Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about "Ceramic shaping apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

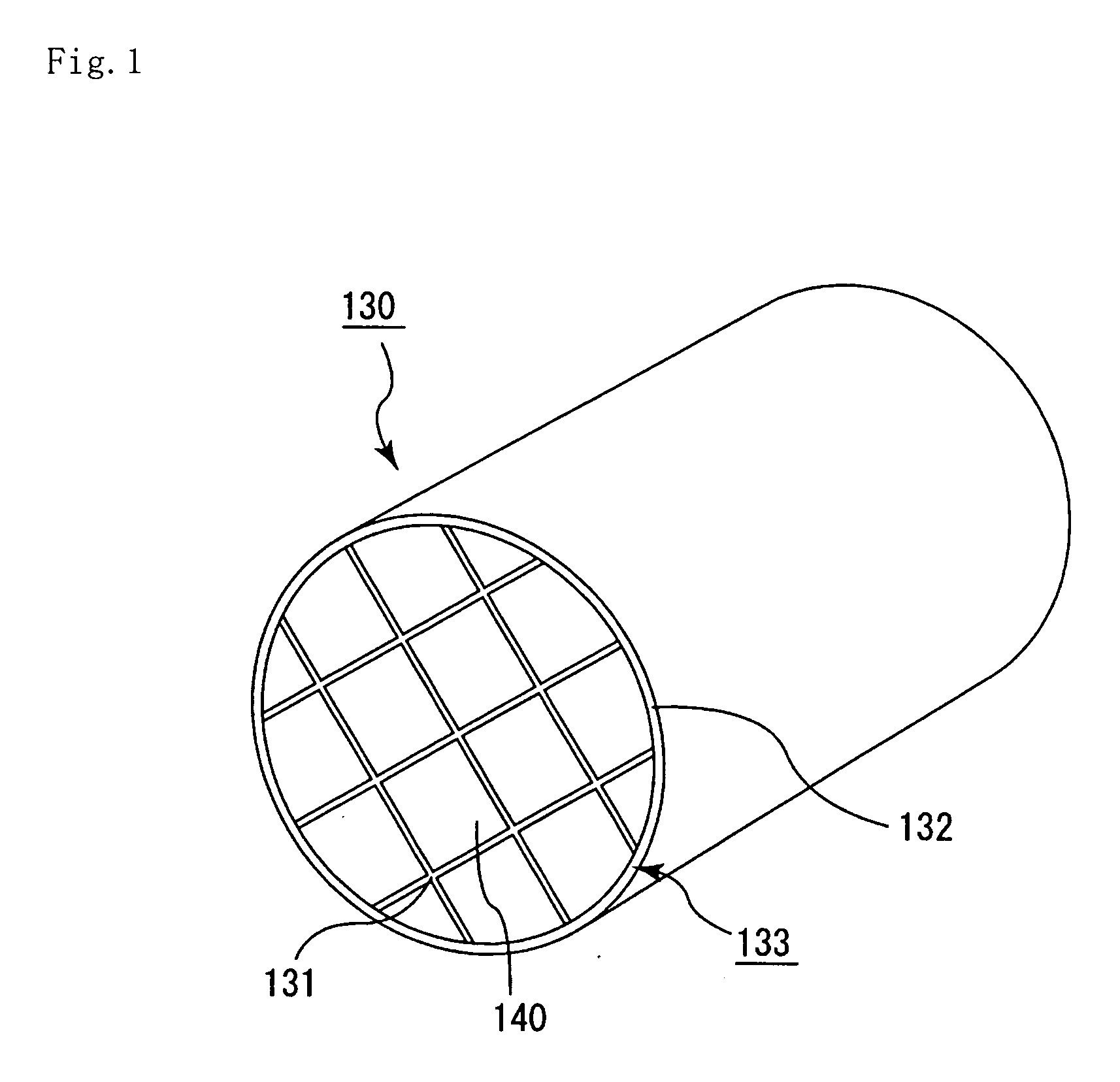

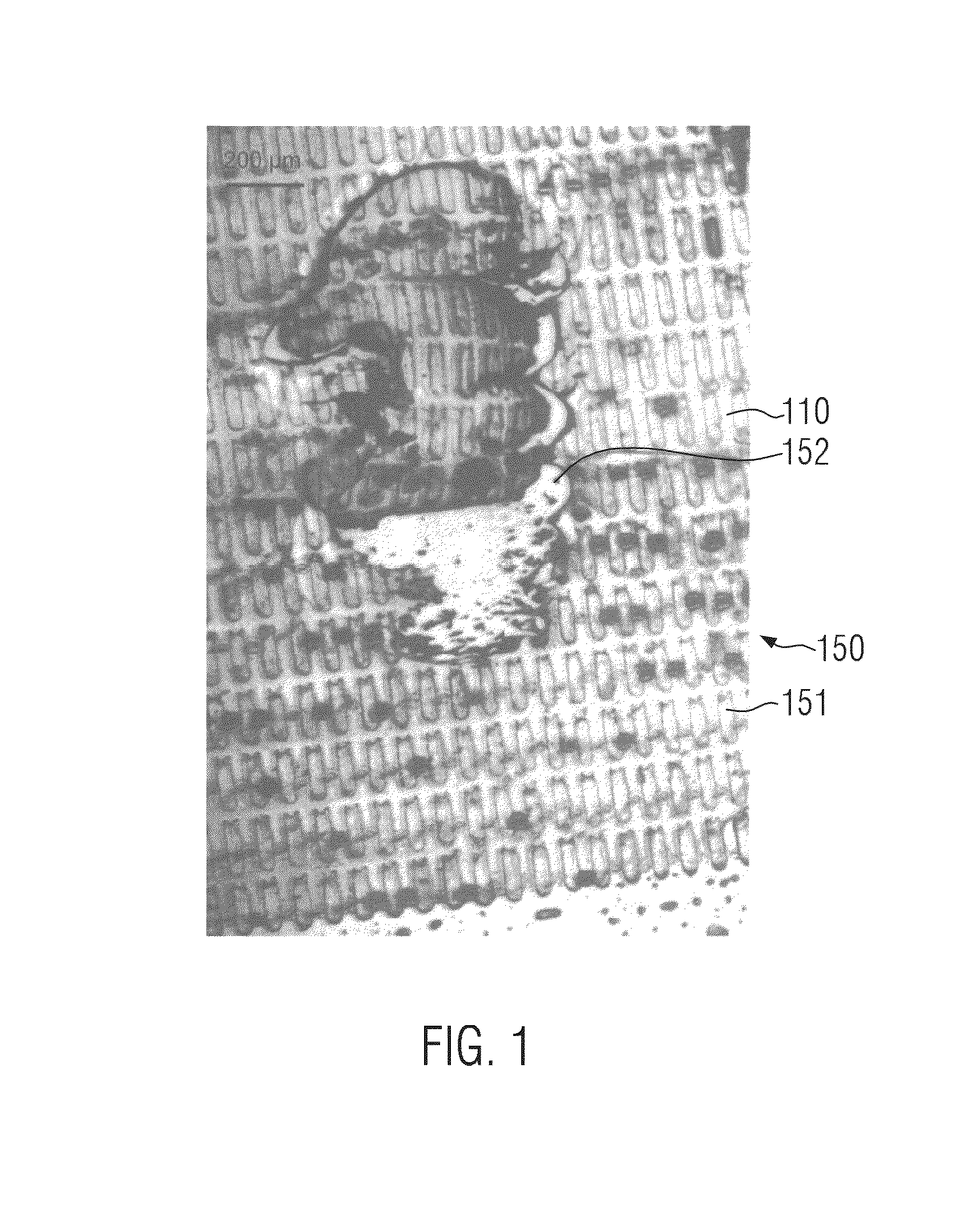

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

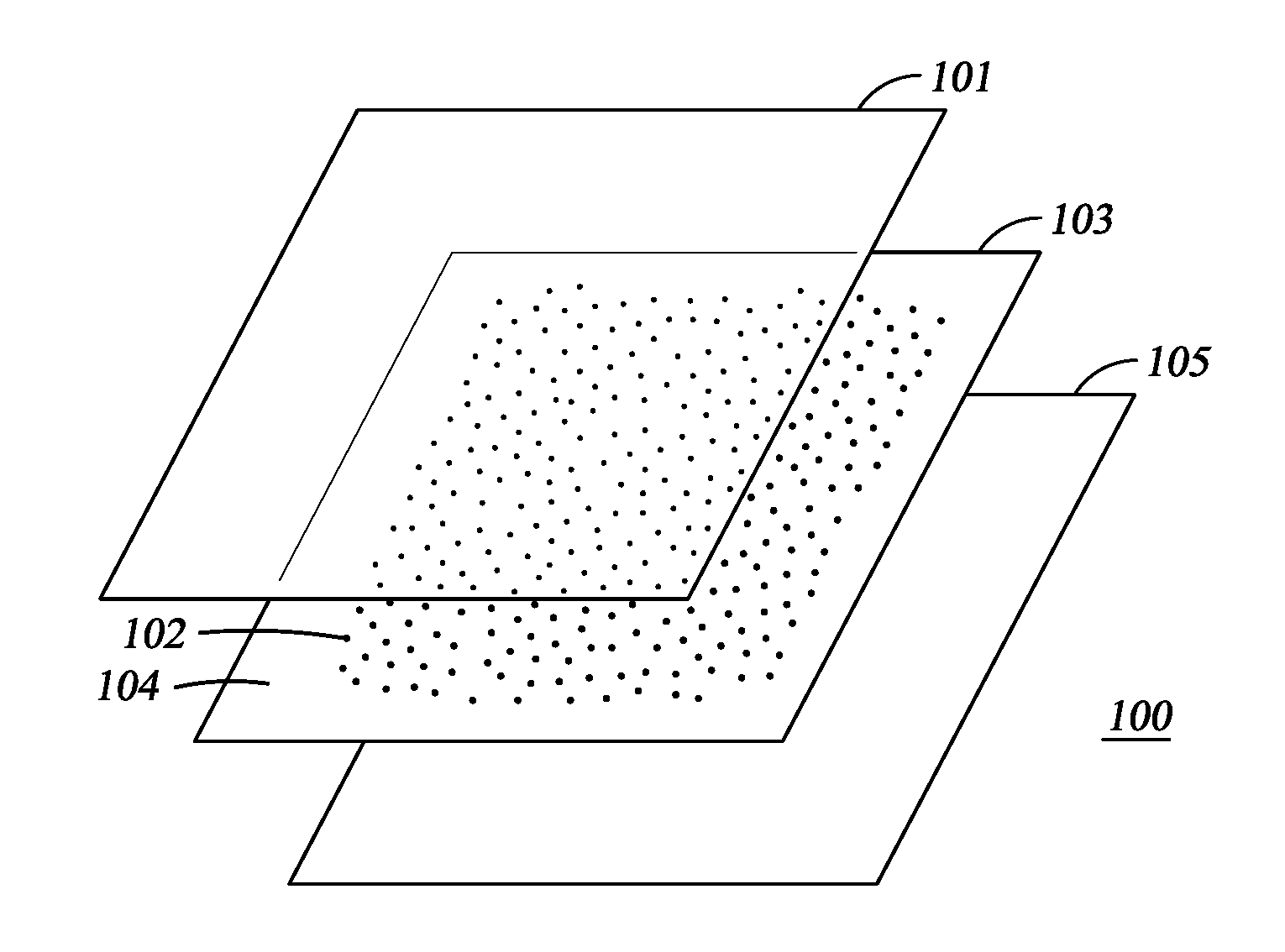

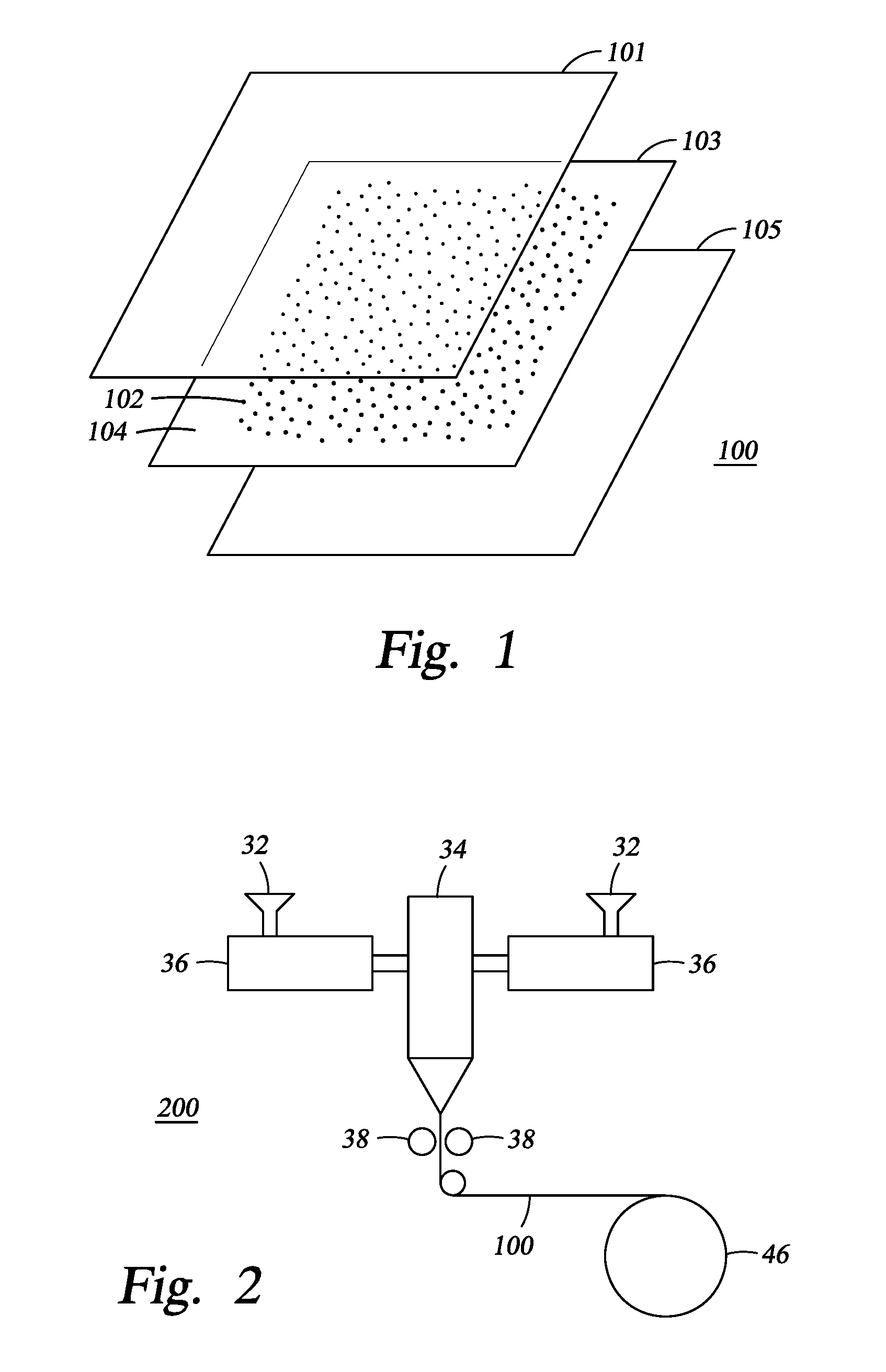

Films and articles with reversible opacity change upon stretching, and methods of making and using same

Owner:KIMBERLY-CLARK WORLDWIDE INC

Cross point memory arrays, methods of manufacturing the same, masters for imprint processes, and methods of manufacturing masters

Owner:SAMSUNG ELECTRONICS CO LTD

Microrelief structural body, decorative sheet, decorative resin molded body, method for producing microrelief structural body, and method for producing decorative resin molded body

ActiveUS20160052227A1Increase flexibilityGood stretchabilitySynthetic resin layered productsRecord information storagePolymer sciencePolymer chemistry

A structural body which comprises a base and a microrelief structure layer having a microrelief structure. The microrelief structure layer is laminated on the base so as to form the surface layer of this structural body, and the microrelief structure layer has at least one physical property selected from the group consisting of (A) and (B) described below. (A) The elastic modulus at 25° C. is 50 MPa or more, and the elastic modulus at 80° C. is 30 MPa or less. (B) The tensile elongation at break at 80° C. is from 20% to 100% (inclusive).

Owner:MITSUBISHI CHEM CORP

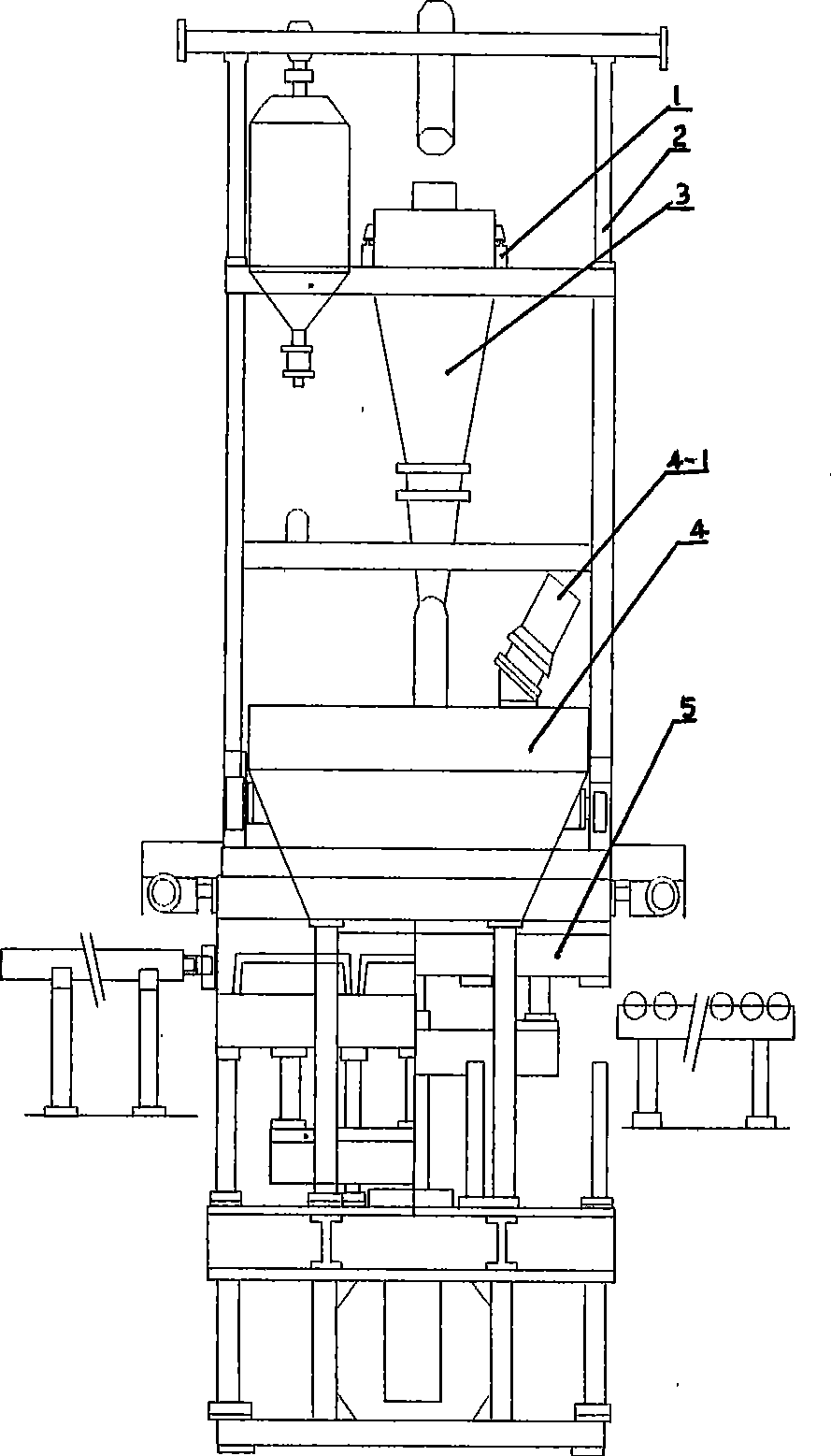

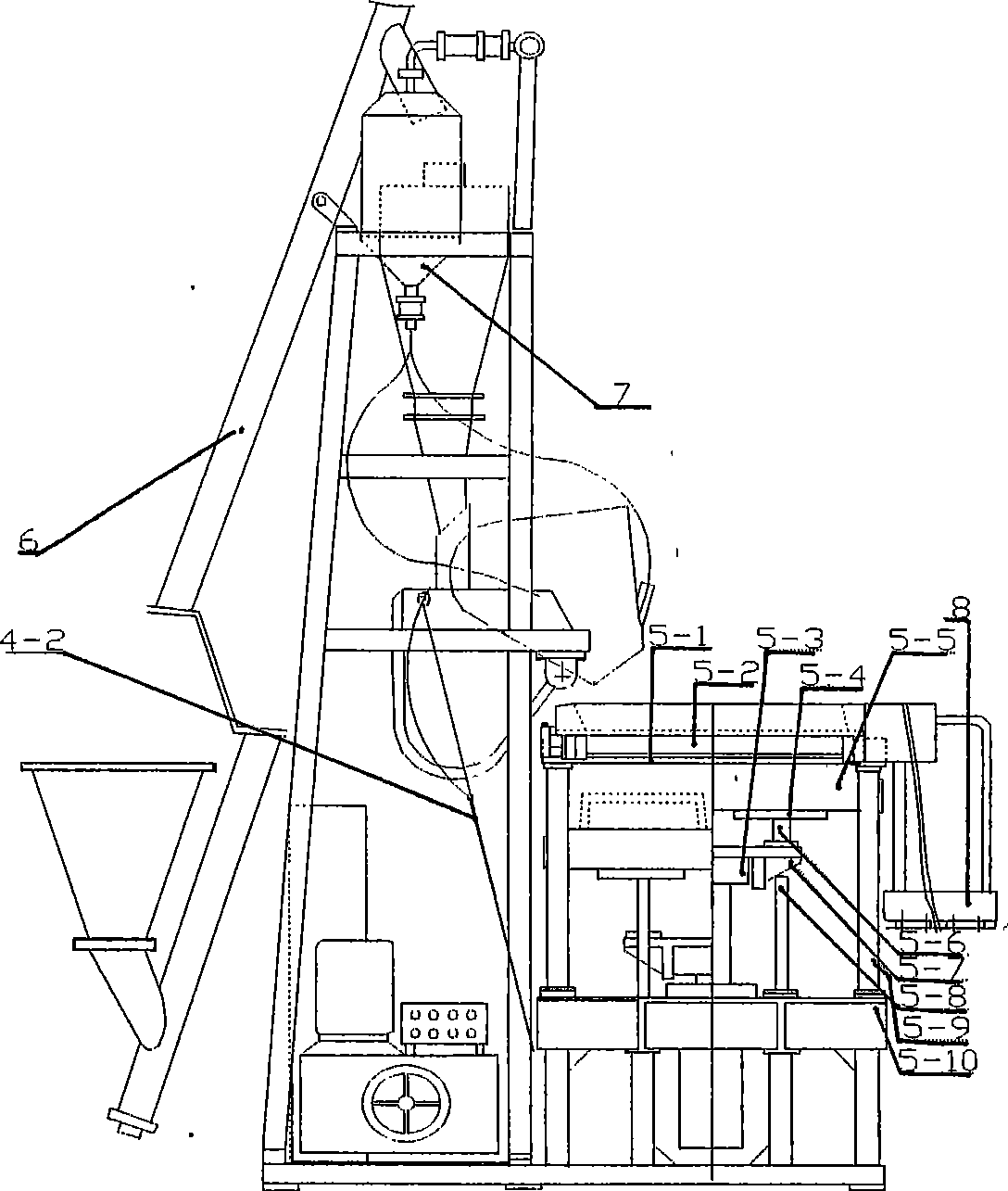

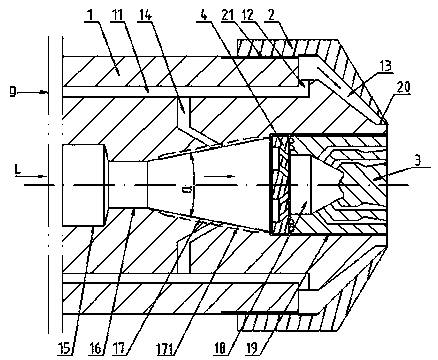

Method of making granules and the granulator

InactiveUS6582638B1Granulation in rotating dishes/pansCeramic shaping apparatusEngineeringMechanical engineering

A granulator comprising a perforate screen located within a housing, a roller having a curved convex outer surface wherein the roller is pivotable relative to the screen so that in operation plastic material is able to be forced through the perforate screen by the roller surface so the roller pivots. The granulator is useful for wet and dry granulation.

Owner:CROP CARE AUSTRALASIA PTY LTD

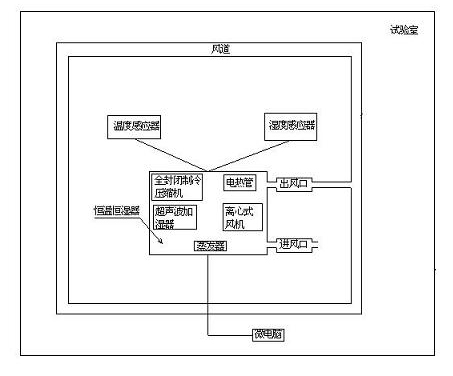

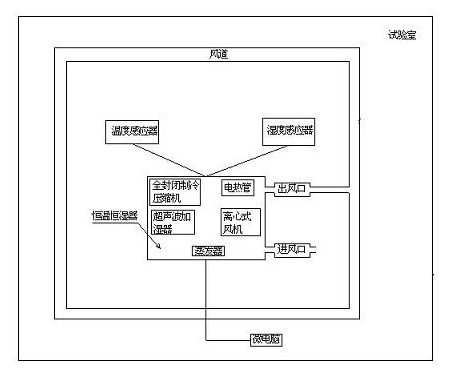

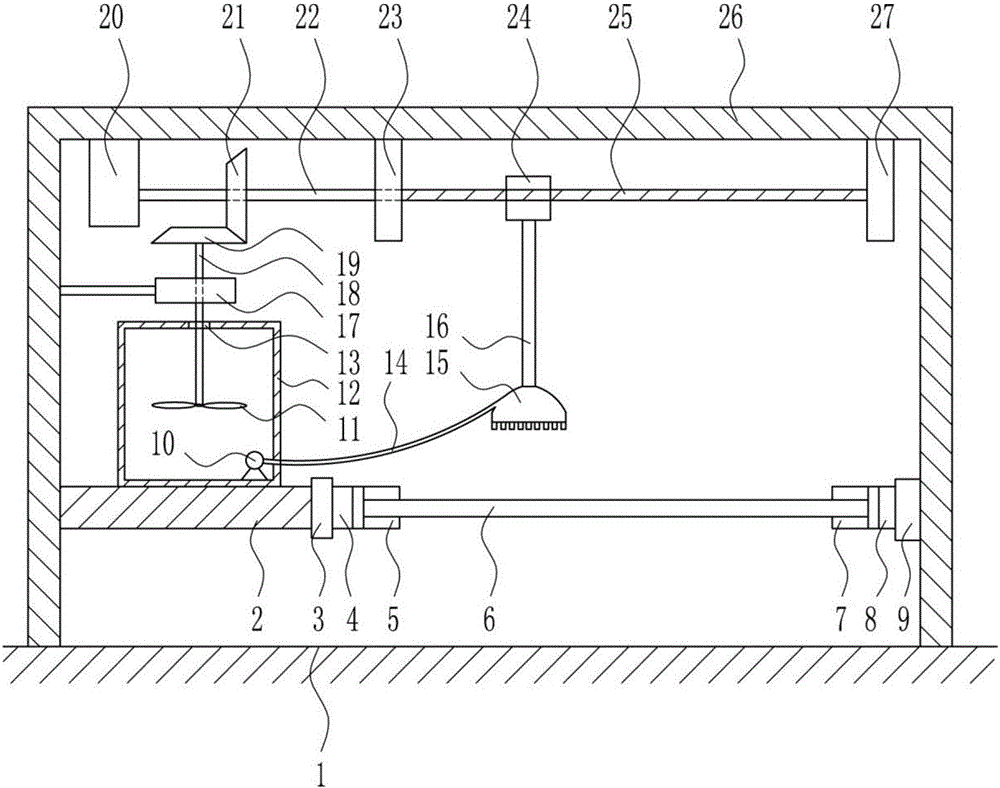

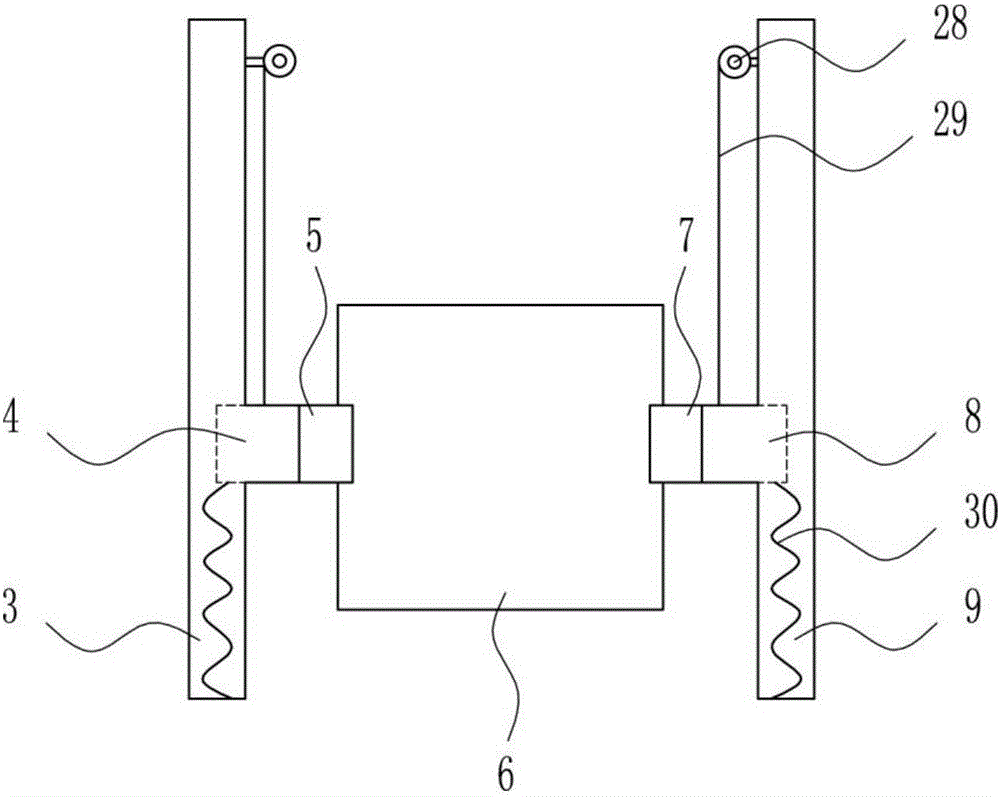

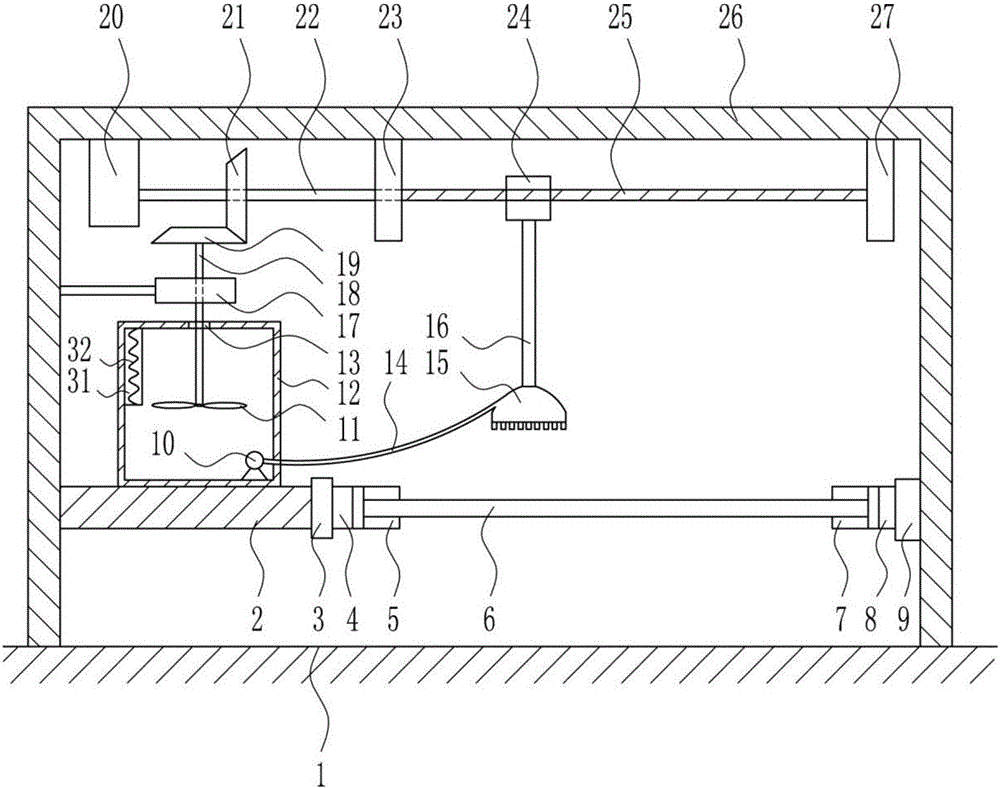

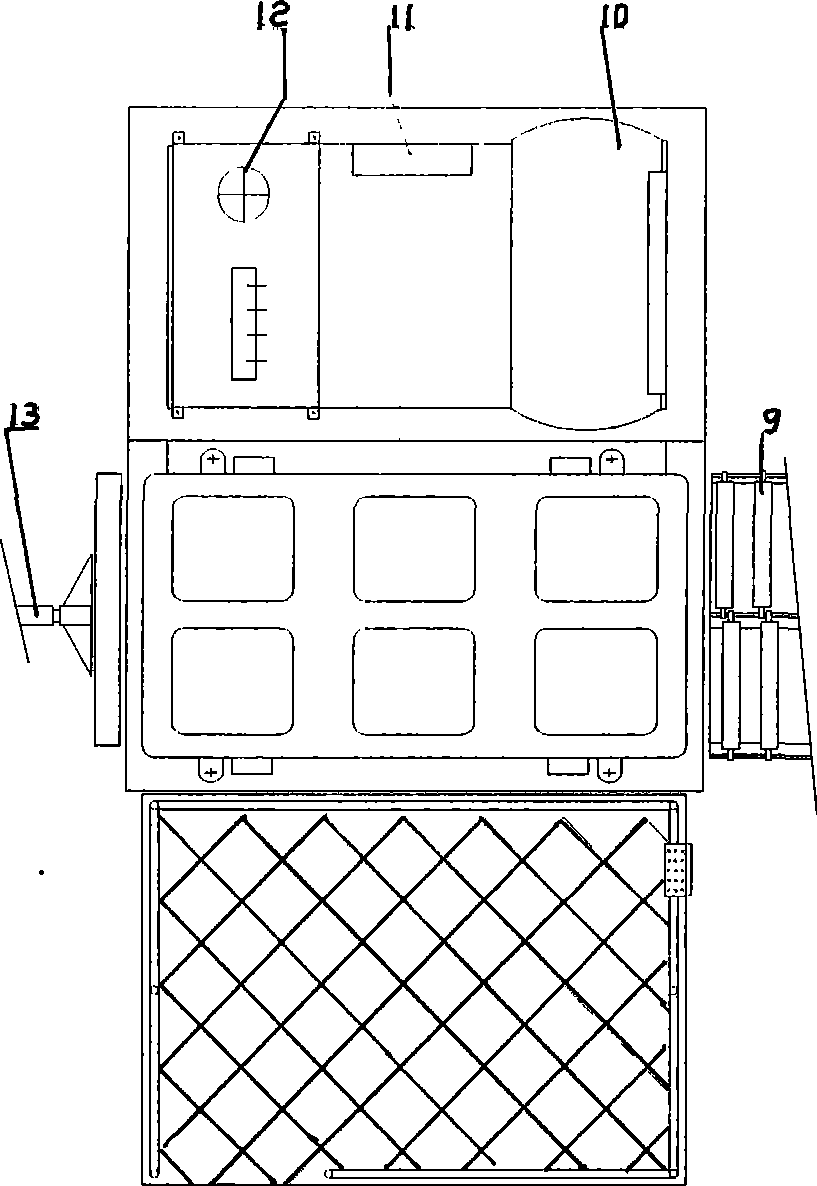

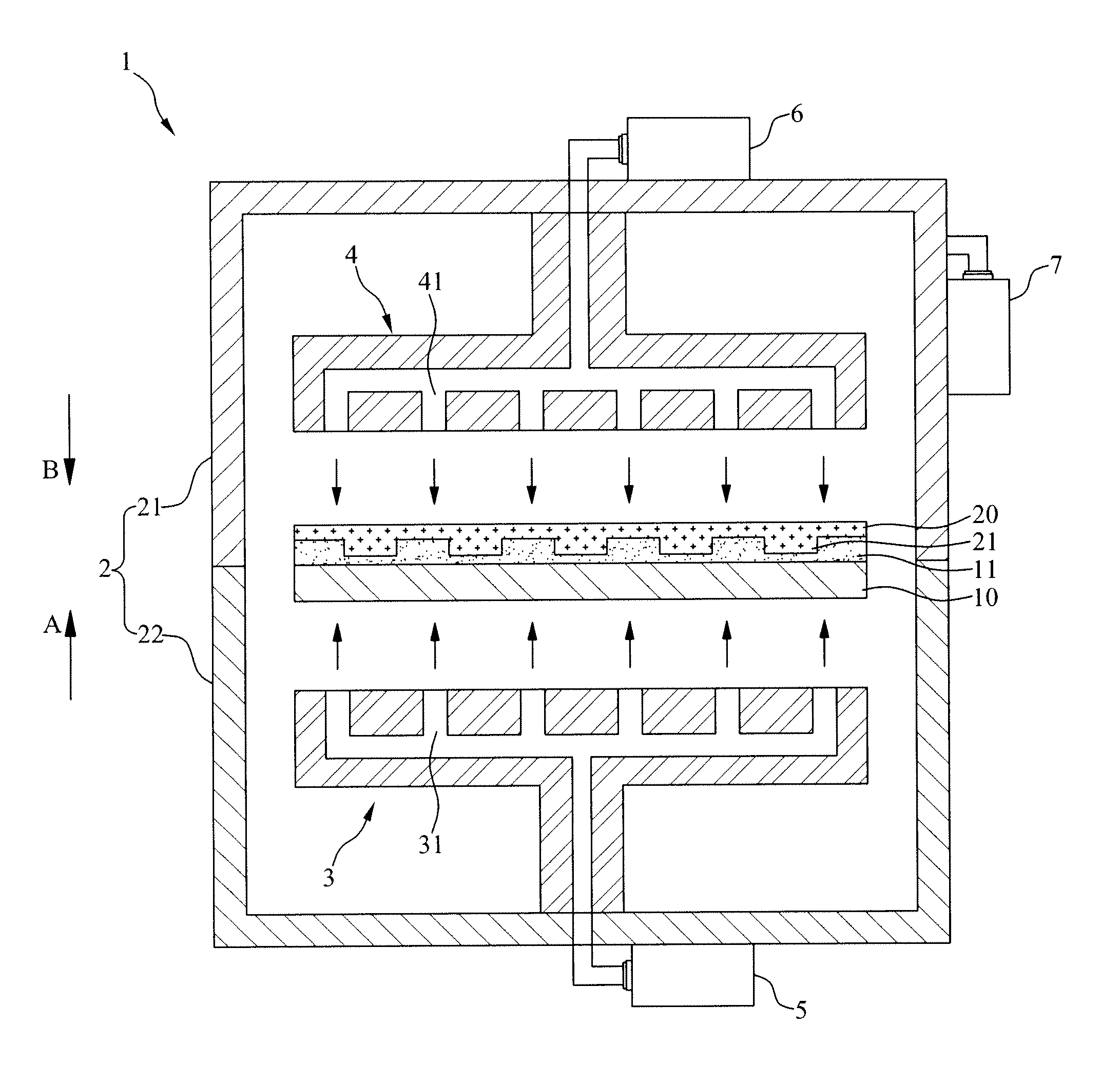

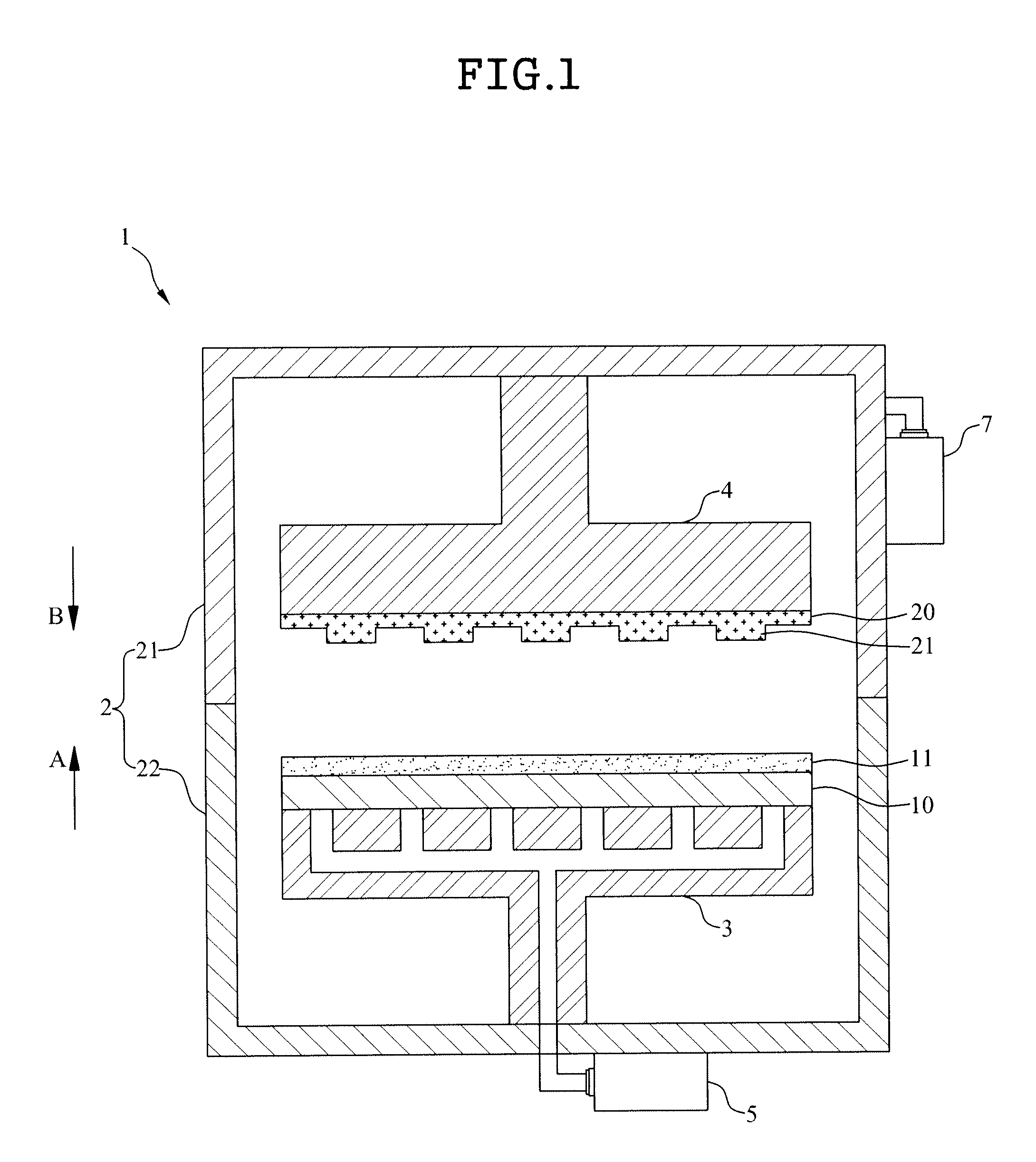

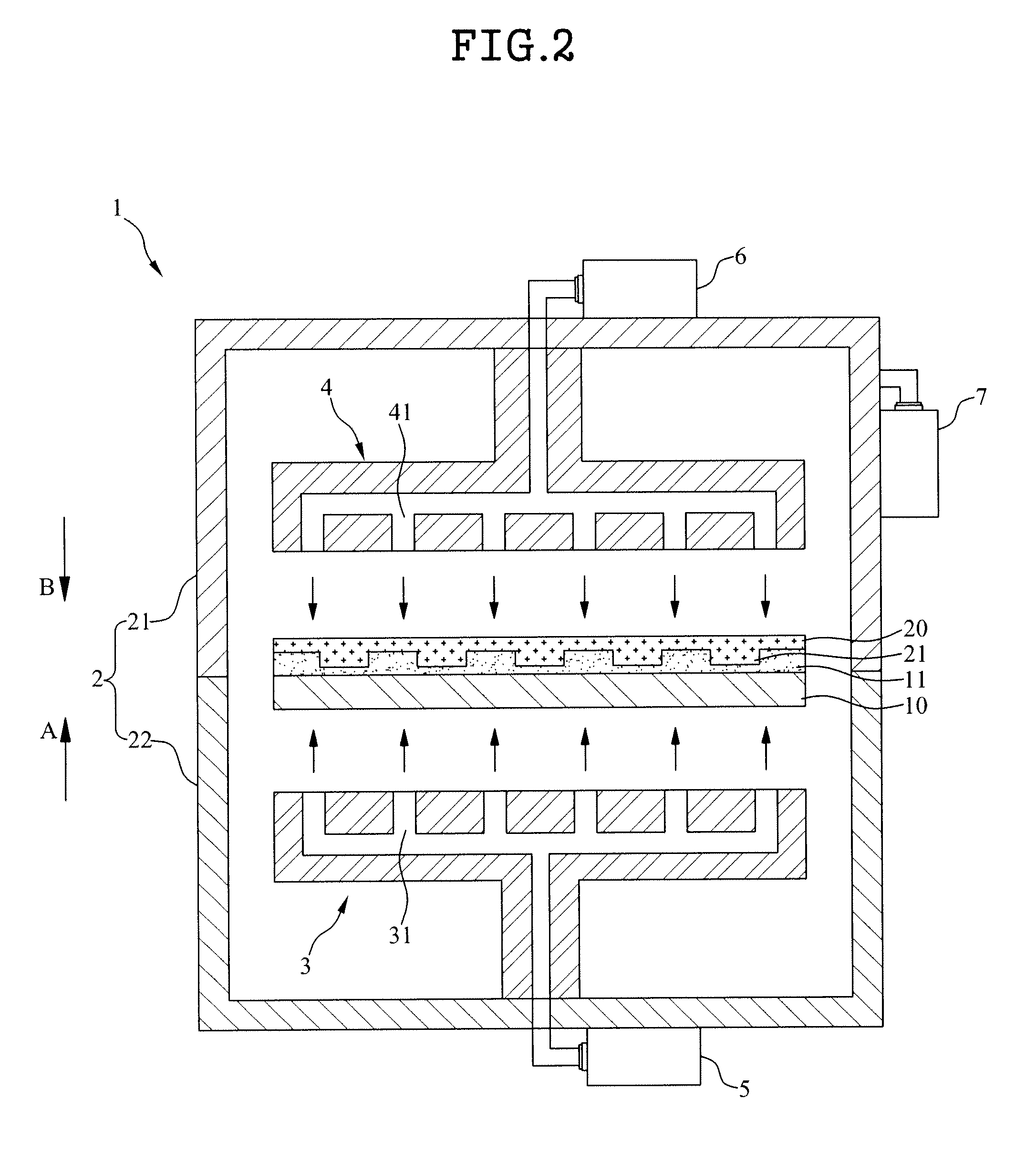

Concrete sample curing room

ActiveCN101947810AUniform temperatureUniform humidityCeramic shaping apparatusMicrocomputerThermodynamics

Owner:JSTI GRP INSPECTION & CERTIFICATION CO LTD

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

Owner:EI DU PONT DE NEMOURS & CO

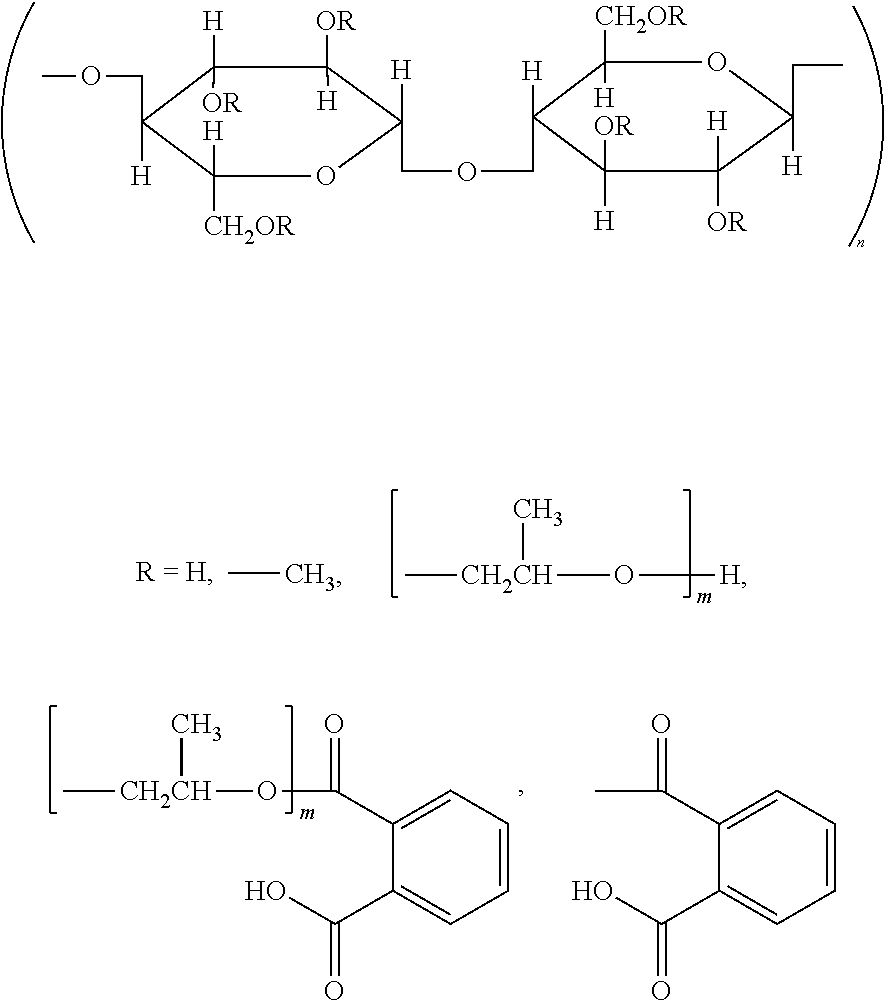

Aqueous composition for enteric hard capsule, method of preparing enteric hard capsule, and enteric hard capsule prepared using the method

ActiveUS20120161364A1Ceramic shaping apparatusPharmaceutical non-active ingredientsBiomedical engineeringHard Capsule

Owner:LOTTE FINE CHEM CO LTD

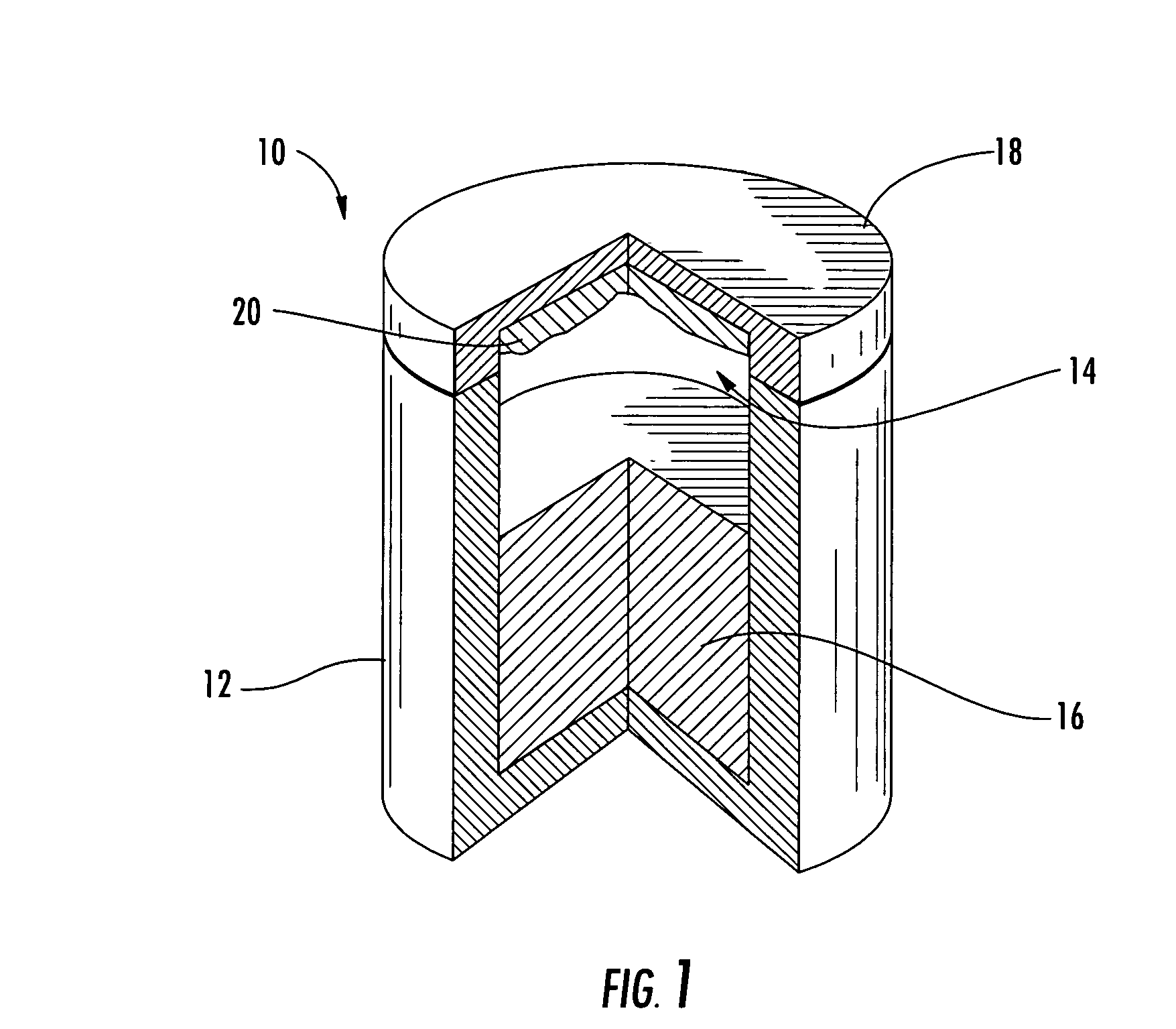

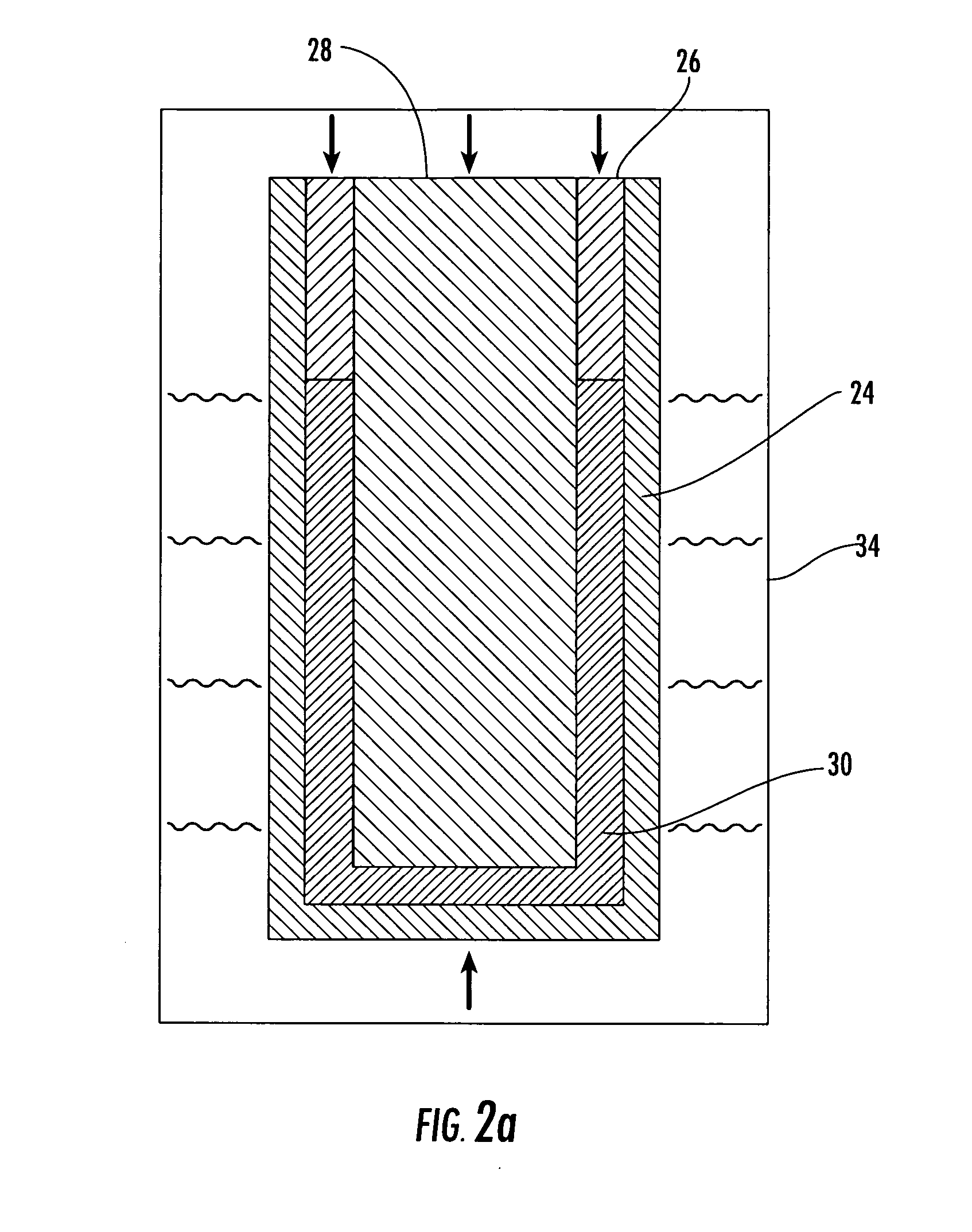

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

Glaze spraying device for mosaic tile manufacturing

ActiveCN106313288ASuitable temperatureGood glazing effectCeramic shaping apparatusViscosityMaterials science

Owner:肇庆市宏润陶瓷有限公司

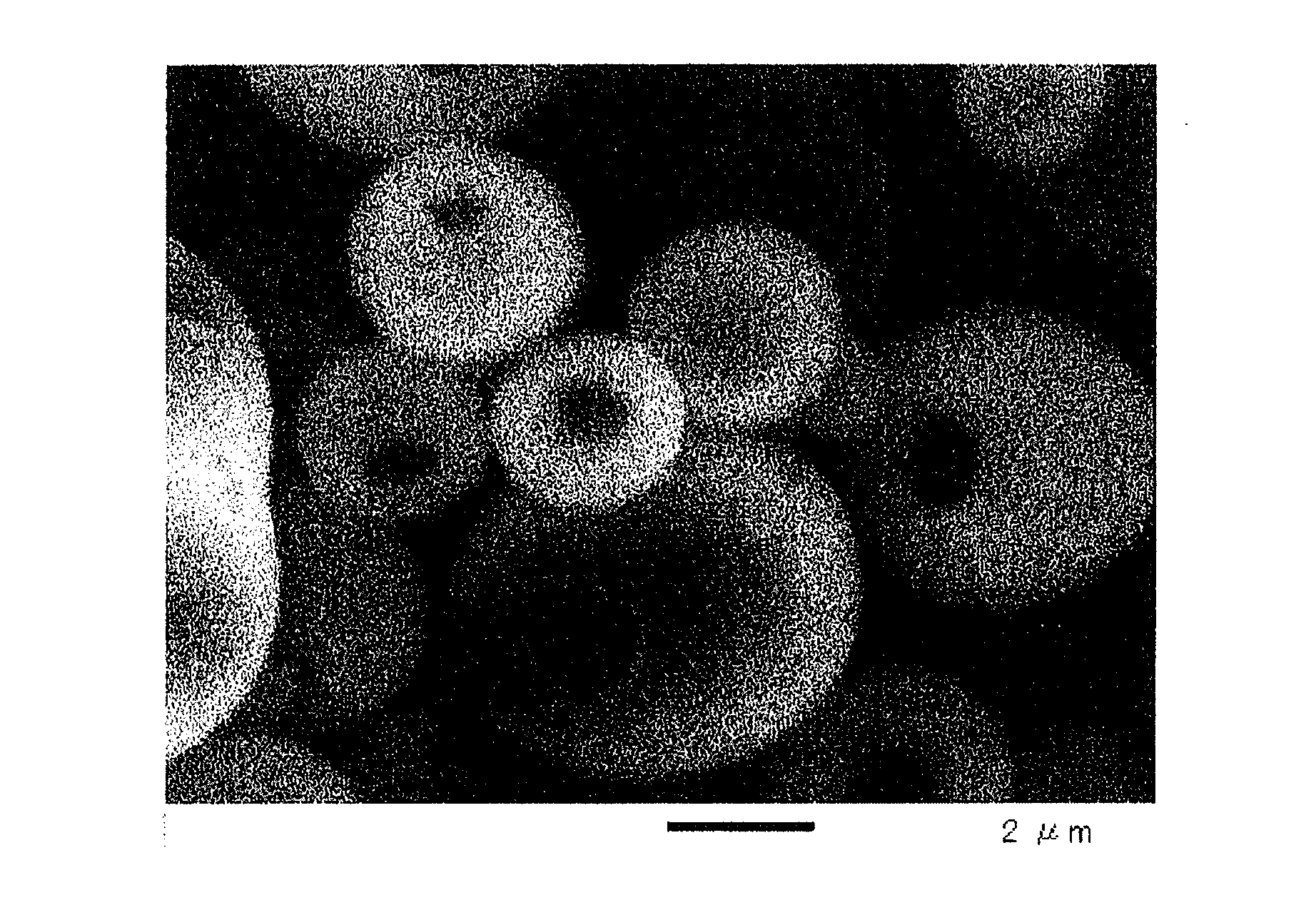

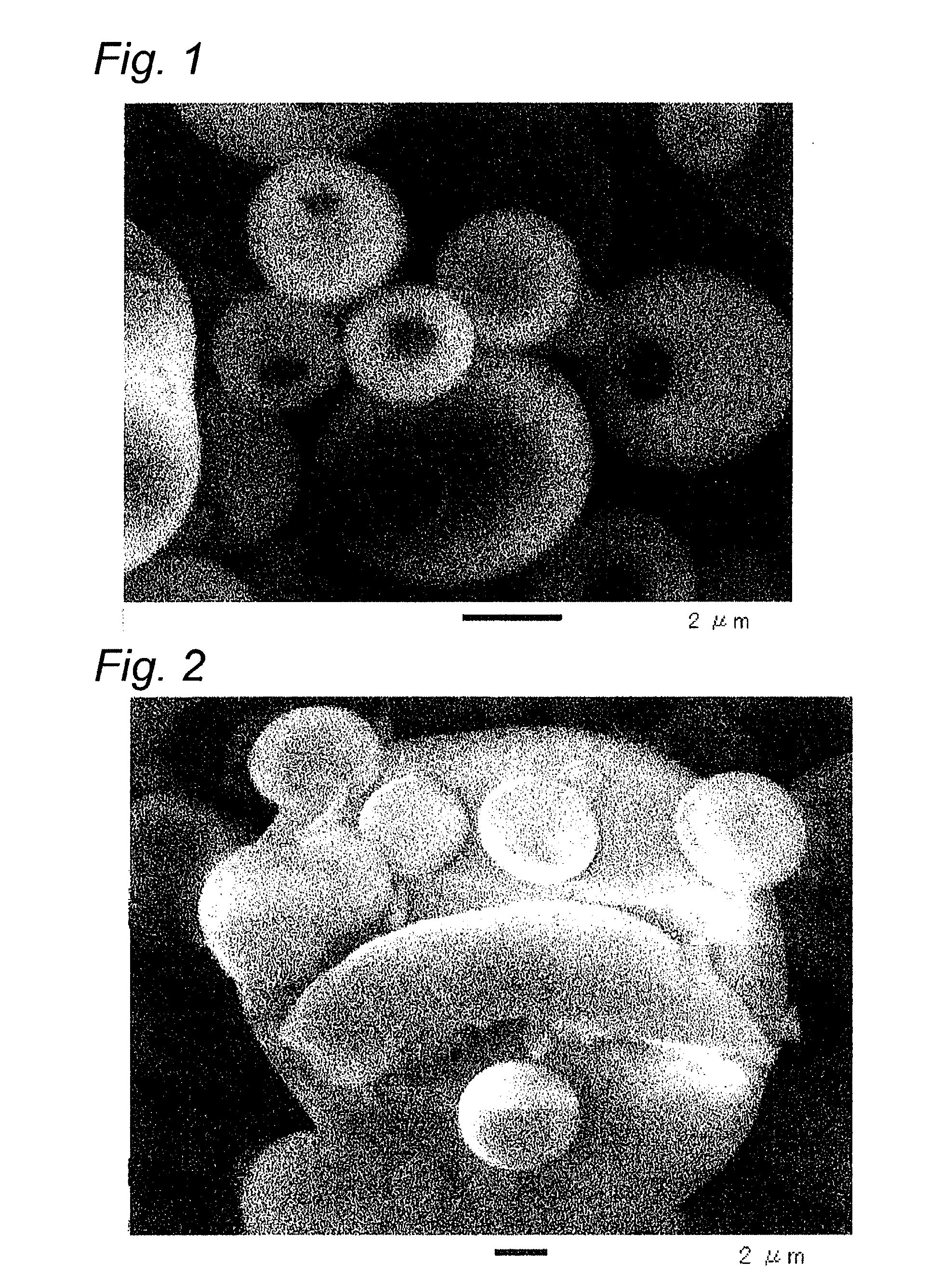

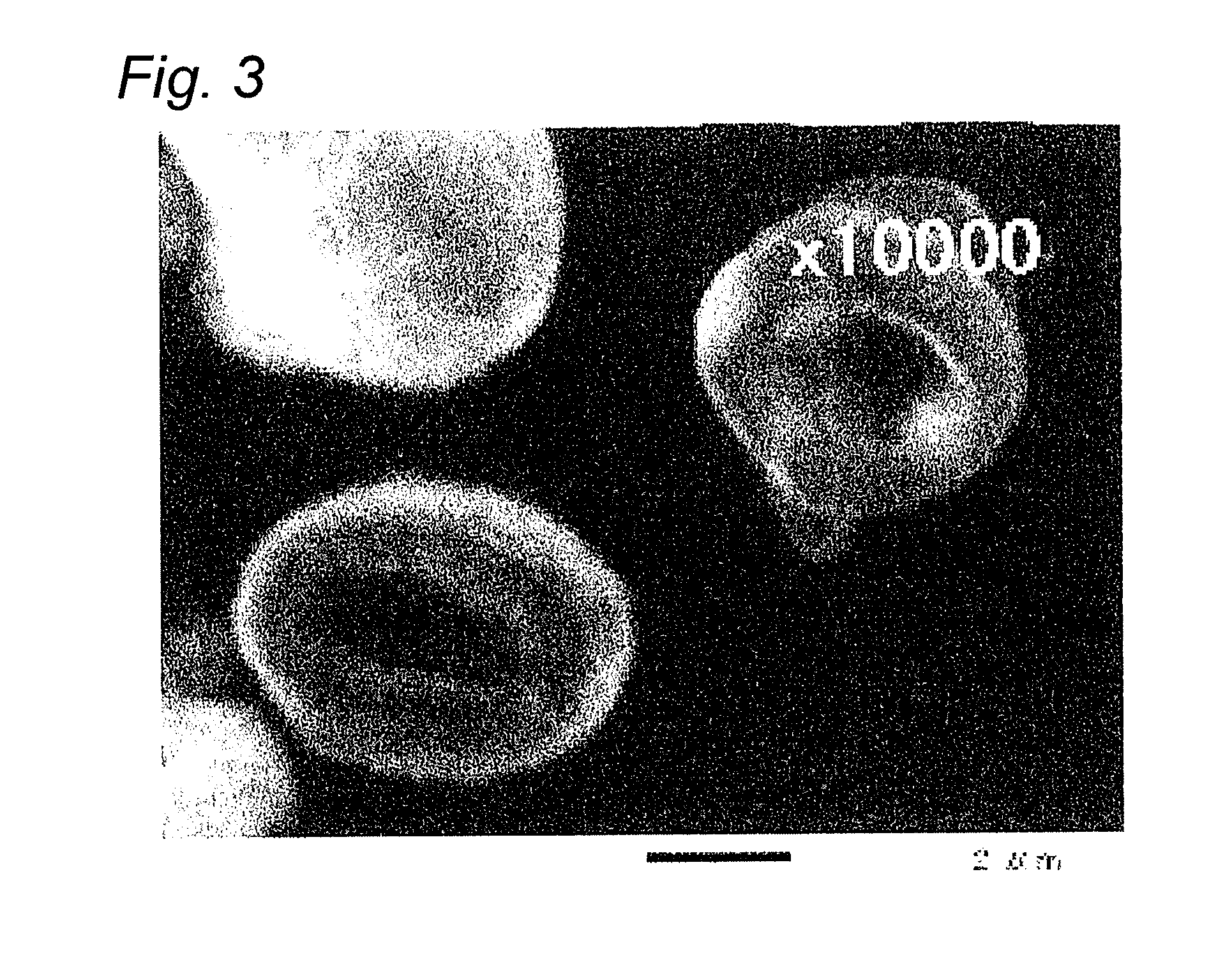

Bead-like hollow particles, method for producing the same, and friction material using the bead-like hollow particles

InactiveUS20120196129A1Reduce brake noiseHigh material strengthAluminium compoundsSilicaBiological materialsParticulate metal

Owner:AKEBONO BRAKE IND CO LTD

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

Multi additive multifunctional composite for use in a non-metallic fuel conveyance system

A multifunctional composite material may include a polymer matrix, at least one nano-additive, micro-additive, and / or a spherical nano-additive. The non-metallic composite material may be used to make non-metallic parts for fuel conveyance systems for use in aircraft.

Owner:EATON INTELLIGENT POWER LTD

Completely-asbestos-free environment-friendly sealing plate and method for preparation thereof

Owner:浙江国泰萧星密封材料股份有限公司

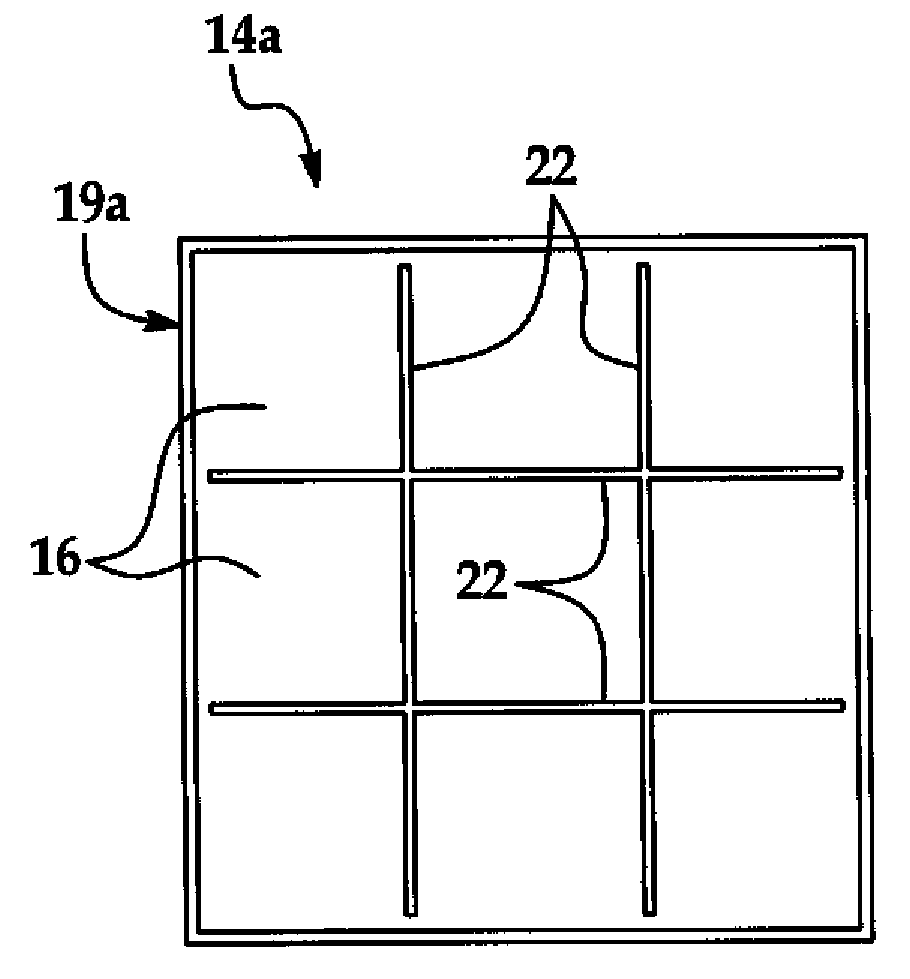

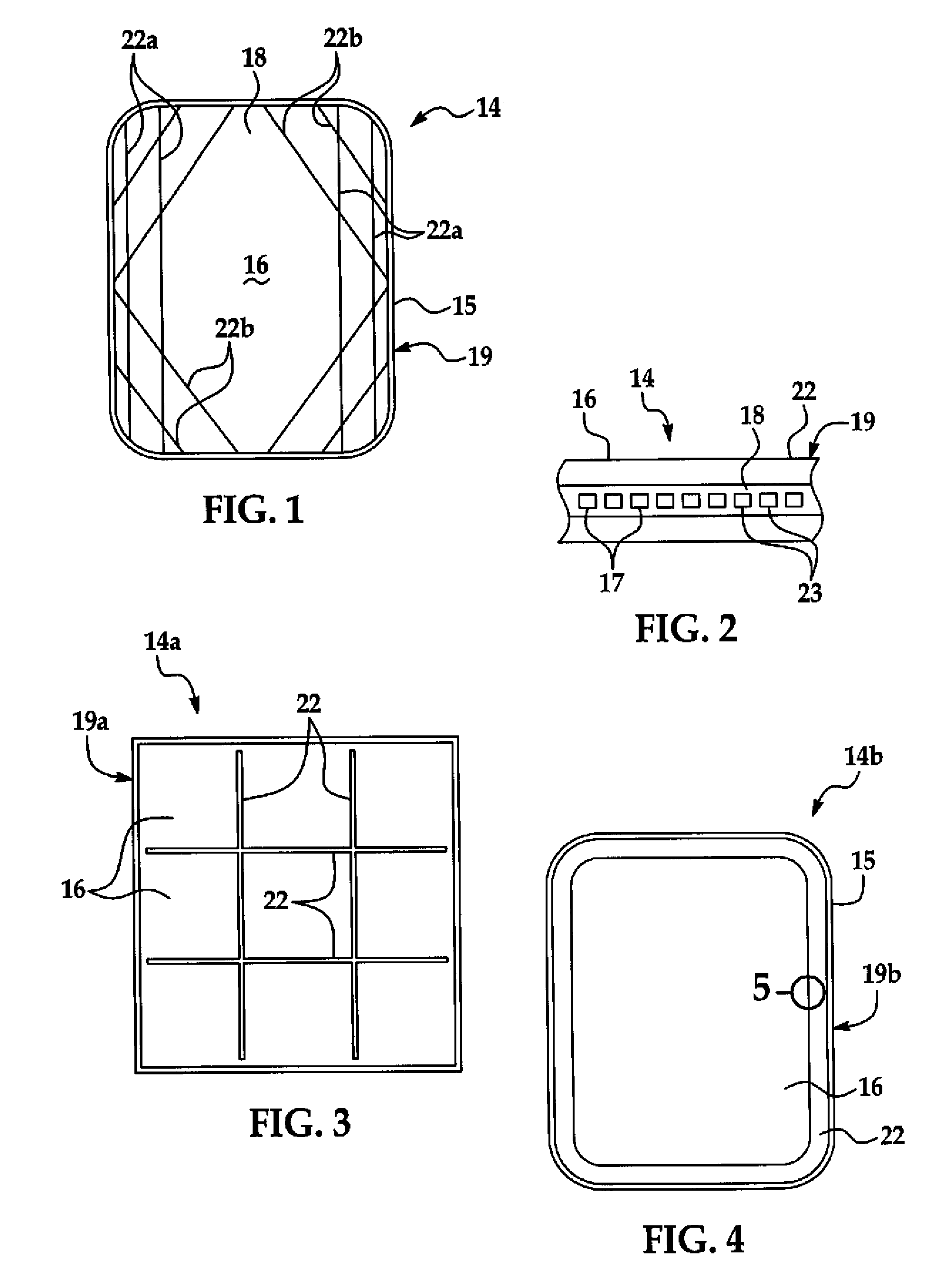

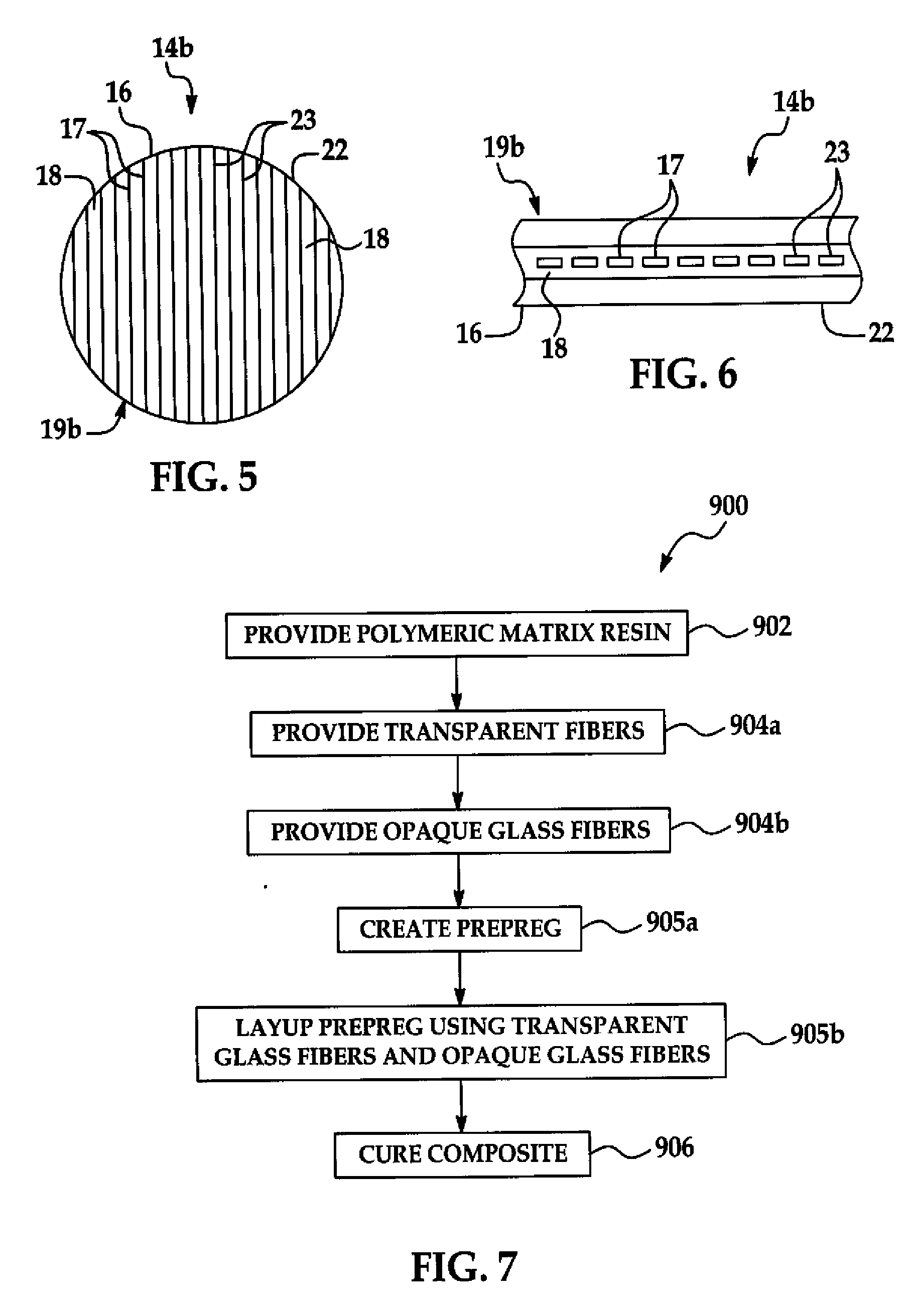

Opaque fiber reinforcement of composites

ActiveUS20100011702A1Synthetic resin layered productsEfficient propulsion technologiesFiber reinforcementPolymeric matrix

Owner:THE BOEING CO

Full automatic machine for forming plaster mould box

InactiveCN101439539AMixing operation control apparatusCeramic shaping apparatusMechanical engineeringMixed materials

Owner:黄梅龙源石膏有限公司

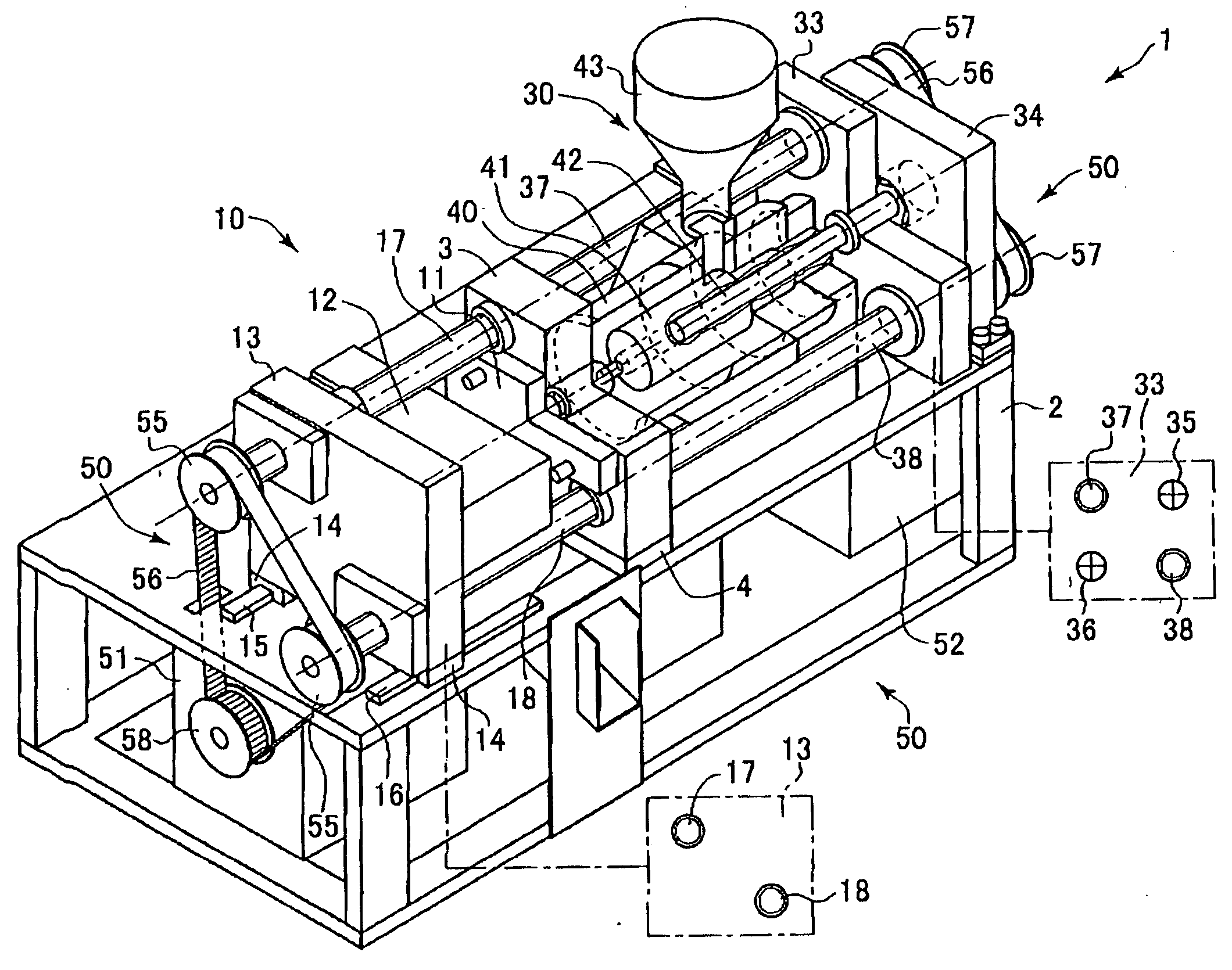

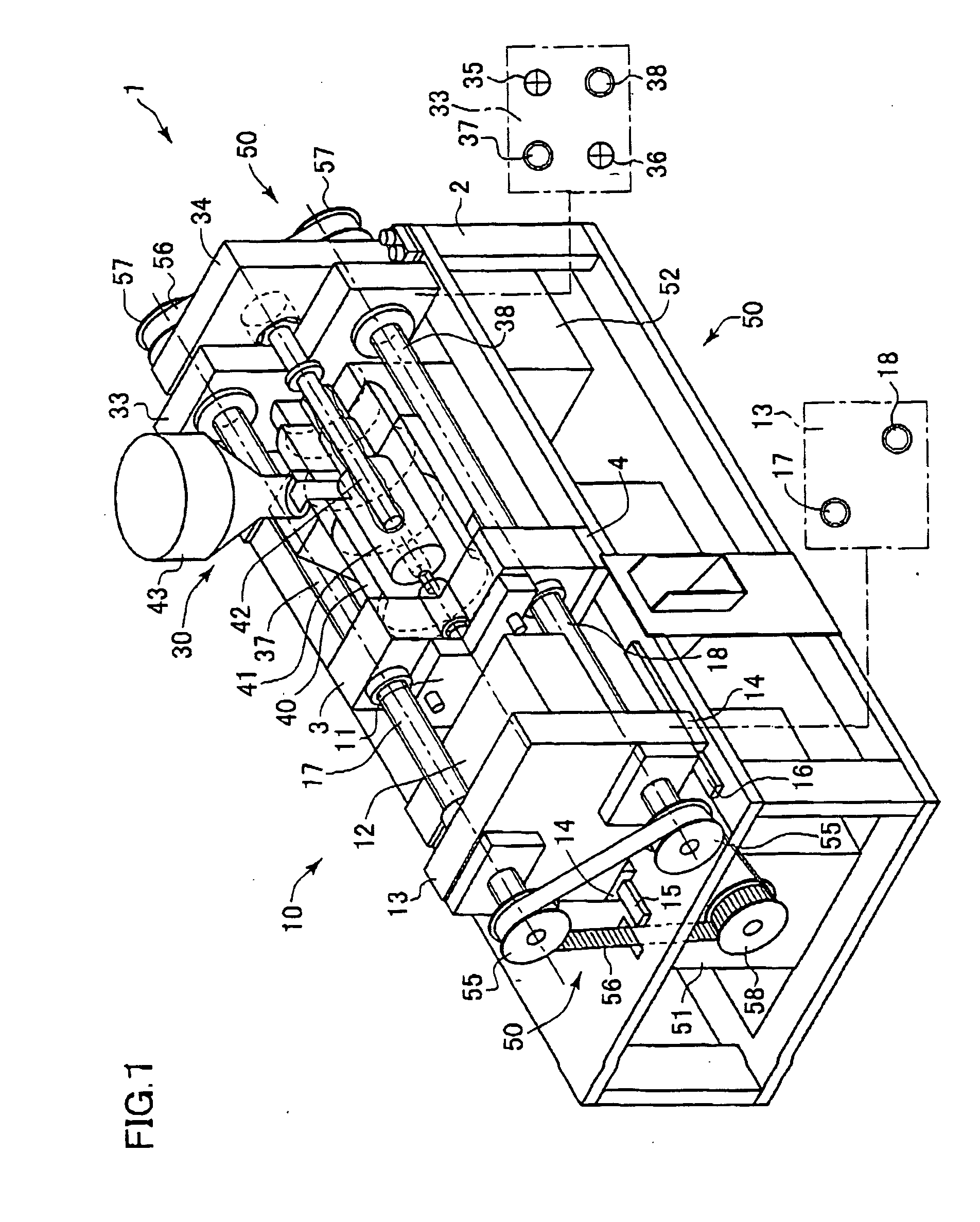

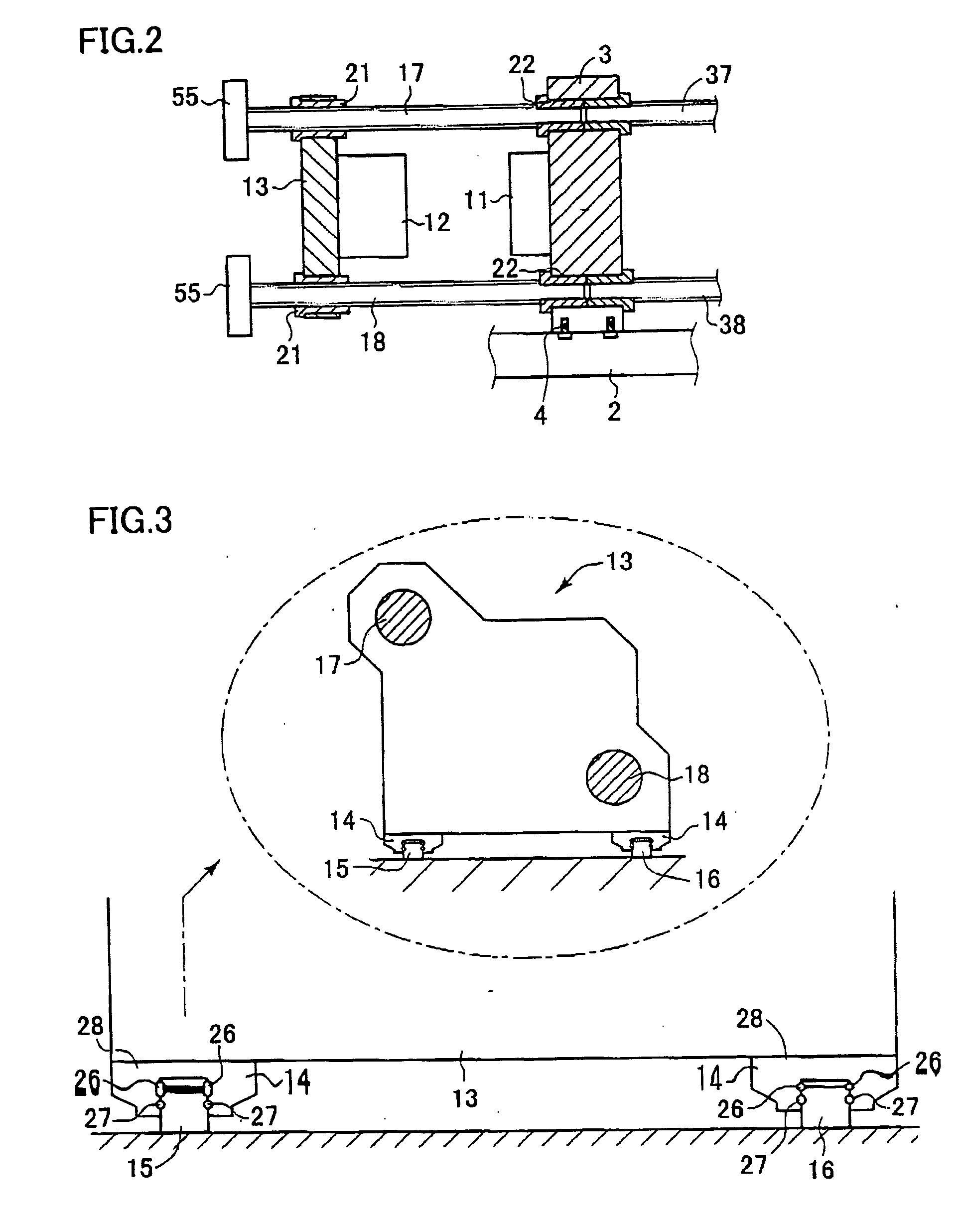

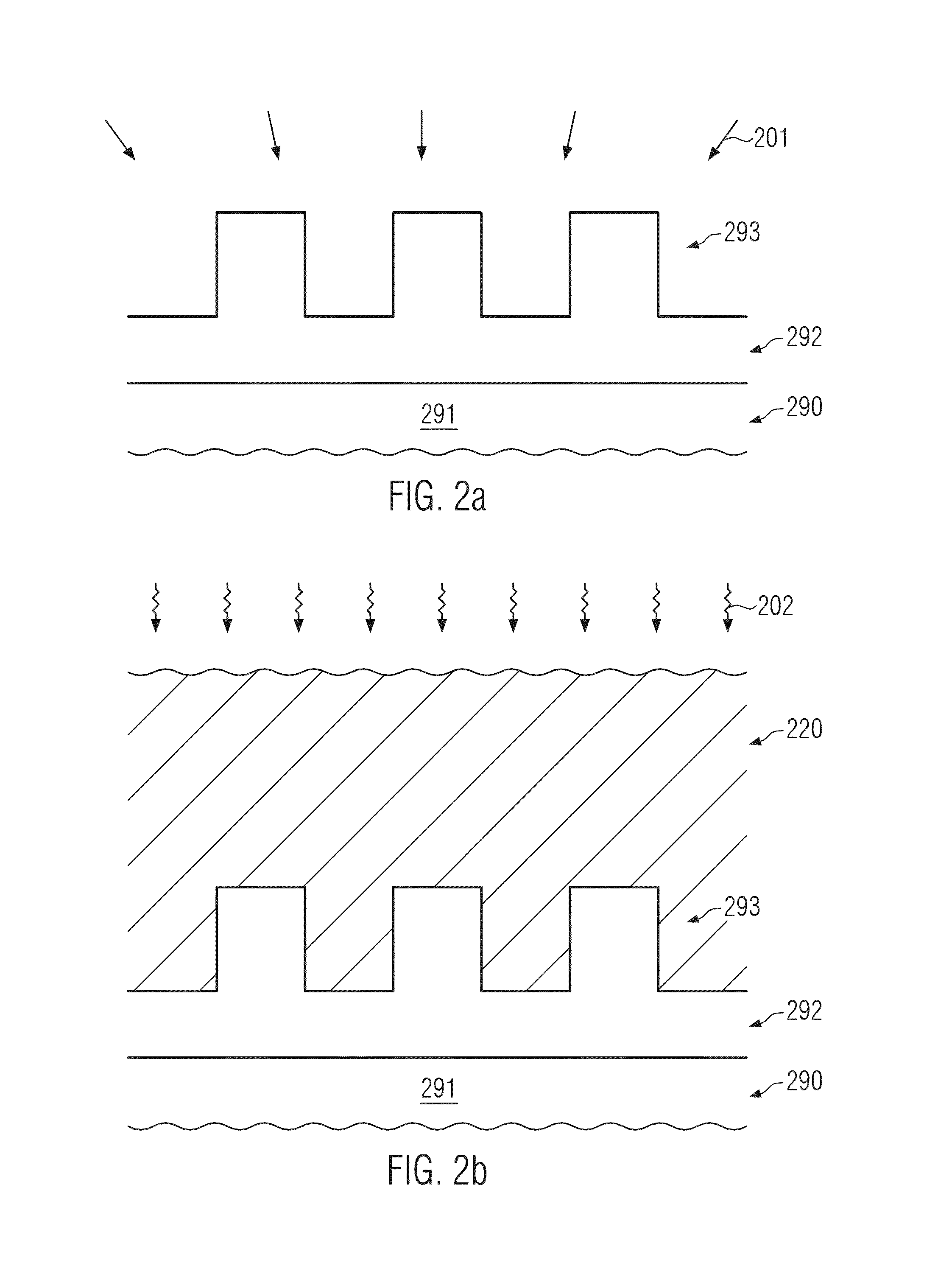

Imprinting apparatus and imprinting method using the same

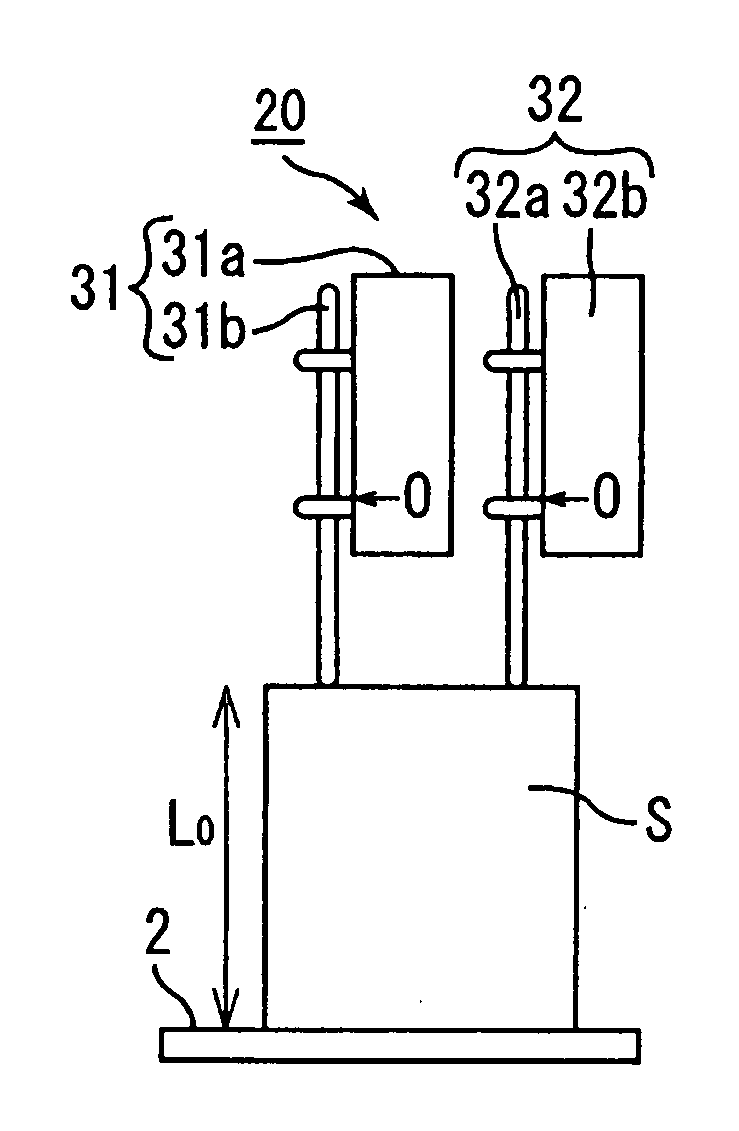

InactiveUS20110298159A1Easy to solveTailstocks/centresConfectioneryEngineeringMechanical engineering

Owner:LG DISPLAY CO LTD

Method for manufacturing ecological building blocks of riverway protection slope from sewage plant sludge

ActiveCN102152383AAvoid secondary pollutionRealize the utilization of renewable resourcesCeramic shaping apparatusEnvironmental resource managementRiver routing

Owner:JIANGSU MINGXUAN ENVIRONMENT TECH

Ceramic blank shaping mold help for resolving problem of difficult demoulding

InactiveCN101462299ASolve the difficult problem of demouldingCeramic shaping apparatusChain structureMaterials science

The invention relates to a ceramic blank forming die favorable for solving problem of difficult demoulding, belongs to the field of ceramic formation, and aims to solve the problem that the prior ceramic forming die is difficult to demould during use. The die comprises a die cushion, a die cavity, and an upper punch, which are mutually packaged in turn and used together; and the die adopts the key point that the die cavity consists of two valve groove shaped objects, the structure of the die also comprises six supporting arm shaped objects, wherein four supporting arm shaped objects of the six supporting arm shaped objects are mutually hinged from beginning to end to form a closed chain structure, a pair of opposite vertex angles of the chain structure is hinged with one end of each of the rest two supporting arm shaped objects respectively, the rest other end of each of the rest two supporting arm shaped objects is connected with the two valve groove shaped objects respectively, the arm shaped objects are made of magnetic conducting materials, and the surface of at least one arm shaped object close to the groove shaped objects at structural position is wound with a magnet exciting coil. The die can conveniently control opening, closing, loosening, and fastening by a power supply switch.

Owner:NINGBO UNIV

Pigment spraying device for ceramic product production process

Owner:景德镇一牧堂陶瓷科技有限公司

Cement-based fire door core

Owner:GEORGIA PACIFIC GYPSUM LLC

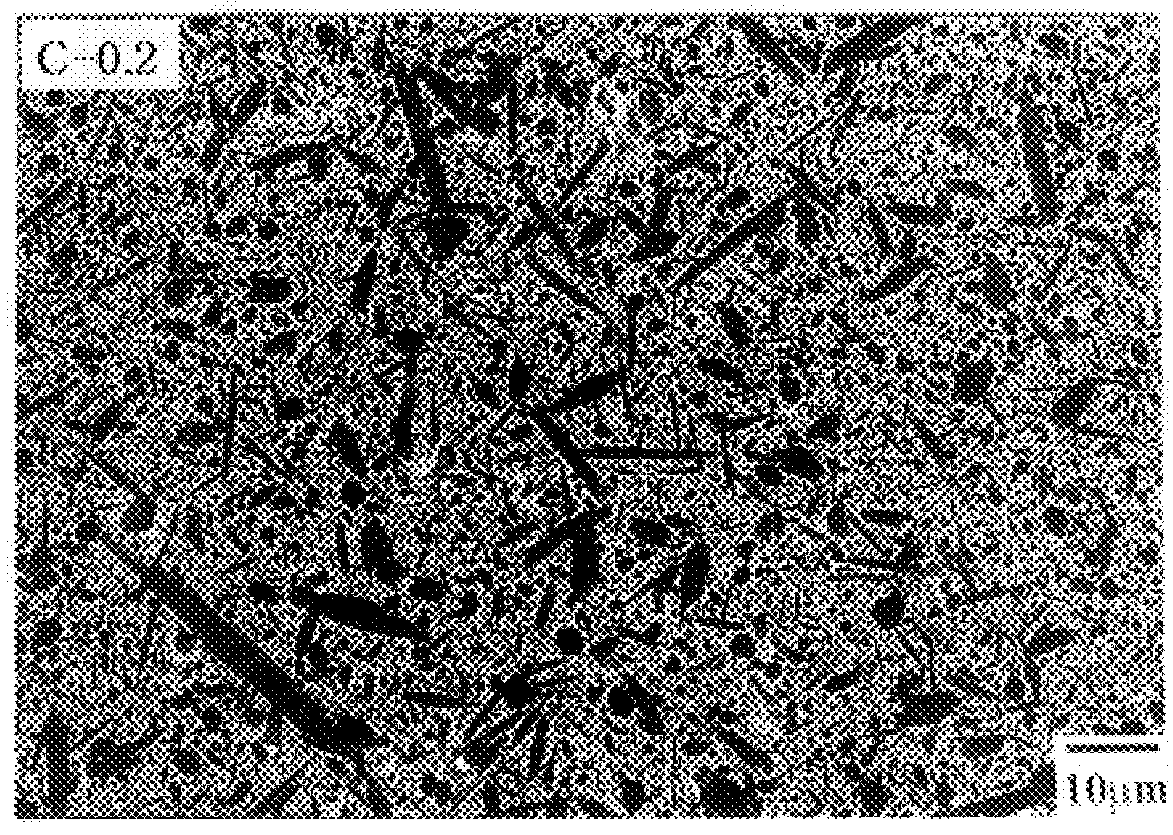

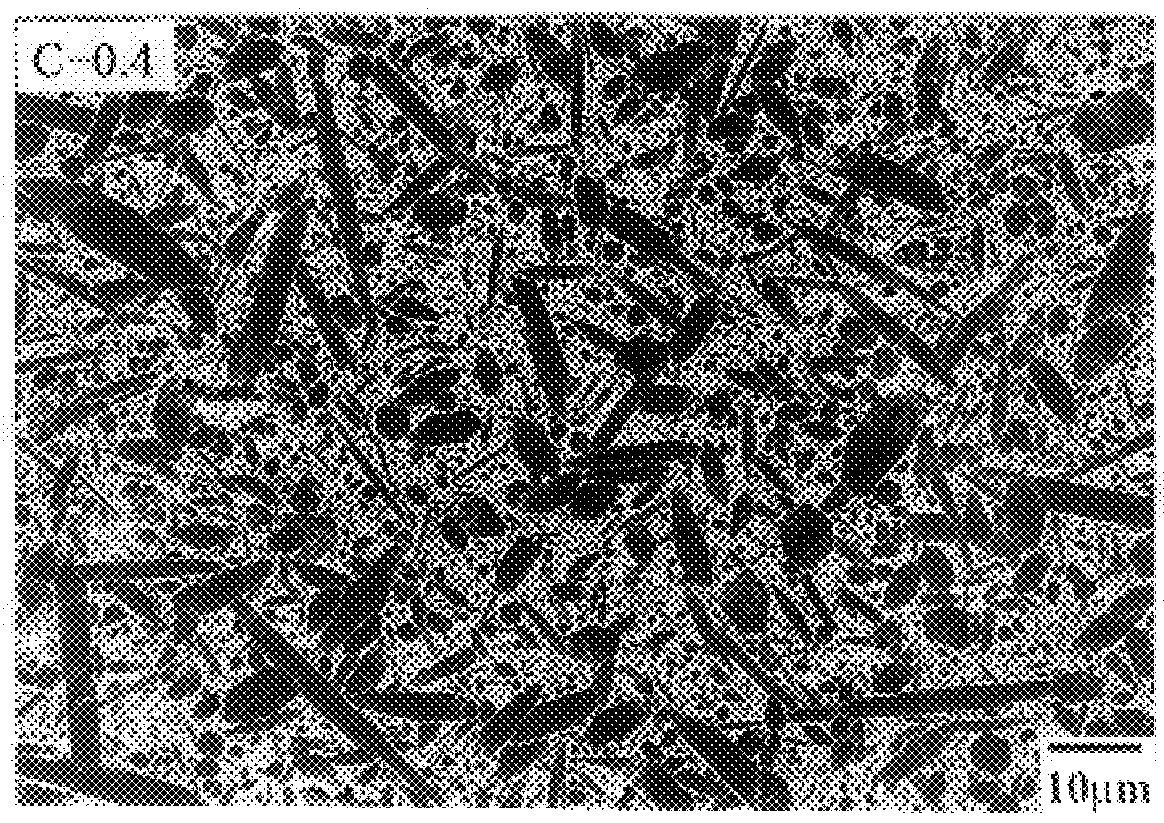

Method for preparing silicon nitride ceramic with high strength and toughness

InactiveUS6232252B1High strengthImprove toughnessCeramic shaping apparatusClaywaresHigh intensityReduction treatment

Provided with a method for preparing a silicon nitride ceramic with high strength and toughness including: mixing 0.2-0.9 wt % of carbon (C) powder with silicon nitride powder containing 5.0-6.0 wt % of yttria (Y2O3) and 1.0-2.0 wt % of alumina (Al2O3) added thereto as a sintering agent, and preparing a molding; subjecting the molding to a carbothermal reduction treatment at 1400-1500° C.; and gas pressure sintering the molding at a temperature above 1850° C. after the carbothermal reduction treatment.

Owner:KOREA INST OF MASCH & MATERIALS

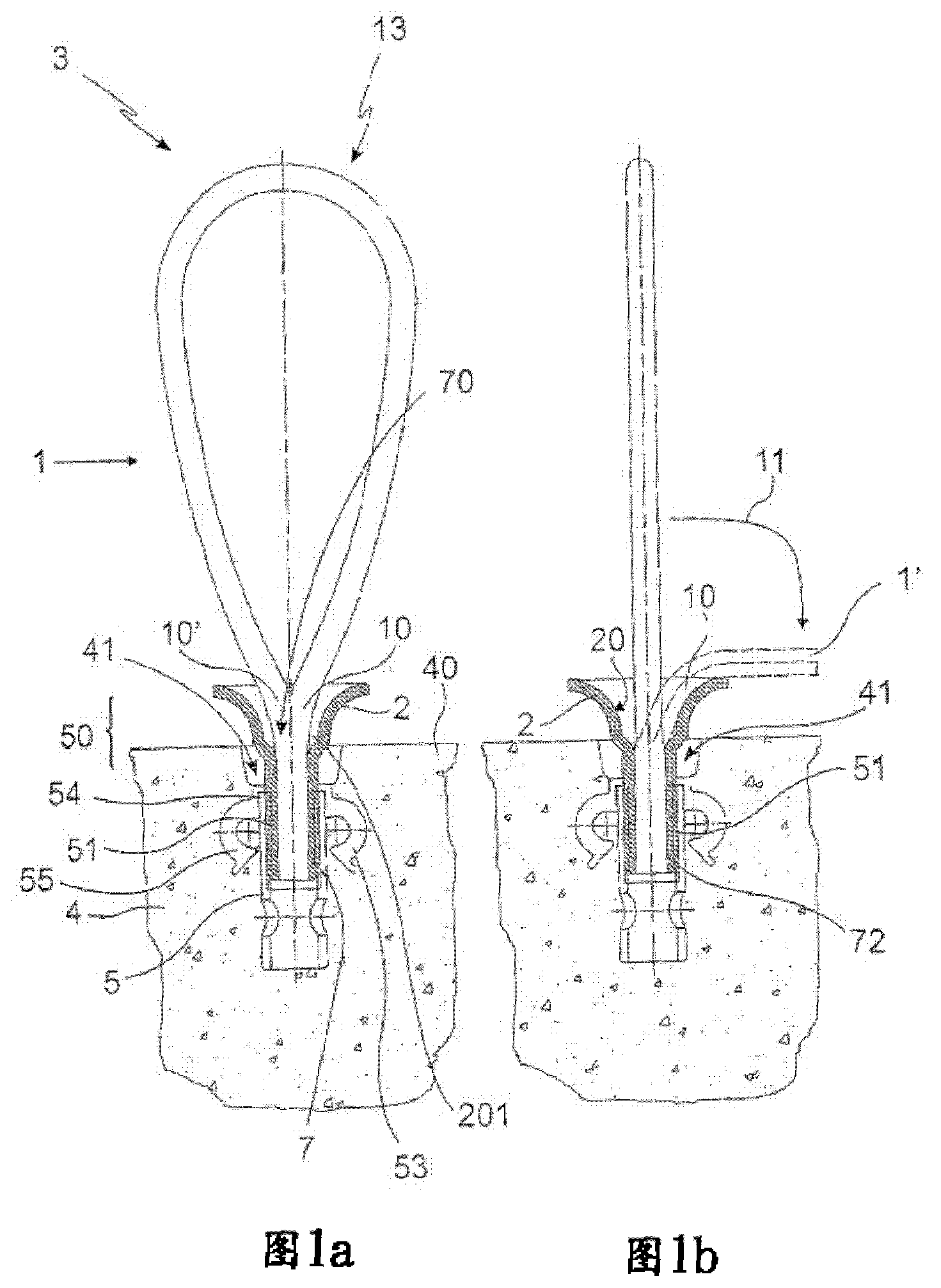

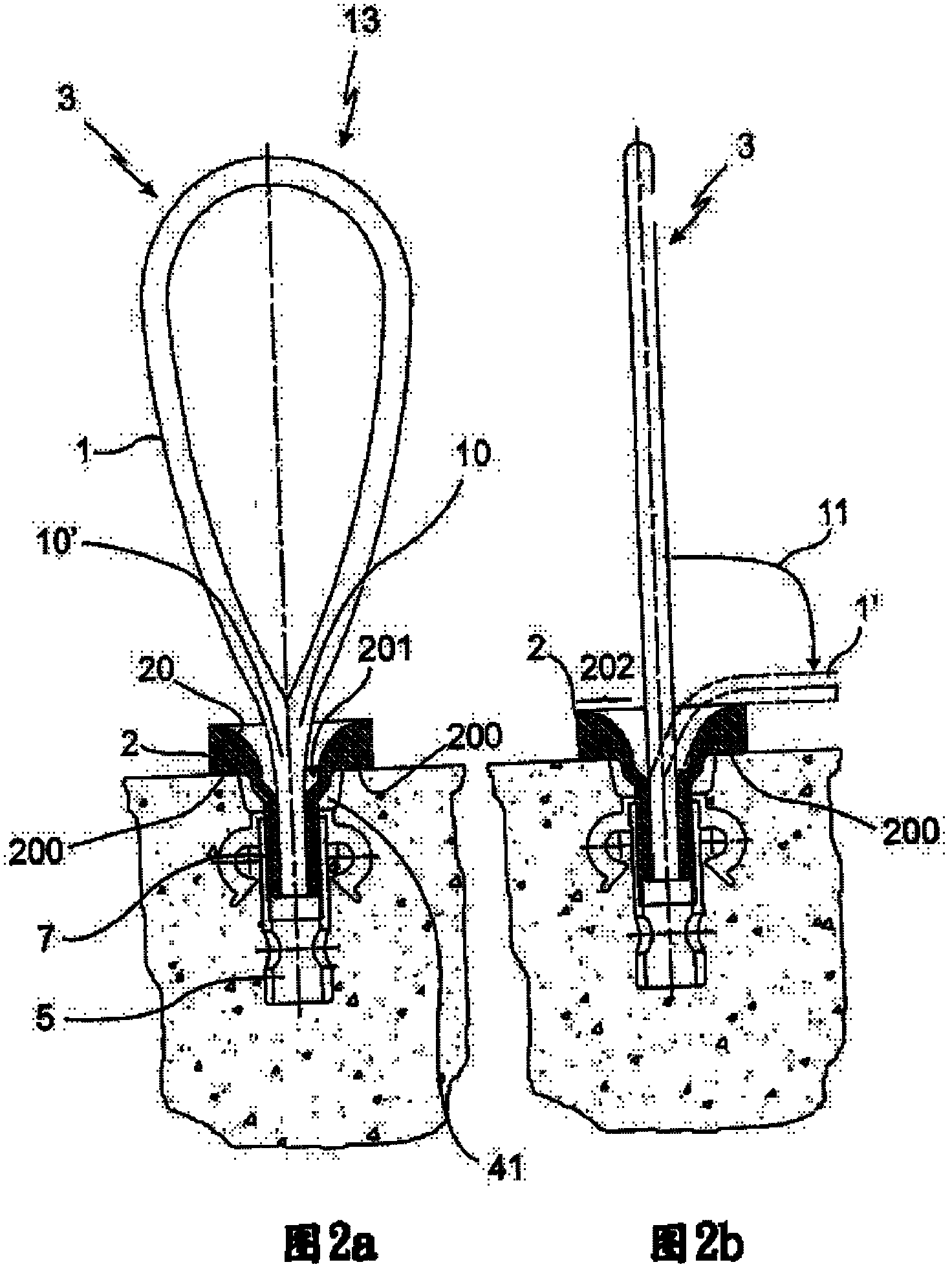

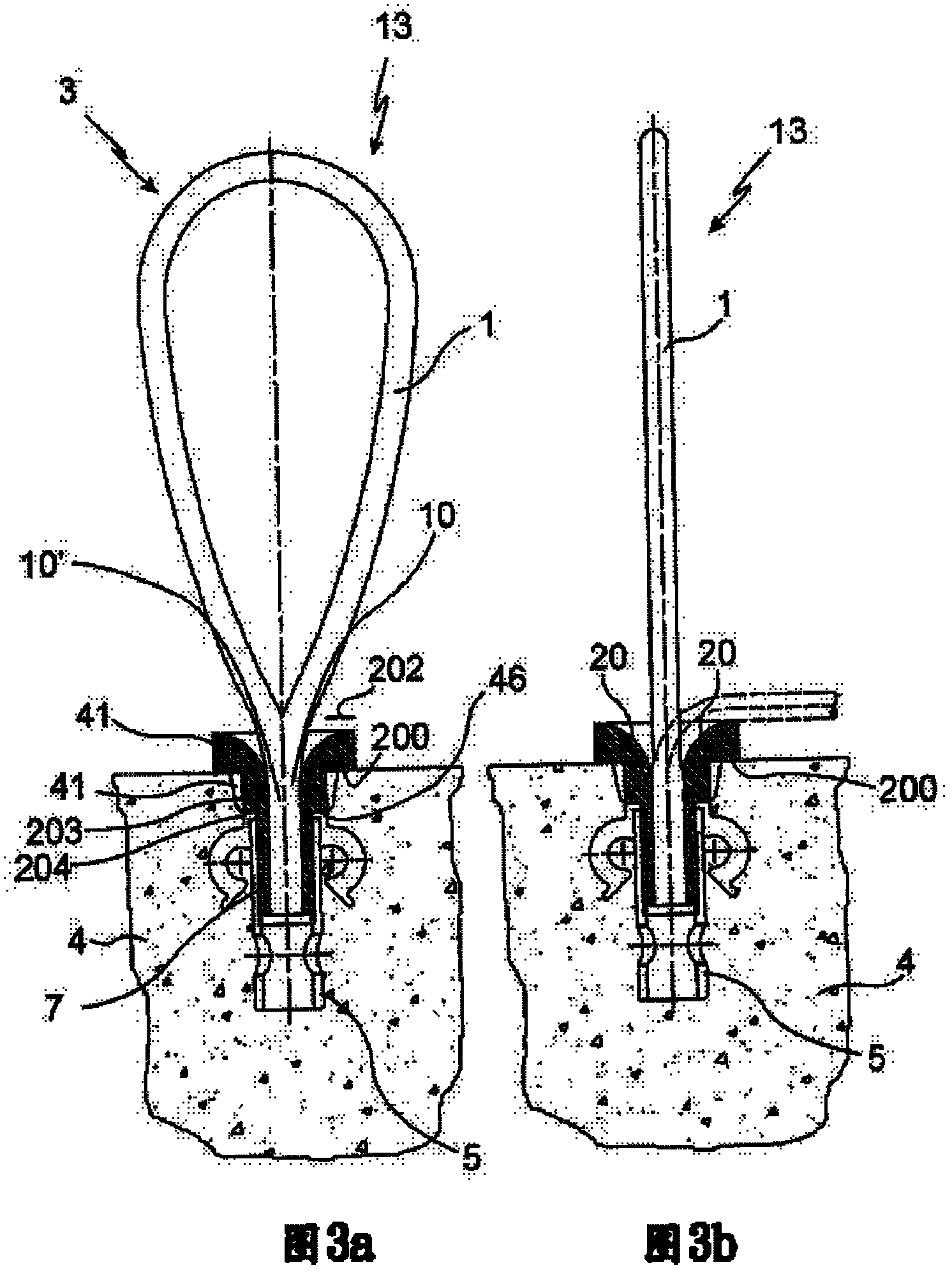

Load receiving means

ActiveCN102388194ACeramic shaping apparatusBuilding material handlingStructural engineeringArchitectural engineering

Owner:PFEIFER SEIL & HEBETECHNIK GMBH & CO

Motor-driven injection molding apparatus

InactiveUS20050074517A1Reduce the number of partsSimple structureCeramic shaping apparatusFood shapingTiming beltBall screw

Owner:DAIWA KASEI IND CO LTD

Light sandwich paperless gypsum board containing high-temperature phosphogypsum as well as preparation method and application thereof

ActiveCN111268987ANot easy to moldLight weightLaminationLamination apparatusFiberglass meshGlass fiber

The invention discloses a light sandwich paperless gypsum board containing high-temperature phosphogypsum. The paperless gypsum board is prepared from the following raw materials in parts by weight: 10-20 parts of high-temperature phosphogypsum, 80-90 parts of high-strength alpha-phosphogypsum, 3-10 parts of lime, 3-10 parts of heavy calcium carbonate, 1-3 parts of glass fiber gridding cloth, 0.05-1 part of a composite foaming agent and 0.01-0.1 part of a composite foam stabilizer. According to the invention, the core layer takes high-temperature phosphogypsum and high-strength alpha-phosphogypsum as main raw materials for the first time, and lime and coarse whiting inorganic powder are doped to serve as filler; by means of the idea of foaming by introducing a foaming agent and a foam stabilizer, a layered cast-in-place method, a combined pouring method and an integral assembly method after layered manufacturing are adopted for preparation. The production process is simplified, dryingis easy, the prepared paperless gypsum board is not prone to mildewing, the strength of a core layer is 0.6 MPa or above, the volume weight is smaller than 550 kg / m3, the volume weight of a paperlessgypsum board wall is reduced, and the heat preservation performance of the paperless gypsum board wall is improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

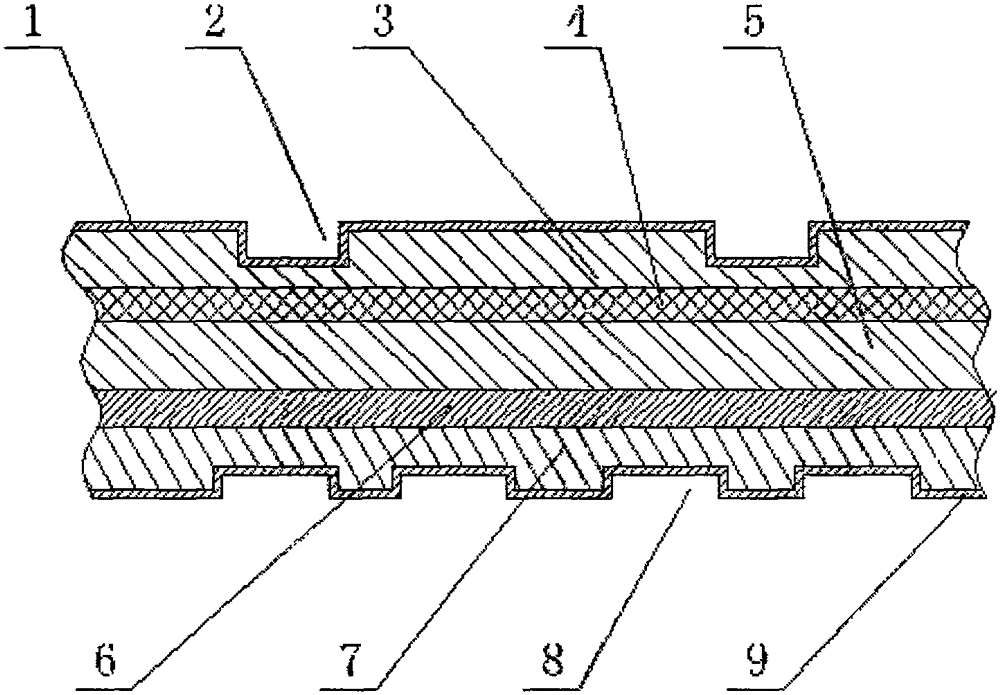

Inorganic fireproof thermal insulation plate and preparation method thereof

InactiveCN105239681AGood thermal insulation performanceLow thermal conductivitySolid waste managementCeramic shaping apparatusHollow corePerlite

The invention discloses an inorganic fireproof thermal insulation plate and a preparation method thereof. The inorganic fireproof thermal insulation plate is characterized by comprising a hollow ceramic bead surface layer, a fiberglass gridding cloth layer, an expanded perlite composite layer, a fiberglass gridding cloth layer and a hollow ceramic bead bottom layer in sequence from top to bottom. A pit slot is formed in the hollow ceramic bead surface layer; and a groove is formed in the hollow ceramic bead bottom layer. Non-woven fabric layers are respectively arranged on the hollow ceramic bead surface layer and the hollow ceramic bead bottom layer. The hollow ceramic bead surface layer and the hollow ceramic bead bottom layer are made of hollow ceramic bead slurry; and the expanded perlite composite layer is made of expanded perlite composite layer slurry. The preparation method comprises the following steps of preparing the hollow ceramic bead bottom layer, flatly laying the fiberglass gridding cloth layer, preparing the expanded perlite composite layer, flatly laying the fiberglass gridding cloth layer, preparing the hollow ceramic bead surface layer, compacting and molding these layers, and demolding and curing these layers. The invention is advantaged in that the thermal insulation performance of the inorganic fireproof thermal insulation plate is good, the heat conductivity coefficient of the inorganic fireproof thermal insulation plate is low, flame retardant grade and fireproofing grade of the inorganic fireproof thermal insulation plate are high, the inorganic fireproof thermal insulation plate is green and environment-friendly, and the integral compressive strength of the inorganic fireproof thermal insulation plate is greatly enhanced and so on.

Owner:张琳

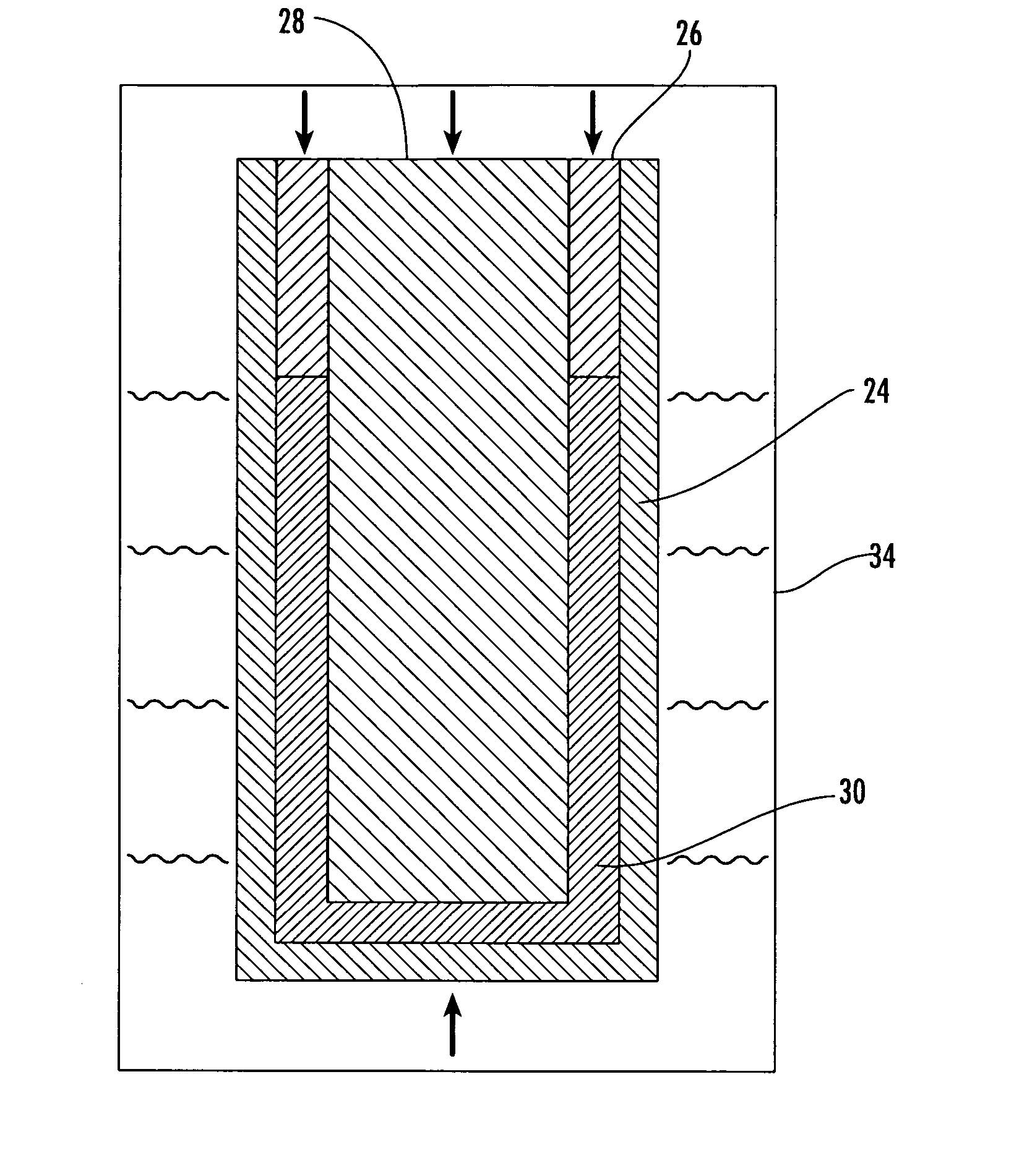

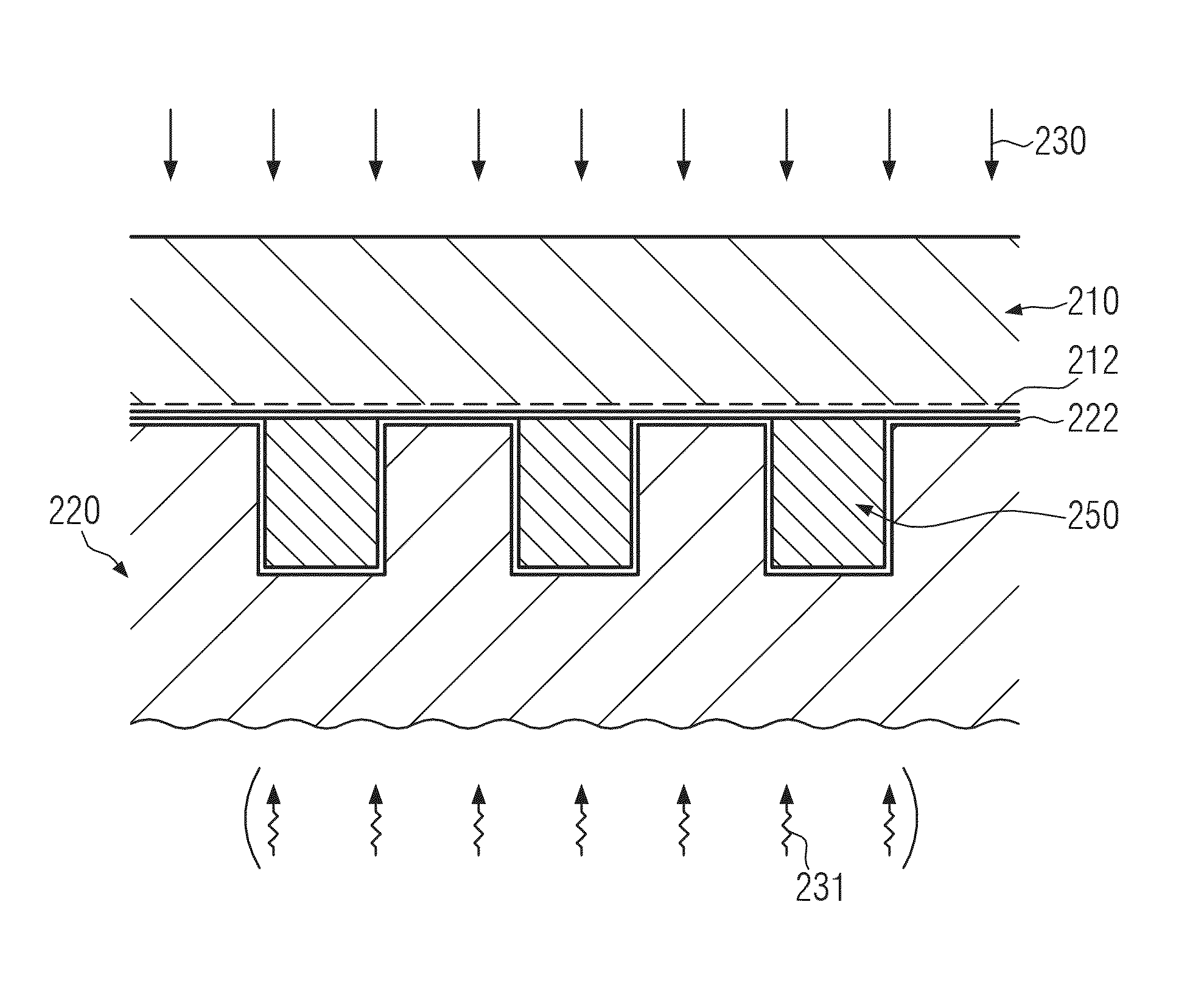

Methods and a mold assembly for fabricating polymer structures by imprint techniques

InactiveUS20140084519A1Highly hydrophobic surfaceReduced surface wettabilityConfectioneryPhotomechanical apparatusLithography processMaterials science

Owner:STMICROELECTRONICS SRL +1

Superparamagnetic iron cobalt ternary alloy and silica nanoparticles of high magnetic saturation and a magnetic core containing the nanoparticles

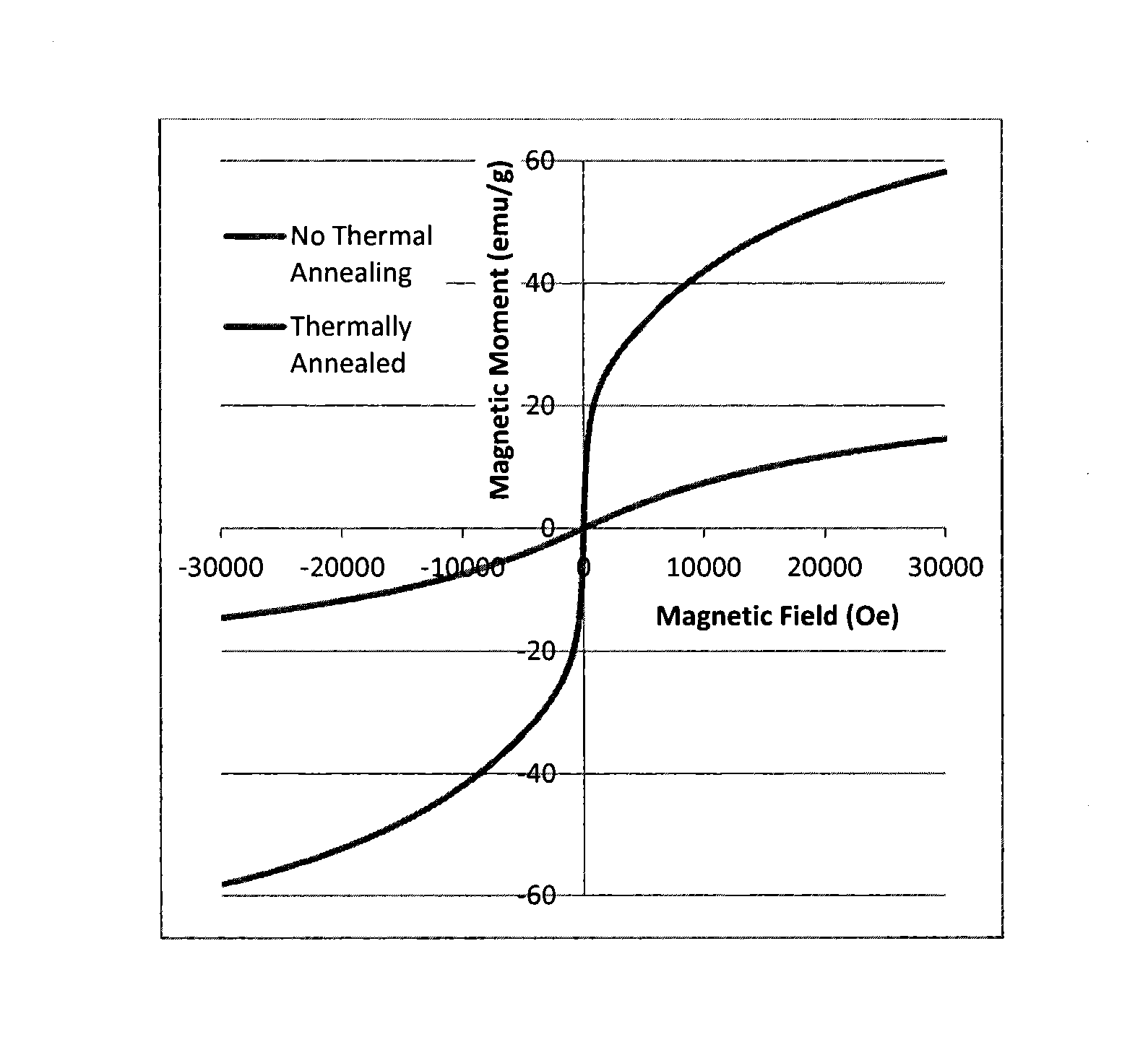

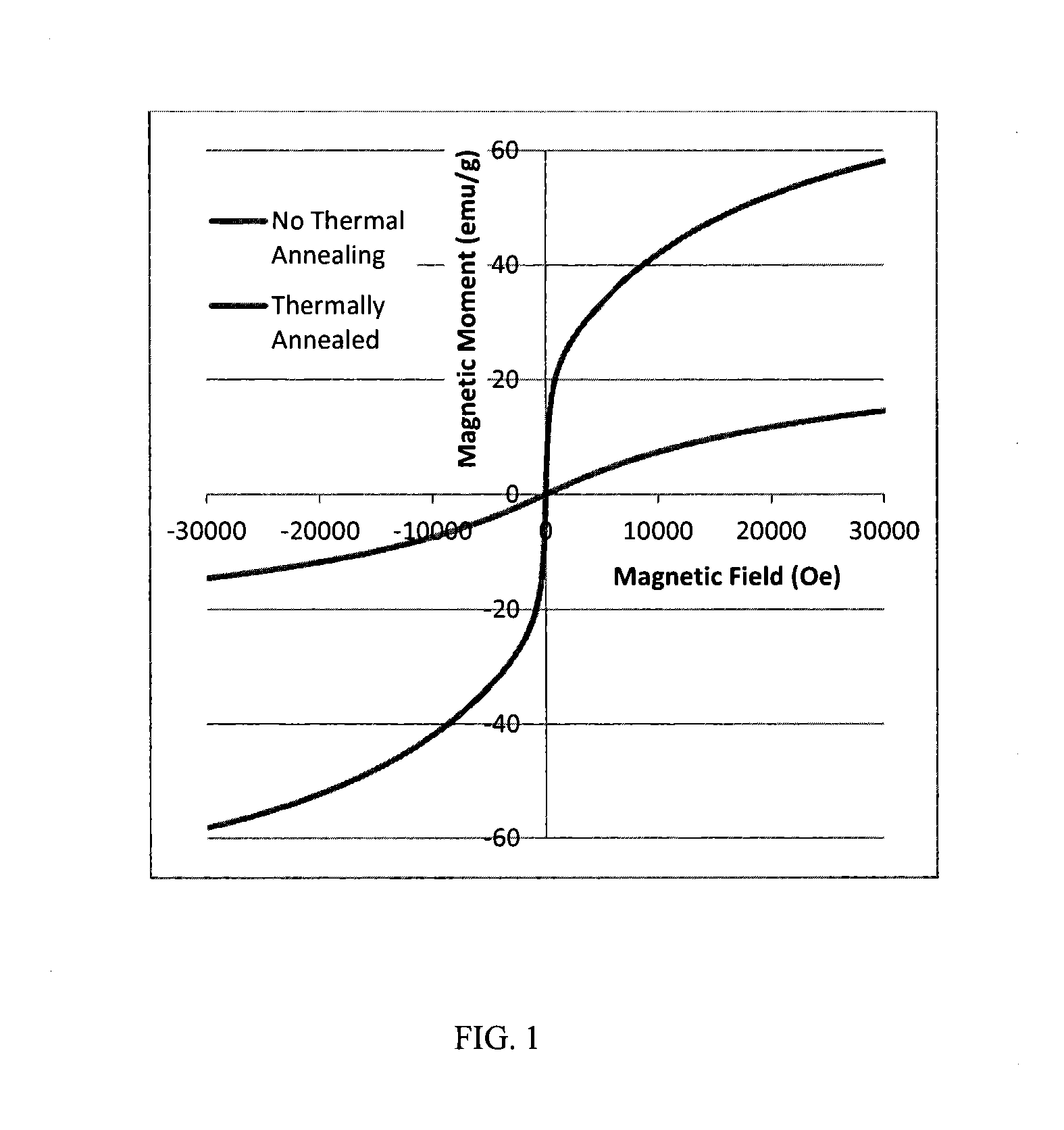

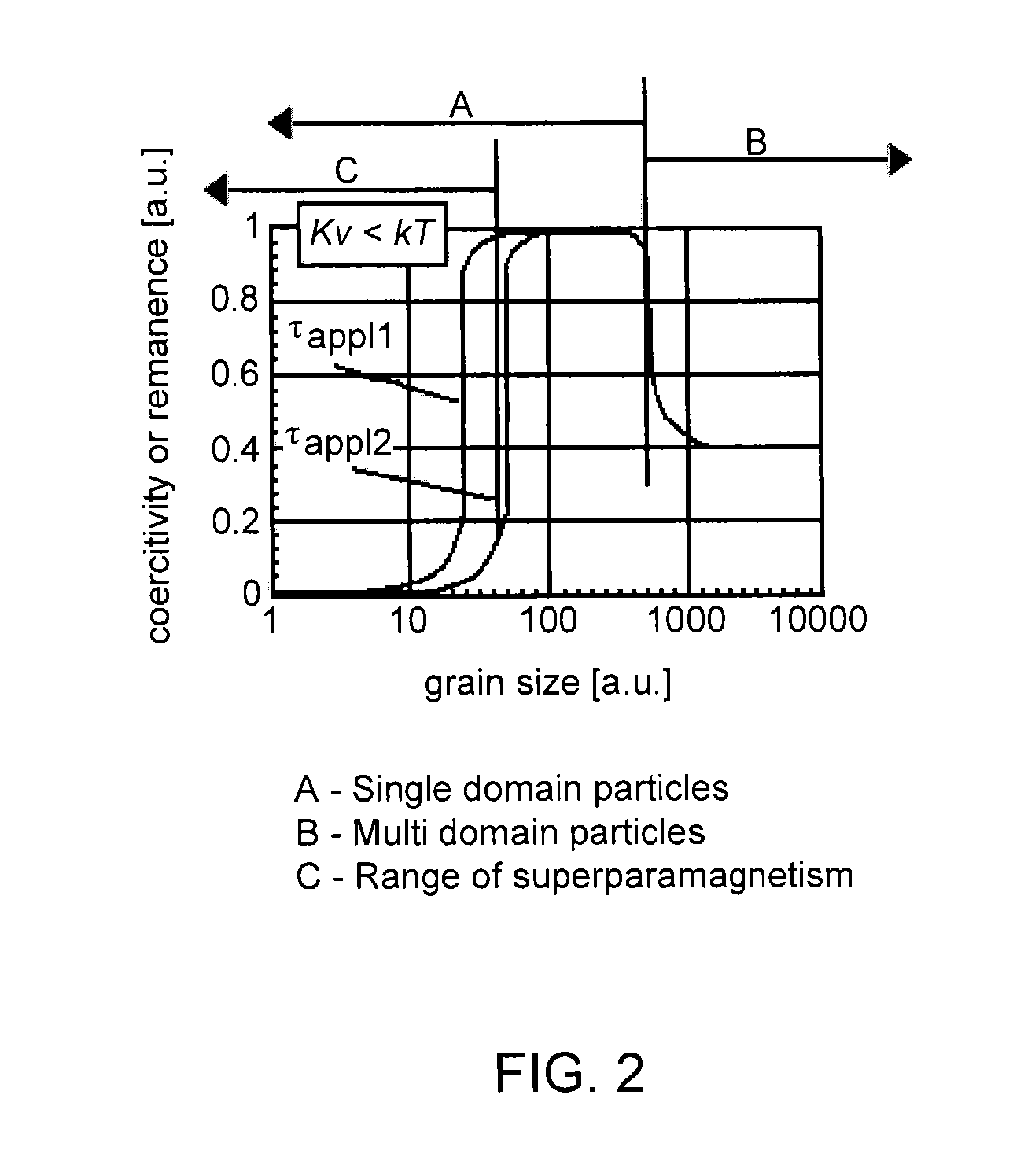

ActiveUS20140375403A1Inorganic material magnetismCeramic shaping apparatusMagnetic coreSuperparamagnetism

Owner:TOYOTA JIDOSHA KK

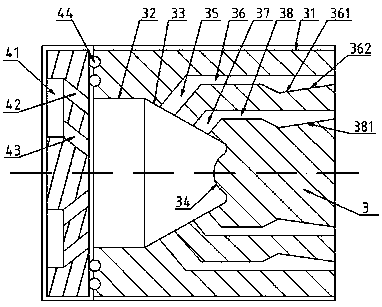

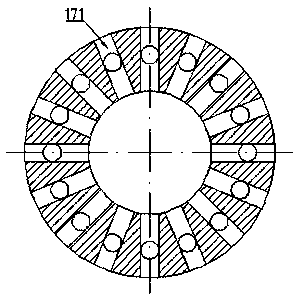

Rotary apparatus and method for winding protective GRP layer to make heavy concrete pipe pile

InactiveCN1526531AIncrease the rotary line speedPrevent problems such as contact surface peelingCeramic shaping apparatusReduction driveEngineering

The present invention is rotary apparatus and method for winding protective GRP layer to make heavy concrete pipe pile. The apparatus includes mainly motor, conveying belt, reducer, cardan shaft, connecting hoop and two-limit hoop connected together. The apparatus rotates pipe pile with its end axial driving system synchronously; there are rubber cushions set between each of the hoop and pipe pile to prevent damage of the pipe pile; and the two-limit hoop fixed onto the pipe pile makes the axial force the roller produces first absorbed by the track, then counteracted by the friction between the track and the pipe pile and transmitted to roller via the track to avoid the axial shift of the pipe pile.

Owner:TIANJIN TIANLIAN BINHAI COMPOSITE MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap