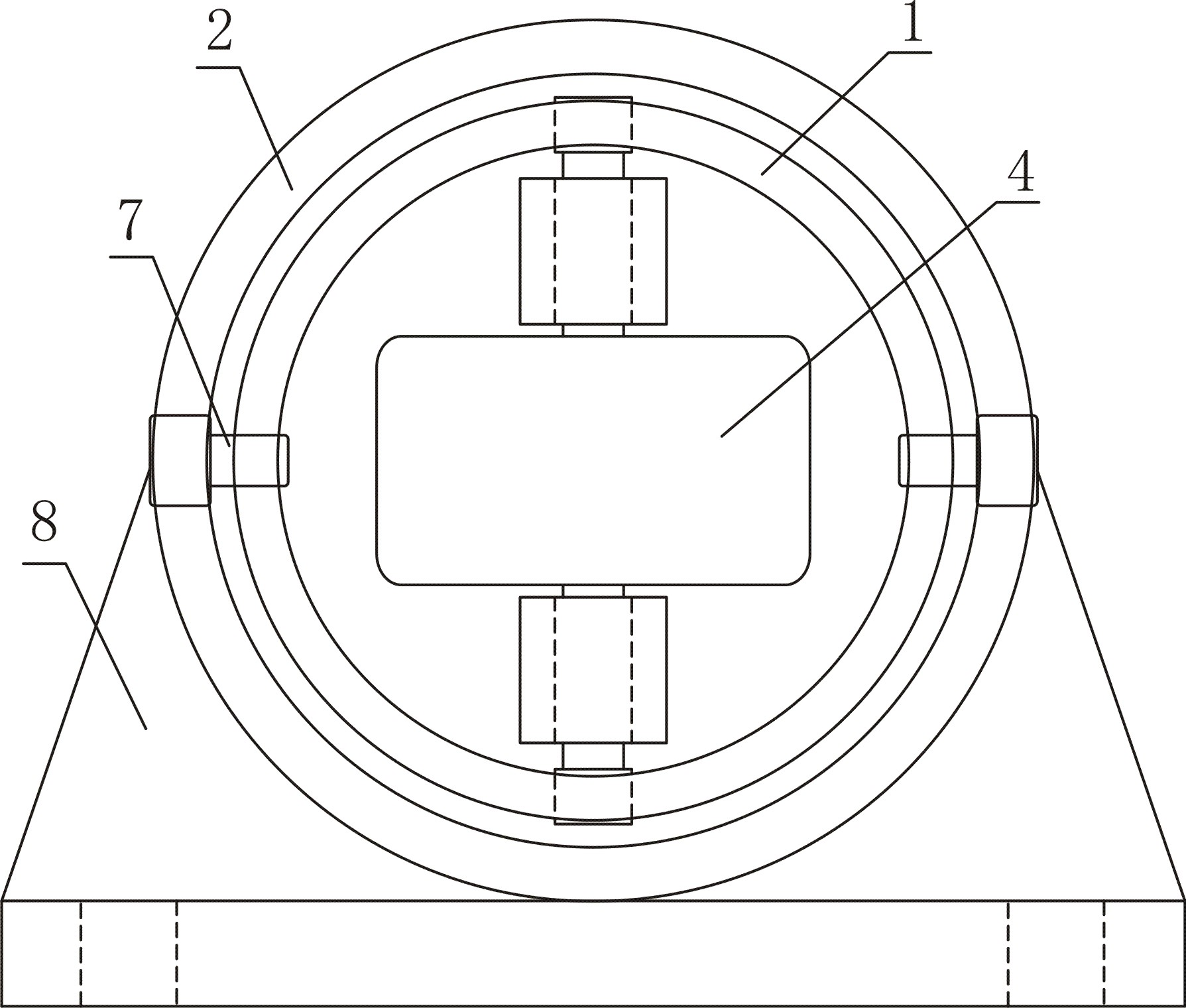

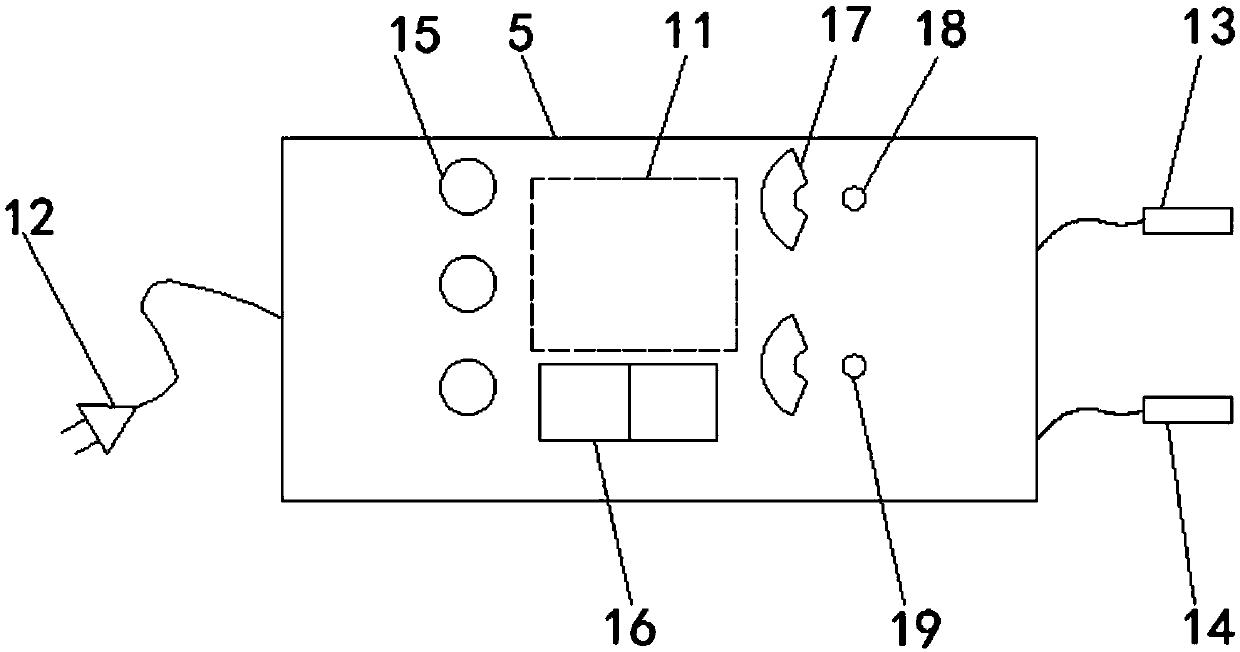

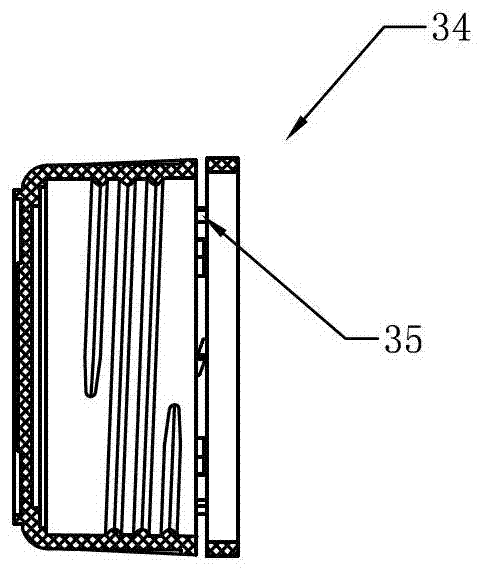

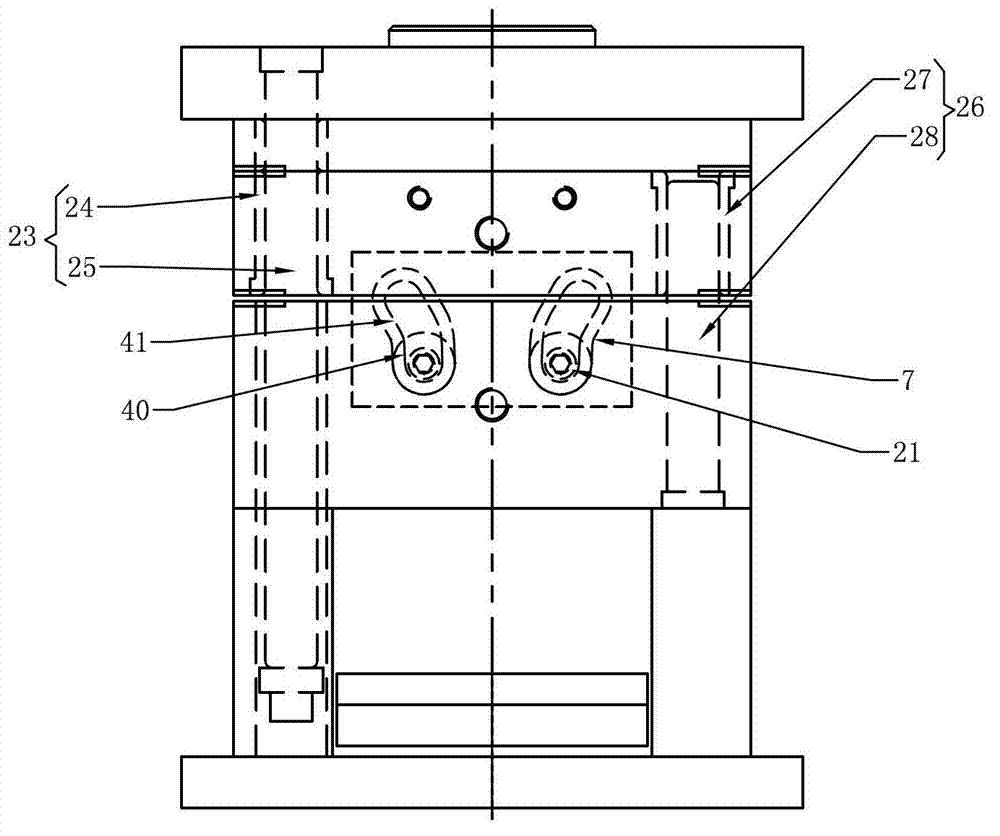

Injection mold for manufacturing PLC (programmable logic controller) cover

Owner:南通海睿知新信息科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap