Flame-retardant yarn/fabric/clothing

a flame-retardant yarn and flame-retardant technology, applied in the field of flame-retardant yarn/fabric/clothing, can solve the problems of insufficient char length of a fabric, inability to fully understand and master the properties of a fabric to carry out proper blending processing, and inability to be put into mass production, so as to prevent further combustion of the modacrylic, promote the charring of the modacrylic, and reduce the effect of heat resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

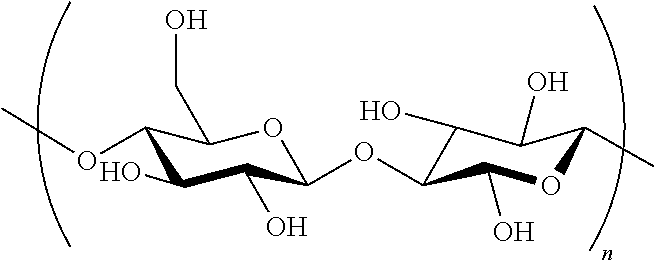

[0042]A flame-retardant yarn is composed of materials in percentage by weight as follows:

modacrylic: 75%;

cellulose (cotton): 10%;

polyimide: 13%; and

polyester-based carbon-containing anti-static fibers: 2%.

example 2

[0043]A flame-retardant yarn is composed of materials in percentage by weight as follows:

modacrylic: 48%;

cellulose (cotton): 49%;

polyimide: 1%; and

polyester-based carbon-containing anti-static fibers: 2%.

example 3

[0044]A flame-retardant yarn is composed of materials in percentage by weight as follows:

modacrylic: 45%;

cellulose (cotton): 45%;

polyimide: 8%; and

polyester-based carbon-containing anti-static fibers: 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap