Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389 results about "Fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber (or fibre in British English, see spelling differences; from the Latin fibra) is a natural or synthetic substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate fibers, for example carbon fiber and ultra-high-molecular-weight polyethylene.

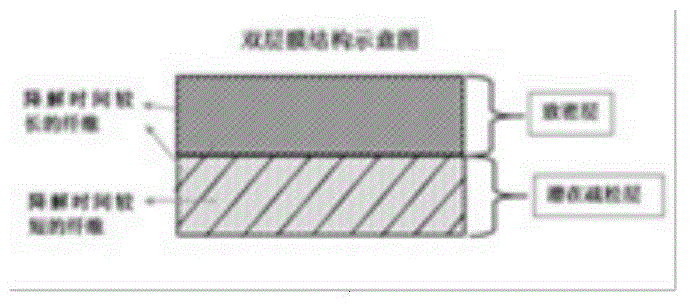

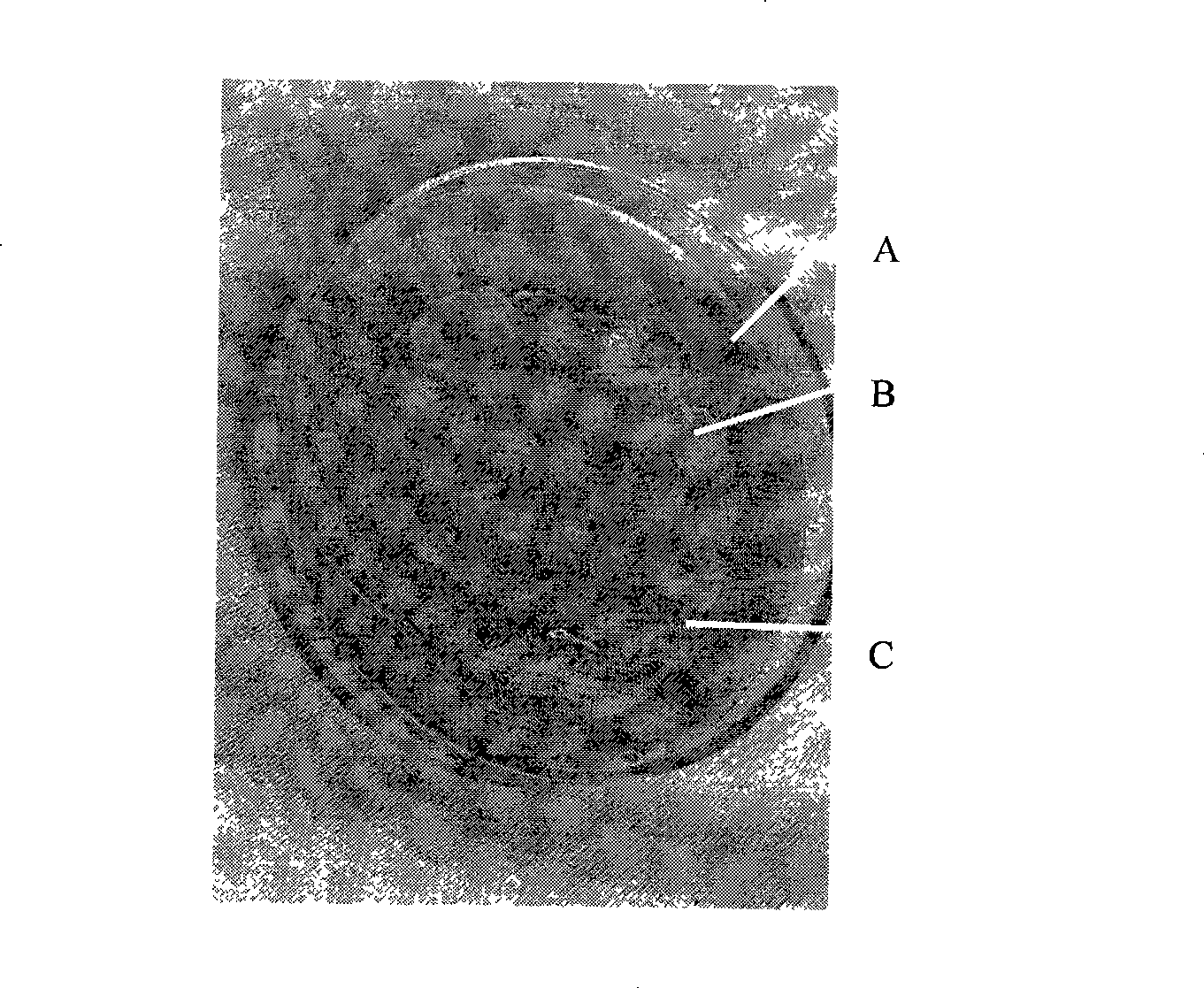

Guided tissue regeneration membrane as well as preparation method and application thereof

ActiveCN104474589APromote degradationLarge apertureCellulosic plastic layered productsProsthesisFiberTissue repair

Owner:烟台蓝创生物技术有限公司

Comfortable and dry absorbent article

Acquisition members having 20 to 40 weight percent of a latex binder and 60 to 80 weight percent of polyester fibers are useful in absorbent articles such as diapers and sanitary napkins. The polyester fibers may further include 20 to 80 weight percent of a first type of fiber, and 20 to 80 weight percent of a second type of fiber, wherein the second type of fiber has spiral-crimped fibers.

Owner:PROCTER & GAMBLE CO

Graphene conductive polyester fibers and preparation method thereof

ActiveCN104164707AOvercome cohesionOvercome uniformity issuesElectroconductive/antistatic filament manufactureSpinnerette packsPolyesterFiber

Owner:湖州市中磊化纤有限公司

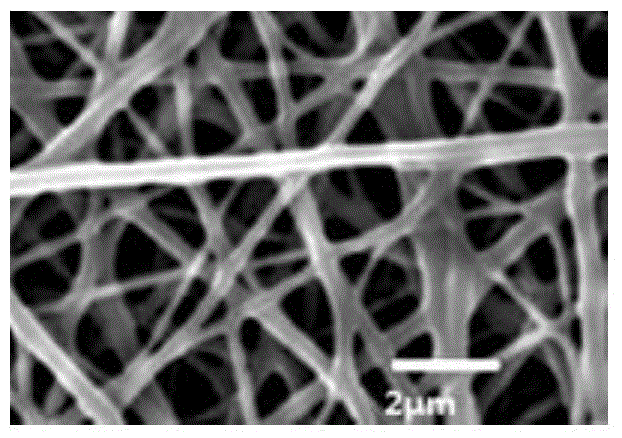

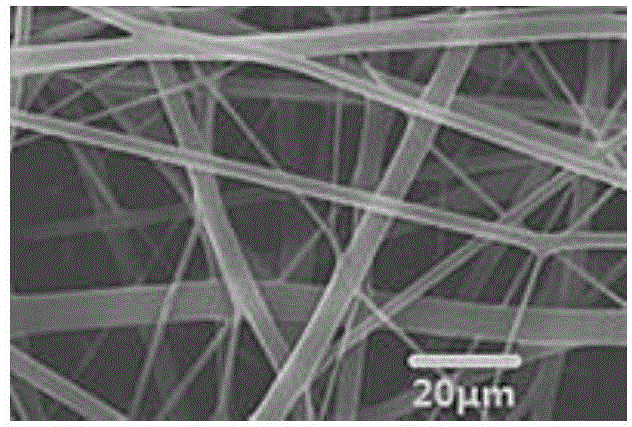

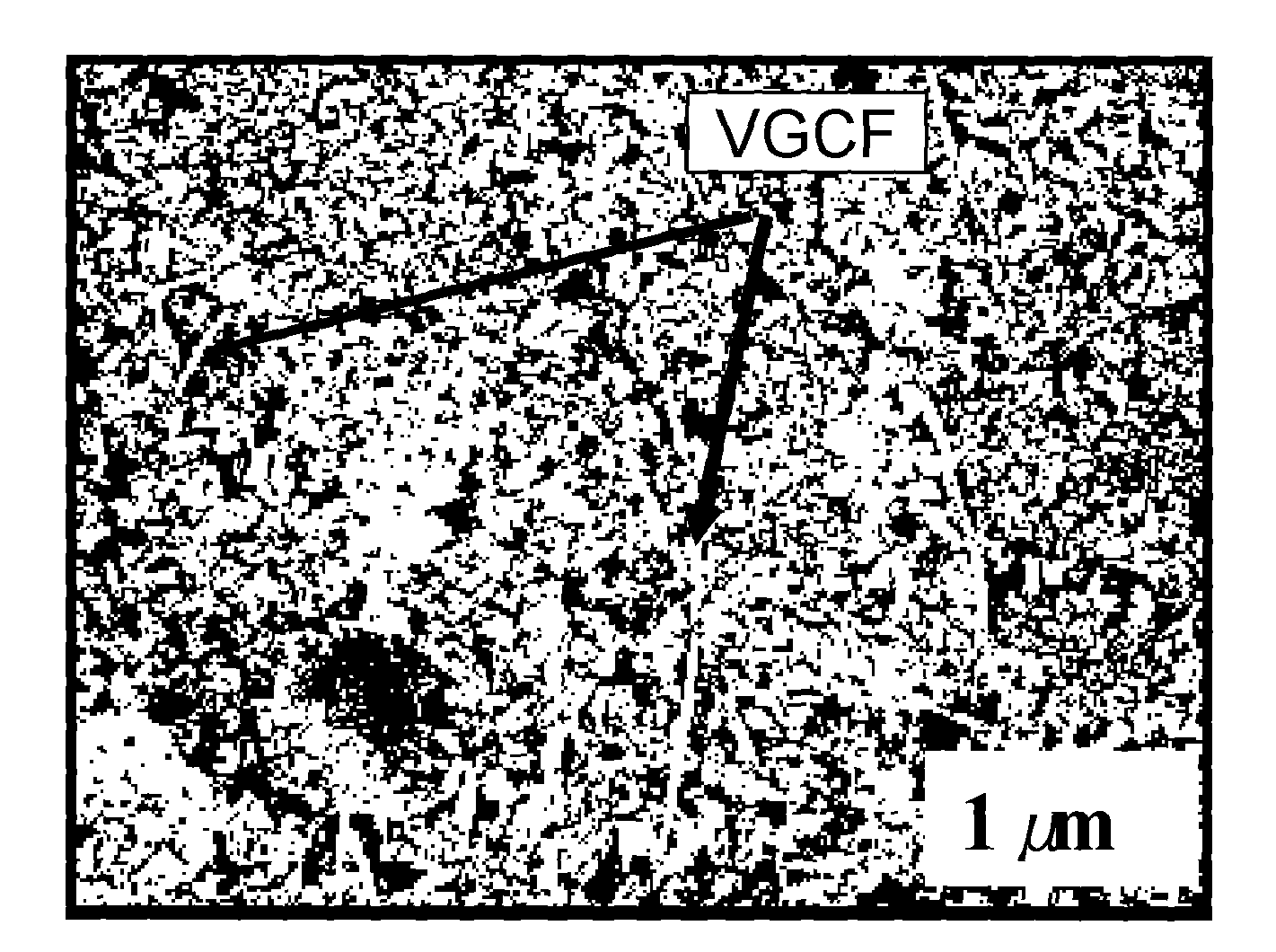

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

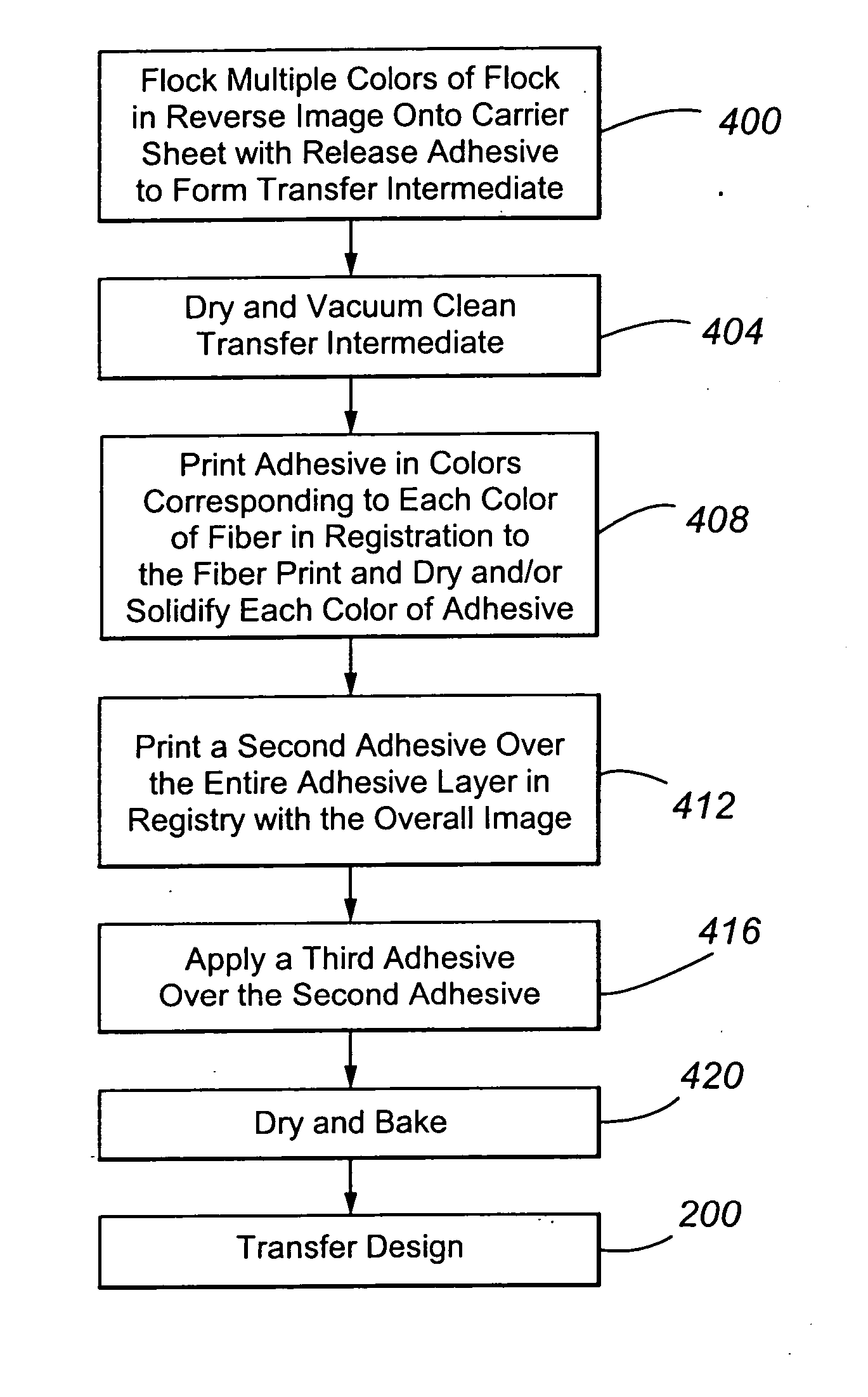

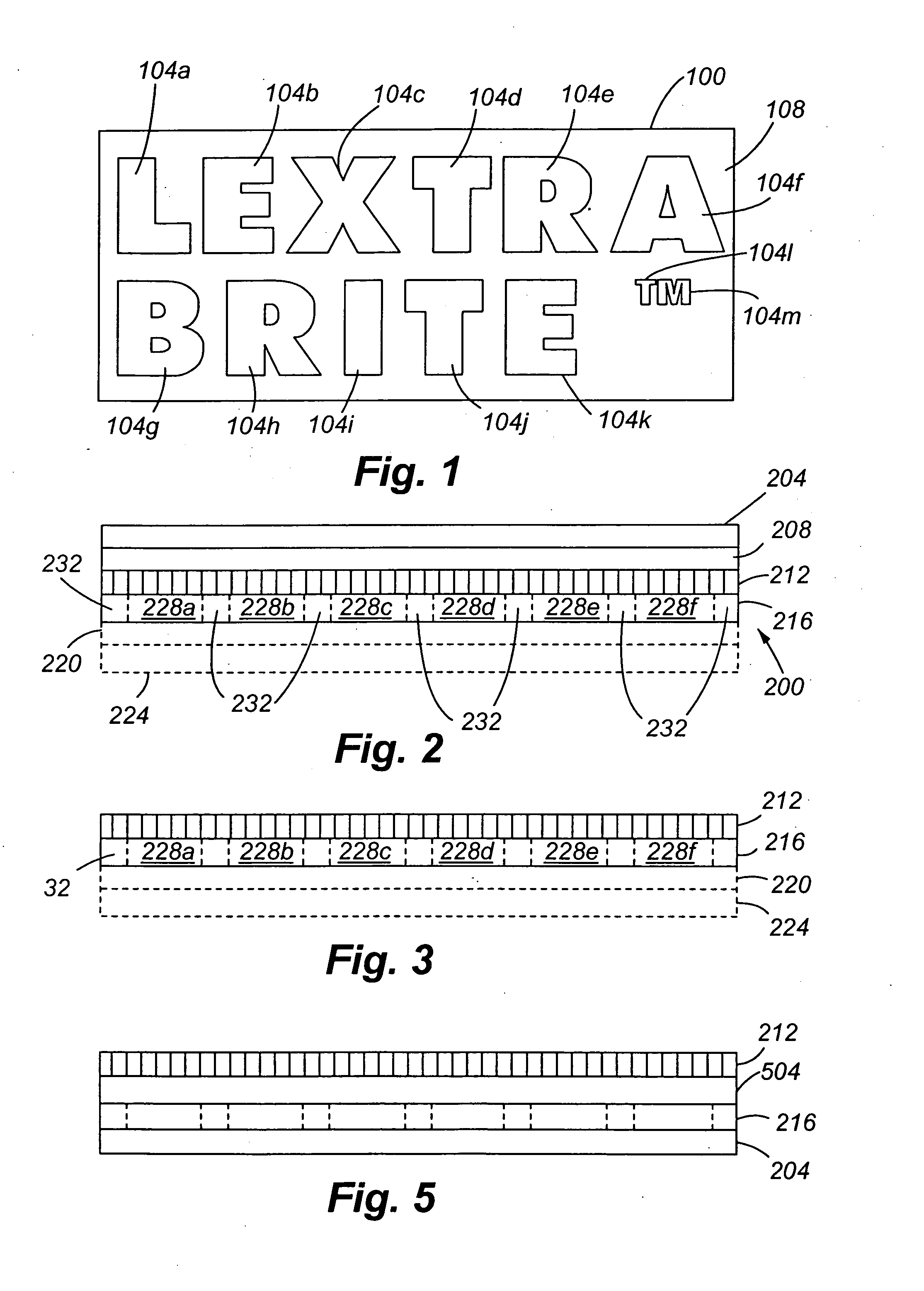

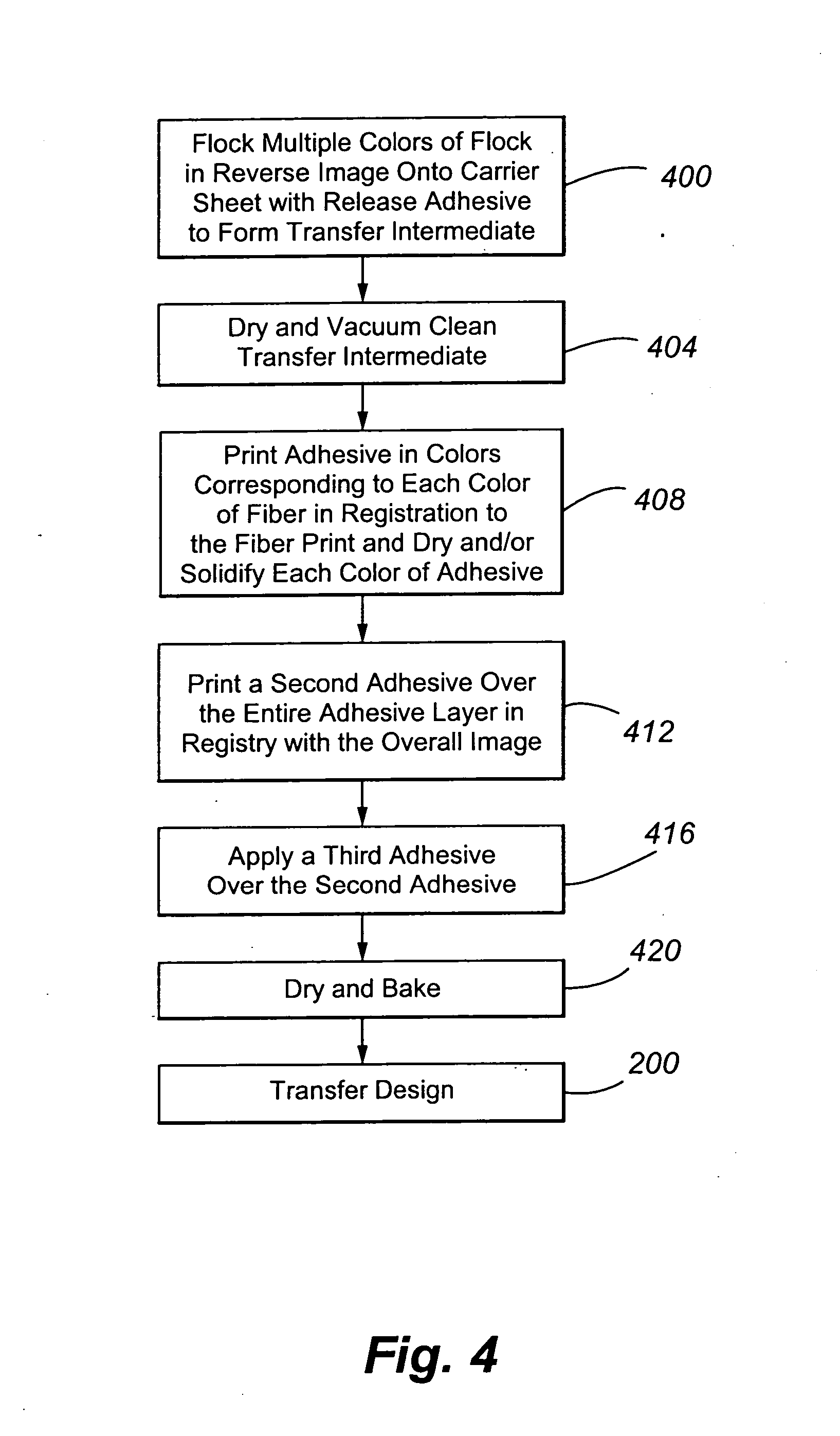

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

Conductive composite fiber and preparation method thereof

The invention relates to a conductive composite fiber and a preparation method thereof. The conductive composite fiber comprises a skin core structure including conductive particles and organic fibers, wherein the mass percentage composition of the conductive particles is 0.5-10%, and the mass percentage composition of the organic fibers is 90-99.5%. The preparation method comprises the following steps: (1) pre-treating the organic fibers in pretreatment liquid, and blowing; (2) soaking the fibers into water dispersion liquid of the conductive particles, ultrasonically assisting the conductive particles to outer layers of the fibers in ice water bath, soaking, drying, and soaking, cleaning and drying through hydrochloric acid solution to obtain the conductive composite fiber. According to the invention, the conductive composite fiber has the advantages of no organic solvent in preparation, greenness and environmental friendliness, simple process, low cost, continuous large-scale production, high conductivity of a product, difficulty in falling conductive components, durable conductive performance, soft hand feel and capability of being knitted; and the conductive composite fiber is used as an antistatic and electromagnetic shield material and an energy storage electrode material.

Owner:DONGHUA UNIV

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

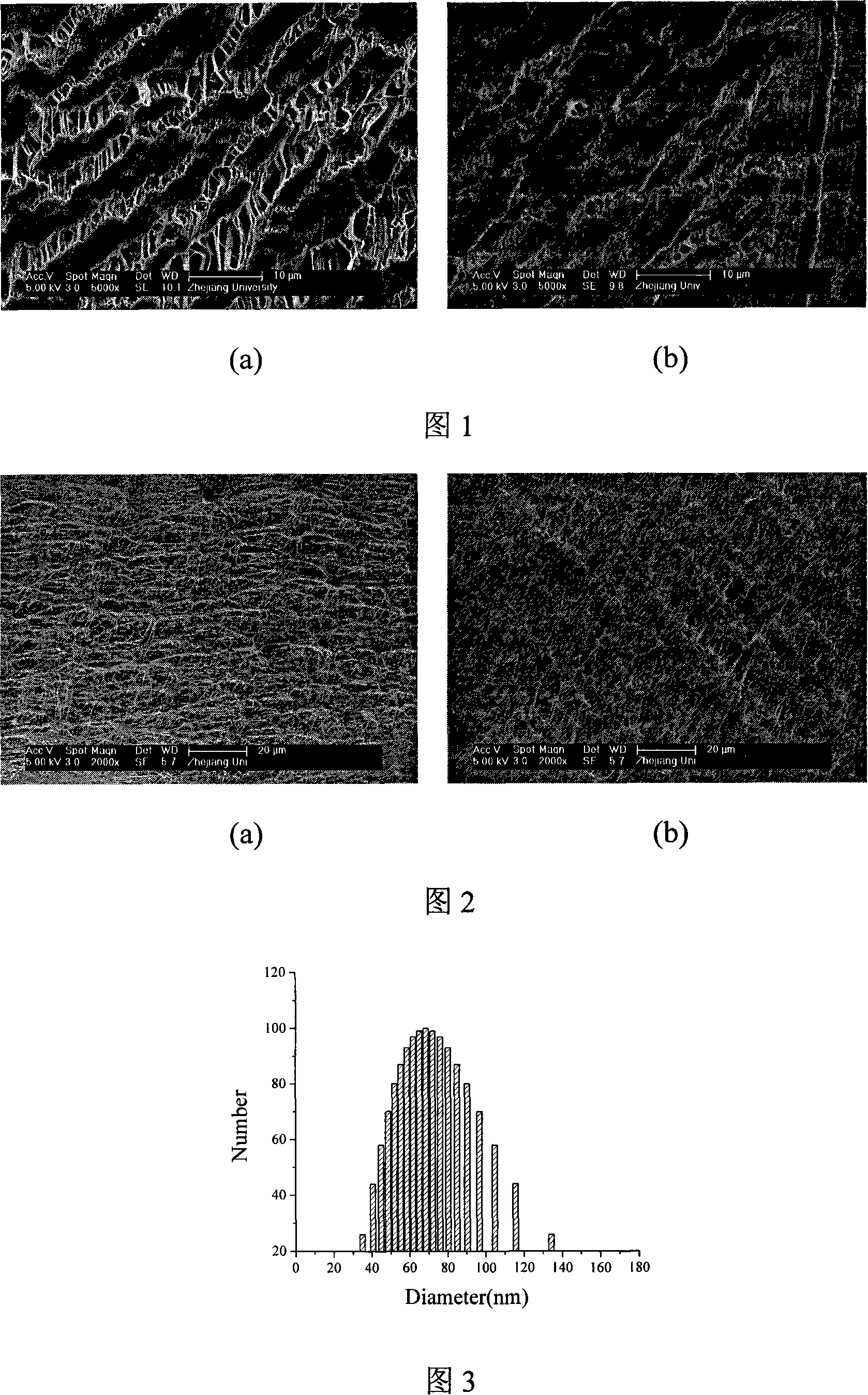

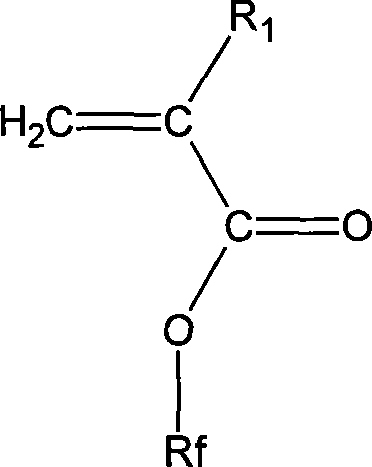

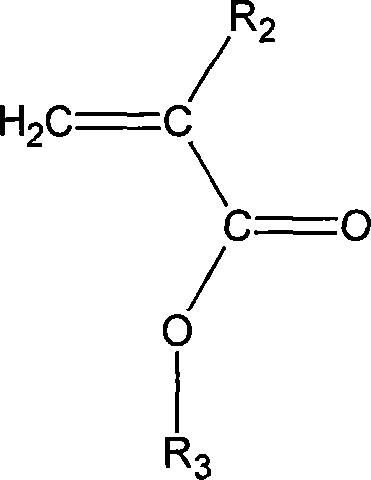

Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

InactiveCN101108313AImprove anti-pollution performanceImprove hydrophilic abilitySemi-permeable membranesFiberTetrafluoroethylene

Owner:ZHEJIANG UNIV

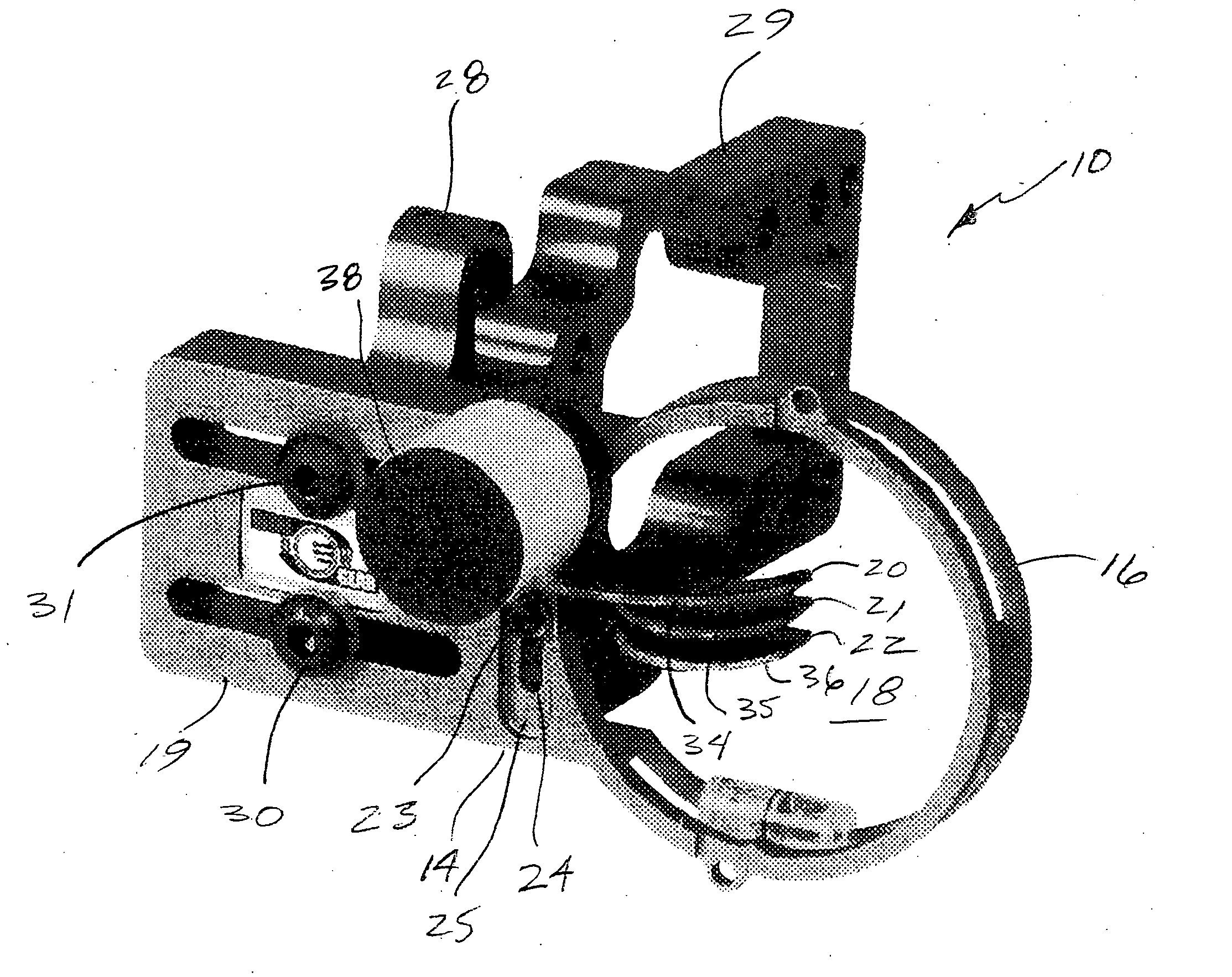

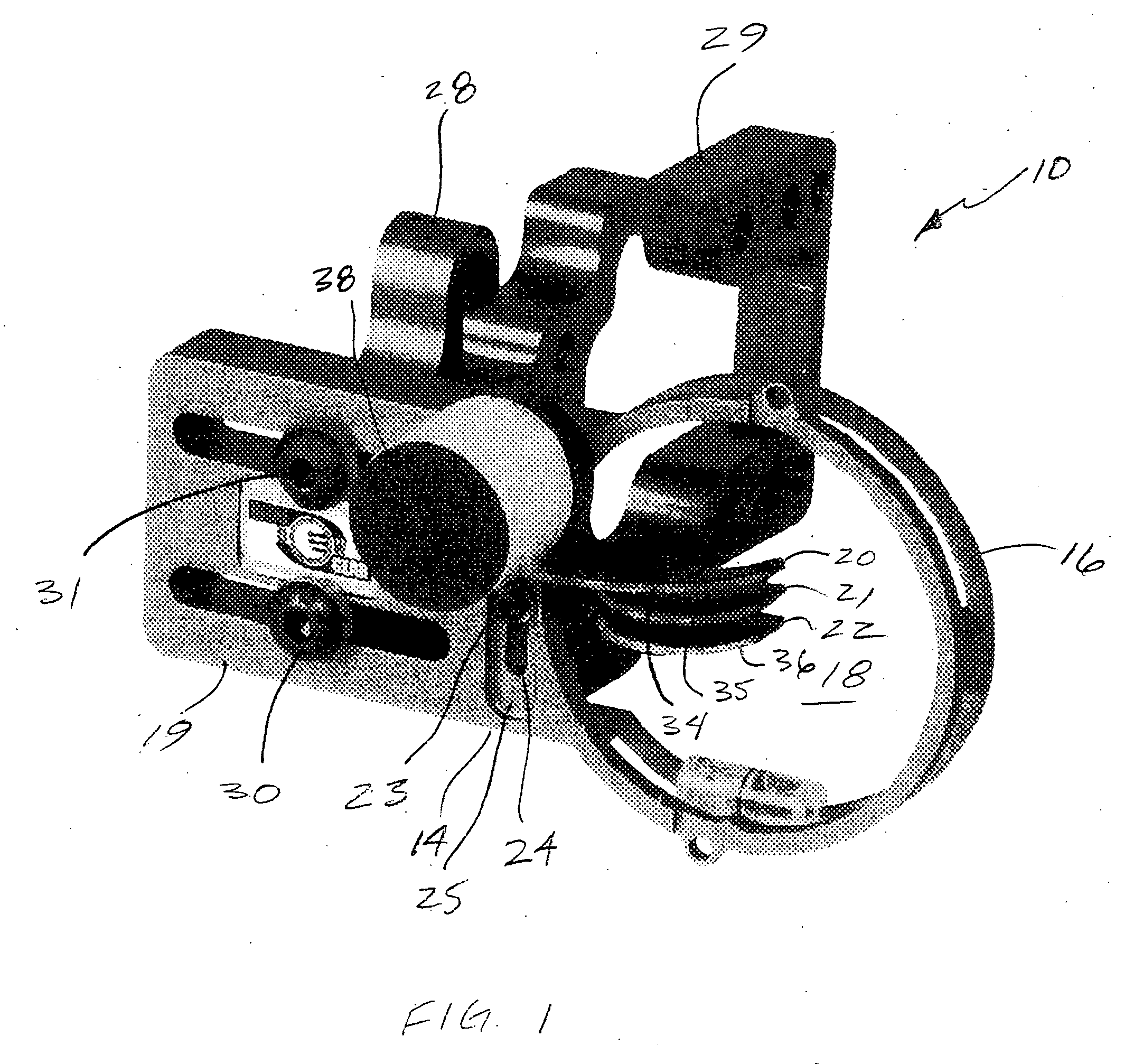

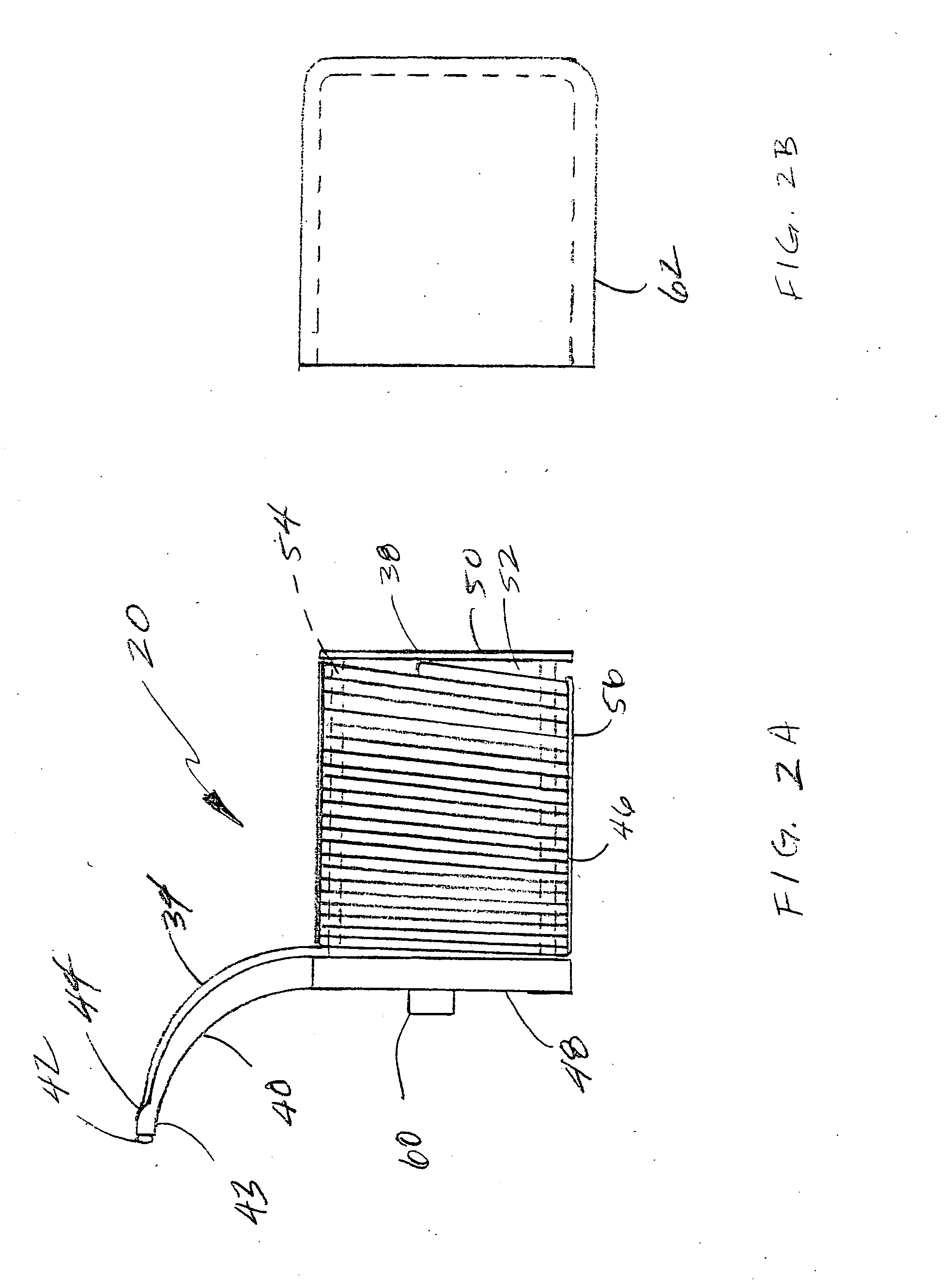

Fiber optic sight pin

InactiveUS20050138824A1Increase surface areaEnhanced light absorptionSighting devicesEngineeringFiber

Owner:AFSHARI ABBAS BEN

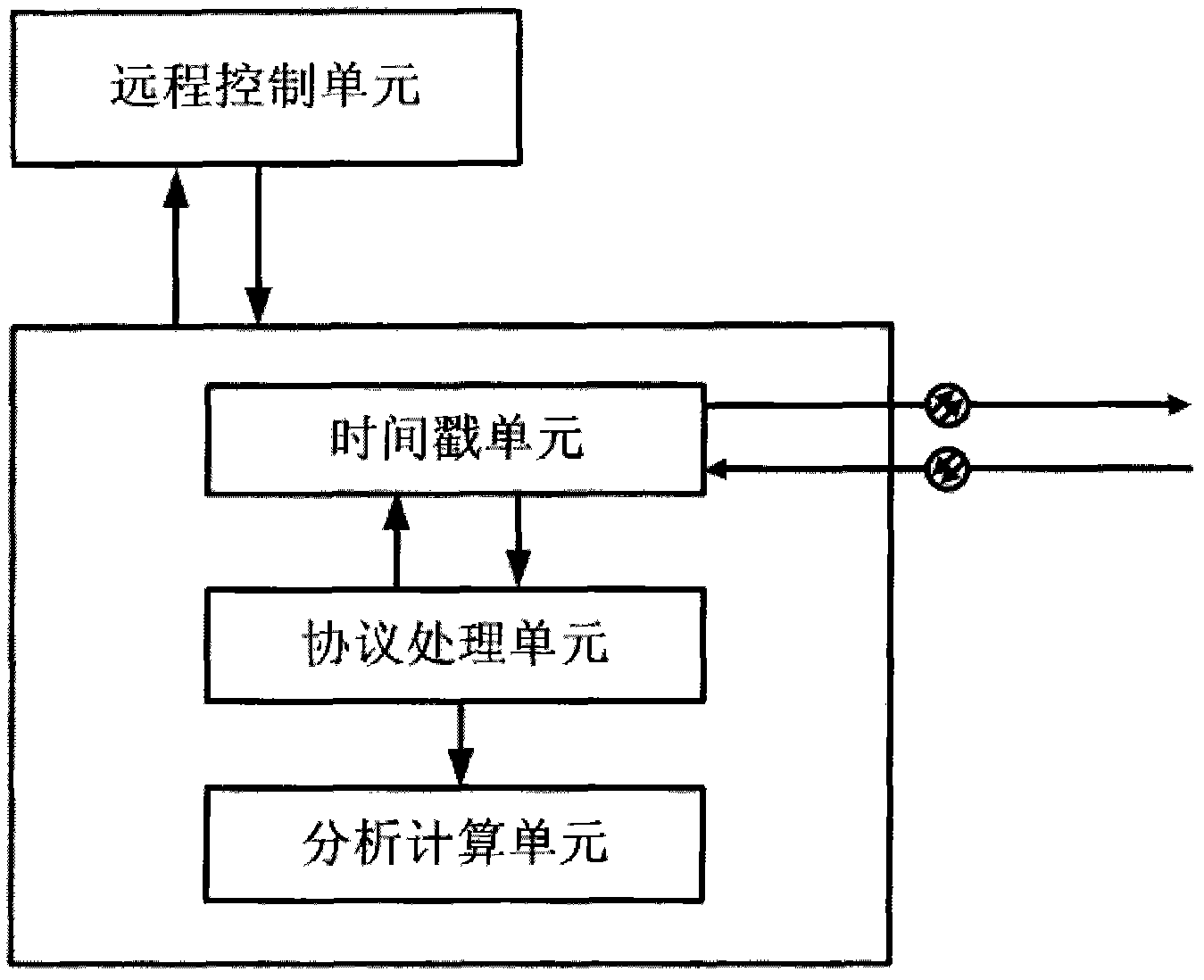

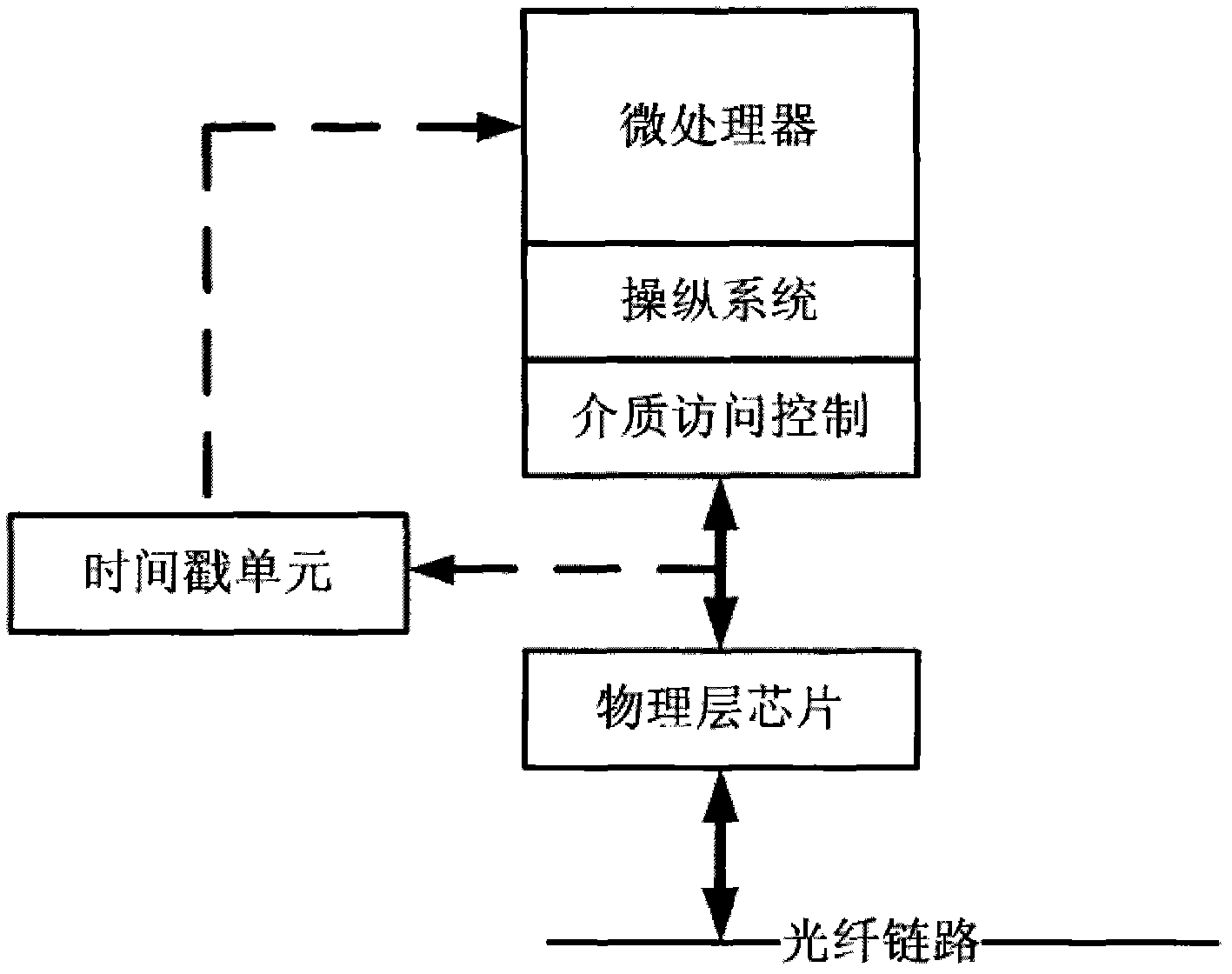

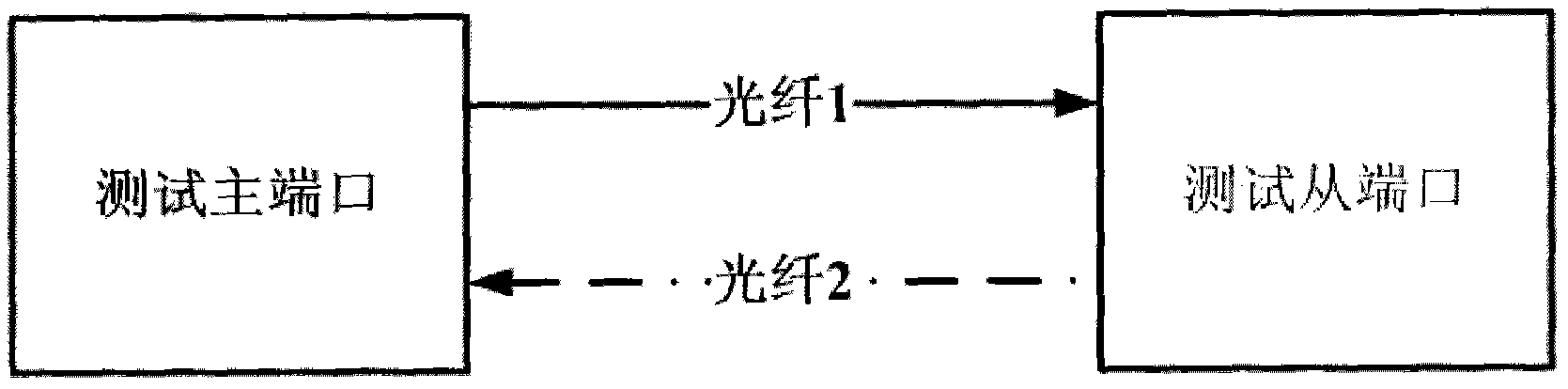

Method and device for measuring optical fiber asymmetry time delay

ActiveCN102291178ASave moneySave labor costsTime-division multiplexElectromagnetic transmissionTime delaysFiber

Disclosed are a method and apparatus for measuring optical fiber asymmetry time delay. The method comprises: an RTU configuring working states of a Master and a Slave at two ends of an optical fiber line; the RTU delivering an instruction to measure a first optical fiber, and a Master side PPU sending a message, recording a sending time stamp t1 and transmitting the sending time stamp t1 to the Slave; a Slave side PPU receiving the message, recording an arrival time stamp t2, and storing the arrival time stamp t2 corresponding to t1; the RTU displaying that measurement for the first optical fiber is completed, preparing to measure a second optical fiber, and swapping the two optical fibers; the RTU delivering an instruction to measure the second optical fiber, and the Master side PPU sending a message, recording a sending time stamp t'1 and transmitting the sending time stamp t'1 to the Slave; the Slave side PPU receiving the message, recording an arrival time stamp t'2, and storing the arrival time stamp t'2 corresponding to t'1; and an ACU calculating an asymmetry time delay compensation value and sending the asymmetry time delay compensation value to the RTU. The present invention is not limited by sites, saves cost and labor, is simple and fast, and has short stabilization time as well as high testing efficiency and precision.

Owner:FENGHUO COMM SCI & TECH CO LTD

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsFiberChemical reaction

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

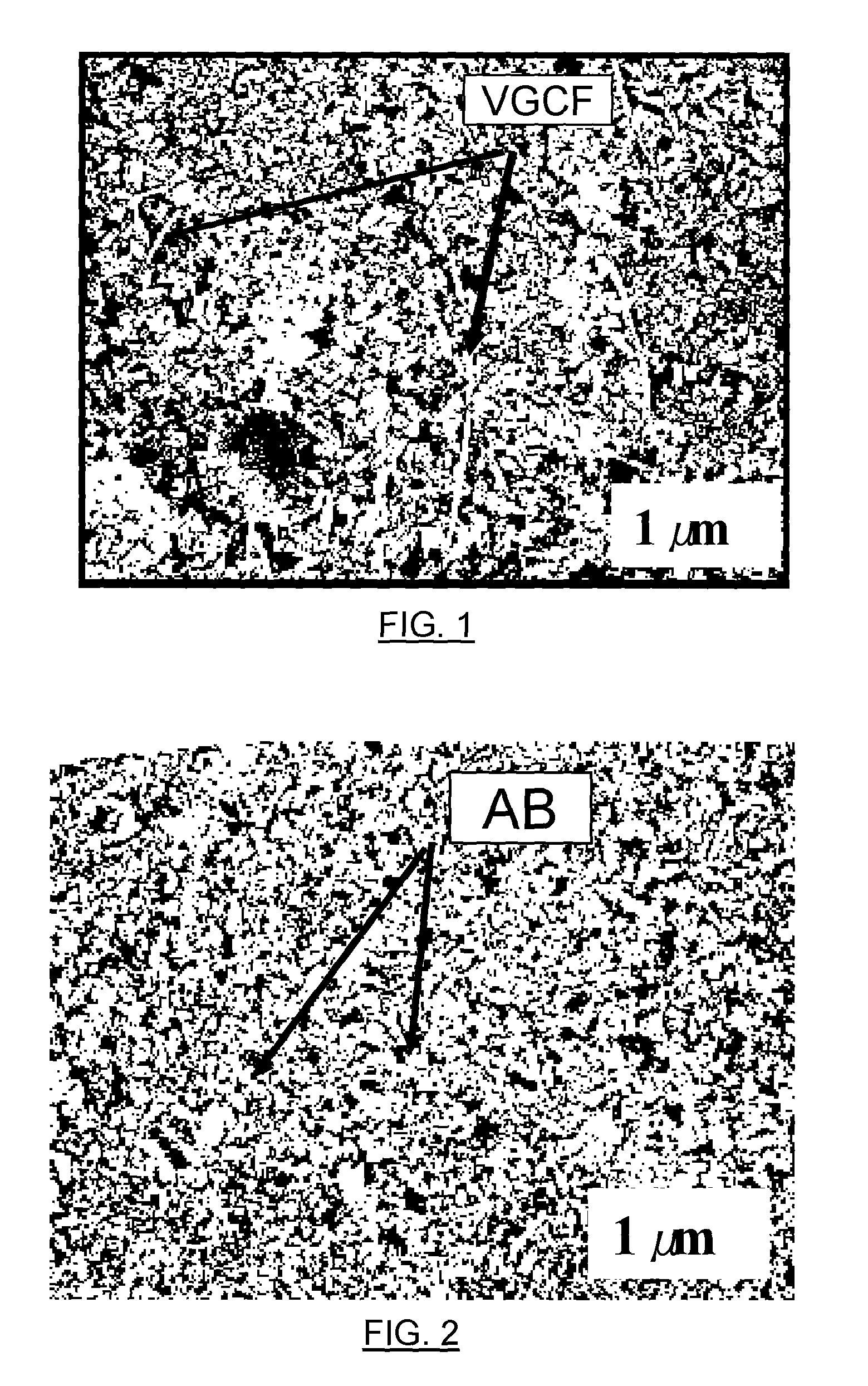

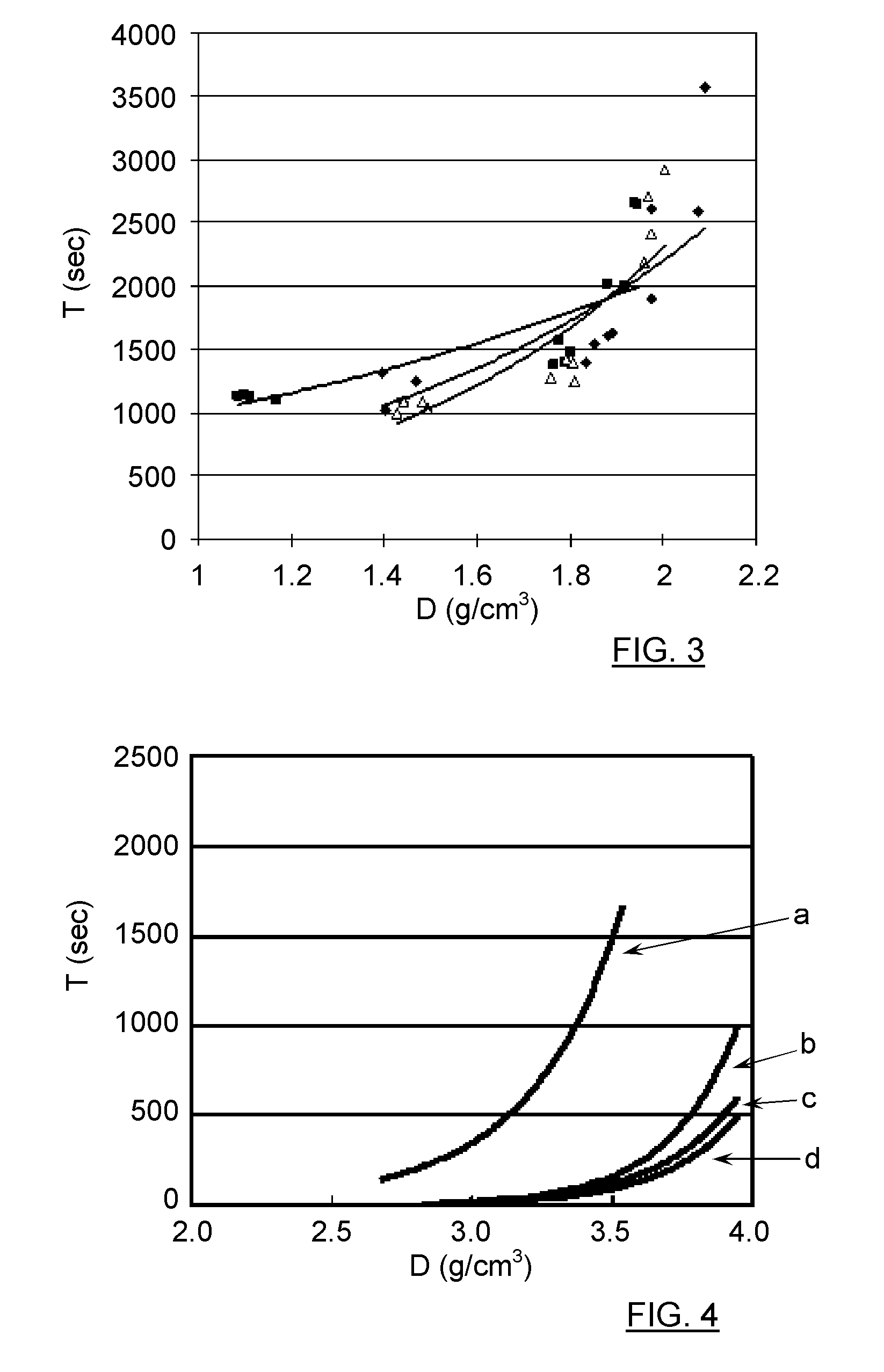

Composite electrode material

ActiveUS20110068294A1Low viscosity of mixtureElectrode manufacturing processesPositive electrodesCarbon coatedFiber

Owner:HYDRO QUEBEC CORP +1

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

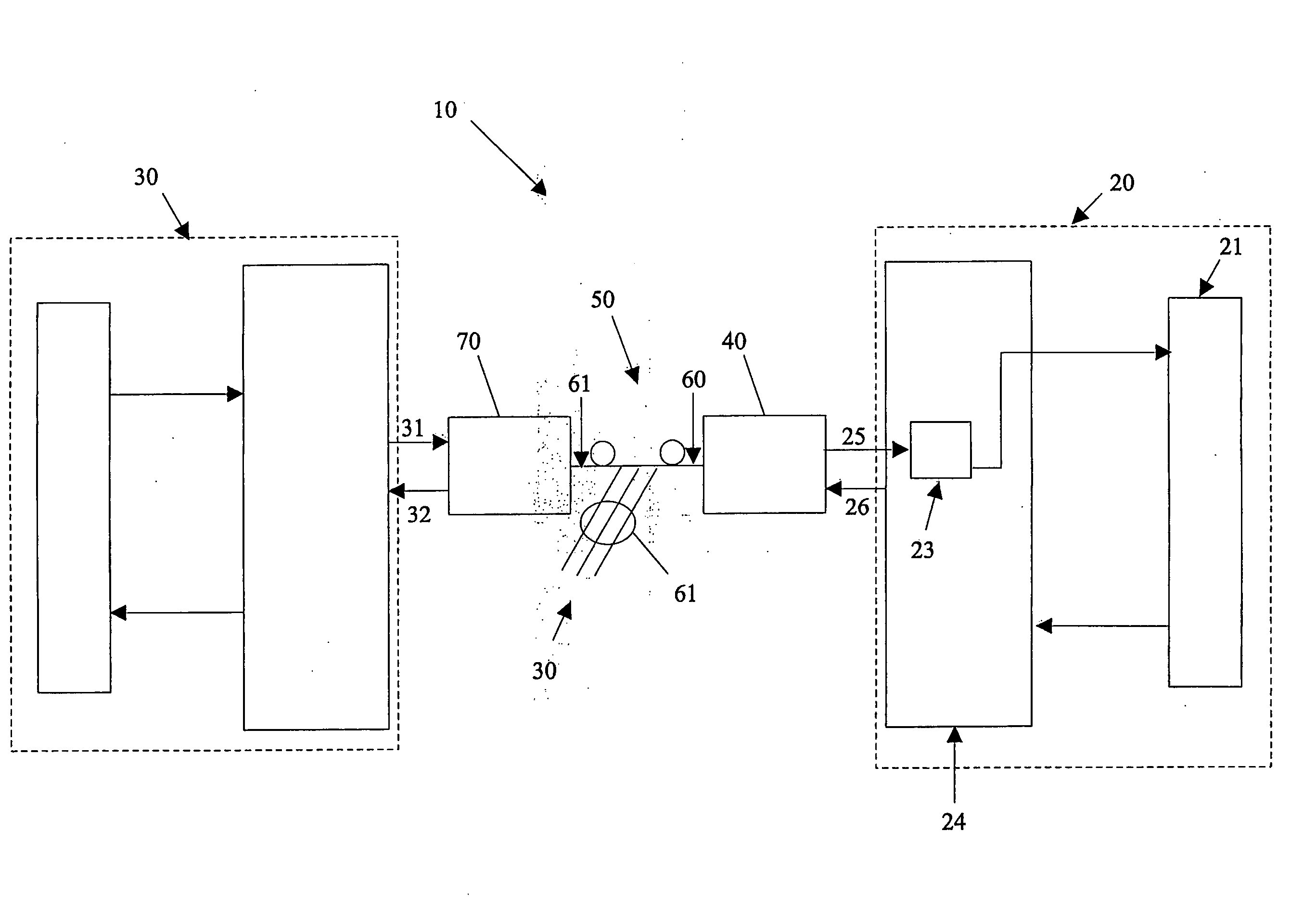

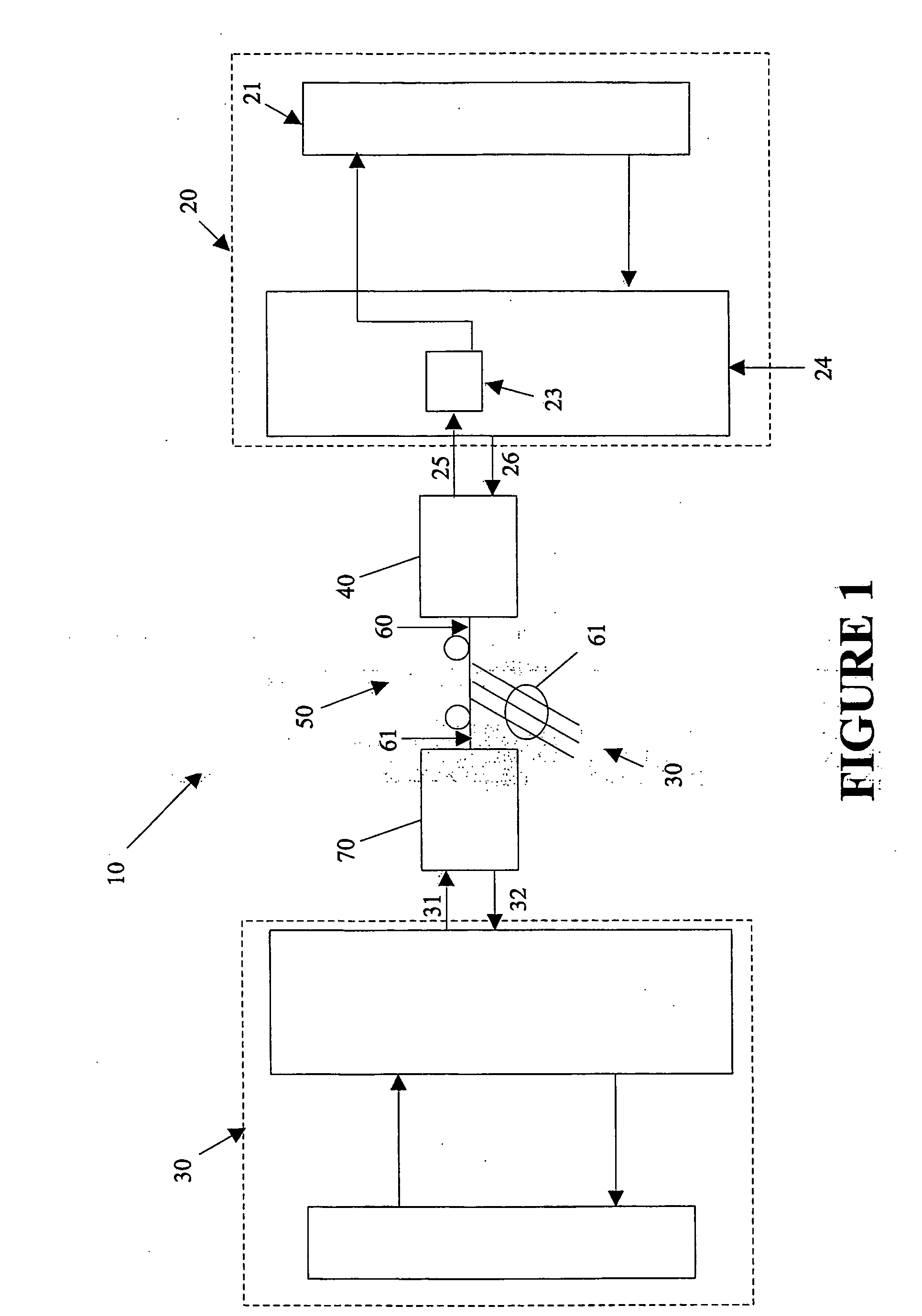

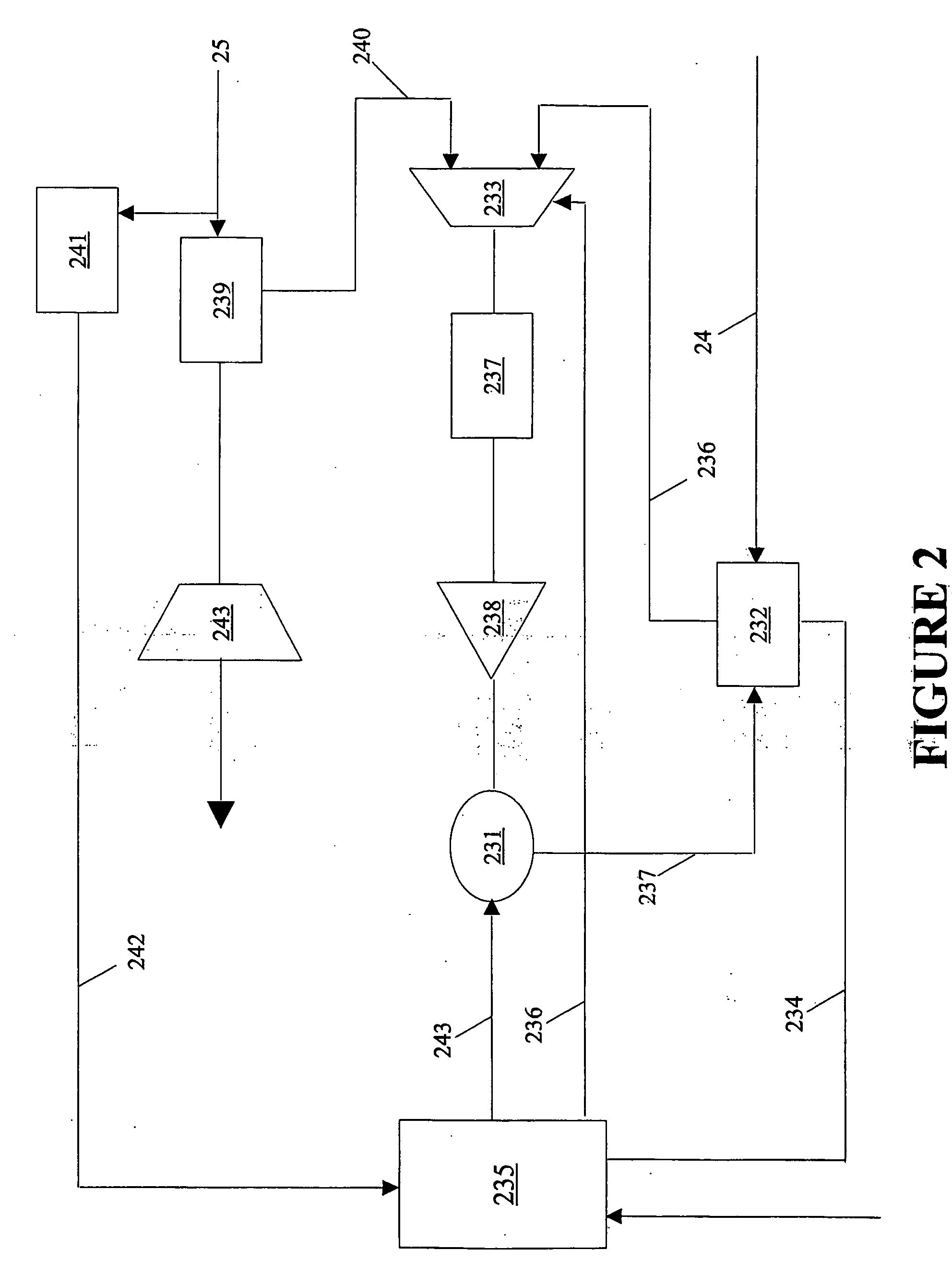

Testing system for ring-digital and physical mixed real-time power simulation and test method thereof

The invention discloses a testing system for ring-digital and physical mixed real-time power simulation. A digital simulation work station is connected with an RTDS digital simulator through the Ethernet, the RTDS digital simulator is connected with an analog output interface card through fibers, and the analog output interface card is connected with a controller through hard wiring. The controller is connected with a four-quadrant linear power amplifier through hard wiring, and the four-quadrant linear power amplifier is connected with a power type physical model through a cable conductor to output voltage analog of the RTDS digital simulator to the power type physical model. The power type physical model is connected with a current measurement sensor, the current measurement sensor is connected with the analog input interface card through hard wiring, and the analog input interface card is connected with the RTDS digital simulator through fibers to return the current of the power type physical model to the RTDS digital simulator.

Owner:POWER GRID TECH RES CENT CHINA SOUTHERN POWER GRID +2

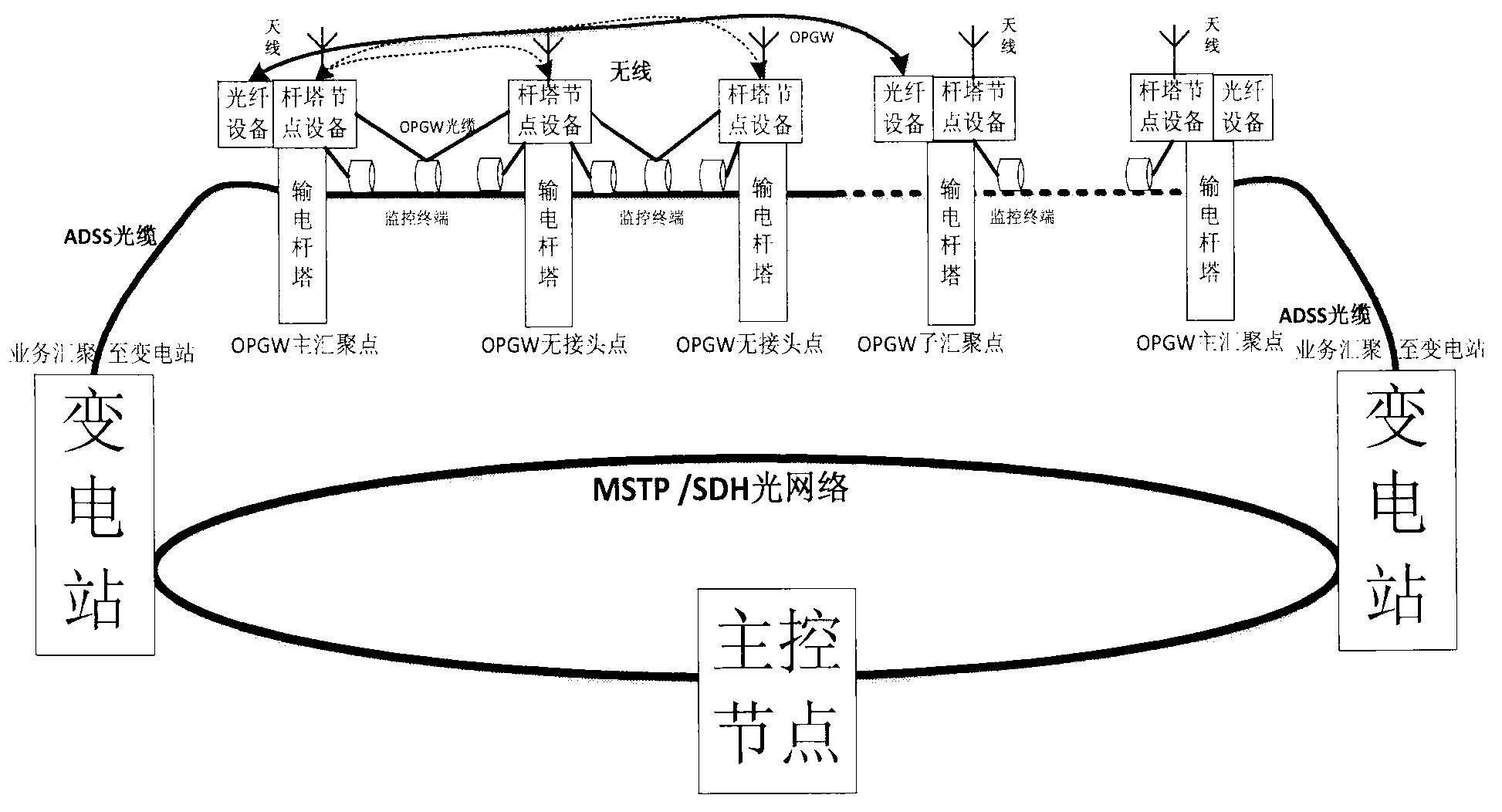

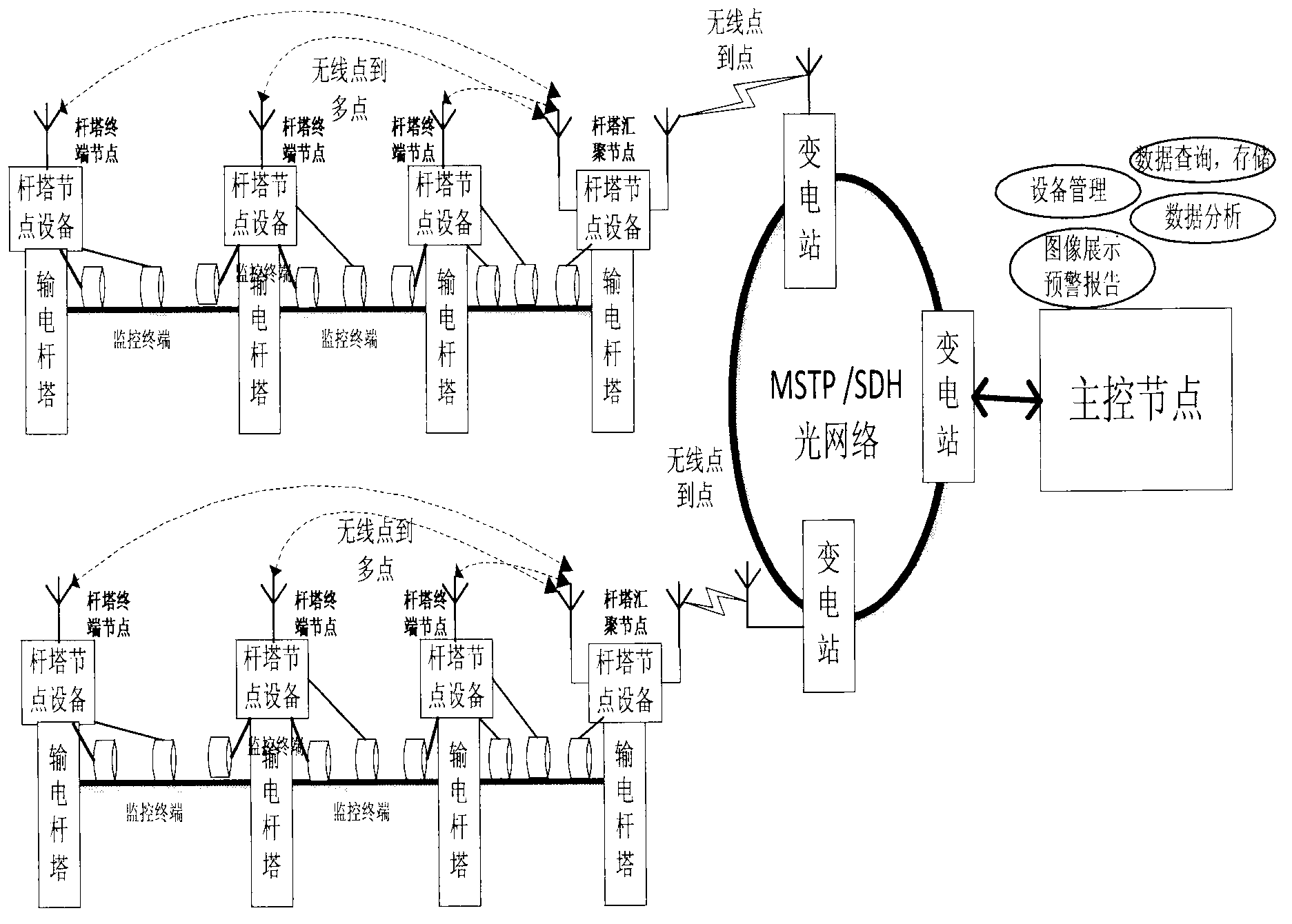

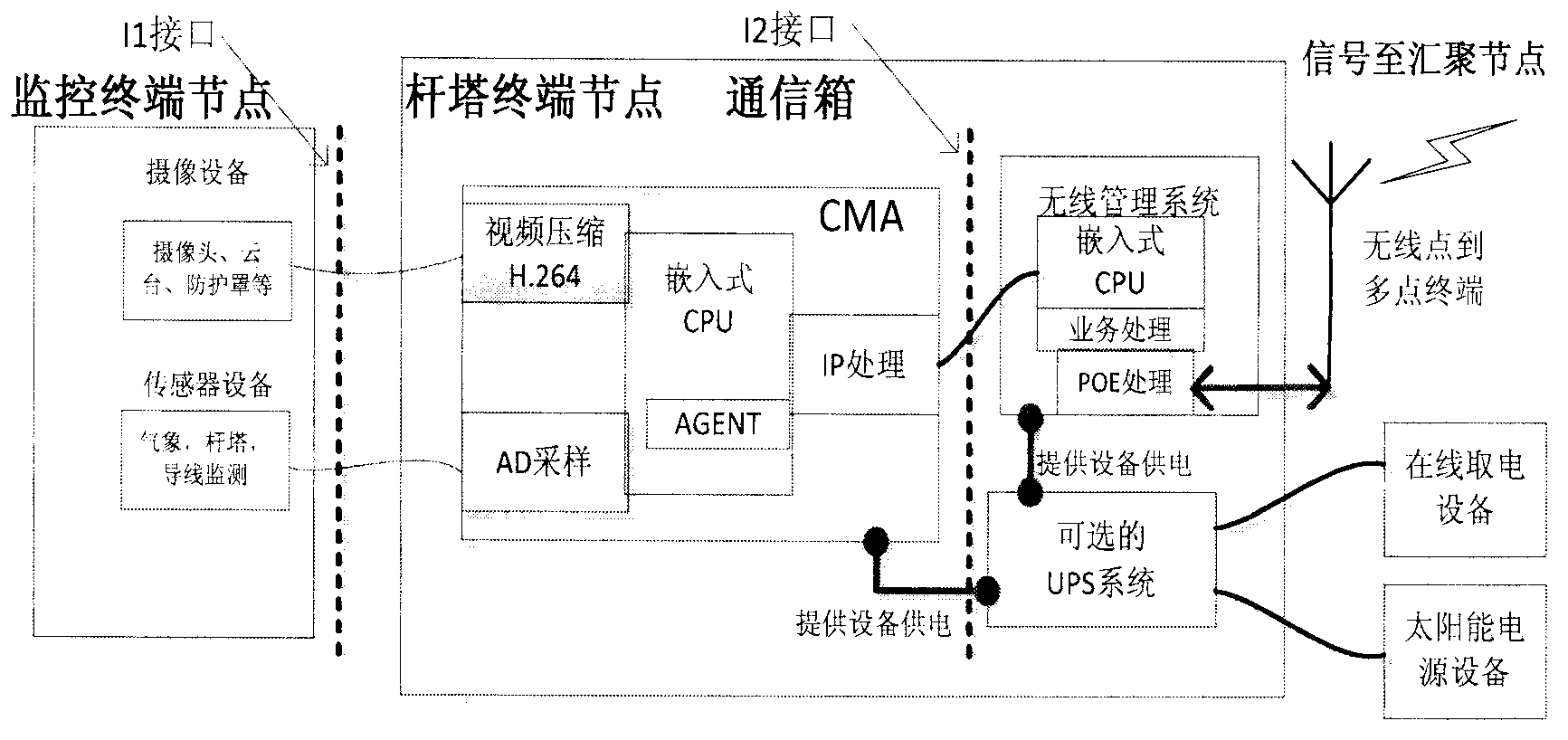

Electric transmission line monitoring communication system based on super-distance wireless optical network

InactiveCN103178902AIncrease transfer rateImprove real-time performanceRadio-over-fibrePower utilityFiber

Owner:千江(上海)信息科技有限公司

Preparation method and application of water-soluble carbon fiber sizing agent

InactiveCN104975508AImprove protectionImprove smoothnessFibre treatmentFibre chemical featuresFiberCarbon fibers

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Face mask material containing alginic acid fiber, preparation method and use thereof

InactiveCN101361700AImprove the humidification effectGood application functionCosmetic preparationsToilet preparationsFiberNon toxicity

Owner:秦益民

Adaptive focusing system and focusing method for fast imaging of spatial optical camera

InactiveCN105629629AEnsure fast, high-quality imaging of issuesJudgment to solve out-of-focusMountingsFocusing aidsRapid imagingCamera control

The invention relates to an adaptive focusing system and focusing method for fast imaging of a spatial optical camera. The adaptive focusing system comprises a main reflector temperature collection unit, a camera controller unit and a focusing mechanism unit, wherein the camera controller unit is connected with the main reflector temperature collection unit and the focusing mechanism unit. The adaptive focusing system solves the problem of out-of-focus judgment on a temperature change caused by a coaxial three-mirror carbon fiber optical system of the spatial optical camera, omits the processes of artificial out-of-focus judgment of downloaded data, out-of-focus amount calculation, focusing instruction injection and the like, achieves real-time closed-loop adjustment of a focal plane of the optical system of the camera and the camera temperature, solves the fast high-quality imaging problem under the condition of an unbalanced temperature after the spatial optical camera enters an orbit, and provides a technical support for fast imaging development of a spatial optical satellite of our country.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for compression moulding reinforced thermoplastic article

A method for manufacturing a polymeric article having an integrated reinforcing element. A thermoplastic material is introduced into a mould, after which reinforcing elements are inserted into the mould cavity. A second layer of the thermoplastic material is introduced into the mould, after which the mould is closed, pressing and heating the mould to melt the thermoplastic material and form the article. The thermoplastic layers may be provided in powder, sheet, or pellet form. The reinforcing elements may comprise reinforcing fibres or reinforcing fabrics. A polymeric track for a vehicle may be produced from this method.

Owner:POLARIS IND INC +1

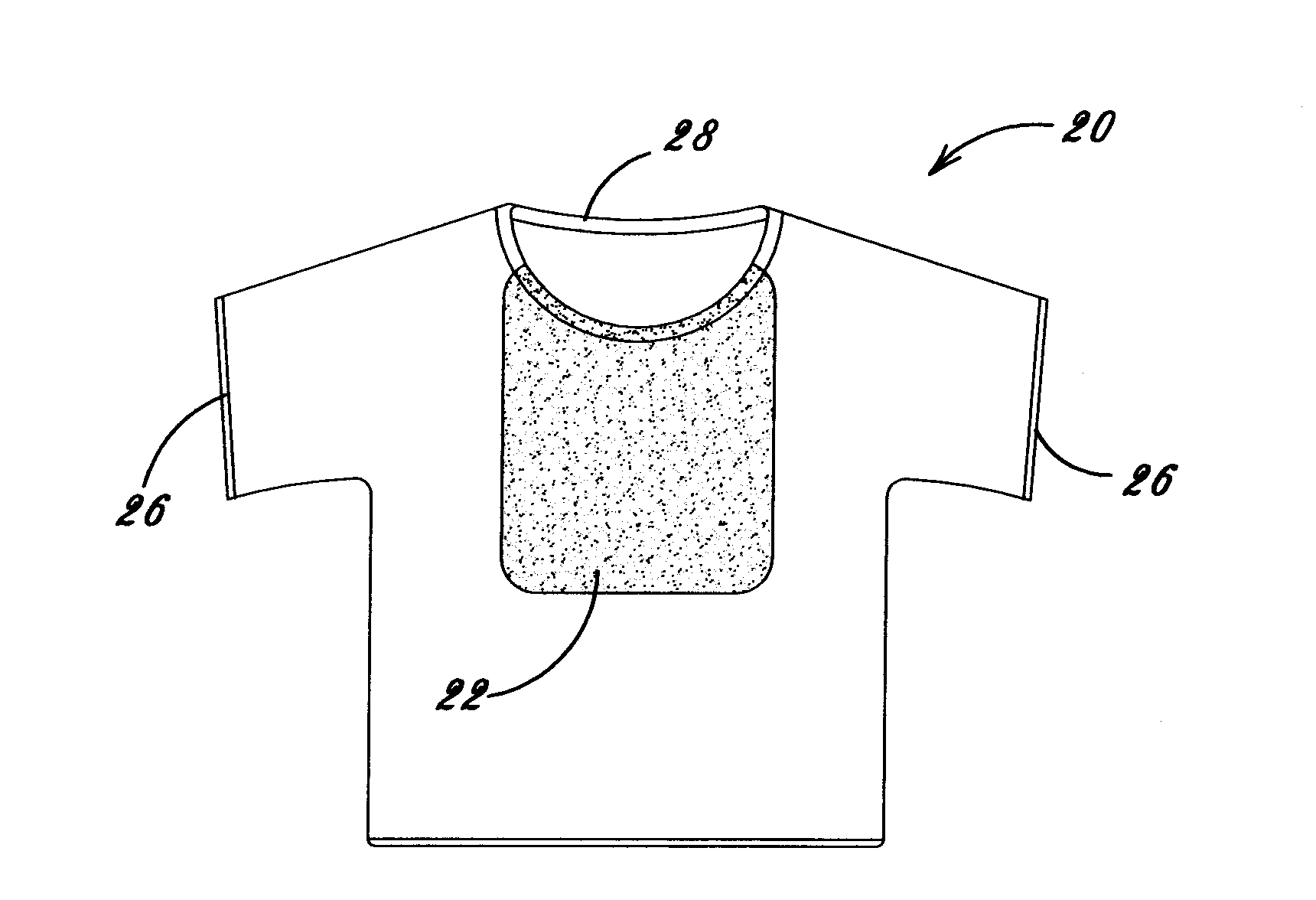

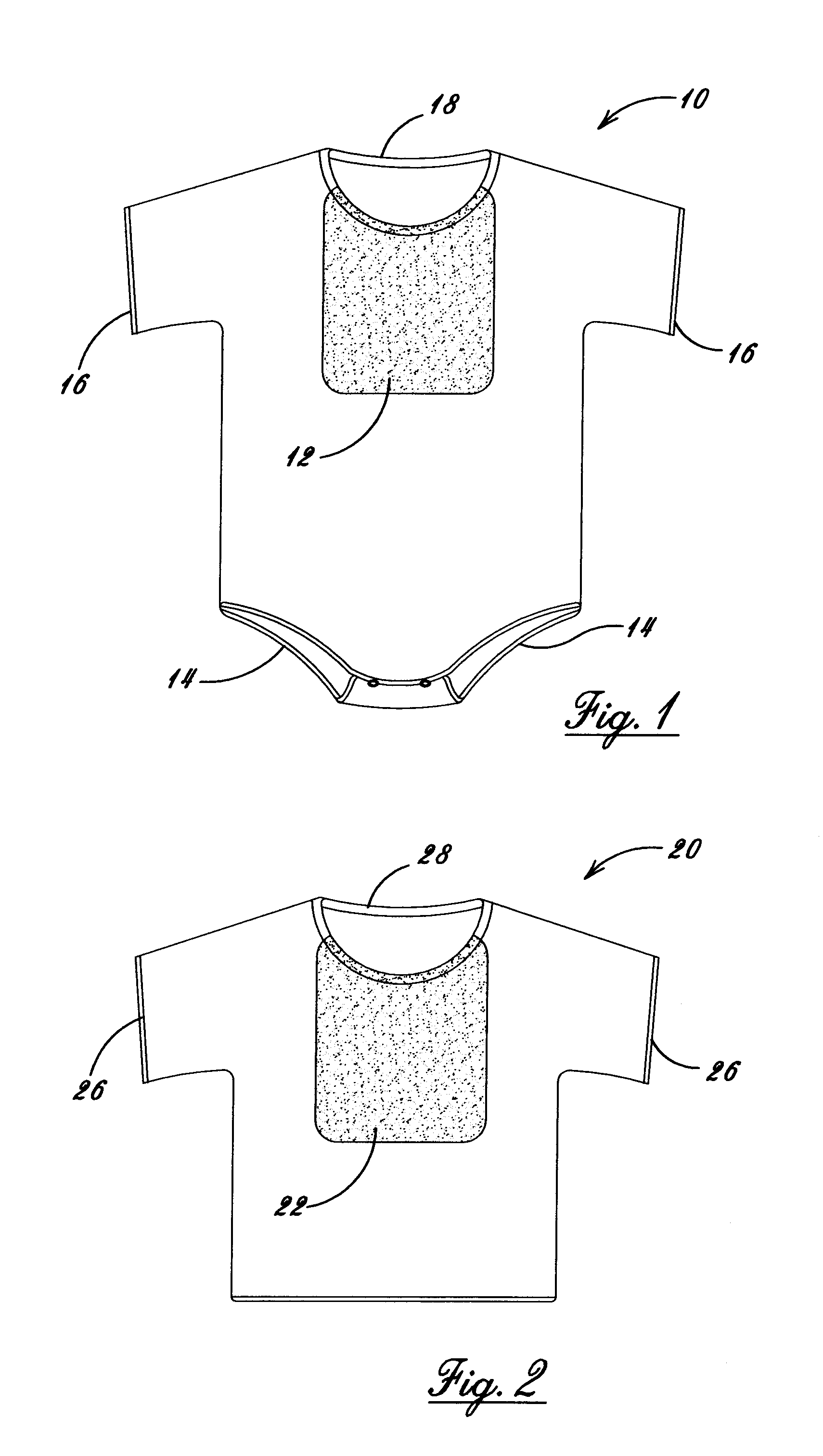

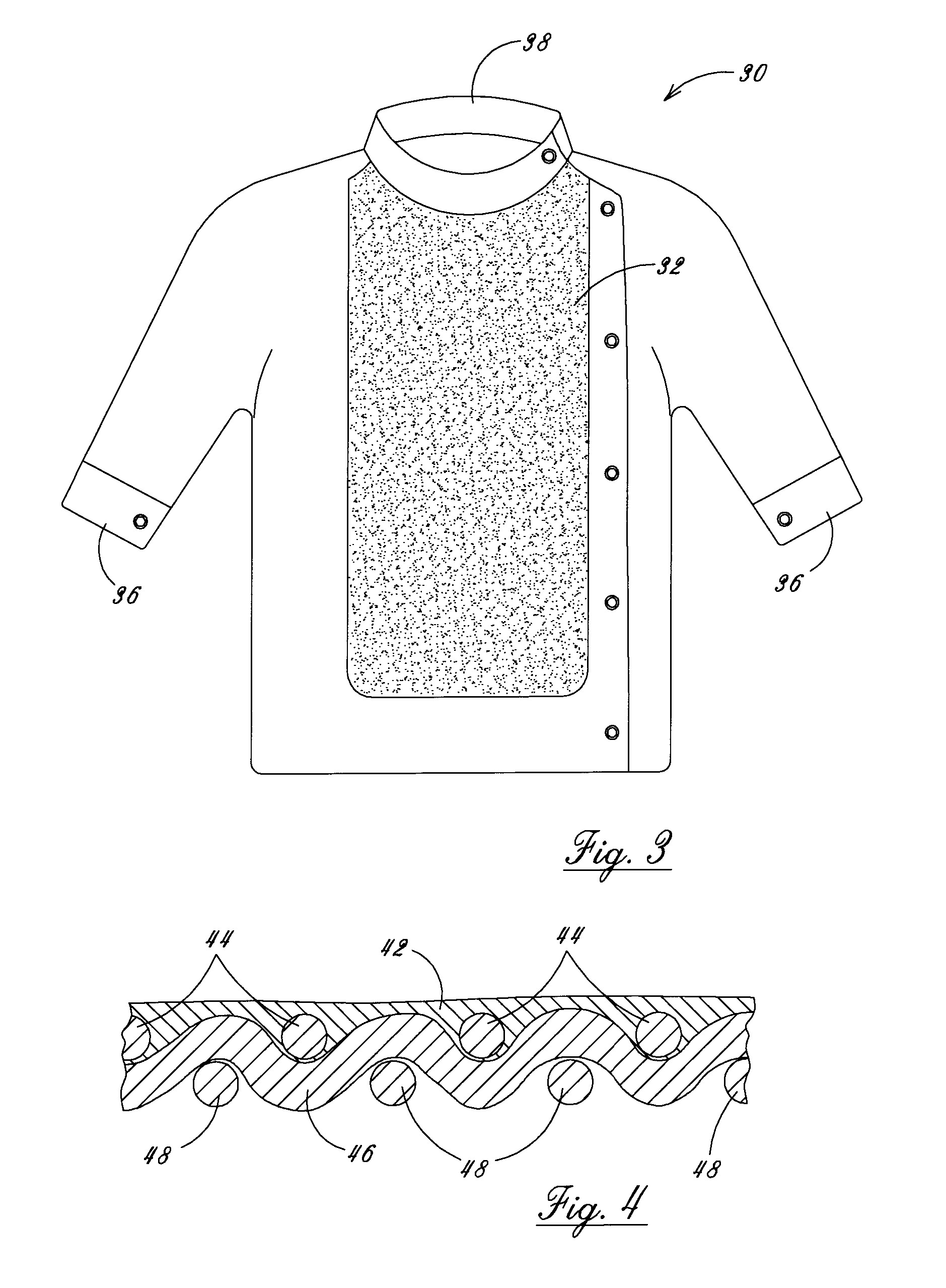

Permanently Embedded Protective Covering for Articles of Clothing

InactiveUS20120131733A1Easily wiped awayEasy to cleanChemical protectionHeat protectionFiberEngineering

Owner:MERTZ JUDY

Production method of permanent ultraviolet protecting, moisture absorbing and sweat removing fabric

ActiveCN104799458AReduce surface tensionImprove permeabilitySingeingHeating/cooling textile fabricsFiberPolyester

The invention discloses a production method of a permanent ultraviolet protecting, moisture absorbing and sweat removing fabric. The method comprises the steps of blending and weaving; singeing; desizing-scouring-bleaching; mercerizing; sizing; dyeing; softening and tentering; pre-shrinking and arranging. The fabric manufactured by the production process is outstanding in permanent ultraviolet resisting function; the UPF is not less than 150; micro pores of CTATEX super-comfortable polyester fibers can be opened fully by the desizing-scouring-bleaching and mercerizing, holes in the fibers are smooth, the moisture absorbing and breathing performances of the fabric can be improved under the absorbing effect of hole cores, and the water drops can be absorbed within 3 seconds according to the test; the fuzzing and pilling resistance of the fabric is more than 4 grades; the advantages of wearing resistance, non-ironing, wrinkle preventing and quick drying of the polyester fibers are remained to the maximum; the fabric is particularly suitable for wearing when working and living outdoor in a hot season.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Linear burst mode synchronizer for passive optical networks

ActiveUS20080022143A1Improves synchronized jitter performanceImprove Timing MarginPulse automatic controlSynchronisation signal speed/phase controlFiberTiming margin

Owner:REALTEK SINGAPORE PTE LTD

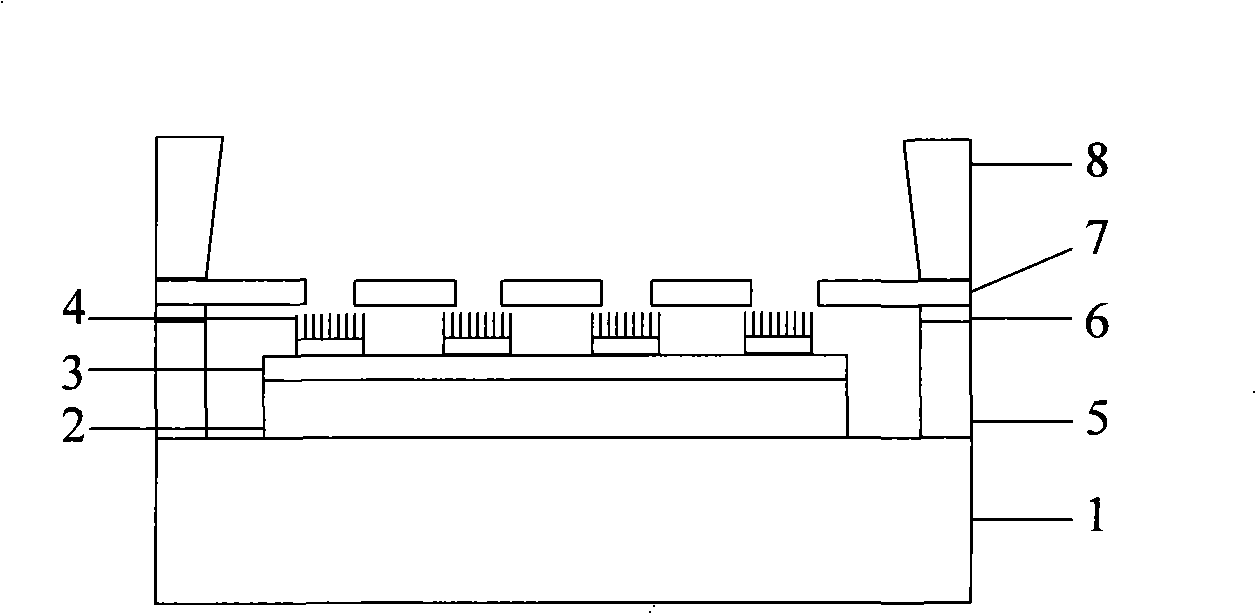

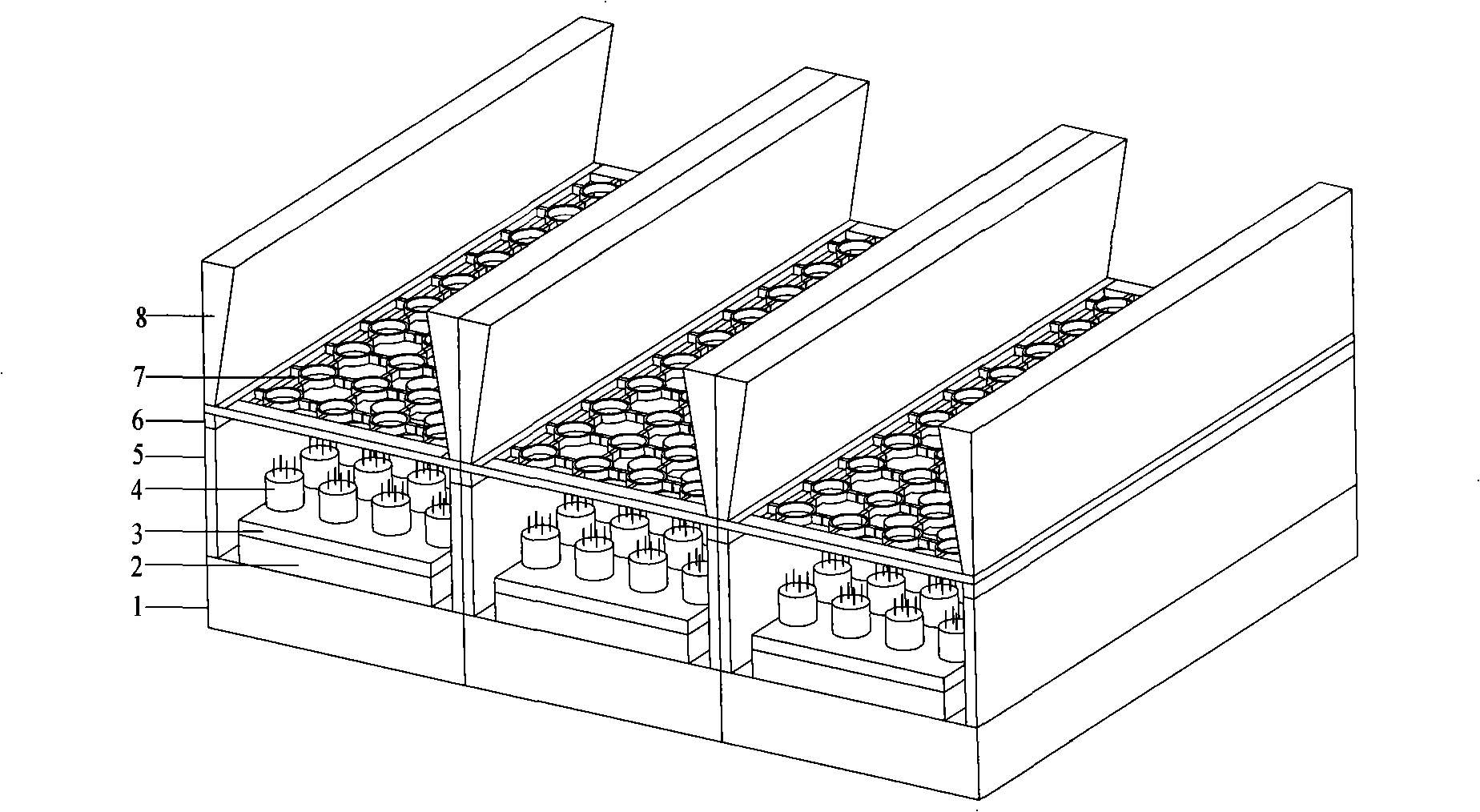

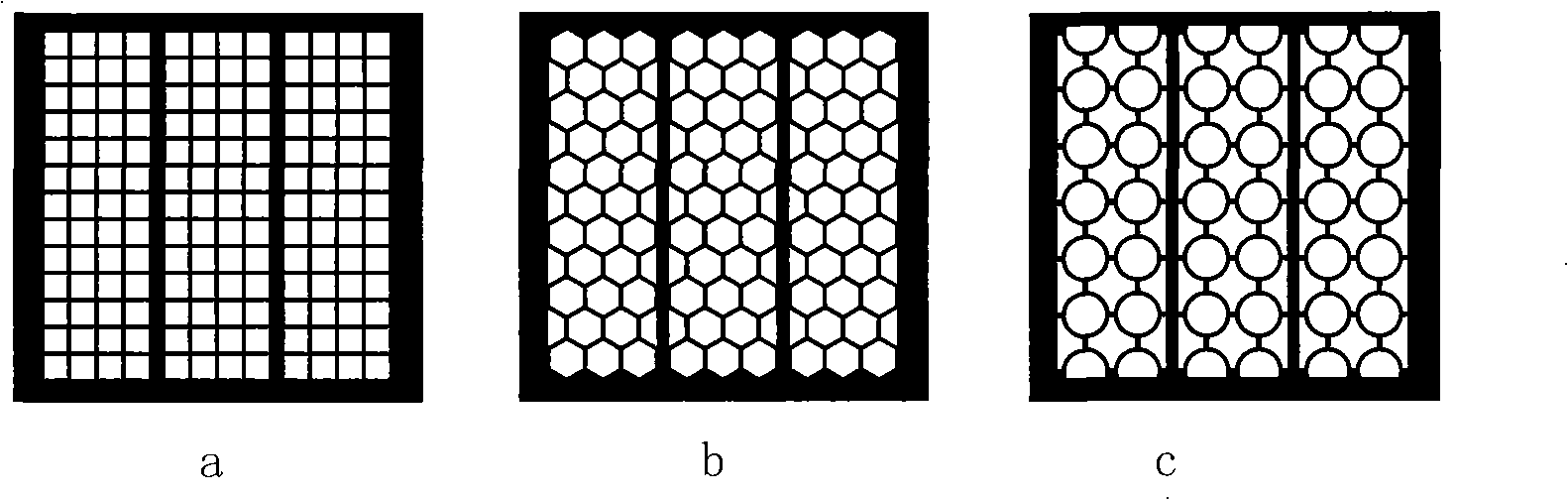

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

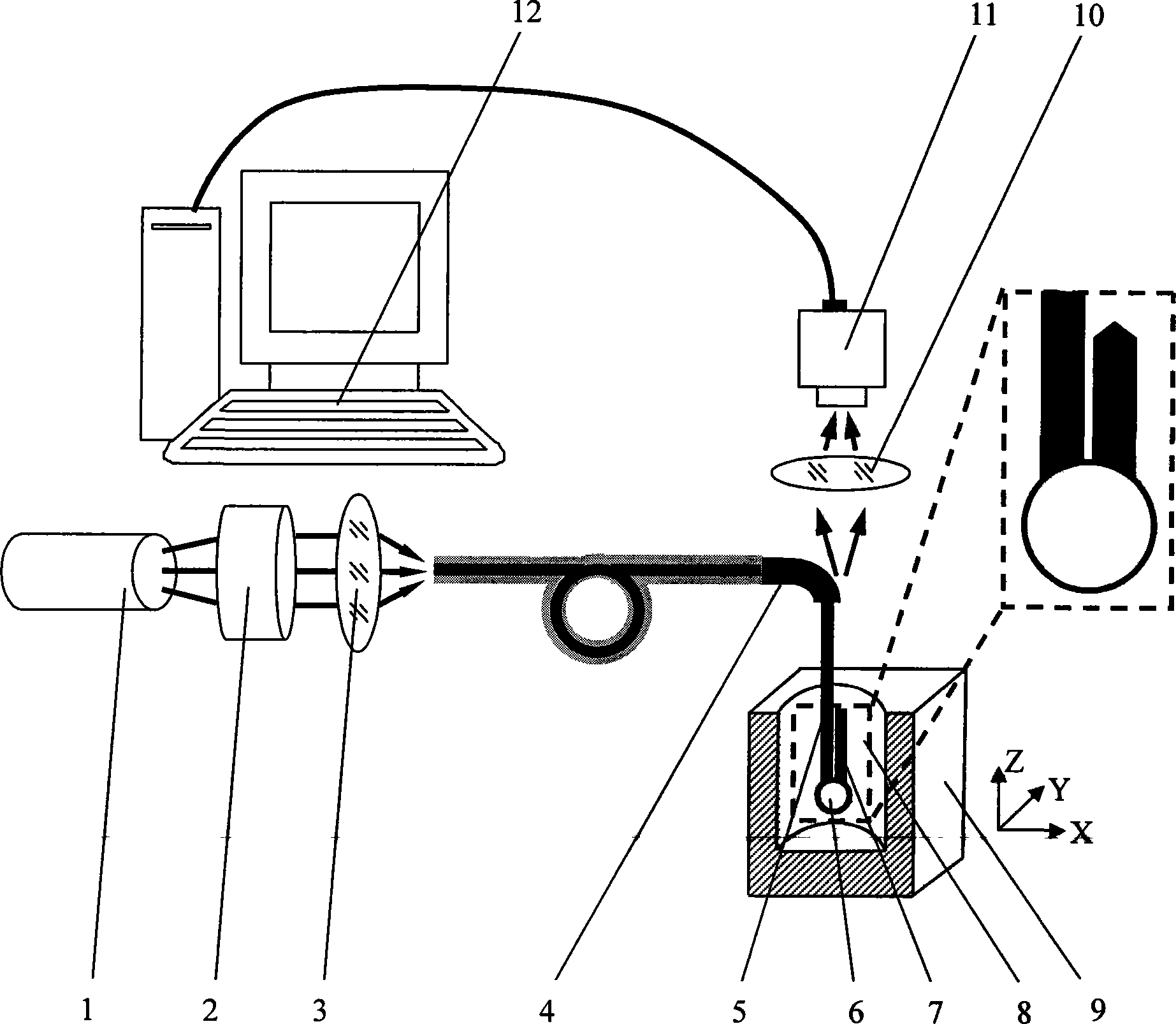

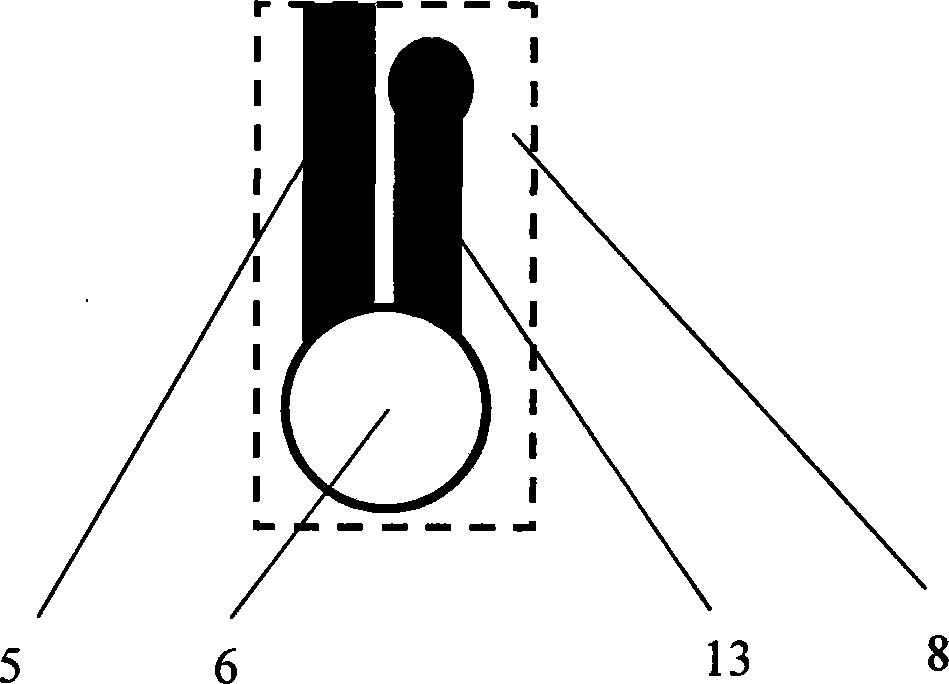

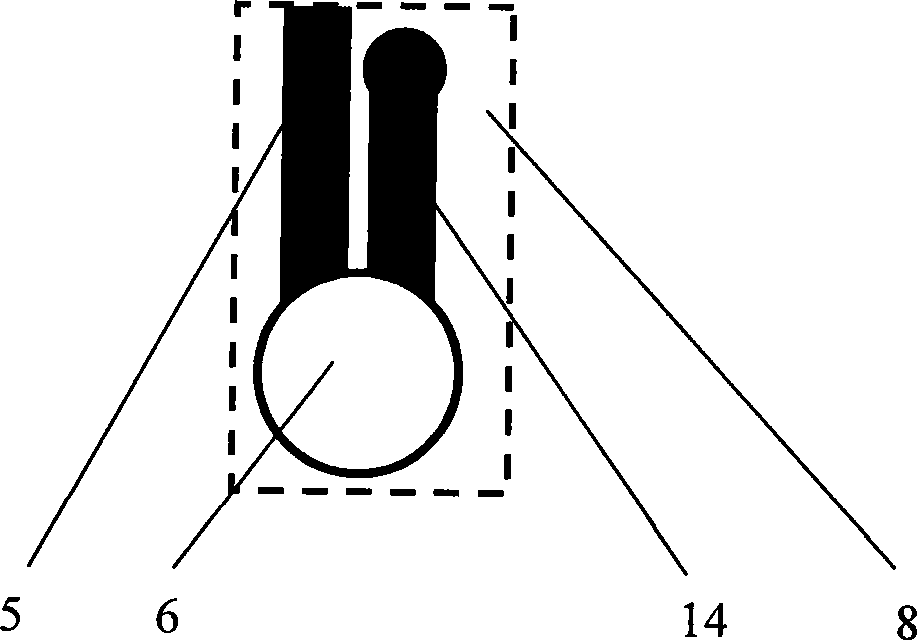

Double-fiber ball-shared coupling micro-measuring-force targeting sensor with end face micro-structure

InactiveCN103900468AImprove resolutionImprove signal-to-noise ratioUsing optical meansFiberMicro structure

Owner:HARBIN INST OF TECH

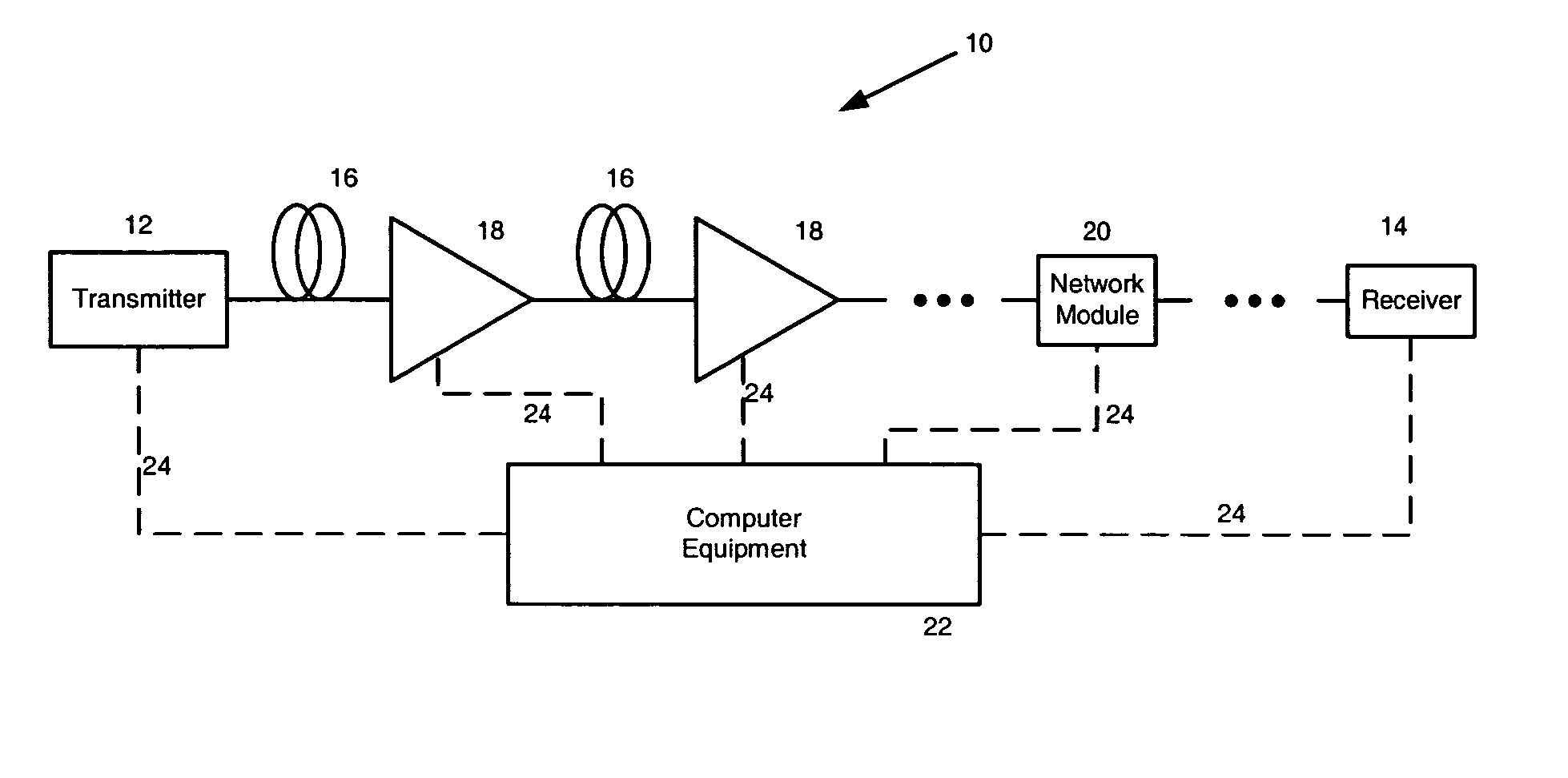

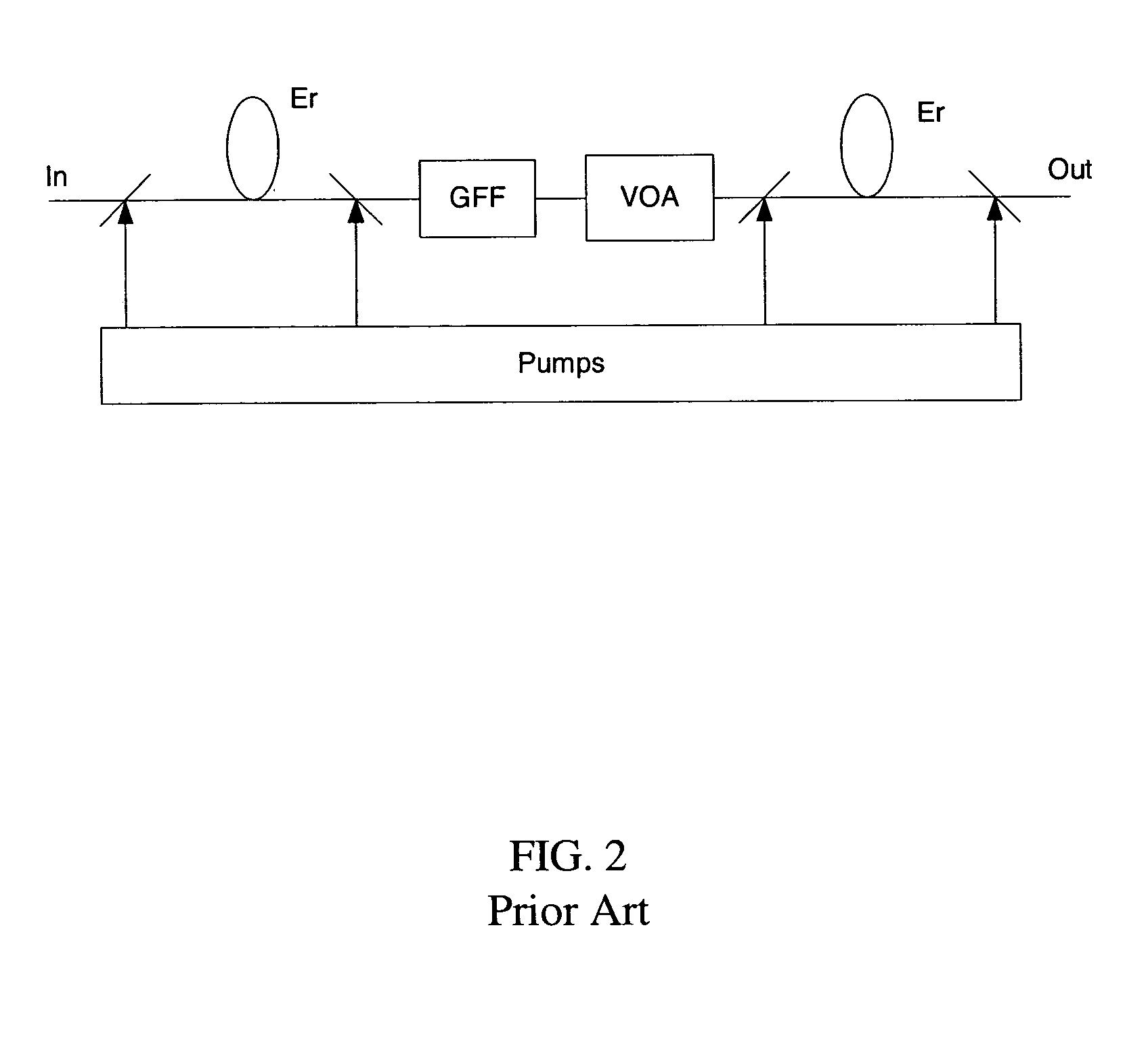

Pre-programmable optical filtering / amplifying method and apparatus

Owner:WILSON GORDON +2

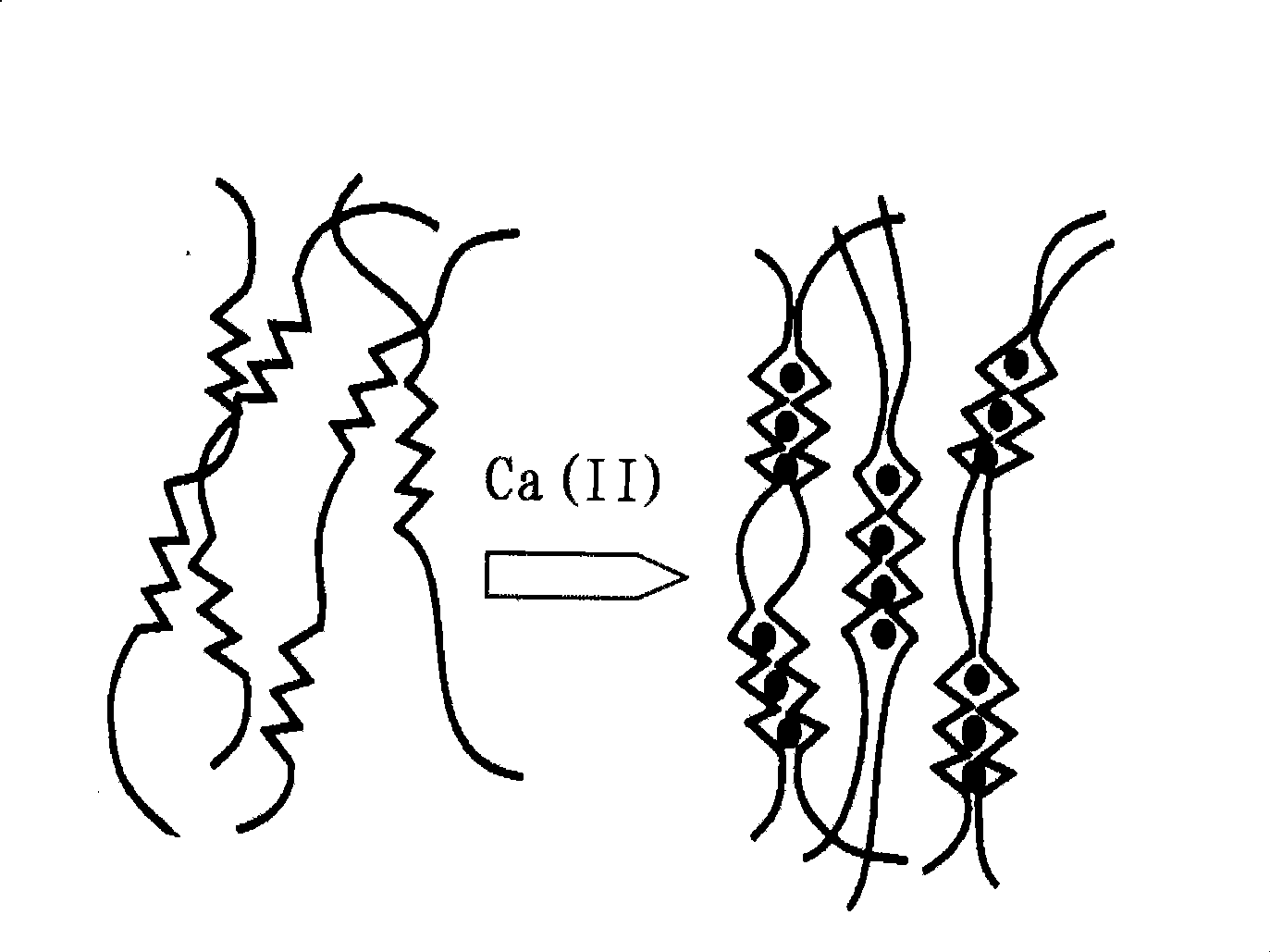

Konjaku high hygroscopicity fibre and its preparation method

Owner:WUHAN NONGXIANG BIO TECH

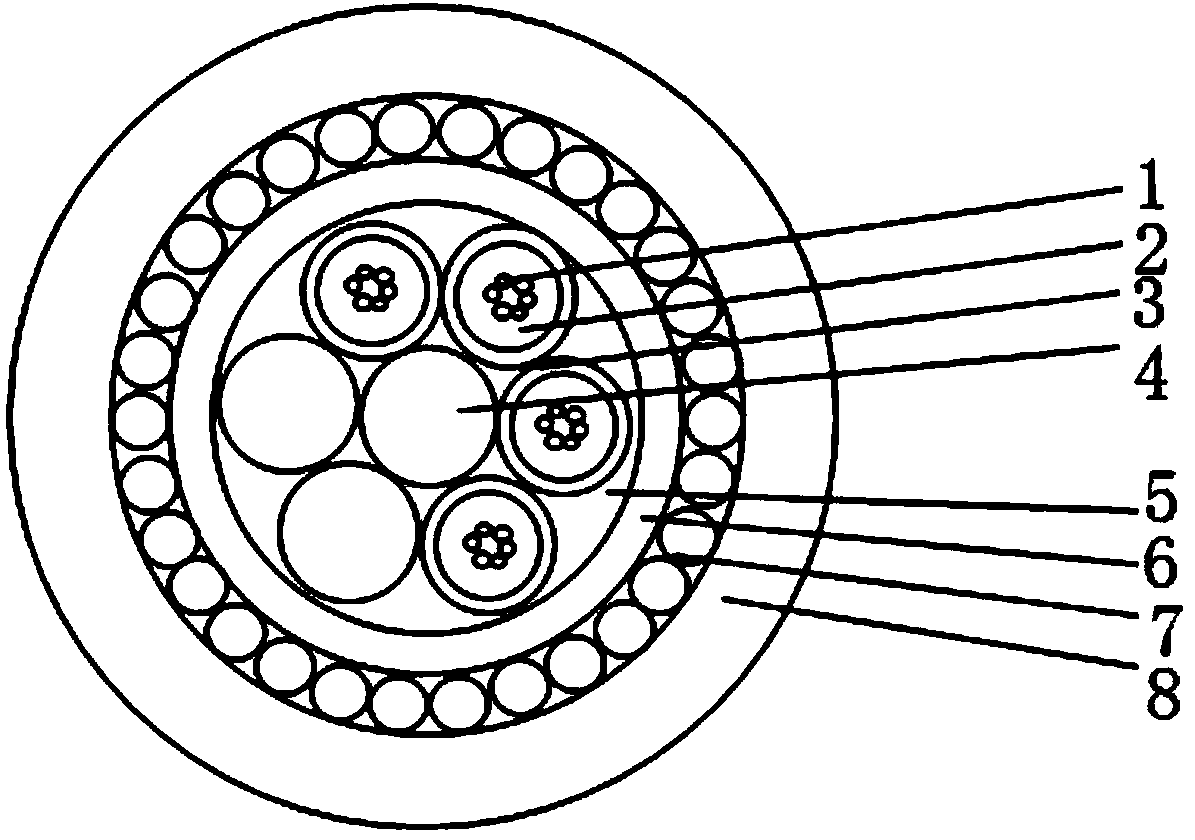

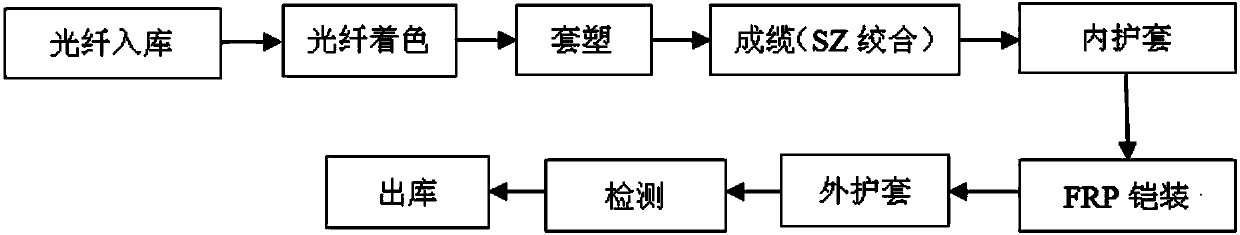

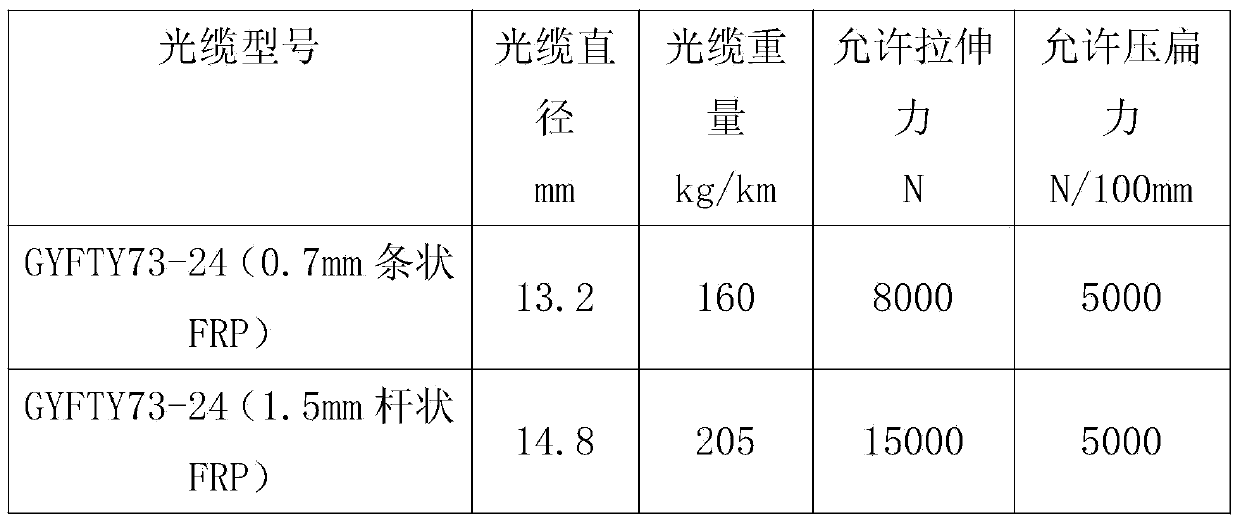

Reinforced type all-dielectric and rodent-resistant cable and manufacturing process thereof

InactiveCN103728701AGood anti-rat effectReduce weightFibre mechanical structuresOptical communicationFiber

The invention discloses a reinforced type all-dielectric and rodent-resistant cable and a manufacturing process of the reinforced type all-dielectric and rodent-resistant cable, and relates to the technical field of communication cables. The reinforced type all-dielectric and rodent-resistant cable comprises multiple optical fibers, fiber paste, a loose casing pipe, a center reinforcement piece, a cable core water-resistant compound, an inner sheath, multiple rod-shaped FRPs 7 and an outer sheath, wherein the multiple rod-shaped FRPs 7 are arranged between the inner sheath and the outer sheath; the multiple optical fibers are arranged inside the inner sheath; the loose casing pipe is arranged outside the optical fibers; the position between the optical fibers and the loose casing pipe is filled with the fiber paste; the position between the loose casing pipe and the inner sheath is filled with the cable core water-resistant compound; the center reinforcement piece is arranged in the center of the optical fibers. According to the reinforced type all-dielectric and rodent-resistant cable and the manufacturing process of the reinforced type all-dielectric and rodent-resistant cable, the weight of FRP sheathed rodent-resistant cables is reduced greatly, the difficulty of laying construction is not added under the condition that the cables have the good rodent-resistant effect, and the solution is provided for optical communications at areas with serious damage caused by rodents, such as mountainous areas and sewer lines of cities.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

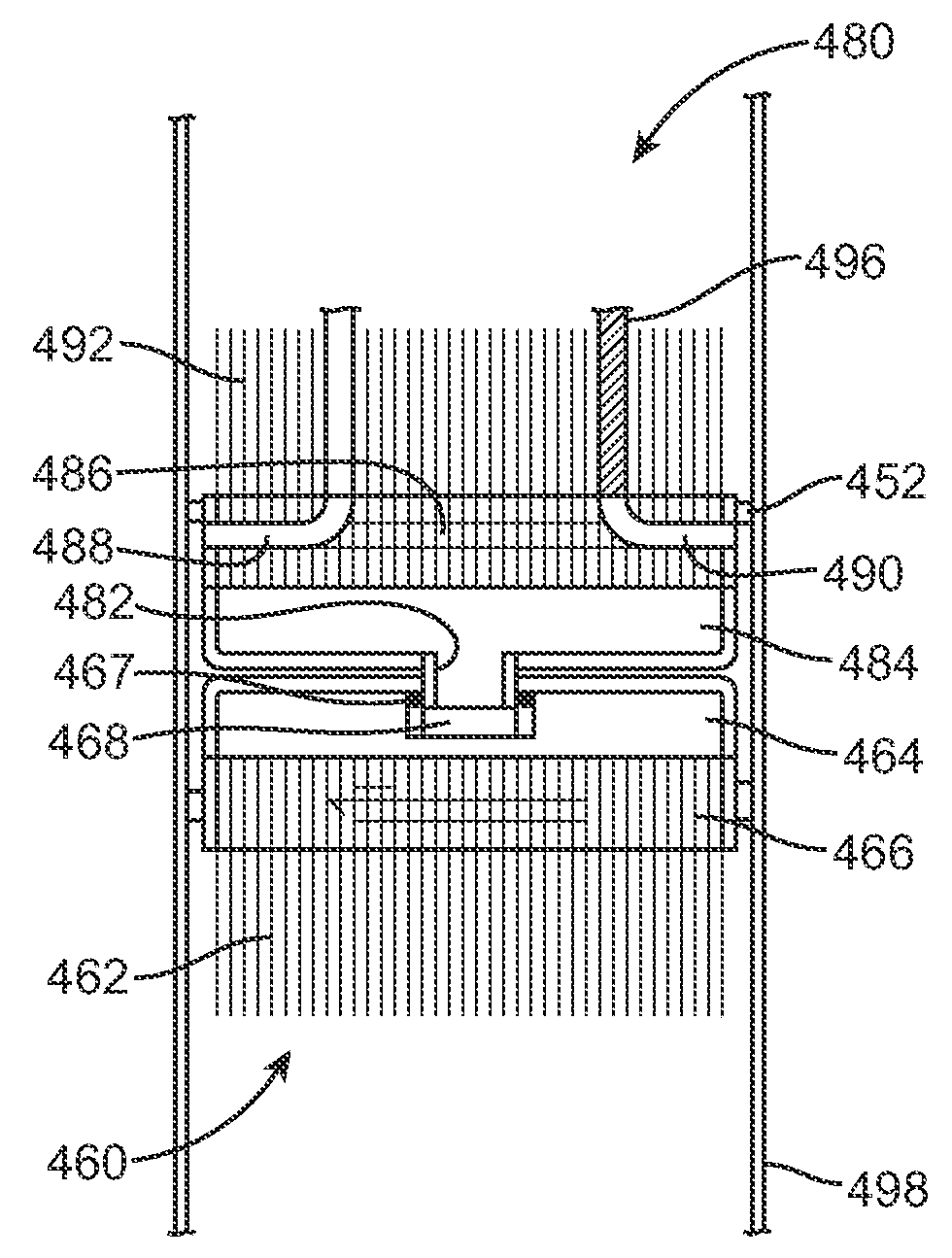

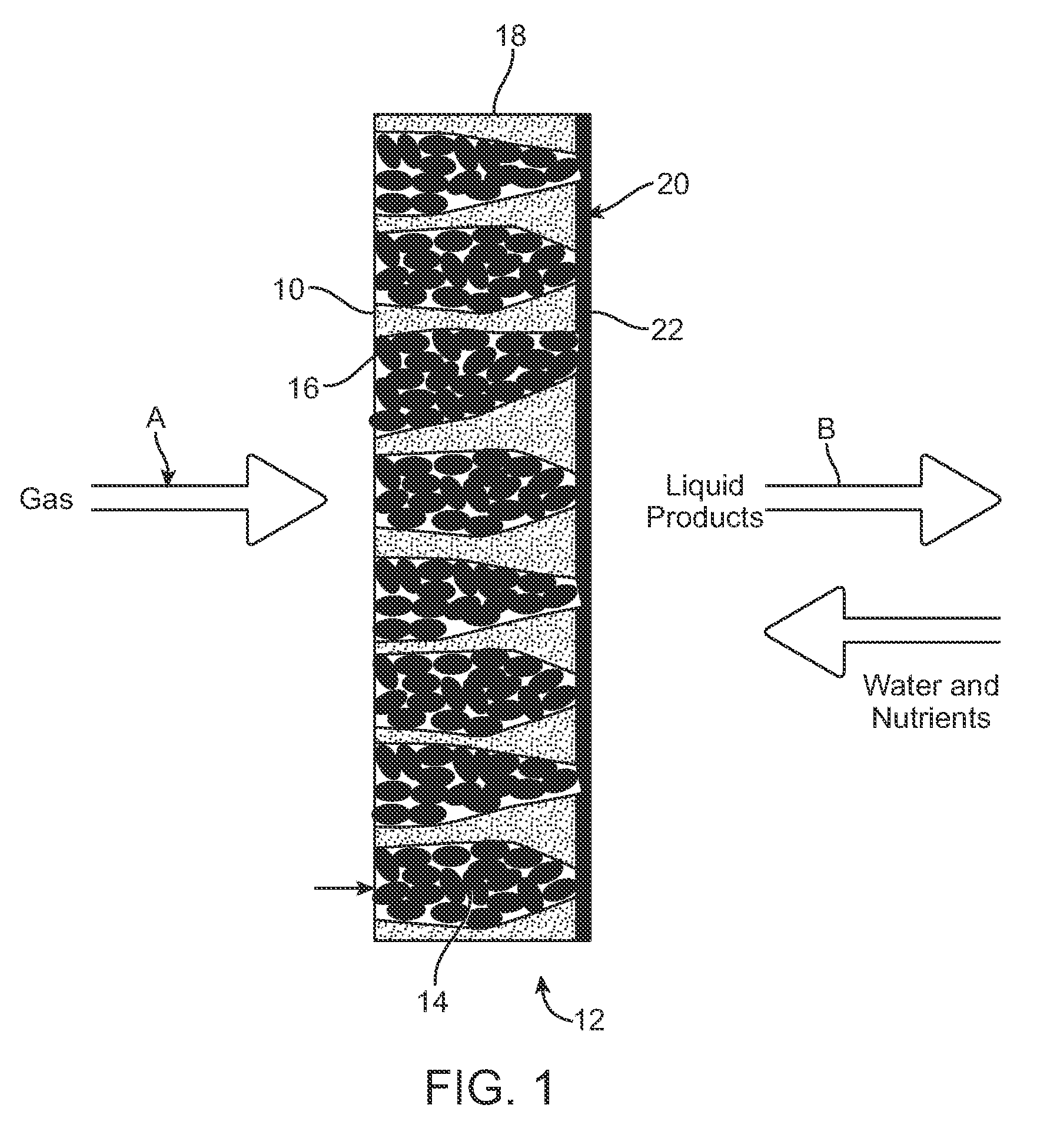

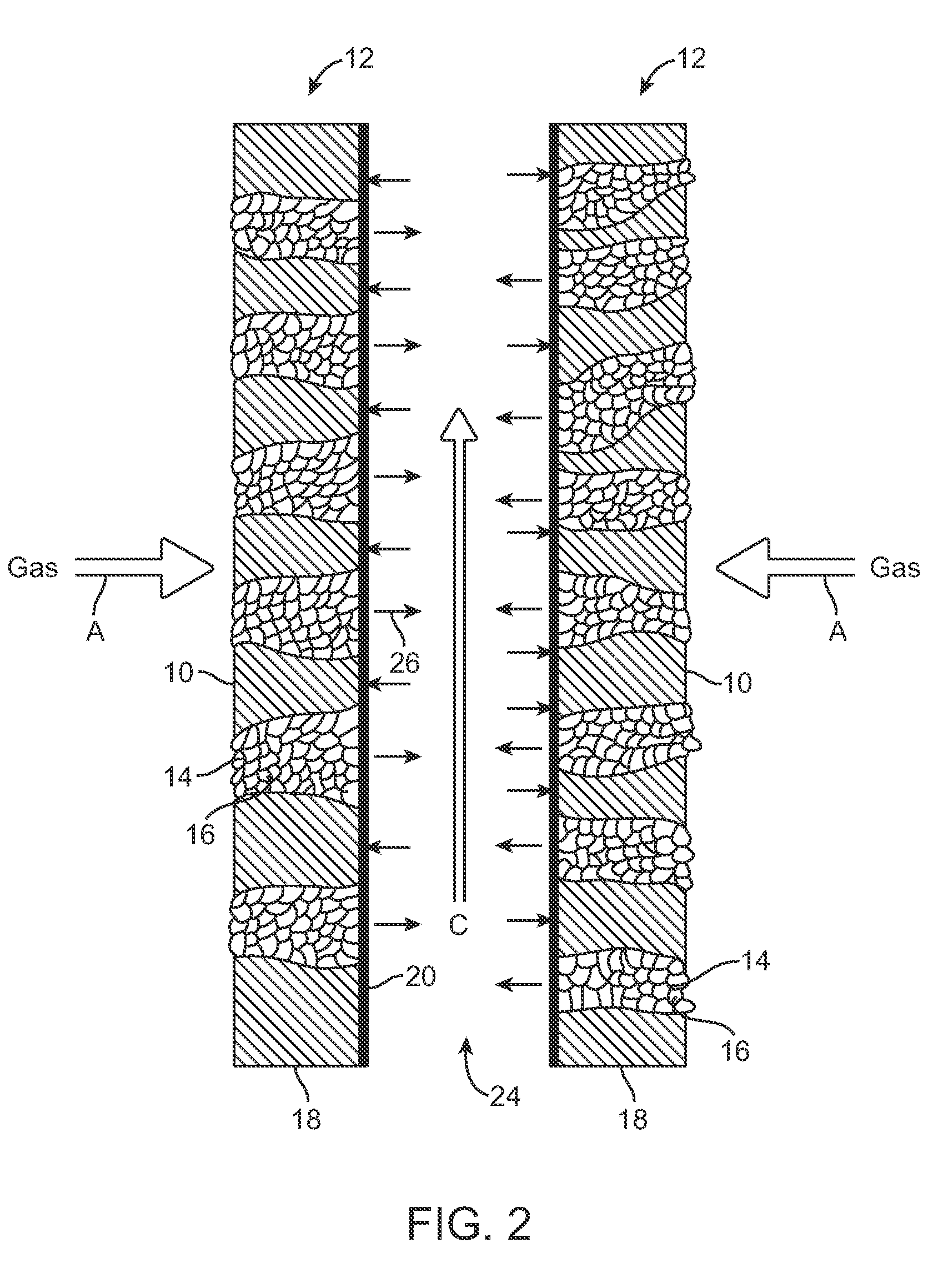

Stacked Array Bioreactor for Conversion of Syngas Components to Liquid Products

InactiveUS20090215153A1Promote and controlLess permeabilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productFiber

Owner:SYNATA BIO INC

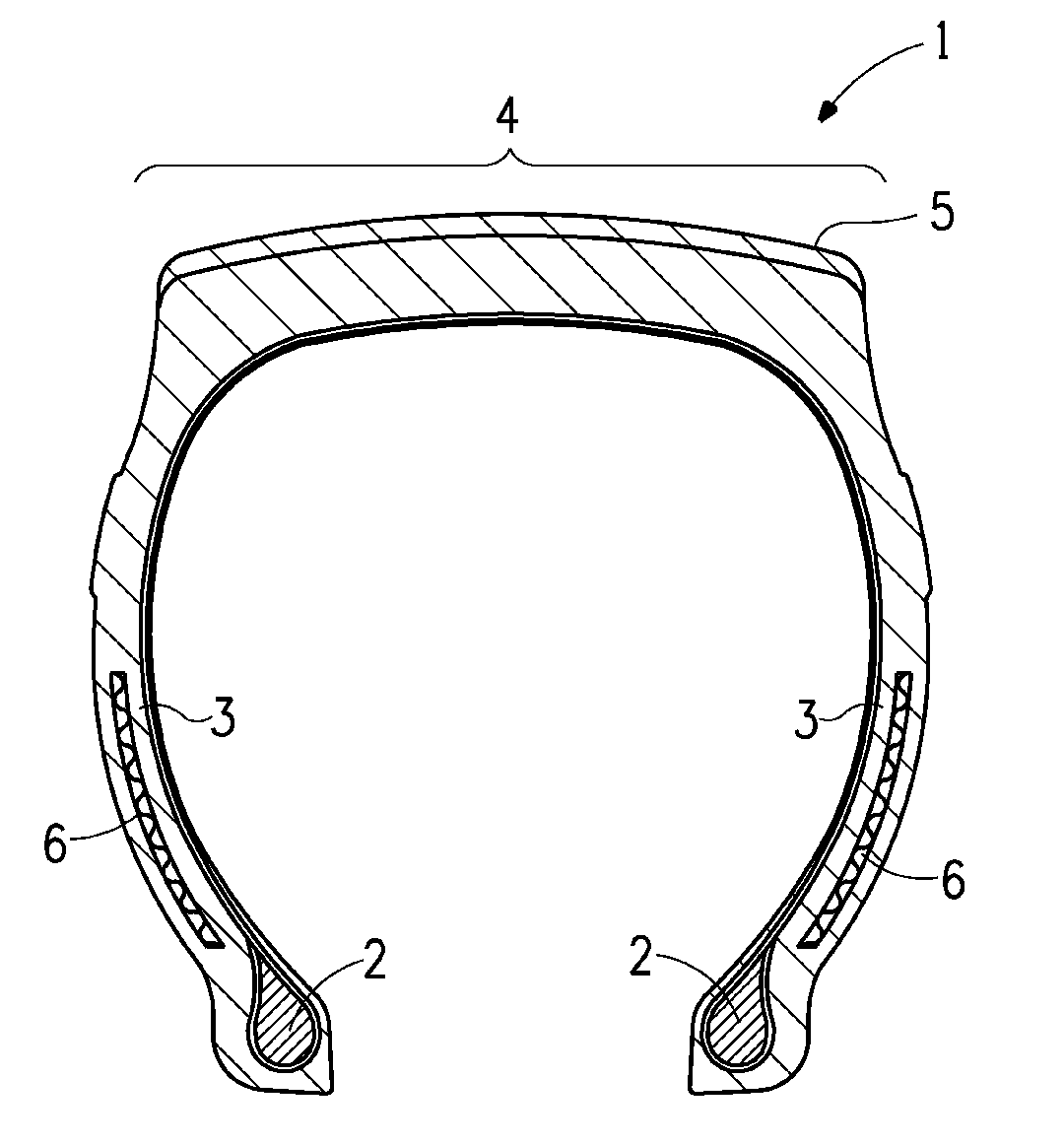

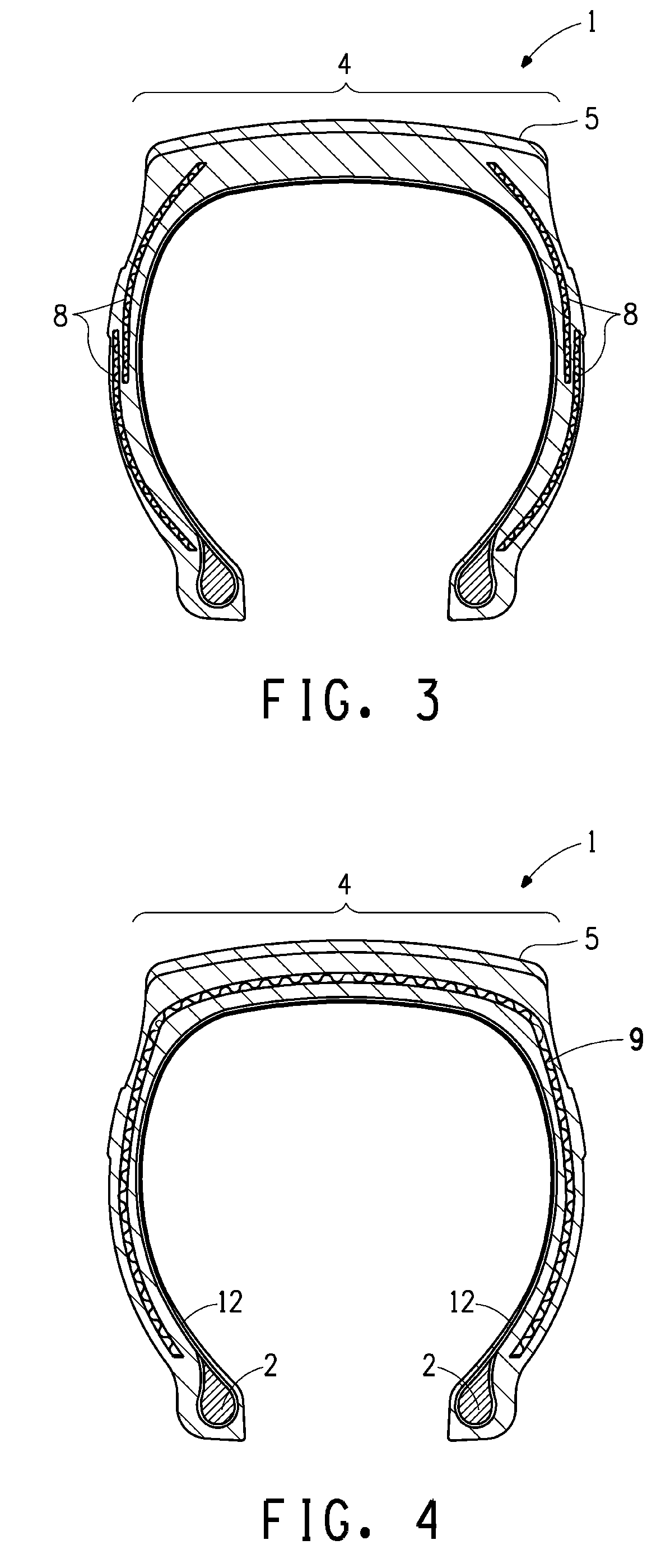

Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same

InactiveUS20100108218A1Improved adhesion of fabricLayered productsPneumatic tyre reinforcementsYarnFiber

Owner:EI DU PONT DE NEMOURS & CO +1

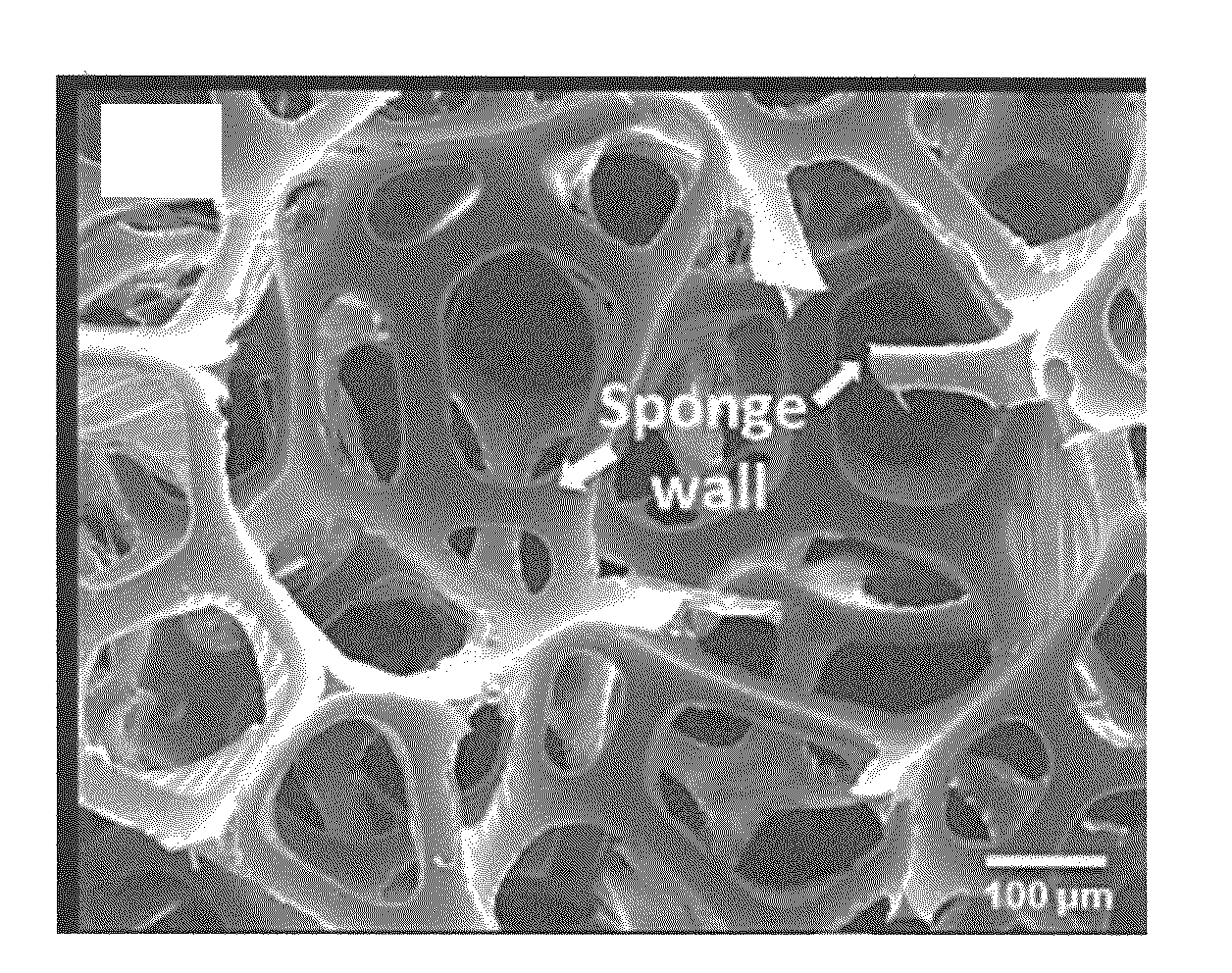

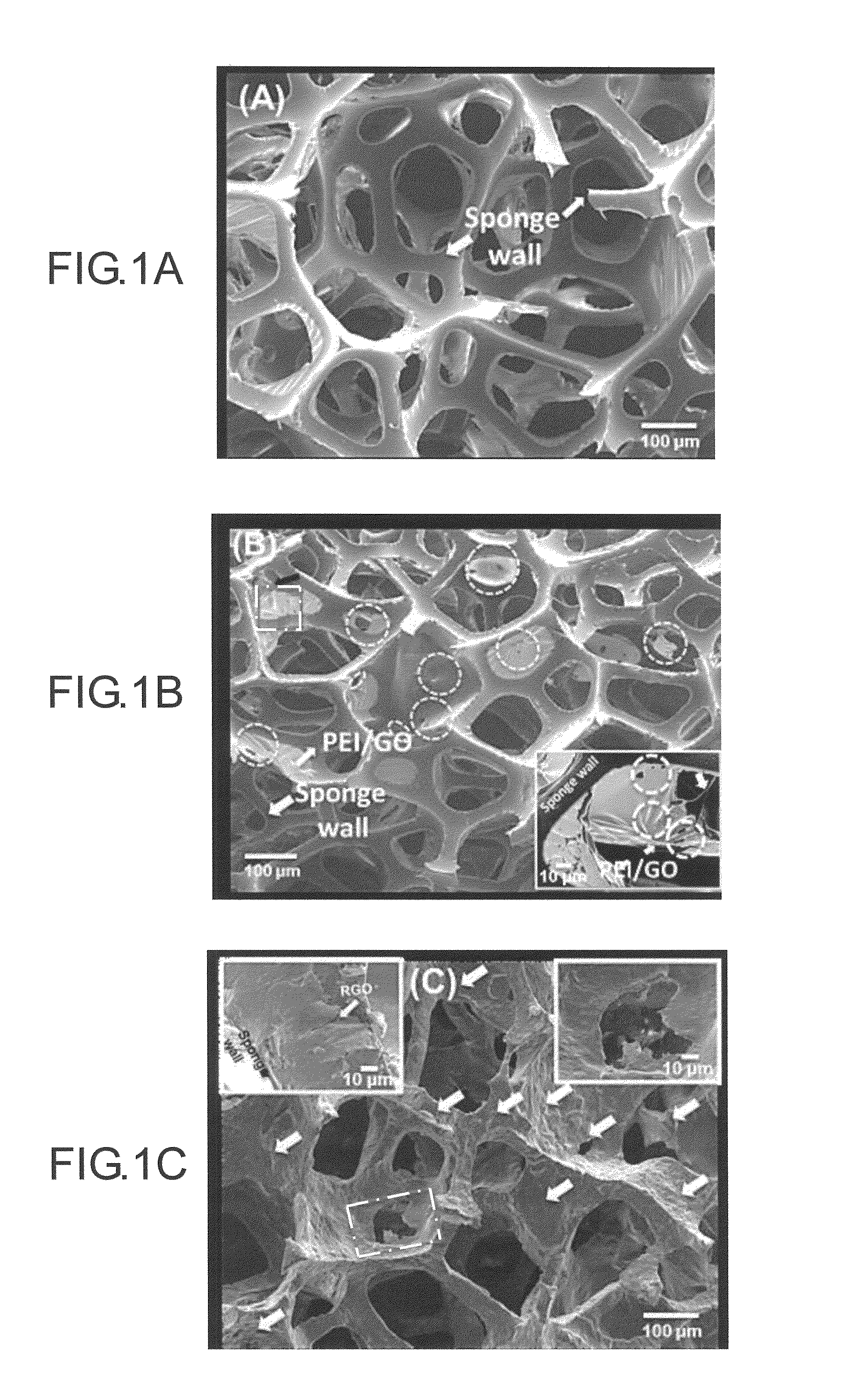

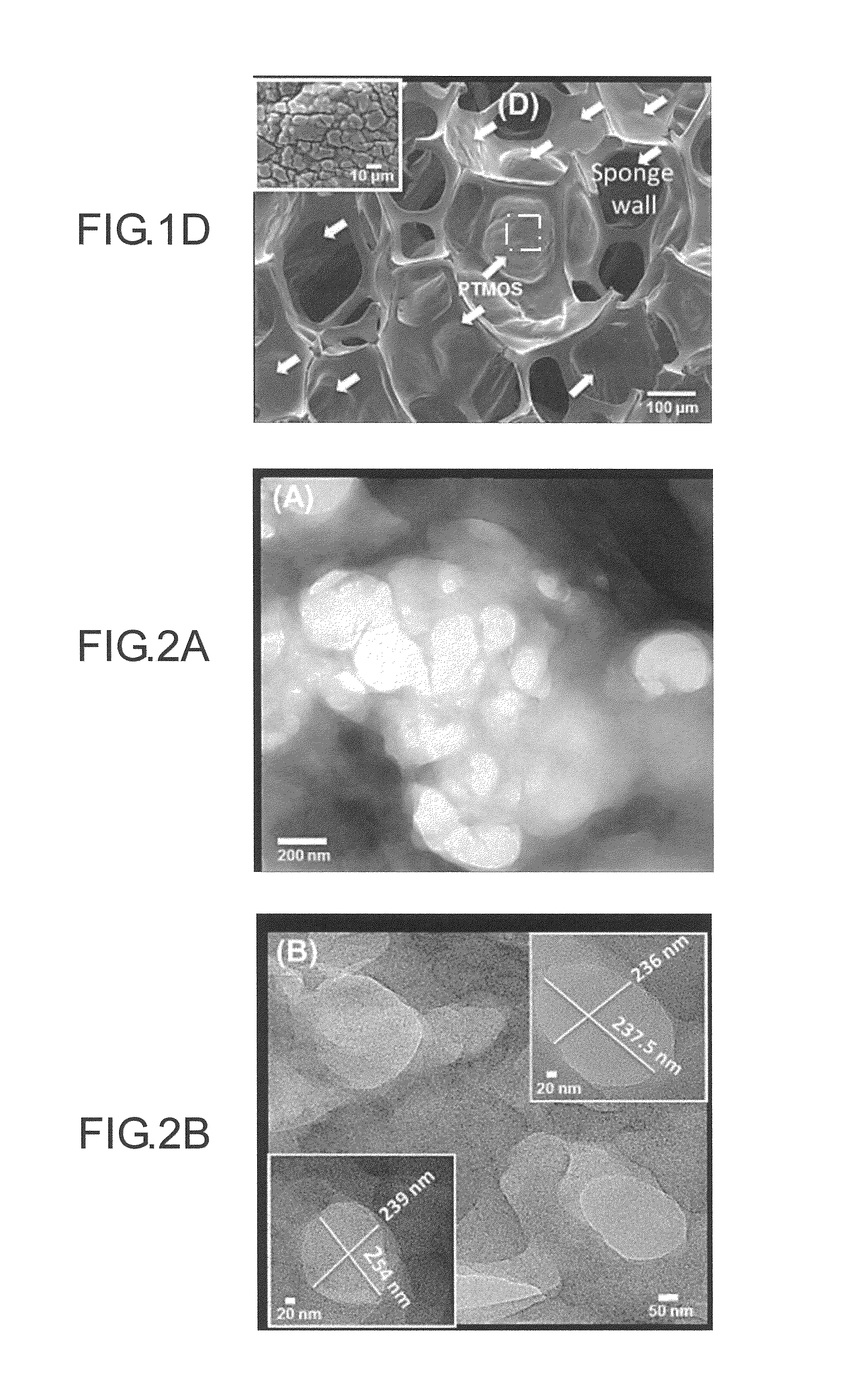

Reduced graphene oxide composite material

InactiveUS20160121299A1Improve oil absorption capacityLow costOther chemical processesFiberAbsorption capacity

Owner:NAT TAIWAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap