Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about "Other manufacturing equipments/tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

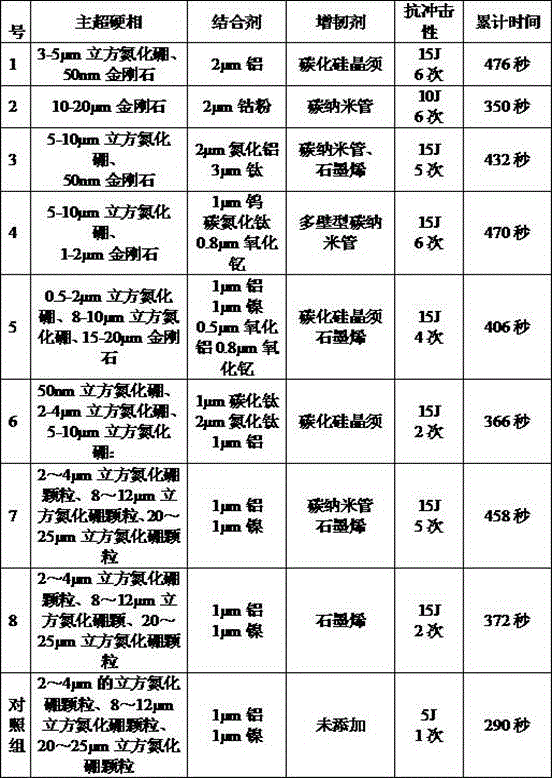

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

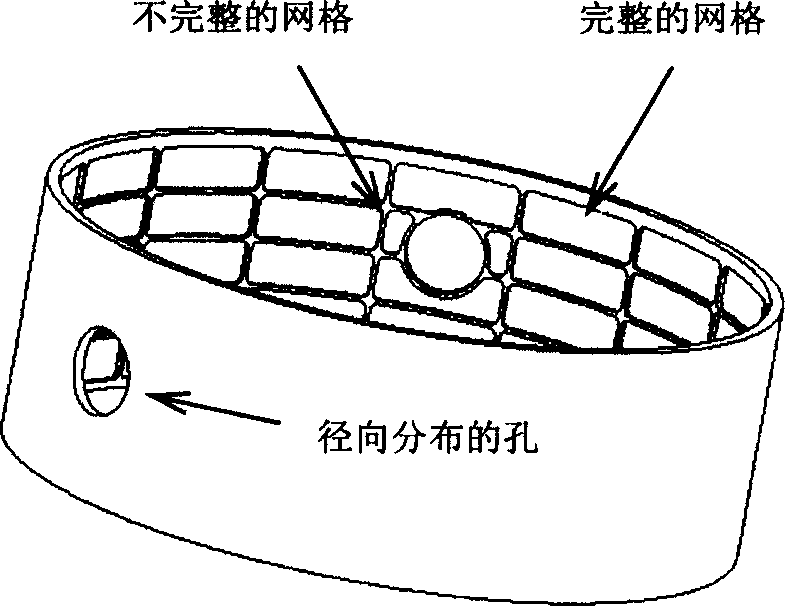

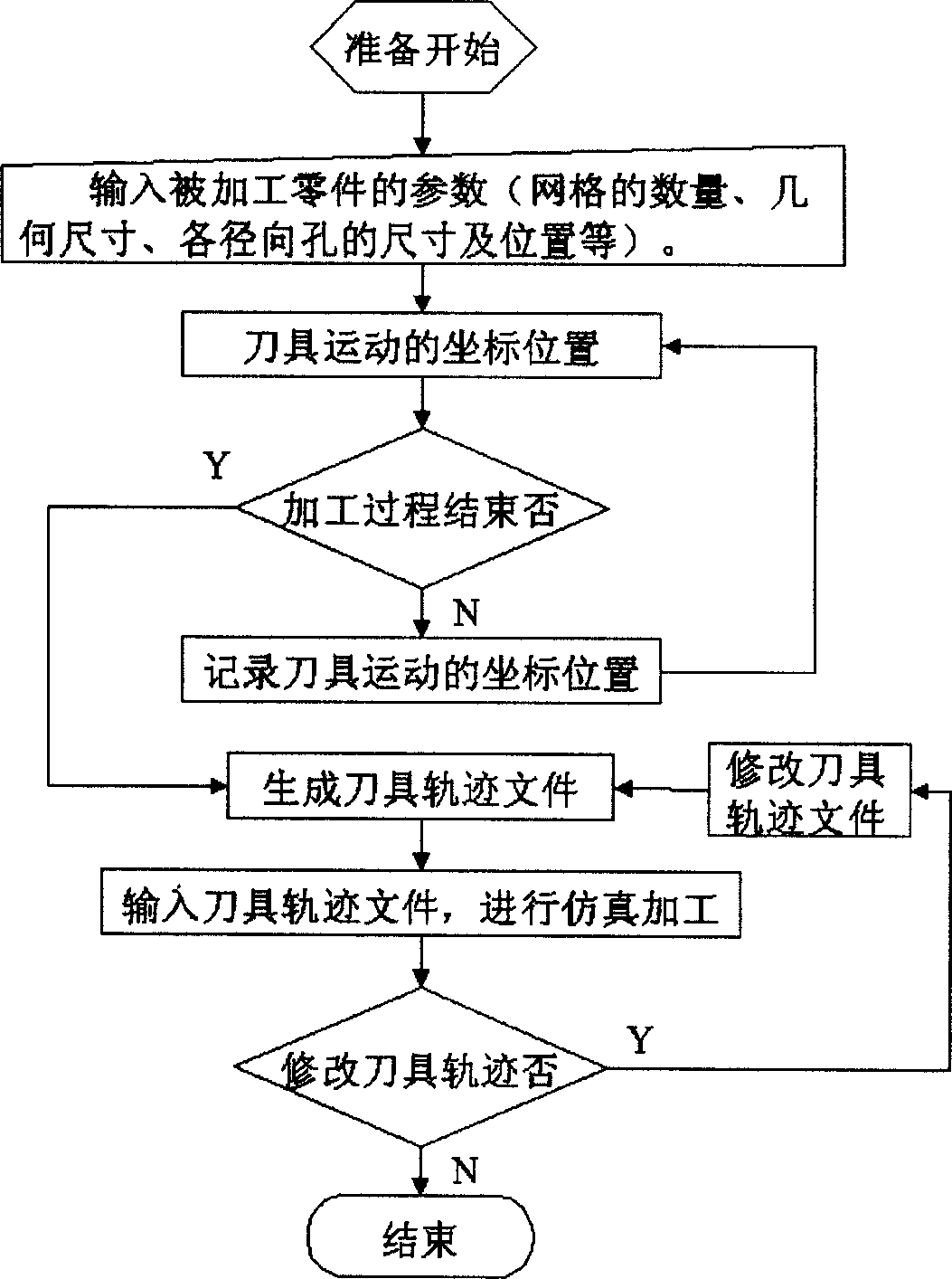

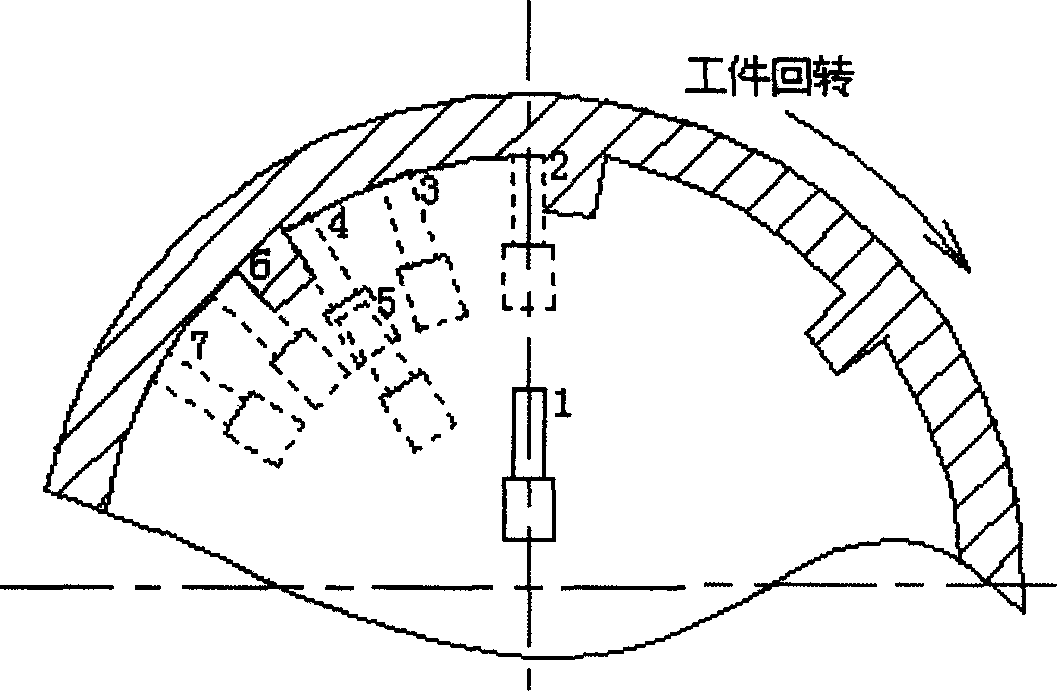

Fast automatic processing method utilized in lathe and milling machine for large thin wall part with cylindrical grids

InactiveCN1562542AMeet the technical requirements of high-speed turning and millingSimple processing technologyProgramme controlComputer controlMachining processAutomatic processing

Owner:沈阳工业学院

Magazine quick-release blocking apparatus and method

ActiveUS20110010977A1Simple methodInexpensive apparatusSafety arrangementBreech mechanismsFast releaseBiomedical engineering

Apparatuses, methods, and kits are disclosed for preventing quick release of a magazine from a magazine well of a Sa vzor 58 rifle without the need to substantially disassemble the rifle, thereby providing a means to modify Sa vzor 58 rifles to bring such rifles within permissible limitations of certain local, state, and federal guns laws.

Owner:QUIS TOMAS

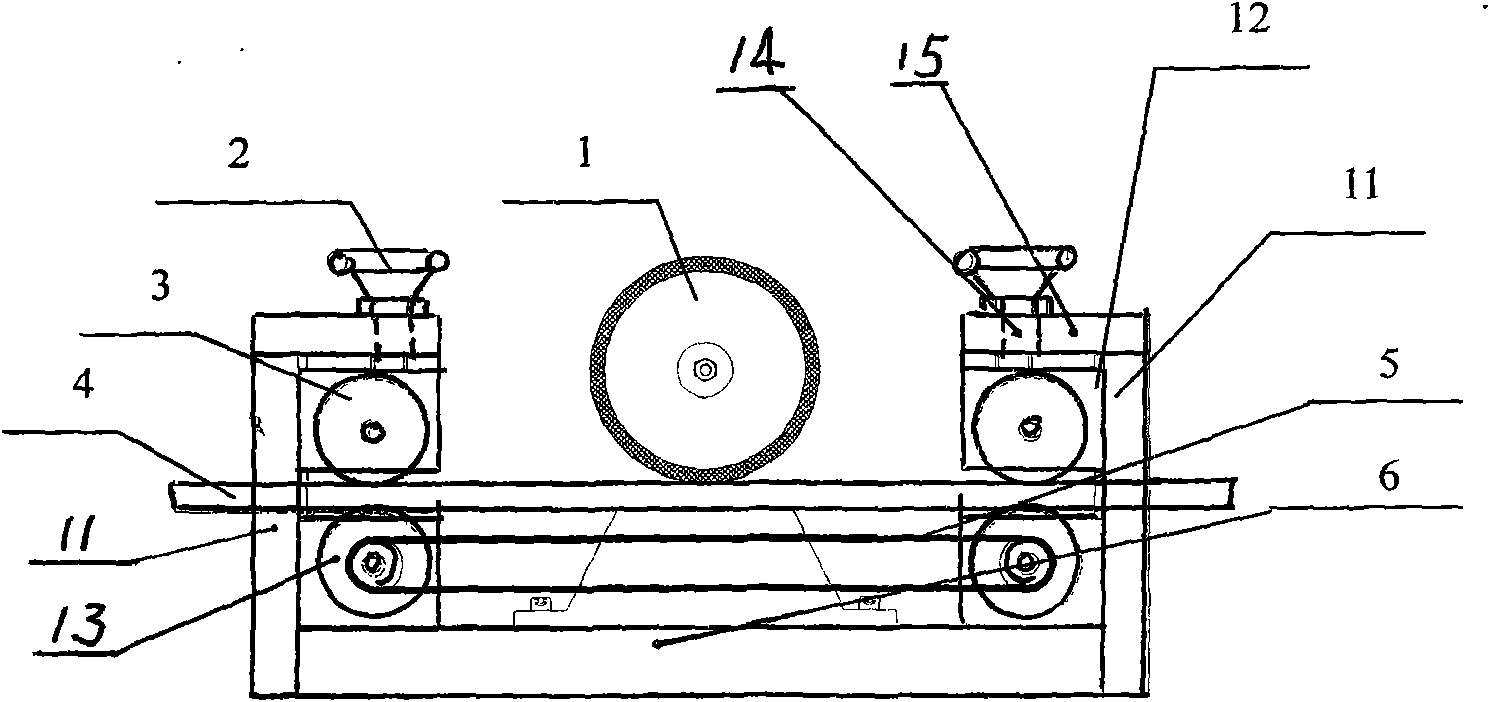

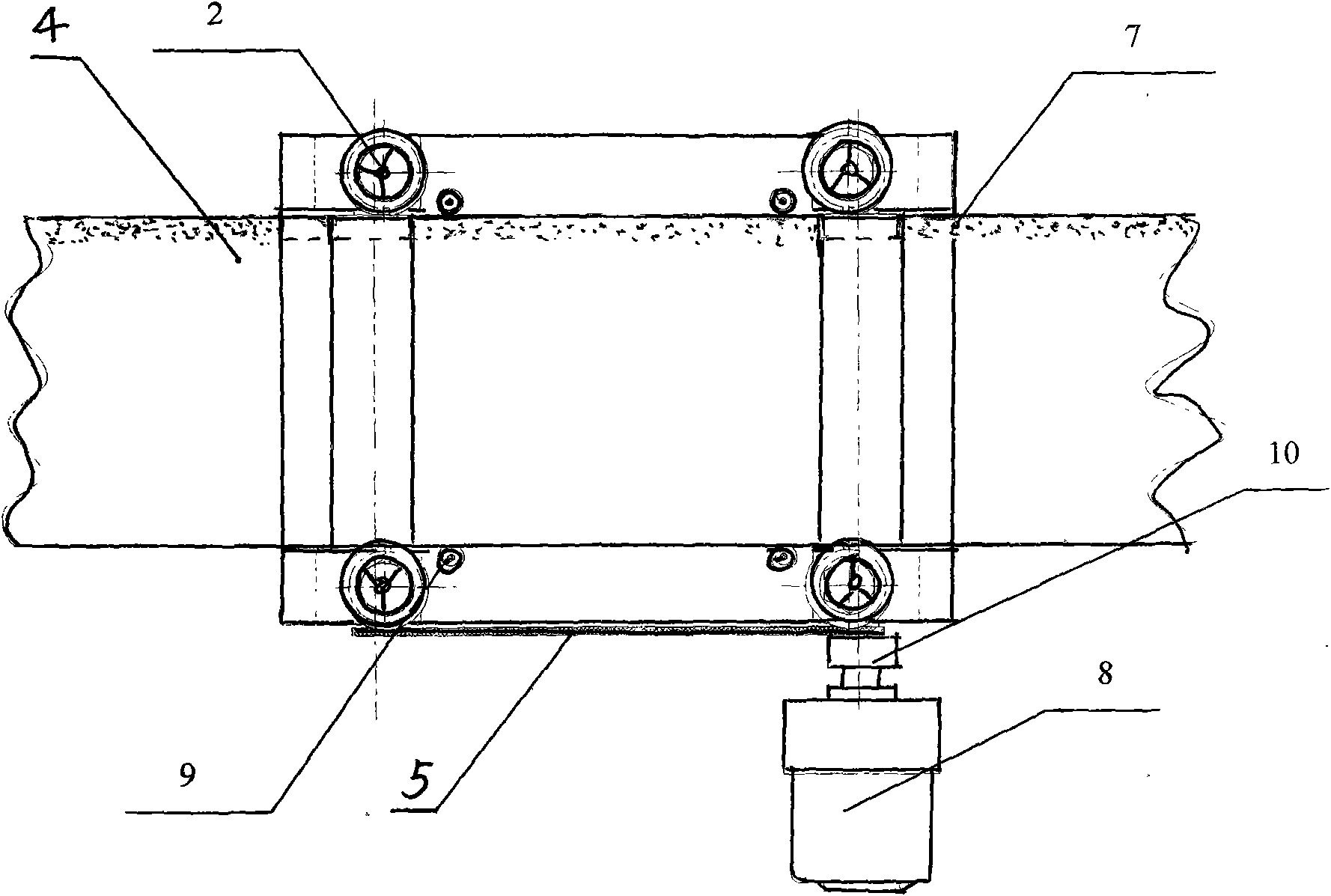

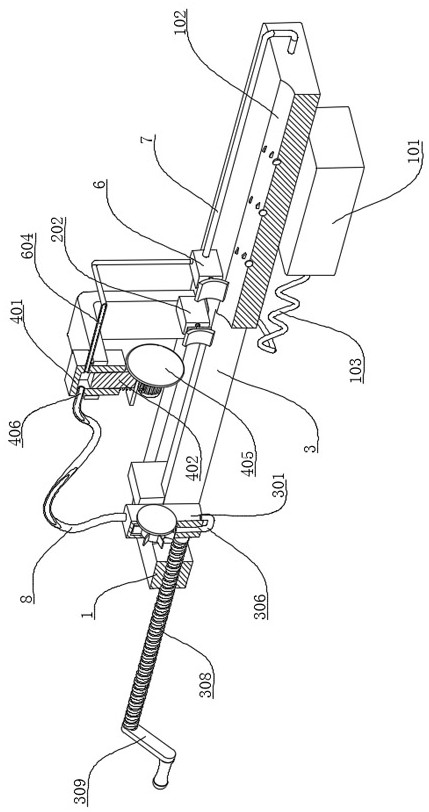

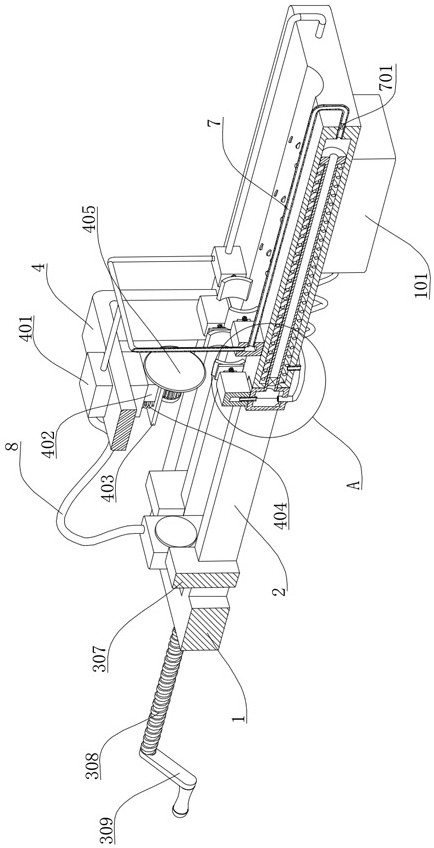

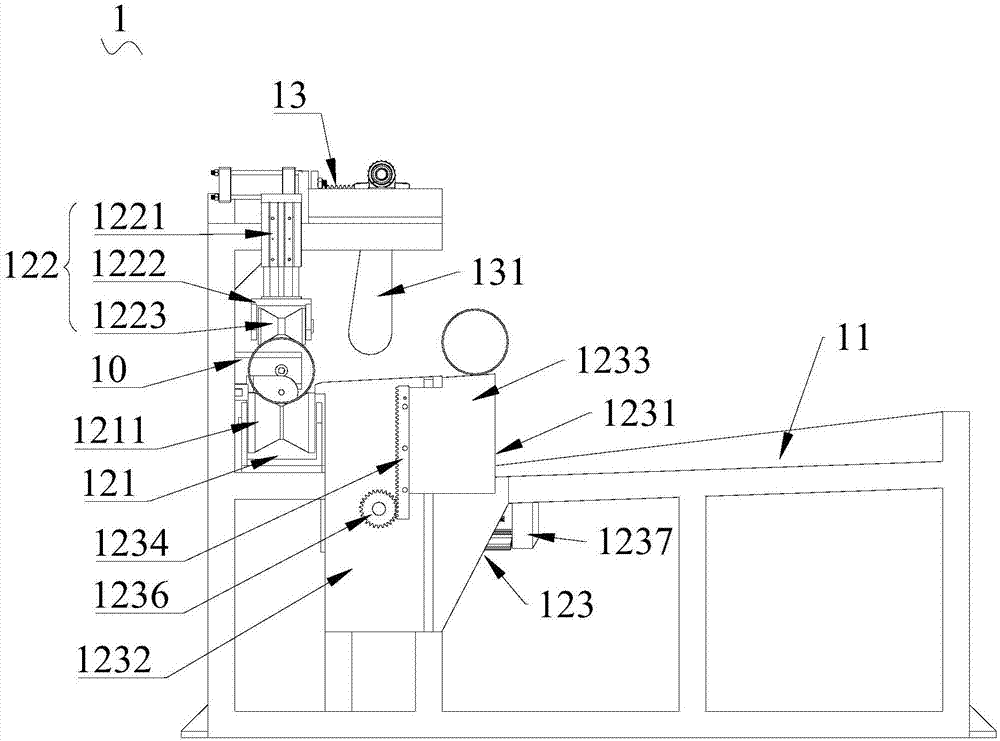

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

Dust-free type building material cutting and polishing device

InactiveCN107649882AOther manufacturing equipments/toolsMaintainance and safety accessoriesBuilding materialEngineering

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

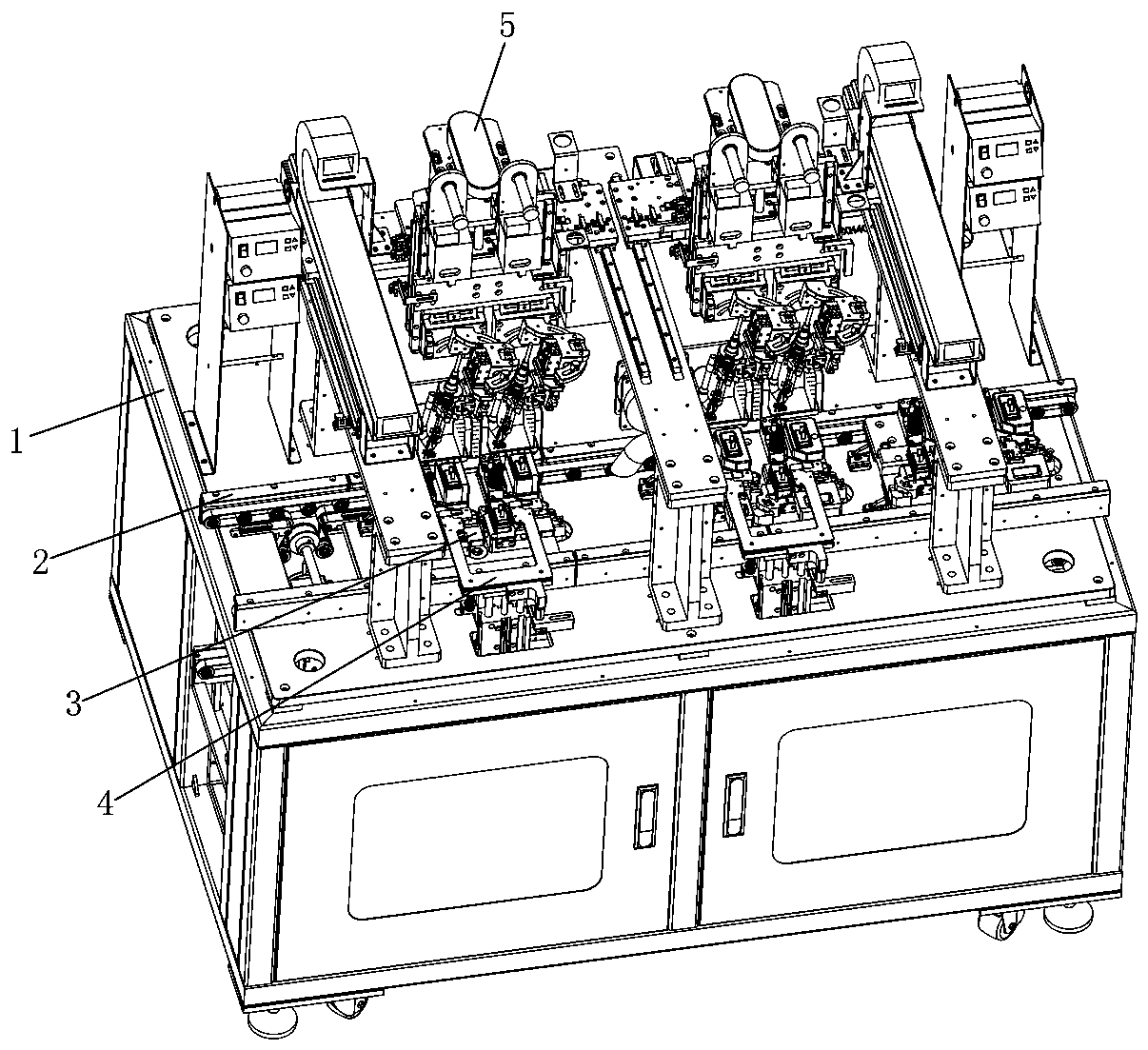

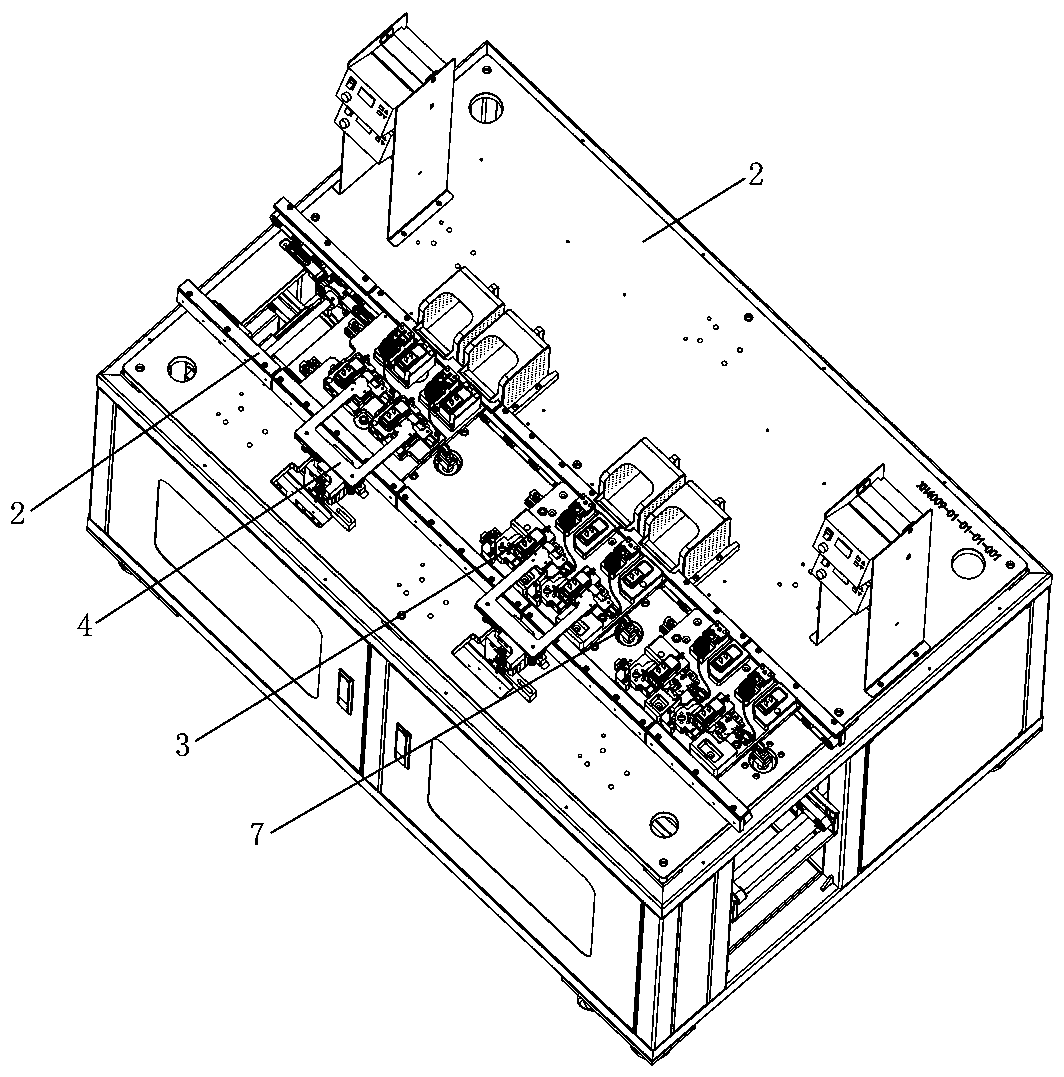

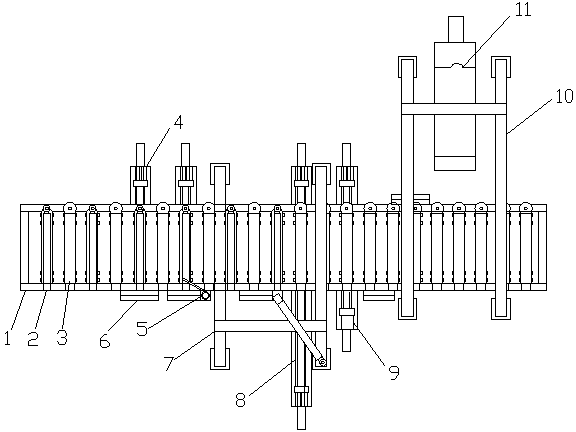

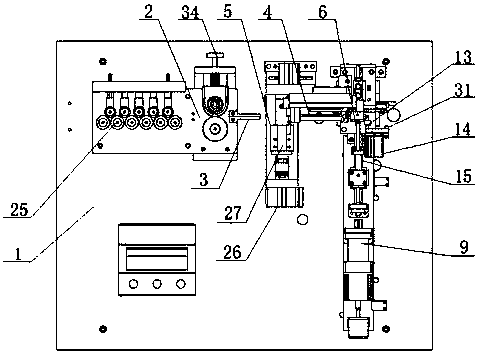

Automatic welder for DC wire of power supply

PendingCN108213645AImprove welding efficiencyPrecision weldingOther manufacturing equipments/toolsSoldering auxillary devicesFine-tuningWelding

The invention discloses an automatic welder for DC wires of a power supply. The automatic welder comprises a conveying pulling body, jigs, a jig positioning mechanism, a pressing mechanism and a welding mechanism, wherein the conveying pulling body is arranged on a rack along a left-right direction; the at least two jigs are arranged on the conveying pulling body; at least two PCBs of the power supply and DC wires of the power supply are placed on the jigs; a welding station is arranged on the side part of the conveying pulling body; the jig positioning mechanism is arranged at the welding station; the pressing mechanism is arranged on the front side of the jig positioning mechanism; the welding mechanism bestrides the upper side of the conveying pulling body and is arranged correspondingto the jig positioning mechanism, and the welding mechanism solders and fixes the connecting parts of the DC wires of the power supply and the PCBs of the power supply; and the jig positioning mechanism loosens the jigs after being soldered. The PCBs and the DC wires which are automatically conveyed and welded are effectively jointed, the PCBs and the DC wires are clamped stably; and the welding mechanism with a flexible fine tuning function achieves precise welding and automatic smoke exhaust and is high in welding efficiency.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Precision grinding frock clamp, grinding method and product of coating scraper ceramic coating

InactiveCN102059594ALess investmentReduce manufacturing costOther manufacturing equipments/toolsDoctorsCeramic coatingSurface roughness

Owner:SHANDONG UNIV OF SCI & TECH

Device capable of stably clamping safety valve

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE +1

Novel precise numerical-control machine tool

InactiveCN107791023AAdaptableFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention relates to the technological field of precise numerical-control machine tool equipment and provides a novel precise numerical-control machine tool comprising a machine tool body. A spindle box and an auxiliary spindle box are arranged on the machine tool body. A cutter rest is arranged between the spindle box and the auxiliary spindle box. A first machining cutter is arranged on thecutter rest. The auxiliary spindle box comprises an auxiliary spindle and a clamp which is detachably installed on the auxiliary spindle and used for clamping a special-shaped workpiece. The clamp isan internal expanding mandrel or a chuck. During work, the first machining cutter can machine the workpiece on the auxiliary spindle box. A workpiece in a regular shape is clamped by the spindle box,and the auxiliary spindle box clamps the special-shaped workpiece. Specifically, when the first machining cutter machines the workpiece on the auxiliary spindle box, since the clamp is detachably installed on the auxiliary spindle box and is the internal expanding mandrel or the chuck, different clamps, such as the internal expanding mandrel or the chuck, are selected according to different special-shaped workpieces. In this way, the novel precise numerical-control machine tool achieves the purpose that both the workpiece in the regular shape and the special-shaped workpieces can be machined,and the novel precise numerical-control machine tool is wide in application range and high in applicability.

Owner:TODAY STANDARD PRECISION MASCH TOOL CO LTD

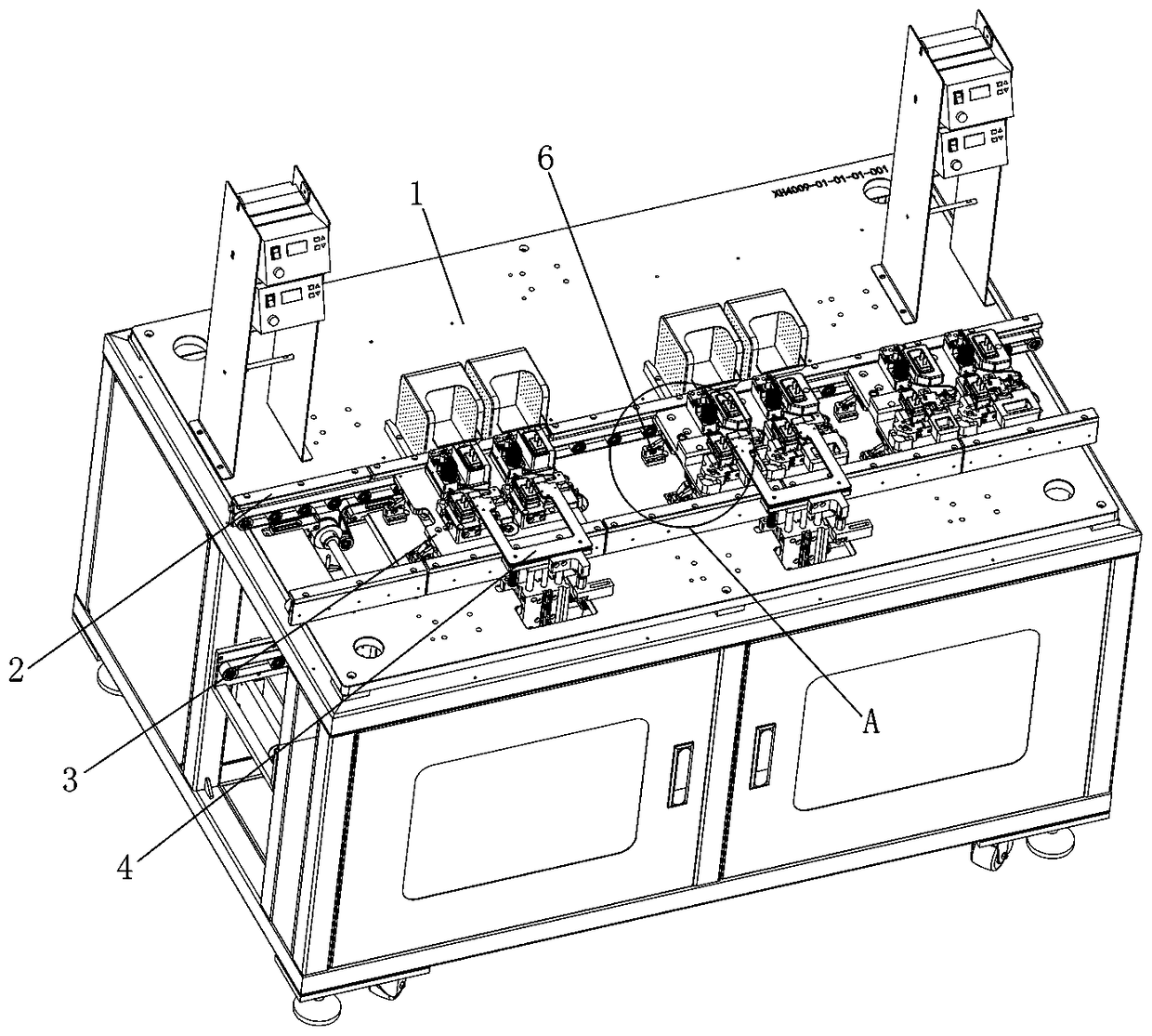

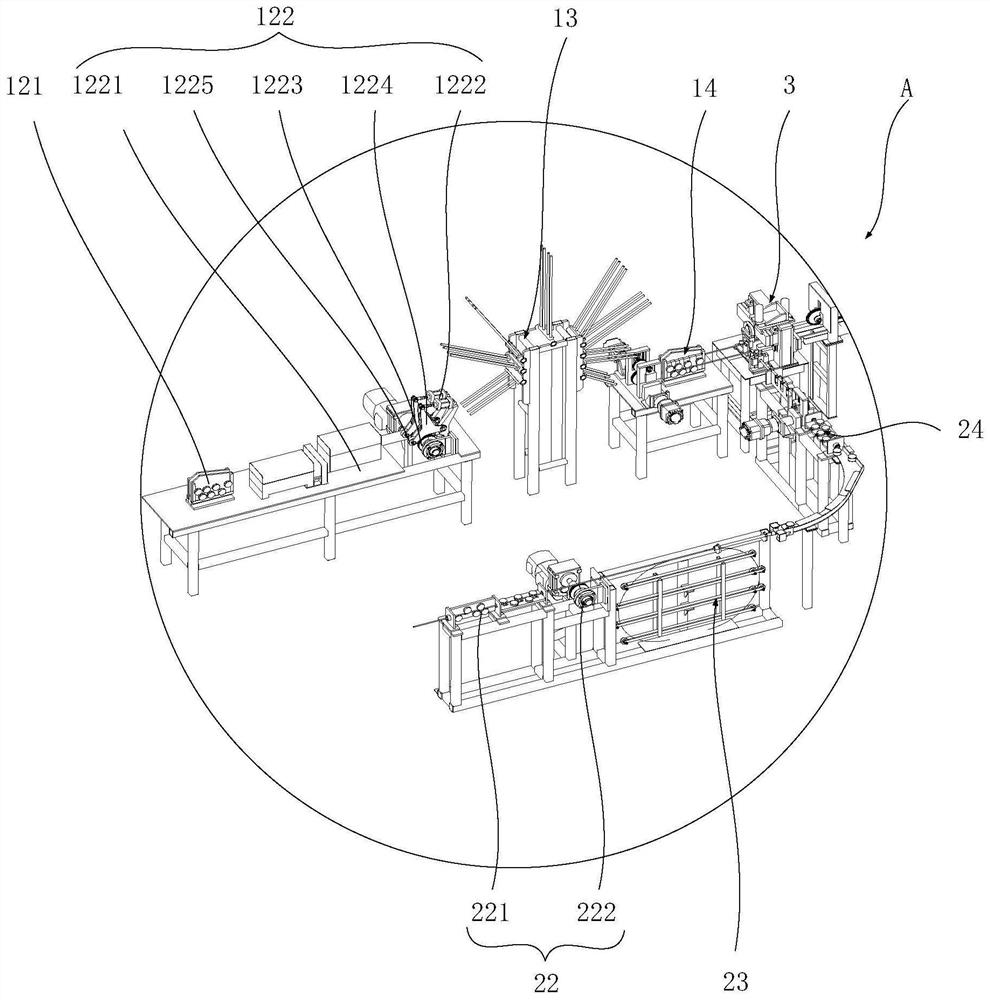

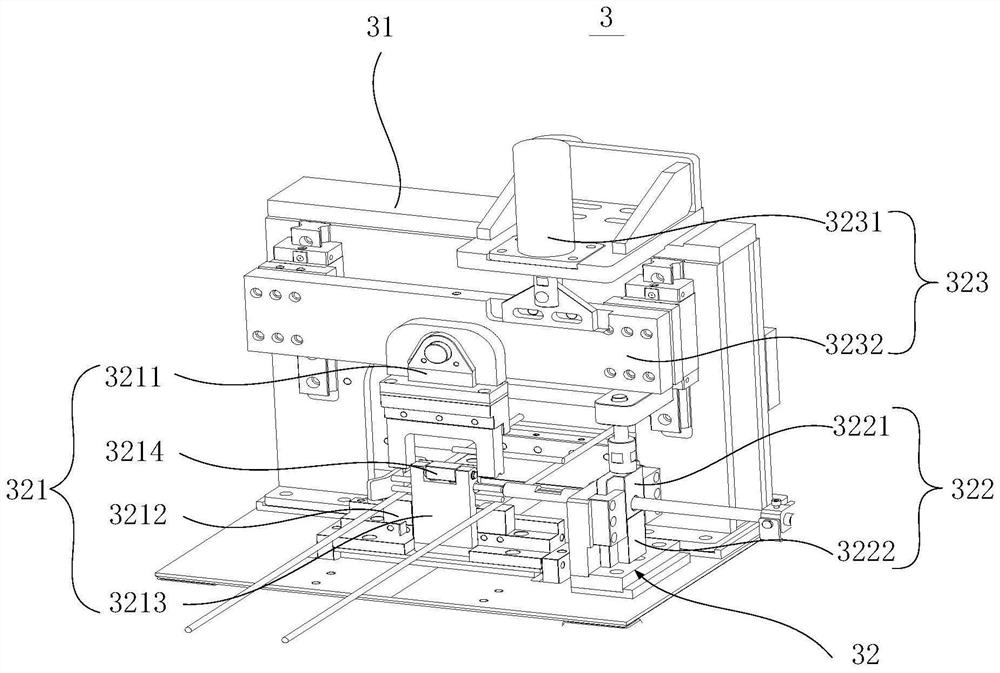

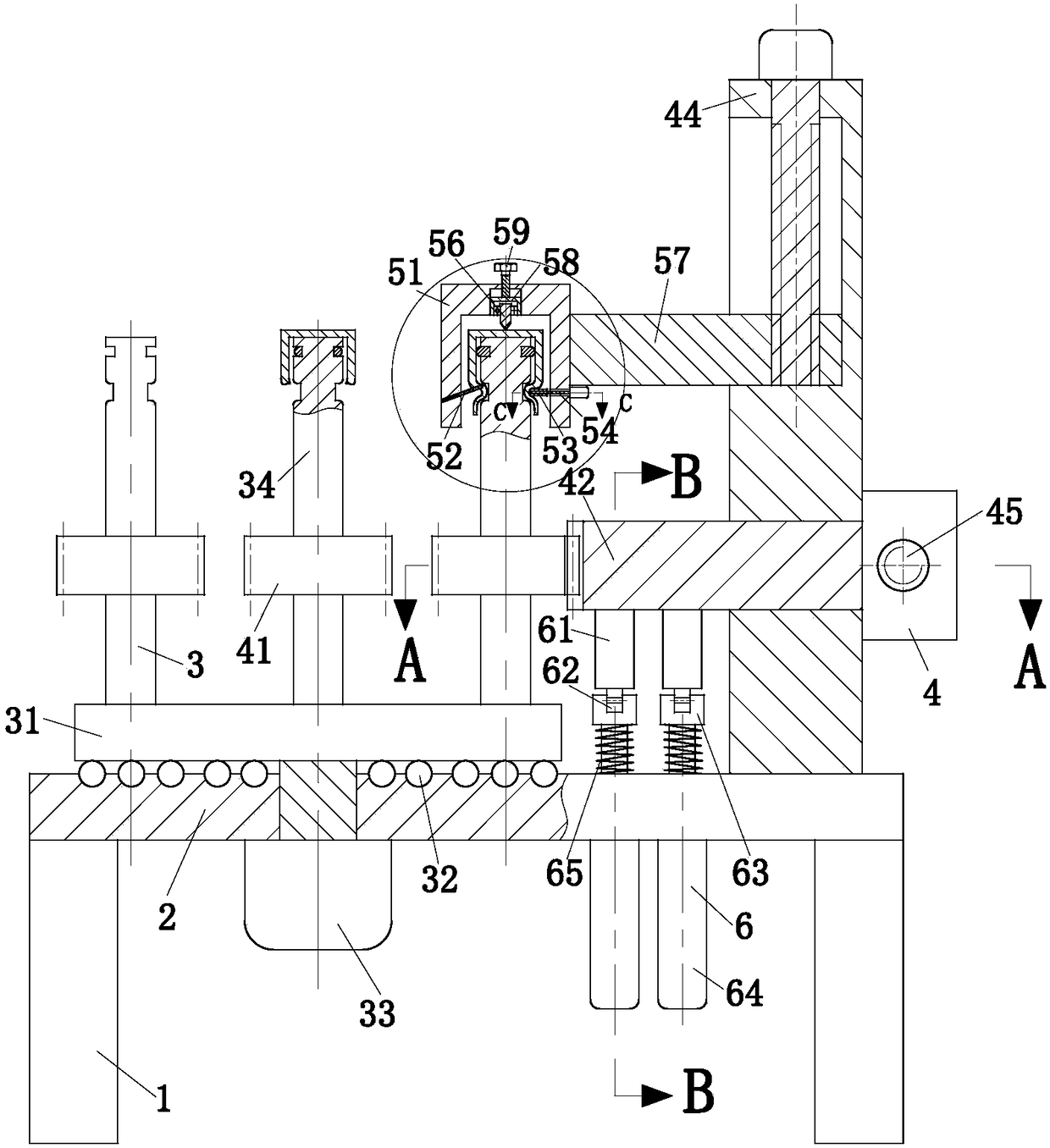

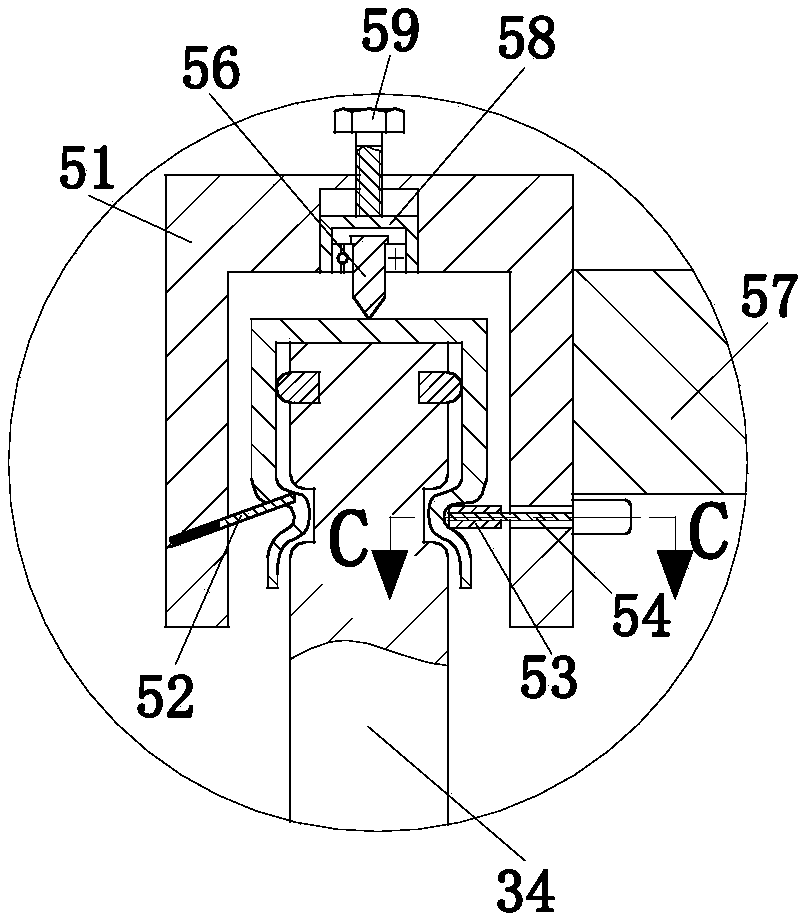

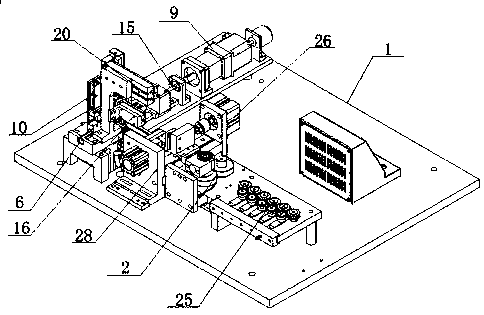

Oil cylinder assembly production line

ActiveCN103659247AHigh degree of automationSave human effortOther manufacturing equipments/toolsMetal working apparatusProduction lineIndustrial engineering

Owner:无锡金峰园弹簧制造有限公司

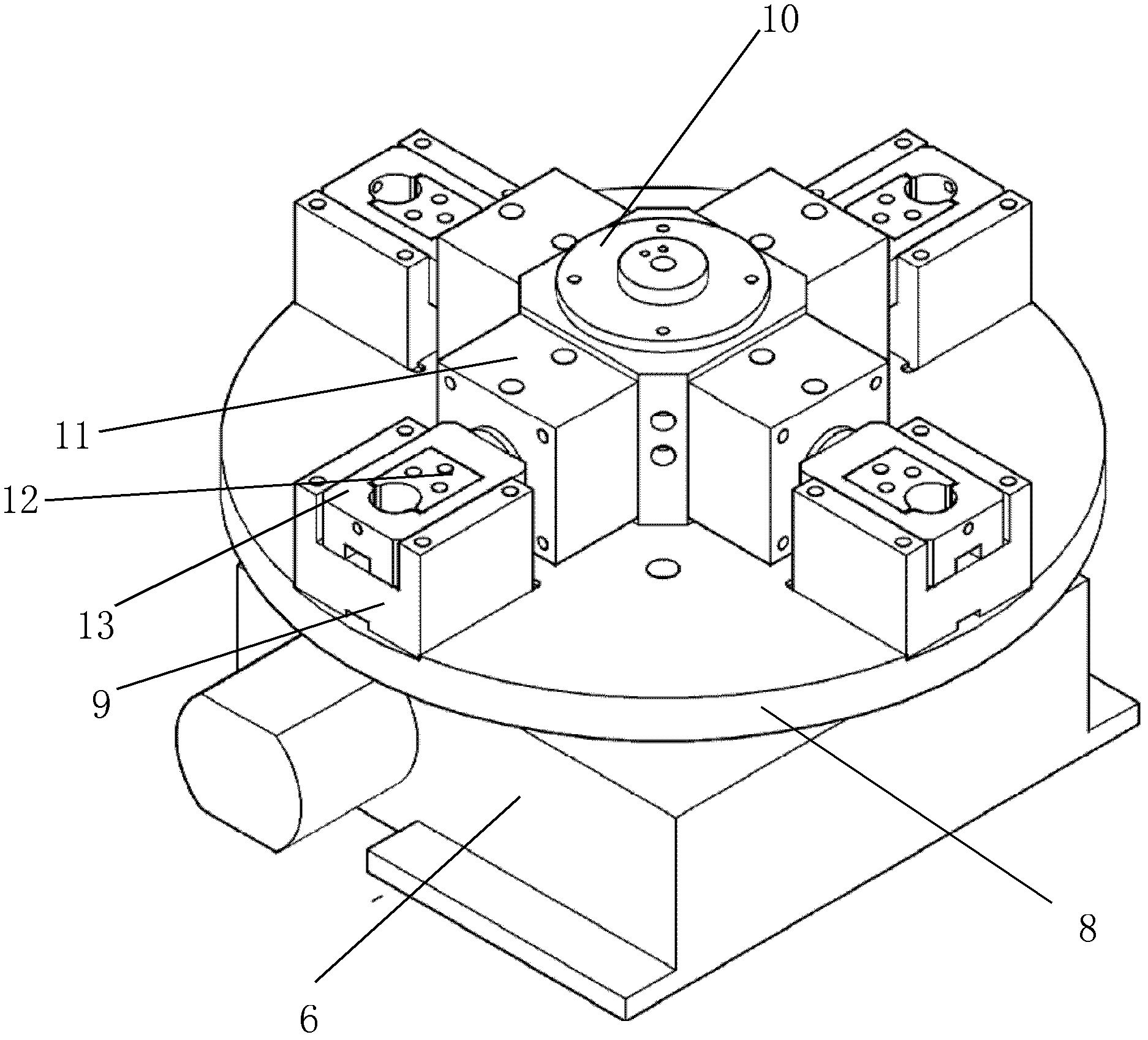

Special four-station machine tool for jackscrew holes of worms

InactiveCN102909554ANot affected by processing qualityFully automatedOther manufacturing equipments/toolsPositioning apparatusTransverse axisDrill hole

The invention relates to a special four-station machine tool for jackscrew holes of worms. The special four-station machine tool is characterized by comprising a tool body, a tray, a chamfering power head, a drilling power head, a tapping power head, a hydraulic turntable and fixtures; the hydraulic turntable is fixedly connected to the center of a working table of the tool body, the chamfering power head and the tapping power head are symmetrically fixedly connected onto the working table of the tool body along the transverse axis of the hydraulic turntable, the drilling power head is fixedly connected to the central position between the chamfering power head and the tapping power head along the radial direction of the hydraulic turntable, and the fixtures for mounting a workpiece are arranged on rotary work stations of the hydraulic turntable. The special four-station machine tool has the advantages that the special four-station machine tool are fully automatic, and labor cost is greatly reduced; various working procedures are centralized and can be carried out simultaneously, and accordingly the efficiency is improved; and influence of skills of operators to the machining quality is avoided, and the special four-station machine tool is stable and reliable.

Owner:天津市中马骏腾精密机械制造有限公司

Cutting machine for production and processing of fitness equipment

Owner:南通力人健身器材有限公司

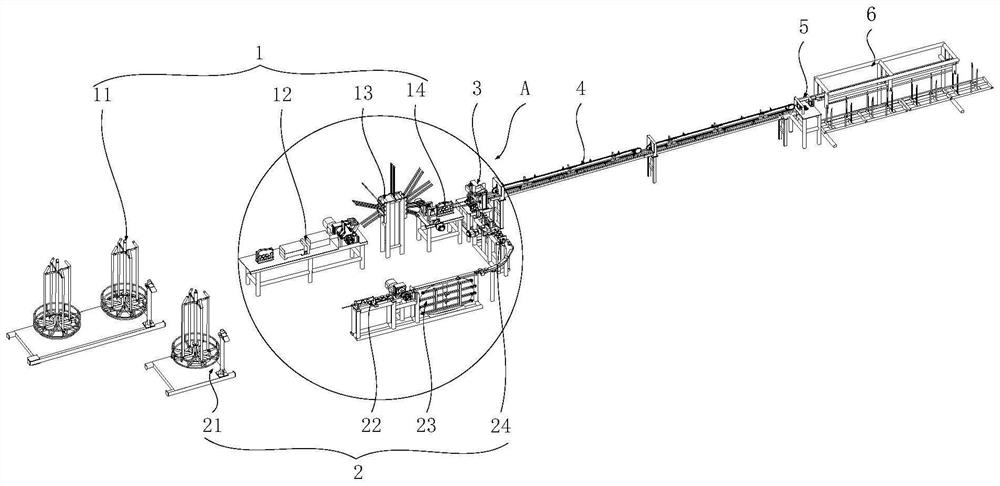

Reinforcing mesh welding production equipment

ActiveCN112045440AImprove structural strengthRealize automatic feeding processWire networkOther manufacturing equipments/toolsMesh reinforcementRebar

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Crown cap cutting system with deburring function

Owner:博瑞特东乡(江苏)包装有限公司

Novel aluminum alloy heat transmission material composite line

InactiveCN107443093AIncrease productivityImprove grindingOther manufacturing equipments/toolsHeat transmissionElectric control

The invention relates to a new aluminum alloy heat transmission material composite line: including a grinding device, a turning device, a vacuum suction crane, a feeding buffer device, a feeding roller table, a brazing pressurizing device, a turning device, a strapping machine, Outfeed roller table, hydraulic pneumatic system and electric control system. The milled aluminum ingots are transported to the feeding roller table, the grinding device grinds and removes the oxide layer on the alloy plate placed on the grinding platform, the turning device turns the polished composite surface downward, and the vacuum suction crane absorbs the composite sheet and places it on the On the aluminum ingot, the feed roller transports the aluminum ingot and the alloy plate to the brazing pressure device for brazing, and the welded composite aluminum ingot is sent to the turning device, which turns the composite aluminum ingot 180° to make the other compound aluminum ingot Facing up, it is transported to the upper alloy plate position towards the feed side, and after the alloy plate is placed again for brazing, the double-sided composite aluminum ingot is sent to the baler through the turning device, and sent to the discharge roller table, and the composite aluminum ingot is hoisted by the driving car. Walk. The invention has the beneficial effects of simple operation, high production efficiency, low labor intensity, safety and reliability.

Owner:ZOUPING QIXING ALUMINUM IND CO LTD

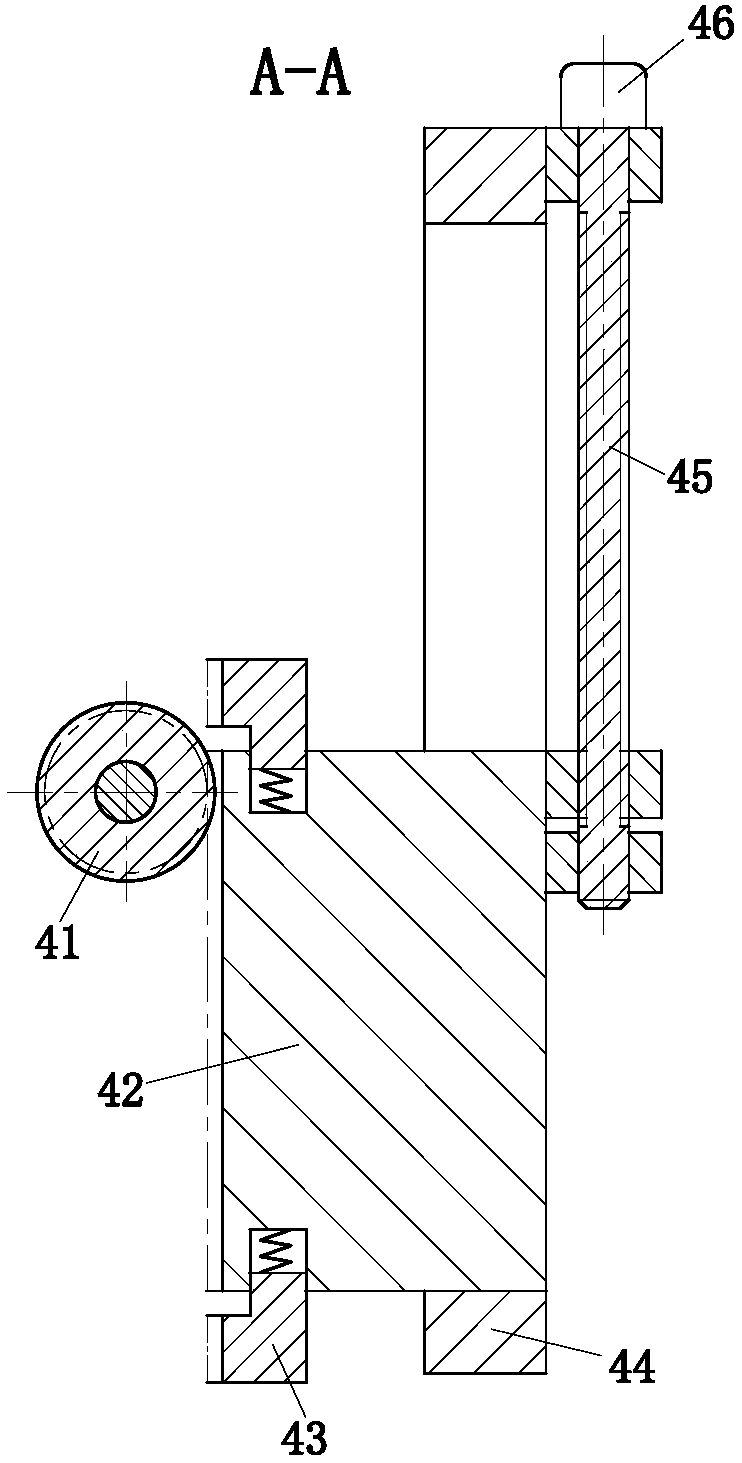

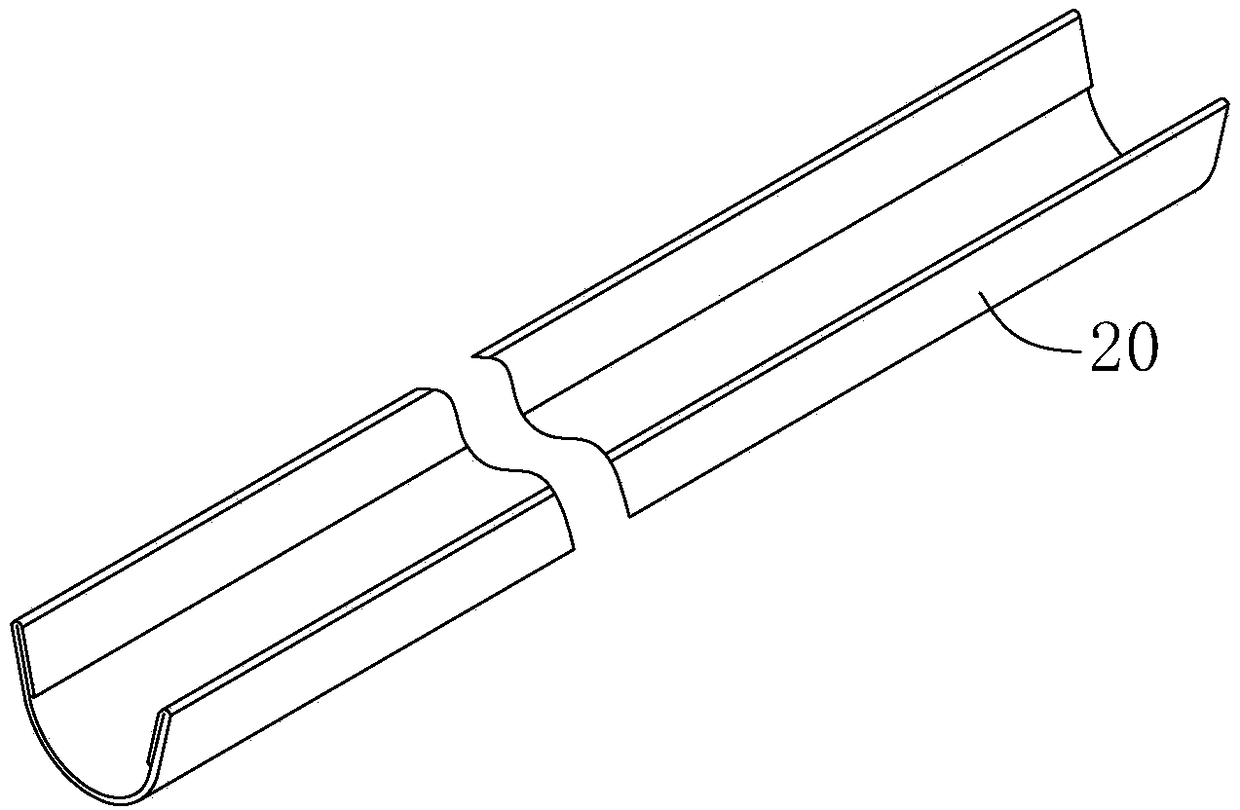

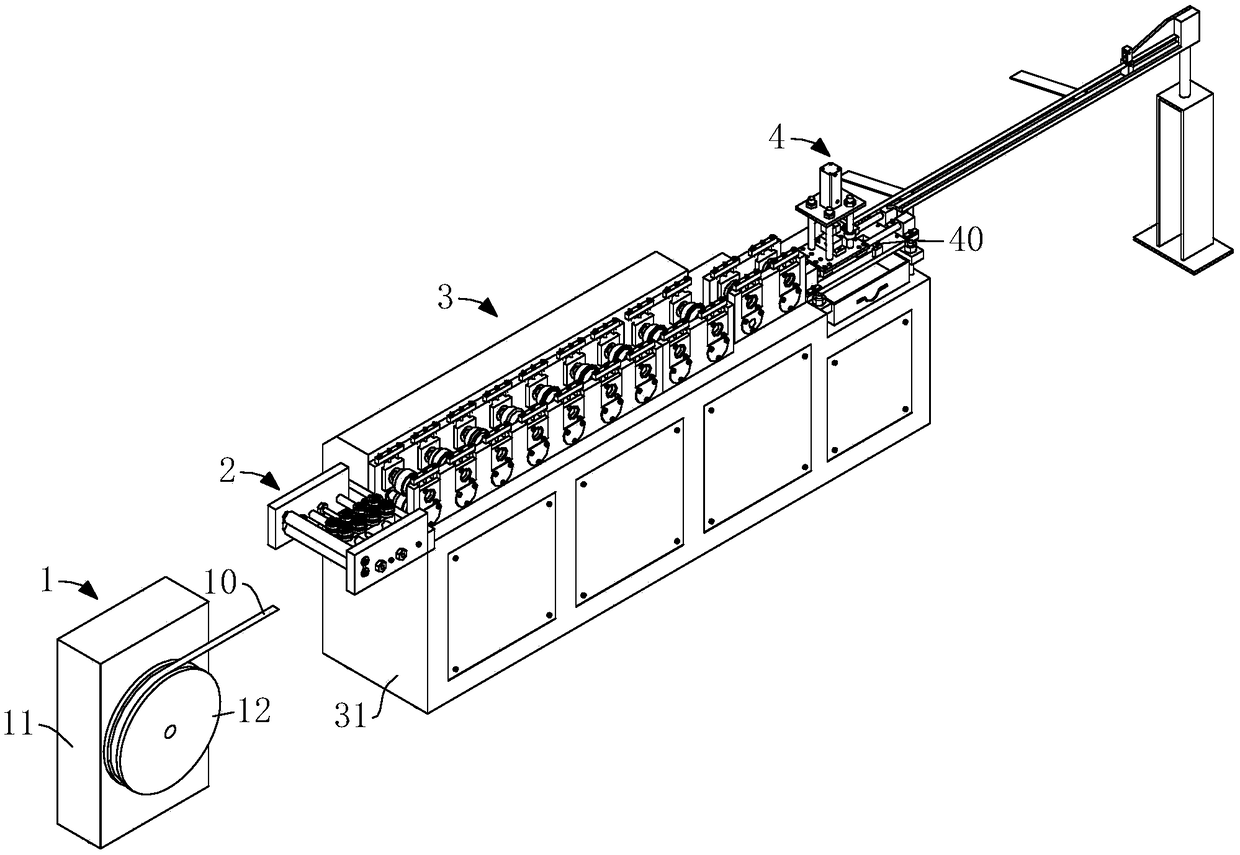

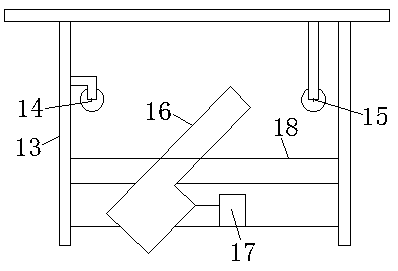

Cutting and discharging device and control method thereof and roll forming machine

PendingCN109127800AWill not affect normal deliveryFacilitate automated productionOther manufacturing equipments/toolsEjection devicesRoll formingSlide plate

Owner:HONORFAITH FURNITURE

Automatic production line for pipelines

Owner:中远泰工业自动化科技有限公司

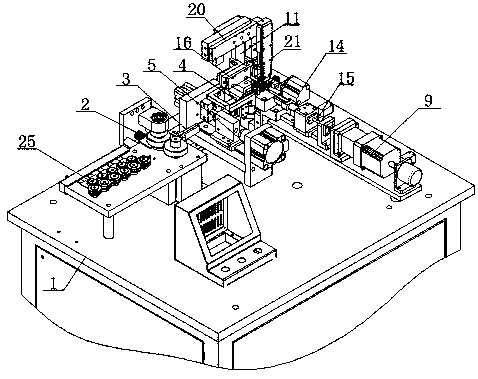

Automatic assembling equipment for electronic ignition element

PendingCN110961921AImprove assembly efficiencySpacing solutionOther manufacturing equipments/toolsMetal working apparatusEngineeringMaterial distribution

The invention provides automatic assembling equipment for an electronic ignition element. The automatic assembling equipment comprises a cutting mechanism, a crimping mechanism, a control mechanism and a material distribution mechanism, the material distribution mechanism comprises a plurality of clamping jaws, a first driving assembly and a second driving assembly, the multiple clamping jaws areconnected to the first driving assembly and driven by the first driving assembly to increase or decrease the distance, and the multiple clamping jaws and the first driving assembly are arranged on thesecond driving assembly and driven by the second driving assembly to move back and forth between the cutting station and the crimping station. Multiple electronic integrated ignition modules cut offby the cutting mechanism are conveyed to the crimping station through the material distribution mechanism, and the distance between the electronic integrated ignition modules is adjusted to be matchedwith the distance between multiple connectors on a transportation jig, so that the crimping mechanism can accurately crimp leg wires of a plurality of the connectors on a plurality of the electronicintegrated ignition modules at the same time, the whole process is controlled by the control mechanism, manual participation is not needed, and efficient assembly of the electronic ignition elements is achieved.

Owner:BEIJING JINYUAN HENGYE TECH DEV CO LTD

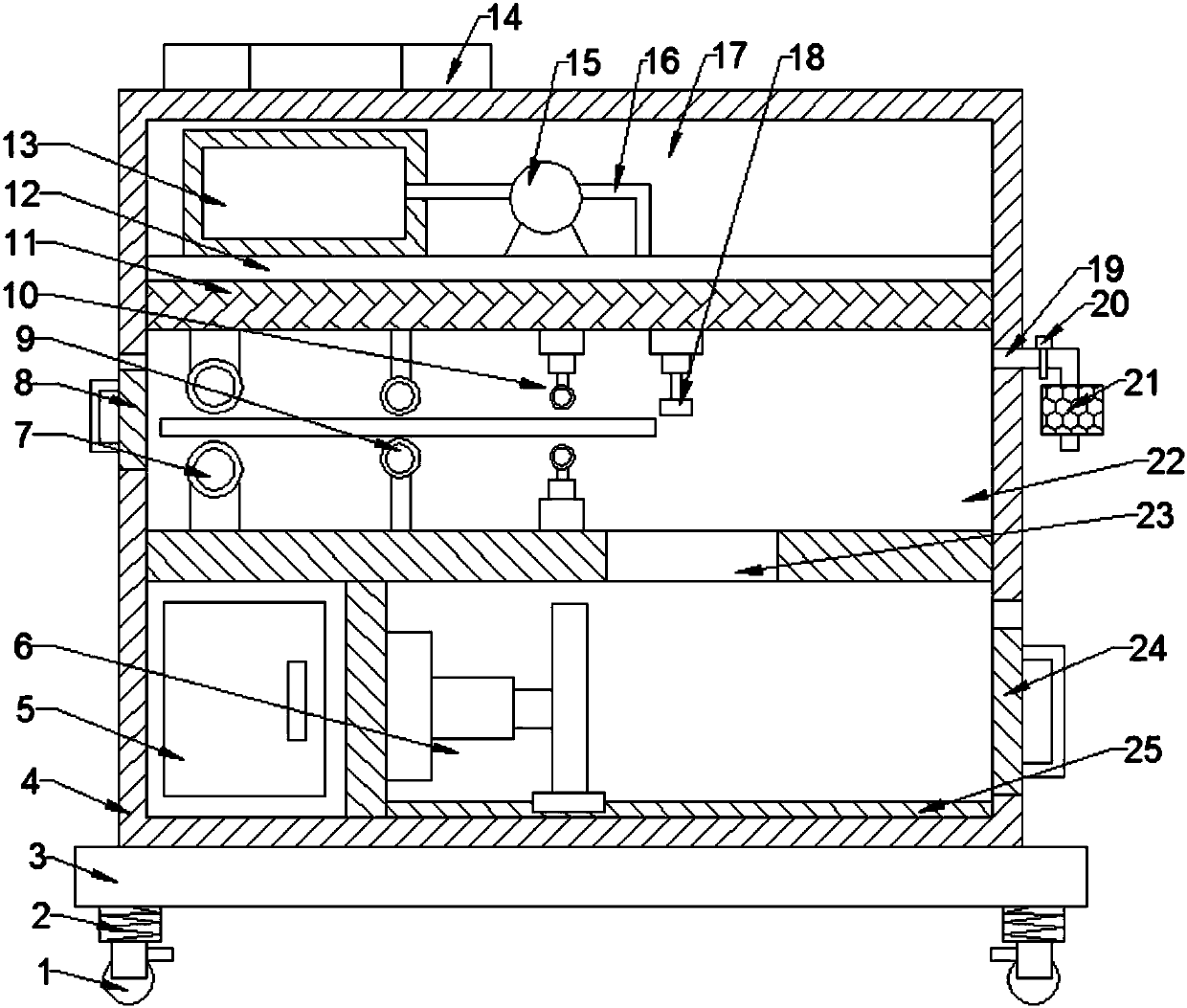

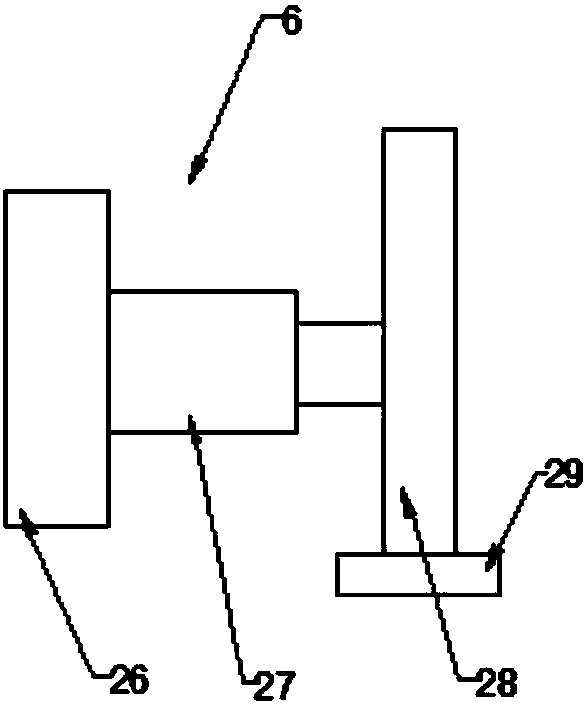

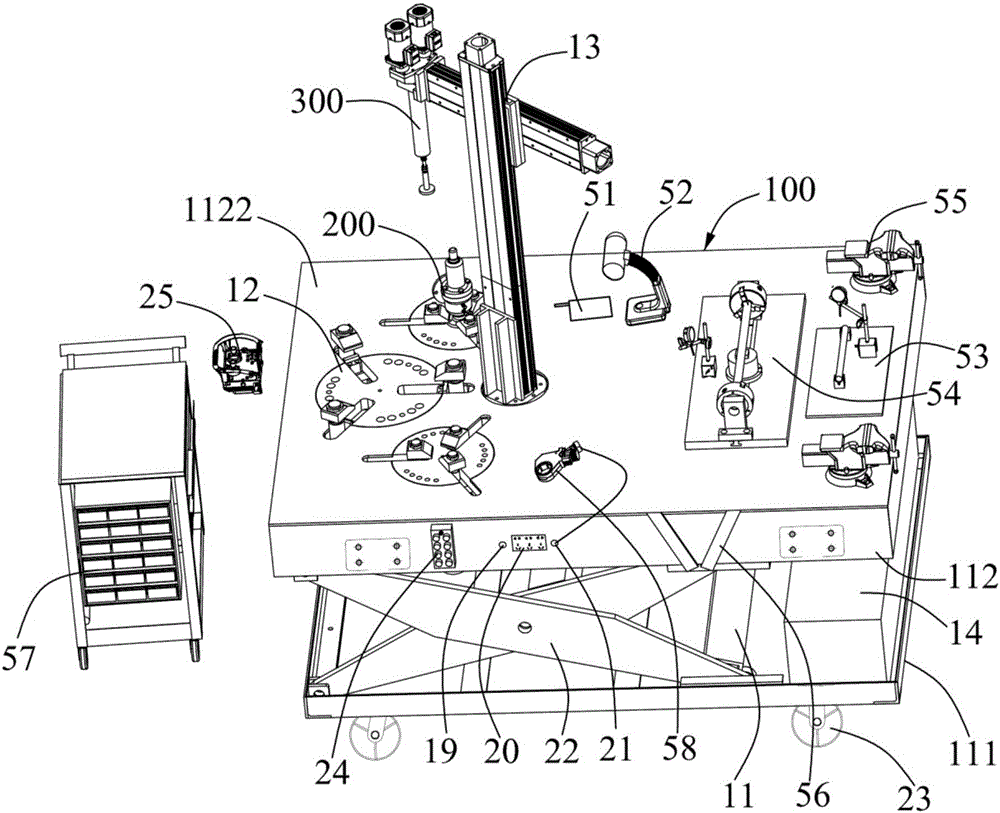

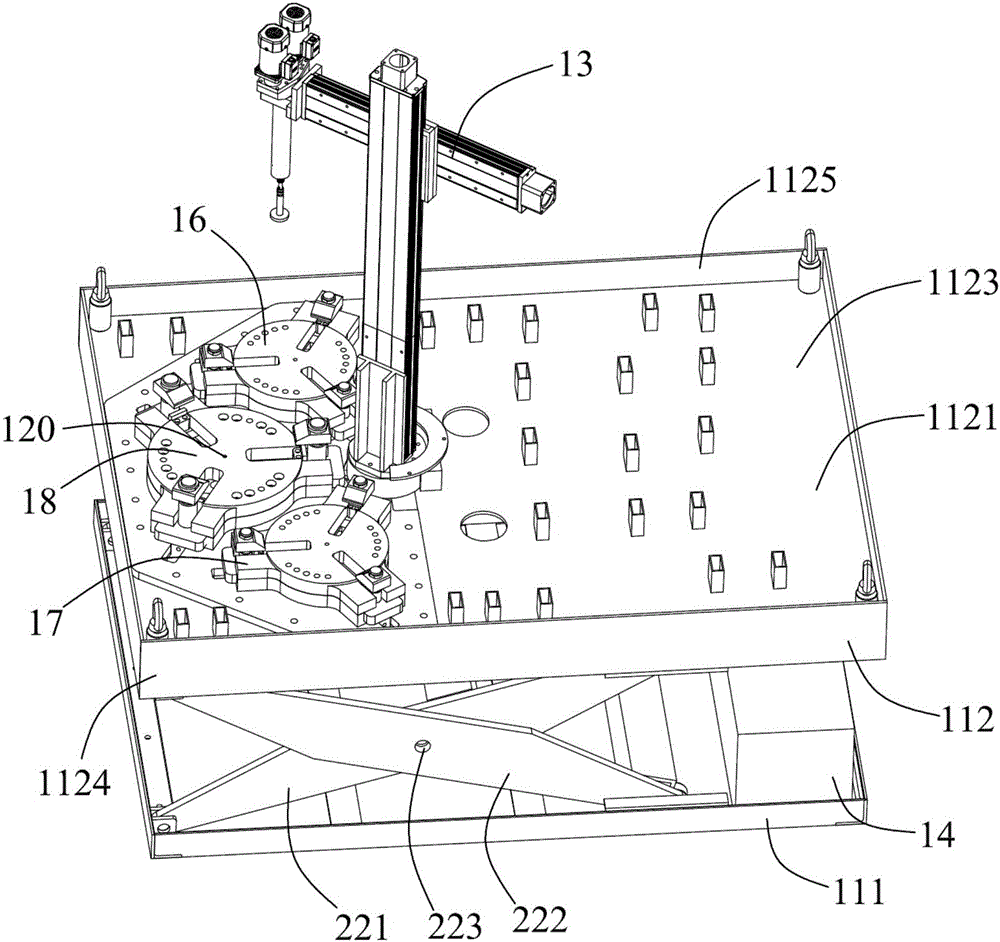

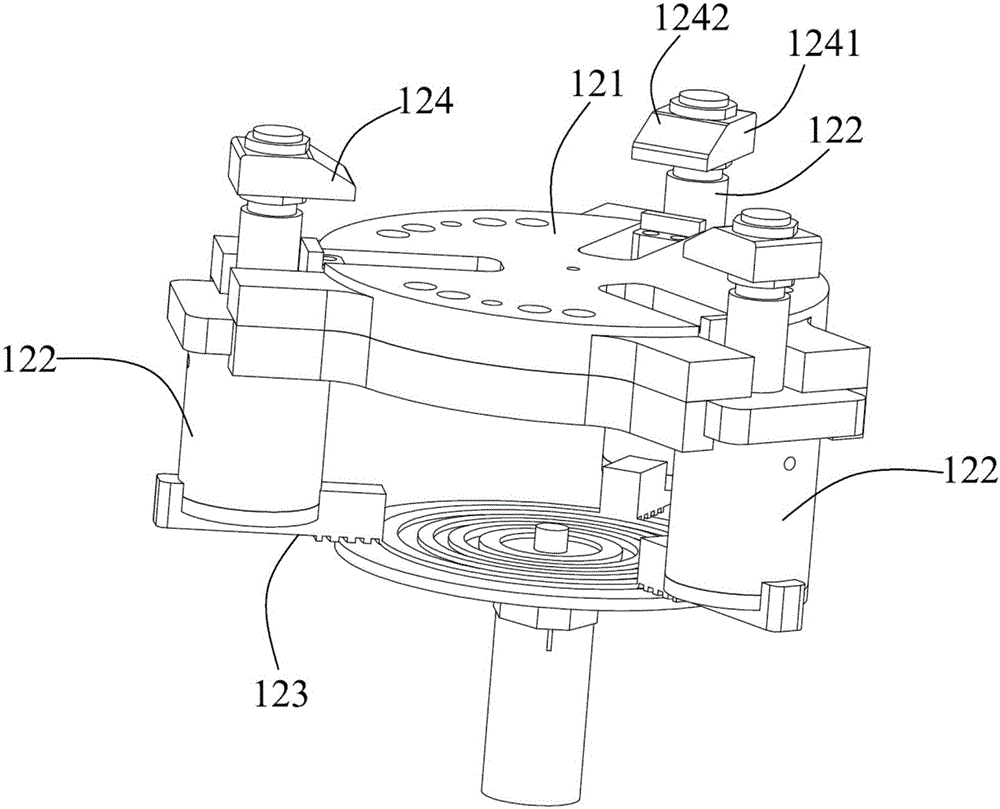

Drilling and rivet pressing equipment

PendingCN112828604ACompact structureHigh degree of automationOther manufacturing equipments/toolsEngineeringMachine

The invention belongs to the technical field of drilling equipment, and discloses drilling and rivet pressing equipment which comprises a cabinet. A platen is arranged on the cabinet, and a station rotating mechanism is arranged in the middle of the platen; a drilling mechanism is fixed to the left side of the station rotating mechanism, and a rivet feeding and pre-pressing mechanism is fixed to the rear side of the station rotating mechanism; a rivet pressing mechanism is fixed to the right side of the station rotating mechanism, and a control mechanism is arranged on the cabinet; and a workpiece is installed on the station rotating mechanism. According to the drilling and rivet pressing equipment, the station rotating mechanism, the drilling mechanism, the rivet feeding and pre-pressing mechanism, the rivet pressing mechanism and the control mechanism are arranged on one device, the structure is compact, and drilling, rivet insertion, pre-pressing and pressing of a plurality of rivet holes can be completed at a time, and all automatically completed by the equipment except for assembly and disassembly actions; the automation degree is high, and working procedures are reduced; manpower is reduced; and the machining efficiency and the machining precision are greatly improved.

Owner:JINHUA DEQI AUTOMATION TECH CO LTD

Automatic accurate cutting and chamfering all-in-one machine for pipes

PendingCN113977280AReduce weightRealize simultaneous movement in the same directionOther manufacturing equipments/toolsStructural engineeringMachine

The invention relates to the technical field of round pipe processing equipment, and provides an automatic accurate cutting and chamfering all-in-one machine for pipes, wherein the machine comprises a rack, a first sliding table, a first lifting assembly, a clamping mechanism, a second lifting assembly, a processing mechanism and a controller, and the processing mechanism comprises a processing bin arranged on a second lifting plate; a driving main shaft is rotationally arranged on the processing bin and is provided with a through hole; a bearing plate is arranged at the end part of the driving main shaft; knife holders areslidably arranged on the bearing plate; a cut-off knife is fixedly arranged on each knife holder; an inner chamfering cutter and an outer chamfering cutter are arranged on each cutter holder in a swinging manner; pushing pieces are arranged on the bearing plate and are provided with pushing ends; a turntable is rotationally arranged on the driving main shaft; a driving part is arranged on the processing bin and is provided with a driving end capable of pushing the turntable; and the plurality of cutter holders move at the same time by means of pushing of the pushing pieces. By means of the technical scheme, the problem that in the prior art, the processing efficiency of a round pipe is low due to transfer in the processing process of the round pipe is solved.

Owner:SHIJIAZHUANG YUBANG MASCH EQUIP CO LTD

Crushing and packing device for recycling irregular aluminum materials

ActiveCN113102059AFlat cutting edgeOther manufacturing equipments/toolsProcess efficiency improvementStructural engineeringCutting tool

Owner:HUBEI UNIV OF ARTS & SCI

Improved hank reeling machine

InactiveCN107164861AIncrease stranding efficiencyOther manufacturing equipments/toolsTextiles and paperYarnStructural engineering

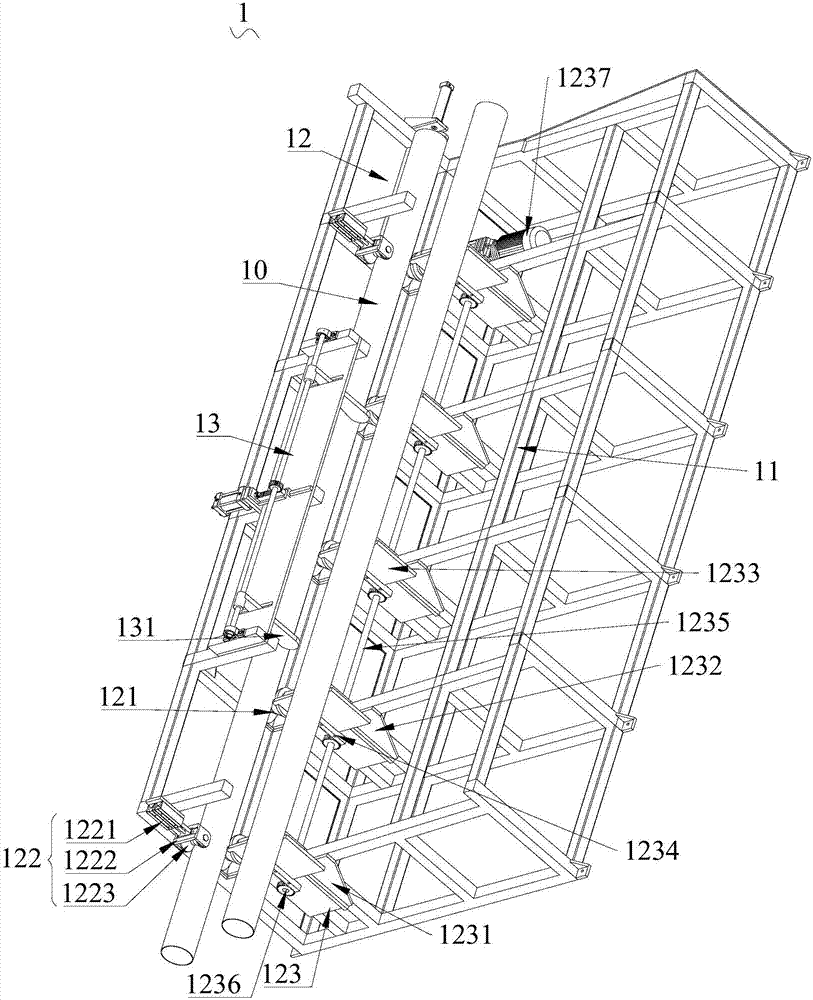

The invention provides an improved hank reeling machine, belongs to the technical field of textile industries, and solves the problem on improvement of the hank reeling efficiency in the prior art. The improved hank reeling machine comprises a base and a rack fixed on the base, wherein a hank reeling mechanism capable of reeling yarn into a hank is arranged on the rack; the hank reeling mechanism comprises a long pipe I and a plurality of frame rods I parallel to the long rod I; the multiple frame rods I are arranged around the long pipe I in a surrounding manner; the hank reeling mechanism further comprises a long pipe II and a plurality of frame rods II parallel to the long pipe II; the multiple frame rods II are arranged around the long pipe II in a surrounding manner; the long pipe I and the long pipe II are arranged on the left and right sides; a driving structure capable of driving the long pipe I and the long pipe II to rotate is arranged between the long pipe I and the long pipe II; and an adjustment structure I capable of adjusting the frame rods I to get close to the long pipe I is arranged between the long pipe I and the frame rods I. The improved hank reeling machine has the advantage of improving the hank reeling efficiency.

Owner:HAINING YONGXIN TECH CONSULTING CO LTD

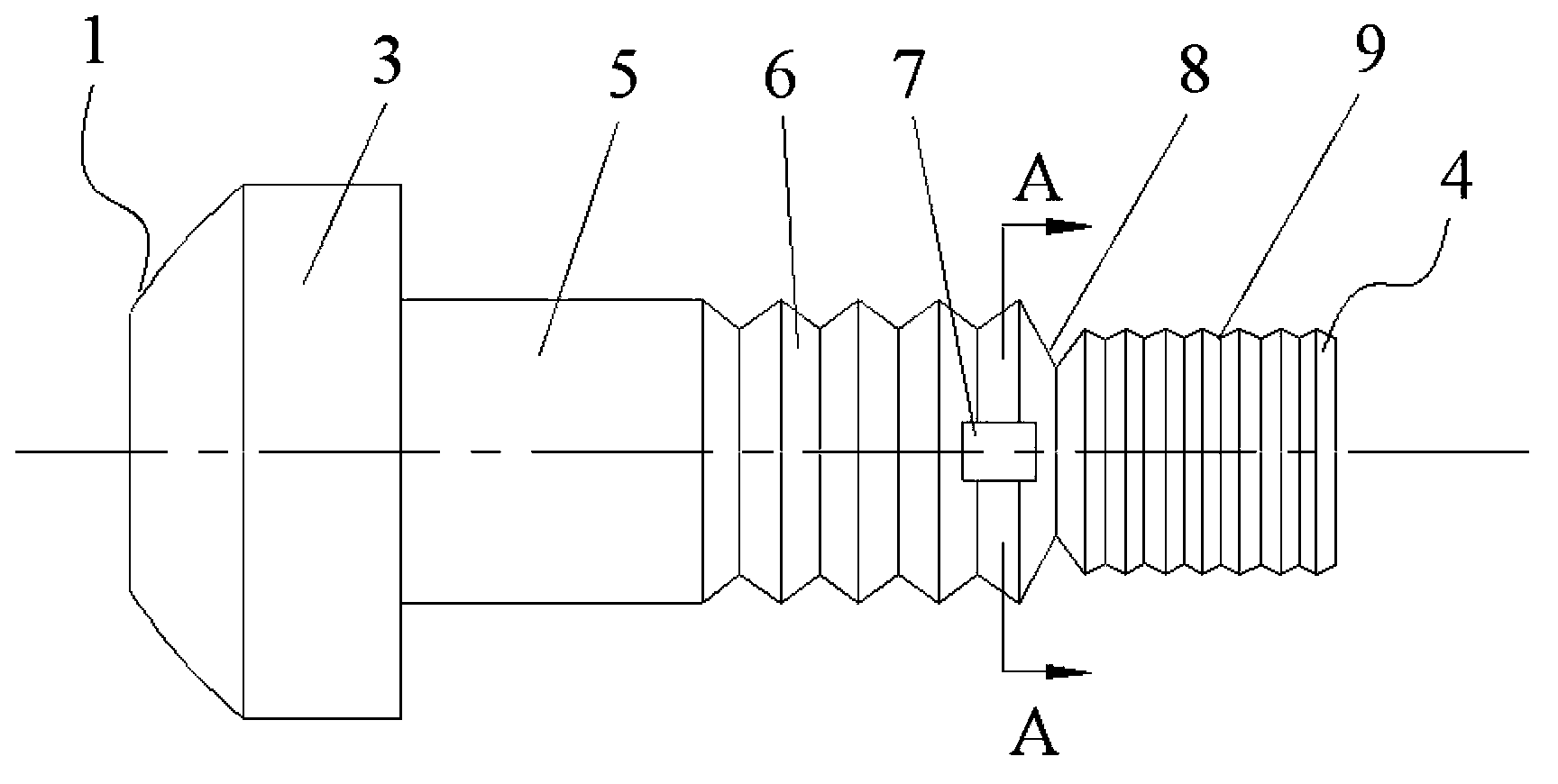

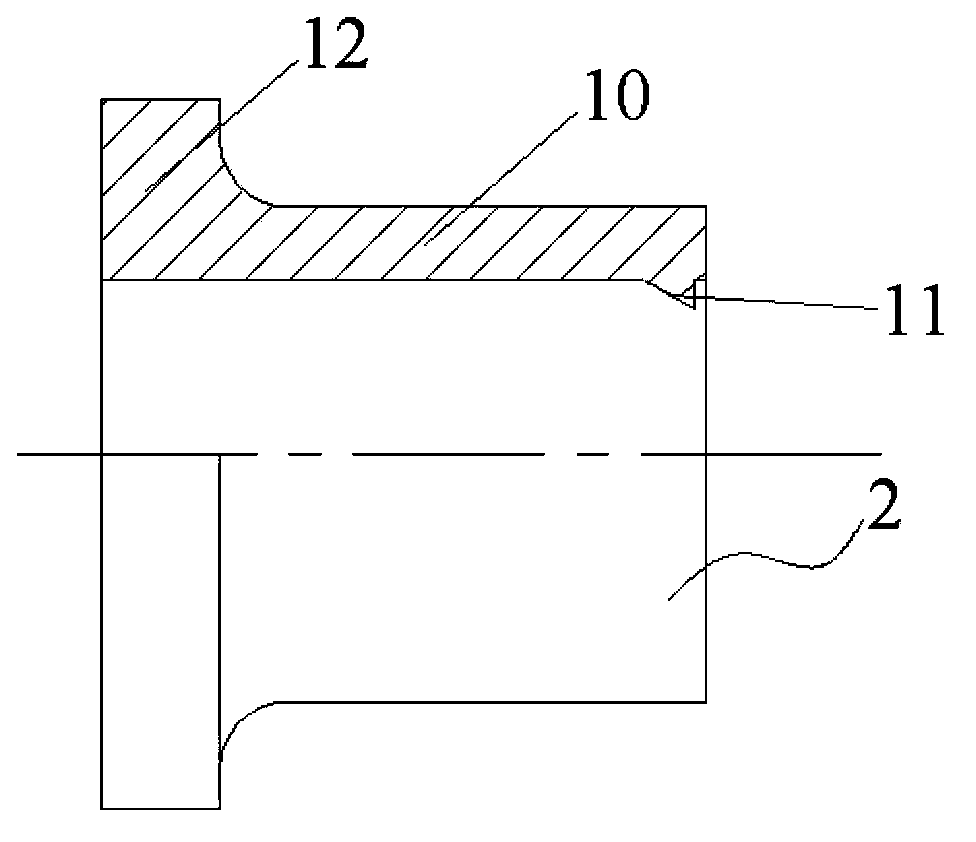

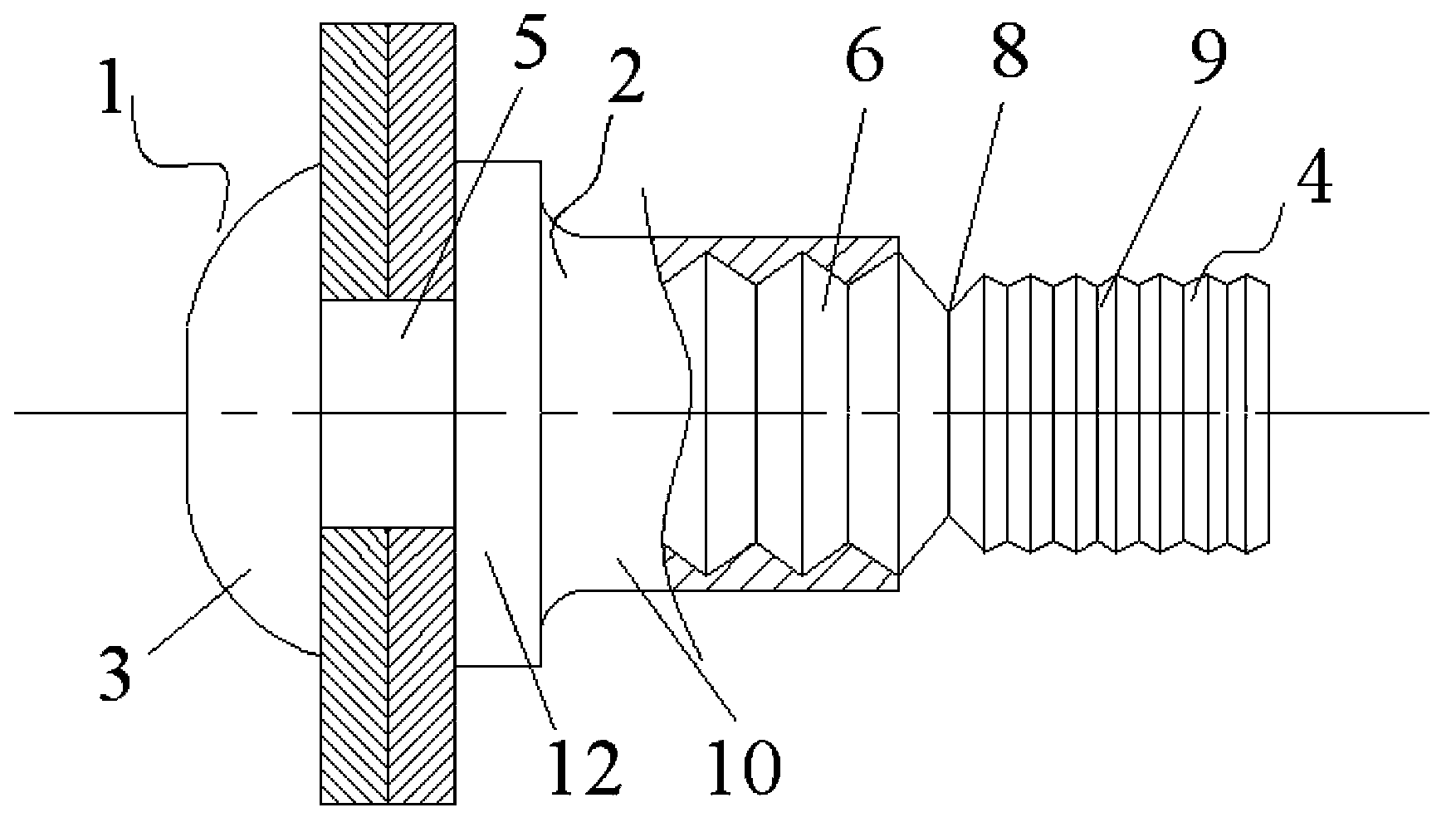

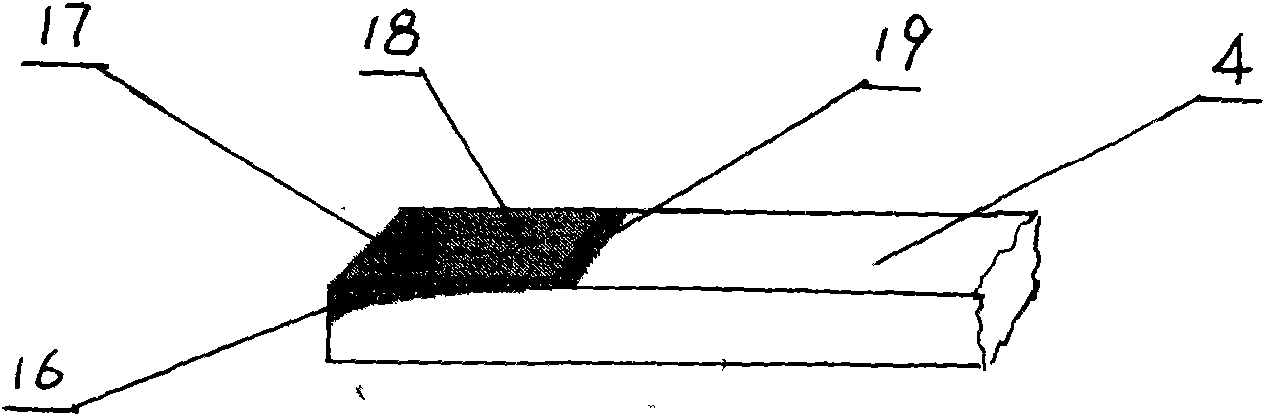

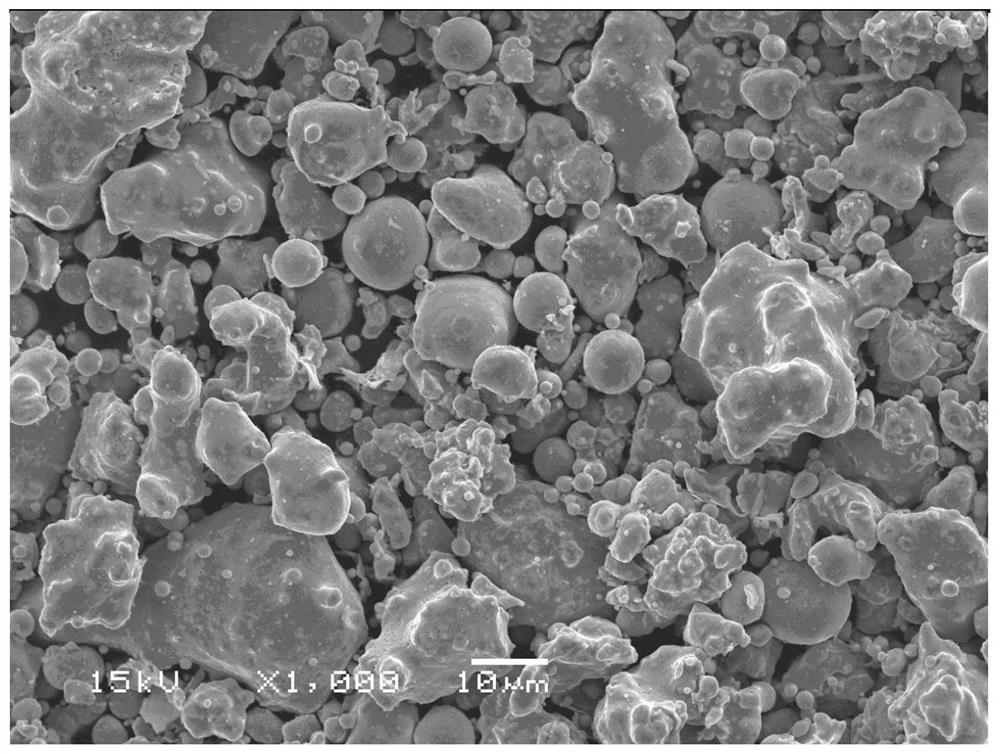

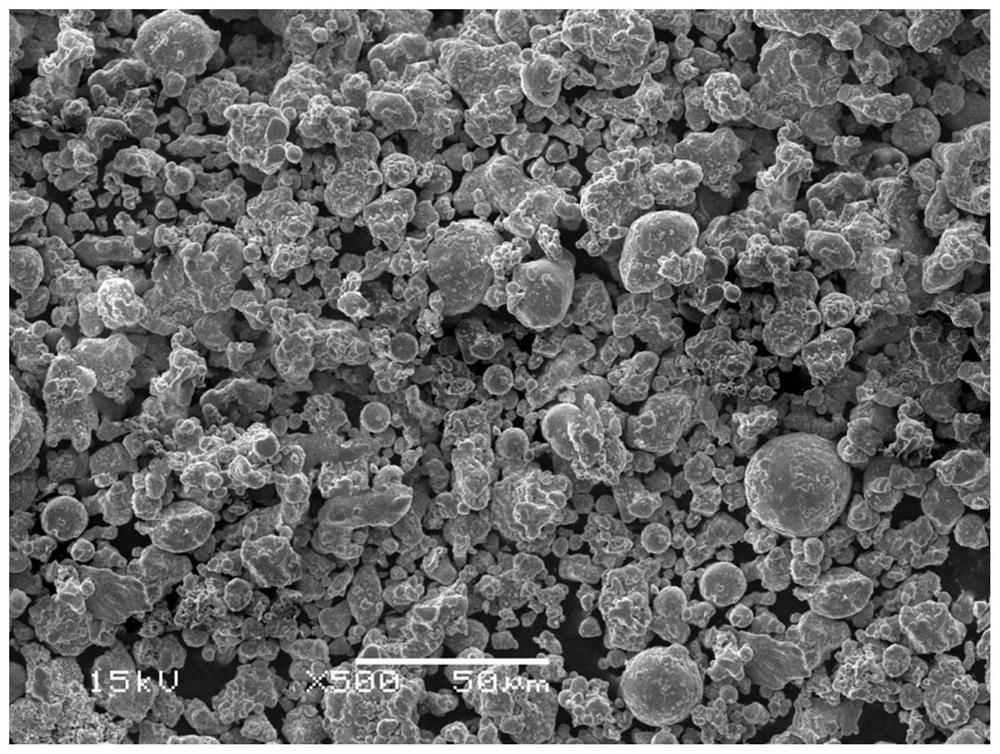

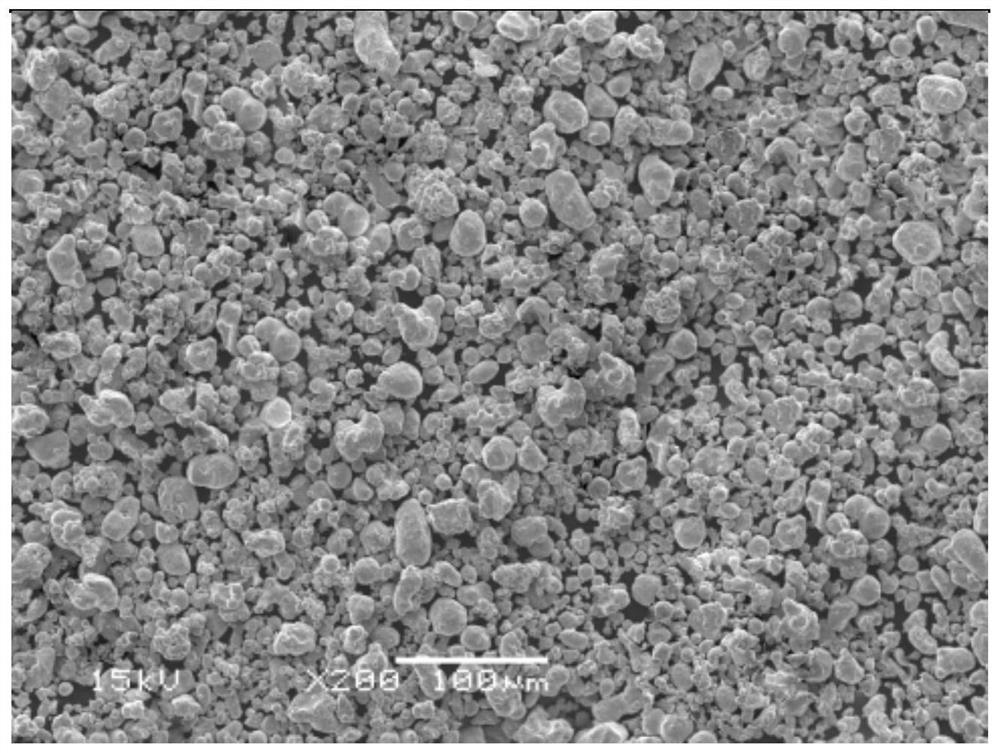

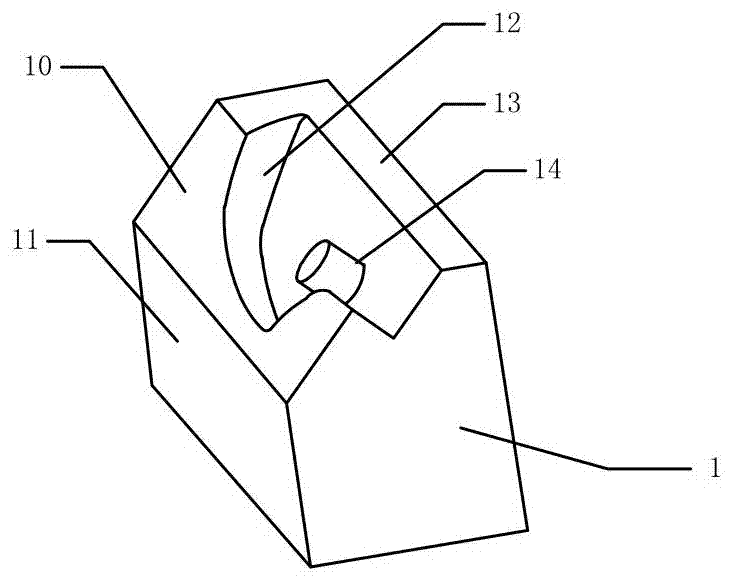

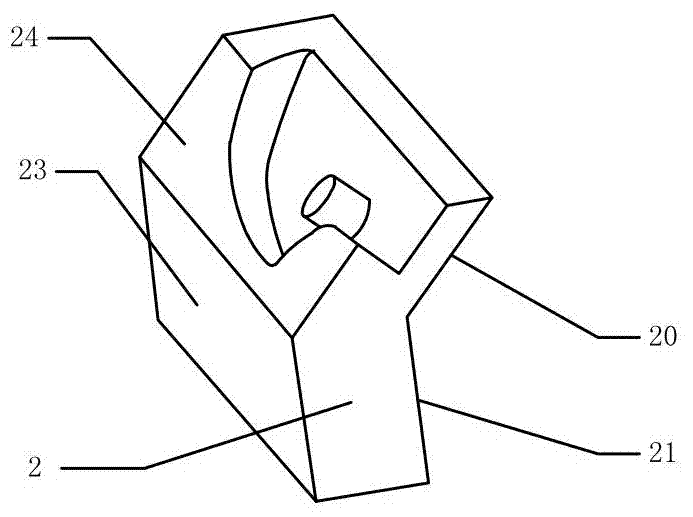

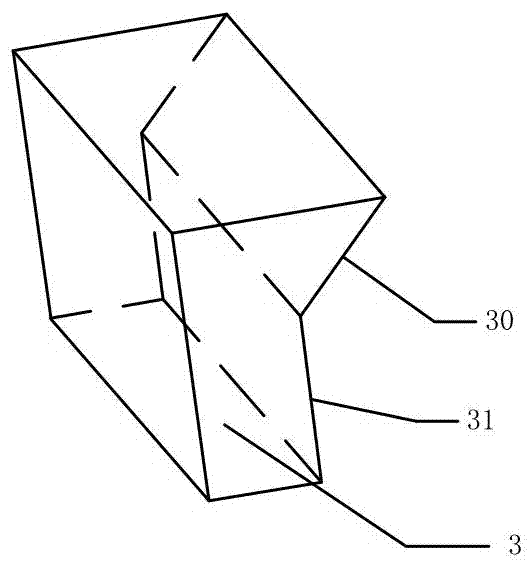

Machine tool, its manufacture method and welding plate therefor

InactiveCN100415434CContains inhomogeneityTool workpiece connectionReaming toolsVolumetric Mass DensityThermal expansion

The invention relates to a machine tool with a tool shank (10) and a cutting head (12) made from different materials, which are joined to each other on opposite joint surfaces (14,16) in a positive material fit by means of a joint layer (18') made of a ductile solder material. According to the invention, in order to obtain a solder connection which is substantially stress-free, powder particles (31) made of a temperature-resistant material with a thermal expansion coefficient which is lower than the solder material (30) are embedded into the joint layer (18') and the density of the powder particles (31) varies along the entire thickness of the joint layer (18').

Owner:KOMET GROUP GMBH

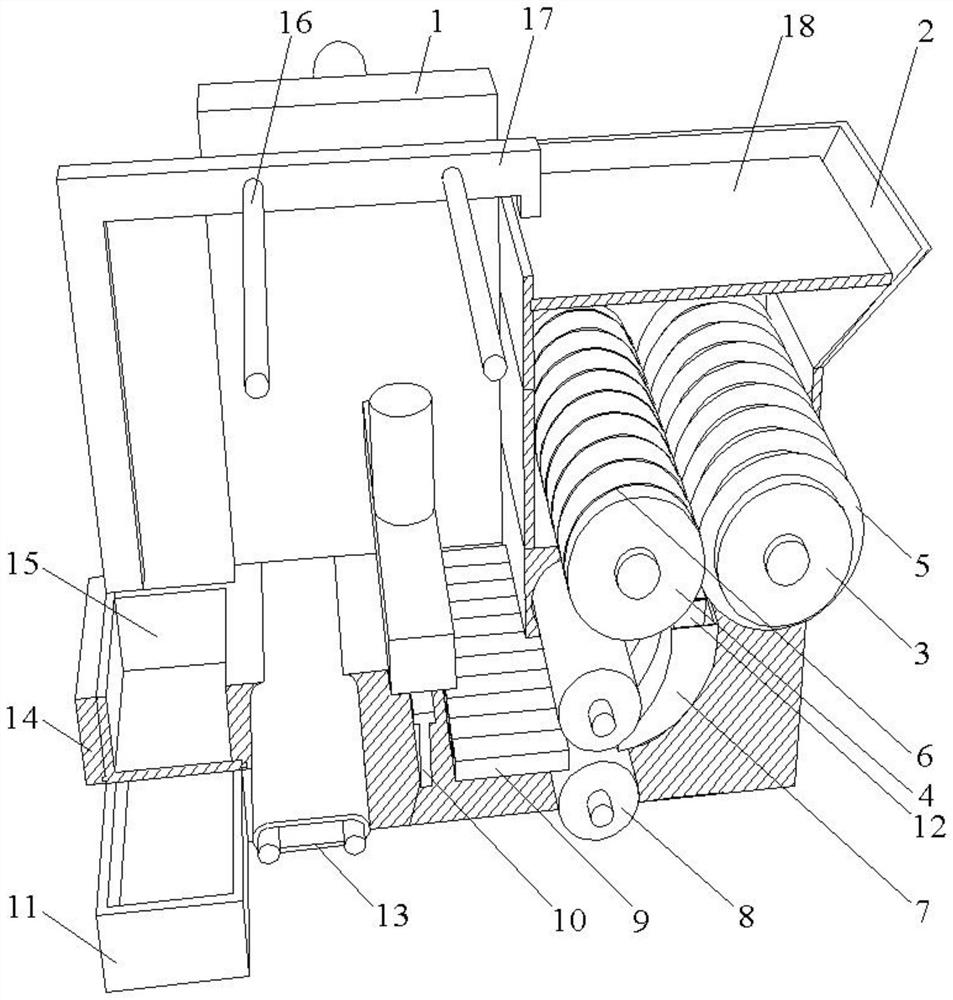

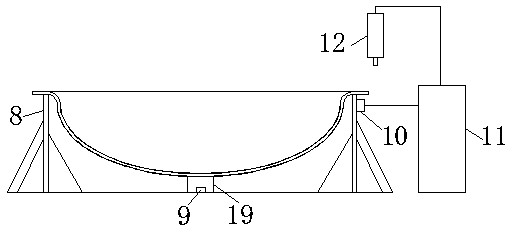

Forming machine for bimetallic strip

PendingCN108746263AMetal-working feeding devicesOther manufacturing equipments/toolsBimetallic stripIdler-wheel

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

Zirconium hydride reinforced diamond-impregnated drill bit iron-based matrix material and method for preparing drill bit material by using zirconium hydride reinforced diamond-impregnated drill bit iron-based matrix material

ActiveCN114351023AImprove wettabilityPromote densificationTurbinesOther manufacturing equipments/toolsZirconium hydrideAlloy

Owner:HENAN HUANGHE WHIRLWIND CO LTD

Compacting device for blade sharpening of scissor

PendingCN107253104AQuantity free adjustmentIncrease productivityOther manufacturing equipments/toolsGrinding work supportsStructural engineeringKnife blades

Owner:湖州泉欣五金科技有限公司

Machine tool special for turning inner holes of flywheel gear rings

ActiveCN104526357AGuaranteed positioning accuracyOther manufacturing equipments/toolsChucksSlide plateFlywheel

Owner:JINAN FIRST MACHINE TOOL GROUP

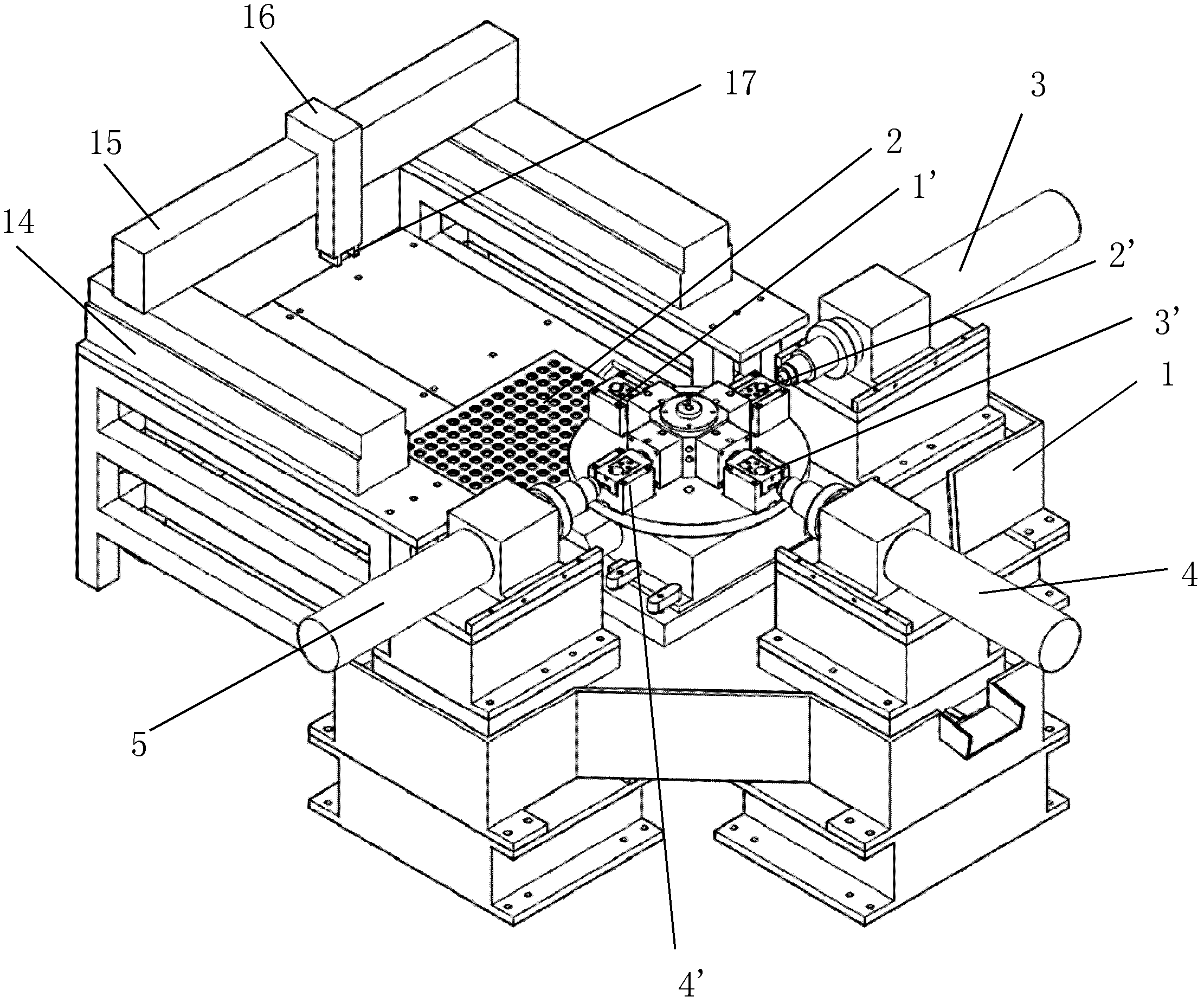

Cutting edge passivation device for magneto-rheological diamond cutter

InactiveCN112975599AHigh passivation precisionHigh removal rateOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention belongs to the field of cutter passivation, and particularly relates to a cutting edge passivation device for a magneto-rheological diamond cutter. The cutting edge passivation device comprises a bottom plate, a supporting plate, a side plate and a rotating plate, wherein the side plate is perpendicular to the bottom plate, the rotating plate and the supporting plate are sequentially arranged on the side plate from top to bottom, the supporting plate is parallel to the bottom plate, a grinding fluid basin is arranged on the supporting plate, a centrifugal pump is installed on the side portion of the grinding fluid basin, an electromagnet is arranged on the bottom plate and located on the lower portion of the grinding fluid basin, the rotating plate is perpendicularly installed on the side plate, the rotating plate is turnable, a clamping mechanism for fixing a cutter is arranged on the rotating plate, and a cutter is inserted into the grinding fluid basin. According to the cutting edge passivation device, the passivation efficiency and effect can be improved, the passivation cost is reduced, and the designated position of the cutting edge of the cutter is passivated.

Owner:YANCHENG INST OF TECH

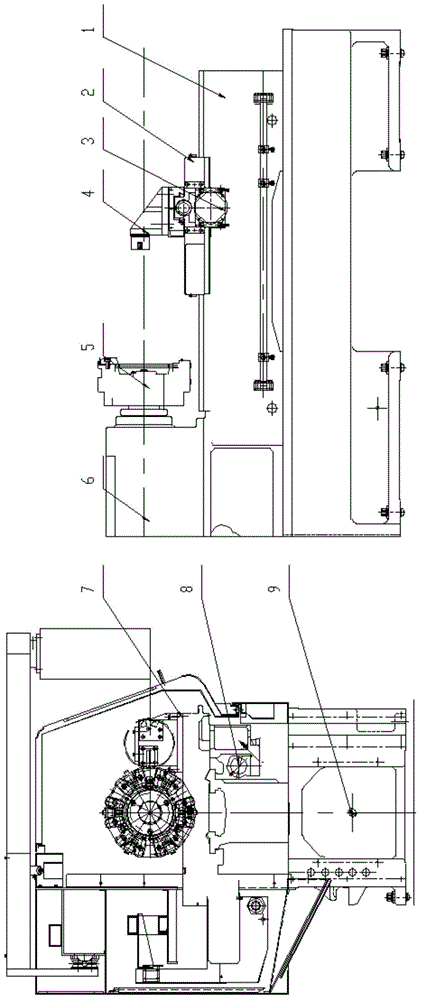

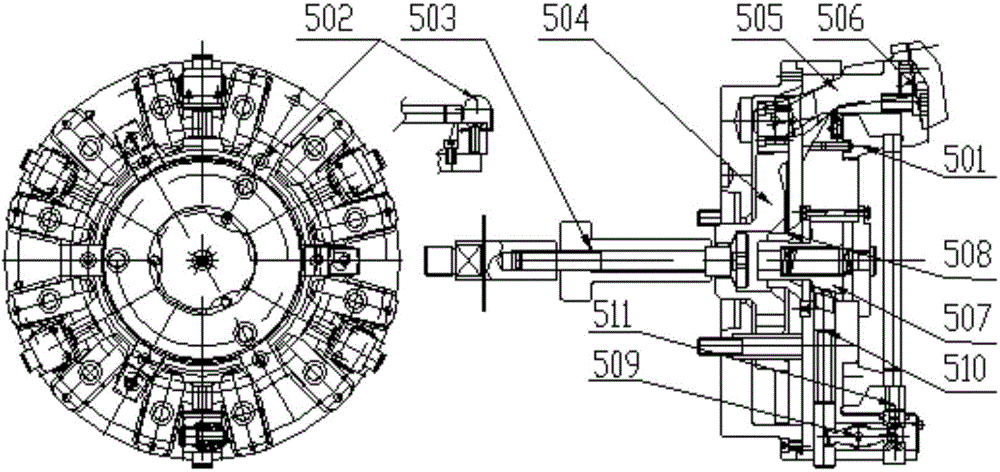

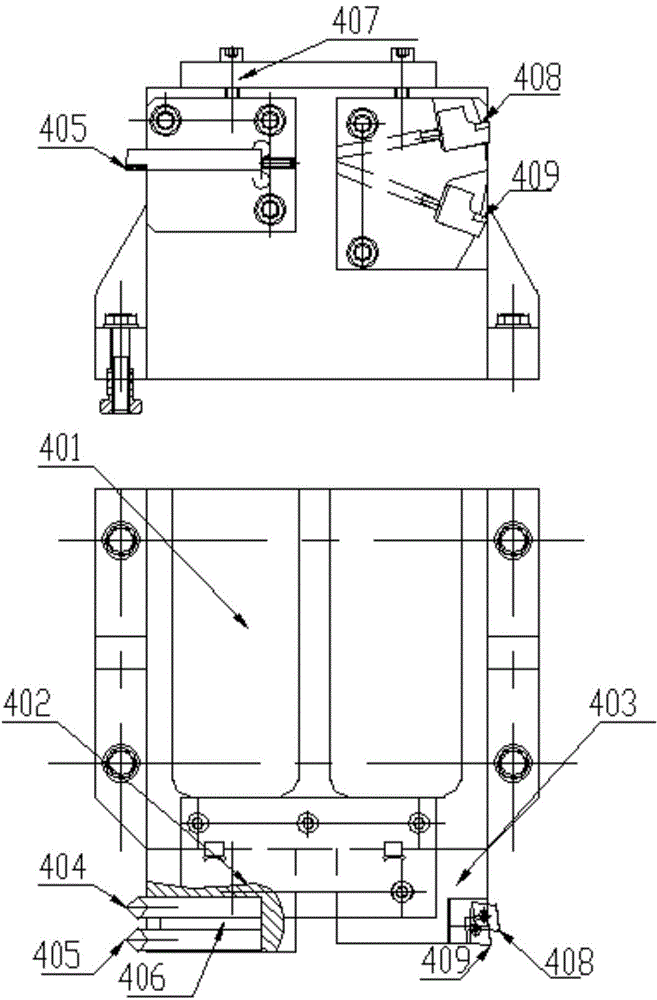

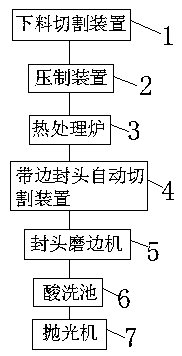

Band edge sealing head production system

Owner:宜兴市九洲封头锻造有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap