Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72 results about "Measurement device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measuring device - instrument that shows the extent or amount or quantity or degree of something. gauge, gage - a measuring instrument for measuring and indicating a quantity such as the thickness of wire or the amount of rain etc.

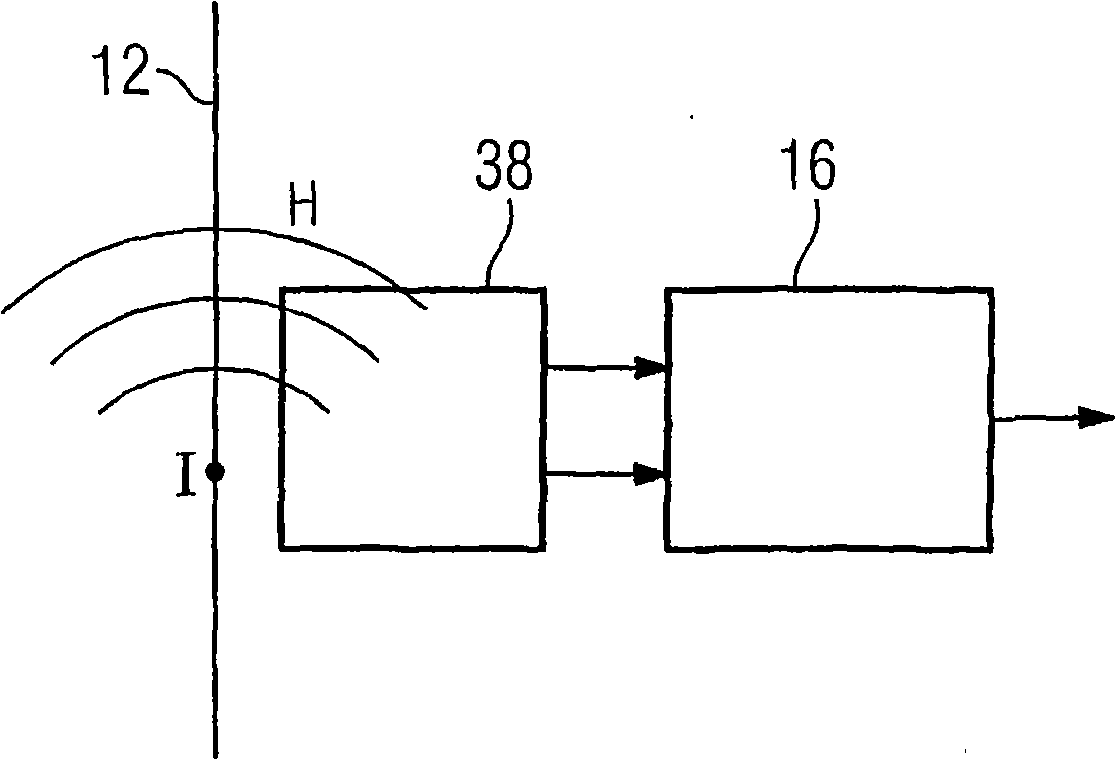

Sample measurement device, sample measurement system and sample measurement method

ActiveUS20100283488A1Reduce measurement errorImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceVoltage source

A sample measurement device (110), in which a biosensor (30) having an electrode is mounted, voltage is applied to the electrode, and the concentration of a specific component in a sample deposited on the biosensor (30) is measured, comprises a voltage source (19) configured to apply voltage to the electrode, a time measurement component (22), and a controller (18) configured to control the voltage to be applied and measure the concentration of the specific component. The time measurement component (22) measures a detection time, which is the length of time between the mounting of the biosensor (30) and the deposition of a sample on the biosensor (30). The controller (18) changes a set value for measuring the concentration of a specific component according to the detection time. Consequently, measurement accuracy can be improved regardless of the temperature of the biosensor (30).

Owner:PHC HLDG CORP

Method and device for measuring tunnel lining cracks

ActiveCN101957178ALow costQuick fixImage analysisUsing optical meansMeasurement deviceImage segmentation

The invention relates to a method for measuring tunnel lining cracks. The method comprises the following steps of: acquiring an image of a crack by a digital camera and measuring the acquisition distance by a laser ranger; selecting an area needing to be measured from the acquired image so as to prevent processing deviation due to excessively big picture and relatively small target crack, and changing the selected area into a gray image; determining a threshold for the selected gray image and performing binarization image division to obtain a target area; extracting a white area only comprising the crack from the target area; extracting the border of the crack to obtain a border graph; calculating the pixel width of the crack by a minimum distance method; and obtaining the actual width of the crack according to a predetermined calibration proportion between the actual pixel size and the photographing distance. The method has the advantages of low cost, high speed, convenient carrying and high measurement precision.

Owner:SHANGHAI TONGYAN CIVIL ENGINEERING TECHNOLOGY CORP LTD

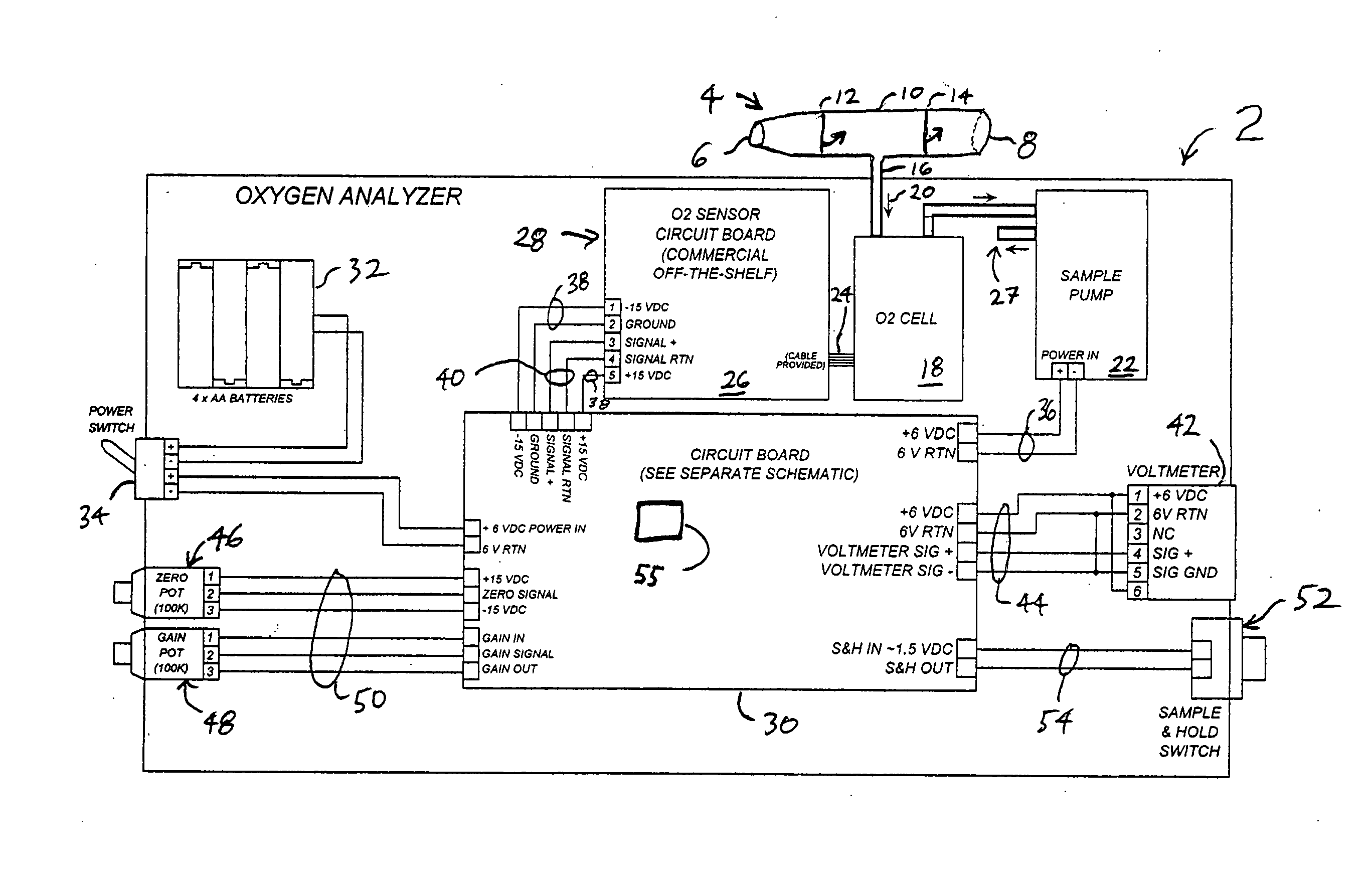

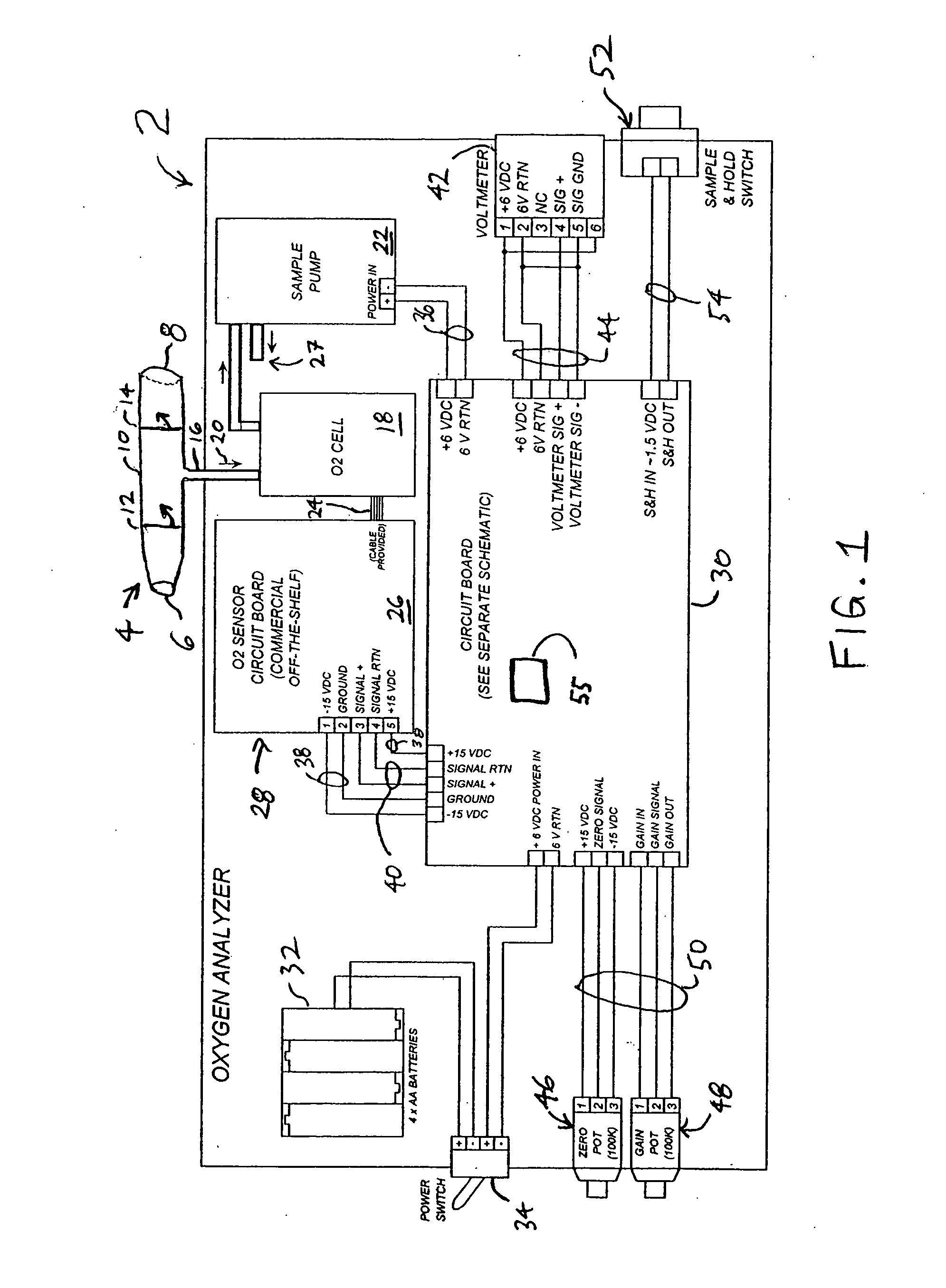

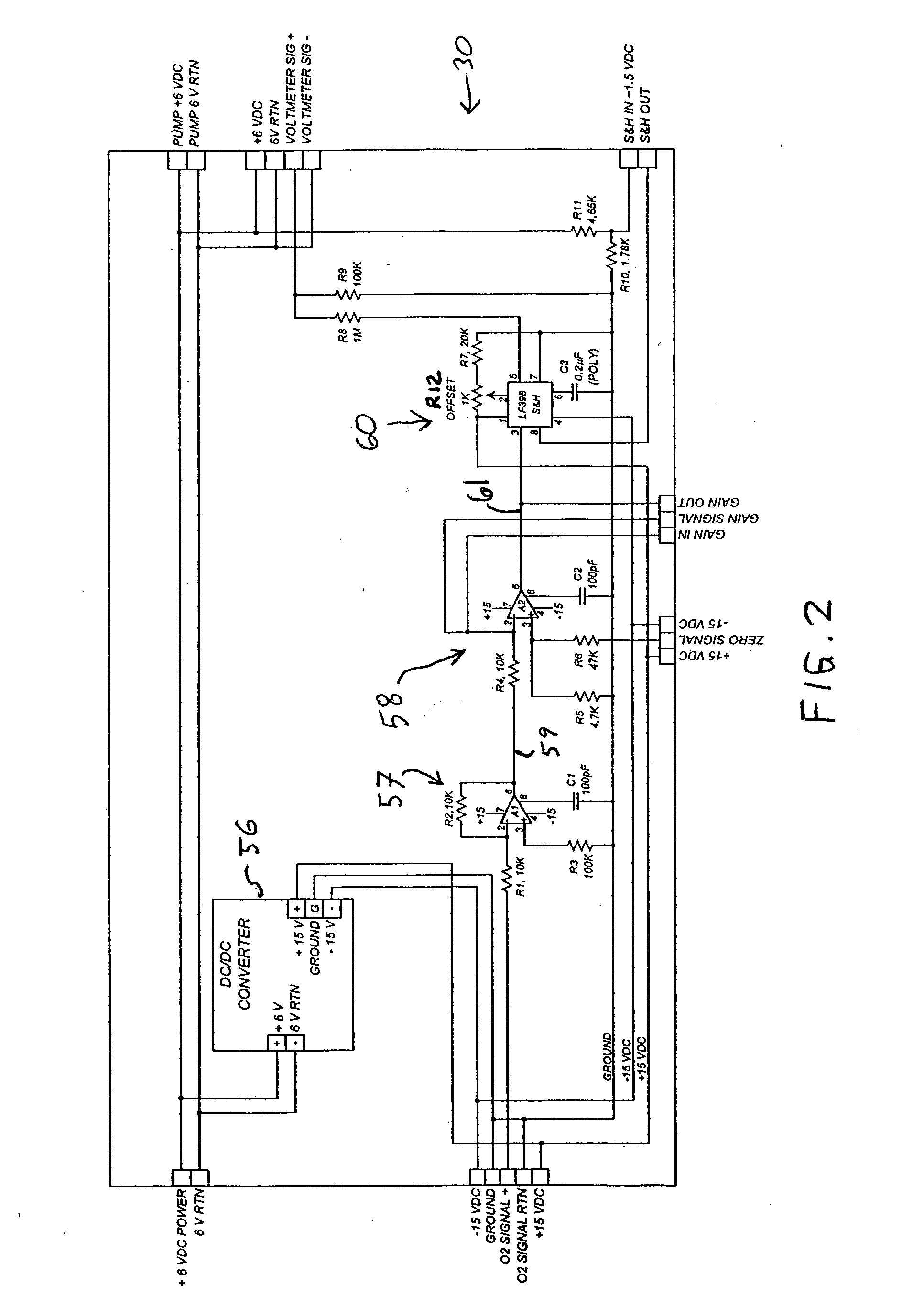

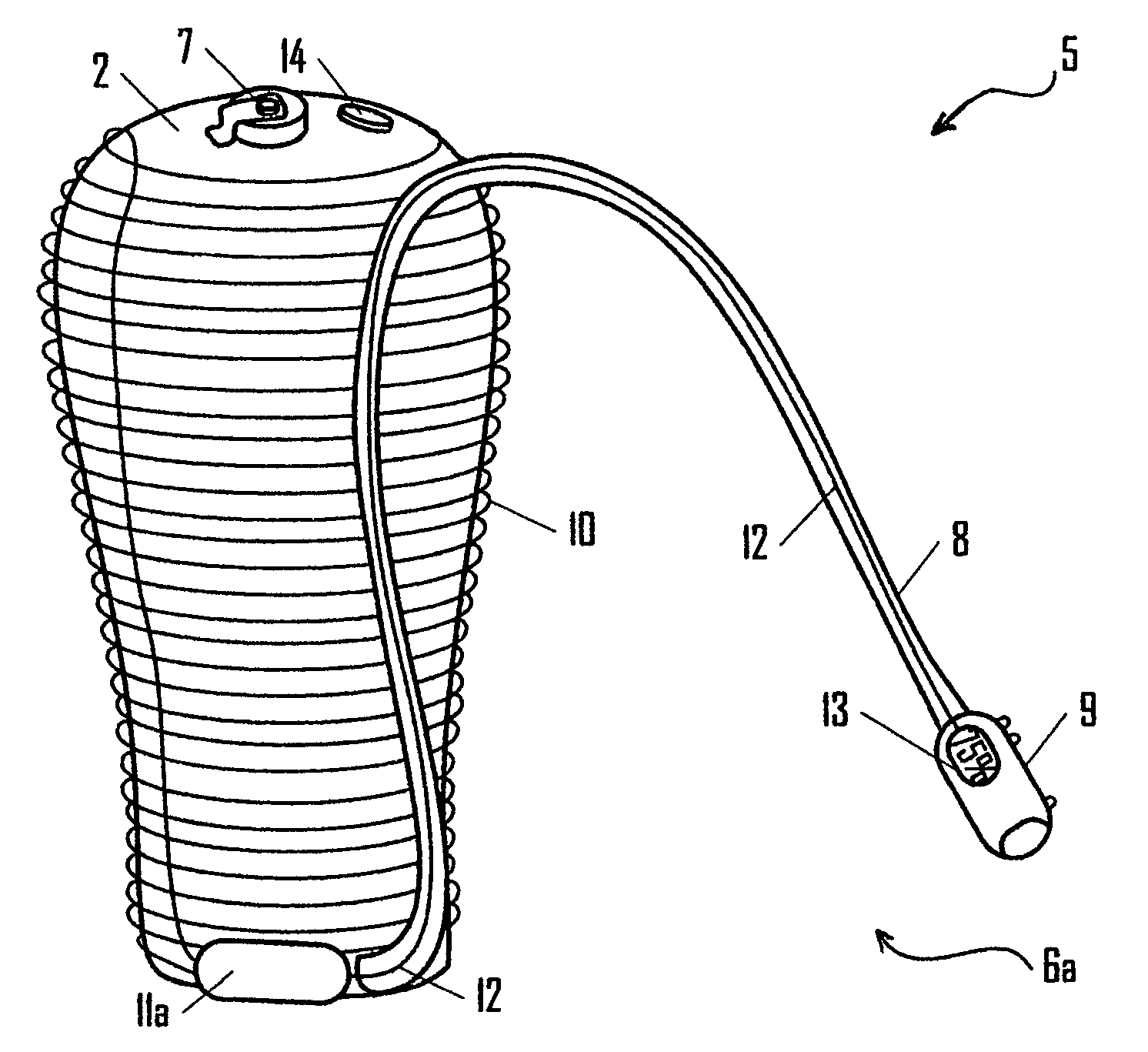

Portable Alveolar Gas Meter

ActiveUS20070232950A1Withdrawing sample devicesRespiratory organ evaluationMeasurement deviceEngineering

Owner:RGT UNIV OF CALIFORNIA

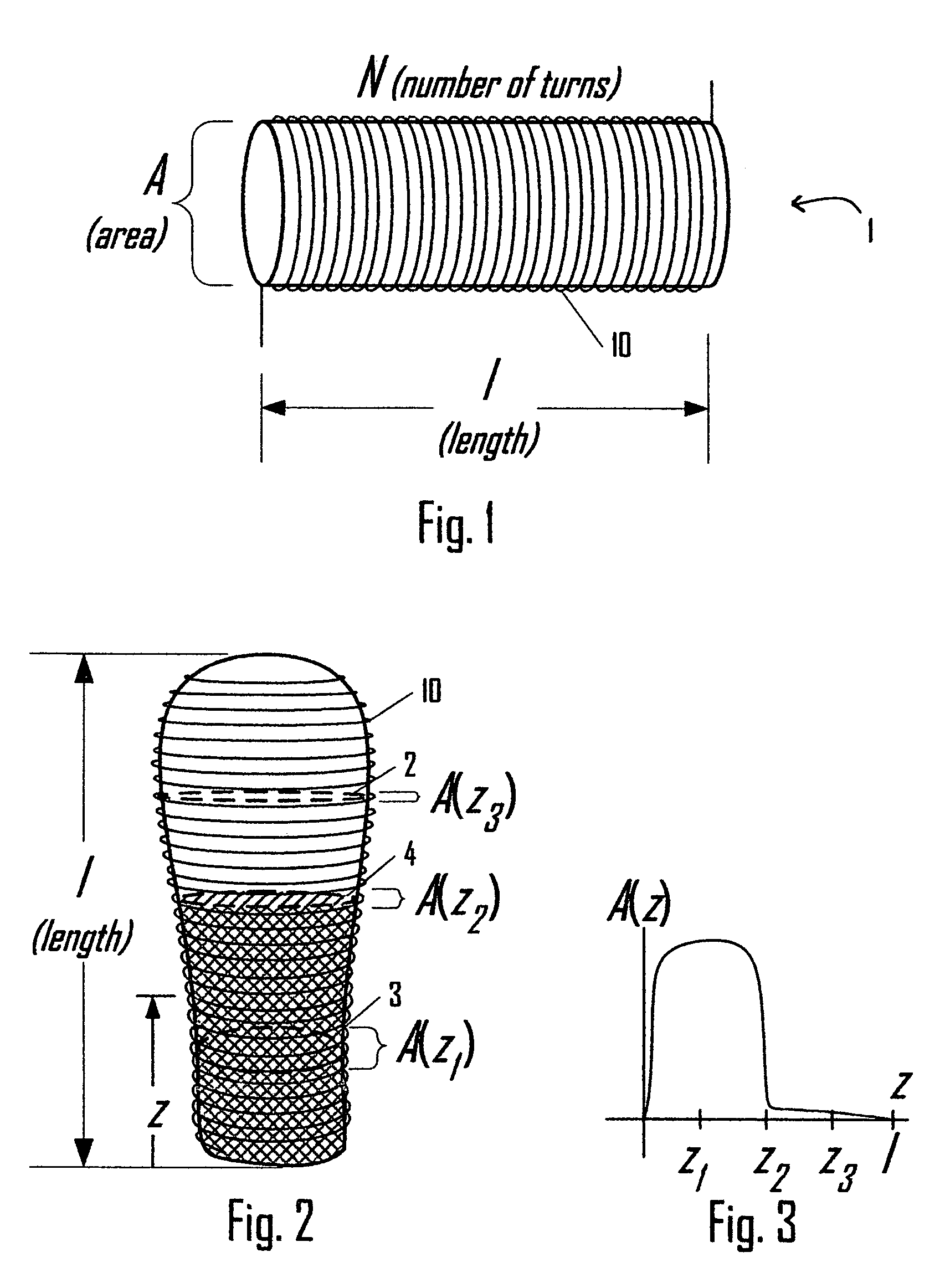

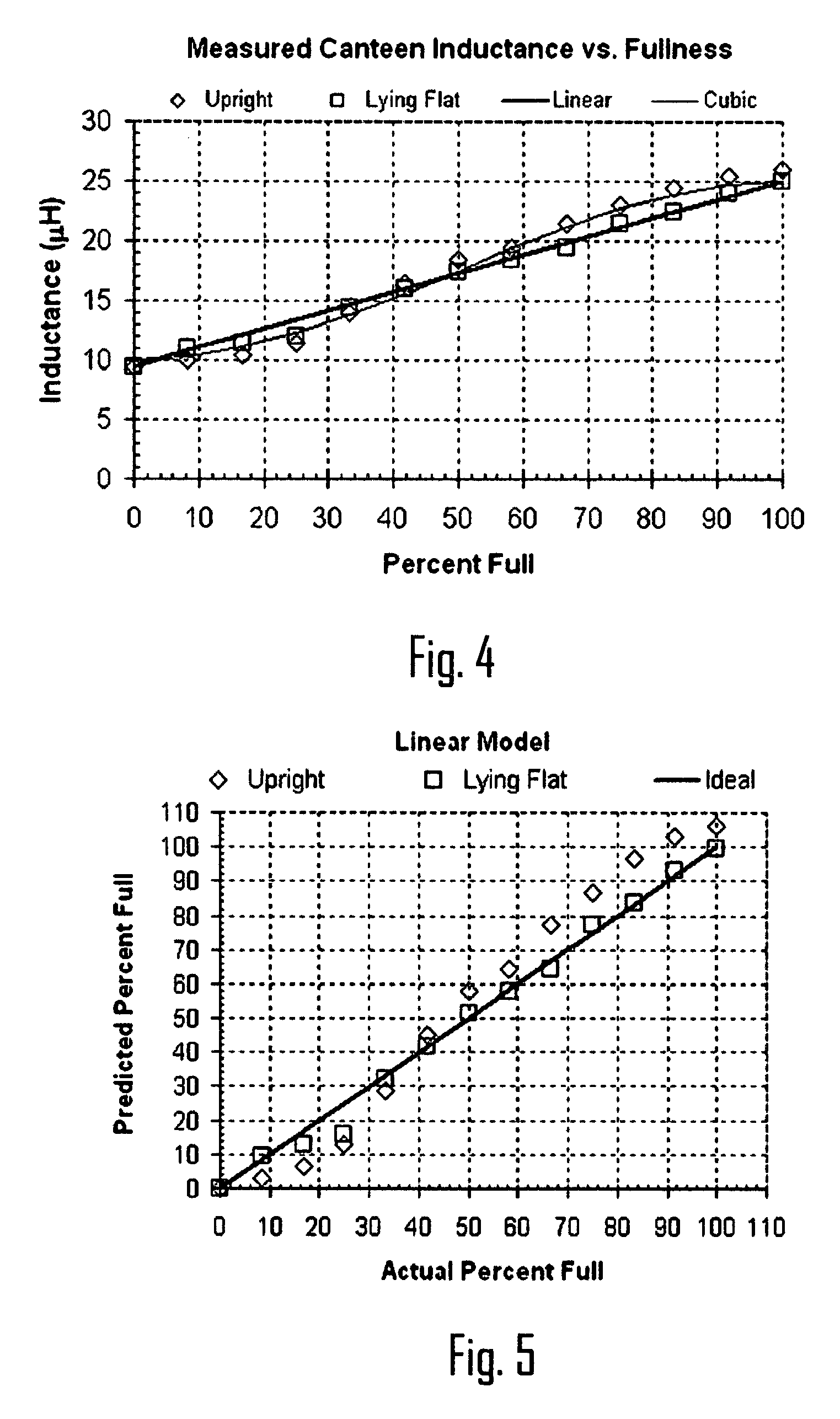

Volume or fluid level sensing system and method

ActiveUS7600423B1Easy to manufactureLow costMachines/enginesLubrication indication devicesMeasurement deviceFluid level

Owner:INNOVATE TECH INC (US)

Method, system and device for measuring and calculating external insulation pollution degree of electric transmission and transformation device

InactiveCN101598692AAccurate measurementLess disturbedMaterial resistanceElectric power transmissionMeasurement device

Owner:邱雪 +1

Flow rate measuring system and method for multiphase fluid

InactiveCN101750124AReduce complexityHigh measurement accuracyVolume/mass flow measurementFluid speed measurementMeasurement deviceMathematical model

Owner:北京中油联自动化技术开发有限公司

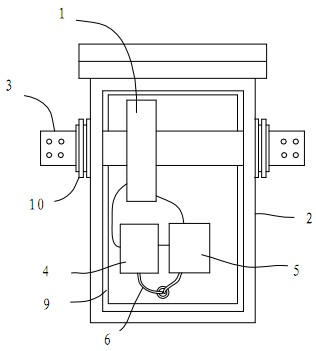

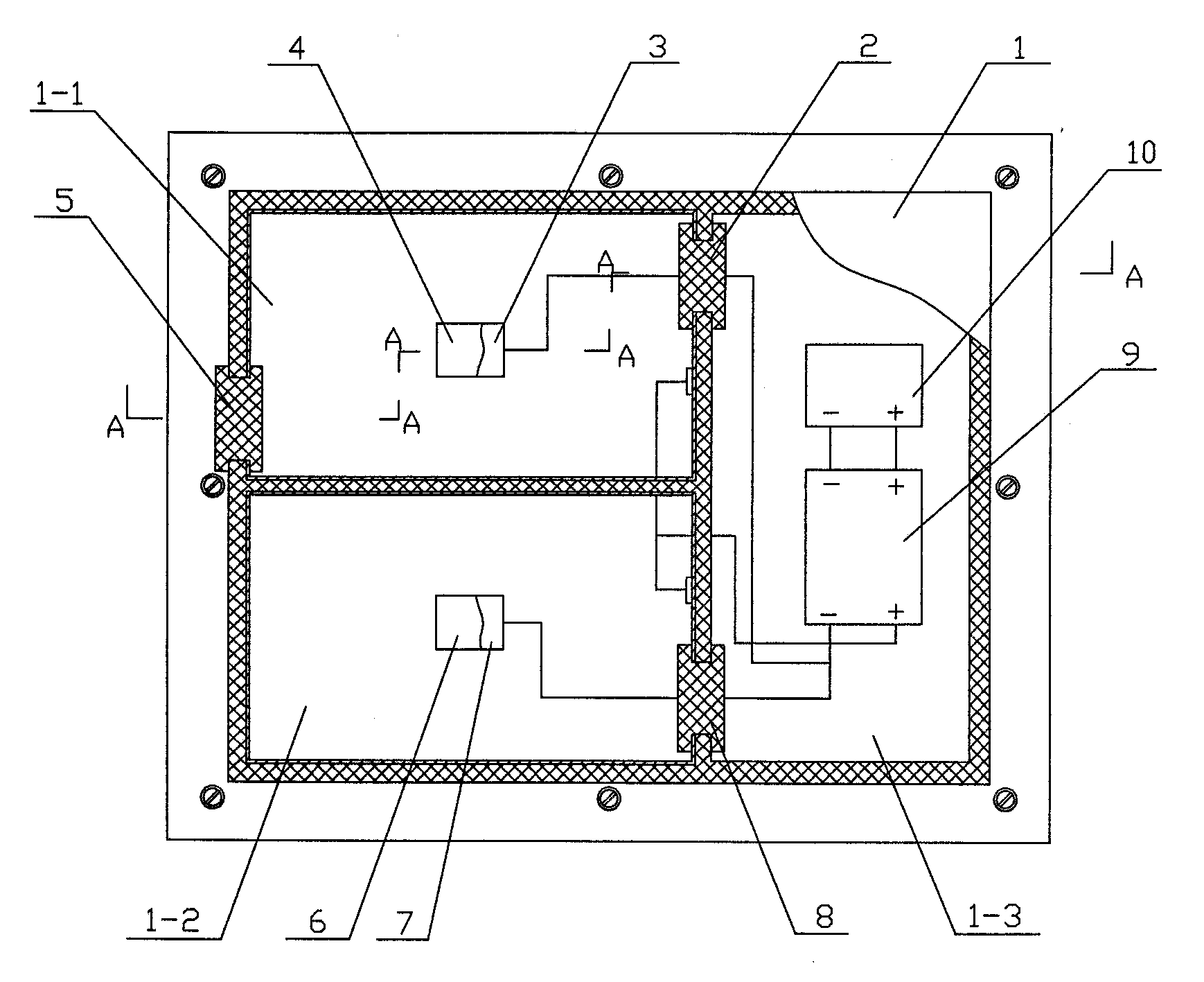

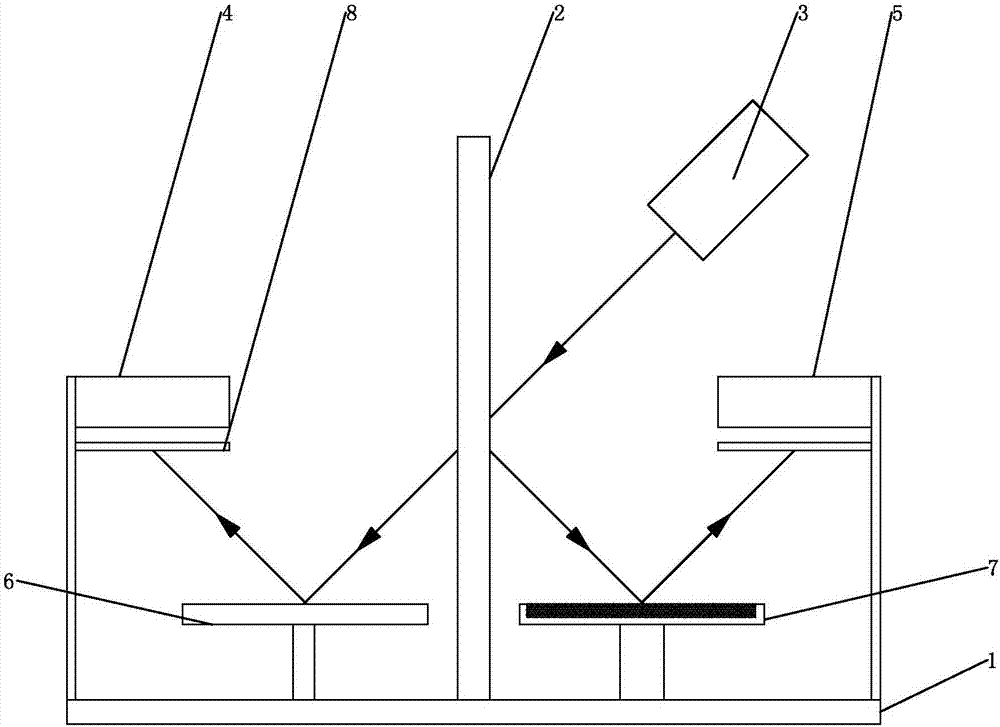

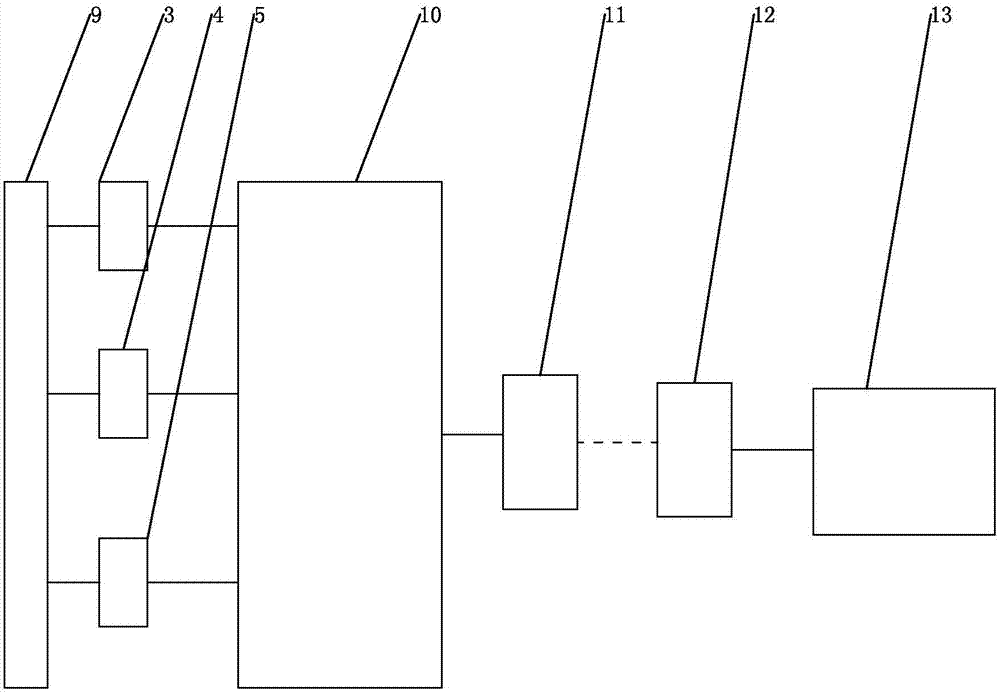

Device and method for measuring heat exchange coefficient of interface in hot stamp process

ActiveCN103033530ARealize the test of interface heat transfer coefficientAvoid incomingMaterial heat developmentSheet steelMeasurement device

The invention discloses a device for measuring a heat exchange coefficient of an interface between a high-temperature steel plate and a die in a hot stamp process. The device comprises a pressure applying device and a measurement device, wherein the pressure applying device comprises a pressurization device, an upper workbench and a lower workbench, wherein the pressurization device is connected with the upper workbench and the lower workbench respectively; the measurement device comprises an upper fixture, a lower fixture and a test sample fixing fixture; the upper fixture is fixed on the upper workbench; the lower fixture is fixed on the lower workbench; and the test sample fixing fixture is arranged between the upper fixture and the lower fixture. The invention also discloses a method for measuring the heat exchange coefficient of the interface between the high-temperature steel plate and the die in the hot stamp process. By the device and the method, the limitation to samples with the thickness being more than 30mm in the prior art is avoided; the heat exchange coefficient of the interface between the steel plate and the die in the hot stamp process can be measured; and by an elastic energy storage element, stabilization of interface pressures between a boron steel test sample and an upper die and between the boron steel test sample and a lower die can be guaranteed.

Owner:TENGZHOU PROD QUALITY SUPERVISION & INSPECTION INST

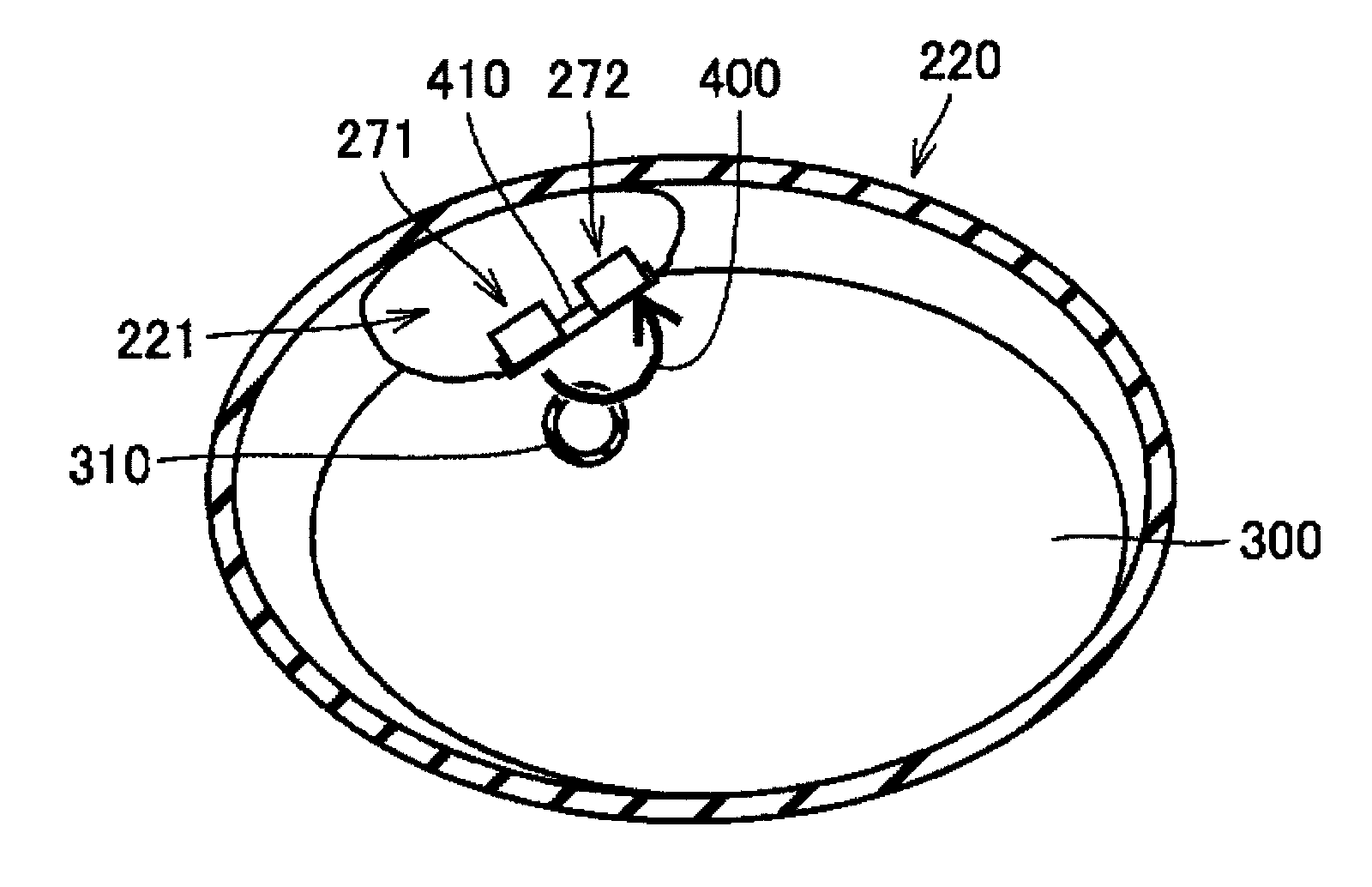

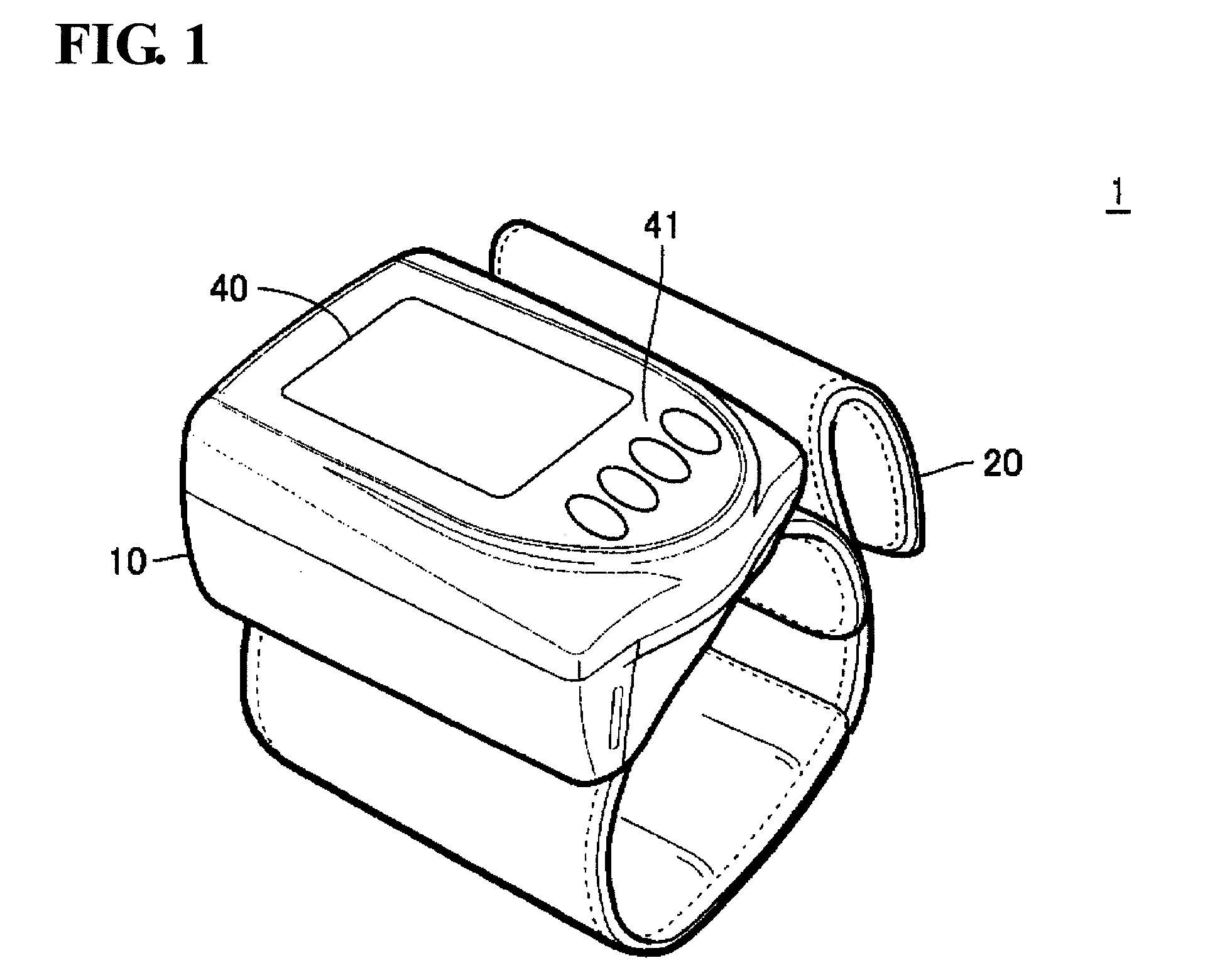

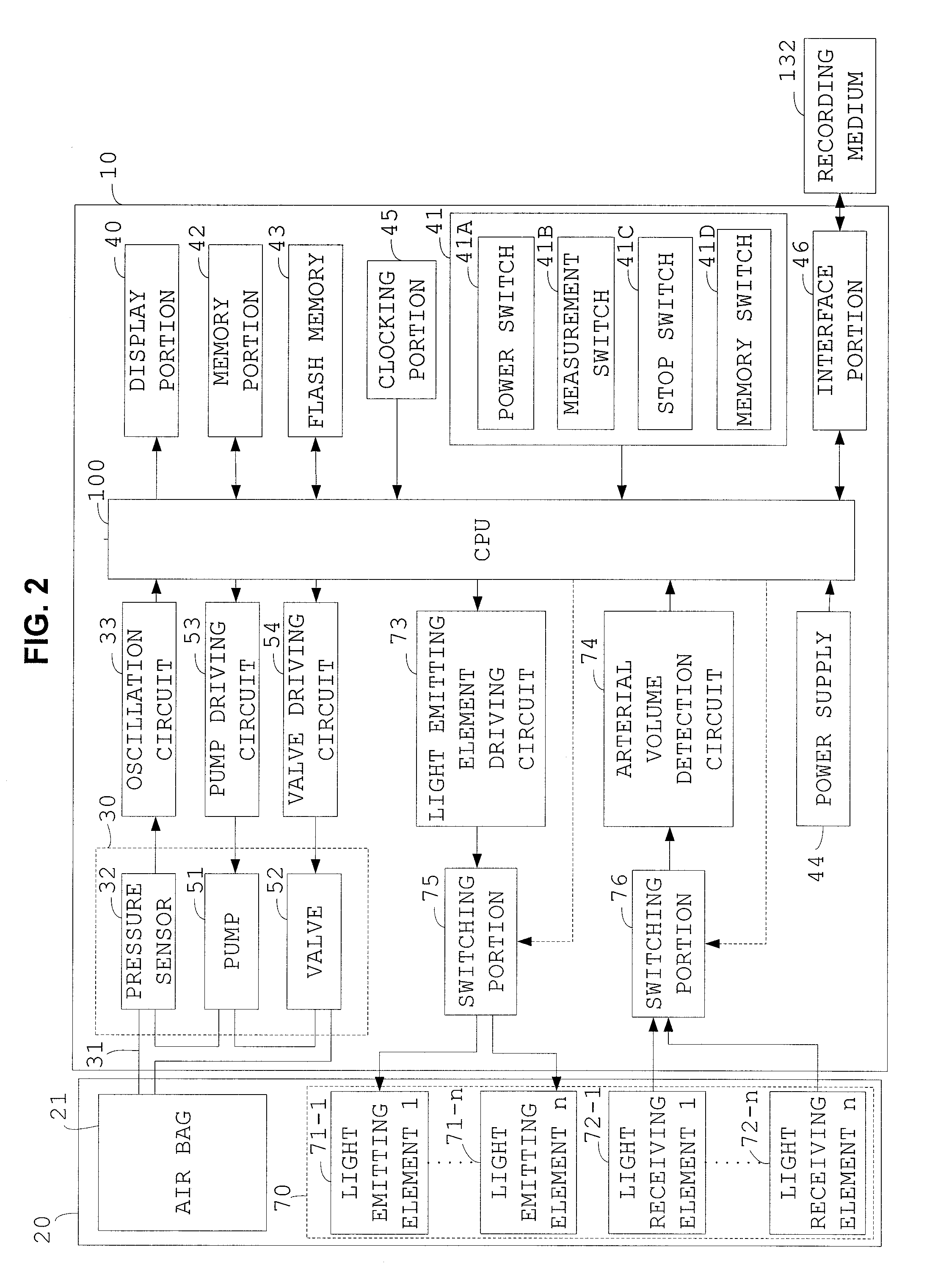

Blood pressure information measurement device

InactiveUS20120071768A1Easy alignmentAccurate detectionEvaluation of blood vesselsCatheterMeasurement deviceSpecific volume

Owner:OMRON HEALTHCARE CO LTD

Neutral point direct current online measurement device for transformer

InactiveCN102116786AEliminate the effects ofEnables isolated measurementsCurrent/voltage measurementVoltage/current isolationMeasurement deviceTransformer

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

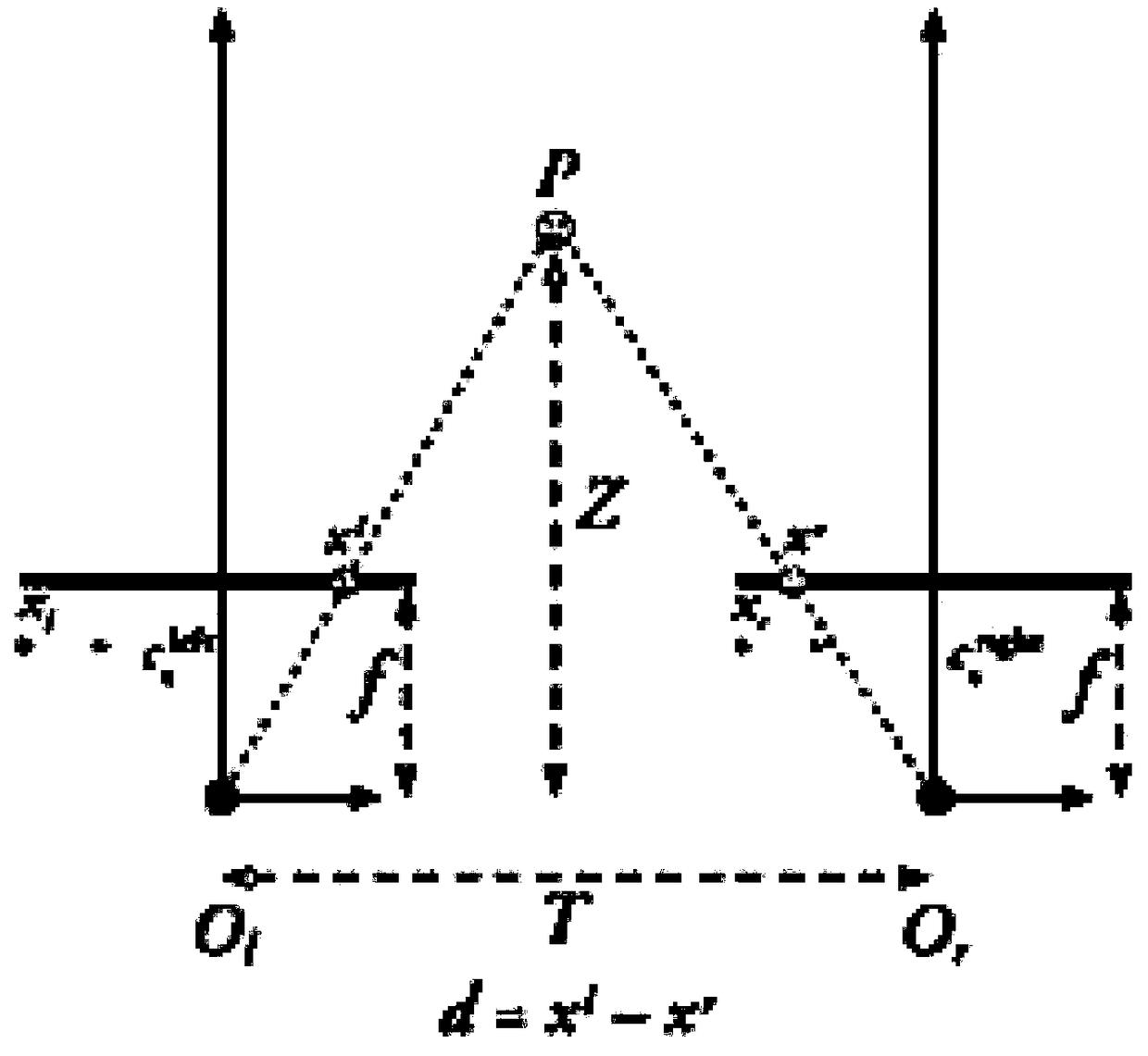

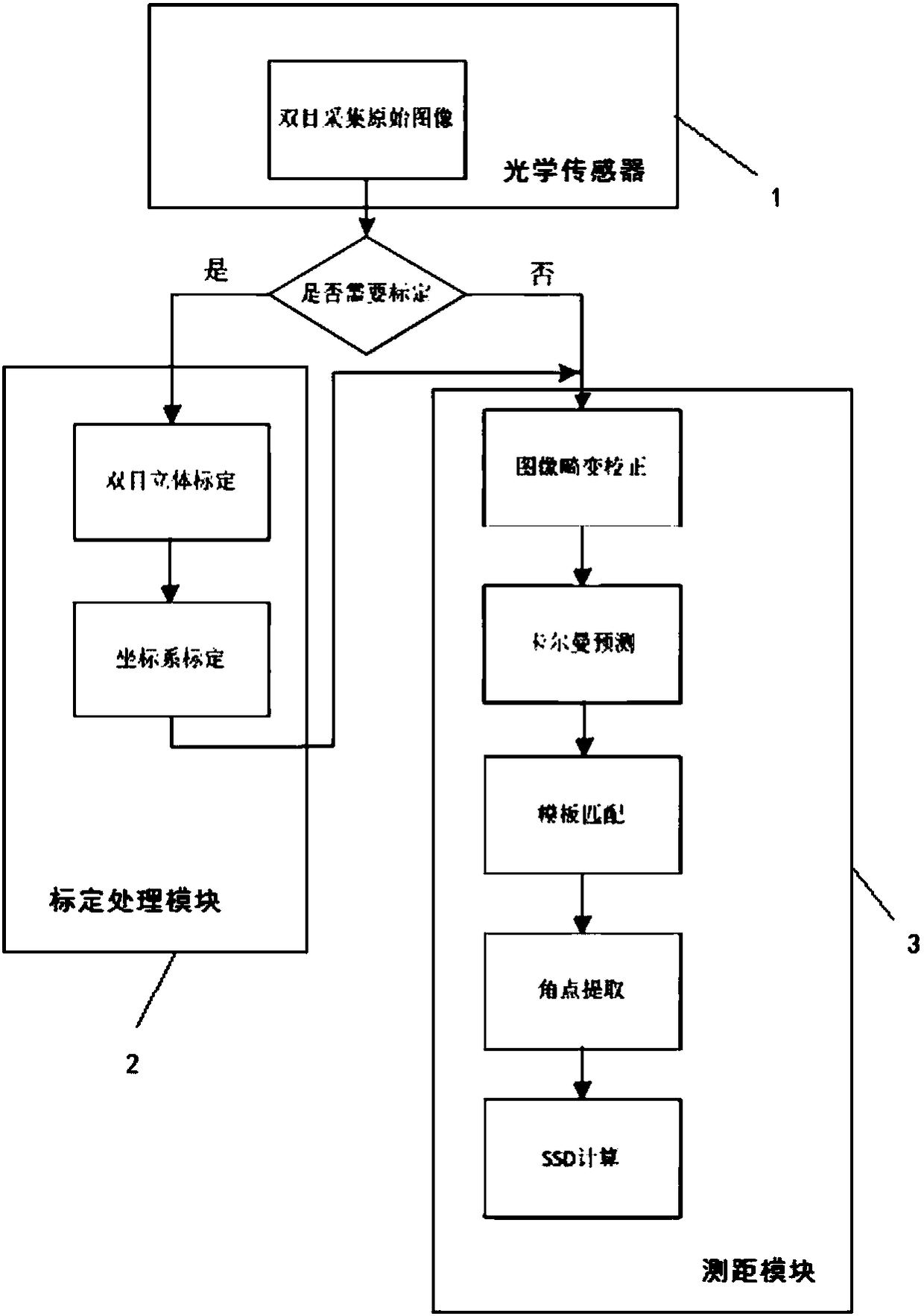

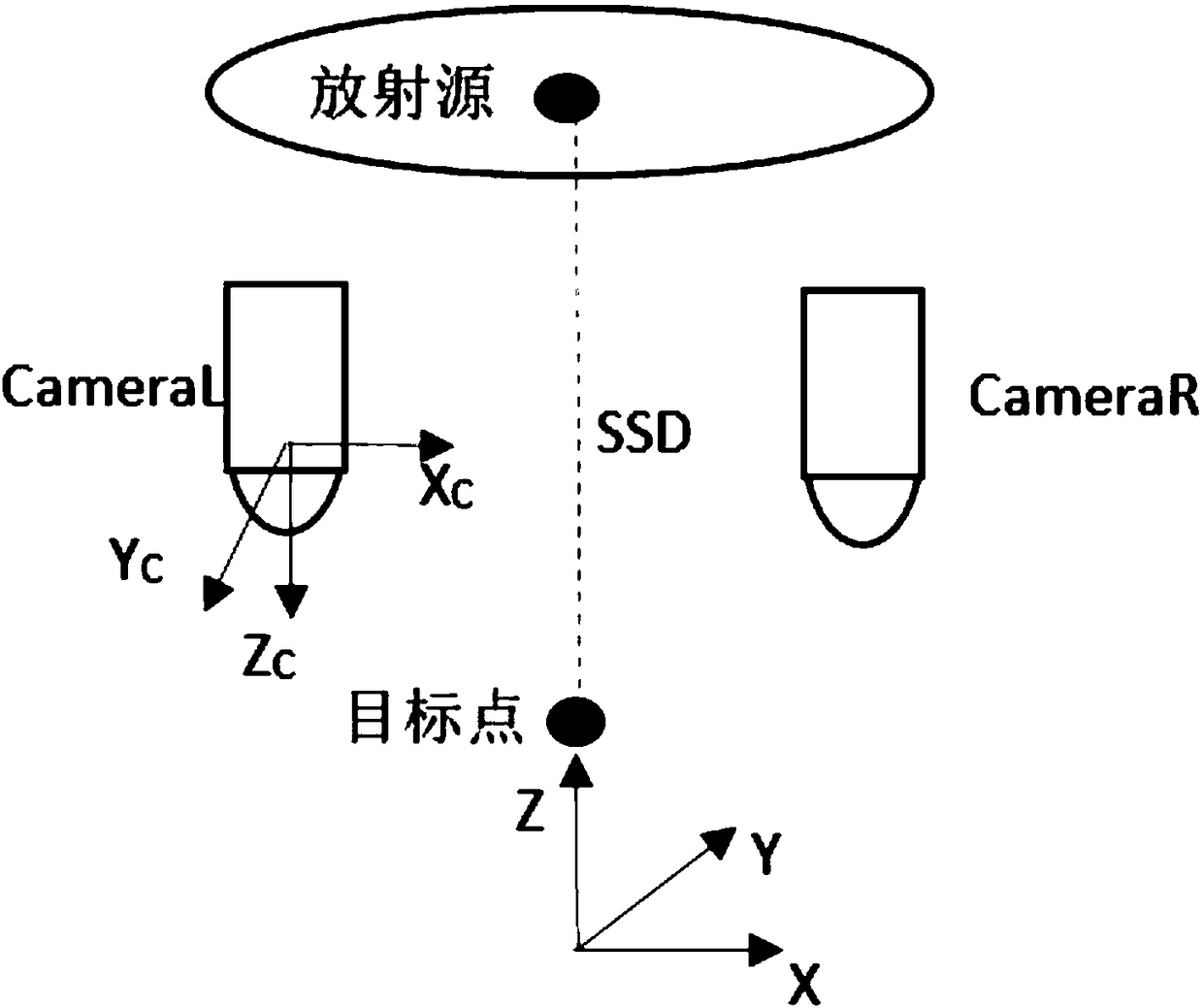

Binocular distance measurement device and method, and accelerator radiotherapy system comprising the same

ActiveCN108245788AImprove calculation accuracyProcessing speedOptical rangefindersX-ray/gamma-ray/particle-irradiation therapyMeasurement devicePrediction algorithms

Owner:SUZHOU LINATECH MEDICAL SCI & TECH CO LTD

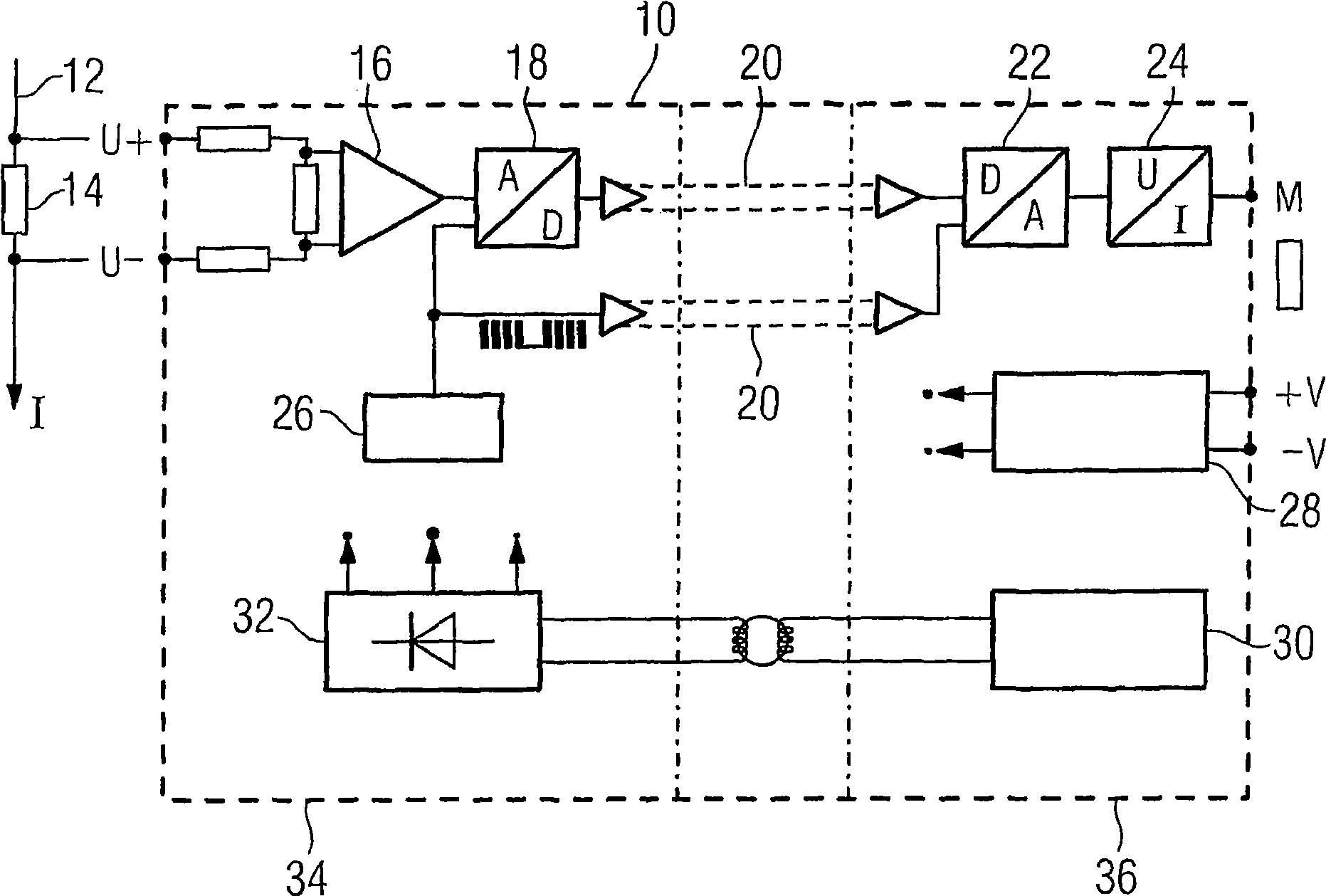

Measuring apparatus

InactiveCN101484813AImplementing rotational motion (spin)Implementation locationCurrent/voltage measurementVoltage/current isolationMeasurement deviceCoupling

Owner:SIEMENS AG

Three-dimensional measurement apparatus, method for controlling a three-dimensional measurement apparatus, and storage medium

A three-dimensional measurement apparatus comprises a detection unit configured to detect a plurality of intersection positions between first pattern light in which a bright part and a dark part are alternately arranged and second pattern light in which a phase of the first pattern light is shifted, by using tone values of a first image obtained by capturing a target object onto which the first pattern light is projected and tone values of a second image obtained by capturing the target object onto which the second pattern light is projected; and a measurement unit configured to calculate a third position based on a first intersection position included in the plurality of intersection positions and a second intersection position that is adjacent to the first intersection position and measure a three-dimensional position of the target object based on an interval between the third positions.

Owner:CANON KK

Digital display measuring equipment

InactiveCN101122455AEasy to achieve absolute measurementHigh protection levelSlide gaugesUsing electrical meansMeasurement deviceAbsolute measurement

The invention discloses a numerical display measurement device for measuring, including a large number measuring amount device, of which the measure range is the measure range of the whole numerical display measurement device. The large number measuring amount device can roughly divide the measure range of the whole numerical display measurement device into a plurality of small measure sections and can calibrate the position of every small measure section onto every small measure section one by one. The invention also includes a small number measuring amount device, of which the measure range is larger than the largest small measure section. The invention still includes a calculation device, which calculates the total measuring result according to the measuring amounts of the large number measuring amount device and the small number measuring amount device. The invention is best suitable for being used in a numerical display scale. The large number measuring amount device of the numerical display scale is a capacitance sensor for sensing the depths of varied deep grooves, which are solidified in the scale with same intervals. The small number measuring amount device of the numerical display scale is a percent meter for sensing the moving distance of a scale frame clamping jaw within the intervals of the grooves. The invention divides the measuring amount into large numbers and small numbers for accumulation account, which makes the absolute measurement realized.

Owner:赵志强

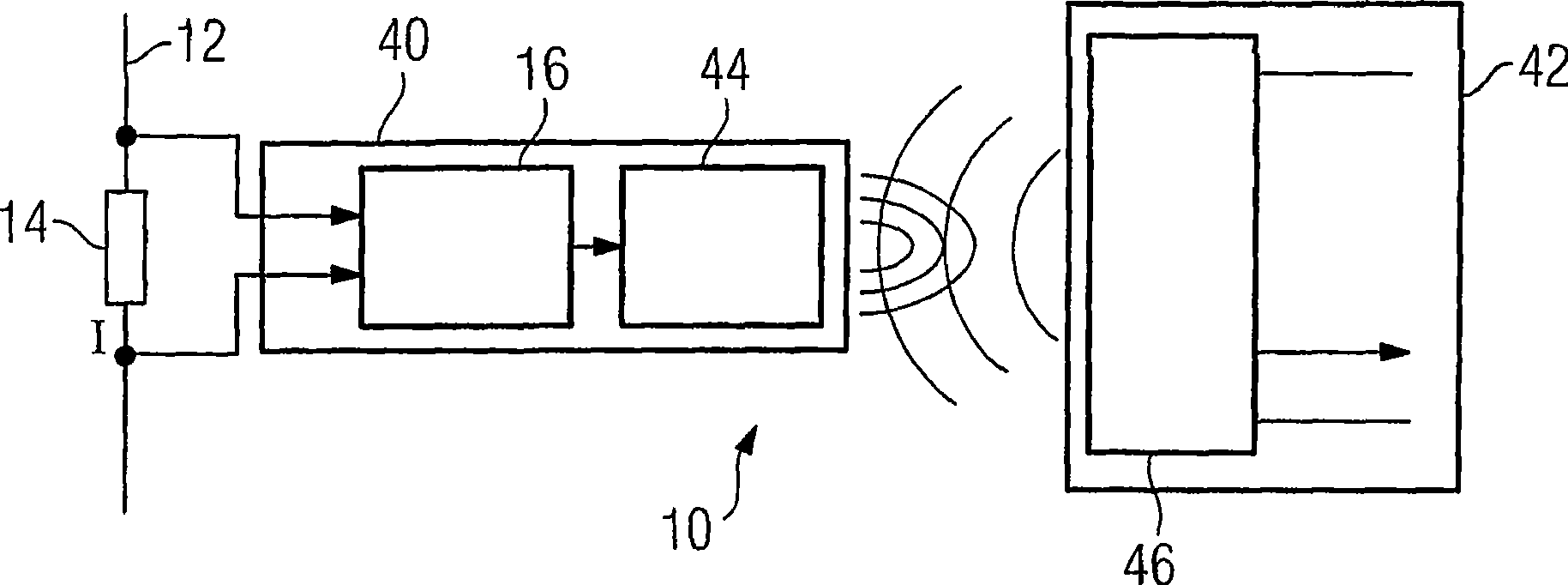

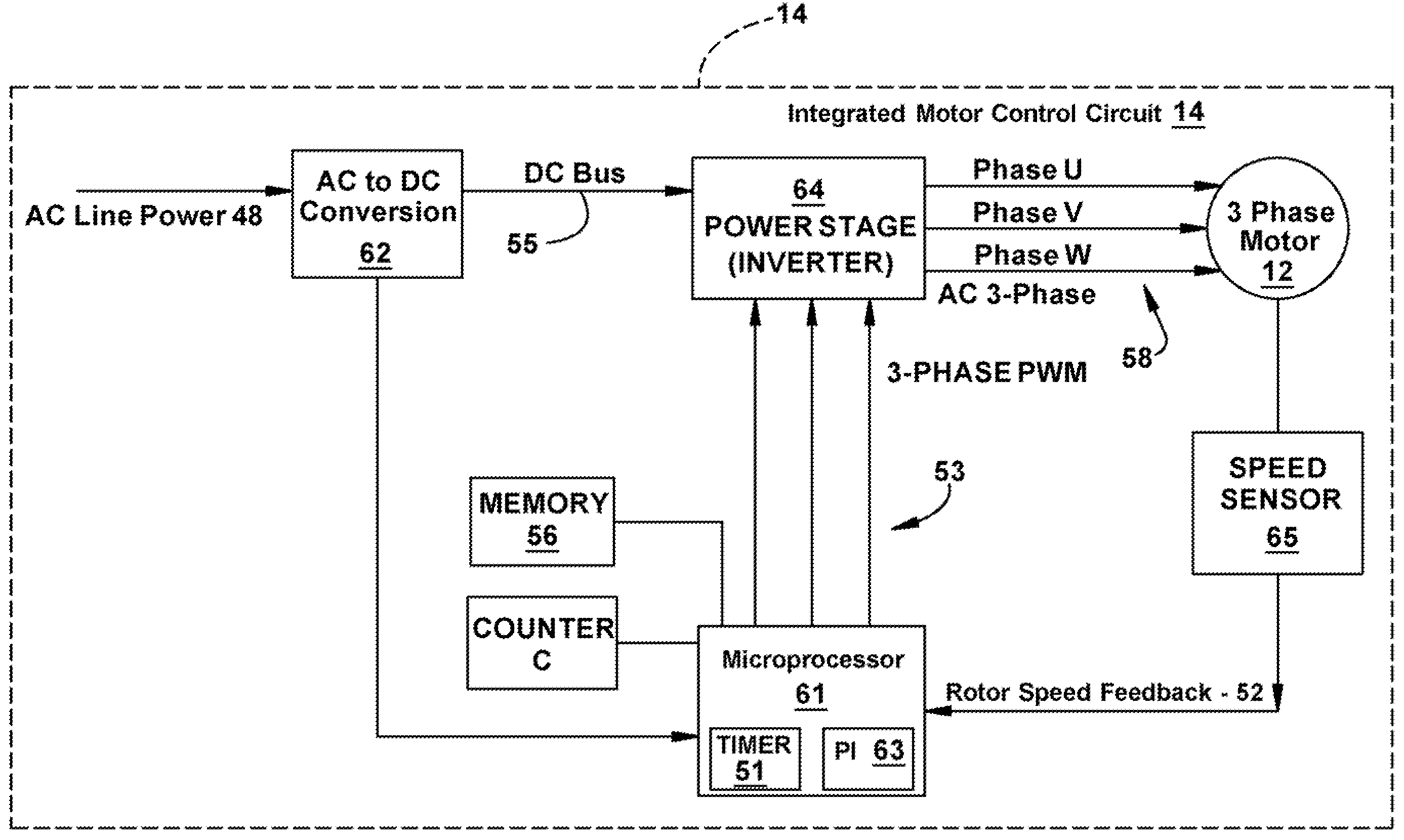

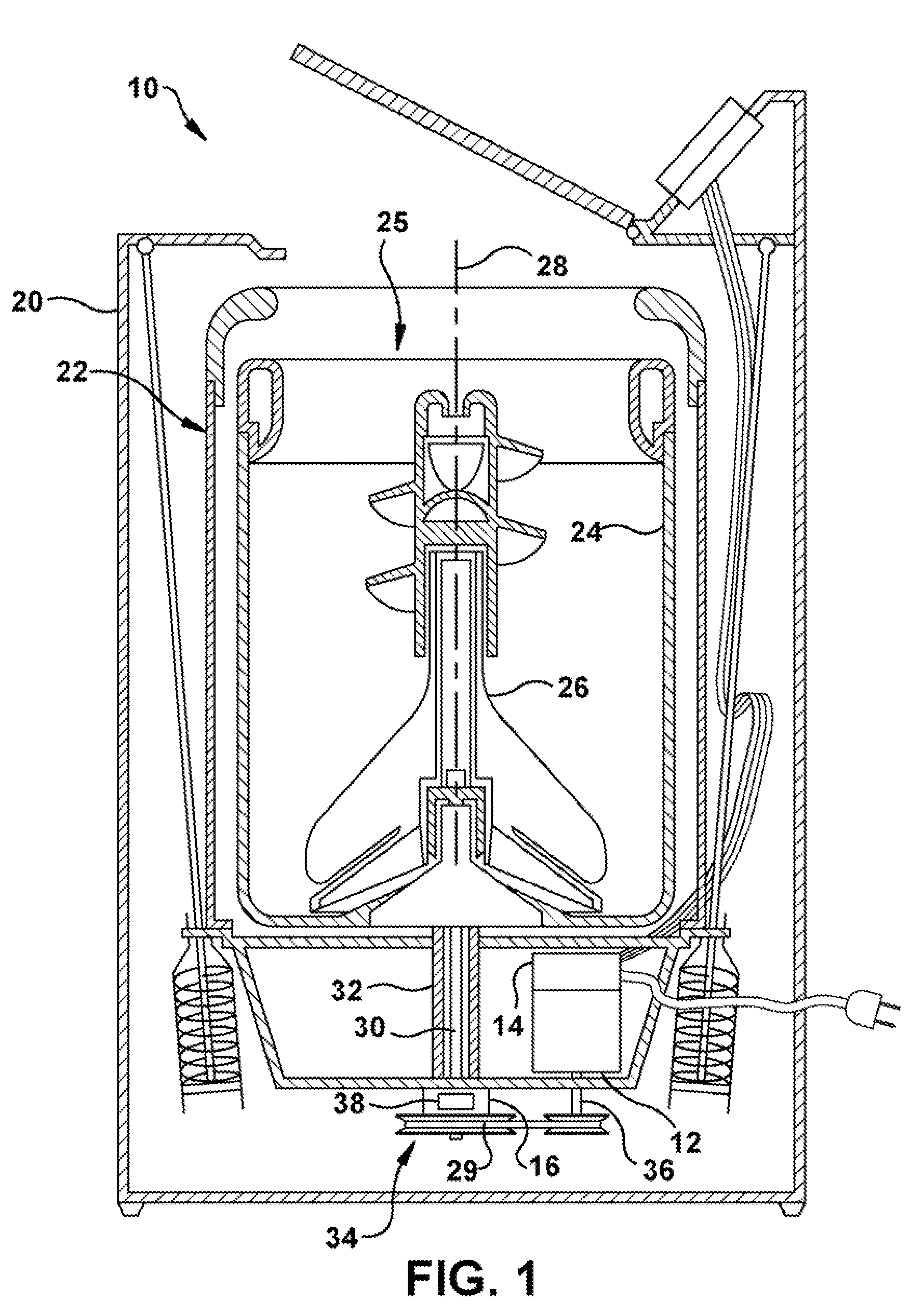

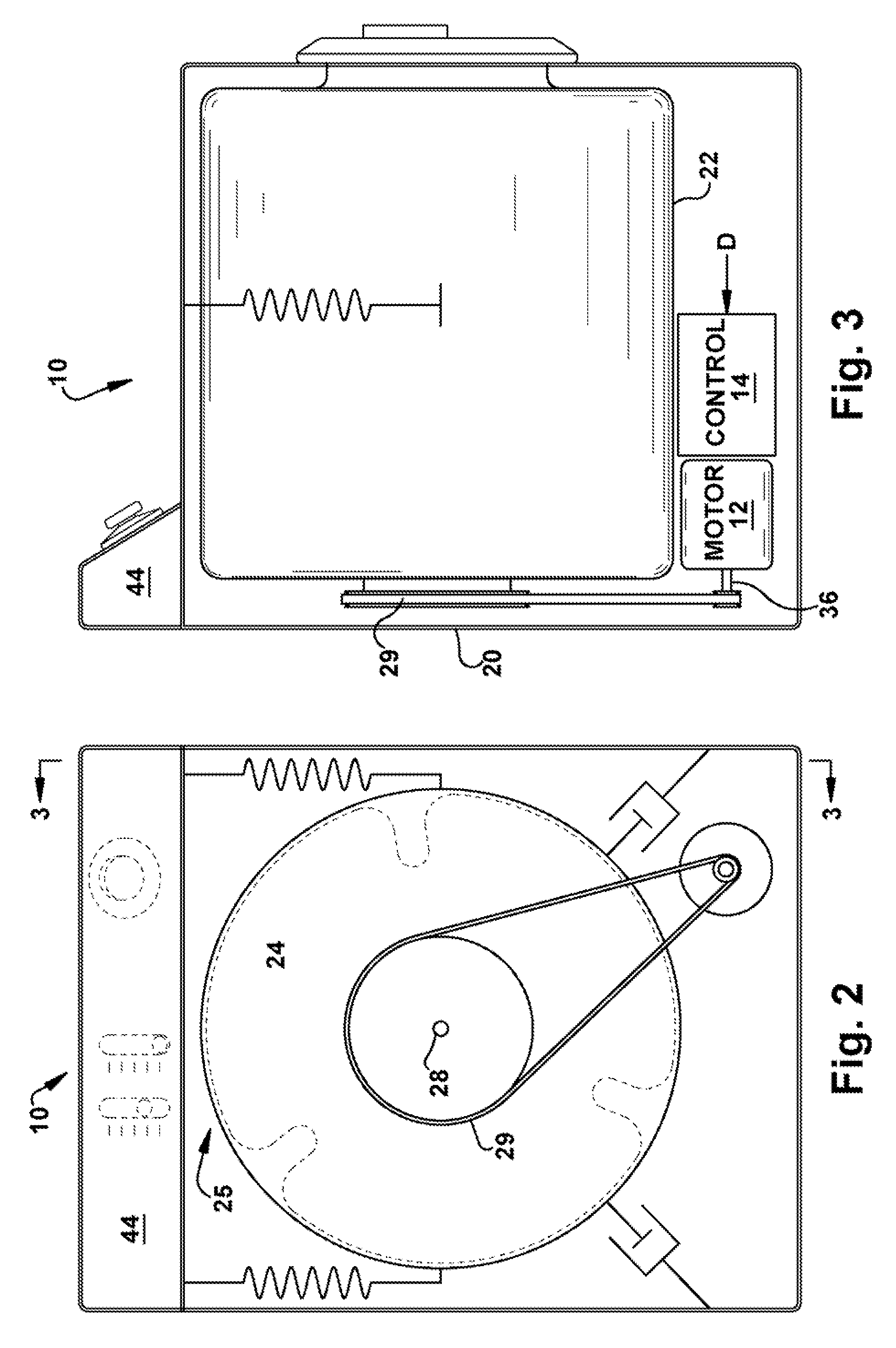

Load size measuring apparatus and method

InactiveUS20090112513A1Easy to useQuick fixOther washing machinesDigital computer detailsMeasurement deviceVoltage

Owner:GENERAL ELECTRIC CO

Operating condition simulation method and operating condition simulation test bench for anchor bolt support system

Owner:TIANDI SCI & TECH CO LTD

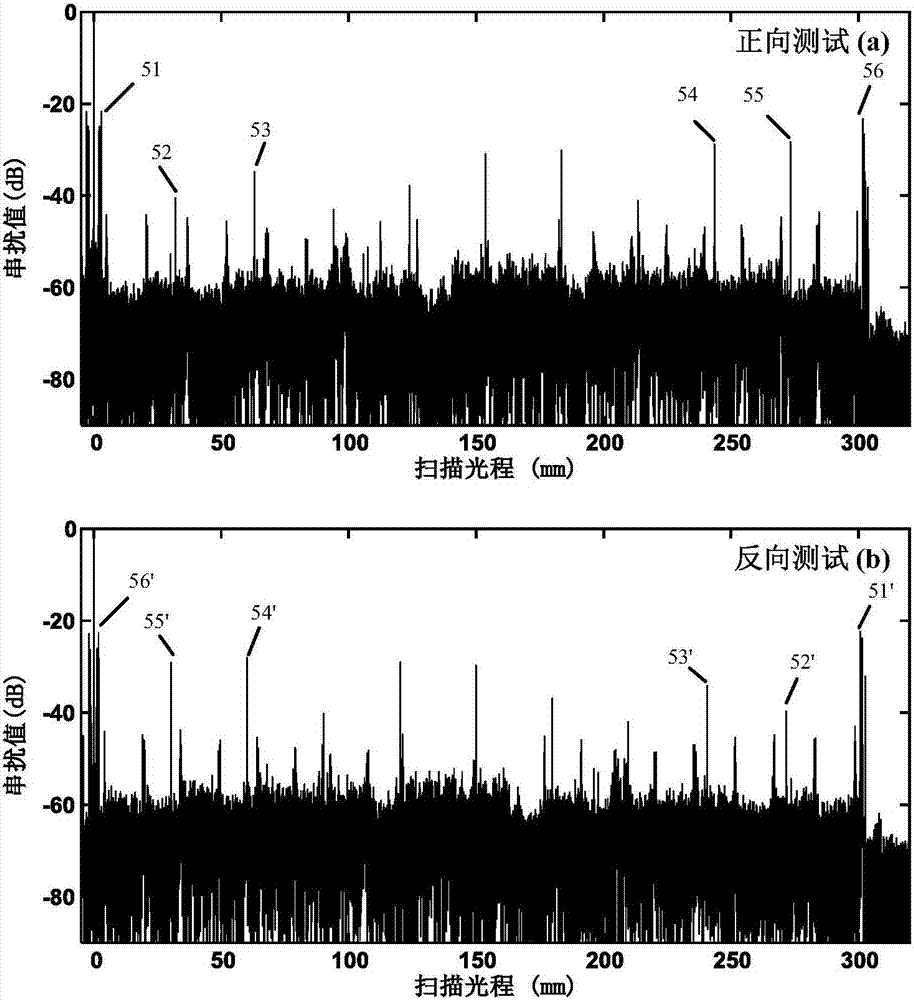

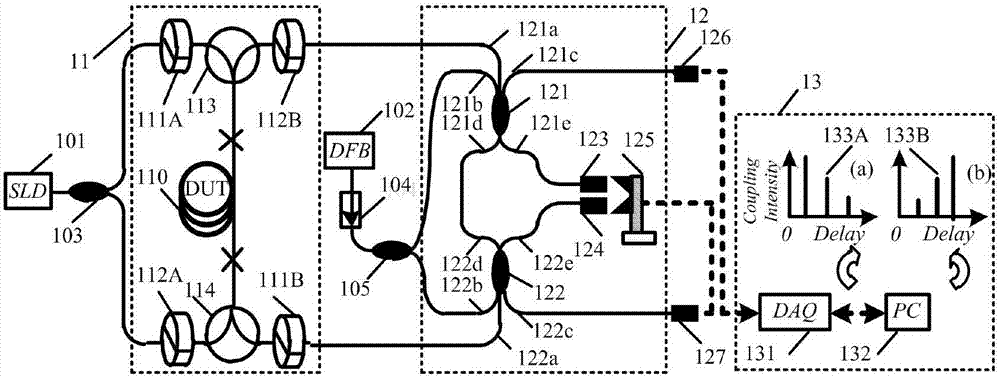

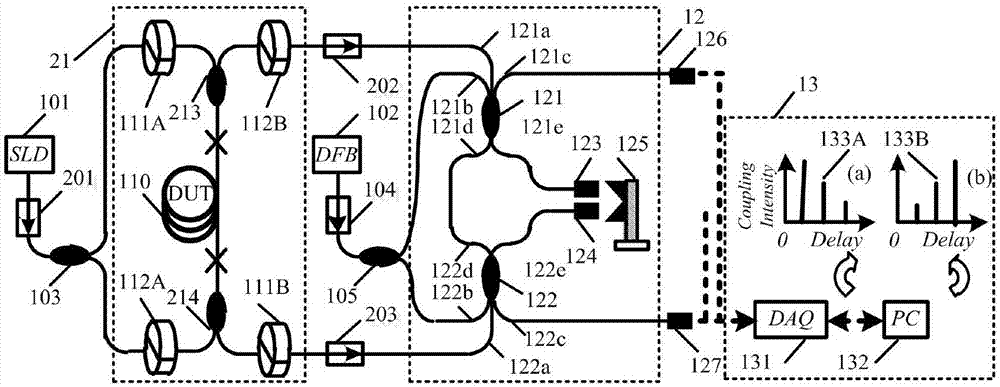

Common-path forward-reverse simultaneous measuring device for fiber optic gyroscope ring

ActiveCN107289922AObtaining Polarization Coupling SymmetryRealize forward/reverse simultaneous measurementSagnac effect gyrometersFiberMeasurement device

Owner:HARBIN ENG UNIV

Device and method for measuring concentration of <222>Rn and <220>Rn synchronously by adopting electrostatic collection and solid nuclear track

ActiveCN103983999ASimple and reliable measurement processThe calculation method is simple and reliableRadiation intensity measurementMeasurement deviceEtching

Owner:HENGYANG NORMAL UNIV

Dense core permeability measuring device and method

ActiveCN110208164AEasy to operateAvoid the problem of inaccurate flow meteringComponent separationPermeability/surface area analysisVacuum pumpingLine tubing

The invention discloses a dense core permeability measuring device and method. The dense core permeability measuring device comprises a core holder, a standard gas mixture supply system, a confining pressure pump, a vacuum pump, a gas chromatograph and a thermostat, wherein an air inlet end of the core holder is connected with the standard gas mixture supply system through a pipeline. The method for measuring the dense core permeability of the dense core permeability measuring device comprises the following steps: S1, placing a rock sample to be measured with a length L into a rock sample cavity, and performing vacuum pumping on the rock sample and gas in the device by using the vacuum pump; and S2, starting the confining pressure pump, increasing the confining pressure of a confining pressure cavity to a required confining pressure value, and keeping the pressure constant. Through adoption of the dense core permeability measuring device and method, the problems of difficulty in measuring flow and no consideration of dispersion and slip in the process of measuring the permeability with the existing steady state method are solved.

Owner:SOUTHWEST PETROLEUM UNIV

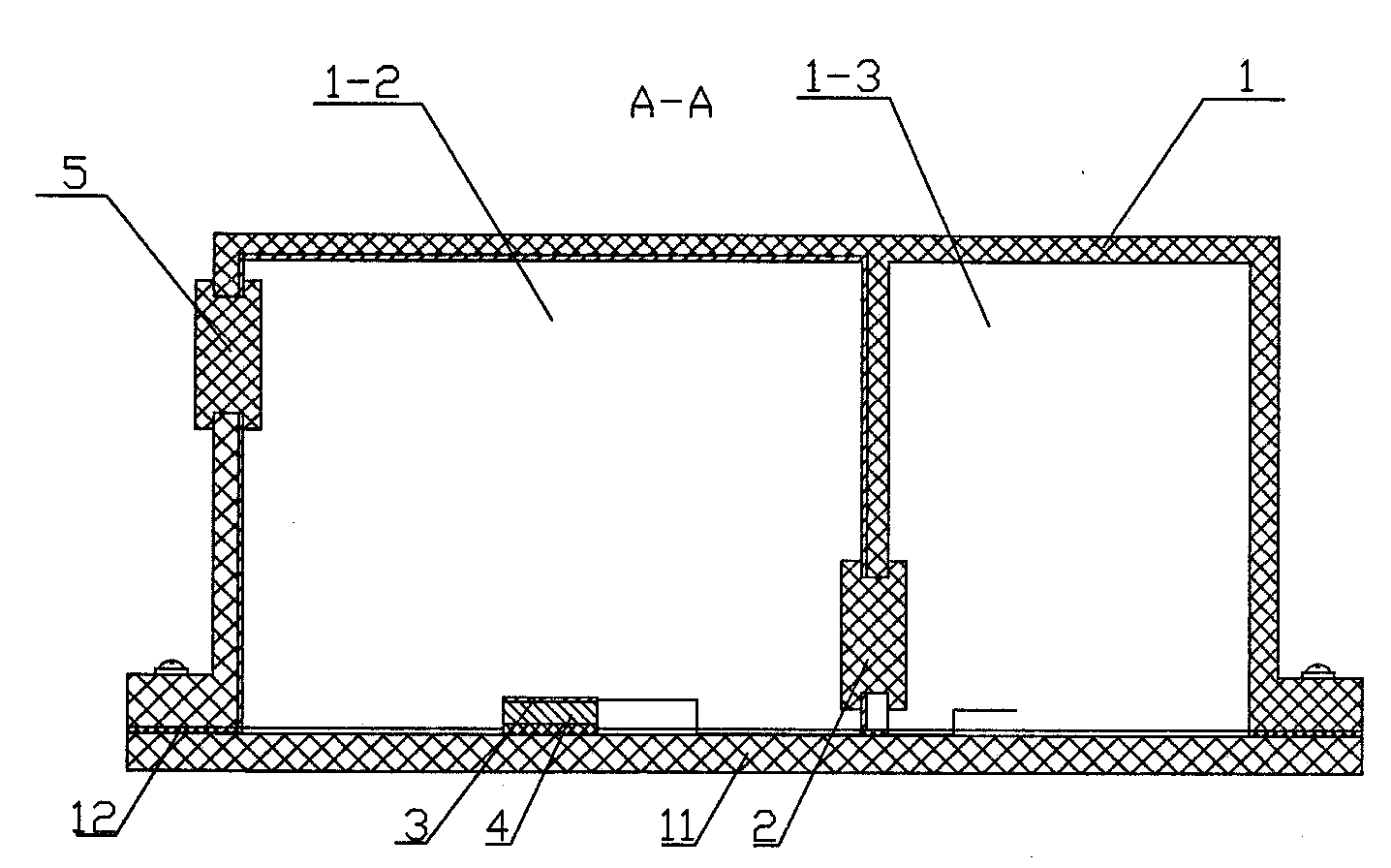

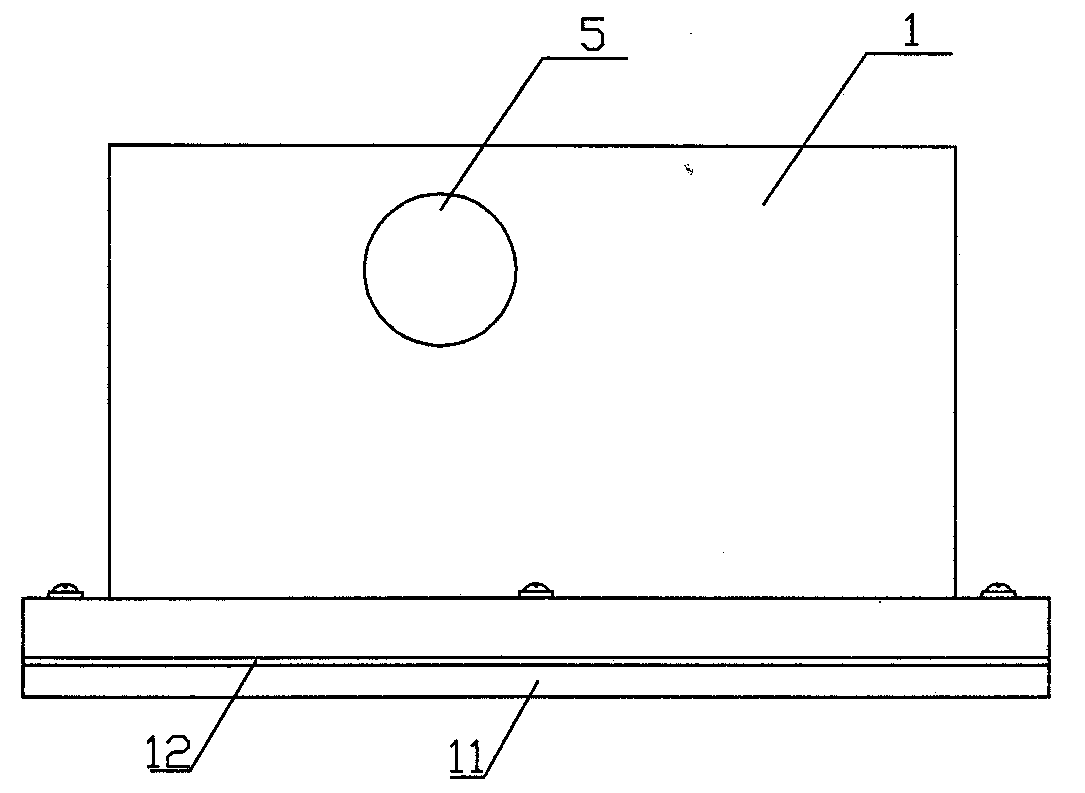

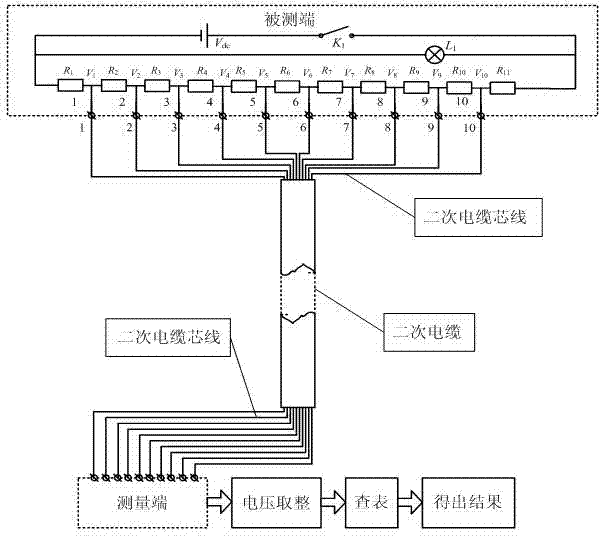

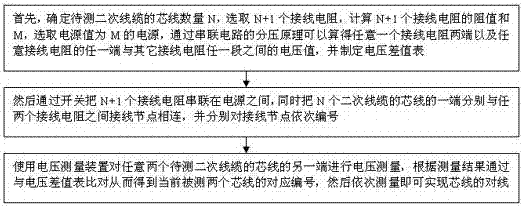

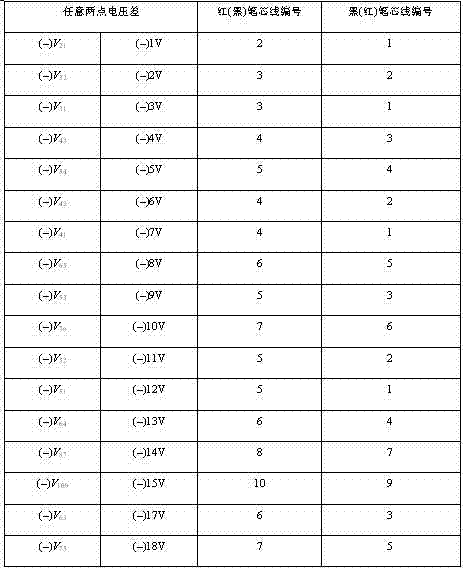

Novel transformer station secondary cable alignment device and method

ActiveCN107271831ALow costHigh precisionElectrical testingElectrical resistance and conductanceMeasurement device

Owner:STATE GRID CORP OF CHINA +1

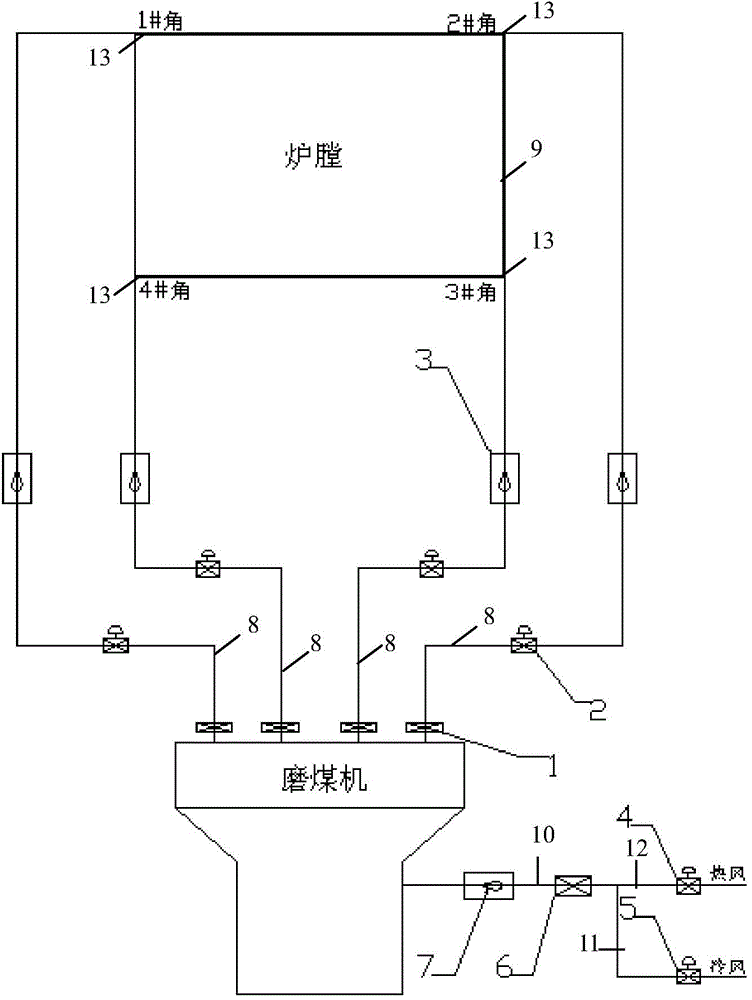

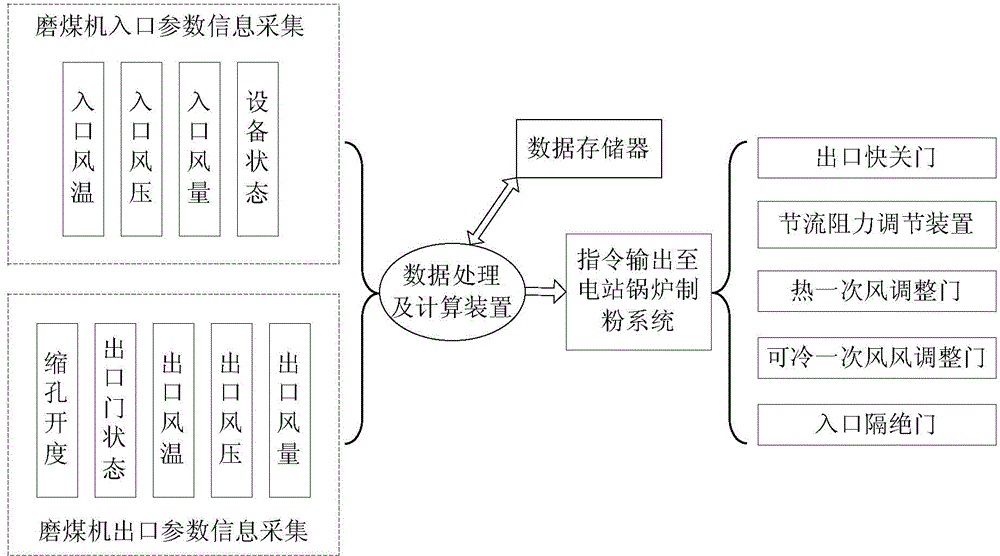

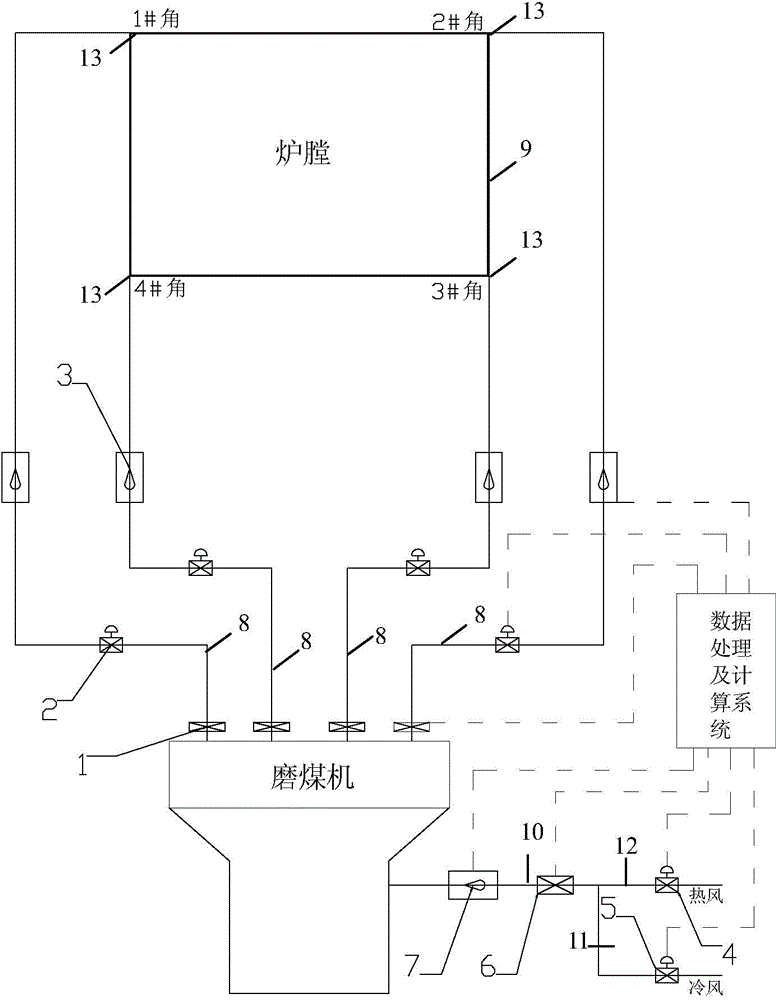

Automatic verification method and system of coal mill inlet air quantity measuring apparatus

ActiveCN105699040AIncrease job securityHigh working reliabilityAerodynamic testingMeasurement devicePower station

Owner:STATE GRID CORP OF CHINA +1

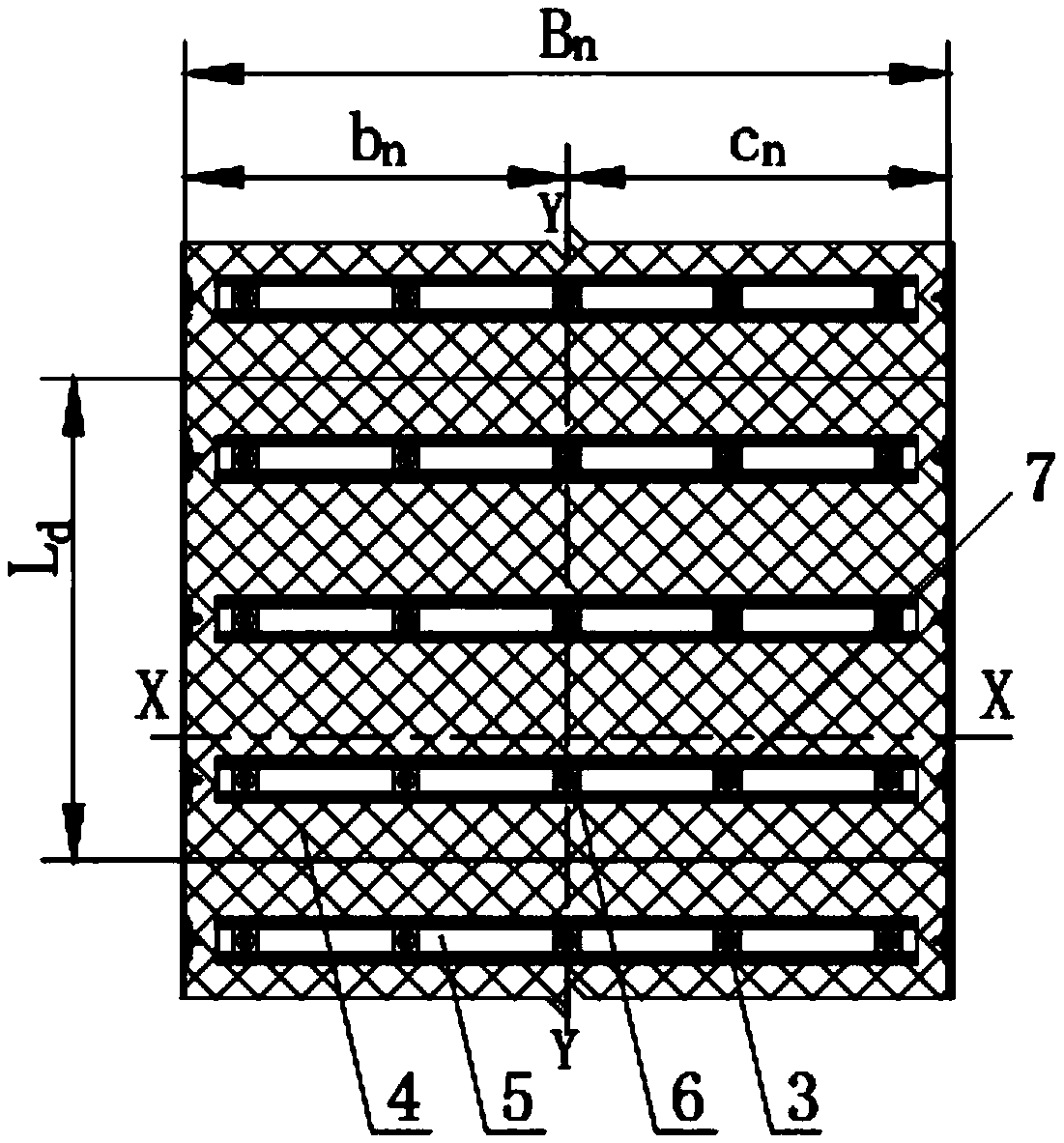

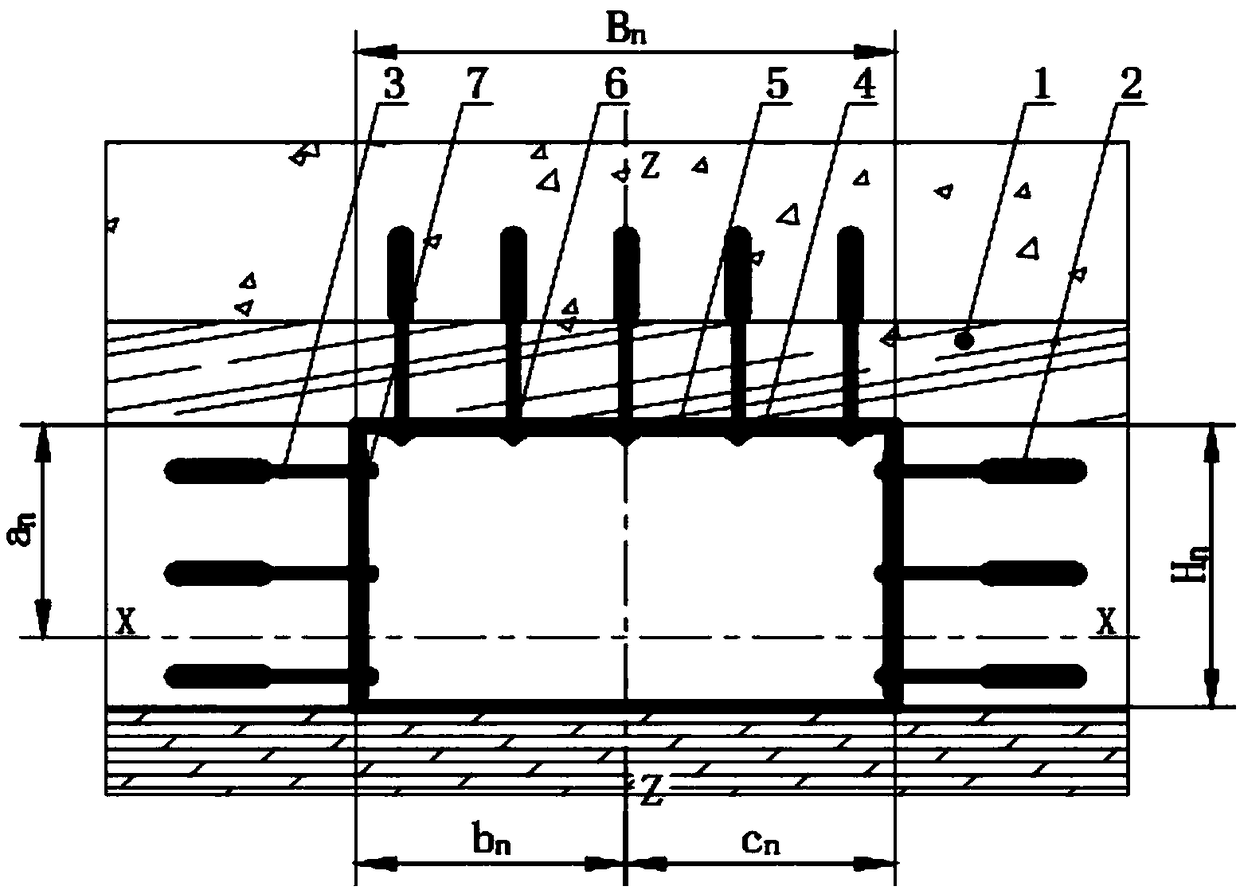

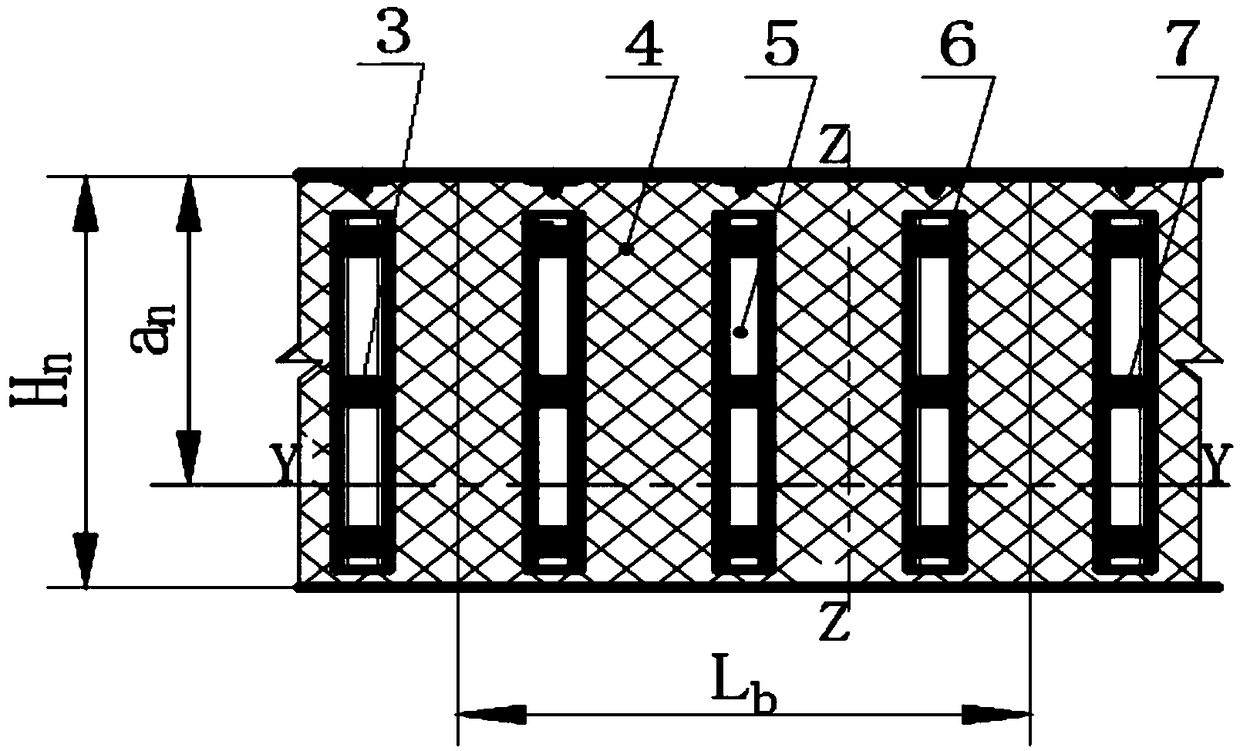

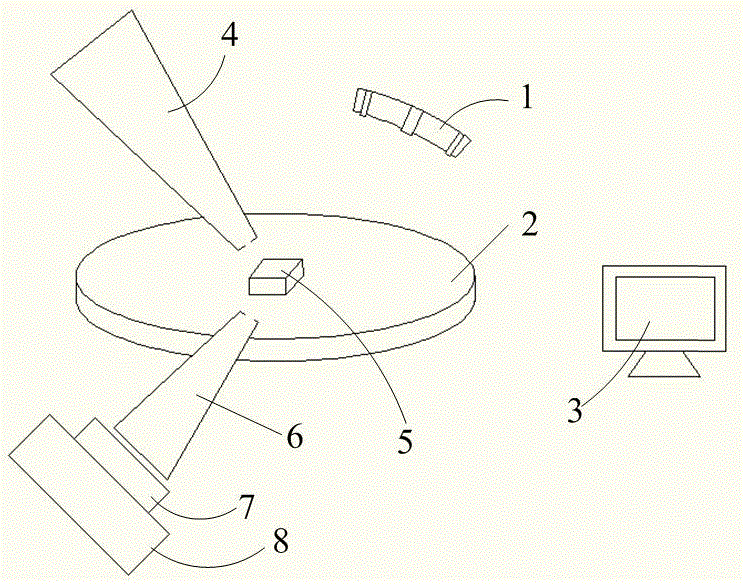

Three-dimensional calibrating measurement device for neutron diffraction stress analysis

PendingCN106770402ASmall space requirementRealize accurate 3D calibrationMaterial analysis using wave/particle radiationStress measurementMeasurement device

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

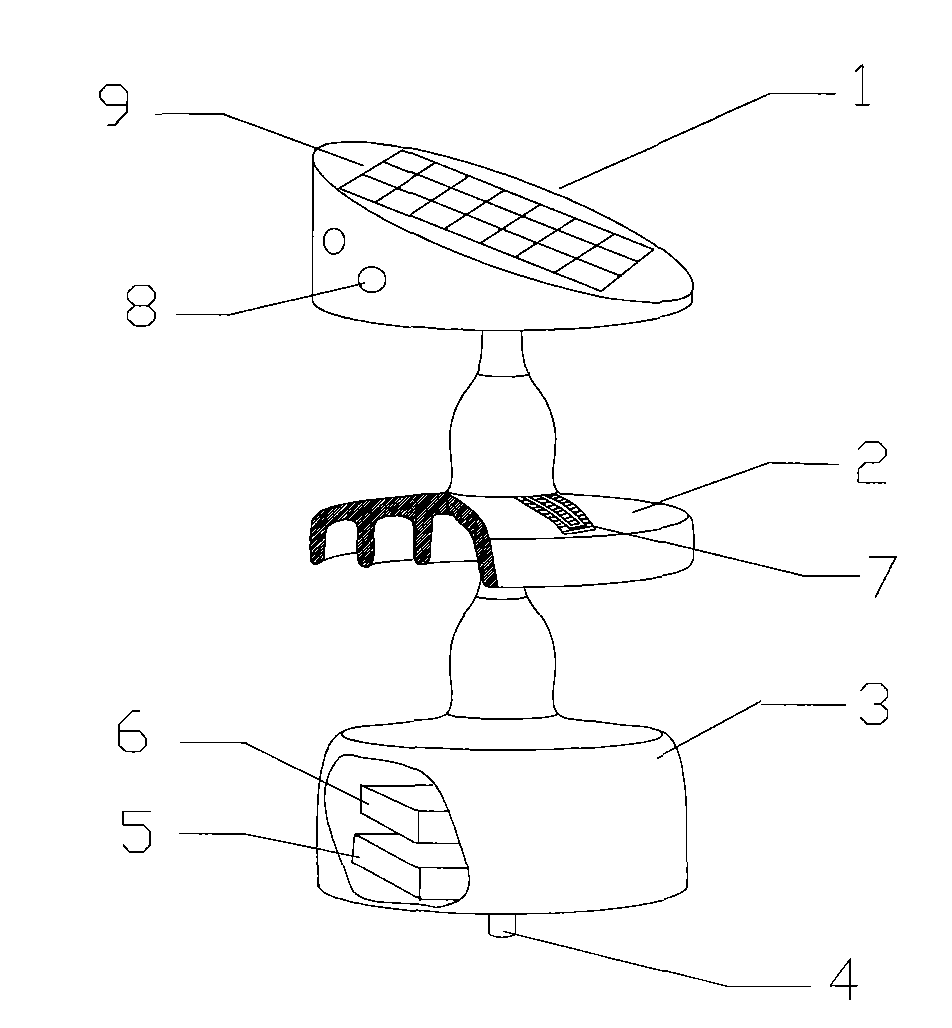

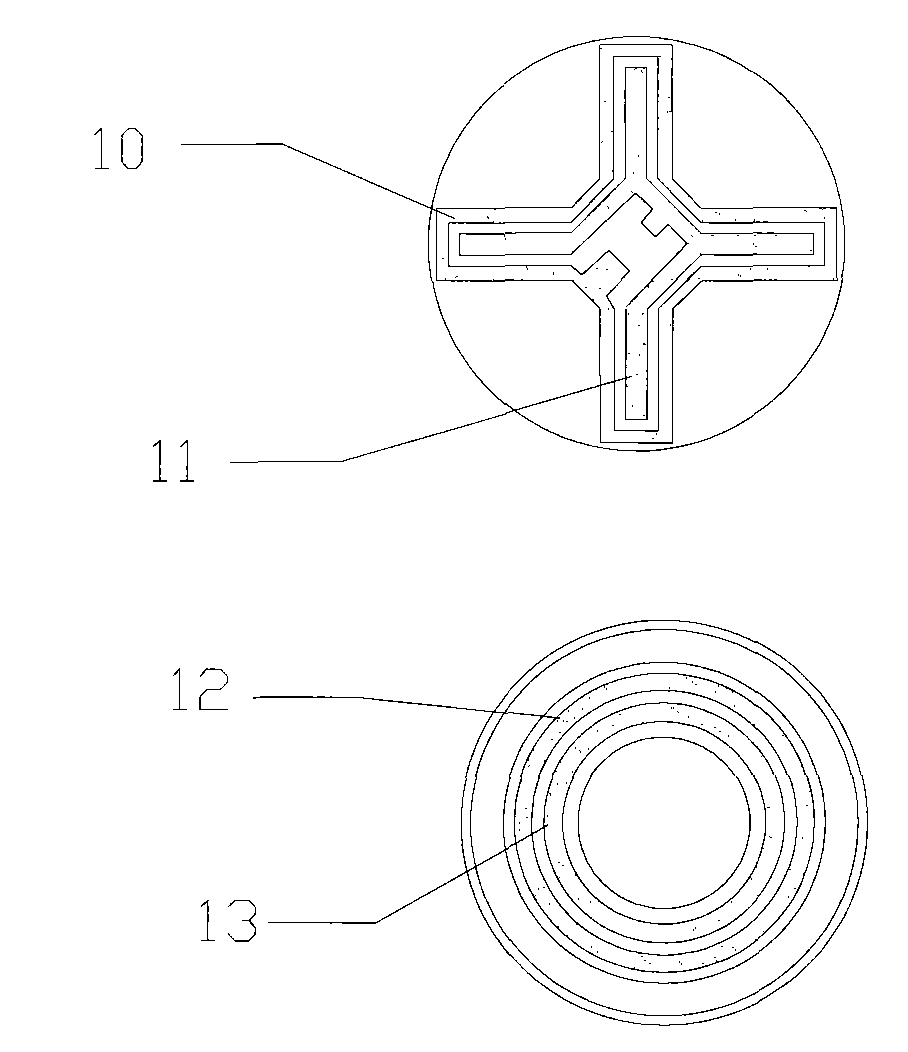

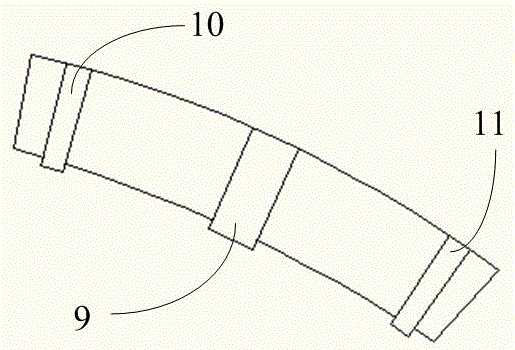

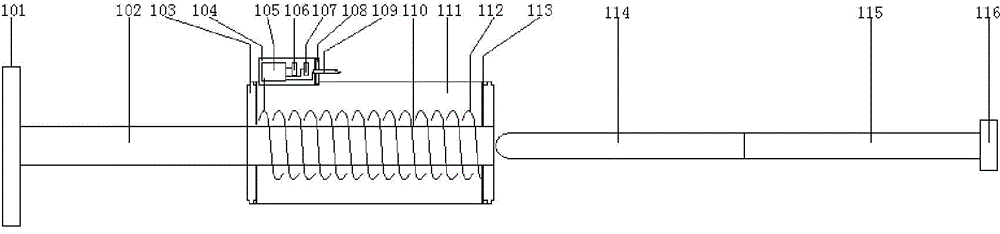

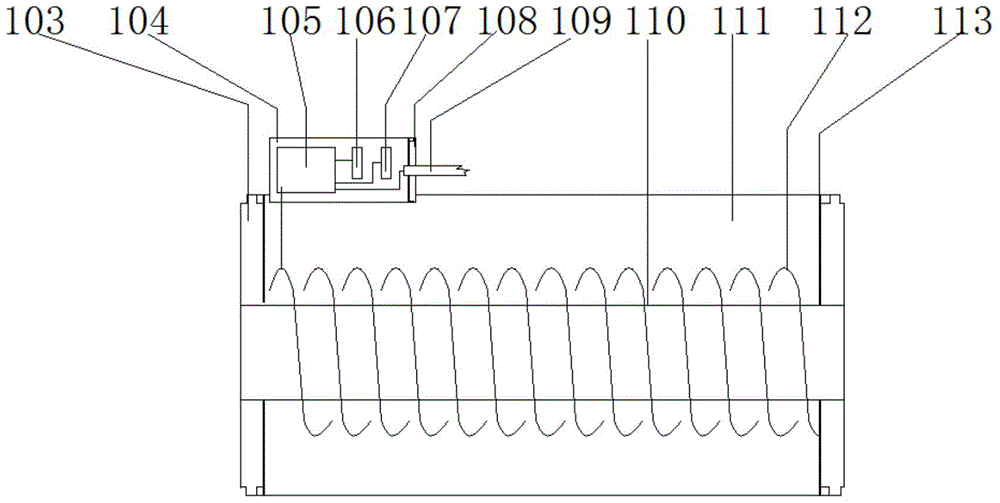

Laser measuring instrument for track lifting and lining for railway works

ActiveCN101592473AConvenient construction inspectionEasy to use and maintainTransmission systemsUsing optical meansLaser transmitterMeasurement device

The invention discloses a laser measuring instrument for track lifting and lining for railway works, which comprises a laser emitter device, a measuring device, a monitoring and correcting device and three walking trolleys. The laser emitter device, the measuring device and the monitoring and correcting device are arranged on one walking trolley respectively; the laser emitter device, the measuring device and the monitoring and correcting device are all provided with wireless communication devices and are communicated in a wireless mode; the laser emitter device comprises a track lifting laser, a track lining laser, a laser processor and a touch screen; and the measuring device and the monitoring and correcting device comprise an optical imaging system, a CCD sensor, a measuring processor, a touch screen, a horizontal sensor, and the like. The laser measuring instrument uses laser as a reference line, solves the problem of measuring the track lifting and track lining amount of long distance (more than 200 meters) in railway works department by measuring the position of the laser through the optical system and the CCD sensor, can carry out high-precision detection for railway line smoothness, provides reliable measuring basis for railway maintenance, and has high measuring precision.

Owner:JINAN LANDONG LASER TECH CO LTD

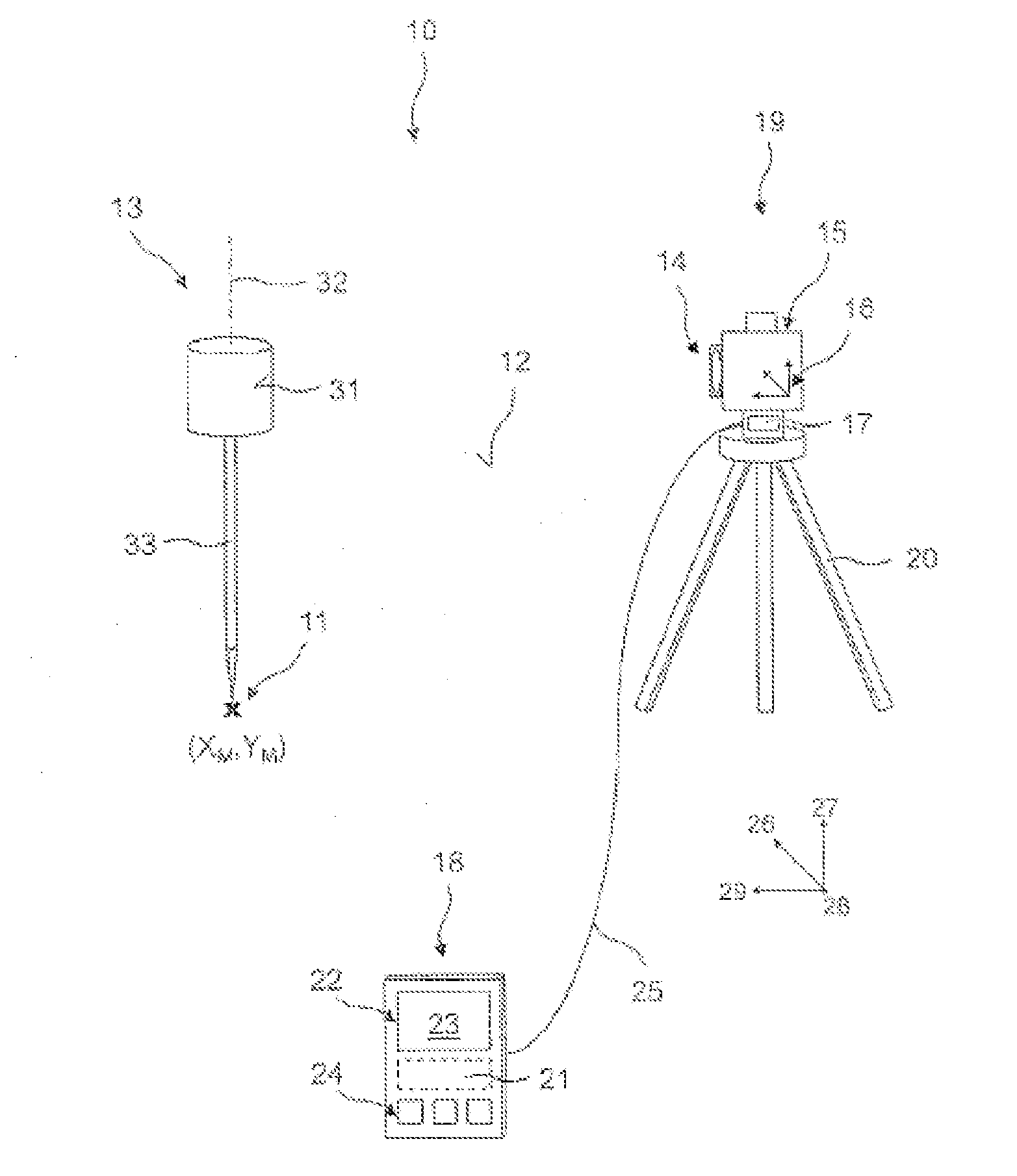

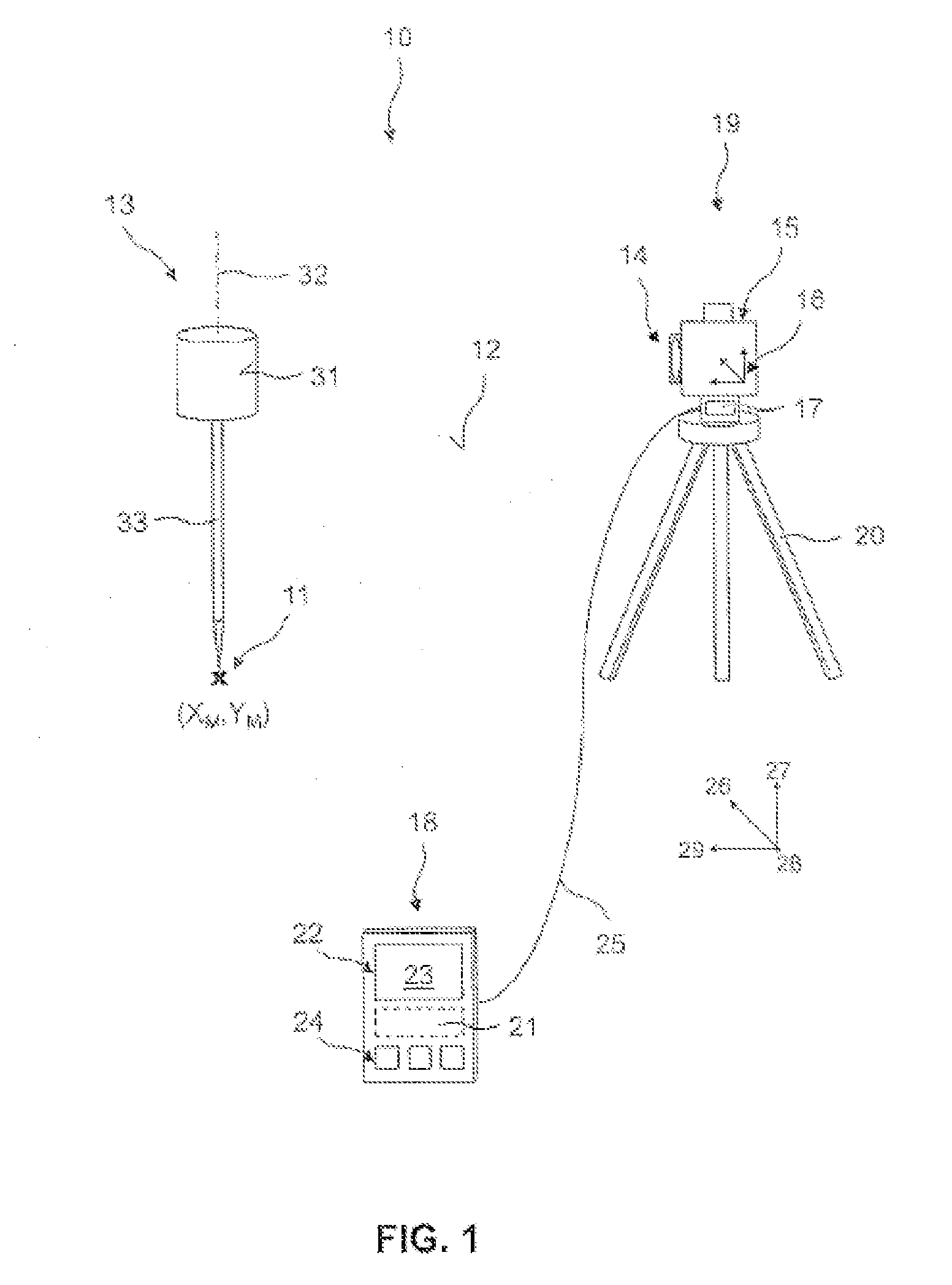

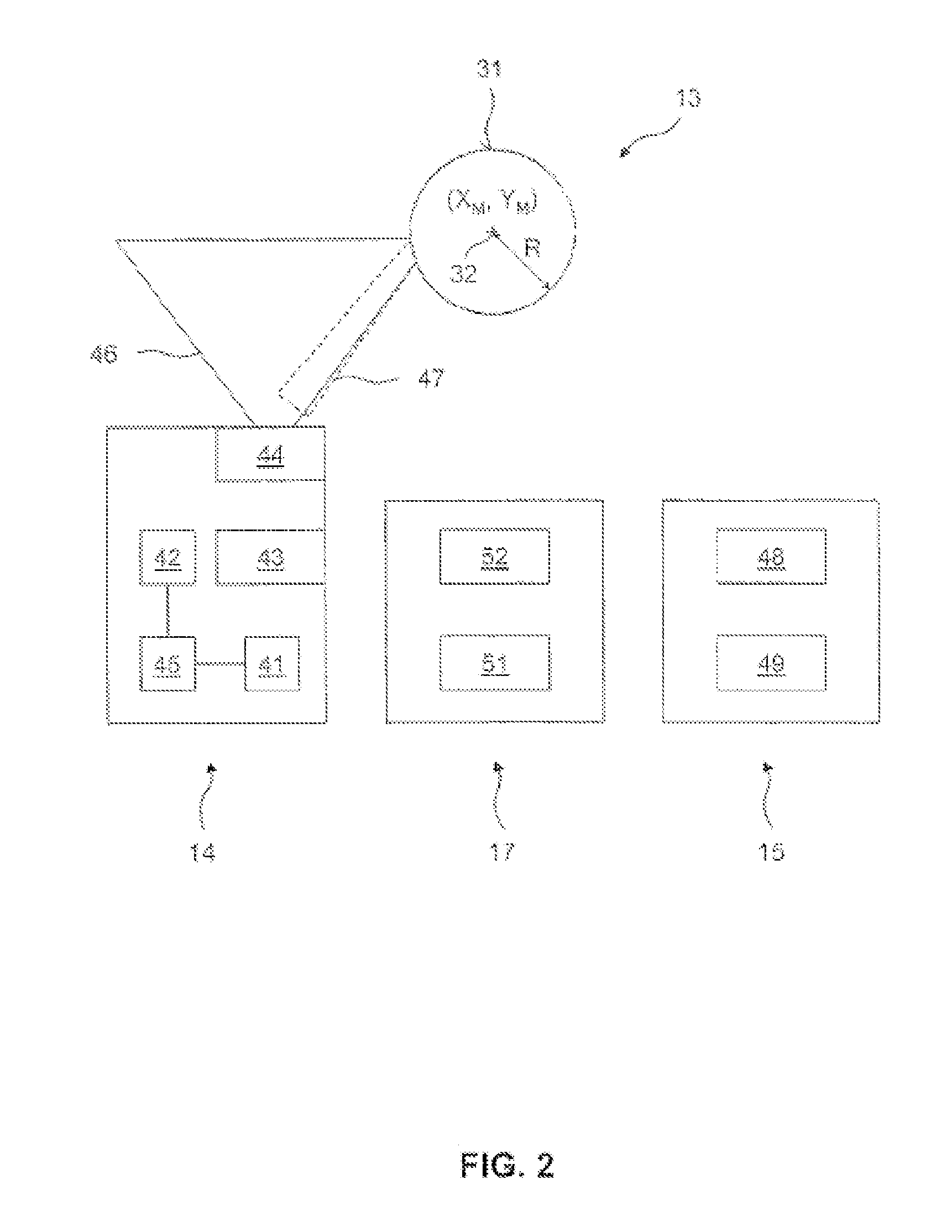

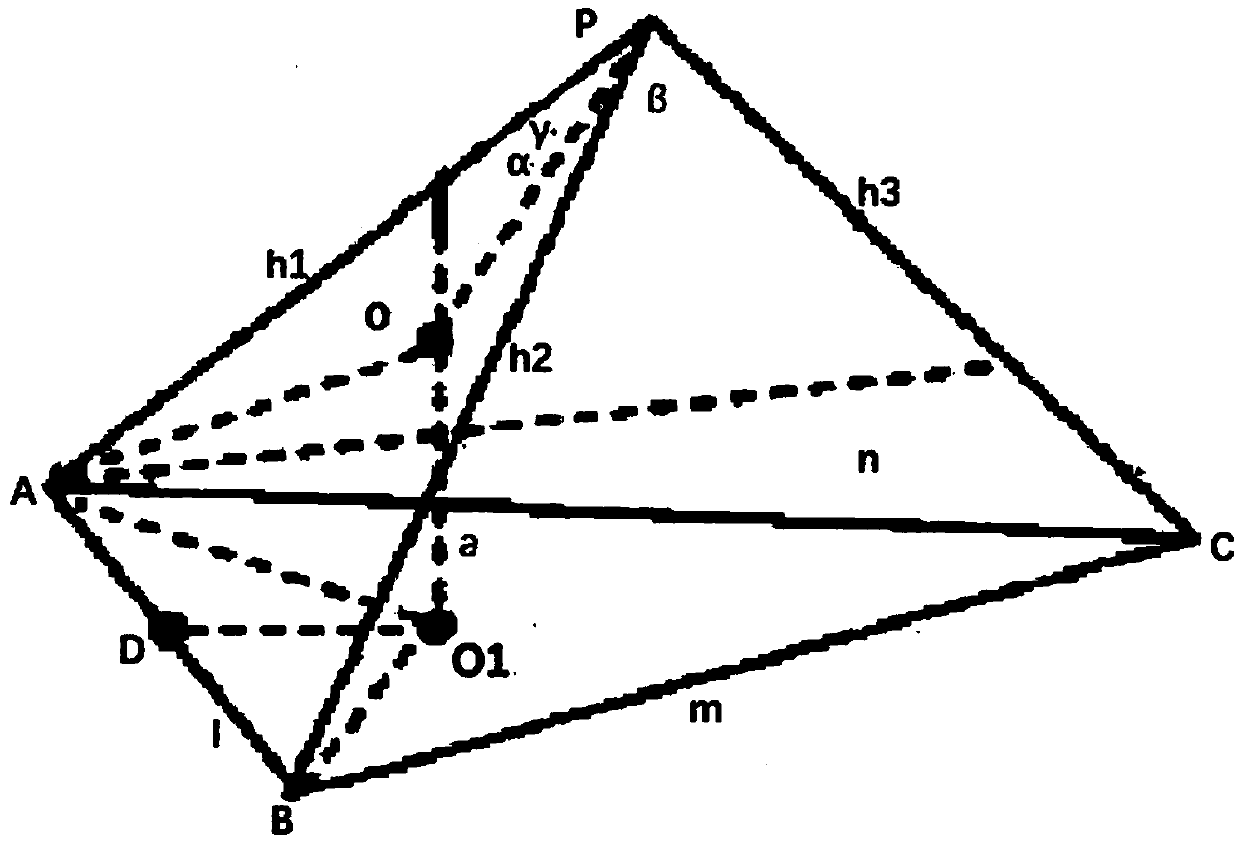

Method and Device for Determining the Position Coordinates of a Target Object

ActiveUS20150346341A1Improve accuracyLimited equipment expenseOptical rangefindersActive open surveying meansMeasurement deviceLight beam

Owner:HILTI AG

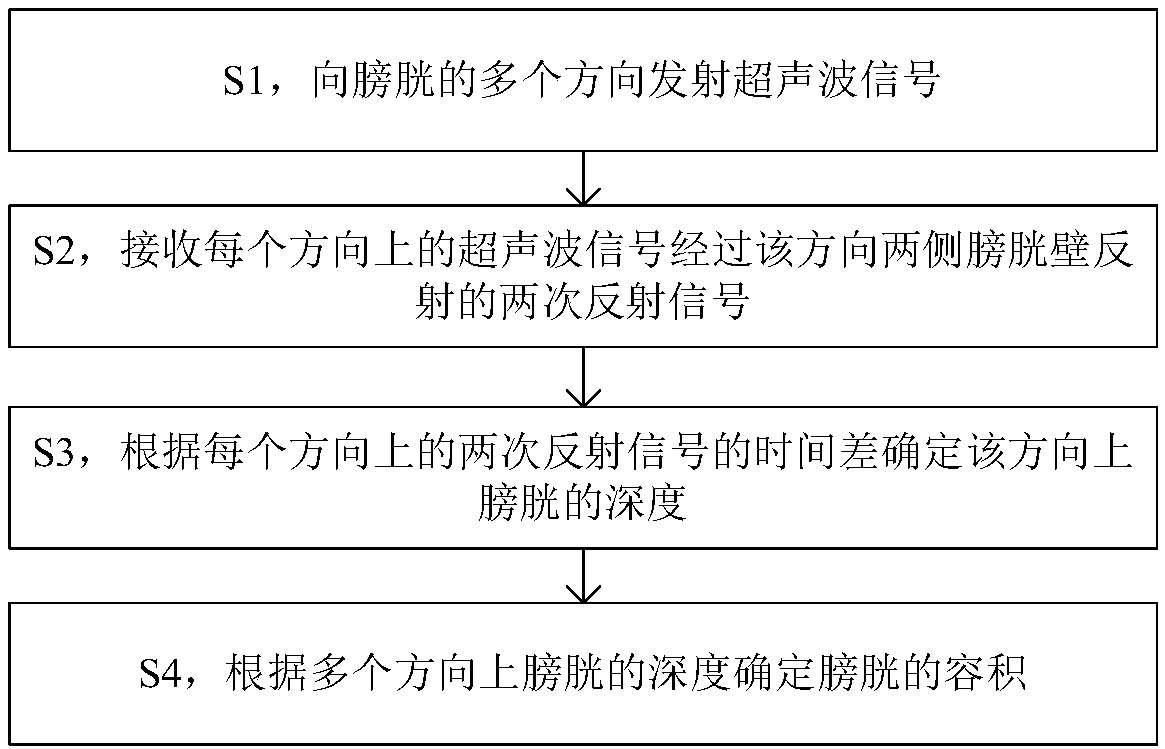

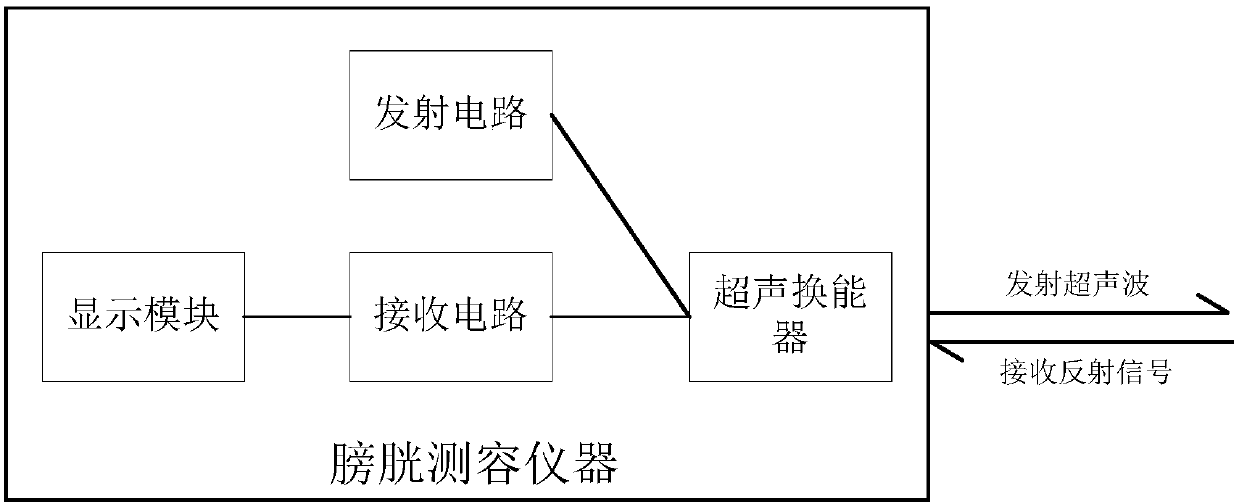

Bladder volume measuring method and instrument

InactiveCN107802290AImprove operational efficiencyPromote resultsInfrasonic diagnosticsSonic diagnosticsMeasurement deviceUltrasonic imaging

Owner:HUAZHONG UNIV OF SCI & TECH

Wide-range inductive frequency-modulation type displacement measurement device and method

ActiveCN104534974ANo change in precisionLarge rangeUsing electrical meansMeasurement deviceDeformation monitoring

Owner:湖南亿测物联传感技术研发有限公司

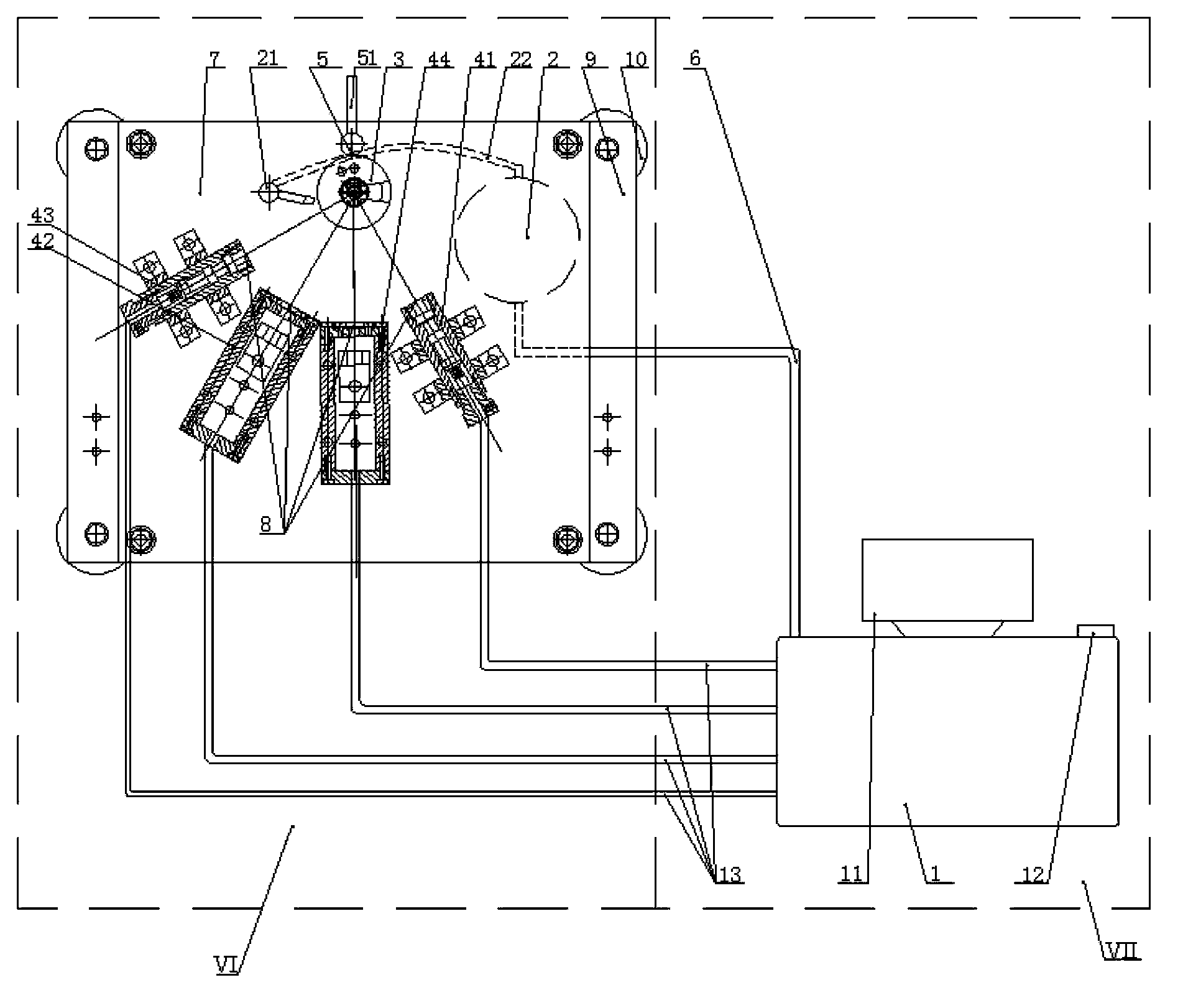

Forest dead combustible moisture online measuring device and measuring method thereof

Owner:NORTHEAST FORESTRY UNIVERSITY

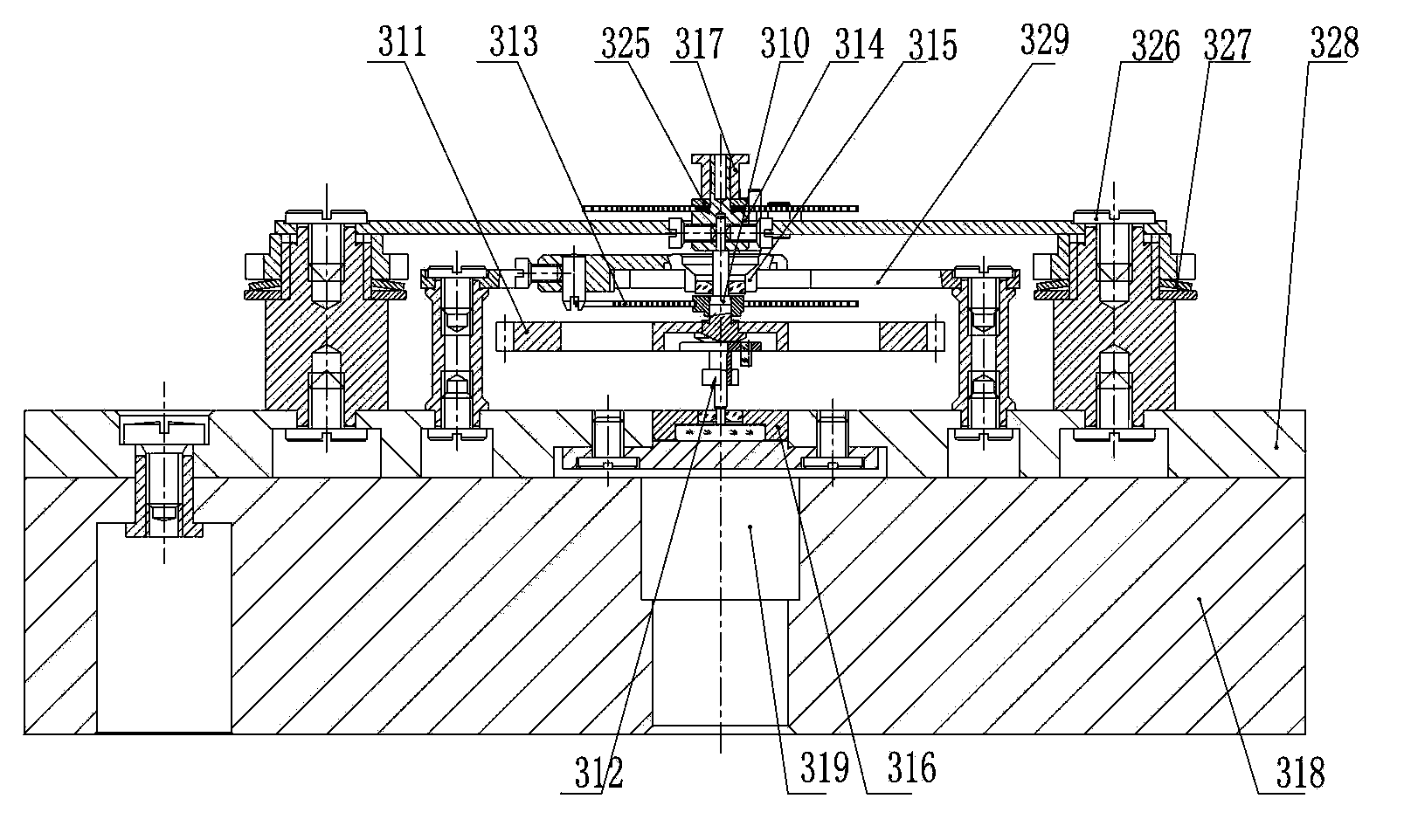

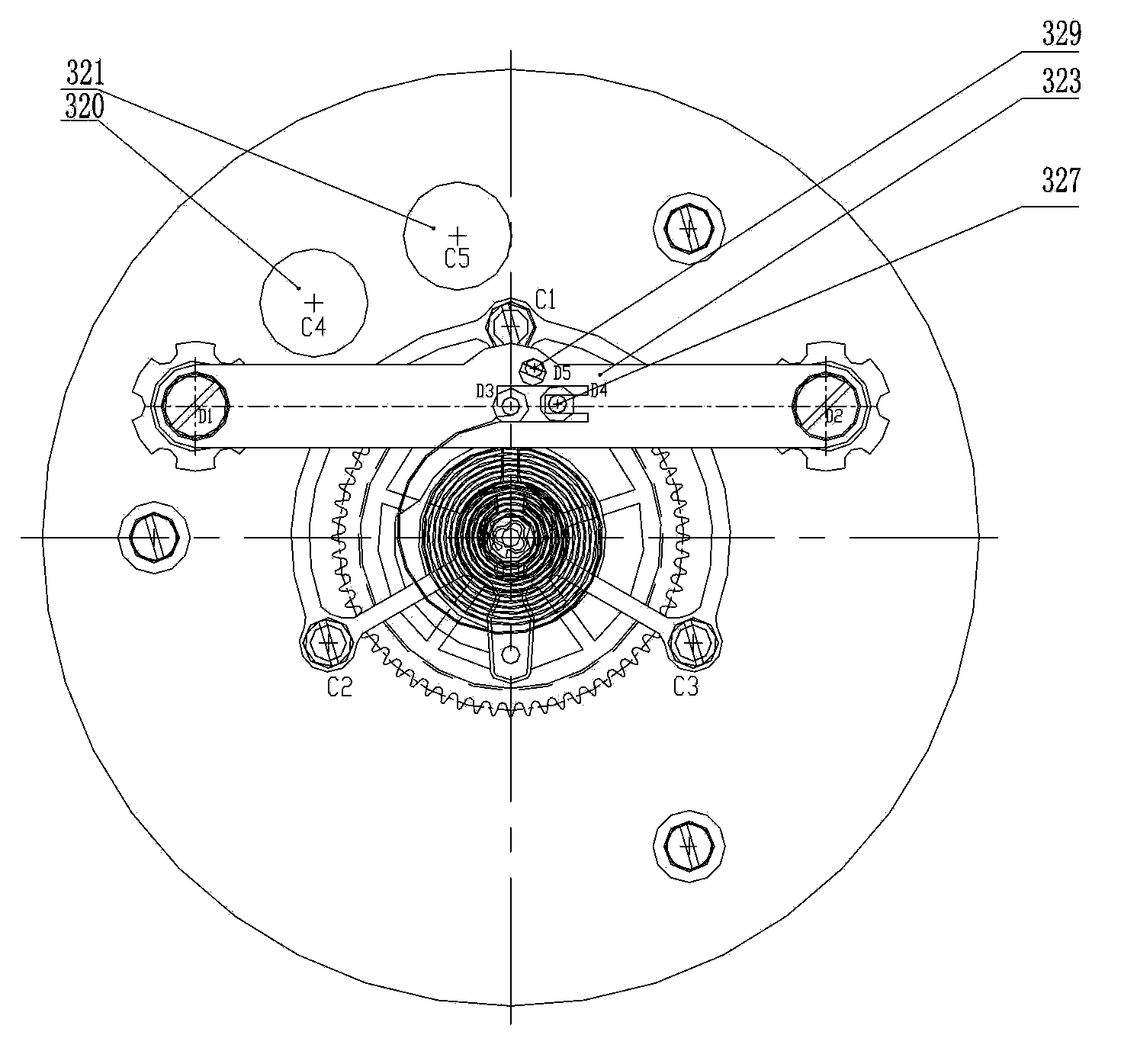

Method for dynamically measuring rigidity of silicon balance spring and rotational inertia of balance wheel and measurement device

ActiveCN103674742AEliminate measurement effectsFast measurementStatic/dynamic balance measurementMaterial strength using repeated/pulsating forcesMeasurement deviceMoment of inertia

Owner:TIANJIN SEAGULL WATCH CO LTD

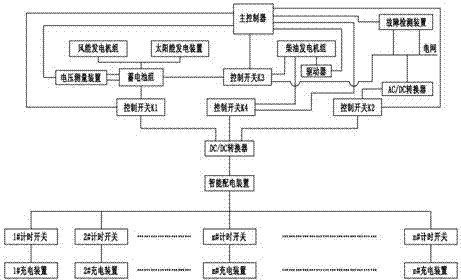

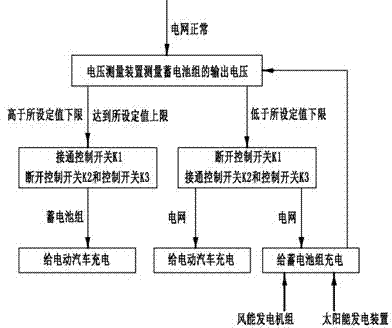

Energy-saving type electric vehicle charging station

InactiveCN104767263ABatteries circuit arrangementsPower network operation systems integrationMeasurement devicePower grid

Owner:曹进

Non-contact diameter measuring instrument based on LED light source

The invention provides a measuring device for detecting the diameter, thickness and other information of an object in a non-contact manner based on an LED light source. A diameter measuring instrumentis composed of an LED light source parallel light tube, a linear array CCD sensor and an image processing system. A measured object is placed between the LED light source parallel light tube and thelinear array CCD sensor for non-contact measurement. An LED (Light Emitting Diode) produces parallel light after passing through a series of optical lenses and small holes, and the parallel light hitsthe measured object and is finally projected to the linear array CCD sensor. The linear array CCD sensor converts an optical signal into an electrical signal. The digital image processing system processes the electrical signal, and displays the processing result through a display system.

Owner:王威立

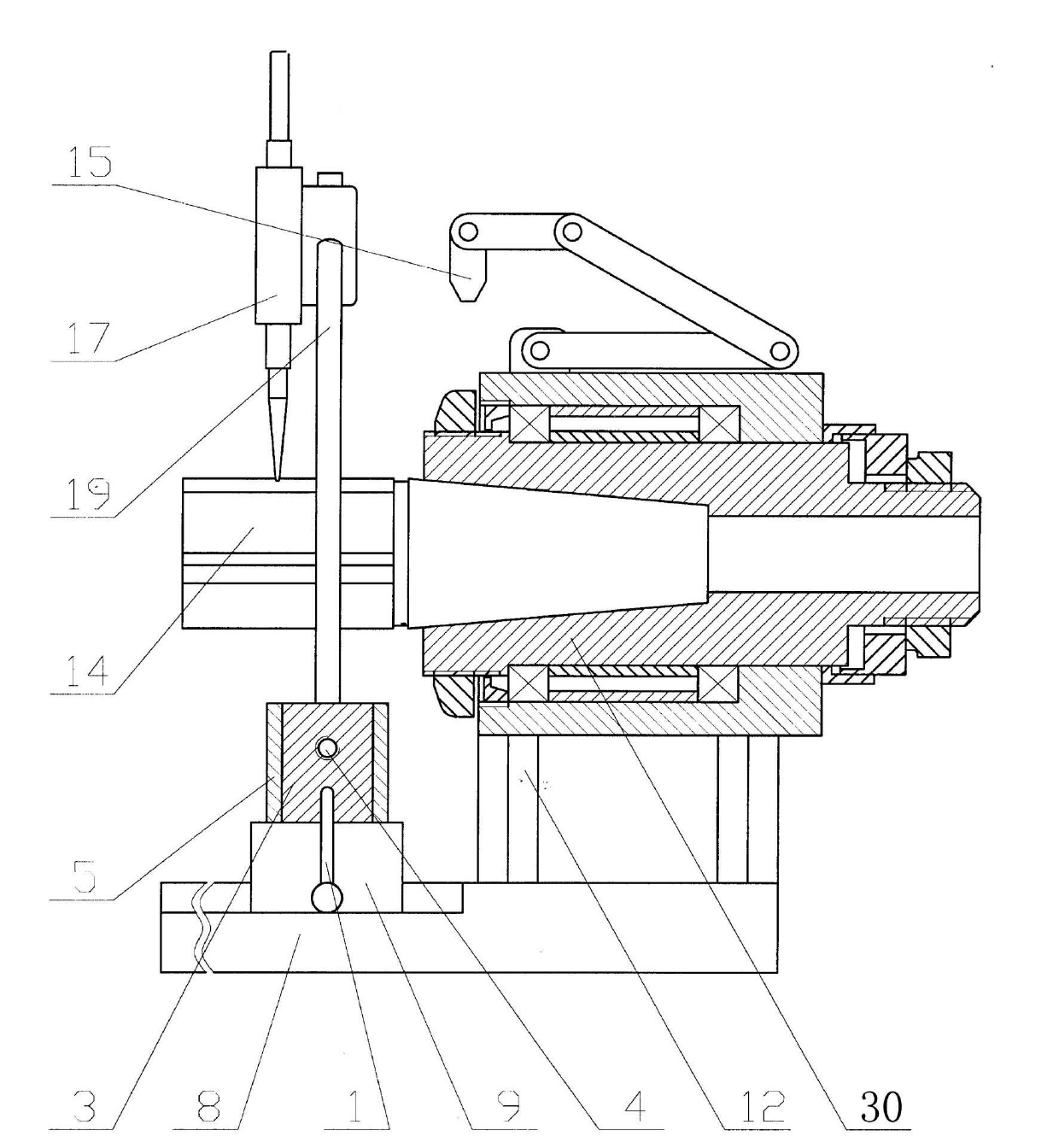

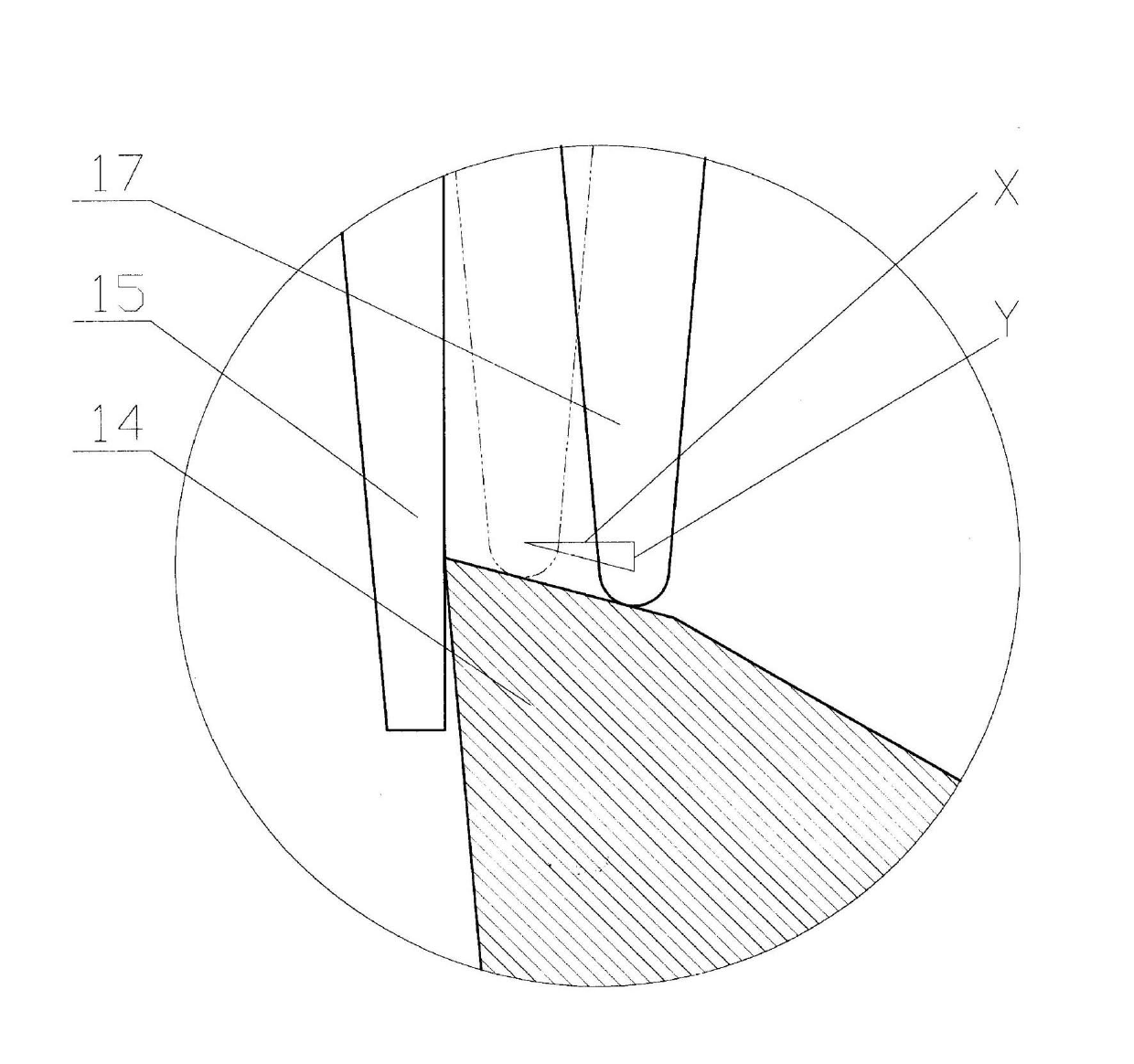

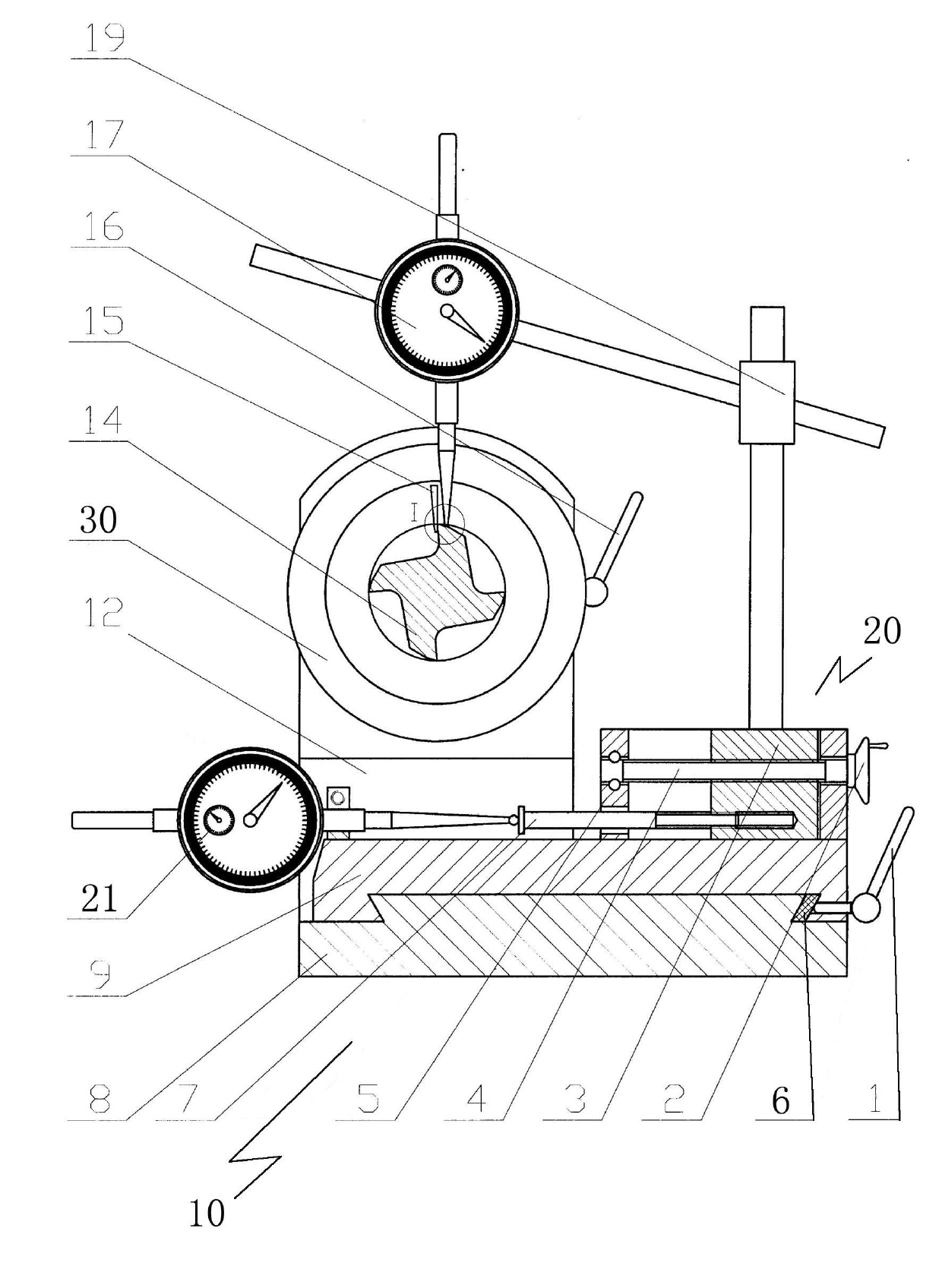

Cutting tool angle measuring instrument

Owner:SHENYANG AIRCRAFT CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap