Apparatus for sensing a mount for optical lenses and associated method

a technology of optical lenses and mounts, applied in the field of apparatus for sensing mounts for optical lenses, can solve the problems of inaccurate measurement of mount dimensions, difficulty in assembling lenses, and apparatus of the above-mentioned typ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

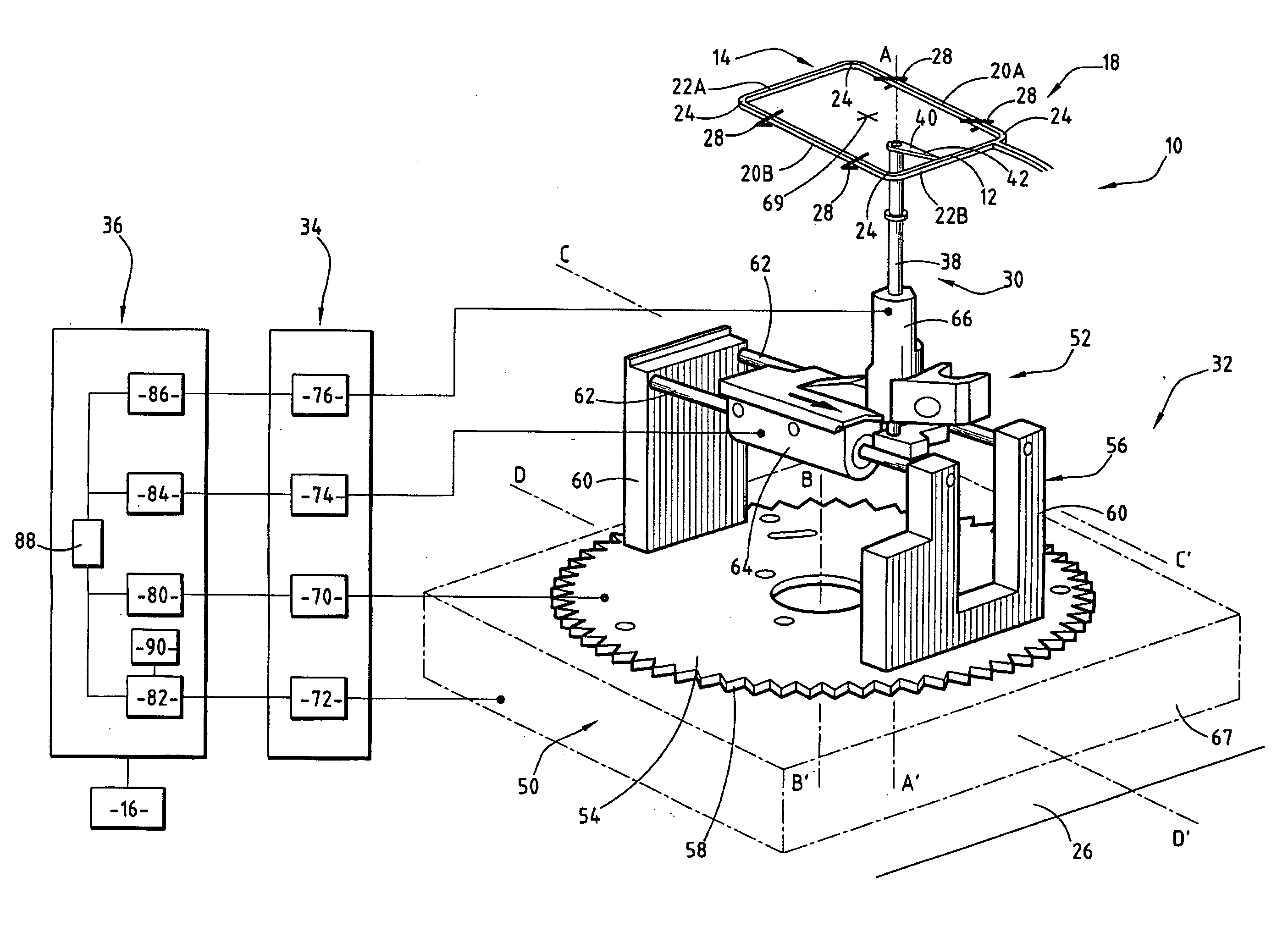

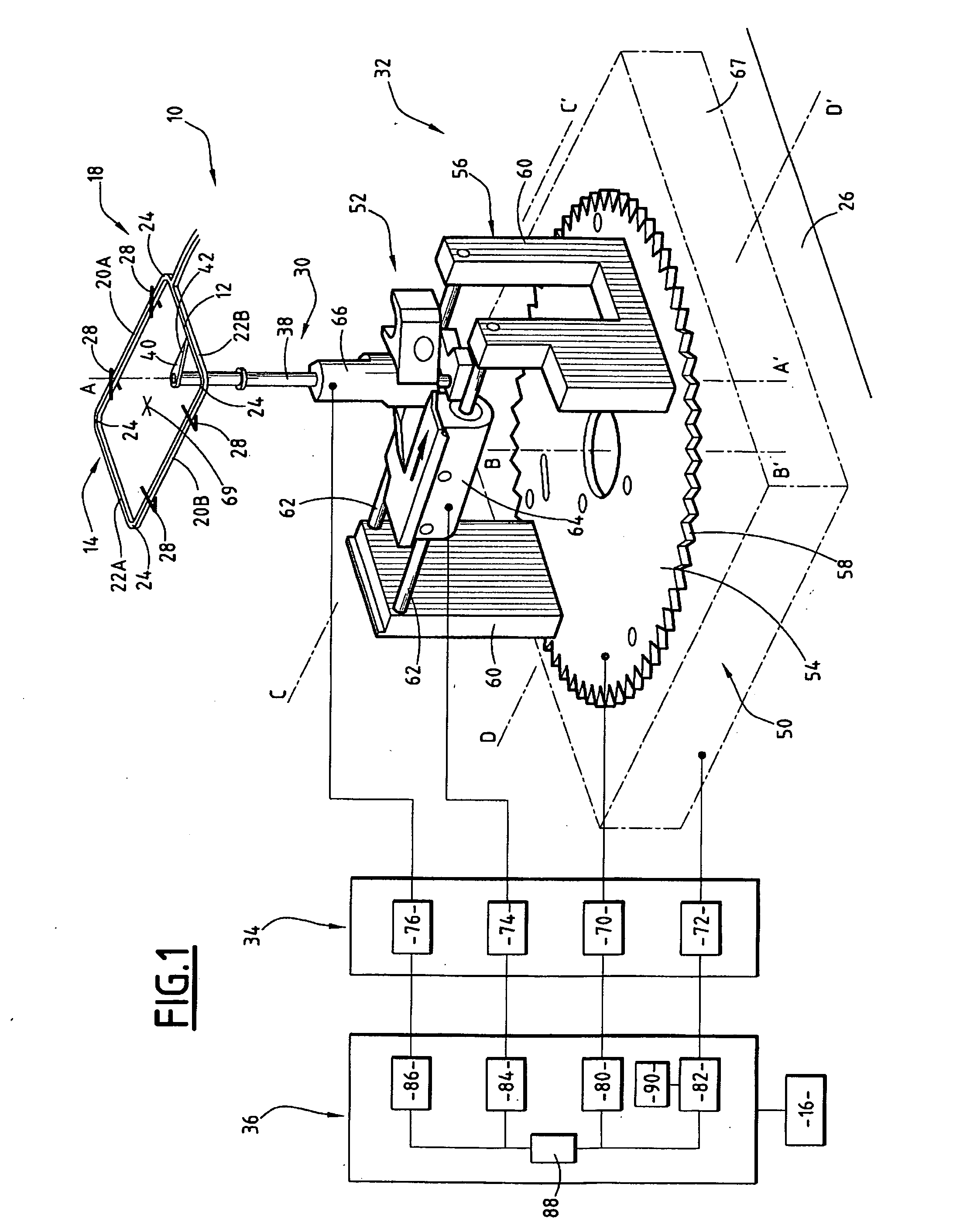

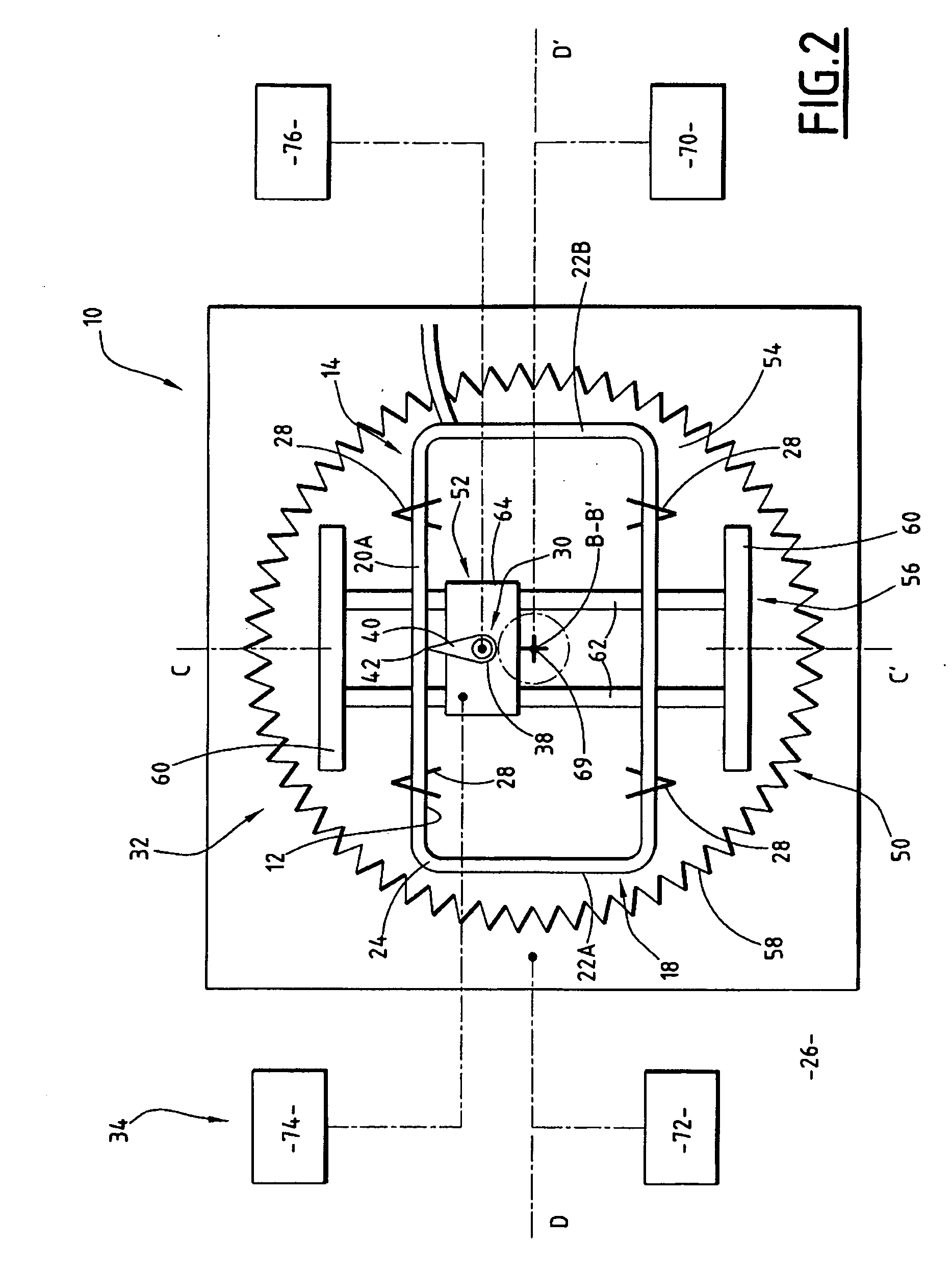

[0043]A first sensing apparatus 10 according to the invention is shown in FIGS. 1 to 3.

[0044]The apparatus 10 is intended to measure the exact profile of a groove 12 defined in a mount 14 for optical lenses, shown partially in FIGS. 1 to 3. The sensing apparatus 10 is arranged in a machine 16 for grinding optical lenses, for example of the type described in application FR-A-2 852 878 by the Applicant.

[0045]As illustrated in FIGS. 1 and 2, the mount 14 comprises two mount rims 18, only one of which is visible in these Figures. Each mount rim 18 defines internally a groove 12.

[0046]Each mount rim 18 has a substantially horizontal mean directrix surface in FIG. 1. Each rim 18, in projection in a horizontal plane, has an elongate and angular contour. Thus, it comprises two sections, upper 20A and lower 20B, connected to each other by two lateral sections 22A, 22B having a length which is shorter by a factor of at least two. Each rim 18 comprises between each section 20A, 20B and an adjacen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap