Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Cocoa" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

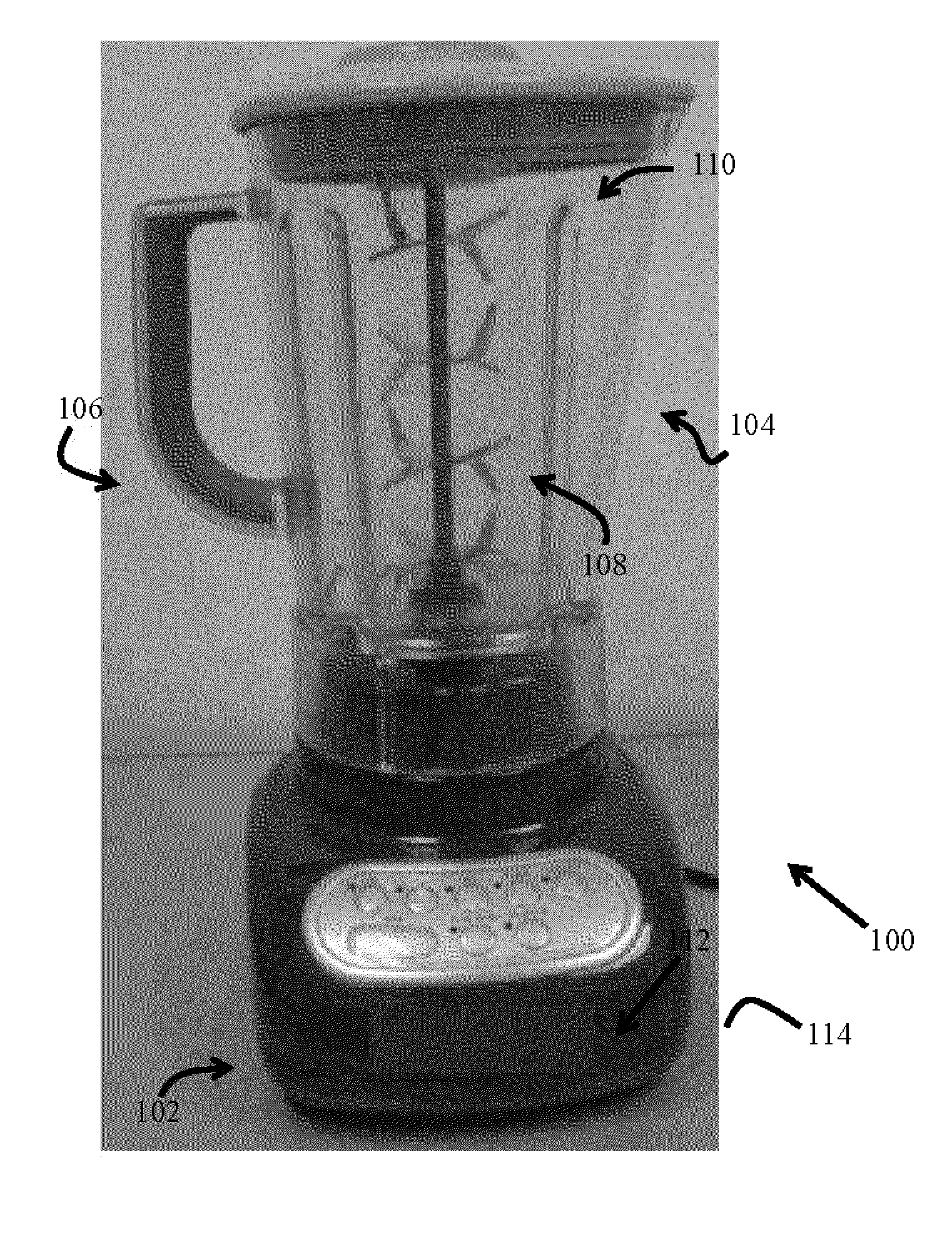

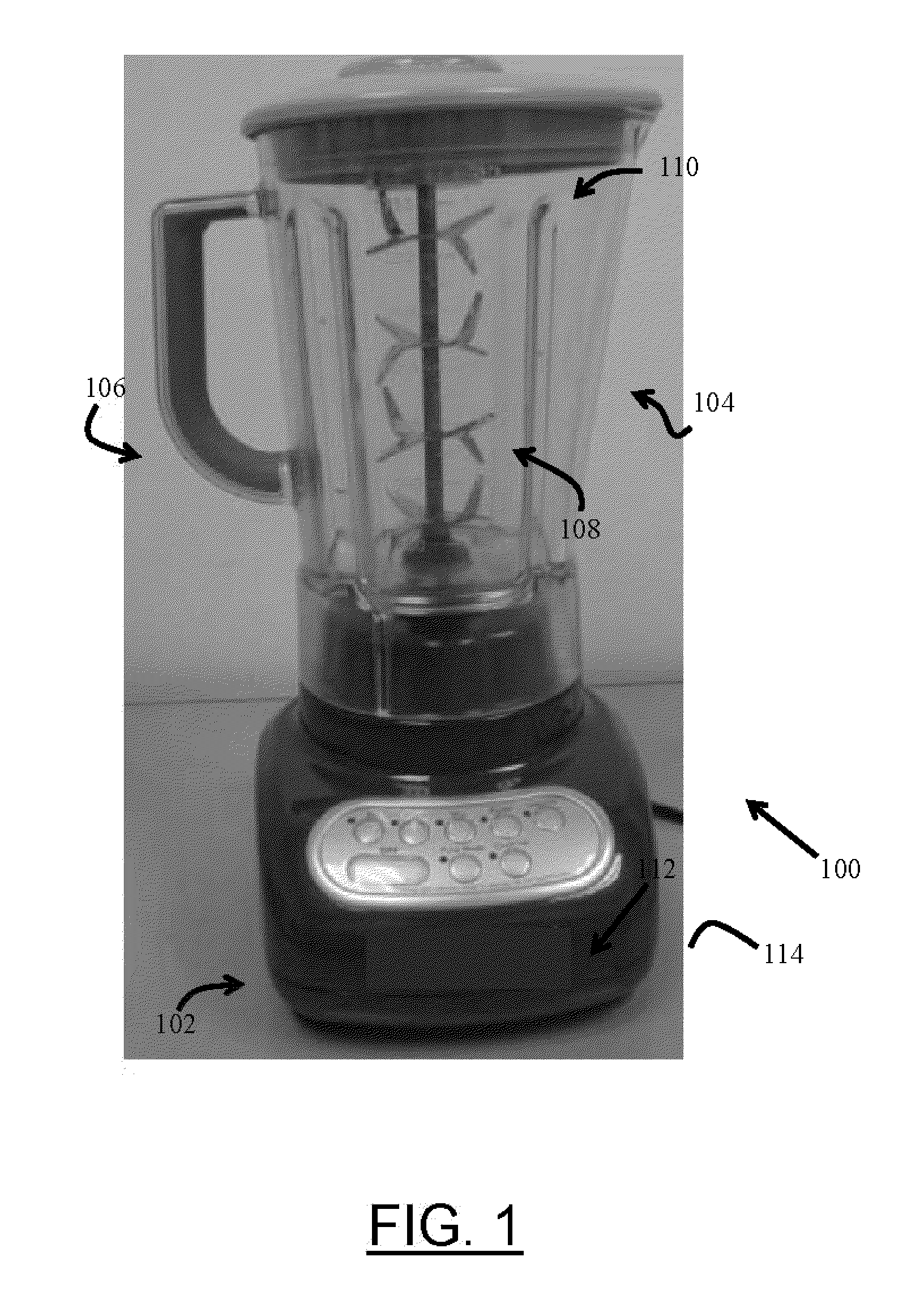

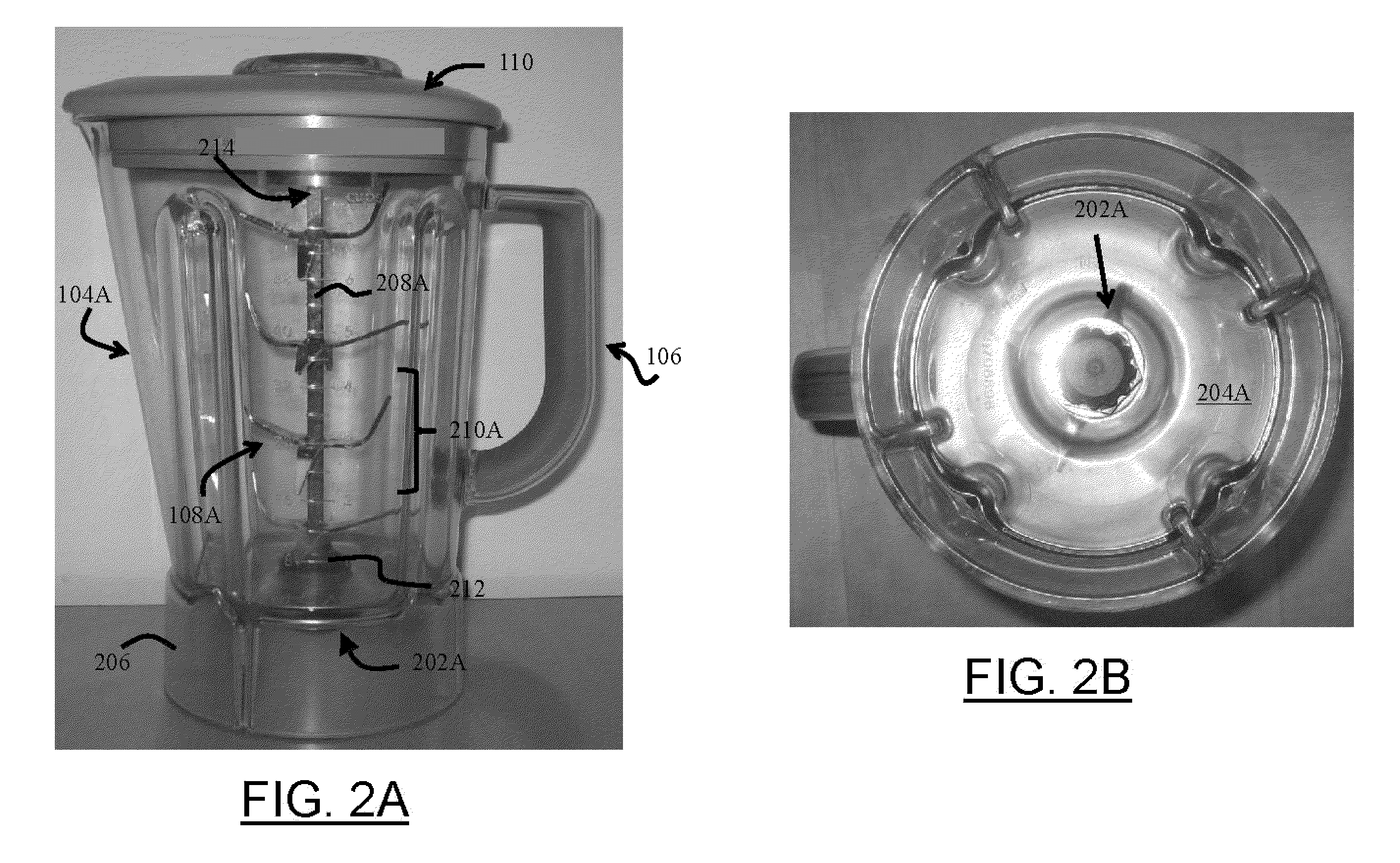

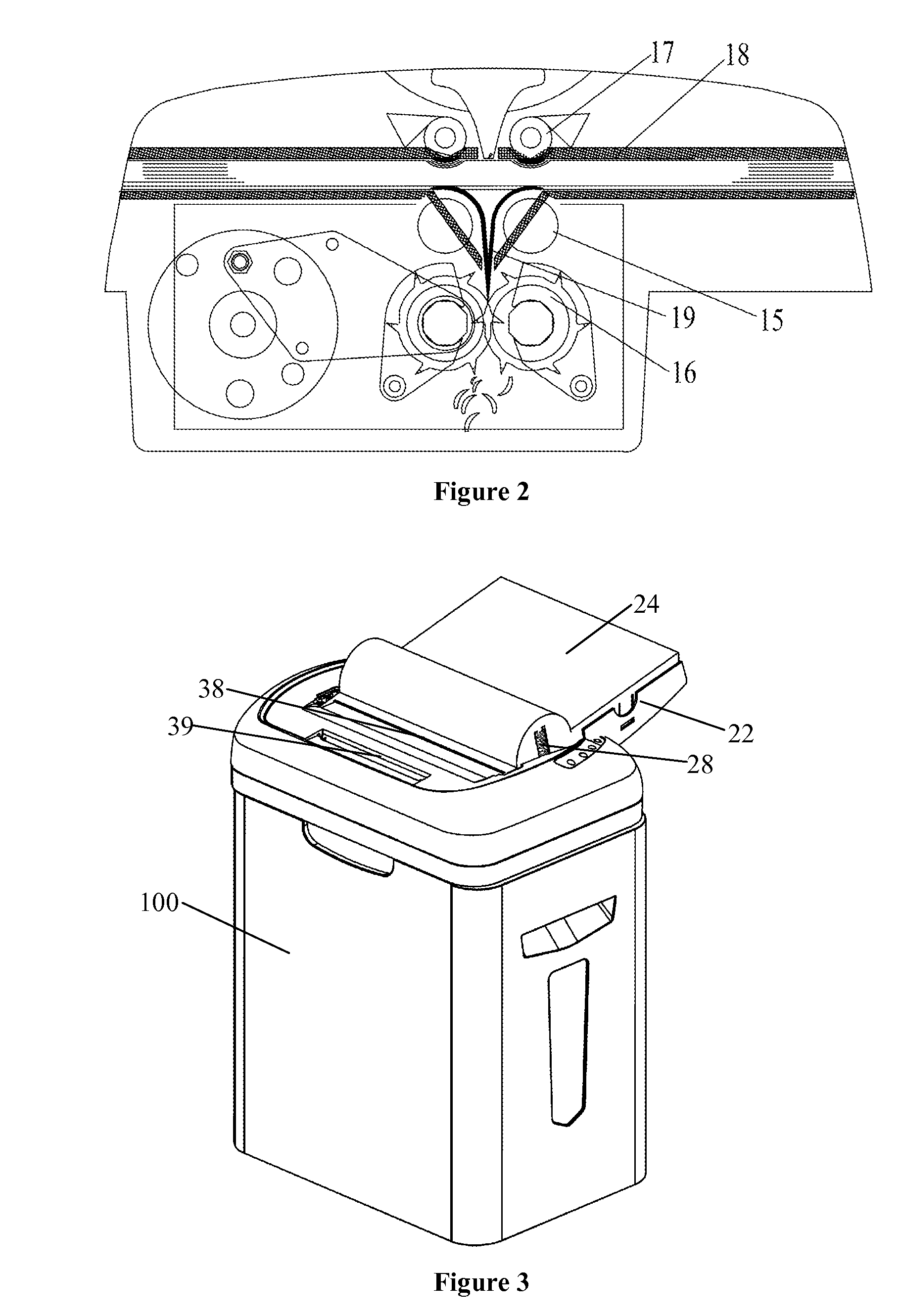

Blender and food processor device

Owner:CARRIERE MARK C

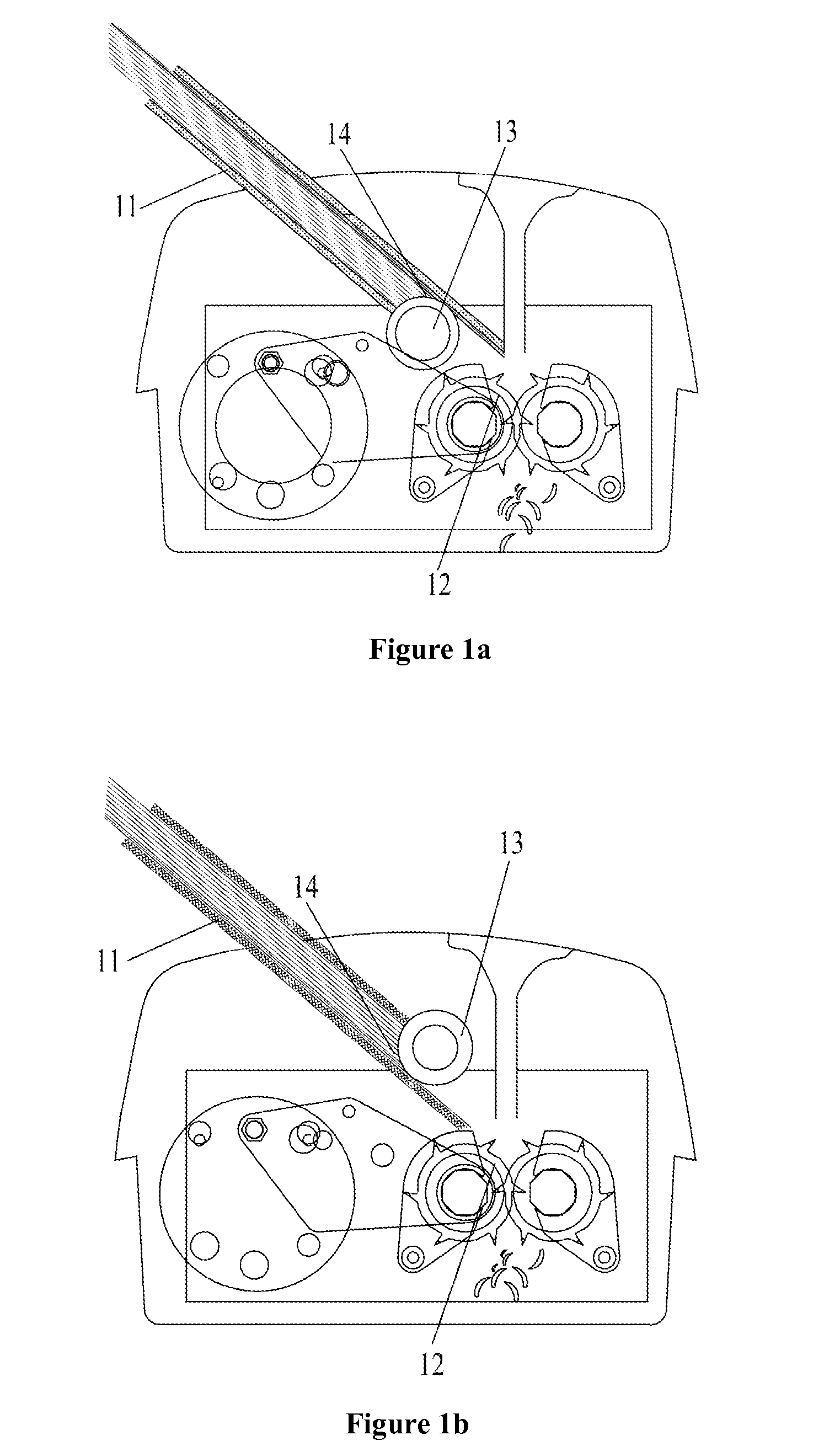

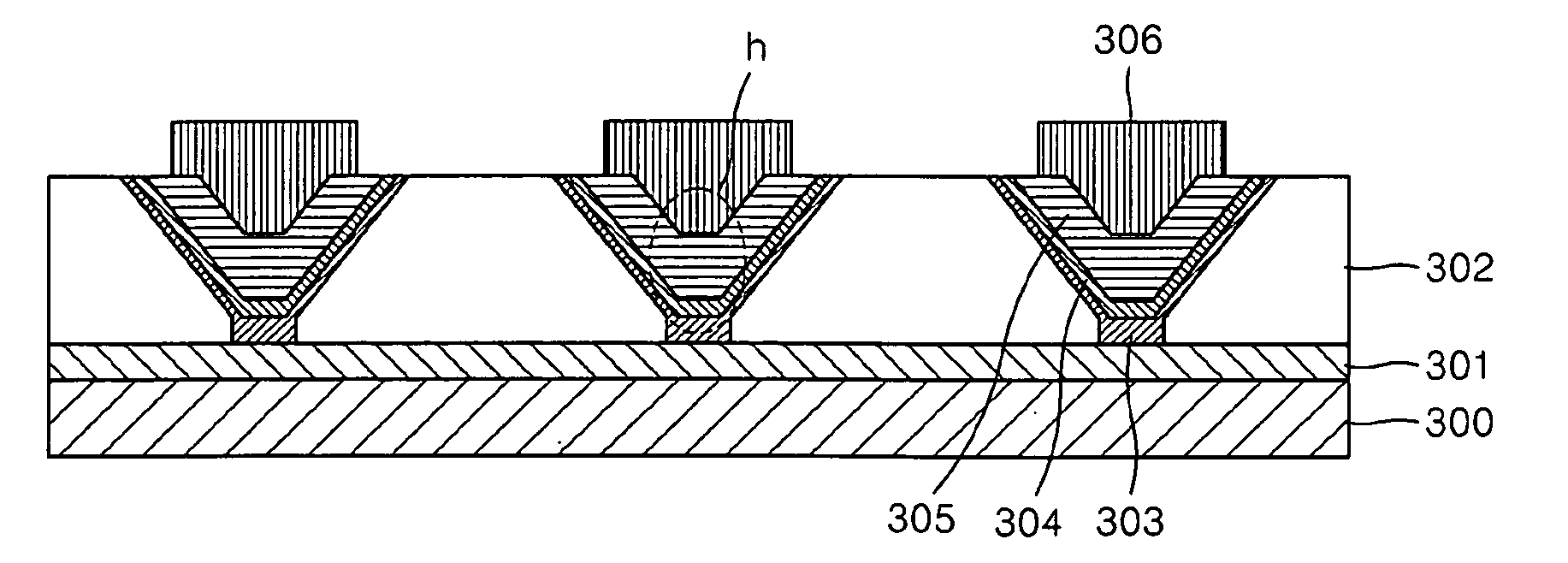

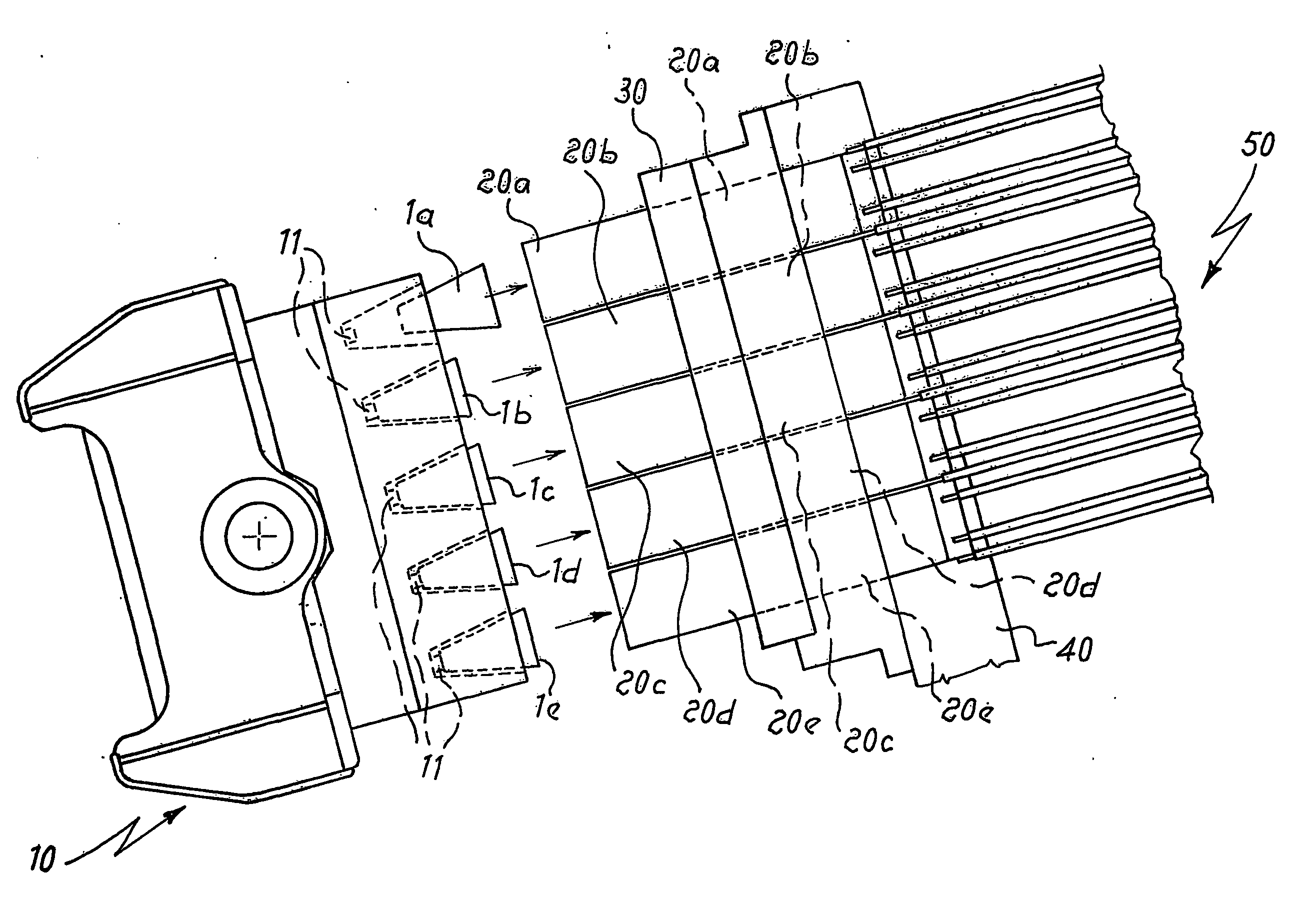

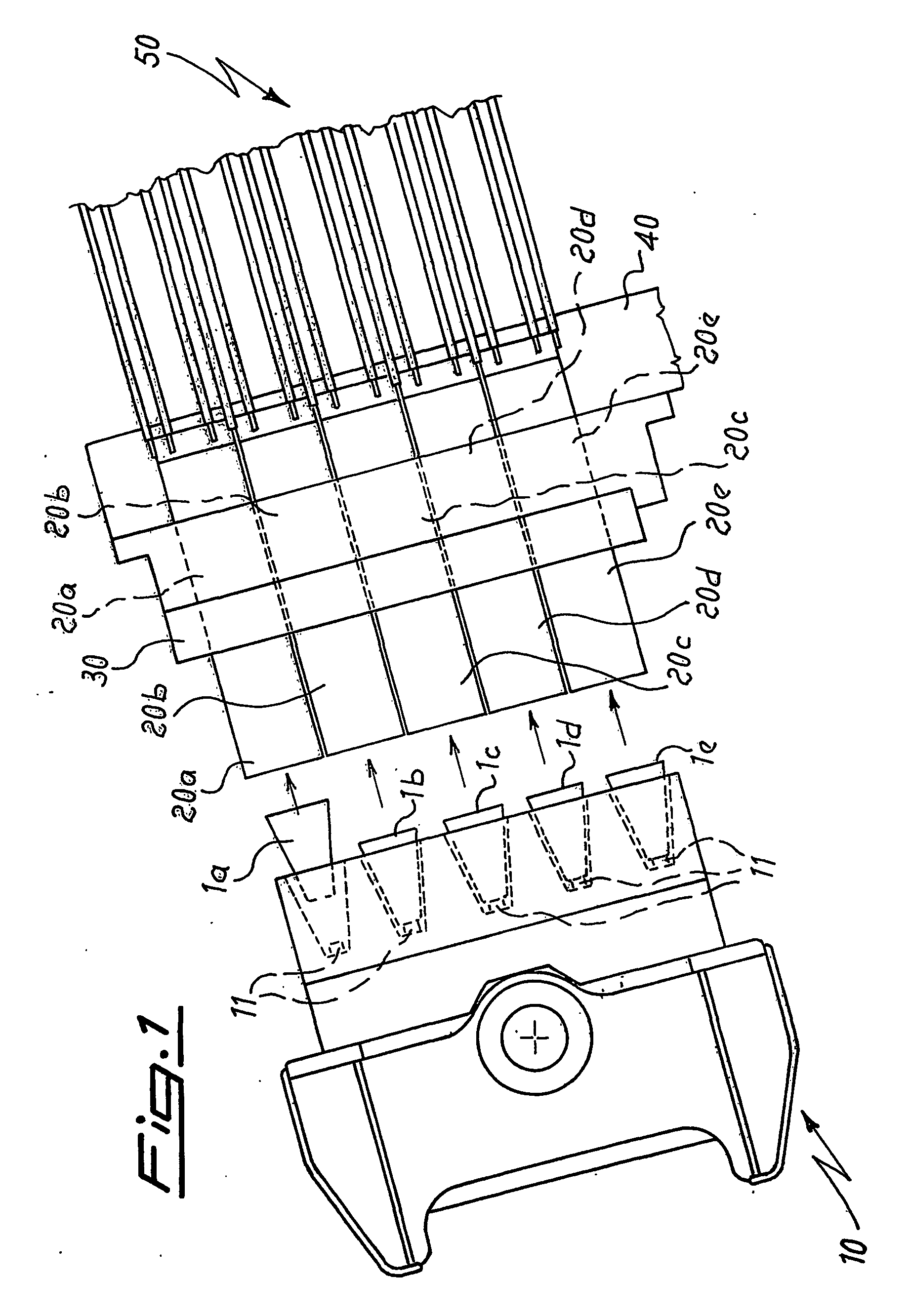

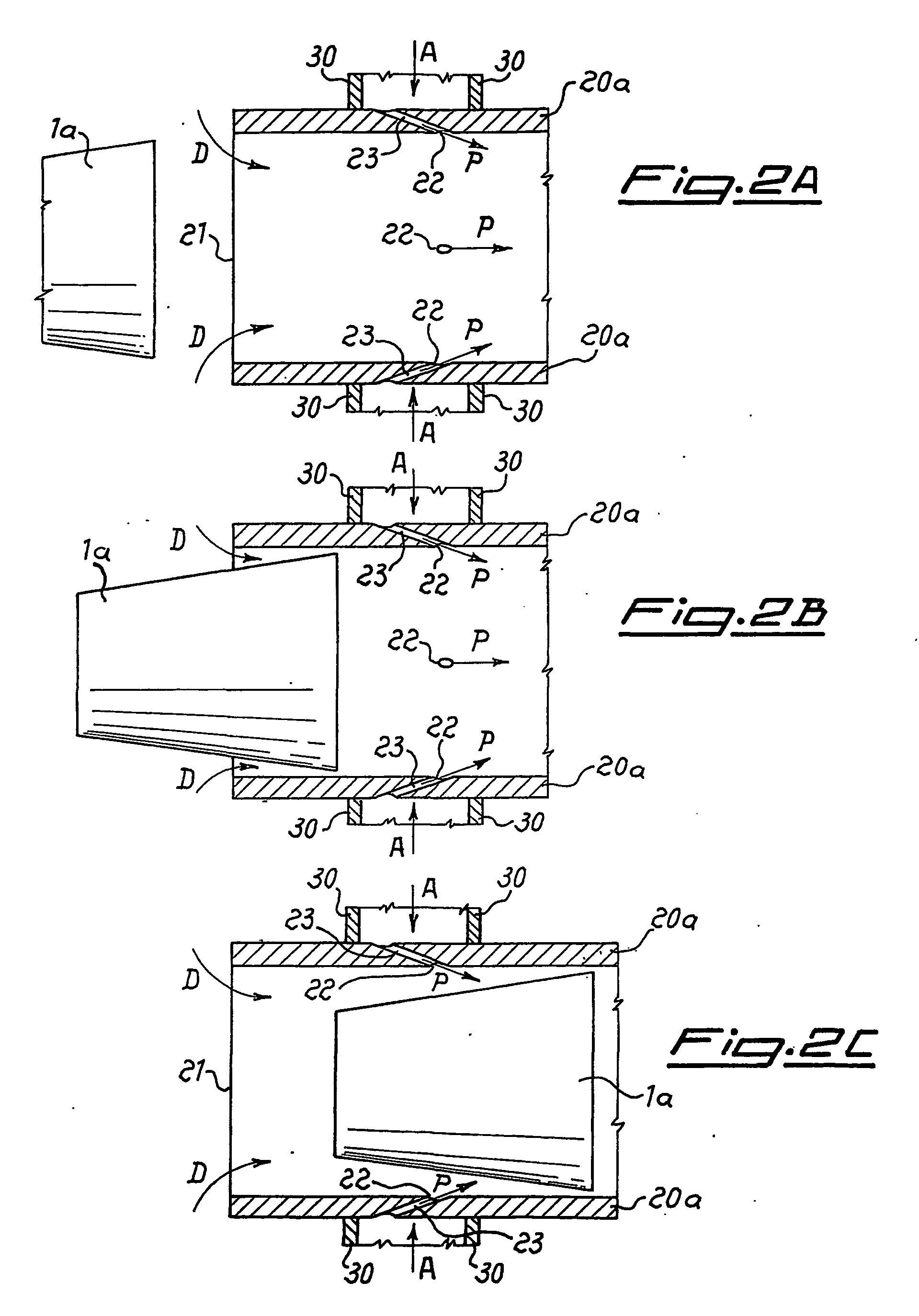

Automatic shredder without choosing the number of paper to be shredded

Owner:AURORA OFFICE EQUIP

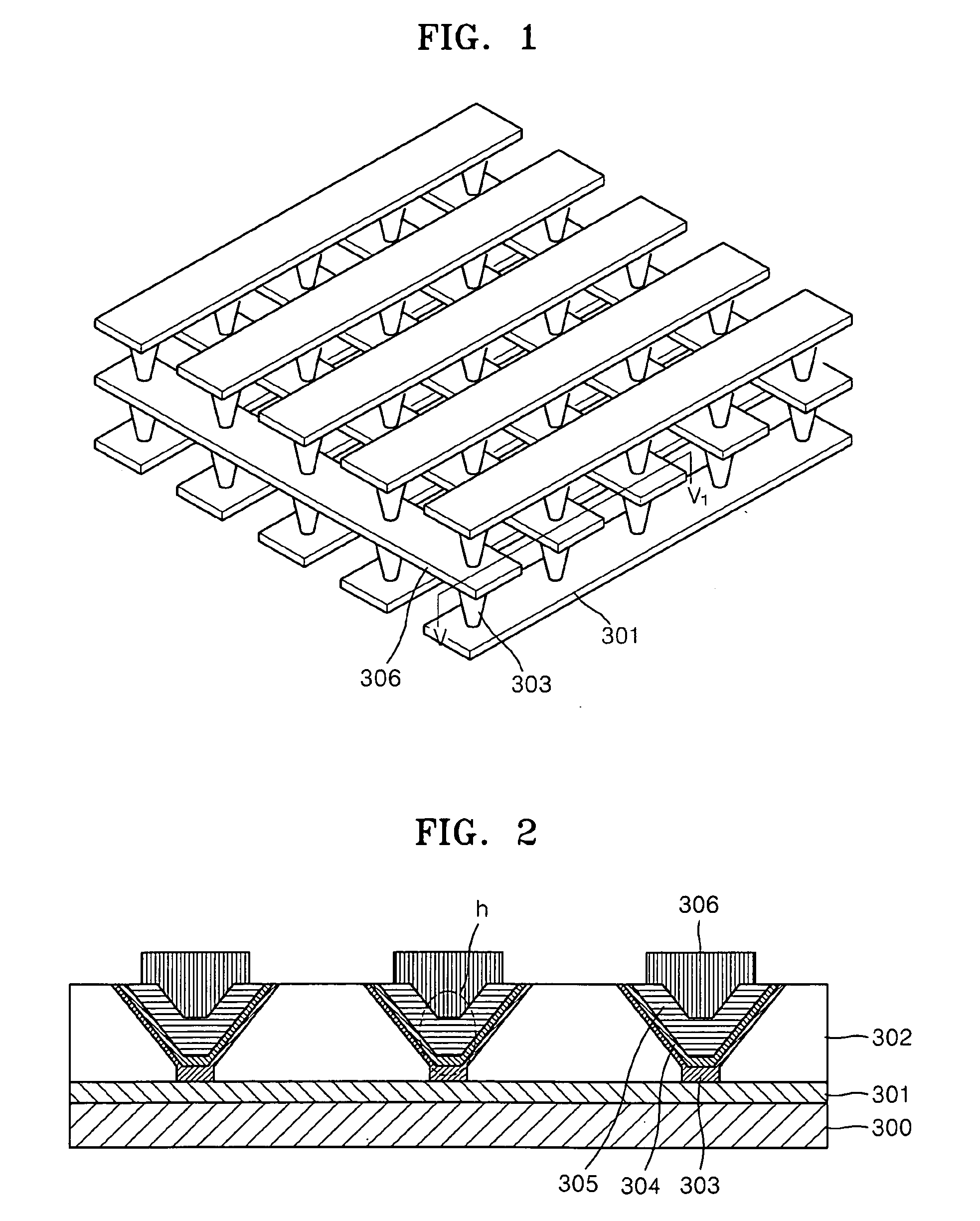

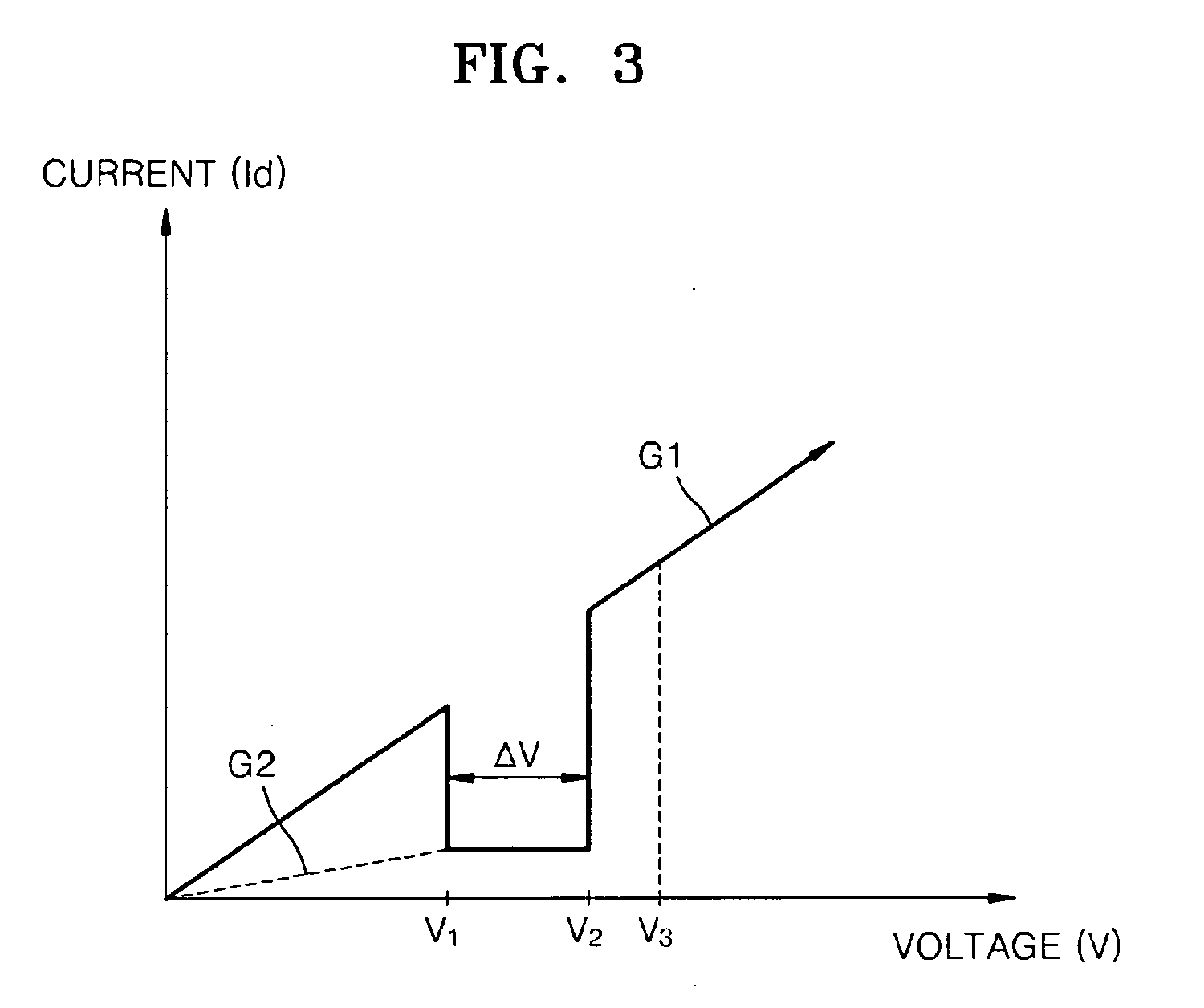

Cross point memory arrays, methods of manufacturing the same, masters for imprint processes, and methods of manufacturing masters

Owner:SAMSUNG ELECTRONICS CO LTD

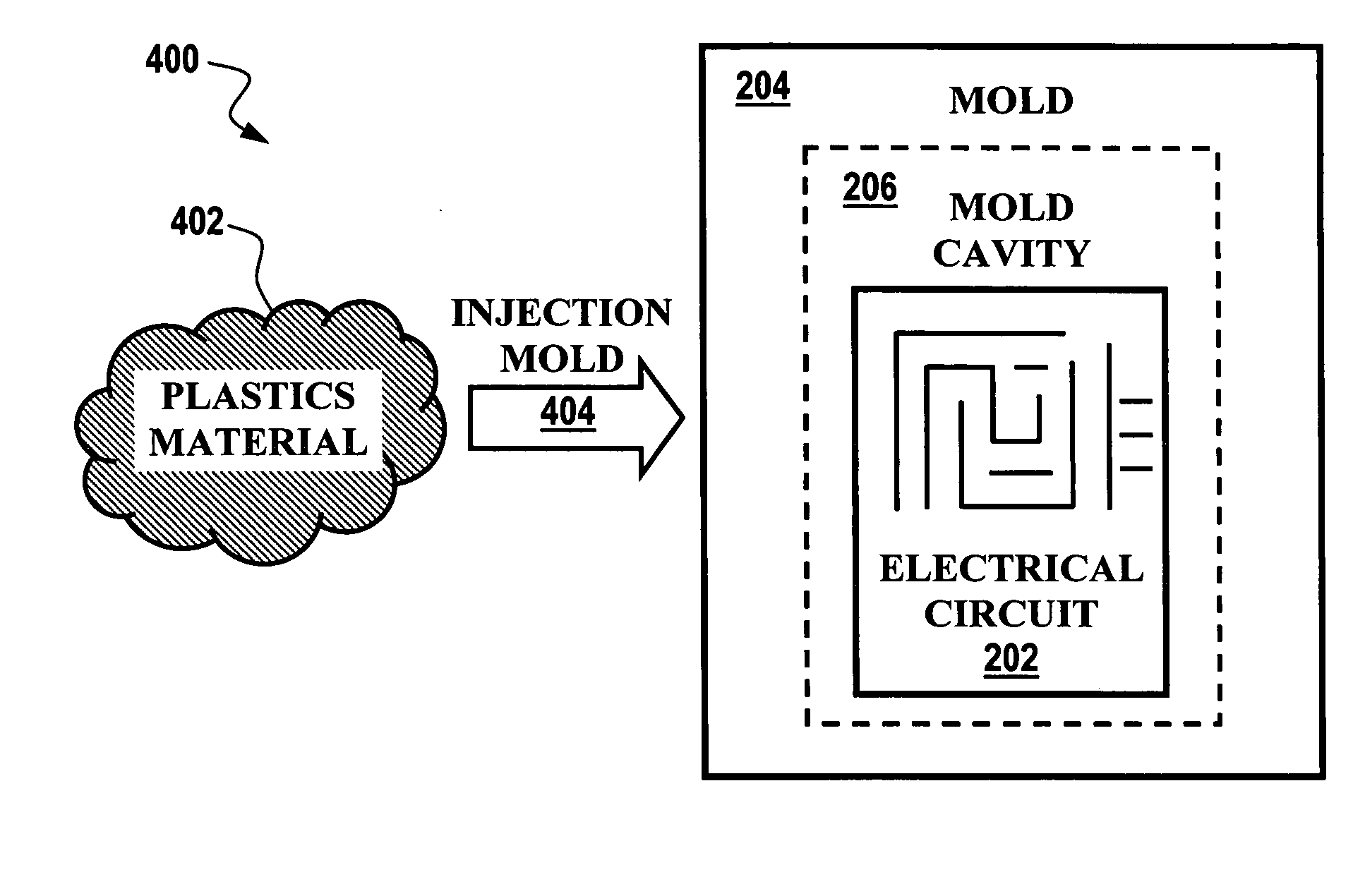

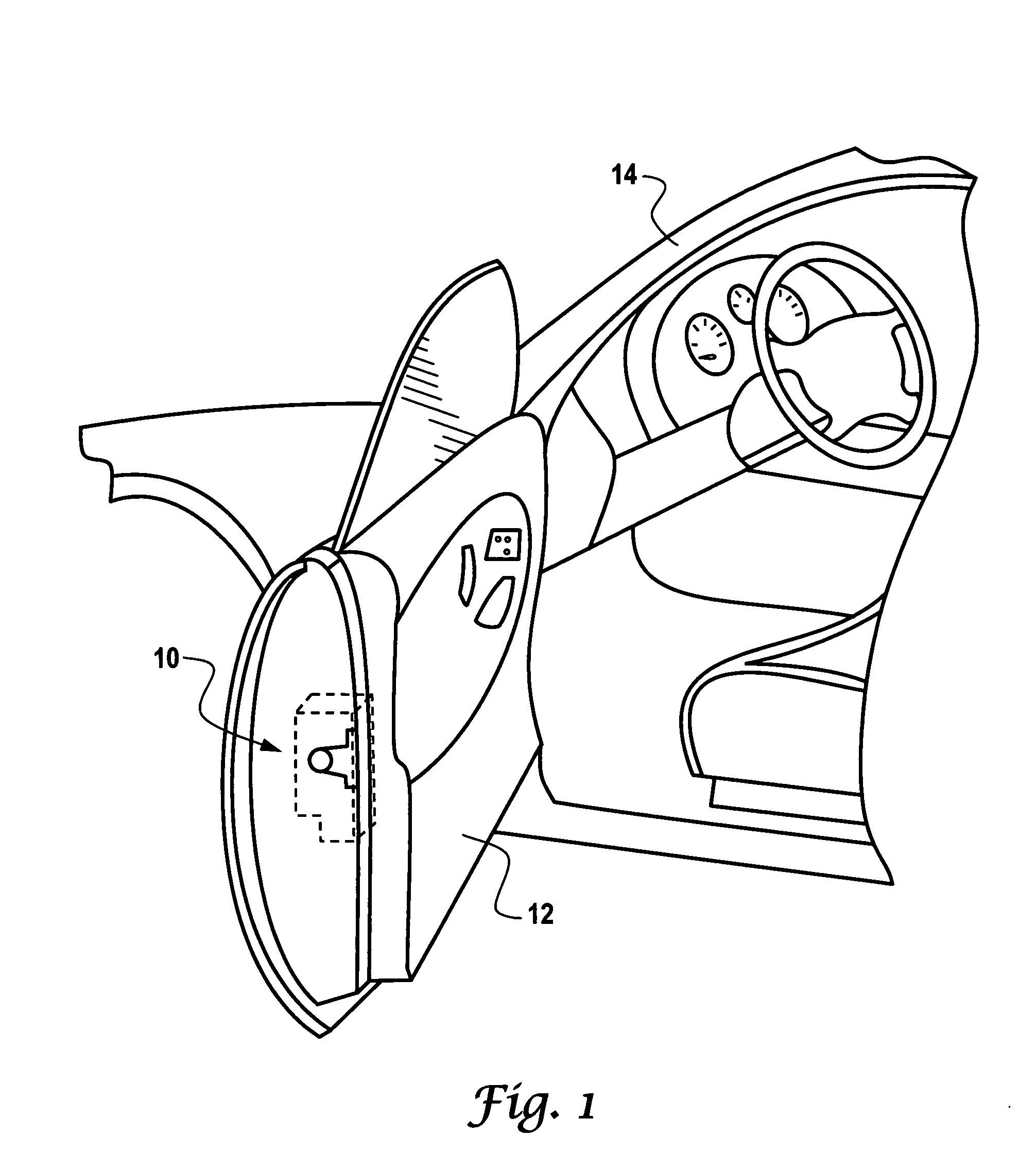

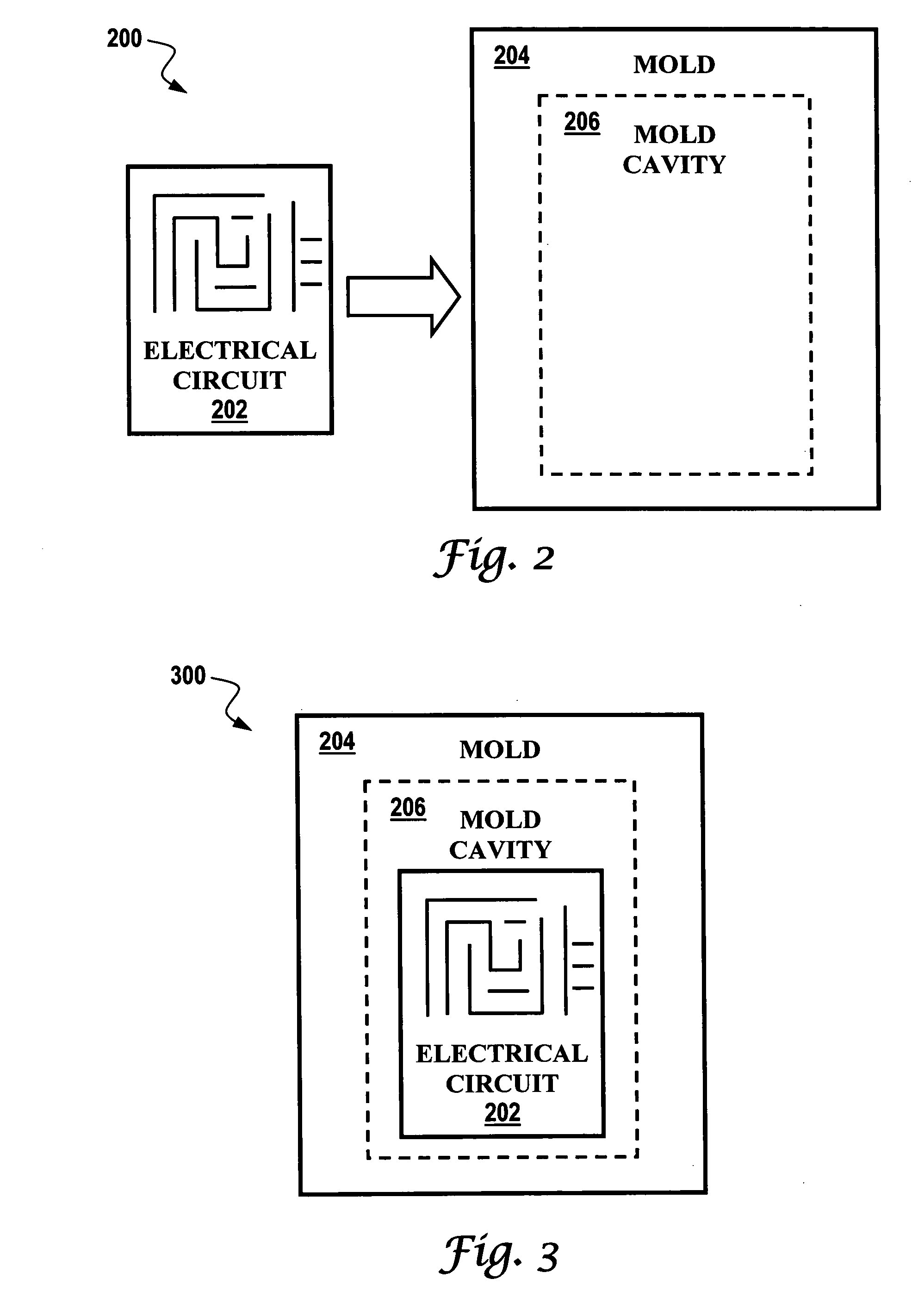

Circuit insulation methods and systems for vehicle door latches

Owner:HONEYWELL INT INC

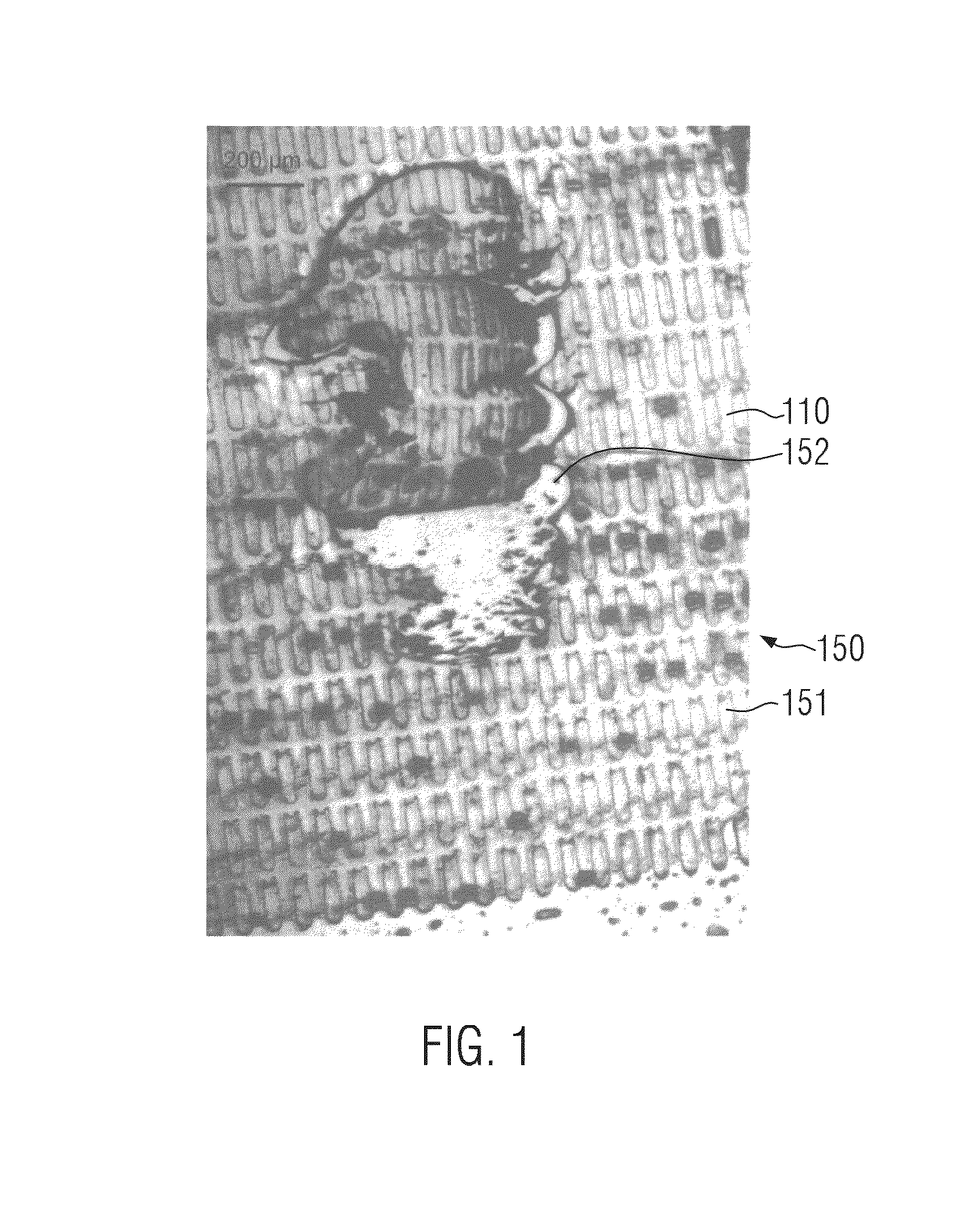

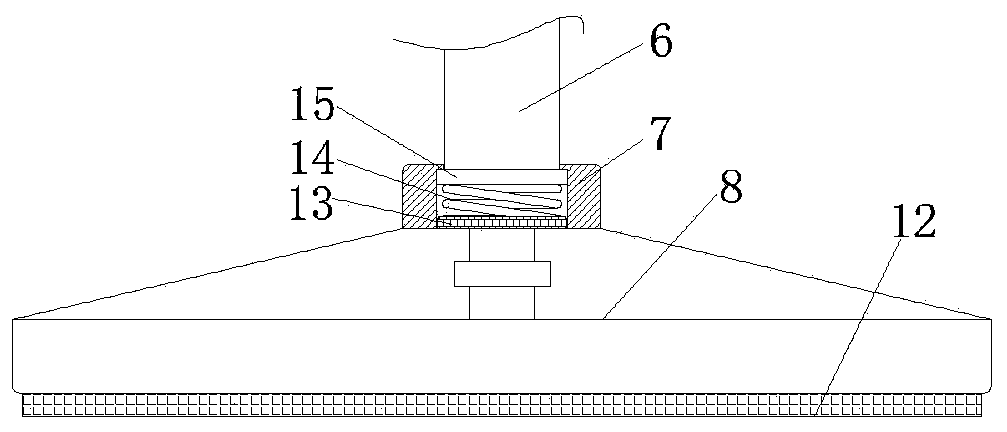

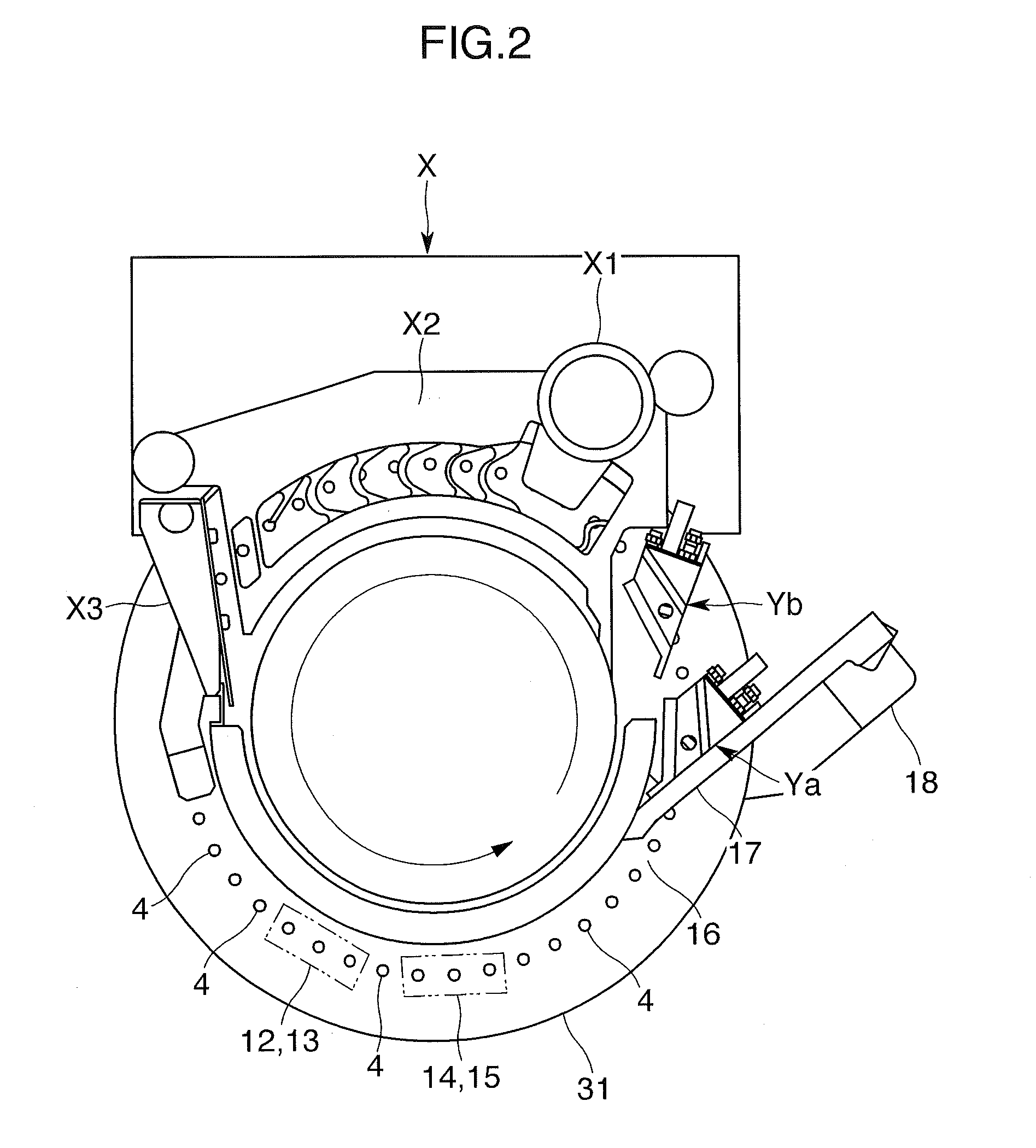

Stump grinder cutting system

Embodiments provide a cutting system for the stump grinder including a cutting assembly configured to be coupled to a wheel on the stump grinder. The cutting assembly may include a mounting block and a cutting block. The mounting block may be disposed in a pocket of the wheel that extends inward from a circumferential outer edge of the wheel. The cutting block may be coupled to the mounting block. The cutting block may have a continuous cutting edge that extends from a first side of the wheel to a second side of the wheel around a circumferential outer edge of the wheel.

Owner:CAIRNS KEITH

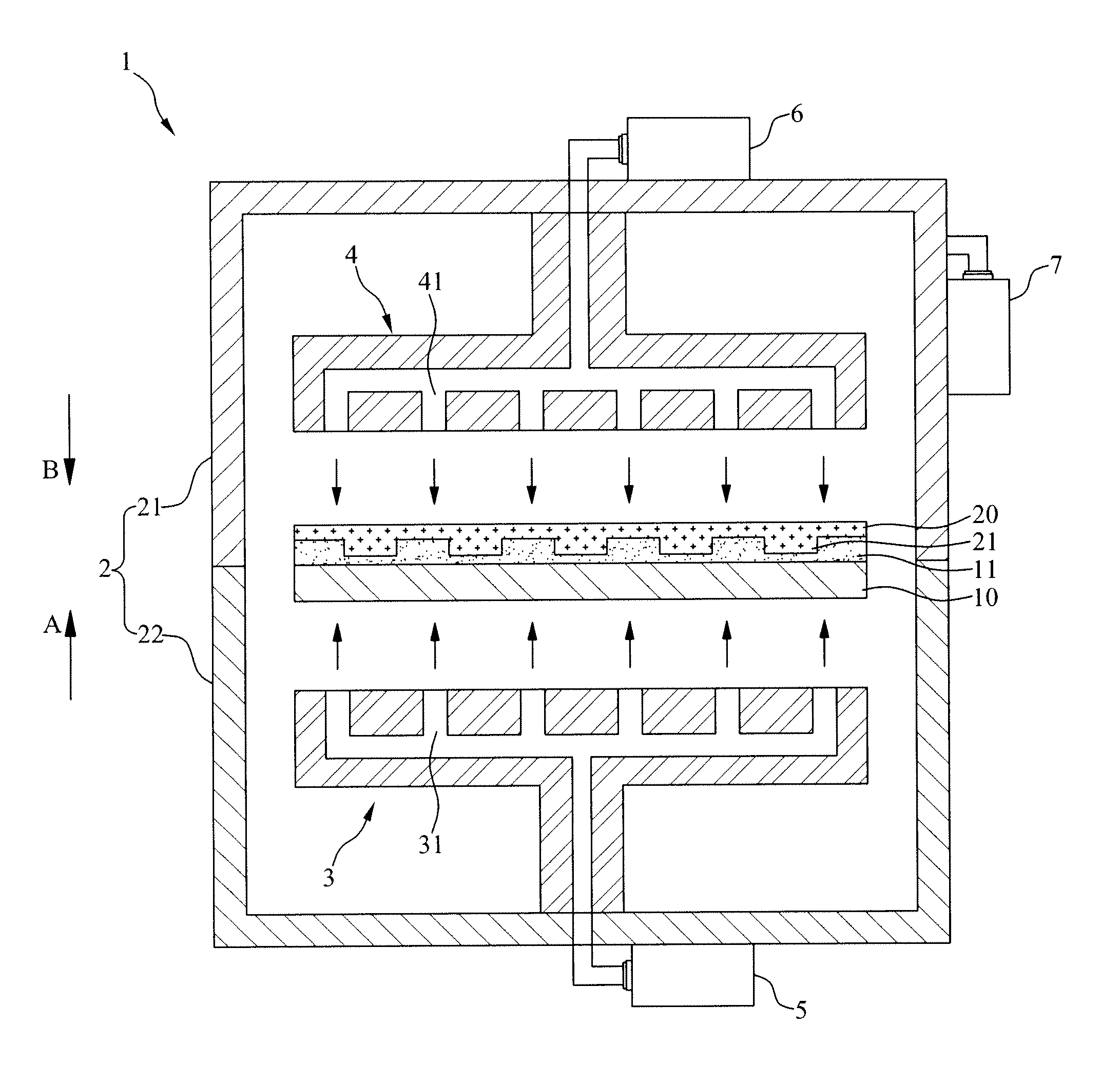

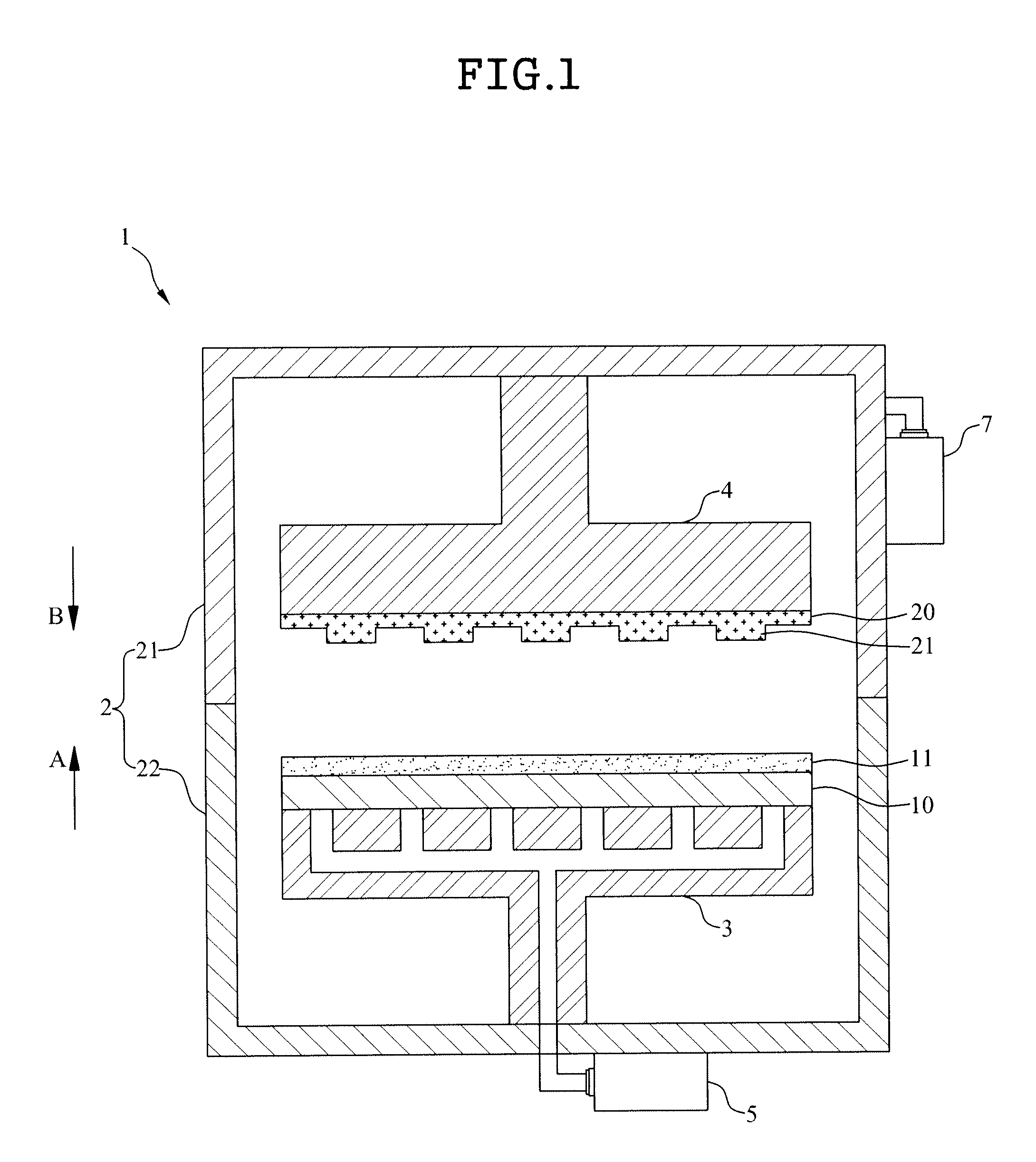

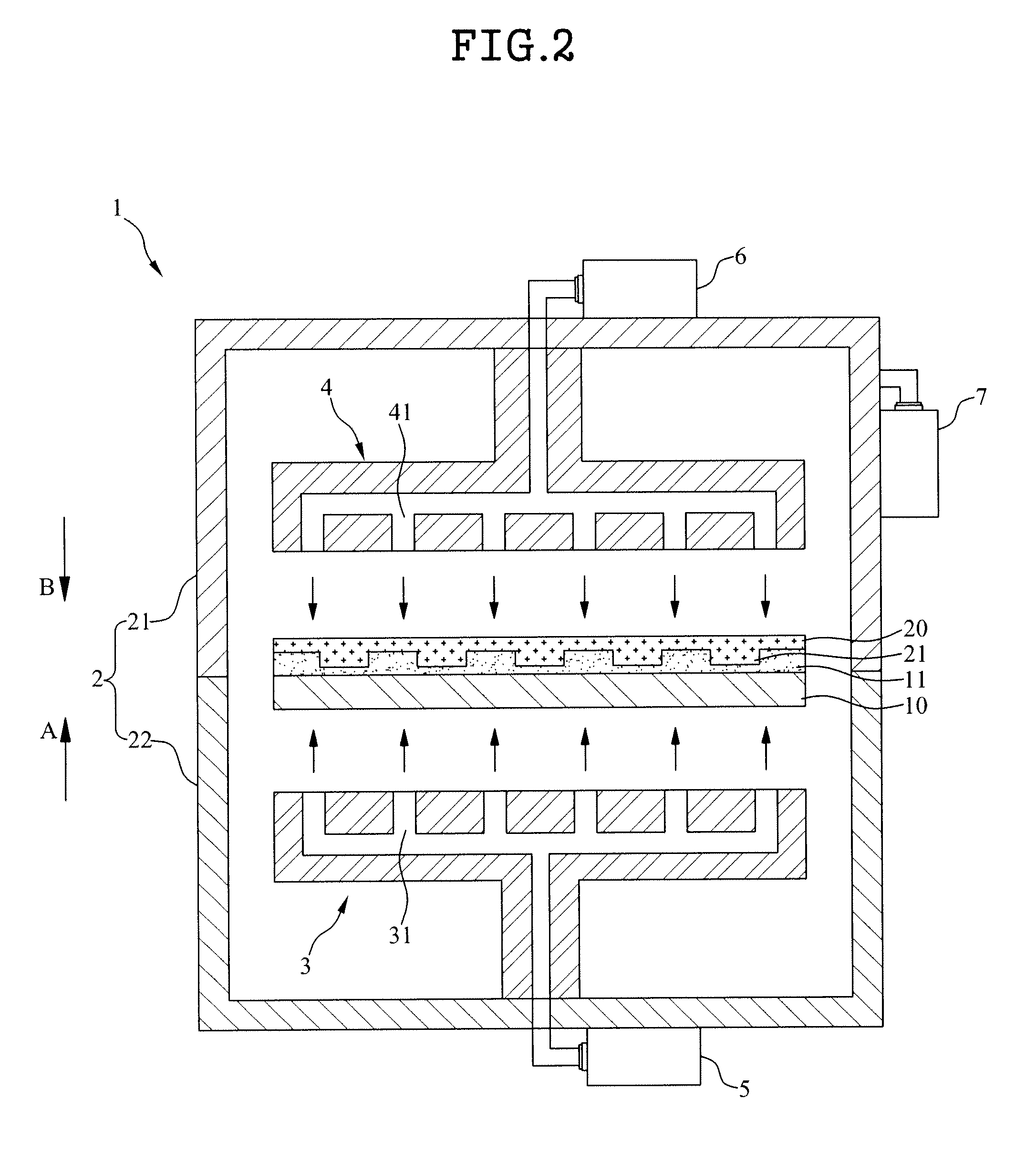

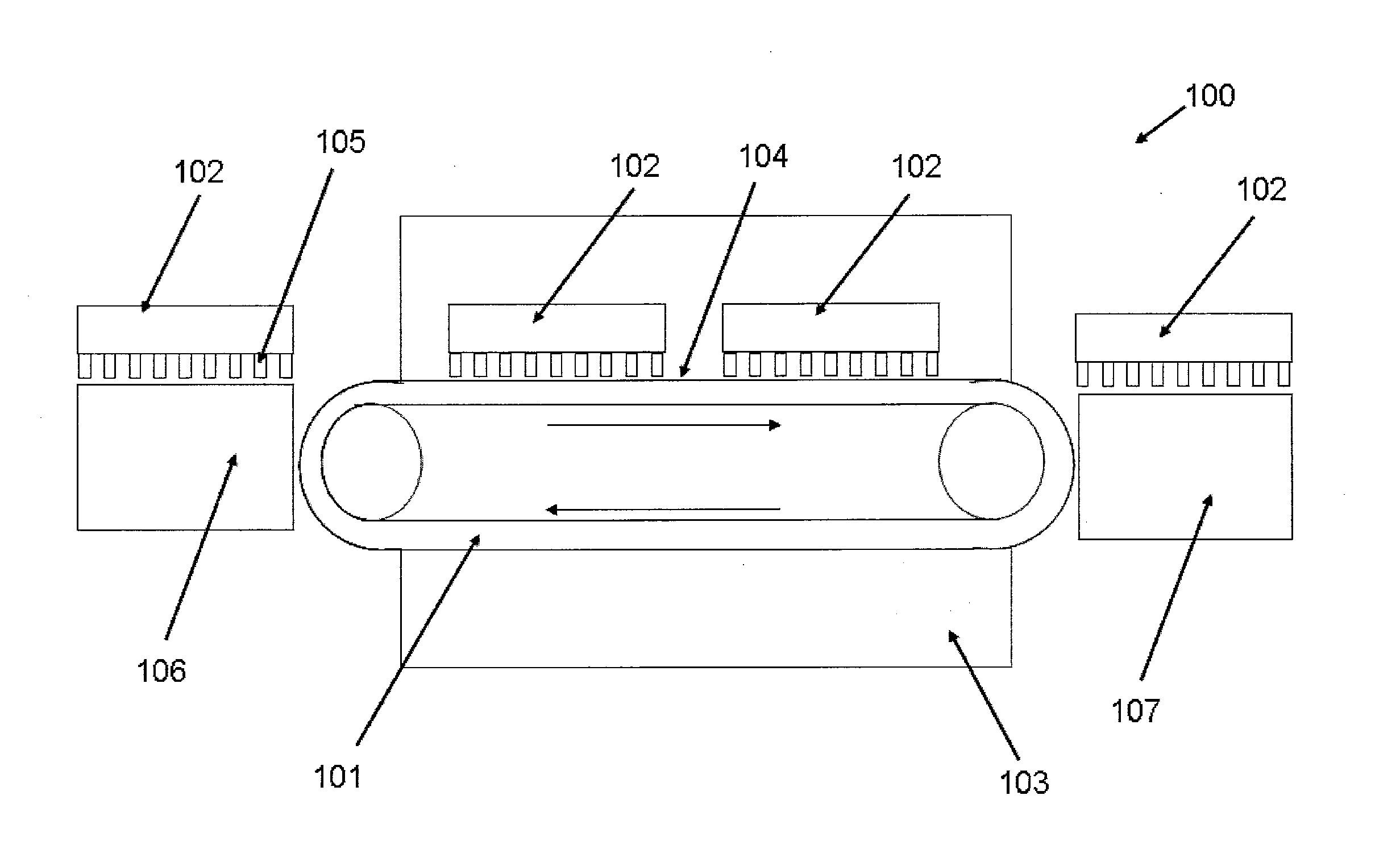

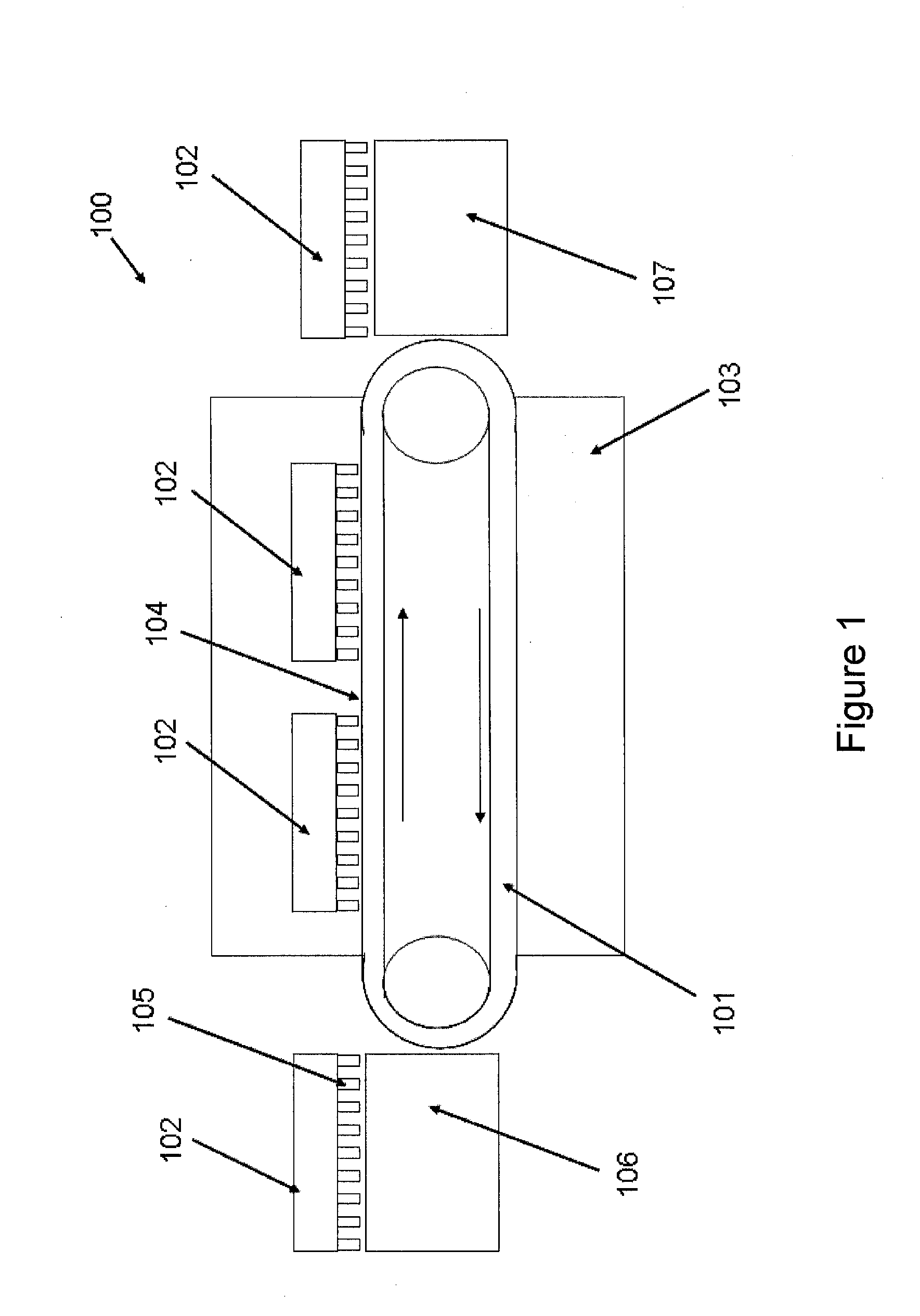

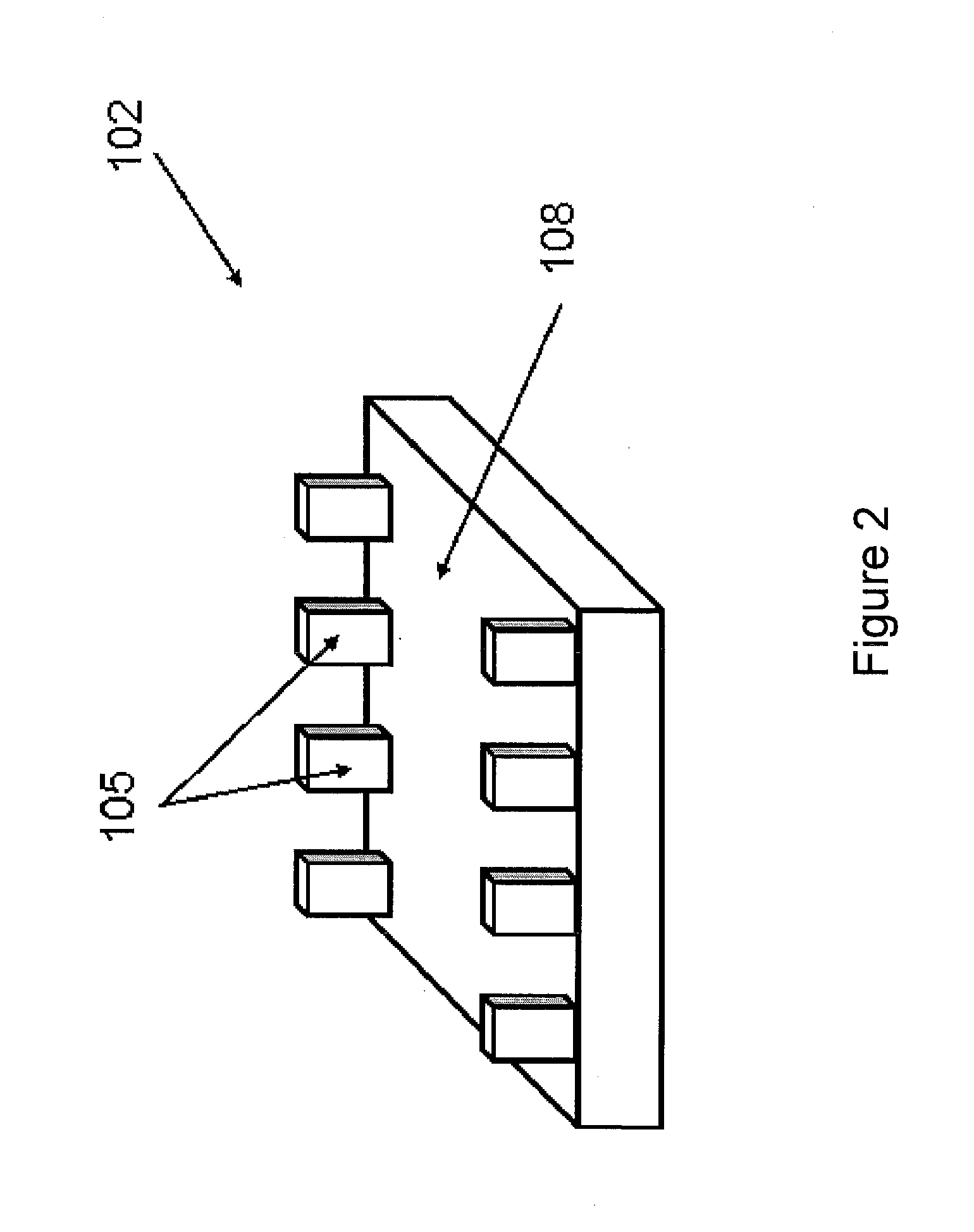

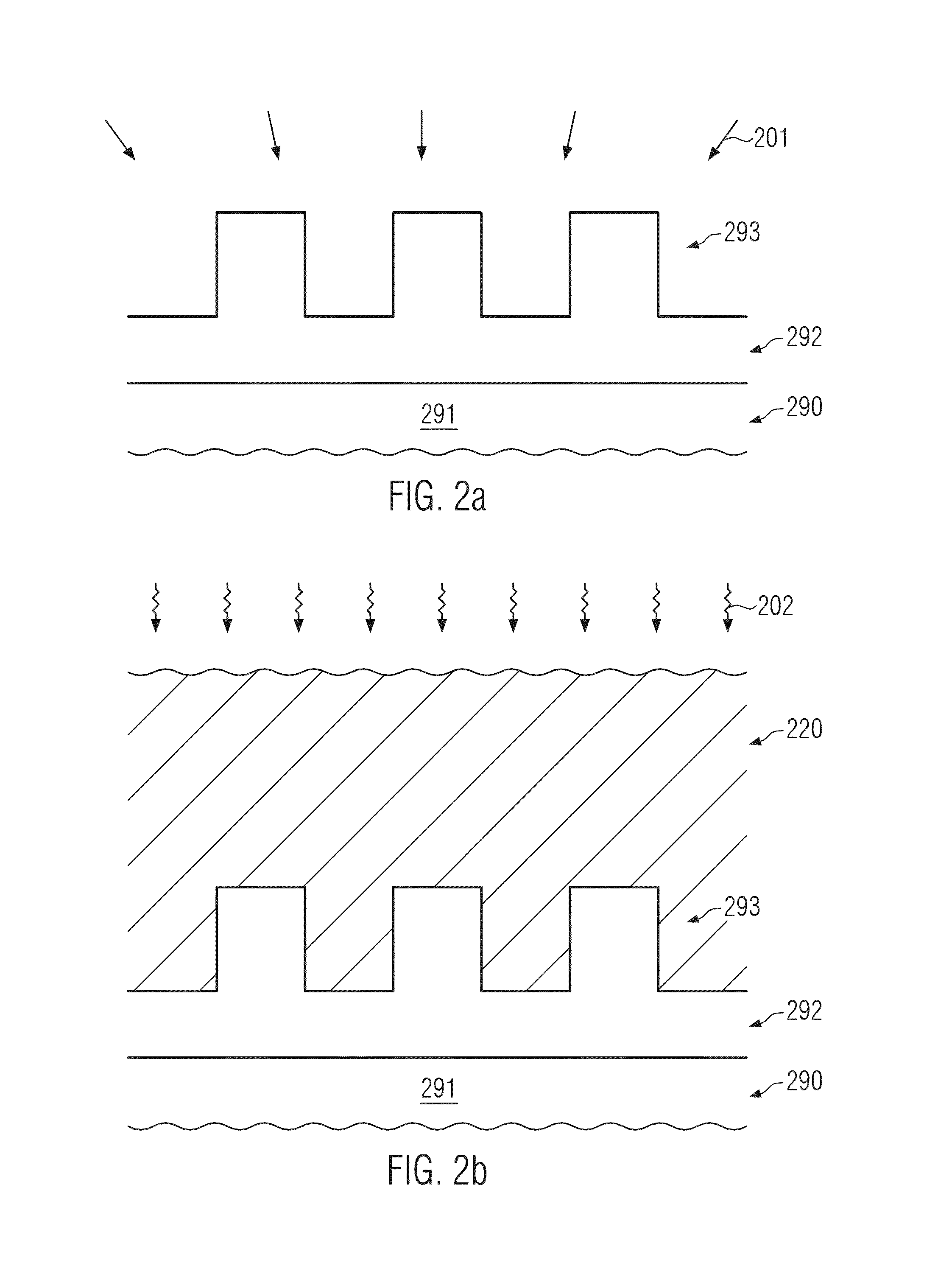

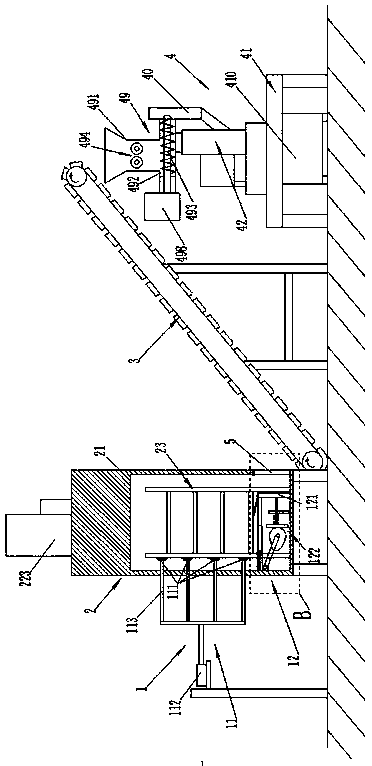

Imprinting apparatus and imprinting method using the same

InactiveUS20110298159A1Easy to solveTailstocks/centresConfectioneryEngineeringMechanical engineering

Owner:LG DISPLAY CO LTD

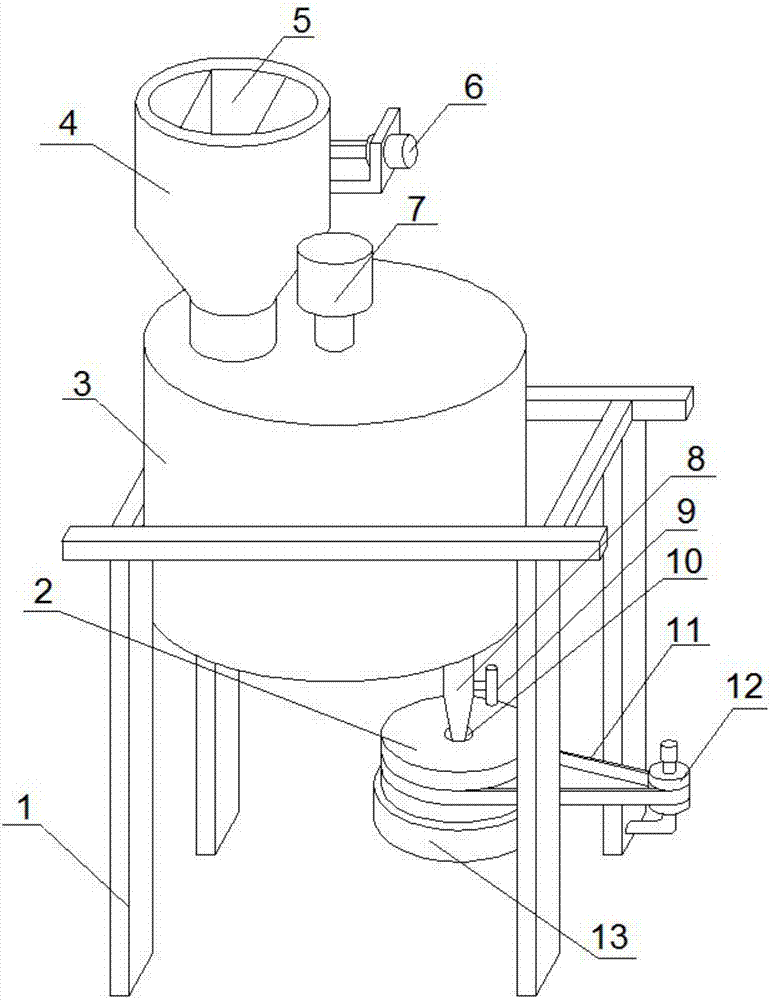

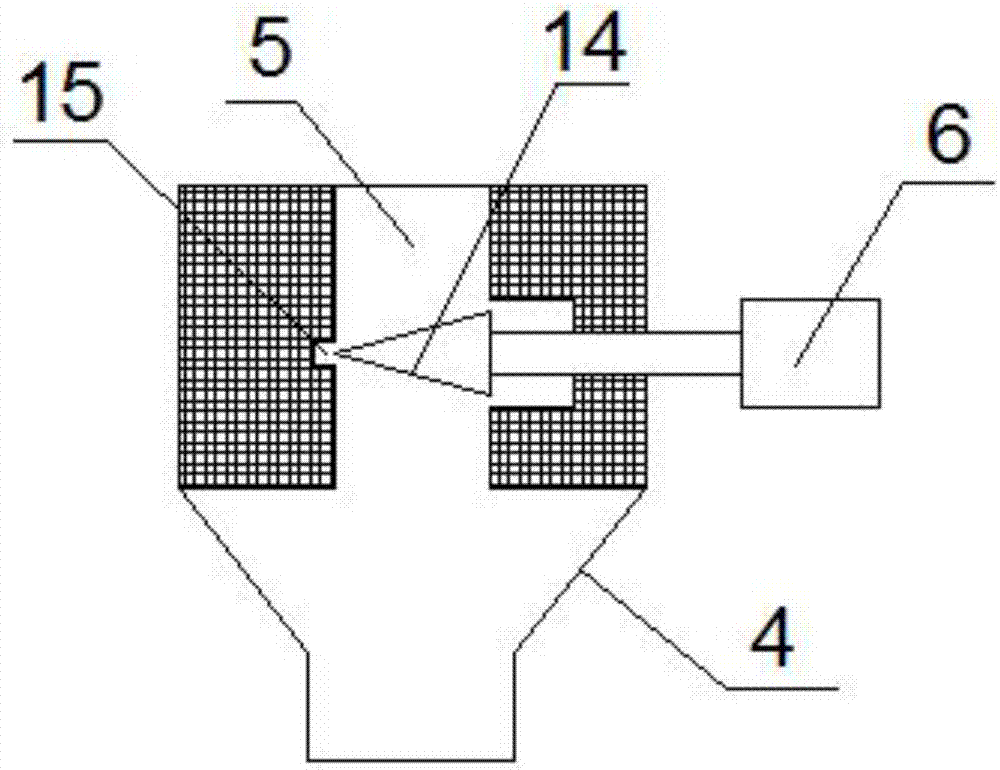

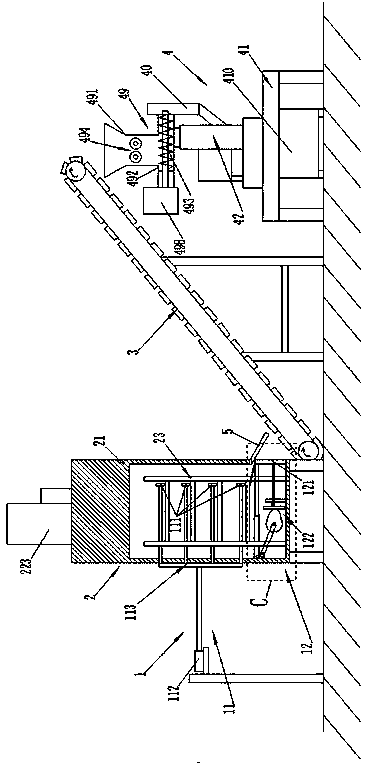

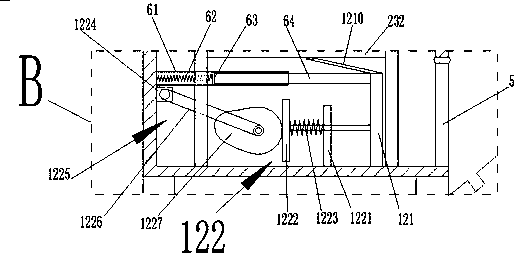

Straw crushing and grinding device and operation method thereof

Owner:合肥荣电环境电器有限公司

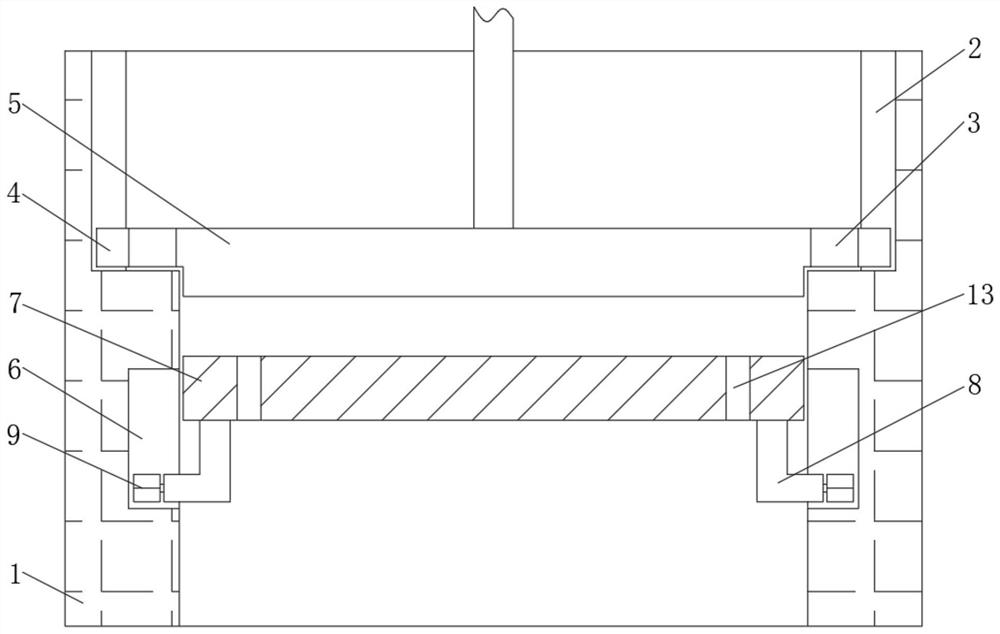

Substrate forming mold, and plate thickness adjusting method of formed substrate in substrate forming mold

A substrate forming mold for forming a substrate by filling a cavity formed between a pair of matching molds 1, 2 with resin, that is, this substrate forming mold has shims 9, 12 disposed at least between a mirror finished surface plate 6 for composing one mold 1 and a stable mold base 8, and in a region inside of a fixed abutting ring 13, depending on fluctuations of plate thickness of formed substrate. As a result, the plate thickness of formed substrate can be adjusted finely, and fluctuations occurring in the radial direction or peripheral direction of the formed substrate can be decreased.

Owner:PANASONIC CORP

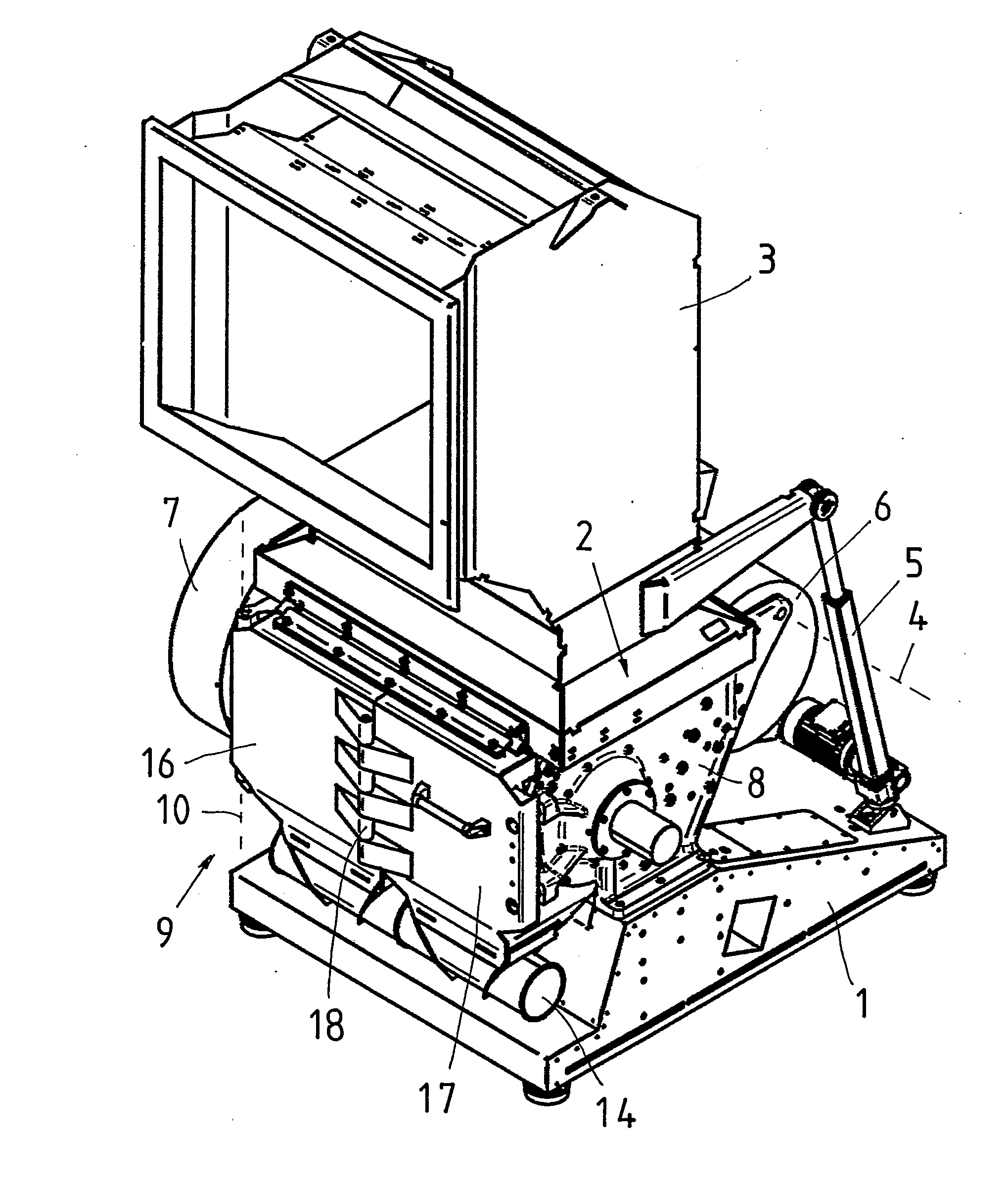

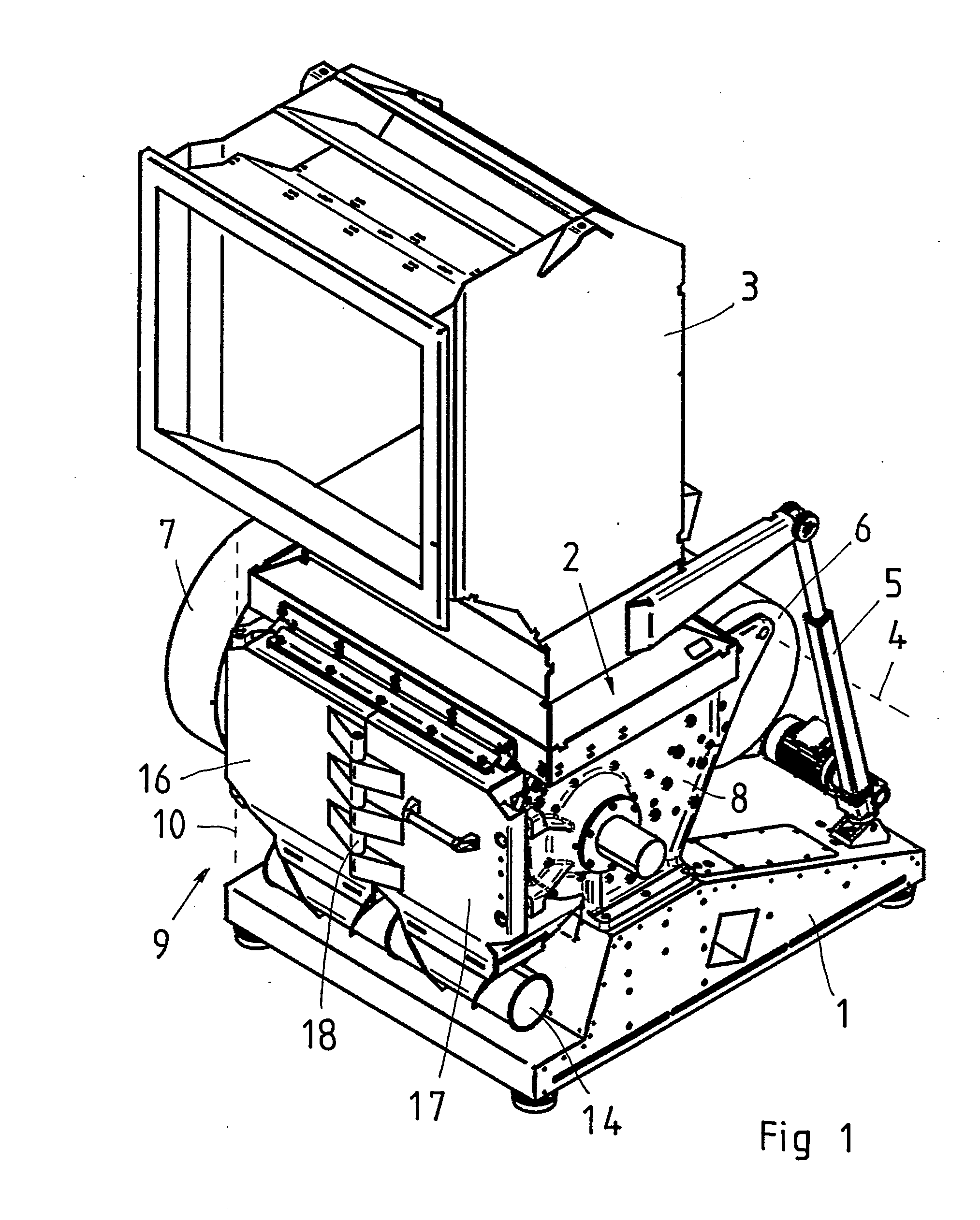

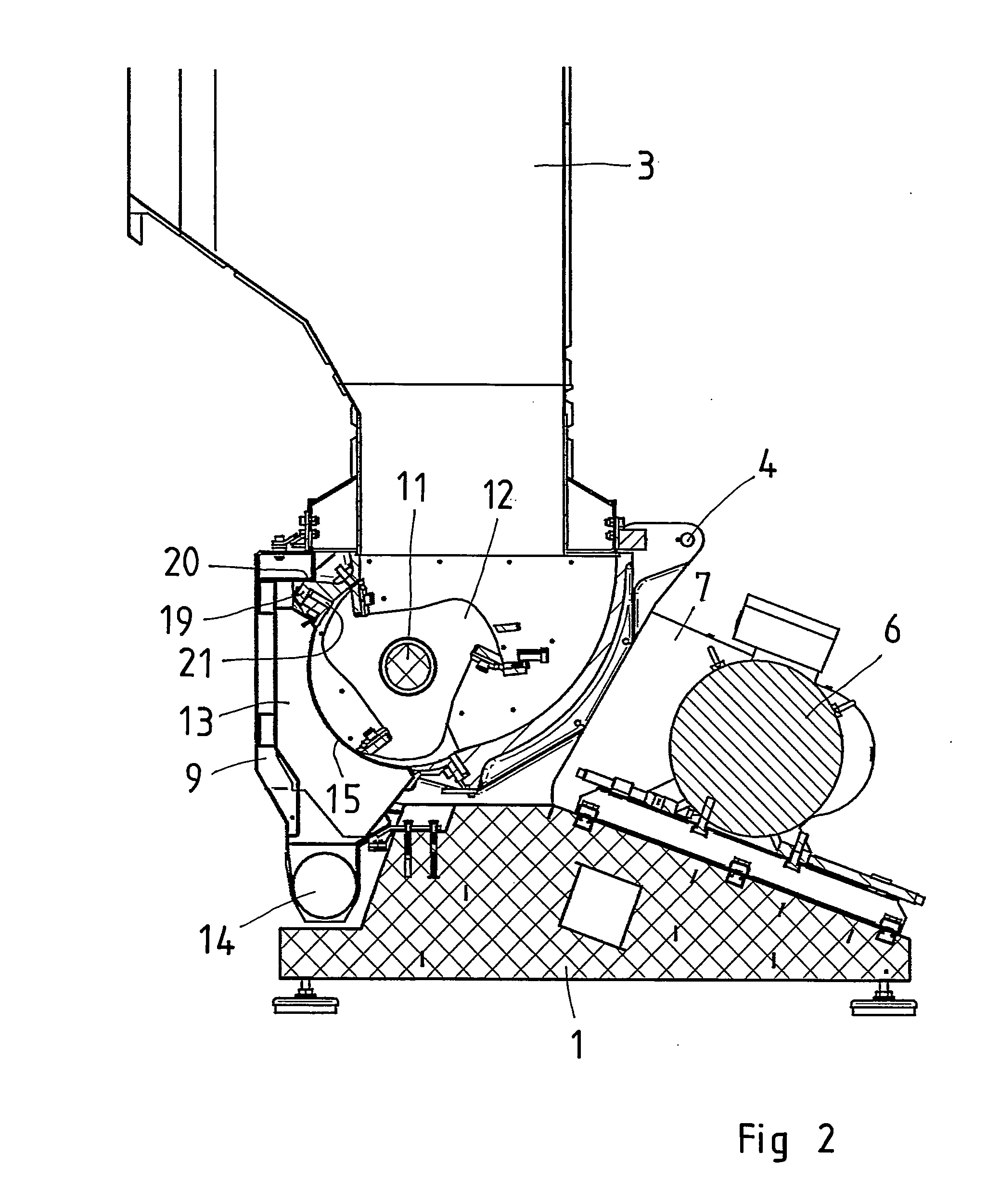

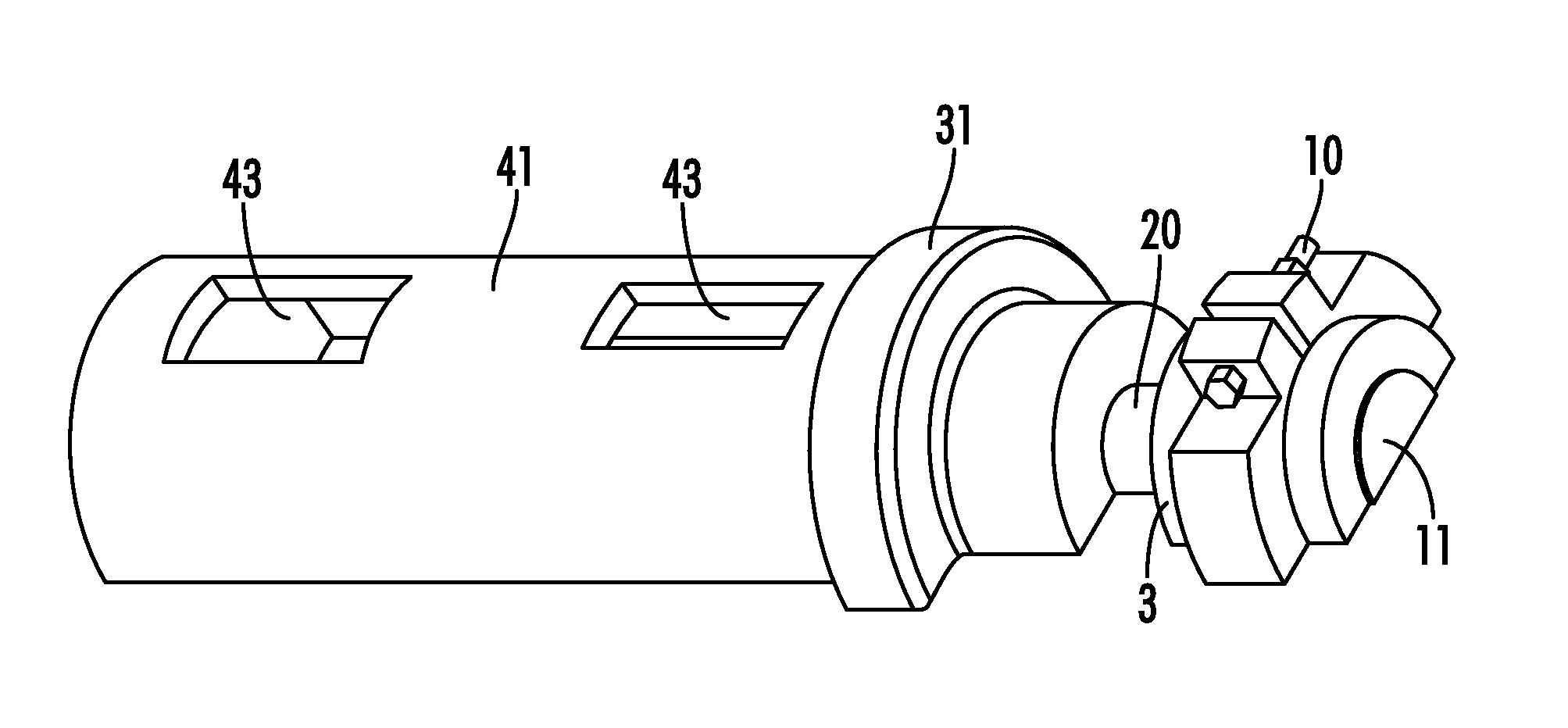

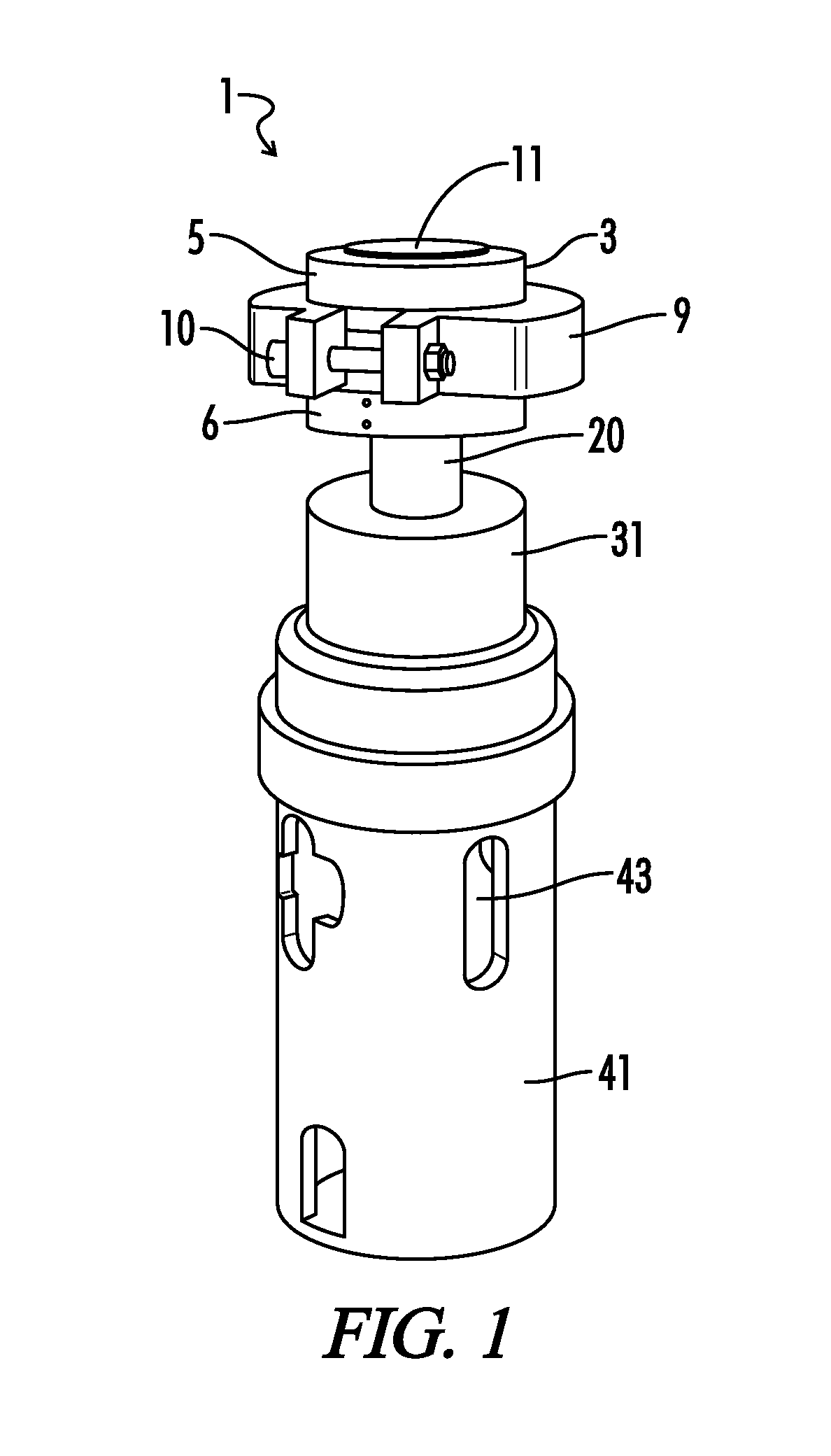

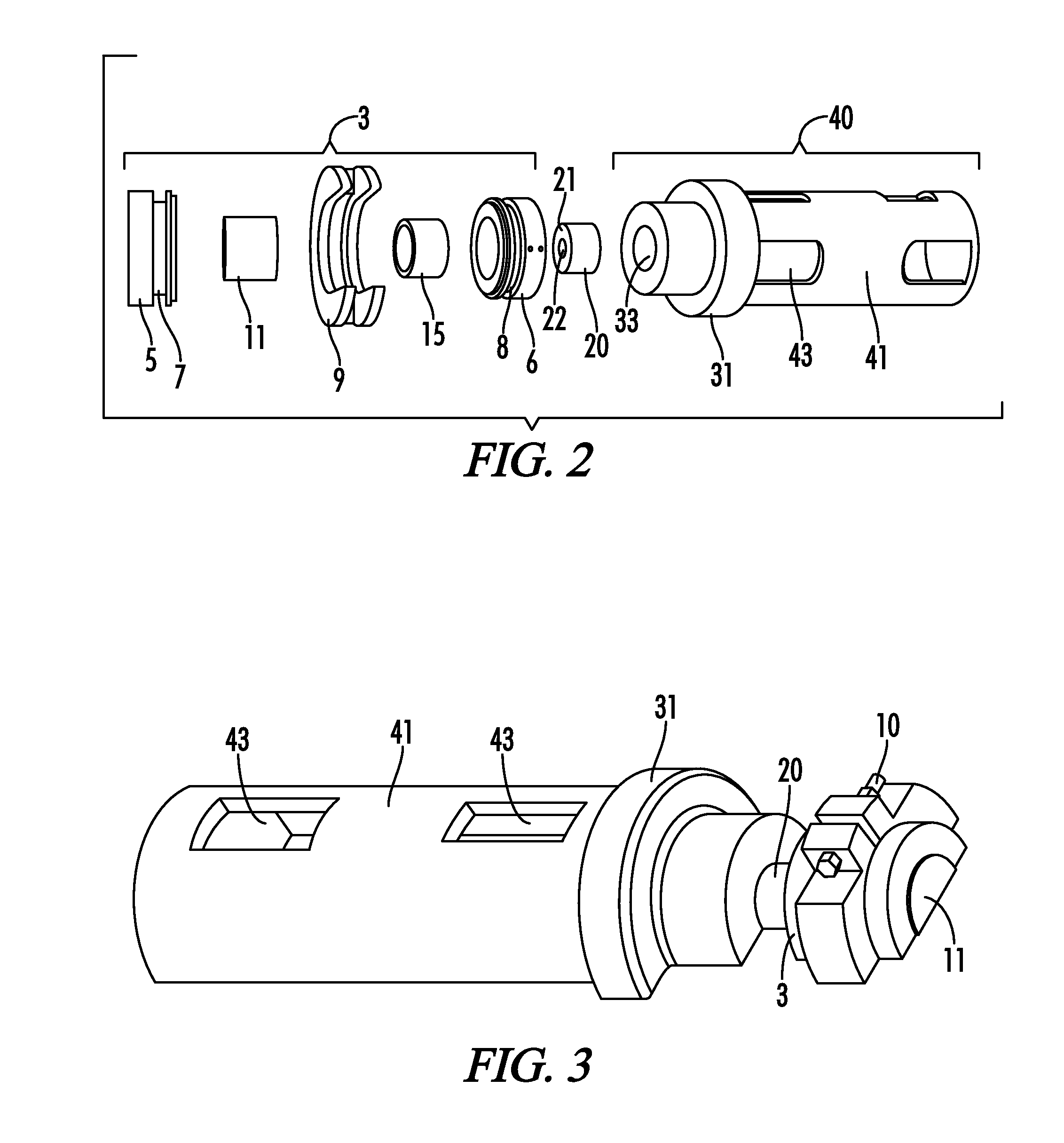

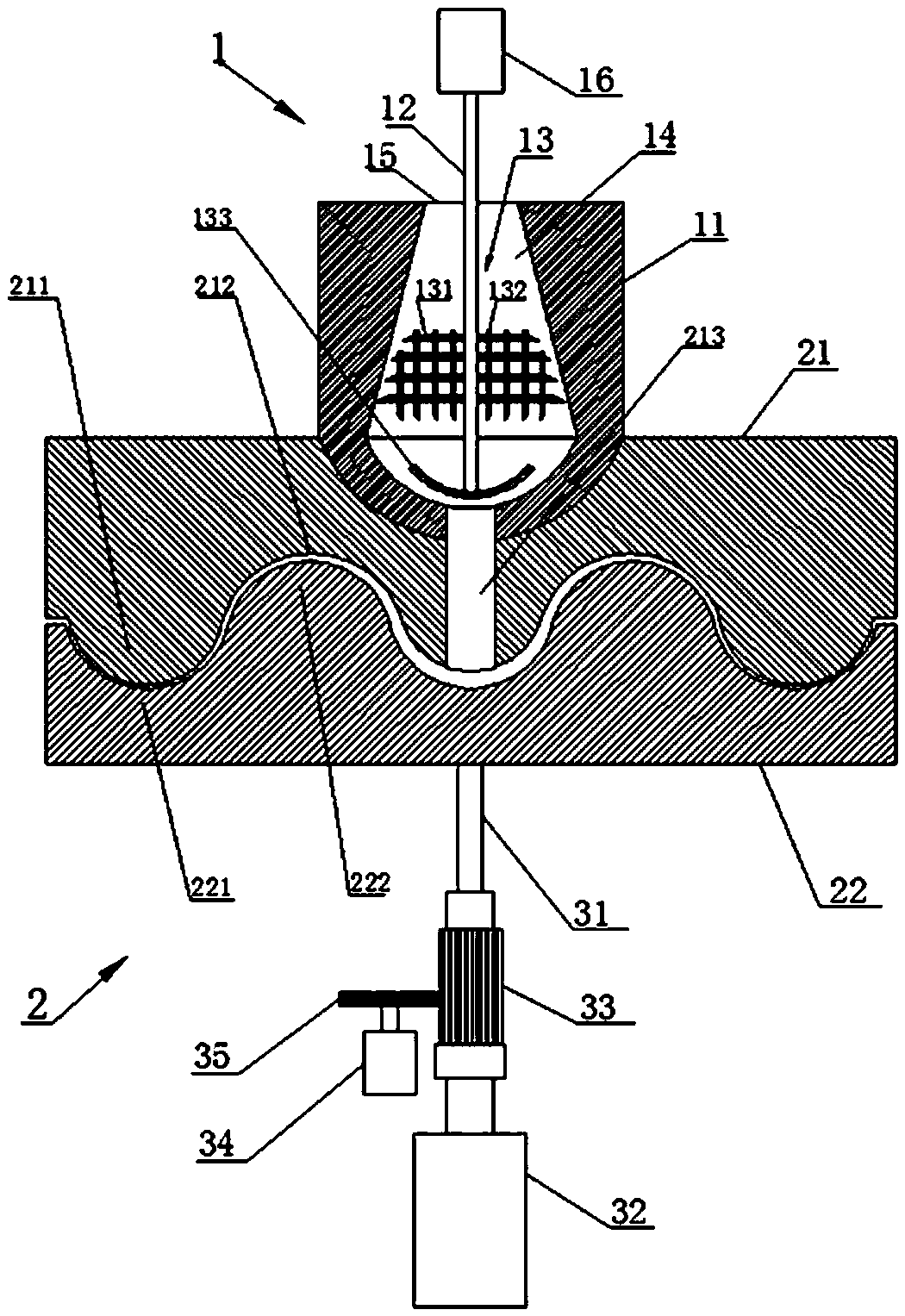

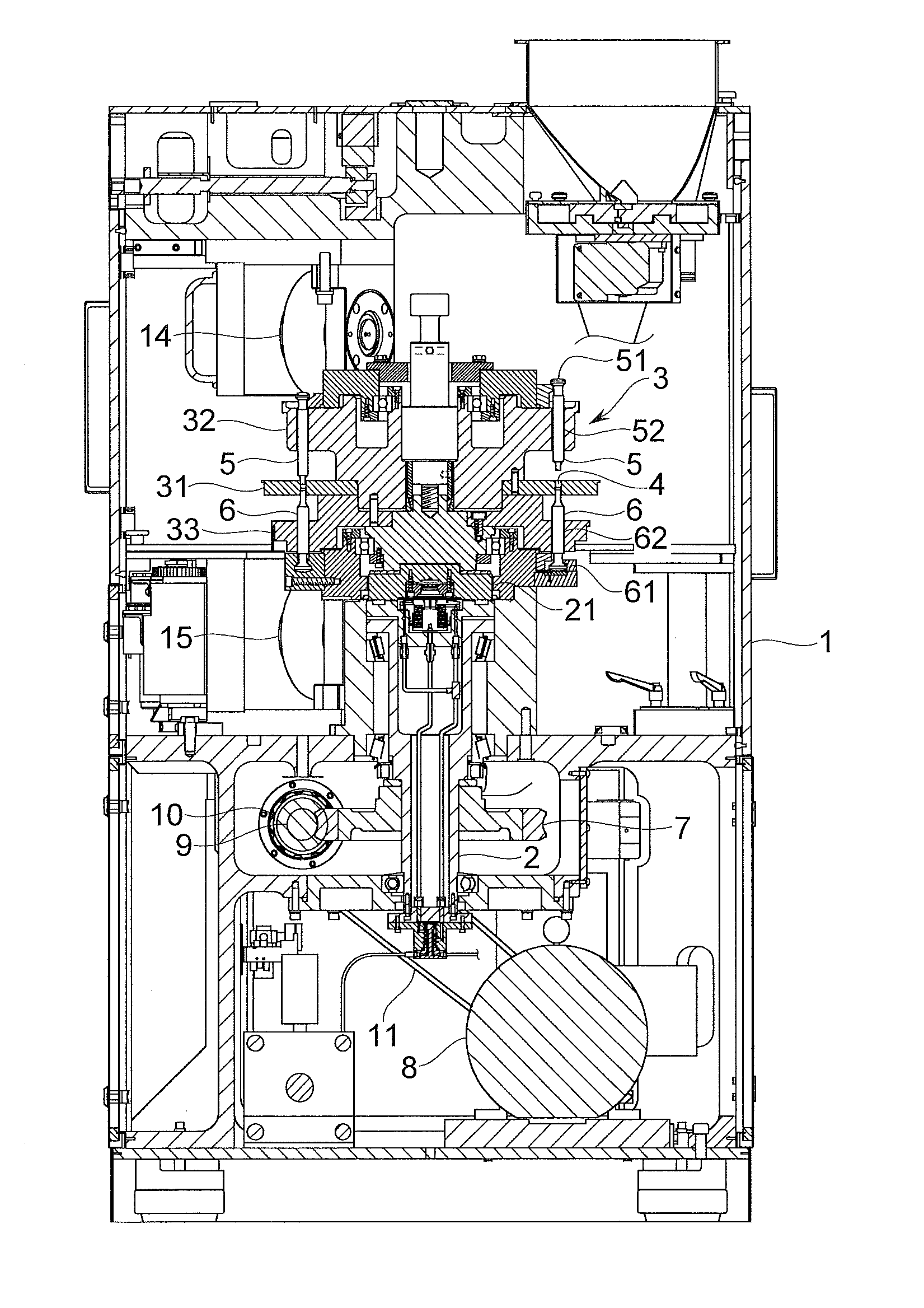

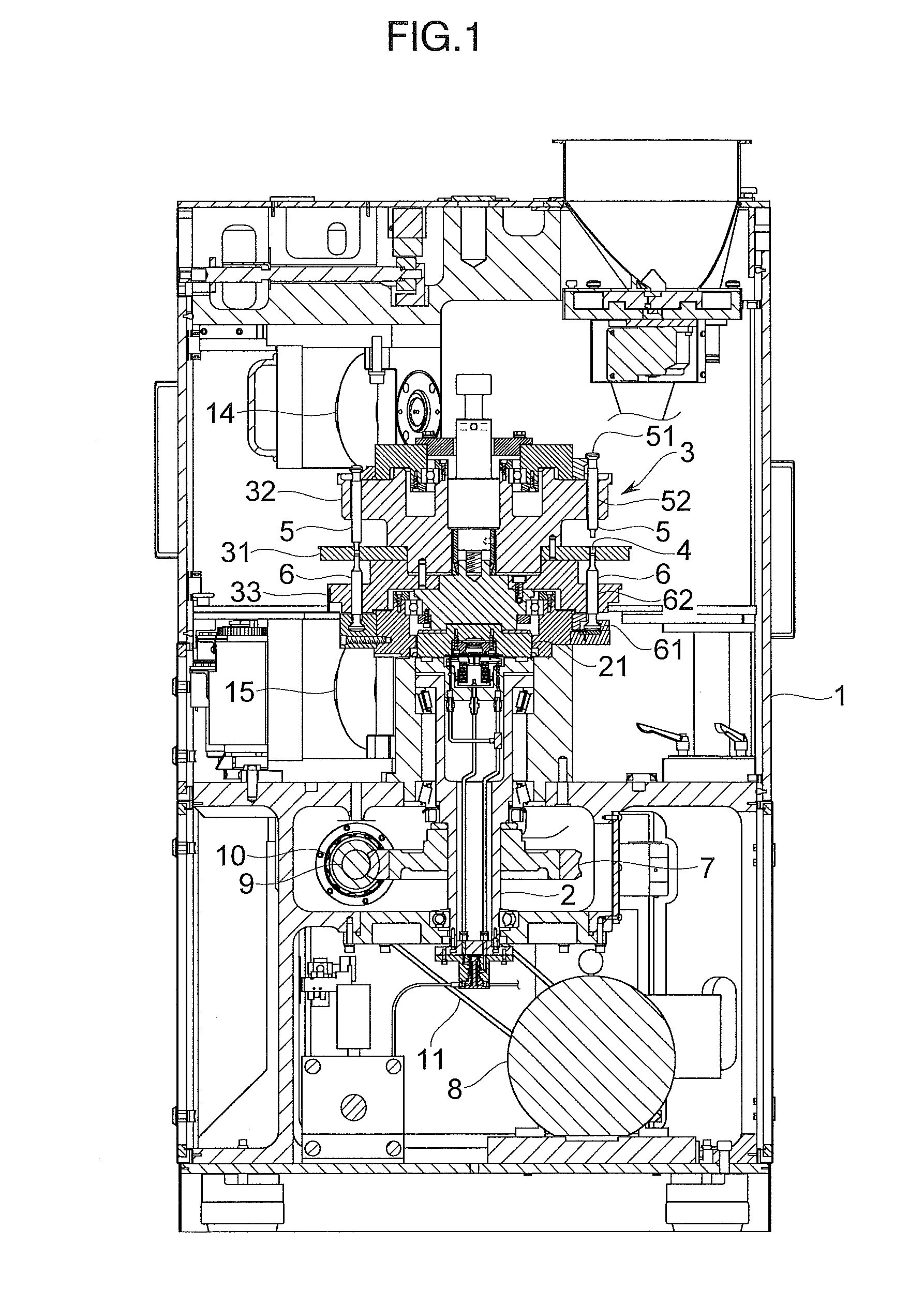

Granulator mill

InactiveUS20110095114A1Improve accessibilityDrawback can be obviatedGrinding machine componentsCocoaEngineeringMechanical engineering

Owner:RAPID GRANULATOR

System for producing chocolate-based articles in solidifying form

Owner:IPCO PROCESS SYST BV

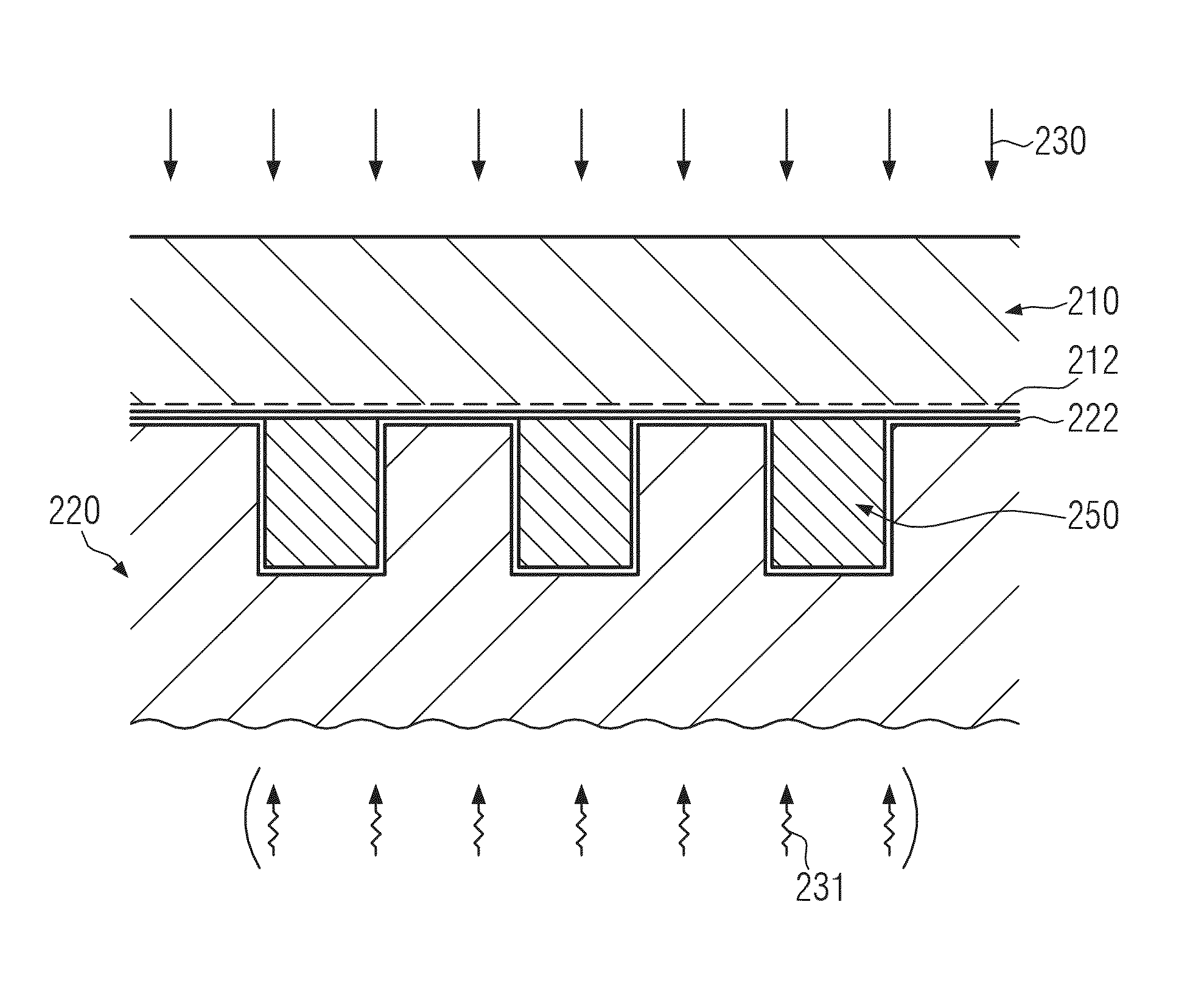

Methods and a mold assembly for fabricating polymer structures by imprint techniques

InactiveUS20140084519A1Highly hydrophobic surfaceReduced surface wettabilityConfectioneryPhotomechanical apparatusLithography processMaterials science

Owner:STMICROELECTRONICS SRL +1

Accurate grinding device for producing waterproof agent

Owner:上海桑格化工科技有限公司

Methods and Systems for Extrusion

Owner:MISSISSIPPI STATE UNIV RES TECH RTC

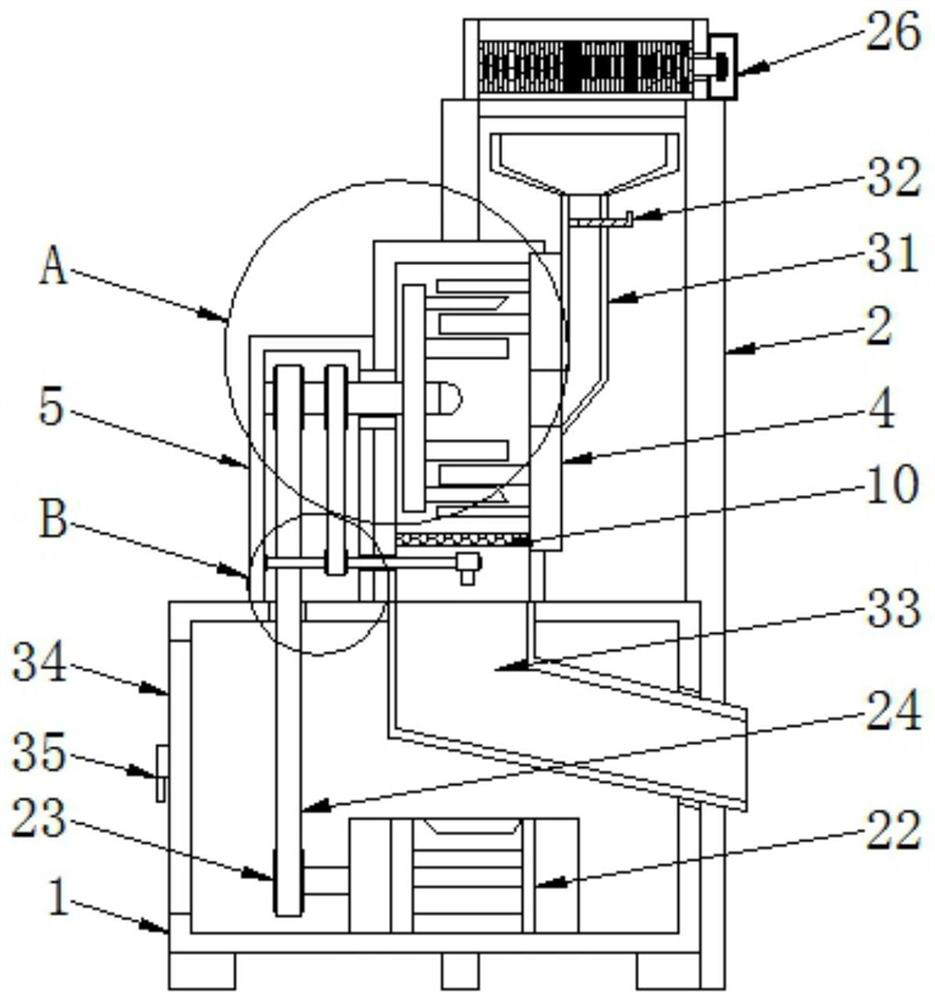

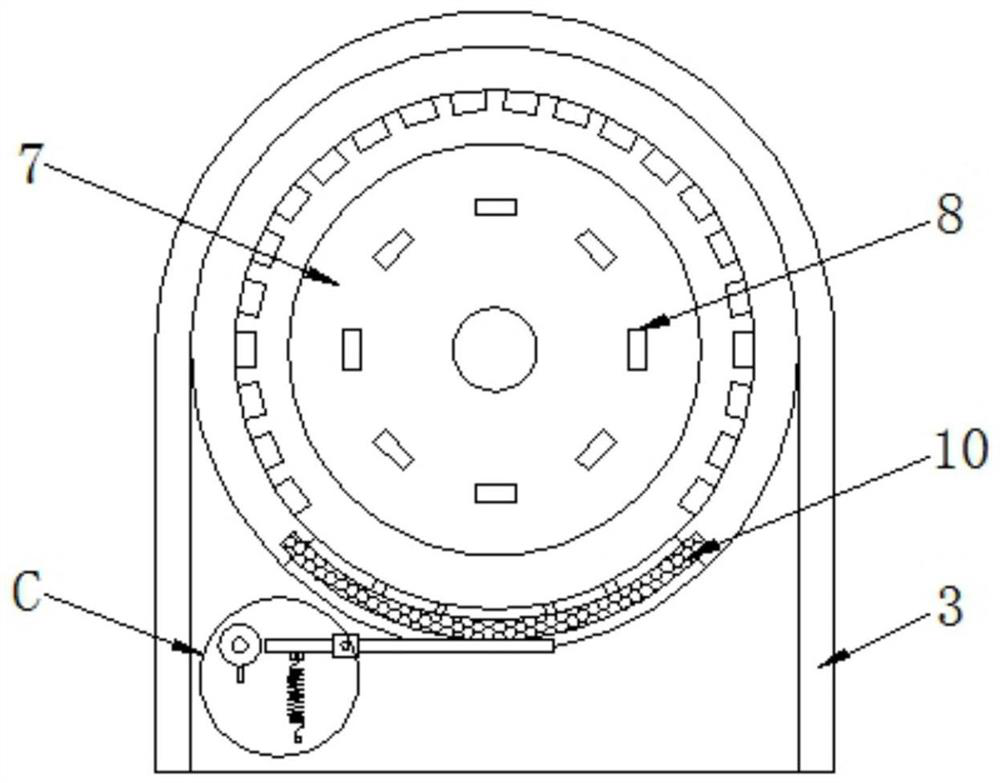

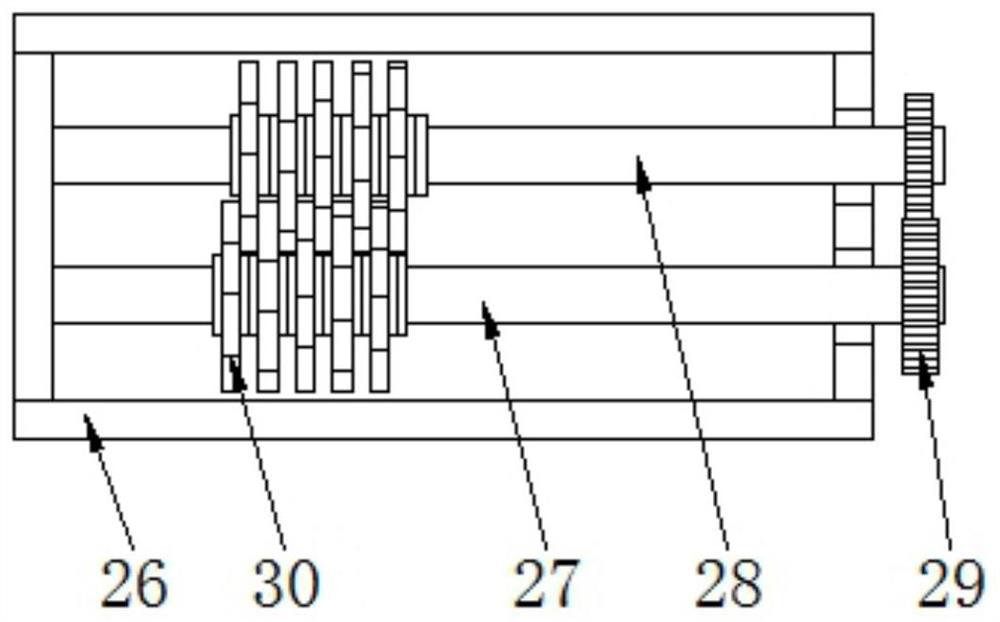

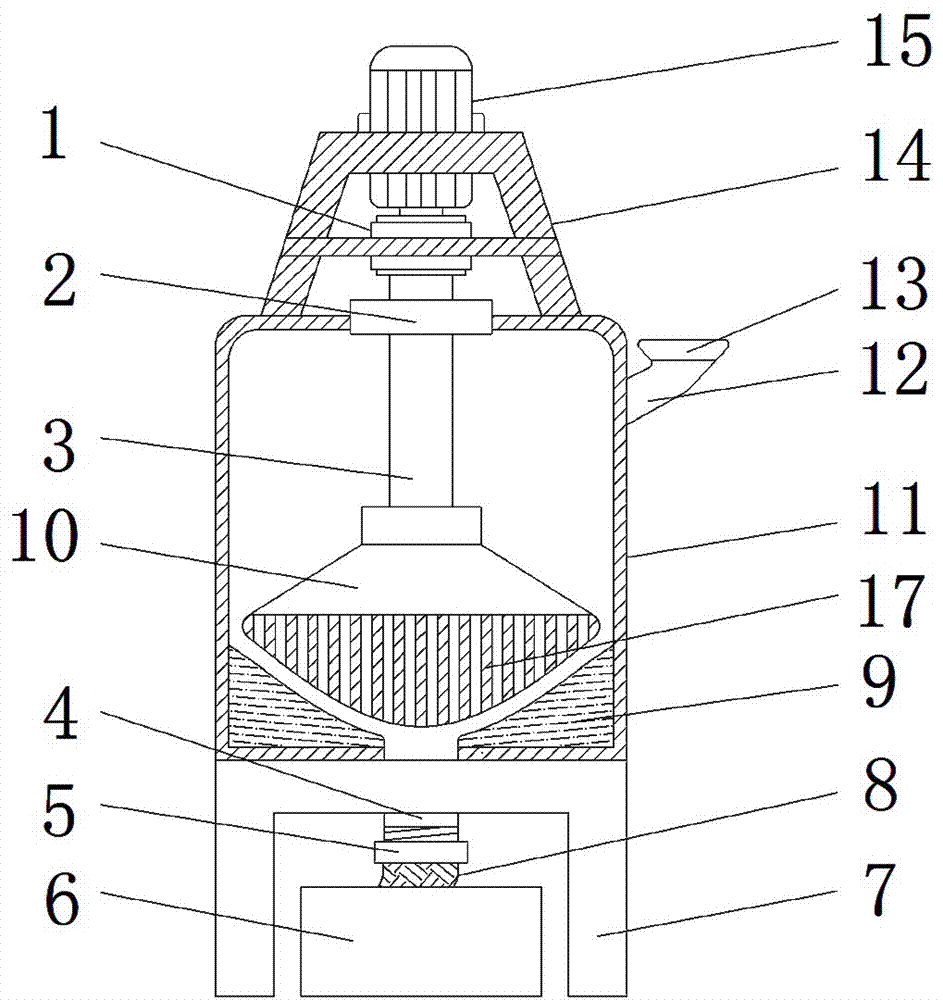

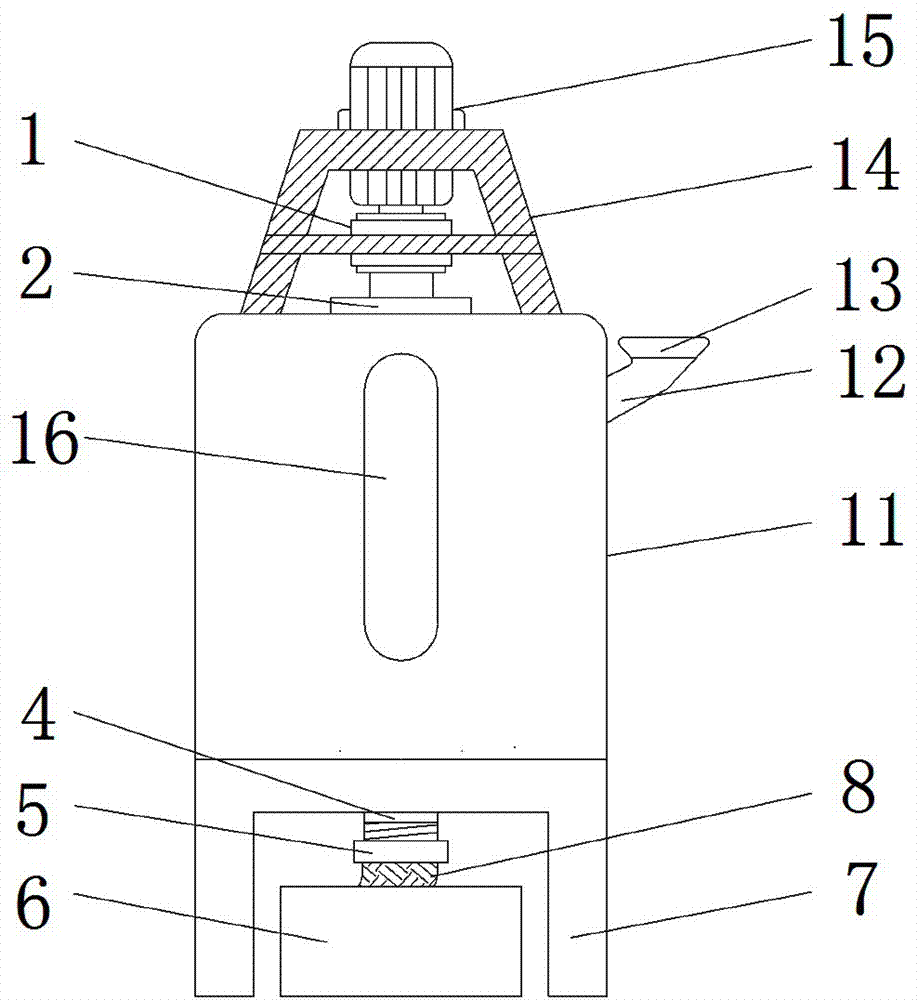

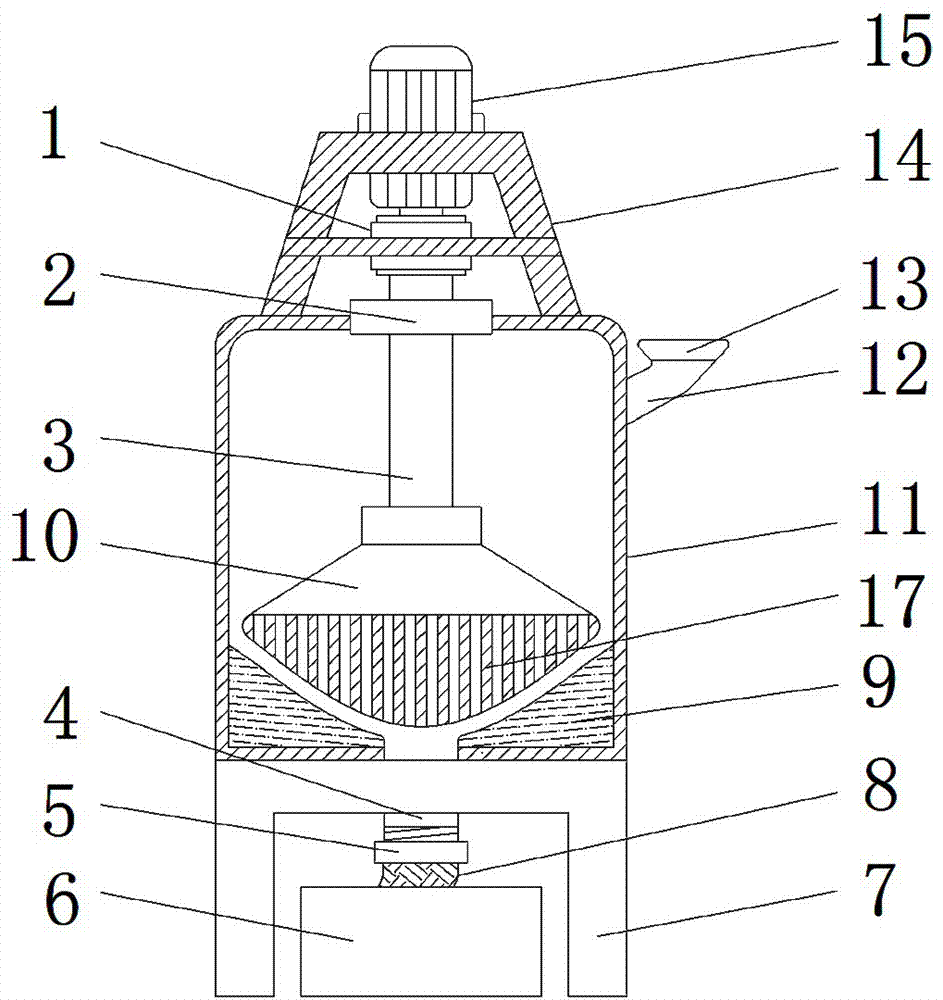

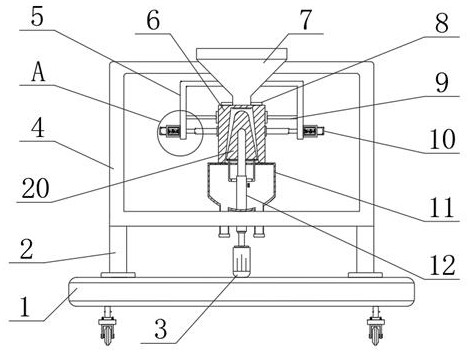

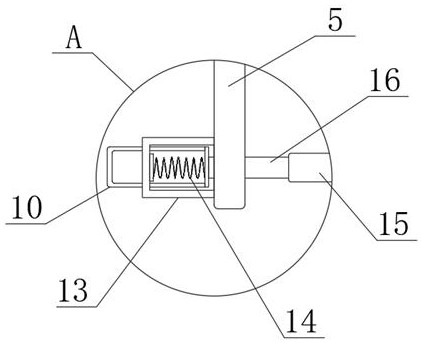

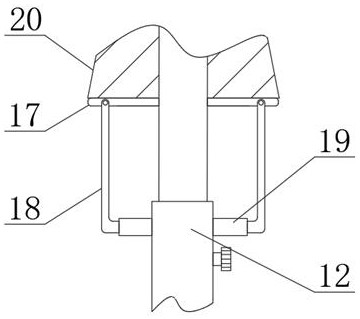

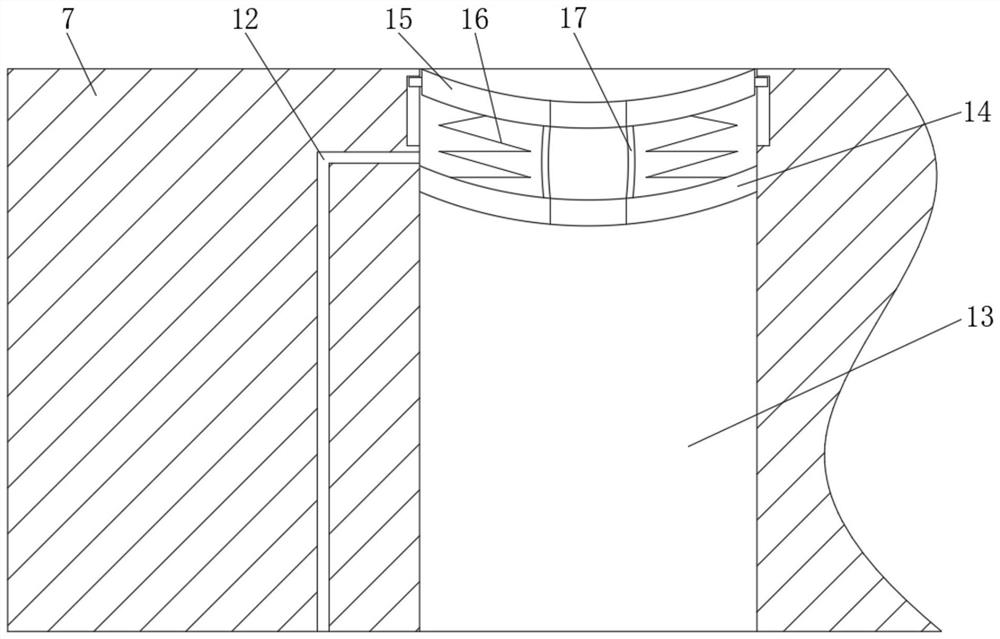

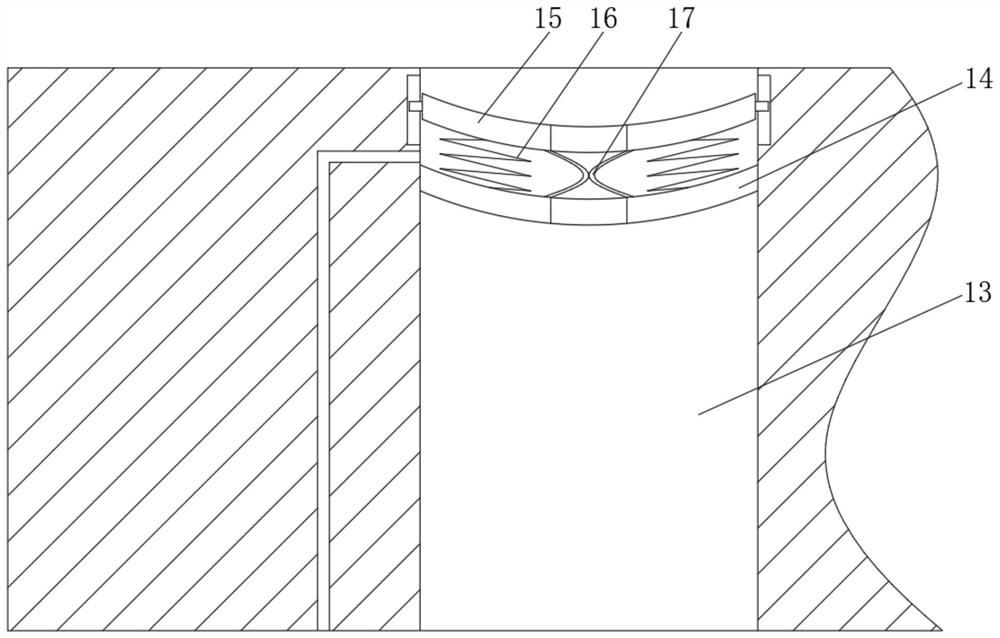

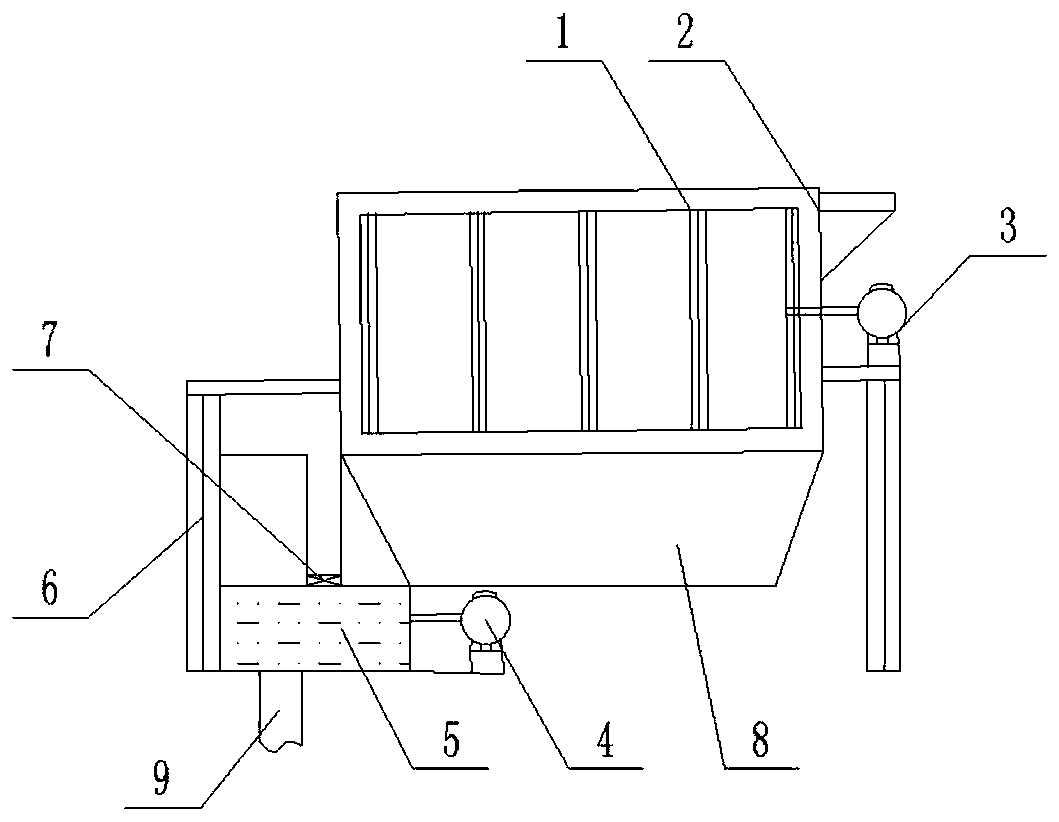

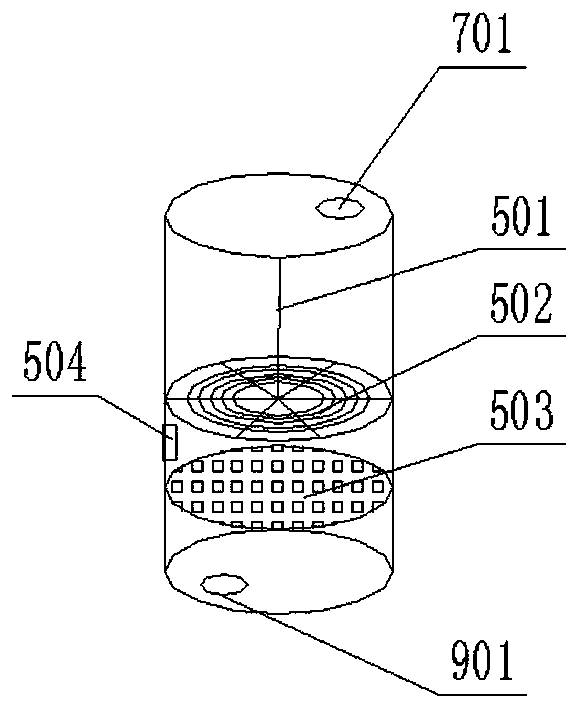

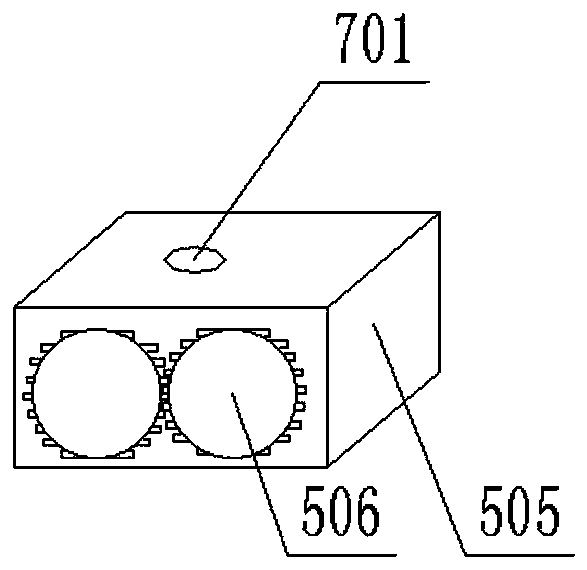

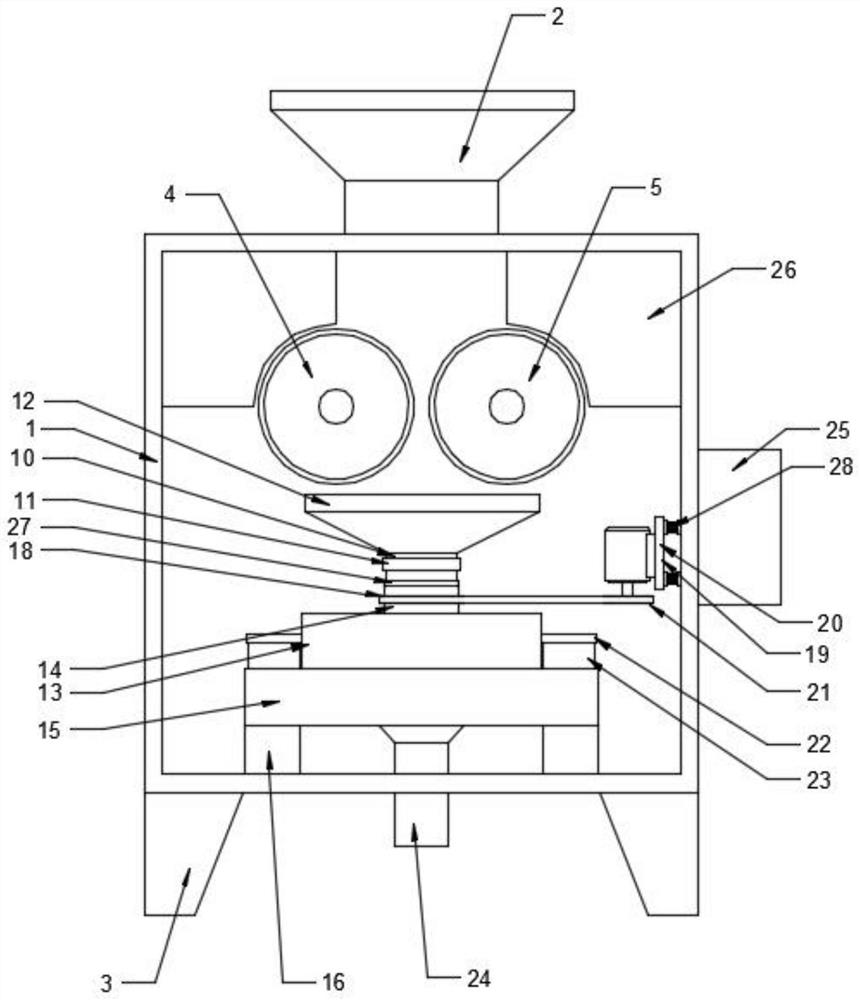

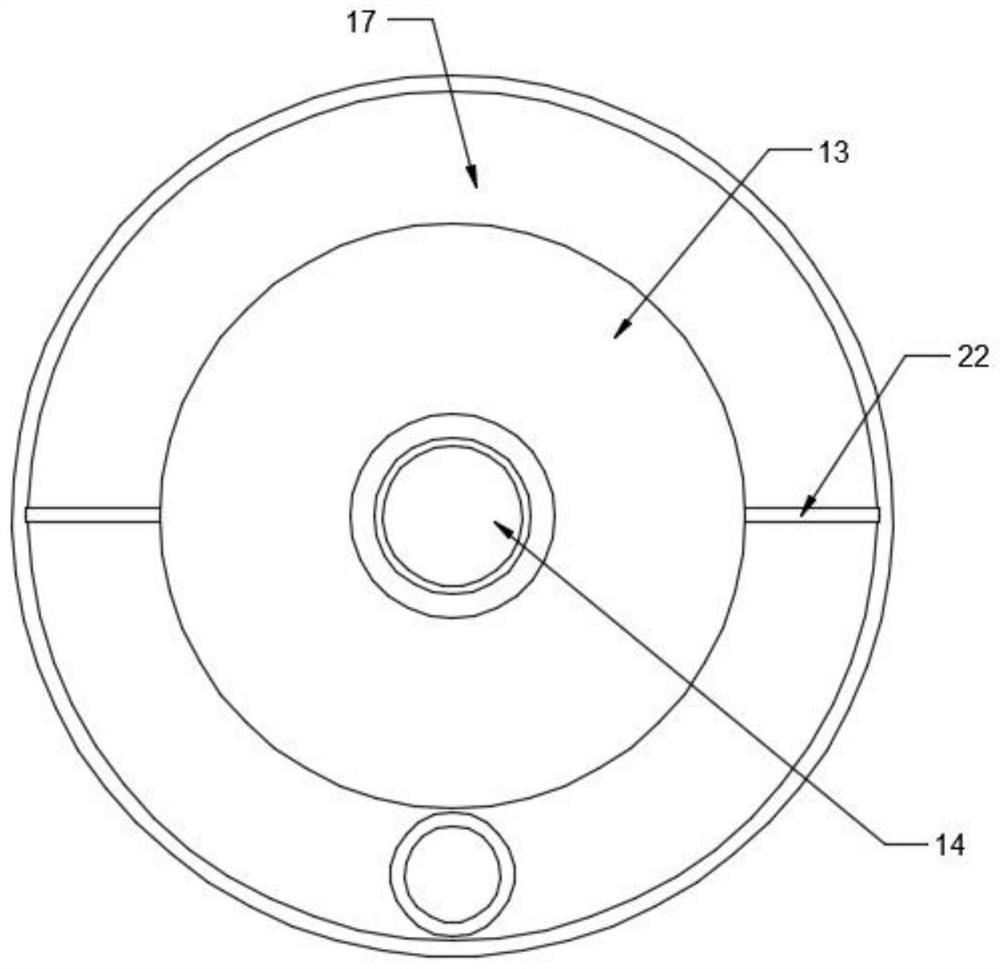

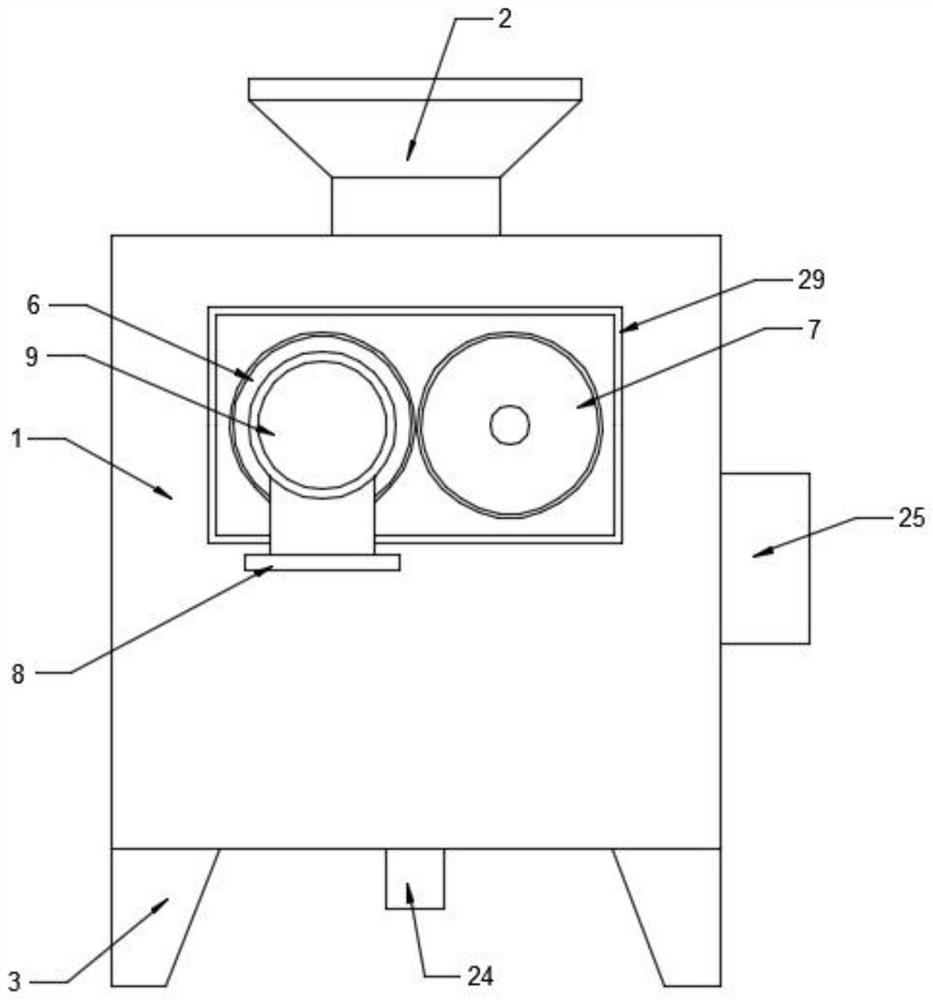

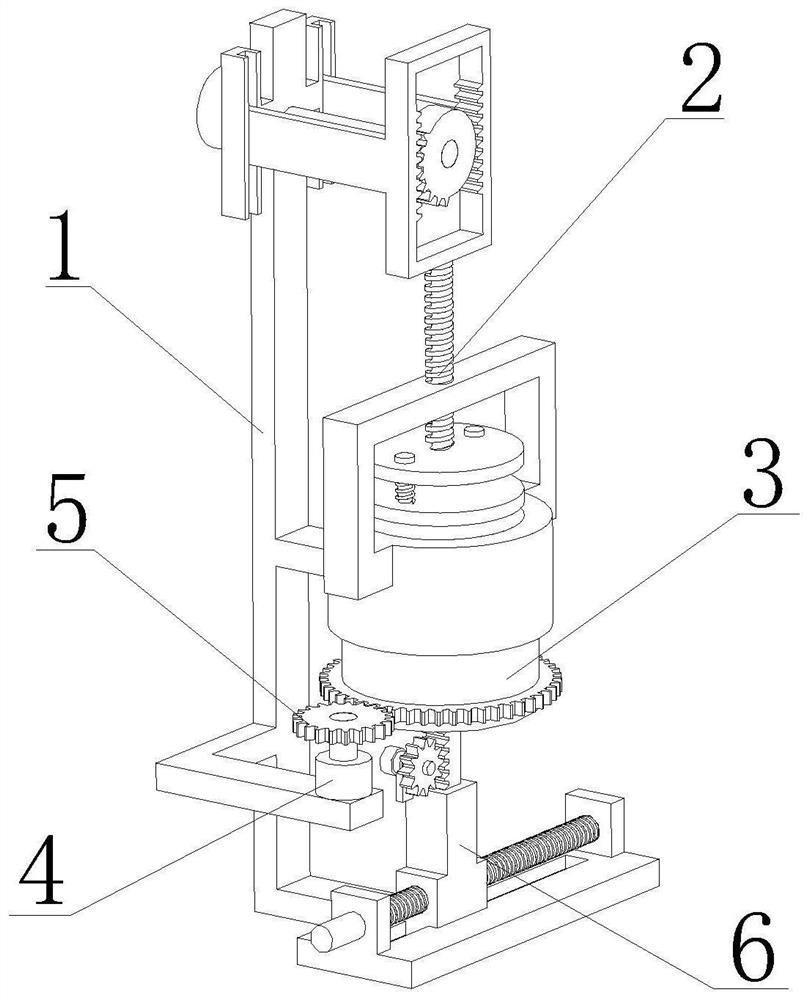

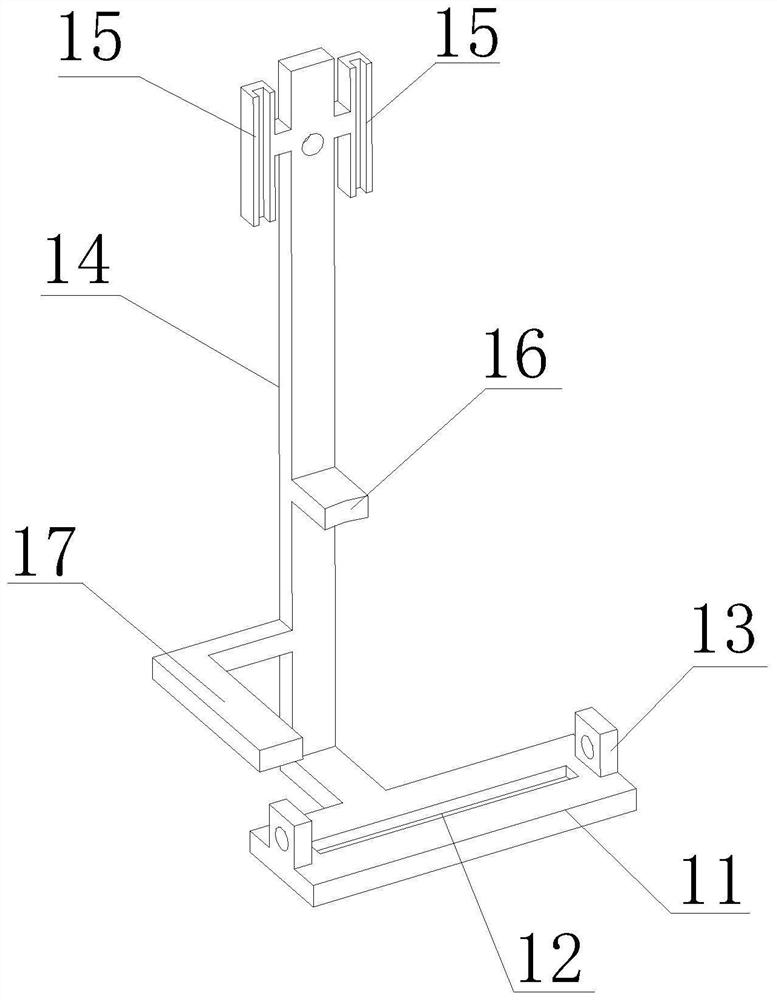

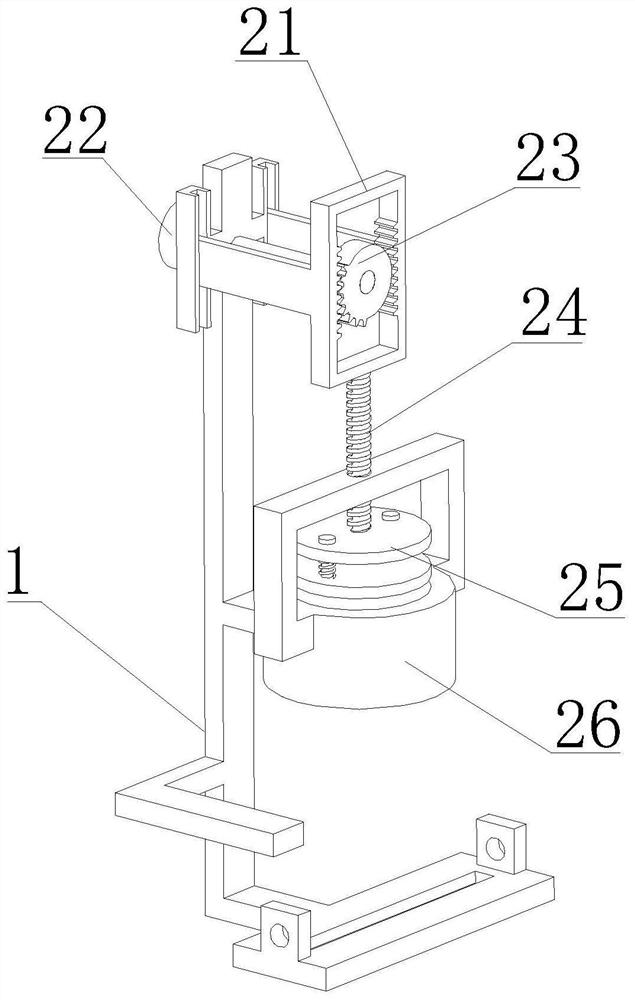

Food processing and crushing mechanism with high reliability

InactiveCN111921670AImprove reliabilityImprove stabilitySievingScreeningStructural engineeringMechanical engineering

Owner:陈飞

Corn particle crushing machine

InactiveCN109395842ASimple structureImprove crushing effectCocoaGrain treatmentsEngineeringMechanical engineering

Owner:闽清县金沙大龙湾生态养殖场有限公司

Preparation method of pure-butter and sugar-free dark chocolate with anti-oxidation and anti-aging effects

InactiveCN110012955AHas anti-maintenance and anti-aging functionsDelicate tasteCocoaNatural extract food ingredientsButter cocoaThermal insulation

The invention discloses a preparation method of pure-butter and sugar-free dark chocolate with anti-oxidation and anti-aging effects and relates to the technical field of chocolate production. The preparation method comprises the following steps: step 1, adding a cocoa butter material to a hydrogenation reactor, performing hydrogenation refining on the cocoa butter material, and finally, removinglight components by flash evaporation to obtain treated cocoa butter; step 2, adding the cocoa butter to a thermal insulation container to be molten; step 3, adding the molten cocoa butter to a refiner to be ground; step 4, transferring ground chocolate paste to a high-speed shear emulsifying machine to be concentrated under reduced pressure; step 5, transferring the sheared chocolate paste to a stirring device to be stirred; step 6, then pouring the chocolate paste into a mold, and performing cooling molding to prepare chocolate material blocks; and step 7, packaging and storing the chocolatematerial blocks. The preparation method can improve oxidation resistance by cooperation of all components and processes.

Owner:ANHUI LAYSEN FOOD CO LTD

Method and device for transferring thermoformed articles

Owner:AMUT SPA

Graphite producing particle grinding device

Owner:SICHUAN CHAOYING TECH CO LTD

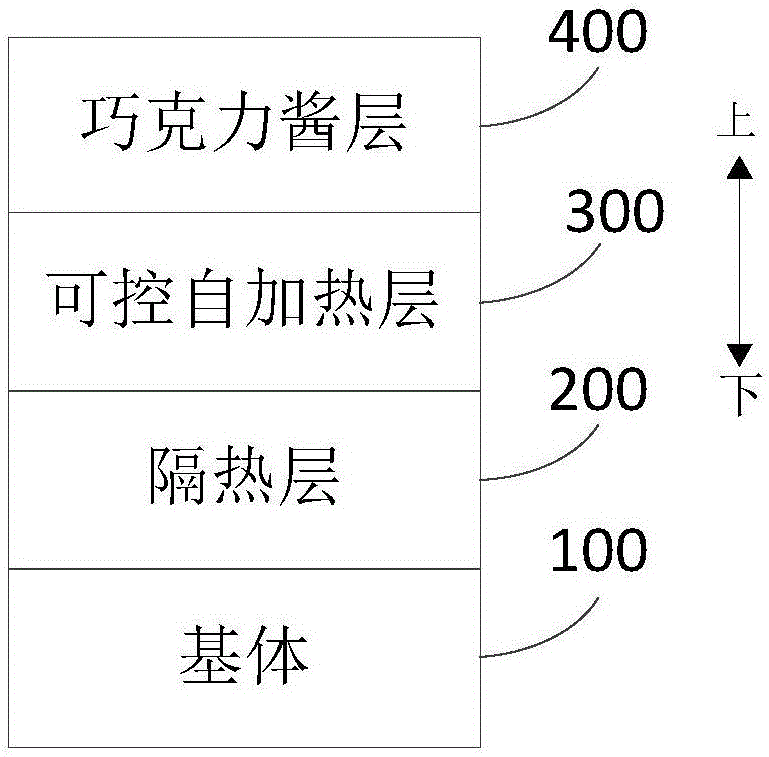

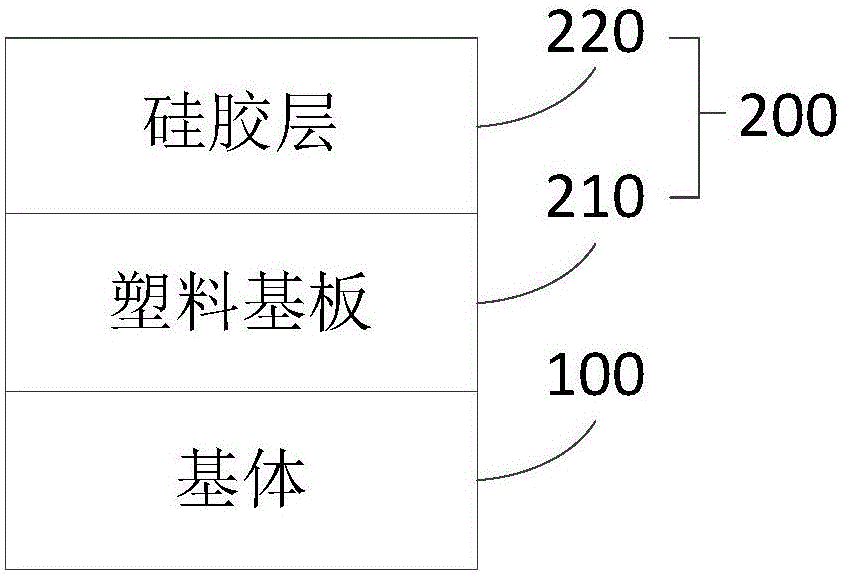

Frozen beverage and chocolate sauce

ActiveCN106260373AImprove the heating effectIncrease temperatureFrozen sweetsCocoaChocolate cakeThermal insulation

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Fat composition for low-trans fat, non-tempered chocolate and chocolate

InactiveUS20180352827A1Strong tasteImprove melting effectFatty acid esterificationCocoaButter cocoaHealth risk

Owner:FUJI OIL CO LTD

Special colloid mill for konjak processing

Owner:南宁市农业科学研究所

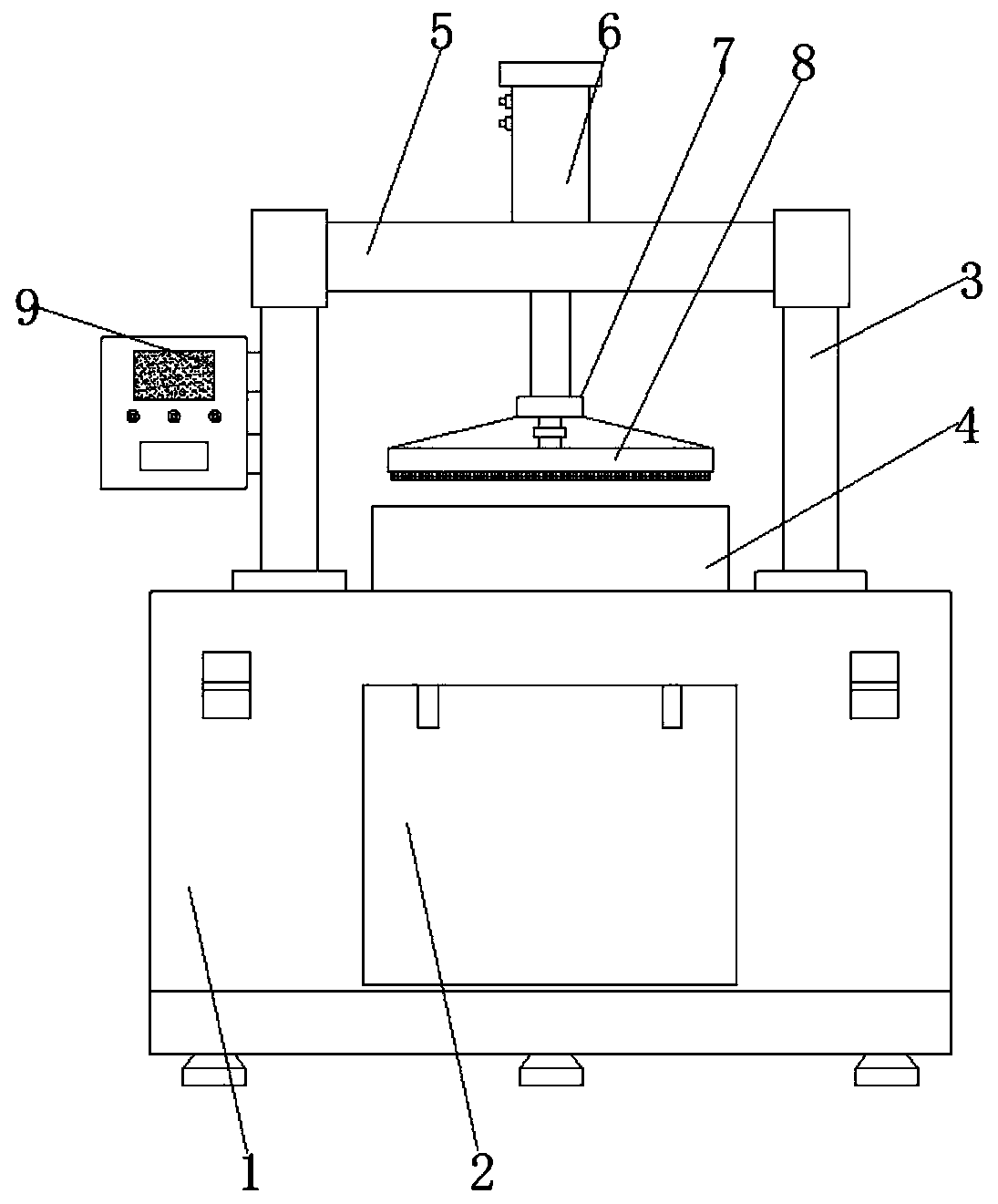

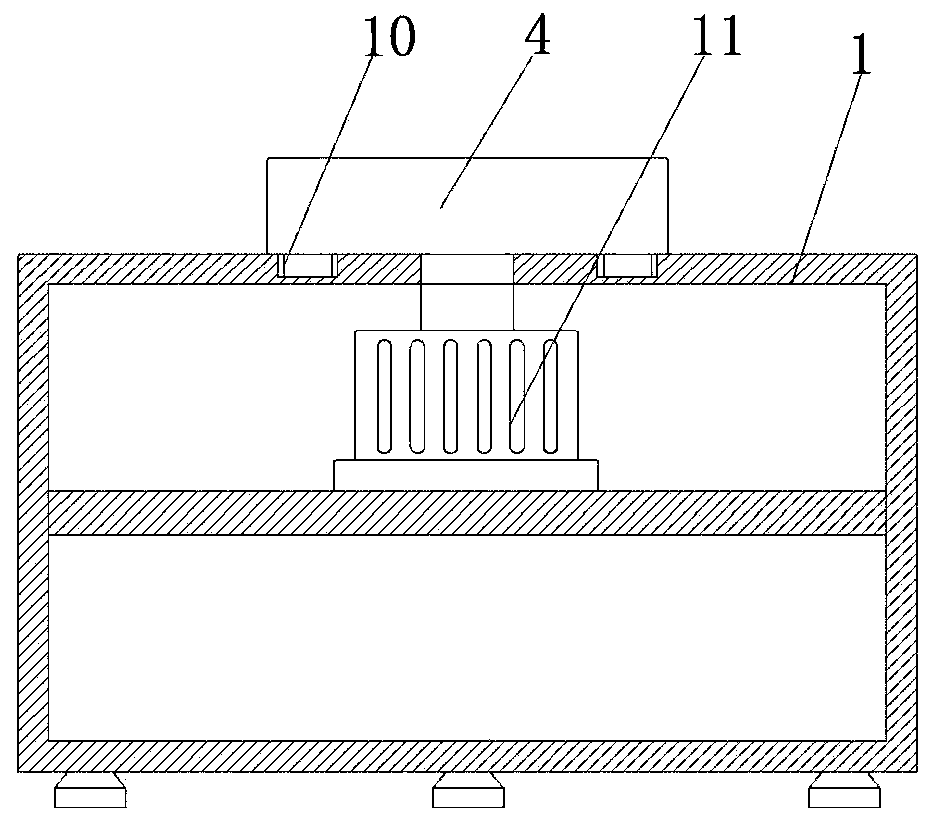

Compression Molding Machine and Method of Producing Molded Product

Owner:KIKUSUI SEISAKUSHO LTD

Medicinal material grinding machine capable of avoiding weakening of material grinding effect

Owner:湖南攀丰生物科技有限公司

Integrated type fertilizer processing platform

Owner:四川中农润泽生物科技有限公司

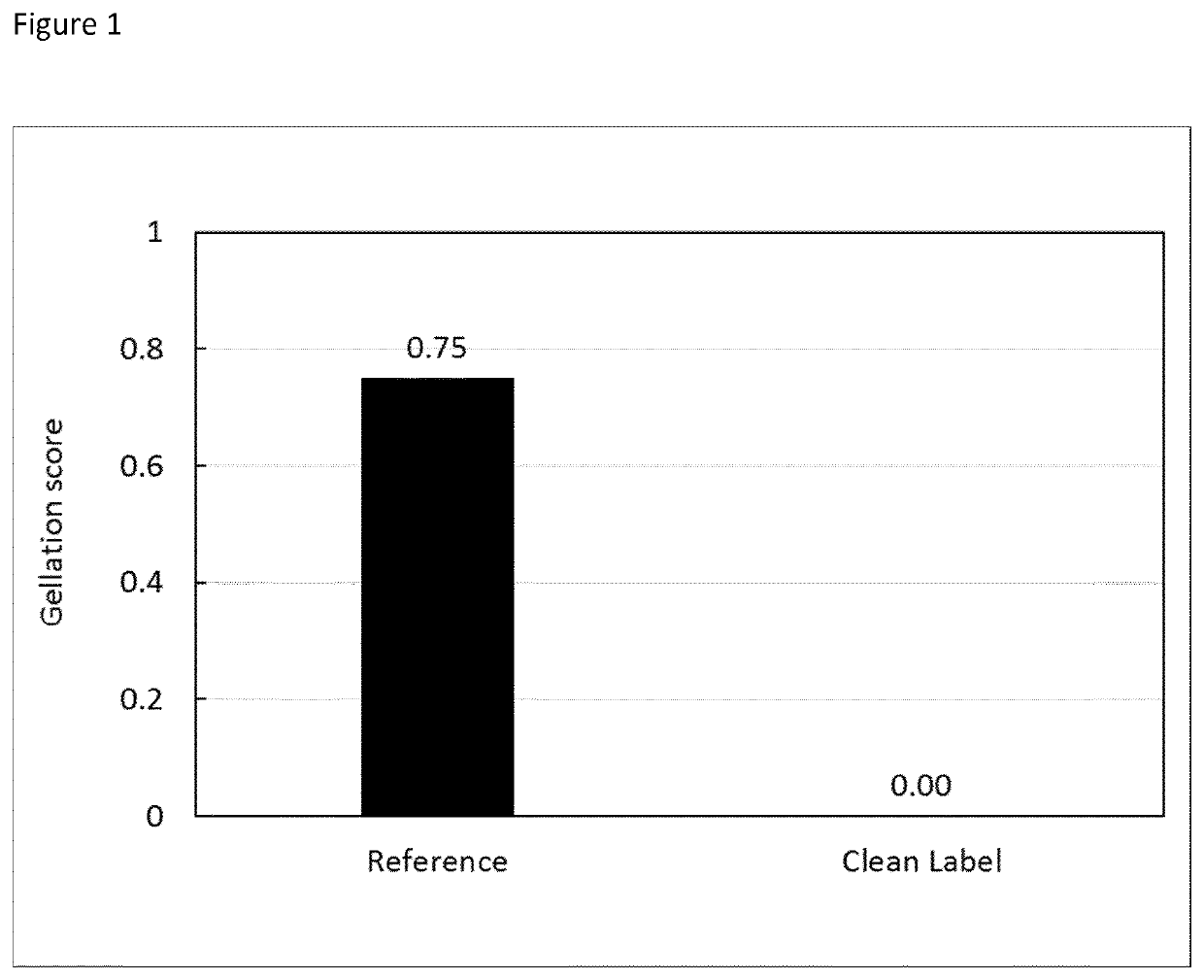

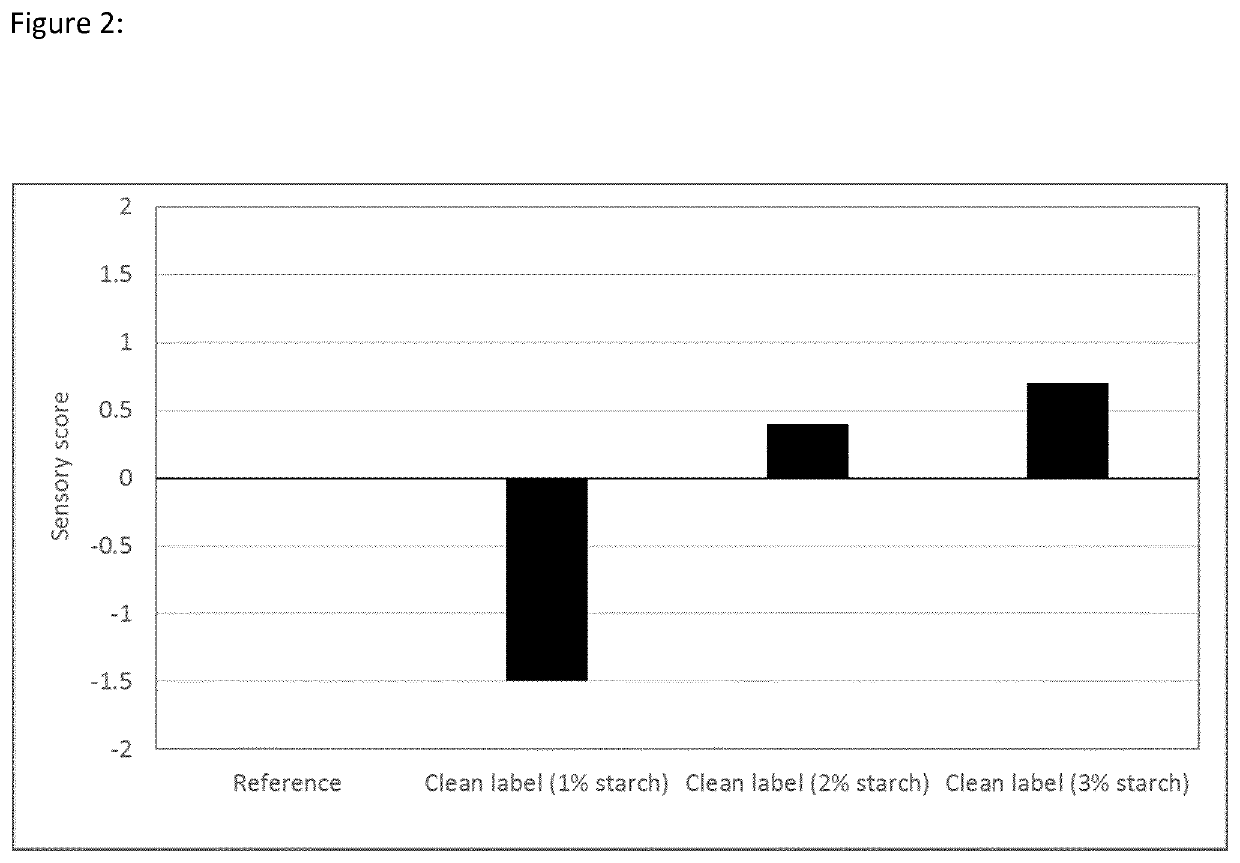

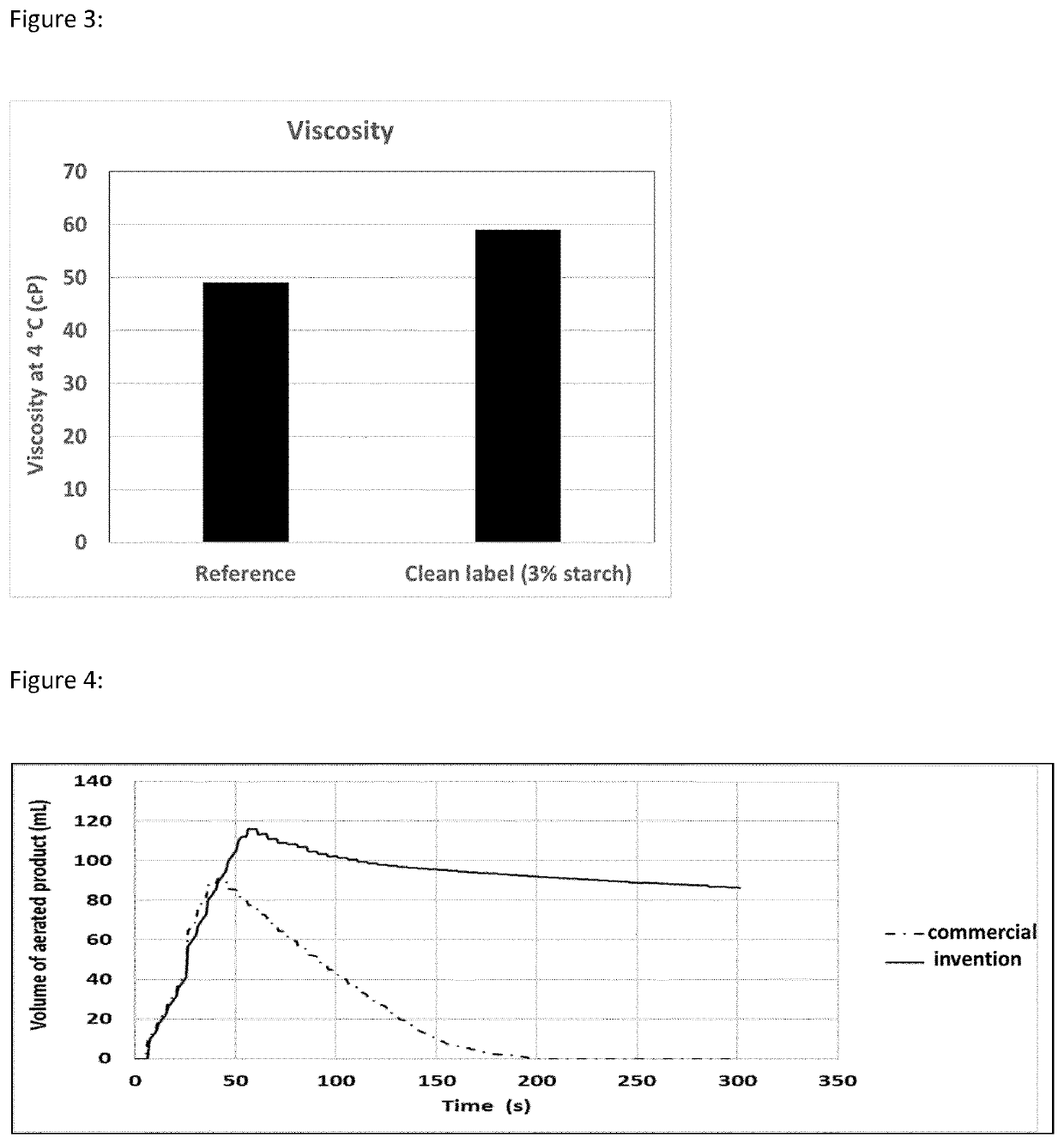

Aerated shelf-stable dairy-based ready-to-drink beverage

Owner:SOC DES PROD NESTLE SA

Edible mushroom powder preparing system

Owner:罗源县起步镇农业服务中心

Accurate grinding device for kaolin production

InactiveCN112871308AImprove sufficiencyAvoid affecting useCocoaGrain treatmentsKaolin clayStructural engineering

Owner:高州市兆翔新材料有限公司

Frozen beverage with chocolate coated particles and preparation process thereof

The invention discloses a frozen beverage with chocolate coated particles and a preparation process thereof. The preparation process comprises the steps that firstly, chocolate is coated on the surface of the frozen beverage to form chocolate crisps; and before chocolate crisps are dried, chocolate crisps are subjected to particle throwing and coating. The particle throwing speed of particle throwing and coating is controlled to be 2 to 8m / s, and the particle throwing direction of particle throwing and coating is obliquely above chocolate crisps, and sharp included angle between the particle throwing direction and chocolate crisps is 40 to 70 degrees. By controlling the particle throwing speed and the particle throwing direction, strong binding force between the particles and chocolate crisps can be ensured. The coverage rate of the particles coated in the frozen beverage with chocolate coated particles in chocolate crisps is improved. Tests show that the surface area of chocolate crisps covered by the particles in chocolate crisps exceeds more than 80% of the total surface area of chocolate crisps.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap