Walnut kernel and broken shell separation equipment after walnut shelling

A separation equipment, walnut kernel technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve problems such as inapplicability, and achieve the effect of easy cleaning and easy screening of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

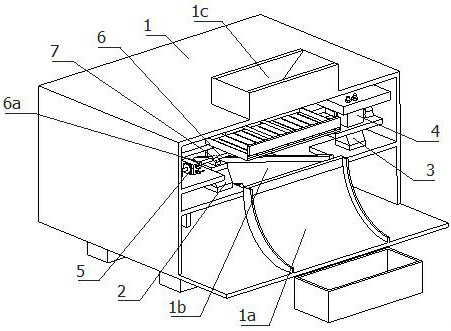

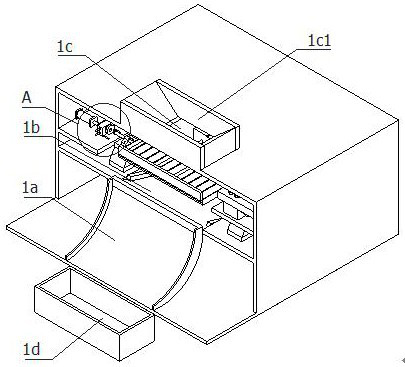

[0029] refer to figure 1 Shown, a kind of equipment for separating walnut kernels and broken shells after walnut shelling includes:

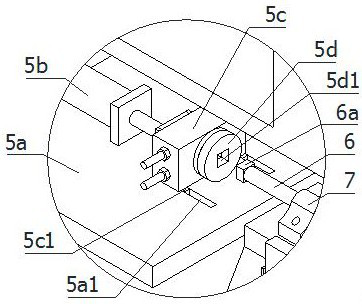

[0030]Equipment support 1, the inside of the equipment support 1 is provided with a slant plate 1a and a slant plate 1b whose bottom runs through the opposite side of the equipment support 1. The material inlet 1c on the top of the sloping plate 1b; the first vibration motor 2 and the second vibration motor 3, the working ends of the motors are vertically upward and arranged side by side on the top of the sloping plate connection point; butt joint self-locking device 4. The docking self-locking device 4 is arranged on the working end of the second vibration motor 3; the docking

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap