Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Improve processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

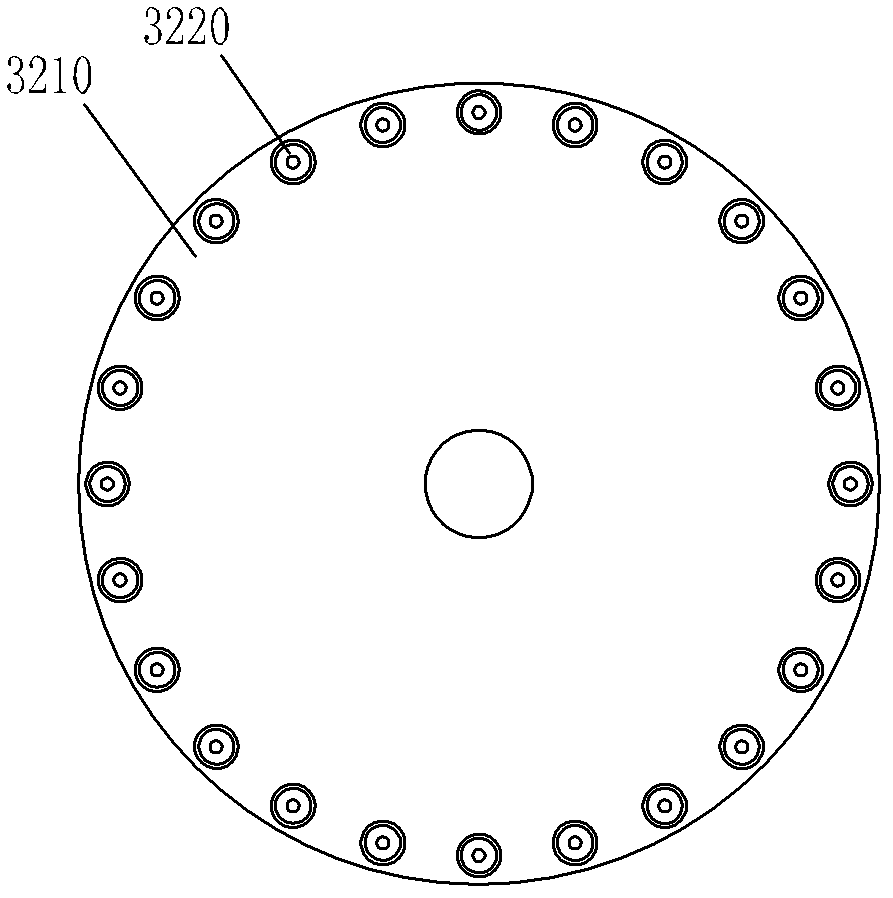

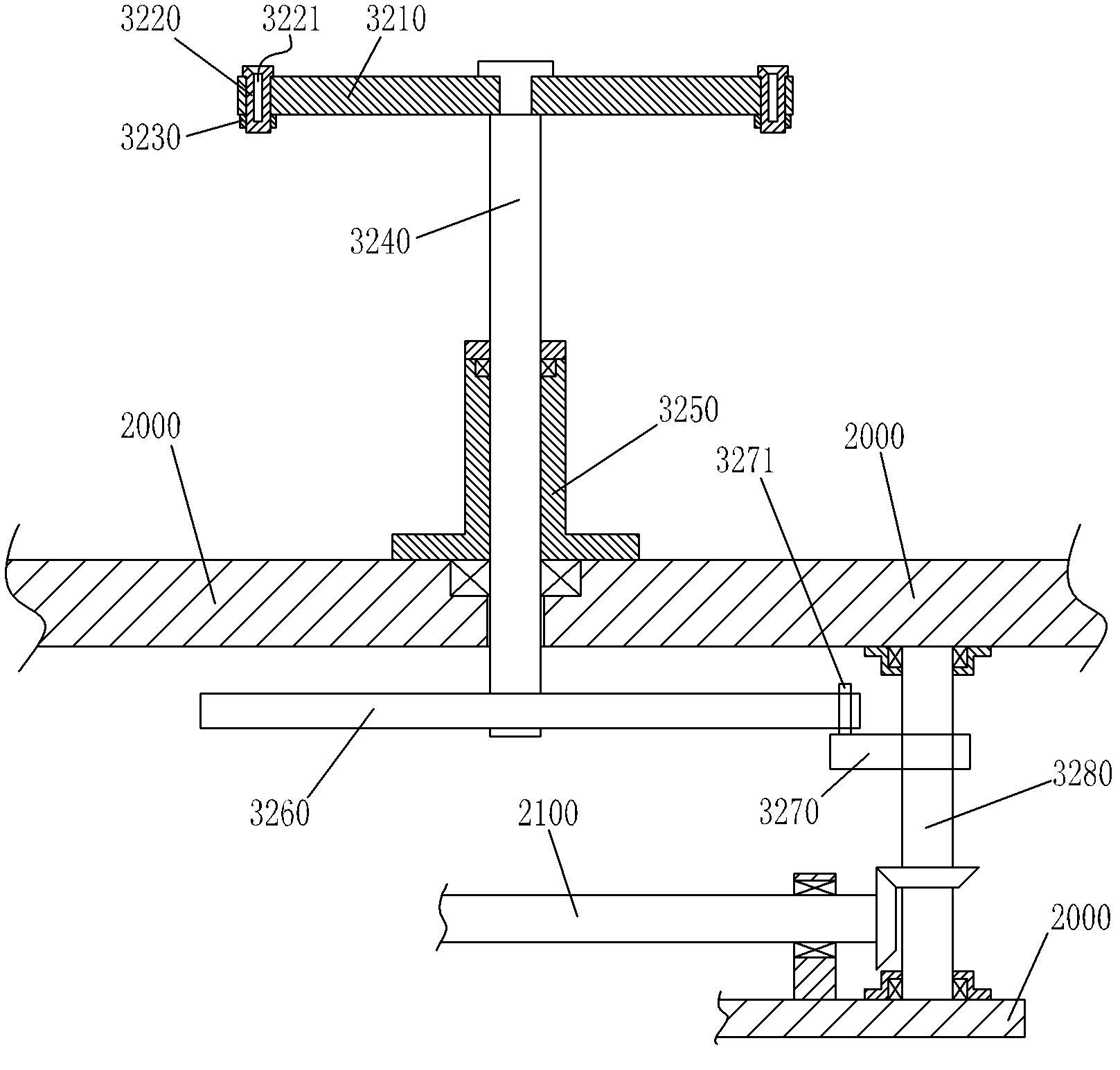

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

InactiveCN108857605ARealize finishingAchieve extrusionEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

Suction sludge dewatering sand dredger

InactiveCN102121256AAdaptableEasy to operateWaterborne vesselsMechanical machines/dredgersWastewaterDewatered sludge

The invention relates to a suction sludge dewatering sand dredger which is characterized in that a sludge processing device is arranged on a boat body and comprises an extracting unit, a sieving unit, a heavy metal processing unit, a dewatering unit, a deodorizing unit, a dewatered sludge collecting unit and a wastewater processing and discharging unit. In the invention, the integral design of sediment dewatering processing device for urban landscape water pollution is realized; the sludge is immediately dried and dewatered while dredging; and the processed sludge can be directly used in the agricultural field, therefore, the pollution on the environment is avoided.

Owner:TIANJIN UNIV OF SCI & TECH

Hardcover book soft inserting sleeve paste making machine

Owner:北京天工印刷有限公司

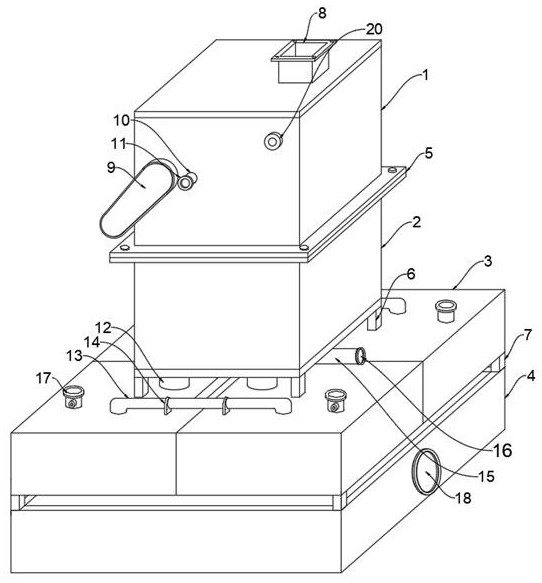

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

Industrial fault analysis expert system based on knowledge graph

InactiveCN110705710AEnhance expressive abilityProcessing speedKnowledge representationInference methodsFuzzy inferenceEngineering

The invention provides an industrial fault analysis expert system based on a Knowledge Graph. The industrial fault analysis expert system based on the Knowledge Graph comprises the following steps that expert experience knowledge is obtained and preprocessed to eliminate anomalies and complement missing values; knowledge data fuzzification is carried out, and a knowledge graph is constructed in the field of industrial fault analysis by applying a semantic net technology and a graph calculation engine according to the knowledge data fuzzification. The simplification and high efficiency of a knowledge graph structure are ensured through a graph dynamic self-optimization process, and the calculation efficiency is improved; industrial faults are diagnosed and analyzed based on a fuzzy reasoning method, and data or equipment abnormity is efficiently and accurately judged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

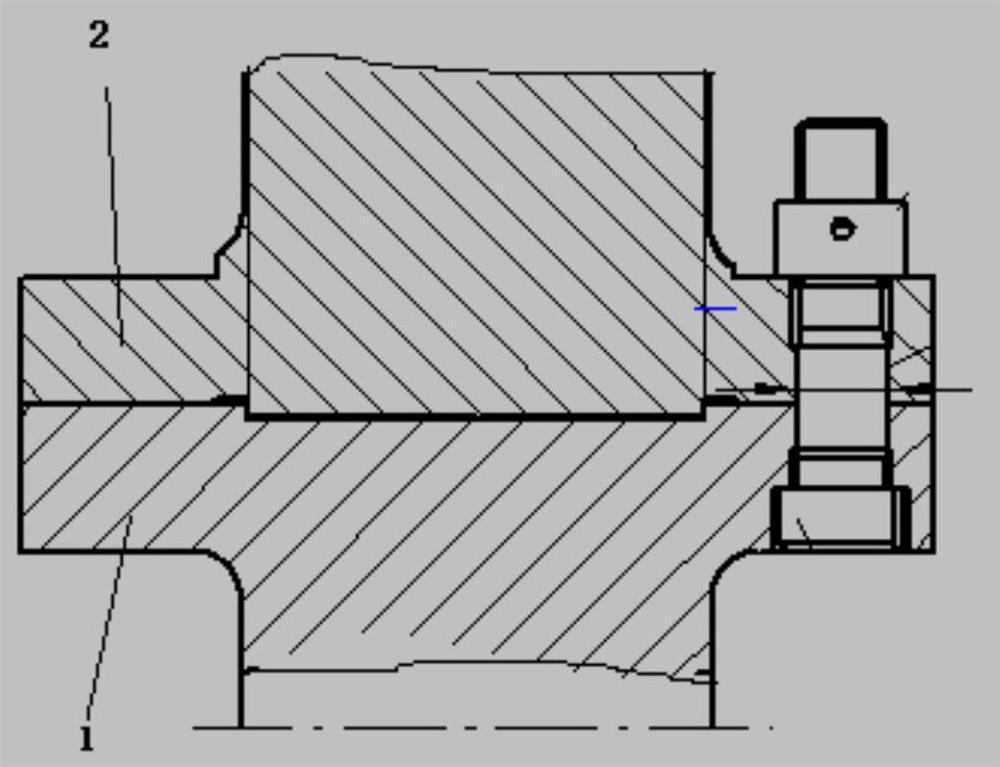

Pressing process for lining stainless steel composite end socket

ActiveCN112077535AImprove connection strengthImprove processing efficiencyMetal-working holdersOther workshop equipmentButt weldingCarbon steel

Owner:绍兴市奥达化工设备有限公司

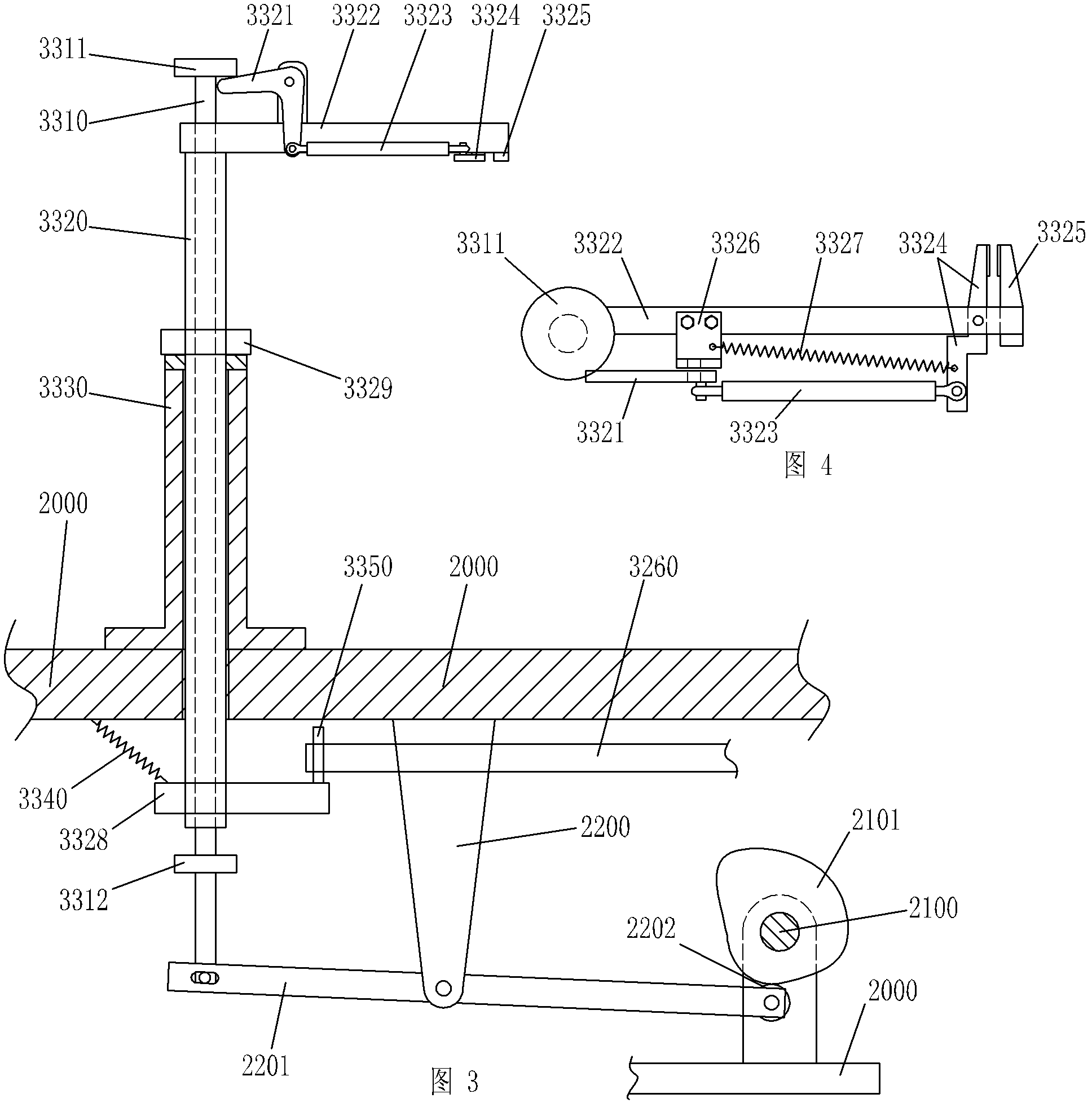

High-universality feeding device of pipe end-facing machine and feeding method

ActiveCN104907879AImprove processing qualityEasy to correctMetal working apparatusEngineeringScrew thread

The invention discloses a high-universality feeding device of a pipe end-facing machine and a feeding method. The feeding device of the pipe end-facing machine comprises a feeding mechanism and a manipulator, wherein the feeding mechanism comprises a feeding rack, a chain conveying mechanism and a plurality of pipe end-facing feeding supporting plates; each pipe end-facing feeding supporting plate comprises a supporting plate body, a main supporting block and a first auxiliary supporting block, wherein a first adjustment through hole is further formed in one side of the supporting plate body; the first auxiliary supporting block comprises a first adjustment block, a supporting screw rod, a first locking screw and a first locking nut; the supporting screw rod comprises a screw rod part and a screw rod fork part; a plurality of threaded holes are formed in the first adjustment block; the first locking screw penetrates through the first adjustment through hole in the supporting plate body and is screwed into one threaded hole of the first adjustment block; the screw rod part of the supporting screw rod penetrates through the first locking nut, is screwed into another threaded hole in the first adjustment block and then is locked through the first locking nut; a main fork part is formed on the main supporting block; the pipe is supported by the main fork part and the screw rod fork part. According to the invention, the processing quality is improved.

Owner:GUANGDONG GLORY METAL PROD CO LTD

Sewage treatment device capable of performing multi-stage filtration on sewage

PendingCN114477574ASmall footprintImprove processing efficiencyWater/sewage treatmentMultistage water/sewage treatmentSewage treatmentSewage

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Waste cloth regenerating and reusing device and recycling method thereof

PendingCN107043966AImprove processing efficiencyImprove the environmentContinuous processingFibre disintegrationCombingFiber

Owner:桐乡河山巨瑞纺织有限公司

Recommendation module interleaved wagering system

InactiveUS20160163158A1Efficient in operationImprove processing efficiencyApparatus for meter-controlled dispensingSpecial data processing applicationsApplication softwareInteractive processing

Owner:GAMBLIT GAMING

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Glass edge grinding machine

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesMotor driveFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:HANGZHOU TUOCHUAN MASCH CO LTD

Information processing method and electronic equipment

ActiveCN105718427AFast processingImprove processing efficiencySpecial data processing applicationsText processingComputer scienceElectric equipment

Owner:LENOVO (BEIJING) CO LTD

Coaxiality precision machining guarantee method of long-overhanging combination machining part

InactiveCN109262008AImprove processing efficiencyImprove processing pass rateCoordinate differenceEngineering

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Small ball head magneto-rheological polishing method based on common assistance of laser heating, water bath heating and chemical action

ActiveCN114012512AImprove polishing efficiencyImprove processing efficiencyControl of fluid heatersGrinding machine componentsChemical ActionsFused quartz

Owner:HARBIN INST OF TECH

Rack billet chamfering machine with four-edge chamfering function

ActiveCN103862089AImprove processing efficiencyReasonable structural designMetal working apparatusMilling equipment detailsEngineeringMechanical engineering

Owner:南通众仁金属制品科技有限公司

Dimension compensation quantity determining method for bearing machining

InactiveCN108262667AImprove machining accuracyImprove processing efficiencyGrinding feed controlAutomatic grinding controlEngineeringMachining

The invention belongs to the technical field of bearing machining, and particularly relates to a dimension compensation quantity determining method for bearing machining. The dimension compensation quantity determining method for bearing machining comprises the steps that the type of a to-be-machined workpiece is determined; the standard workpiece temperature T2 and the machined workpiece temperature T1 are detected; a pre-stored machining model and corresponding machining parameters are selected according to the type of the to-be-machined workpiece; and the bearing machining model is assignedaccording to the standard workpiece temperature T2, the machined workpiece temperature T1 and the corresponding machining parameter, so that the dimension compensation quantity of the to-be-machinedworkpiece is obtained through calculation. By adoption of the dimension compensation quantity determining method for bearing machining, machining dimension compensation quantity errors caused by experience-based judgment by operators are avoided, the machining precision and machining efficiency of bearings are improved, the machining repair rate of the bearings is greatly decreased, and the numberof rejected products is reduced; and operation is easy.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

Plate tapping equipment

ActiveCN104647465AImprove processing efficiencyImprove yieldDrilling machinesMetal working apparatusCamConical surface

Owner:XINGHUA GUANGFU METAL PROD

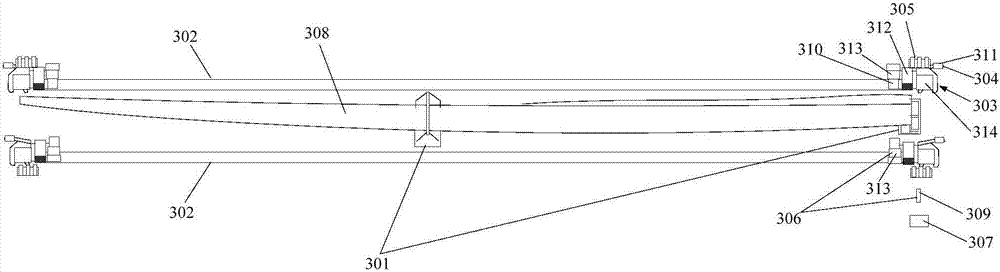

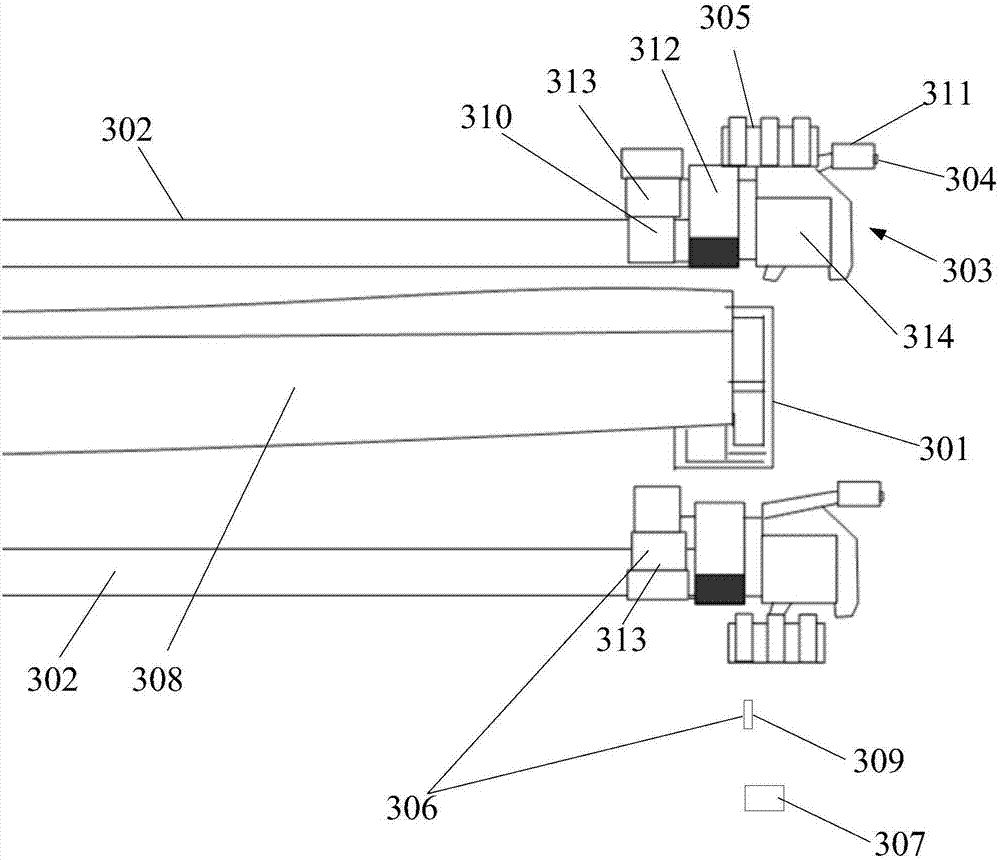

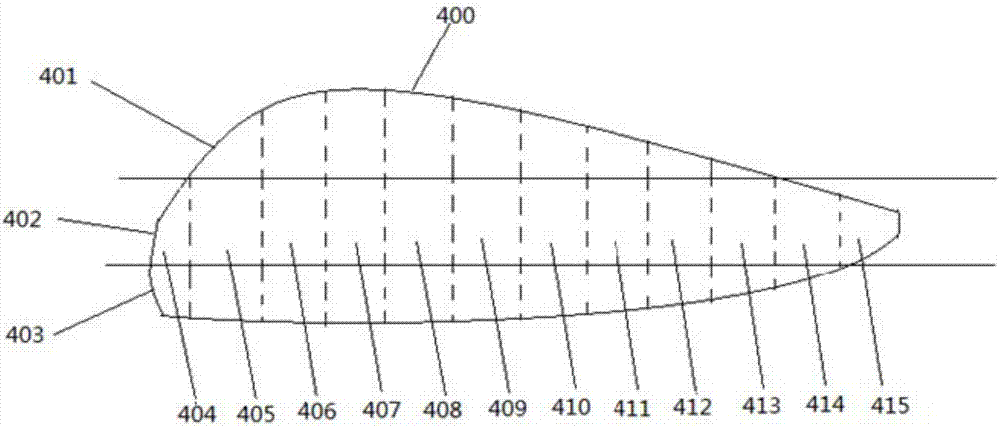

Large blade type workpiece robot collaborative grinding system and method

PendingCN107263255AGuarantee processing quality and consistencyHigh degree of automationGrinding feed controlGrinding machinesCorner angleControl theory

The invention provides a large blade type workpiece robot collaborative grinding system. The large blade type workpiece robot collaborative grinding system comprises a blade turnover clamping module, horizontal guide rails, N robot grinding units, N measuring modules corresponding to the robot grinding units, a control module and an upper computer module, wherein the control module comprises a tool control submodule and N robot grinding unit control submodules; the blade turnover clamping module is used for mounting and clamping blades to be ground; the two horizontal guide rails are arranged on the two sides of the blades in the long axis direction of the blades, and each horizontal guide rail is at least provided with one robot grinding unit; each robot grinding unit comprises a robot, a matched robot controller and a grinding device; each grinding device is mounted at the tail end of the robot corresponding to the grinding device, and each measuring module is mounted at the tail end of the corresponding robot; and the tool control submodules are connected with the blade turnover clamping module and control the turnover direction, turning angles and clamping operation of the blades. The large blade type workpiece robot collaborative grinding system can improve the grinding efficiency and quality of the blades.

Owner:无锡中车时代智能装备研究院有限公司

Data transmission method and device of virtual network interface card

ActiveCN105939239AEnsure information securityImprove processing efficiencyNetworks interconnectionData transmissionInformation security

Owner:HANGZHOU DPTECH TECH

Integrated sewage treatment reactor

PendingCN106186334AEasy to operateImprove processing efficiencyBiological treatment apparatusTreatment with aerobic and anaerobic processesBacterial strainDecomposition

Owner:张国明

Laser beam splitting and processing device

ActiveCN103658975AFast focus switching High precision focus switching capabilityImprove processing efficiencyLaser beam welding apparatusBeam steeringLaser processing

Owner:张立国

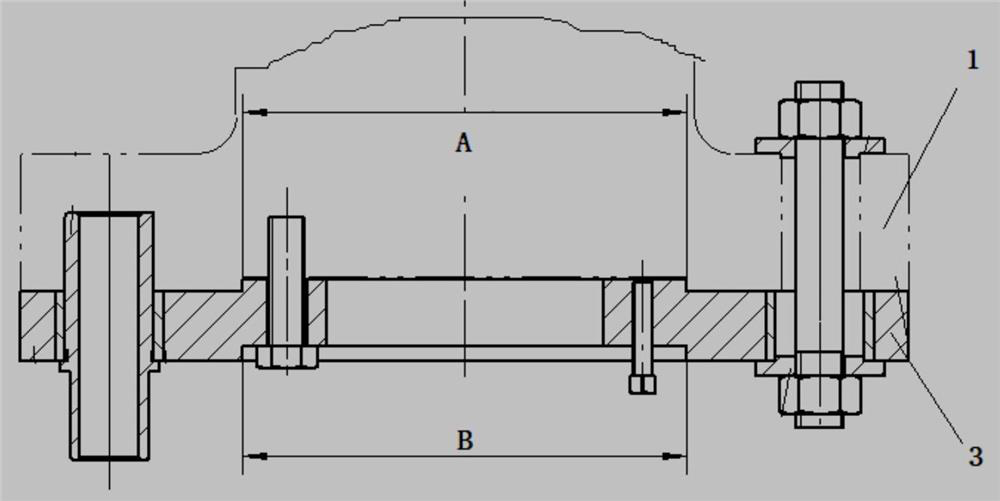

Processing technology for precisely-matched connecting holes of water pump main shaft and motor main shaft

PendingCN114799758AGuarantee machining accuracyImprove processing efficiencyDrill holeMachining process

Owner:CHONGQING WATER TURBINE WORKS

Capacitive touch screen processing technology and processing equipment thereof

ActiveCN108170326AImprove processing efficiencyImprove yield rateInput/output processes for data processingAssembly lineElectrically conductive

Owner:JIANGSU DIJIA ELECTRONICS CO LTD

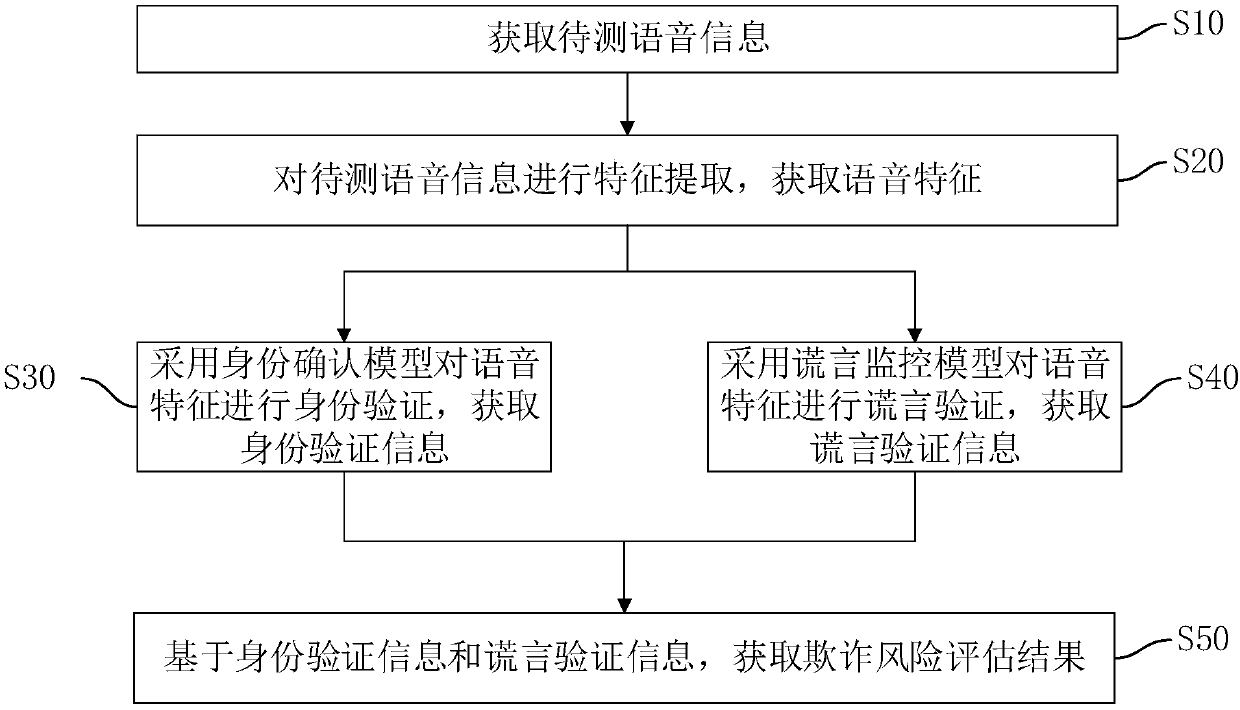

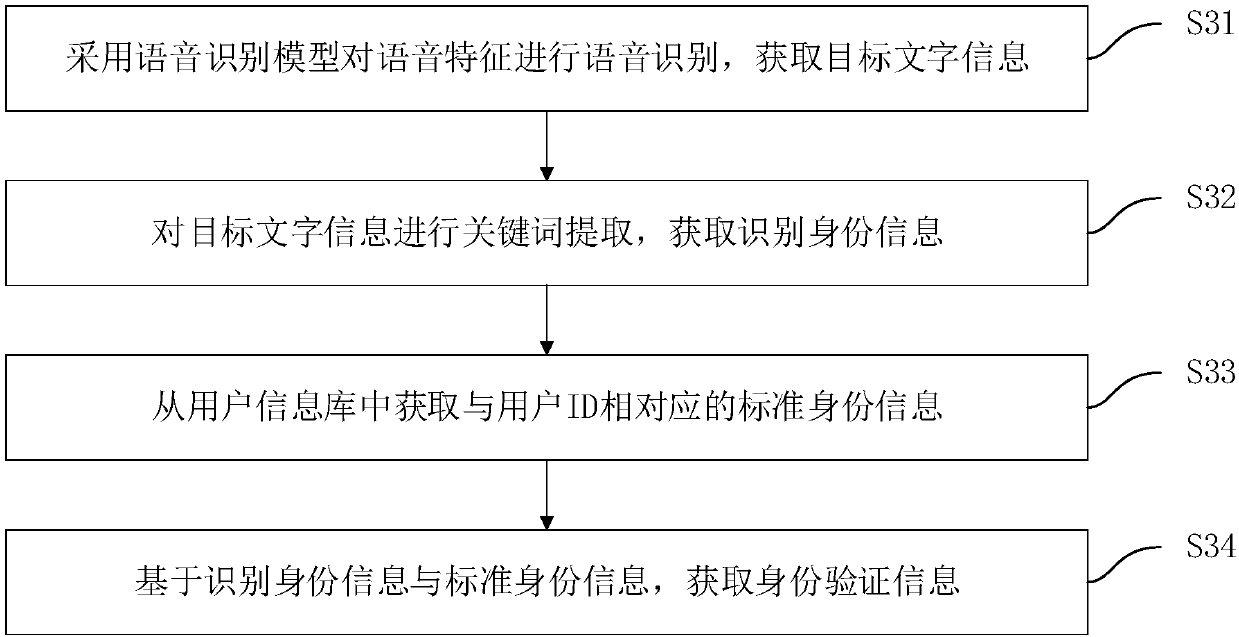

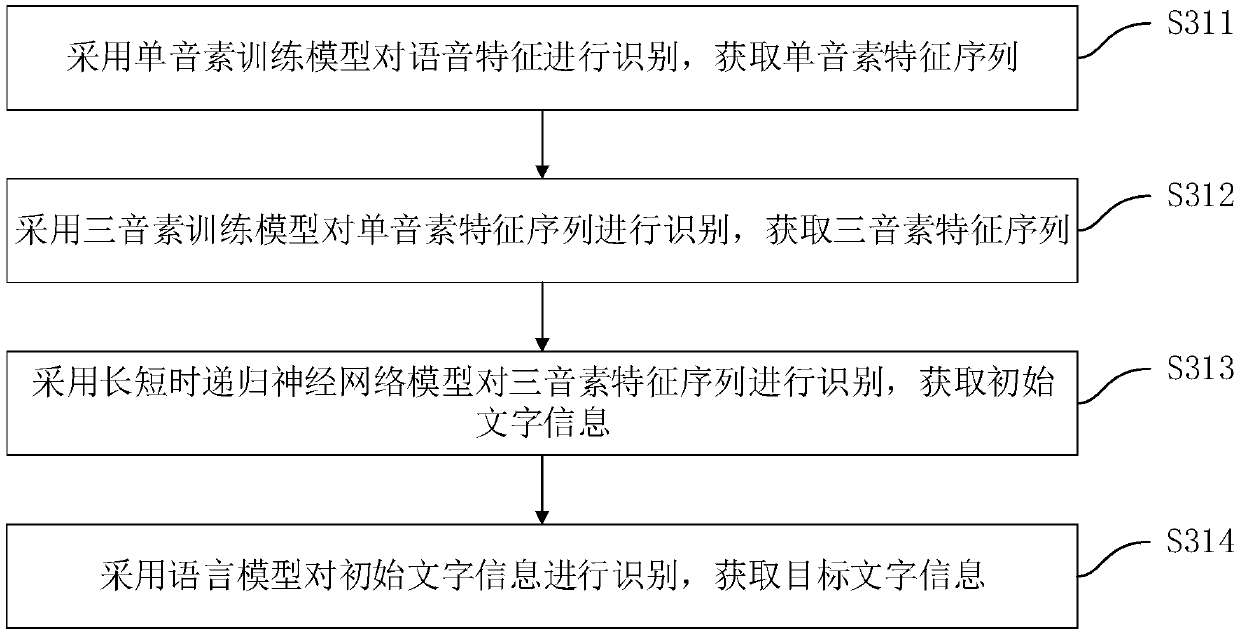

Voice fraud identification method and apparatus, terminal equipment and storage medium

InactiveCN107680602AImprove processing efficiencyReduce labor costsSpeech analysisAutomatic exchangesSpeech soundFeature extraction

Owner:PING AN TECH (SHENZHEN) CO LTD

Rapid riveting mold for Teflon lining

InactiveCN106955934AImprove processing efficiencySmooth and even connectionShaping toolsMechanical engineering

Owner:海口宗恒实业有限公司

Feeding manipulator

InactiveCN102658974AHigh degree of automationImprove processing efficiencyConveyor partsEngineeringManipulator

Owner:DEQING MINGYU LIGHTING

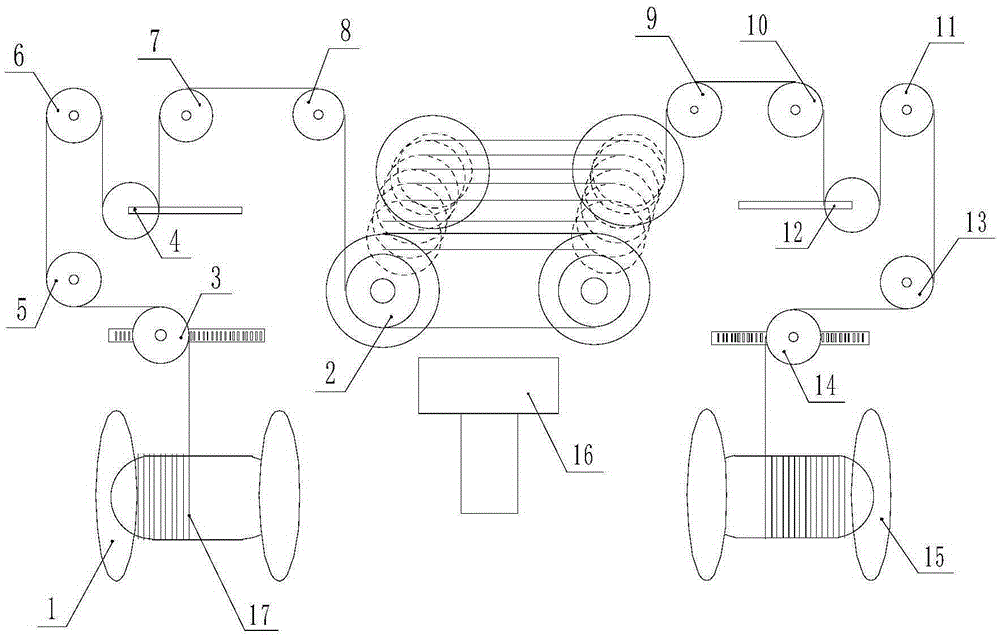

Multi-wire sawing machine used for machining solar cell panel

InactiveCN105235080AGood parallelismImprove processing efficiencyFine working devicesWorking accessoriesMechanical engineeringMulti-wire saw

Owner:JIANGSU YAOYANG ELECTRONICS

Visitor processing system and method based on face recognition technology

InactiveCN109544749AImprove processing efficiencyEasy to handleIndividual entry/exit registersComputer science

The invention discloses a visitor processing system and method based on a face recognition technology. The system includes a visitor registration module for registering visitor information, a query statistics module for querying visitor registration information and modifying the registration information, and an information publishing and pushing module for posting and pushing the registered different types of information to all the booths in real time. Visitors are subjected to verification of combination of a person and a certificate, after the verification passes, the visitor information isregistered, after the registration is completed, the authorized visitors enter a gate through face recognition and the registration information is pushed to all the booths in real time to avoid the problem that it is determined whether the visitor is the same person as a person shown on an identity card or not in the work of visitor visiting verification passing to ensure the authenticity of the visitor identity, greatly increase the safety of the visitor processing system and improve the visitor processing efficiency and the processing level.

Owner:FOSHAN YUNTUAN TECH CO LTD

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap