Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about "Screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

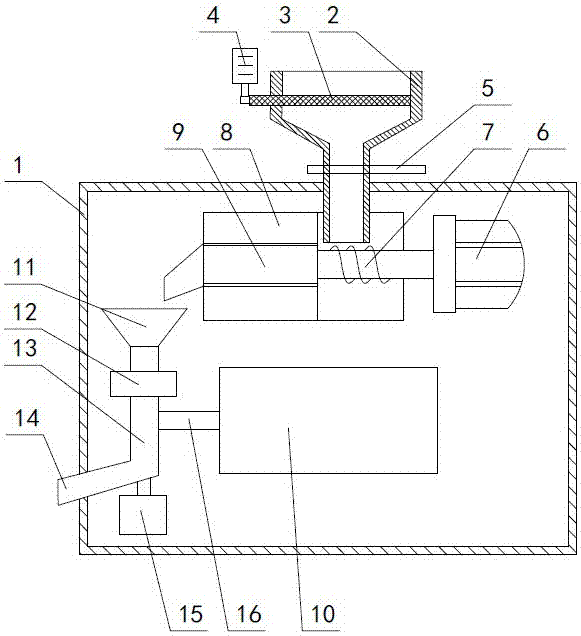

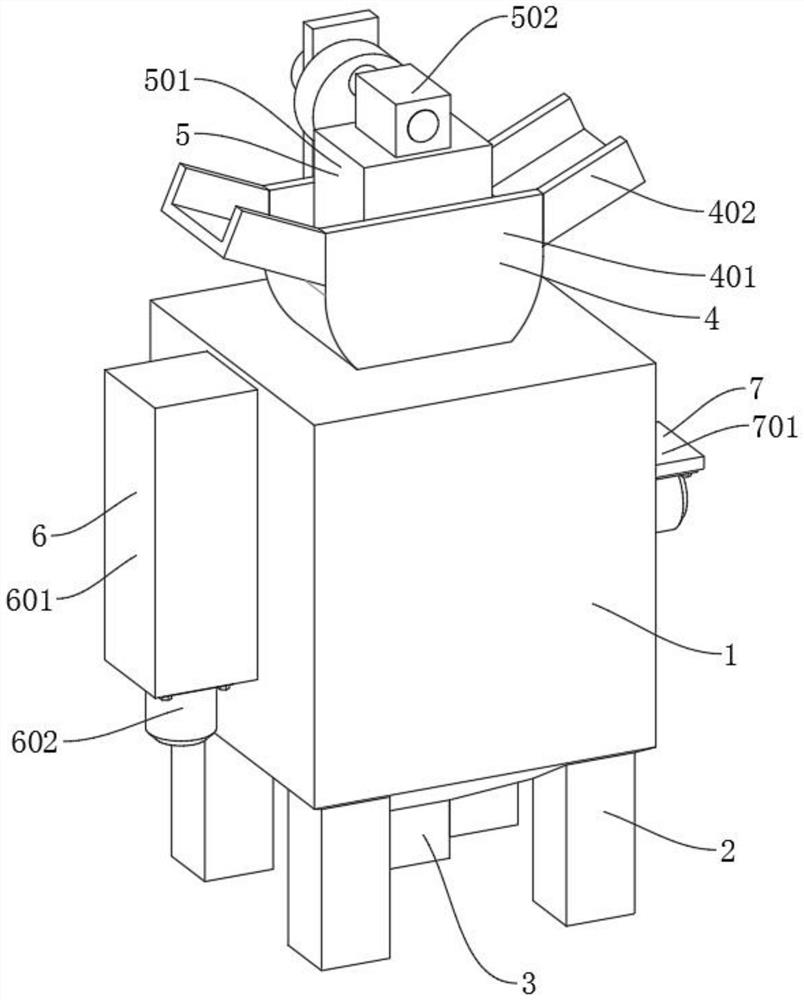

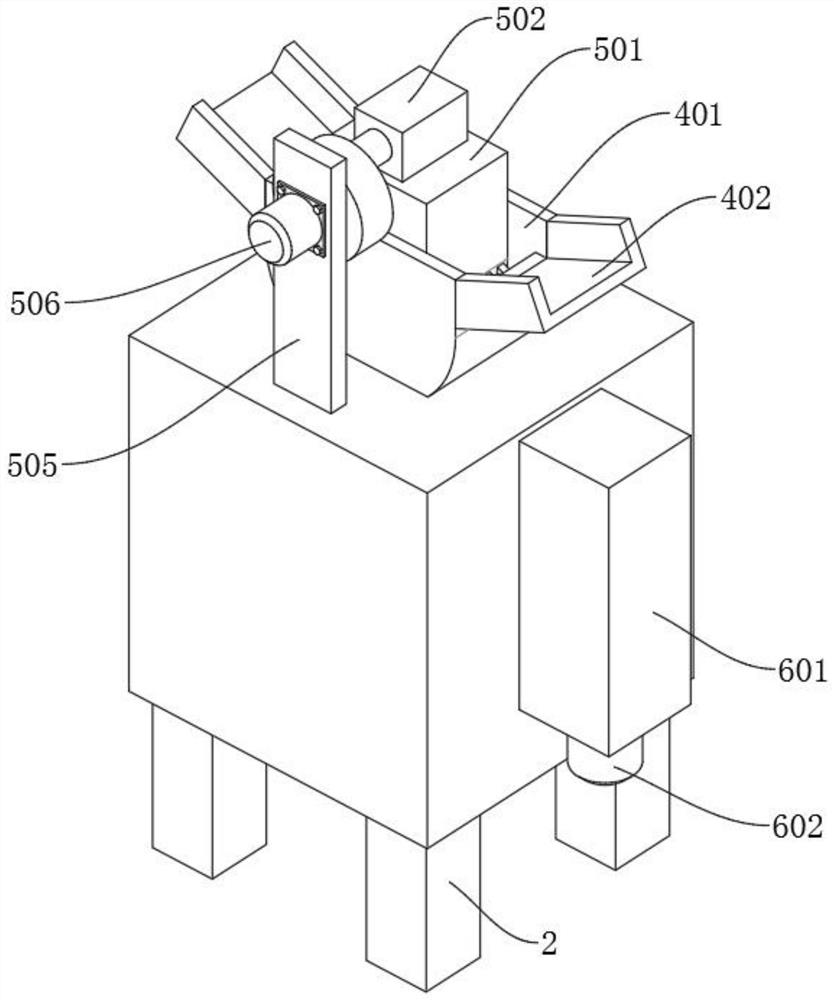

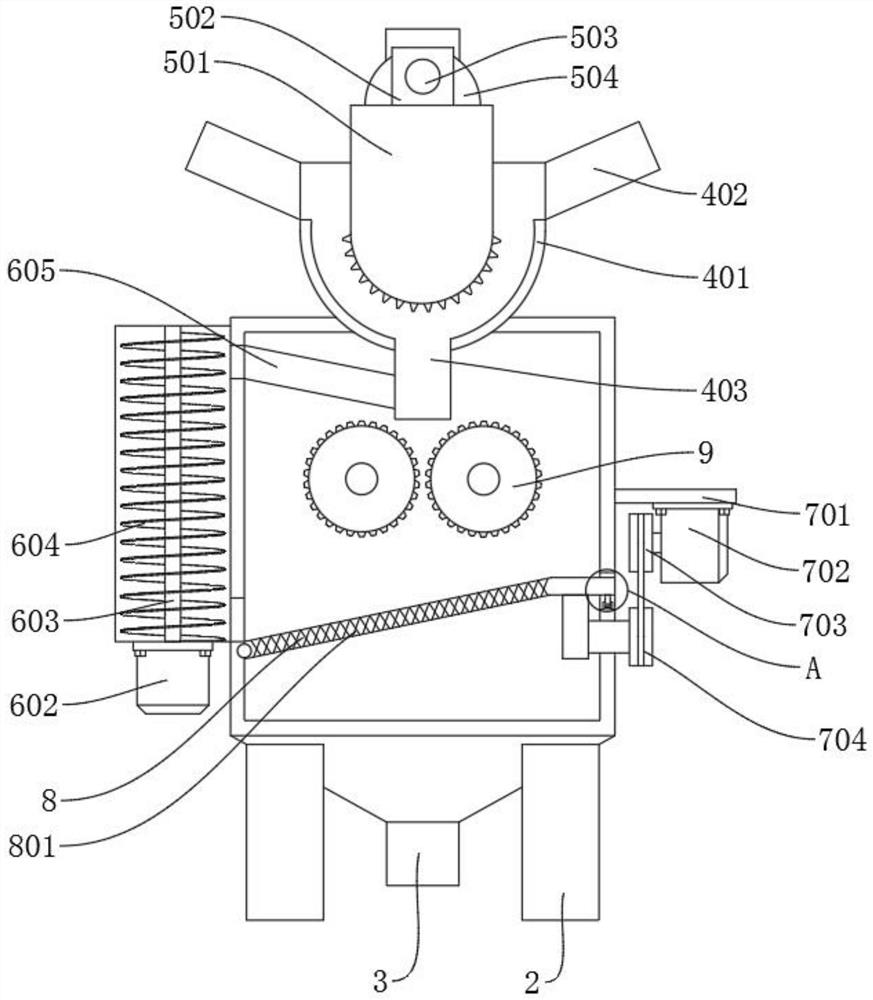

Sesame air-drying and screening integrated device

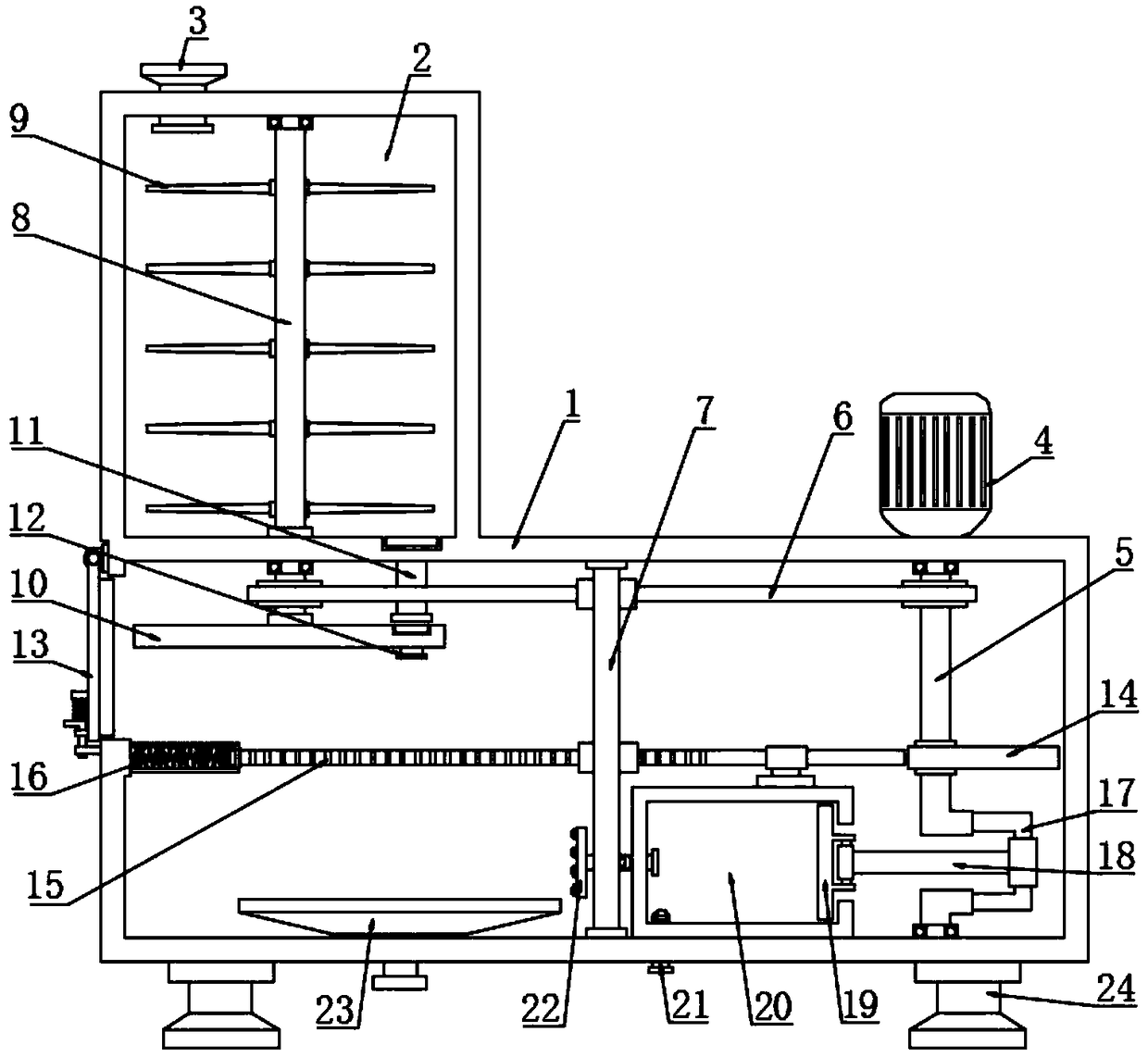

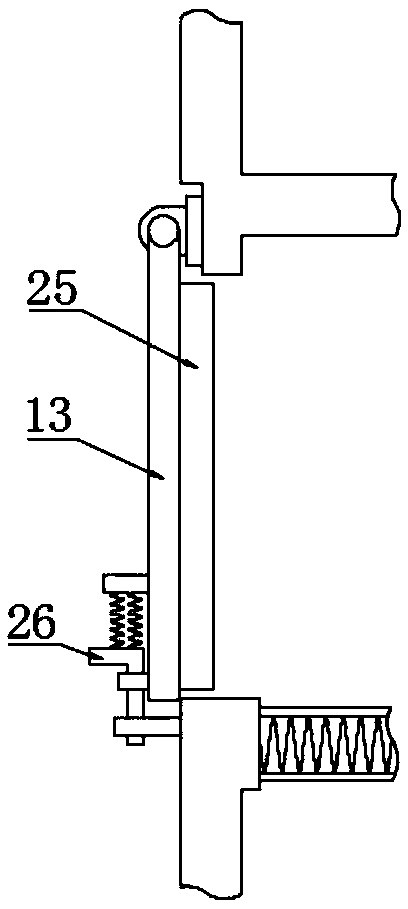

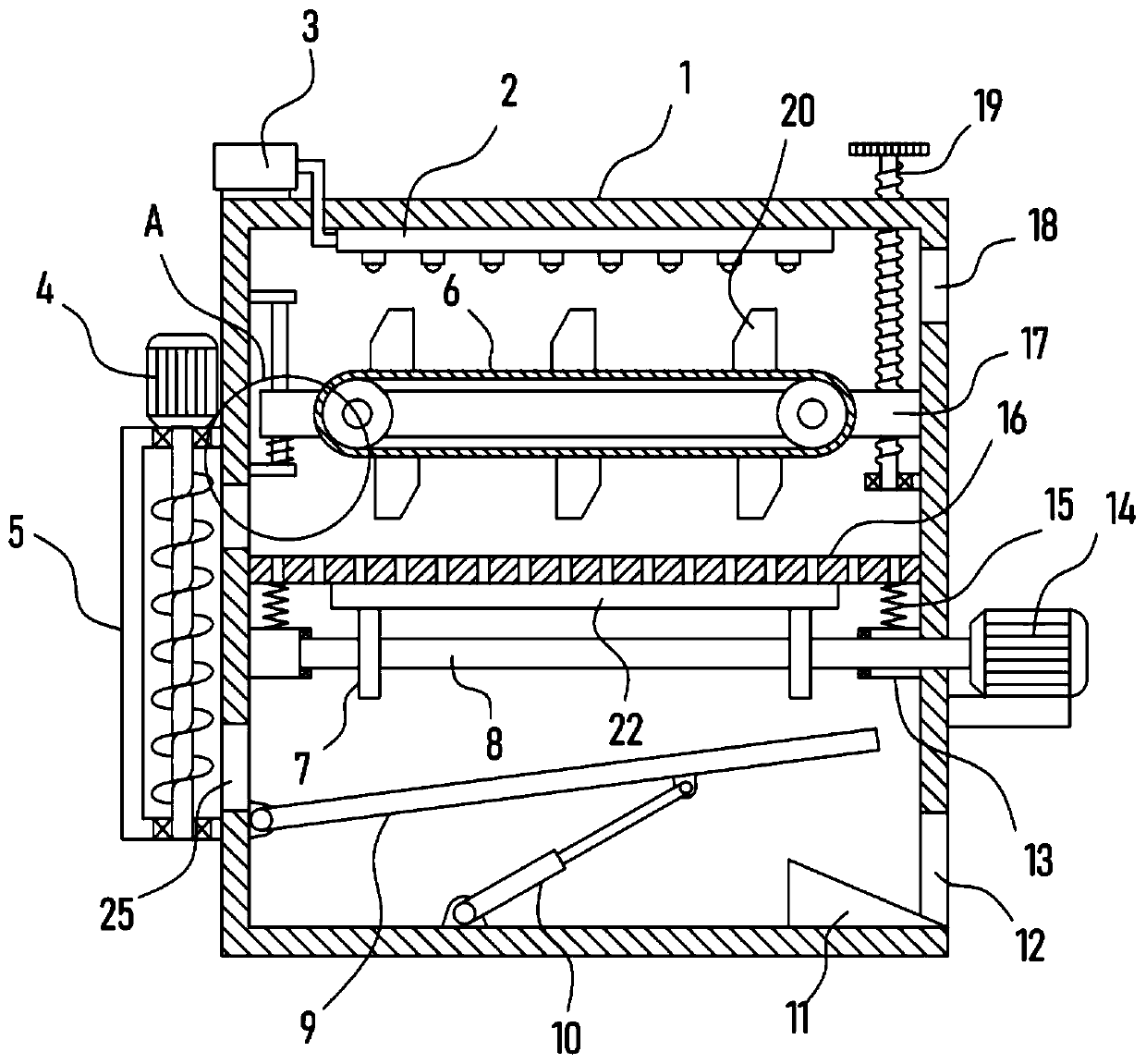

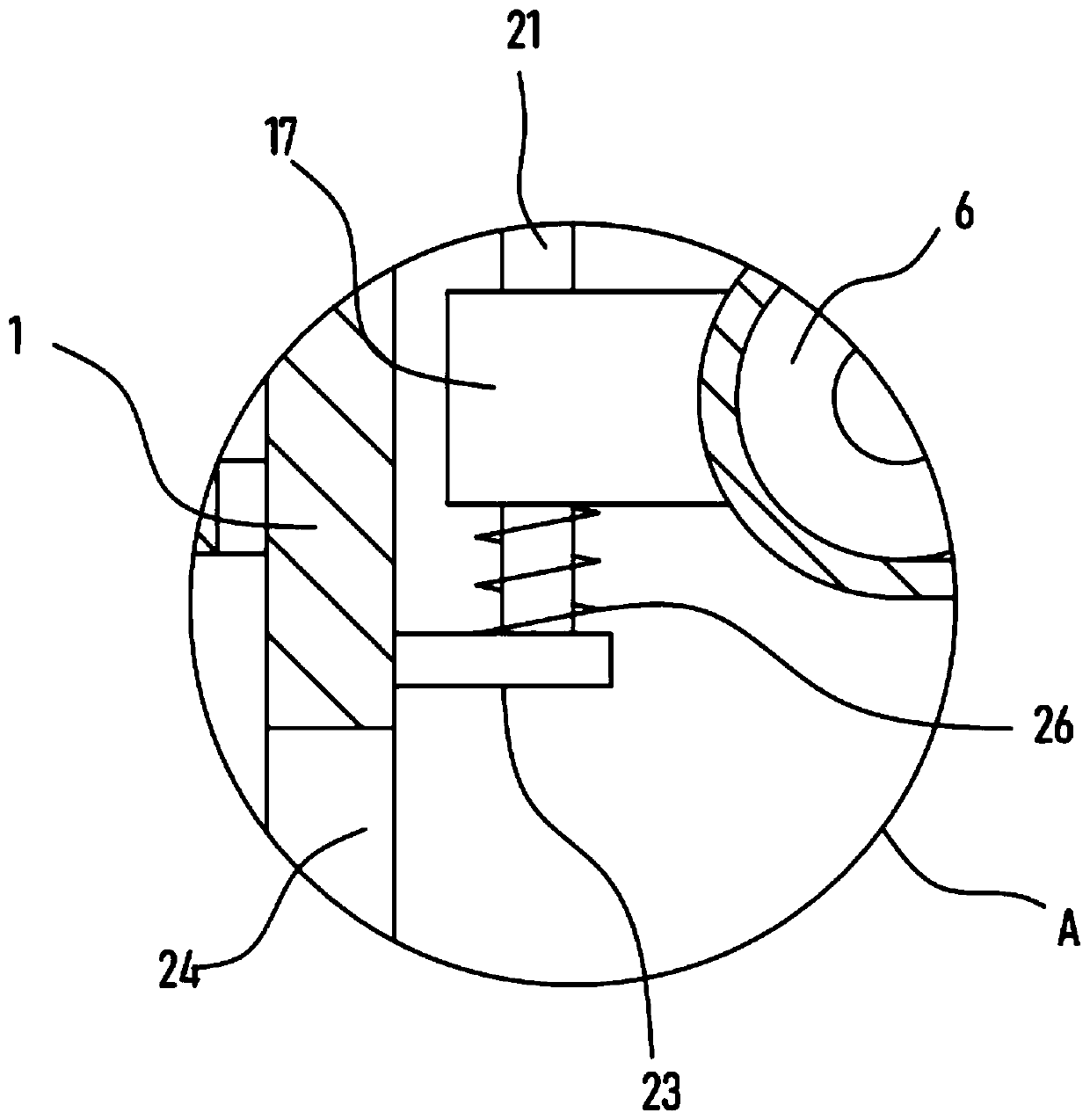

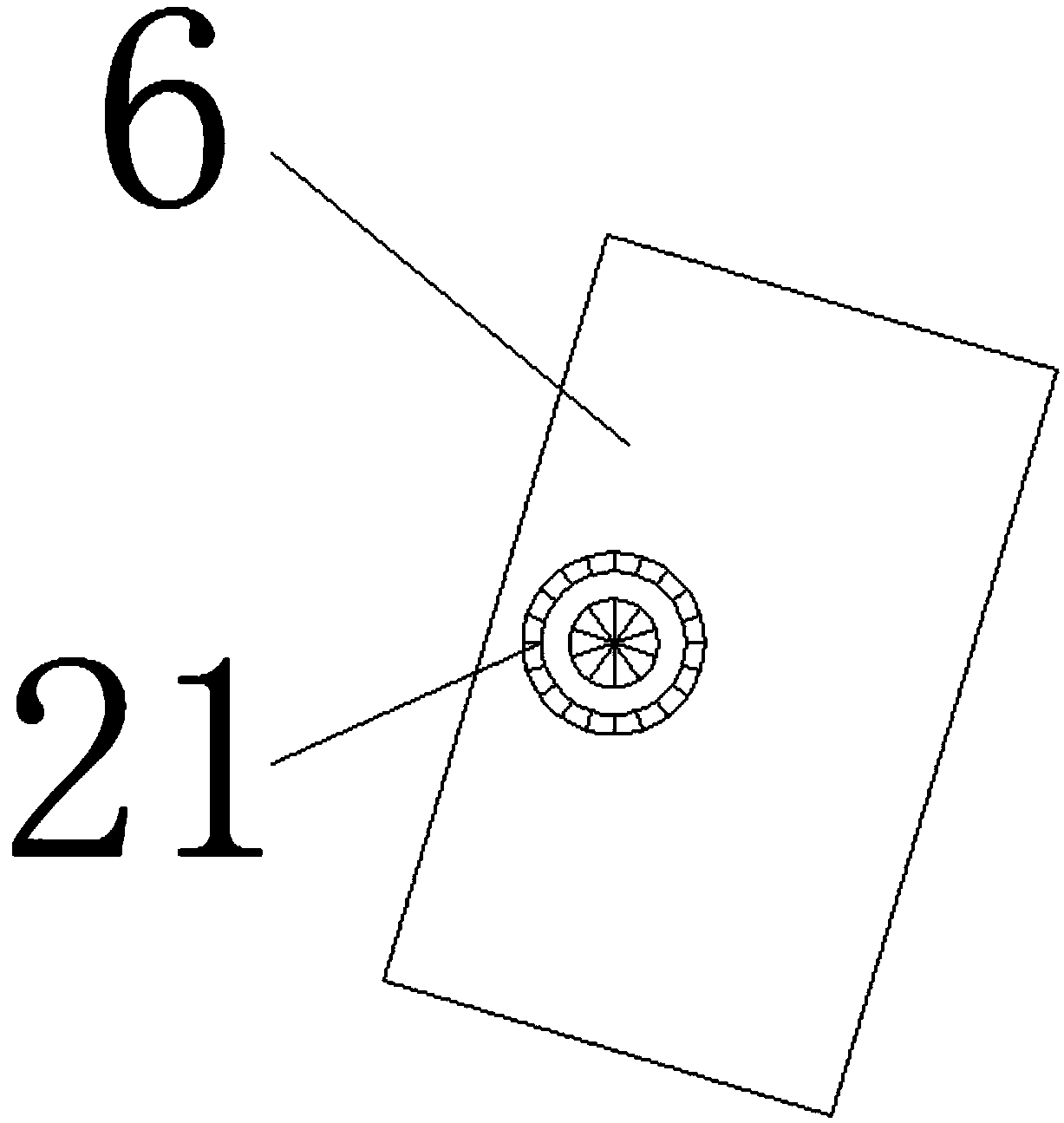

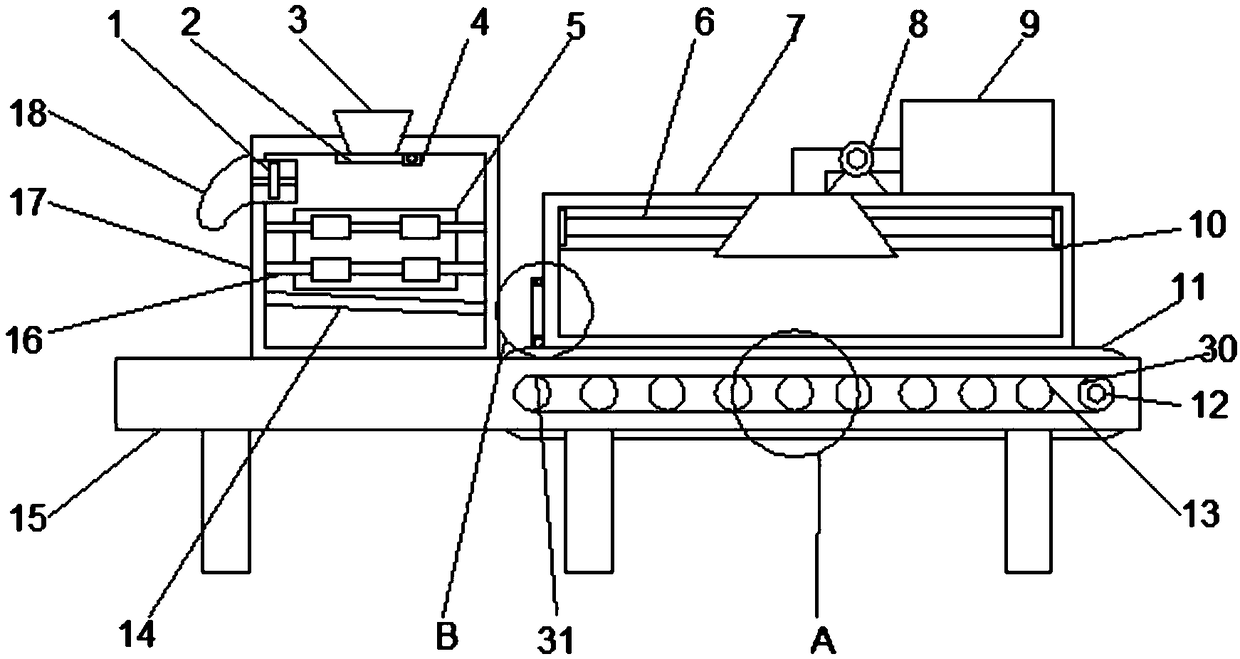

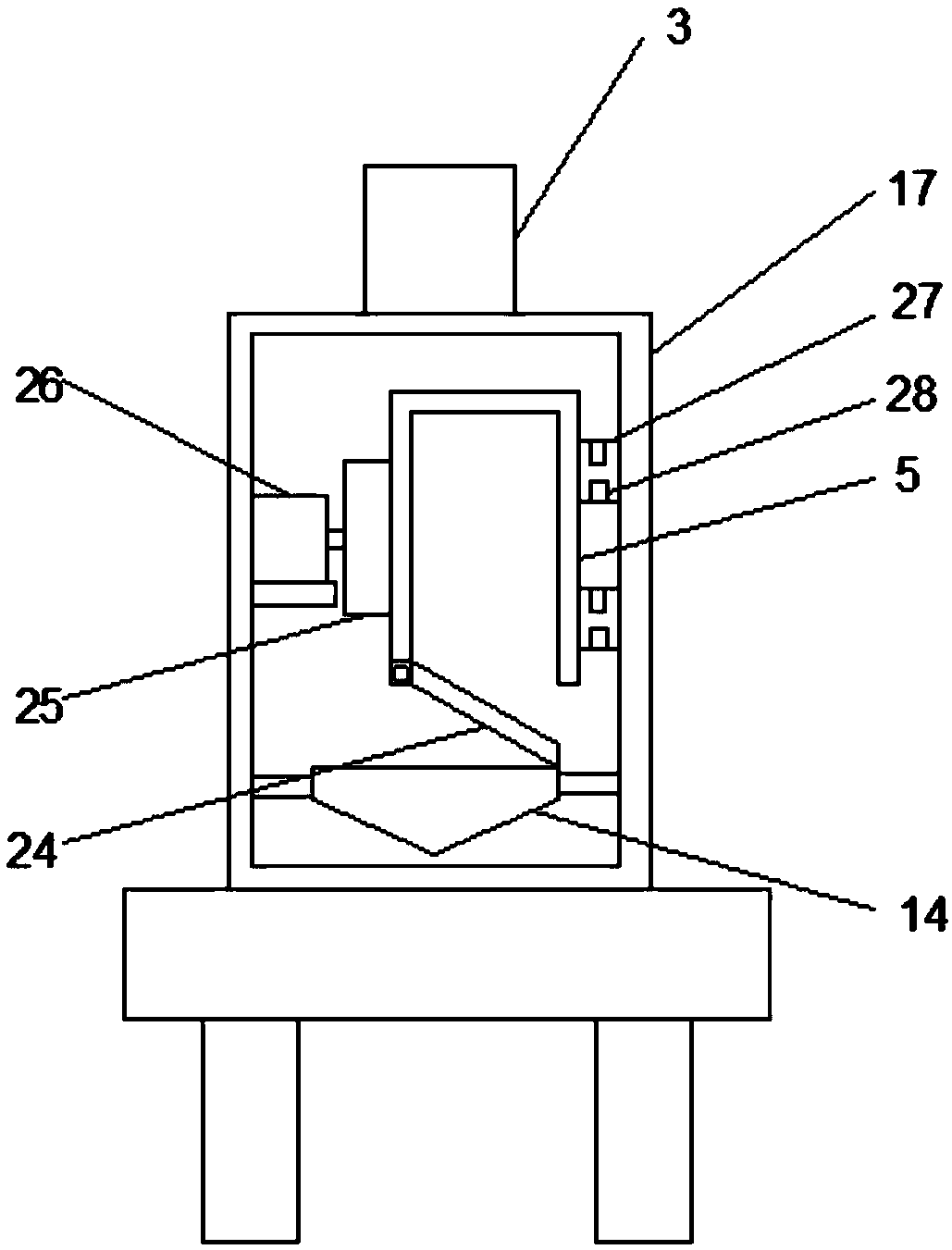

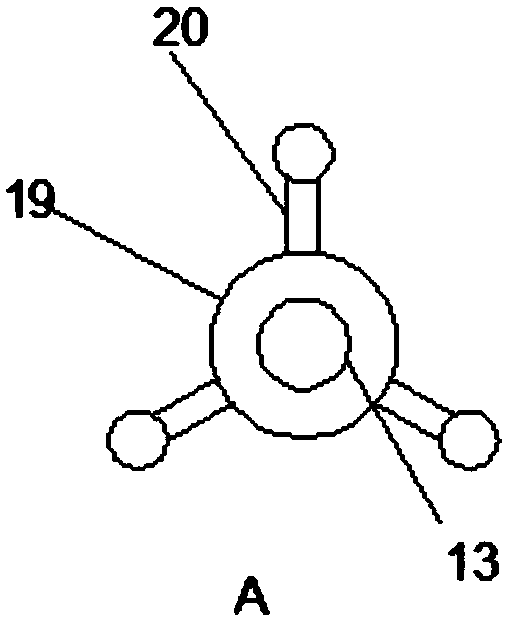

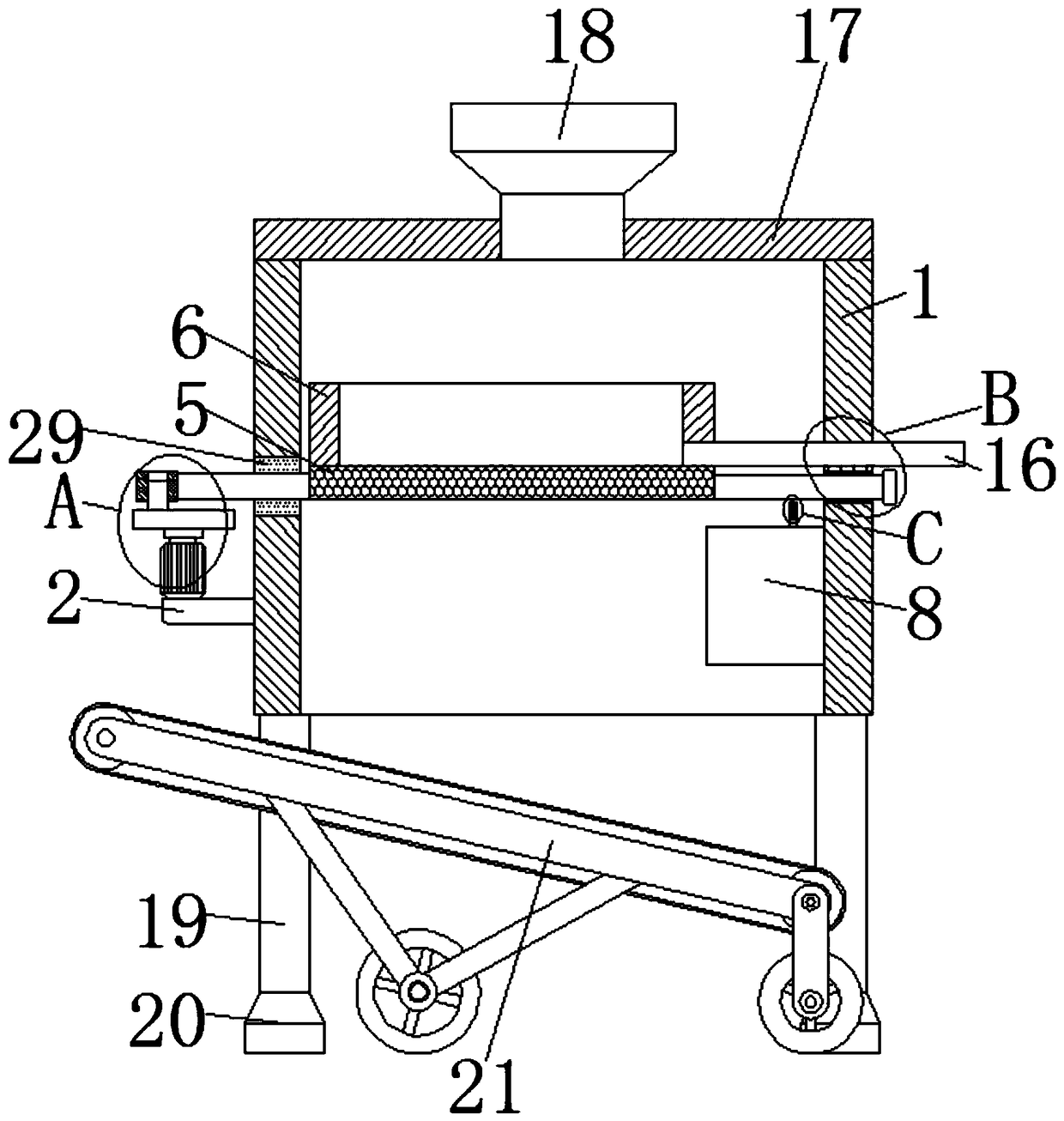

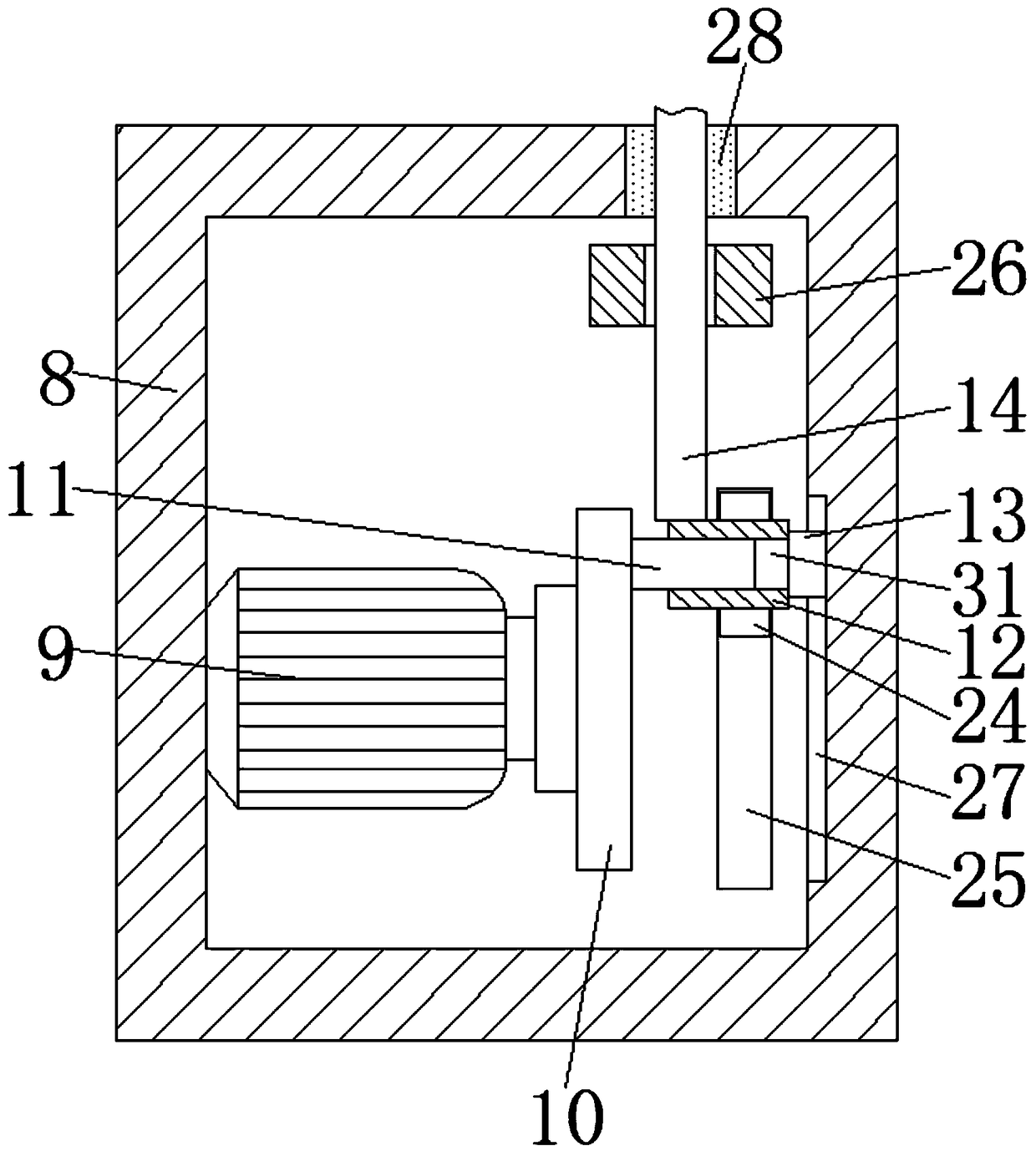

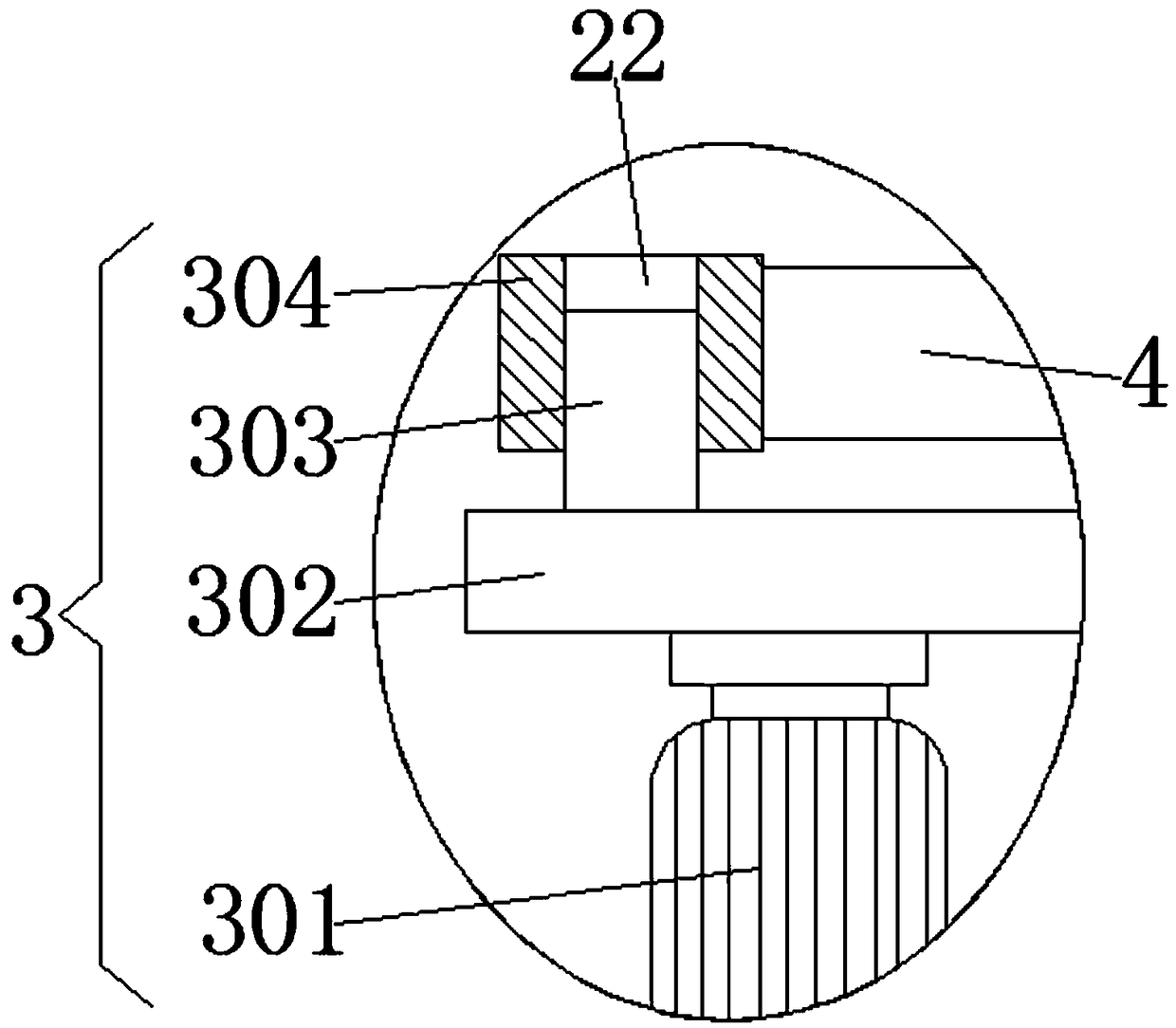

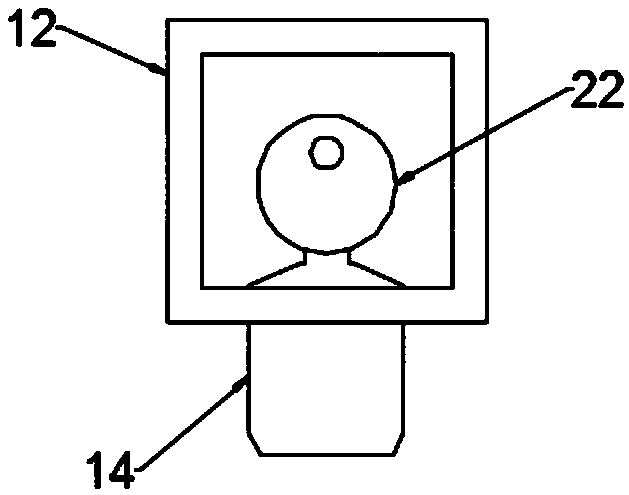

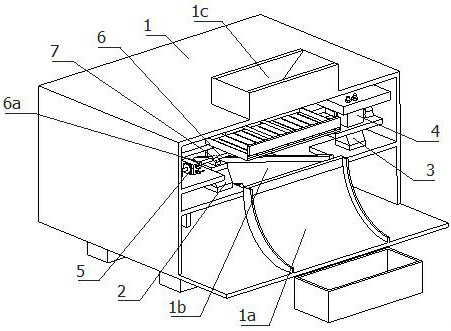

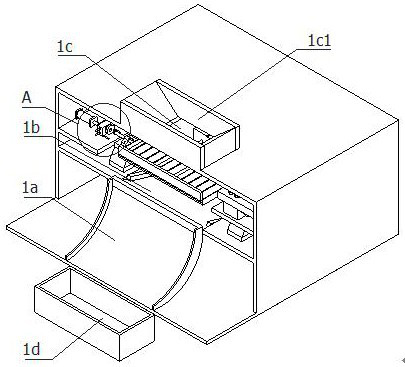

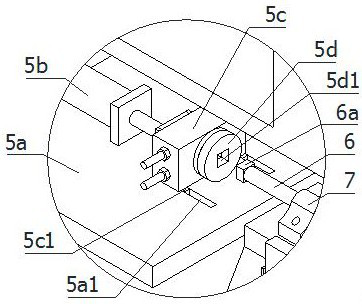

The invention discloses a sesame air-drying and screening integrated device. The upper portion of a driving shaft is in rolling connection with the right side of a synchronous belt. The middle of a device body is fixedly connected with a partition plate, and a through groove is formed in the upper portion of the partition plate. The left side of the synchronous belt is in rolling connection with the lower portion of a driven shaft, the upper end of the driven shaft is in bearing rotational connection with the upper wall of a storage barrel, and the lower end of the driven shaft is fixedly connected with a rotating disc. The bottom of the storage barrel communicates with a discharging pipe, the upper end of the discharging pipe communicates with the storage barrel, the lower end of the discharging pipe is attached to the upper surface of the rotating disc, and a through pipe is arranged at the edge of the rotating disc. A screening plate is arranged on the lower portion of the rotatingdisc, and the left side of the screening plate is sleeved with a sleeving plate. According to the sesame air-drying and screening integrated device, the driving shaft and the synchronous belt rotate to drive the driven shaft to rotate, the driven shaft drives the rotating disc and the through pipe to rotate to communicate with the storage barrel in a reciprocating mode, and thus the intermittent material falling function is achieved; and a cam drives the screening plate to move leftwards and rightwards in a reciprocating mode under the action of the sleeving plate and a spring so as to screensesame, a piston plate moving leftwards and rightwards in a reciprocating mode enables air to be sucked into an air blowing cylinder continuously through an air inlet pipe and discharged from an air spraying head, and thus the sesame falling from the screening plate is blown and dried.

Owner:安徽道源食品有限公司

Self excited vibration type screen mesh cleaning device for vibrating screen

Owner:AURY TIANJIN IND TECH

Sand screening device for bridge construction

Owner:赣州市兴顺辉科技有限公司

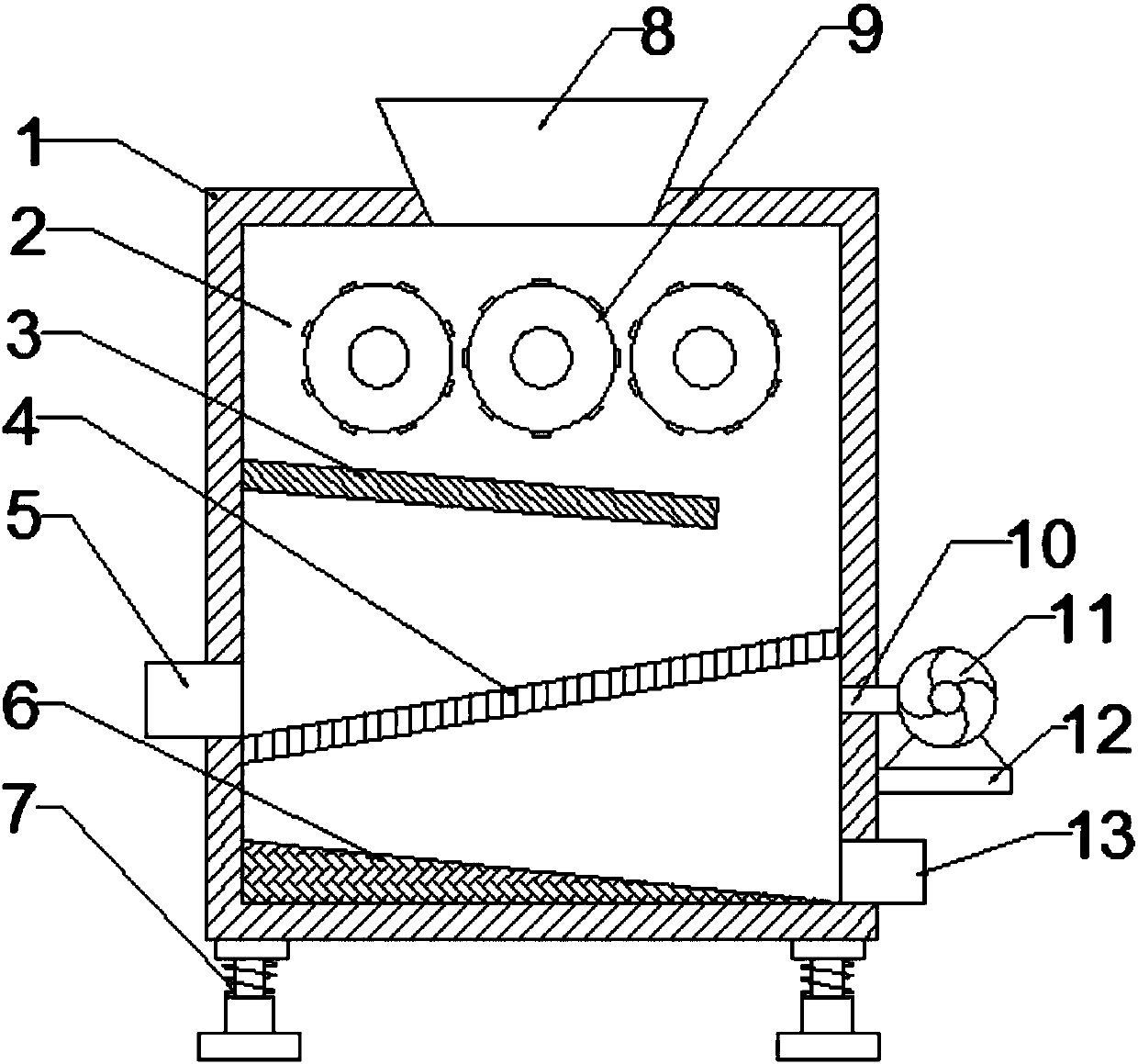

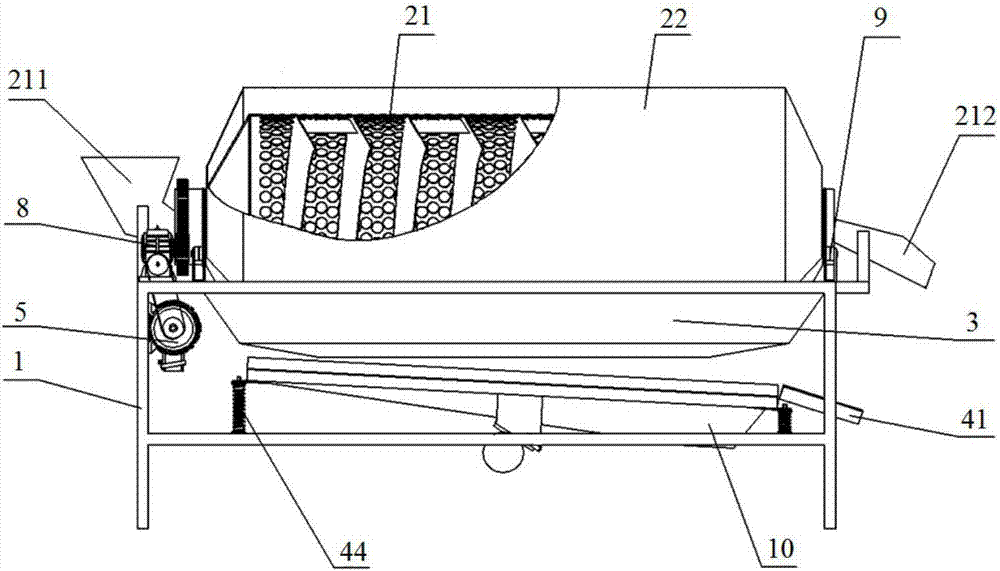

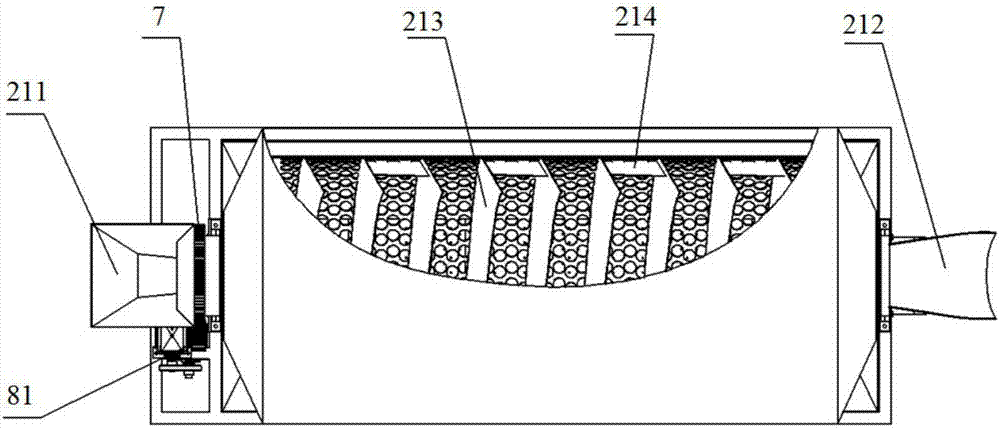

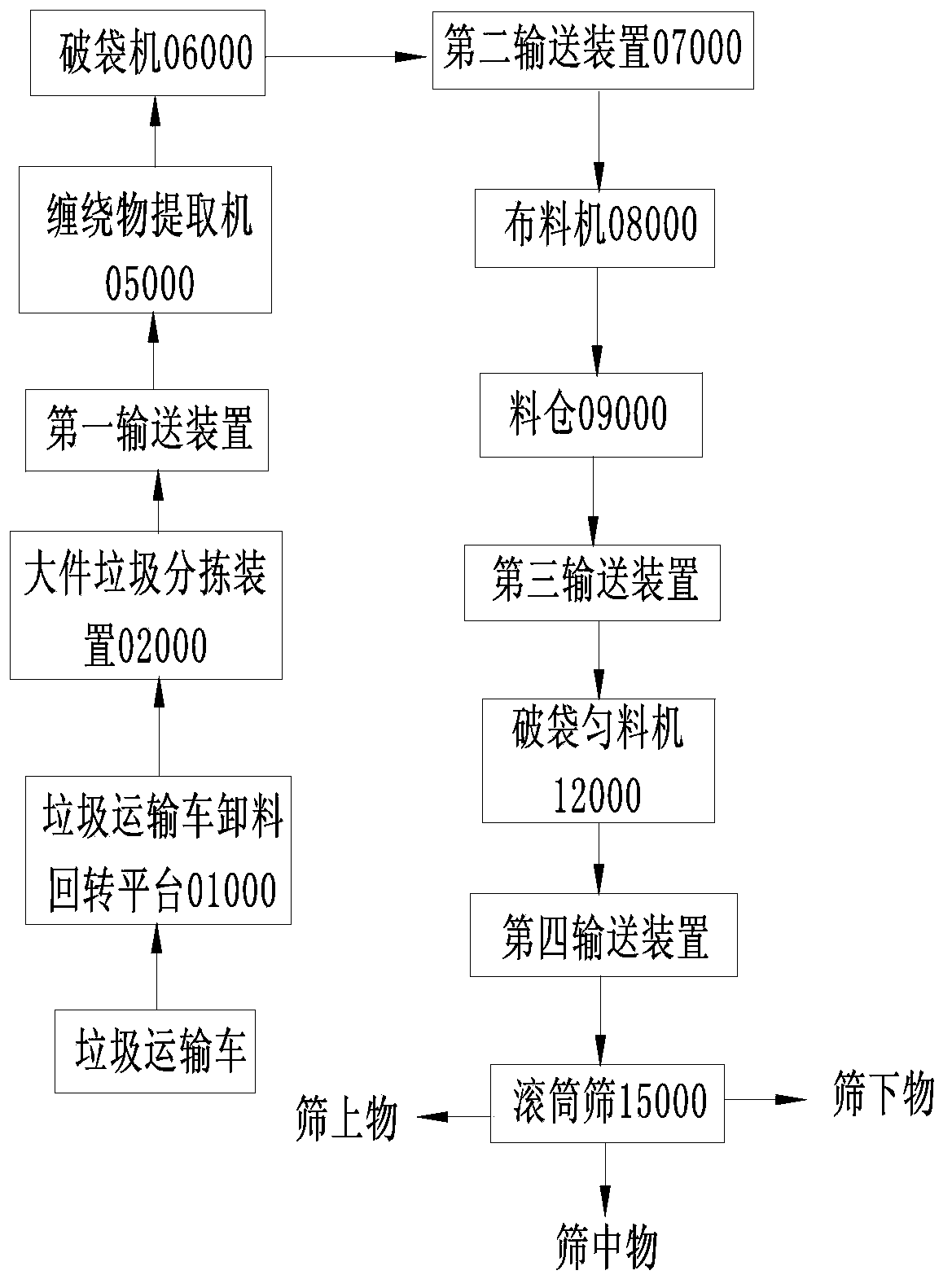

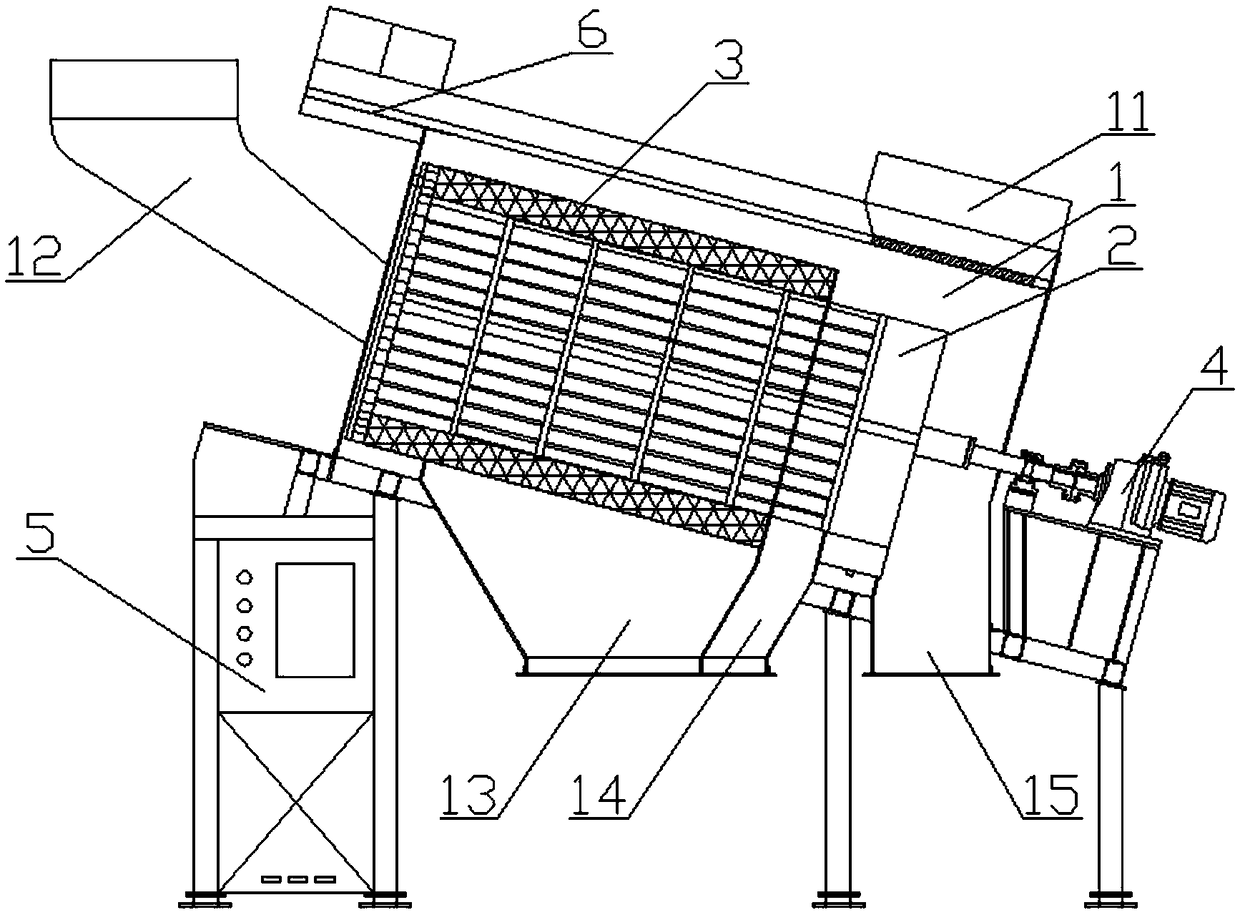

Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

InactiveCN104722494AAchieve separationRealize sortingSievingGas current separationMagnetic separatorEngineering

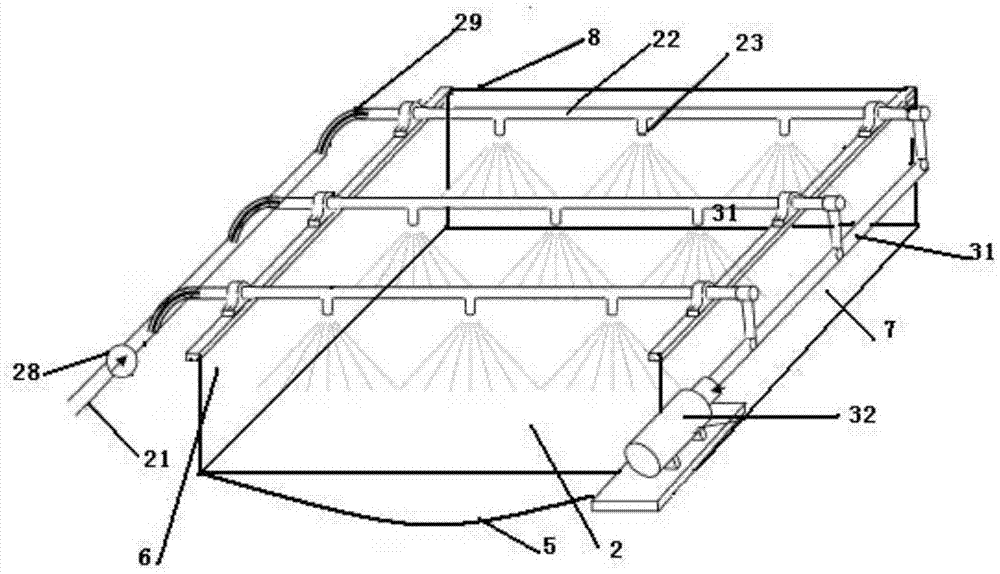

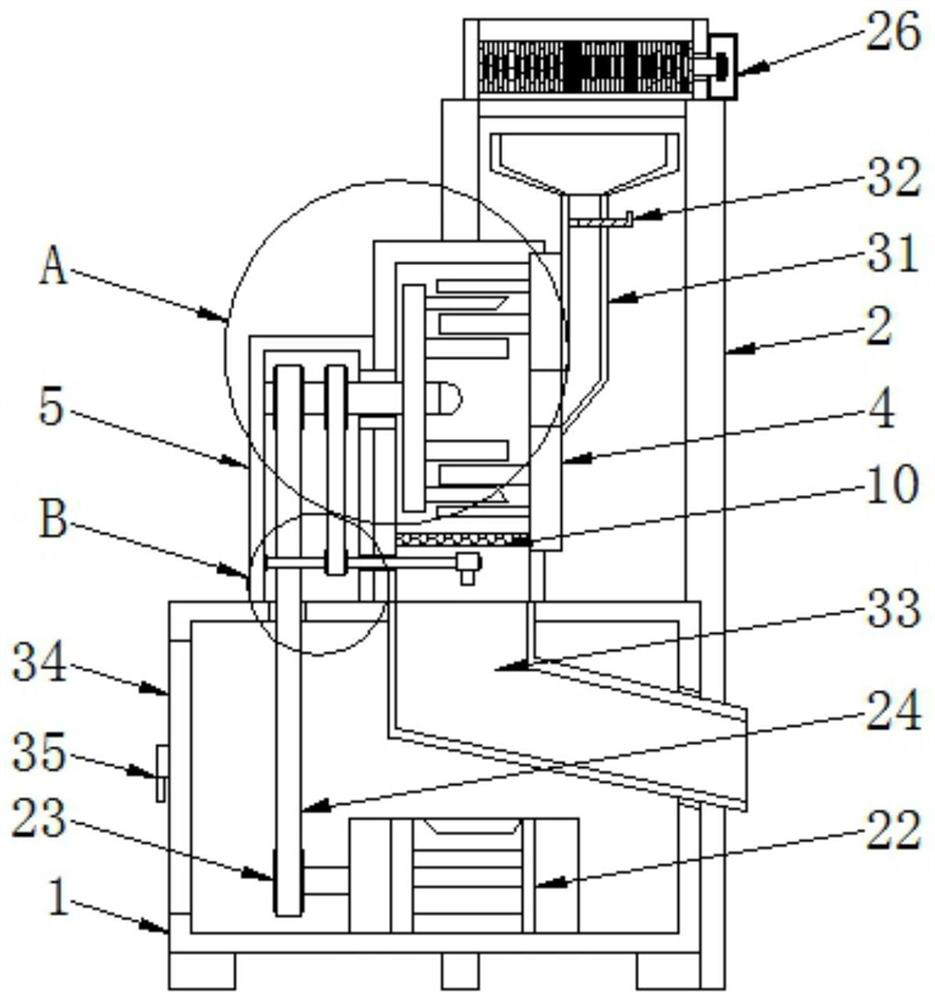

A comprehensive garbage sorting technology includes the steps of garbage grinding, bag breaking, magnetic separation, primary winnowing, two-grade sorting in a rotary screen and secondary winnowing. A comprehensive garbage sorting machine comprises a plate-type feeder, a garbage grinding and bag breaking machine and a magnetic separator are mounted in a feeding section and a discharging section of the plate-type feeder respectively, a first winnower and a first U-shaped belt conveyer are sequentially arranged below the discharging end of the plate-type feeder, the rotary screen comprising a first screening section and a second screening section is arranged at the rear end of the plate-type feeder, a first discharging hopper and a second discharging hopper are arranged below the first screening section and the second screening section of the rotary screen respectively, a second U-shaped belt conveyer and a third U-shaped belt conveyer are arranged below the two discharging hoppers respectively, a fourth U-shaped belt conveyer is arranged at the rear end of the rotary screen, and a second winnower is mounted below the discharging end of the rotary screen. The comprehensive garbage sorting technology and the comprehensive garbage sorting machine have the advantages that magnetic metal, building garbage, organic matters and the like in garbage can be sorted out step by step, thorough separation of various materials in household garbage is achieved, and recovery and utilization of useful materials are facilitated.

Owner:TIANJIN BAILI SUN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Peanut sheller for grain and oil processing

Owner:M & J MACHINERY ENGINEER

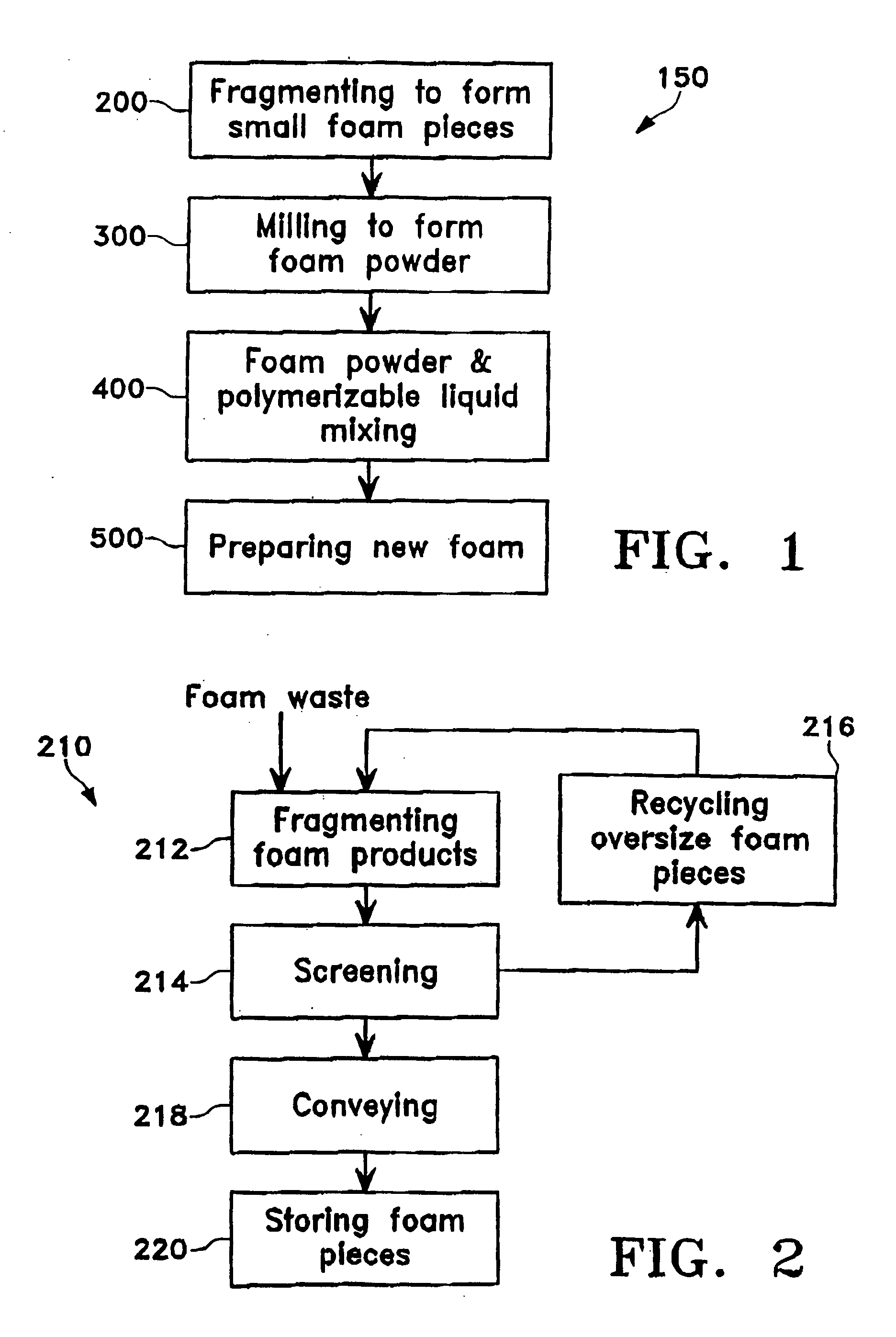

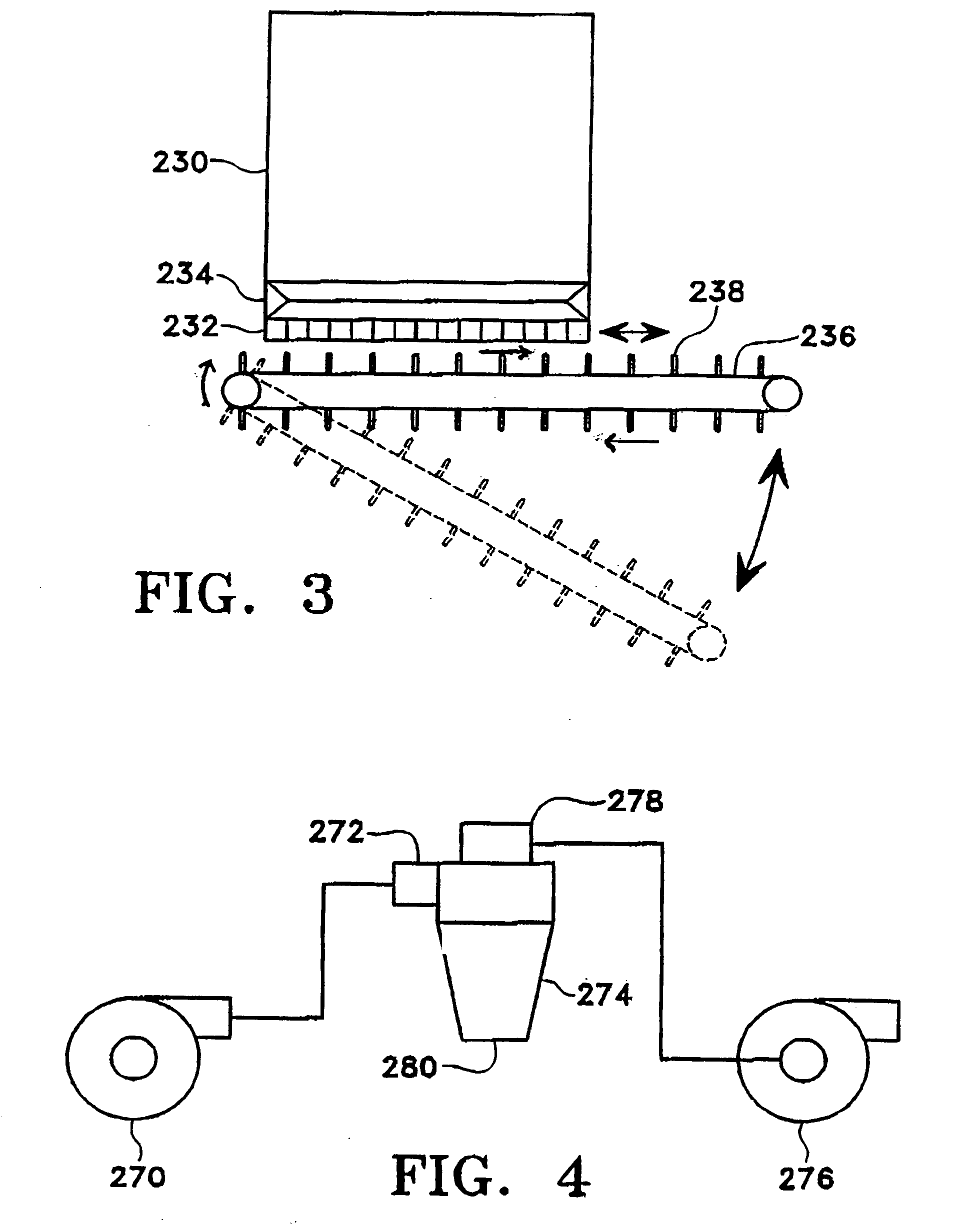

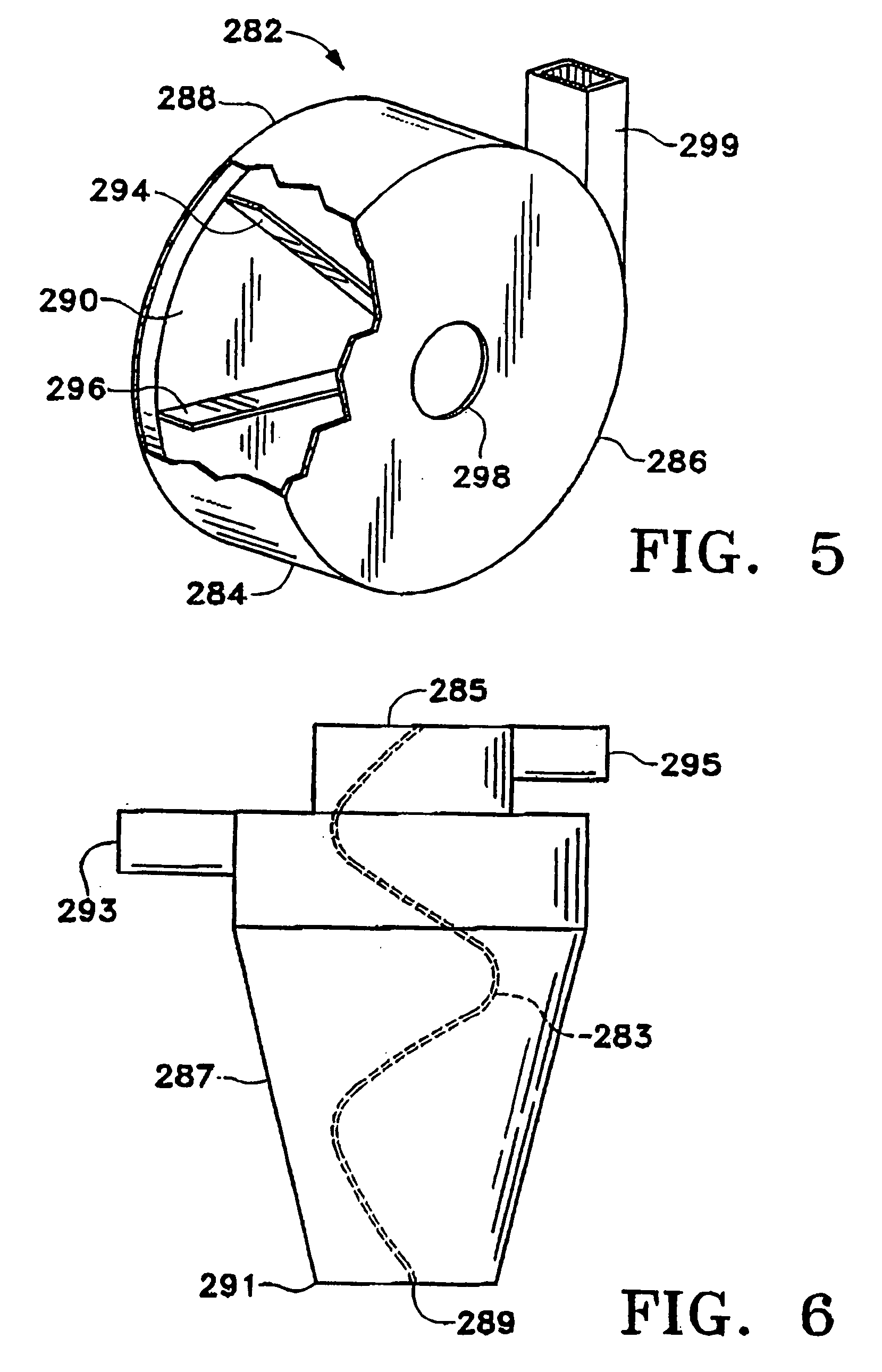

Polymeric foam powder processing techniques, foam powders products, and foams produced containing those foam powders

Owner:MOBIUS TECH

Building waste residue treatment device

InactiveCN111790477AAvoid damageImprove screening efficiencySievingScreeningWinding machineElectric machine

The invention discloses a building waste residue treatment device, and belongs to the technical field of building waste residue treatment tools. The building waste residue treatment device comprises ascreening device and a crushing device, wherein the screening device is arranged above the crushing device, the screening device is used for separating waste residues with different sizes, the crushing device is prevented from being damaged due to the fact that part of waste residues are too large in size and too hard, and the crushing device is used for crushing small waste residues; and the screening device comprises a screening shell, a screening net, a steel wire, a winding machine, a winding motor, a left side plate and a right side plate, after the screening net screens small waste residues in the waste residues, the winding machine is driven to rotate through work of the winding motor, the steel wire is lengthened, and the screening net is driven to turn over downwards, large wasteresidues left on the screening net are discharged, a part of overlarge and hard building waste residues are prevented from damaging the crushing device to a certain extent, and the service life of the crushing device is prolonged.

Owner:过蕊

Concrete crushing and recycling device

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

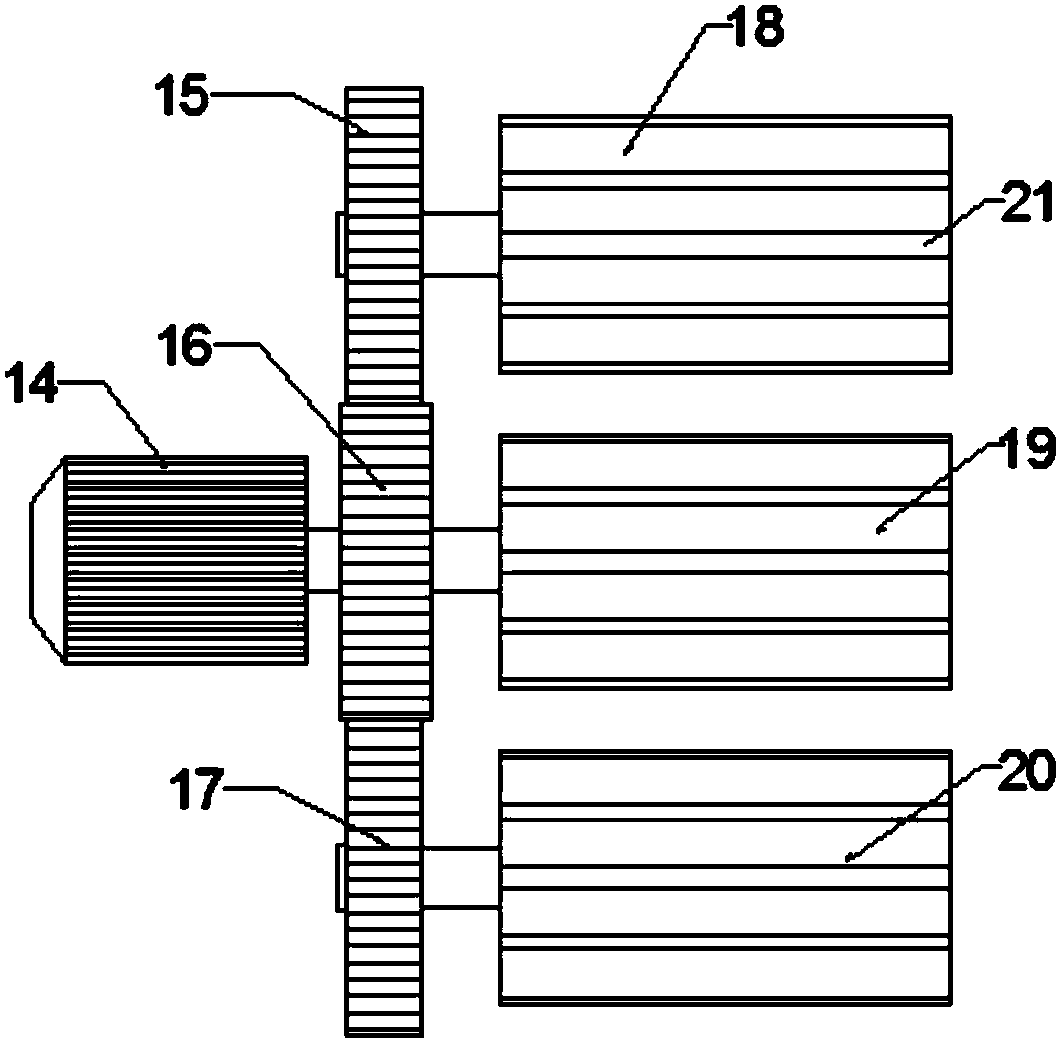

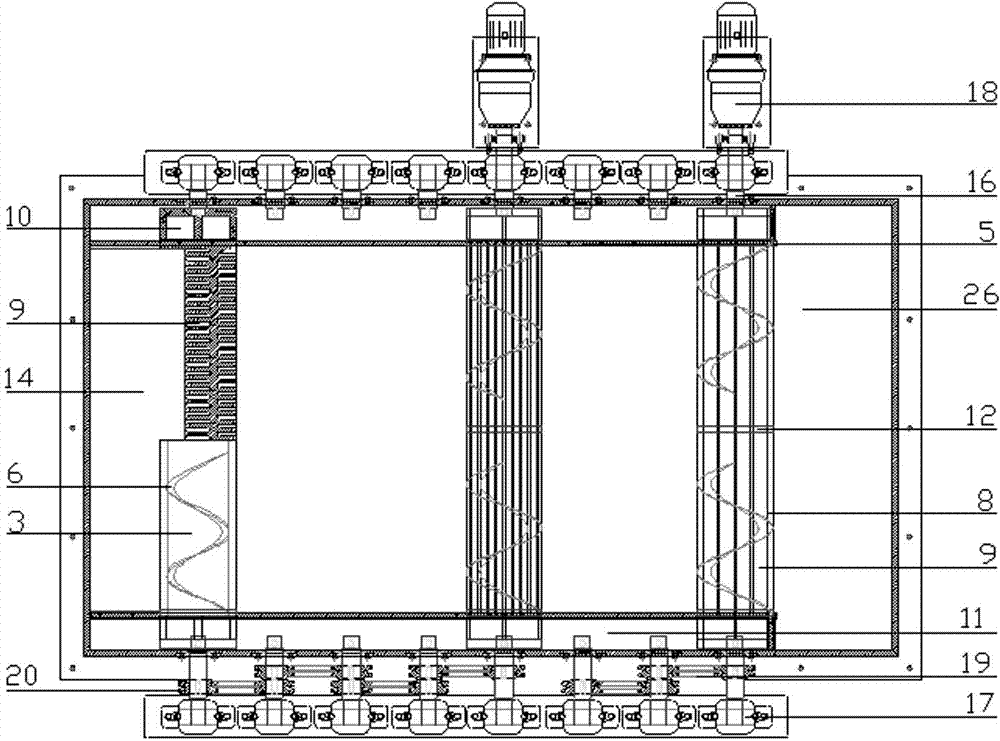

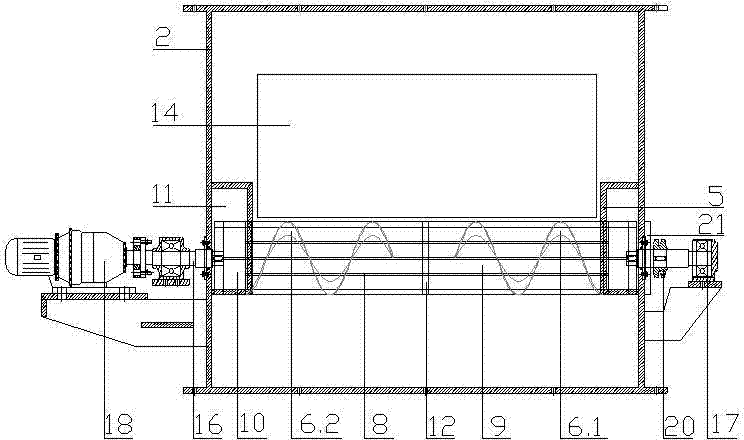

Coal classifying screen

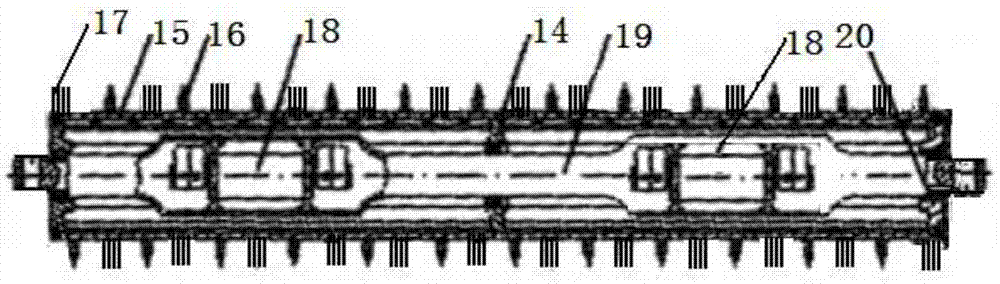

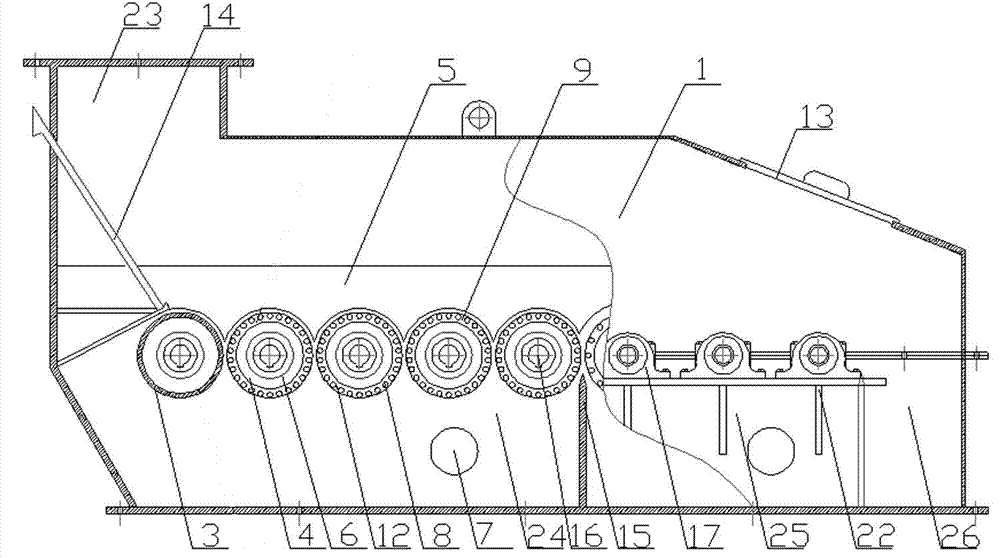

The invention discloses a coal classifying screen. A distribution plate (14) is arranged below a feeding port (23) in an inclined mode. The two ends of a roller screen shaft (3) are installed on the two sides of a case (2) through bearing pedestals (17) respectively, and the two ends of each screen bar screen shaft (4) are installed on the two sides of the case (2) through bearing pedestals (17) respectively. Spiral guide parts (6) are arranged in the roller screen shaft (3) and the screen bar screen shafts (4) respectively and composed of forward spiral guide parts (6.1) and backward spiral guide parts (6.2), the forward spiral guide parts (6.1) are fixedly installed on one side inside the roller screen shaft (3) and one sides inside the screen bar screen shafts (4) respectively, and the backward spiral guide parts (6.2) are fixedly installed on the other side inside the roller screen shaft (3) and the other sides inside the screen bar screen shafts (4) respectively. Anti-blocking holes (10) are formed in the two ends of the roller screen shaft (3) respectively, and anti-blocking holes (10) are formed in the two ends of each screen bar screen shaft (4) respectively. The coal classifying screen is uniform in distribution and high in impact resistance, a screen surface and the screen shafts are not blocked, the requirement for two or more particle sizes of discharged materials is met, and spare parts are convenient to maintain and replace.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Natural stone crushing and grinding equipment

InactiveCN111389567ASimple and fast operationReduce manufacturing costSievingScreeningCrushed stoneStructural engineering

Owner:杭州瑞芳容科技有限公司

Rice husking machine

Owner:四川东工电机有限公司

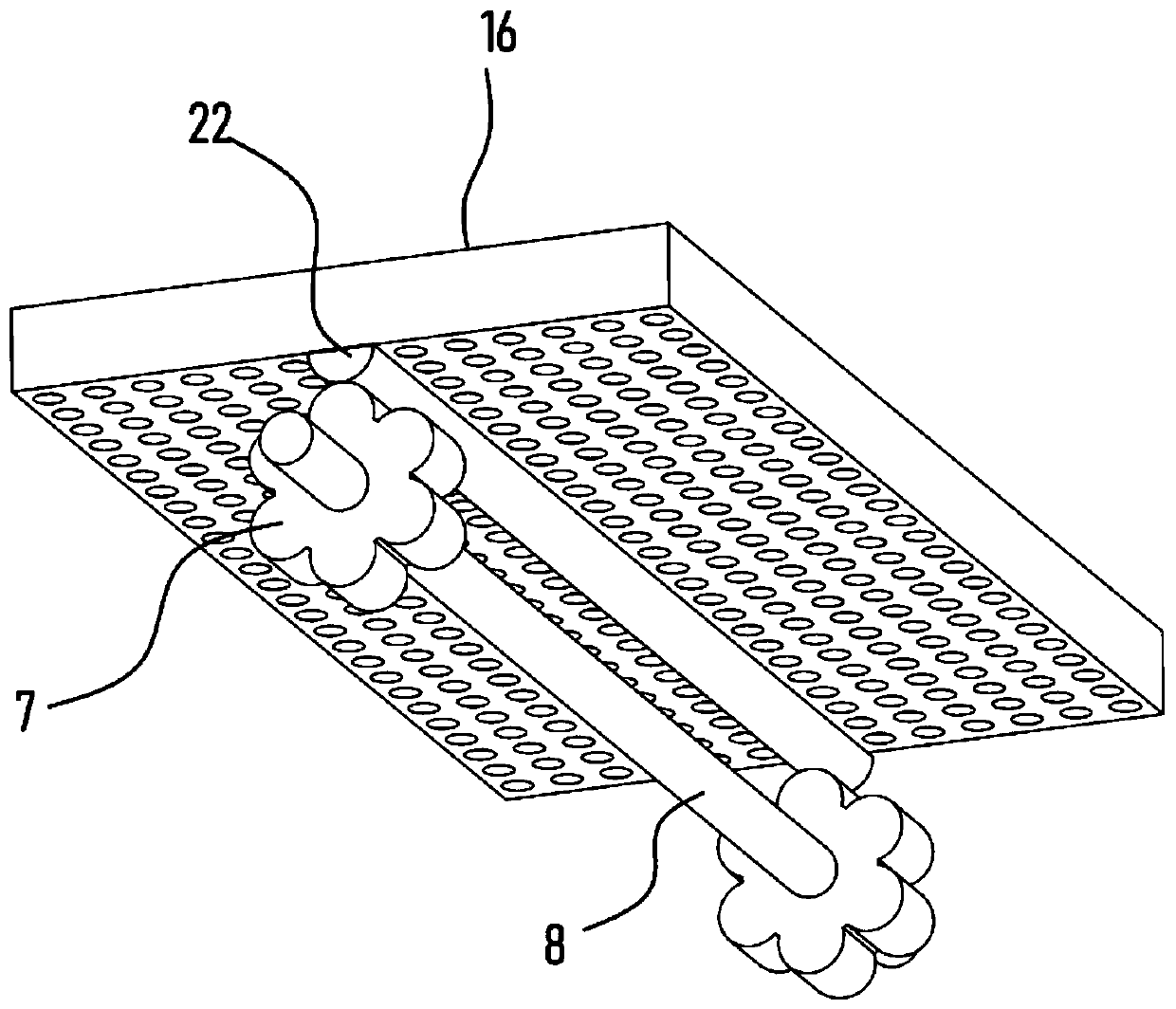

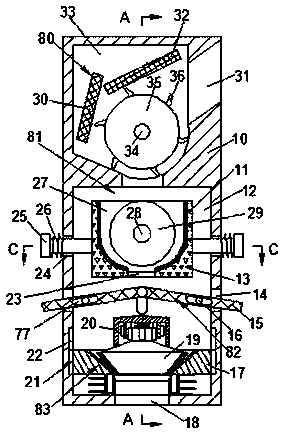

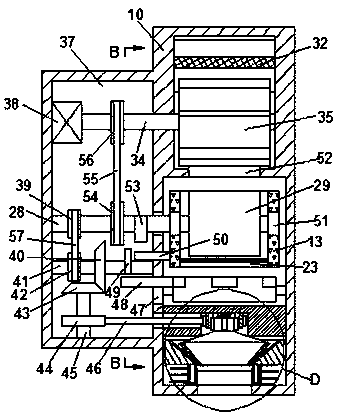

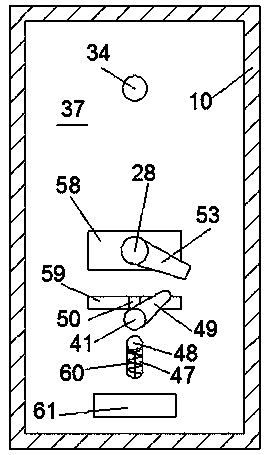

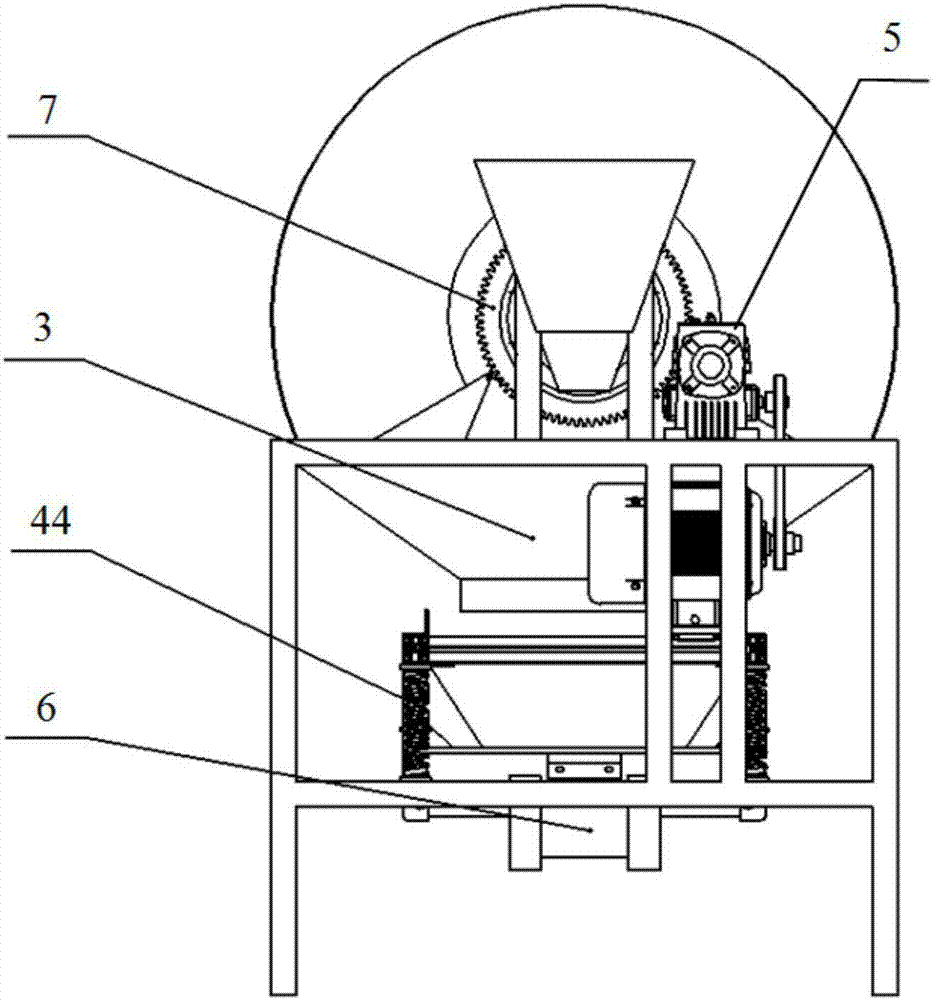

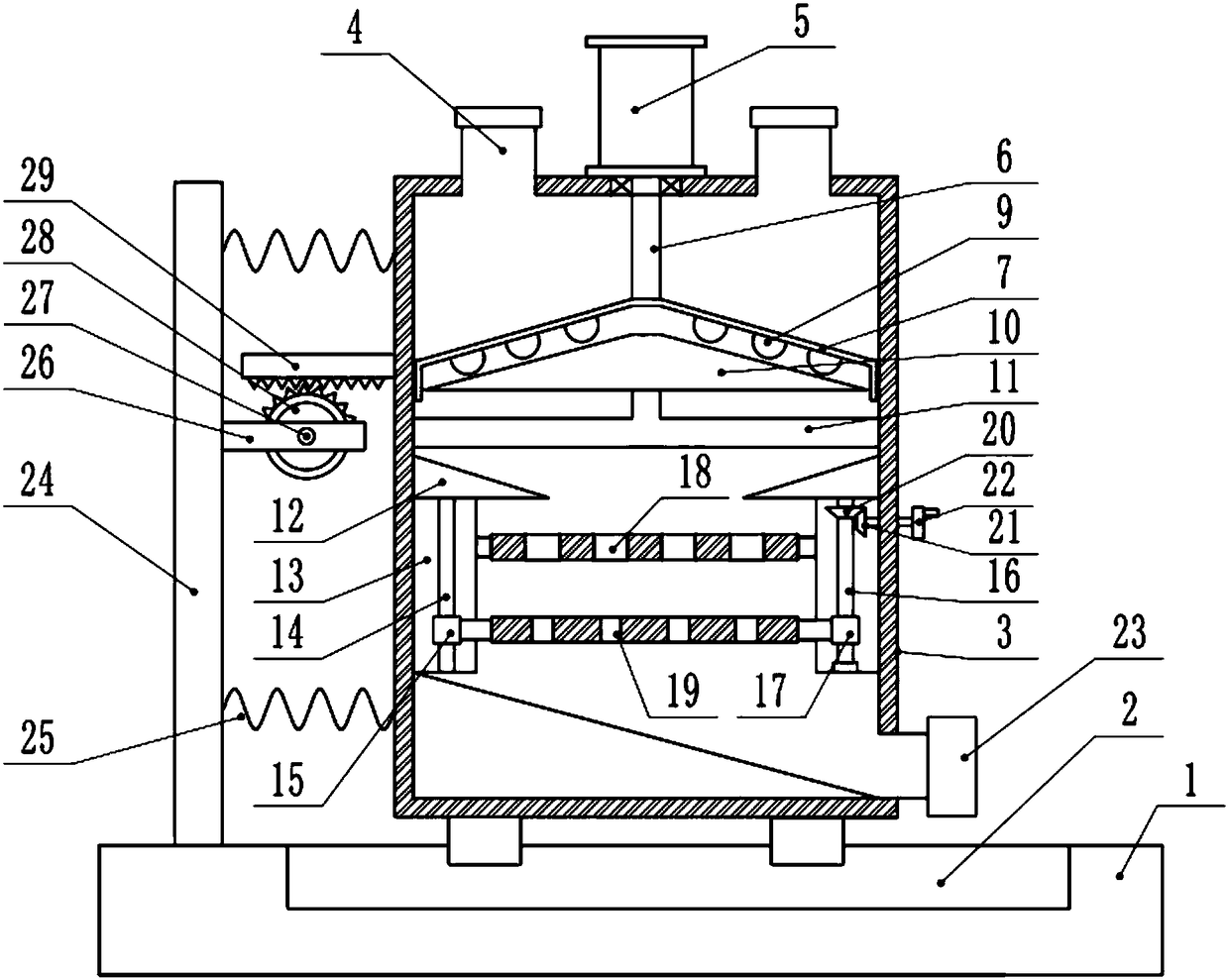

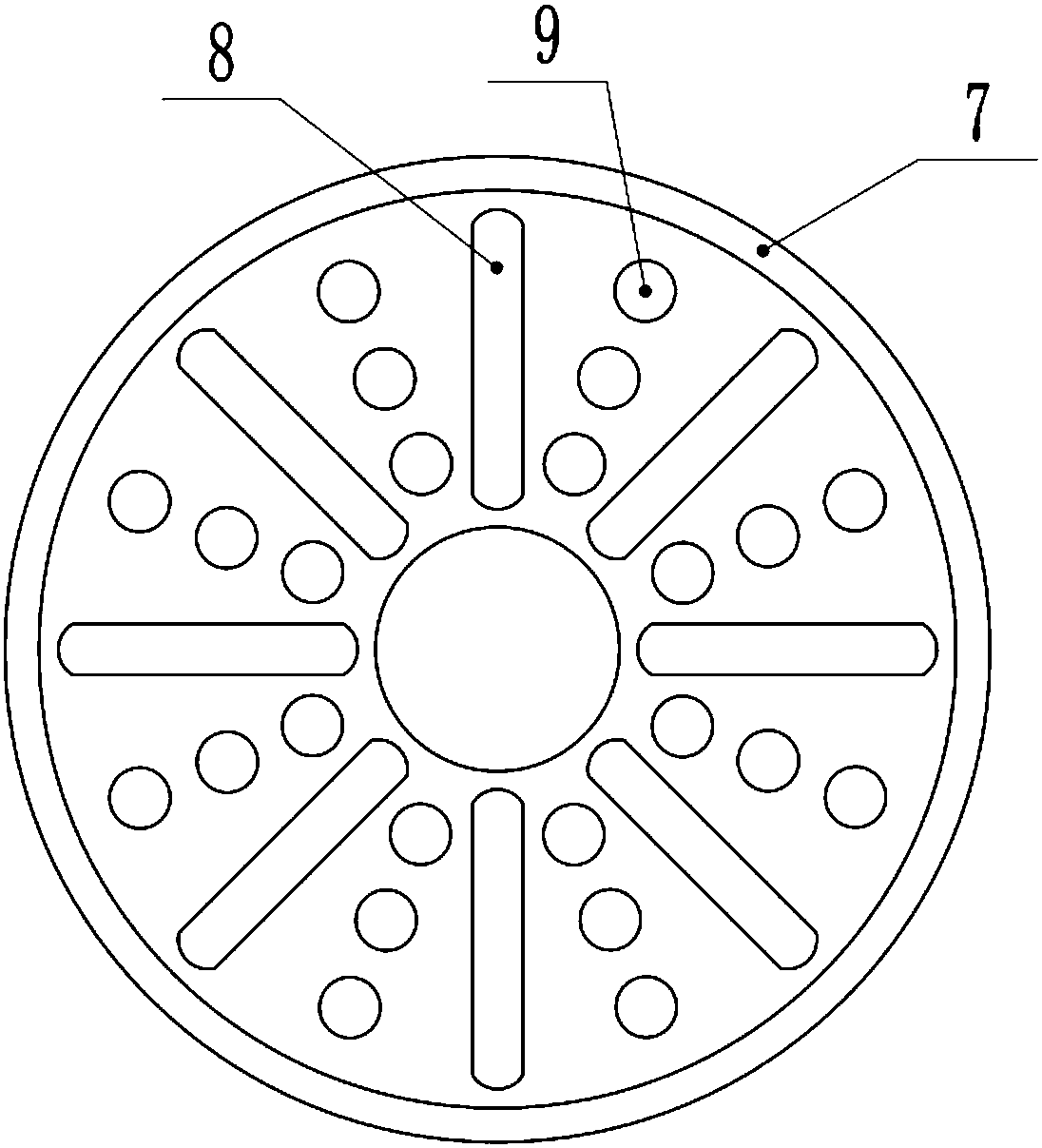

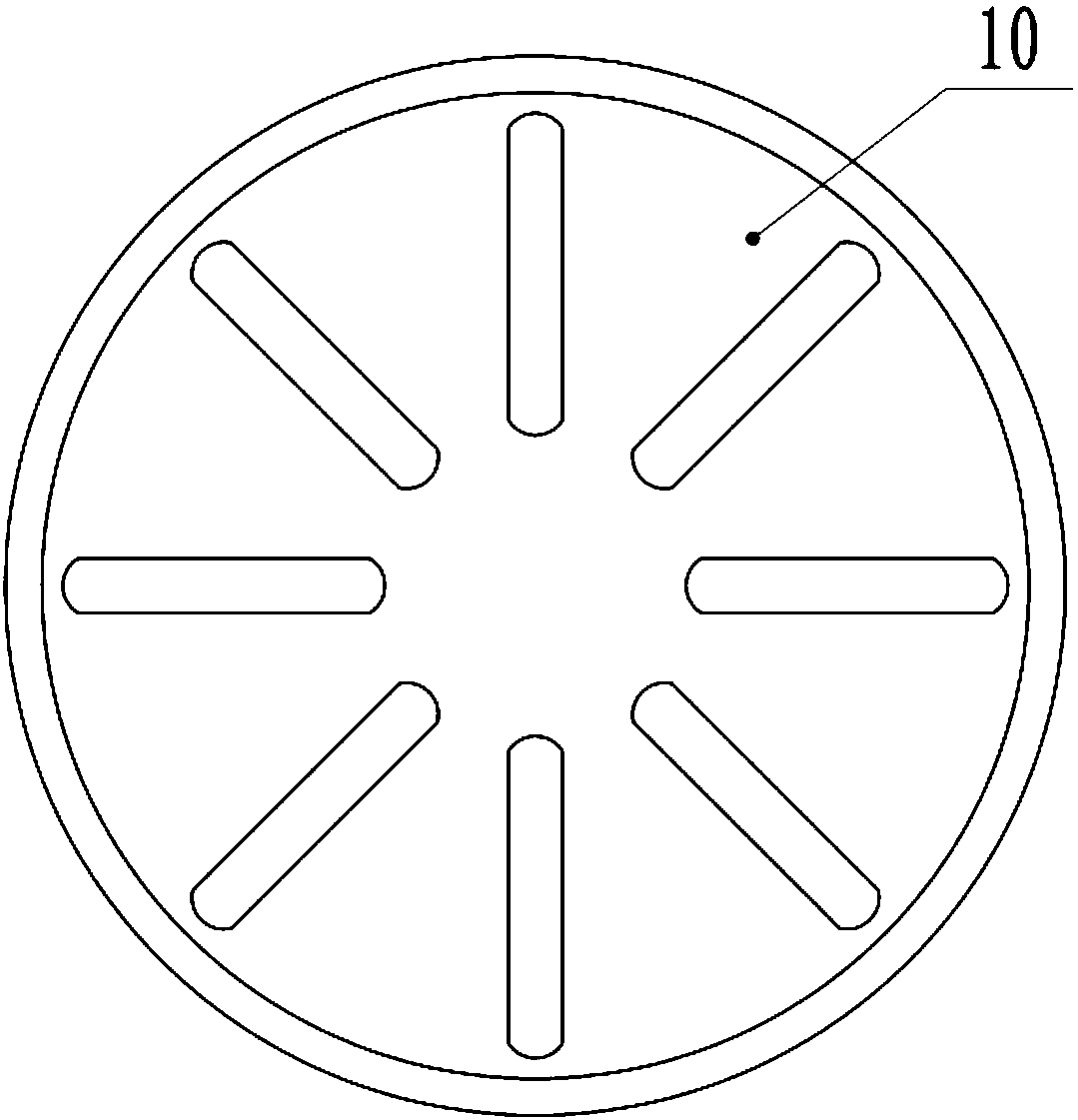

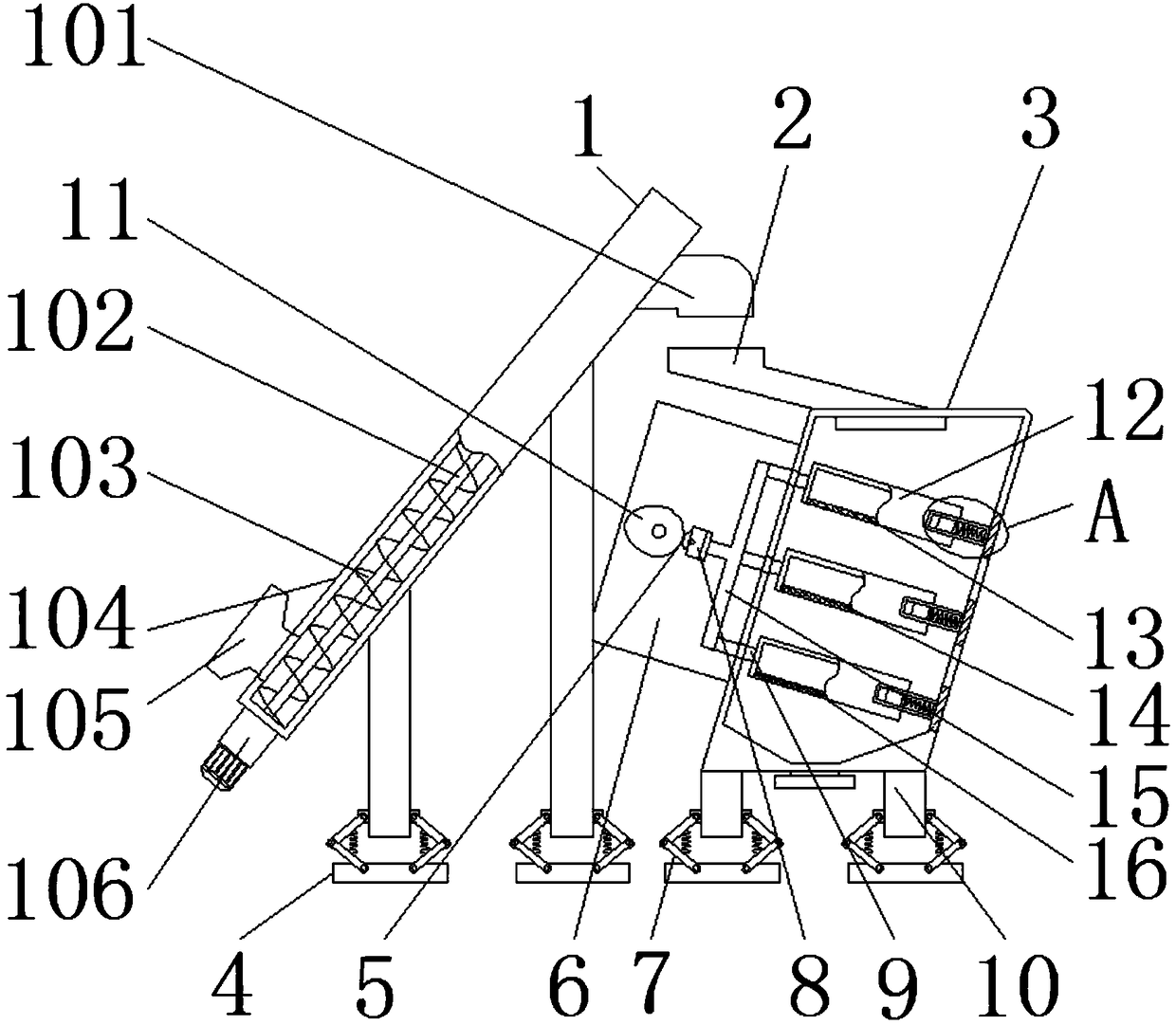

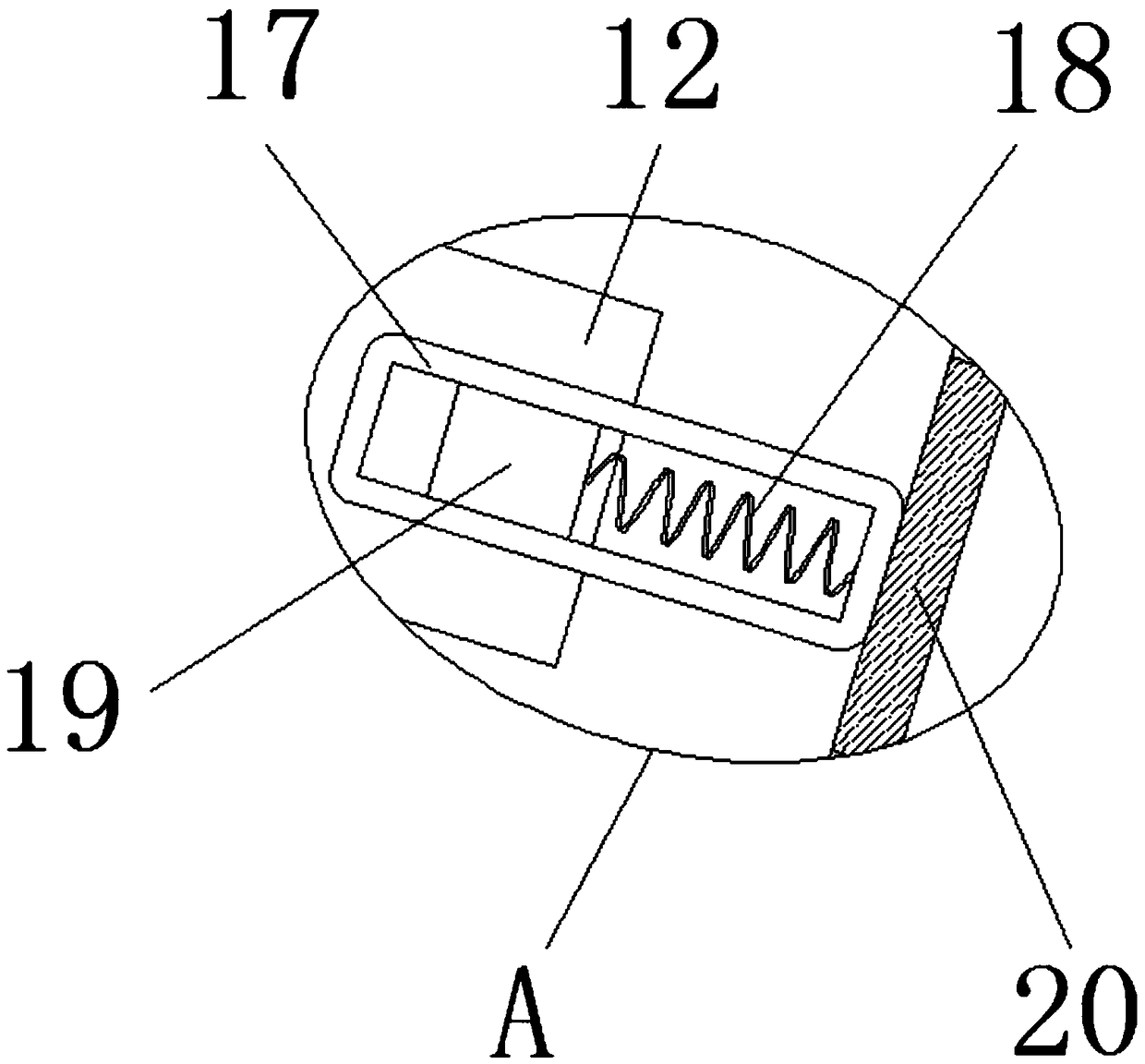

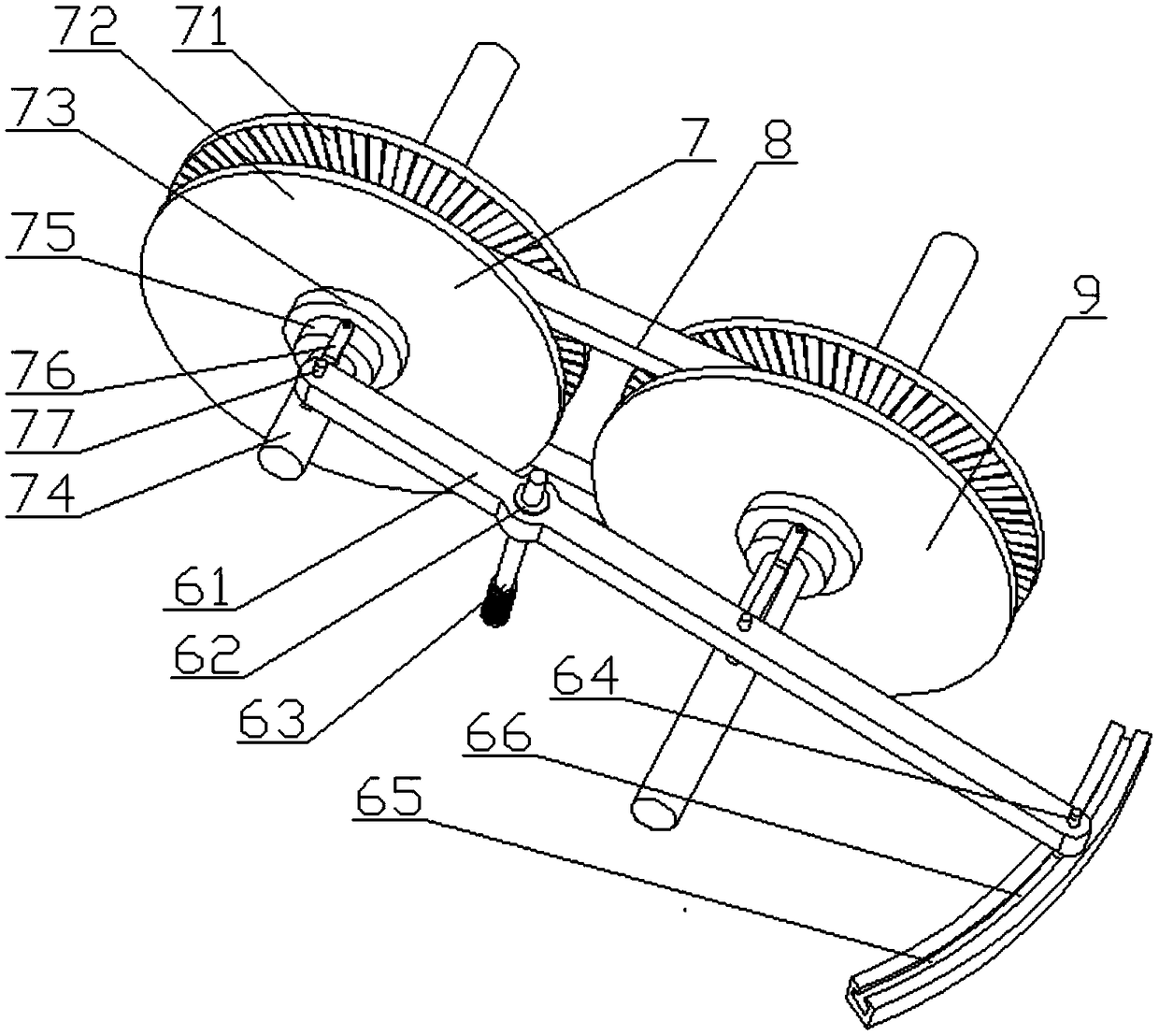

Cam-driving-type Maojian tea double-station multidimensional screening device

InactiveCN108554779AImprove screening efficiencyRealize automatic sortingSievingScreeningAgricultural engineeringCam

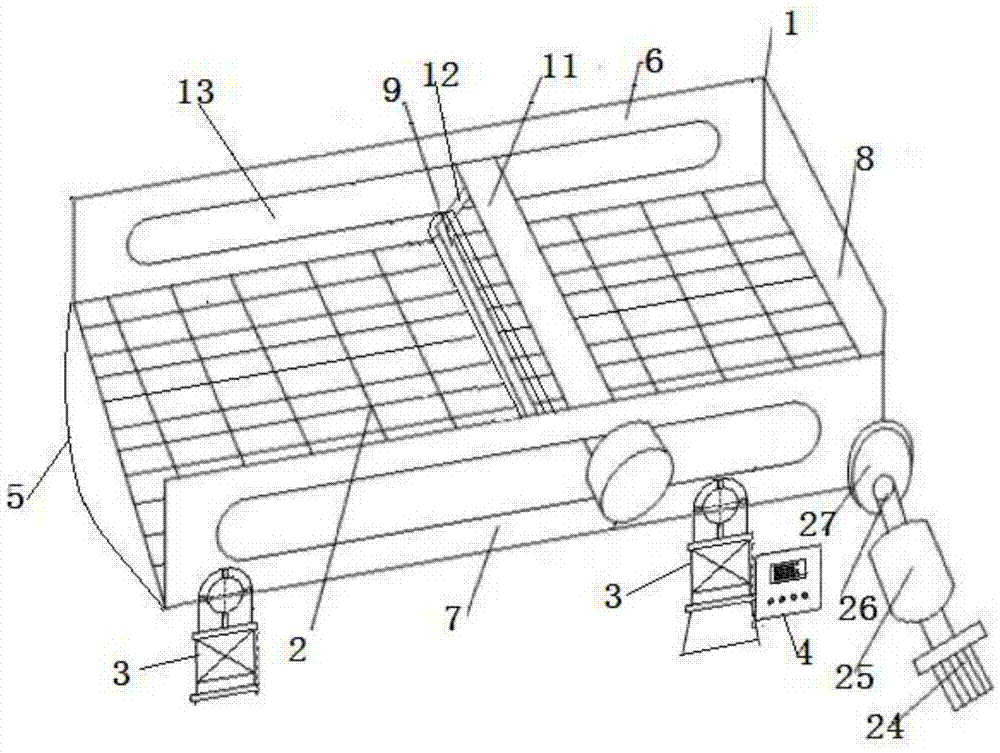

The invention discloses a cam-driving-type Maojian tea double-station multidimensional screening device which comprises a base, a supporting table, a first screening box, a second screening box, first-stage screening grooves, second-stage screening grooves and third-stage screening grooves. A plurality of sets of electromagnets are arranged on the upper surface of the base, a plurality of sets ofmagnets are arranged on the lower side of the supporting table, and the magnets and the electromagnets correspond mutually. The first screening box and the second screening box are slidably mounted onfirst sliding rails located on the left side and right side correspondingly. During tea screening, the efficiency of tea screening in the first screening box and the second screening box is improvedgreatly through leftward and rightward sliding of the first screening box and the second screening box; and large-particle tea is left in the first-stage screening grooves, small-particle tea is leftin the third-stage screening grooves, impurities in the tea are discharged from impurity outlets, thus the tea is automatically sorted, manual sorting is not needed, and the working efficiency is greatly improved.

Owner:张春分

Multifunctional lotus nut screening machine

InactiveCN107051882AImprove qualityImprove separation rateSievingGas current separationVibration controlHusk

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Building paint powder grinding and screening device

Owner:砀山县展望罐头食品厂

Straw impurity removing device

Owner:咸丰隆态生物科技有限公司

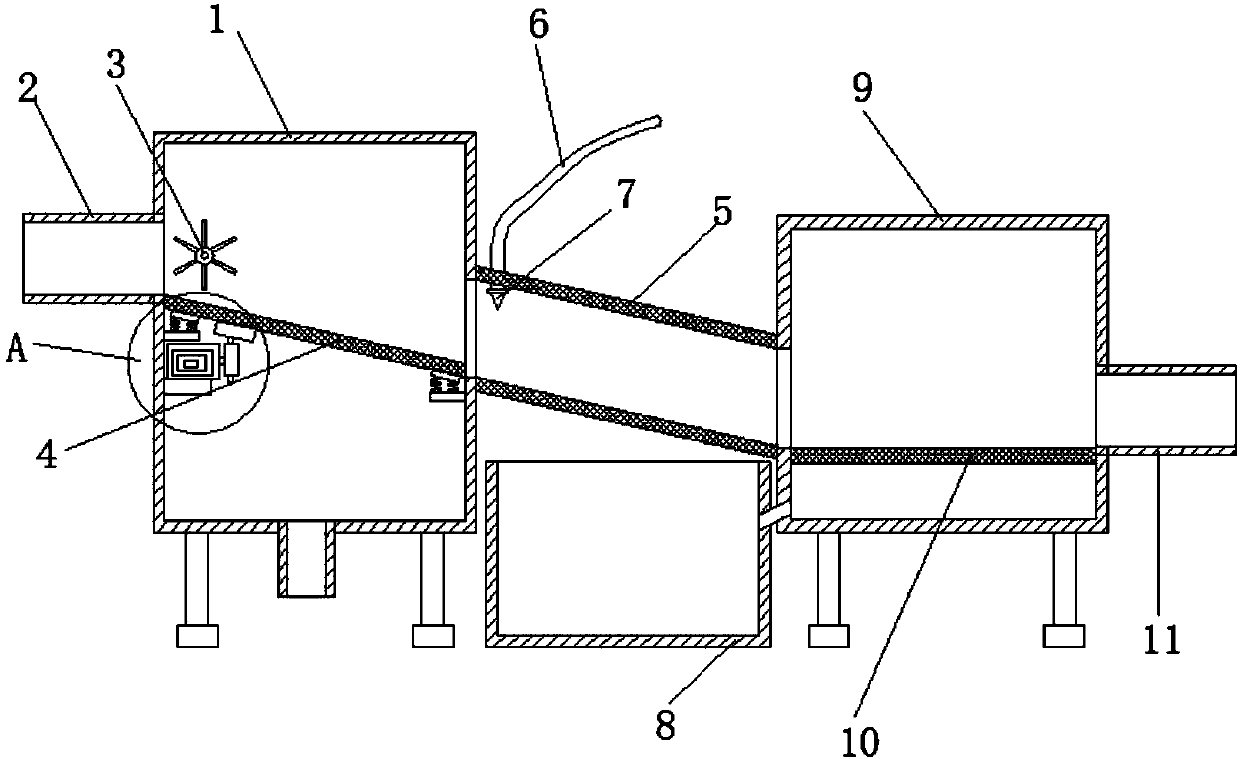

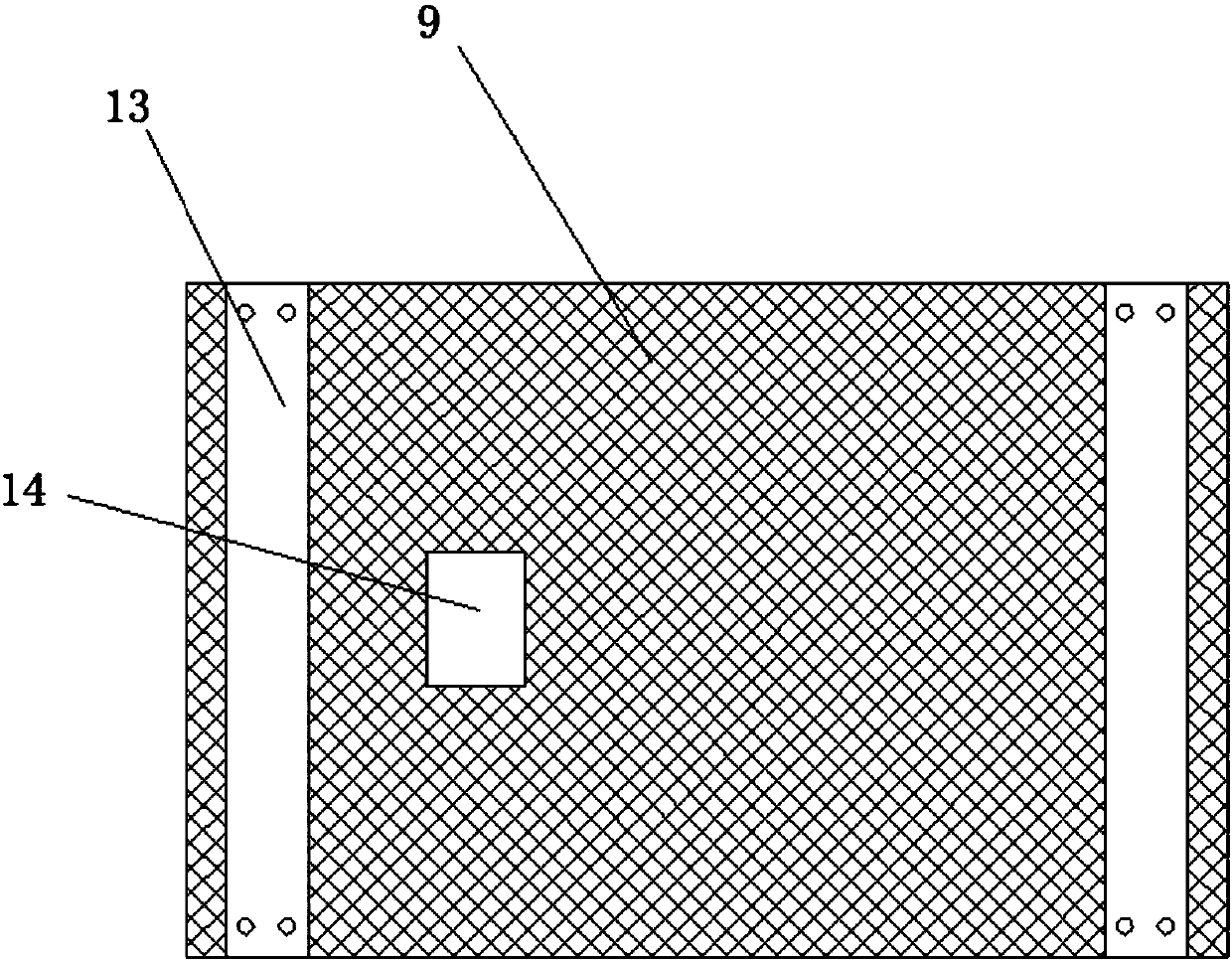

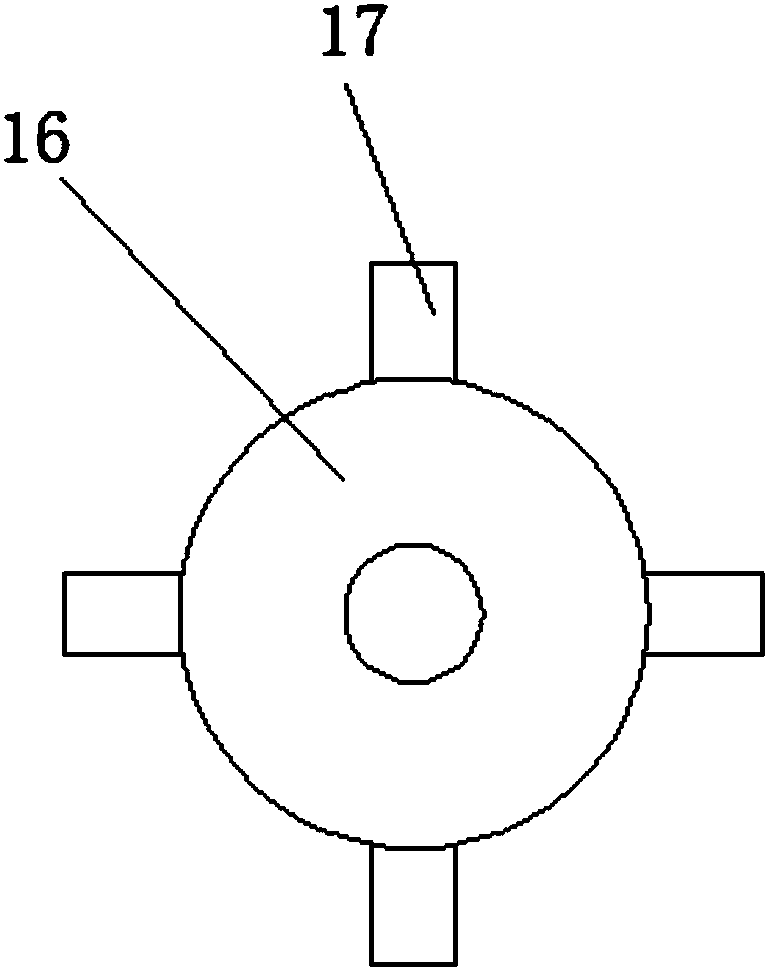

Garbage sorting system and method

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Intelligent ore crushing device with automatic adjusting function

ActiveCN113499819AWith automatic adjustment functionAutomatically adjusts the rotation rateSievingScreeningFrequency changerElectric machine

The invention discloses an intelligent ore crushing device with an automatic adjusting function. The intelligent ore crushing device comprises a machine body, a frequency converter and gravity sensors, a feeding opening is fixedly formed in the upper portion of the machine body, a forward and reverse motor is installed on the left side of the feeding opening, a second sliding groove is formed in the inner surface of the feeding opening, an opening is formed in the upper portion of the machine body, a driving motor is installed on the left side of the machine body, the output end of the driving motor is connected with a crushing roller on the upper portion in the machine body, and a second open groove is formed in the surface of the right side of the machine body. According to the intelligent ore crushing device with the automatic adjusting function, the feeding quantity can be detected through a feeding gravity detection device formed by the froward and reverse motor in the feeding opening and the gravity sensors on the surfaces of material separation plates, through cooperation with use of the frequency converter installed on the surface of the output end of the driving motor, the device can automatically adjust the rotating speed of the crushing roller driven by the driving motor conveniently by combining the material feeding quantity with use of the frequency converter, and then the ore crushing effect is improved.

Owner:SHANDONG JIUCHANG HEAVY IND TECH

Sandy soil screening device for building construction

ActiveCN108636784AImprove screening efficiencyImprove work efficiencySievingScreeningPore diameterEngineering

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

Grain conveying and screening machine

InactiveCN109351624AEasy to storeTransport dust wellSievingGas current separationEngineeringMechanical engineering

Owner:安徽粮友机械科技有限公司

Filter screen

InactiveCN103433208ASimple structureReasonable designSievingScreeningScreening effectElectric machine

The invention discloses a filter screen, and relates to a filtering device. The filter screen comprises a bracket. Screen cloth is arranged on the bracket. Two connecting plates are arranged at the rear end of the bracket. A rotating shaft is arranged on the connecting plates. A belt pulley is arranged at one end of the rotating shaft, and is connected with a motor on the ground through a belt. The other end of the rotating shaft is connected with a connecting rod in a staggered way. The connecting rod is arranged on a movable plate which is movably connected with the screen cloth. The filter screen is simple in structure and reasonable in design; the belt pulley and the rotating shaft are driven by the motor to rotate, then the movable plate can be driven by the connecting rod in staggered connection to cyclically move forwards and backwards, and the screen cloth is further driven to cyclically vibrate forwards and backwards to finish filtering in a continuous vibration process, so that a better screening effect is achieved, and the working efficiency is improved.

Owner:陈学军

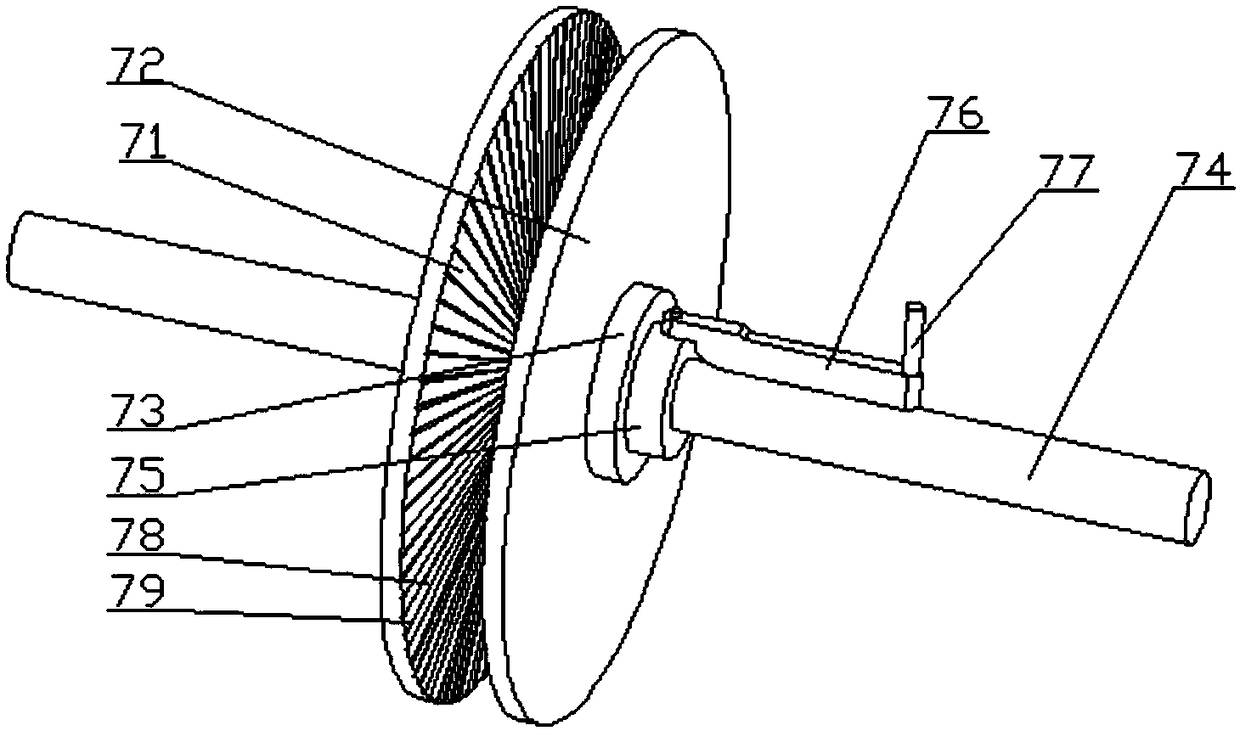

Screening device

ActiveCN109158294AEasy to useEasy to block and not easySievingScreeningScreening effectTransmission belt

Owner:安徽昊华环保科技有限公司

Efficient solid waste treatment device

InactiveCN114471824AAccurate removalEasy to removeSievingScreeningEnvironmental engineeringWaste treatment

The invention discloses a treatment device for efficient solid waste treatment, and belongs to the technical field of solid waste treatment.The treatment device comprises a solid waste treatment box, a crushing assembly is fixedly installed at the top of the solid waste treatment box, a solid waste screening plate is arranged in an inner cavity of the solid waste treatment box, and a magnet plate is embedded in the surface of the solid waste screening plate; screening holes are formed in the surface of the magnet plate at equal intervals, and an anti-blocking assembly is arranged at the bottom of the solid waste screening plate. According to the solid waste treatment device, through the arrangement of a magnet plate and screen holes formed in the surface of the magnet plate, metal substances carried in solid waste can be adsorbed by the magnet plate, and waste liquid carried in the solid waste can be filtered through the screen holes; metal substances adsorbed on the surface of a magnet plate can be cleaned, the cleaned metal substances are pushed into an inner cavity of a collecting box through a discharging groove to be collected and treated, and through the arrangement of the device, water and metal components in solid waste can be effectively removed.

Owner:JIANGSU YUANKANG RENEWABLE RESOURCES CO LTD

Efficient alloy baking device and baking method thereof

The invention discloses an efficient alloy baking device and a baking method thereof in the field of alloy baking. The efficient alloy baking device comprises a hot-blast stove, the hot-blast stove isconnected with an air inducing mechanism through a hot-blast pipeline, a temperature adjusting mechanism is further arranged between the air inducing mechanism and the hot-blast stove, the air inducing mechanism is connected with a baking bin, and the baking bin is arranged on a rack. The hot-blast stove is arranged on one side of the rack, a weighing and discharging mechanism is arranged below the baking bin, the baking bin is further provided with a feeding mechanism in a matched mode, and the hot-blast stove is controlled by an intelligent detection control system. The hot-blast stove andthe baking bin are of a separated structure, coal gas can be fully combusted, carbon monoxide poisoning accidents are avoided, safety measures are complete, the hot-blast stove is controlled by the intelligent detection control system, the hot-blast stove and the baking bin can be monitored in real time, and the heat energy utilization efficiency is greatly improved through the air inducing mechanism and the temperature adjusting mechanism. The efficient alloy baking device and the baking method thereof can be used for iron alloy baking.

Owner:JIANGSU EURASIA ENVIRONMENTAL PROTECTION TECH CO LTD

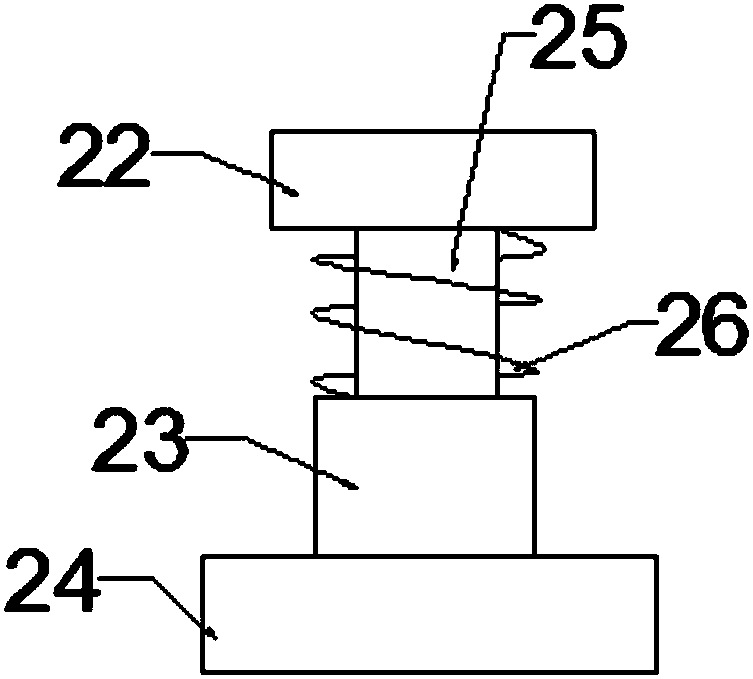

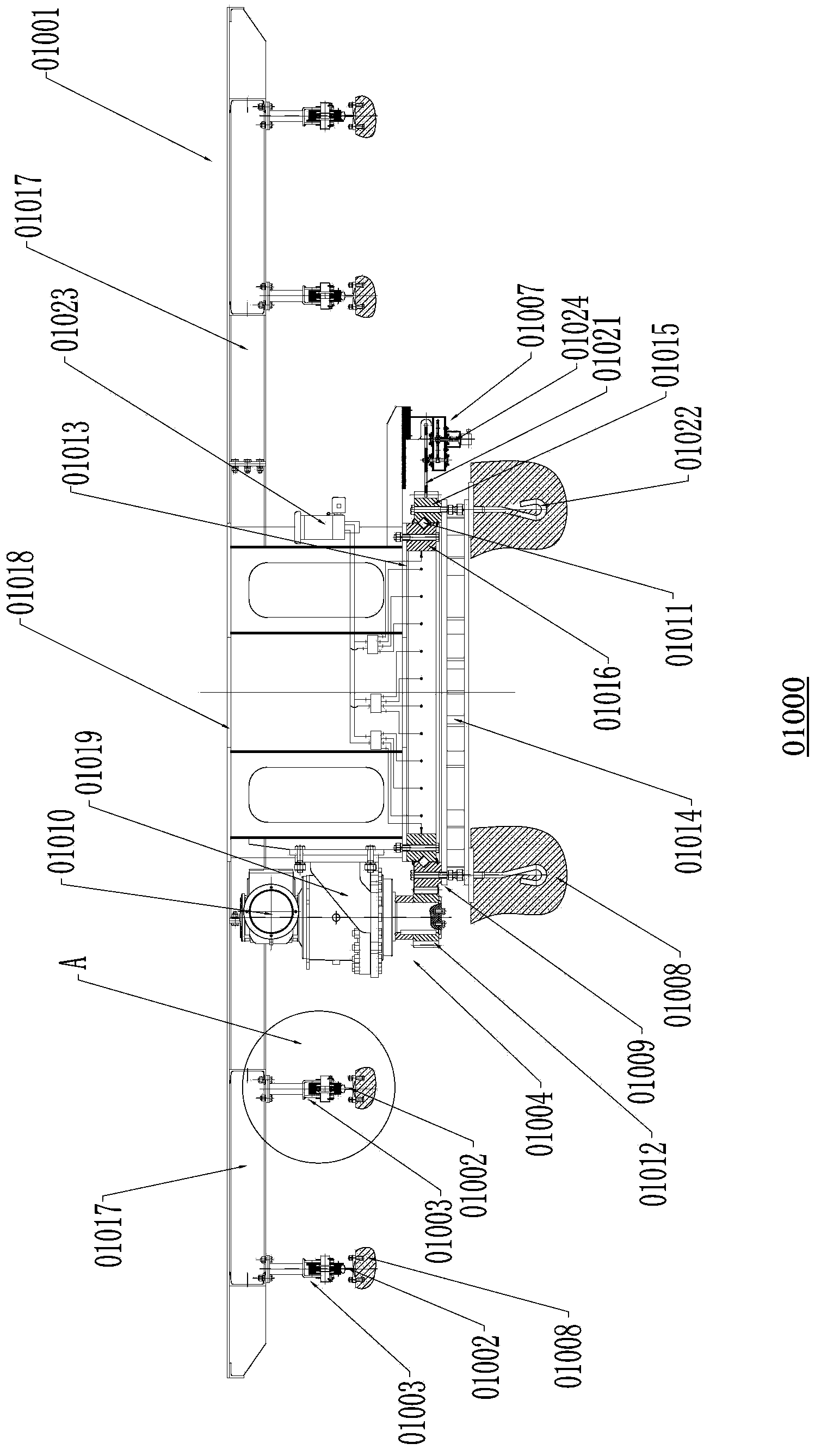

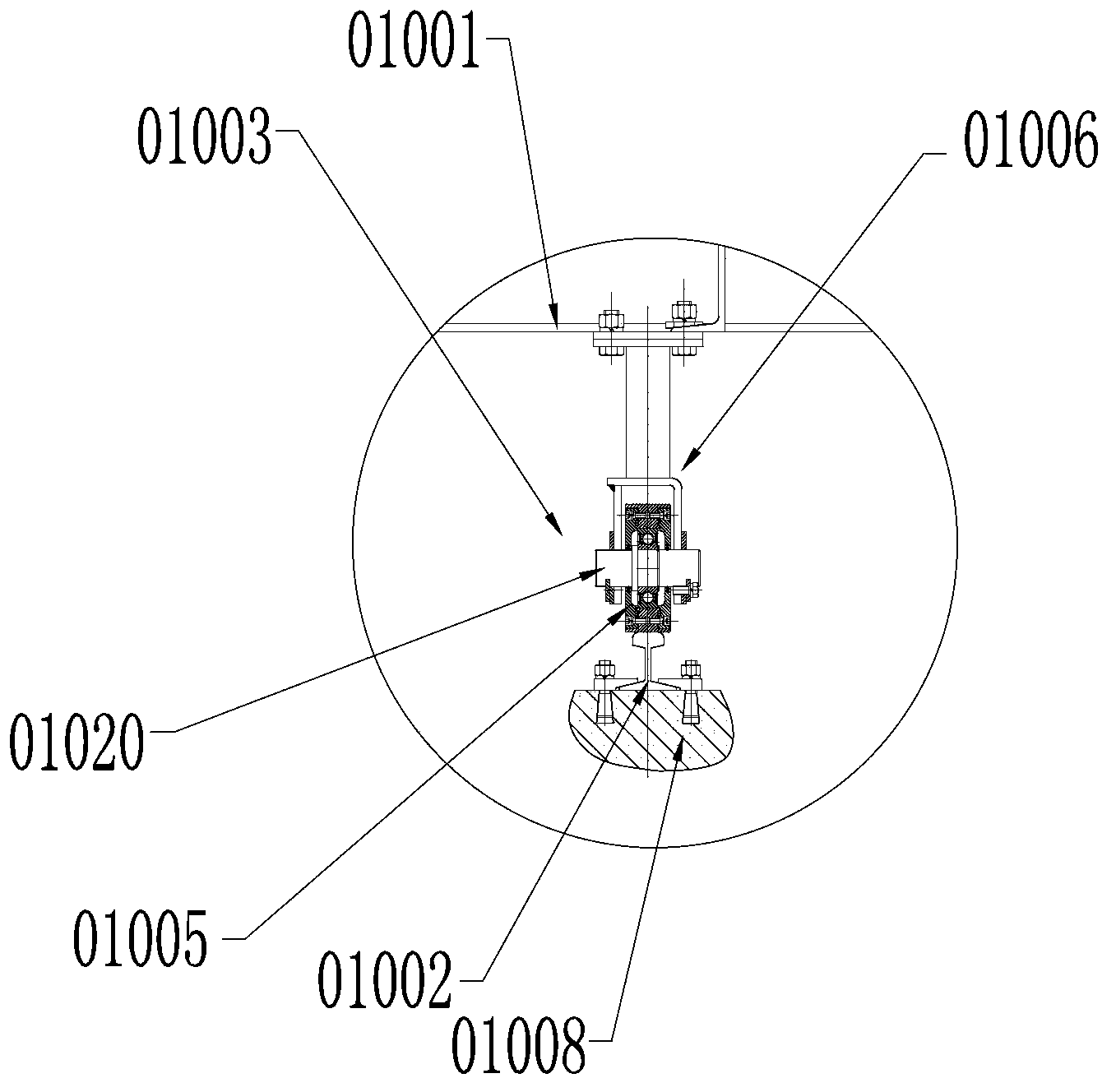

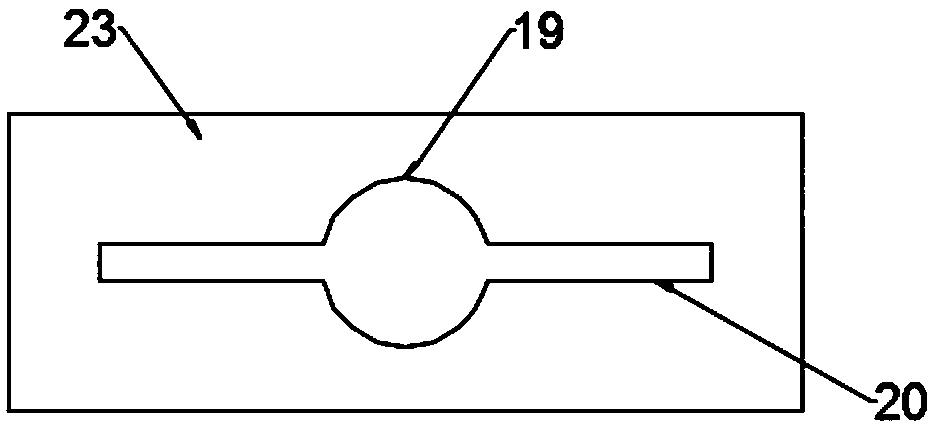

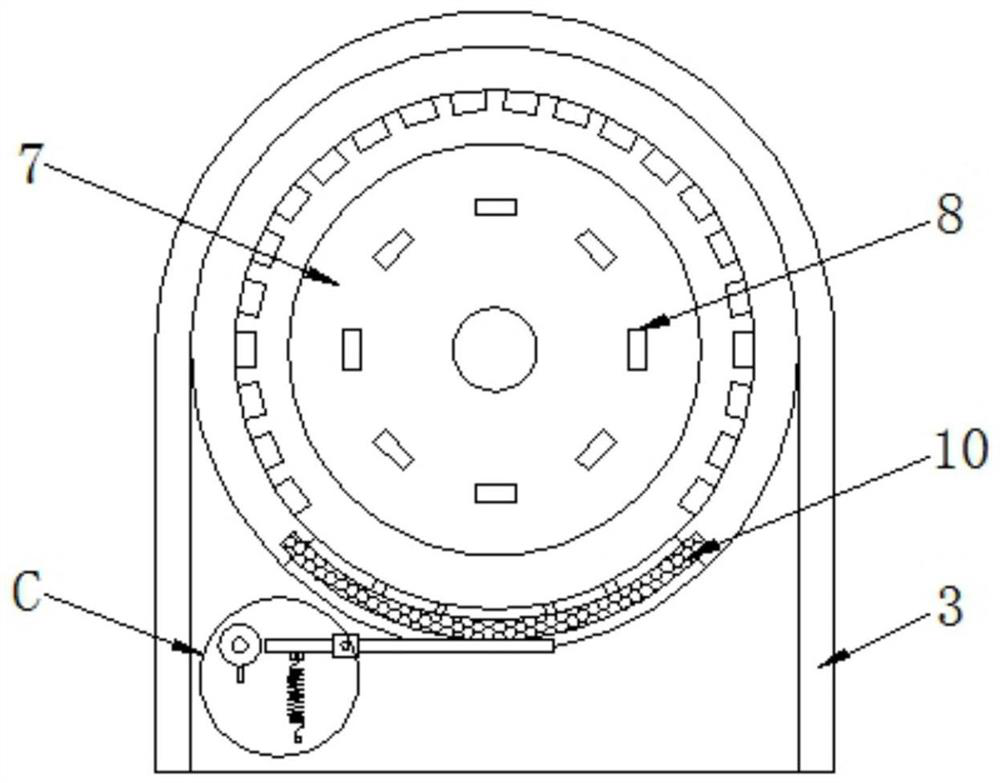

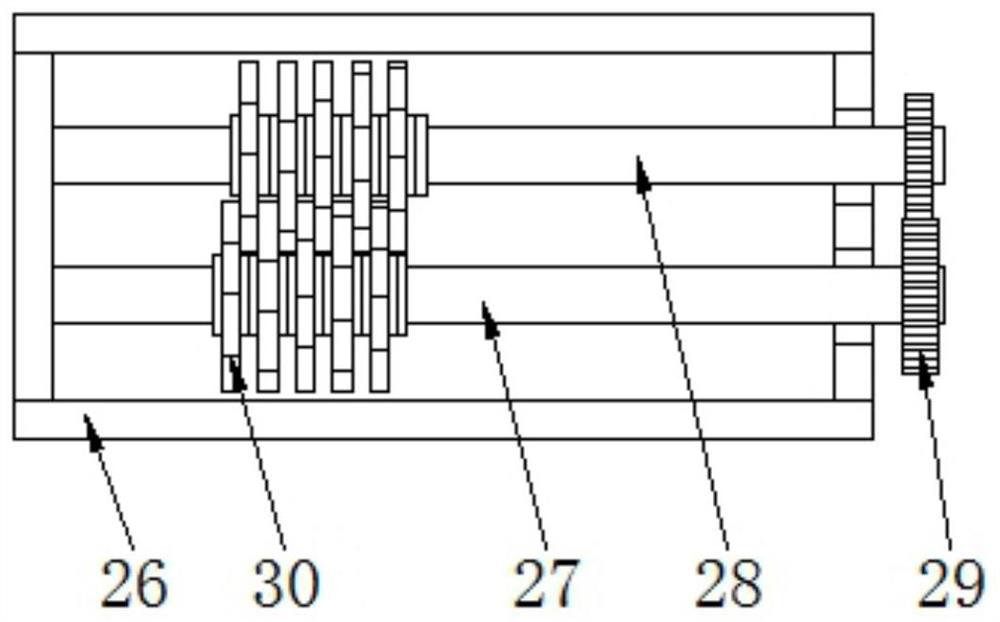

Intermittent feeding type sand sieving device for building

ActiveCN108906576AImprove screening efficiencyAvoid affecting the screening effectSievingScreeningCircular cavitySieve

The invention discloses an intermittent feeding type sand sieving device for building. The intermittent feeding type sand sieving device comprises a storage cavity and a sieving cavity and is characterized in that the storage cavity is arranged at the upper end of the left side of the sieving cavity and communicated with the sieving cavity through a discharge outlet, a transverse plate is fixedlymounted in the sieving cavity, the inner side of the transverse plate is provided with a circular cavity, a first eccentric wheel is arranged on the inner side of the circular cavity, push rods are symmetrically arranged at the left end and the right end of the first eccentric wheel, fixing parts are mounted at the lower ends of the push rods, the lower ends of the fixing parts are hinged to one ends of the connecting rods, and the other ends of the connecting rods are hinged to the upper end of a sieve plate. The intermittent feeding type sand sieving device has the advantages that the deviceis novel in design, a second eccentric wheel rotates to drive a retaining plate to move vertically in a reciprocating manner to intermittently open the discharge outlet so as to achieve intermittentfeeding, and accordingly the sieving effect can be effectively prevented from being affected by the fact that excessive sand enters the sieving cavity at the same time; the push rods move leftwards and rightwards to drive the sieve plate to swing in a reciprocating manner through the connecting rods, and accordingly the sieving efficiency of the sieve plate is increased, and high practicality is achieved.

Owner:安徽谦源项目管理有限公司

Environment-friendly civil engineering construction waste treatment equipment

PendingCN113713889ASave human effortImprove processing efficiencySievingScreeningConstruction engineeringWaste material

Owner:华新建工集团有限公司

Food processing and crushing mechanism with high reliability

InactiveCN111921670AImprove reliabilityImprove stabilitySievingScreeningStructural engineeringMechanical engineering

Owner:陈飞

Garbage sorting and screening mechanism of automatic sorting processor for kitchen wastes

InactiveCN112808749AEasy to cleanImprove screening efficiencySievingScreeningElectric machineProcess engineering

The invention discloses a garbage sorting and screening mechanism of an automatic sorting processor for kitchen wastes, in particular to the technical field of sorting and screening of the kitchen wastes. The garbage sorting and screening mechanism comprises a box body and an oily water collection box, wherein a water drain plate is horizontally and fixedly connected to the interior of the box body; reserved holes are formed in the water drain plate; and the oily water collection box is arranged at the bottom end of the water drain plate and is positioned in the box body. According to the garbage sorting and screening mechanism disclosed by the invention, through arrangement of a driving motor, rotary shafts, a frame body, a screening box, clamping slots, a cover plate, a handle and fixed blocks, the cover plate is opened, garbage is poured into the screening box, and then the fixed blocks are embedded in the clamping slots; the driving motor is started, the rotary shafts are driven through a driving shaft to be rotated; and because round holes are formed in the screening box, oily water and small solid garbage can be screened to the bottom of the screening box in a rotation process of the screening box, so that large solid garbage can be remained in the screening box, and therefore, the screening effect is better, the screening efficiency is higher, and the oily water can be conveniently separated from the solid garbage.

Owner:FUJIAN ZHONGHUI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Drum screen

Owner:万花秀

Garbage smashing device

The invention discloses a garbage smashing device, which comprises a feeding hole, a charging barrel and a flywheel chopping disc, wherein the feeding hole is connected with the charging barrel; the flywheel chopping disc is arranged at an outlet of the charging barrel; and a vibrating screen is arranged below the outlet of the charging barrel. The garbage smashing device has the advantages that garbage can be subjected to vibrating separation, large impurities can be smashed for a second time, and the smashing quality of the garbage which enters into a series of matched equipment can be ensured; and the garbage can be recycled, so that the garbage smashing device is energy-saving and environment-friendly.

Owner:SUZHOU ZHANGYANG ENERGY TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap