Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Wire rope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as "cable laid".

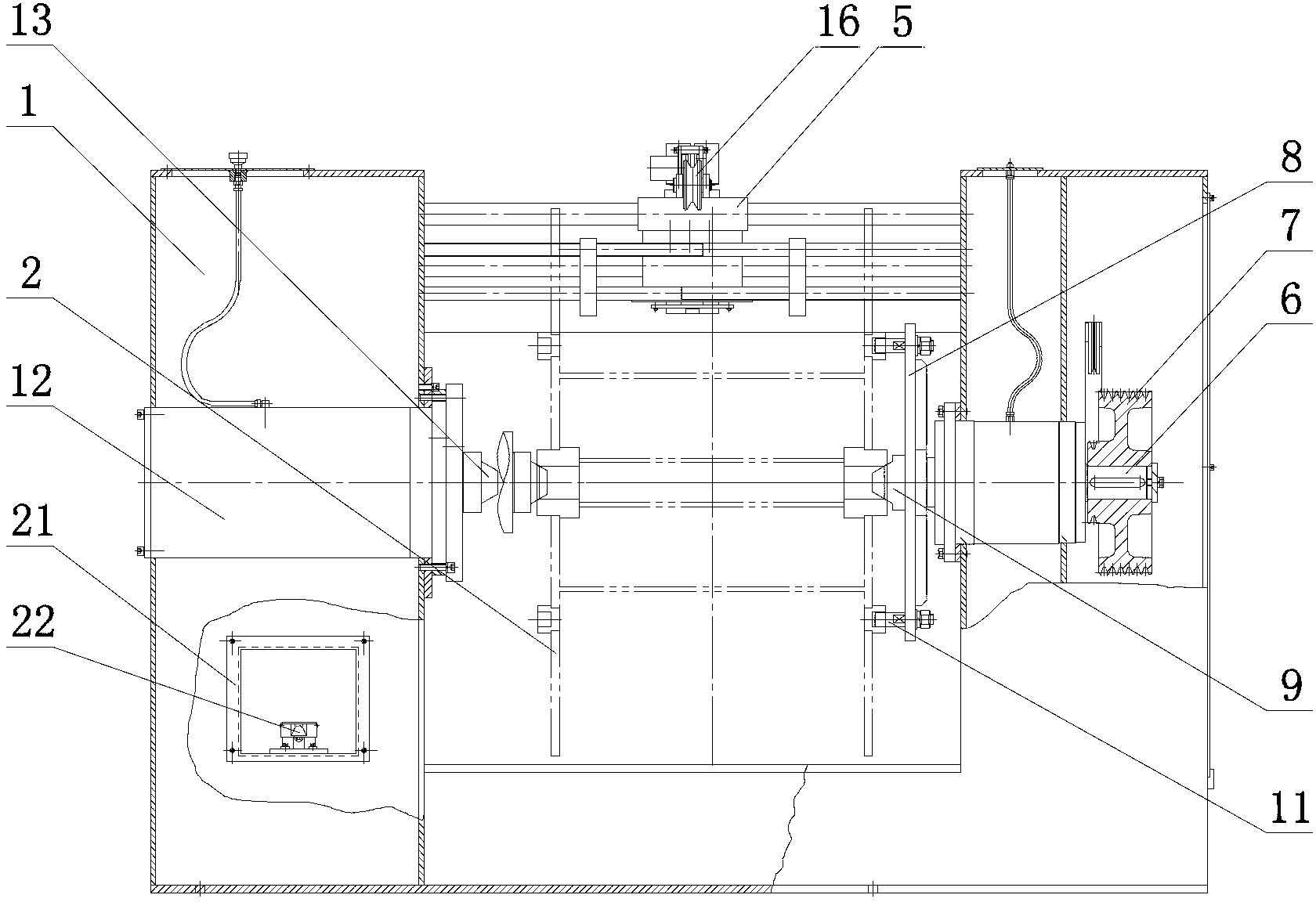

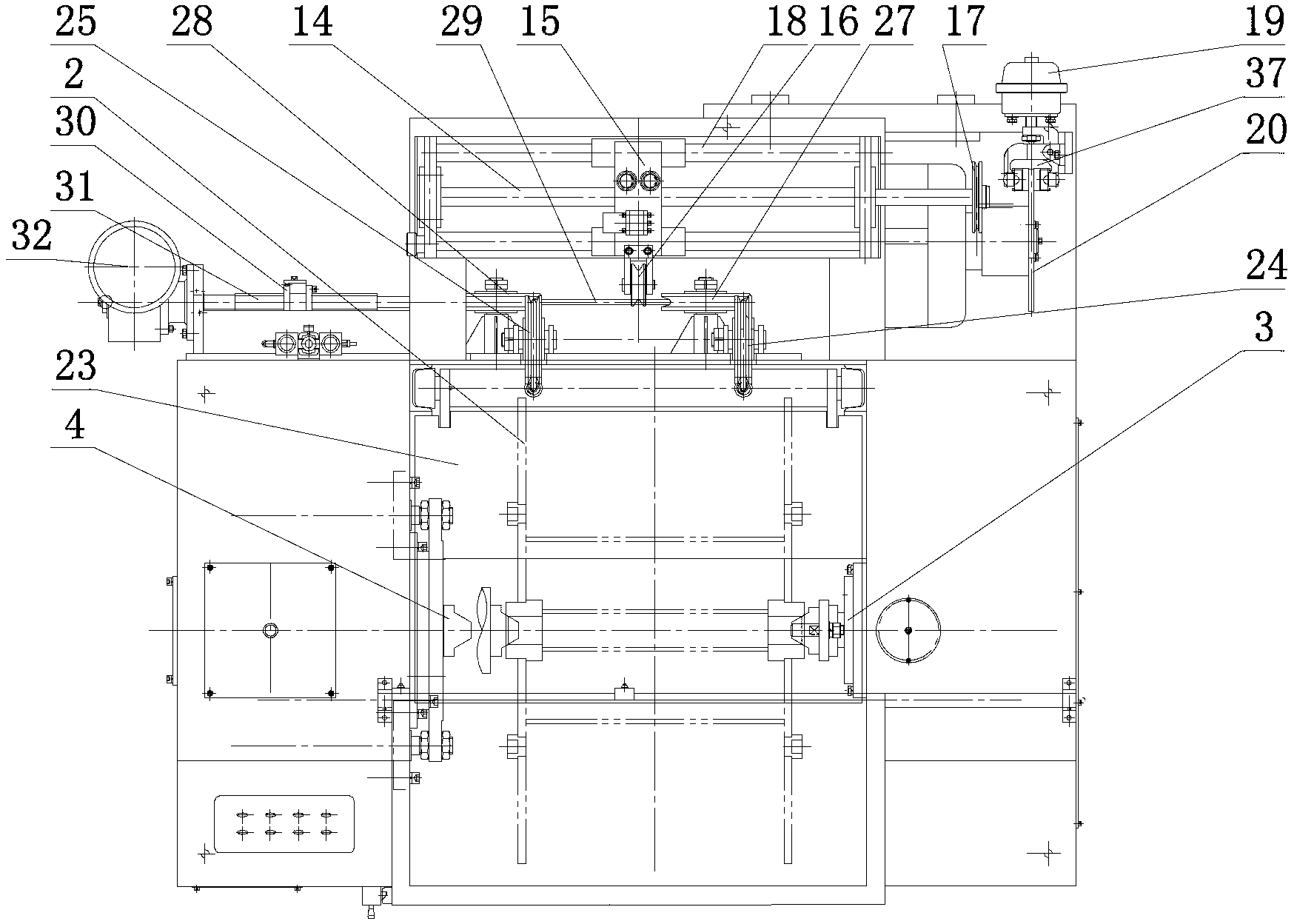

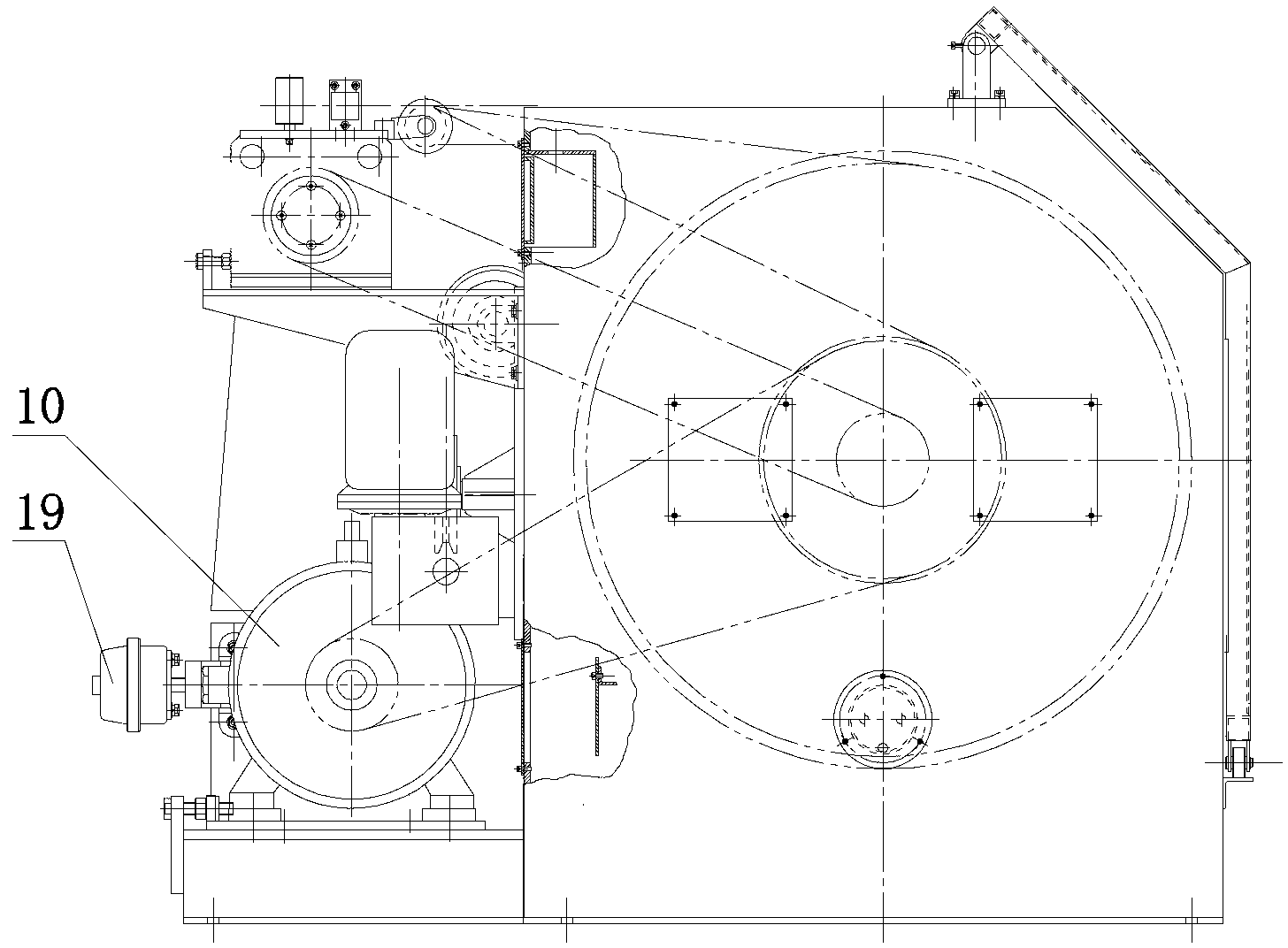

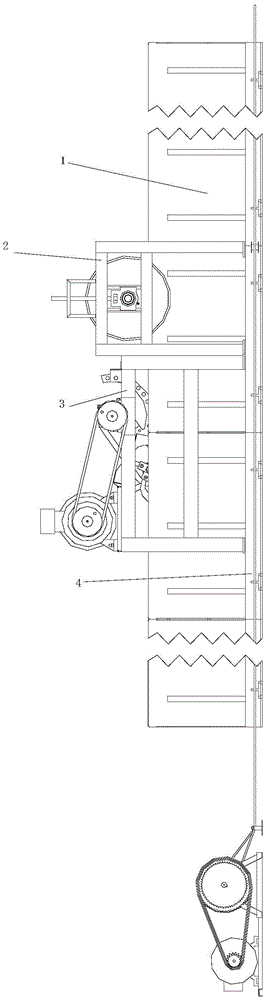

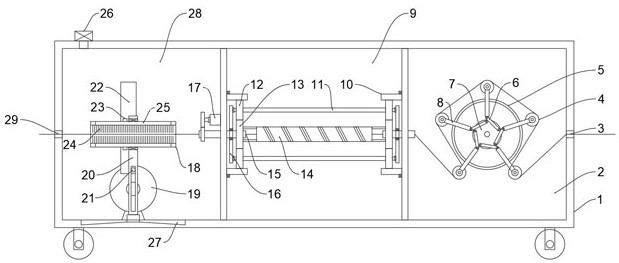

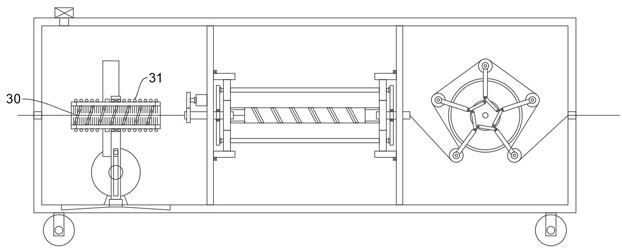

Bobbin-equipped wire take-up machine

Owner:WUXI PINGSHENG SCI & TECH

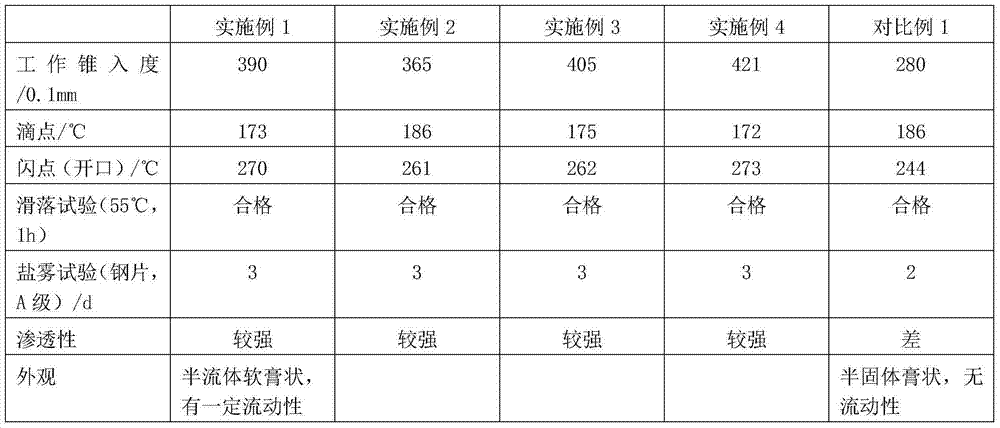

Lubricating grease composition for elevator wire ropes and preparation method thereof

ActiveCN103484218AImprove adhesionImprove permeabilityLubricant compositionMicrocrystalline waxOleic Acid Triglyceride

Owner:WUJIANG JUNDA ELEVATOR PARTS

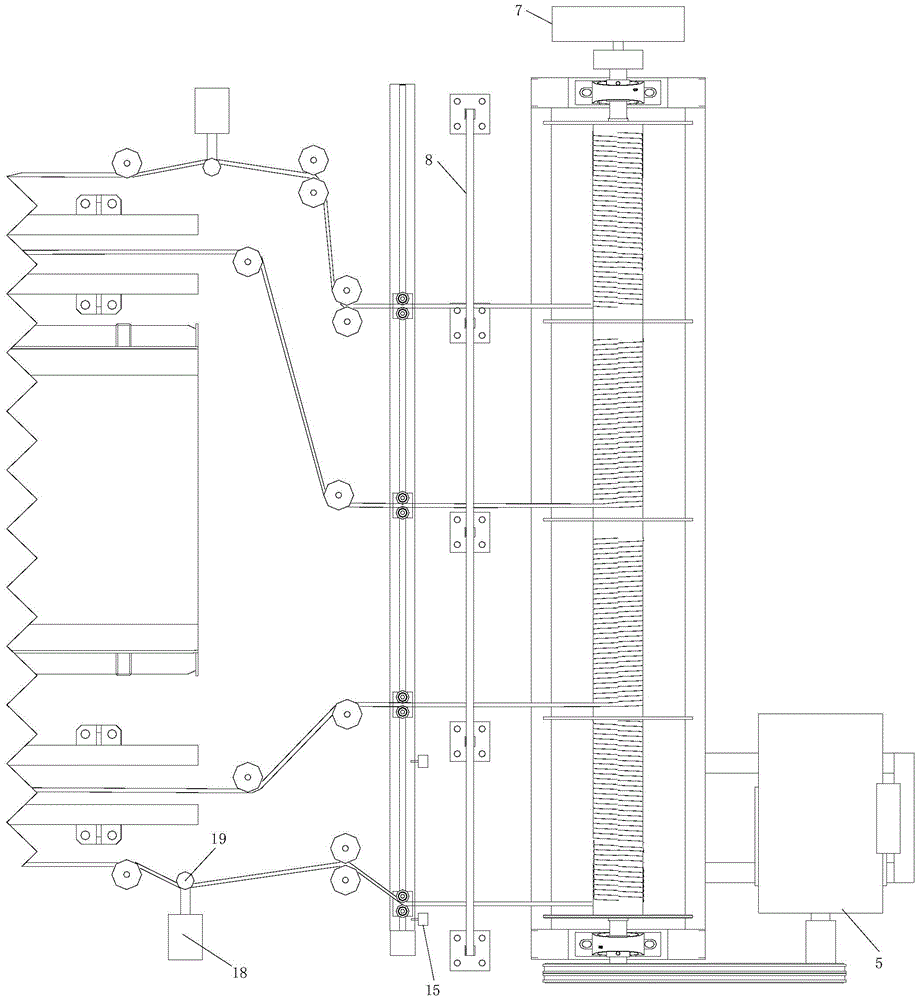

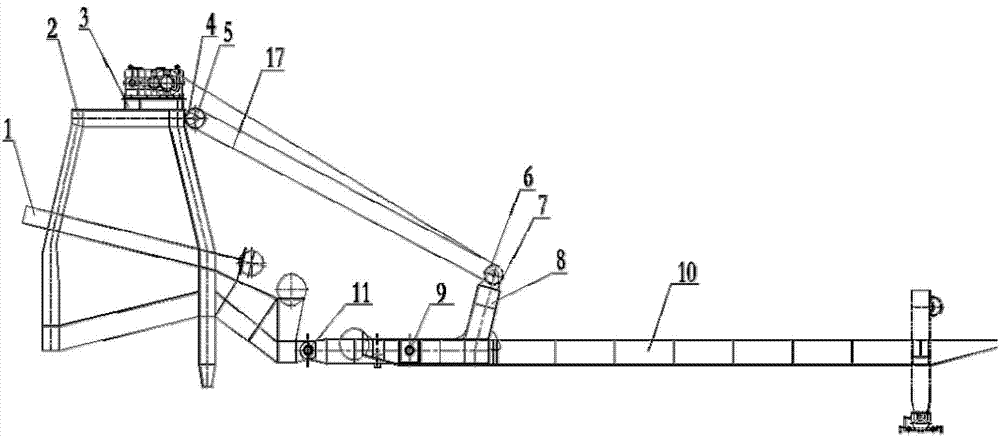

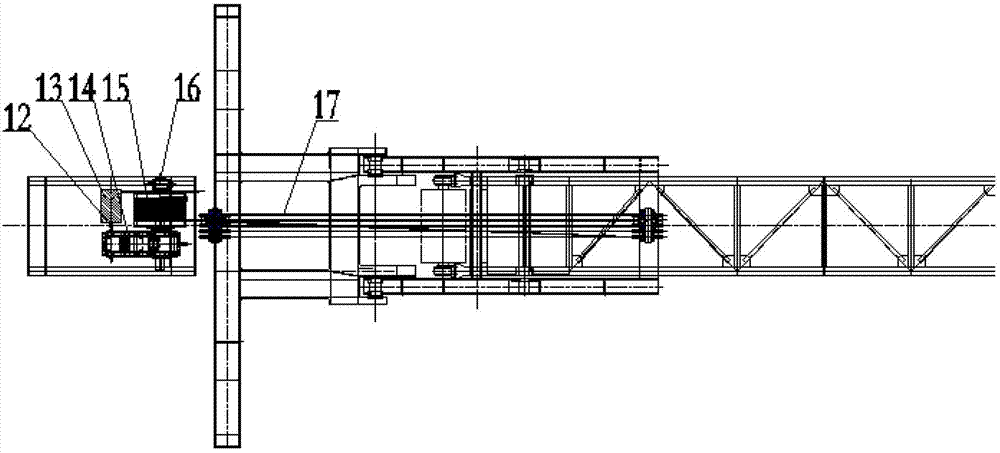

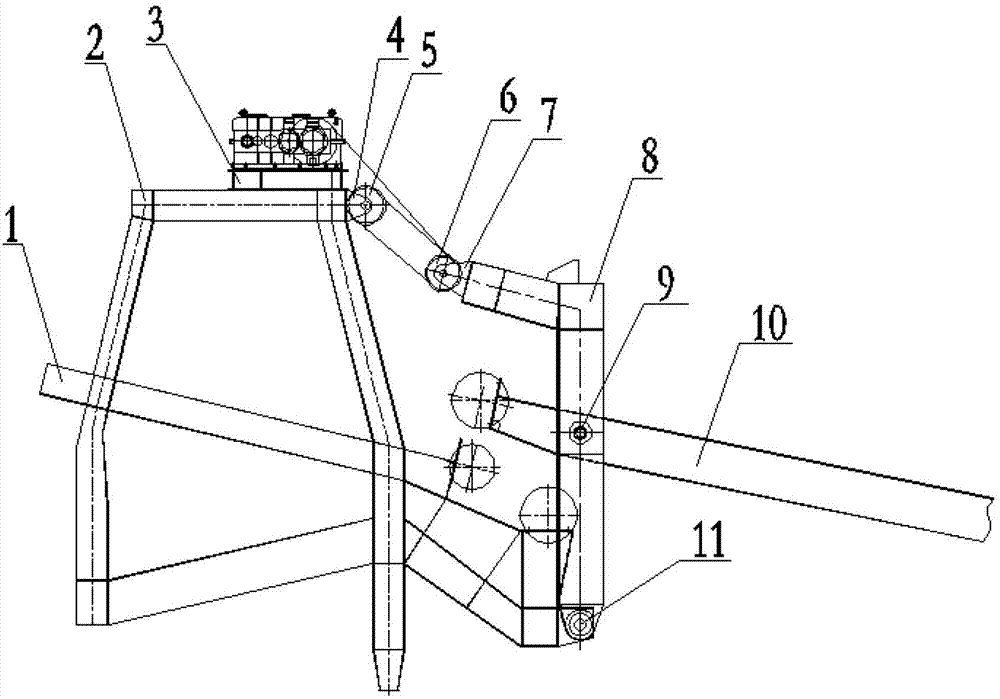

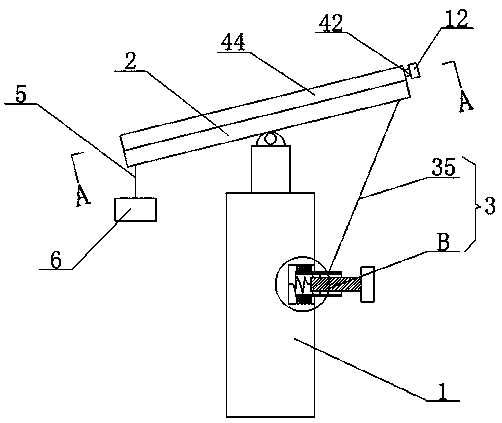

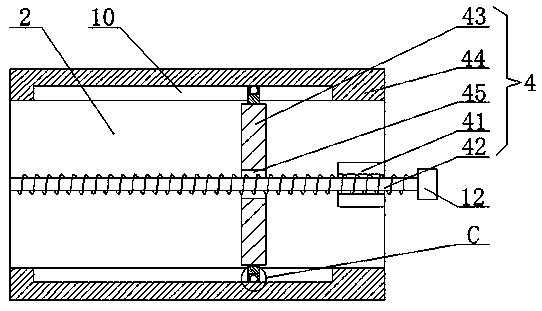

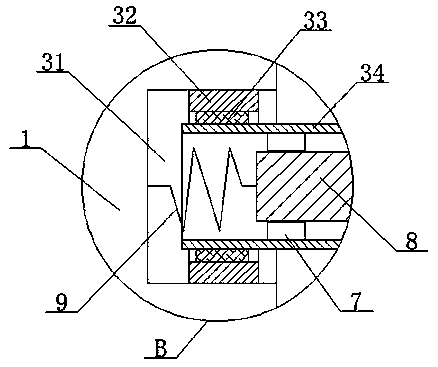

Soil tank test platform for testing agricultural implements

ActiveCN105547727ARetractableIngenious structureStructural/machines measurementControl systemEngineering

Owner:SOUTH CHINA AGRI UNIV

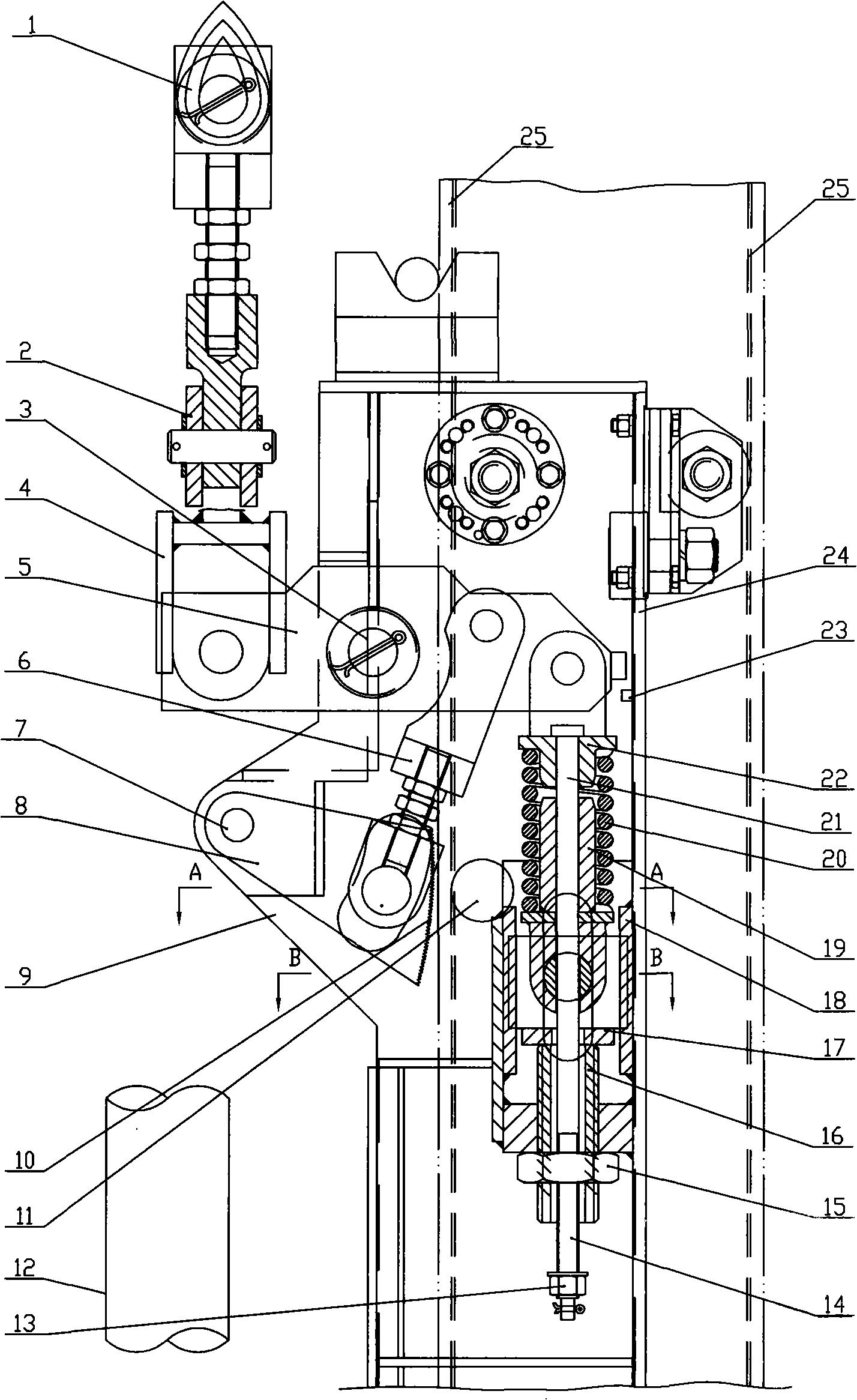

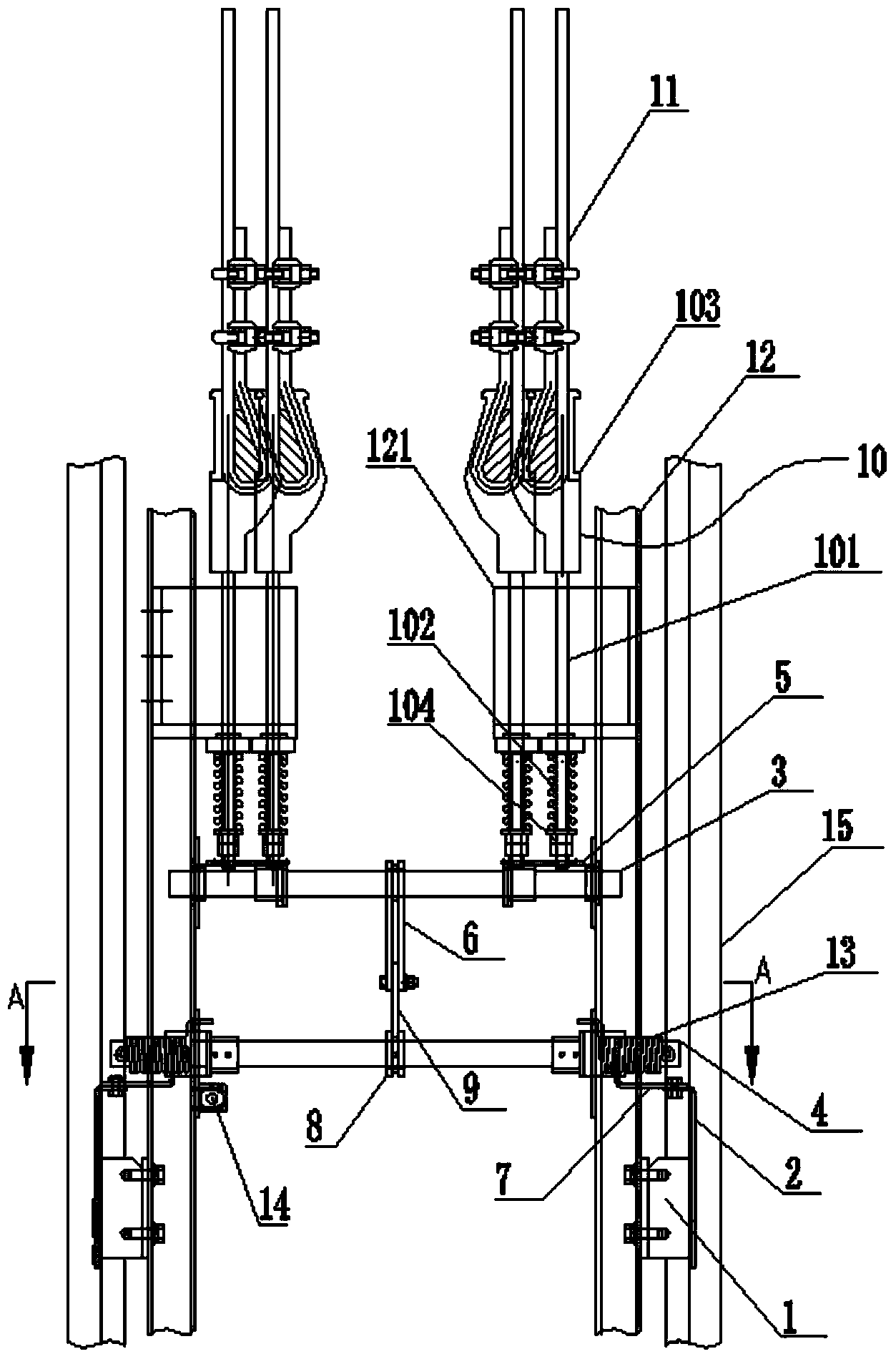

Sublance trolley anti-falling mechanism

InactiveCN101285110APrevent fallingReduce tensionManufacturing convertersVehicle frameOxygen converter

Owner:WISDRI ENG & RES INC LTD

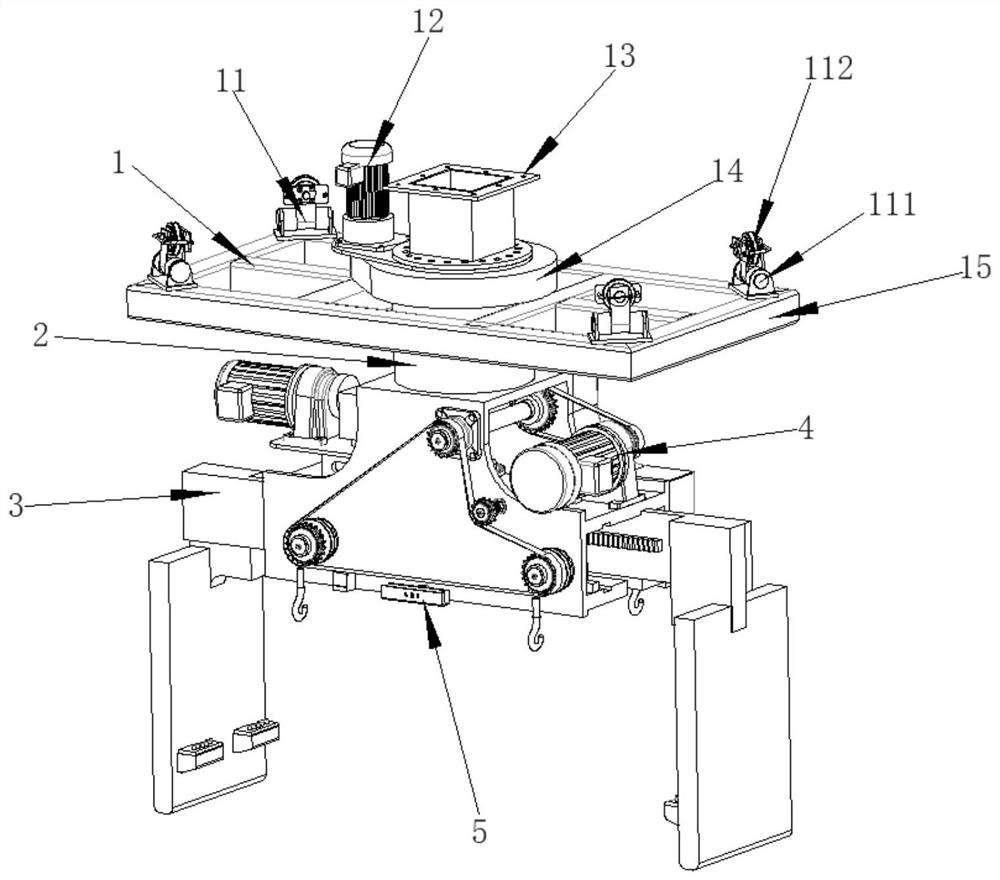

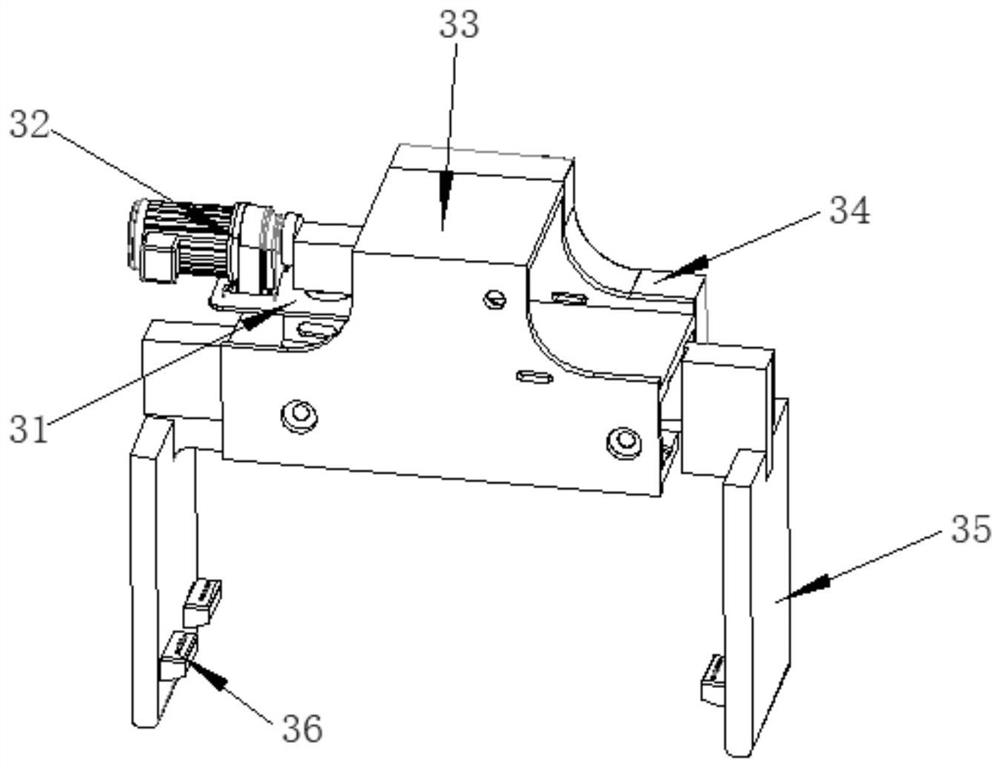

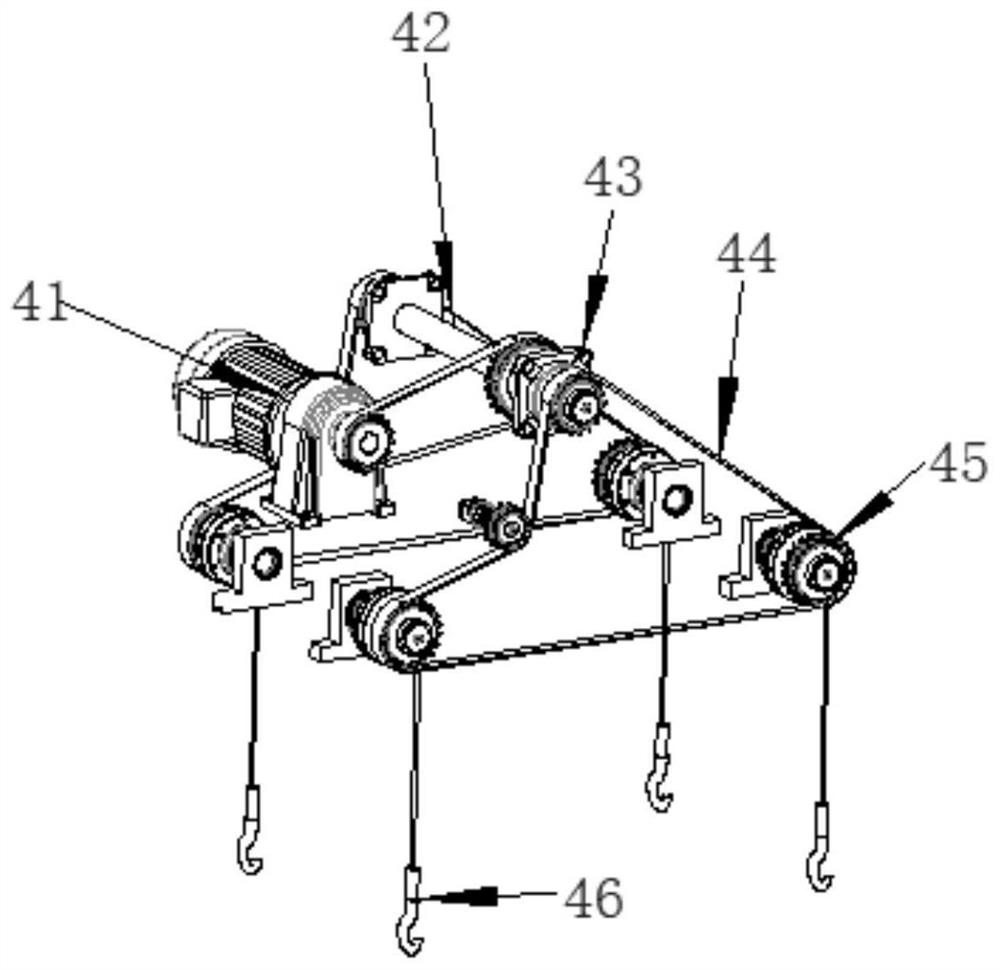

Device for drop test of mobile phone

The invention discloses a device for drop tests of a mobile phone. The device comprises a stand column, a lifting assembly, a control assembly, and a transportation assembly. The stand column is provided with a lifting guide rail. The lifting assembly can slide on the lifting guide rail. Sliding of the lifting assembly on the lifting guide rail is driven by a first wire rope pulley lifting assembly. The lifting assembly comprises a sliding base body, and the sliding base body is rotatably connected with an L-shaped pneumatic finger, and the sliding base body is provided with a rotating assembly. The transportation assembly comprises a feed assembly. The feed assembly comprises a feed sliding rail, and the feed sliding rail is slidably provided with a belt base. The sliding of the belt base on the feed sliding rail is driven by a second wire rope pulley lifting assembly. The belt base is connected with a conveyor belt. A plurality of placing frames are placed on the conveyor belt. The distances between each two adjacent placing frames are equal. Each placing frame is rotatably provided with a clamp. Beneficial effects of the device are that free-fall tests on edges of a mobile phone are realized, and detection efficiency is improved.

Owner:CHONGQING BASICOM SCI & TECH

Self-stable suspension type unloading platform and construction process thereof

PendingCN107965147AShorten the installation and dismantling periodSimple installation and disassemblyBuilding material handlingSocial benefitsArchitectural engineering

The invention discloses a self-stable suspension type unloading platform and a construction process thereof. The unloading platform comprises main beams. Auxiliary beams are arranged between the mainbeams. Platform embossing steel plates are arranged among the main beams and the auxiliary beams. Vertical beams are arranged on the upper sides of the main beams. A rebar pull rod upper support is arranged among the vertical beams. A rebar pull rod lower support parallel to the rebar pull rod upper support is arranged at the bottom ends of the main beams. Rebar pull rods are arranged between therebar pull rod upper support and the rebar pull rod lower support. Upper floor system edge beams are arranged at the top ends of the vertical beams. A feed channel plate is arranged at the upper endsof lower floor system edge beams and the platform embossing steel plates. Compared with a traditional steel overhung unloading platform, embedded steel wire rope ring hanging, profile steel support ring anchoring, ending anchoring ring hole blocking and hanging ring rebar cutting treatment are not needed, and a passenger channel can be laid along a floor; construction installation and detachment operation is simple, safe and convenient, the installation and detaching construction period is shortened, embedded pieces and labor cost are greatly saved, the platform has remarkable economic and social benefits and meets the efficient, energy-saving and green construction requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

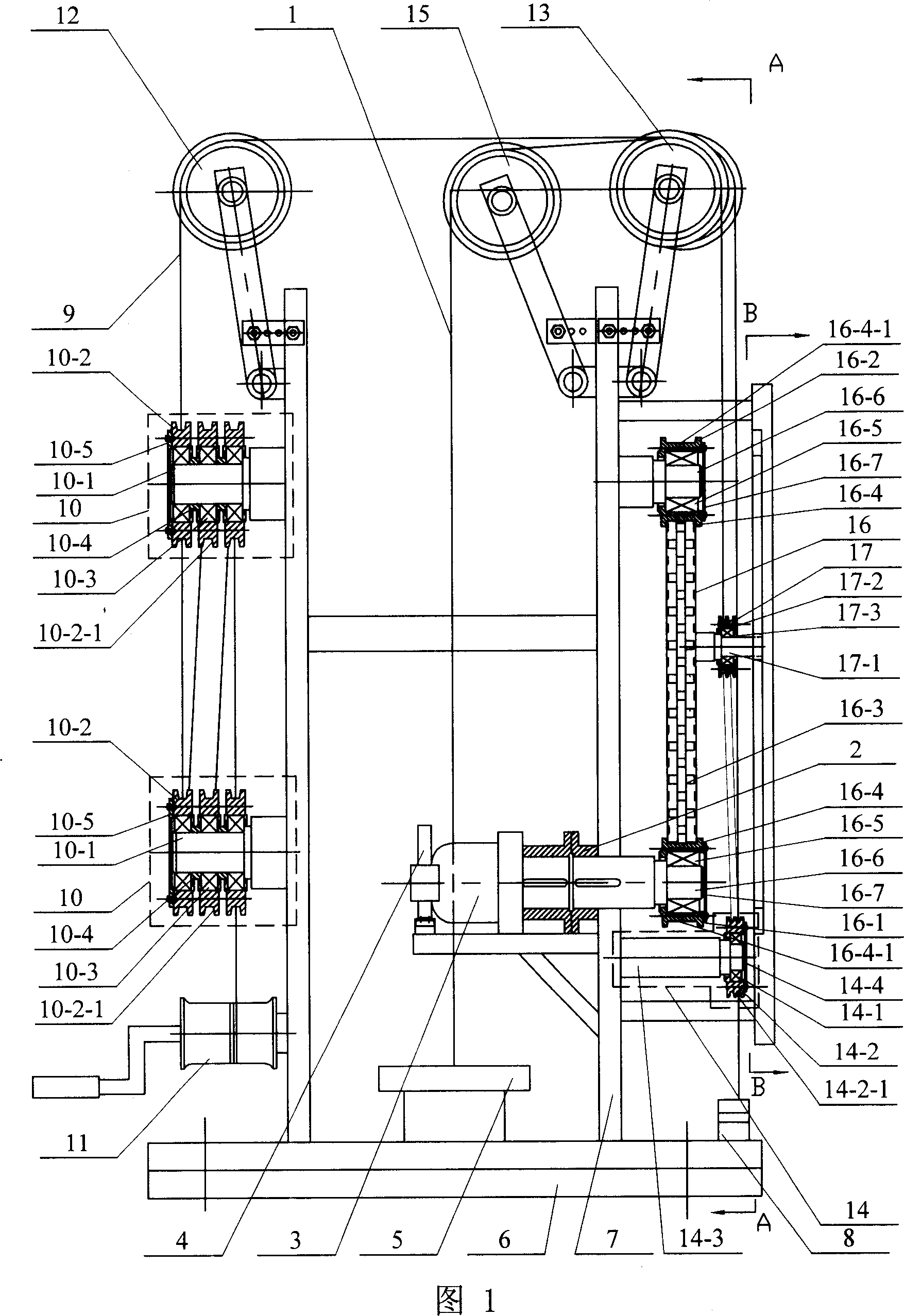

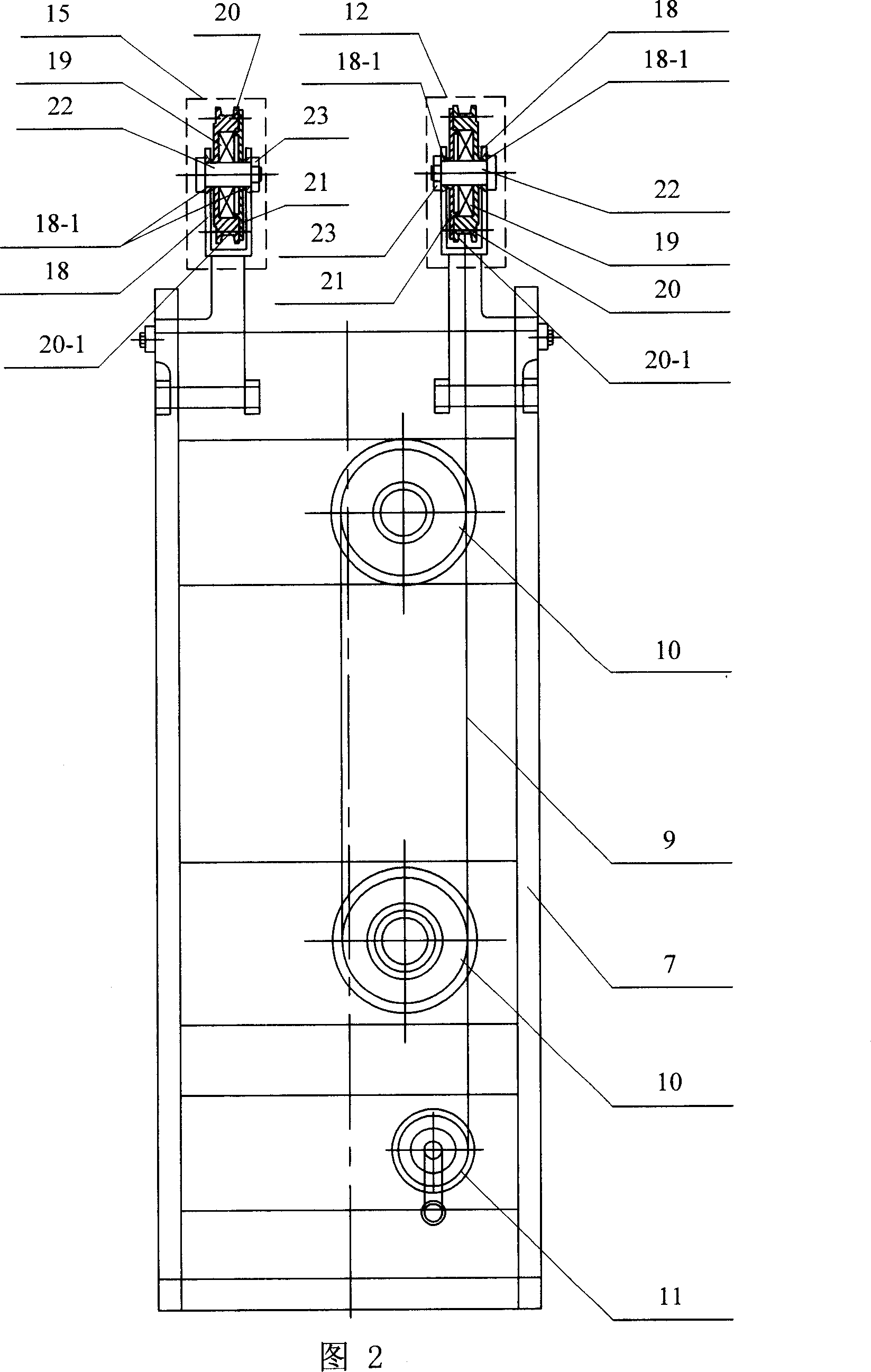

Two tripper cars of electric variable-amplitude type wheel-bucket stack-taking machine

InactiveCN102765606ASave design spaceReduce weightWinding mechanismsLoading/unloadingSmall footprintEngineering

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

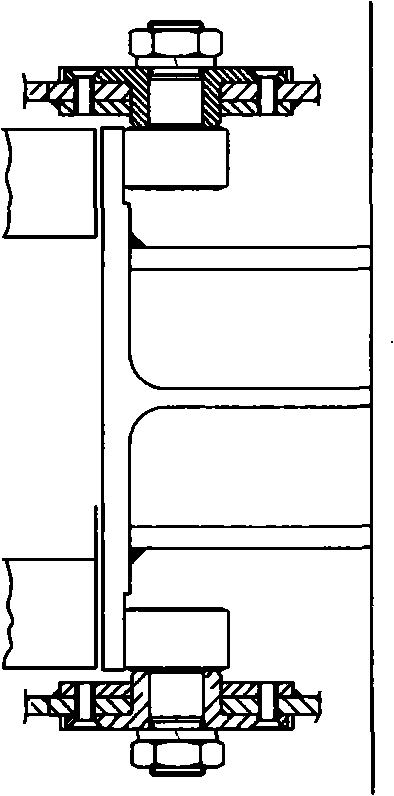

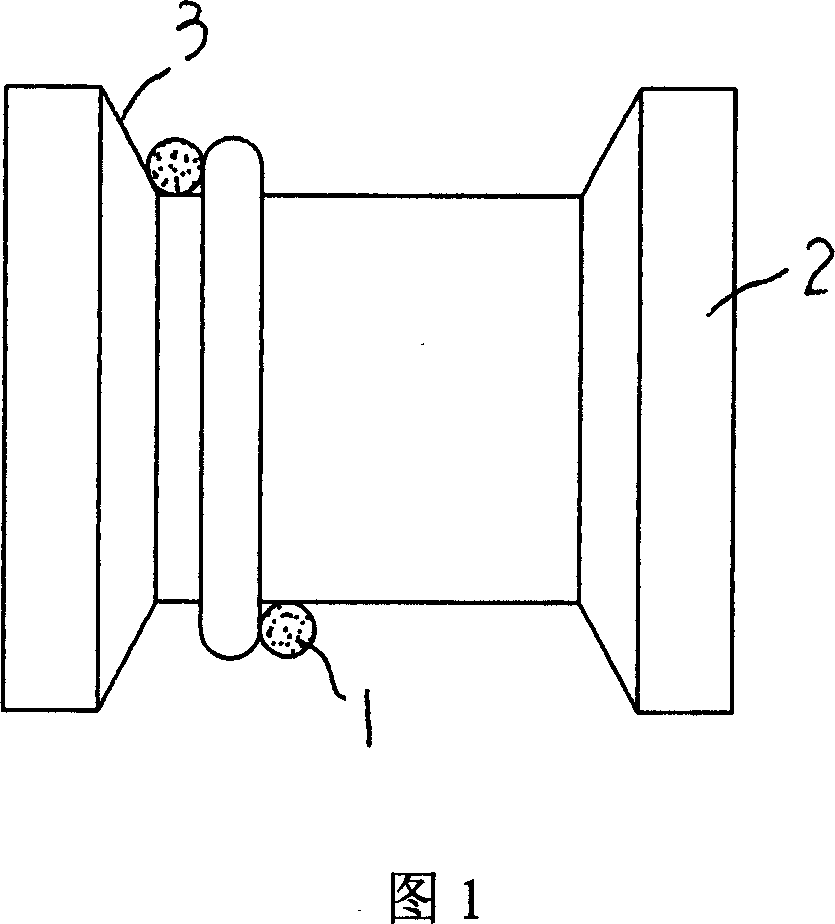

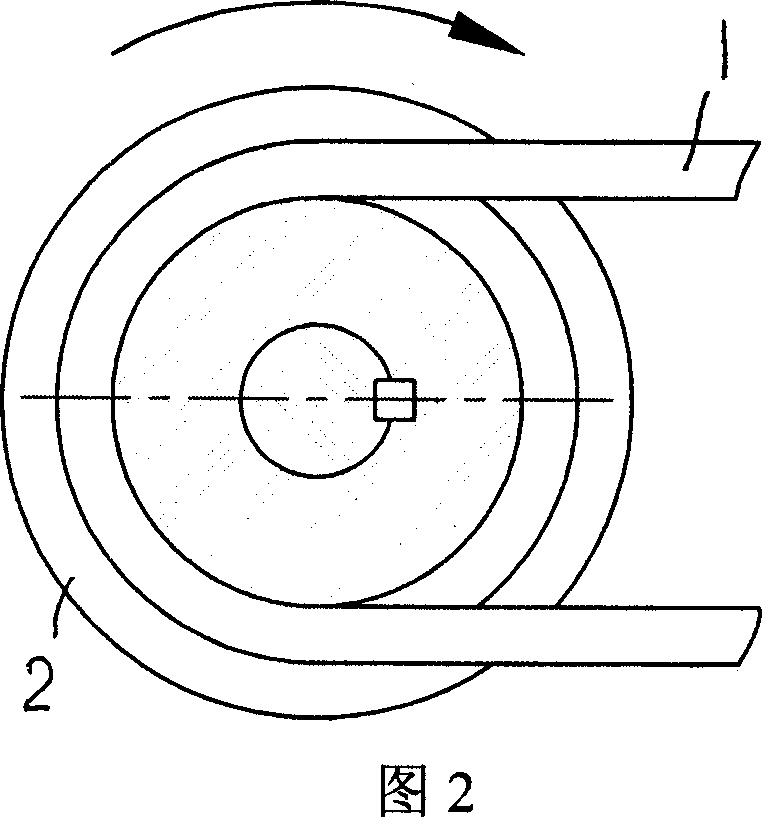

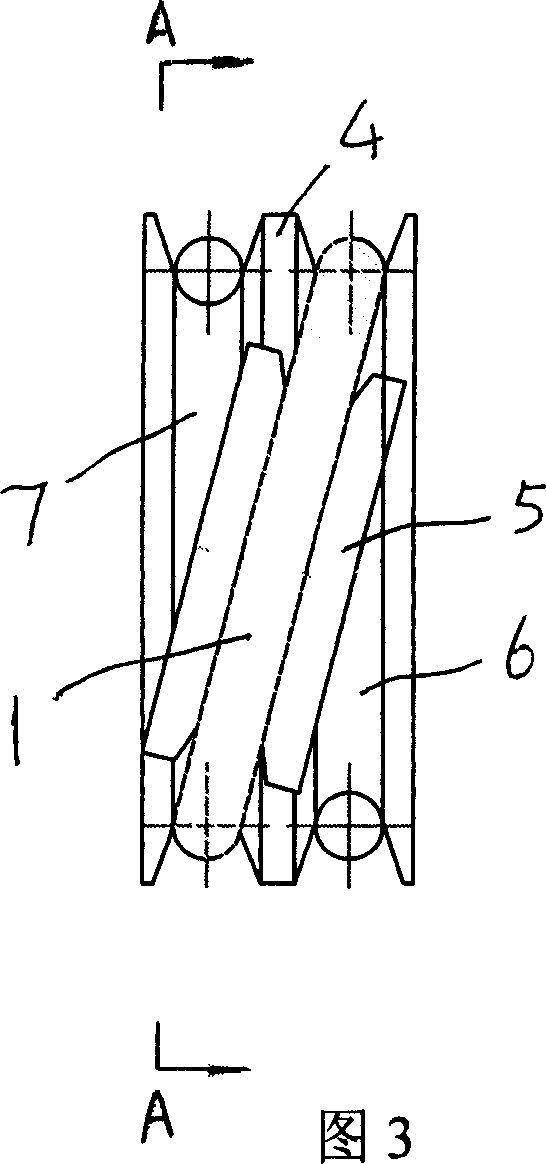

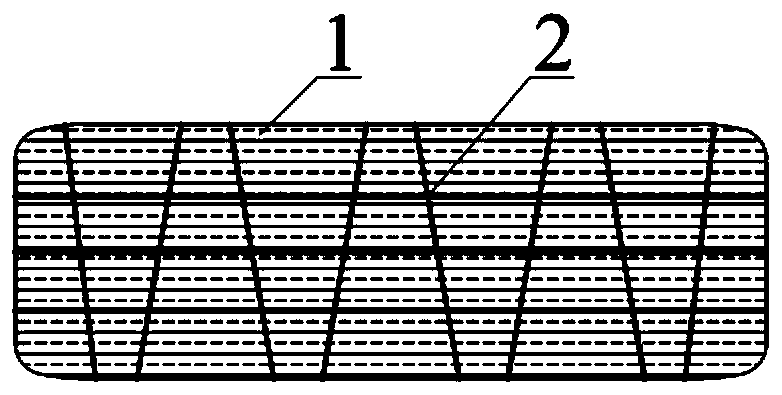

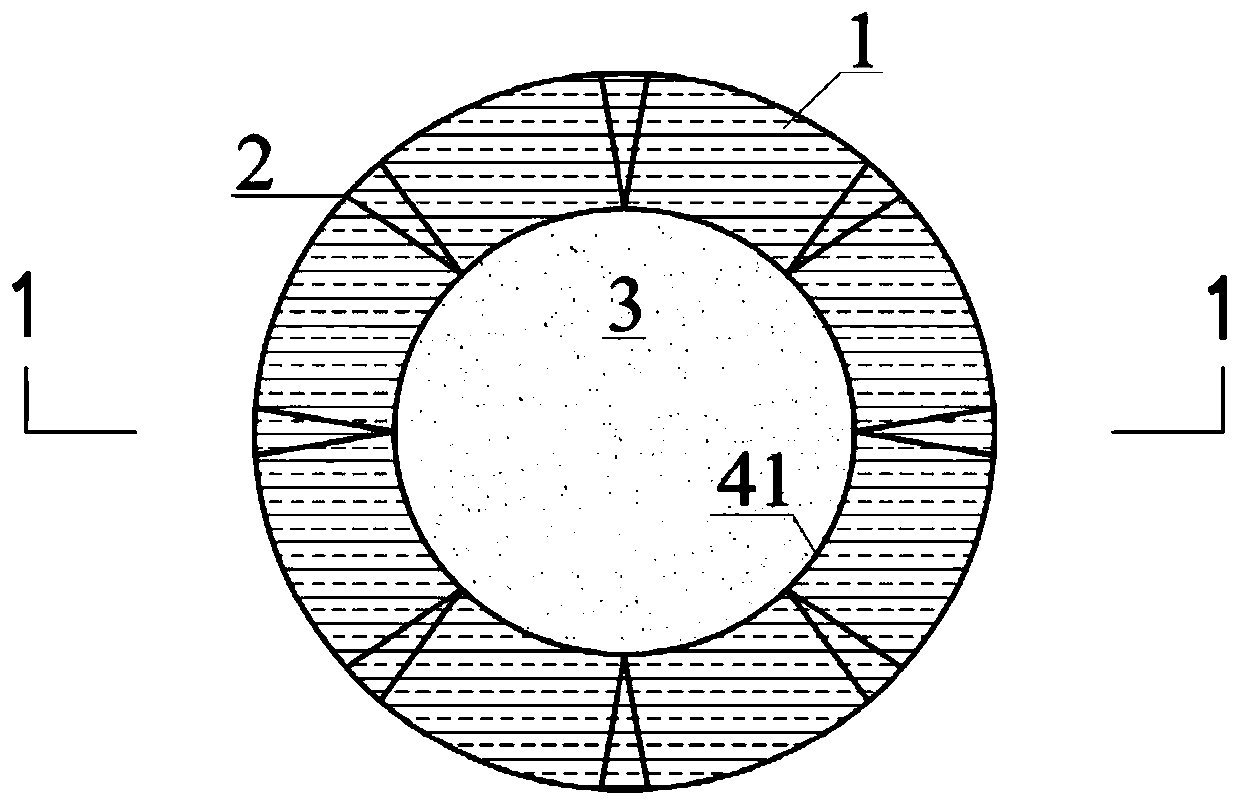

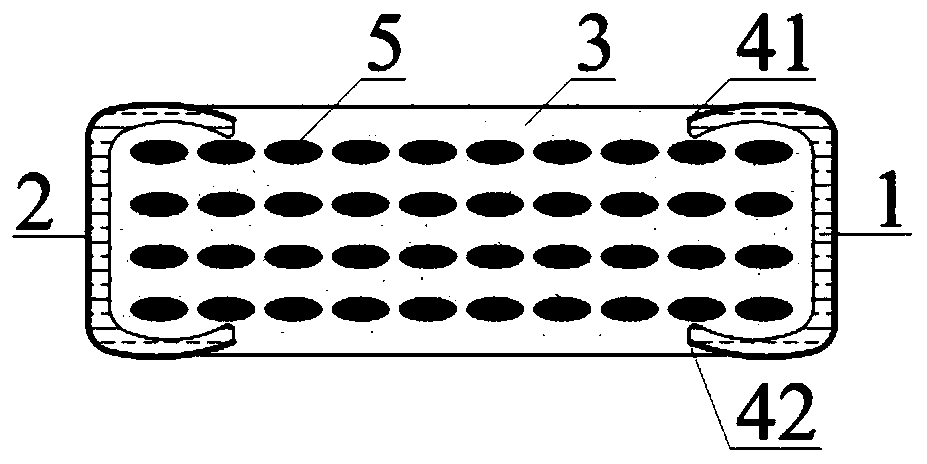

Cross cramp for steel wire

ActiveCN101105025AImprove protectionSave materialProtective constructionRopes and cables for vehicles/pulleyCruciformMaterial consumption

The invention discloses a steel wire rope cross-fixation device used for wire rope net, i.e. a cruciform latch which comprises an upper latching sheet (1), a lower latching sheet (2), and at least two claws (3) equipped at the bottom of the upper latching sheet (1) and / or the lower latching sheet (2). The bottom surfaces of the upper latching sheet (1) and the lower latching sheet (2) are shaped to a depressed arc surface. Crisscross grooves are correspondingly formed on the inner surfaces of the upper and the lower latching sheets. The circumferences of the upper and the lower latching sheets extend along the crisscross grooves out of the claws (3), forming a smooth notch (5) when the upper and the lower latching sheets are closed oppositely. The steel wire rope cross-fixation device solves the problem that the steel wire rope is easy to be damaged in the prior art, and has the advantages of good appearance, reduced material consumption, no need of perforation and low processing cost.

Owner:BROOKE (SUZHOU) ENG CO LTD

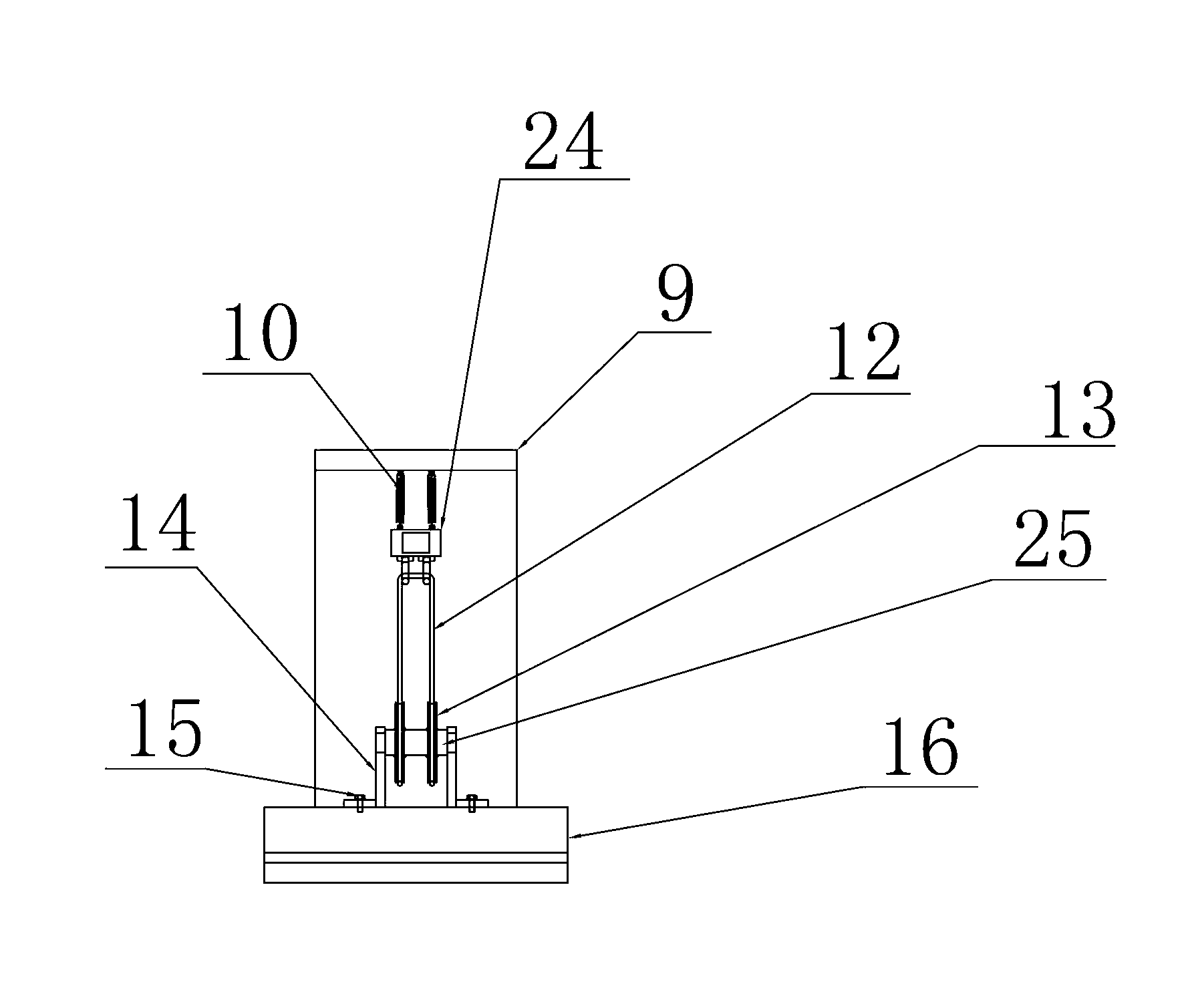

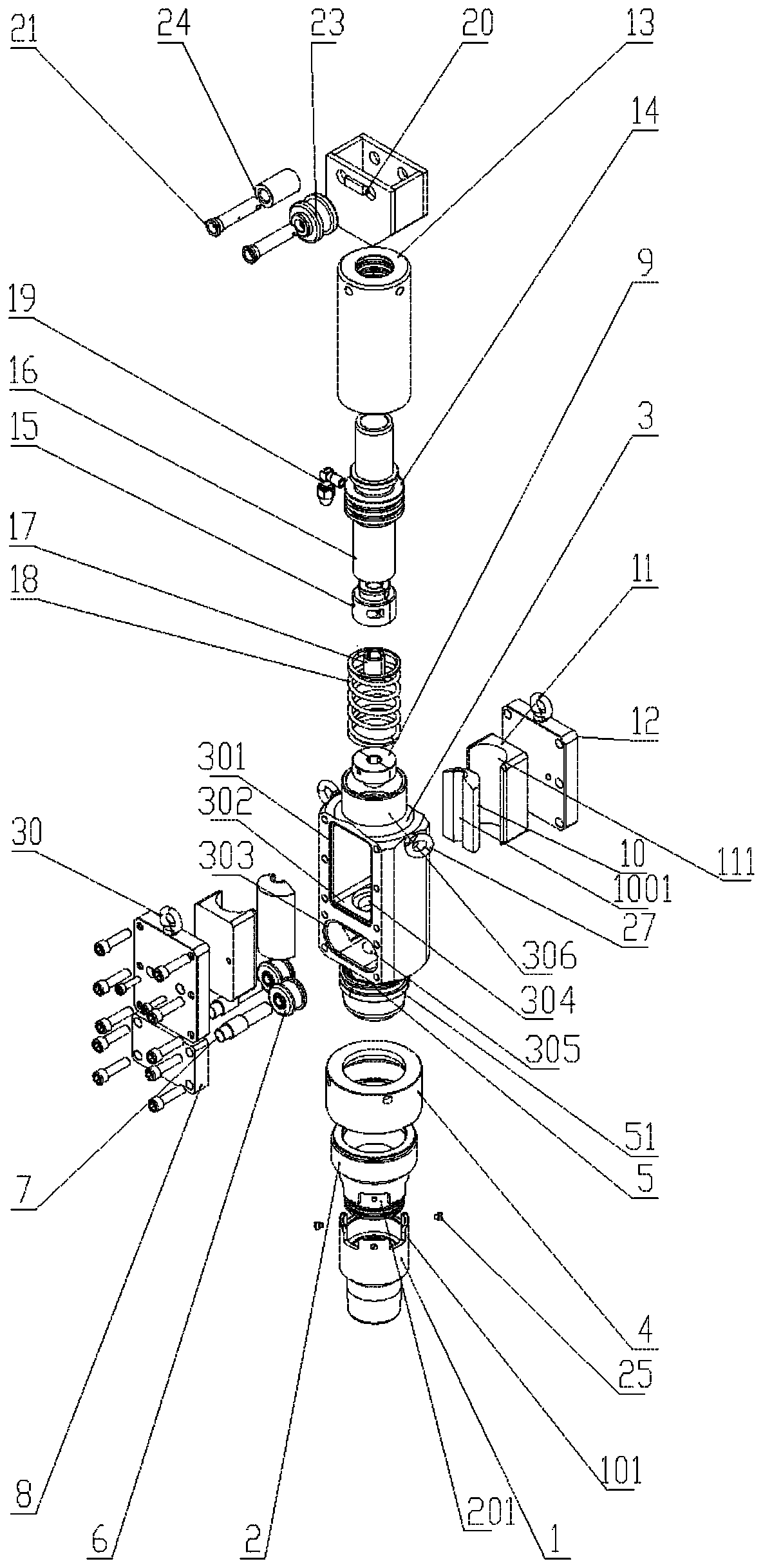

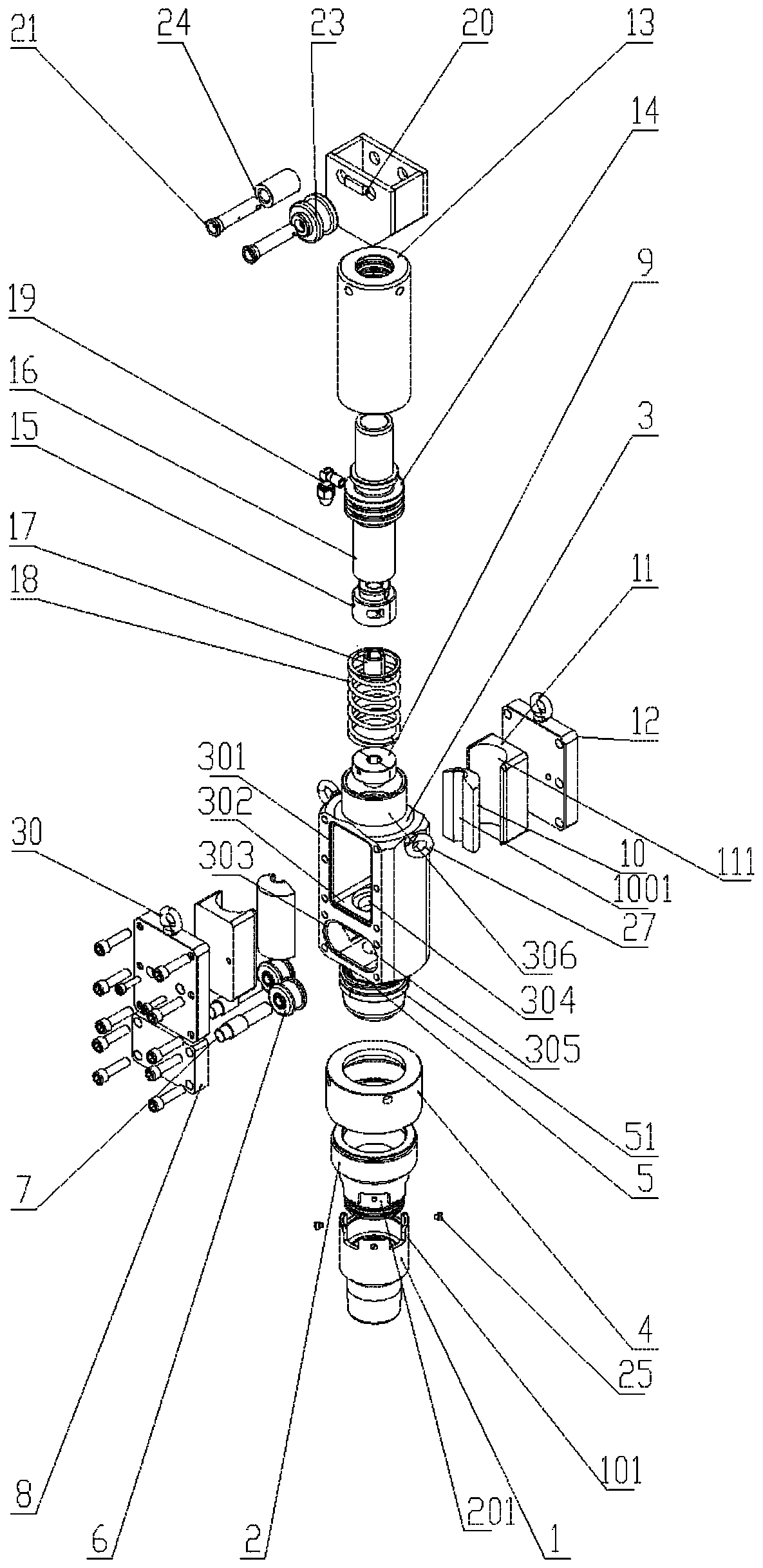

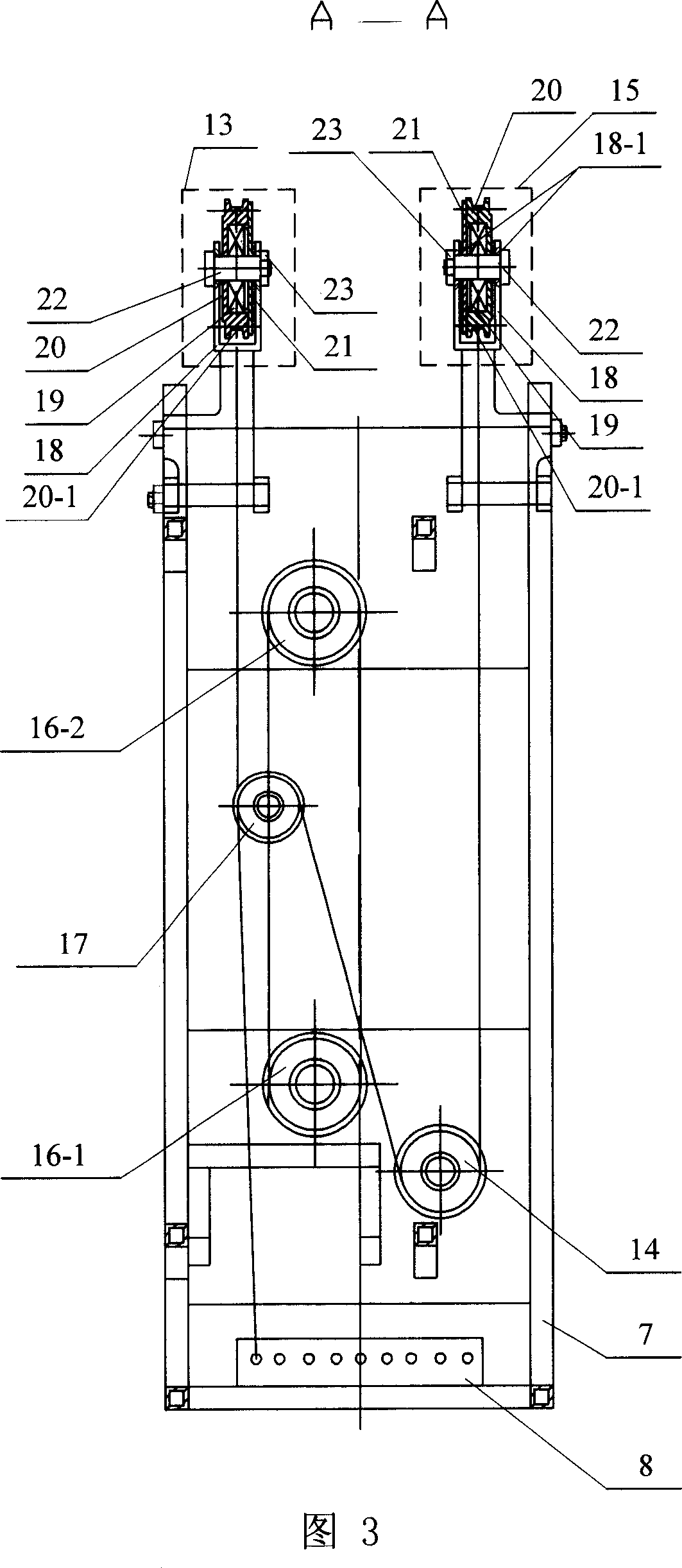

Planetary gear train built-in construction winch device

Owner:ANHUI KUDZUVINE ROOT PRODUCTIVITY PROMOTION CENT CO LTD

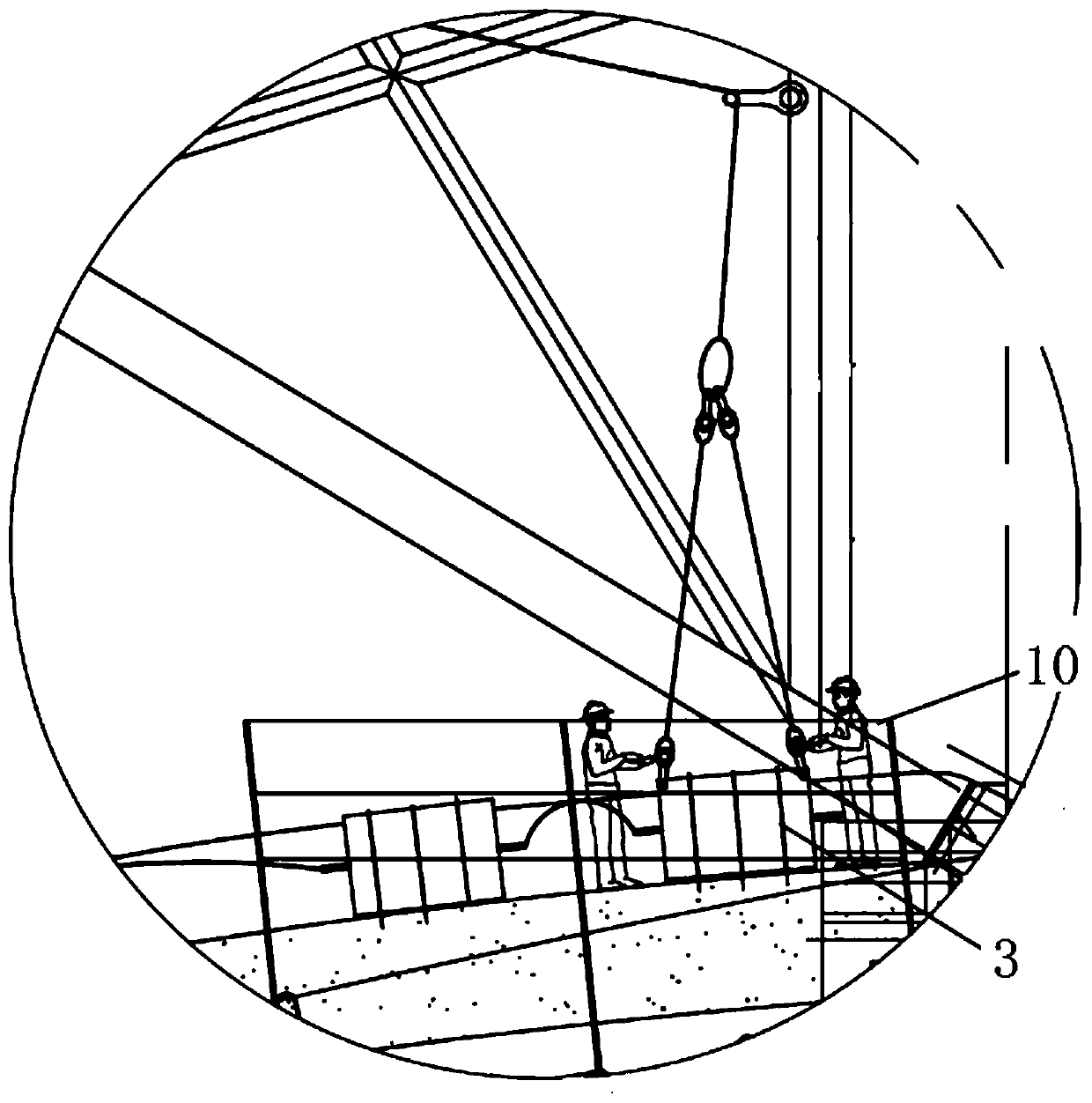

Construction method of lift ceiling of auditorium hall

ActiveCN103912089AShorten the lifting timeEnsure construction safetyCeilingsArchitectural engineeringDropped ceiling

Owner:CHINA CONSTR EIGHTH ENG DIV

Safe monitoring device of winding engine

InactiveCN102701098ALocation real-time monitoringRepair in timeWinding mechanismsEngineeringPosition sensor

Owner:WISDRI ENG & RES INC LTD

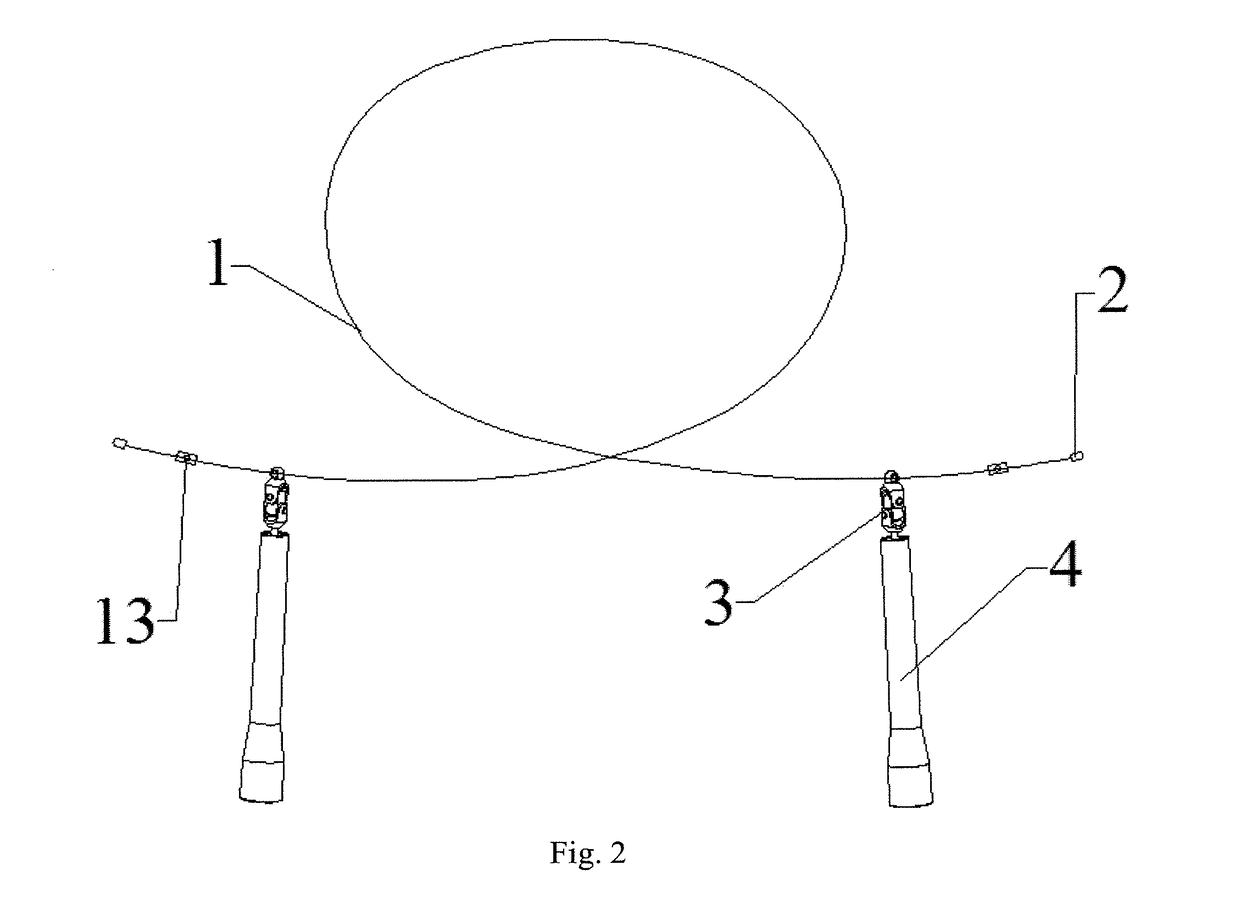

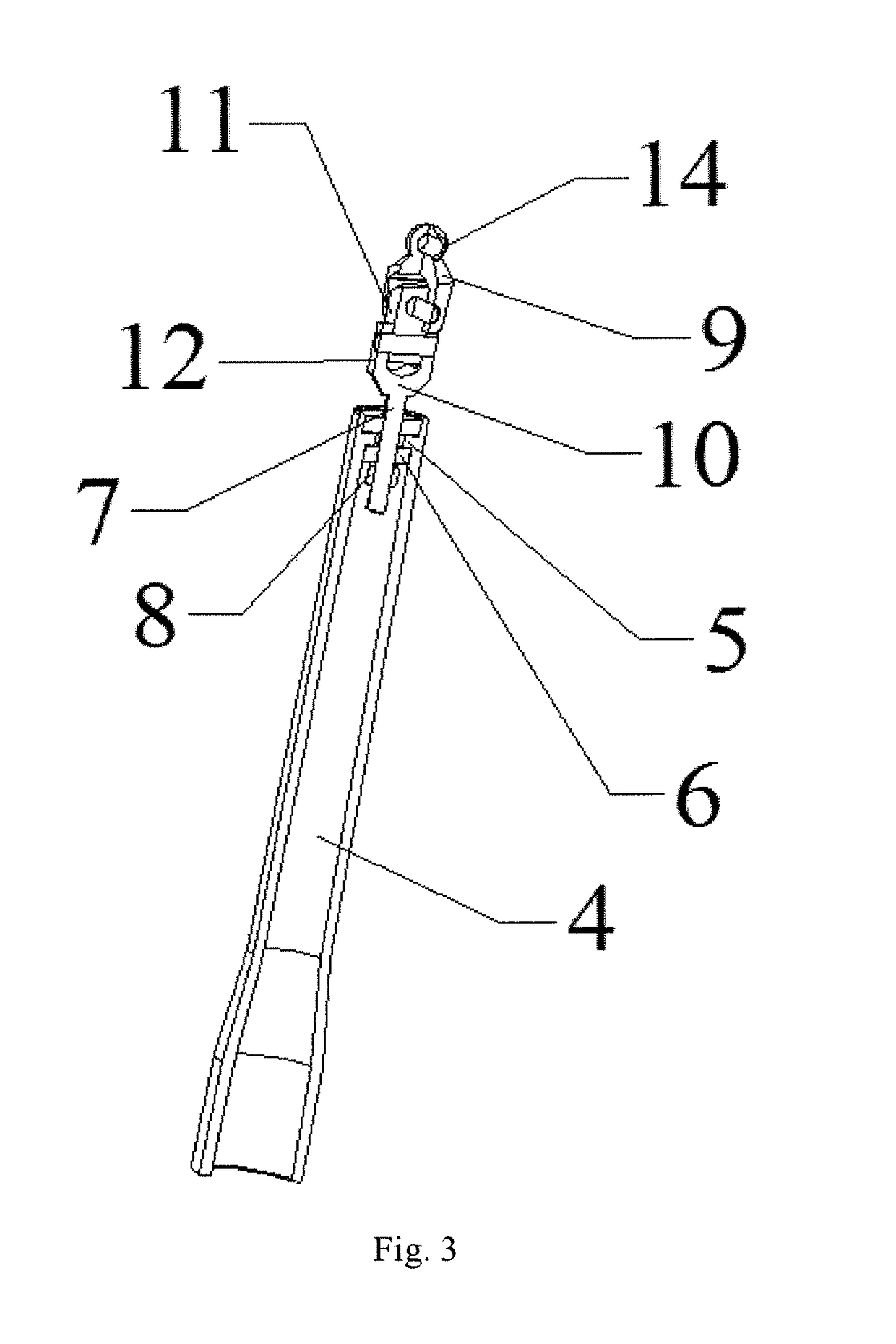

360º universal joint jump rope

InactiveUS20190046825A1Increase the angle of motionSkipping-ropesMuscle exercising devicesJumping ropeUniversal joint

Owner:SUZHOU RUIMENG PRECISE MOLD CO LTD

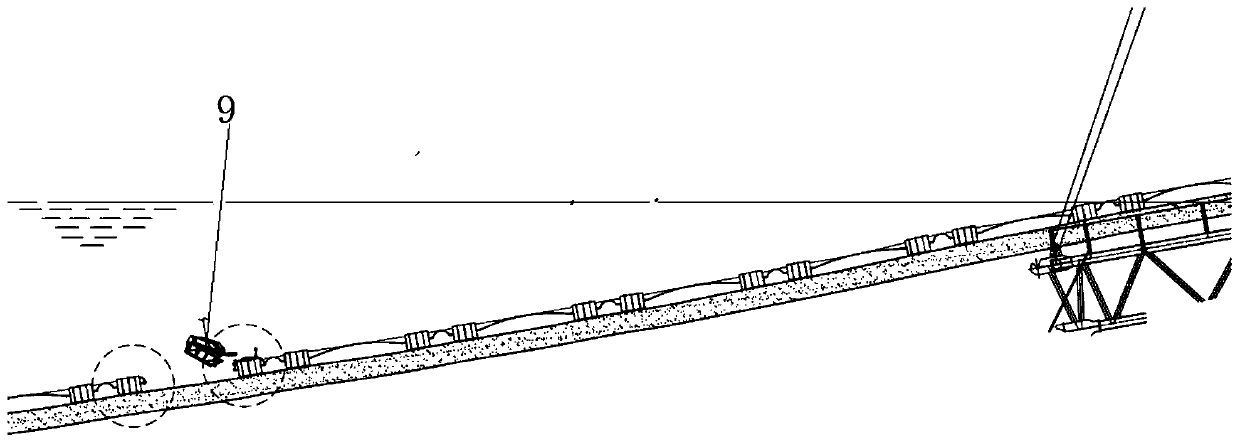

Submarine pipeline floating barrel mounting and recycling method

InactiveCN110848459AReduce loss rateImprove installation efficiencyPipe laying and repairSubmarine pipelineSubmarine

Owner:OFFSHORE OIL ENG

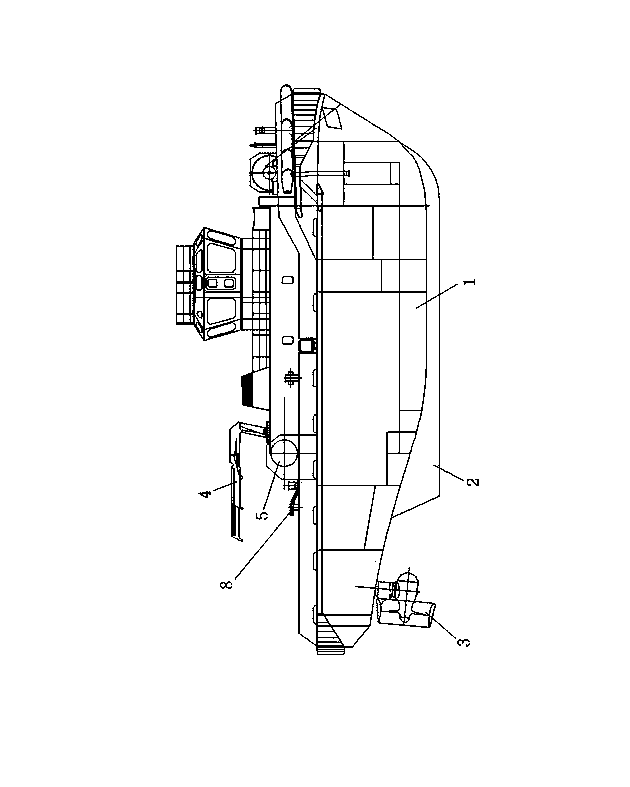

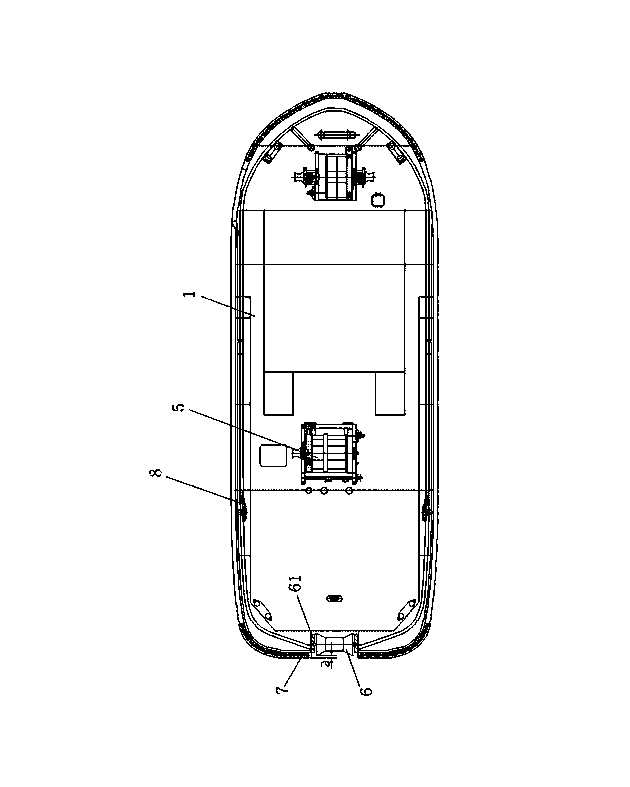

Full-revolving tugboat with stern roller

Owner:JIANGSU ZHENJIANG SHIPYARD GROUP

Hydraulic lift car safety protection device

Owner:苏州威尔森电梯有限公司

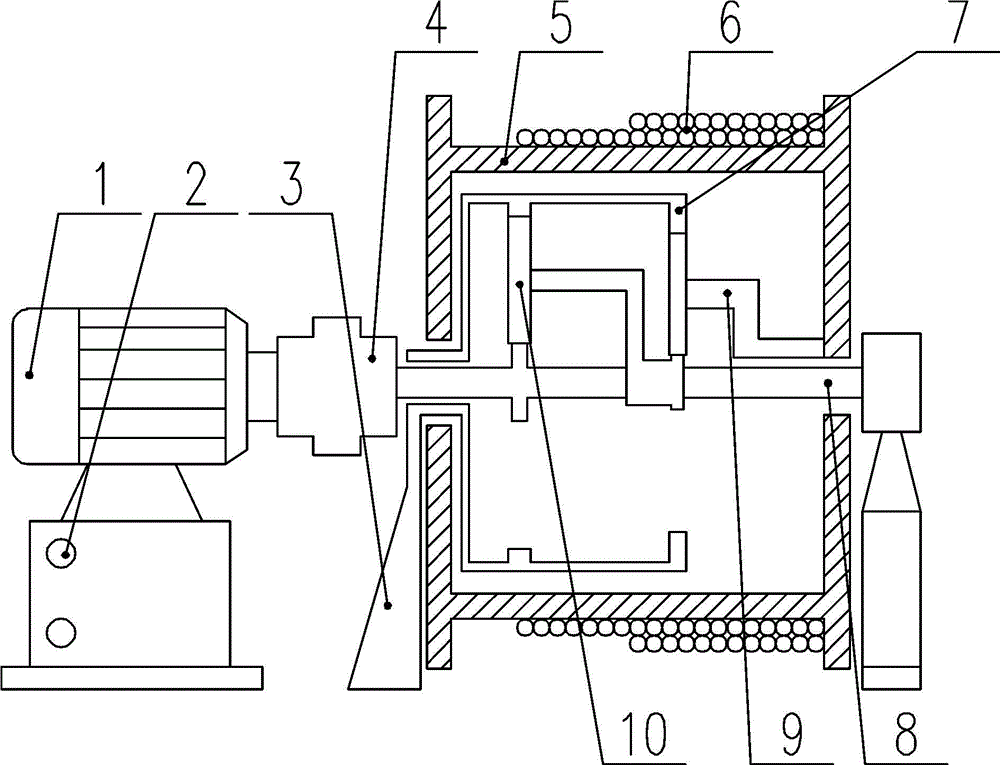

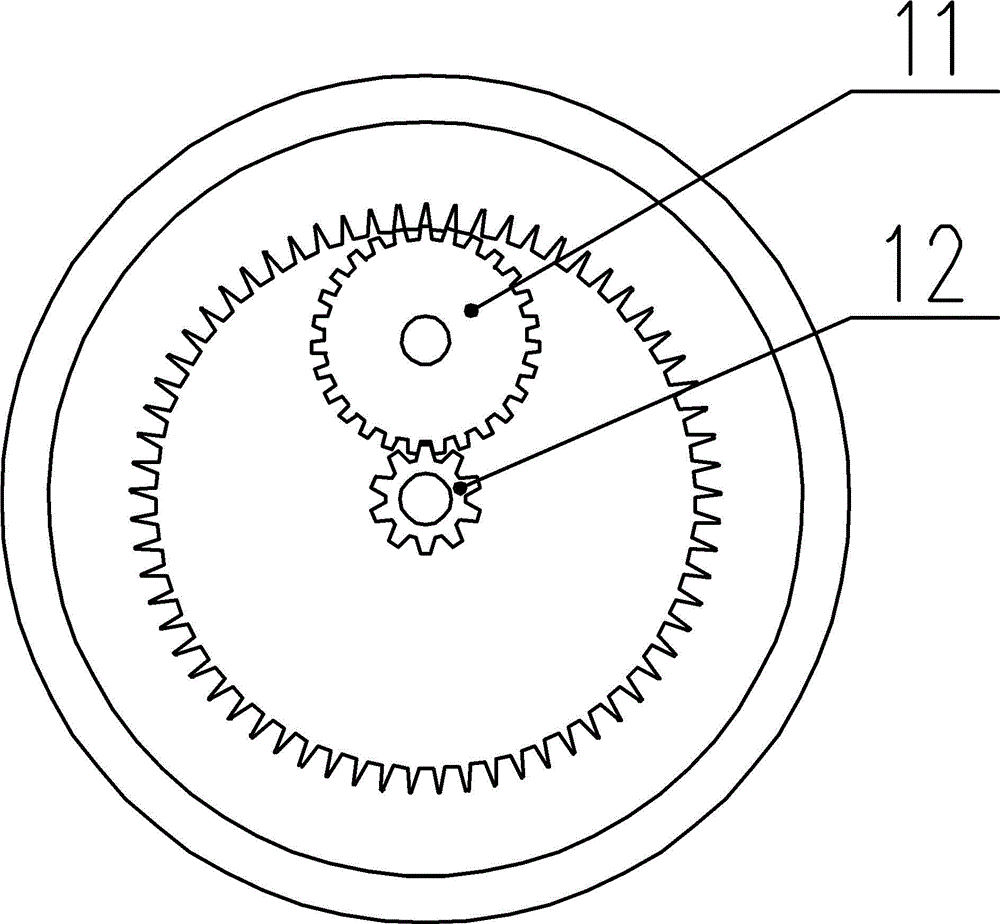

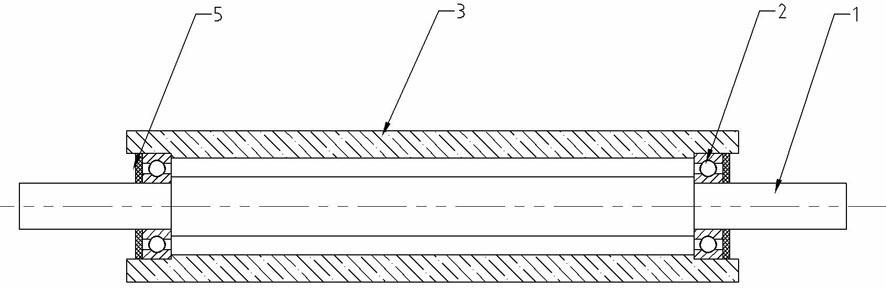

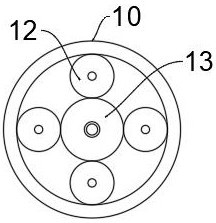

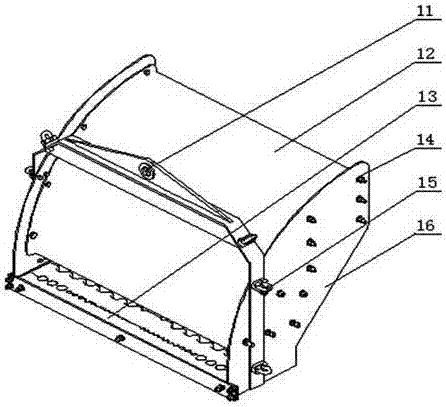

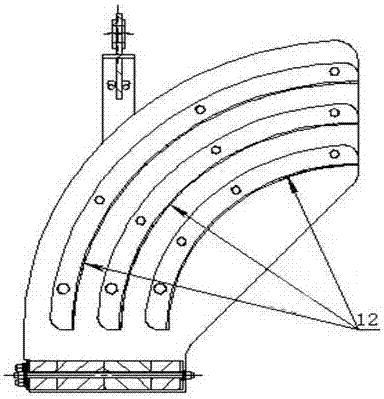

Annealing equipment for invisible protective net steel wire rope machining

ActiveCN113564340AExtend heating timeFully heatedFurnace typesHeat treatment furnacesStampingGear wheel

Owner:江苏鑫平金属制品有限公司

Removal method of outdoor hanging steps

InactiveCN112727147AReduce demandNo drop phenomenonBuilding repairsBridge strengtheningArchitectural engineeringCrusher

Owner:ZHEJIANG YIJIAN CONSTR GROUP

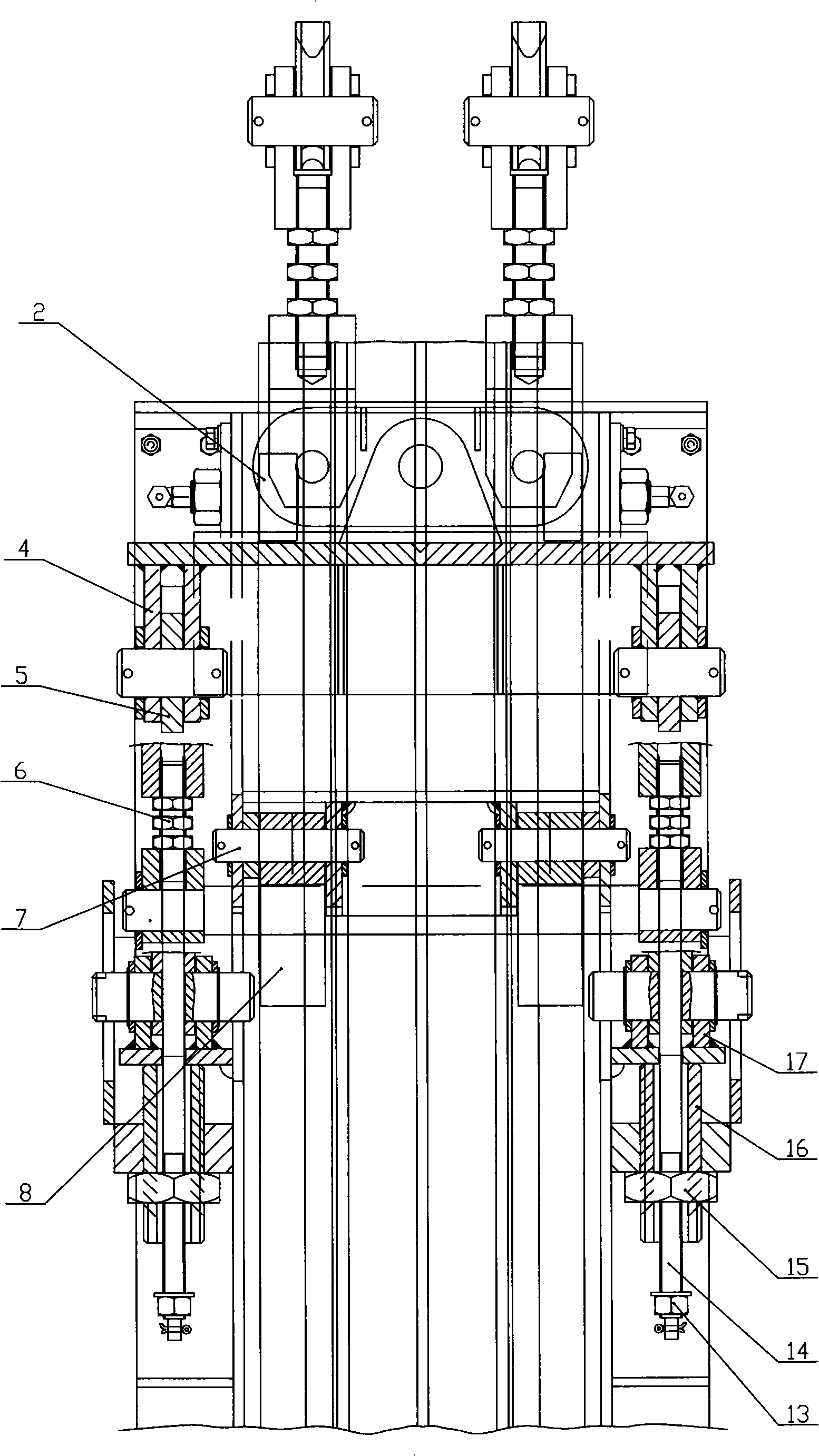

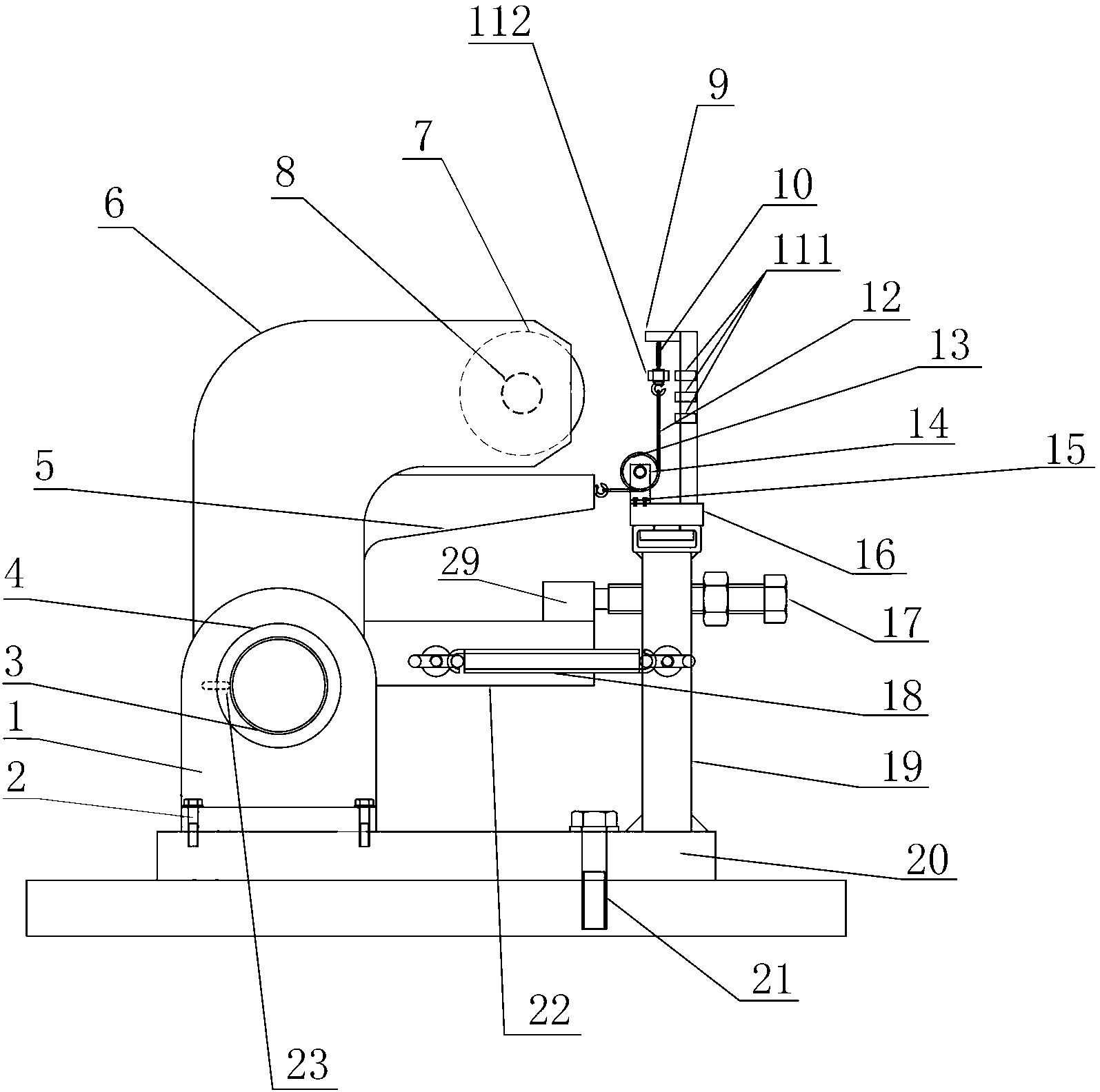

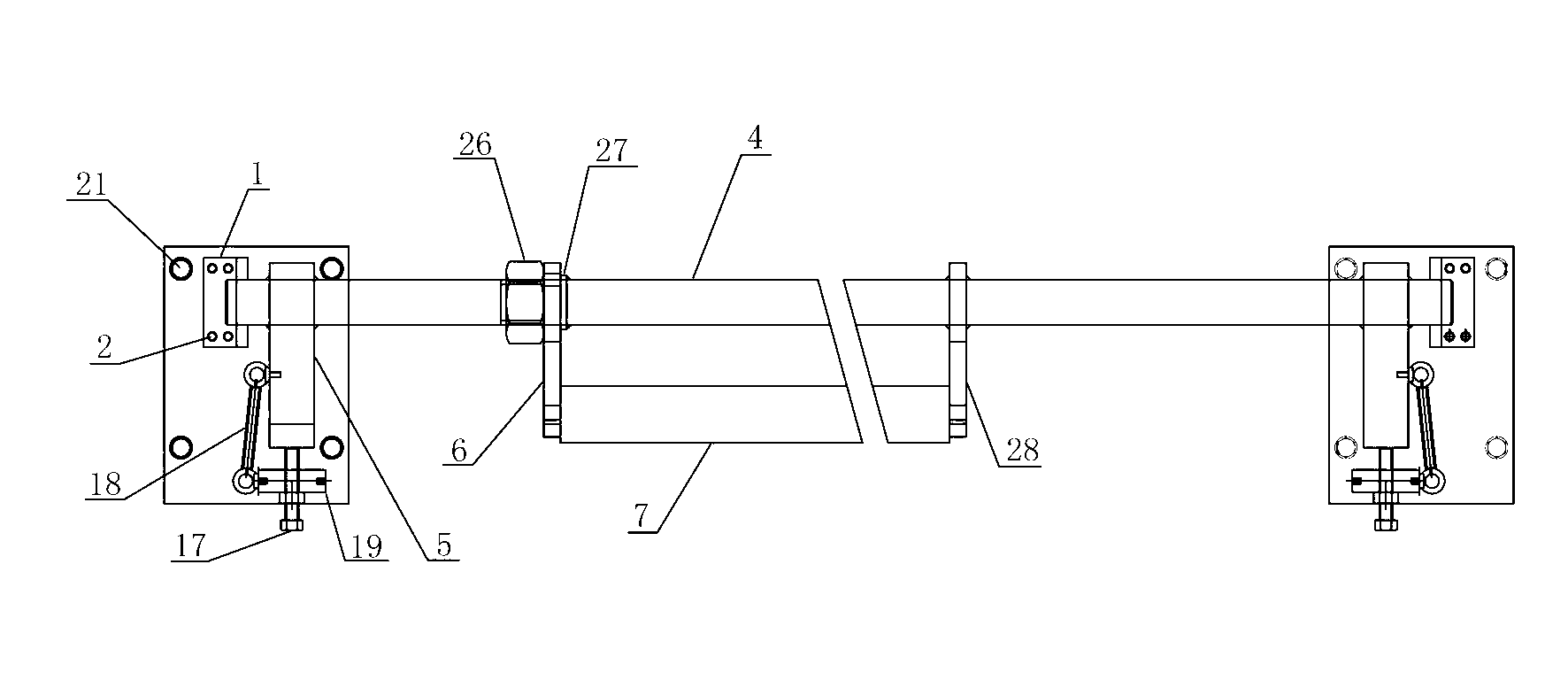

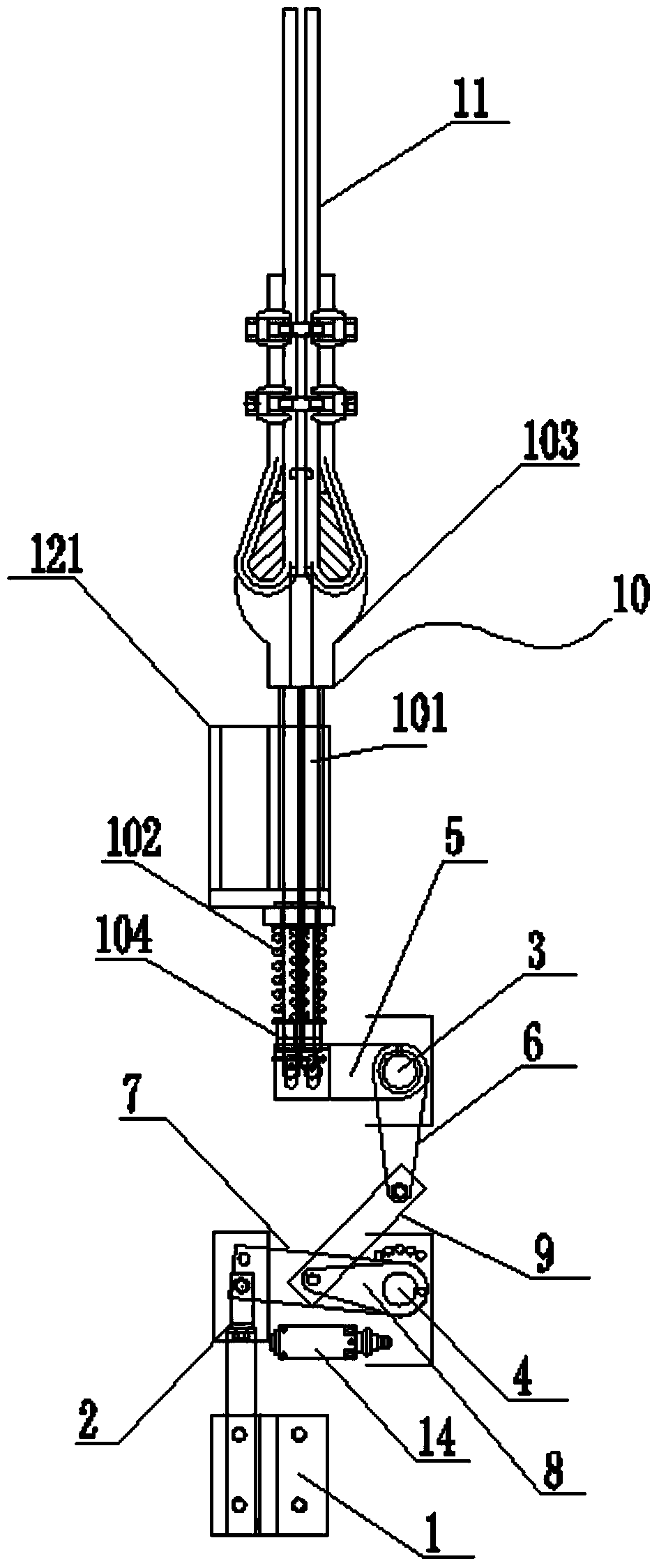

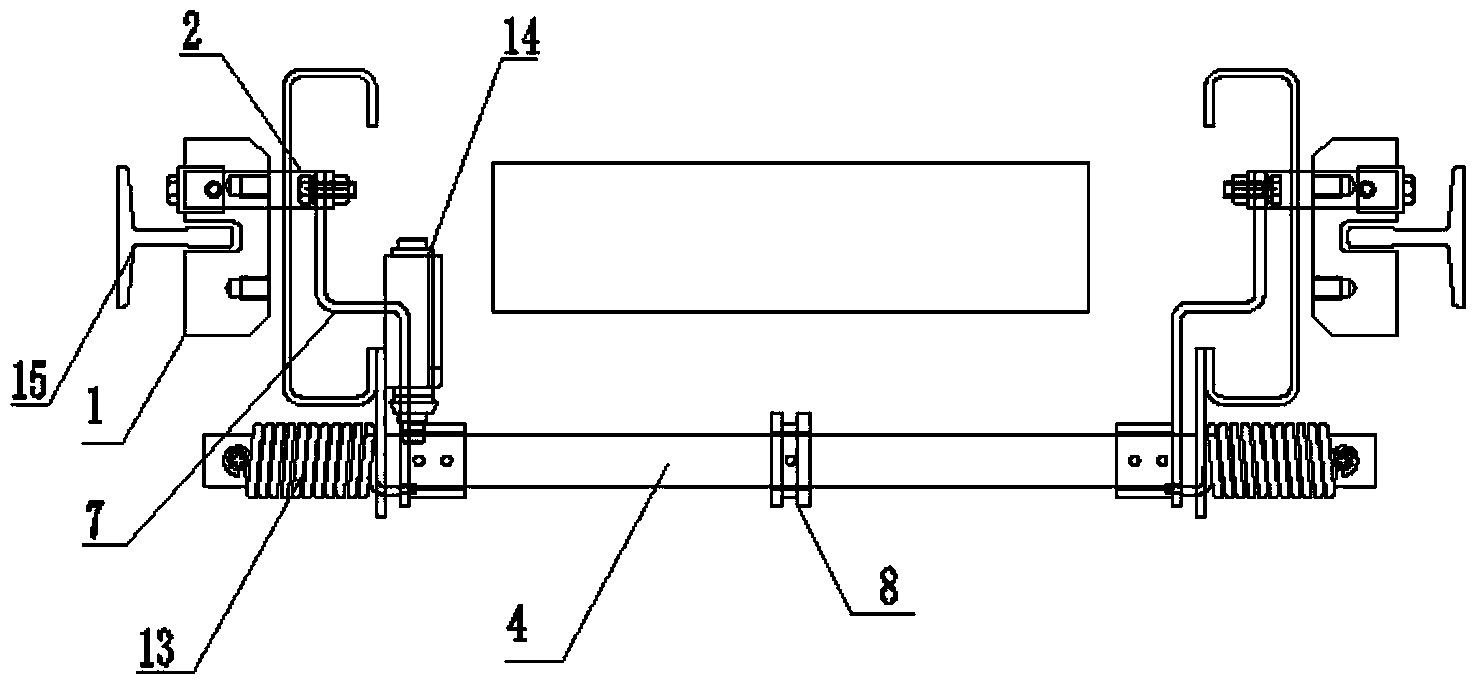

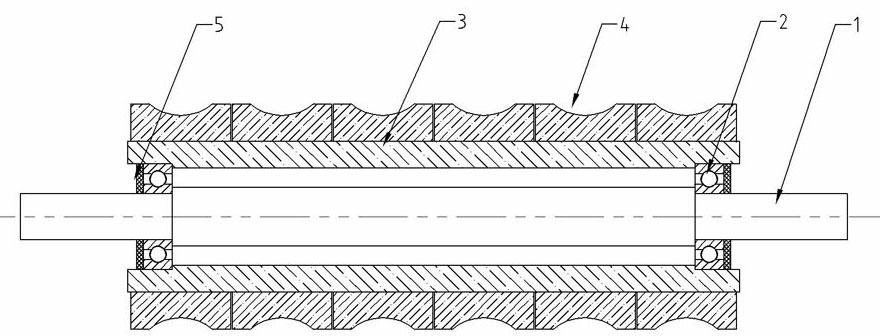

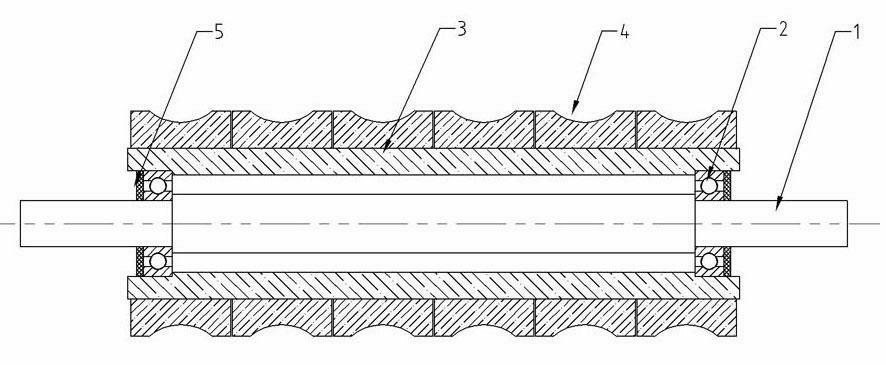

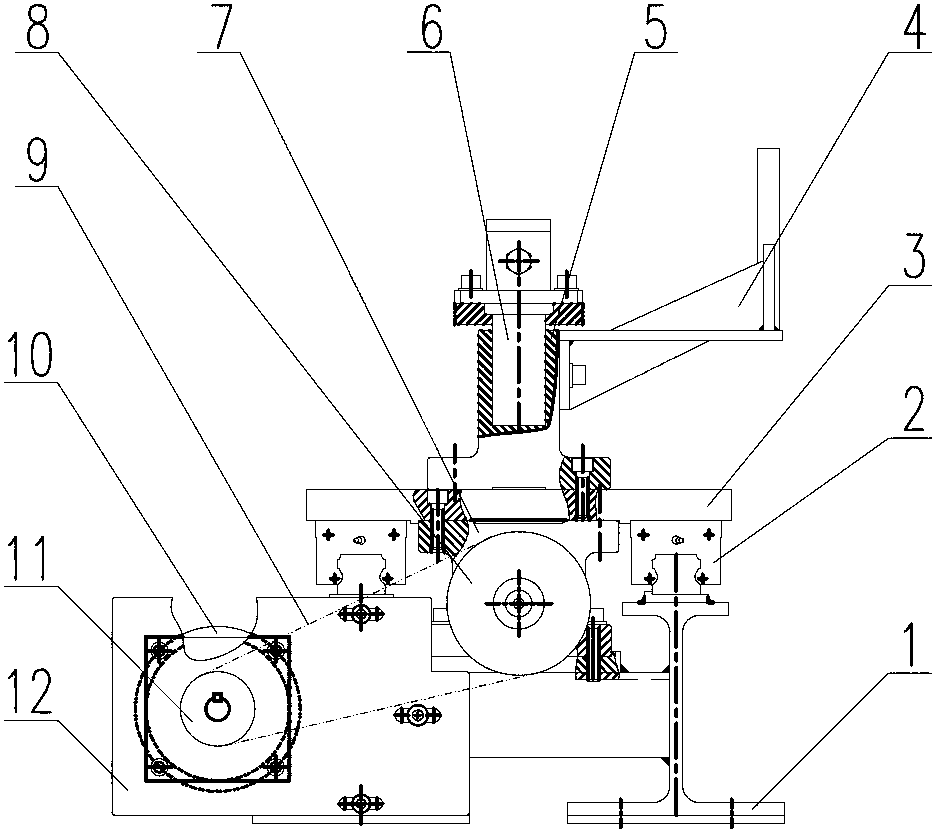

Numerical-control rope moving mechanism

InactiveCN103341749AReduce labor intensityIt takes two people to solveMetal working apparatusNumerical controlBall screw

Owner:WUXI HONGYUAN DEVFLEX

Blowout preventing box

Owner:YANCHENG DONGRONG PETROLEUM MACHINERY CO LTD

Flexible balance small-sized energy-saving oil pump

InactiveCN1924289AReduce consumptionEasy to adjustGearingFluid removalCouplingUltimate tensile strength

Owner:DAQING OILFIELD CO LTD

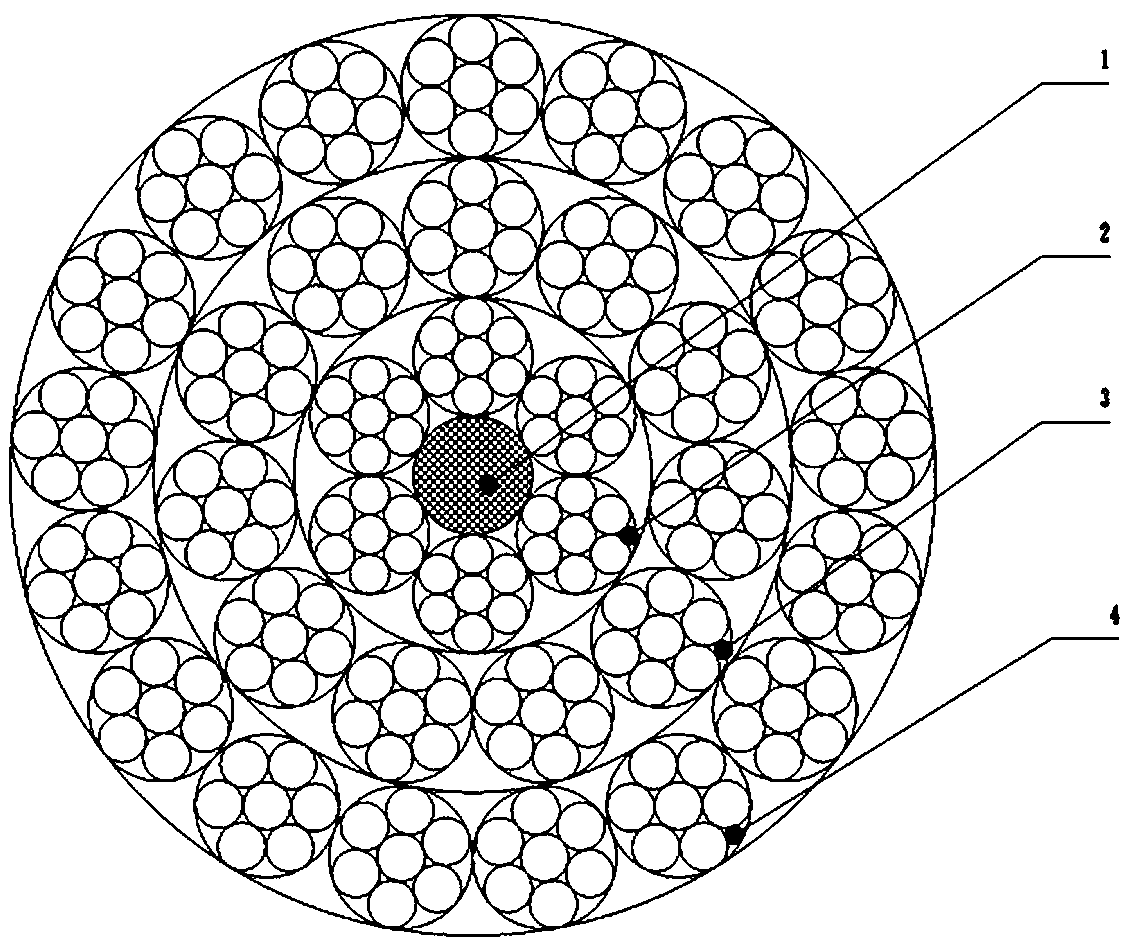

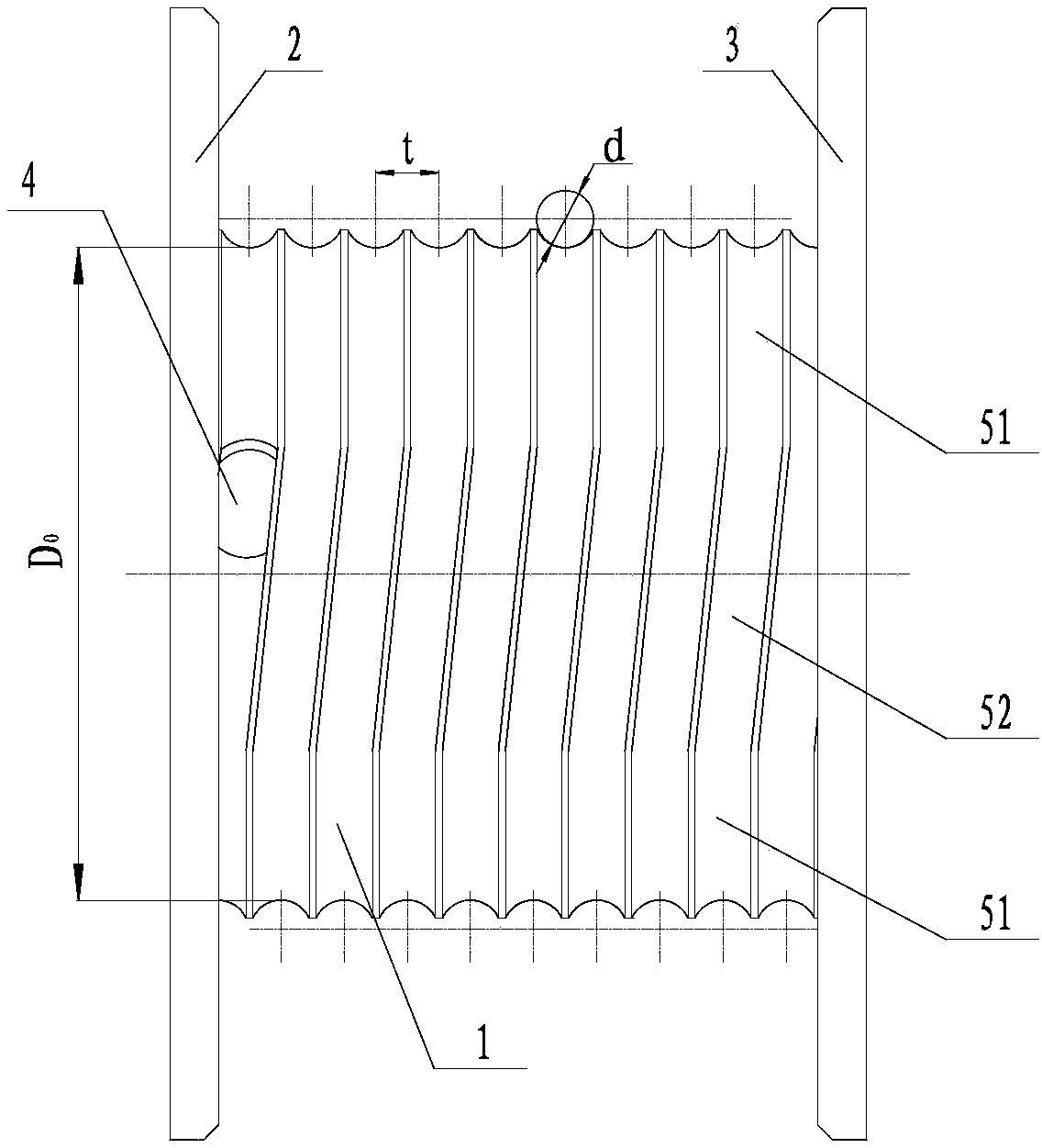

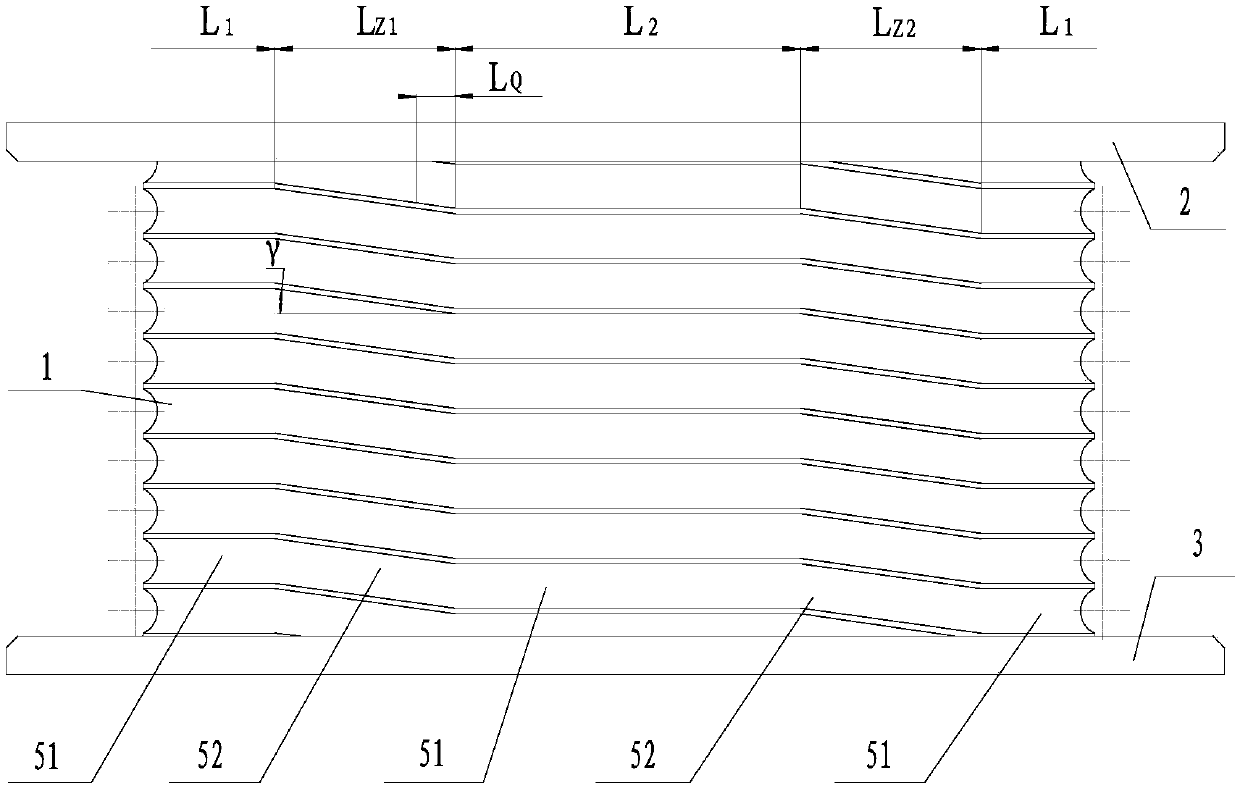

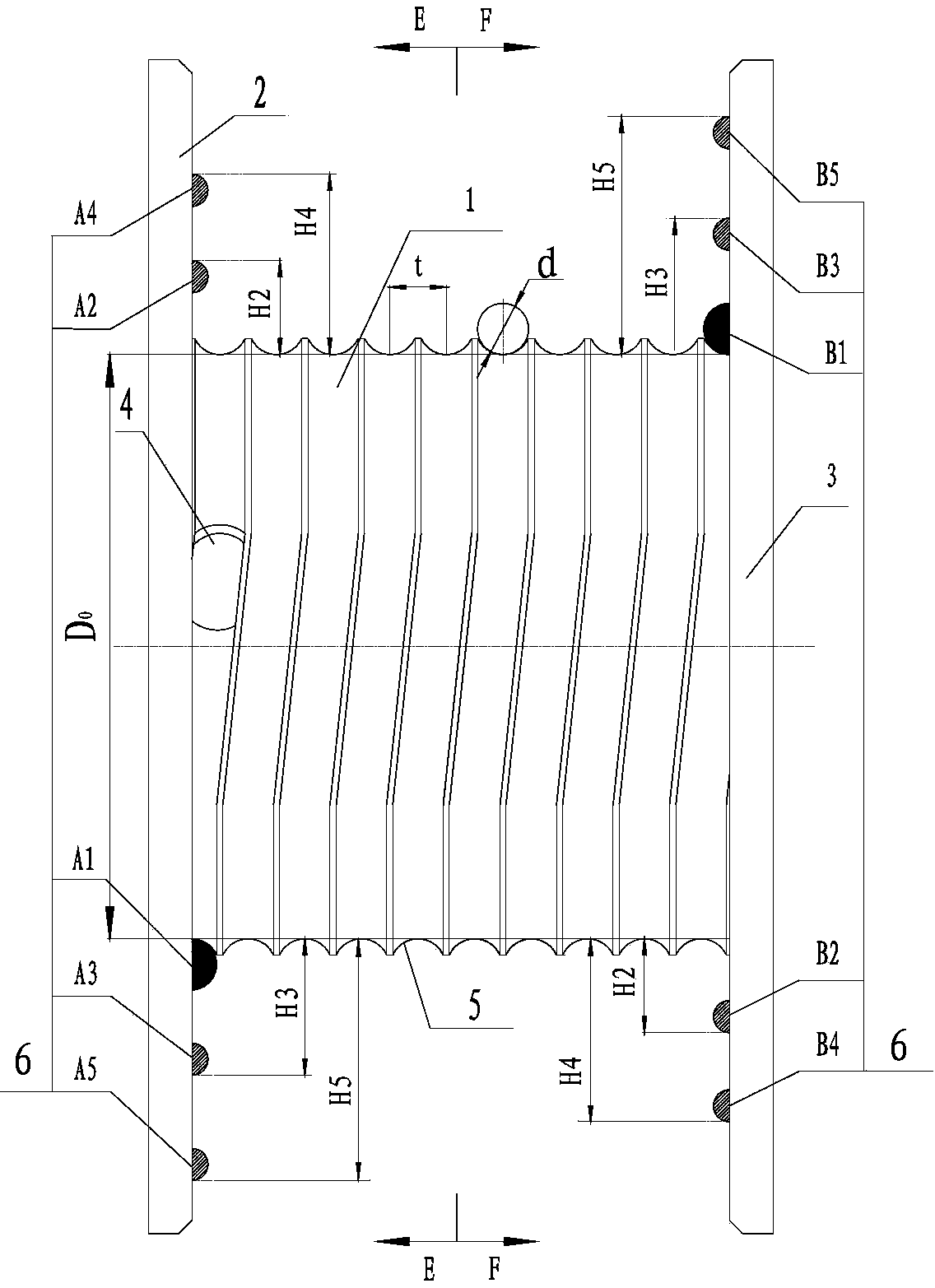

Structure design method of strand compacted non-rotating steel wire rope with diameter of 45mm

PendingCN110055781ACompact structureImprove fatigue resistanceRope making machinesFiberCarrying capacity

Owner:GUIZHOU WIRE ROPE

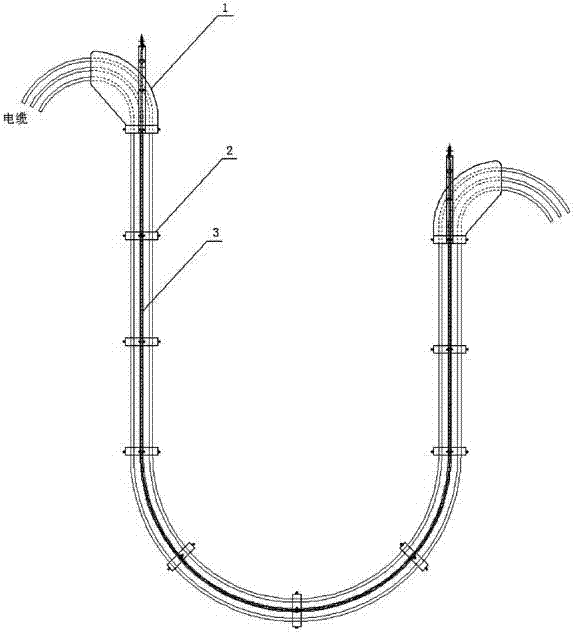

Tool for connecting whole movable cable between ocean engineering equipment

InactiveCN107026422AEasy to assemble and disassembleEliminate CollisionsCable arrangements between relatively-moving partsEngineeringConductor Coil

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

Hinged rigid body motion control device applied to underwater large-pulse-width explosion experiment

ActiveCN112179615AEliminate Rigid Body DisplacementAddressed issues with true-scale damage featuresHydrodynamic testingShock testingExperimental testingTEX-explosive

The invention belongs to the technical field of model experiment target cabin design experiment testing, and particularly relates to a hinged rigid body motion control device applied to an underwaterlarge-pulse-width explosion experiment. A traditional buoy is replaced with the circular water tank, the floating height is convenient to adjust, the up-down swing amplitude problem of the traditionalbuoy is effectively reduced, the rigid body motion displacement of the whole device is controlled, and the influence of impact waves on the device can be reduced. The circular water tank and the annular water tank are connected through the triangular frame and the one-way hinge, and the distance between the circular water tank and the annular water tank can be conveniently adjusted; the steel wire ropes are made of flexible materials, and the impact influence of instant explosion on the annular water tank is reduced through the flexible characteristics. The position relation between the explosive and the ship body is convenient to adjust, compared with a traditional buoyancy tank, the annular water tank enables shock waves to penetrate through the middle, and the influence of the shock waves on experiments is reduced; the plate frame provides balance weight, and huge shaking caused by explosion impact is reduced.

Owner:HARBIN ENG UNIV

Intelligent carrying device based on visual identification

ActiveCN113479542AThe solution requires the cooperation of multiple peopleSolve the problem that the sling is easy to loseConveyorsControl devices for conveyorsControl engineeringVisual recognition

Owner:南京宝珵软件有限公司

Photovoltaic power generation charging pile applied to smart city

ActiveCN110429901AGuaranteed to workEasy to cleanPhotovoltaic supportsBatteries circuit arrangementsSmart cityEngineering

Owner:嘉兴博创智能传感科技有限公司

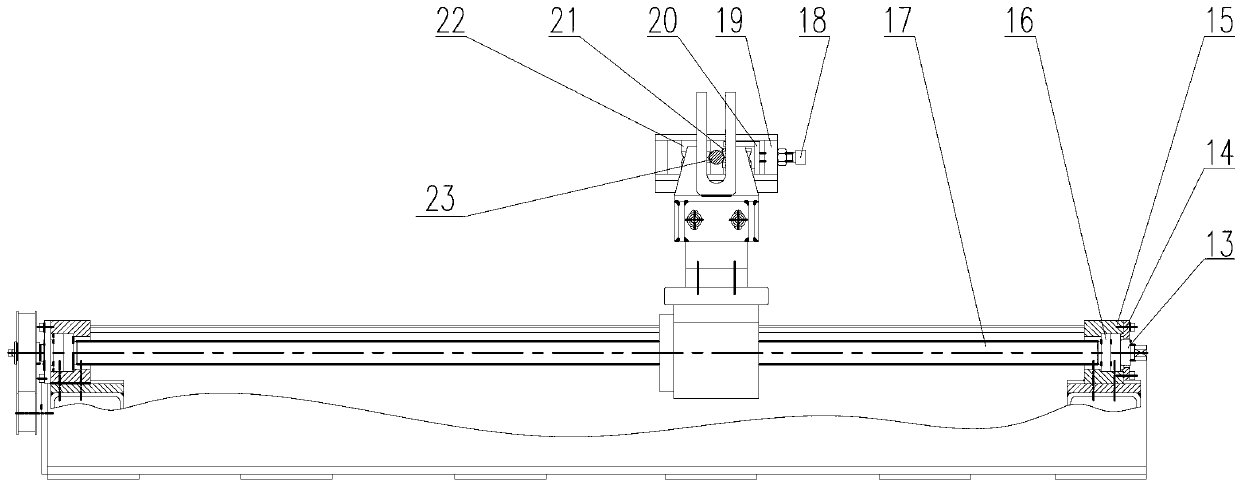

Take-up tension closed-loop control system

The invention relates to a control system, in particular to a take-up tension closed-loop control system. According to the technical scheme, the take-up tension closed-loop control system comprises an analog quantity given module, a frequency converter module, a motor output module, an encoder feedback module and a PG card. The analog quantity given module, the frequency converter module and the motor output module are sequentially connected. The motor output module is connected with the encoder feedback module. The PG card transmits sensed signals to the frequency converter module so that the closed-loop control system can be formed. The take-up tension closed-loop control system has the advantages that the take-up tension of a steel wire rope can be guaranteed to be relatively constant, the steel wire rope does not move any longer in the take-up process, and a spool cannot be damaged due to take-up operation.

Owner:BOERFU JIANGSU IND CO LTD

Large-rope-capacity winding drum

Owner:SICHUAN CONSTR MACHINERY GRP

Shock isolation support using waste tires

PendingCN110259243ALow costSimple structureProtective buildings/sheltersShock proofingNatural sandWaste tires

Owner:HUAQIAO UNIVERSITY

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap