Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Building reinforcements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

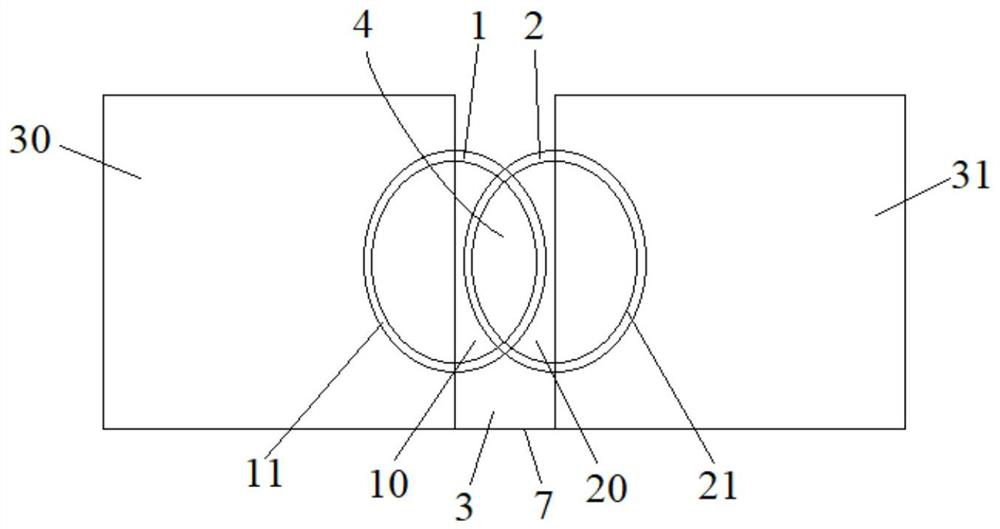

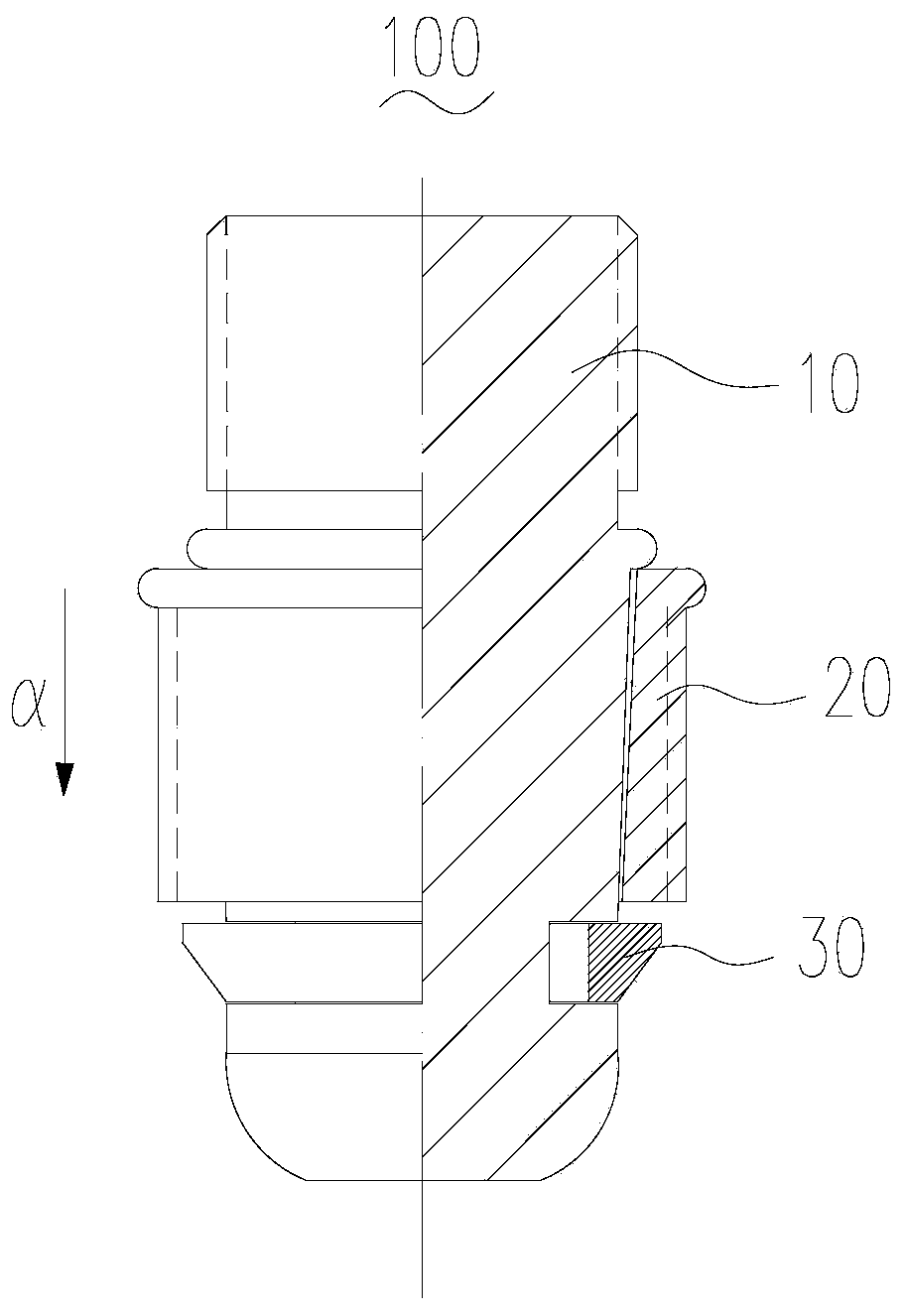

Grout sleeve for connecting prefabricated member steel bars and construction method of grout sleeve

Owner:SHENYANG JIANZHU UNIVERSITY

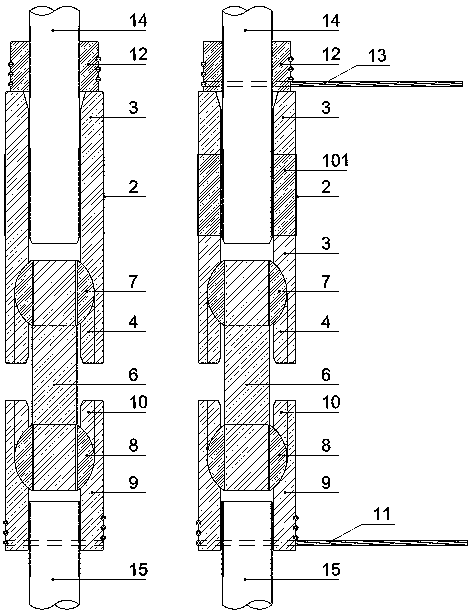

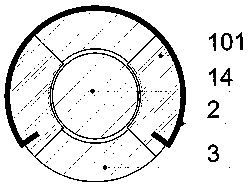

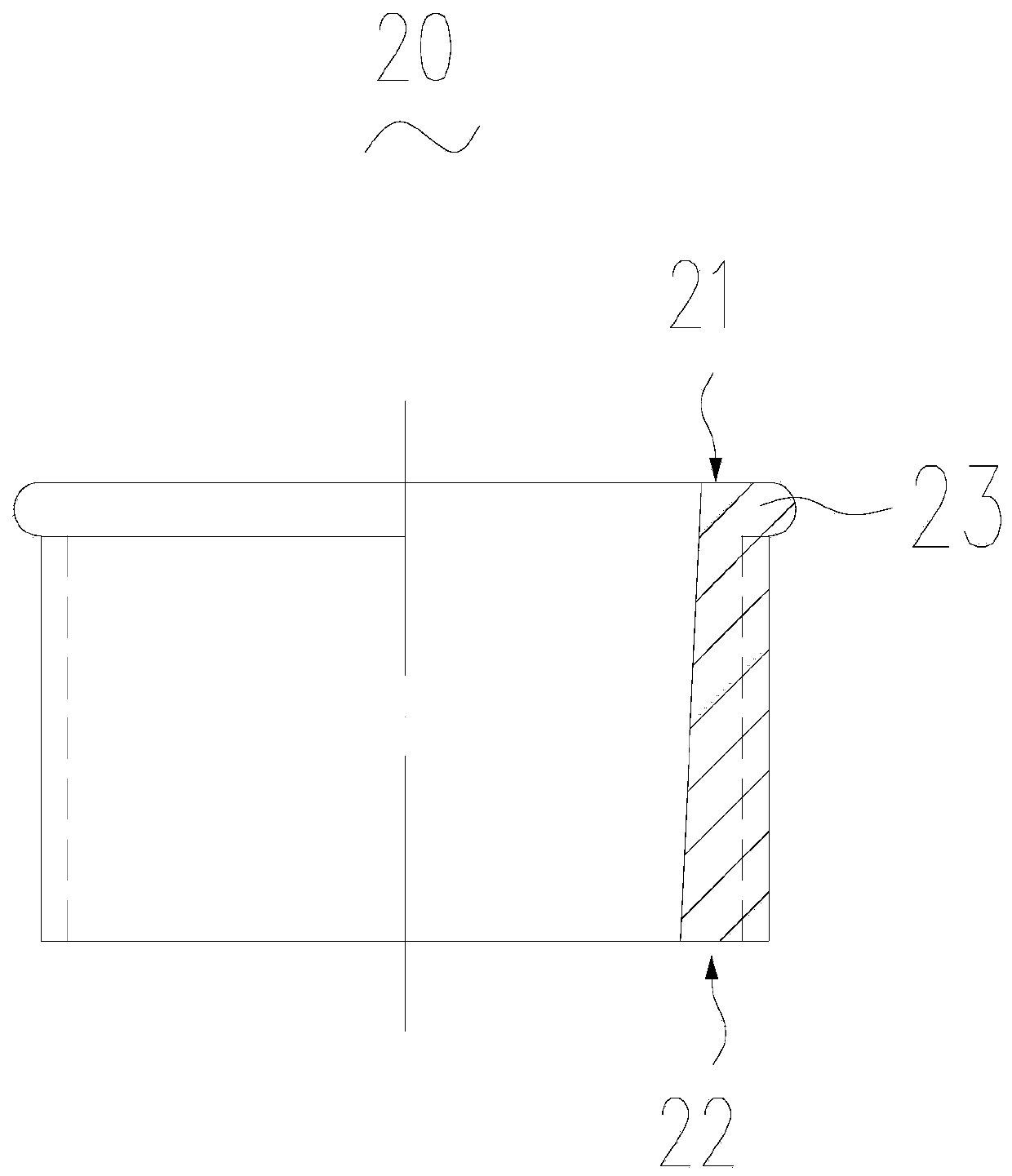

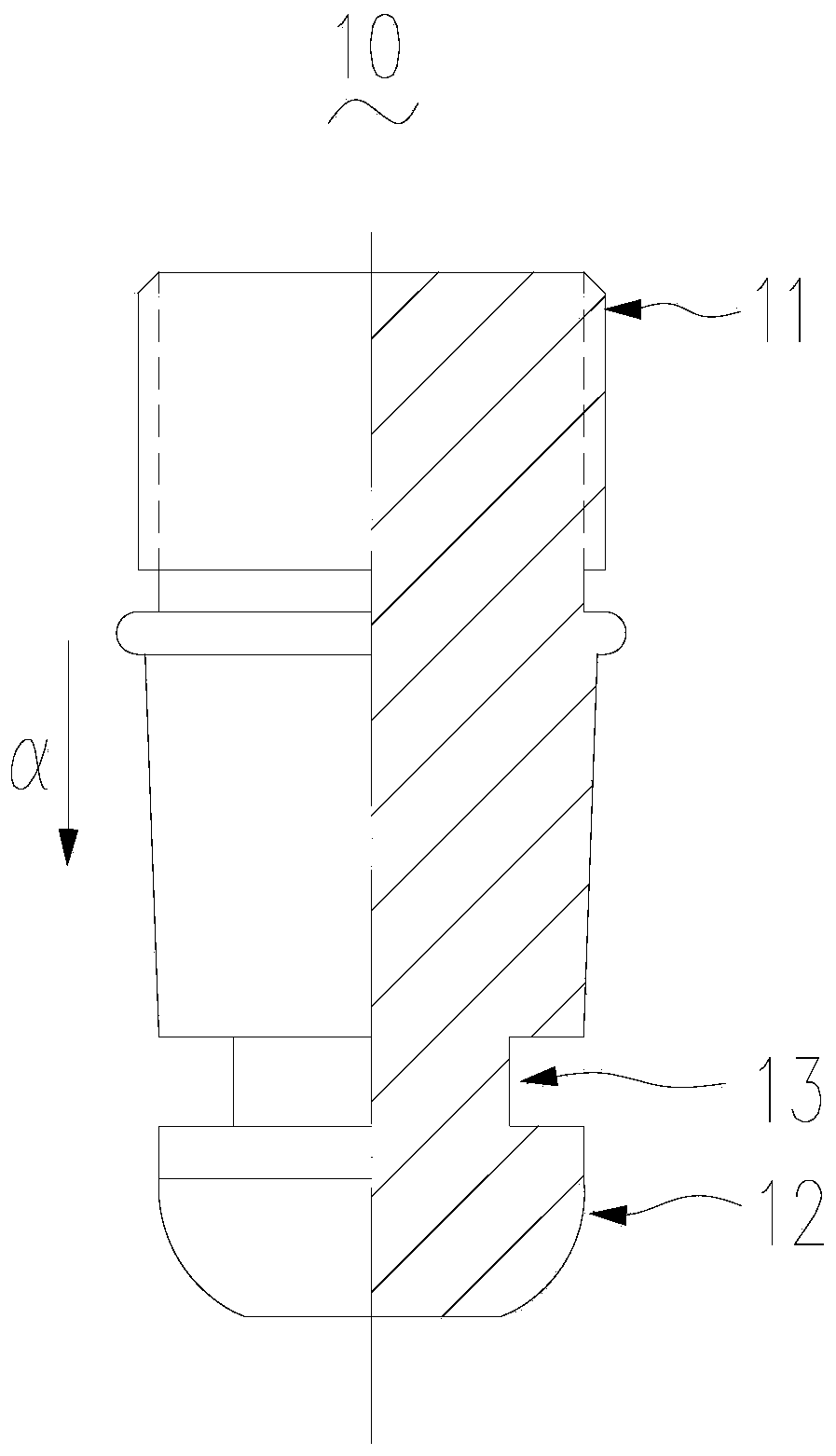

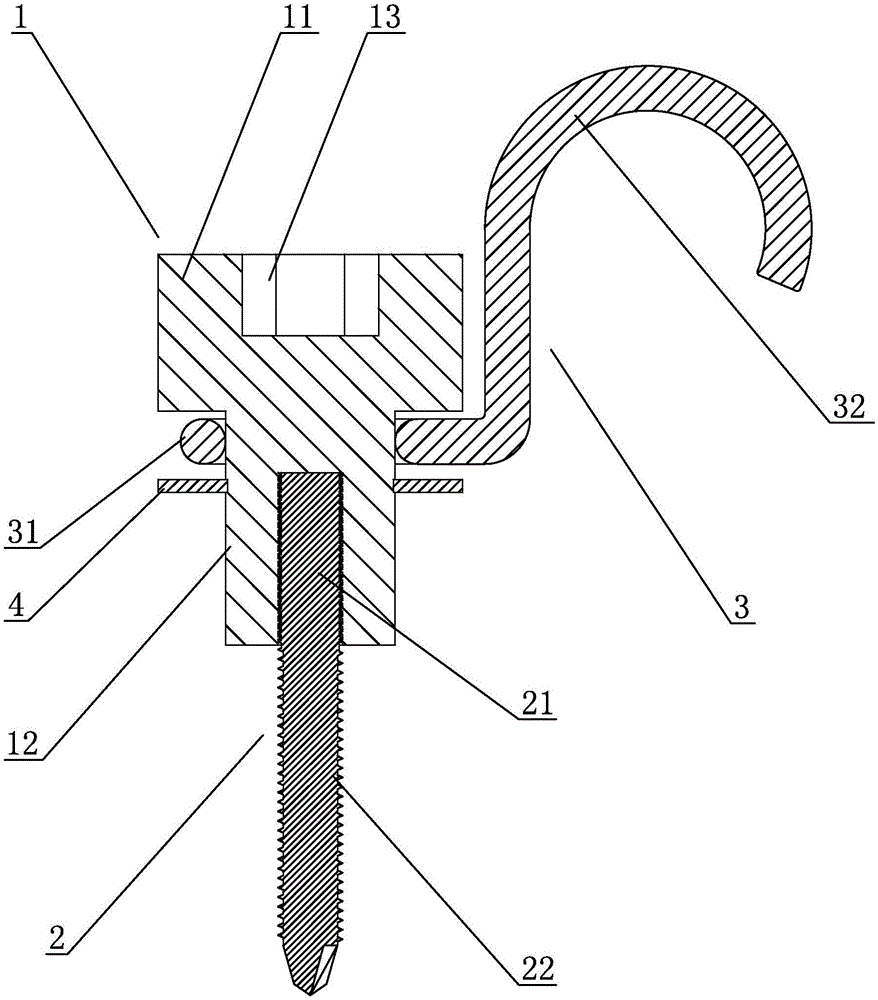

Building embedded part device for shaping, positioning and adjusting

ActiveCN112709338AGuaranteed limit effectQuick alignment insertionBuilding reinforcementsBuilding material handlingArchitectural engineeringRebar

Owner:安徽华盛建设集团有限公司

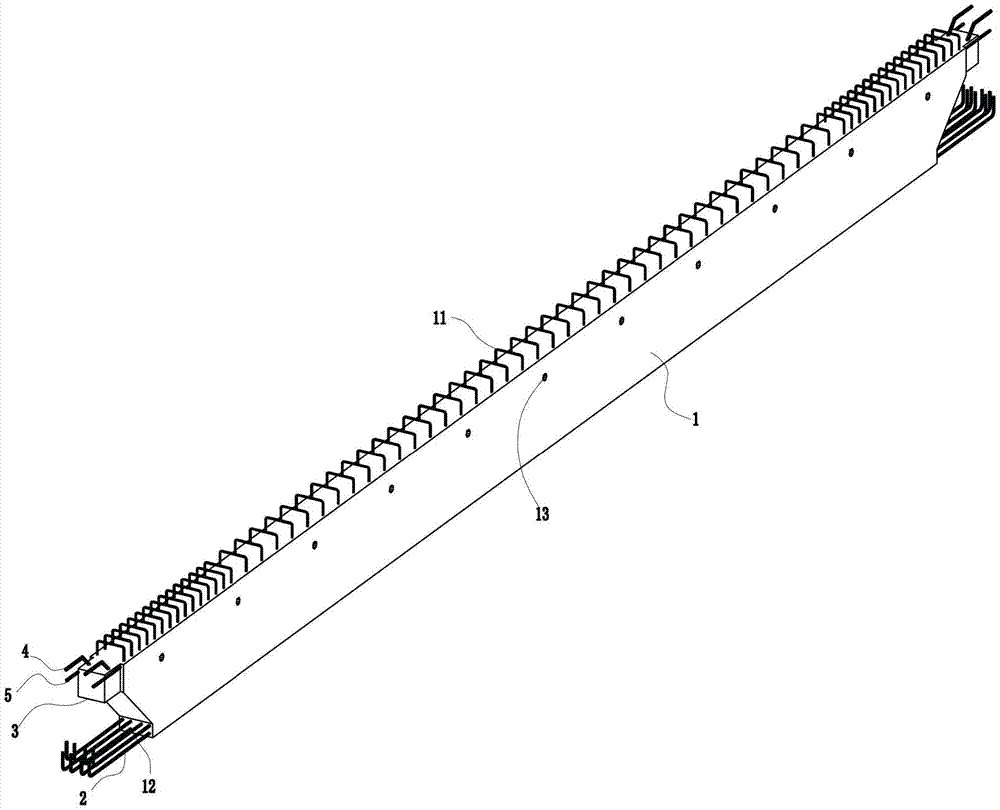

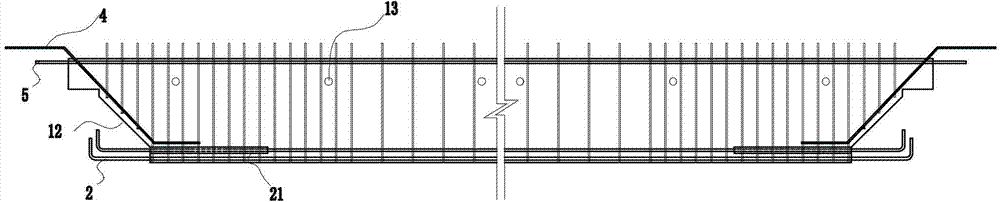

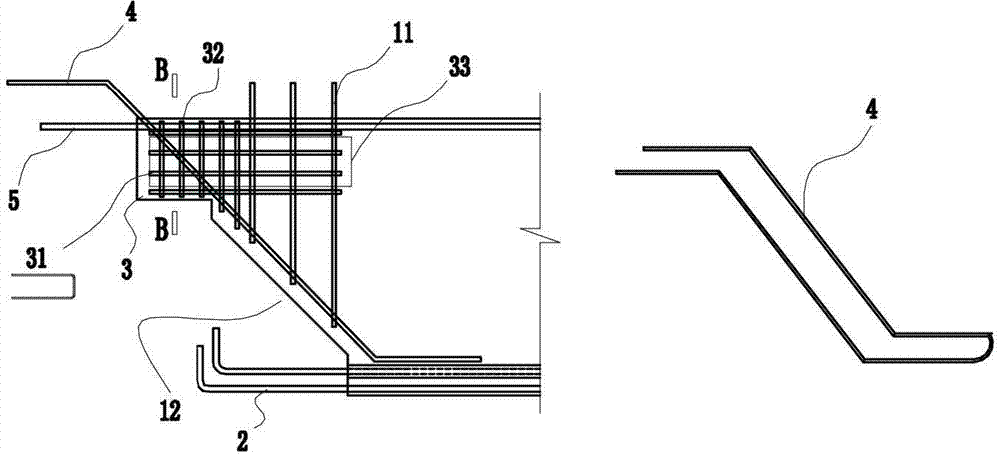

Precast pre-stressed beam with shelving corbel outs

ActiveCN102852280AEasy to set upShelving is safe and reliableGirdersJoistsPre stressPre stressing

Owner:杨众 +1

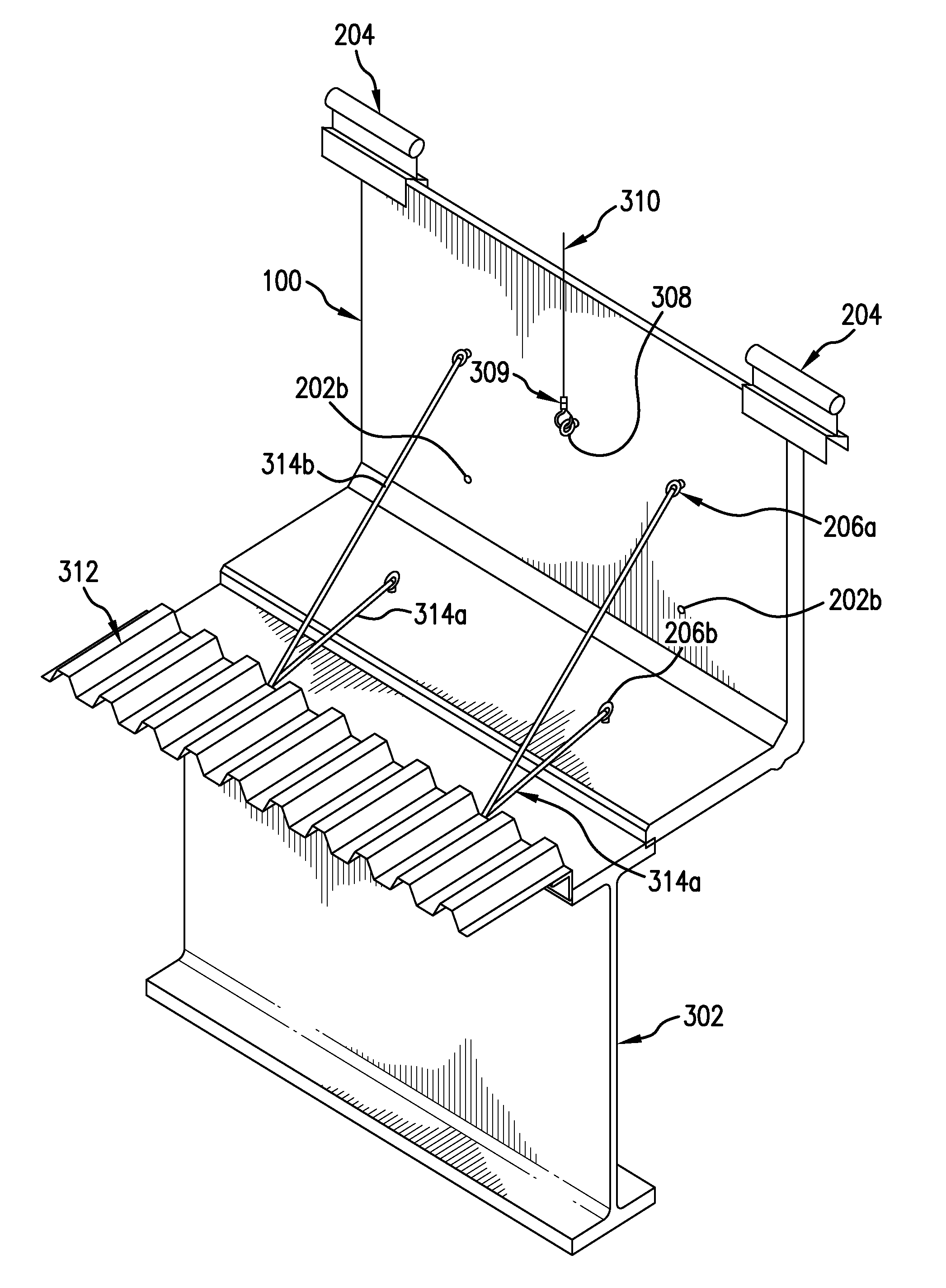

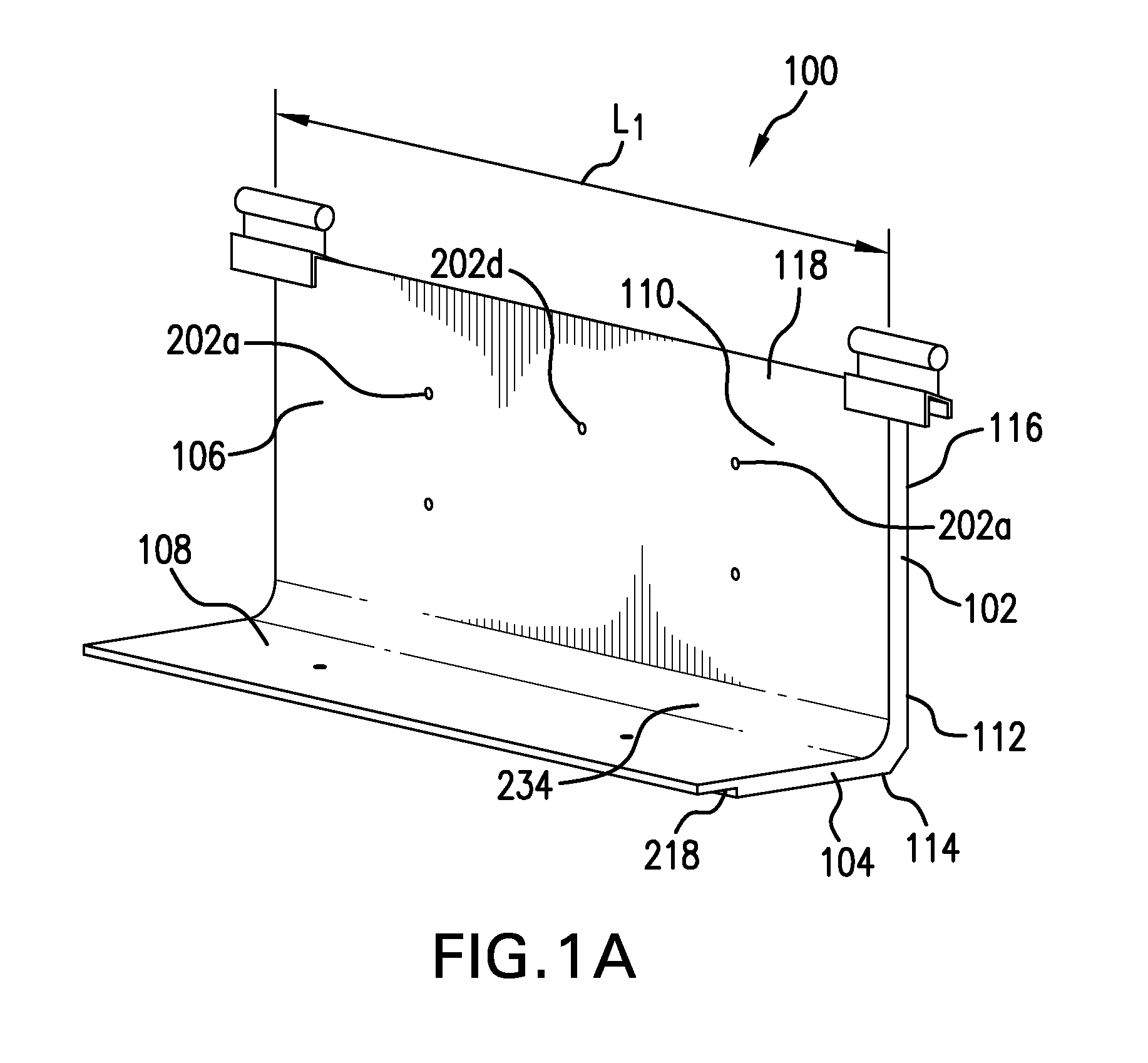

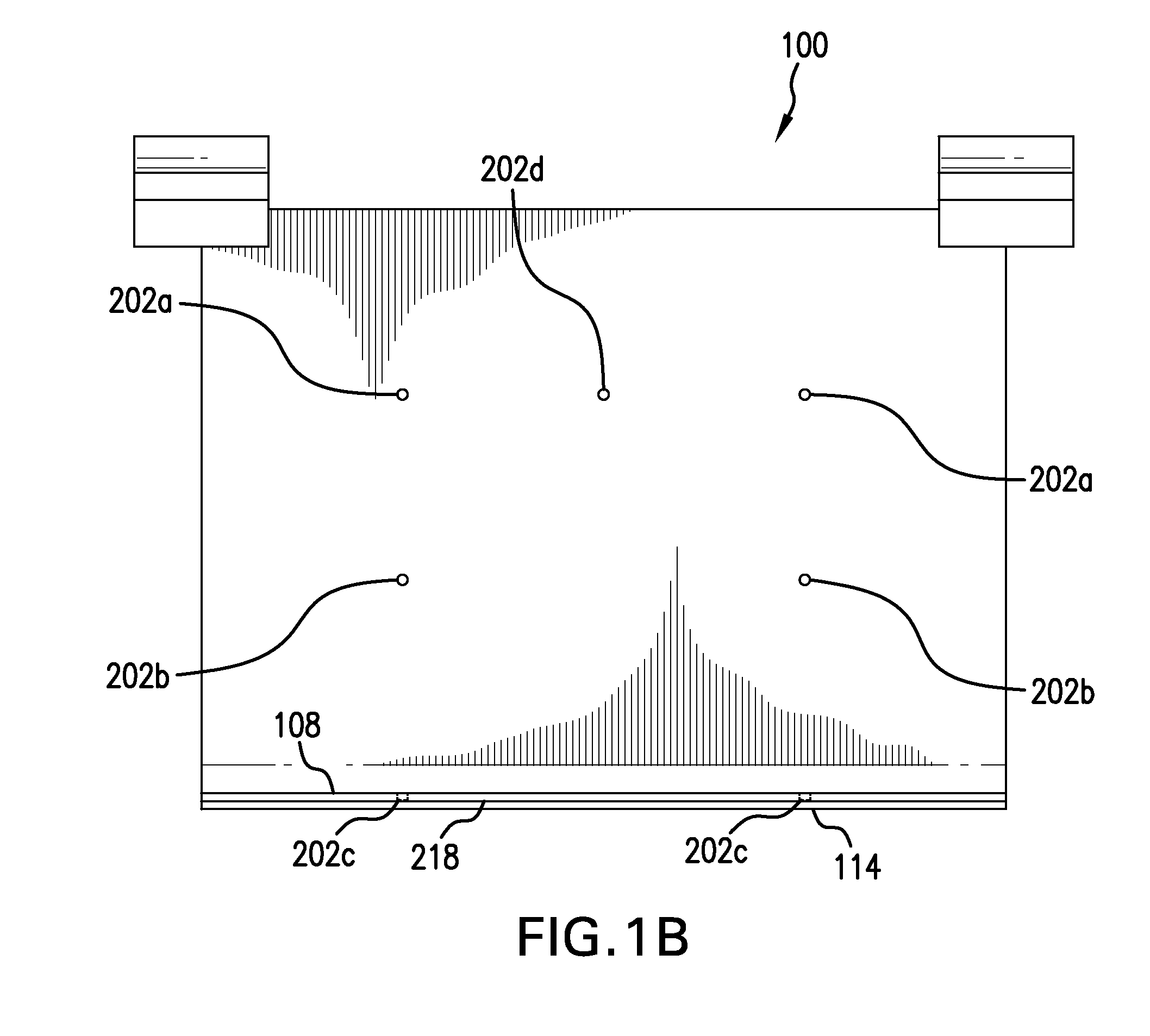

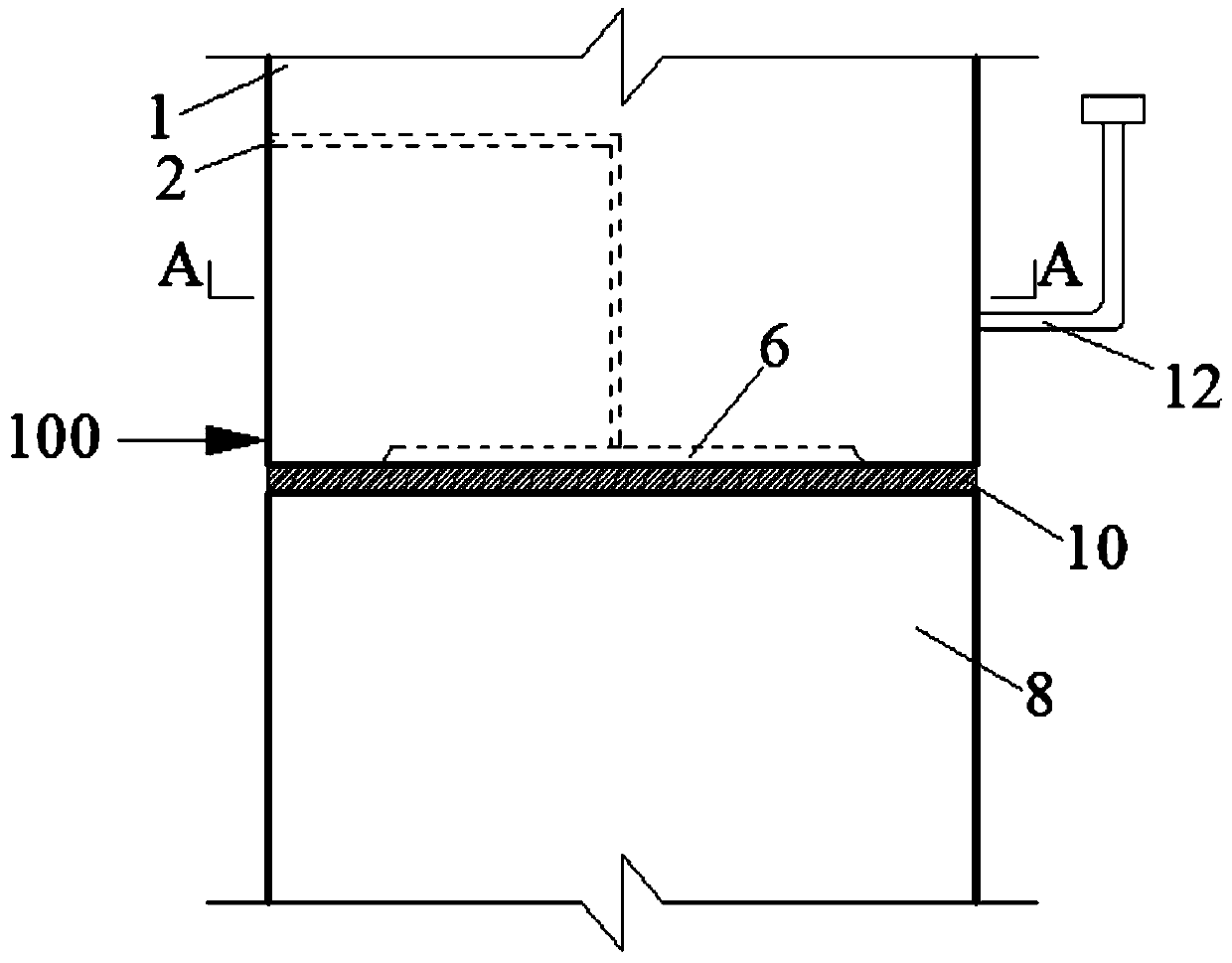

Assembled prefabricated floor connecting system and construction method thereof

PendingCN110761462AEasy to operateFast constructionFloorsBuilding reinforcementsFloor slabArchitectural engineering

Owner:CHONGQING UNIV

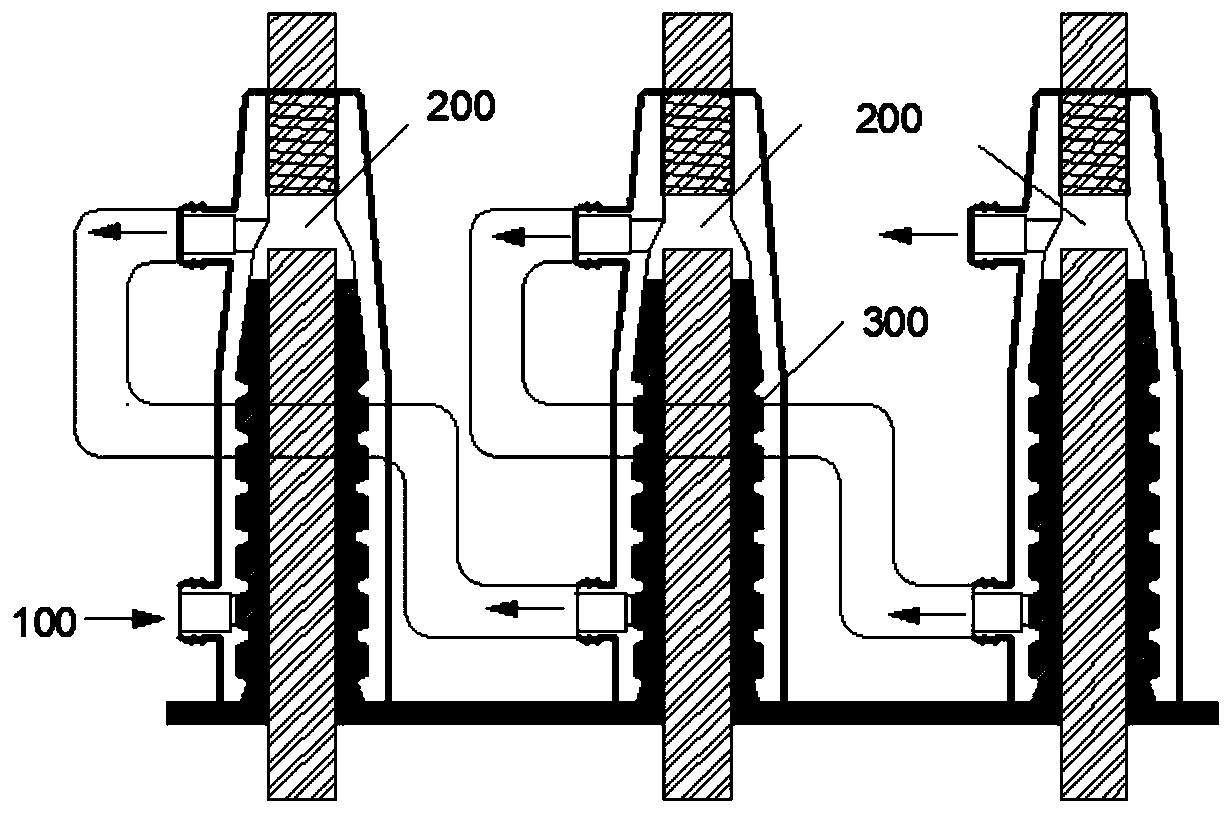

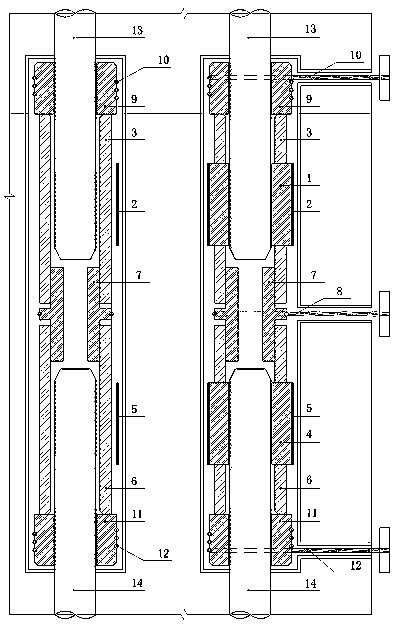

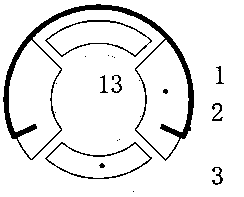

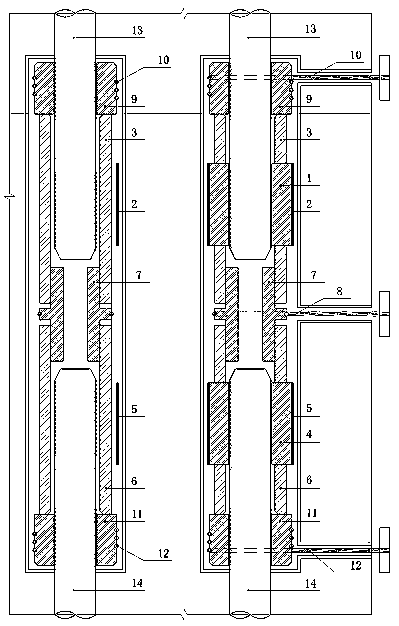

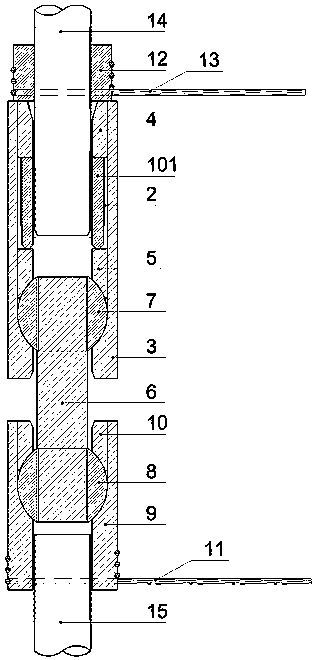

Assembly prefabricated component series-connection sleeve connecting structure and grouting method thereof

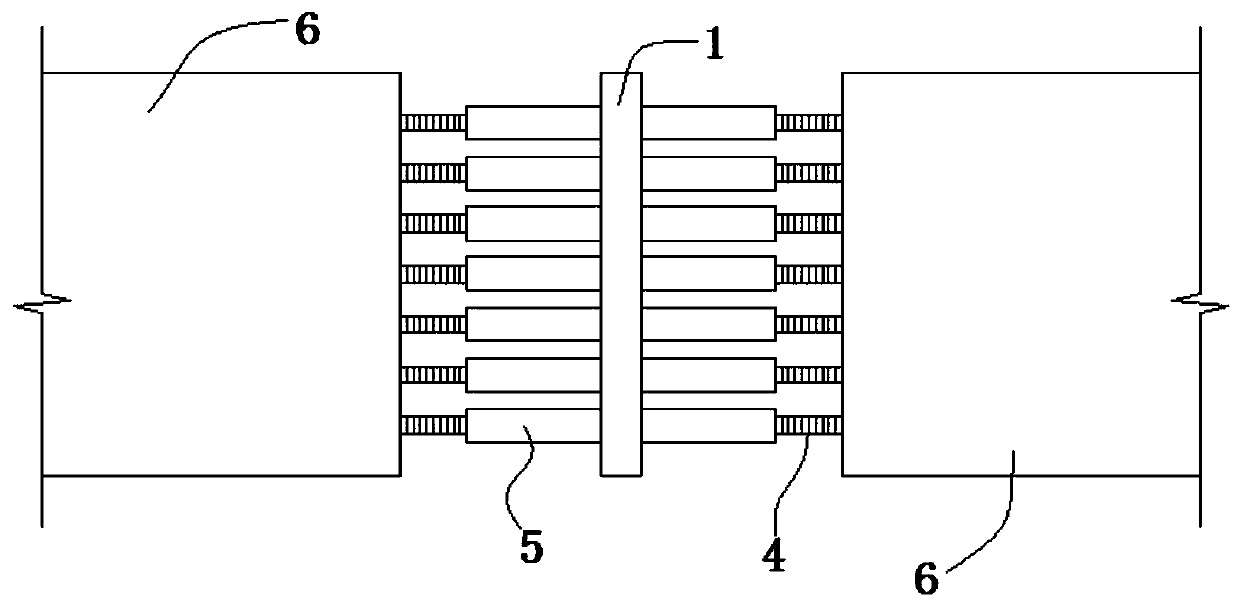

The invention relates to an assembly prefabricated component series-connection sleeve connecting structure and a grouting method thereof, and belongs to the field of residential PC industrialization.The assembly prefabricated component series-connection sleeve connecting structure comprises one or more sets of series-connection sleeves and connecting pipes; a gap is formed between an assembly prefabricated upper component and an assembly prefabricated lower component; each set of series-connection sleeves is formed by a plurality of sleeves which are connected in series through the corresponding connecting pipe, and the two ends of the connecting pipes are connected with upper openings and lower openings of the adjacent sleeves correspondingly; and a shear key forming groove is formed inthe bottom end of the upper component, communicates with the gap between the upper component and the lower component and is poured with a primary grouting material, and the series-connection sleeves are poured with secondary grouting materials. The grouting method of the assembly prefabricated component series-connection sleeve connecting structure comprises the steps: primary pouring, still standing and secondary pouring. The assembly prefabricated component series-connection sleeve connecting structure is improved based on a single-point grouting method, and has the characteristics of beingeasy to construct, excellent in performance and free of grouting defects.

Owner:河北冀科工程项目管理有限公司

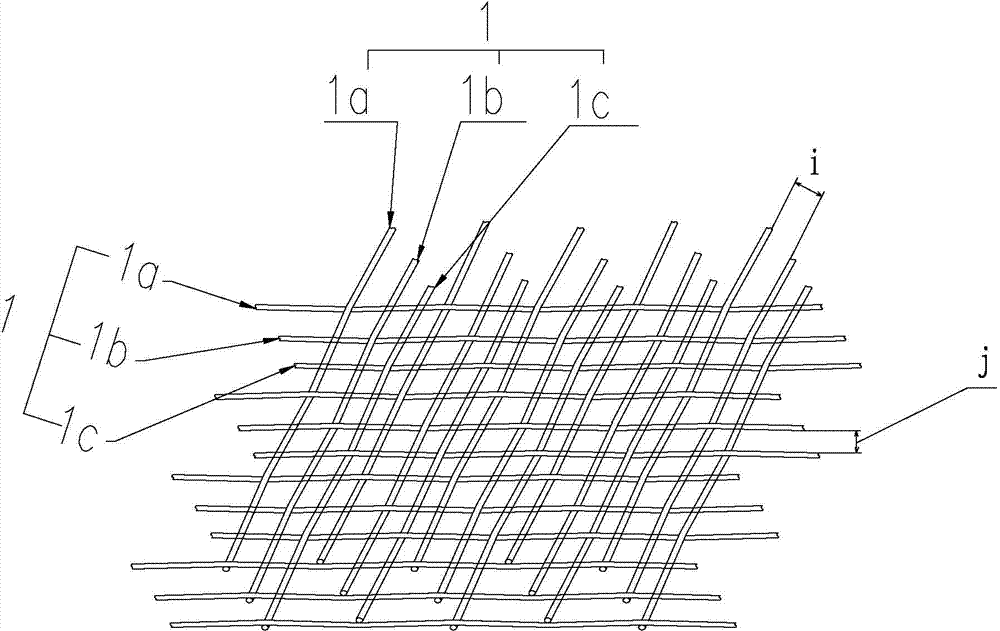

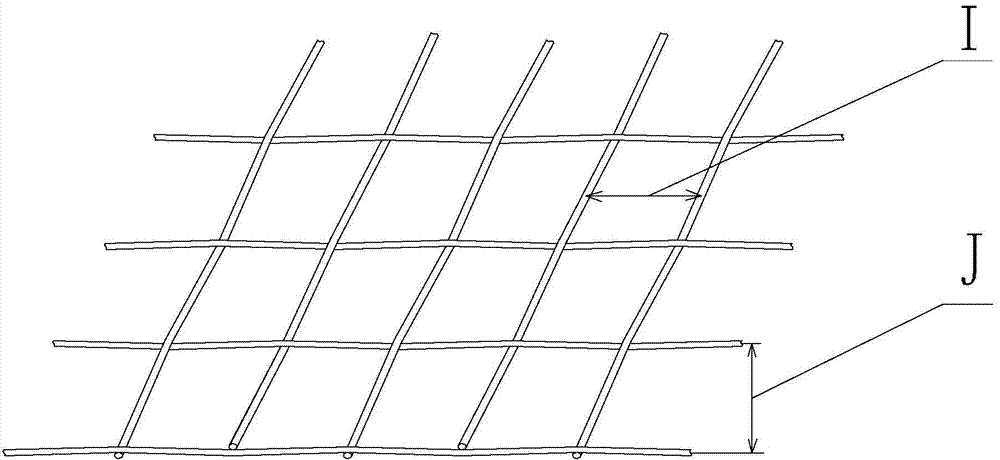

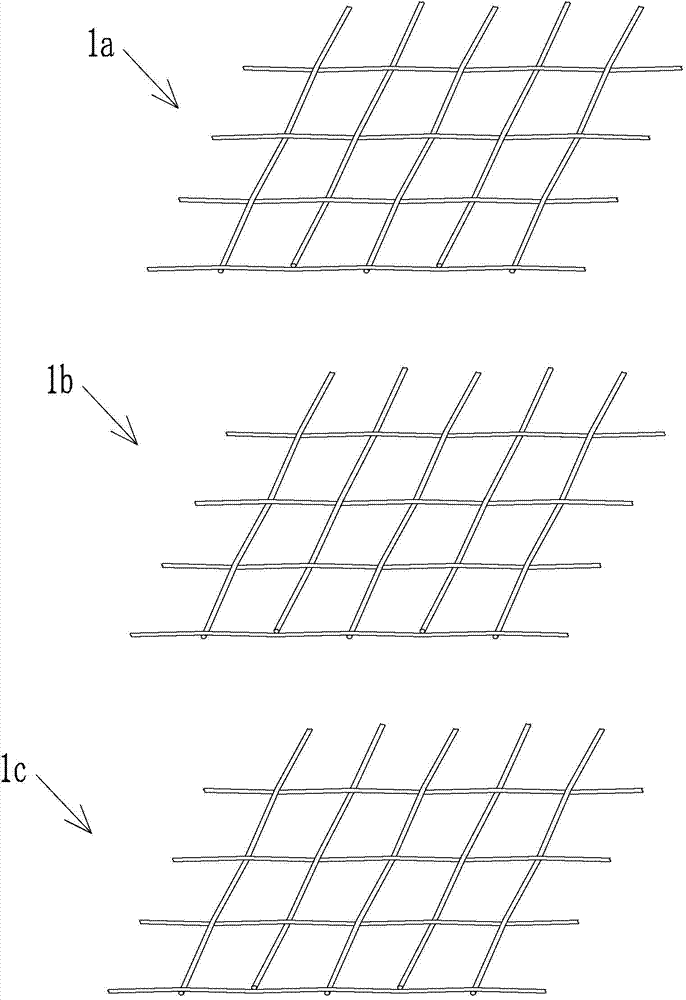

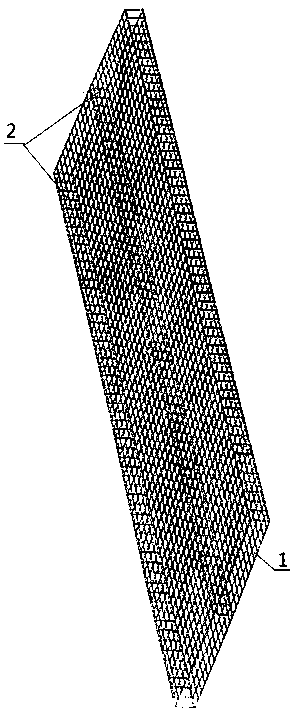

Combined-type fiber gridding rib layer product and preparation method thereof

ActiveCN103938804AThe number of monofilaments is reducedReduce the number of monofilamentsLaminationLamination apparatusFiber bundleEngineering

Owner:JINGTAI COUNTY JINLONG CHEM BUILDING MATERIALCO

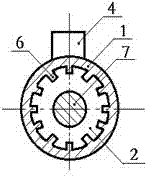

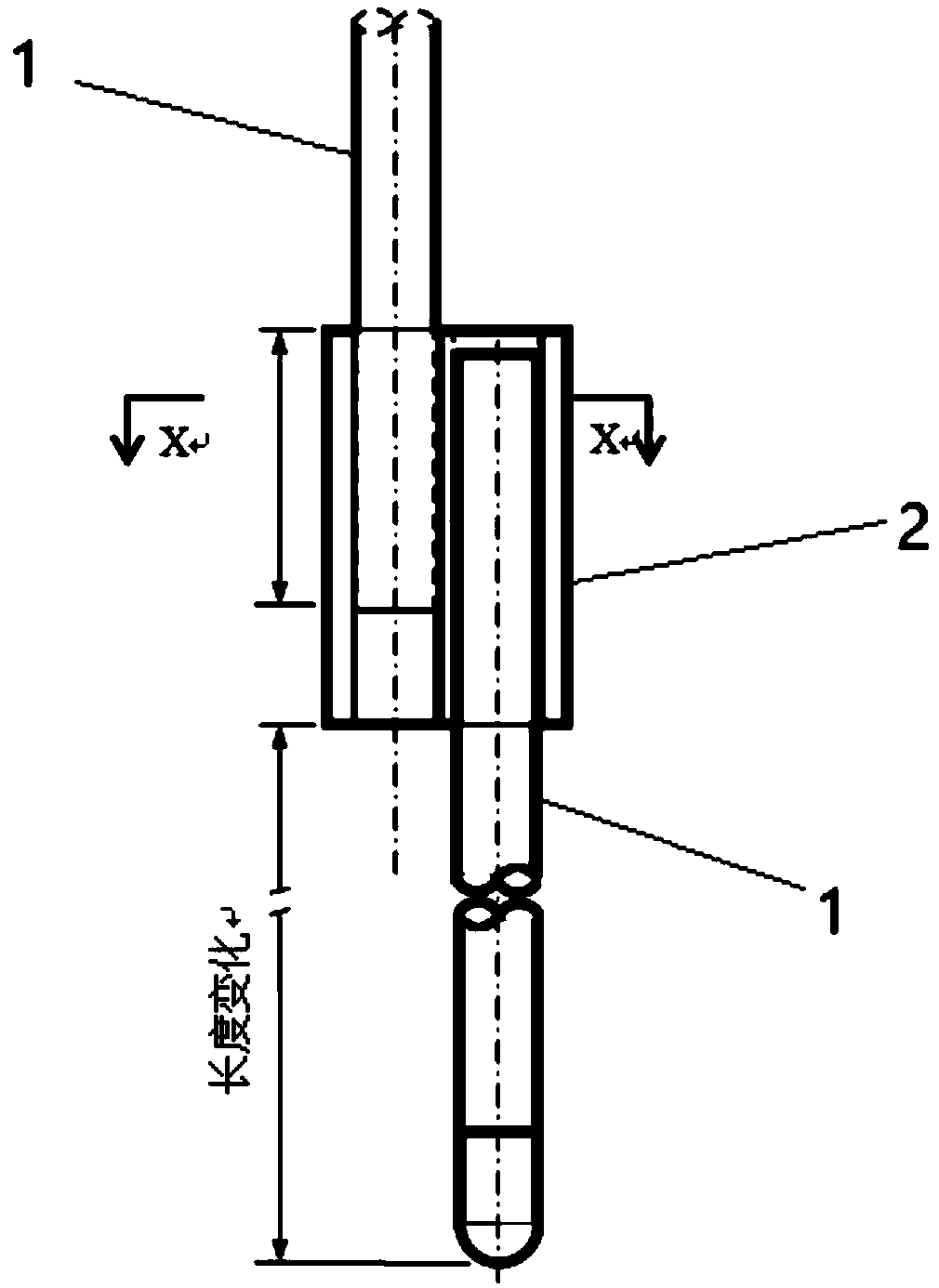

Steel bar connecting sleeve for concrete construction and construction process of steel bar connecting sleeve

ActiveCN105714985ASpeed up the installation processGuarantee the construction progressBuilding reinforcementsBuilding material handlingRebarScrew thread

The invention relates to a steel bar connecting sleeve for concrete construction and a construction process of the steel bar connecting sleeve. The steel bar connecting sleeve for concrete construction comprises a first steel bar body and a second steel bar body. A thread female head connecting sleeve of the first steel bar body is in threaded fit with a thread male head connecting sleeve of the second steel bar body. The steel bar connecting sleeve has the advantages that the construction process of the steel bar connecting sleeve for concrete construction is adopted, after the thread male head connecting sleeve of the second steel bar body is connected with the thread female head connecting sleeve of the first steel bar body through straight threads, the steel bar installing progress is accelerated, and the influence of joint bar installation on formworks is avoided; large turnup steel formworks can be used for a first-stage concrete structure, the construction progress of the first-stage concrete structure is effectively guaranteed, mutual interference of construction of the first-stage concrete structure and a second-stage concrete structure is relieved, the construction progress of the first-stage concrete structure and the second-stage concrete structure is greatly increased, and meanwhile the construction quality of the concrete structures is guaranteed.

Owner:SINOHYDRO BUREAU 11 CO LTD

Prefabricated whole filling wall and structural connection method thereof

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

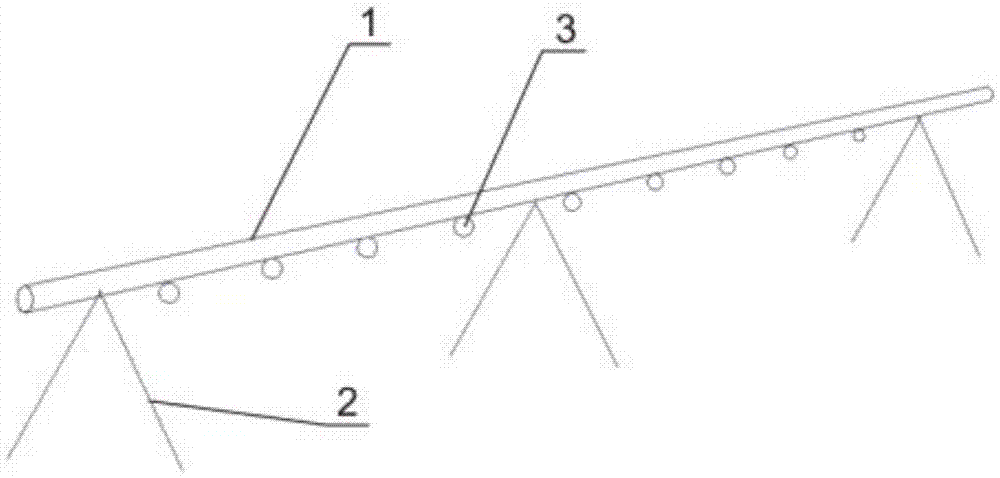

Construction method of long steel bar stool cast-in-situ floor

InactiveCN105442735AControl thickness deviationEasy constructionFloorsBuilding reinforcementsFloor slabSurface level

Owner:广西华业建筑工程有限公司

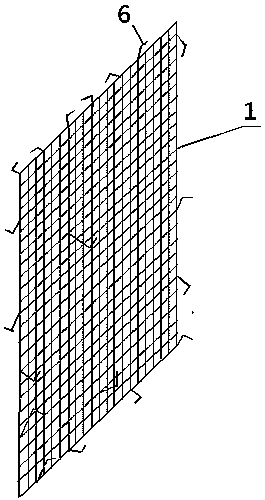

Reinforcing protection and repairing method for historical earthen site and ancient building city wall

PendingCN112878731AAdd supportEasy to pourBuilding repairsForms/shuttering/falseworksArchitectural engineeringMesh reinforcement

Owner:河南朴之原建筑肌理研究院有限公司

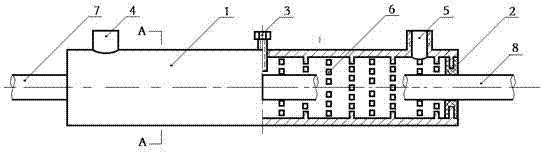

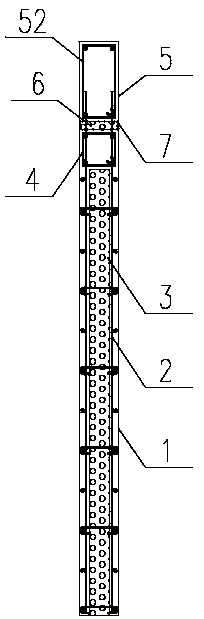

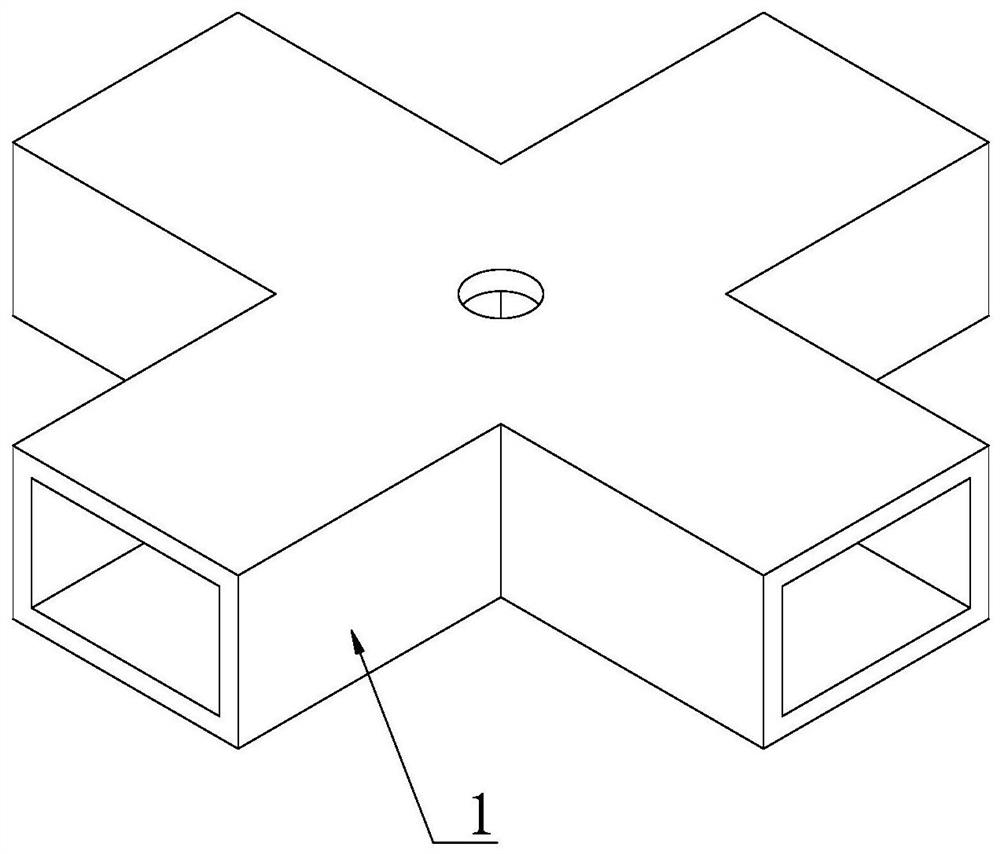

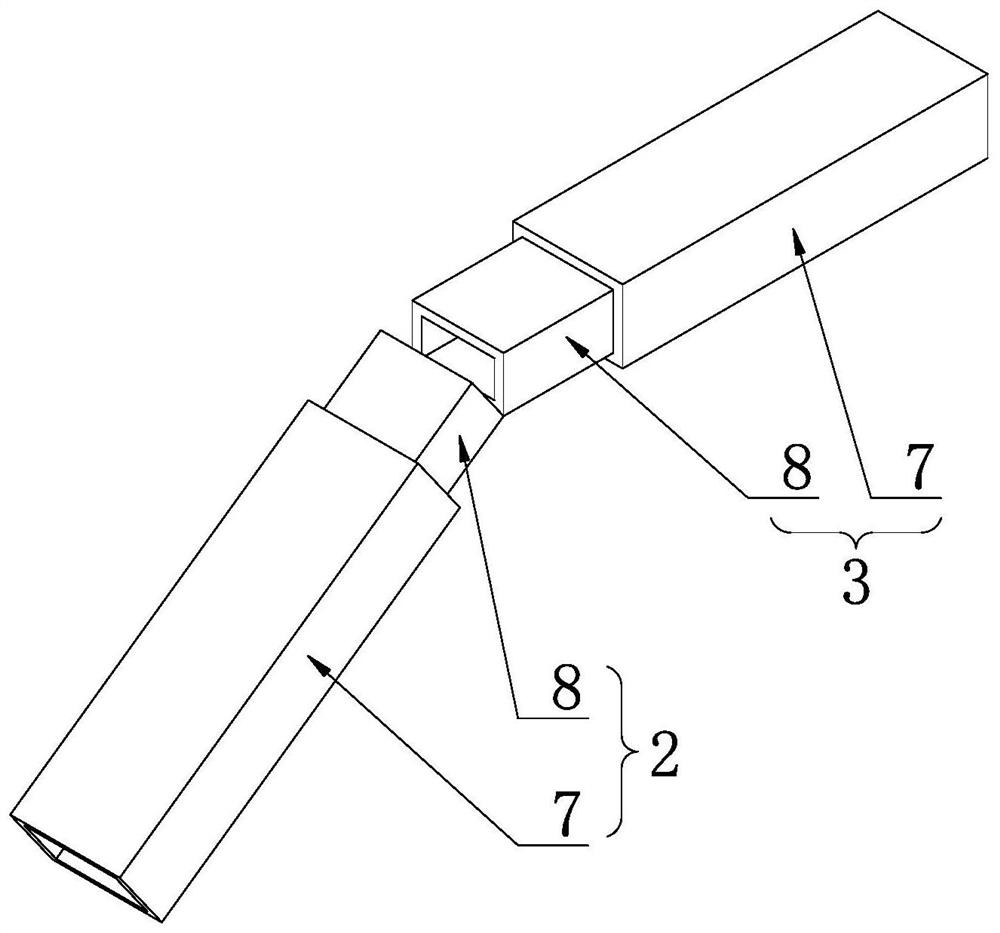

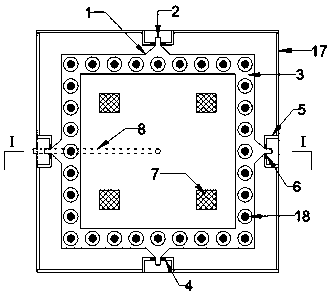

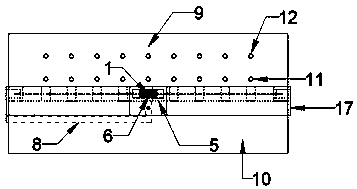

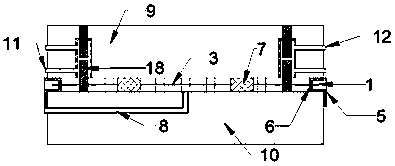

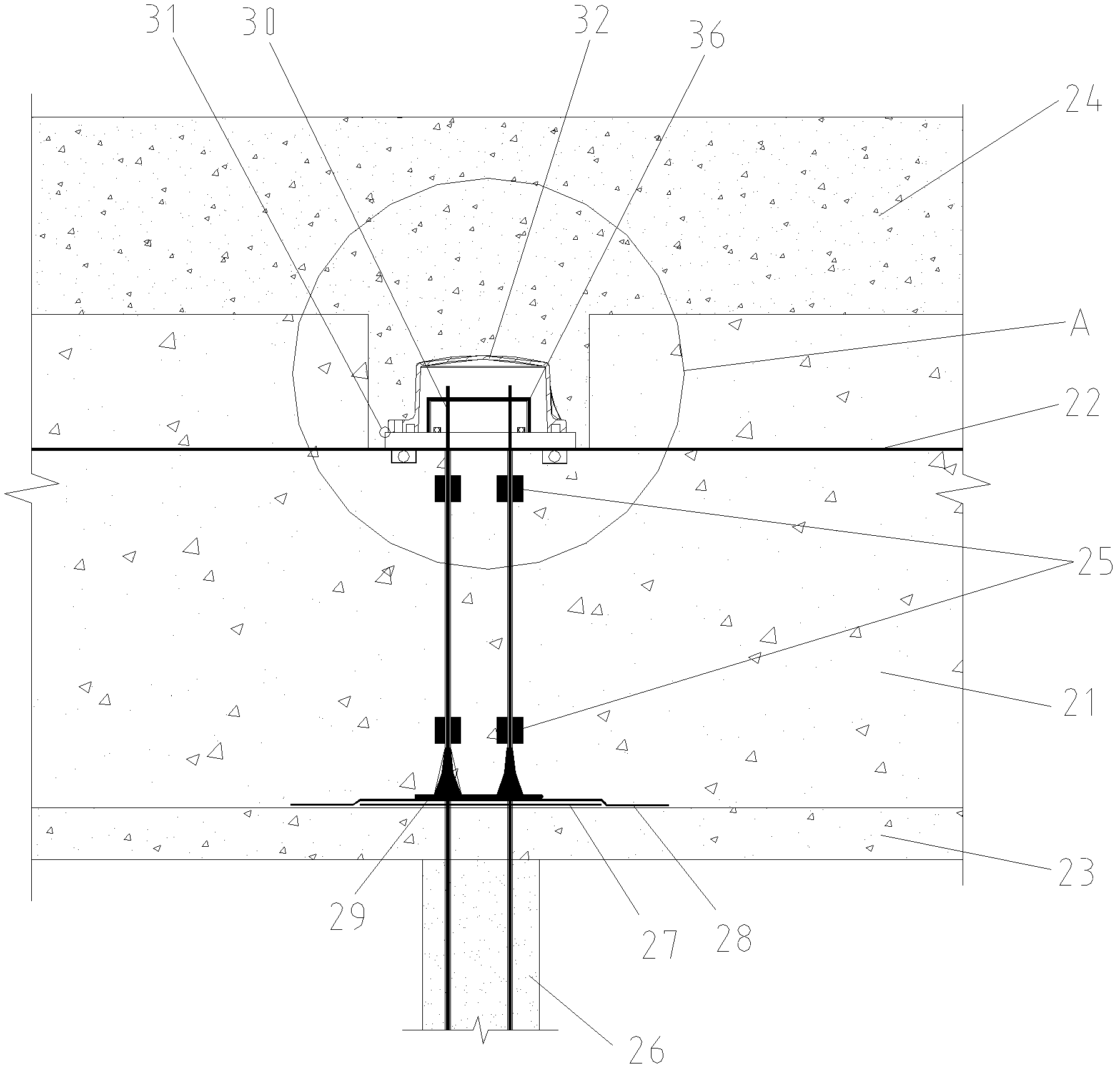

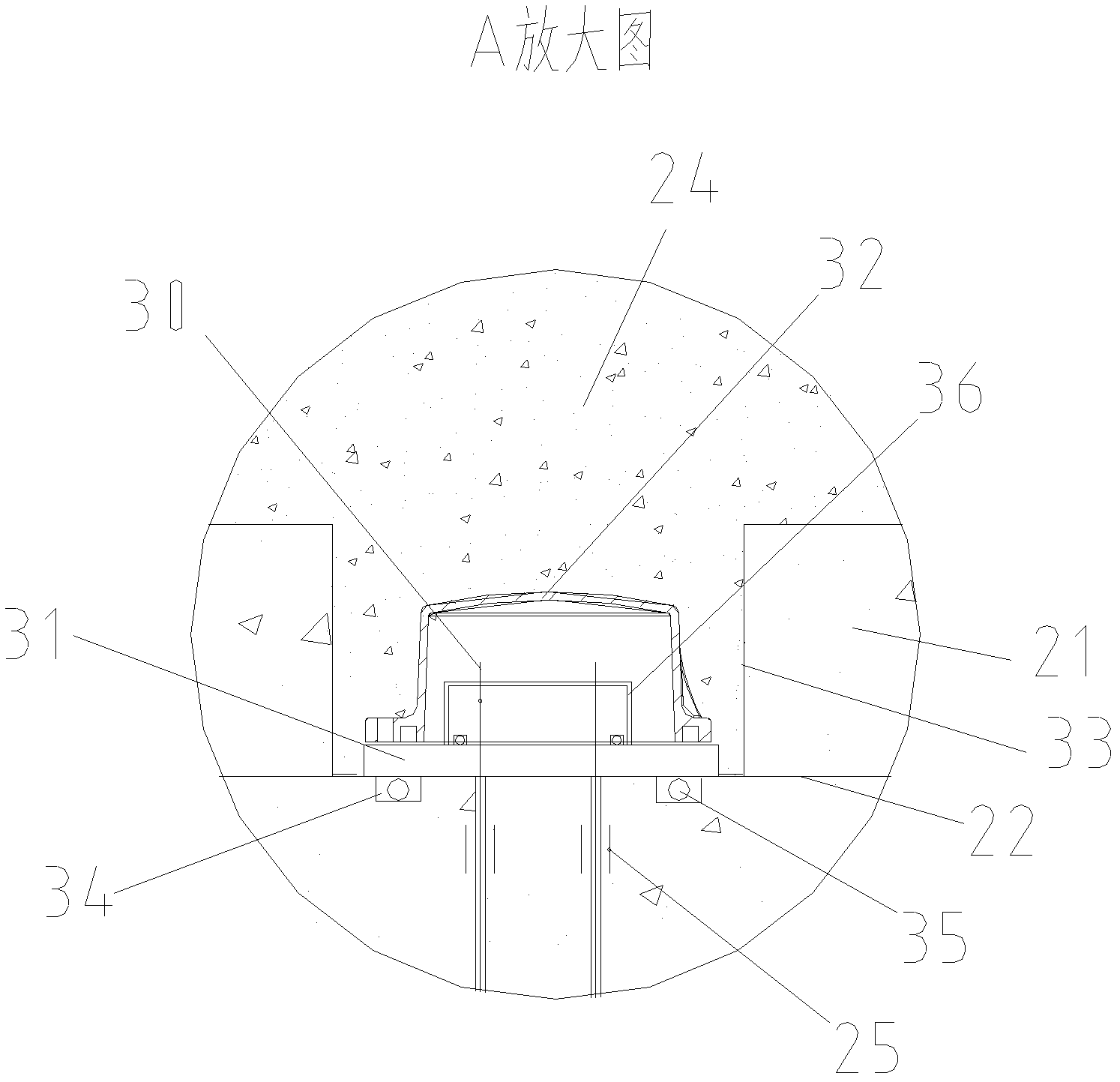

Built-in vibrating device based on sleeve post-grouting construction

Owner:SOUTHEAST UNIV

Side wall open-hole anchoring bidirectional off-position rod piece connector

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

Elastic combined anchoring ring spherical hinge steering connector of offset rod piece

PendingCN109853860AAchieve mechanical connectionEliminate reliabilityBuilding reinforcementsMaterial consumptionEngineering

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

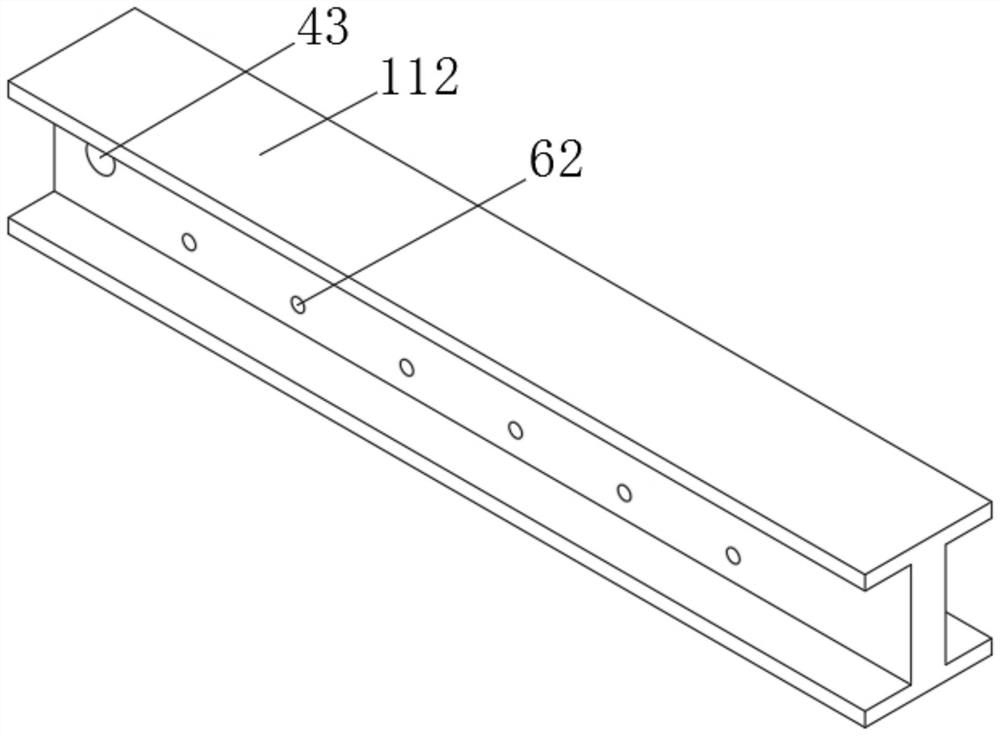

Frame beam steel bar connecting system of profile steel column and concrete and pouring construction method

InactiveCN113062448AAccurate and quick installationReduce labor intensityBuilding reinforcementsBuilding material handlingReinforced concreteClassical mechanics

Owner:潮峰钢构集团有限公司

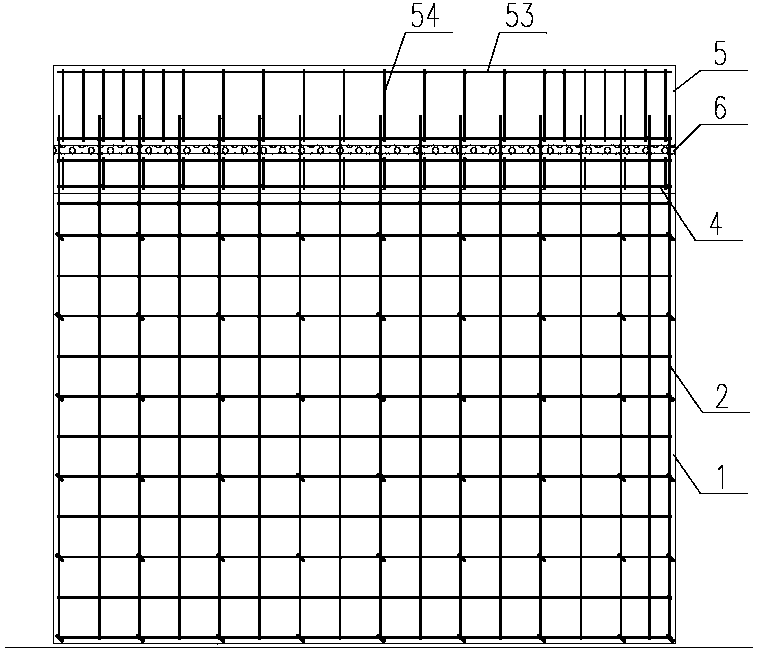

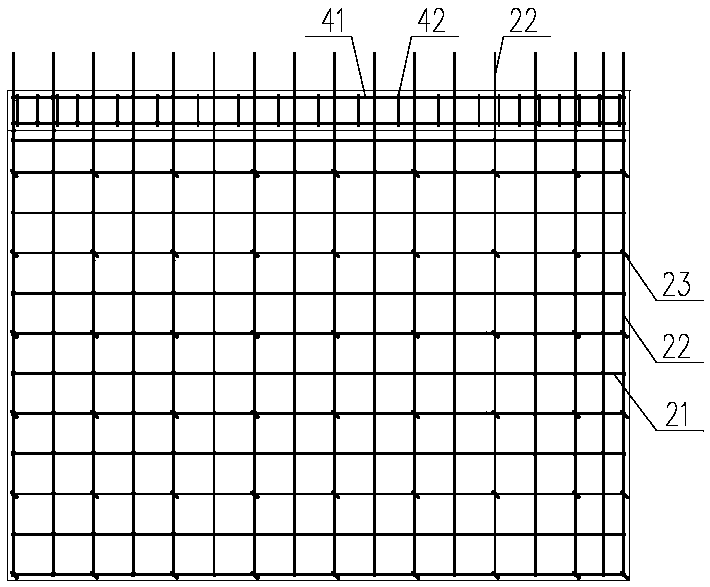

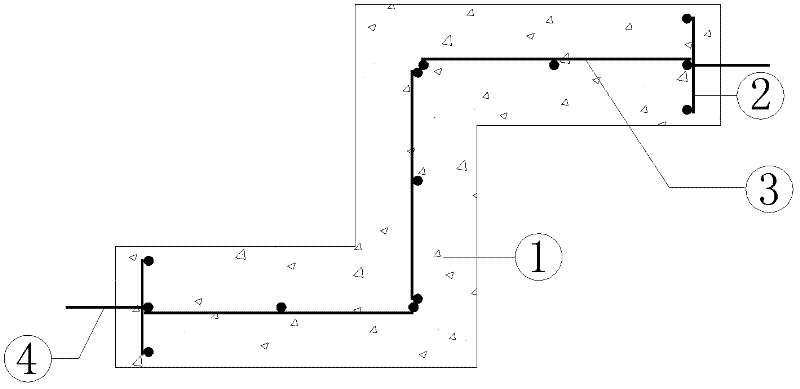

Unbonded prestressed steel reinforced concrete wall and construction method thereof

PendingCN108517985ASolve the problem that the bonding force cannot be guaranteedSimple processWallsBuilding reinforcementsReinforced concretePre stress

The invention discloses an unbonded prestressed steel reinforced concrete wall and a construction method thereof. The concrete wall comprises a concrete wall body, non-prestressed rib meshes, unbondedprestressed rib strands, I-shaped steel and a prestressed rib strand anchoring device. The method comprises the steps of 1, deepening a design drawing; 2, processing and manufacturing the horizontalunbonded prestressed rib strands and the vertical unbonded prestressed rib strands; 3, fixing the I-shaped steel; 4, fixing positioning bracket reinforcing steel bars; 5, binding the unbonded prestressed rib strands; 6, binding the non-prestressed rib meshes; 7, supporting a lateral formwork; 8, pouring and maintaining concrete, and tensioning prestressed ribs; 9, conducting sealed anchoring. Theunbonded prestressed steel reinforced concrete wall solves the problems that in an existing prestressed steel reinforced concrete structure, grouting of bonded prestressed ribs is difficult, and the corrosion prevention of the vertical prestressed ribs and the whole bonding force of the vertical prestressed ribs and concrete cannot be ensured, and the steps of the construction method are simple and convenient.

Owner:CHONGQING CONSTR ENG GRP +1

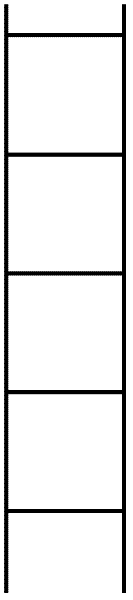

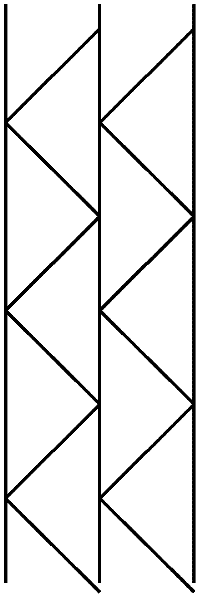

Latticed single-row reinforced Z-shaped sectional concrete column and making method

InactiveCN102561594AReduce dosageImprove shear resistanceStrutsBuilding reinforcementsBrickSteel bar

Owner:BEIJING UNIV OF TECH

Full grout sleeve for building steel bar connecting

Owner:恒荣建设集团有限公司

Waterproof node for steel strand

Owner:SUZHOU NG FOUND ENG

Joint structure, building body and joint structure construction method

ActiveCN113756453AImprove tensile and shear strengthImprove anchor strengthBridge erection/assemblyBuilding reinforcementsUltimate tensile strengthJoint (building)

Owner:CHINA FIRST HIGHWAY ENG +2

Reinforcing steel bar lapping connector

Owner:NANJING UNIV OF TECH

Composite wall

Owner:金国洪

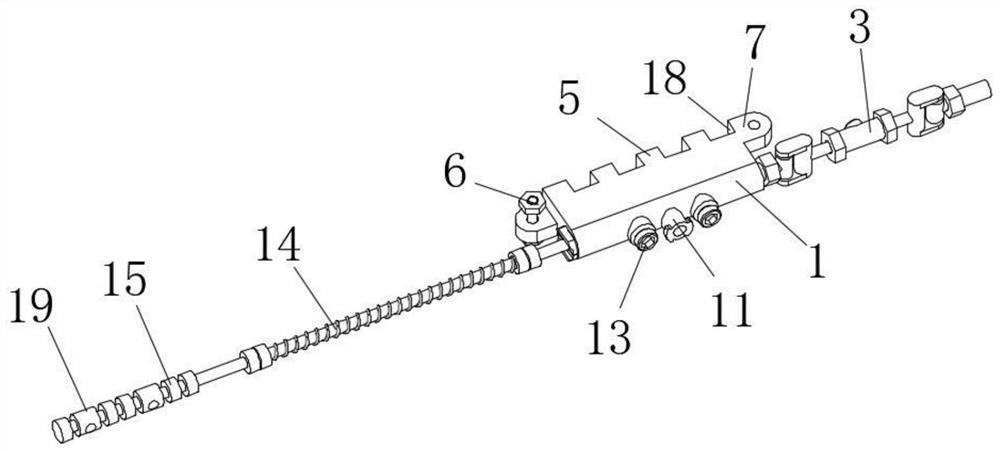

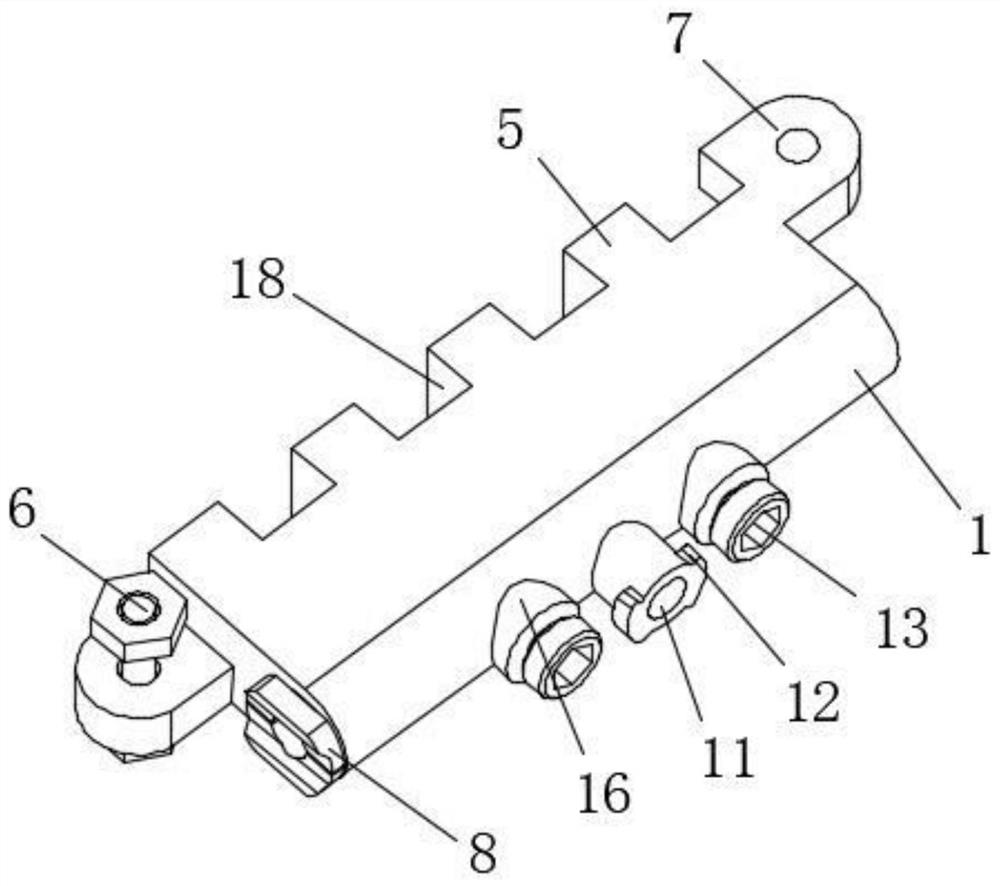

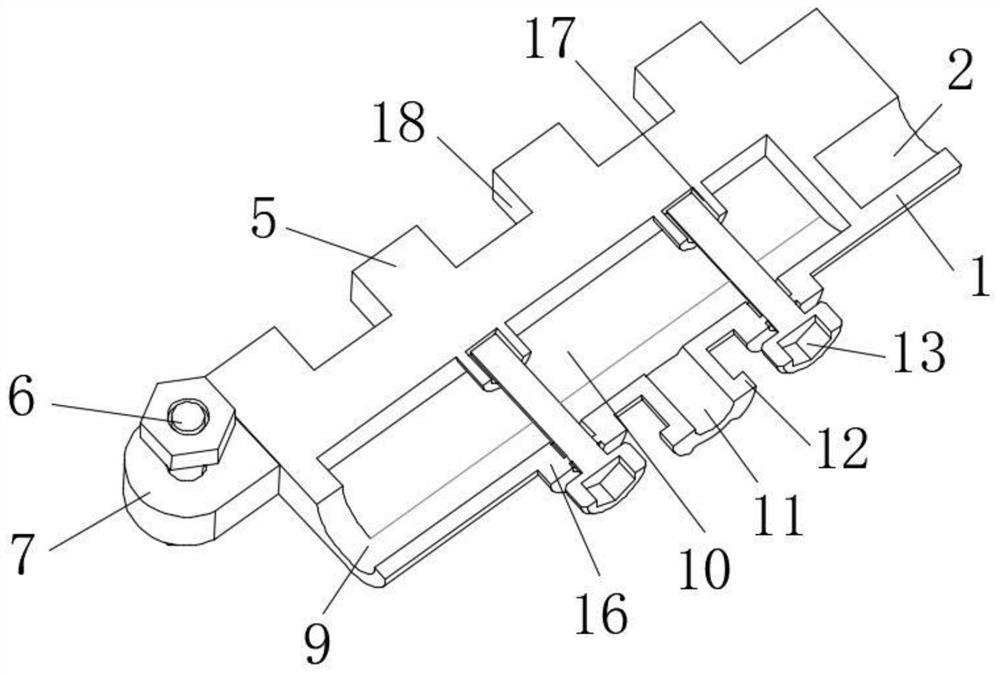

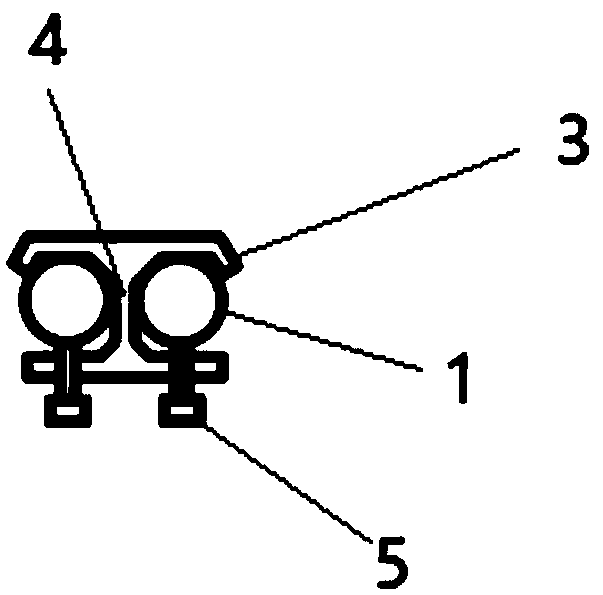

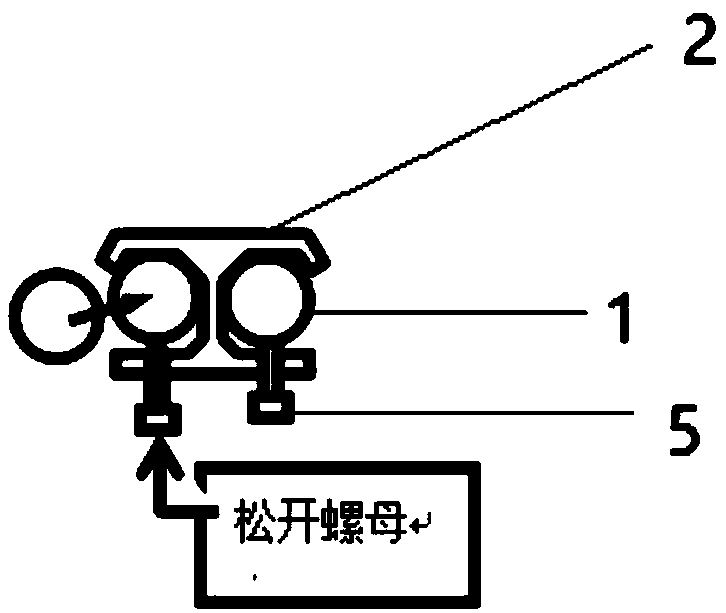

Quick butt joint assembly and quick butt joint mechanism

PendingCN111042110AEasy to installShorten construction timeBuilding reinforcementsBulkheads/pilesButt joint

The invention provides a quick butt joint mechanism. The quick butt joint mechanism comprises an inserting table, a base and a ring buckle, wherein the inserting table comprises a fixed part and an inserting part which are oppositely arranged, and the inserting part is provided with a first groove; the base is provided with a first end face and a second end face which are oppositely arranged; thering buckle is provided with an opening and can elastically contract, and the ring buckle is arranged on the inserting table in a sleeve mode and is accommodated in the first groove; the ring buckle can be inserted into the base in the inserting direction together with the inserting part of the inserting table, and the ring buckle can abut against the second end face of the base through elastic expansion, and limits the reverse movement of the inserting table in the inserting direction; the base is provided with a second boss, and the second boss is used for positioning the relative positionalrelationship between the base and a second embedded assembly in the quick butt joint mechanism. According to a quick butt joint assembly provided by the invention, the relative position relationshipbetween the base and the second embedded assembly is rapidly determined through the second boss, and the phenomena of dislocation and the like generated after the joint between the second embedded assembly and the base is stressed can be avoided.

Owner:许顺良

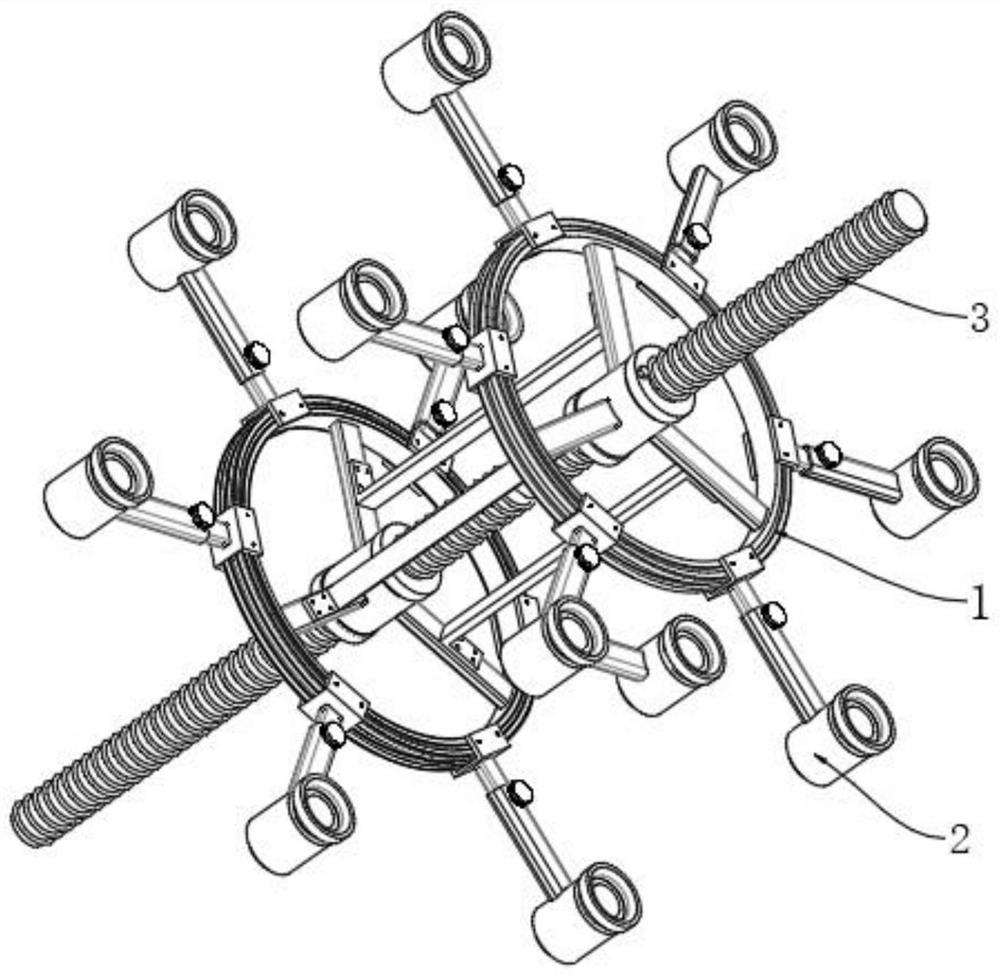

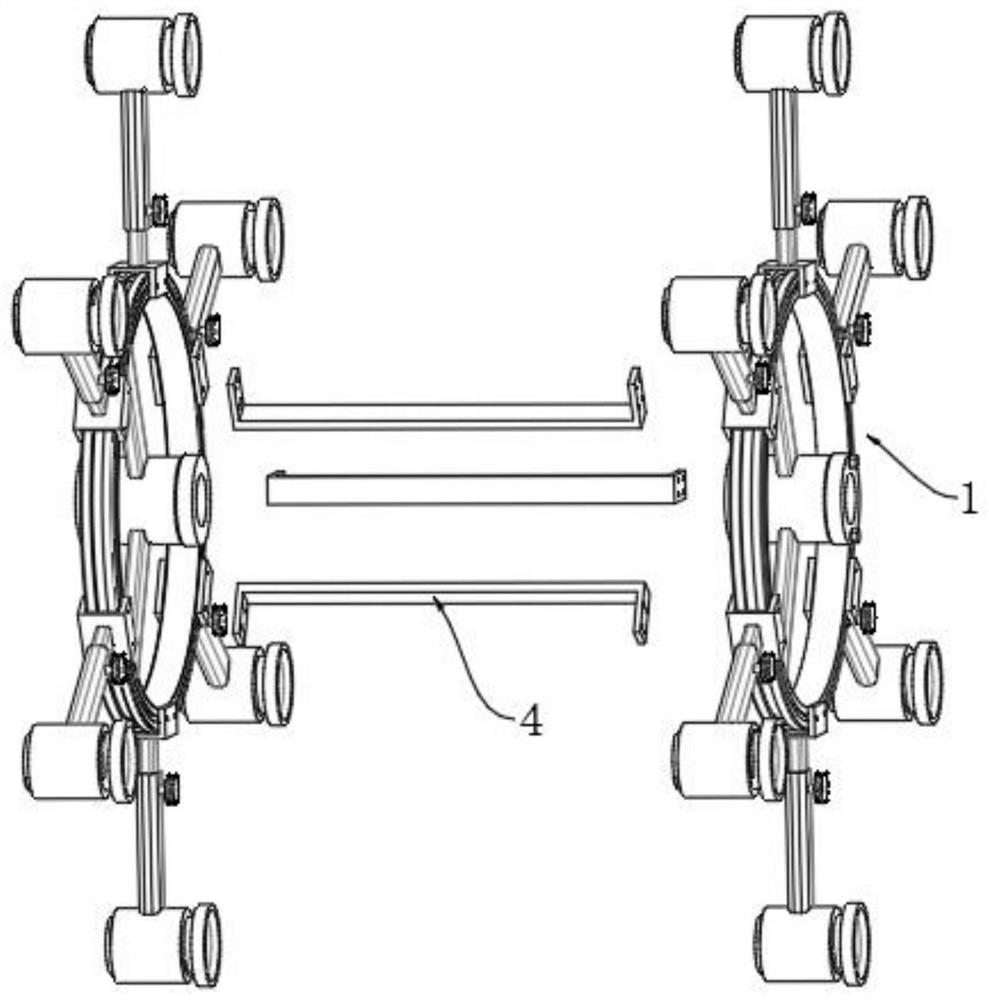

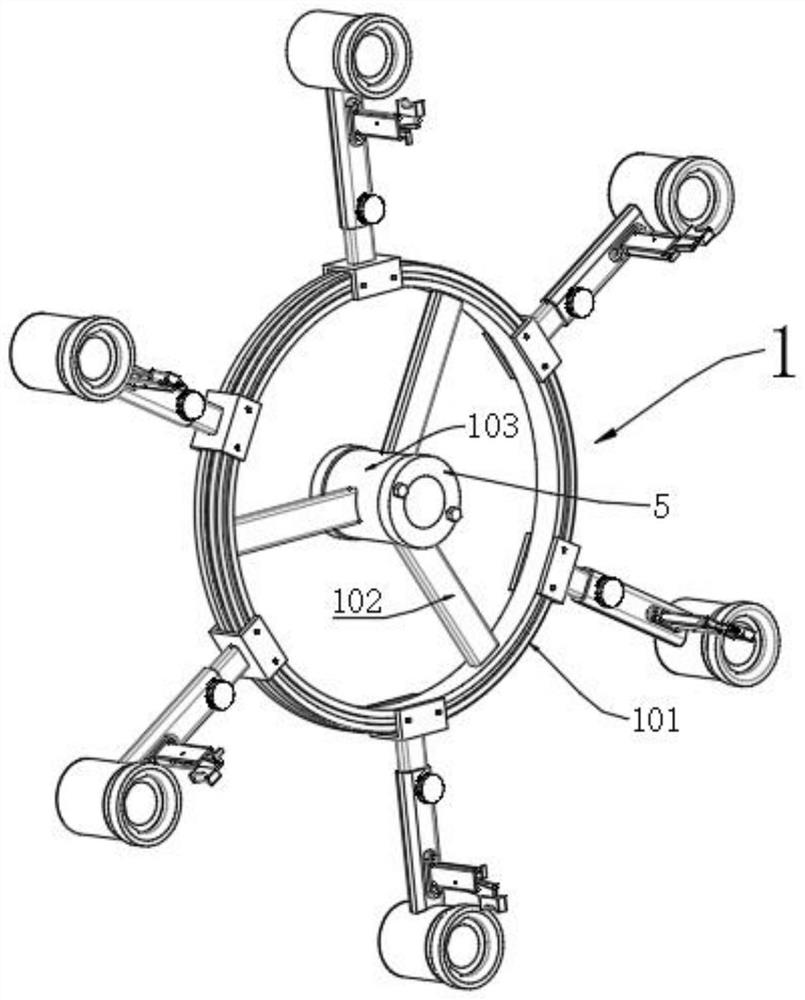

Tree-like ecological photovoltaic pipe pile with reinforced ribs

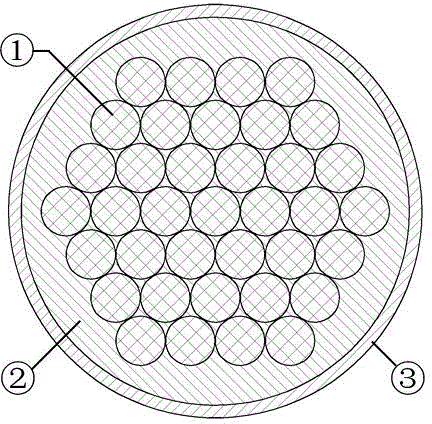

PendingCN112695747AWon't hurtEnhanced bending, tensile and shearing capabilitiesBuilding reinforcementsBulkheads/pilesLight reflectionZoology

The invention relates to a tree-like ecological photovoltaic pipe pile with reinforced ribs. The tree-like ecological photovoltaic pipe pile comprises a rib cage and an end plugging device, wherein the rib cage comprises main ribs and an auxiliary rib cage; the auxiliary rib cage comprises auxiliary main ribs and annular ribs; the main ribs are arranged in the circumferential direction at intervals; the annular ribs are arranged around the auxiliary main ribs and connected with the auxiliary main ribs; the main ribs correspond to the auxiliary main ribs one to one and are detachably connected with the auxiliary main ribs; upset heads are arranged at the ends of the main ribs and connected with sleeve nuts; the end plugging device comprises rib nets, a tray and connecting ribs; and the rib nets are arranged at the two ends of the rib cage. The appearance of the pipe pile is in a tree bark texture imitation mode, the pipe pile can be easily integrated into the natural environment, environment pollution such as light reflection and chromatic aberration is avoided, the prestress high-strength wire main ribs poor in weldability do not need to be welded, and the main ribs cannot be damaged; meanwhile, the main ribs and the auxiliary main ribs are fixed together, and therefore the bending resistance, tensile resistance and shearing resistance of the pipe pile are indirectly enhanced; and the upset heads of the prestress high-strength wire main ribs do not need to be formed through heavy hot upsetting equipment, and the main ribs can be upset at the normal temperature only through a portable cold upsetting machine.

Owner:李近朱

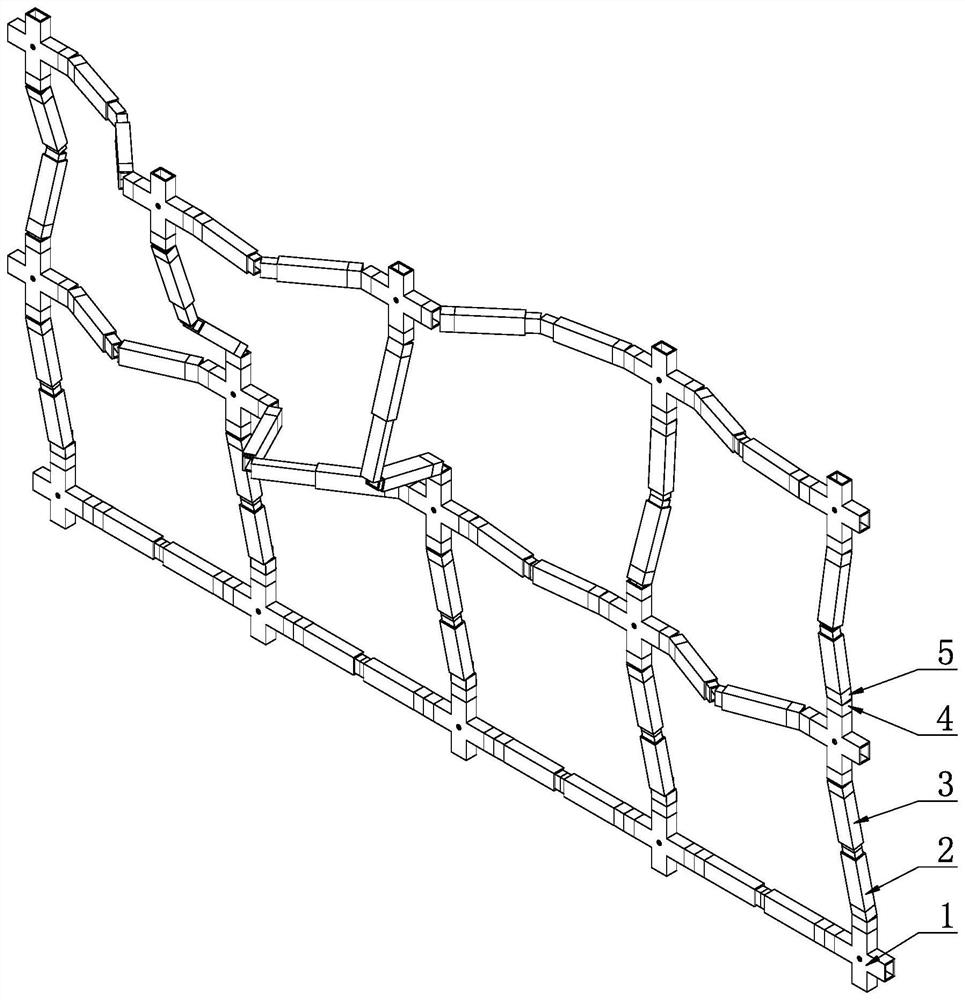

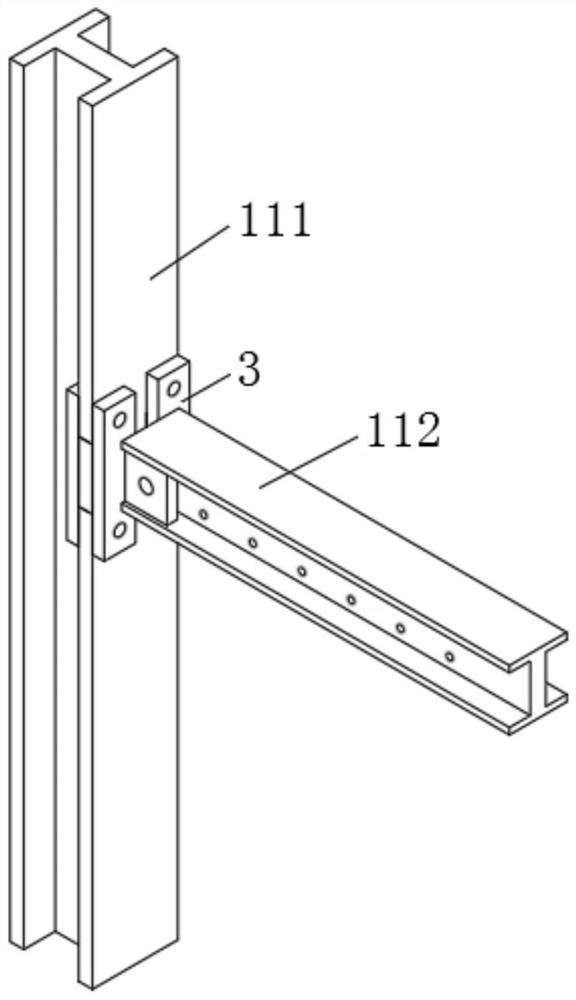

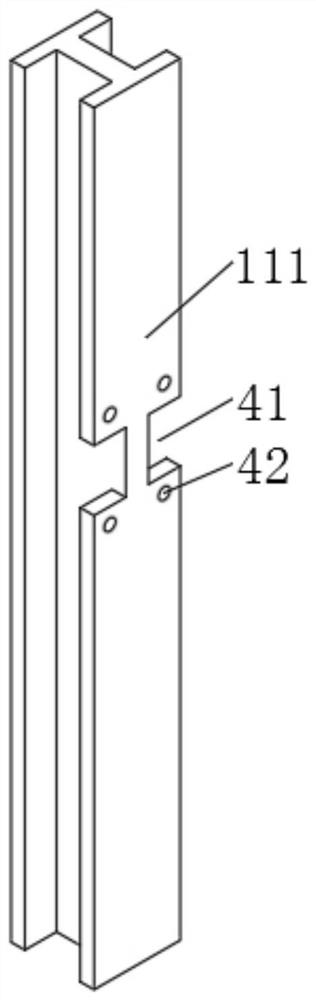

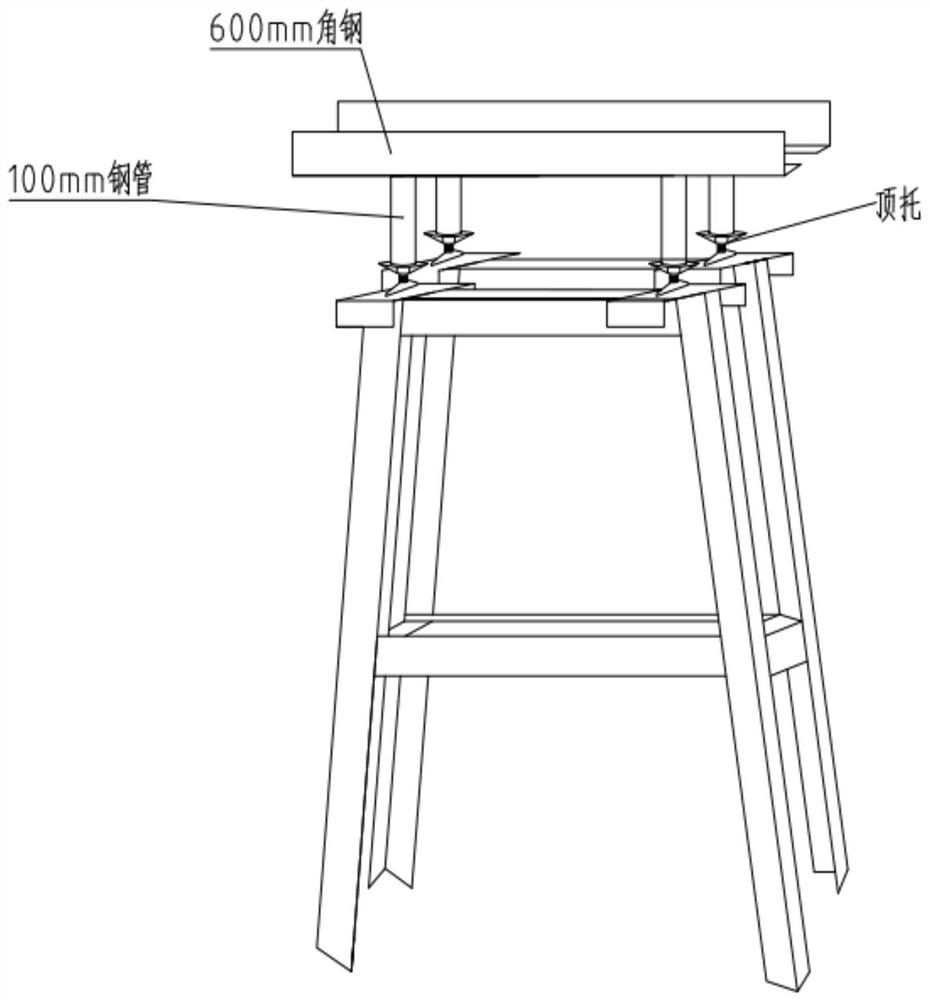

Construction method of adjustable assembly type stirrup bracket

PendingCN112343341AEasy to makeSimple structureBuilding reinforcementsBuilding material handlingClassical mechanicsStirrup

Owner:广西桂林地建建设有限公司

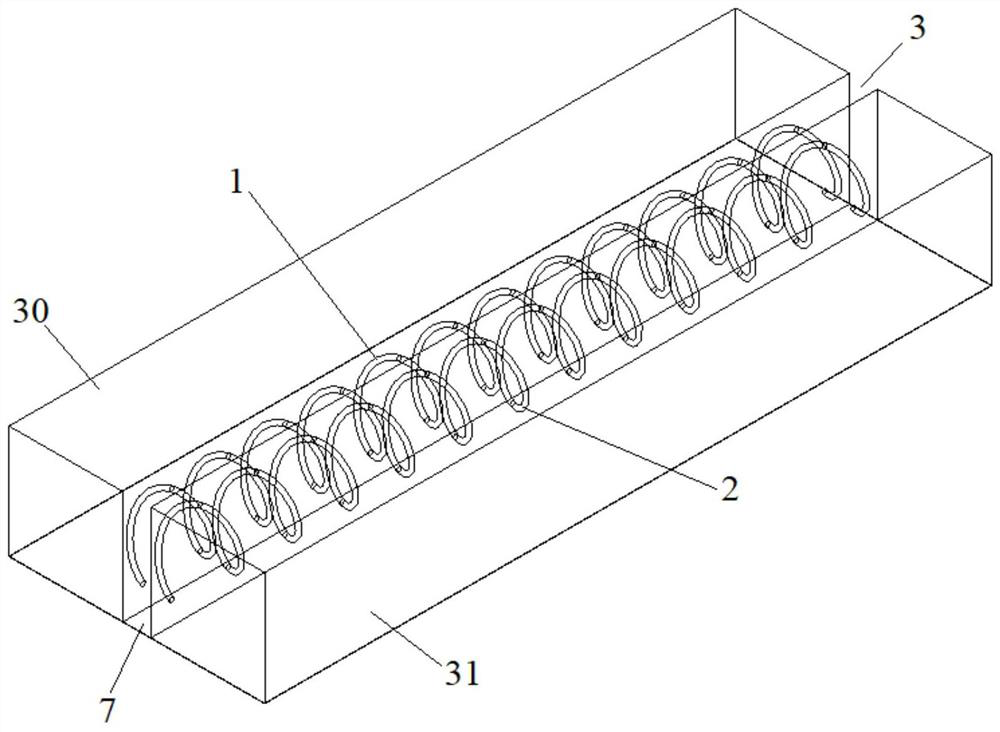

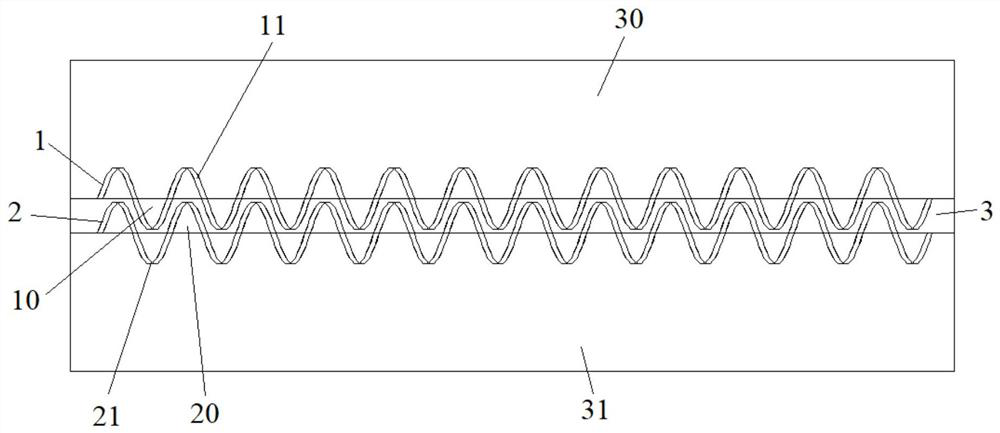

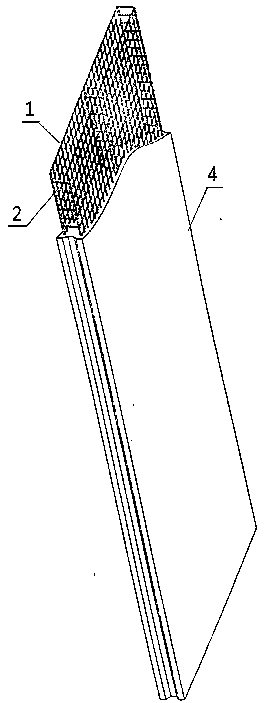

Bendable fiber rib

Owner:青岛天力多维生态有限公司

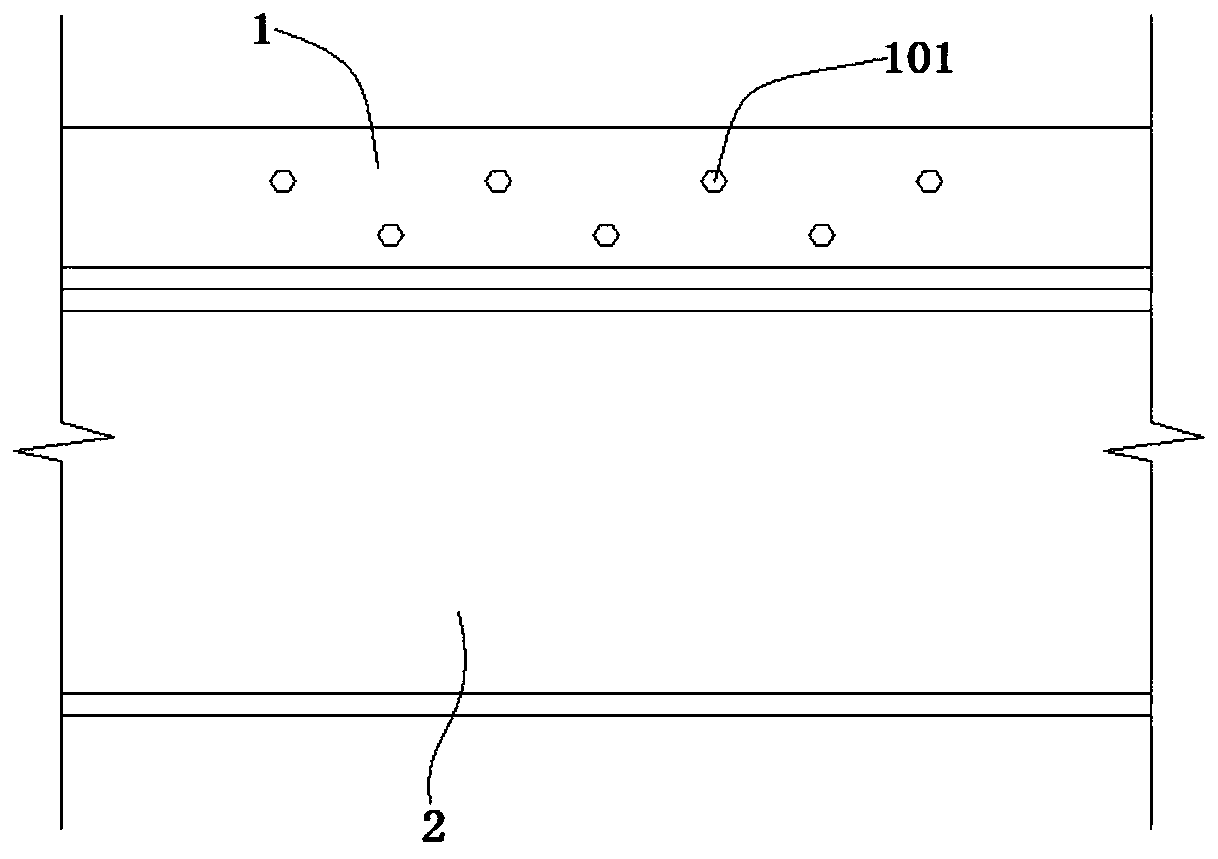

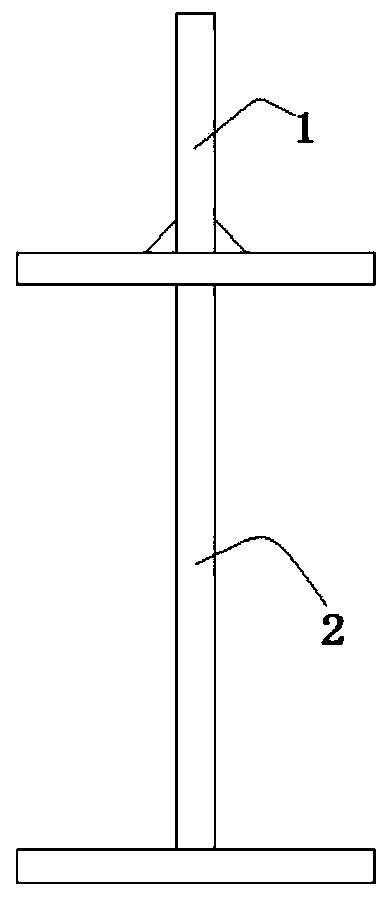

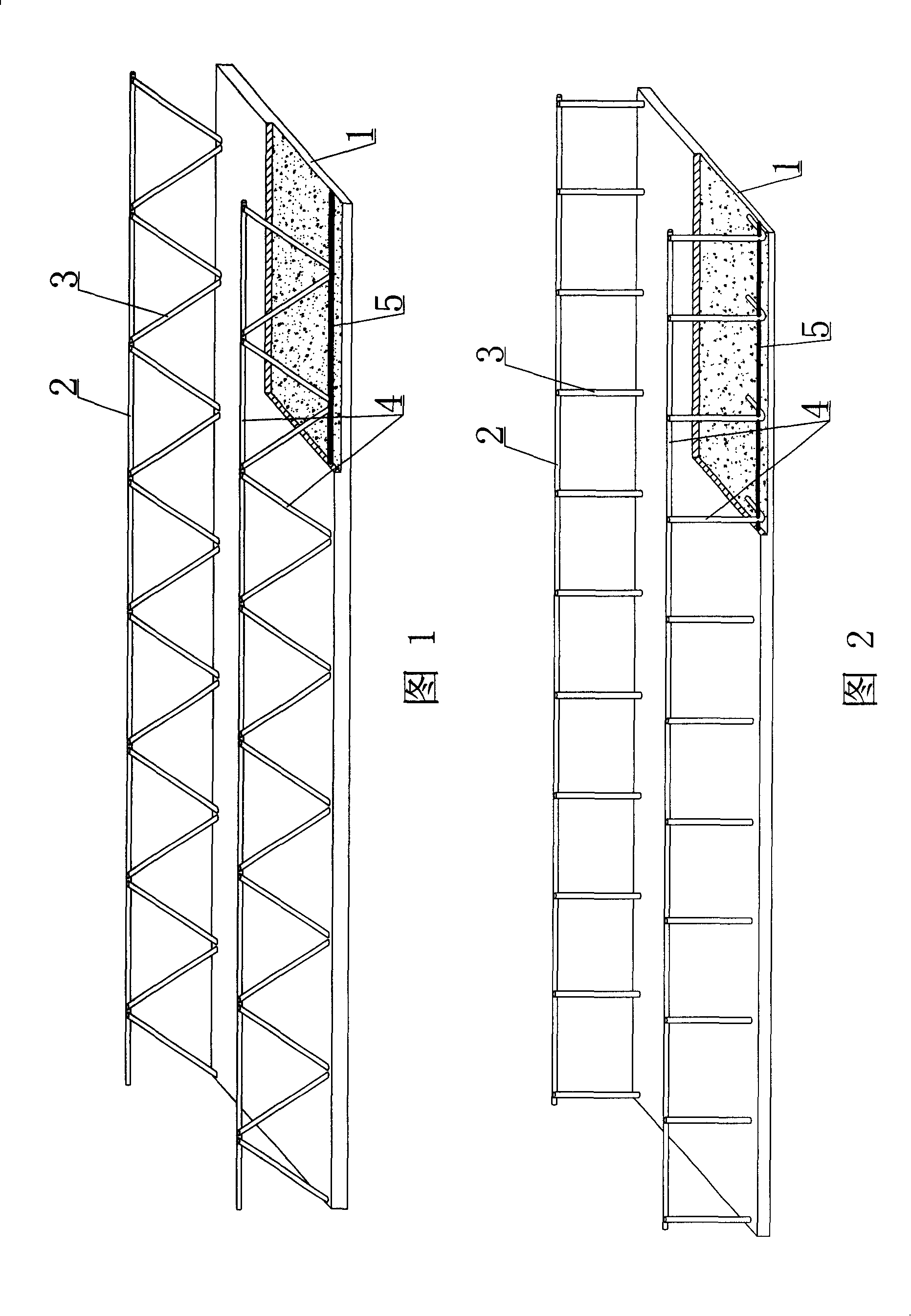

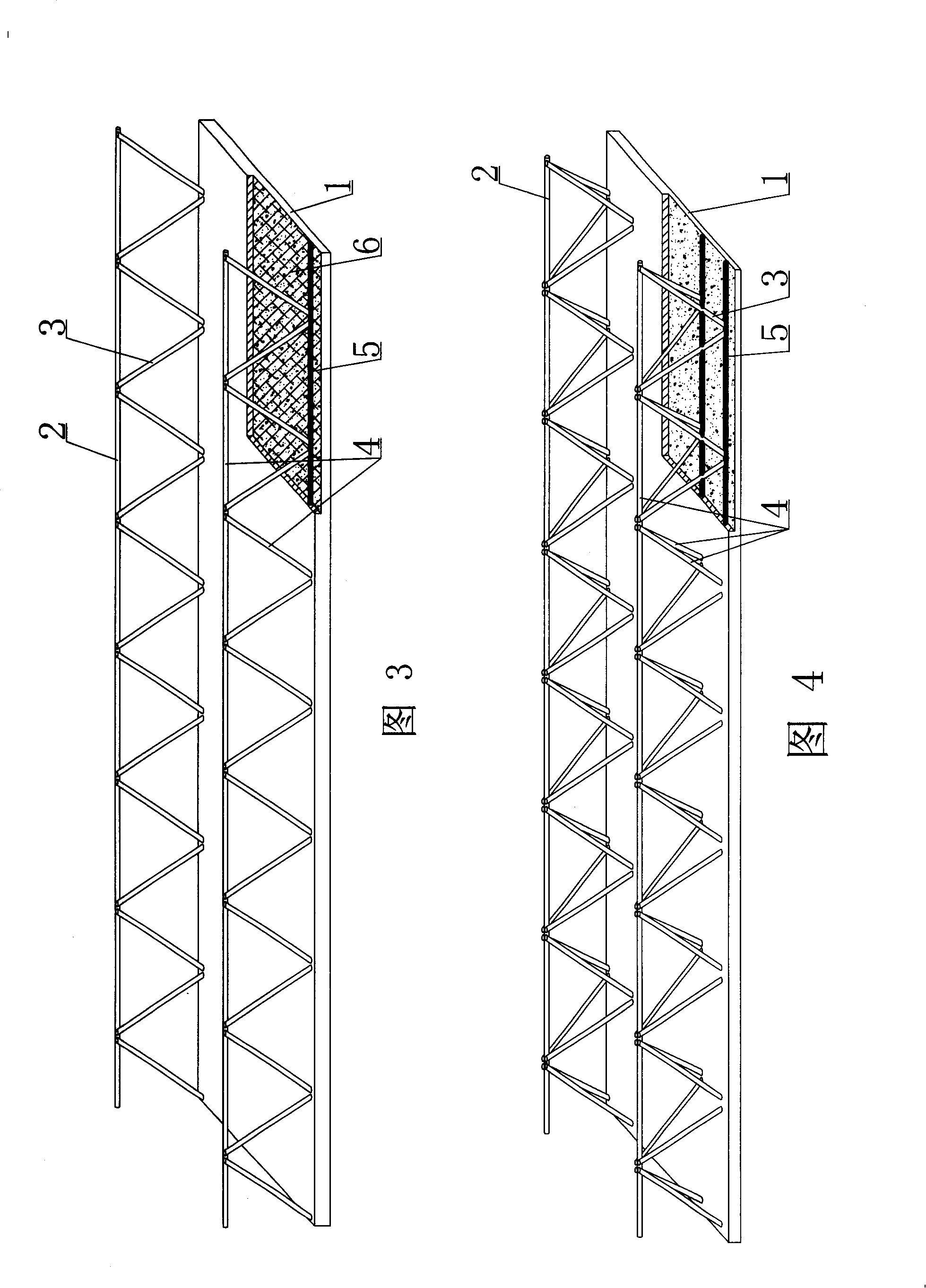

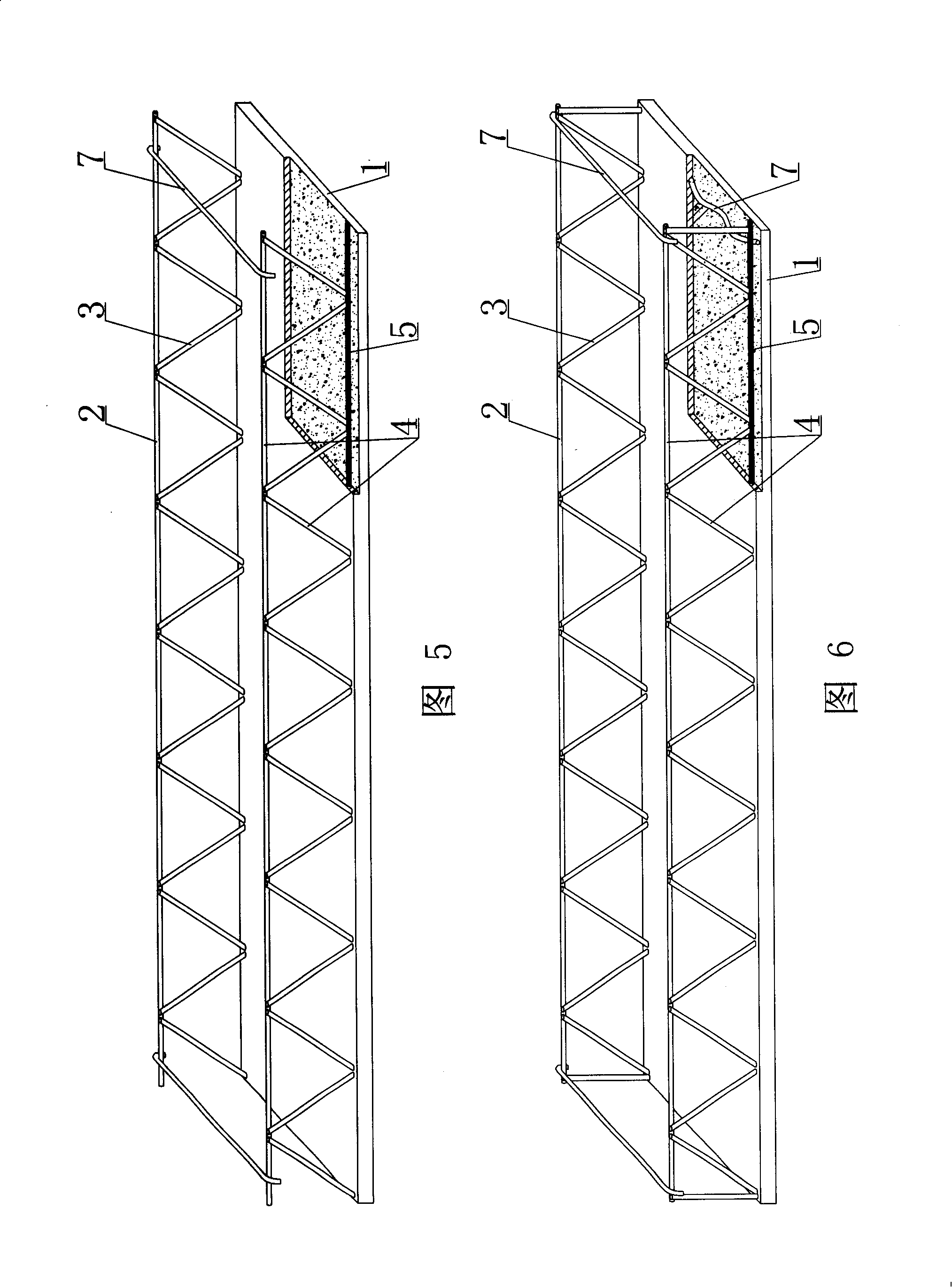

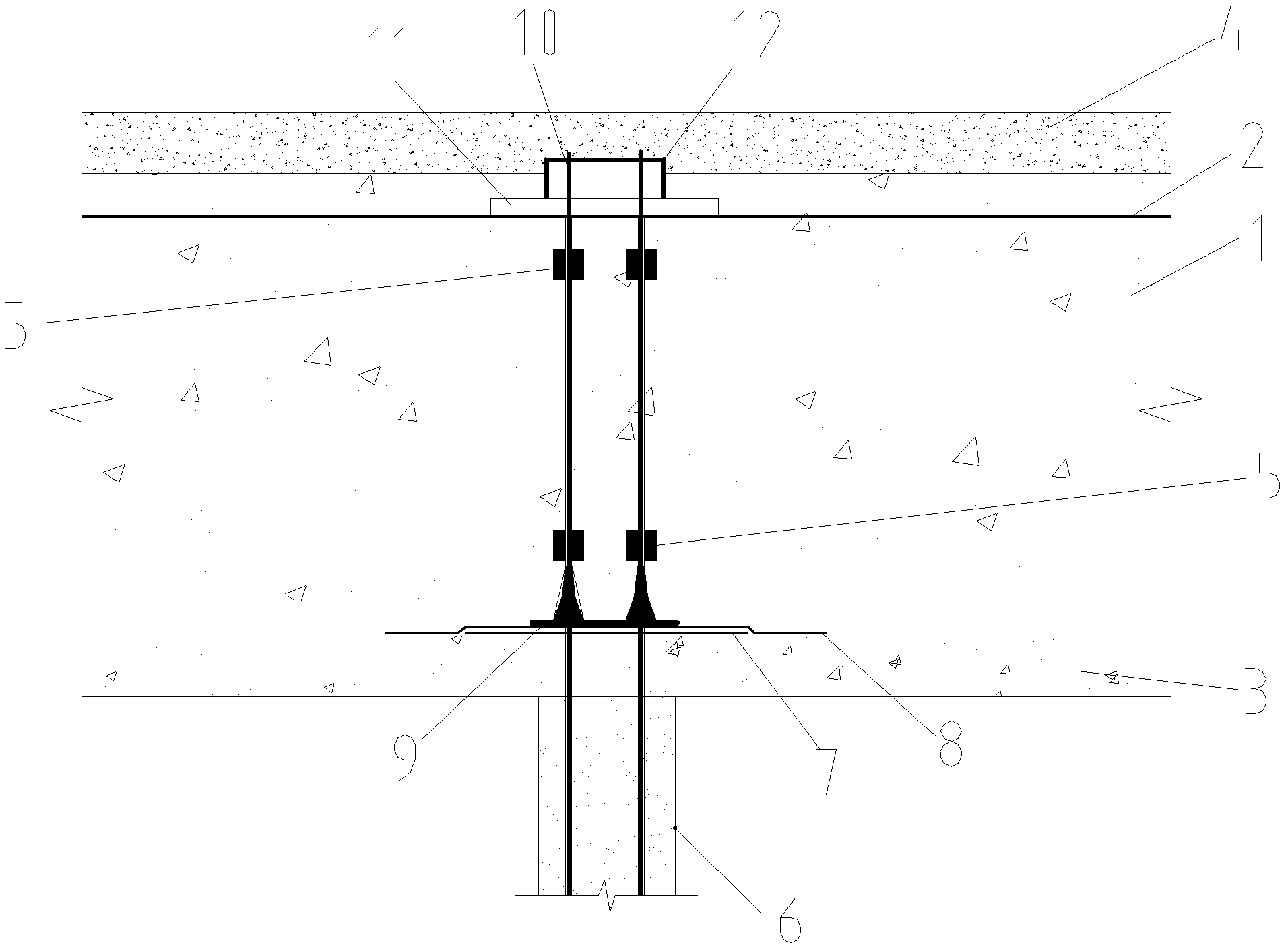

In-situ cast hollow concrete slab

InactiveCN1847545AImprove mechanical propertiesBeautiful external structureWallsFloorsFloor slabReinforced concrete

The in-situ cast hollow concrete slab includes reinforced concrete and shuttering members ranged at intervals and wrapped with the in-situ cast reinforced concrete. The shuttering member includes upper slab, side walls and bottom, which enclose to form polyhedral shuttering member and contain reinforcement in at least one of the parts. The present invention features that the in-situ cast hollow concrete slab includes also at least one prefabricated rod connected with in-situ cast concrete to the upper slab, the side walls or the bottom integrally. The present invention is suitable for use in various kinds of in-situ cast or pre-stressed reinforced concrete hollow floor slab, roof, wall, foundation slab and hollow bridge.

Owner:HUNAN QIUZEYOUZHUANLIZHANLVE PLANNING CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap