Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Internal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A practical electrical power source which is a linear electric circuit may, according to Thévenin's theorem, be represented as an ideal voltage source in series with an impedance. This impedance is termed the internal resistance of the source. When the power source delivers current, the measured voltage output is lower than the no-load voltage; the difference is the voltage drop (the product of current and resistance) caused by the internal resistance. The concept of internal resistance applies to all kinds of electrical sources and is useful for analyzing many types of electrical circuits.

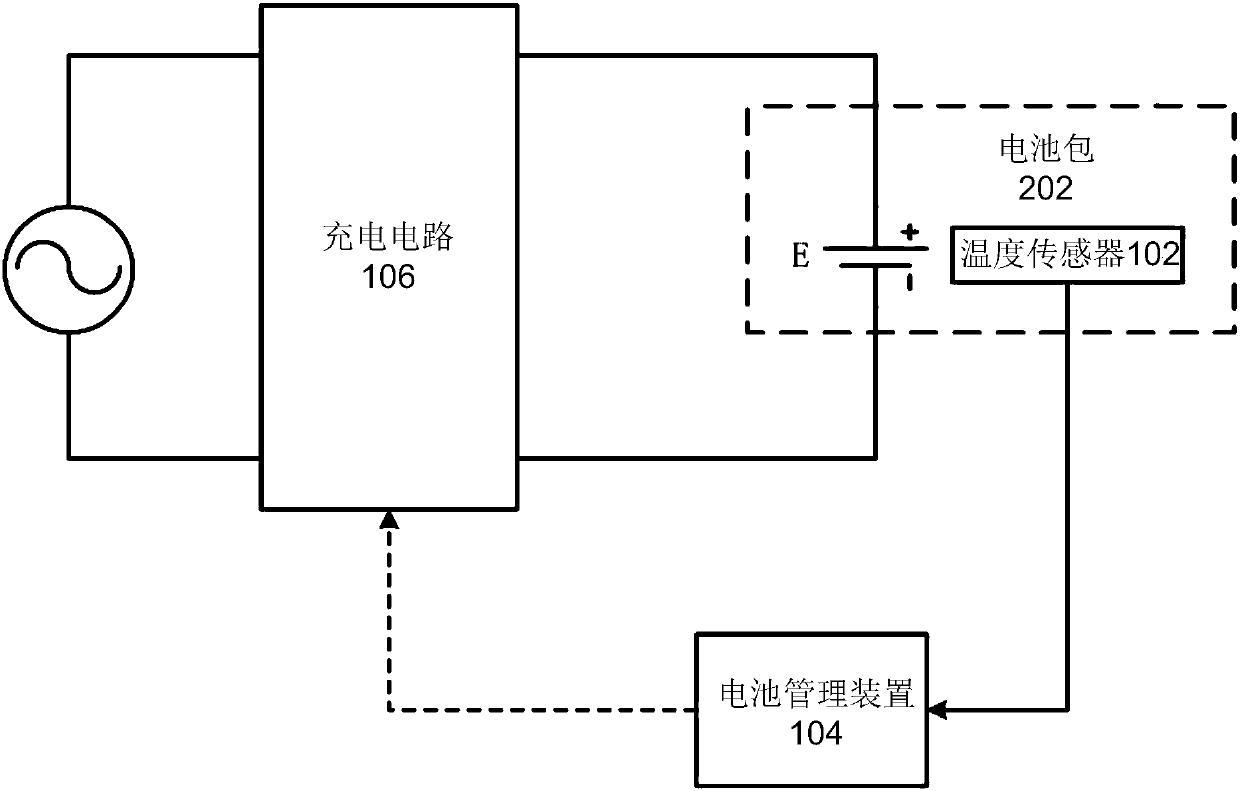

Device and method of testing an internal resistance of a battery pack

ActiveUS20110101986A1High measurement accuracyCurrent/voltage measurementElectrical testingElectrical resistance and conductanceInternal resistance

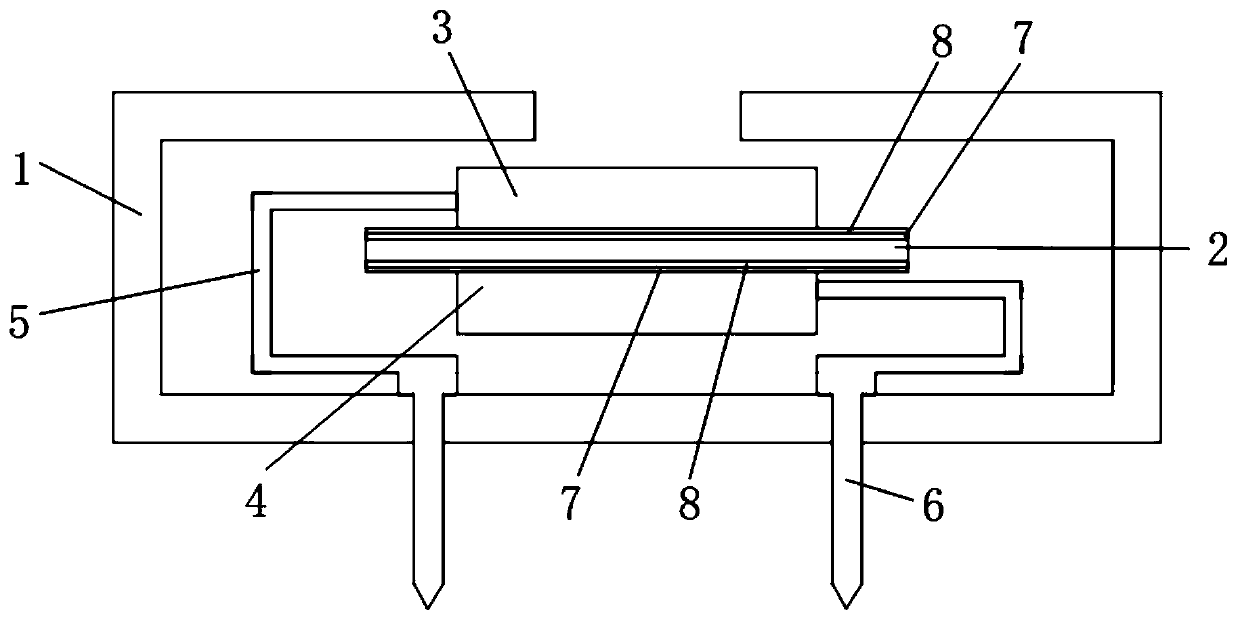

An internal resistance testing device includes an excitation source and a battery pack, an adjustable resistance R, a sampling unit, and a control unit. The excitation source and the battery pack form a loop circuit. The adjustable resistance R may be located at the loop circuit formed by the excitation source and the battery pack. The sampling unit samples the voltage between two sides of the battery pack, the voltage between two sides of the adjustable resistance R, and the value of the adjustable resistance R. The control unit calculates internal resistance of the battery pack according to the signal value collected by the sampling unit. The internal resistances of different voltage-ranges the battery pack are determined by adjusting the value of the adjustable resistance R to cause the actual excitation voltage to be equal to the range voltage of the sampling unit. The voltage between two sides of the adjustable resistance R is made equal to the range voltage of the sampling unit by adjusting the value of the adjustable resistance R, which effectively improves measurement accuracy of the internal resistance.

Owner:BYD CO LTD

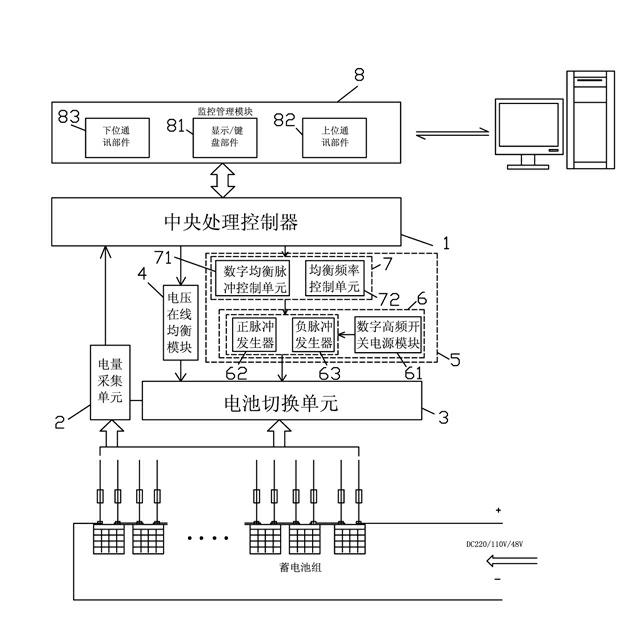

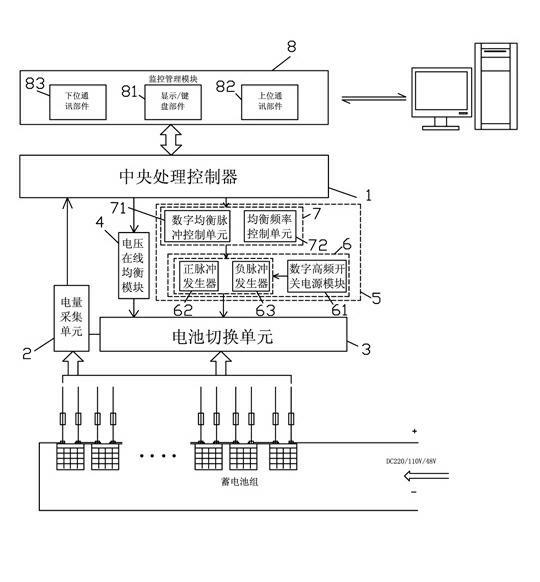

Accumulator battery online equalizing system

ActiveCN102136751AIncreased operating lifeImprove reliabilityBatteries circuit arrangementsElectric powerElectricitySocial benefits

Owner:ZHUHAI LONL ELECTRIC

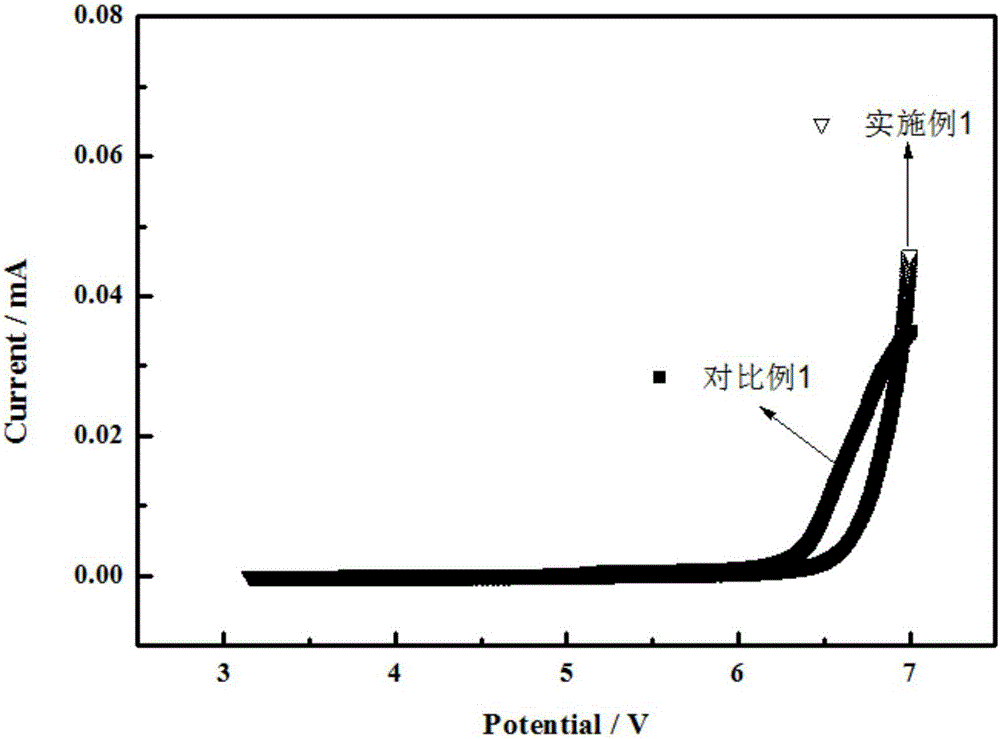

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

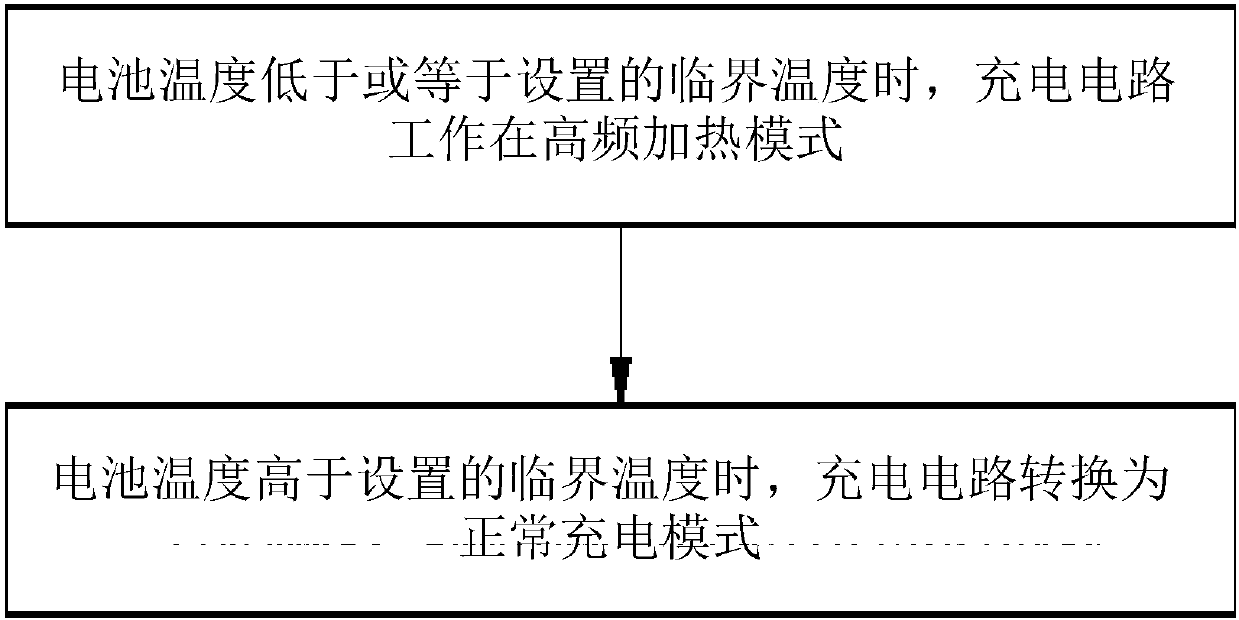

Heating circuit of battery

PendingCN107845840ADoes not affect the normal charging functionRealize low temperature heating functionBatteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryInternal resistance

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

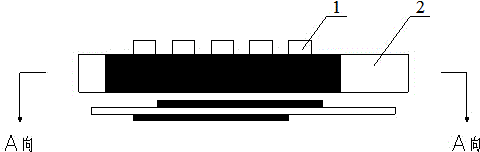

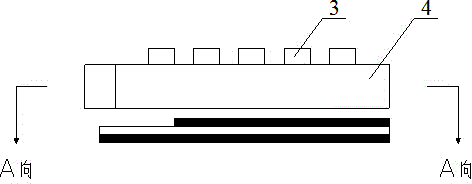

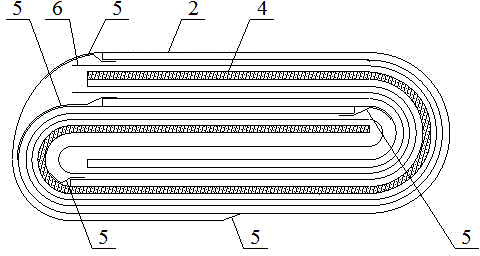

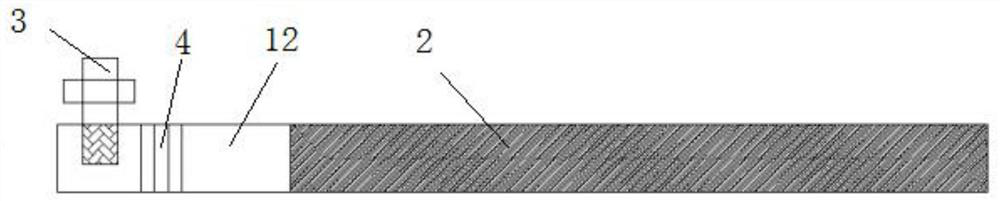

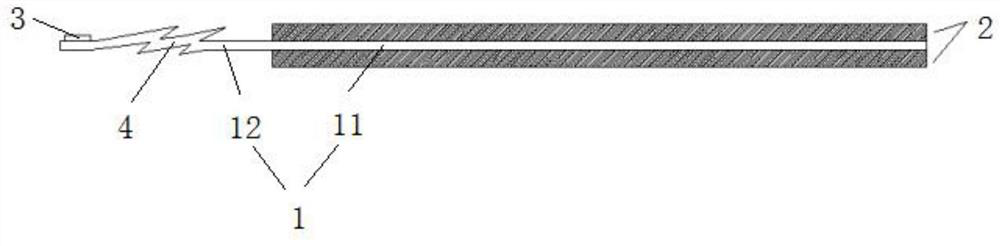

Manufacturing method of winding type lithium ion battery and winding type lithium ion battery

InactiveCN104681878AIncrease productivityImprove securityFinal product manufactureSecondary cellsPower flowInternal resistance

Owner:王文斌

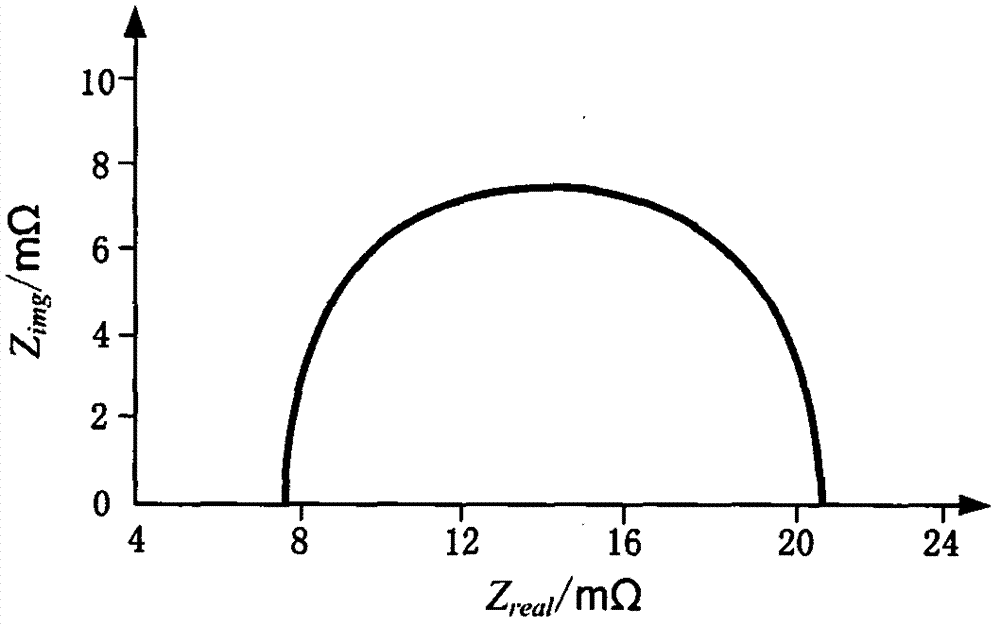

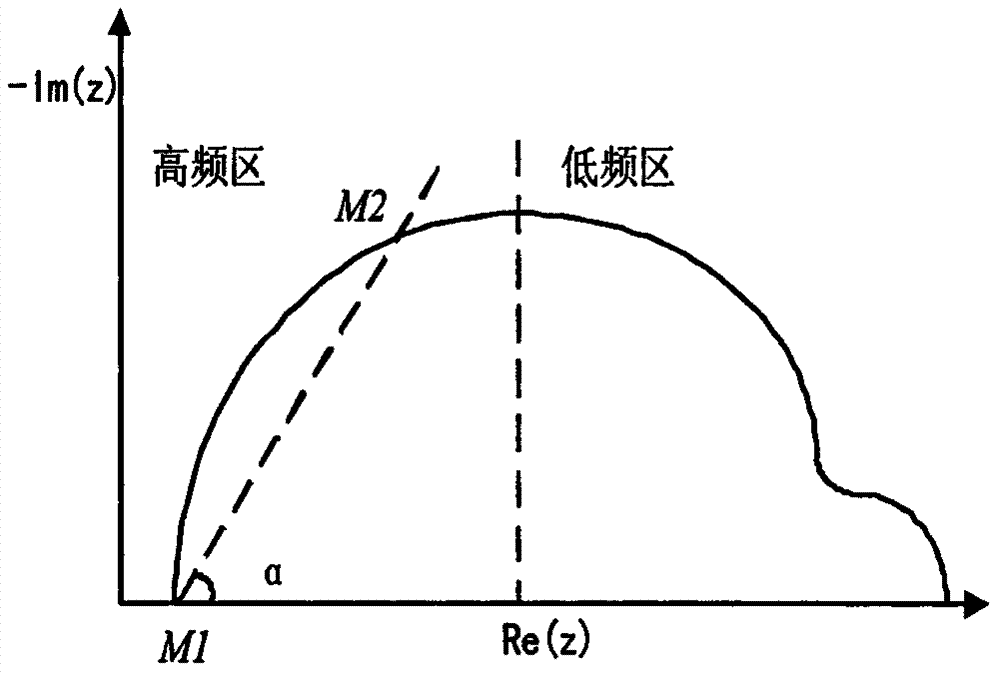

Method for optimizing PEMFC output performance based on frequency secant angle method

InactiveCN107391817AImprove output performanceOvercoming the large hysteresisElectrical testingDesign optimisation/simulationHysteresisInternal resistance

Owner:CHINA JILIANG UNIV

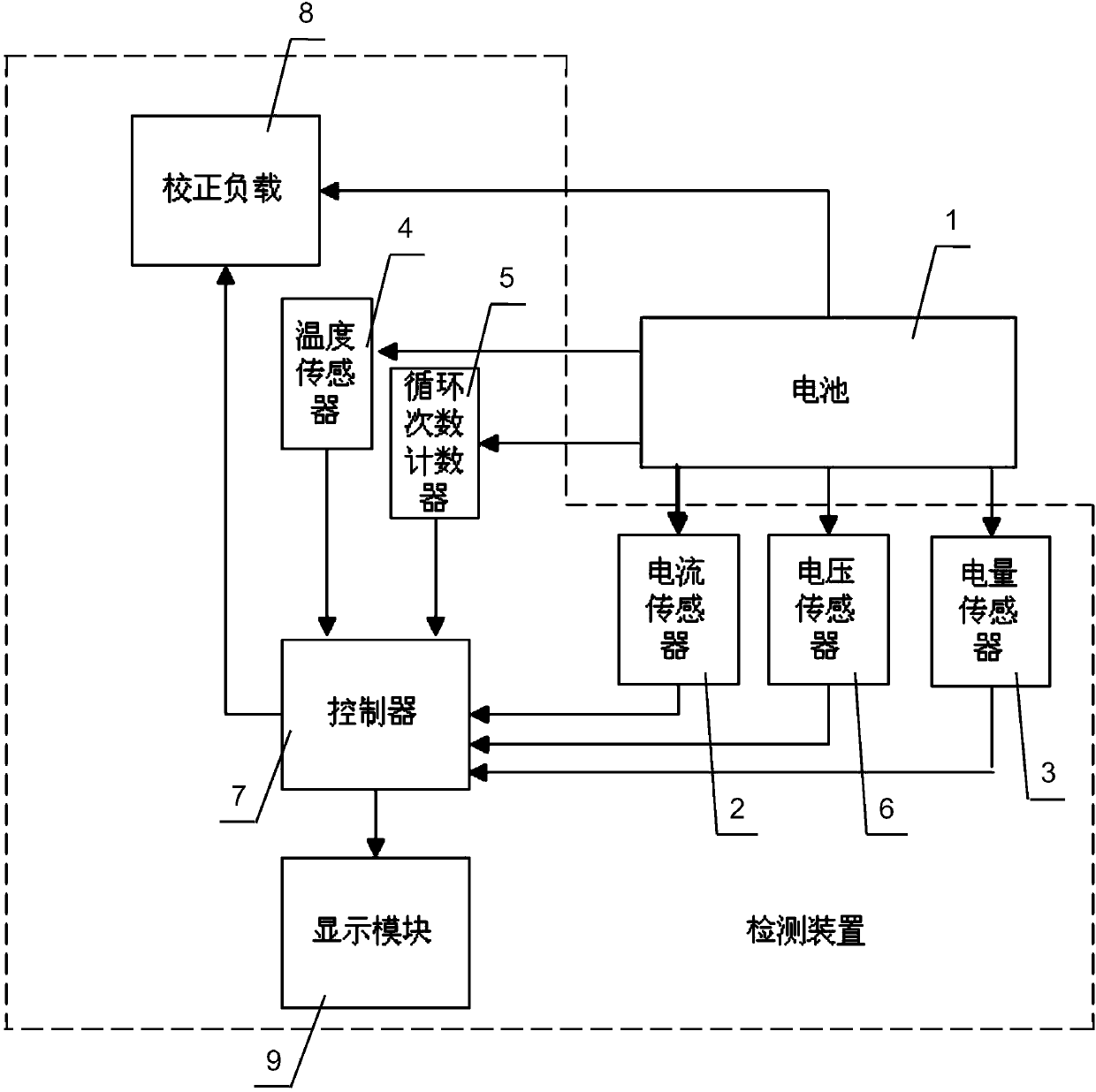

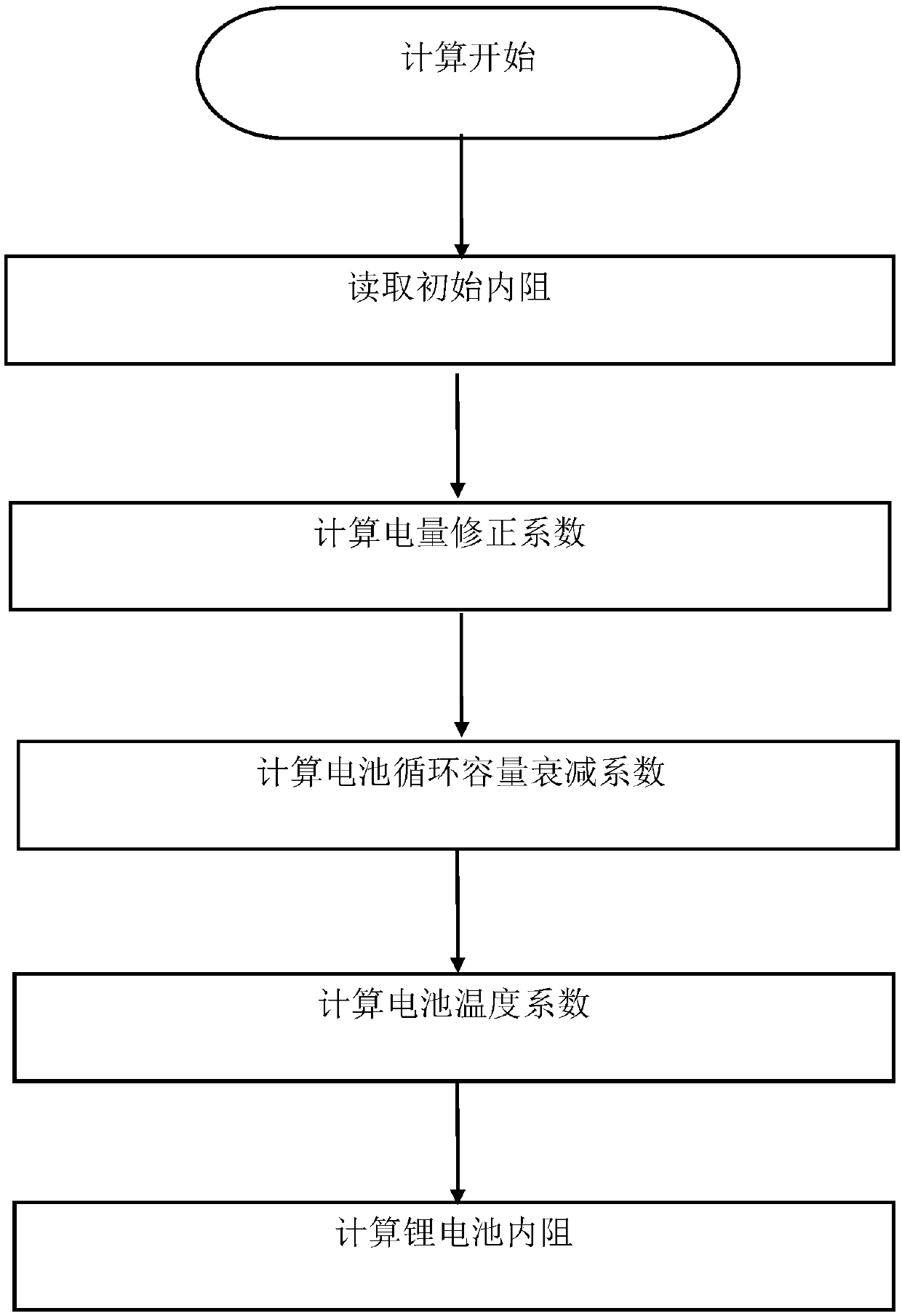

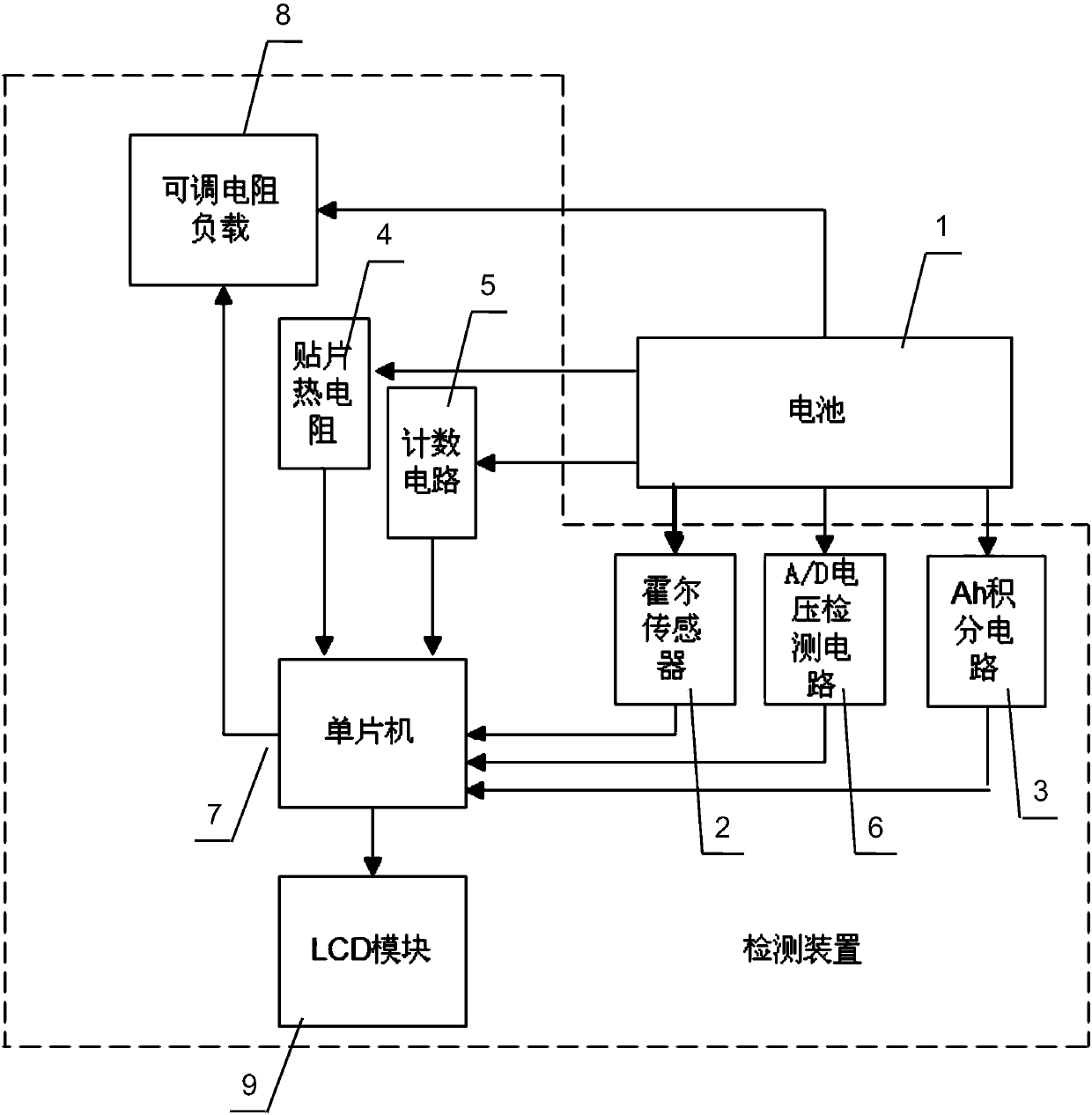

Online self-learning measurement device for internal resistance of lithium battery and measure method thereof

ActiveCN110133528AHigh precisionImprove robustnessElectrical testingMeasurement deviceTerminal voltage

Owner:BAOSHAN IRON & STEEL CO LTD

Lithium ion battery positive pole pieceand preparation method thereof

InactiveCN112928240AImprove conductivityEasy to prepareCell electrodesSecondary cellsInternal resistancePole piece

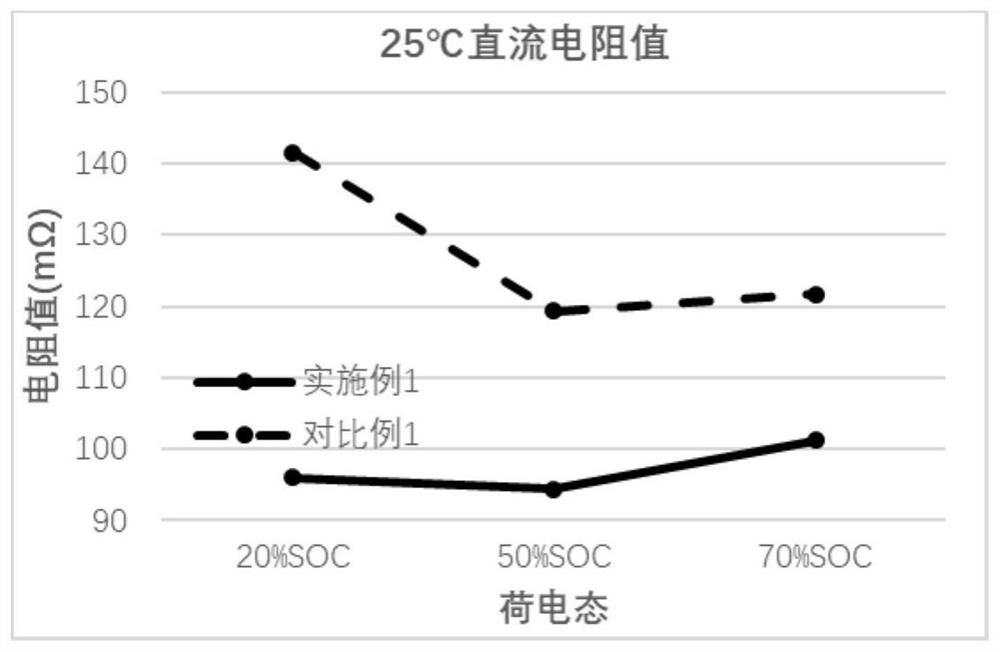

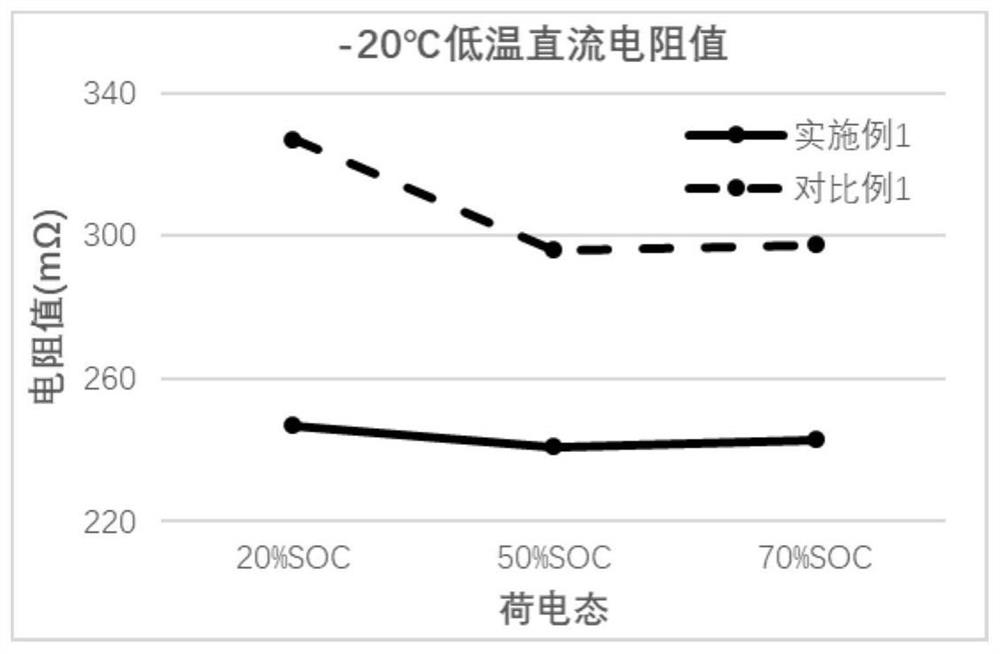

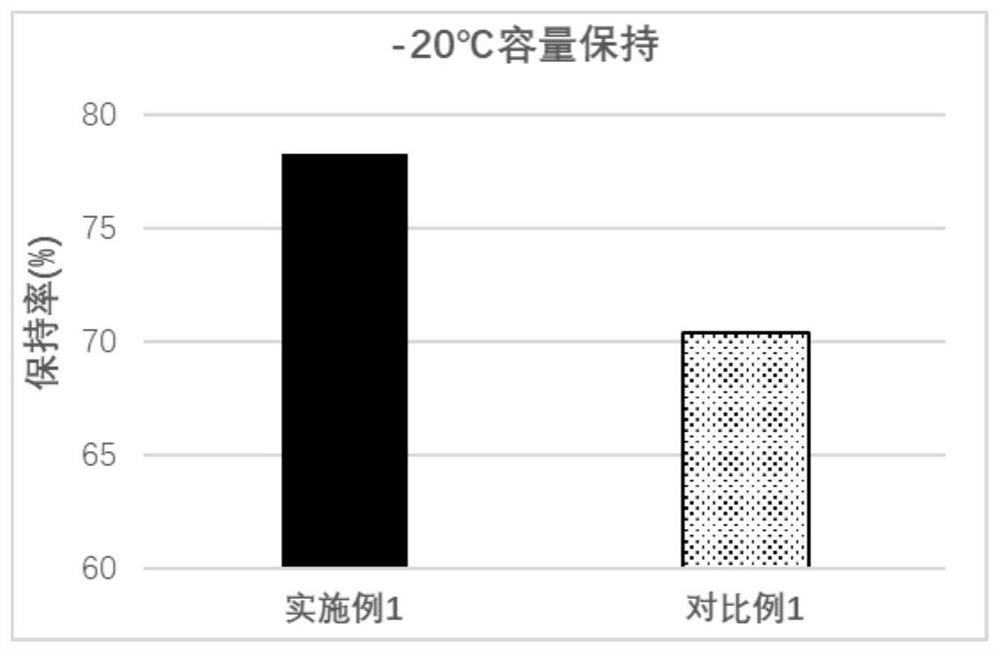

The invention provides a lithium ion battery positive pole piece, which comprises a positive current collector, a conductive coating layer and an active slurry layer, wherein the conductive coating layer and the active slurry layer are sequentially coated on the positive current collector, and the active slurry layer comprises, by mass, 95% of a LiFePO4 active substance, 2.8% of a conductive agent and 2.2% of a binder; the conductive coating layer comprises the following components in percentage by mass: 10% of a conductive agent, 2% of a binder, 1% of ethanol, 1% of acetone and 86% of deionized water; the binder is polyvinylidene fluoride, the conductive agent is conductive carbon black, and the positive active substance is LiFePO4. The preparation method is simple, the conductivity of the pole piece can be effectively improved, the lithium ion transfer impedance in the battery is obviously reduced, the direct-current internal resistance of the battery is obviously reduced, and the cycling stability of the battery can be improved.

Owner:JIANGSU PYLON BATTERY CO LTD

Battery pack charging method, apparatus and equipment

ActiveCN107359377AExtended service lifeSecondary cells charging/dischargingVehicular energy storagePower batteryCharge current

The invention discloses a battery pack charging method, apparatus and equipment. The battery pack charging method comprises the steps of setting a charging current value I<n> in each charging stage of a charging process; when the structure of the battery pack is a series branch of a battery module, calculating a charging cut-off voltage value corresponding to I<n> in the n charging stage based on the maximum internal resistance value of the battery module; when the structure of the battery pack is a series branch of a cell, calculating a charging cut-off voltage value corresponding to I<n> in the n charging stage based on the maximum internal resistance value of the cell; and in the (n-1) charging stage, charging the battery pack by I<n-1>, when the charging voltage of the battery pack reaches V<n-1> and when (n-1) is smaller than the set total number of charging stages, entering the n charging stage, and when the charging voltage of the battery pack reaches V<n-1> and when (n-1) is equal to the set total number of charging stages, stopping charging. By virtue of the battery pack charging method provided by the embodiments, battery pack charging safety can improved, and the service life of the power battery can be prolonged.

Owner:CONTEMPORARY AMPEREX TECH CO LTD

Cylinder lithium battery

InactiveCN103296245ALower internal resistanceImprove discharge rateCell component detailsInternal resistancePole piece

The invention discloses a cylinder lithium battery, which belongs to the field of lithium battery. The invention solves the problems of over high internal resistance and insufficient discharge rate of the lithium battery in the prior art. The cylinder lithium battery comprises an anode pole piece and a cathode pole piece, and the cathode pole piece is provided with a first cathode tab, and the cathode pole piece is provided with a second cathode tab. After the lithium battery cathode is arranged with the second cathode tab, the internal resistance of the lithium battery decreases 1 / 3, thereby the discharge rate of the lithium battery increases correspondingly, and the output power of the lithium battery increases.

Owner:ZHEJIANG NUOCISS NEW ENERGY TECH

Pole piece for button battery, button battery and production method thereof

PendingCN112635774AAvoid breakingElectrode rolling/calenderingFinal product manufactureButton batteryInternal resistance

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

Preparation method of thick-film lithium battery and thick-film lithium battery

InactiveCN113013374AHigh degree of bindingReduce the ratioElectrode rolling/calenderingFinal product manufactureInternal resistanceHigh energy

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a thick-film lithium battery and the prepared lithium ion battery. The preparation process of the lithium ion battery comprises the following steps: covering a current collector with positive and negative electrode materials in a coating manner, then carrying out rolling treatment, combining a diaphragm with the positive and negative electrodes into a complete battery cell in a winding or lamination manner, and packaging the battery cell to obtain the thick-film lithium battery. The positive and negative current collectors adopt a latticed structure, so that the electron transmission rate in the electrode is improved, the internal resistance of the battery is greatly reduced, and meanwhile, the overall cost of the battery is further reduced and the energy density is improved by adopting the high-coating-amount electrode. The preparation process is simple, the repeatability is good, and large-scale production can be realized.

Owner:ZHEJIANG GODSEND POWER TECH

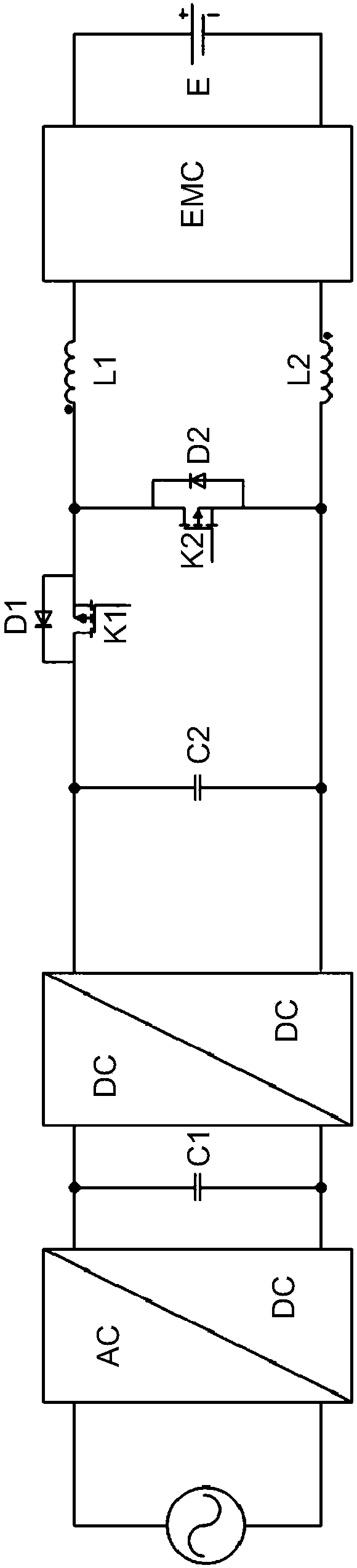

Input surge current suppression circuit and method of capacitor

ActiveCN114006362AEnhanced inhibitory effectDoes not affect power supplyEmergency protective arrangements for limiting excess voltage/currentCapacitanceInternal resistance

The invention discloses an input surge current suppression circuit and method of a capacitor, and relates to the technical field of power electronics. The input surge current suppression circuit comprises a variable resistance circuit, a detection control unit is arranged for the conduction internal resistor of a field effect transistor Q1 in the variable resistance circuit, the detection control unit is used for detecting the flowing surge current, and when the surge current is greater than a set value, the variable resistance circuit is immediately recovered to high resistance, so that the energy storage capacitor branch is cut off from the load of the input power supply, and the input surge current is suppressed. The input surge current suppression circuit is simple, low in cost, good in power-on surge current suppression effect and high in universality.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Novel formaldehyde sensor

InactiveCN110208340ASmall form factorAvoid exceptionMaterial electrochemical variablesInternal resistanceProton

Owner:深圳市安诺意环境技术有限公司

Positive electrode material and preparation method and application thereof

PendingCN114122379ALifting ionsImprove conductivityPolycrystalline material growthCell electrodesElectrical batteryInternal resistance

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

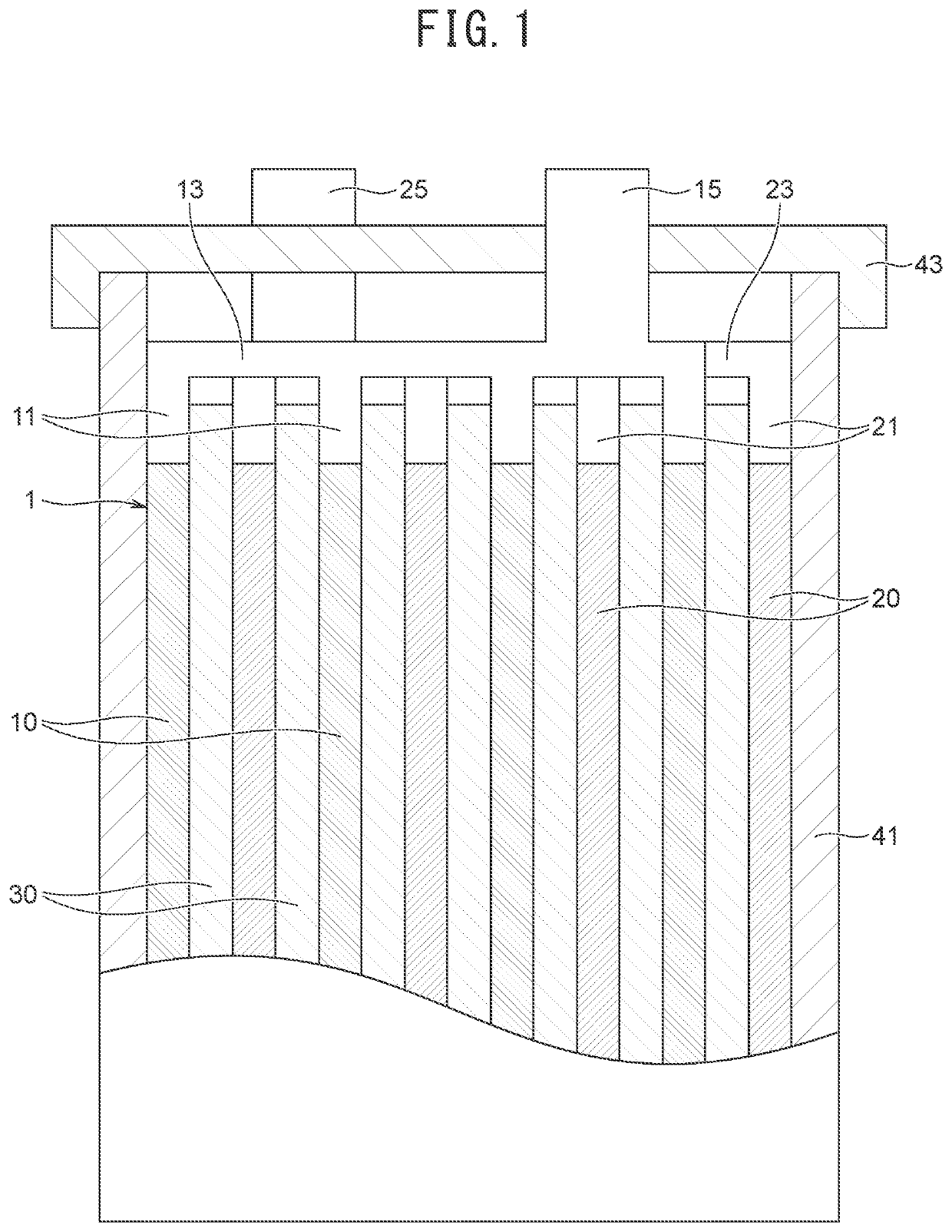

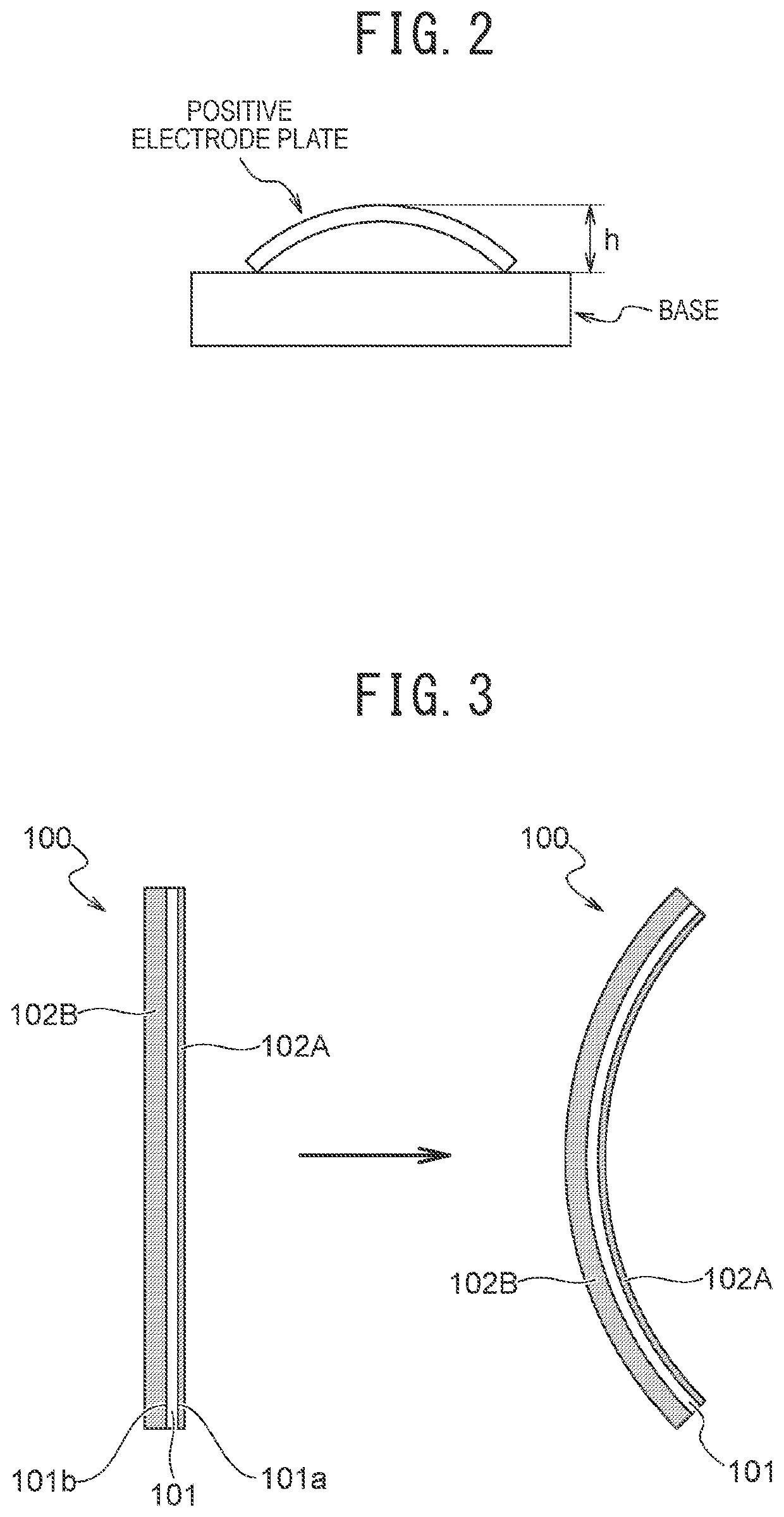

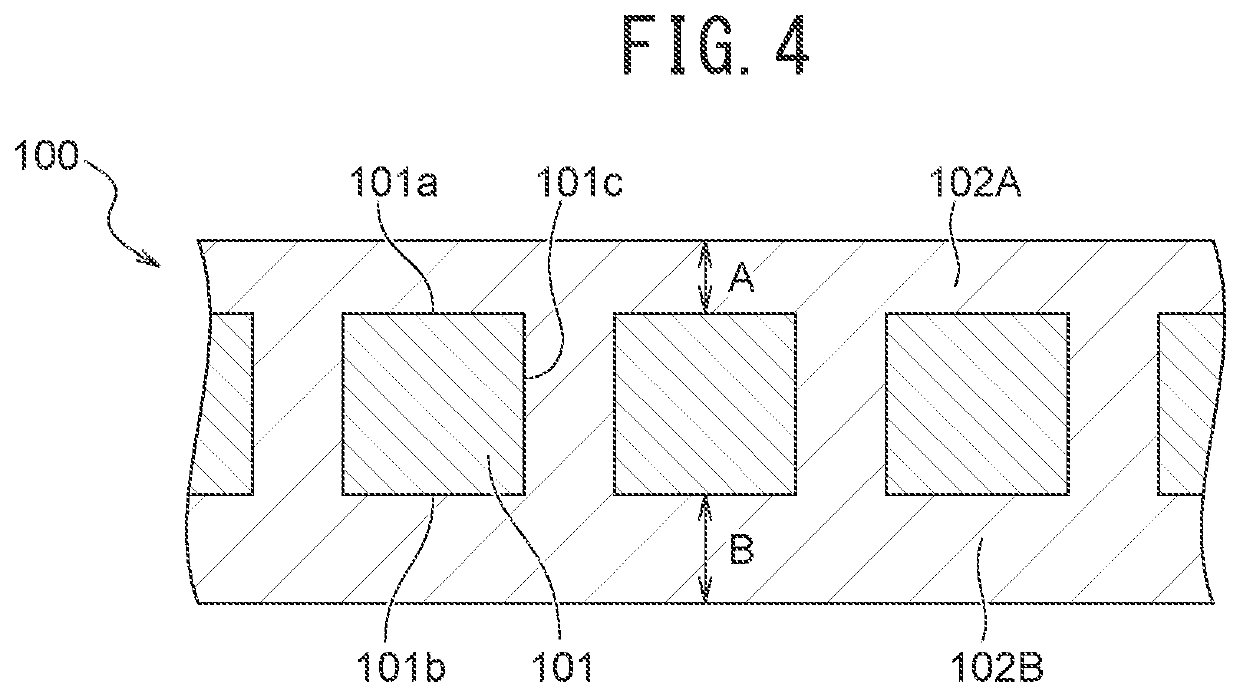

Lead Storage Battery

PendingUS20210167363A1Suppress increaseAccurately determineFinal product manufactureElectrode carriers/collectorsElectrolytic agentLead dioxide

Owner:THE FURUKAWA BATTERY CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap