Shaping device for correcting roundness of split conductor

A technology for dividing conductors and shaping devices, which is used in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as difficult adjustment of insulation eccentricity, influence of insulation eccentricity, inner shielding interface roundness, and large insulation eccentricity. The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

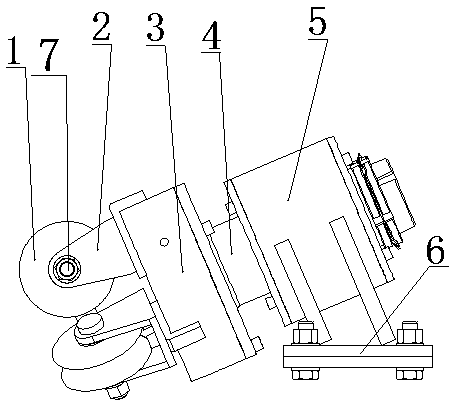

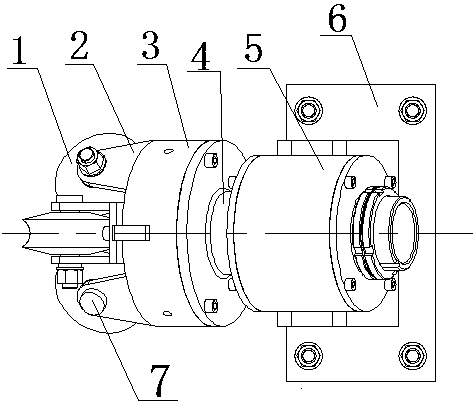

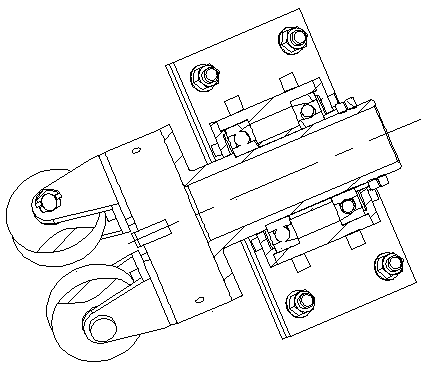

[0021] Such as Figure 1 to 3 A shaping device for correcting the roundness of divided conductors is shown, comprising a guide wheel 1, a guide wheel support 2, a chuck 3, a connecting shaft 4, and a sleeve 5. One end of the chuck 3 is connected with a plurality of guide wheels Support 2, the end of each guide wheel support 2 is movably connected with a guide wheel 1 through a guide wheel shaft 7; the other end of the chuck 3 is movably connected with a sleeve 5 through a connecting shaft 4, and the connecting shaft 4 is opposite The shaft sleeve 5 can rotate freely, the connecting shaft 4 has a hollow structure, and the connecting shaft 4 and the through hole on the chuck 3 penetrate each other.

[0022] In the shaping device, the guide wheel 1 and the chuck 3 and the connecting shaft 4 can all rotate freely, and the chuck 3 and the connecting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap