Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Machining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining is manufacturing process that involves removing materials using cutting tools for getting rid of the unwanted materials from some workpiece and converting it into the shape you desire.

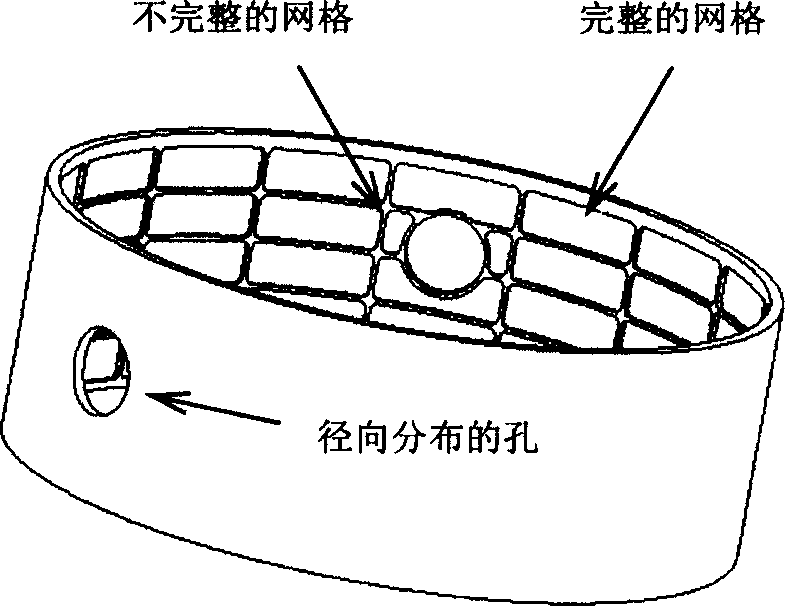

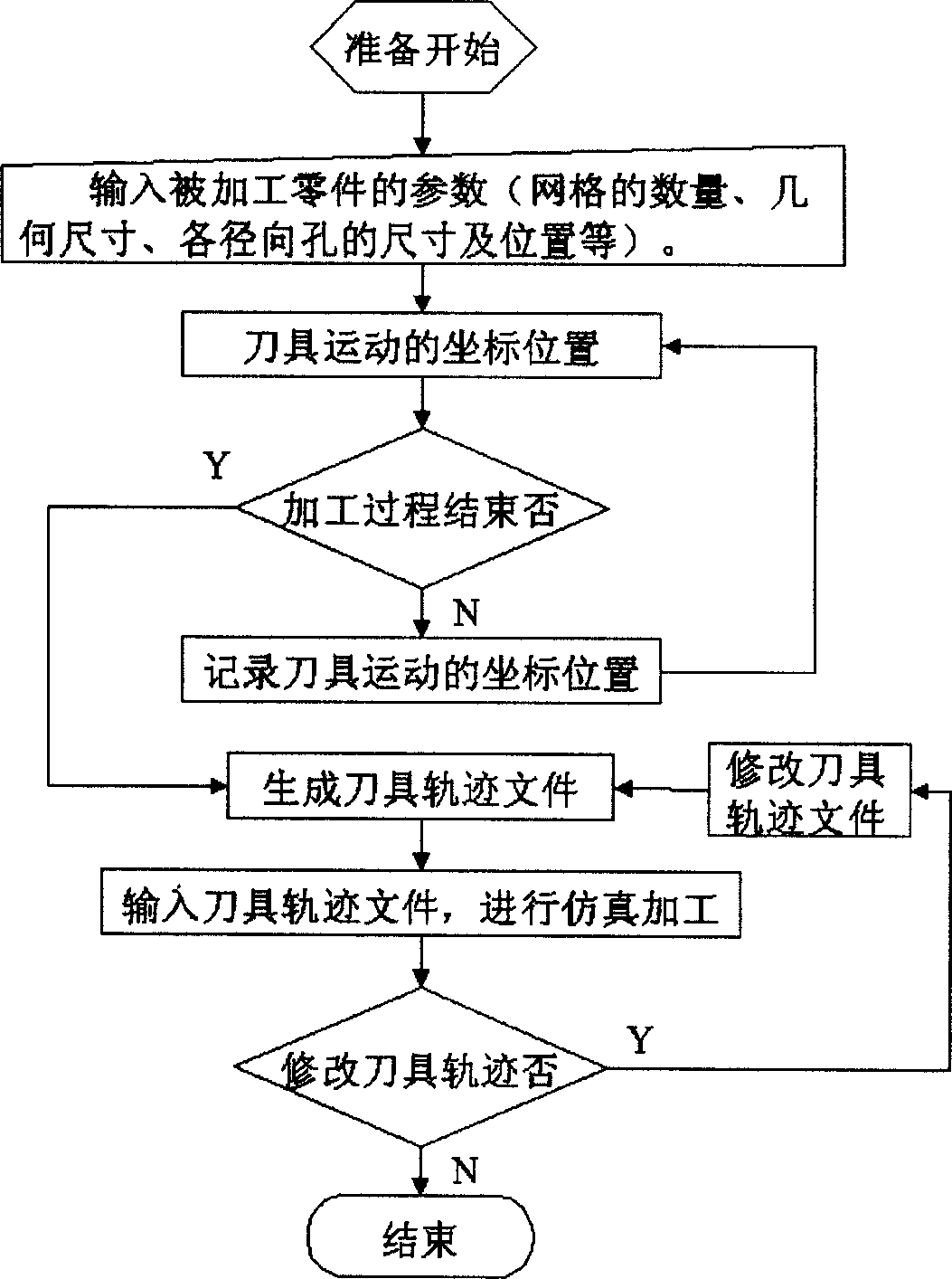

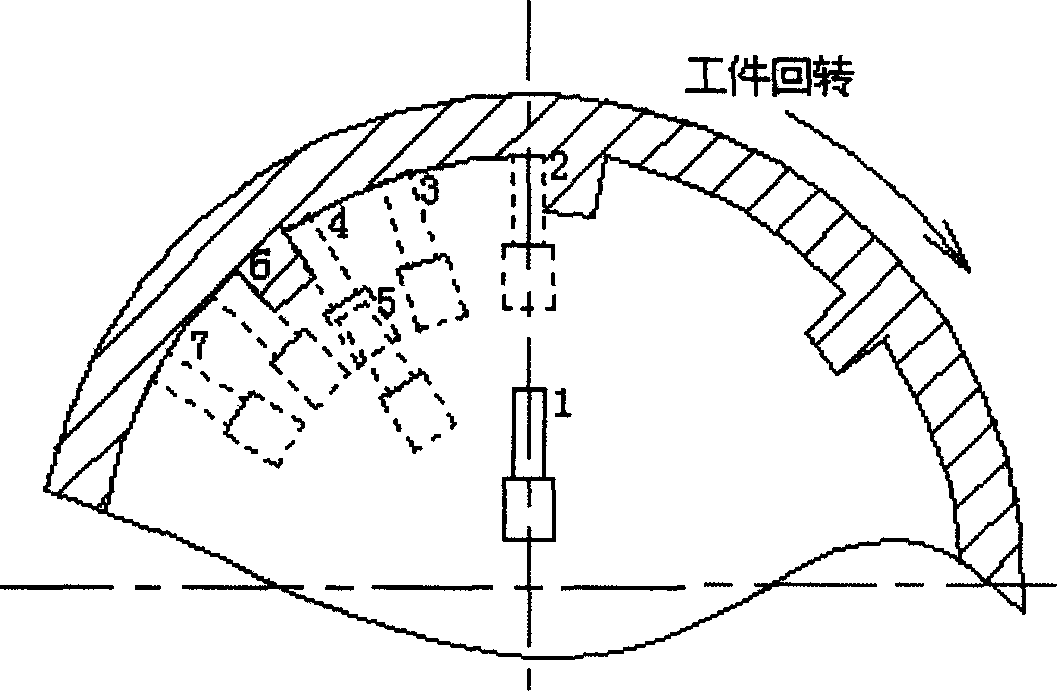

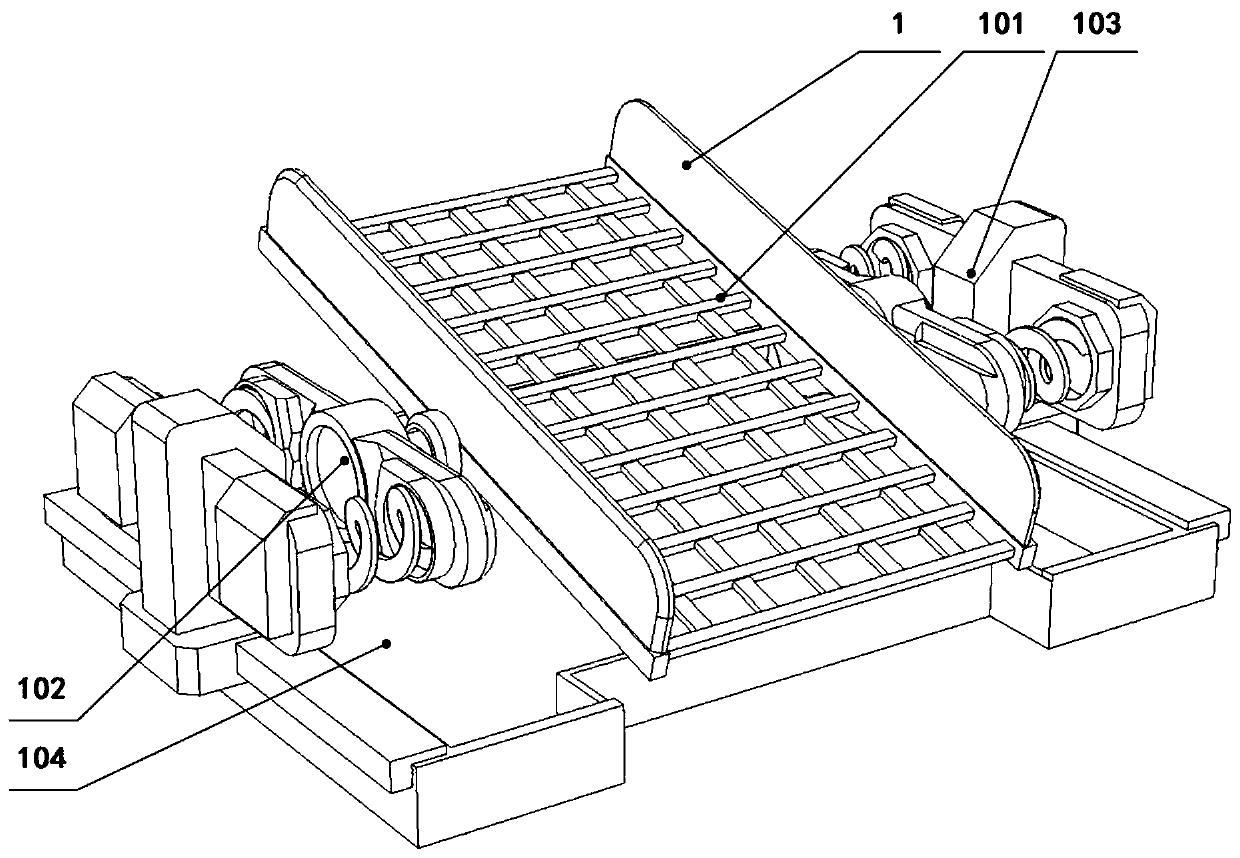

Fast automatic processing method utilized in lathe and milling machine for large thin wall part with cylindrical grids

InactiveCN1562542AMeet the technical requirements of high-speed turning and millingSimple processing technologyProgramme controlComputer controlMachining processAutomatic processing

Owner:沈阳工业学院

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

Deep processing device for magnetic iron ore

Owner:承德旭升矿业有限公司

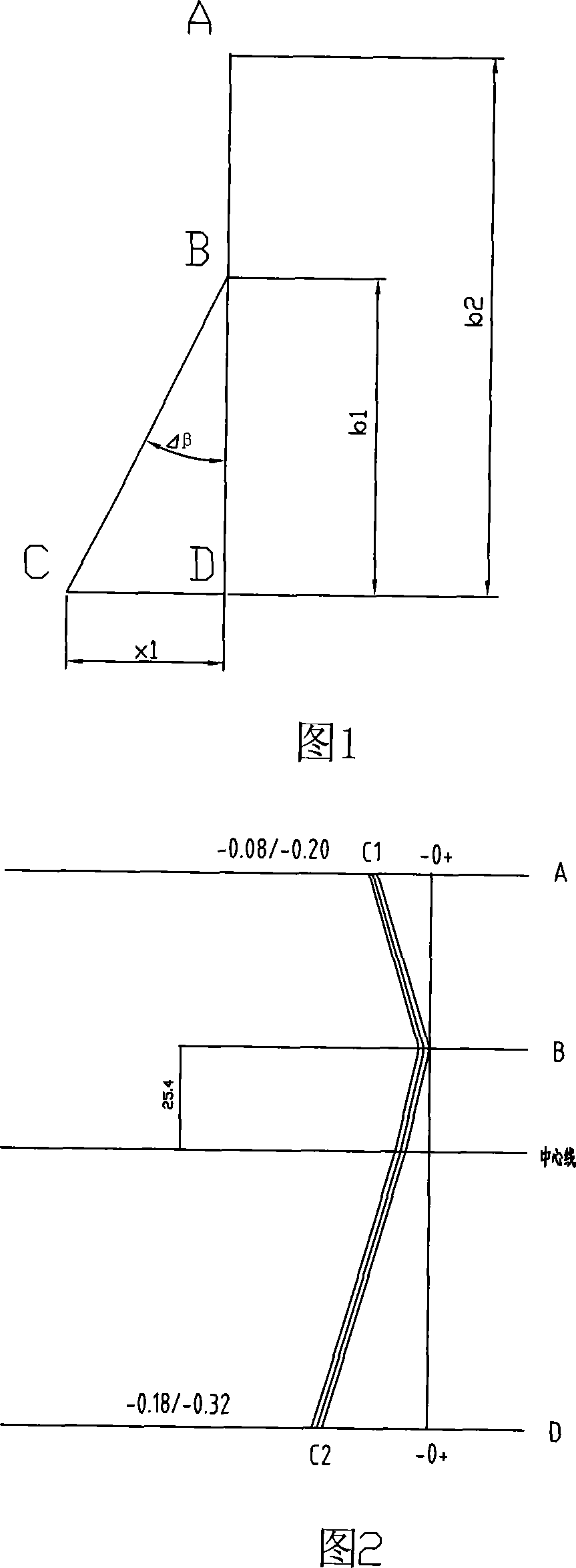

Tooth direction shaping gear hobbing processing technique

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for optimizing cutting path of spacer frame type integral structural member

ActiveCN105069249AShorten the production cycleOptimize cutting pathForecastingSpecial data processing applicationsElement modelManufacturing technology

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Magnetic collector for magnetic pulse forming

Owner:HARBIN INST OF TECH

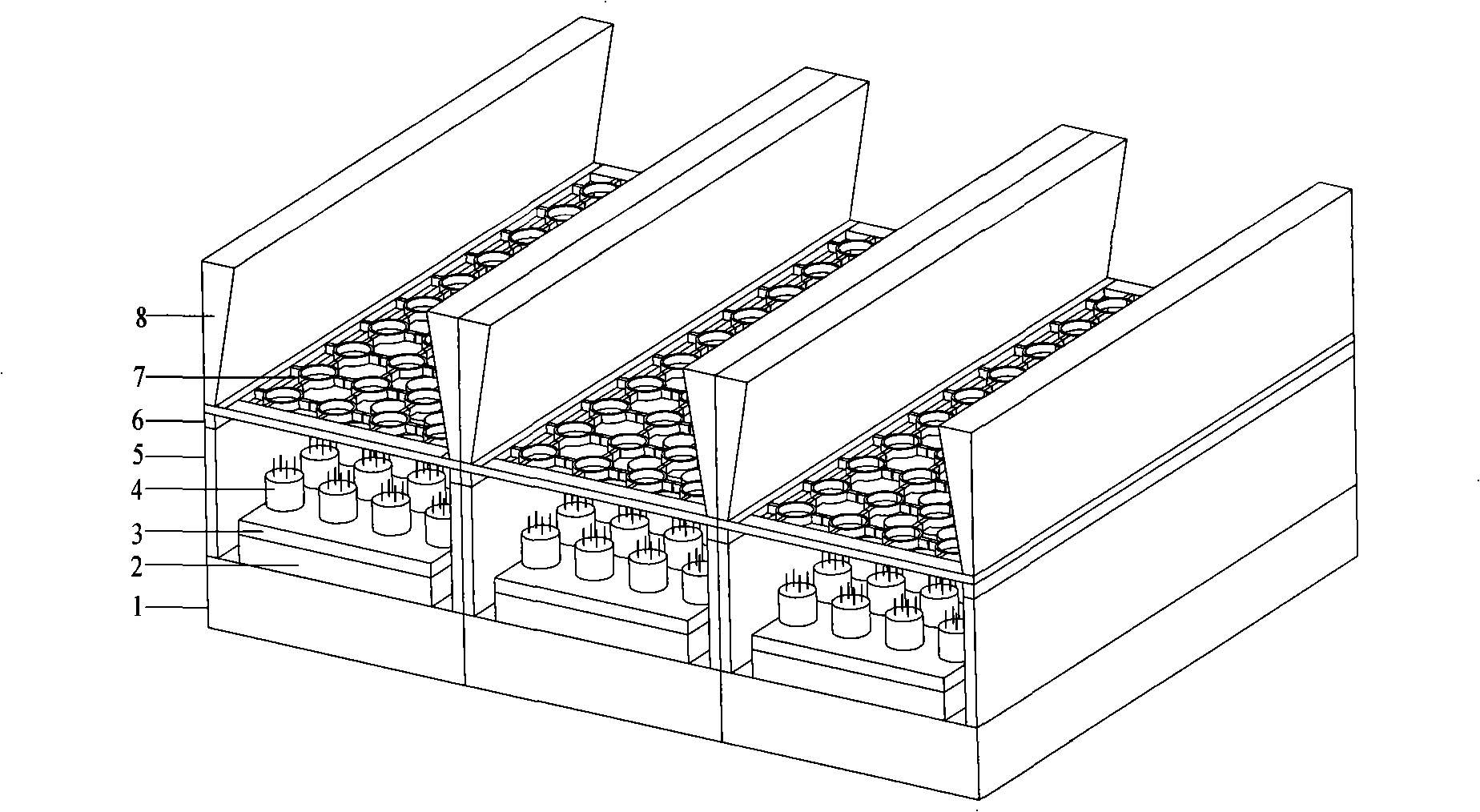

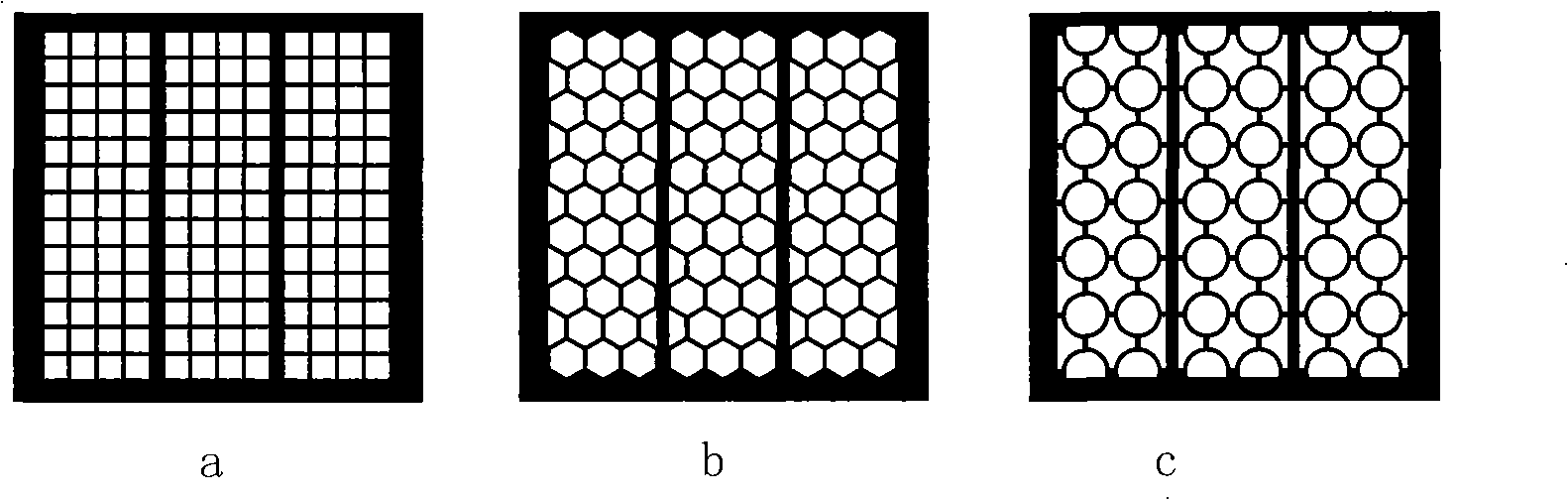

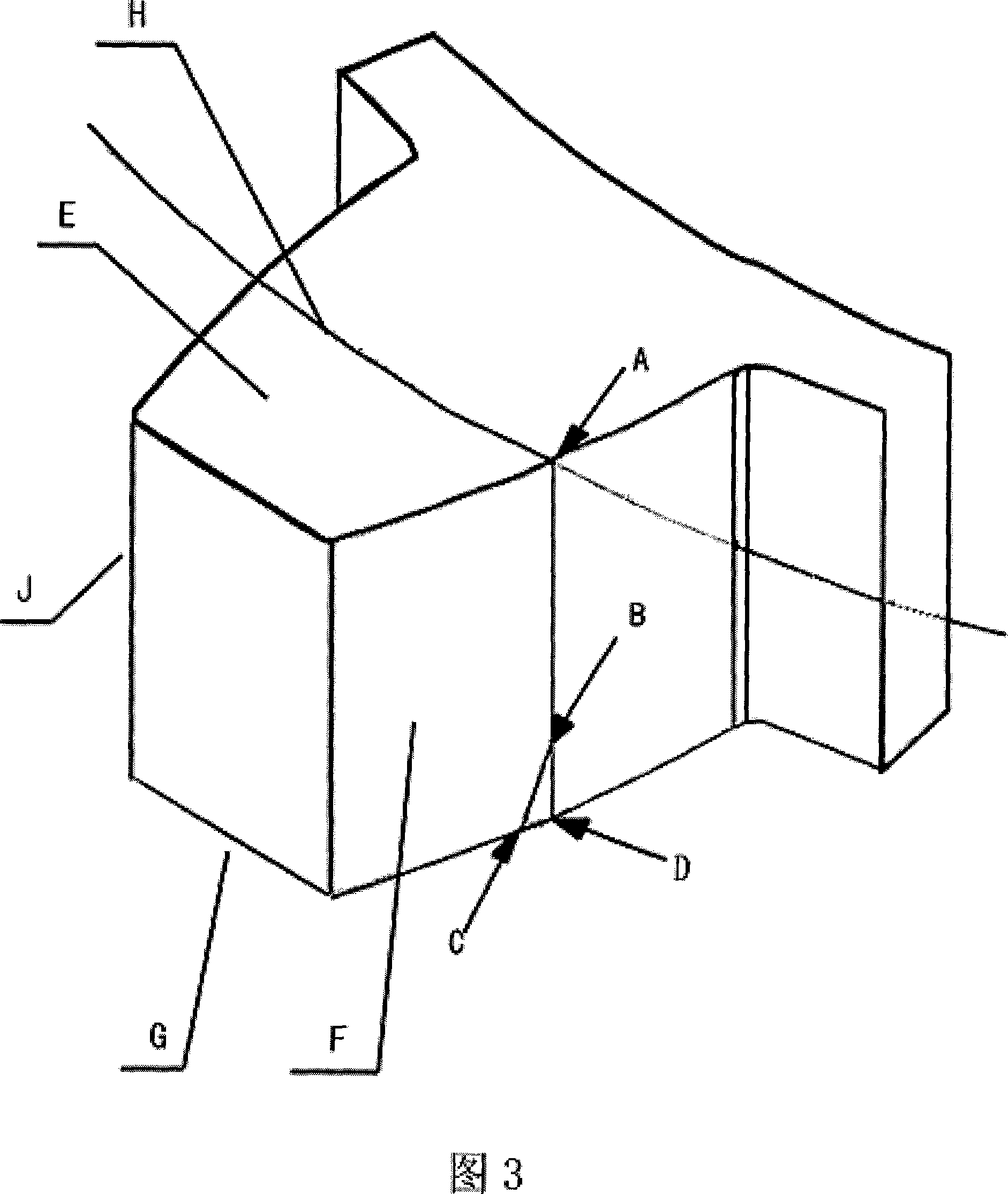

Heat-preservation wall body of wood-frame shear wall

InactiveCN101929207AQuality improvementHigh precisionWallsClimate change adaptationWall studEngineering

The invention belongs to the technical field of structural engineering, and particularly relates to a heat-preservation wall body for a mixed structure of a wood frame and a wooden shear wall, and assembly technology. The assembled heat-preservation wall body consists of wall studs, a wood base structural slab, a gypsum board, heat-preservation cotton, a wood-frame pillar, a mudsill board and a top beam board, wherein a horizontal interval between every two adjacent wall studs is 400 to 600 millimeters, and the wall studs on both sides are connected with the wood-frame pillar through nails; the wood base structural slab covers the wall body, is connected with the wall studs, the top beam board and the mudsill board through the nails, and is flush with the outer side of the wood-frame pillar; the gypsum board is covered on the inner side of a wallboard and is connected with the wall studs through screws; and the heat-preservation cotton is filled between inner and outer cladding boards. Materials for the assembled wall body provided by the invention can improve the natural environment in the process of growth, have the advantages of low energy consumption in the machining process, regeneration and natural degradation after abandonment, and have the functions of quick construction, vibration prevention, energy conservation, heat preservation, heat insulation and the like; the heat-preservation wall body has the advantages of high industrial production degree, high production efficiency, less on-site wet operation, a plurality of operational surfaces and quick construction; and the materials, such as dimension stocks, connectors, plywood, laminated wood and the like can be localized to reduce the construction cost.

Owner:TONGJI UNIV

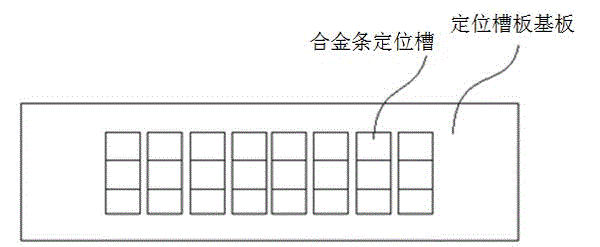

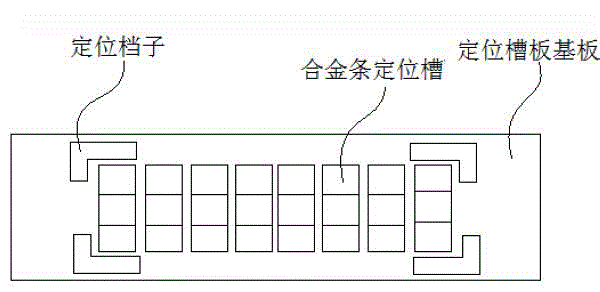

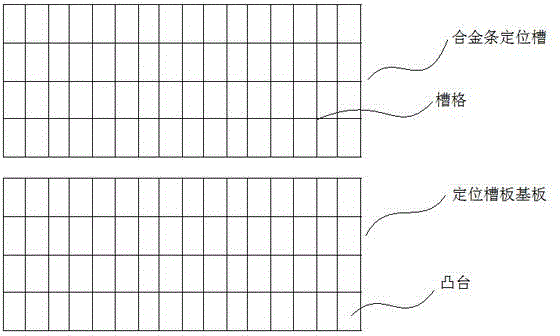

Double-sided bonding method applicable to hard alloy bars in hard alloy hard-surface machining process and application thereof

ActiveCN104976200APrecise processing sizeHigh speedMaterial gluingWelding apparatusMachined surfaceAlloy

Owner:株洲金韦硬质合金有限公司

Machining process for flow spoiler bands

Owner:CHONGQING YUQING MACHINERY MFR

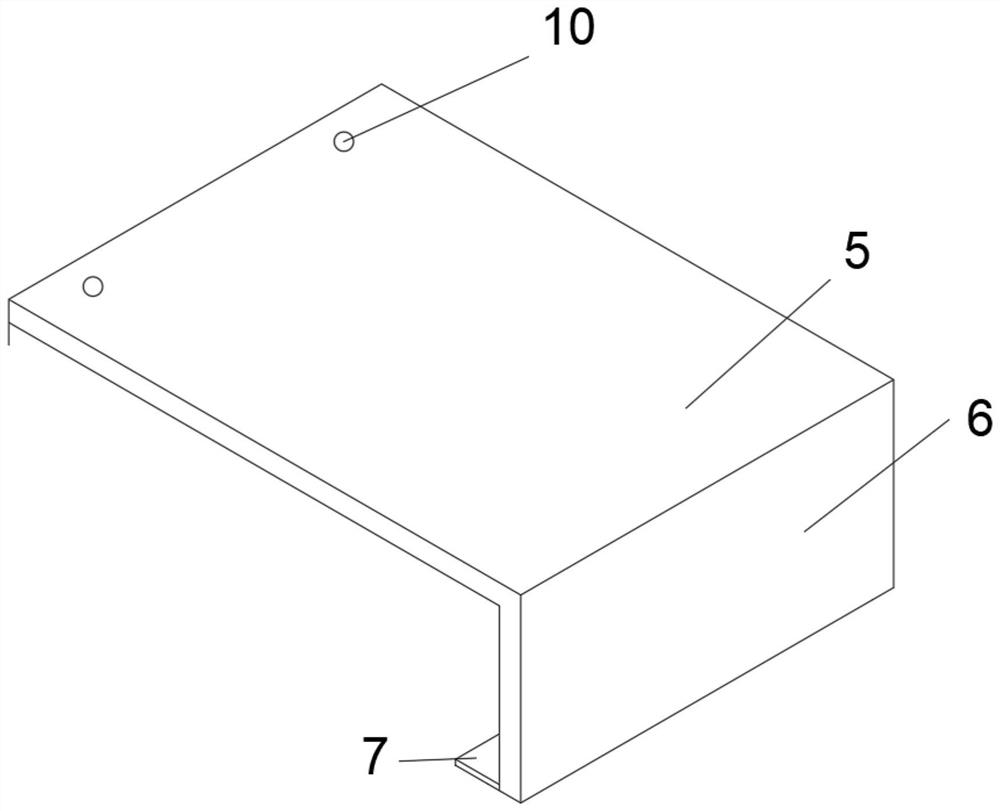

Processing technique of liquid crystal television metal frame

ActiveCN101332483ASmall Bend Edge Fillet RadiusReduce shockShaping toolsEngineeringMachining process

The invention discloses a processing technology of a metal face frame of a liquid crystal television, and the processing technology comprises a processing procedure of folding edges and a processing procedure of ambient round angles. The processing technology is characterized in that an aluminum sheet with a cut in the middle is fixed between a concave pattern plate and a fixing plate in the processing procedure of folding edges, wherein the edge of a concave pattern cavity of the concave pattern plate is added with a ring of pressed rib pressed into the aluminum sheet, and the inner edge of the aluminum sheet is pressed by a convex pattern plate to form the folding edge; in the processing procedure of ambient round angles, three pairs of concave-convex pattern insert block components are adopted to bend, punch and shape the four round angles at the connecting places of the four straight edges on the folding edges in three steps, and the radiuses of the arc surfaces on the three convex pattern insert blocks of the concave-convex pattern insert block components are decreased sequentially. The processing technology of the invention can press the folding edges with smaller round angle radius and the four round angles at the connecting places of the four straight edges on the folding edges, and effectively prevent rupture at the four round angles in the processing course, which improves the product quality greatly.

Owner:SUZHOU VICTORY PRECISION MFG

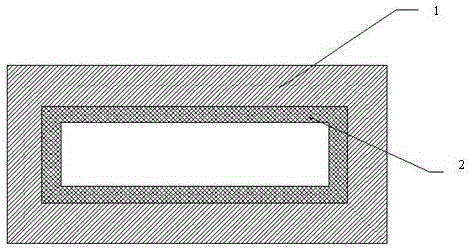

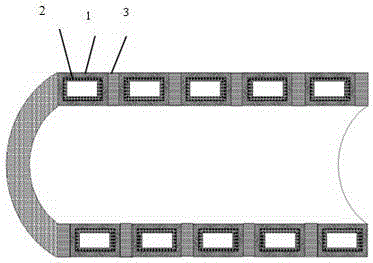

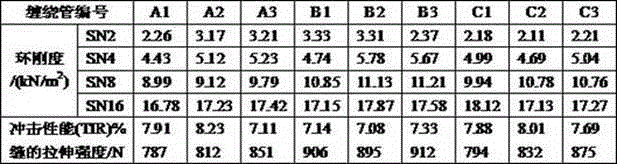

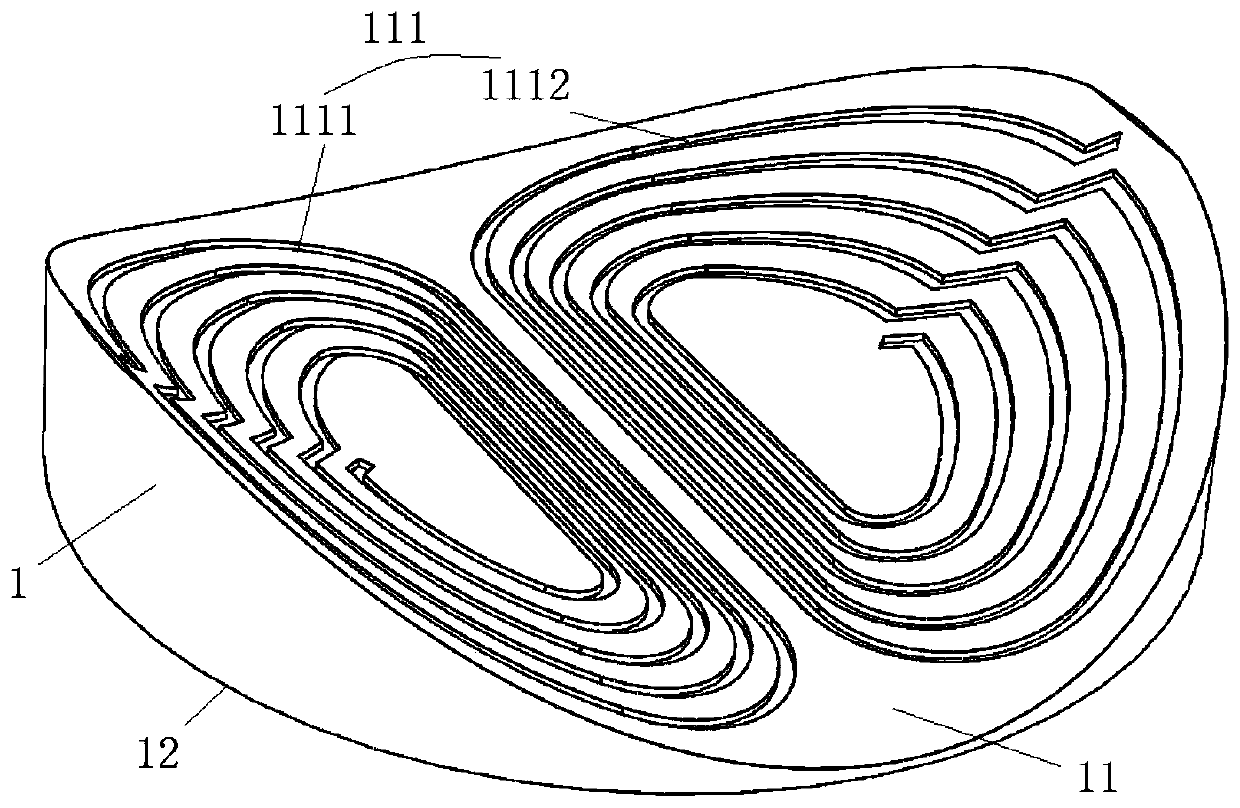

Winding pipe with fiber reinforced polypropylene (FRPP) reinforced hollow-structure wall and machining process for winding pipe

Owner:HUBEI KINGBULL PIPE IND

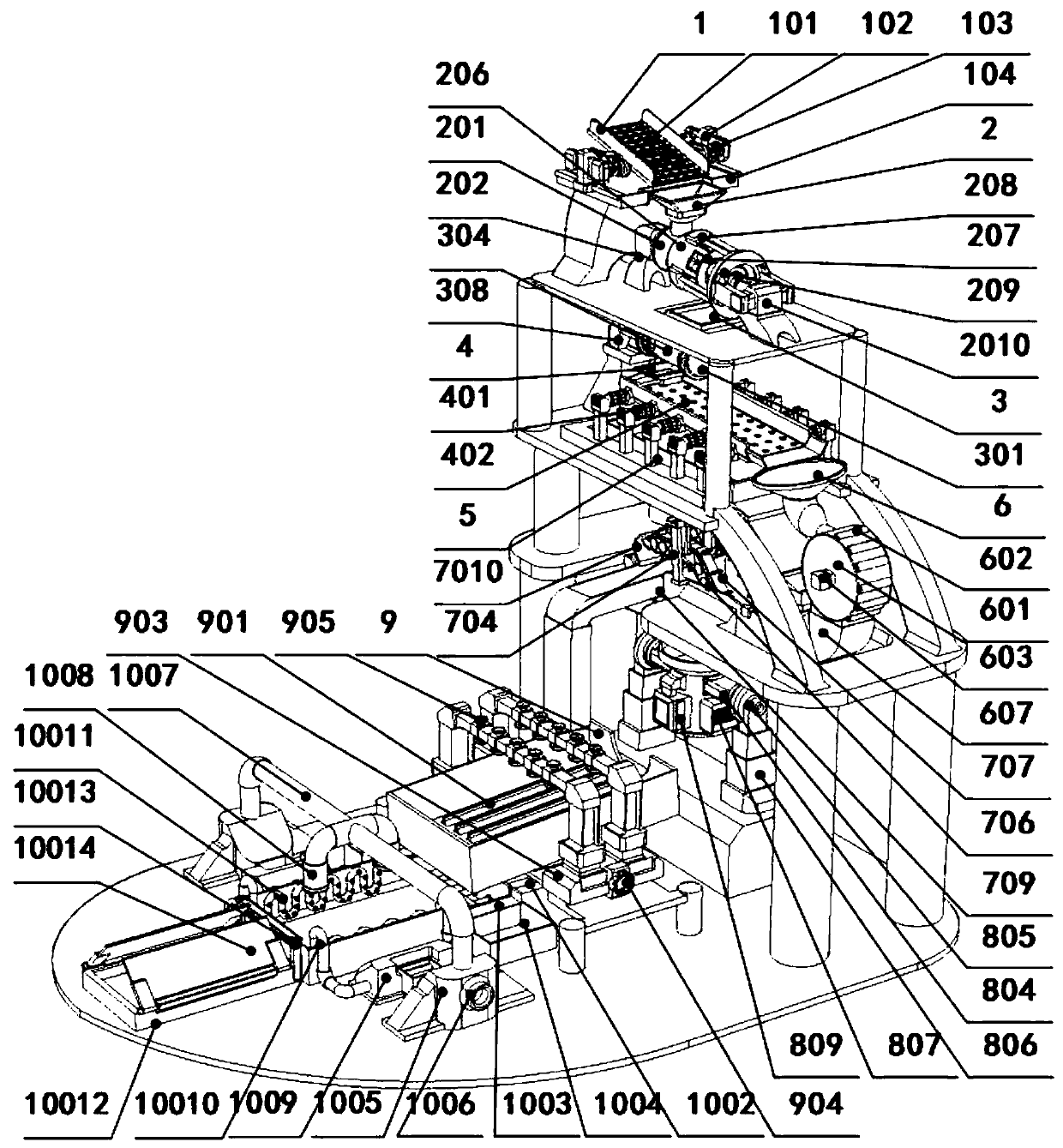

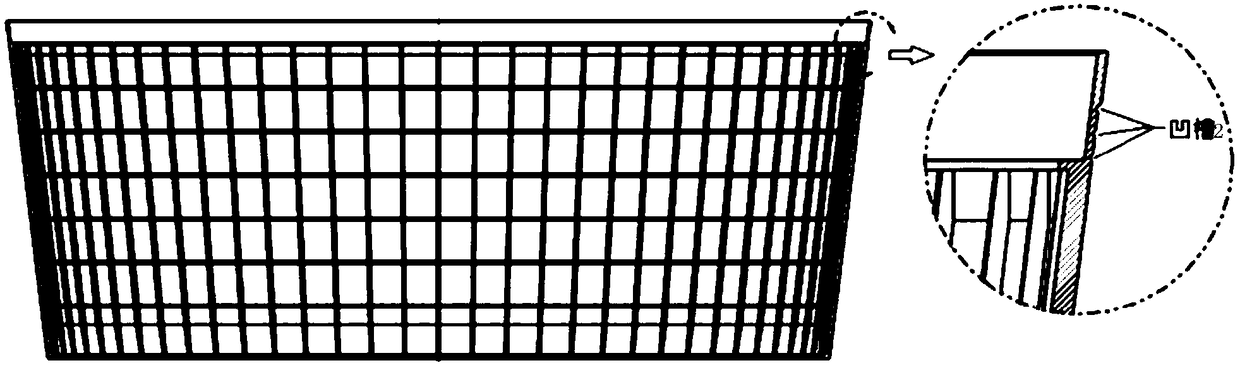

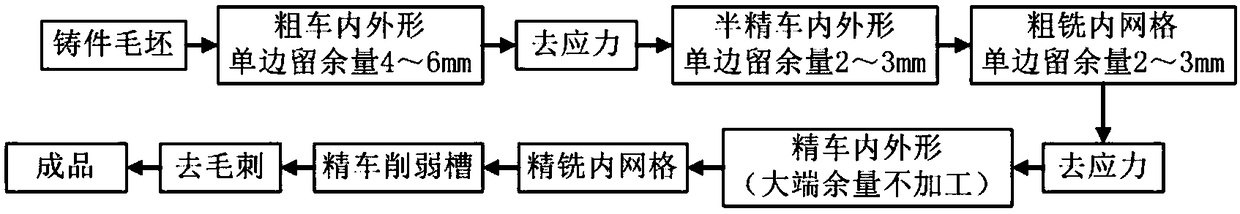

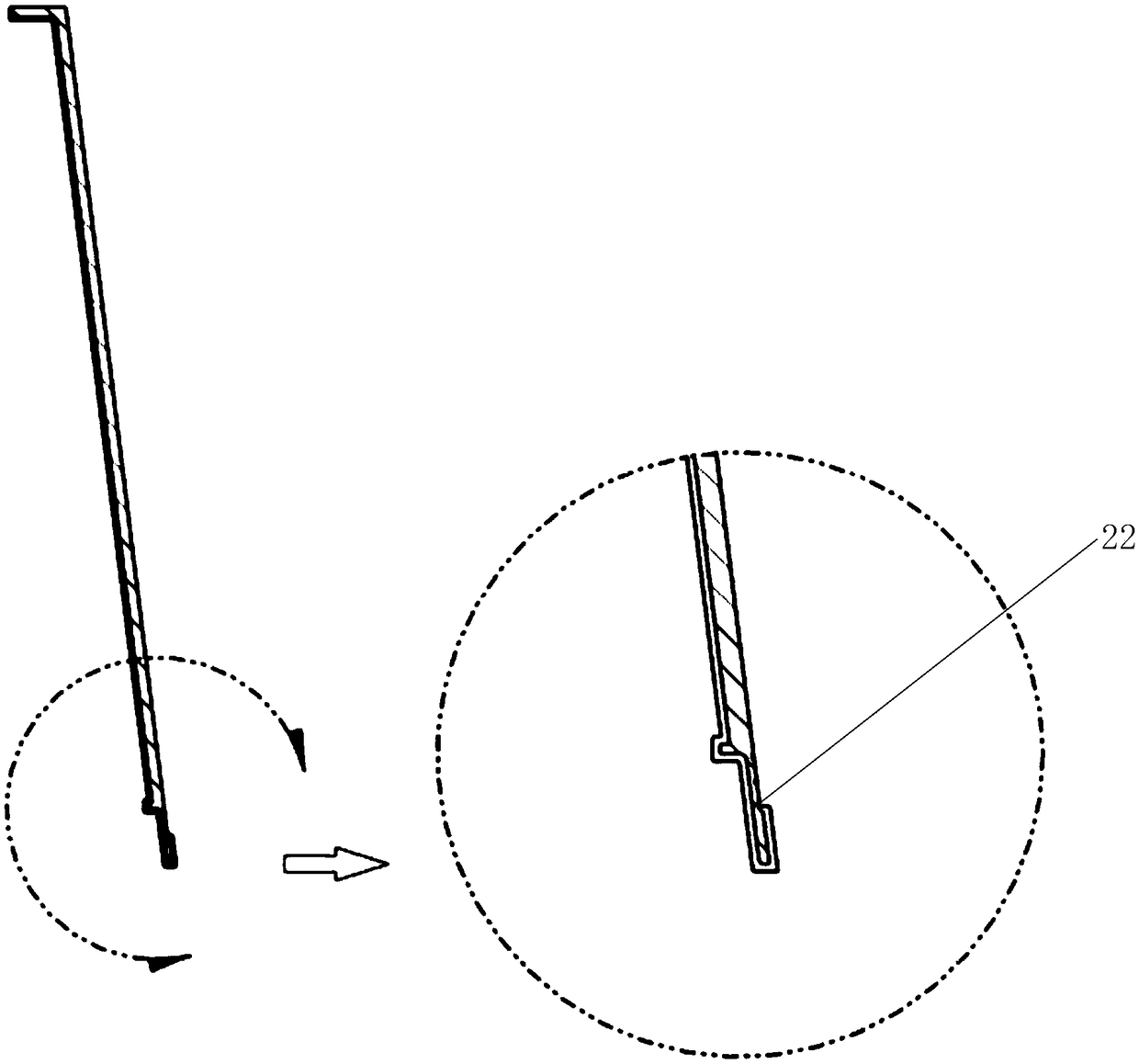

Processing method of thin-walled shell with complex grids

Owner:CAPITAL AEROSPACE MACHINERY +1

Superconducting niobium pipe and preparation method thereof

ActiveCN103219459ALow residual resistivity dropSuperconductor device manufacture/treatmentHydrogenIngot

The invention relates to the technical field of metal materials and provides a superconducting niobium pipe and a preparation method thereof. The preparation method comprises the specific steps of: forging superconducting niobium ingots, wherein the temperature during a forging process is lower than or equal to 60 DEG C; carrying out first thermal treatment on the forged superconducting niobium ingots; coating a lubricating agent on the surfaces of the superconducting niobium ingots after the first thermal treatment, and carrying out reverse extrusion; and carrying out secondary thermal treatment on the superconducting niobium ingots after the reverse extrusion, so as to obtain the superconducting niobium pipe. According to the superconducting niobium pipe and the preparation method thereof, the forging temperature is controlled in a forging process, and the lubricating agent is coated on the surfaces of the niobium ingots in an extrusion process, so that the carbon absorption, the hydrogen absorption and the oxygen absorption of the niobium ingots in a machining process are effectively avoided, and the decreasing amplitude of the residual resistivity of the prepared superconducting niobium pipe is relatively small.

Owner:NINGXIA ORIENT TANTALUM IND

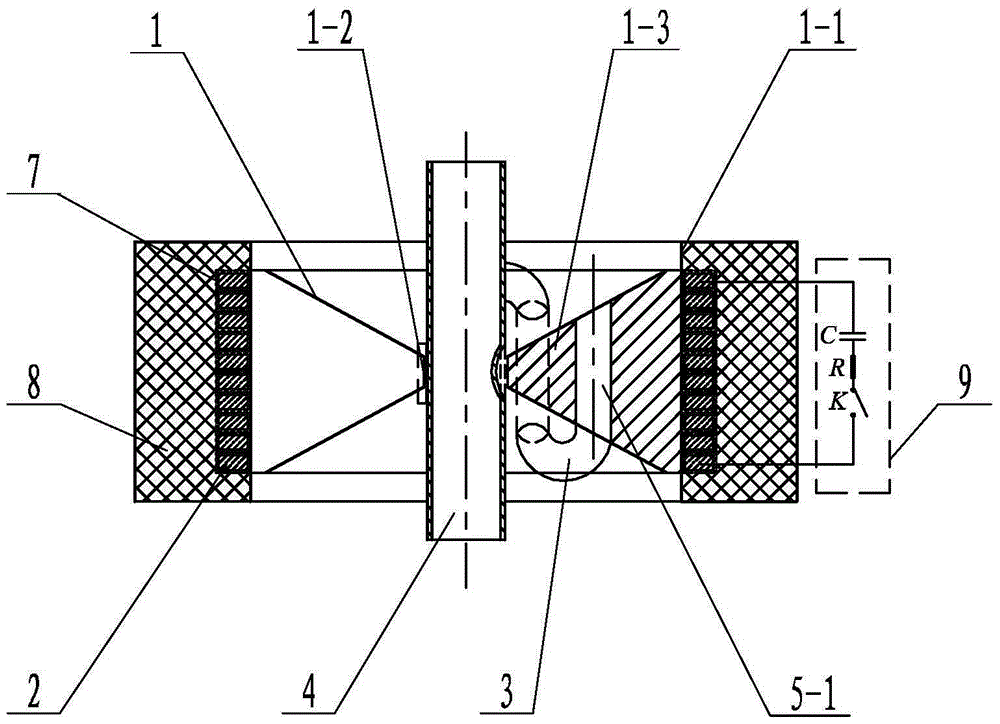

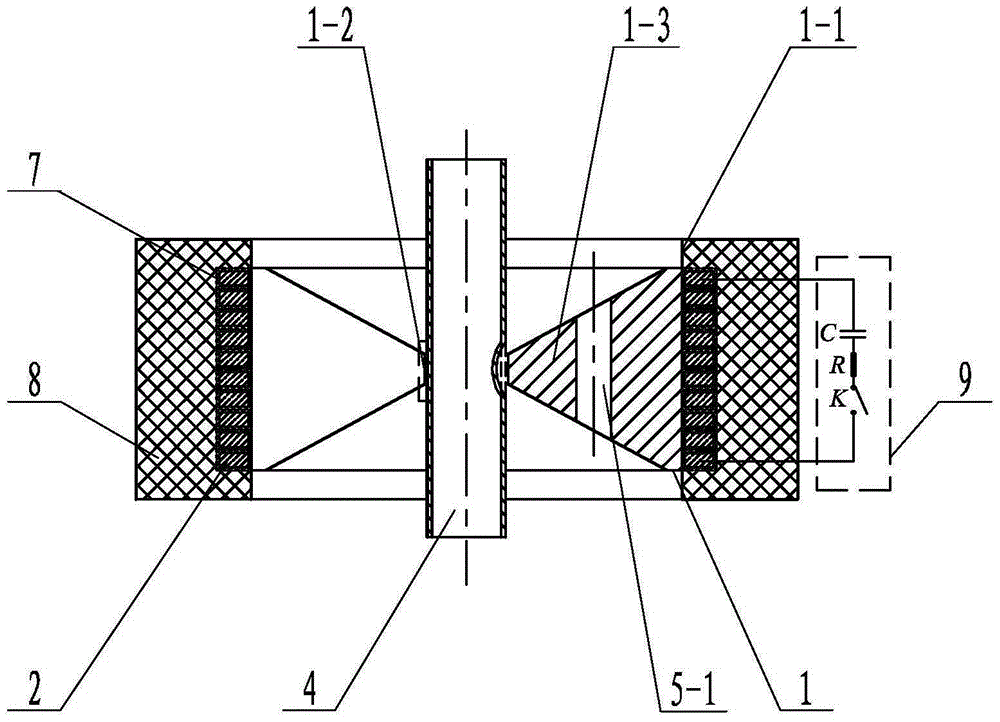

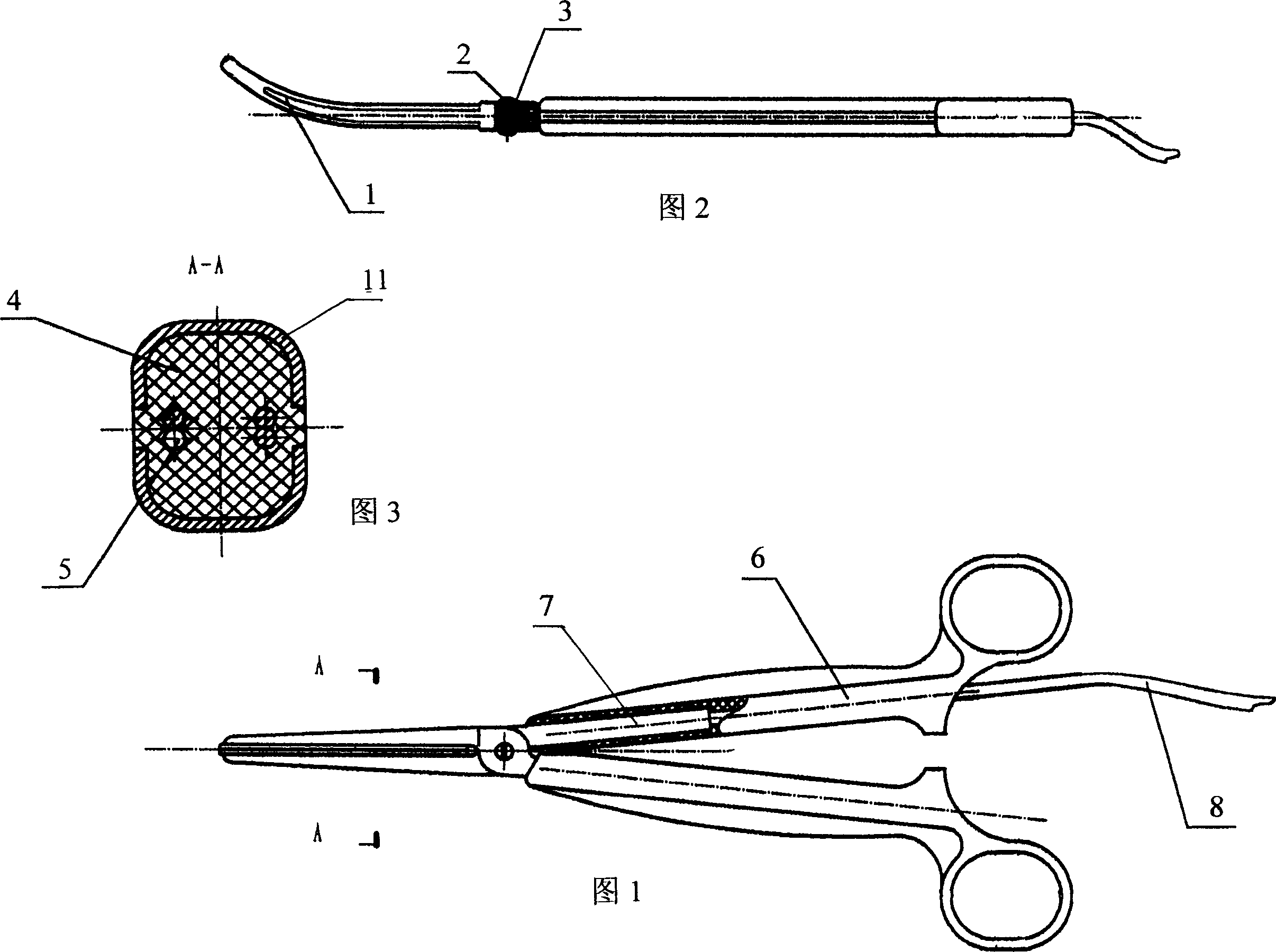

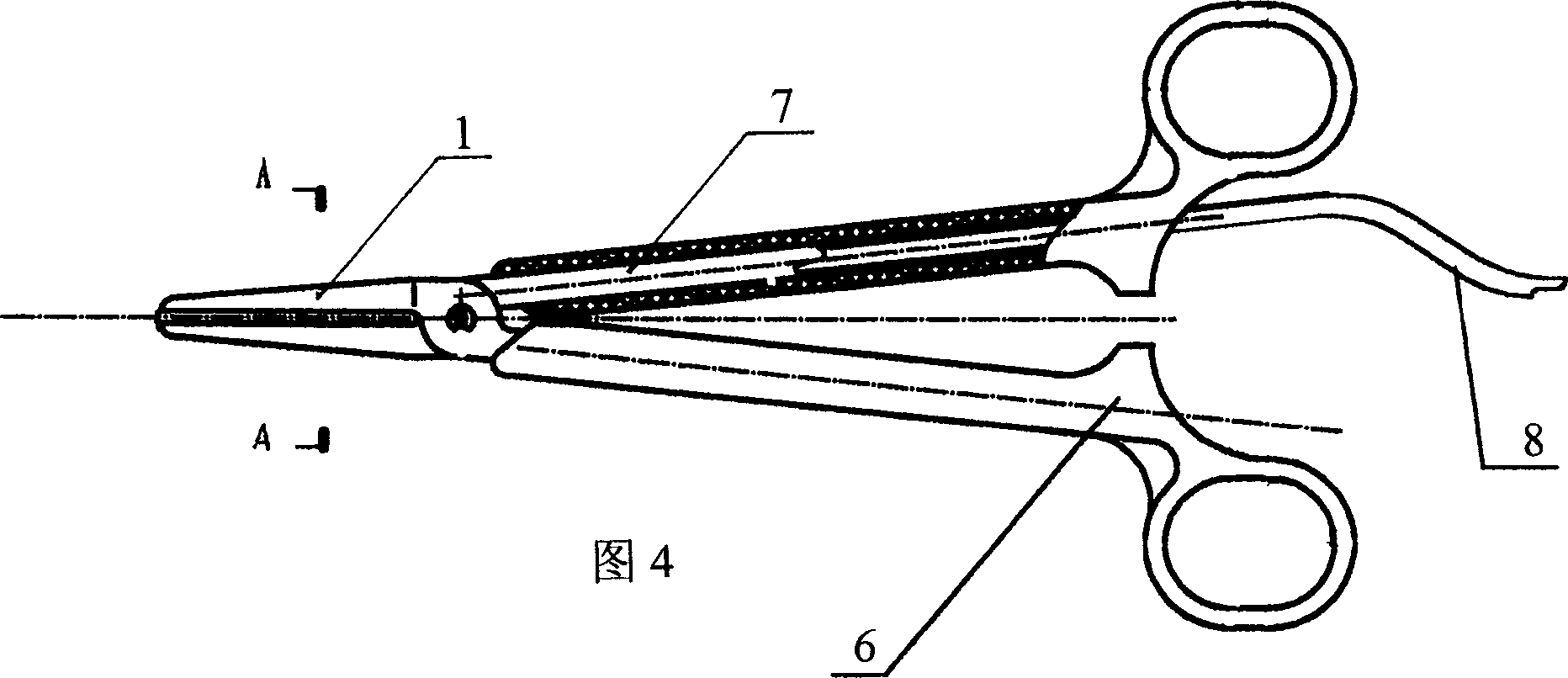

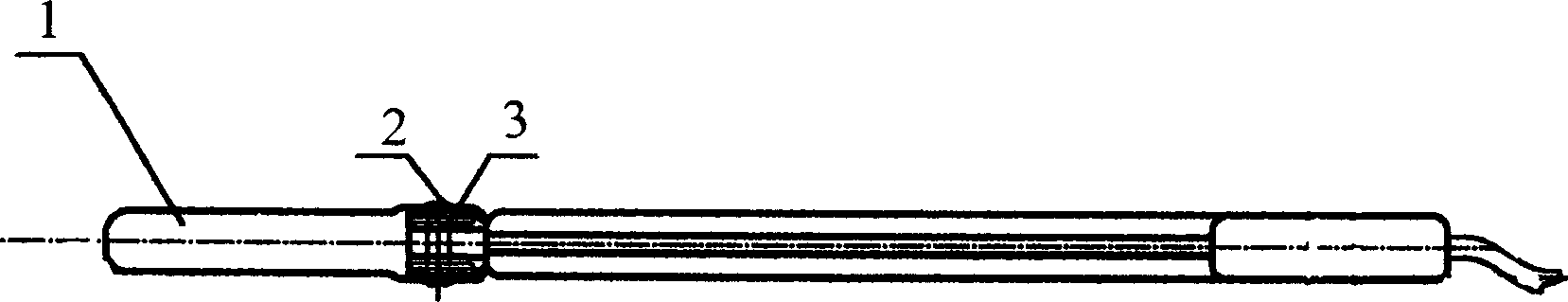

Fast ligaturing and closing electrical medical pliers and the making process

ActiveCN1608597AIncrease profitSimple and complicated processing procedureSurgical instruments for heatingCapacitancePunching

Owner:寿张根

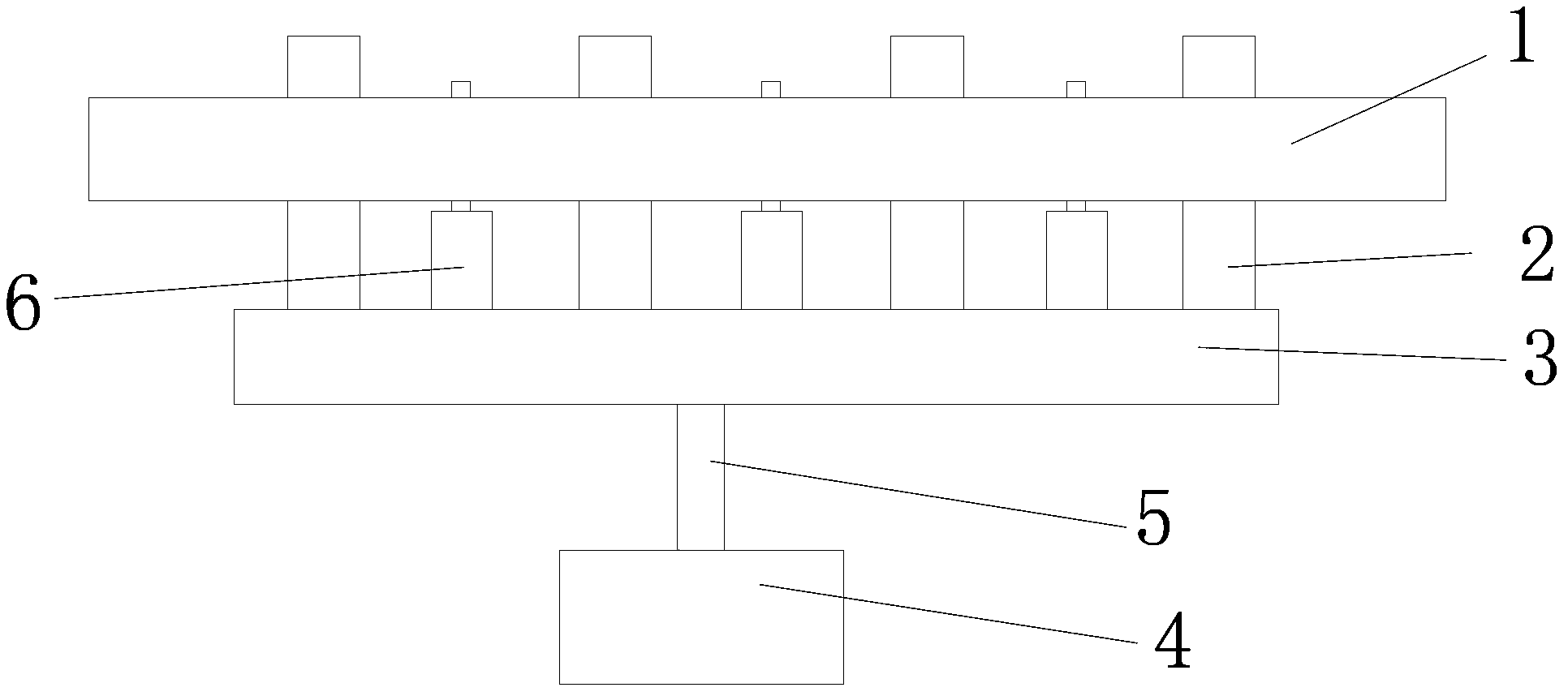

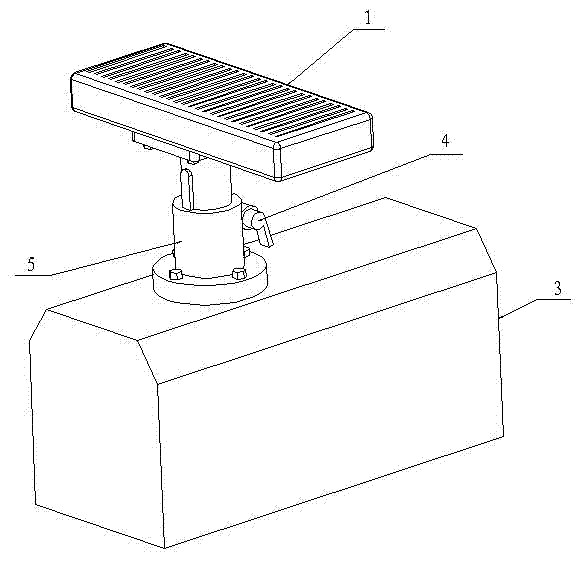

Supporting and adsorbing jig for PCB

InactiveCN103406848AMove doesn't happenImprove versatilityPrinted circuit assemblingWork holdersEngineeringMachining process

Owner:KUSN MAIZHI FIXTURE TECH

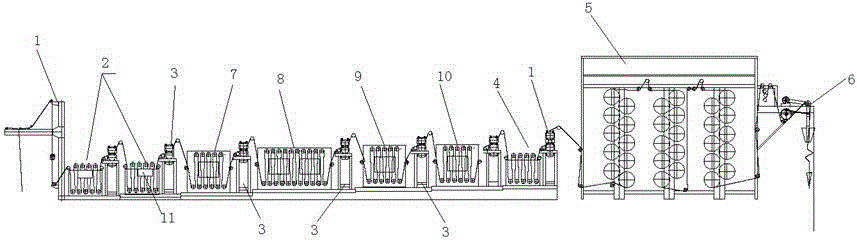

Woven fabric and jean desizing and boiling-off combined machine

InactiveCN104947339ASoft and comfortableSucessive textile treatmentsTextile treatment containersFiberDenim

Owner:扬州市江都区东盛印染机械厂

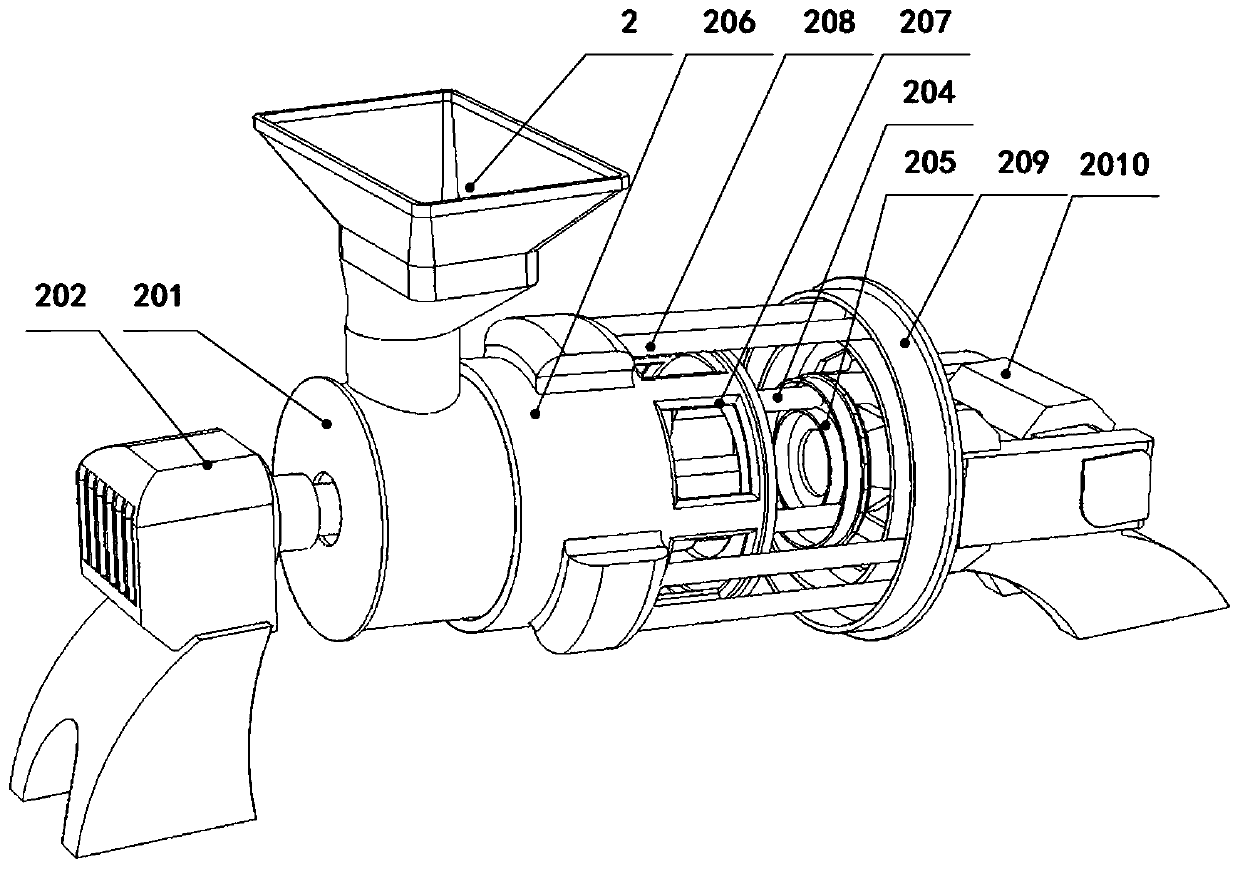

Breaking and smashing integrated device

ActiveCN106362842ARapid tumblingIncrease the feeding speedGrain treatmentsEngineeringMachining process

Owner:徐晨炫

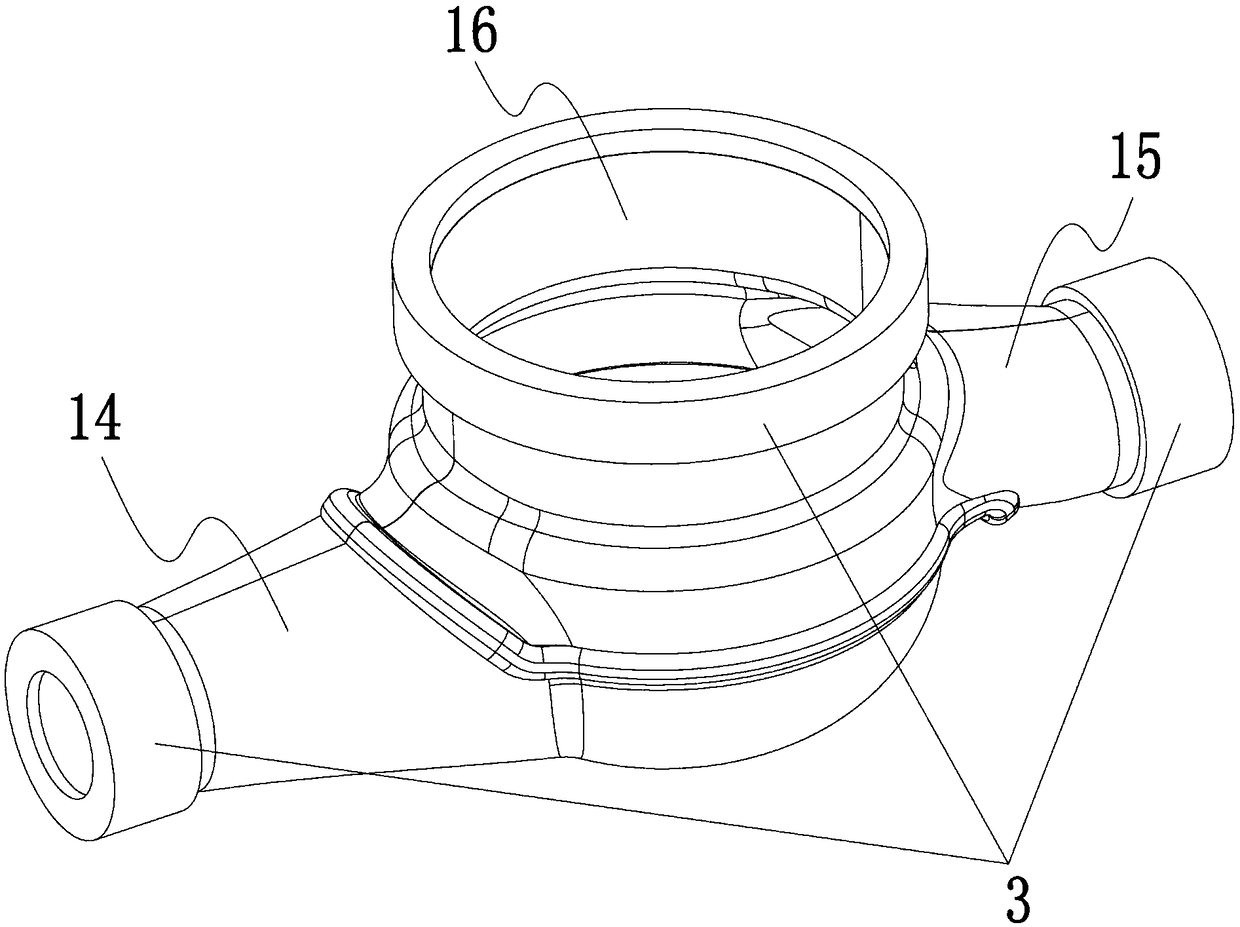

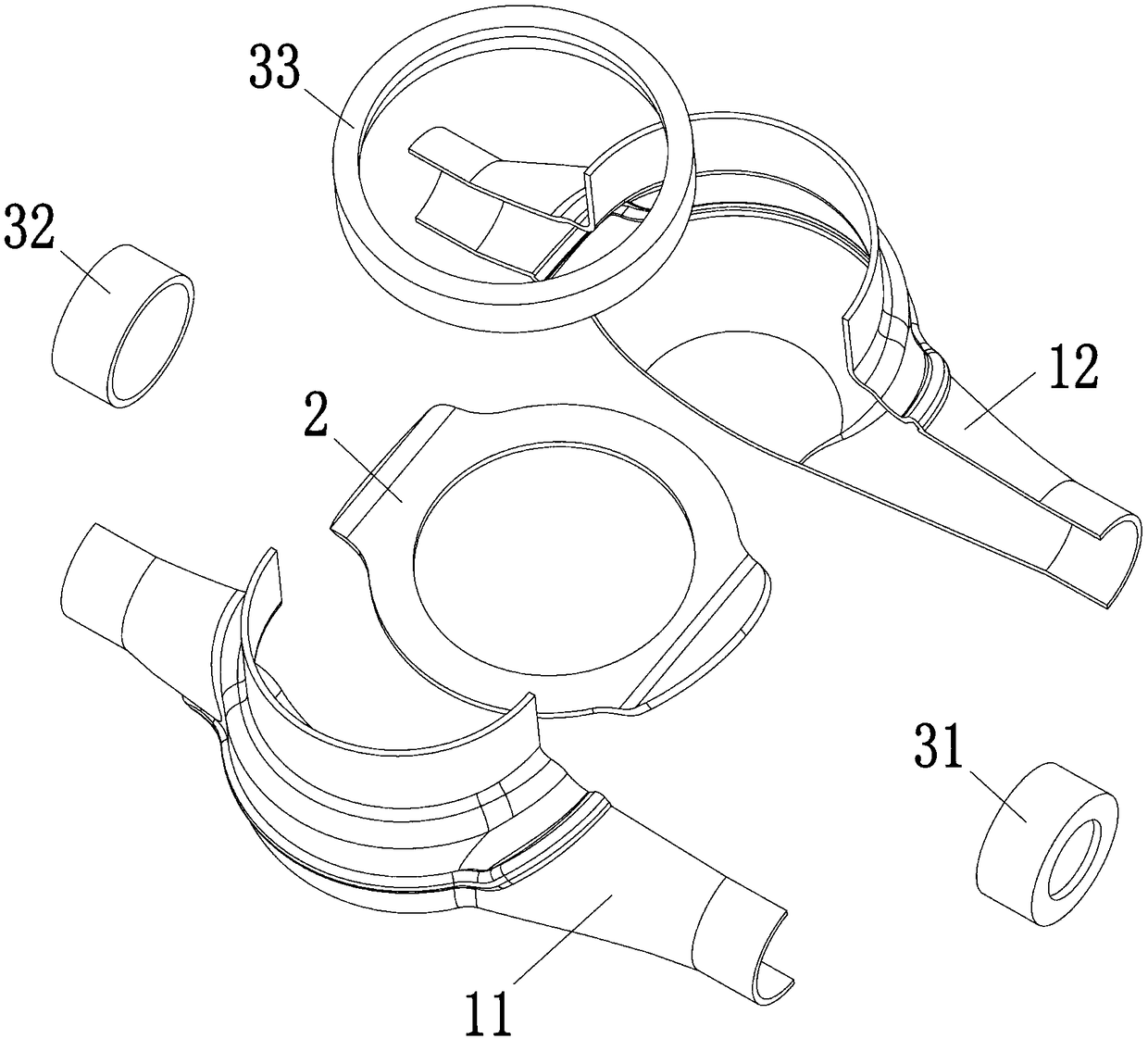

Stainless steel water meter shell blank and machining method thereof, stainless steel water meter shell and water meter

Owner:ZHEJIANG YOULIPU METROLOGY TECH CO LTD

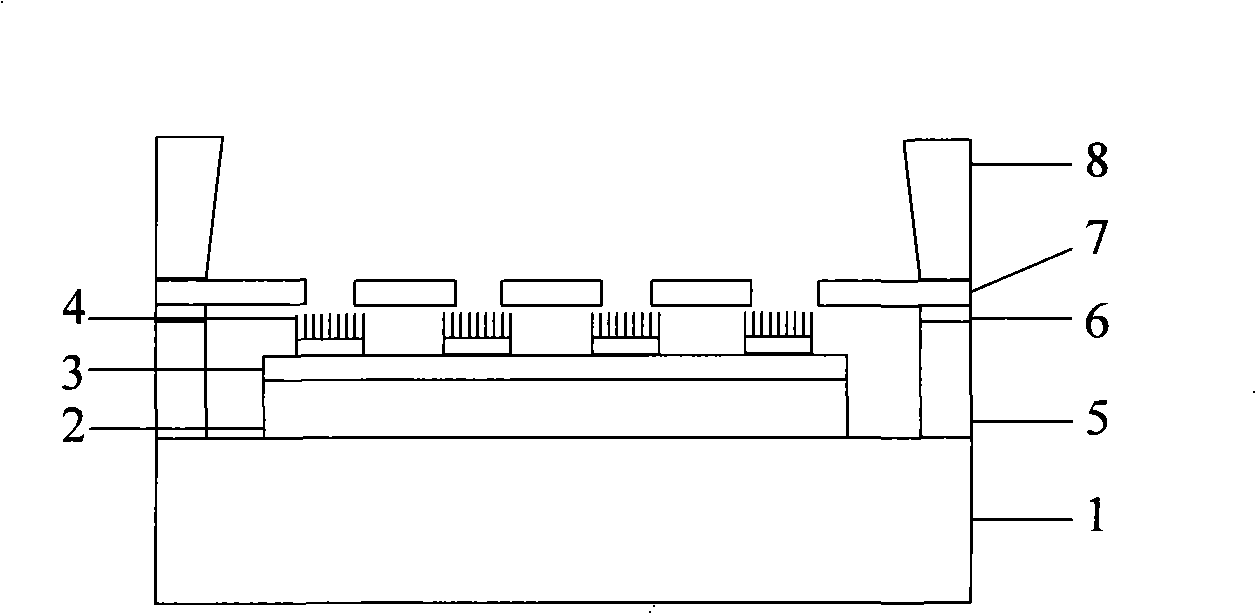

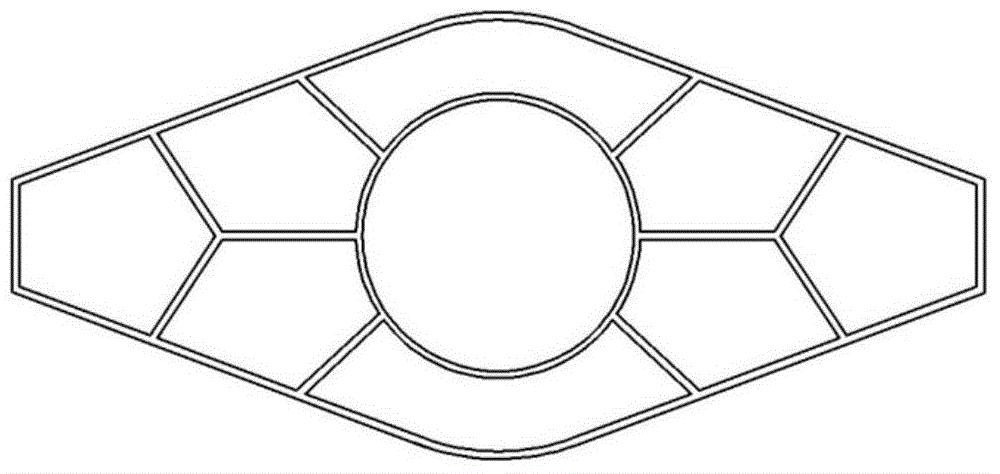

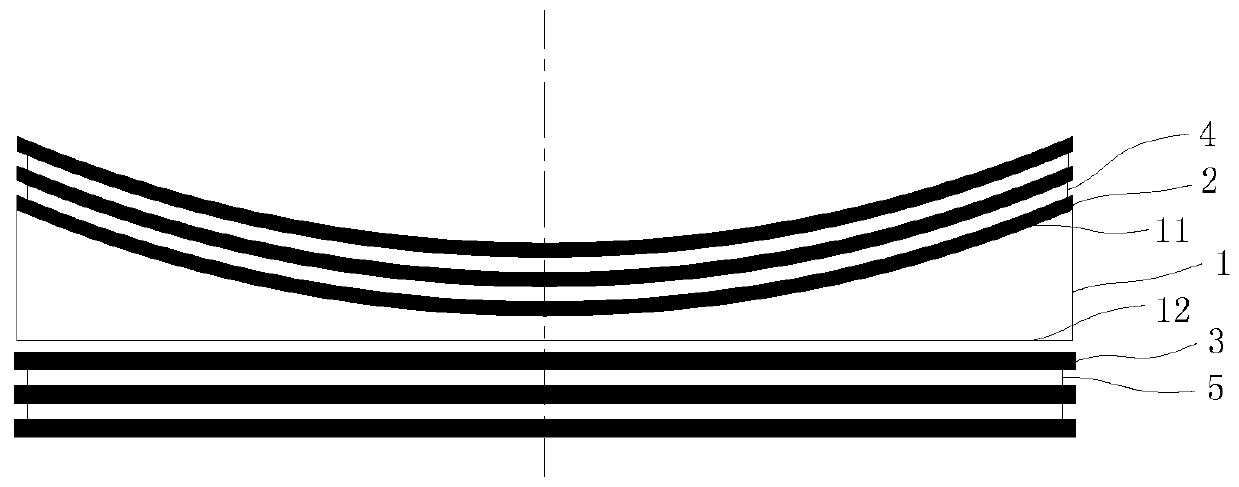

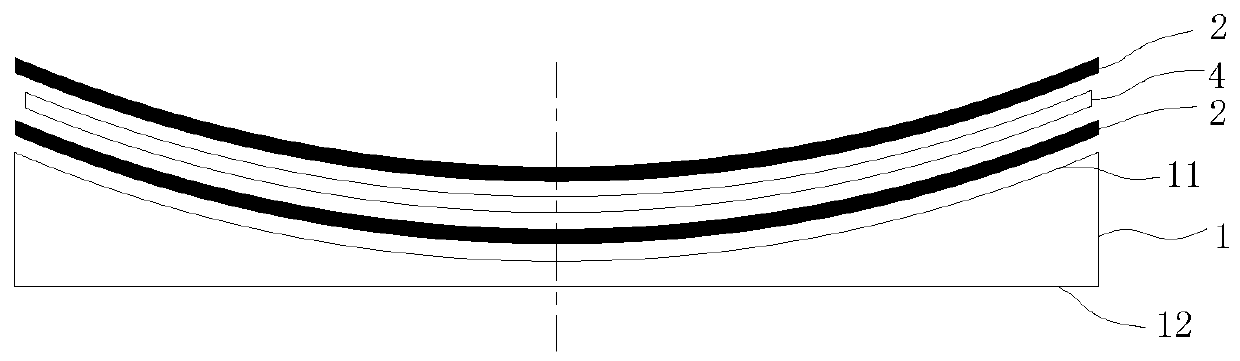

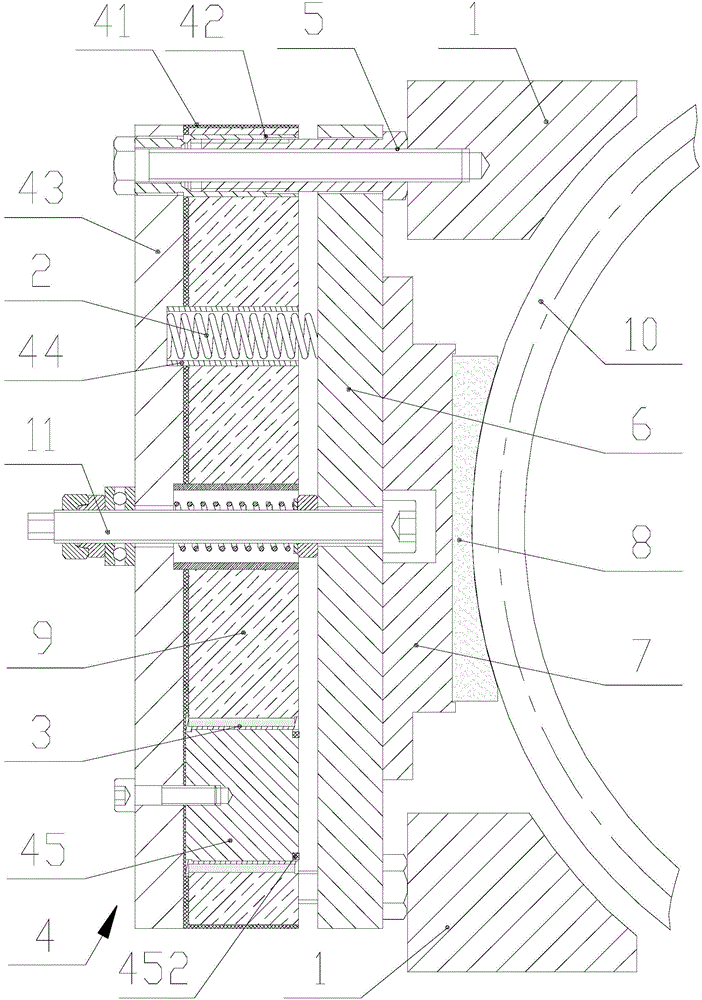

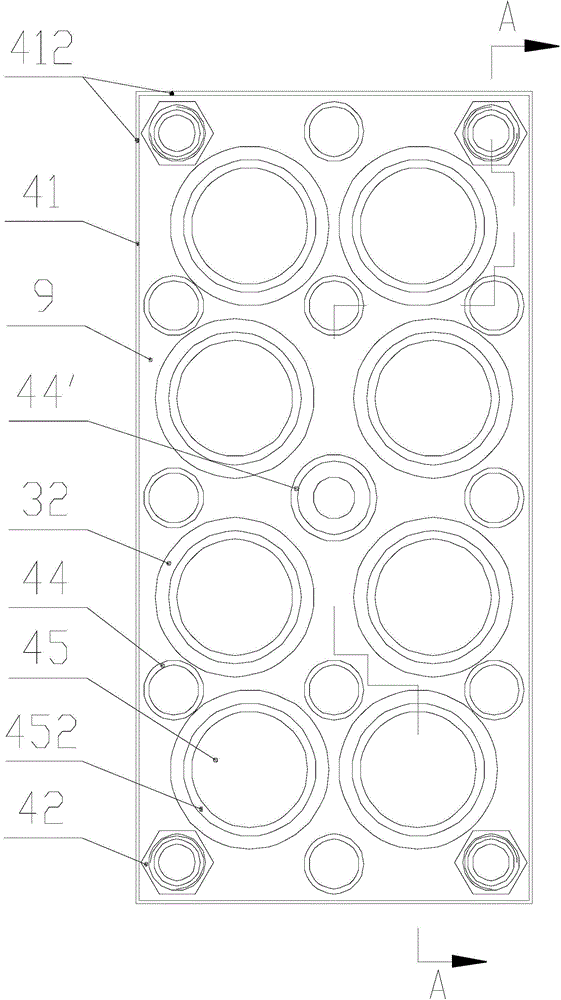

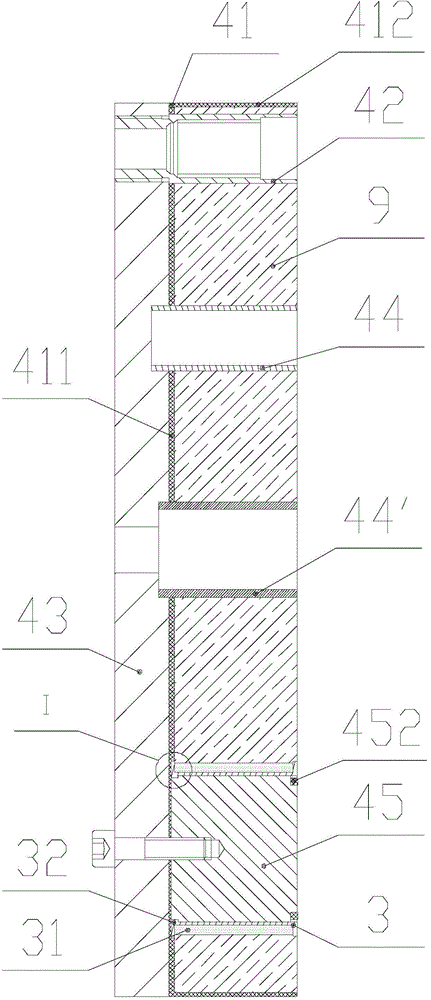

Gradient coil for magnetic resonance imaging and processing method thereof

ActiveCN109917312AImprove efficiencyHigh strengthMagnetic measurementsGradient strengthImaging quality

Owner:RAY PLUS MEDICAL TECH CO LTD

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

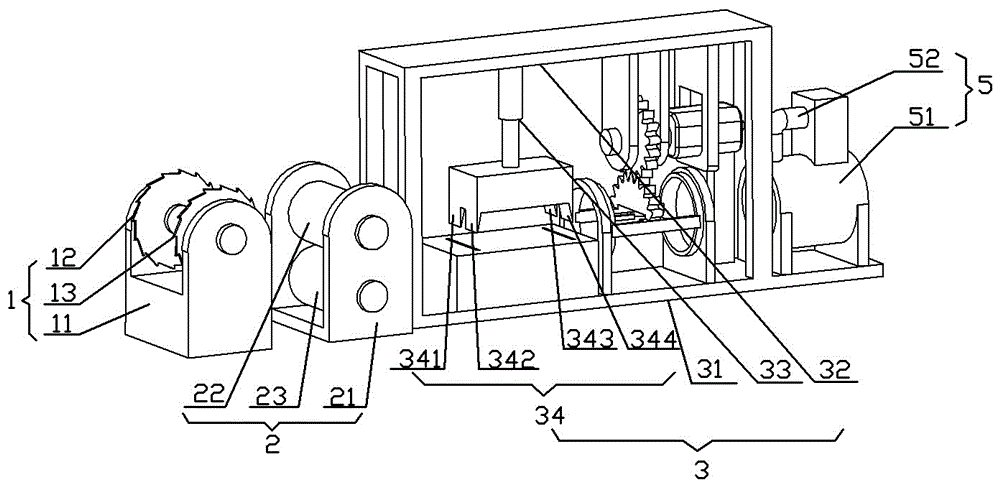

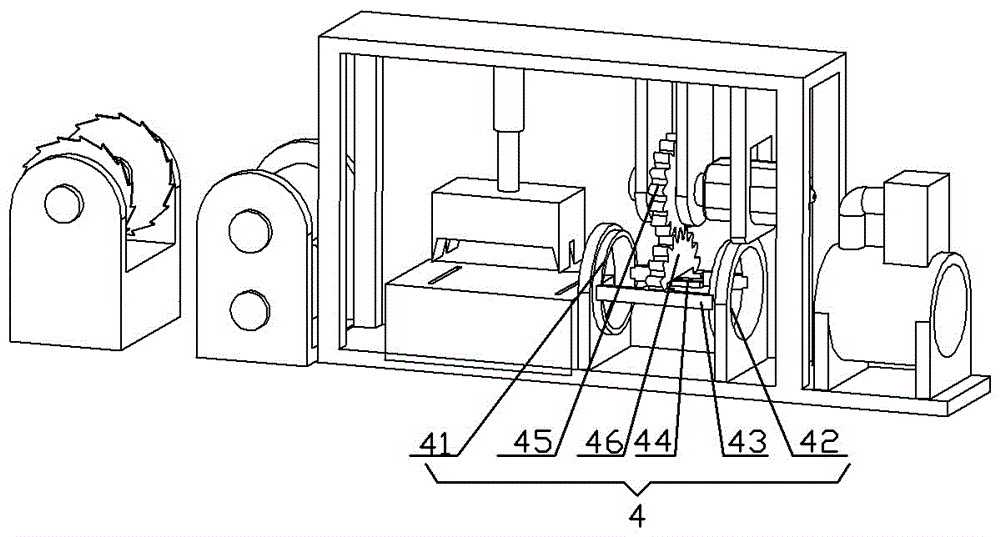

Method for fabricating radiating pipes of water tank in car heat exchanger made from aluminum alloy, and dedicated device

InactiveCN101092000AOvercoming Pollution DefectsRealize green industrial productionLiquid surface applicatorsWelding/cutting media/materialsEngineeringMachining process

The invention relates to a machining method and special device for vehicle aluminum alloy heat exchange water tank radiator pipe. It puts the machining radiator pipe between two rollers of special device, which has flux on the surface. The flux would coat equally onto the surface of radiator pipe. The special device includes upper roller and down roller. The down part of driving upper roller drainage wheel and down roller is dipped in stock solution slot containing flux solution. The invention decreases a machining process, shortens machining time, improves producing efficiency, and decreases pollution to environment. The defective fraction of using the method could be under 0.3%. And the surface of the product is smoothing and bright.

Owner:林世东

Elevator brake of novel structure

ActiveCN104085819ASimple structureReduce processing requirementsHoisting equipmentsAgricultural engineeringMachining process

Owner:成都瑞迪智驱科技股份有限公司

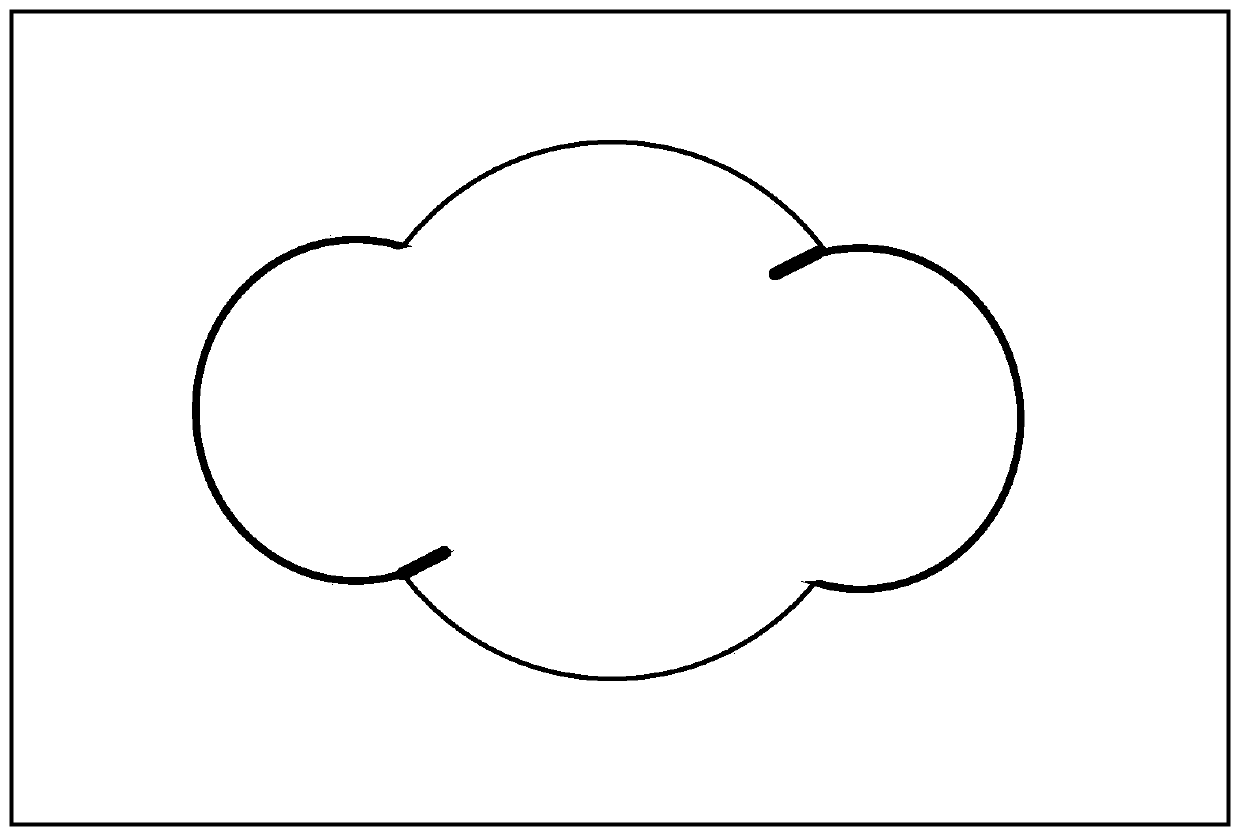

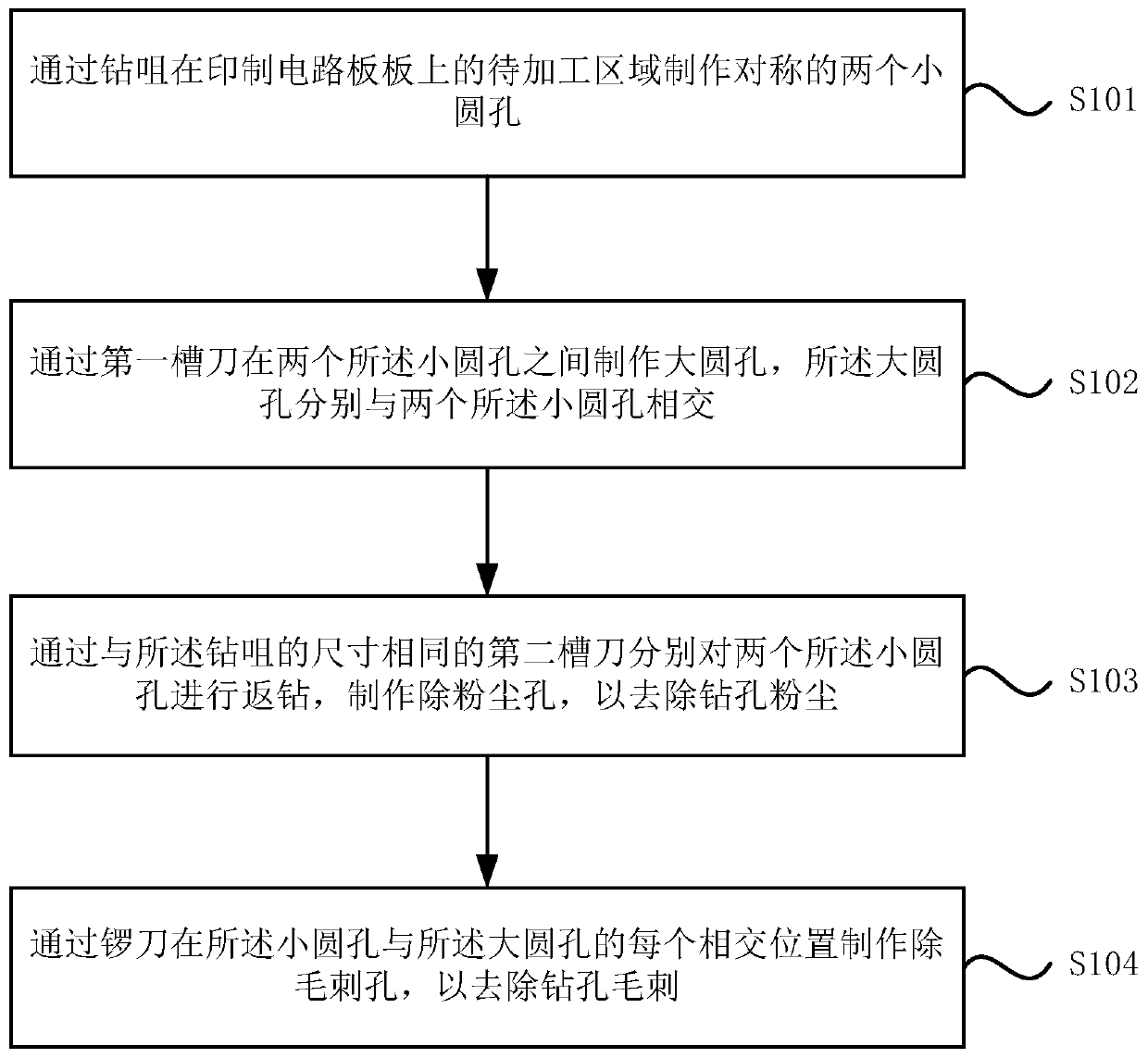

Tree core groove processing method and printed circuit board

ActiveCN111182731AMeet the installation requirementsAvoid the frontPrinted circuit manufactureMilling cutterStructural engineering

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

Processing platform assembly of wood polishing machine

InactiveCN102328264AIncrease resistanceNot easy to slideGrinding machine componentsPolishing machinesWood processorMachining process

Owner:芜湖宏春木业集团有限公司

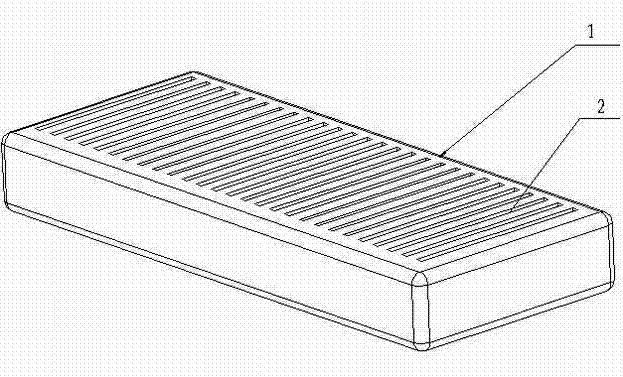

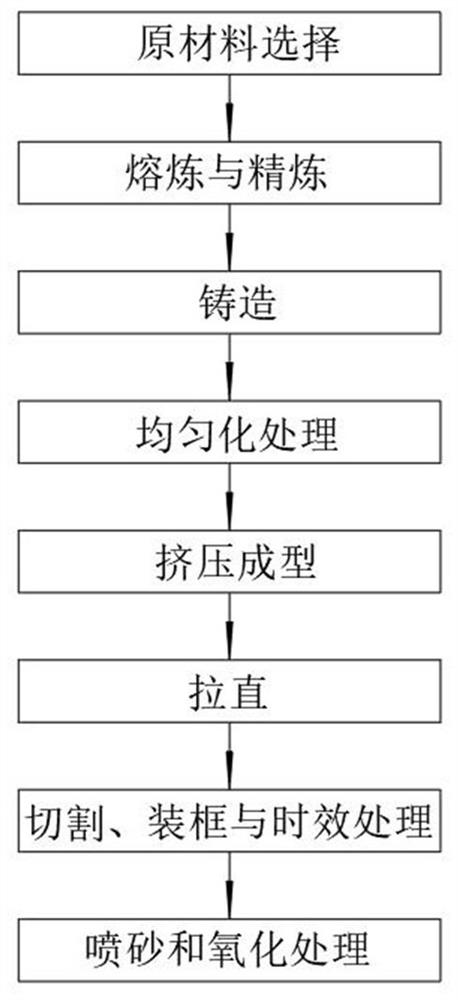

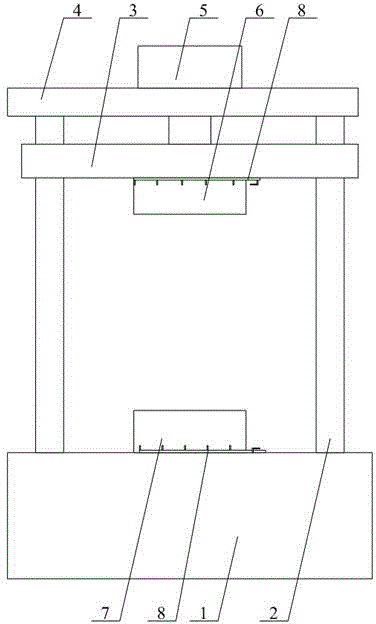

Production process of solar support frame aluminum alloy profile

Owner:四川阳光坚端铝业有限公司

Hydraulic machine with molds capable of being cooled

Owner:江苏一机机械科技有限公司

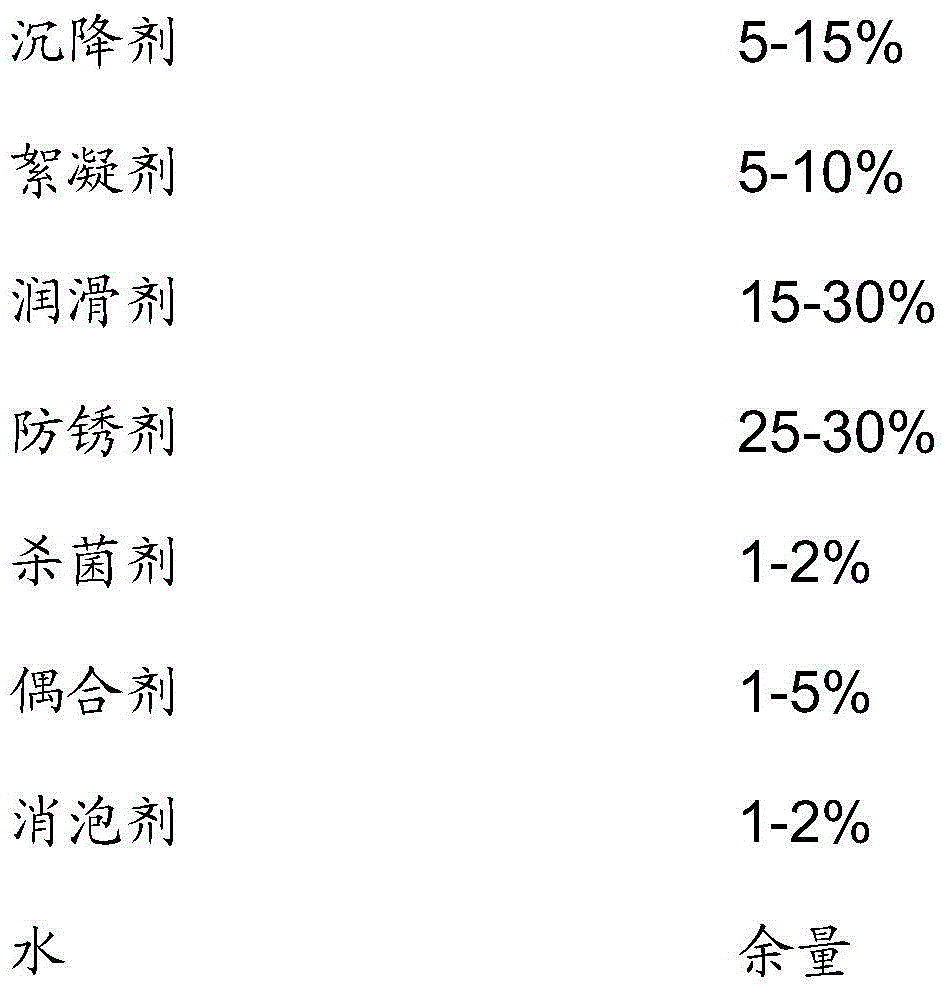

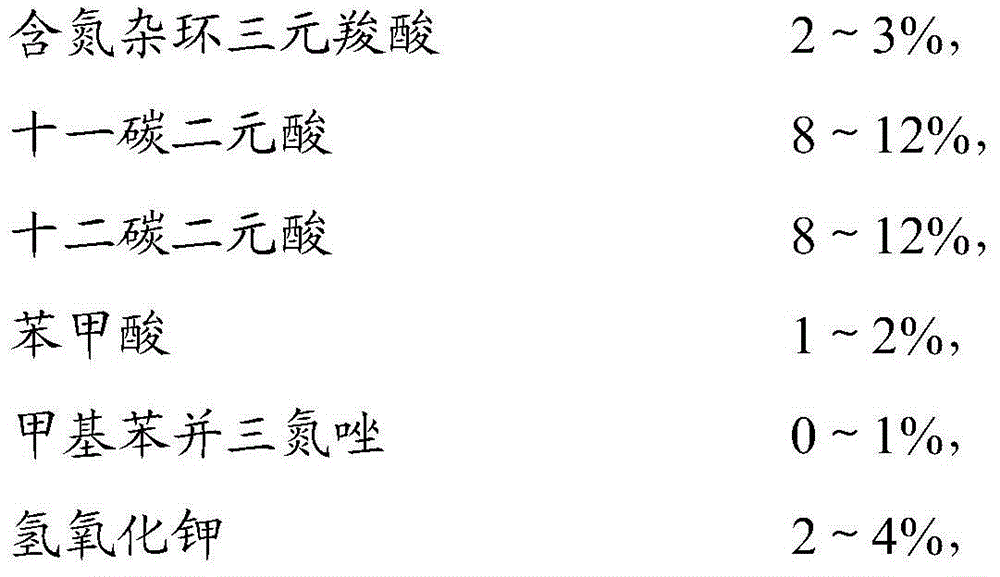

Rustproof water-based grinding fluid with high settleability and preparation method thereof

Owner:马艳荣

Universal sheet metal case and machining process thereof

Owner:南京翼之锋机电制造有限公司

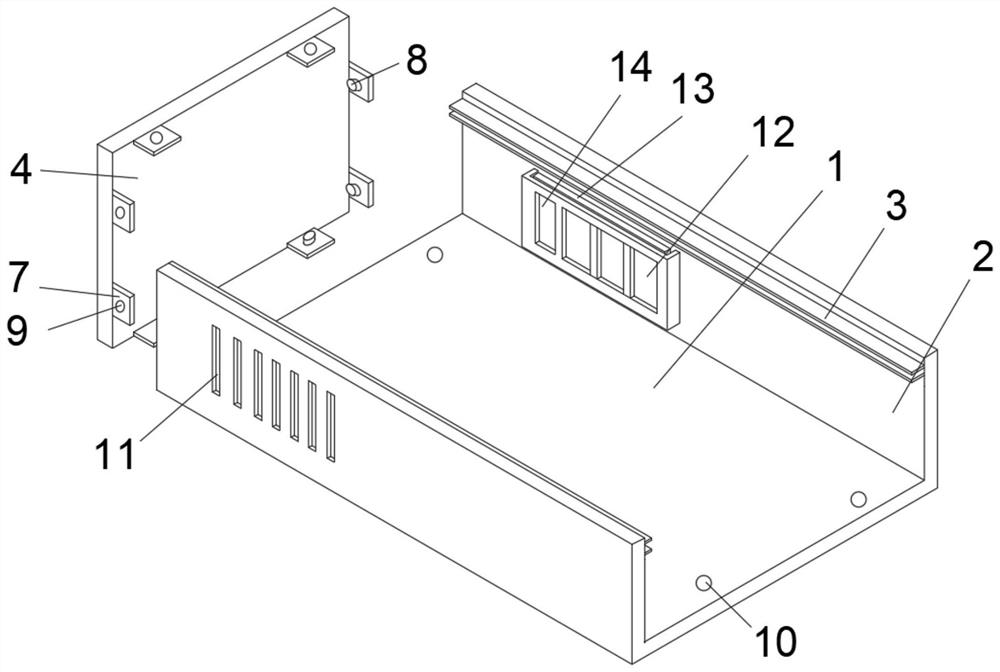

Cooling liquid recovery device for numerical control machine tool

PendingCN107470976AEfficient collectionImprove recycling rateMaintainance and safety accessoriesNumerical controlEconomic benefits

Owner:苏州富强加能精机有限公司

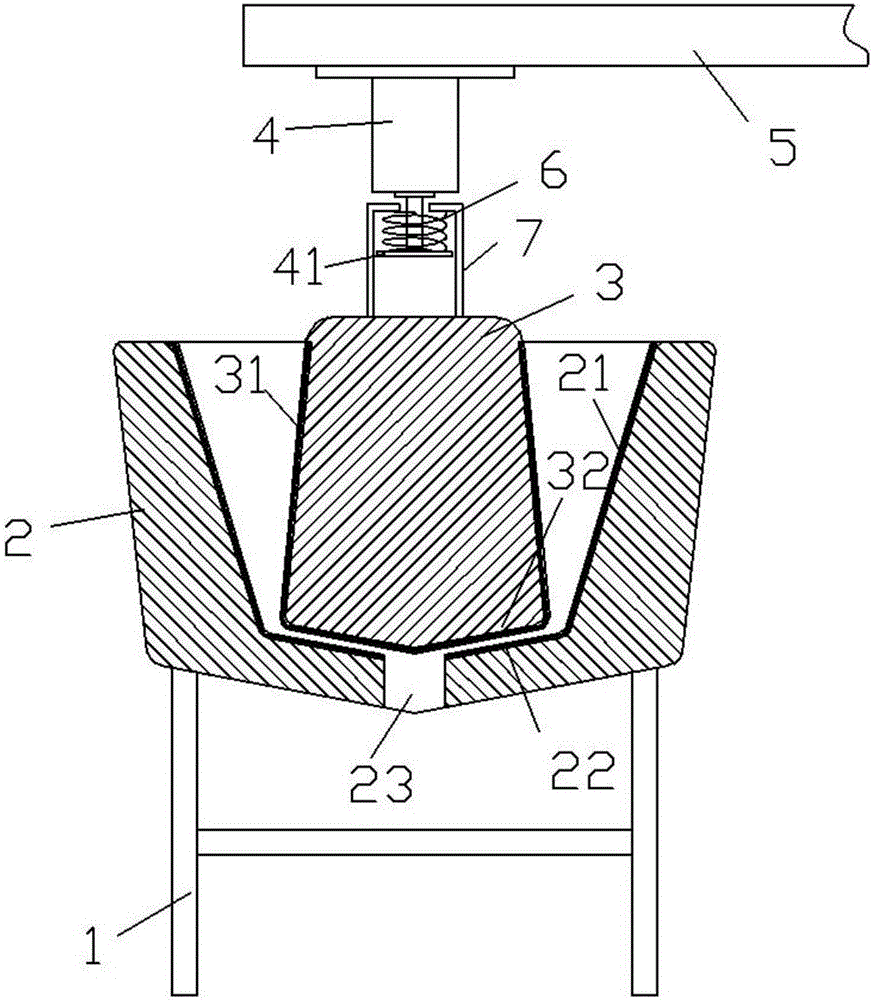

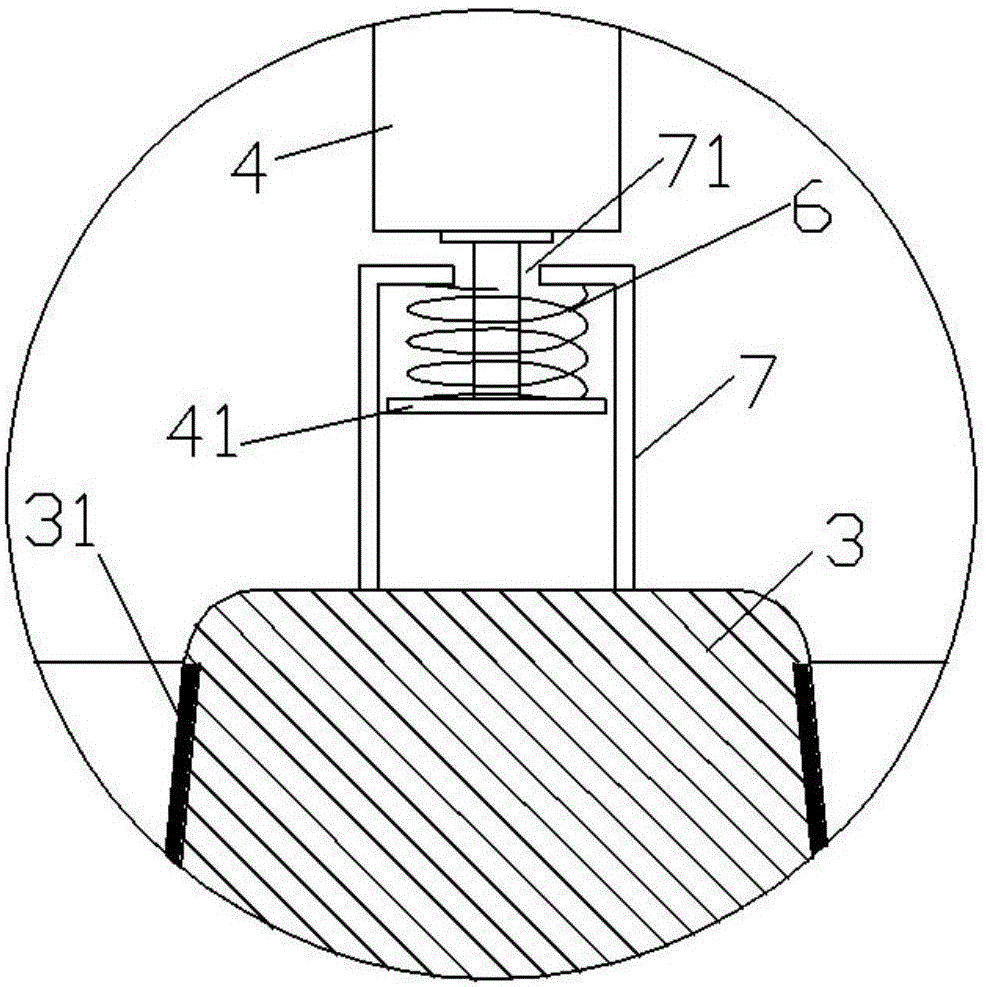

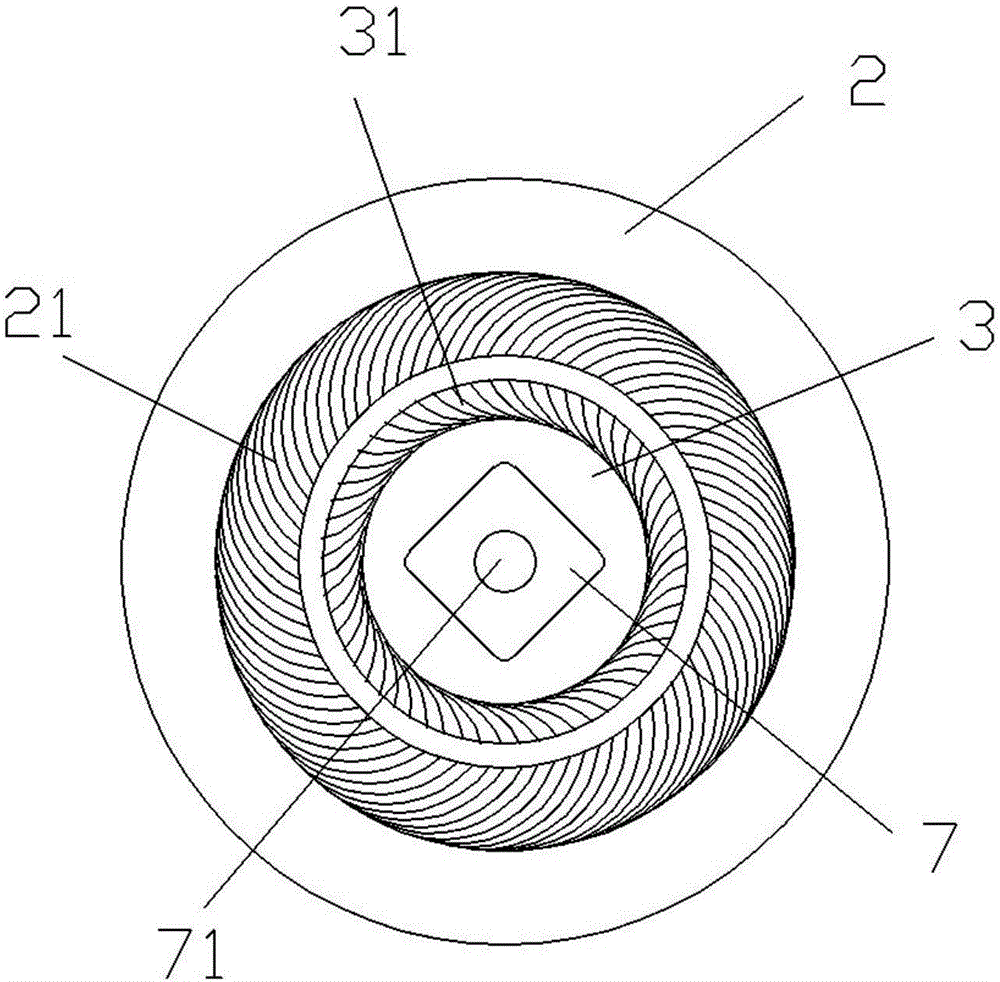

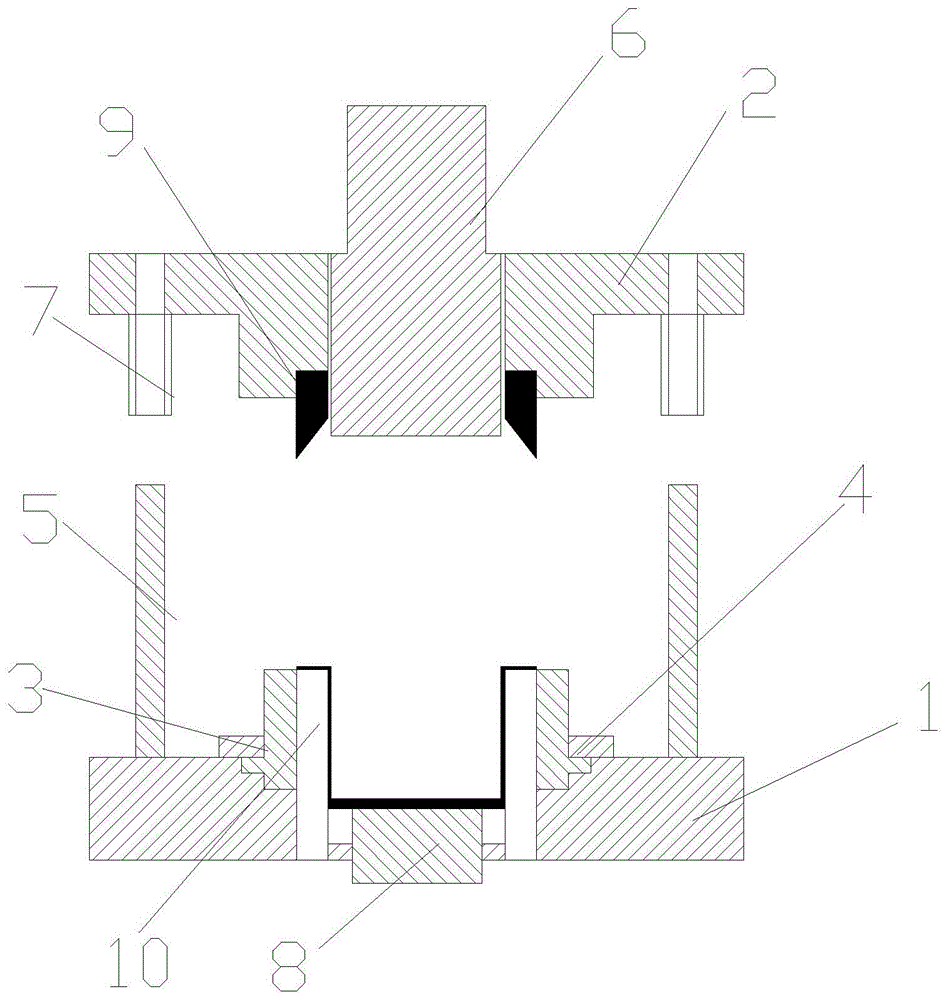

Punching forming clamp

InactiveCN104438879AGuaranteed stabilityImprove pass rateShaping toolsMetal-working feeding devicesPunchingEngineering

Owner:SUZHOU SONGSHUN HARDWARE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap