Chemical mechanical stirrer based on paddle wing barbs for organic silica gel

A technology of organic silica gel and chemical machinery, which is applied in the field of chemical mixing, which can solve the problems of sudden stop and paralysis, wear and tear of the mixer, and reduce the efficiency, quality and time period of the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

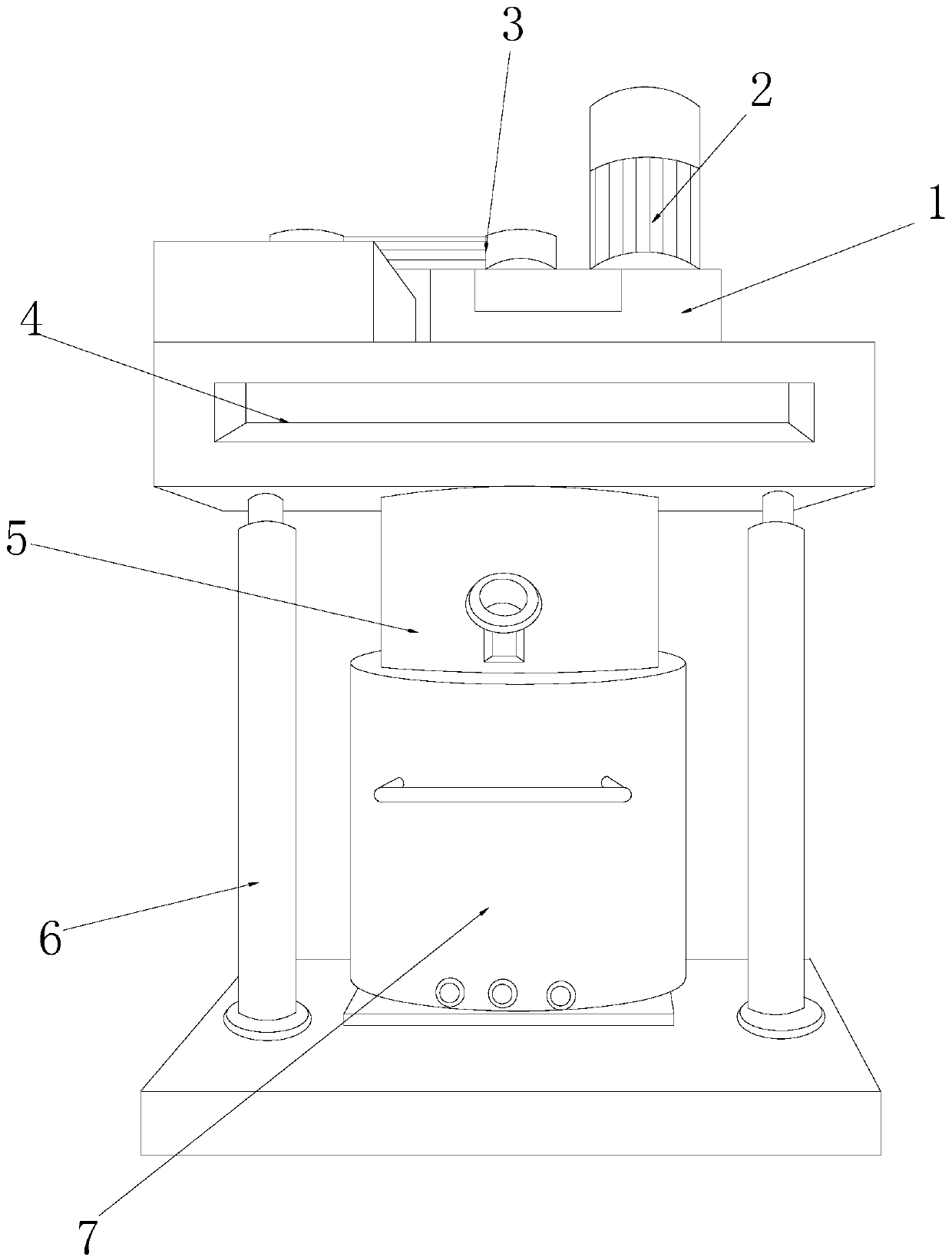

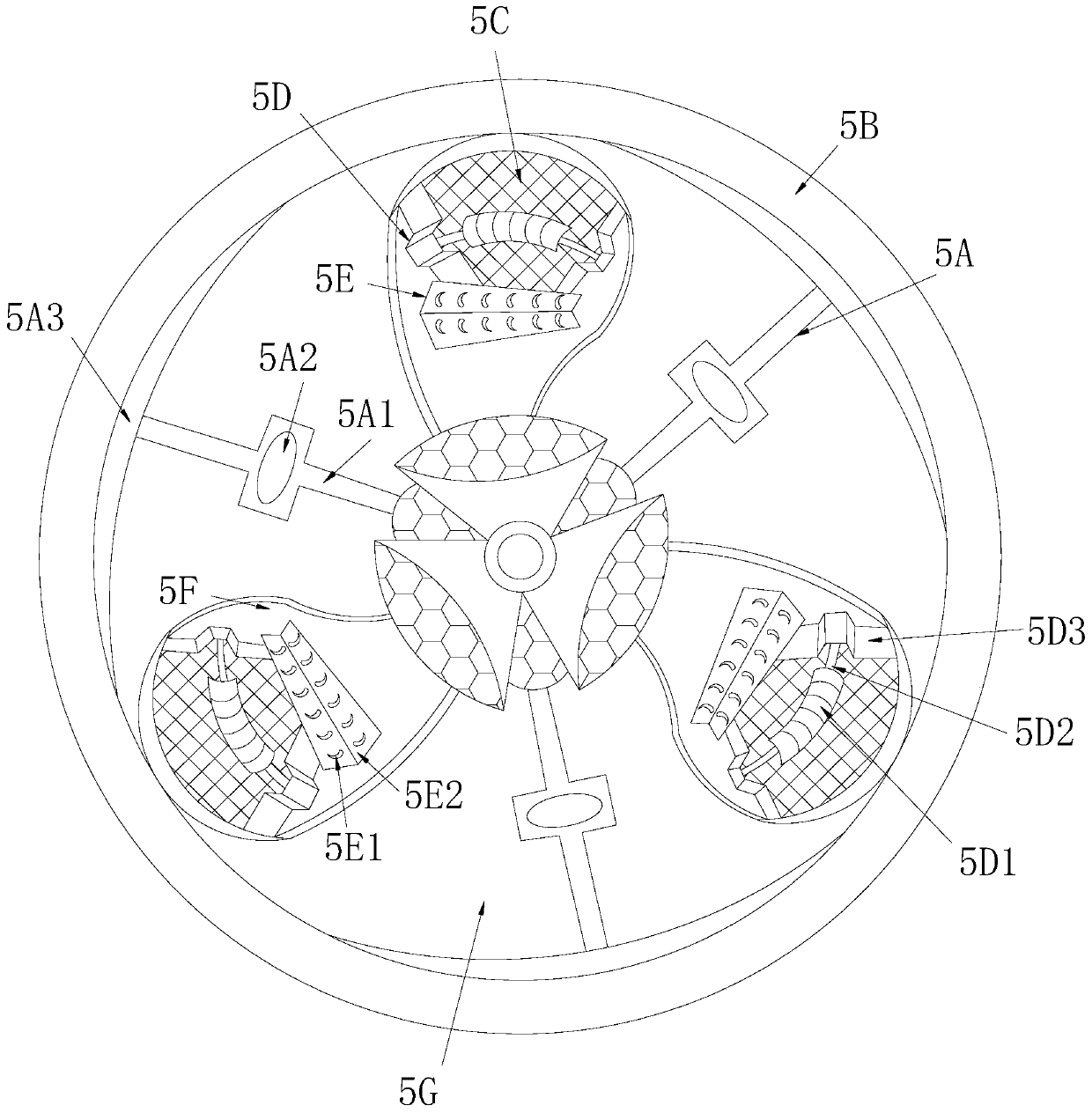

[0032] see Figure 1-Figure 6, the present invention provides a chemical machinery mixer based on paddle barbs for organic silica gel, its structure includes: gear box 1, shaft motor 2, transmission wheel belt 3, cover counterweight 4, propeller stirring tank tank 5. The hydraulic cylinder rod 6, the loading tank groove 7, the propeller stirring tank tank 5 is nested on the top of the loading tank tank 7 and communicates with each other, the shaft motor 2 is connected to the transmission wheel belt through the gear box 1 3 Mechanically connected, the gearbox 1 is installed on the top of the cover counterweight 4 and is on the same level, the cover counterweight 4 is nested on the top of the propeller stirring tank tank 5 and the axes are in common line, the cover counterweight 4 is mechanically connected with the hydraulic cylinder rod 6 and is perpendicular to each other. Stirring tank tank 5 is equipped with machete strut frame 5A, tank wall frame ring 5B, blade lining net 5C,

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of chemical machinery mixer based on the blade barb that organic silica gel is used, other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 , the scimitar brace frame 5A is composed of rib buckle rod 5A1, ellipsoid rotor 5A2, and willow leaf machete 5A3. The willow leaf scimitar 5A3 and the rib buckle 5A1 are nested into one body, and the willow leaf scimitar 5A3 is rotated through the rib buckle 5A1 to form the circular cutting and granulation effect of the silicone thread, ensuring the effect of silicone reshaping and uniform granulation .

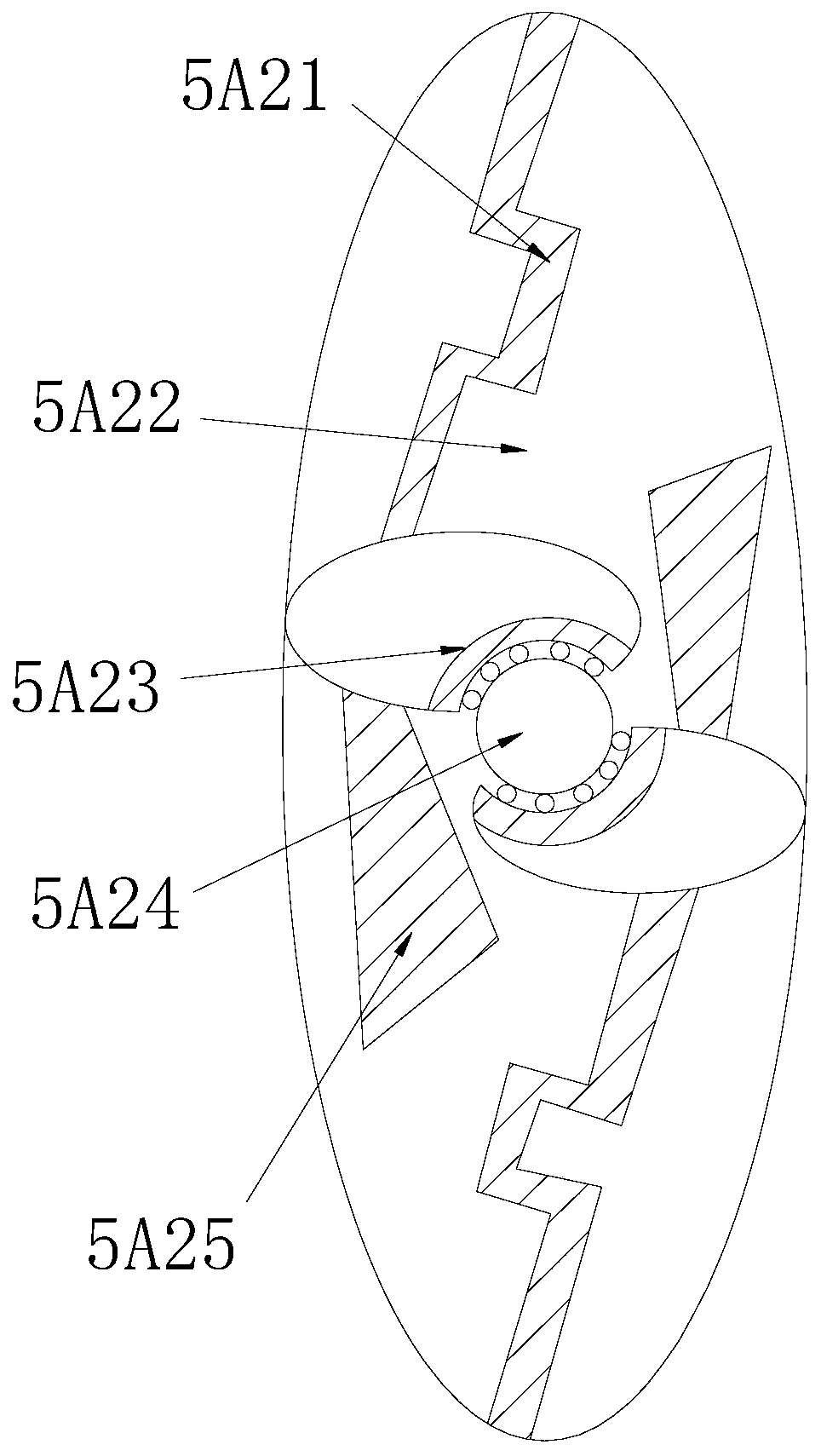

[0041] see image 3 The ellipsoidal rotor 5A2 is composed of a bow-shaped bead 5A21, an ellipsoidal shell groove 5A22, a ball petal 5A23, a rotor ball 5A24, and a fin plate 5A25. The two bead 5A21 are respectively inserted into On the upper and lower sides of the elliptical shell groove 5A22, the ball petals 5A23 and the rotor balls

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap