Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about "Conveyor parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for producing semiconductors and other devices and cleaning apparatus

InactiveUS6035871AWater/sewage treatment by electrochemical methodsSemiconductor/solid-state device manufacturingSemiconductorBiomedical engineering

Provided is an apparatus for producing semiconductor and other devices, which can improve the quality of deposited films and increase the yield of produced devices in comparison with the conventional apparatus. The apparatus of the invention comprises a plurality of dry treatment chambers (7a, 7b, 7c, 7d, 7e), a transfer room (6) interconnecting the dry treatment chambers (7a, 7b, 7c, 7d, 7e), loading / unloading chambers (8a, 8b, 8c, 8d), and a cleaning apparatus (13). The transfer room (6) and the cleaning apparatus (13) are directly or indirectly connected to each other.

Owner:ALPS ALPINE CO LTD

Automatic screw rod feeding device

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

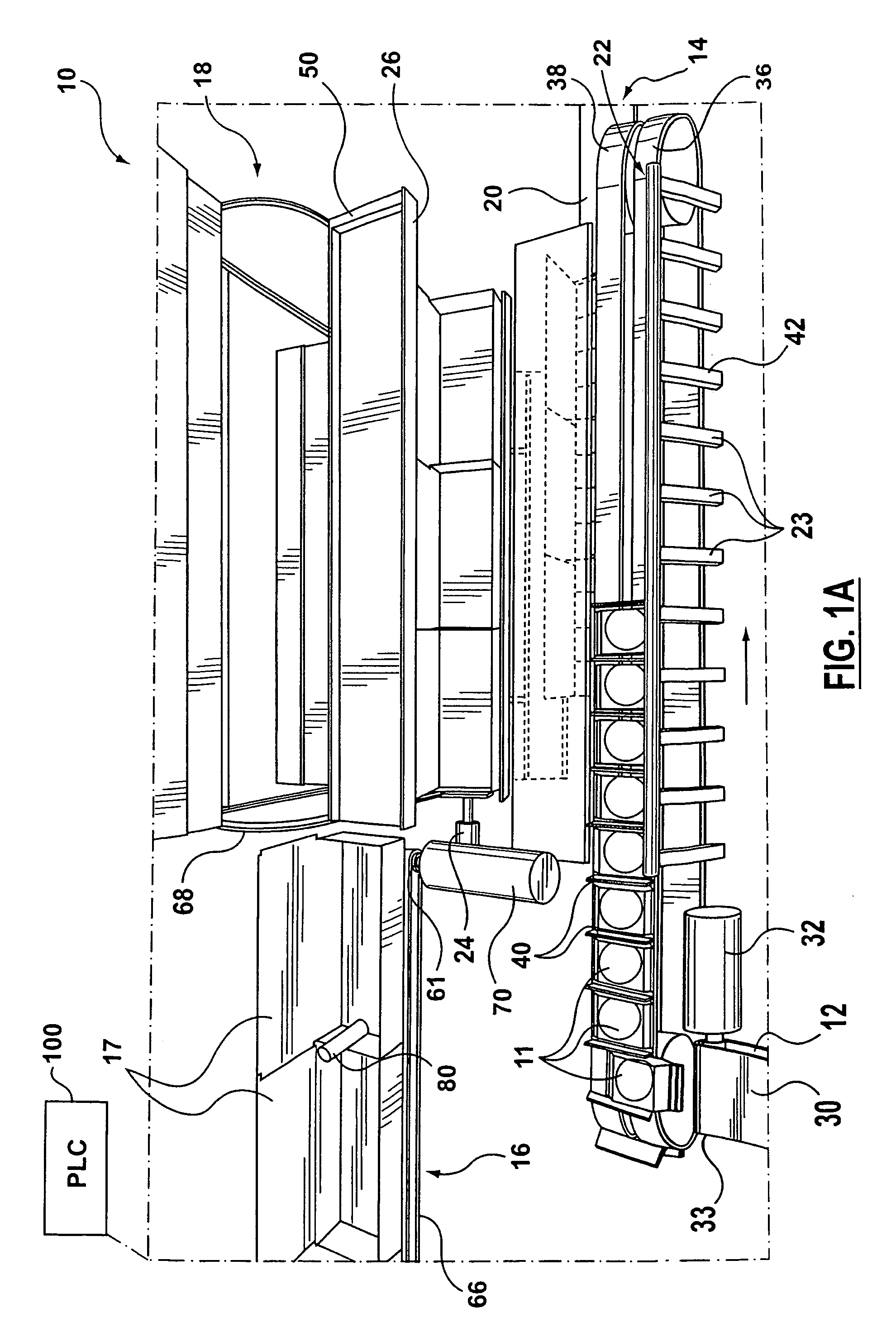

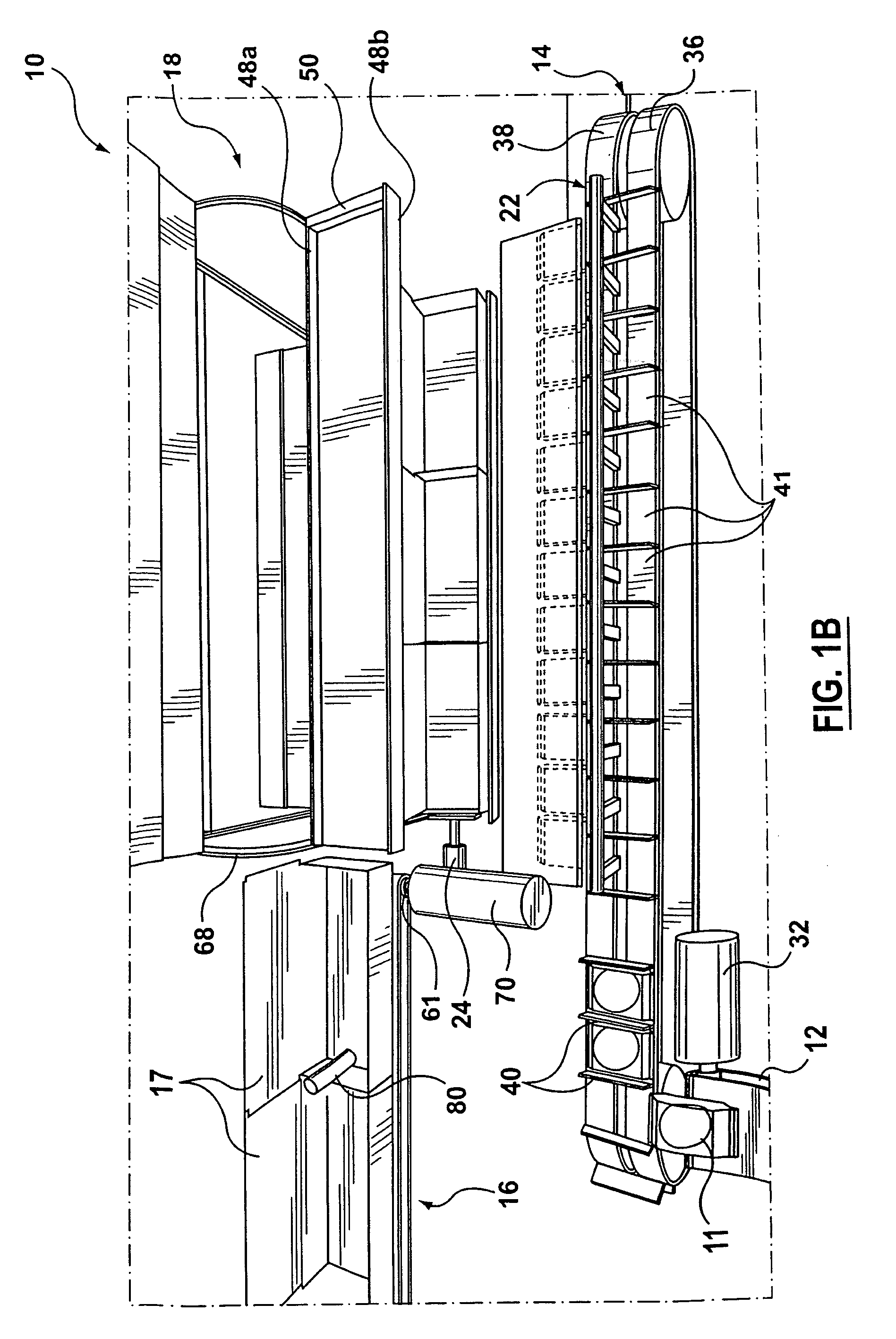

Methods and apparatuses for applying a handling tab to continuous glass ribbons

InactiveUS20120255672A1Reduce harmMaintain integrityMechanical working/deformationLaminationAdhesive beltEngineering

Methods and apparatuses for forming a handling tab on a glass substrate are disclosed. The method may include conveying a glass substrate in a conveyance direction. An adhesive tape ribbon may be positioned adjacent to the first lateral edge of the glass substrate such that an adhesive surface of the adhesive tape ribbon is spaced apart from the first lateral edge of the glass substrate and the adhesive surface is substantially perpendicular to the first surface and the second surface. The adhesive tape ribbon may be folded such that at least a portion of the glass substrate is positioned between the adhesive surface of a first portion of the adhesive tape ribbon and the adhesive surface of a second portion of the adhesive tape ribbon, and a third portion of the adhesive tape ribbon forms a handling tab extending beyond the first lateral edge of the glass substrate.

Owner:CORNING INC

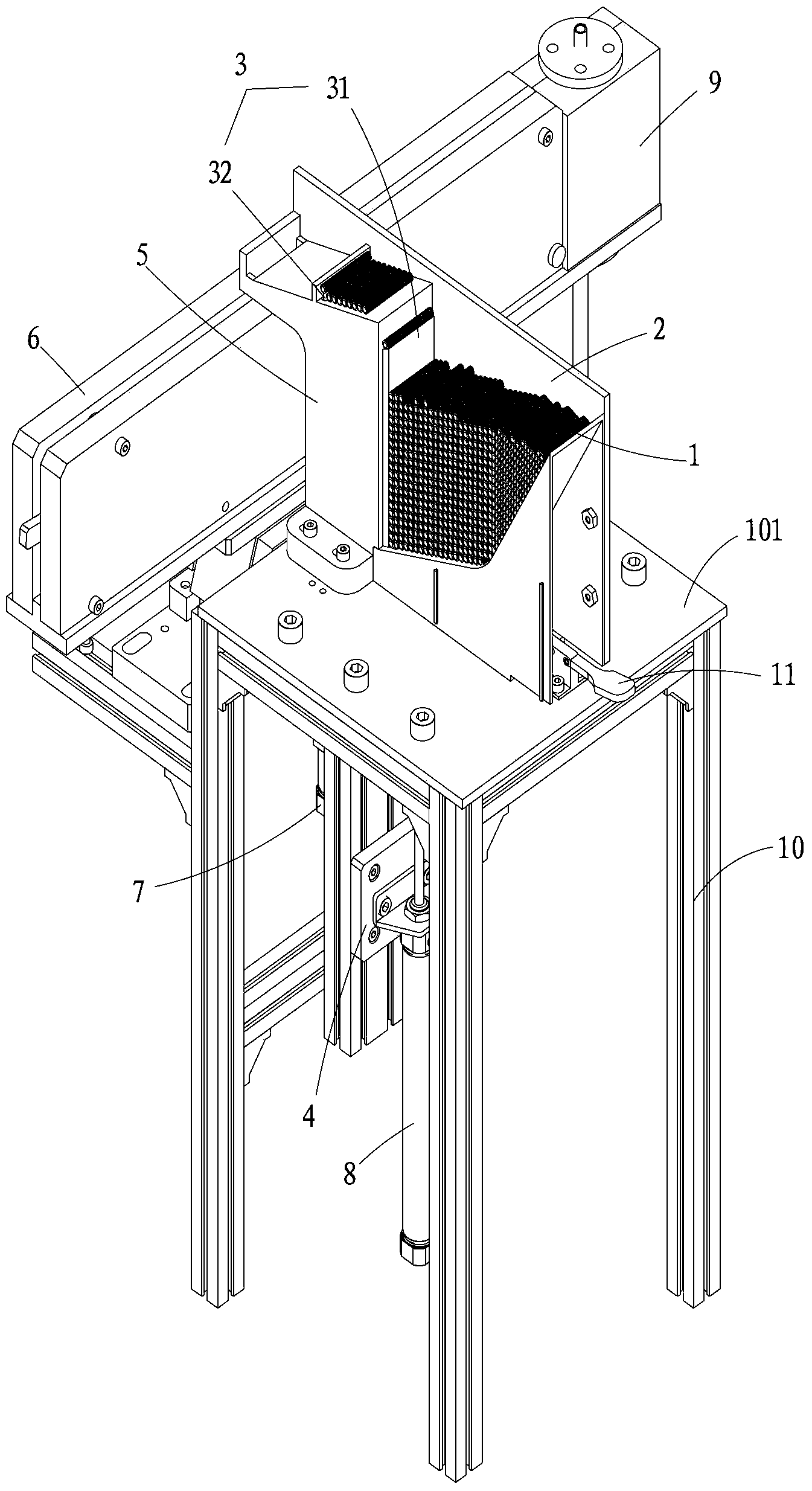

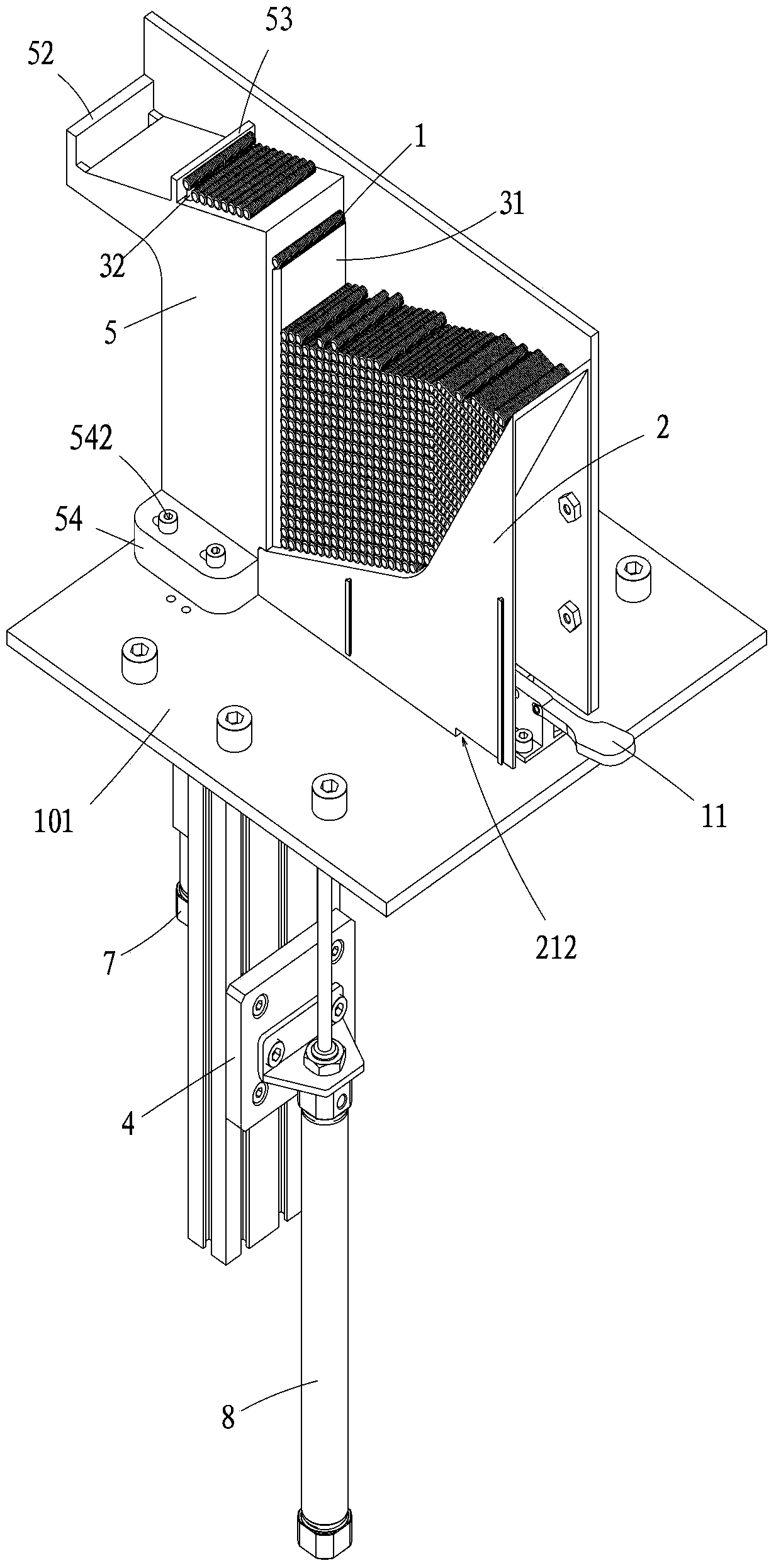

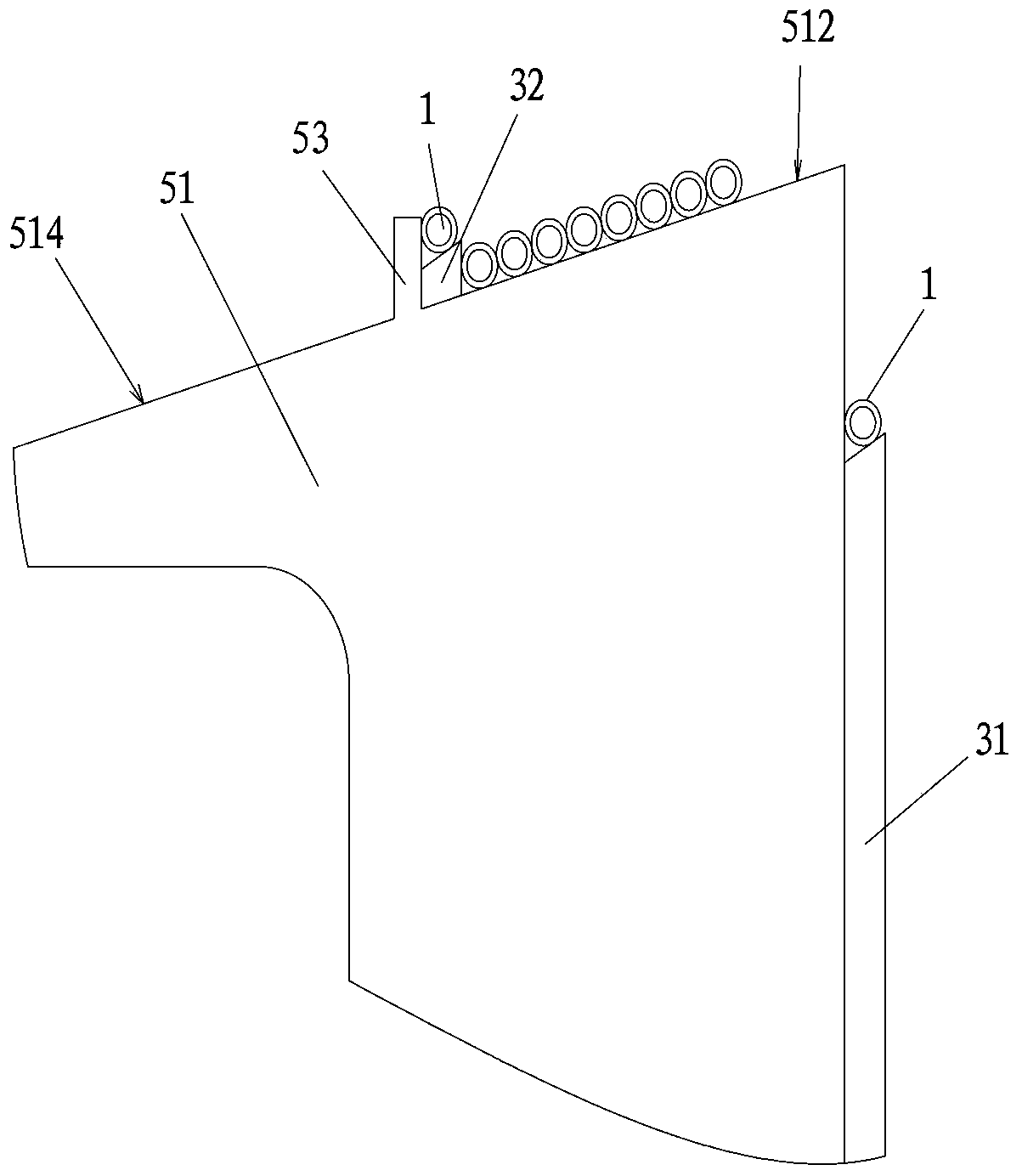

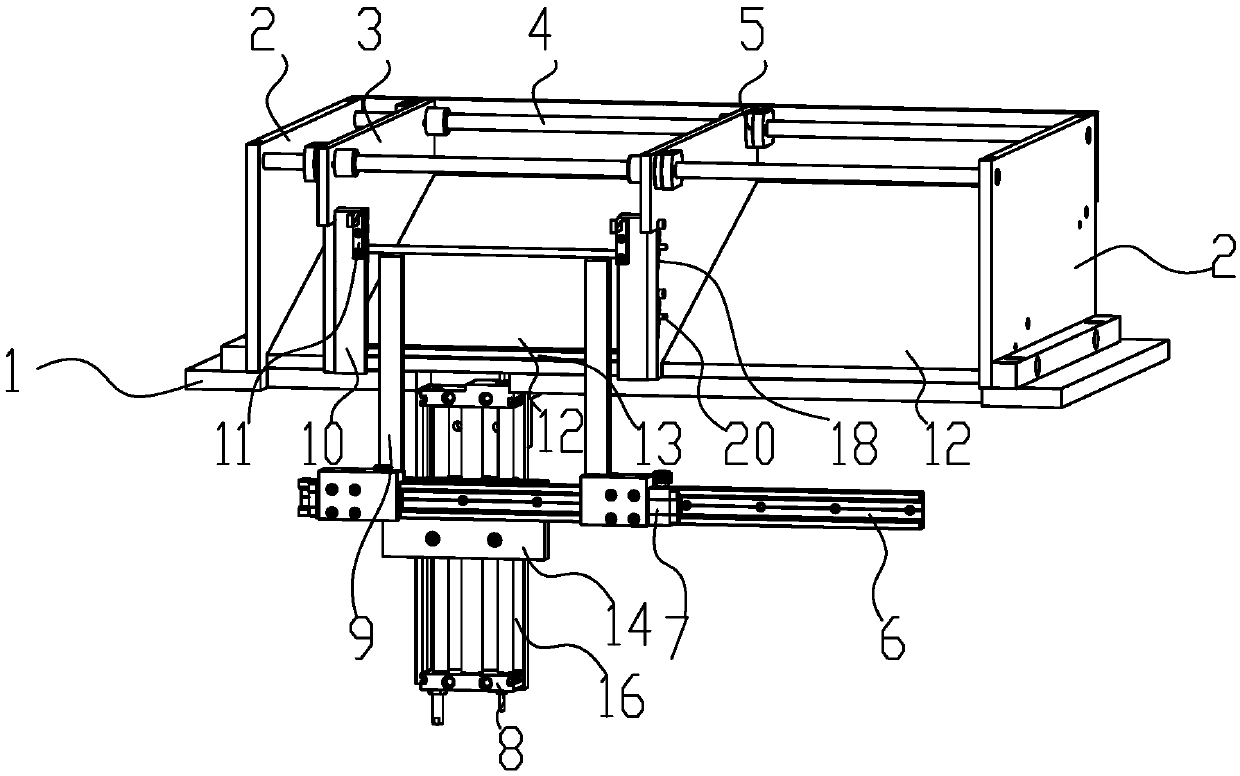

Grabbing device of metal waste block conveying mechanism

ActiveCN105858208AEasy to placeImprove the installation effectConveyor partsBottom pressureEngineering

The invention discloses a grabbing device of a metal waste block conveying mechanism. The grabbing device comprises a main support frame and a bottom pressure block, wherein the bottom pressure block is inserted in a mounting through hole at the middle part of the main support frame in a sleeving manner and fixed on the inner side wall of the mounting through hole; the bottom surface of the bottom pressure block is fixed on a bottom support seat; the bottom support seat is positioned below the top plate of the main support frame; a grabbing moving frame is arranged on the ground on the right side of the main support frame; the left end of the top plate of the grabbing moving frame is positioned above the right side of the main support frame; grabbing support plates are fixed on the two sides of the top plate of the grabbing moving frame; the two ends of a grabbing screw are articulated on two grabbing support plates, and a grabbing transmission motor is fixed on one grabbing support plate; a vertical groove body is arranged at the middle part of the top surface of the bottom pressure block; a placing block body is arranged in the vertical groove body; a waste placing groove is formed in the top surface of the placing block body; and a lifting oil cylinder is fixed on the bottom surface of the bottom pressure block. The metal waste block is convenient to fetch, and the fetched metal waste block is convenient to place.

Owner:CHINA FORGING MACHINERY

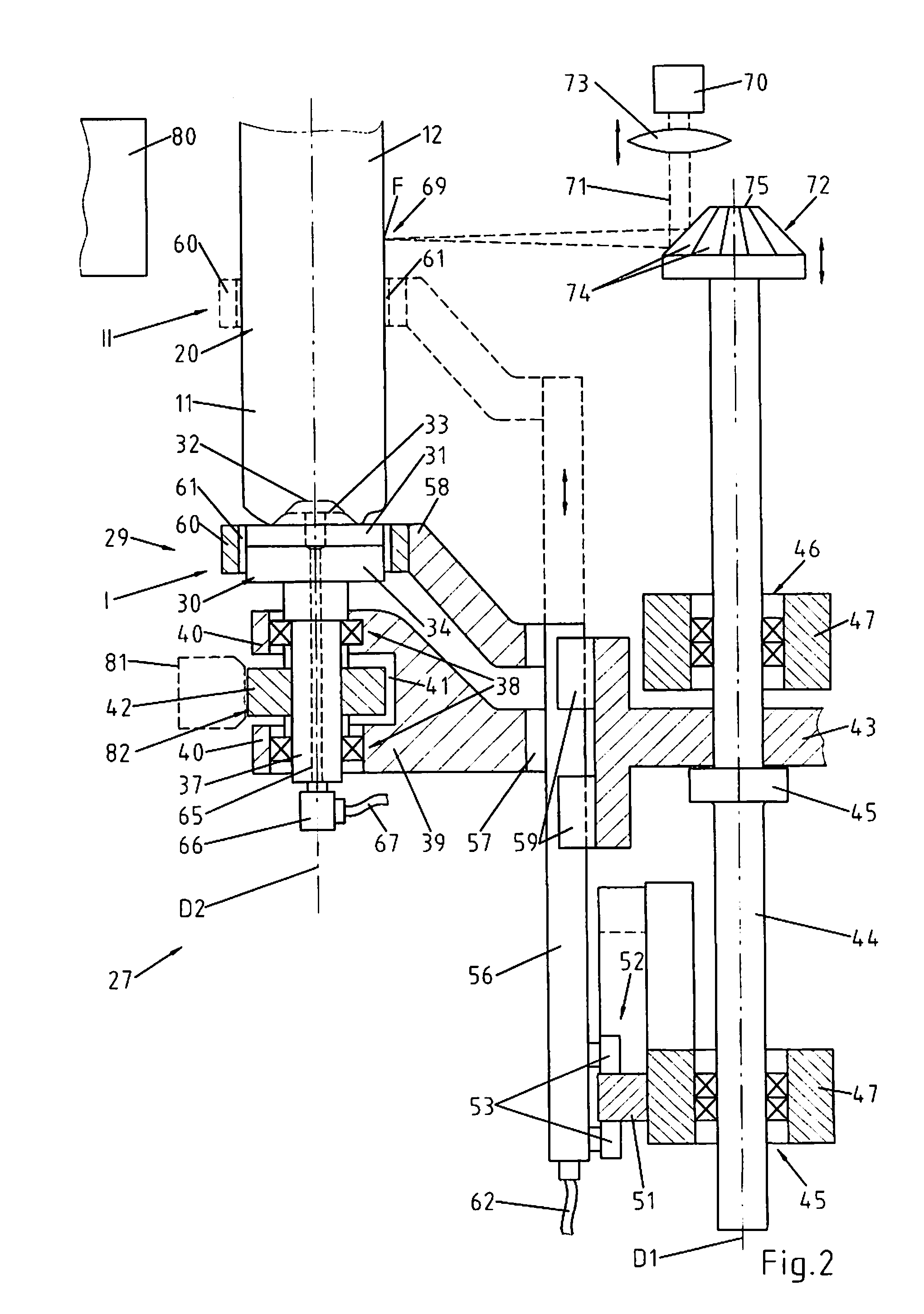

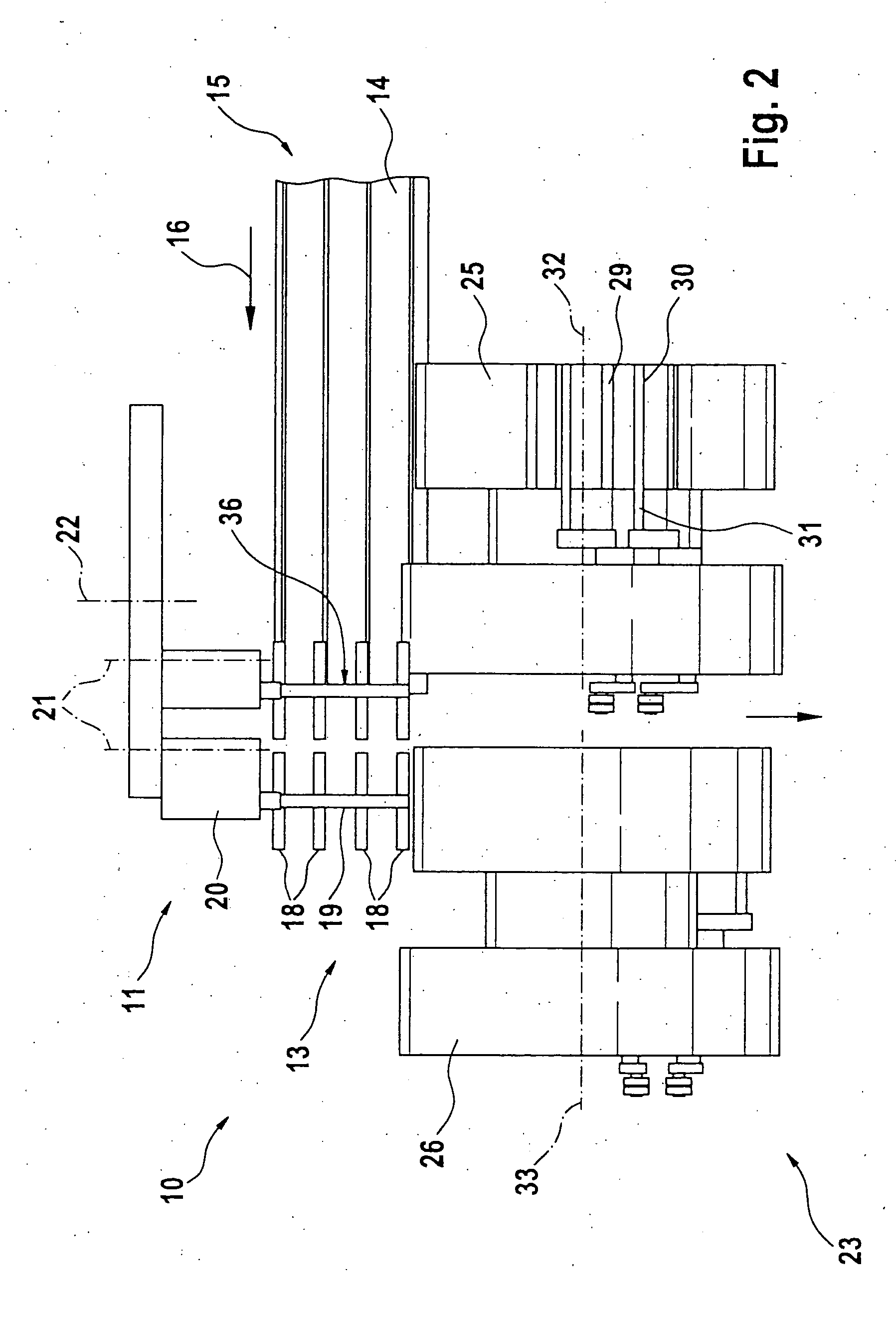

Device and method for cutting off an end section of a can blank

InactiveUS20140346154A1Sufficient time availableStock shearing machinesMetal working apparatusEngineeringLaser cutting

Owner:SCHULER PRESSEN GMBH & CO KG

Tray loader

Owner:LANGEN PACKAGING

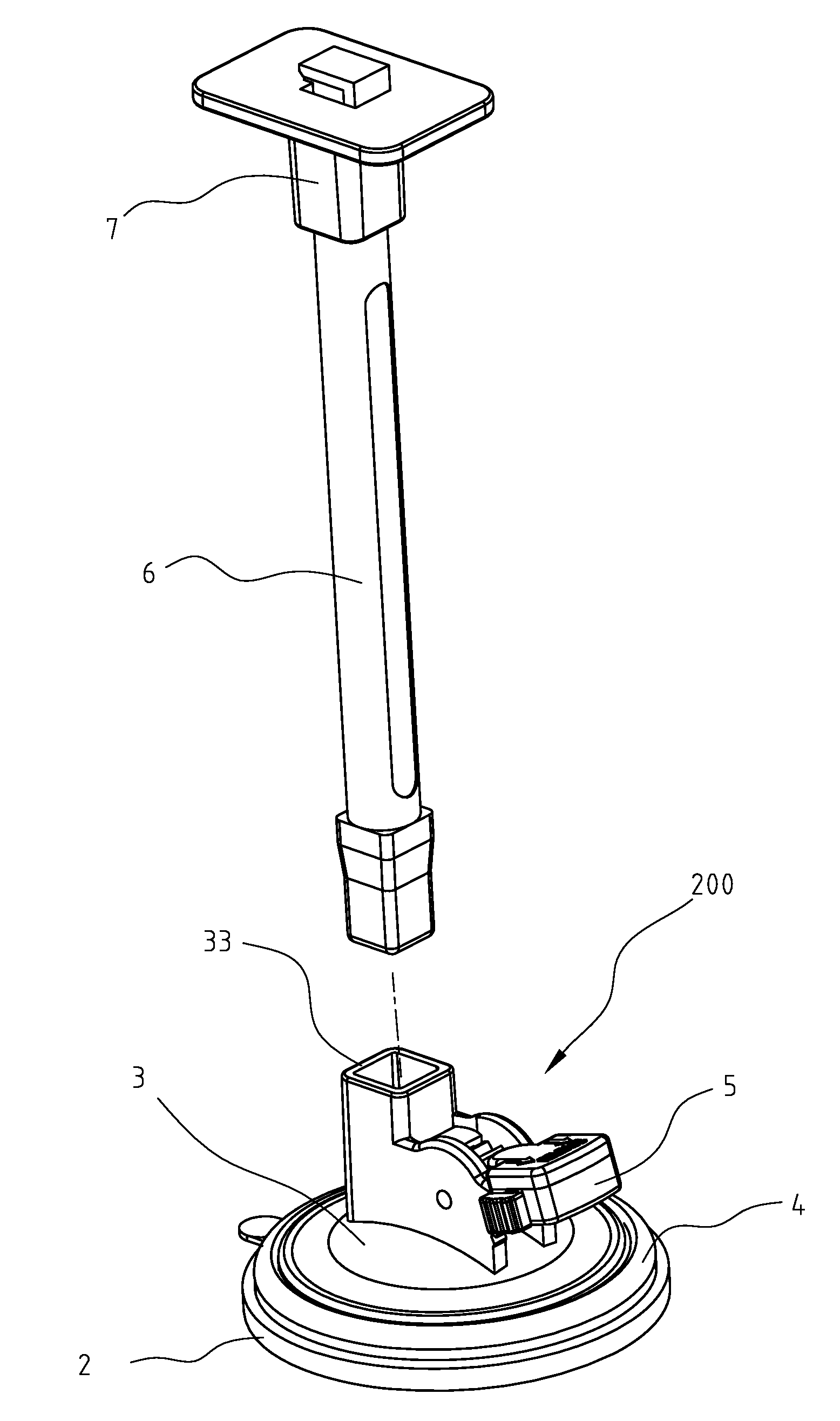

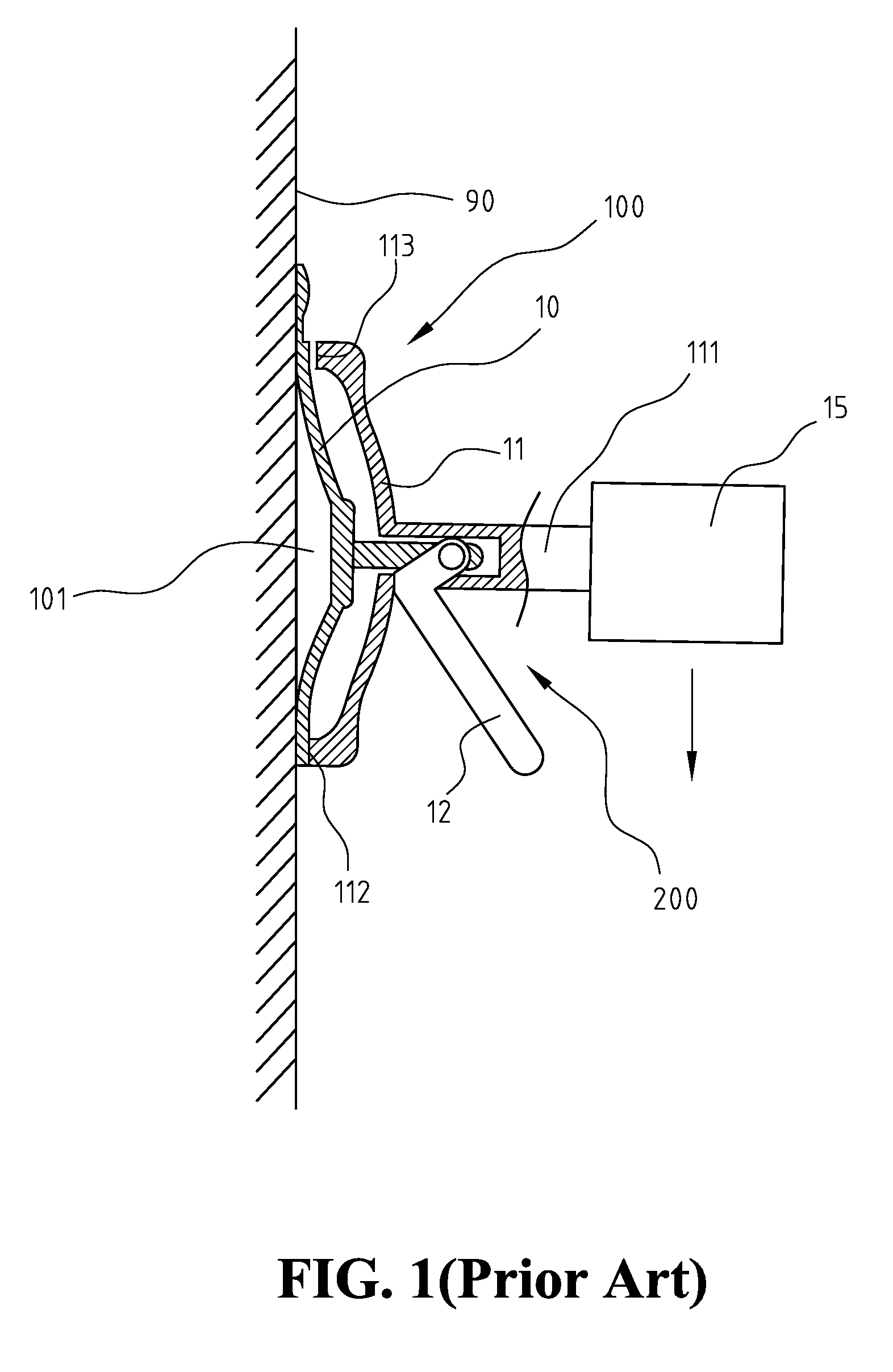

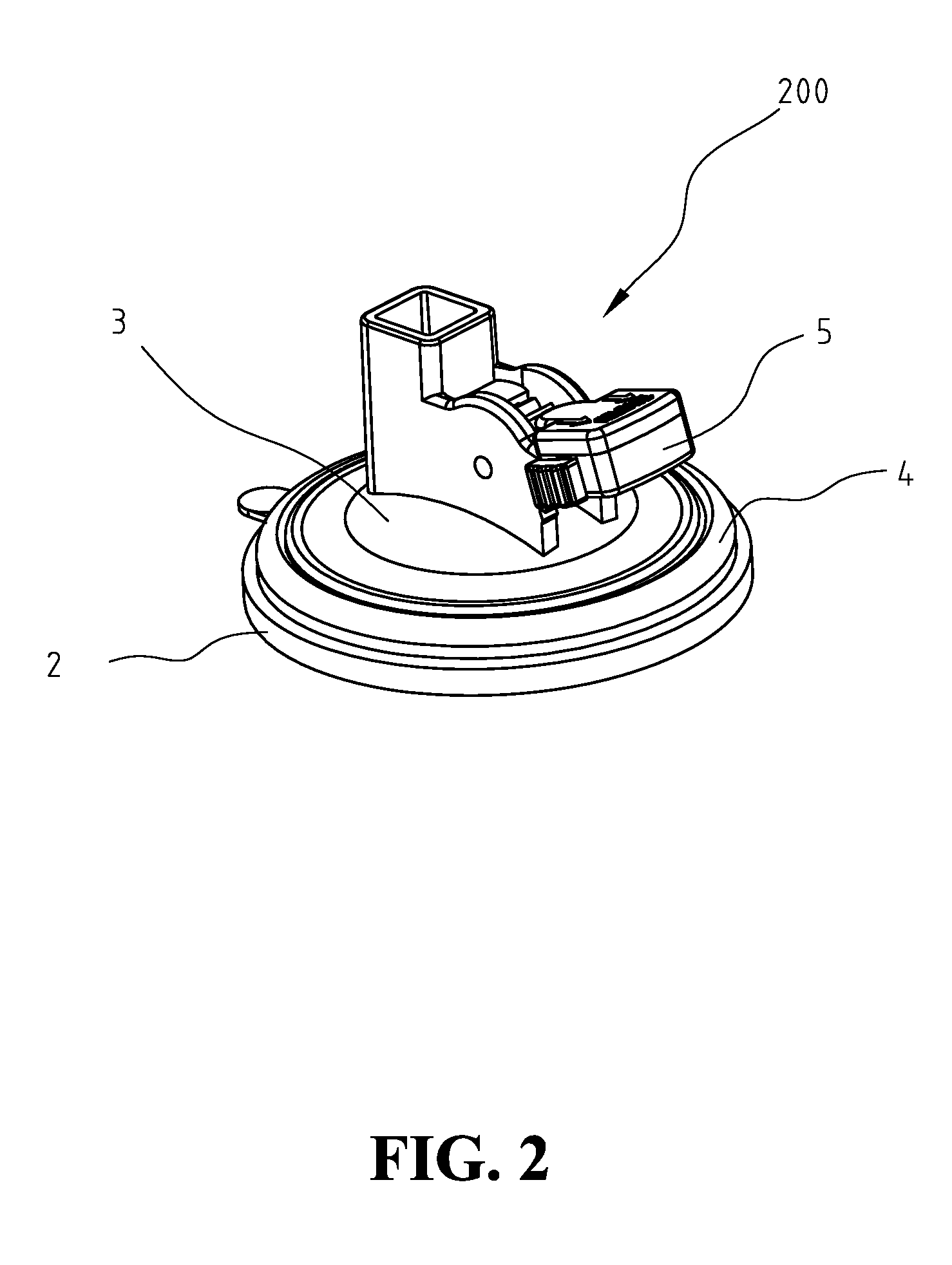

Structure For A Suction Device

Owner:FAN EAGLE

Automatic tube-type specimen container supply apparatus

An automatic tube-type specimen container supply apparatus includes a container storing box a bottom of which has a tapered surface having a container collecting position in a lowest part thereof to collect a plurality of tube-type specimen containers in one spot, a container individually-sending mechanism which lifts up the collected specimen containers one by one along one-side wall located close to the position, an outlet which allows the specimen containers to be discharged outside the box, and a container carry-out mechanism including a conveyor to automatically carry out the discharged specimen containers. The container individually-sending mechanism includes a lifting plate driven up and down and having a top end with a tapered surface. The tapered surface has a space to place only one specimen container lying on a side thereof and descending toward an outside of the container storing box.

Owner:IDS CO LTD

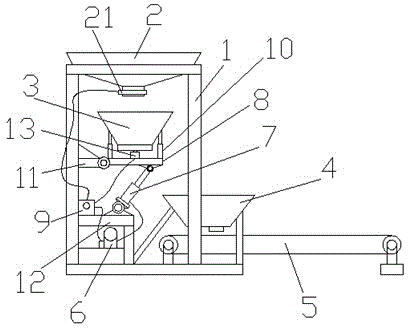

One-by-one feeding device for small pipes

Owner:SOUTH CHINA UNIV OF TECH +1

Nut feeding system

ActiveUS20130299510A1Smoothly and efficiently supplyRaise highCoin-freed apparatus detailsSpannersEngineeringMechanical engineering

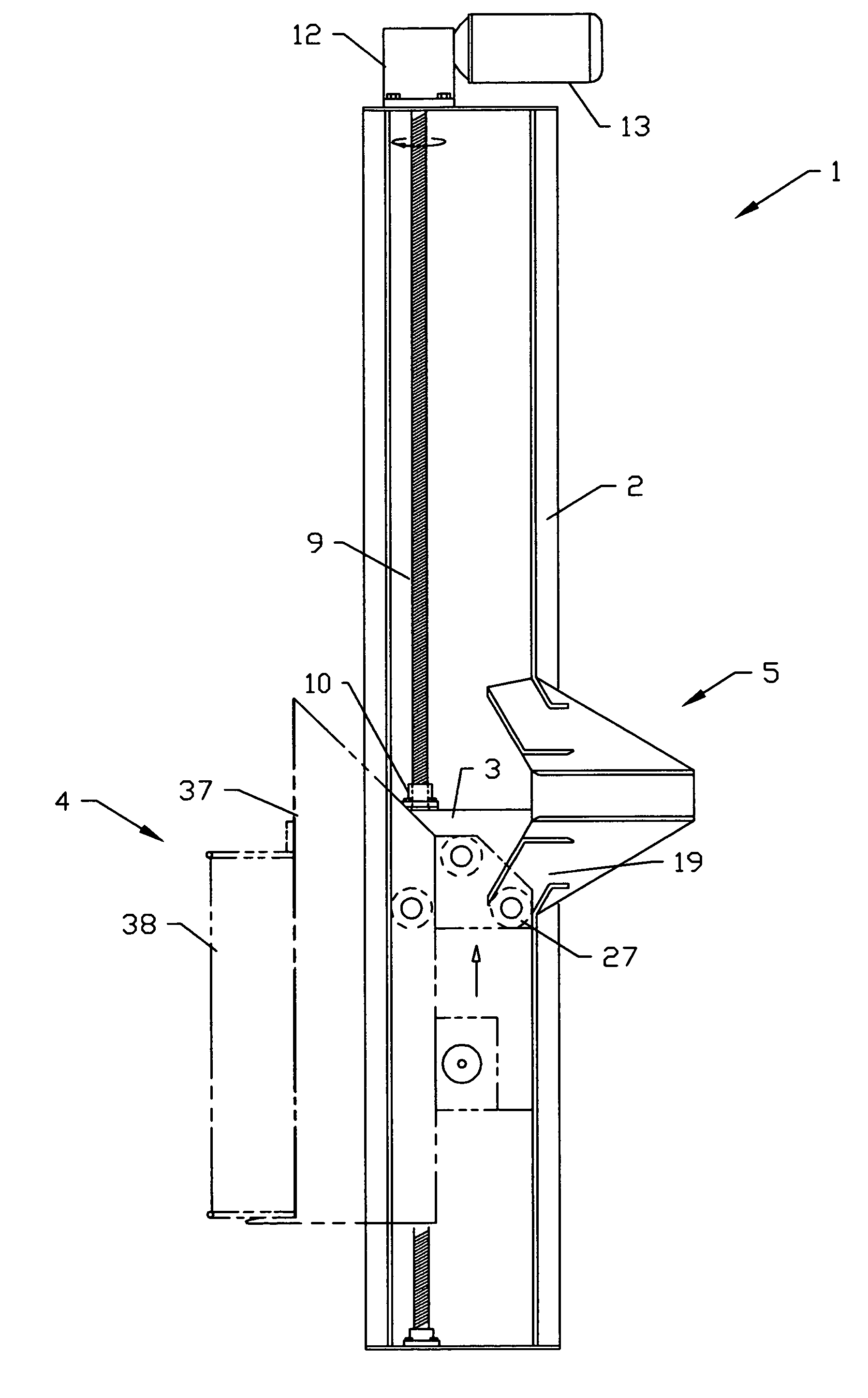

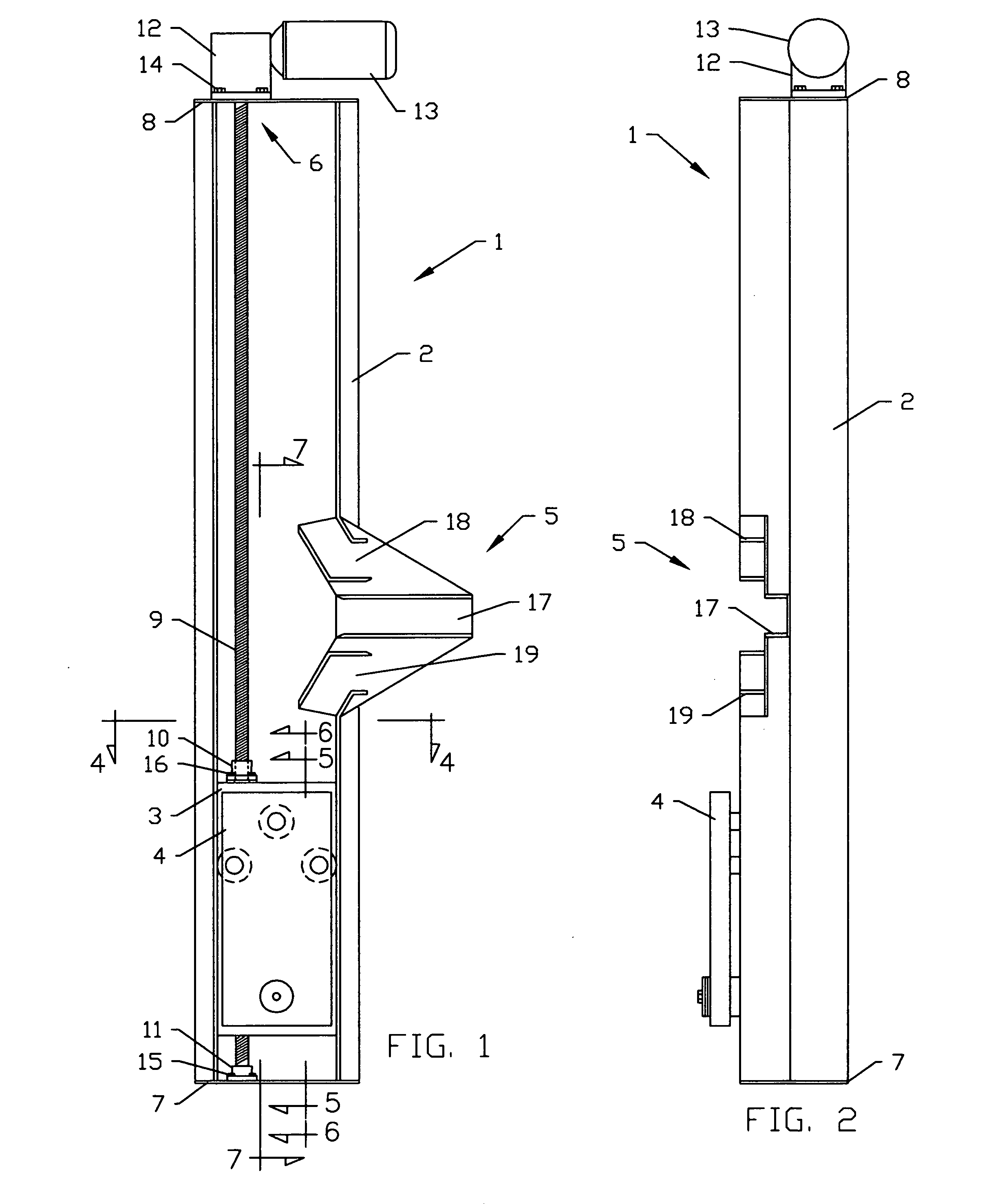

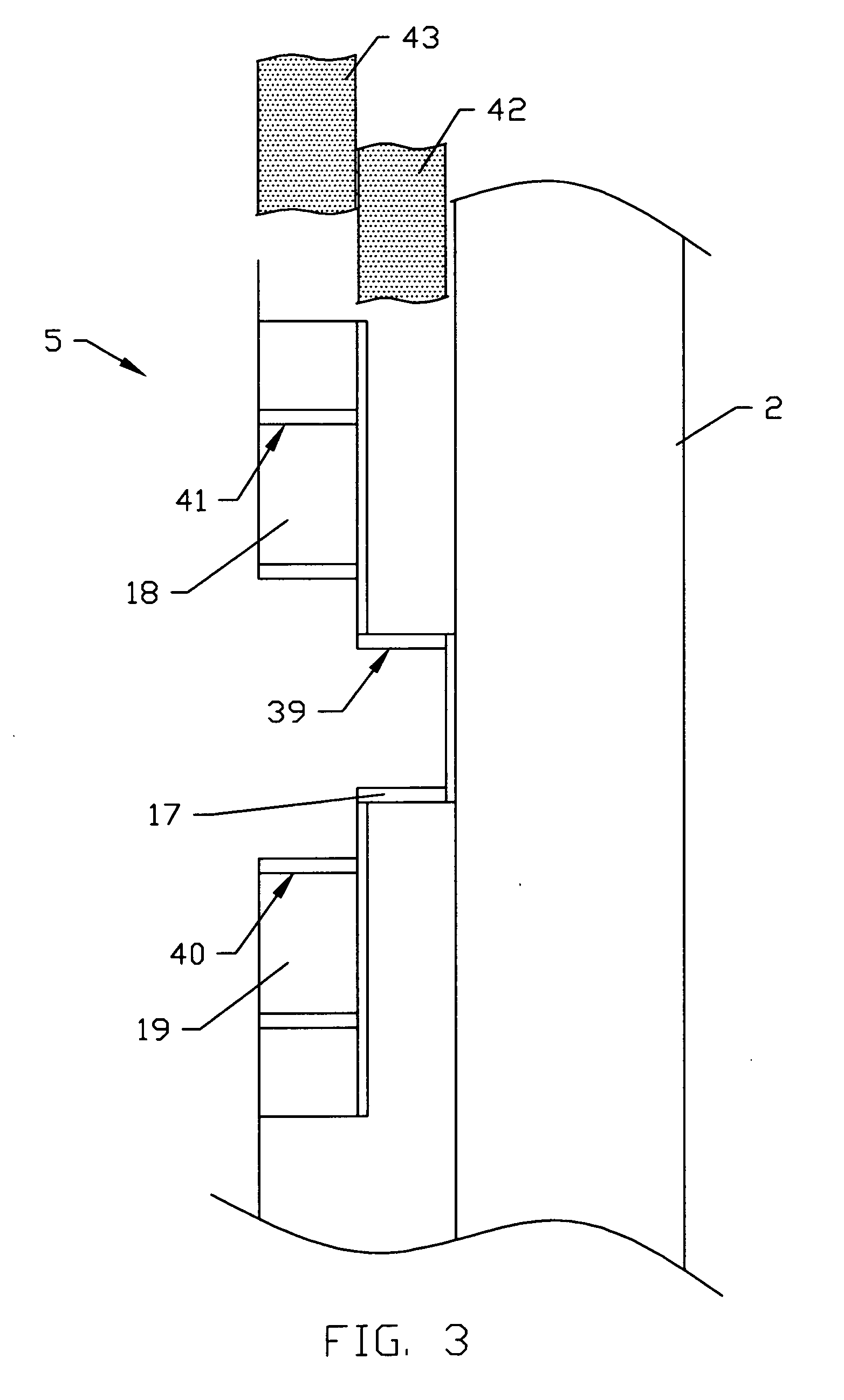

Provided is a nut feeding system for feeding a nut smoothly and efficiently without the occurrence of nut clogging or the like. A posture alignment device 2 of the nut feeding system 1 repeats an advance and retreat motion of an insert pin 19. After the insert pin 19 is inserted into a screw hole of the nut N, the nut N is raised and transferred from the posture alignment device 2 towards a supply placing unit 5.

Owner:HONDA MOTOR CO LTD

Automatic overturning and coal-blending device

Owner:JIANGSU ZHENGDONG PORT MACHINERY MANUFACYURING

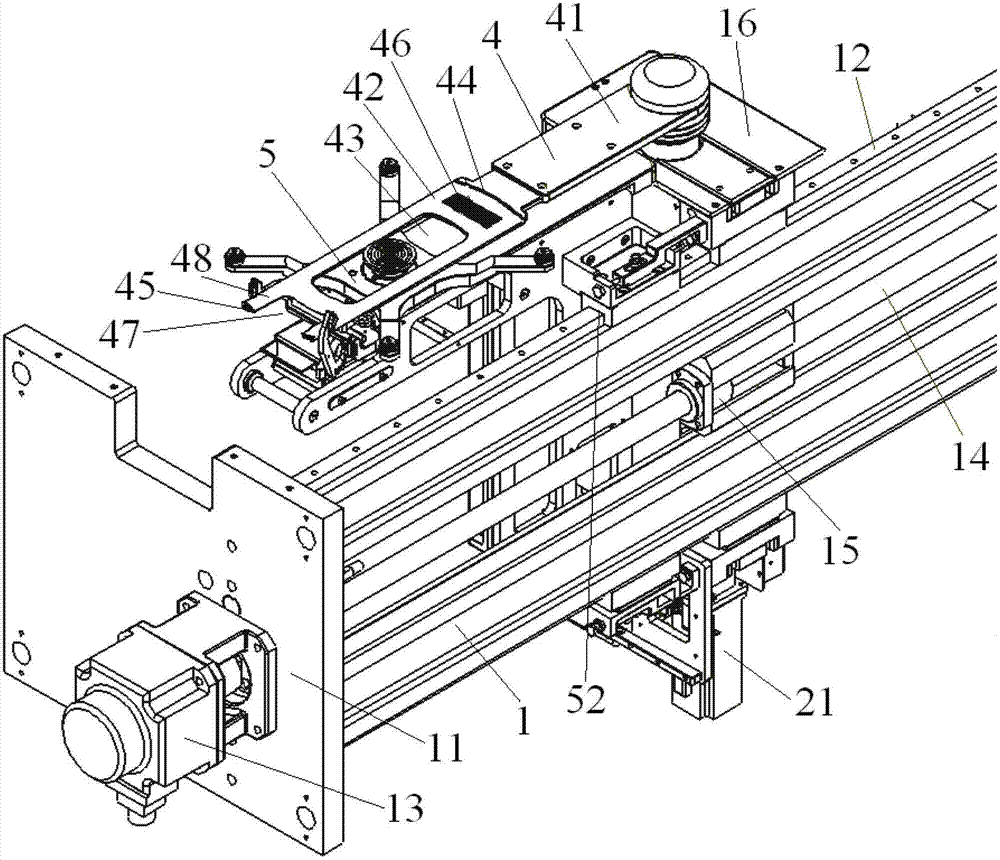

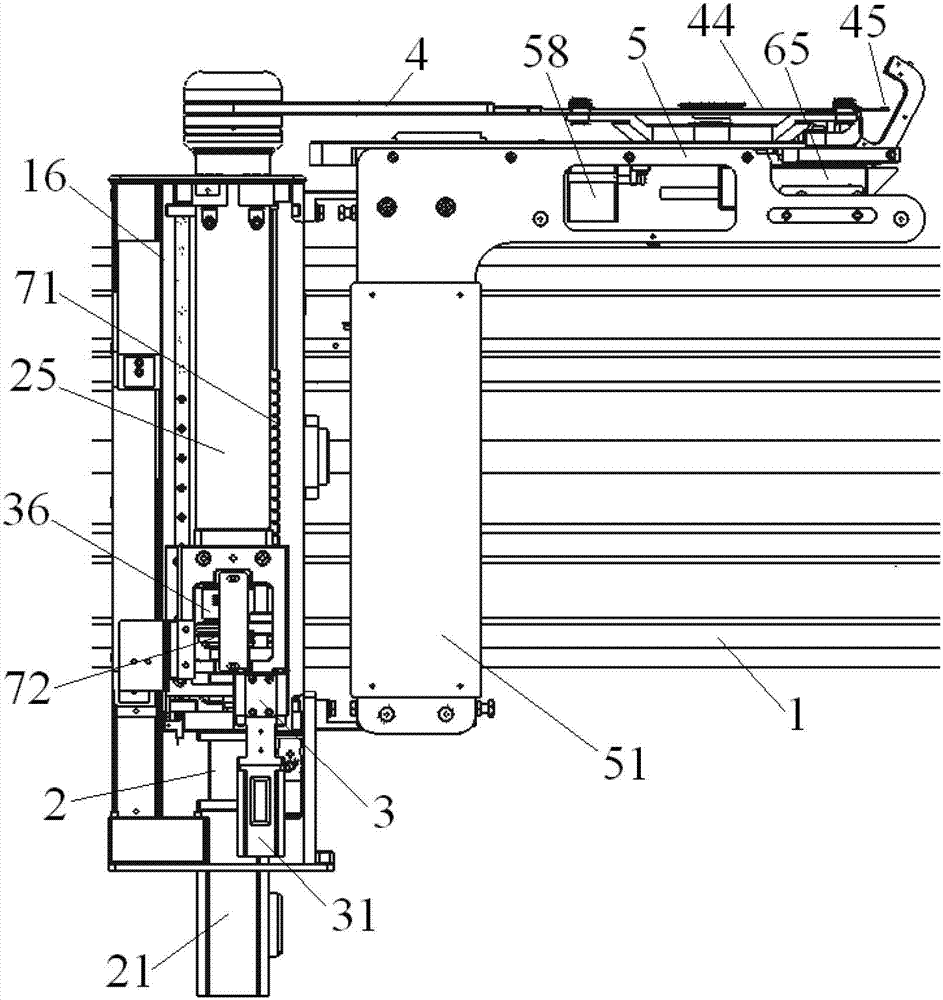

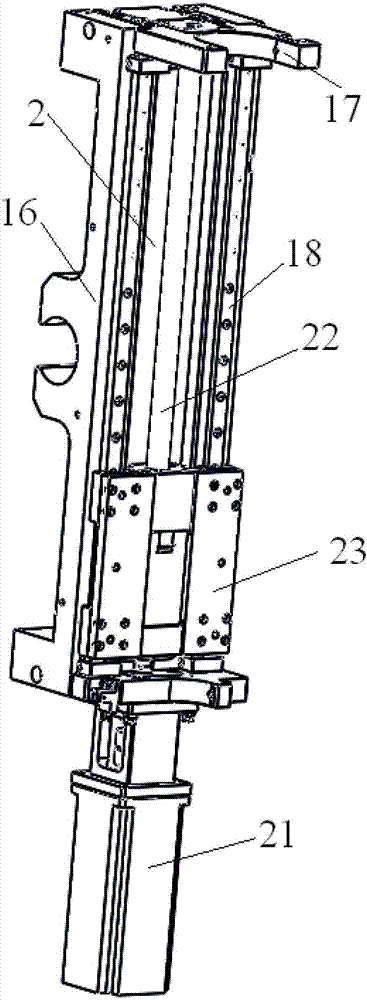

Silicon wafer sorter

PendingCN110379736ASolve low production efficiencyIncrease productivitySemiconductor/solid-state device manufacturingConveyor partsSolar cellSilicon chip

Owner:WUXI AUTOWELL TECH

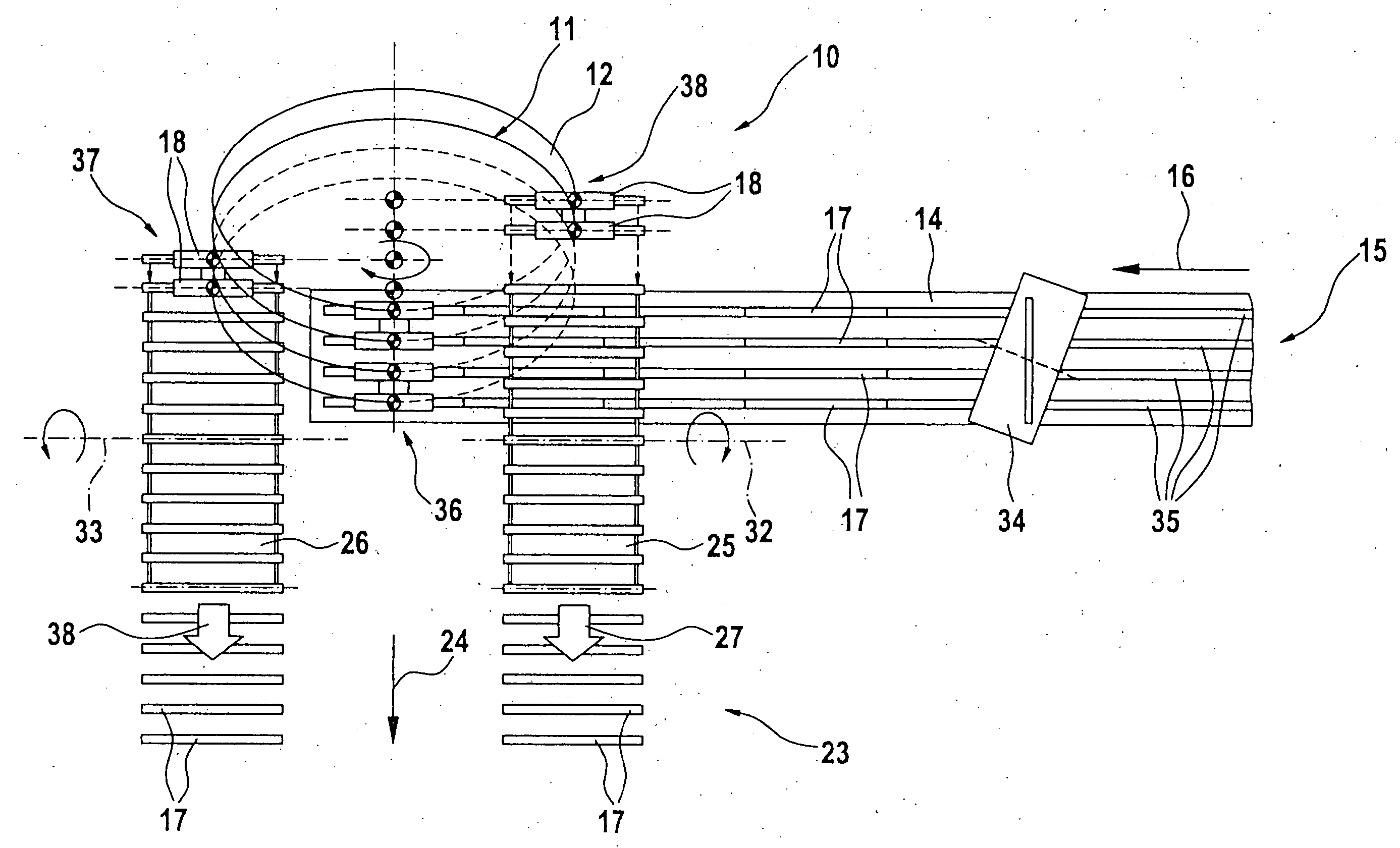

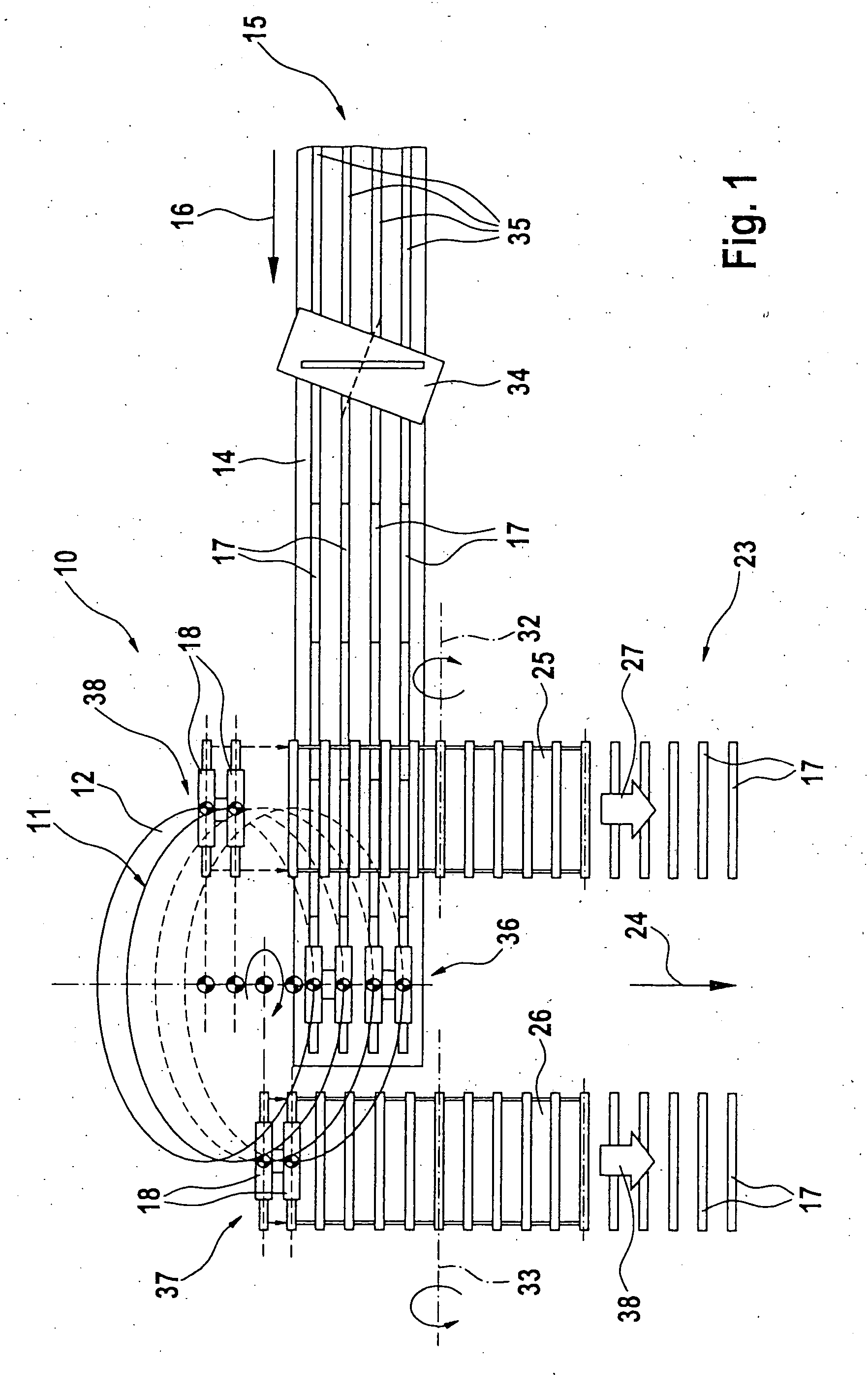

Apparatus and method for the transfer of rod-shaped articles

InactiveUS20050077149A1Improve throughputThe method is simple and flexibleCigarette manufactureConveyor partsEngineeringMechanical engineering

Owner:HAUNI MASCHINENBAU AG

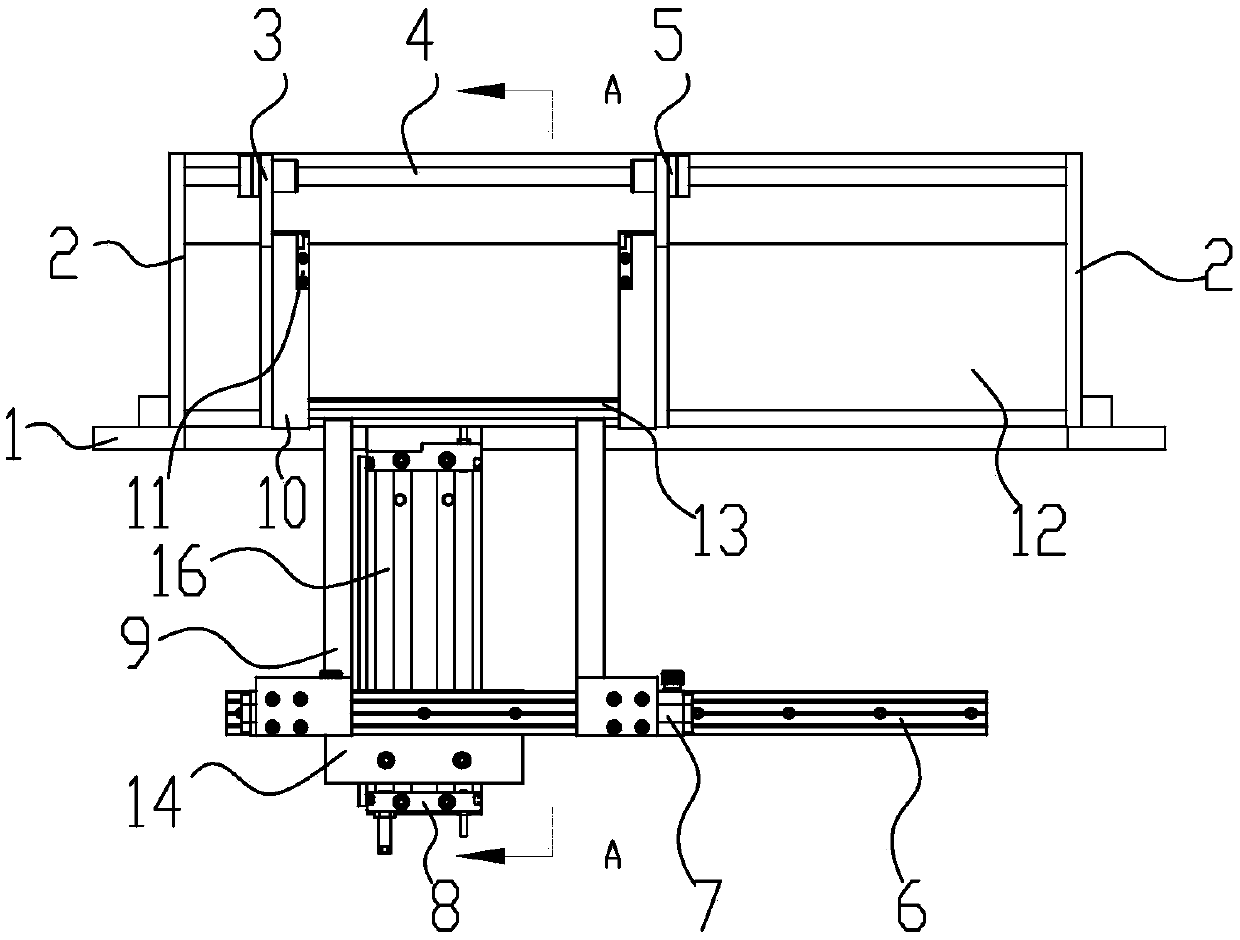

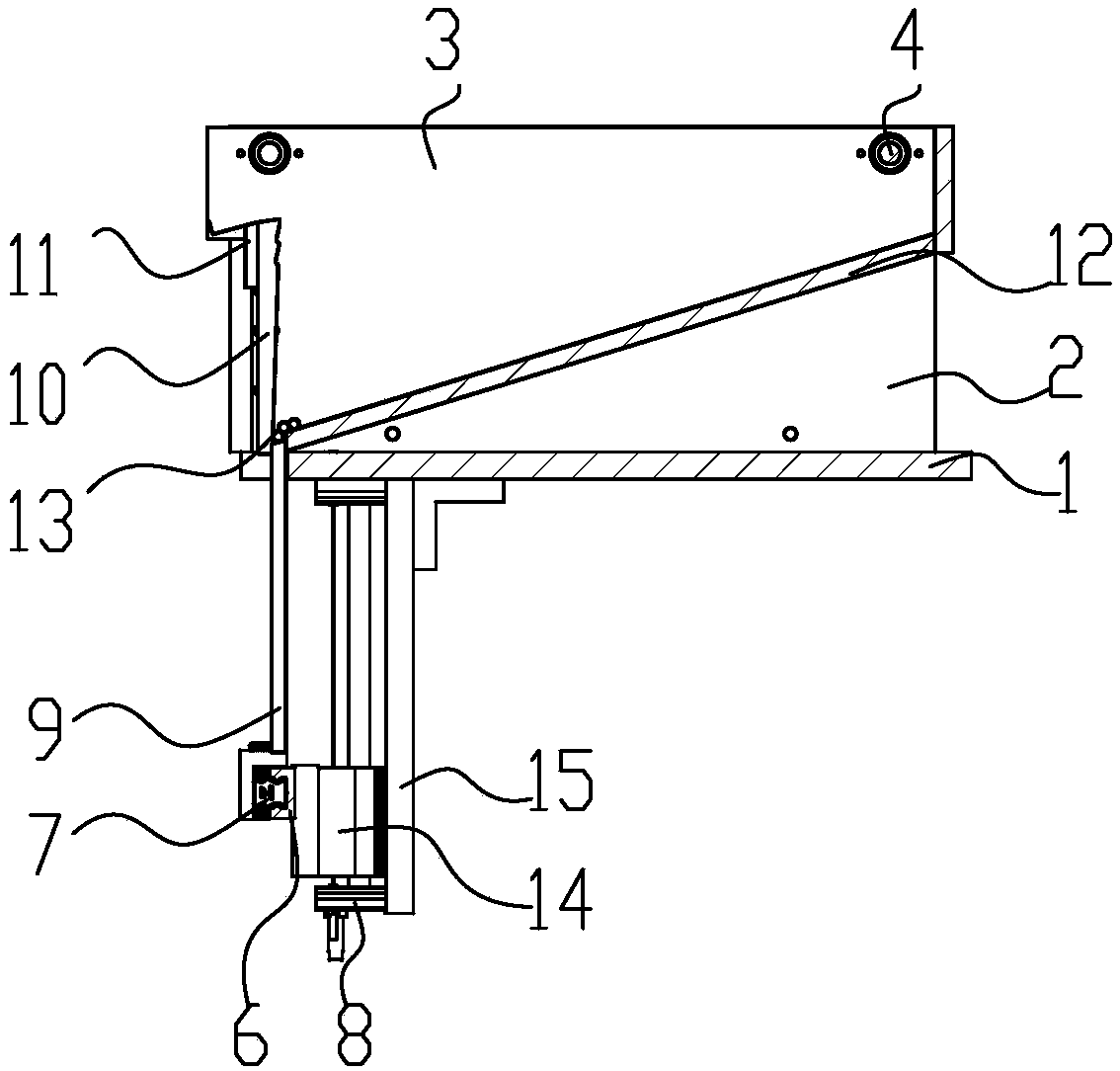

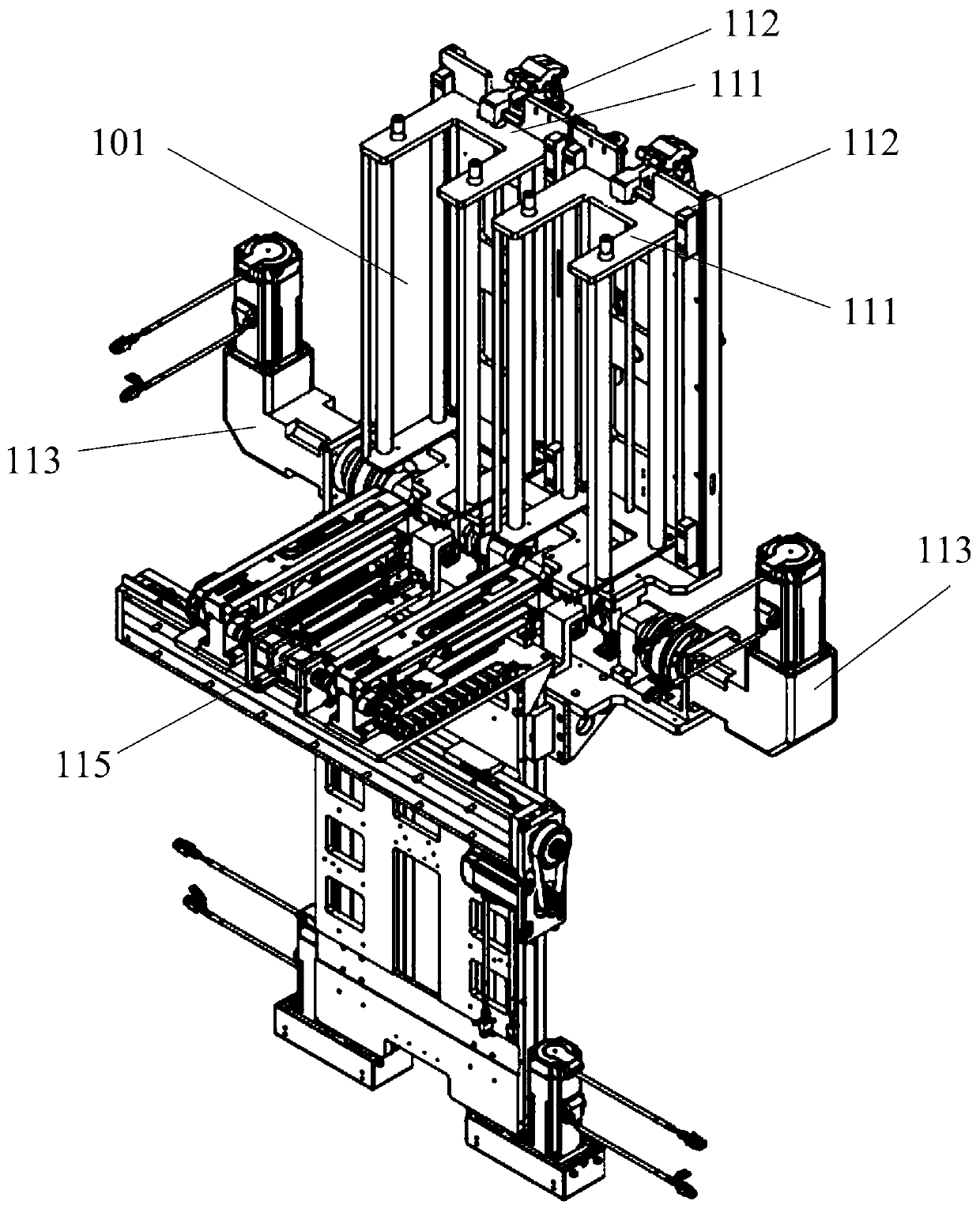

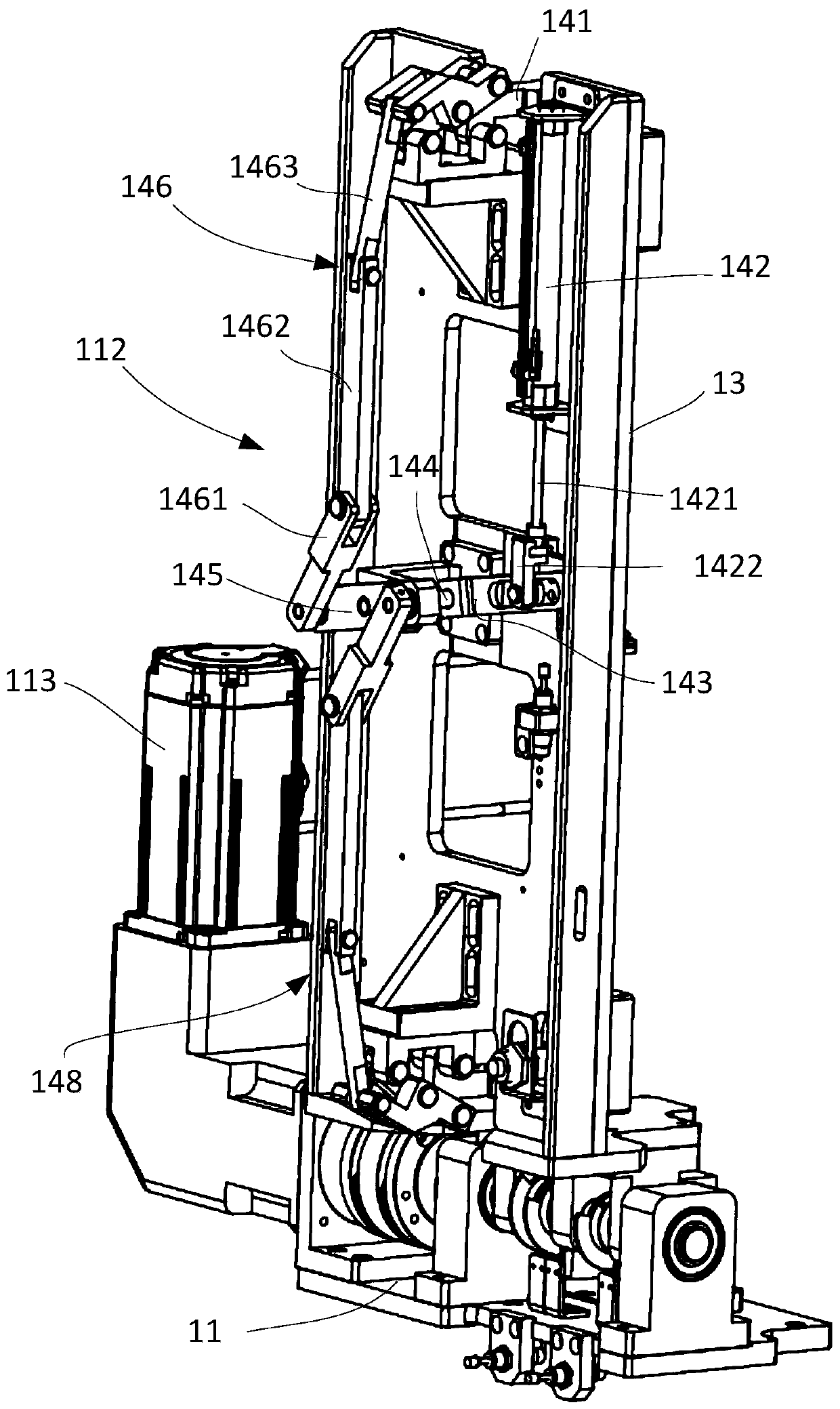

Handling car

The invention relates to a handling car. The handling car comprises an adsorption device, a lifting device, a transport device and a travel path fixing device, wherein the adsorption device is arranged inside the lifting device; the lifting device is used for controlling the lifting of the adsorption device and is arranged on the periphery of the transport device. Due to the adoption of the mounting mode, a plurality of materials can be handled in one annular handling cycle; the travel path fixing device is positioned at the lower end of the transport device and can be used for bearing a load and controlling to switch a traveling state and a fixing state of the handling car. The handling car disclosed by the invention has the characteristics of novel structure and high degree of automation; on the basis of the functions of the traditional handling device, the handling car has the advantage that the handling and conveying efficiency of the materials is further enhanced; particularly the handling of multiple groups of materials can be realized in one circumference carrying period without mutual interference.

Owner:JIANGSU HONGXUN LOCOMOTIVE CO LTD

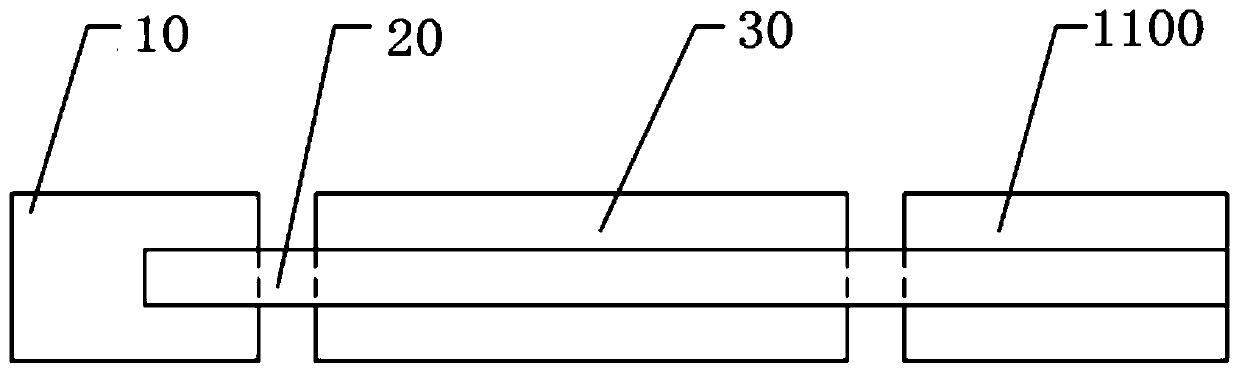

Silicon slice conveying device

ActiveCN103199044ASemiconductor/solid-state device manufacturingConveyor partsManipulatorConnection control

Owner:北京京仪仪器仪表研究总院有限公司

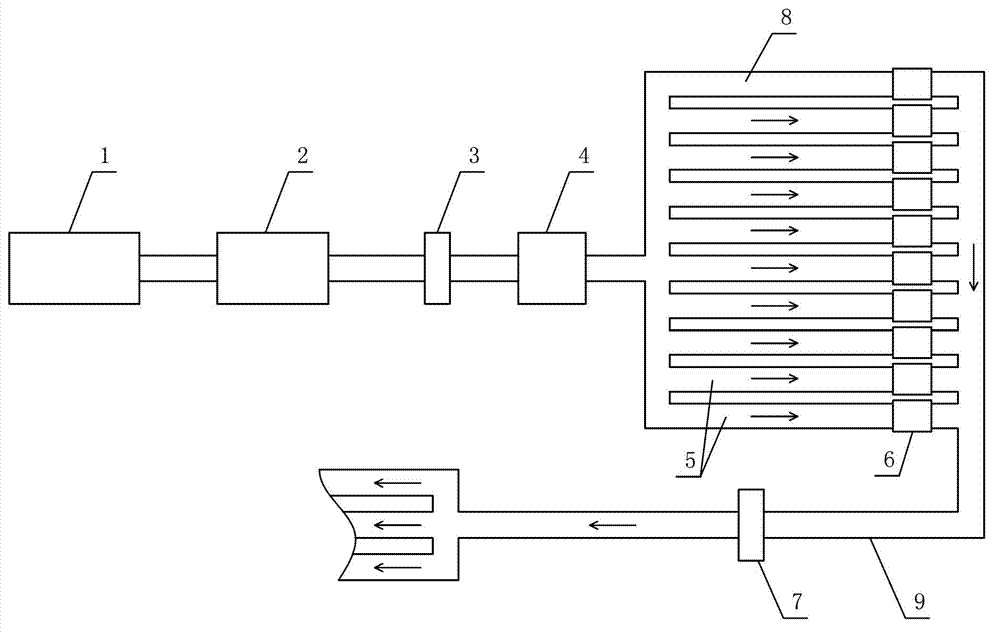

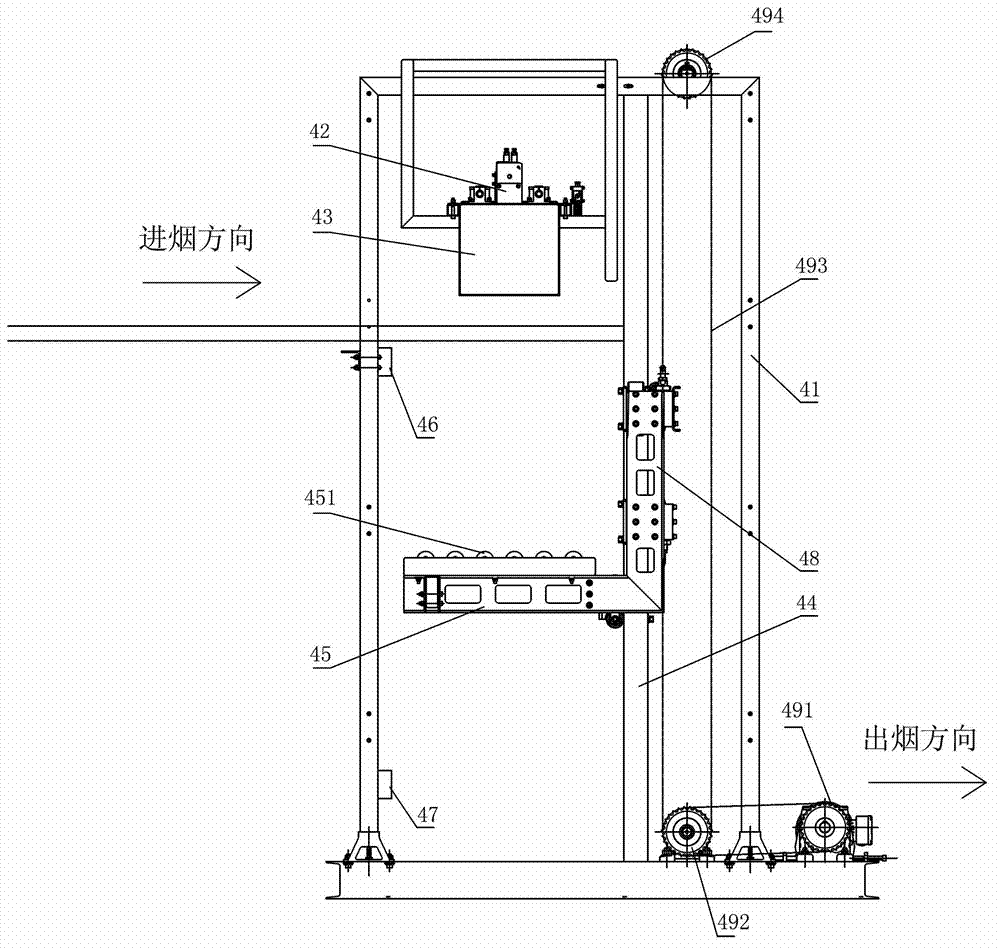

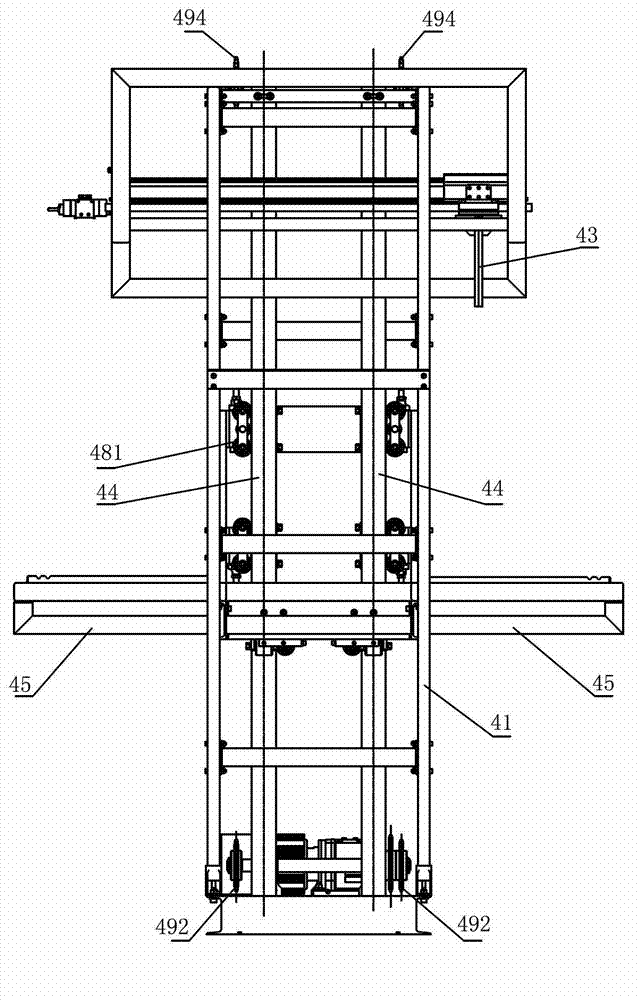

Stocking-up system and method

InactiveCN102862809ASmall footprintImprove replenishment efficiencyConveyor partsLogistics managementStack machine

Owner:浙江省烟草公司绍兴市公司

Automatic sorting and processing assembly line of logistics warehouse

ActiveCN111545477AImprove work efficiencyIncrease sliding forceStacking articlesSortingLogistics managementProcess engineering

The invention relates to an automatic sorting and processing assembly line of a logistics warehouse. The automatic sorting and processing assembly line of the logistics warehouse comprises a sorting device and conveying and stacking devices, wherein the conveying and stacking devices are symmetrically arranged front and back on the left side of the sorting device, and the lower ends of the sortingdevice and the conveying and stacking devices are arranged on the existing working ground. According to the design concept of the sorting-stacking integrated structure, automatic sorting of goods inthe logistics warehouse is carried out, the adopted sorting device can be used for screening different specification types of packages in a uniform shape integrally, the screened goods can be rapidlytransported and stacked by the aid of the arranged conveying and stacking devices, and compared with a traditional manual sorting and arranging mode, the automatic cooperation operation mode between the sorting device and the conveying and stacking devices greatly improves working efficiency.

Owner:ZHEJIANG YIXINGDA WISDOM TECH CO LTD

Steel seal stamping machine with automatic feeding and discharging functions

InactiveCN105035638AProcess stabilitySimple structureConveyorsConveyor partsDrive wheelElectric machine

The invention provides a steel seal stamping machine with automatic feeding and discharging functions. The steel seal stamping machine comprises a working table, a supporting plate, a motor, a controller, a driving wheel, a driven wheel, a plurality of conveying plates, a chain and a steel seal stamping device. The working table further comprises a table top, table legs, a rocking handle, a rotating disc, a slide rod and track grooves, the rocking handle is fixedly connected with the rotating disc, the rotating disc and the slide rod are fixedly connected, the driving wheel is arranged above the table top, a motor shaft penetrates through the table top and is connected with the driving wheel, and the driven wheel is located above the table top. The steel seal stamping machine is simple in structure; as the chain is used for transmission, it is ensured that the transmission ratio is accurate, the transfer power is large, force exerted on the shaft is small, and the transmission efficiency is high; the steel seal stamping machine can work in an atrocious environment, the rotating speed can be controlled by the controller, the automation degree is high, the rotating speed is appropriate, steel seals can be replaced, and the steel seal stamping machine is wide in application range, high in the steel seal stamping quality, capable of automatically feeding and discharging materials and high in working efficiency.

Owner:ZHEJIANG YATAI FORGING MFG CO LTD

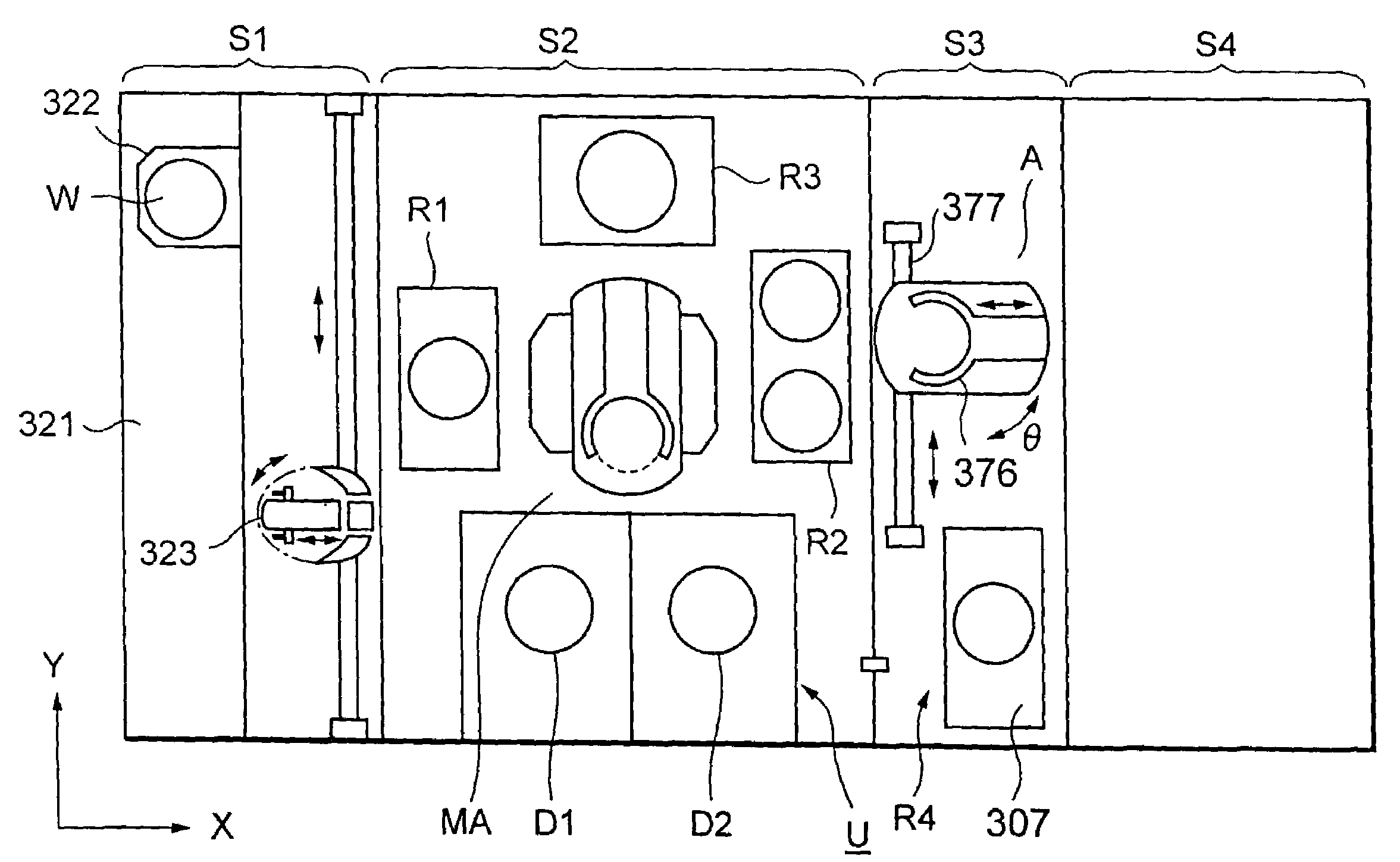

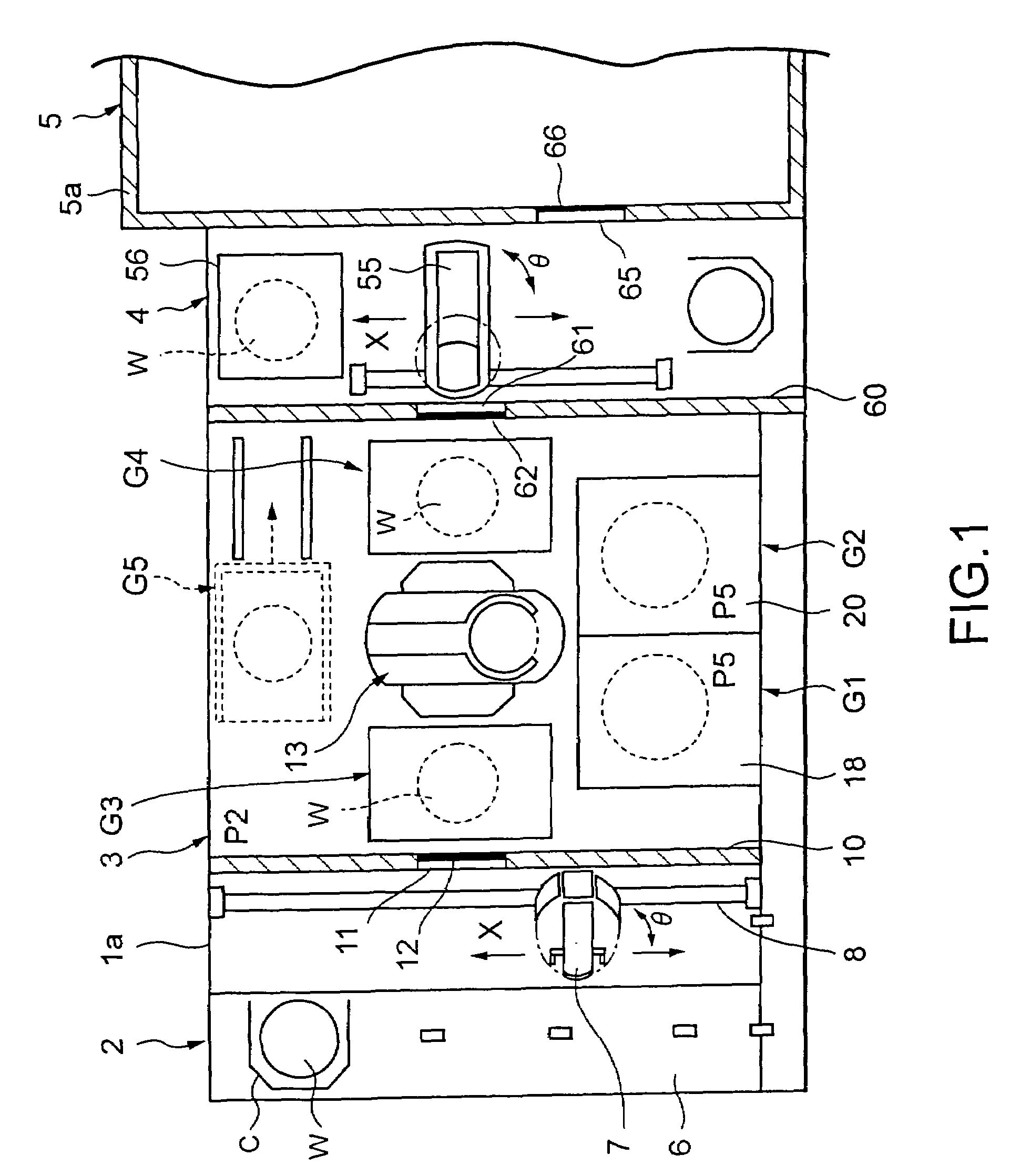

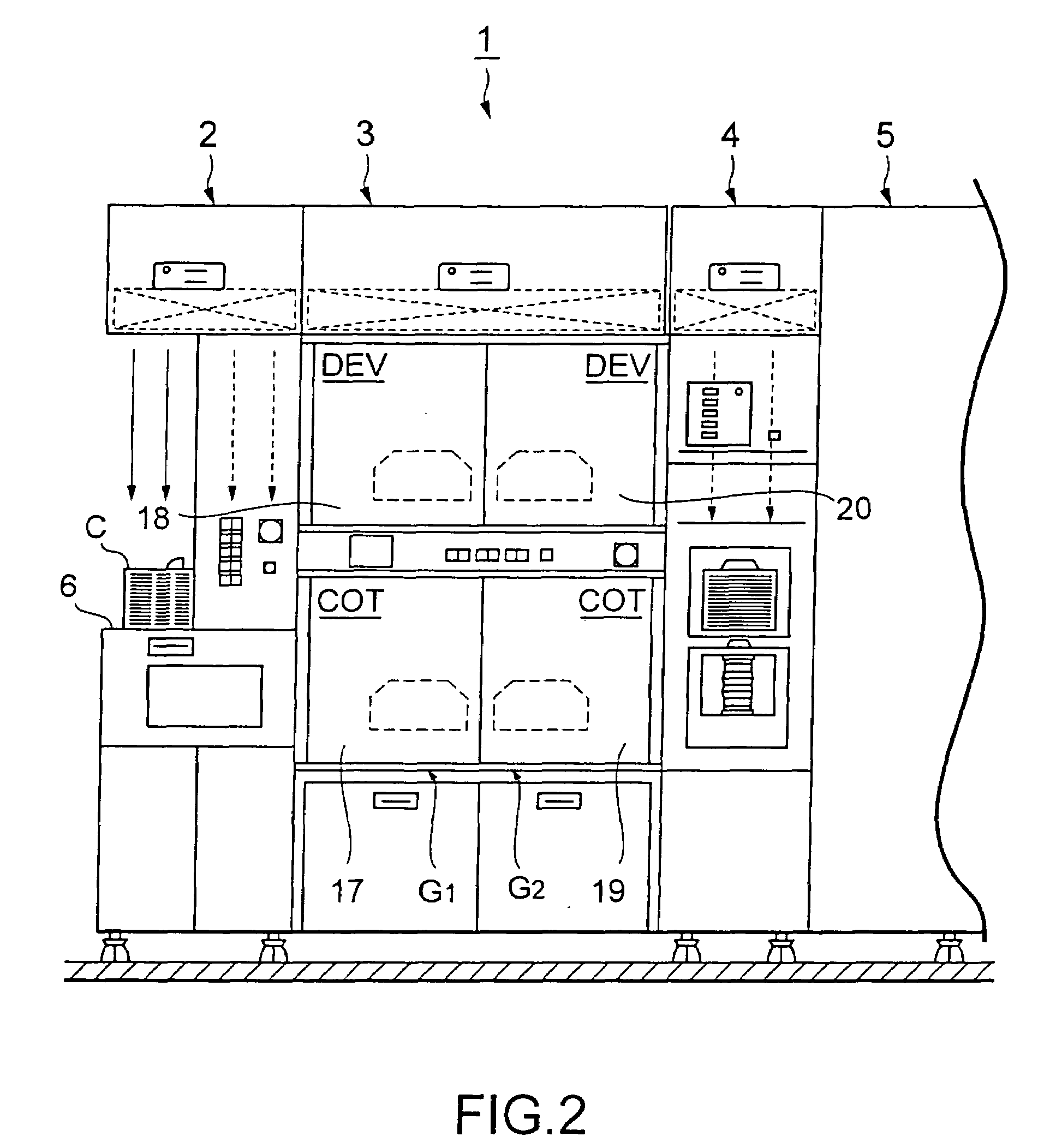

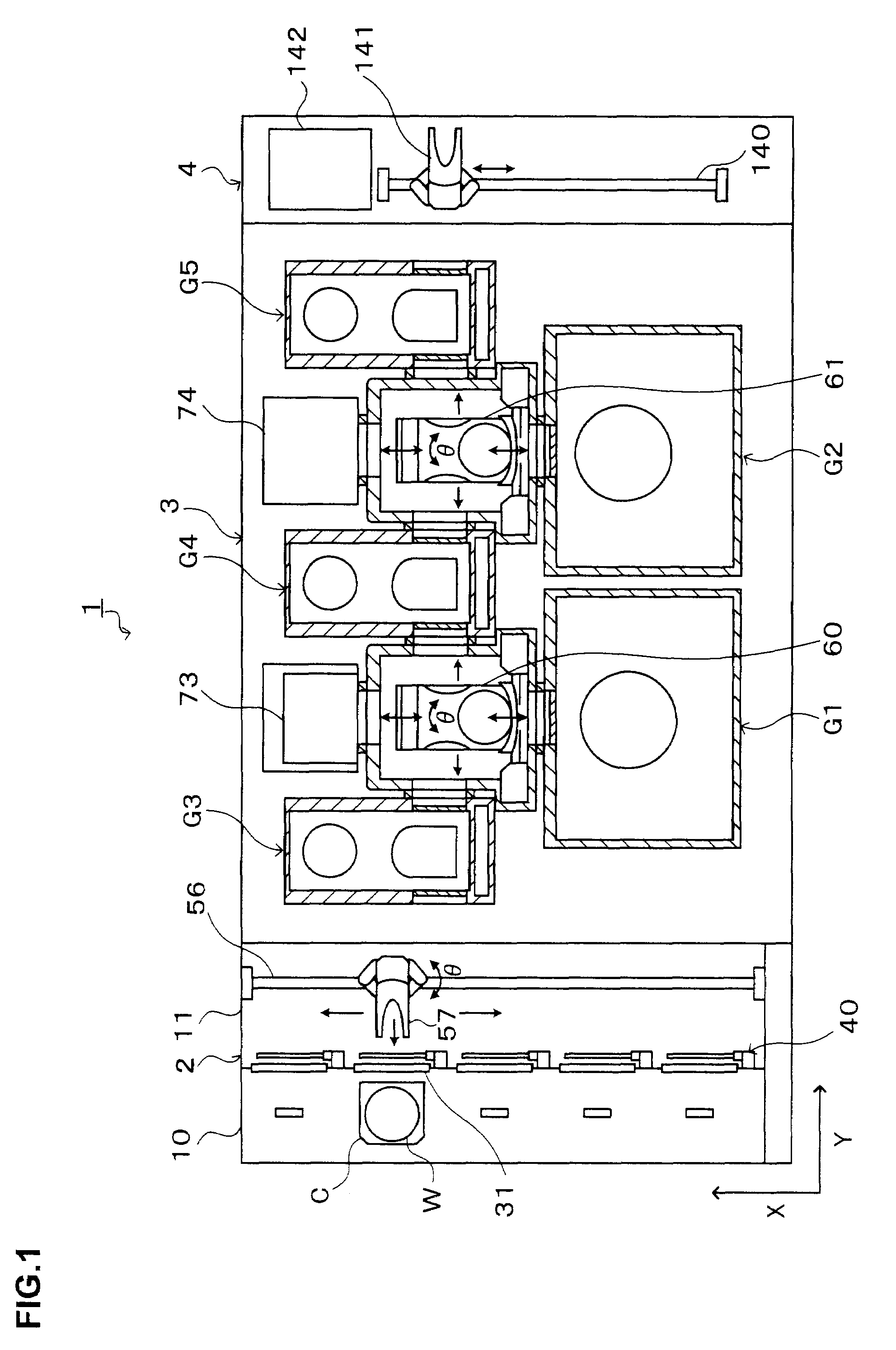

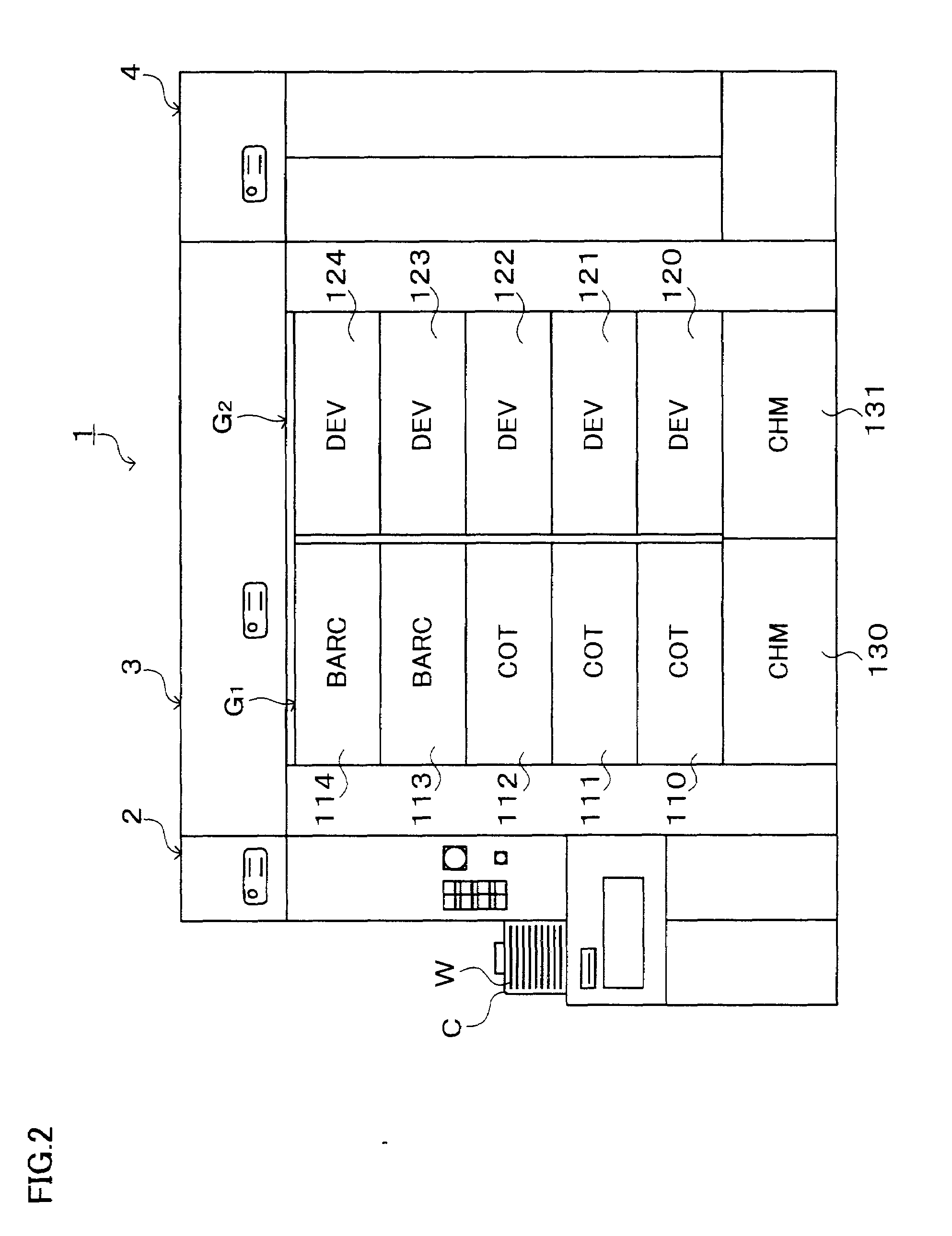

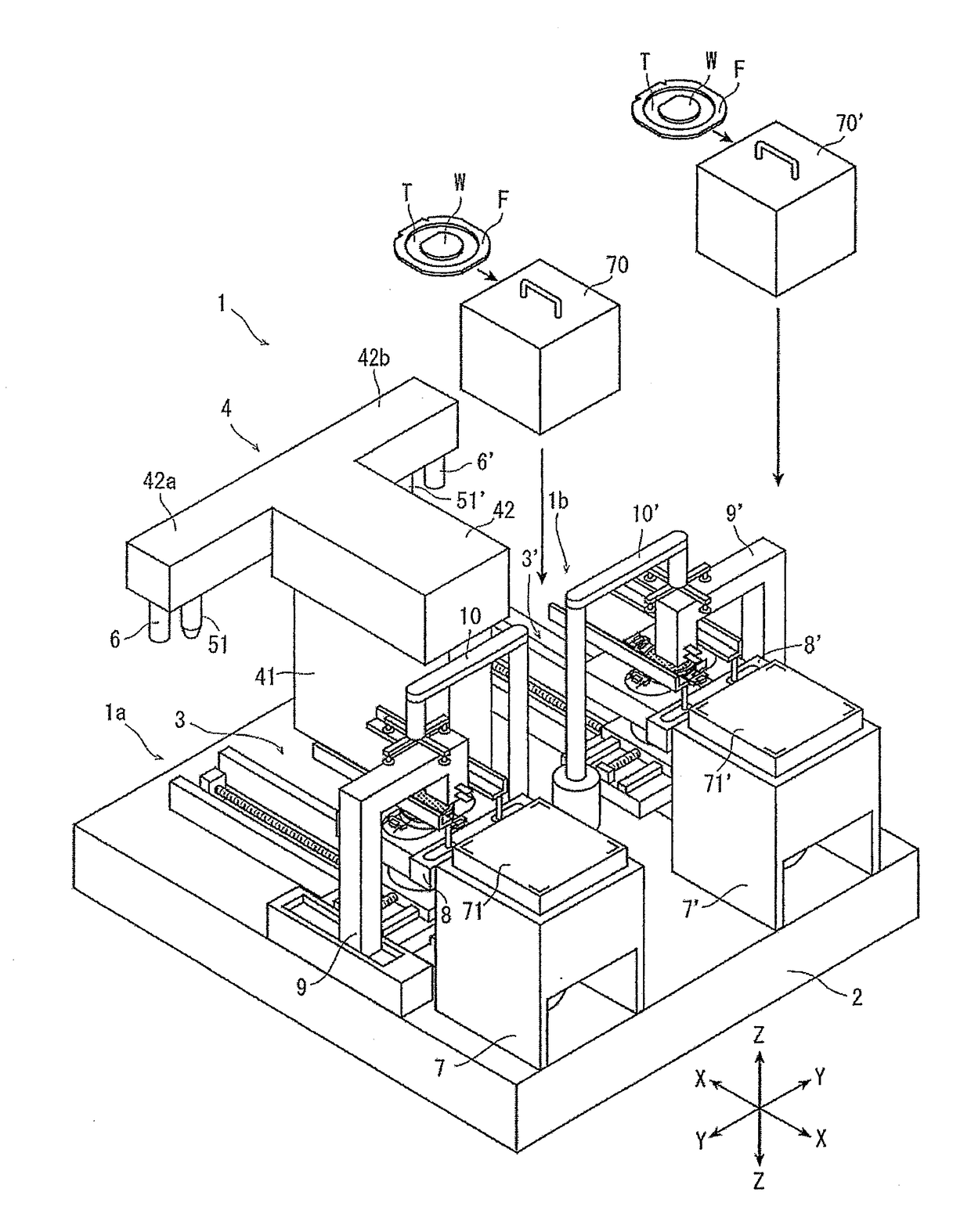

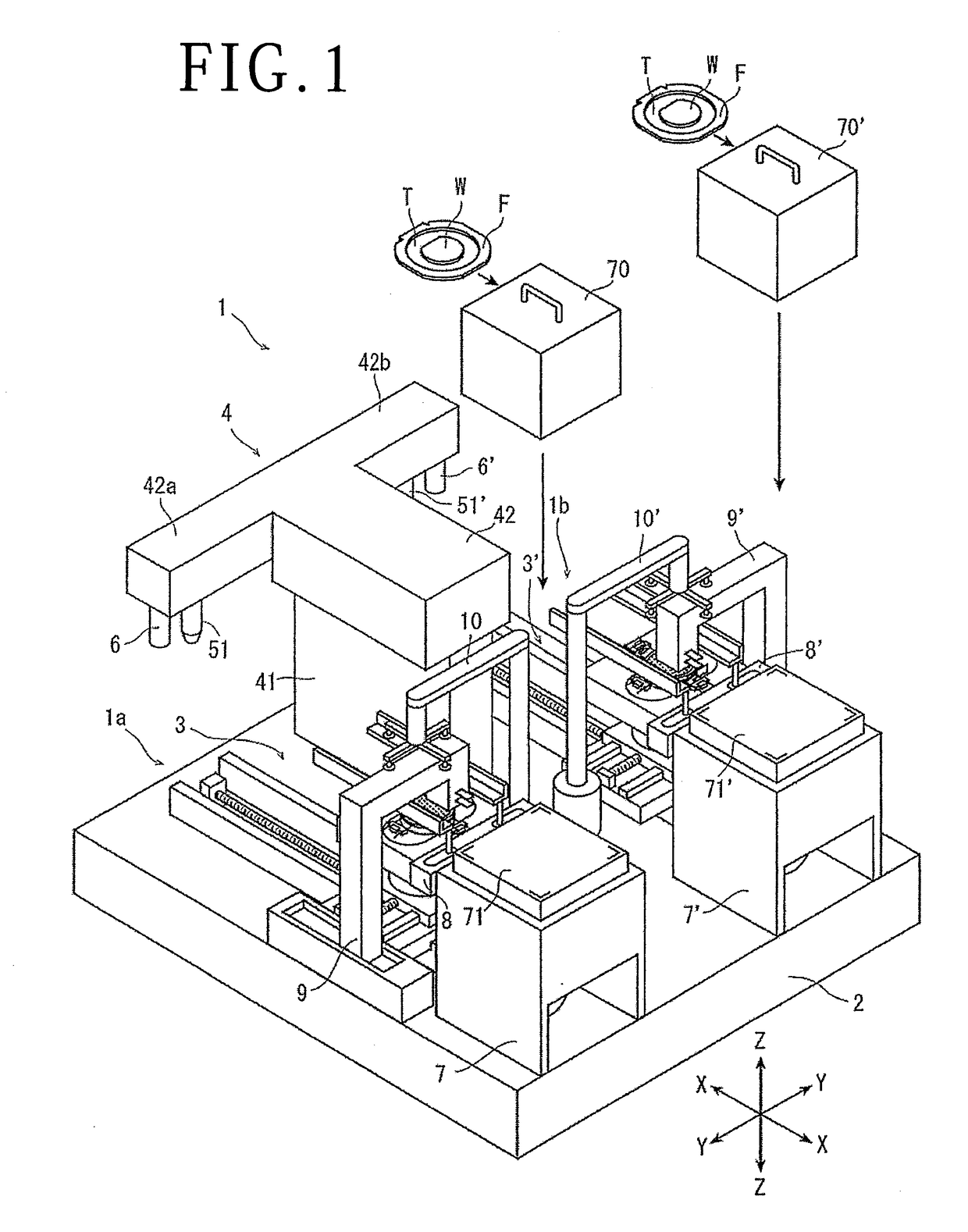

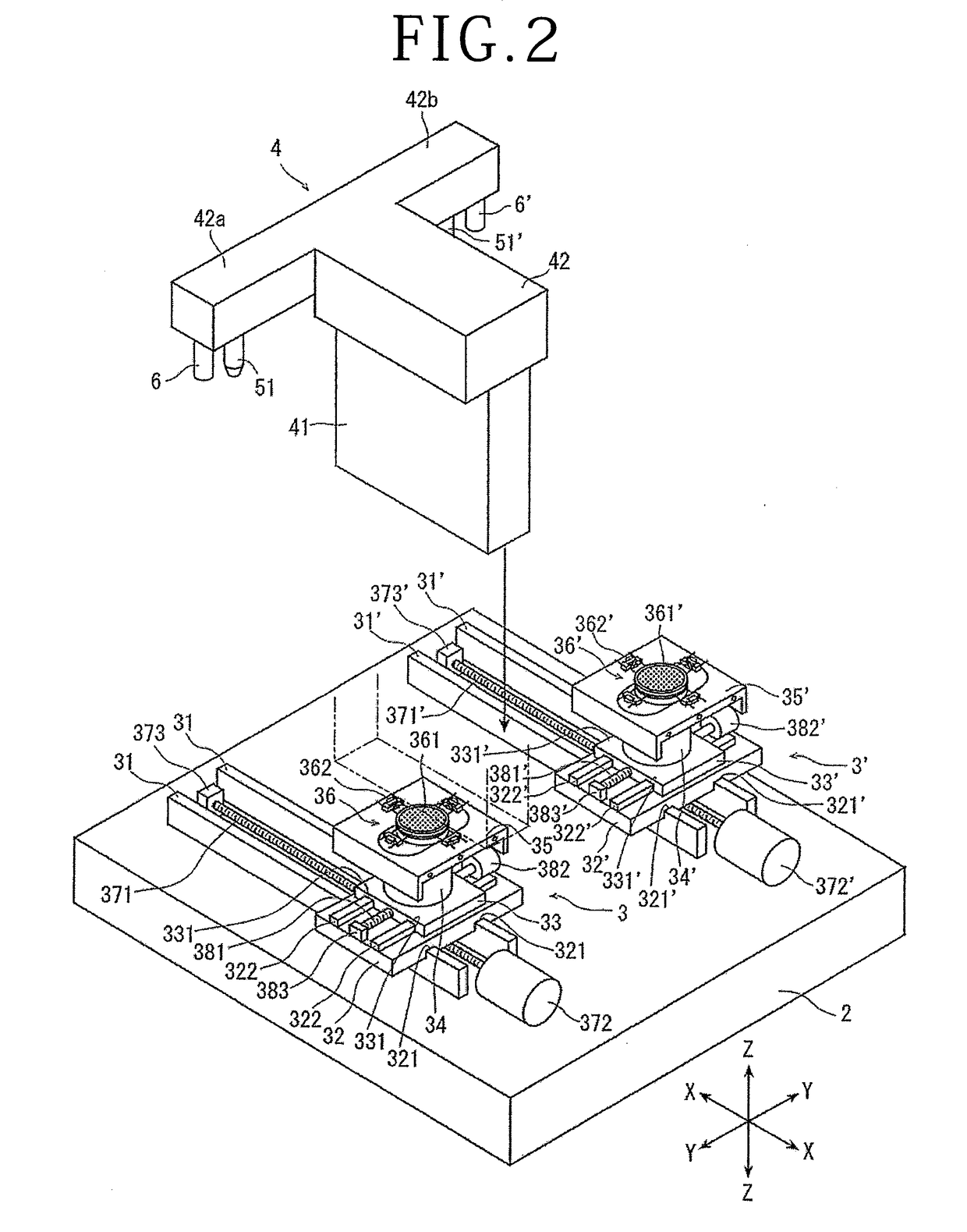

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

Powerless pile separation device

ActiveCN109160273AGuaranteed uptimeSimple structureConveyorsDe-stacking articlesProduction lineEngineering

The invention discloses a powerless pile separation device. The powerless pile separation device comprises a machine body, a pile separation module, a conveying module and a connecting rod module, wherein the machine body is provided with a first slide way and a second slide way arranged at intervals; the first slide way and the second slide way are used for conveying goods containers; the pile separation module is connected with the machine body, is arranged above the first slide way, and is used for separating the goods containers on the first slide way; the conveying module is arranged between the first slide way and the second slide way, and is used for conveying the goods containers to the second slide way after separation by the pile separation module; the connecting rod module is rotationally arranged on the machine body; one end of the connecting rod module is connected with the pile separation module, and the other end of the connecting rod module is connected with the conveying module; the connecting rod module is provided with a handle; and when the handle pulls the connecting rod module to move, the connecting rod module drives the pile separation module to separate thegoods containers on the first slide way, and the connecting rod modules drives the conveying module to convey the goods containers, separated on the first slide way, to the second slide way. The powerless pile separation device is simple and small in structure and convenient for operation and application to a small production line.

Owner:GAC TOYOTA MOTOR

Self-locking grabbing mechanism

The invention belongs to a grabbing device, in particular to a self-locking grabbing mechanism. The self-locking grabbing mechanism comprises a stand, the stand comprises a paw and a movement part, the paw is composed of two paw rods and paw handles, each paw rod is provided with a horizontal short side and a vertical long side, the paw handles are fixed at the inner sides of the lower ends of the two long sides, and one ends of the two short sides are hinged to the stand; the movement part comprises a left connecting rod, a right connecting rod and a pull rod, one ends of the left connecting rod and right connecting rod are hinged to each other and coaxial with the pull rod, and the other ends are hinged to the upper end points of the long sides of the paw rods. The self-locking grabbing mechanism is simple in structure and capable of performing self-locking when the connecting rods are located at a horizontal state so as to prevent a pipe fitting sliding in carrying.

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

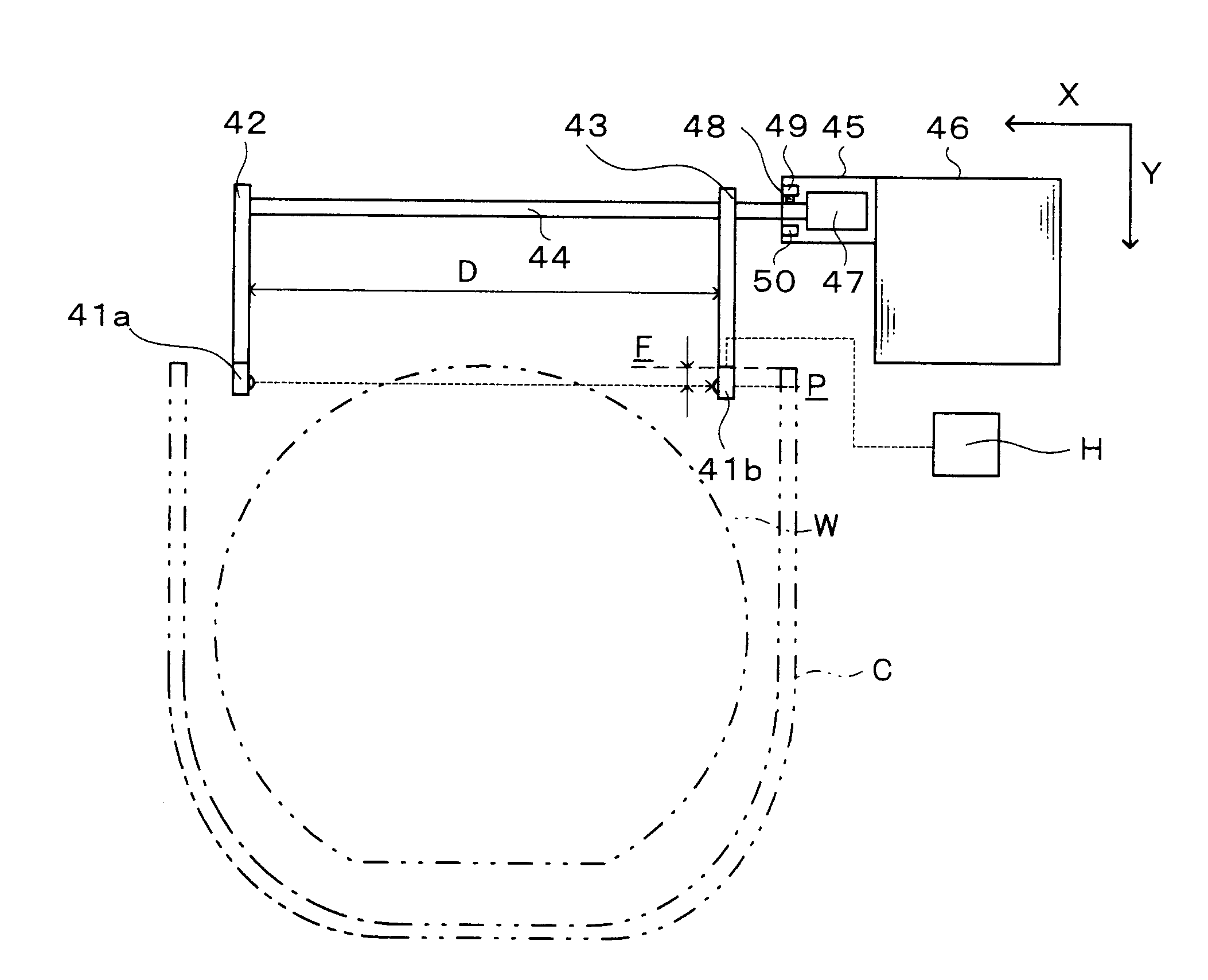

Detecting apparatus and detecting method

ActiveUS20080100852A1Reduce spacingSmall sizeLiquid processingSemiconductor/solid-state device testing/measurementEngineering

Owner:TOKYO ELECTRON LTD

180 Degree inverting mechanism

Owner:NUMOTION TECH LLC

Handling mechanism

InactiveUS20130136568A1Easily distorted and even destroyedProgramme-controlled manipulatorConveyorsEngineeringMechanical engineering

A handling mechanism comprises a mounting seat, a driving assembly, a sliding member, an extending mechanism and a clamping assembly. The driving assembly is mounted on the mounting seat. The sliding member is slidably mounted on the mounting seat and driven by the driving assembly. The extending mechanism comprises an extending member and a strength member. The extending member is positioned on the sliding member being capable of moving along a direction perpendicular to a direction of the movement of the mounting seat. The strength member is slidably positioned on the sliding member and connects with the extending member. The clamping assembly is fixed to the strength member for clamping very heavy workpieces.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Improved plate turnover machine with quick turnover function

PendingCN113060519ASafe and reliable actionThe rotating structure is reasonable and effectiveConveyor partsRotational axisElectric machine

The invention belongs to the technical field of plate processing, and particularly relates to an improved plate turnover machine with a rapid turnover function. According to the improved plate turnover machine, through arrangement of a rotating shaft, a rotating plate, a motor pressing unit and an elastic plate unit on a driving motor, the purposes that plates are turned over quickly and stably, and are not prone to collide and damage are achieved. The improved plate turnover machine has the advantages that a rotating structure for plate turnover is reasonable and effective, and the plate clamping type rotating turnover action is safe and reliable; the plate is not prone to damage, and a plate pushing feeding and discharging structure is simple and efficient; the mode that an elastic plate unit is pressed to store energy firstly and then assists in pushing out the plate is flexible and ingenious, and the overall plate feeding and discharging structure is rapid, labor-saving, stable and accurate; and the whole turning plate structure is stable and compact, flexible, adjustable, energy-saving and economical.

Owner:ZHEJIANG YASHA DECORATION

Clamping device of photovoltaic junction box body

PendingCN107826742ANot easy to damageImprove efficiencyConveyorsConveyor partsEngineeringMaterials science

The invention discloses a clamping device of a photovoltaic junction box body, which mainly solves the technical problems of easiness in damage and lower efficiency during movement of the photovoltaicjunction box body. The clamping and conveying device of the photovoltaic junction box body comprises a fixed side plate, wherein a clamping device is arranged on the top of the side plate, a channelis formed in the side plate below the clamping device, and a push device is arranged at the bottom of the channel, so that the problem is preferably solved. The clamping and conveying device can be used for clamping and conveying photovoltaic junction boxes.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

Laser processing apparatus

ActiveUS20170087671A1Improve economyLow costSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingOptoelectronics

Owner:DISCO CORP

Automatic production line of laminated board and automatic production method of laminated board

ActiveCN109928209ARealize automated productionNo manual operationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineFixed frame

The invention provides an automatic production line of a laminated board and an automatic production method of the laminated board. The automatic production line comprises a double-head spot welding machine, a feeding mechanical arm, a discharging device and a conveying line; the discharging device comprises a machine frame, an overturning mechanism, a clamping mechanism, a clamping and positioning mechanism, a lifting discharging mechanism and a pushing mechanism, wherein the machine frame is arranged on the front side of a positioning mold, and the overturning mechanism is erected between the machine frame and the positioning mold; the overturning mechanism comprises a bearing seat, a swinging shaft, two overturning arms, a swinging driving part and a fixing frame, wherein the bearing seat and the swinging driving part are oppositely arranged, one end of the swing shaft is rotationally arranged on the bearing block, and the other end of the swing shaft is arranged on the swing driving part, the fixing frame is fixedly connected to the swing shaft, one ends of the two overturning arms are arranged on the fixing frame in a spaced mode through the clamping mechanism, the clamping and positioning mechanism is arranged at the extending end of each overturning arm, and the lifting discharging mechanism is arranged on the machine frame and is positioned between the two overturning arms. According to the automatic production line, the automatic production of the laminated board can be realized, and the working efficiency is improved.

Owner:HONORFAITH FURNITURE

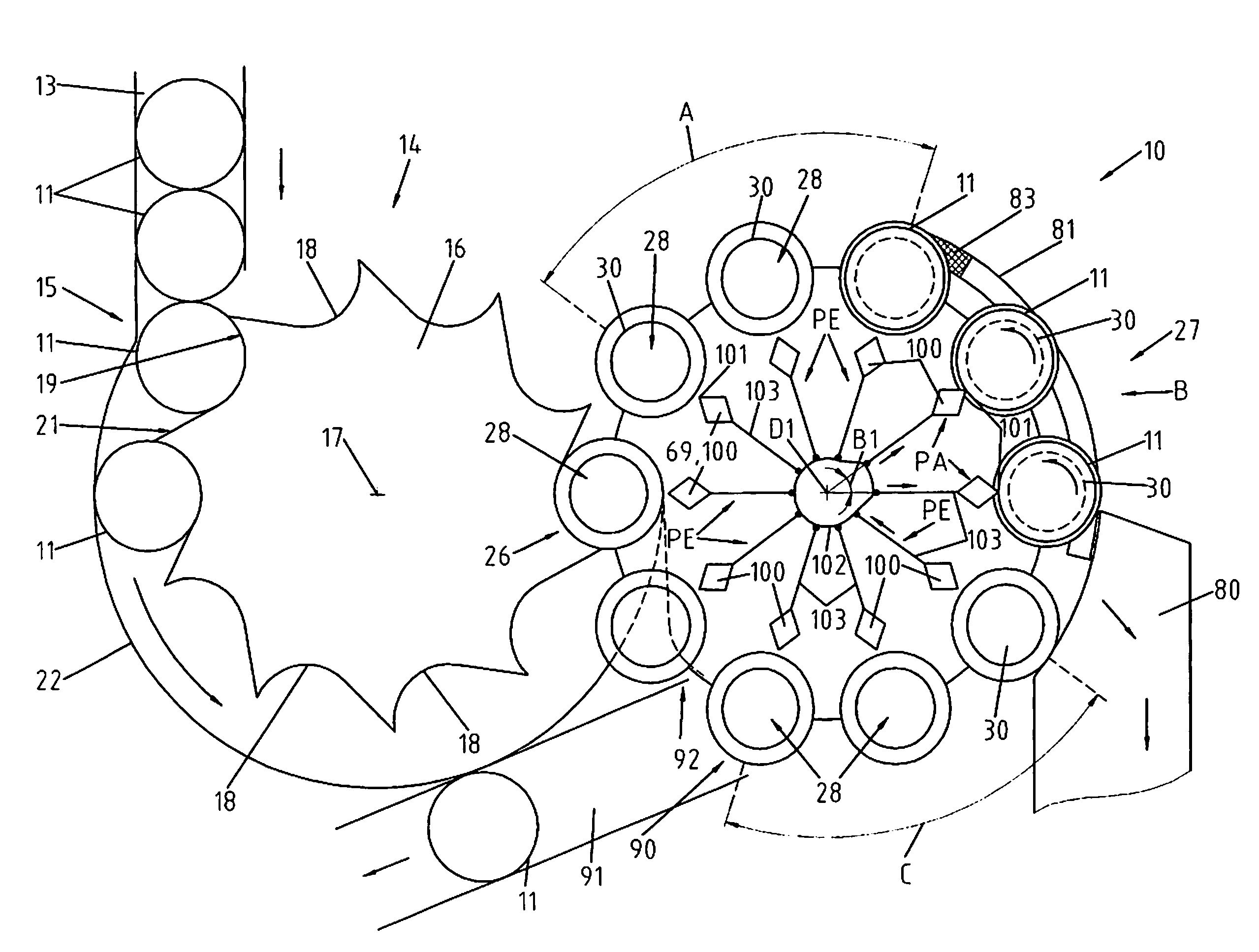

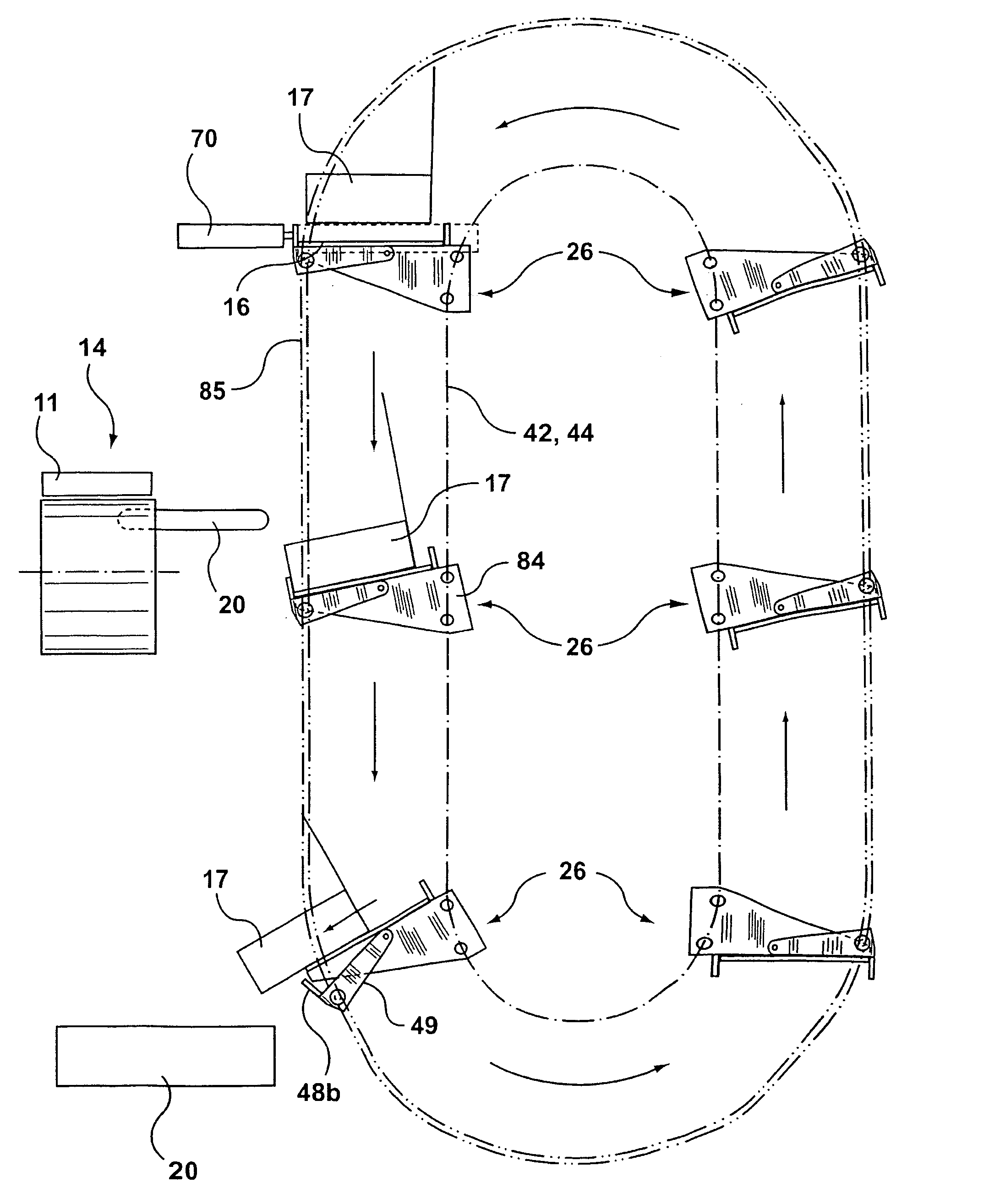

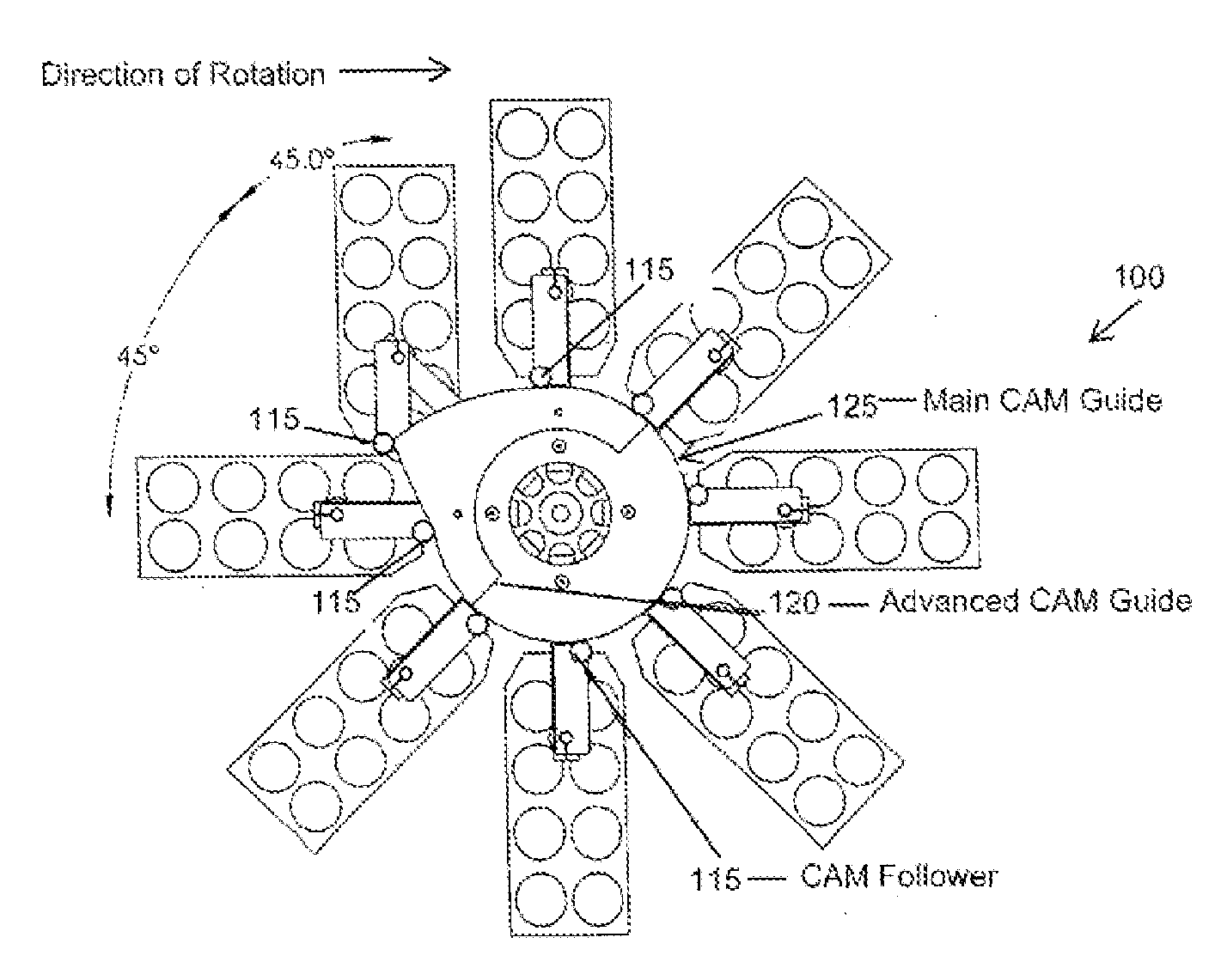

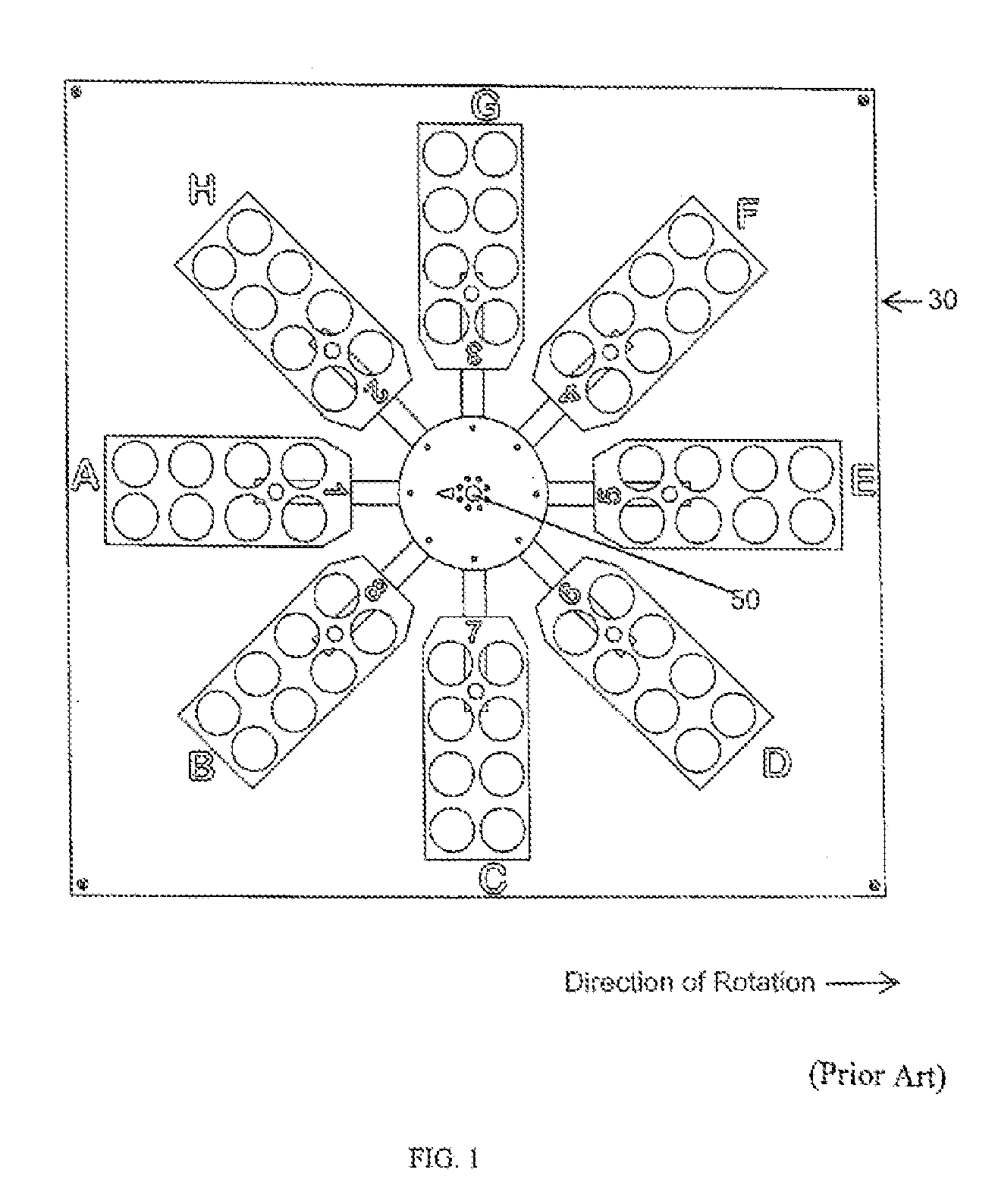

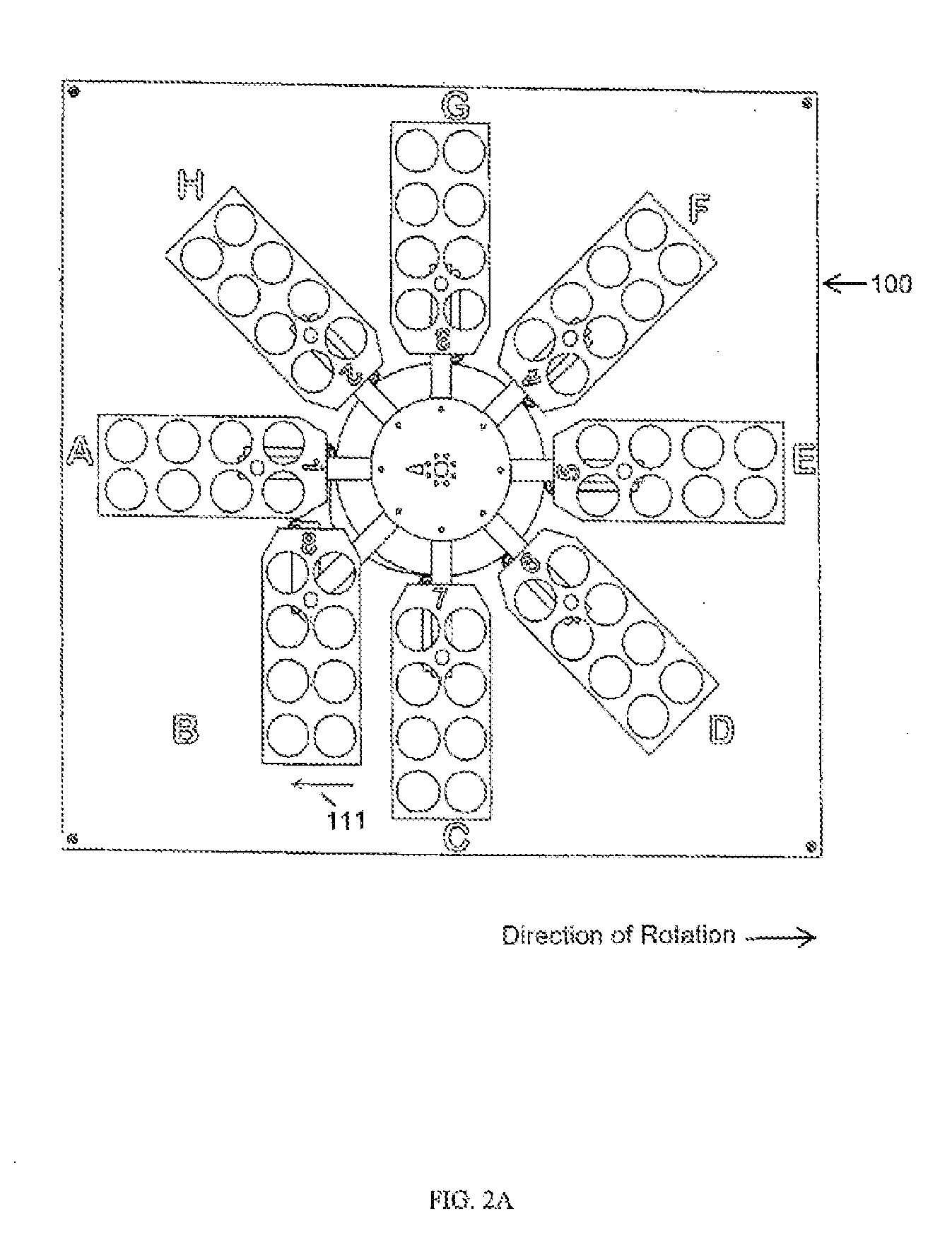

System and method for independently rotating carriers

InactiveUS20130105279A1Shorten speedReduce the impactConveyor partsMechanical conveyorsSatelliteVelocity index

Owner:RAMIREZ HERNANDO

Ceramic forming mold automatic exchange machine

InactiveCN108724449APositioning synchronizationPrecise positioningConveyorsAuxillary shaping apparatusProduction lineCeramic molding

The invention relates to the field of ceramic forming production equipment, in particular to a ceramic forming mold automatic exchange machine. The ceramic forming mold automatic exchange machine is characterized by comprising a longitudinal moving mechanism, an exchange mechanism and a clamping mechanism; the longitudinal moving mechanism comprises a mold clamping rack, a longitudinal slide railfixedly arranged on the mold clamping rack, a longitudinal moving rack slidably arranged on the longitudinal slide rail and a longitudinal driving unit driving the longitudinal moving rack to move; the exchange mechanism comprises an exchange servo motor fixedly arranged on the longitudinal moving rack and a rotary frame driven by the exchange servo motor to rotate. According to the ceramic forming mold automatic exchange machine provided by the invention, rising, dropping, position exchange and clamping of plaster molds can be implemented through the longitudinal moving mechanism, the exchange mechanism and the clamping mechanism; unformed plaster molds on a production line and formed plaster mold on an automatic forming machine can be exchanged; the automation degree is high, manual carrying of molds is omitted; the production efficiency is improved; and the labor cost is lowered.

Owner:FUJIAN DEHUA BOLONG CERAMICS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap