Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Carbon compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

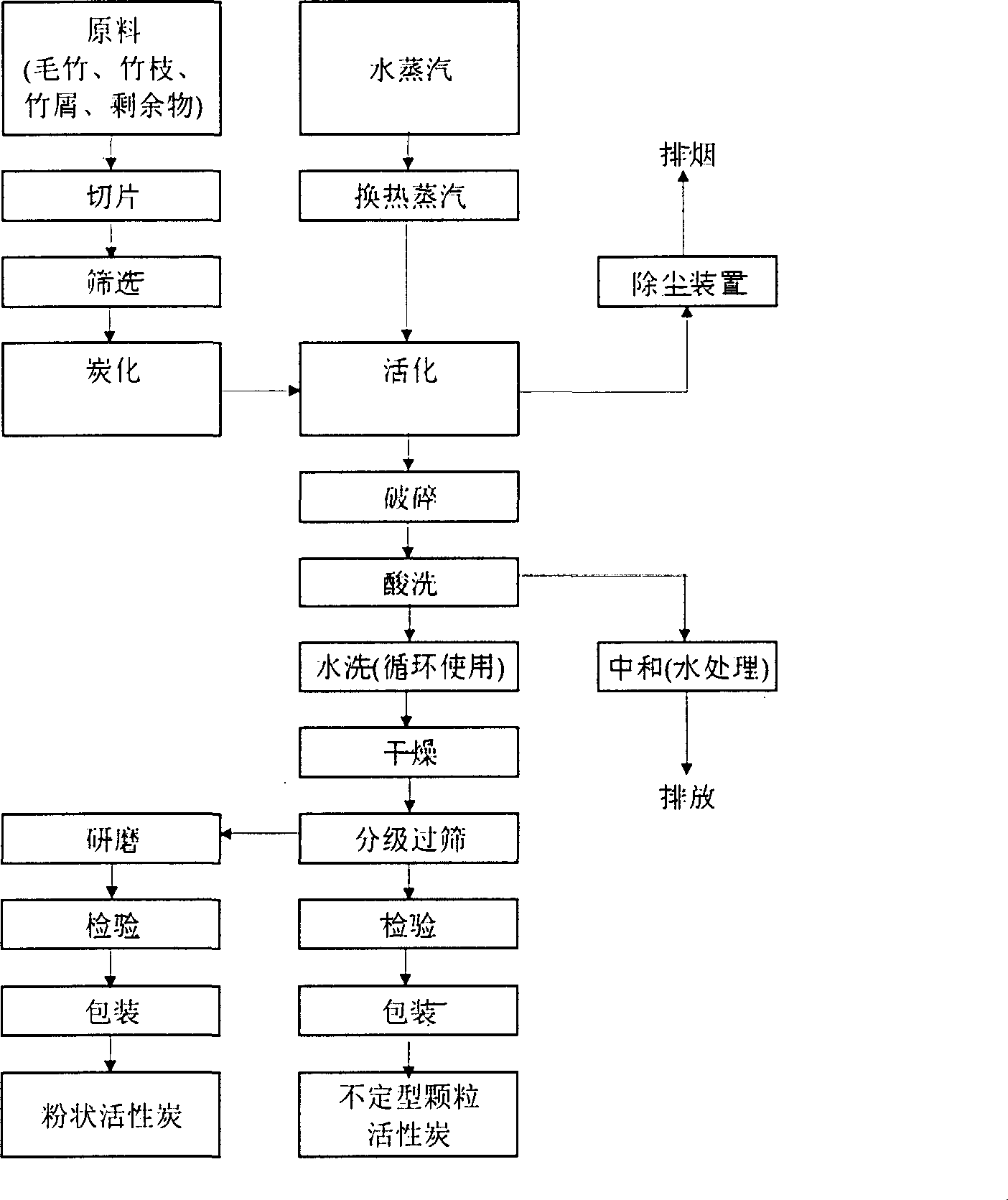

Method for preparing activated char from bamboo material

InactiveCN1333180AImproved decolorizationMesopore developedCarbon compoundsDistillationPhosphoric acid

Owner:尤匡银

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

Surface treatment method of boron carbide powder

Owner:中国科学院上海硅酸盐研究所苏州研究院

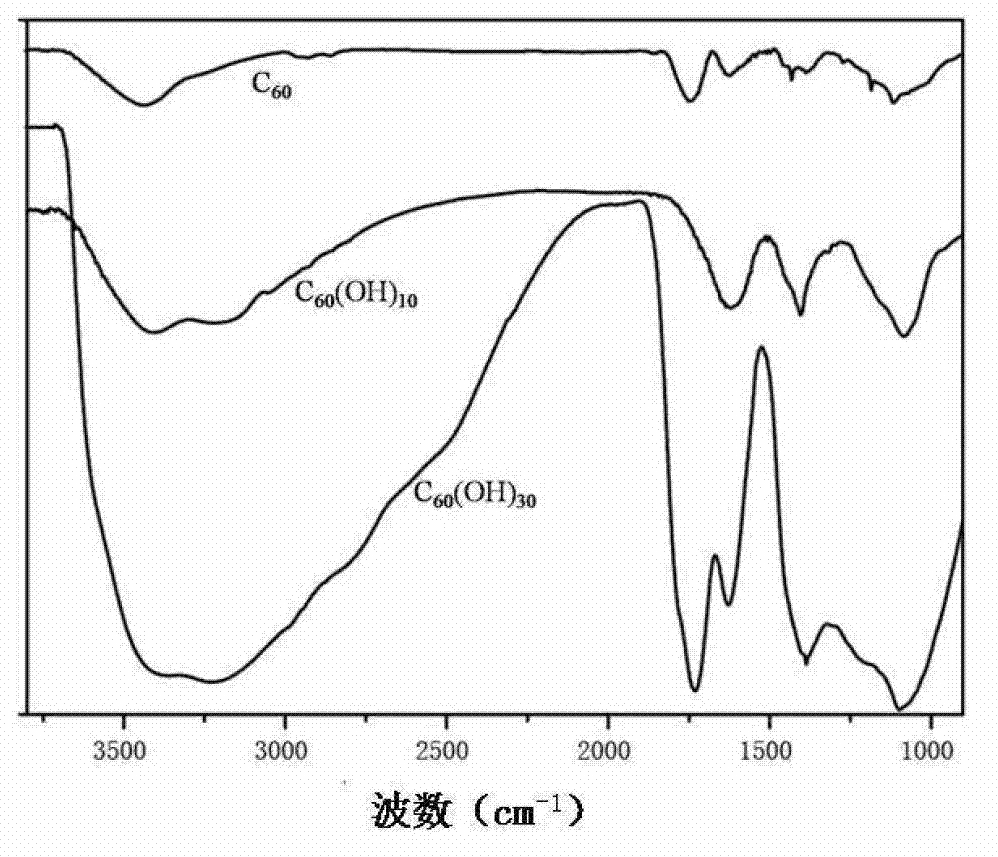

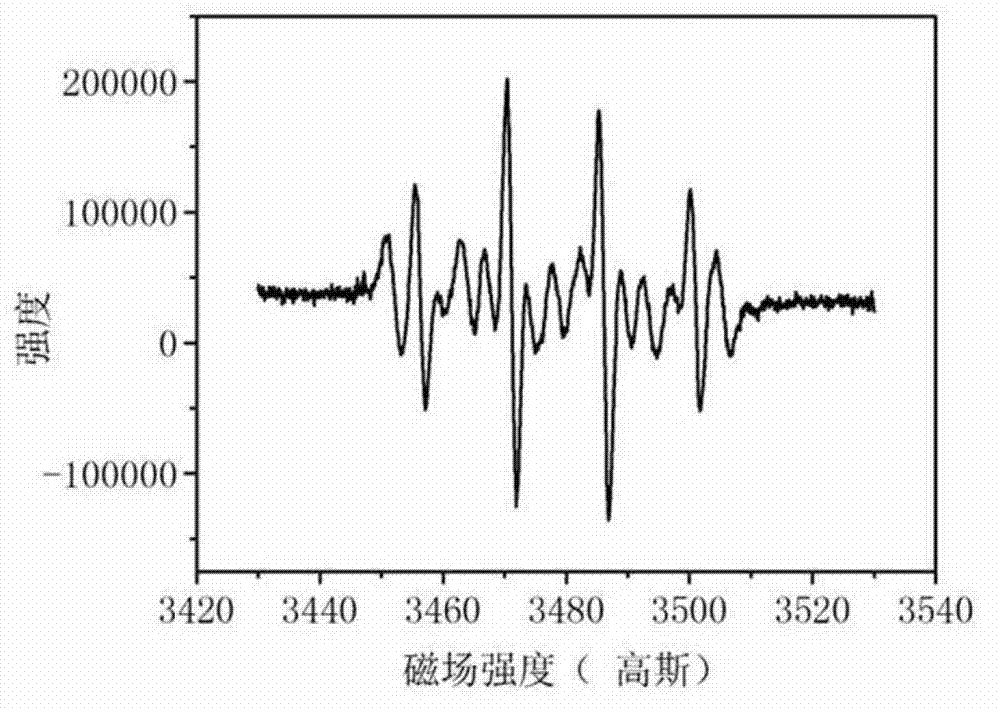

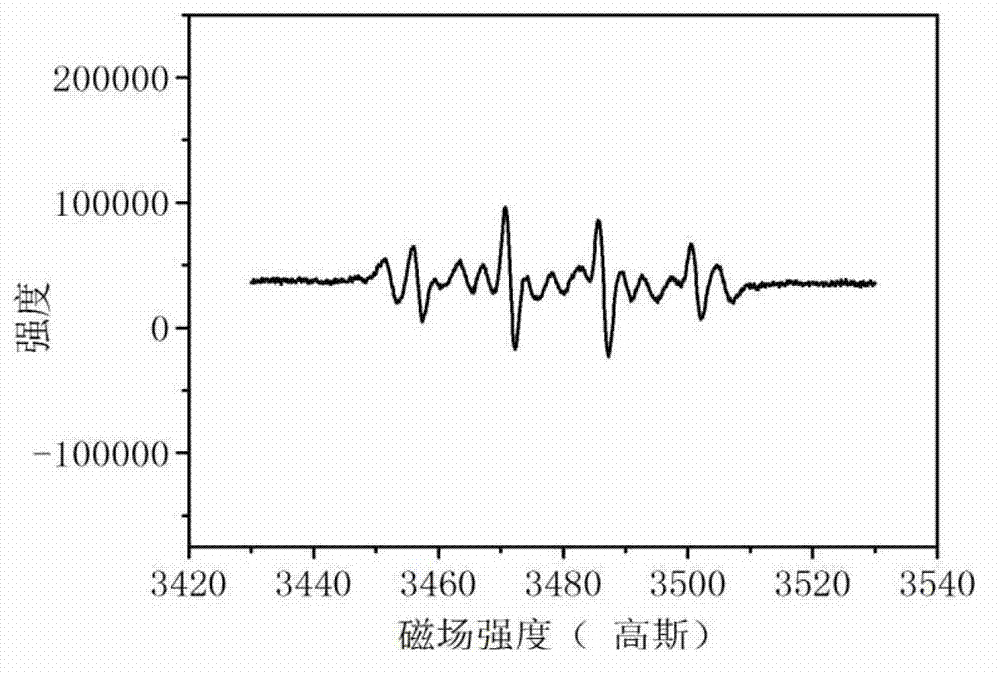

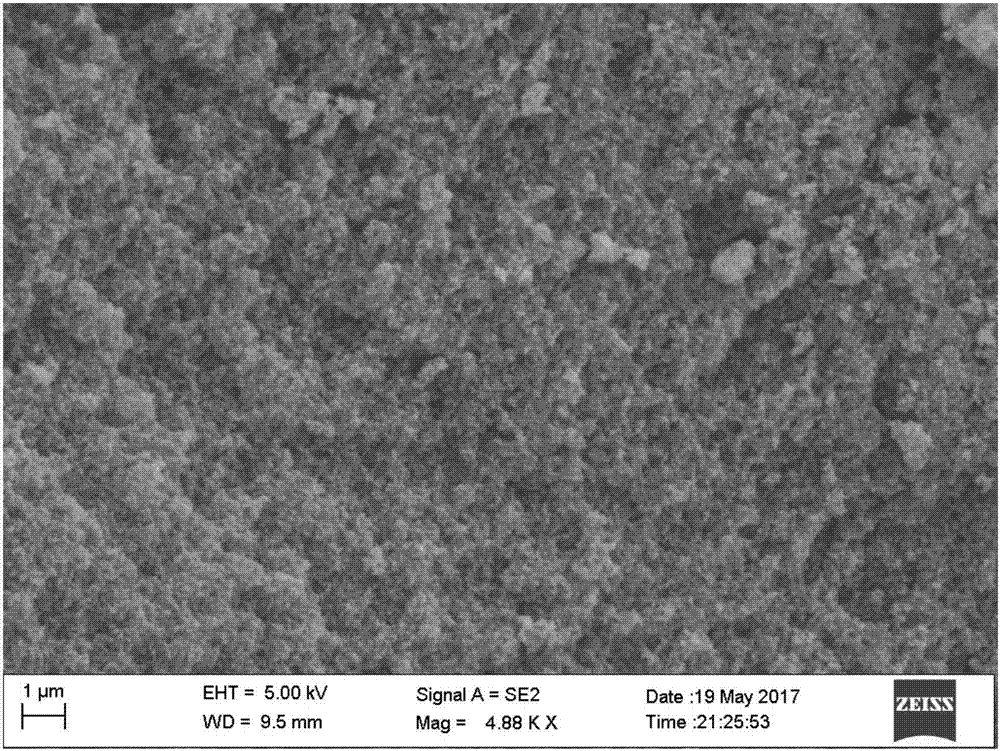

Fullerol and preparation method thereof

ActiveCN102849717AGuarantee normal performanceReduce security risksCarbon compoundsAntinoxious agentsSolventFullerene

Owner:SHENZHEN BEAUTY STAR

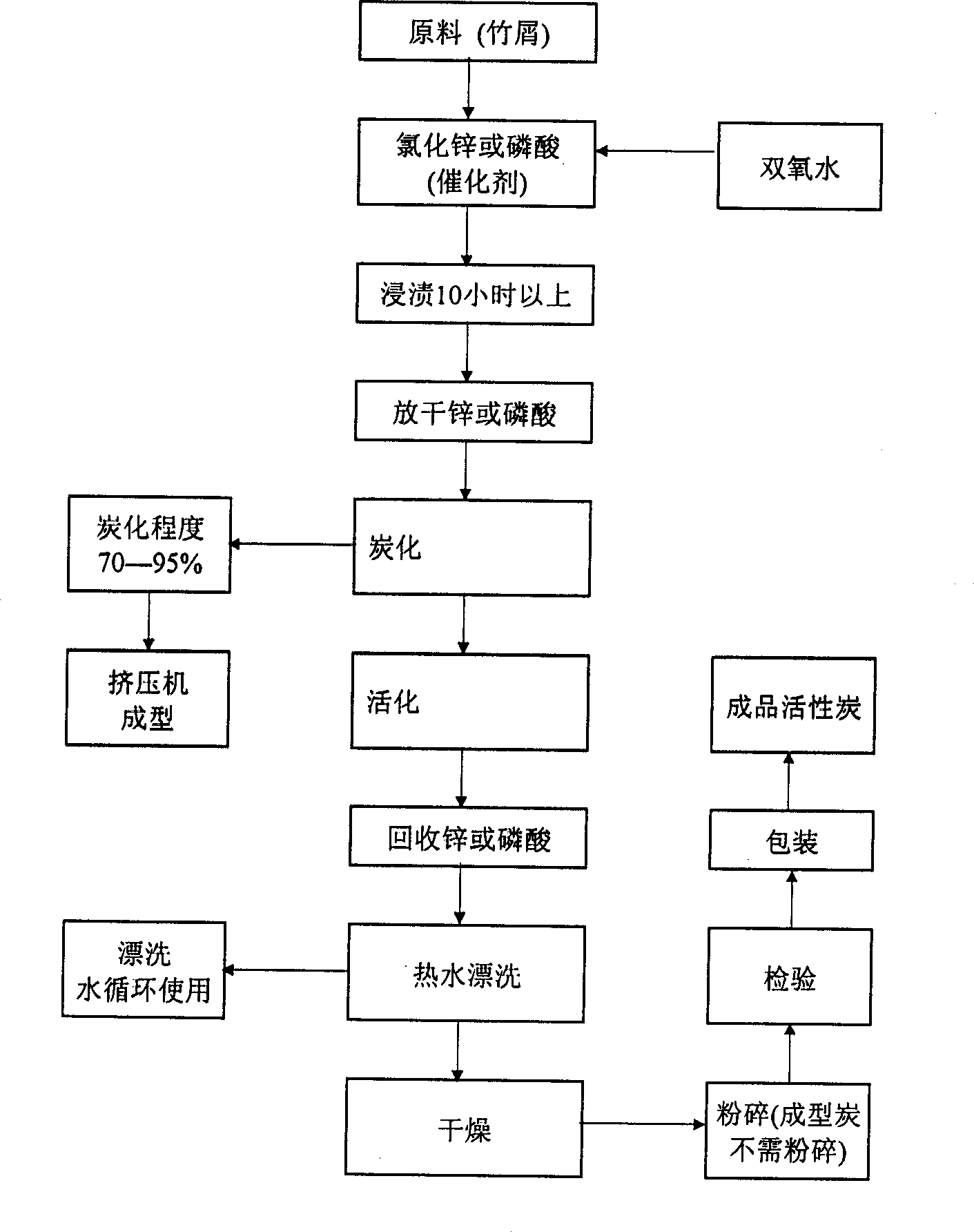

Method for preparing active carbon from biomass, and prepared active carbon

InactiveCN107337206AReduce pollutionRecycling reducesZinc halidesCarbon compoundsActivated carbonAcid washing

Owner:HEFEI UNIV OF TECH

Method for increasing concentration of carbon dioxide in tail gas of lime rotary kiln

InactiveCN110683544AIncrease concentrationHigh purityCalcium/strontium/barium carbonatesMaterial nanotechnologyCo2 absorptionDust control

The invention discloses a method for increasing the concentration of carbon dioxide in tail gas of a lime rotary kiln. The method is characterized by comprising the following steps: (1) the tail gas of the lime kiln passes through dedusting equipment to remove dust particles; (2) the dedusted tail gas is sprayed through a washing tower, the sprayed tail gas is desulfurized through a desulfurizingtower; (3) the desulfurized tail gas passes through a booster fan to enter a surge flask and then is conveyed into a carbon dioxide absorption tower, alkanolamine in the absorption tower absorbs the carbon dioxide, and the tail gas is metered and then emptied; (4) a carbon-dioxide-absorbed alkanolamine solution is pressurized through a rich solution pump to enter a regeneration tower; (5) the carbon-dioxide-absorbed alkanolamine solution is heated in the regeneration tower to desorb the carbon dioxide, the desorbed carbon dioxide is cooled, dried, analyzed and stored; and (6) a regenerated barren solution is cooled by a barren solution cooler and then pressurized through a barren solution pump to enter an absorption tower, and the carbon dioxide is absorbed again. An enrichment technologyfor the carbon dioxide in the tail gas of the lime rotary kiln brings certain economic benefits for enterprises while according with national industrial structure adjustment and environmental protection.

Owner:HUBEI UNIV

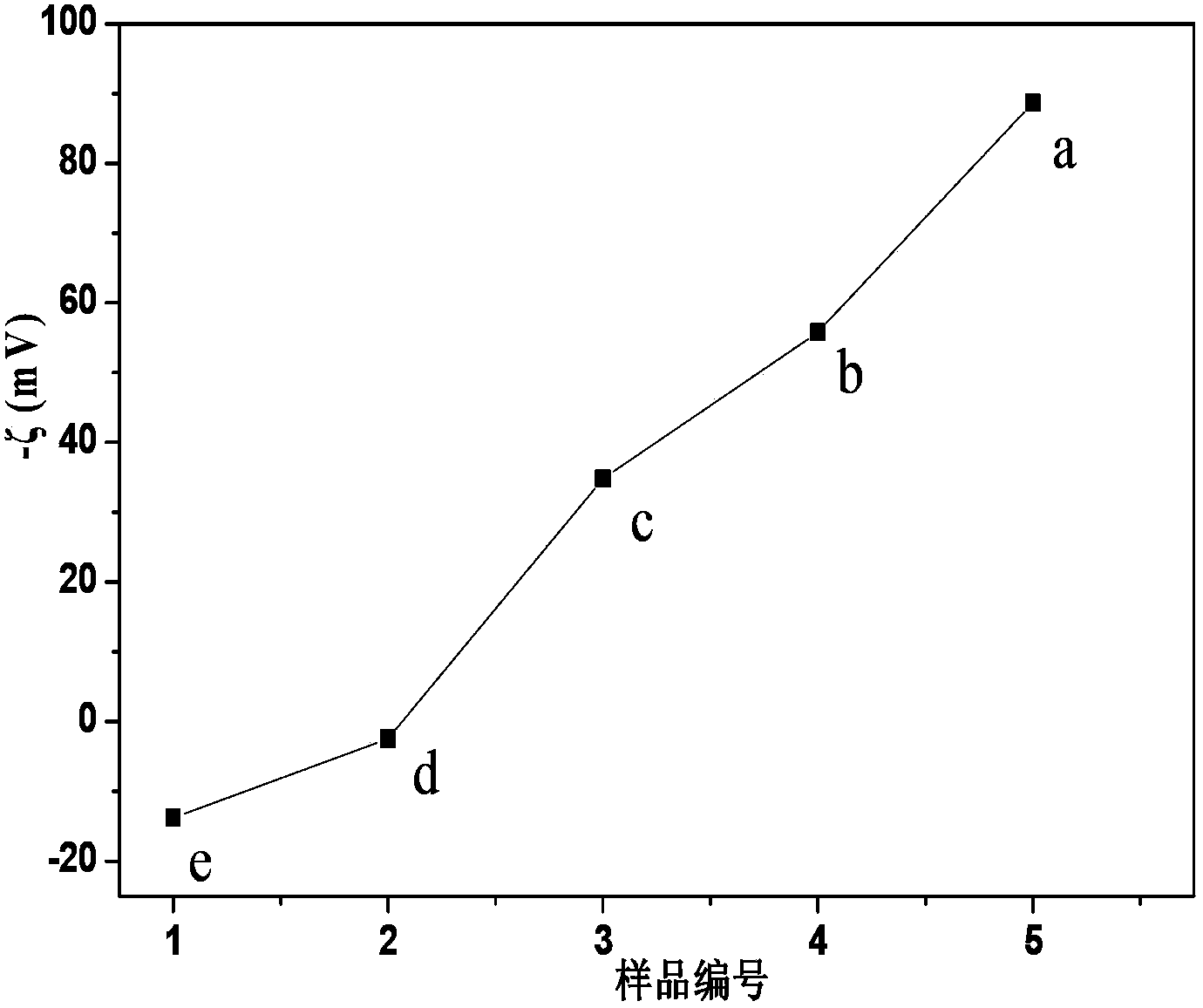

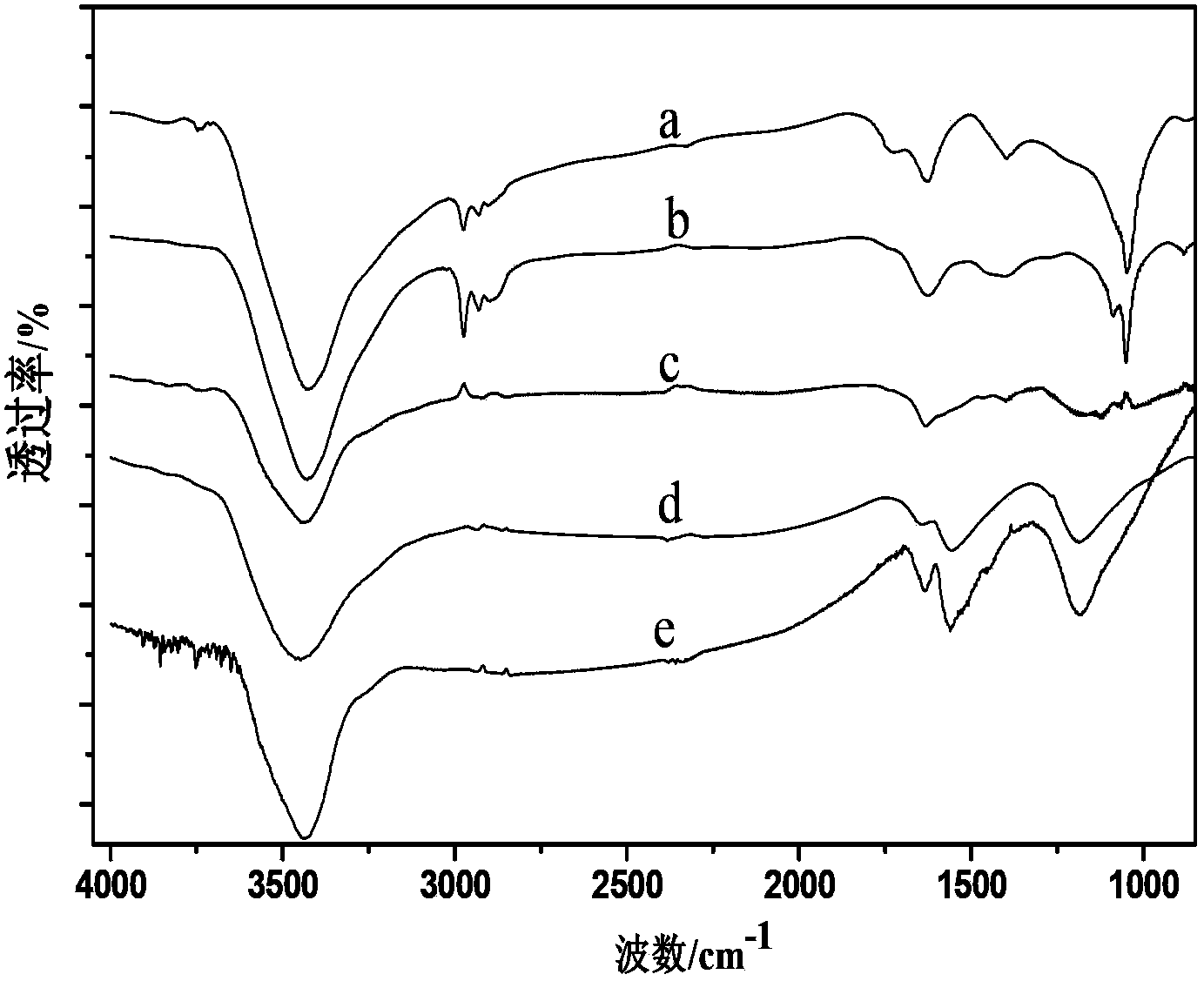

Method for controlling surface potentials of graphene-based material

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

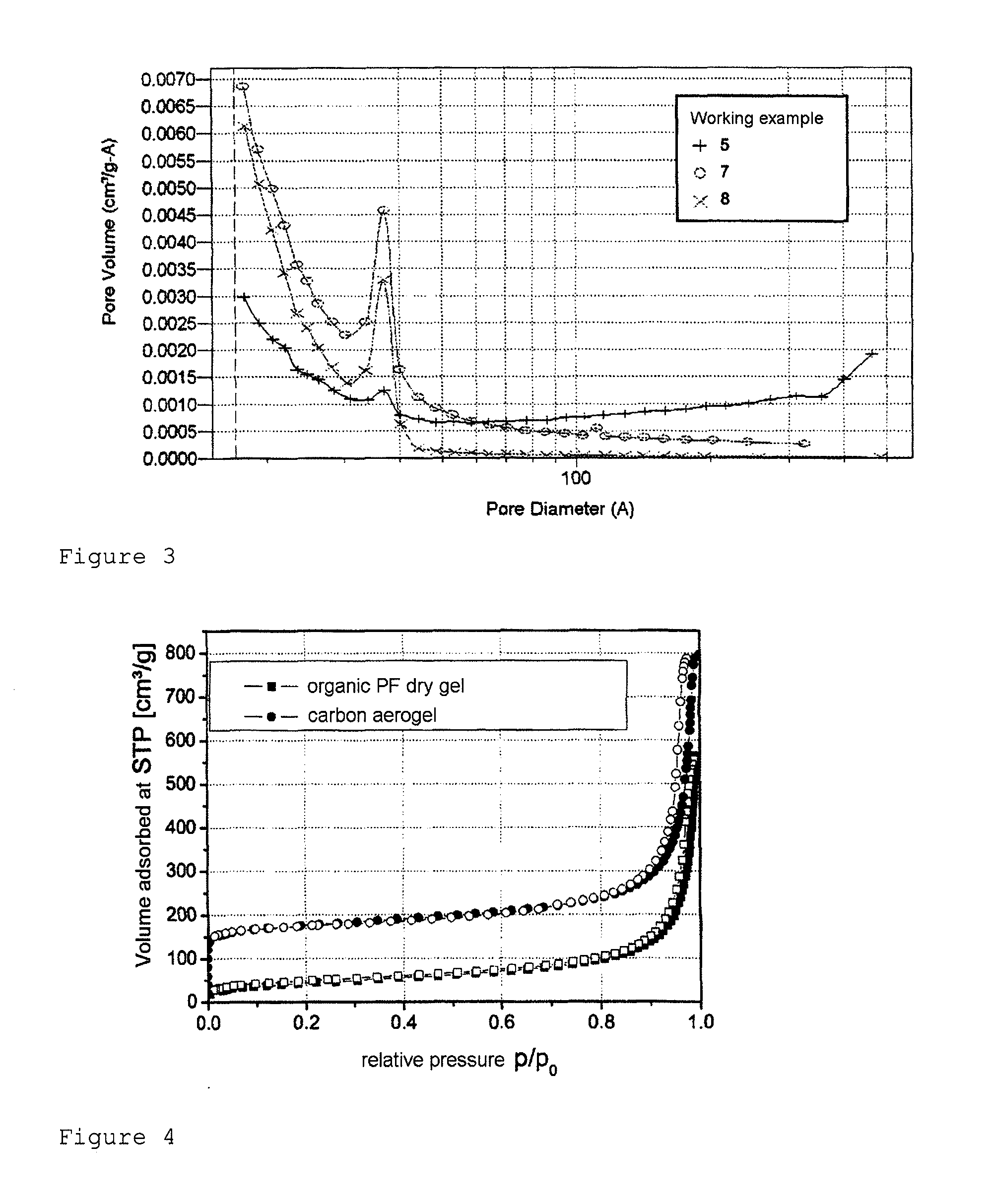

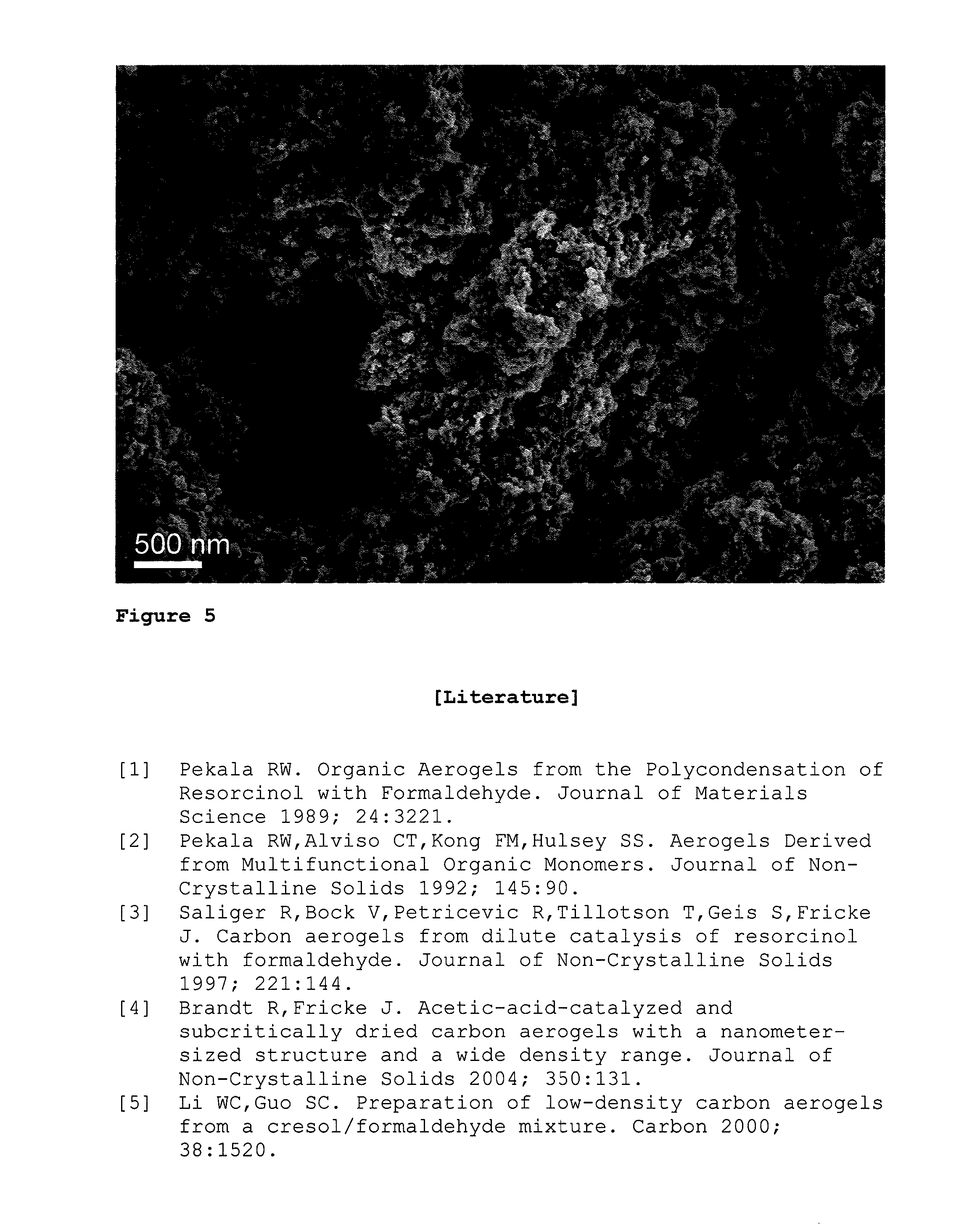

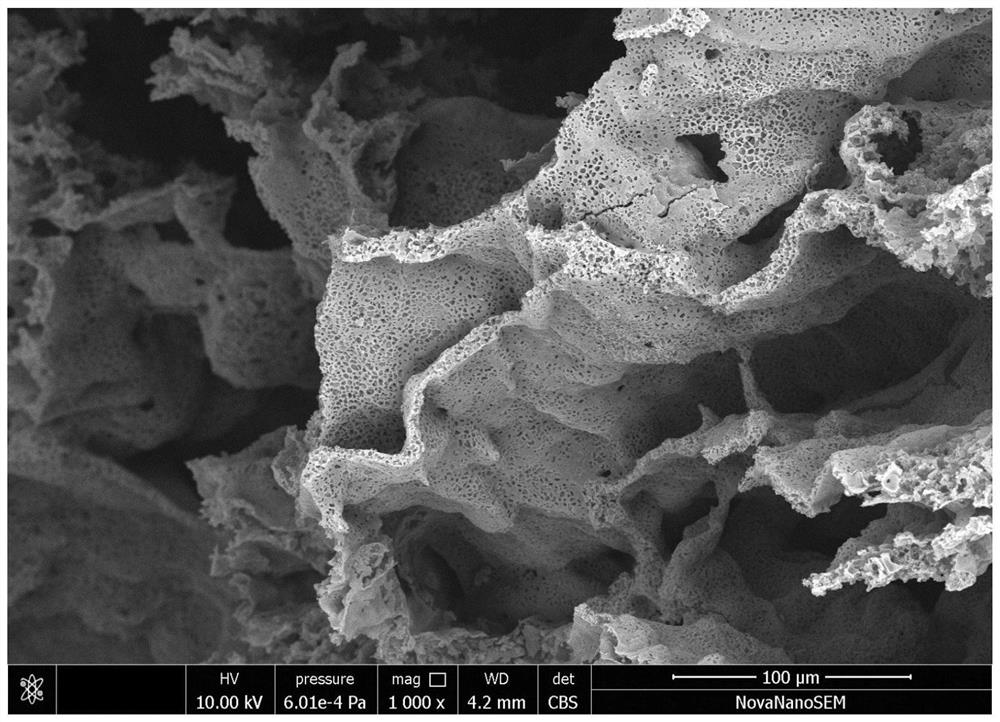

Microporous and Mesoporous Carbon Xerogel Having a Characteristic Mesopore Size and Precursors Thereof and Also a Process for Producing These and Their Use

InactiveUS20120020869A1Simple and cost-effective processPrevent crashOrganic chemistryCarbon compoundsSolventSupercritical drying

Owner:EVONIK CARBON BLACK GMBH

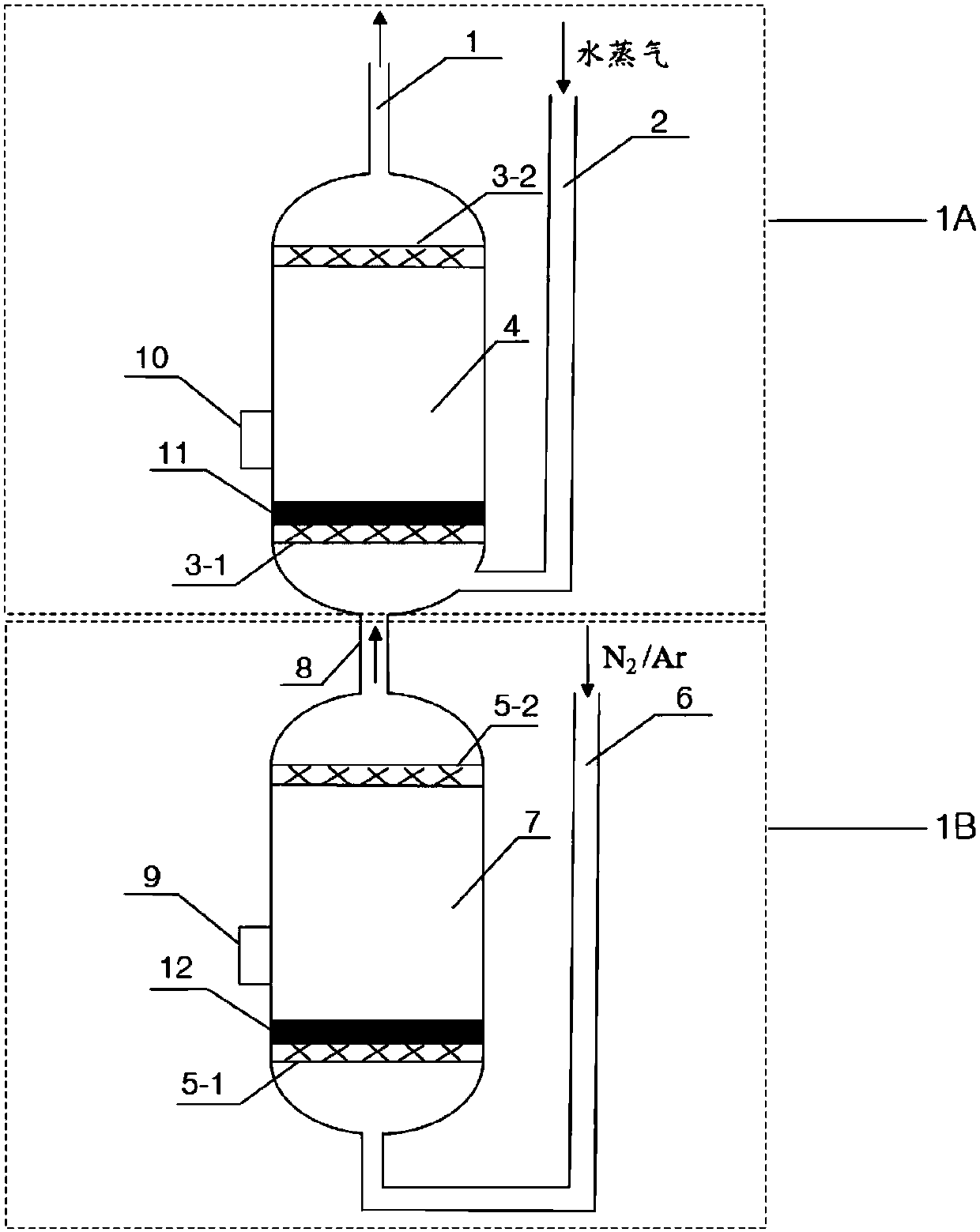

Two-section system and method for coproducing coal-based graphite and carbon nano-tubes

Owner:HUAZHONG UNIV OF SCI & TECH

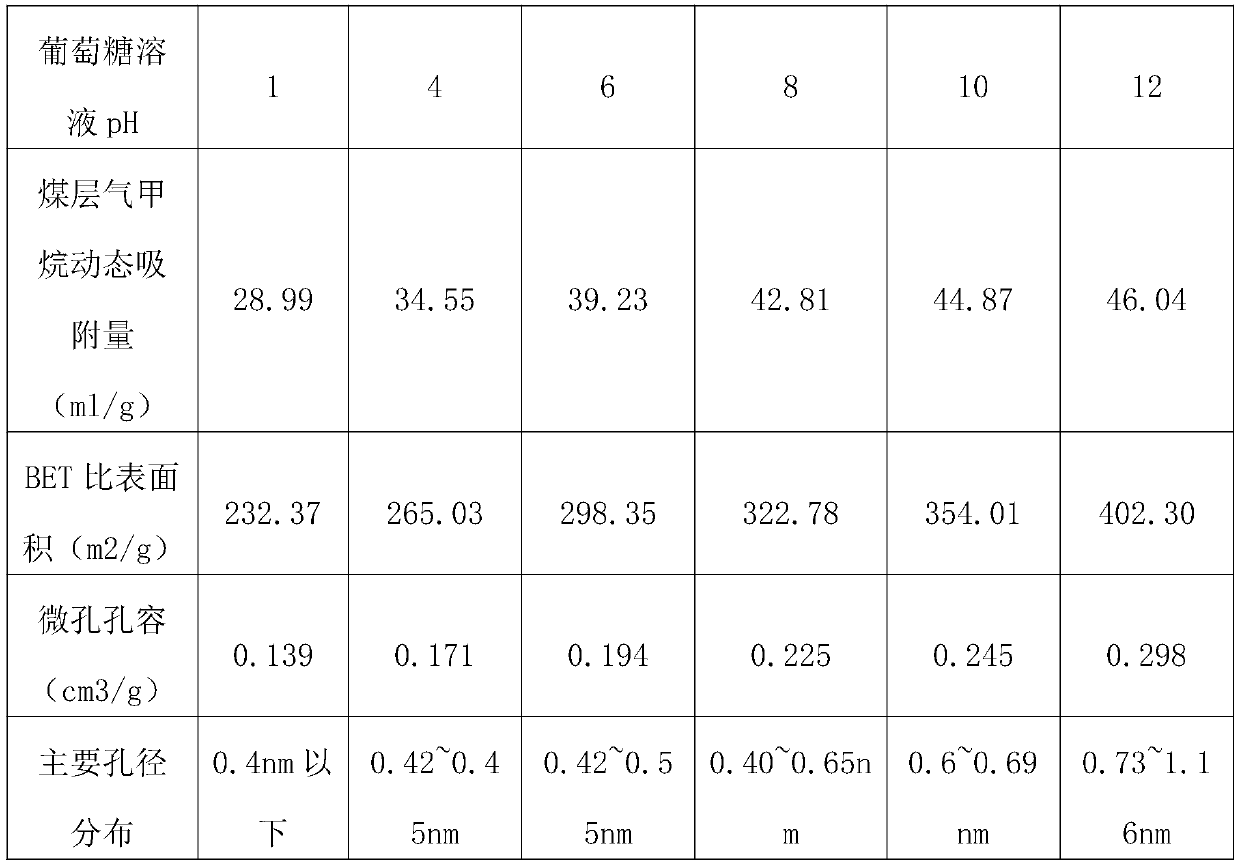

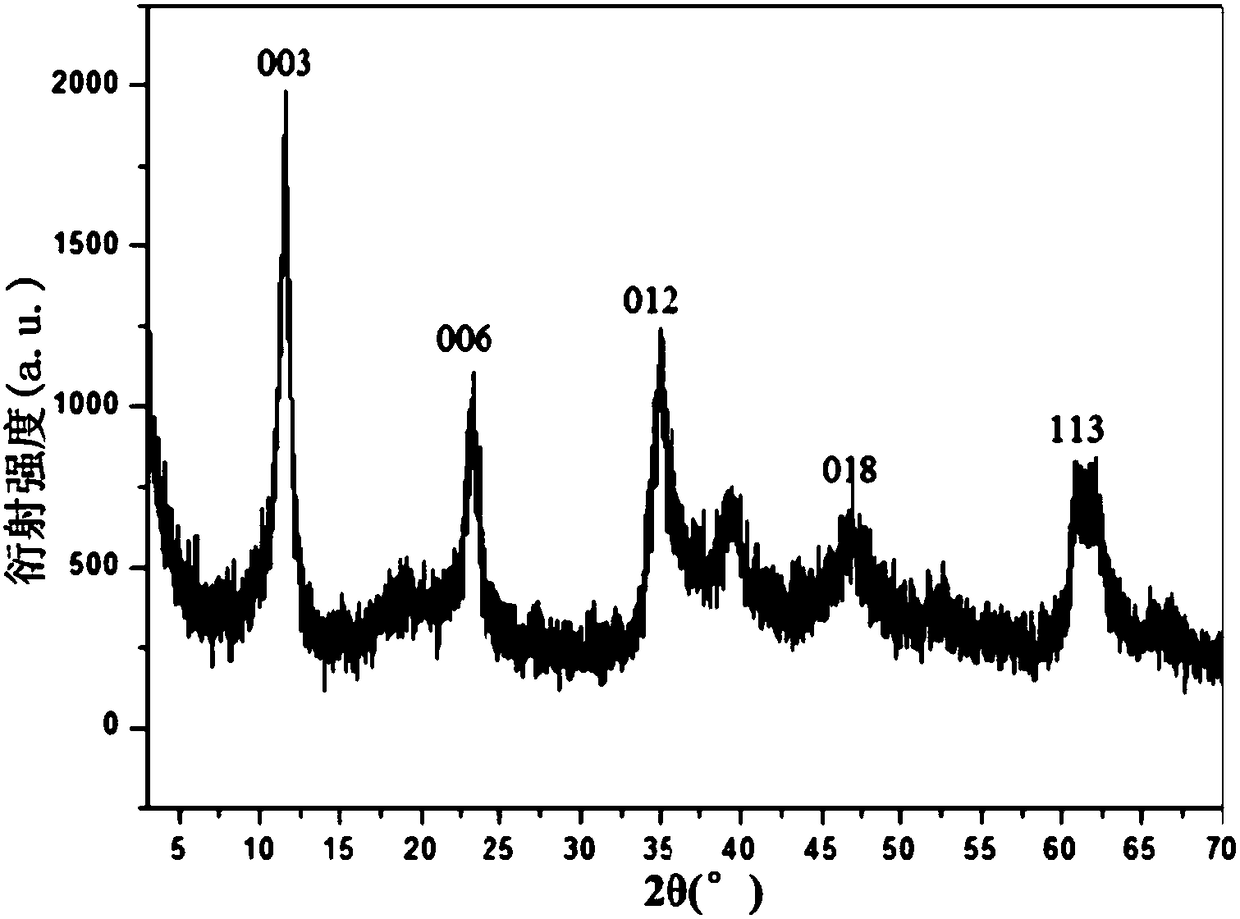

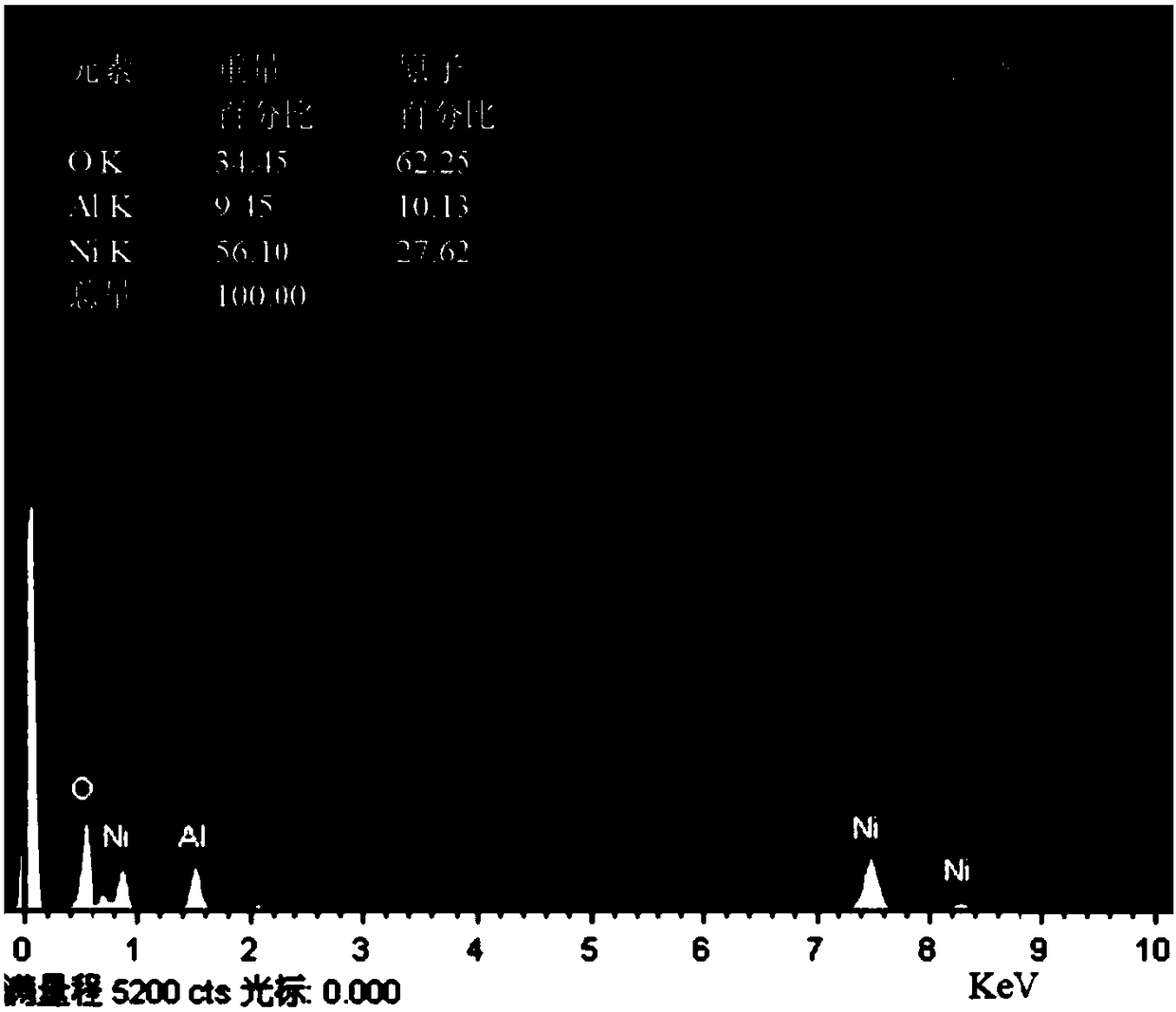

Preparation method of ultramicroporous active carbon balls used for absorbing coalbed methane

Owner:GUIZHOU UNIV

Production method for microwave catalytic pyrolysis of Eupatorium adenophorum

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles

ActiveCN112010305AReduce energy consumptionSimple and time-saving operationCarbon compoundsNegative electrodesAl powderArgon atmosphere

The invention relates to a method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles. The method comprises: mixing dried V powder, Ti powder, Al powder, Sn powder and C powder according toa molar ratio of (1.8-1): 1, (0.2-1): (0.2-1): (1-1.5): (0-0.35): (0.85-1.2), grinding in a ball mill, carrying out high-temperature self-propagating synthesis on the obtained powder in an argon atmosphere, so that (V, Ti) 2AlCMAX phase materials are obtained, crushing and grinding the (V, Ti) 2AlCMAX phase materials, carrying out solvent ultrasonic treatment, carrying out standing precipitation on a solution obtained after ultrasonic treatment for 2-5 days, taking an upper-layer solution, and carrying out centrifugation, wherein a lower-layer precipitate comprises (V, Ti) 2AlC submicron sheets, and the supernatant comprises a colloidal solution of (V, Ti) 2AlC nanoparticles. The method is low in energy consumption, safe, environmentally friendly, easy to operate, capable of saving time and low in cost, and the prepared (V, Ti) 2AlC submicron sheets and nanoparticles are suitable for being used as lithium ion battery negative electrode materials.

Owner:YANCHENG INST OF TECH

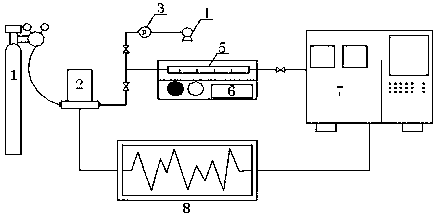

Nickel-carbon nanotube composite material and preparation method thereof

ActiveCN108314007ALow costHigh saturation magnetizationMaterial nanotechnologyCarbon compoundsFlower likeMagnetization

Owner:CHINA PETROLEUM & CHEM CORP +2

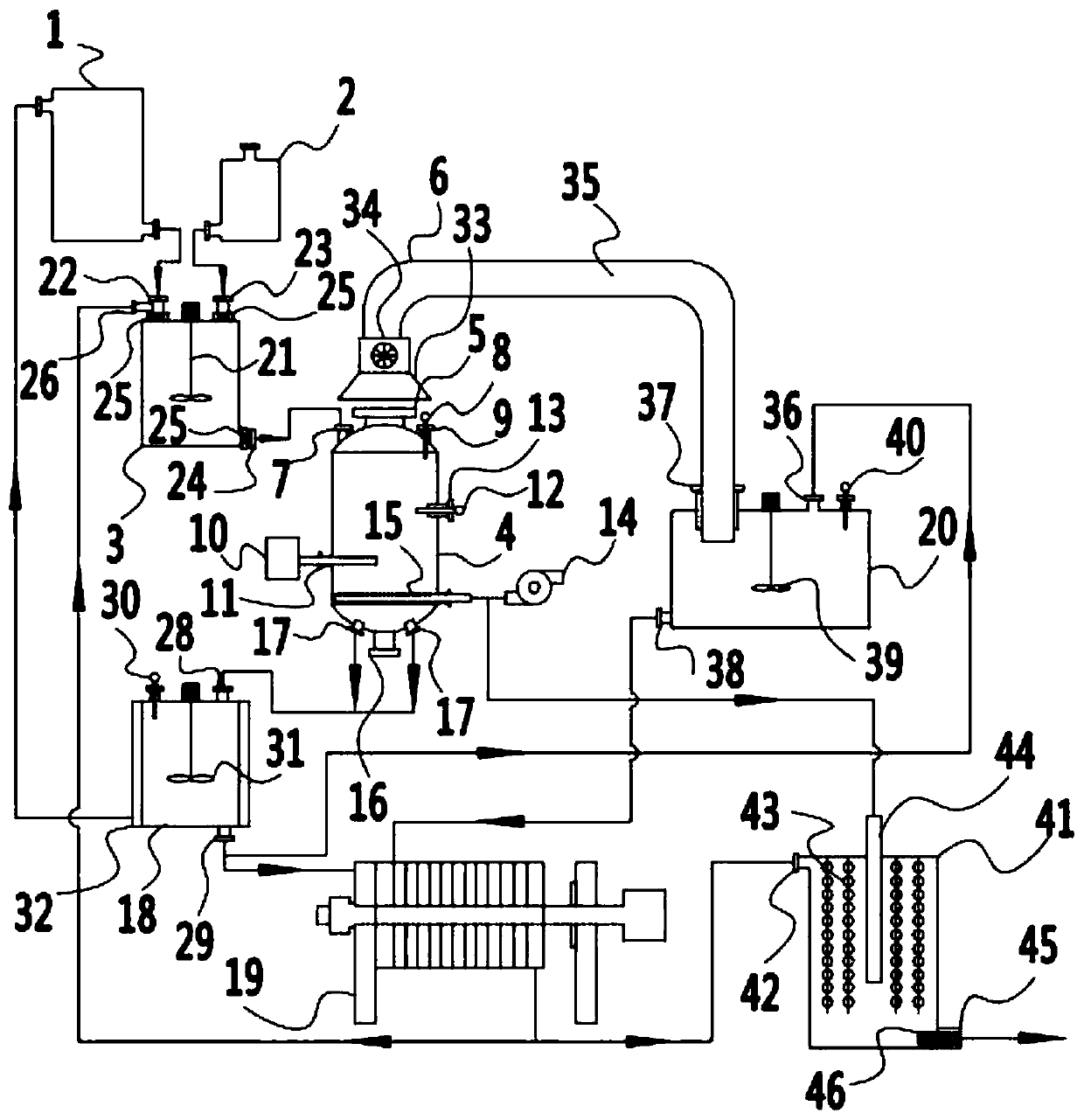

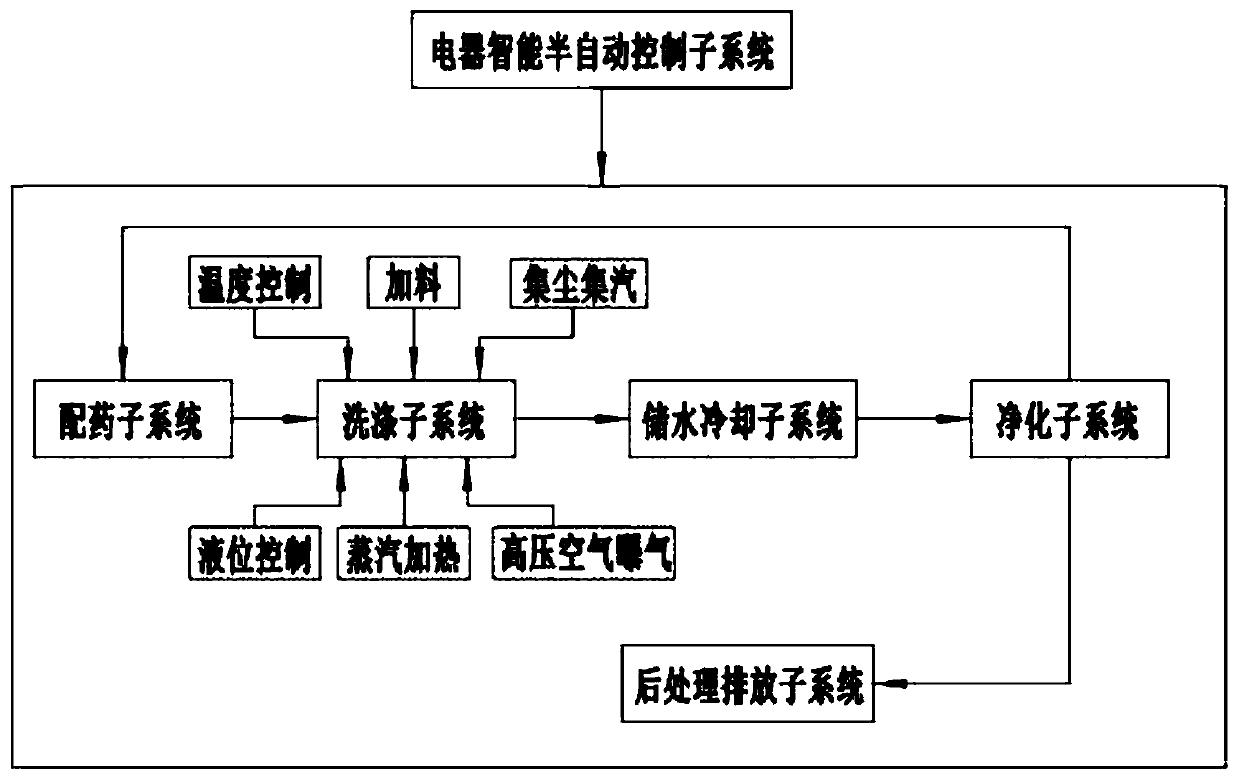

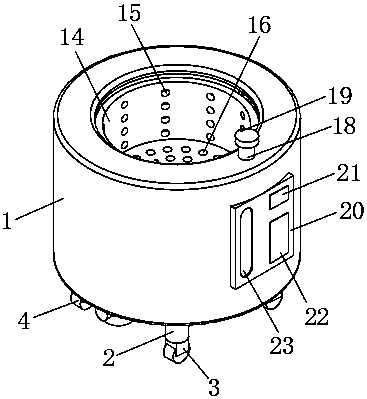

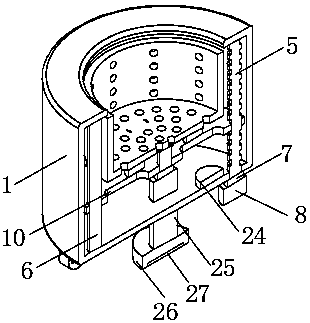

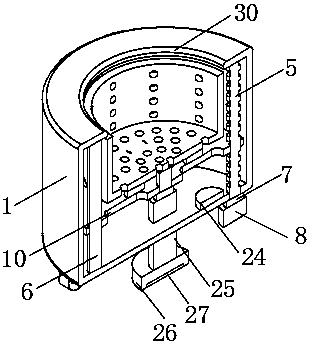

Activated carbon washing system and washing process

ActiveCN110255562AQuality improvementRealize repeated rinsingCarbon compoundsAir quality improvementWater storageActivated carbon

Owner:江苏哈特尔碳材料科技有限公司

LED driver and method of operating a camera

Disclosed is a method of capturing an image of a scene using a user device having a rolling shutter camera. The scene is subjected to an illumination by an LED light source. The method includes providing, by the user device, a notification signal to the LED light source, the notification signal being indicative of a capturing or imminent capturing of an image; adjusting, by the LED light source, an operating characteristic of the LED light source, based on the notification signal; and capturing, by the rolling shutter camera, the image of the scene, while the LED light source is operating at the adjusted operating characteristic.

Owner:ELDOLAB HLDG BV

Preparation method of self-supporting porous carbon electrode material

Owner:YANCHENG INST OF TECH

Preparation method of biomass derived carbon material

Owner:ZHEJIANG FORESTRY UNIVERSITY

Manufacturing method for graphite film

The invention provides a manufacturing method for a graphite film. A polyimide film is taken as a precursor, and heat treatment conditions are as follows: the average heating rate in a heating sectionof 500-800 DEG C is 2 DEG C or below per minute, and the highest carbonization temperature is 1000 DEG C or higher. According to the manufacturing method for the graphite film, the average heating rate from 2200 DEG C to the highest graphitization temperature is smaller than 3 DEG C per minute, and 2500 DEG C or a higher temperature is the highest graphitization temperature of the process.

Owner:TAIMIDE TECH

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

Rinsing equipment used for active carbon production

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

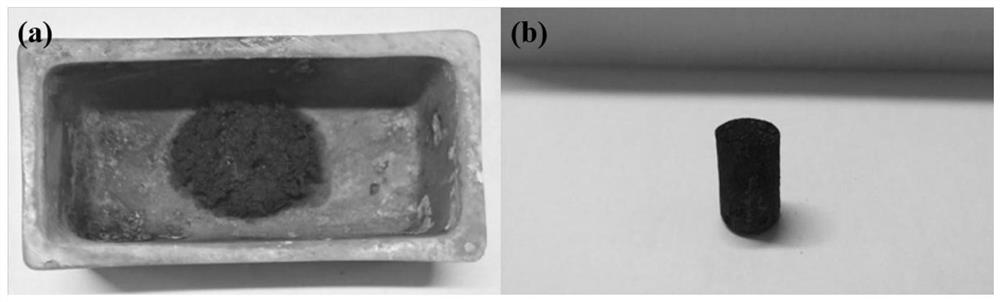

Preparation method of medicinal active carbon

InactiveCN106976873AFast decolorizationImprove adsorption capacityCarbon compoundsEcological environmentCarbonization

Owner:句容市盛达环保净化材料有限公司

Fish roe based porous carbon material preparation and application

InactiveCN108793158ASimple design processLow activation temperatureCarbon compoundsMaterials preparationCapacitance

Owner:GUILIN UNIV OF ELECTRONIC TECH

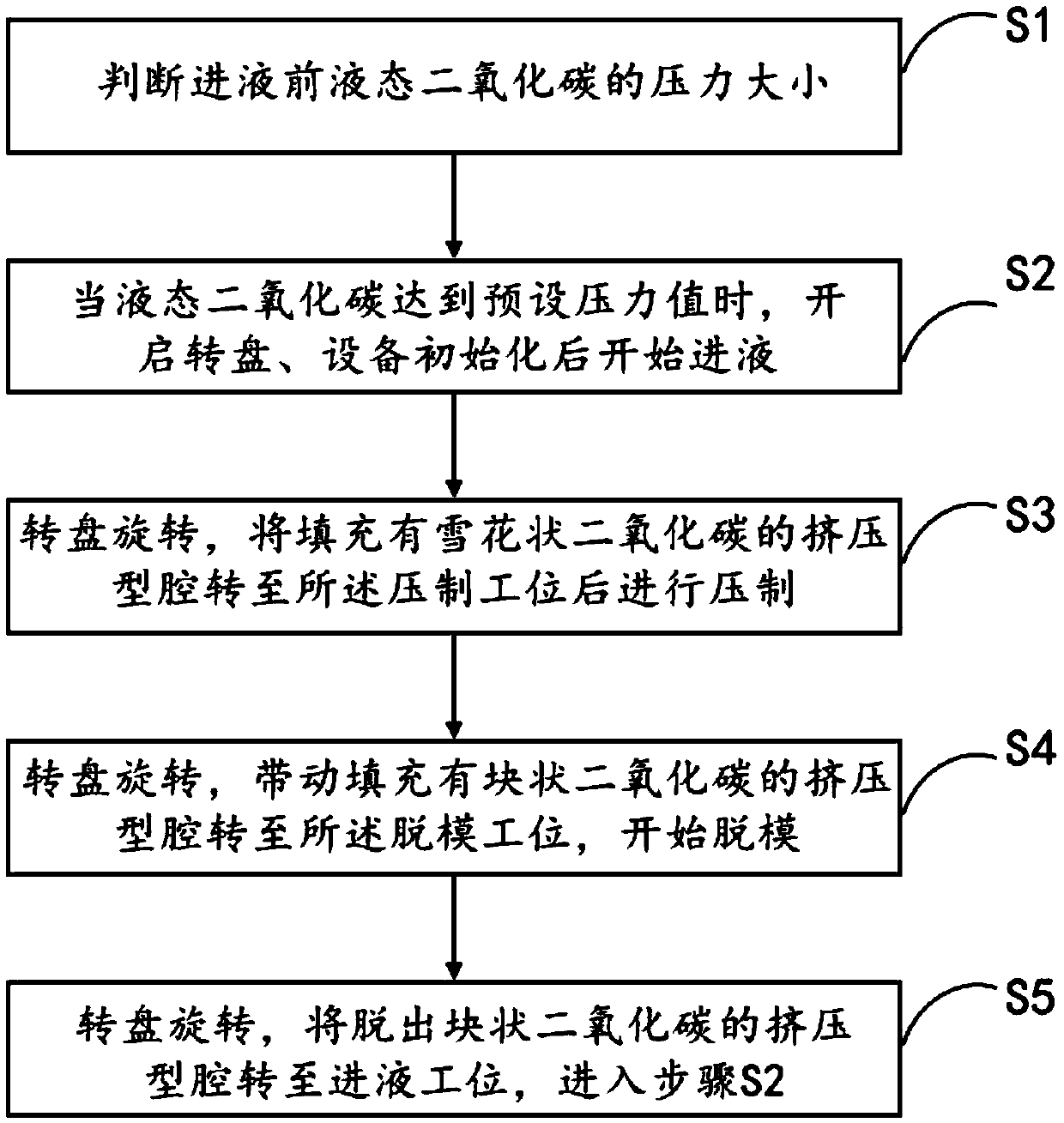

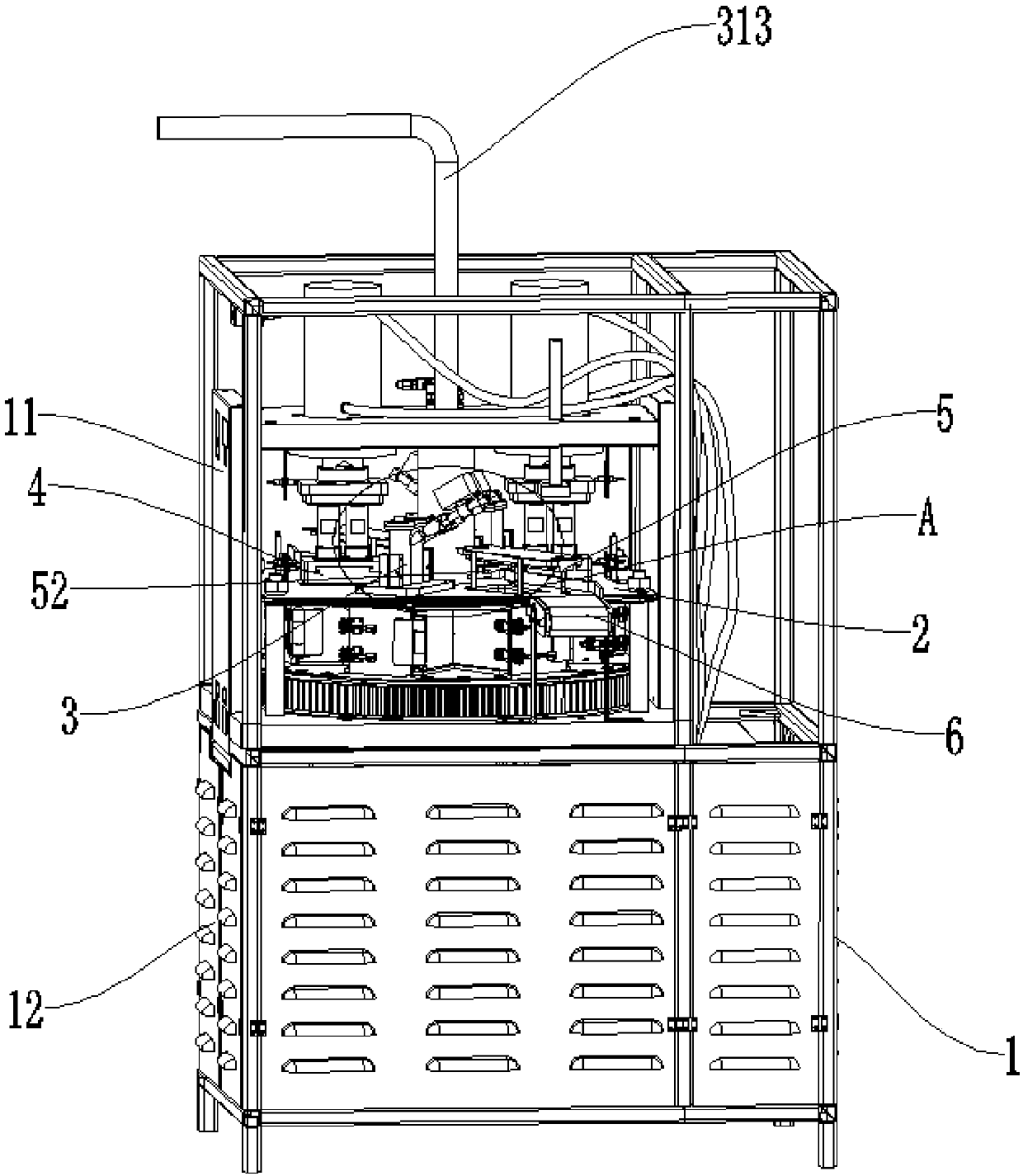

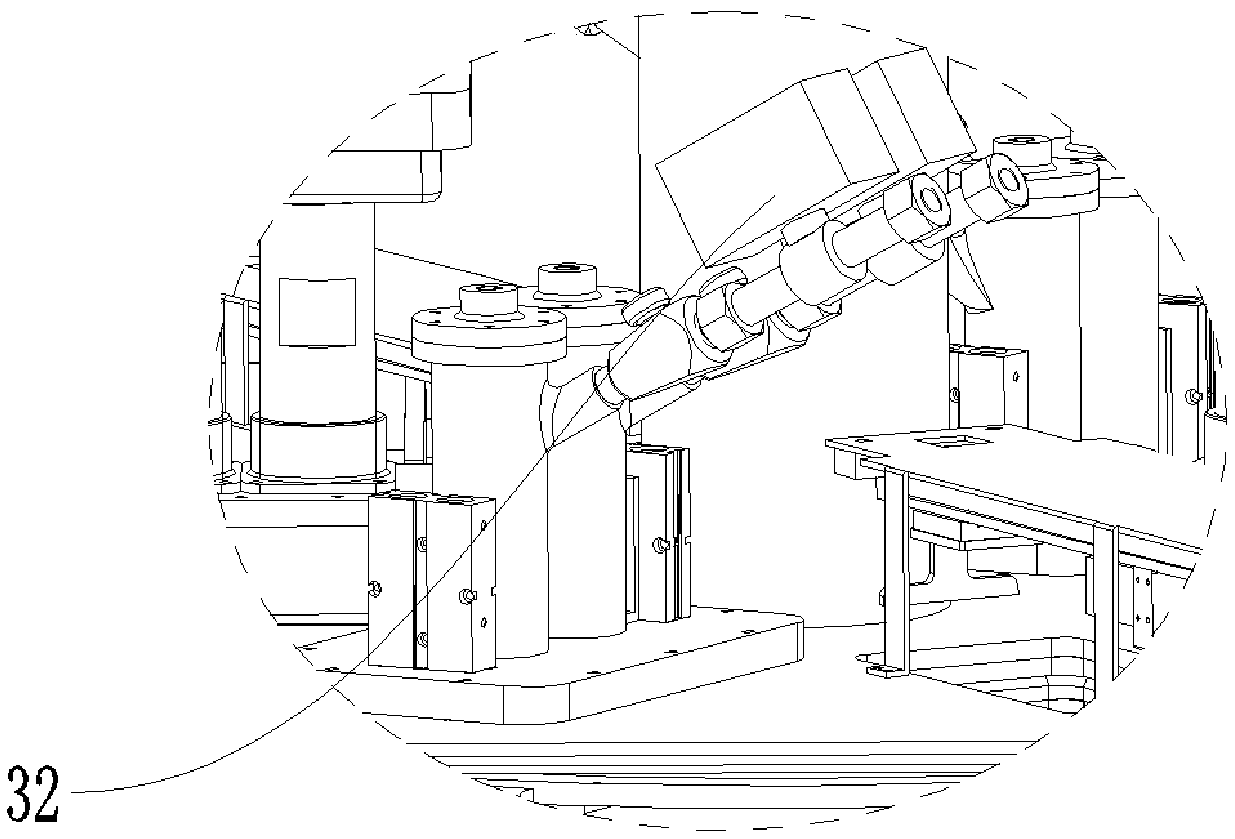

Control method for preparation of high-density carbon dioxide

ActiveCN109553102ASmall shock and vibrationLow input costProductsCarbon compoundsEngineeringMechanical engineering

The invention provides a control method for preparing high-density carbon dioxide. The control method comprises the following steps: judging the pressure of liquid carbon dioxide before the liquid carbon dioxide enters; when the pressure of the liquid carbon dioxide reaches a preset pressure value, opening a rotating disk, and after a device is initialized, starting feeding the liquid carbon dioxide; allowing the rotating disk to rotate to drive an extrusion type cavity filled with snowflake-like carbon dioxide to be rotated to a press molding station, and carrying out press molding; allowingthe rotating disk to rotate to drive the extrusion type cavity filled with block-shaped carbon dioxide to be rotated to a demolding station, and carrying out demolding; allowing the rotating disk to rotate to drive the block-shaped carbon dioxide demolded extrusion type cavity to be rotated to a liquid feeding station; and cyclically performing the step 2 to the step 5, and simultaneously performing liquid feeding, press molding and demolding respectively at the liquid feeding station, the press molding station and the demolding station. According to the invention, through controlling of the rotating disk to a plurality of stations, the steps of liquid feeding, press molding and demolding are simultaneously carried out at different stations, so equipment operation is streamlined; the costof investment is reduced; and the efficiency of working is improved.

Owner:XIAMEN UNIV OF TECH

Preparation method of active carbon

InactiveCN109399634AIncrease acquisition rateReduce stacking spaceCarbon compoundsActivated carbonEconomic benefits

Owner:湖南中炭新能源科技有限公司

Ion additive for carbon dioxide absorbent of organic amines

ActiveCN102173416AReduce oxidation rateReduces galvanic corrosionProductsCarbon compoundsElectrochemical corrosionIon

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

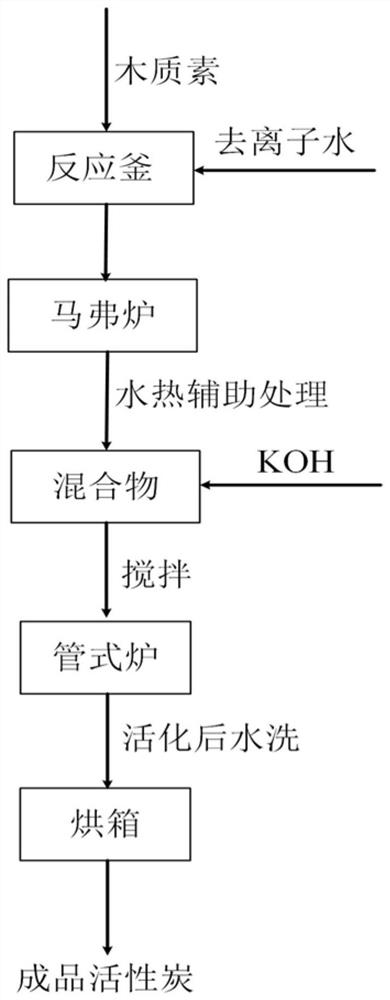

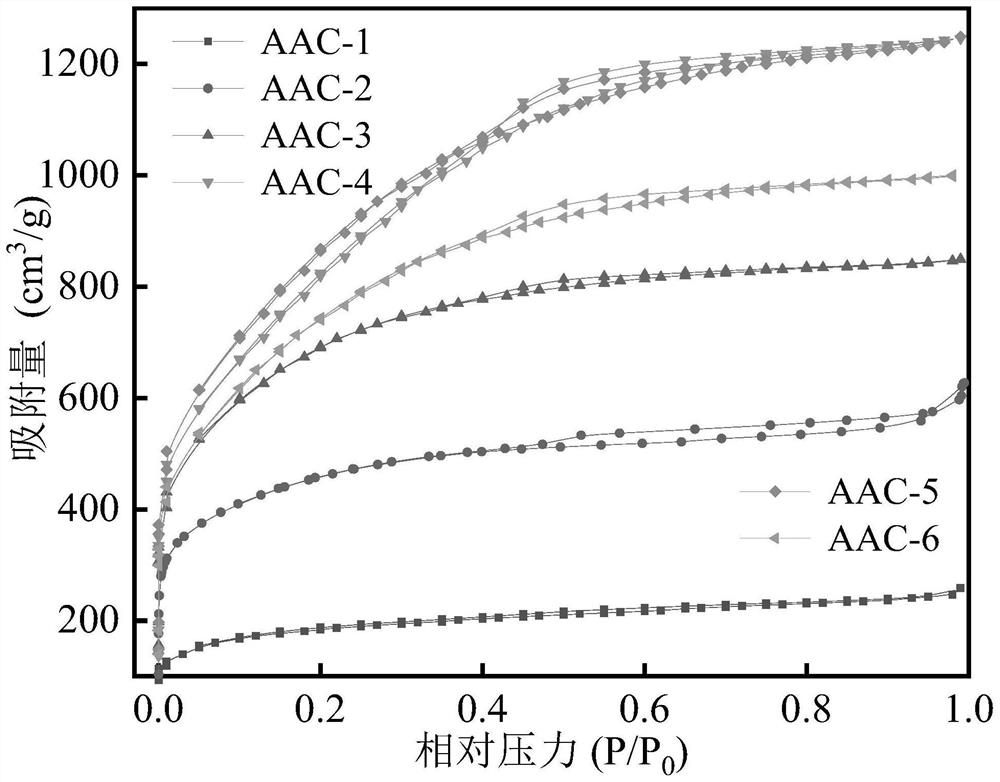

Method for hydrothermally assisted production of lignin activated carbon with high specific surface area

Owner:NANJING FORESTRY UNIV +1

Doped graphene hydrogel and preparation method thereof

InactiveCN113694893AEasy to shapePrevent collapseCarbon compoundsOther chemical processesDoped grapheneDistilled water

Owner:宁夏师范学院

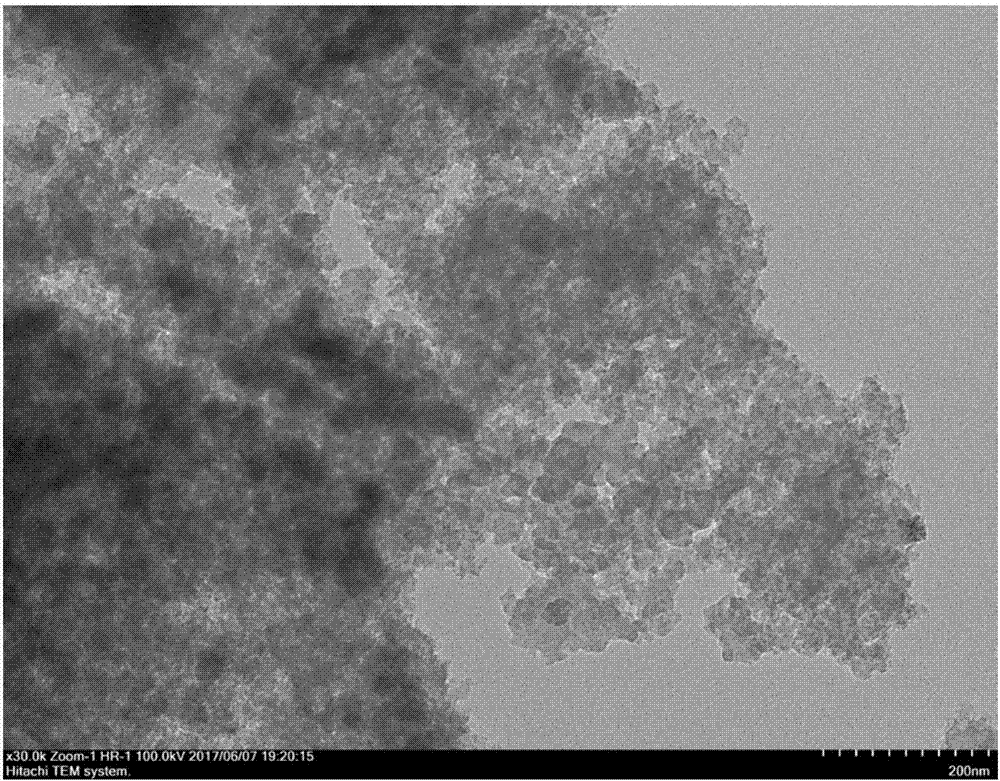

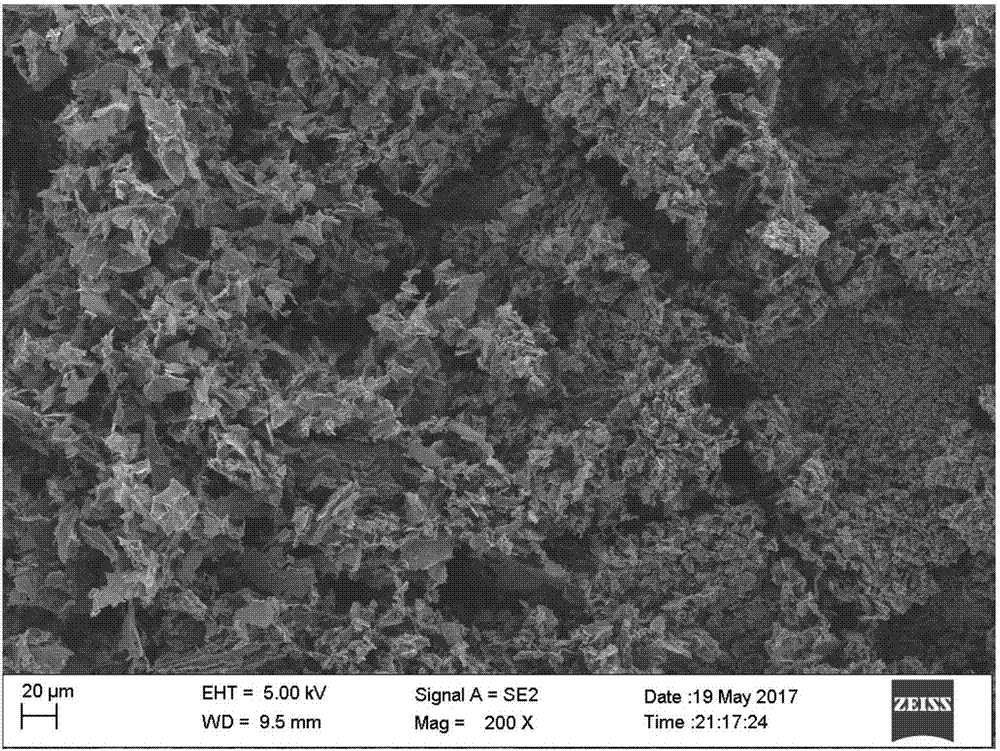

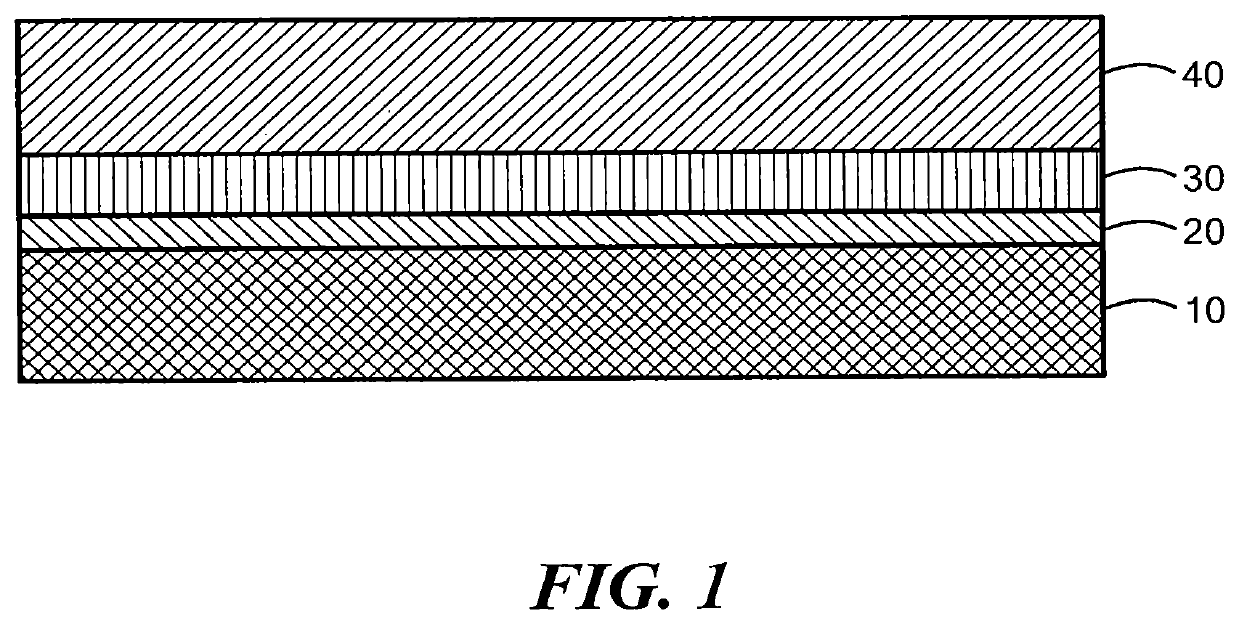

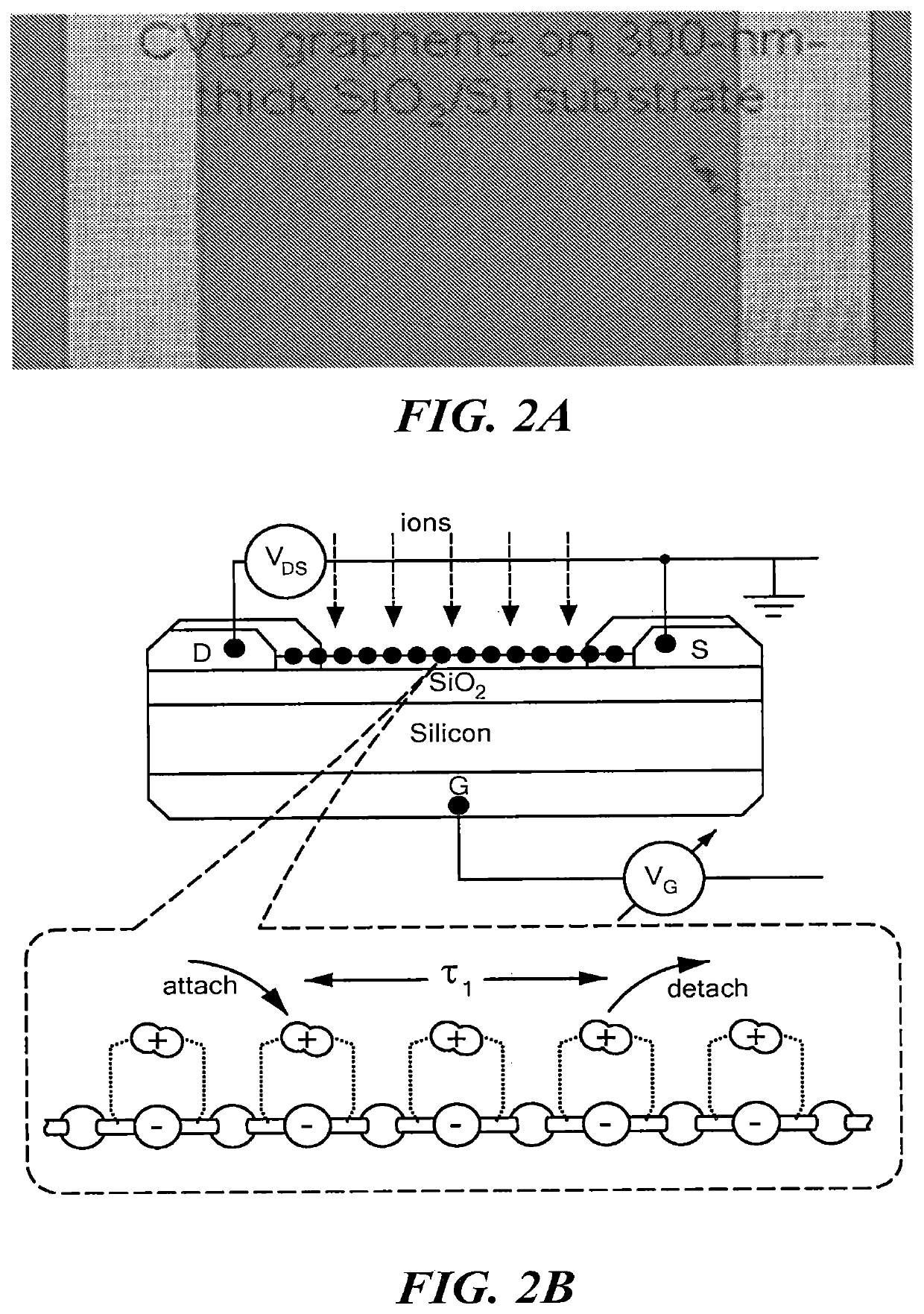

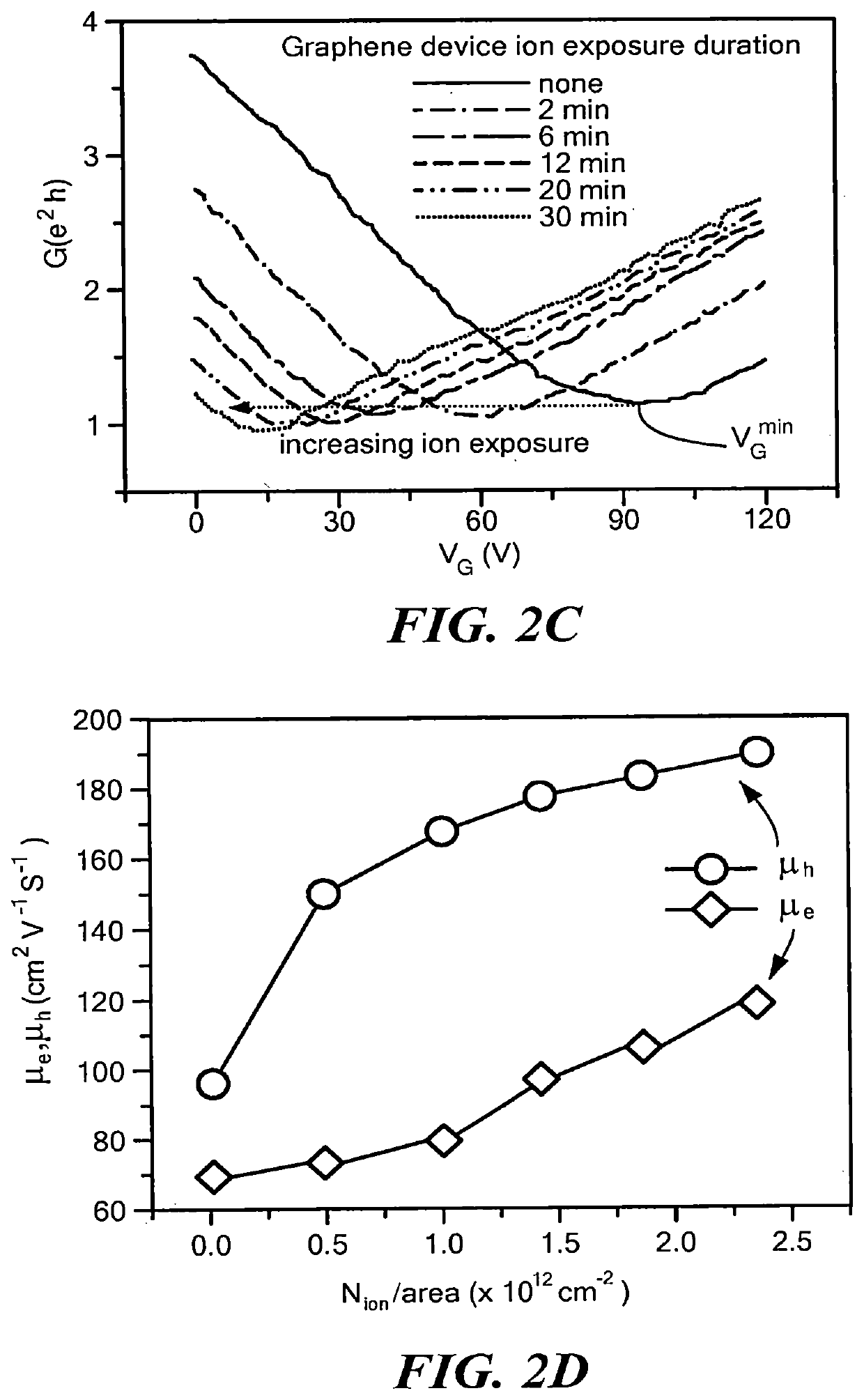

Ion-Doped Two-Dimensional Nanomaterials

Owner:NORTHEASTERN UNIV

Activated carbon preparation process

ActiveCN111874904AReduce processing efficiencyReduce air pressureCarbon compoundsDrying gas arrangementsActivated carbonHoneycomb

The invention belongs to the technical field of activated carbon preparation, and particularly relates to an activated carbon preparation process which comprises the following steps: step 1, drying and grinding: carbonizing and grinding sawdust after drying to obtain dried carbon powder; step 2, processing and forming: processing the carbon powder into a cylindrical carbon block by using a mold, and forming a plurality of honeycomb-shaped through holes; step 3, cleaning of the carbon block: washing the formed carbon block with water to remove impurities on the surface of the carbon block; step4, drying of the carbon block: drying the cleaned carbon block to remove moisture in honeycomb-shaped through holes of the carbon block, wherein the drying process of the cleaned carbon block in thestep 4 is completed by adopting an activated carbon preparation machine in a matching manner. The invention solves the problems that at present, when the interiors of cylindrical activated carbon honeycomb holes are dried, part of moisture on the inner walls of the honeycomb holes permeates into the surface layers of activated carbon, sufficient drying is difficult, and moisture residues are likely to be caused, and conveying and drying cannot be conducted synchronously, and the machining efficiency is low.

Owner:JIANGSU QIANHUIHE ENVIRONMENTAL REGENERATION CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap