Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about "Secondary cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

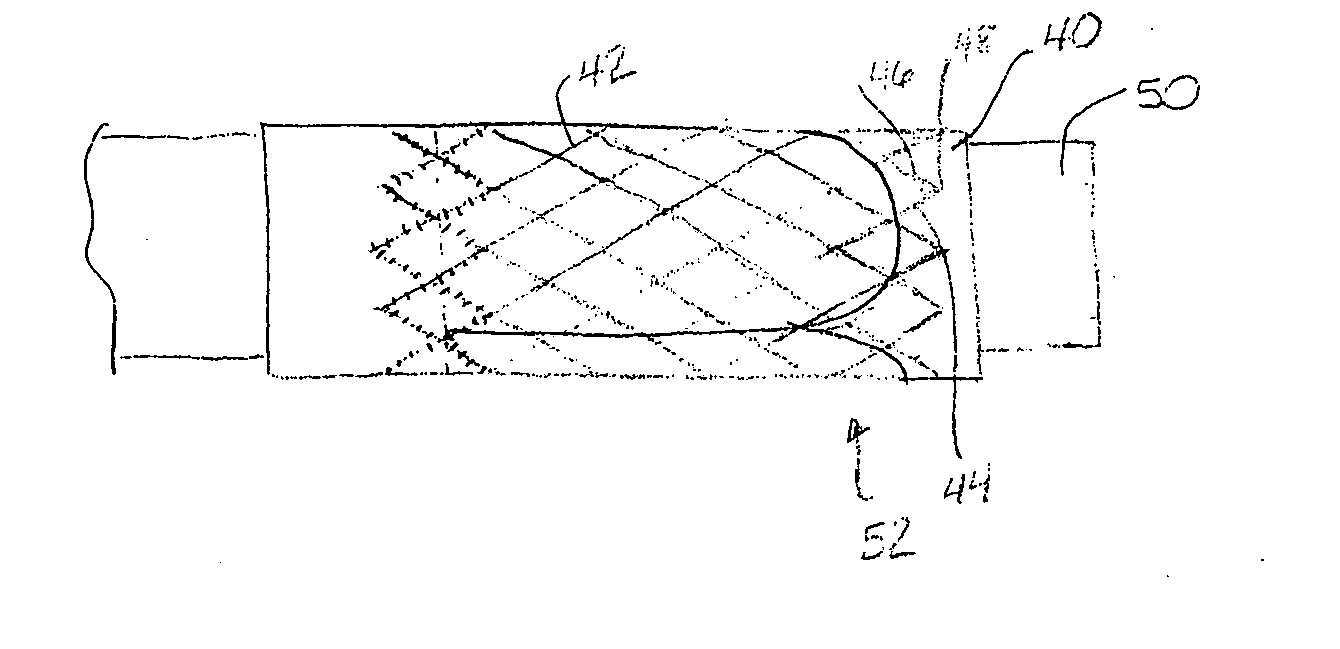

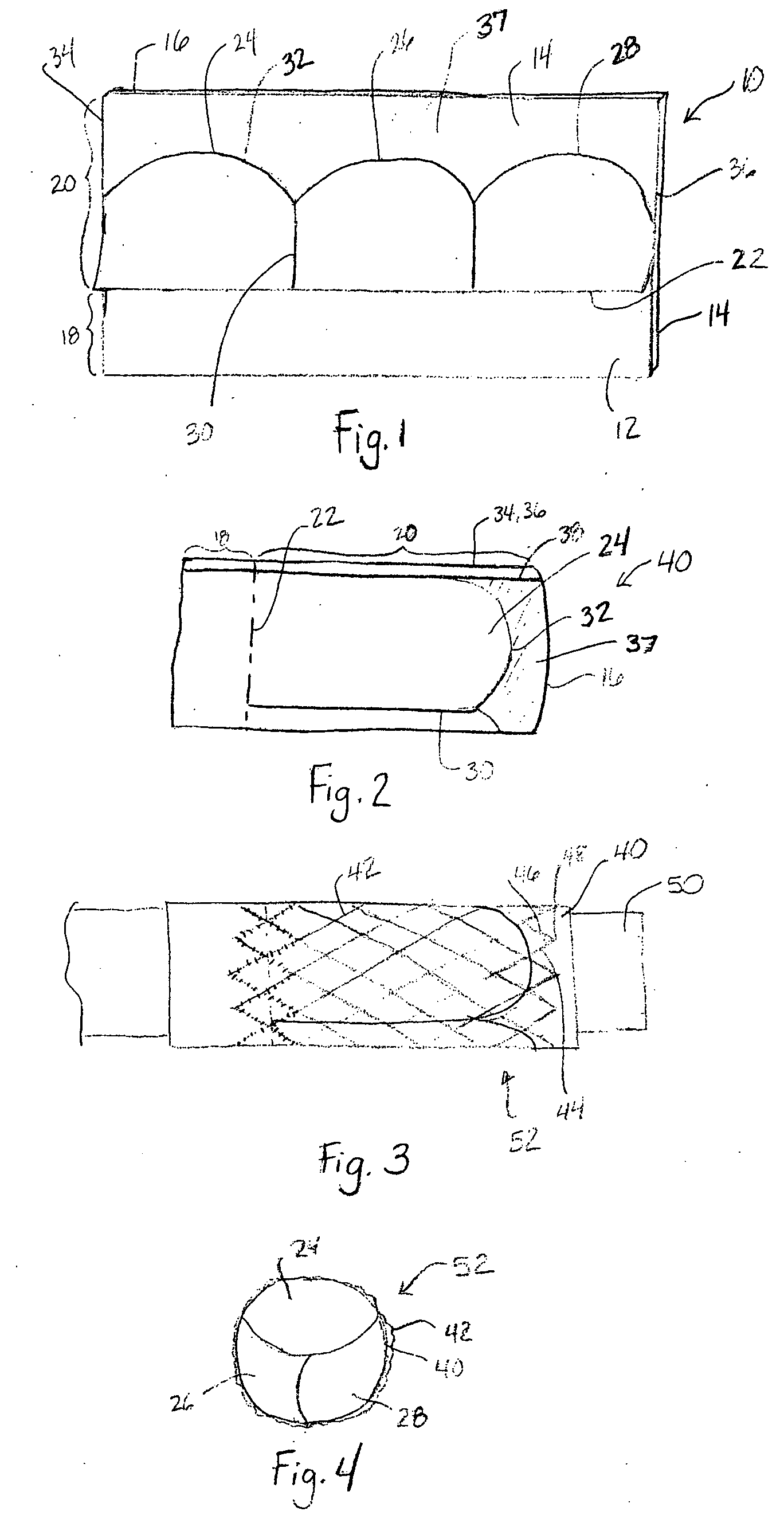

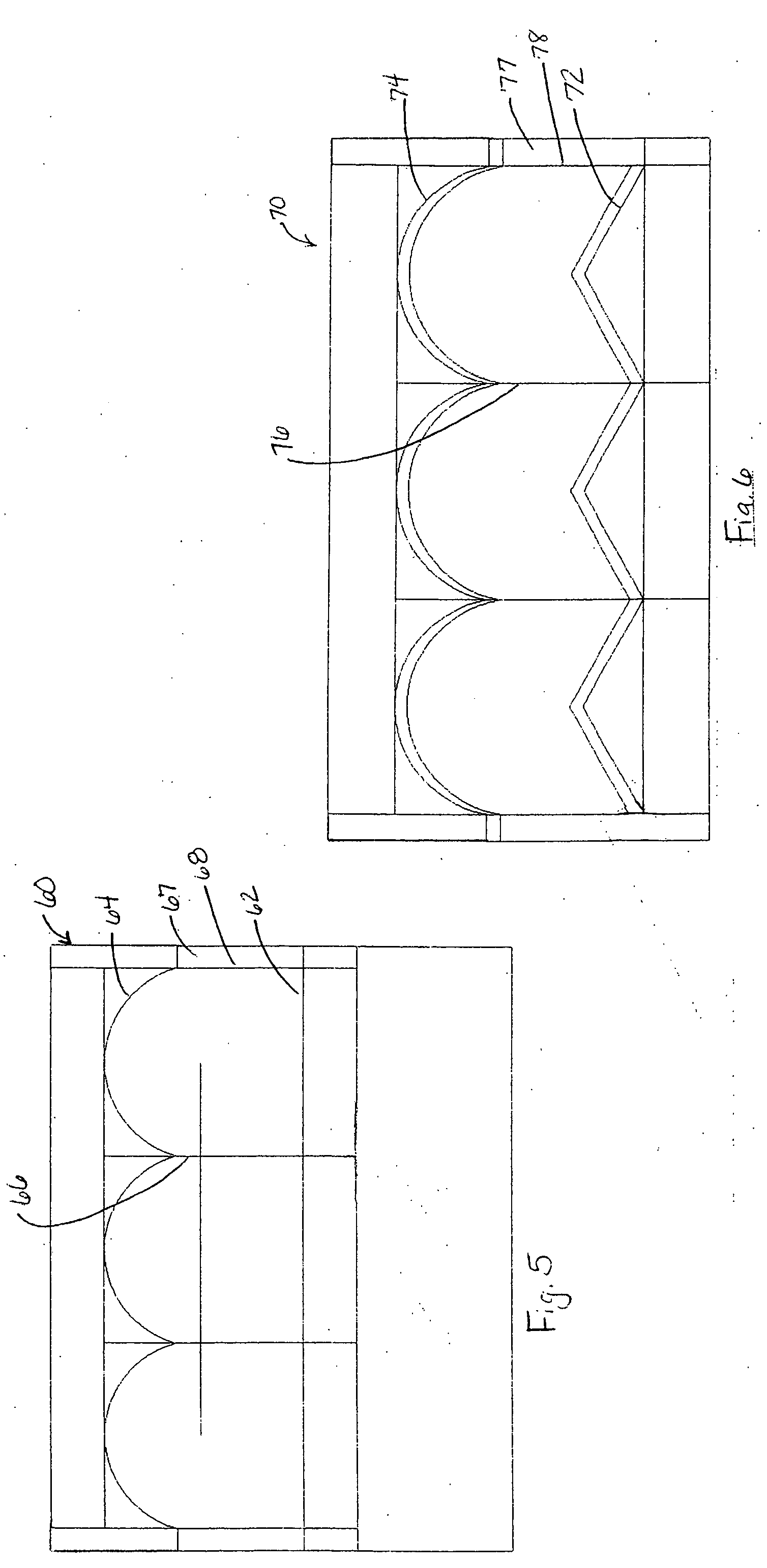

Prosthetic cardiac valve formed from pericardium material and methods of making same

ActiveUS20070233228A1Barrier to undesired abrasionPrevent and minimize valve leakageCell electrodesHeart valvesProsthetic valveProsthesis

Owner:MEDTRONIC INC

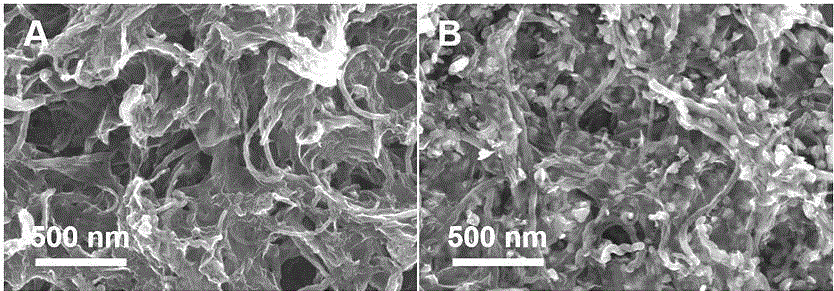

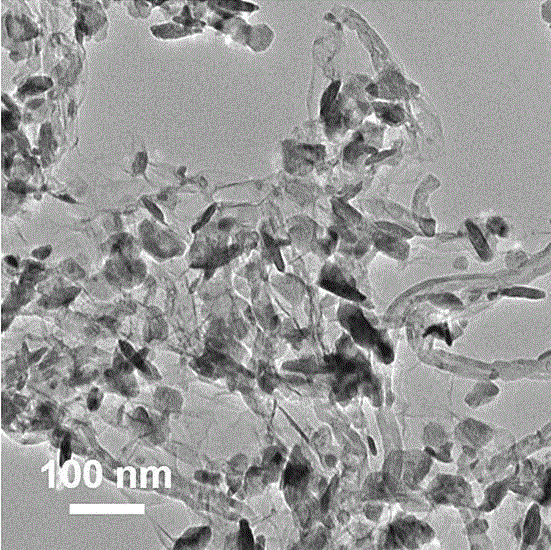

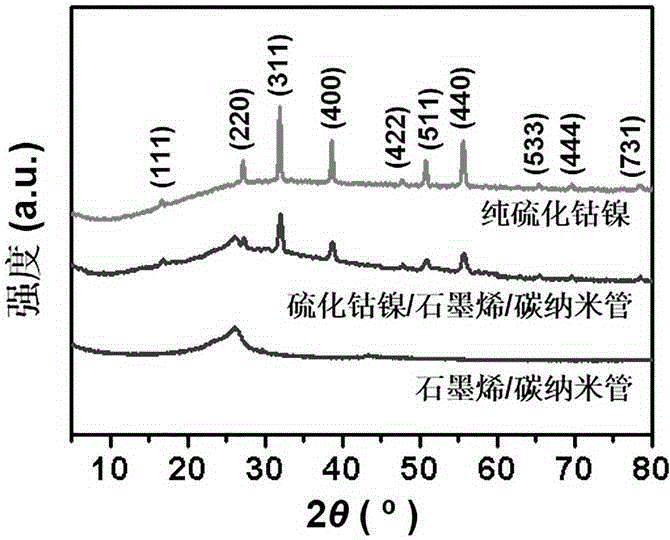

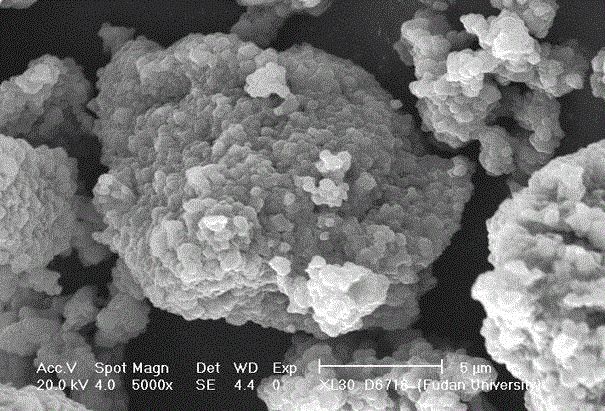

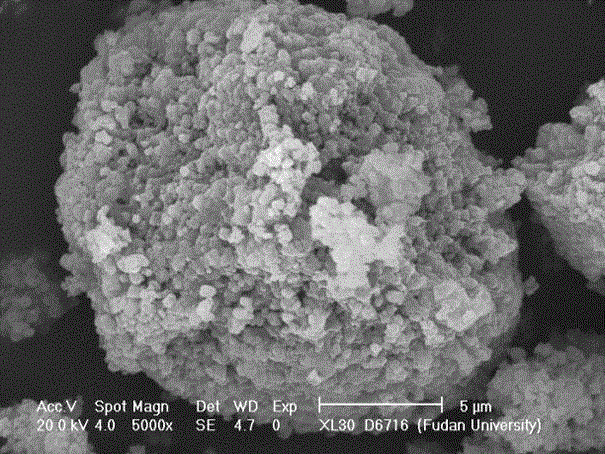

Nickel cobalt sulfide/graphene/carbon nanotube composite material and preparation method and application thereof

Owner:FUDAN UNIV

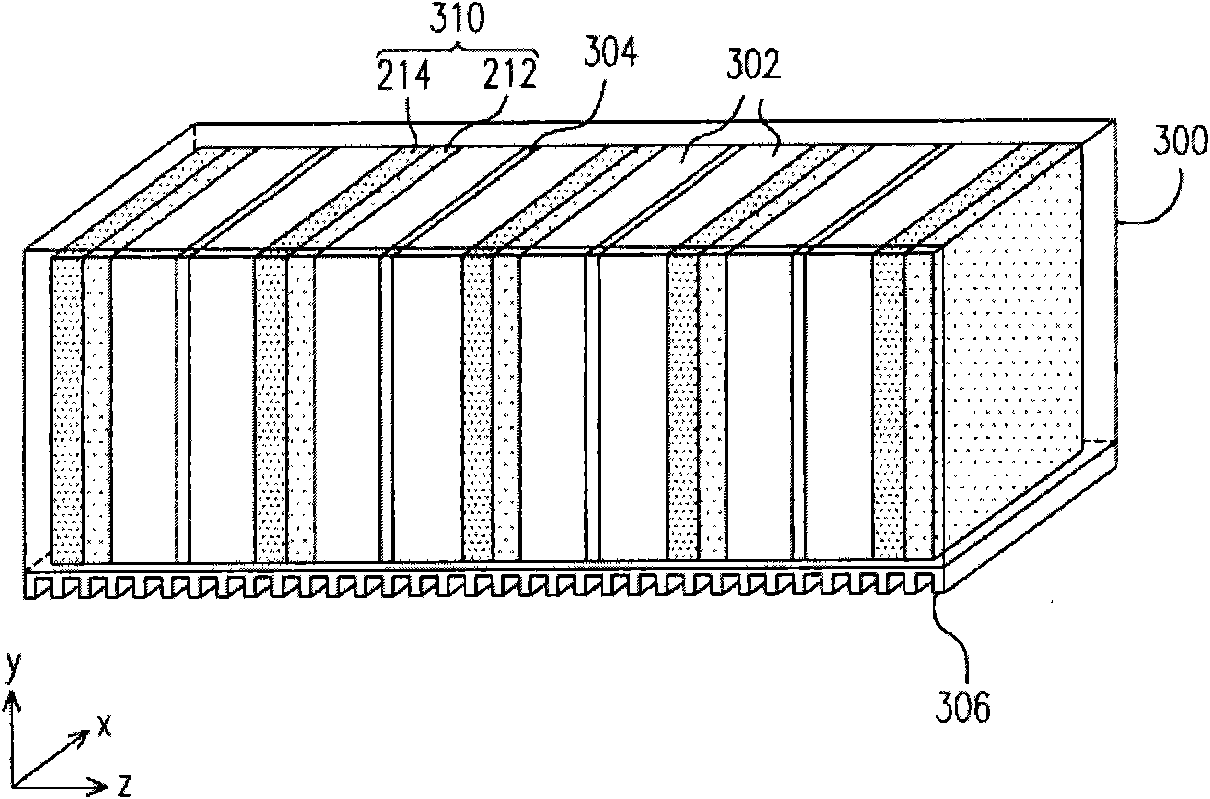

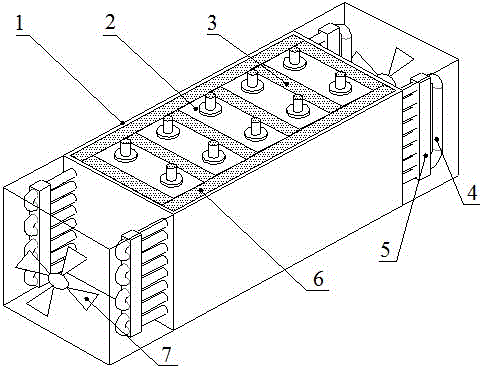

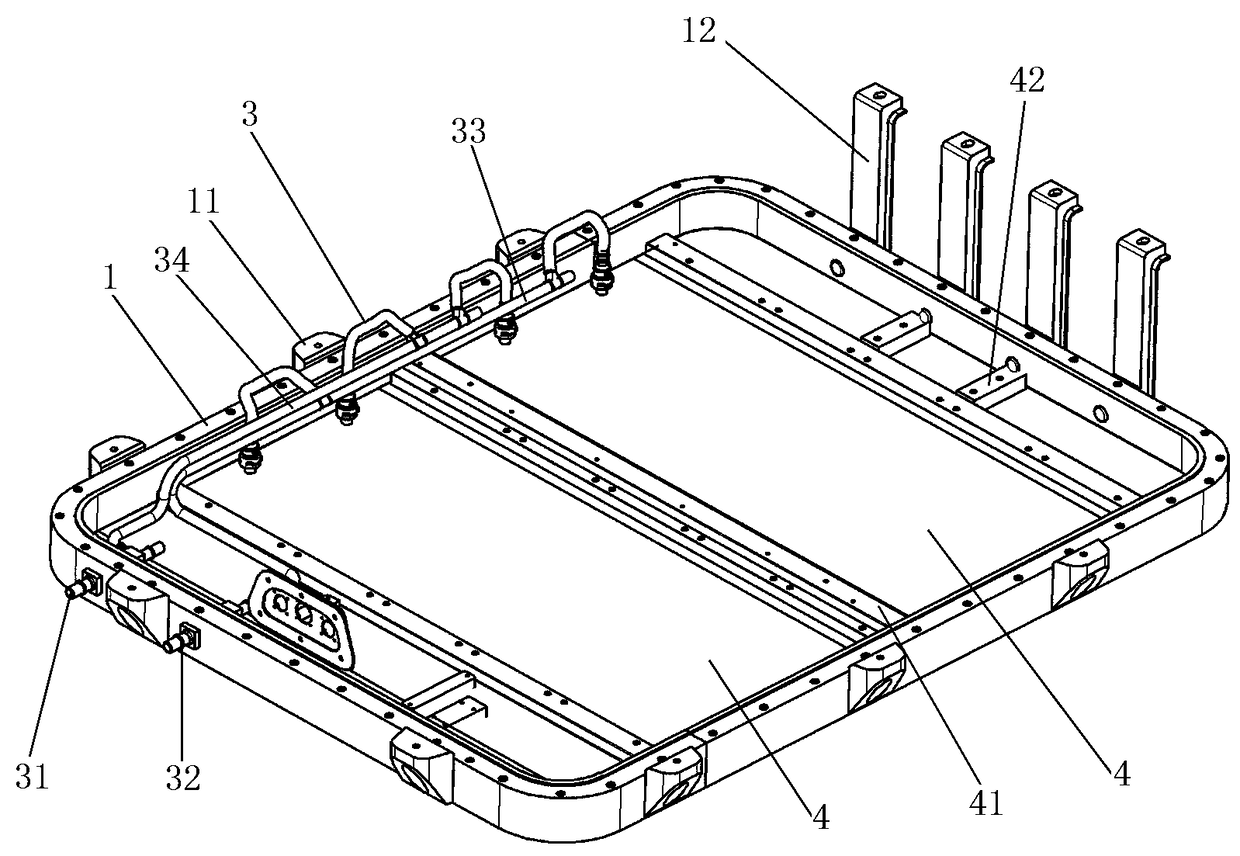

Heat dissipation and thermal runway dispersion protection structure in cell system

Owner:IND TECH RES INST

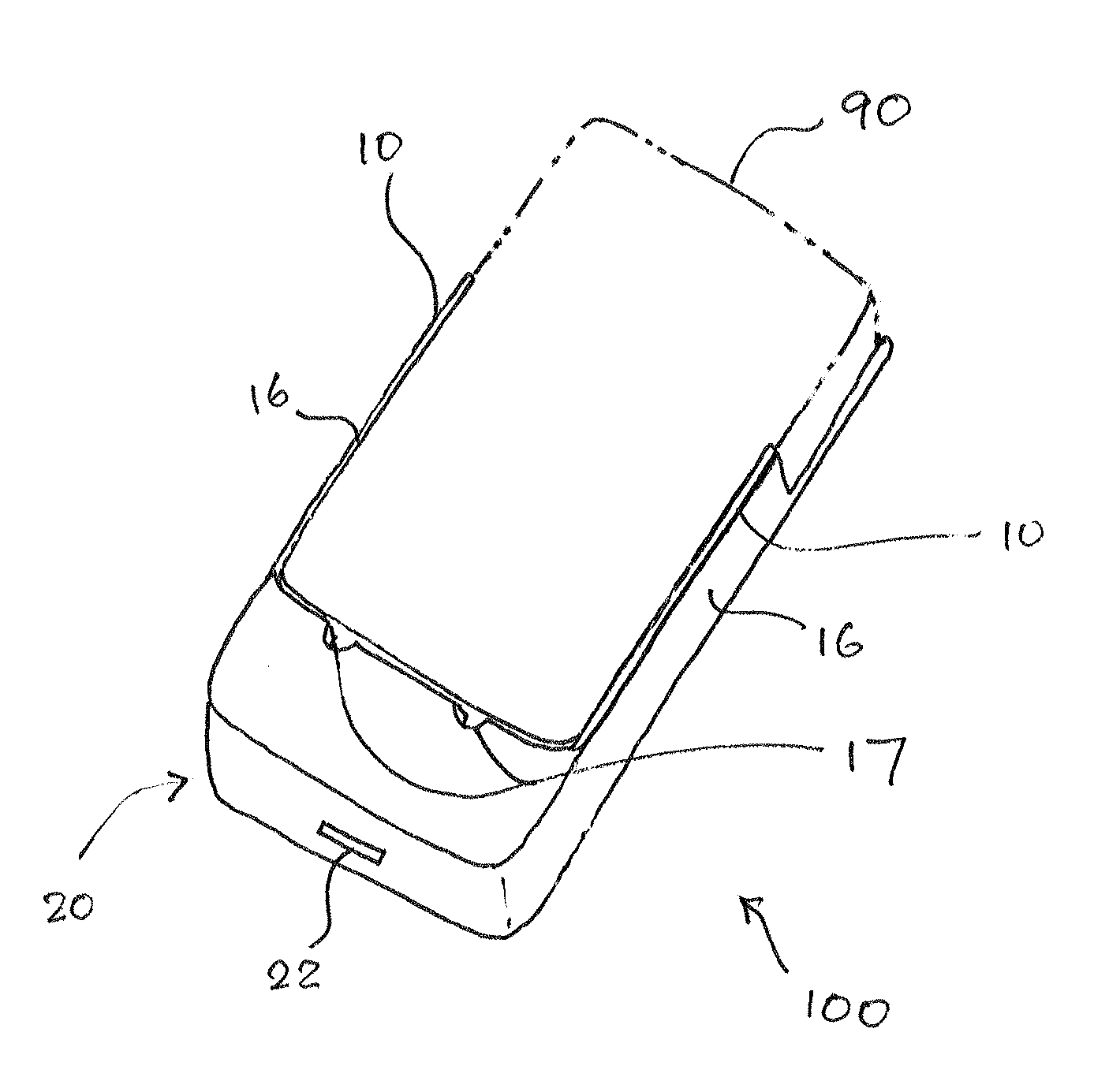

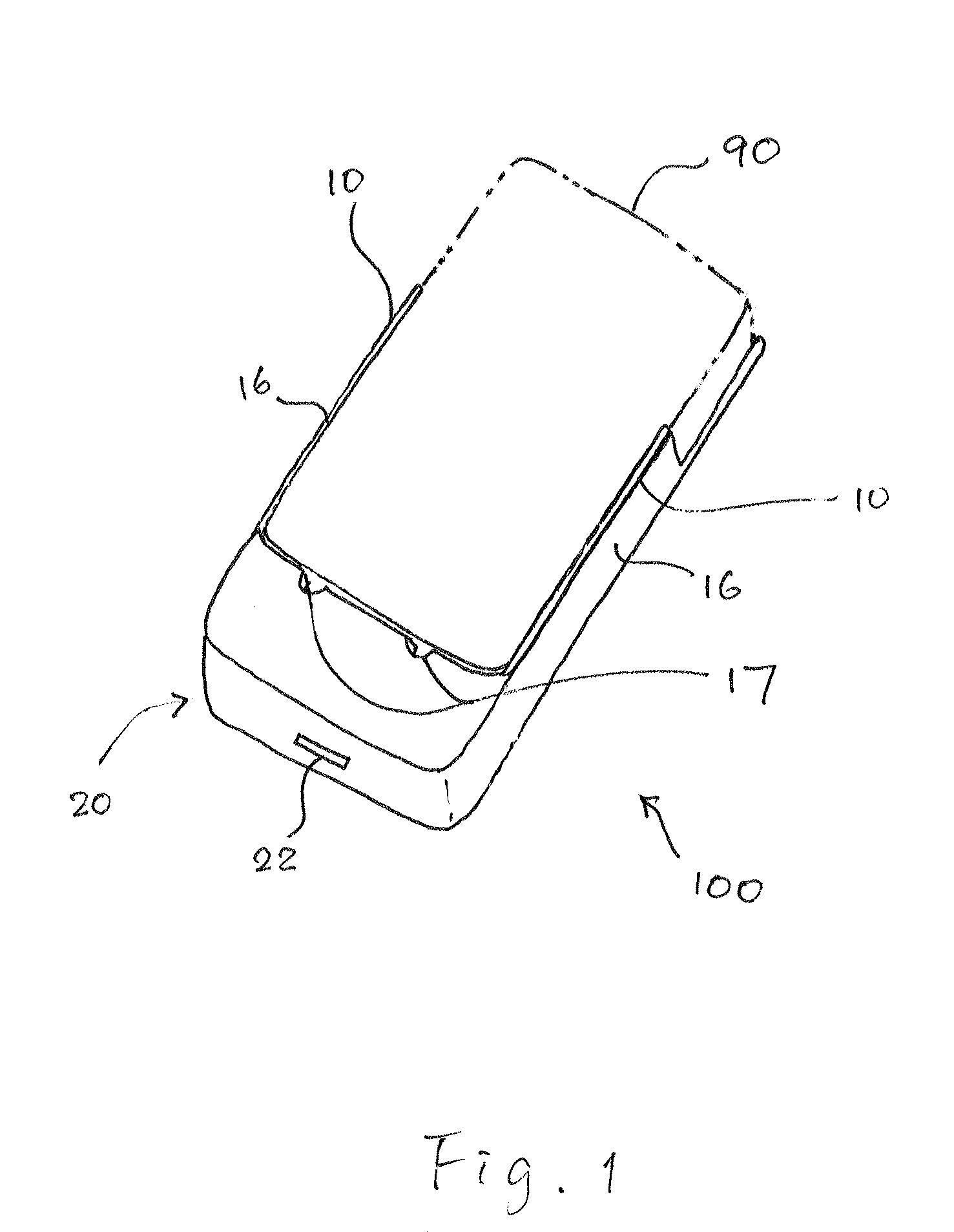

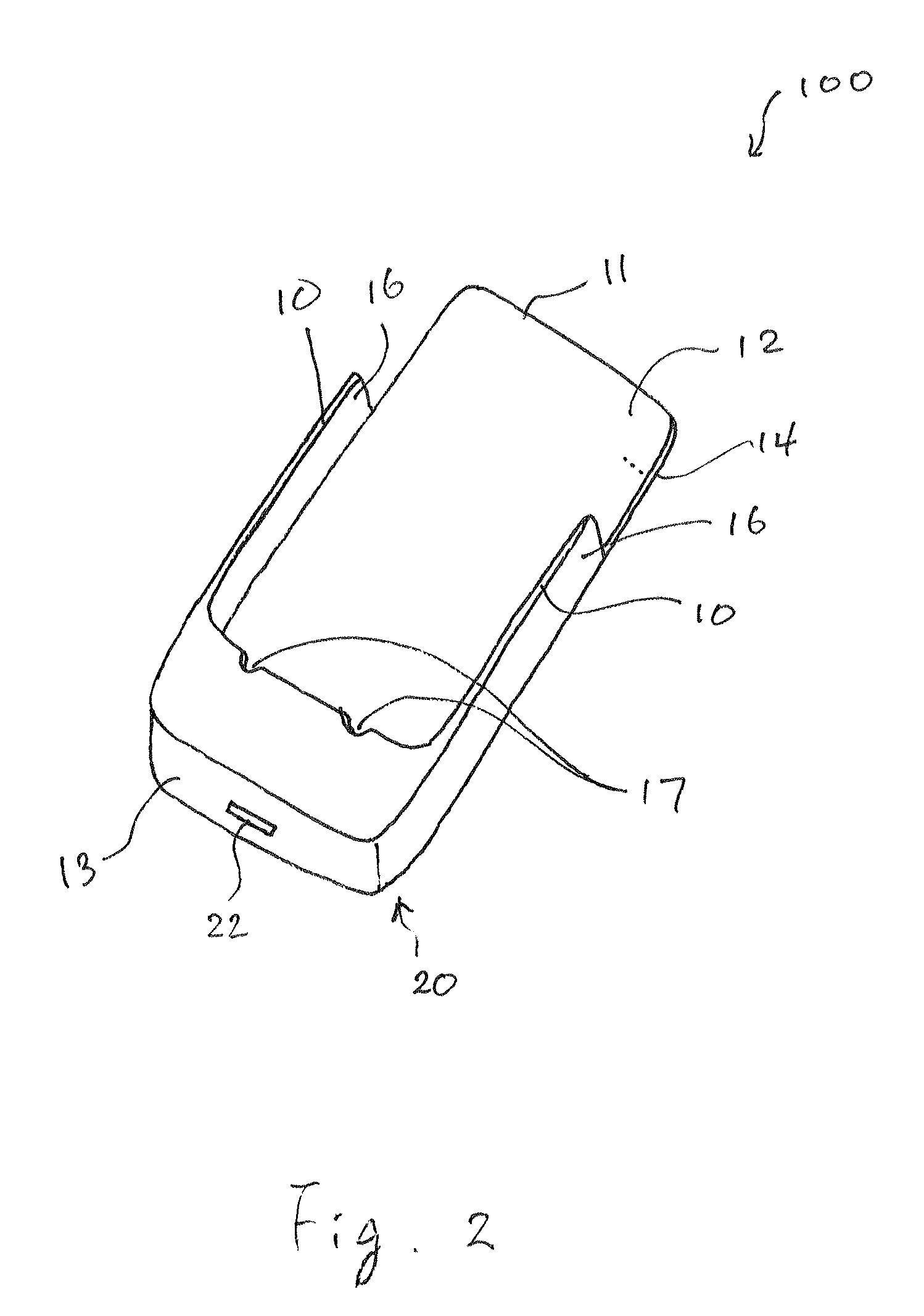

Case battery

InactiveUS20090108800A1Extended use timeBatteries circuit arrangementsDigital data processing detailsElectricityEngineering

Owner:WOUD STEVEN

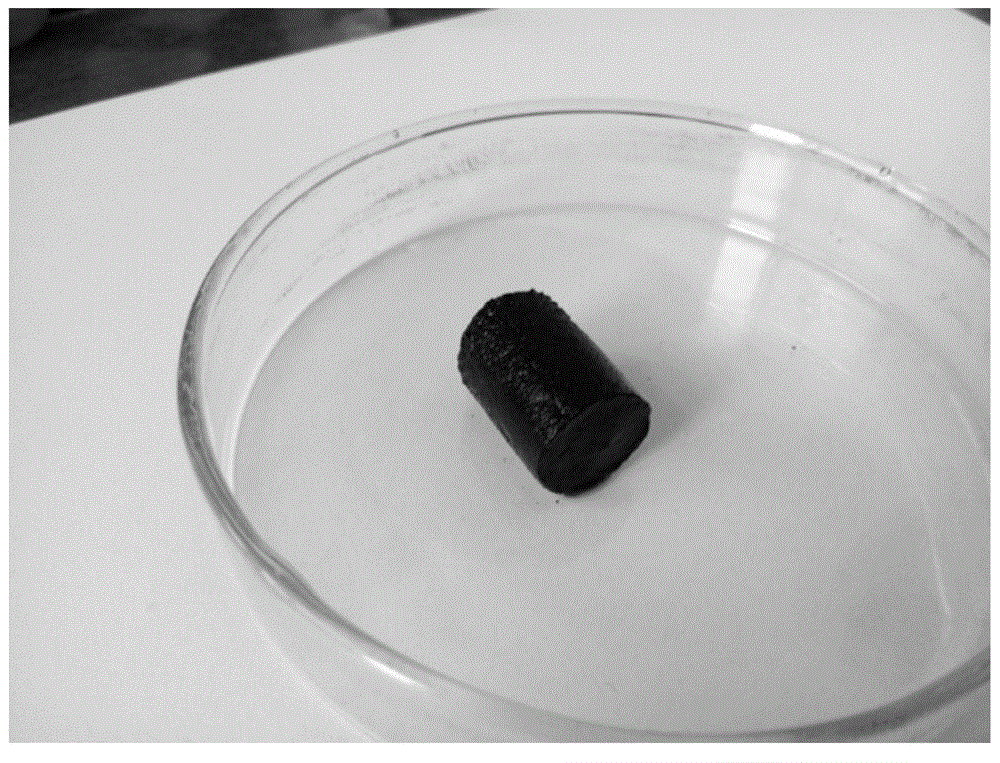

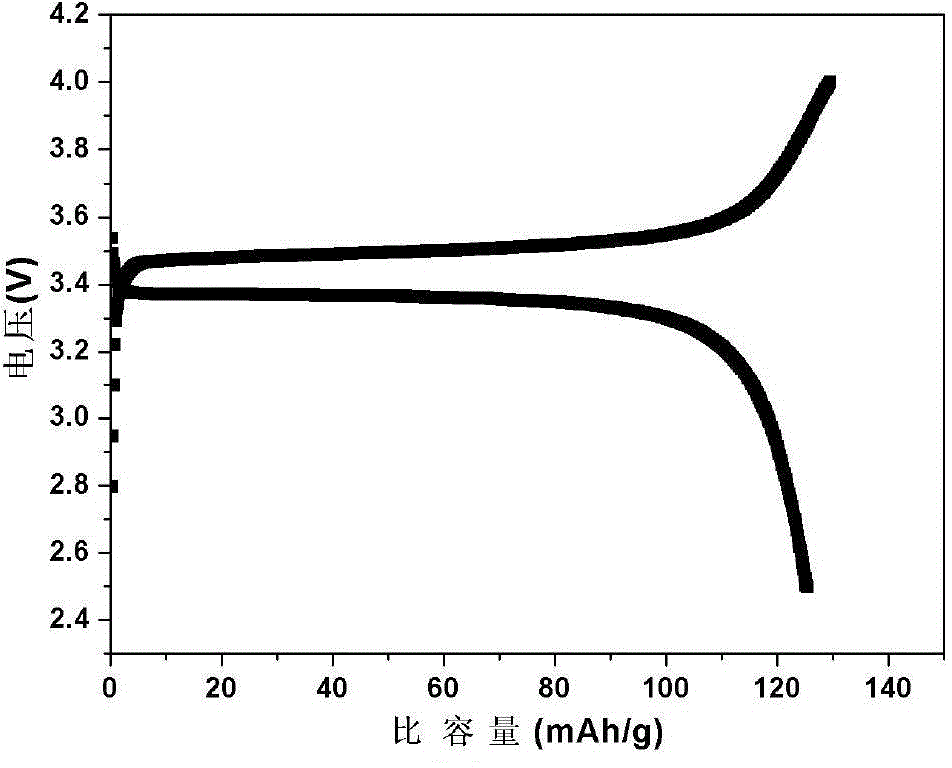

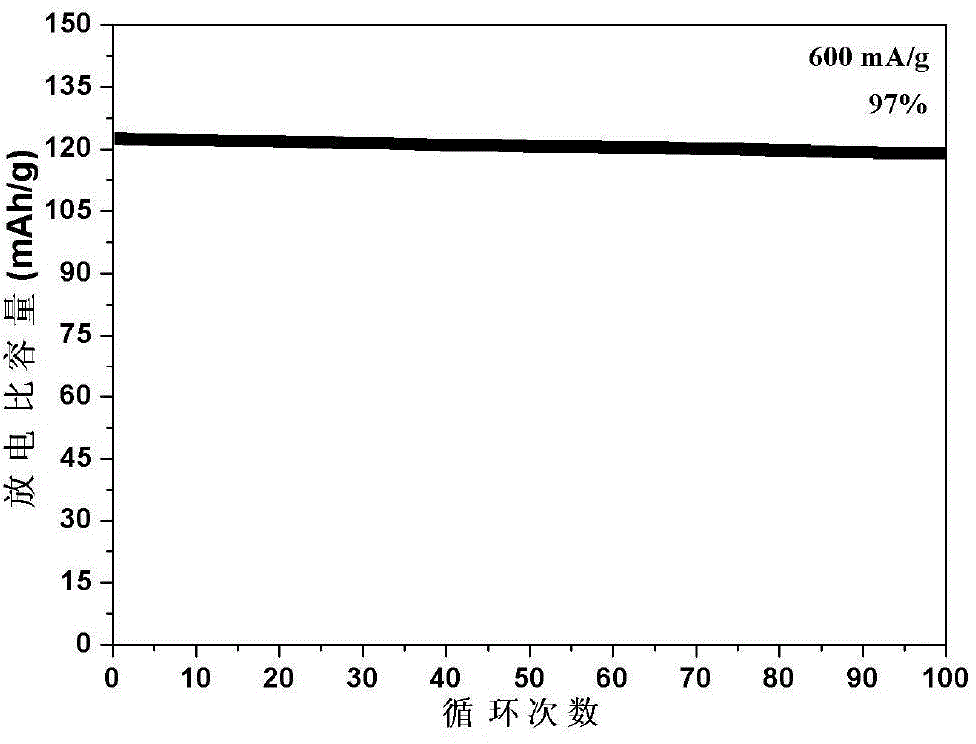

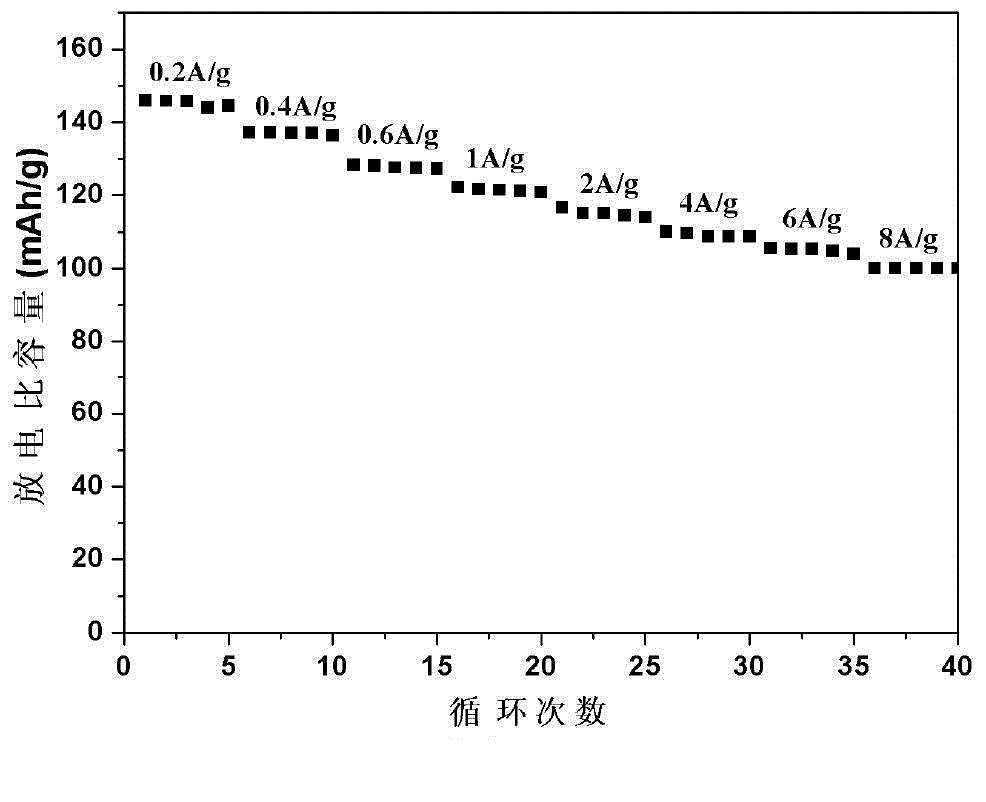

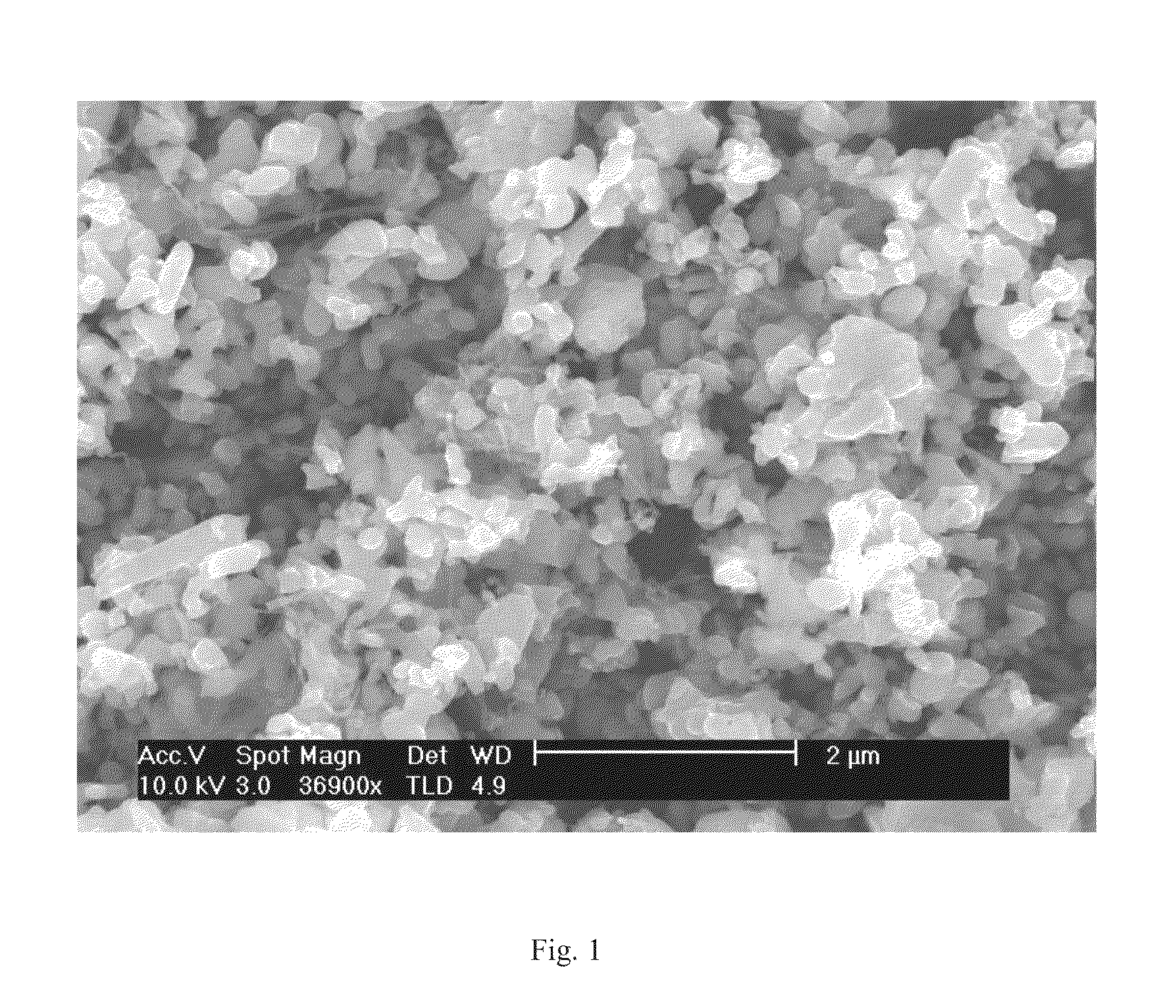

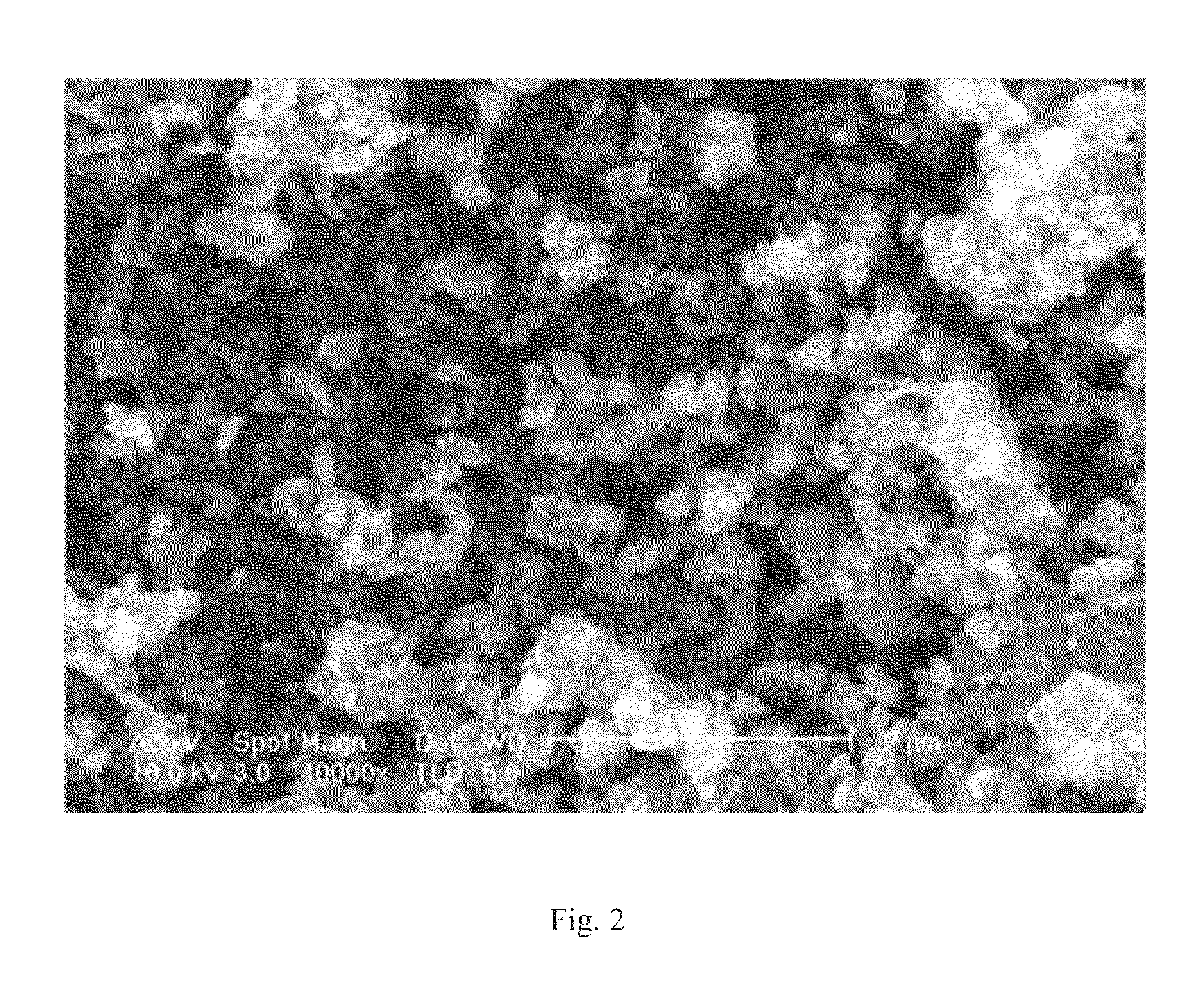

Method for preparing lithium iron phosphate/carbon composite material of lithium ion battery

InactiveCN102013477AImprove performanceImprove conductivityCell electrodesSecondary cellsLithium electrodeCarbon composites

The invention relates to a method for preparing a lithium iron phosphate / carbon composite material of a lithium ion battery, which belongs to the technical field of lithium ion batteries. The method for preparing the lithium iron phosphate / carbon composite material of the lithium ion battery comprises the following steps of: 1) preparing a suspending graphene-dispersed aqueous solution system, namely, crushing graphite to 1 to 5 microns, adding the crushed graphite into distilled water or purified water, adding 0.1 to 5 percent of surfactant, heating with stirring the mixed solution to 180 to 250 DEG C in a sealing way, performing stirring for 2 to 6 hours and reducing the temperature; 2) crushing lithium iron phosphate to the particle size of 1 to 5 microns, adding the crushed lithium iron phosphate into the distilled water or the purified water, adding with stirring 0.01 to 1 percent of coupling agent, performing uniform stirring, adding the graphene-dispersed aqueous solution, and performing stirring and filtration; and 3) vacuum-drying solid powder obtained by the filtration, and calcinating the dried solid powder for 2 to 12 hours to obtain the graphene-coated lithium iron phosphate cathode material. The method has the advantages of simple process, high material performance, high conductivity, high bulk density, high compacted density and the like.

Owner:HEBEI LITAO BATTERY MATERIAL

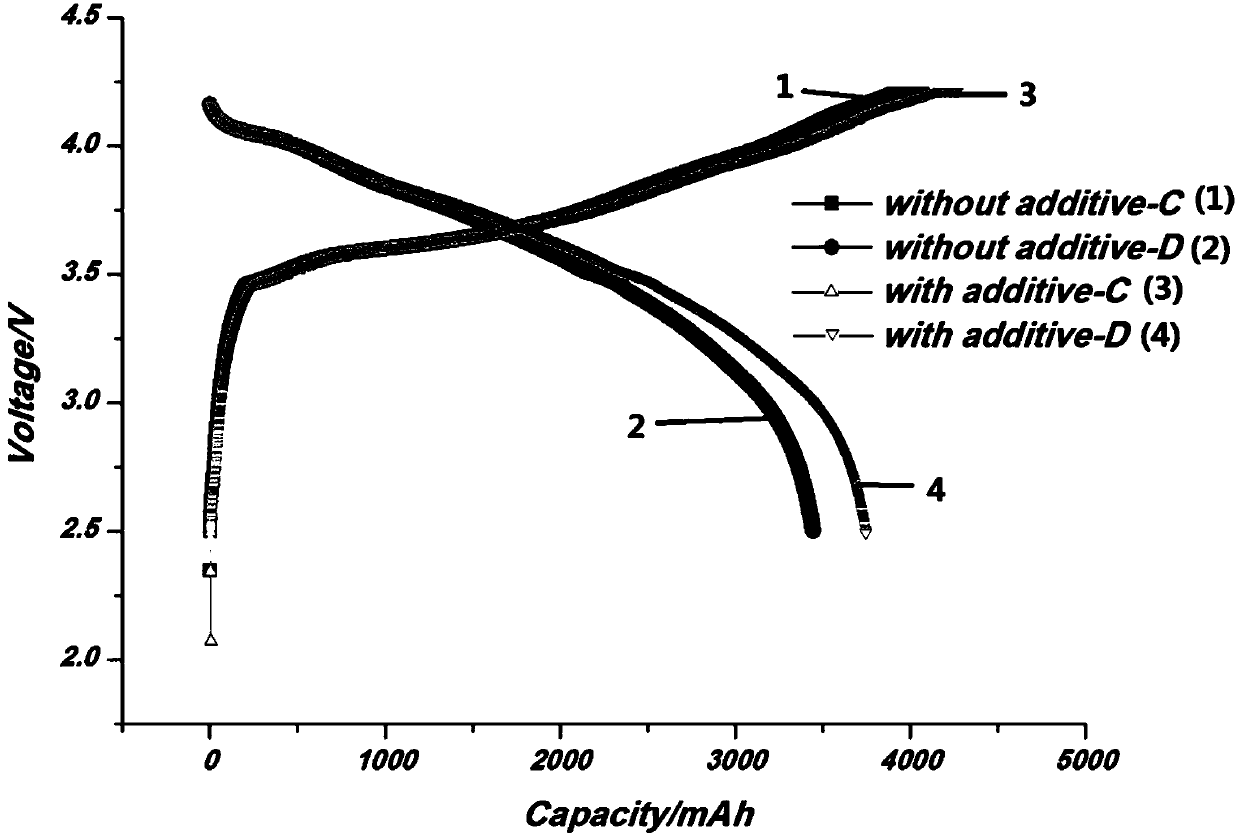

Lithium-supplementing additive as well as preparation method and application thereof

Owner:SHENZHEN BAK POWER BATTERY CO LTD

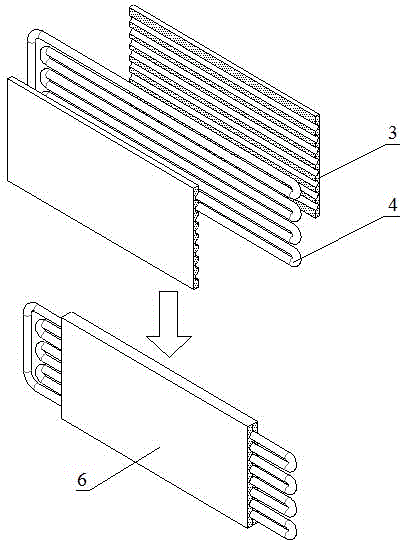

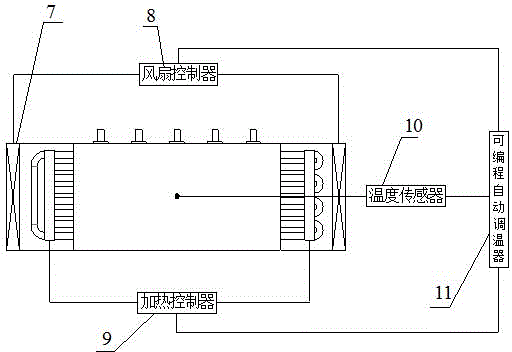

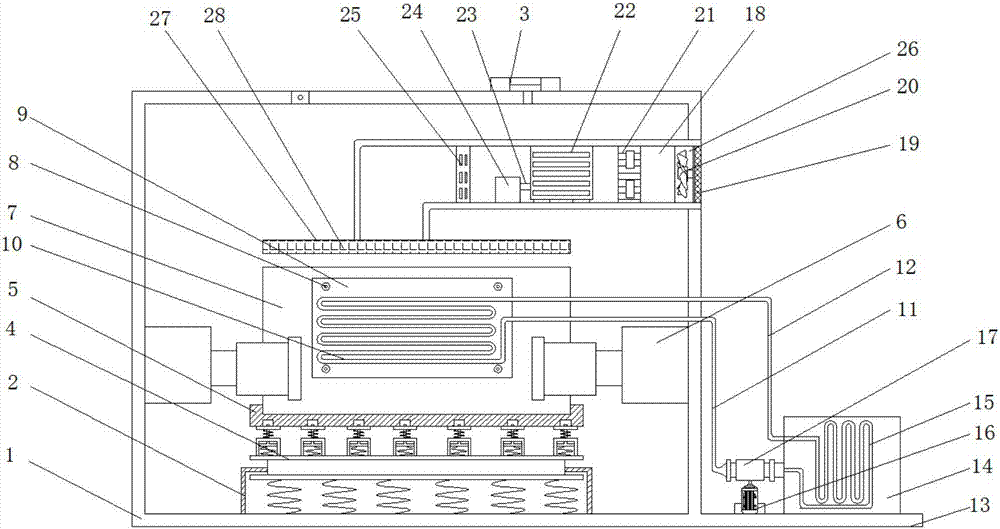

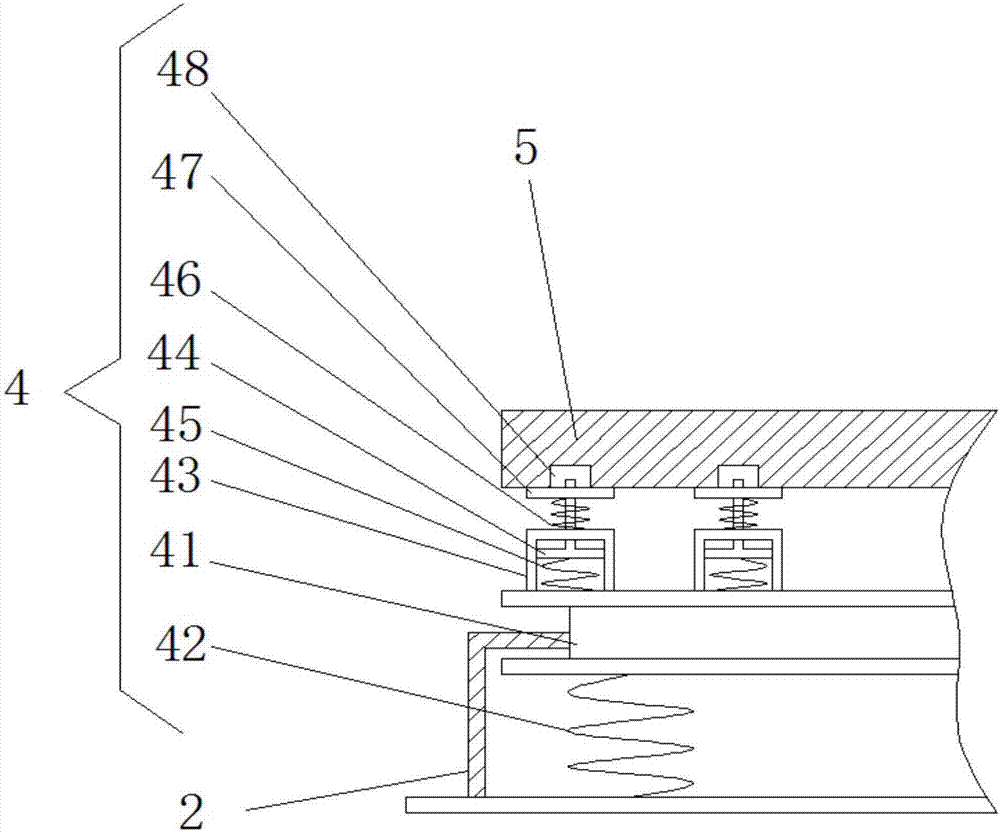

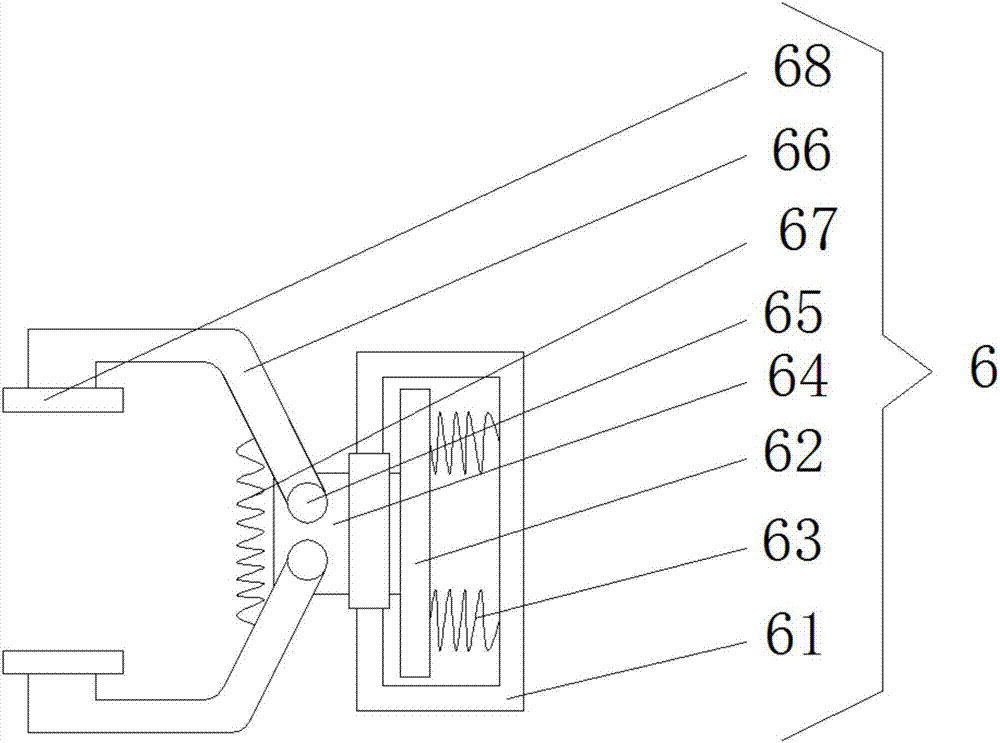

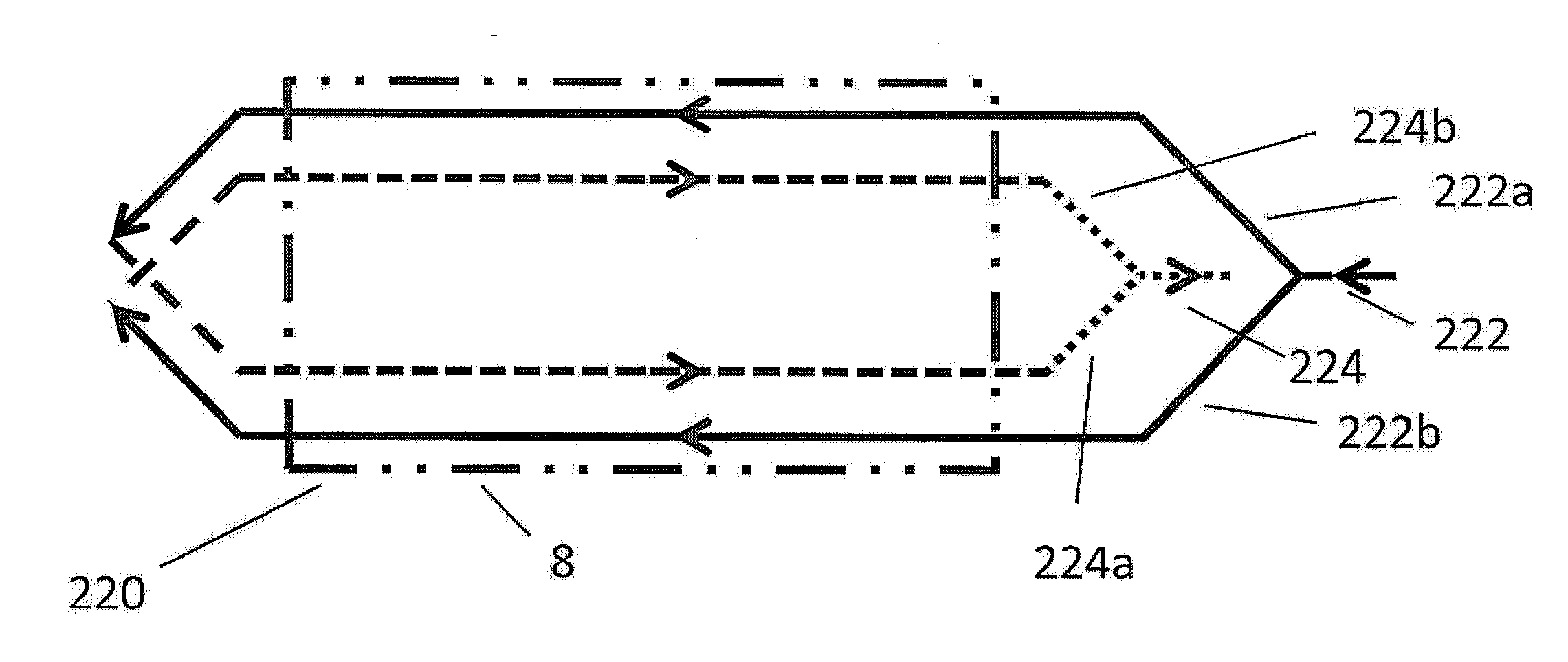

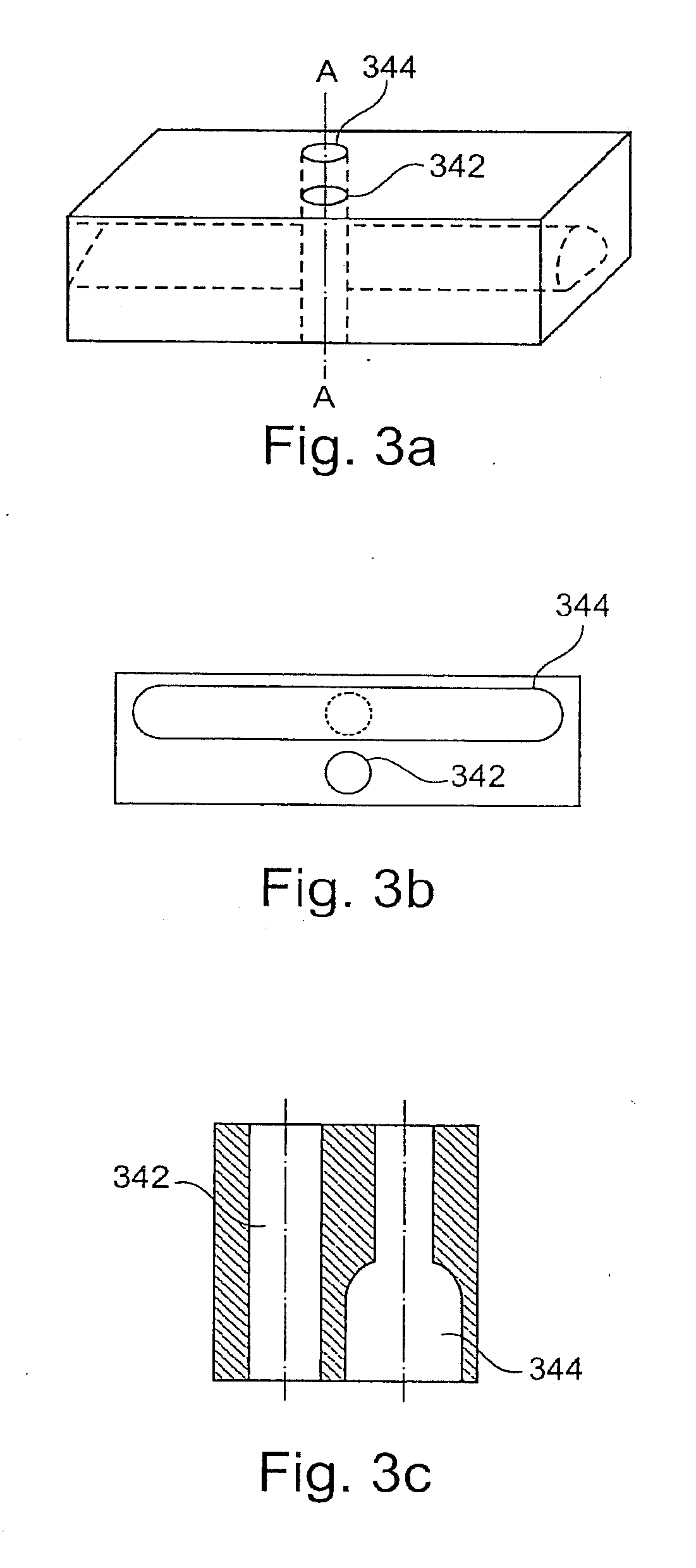

Power battery thermal management system with functions of efficient heat dissipation and efficient heating

InactiveCN106033827AEfficient dischargeAchieve temperature control effectSecondary cellsBatteriesAutomotive batteryElectrical battery

Owner:广东万锦科技股份有限公司

Core-shell structured carbon for cathode material of lithium ion battery and preparation method thereof

Owner:DONGGUAN MCNAIR NEW POWER

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

Owner:HARBIN INST OF TECH

Method for preparing nickel-cobalt-manganese ternary material precursor

ActiveCN103943847ARealize comprehensive utilizationIncrease profitCell electrodesSecondary cellsManganeseCobalt

Owner:北京盟固利新材料科技有限公司

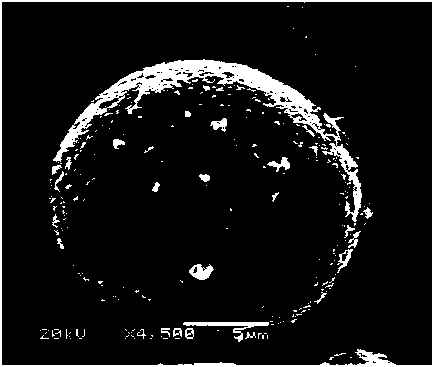

Process For Producing Spherical Carbon Material

InactiveUS20070212610A1High yieldGood spherical shapeAlkali metal halidesSecondary cellsNon aqueous electrolytesElectrode material

Owner:KUREHA KAGAKU KOGYO KK

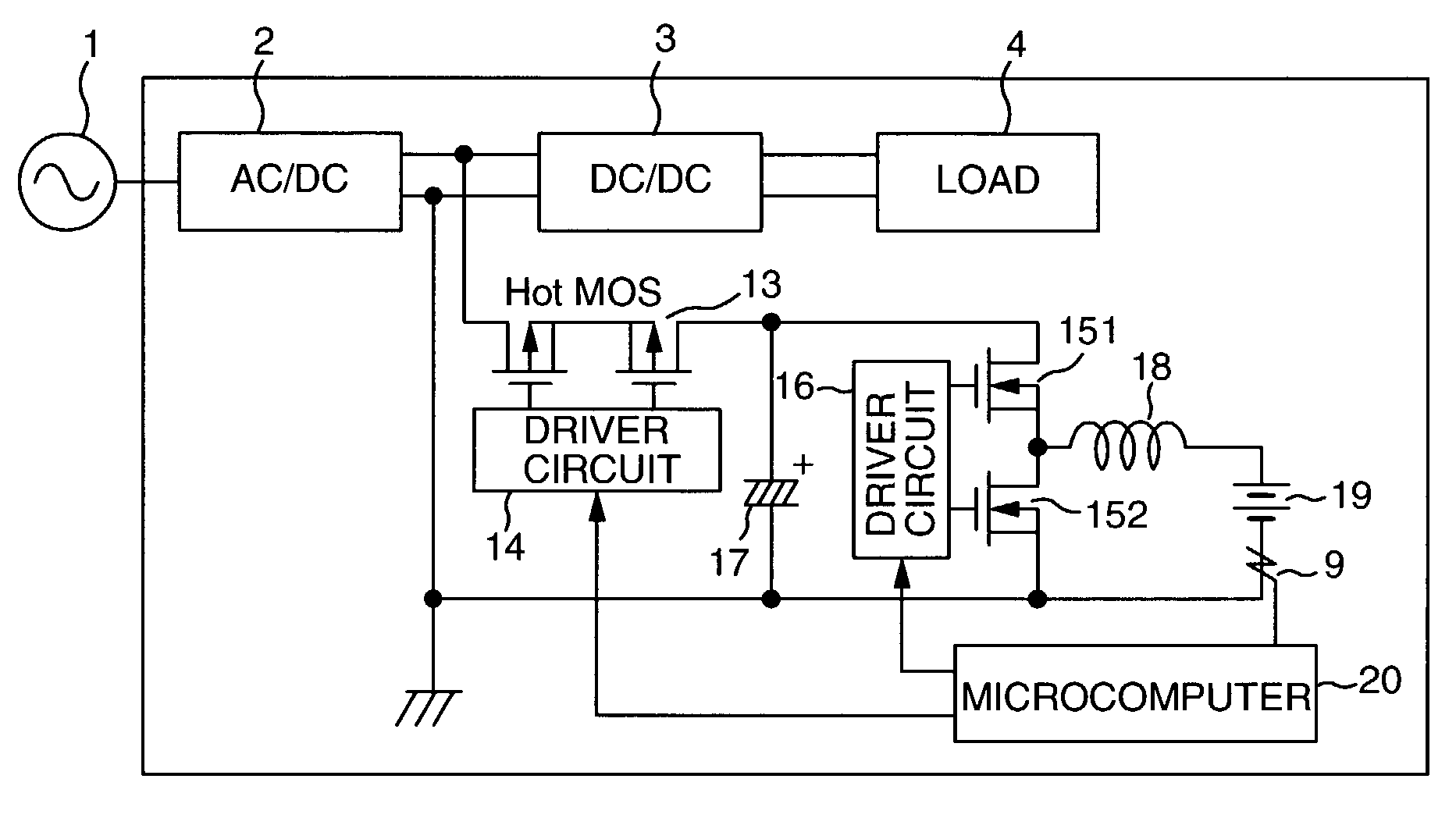

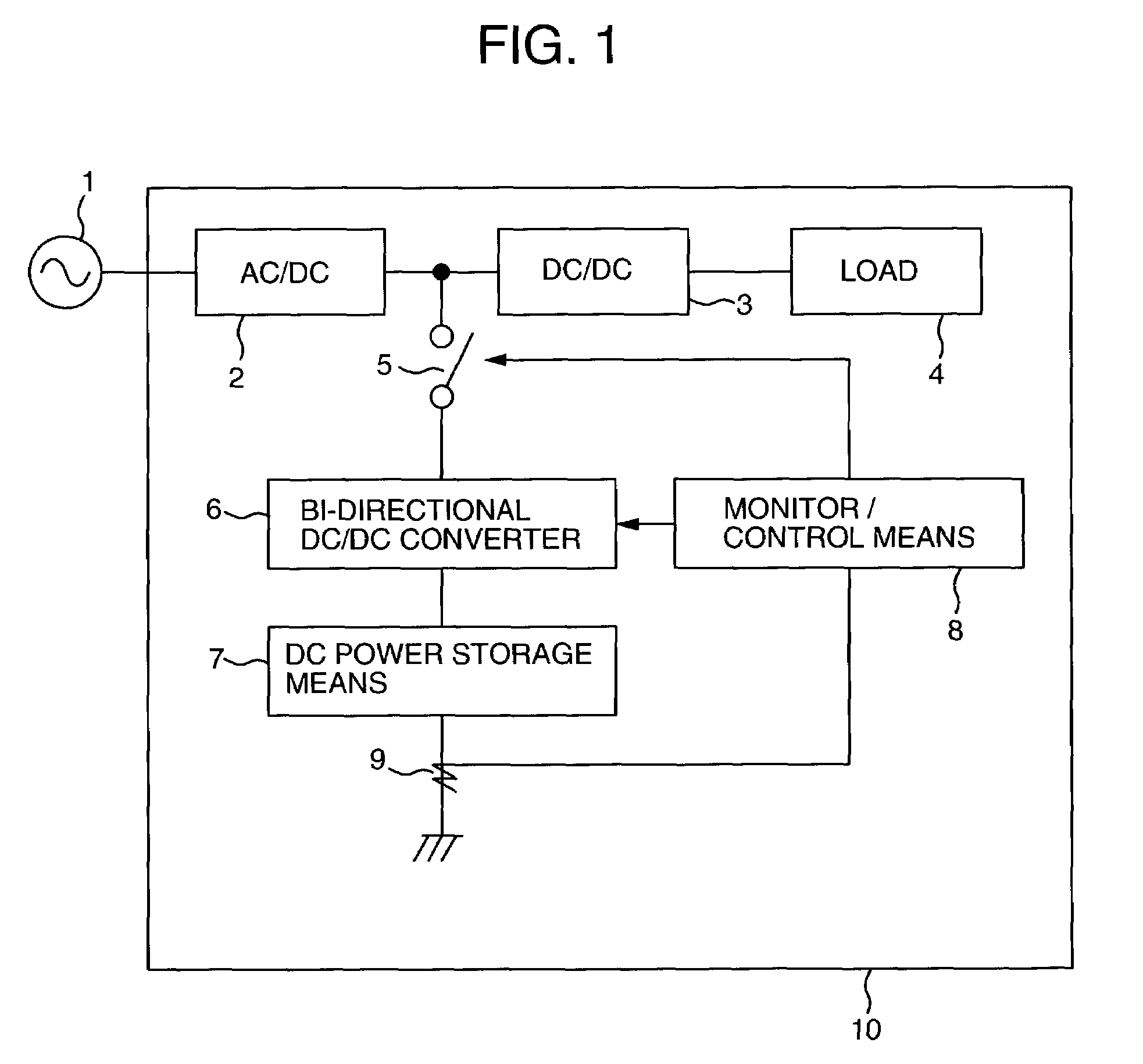

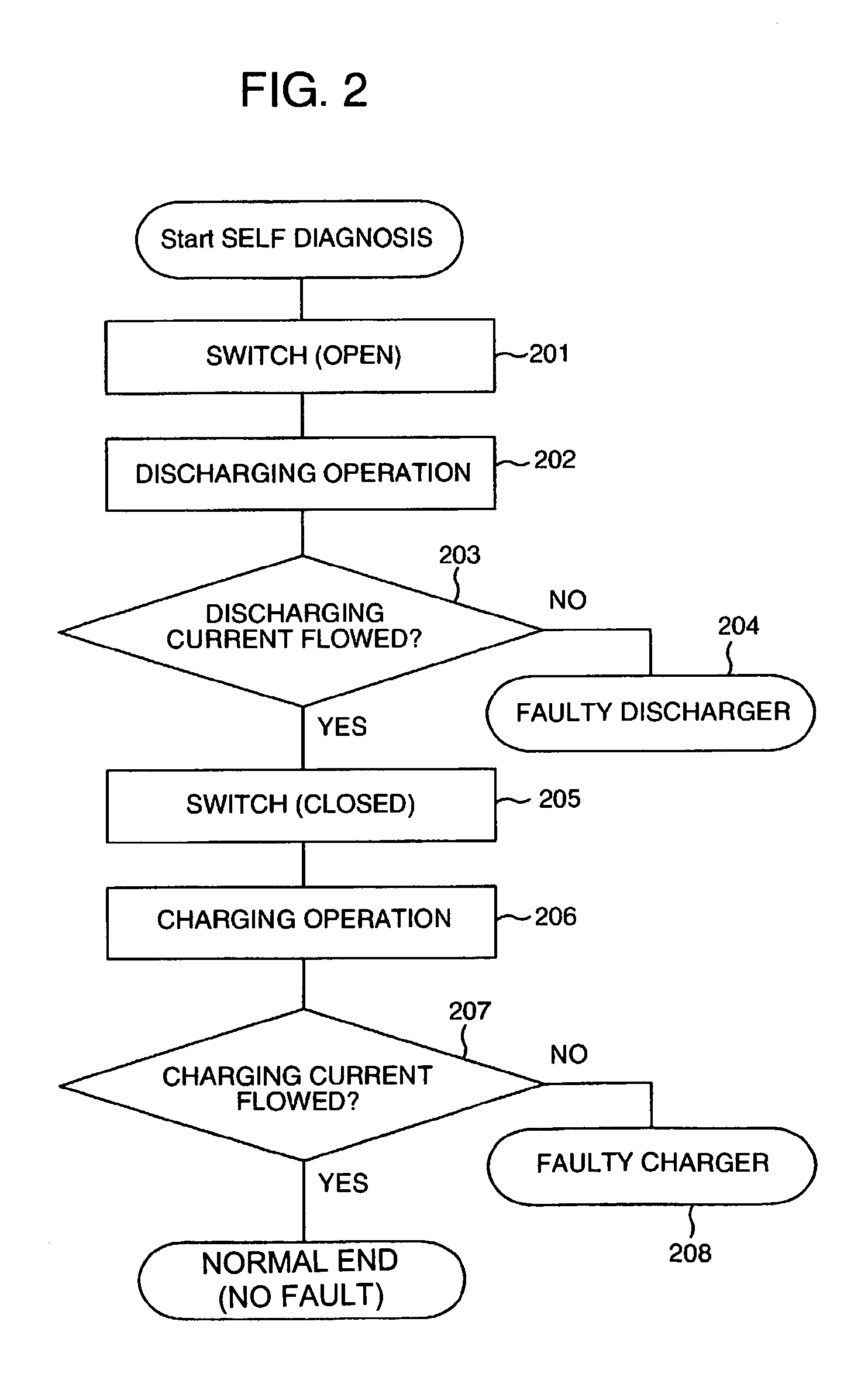

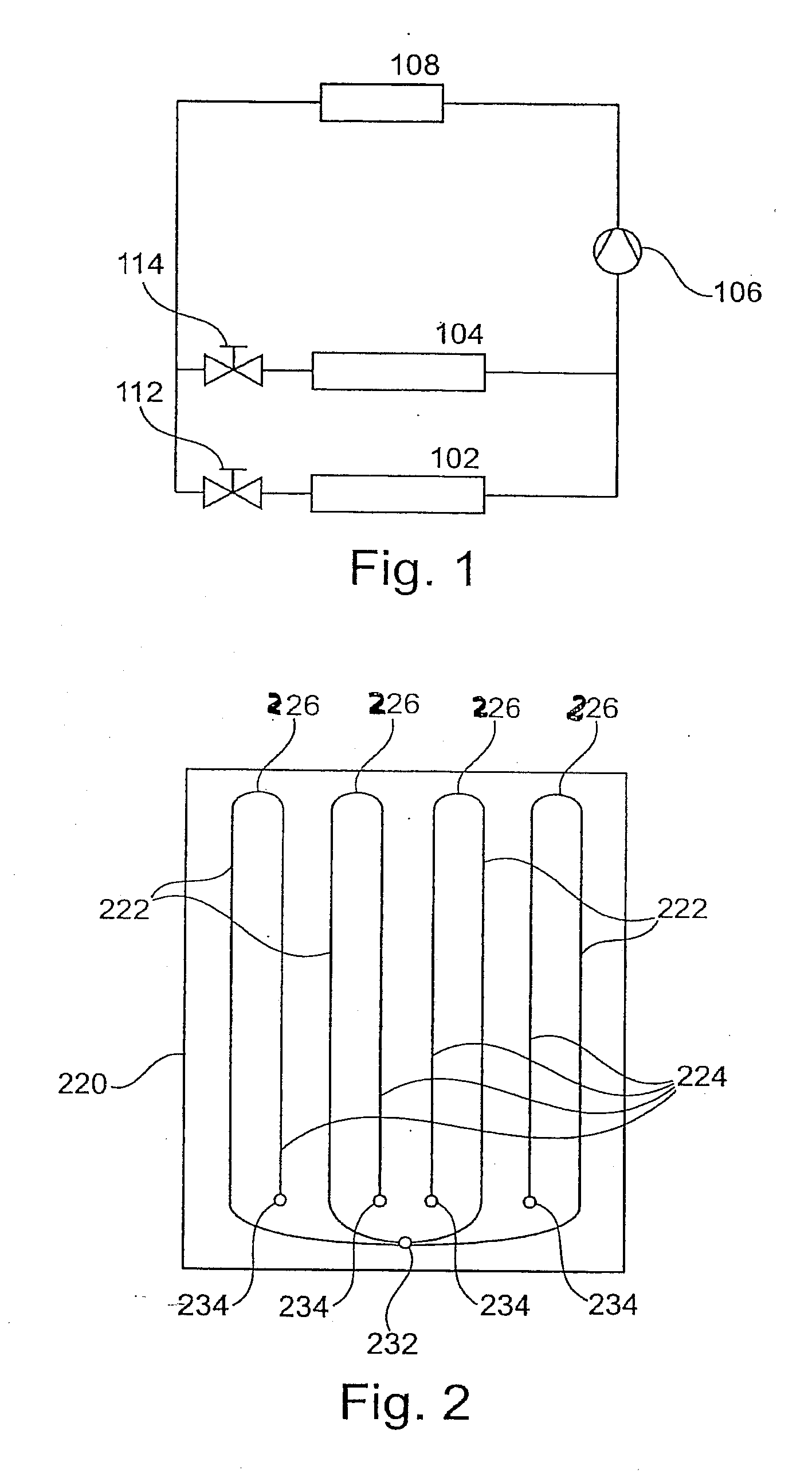

DC backup power supply device and method for diagnosing the same

InactiveUS7245469B2High reliabilityDiagnosing deviceDc network circuit arrangementsSecondary cellsSelf-diagnosisAdverse effect

A reliable uninterruptible DC power supply device. The DC backup power supply device includes an AC / DC converter, a DC / DC converter, voltage step-up / down choppers and a battery connected to a DC path of a main circuit connected with a load via a switch, and a microcomputer. In the device, under control of the microcomputer, the voltage step-up / down choppers are first operated under a condition that the MOS FET was turned OFF for self diagnosis of the backup power supply device. Next, the switch is turned ON to execute the remaining self diagnosis. The DC backup power supply device can execute its self diagnosis with a reduced likelihood of danger of exerting an adverse effect on the main circuit and also can exhibit a reliable uninterruptible power supply function.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

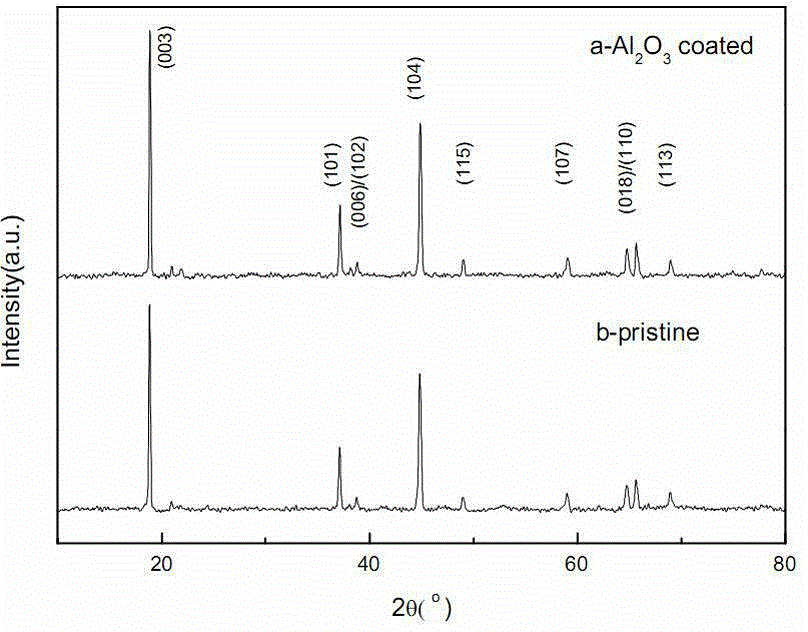

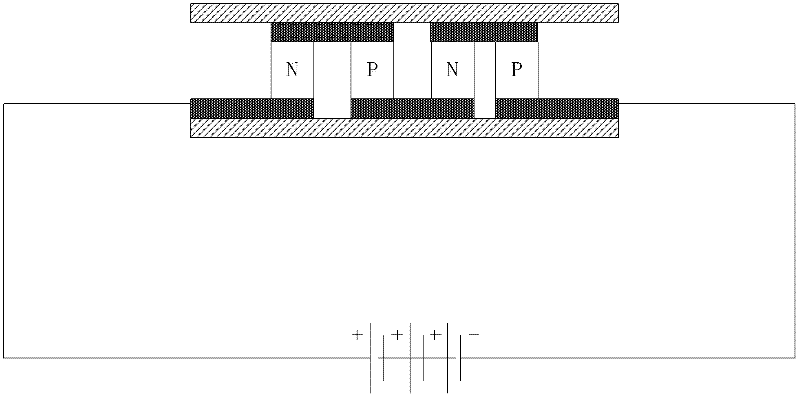

Alumina coating method of lithium ion battery positive electrode material

InactiveCN104577128AImprove cycle stabilitySmall capacity attenuationCell electrodesSecondary cellsAir atmosphereLithium-ion battery

Owner:WUXI XINGBO ENERGY TECH

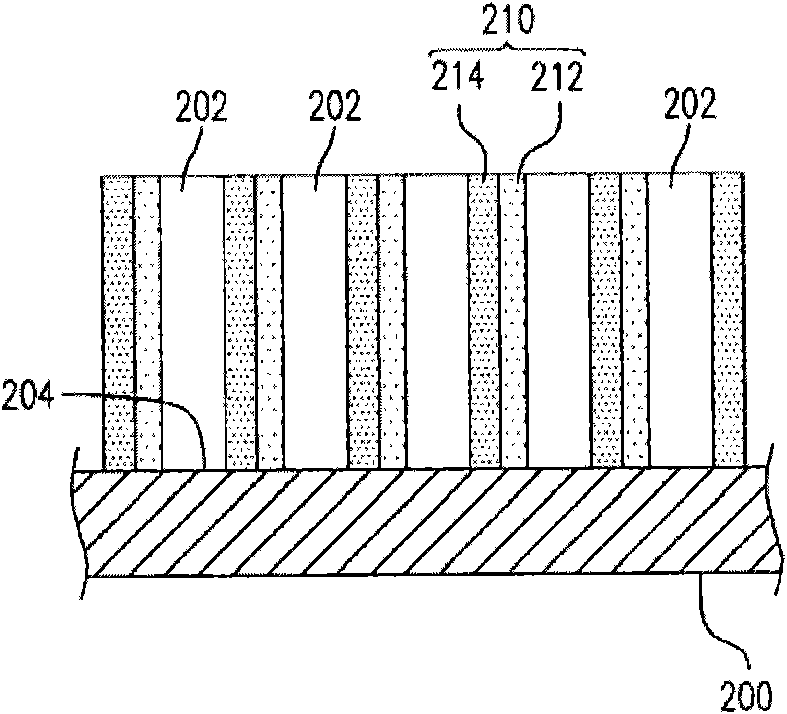

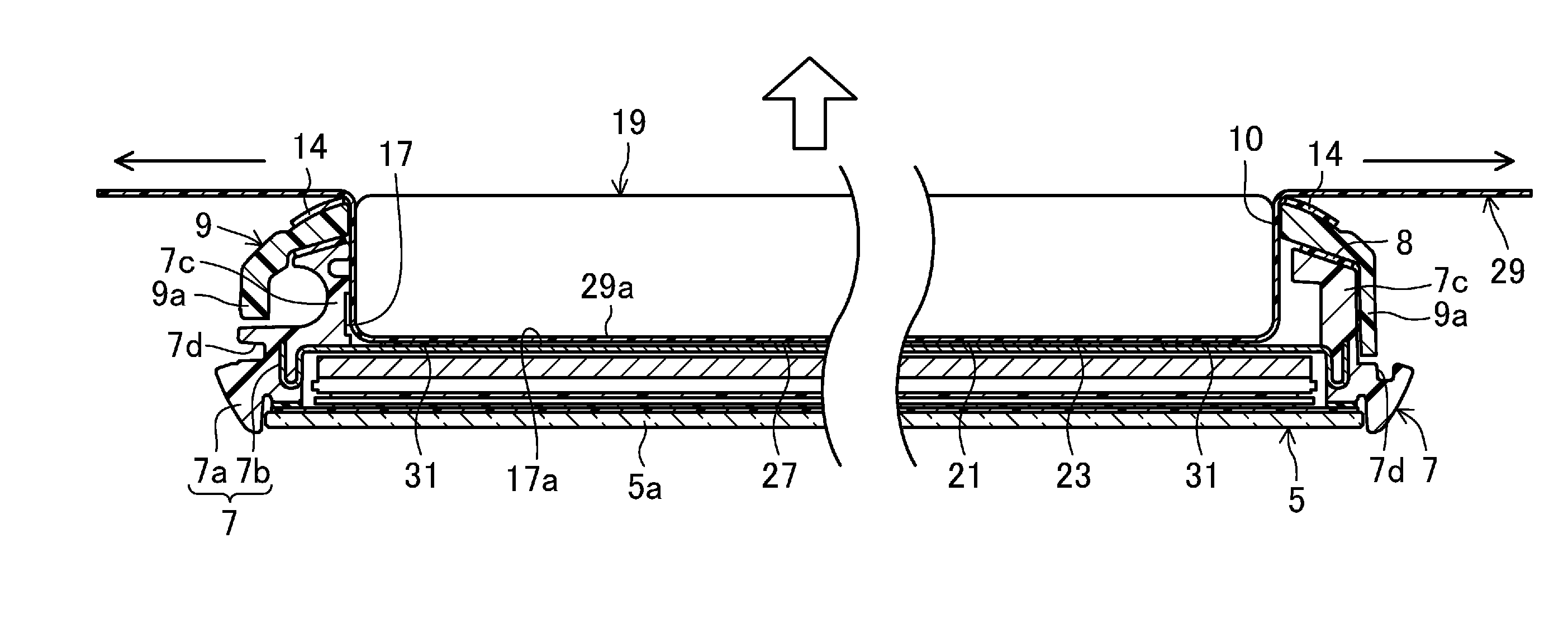

Power supply device, and vehicle and storage battery device equipped with power supply device

InactiveUS20150093607A1Avoid damagePrevent gas leakageSecondary cellsCell component detailsSafety valveBattery cell

A power supply device comprises a battery assembly formed by stacking secondary battery cells having safety valves for exhausting gas, end plates being arranged at both end faces of the battery assembly in the stacking direction, a gas duct guiding gas emitted from the safety valves in a prescribed gas exhaust passage, and fixing portions fixing both ends of the gas duct to the end plates in a position where the gas duct faces the safety valves. In a state in which the gas duct is fixed to the end plates in at least one of the fixing portion a fixing opening of a slit is formed extending in the direction parallel to the direction in which the secondary battery cells are stacked, and a fixing member is inserted into the slit fixing opening.

Owner:SANYO ELECTRIC CO LTD

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

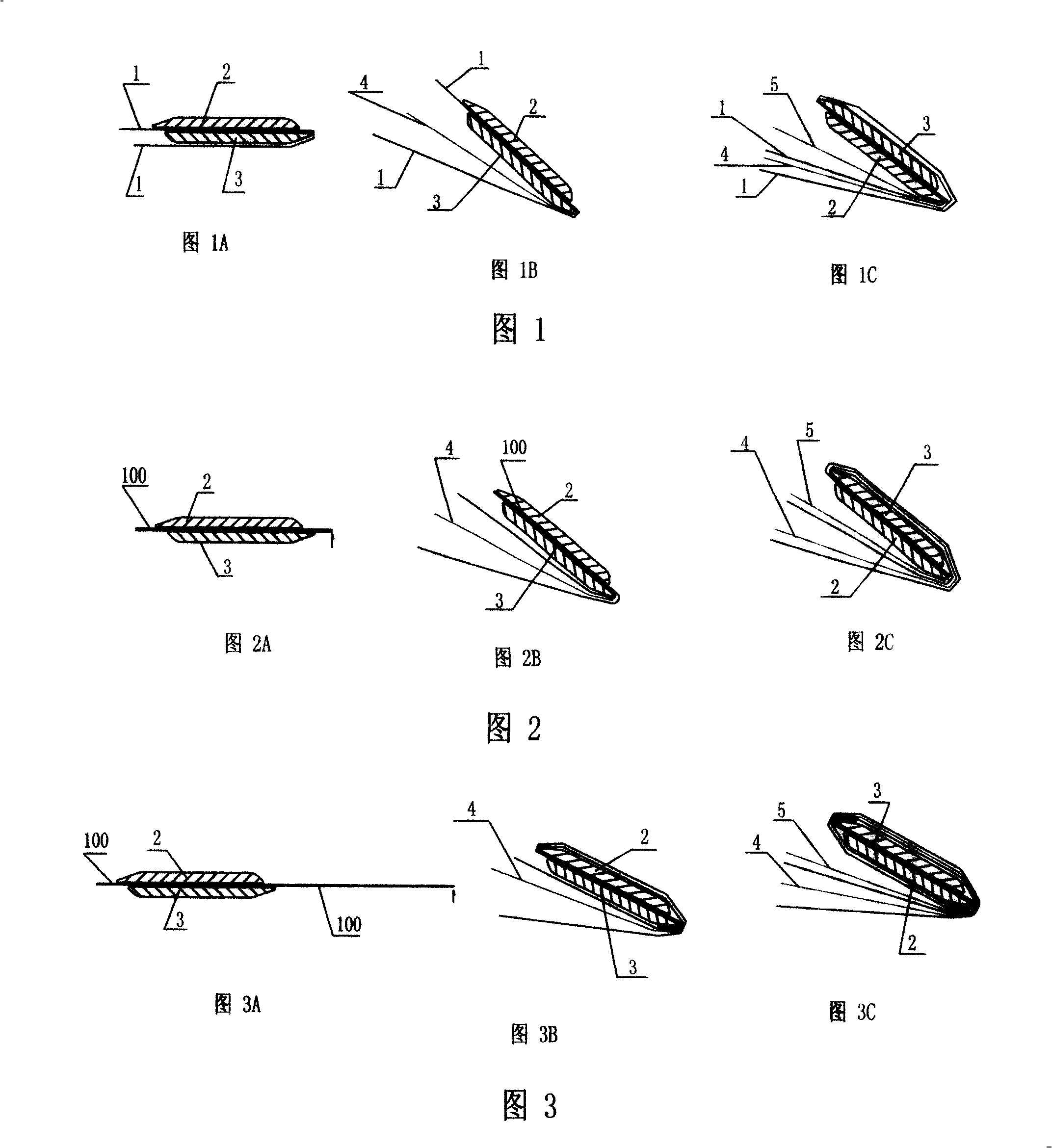

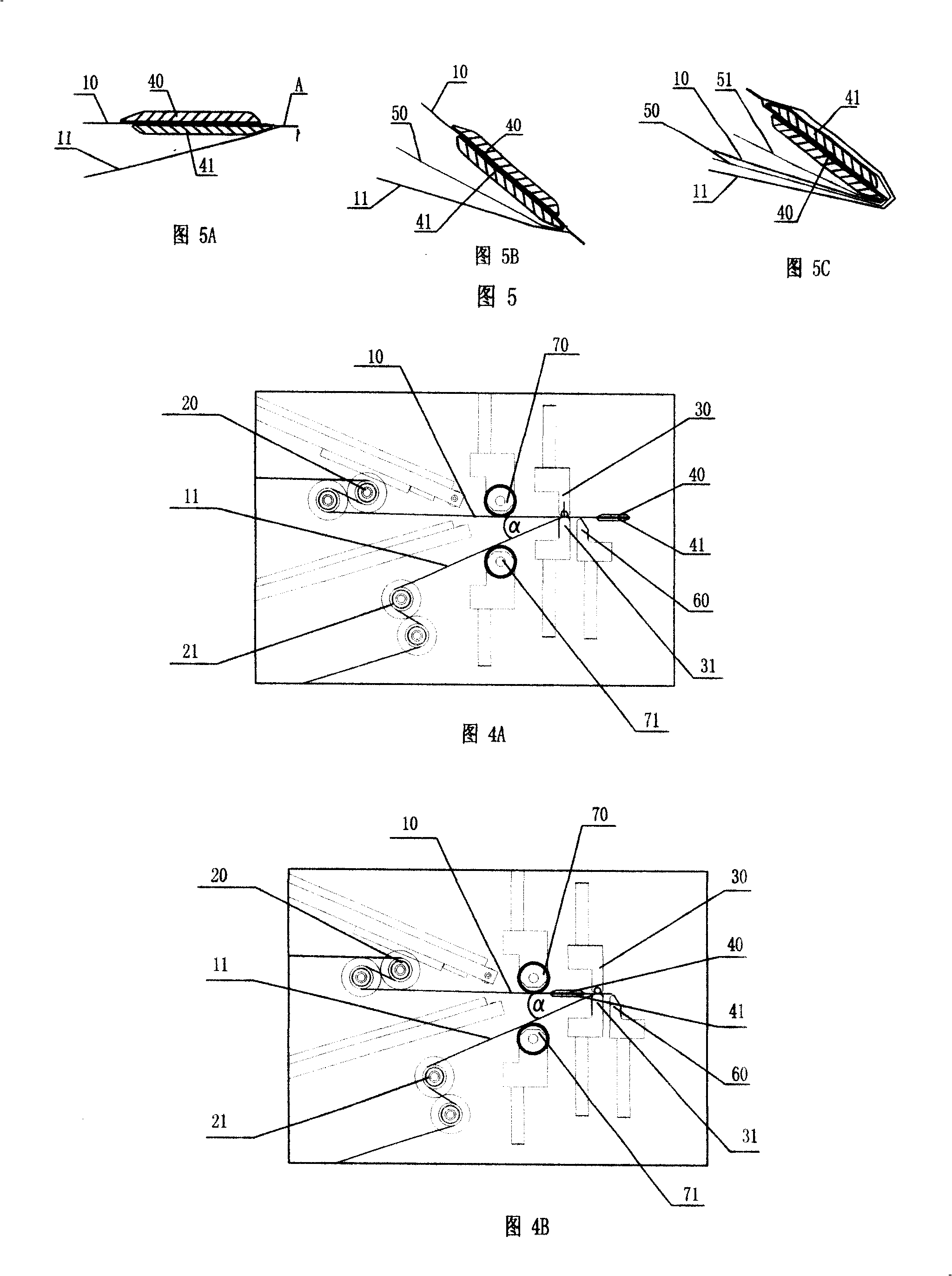

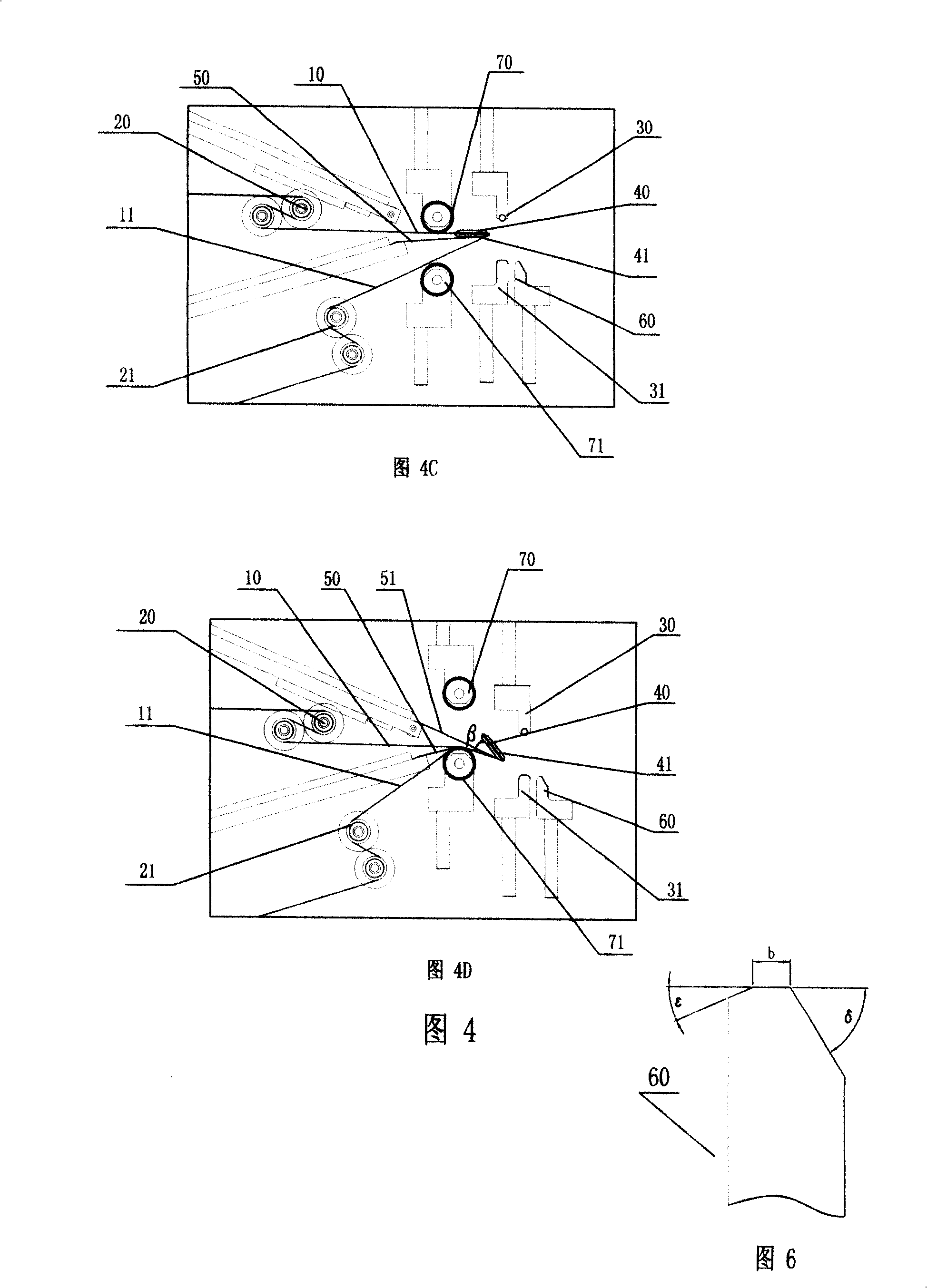

Winding method of lithium ion battery coiled core

ActiveCN101246970AConsistent tensionGuaranteed reliabilityFinal product manufactureSecondary cellsSemi automaticEngineering

Owner:GEESUN AUTOMATION TECH

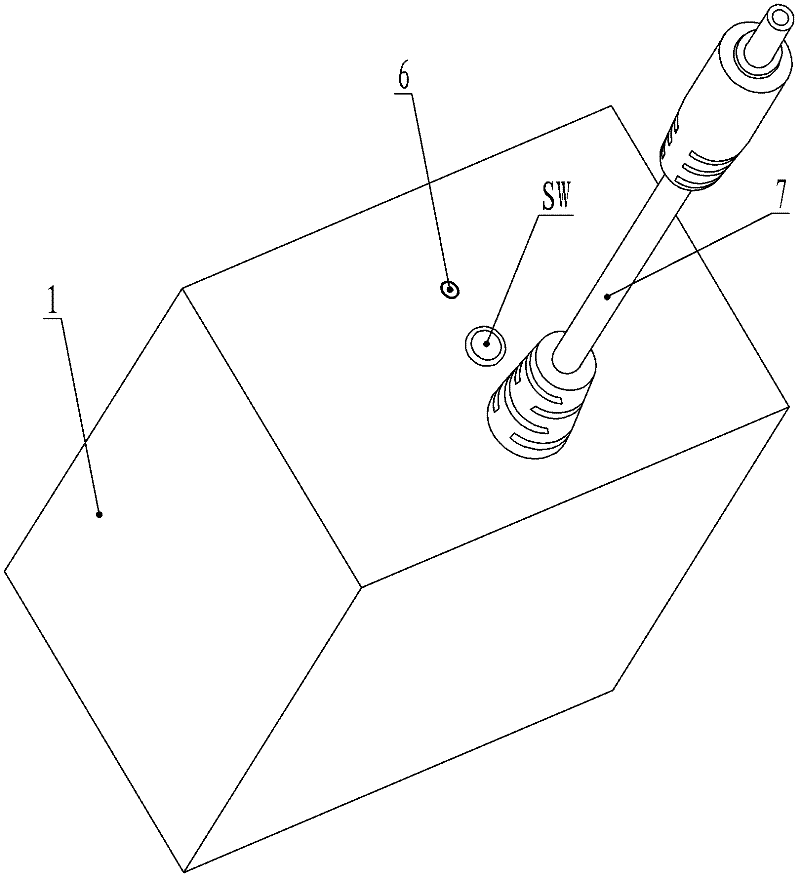

Device and method of testing an internal resistance of a battery pack

ActiveUS20110101986A1High measurement accuracyCurrent/voltage measurementElectrical testingElectrical resistance and conductanceInternal resistance

An internal resistance testing device includes an excitation source and a battery pack, an adjustable resistance R, a sampling unit, and a control unit. The excitation source and the battery pack form a loop circuit. The adjustable resistance R may be located at the loop circuit formed by the excitation source and the battery pack. The sampling unit samples the voltage between two sides of the battery pack, the voltage between two sides of the adjustable resistance R, and the value of the adjustable resistance R. The control unit calculates internal resistance of the battery pack according to the signal value collected by the sampling unit. The internal resistances of different voltage-ranges the battery pack are determined by adjusting the value of the adjustable resistance R to cause the actual excitation voltage to be equal to the range voltage of the sampling unit. The voltage between two sides of the adjustable resistance R is made equal to the range voltage of the sampling unit by adjusting the value of the adjustable resistance R, which effectively improves measurement accuracy of the internal resistance.

Owner:BYD CO LTD

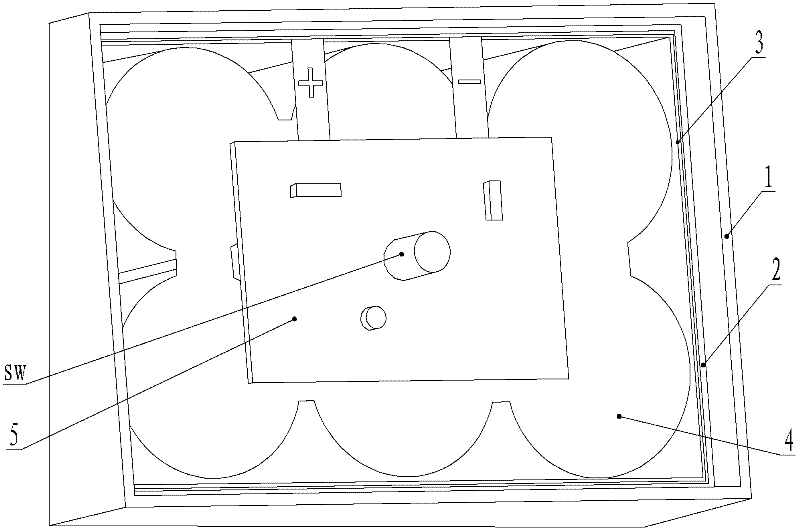

Automobile battery fixing device

InactiveCN107394083AAchieving oil-cooled car batteriesClamp firmlyElectric propulsion mountingSecondary cellsAutomotive batteryCooling effect

Owner:安吉天剑电器科技有限公司

Lithium-ion battery heat insulation device and control method thereof

Owner:DONGGUAN LARGE ELECTRONICS CO LTD

Coating modification method for improving performance of rich-lithium manganese-base positive electrode material

Owner:UNIV OF SCI & TECH BEIJING

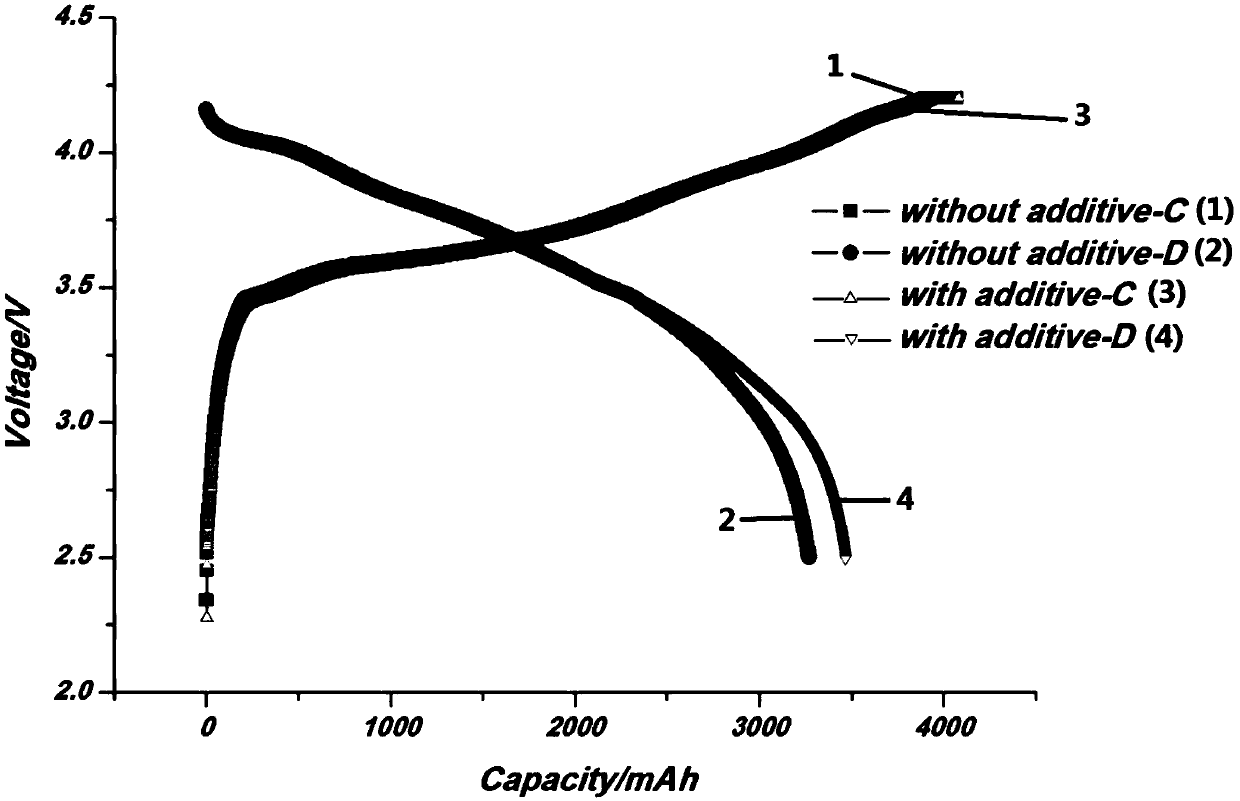

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

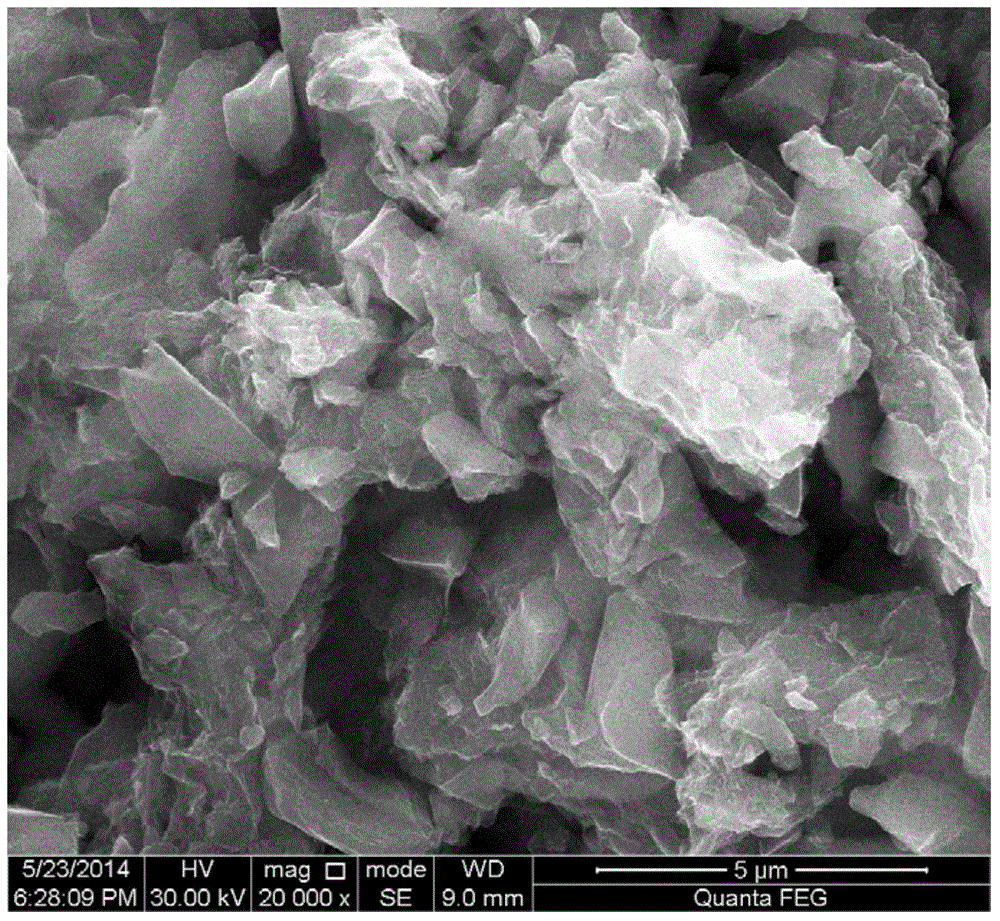

Preparation method of positive electrode material of lithium-ion battery

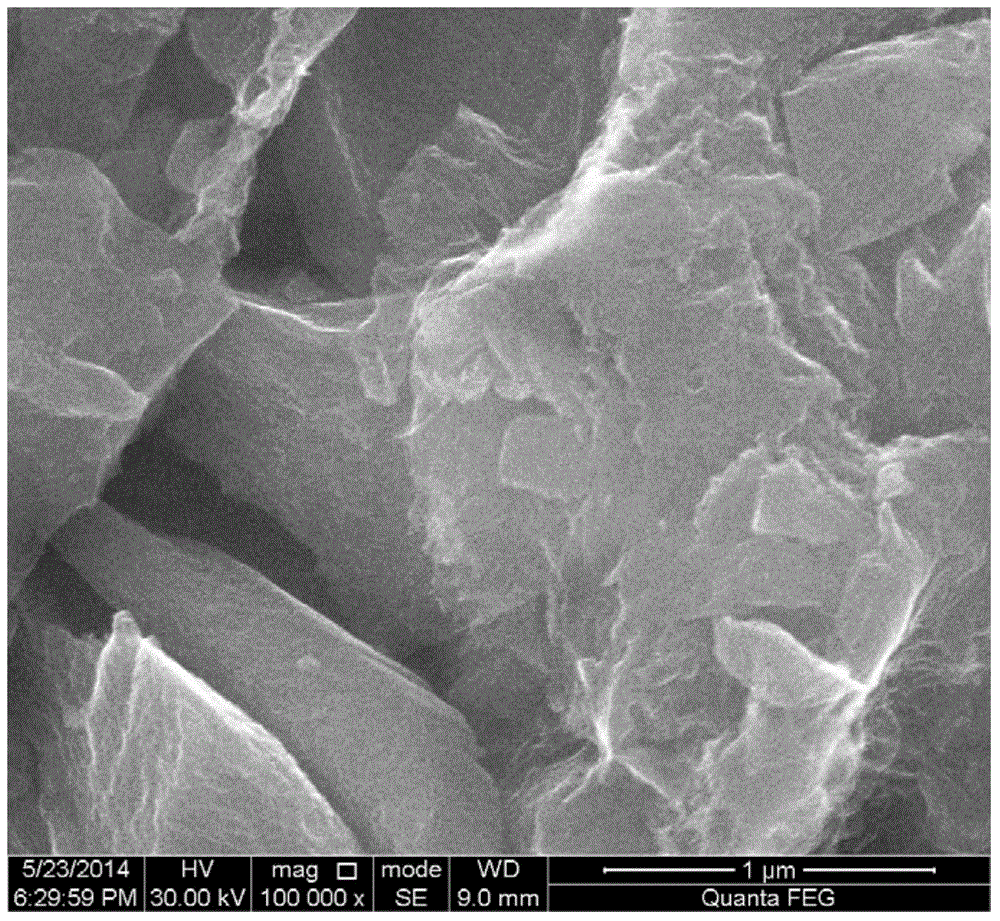

InactiveCN106207167AObvious lamellar structureUniform sizeElectrode manufacturing processesSecondary cellsUltrasonic cavitationLithium-ion battery

The invention discloses a preparation method of a positive electrode material of a lithium-ion battery. The method comprises the specific steps of dropwise adding a metal salt solution and a mixed solution of a precipitant and a complexing agent to a surfactant solution; controlling a pH value and a temperature under a synergistic effect of an inert atmosphere, ultrasonic cavitation and stirring dispersion until the metal salt solution is dropwise added; carrying out spray drying and roasting to obtain a spherical product, mixing the spherical product with a lithium source and roasting the mixture again to obtain the positive electrode material of the lithium-ion battery. The crystalline morphology can be effectively controlled by using a surfactant; the early synthesized material has an obvious sheet structure; particles agglomerated by a spray-dried product are uniform in size; a foundation is laid for later roasting to obtain the spherical particles with uniform sizes; and meanwhile, another foundation is laid for a relatively good morphology of the final product positive electrode material.

Owner:KUNMING UNIV OF SCI & TECH

Solid sodium battery electrolyte and preparation and application thereof

ActiveCN105633468AHigh room temperature ionic conductivityExcellent rate performanceSecondary cellsHost materialElectrochemical window

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

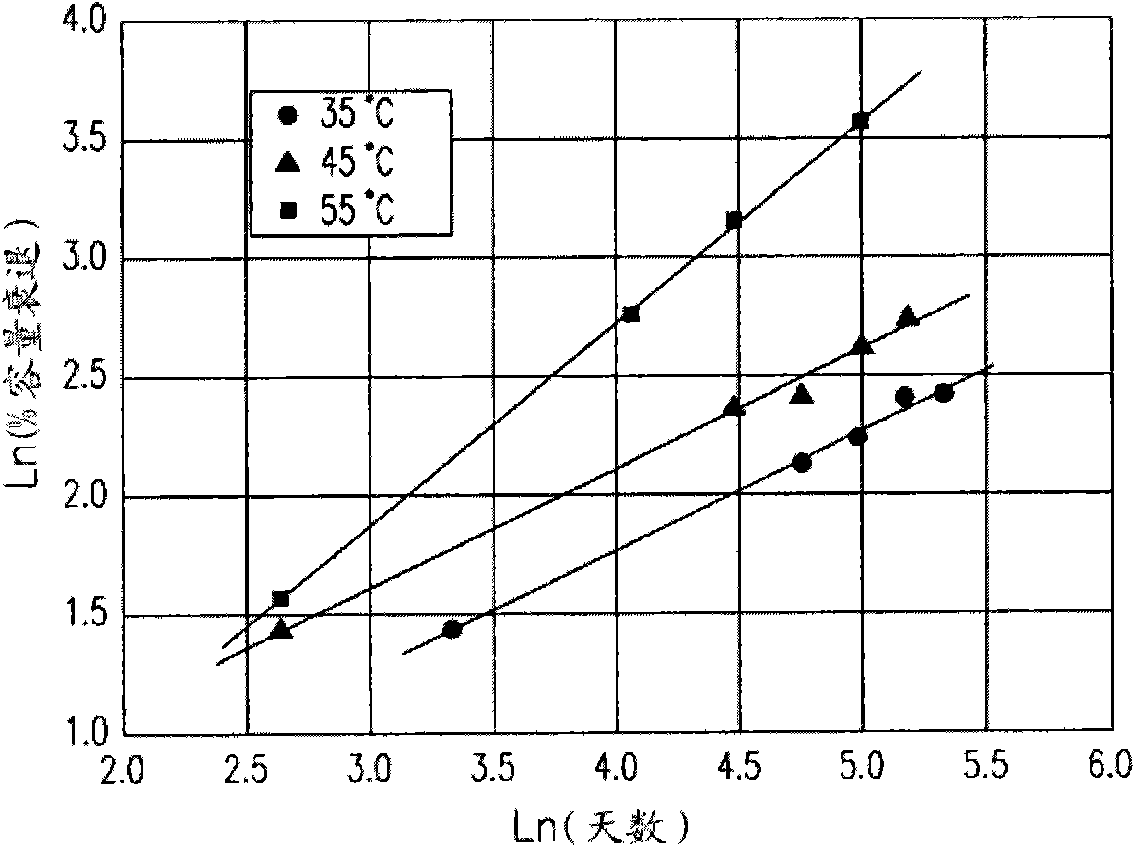

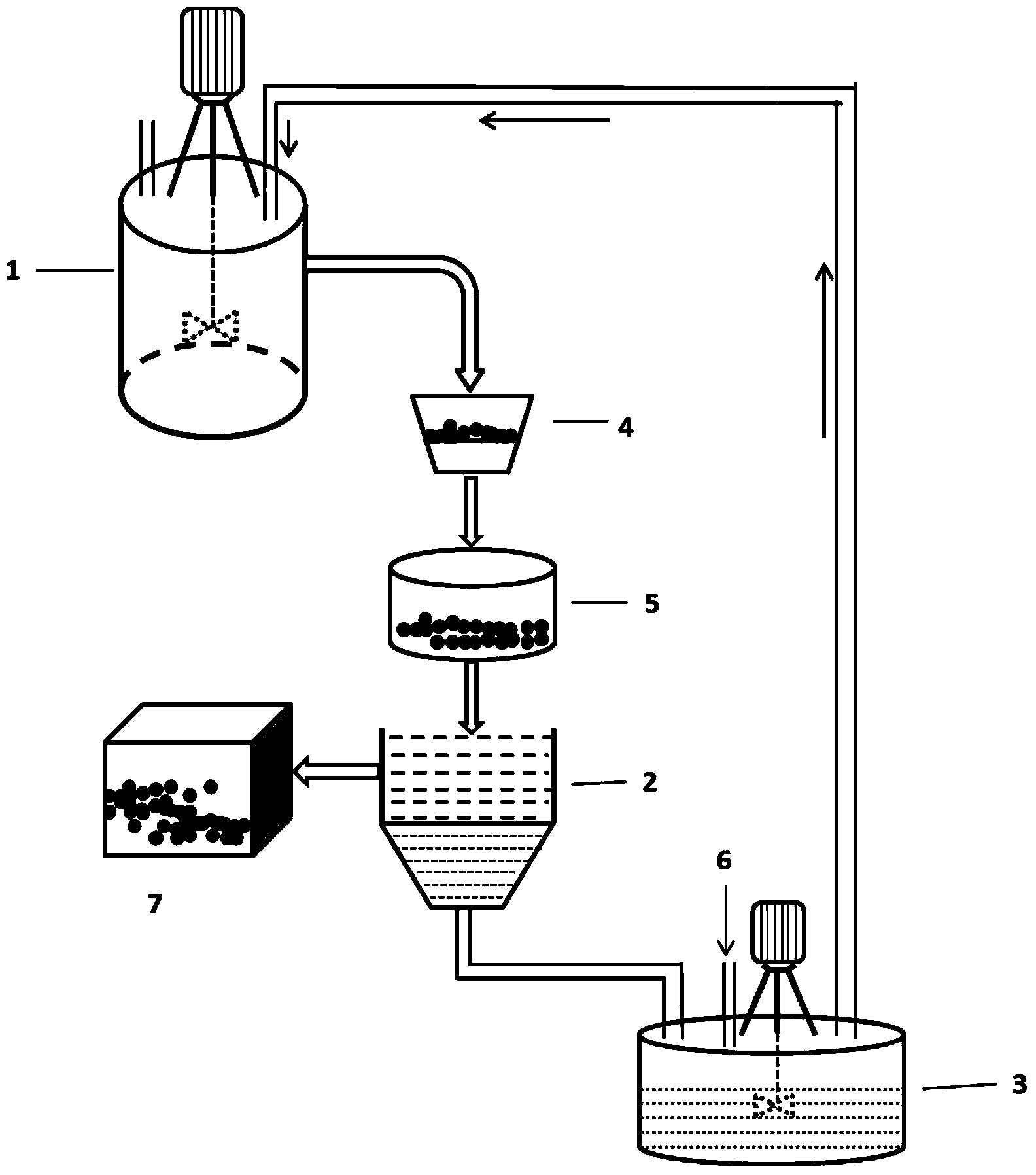

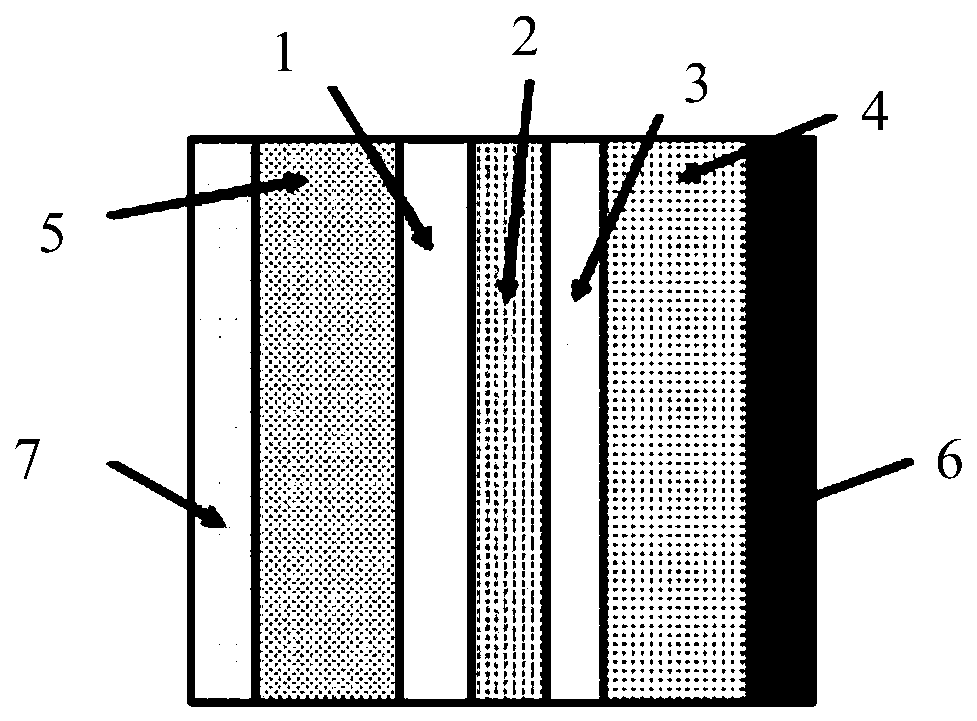

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

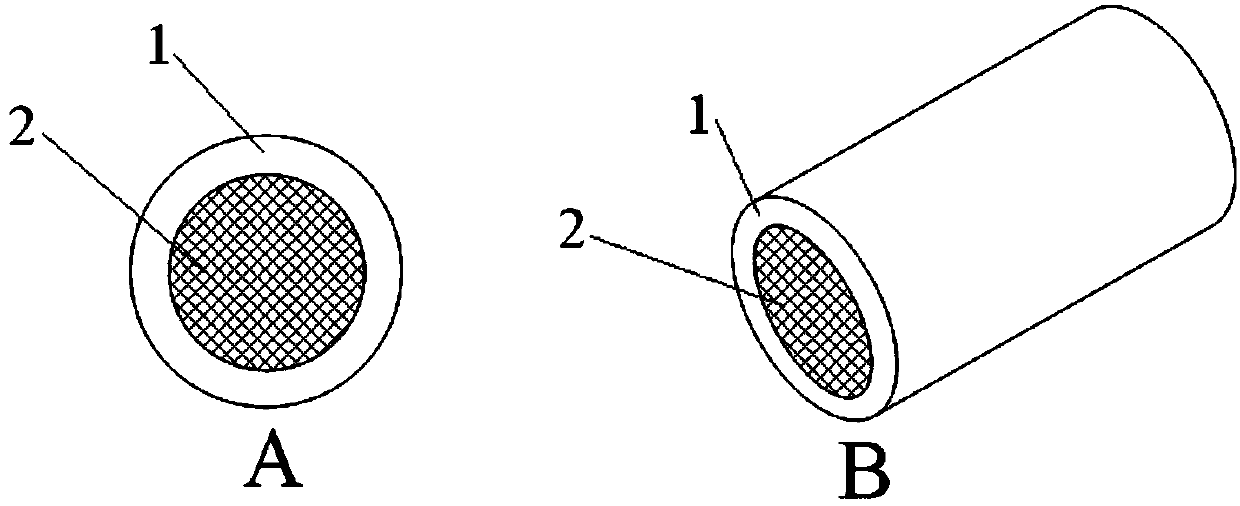

Lithium supplementing diaphragm of lithium ion battery

Owner:复阳固态储能科技(溧阳)有限公司

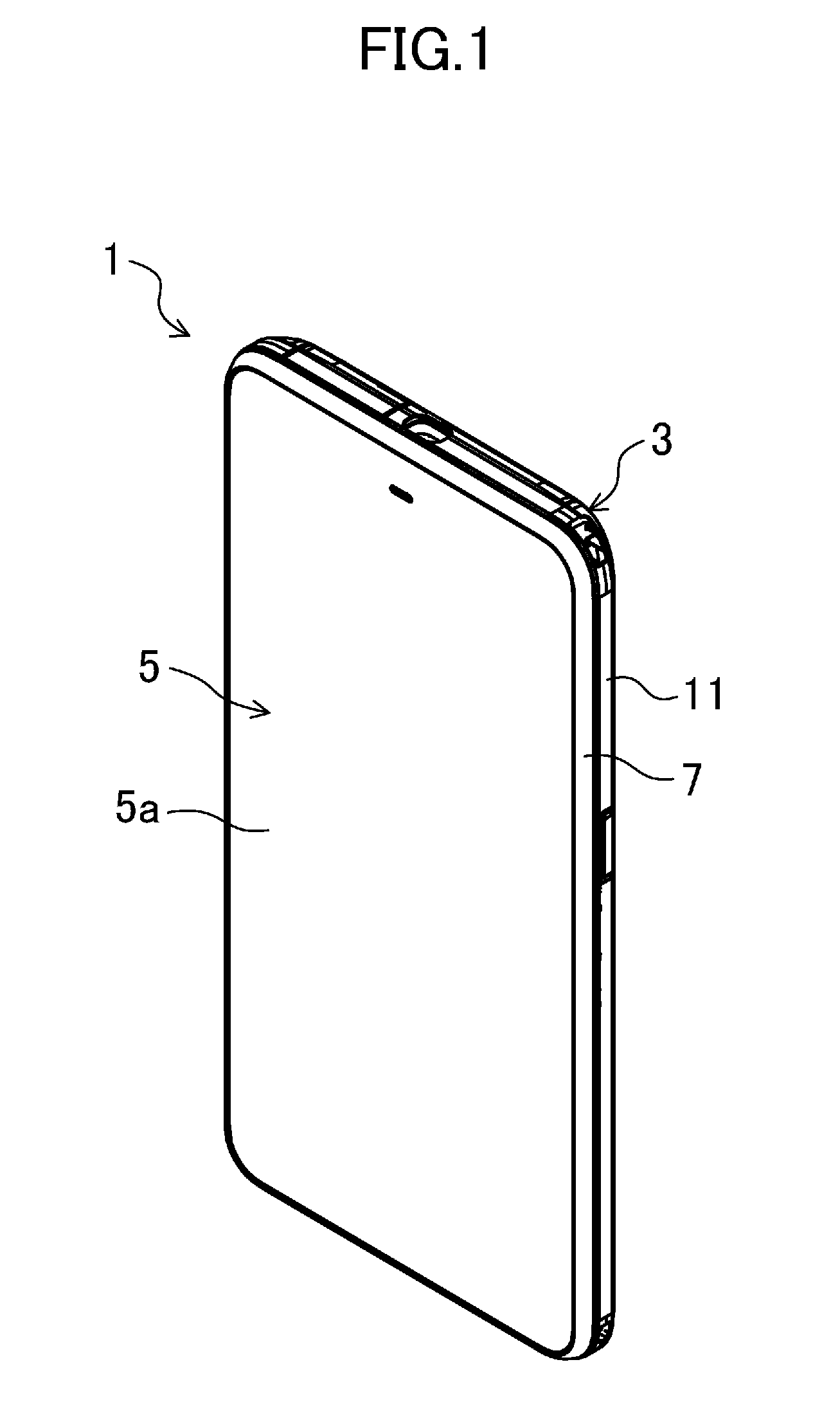

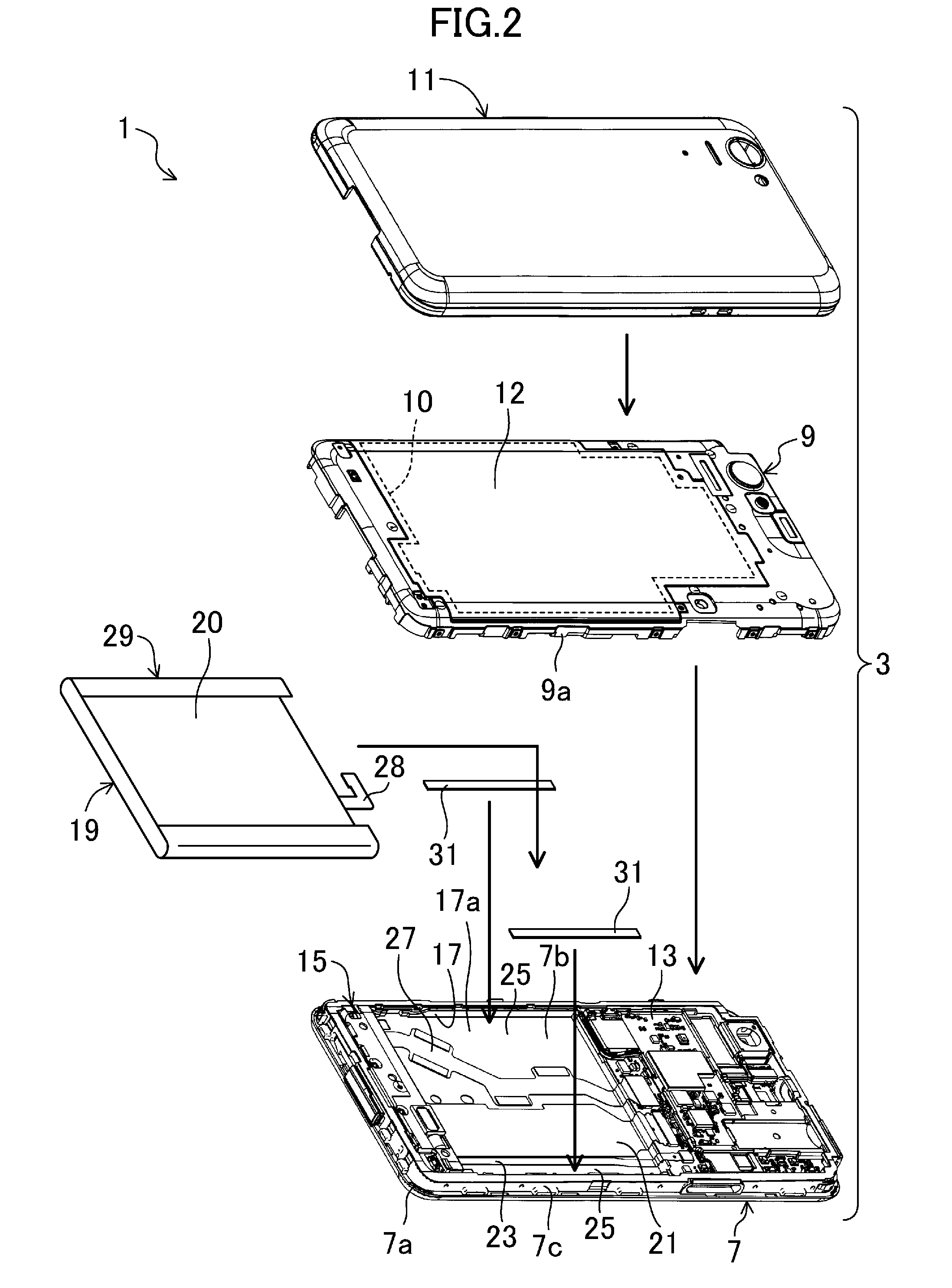

Mobile device

Owner:SHARP KK

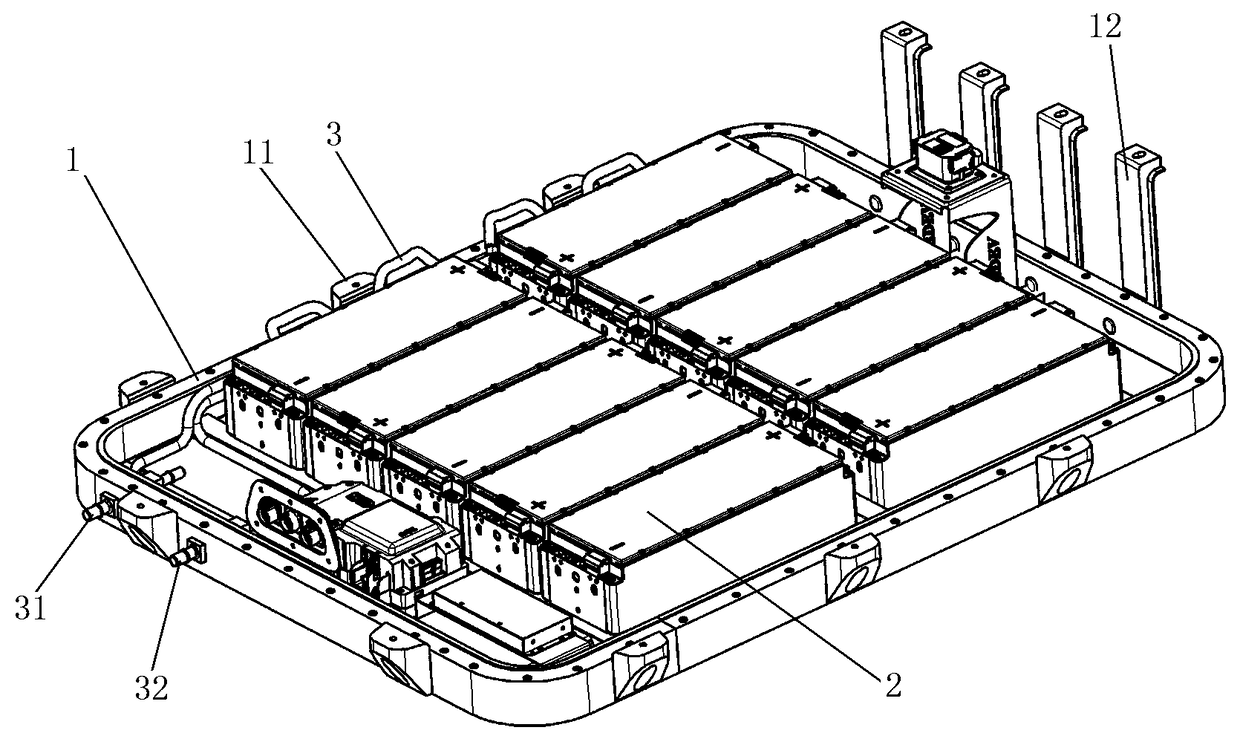

Device for cooling a heat source of a motor vehicle

InactiveUS20110174004A1Domestic cooling apparatusCompression machines with non-reversible cycleEngineeringMechanical engineering

Owner:BEHR GMBH & CO KG

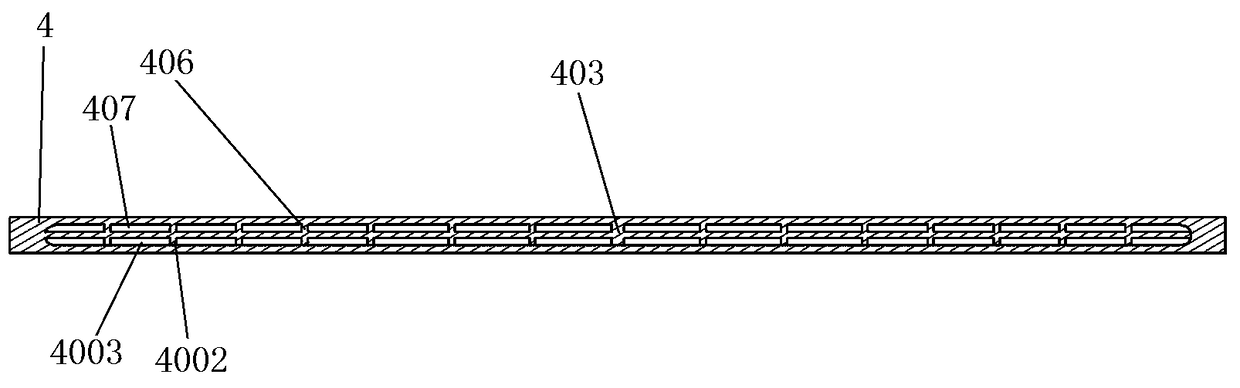

Electric vehicle, battery box body thereof, and battery box

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

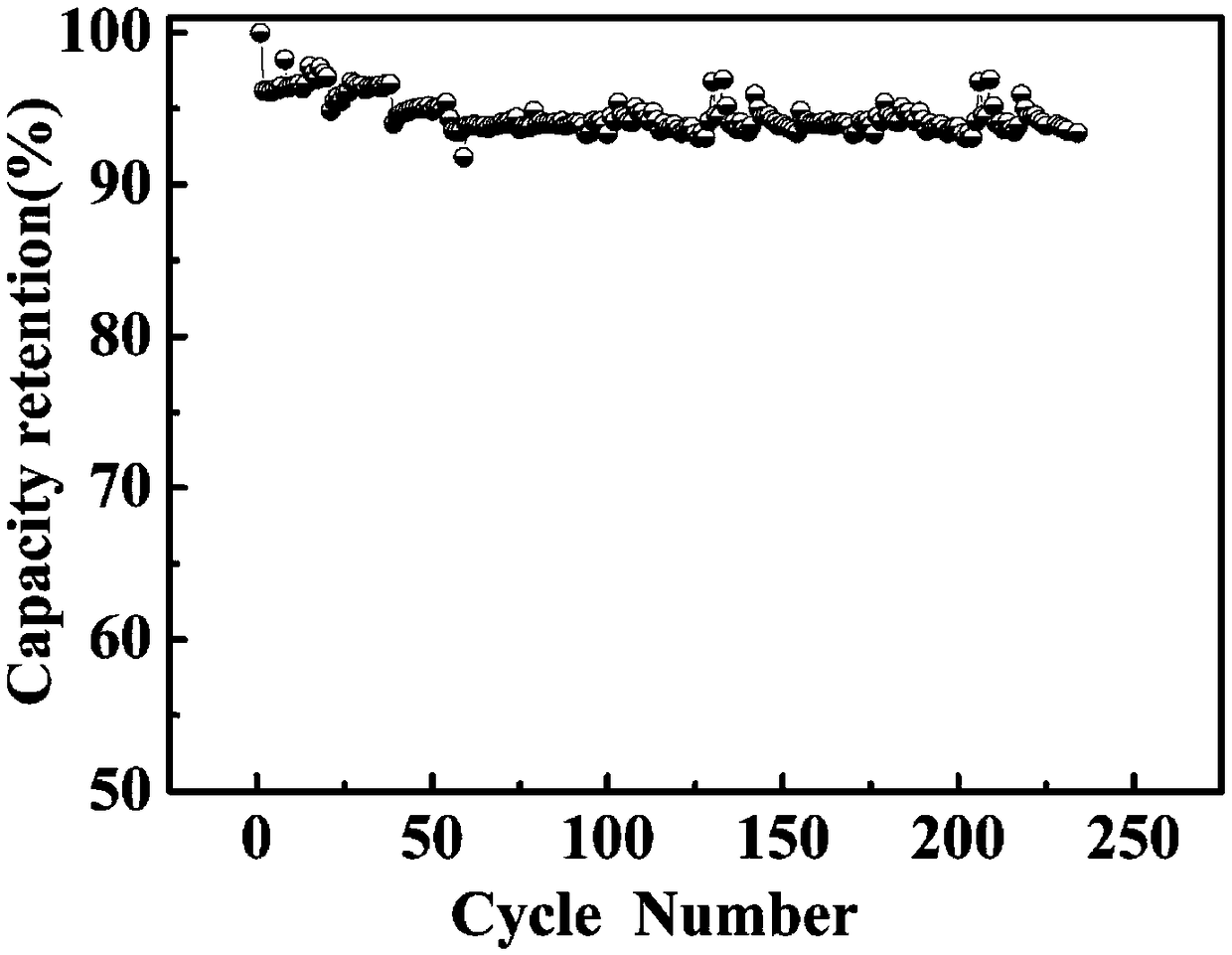

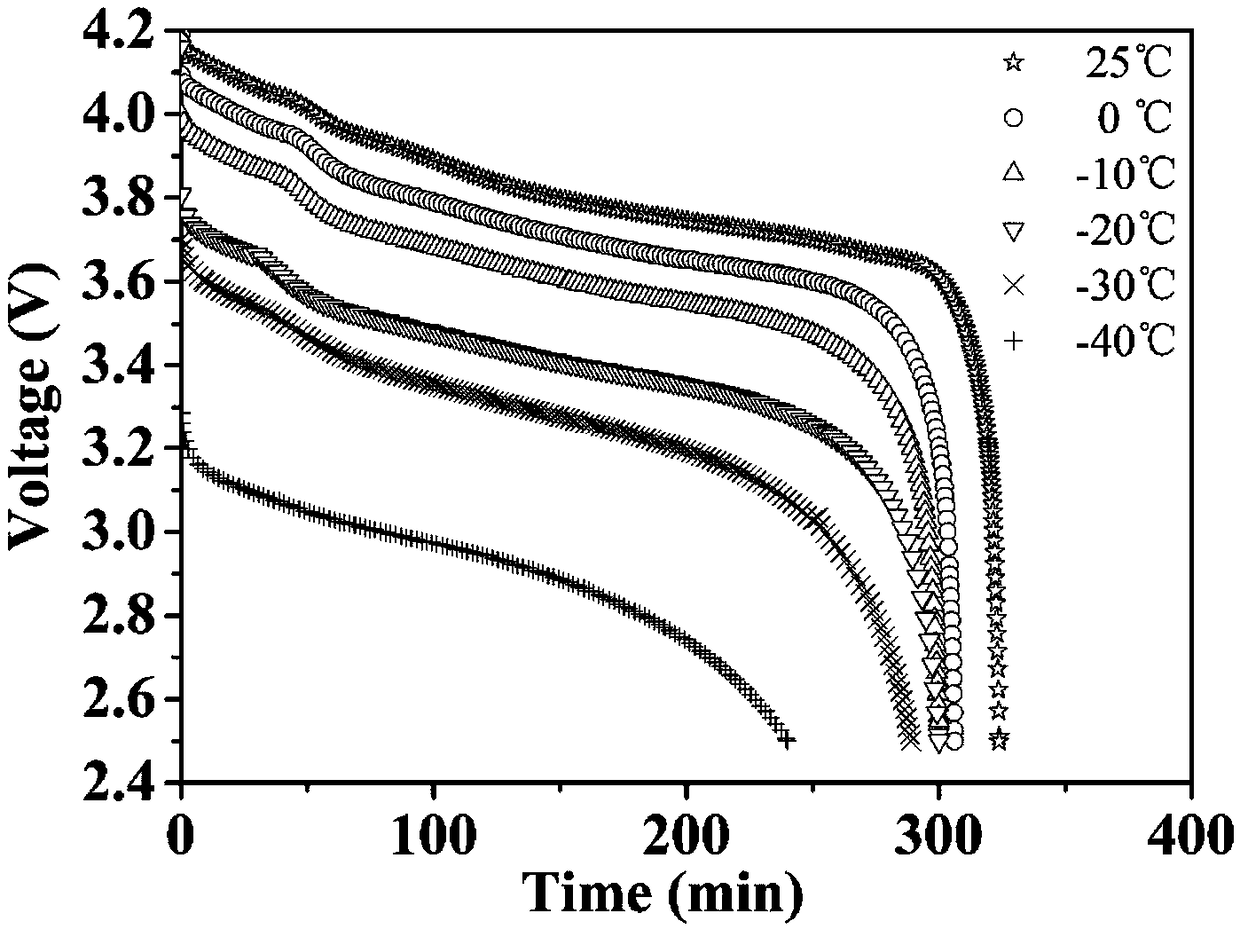

Graphite negative electrode material of low-temperature lithium ion battery and preparation method thereof

Owner:CENT SOUTH UNIV

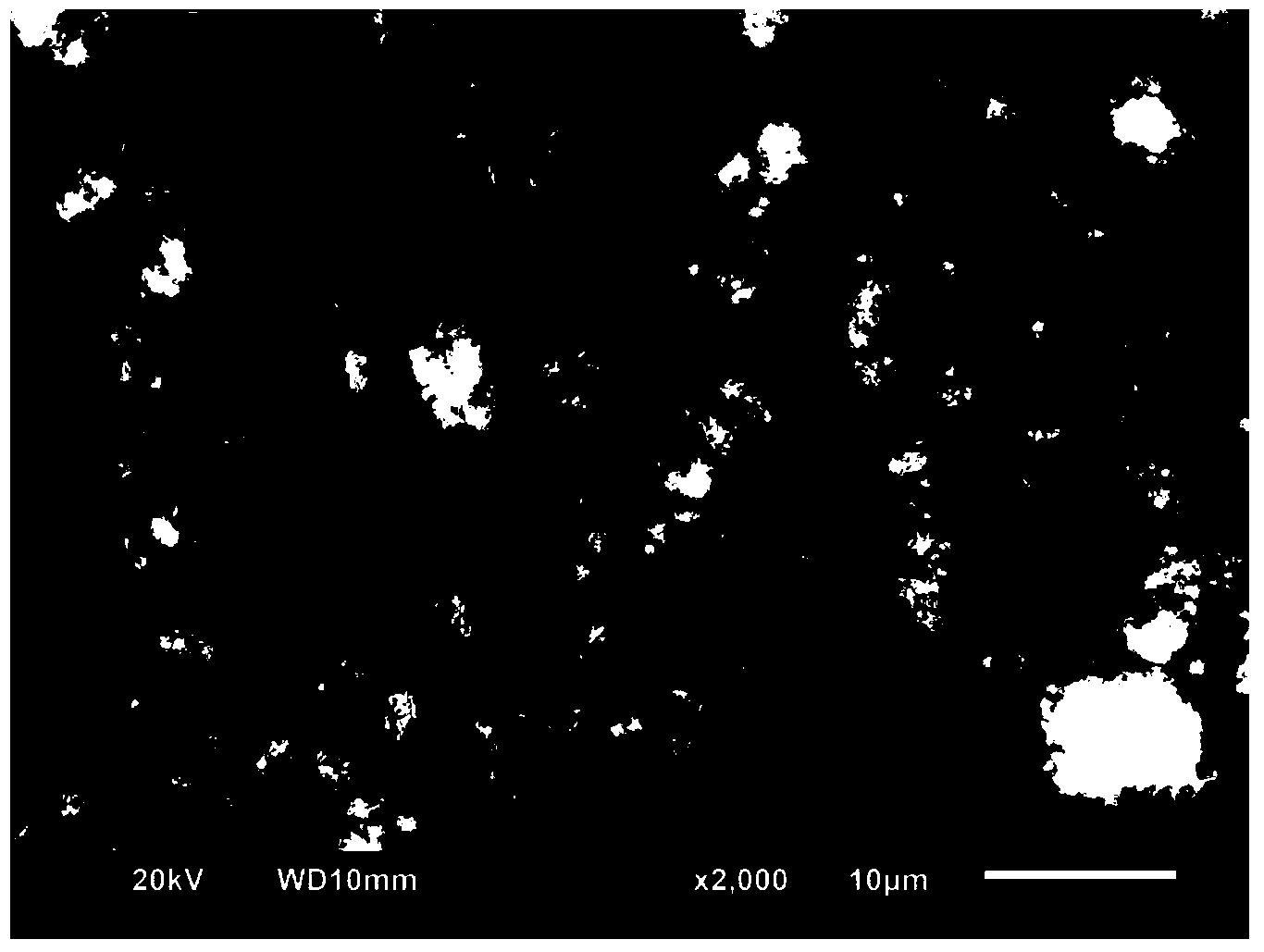

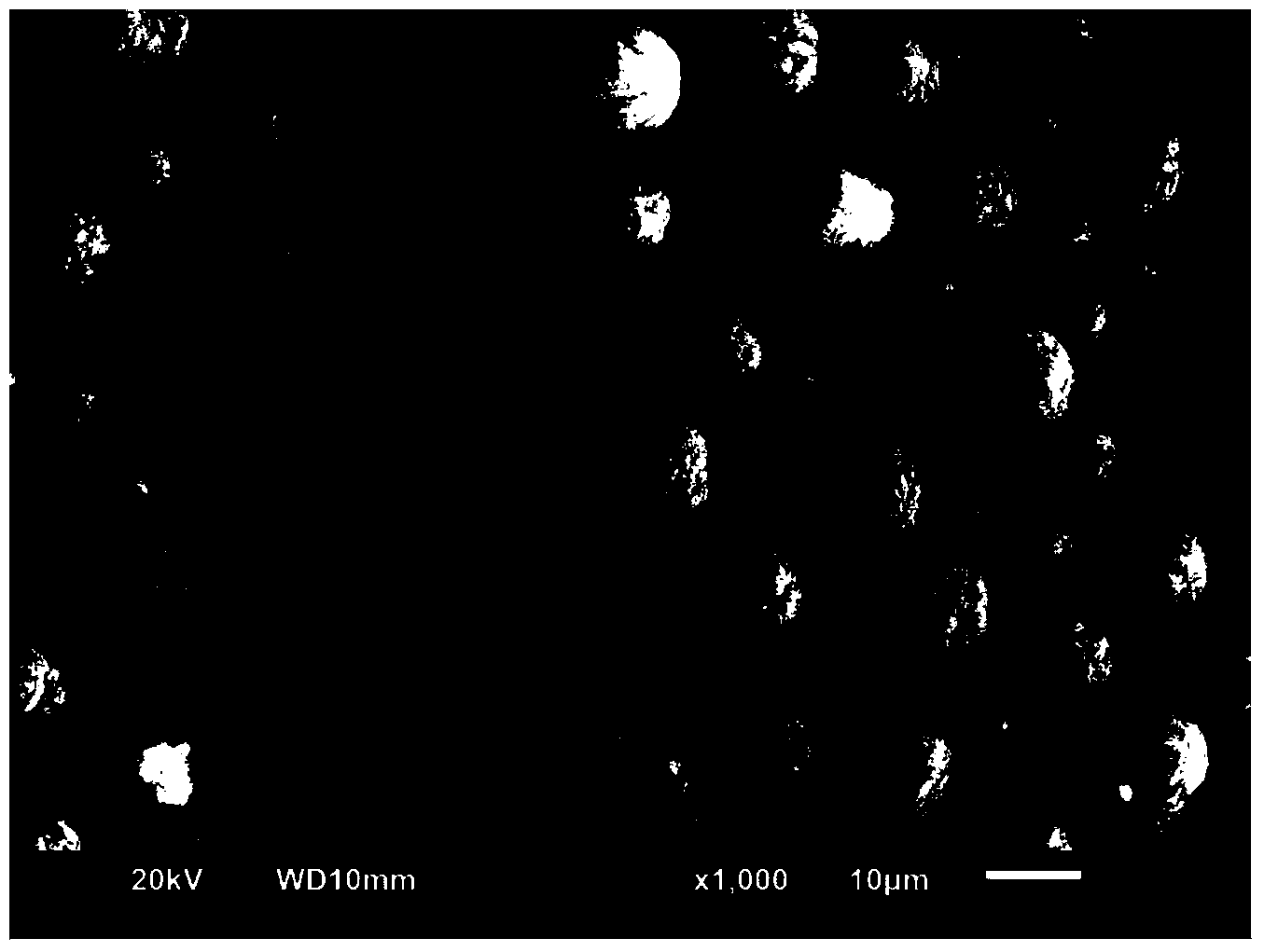

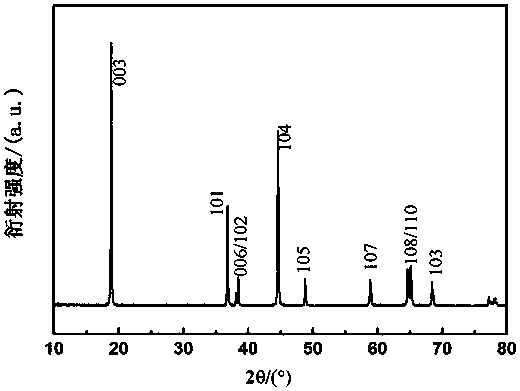

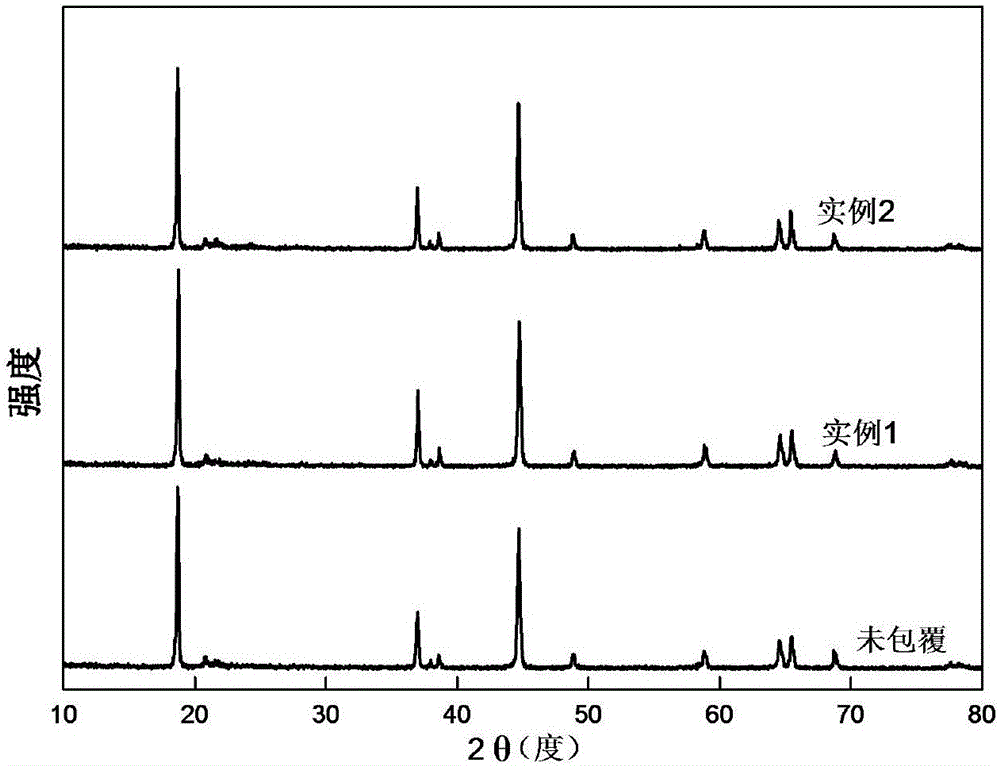

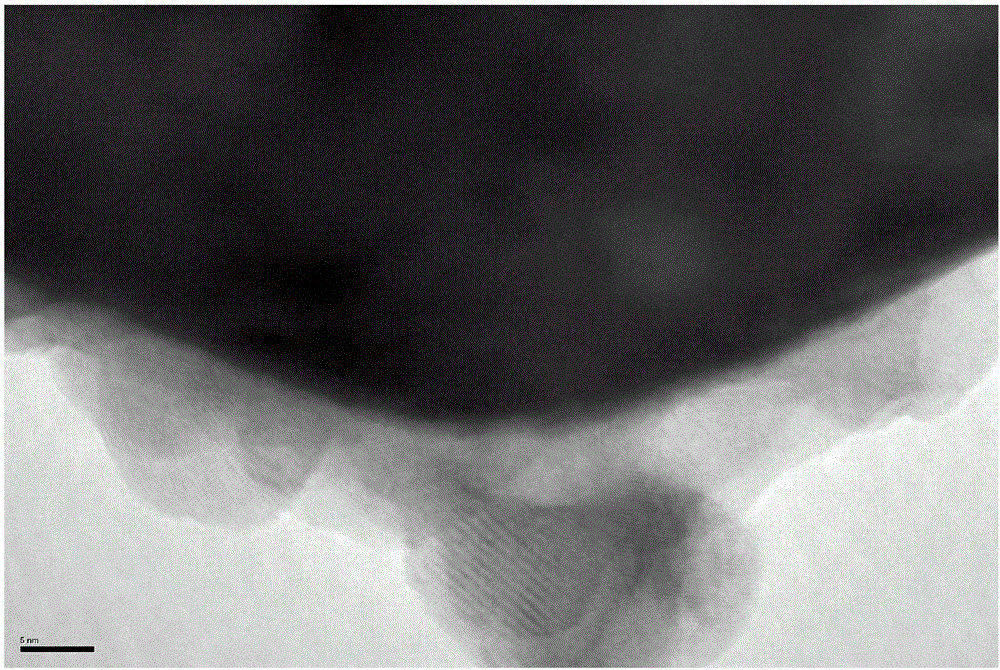

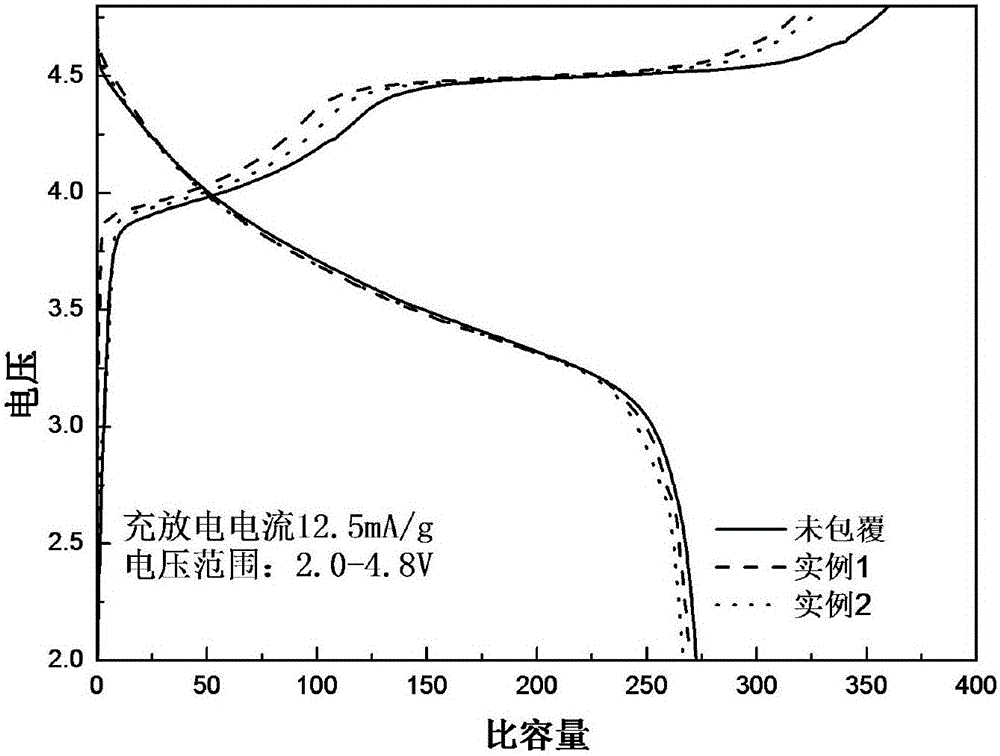

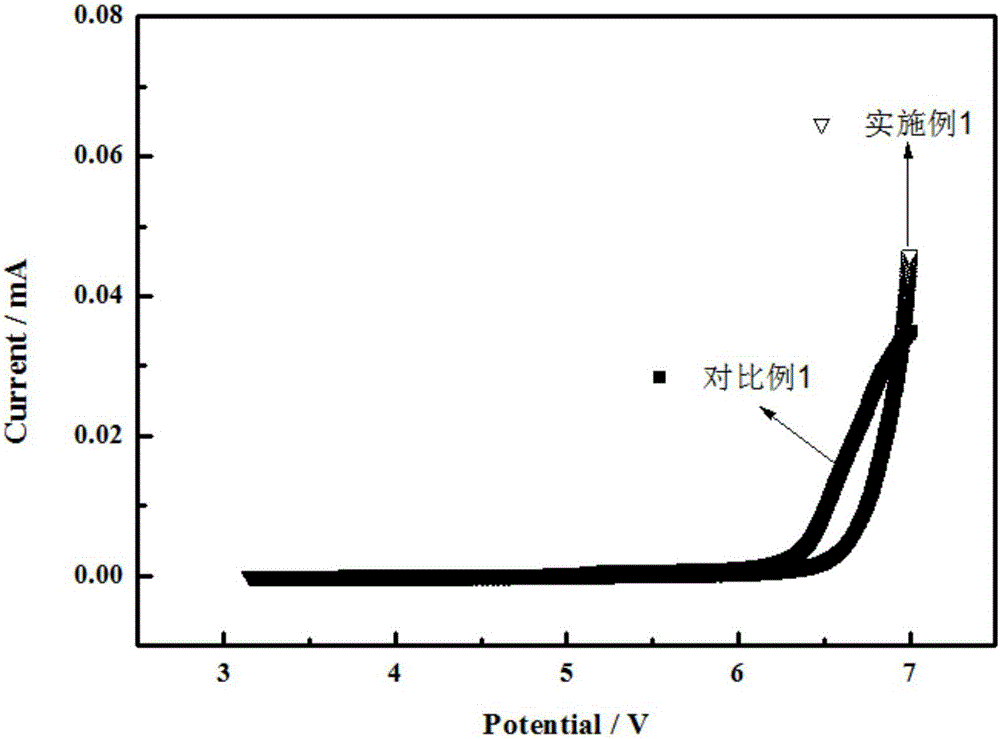

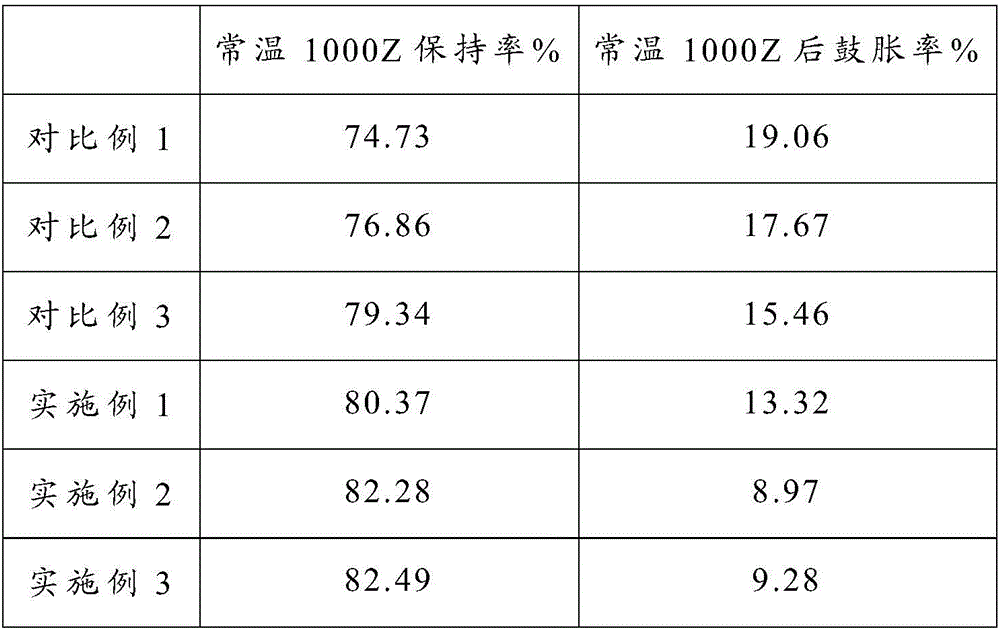

LiAlO2 coated LiNi1-xCoxO2 lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105185954AImprove thermal stabilityGood discharge specific capacityCell electrodesSecondary cellsPower batteryElectrical battery

The present invention belongs to the field of lithium-ion batteries, and provide a modified lithium-ion battery positive electrode material LiNi1-xCoxO2@LiAlO2 with high thermal-stability LiAlO2 coated on the LiNi1-xCoxO2 surface, and a preparation method thereof. A purpose of the present invention is to overcome the disadvantages of overcharging intolerance and pool thermal-stability of the lithium-ion battery LiNi1-xCoxO2 (x is more than 0 and is less than or equal to 0.5) positive electrode material. According to the present invention, the positive electrode material of the present invention has characteristics of good thermal-stability, good discharge specific capacity and excellent cycle stability compared with the LiNi1-xCoxO2 positive electrode material, can meet the large rate charge and discharge requirements, and is especially suitable for the positive electrode material of the electric vehicle power battery; and the product prepared through the preparation method has characteristics of high purity, high chemical uniformity, good coating effect, high crystal quality, fine particle, uniform distribution, excellent electrochemical performance and low manufacturing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Popular searches

Electric power Non-aqueous electrolyte accumulator electrodes Vehicular energy storage Emergency protective arrangements for limiting excess voltage/current Electric variable regulation Material analysis by electric/magnetic means Conductive material Non-conductive material with dispersed conductive material Transmission Vehicle heating/cooling devices

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap