Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Control devices for conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

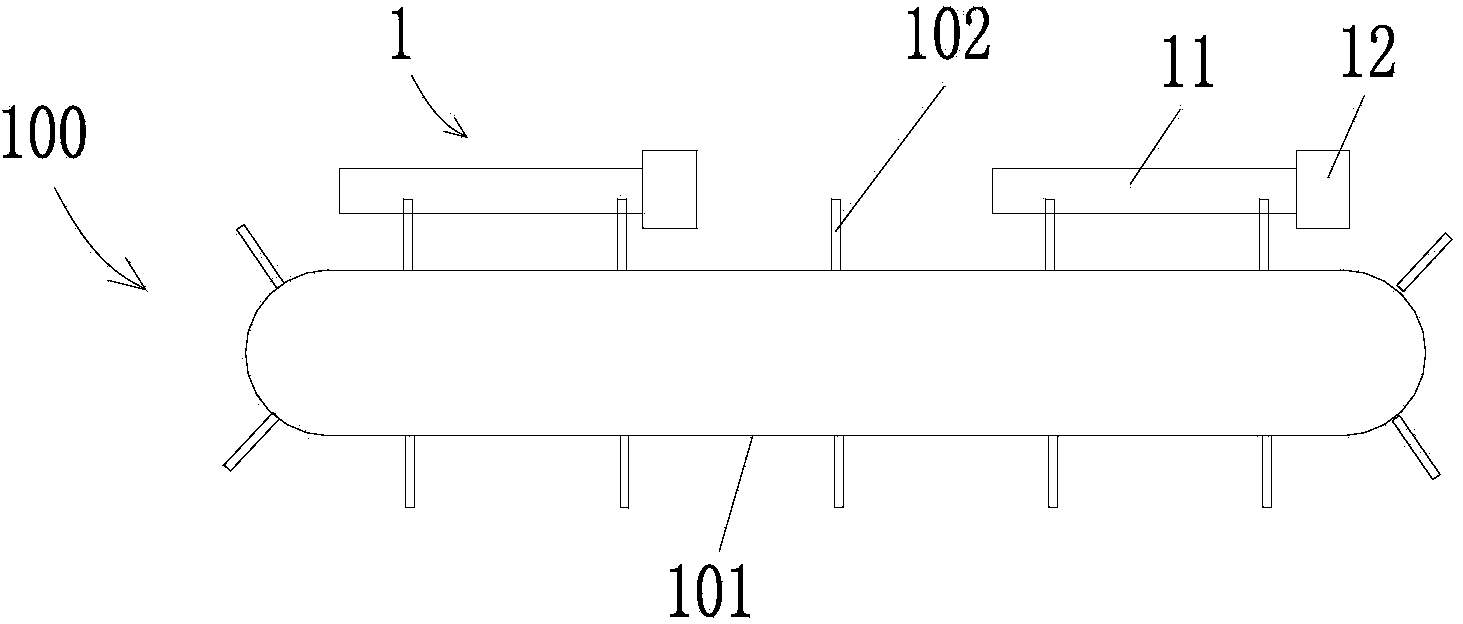

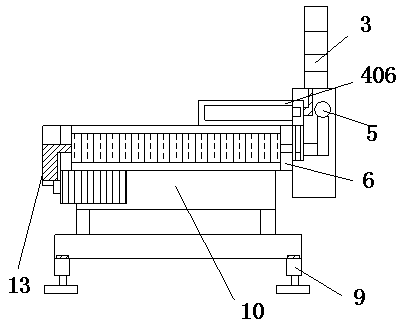

Cast pipe conveying device

PendingCN108557401AAvoid collision problemsGuaranteed appearance qualityControl devices for conveyorsMechanical conveyorsProgrammable logic controllerEngineering

Owner:河北新兴铸管有限公司

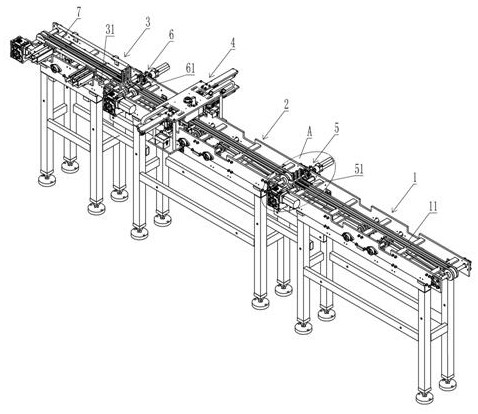

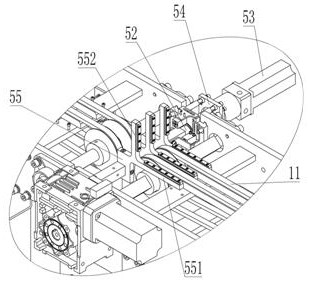

Box body conveying, pushing and clamping system for instrument glass sheet assembly

InactiveCN107380967ASmooth feedingShorten the timeConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:新朗思(新沂)智能科技有限公司

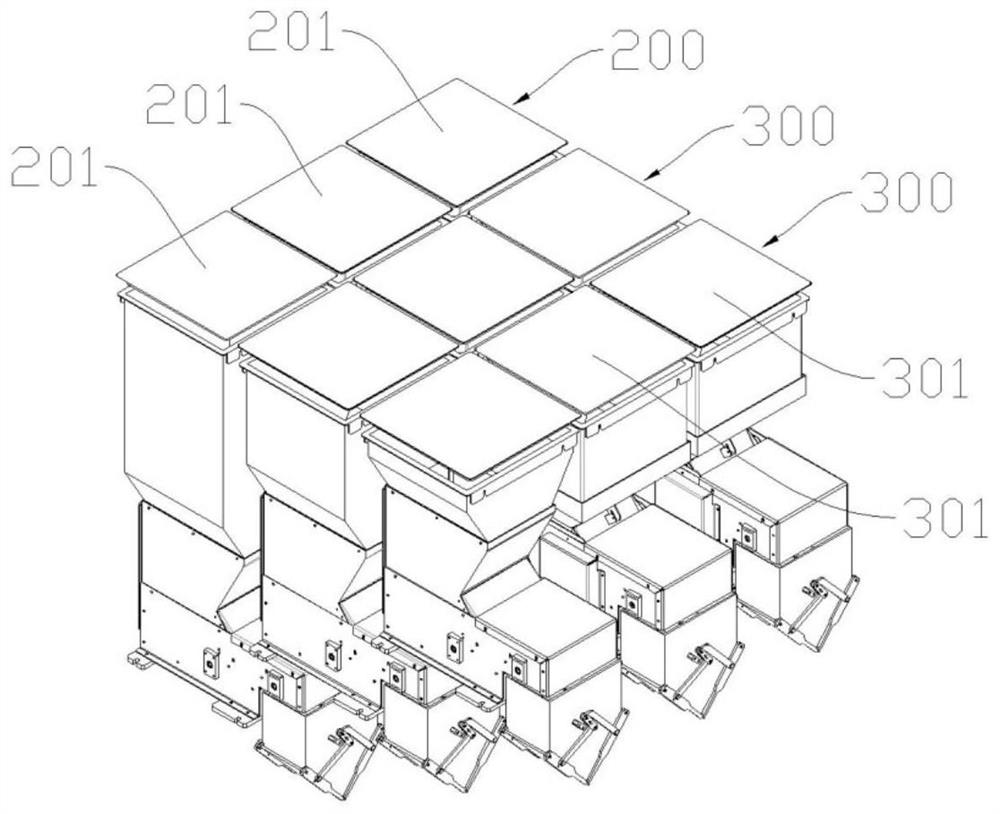

Automatic traditional Chinese medicine dispensing system

ActiveCN112722725AStable outputImprove adjustment efficiencyControl devices for conveyorsPackagingMedicinal herbsProcess engineering

Owner:SUZHOU IRON TECH

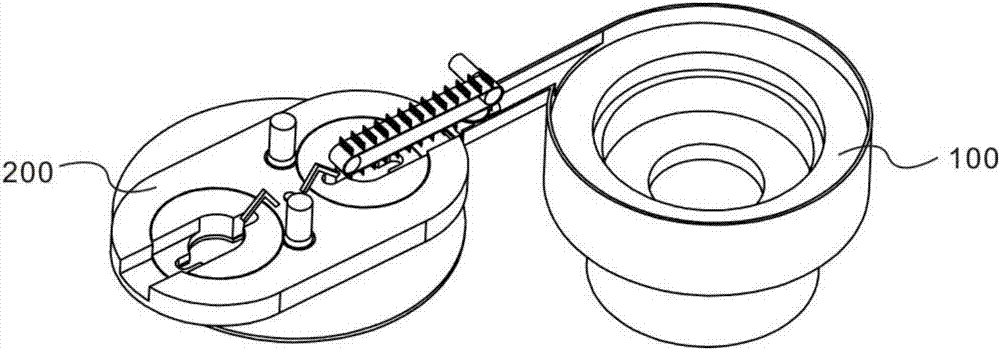

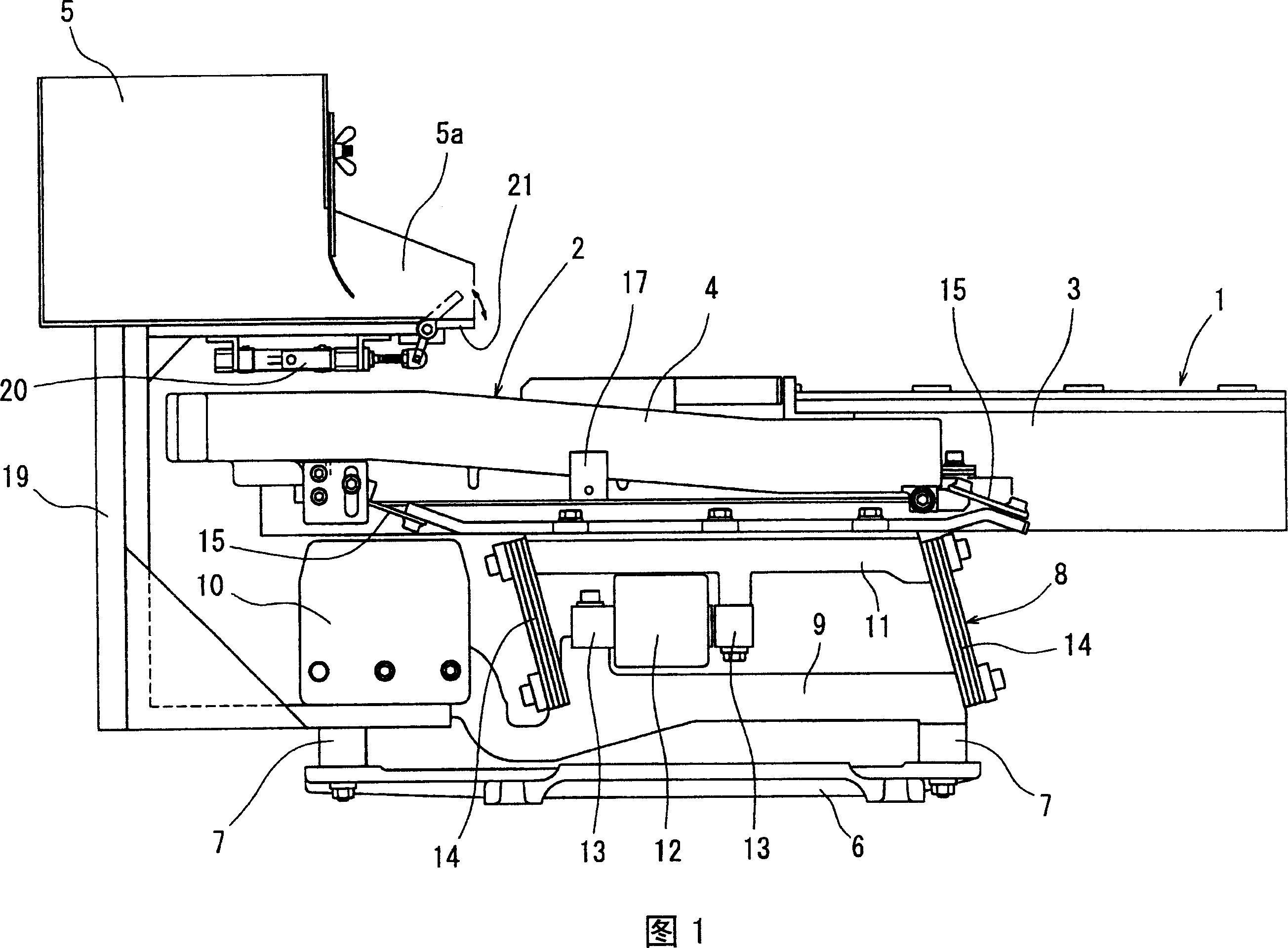

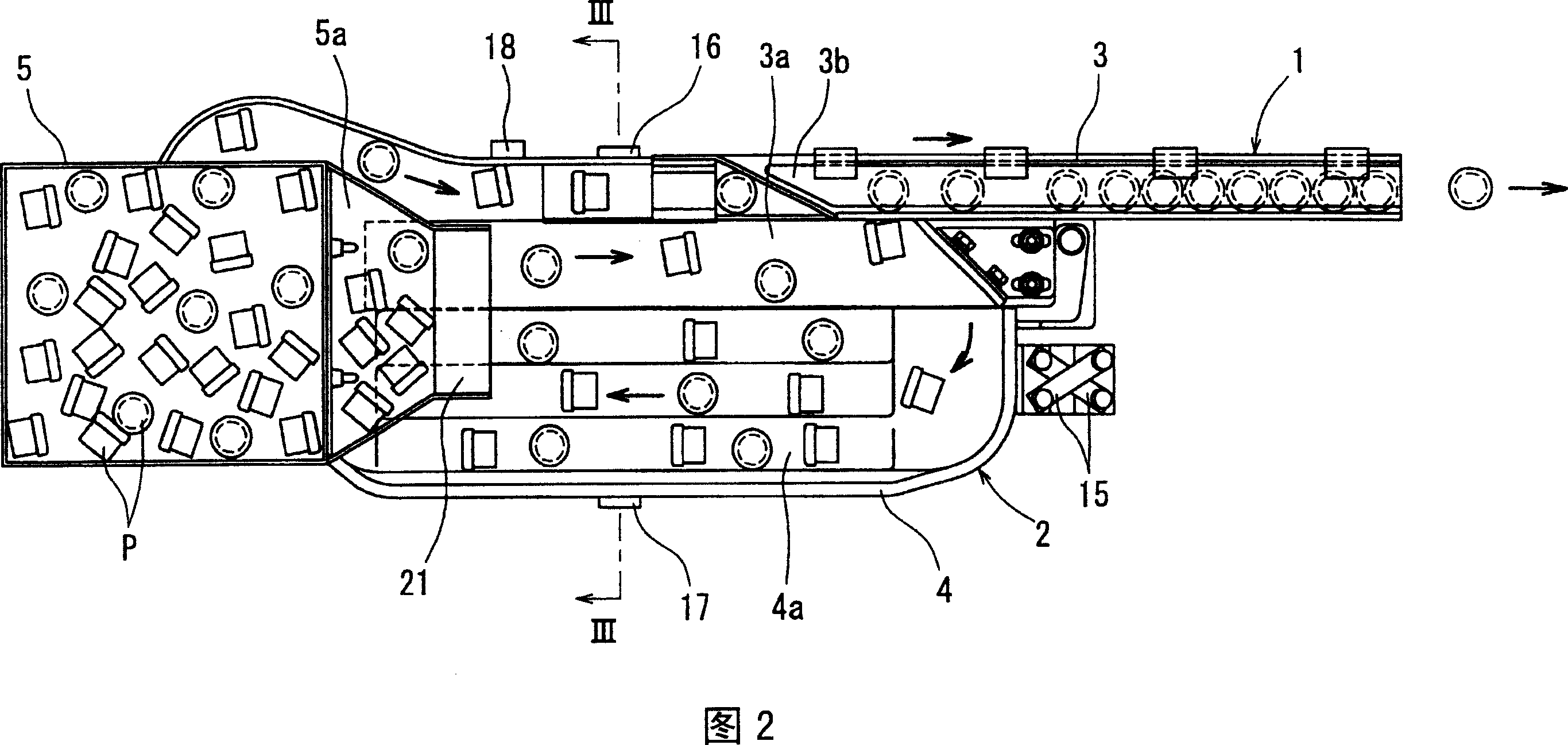

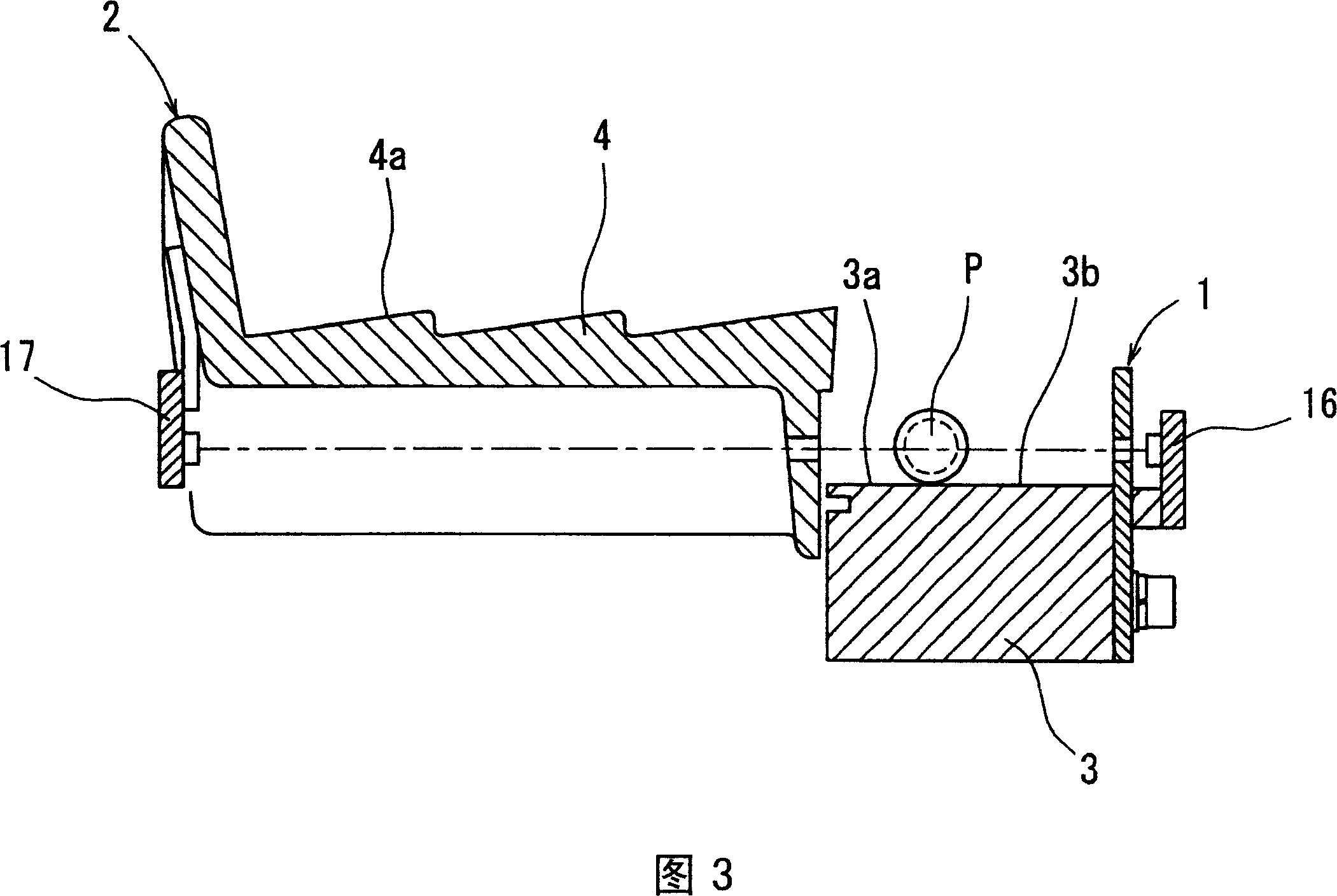

Vibrating parts feeder

InactiveCN1955091ASmooth delivery/arrangementEasy inputControl devices for conveyorsJigging conveyorsEngineeringMechanical engineering

Owner:NTN CORP

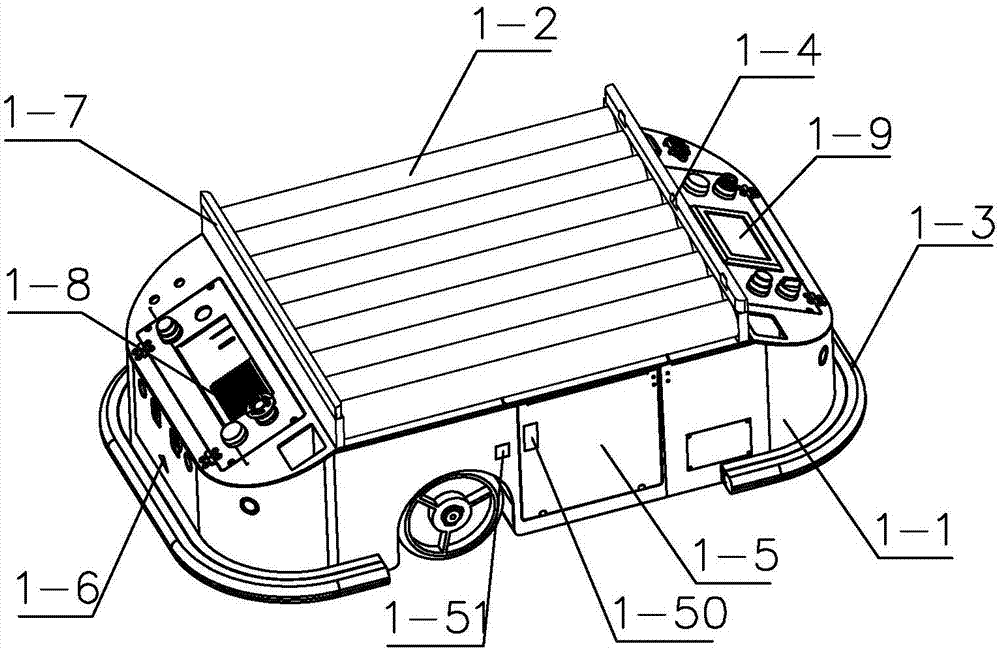

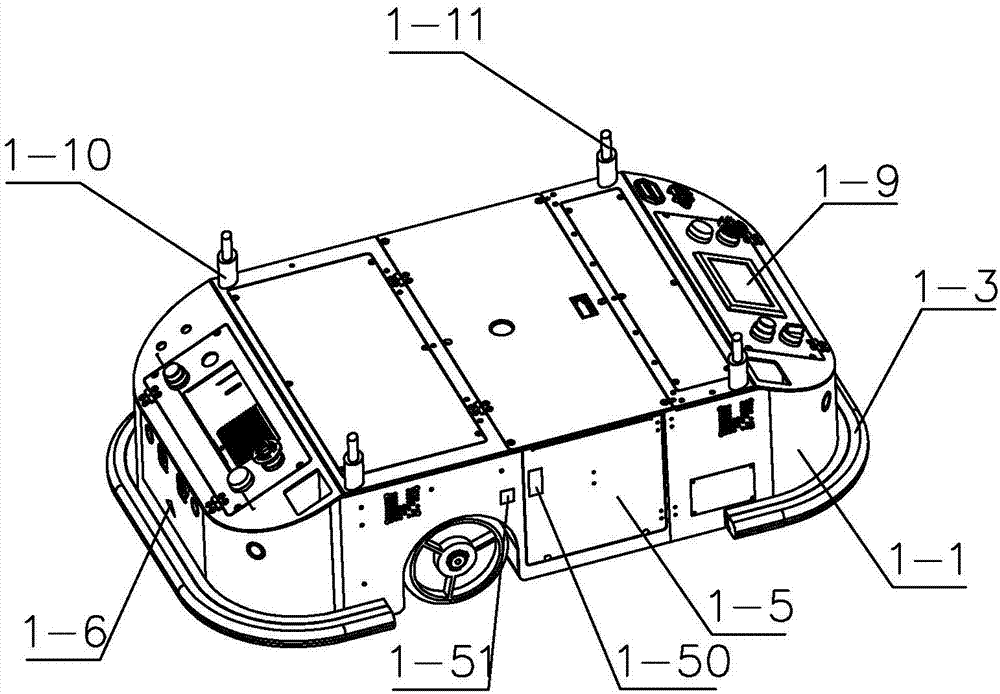

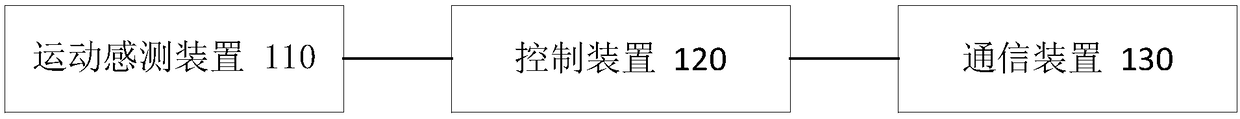

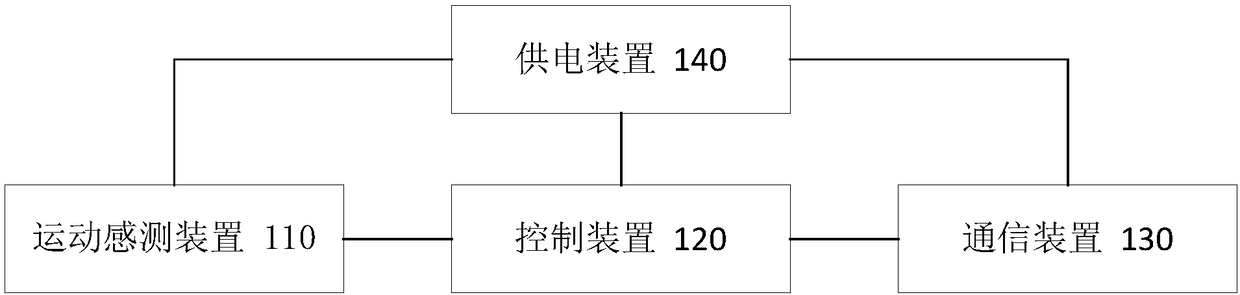

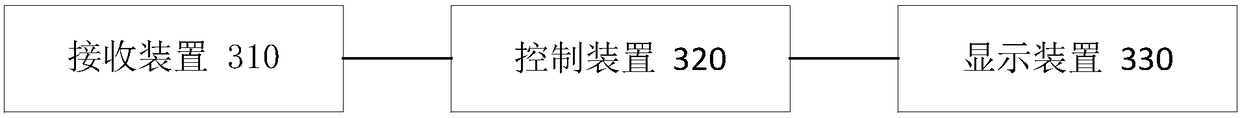

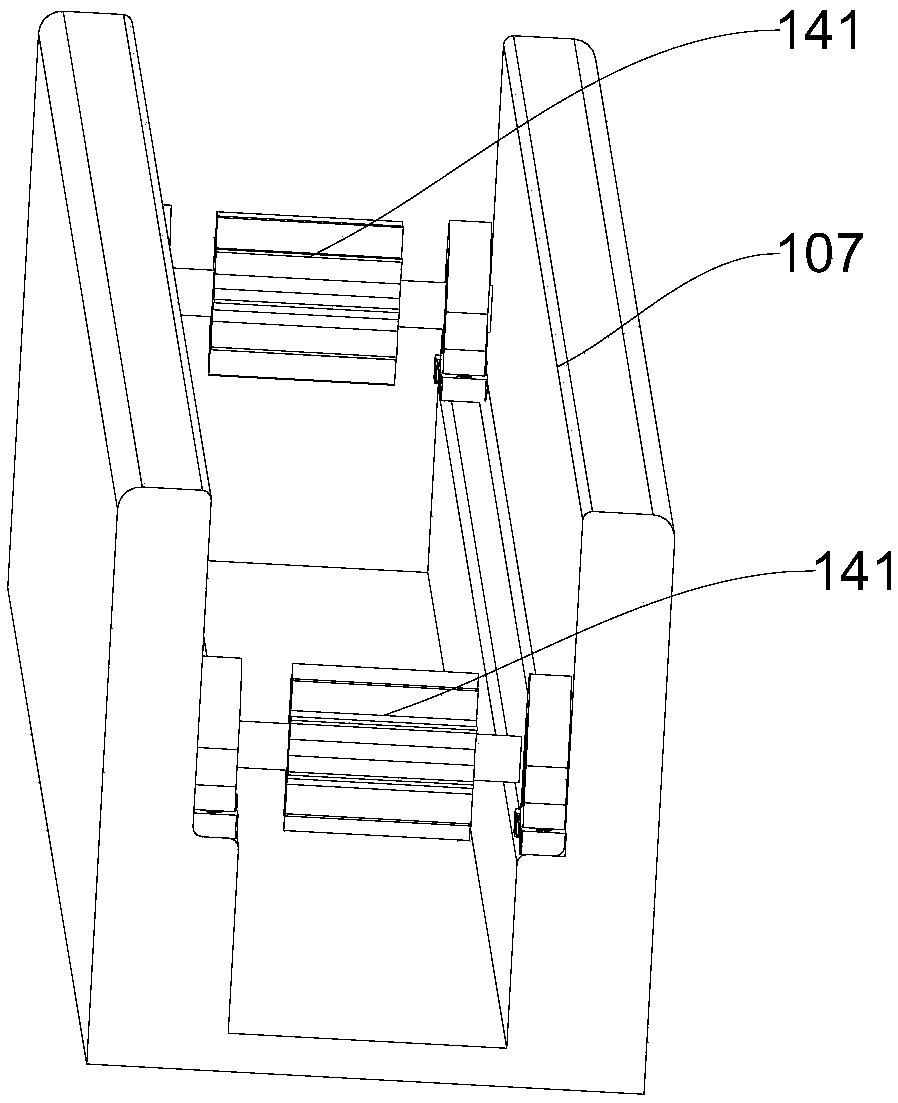

Intelligent storage transfer vehicle

InactiveCN107323982AControl devices for conveyorsStorage devicesIntelligent transportAutomotive engineering

Owner:平湖拓伟思自动化设备有限公司

Turnover device

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

Apparatus for the Distribution of a Random Stream of Cylindrical Items, for Example Drinks Bottles, into Several Lanes

Owner:HEUFT SYSTTECHN GMBH

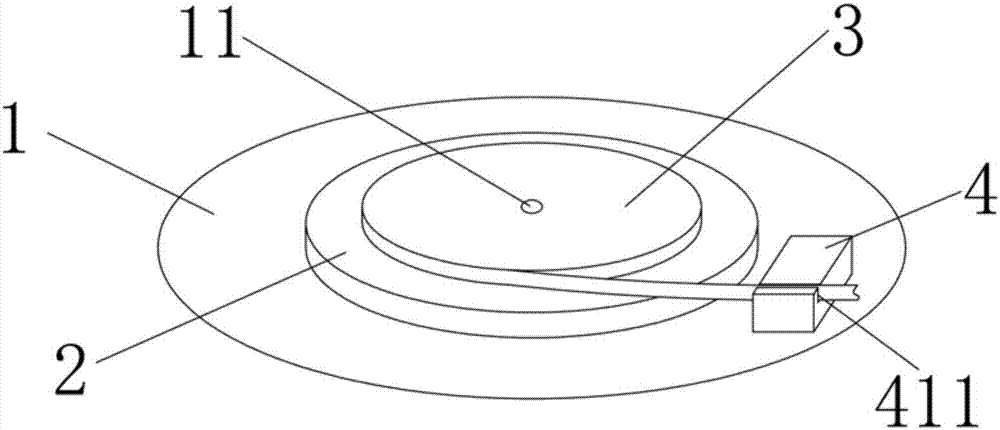

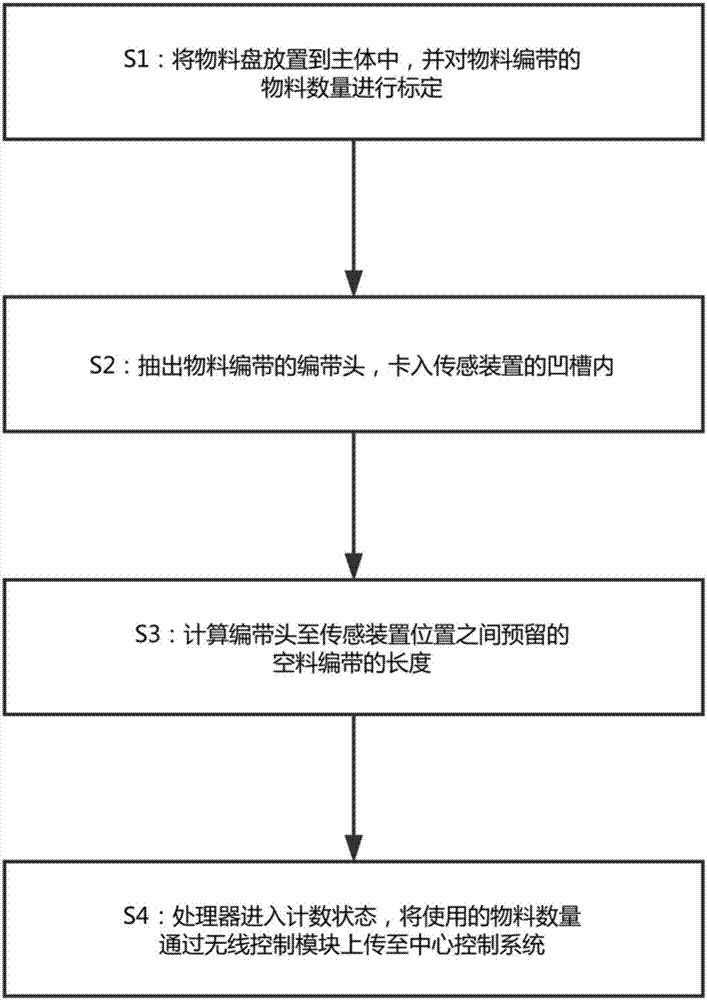

Equipment and method for acquiring feeding and using quantity of chip mounter

Owner:台州市吉吉知识产权运营有限公司

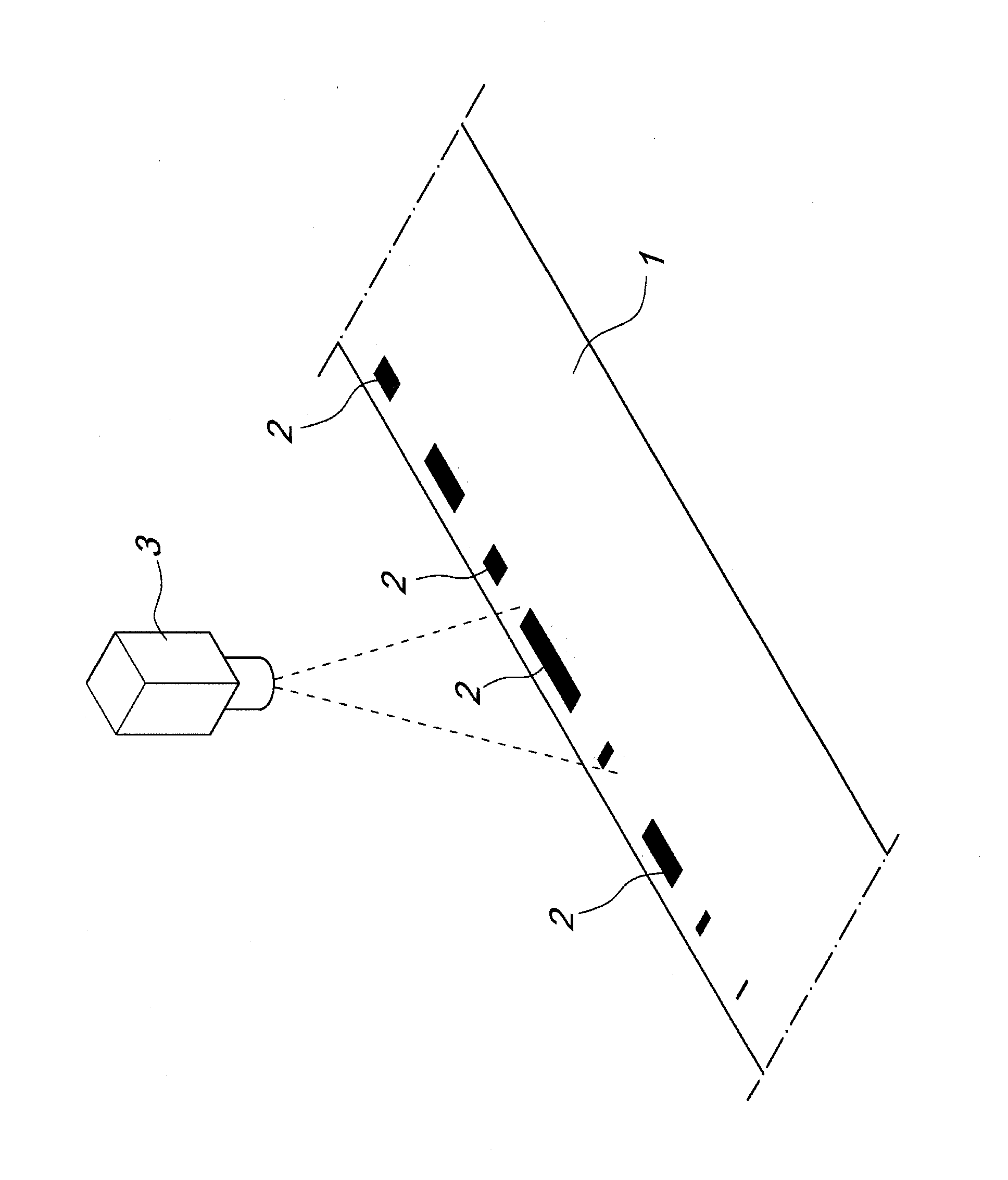

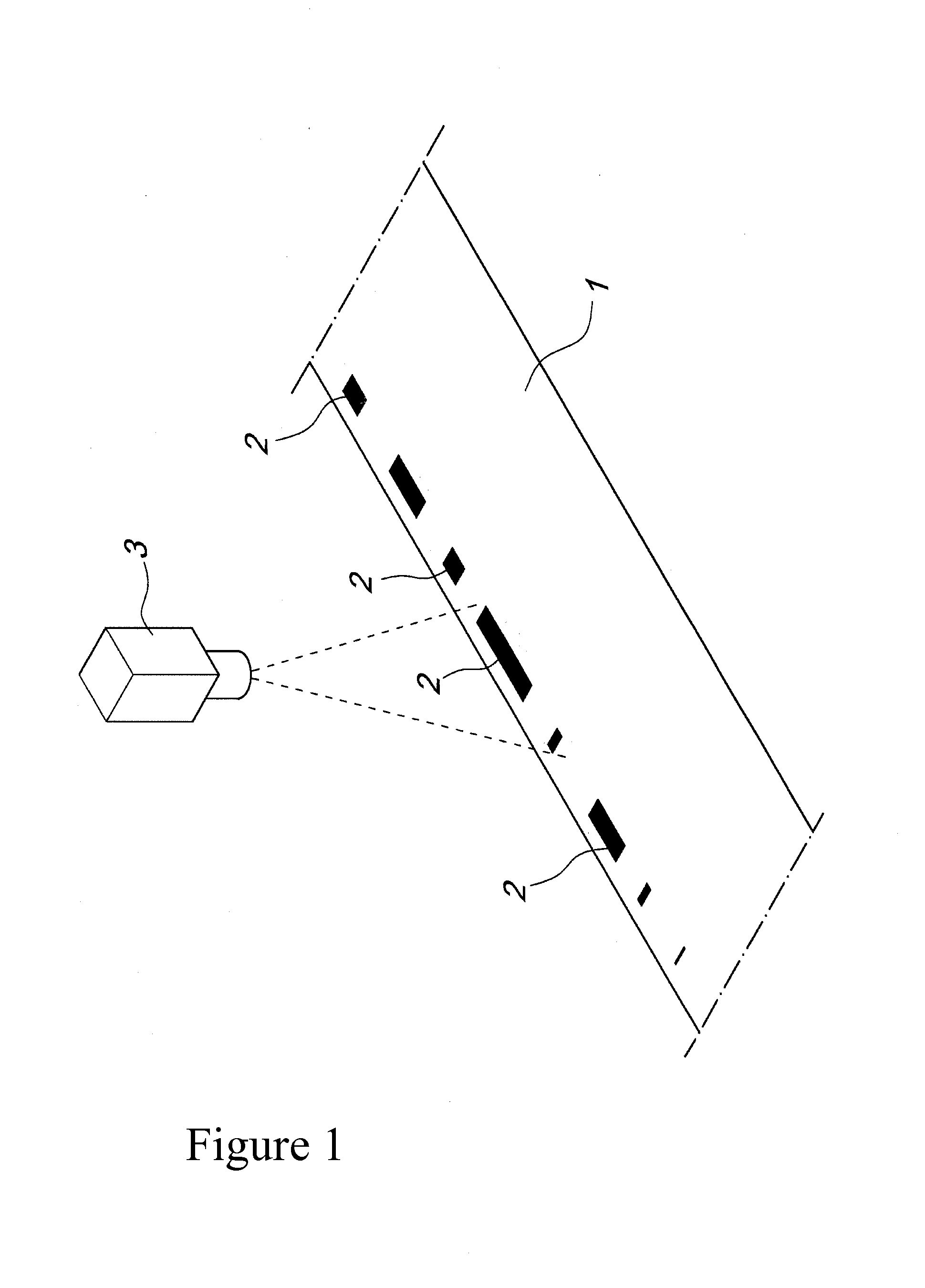

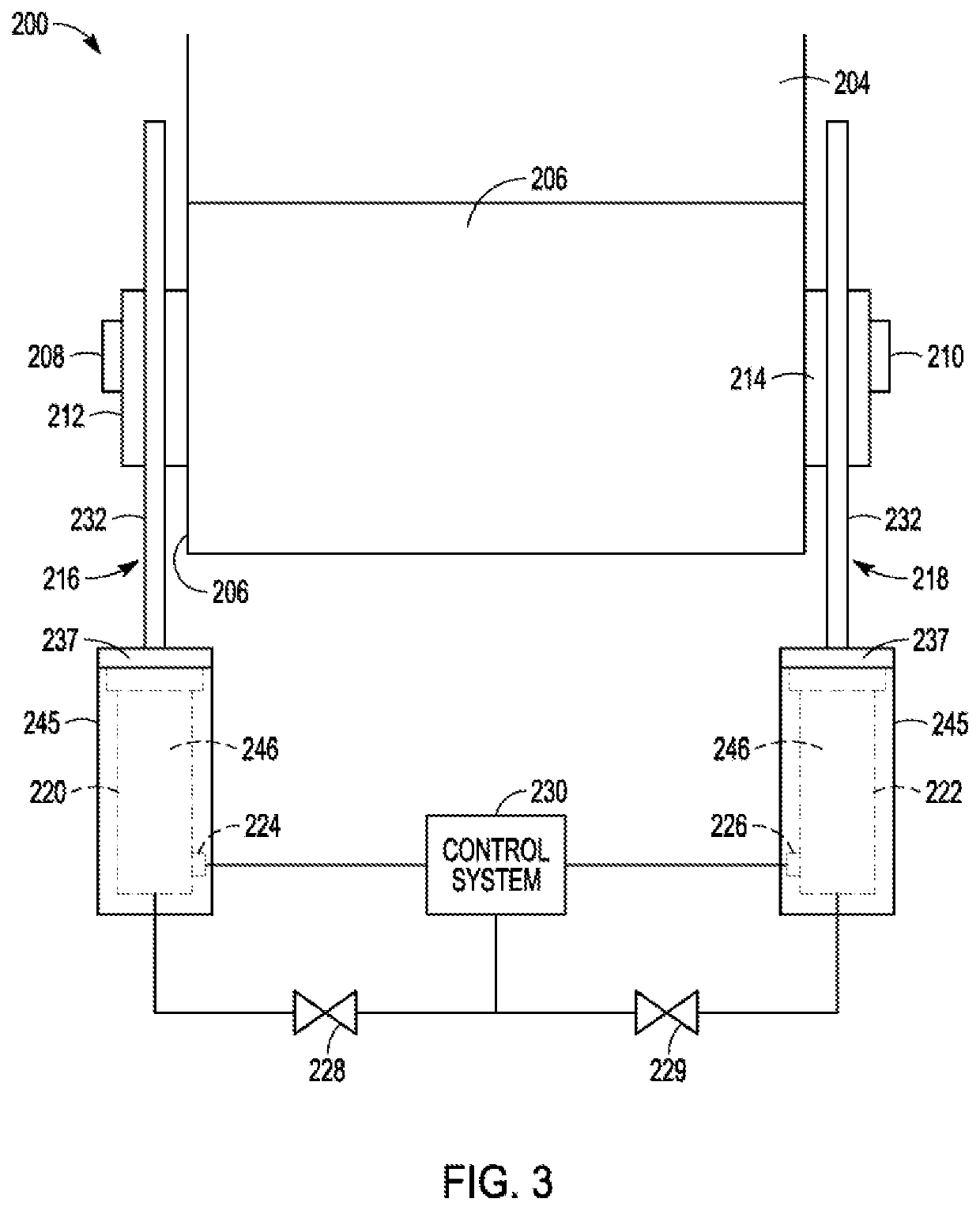

Method and device for detecting the position of a conveyor

ActiveUS20140022562A1Keep full controlConveyorsControl devices for conveyorsEngineeringConveyor belt

Owner:COMELZ SPA

Automatic overturning equipment

InactiveCN105645089AReduce labor intensitySafe delivery of process deliveryControl devices for conveyorsRotary conveyorsHydraulic cylinderVertical plane

Owner:TIANJIN CLP HUALI ELECTRICAL SCI & TECH GROUP

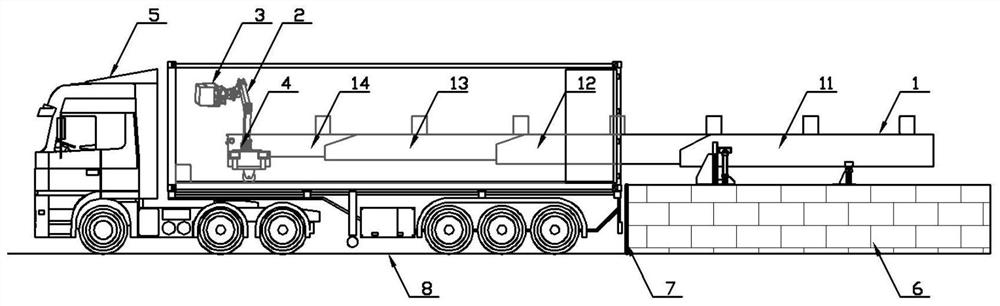

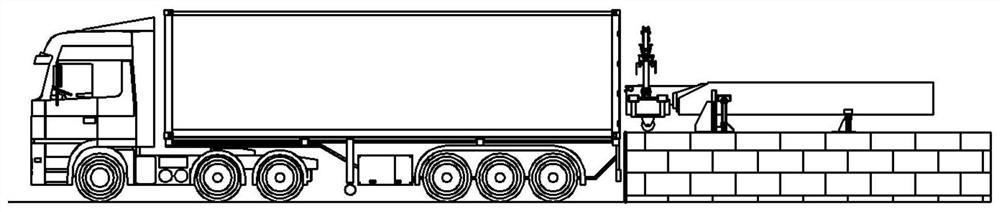

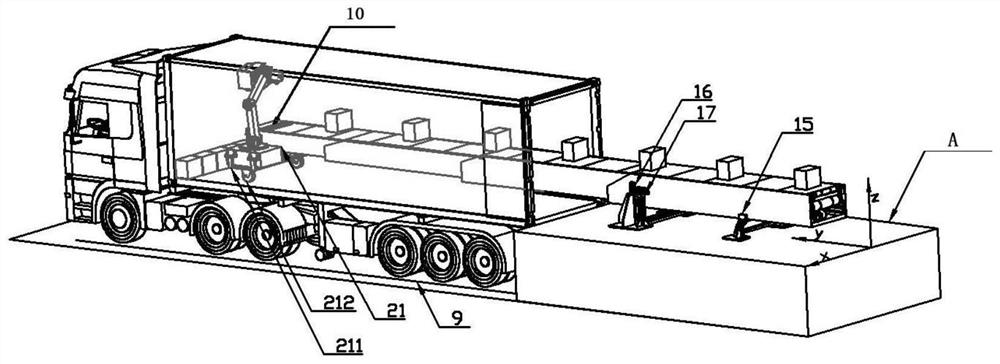

Device for van to automatically load and unload cargoes packaged in cartons

Owner:WUHAN YANCHENG TECH CO LTD

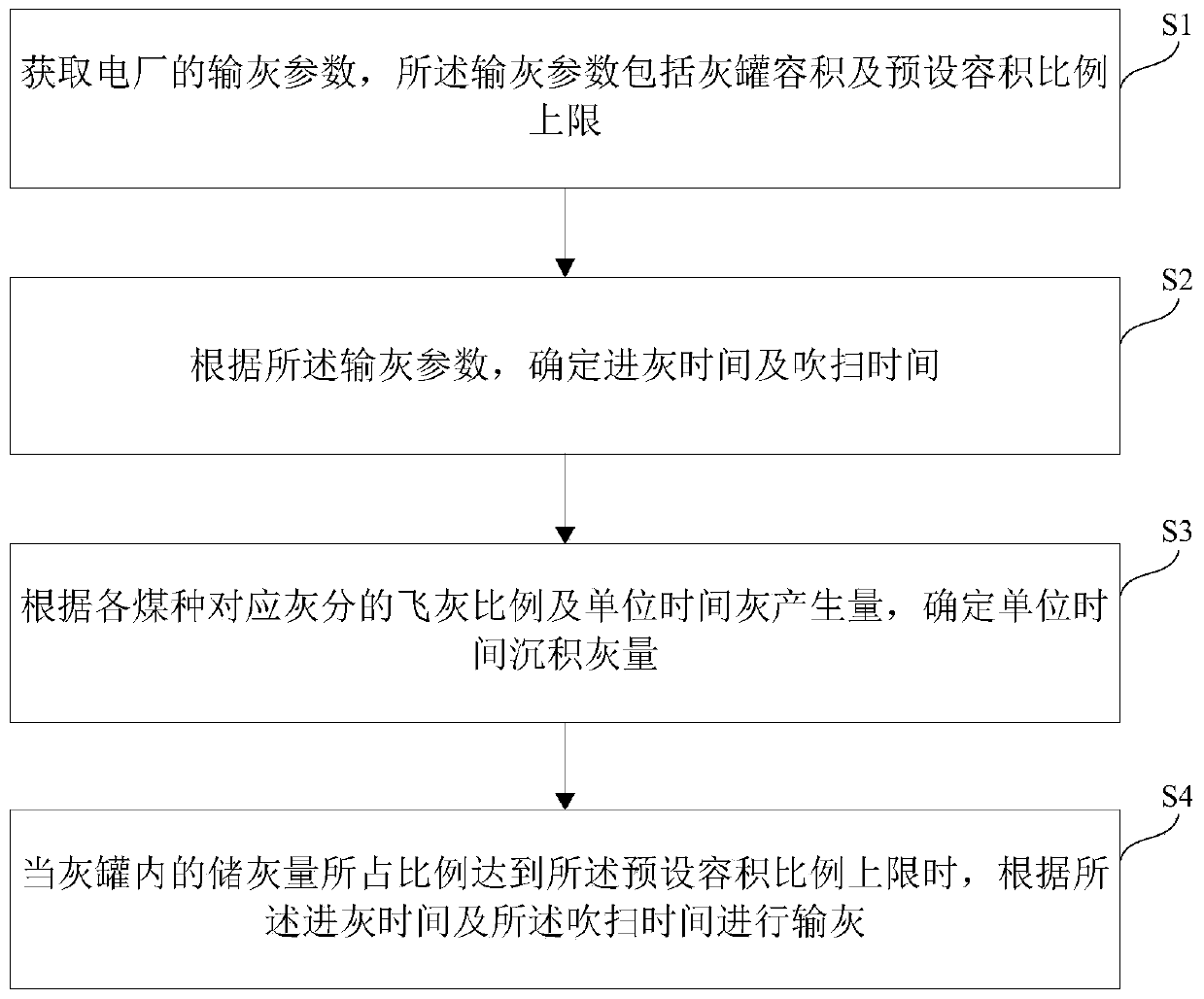

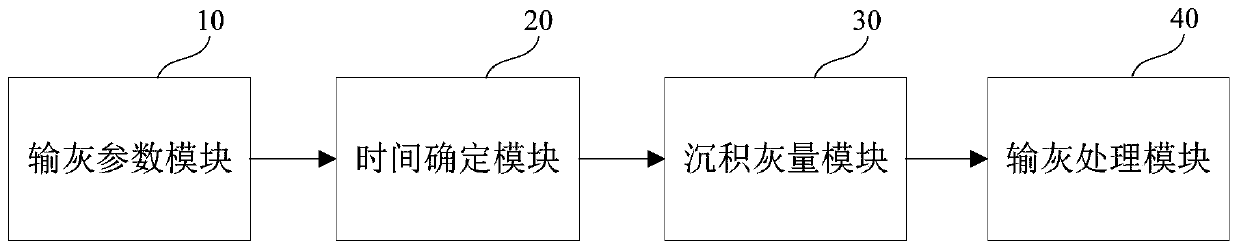

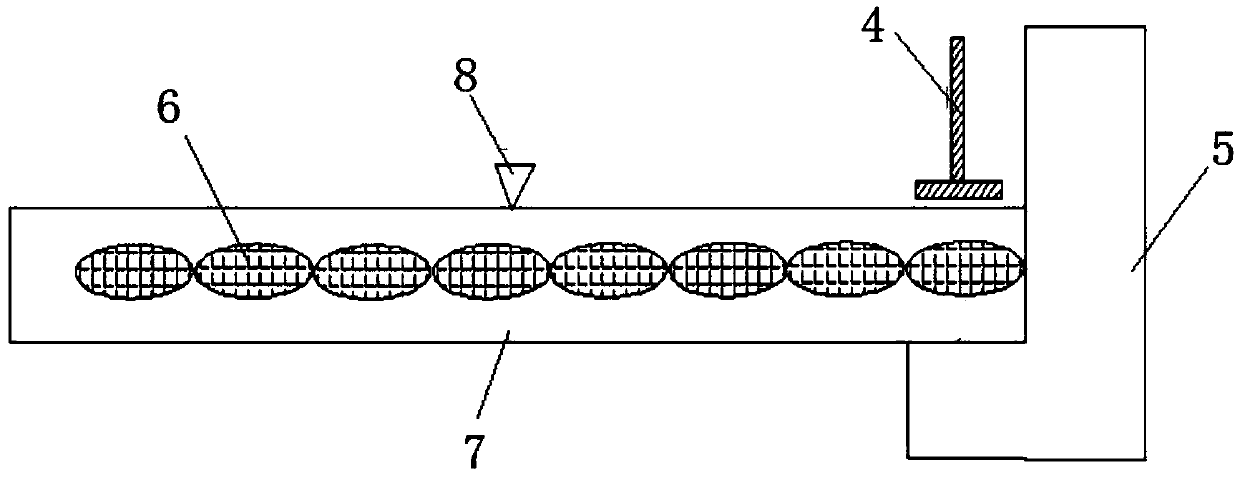

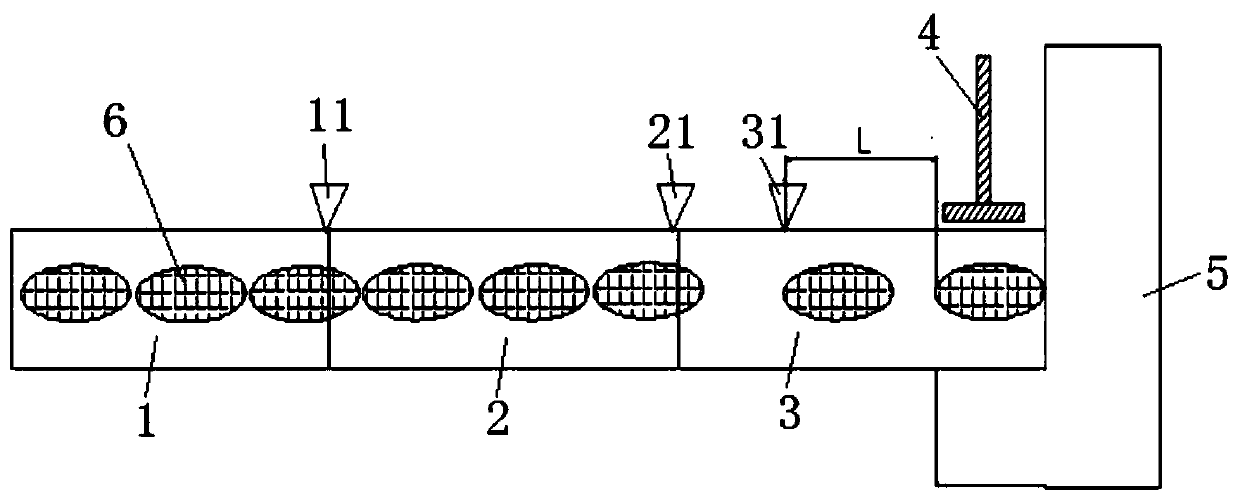

Intelligent ash conveying method and device for power plant

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

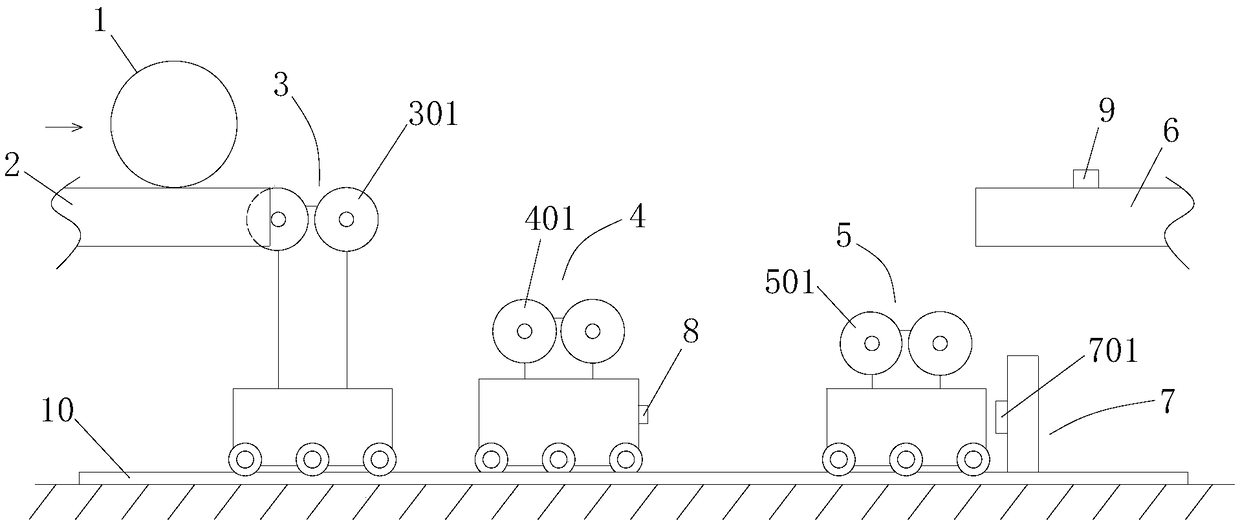

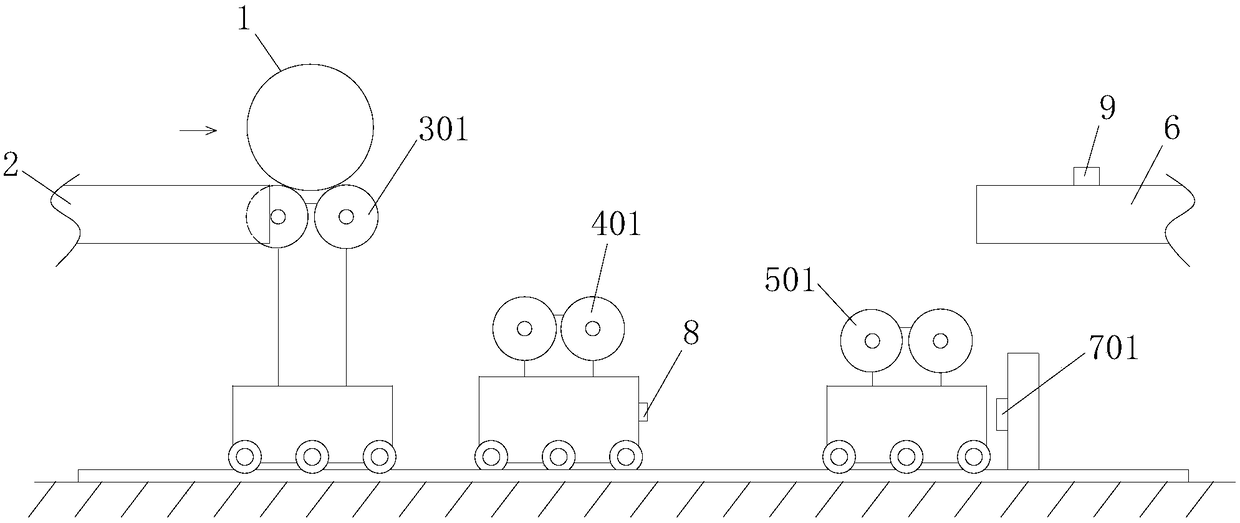

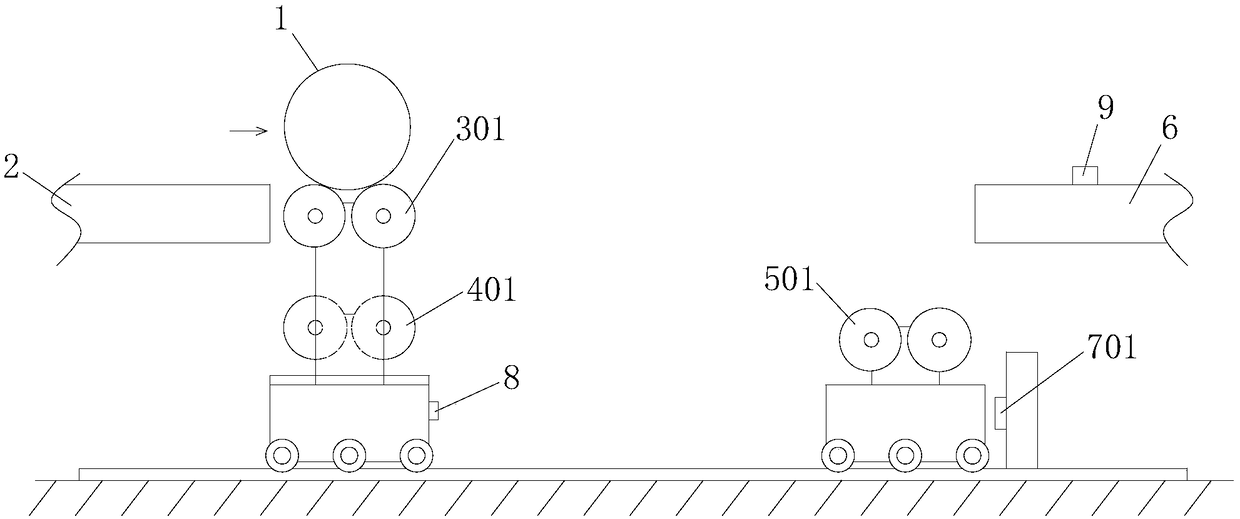

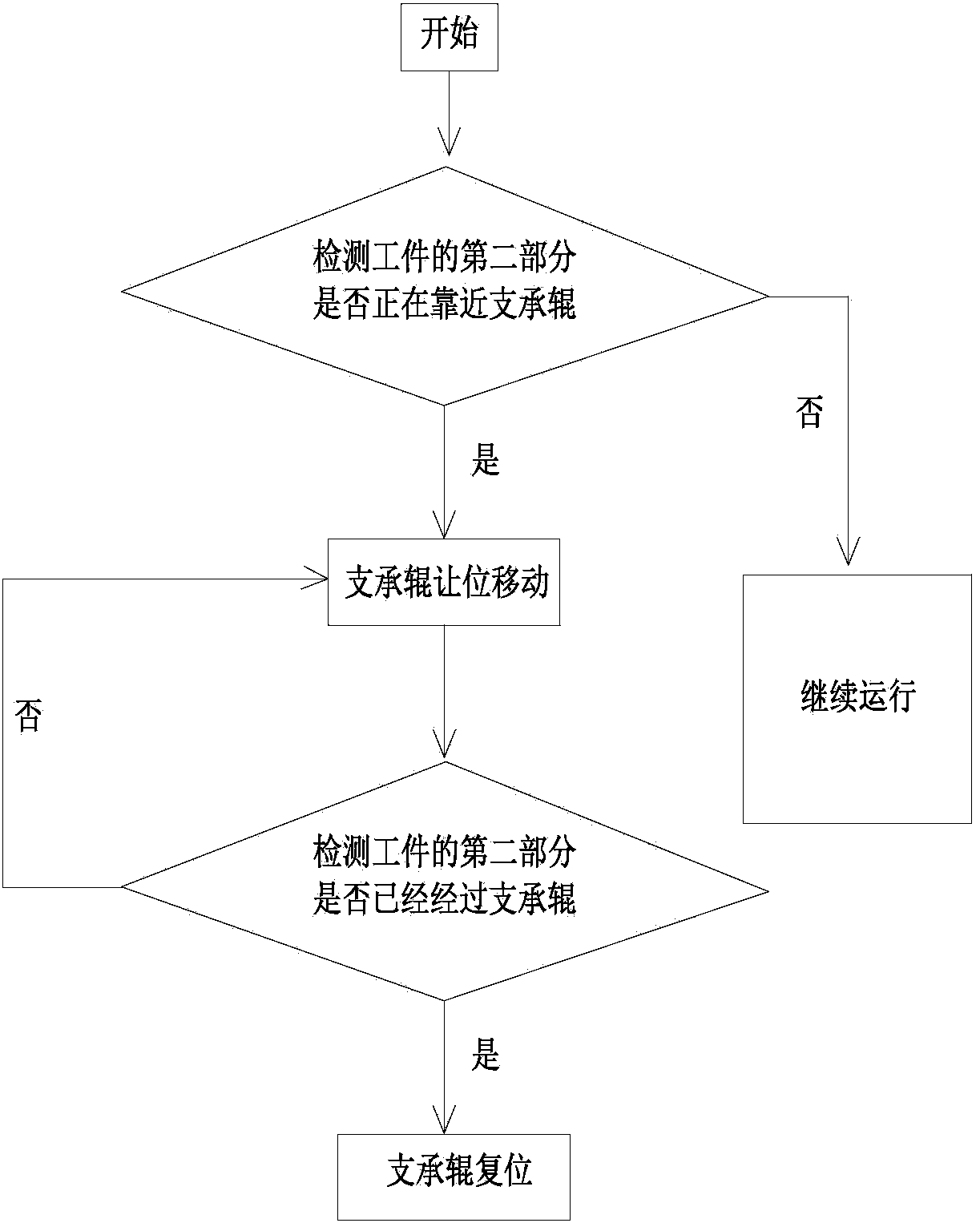

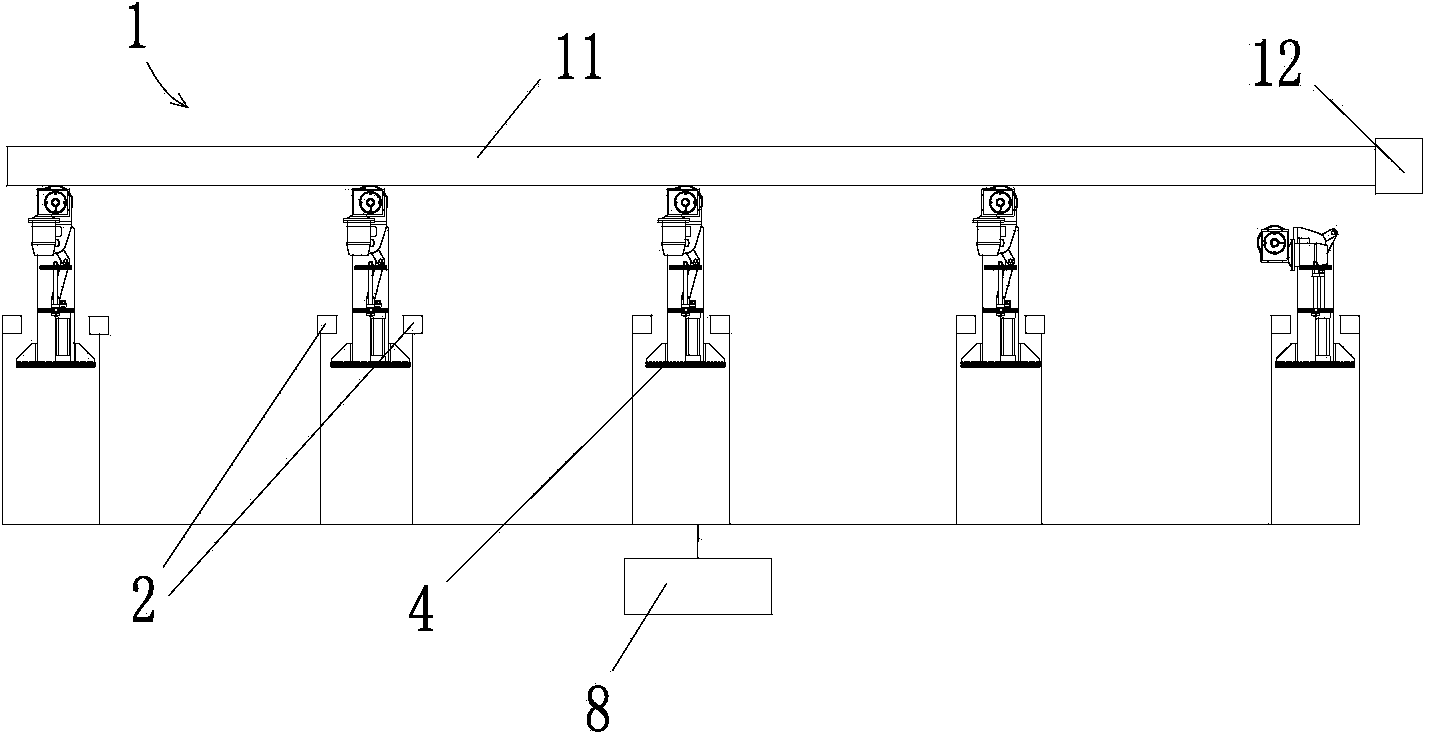

Workpiece conveying method and device

ActiveCN103662585AStable deliverySmall footprintControl devices for conveyorsRollersMechanical engineering

Owner:HUNAN TELI HYDRAULIC +1

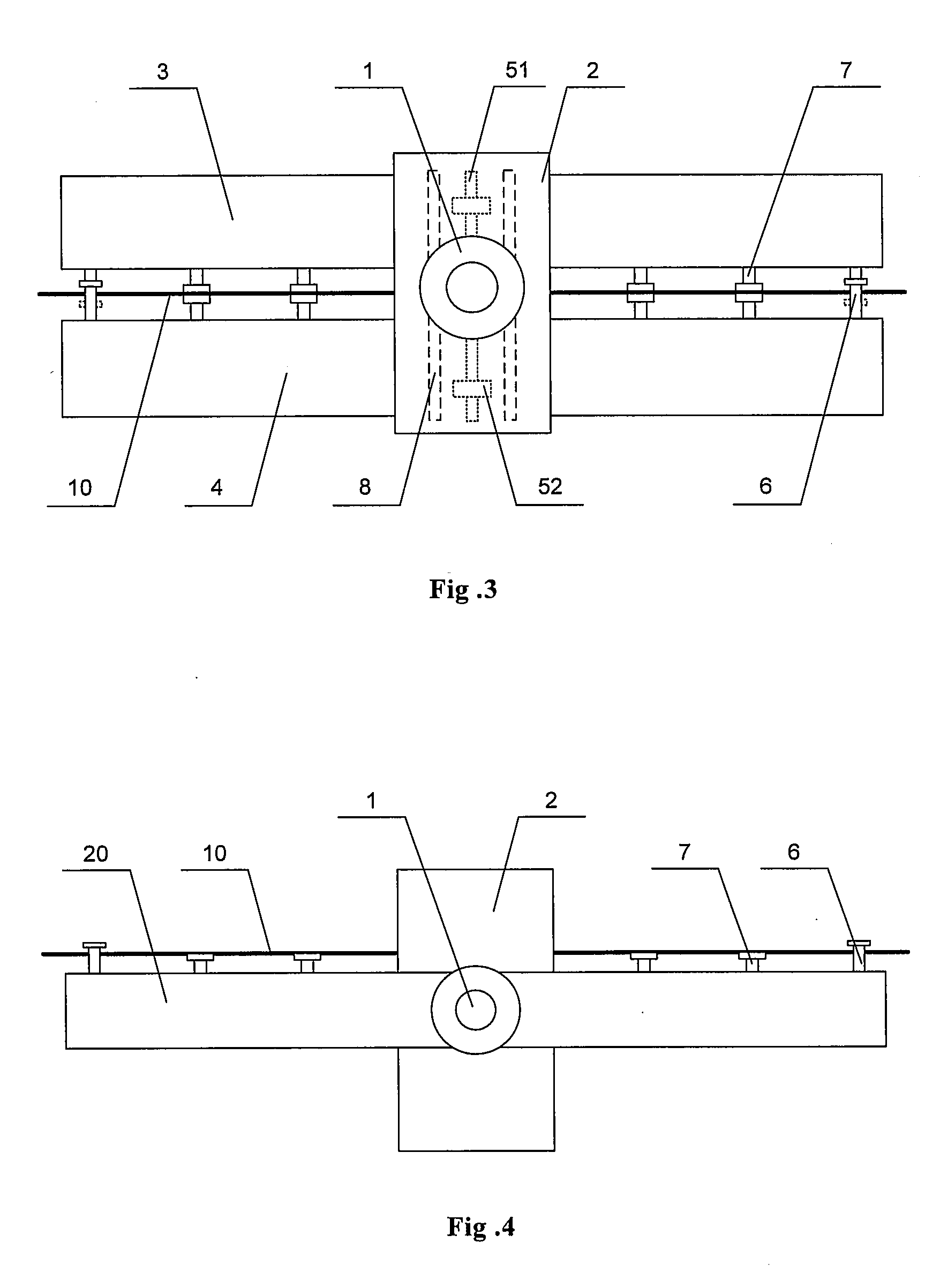

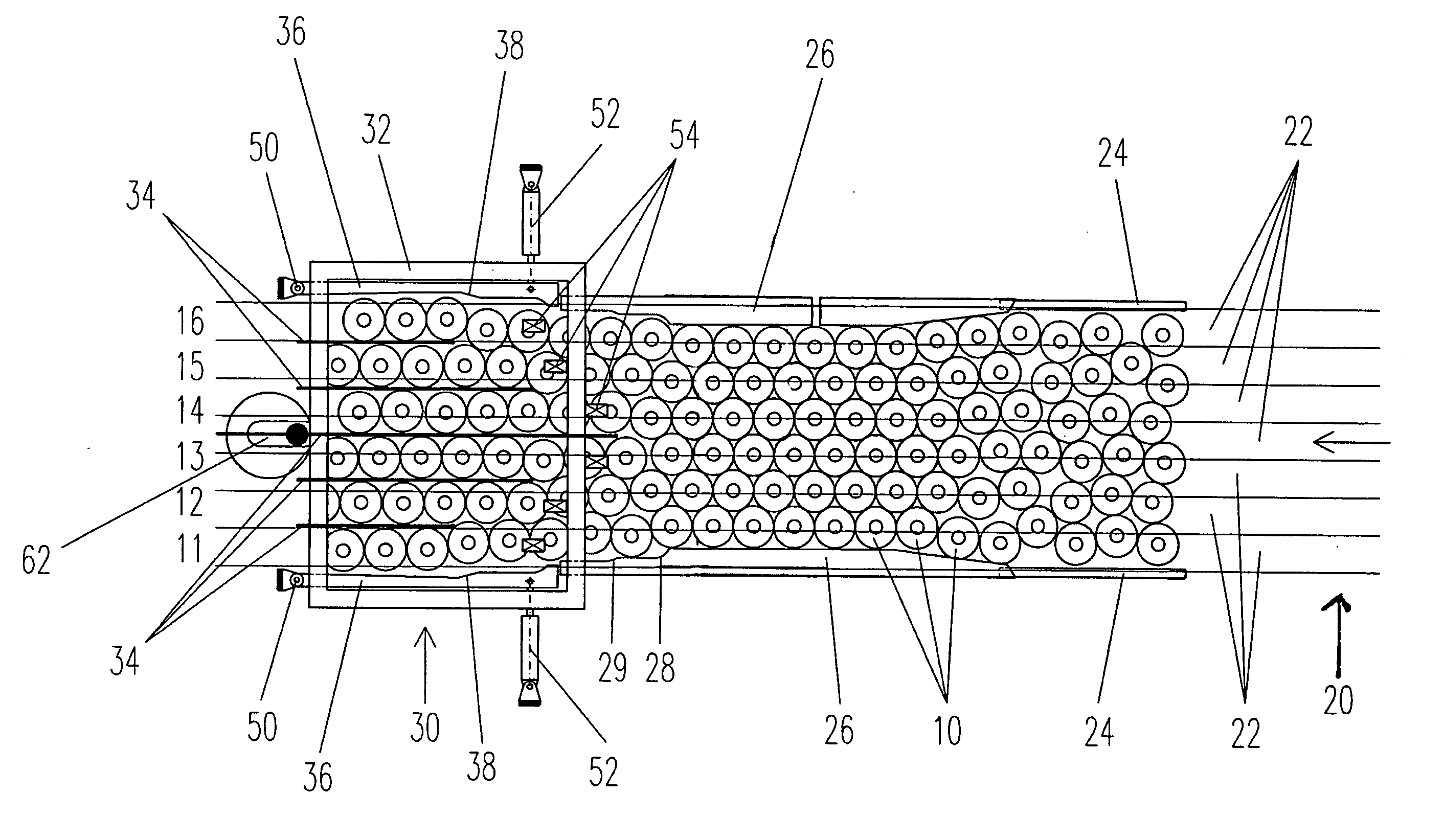

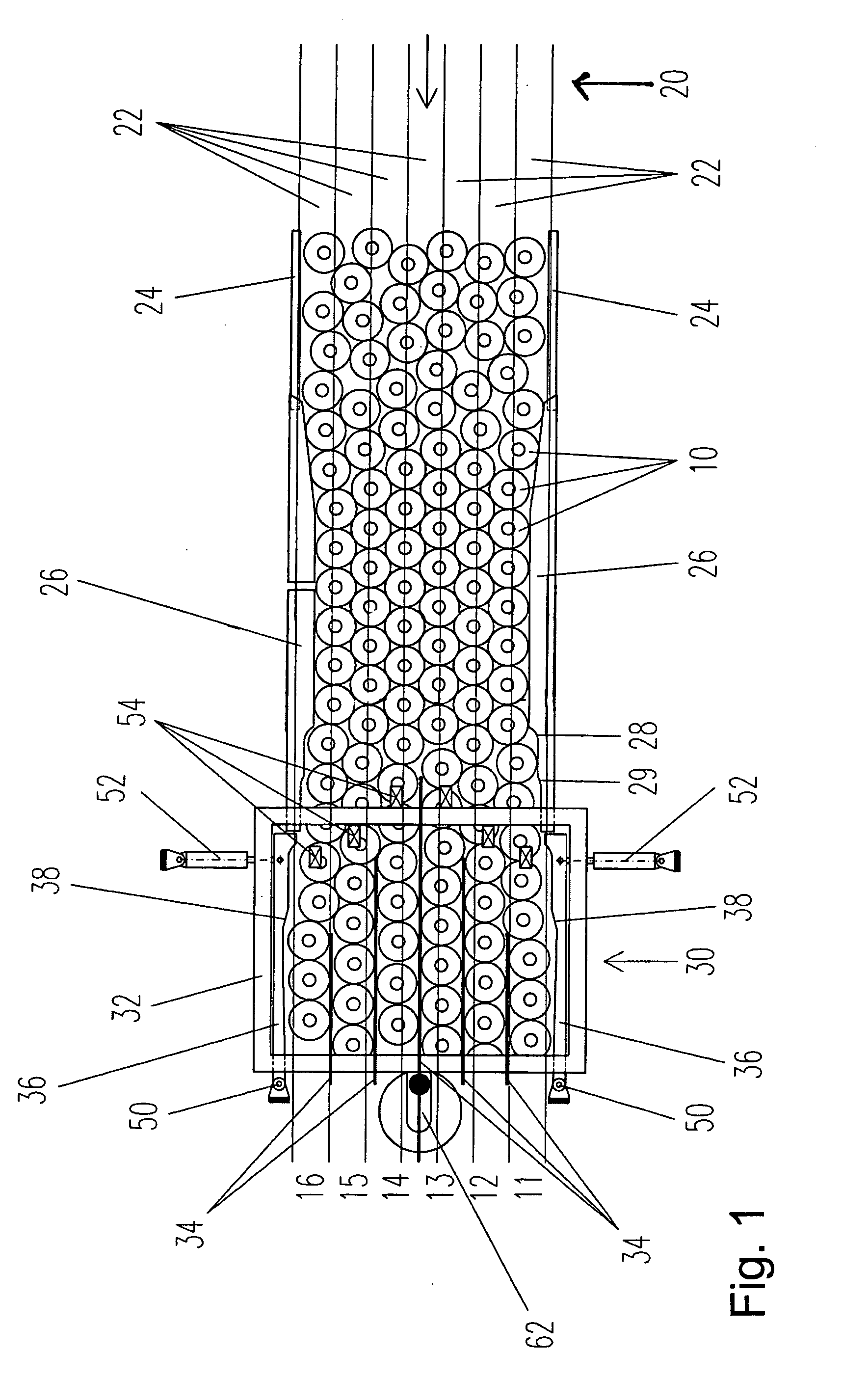

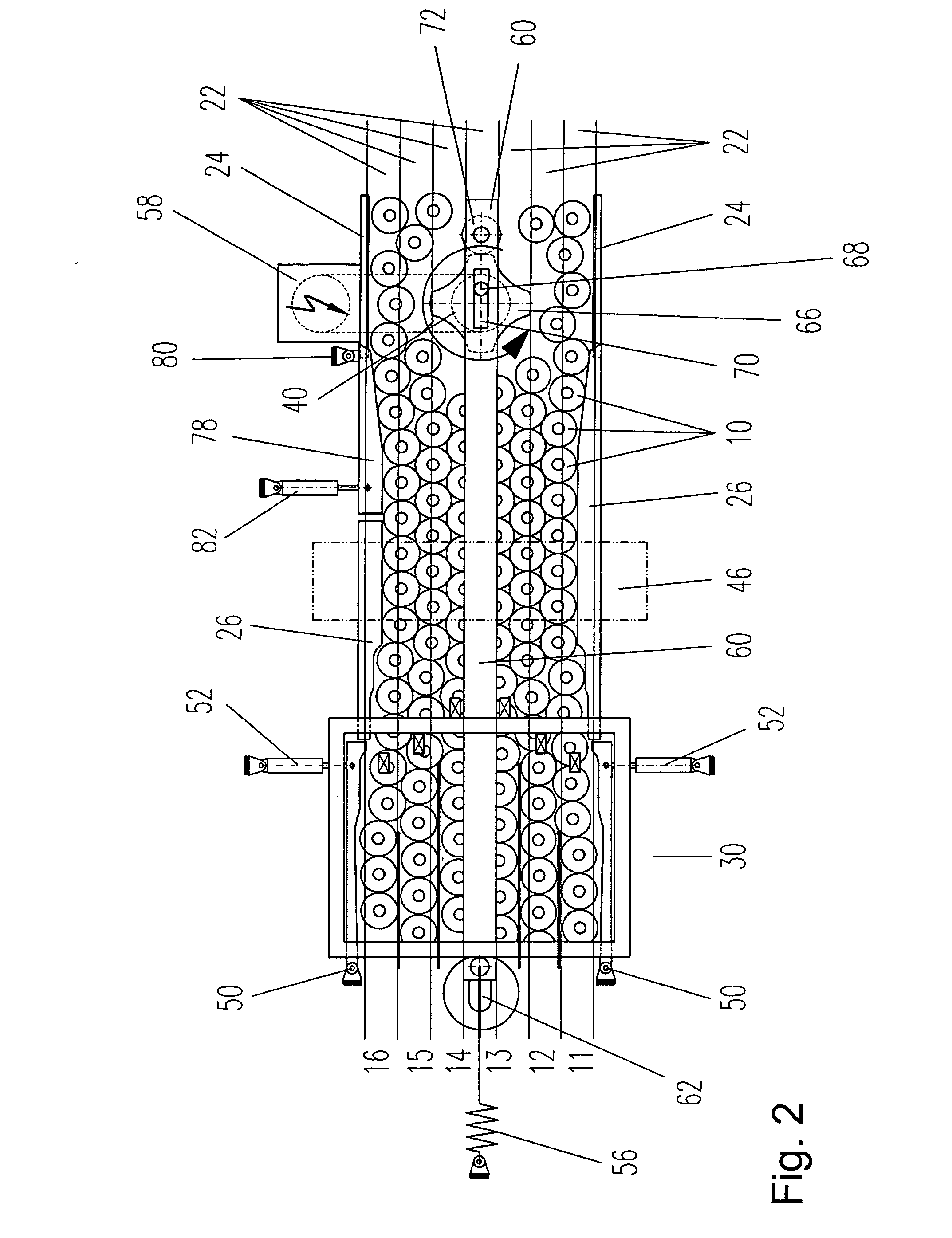

Process for controlling the conveying speed of a transporting track

InactiveUS6895303B1Optimized for speedRaise the ratioDigital data processing detailsCoin countersTrackwayProcess engineering

In the case of a method of controlling the transport speed of a transport and gathering unit, wherein filling-material stacks are moved from an inlet to an outlet of the gathering path making use of at least one transport means and wherein filling-material units can selectively be added to the filling-material stacks at one or at several adding stations, at least one measure is determined for each filling-material stack at the inlet of the gathering path, each measure for each filling-material stack is increased at each adding station by a respective value corresponding to the filling-material unit added, if the filling-material stack has added thereto a filling-material unit, each measure of each filling-material stack is compared with a respective set value associated with the transport means, and the transport speed is controlled in dependence upon the result of the comparison.

Owner:BOWE SYSTEC AG

Belt conveyor with variable discharge port

ActiveCN112830281AQuick storageEnsure safetyConveyorsControl devices for conveyorsAir velocityAir volume

The invention relates to the field of belt conveyors, and discloses a belt conveyor with a variable discharge port, which is characterized in that a controller is started, a humidity detector detects the humidity of grains, a detection signal is transmitted into the controller through a data line after detection, the detected humidity is compared with a numerical value set by the controller, an air supply motor and a heating frame are started according to the humidity comparison result, so that the air supply motor enables a fan to rotate to different speeds according to the control of the controller, meanwhile, a heating wire is controlled to heat to different temperatures, the fan rotates to generate a certain amount of air, and the air is blown into the heating frame, heated through the heating wire and then blown into an anti-skid groove, so that the grains can be dried, and meanwhile, the air speed and the heating temperature are controlled through the controller according to the humidity comparison value, and therefore the purpose of saving energy is achieved.

Owner:COFCO ENG EQUIP WUXI CO LTD

Stable type electric conveying device for construction

Owner:JINLING INST OF TECH

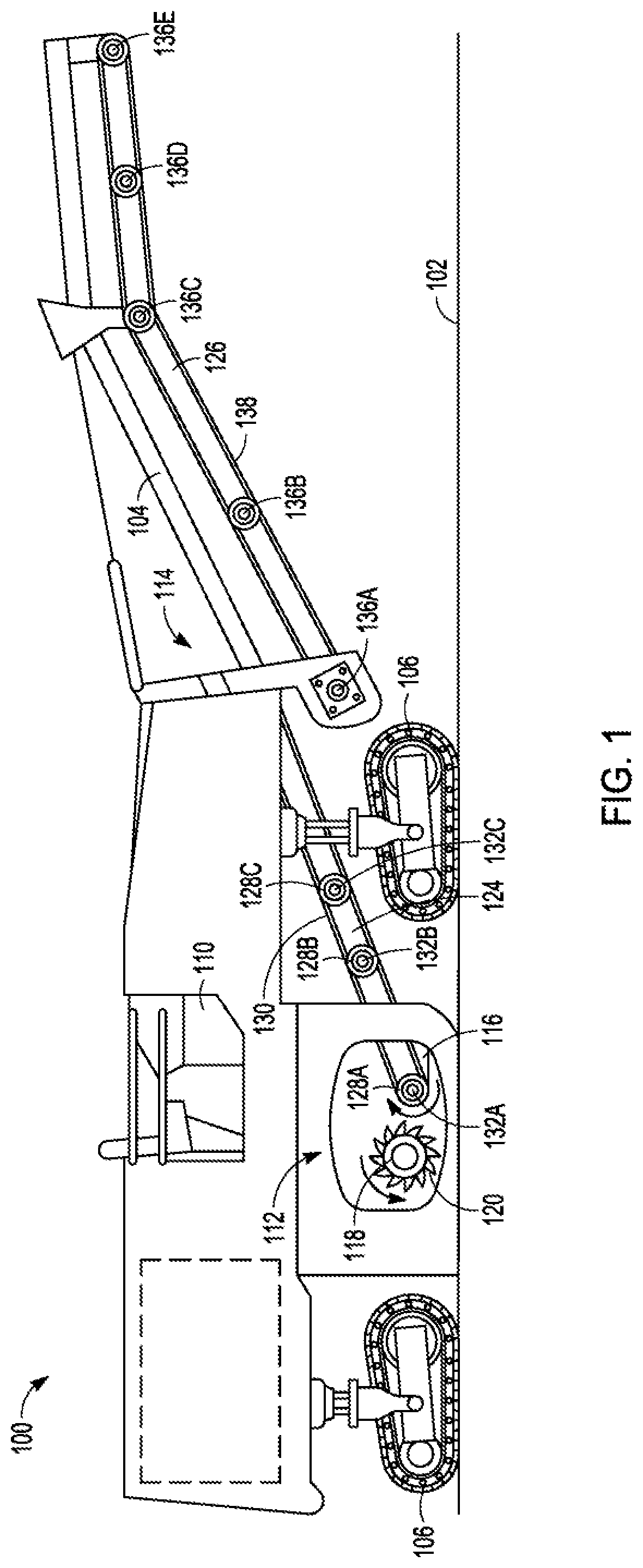

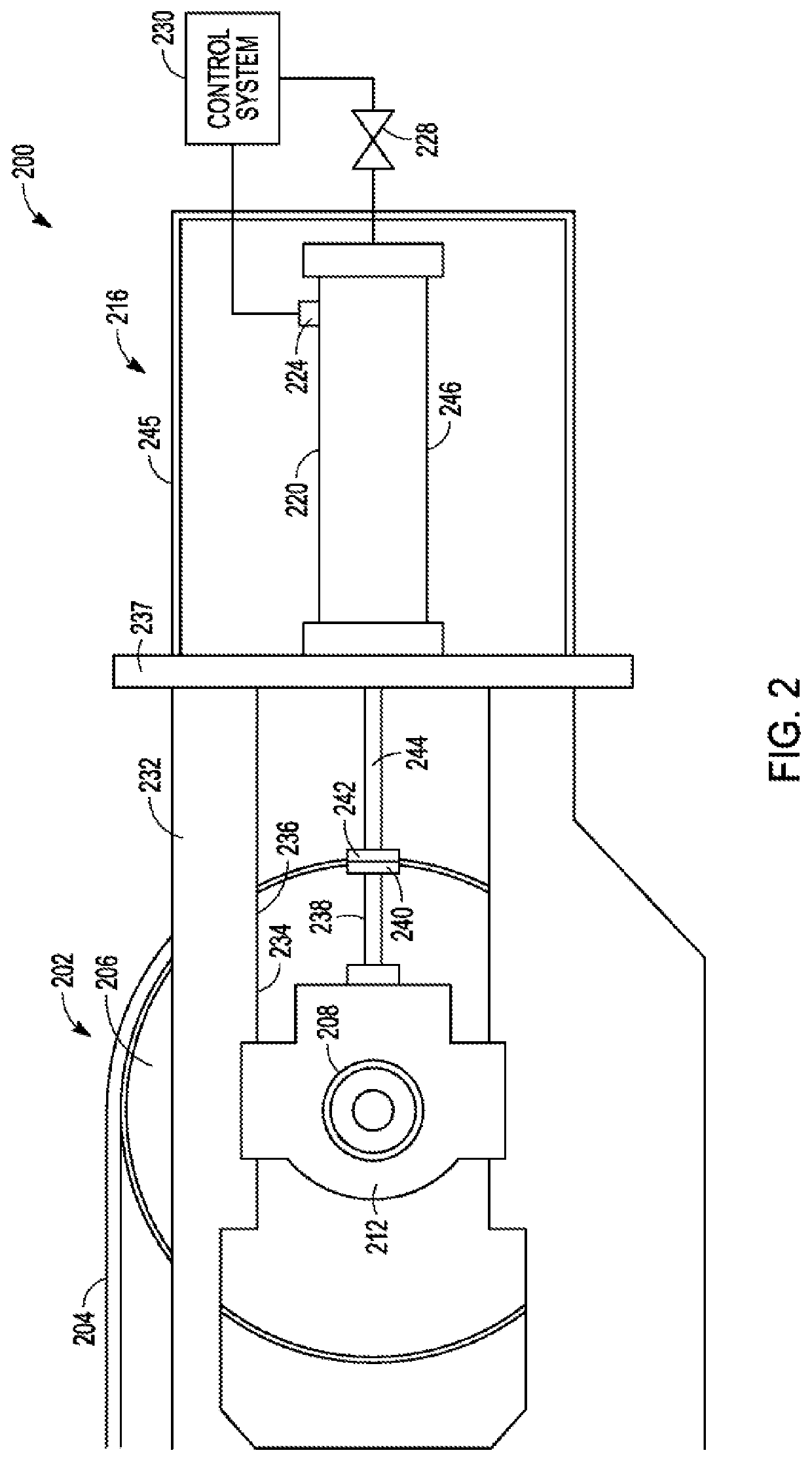

Cold planer with self-adjusting conveyor system

ActiveUS20190367286A1Operating tensionConveyorsControl devices for conveyorsTransmission beltEngineering

Owner:CATERPILLAR PAVING PROD INC

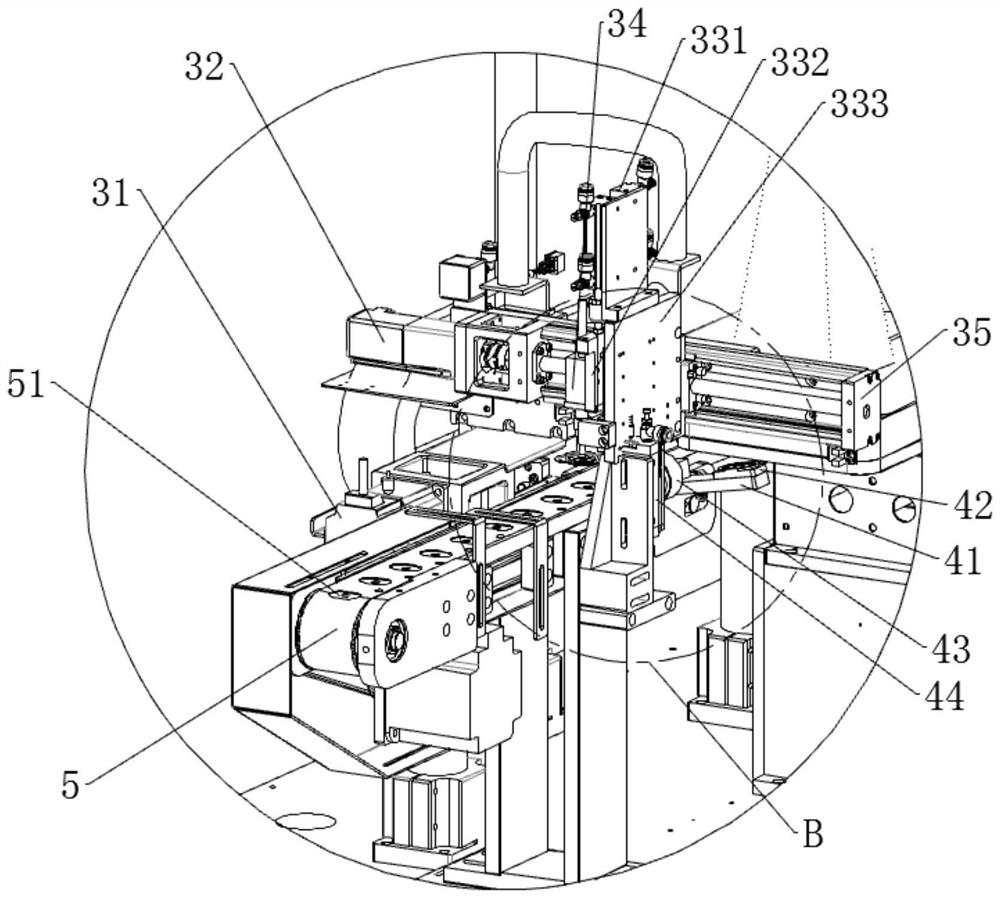

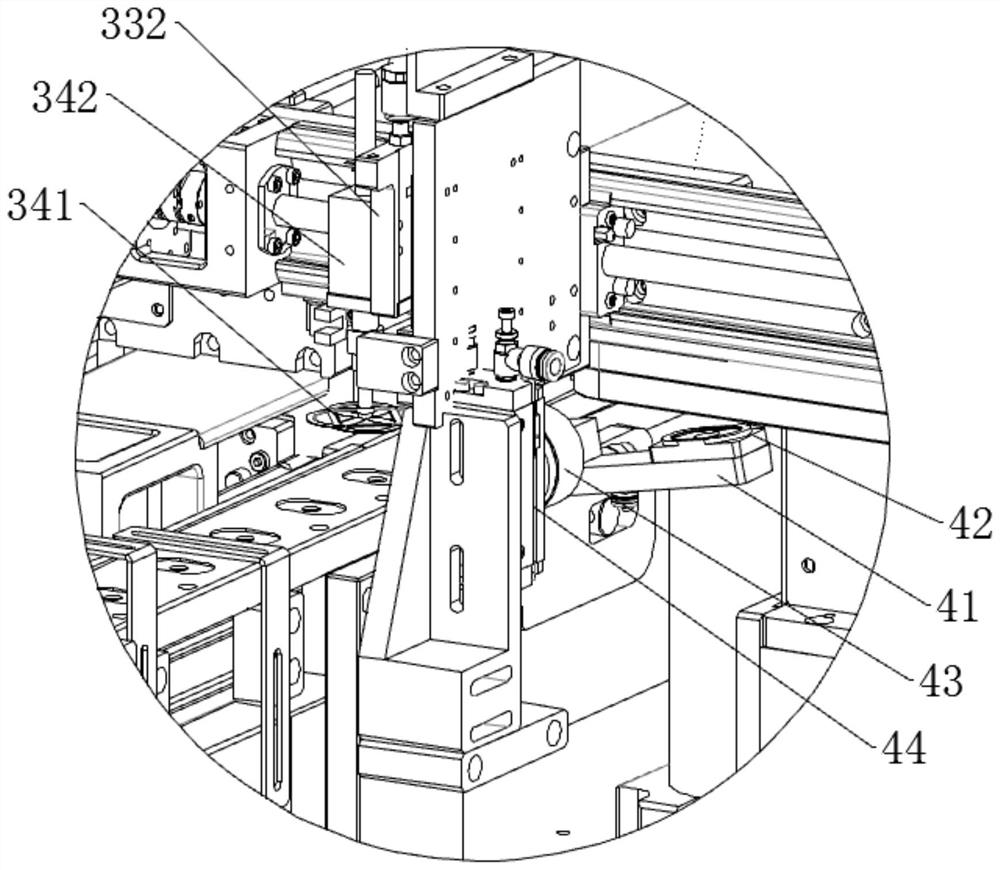

Automatic pasting machine

ActiveCN113928856ACompact structureSimple structureConveyorsArticle unpackingEngineeringMechanical engineering

The invention discloses an automatic pasting machine. The machine comprises a feeding device, a conveying device, a loading device, a bottom paper tearing device, a pasting device, a pasting table, a film tearing table, a top film tearing device and a discharging device which are electrically connected with a controller, and the feeding device and the discharging device are used for loading and unloading workpieces before and after pasting; and the pasting table and the film tearing table are used for bearing workpieces to be subjected to pasting and workpieces to be subjected to film tearing, and the conveying device is used for synchronously transferring the workpieces to be subjected to pasting on the feeding device, the workpieces to be subjected to film tearing on the pasting table and the workpieces after film tearing on the film tearing table to the corresponding pasting table, the film tearing table and the discharging device. The loading device is used for separating and loading stacked adhesive tapes one by one, the pasting device moves back and forth among the loading device, the bottom paper tearing device and the pasting table, the first film tearing device is matched to tear bottom paper of the adhesive tapes, then the adhesive tapes are pasted on the workpieces, and the second film tearing device is used for tearing top films of the adhesive tapes pasted on the workpieces. The machine is simple in structure, high in laminating precision and efficient.

Owner:WORLD PRECISION MANUFACTURING (DONGGUAN) CO LTD

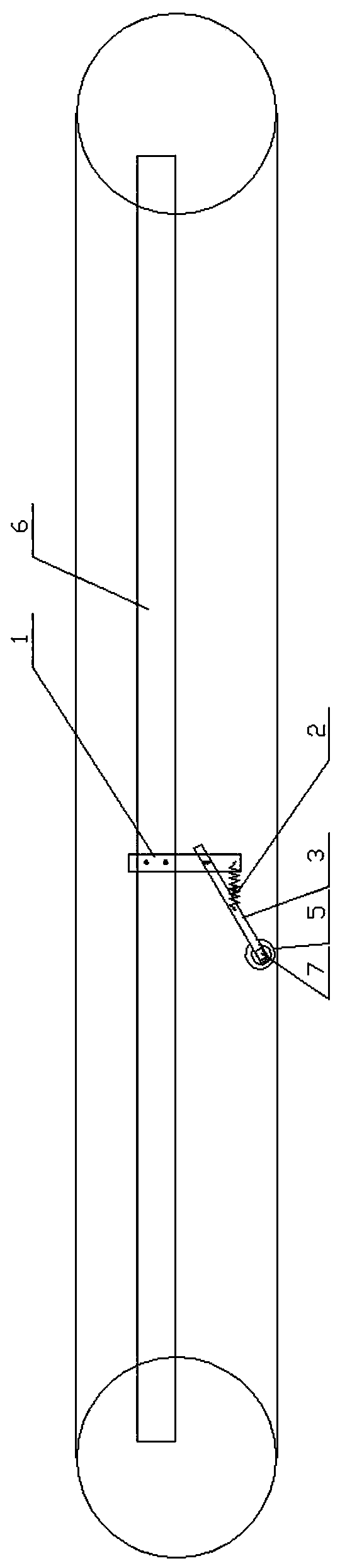

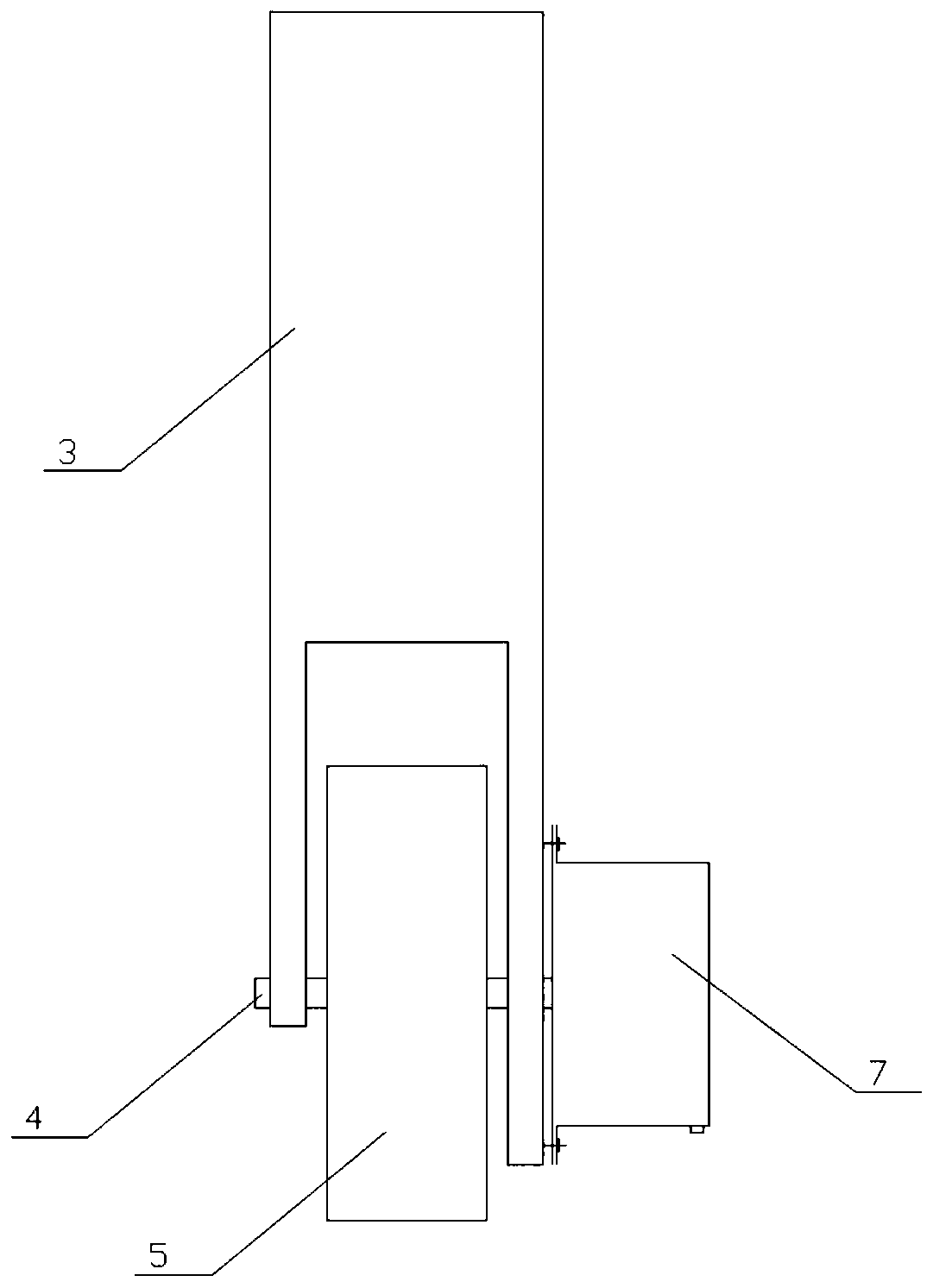

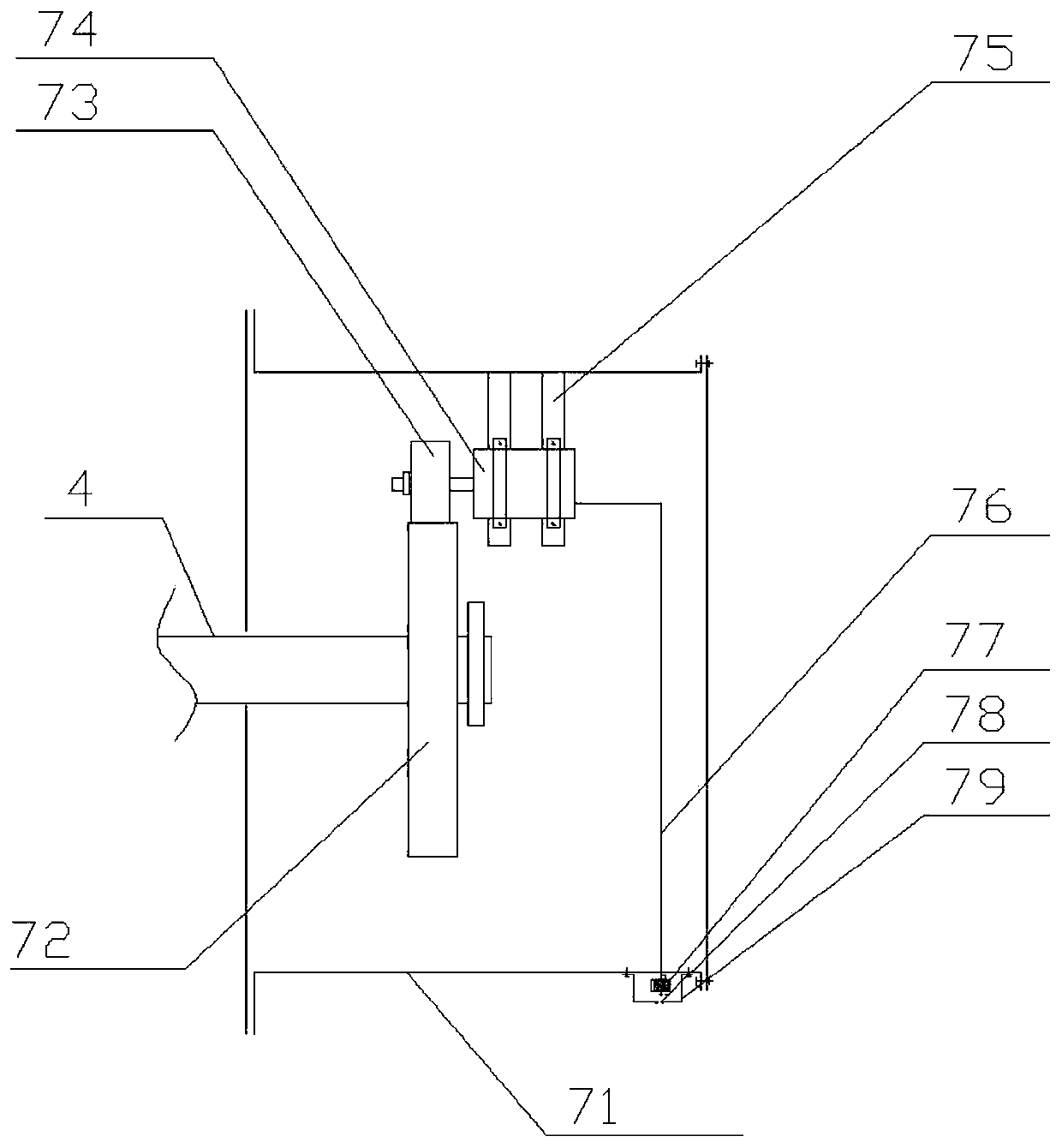

Explosion-proof plate feeding device

PendingCN111891753ASimple structureImprove efficiencyFinal product manufactureControl devices for conveyorsStructural engineeringVisual system

The invention discloses an explosion-proof plate feeding device. The device comprises a machine frame. The machine frame is provided with a material conveying belt, a control end, a visual system, anexplosion-proof plate grabbing mechanism, and an explosion-proof plate turnover mechanism. The visual system is used for distinguishing between the front side and the back side of an explosion-proof plate and locating. After receiving a signal form the visual system, the control end controls the explosion-proof plate grabbing mechanism to move explosion-proof plates with the front sides upward tothe material conveying belt and move explosion-proof plates with the back sides upward to a turnover plate, and controls a turnover cylinder to drive the turnover plate to turn the explosion-proof plates with the front sides upward into the explosion-proof plates with the back sides upward. The explosion-proof plate feeding device is redesigned, and adopts the visual system to identify the front side and the back side and to locate, the grabbing mechanism to grab and place on the material conveying belt or the turnover mechanism, and the turnover mechanism to turn the explosion-proof plates over to make the front sides of the explosion-proof plates upward. The device is simple in structure, high in efficiency, and low in cost.

Owner:宁波震裕汽车部件有限公司

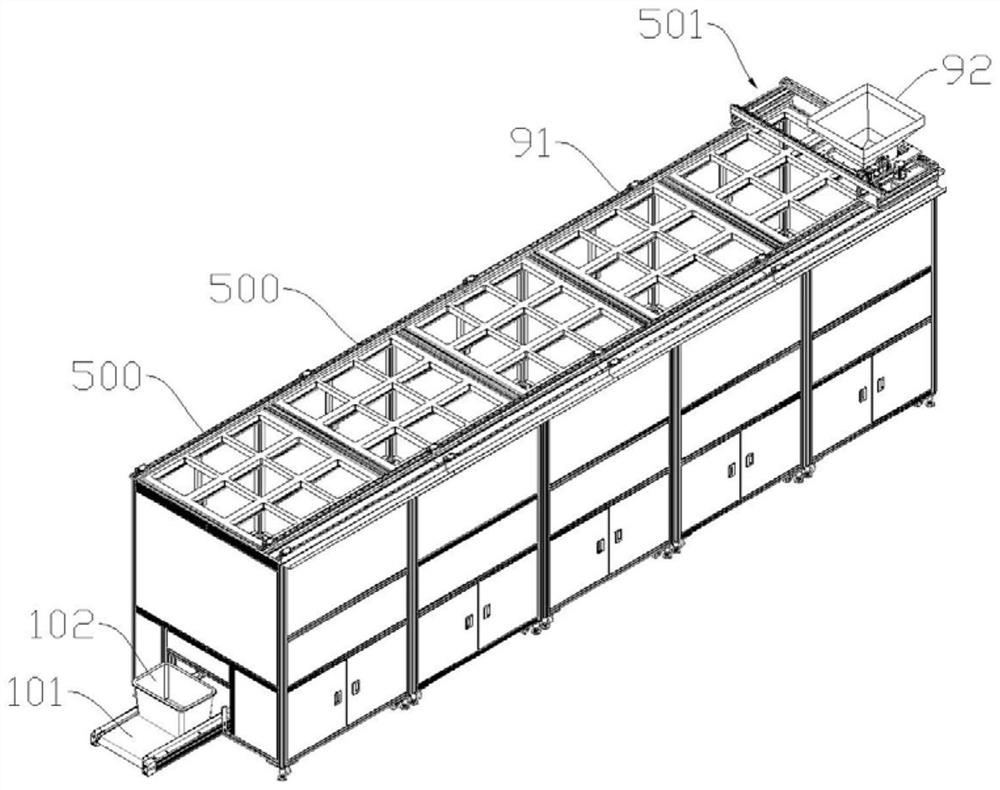

Automatic part taking system

ActiveCN113955506AHigh degree of automationRealize automatic box change functionEdge grinding machinesControl devices for conveyorsEngineeringMachining system

The invention relates to an automatic part taking system. The system comprises a first mechanical arm, a cooling device, a cinder ladle removing device, a deburring device and a second mechanical arm and further comprises an automatic box replacing device arranged at a box filling station and used for replacing part boxes and an automatic stacking device used for stacking the full part boxes. The automatic box replacing device comprises a conveying frame, a conveying roller set rotationally installed on the conveying frame and a driving part for driving the conveying roller set to rotate, and the box filling station is located on the conveying roller set. The automatic stacking device comprises a clamping mechanism used for clamping or loosening the part boxes and a stacking control mechanism used for controlling the clamping mechanism to move between the box filling station and a stacking station in a reciprocating manner and achieving stacking. The automatic part taking system has the effects that the work of replacing and stacking part boxes can be automatically carried out, and the automation degree of a part die-casting machining system is improved.

Owner:AIMI (SHANGHAI) TECH CO LTD

Voltage type adhesive tape running speed and slip detection device and detection method

Owner:中冶北方(大连)工程技术有限公司

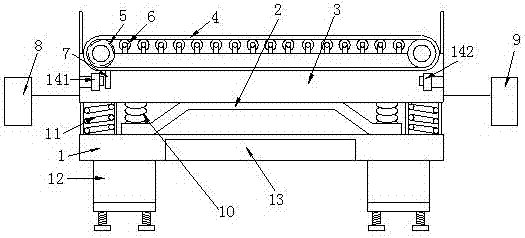

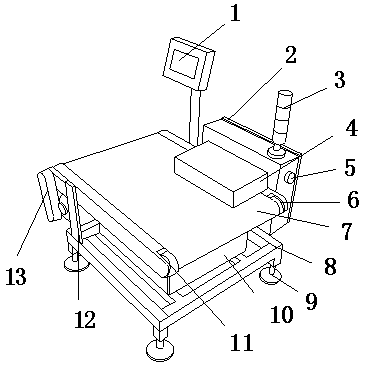

Automatic belt line weighing equipment

InactiveCN107651409AHigh degree of intelligenceReduce work intensityConveyorsControl devices for conveyorsElectricityEngineering

Owner:江苏瑞天建设有限公司

Anti-theft equipment for warehousing, terminal and method

Owner:华睿企业管理咨询(衢州)有限公司

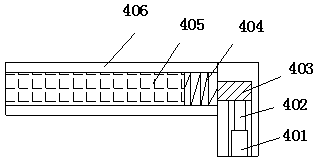

Plate conveying device of plate punching equipment

InactiveCN107572229APrevent deviationPrecise automatic deliveryDrilling machinesControl devices for conveyorsPunchingEngineering

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Multifunctional belt conveyer tour-inspection system

Owner:XIAN UNIV OF SCI & TECH

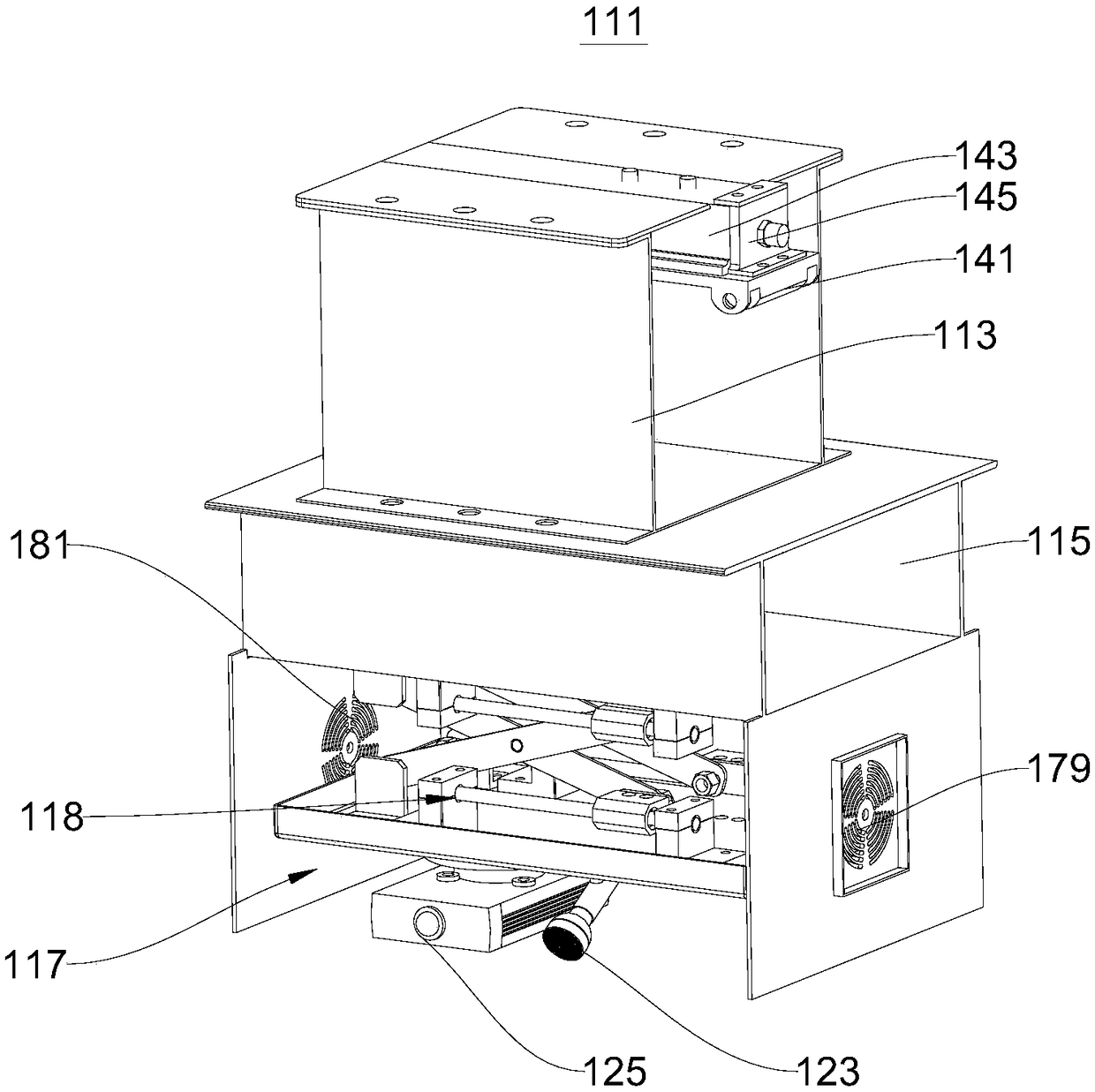

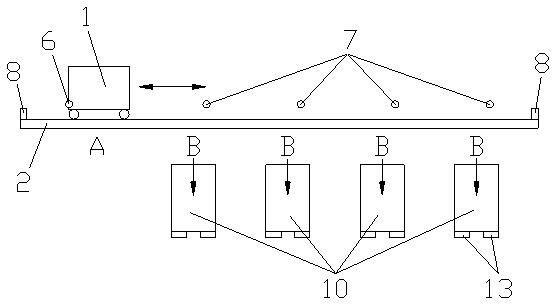

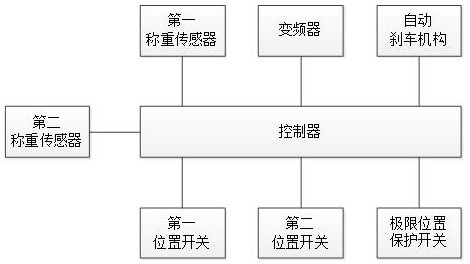

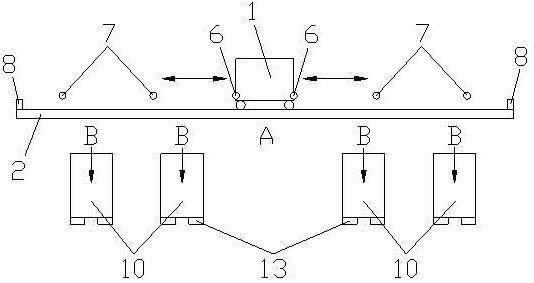

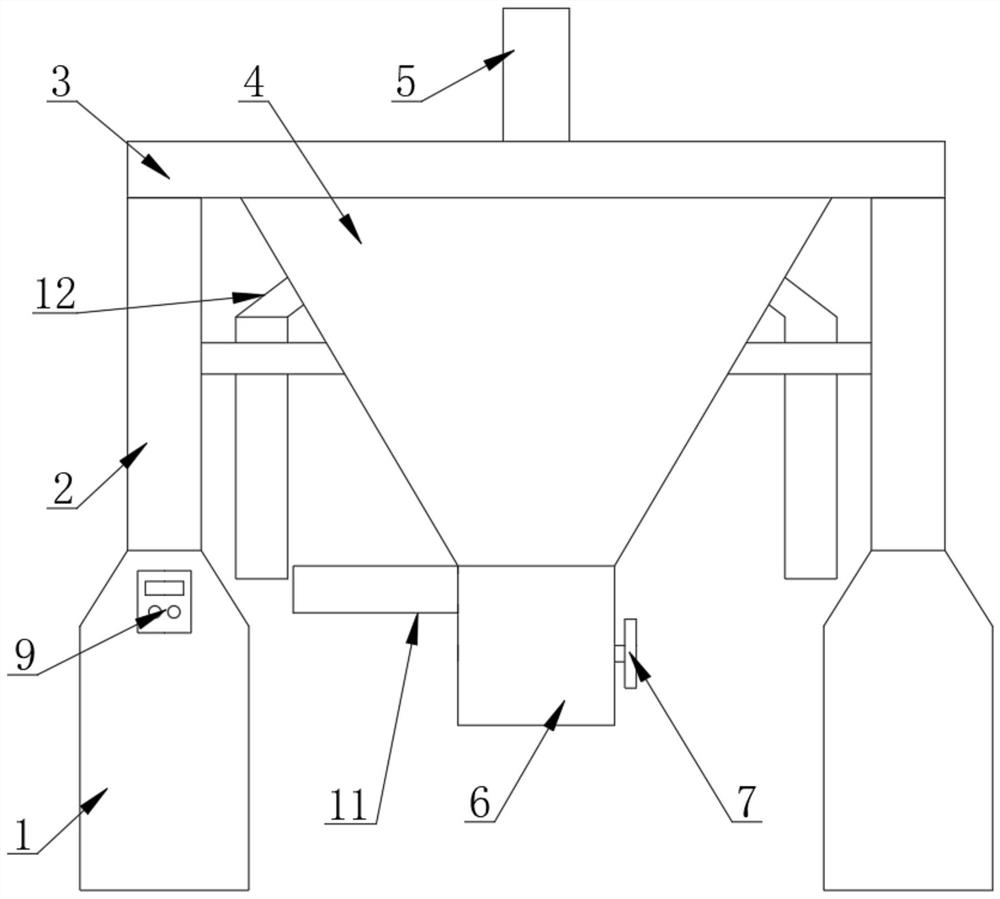

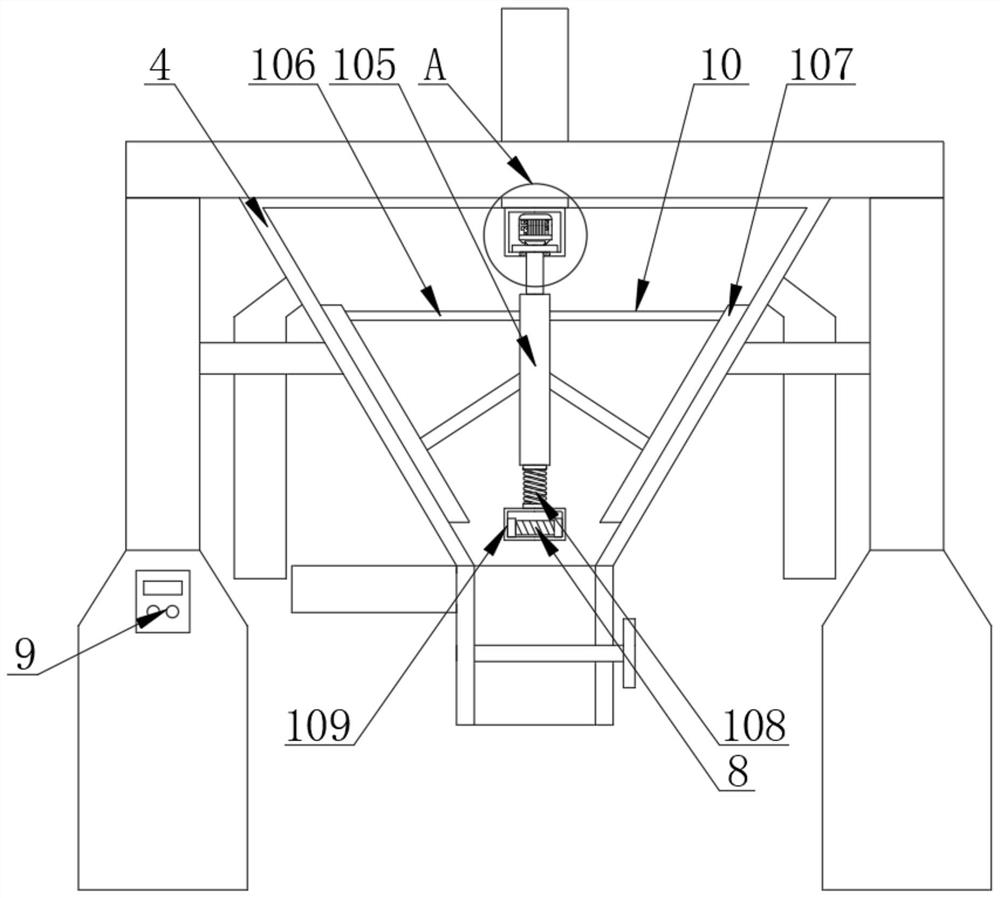

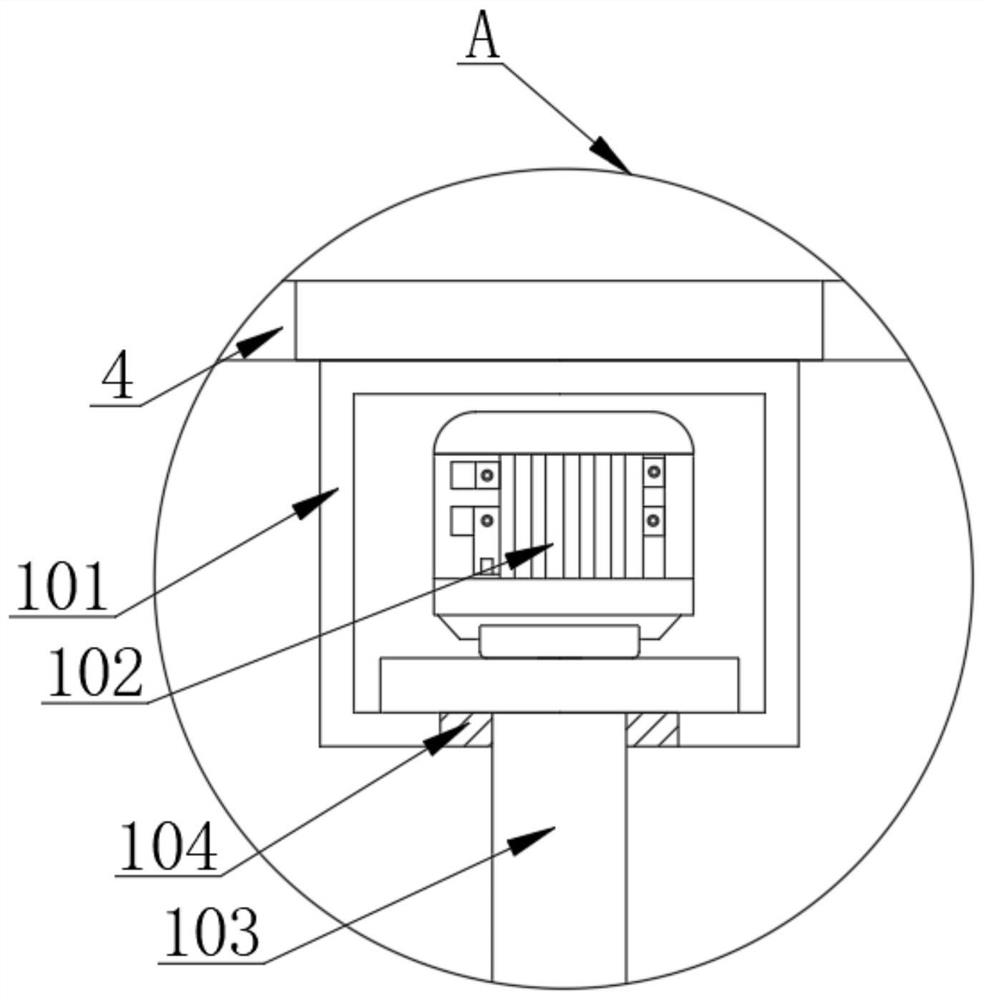

Efficient feeding system and method for asphalt mixture level batching bins

InactiveCN112061707ATimely replenishmentImprove efficiencyControl devices for conveyorsWeighing apparatus with automatic feed/dischargeFrequency changerAutomatic braking

Owner:FUJIAN QUANCHENG MACHINERY

Ash bucket feeding equipment for thermal power plant

InactiveCN112938405AReduced service lifePrevent leakageConveyorsHollow article cleaningPower stationElectric machine

Owner:DATANG HUAIBEI POWER PLANT

Detection conveying line and detection conveying method for refractory bricks

PendingCN113834522AHigh degree of automationShorten the lengthMeasurement devicesControl devices for conveyorsFire brickTransfer line

Owner:福州舜鑫科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap