Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Small footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated warehouse system

ActiveUS20140212249A1Small footprintStorage devicesLoading/unloadingStructural engineeringStorage area

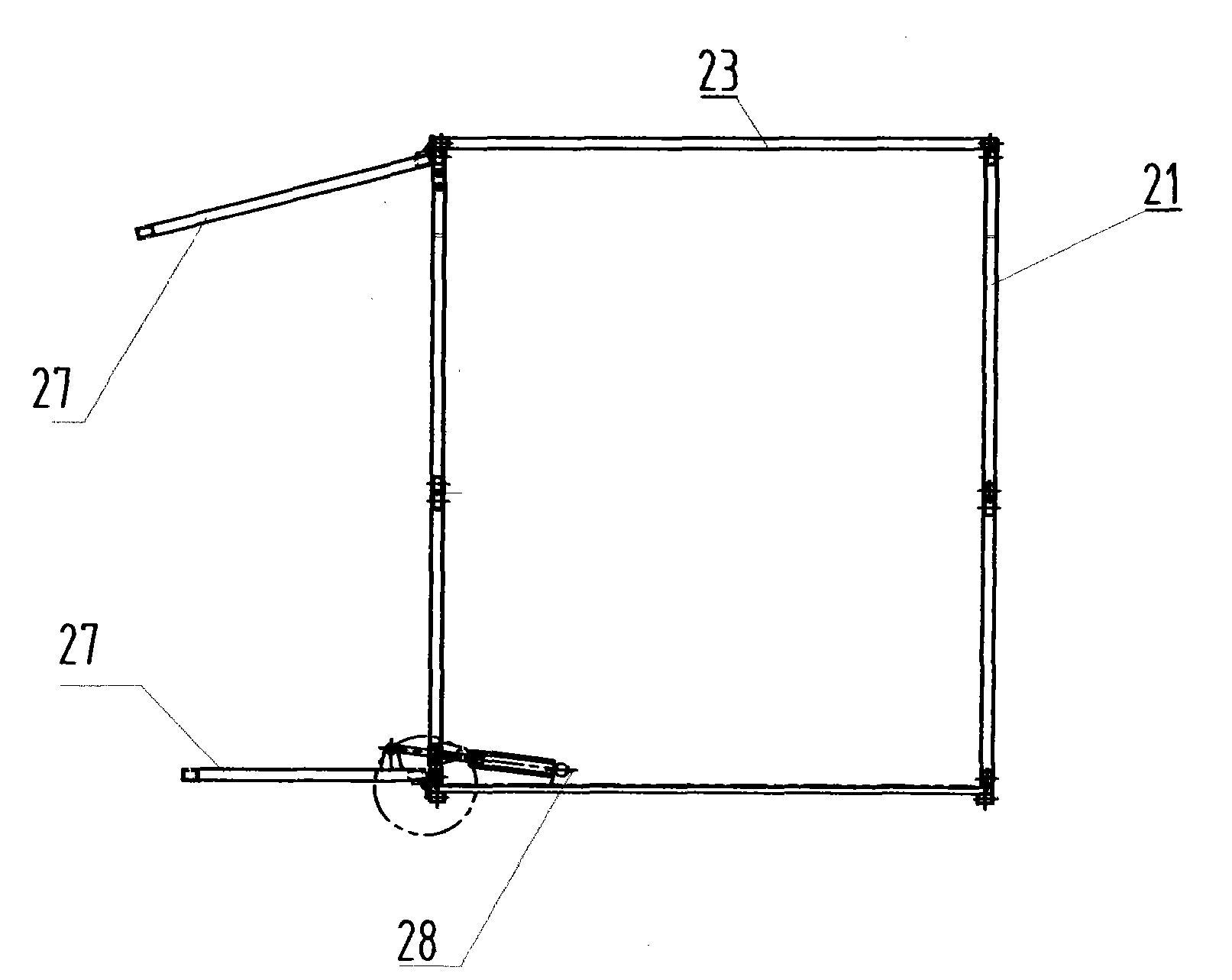

An automated warehouse system may require less space than conventional warehouse systems. The automated warehouse system is configured so that loads are stored in storage areas formed by vertically extending support pillars and horizontally extending beams. The loads are loaded into the storage areas, and the loads are unloaded from storage areas. The automated warehouse system comprises: vertical guide rails disposed on the support pillars; horizontal guide rails disposed on the beams; and a movable platform having a frame body and guide rollers, at least part of the frame body having the same rectangular shape as a shape of at least part of at least one of the storage areas and having vertical frame members and horizontal frame members, the guide rollers being disposed on the vertical frame members and engaging the vertical guide rails or disposed on the horizontal frame members and engaging the horizontal guide rails.

Owner:AMAZON TECH INC

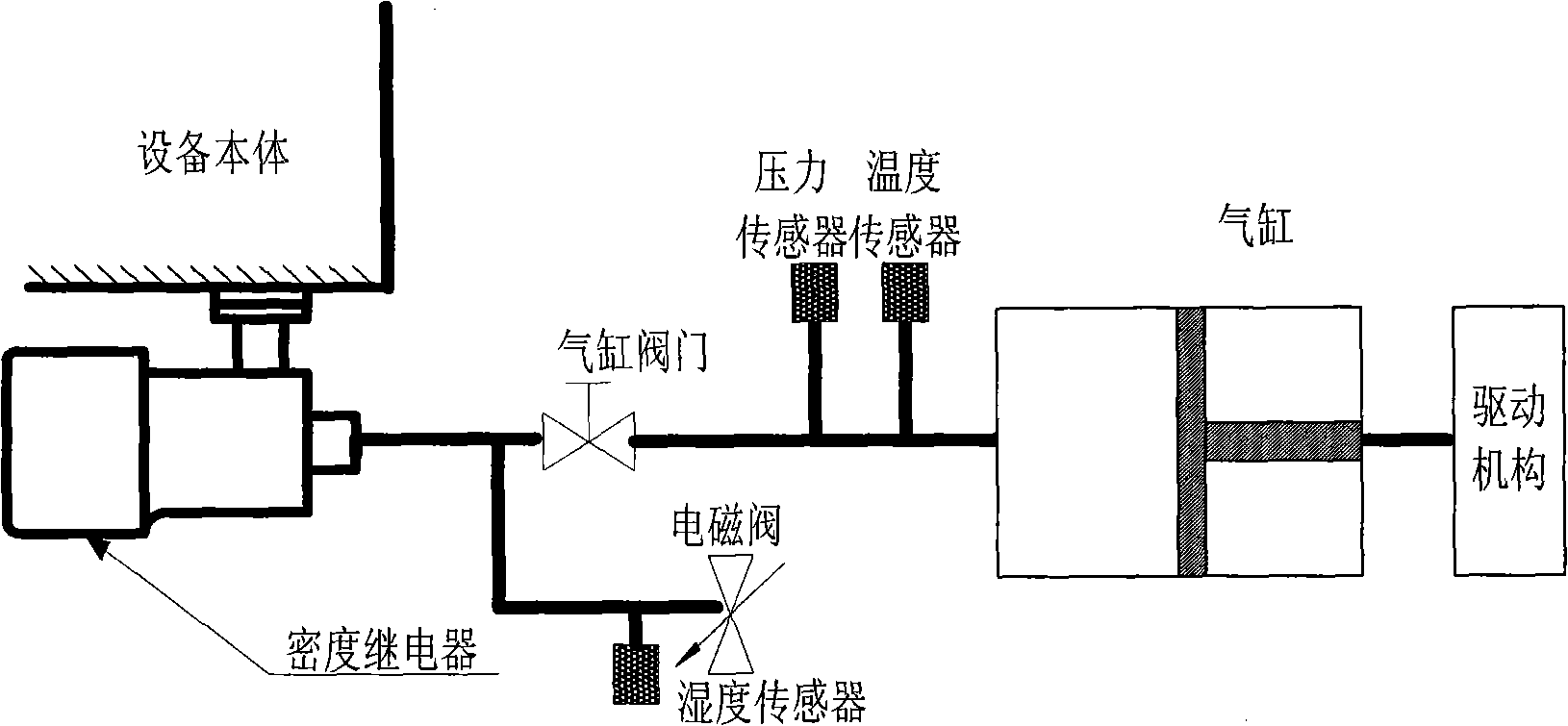

Density relay comprehensive checking instrument of sulfur hexafluoride breaker

InactiveCN102033198AReasonable structureGuaranteed uptimeMeasurement of fluid loss/gain rateCircuit interrupters testingBus networkHardware structure

The invention provides a density relay comprehensive checking instrument of a sulfur hexafluoride (SF6) breaker. The density relay comprehensive checking instrument consists of a hardware structure, a software structure and a pneumatic unit. Under the control of the software structure, the hardware structure drives the pneumatic unit to perform data acquisition and data analysis, and to communicate with a monitoring centre server unit; the hardware structure is divided into lower computer hardware and upper computer hardware; the lower computer hardware is arranged under a spot SF6 breaker, and the upper computer hardware is arranged on a main control chamber power measuring counter, so the communication is realized by a controller area network (CAN) bus network; the software structure is also divided into lower computer software and upper computer software; the lower computer software controls the lower computer hardware to monitor a checking spot and transmits relevant data to the upper computer hardware; the upper computer software controls the upper computer hardware to receive and process the data; the pneumatic unit consists of an air cylinder and a pipeline; a piston in the air cylinder performs stretching and propelling under the driving of a stepping motor; and under the control of an intelligent control output unit, a pressure value of air in an air path can be changed. The density relay comprehensive checking instrument of the SF6 breaker has wide application prospect in the monitoring technical field.

Owner:BEIHANG UNIV +2

Foldable wing extensible in wingspan

InactiveCN105818962ACompact structureWide range of wingspanWing adjustmentsWingspanAerospace engineering

The invention discloses a foldable wing extensible in wingspan .The foldable wing comprises a front wing, a rear wing, a base and an actuating system, wherein the front wing comprises a left front inner wing and a right front inner wing which are arranged symmetrically, the rear ring comprises a left rear wing and a right rear wing which are arranged symmetrically, the end of the left front inner wing and the end of the right front inner wing are hinged and installed to one end of the base though front wing installing shafts, the actuating system is arranged at the other end of the base, a left front outer wing and a right front outer wing which slide in the length directions of the inner wings are respectively arranged on the left front inner wing and the right front inner wing, one end of the left rear wing and one end of the right rear wing are hinged and installed to a sliding block, the other end of the left rear wing and the other end of the right rear wing are in hinged connection with the left front outer wing and the right front outer wing, and the sliding block is driven by the actuating system to longitudinally move along the base back and forward .The foldable wing is large in wingspan variation amplitude and small in occupied space, leans against the base when being folded, the left front outer wing and the right front outer wing are rotatably unfolded around the front wing installing shaft, meanwhile the left front outer wing and the right front outer wing increase the wingspan width, a lift force and the lift-drag ratio are increased, and the flight efficiency is improved .

Owner:CETC SPECIAL MISSION AIRCRAFT SYST ENG

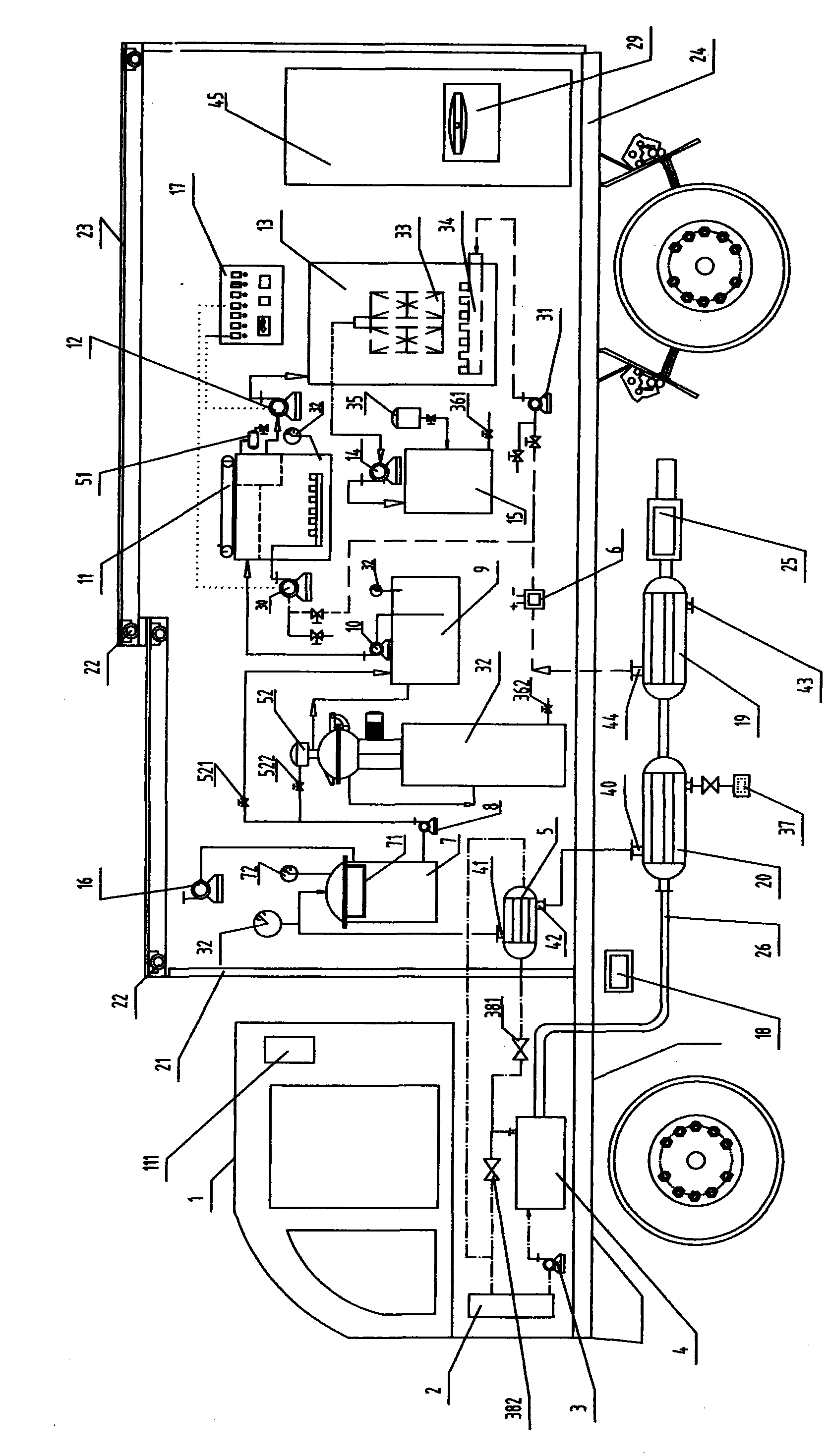

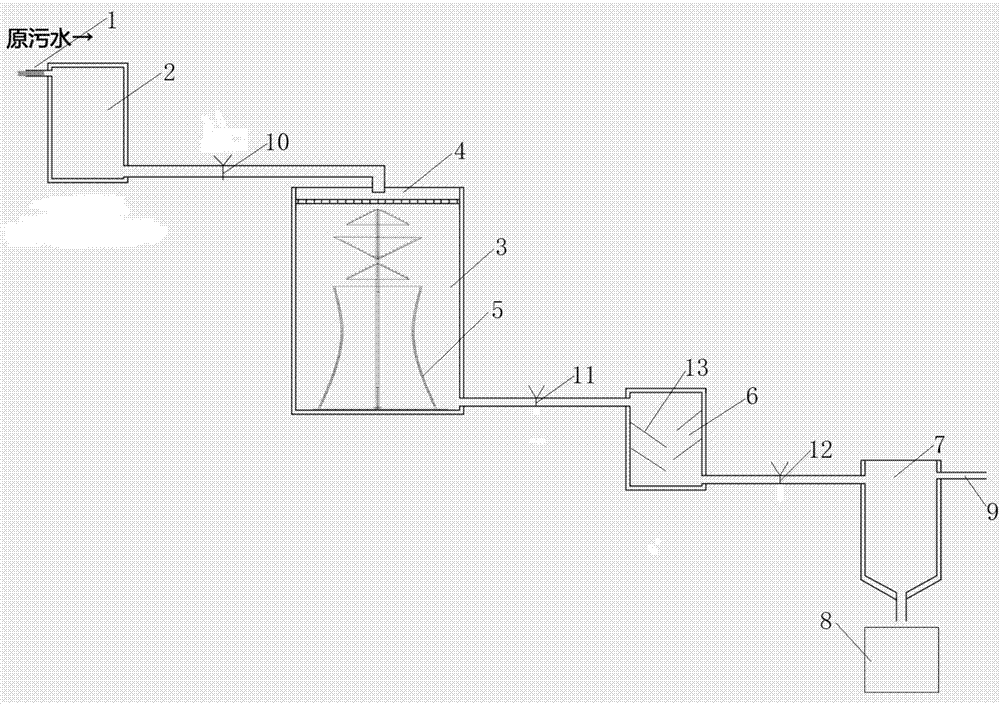

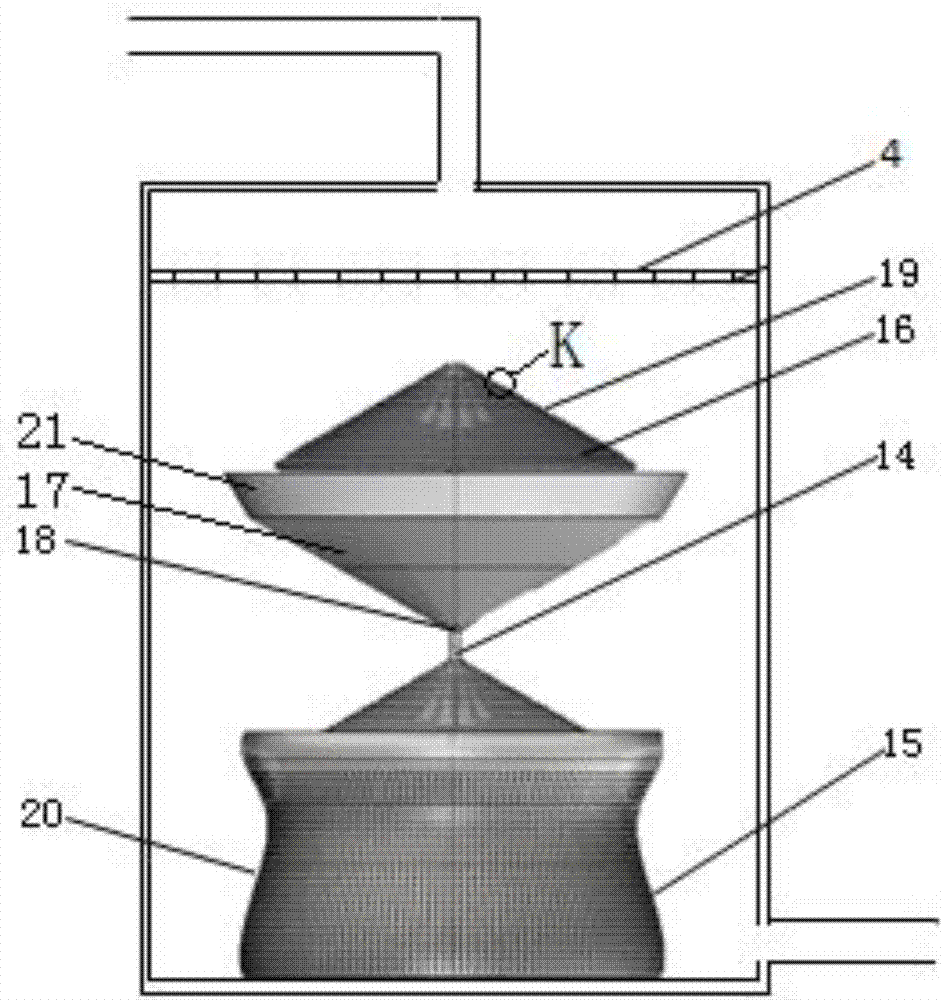

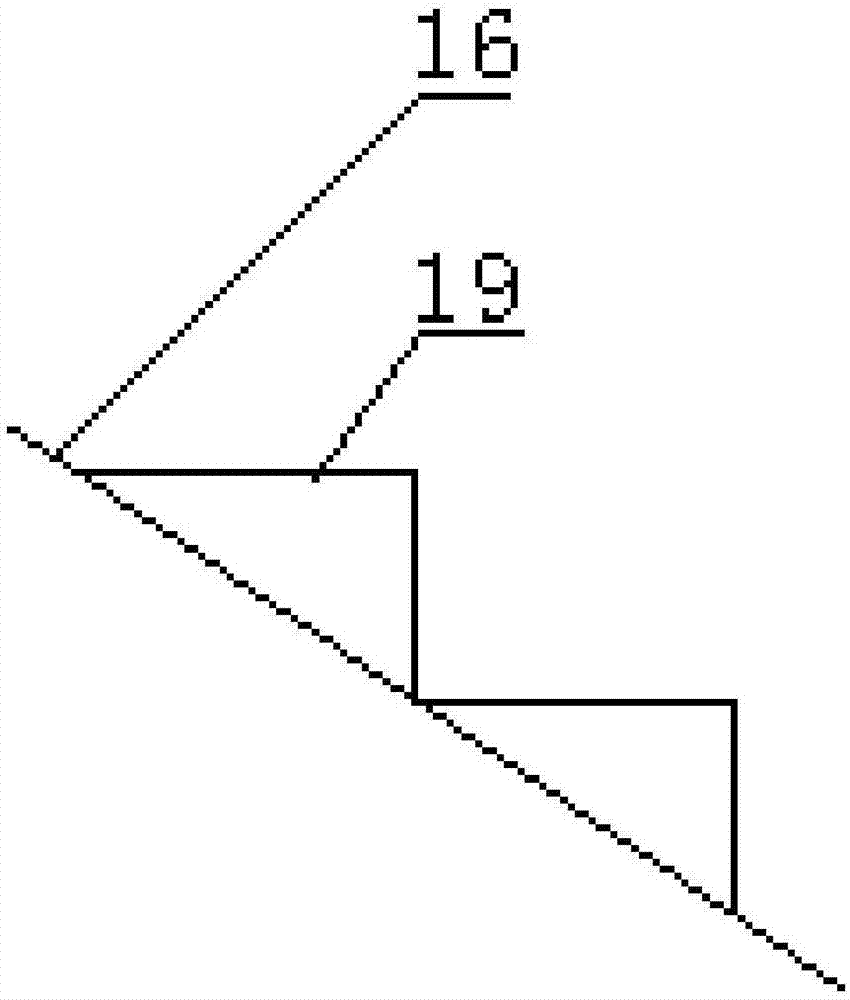

Movable type method and special vehicle for oil-water separation and wastewater purification of mobile kitchen waste

InactiveCN103011494AReduce pollutionStable water qualityBiological treatment apparatusMultistage water/sewage treatmentSmall footprintSewage treatment

The invention relates to a method and equipment for the oil-water separation and wastewater purification and treatment of kitchen wastes. The method and the equipment can carry out field collection or wastewater purification and standarization treatment on the kitchen wastes swill or domestic wastewater in the fields of a restaurant, a hotel, a department, a house, milk plant, a food products factory, a brewery, a hospital, a beverage plant, a slaughterhouse, a chemical plant and the like, separates the swill into drainage oil and kitchen wastewater, continuously carries out fast and continuous purification treatment on the domestic wastewater anytime and anywhere and ensures that the quality of purified water achieves the nationally specified (GB18918-2002) emission standard of a town sewage processing plant. The heating and temperature-regulating type wastewater purification treating equipment disclosed by the invention has the advantages of small occupied area, high wastewater purification starderization speed, low wastewater treating equipment investment, low wastewater treatment cost, and the like. The method and the equipment which are disclosed by the invention have the advantages of good industrial practicability, novelty and creativity.

Owner:周鼎力

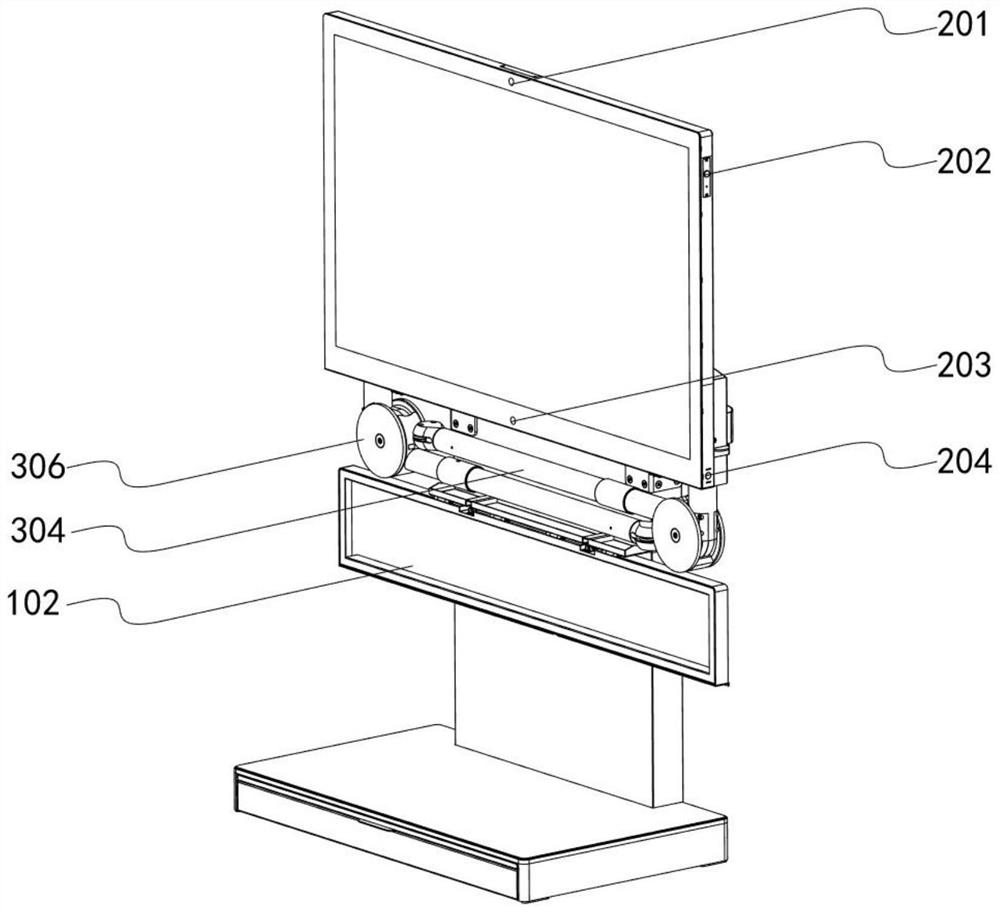

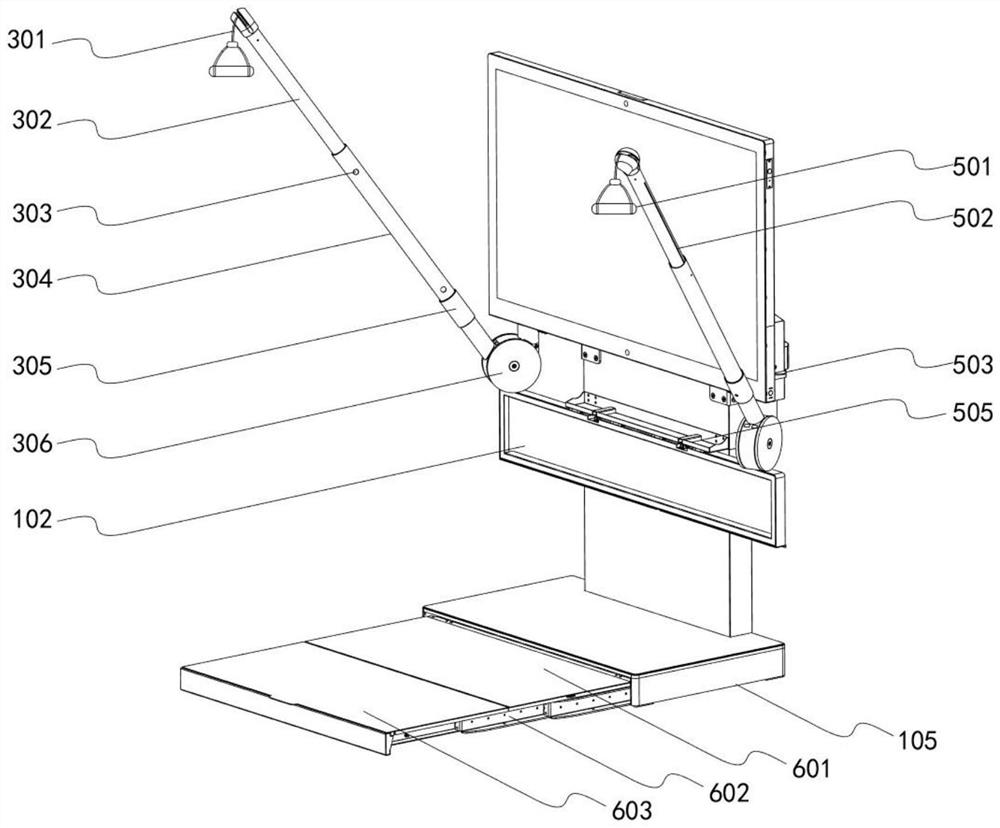

Intelligent file shooting instrument and display method thereof

Owner:SHENZHEN KERUN VISUAL TECH CO LTD

A new type of milling device

Owner:四川欧曼机械有限公司

Multifunctional integrated cleaner unit machine

InactiveUS20100294004A1Small footprintReduce manufacturing costOther washing machinesTextiles and paperEngineeringSmall footprint

A multifunctional integrated cleaner unit machine includes a cabinet, washing basin and a full-automatic washing machine located in the cabinet. An enclosing frame is provided on an upper part of the cabinet. A cover corresponding with the full-automatic washing machine is hinged on the enclosing frame. A control panel and a main water inlet are provided at the enclosing frame. A dryer machine is located on one side of the full-automatic washing machine in the cabinet. The washing basin is located in the enclosing frame above the dryer machine. The washing machine, the washing basin and the dryer are combined into an integral machine with the security standard, thereby the multifunctional integrated cleaner unit machine has the advantages of small occupied area, low manufacturing cost, full functions, proper height, time saving in use, convenience, energy saving, convenient installation, little vibration and noise, low transporting cost and uniform integral style.

Owner:HU JIEBO

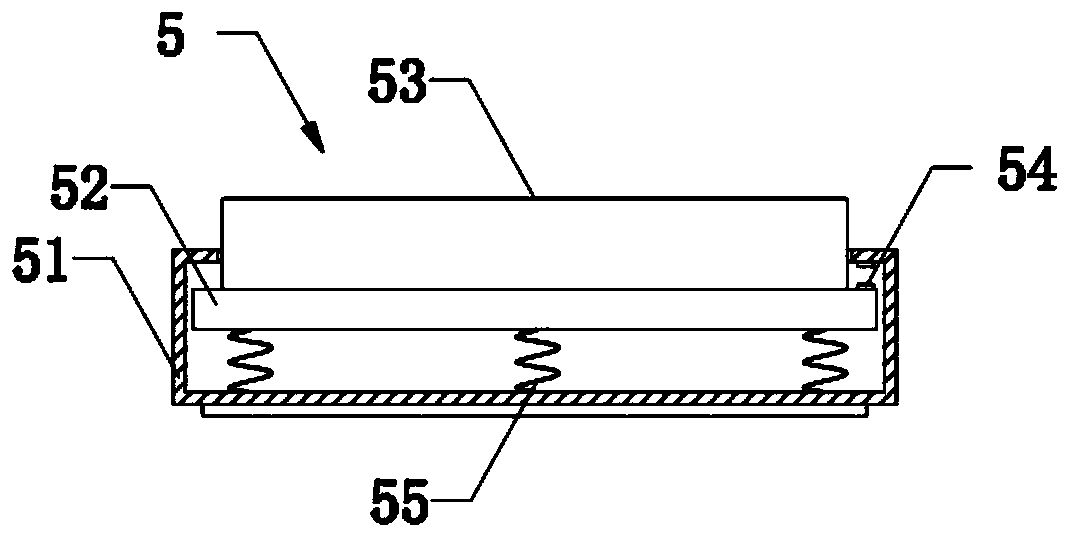

Clothing cloth drying equipment

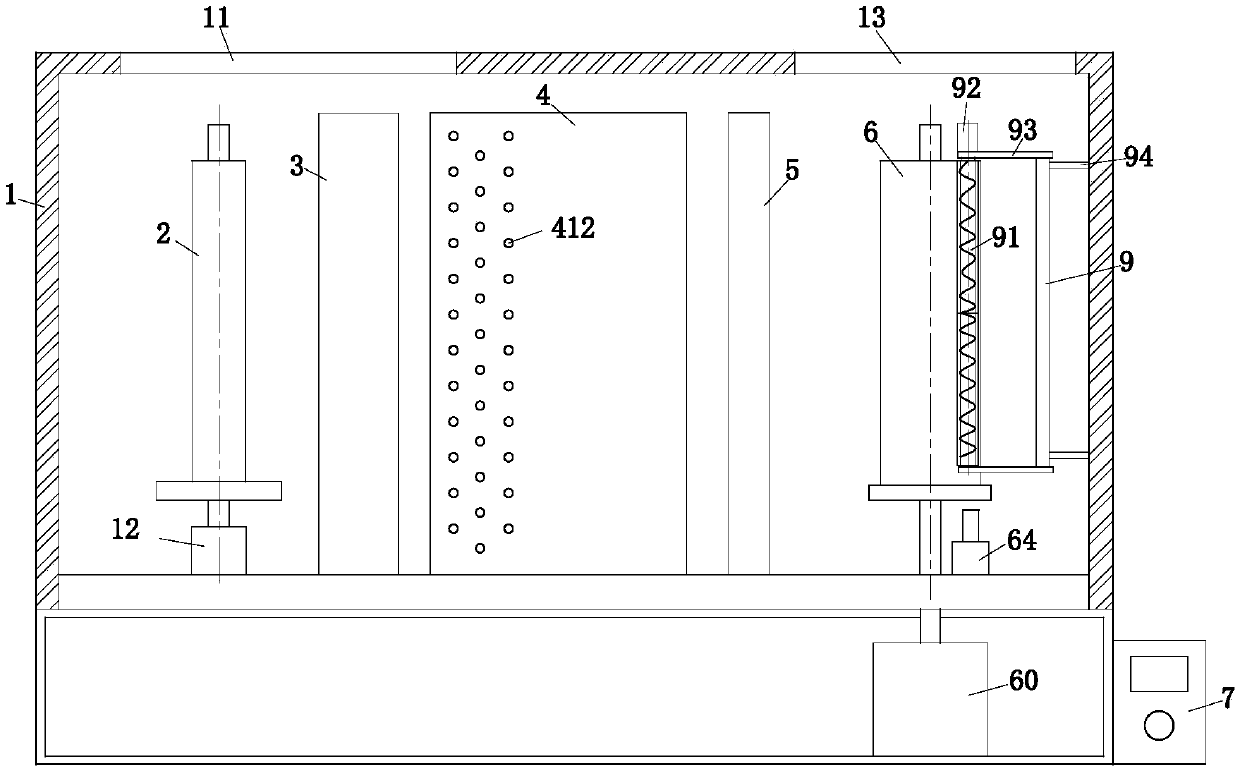

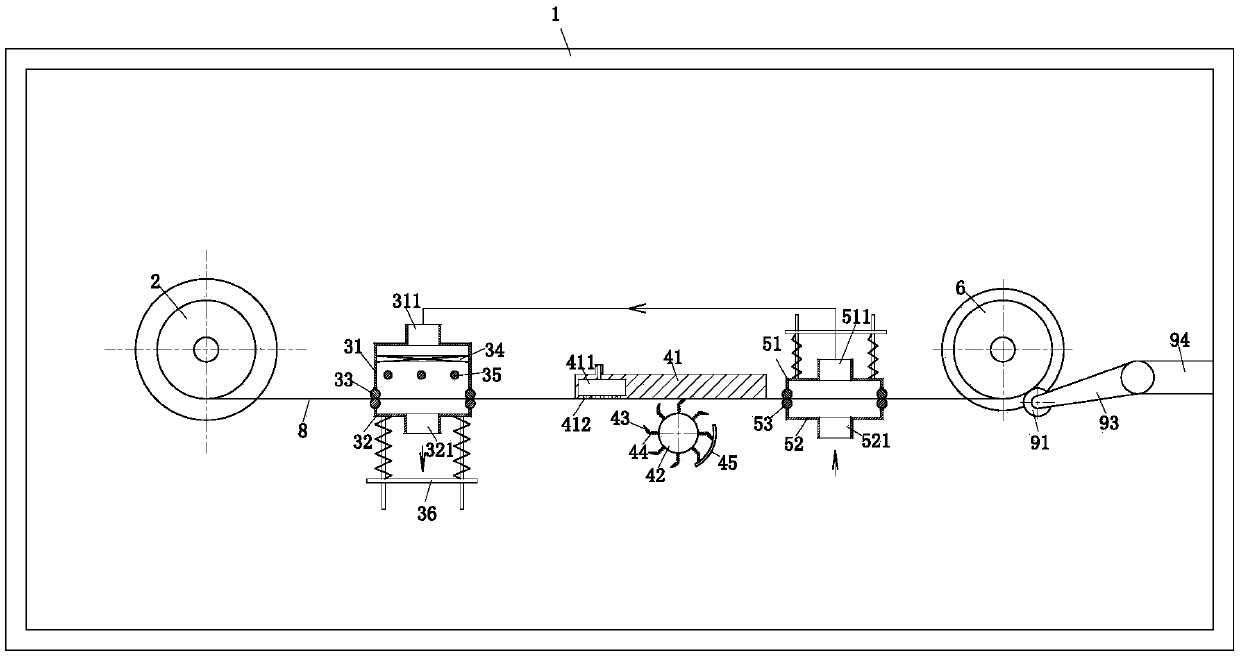

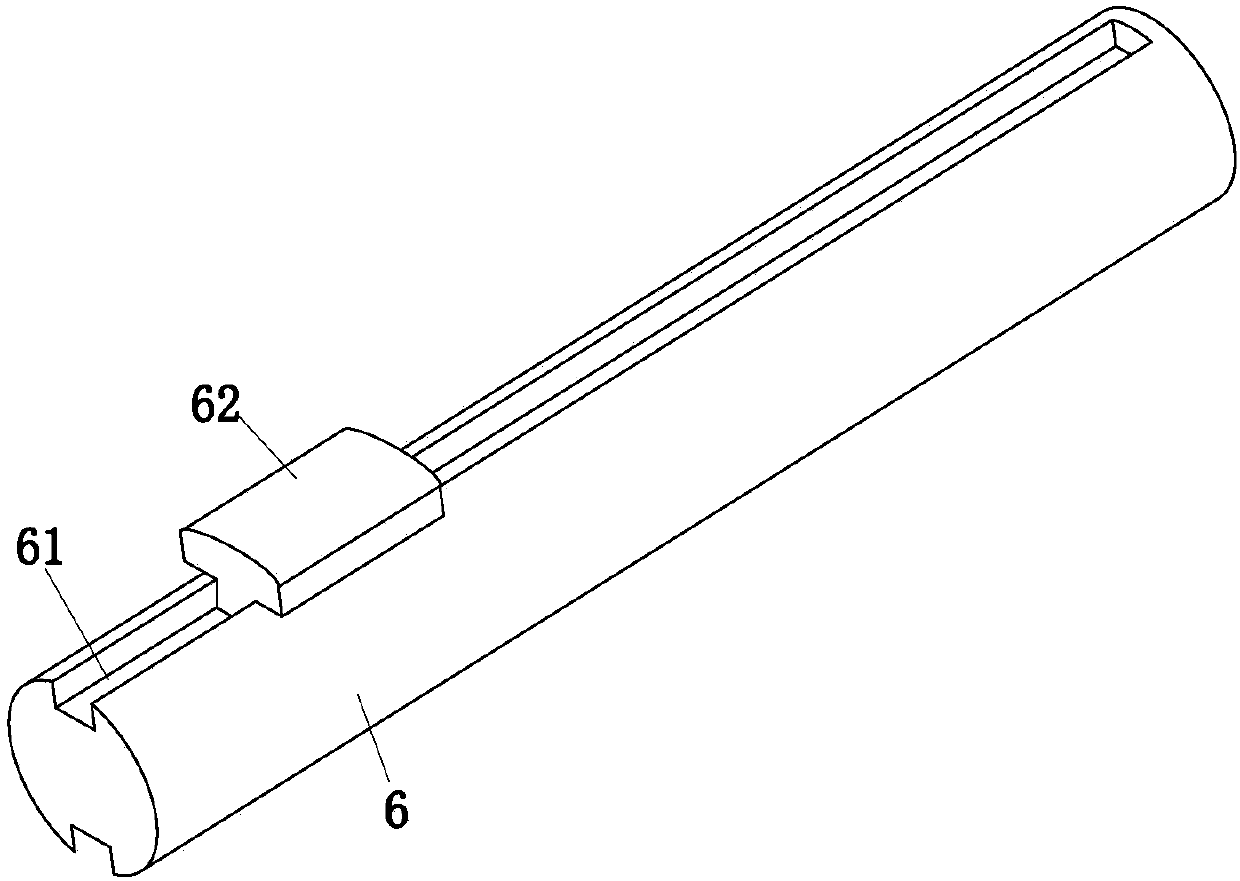

ActiveCN107677084AEasy to acceptSmall footprintDrying gas arrangementsDrying machines with progressive movementsAir dryingEnergy consumption

The invention relates to the technical field of drying equipment, in particular to clothing cloth drying equipment. The clothing cloth drying equipment comprises a box body, a discharging shaft for discharging cloths, a drying module, an ironing module, an air-drying module, a rolling shaft for rolling the cloths and a controller. The top of the left side of the box body is provided with a storinghole for storing the cloths, a damping piece mounted at the bottom of the box body is arranged under the storing hole, and the discharging shaft is vertically mounted on the damping piece. The dryingmodule is used for drying the cloths, the ironing module is used for ironing the cloths, and the air-drying module is used for air-drying the ironed cloths. The rolling shaft is located on the rightside of the air-drying module, a material taking hole for taking out the cloths is formed in the top of the box body over the rolling shaft, the rolling shaft is driven through a rolling motor, and the rolling motor is electrically connected with the controller. The clothing cloth drying equipment is mainly suitable for being used in a clothing manufacturing shop and has the characteristics that the size is small, the weight is small, the price is low, and energy consumption is little.

Owner:安徽衣信纺织科技有限公司

Sewage treatment device capable of performing multi-stage filtration on sewage

PendingCN114477574ASmall footprintImprove processing efficiencyWater/sewage treatmentMultistage water/sewage treatmentSewage treatmentSewage

Owner:YELLOW RIVER CONSERVANCY TECHN INST

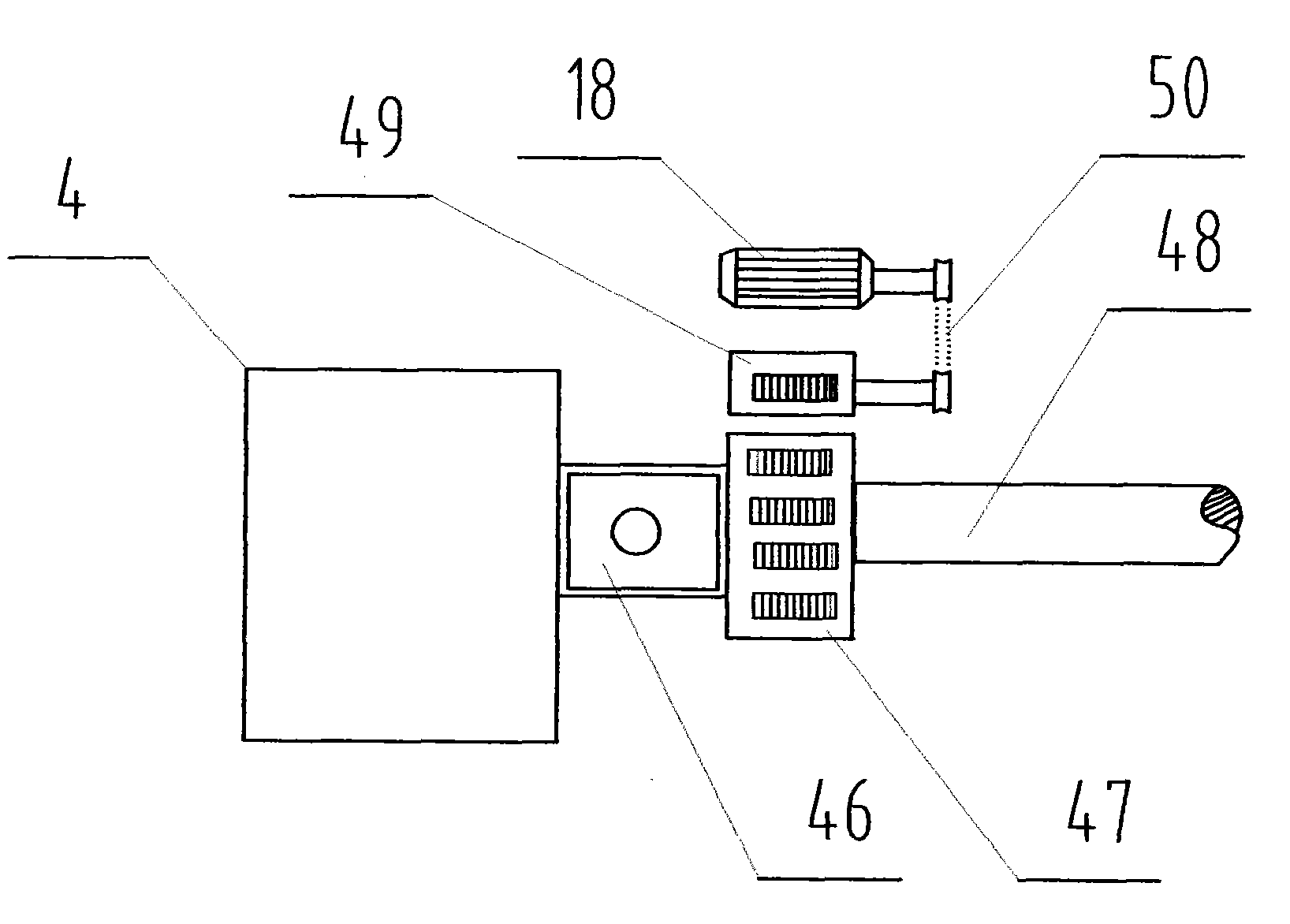

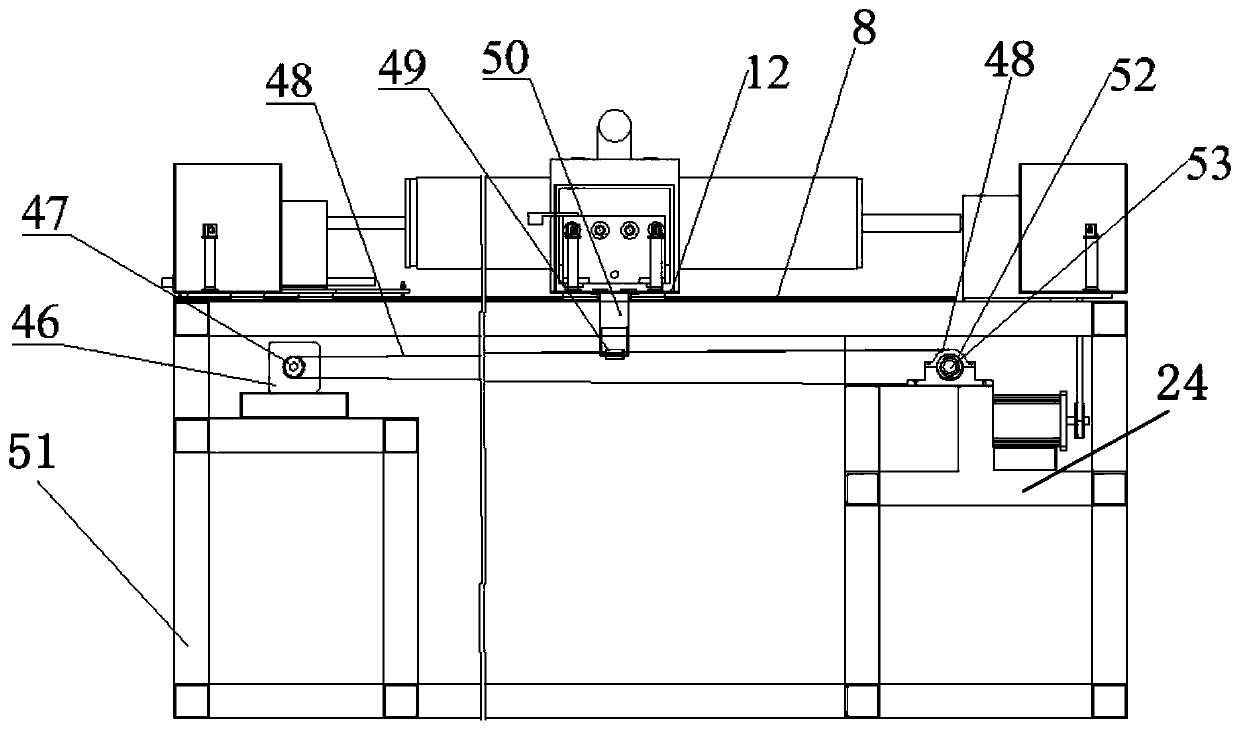

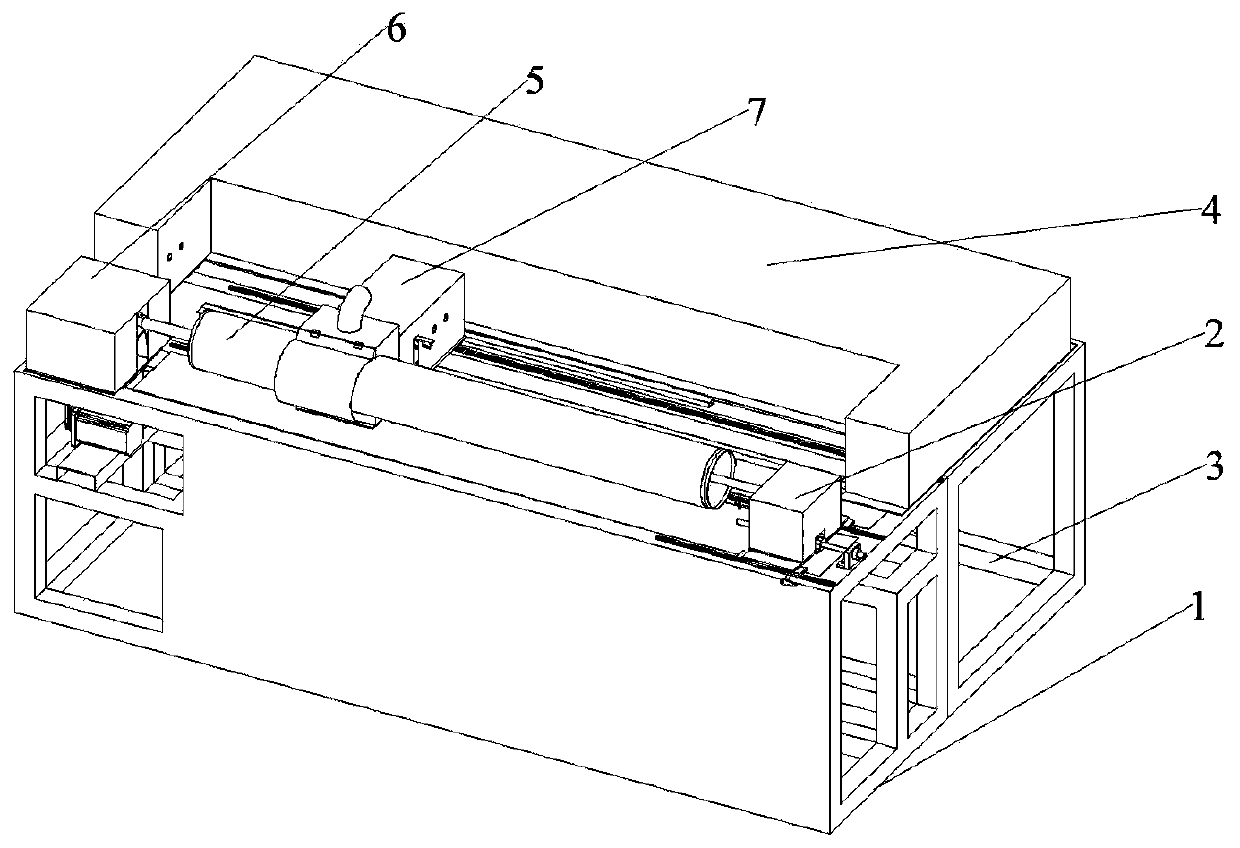

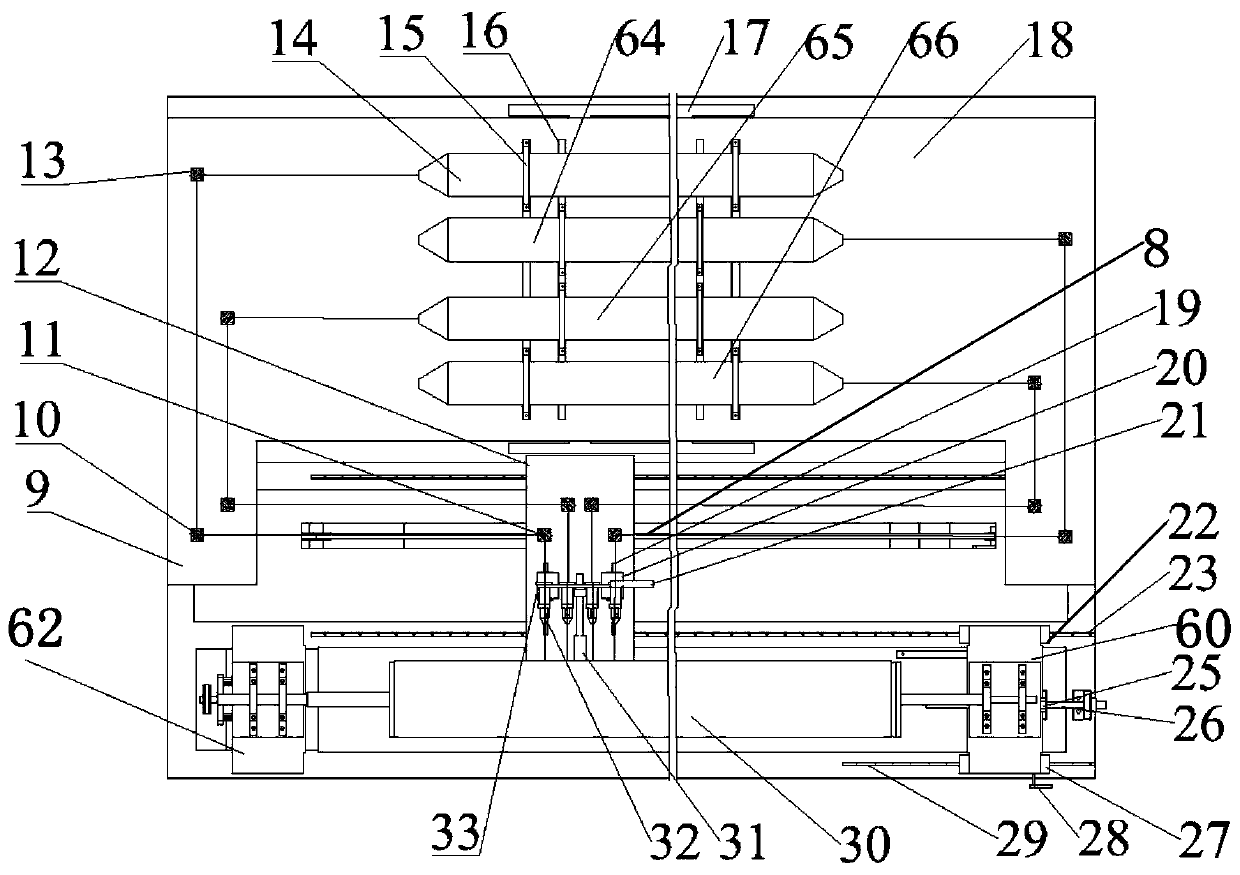

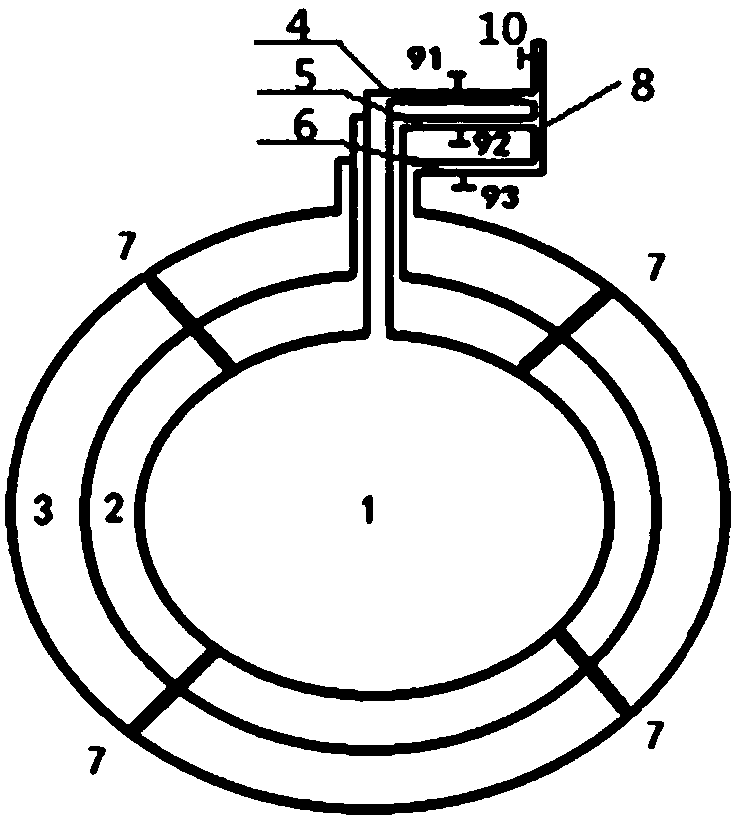

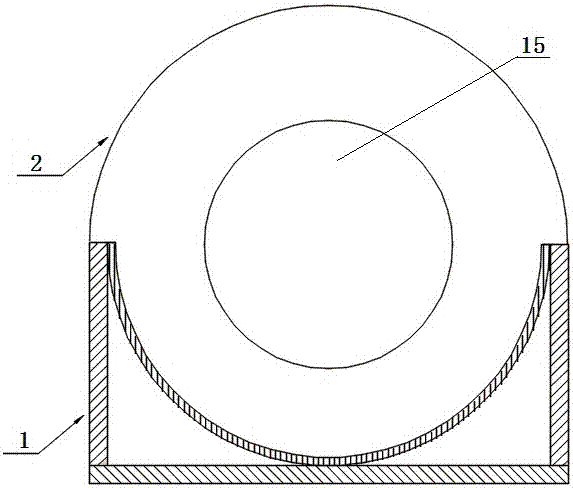

Laser cleaning machine for cylindrical nickel screen

ActiveCN111085507ASmall footprintReduce lateral distanceCleaning processes and apparatusPrinting press partsElectric machineryBeam direction

Owner:NANTONG UNIVERSITY

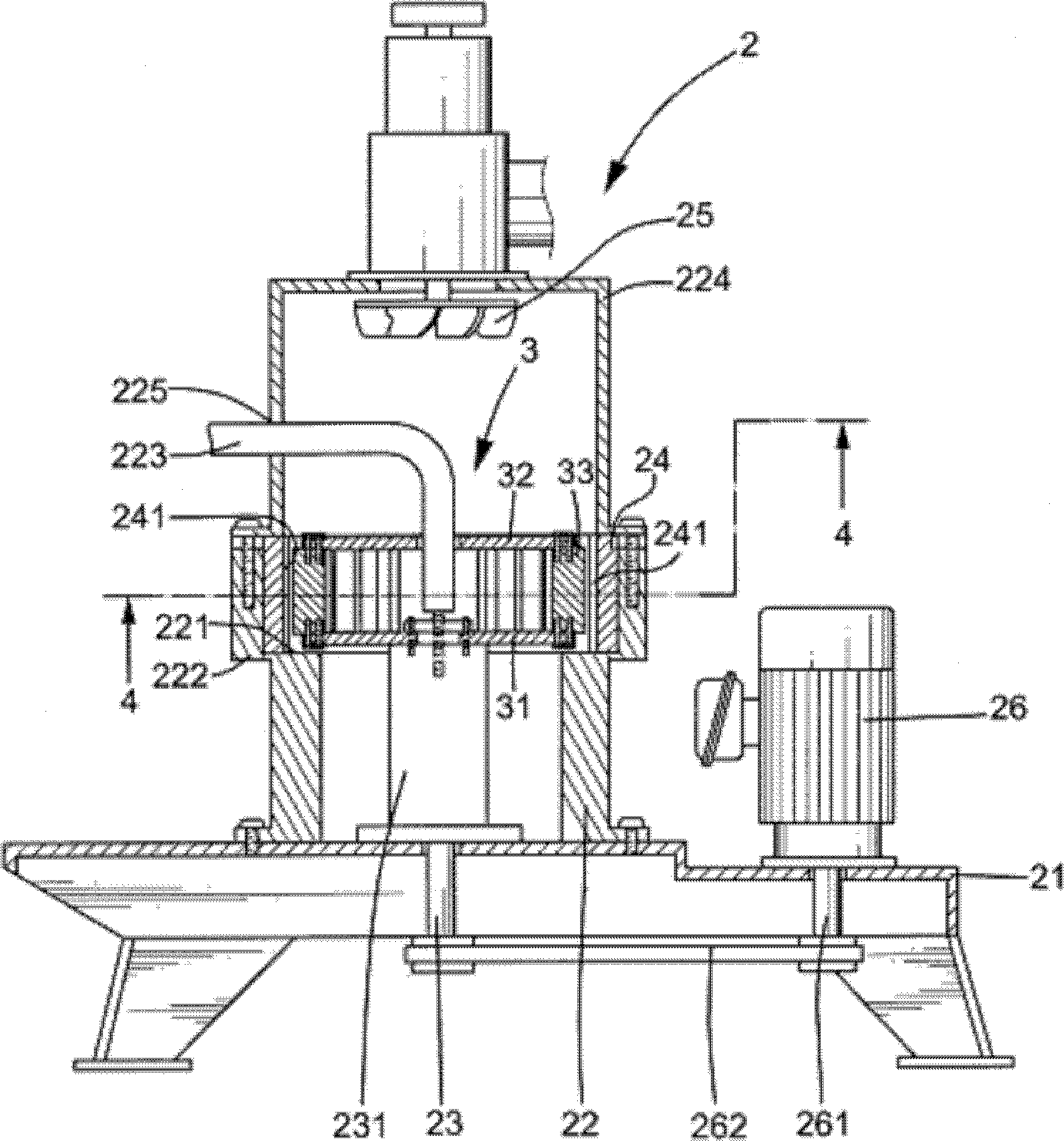

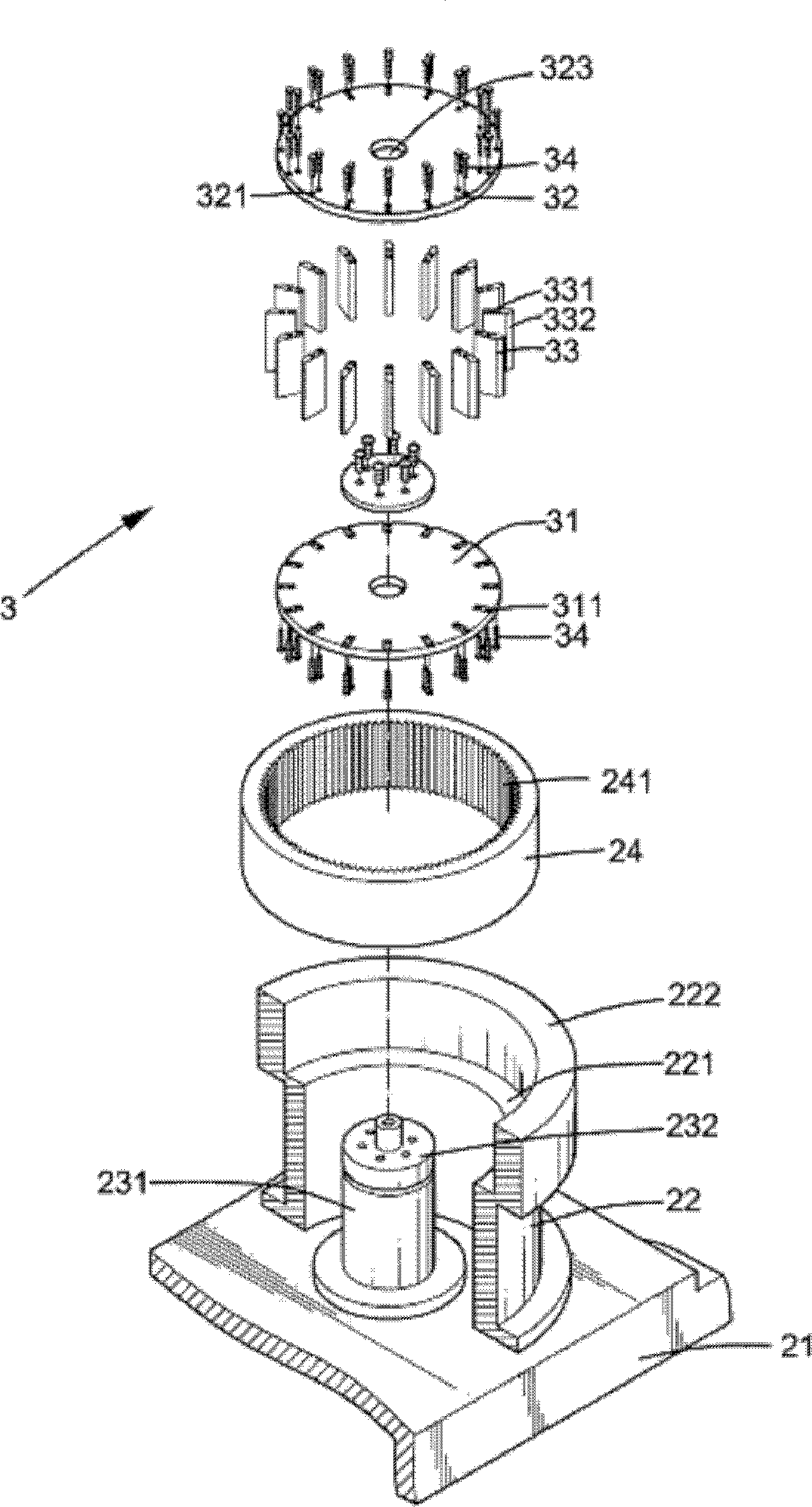

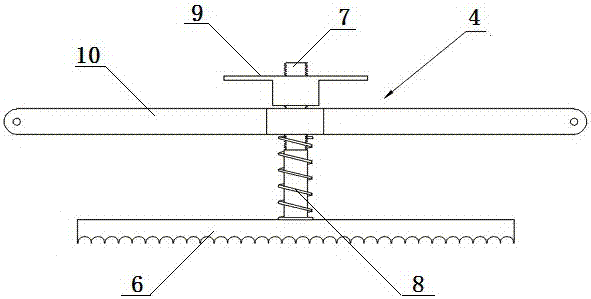

Device and method for measuring yield stress of fresh mixed concrete

ActiveCN108225939ASimple structureSmall footprintMaterial strength using steady torsional forcesElectric machineryFan blade

Owner:SHANGHAI CONSTRUCTION GROUP

Atmosphere window and vehicle

PendingCN112677879ASmall footprintThinningAircraft accessoriesAircraft crew accommodationEngineeringLight source

Owner:FUYAO GLASS IND GROUP

Production assisting robot for numerical control machine tool

Owner:WENZHOU POLYTECHNIC

Glass edge grinding machine

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesMotor driveFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:HANGZHOU TUOCHUAN MASCH CO LTD

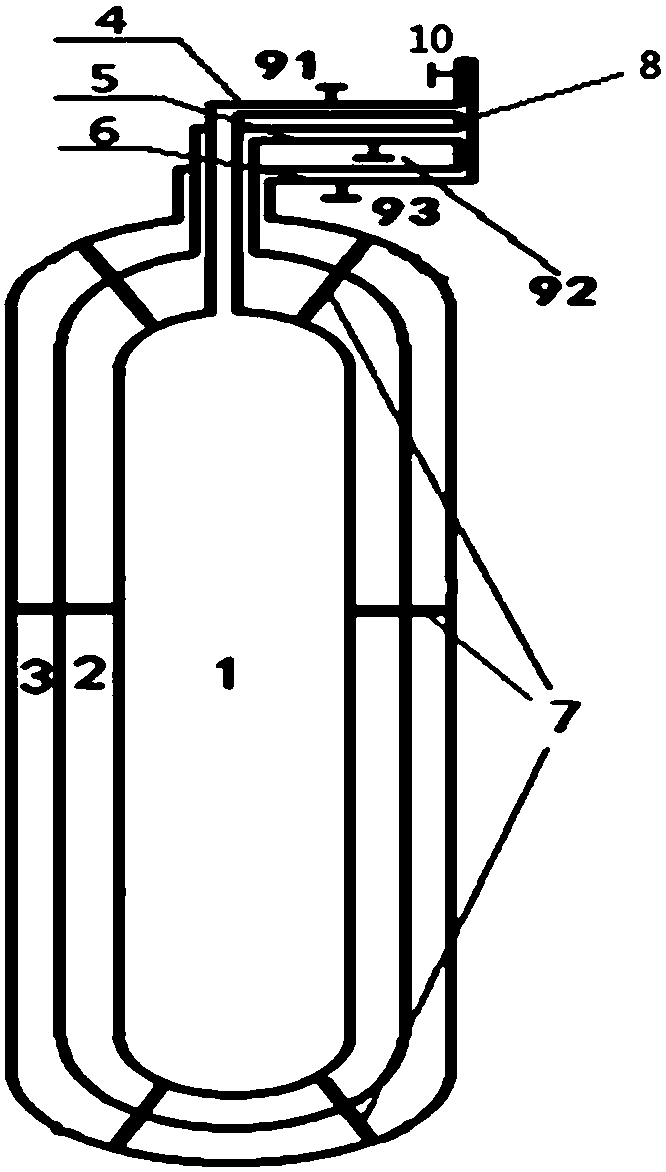

Gas storage tank

ActiveCN110159911ALarge gas storage capacitySmall footprintContainer discharging methodsContainer filling methodsAlternative fuel vehicleCar driving

Owner:CHINA PETROLEUM & CHEM CORP +1

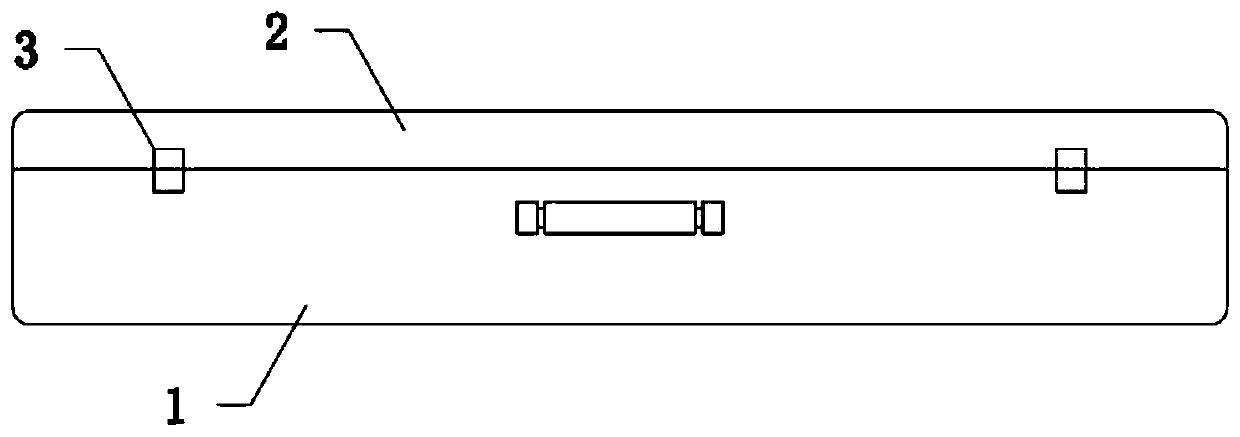

Inspection tool box for information security classified protection

PendingCN111251265AEasy to storeSmall footprintWork tools storageIndustrial engineeringInformation security

Owner:JIANGHAI POLYTECHNIC COLLEGE

Alarm method, optical network unit, optical line terminal, and system

PendingCN106941632AInformation Transmission SecuritySmall footprintMultiplex system selection arrangementsOptical network unitReal-time computing

Owner:SANECHIPS TECH CO LTD

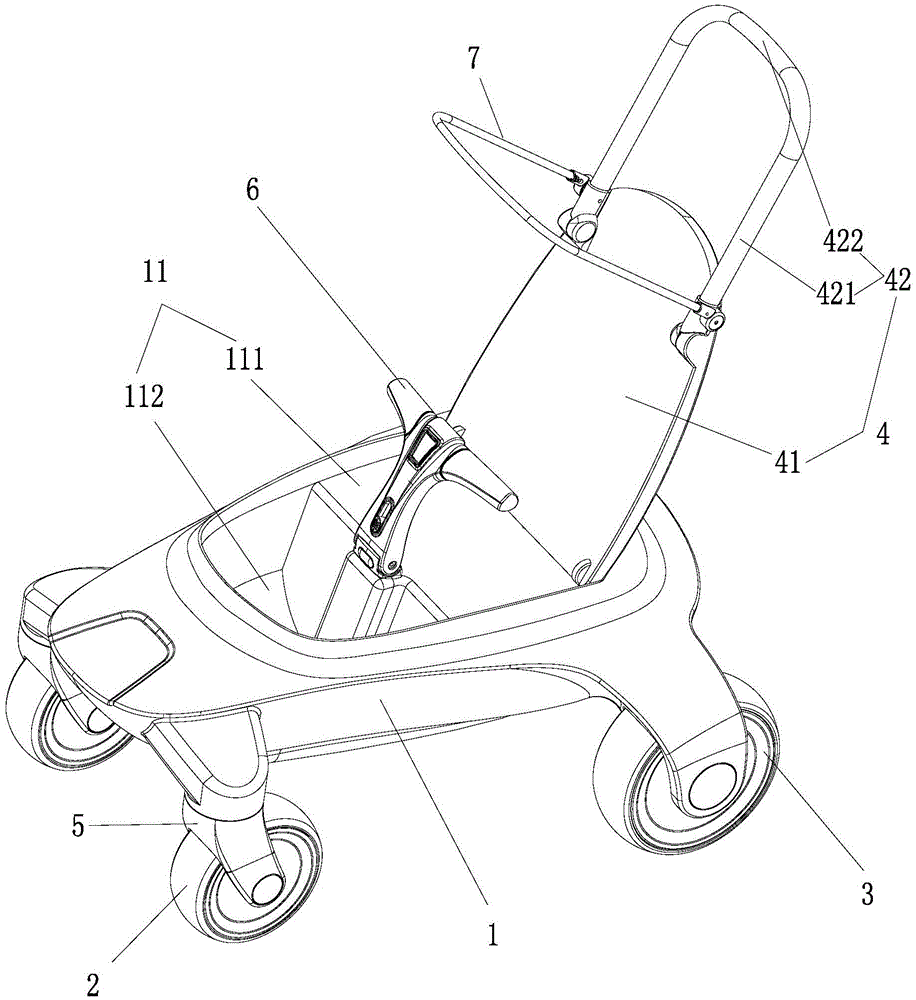

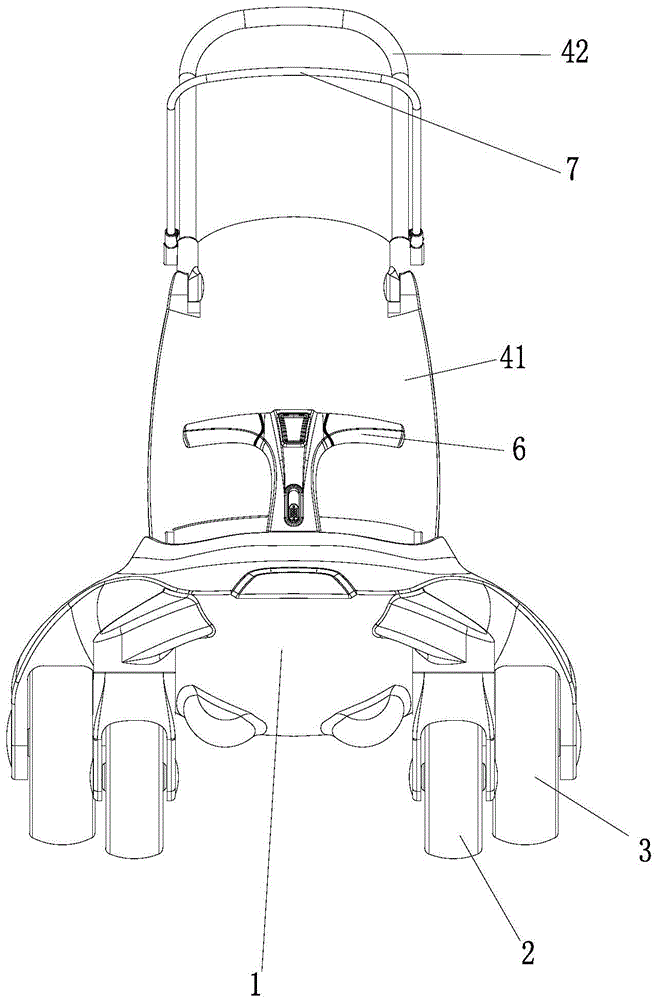

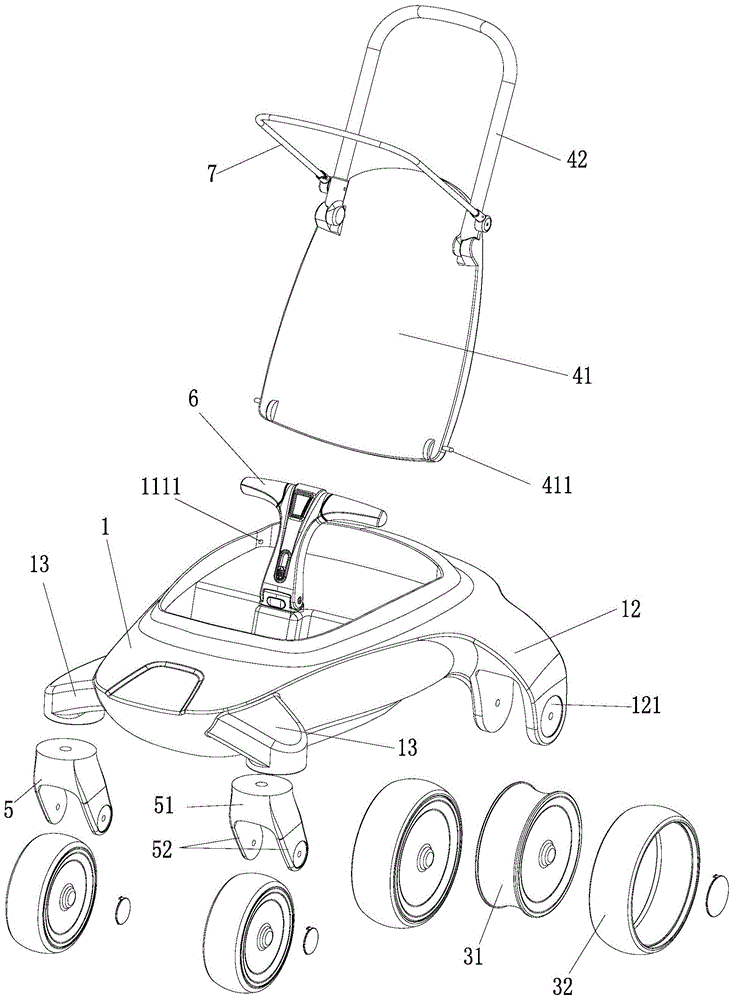

Amphibious baby stroller

InactiveCN105644609ASmall footprintCarriage/perambulator accessoriesWheelsSitting PositionsEngineering

Owner:东莞久煜婴幼儿用品有限公司

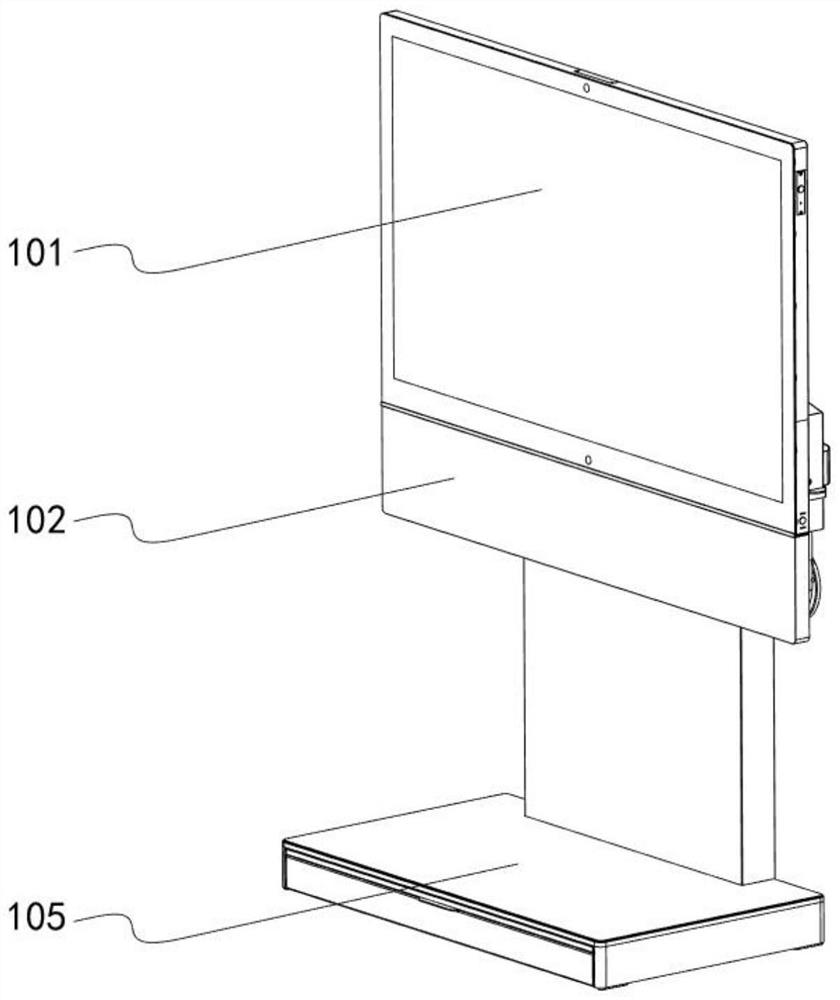

Device with fitness function

PendingCN114699760ABeautiful appearanceSmall footprintColor television detailsElectrical appliancesEngineeringMechanical engineering

Owner:原体人(北京)科技有限公司

Production line for fireproof heat-insulating wall plates, and method for on-site processing of fireproof heat-insulating wall plates by utilizing production line

InactiveCN102699994AImprove foaming qualityImprove insulation effectCeramic shaping plantsProduction lineEngineering

The invention relates to a production line for fireproof heat-insulating wall plates, and a method for on-site processing of the fireproof heat-insulating wall plates by utilizing the production line, and solves the problems that the conventional multi-layer fireproof heat-insulating wall plate processing equipment has a large occupied area, high investment and failure in on-site processing. Therefore, the production line comprises a stirrer, a pouring vehicle, and two lines of pouring molds, wherein the stirrer comprises an agitation tank; a stirring paddle driven by an external motor is arranged in the agitation tank; the agitation tank is provided with a liquid feeding device, a solid feeding device and a baiting valve, and is fixed on four support legs; the pouring vehicle comprises a vehicle body and a wagon box; the wagon box is fixed on the vehicle body; wheels are arranged below the vehicle body; the opening of the wagon box faces upwards; an emptying gate is arranged at the rear part of the wagon box; and a scraping plate is arranged on a fixing bracket behind the emptying gate. The invention further relates to a corresponding processing method. The production line has the advantages of low investment and small occupied area, ensures on-site processing, saves transportation cost, and is an ideal upgrading product for the conventional fireproof heat-insulating wall plate production line.

Owner:SHANDONG XINFA ENVIRONMENTAL PROTECTION TECH CO LTD

Fiber radical sewage decoloration and purification material and preparing method thereof

InactiveCN103466731AWide variety of sourcesEasy to manufactureOther chemical processesWaste water treatment from textile industryFlocculationReclaimed water

The invention discloses a fiber radical sewage decoloration and purification material which is characterized by comprising a component (I) and a component (II). The component (II) occupies 5%-10% of the total mass. The component (1) is a product obtained by reaction of 36% formaldehyde solutions, dicyandiamide, ammonium chloride and property-modifying additives A, wherein the mass ratios of the 36% formaldehyde solutions, the dicyandiamide, the ammonium chloride and the property-modifying additives A are sequentially 1.0-1.3:0.50-0.65:0.60-0.70:0.06-0.09. The property-modifying additives A are a mixture obtained by mixing magnesium sulfate and magnesium chloride according to a proportion, wherein the mass ratio of the magnesium sulfate and the magnesium chloride is 2.0-3.5:8.0-6.5. The component (II) is a natural fiber (plant and / or animal) which is modified by cation modifiers. The fiber radical sewage decoloration and purification material integrates multiple functions such as decoloration, flocculation, entanglement and COD removing. The decoloration ratio of sewage can reach more than 93%, the COD value removing rate is higher than that of the prior art by more than 10%, reclaimed water reusing can be achieved, and sewage discharging is reduced.

Owner:HEFEI DONGFANG MEIJIE MOLECULAR MATERIAL TECH CO LTD

Fed wire fixing device for wire feeding machine

Owner:SHANDONG IRON & STEEL CO LTD

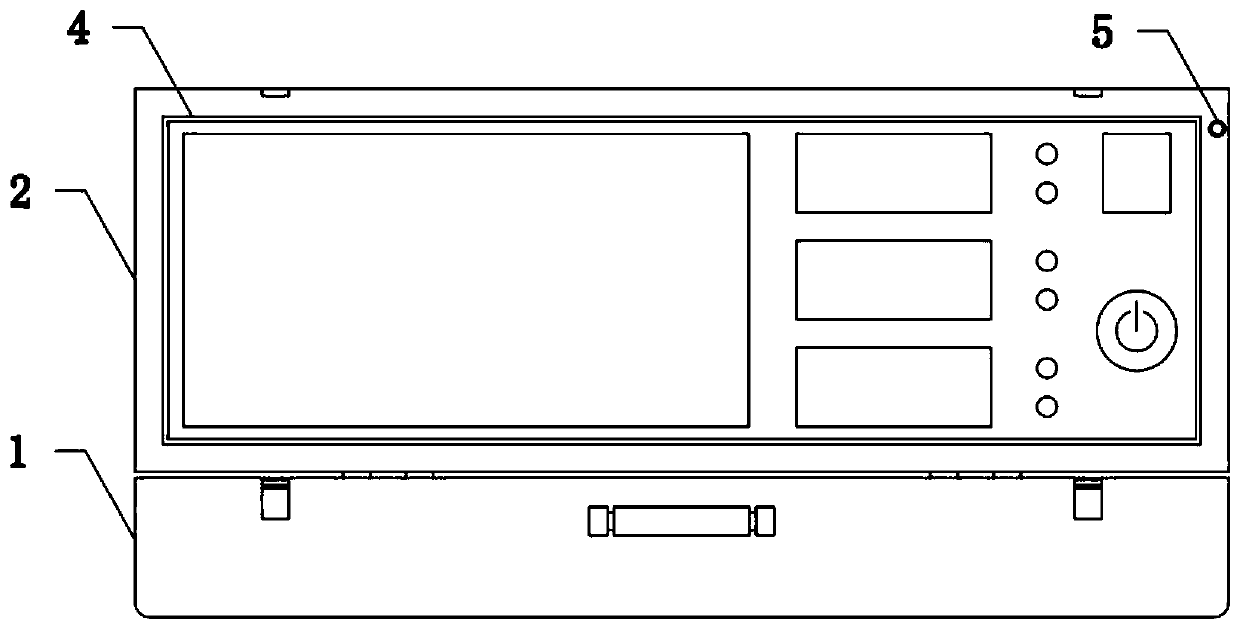

Controller of double-voltage output alternating-current generator for motorcar

ActiveCN101662253AStable output voltageCompact structureGenerator control by field variationElectrical resistance and conductanceLow voltage

The invention provides a controller of an alternating-current generator for a motorcar, which can simultaneously provide a high voltage (42V) and a low voltage (14V) power sources. The controller comprises a rectification circuit (1), a high voltage (42V) division circuit (2), a high voltage (42V) comparison circuit (3), an excitation circuit (4), a low voltage (14V) division circuit (5), a low voltage (14V) comparison circuit (6) and a low voltage (14V) trigger circuit (7). The controller is characterized in that voltage obtained by division by a second resistor (R2) in the high voltage (42V)division circuit (2) is compared with a reference voltage by the high voltage (42V) comparison circuit (3) so as to control the excitation circuit (4) to be opened or closed, namely that 42 V directcurrent is guaranteed to be outputted by controlling the level of exciting current; voltage obtained by division by a seventh resistor (R7) of the low voltage (14V) division circuit (5) is compared with the reference voltage by the low voltage (14V) comparison circuit (6), and the low voltage (14V) trigger circuit (7) is utilized for controlling the opening and the closing of a low voltage (14V) output end so that the outputted average voltage can be stabilized on 14V; and the low voltage (14V) output end of the motor is led out from the neutral point O of an exciting winding, and the voltageof the neutral point and the pulse coefficient of the outputted 14V voltage are low. The controller can simultaneously output the high voltage (42V) and the low voltage (14V) power sources, and has stable voltage and low cost.

Owner:史立伟

Pesticide sprayer with self-propelled spraying frame and of which height is adjustable to adapt to various crops with high or short stalks

PendingCN107743948AWon't hurtGuaranteed stabilityInsect catchers and killersAgricultural scienceSprayer

The invention relates to the technical field of equipment for plant protection, in particular to a pesticide sprayer with a self-propelled spraying frame and of which the height is adjustable to adaptto various crops with high or short stalks. The pesticide sprayer comprises a rack, a walking transmission device and a spraying device; a driving chamber is arranged at the upper end of the front part of the rack, and a left stand shaft frame and a right stand shaft frame are fixed to the left and right sides of the front part of the rack, and a left front walking wheel and a right front walkingwheel are installed at the left and right sides of the front part of the rack respectively; left and right pesticide boxes are arranged at the left and right sides of the lower end of the rack respectively, and thus the stability of the equipment is ensured; the chassis height of the equipment is increased through the left stand shaft frame, the right stand shaft frame, a left rear wheel frame and a right rear wheel frame, and thus the equipment can adapt to spraying of the high-stalk crops, while the crops will not be damaged; pesticide spraying operation in a wide work range can be achievedby spreading a folding arm frame, the equipment can be convenient to transport and park by folding the folding arm frame, the occupation area is reduced, and the pesticide sprayer with the self-propelled spraying frame and of which the height is adjustable to adapt to the various crops with the high or short stalks has the advantages of being high in pesticide spraying speed and efficiency, simple in structure and low in cost.

Owner:王洪连

Display model for garment and leather product design

The invention belongs to the technical field of garment design, and particularly relates to a display model for garment and leather product design. The display model comprises a base, a bearing blockis arranged at the top of the base, and a lower threaded sleeve is inserted into an inner cavity of the bearing block; the top of a rotating handle is provided with an upper threaded rod, the top of the outer wall of the upper threaded rod is in threaded connection with an upper threaded sleeve, an exhibition stand is arranged at the top of the upper threaded sleeve, and a display model body is arranged at the top of the exhibition stand; the top of the exhibition stand is in sliding connection with bottoms of two shanks, the other side of each universal connecting ball is provided with a screw rod, and the other side of each screw rod is in threaded connection with the top of the side wall of the upper body part. The model is convenient to move, convenient to disassemble and assemble, convenient to convey and capable of saving occupied area. During use, the display model can make various poses, the display effect is improved, defects of garment and leather product design can be foundconveniently, and use requirements are met.

Owner:SHAANXI INST OF INT TRADE & COMMERCE

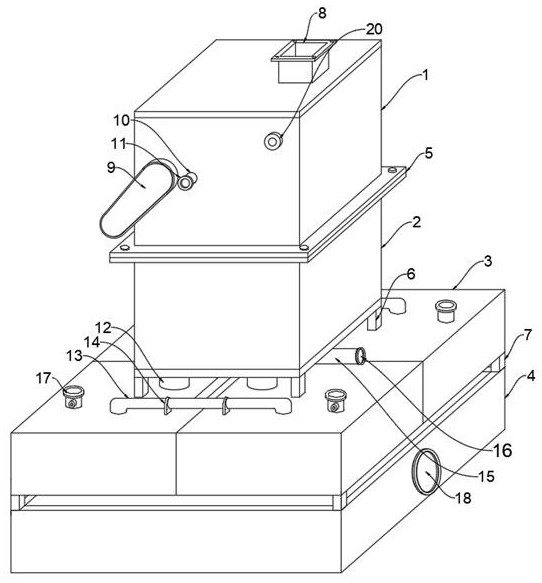

Stirring and pouring device for building blocks

ActiveCN109291249AReduce equipment costsSmall footprintCement mixing apparatusDischarging apparatusArchitectural engineeringDrive shaft

Owner:温州陆华科技有限公司

Sliding table air cylinder structure

Owner:SHENZHEN SUNWAY COMM

Turnover transport vehicle with limiting mechanism

InactiveCN111661120AShorten the timeImprove turnover efficiencyHand carts with multiple axesHand cart accessoriesPush and pullElectric machine

Owner:何红侠

High-efficiency zero-energy-consumption AOA sewage treatment device and method

InactiveCN107055782AZero energy consumptionSmall footprintWater treatment parameter controlWater contaminantsTerrainWater pipe

Owner:WUHAN UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap