Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195 results about "Steel plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

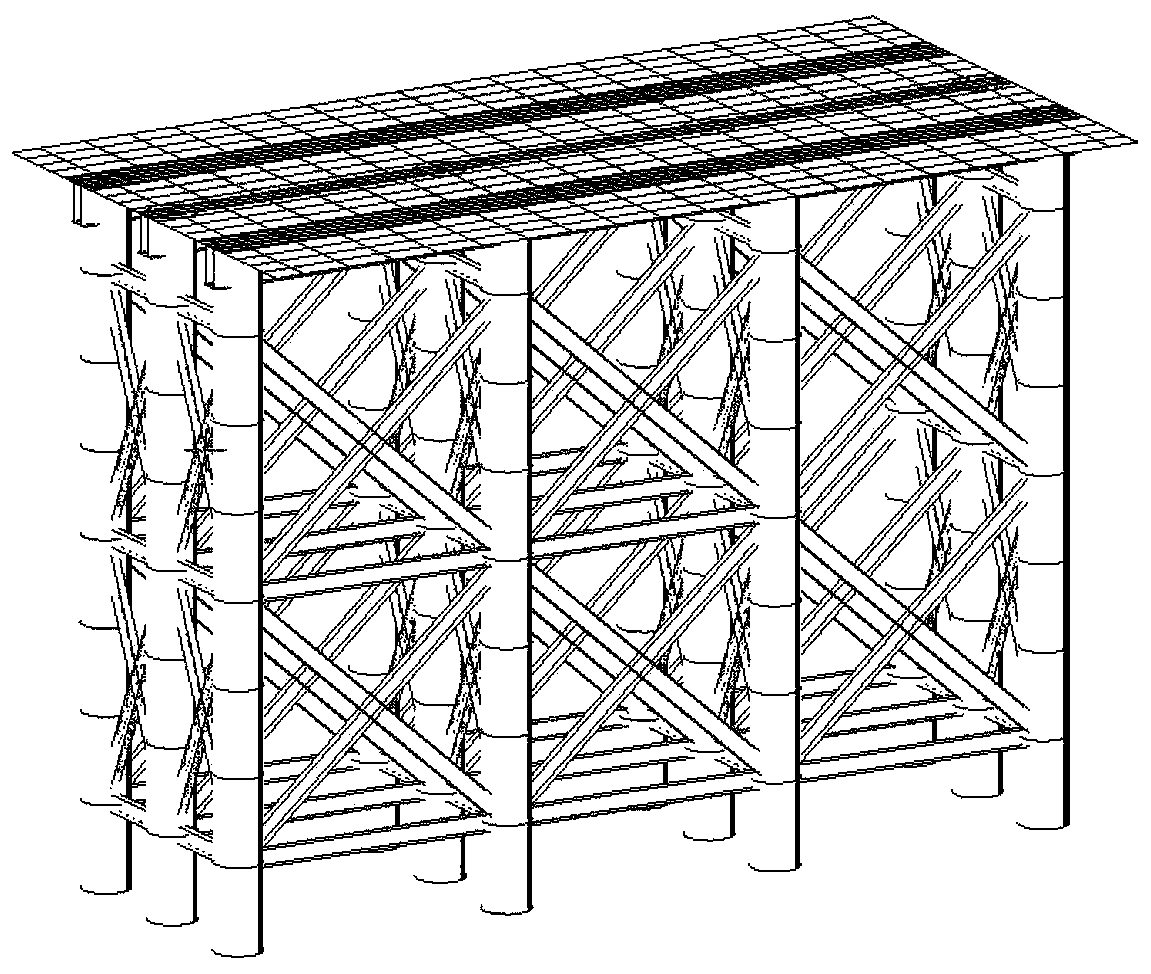

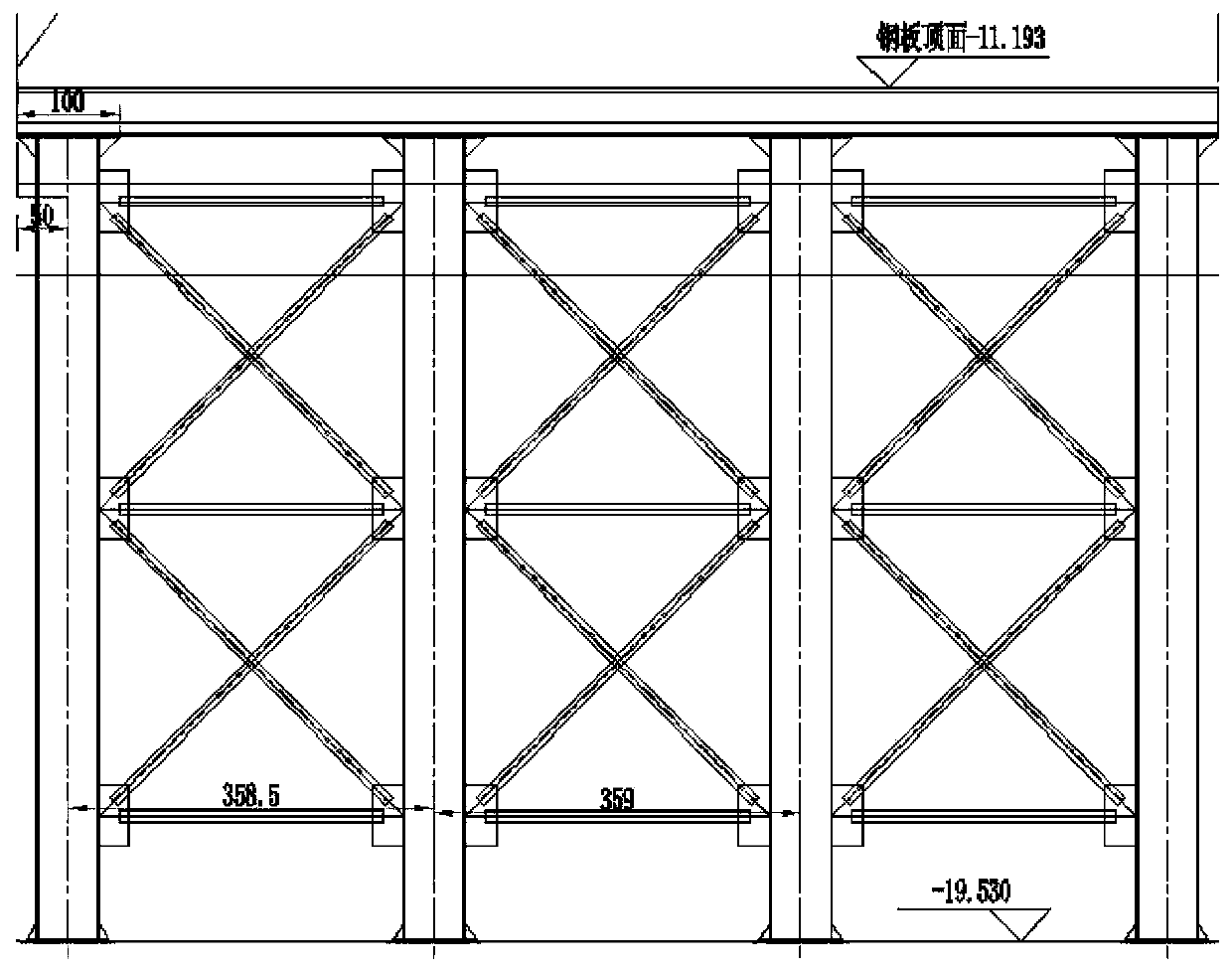

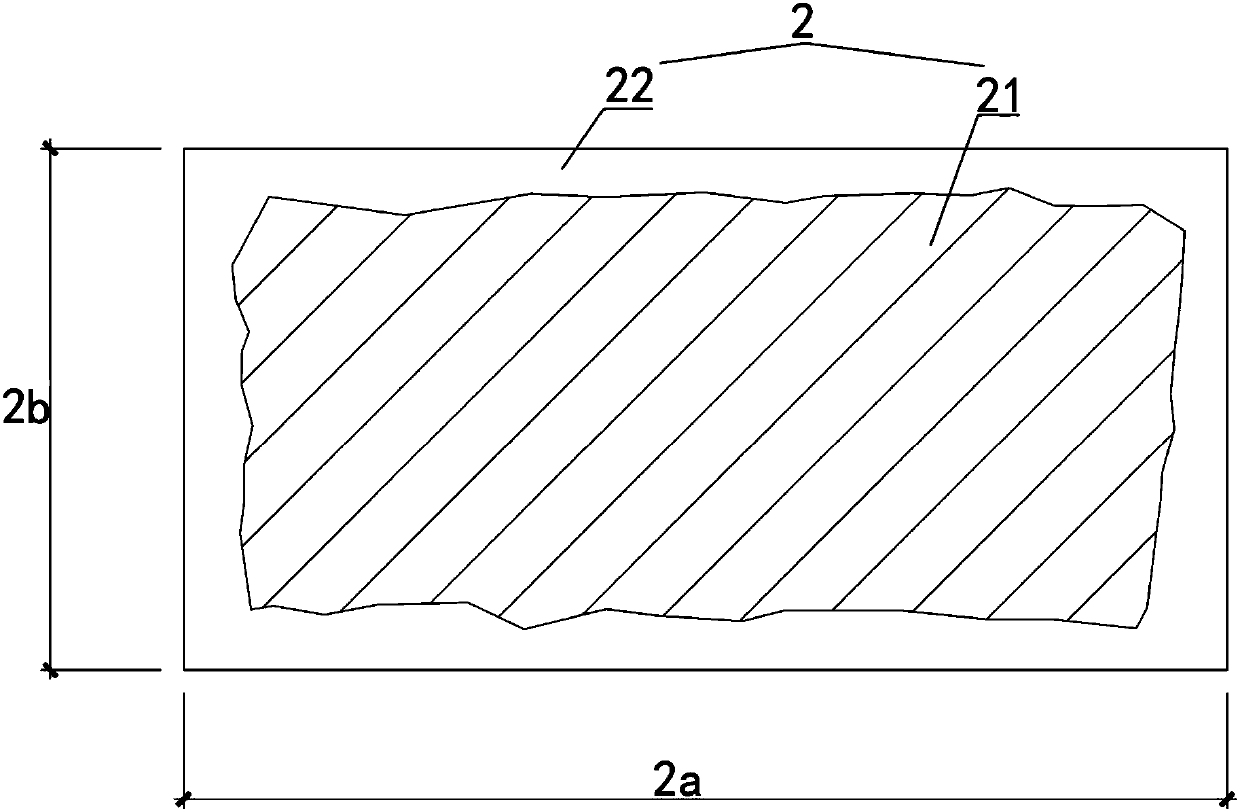

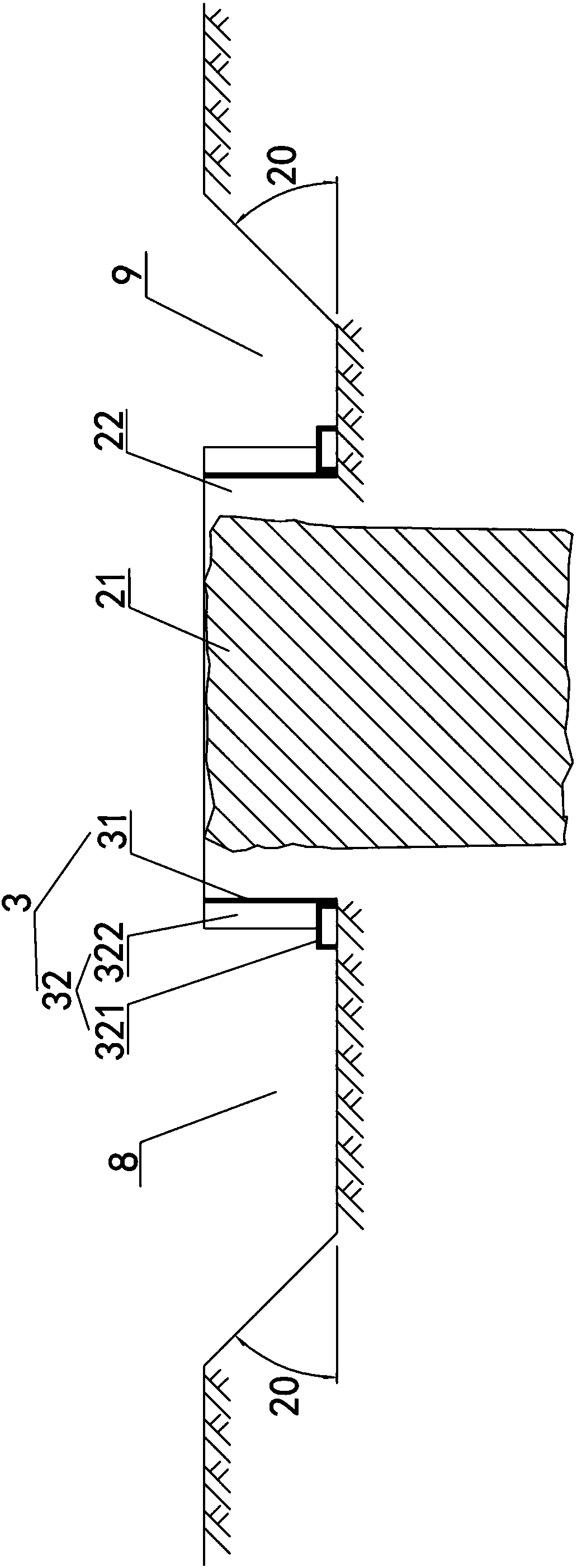

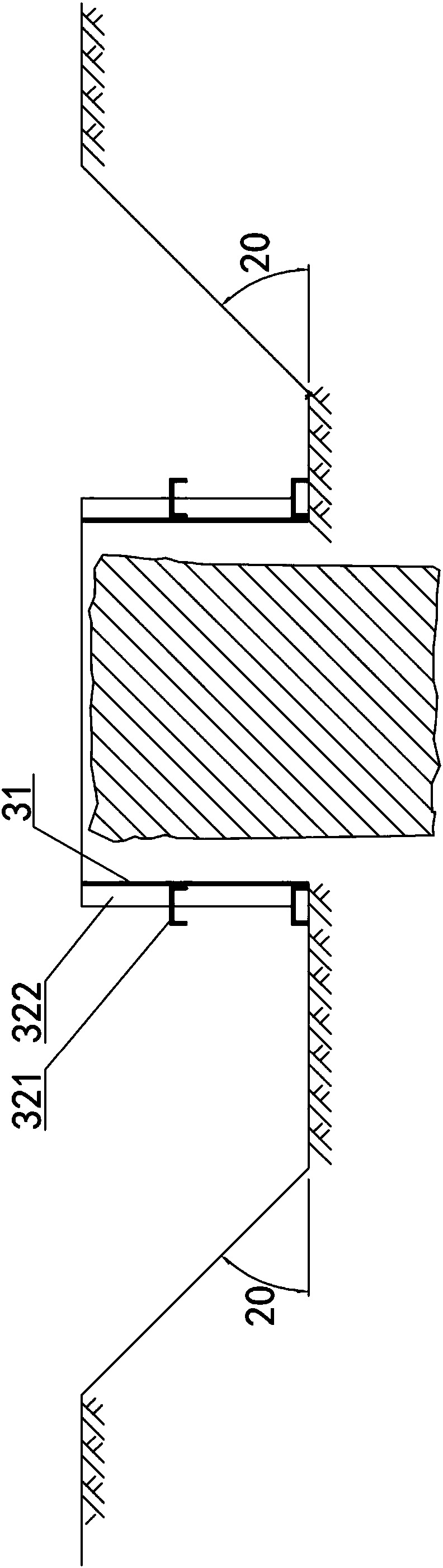

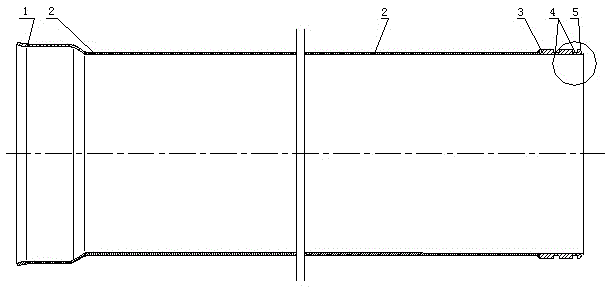

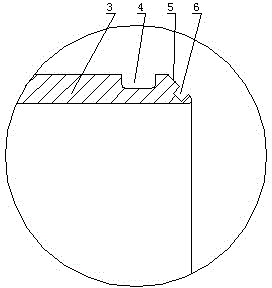

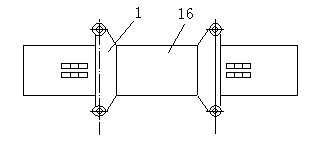

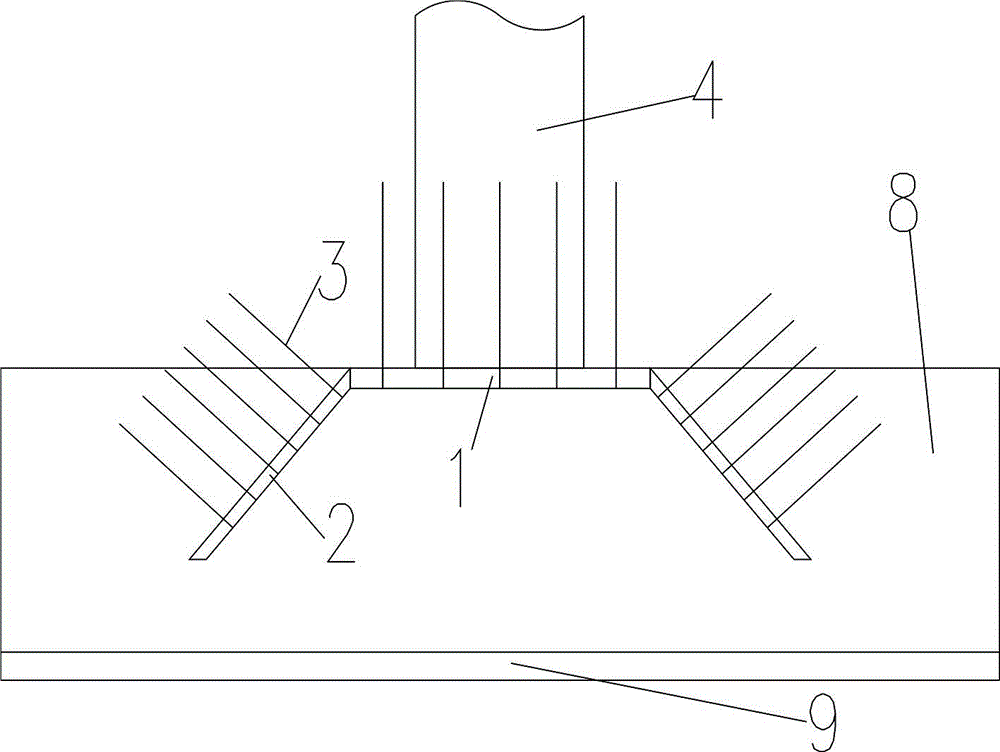

Wavelike steel plate and concrete combined shear wall

InactiveCN101922187AEffective energy dissipationHigh resistance to lateral forceConstruction materialWallsSheet steelWave shape

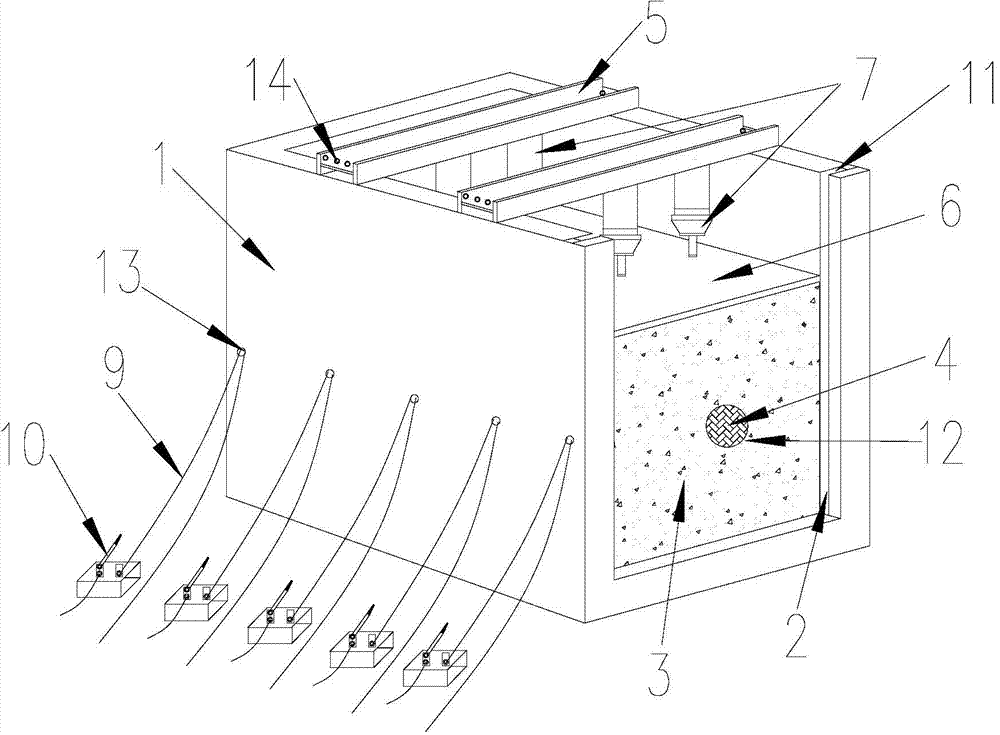

The invention discloses a wavelike steel plate and concrete combined shear wall, which belongs to the technical field of structural engineering. The wavelike steel plate and concrete combined shear wall is characterized by consisting of a wavelike steel plate, concrete, a reinforcing fabric, shear-resistant studs and connecting plates, wherein the shear wall is embedded into an edge frame; the connection modes of the wavelike steel plate and the edge frame are divided into two modes that: if the edge frame is a steel frame, the wavelike steel plate is welded with the edge steel frame at the periphery; and if the edge frame is a concrete frame, the wavelike steel plate is first welded with the four connecting plates at the periphery and then connected with the edge frame through the shear-resistant studs on the connecting plates. The outer surface of the wavelike steel plate on the side with concrete is provided with the shear-resistant studs, and the concrete is poured after the reinforcing fabric is arranged, so that the wavelike steel plate and concrete combined shear wall can be obtained.

Owner:TSINGHUA UNIV

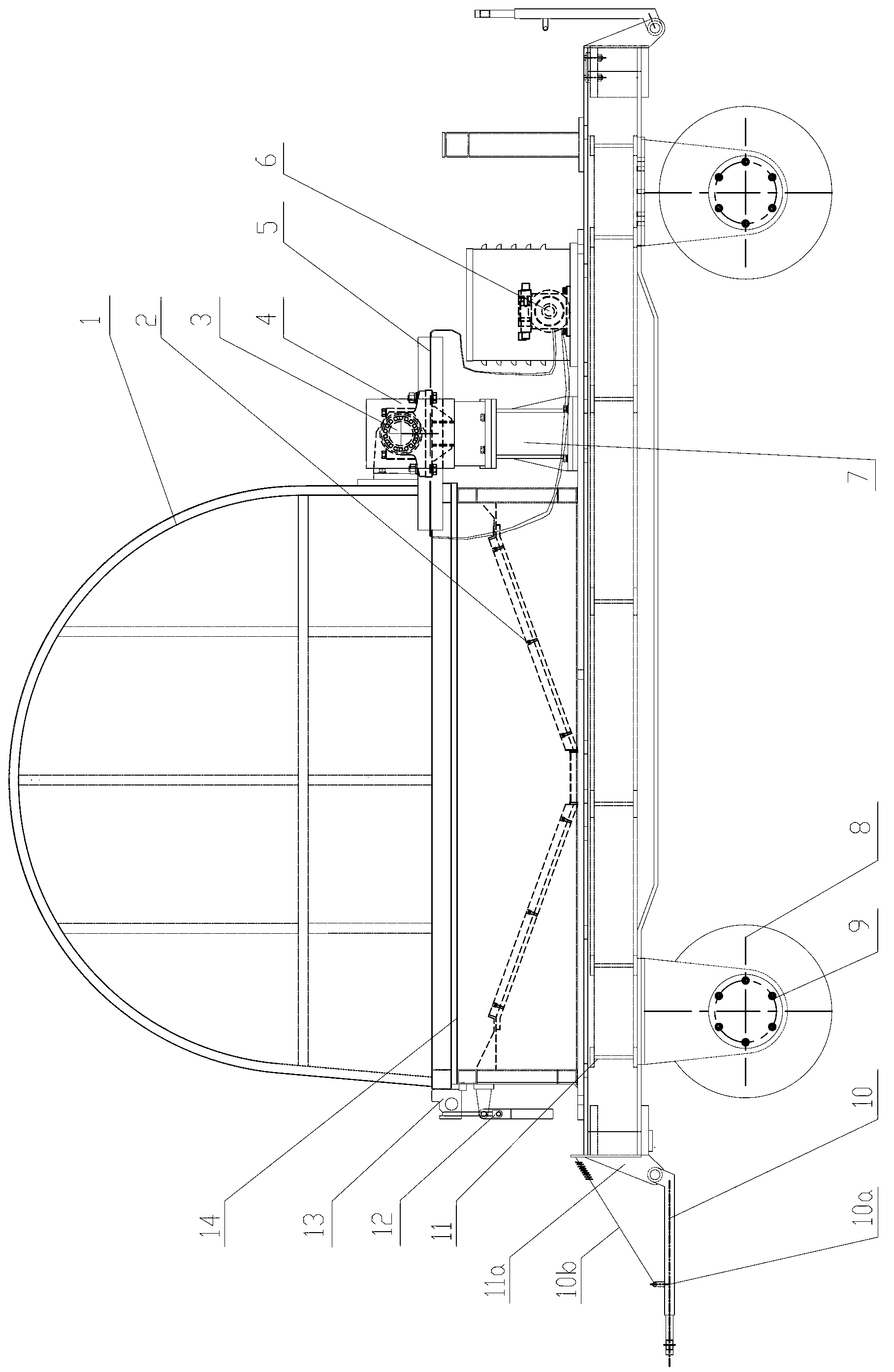

Laboratory model testing device for tunnel excavation

InactiveCN103616287AHigh simulationAvoid the influence of surrounding fillersMaterial strength using tensile/compressive forcesModel testingEngineering

Owner:HUNAN UNIV

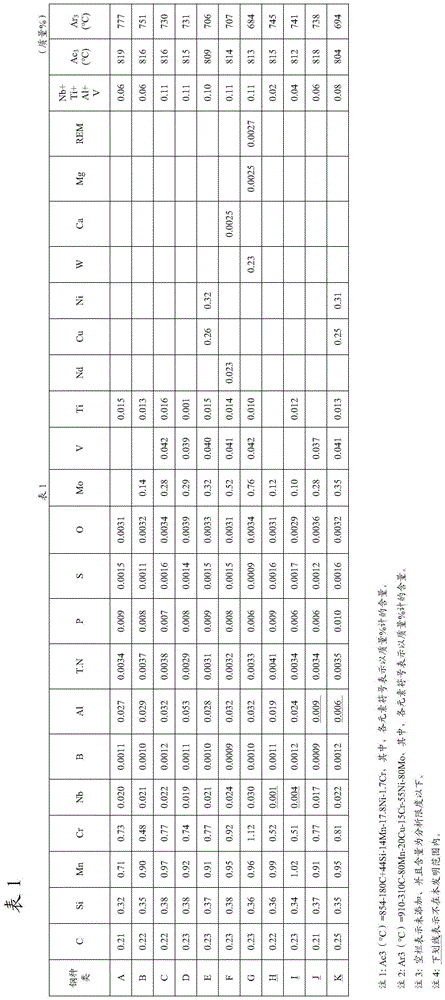

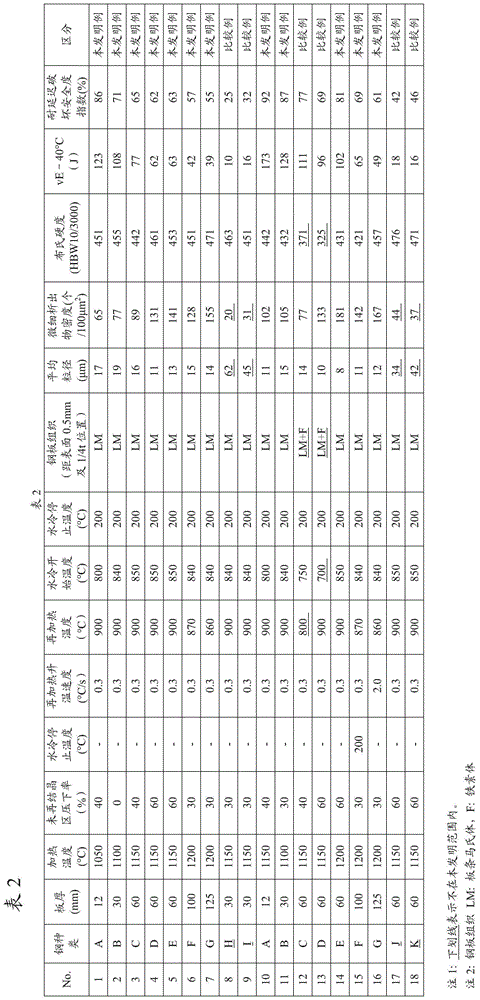

High-strength steel plate and manufacturing method thereof

Owner:BAOSHAN IRON & STEEL CO LTD

Stainless steel plate 8K mirror surface processing method

ActiveCN102962731AImprove the finishImprove anti-corrosion performancePolishing machinesFlexible-parts wheelsRough surfacePolishing

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Control method of inclusions in thick steel plate used for high heat input welding

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-dry rock fracturing high-pressure extraction laboratory simulation device

InactiveCN103790564AEnhanced Thermal RecoveryReduce mining costsFluid removalFracturing fluidHigh pressure

Owner:JILIN UNIV +1

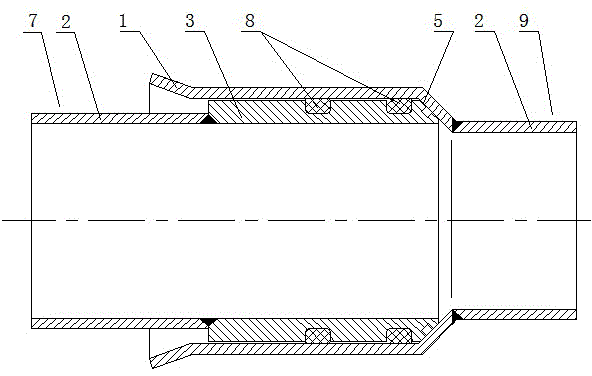

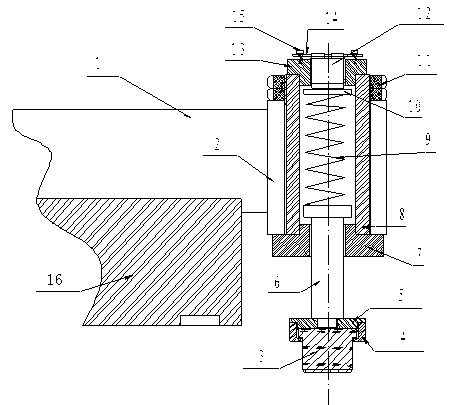

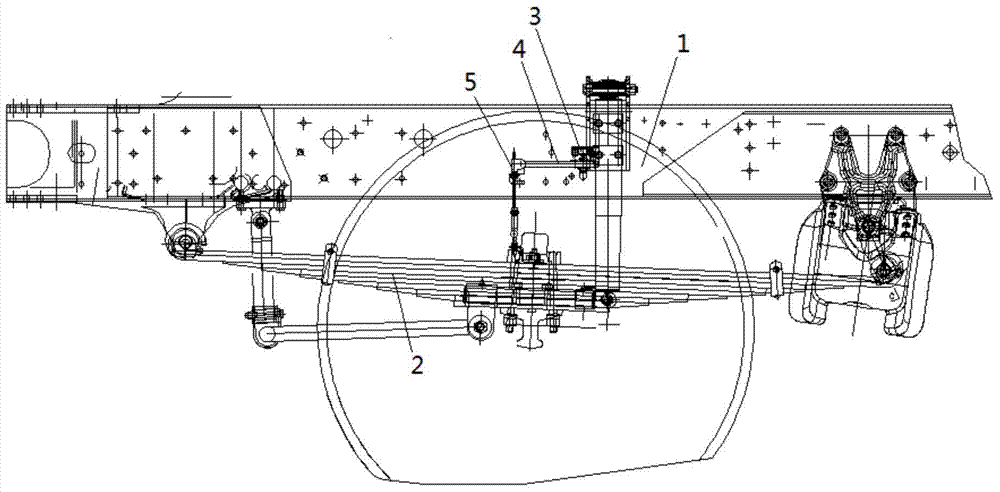

Device and method for measuring heat exchange coefficient of interface in hot stamp process

ActiveCN103033530ARealize the test of interface heat transfer coefficientAvoid incomingMaterial heat developmentSheet steelMeasurement device

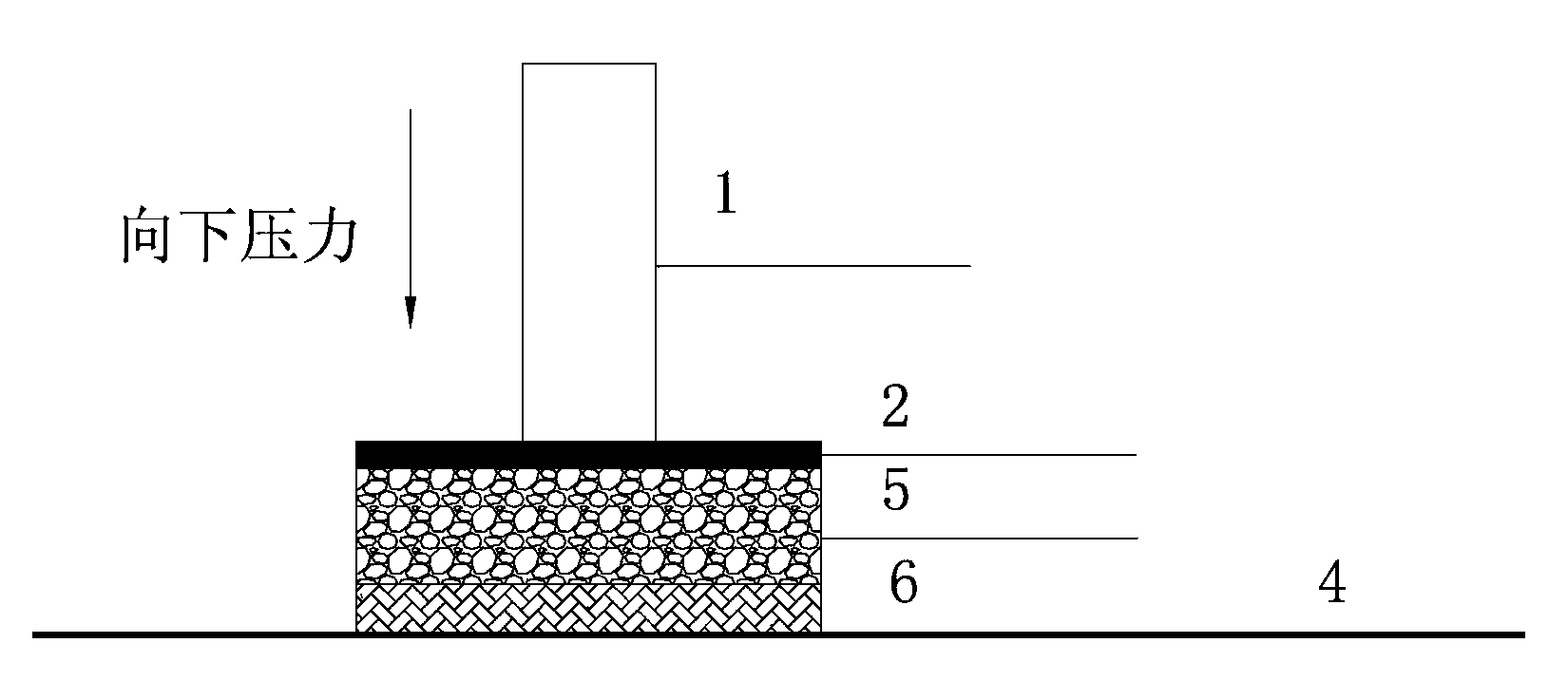

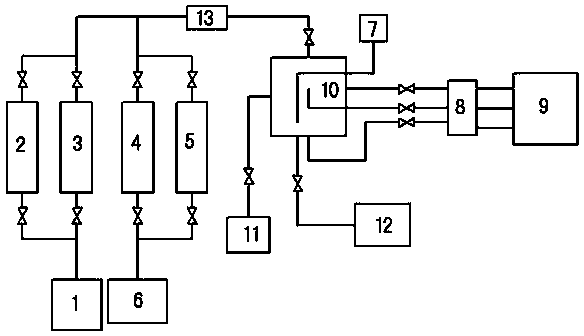

The invention discloses a device for measuring a heat exchange coefficient of an interface between a high-temperature steel plate and a die in a hot stamp process. The device comprises a pressure applying device and a measurement device, wherein the pressure applying device comprises a pressurization device, an upper workbench and a lower workbench, wherein the pressurization device is connected with the upper workbench and the lower workbench respectively; the measurement device comprises an upper fixture, a lower fixture and a test sample fixing fixture; the upper fixture is fixed on the upper workbench; the lower fixture is fixed on the lower workbench; and the test sample fixing fixture is arranged between the upper fixture and the lower fixture. The invention also discloses a method for measuring the heat exchange coefficient of the interface between the high-temperature steel plate and the die in the hot stamp process. By the device and the method, the limitation to samples with the thickness being more than 30mm in the prior art is avoided; the heat exchange coefficient of the interface between the steel plate and the die in the hot stamp process can be measured; and by an elastic energy storage element, stabilization of interface pressures between a boron steel test sample and an upper die and between the boron steel test sample and a lower die can be guaranteed.

Owner:TENGZHOU PROD QUALITY SUPERVISION & INSPECTION INST

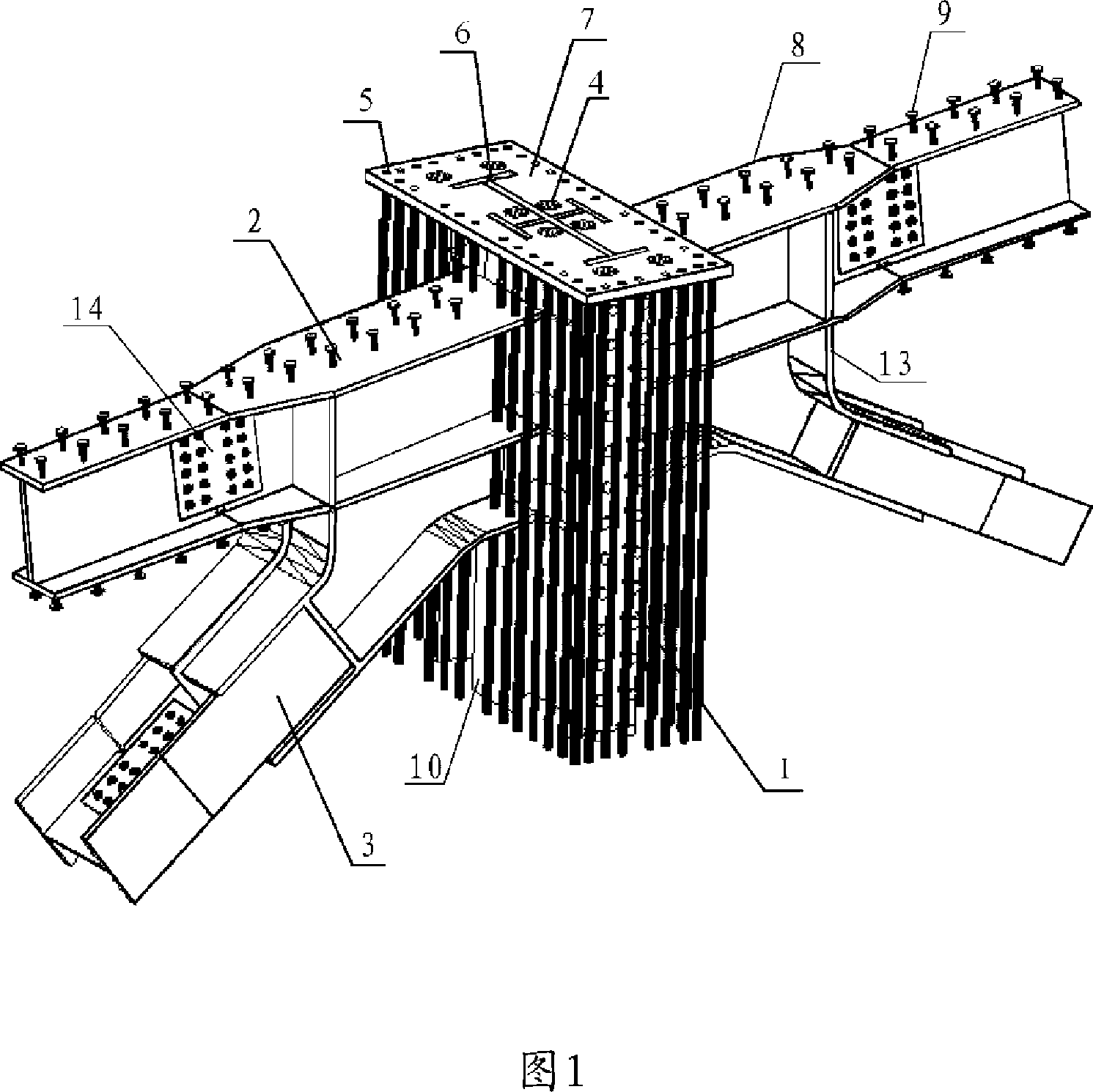

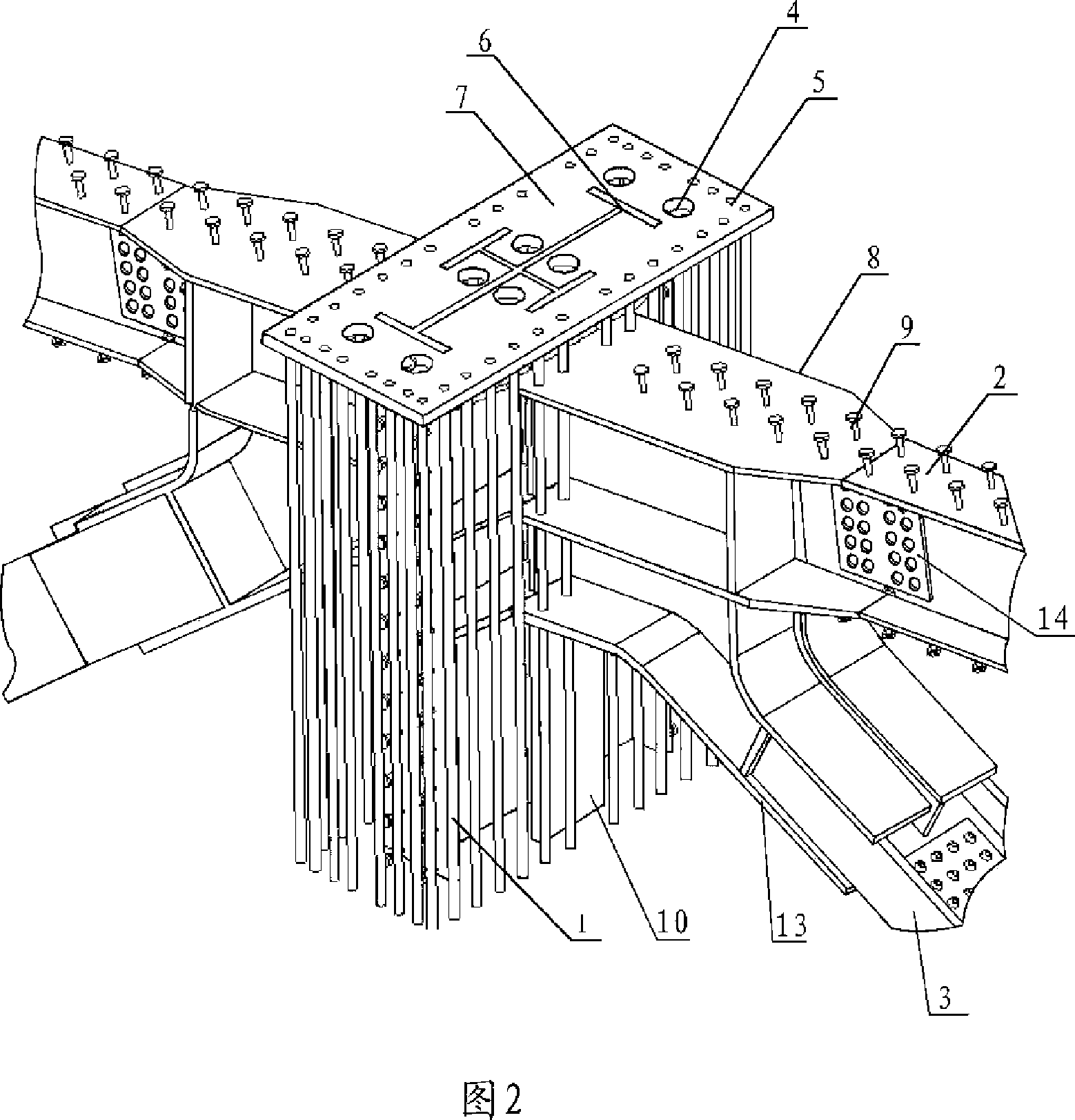

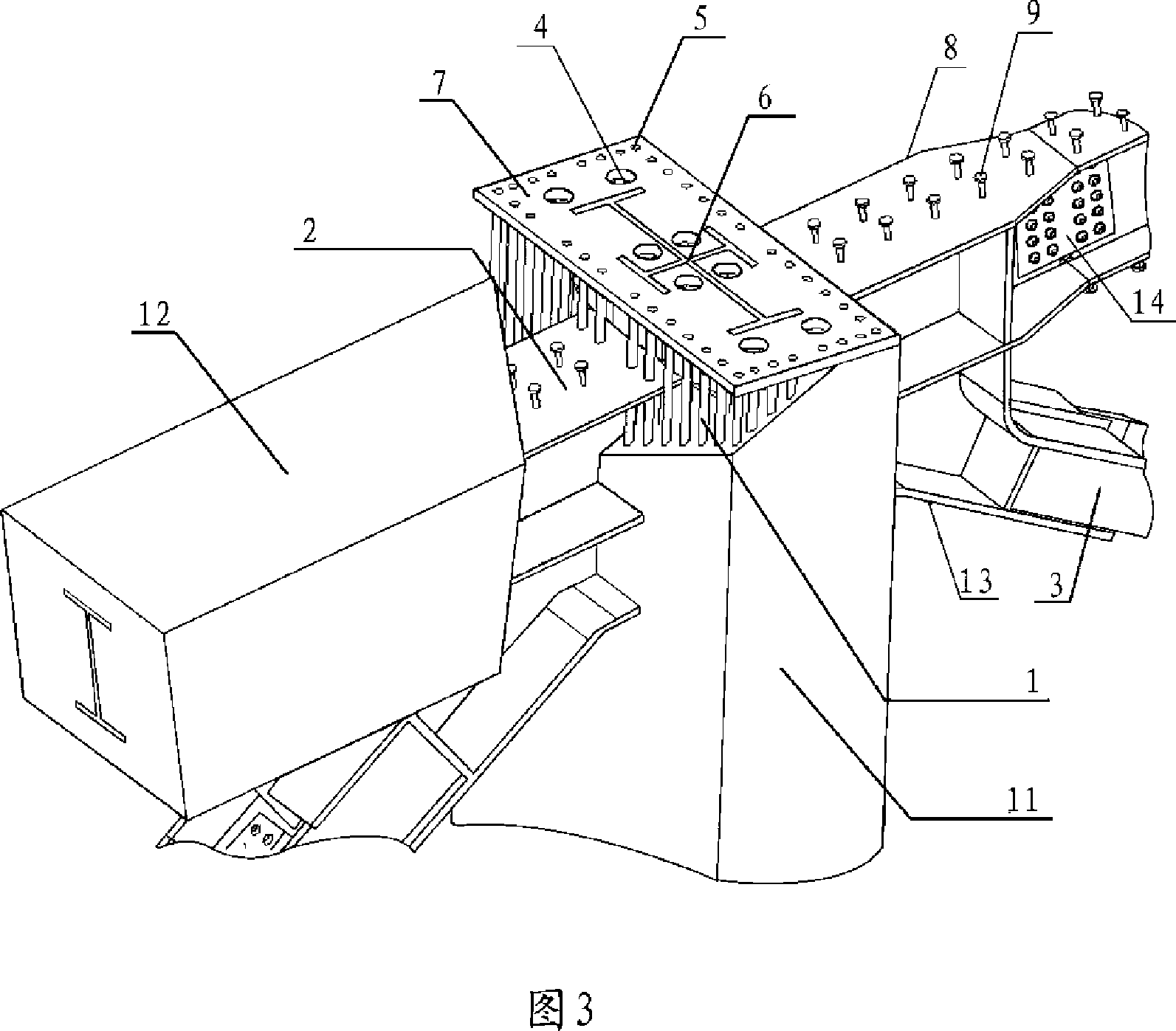

Shaped-steel concrete frame-steel supporting structure type steel column preconstraint node

ActiveCN101024974AImprove integritySafe and reliable connectionBuilding constructionsSheet steelSteel bar

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

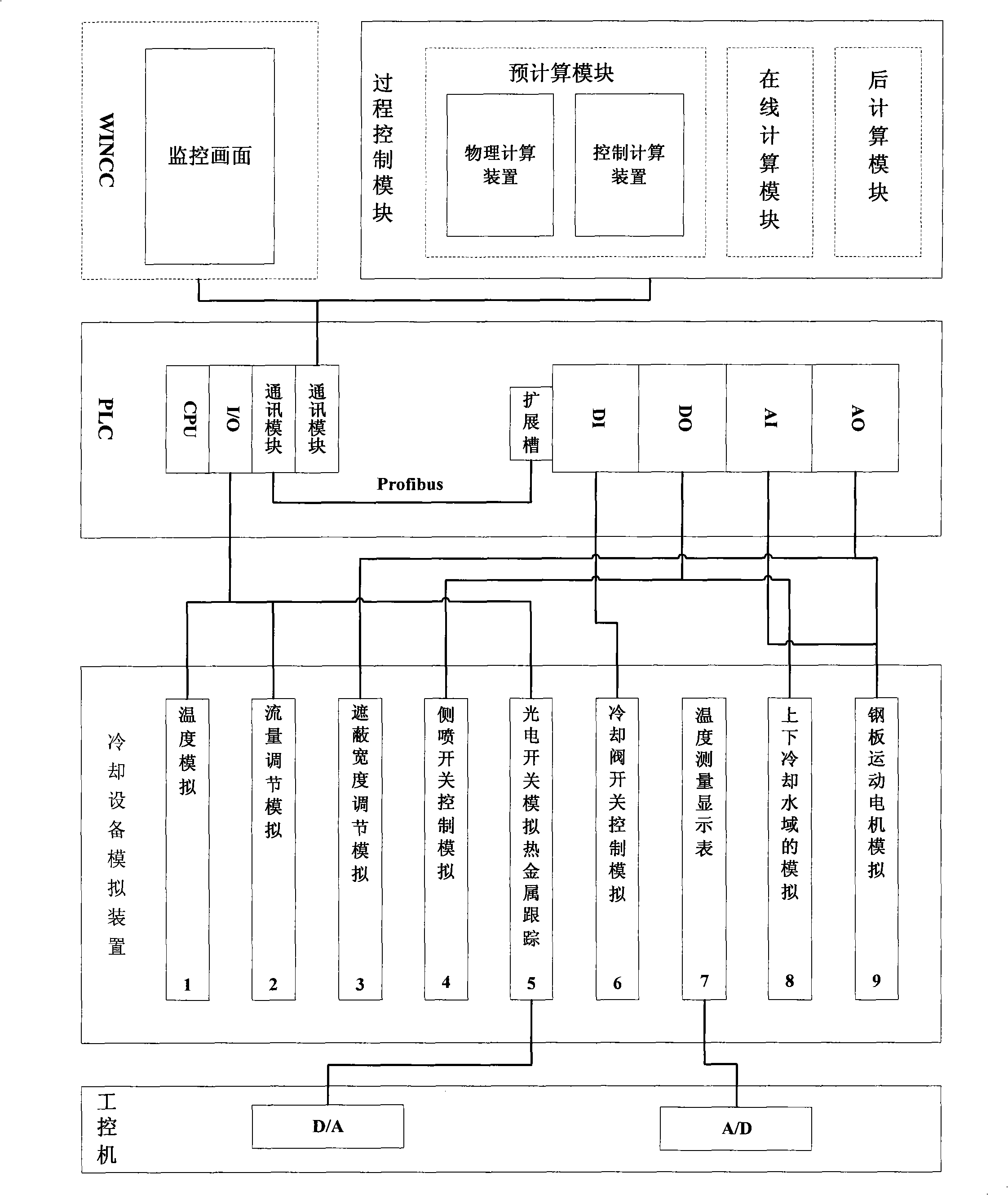

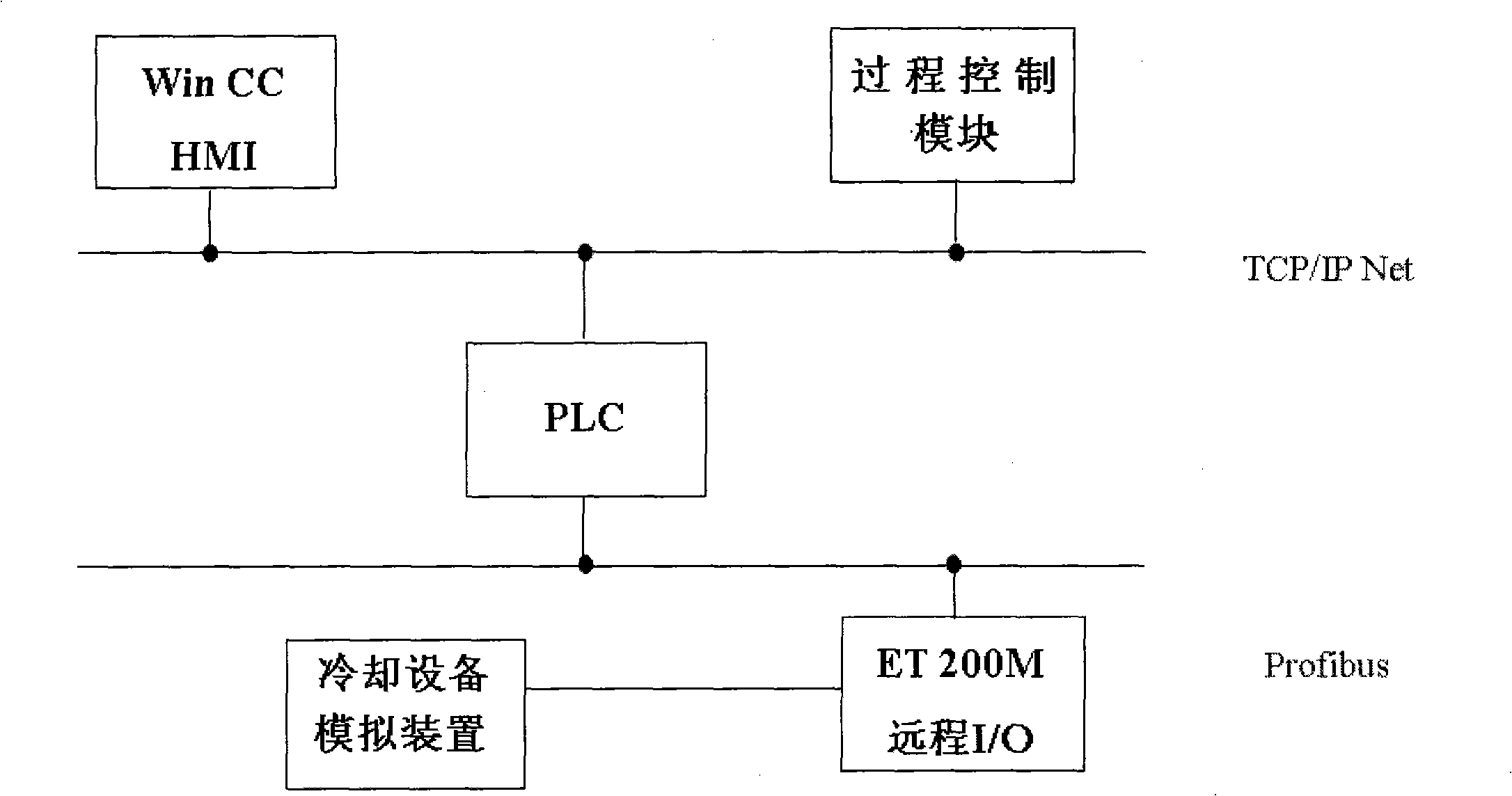

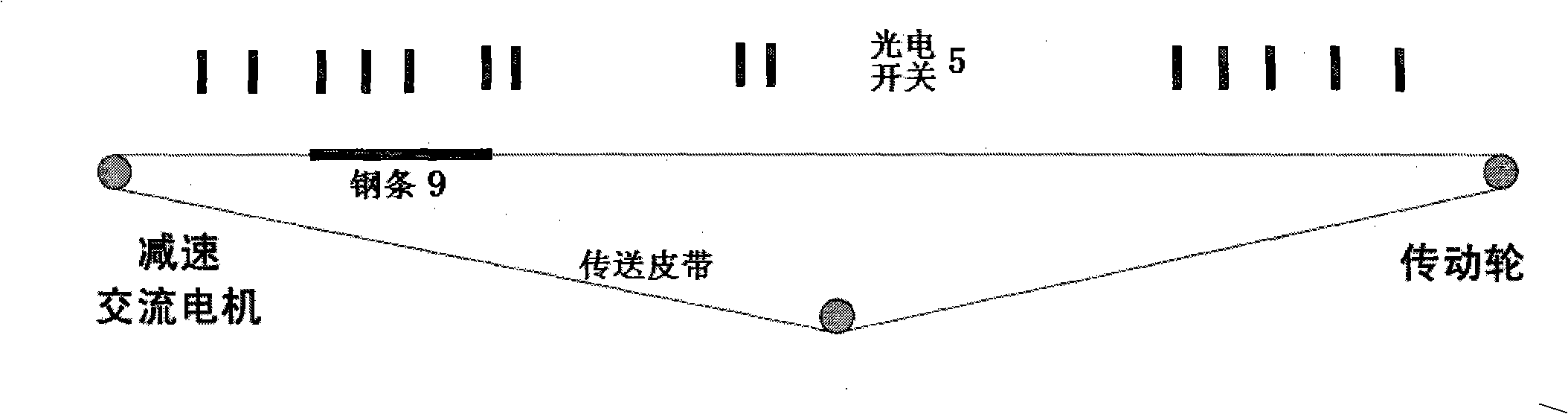

Steel plate cooling control analog system and method

ActiveCN101276209AGood simulation environmentSave time during in-circuit debuggingSimulator controlWork treatment devicesProcess systemsDevice simulation

Owner:BAOSHAN IRON & STEEL CO LTD

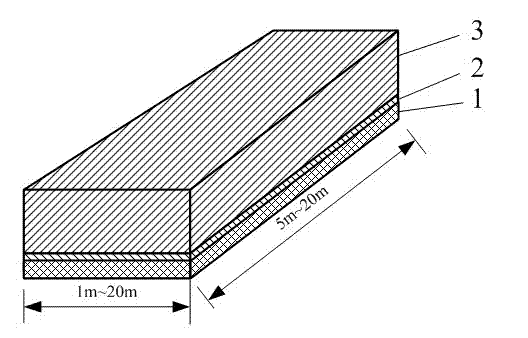

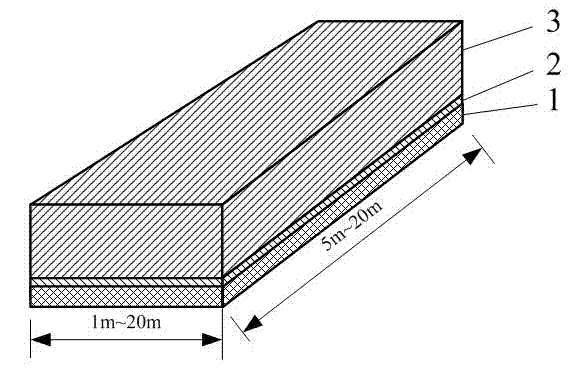

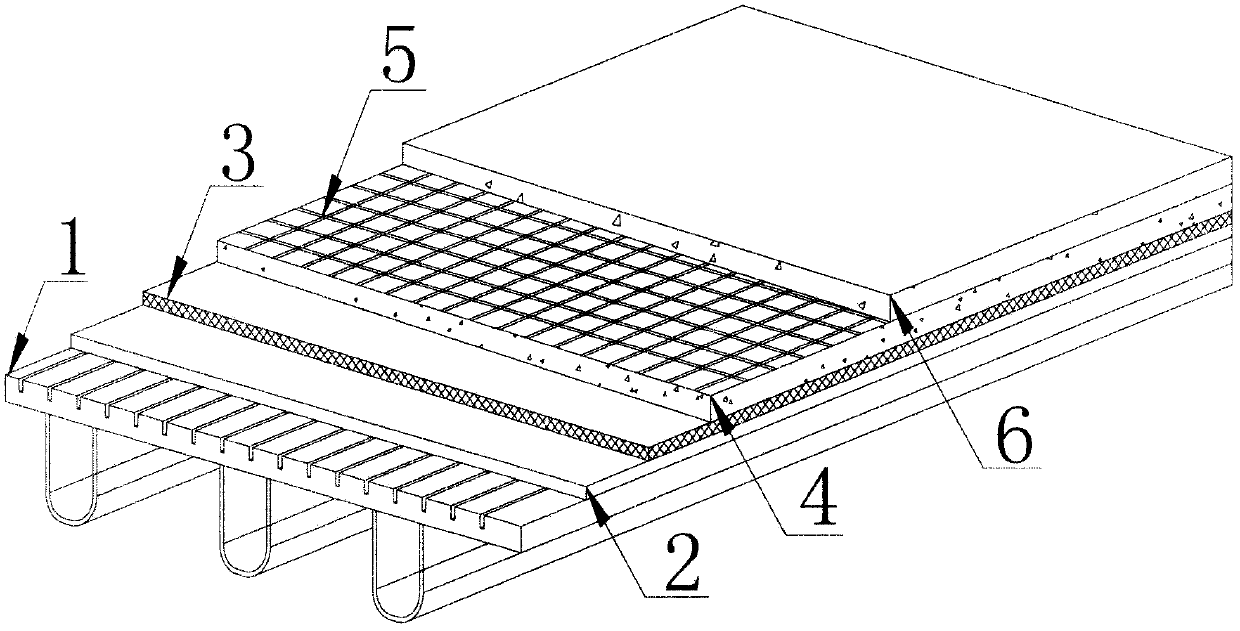

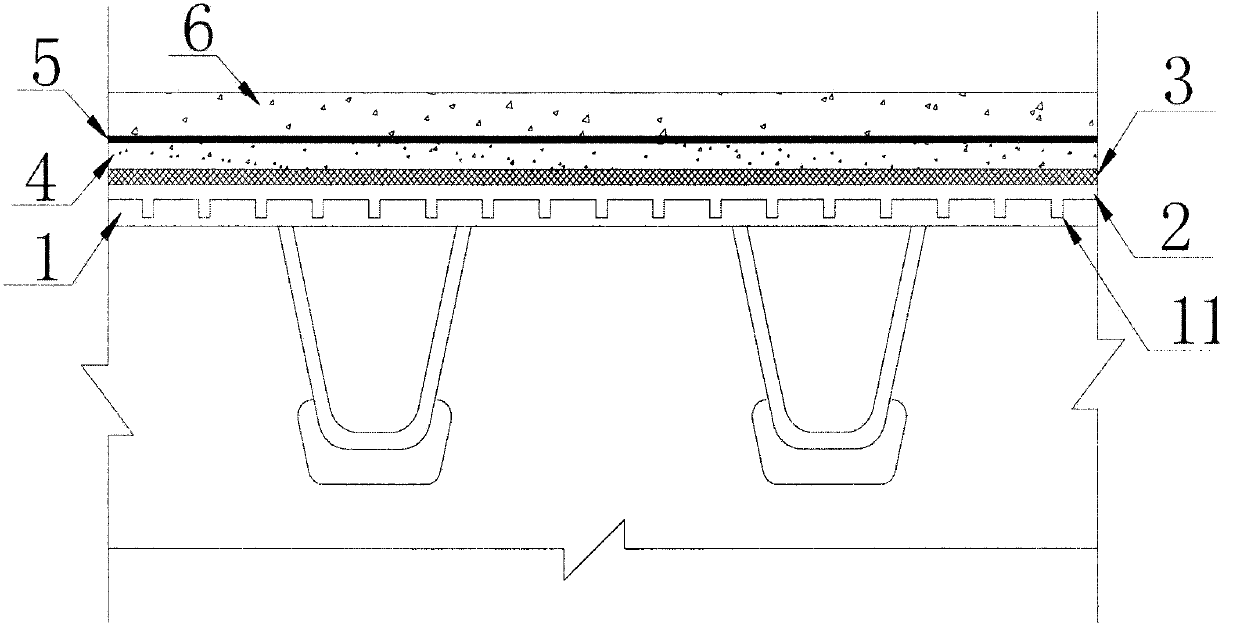

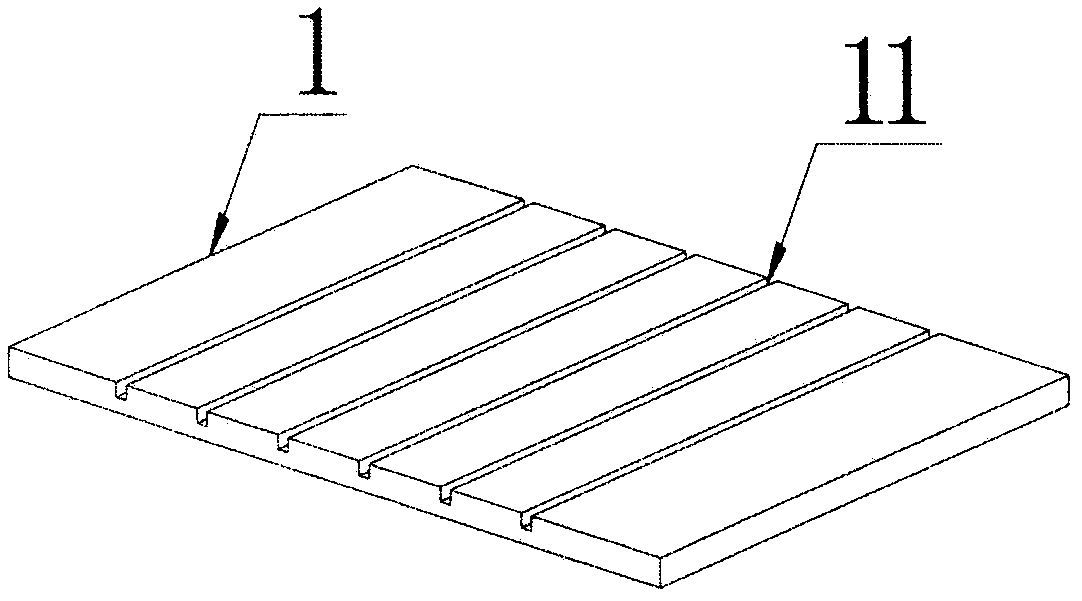

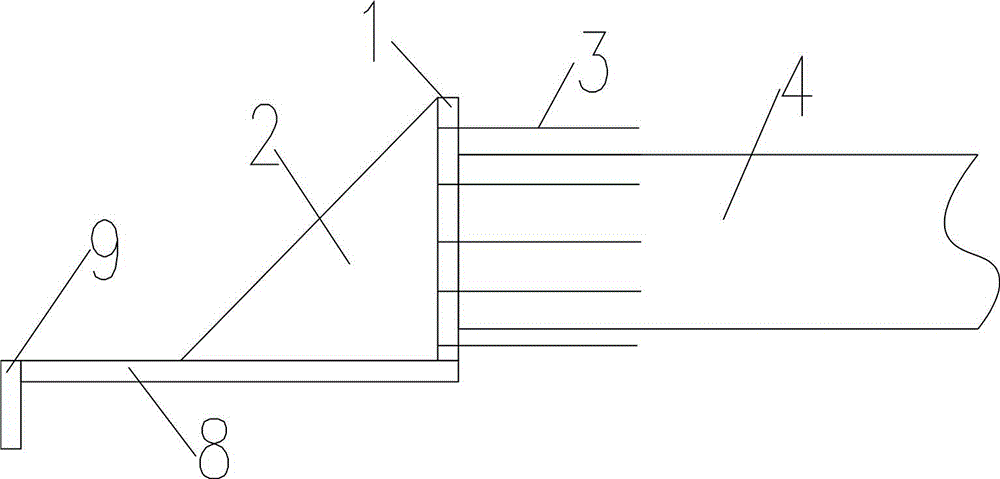

Steel-concrete combination deck plate and construction method thereof

ActiveCN106638302AReduce thicknessImprove binding structureBridge structural detailsBridge erection/assemblySheet steelRebar

The invention relates to a steel-concrete combination deck plate and a construction method thereof, wherein the steel-concrete combination deck plate comprises: bottom steel plates arranged on steel girders, wherein the bottom steel plates in the bearing regions of the steel girders are bent in shape, and the bottom steel plates are 8-10 mm in thickness; a plurality of shear plates vertically connected to the bottom steel plates; a concrete tier including reinforcement fabric penetrating through the shear plates, wherein the concrete tier is cast to the bottom steel plates, and the combination deck plate is 10-15 cm in thickness. The steel-concrete combination deck plate uses the bottom steel plates as stress-bearing parts as well as a formwork for a cast-in-place desk concrete tier, and steps of mounting and releasing concrete formwork are omitted; the shear plates serve as stiffeners for the bottom steel plates, good combination of the bottom steel plates with the concrete tier can be guaranteed, and cracking of the concrete tier is prevented; the deck thickness is controlled to 10-15 cm and is reduced, the weight is 25% and above lower than that of a composite beam deck system, dead load is reduced, crossing ability, structural strength and durability of the main structure are improved, construction input is reduced, and the efficiency of a construction method is high.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Asphalt pavement prefabricated block and construction method for prefabricated asphalt pavement

Owner:广州大象超薄路面技术开发有限公司

High-toughness steel plate with yield strength at 460 MPa grade and production method thereof

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Reinforcement method and structure for improving post-installed anchorage shear bearing capacity of concrete beam

InactiveCN106351461AIncreased shear capacityAvoid destructionBuilding repairsGirdersFloor slabConcrete beams

The invention discloses a reinforcement method and a structure for improving the post-anchor shear bearing capacity of concrete beams, comprising the following steps: connecting and fixing post-anchor steel beams with concrete beams; making installation holes at floor positions on both sides of the concrete beams; The screw goes through the installation hole of the floor; the steel plate is attached to the bottom of the concrete beam; the steel plate and the concrete beam are fixed by chemical anchor bolts; the U-shaped hoop plate is sleeved on the concrete beam from the lower part of the concrete beam; the screw is connected to the top hoop set on the top of the floor The two sides of the plate and the U-shaped hoop plate are welded; the U-shaped hoop plate and the steel plate at the bottom of the concrete beam are welded and fixed at the bottom of the concrete beam; the invention improves the shear bearing capacity at the anchorage position of the concrete beam and is no longer limited The cross-sectional size and concrete strength of the original structure concrete beams; increase the construction flexibility, avoid the wedge-shaped shear damage of the concrete edge, and effectively avoid the wedge-shaped shear damage of the concrete edge.

Owner:TIANJIN ARCHITECTURE DESIGN INST

Production method for improving surface quality of thin-gauge pipeline steel

Owner:NANJING IRON & STEEL CO LTD

Self-stable suspension type unloading platform and construction process thereof

PendingCN107965147AShorten the installation and dismantling periodSimple installation and disassemblyBuilding material handlingSocial benefitsArchitectural engineering

The invention discloses a self-stable suspension type unloading platform and a construction process thereof. The unloading platform comprises main beams. Auxiliary beams are arranged between the mainbeams. Platform embossing steel plates are arranged among the main beams and the auxiliary beams. Vertical beams are arranged on the upper sides of the main beams. A rebar pull rod upper support is arranged among the vertical beams. A rebar pull rod lower support parallel to the rebar pull rod upper support is arranged at the bottom ends of the main beams. Rebar pull rods are arranged between therebar pull rod upper support and the rebar pull rod lower support. Upper floor system edge beams are arranged at the top ends of the vertical beams. A feed channel plate is arranged at the upper endsof lower floor system edge beams and the platform embossing steel plates. Compared with a traditional steel overhung unloading platform, embedded steel wire rope ring hanging, profile steel support ring anchoring, ending anchoring ring hole blocking and hanging ring rebar cutting treatment are not needed, and a passenger channel can be laid along a floor; construction installation and detachment operation is simple, safe and convenient, the installation and detaching construction period is shortened, embedded pieces and labor cost are greatly saved, the platform has remarkable economic and social benefits and meets the efficient, energy-saving and green construction requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

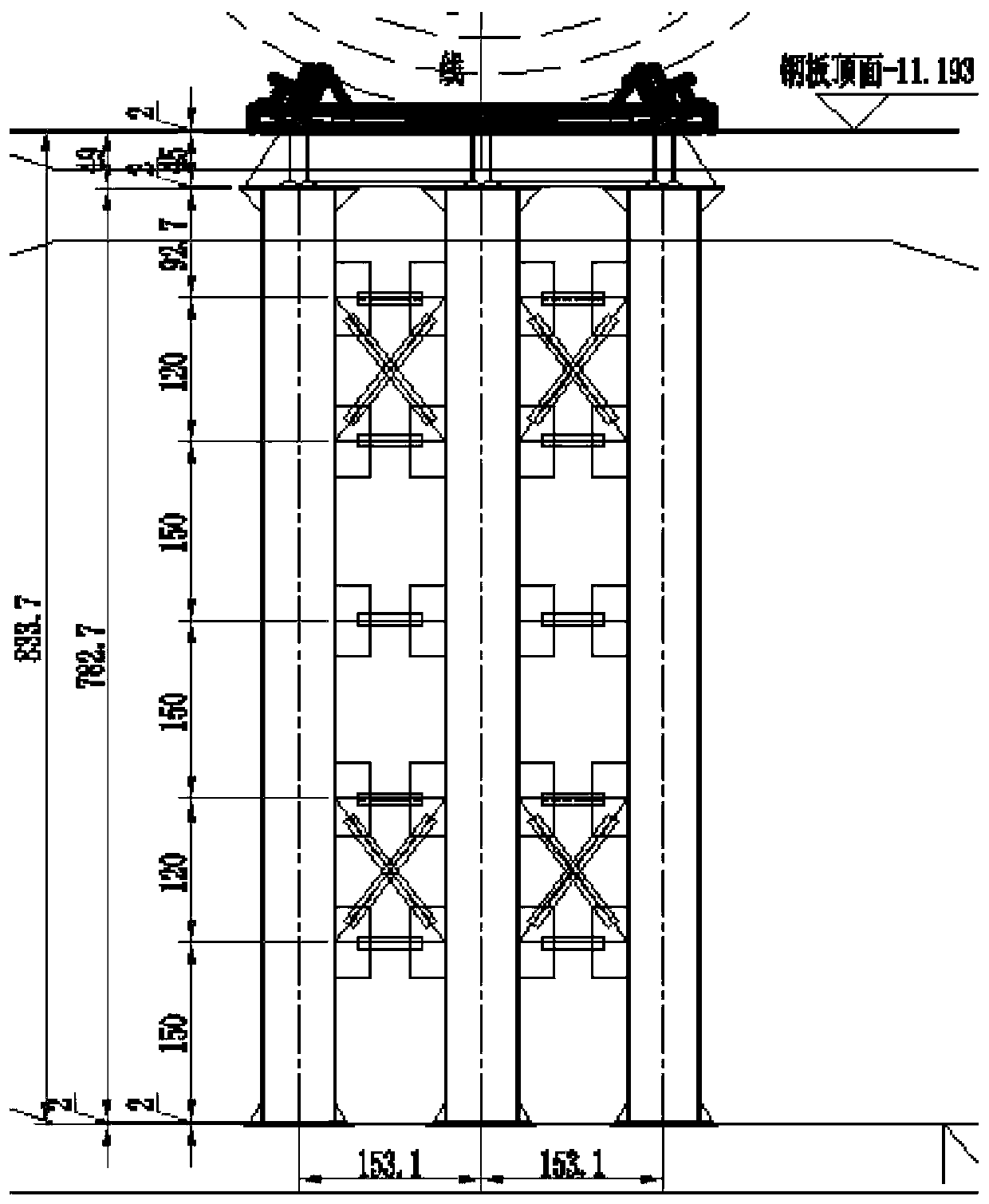

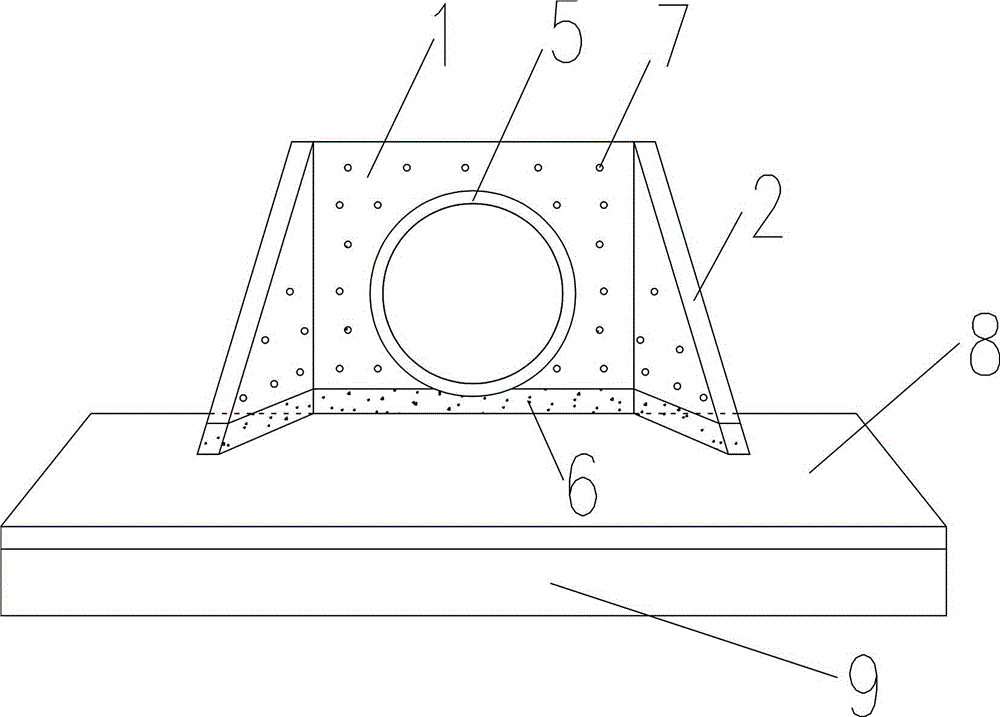

Shield machine receiving steel platform

InactiveCN109763835AGuaranteed normal formationImprove stabilityUnderground chambersTunnel liningSheet steelShield machine

Owner:中建铁投轨道交通建设有限公司

Jacking pipe cutting protective structure for building remains and construction method thereof

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

Steel pipe with bell and spigot joints

Owner:JILING YULINGLONG STEEL PIPE STEEL STRUCTURE MFG

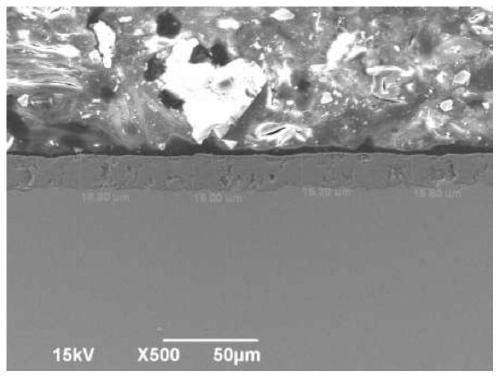

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

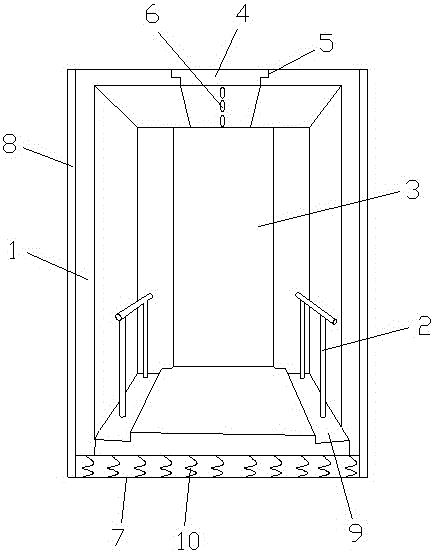

Elevator car

InactiveCN106467265ACorrosion-resistantKeep the structure corrosion resistantBuilding liftsEngineeringLED lamp

Owner:成都聚立汇信科技有限公司

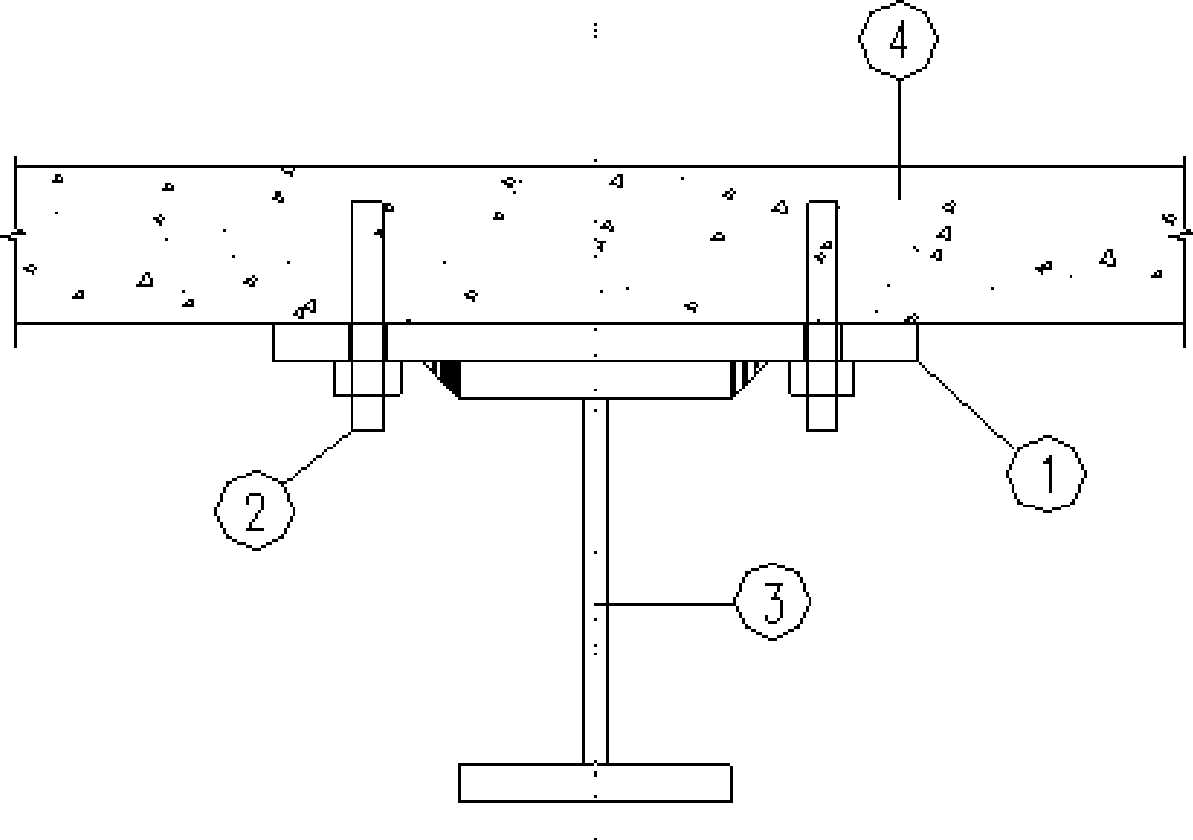

Method for the combination of a post-increasing steel beam and a concrete slab

Owner:GUIYANG AL-MG DESIGN & RES INST

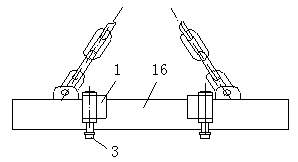

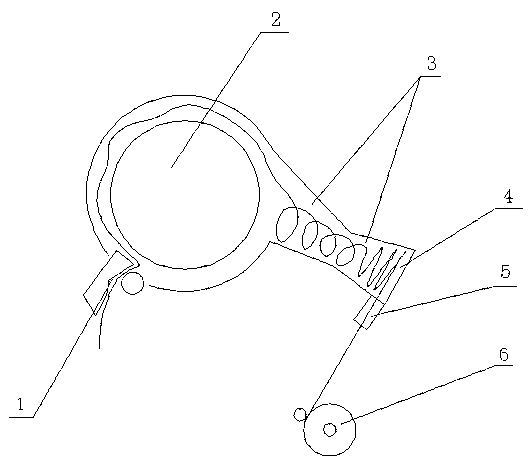

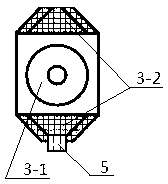

Method for hoisting and transporting steel plates by adopting electromagnet in steel plants

ActiveCN103241638AAvoid scratchesAvoid impact damageShock absorbersLoad-engaging elementsMagnetic tension forceSheet steel

Owner:CHONGQING IRON & STEEL CO LTD

One-step spinning machine capable of conducting entwisting clockwise and one-step spinning method

Owner:吴江赴东扬程化纤有限公司

Vehicle-mounted silicon steel coil thermostat

InactiveCN103057842AConvenient finishingIngenious structureShock-sensitive articlesVehiclesRotational axisCaster

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

Steel bridge deck pavement structure with reinforced construction

Owner:NANJING FORESTRY UNIV

Abrasion resistant steel plate having low-temperature toughness and hydrogen embrittlement resistance, and manufacturing method therefor

Owner:JFE STEEL CORP

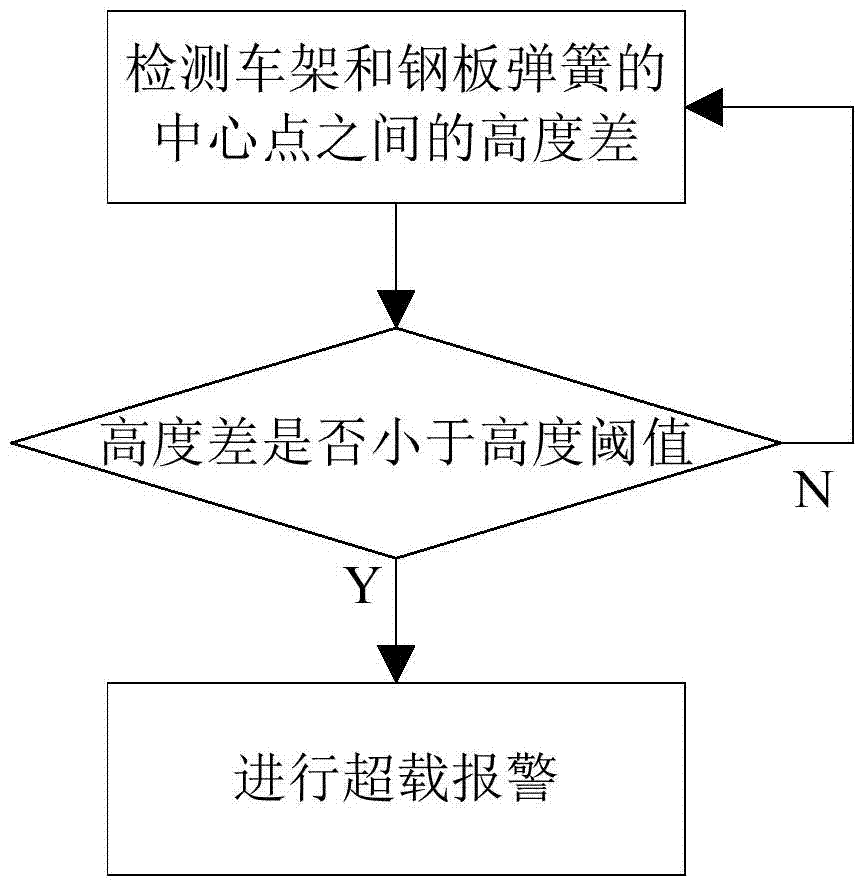

Vehicle, vehicle overload alarm method and overload alarm system

Owner:BEIQI FOTON MOTOR CO LTD

Culvert mouth of corrugated steel pipe culvert

Owner:CHINA THREE GORGES UNIV

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

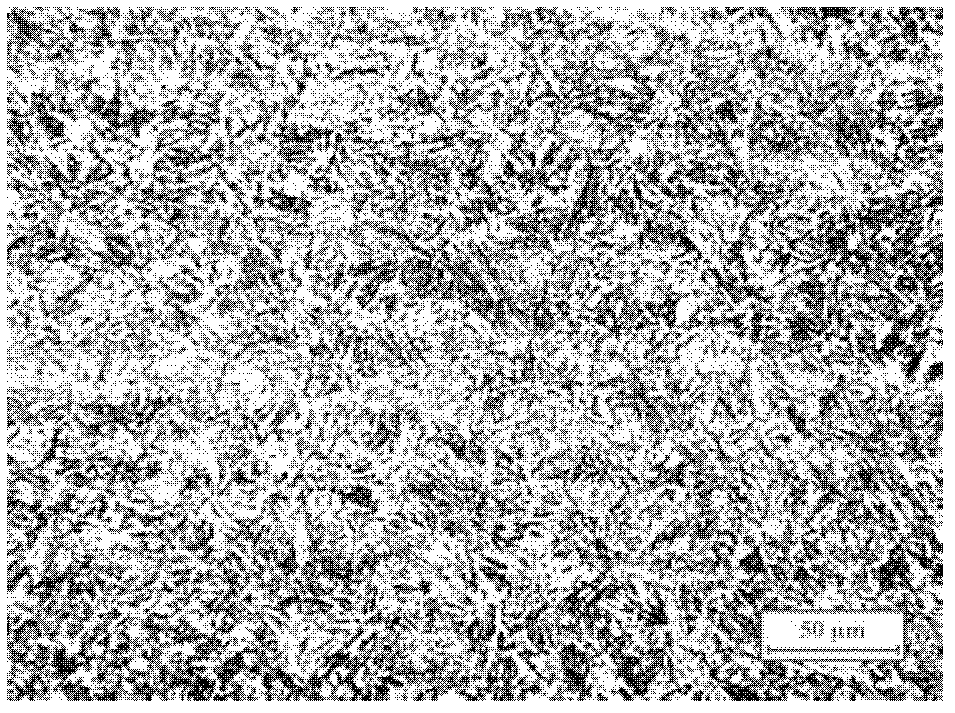

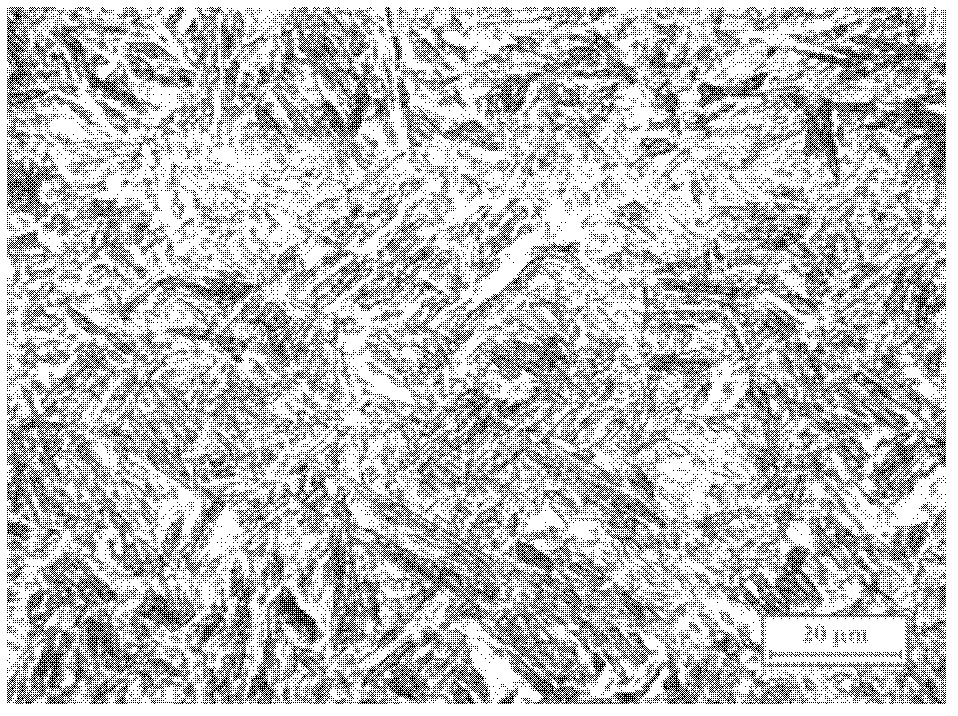

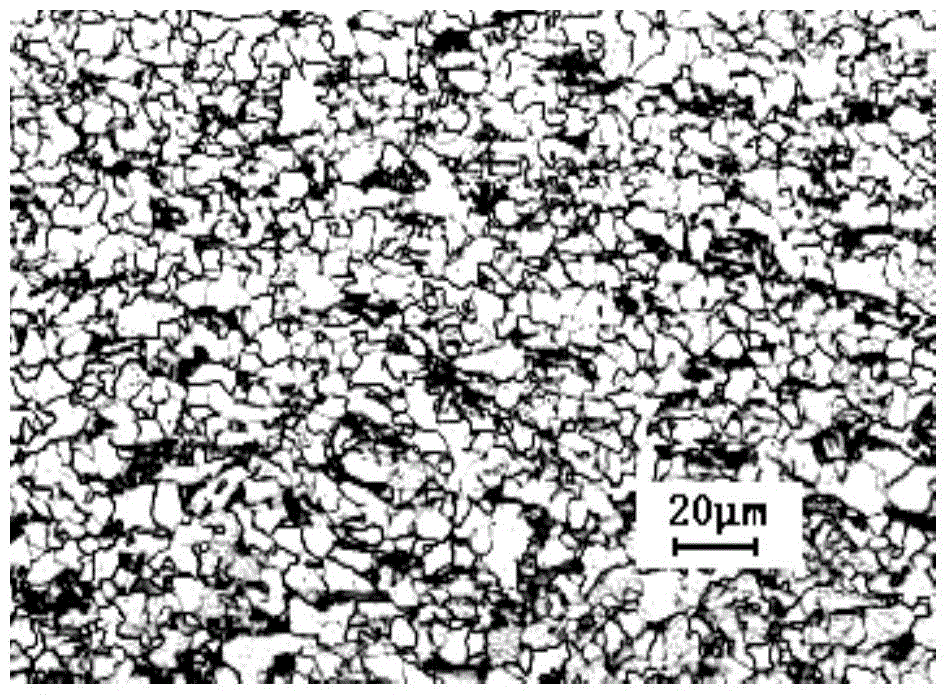

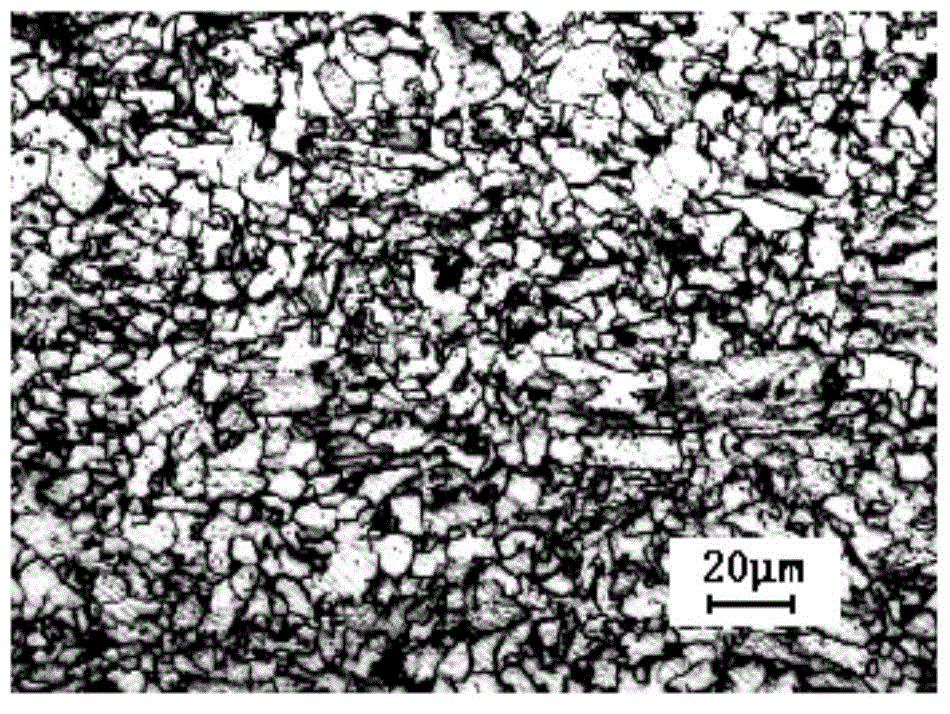

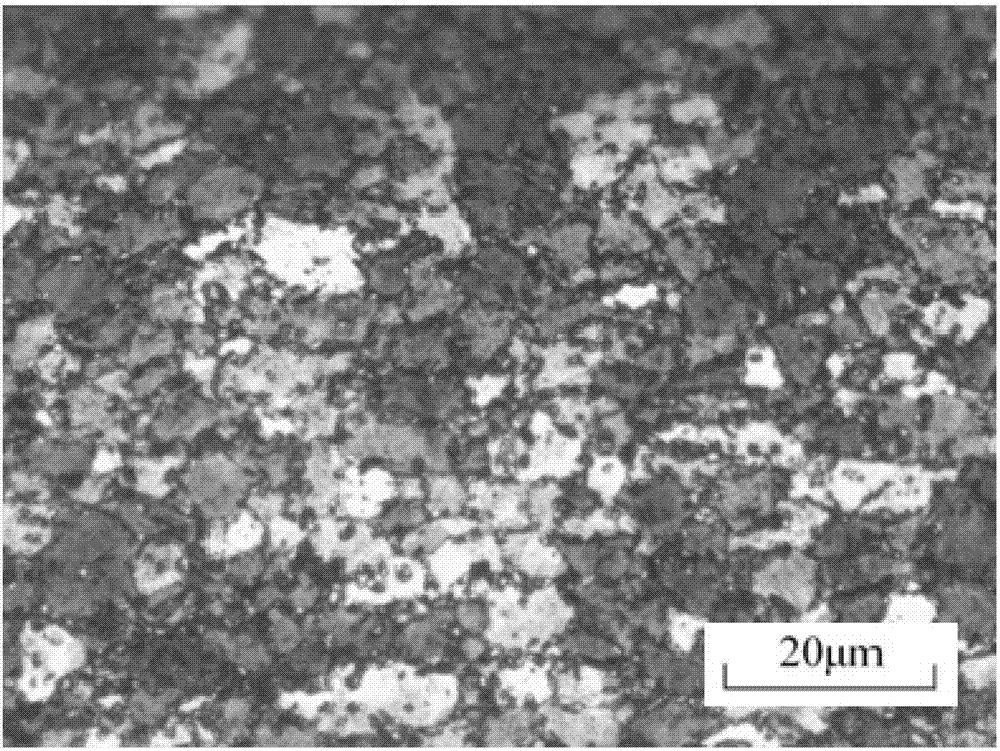

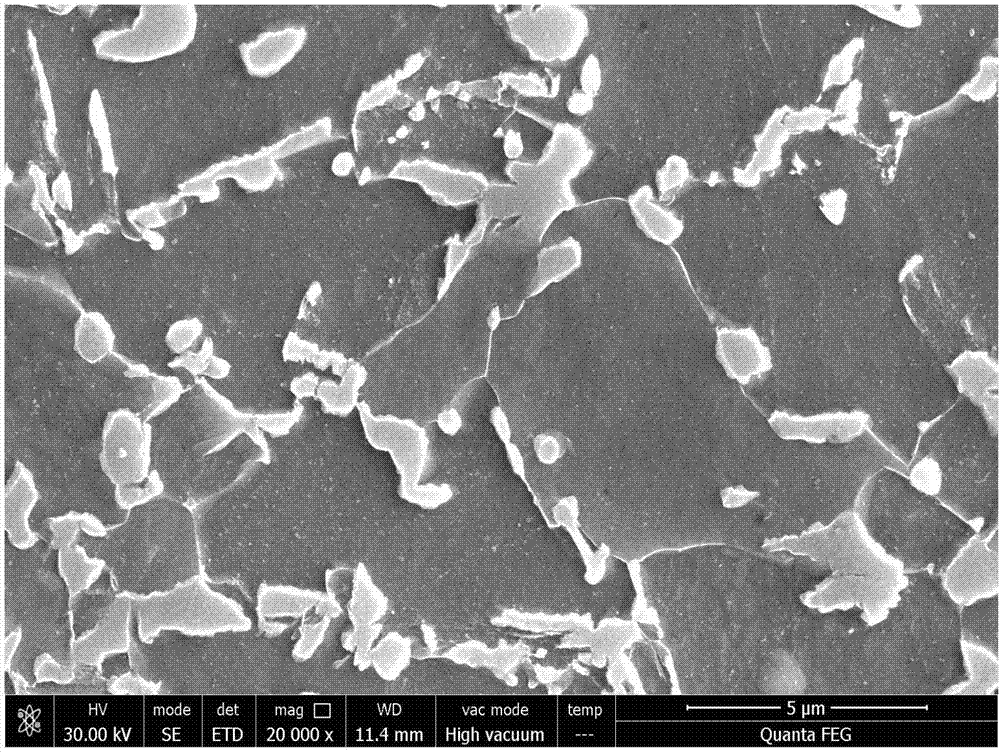

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap