Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Reduce labor costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

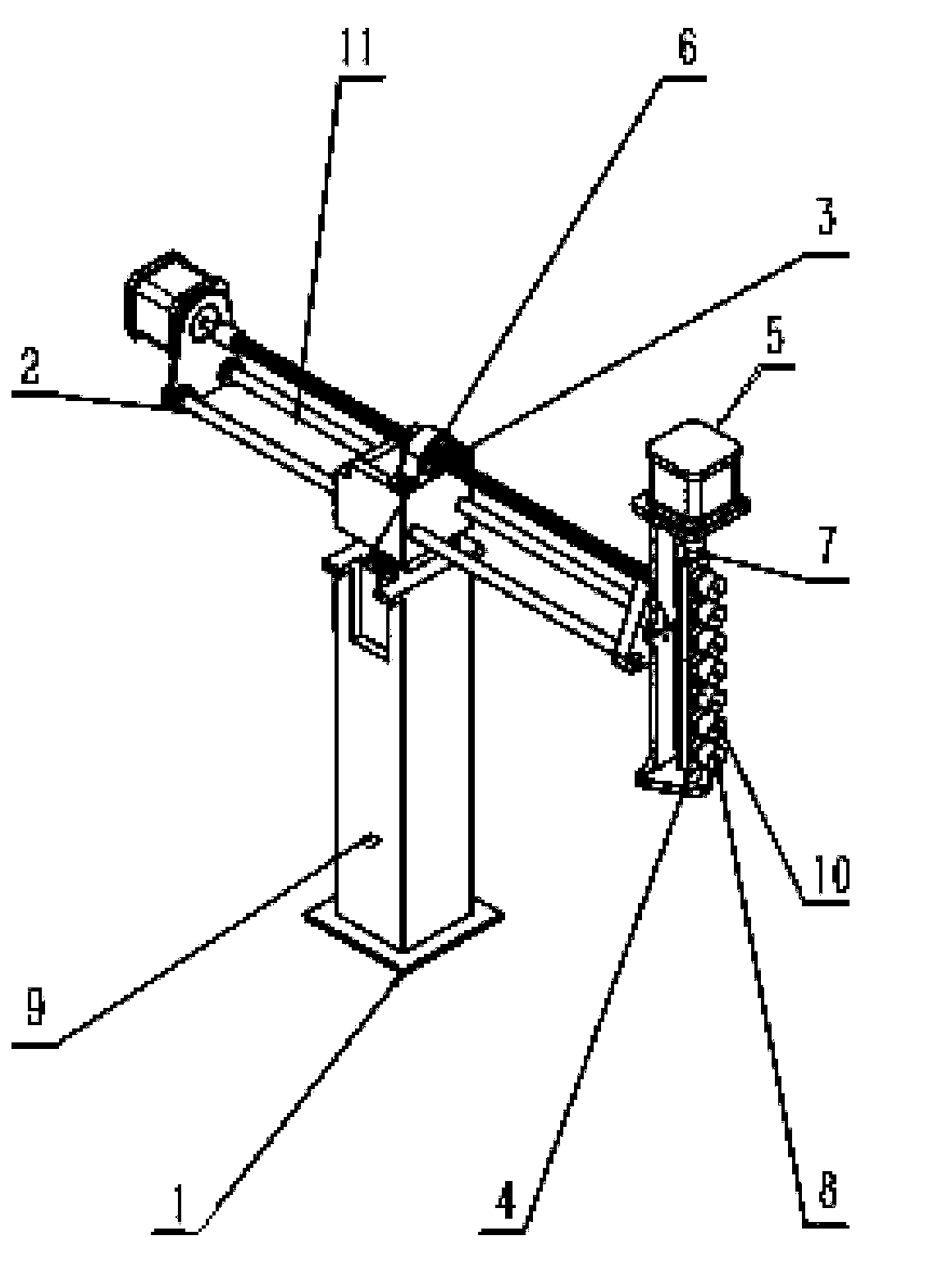

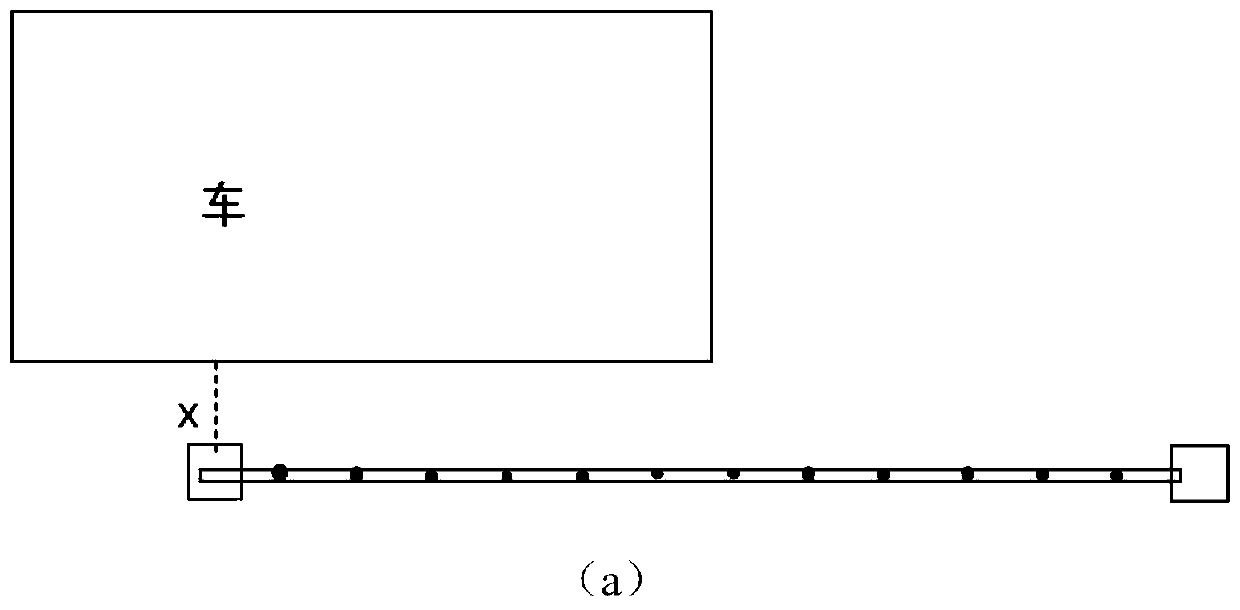

Traffic surveillance method and system

InactiveUS20050151846A1Avoid high pressureGuaranteed accuracyTelevision system detailsColor television detailsTamper resistanceVideo recording

The invention relates generally to a method and system for monitoring traffic events at a predetermined location, using a temporary video camera set up to record traffic movements through an intersection or other location along a road. The method preferably comprises taking a video recording of the location, and then sending the recording to a foreign country where the recording can be reviewed manually at a reduced cost. To facilitate an accurate and consistent review of the recording, the invention preferably uses “event lines” that can be superimposed on the video monitor, wherein the event lines help determine when a vehicle has passed through an intersection, i.e., when a recordable traffic event occurs. The system also preferably uses a computer-operated program adapted to assist the operator in reviewing, verifying and summarizing the recorded information, wherein a particular key or keys can be pressed depending on the type of event to be indicated. The system is also able to identify the exact frame number of a recordable event that corresponds to an exact moment in real time, i.e., when the event actually occurred. A tripod-like apparatus for temporarily setting up a video camera in locations where no existing pole or structure is available, as well as a tamper-proof housing in which the video recording device can be temporarily mounted, can also be provided.

Owner:THORNHILL WILLIAM

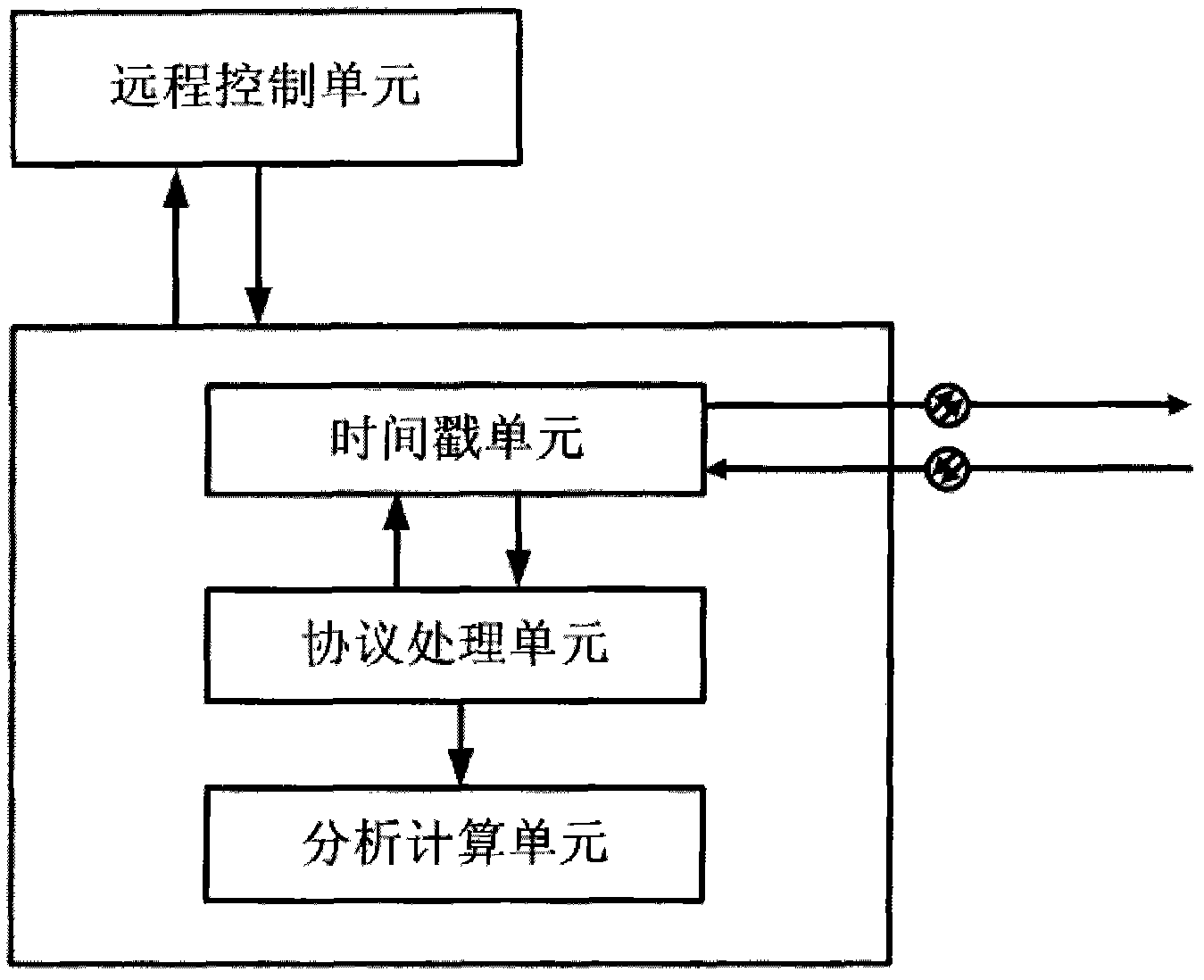

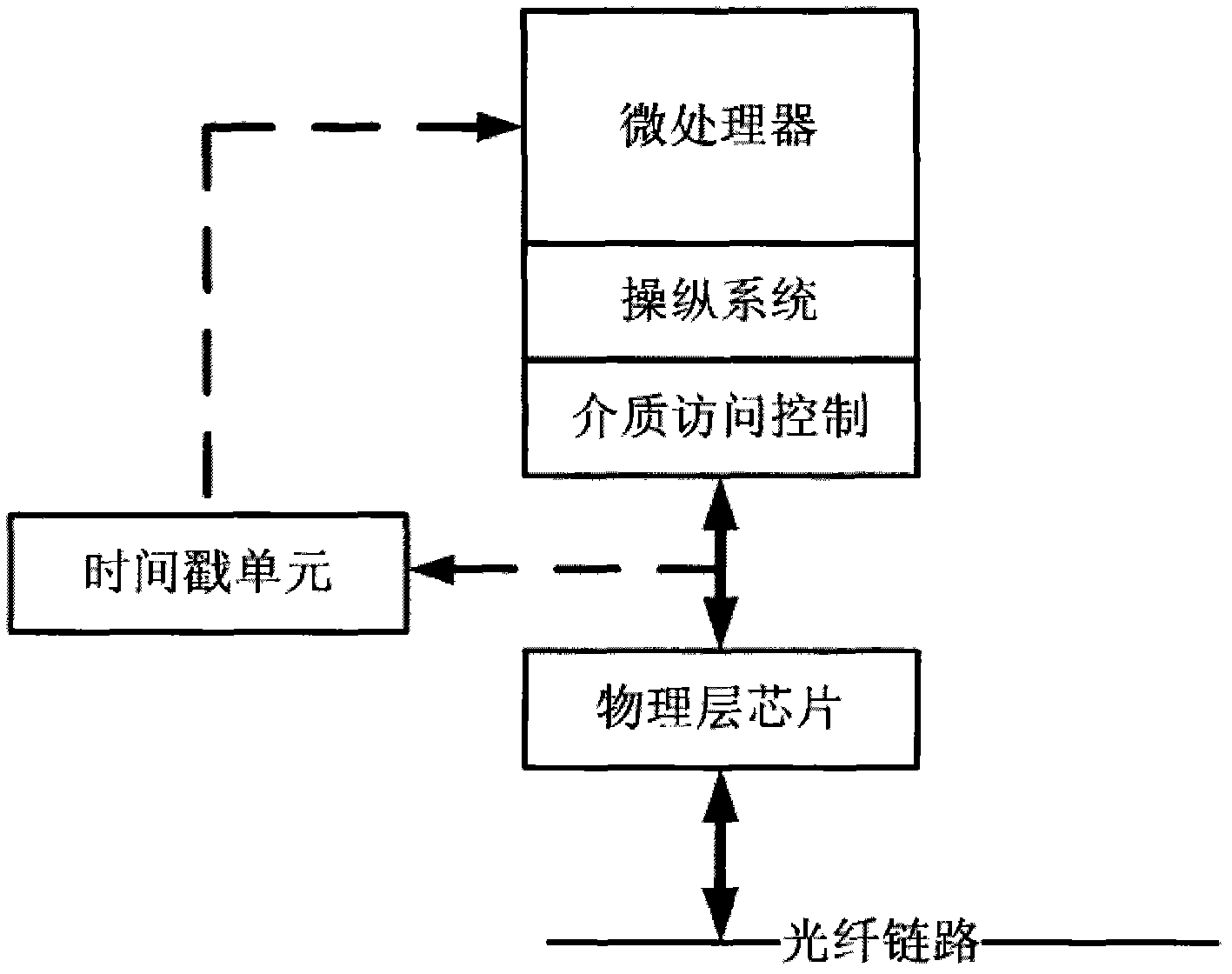

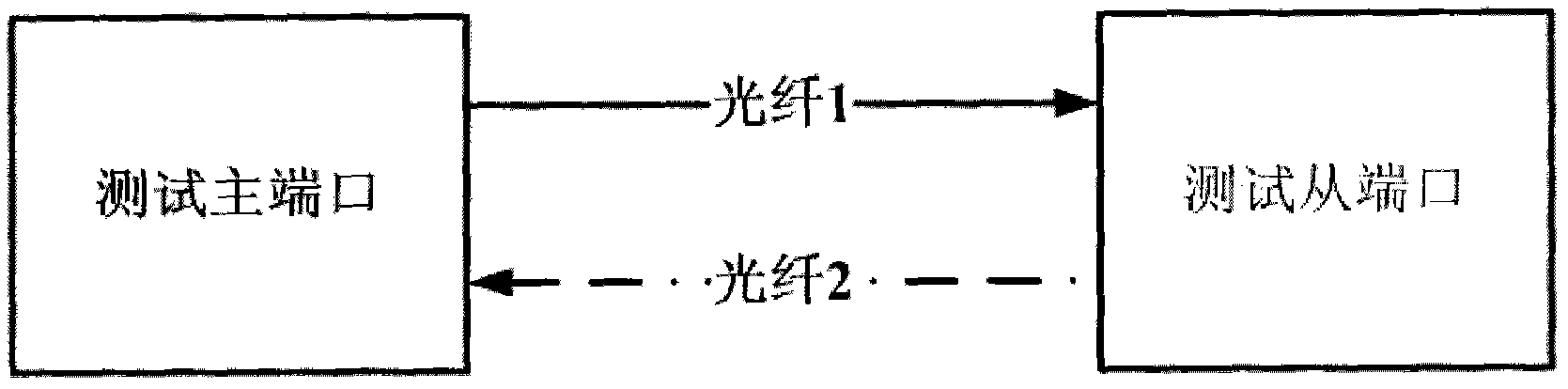

Method and device for measuring optical fiber asymmetry time delay

ActiveCN102291178ASave moneySave labor costsTime-division multiplexElectromagnetic transmissionTime delaysFiber

Disclosed are a method and apparatus for measuring optical fiber asymmetry time delay. The method comprises: an RTU configuring working states of a Master and a Slave at two ends of an optical fiber line; the RTU delivering an instruction to measure a first optical fiber, and a Master side PPU sending a message, recording a sending time stamp t1 and transmitting the sending time stamp t1 to the Slave; a Slave side PPU receiving the message, recording an arrival time stamp t2, and storing the arrival time stamp t2 corresponding to t1; the RTU displaying that measurement for the first optical fiber is completed, preparing to measure a second optical fiber, and swapping the two optical fibers; the RTU delivering an instruction to measure the second optical fiber, and the Master side PPU sending a message, recording a sending time stamp t'1 and transmitting the sending time stamp t'1 to the Slave; the Slave side PPU receiving the message, recording an arrival time stamp t'2, and storing the arrival time stamp t'2 corresponding to t'1; and an ACU calculating an asymmetry time delay compensation value and sending the asymmetry time delay compensation value to the RTU. The present invention is not limited by sites, saves cost and labor, is simple and fast, and has short stabilization time as well as high testing efficiency and precision.

Owner:FENGHUO COMM SCI & TECH CO LTD

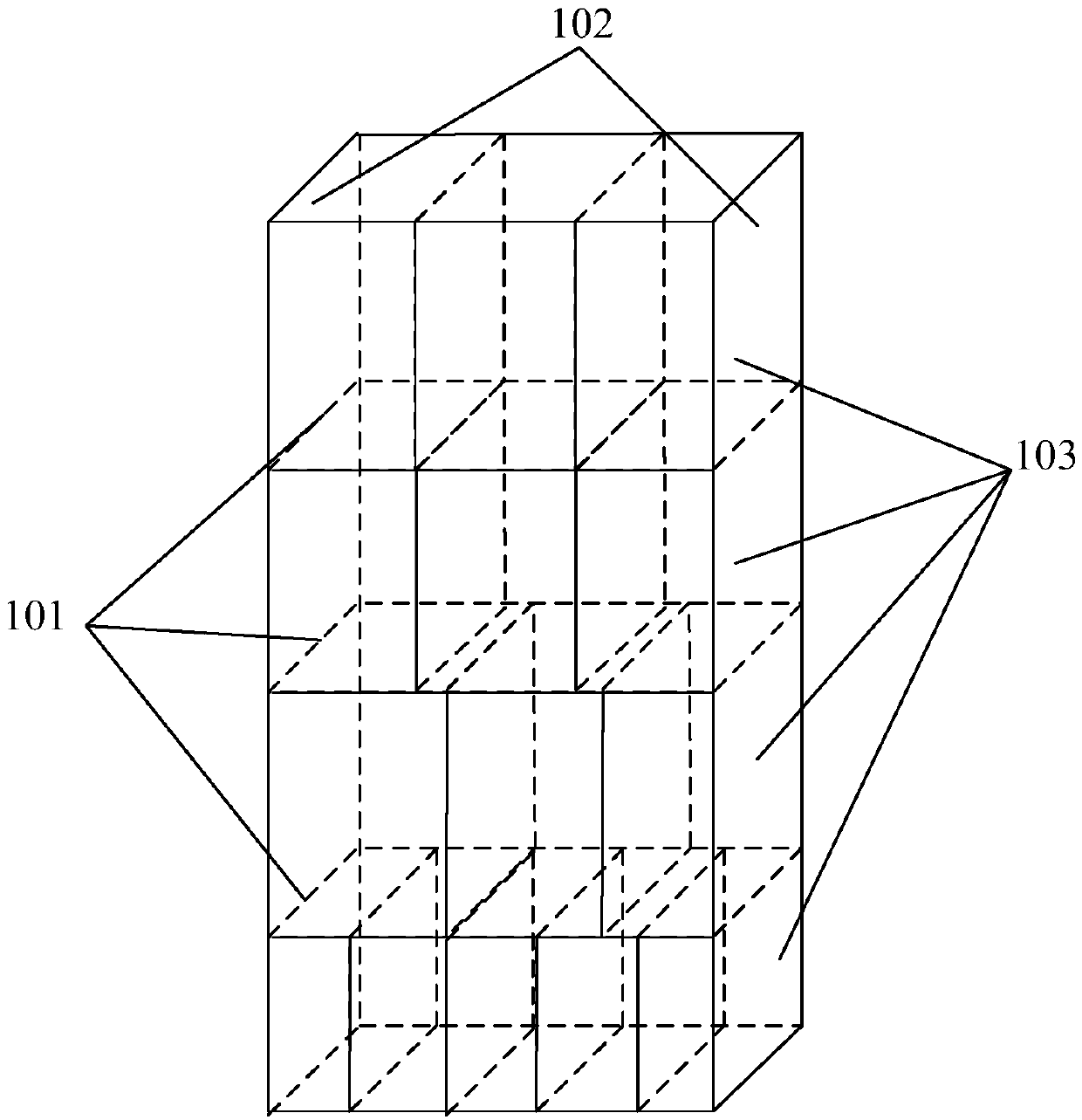

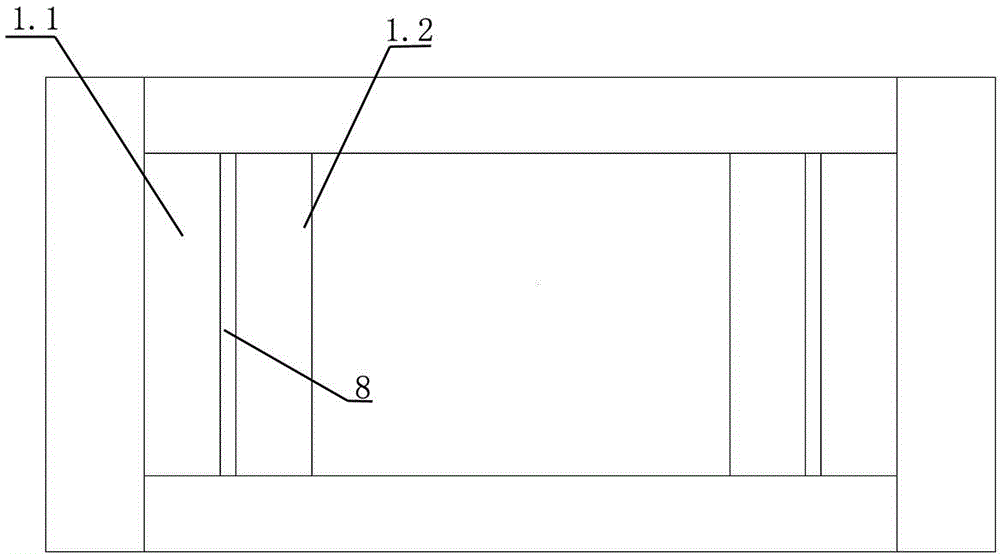

Bricklaying device and bricklaying robot

The invention discloses a bricklaying device and a bricklaying robot. The bricklaying device comprises a base, a brick transfer assembly, a brick feeding assembly and a plastering assembly. The bricktransfer assembly comprises a mechanical arm and a grabbing part. The mechanical arm is connected with the grabbing part to transfer bricks. The mechanical arm is movably arranged on the base and cando up-down lifting motion relative to the base. The brick feeding assembly comprises a bearing platform. The bearing platform is suitable for bearing the bricks. The bearing platform can do up-down lifting motion relative to the base, and the highest distance of the bearing platform relative to the base can be adjusted, so that the bricks are located within the grabbing range of the grabbing partall the time. The plastering assembly is arranged on the base and comprises a plastering head. The plastering head is used for plastering the bricks. The bricklaying device provided by the embodimentof the invention integrates brick transferring, brick plastering and bricklaying, can automatically complete the multiple working procedures, liberates manpower and accelerates the bricklaying progress; and shorter time required for brick taking is consumed, plastering and bricklaying can be quickly carried out after brick taking, the whole working procedure time is short, and the bricklaying efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Oil pumping well semi-supervised fault diagnosis method based on curvelet transformation and kernel sparsity

ActiveCN107165615AReduce labor costsStrong generalization abilityCharacter and pattern recognitionConstructionsCoefficient matrixDiagnosis methods

Owner:NORTHEASTERN UNIV

Enterprise material management system and method

InactiveCN104134124ASolve the high time costShorten the timeResourcesManufacturing computing systemsData matchingTime distribution

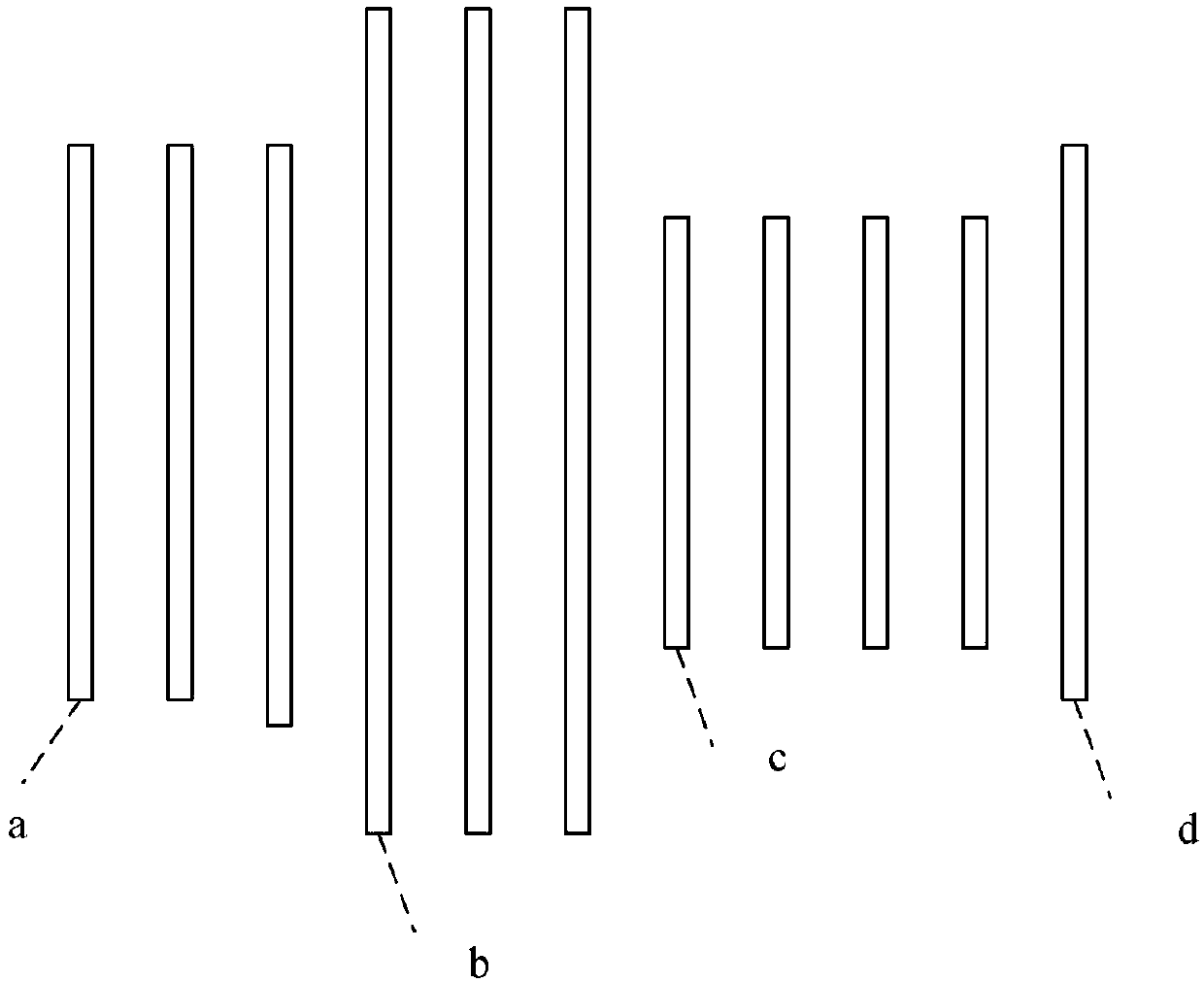

The invention discloses an enterprise material management system and method. The enterprise material management system comprises a data collection module, a data matching module, a control rule management module, an interface displaying module and a data storage module. The method comprises the steps of dividing a material yard, matching measured materials in an MES and materials of an ERP system of an up one level, associating the material yard with the measured materials, dividing the material yard into material strips, dividing the material strips into material piles, storing the specific measured materials into the specific material piles and generating a material inventory information real-time distribution diagram of the material yard, wherein the positions of the material piles and the stacked materials can be revised. According to the enterprise material management system and method, it only needs one or two persons to analyze the material inventory information real-time distribution diagram of the material yard, then the positions, the orders and the materials of the material piles in the material yard can be fast adjusted according to the material warehousing plan, and the material piles can be increased or decreased or split or combined; the operators can set the frequently-used material pile positions nearby according to the accumulated production experience and vacate or merge or replace the positions of the material piles so as to meet the requirement of the materials with the large inventory in a short time.

Owner:WUKUN STEEL

Real-time task calculation control method, device, server and storage medium

InactiveCN110377429AImprove development efficiencyFast and efficient real-time data processingProgram initiation/switchingResource allocationReal-time dataData source

The invention discloses a real-time task calculation control method, a real-time task calculation control device, a server and a storage medium. The method comprises the steps of obtaining the information of a data source, and enabling the information of the data source to be configured and input through executing a first page; obtaining calculation result storage information after the data sourceis calculated, wherein the storage information is input by executing second page configuration; obtaining calculation logic formed by an SQL control chain based on a page, the SQL control chain configuring input by executing a third page, the SQL control chain comprising one or more controllable SQL controls based on the page, and the calculation logic being execution logic for calculating the data source; and packaging the information of the data source, the calculation result storage information and the calculation logic of the same real-time task into an executable file, and sending the executable file to a cluster system for running. According to the technical scheme, the effect of rapidly and efficiently completing real-time data processing through SQL control operation and SQL statement writing is achieved.

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

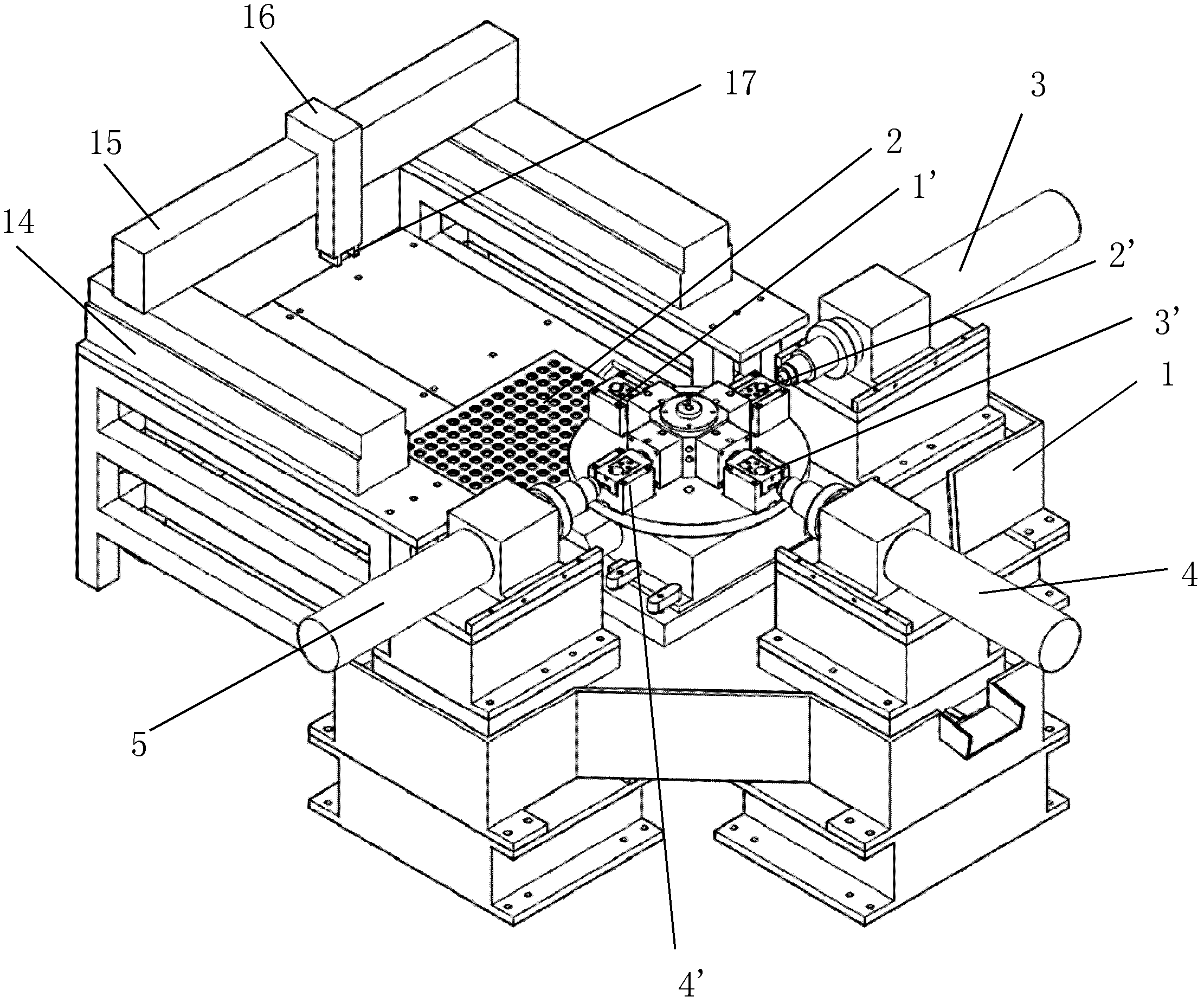

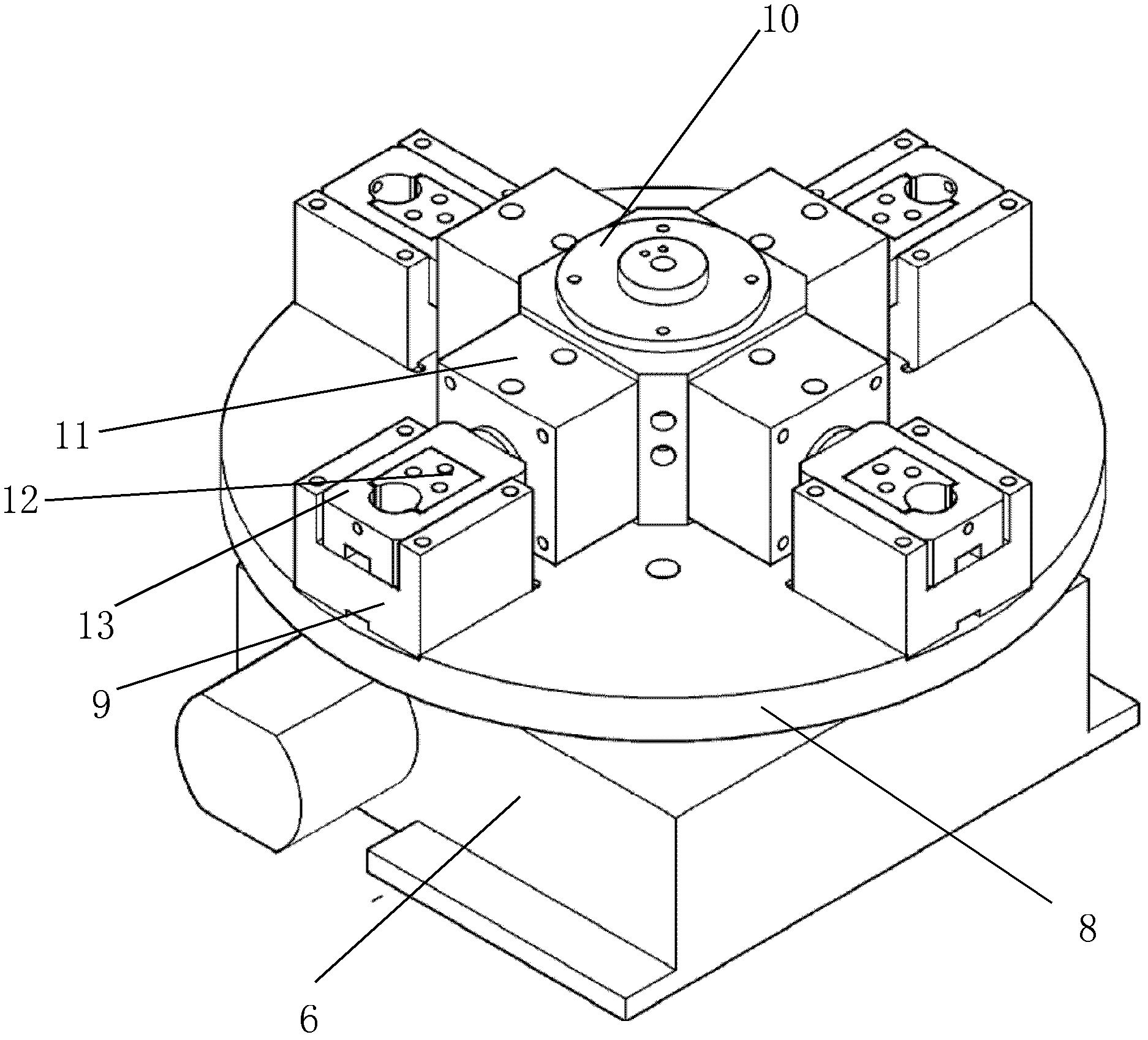

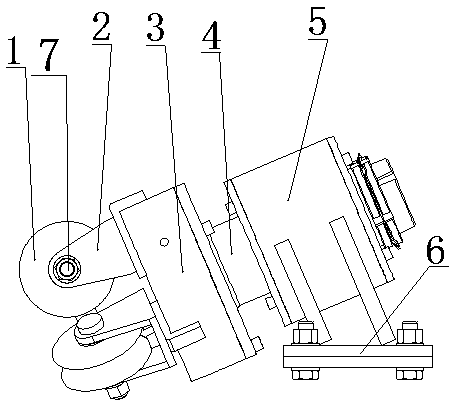

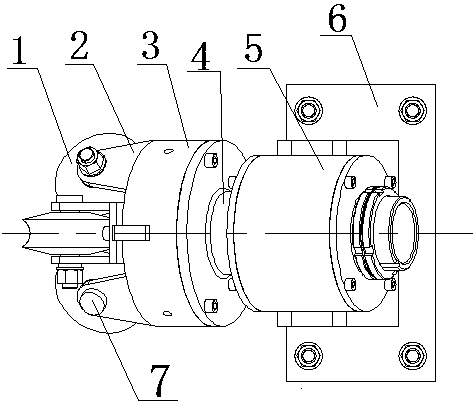

Special four-station machine tool for jackscrew holes of worms

InactiveCN102909554ANot affected by processing qualityFully automatedOther manufacturing equipments/toolsPositioning apparatusTransverse axisDrill hole

The invention relates to a special four-station machine tool for jackscrew holes of worms. The special four-station machine tool is characterized by comprising a tool body, a tray, a chamfering power head, a drilling power head, a tapping power head, a hydraulic turntable and fixtures; the hydraulic turntable is fixedly connected to the center of a working table of the tool body, the chamfering power head and the tapping power head are symmetrically fixedly connected onto the working table of the tool body along the transverse axis of the hydraulic turntable, the drilling power head is fixedly connected to the central position between the chamfering power head and the tapping power head along the radial direction of the hydraulic turntable, and the fixtures for mounting a workpiece are arranged on rotary work stations of the hydraulic turntable. The special four-station machine tool has the advantages that the special four-station machine tool are fully automatic, and labor cost is greatly reduced; various working procedures are centralized and can be carried out simultaneously, and accordingly the efficiency is improved; and influence of skills of operators to the machining quality is avoided, and the special four-station machine tool is stable and reliable.

Owner:天津市中马骏腾精密机械制造有限公司

Multiple-use two-reservoir bucket

InactiveUS20070241049A1Easy to manufactureInexpensiveLoose filtering material filtersCartridge filtersSprayerEngineering

A multi-use two-reservoir bucket that combines various separate tasks and methods to make available more options. More specifically, the multi-use two-reservoir bucket is a two-reservoir system to supply liquid or material to a pump / sprayer, tools and accessories.

Owner:TYTAR FR A

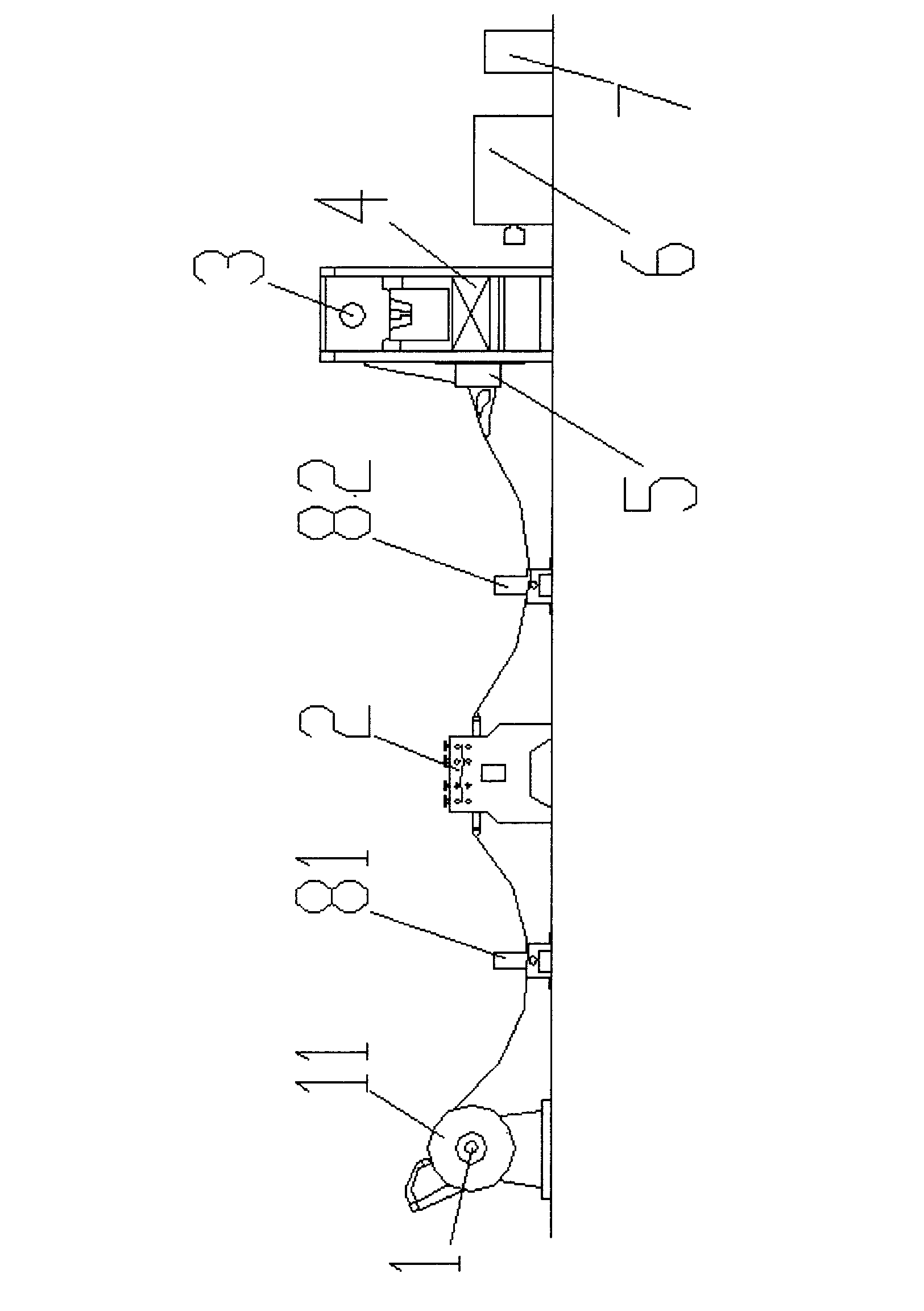

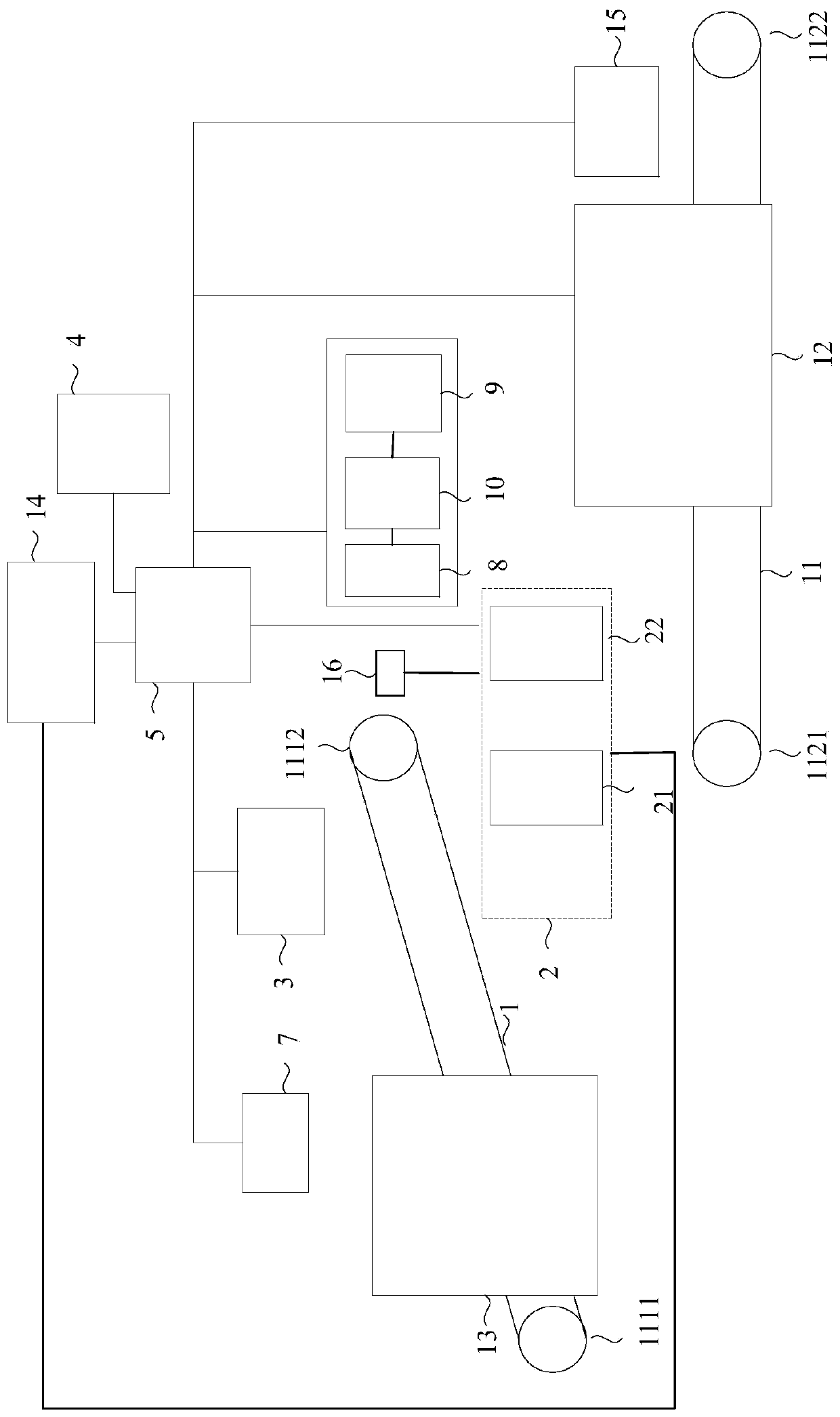

Full-automatic wire bundle machining and assembling equipment

ActiveCN108666841AAutomate operationsReduce manual operationsLine/current collector detailsRubber ringEngineering

Full-automatic wire bundle machining and assembling equipment is characterized in that a wire bundle feeding and cutting mechanism comprises a wire bundle cutting mechanism, a first wire bundle transferring mechanism, a wire bundle coil mechanism, a second wire bundle transferring mechanism, a wire bundle binding mechanism, a wire bundle end positioning mechanism and a third wire bundle transferring mechanism which are sequentially arranged from left to right. A wire bundle end machining and assembling system comprises a plurality of machining stations and a synchronous positioning and transferring mechanism. Each machining station is sequentially provided with a rubber ring sleeving mechanism, a copper ring sleeving mechanism, a peeling mechanism, a pin welding mechanism and a connector riveting and pressing mechanism. The equipment has the advantages that feeding, cutting, winding, binding, rubber ring sleeving, copper ring sleeving, peeling, pin welding, connector riveting and pressing and discharging are completed automatically, automation of the whole process is achieved, manual operation is reduced, the working efficiency is improved, the labor cost is reduced, the working precision is high, and the qualified rate of products is guaranteed.

Owner:ZHEJIANG XIAOYU TECH CO LTD

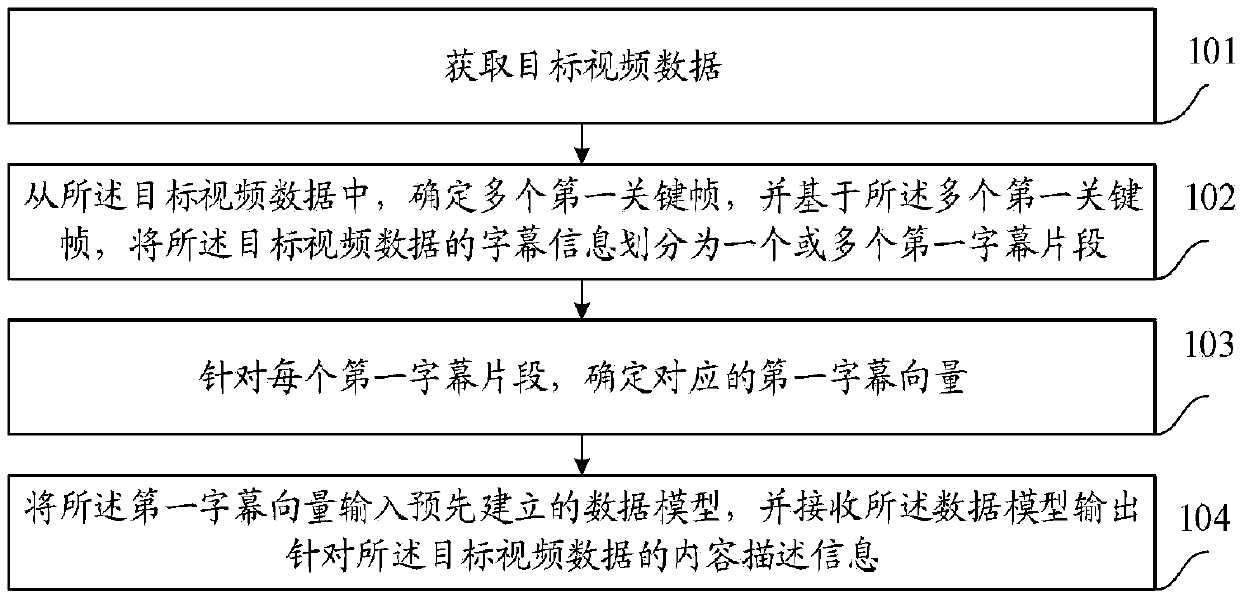

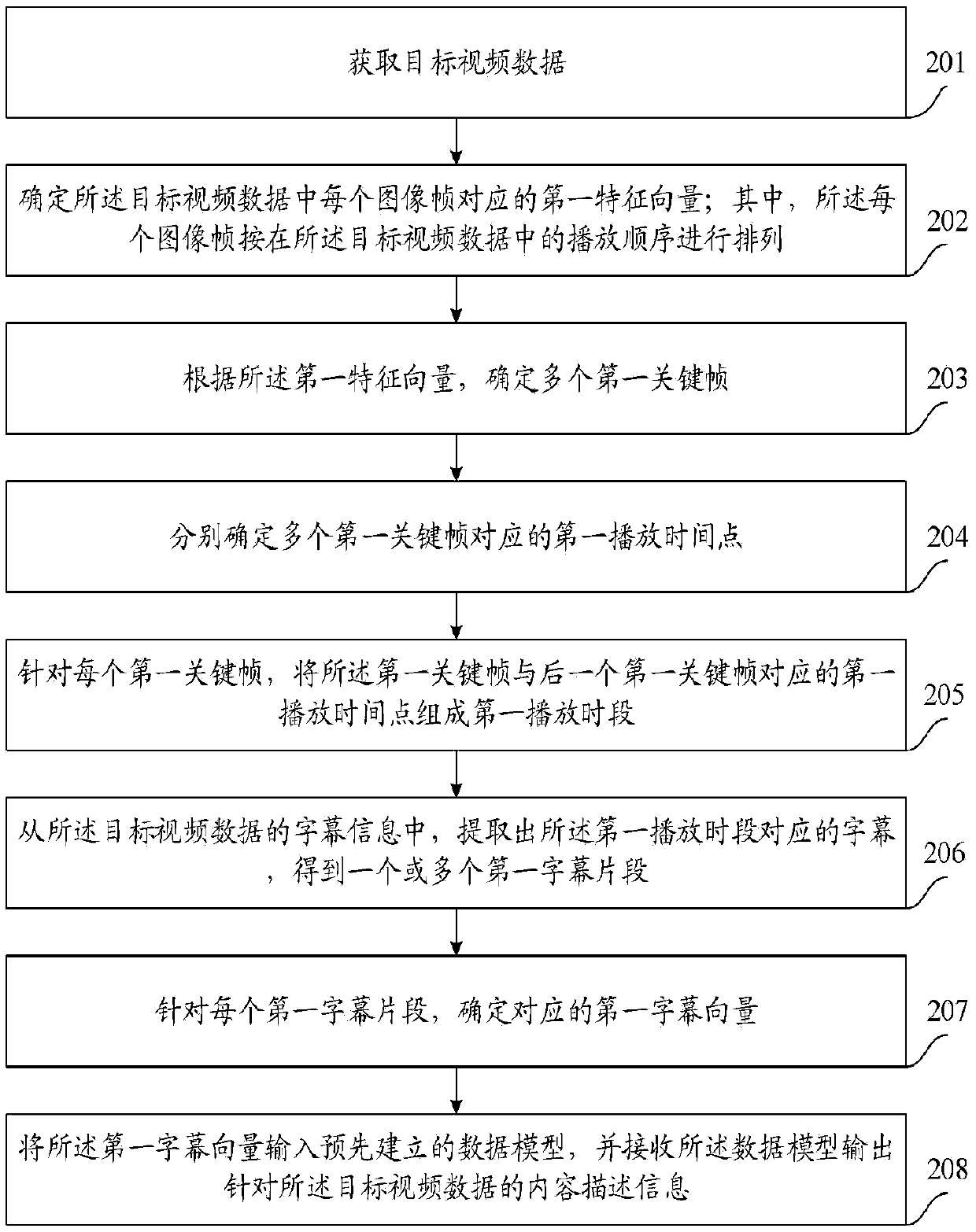

Method and device for video processing

ActiveCN108683924AImprove efficiencyReduce labor costsSelective content distributionData modelVideo processing

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

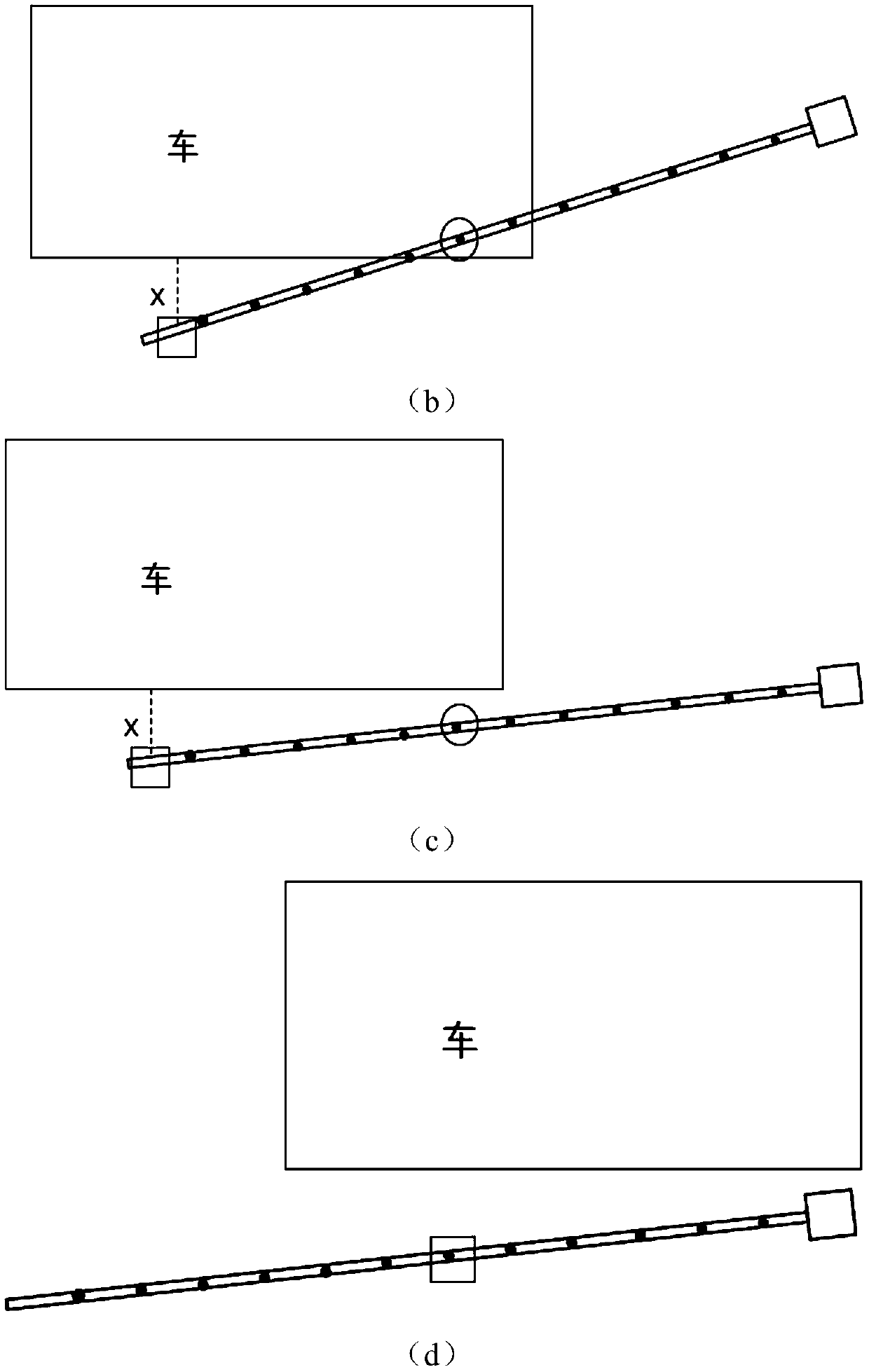

Automatic car washing system and method

ActiveCN109849859AReduce labor costsSimple structureCleaning apparatus for vehicle exteriorsElectric machinerySpray nozzle

Owner:GUILIN UNIV OF ELECTRONIC TECH

Self-stable suspension type unloading platform and construction process thereof

PendingCN107965147AShorten the installation and dismantling periodSimple installation and disassemblyBuilding material handlingSocial benefitsArchitectural engineering

The invention discloses a self-stable suspension type unloading platform and a construction process thereof. The unloading platform comprises main beams. Auxiliary beams are arranged between the mainbeams. Platform embossing steel plates are arranged among the main beams and the auxiliary beams. Vertical beams are arranged on the upper sides of the main beams. A rebar pull rod upper support is arranged among the vertical beams. A rebar pull rod lower support parallel to the rebar pull rod upper support is arranged at the bottom ends of the main beams. Rebar pull rods are arranged between therebar pull rod upper support and the rebar pull rod lower support. Upper floor system edge beams are arranged at the top ends of the vertical beams. A feed channel plate is arranged at the upper endsof lower floor system edge beams and the platform embossing steel plates. Compared with a traditional steel overhung unloading platform, embedded steel wire rope ring hanging, profile steel support ring anchoring, ending anchoring ring hole blocking and hanging ring rebar cutting treatment are not needed, and a passenger channel can be laid along a floor; construction installation and detachment operation is simple, safe and convenient, the installation and detaching construction period is shortened, embedded pieces and labor cost are greatly saved, the platform has remarkable economic and social benefits and meets the efficient, energy-saving and green construction requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Method and device for generating geographical fence

ActiveCN106162544AIncrease coverageReduce labor costsLocation information based serviceTransmissionData scienceGeo-fence

Owner:ADVANCED NEW TECH CO LTD

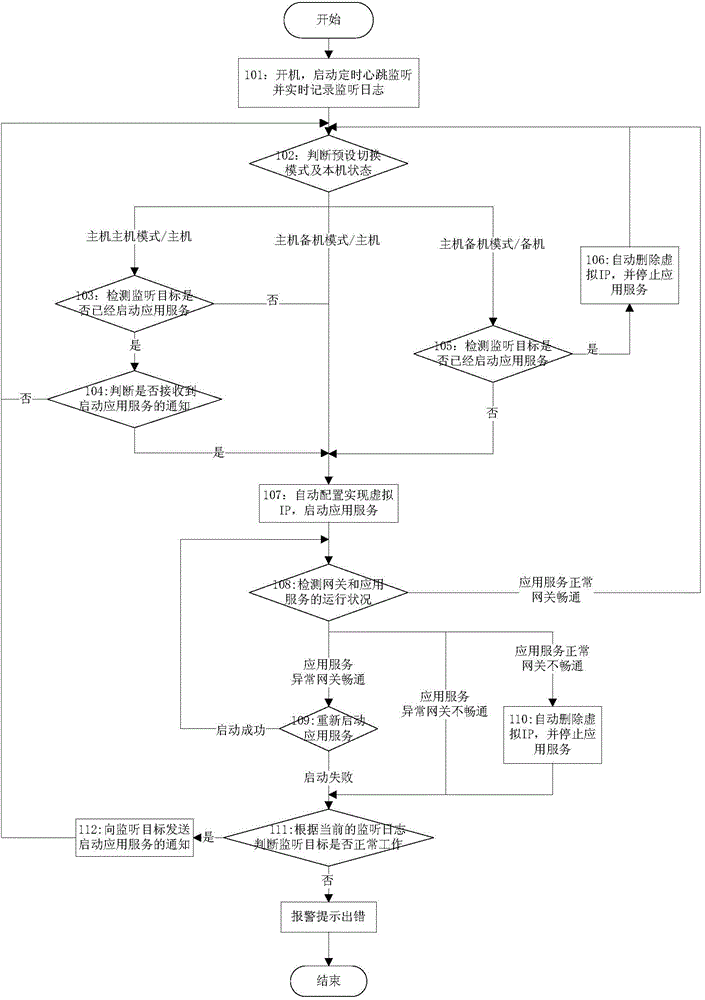

Monitoring event processing method and system

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Vertical type electronic transformer electric performance testing and ultraviolet curing device

InactiveCN103728519AIncrease productivityReduce labor costsElectrical testingInductances/transformers/magnets manufactureElectricityMagnetic core

Owner:上海美星电子有限公司

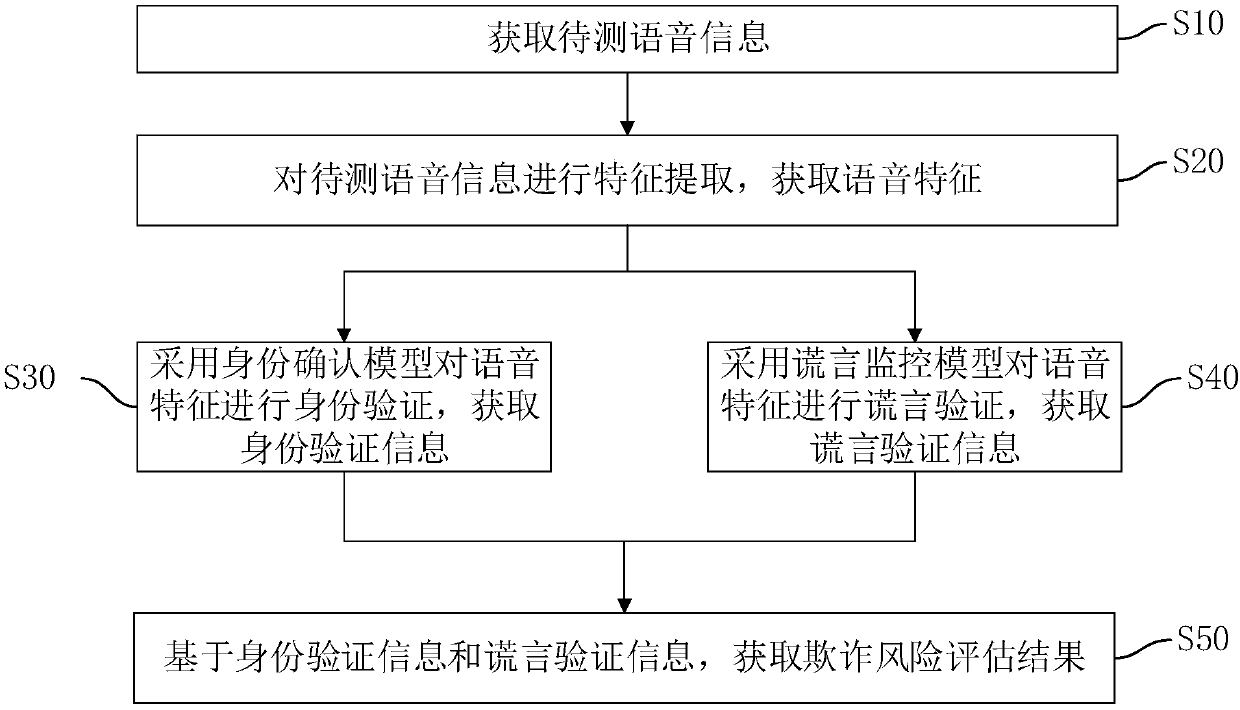

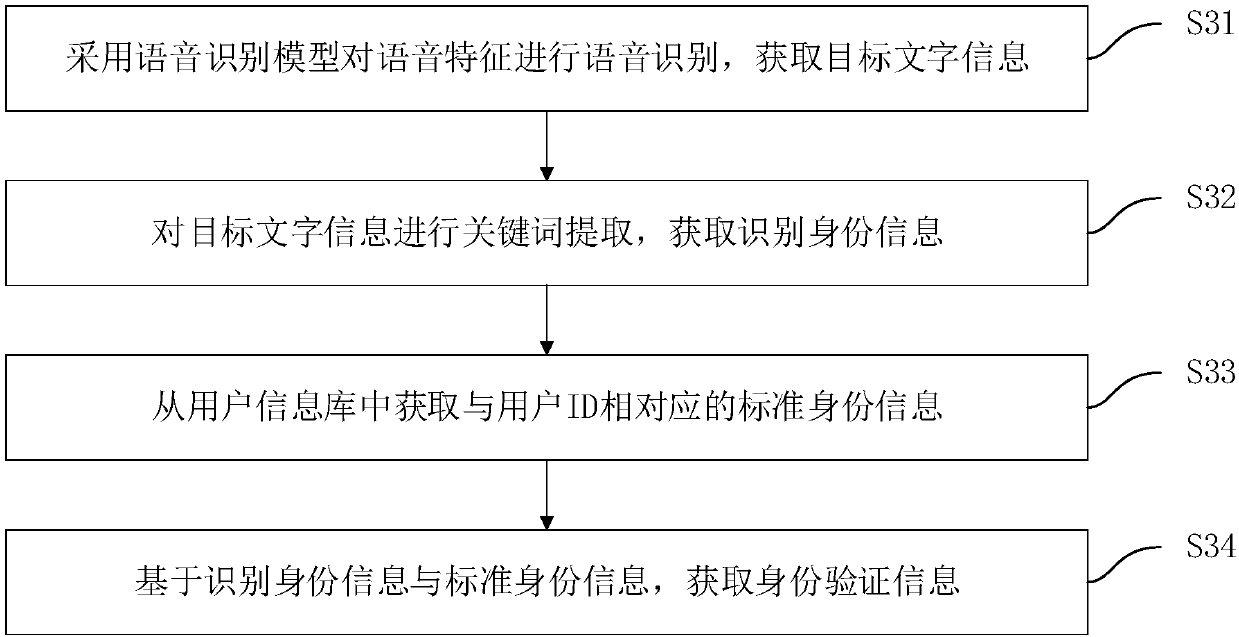

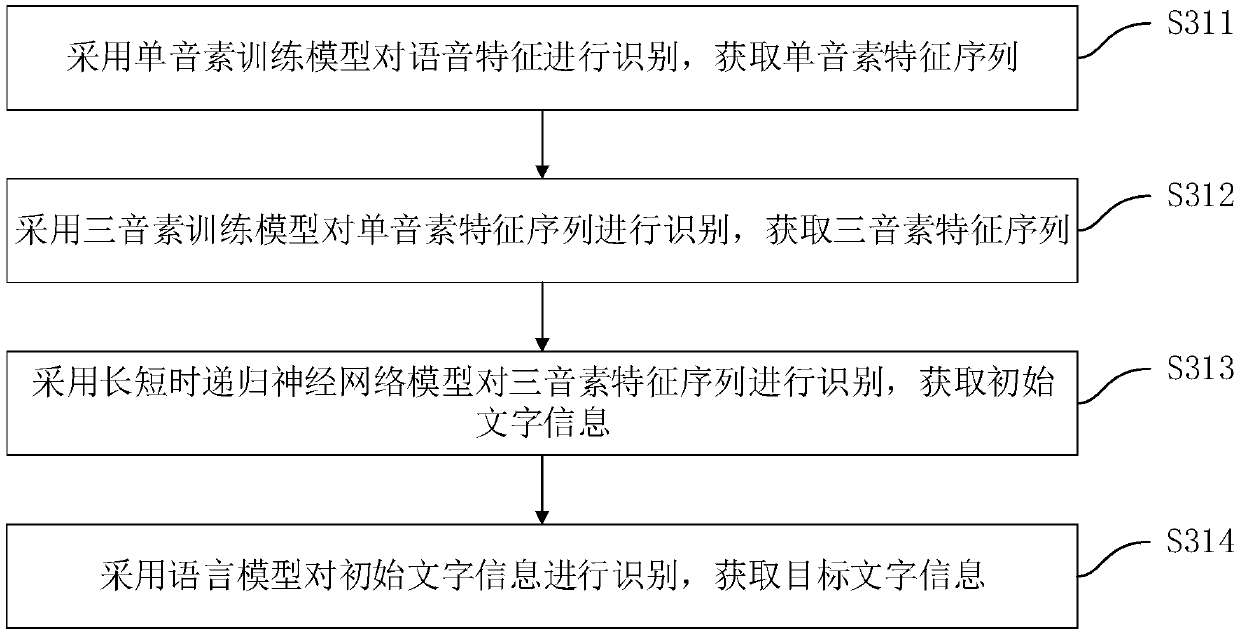

Voice fraud identification method and apparatus, terminal equipment and storage medium

InactiveCN107680602AImprove processing efficiencyReduce labor costsSpeech analysisAutomatic exchangesSpeech soundFeature extraction

Owner:PING AN TECH (SHENZHEN) CO LTD

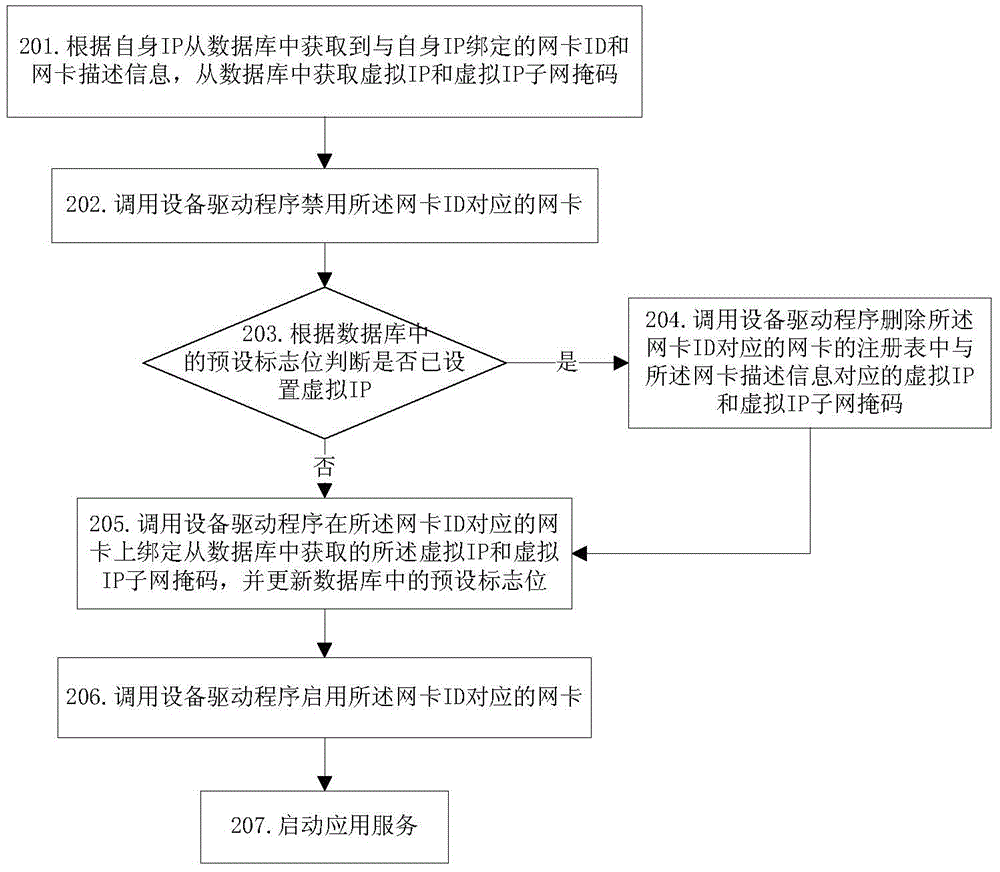

Virtual IP realization method

ActiveCN104378449AReduce manual operationsReduce labor costsTransmissionSwitched communication networkComputer communication networks

Owner:FEITIAN TECHNOLOGIES

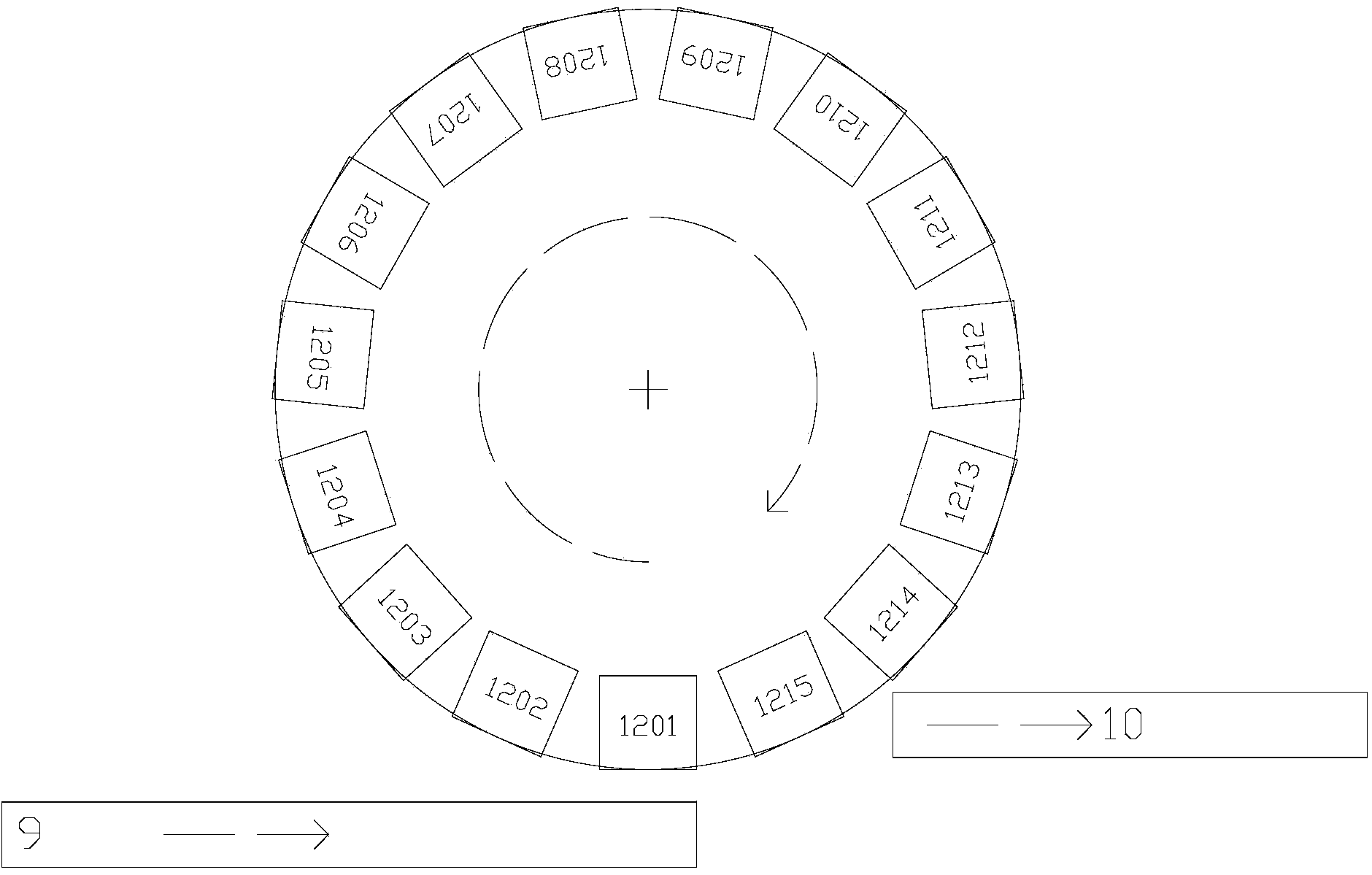

Multi-point pulsation monitoring system

PendingCN114424750AImprove overall economic efficiencyReduce labor costsMilking devicesComputer scienceControl engineering

Owner:北京楚基伟业科技有限公司

Warehousing method, device, equipment and machine readable medium

PendingCN109784793AImprove accuracyReduce labor costsLogisticsComputer scienceMachine-readable medium

Owner:CAINIAO SMART LOGISTICS HLDG LTD

Iron phosphate synthesizing process and device

ActiveCN109734067AImprove automationReduce labor costsPhosphorus compoundsAutomatic controlConversion reaction

Owner:博创宏远新材料有限公司

Invoicing method of networked sharing fiscal cash register

ActiveCN104700516AImprove work efficiencyReduce labor costsCash registersTransmissionCopyingData cache

Owner:AEROSPACE INFORMATION

Three-stage air filtering system for gas turbine

InactiveCN104548774AReduce labor costsDispersed particle filtrationGas turbine plantsAir filterEngineering

Owner:CHENGDU BOOST ENERGY TECH

Automatic screw locking device

InactiveCN103465011AMass production labor costReduce labor costsMetal working apparatusComputer moduleMoving parts

Owner:TERA AUTOTECH CORP

Stamping production equipment and stamping production technology

Owner:NINGBO HAIHONG RADIATOR

Method and device for comprehensively processing pig dung in large-scale pig farm

PendingCN110127970AEasy to handleSimple process conditionsBio-organic fraction processingSpecific water treatment objectivesPig farmsBiological filter

The invention discloses a method and a device for comprehensively processing pig manure in a large-scale pig farm. The method for comprehensively processing pig dung in the large-scale pig farm comprises the following steps: S1, the pig dung in pig houses is collected by a mechanical dung scraping facility, and is transported into a dung collecting tank; S2, the pig dung in the dung collecting tank is added into a fermentation tower by a screw conveyor, undergoes anaerobic dry fermentation to produce biogas, and then undergoes aerobic composting; S3, the biogas generated in the anaerobic dryfermentation process is introduced into and stored in a gas storage cabinet, odorous gas generated during the aerobic composting is introduced into a biological filter and is processed, the above produced organic fertilizer is transported to a curing workshop and is cured, and generated biogas slurry and leachate enter an anaerobic fermentation reactor by a pump, and are used to produce biogas; and S4, the biogas obtained in step S2 and step S3 is purified, and then used, the produced organic fertilizer is returned to the field, and the generated biogas slurry is used for irrigating crops after being discharged into an oxidation pond and processed. The method and the device have the advantage of good processing effect, simple process conditions, no secondary pollution and high economic benefits.

Owner:GUANGDONG GUANGKEN ANIMAL HUSBANDRY ENG RES INST CO LTD

Shaping device for correcting roundness of split conductor

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

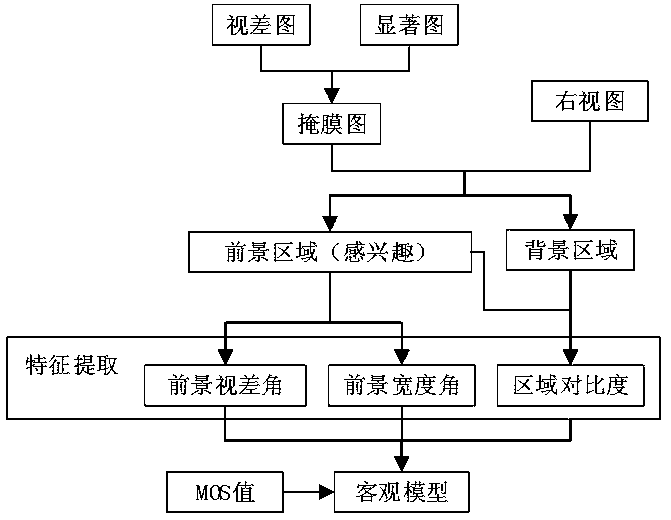

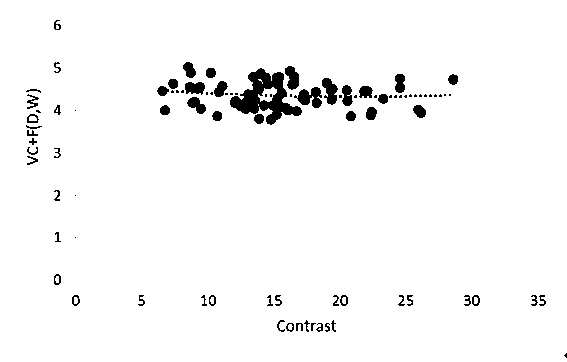

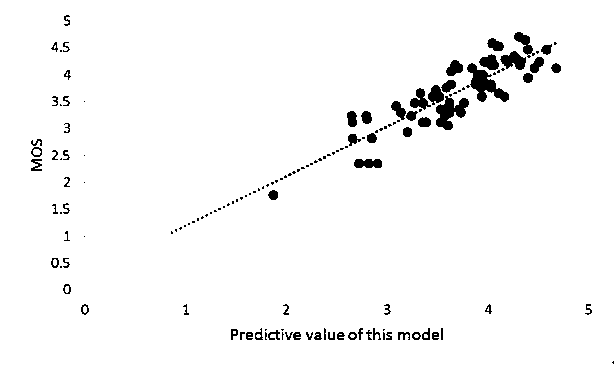

A stereoscopic image visual comfort evaluation method based on D + W model and contrast

ActiveCN109167988AReduce labor costsThe model evaluation results are accurateImage enhancementImage analysisRegion of interestViewpoints

Owner:CHANGCHUN UNIV OF SCI & TECH

Bracket for anchorage device quiescent-load anchorage property test and usage method of bracket

ActiveCN103149083AConvenient steel strand threadingReduce labor costsStrength propertiesSquare pyramidEngineering

Owner:中国建筑土木建设有限公司 +1

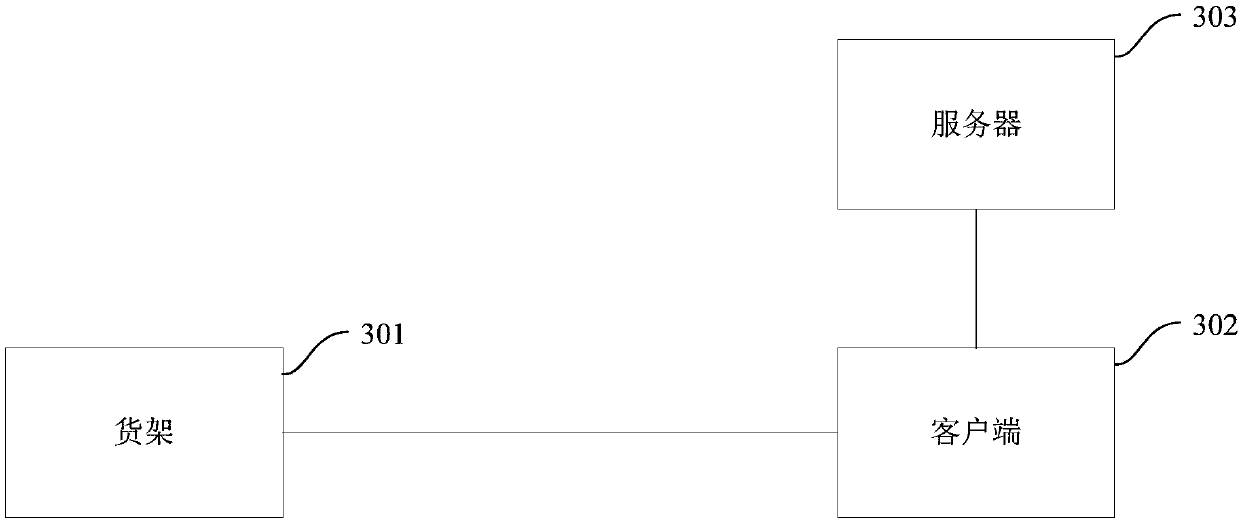

An article detection system and method

ActiveCN109919940AReduce labor costsCo-operative working arrangementsImage analysisConveyor beltElectrical and Electronics engineering

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Relay testing device

Owner:贵州天义技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap