Processing platform assembly of wood polishing machine

A technology for processing platforms and machine tools, which is applied to surface-polished machine tools, parts of grinding machine tools, and metal processing equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

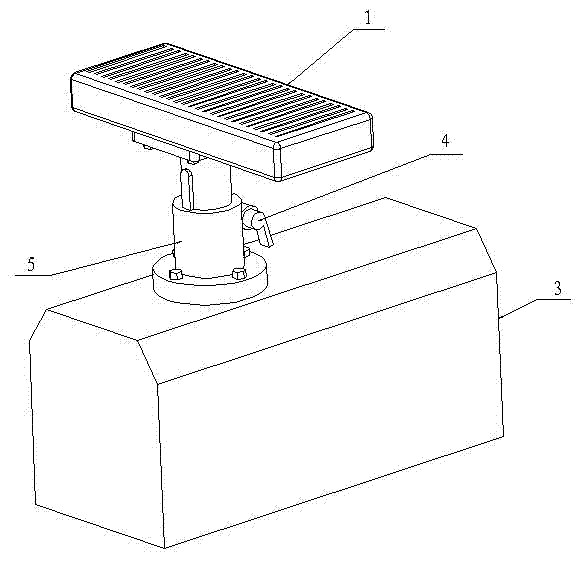

[0015] Such as figure 1 As shown, a processing platform assembly of a wood polishing machine tool includes a bracket 3 on which a sleeve-type lifting column 5 is arranged. The sleeve-type lifting column 5 is fixed and limited by fastening bolts 4. The sleeve-type lifting column The top of 5 is equipped with processing platform 1.

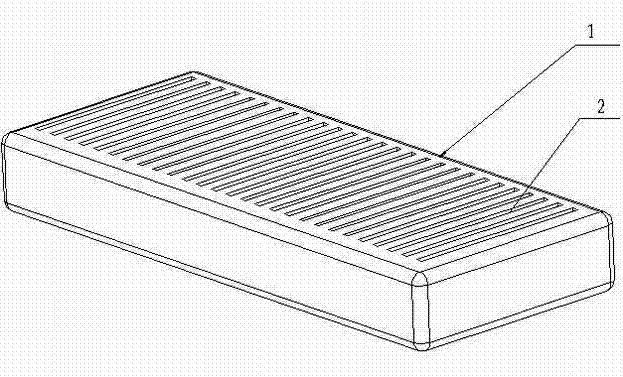

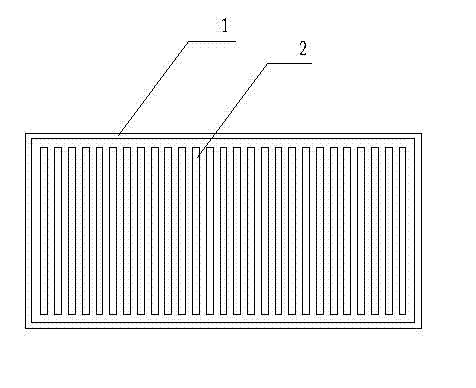

[0016] figure 2 and image 3 An embodiment of the processing platform 1 is shown. The processing platform 1 is in the shape of a cuboid, and several cuboid hollow slots 2 penetrating the processing platform 1 are opened along the height direction of the processing platform 1 .

[0017] The length direction of the cuboid cavity 2 is parallel to the length direction of the processing platform 1. If it is not parallel, it will cause some inconvenience when discharging, but the running resistance of the wood will be further improved.

[0018] The distance between the rectangular parallelepiped slots 2 is 1 / 30-1 / 3 of the length of the processing pla

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap