Waterproof node for steel strand

A technology of steel strands and nodes, applied in structural elements, building components, building reinforcements, etc., can solve the problems of limited leveling layer thickness and limited waterproof performance, and achieve the effect of increasing waterproof capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

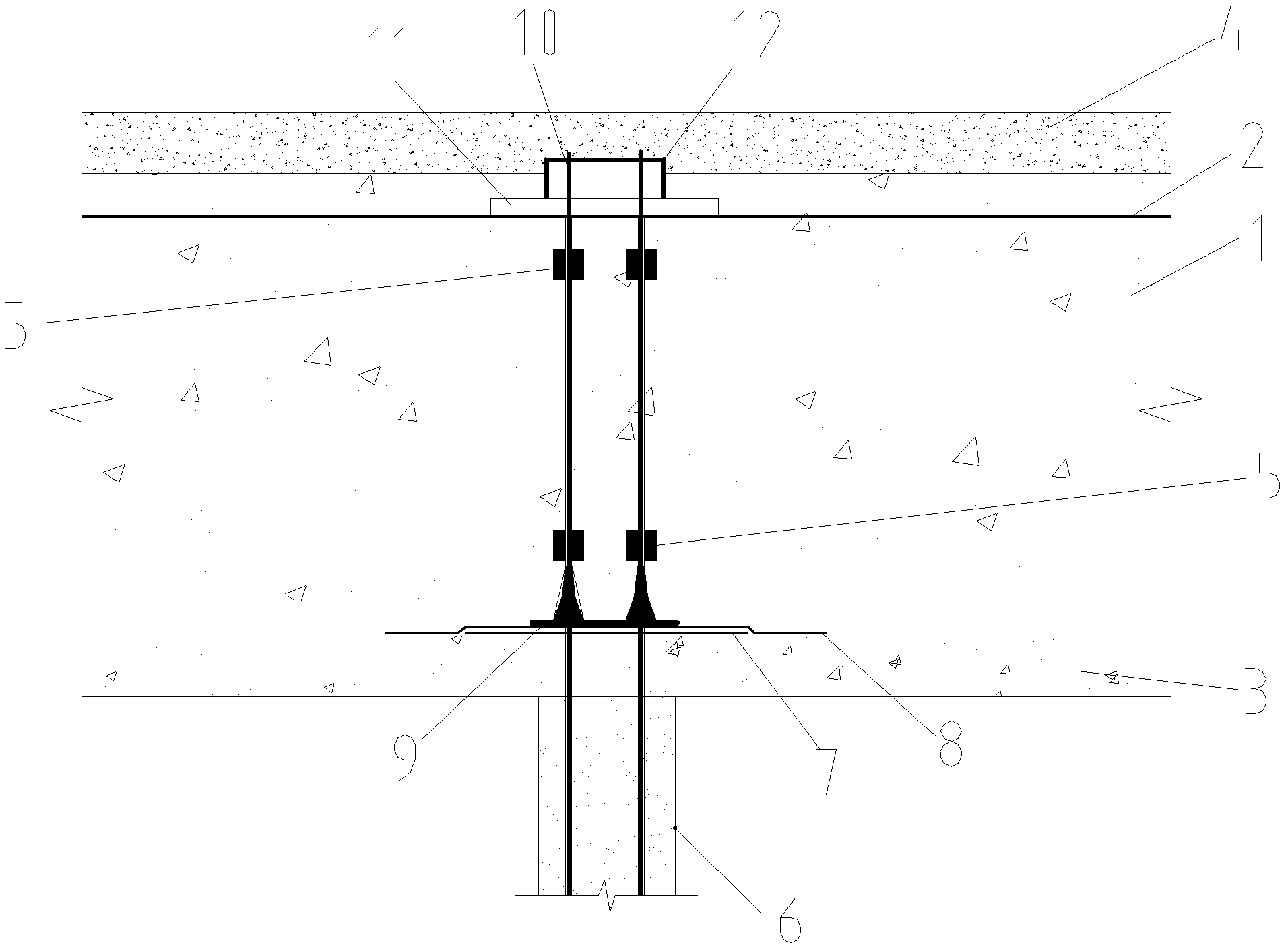

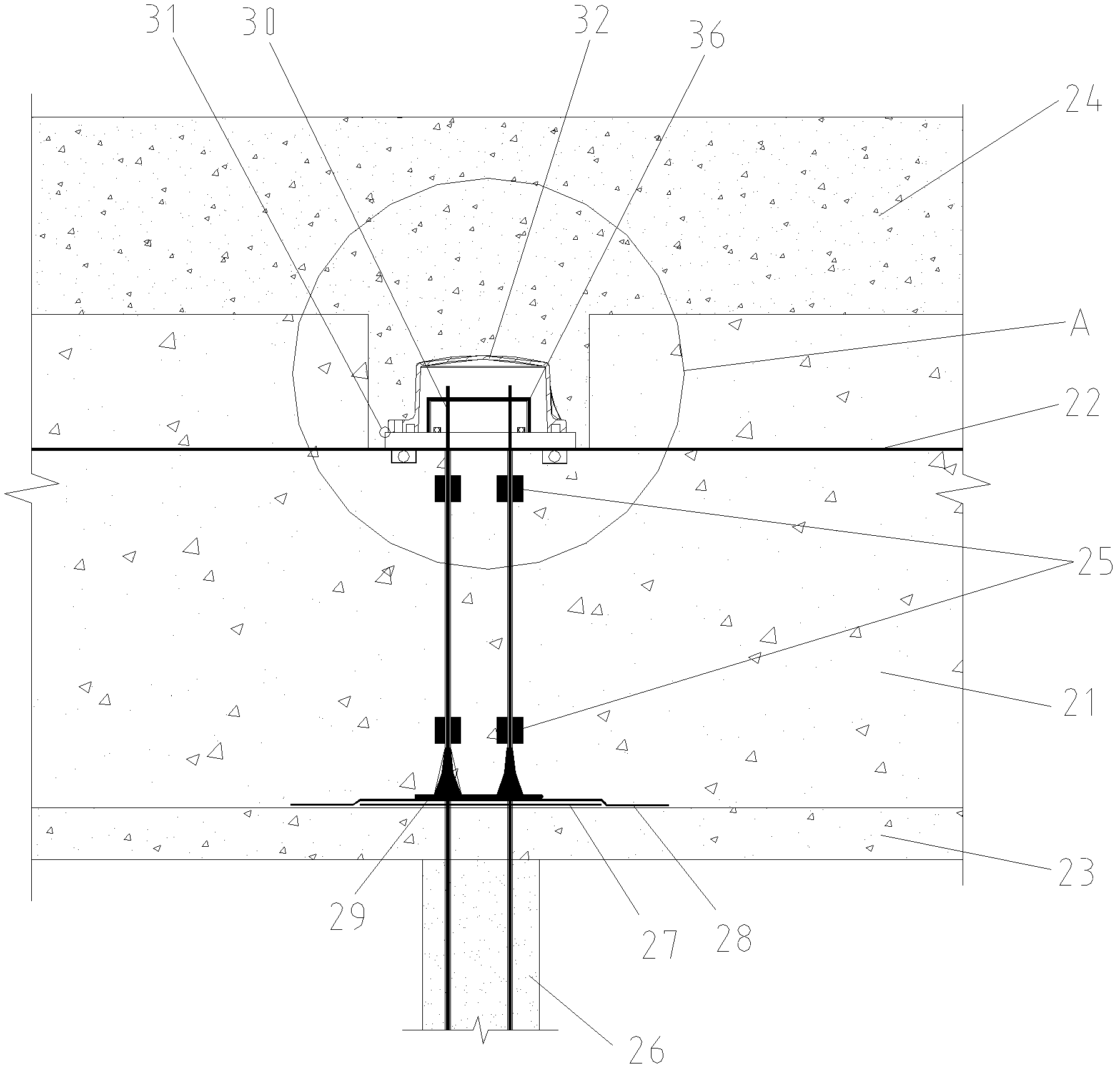

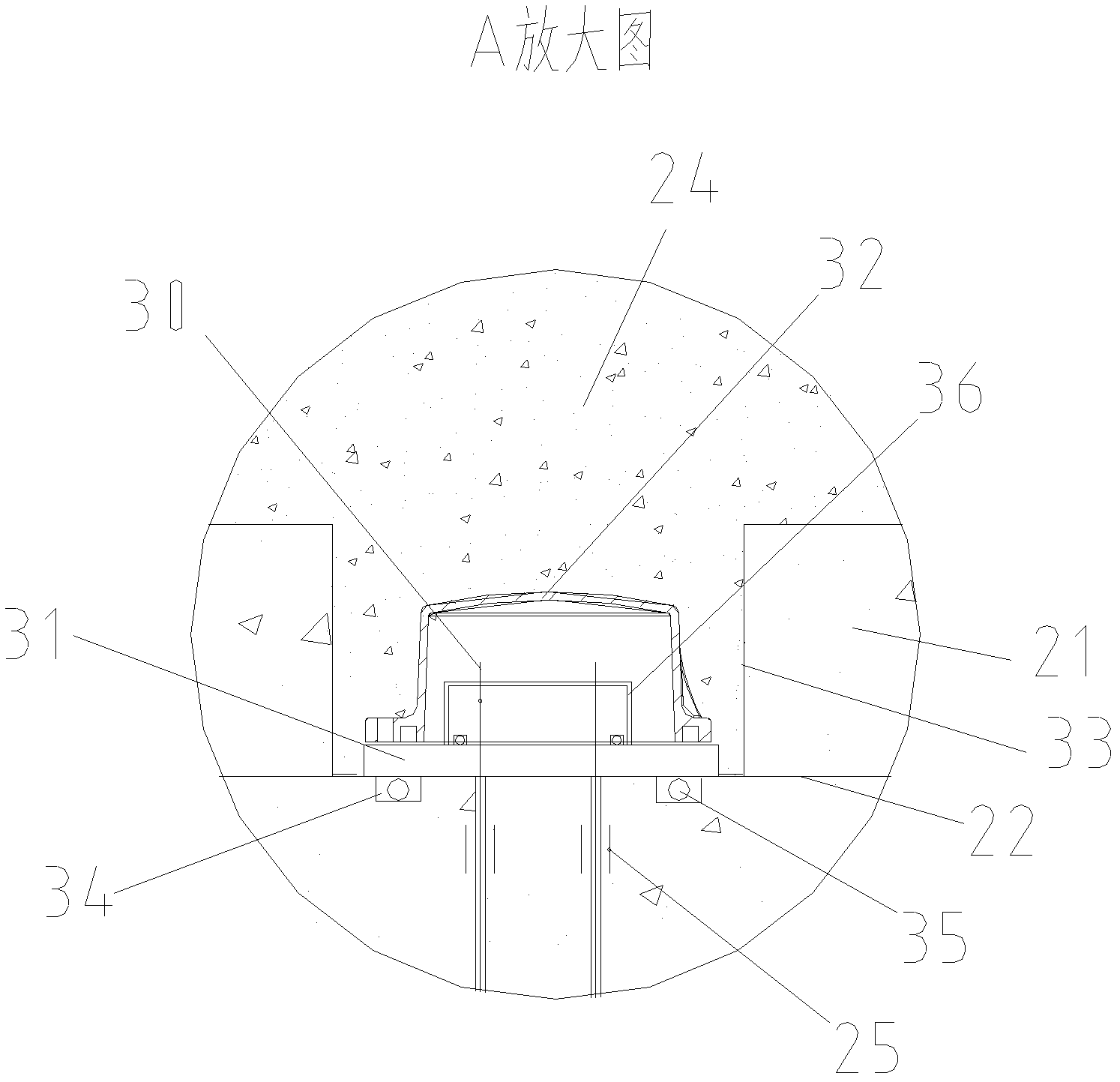

[0017] Such as figure 2 , 3 , 4, 5 show a waterproof node of a steel strand according to the present invention, comprising: a structural bottom plate 21, a main reinforcement 22, a cushion 23, a leveling layer 24, a water-swellable water-stop strip 25, an anchor 26, First layer of elastic waterproof coating 27, second layer of elastic waterproof coating 28, third layer of elastic waterproof coating 29, unbonded steel strand 30, steel plate 31, new waterproof cover 32, circular groove 33, first ring Groove 34, waterproof rubber ring 35; The anchor 26 is arranged below the cushion 23; The structural bottom plate 21 is arranged on the top of the cushion 23; The unbonded steel strand 30 passes through the anchor 26, the cushion layer 23, structural bottom plate 21; on the upper surface of the cushion layer 23, the first layer of elastic waterproof coating 27, the second layer of elastic wat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap