Gas storage tank

A technology of gas storage tanks and gas pipes, which is applied in fixed-capacity gas storage tanks, gas processing/storage purposes, gas/liquid distribution and storage, etc., and can solve problems such as potential safety hazards, temperature rise, and complicated control of hydrogen storage systems. Achieve the effect of small footprint and large gas storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0058] Example 1

[0059] The prior art 70L vertical cylindrical hydrogen storage tank with only one layer of space, if its design pressure is 30MPa, can hold 1.75kg of hydrogen and 14.02kg of methane.

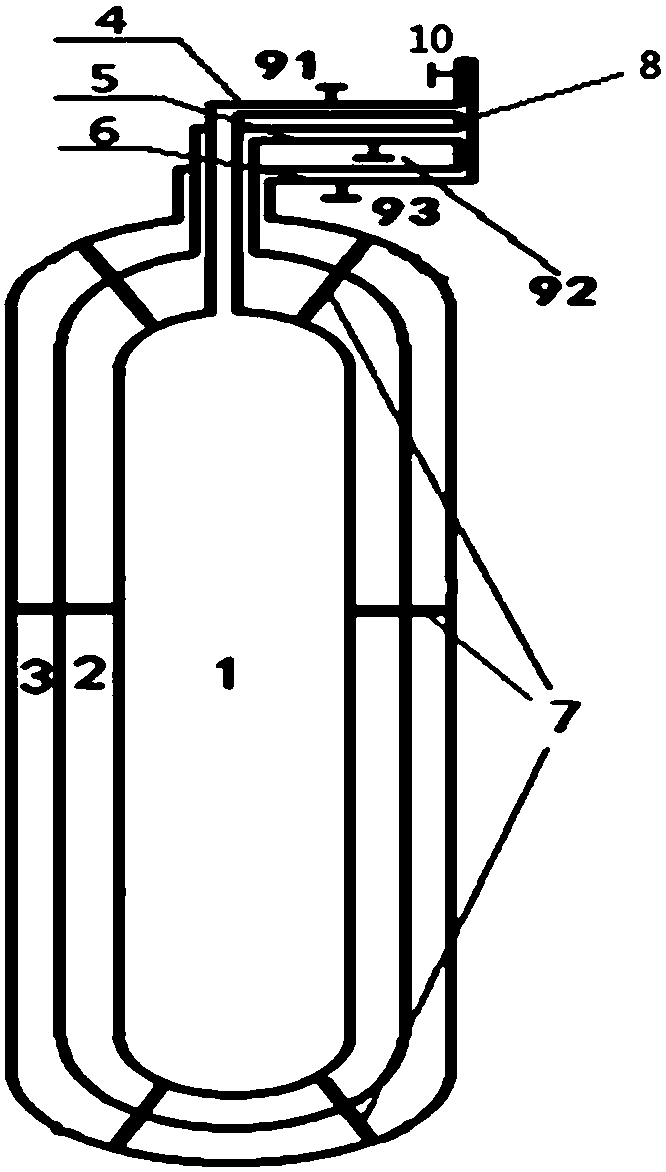

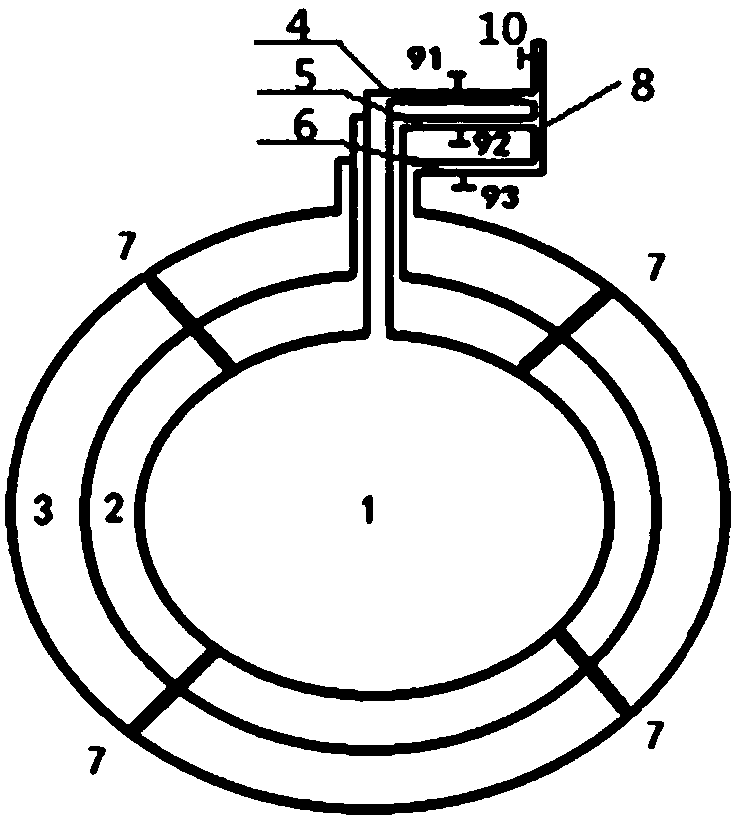

[0060] This embodiment provides a gas storage tank with a total volume of 70L and a three-layer tank. Among them, the design pressure of the three-layer tank is 30MPa. The volume of the inner space 1, the middle space 2 and the outer space 3 of the gas storage tank account for 70%, 20% and 10% of the volume of the gas storage tank respectively, and the gas pressures of the three layers are 90MPa, 60MPa and 30MPa respectively . After calculation, the total hydrogen storage capacity of the gas storage tank can reach 4.56kg, and the storage of methane 36.44kg.

[0061] In addition, if three conventional cylindrical hydrogen storage tanks of 70L and 30MPa withstand pressure are used, although they can store 5.25kg of hydrogen and 42.06kg of methane, they occupy up to 210L, which is much

Example Embodiment

[0062] Example 2

[0063] The prior art 70L vertical cylindrical hydrogen storage tank with only one layer of space can hold 2.92 kg of hydrogen and 23.37 kg of methane if its design pressure is 50 MPa.

[0064] This embodiment provides a gas storage tank with a total volume of 70L and a three-layer tank. Among them, the design pressure of the three-layer tank is 50MPa. The volumes of the inner space 1, the middle space 2 and the outer space 3 of the gas storage tank account for 70%, 20% and 10% of the volume of the 70L gas storage tank respectively, and the gas pressures stored in the 3 layers are 150MPa and 100MPa respectively And 50MPa. After calculation, the total hydrogen storage capacity of the gas storage tank can reach 7.59kg, and the storage of methane is 60.73kg.

Example Embodiment

[0065] Example 3

[0066] The prior art 70L vertical cylindrical hydrogen storage tank with only one layer of space, if its design pressure is 70MPa, can hold 4.09kg of hydrogen and 32.72kg of methane.

[0067] This embodiment provides a gas storage tank with a total volume of 70L and a three-layer tank. Among them, the design pressure of the three-layer tank is 70MPa. The volumes of the inner space 1, the middle space 2 and the outer space 3 of the gas storage tank account for 70%, 20%, and 10% of the volume of the gas storage tank, respectively, and the gas pressures stored in the three layers are 210MPa, 140MPa and respectively. 70MPa. According to calculations, the total hydrogen storage capacity of the gas storage tank can reach 10.63kg and the methane storage capacity is 85.04kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap