Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Polyimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

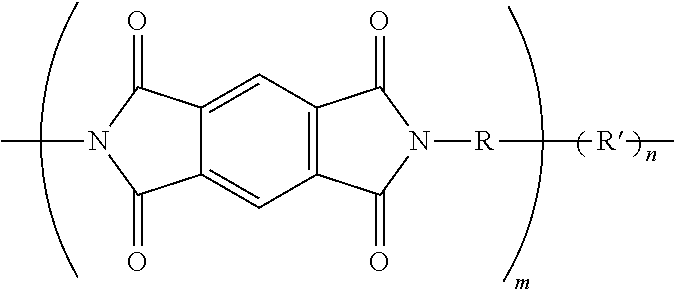

Polyimide (sometimes abbreviated PI) is a polymer of imide monomers. Polyimides have been in mass production since 1955. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, e.g. high temperature fuel cells, displays, and various military roles. A classic polyimide is Kapton, which is produced by condensation of pyromellitic dianhydride and 4,4'-oxydianiline.

High-thermal-conductivity polyimide film prepared from core-shell structure heat-conducting filler and preparation method of film

Owner:GUILIN UNIV OF ELECTRONIC TECH

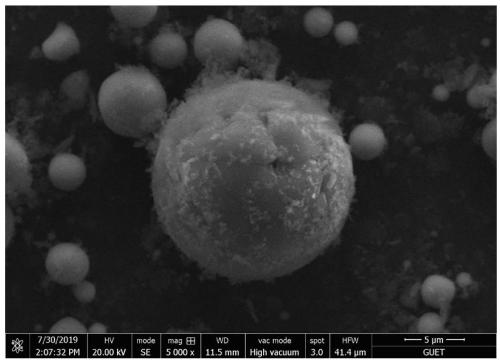

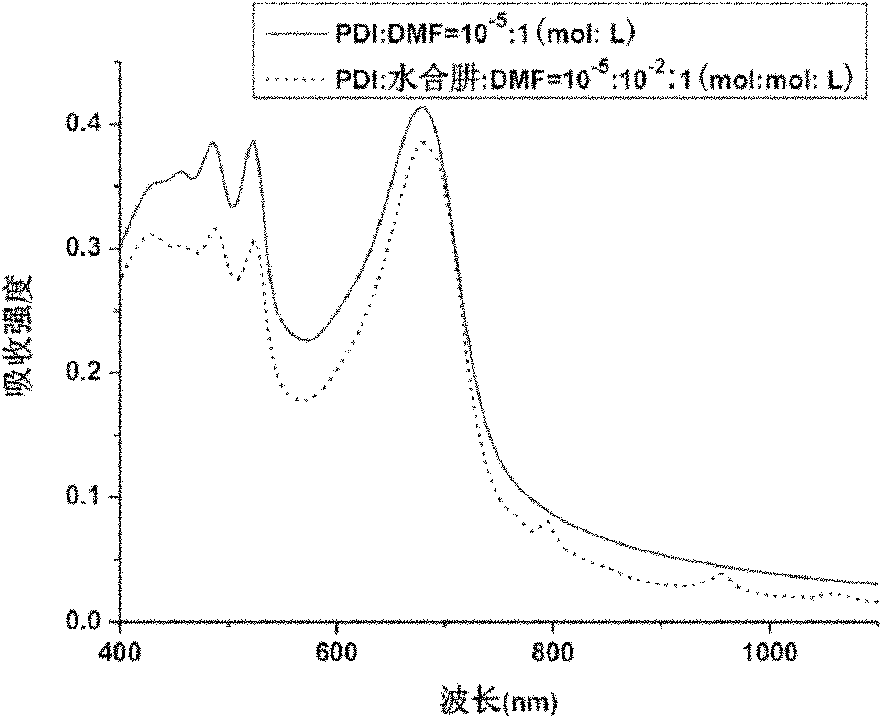

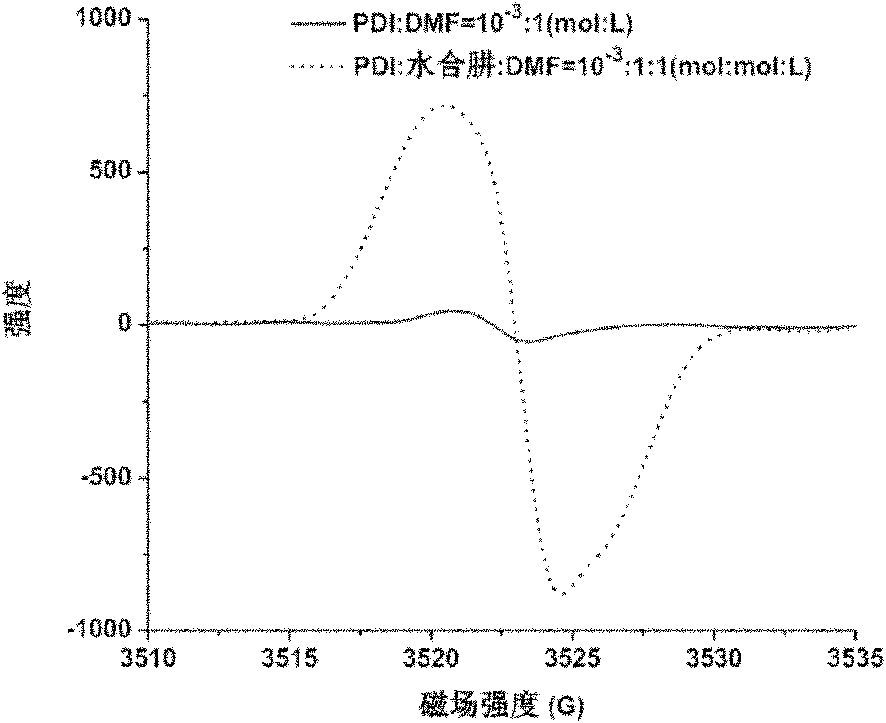

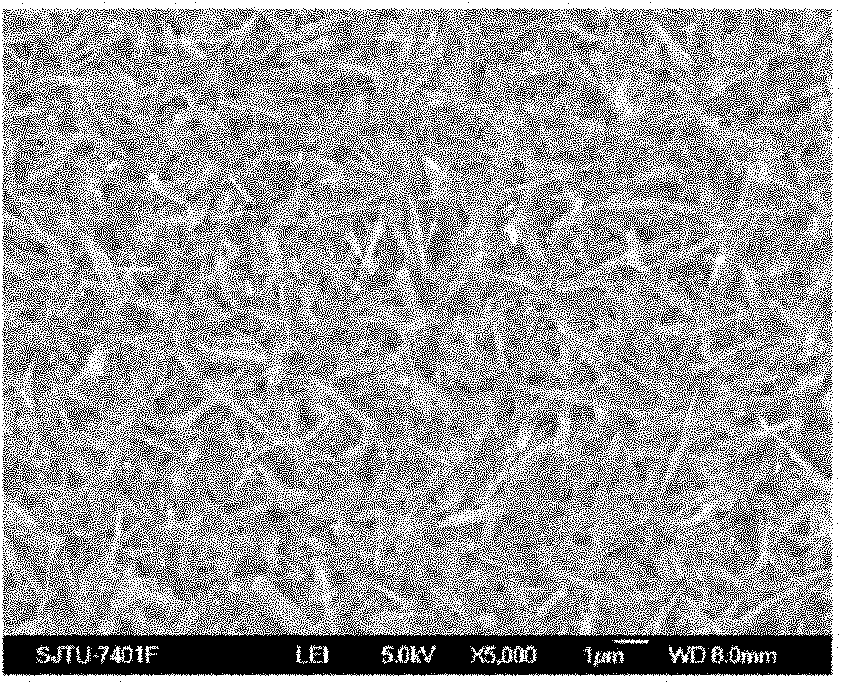

Method for preparing perylene polyimide derivative film

InactiveCN101949026AQuality improvementElectrolysis componentsElectrolytic organic productionComposite filmPolymer science

Owner:SHANGHAI JIAO TONG UNIV

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

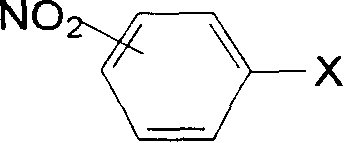

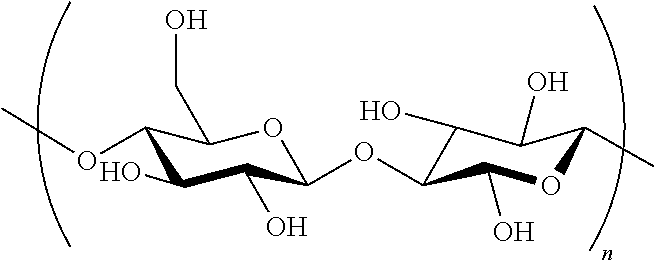

Optical diamine monomer containing di-dehydrated-hexitol unit and process for preparing same

Owner:TSINGHUA UNIV

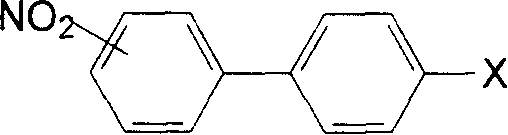

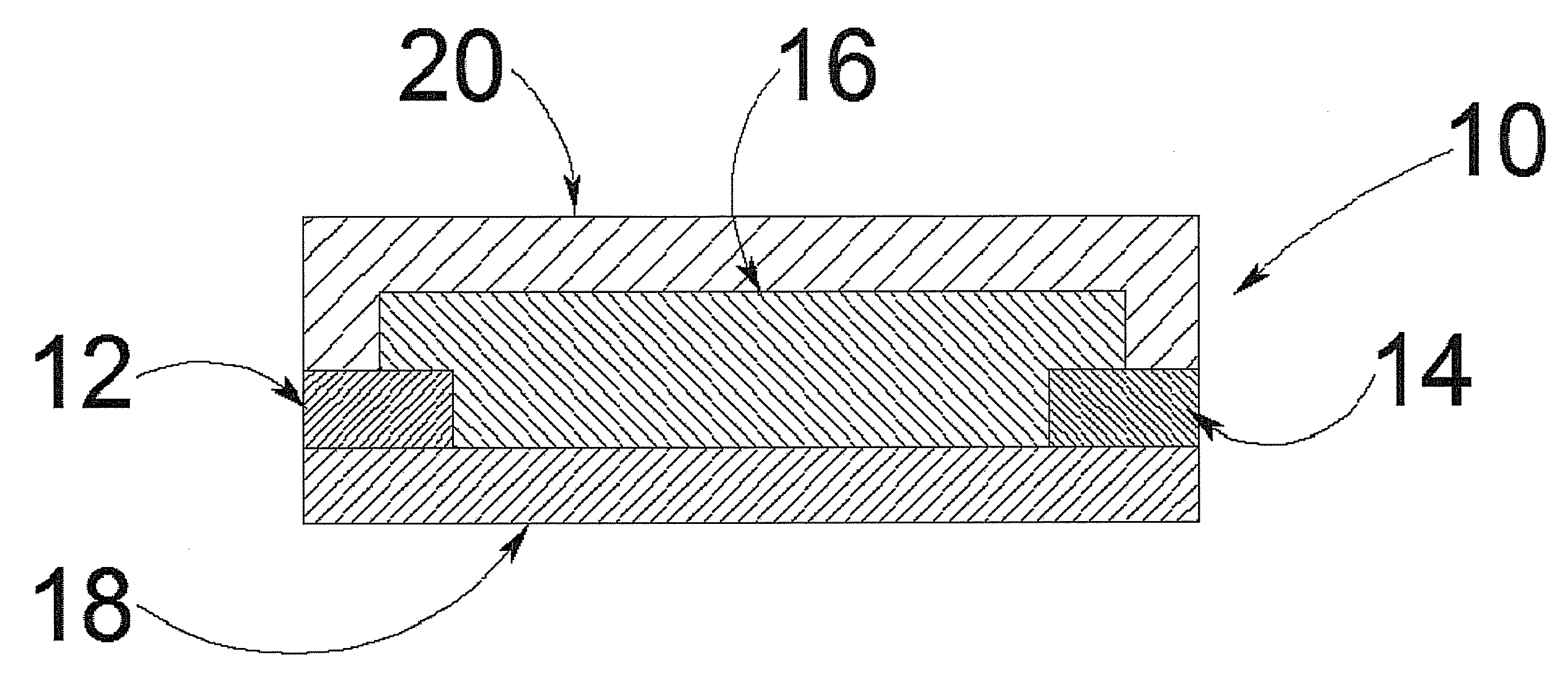

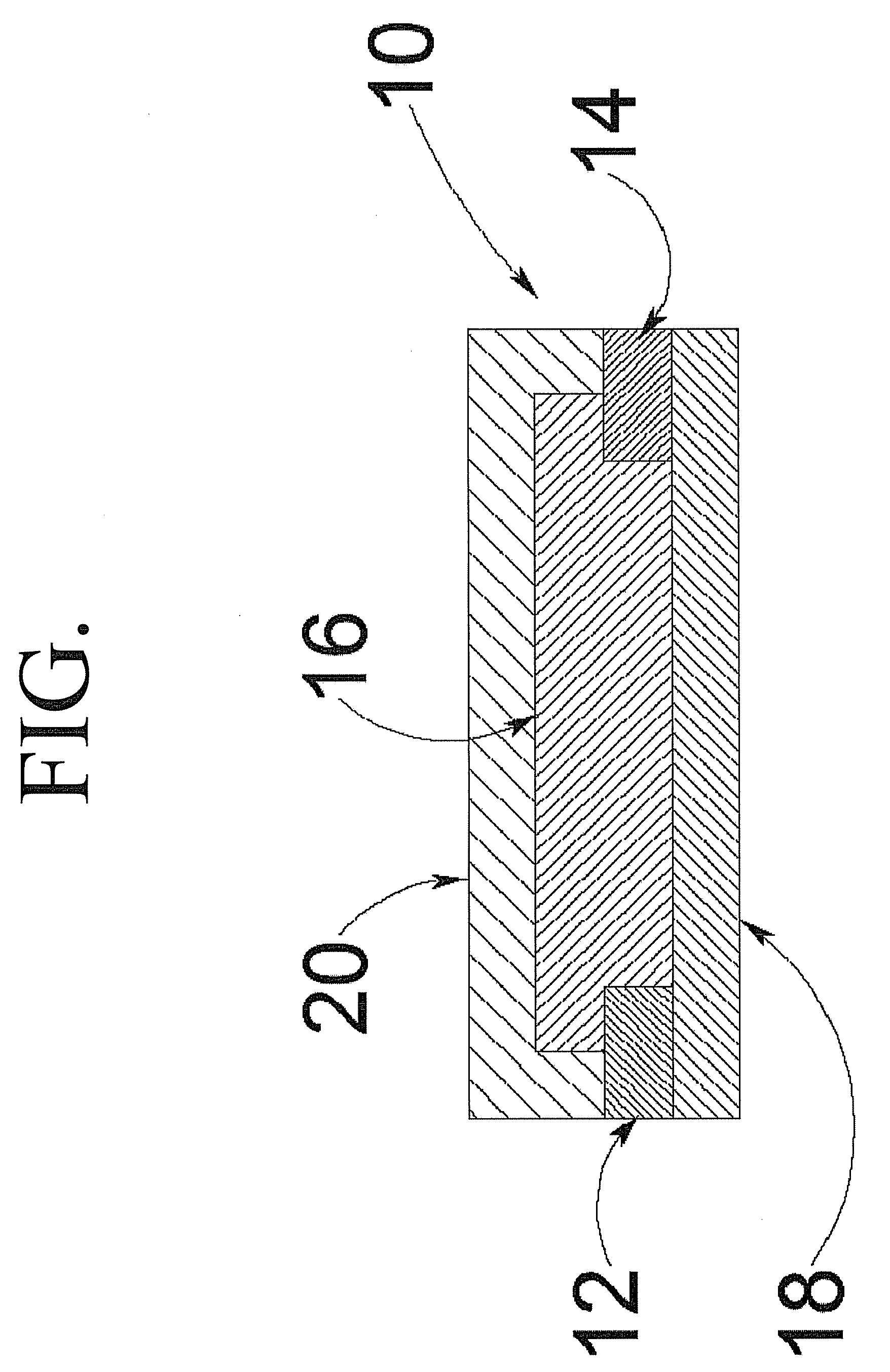

Novel polymide film and use thereof

It is an object to provide a polyimide film that has little dimensional change in the step of laminating metal on the polyimide film and the step of etching the metal to form a circuit, and can stabilize the rate of dimensional change over the entire width. It is a continuously produced polyimide film. When measuring the linear expansion coefficient a in the direction of the molecular orientation axis and the linear expansion coefficient b in the direction perpendicular to the molecular orientation axis at 100°C to 200°C over the entire width of the film, a and b A polyimide film satisfying a specific relationship, or when the tear propagation resistance value c in the direction of the molecular orientation axis and the tear propagation resistance value d in the direction perpendicular to the molecular orientation axis are measured for the entire width of the film, c and d A polyimide film satisfying a specific relationship can solve the above-mentioned problems.

Owner:KANEKA CORP

Low viscosity polymeric printing solutions and electronic components bearing polyimide based upon the low viscosity polymeric printing solutions

Owner:INFINEON TECH AG

Flame-retardant yarn/fabric/clothing

Owner:SINOPPE BEIJING CO LTD

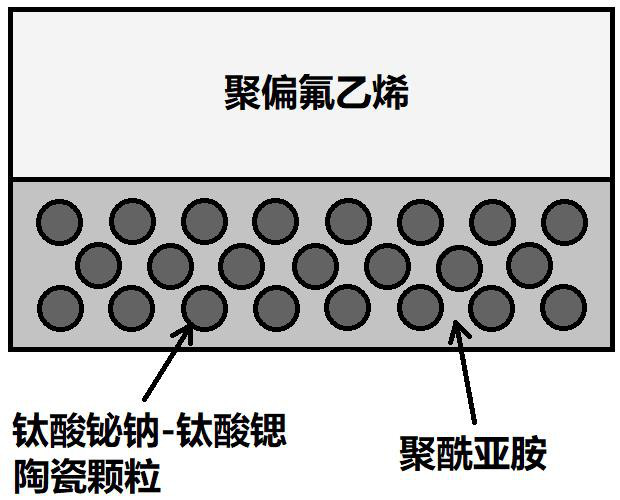

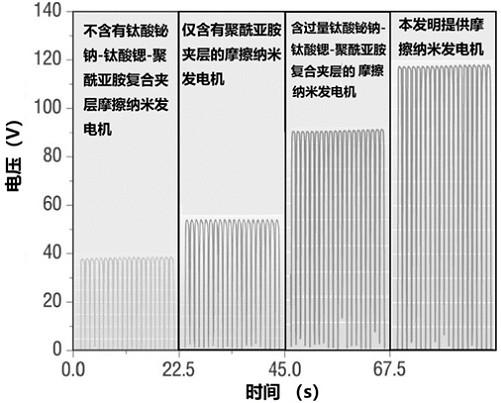

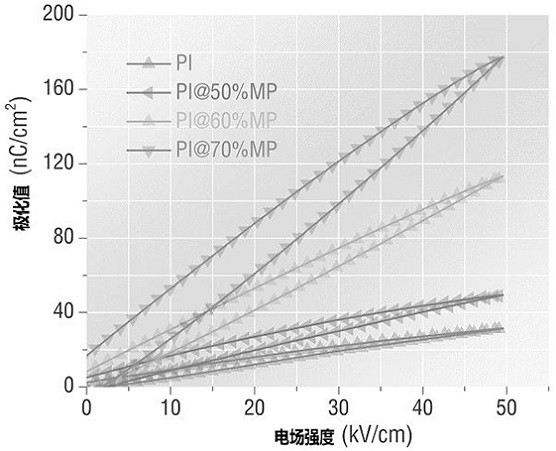

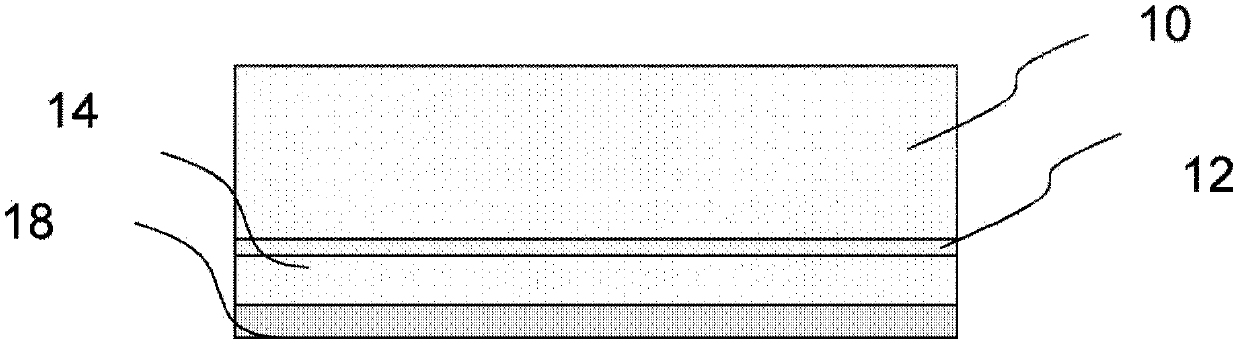

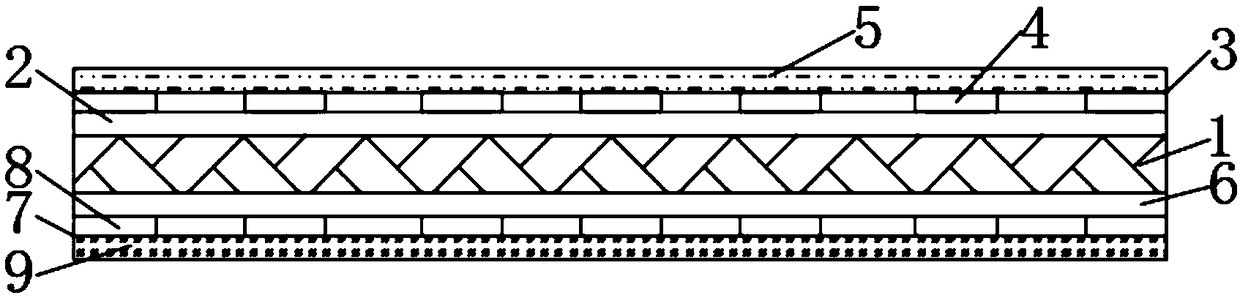

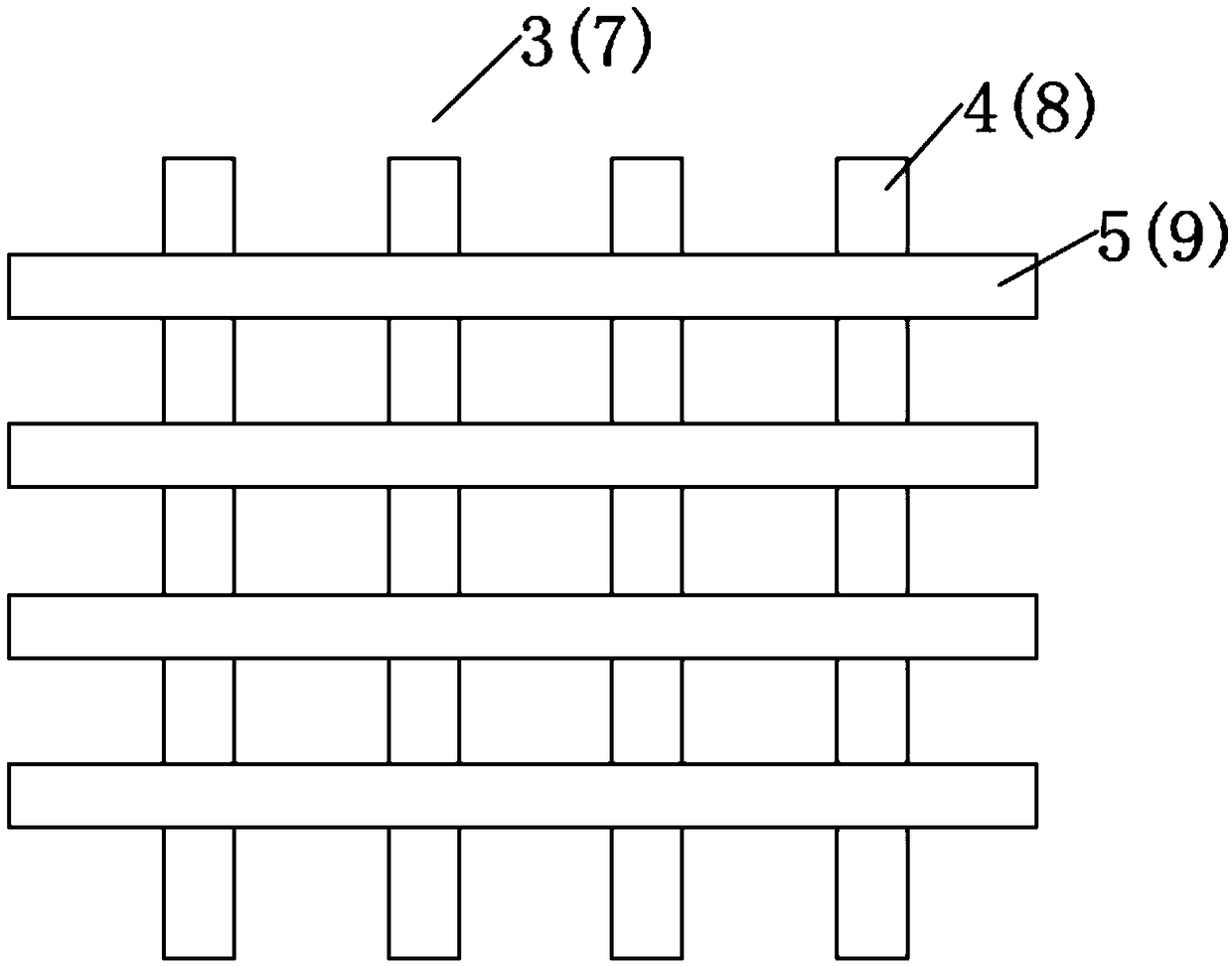

Friction layer for improving electrical properties of nano-generator by utilizing composite interlayer and preparation method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH

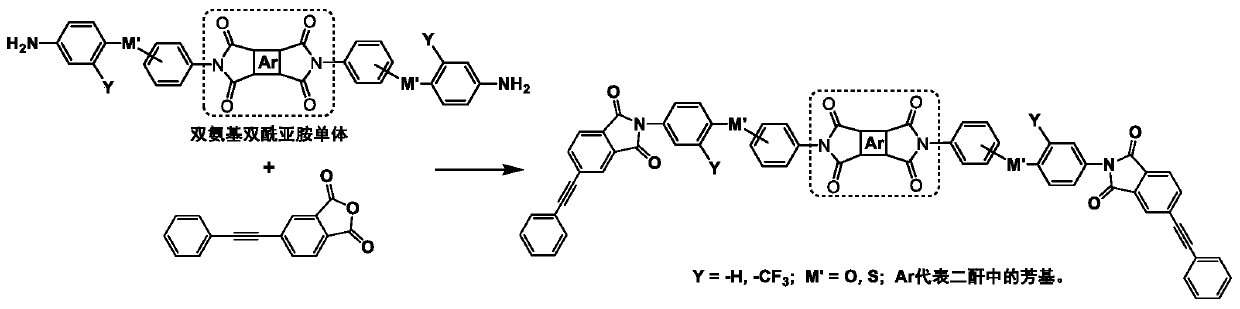

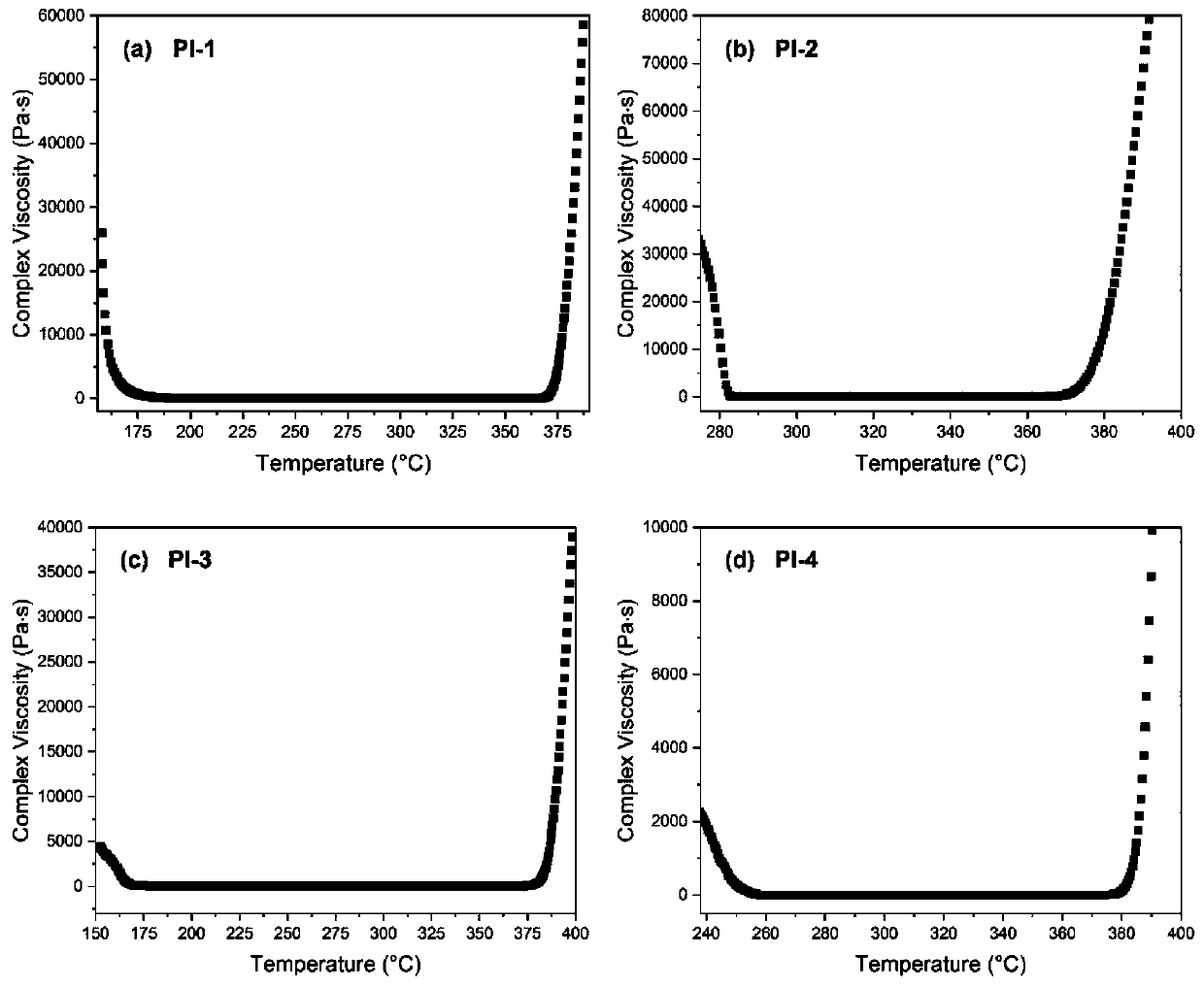

Low melt viscosity imide oligomers and polyimides therefrom

The present invention relates to novel imide oligomer compositions, polyimides formed therefrom, and methods for making and using the same. In particular, the invention relates to novel polyimide oligomers comprising 3,3′,4,4′-benzophenone tetracarboxylic dianhydride (BTDA), 2-(3,4-dicarboxy phenyl)-1-phenylacetylene anhydride (PE), and a mixture of 1,3-diaminobenzene and 4,4′-(1,3-phenylenediisopropylidene) bisaniline. The polyimide oligomers demonstrate low melt viscosity (these resins are melt processable) while retaining exceptional thermo-oxidative stability, high glass transition temperature, and good mechanical properties in the cured state.

Owner:PERFORMANCE POLYMER SOLUTIONS

Manufacturing method for graphite film

The invention provides a manufacturing method for a graphite film. A polyimide film is taken as a precursor, and heat treatment conditions are as follows: the average heating rate in a heating sectionof 500-800 DEG C is 2 DEG C or below per minute, and the highest carbonization temperature is 1000 DEG C or higher. According to the manufacturing method for the graphite film, the average heating rate from 2200 DEG C to the highest graphitization temperature is smaller than 3 DEG C per minute, and 2500 DEG C or a higher temperature is the highest graphitization temperature of the process.

Owner:TAIMIDE TECH

Dispersing method of inorganic filler

The invention discloses a dispersing method of inorganic filler. The method specifically includes: subjecting the inorganic filler to ultrasonic soaking in an aprotic polar solvent, and dispersing theobtained mixed liquid in a sand mill containing zirconium beads of different particle sizes at specific rotation speed. By using the method to disperse the inorganic filler, a good dispersing effectis achieved, the obtained inorganic filler dispersed slurry is used for preparing a black matte polyimide film, the obtained film is high in mechanical performance and electric strength, low in shading rate and good in matte performance, and filter element replacing frequency during film preparation is lowered.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Colored resin composition, colored film, decorative substrate and touch panel

InactiveUS20180039176A1Improve reliabilityImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceDisplay device

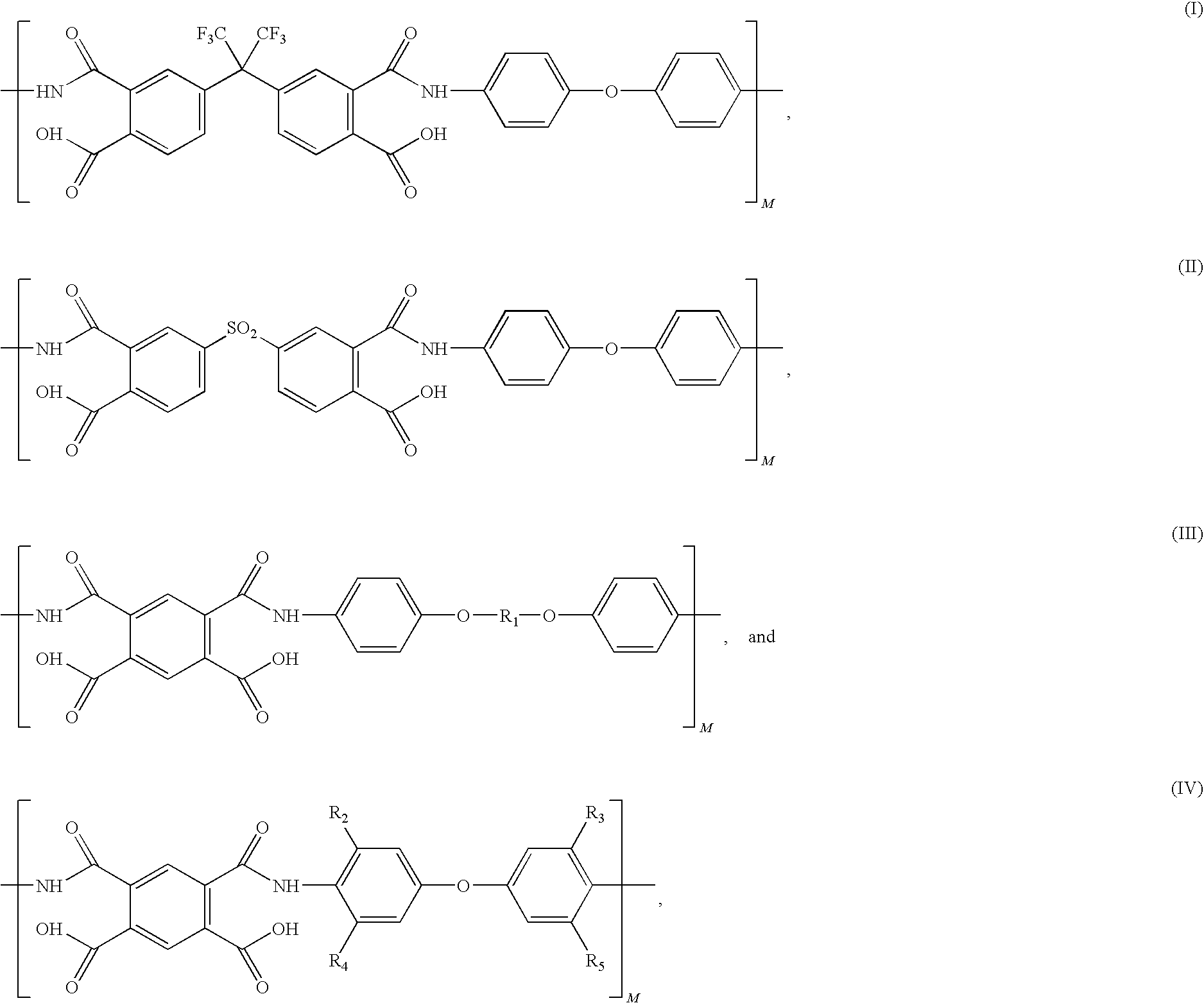

A colored resin composition is disclosed including a polyimide resin having a specified structure to achieve remarkable heat resistance and enabling the formation of a colored film which is excellent in reliability because a coloring material is highly dispersed and stabilized therein. A colored resin composition is disclosed including (A) an alkali-soluble polyimide resin having a structural unit containing a phenolic hydroxyl group, a sulfonic acid group or a thiol group, (B) a coloring material, (C) a polymeric dispersant, and (D) an organic solvent. A patterned colored layer obtained from the composition of the present invention is useful for a decorative substrate, a touch panel, an organic EL display device and the like.

Owner:TORAY IND INC

Polyimide microdenier fiber and preparation method thereof

ActiveCN107151833AImprove performanceThe spinning process is simple and fastArtificial filament washing/dryingFilament/thread formingYarnFiber

The invention discloses a polyimide microdenier fiber and a preparation method of the polyimide microdenier fiber, and belongs to the field of fiber preparation. The polyimide microdenier fiber and the preparation method solve the problems of high end breakage rate, high yarn unevenness rate and low production efficiency of the conventional preparation method of the polyimide microdenier fiber. The preparation method of the polyimide microdenier fiber comprises the following steps: dissolving soluble components in a polyamide acid bicomponent nascent fiber by solvents, and then performing washing, drying, thermal imidization and drafting treatment. The filament number of the polyimide microdenier fiber is 0.5-1.1dtex; the tensile strength of the polyimide microdenier fiber is equal to or greater than 4.0cN / dtex. The preparation method is simple, convenient and quick in spinning technology, low in production cost, stable and safe in spinning process, energy-saving and environmentally friendly; industrial and continuous production is easy to realize; the organic solvents used in the spinning process are easy to recycle; a spinning end breakage rate is reduced; a yarn unevenness rate is increased; the production efficiency is further improved. The polyimide microdenier fiber obtained by the preparation method is excellent in comprehensive performance.

Owner:CHANGCHUN HIPOLYKING

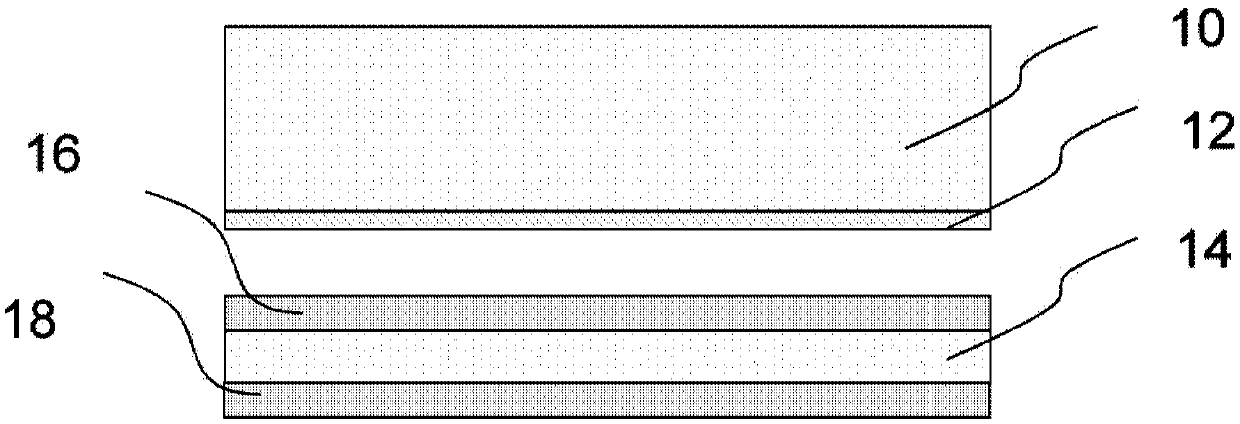

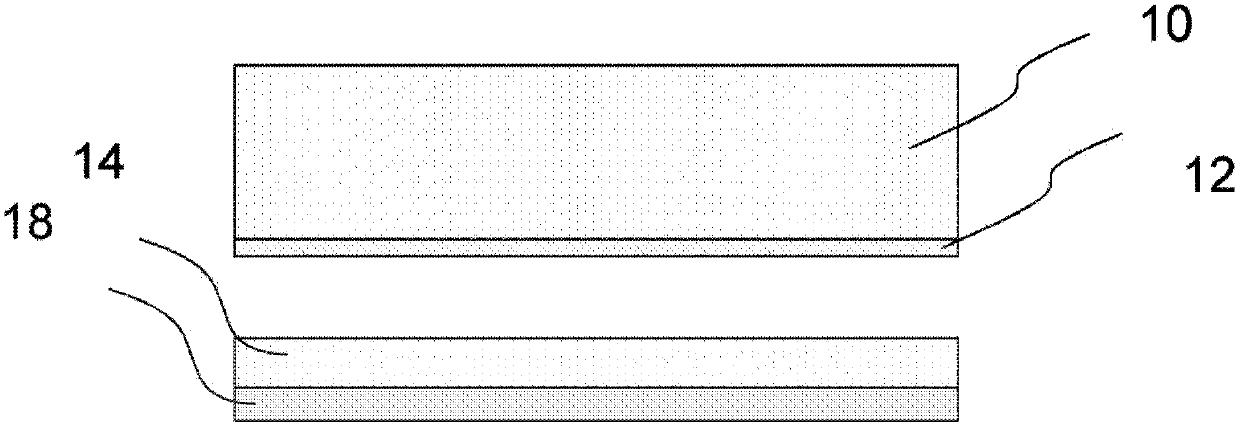

Transparent polyimide composite film for flexible display device, and production method thereof

InactiveCN110791220ASimple processFilm/foil adhesives without carriersFilm/foil adhesive release linersPolymer scienceDisplay device

Owner:TAIMIDE TECH

High-temperature resistant and tensile polyimide base fabric

Owner:江苏汇达森环保材料有限公司

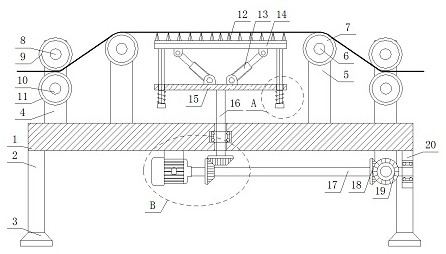

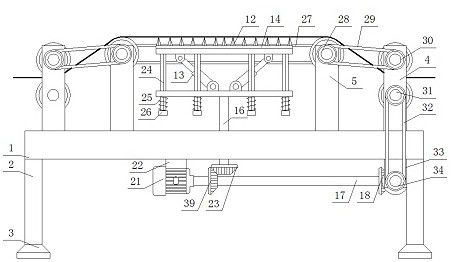

Low-melt-viscosity thermosetting polyimide precursor suitable for RTM and preparation method of precursor

ActiveCN110229158AReduce melt viscosityIncrease melt viscosityOrganic chemistryTransfer moldingChemistry

Owner:NORTHWESTERN POLYTECHNICAL UNIV

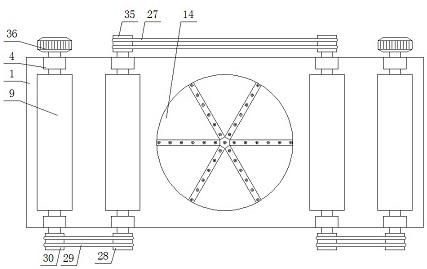

Coating process of silicon-copper alloy foil explosion-proof material

Owner:SHANGHAI HUAPENG EXPLOSION PROOF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap