Culvert mouth of corrugated steel pipe culvert

A corrugated steel pipe and corrugated steel plate technology, applied in the field of corrugated steel pipe culvert openings, can solve problems such as weak connection, poor appearance, cracking, etc., and achieve the effects of wide application range, low cost and prevention of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

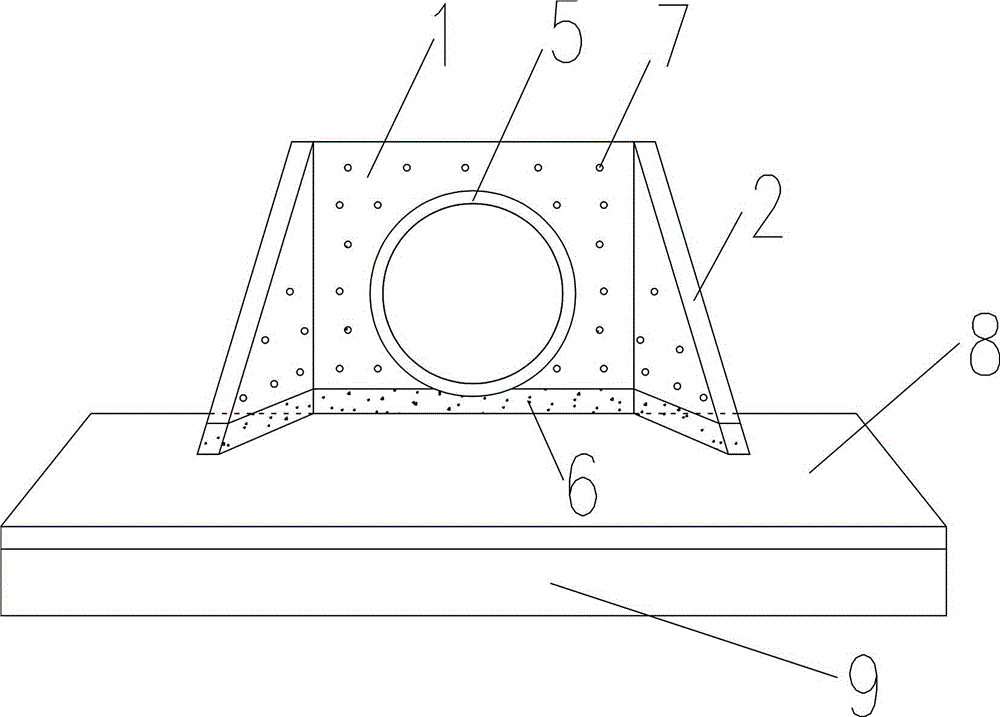

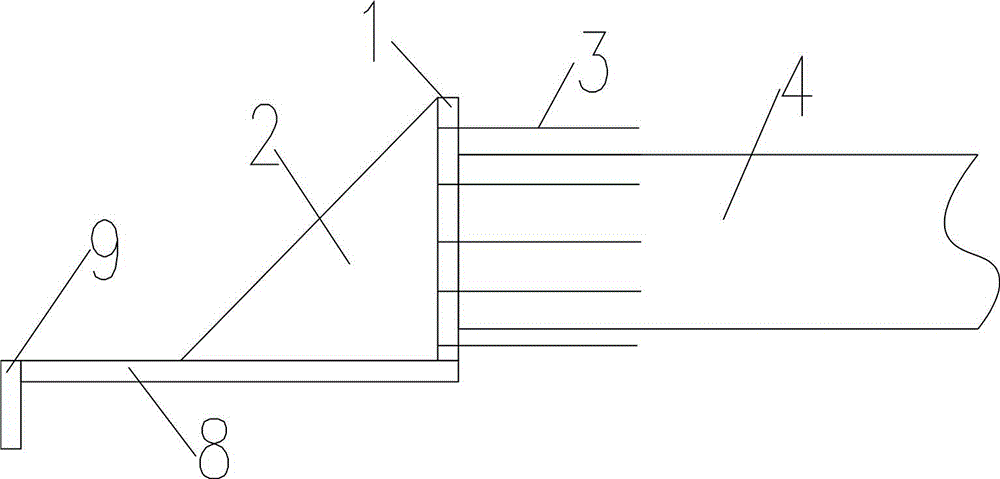

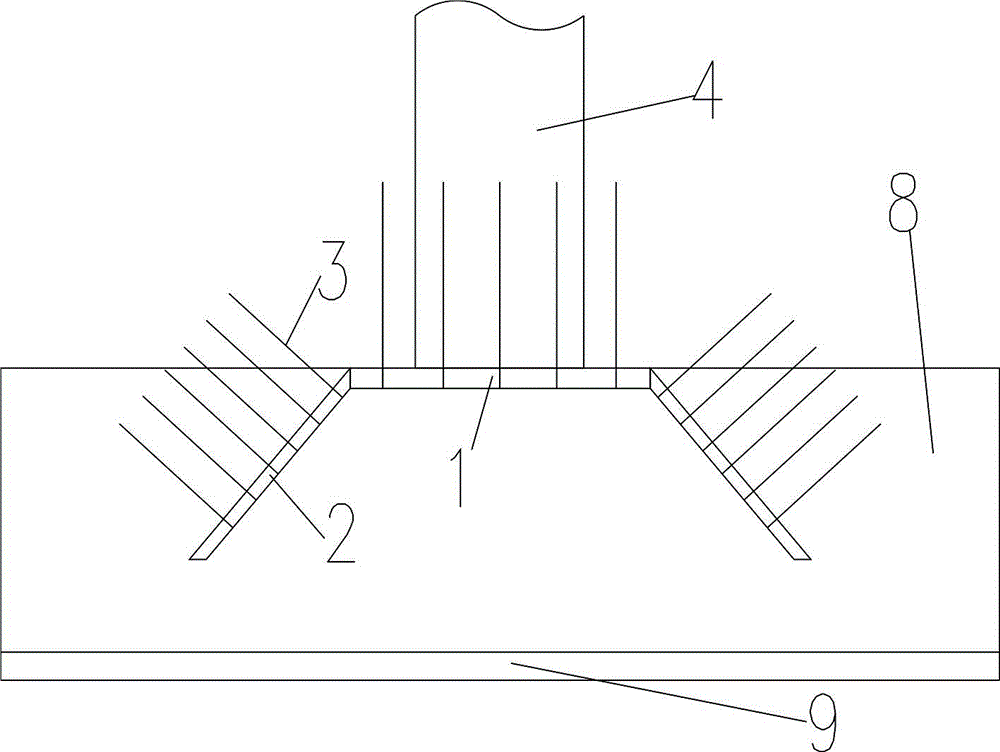

[0020] Such as figure 1 image 3 As shown, a corrugated steel pipe culvert opening includes a main wall board 1 and two side wall boards 2, the main wall board 1 and the side wall boards 2 are plane steel plates composed of corrugated steel plates, and the plane steel plates are provided with Reserve the threaded hole 7, one end of the tie bar 3 is connected to the main wallboard 1 through the reserved threaded hole 7, and the other end of the tie bar 3 is straightened and anchored in the compacted soil material;

[0021] The main wall panel 1 is perpendicular to the section of the culvert body 4, and the main wall panel 1 is provided with an opening whose shape matches the shape of the culvert, and the periphery of the opening is connected to the edge of the metal wall of the culvert through the flange 5. Connection, the two outer sides of the main wall panel 1 are connected with one side of the side wall panel 2. The flange 5 has good sealing performance and high strength, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap