Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Elastic modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elastic modulus (also known as modulus of elasticity) is a quantity that measures an object or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus. An elastic modulus has the form...

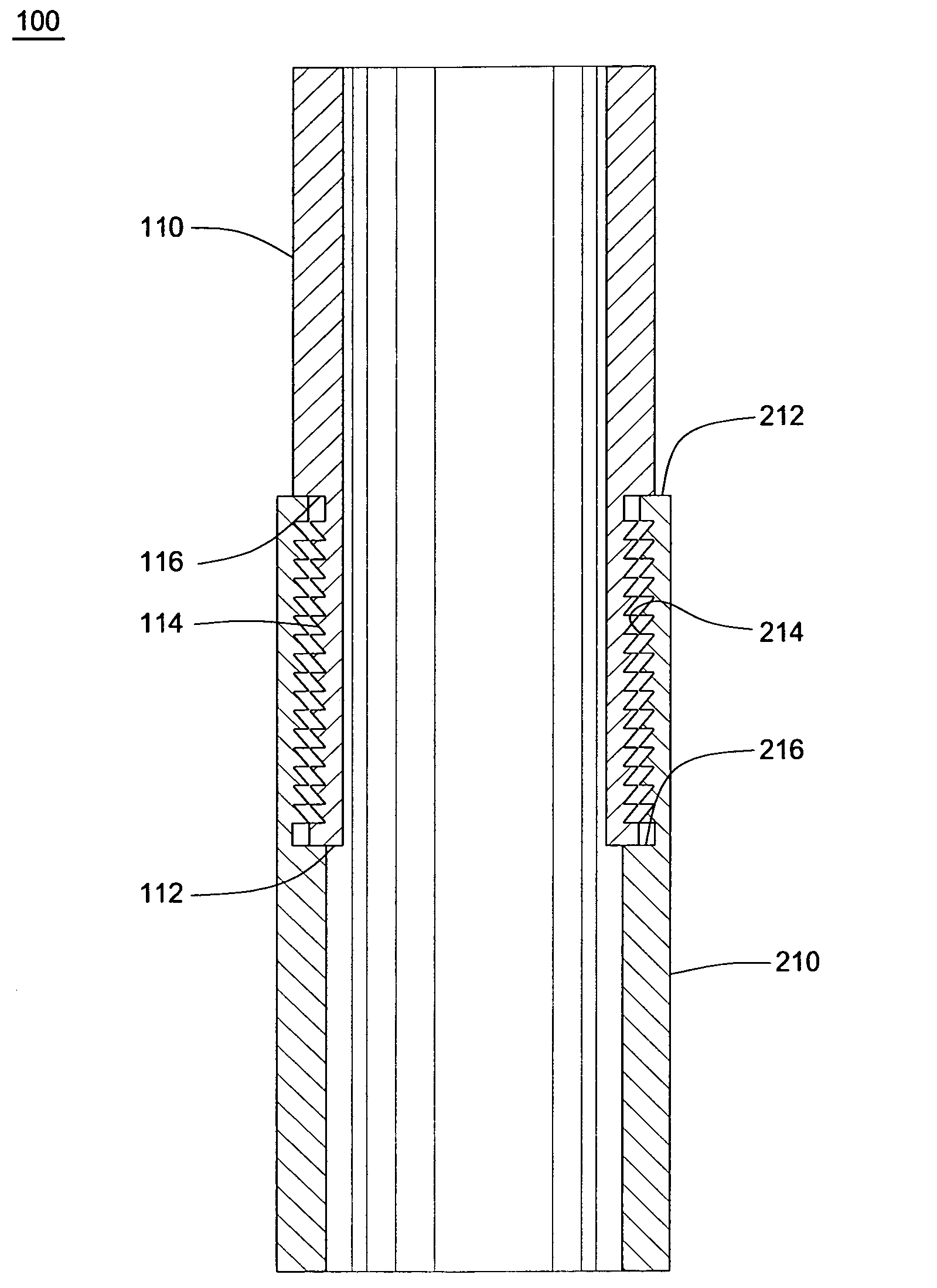

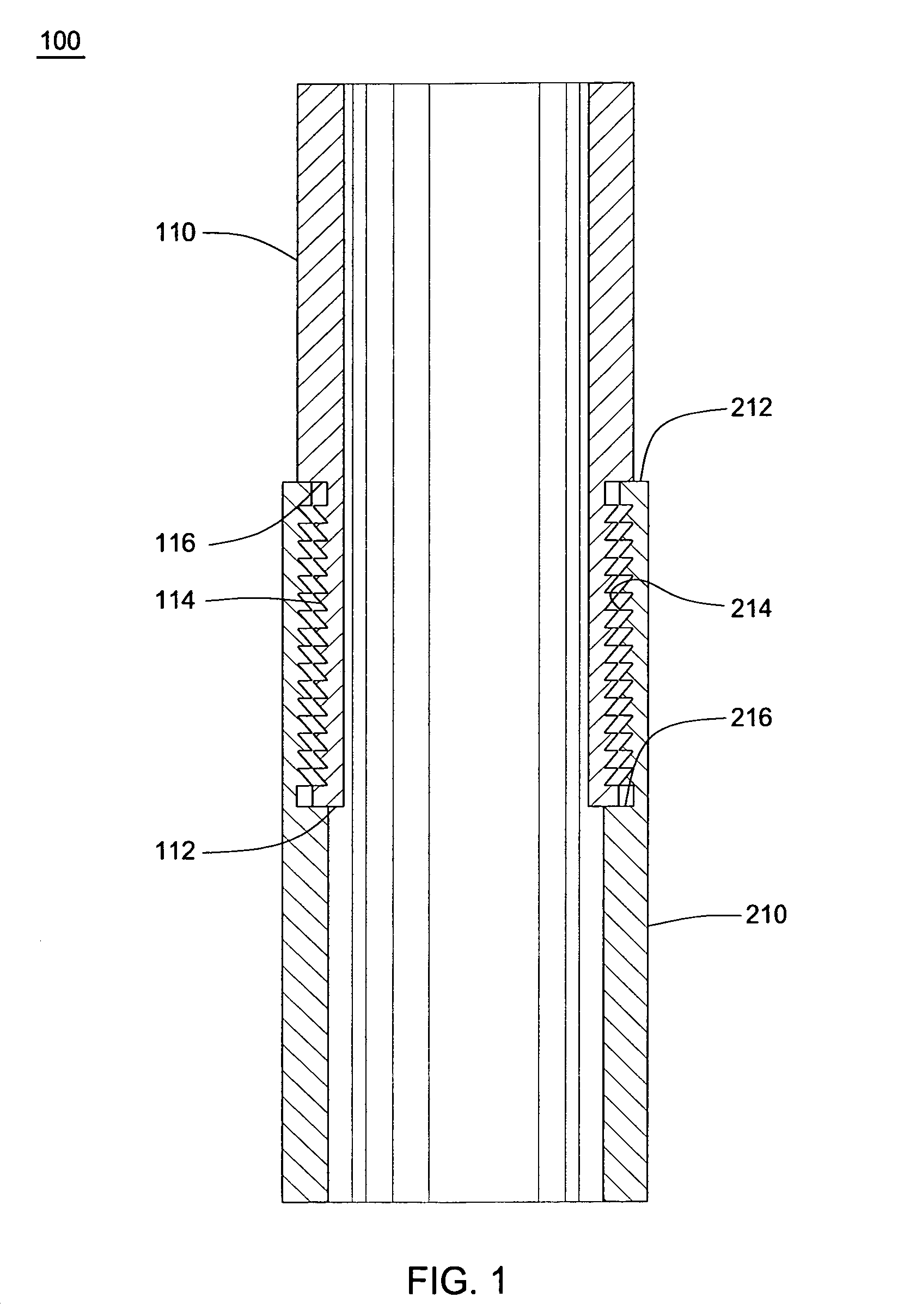

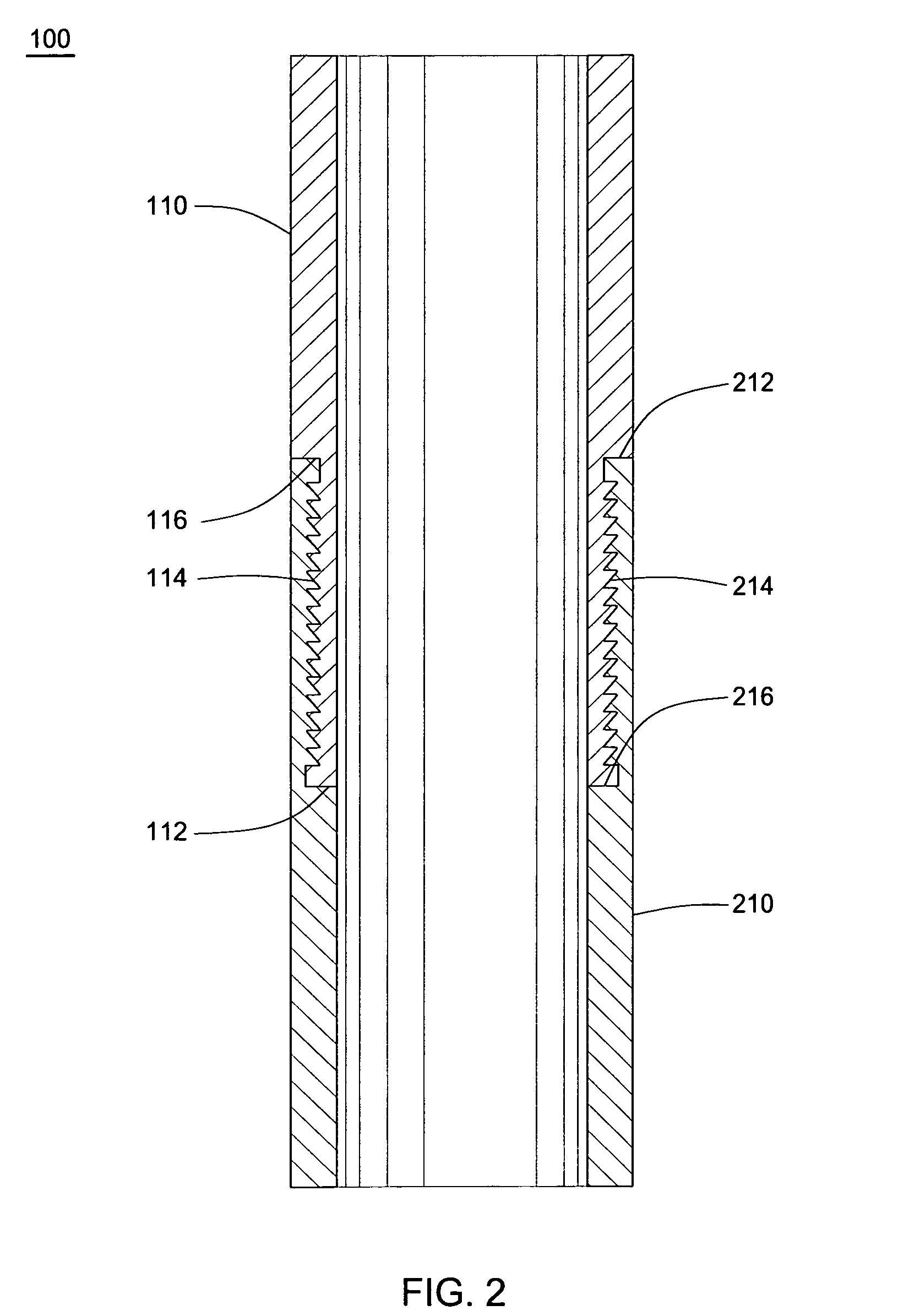

Method of jointing and running expandable tubulars

InactiveUS6997264B2Easily sealImprove sealingDrilling rodsFluid pressure sealed jointsElastic modulusCircumferential rings

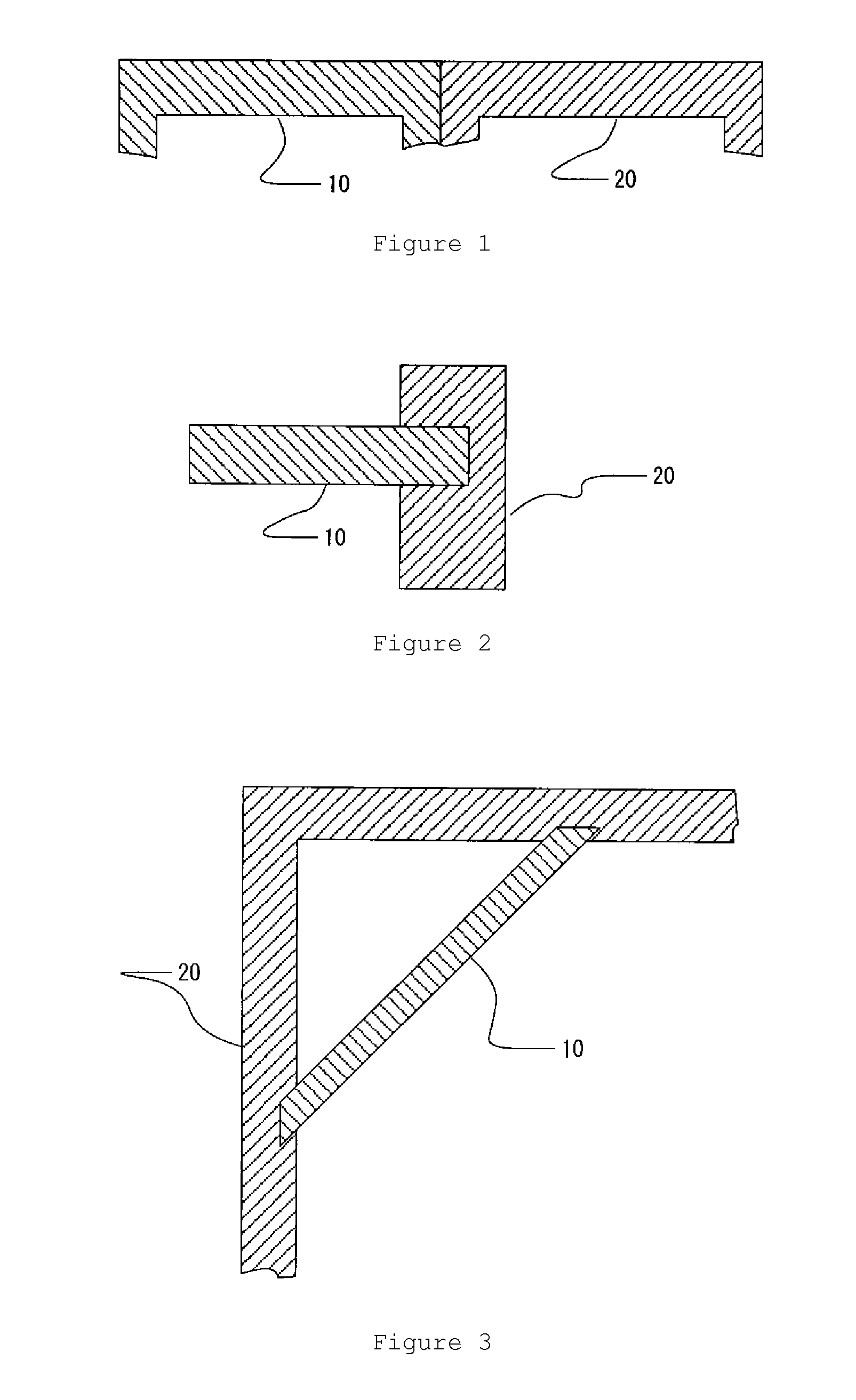

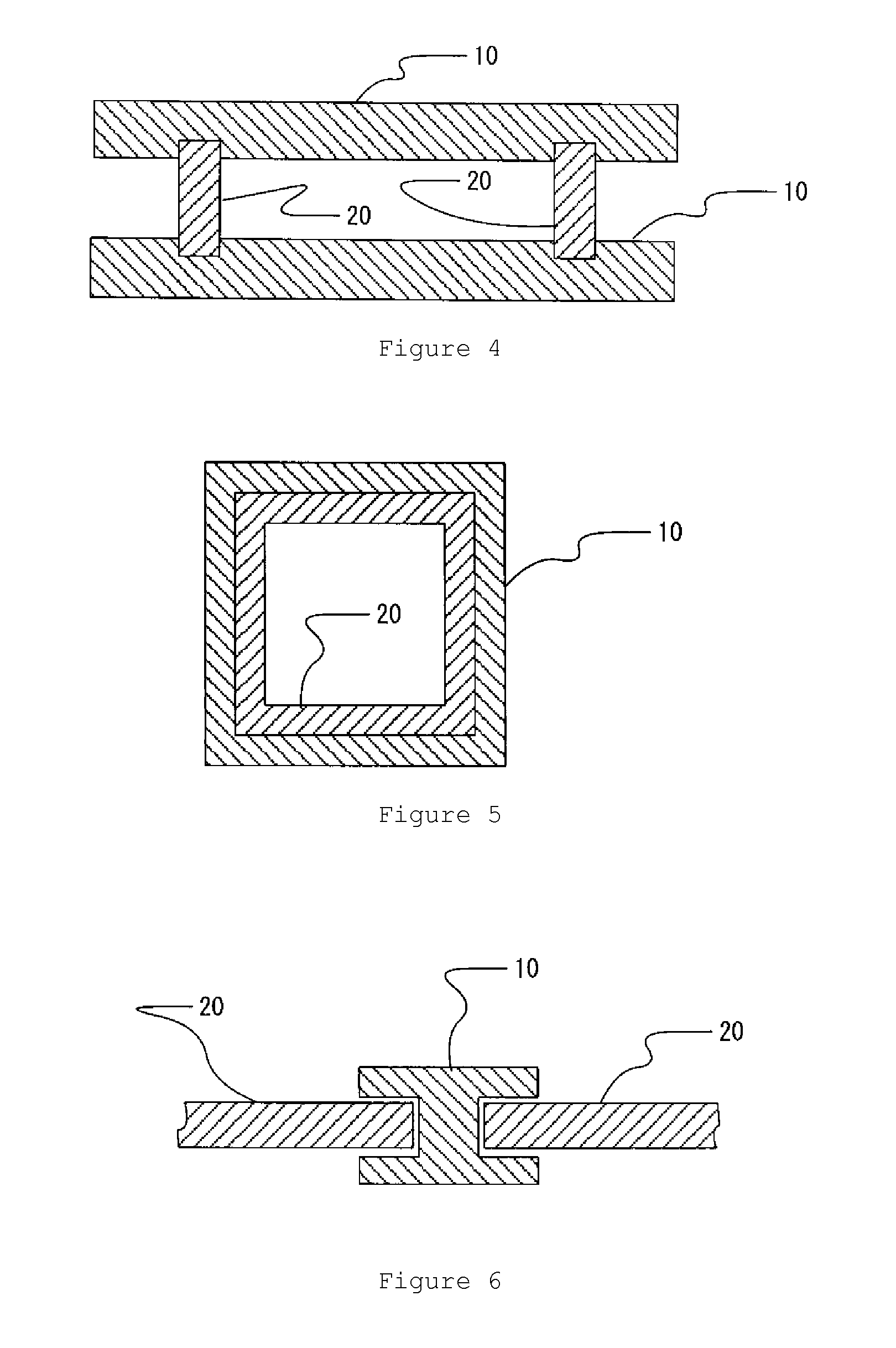

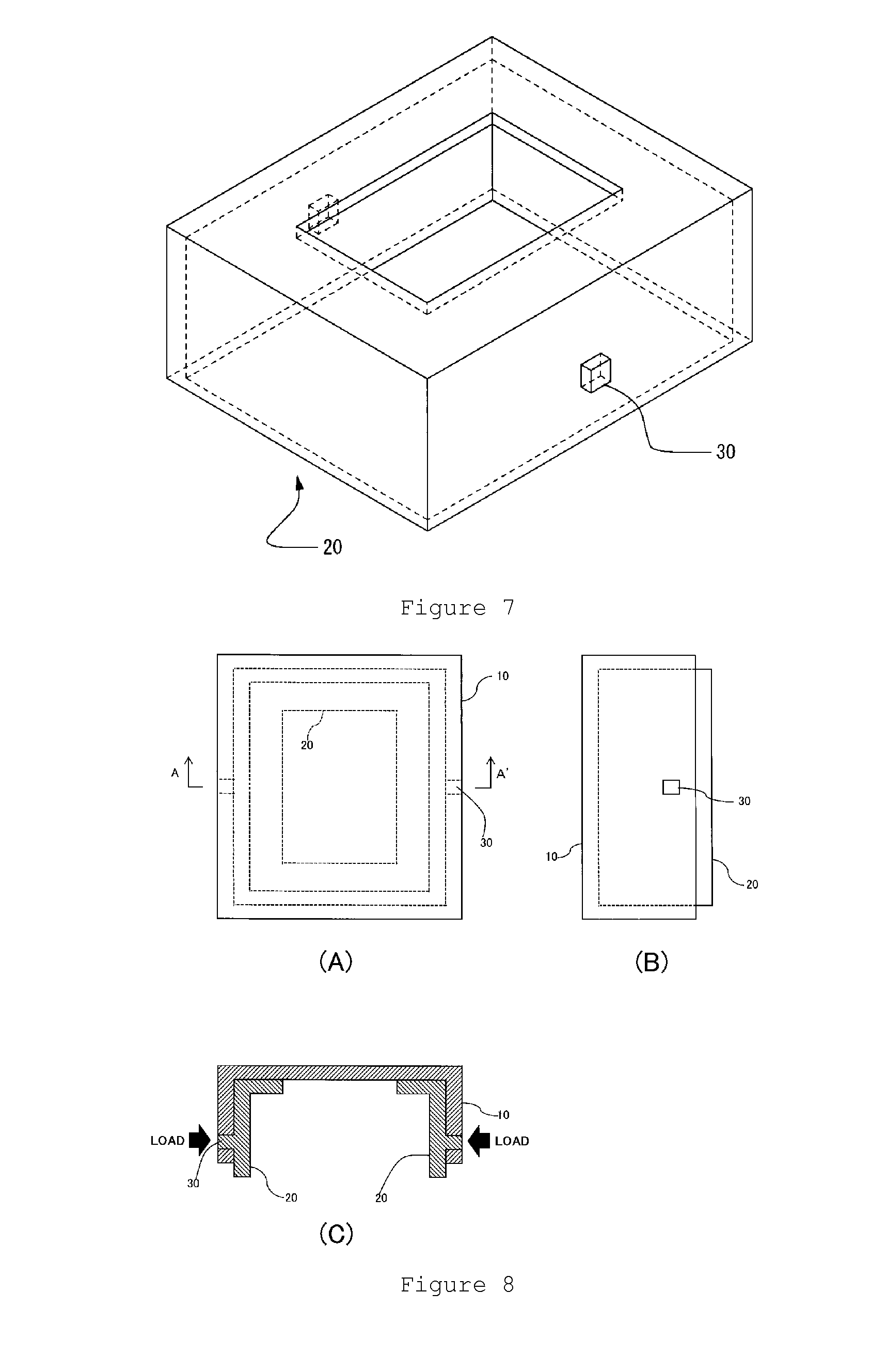

A connector arrangement used for connecting a first tubular to a second tubular. The first tubular member has at least one circumferential ring profile, and the second tubular member has a corresponding number of matching circumferential ring profiles. When the ring profiles of the two tubulars are mated and interlocked, they form separate and independent fluid seals as well as a mechanical lock able to hold the tubulars together during future expansion of the entire tubular and joint. Further, selecting properties of the tubulars such as yield strength and modulus of elasticity or constraining a diameter of one of the tubulars during expansion or compression forms a tight connection due to elastic recovery of the tubulars.

Owner:WEATHERFORD TECH HLDG LLC

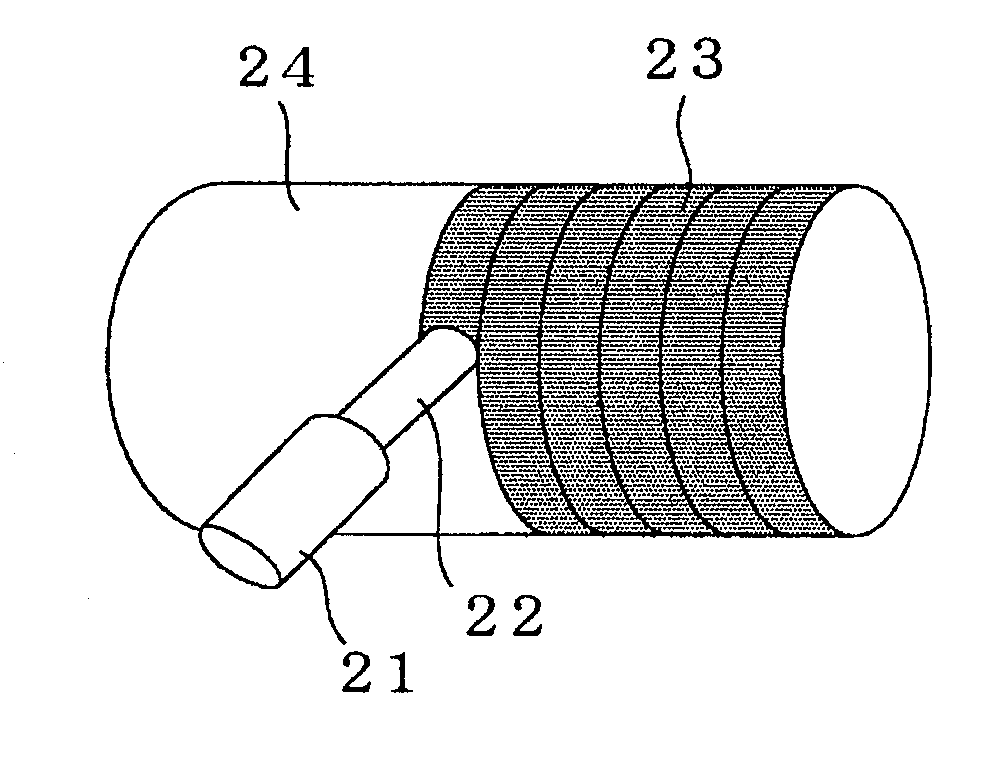

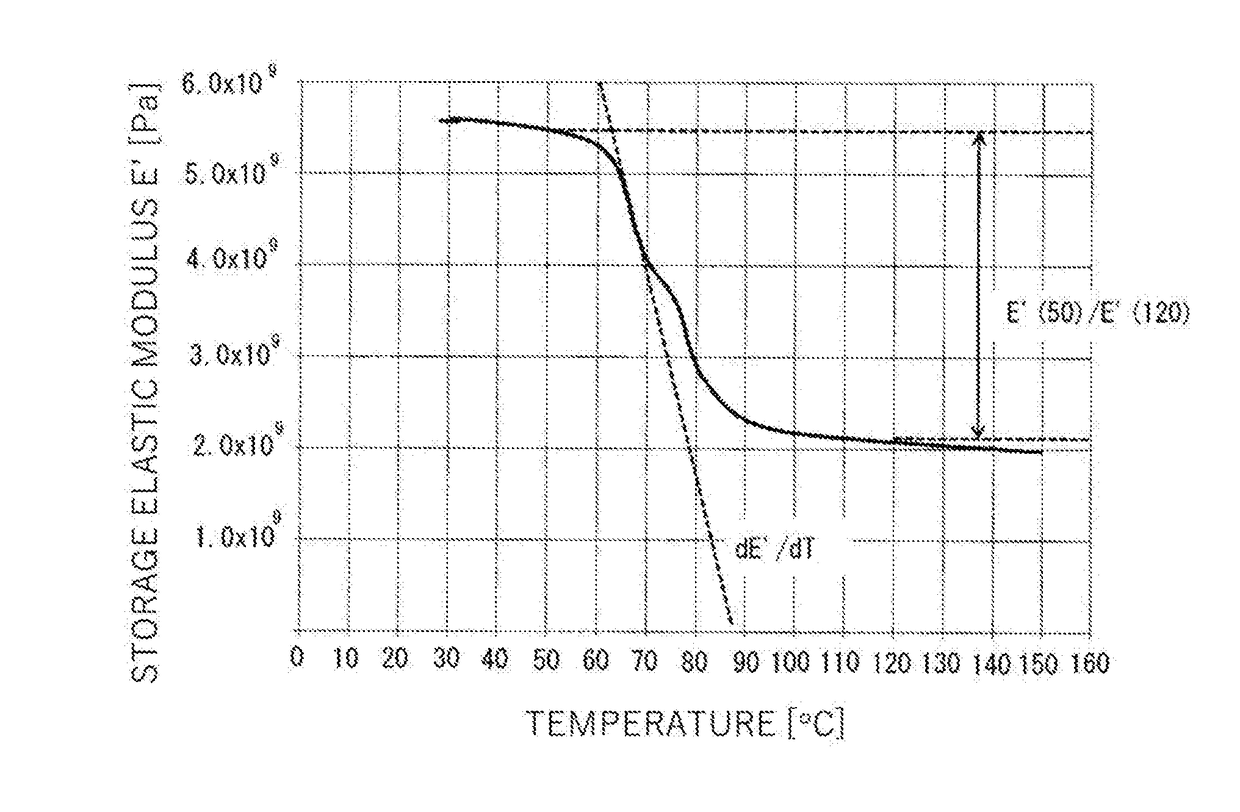

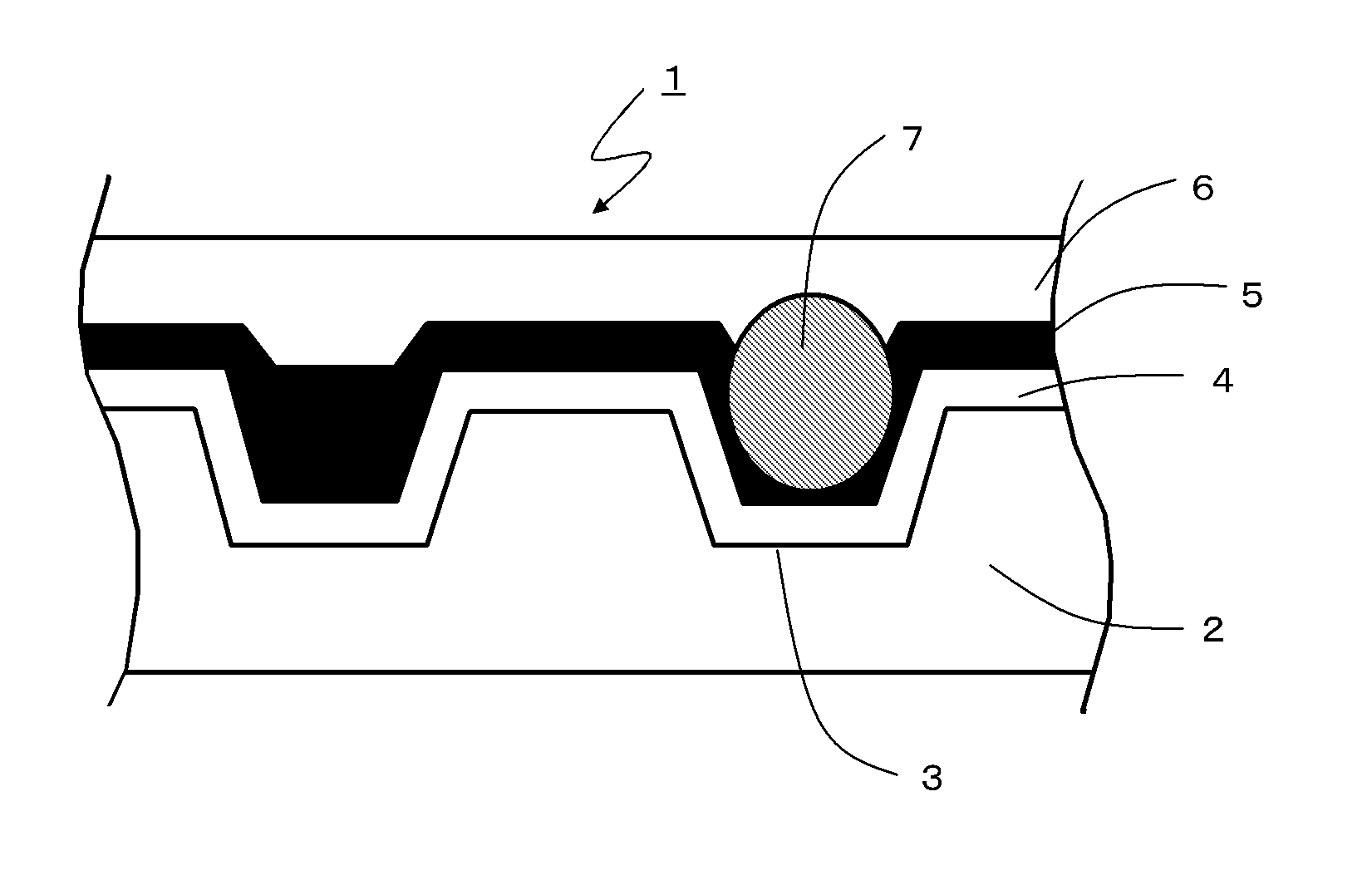

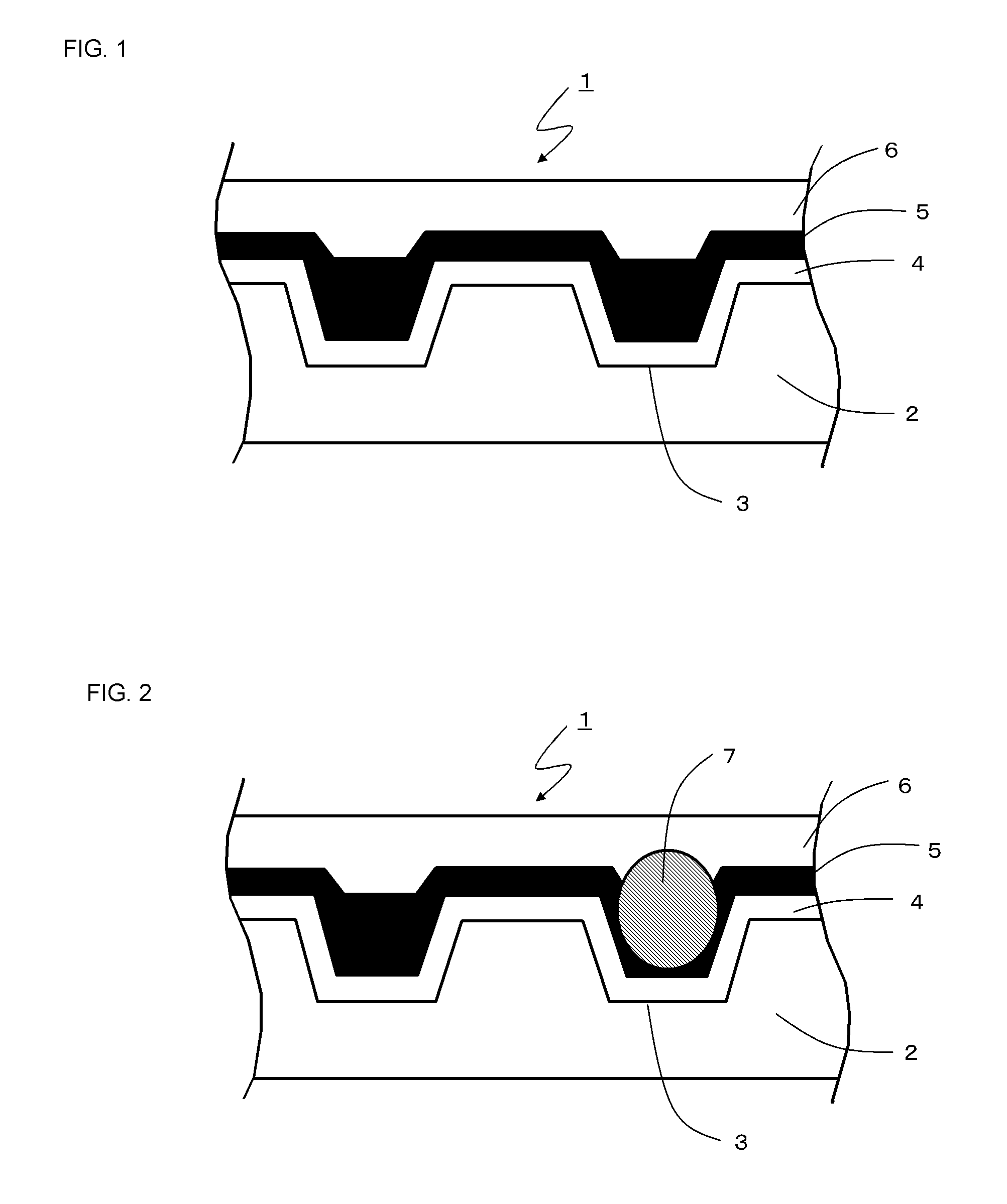

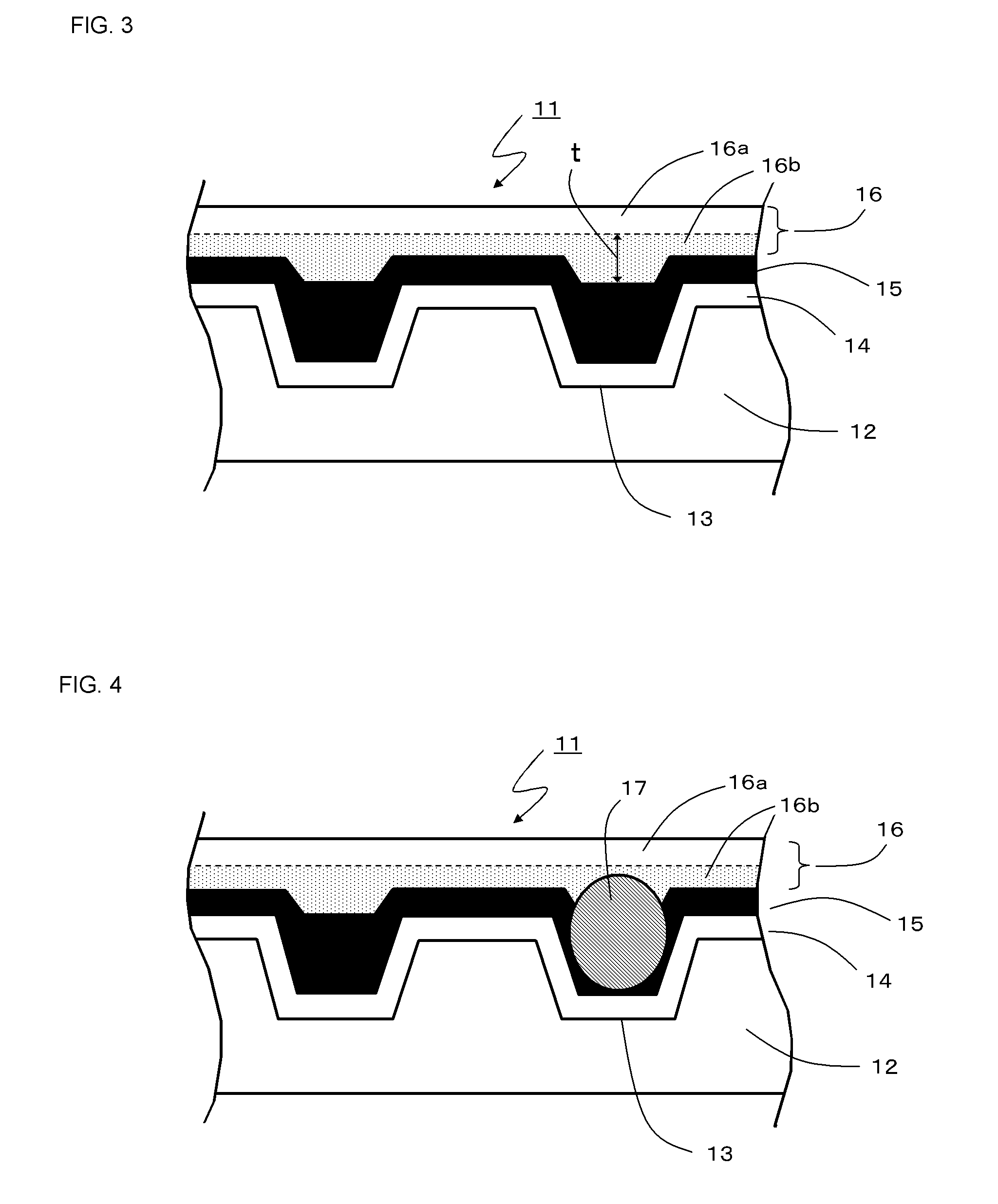

Microrelief structural body, decorative sheet, decorative resin molded body, method for producing microrelief structural body, and method for producing decorative resin molded body

ActiveUS20160052227A1Increase flexibilityGood stretchabilitySynthetic resin layered productsRecord information storagePolymer sciencePolymer chemistry

A structural body which comprises a base and a microrelief structure layer having a microrelief structure. The microrelief structure layer is laminated on the base so as to form the surface layer of this structural body, and the microrelief structure layer has at least one physical property selected from the group consisting of (A) and (B) described below. (A) The elastic modulus at 25° C. is 50 MPa or more, and the elastic modulus at 80° C. is 30 MPa or less. (B) The tensile elongation at break at 80° C. is from 20% to 100% (inclusive).

Owner:MITSUBISHI CHEM CORP

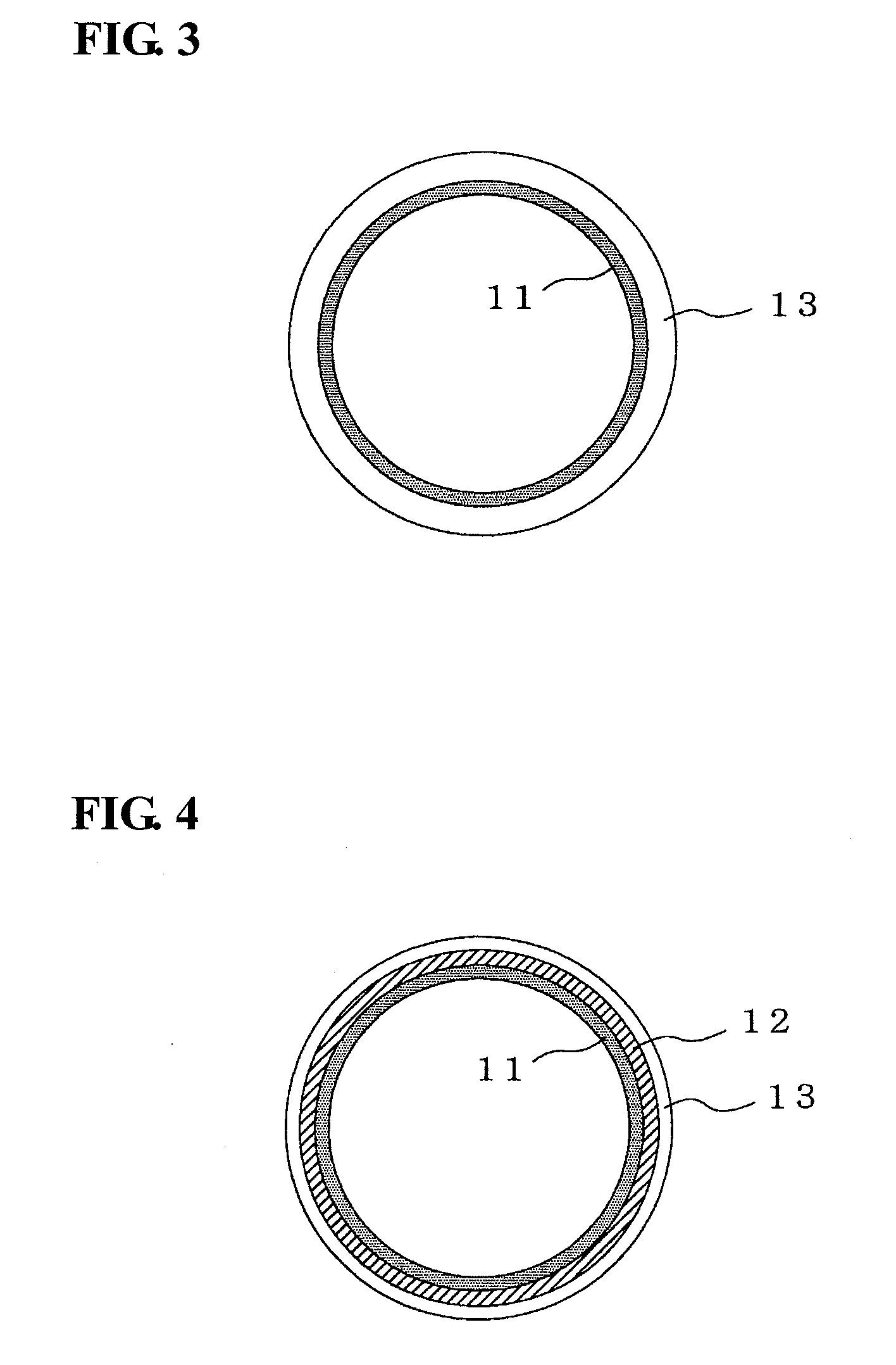

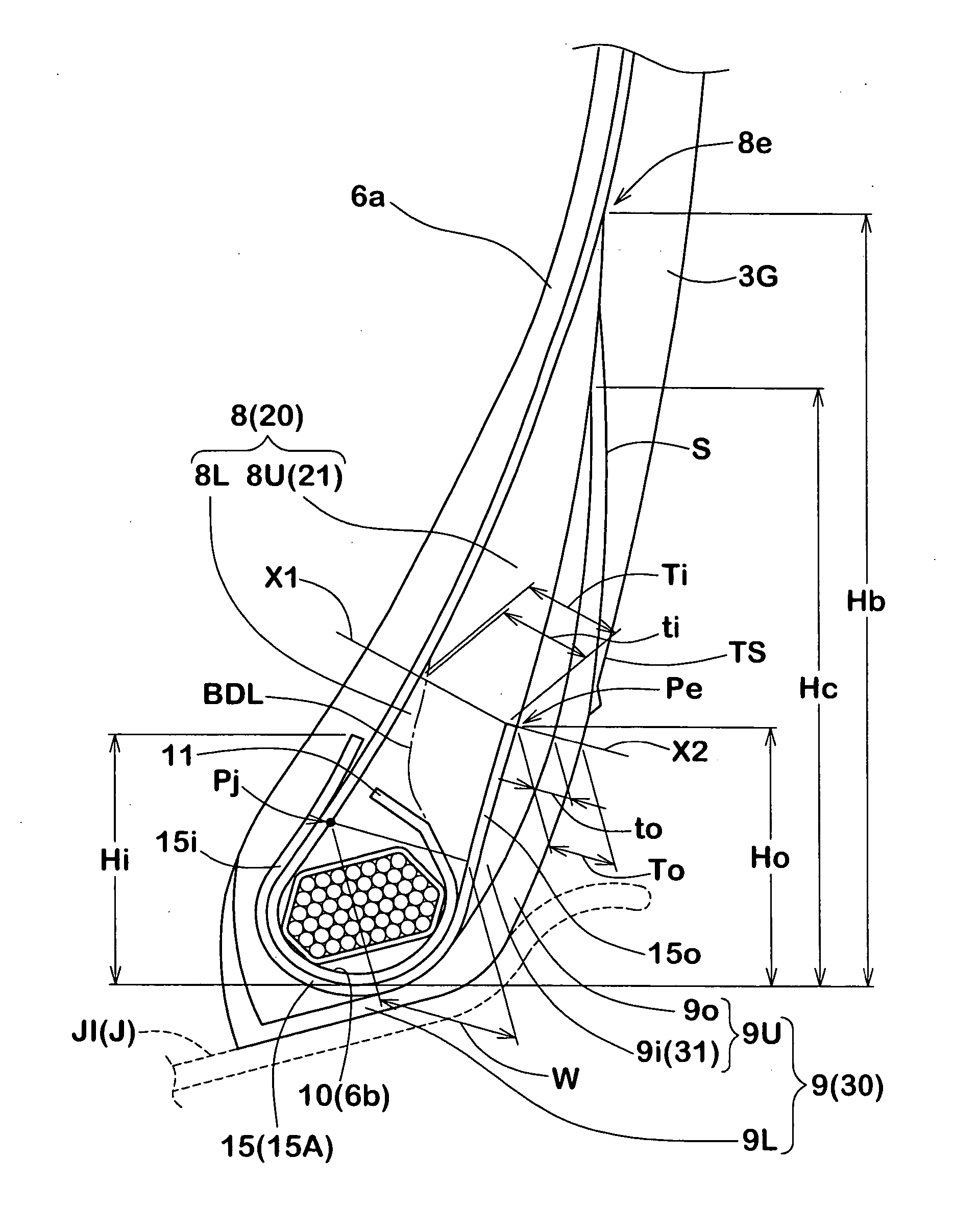

Polyimide tube, process for producing the same and fixing belt

ActiveUS20100279045A1Improve fixation effectHigh mechanical strengthConfectionerySweetmeatsThermal conductivityElastic modulus

Owner:SUMITOMO ELECTRIC IND LTD +1

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

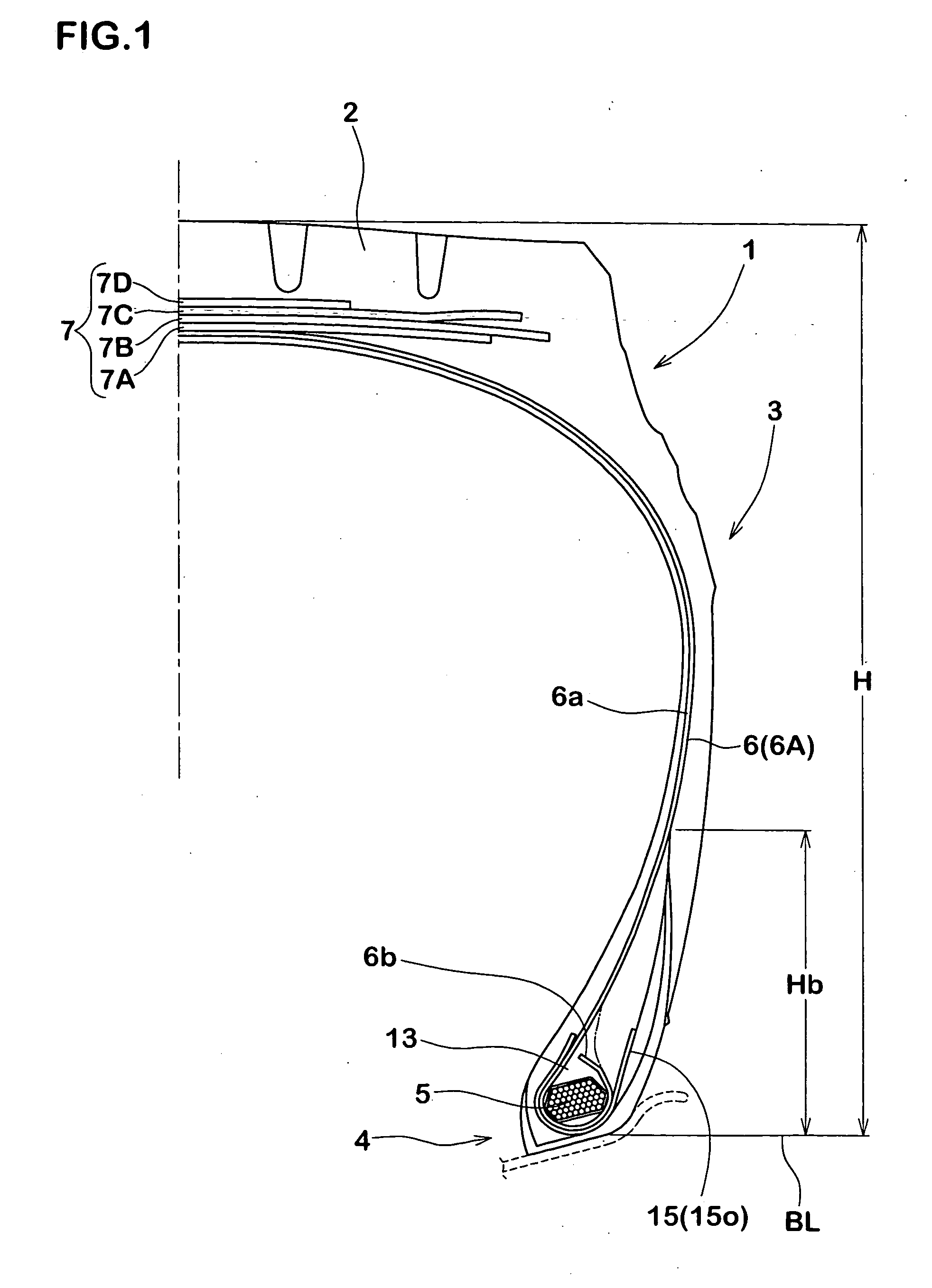

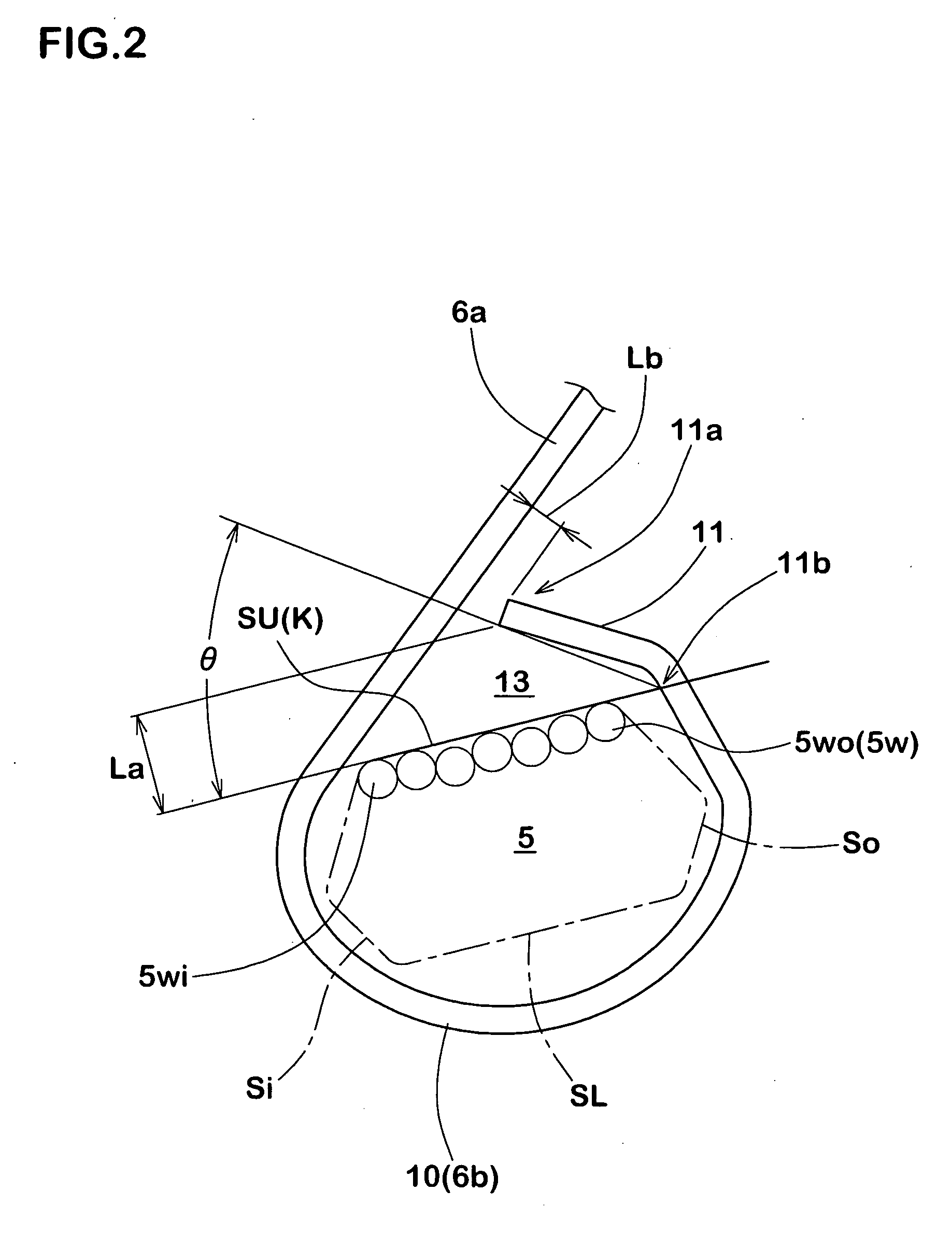

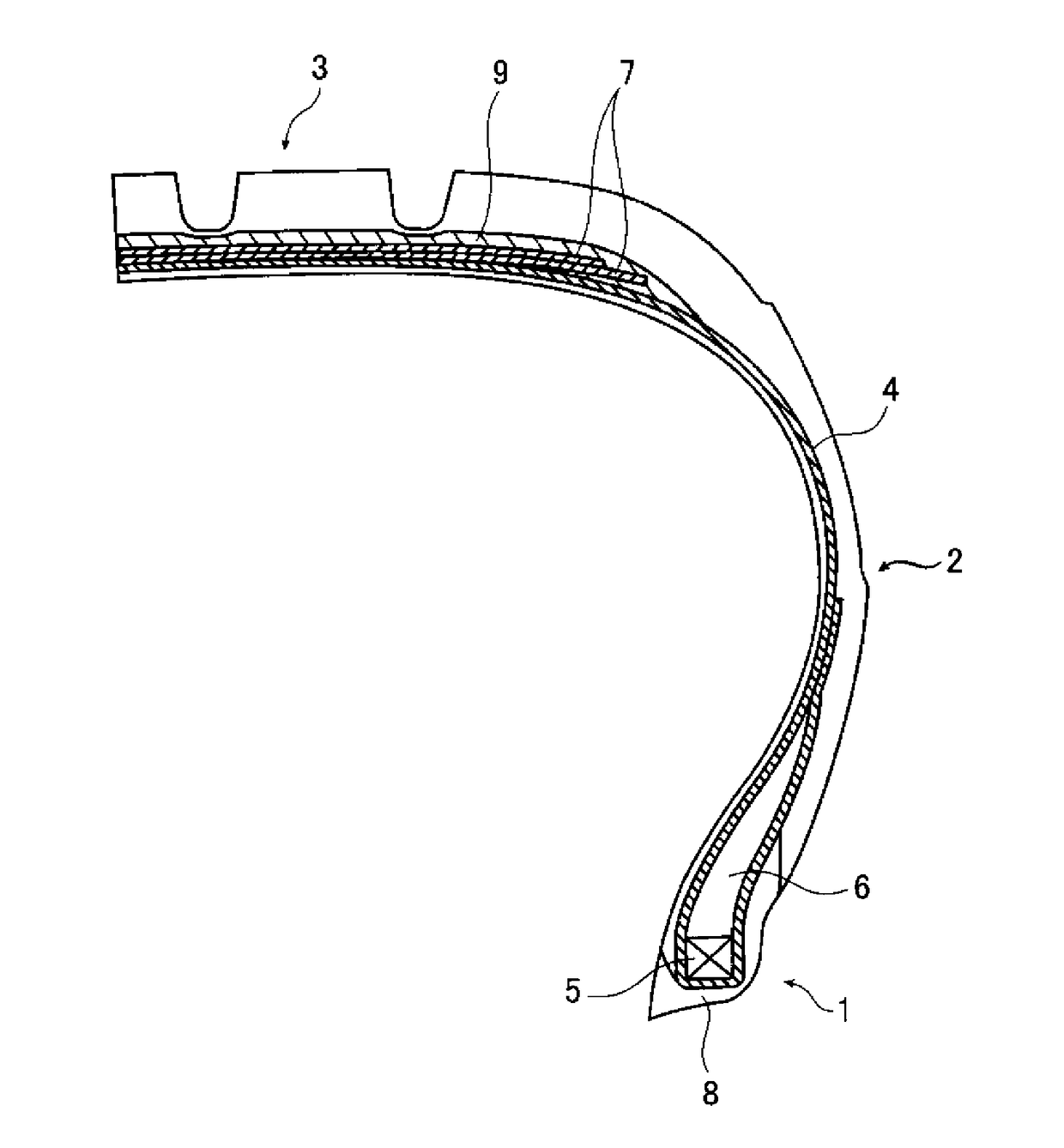

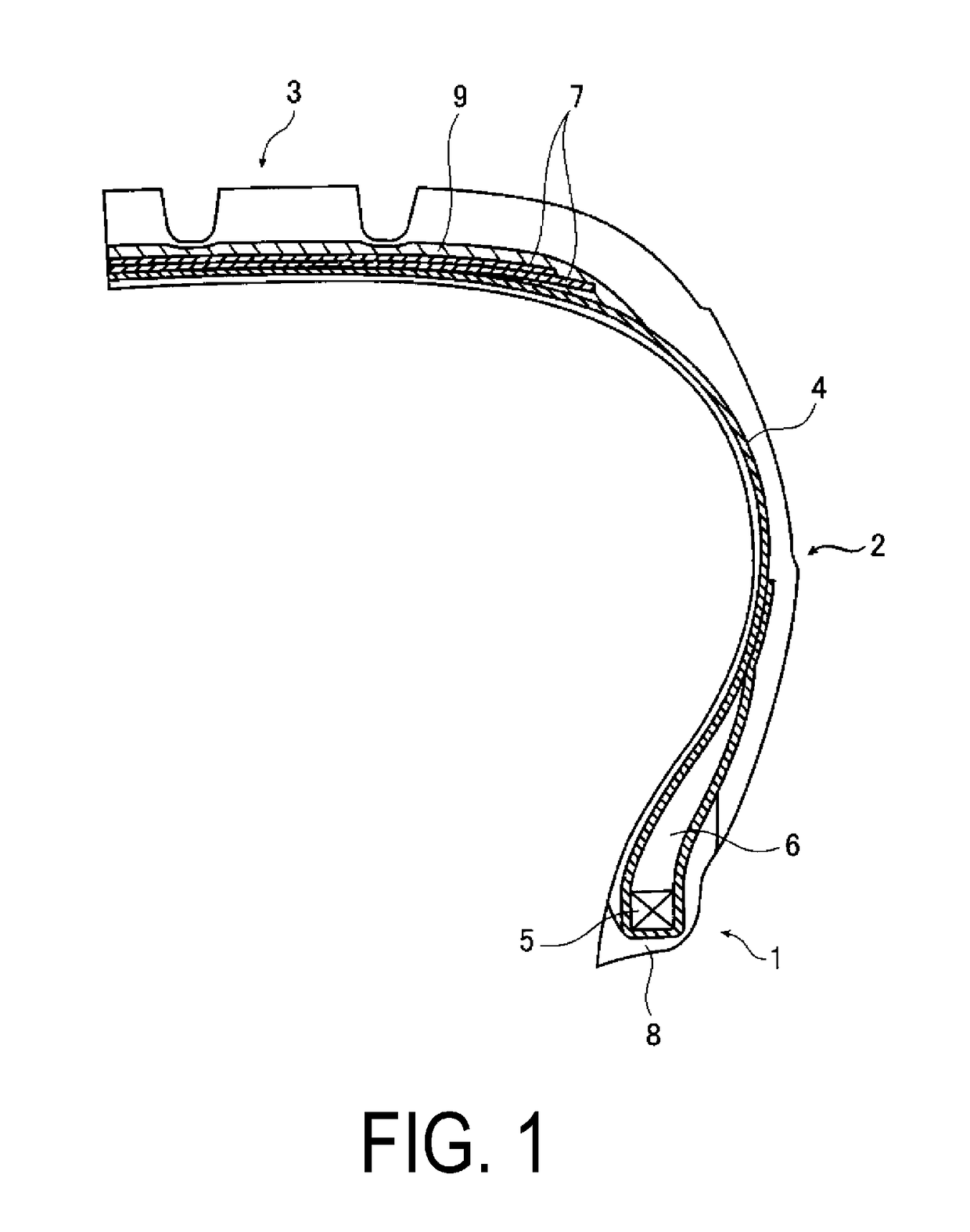

Heavy duty tire

InactiveUS20070102091A1Weak elasticityAvoid damagePneumatic tyre reinforcementsSpecial tyresEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

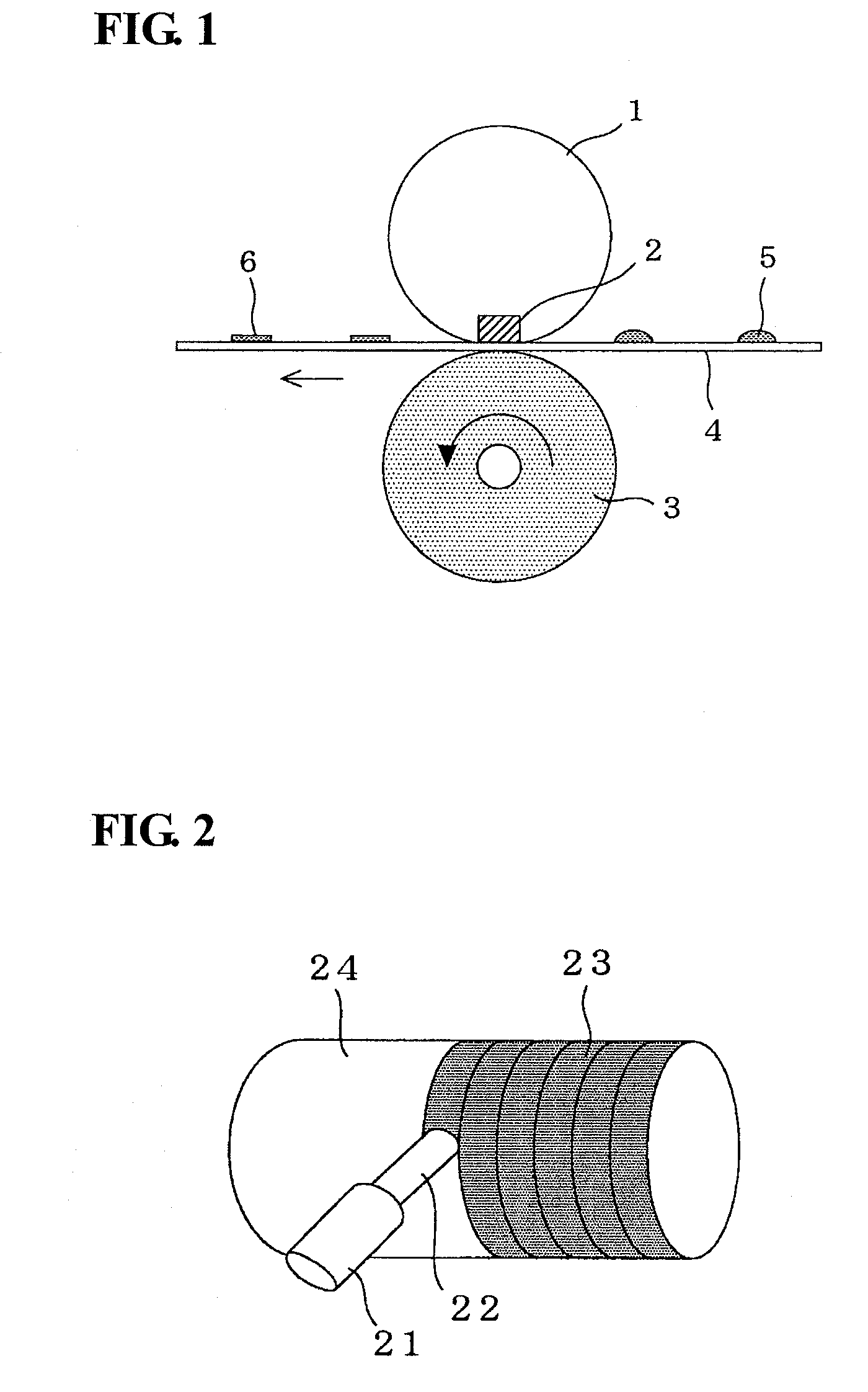

Toner

Owner:CANON KK

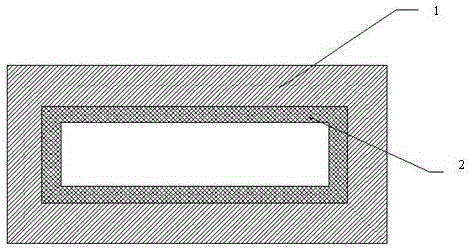

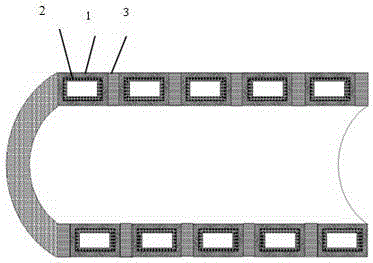

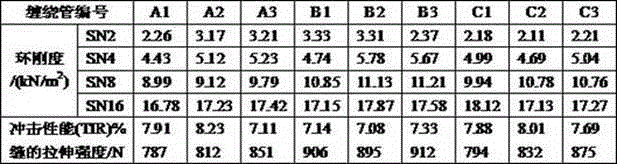

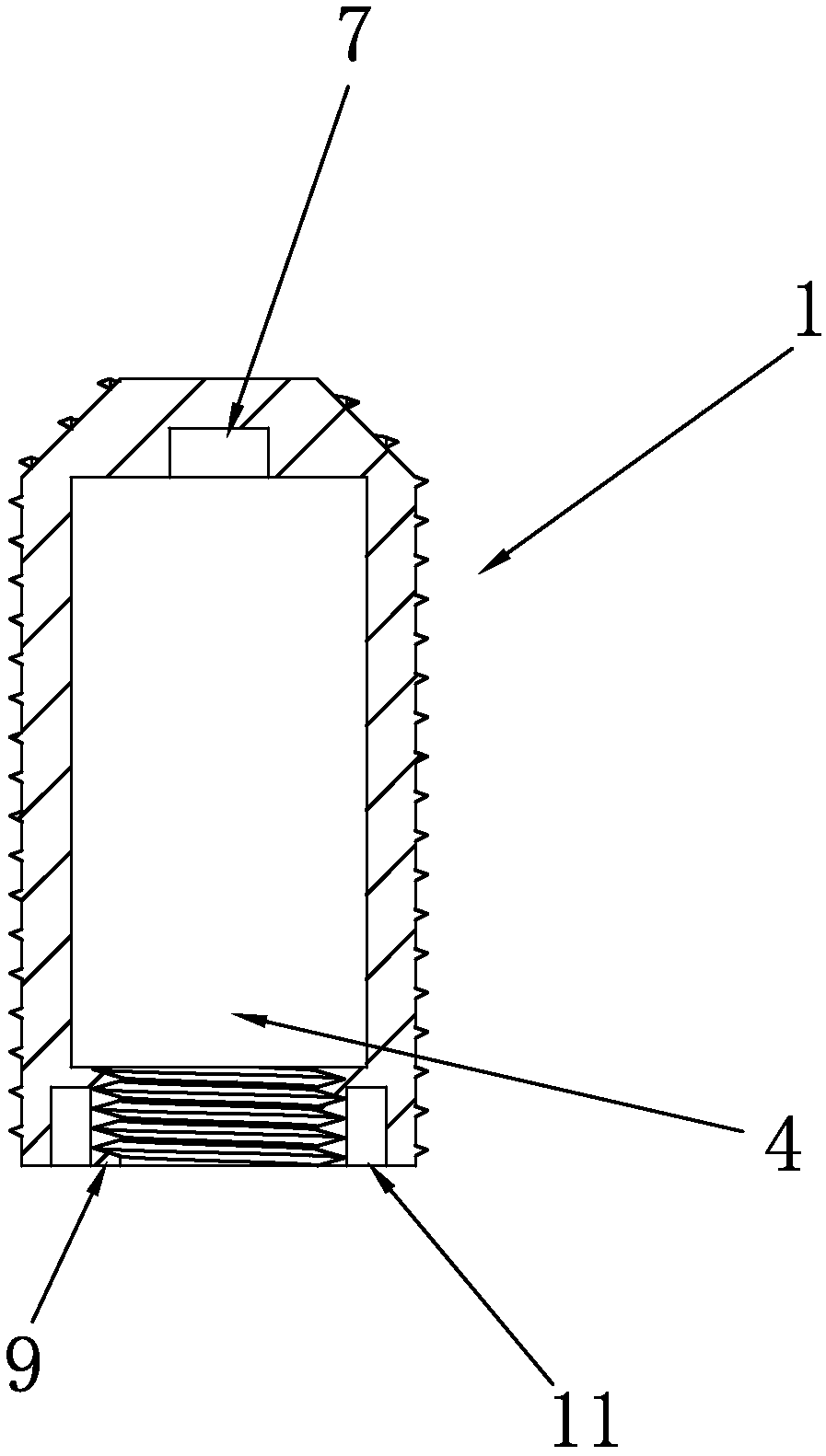

Winding pipe with fiber reinforced polypropylene (FRPP) reinforced hollow-structure wall and machining process for winding pipe

Owner:HUBEI KINGBULL PIPE IND

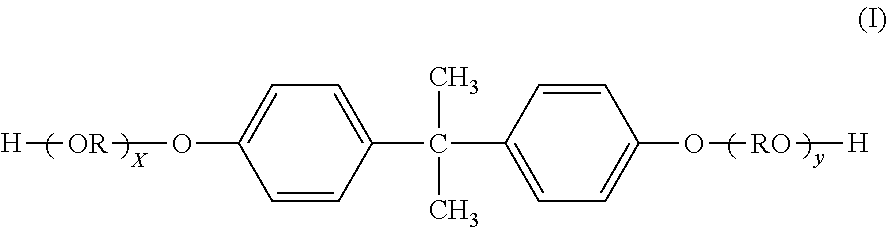

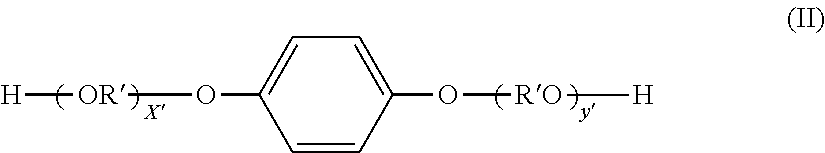

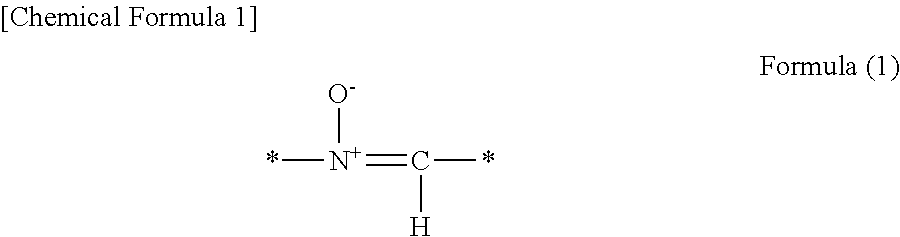

Nematic liquid crystal composition, and liquid crystal display element using same

ActiveCN108779395AWith burn-inImprove display qualityLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

The present invention addresses the problem that a negative [delta][epsilon] value having a large absolute value, a small rotational viscosity ([gamma]1), a large elastic modulus (K33), a low (solid phase)-(nematic phase) transition temperature (Tcn), a high (nematic phase)-(isotropic liquid phase) transition temperature (Tni) and a large voltage holding ratio (VHR) are demanded. The present invention also addresses the problem of providing a rapid-response liquid crystal display element of a VA type, a PSVA type, a PSA type, a FFS type or the like, which is produced using the same, rarely undergoes or never undergoes display failures such as burning-in and display unevenness and has excellent display quality. Provided are: a liquid crystal composition which contains a compound representedby formula (I-1) as a first component and a compound represented by formula (I-2) as a second component and has a negative dielectric anisotropy ([delta][epsilon]) value; and a liquid crystal displayelement produced using the liquid crystal composition.

Owner:DIC CORP

Fluorine-free plasma curing process for porous low-k materials

InactiveUS7011868B2Improving elastic modulusImproving material hardnessSilicaPlastic/resin/waxes insulatorsFluorine freeElastic modulus

Low dielectric constant porous materials with improved elastic modulus and material hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material with a fluorine-free plasma gas to produce a fluorine-free plasma cured porous dielectric material. Fluorine-free plasma curing of the porous dielectric material yields a material with improved modulus and material hardness, and with comparable dielectric constant. The improvement in elastic modulus is typically greater than or about 50%, and more typically greater than or about 100%. The improvement in material hardness is typically greater than or about 50%. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims 37 CFR §1.72(b).

Owner:JSR CORPORATIOON +1

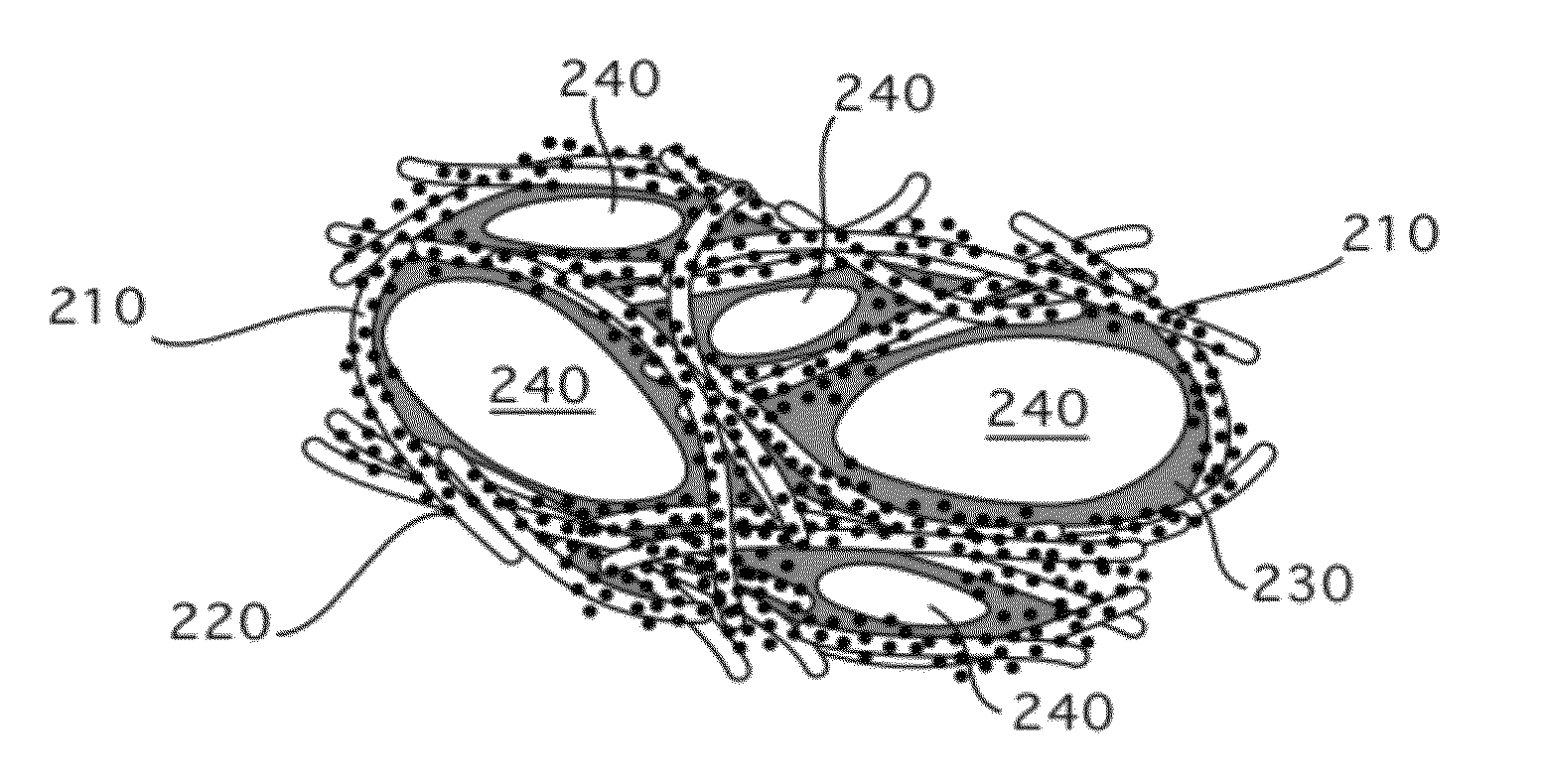

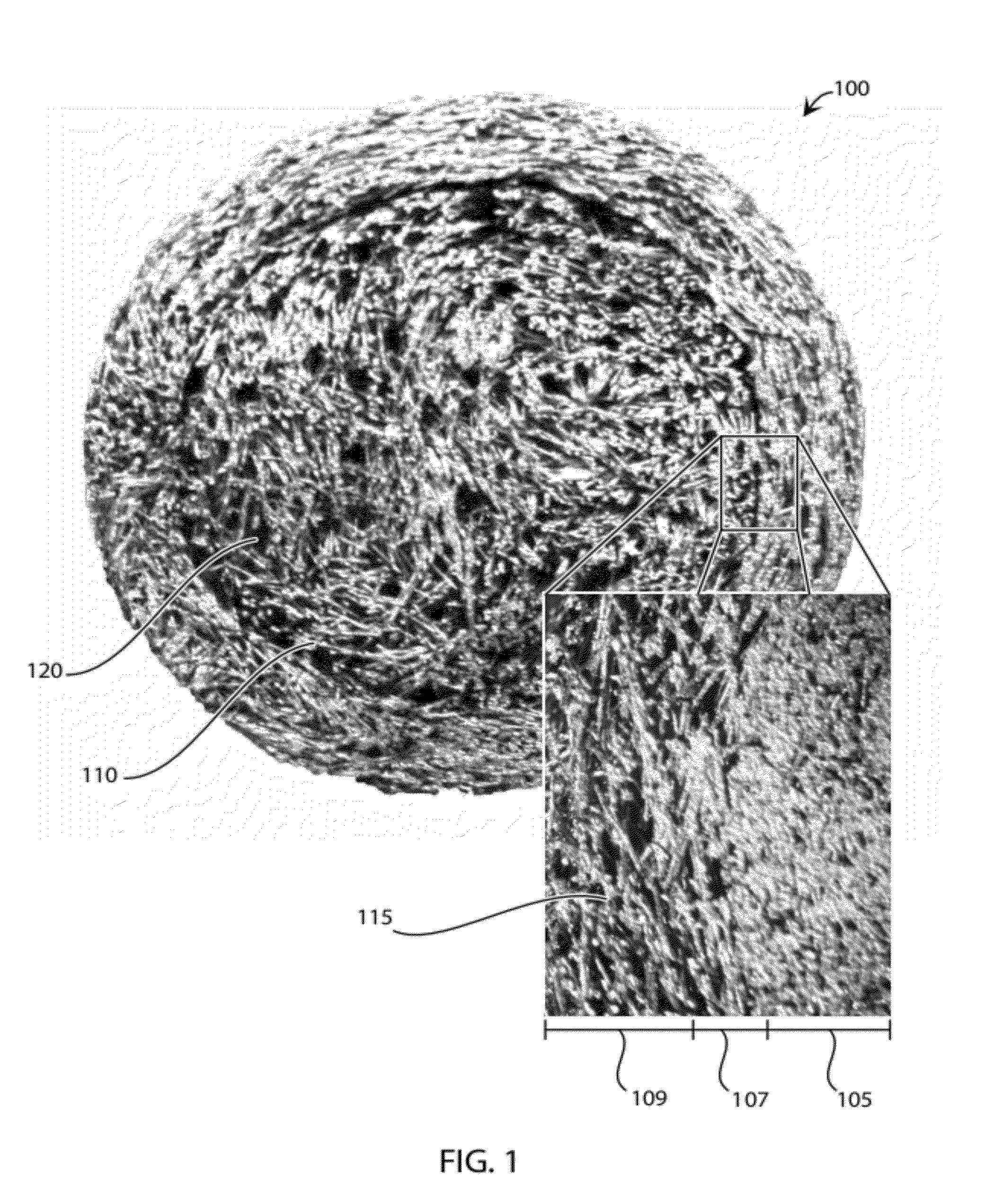

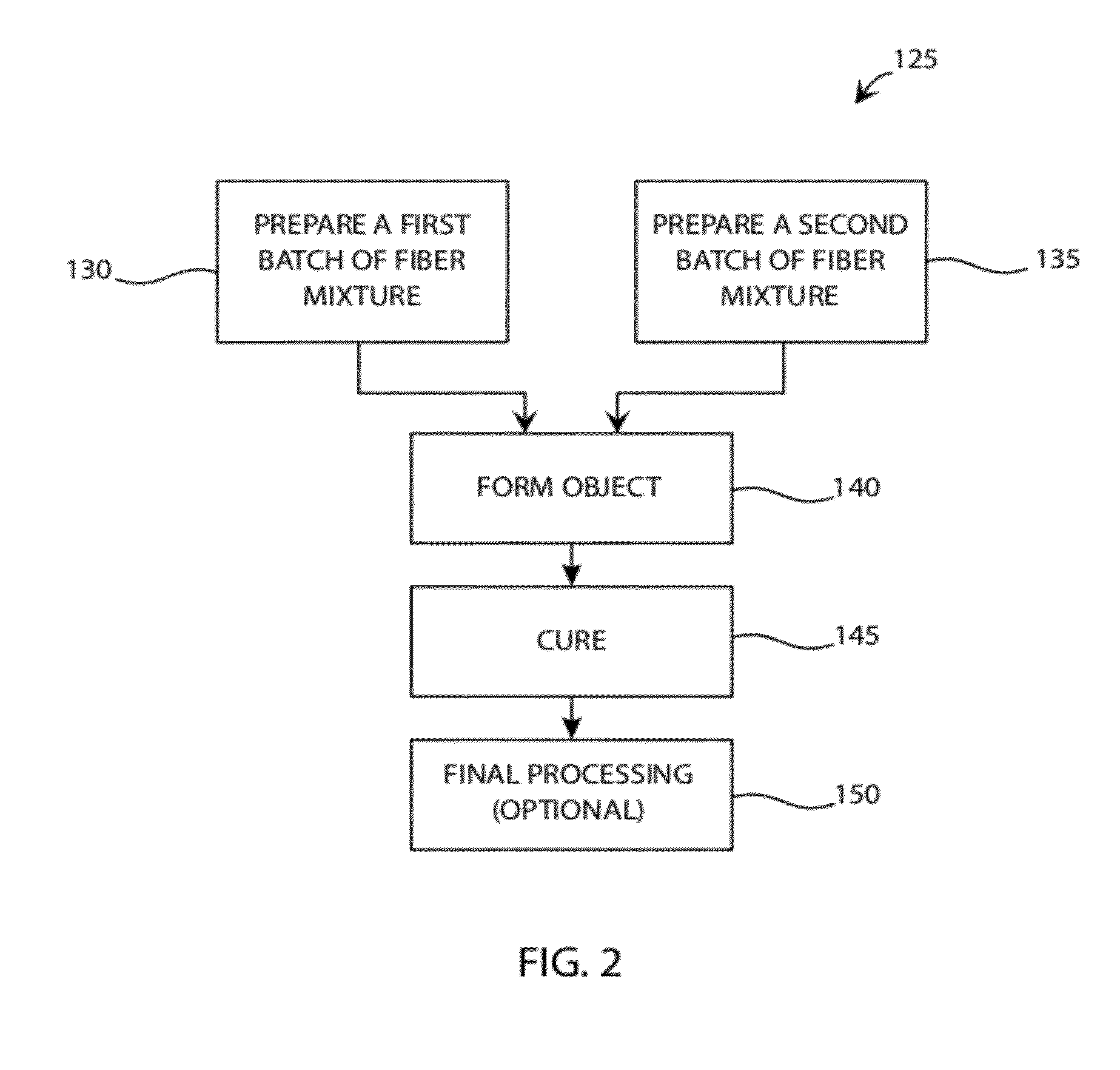

Devices and Methods for Tissue Engineering

Owner:BIO2 TECH

Method for preparing cement asphalt (CA) mortar for China railway track system (CRTS) II slab ballastless tracks

Owner:ZHEJIANG UNIV

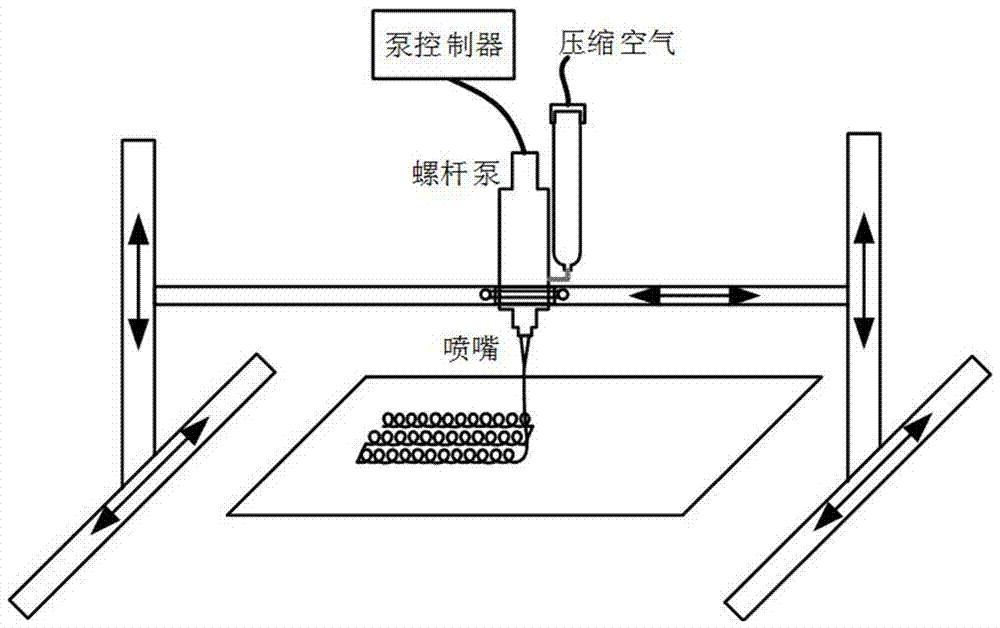

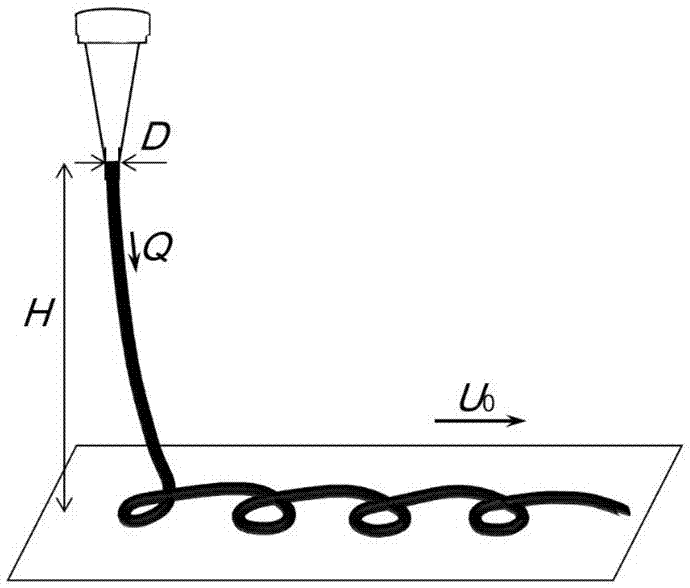

Porous elastic foam production method based on 3D printing of wet cured silica gel

ActiveCN107379516AAdditive manufacturing apparatusAdditive manufacturing with liquidsElastic modulusMoving speed

Owner:HEFEI UNIV OF TECH

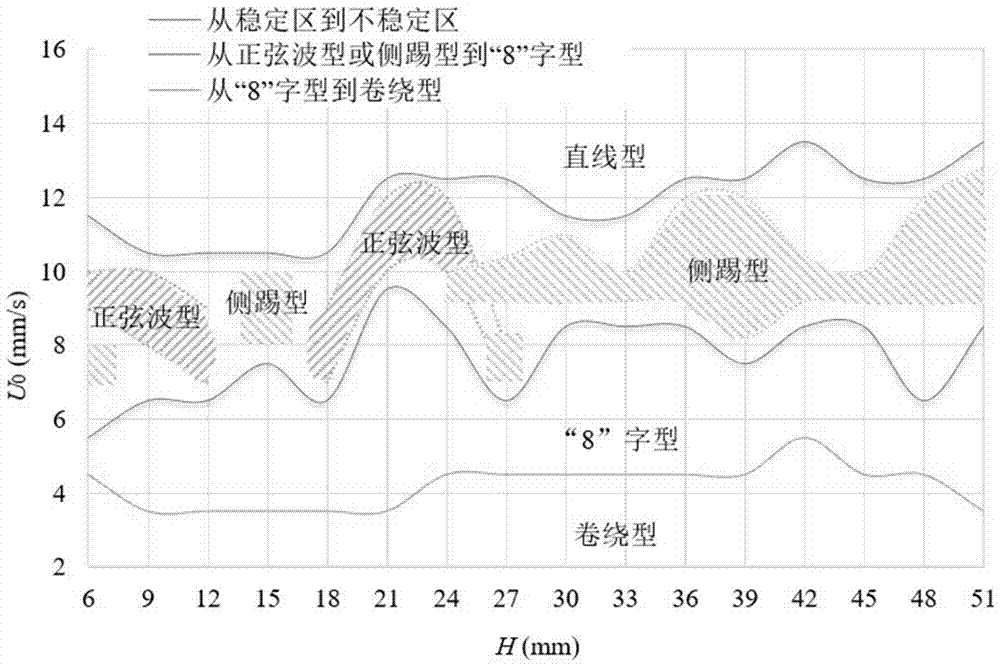

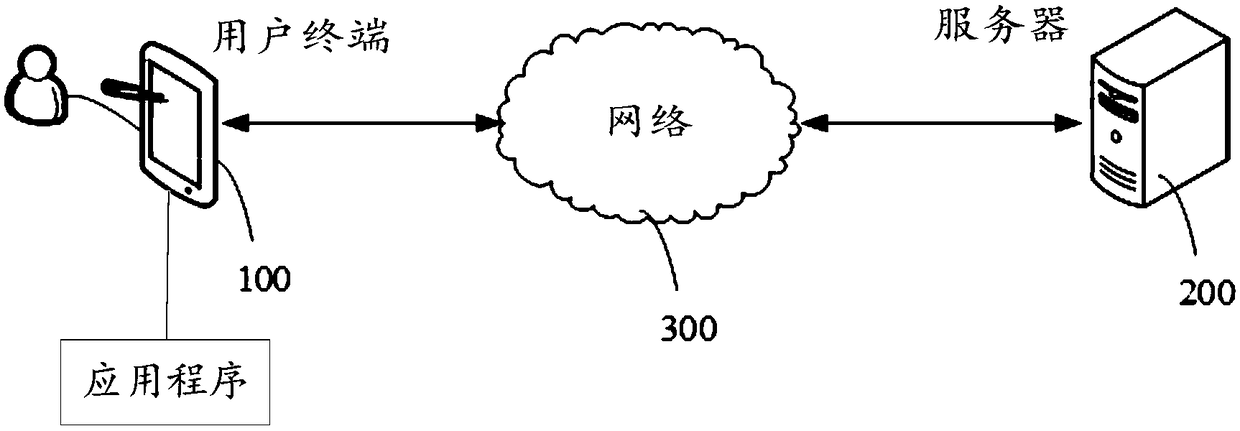

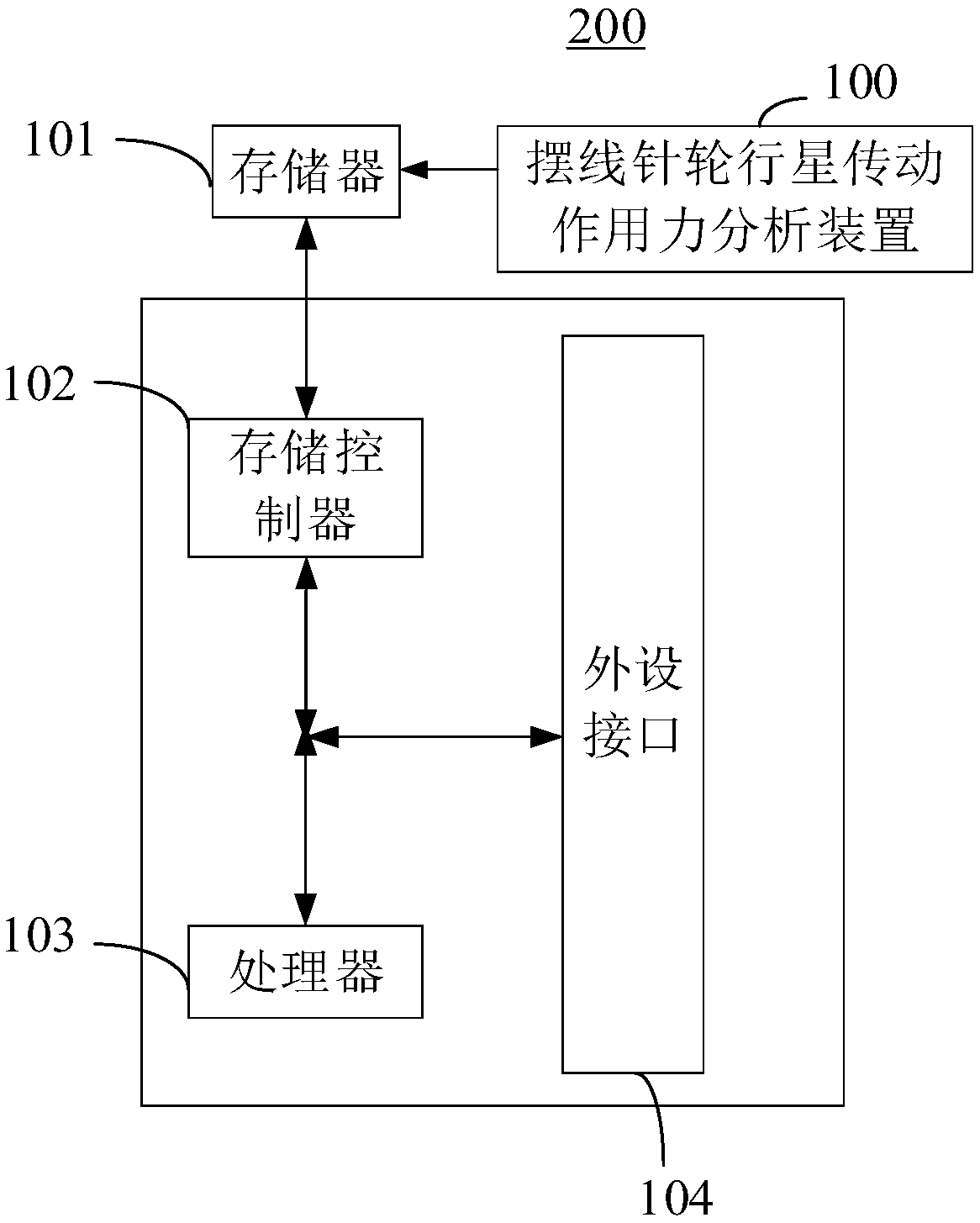

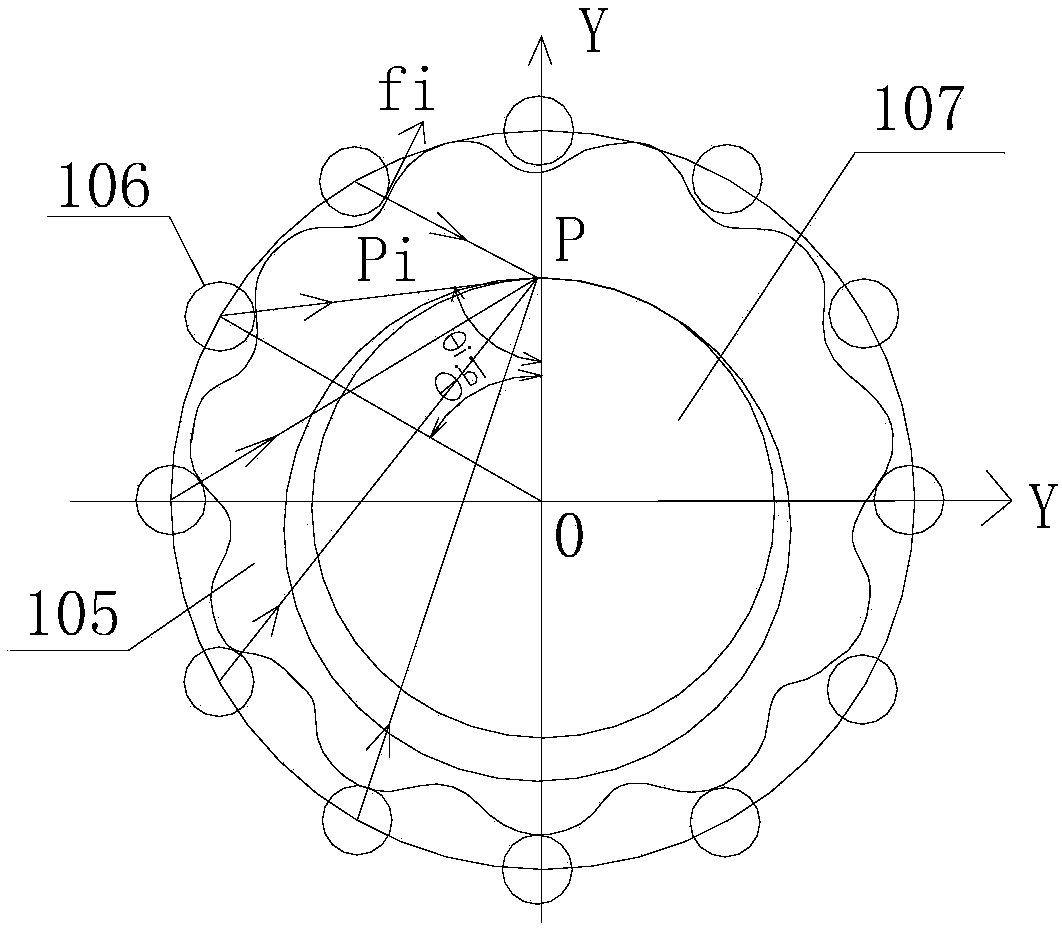

Device and method for analyzing cycloidal-pin wheel planetary transmission acting force

InactiveCN109115492AImprove computing efficiencyHigh precisionMachine gearing/transmission testingReducerEngineering

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Thermoplastic resin composition and molded article

Owner:TECHNO UMG CO LTD

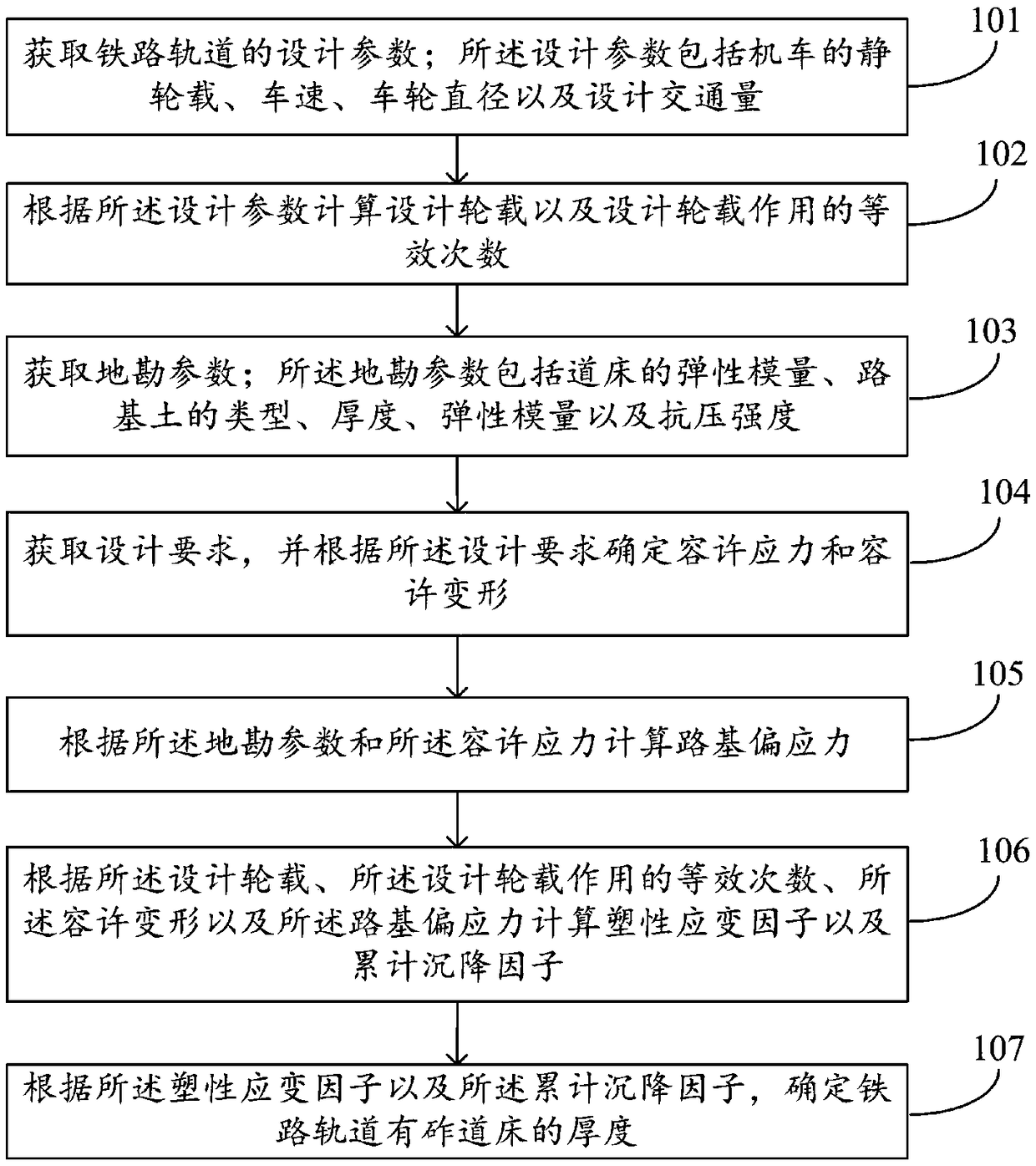

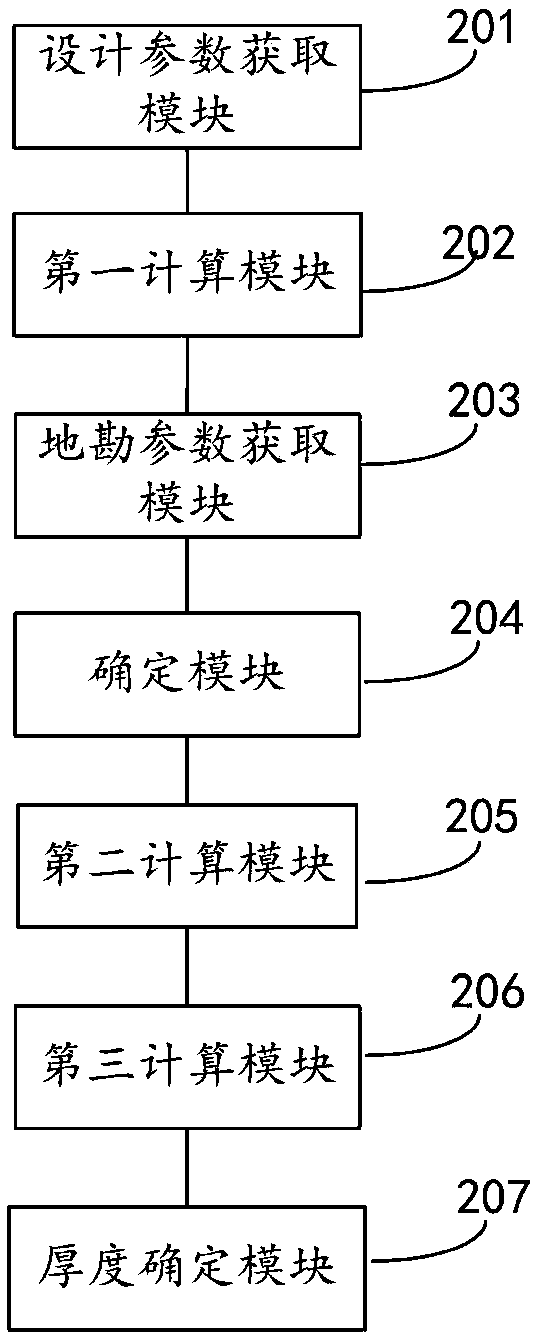

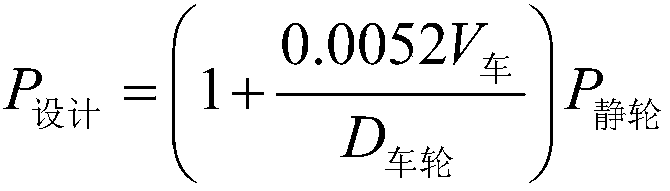

Method and system for calculating that thickness of railway track ballasted track bed

Owner:EAST CHINA JIAOTONG UNIVERSITY

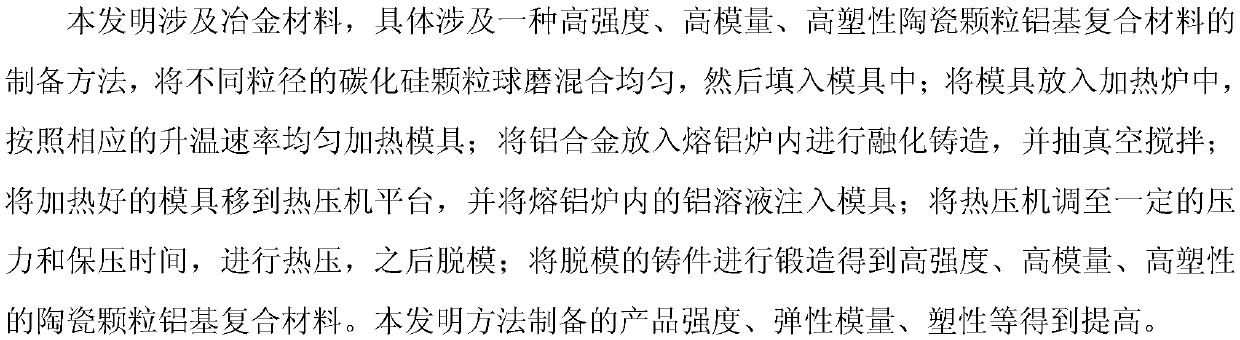

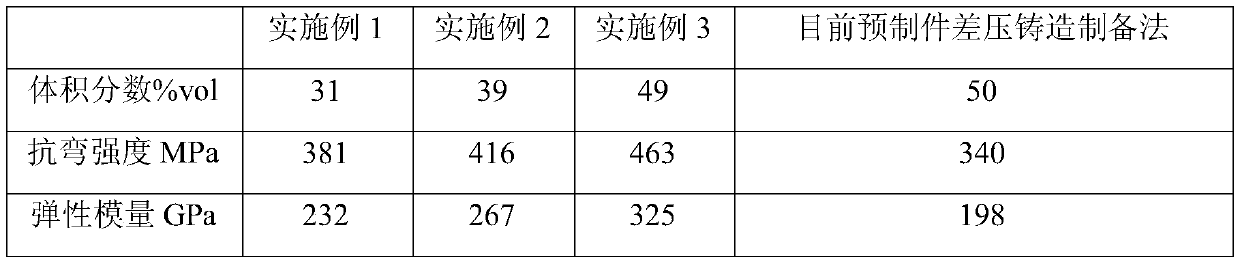

Preparation method of high strength, high modulus and high plasticity ceramic particle aluminum-based composite material

ActiveCN110066937AMeet the technical requirements of aerospaceSimple processHeating furnaceUltimate tensile strength

Owner:西安创正新材料有限公司

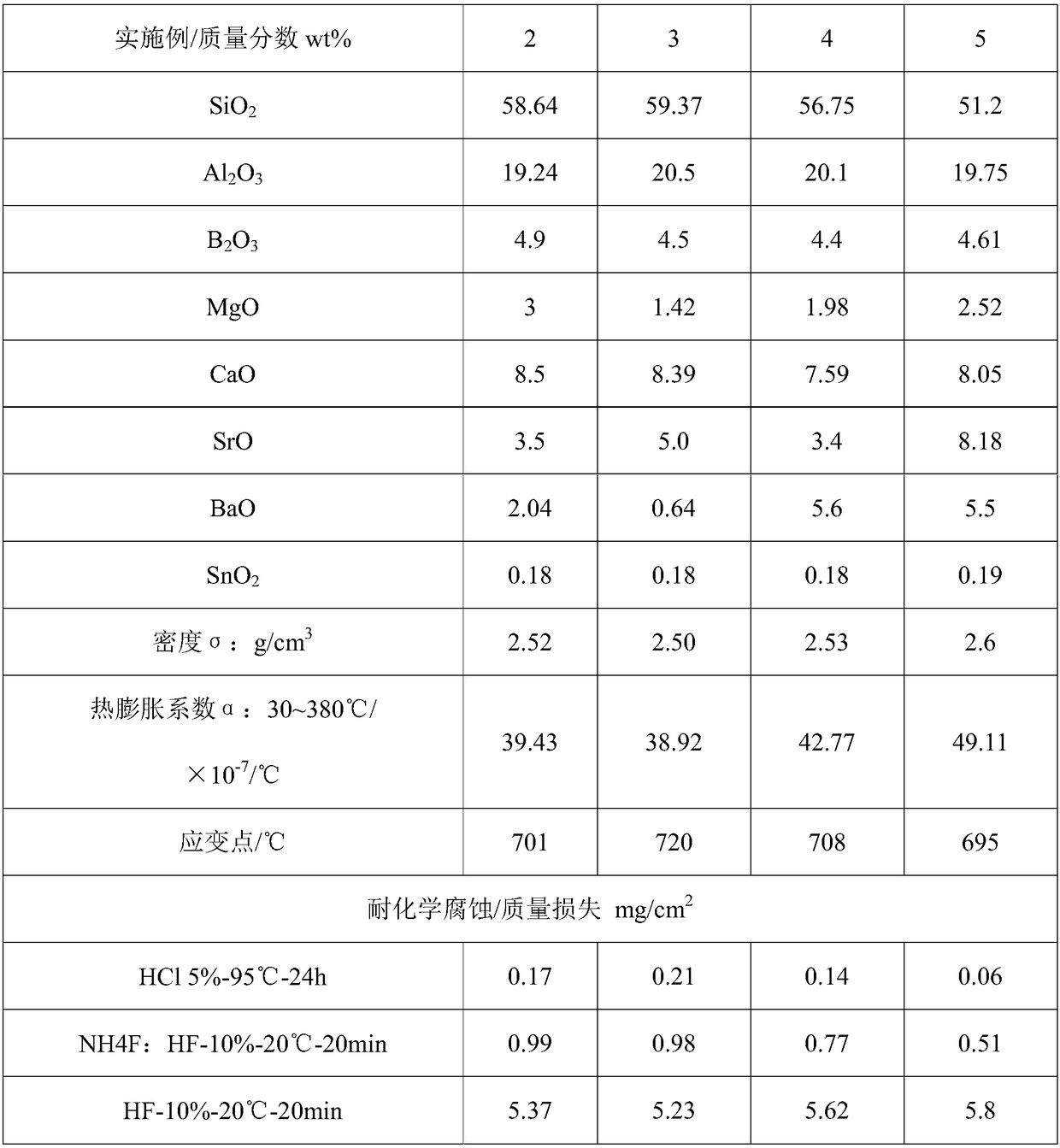

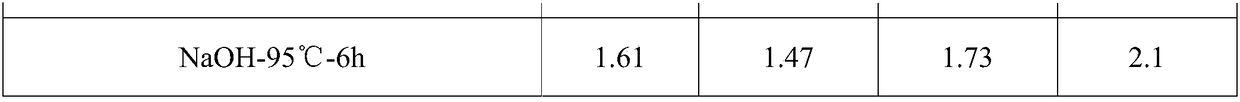

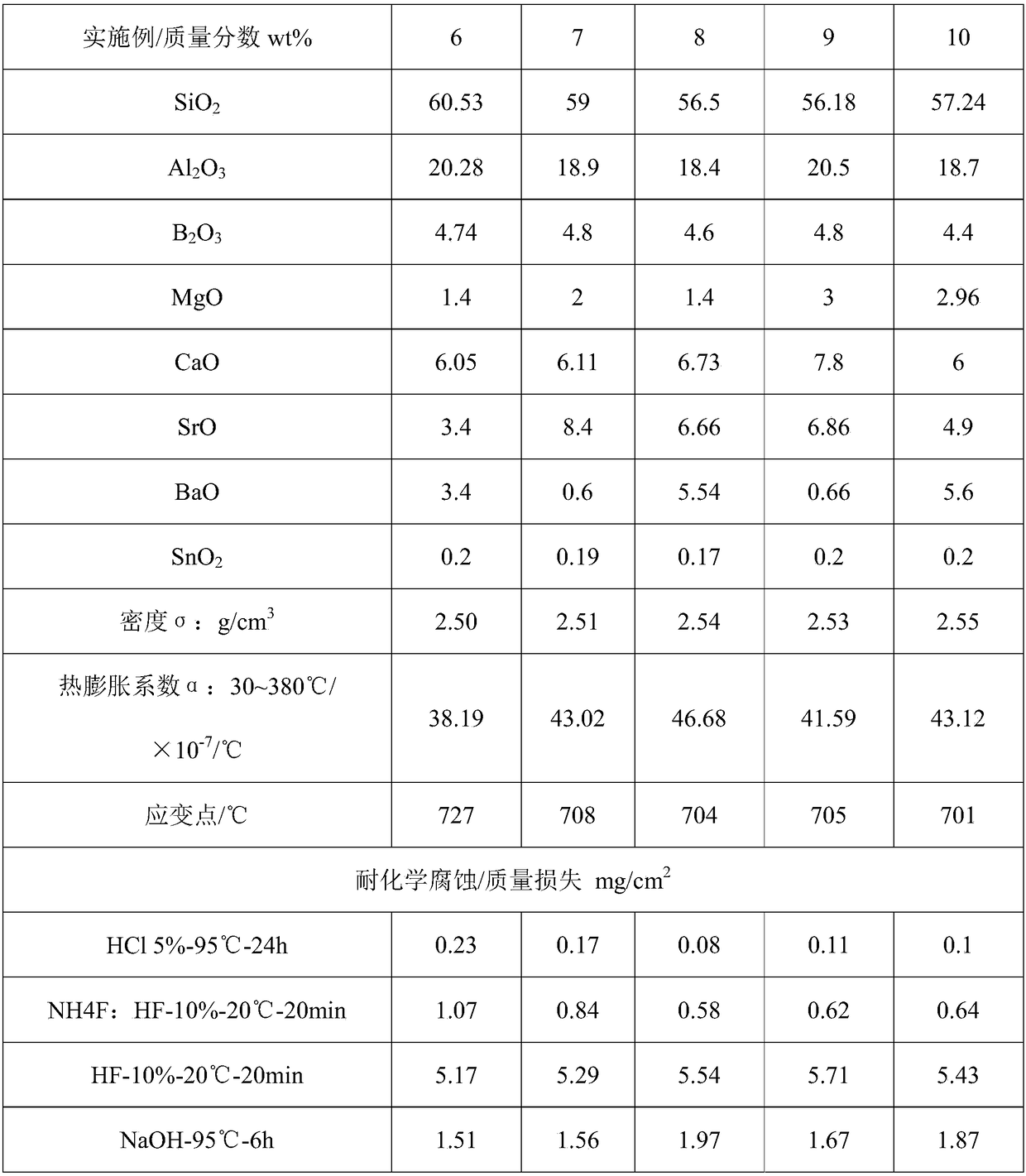

Alkali-free silicate glass with low expansion coefficient and high strain point

Owner:IRICO DISPLAY DEVICES

Under tread rubber composition and pneumatic tire

ActiveUS20170073507A1Excellent low heat build-upHigh elastic modulusSpecial tyresTyre tread bands/patternsPolymer scienceDouble bond

Owner:YOKOHAMA RUBBER CO LTD

Dental implant containing polyether-ether-ketone interlayer and manufacturing method thereof

InactiveCN108542523ALow elastic modulusImprove fatigue lifeDental implantsTissue regenerationEtherKetone

Owner:广东健齿生物科技有限公司

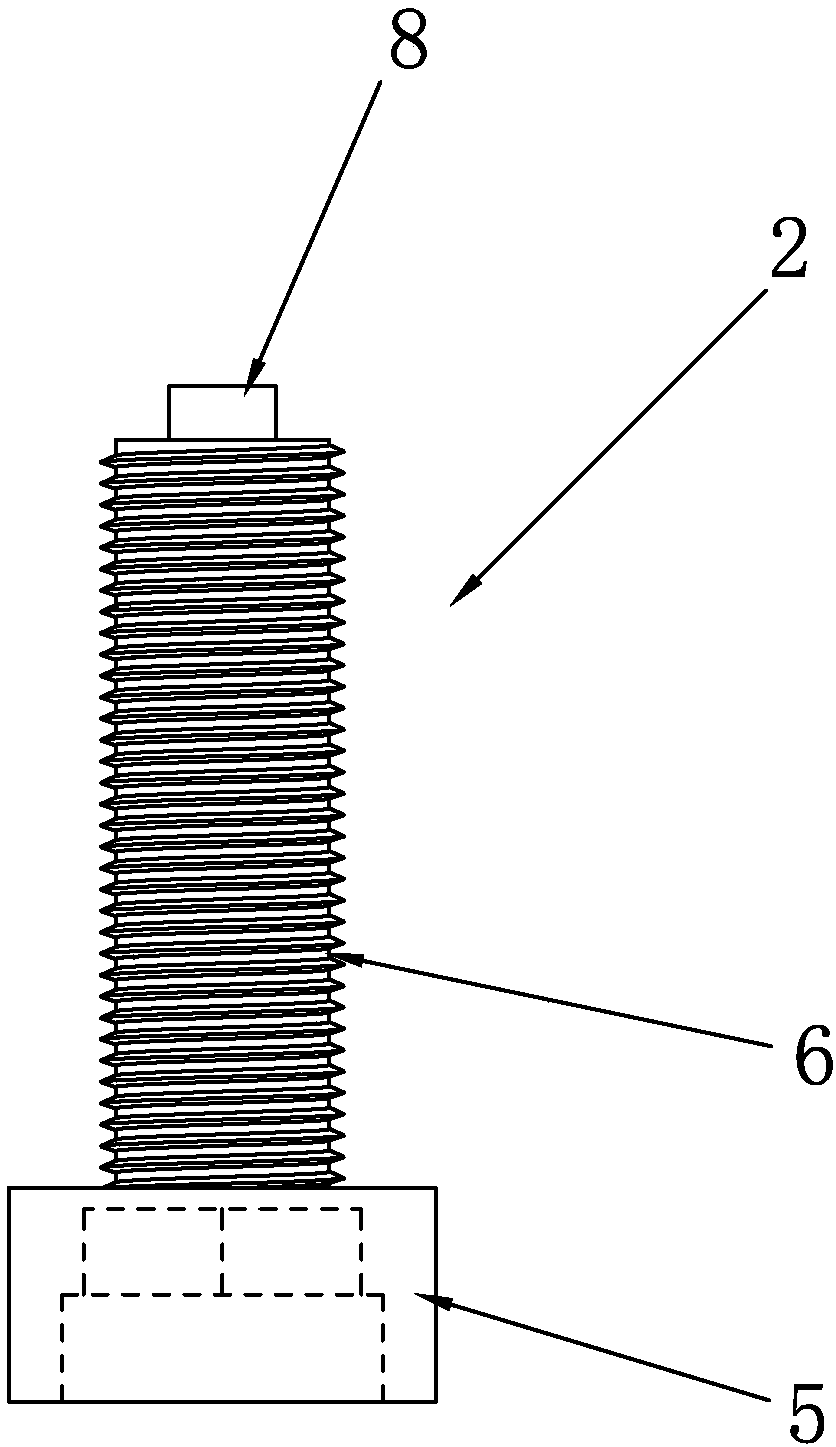

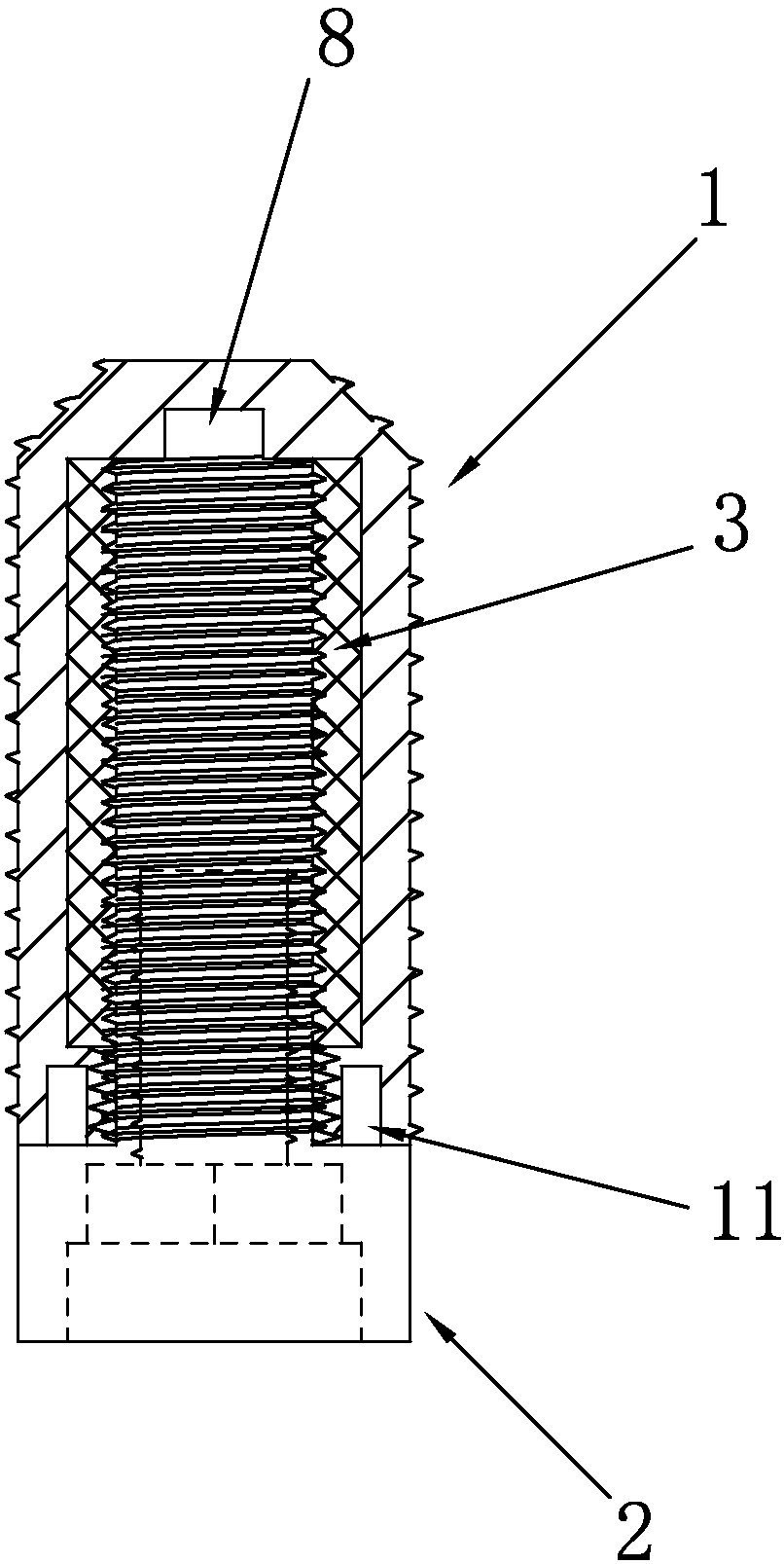

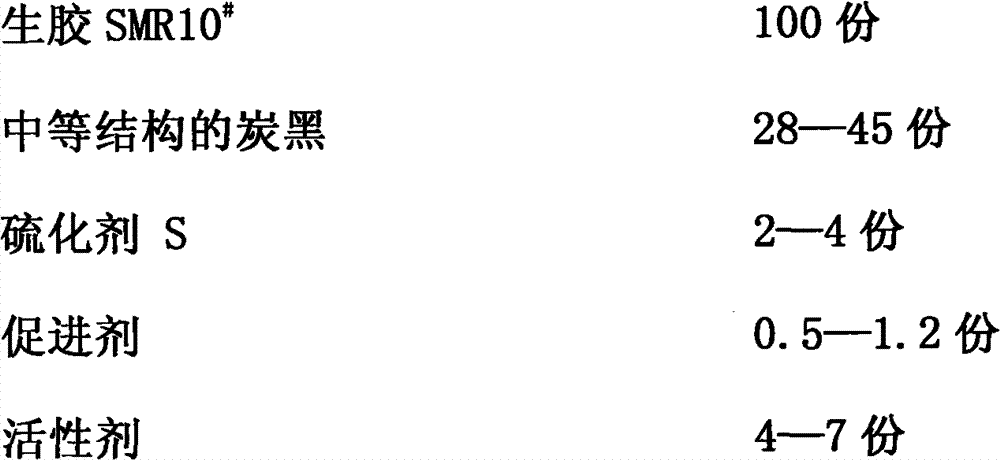

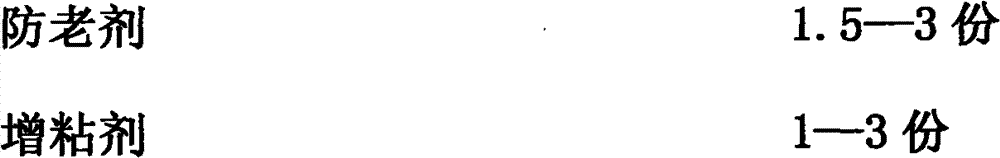

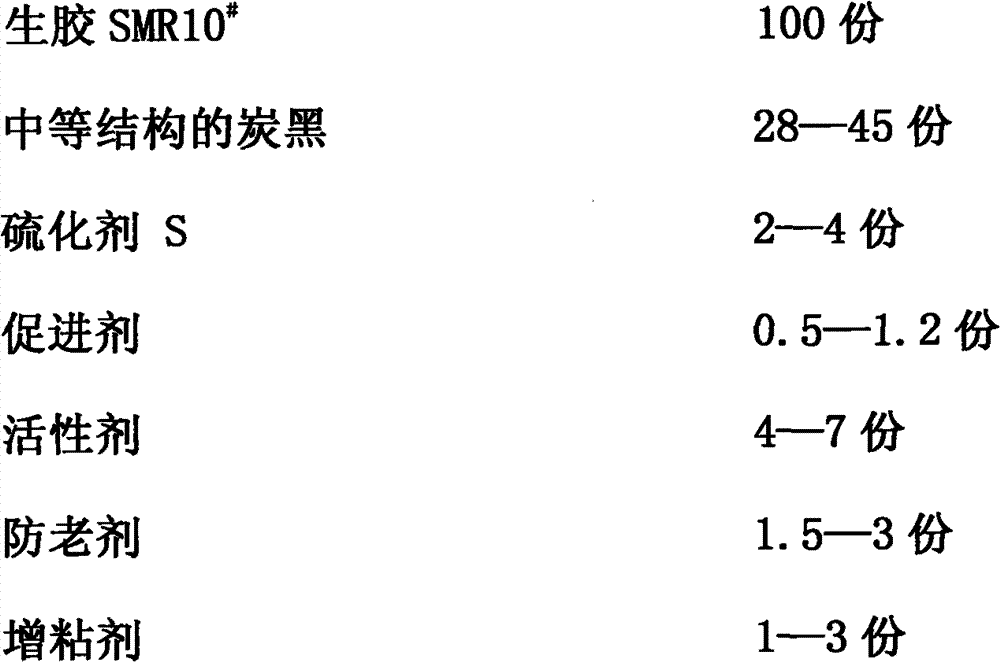

All-steel radial tire shoulder pad rubber formula

Owner:SHANDONG FENGLUN TIRE

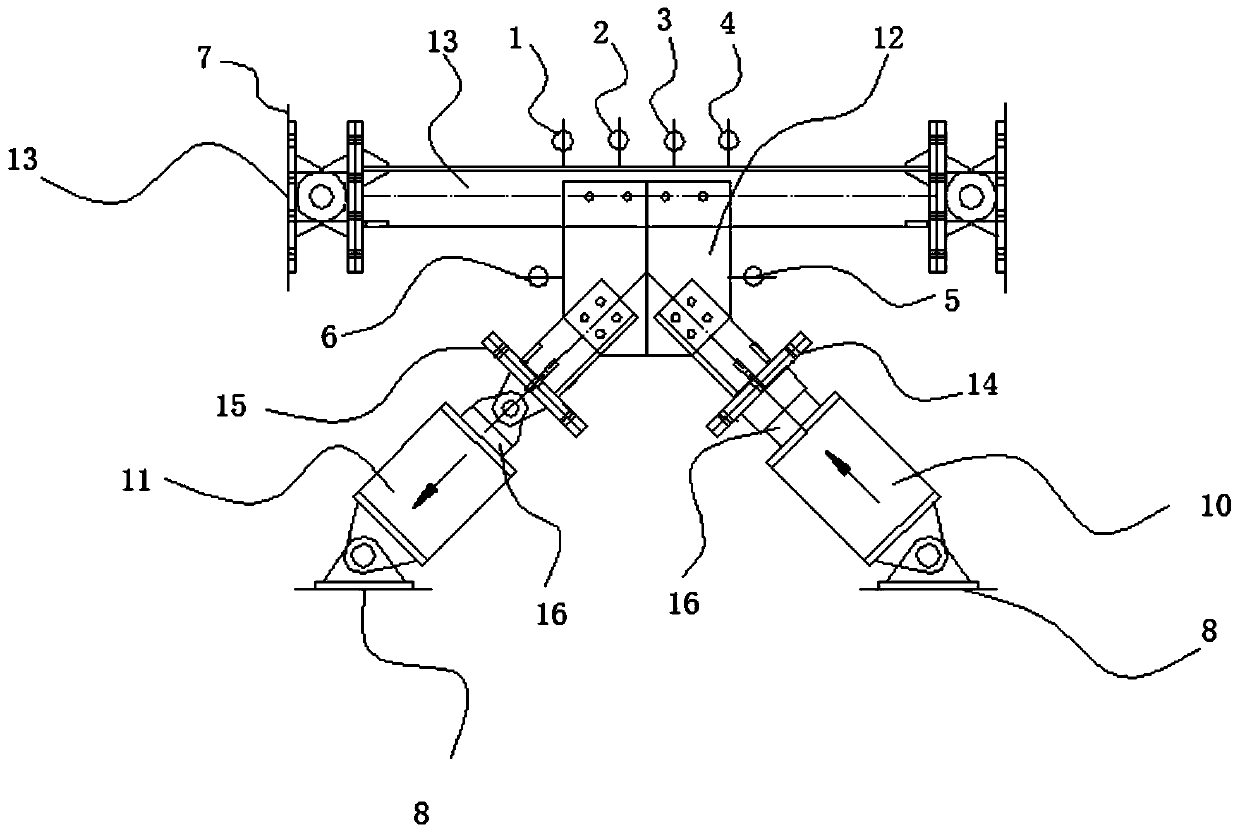

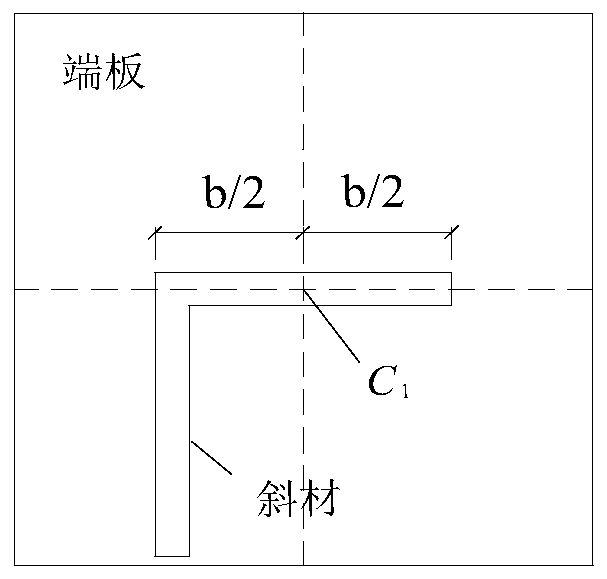

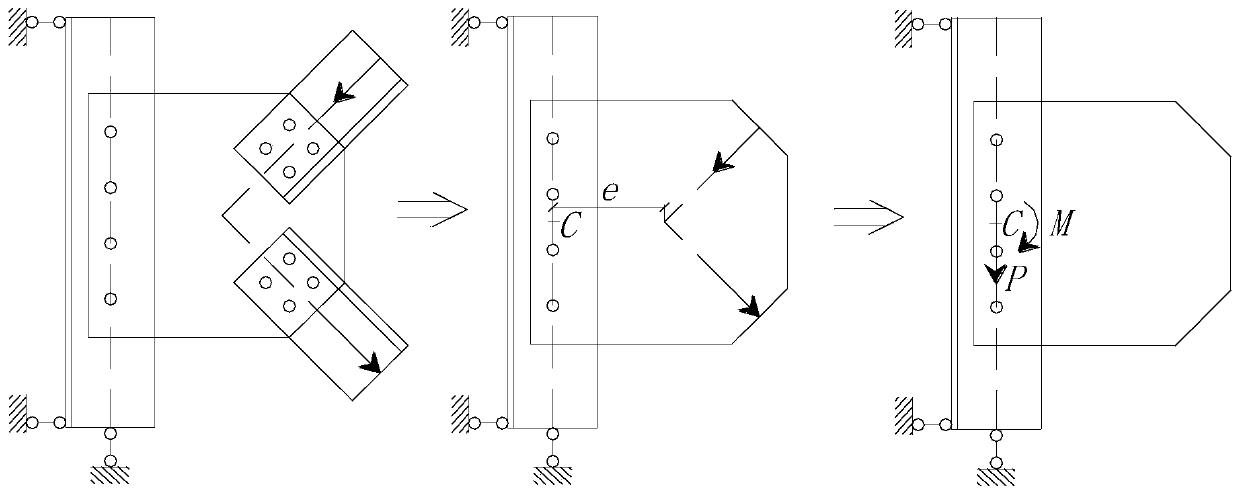

Semi-rigidity detection method for angle steel-gusset plate connection node in power transmission angle steel tower structure

PendingCN110553915ARaise the ratioMaterial strength using tensile/compressive forcesTurn angleGusset plate

Owner:CHONGQING YUHUANG ELECTRIC POWER EQUIP MFG +1

Optical information recording medium

InactiveUS20080118698A1Improve jitter characteristicsExcellent degree of modulationLayered productsRecord information storageEngineeringReflective layer

Owner:TAIYO YUDEN KK

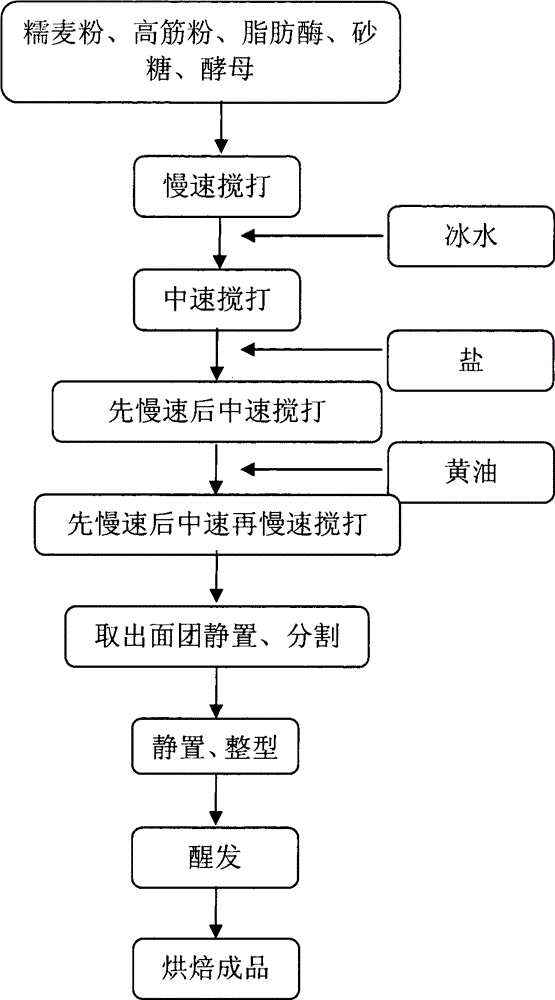

Method for improving elastic modulus of waxy barley leavened bread by using lipase

InactiveCN104304367AHigh nutritional valueImprove featuresPre-baking dough treatmentBakery productsYeastIce water

Owner:JIANGNAN UNIV +2

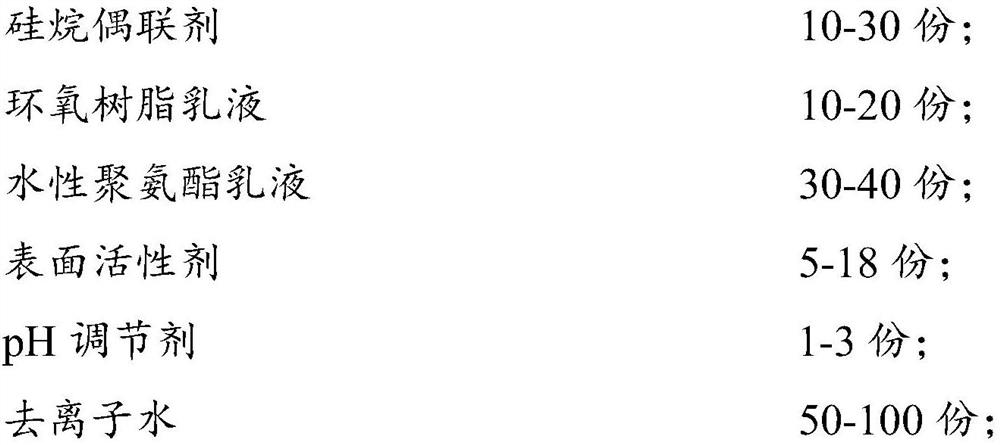

High-elasticity-modulus and high-strength glass fiber laminated board and preparation method thereof

ActiveCN114030250AHigh elastic modulusHigh strengthSynthetic resin layered productsLaminationEpoxyGlass fiber

Owner:SHANDONG FIBERGLASS GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap