Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Dust control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

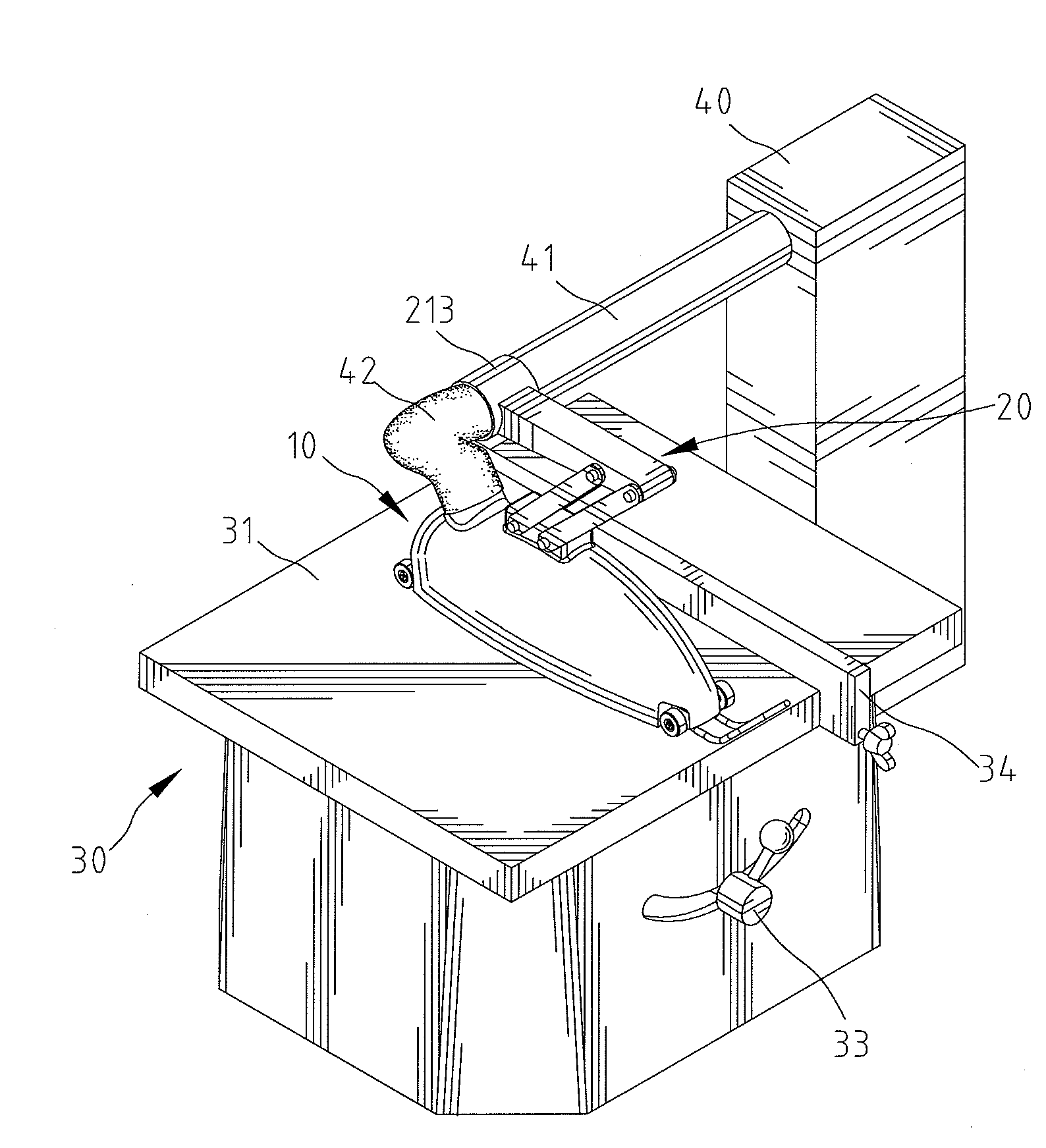

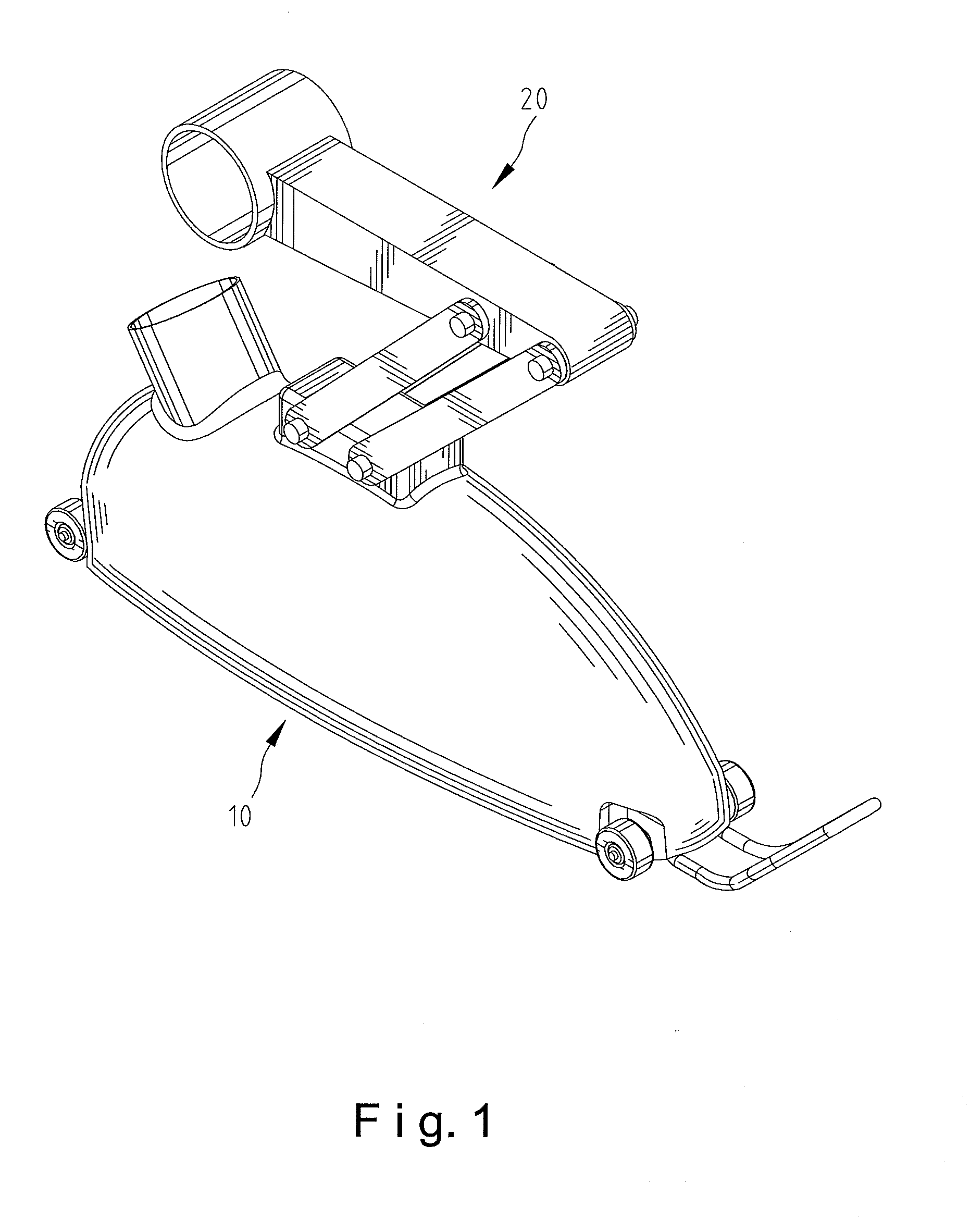

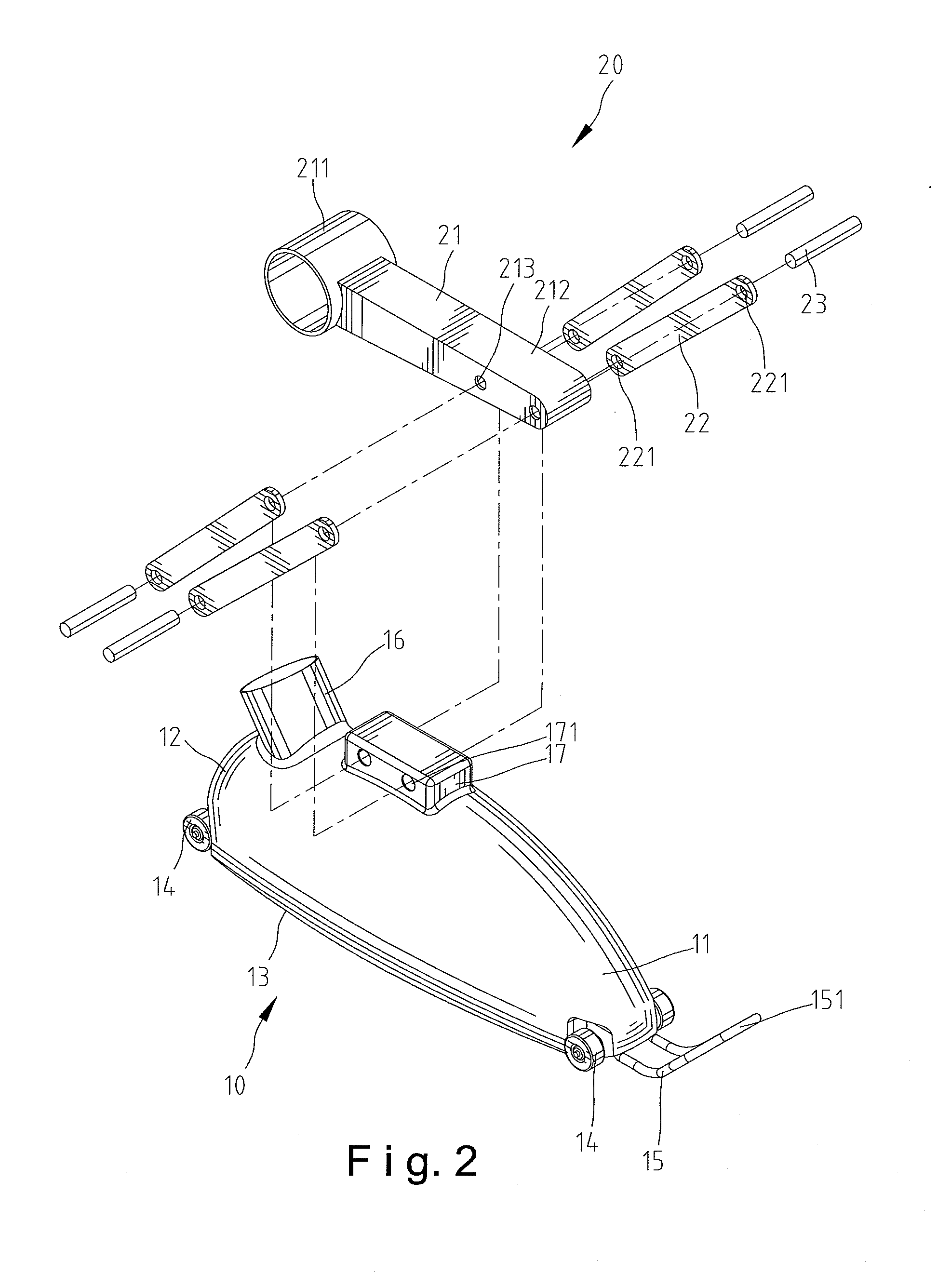

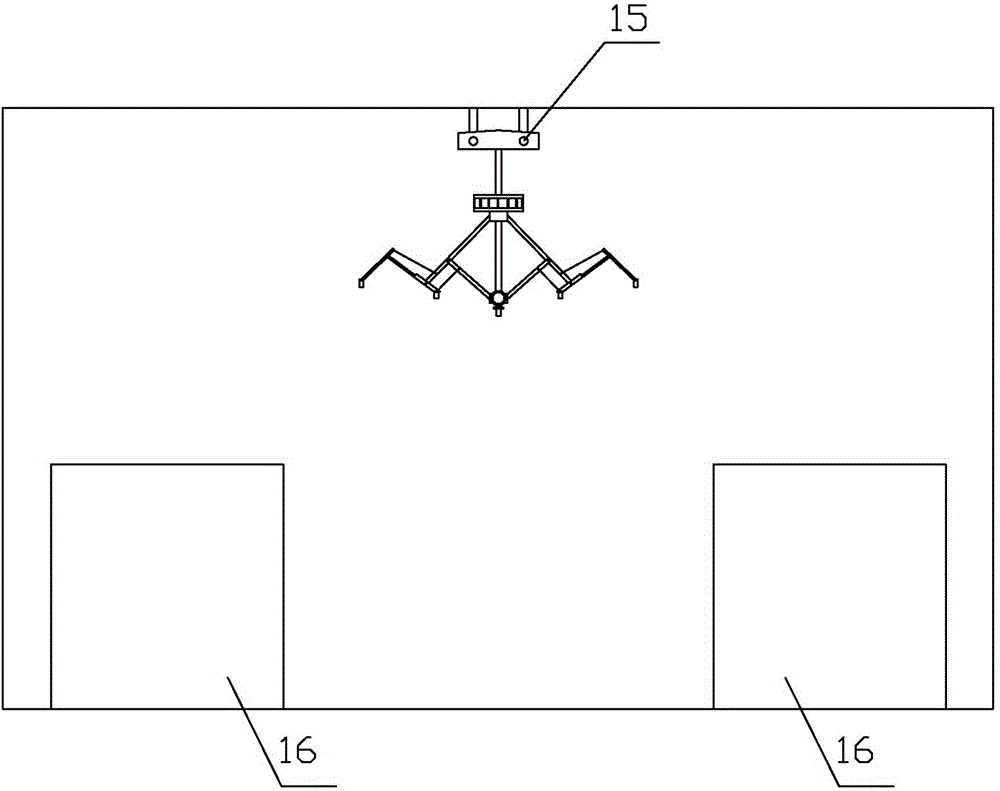

Dust Control Hood Assembly for a Cutting Machine

InactiveUS20100037740A1Easy to moveMetal sawing accessoriesShearing machinesDust controlHOOD assembly

Owner:META INT

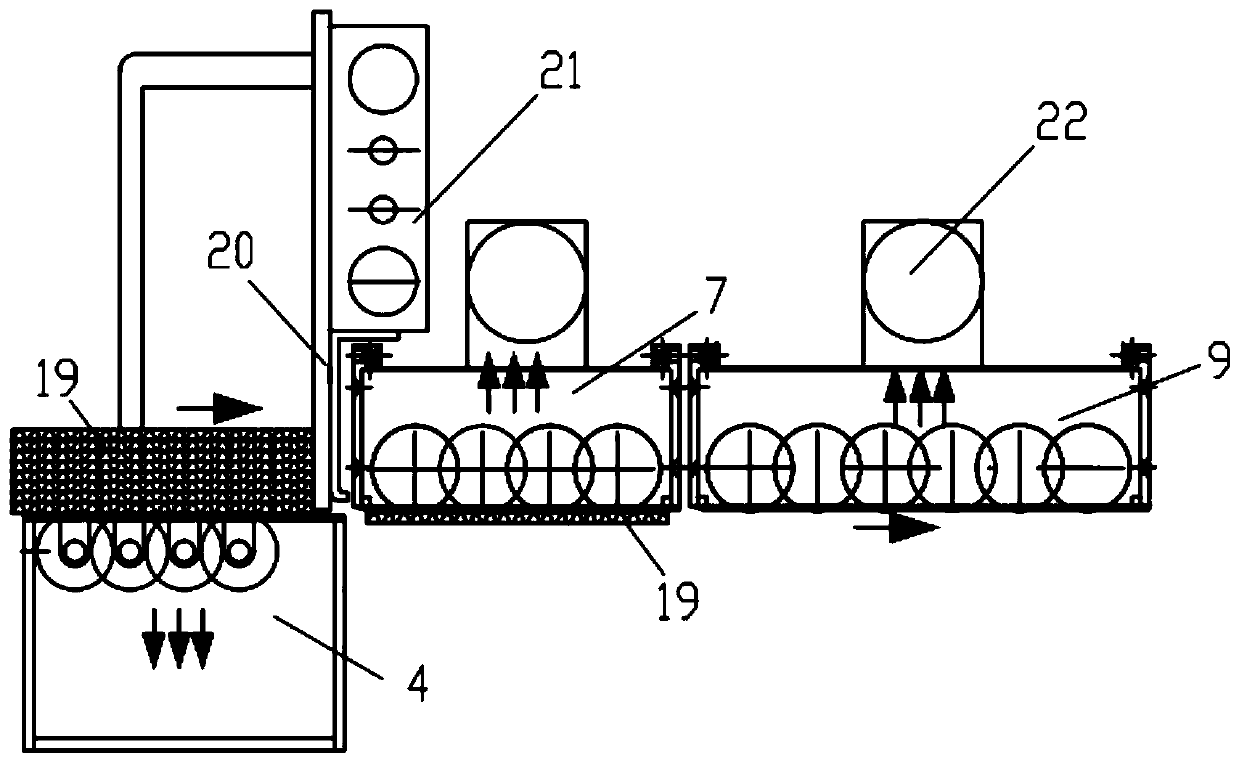

Solar photovoltaic panel dust removal device for sand and dust land

InactiveCN112620205AAvoid damageReduce scratchesDispersed particle filtrationPhotovoltaicsDust controlEngineering

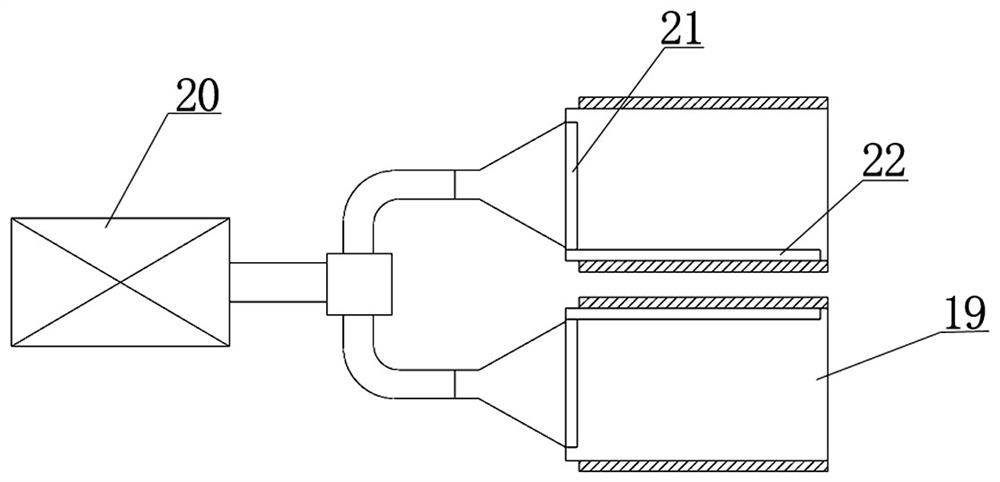

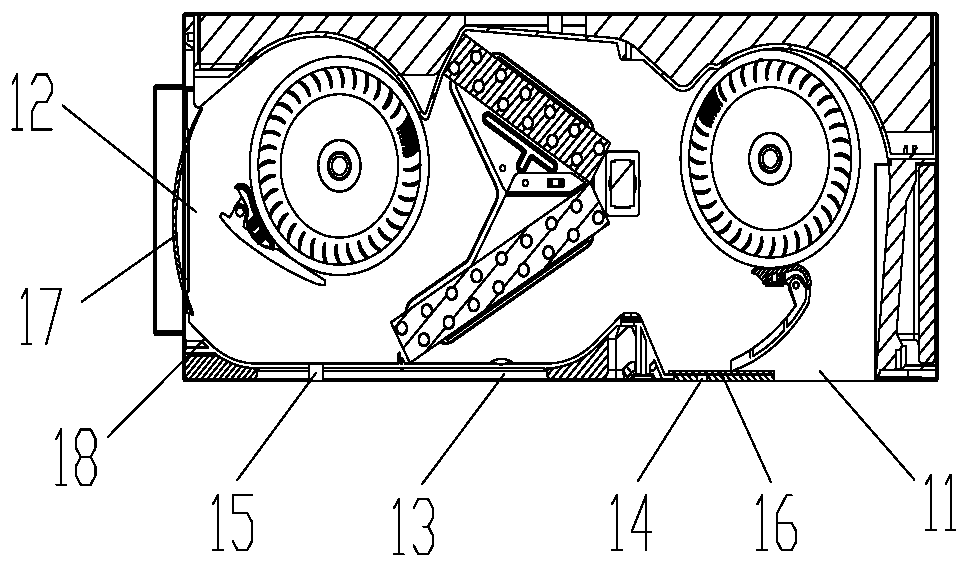

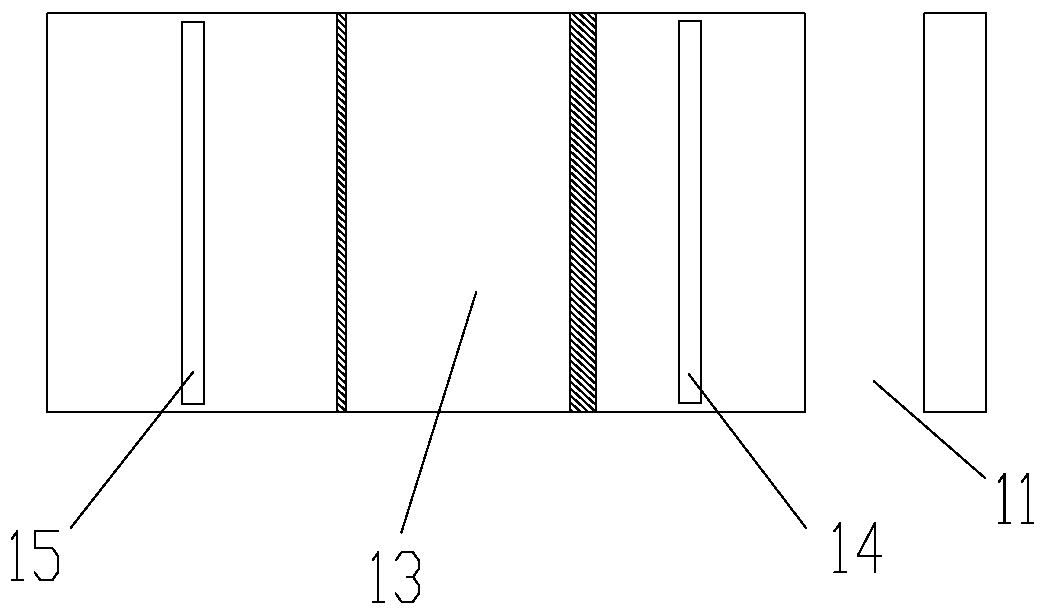

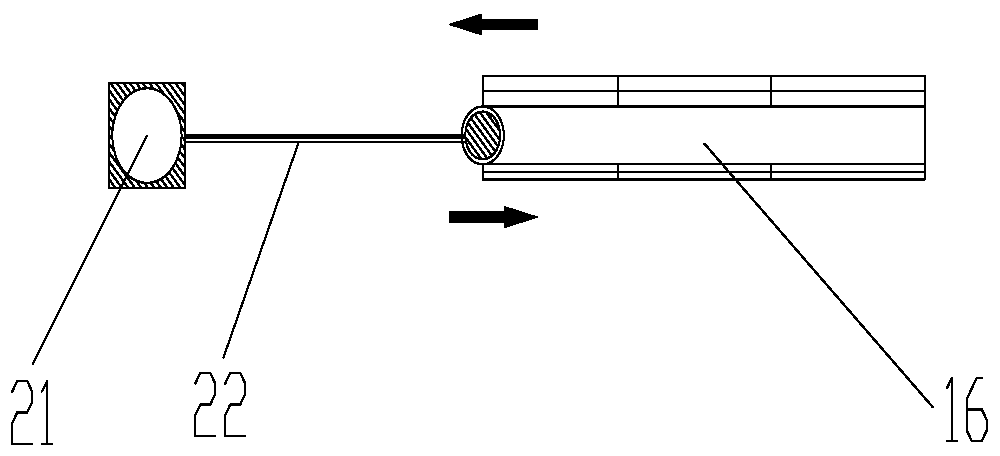

The invention discloses a solar photovoltaic panel dust removal device for sand and dust land, and relates to the technical field of power generation facilities. The solar photovoltaic panel dust removal device for the sand and dust land comprises a photovoltaic panel and a sand and dust removal device, wherein sliding frames are arranged at the front end and the rear end of the upper surface of the photovoltaic panel; sliding ways are formed in the front faces of the sliding frames; and the upper surface of the photovoltaic panel is in lap joint with the bottom of the sand and dust removal device. According to the solar photovoltaic panel dust removal device for the sand and dust land, a cleaning device is arranged on the sand and dust removal device, an air blower conveys strong wind power to the cavity of a rotary drum, the wind power is focused and blown into a dust removal box through air gathering holes, sand on the upper surface of the corresponding photovoltaic panel in the dust removal box can be blown up under the action of the strong wind power, the rotary drum is driven to rotate anticlockwise under the action of a motor, and sand and dust in the dust removal box are blown into a sand storage bag along with the wind direction, so that the sand and dust on the photovoltaic panel are cleaned and collected without coming into contact with the photovoltaic panel, and damage to the photovoltaic panel is avoided.

Owner:SUZHOU BOLI NEW ENERGY TECH CO LTD

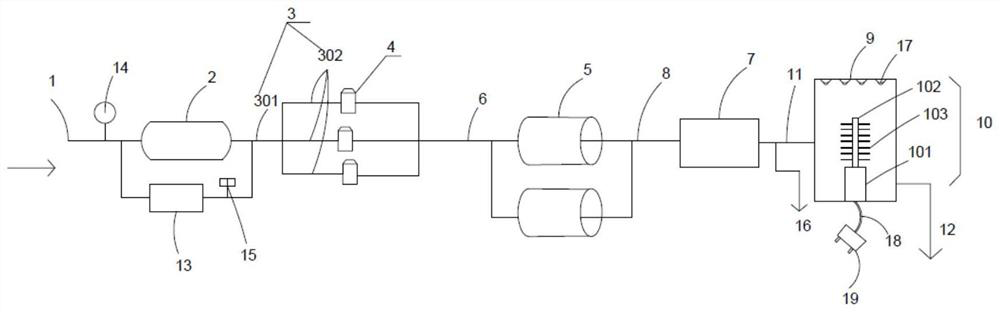

Method for increasing concentration of carbon dioxide in tail gas of lime rotary kiln

InactiveCN110683544AIncrease concentrationHigh purityCalcium/strontium/barium carbonatesMaterial nanotechnologyCo2 absorptionDust control

The invention discloses a method for increasing the concentration of carbon dioxide in tail gas of a lime rotary kiln. The method is characterized by comprising the following steps: (1) the tail gas of the lime kiln passes through dedusting equipment to remove dust particles; (2) the dedusted tail gas is sprayed through a washing tower, the sprayed tail gas is desulfurized through a desulfurizingtower; (3) the desulfurized tail gas passes through a booster fan to enter a surge flask and then is conveyed into a carbon dioxide absorption tower, alkanolamine in the absorption tower absorbs the carbon dioxide, and the tail gas is metered and then emptied; (4) a carbon-dioxide-absorbed alkanolamine solution is pressurized through a rich solution pump to enter a regeneration tower; (5) the carbon-dioxide-absorbed alkanolamine solution is heated in the regeneration tower to desorb the carbon dioxide, the desorbed carbon dioxide is cooled, dried, analyzed and stored; and (6) a regenerated barren solution is cooled by a barren solution cooler and then pressurized through a barren solution pump to enter an absorption tower, and the carbon dioxide is absorbed again. An enrichment technologyfor the carbon dioxide in the tail gas of the lime rotary kiln brings certain economic benefits for enterprises while according with national industrial structure adjustment and environmental protection.

Owner:HUBEI UNIV

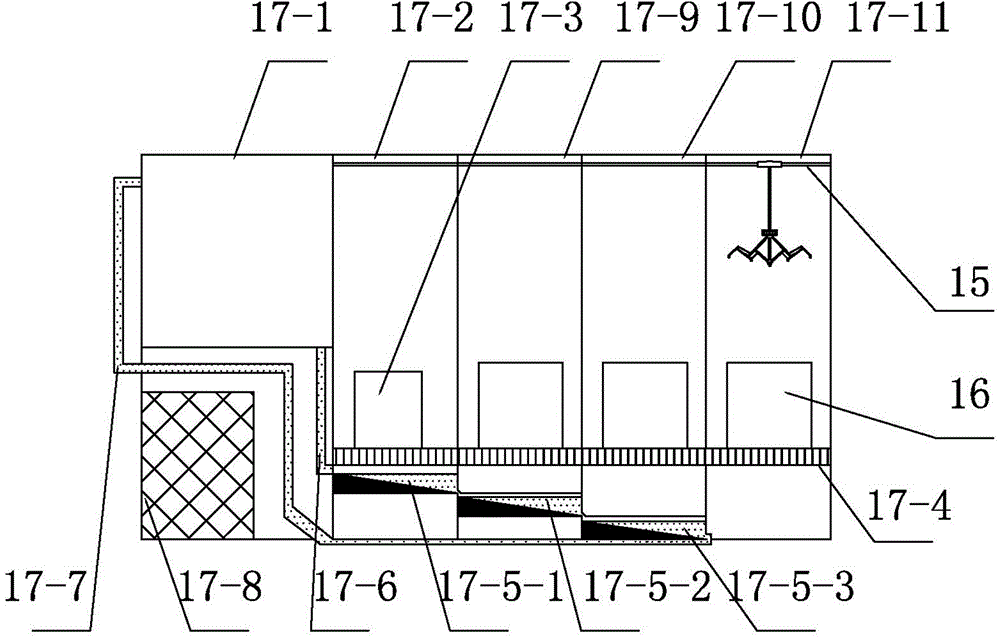

Dust-free workshop

InactiveCN104906892AReasonable designLow running costMeasurement devicesUsing liquid separation agentWater treatment systemDust control

Owner:浙江触捷光电科技有限公司

Flattening and shaping equipment for flocked cloth and flattening method

PendingCN113123058AQuality improvementImprove aestheticsMechanical cleaningPressure cleaningData connectionControl system

Owner:浙江唐艺织物整理有限公司

Intelligent wet-type dust removal equipment

PendingCN113648759AUnique principleReduce volumeUsing liquid separation agentDust detectionDust control

The invention provides intelligent wet-type dust removal equipment which comprises an air outlet, a rear shell, a sewage port, a front shell and an air inlet, the rear shell is connected with the front shell, a gutter channel is installed at the lower end of the rear shell and the lower end of the front shell, the sewage port is installed at the lower end of the gutter channel, a cyclone flow guide body is installed in the rear shell, and the air outlet is formed in one end of the rear shell. A driving device, a swirler and a fan impeller are respectively mounted in the front shell, the swirler is mounted on the driving device, the driving device is connected with the fan impeller, a temperature sensor is mounted on the driving device, an air inlet is formed in one end of the front shell, a dust detection module and a spraying system are respectively arranged on the air inlet, and an electric control water valve is mounted on the air inlet; the electric control water valve is connected with the spraying system through a pipeline, and the pipeline is provided with a flow sensor; the equipment is reasonable in structure, free of consumables, free of a cleaning period, high in trapping and self-cleaning capacity, capable of continuously working for a long time, free of blockage, free of disassembly, cleaning and maintenance, simple in structure and convenient to use.

Owner:SHENWEIDE (TIANJIN) MASCH EQUIP CO LTD

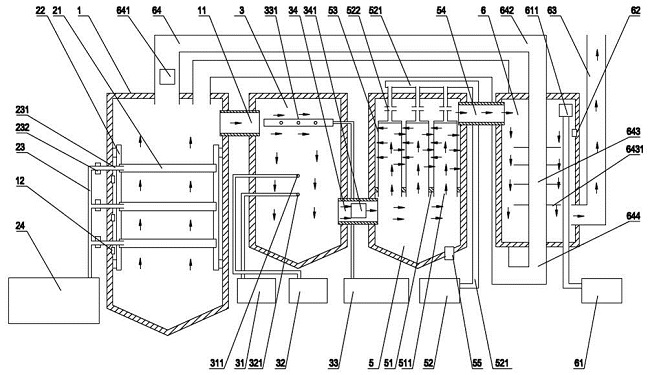

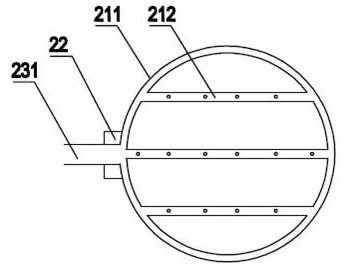

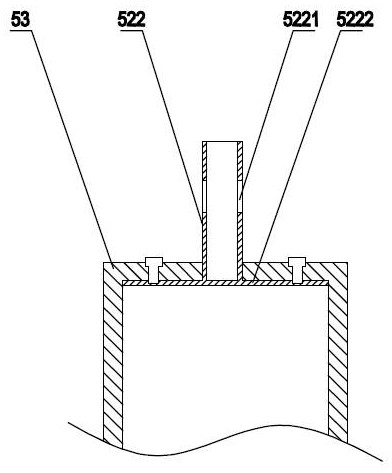

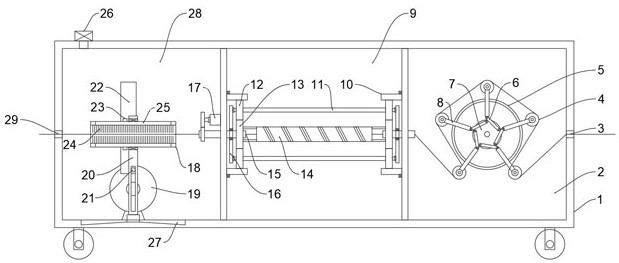

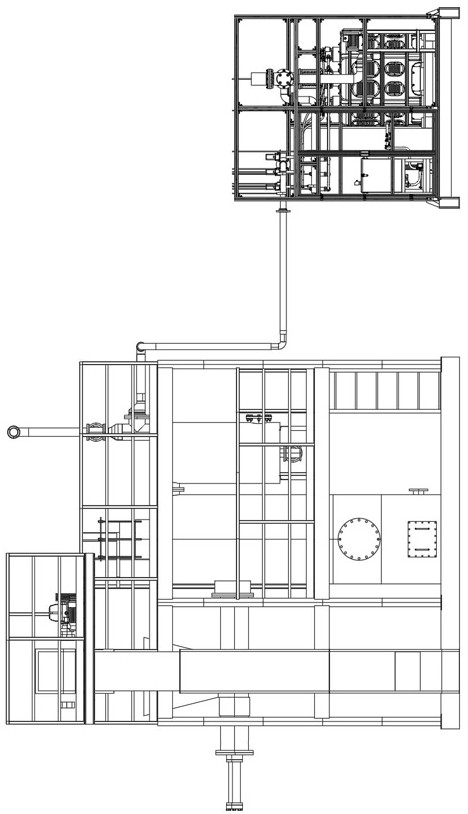

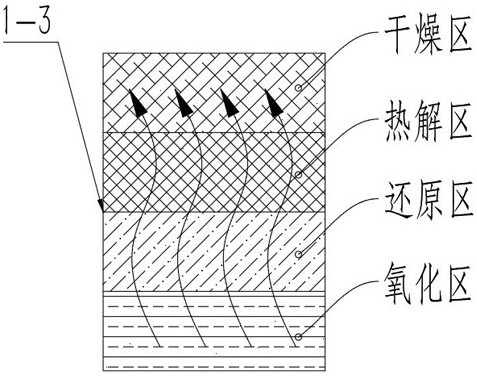

Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

ActiveCN105505422AEfficient dehydrationImprove thermal distillation efficiencyIndirect and direct heating destructive distillationSpecial form destructive distillationThermodynamicsCombustion chamber

The invention discloses an internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method. The system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device, wherein a spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, combustion smoke in the combustion chamber is directly supplied to the interior of a rotary kiln cylinder, and solid materials in the rotary kiln cylinder are supplied to the interior of the spiral pushing dry distillation chamber. Dry distillation of coal is divided into two or more phases according to temperature and is achieved through organic combination of the internal heating rotary kiln dry distillation device and the spiral pushing external heating dry distillation device, winnowing and dust removal, preheating and drying and dehydration are conducted on raw coal by means of a rotary kiln, high-efficiency medium and low temperature dry distillation and high-calorific-value raw gas and tar product precipitation are achieved by means of the spiral pushing external heating dry distillation device, the advantages of the internal heating dry distillation device and the external heating dry distillation are fully combined, dry distillation efficiency, heat utilization efficiency and the quality of dry distillation products are improved greatly, and marketing prospects are broad.

Owner:王崇峰

Household garbage incineration fly ash source reduction treatment system and method

InactiveCN111905535AReduce productionReduce landfill volumeCombination devicesGas treatmentBottom ashFlue gas

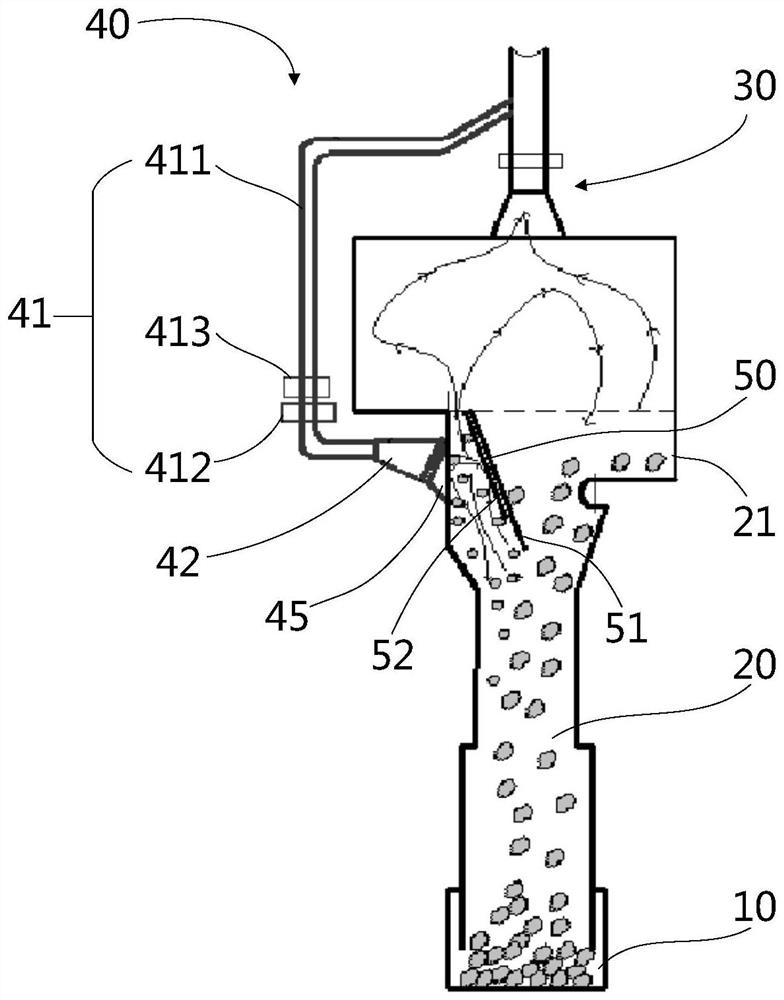

The invention discloses a household garbage incineration fly ash source reduction treatment system and method, and the treatment system comprises a deacidification reaction tower, a classifier and a chelating agent atomization reactor which are sequentially communicated, the bottom of the deacidification reaction tower is connected with a circulating fan, and household garbage incineration flue gas enters the deacidification reaction tower for deacidification treatment; the bottom ash of the deacidification reaction tower enters the deacidification reaction tower again under the action of thecirculating fan to be circulated, the flue gas subjected to deacidification treatment is classified into fine-particle fly ash and coarse-particle fly ash through the classifier, and the fine-particlefly ash enters the chelating agent atomization reactor to be subjected to chelating stabilization treatment for the first time; and the treated fine-particle fly ash and the treated coarse-particle fly ash are converged and subjected to dust removal treatment and secondary chelating stabilization treatment in sequence. According to the method, the consumption of consumables in the flue gas purification process is reduced, the action efficiency of desulfurization and heavy metal fixing agents is improved, the fly ash yield and harmless treatment cost are reduced, and fly ash reduction and efficient stabilization treatment of heavy metals are realized.

Owner:BEIJING CAPITAL ENVIRONMENT TECH CO LTD

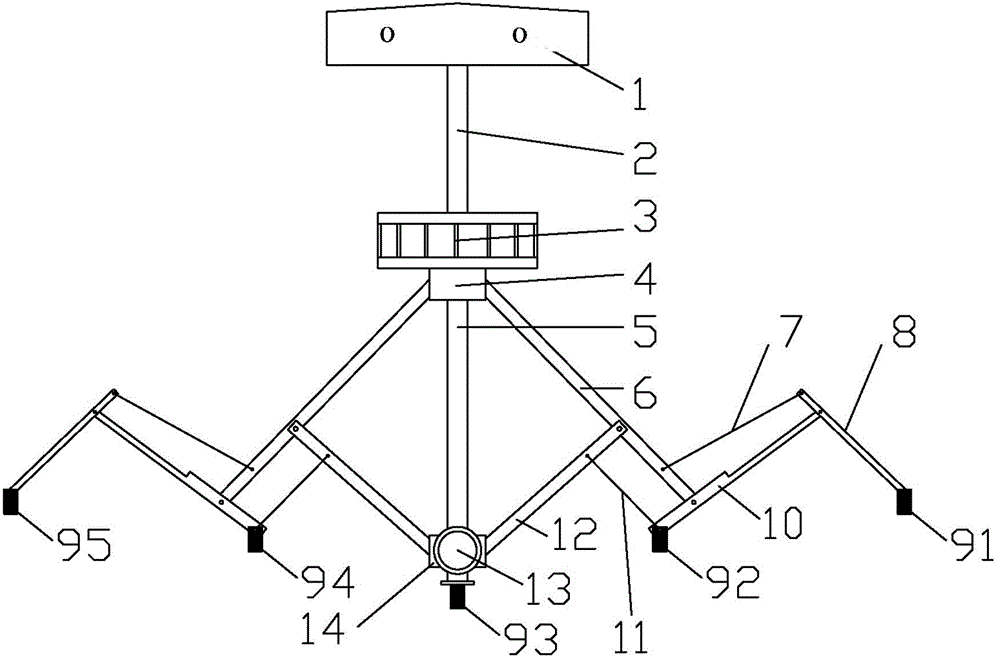

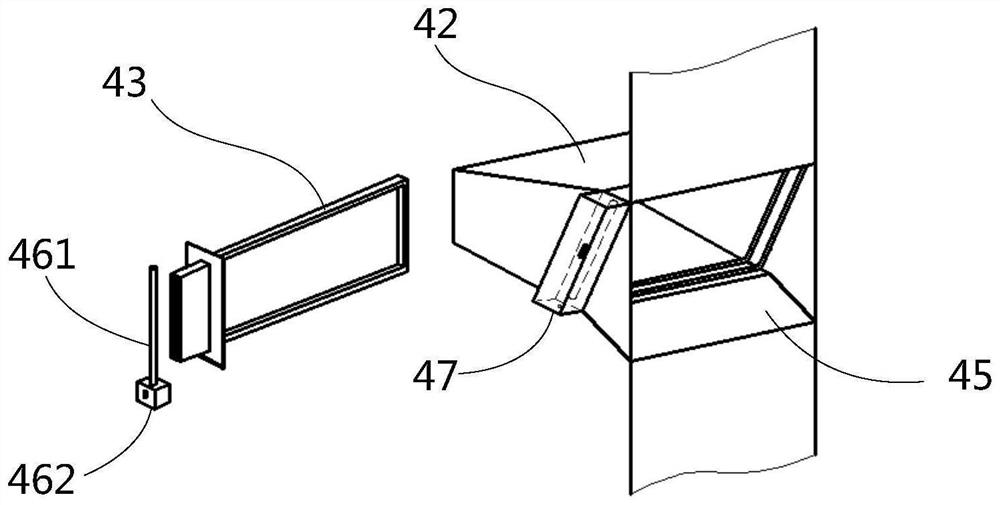

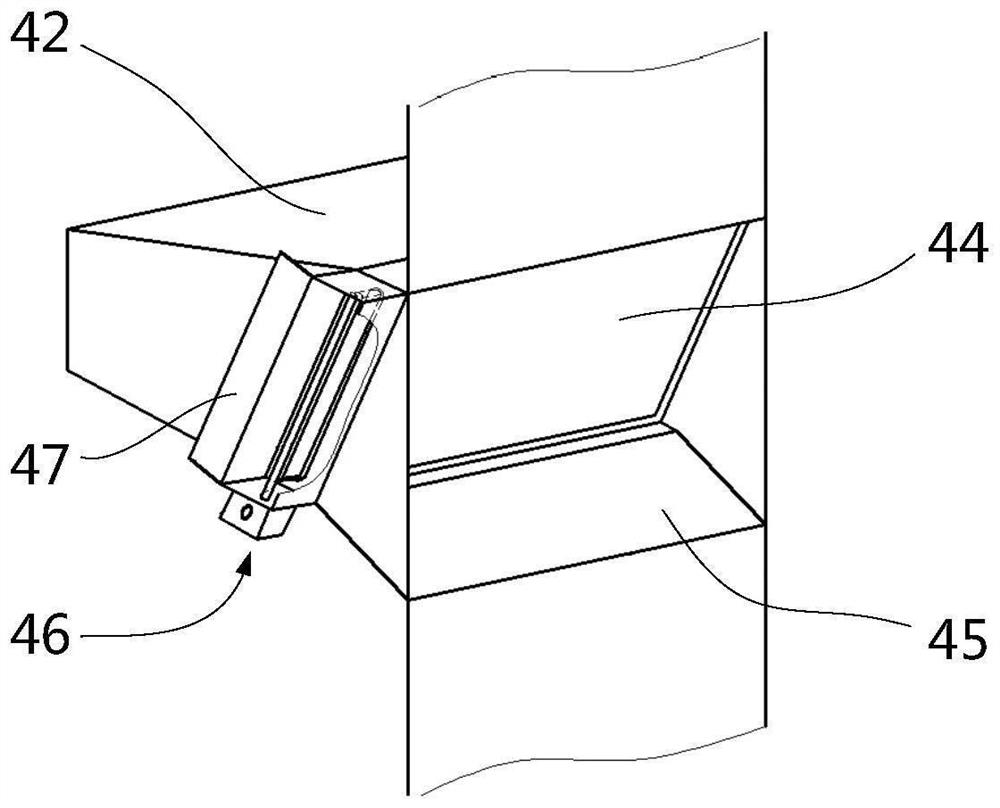

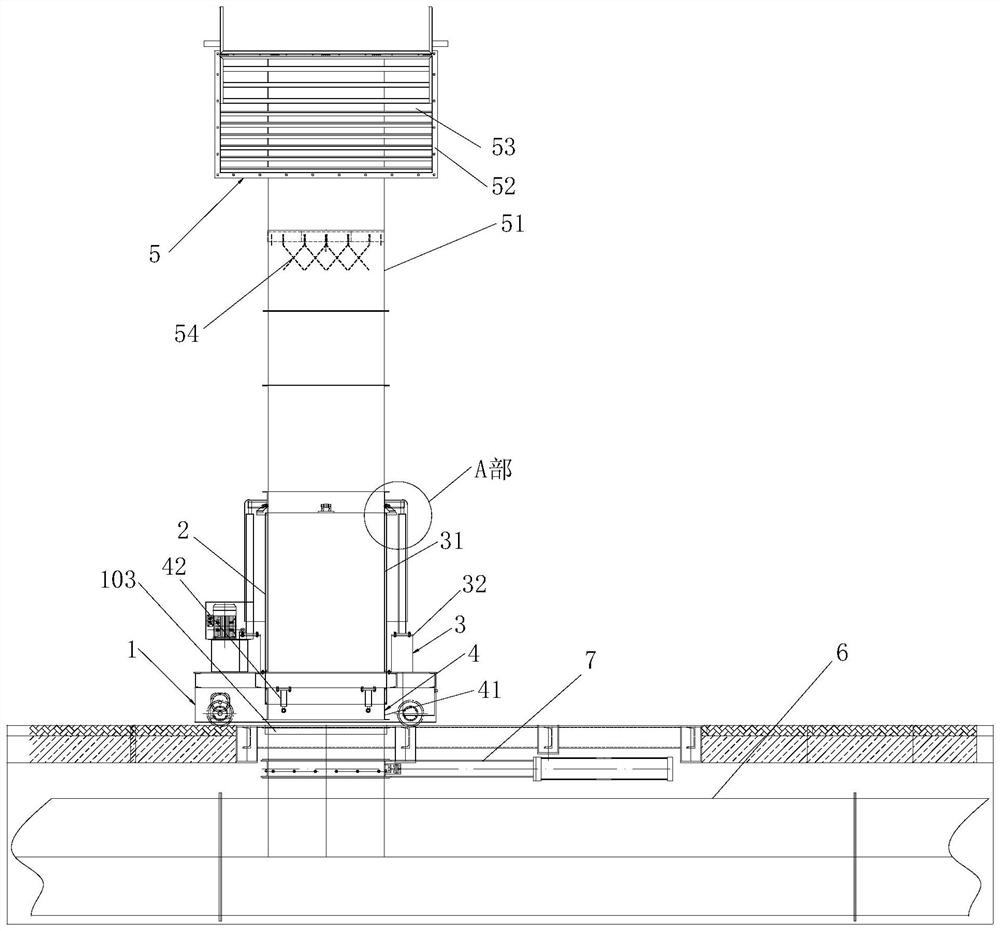

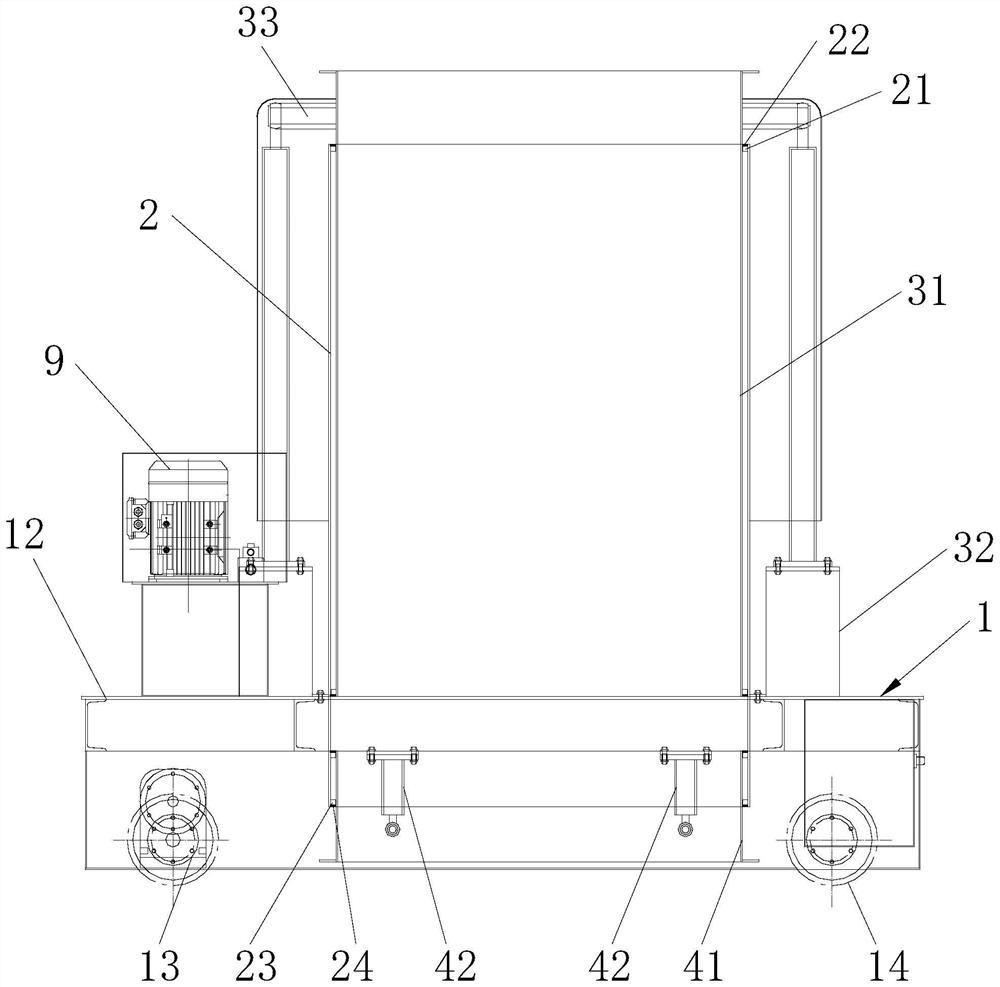

Intelligent robot dust removal system and method based on machine vision

PendingCN113902799AEffective purge cleaningPrevent proliferationImage enhancementImage analysisAutomotive engineeringDust control

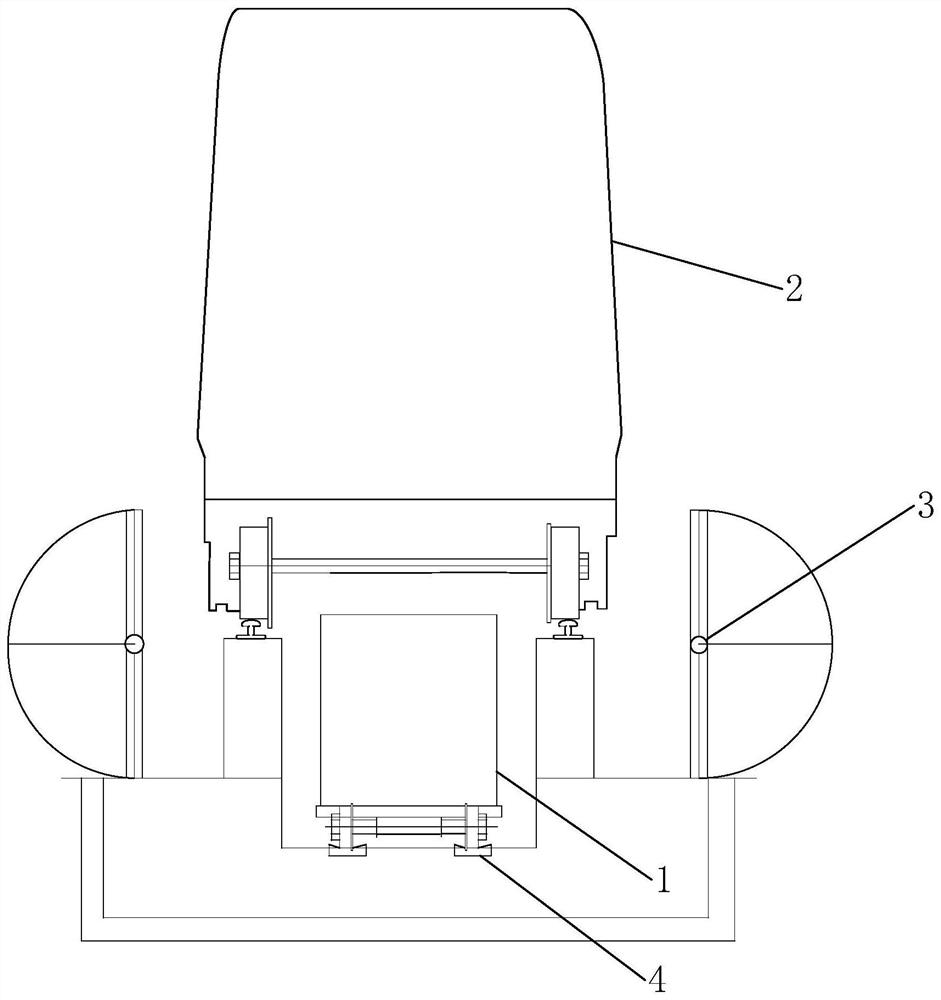

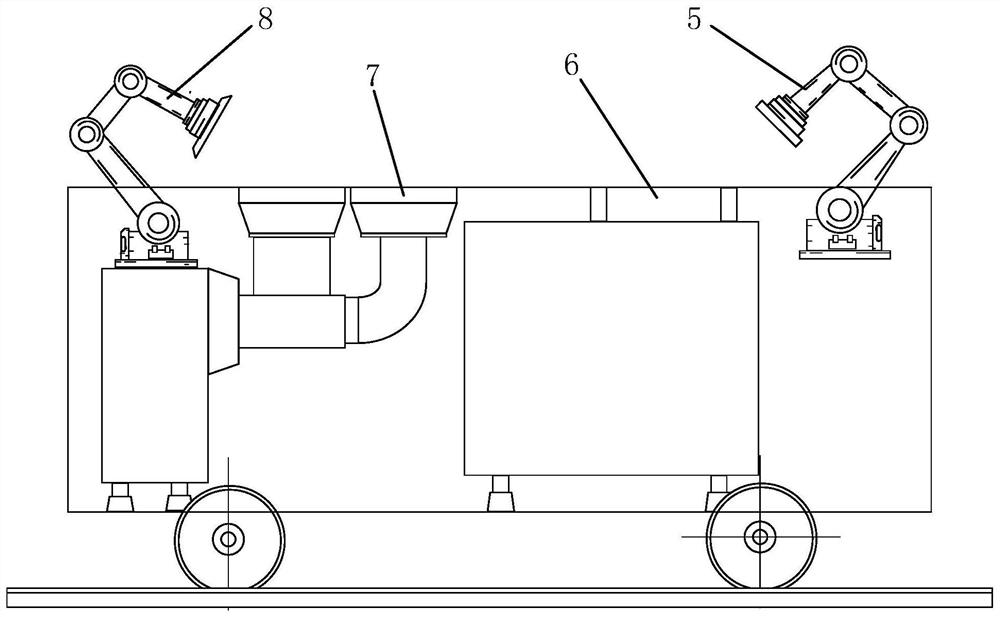

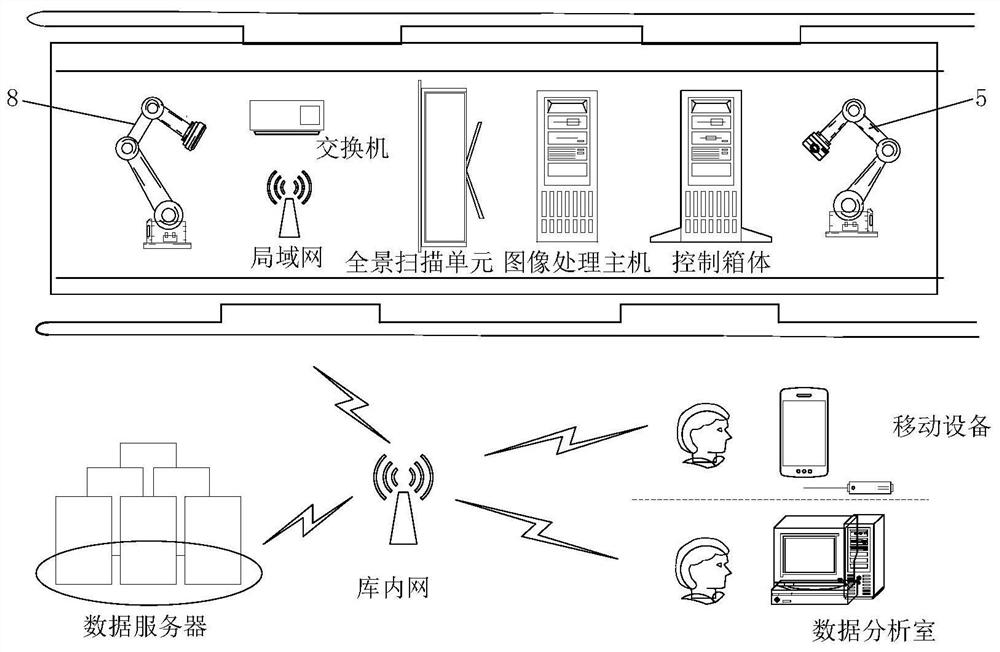

The invention discloses an intelligent robot dust removal system based on machine vision, which is used for removing dust at the bottom of a rail transit vehicle and comprises a dust removal trolley walking in a maintenance trench and air curtain devices on two sides. The dust removal trolley carries a front-end image acquisition mechanical arm which is provided with a linear array camera and a panoramic scanning unit and serves as an acquisition mechanism for shooting vehicle bottom images; a rear-end purging mechanical arm which carries a purging nozzle; a fixed nozzle used for sweeping the vehicle bottom in a large range; and a dust collection device used for synchronously collecting dust while blowing. According to the system, effective blowing and cleaning can be conducted on the vehicle bottom, dead corner and fixed-point blowing is conducted on the vehicle bottom structure, the cleaning effect is improved, a relatively closed space is formed in each blowing station, the good dust collection effect is achieved, dust diffusion generated in blowing operation is prevented, and the working environment in a blowing warehouse is improved. The intelligent robot is used for replacing traditional manual operation, the operation efficiency and quality can be effectively improved, and the manual labor intensity is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Energy-saving environment-friendly low-noise desulfurization, denitrification and dust removal device and treatment method

InactiveCN111617610AImprove responseEffective contactGas treatmentDispersed particle filtrationActivated carbonPtru catalyst

Owner:潘帅

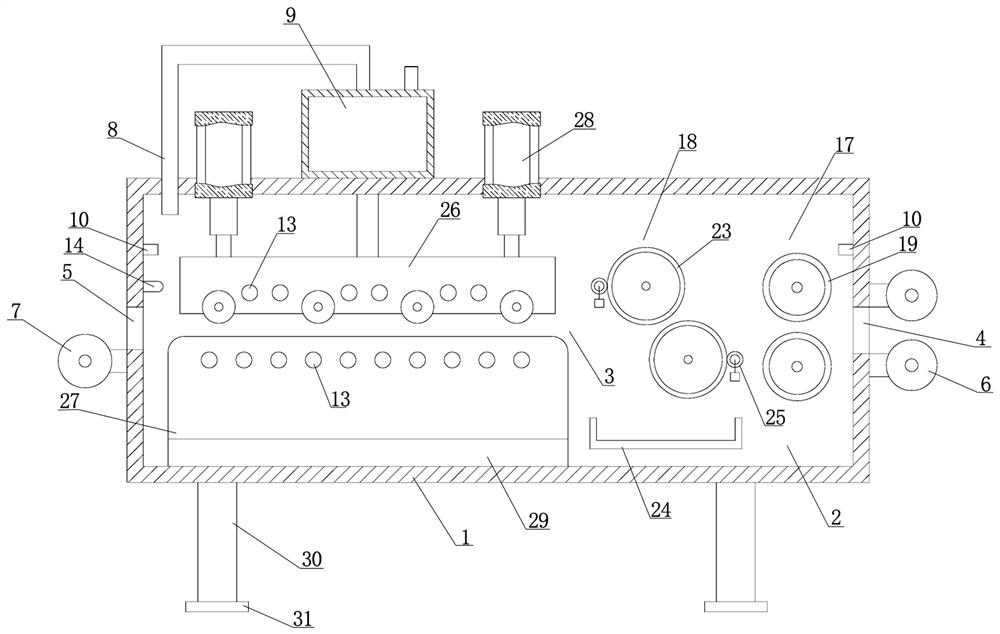

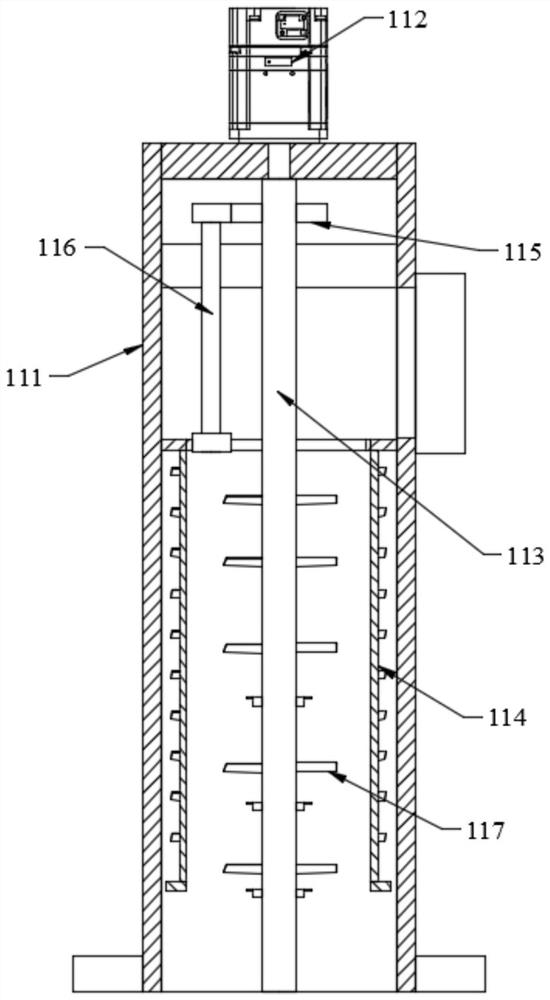

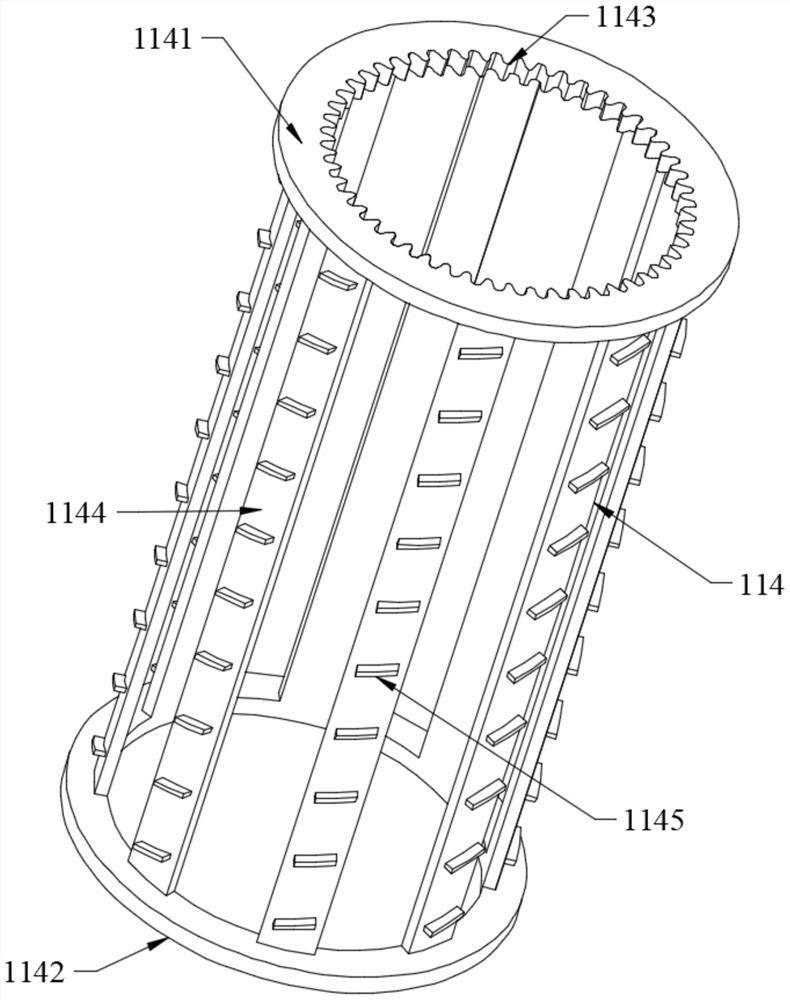

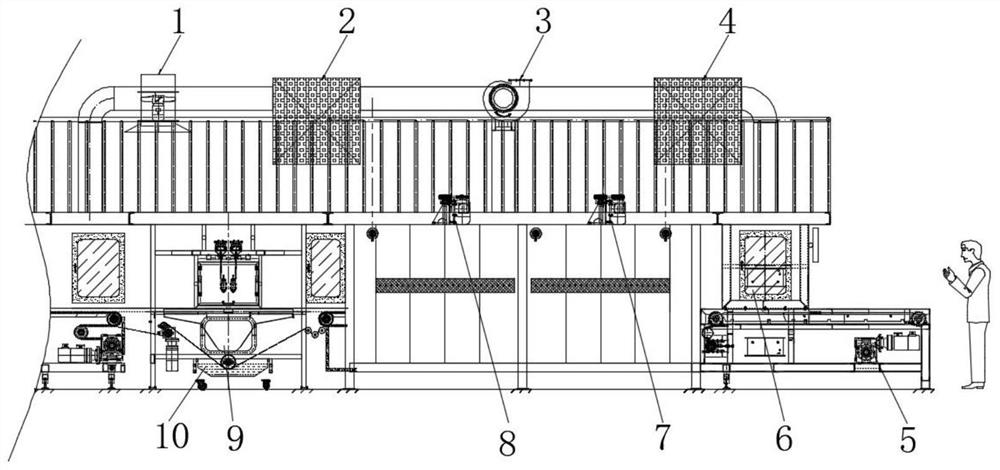

Annealing equipment for invisible protective net steel wire rope machining

ActiveCN113564340AExtend heating timeFully heatedFurnace typesHeat treatment furnacesStampingGear wheel

Owner:江苏鑫平金属制品有限公司

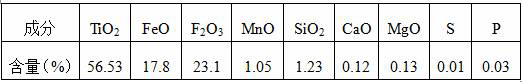

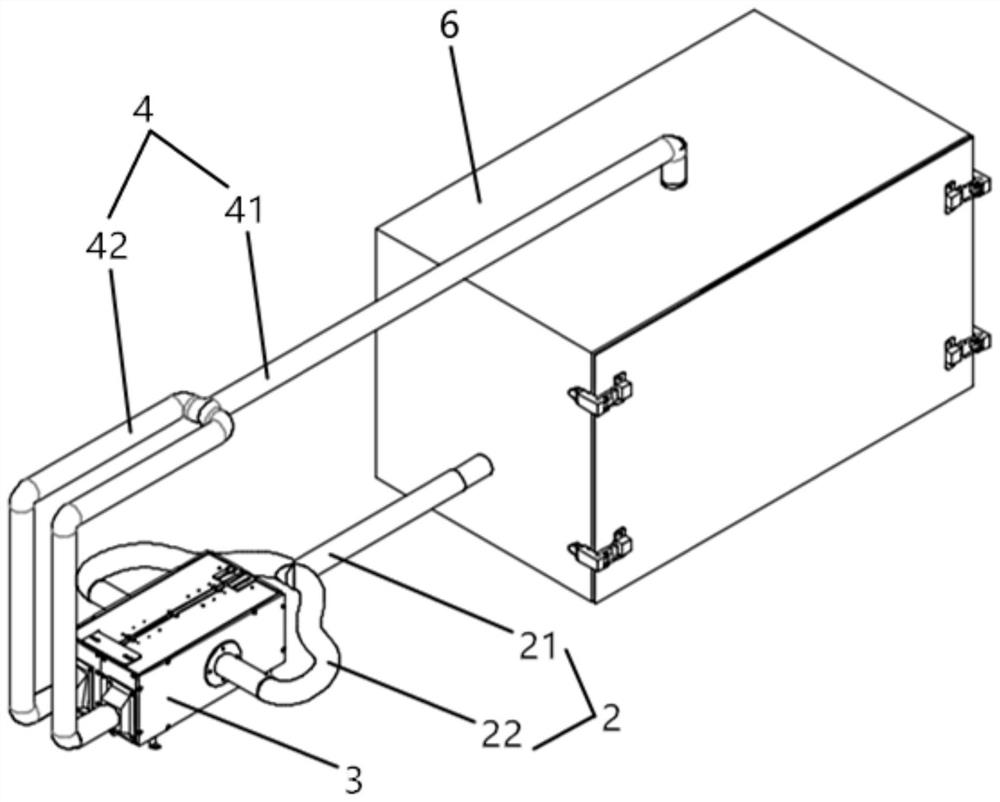

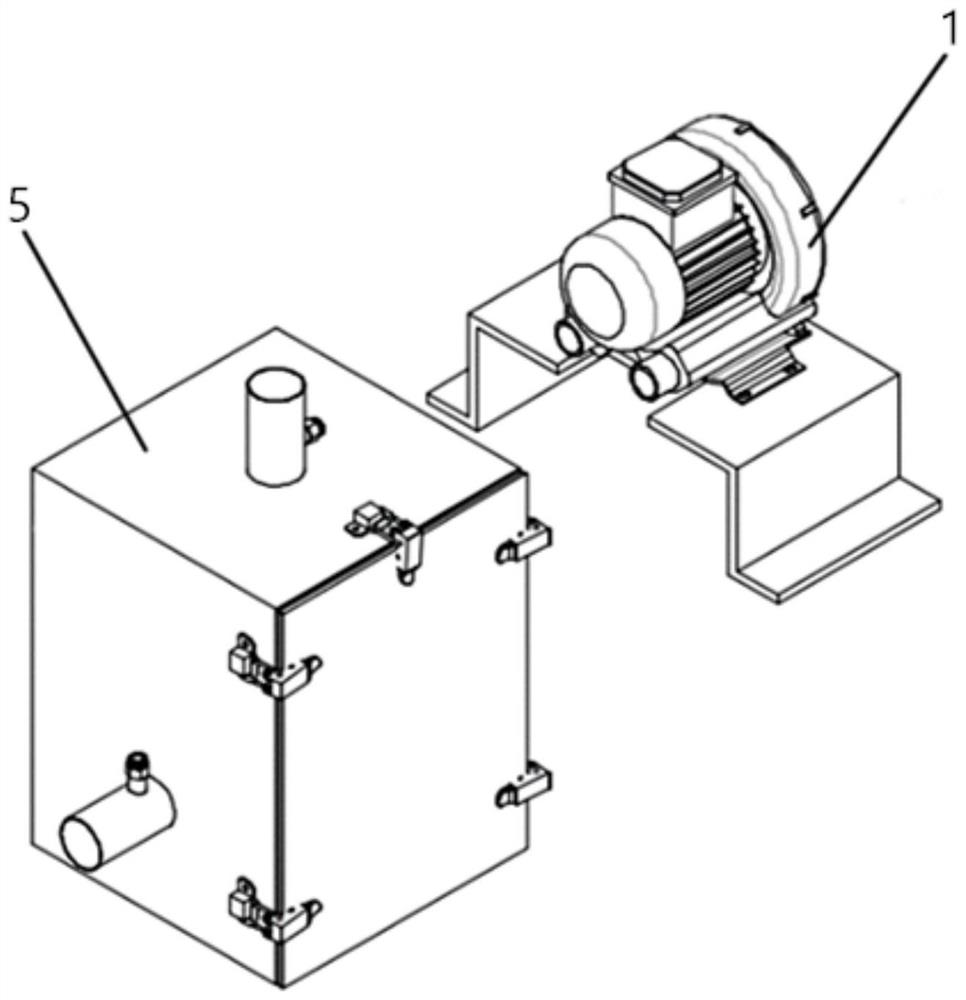

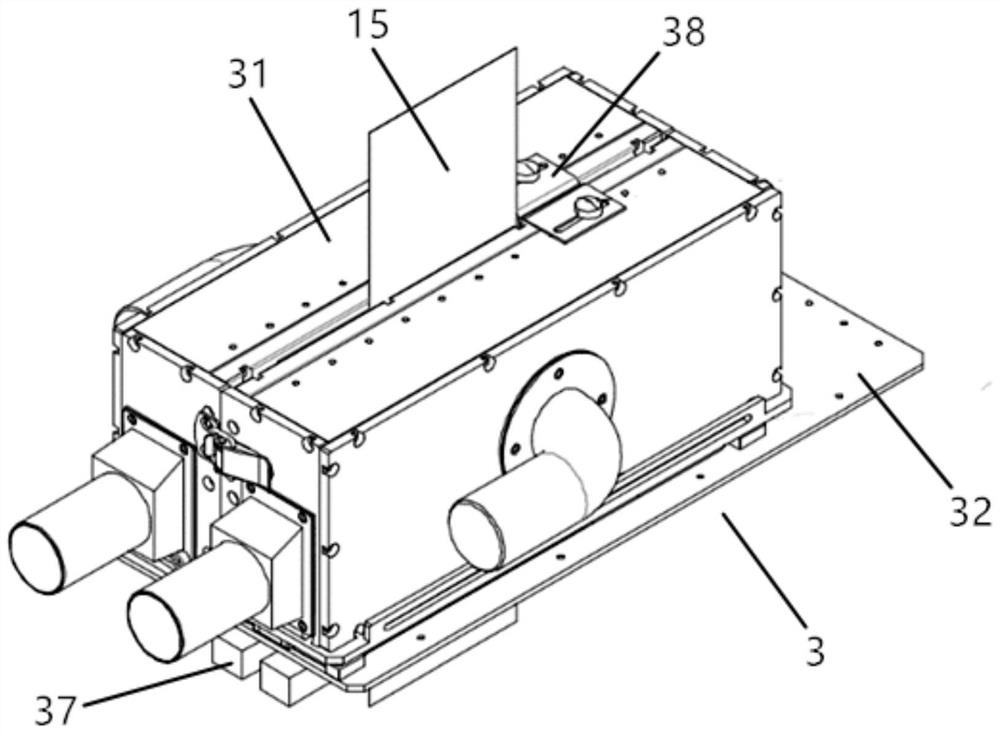

Preparation process and system for producing high-grade titanium-rich material by utilizing ilmenite

ActiveCN111733336AThere is no limit to the choice of materialsLow failure rateRotary drum furnacesMagnetic separationDust controlIlmenite

Owner:湖南碳谷装备制造有限公司

Heat dissipation device for new energy drying machine

PendingCN113339296AResilientSo as not to damagePump componentsDrying solid materialsThermodynamicsNew energy

The invention discloses a heat dissipation device for a new energy drying machine. The heat dissipation device comprises a heat dissipation device body, the heat dissipation device body internally comprises a first shell, circular grooves, dust removal devices, cylinders and fan blades, the circular grooves are formed in the left end and the right end of the top of the first shell correspondingly, and the dust removal devices are arranged at the ends, away from each other, of the inner walls of the two circular grooves correspondingly; and the cylinders are arranged at the axis positions inside the two circular grooves correspondingly. According to the heat dissipation device, a cleaning mechanism is arranged, and therefore dust on the surfaces of the fan blades can be cleaned; when a fixing plate is hit, part of stress can be reduced through a spring, and rapid rebounding can be achieved; stress can be greatly reduced through a rebounding mechanism; an air bag has certain toughness and is not prone to being damaged through an arc-shaped plate arranged inside; an elastic rope pulls an elastic piece to reset when the rebounding mechanism deforms due to the stress; and the elastic piece is arranged so that the air bag can have the toughness and the rebound reset effect.

Owner:黄亮

Non-contact dust removal equipment, system and method

ActiveCN114082712AAvoid secondary pollutionSimple structureDispersed particle filtrationTransportation and packagingProcess equipmentElectrical battery

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

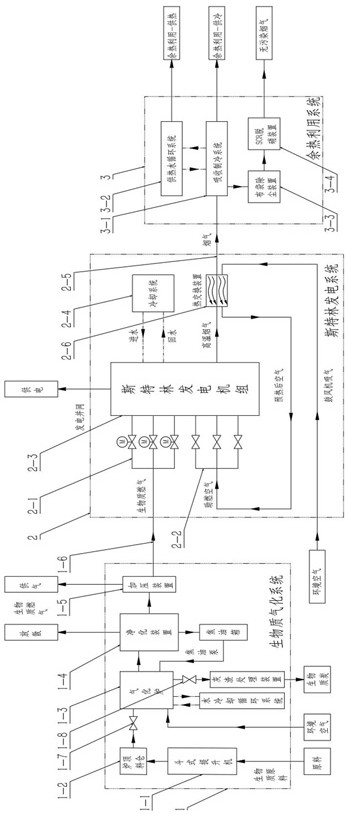

Biomass gasification Stirling power generation system

PendingCN112358896AIncrease profitEfficient use ofClimate change adaptationEnergy efficient heating/coolingDust controlElectric generator

Owner:青岛启迪能源与动力技术研究院

Ceramic tile production equipment facilitating dust removal

InactiveCN112060287ASimple structureLow costAuxillary shaping apparatusShaping conveyorsElectric machineDust control

Owner:耒阳市井阳陶瓷有限公司

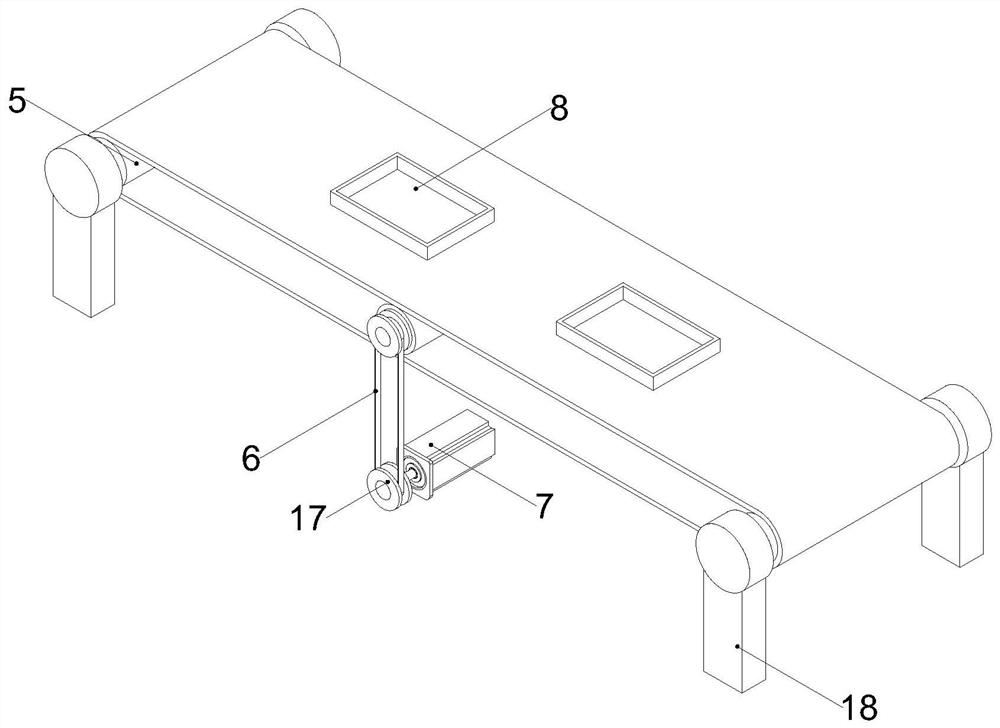

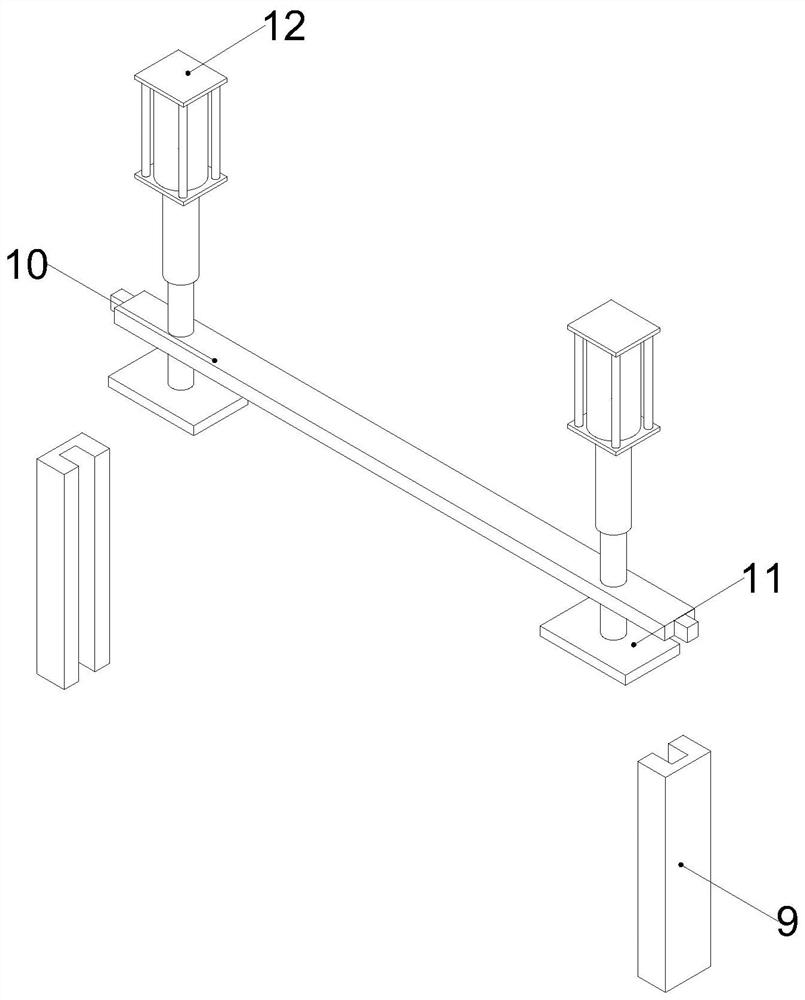

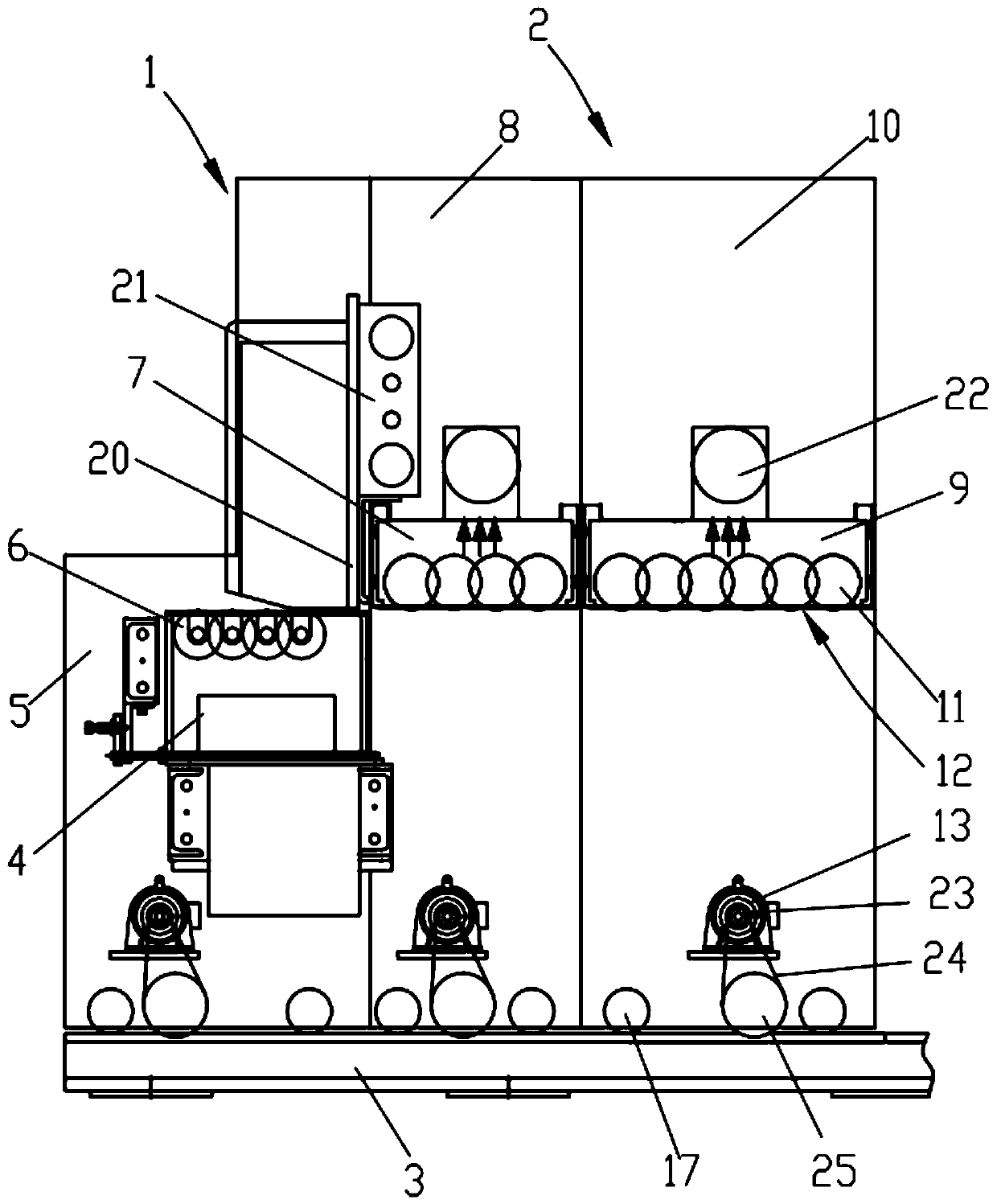

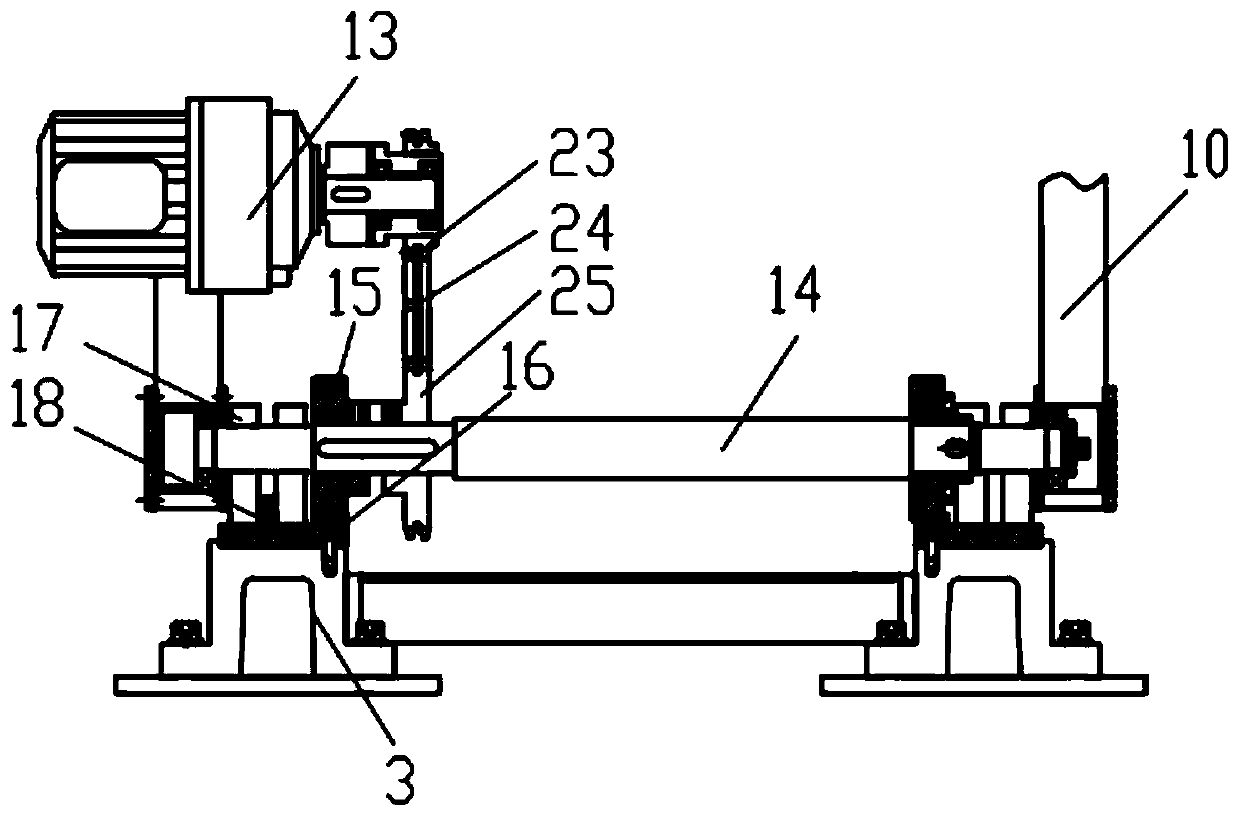

Split type corrugated board adsorption paper feeder

PendingCN110861348AEliminate corrugated crushEliminate collapsePaper-makingBox making operationsCardboardCarton

Owner:ZHUZHOU SINOVAN PACKAGING TECH

Environmentally-friendly air dedusting and purifying apparatus for machinery

InactiveCN110639313AAvoid cloggingExpand the spraying areaCombination devicesDeodrantsAir filtrationAir filter

The invention belongs to the technical field of air filtration, and especially relates to an environmentally-friendly air dedusting and purifying apparatus for machinery. The apparatus is provided tosolve the problem that existing air filtering apparatuses which adopts a physical filtering method to eliminate impurities in air without disinfecting bacteria in the air has low practicality. The apparatus comprises a disinfecting box and a dedusting box, an air inlet pipe is arranged at the top of the disinfecting box in a communicating manner, the disinfecting box and the dedusting box are fixedly connected to the same connecting pipe in a communicating manner, a fixing base is mounted at the bottom of the dedusting box, a partition plate is mounted in the disinfecting box and divides the internal of the disinfecting box into a filtering cavity and a disinfecting cavity, a matched filter screen is arranged in the filtering cavity, and two symmetrically-arranged ultraviolet disinfectinglamps are fixedly mounted on the inner wall of the bottom of the filtering cavity. The apparatus has the advantages of simple structure, realization of disinfection, sterilization and dedusting of gasthrough using the disinfecting box and the dedusting box, simplicity in operation, low production cost and wide market promotion prospect.

Owner:江先庆

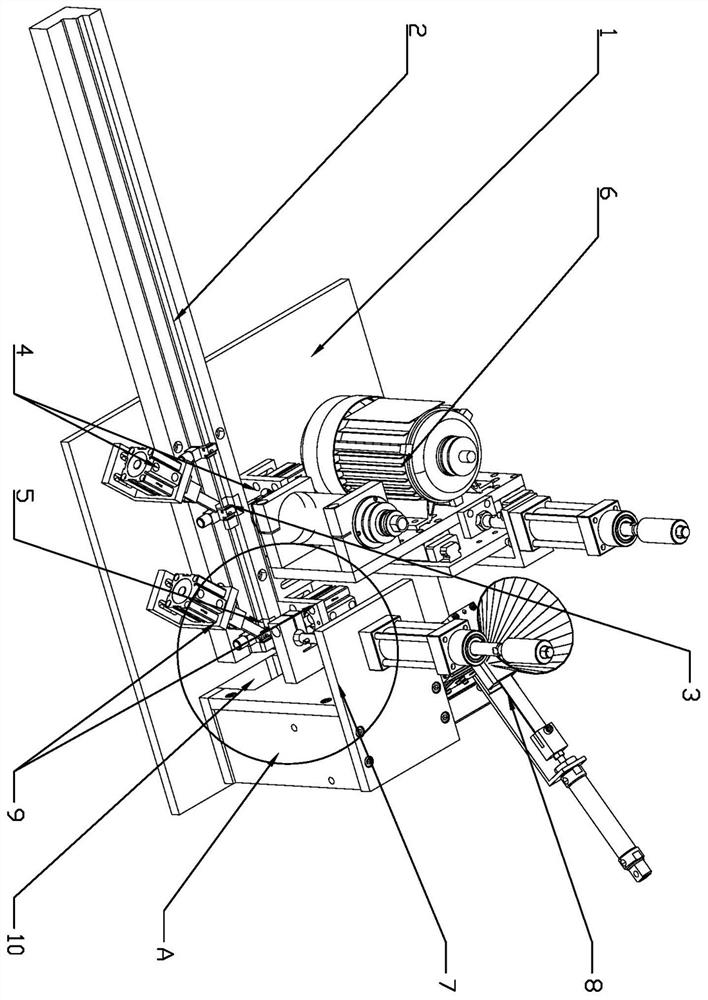

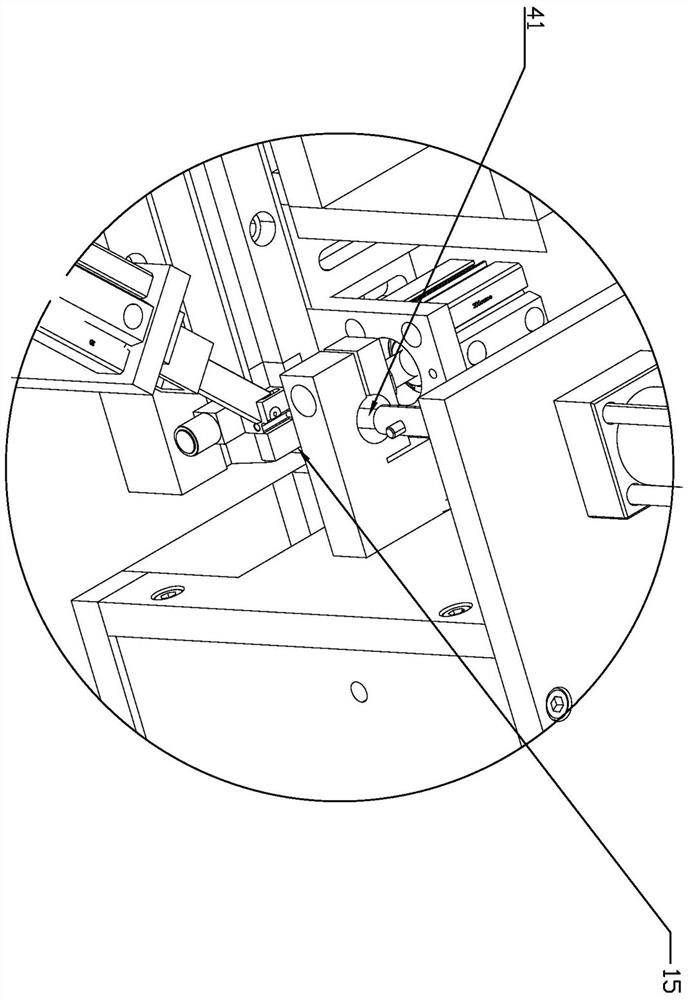

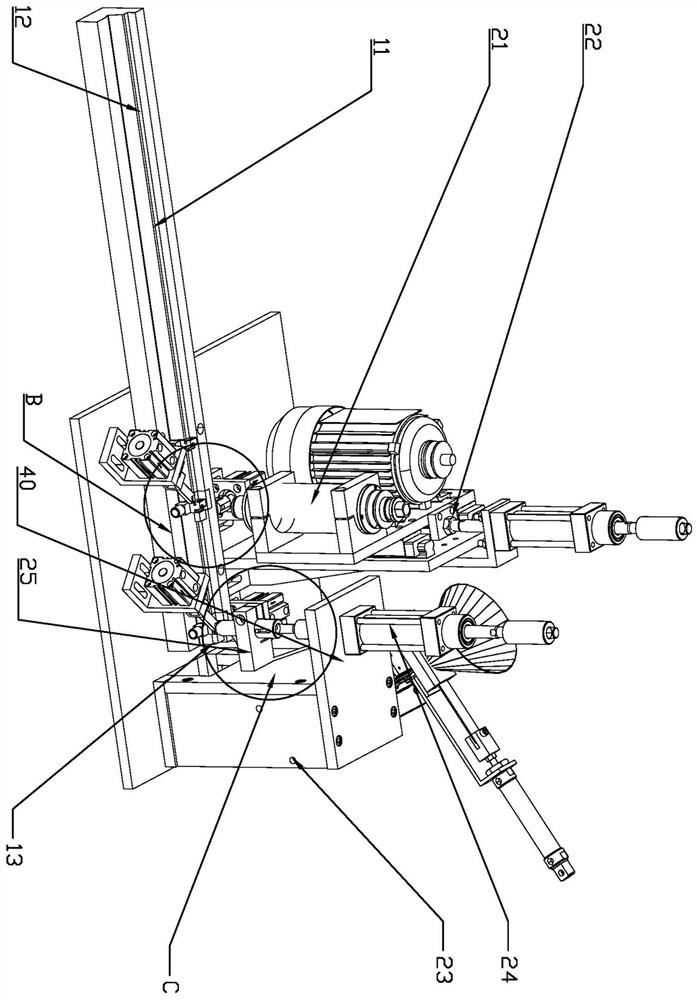

Automatic chamfering and shank riveting integrated equipment for nozzle and chamfering and shank riveting process

ActiveCN112643351AImprove work efficiencyLow costWork clamping meansOther manufacturing equipments/toolsDust controlEngineering

Owner:扬州斯科迪冶金设备有限公司

Dust removal structure of air conditioner and dust removal method thereof

Owner:GREE ELECTRIC APPLIANCES INC

Tobacco leaf packaging and pre-pressing system and method and tobacco leaf packaging and pre-pressing machine

ActiveCN114304696AReduce the spray volumeReduce floatingTobacco preparationGas current separationAir velocityDust control

Owner:FUJIAN LONGYAN JINYE REDRYING

Ground-connected movable molten iron casting ladle dust collection device

Owner:CHANGZHOU SANSI ENVIRONMENTAL PROTECTION TECH

High-cleanliness desulfurization and denitrification dust removal device with circulating synergism

ActiveCN114534474AAchieve separationSimplify classification processing stepsHuman health protectionGas treatmentMetal impuritiesDust control

Owner:江阴市尚时工程装备有限公司

Energy-saving and environment-friendly degreasing and brazing flux spraying drying device

InactiveCN112827732AImprove concentrationNo flowPretreated surfacesCoatingsThermodynamicsCoating system

Owner:盐城市苏文机械有限公司

System and method for preparing sulfuric acid by recycling waste crude ferric sulfate salt in iron and steel industry through pickling

PendingCN113511634ASuppress generationEfficient use of resourcesSulfur compoundsIron sulfateSteelmaking

Owner:佛山市景嘉机电设备有限公司

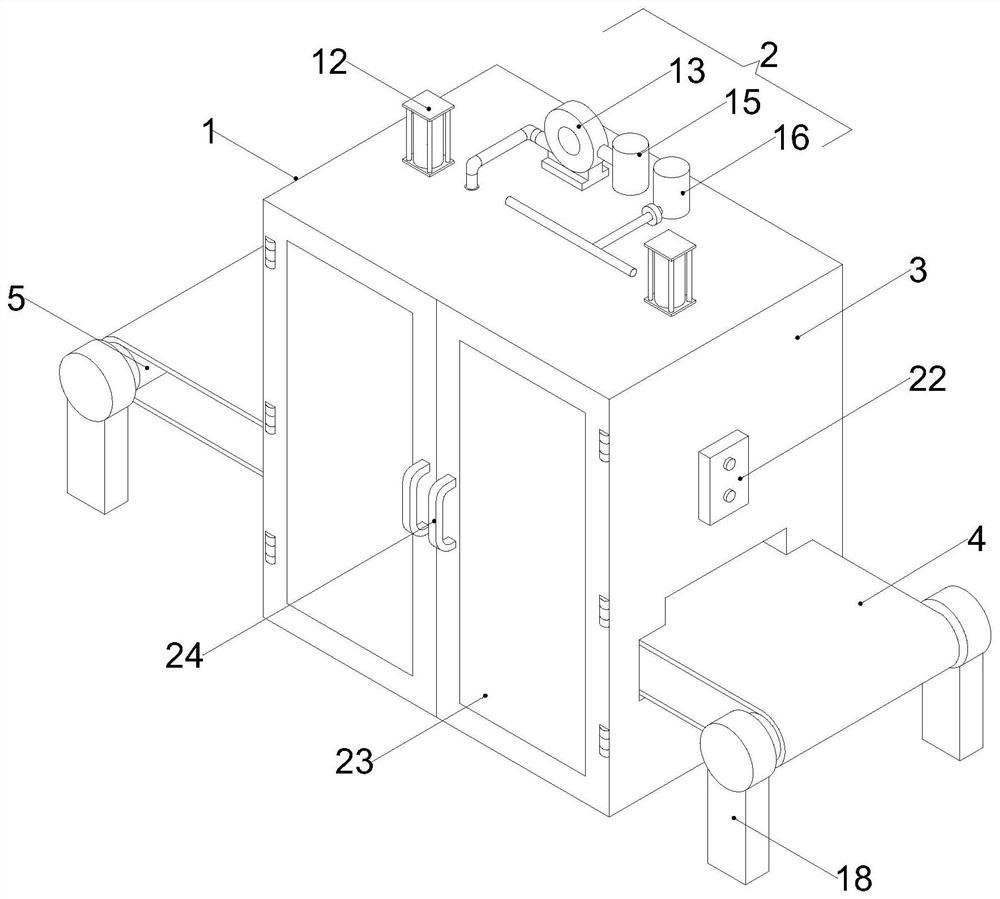

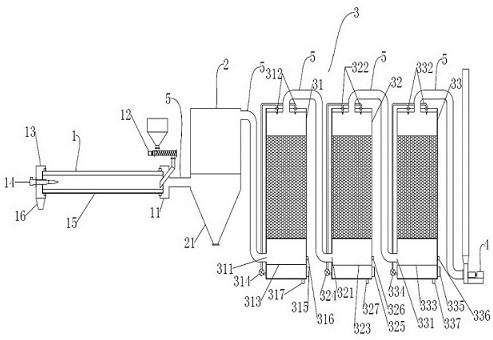

Four-station wet-type anti-explosion dust removal equipment

InactiveCN113752140ASmall footprintImprove space utilizationDirt cleaningGrinding machinesPolishingDust control

The invention discloses four-station wet-type anti-explosion dust removal equipment. The four-station wet-type anti-explosion dust removal equipment comprises a machine body and a plurality of polishing stations which are arranged on the front side and / or the rear side of the machine body respectively and provided with polishing devices, a cabinet barrel provided with a dust collection assembly is arranged at the bottom of each polishing station, and a wet-process dust collection mechanism or a dry-process dust collection mechanism is arranged in each dust collection assembly. Compared with the prior art, the dust-removing explosion-proof equipment has the advantages that by providing the plurality of polishing stations with dust-removing mechanisms, the occupied area of a workshop is reduced as much as possible, and the space utilization rate of the workshop is increased; and switching use of wet-process dust removal and dry-process dust removal is achieved through the replaceable dust collection assemblies, so that the equipment adapts to polishing and dust removal work of different workpieces or different materials, and the practicability of the equipment is improved.

Owner:GUANGDONG SENHAO DUST REMOVAL EQUIP CO LTD

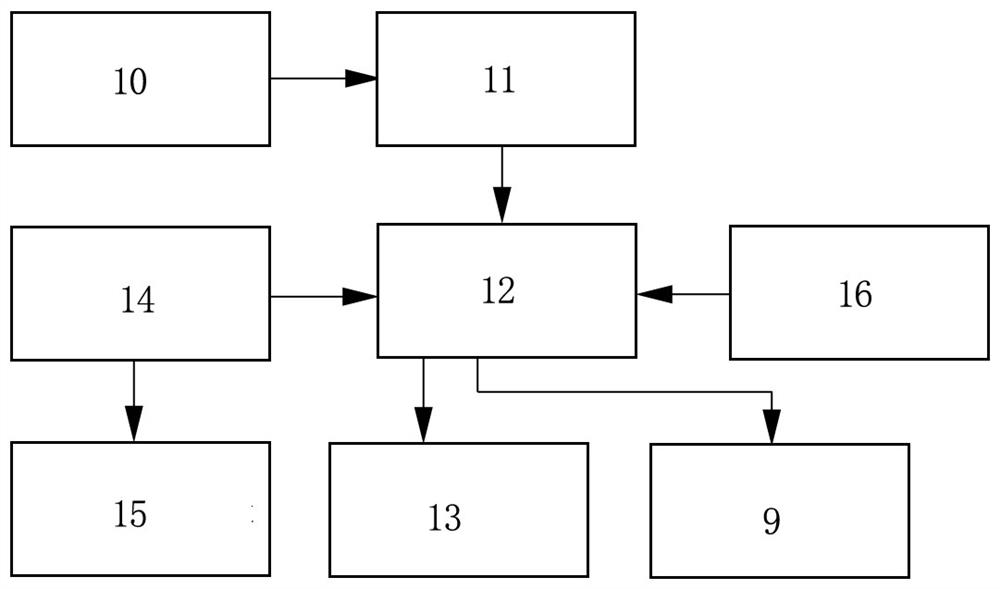

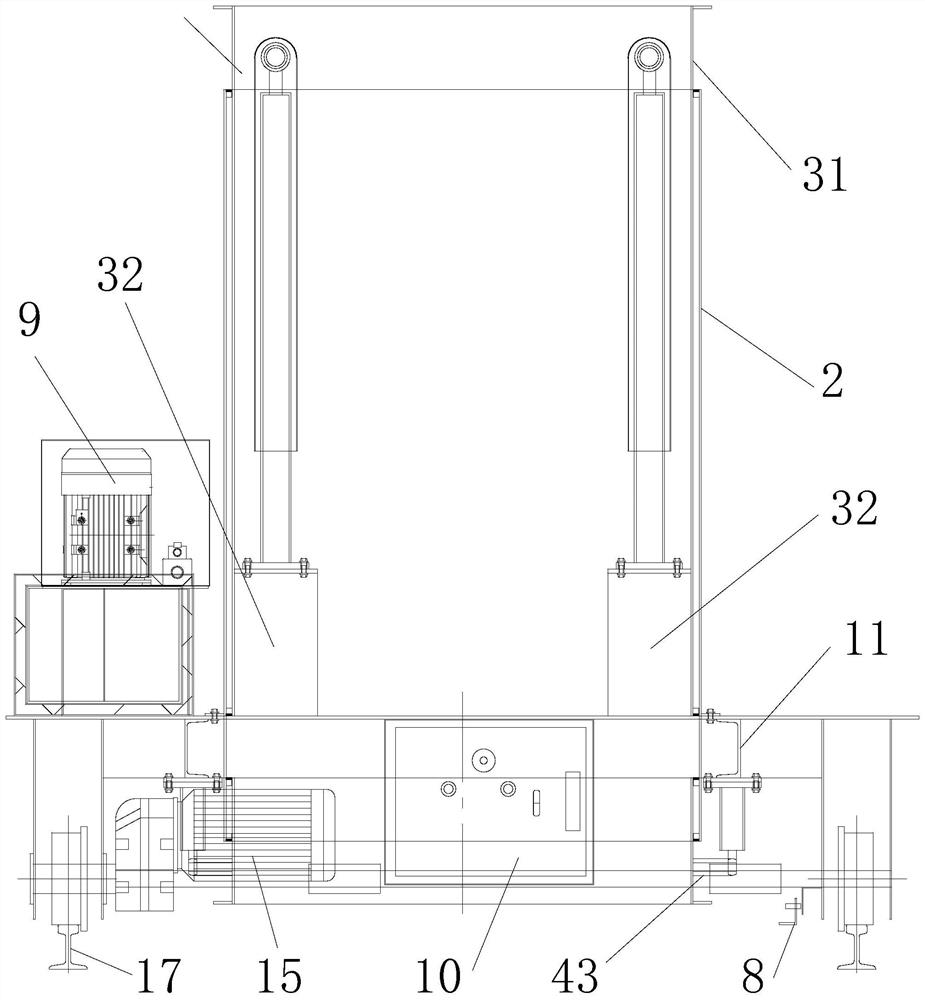

Dedusting equipment and using method thereof

PendingCN111515376AReduce energy consumptionImprove dust removal efficiencyCasting apparatusControl systemTransverter

Owner:KOCEL STEEL

Flue gas semi-dry desulfurization device and method

ActiveCN111545042ASolve the increase in production costsReduce manufacturing costGas treatmentDispersed particle separationFlue gasAir pump

The invention discloses a flue gas semi-dry desulfurization device and method. The device comprises a shell assembly, a desulfurization assembly, a dedusting assembly, a fan and a precipitation tank;the shell assembly comprises a shell, an air inlet pipe and an air outlet pipe; the air inlet pipe is fixedly connected with the shell and extends into the shell; the air outlet pipe is fixedly connected with the shell and away from the air inlet pipe. The desulfurization assembly comprises a desulfurizing agent box and a first spray head; the first spray head is fixedly connected with the desulfurizing agent box; the first spray head extends into the air inlet pipe, a fan and the shell are fixedly connected, and the first spray head penetrates through the air inlet pipe; the dedusting assembly comprises an induced draft pipe and an air pump; the induced draft pipe is fixedly connected with the shell, an air pump is fixedly connected with the induced draft pipe, a desulfurizing agent in the air inlet pipe is mixed with flue gas, then the mixture is blown out through the fan, generated solid particles move outwards due to centrifugal force and are downwards introduced into the precipitation tank through airflow of the air pump for precipitation, pure air is exhausted through the air outlet pipe, reheating is not needed, and thus the production cost is reduced.

Owner:JIANGSU FENGFENG HONGYUN ENVIRONMENTAL PROTECTION TECH DEV CO LTD

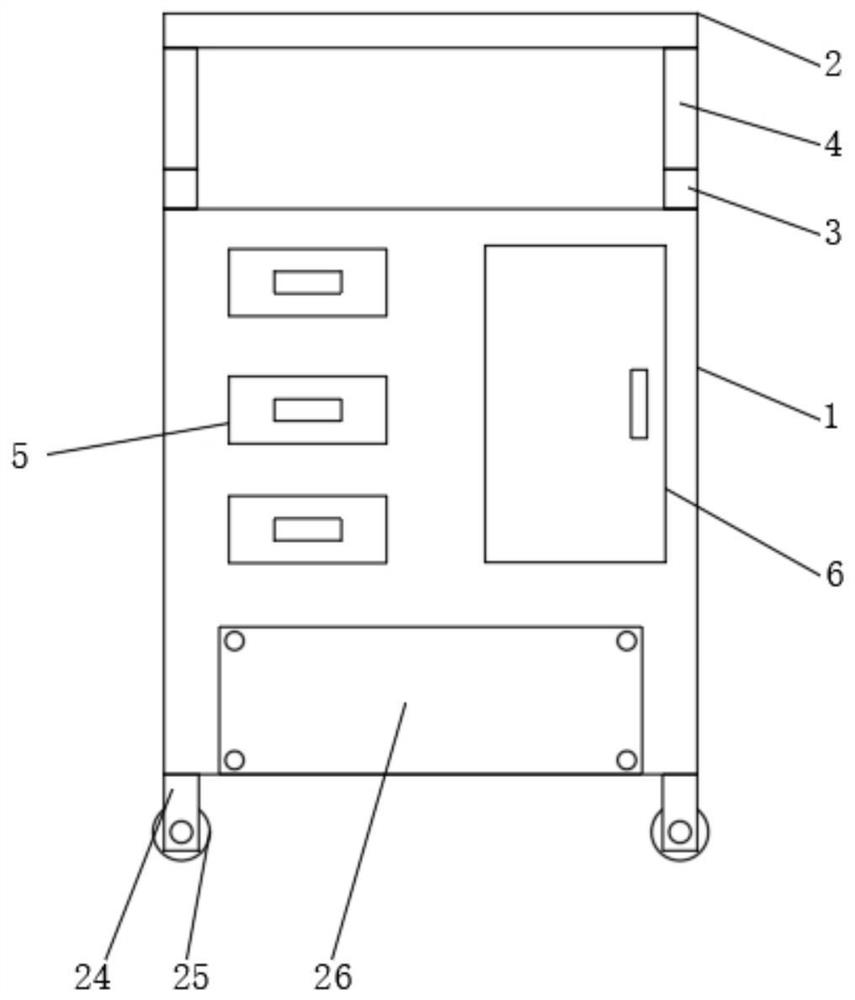

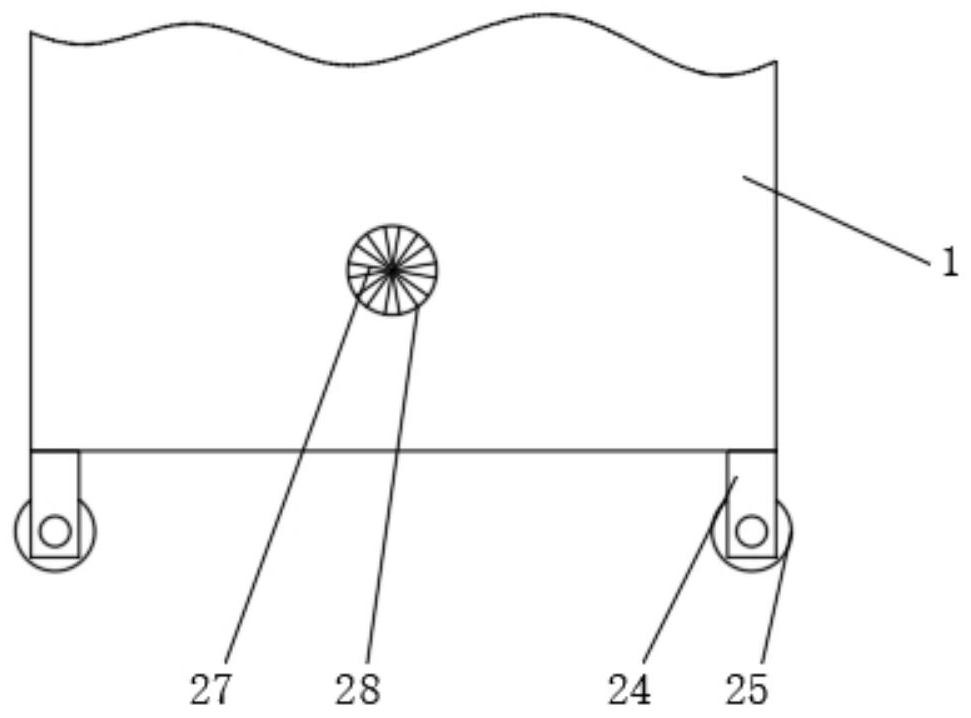

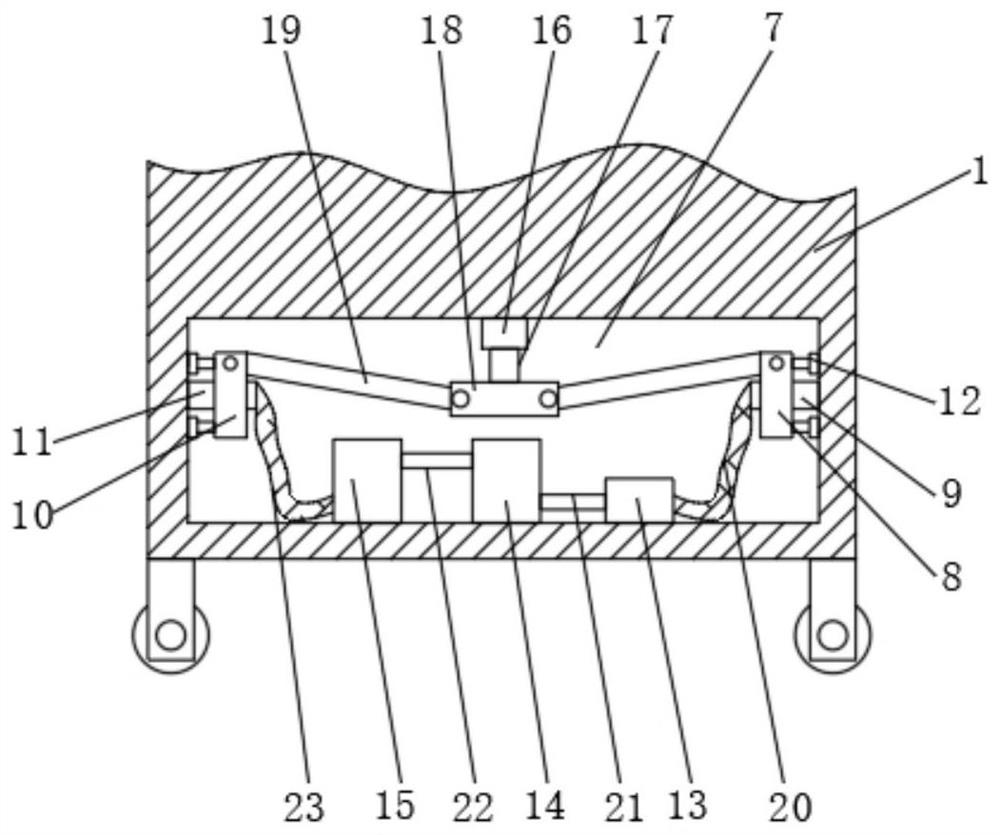

ICU bedside medical nursing vehicle

InactiveCN112155907APowerful storageHealthy recovery environmentDispersed particle filtrationTransportation and packagingNursing careDust control

Owner:楚翠玉

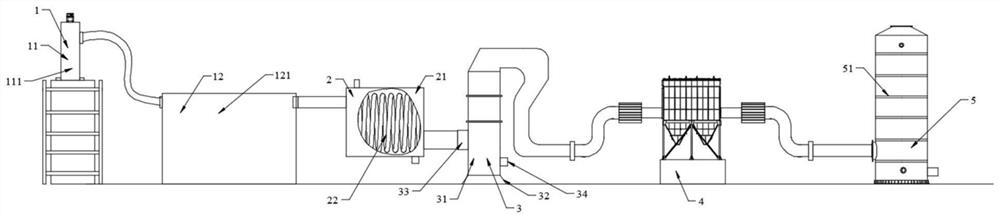

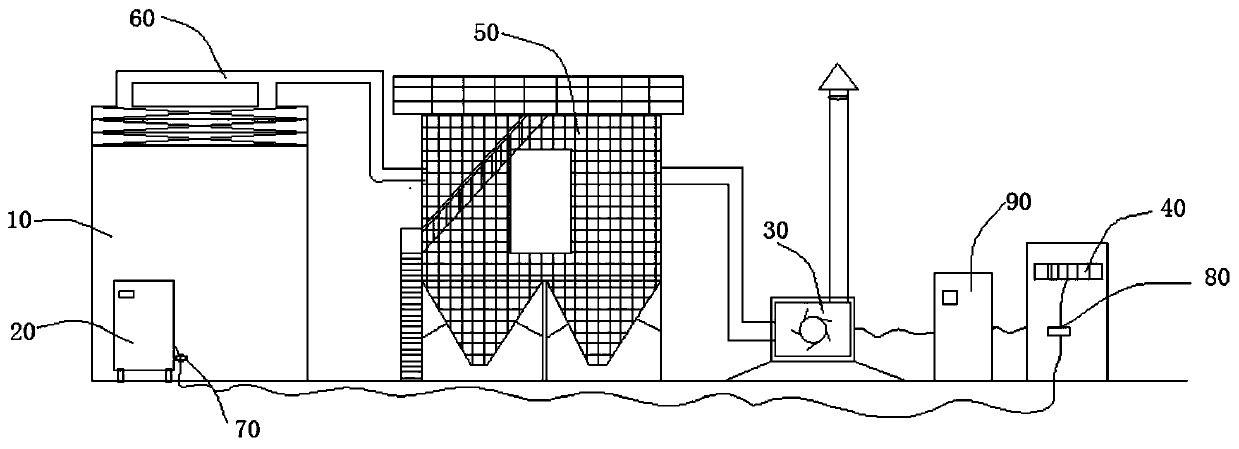

Waste gas purification treatment system

PendingCN112121573ATo achieve the purpose of treatment and adsorptionRealize secondary useCombination devicesGas treatmentDust controlMechanical engineering

The invention relates to a waste gas purification treatment system which comprises a waste gas collection mechanism, a dust removal mechanism, a heat exchange mechanism, a filtering mechanism and a reduction mechanism which are connected in sequence. The collection mechanism comprises an air suction pipe and an induced draft fan connected with the air suction pipe. The dust removal mechanism comprises a dust removal air pipe and a plurality of dust removers connected with the dust removal air pipe, and the two ends of the dust removal air pipe are respectively connected to the outlet of the induced draft fan and the inlet ends of the dust removers. The heat exchange mechanism comprises mixed heat exchangers, and the inlet ends of the mixed heat exchangers are connected with the outlet endsof the dust removers through a heat exchange pipe. The filtering mechanism comprises a filter, and an inlet of the filter is connected with the outlets of the mixed heat exchangers through a filtering pipe. The reduction mechanism comprises a water tank, a stirring mechanism located in the water tank and a catalyst, and the water tank is connected with the outlet of the filter through a water inlet pipe. The system is high in functionality, high in environmental protection value and capable of being widely applied to the technical field of environmental protection equipment.

Owner:王建春

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap