Multifunctional integrated machine

An all-in-one, multi-function technology, applied in the fields of mining and metallurgical processing machinery, food, pharmaceuticals, chemicals, agricultural and sideline products, can solve the problems of changing the essential properties of materials, low degree of mechanization, and simple production tools, and achieve reasonable structure and practicality. Strong, easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

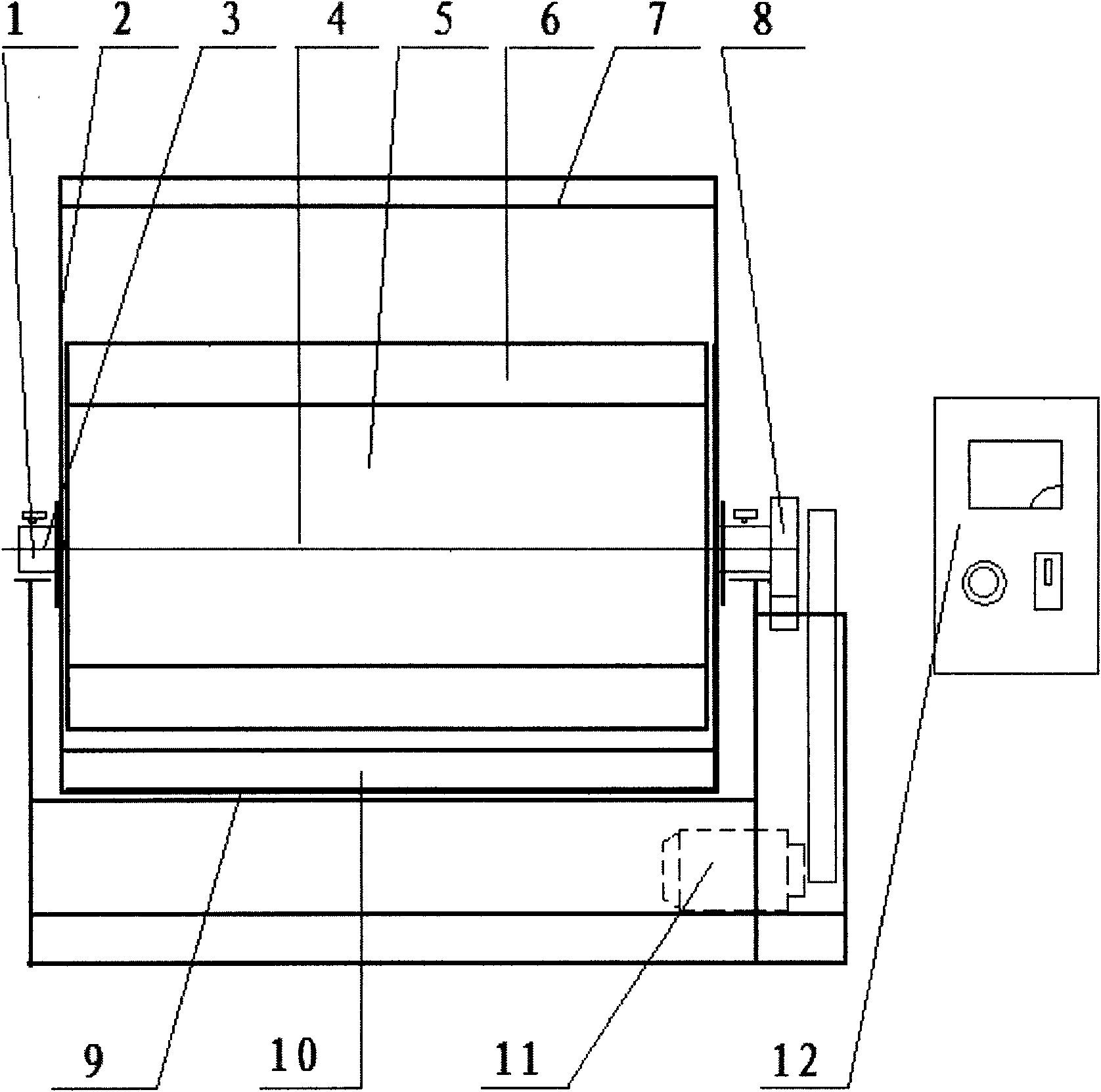

[0014] The working process of the present invention is as follows:

[0015] 1. Replace the accessories of the control valve (10) according to the purpose, and close the discharge port (9).

[0016] 2. Adjust the electric control (12), so that the rotating speed of the motor is adjusted to the minimum degree, and start the machine.

[0017] 3. Open the material inlet (7) and pour in the materials slowly, then close the material inlet (7).

[0018] 4. According to the performance and processing requirements of the material, adjust the electric control (12) to reach the required operating speed of the working device, and complete the operation.

[0019] 5. Open the discharge port (9) to discharge the material, and shut down the machine.

[0020] 6. After that, you can repeat the operation and continue to work.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap