Device and method for treating rough face of the inner groove of quartz base plate for optical fiber coupler

An optical fiber coupler, quartz substrate technology, applied in grinding/polishing safety devices, surface polishing machine tools, machine tools suitable for grinding workpiece edges, etc. , high processing accuracy requirements, to achieve the effect of good processing quality, less workpiece damage and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

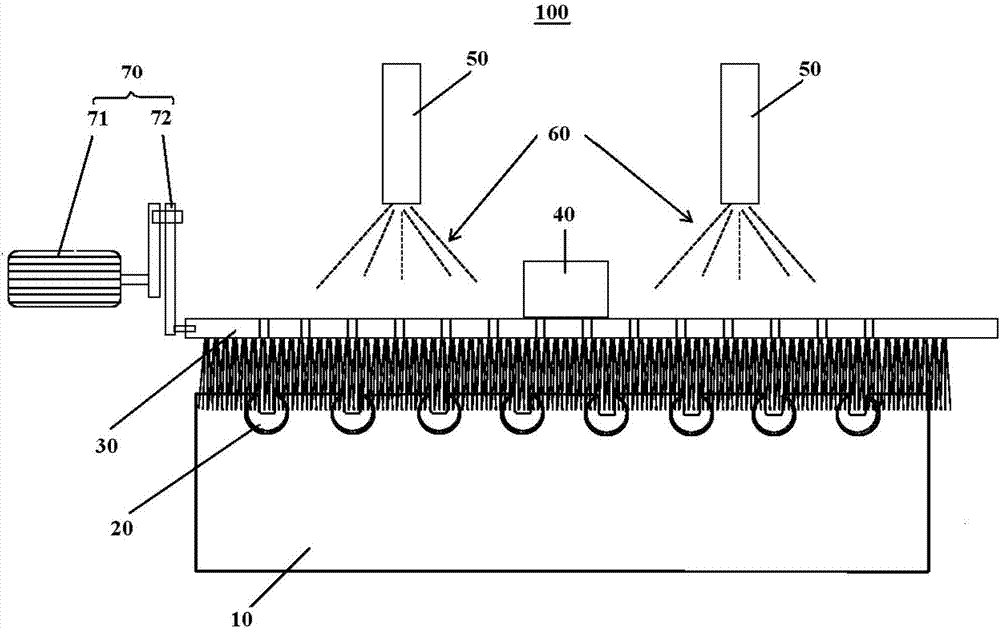

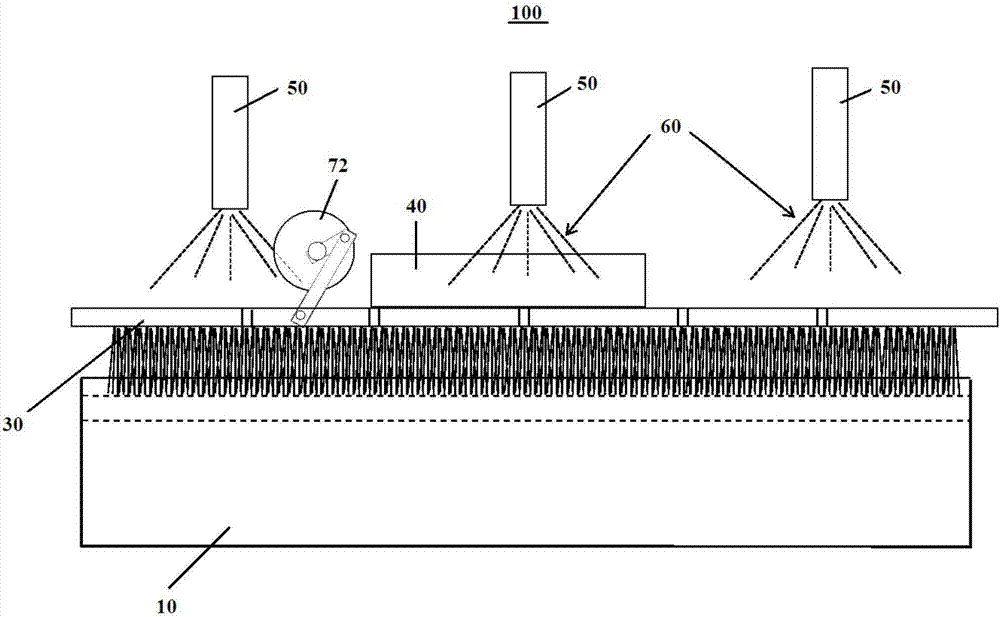

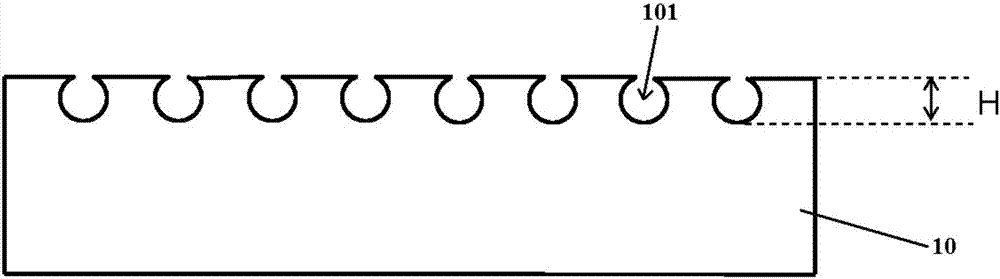

[0029] Such as Figure 1-2 Shown is a rough surface treatment device 100 for the inner groove of the quartz substrate for optical fiber couplers according to a preferred embodiment of the present invention, including a fixed table 10 , a flexible brush 30 , a mortar pipe 50 and a reciprocating drive device 70 . The flexible brush 30 is correspondingly installed above the fixed workbench 10. The flexible brush 30 includes a brush plate 31 and bristles 32 fixed below the brush plate 31. The brush plate 31 is provided with a through hole 311. The mortar pipeline 50 is installed on the flexible brush 30. Above, the mortar 60 can flow out from the mortar pipe 50 and flow into the bristles 32 through the through hole 311. The re

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap