Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about "Article delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

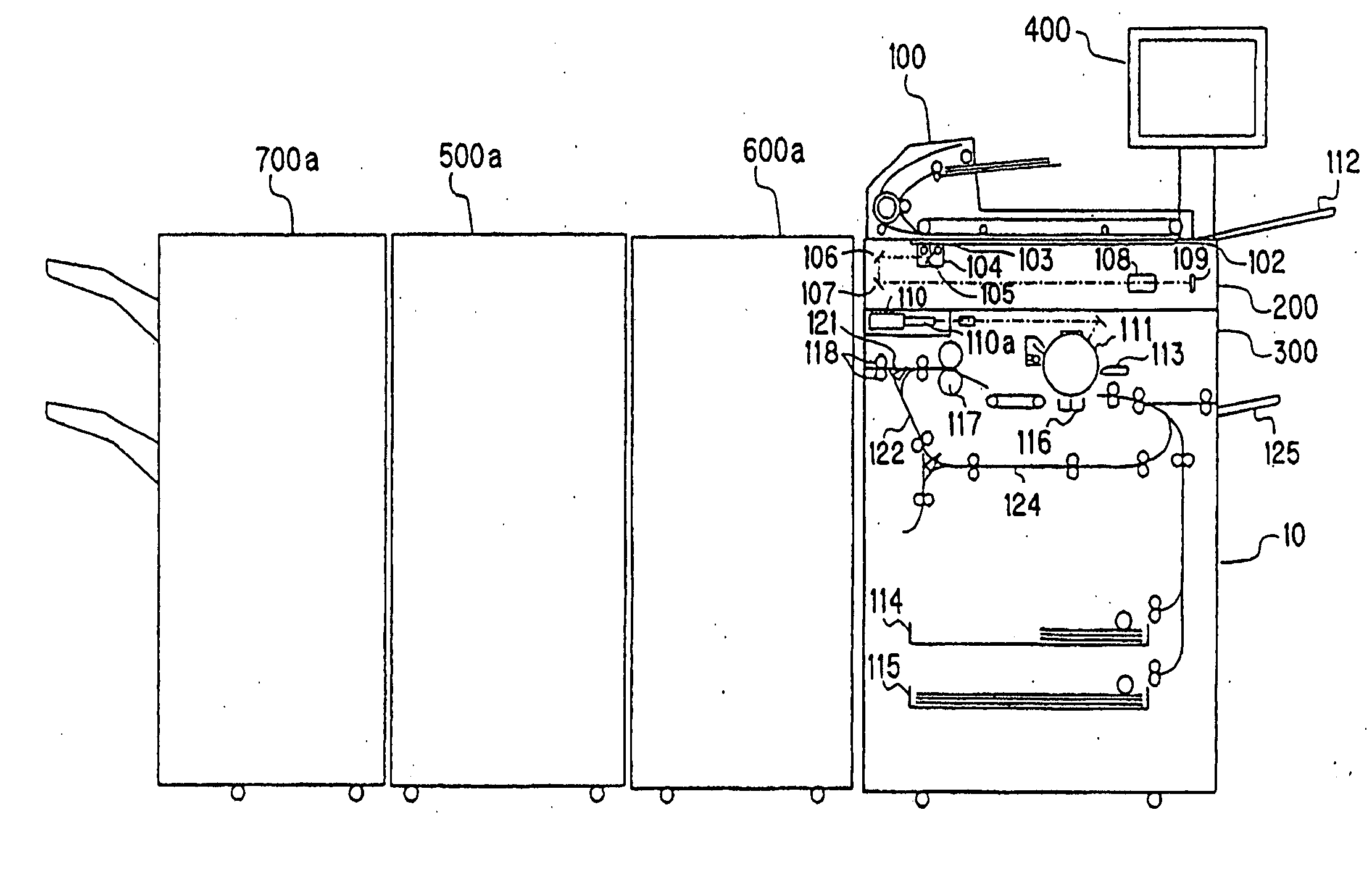

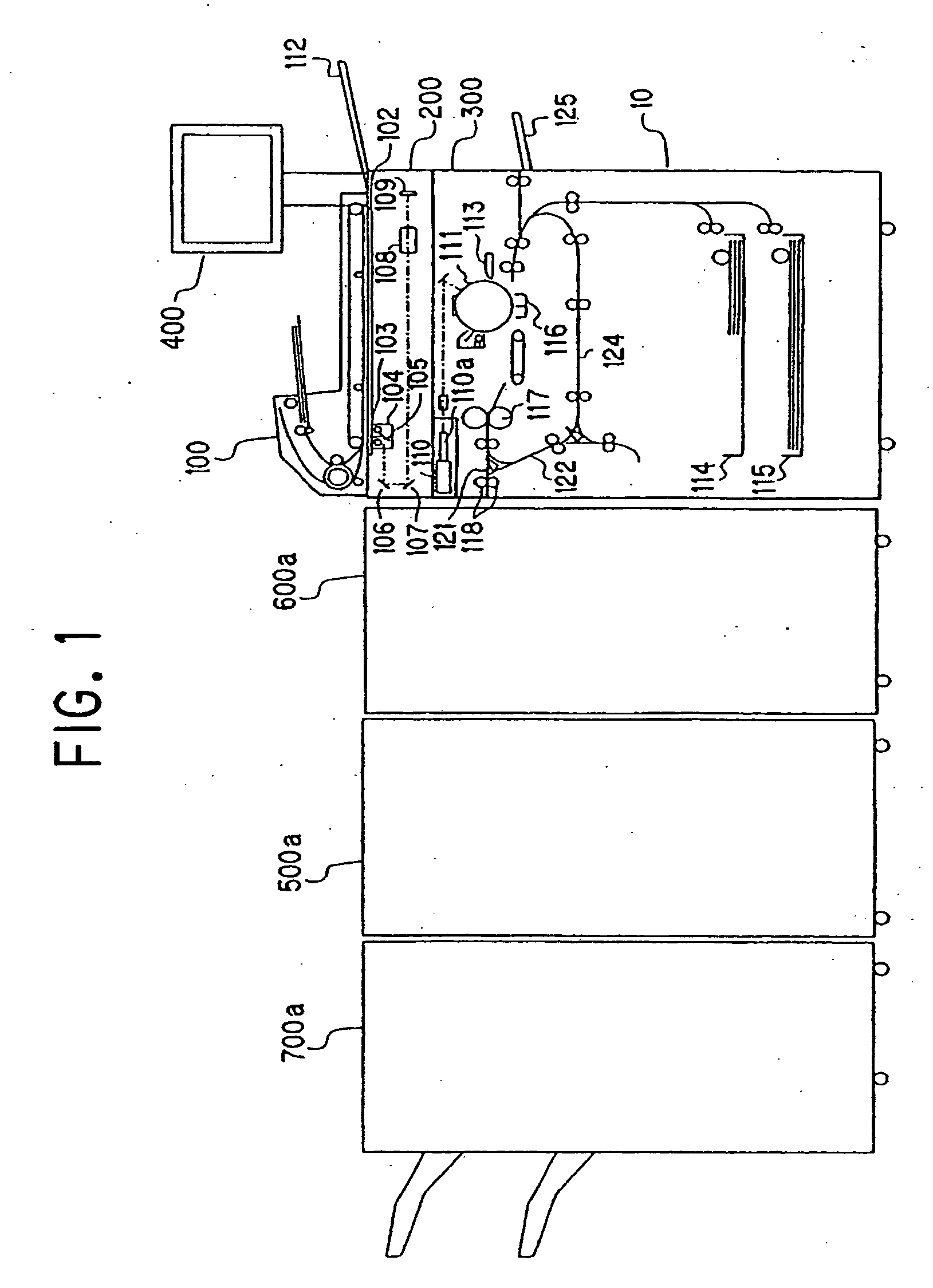

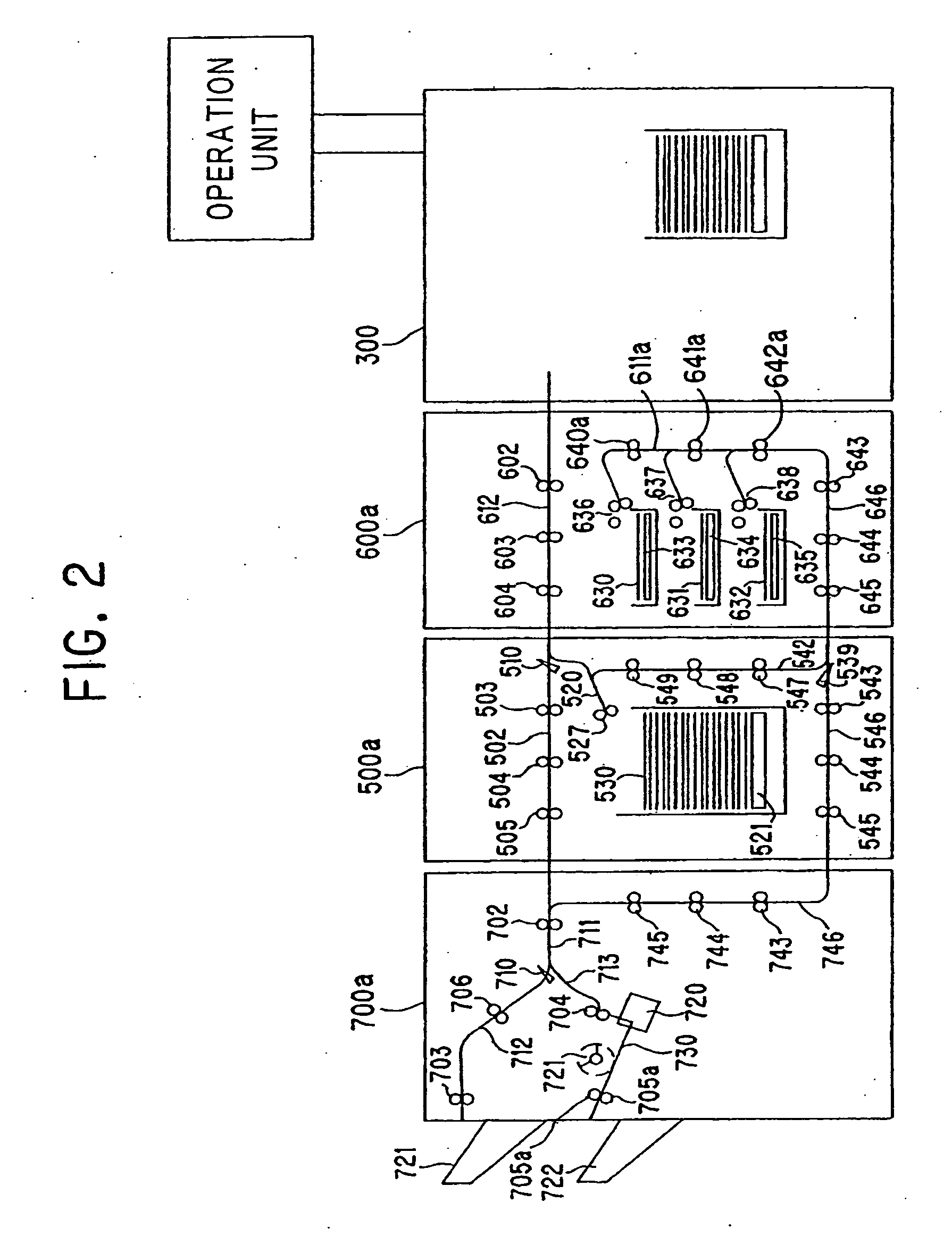

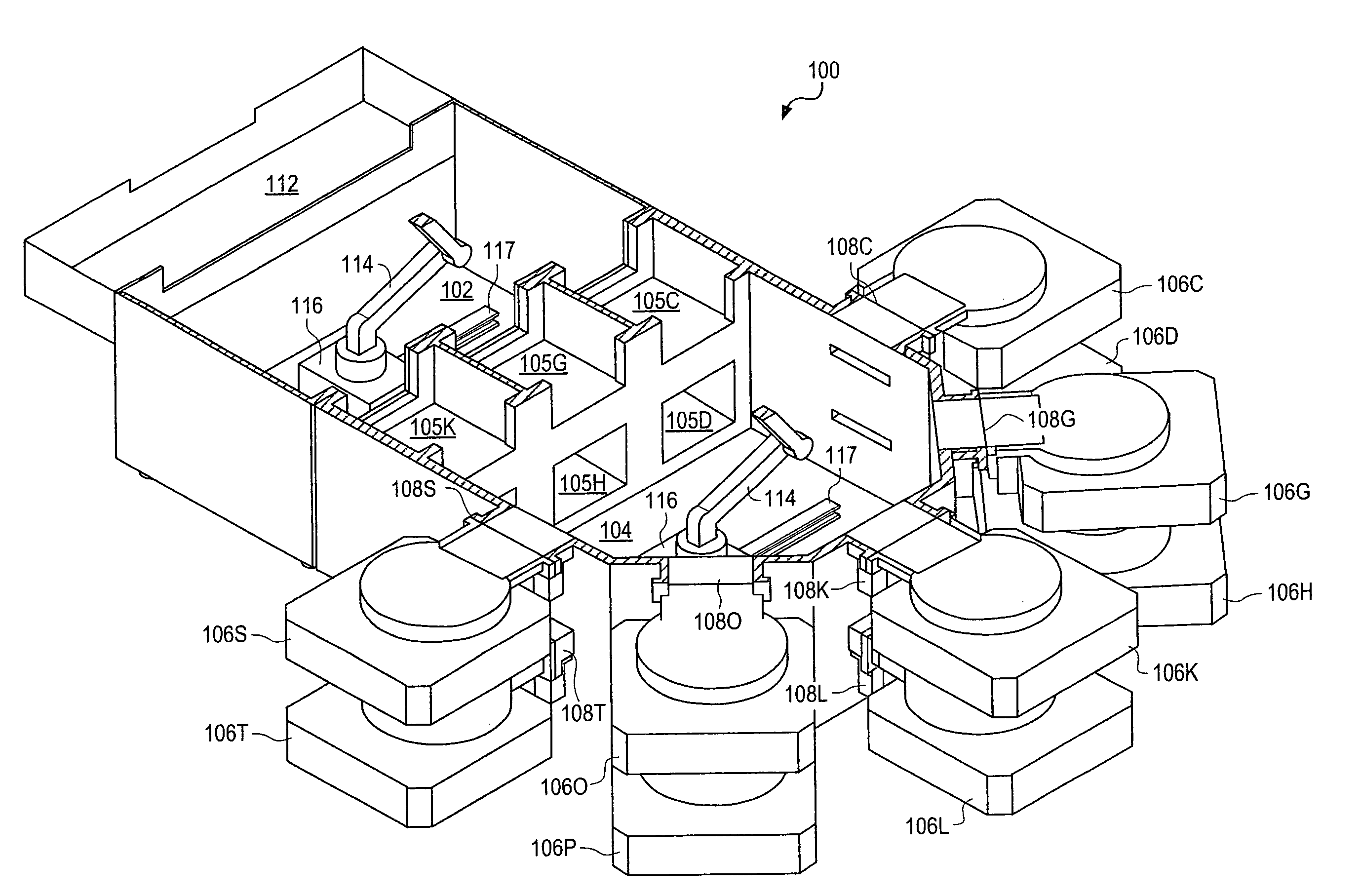

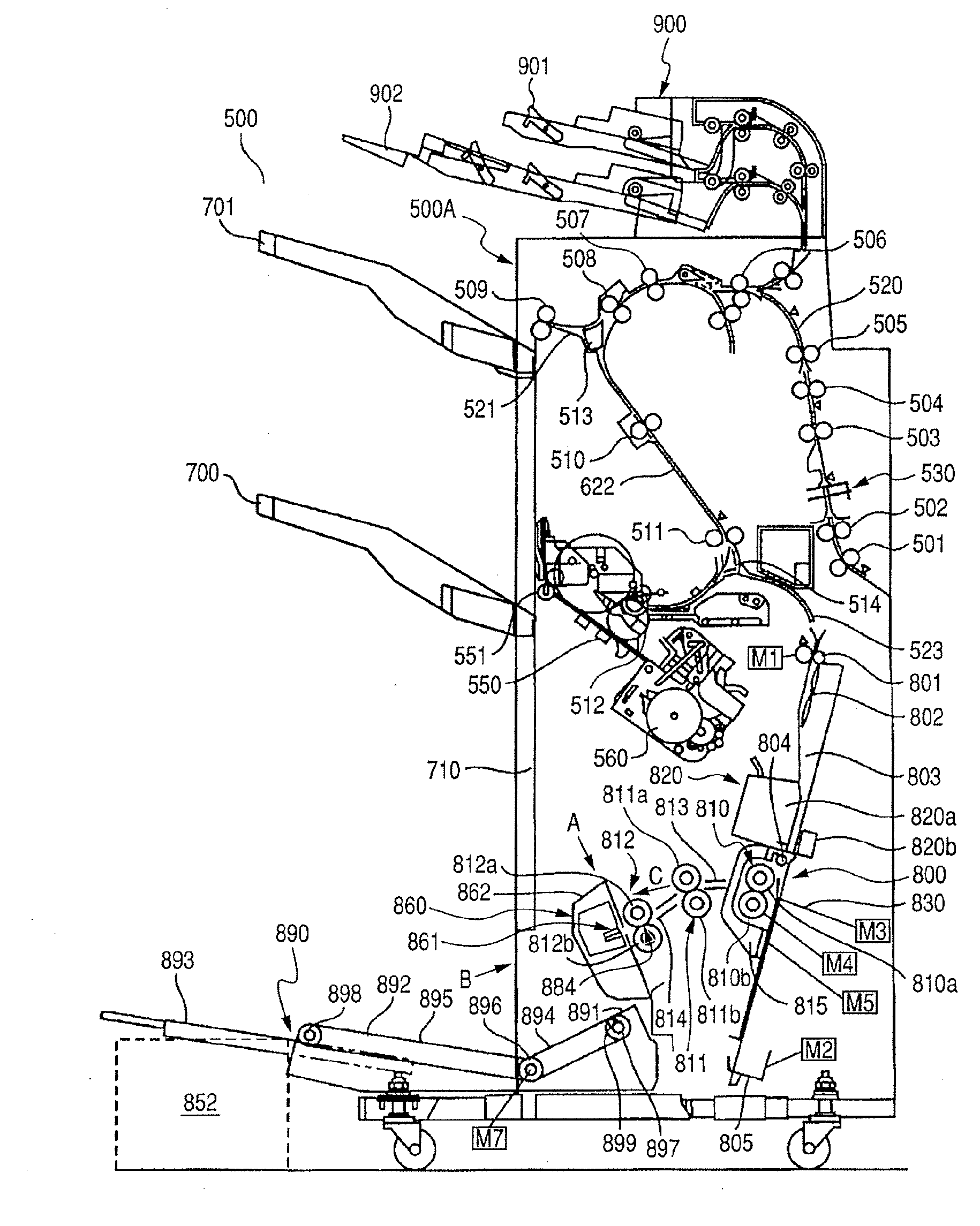

Sheet processing system

InactiveUS20050082735A1Improve productivityFunction indicatorsElectrographic process apparatusEngineeringPaper sheet

Owner:CANON KK

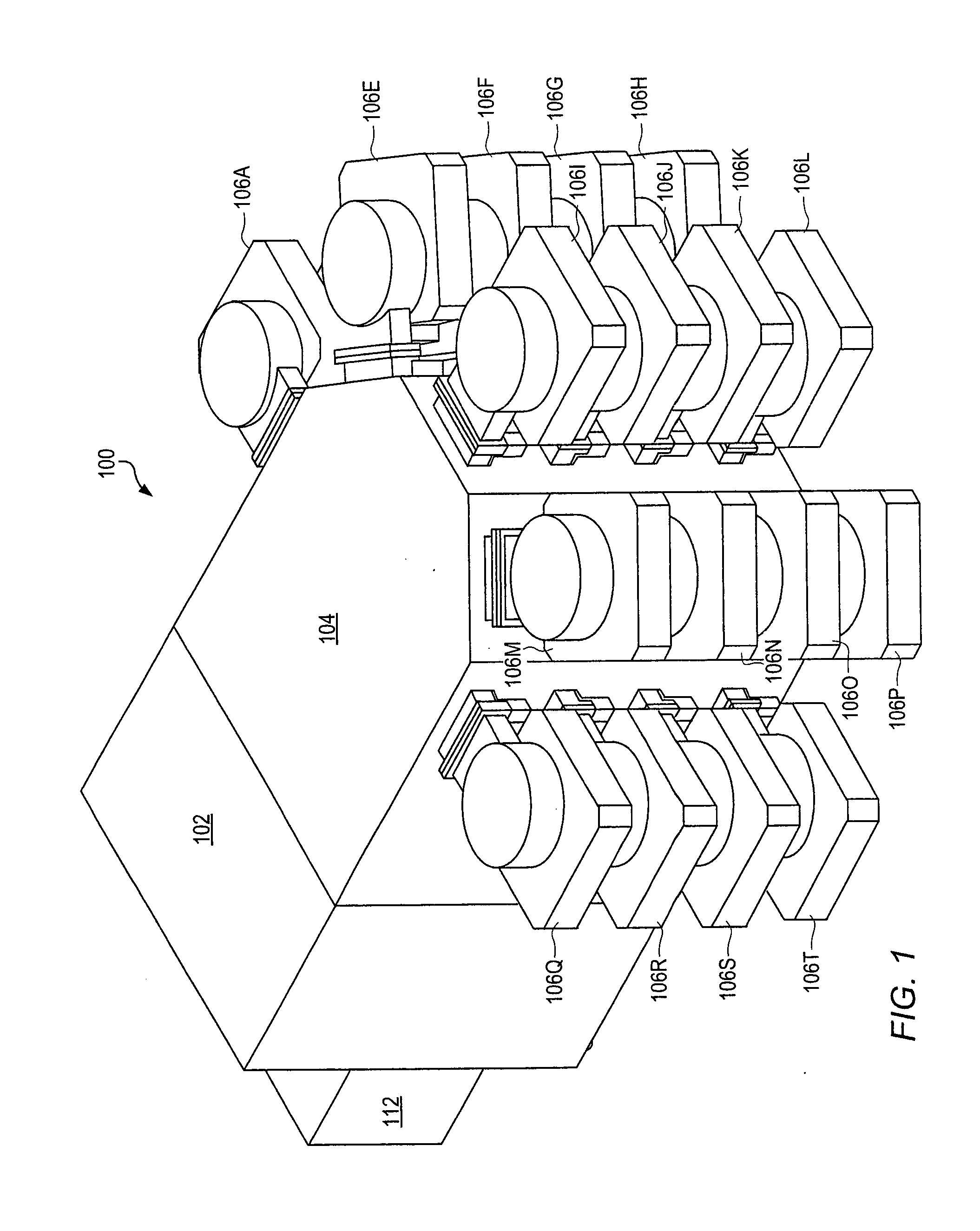

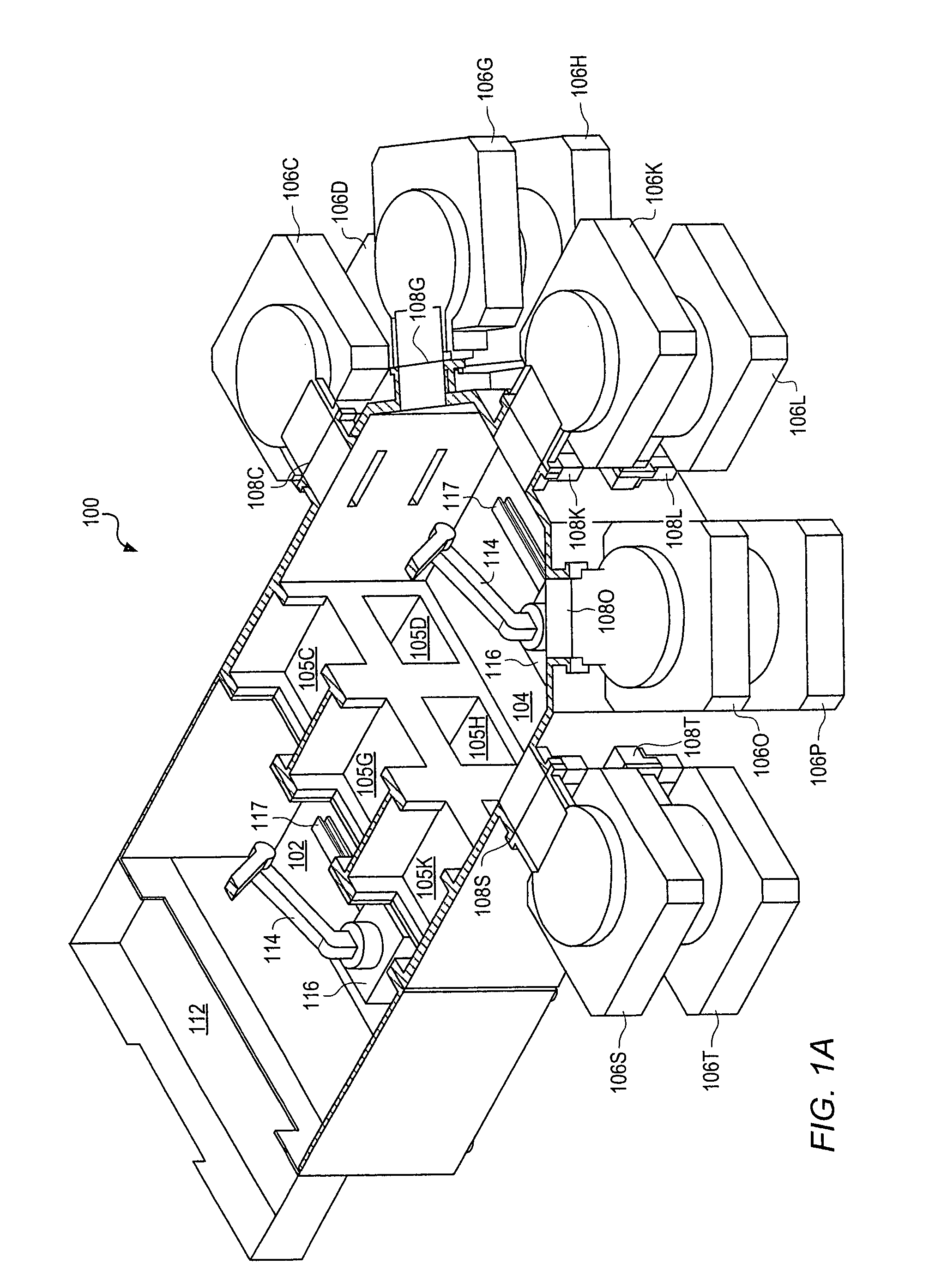

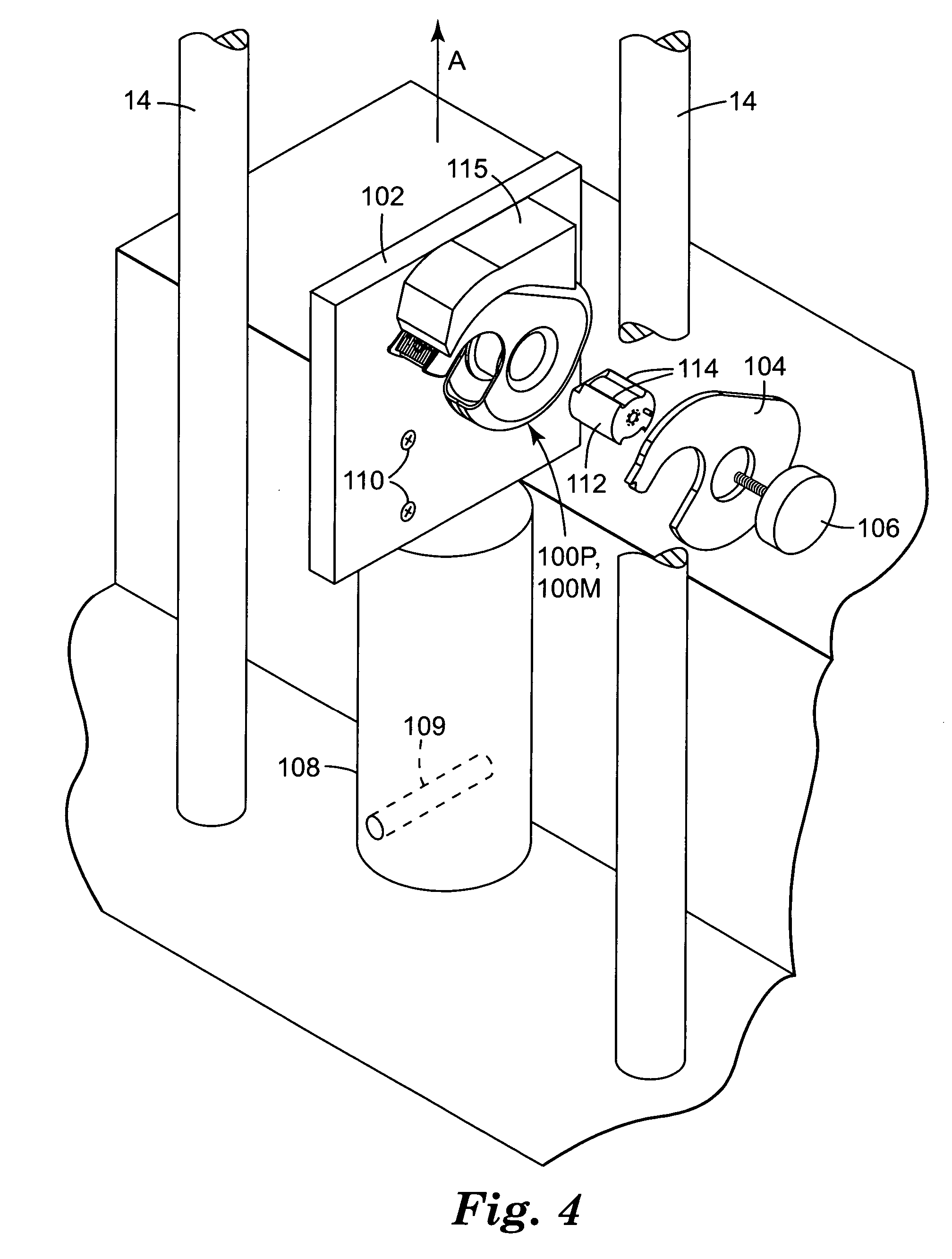

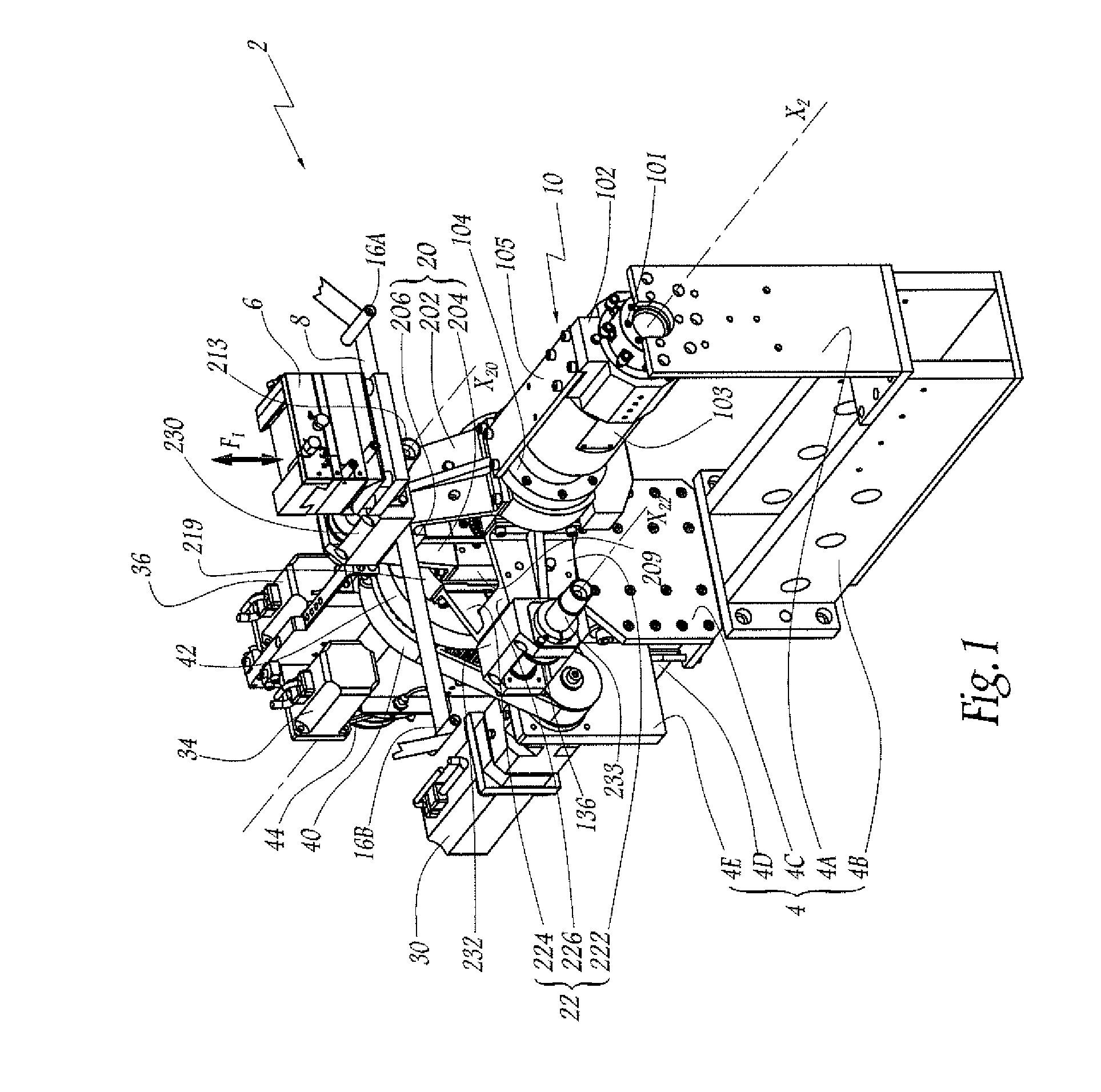

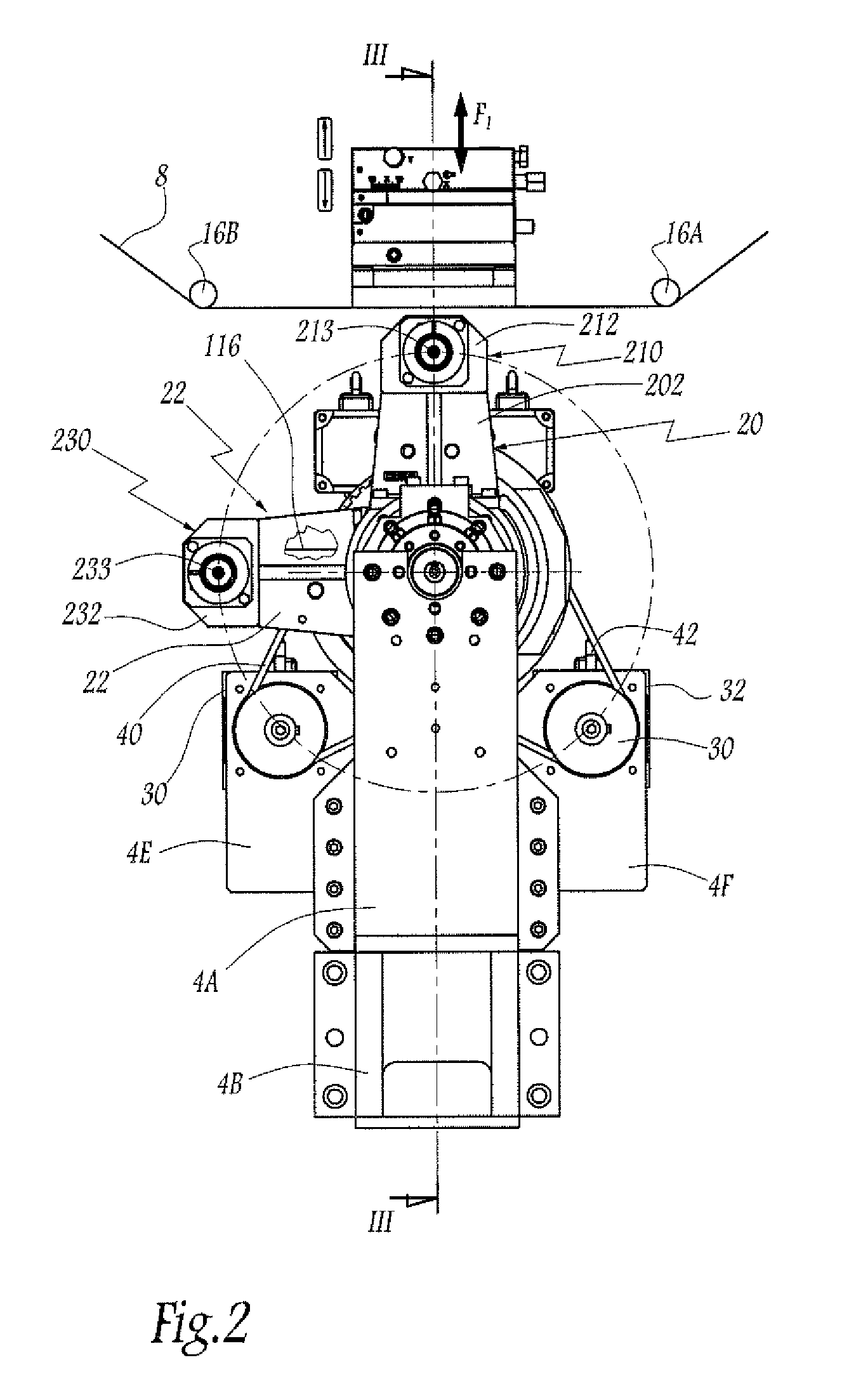

Magnetic media processing tool with storage bays and multi-axis robot arms

InactiveUS20080206036A1Semiconductor/solid-state device manufacturingPackagingMagnetic mediaMulti axis

Owner:SMITH JOHN M +2

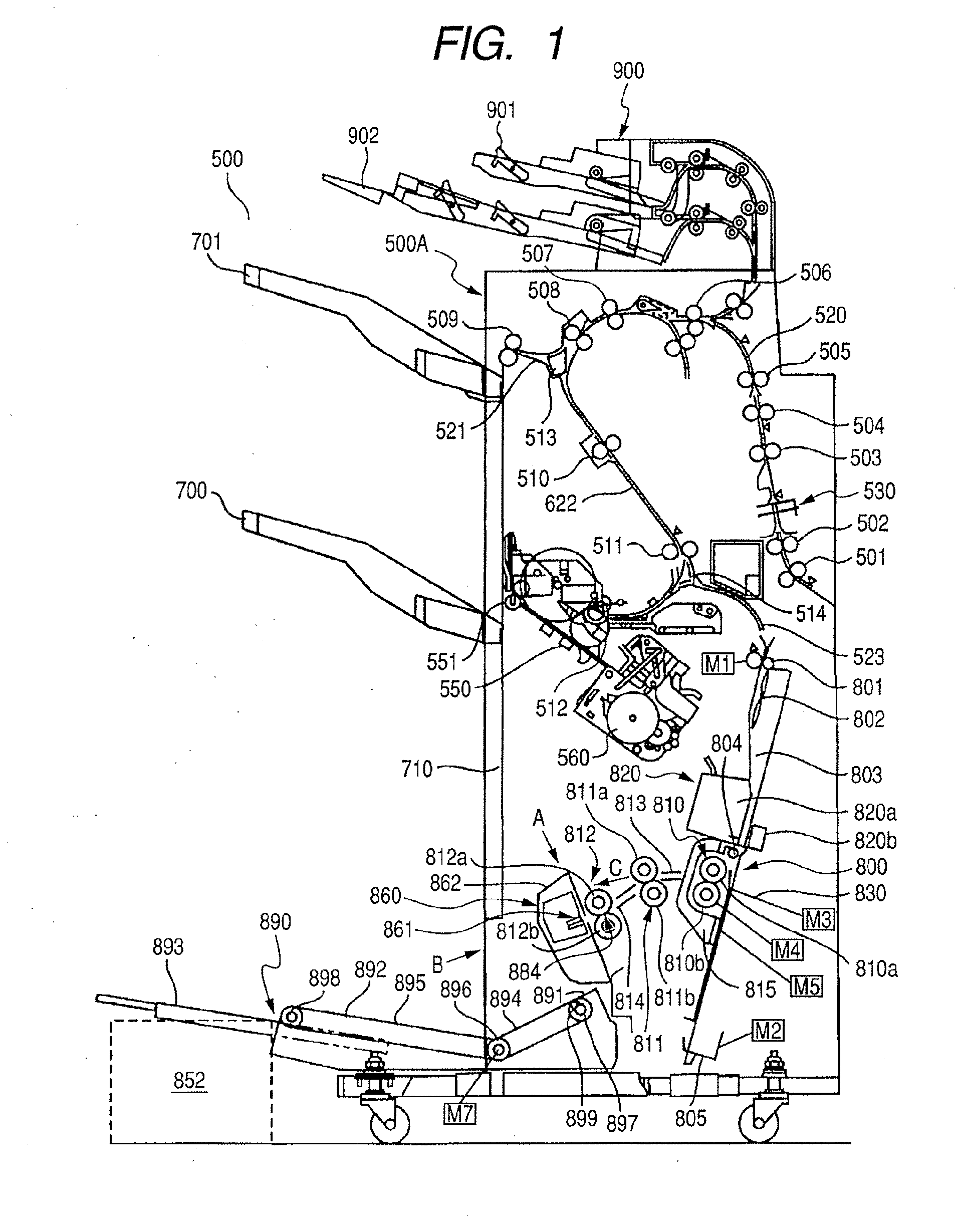

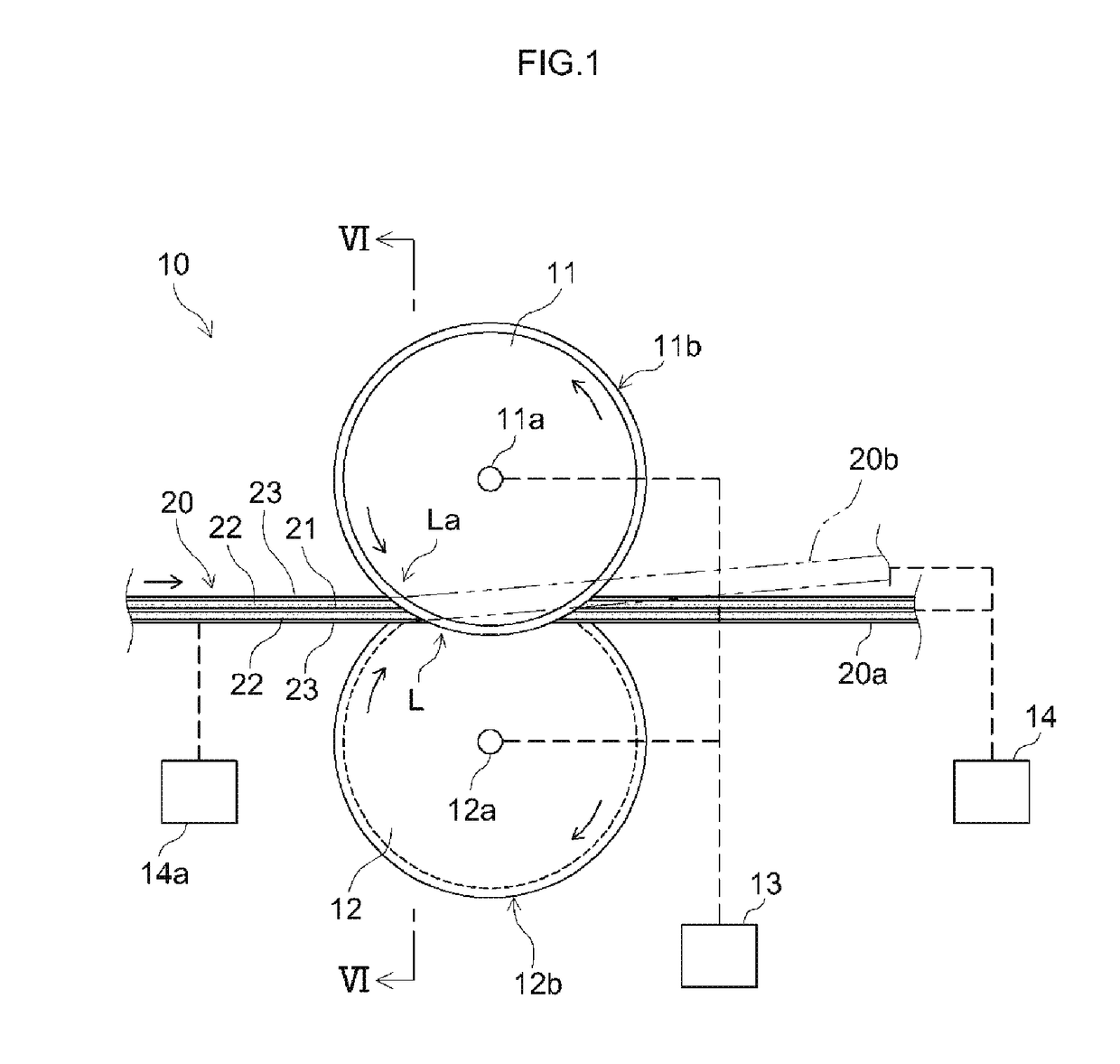

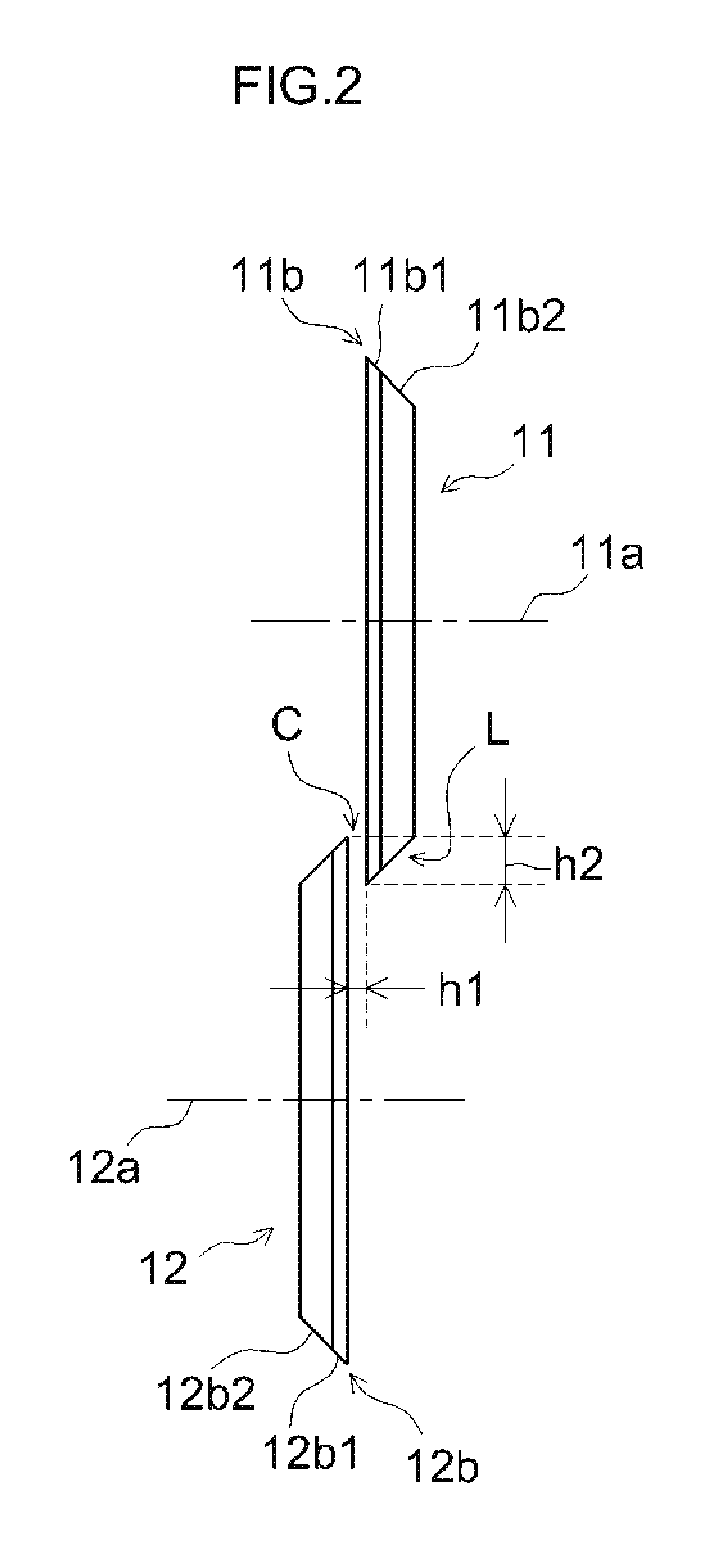

Sheet processing apparatus and image forming apparatus

ActiveUS20070045919A1Folding thin materialsElectrographic process apparatusLeading edgeImage formation

Owner:CANON KK

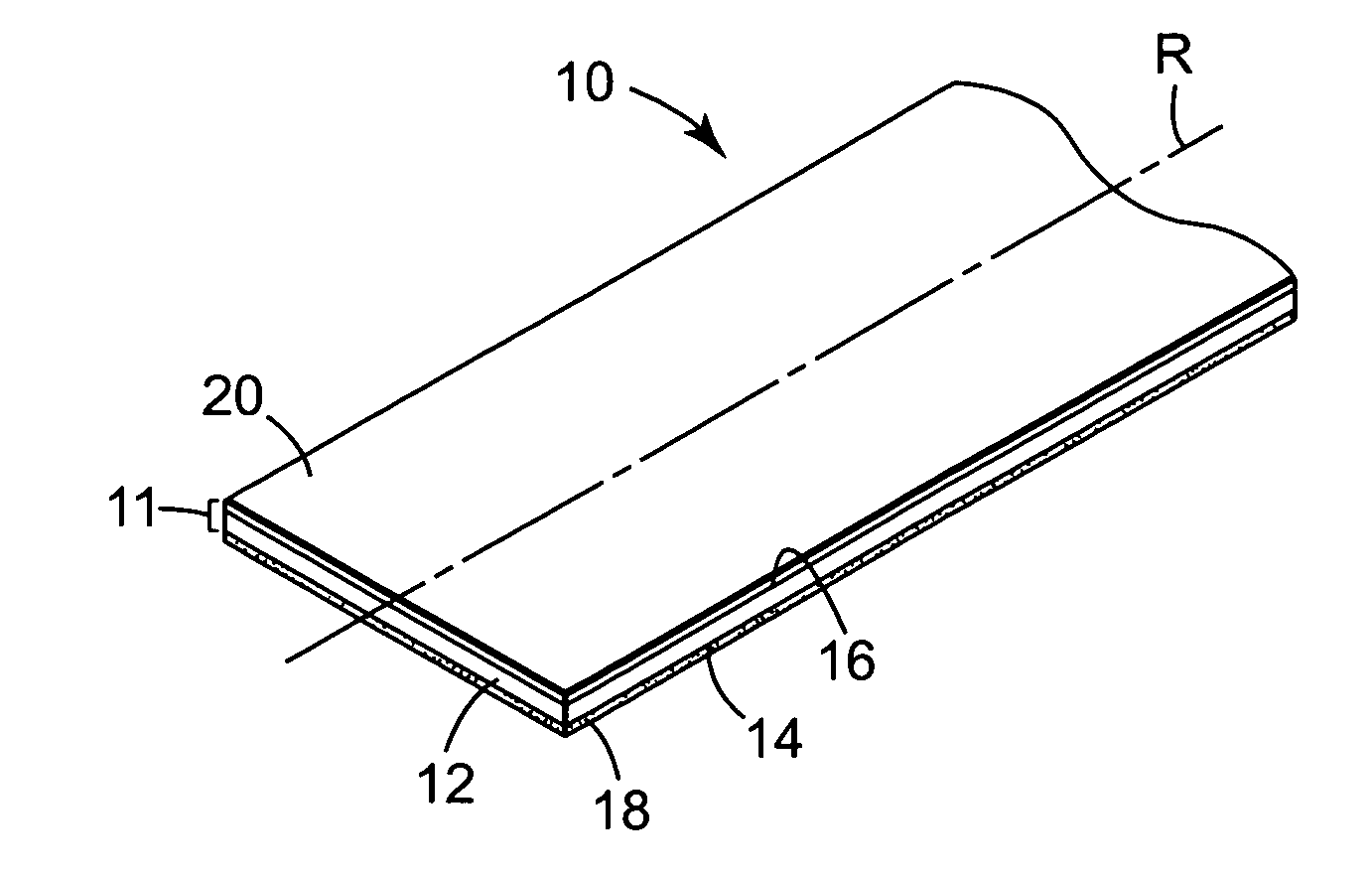

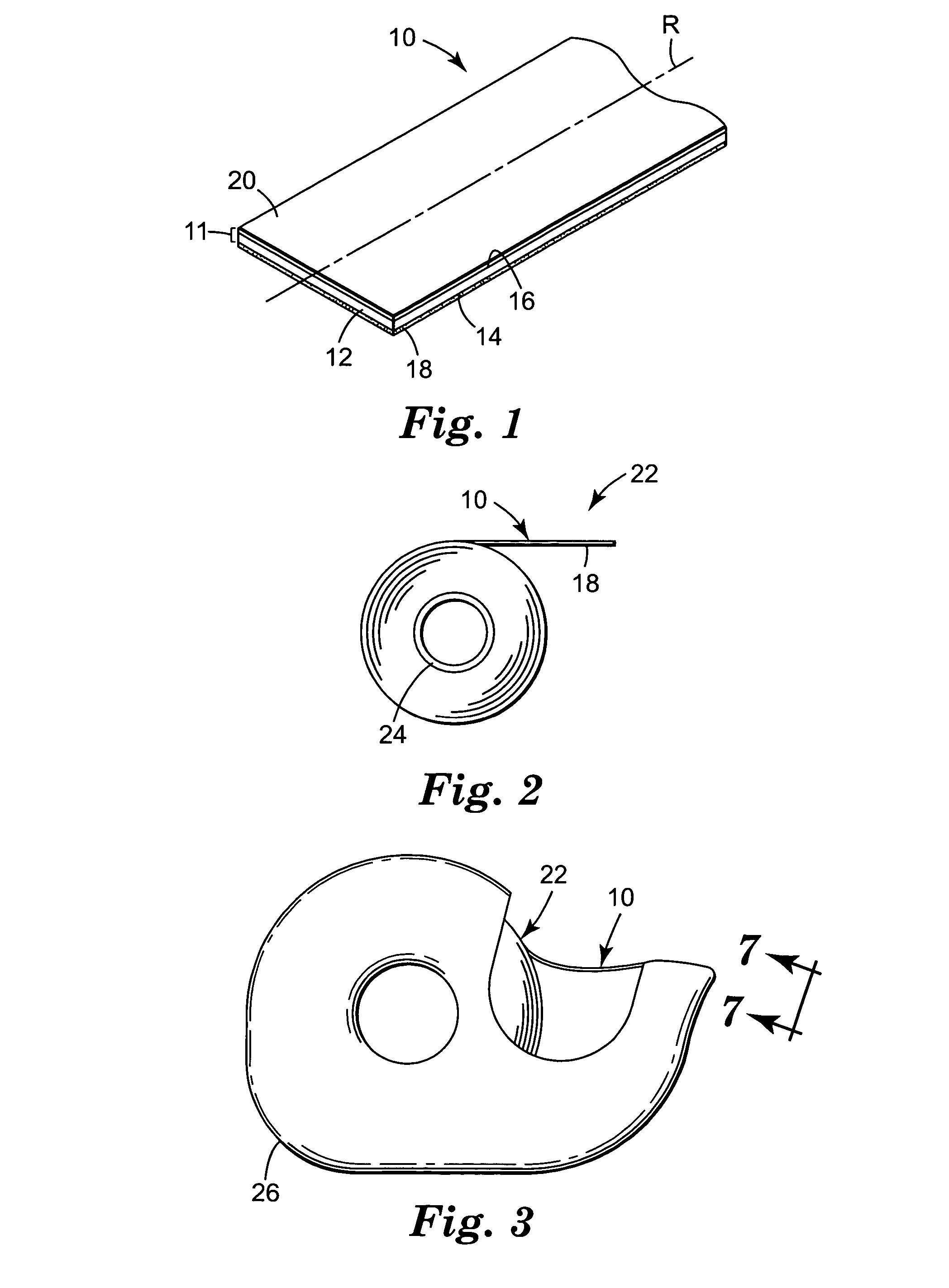

Methods and apparatuses for applying a handling tab to continuous glass ribbons

InactiveUS20120255672A1Reduce harmMaintain integrityMechanical working/deformationLaminationAdhesive beltEngineering

Methods and apparatuses for forming a handling tab on a glass substrate are disclosed. The method may include conveying a glass substrate in a conveyance direction. An adhesive tape ribbon may be positioned adjacent to the first lateral edge of the glass substrate such that an adhesive surface of the adhesive tape ribbon is spaced apart from the first lateral edge of the glass substrate and the adhesive surface is substantially perpendicular to the first surface and the second surface. The adhesive tape ribbon may be folded such that at least a portion of the glass substrate is positioned between the adhesive surface of a first portion of the adhesive tape ribbon and the adhesive surface of a second portion of the adhesive tape ribbon, and a third portion of the adhesive tape ribbon forms a handling tab extending beyond the first lateral edge of the glass substrate.

Owner:CORNING INC

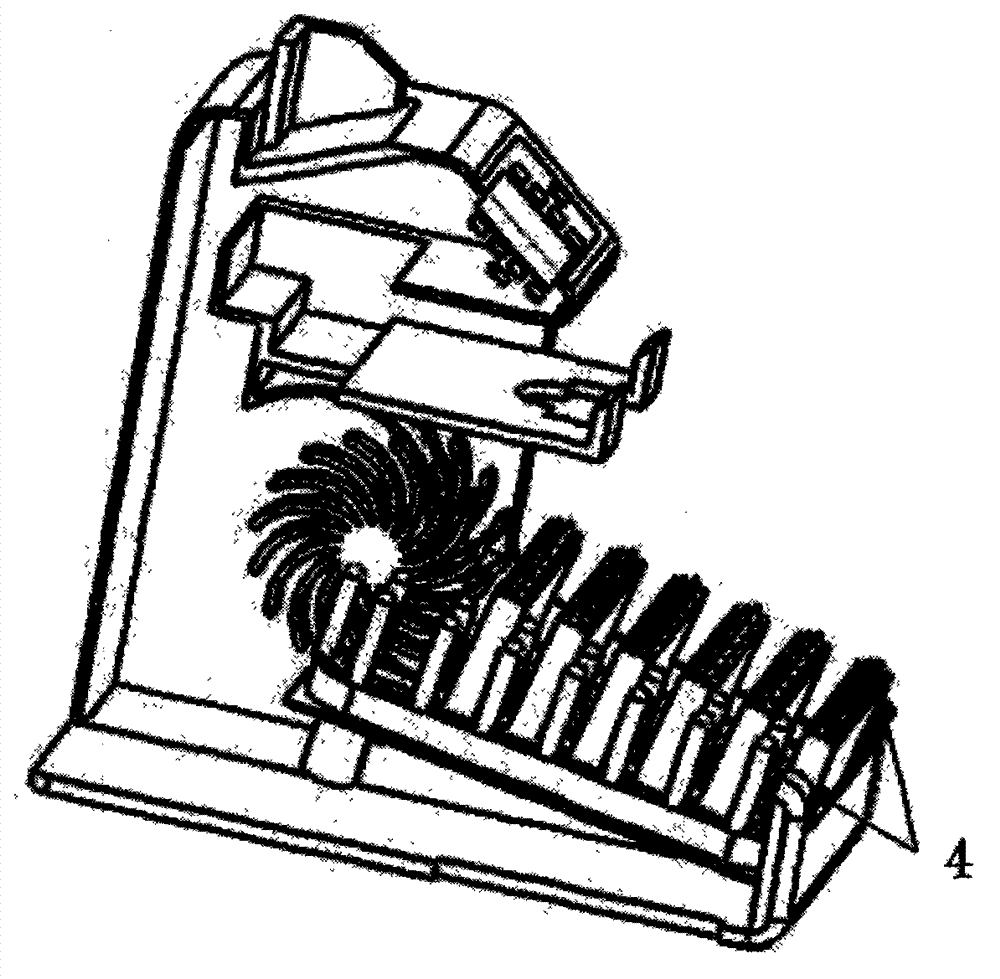

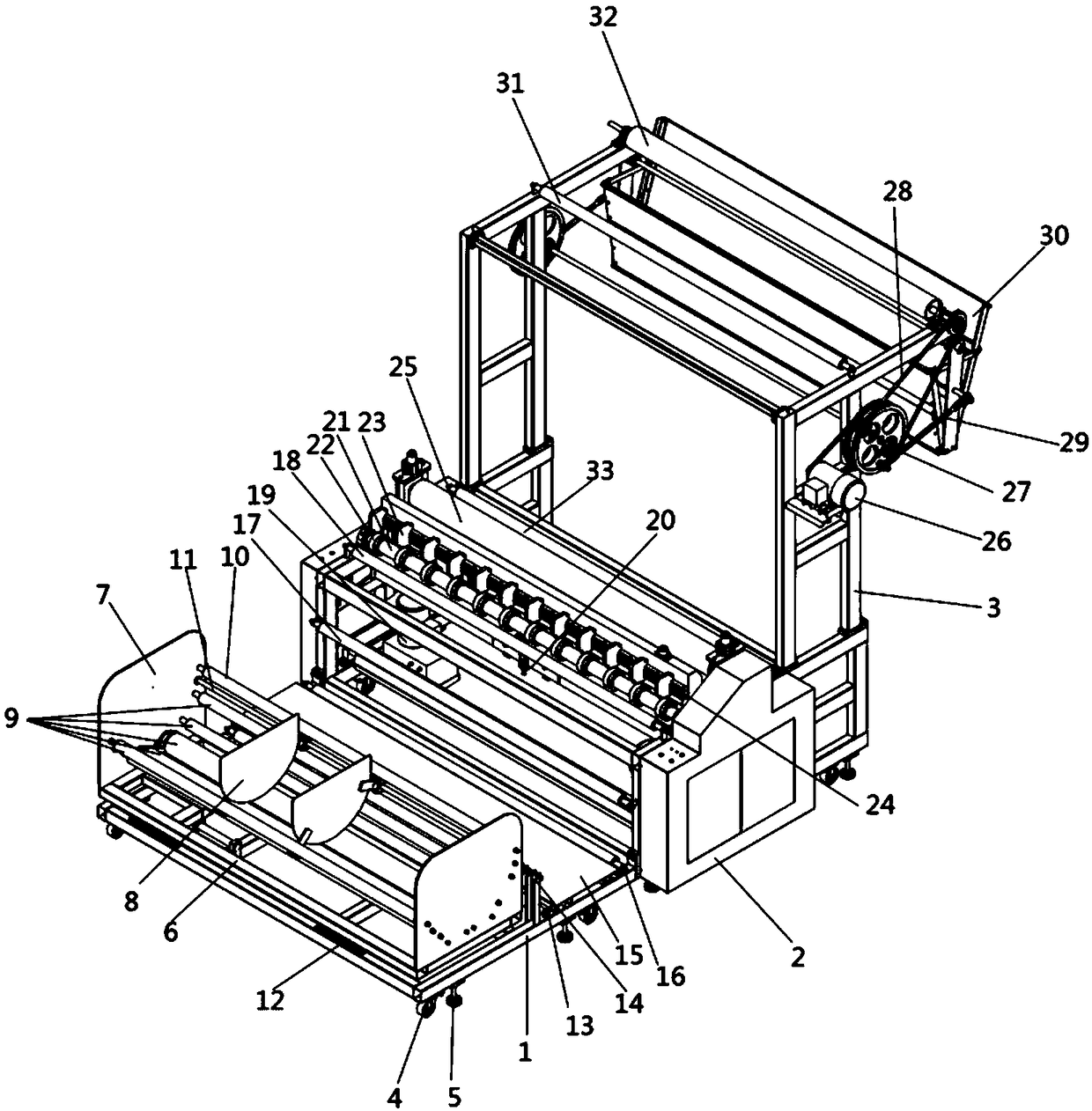

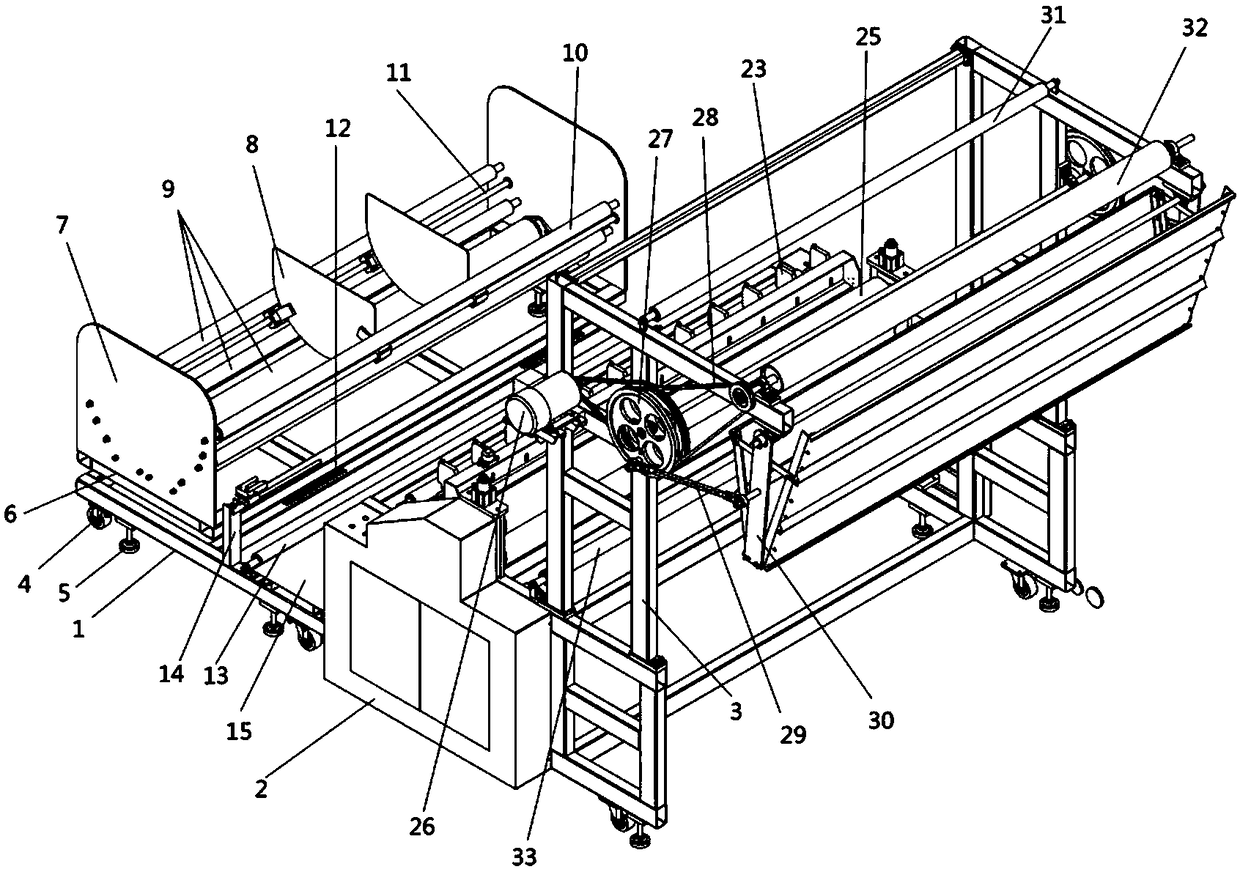

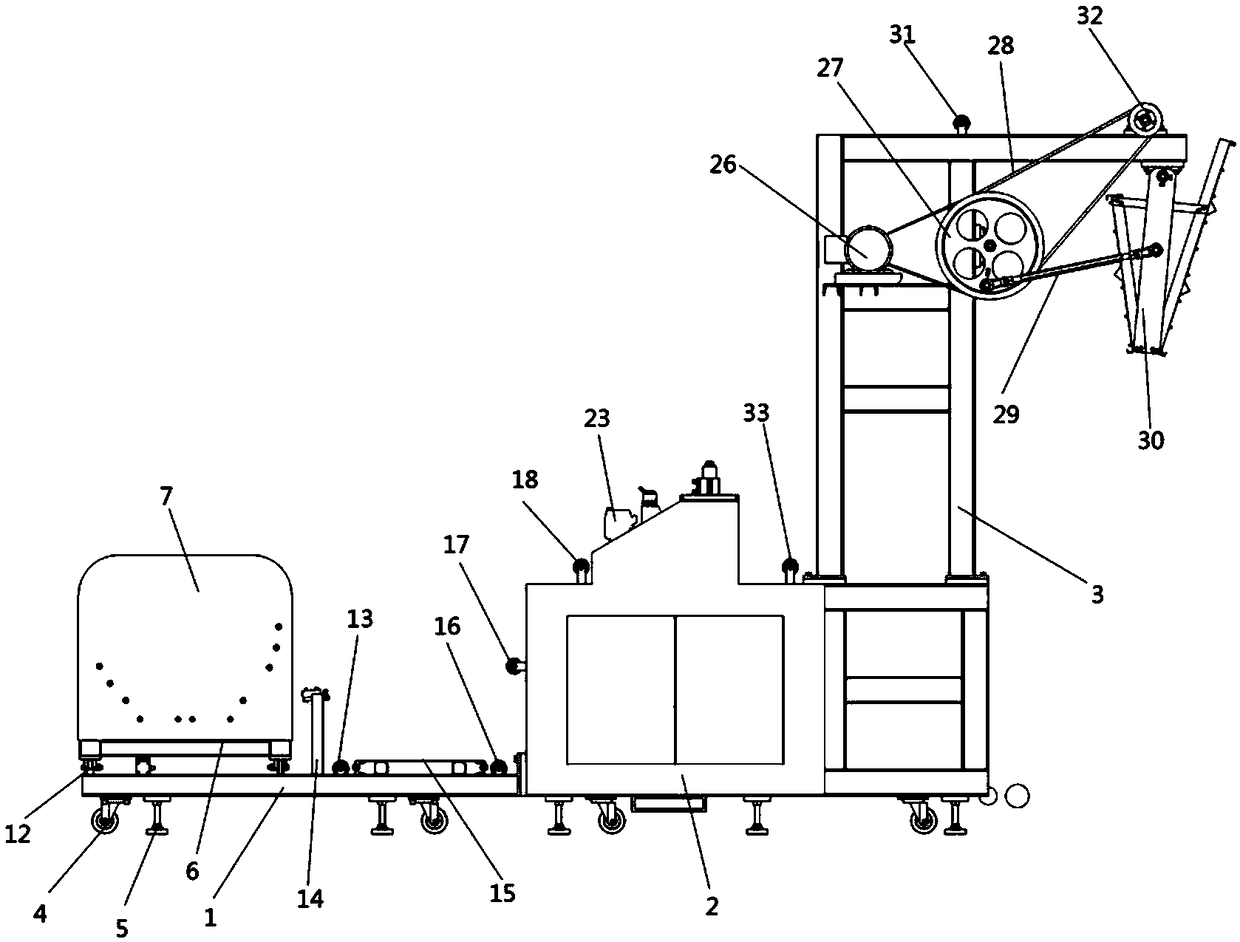

Automatic tube-type specimen container supply apparatus

An automatic tube-type specimen container supply apparatus includes a container storing box a bottom of which has a tapered surface having a container collecting position in a lowest part thereof to collect a plurality of tube-type specimen containers in one spot, a container individually-sending mechanism which lifts up the collected specimen containers one by one along one-side wall located close to the position, an outlet which allows the specimen containers to be discharged outside the box, and a container carry-out mechanism including a conveyor to automatically carry out the discharged specimen containers. The container individually-sending mechanism includes a lifting plate driven up and down and having a top end with a tapered surface. The tapered surface has a space to place only one specimen container lying on a side thereof and descending toward an outside of the container storing box.

Owner:IDS CO LTD

Oriented polypropylene films for adhesive tape

Owner:3M INNOVATIVE PROPERTIES CO

Method for manufacturing semiconductor chips from a semiconductor wafer

ActiveUS20110300647A1Overcome disadvantagesEasy to implementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor chipSemiconductor wafer fabrication

A method for manufacturing semiconductor chips from a semiconductor wafer, including the steps of: fastening, on a first support frame, a second support frame having outer dimensions smaller than the outer dimensions of the first frame and greater than the inner dimensions of the first frame; arranging the wafer on a surface of a film stretched on the second frame; carrying out wafer processing operations by using equipment capable of receiving the first frame; separating the second frame from the first frame and removing the first frame; and carrying out wafer processing operations by using equipment capable of receiving the second frame.

Owner:STMICROELECTRONICS (TOURS) SAS

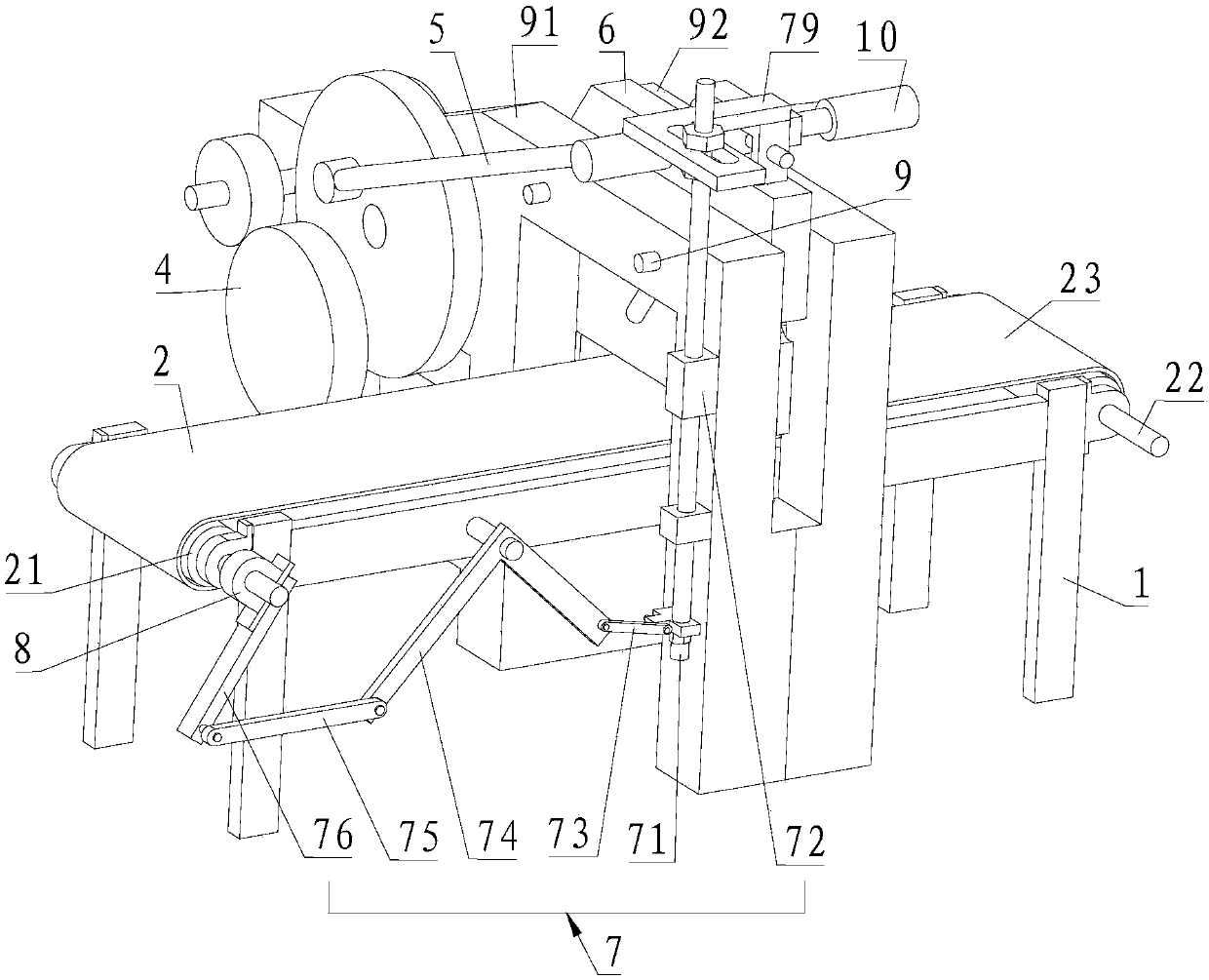

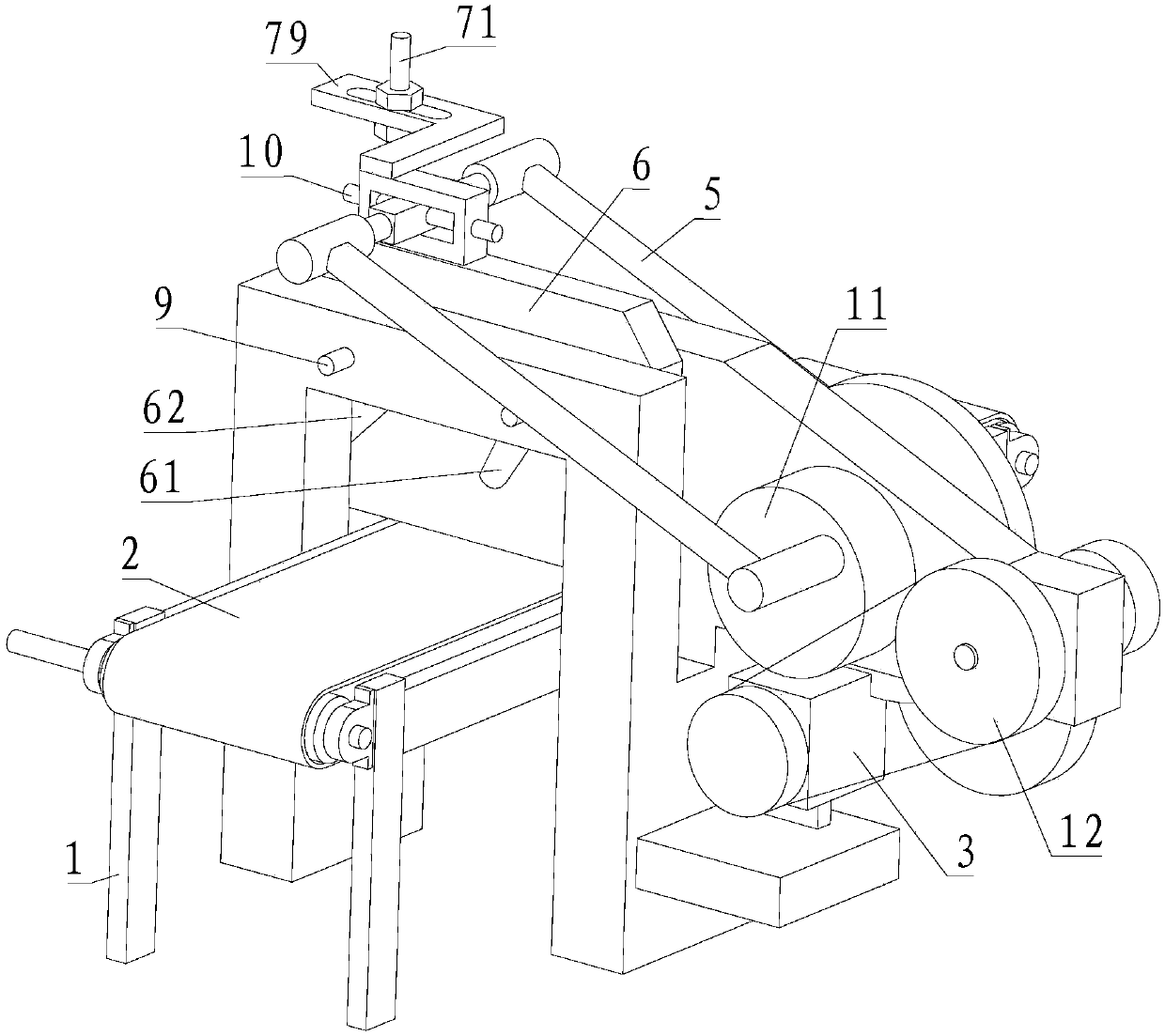

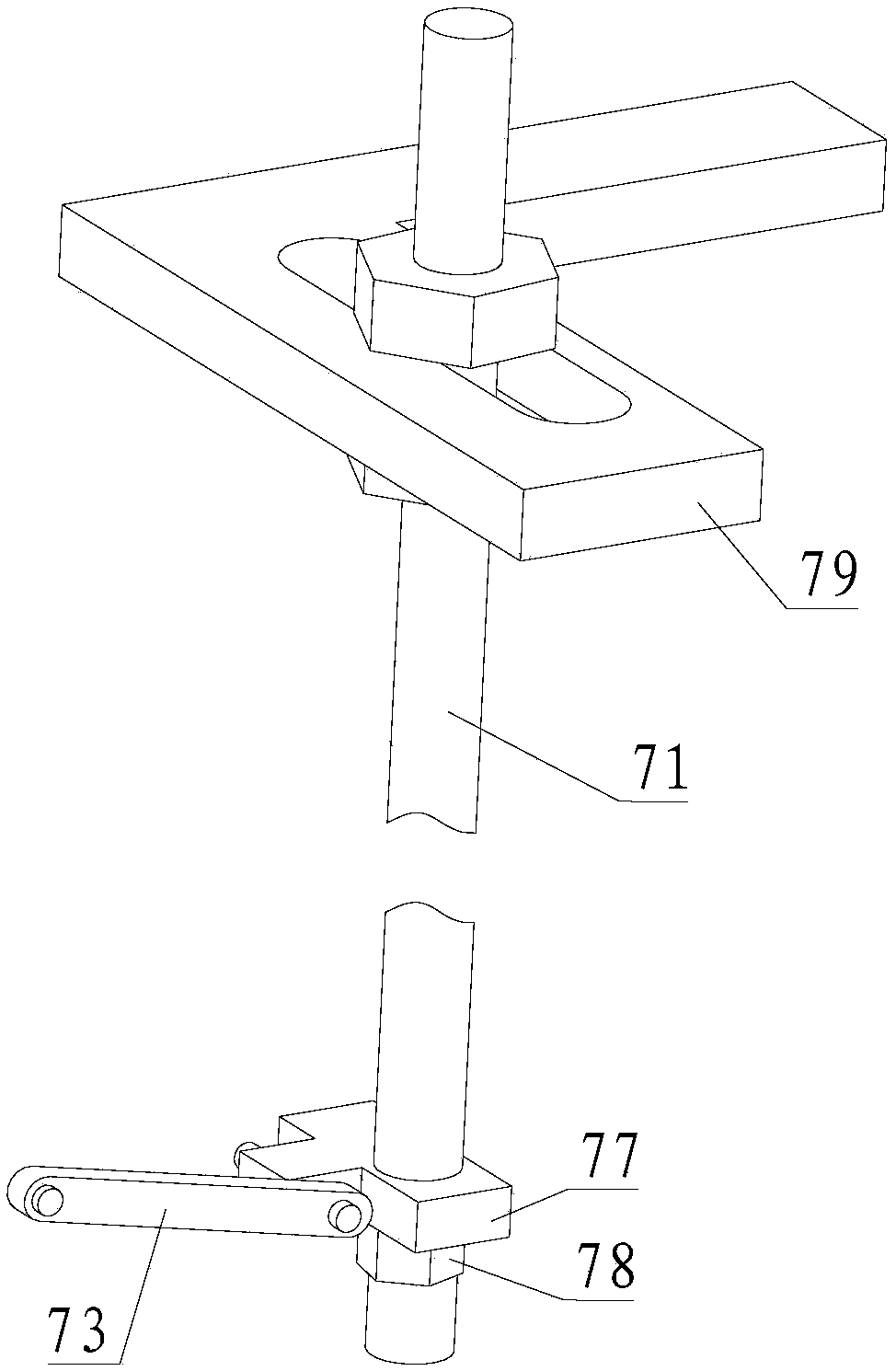

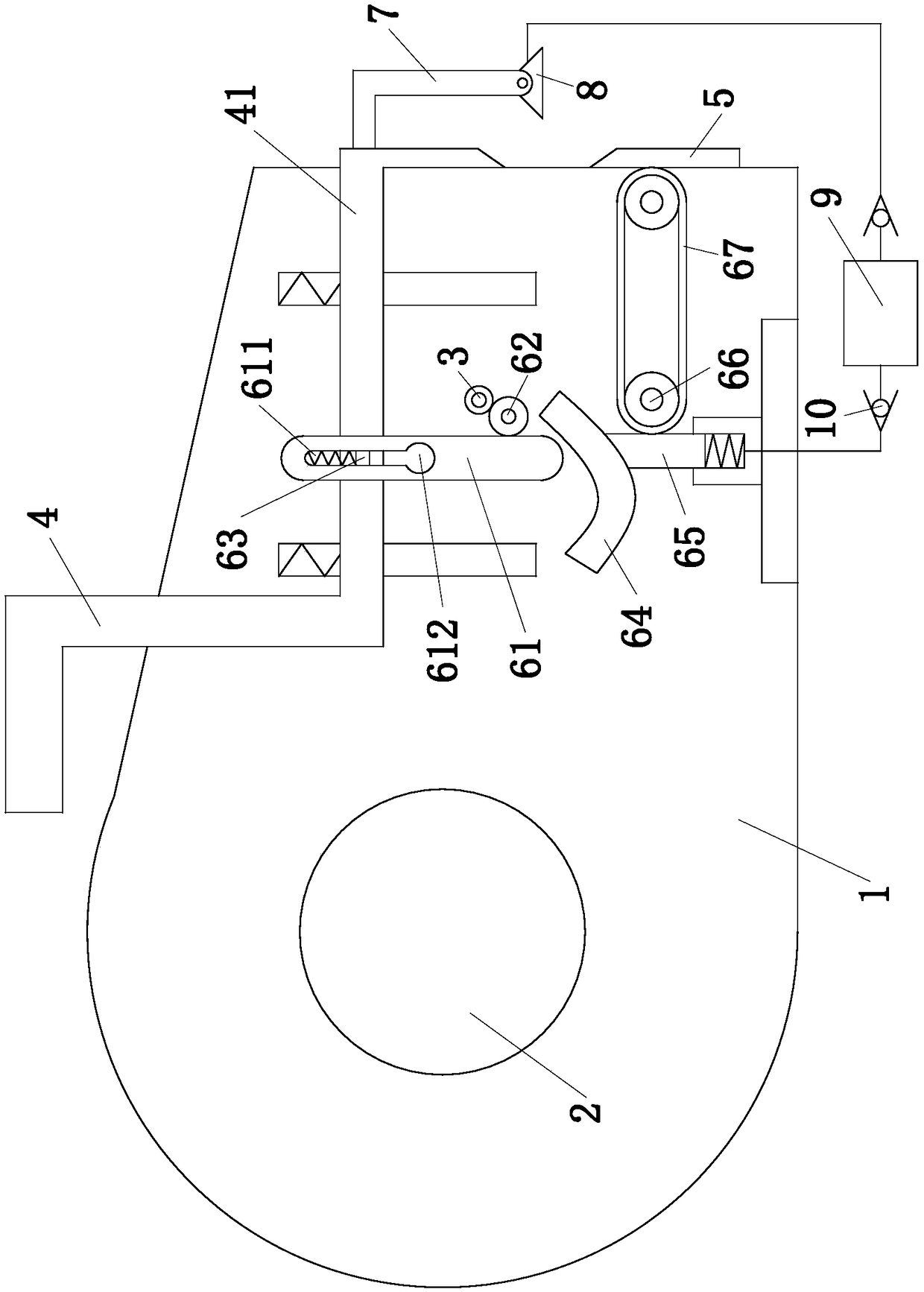

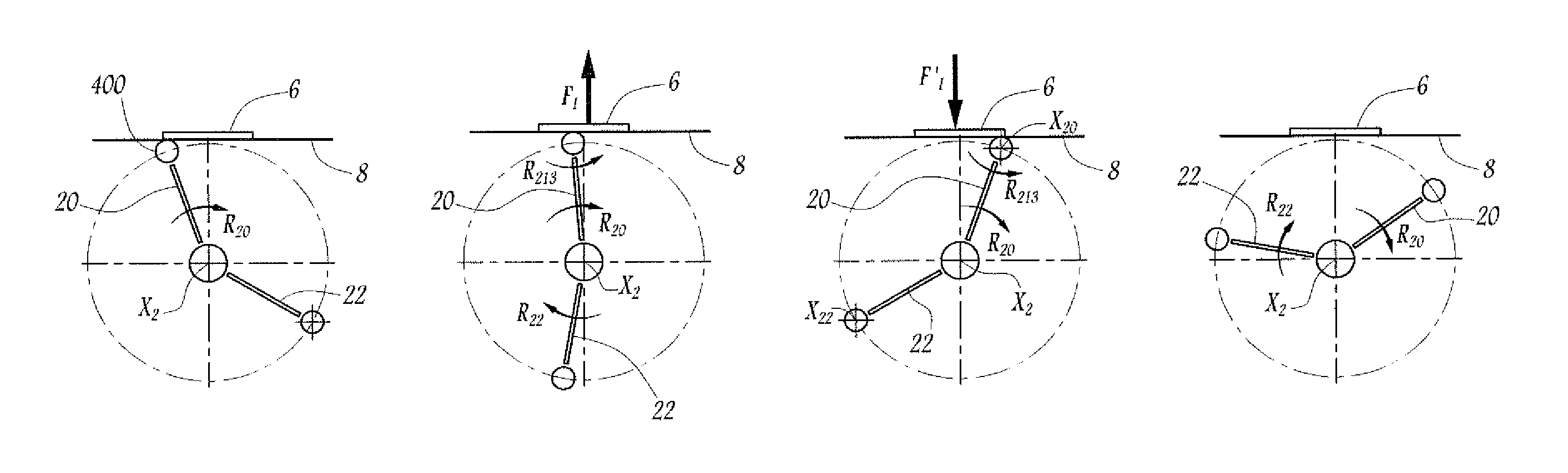

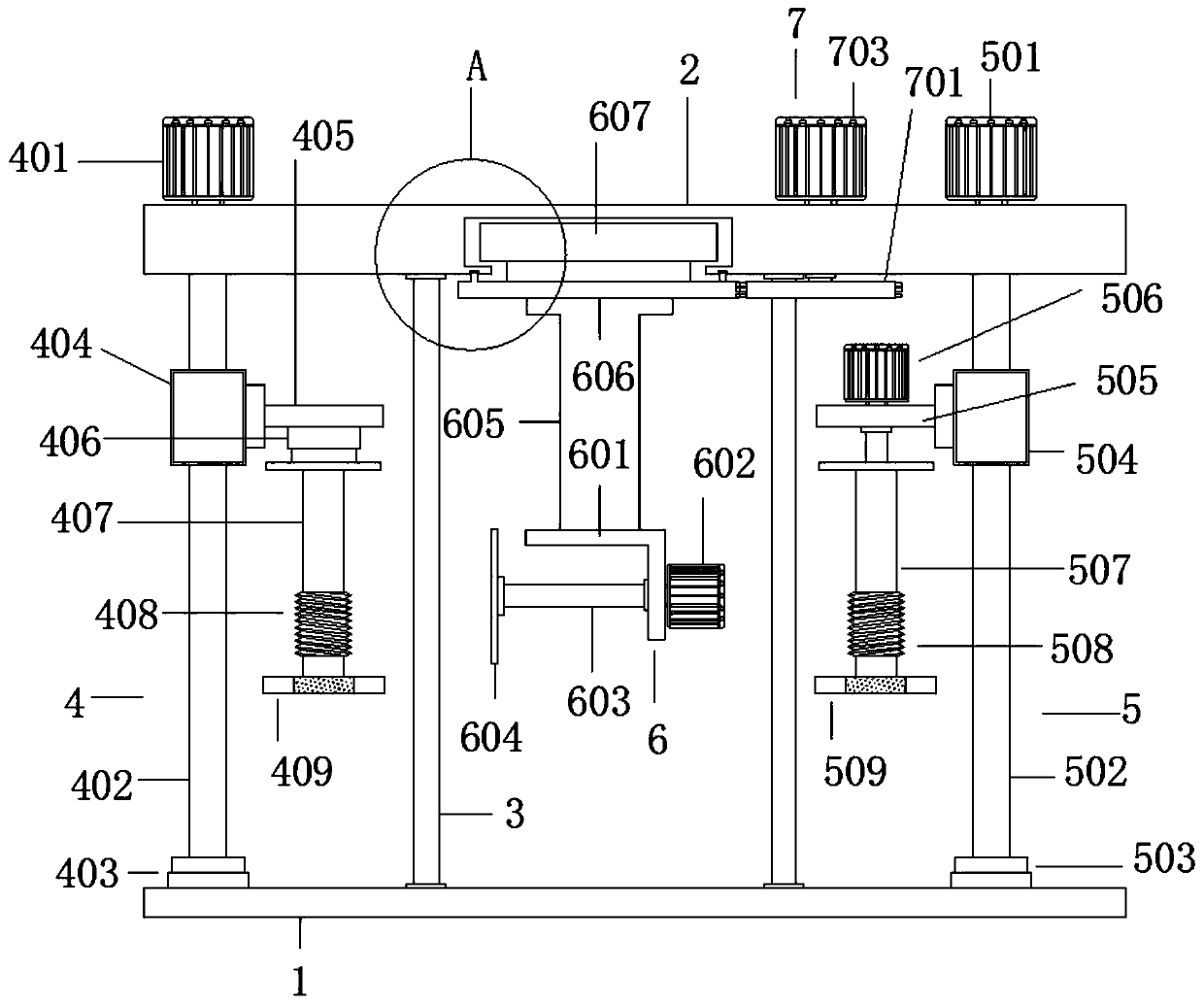

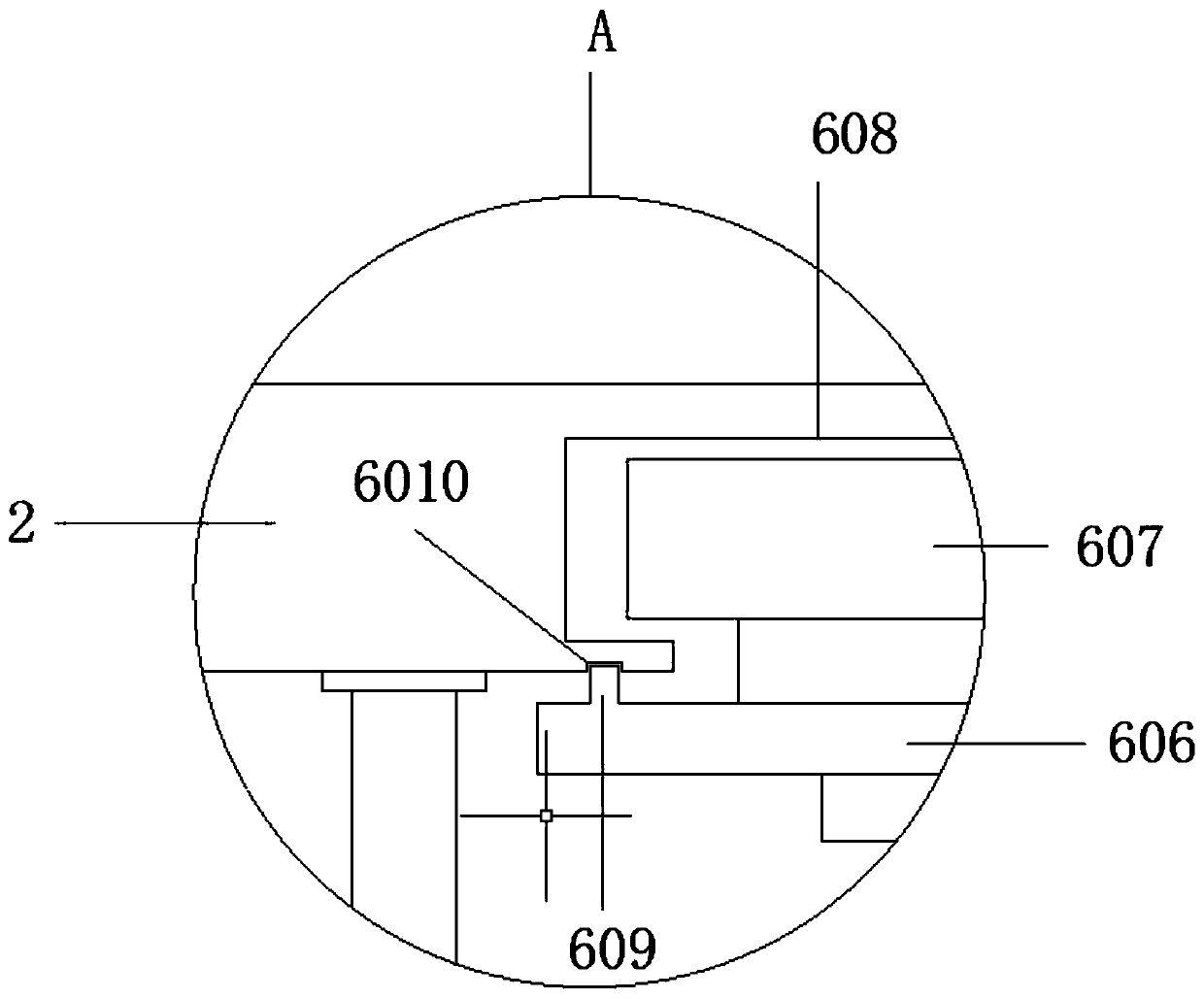

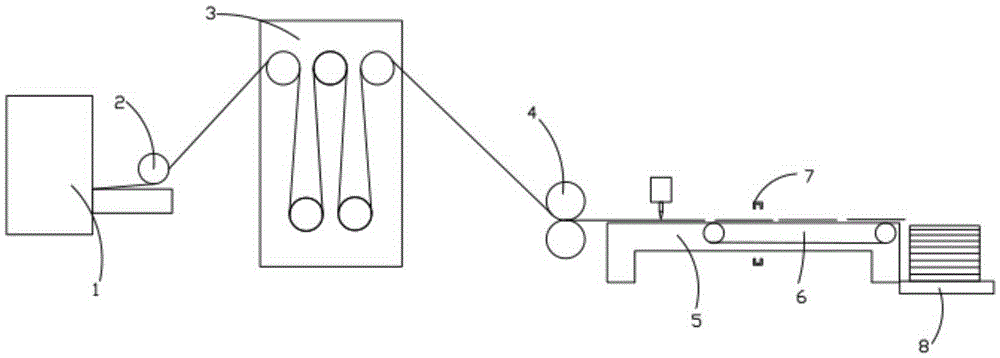

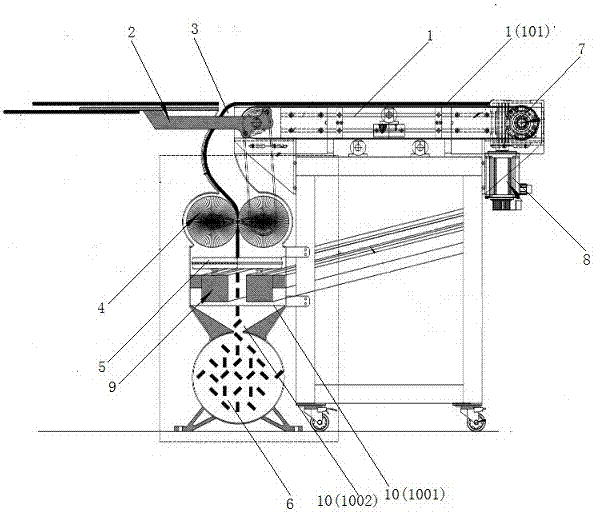

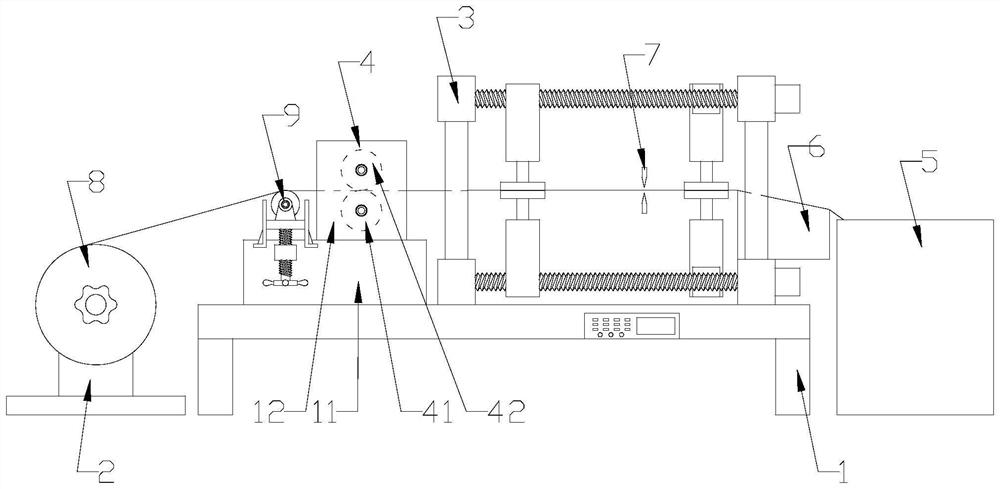

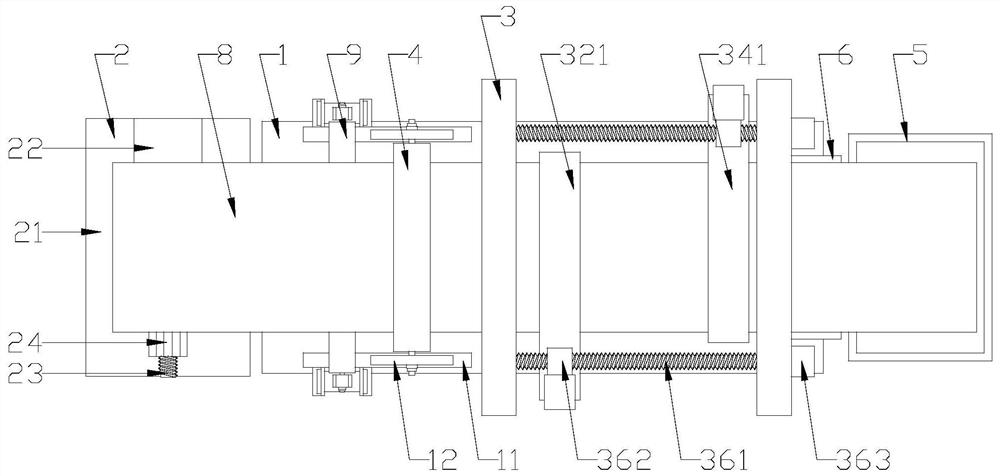

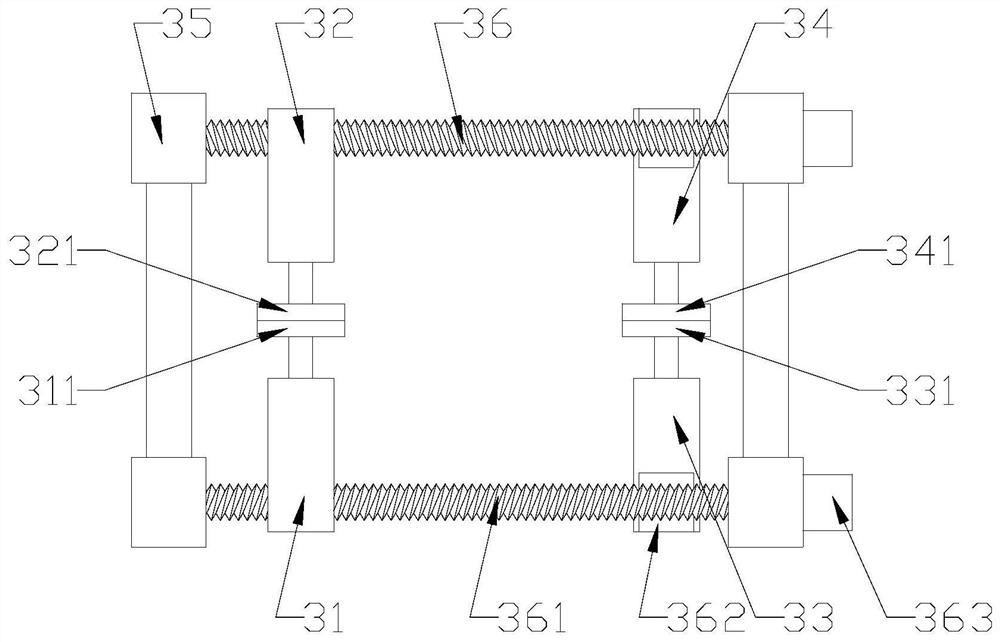

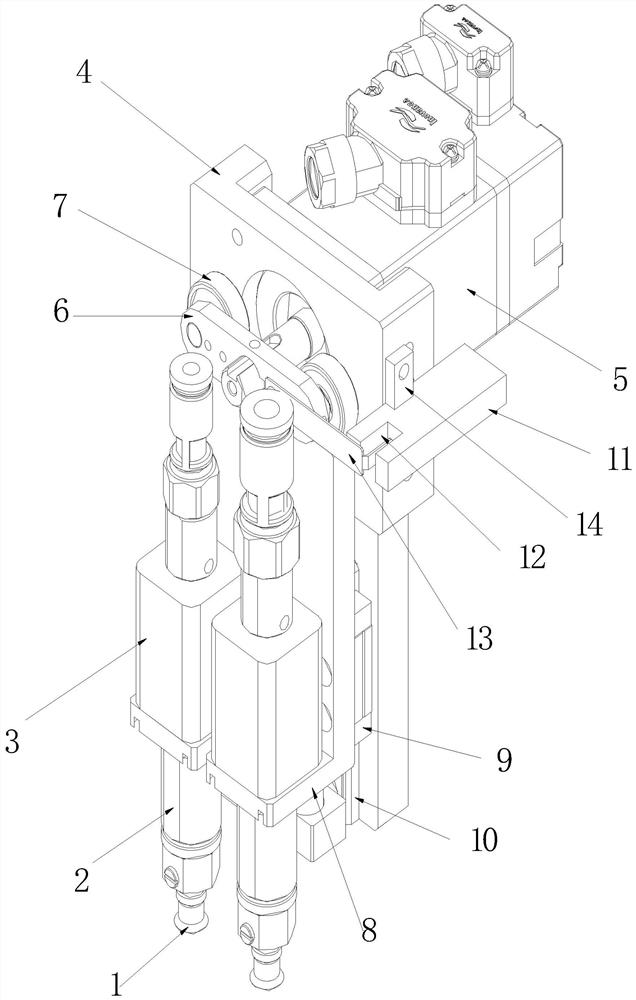

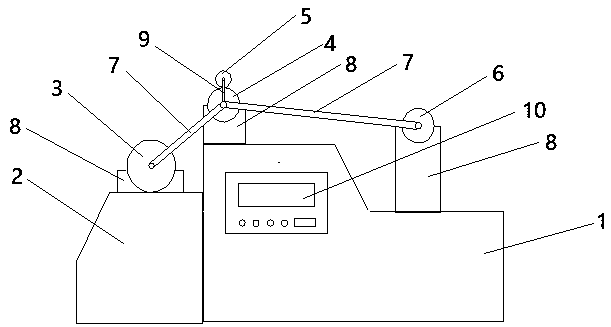

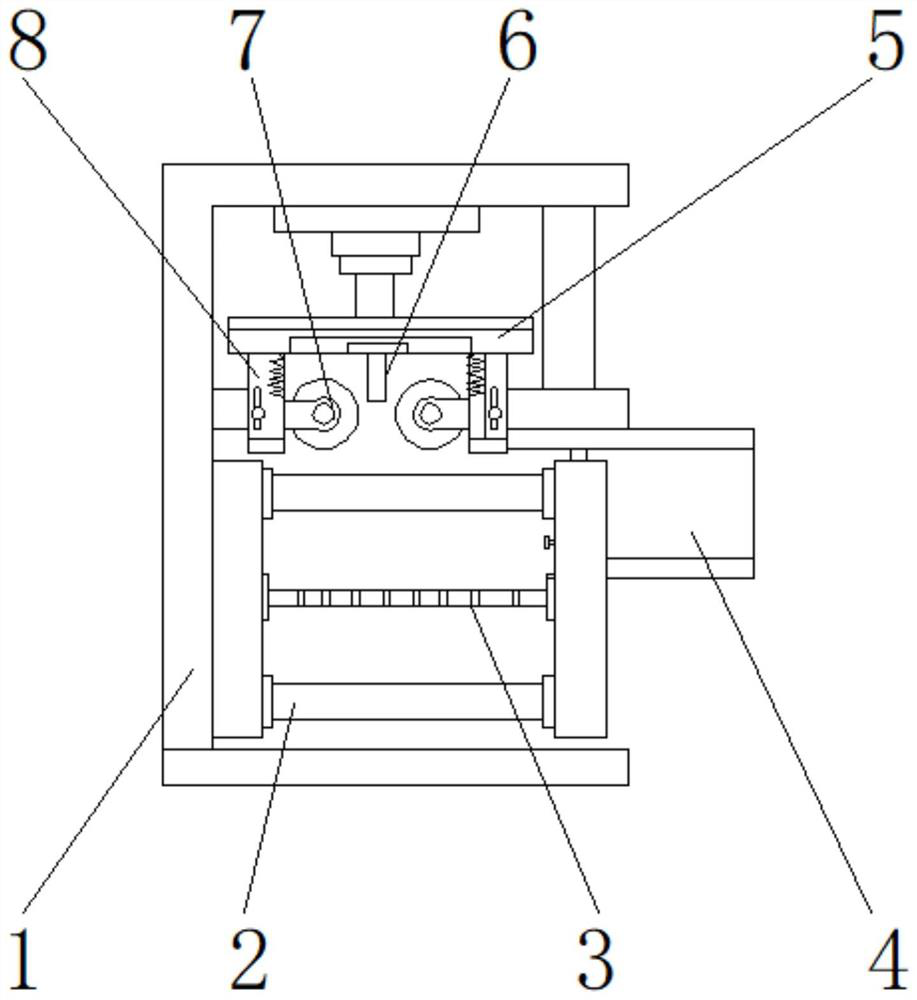

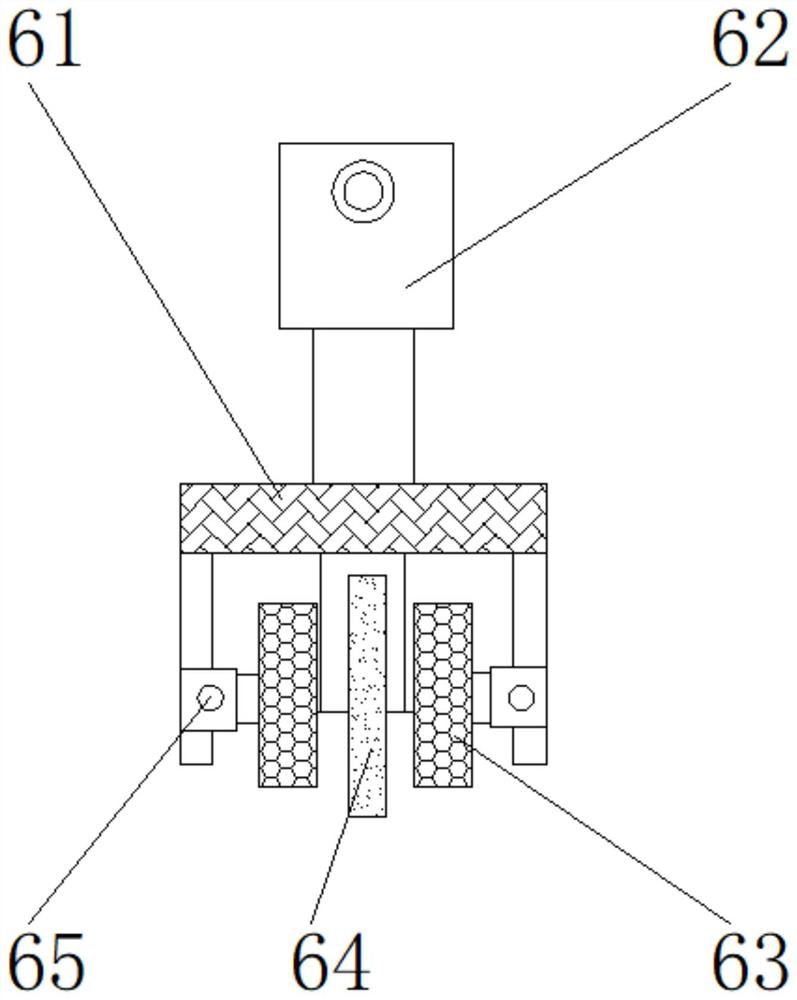

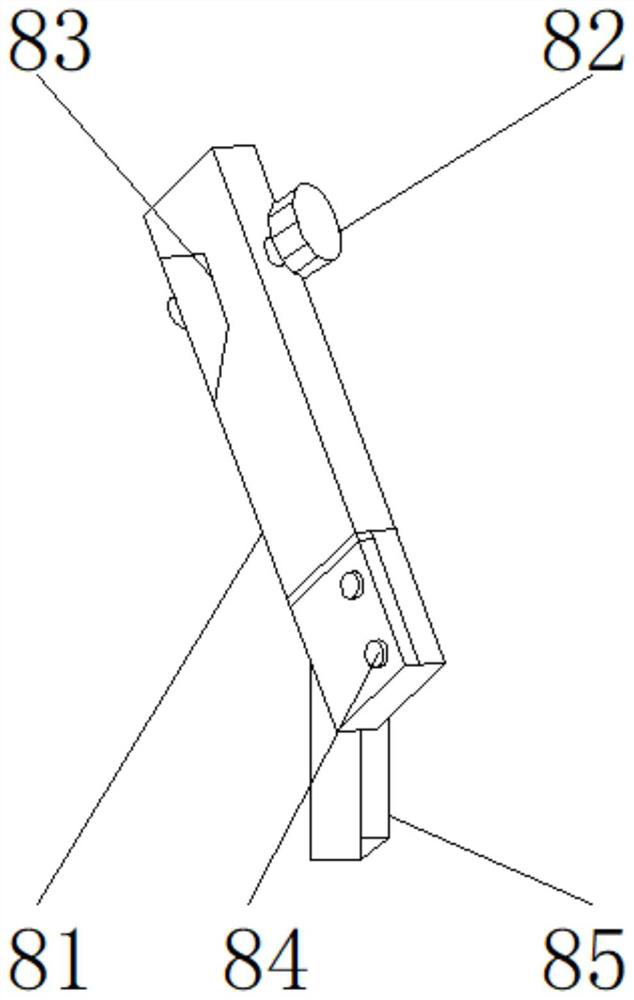

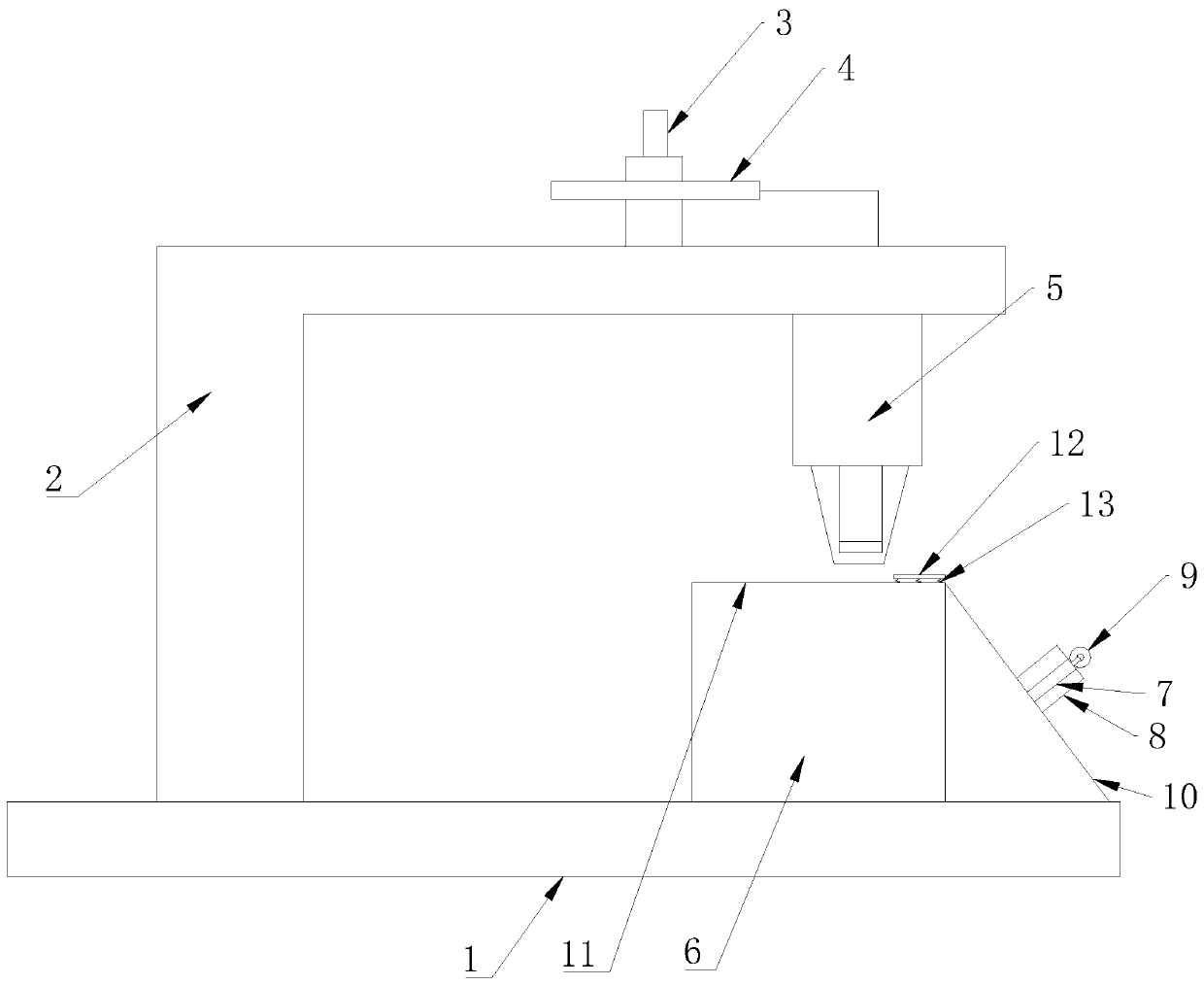

Film cutting device

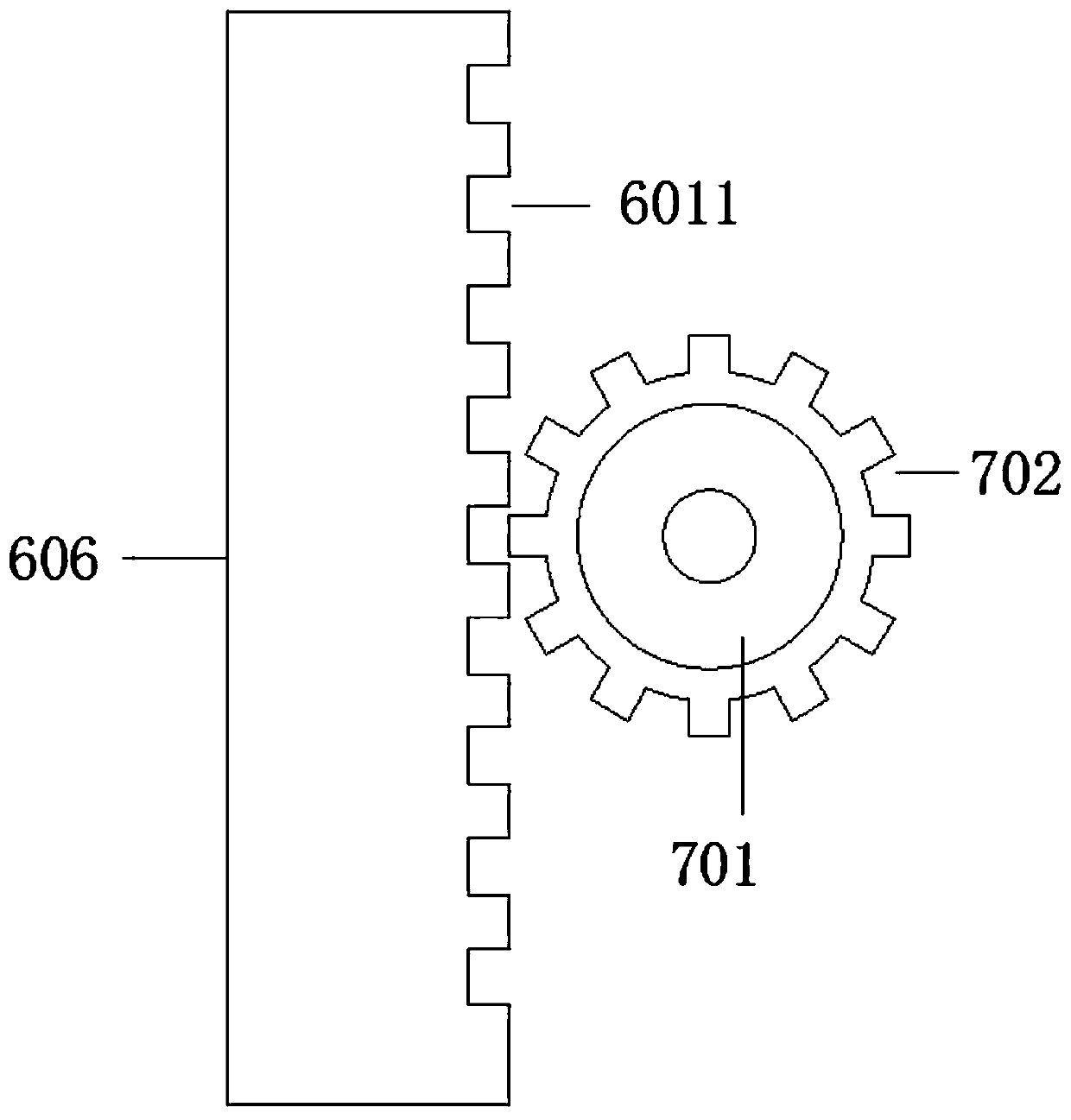

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

Process for controlling the conveying speed of a transporting track

InactiveUS6895303B1Optimized for speedRaise the ratioDigital data processing detailsCoin countersTrackwayProcess engineering

In the case of a method of controlling the transport speed of a transport and gathering unit, wherein filling-material stacks are moved from an inlet to an outlet of the gathering path making use of at least one transport means and wherein filling-material units can selectively be added to the filling-material stacks at one or at several adding stations, at least one measure is determined for each filling-material stack at the inlet of the gathering path, each measure for each filling-material stack is increased at each adding station by a respective value corresponding to the filling-material unit added, if the filling-material stack has added thereto a filling-material unit, each measure of each filling-material stack is compared with a respective set value associated with the transport means, and the transport speed is controlled in dependence upon the result of the comparison.

Owner:BOWE SYSTEC AG

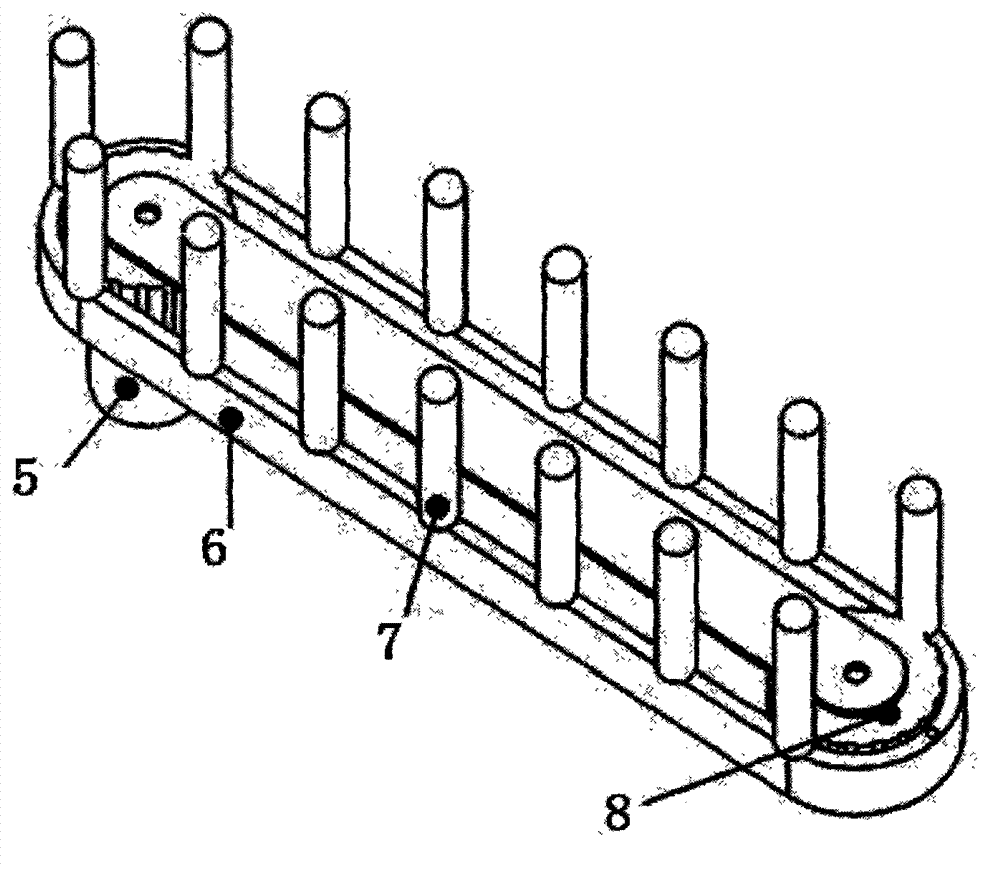

Sheet material supplying device

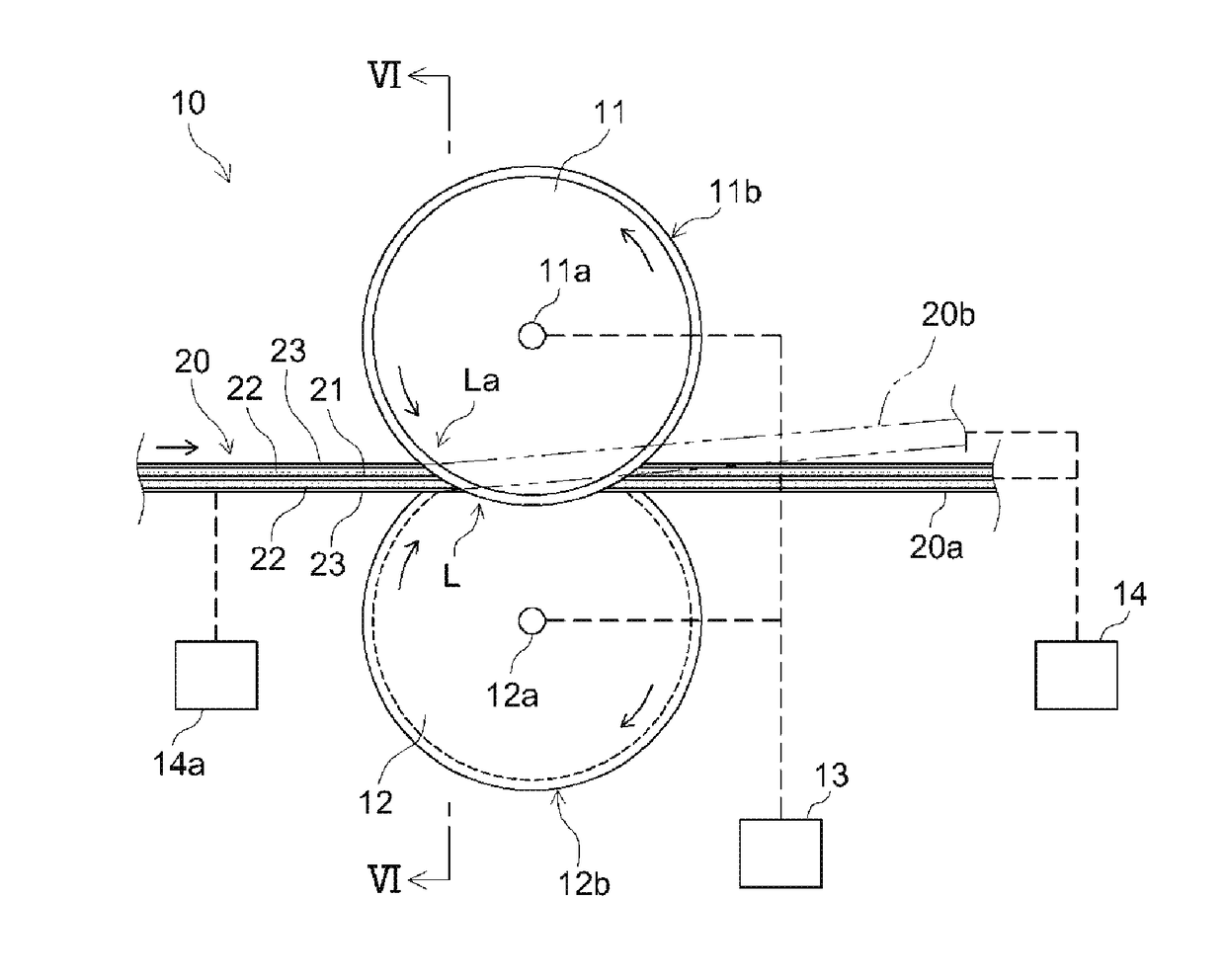

ActiveCN104955749ASmall footprintShock-sensitive articlesGlass severing apparatusSource materialBiomedical engineering

A sheet material supplying device comprises a pair of holding means (5, 6) that hold, in the width direction, both ends of a sheet material (4) made by cutting a strip sheet source material (1) into prescribed lengths, and a pair of guide members (12) that moveably support each of the pair of holding means (5, 6) between a cutting position and a supplying position of the sheet material (4). Each guide member (12) is supported by being suspended from a building beam (20).

Owner:NIPPON ELECTRIC GLASS CO LTD

Adhesive tape cutting machine

Owner:苏州萍升源电子科技有限公司

Marking or labeling machine and a marking or labeling method

ActiveUS8443861B2Increase production capacityMechanical working/deformationOrnamental structuresEngineeringMechanical engineering

Owner:ILLINOIS TOOL WORKS INC

Cutting device for aluminum box adhesive tape processing

ActiveCN110282481AEasy to installEfficient cuttingArticle deliveryWebs handlingEngineeringMechanical engineering

Owner:福建友谊胶粘带集团有限公司

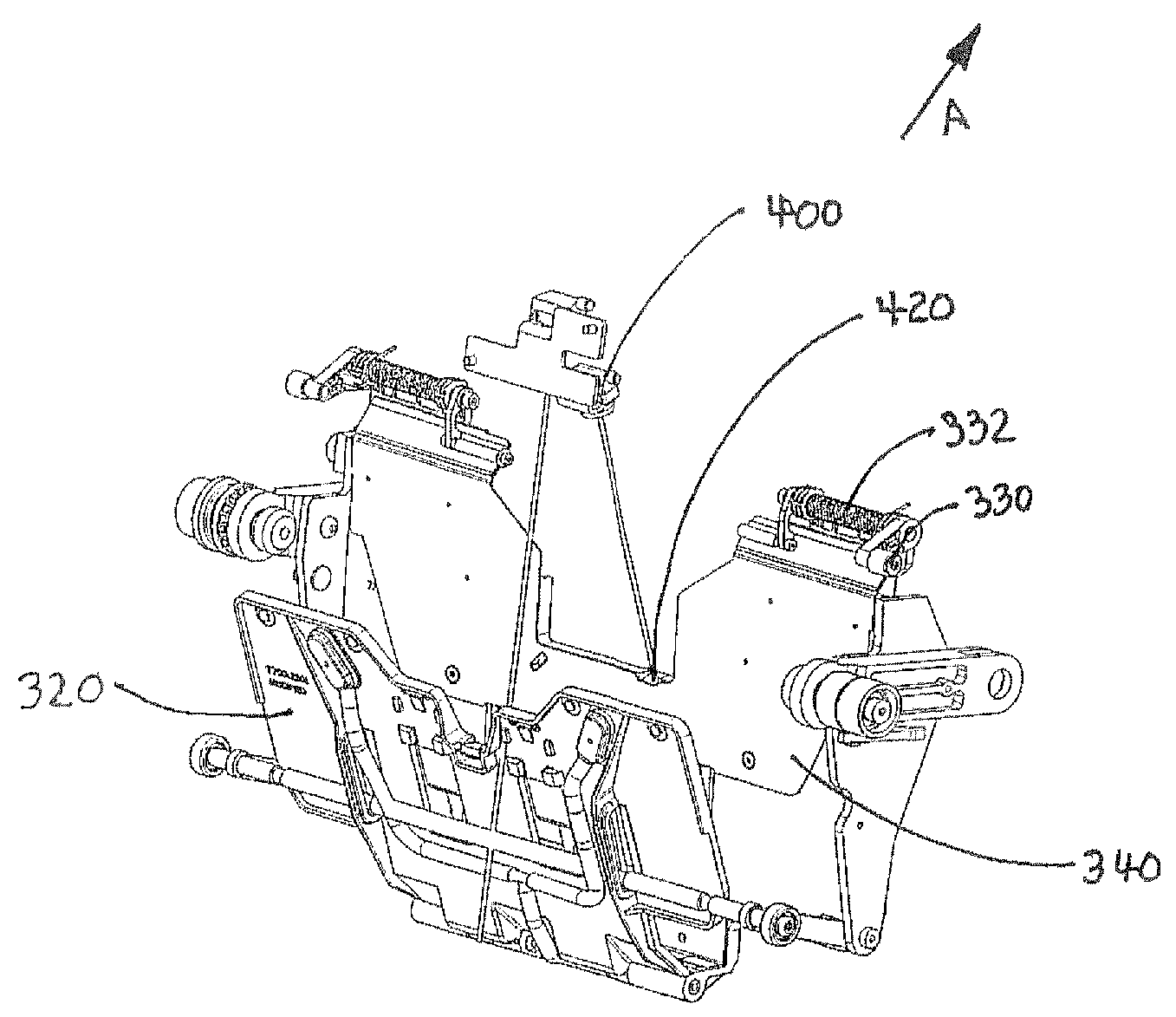

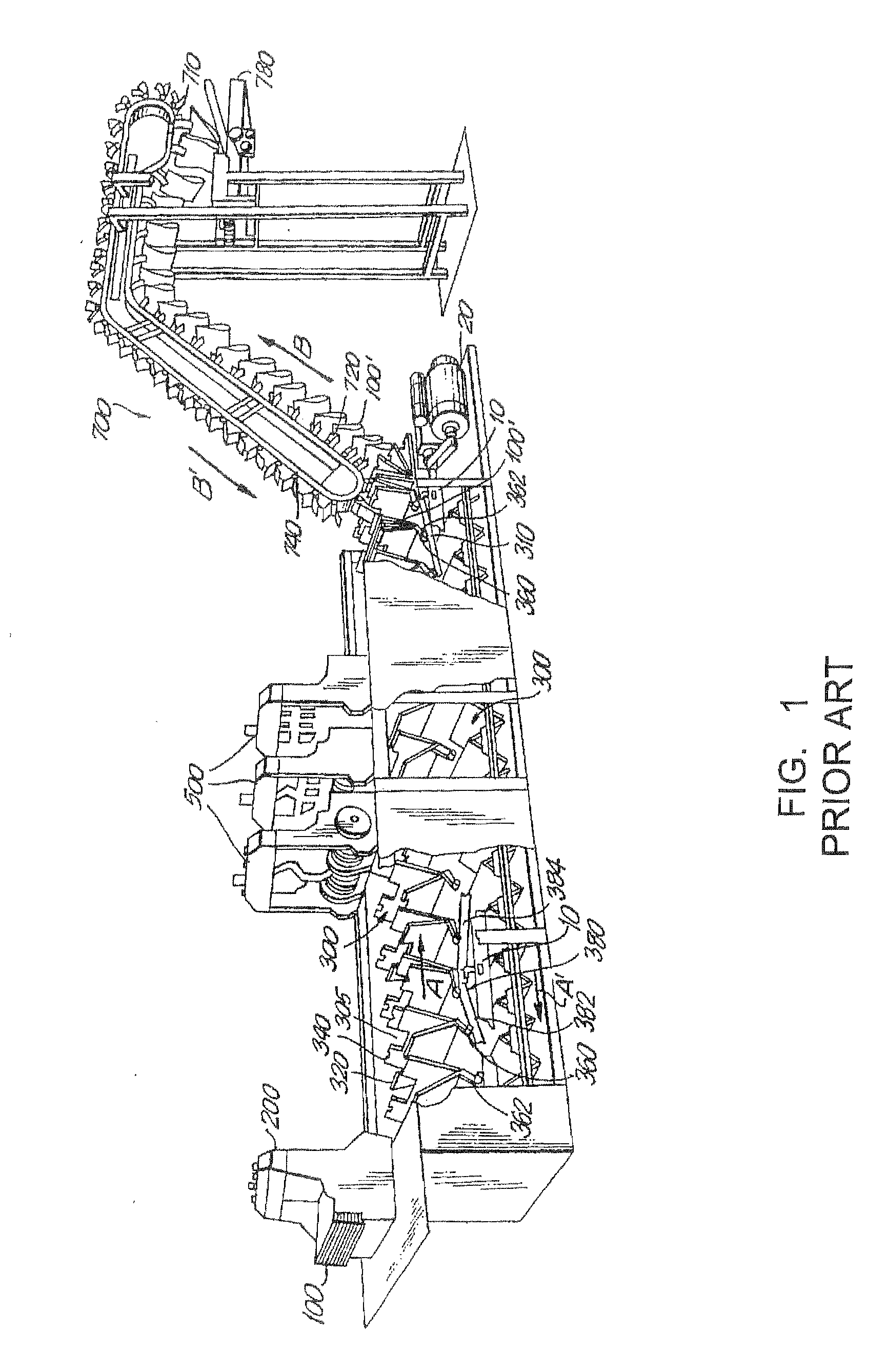

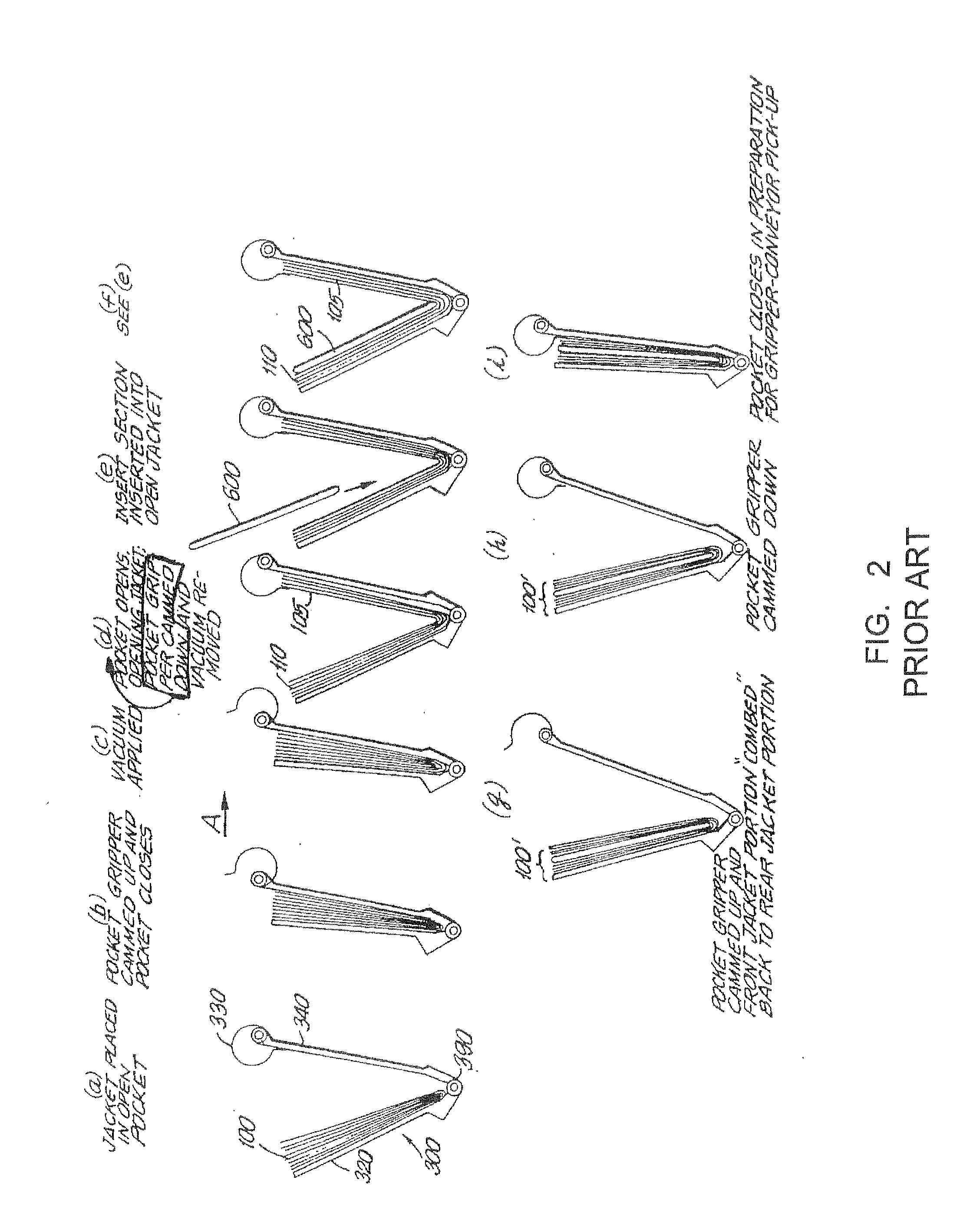

Pocket management system

Owner:MULLER MARTINI

Textile gum application line

InactiveCN105383991AReduce processing stepsReduce manufacturing costArticle deliveryEngineeringMechanical engineering

Owner:苏州长晟无纺科技有限公司

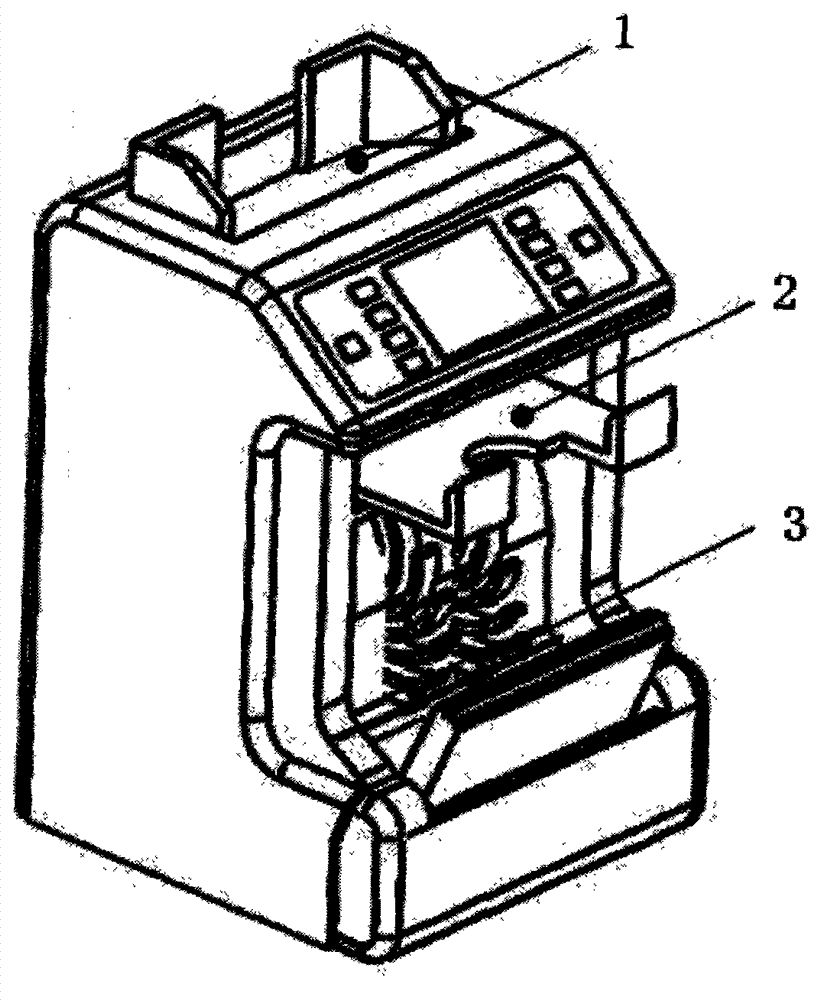

Sorting machine with paper money collecting system

InactiveCN103310534AExtension of timeReduce work intensityCoin/paper handlersArticle deliveryStopped workElectric machinery

Owner:ZHEJIANG FOTA ELECTRIC

Tension-free towel slitting machine

Owner:苏州大喆智能科技有限公司

Flexible material discharging platform capable of realizing waste separation treatment

PendingCN107571321AImprove collection efficiencyMetal working apparatusArticle deliveryEngineeringWaste management

Owner:YANCHENG XIONGYING PRECISION MACHINERY

End conveying device for transfer film

Owner:海盐三湾塑业有限公司

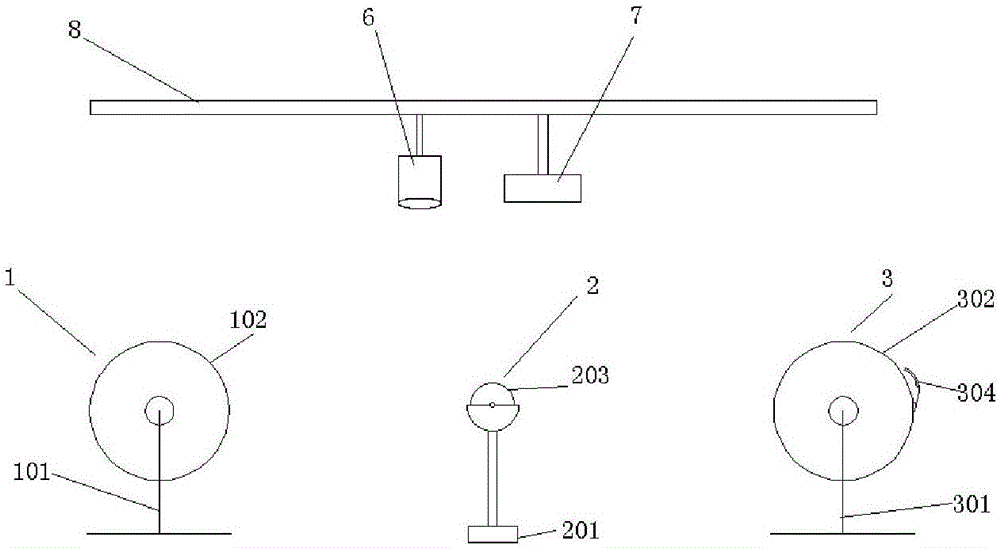

Cutting and winding equipment for silk fabric

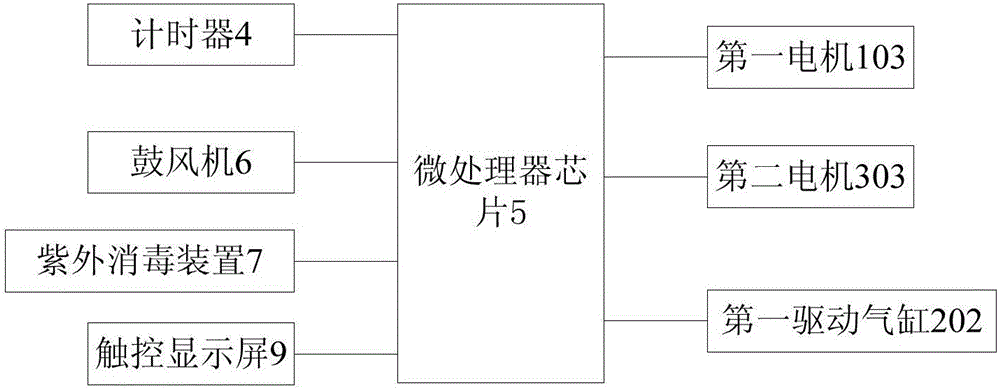

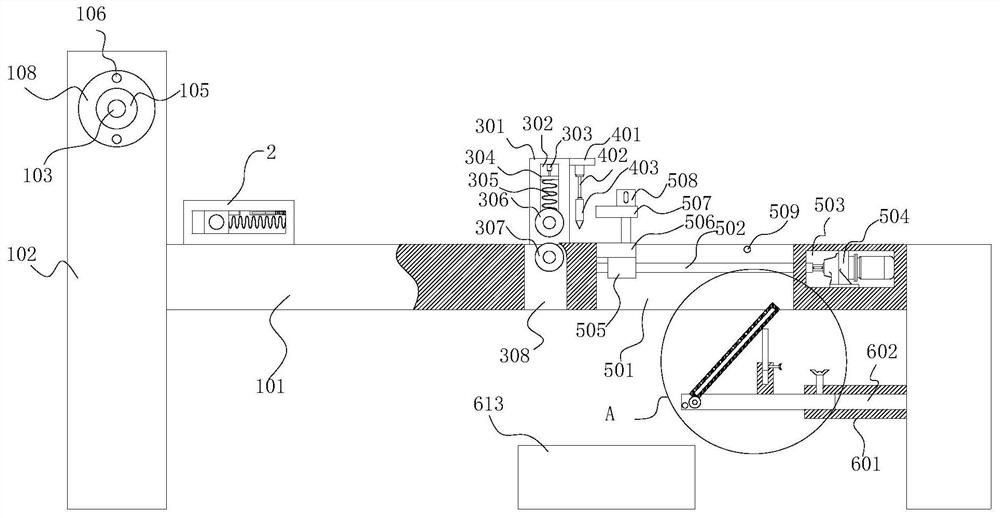

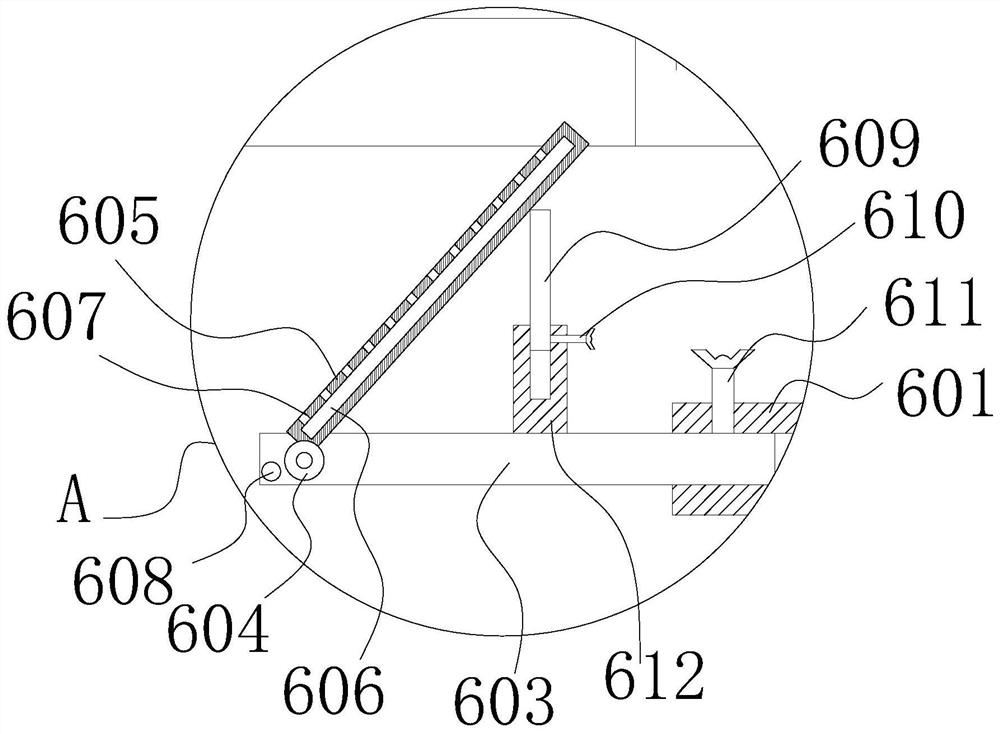

InactiveCN106400453ASimple structureEasy to useSevering textilesArticle deliveryElectric machineryMicroprocessor chip

The invention discloses cutting and winding equipment for a silk fabric. The cutting and winding equipment comprises a pay-off mechanism, an air blower, an ultraviolet disinfection device, a cutting mechanism, a take-up mechanism, a timer and a micro processor chip, wherein the pay-off mechanism comprises a pay-off frame, a pay-off roller and a first motor for driving the pay-off roller to rotate; the air blower and the ultraviolet disinfection device are mounted on a cross beam; the cutting mechanism comprises a base and a cutting tool which is located above the base and is driven by a first driving cylinder; the take-up mechanism comprises a take-up frame, a take-up roller mounted on the take-up frame and a second motor for driving the take-up roller to rotate; a clamping mechanism is arranged on the take-up roller; the output end of the timer is connected with the input end of the micro processor chip; and the output end of the micro processor chip is respectively connected with the first motor, the second motor, the first driving cylinder, the air blower and the ultraviolet disinfection device. The cutting and winding equipment is simple in structure and convenient to use, the use stability of the cutting and winding equipment is greatly improved, the production efficiency is improved, and the production cost of an enterprise is reduced.

Owner:SUZHOU WEIDU SILK

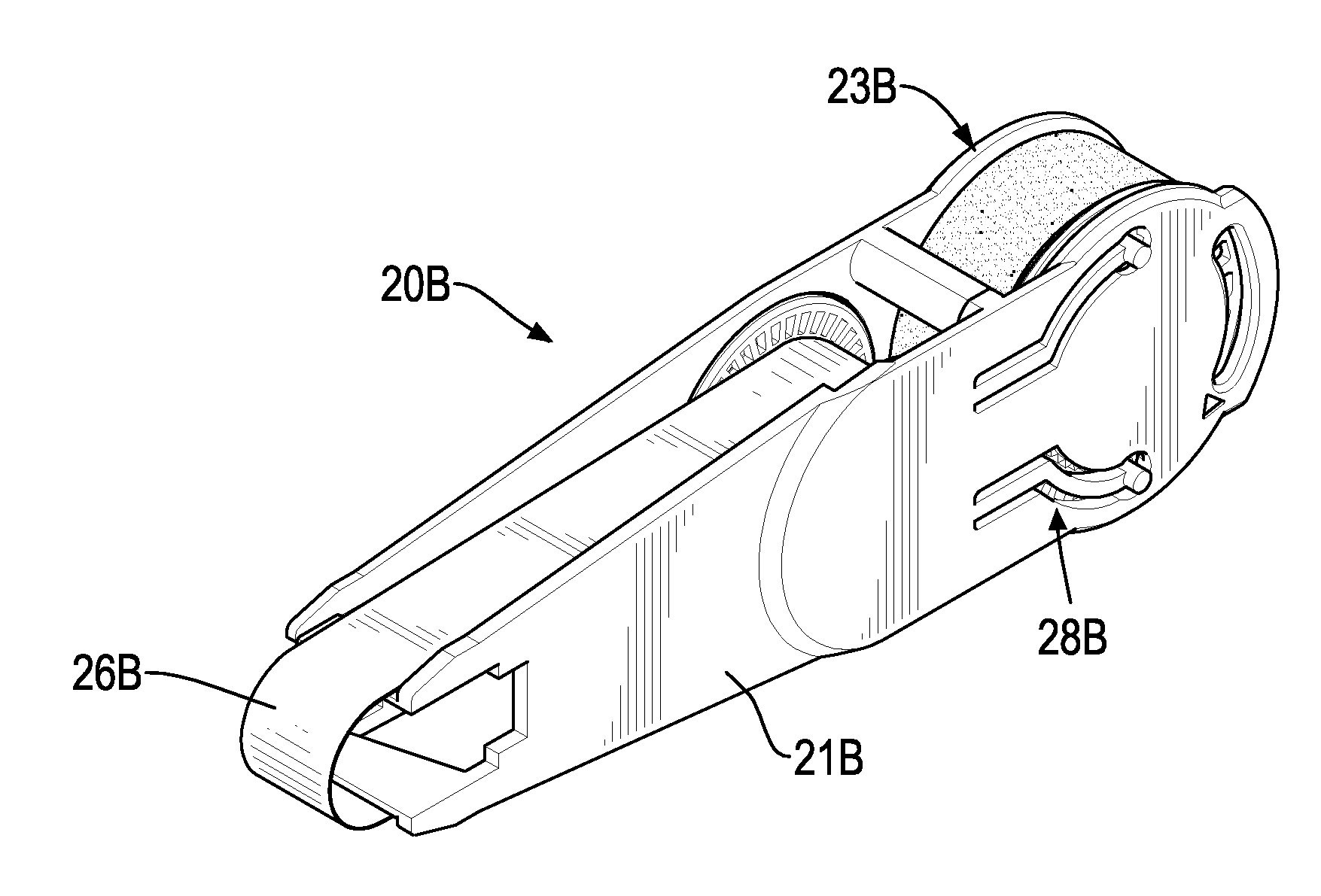

Coating Film Transfer Tool

InactiveUS20110198037A1Reduce component countIncrease production costErasing devicesLaminationGear wheelEngineering

There is provided a coating film transfer tool with a reduced number of components and a high degree of design freedom, comprising a feed spool around which an unused transfer tape is wound, a transfer head from which the transfer tape is suspended and which pressure transfers a coating film on the transfer tape suspended therefrom to a transfer-receiving object by pressing the coating film thereagainst, a take-up spool around which the transfer tape on which transfer of the coating film is completed is wound, a transfer portion case 55 which holds constituent members, a slip member 71 which pivotally supports the feed spool and which is loosely fitted in the transfer portion case, a feed-side gear 73 securely fitted on the slip member 71 in a position lying between the feed spool and the slip member 71, and a take-up-side gear which rotates together with the take-up spool, wherein a rotation of the feed spool is transmitted to the take-up spool by the gears, and wherein the transfer portion case and the slip member configures a load adjusting means, and the slip member and the feed-side gear configures a rotational speed adjusting means.

Owner:PLUS CORP

Web processing system with multiple folding arrangements fed by a single web handling arrangement

A web processing system is provided. The web processing system supplies a processed continuous web of material to a cutting arrangement. The cutting arrangement forms sheets from the continuous web of material. The sheets are then supplied to multiple folding arrangements such that a single web of material is used to supply sheets to multiple folding arrangements.

Owner:C G BRETTING MFG

Processing device and technology for towel production

Owner:安徽省伊贝雅纺织股份有限公司

Cutting apparatus and rotary blade

ActiveUS20180282105A1Prolong lifeGreat tolerance for variationCell electrodesLi-accumulatorsRough surfaceEngineering

Owner:TOYOTA JIDOSHA KK

Efficient film pasting device

Owner:SUZHOU NEW STAR PRECISION MECHANISM

Aluminum foil preservative film semi-automatic high-speed rewinder

InactiveCN107686021AOperation positioning is accurateHigh degree of automationArticle deliveryWebs handlingCouplingSemi automatic

Owner:张家港爱铝铝箔科技有限公司

Food packaging bag film slitting device

PendingCN114261144AAvoid deformationAvoid damageBag making operationsPaper-makingElectric machineryStructural engineering

Owner:德清新顶包装有限公司

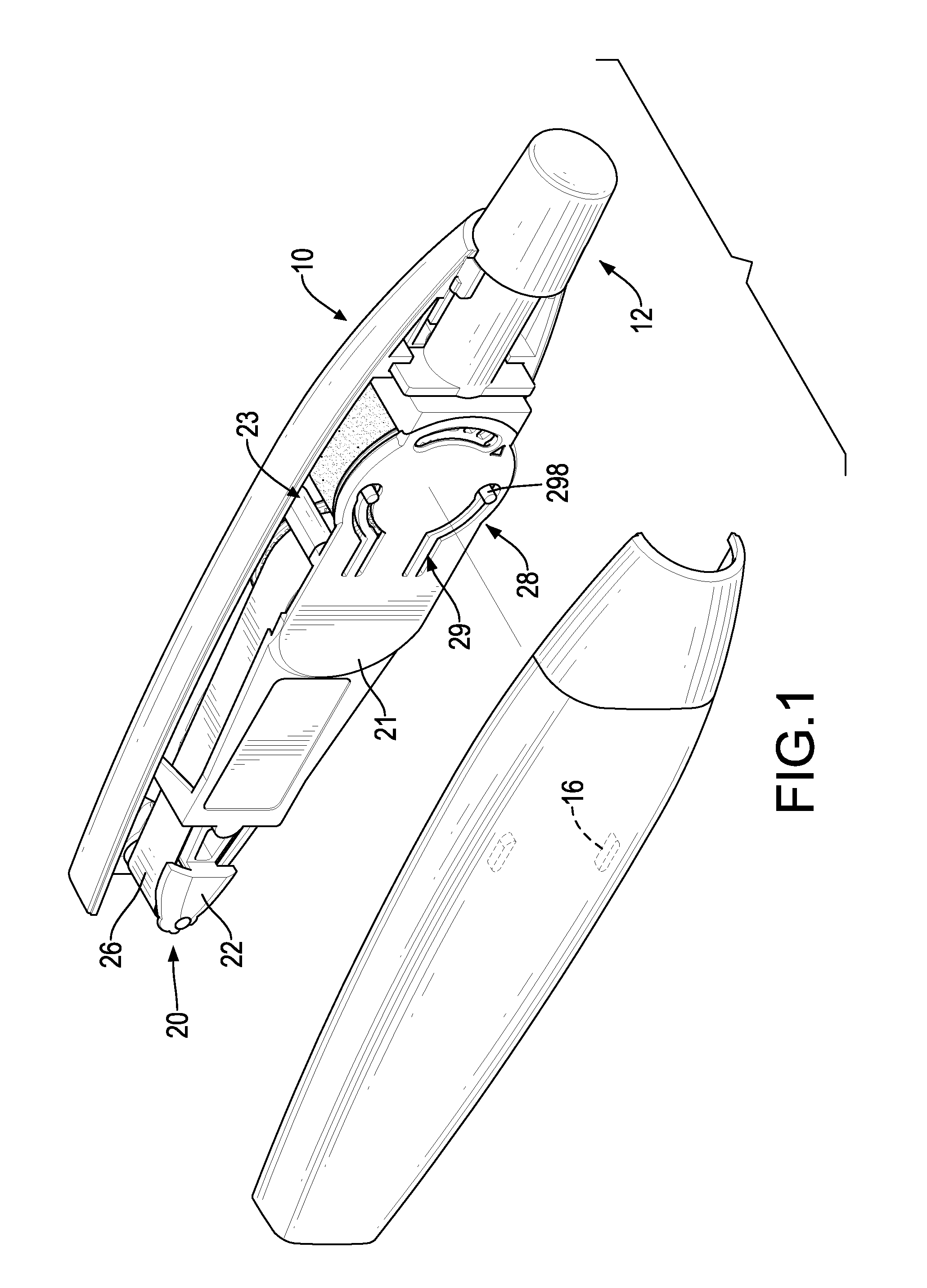

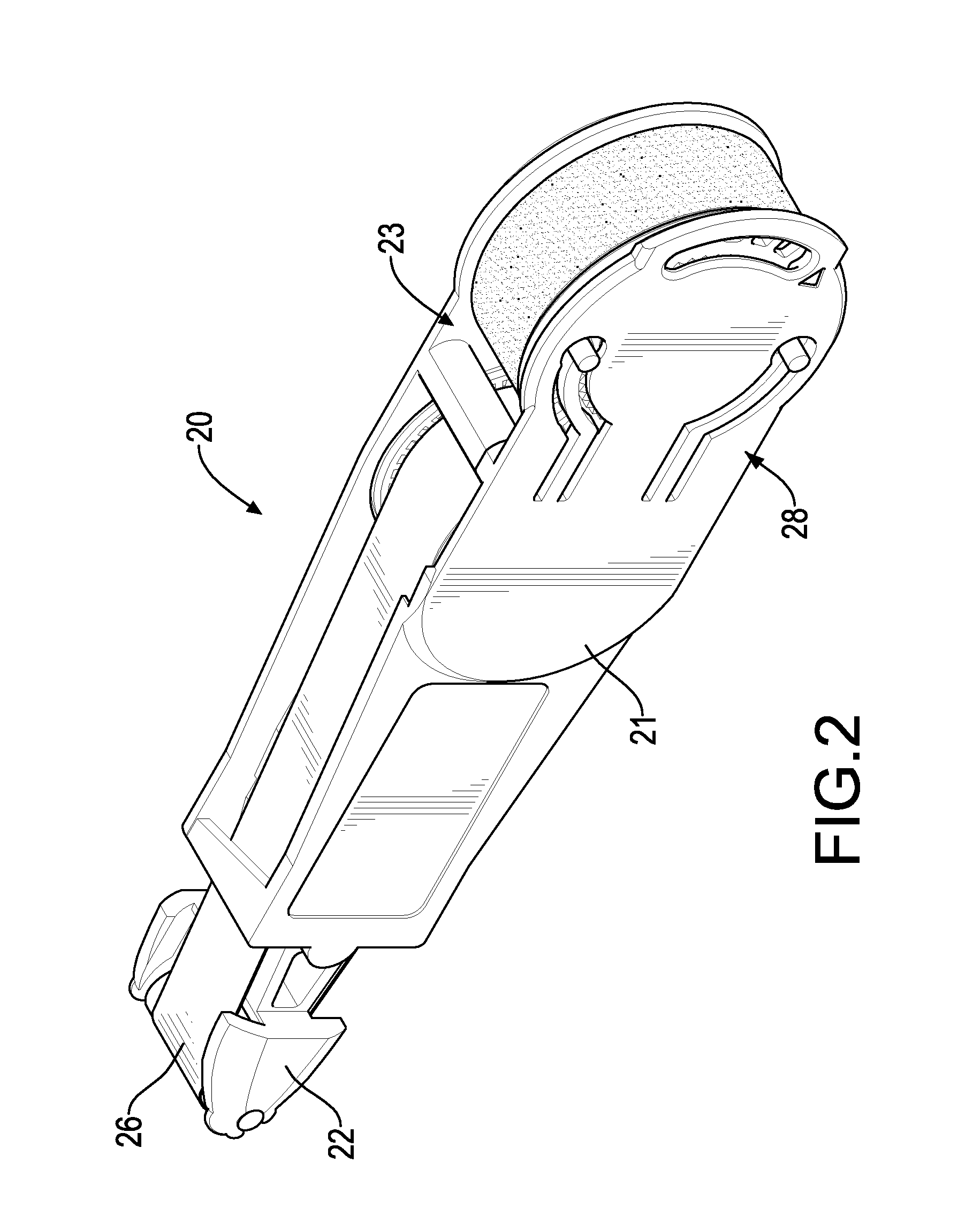

Dispensing unit for a thin film dispenser and thin film dispenser having the same

InactiveUS20130186571A1Improve convenienceImprove versatilityFilament handlingPaperhangingThin membraneEngineering

Owner:SDI CORPORATION

Full-automatic gluing machine

InactiveCN110301706AAvoid the disadvantage of not being able to maintain linearityReduce labor intensityArticle deliveryClothes making applicancesMechanical engineering

Owner:成工业制衣(苏州)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap