Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about "Edge grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

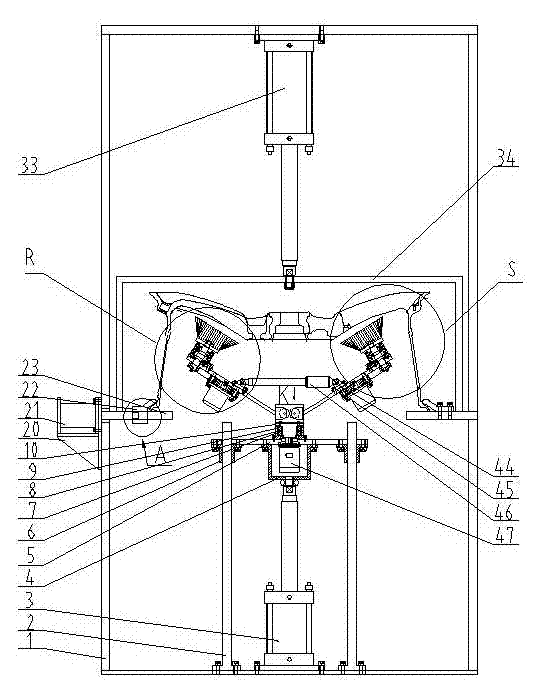

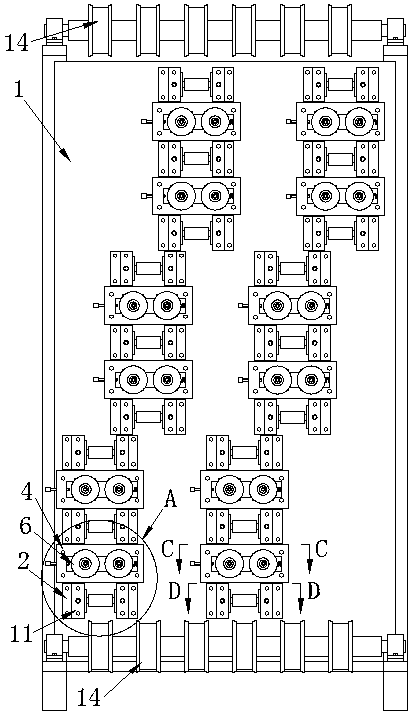

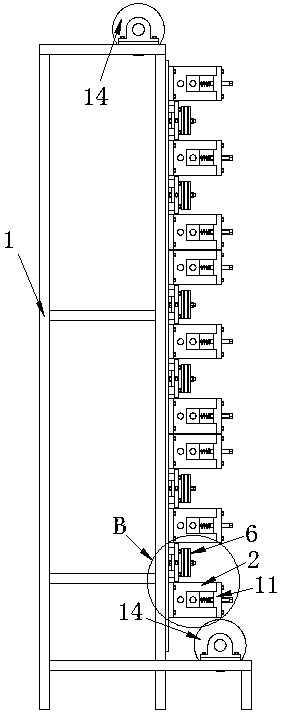

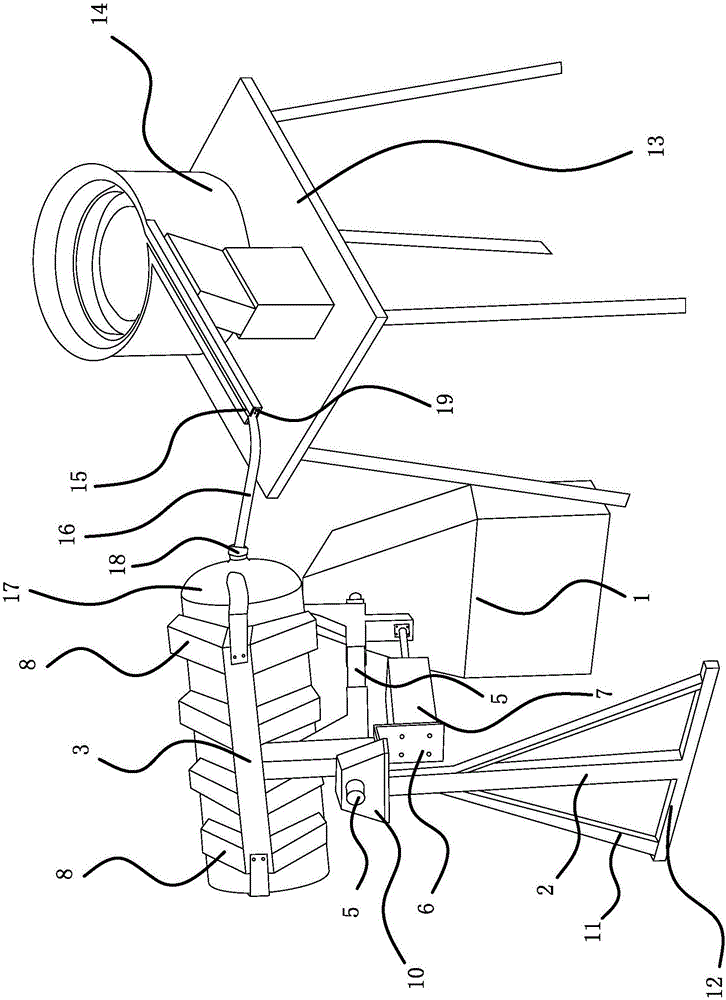

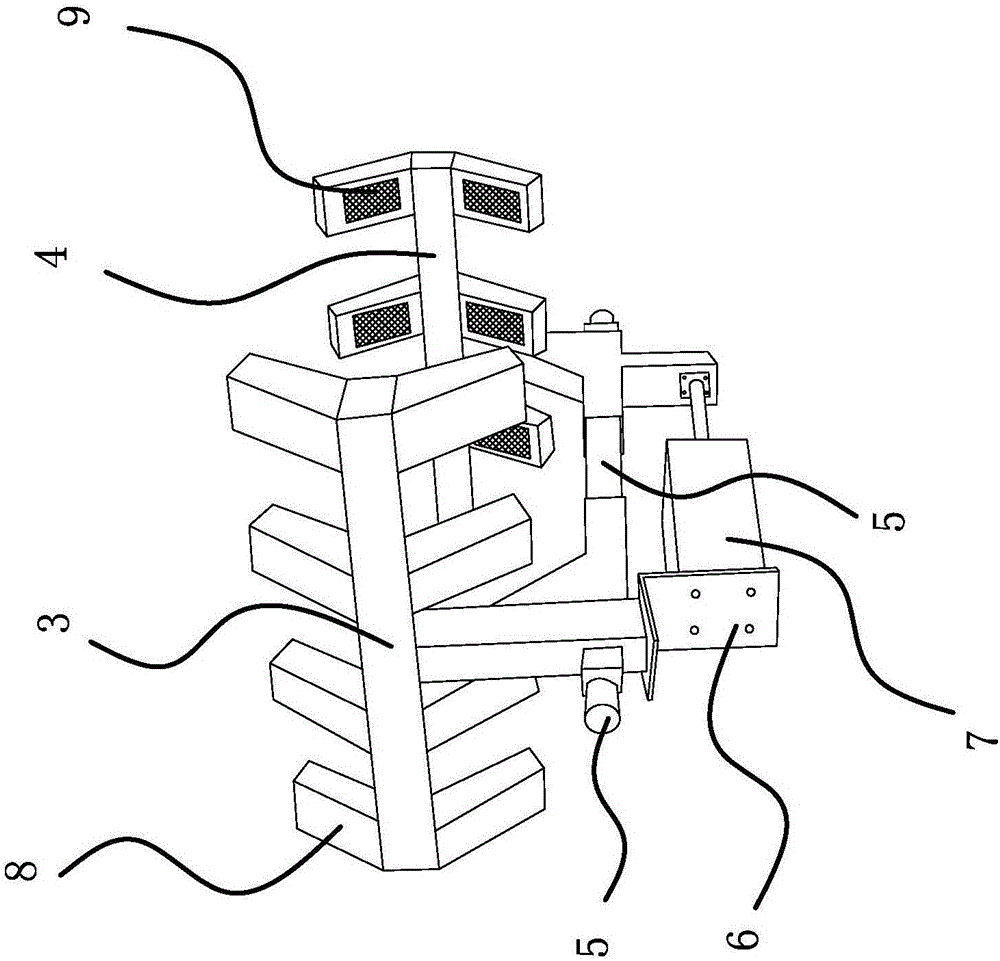

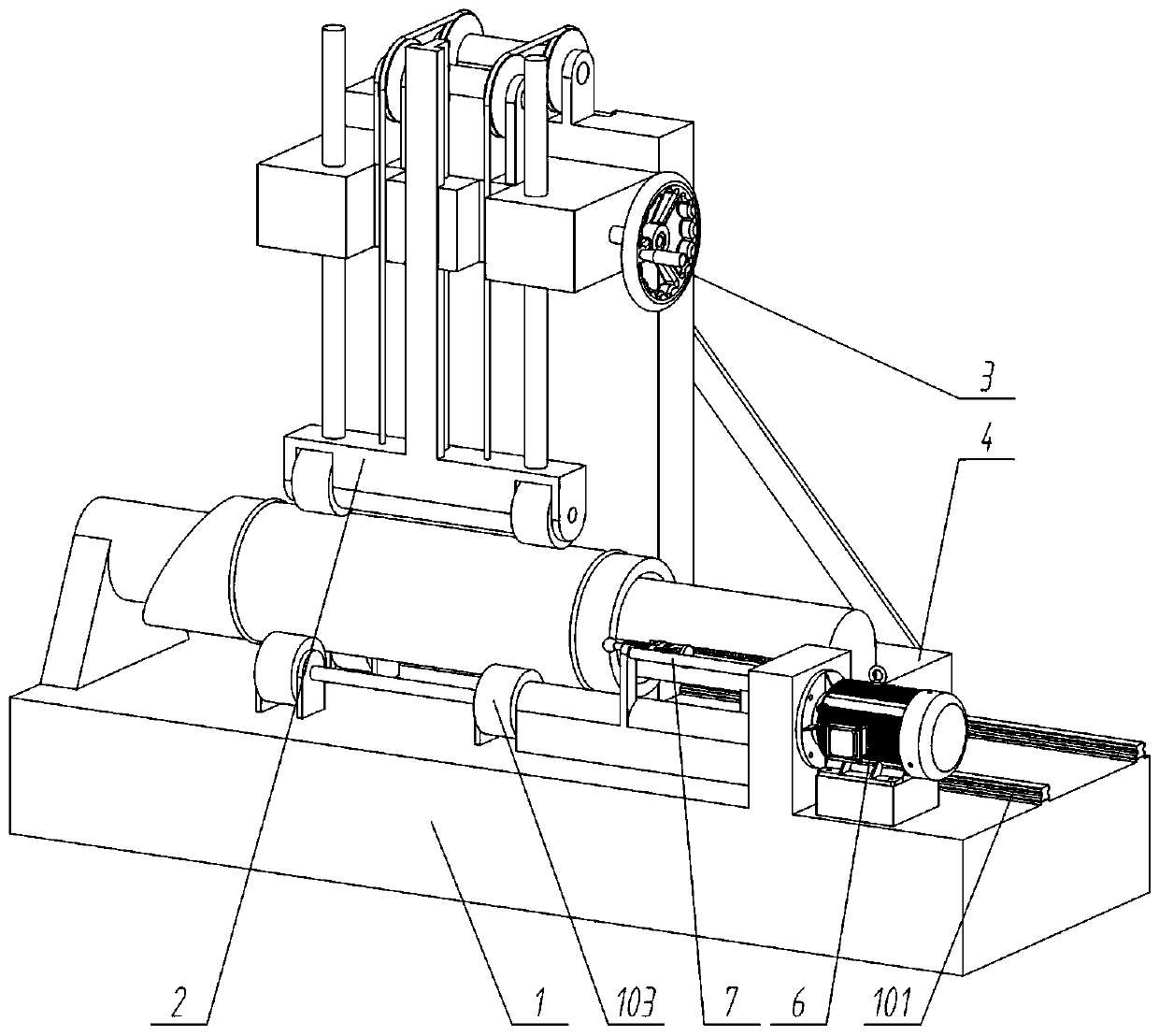

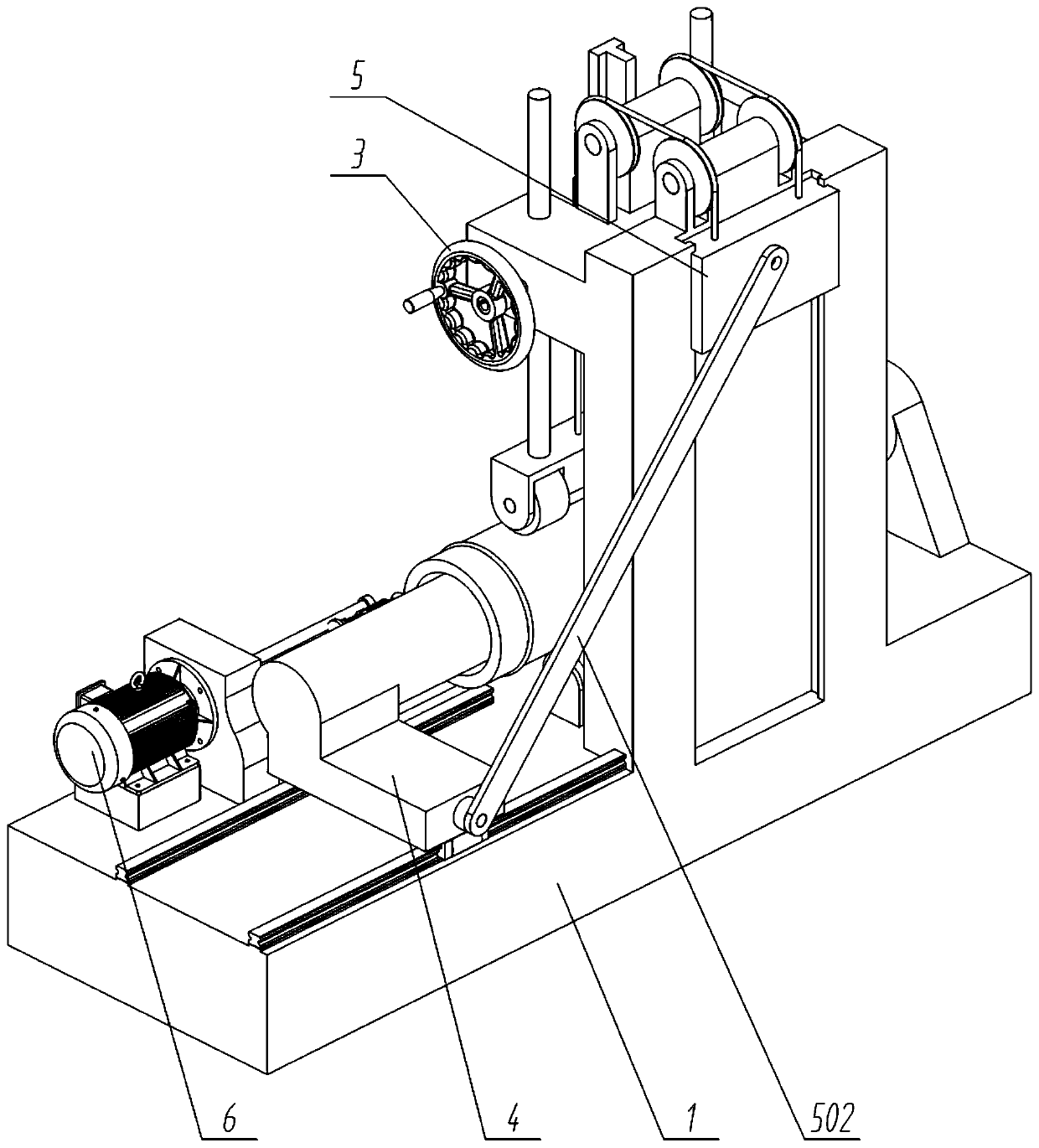

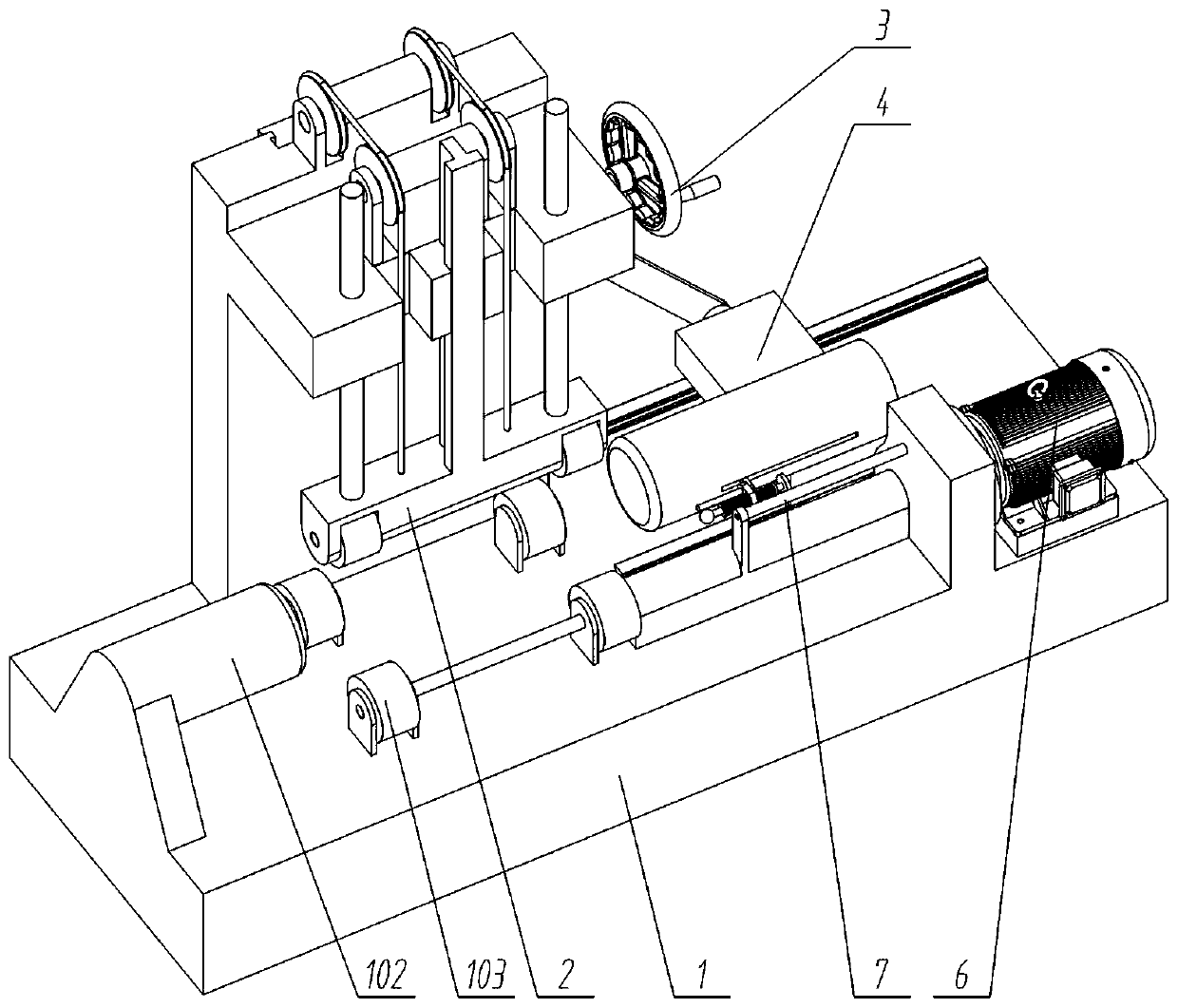

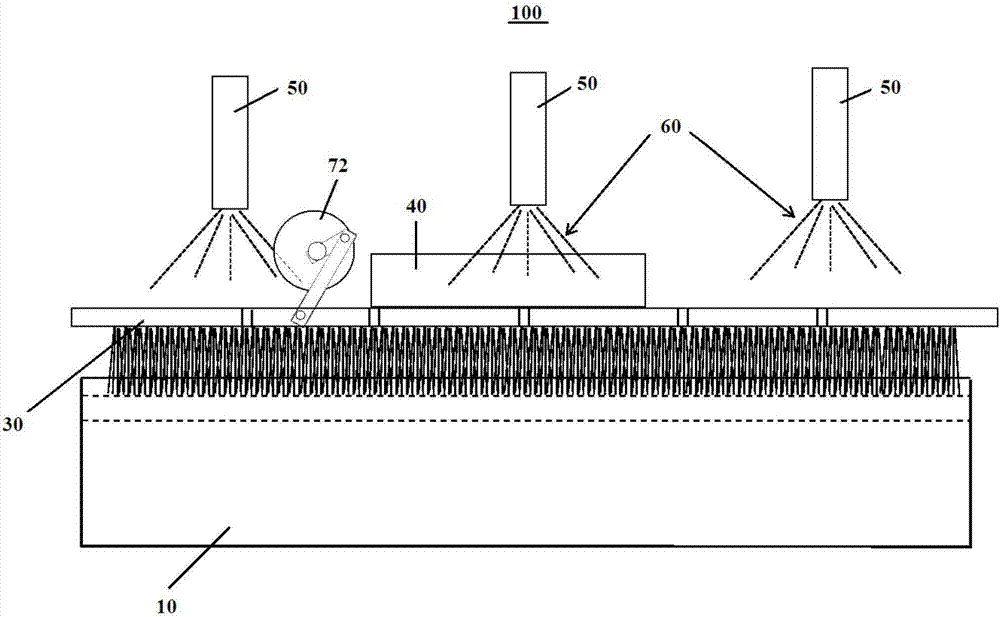

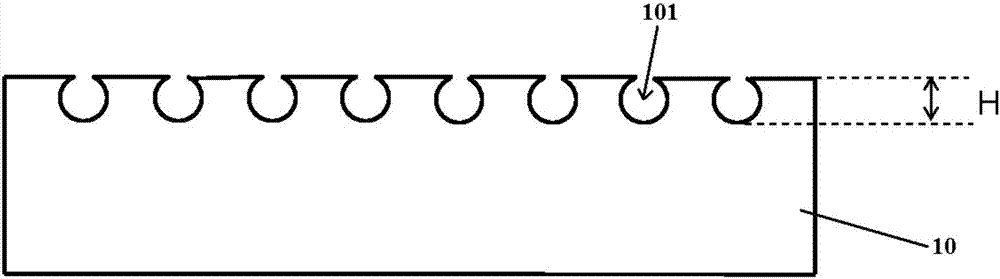

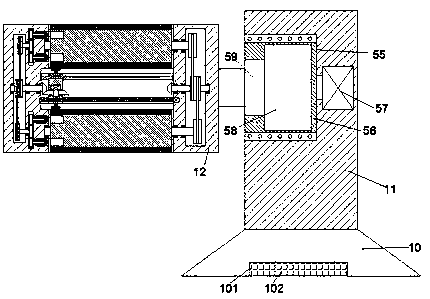

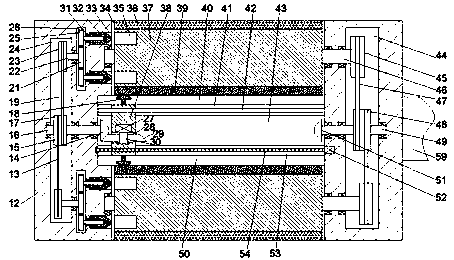

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

InactiveCN108857605ARealize finishingAchieve extrusionEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

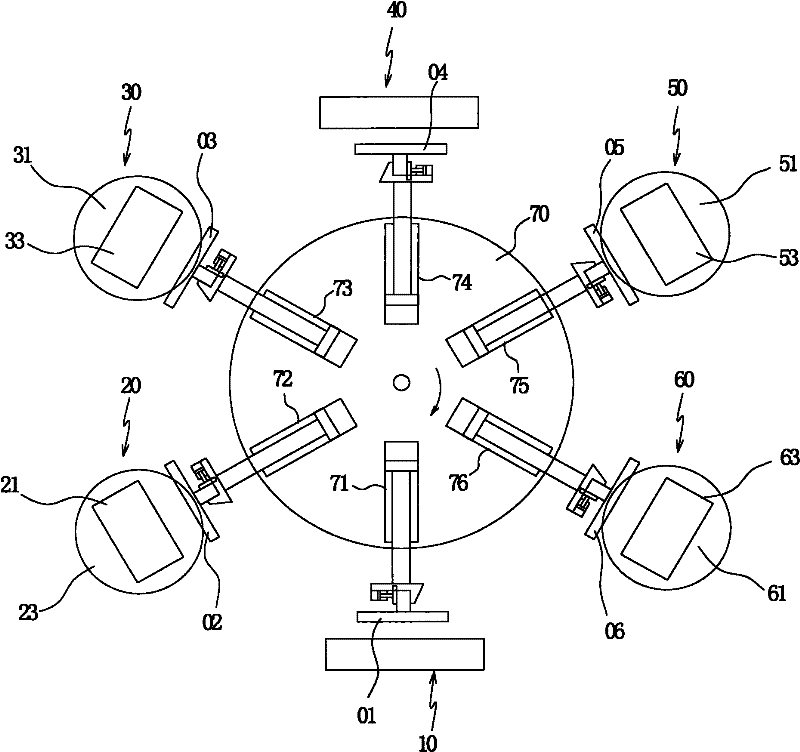

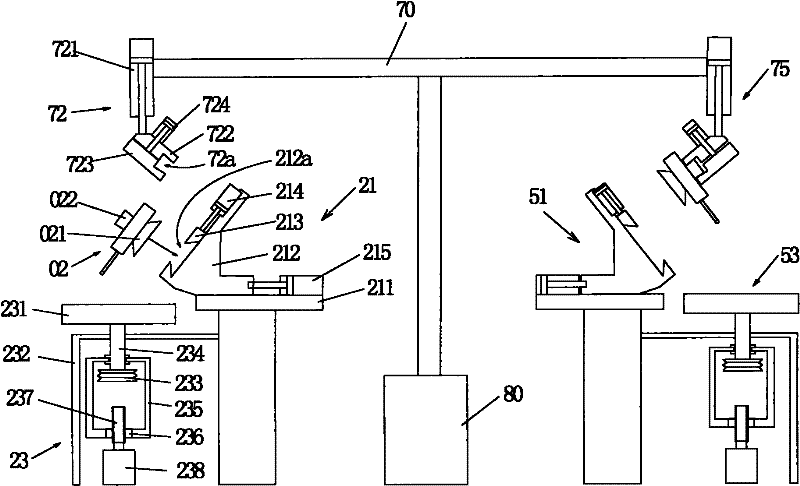

Rhinestone grinding and polishing machine

InactiveCN102294634AEdge grinding machinesProgramme-controlled manipulatorDiamond grindingMature technology

Owner:林泽

Deburring machine tool

The invention discloses a deburring machine tool which relates to an excricle deburring machine tool of shaft parts, in particular to a machine tool used for deburring a straight flute, a transverse groove, a chute of an excircle of a pillar plunger core inside a plunger and barrel assembly. The deburring machine tool comprises a machine body, a fixture drive motor seat, a first micro motor, a fixture driving pulley, a first synchronous belt, a fixture driven pulley, a first flat key, a draw bar, a first compression spring, a supporting block, a clamping head top block, an elastic clamping head, an elastic clamping head seat, a first plane bearing, a space ring, a first deep groove ball bearing, a lower end cover, a rotary disk, a bush, a combination cap, a second micro motor, a horizontal motor support, a first disk type steel brush, a main shaft, a second flat key, a main shaft belt pulley, a second synchronous belt, a bearing seat, a second deep groove ball bearing, a bush, a space ring, a second plane bearing, a third plane bearing, a nut, a main motor support, a third micro motor, a coupler, a reduction box, a second flat key, a driving pulley, an inclined motor seat, a fourth micro motor, a second disk type steel brush, a vertical motor seat, a ninth outer hexagon bolt, a fifth micro motor and a third disk type steel brush.

Owner:JIANGSU REP MASCH TOOLS CO LTD

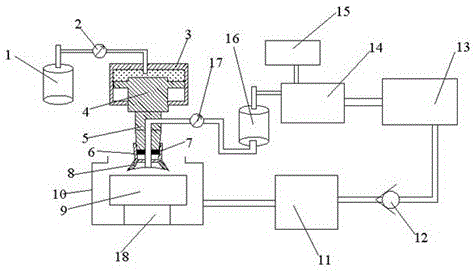

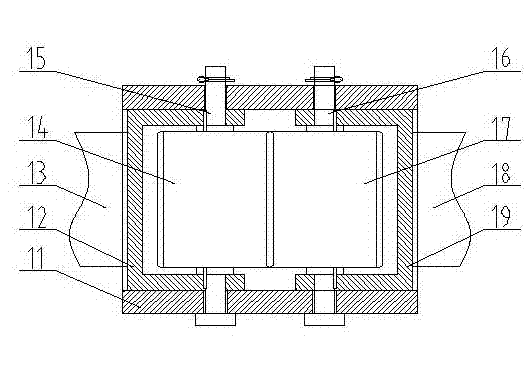

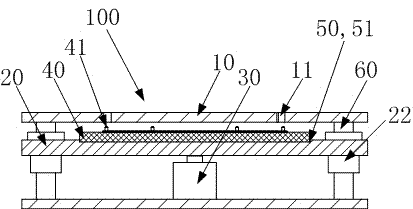

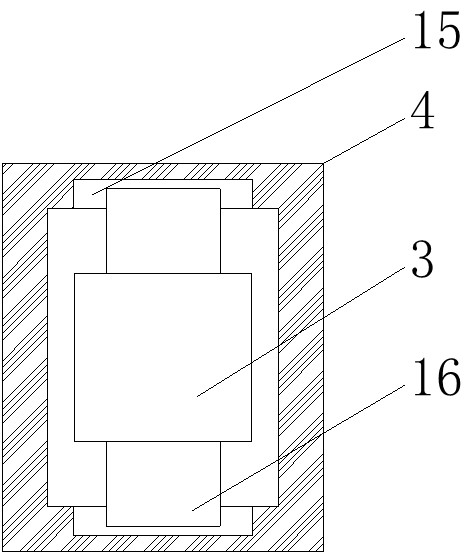

Abrasive particle flow ultra-precision machining device

InactiveCN105058245AImprove machining accuracyGuaranteed accuracyEdge grinding machinesPolishing machinesPneumatic cylinderParticle flow

The invention provides an abrasive particle flow ultra-precision machining device. Injection pressure and speed of abrasive particle flows are adjusted by adjusting threads between a pressure head and an abrasive particle flow injection polishing nozzle, and pressure is provided for a sealed box through a pneumatic cylinder, so that pressure is applied to the pressure head through a pressure plug. According to the abrasive particle flow ultra-precision machining device, the pneumatic cylinder for replacing a spring applies pressure to the pressure head so that accuracy of pressure of the abrasive particle flow injection polishing nozzle to a work-piece can be effectively improved, the abrasive particle flow machining accuracy is improved, and ultra-precision machining is achieved; meanwhile, concentration of abrasive particles in the abrasive particle flows is monitored and controlled in real time, so that machining accuracy and efficiency are guaranteed; Injection pressure and speed of the abrasive particle flows are adjusted by adjusting the threads between the pressure head and the abrasive particle flow injection polishing nozzle, and a pressure-maintaining flow stopping part is arranged at the tail end of the abrasive particle flow injection polishing nozzle so that the machining efficiency can be effectively improved. By means of the abrasive particle flow ultra-precision machining device, both machining efficiency and ultra-precision machining accuracy can be guaranteed.

Owner:CHANGCHUN UNIV OF SCI & TECH

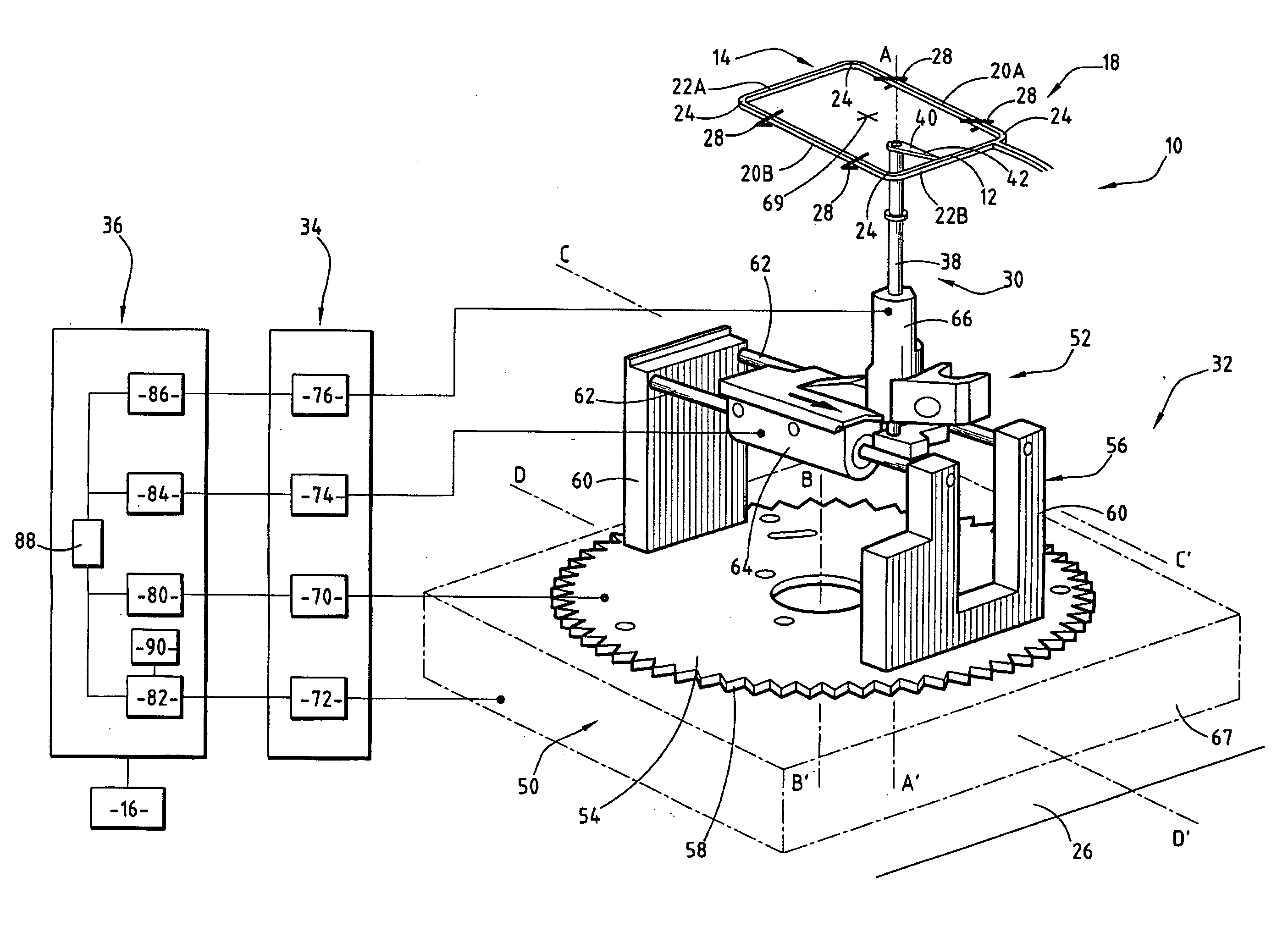

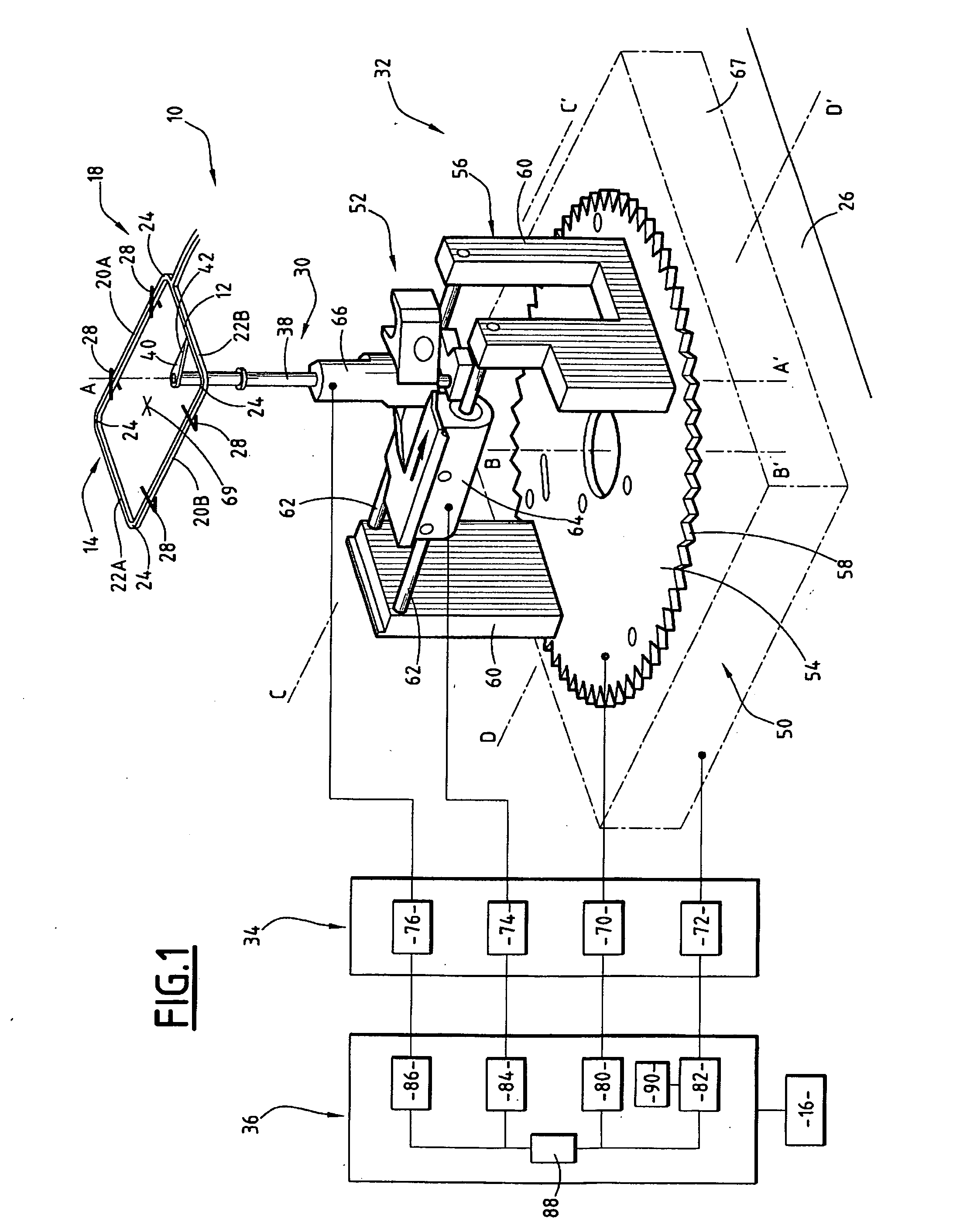

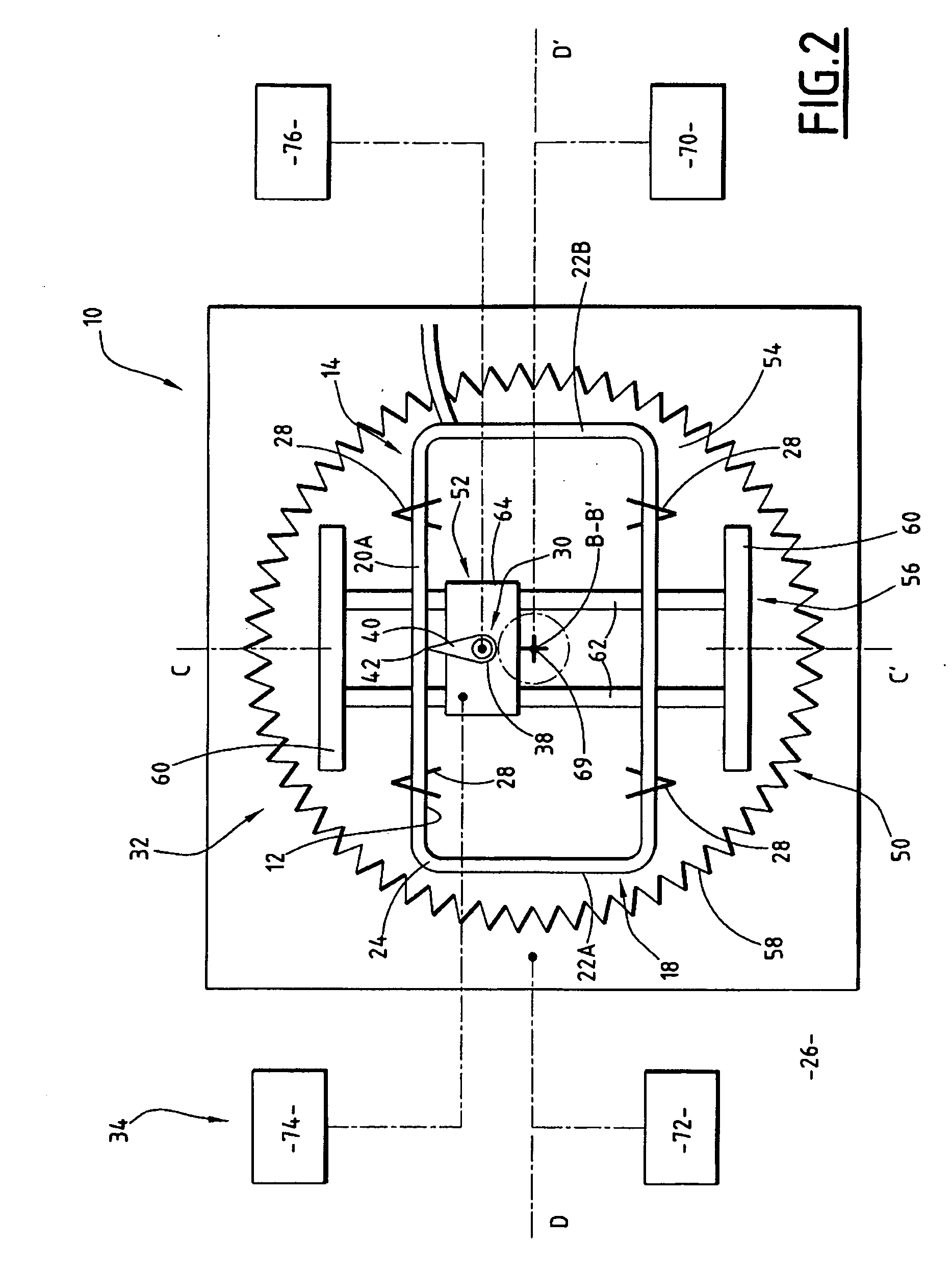

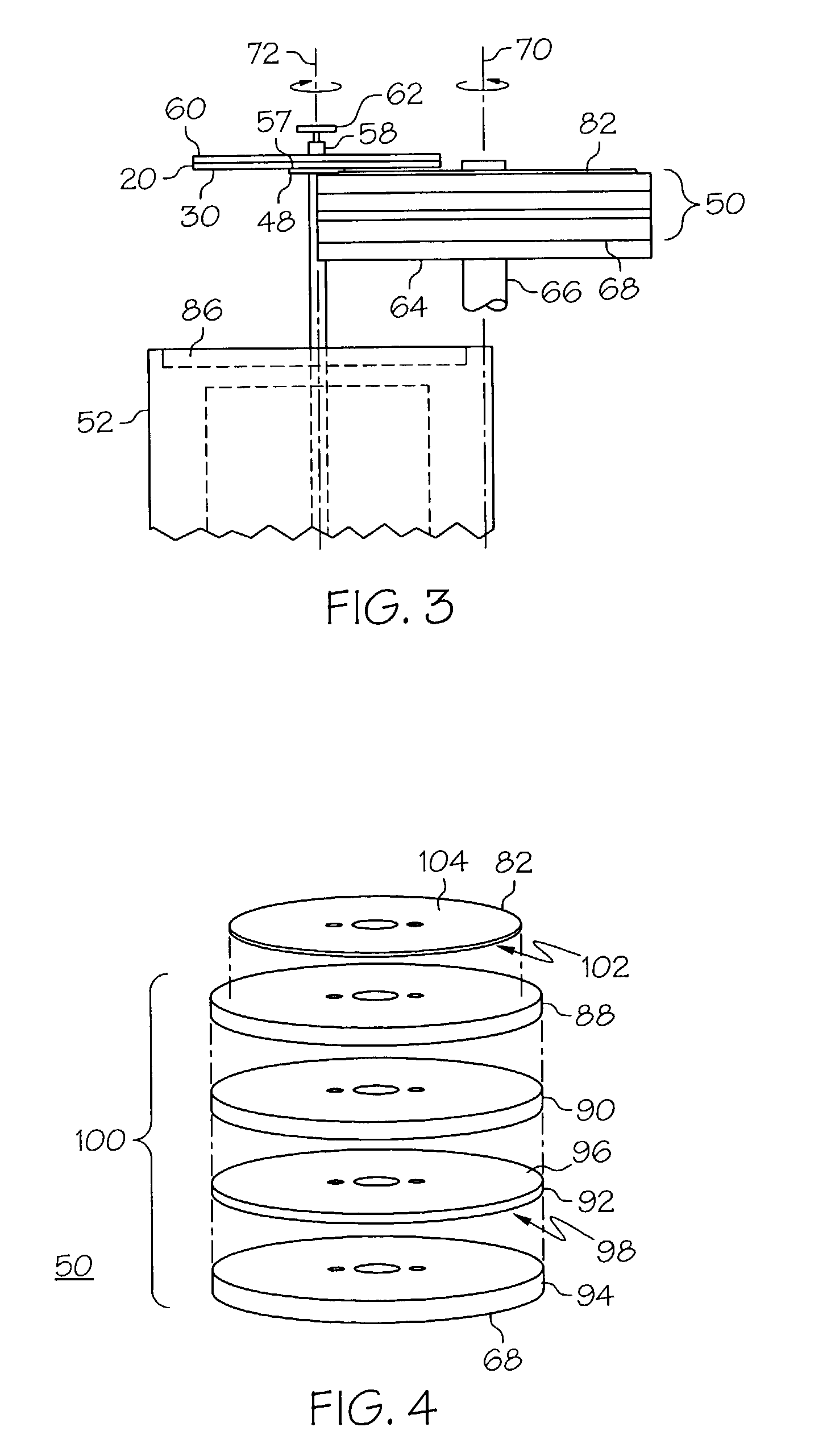

Apparatus for sensing a mount for optical lenses and associated method

ActiveUS20090172960A1Edge grinding machinesMechanical counters/curvatures measurementsEngineeringTurret

Owner:LUNEAU TECH OPERATIONS

Wheel swing deburring device

Owner:CITIC DICASTAL

Prismatic member polishing device

Owner:SINTOKOGIO LTD

Glass edge grinding machine

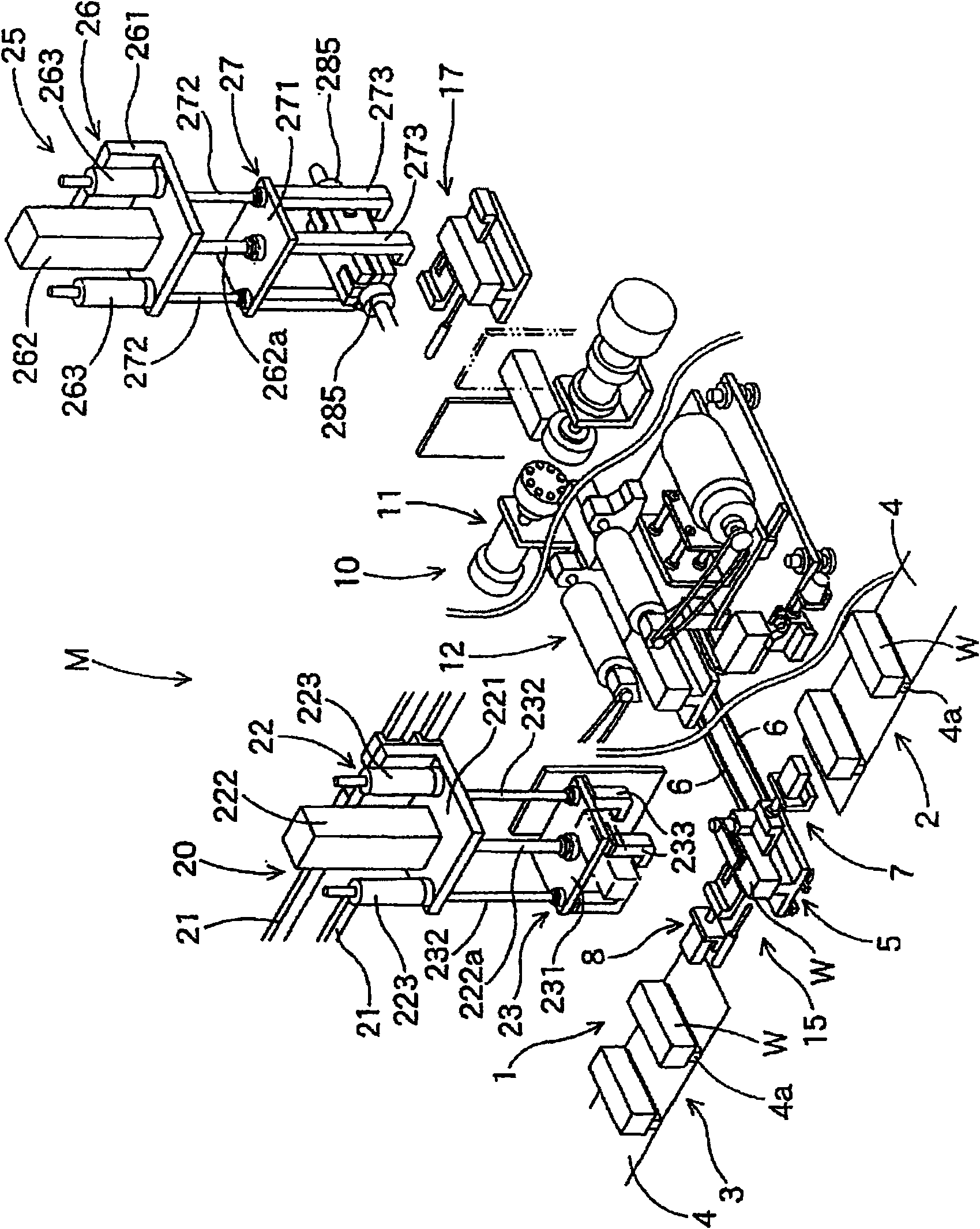

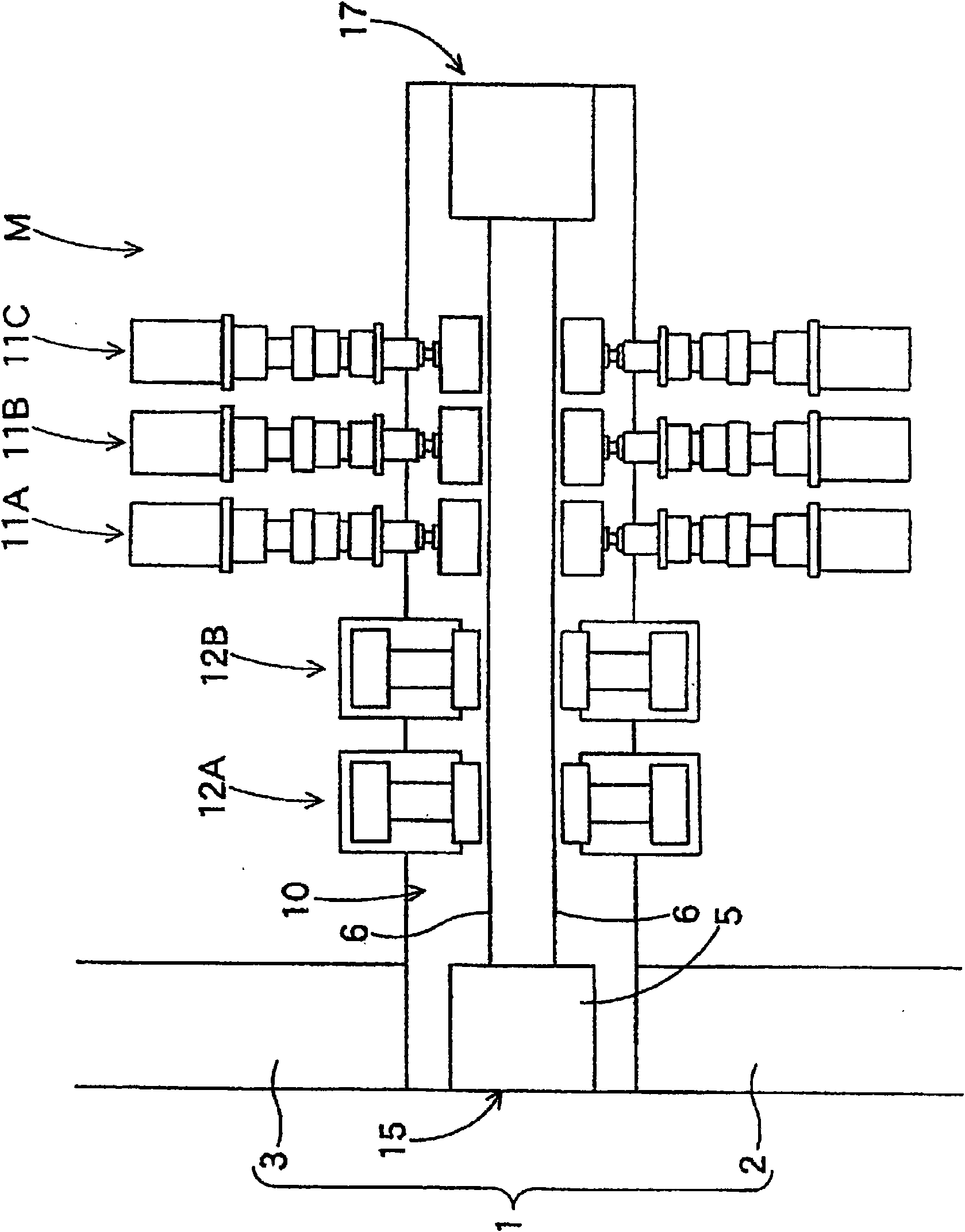

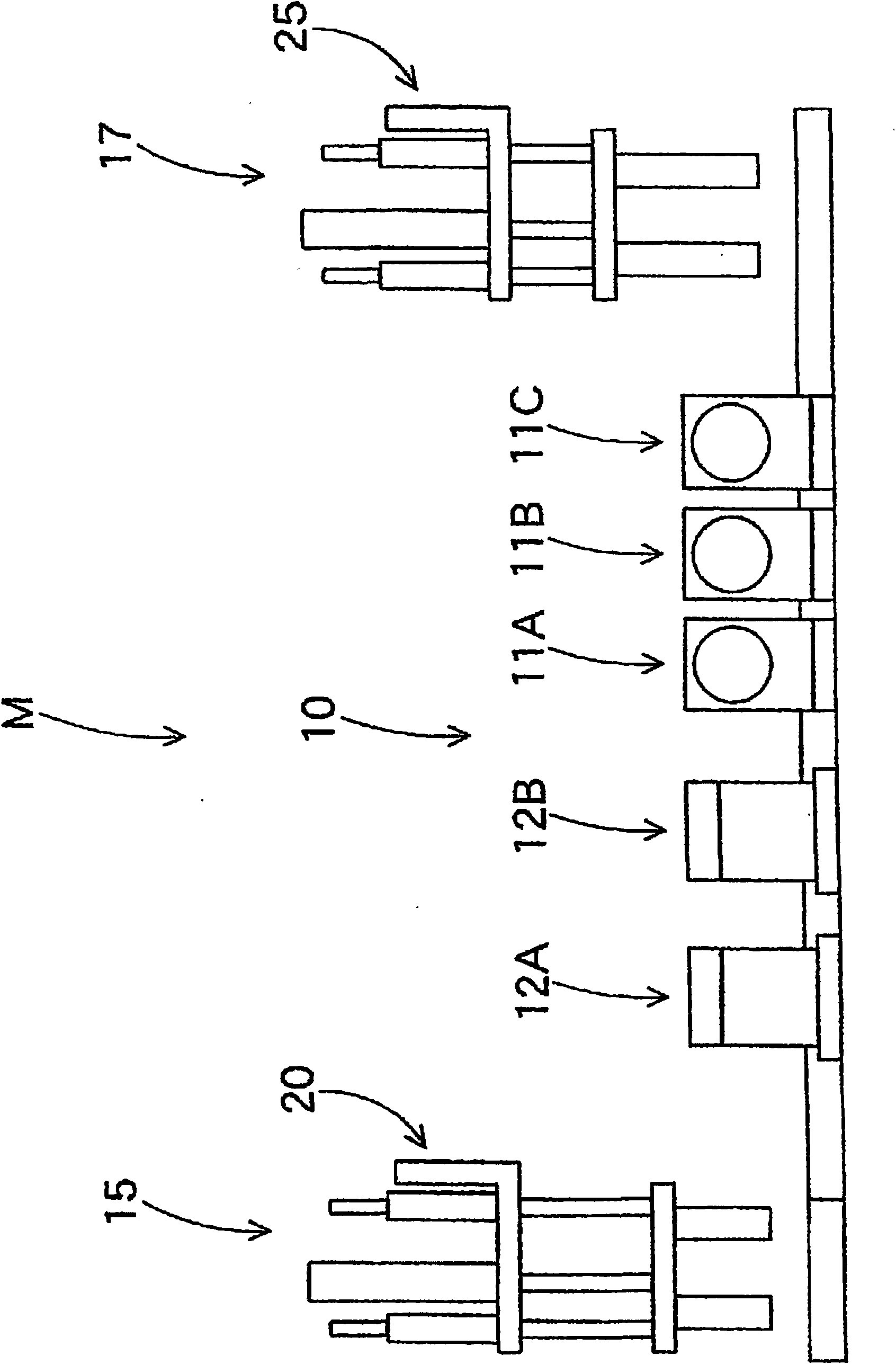

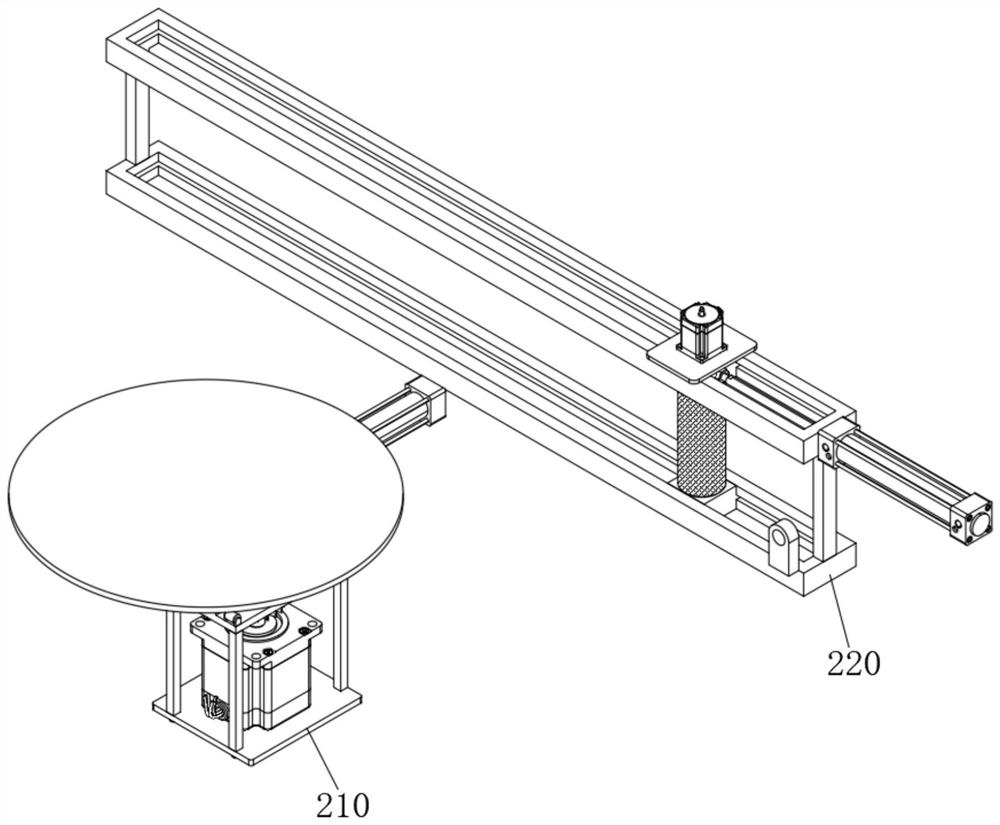

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesMotor driveFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:HANGZHOU TUOCHUAN MASCH CO LTD

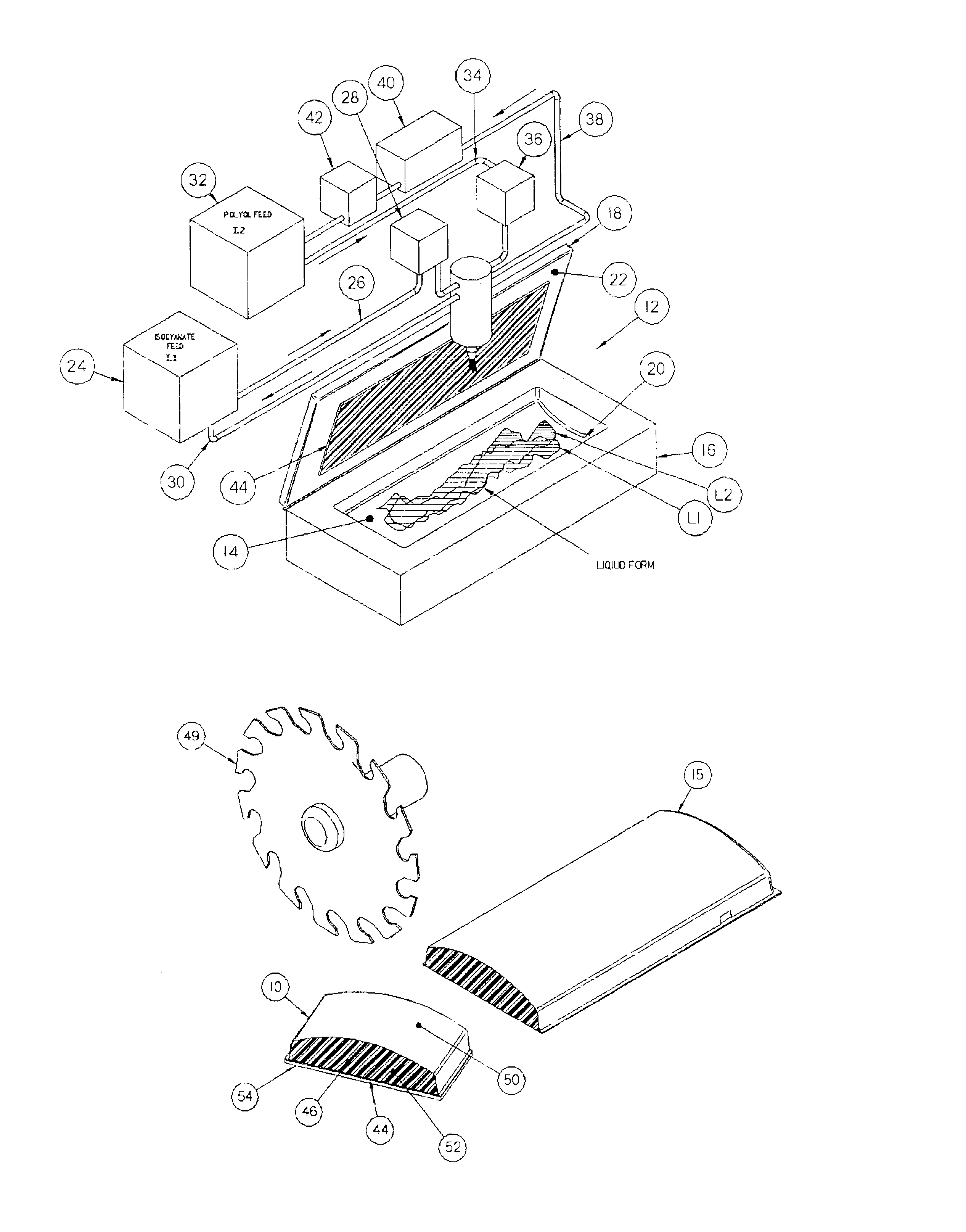

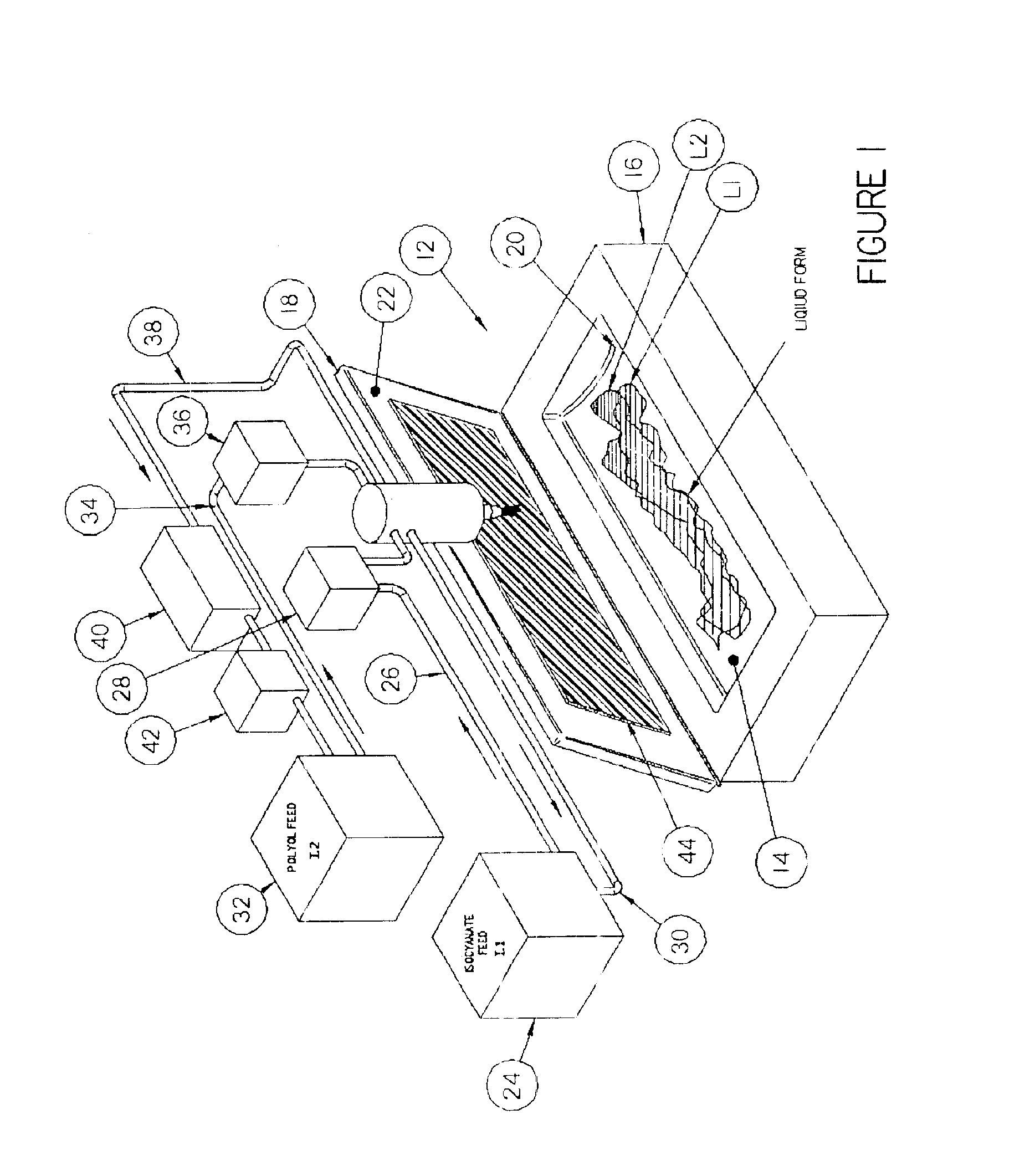

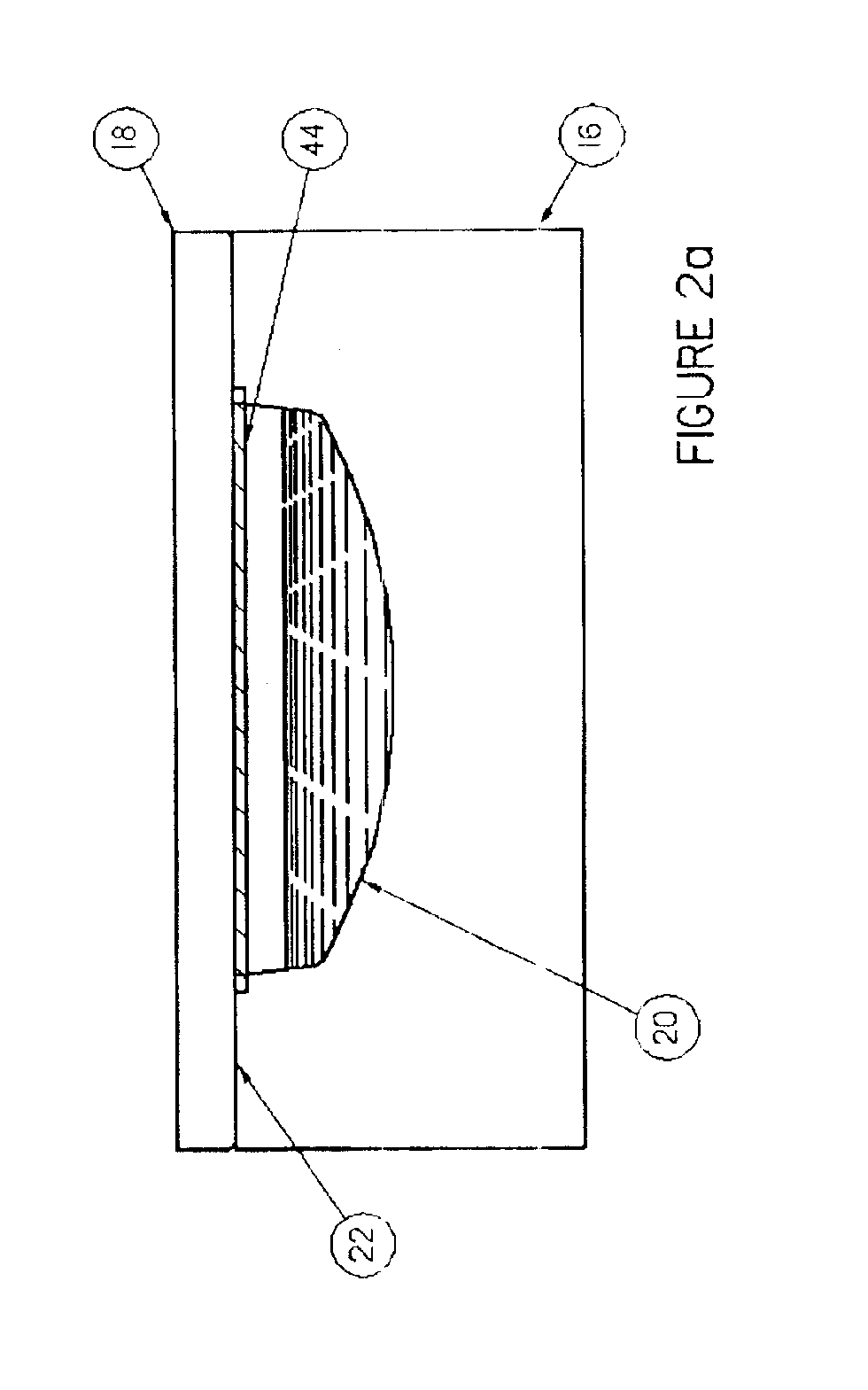

Implement for abrading and method of making same

InactiveUS6852021B1Improve usabilityMaintain validityEdge grinding machinesAbrasion apparatusMaterials science

Owner:ALI IND LLC

Device for removing trimming burrs of cold-rolled steel strip

InactiveCN103447914AHigh surface flatnessSimple structureEdge grinding machinesLeveling mechanismEngineering

Owner:JIANGSU JU HONG BUNDLE BRING MFG

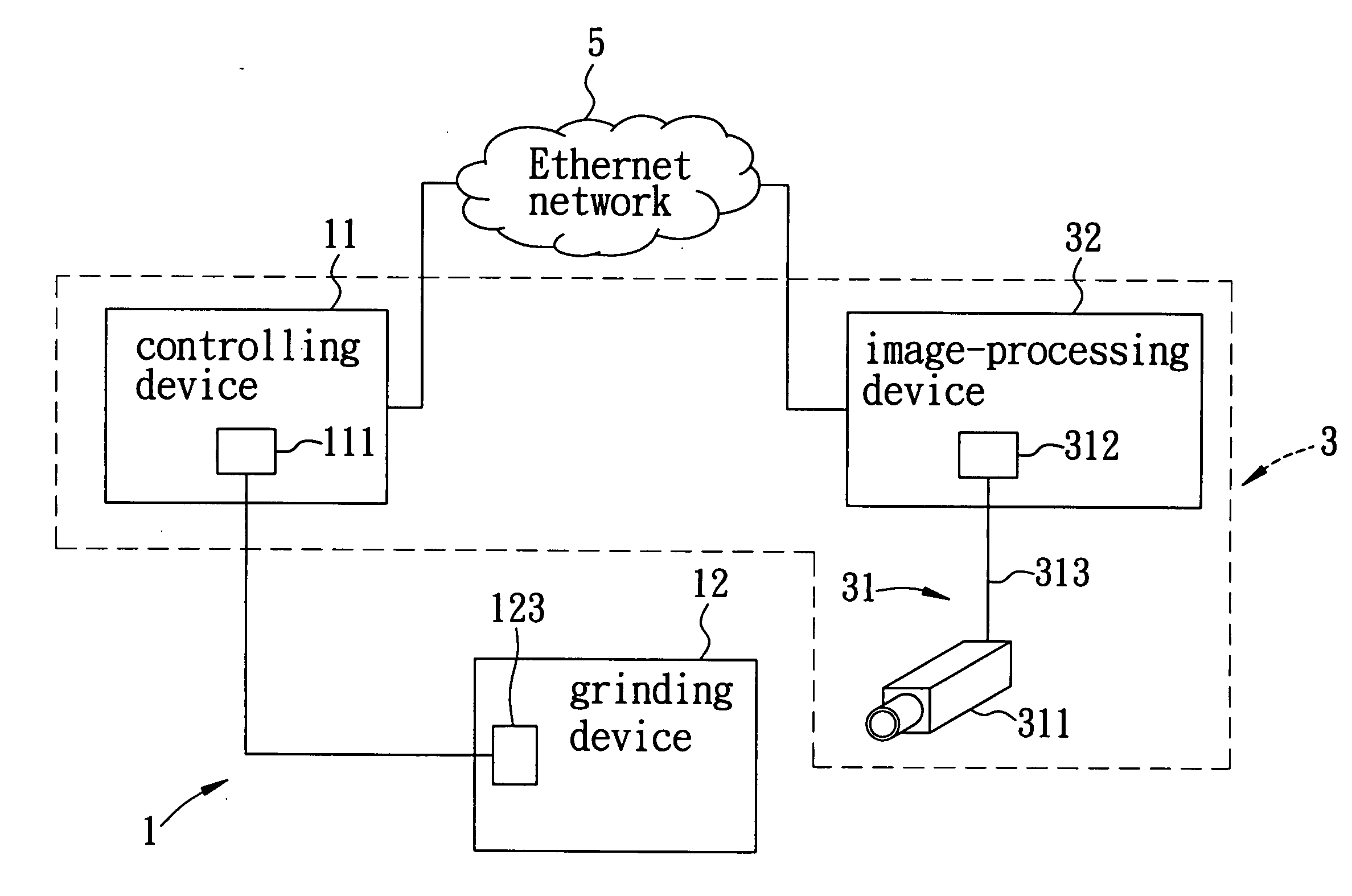

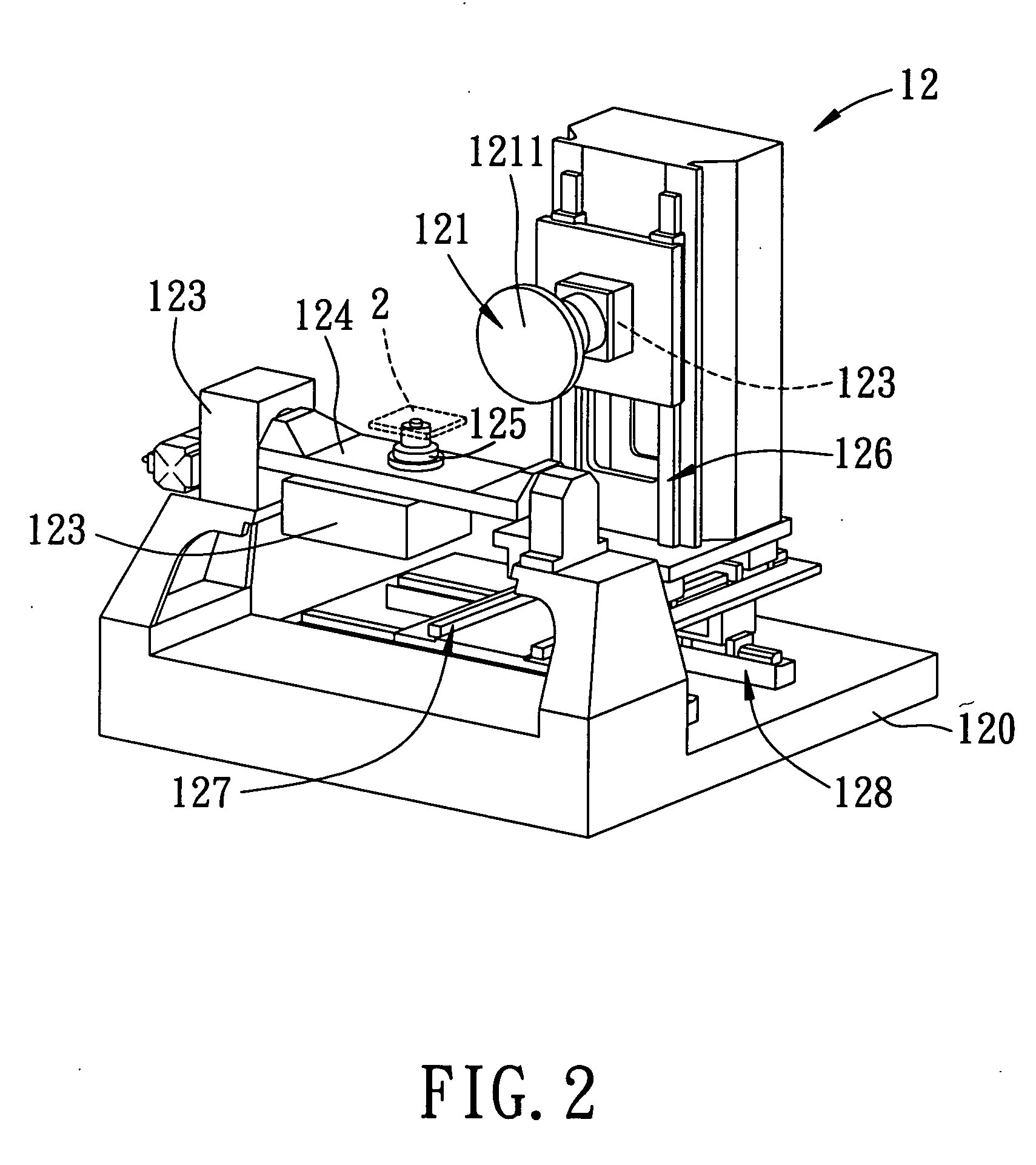

Grinding method and system with non-contact real-time detection of workpiece thickness

InactiveUS20080132149A1Edge grinding machinesCharacter and pattern recognitionImage captureImaging processing

Owner:FENG CHIA UNIVERSITY

Grinder with automatic feeding device

Owner:ZHEJIANG DAUGHTER VESSEL SCI & TECH CO LTD

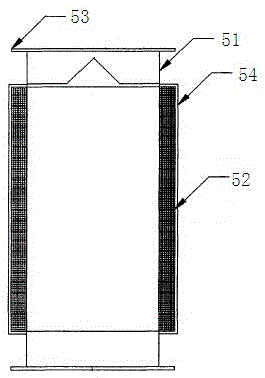

Adjustable swing angle grinding machine assembly

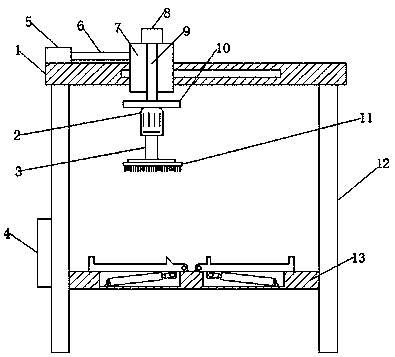

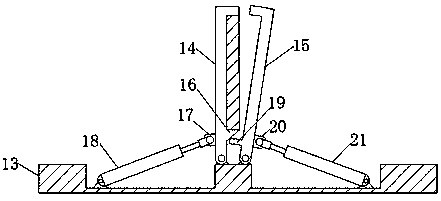

InactiveCN107139036AEasy to adjustSimple structureEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The present invention provides an adjustable swing angle grinding machine assembly, which includes a base, two cylinder supports are fixed on the left side of the upper end of the base, and two grinding supports are fixed on the right side of the upper end of the base. The adjustable swing angle grinding machine assembly has simple structure, convenient operation and good equipment stability; the adjustable swing angle grinder assembly has good grinding effect and high grinding efficiency, which greatly improves production efficiency and reduces The rate of defective products is reduced, which is conducive to saving production costs; the adjustable swing angle grinder assembly has multiple degrees of freedom, and the adjustability is greatly enhanced, which can adapt to the processing of different parts and improve production efficiency.

Owner:JIASHAN BAOHU CLOTHING

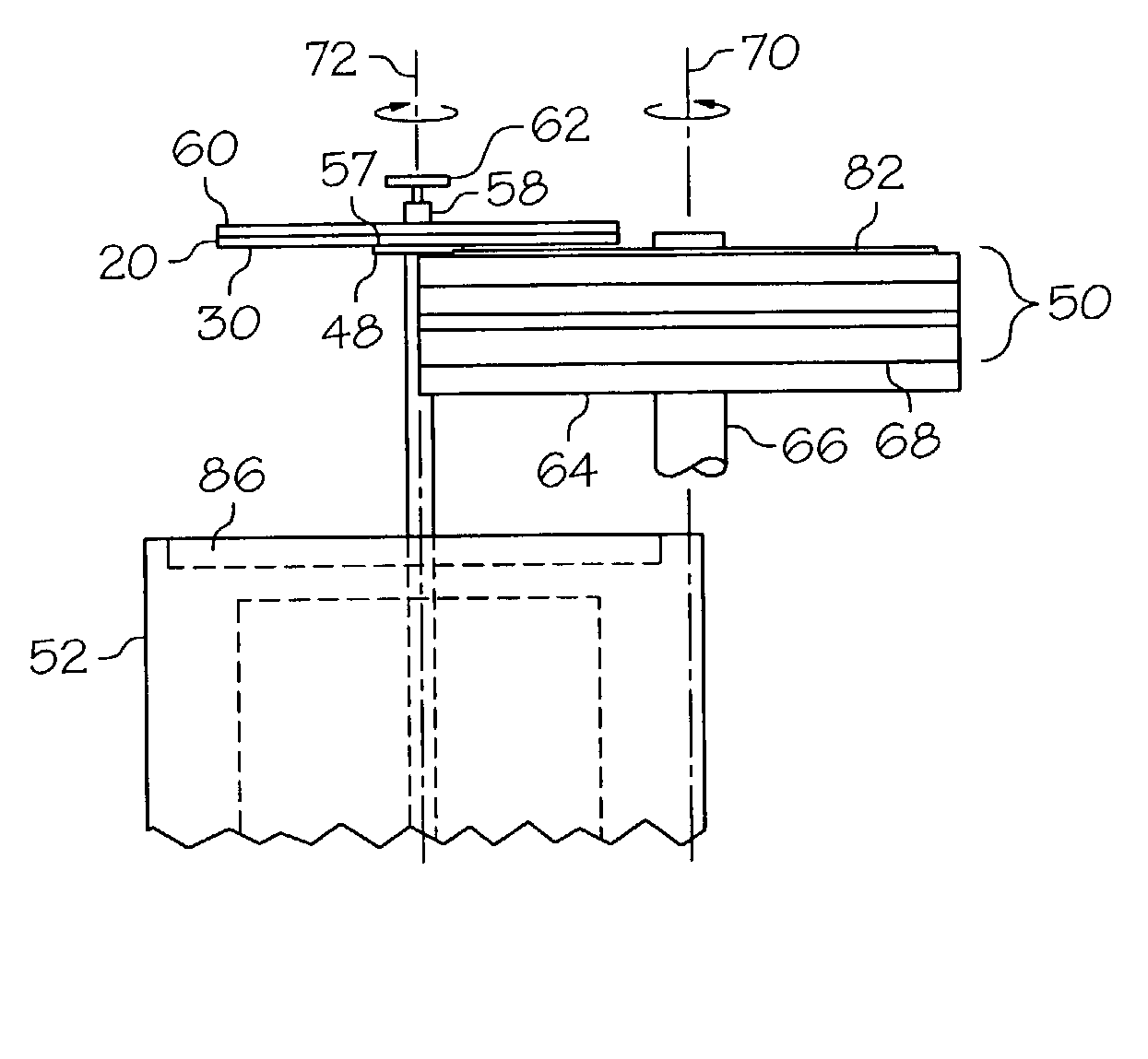

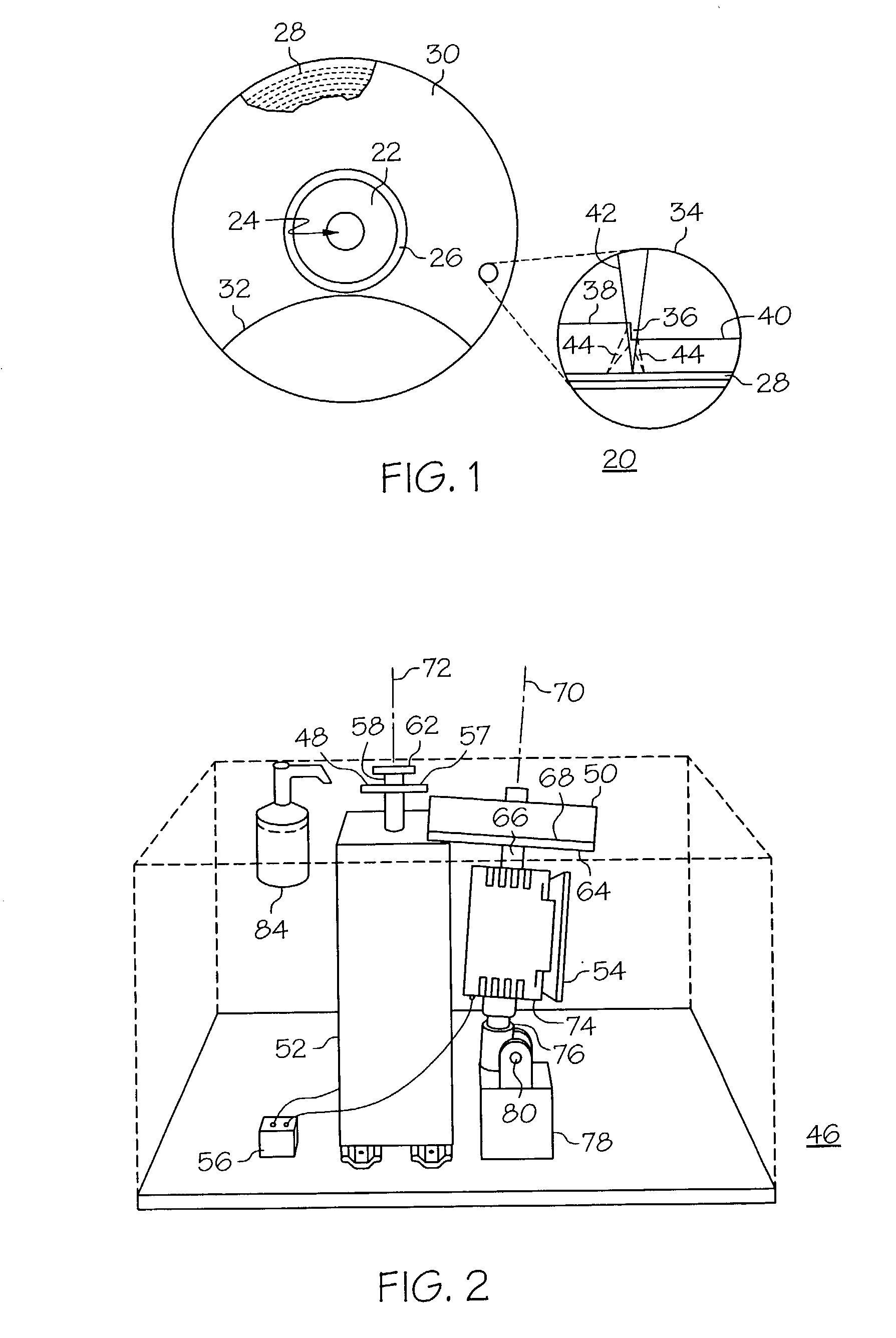

Apparatus and buffing element for reconditioning digital recording discs

InactiveUS20020168927A1Efficient repairUniform wearEdge grinding machinesPolishing machinesDigital recordingEngineering

Owner:BAUER JASON

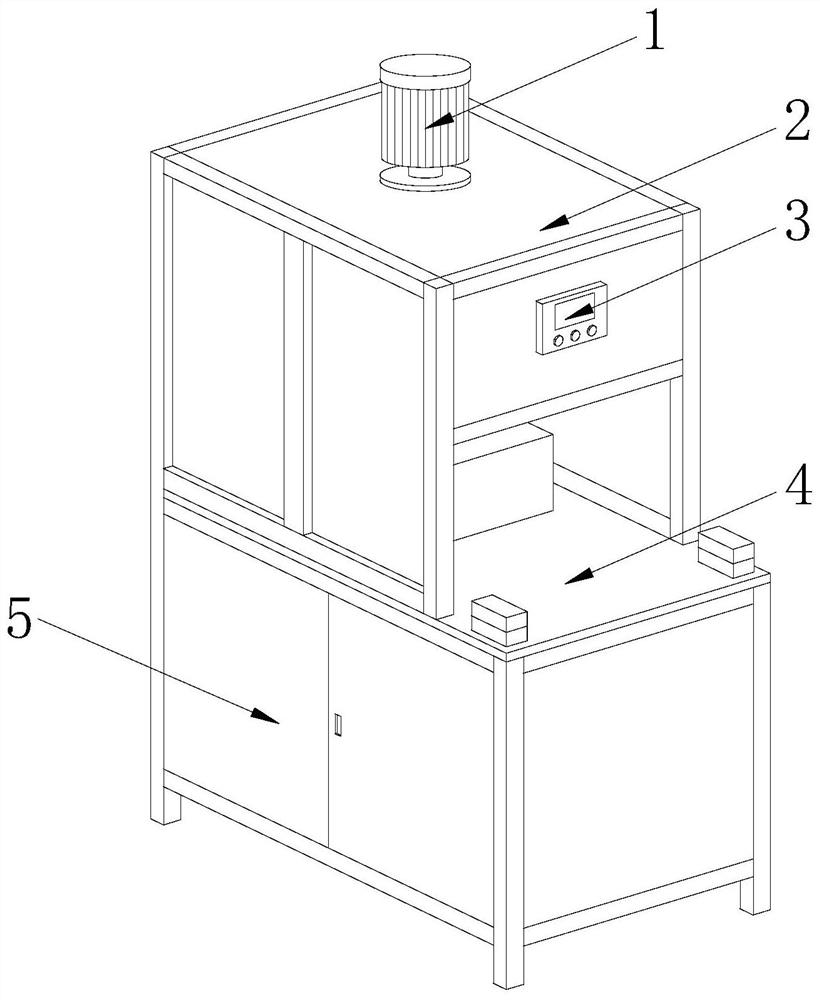

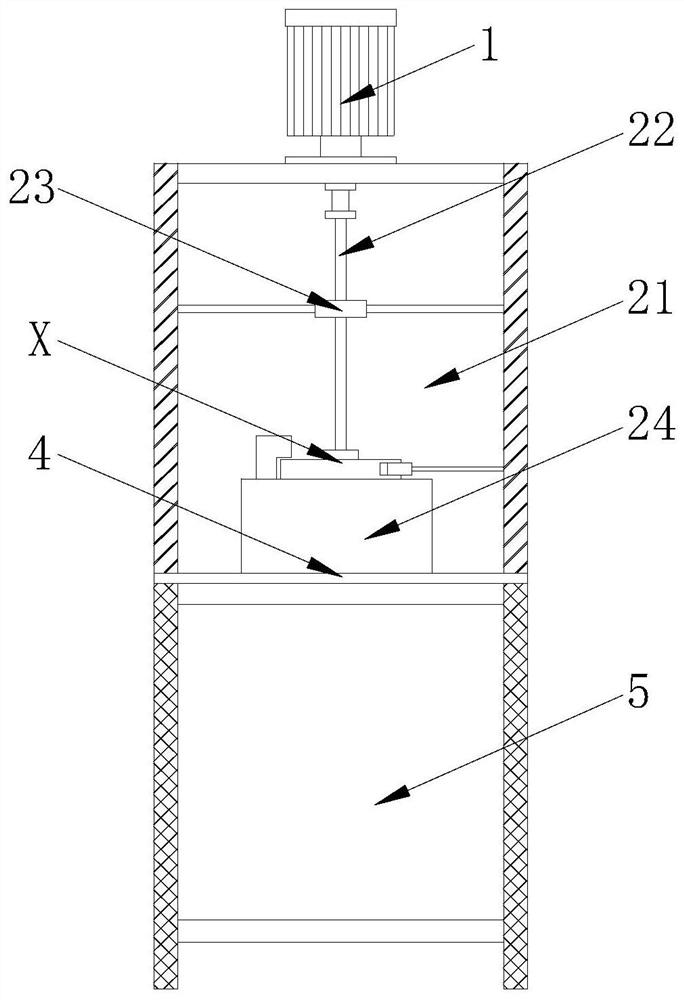

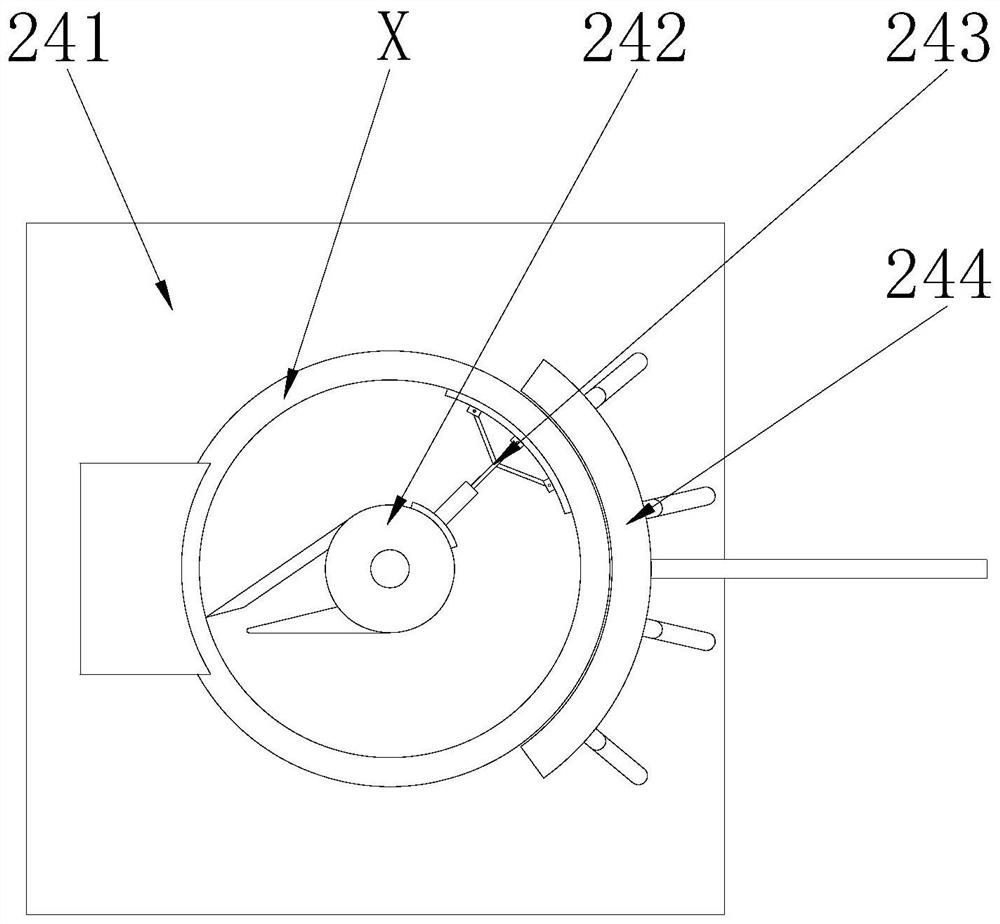

Burr cutting equipment for rubber processing

InactiveCN112060433AImprove sanding effectContact strength is normalEdge grinding machinesGrinding drivesElectric machineryStructural engineering

Owner:成都喃呓商贸有限公司

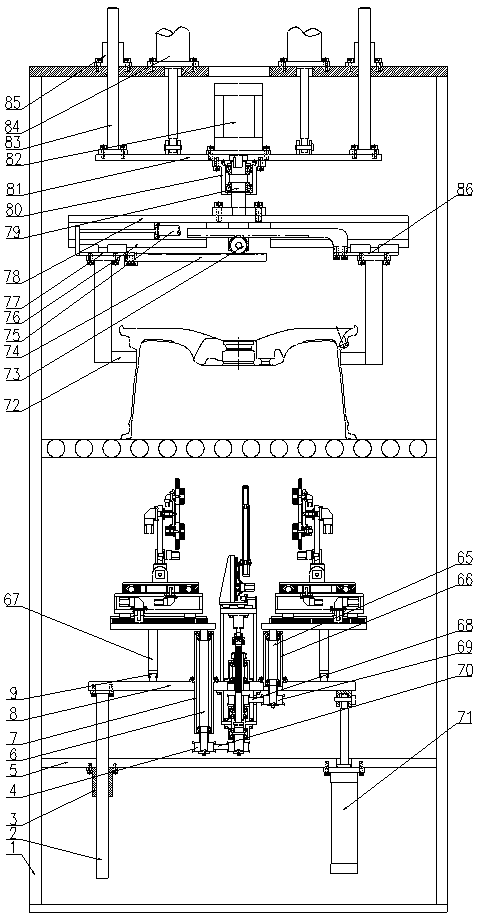

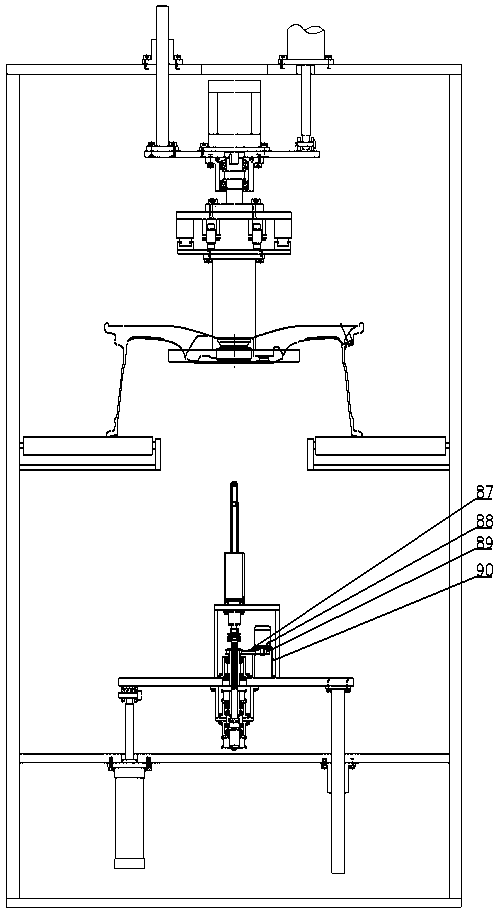

Automatic part taking system

ActiveCN113955506AHigh degree of automationRealize automatic box change functionEdge grinding machinesControl devices for conveyorsEngineeringMachining system

The invention relates to an automatic part taking system. The system comprises a first mechanical arm, a cooling device, a cinder ladle removing device, a deburring device and a second mechanical arm and further comprises an automatic box replacing device arranged at a box filling station and used for replacing part boxes and an automatic stacking device used for stacking the full part boxes. The automatic box replacing device comprises a conveying frame, a conveying roller set rotationally installed on the conveying frame and a driving part for driving the conveying roller set to rotate, and the box filling station is located on the conveying roller set. The automatic stacking device comprises a clamping mechanism used for clamping or loosening the part boxes and a stacking control mechanism used for controlling the clamping mechanism to move between the box filling station and a stacking station in a reciprocating manner and achieving stacking. The automatic part taking system has the effects that the work of replacing and stacking part boxes can be automatically carried out, and the automation degree of a part die-casting machining system is improved.

Owner:AIMI (SHANGHAI) TECH CO LTD

Screw polishing machine

Owner:海盐天奇标准件股份有限公司

Contamination cleaning device

InactiveCN101670550ANo pollutionSimple structureEdge grinding machinesPolishing machinesEngineeringContamination

Owner:郑卫琴

Leather material location device for vertical type edge finishing machine

InactiveCN102490100APrecise positioningStable clampingEdge grinding machinesGrinding work supportsEngineeringMechanical engineering

Owner:SHENZHEN HOCHUEN TECH +1

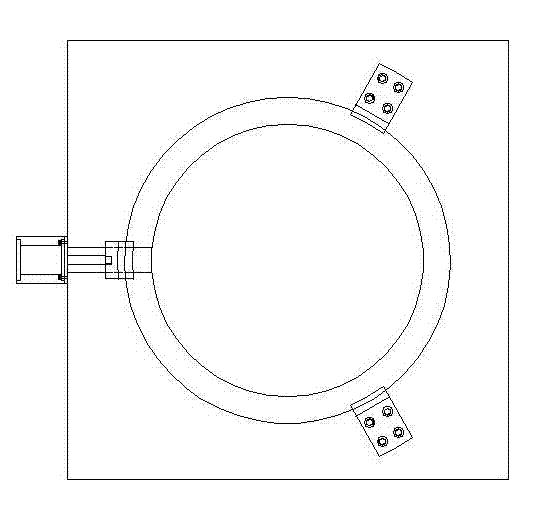

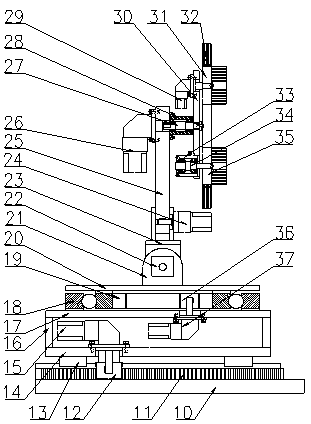

Multi-function grinding filing machine head and grinding filing machine

PendingCN109834542ABest orientation adjustmentAdapted to grinding tasksEdge grinding machinesGrinding drivesEngineeringMachine

The invention provides a multi-function grinding filing machine head and a grinding filing machine, and relates to the field of grinding equipment. The grinding problems that the grinding angle adjustment effect of an existing rotary support is not ideal and the existing rotary support is not suitable for longitudinal line welding inside and outside the cylinder are solved, the multi-function grinding filing machine head includes a machine seat, a power assembly, and a rotary support; the power assembly is provided with a grinding spindle for mounting and driving grinding tools, and the powerassembly is mounted on the machine seat; the machine seat is mounted on an inner ring of the rotary support, and the machine seat and the power assembly can rotate with rotation of the inner ring of the rotary support; and an axis of the grinding spindle is parallel to the rotary surface of the rotary support, and the grinding task of circumferential and longitudinal weld bead welding inside and outside a cylinder vessel can be adapted; and the multi-function grinding filing machine head of the grinding filing machine can adapt to the grinding task of circumferential and longitudinal weld beadwelding inside and outside of the cylinder vessel.

Owner:张敏

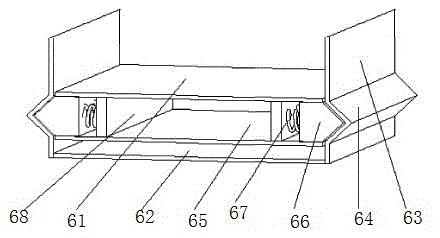

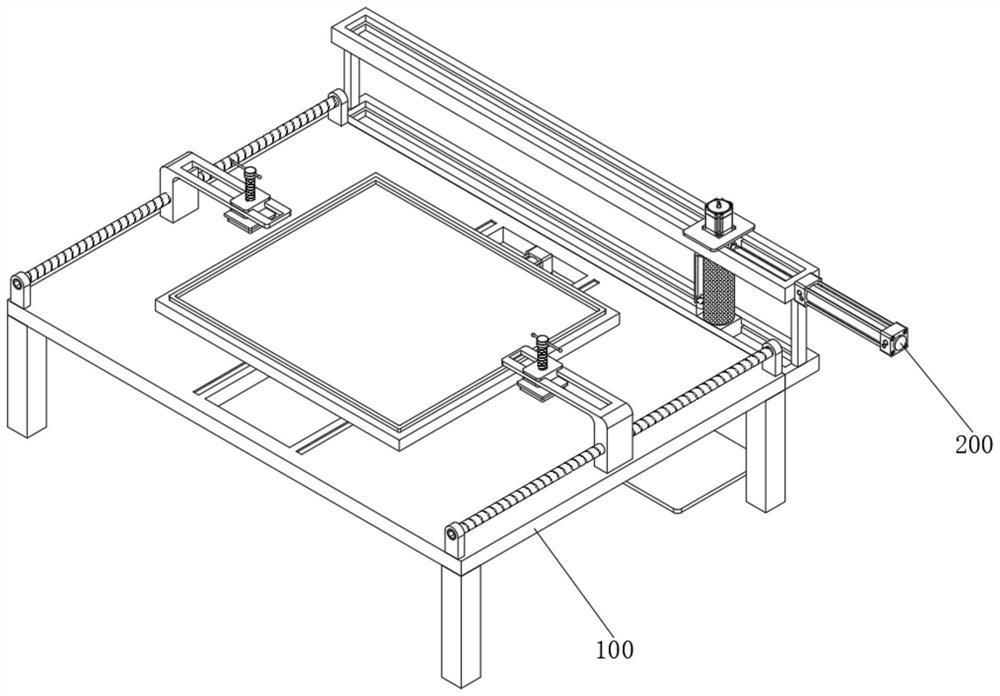

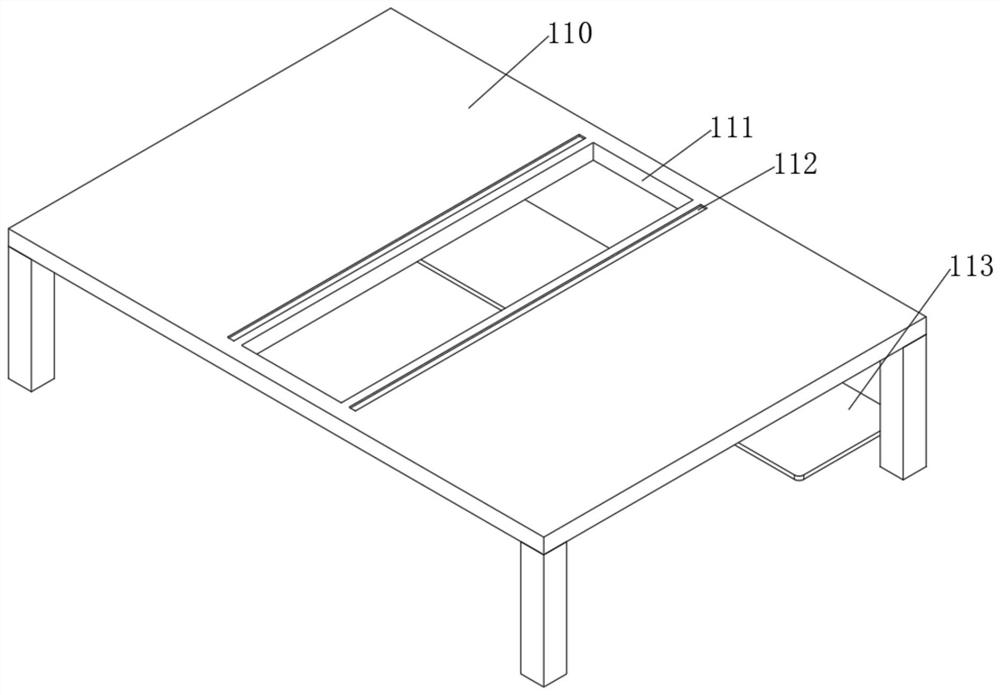

Edging device for high-density fiber cement fireproof board

InactiveCN111660162AStable positionAvoid affecting the working environmentEdge grinding machinesGrinding drivesFiberThermodynamics

The invention belongs to the field of cement fireproof board processing equipment, and in particular is an edging device for a high-density fiber cement fireproof board. Aiming at the problem that manual handheld grinders are required for existing grinding operations, which is time-consuming and laborious, has low grinding efficiency, and is easy to produce large amounts of dust during the grinding to cause pollution of the surrounding environment, the following solution is proposed that the edging device comprises an operating table, wherein the top of the operating table is fixedly installedwith a raised platform, the top of the raised platform is fixedly installed with a placement board, the top of the placement board is placed with a fireproof board, two grooves are formed on the topof the placement board, clamping plates are slidably installed in both grooves, and the sides of the two clamping plates close to each other are in contact with two sides of the clamping plate respectively. The edging device has a reasonable structure and convenient operation. During the edging operation, the grinding head can be controlled automatically for grinding to save time and labor and have high grinding efficiency, and the dust generated can be processed while grinding without polluting the surrounding environment.

Owner:要虎岭

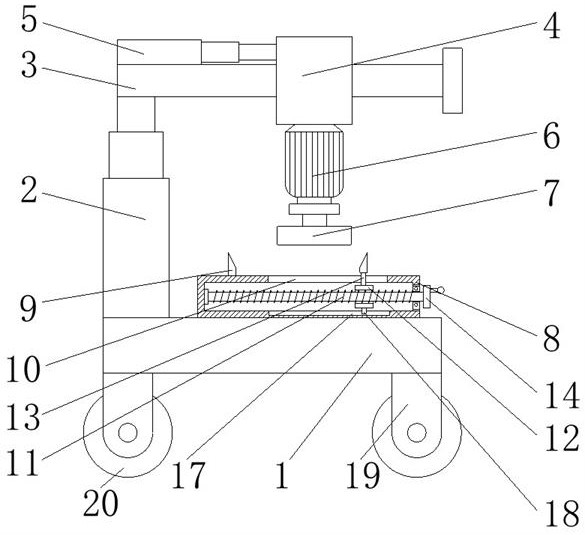

Bamboo tube wine end surface trimmer

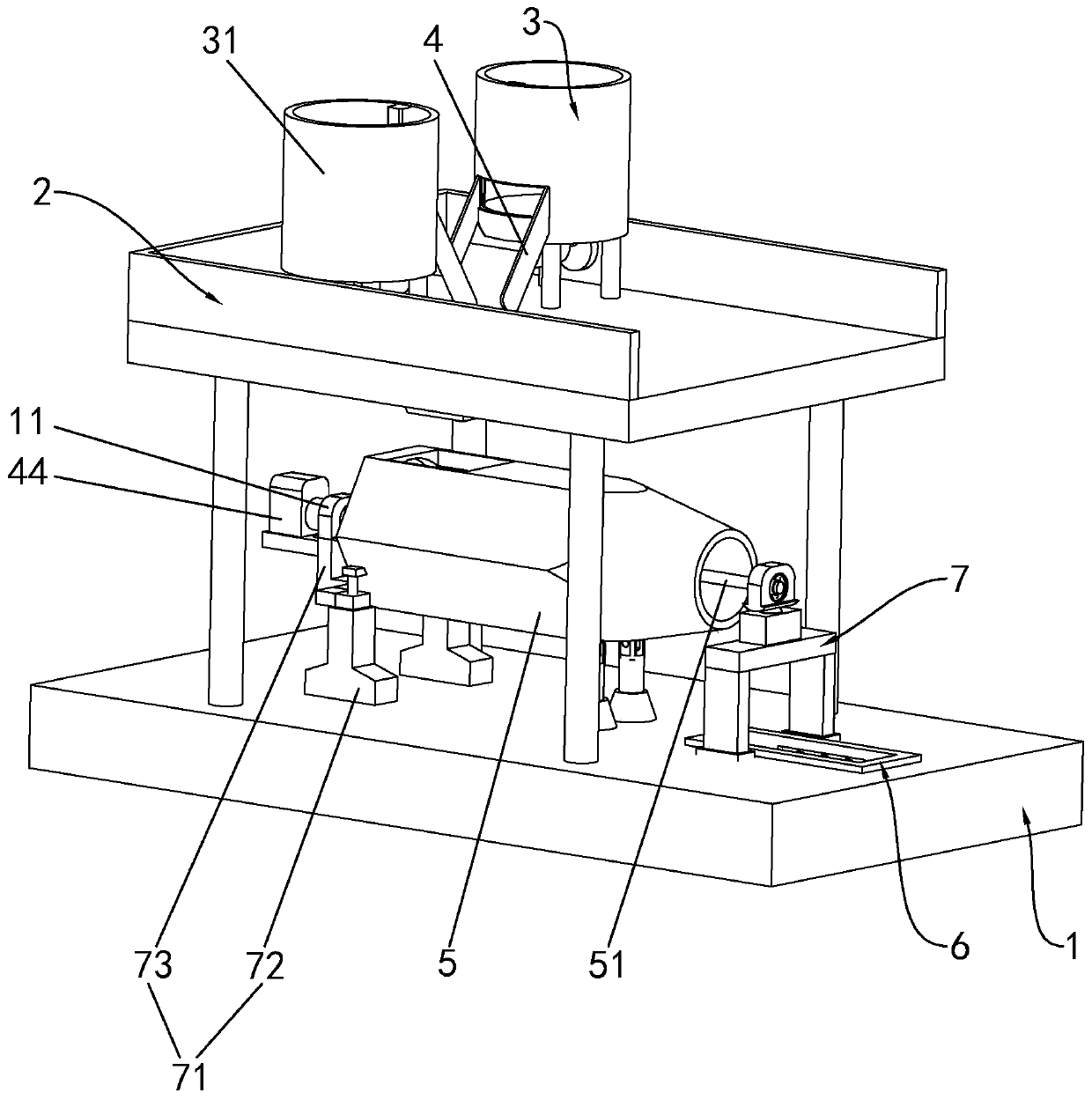

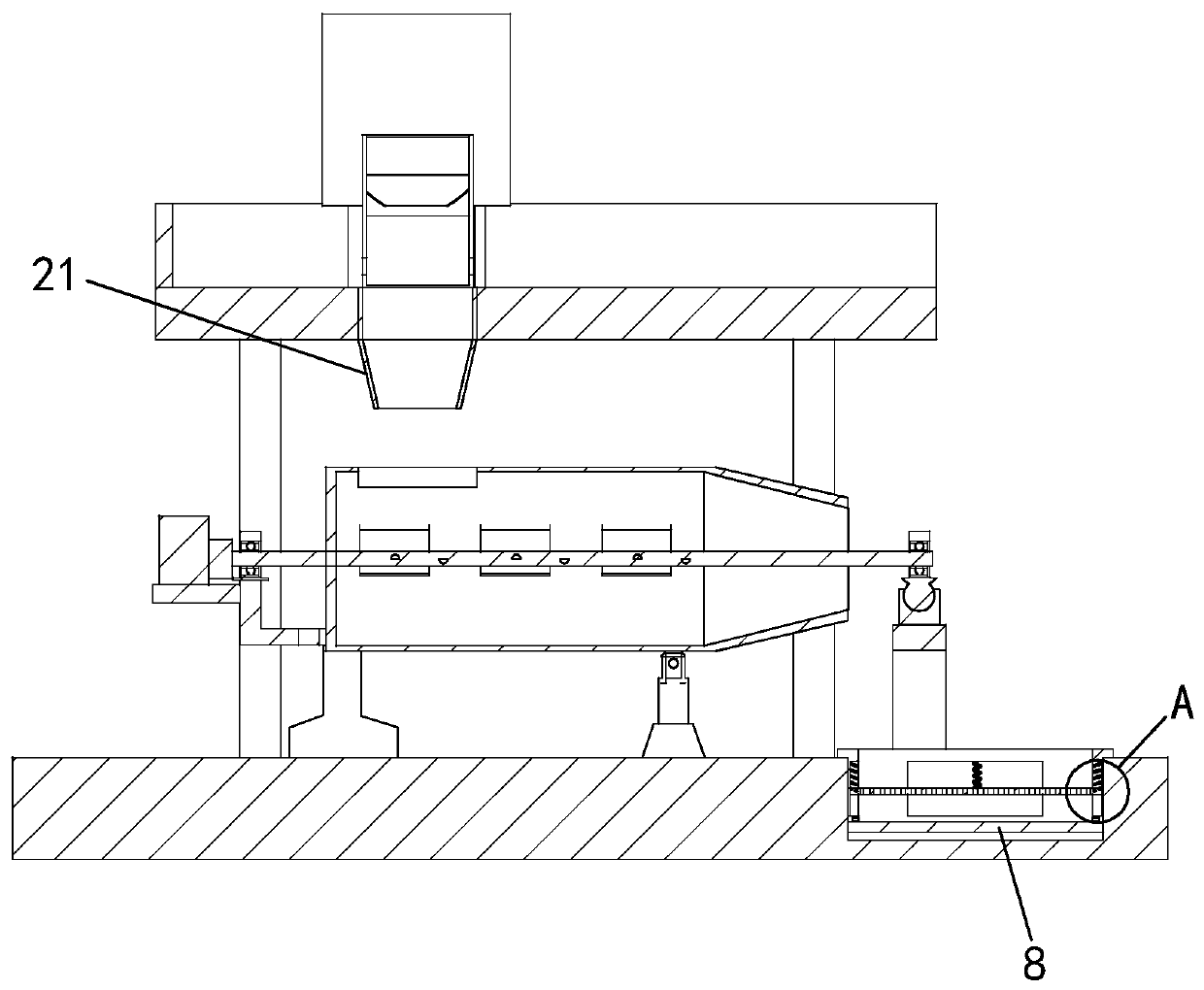

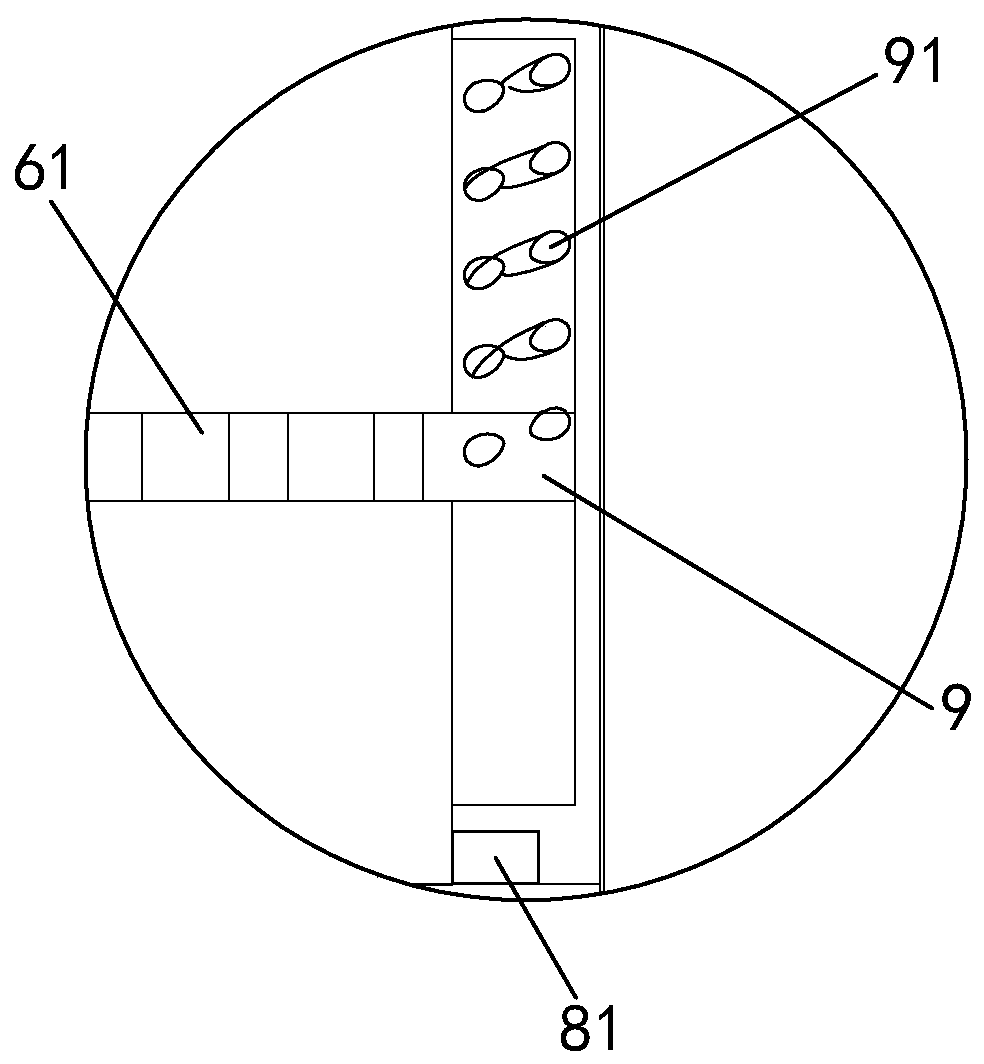

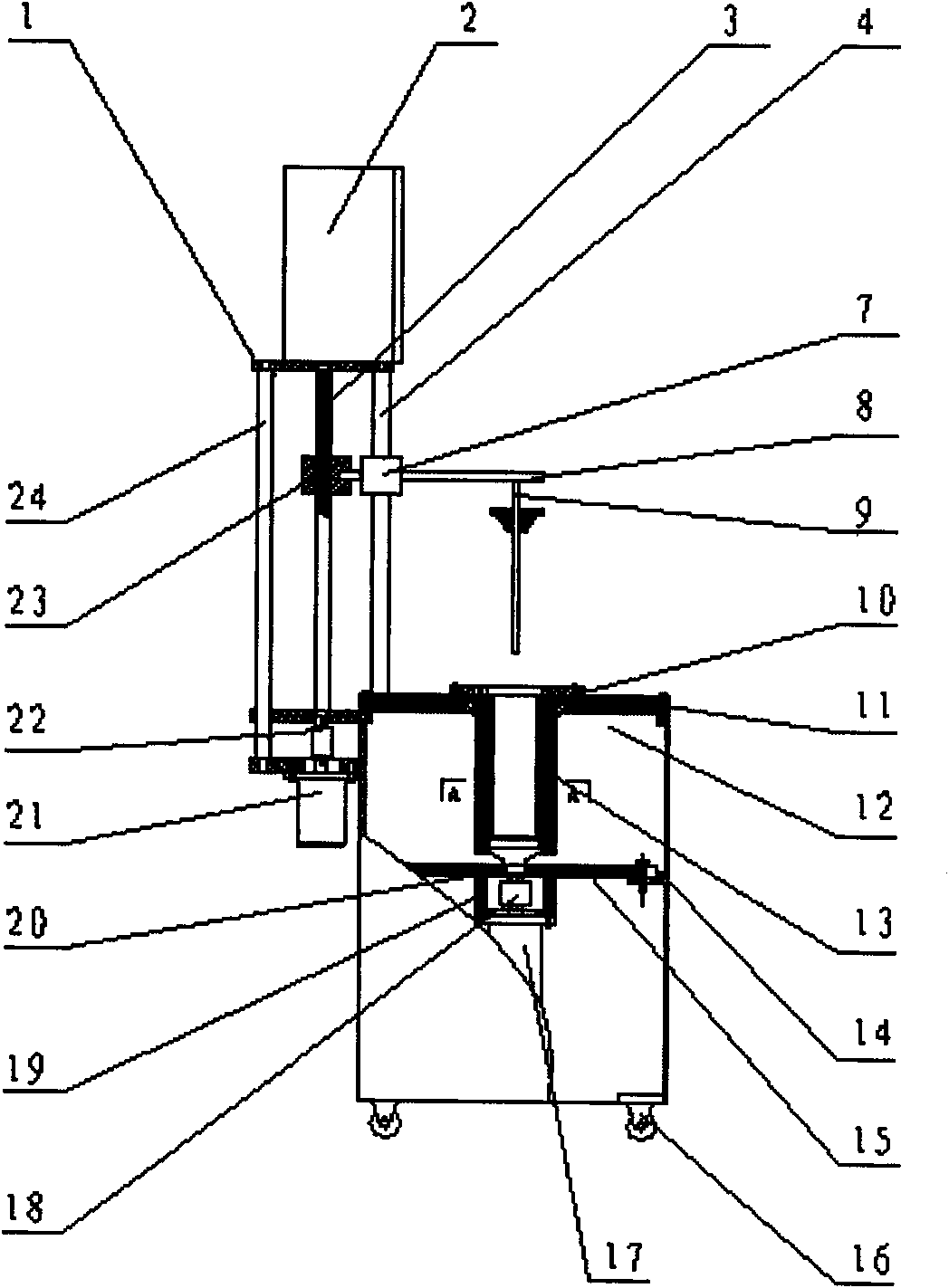

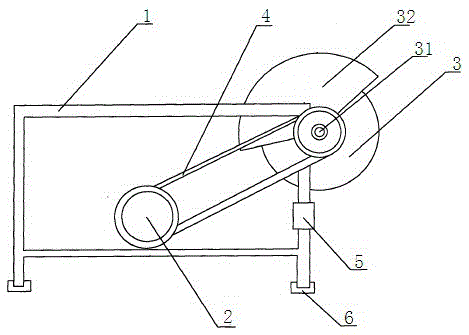

ActiveCN110549197AEasy to operateRealize the grinding actionEdge grinding machinesGrinding carriagesMount usedEngineering

The invention provides a bamboo tube wine end surface trimmer, relates to the technical field of processing equipment, and solves the problems that grinding operation is complex, labor intensity of aworker is great, production efficiency is relatively low, and certain potential safety hazards exist in a using process while an angle grinder has certain risk. The bamboo tube wire end surface trimmer comprises a main body, wherein the upper part of the main body is connected with one group of pressing blocks in a sliding mode; the right side of the main body is in sliding connection with one group of feeding slide tables; the counterweight blocks are connected to the tops of the pressing blocks through fixed pulley groups; the right side of the main body is fixedly connected with one group of motors; and the right side of the main body is axially connected with one group of gear shafts. Leftward sliding of the feeding slide tables is realized while a bamboo tube is pressed by the pressing blocks, so that feeding action is realized; and during mounting use, the bamboo tube does not need to align, so that use operation is simple, use is convenient, grinding effect is good, labor intensity of a worker is reduced, grinding efficiency is high, and a grinding process is safer.

Owner:吴柏青

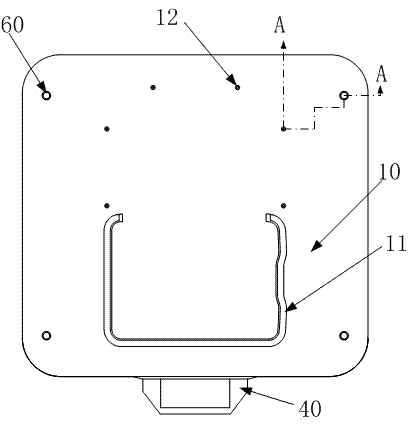

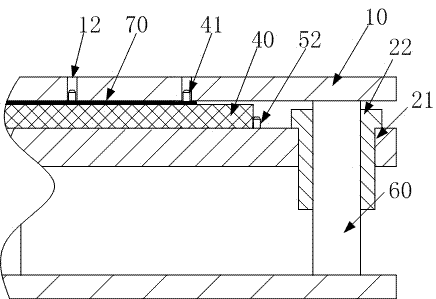

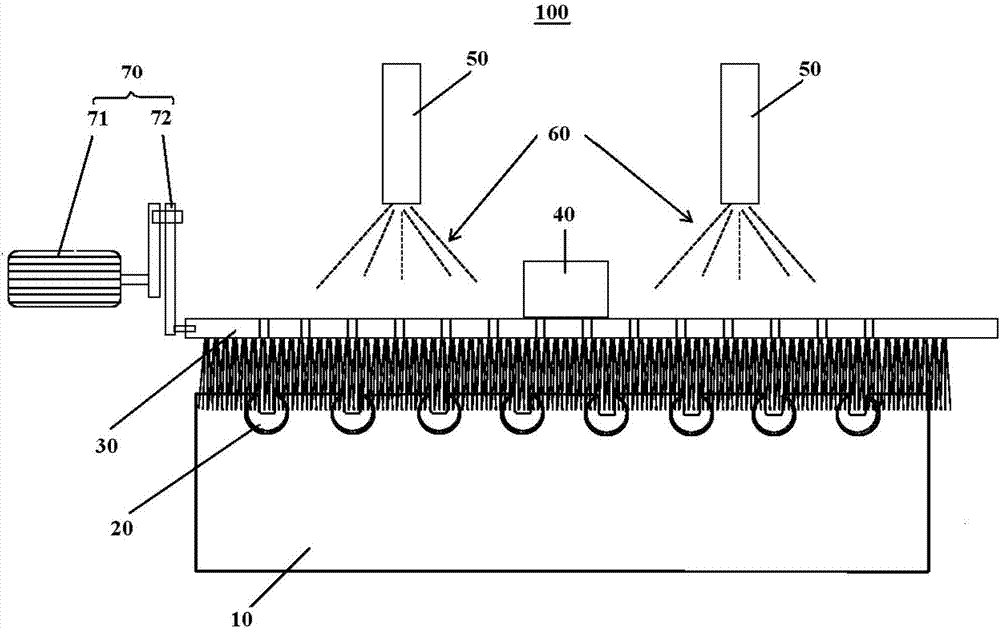

Device and method for treating rough face of the inner groove of quartz base plate for optical fiber coupler

InactiveCN106956185AIncrease the areaAvoid damageEdge grinding machinesPolishing machinesBristleBatch processing

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

High-end cleaning equipment

InactiveCN109176206AEnable mobilityEasy to operateEdge grinding machinesHollow article cleaningEngineeringScrew thread

Owner:广州唐太环保科技有限公司

Device for cleaning vehicle wheel burrs away

Owner:CITIC DICASTAL

Environment-friendly inner end surface grinding device for polyethylene pipe

ActiveCN110202444AIncrease flow rateEnvironmental protectionEdge grinding machinesGrinding machine componentsEngineeringCentrifugal force

The invention provides an environment-friendly inner end surface grinding device of a polyethylene pipe. The device comprises a detachable plate, a polishing assembly and an adsorption assembly, wherein the detachable plate is movably connected below the outer end surface, the polishing assembly is arranged above the interior of the outer end surface, and the adsorption assembly is arranged in themiddle of the interior of the outer end surface. According to the grinding device, a set of first supporting shaft and a set of second supporting shaft are correspondingly arranged on each grinding roller, meanwhile, the outer surfaces of the grinding rollers are uniformly provided with flow guide grooves in a embedding mode, the tail ends of the flow guide grooves are aligned with inclined surface grooves, the tail ends of the flow guide grooves are aligned with the inclined surface grooves, when the flow guide grooves rotate along with the grinding rollers, the gas is driven by the centrifugal force generated by rotation of the grinding rollers to move along the flow guide grooves, and is matched with the inclined surface grooves to enable the flow rate of the gas being larger, furthermore the pipe residue polished by the grinding rollers is moved to the inside of the device, the same non-conductive pipe debris can be further adsorbed, so that the device is more environment-friendlywhen being used.

Owner:SUZHOU LINGYU PLASTIC PIPE TECH CO LTD

Polishing device for automobile part machining

PendingCN114523355APlay a fixed clamping effectHeight adjustableEdge grinding machinesGrinding drivesMotor vehicle partElectric machinery

Owner:WUXI AOYUTE NEW TECH DEV

Casting polishing device capable of preventing vibration and noises

InactiveCN105598774AAvoid manual grinding and grinding of castingsHigh speedEdge grinding machinesGrinding carriagesEngineeringCasting

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Stamping part surface grinding device for refrigerator production

InactiveCN108453583AAchieve grindingEasy to polishEdge grinding machinesGrinding carriagesDrive motorPulp and paper industry

Owner:合肥光华机械有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap