Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Propeller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A propeller is a type of fan that transmits power by converting rotational motion into thrust. A pressure difference is produced between the forward and rear surfaces of the airfoil-shaped blades, and a fluid (such as air or water) is accelerated by the pressure difference. Propeller dynamics, like those of aircraft wings, can be modelled by Bernoulli's principle and Newton's third law. Most marine propellers are screw propellers with helical blades rotating around an approximately horizontal axis or propeller shaft.

Electric, inductively-energized controllable-pitch propeller hub

ActiveUS11225318B1Quick installationQuick removalElectric power distributionPropellersElectrical batteryControl cell

Owner:SEELEY BRIEN AVEN

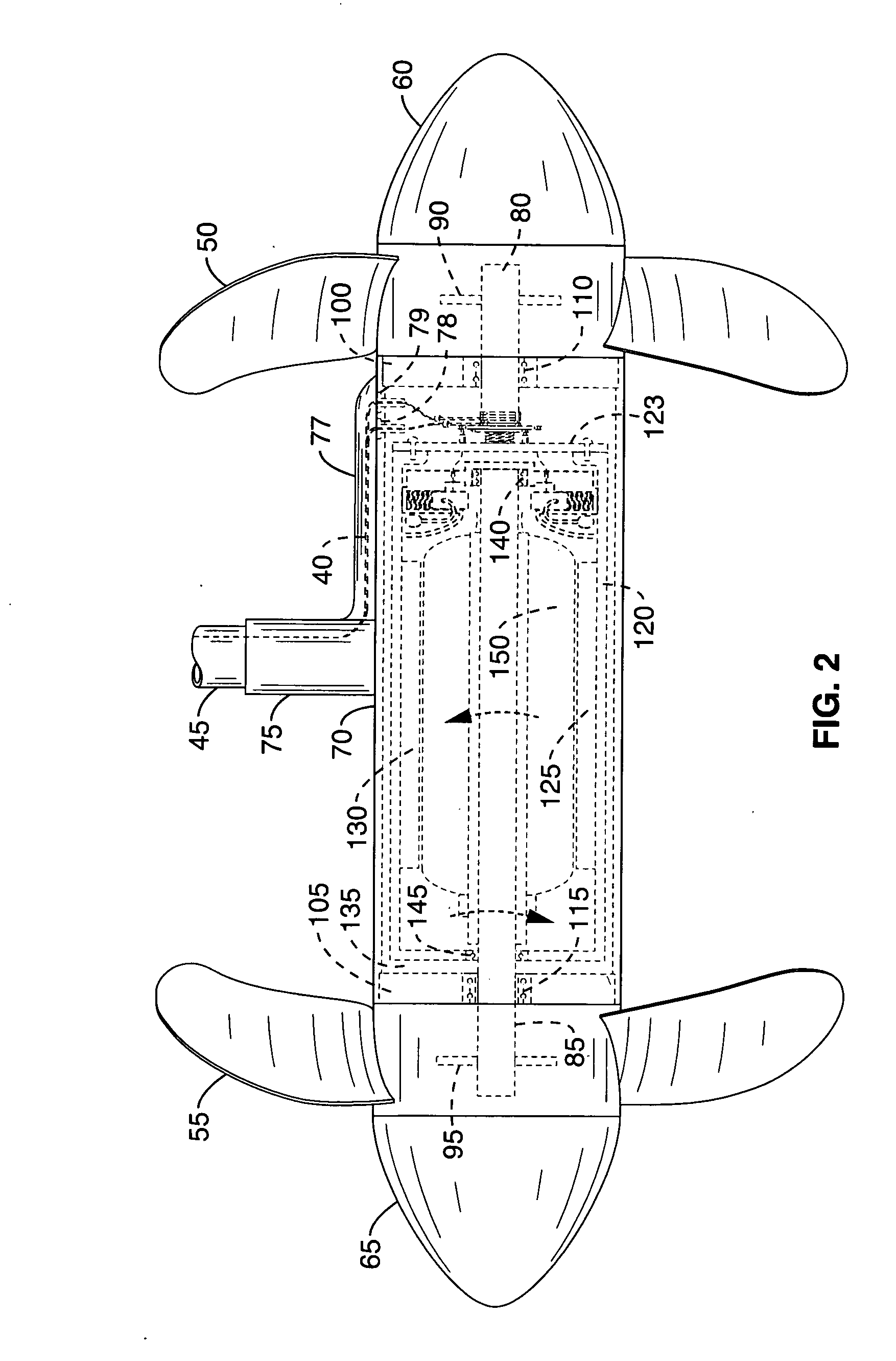

Multipurpose composite power unmanned air vehicle

InactiveCN101332872AEasy to controlRealize remote controlActuated automaticallyPower plant typeJet enginePropeller

The invention relates to a compound power multifunctional small unmanned aerial vehicle which includes a body, a vertical empennage, a horizontal empennage, a changeable energy cabin, the hanging frame of a hanging cabin, a changeable target cabin, a main driver, the screw propeller of the main driver, the fixing ring of an auxiliary driver cabin connector, a wing, an auxiliary driver cabin connector and a flying controller; the vehicle is characterized by the changeable energy cabin and the changeable target cabin. The vehicle can implement the targets of remote sensing and remote detecting, air navigation, air transmission and precious shocking, etc. by changeable target cabin. The vehicle can integrate the engines with different power sources or with same power sources but with different type motors together to use by changeable energy cabin. The vehicle can achieve long period voyage of an electric engine, high thrust weight ratio of a spray engine, instant high speed of a rocket, etc. according to demands. The unmanned aerial vehicle of a compound engine can implement complex target under a complex environment.

Owner:韦世党 +1

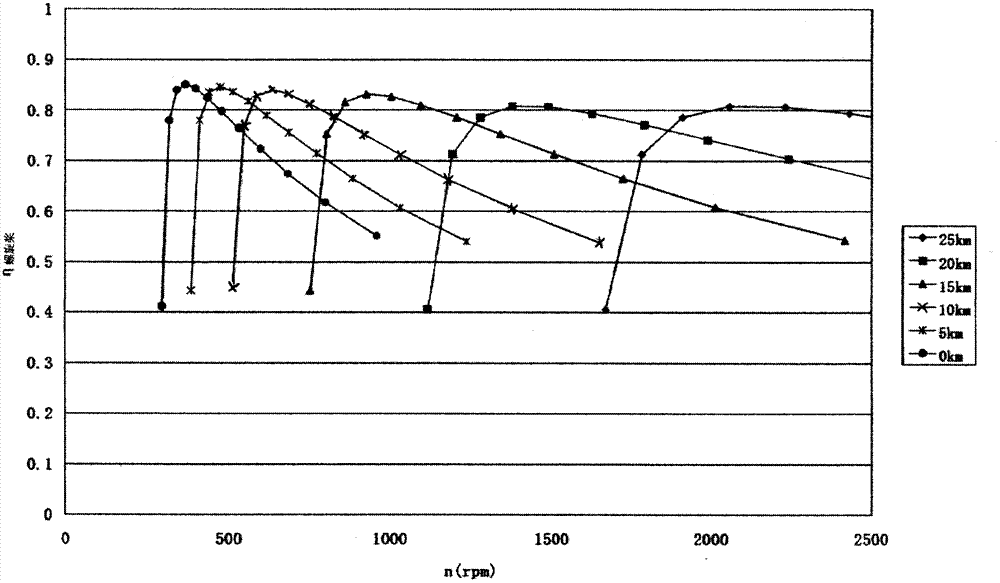

Near space propeller

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

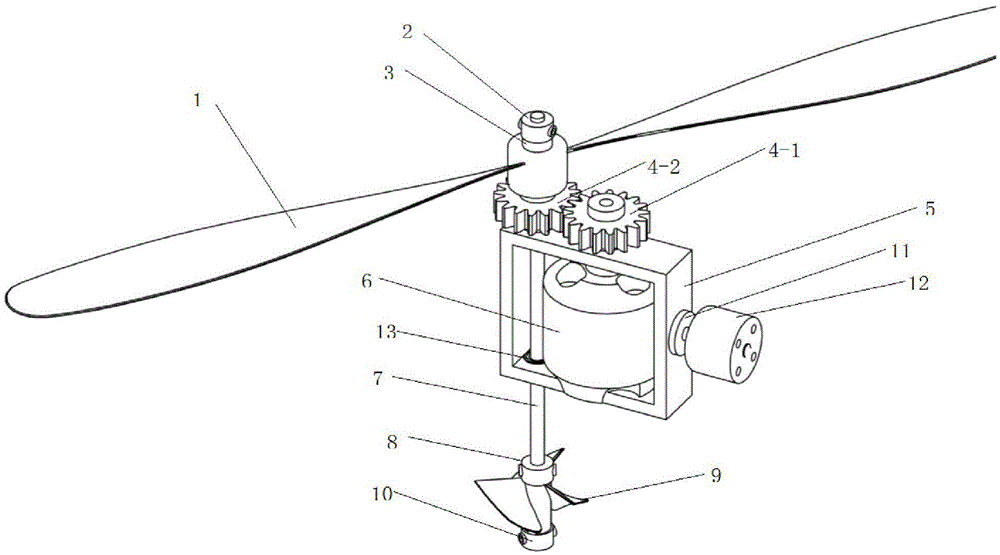

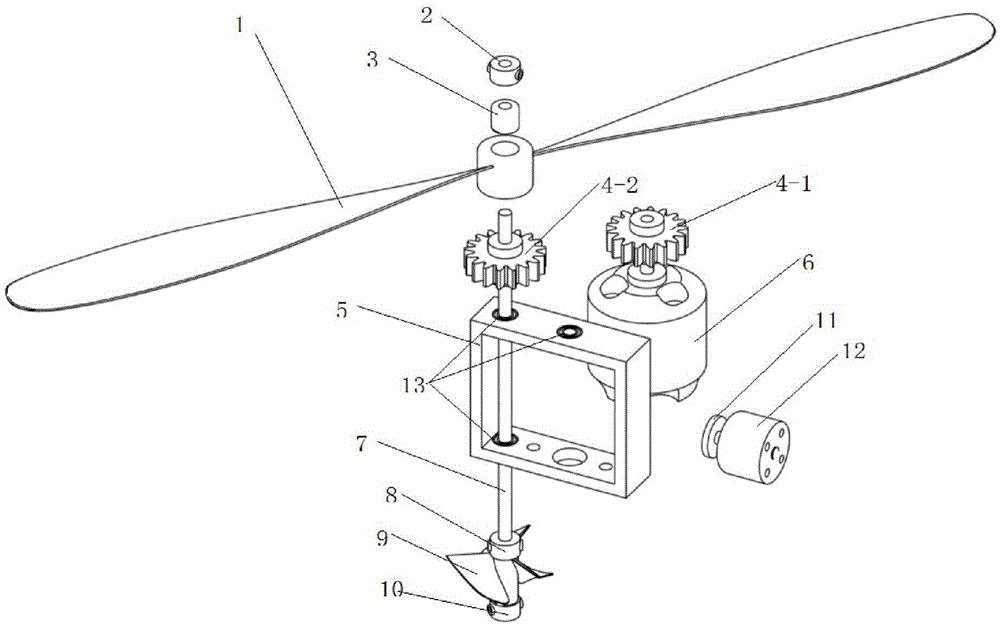

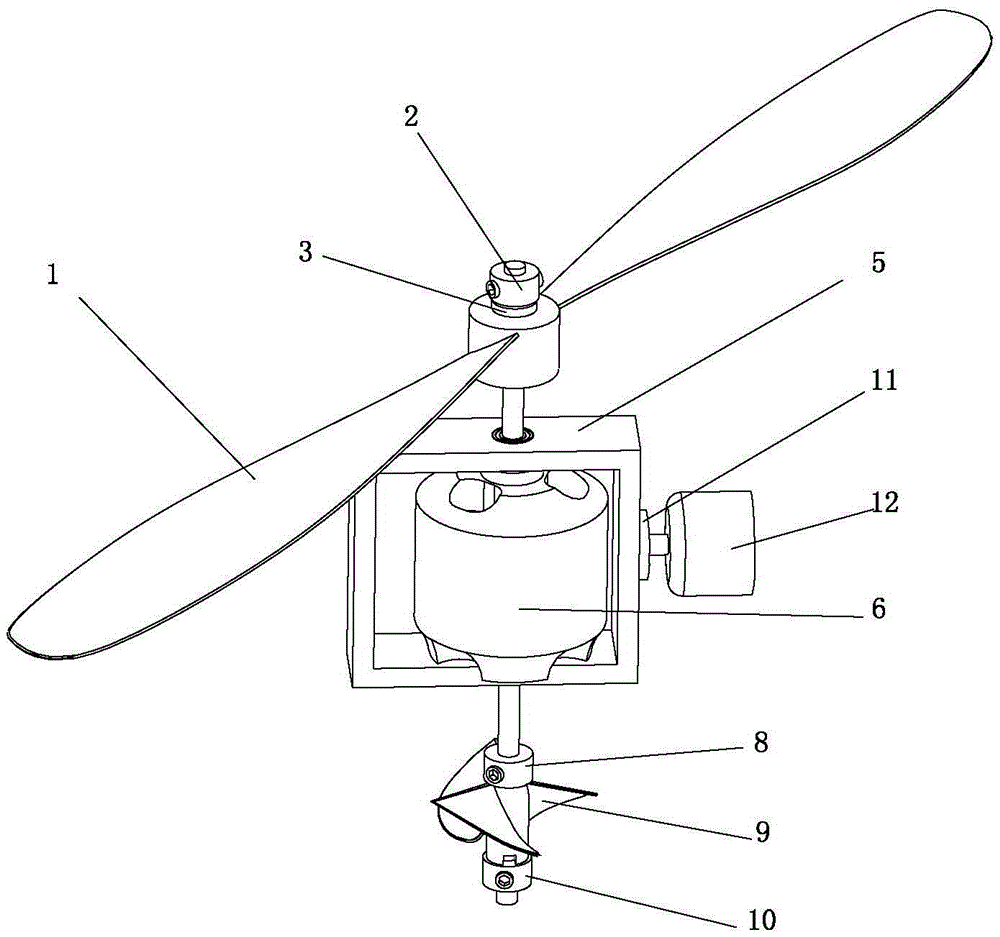

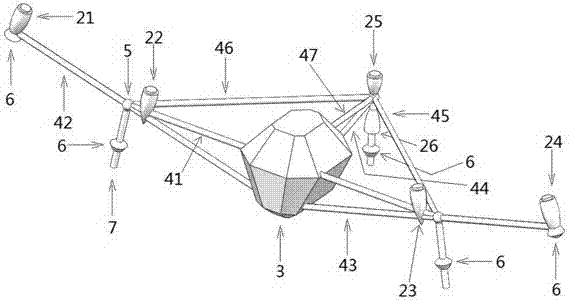

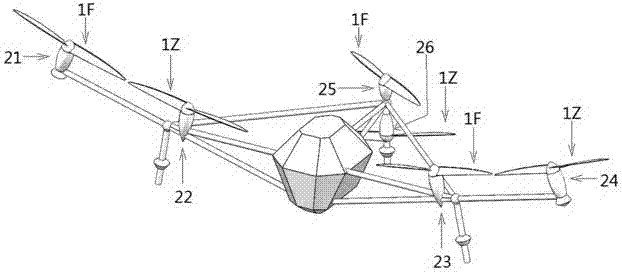

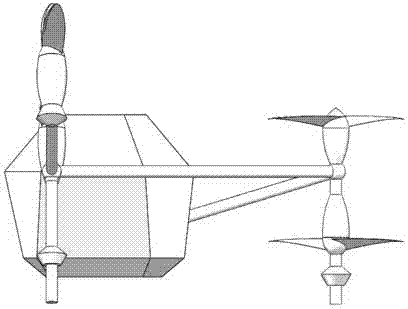

Amphibious power propulsion device suitable for sea and air and multi-axis aircraft

InactiveCN105539831AComplex structureReduce weightPropulsion power plantsOutboard propulsion unitsRotational axisFlight vehicle

Owner:SOUTH CHINA UNIV OF TECH

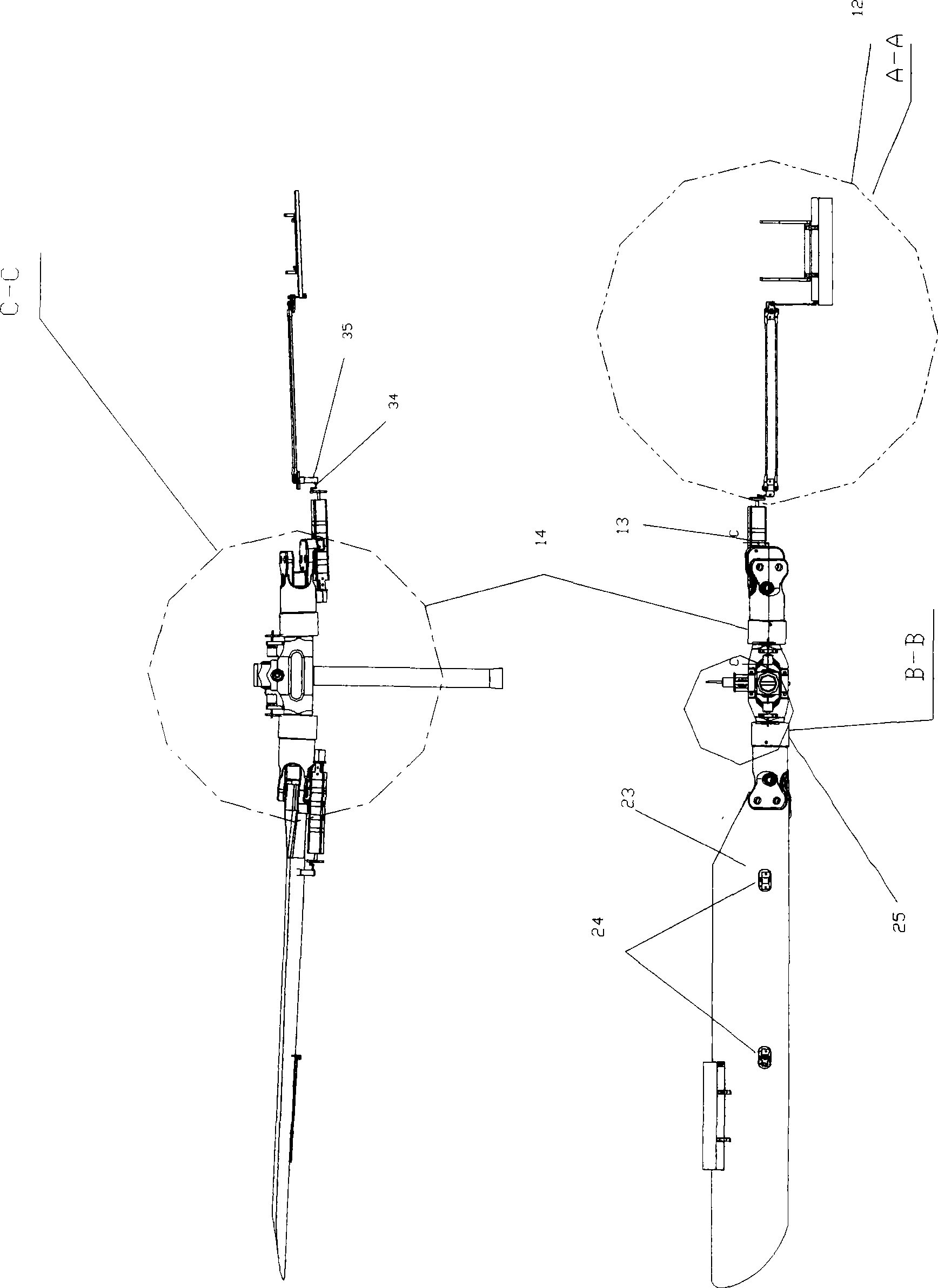

Helicopter rotor operation method and system

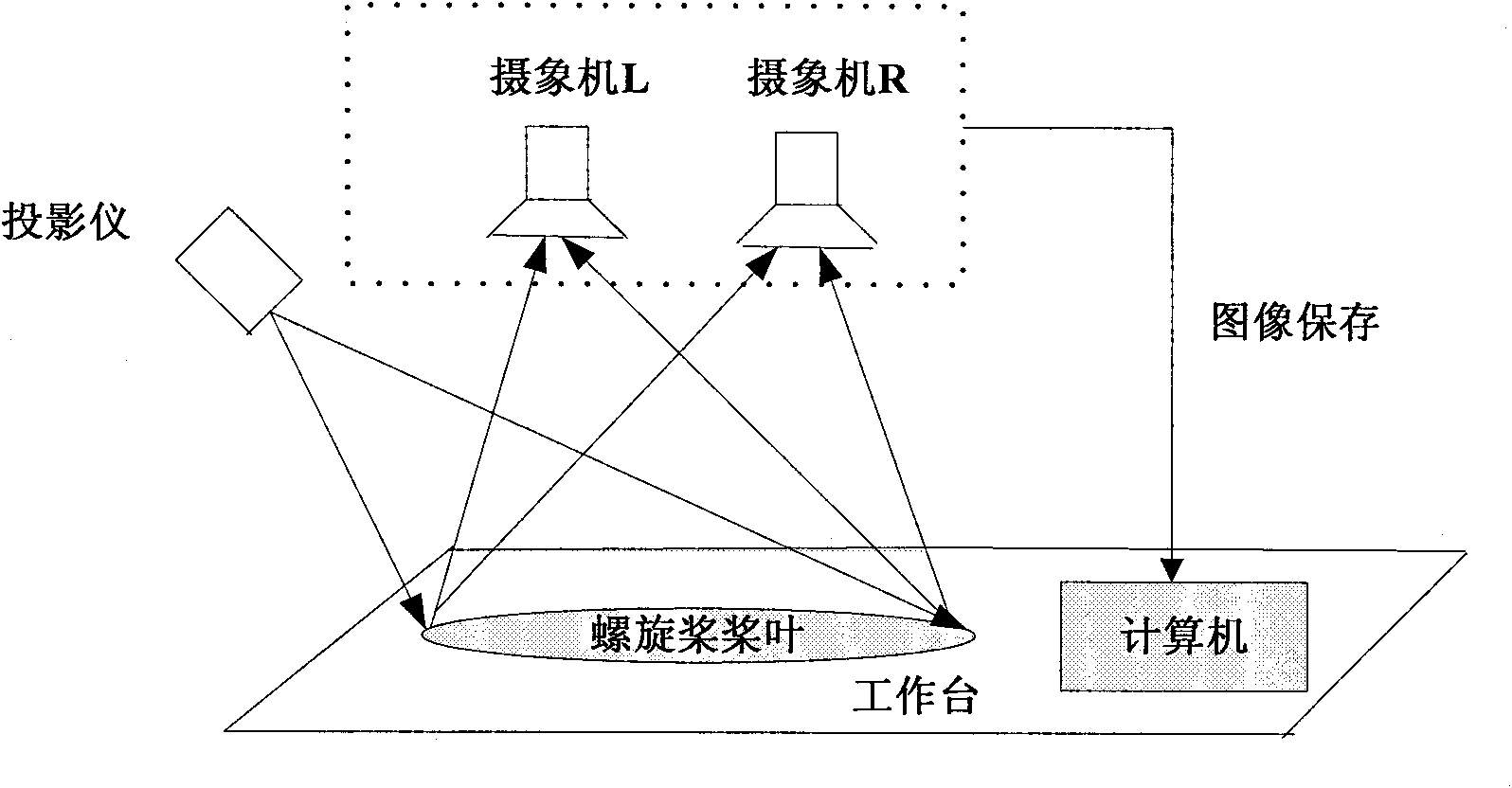

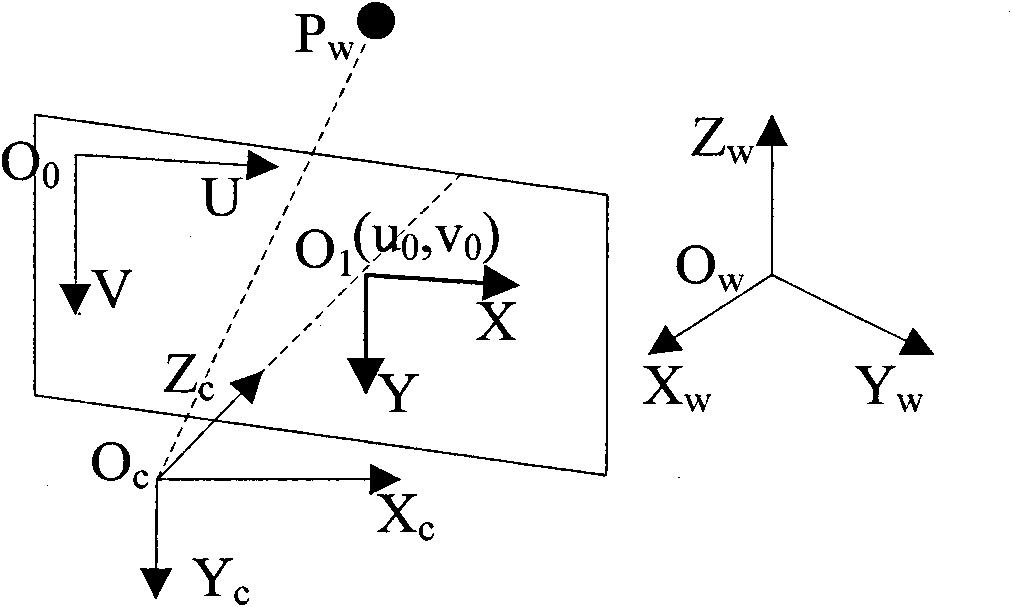

InactiveCN101376433AImprove weighing efficiencyEasy to controlPropellersUsing optical meansControl systemPropeller

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

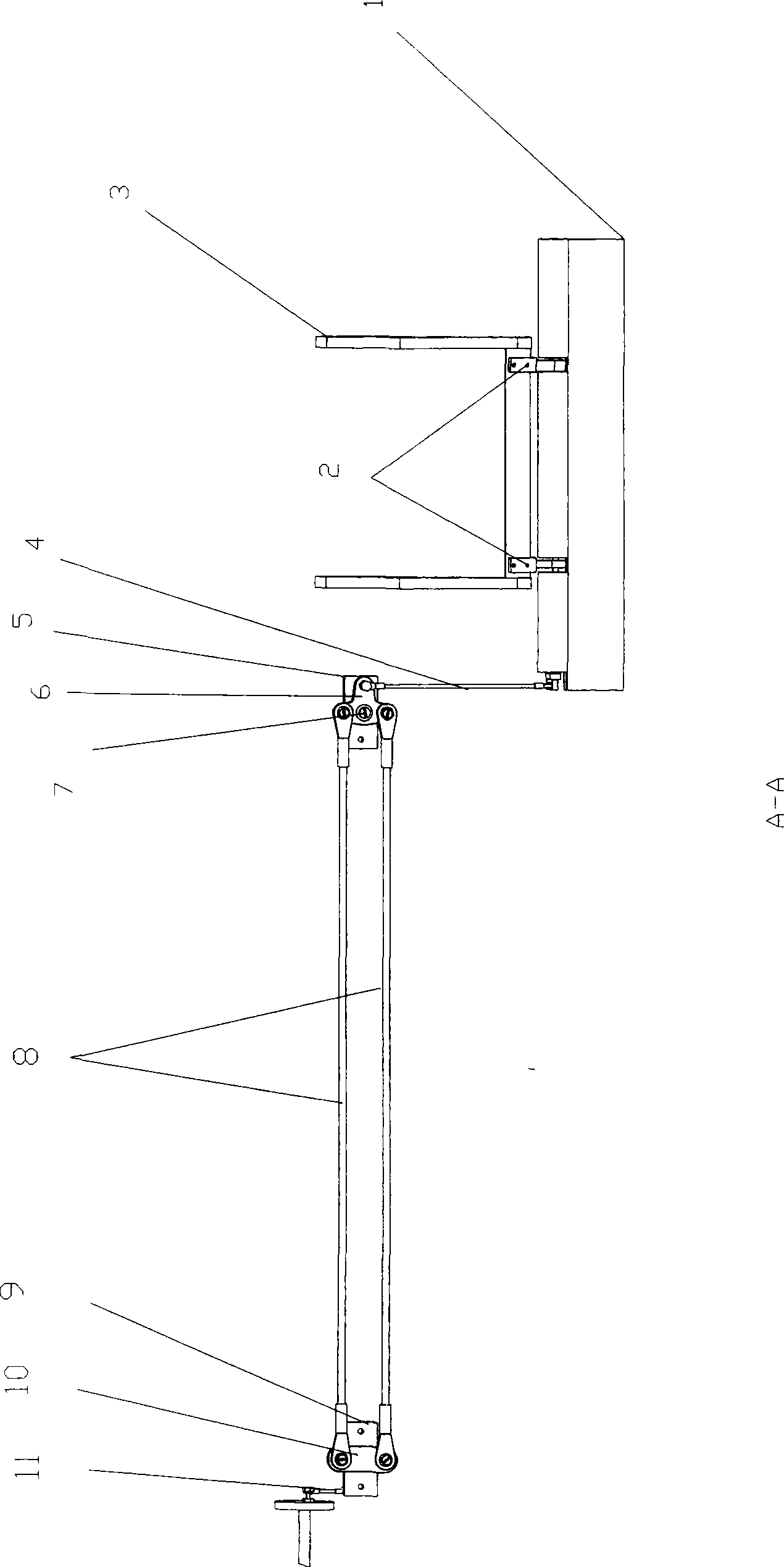

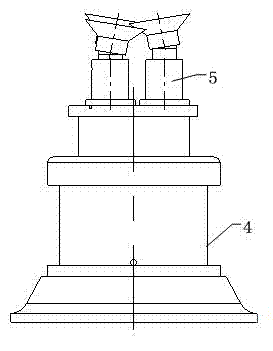

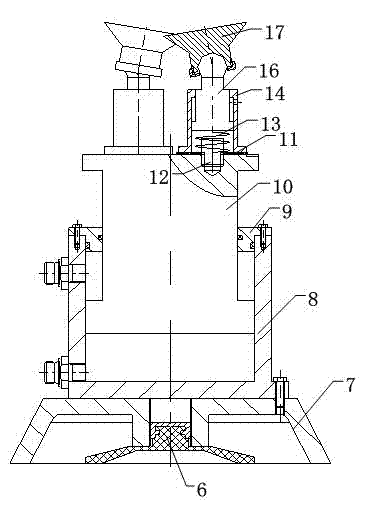

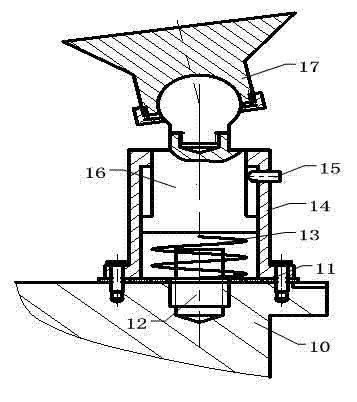

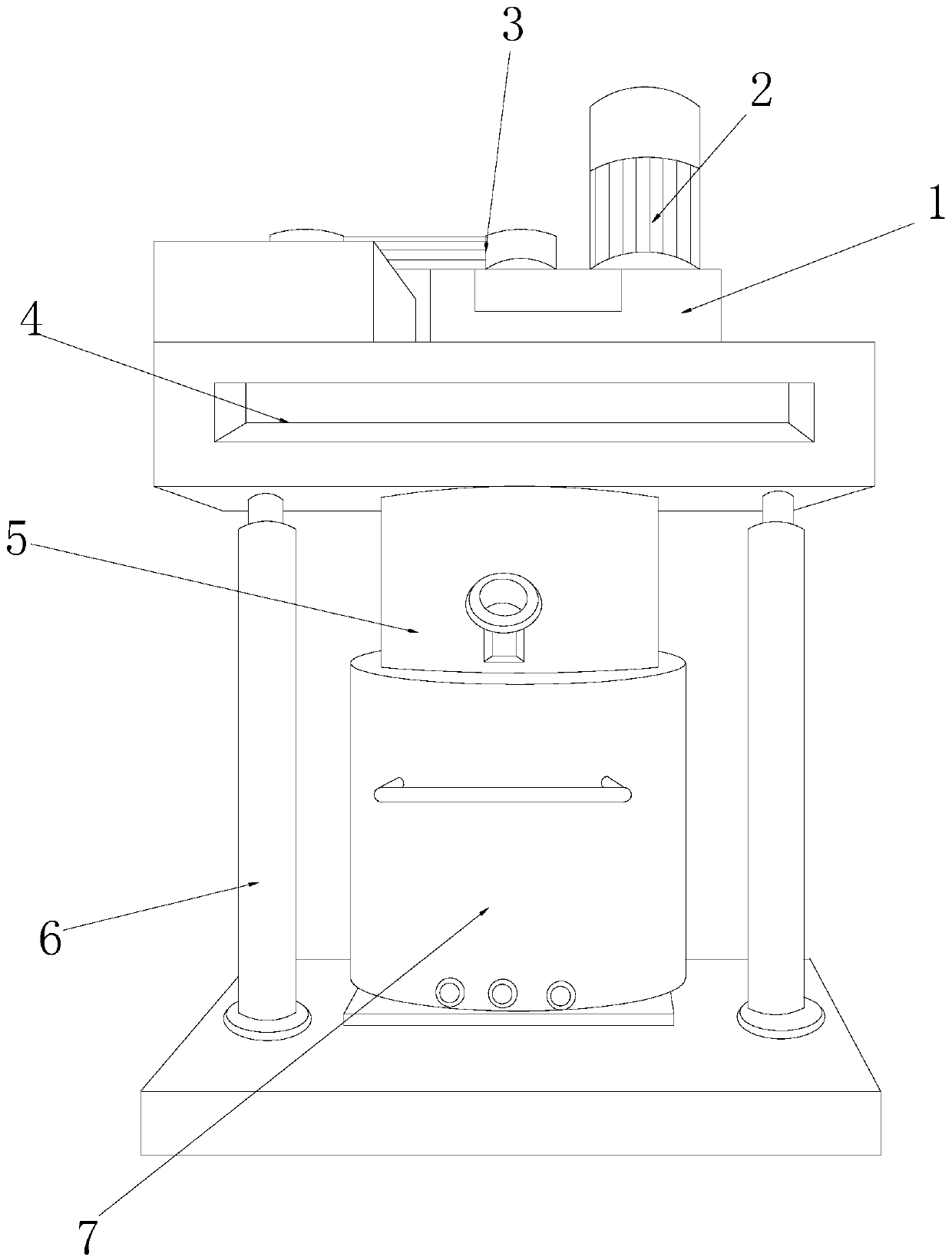

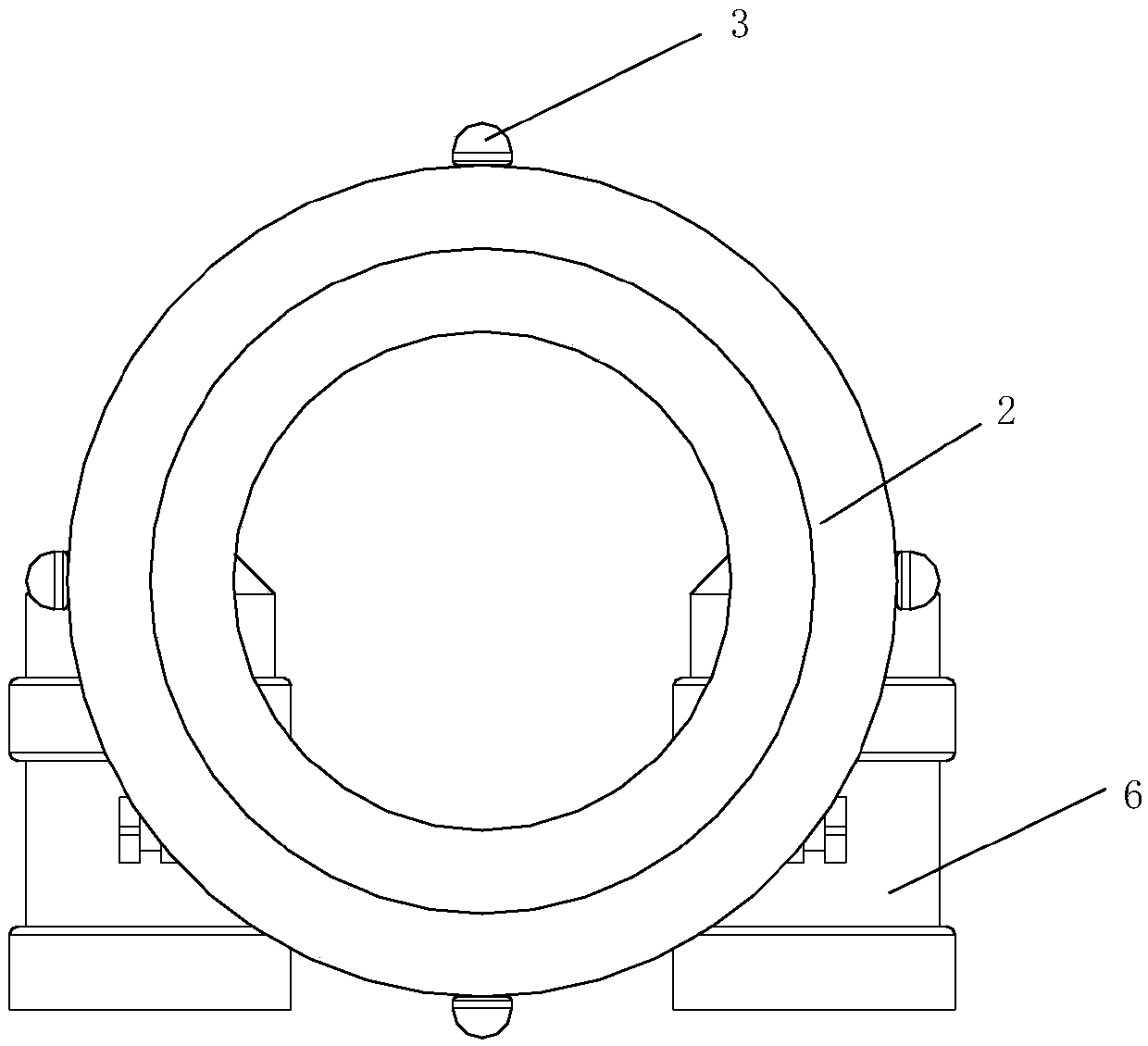

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

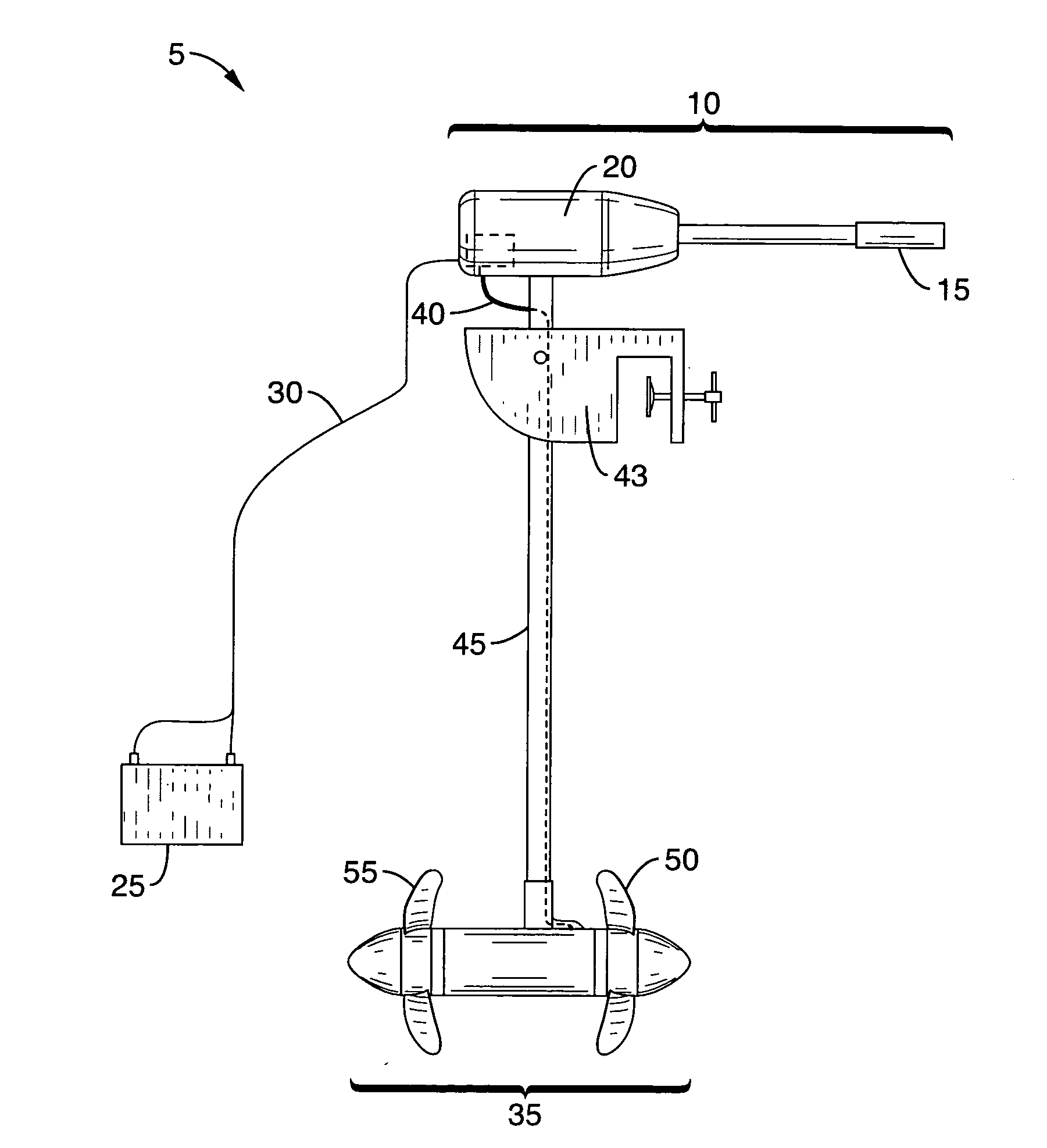

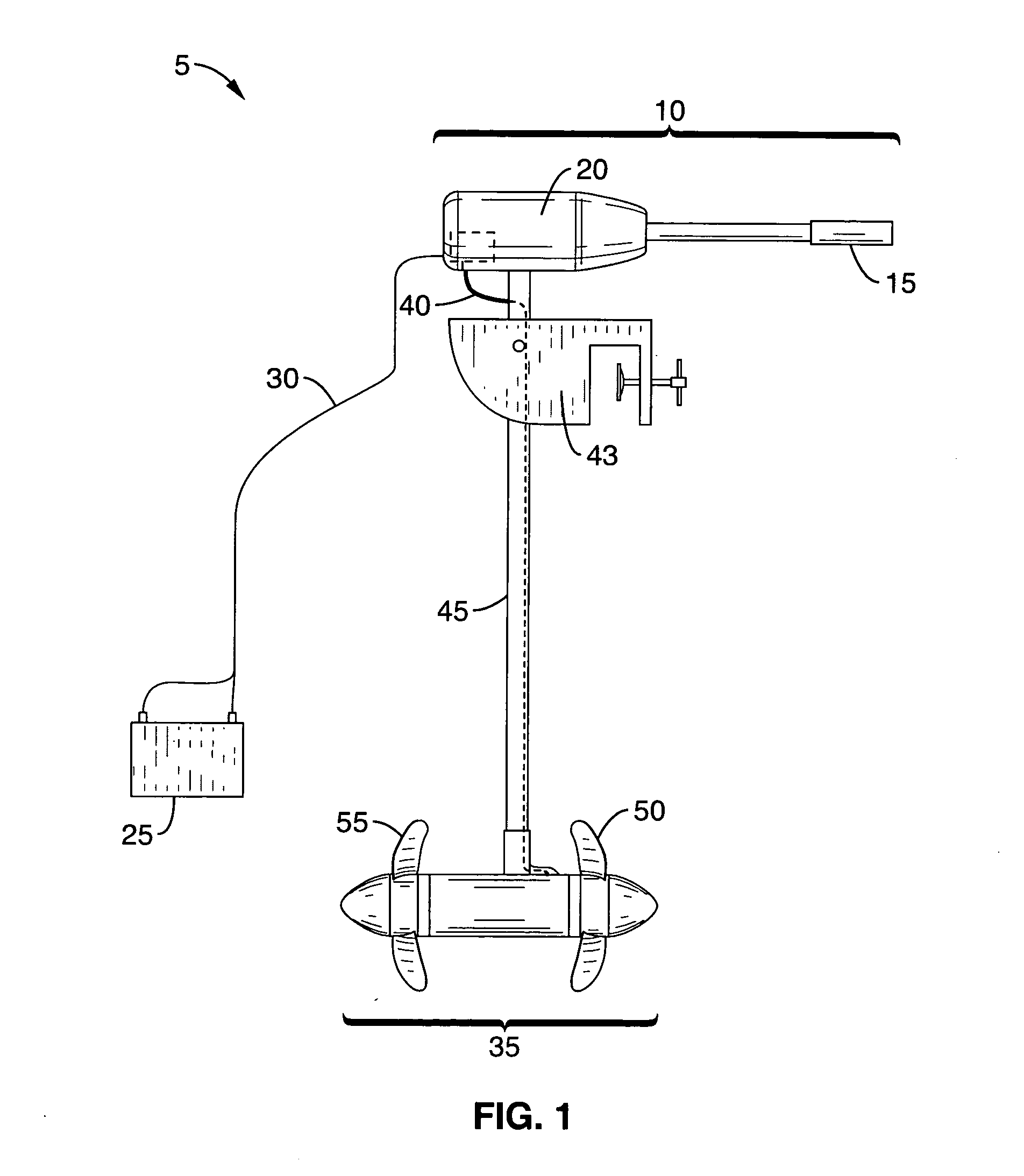

Increased efficiency counter-rotating electric motor for propelling a boat

ActiveUS20100003871A1Improve abilitiesReduce windRotary current collectorPropulsion power plantsElectricityElectrical connection

Owner:E WISH TECH

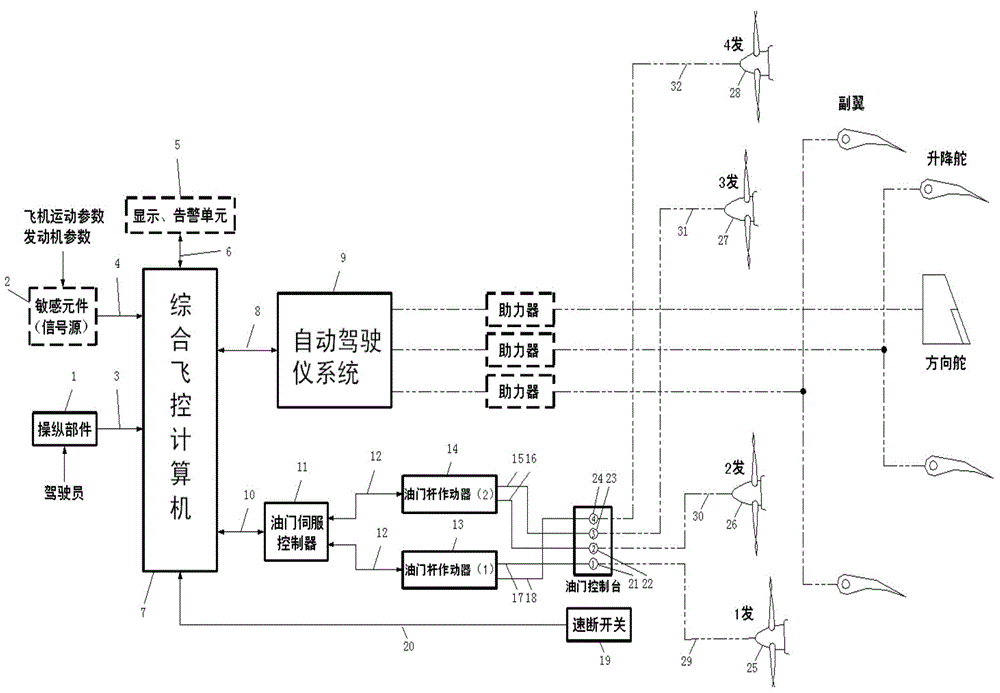

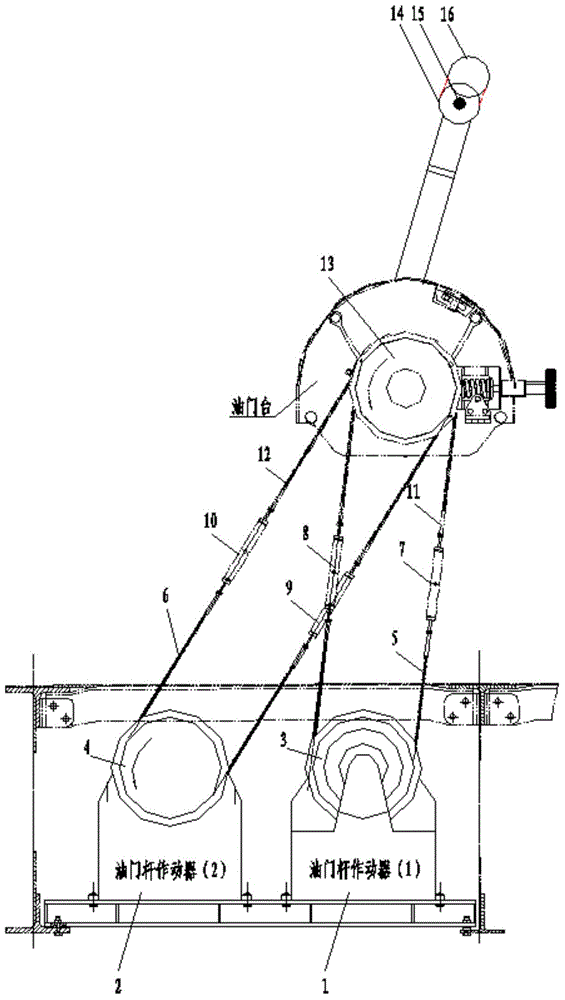

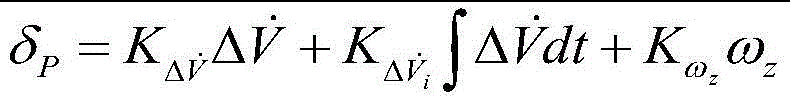

Automatic throttle system of aircraft

Owner:SHAANXI AIRCRAFT CORPORATION

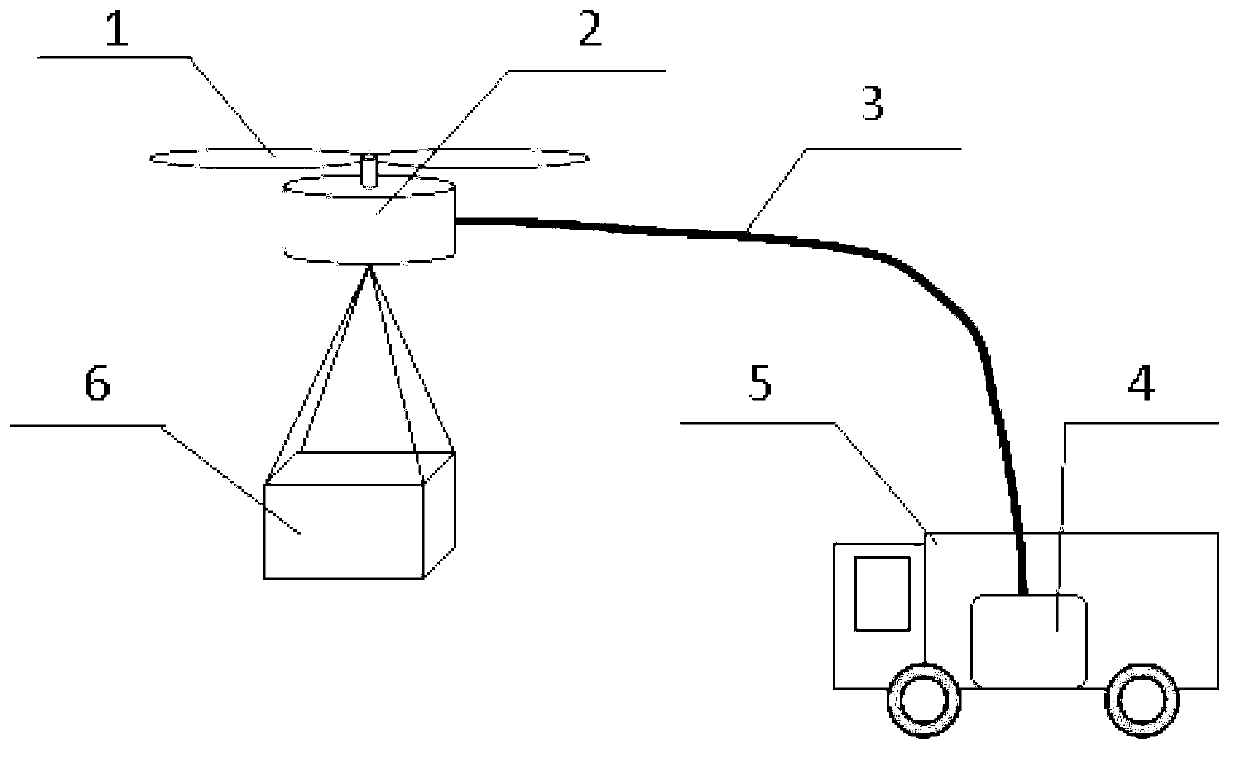

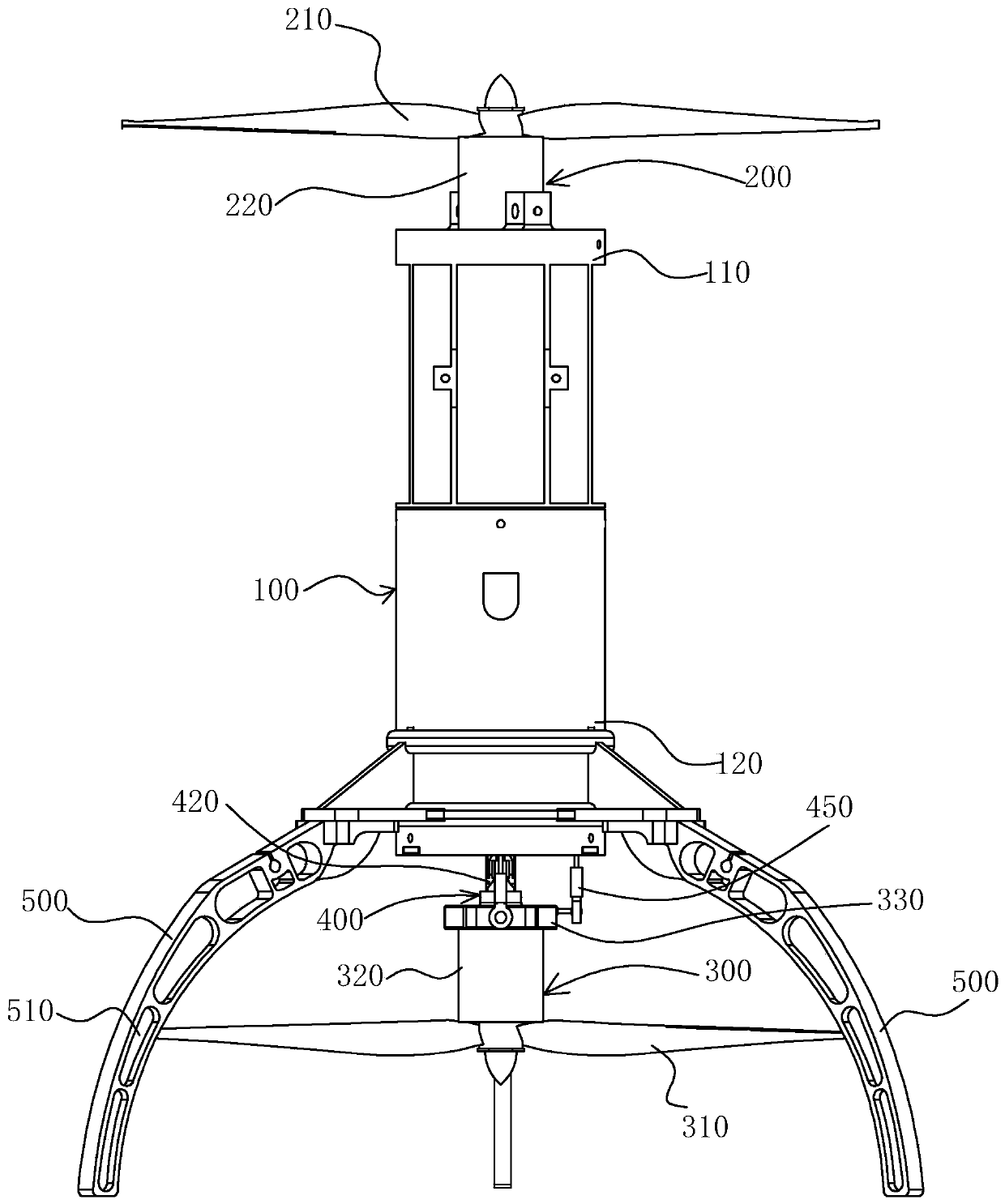

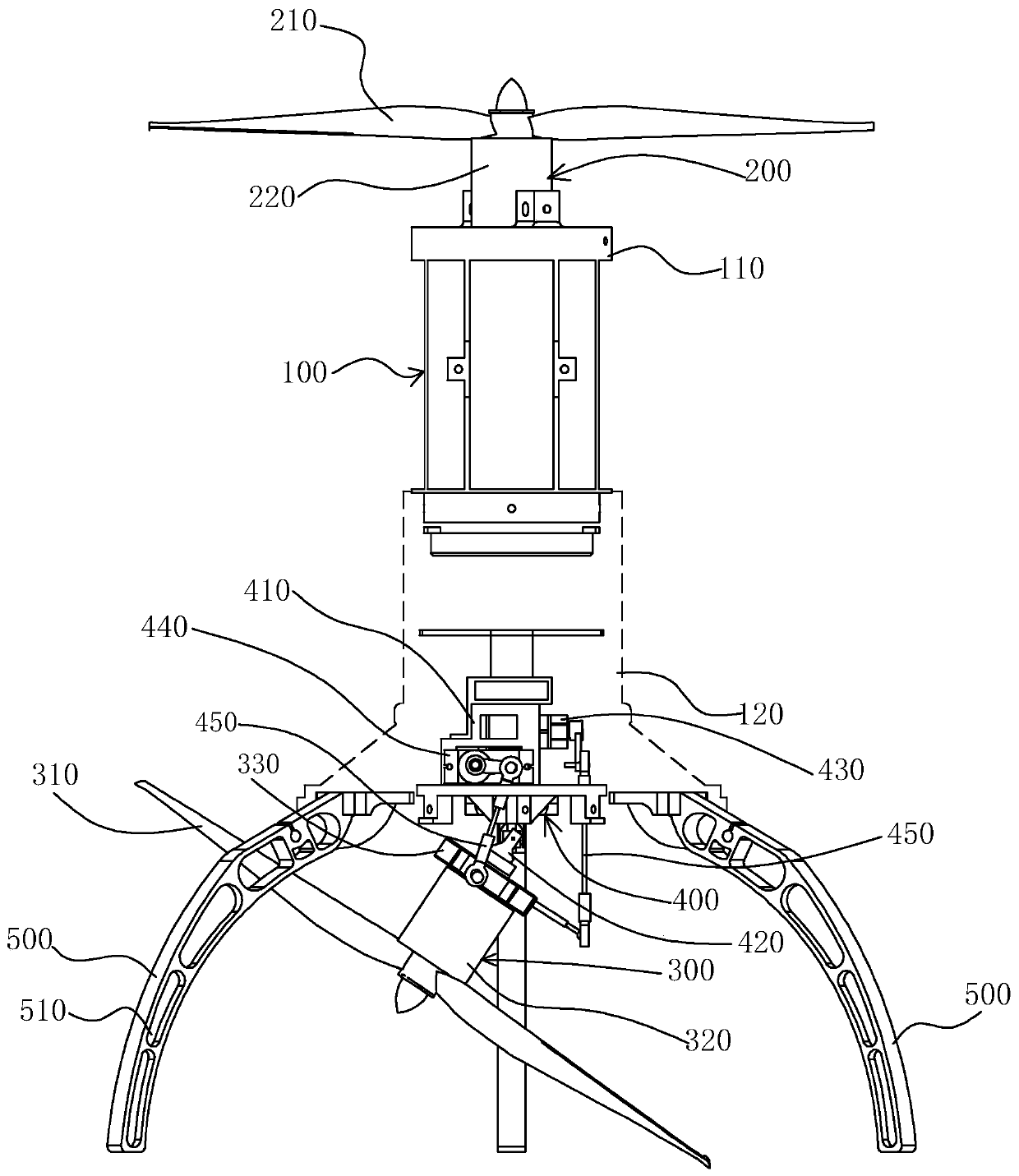

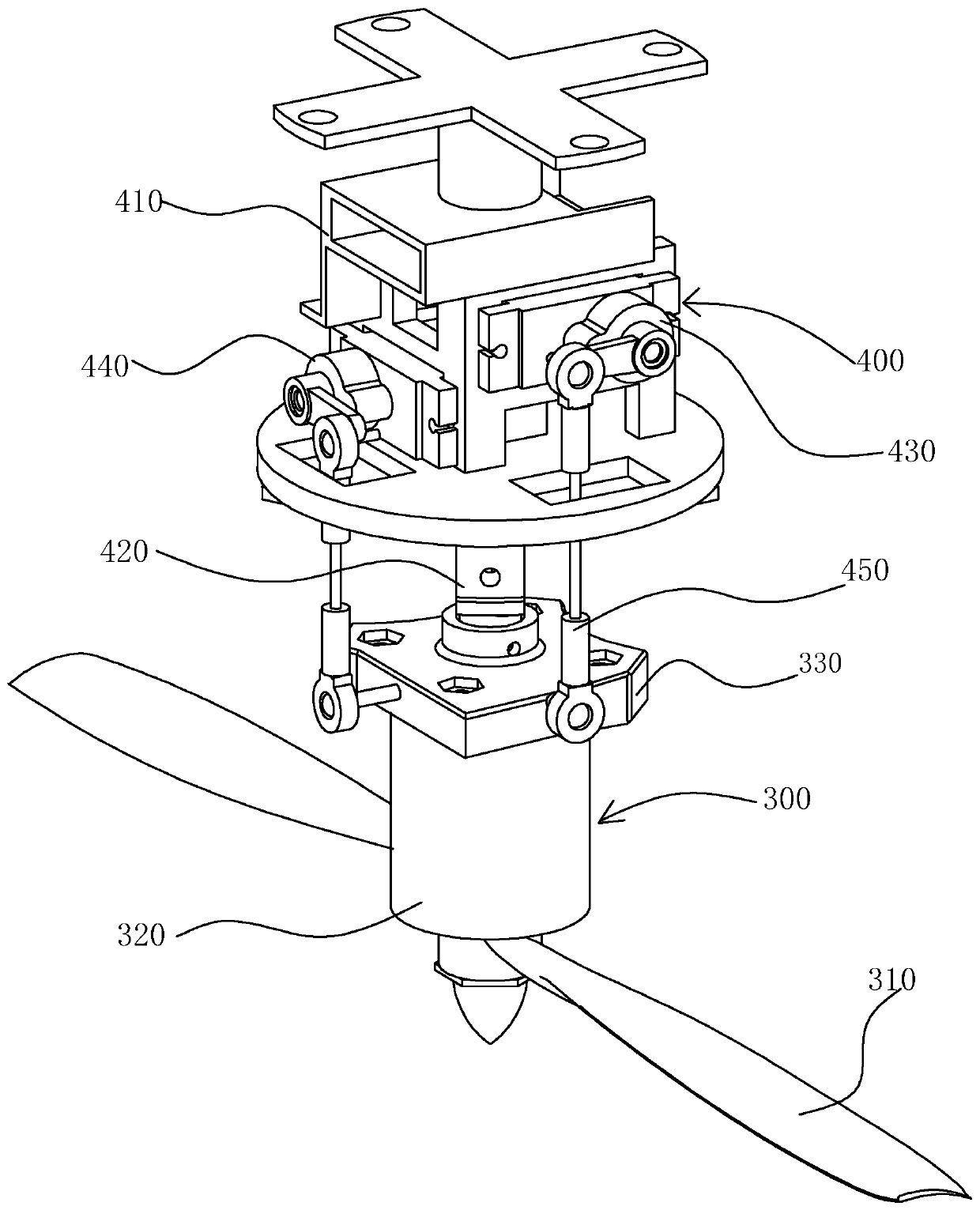

Electric drive lifting unmanned flying platform

Owner:上海交通大学无锡研究院

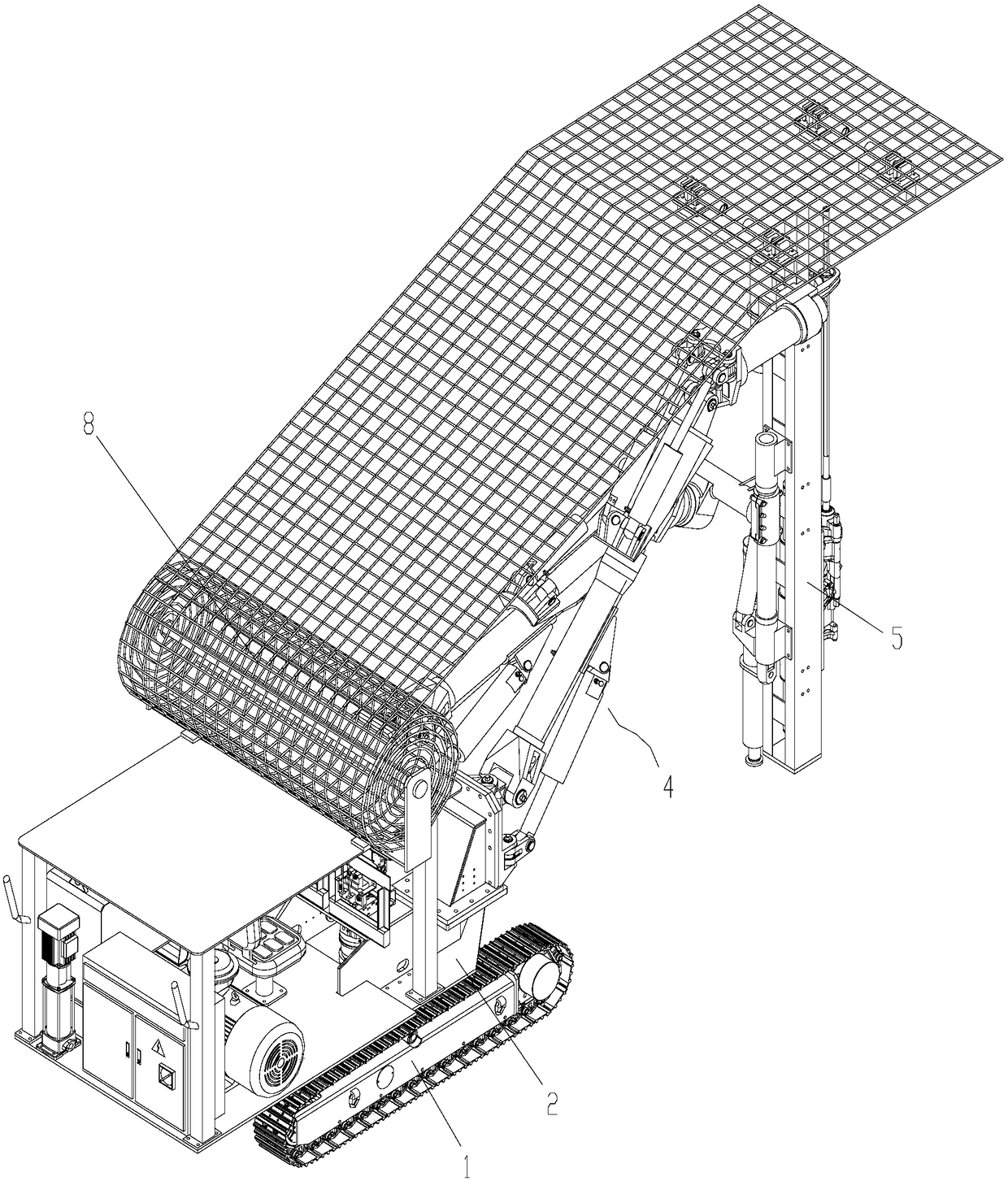

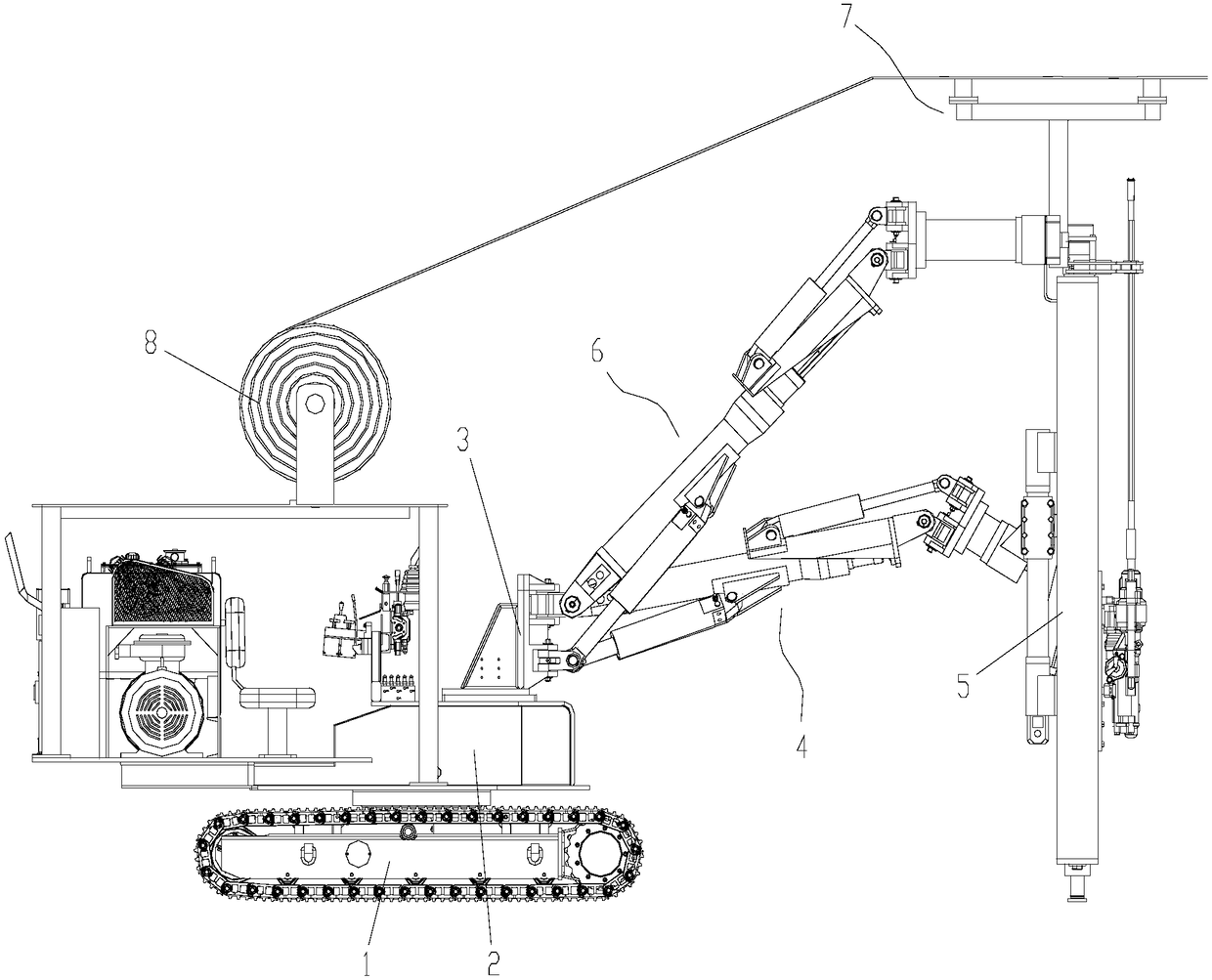

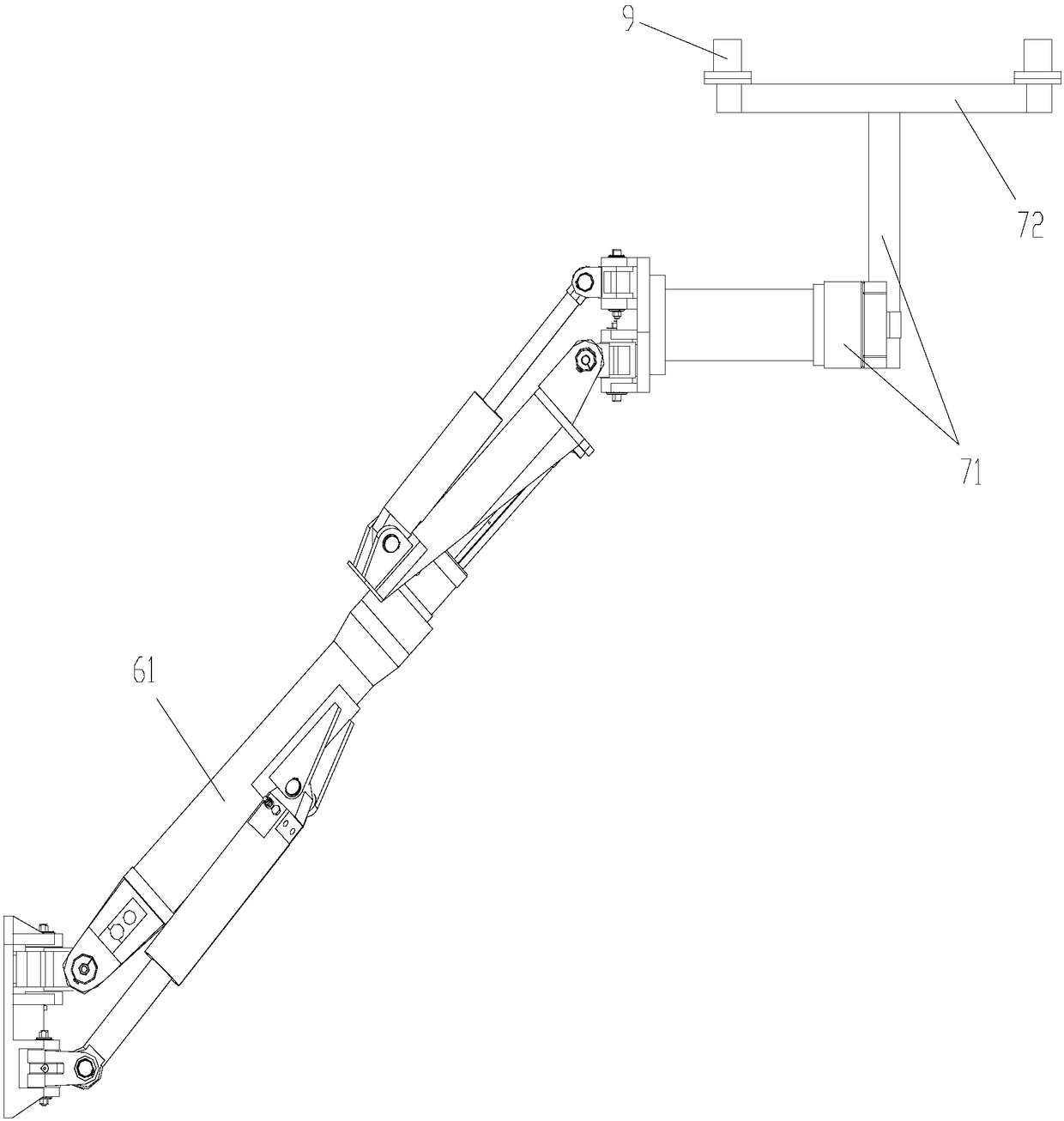

Net anchoring drill carriage

ActiveCN108104844AQuick SetupImprove work efficiencyUnderground chambersDerricks/mastsVehicle framePropeller

Owner:重庆格德瑞重工智能装备研究院 +1

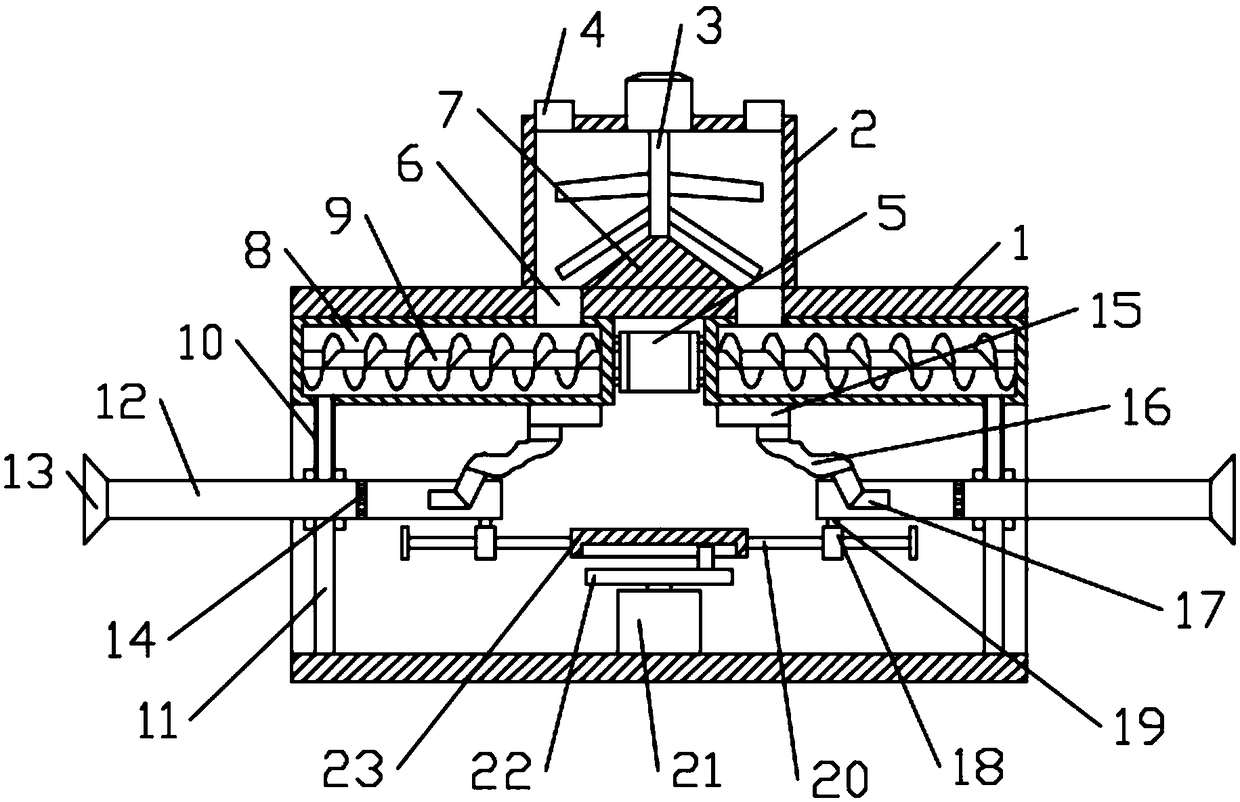

Chemical mechanical stirrer based on paddle wing barbs for organic silica gel

InactiveCN111330474ARotary stirring mixersTransportation and packagingChemical industryHydraulic cylinder

Owner:吴金元

High-intensity high-speed informationization manned spacecraft manufactured by new graphene materials

InactiveCN102745344AHigh hardnessImprove conductivityArtificial satellitesSecondary cellsRe entryNew energy

Owner:WUXI TONGCHUN NEW ENERGY TECH

Intelligent underwater search and rescue robot

Owner:SHANDONG UNIV OF SCI & TECH

Dual-power vertical take-off and landing fixed-wing unmanned aerial vehicle

InactiveCN113148188AVTOLLower request limitBatteries circuit arrangementsAircraft stabilisationUncrewed vehiclePropeller

The invention discloses a dual-power vertical take-off and landing fixed-wing unmanned aerial vehicle. The unmanned aerial vehicle comprises a fuselage, a propeller engine is installed at the right end of the fuselage, propeller blades are connected to the output end of the propeller engine, fixed wings are installed on the front side and the rear side of the fuselage, and a power frame is connected to the bottoms of the fixed wings. A worm wheel thrust engine is installed at the left end of the power frame, an empennage assembly is connected to the left side of the top of the fuselage, and a cover body is hinged to the upper end of the fuselage. The structural design is reasonable, the requirement limitation on the take-off and landing environment is greatly reduced, dual-power driving can be realized in the flight process, the overlarge load of a single engine is avoided, the fault occurrence probability is reduced, the cruising ability of the equipment is enhanced, the functions are diversified, and the application is more diversified.

Owner:NINGBO ARES AUTOMATION TECH CO LTD

Full-revolving tugboat with stern roller

Owner:JIANGSU ZHENJIANG SHIPYARD GROUP

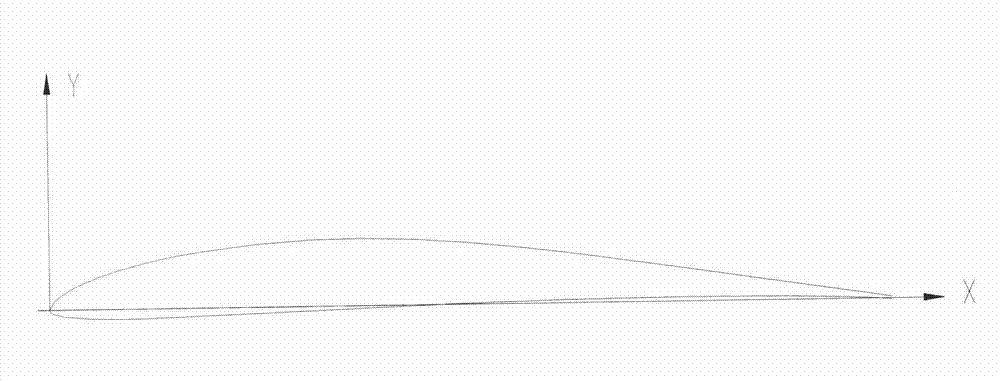

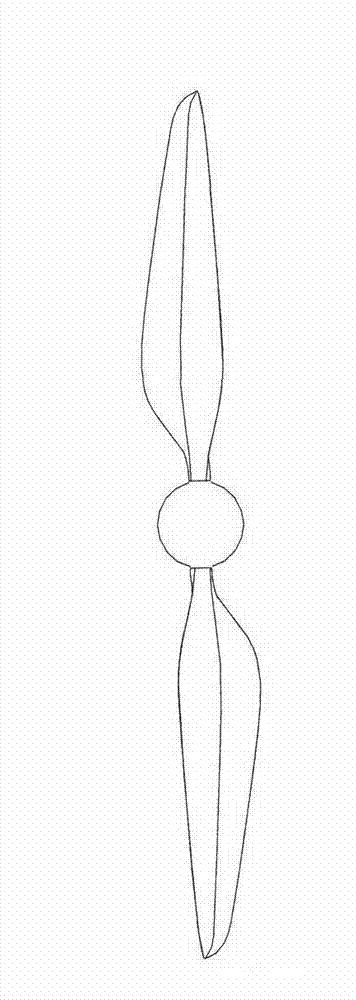

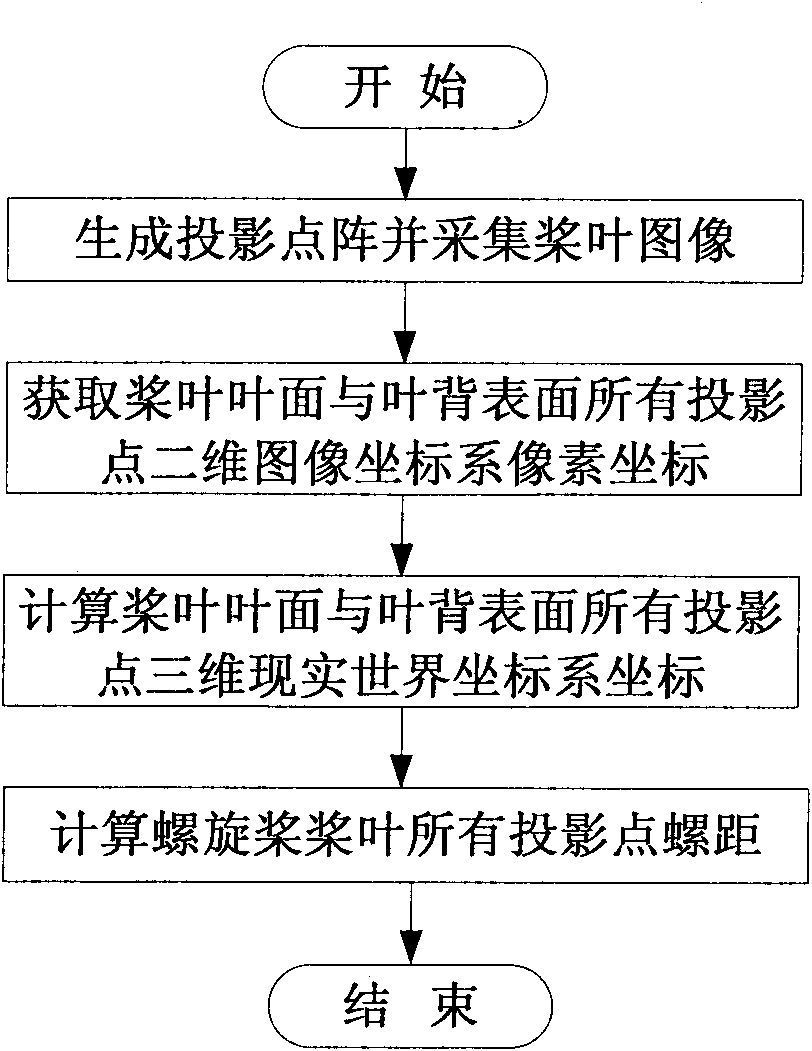

A Method of Parametrically Constructing 3D Model of Propeller

The invention relates to a method for parametrically constructing a three-dimensional model of a propeller, comprising the following steps: 1, determining the geometric characteristic parameters of the propeller; 2, selecting a reference airfoil, and obtaining an optimized airfoil through linear superposition of the reference airfoil and a disturbance function 3. Calculating the coordinates of blade-arbitrary radius r profile point coordinates; 4. Rotating the profile point points at each radius r of the blade obtained in step 3 around the y-axis for coordinate transformation to generate each radius of other blades Type value point of profile at r. The present invention calculates the type value point coordinates of the blade section shape at each radius of the propeller blade in the rectangular coordinate system, and obtains the type value point coordinates of the blade section shapes at each radius of other blades through the method of coordinate transformation, which improves the design efficiency and reduce design cost.

Owner:BEIJING INST OF TECH

Dynamic calibration system for propeller shaft hole boring

ActiveCN107116398AAvoid Quality AccidentsMeasurement/indication equipmentsMeasurement devicePropeller

The invention discloses a dynamic calibration system for propeller shaft hole boring. The dynamic calibration system comprises two transmitting, receiving and alarming integrated machines, two positioning hole units, a position detecting unit and a system host; and the two transmitting, receiving and alarming integrated machines are installed at one ends of two boring rods, the two positioning hole units are installed at the other ends of the two boring holes, the position detecting unit is installed on a supporting bearing of the boring rods, and the system host is connected to a servo motor controller. According to the dynamic calibration system for propeller shaft hole boring, two different measurement devices are used, real time monitoring of the two or more boring rods in one shaft system can be achieved, the boring rods stop running after alarming and can run after resetting, and quality accidents are prevented.

Owner:DALIAN LIAONAN SHIPYARD 4801 FACTORY

Automatic feeding device for fishery culture

Owner:宁波市海翔远洋捕捞用具有限公司

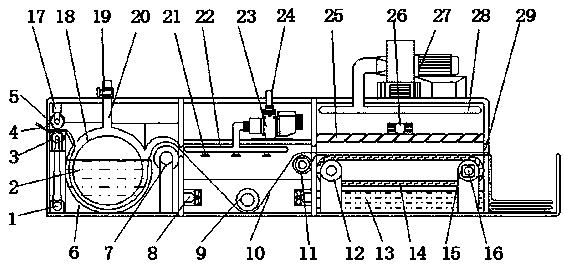

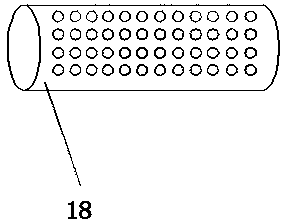

Textile cloth integrated bleaching equipment

PendingCN109423792ABleach fullyImprove bleaching effectLiquid/gas/vapor removalTextile treatment by spraying/projectingPropellerPulp and paper industry

Owner:江苏邦琳纺织有限公司

Boring device, boring method and stern shaft mounting method

ActiveCN113210663AImprove machining accuracyAdvance installation timeBoring/drilling machinesPropellerTarget bow

The invention provides a boring device, a boring method and a stern shaft mounting method. The boring device is used for boring a stern shaft tube and comprises a light target bow base point, a light target stern base point, a boring rod, a positioning device, a first supporting frame, a supporting body and a second supporting frame. The stern shaft mounting method comprises the steps that a stern shaft tube main section is built, boring is conducted through the boring device, a bearing bush is pressed to a fifth through hole, the stern shaft penetrates into the bearing bush and the fifth through hole, and a propeller is installed at one end of the stern shaft. The problems that an existing boring rod is prone to bending deformation in the horizontal boring process, the boring quality is poor and precision is low due to the fact that the center axis of the boring rod cannot be aligned with the theoretical center of a shaft system, the shaft system cannot be installed in advance due to the fact that existing boring operations cannot be conducted on a stern shaft tube main section platform, and the construction period is affected are solved.

Owner:SINOPEC SSC +1

Energy-saving filling machine based on Internet of Things and capable of realizing uniform filling

InactiveCN108996455AUniform densityImprove filling product qualityLiquid bottlingGear driveGear wheel

Owner:郑胜利

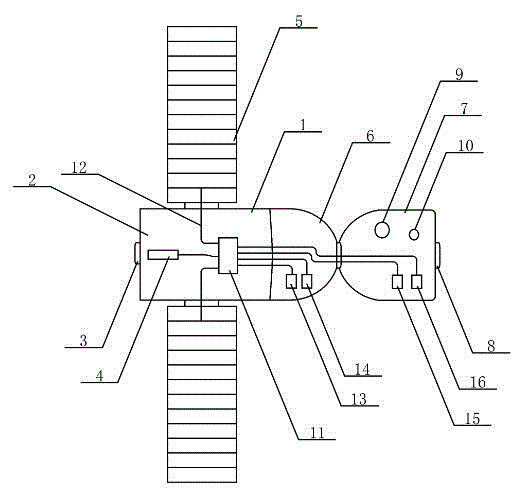

Propeller and abrasive belt grinding processing method of sharkskin surface thereof

The invention discloses an abrasive belt grinding processing method of a sharkskin surface of a propeller, which is used for solving the problem of the abrasive belt grinding processing method of thesharkskin surface of the propeller. The technical scheme is that the abrasive belt processing method of the sharkskin surface is provided, the smooth surface of the propeller is ground by an abrasivebelt grinding head, a cylinder controls a contact wheel driven by the high-speed moving abrasive belt to provide instantaneous micro-pressure while performing feed movement on the propeller surface togrind the required infinitesimal surface, and infinitesimals arranged in a regular pattern are sequentially ground along the propeller surface to achieve the state of the sharkskin surface. An abrasive belt grinding processing method of a sharkskin surface of a propeller is composed of a contact wheel, a contact wheel support, an abrasive belt, a cylinder rod sleeve and a cylinder. Processing ofthe sharkskin-like structure on the propeller surface is achieved, and the method of processing the sharkskin surface of the propeller is created, thereby facilitating actual production and promotion.

Owner:CHONGQING UNIV

Unmanned aerial vehicle

Owner:黄迅

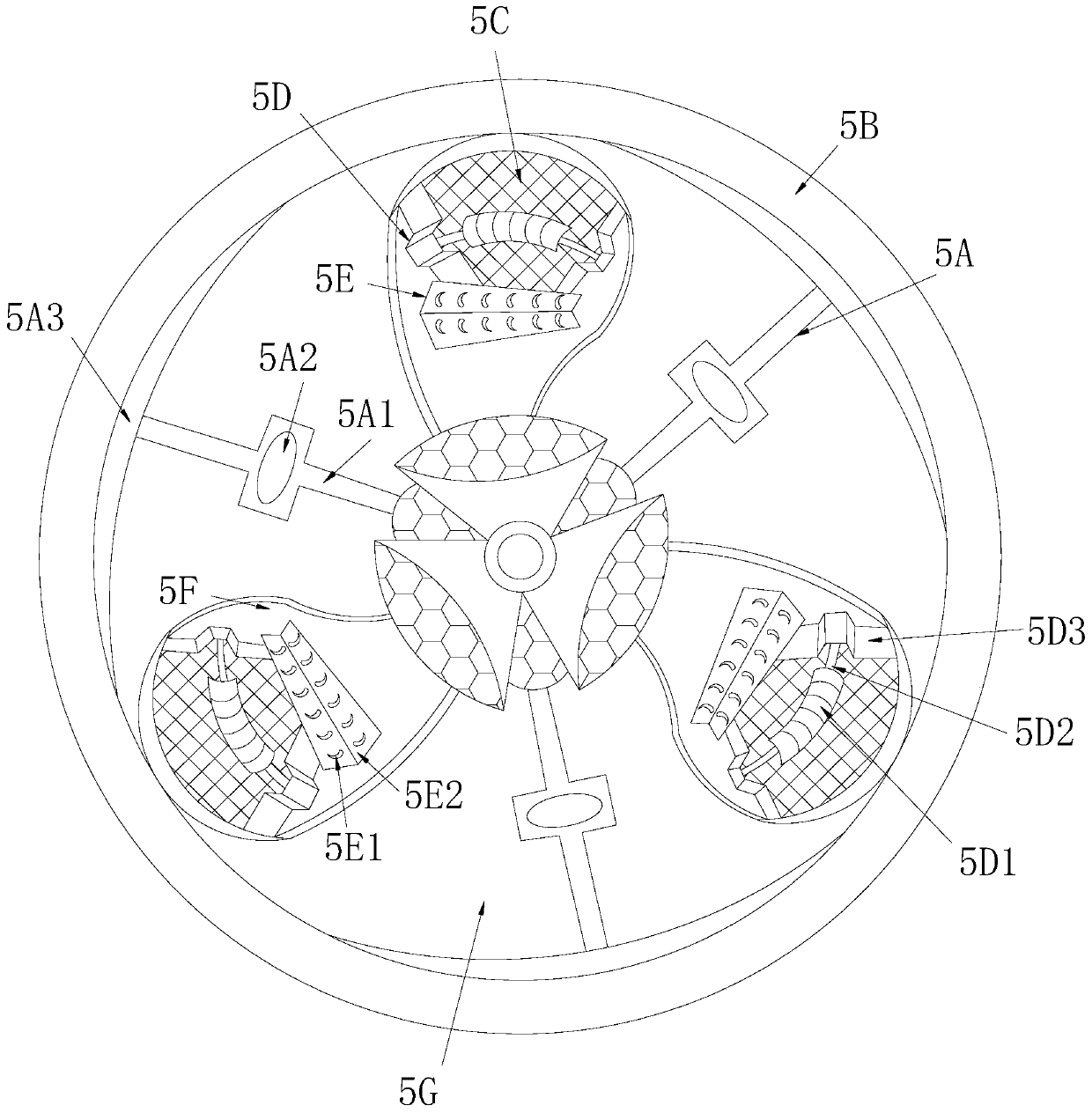

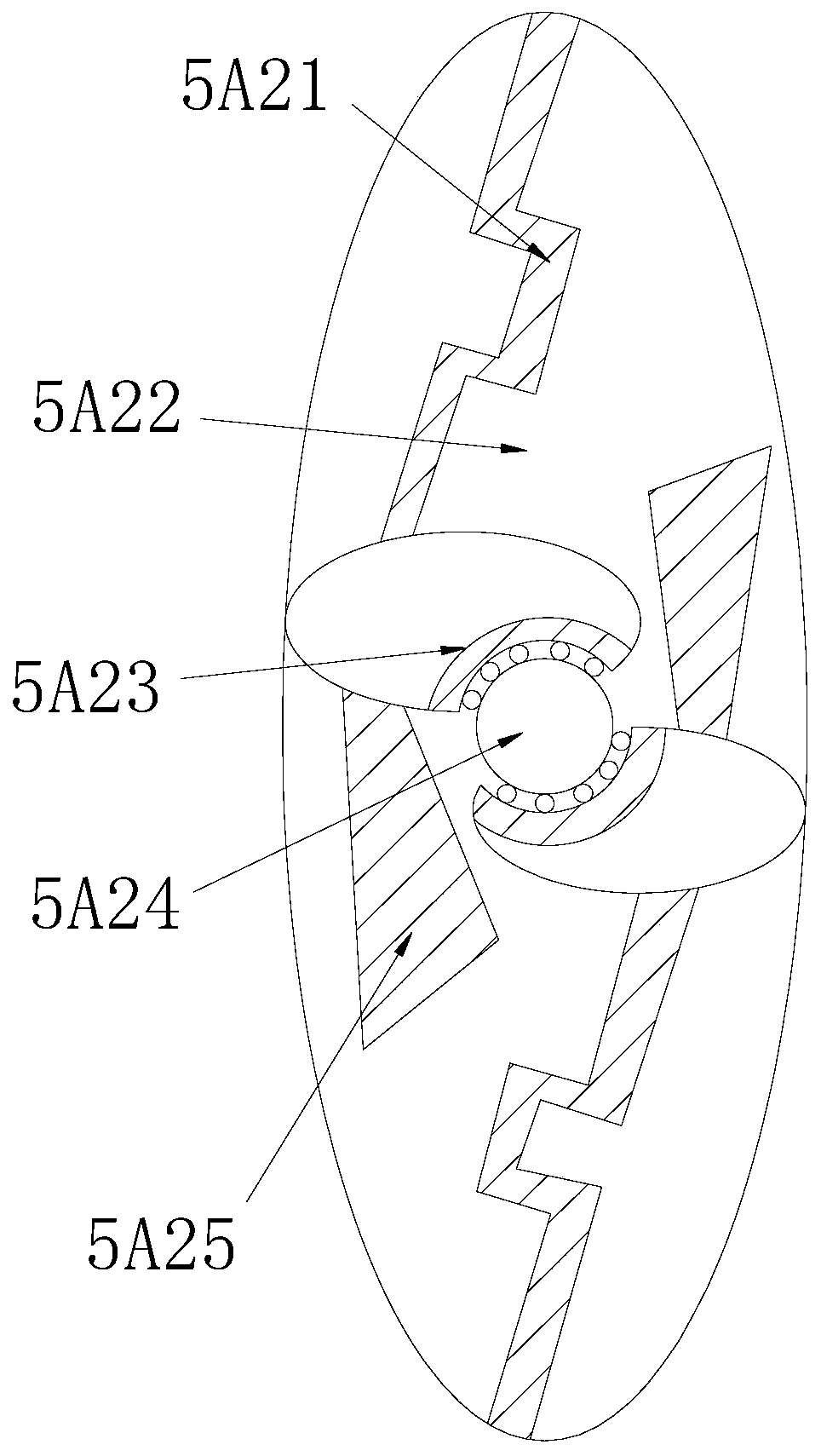

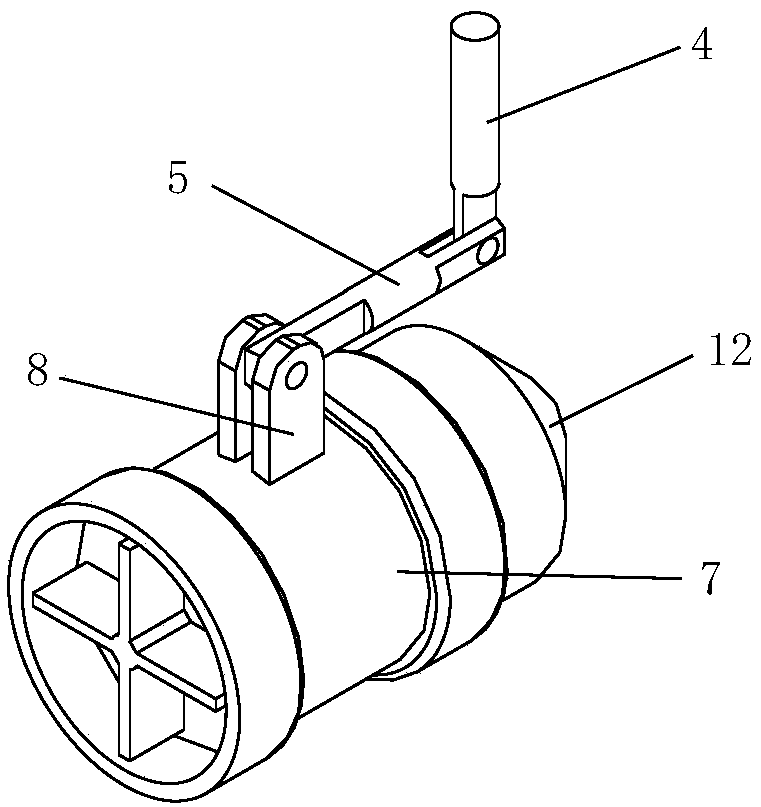

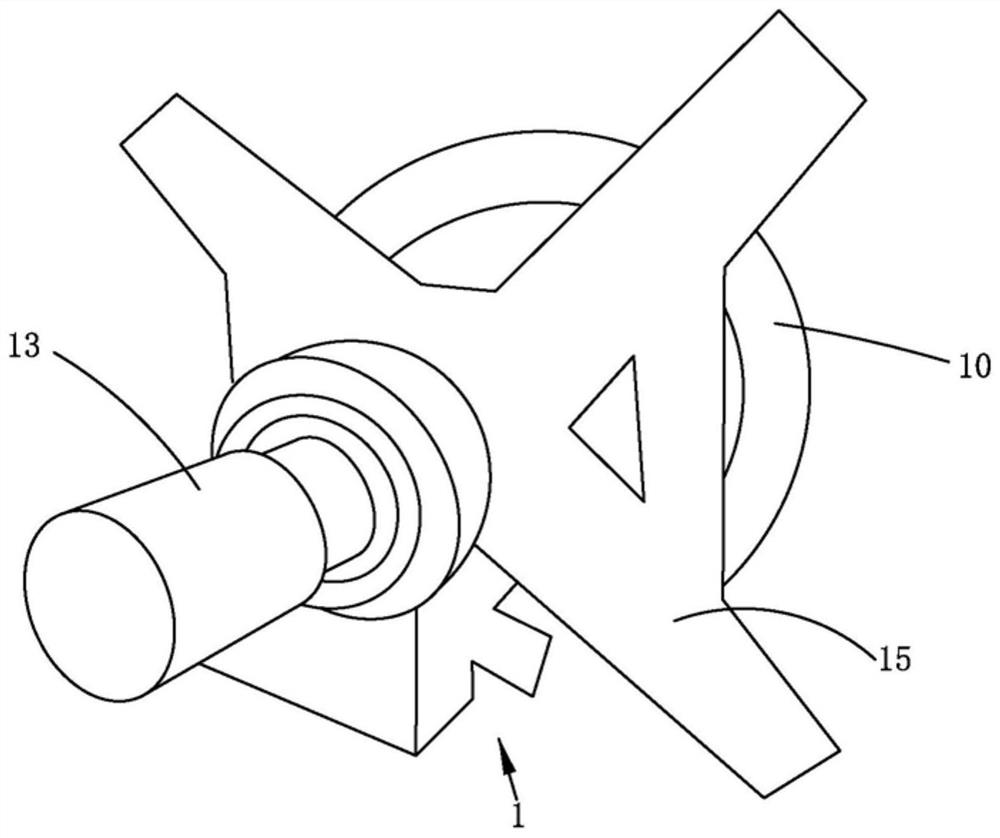

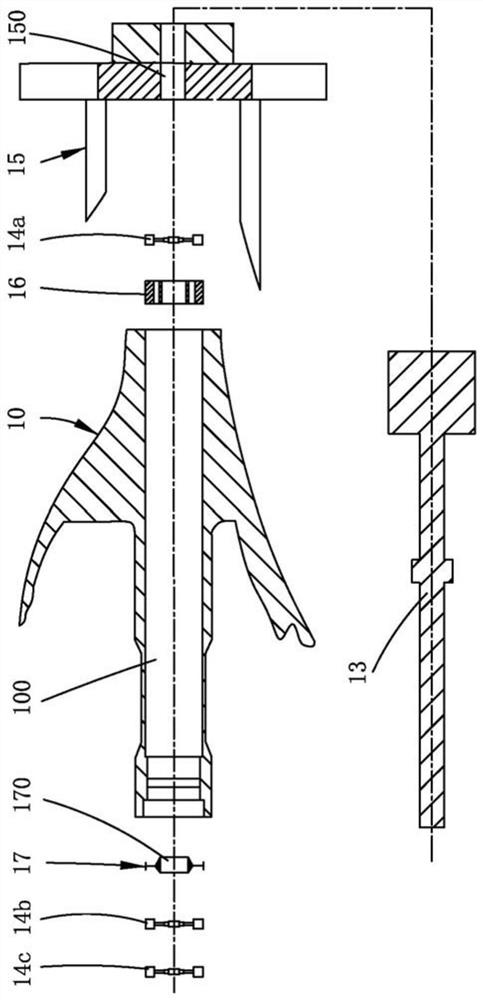

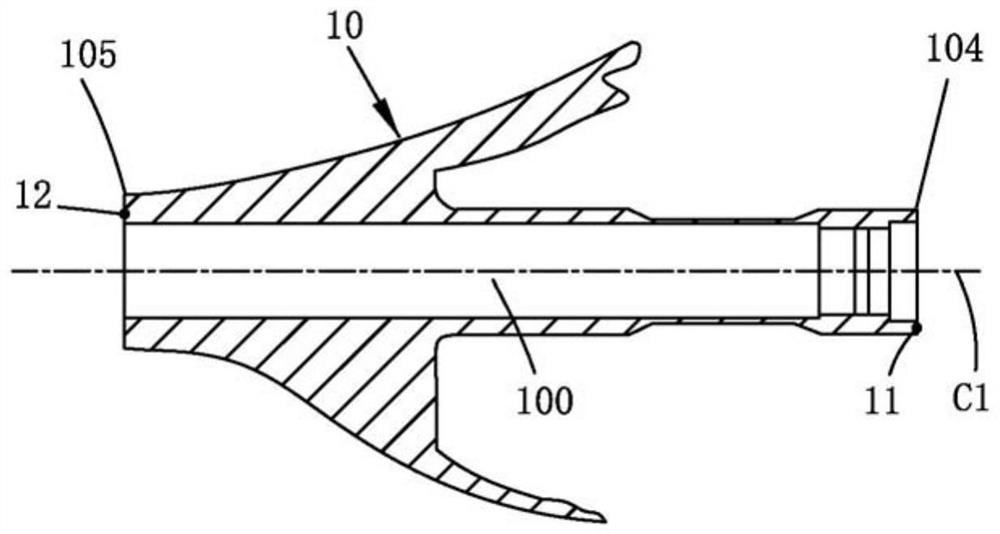

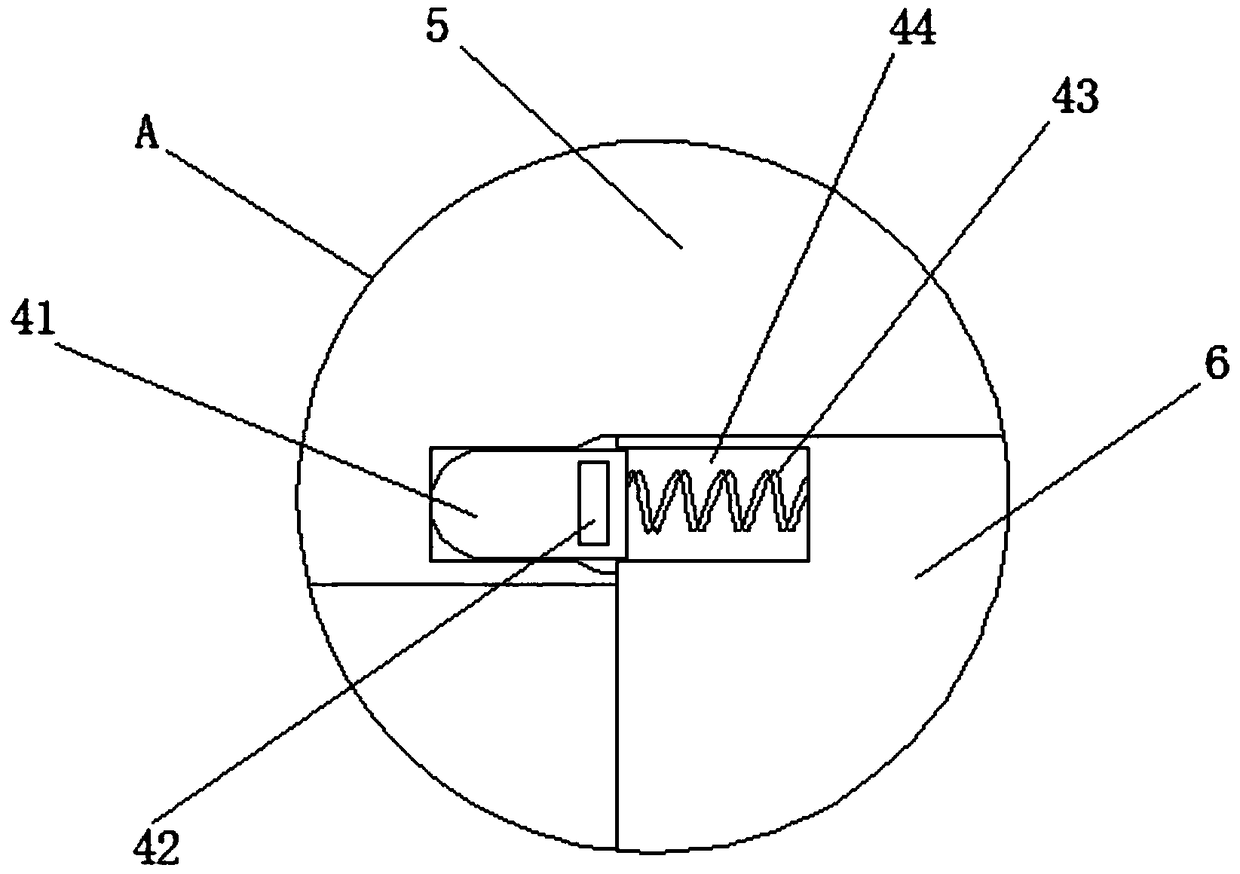

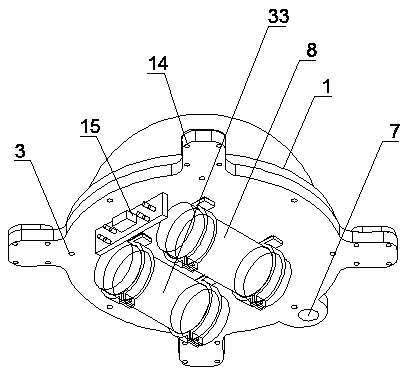

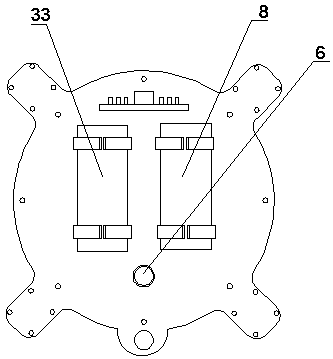

Propeller quick disassembly and assembly structure and aircraft provided with same

PendingCN113815842AEasy to disassemble and operateImprove insurancePropellersFlight vehiclePropeller

The invention discloses a propeller quick disassembly and assembly structure and an aircraft provided with the same, and is characterized in that a locking safety device is provided with a first boss, a button is provided with a first groove, and the first boss matches the first groove; an upper inclined face matches the upper matching face of a propeller blade, the upper inclined face can press the upper matching face corresponding to the propeller blade in the blade disassembling and assembling process, a lower inclined face matches the lower matching face of the propeller blade, in the blade assembling and disassembling process, the lower inclined face of the button can carry out linkage according to the lower matching face through vertical movement of the blade, a propeller hub is in a long strip shape, and when the blade is pressed downwards to be attached to the base, the button tightly presses the two ends of the blade and the two ends of the propeller hub through the upper inclined face or the lower inclined face which is correspondingly matched. According to the propeller quick disassembly and assembly structure and the aircraft provided with the same, disassembly and assembly operation is simple, the safety and safety degree is high, abrasion is reduced, cost is saved, and the service life of a product is prolonged.

Owner:NANCHANG SANRUI INTELLIGENT TECH CO LTD

Small mounted-type underwater robot platform device

Owner:SOUTHWEST PETROLEUM UNIV

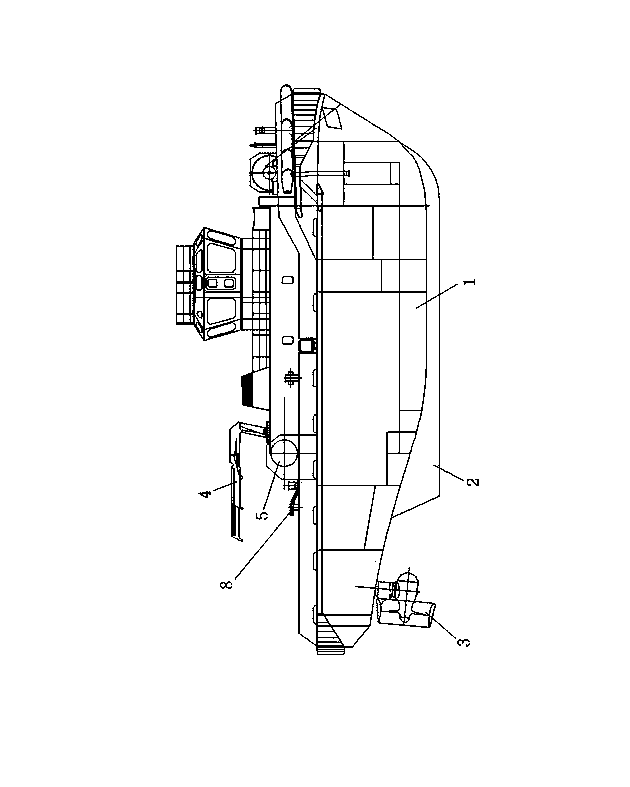

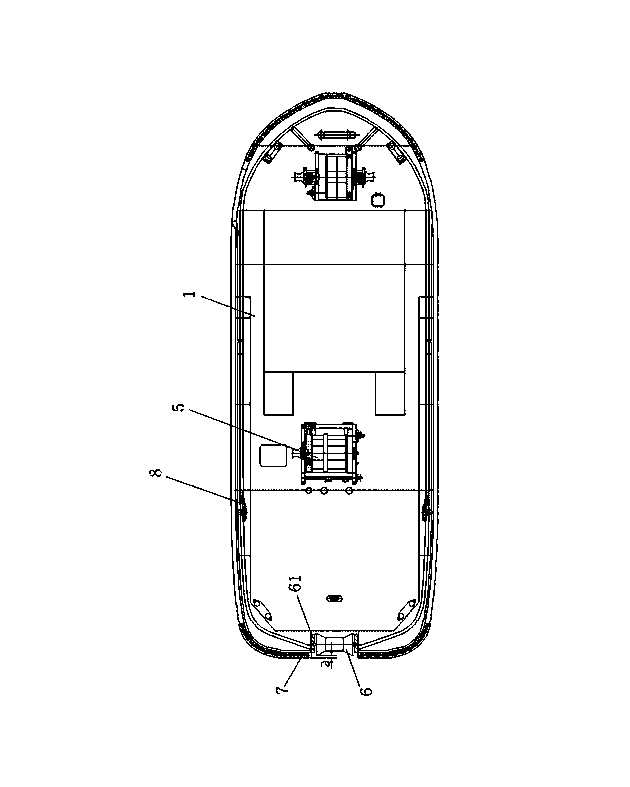

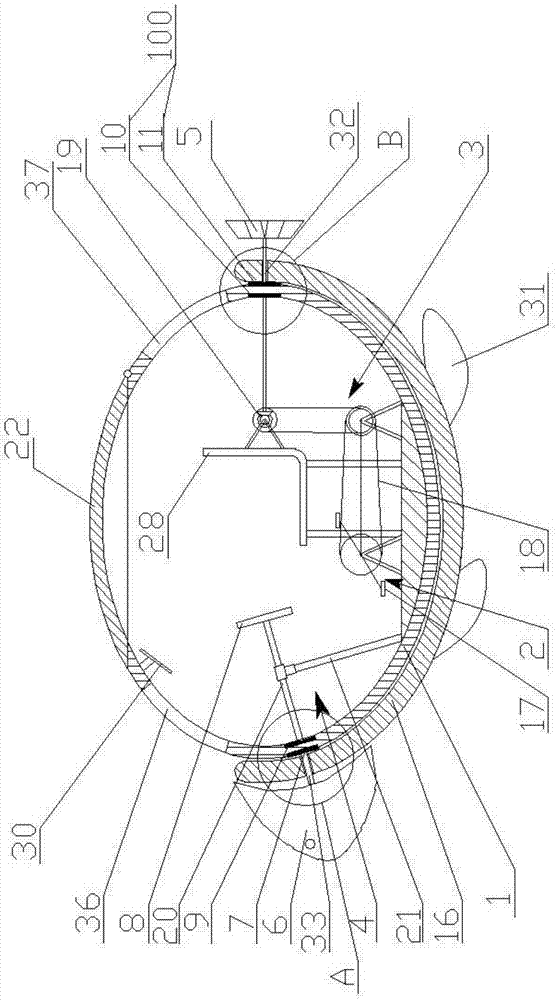

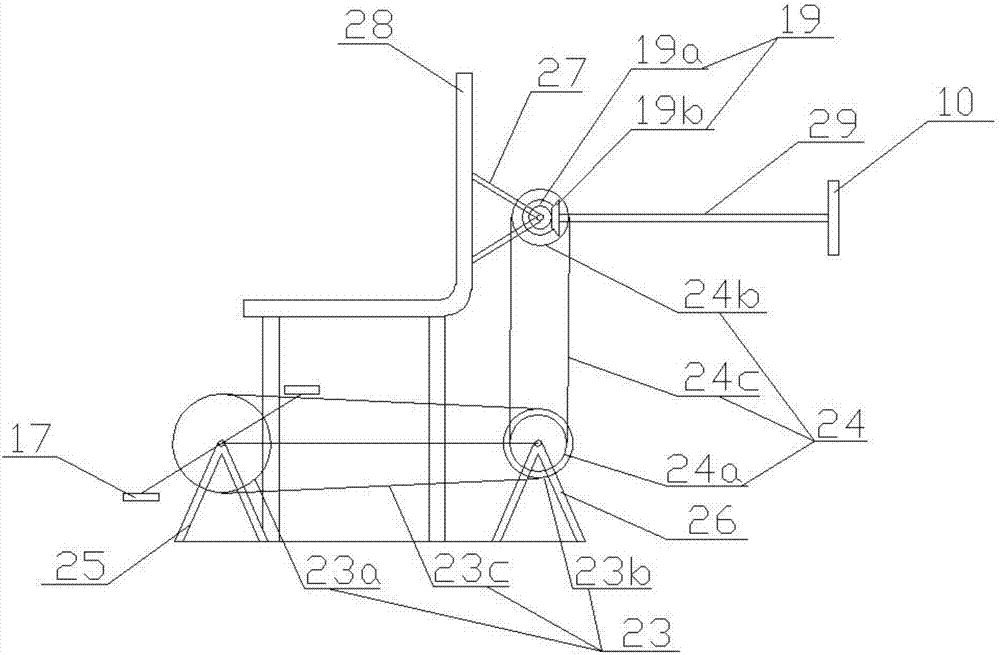

Domestic entertainment semi-snorkeling type submarine

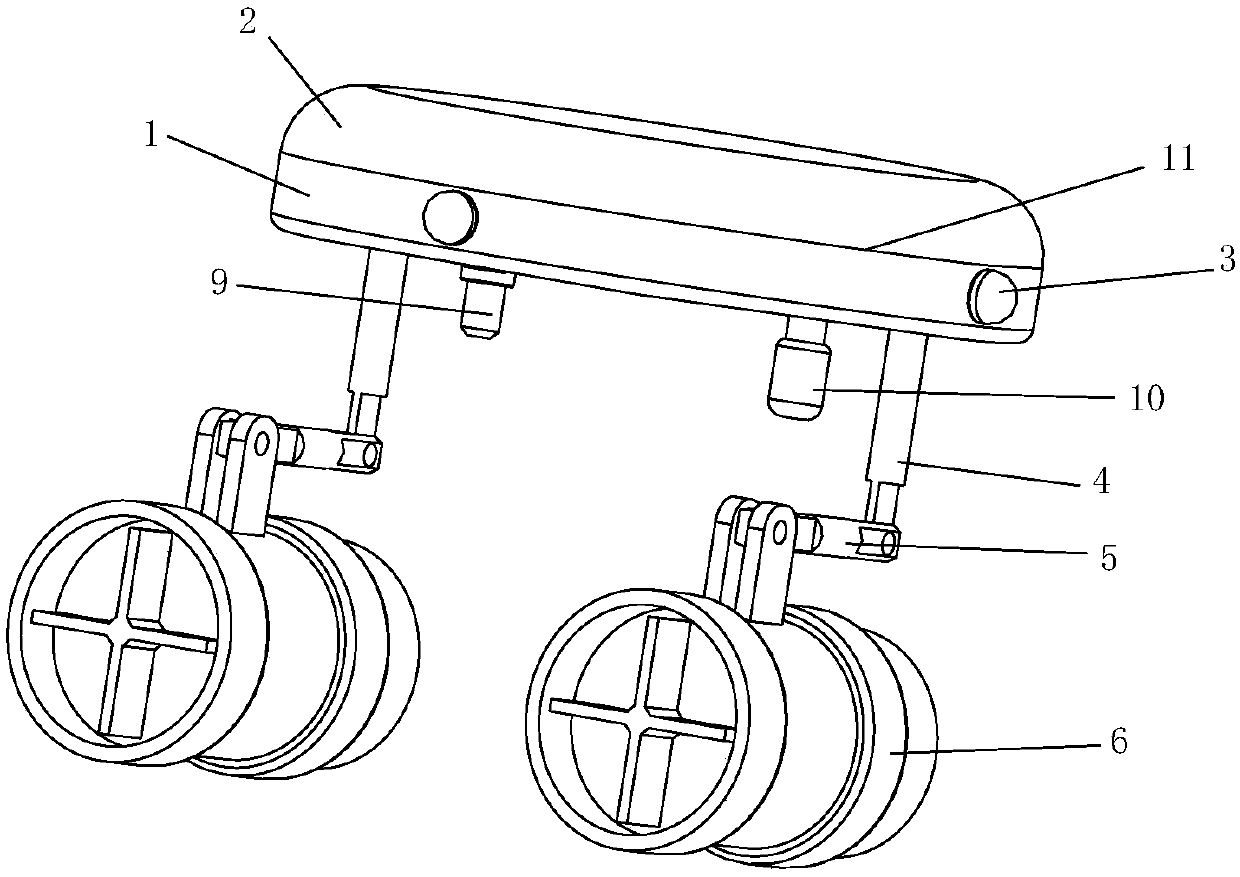

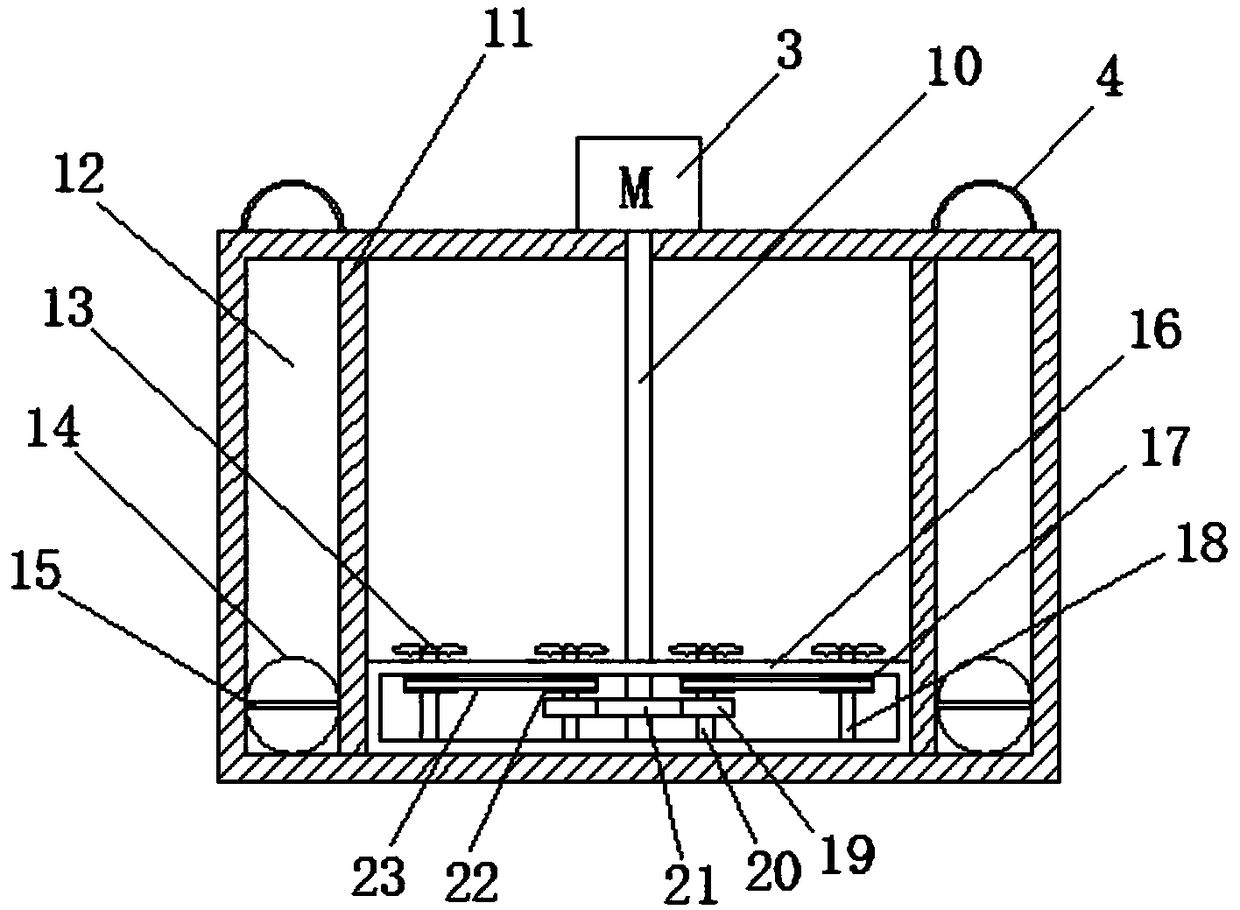

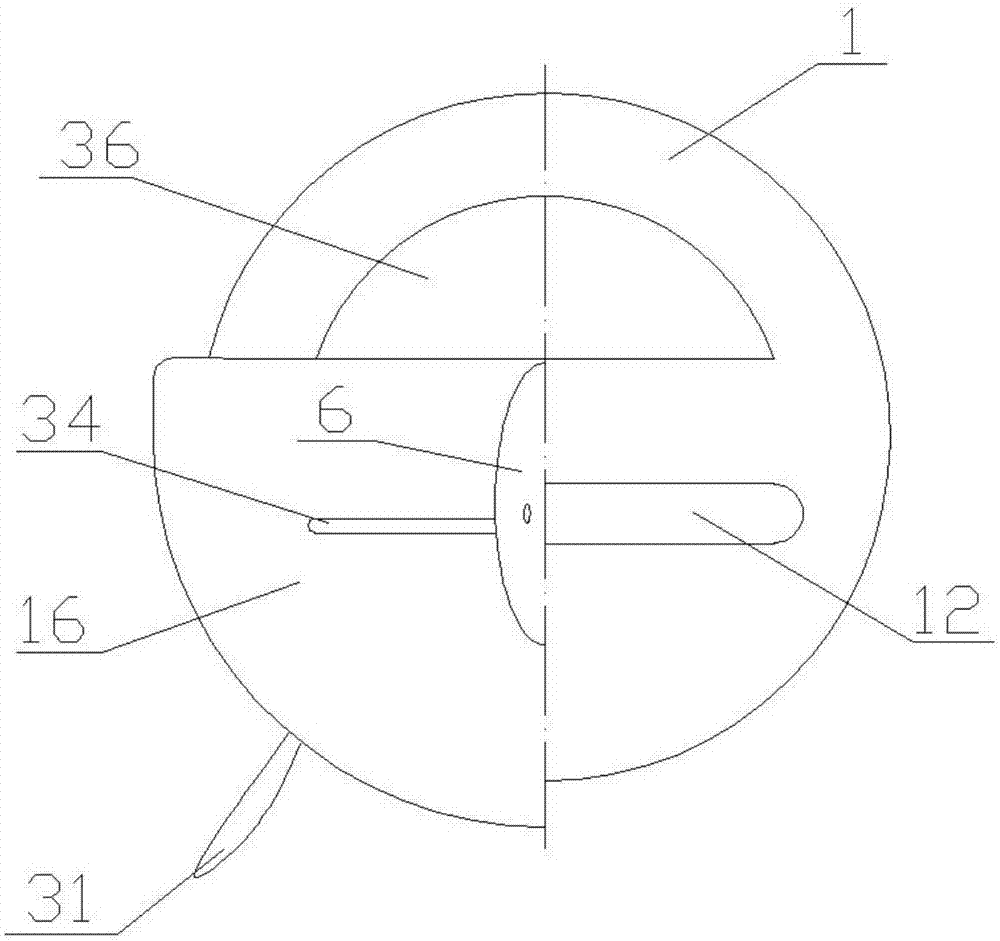

PendingCN107336807AImprove the sealing effectThe transmission mechanism is simpleSteering ruddersMuscle power acting propulsive elementsPropellerSubmarine

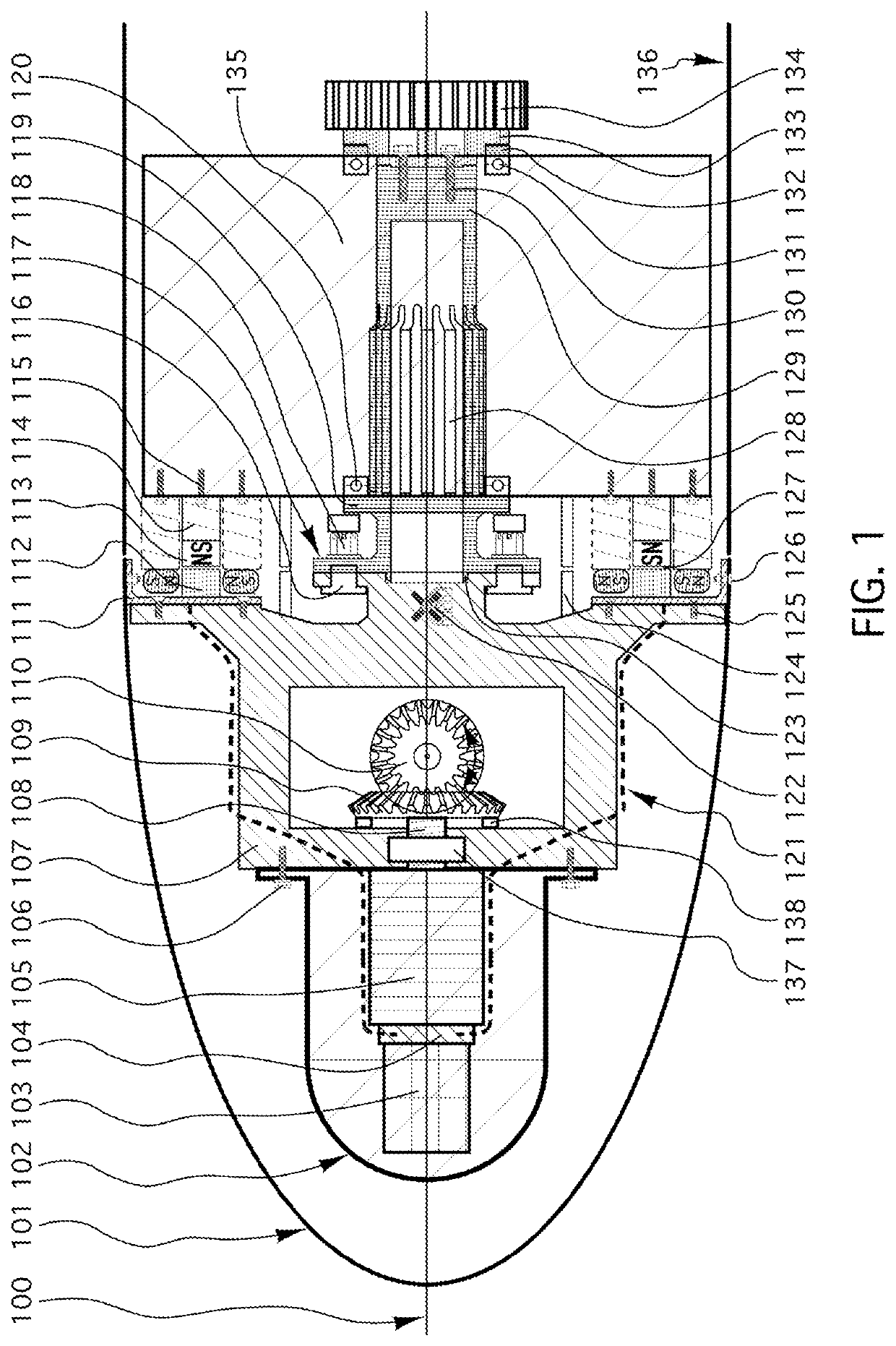

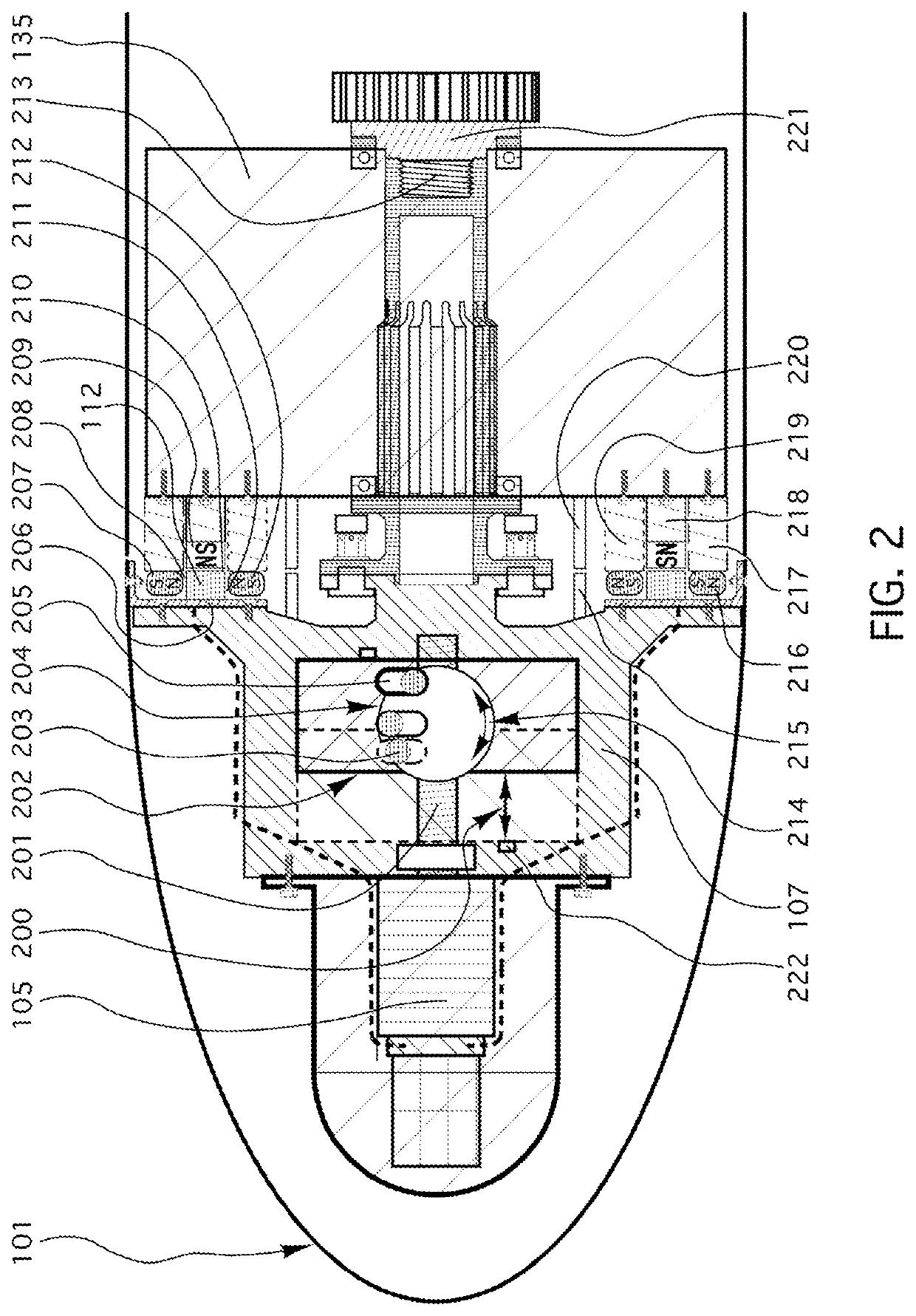

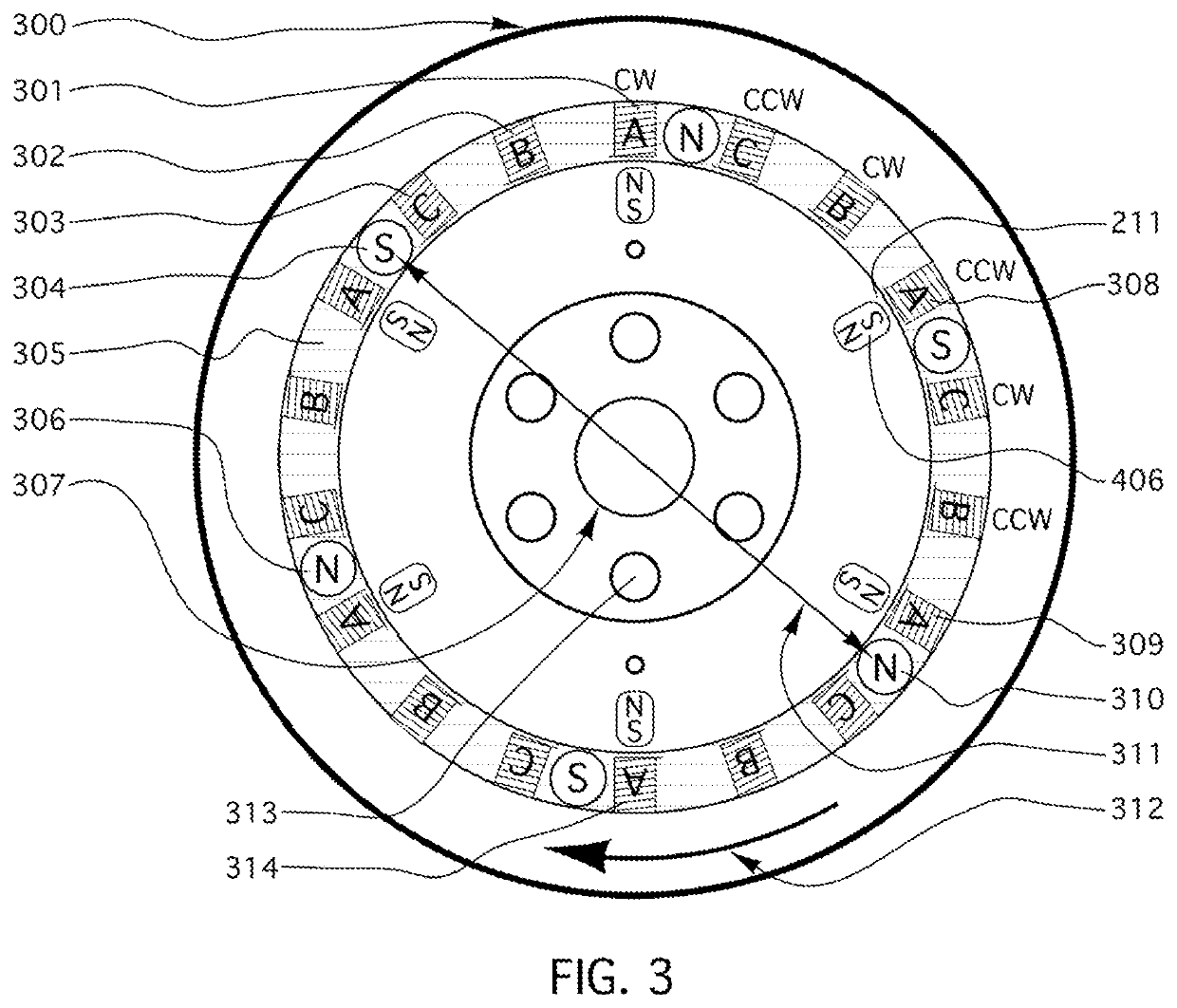

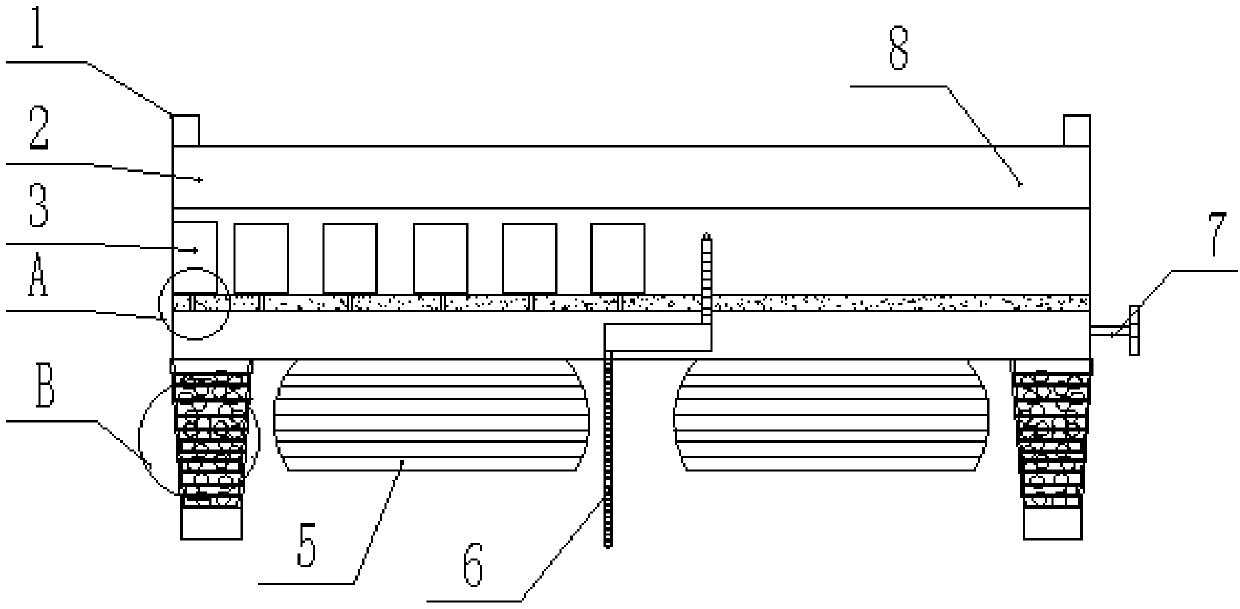

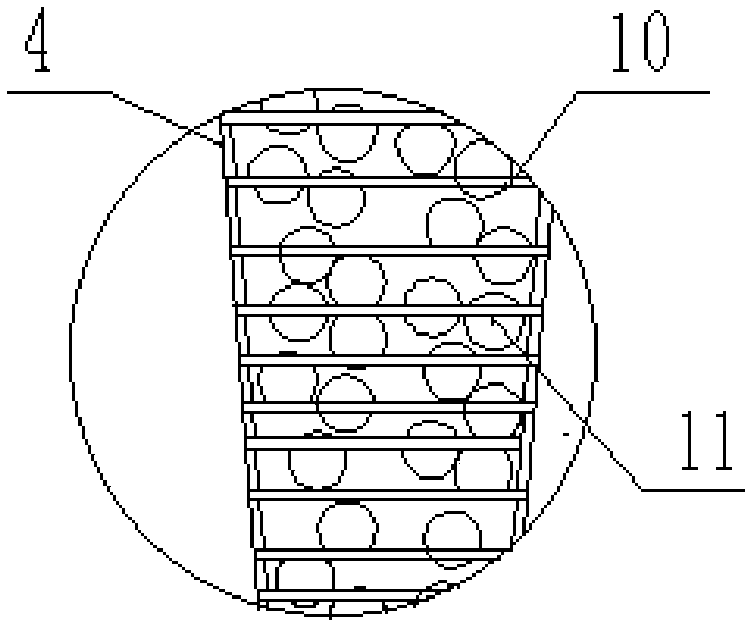

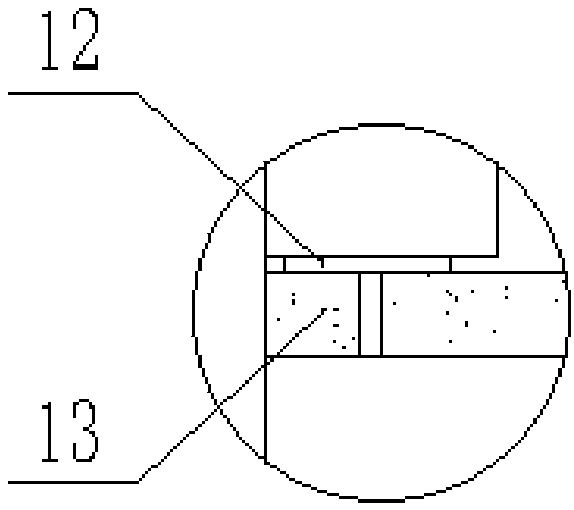

The invention discloses a domestic entertainment semi-snorkeling type submarine. The domestic entertainment semi-snorkeling type submarine comprises a shell (1), a power device (2) installed in the shell (1), a transmission device (3) installed in the shell (1), a guide device (4) and a propeller (5) installed at the tail of the shell (1); and the domestic entertainment semi-snorkeling type submarine is characterized in that the power device (2) drives the transmission device (3), the transmission device (3) comprises magnetic gear pairs (100), and the transmission device (3) drives the propeller (5) to rotate through the magnetic gear pairs (100). The domestic entertainment semi-snorkeling type submarine can be driven by manpower to advance, can dive into the water bottom or float on the water face, and is good in sealing performance, high in safety and suitable for popular entertainment.

Owner:JIANGSU GONGJING GRP CO LTD

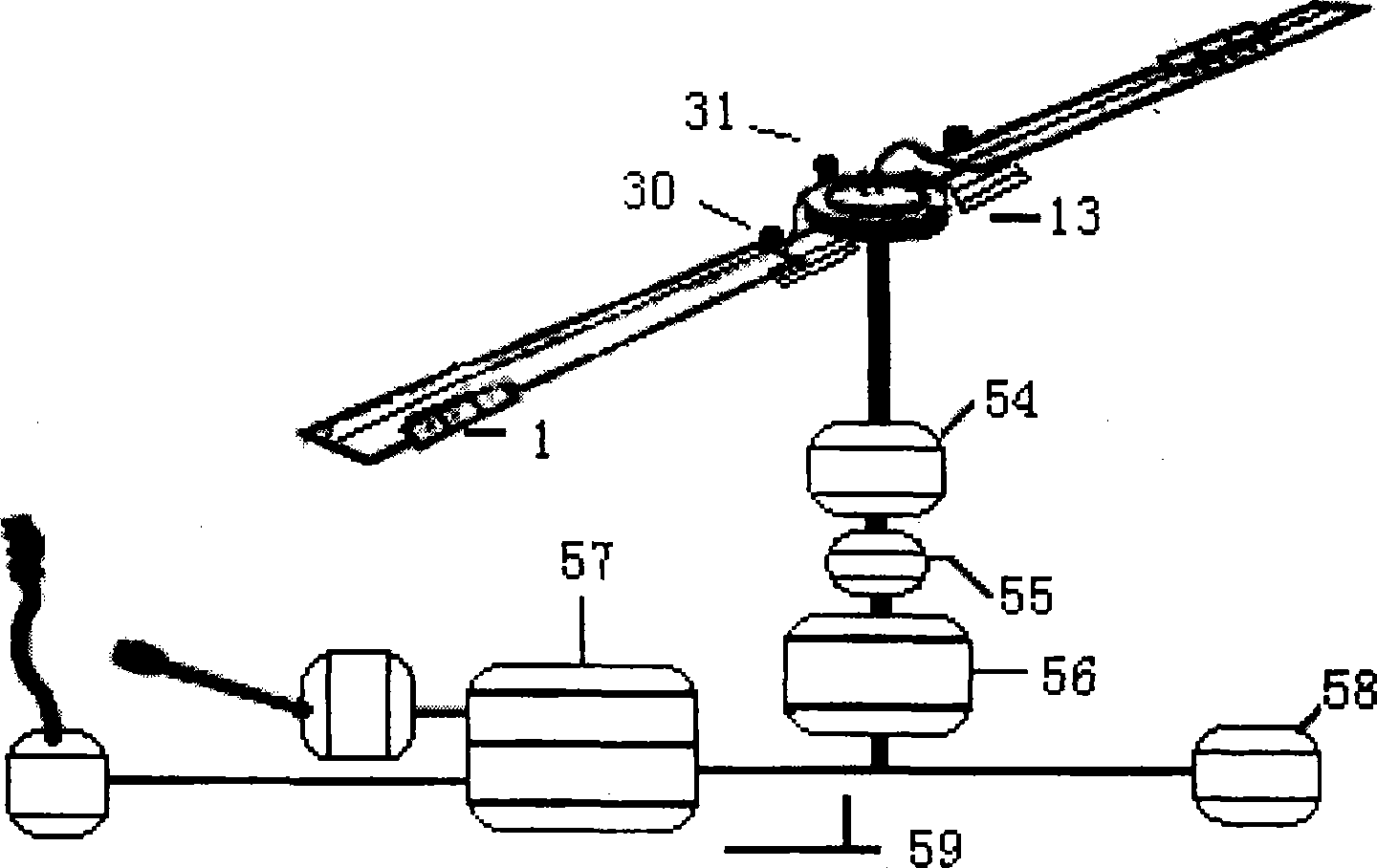

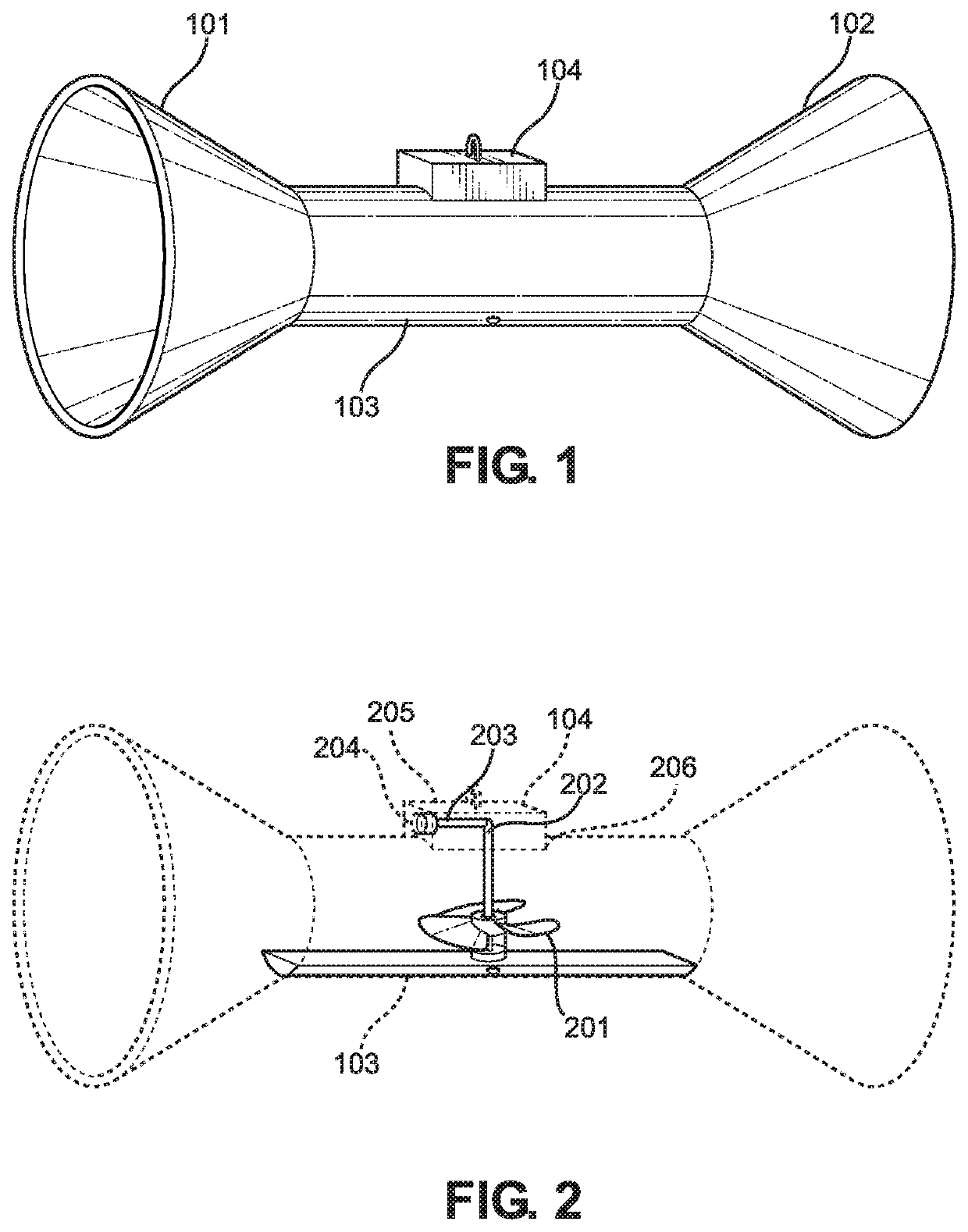

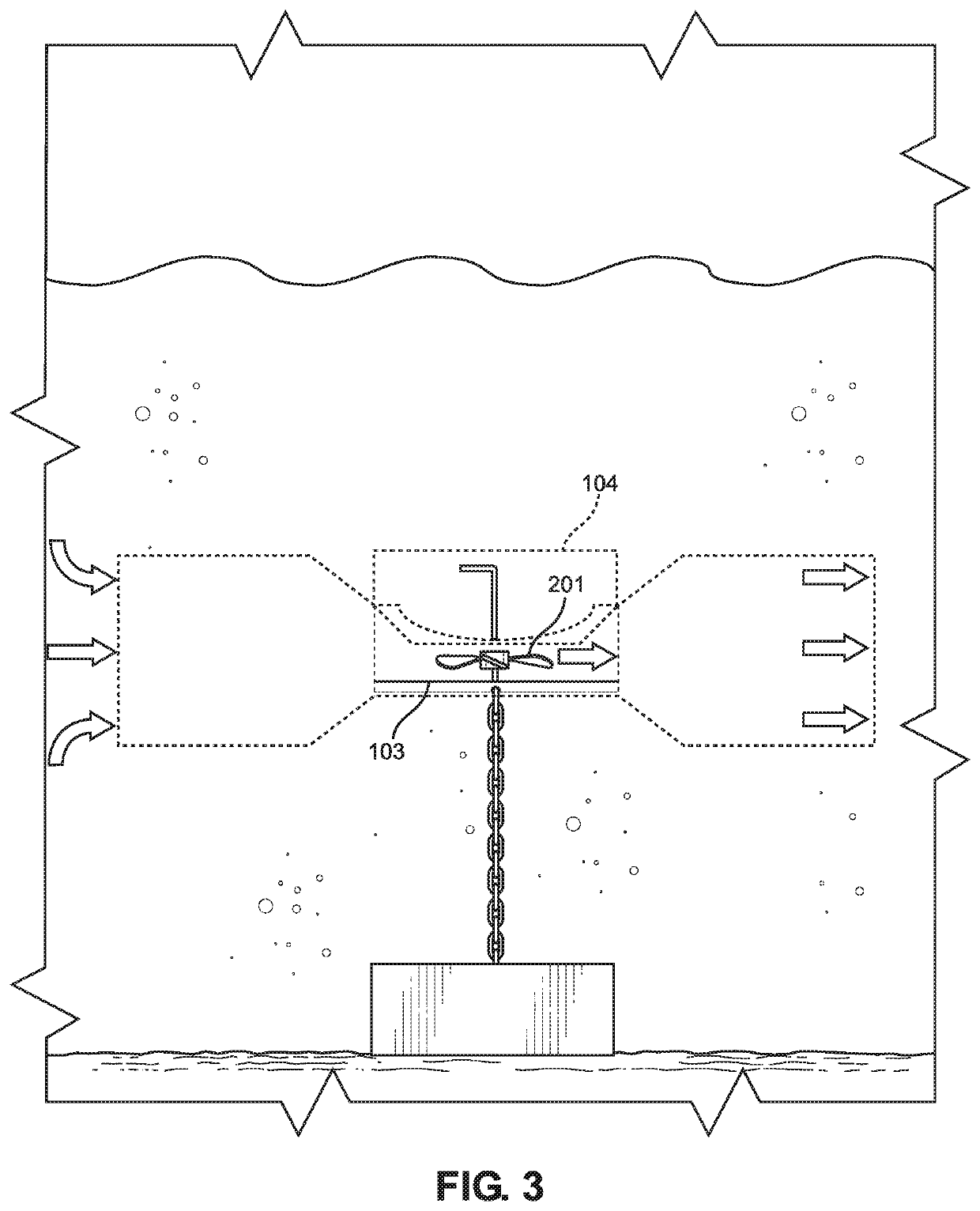

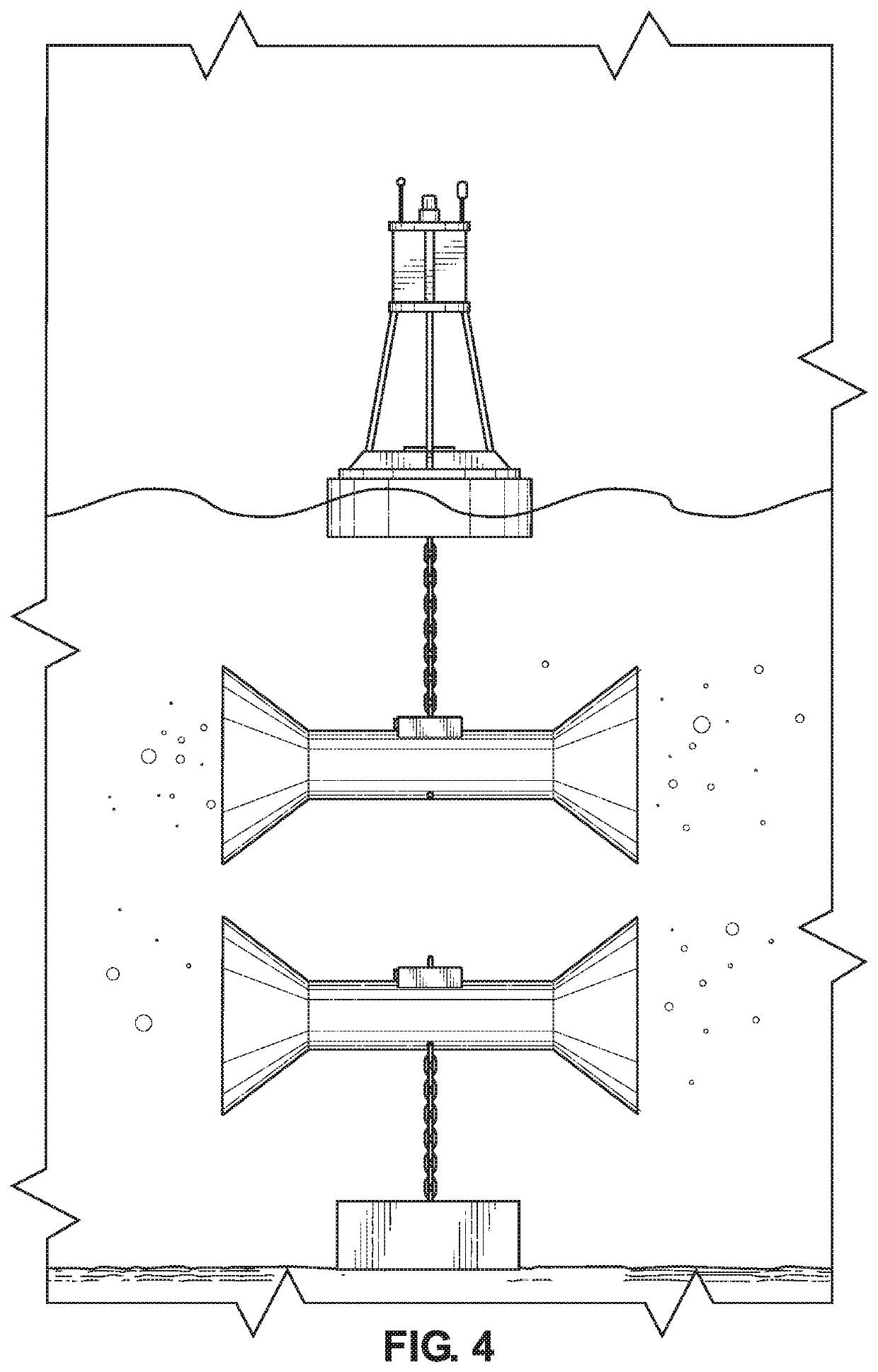

Gulf Current Electric Generator

InactiveUS20210095635A1Provide convenienceHydro energy generationMachines/enginesPower stationCurrent electric

Owner:DERAN BARRY

Water surface floating oil recovery ship

Owner:GUANGXI OUXUN TECH SERVICE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap