Full-automatic gluing machine

A glue sticking machine, fully automatic technology, applied in the direction of sewing tools, thin material processing, sending objects, etc., can solve problems such as easy bending, and achieve the effect of labor-saving operation and labor-intensive reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

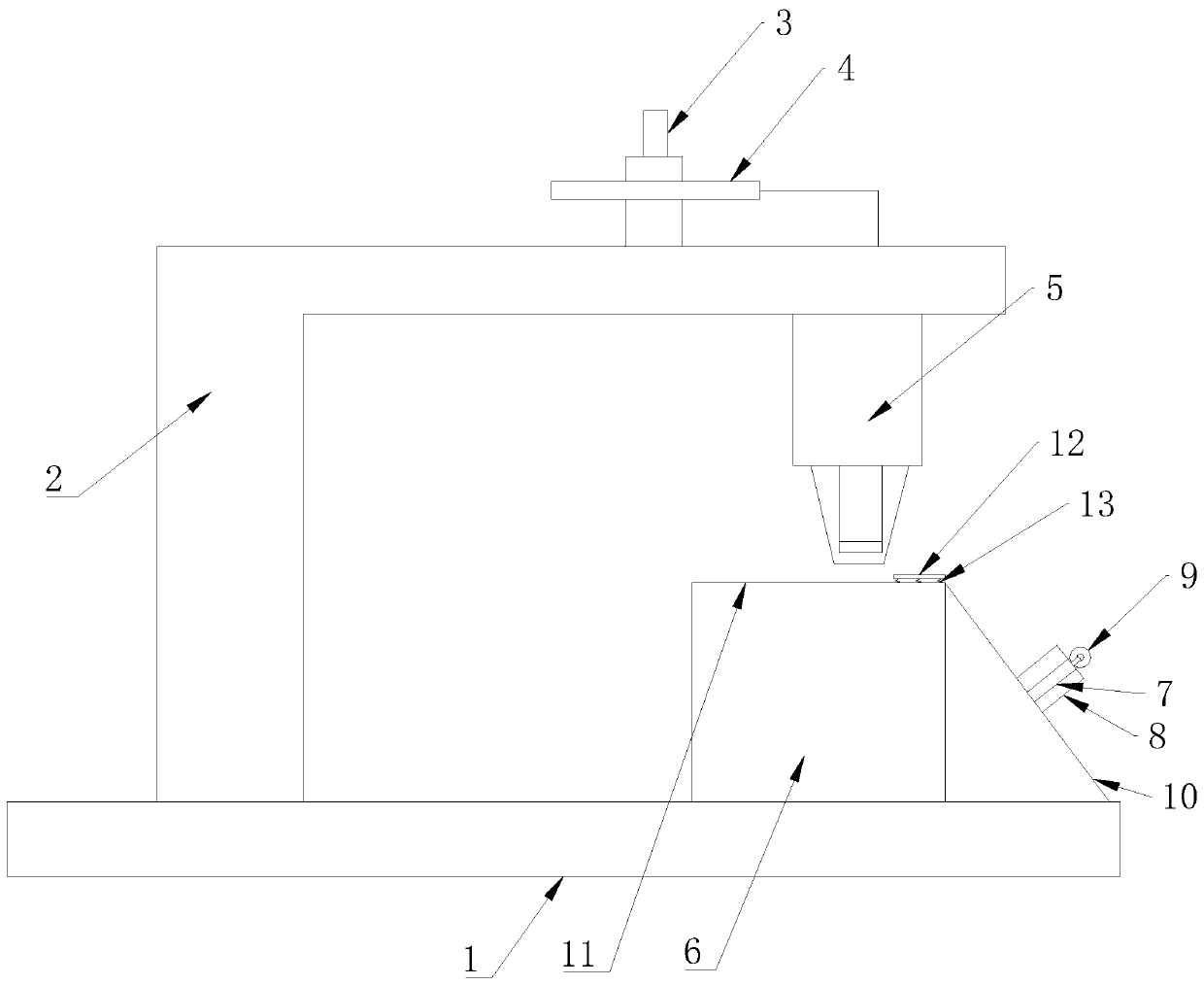

[0013] like figure 1 As shown in the figure, a fully automatic glue sticking machine includes a workbench 1, a support arm 2 is provided on the workbench 1, a glue guide rod 3 and a guide rod arranged on the glue guide rod 3 are provided on the support arm 2 Glue wheel 4, below the support arm 2 is provided with a lifting and sticking block 5 that drives the tape to move up and down, below the support arm 2 is provided with a glue sticking table 6, and a material receiving assembly is arranged on the glue sticking table 6. The receiving assembly includes a bracket 7 , a motor 8 is arranged on the bracket 7 , and a receiving roller 9 is connected to the motor 8 .

[0014] The working principle of the fully automatic glue sticking machine of the present invention is as follows: the roll of adhesive tape is set on the glue guide wheel 4, the glue guide wheel 4 is set on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap