Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Conveyor belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

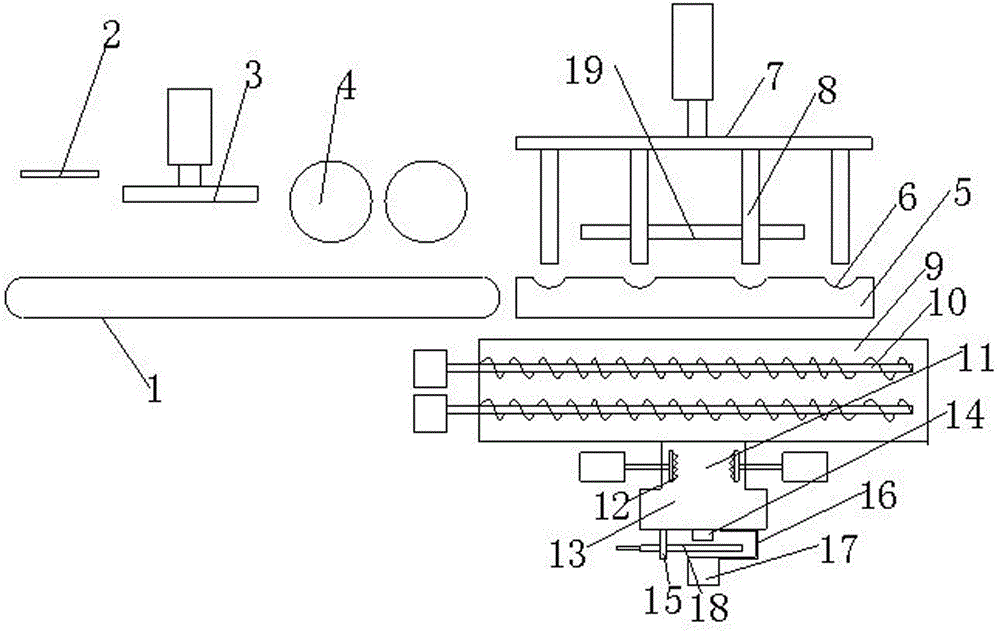

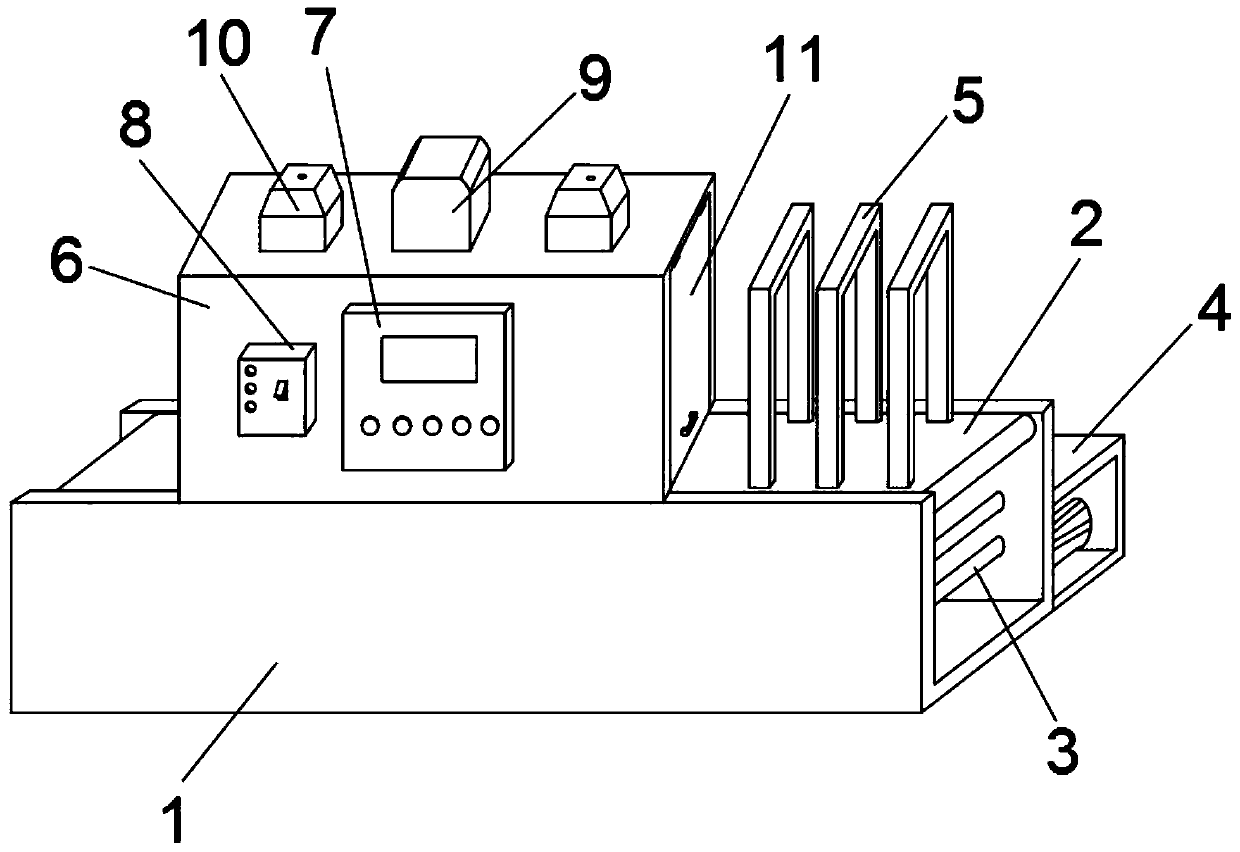

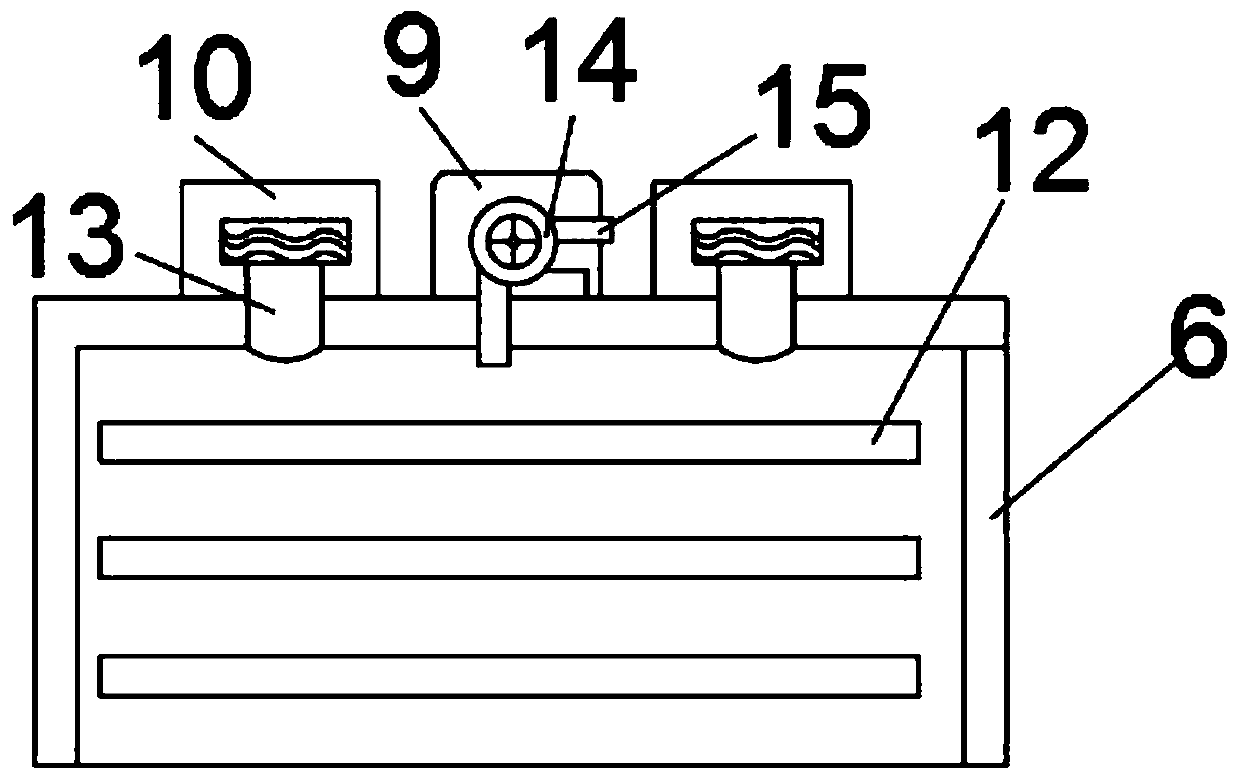

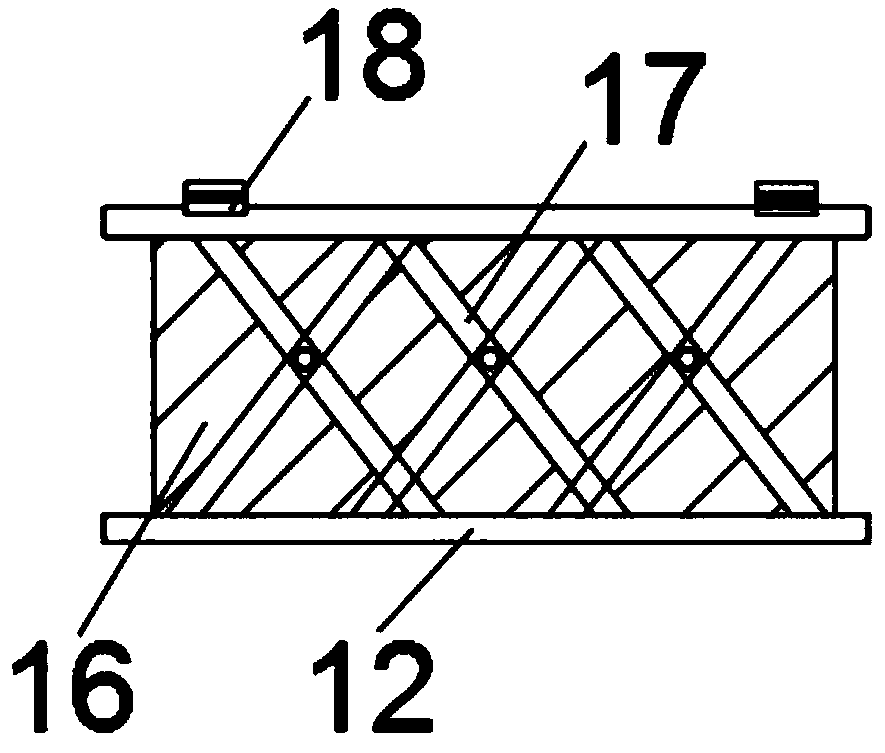

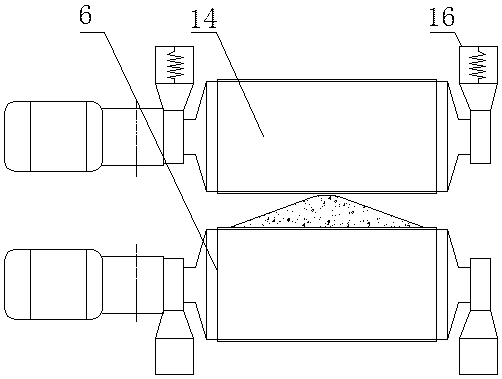

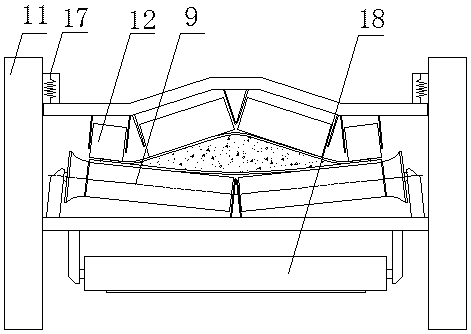

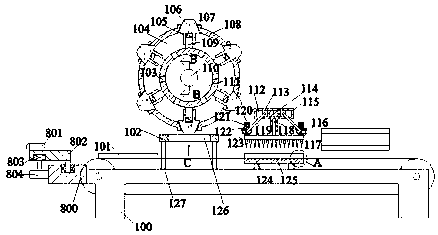

Waste straw treatment device

InactiveCN106576643AEffective secondary crushing utilizationEffective protectionCuttersHydraulic cylinderConveyor belt

Owner:苏州柯米智能科技有限公司

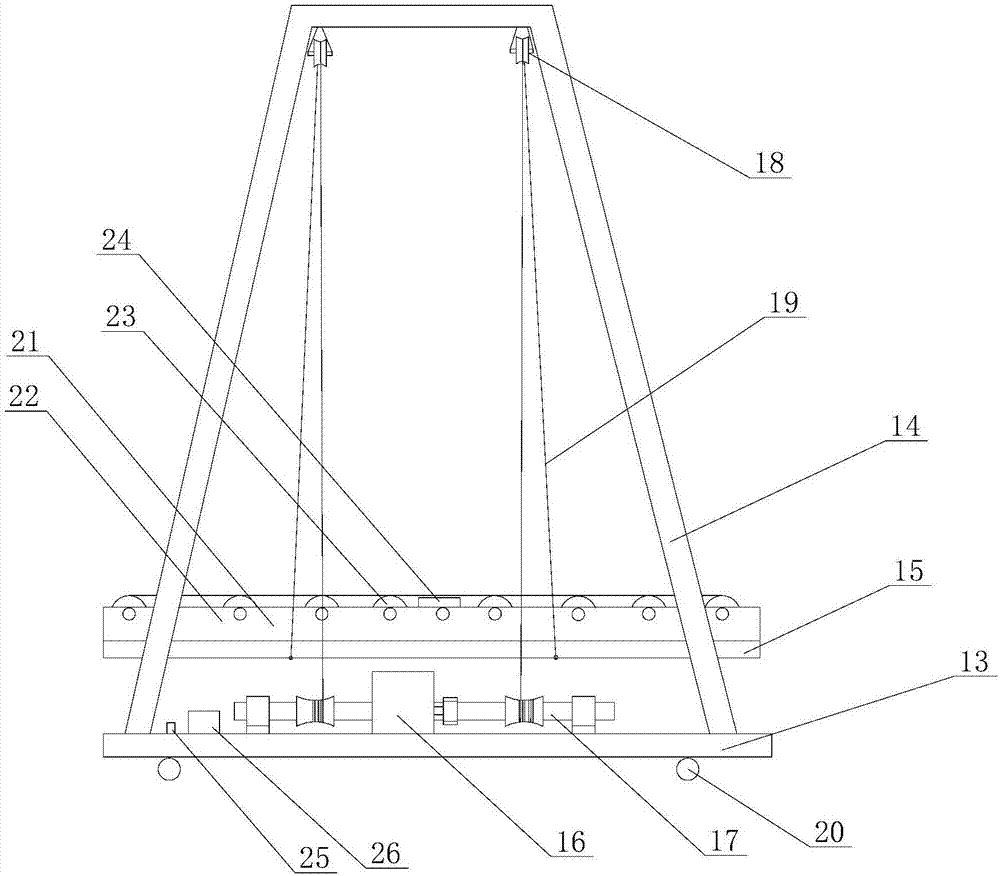

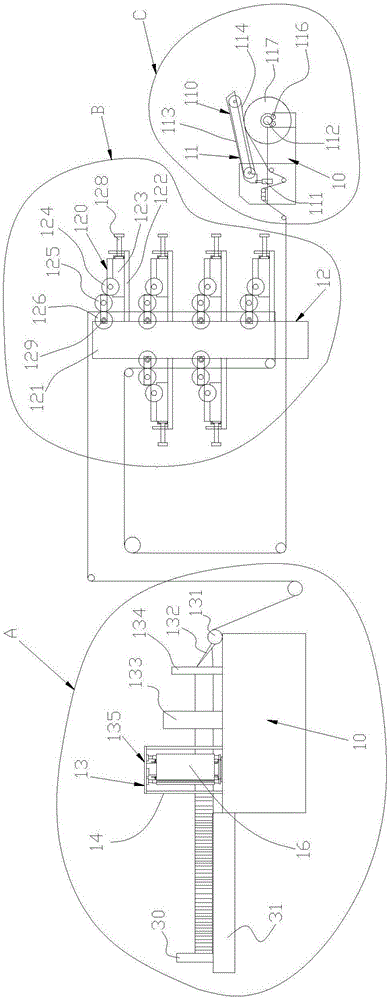

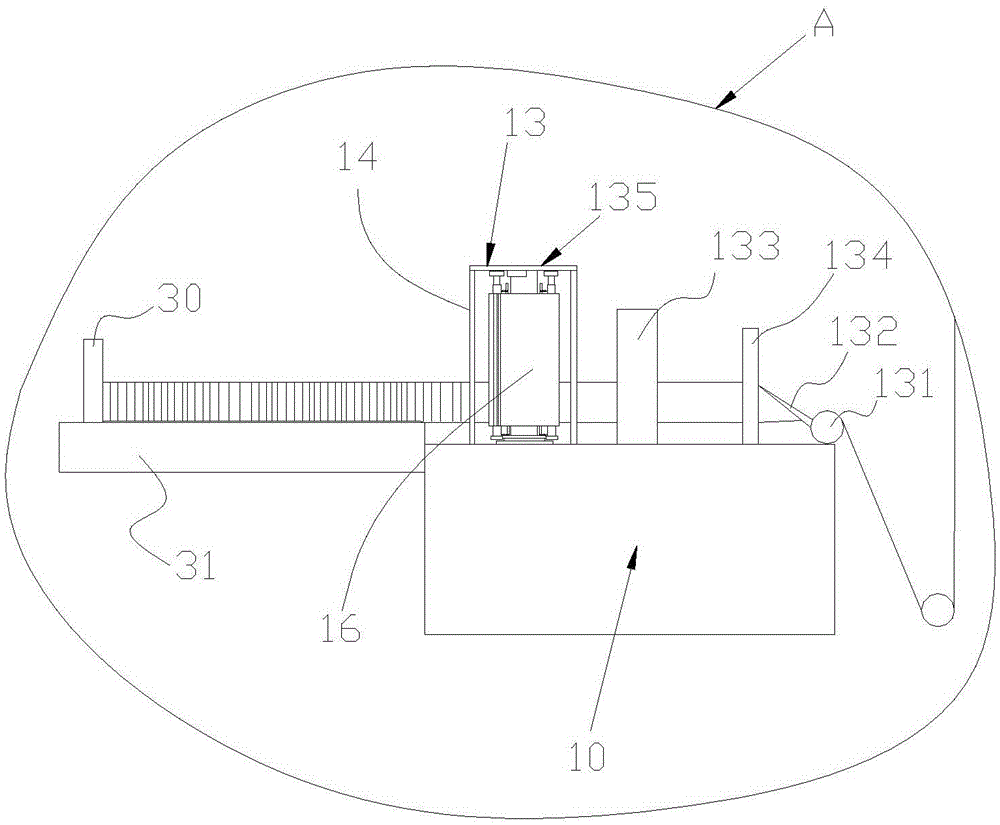

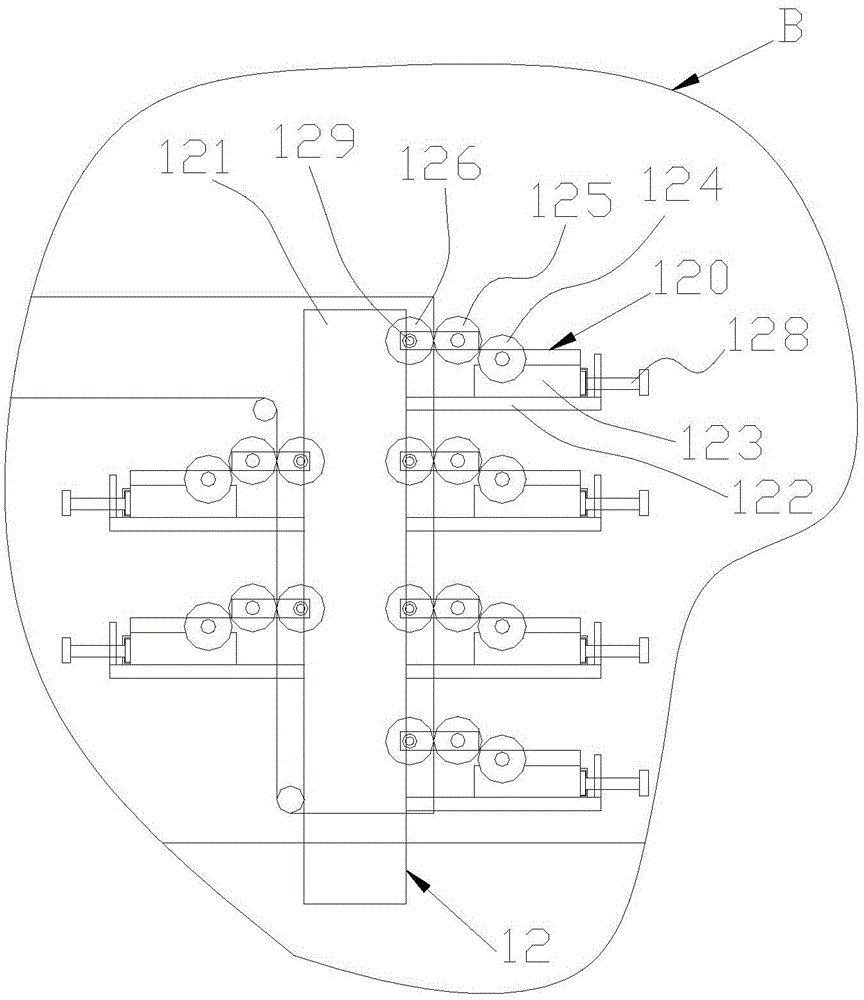

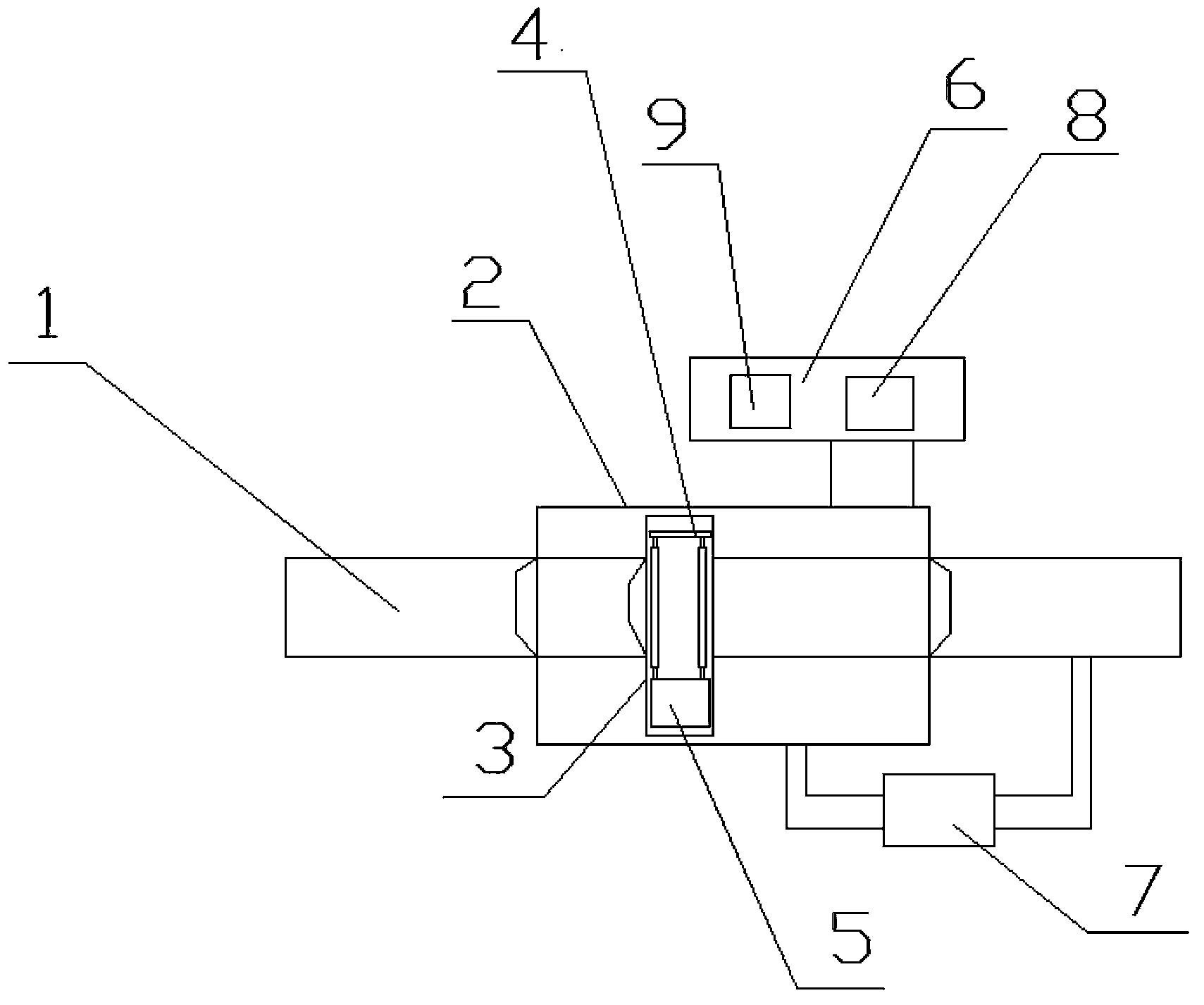

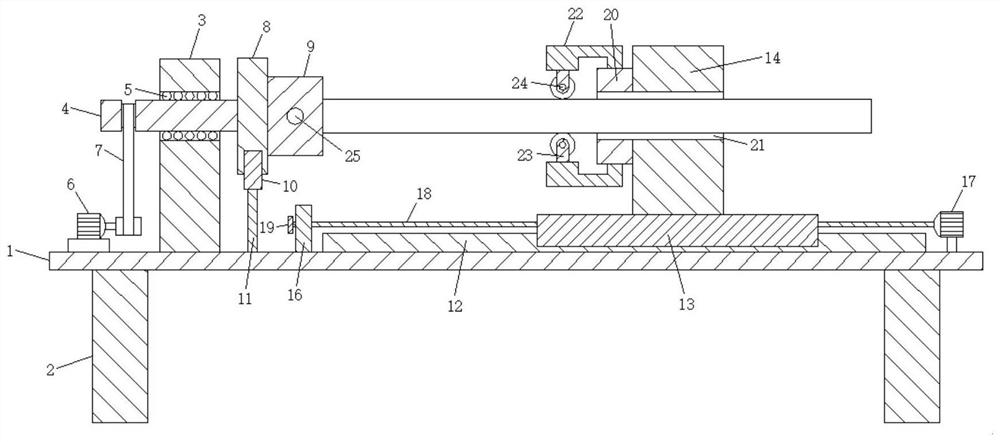

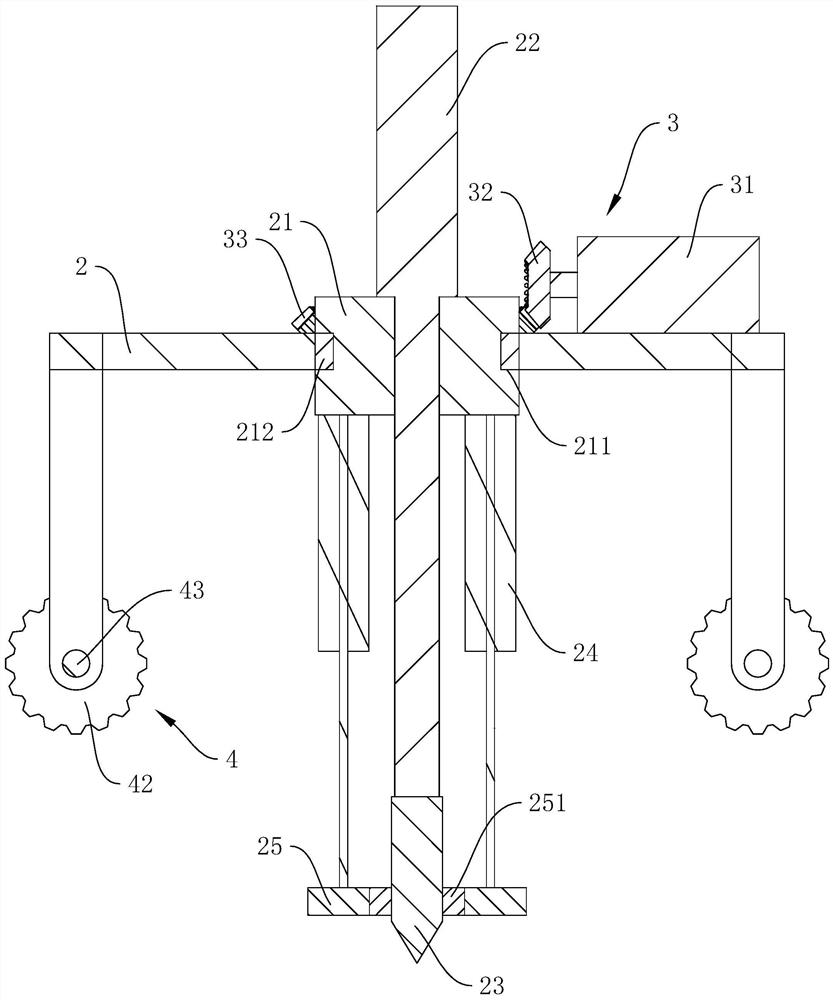

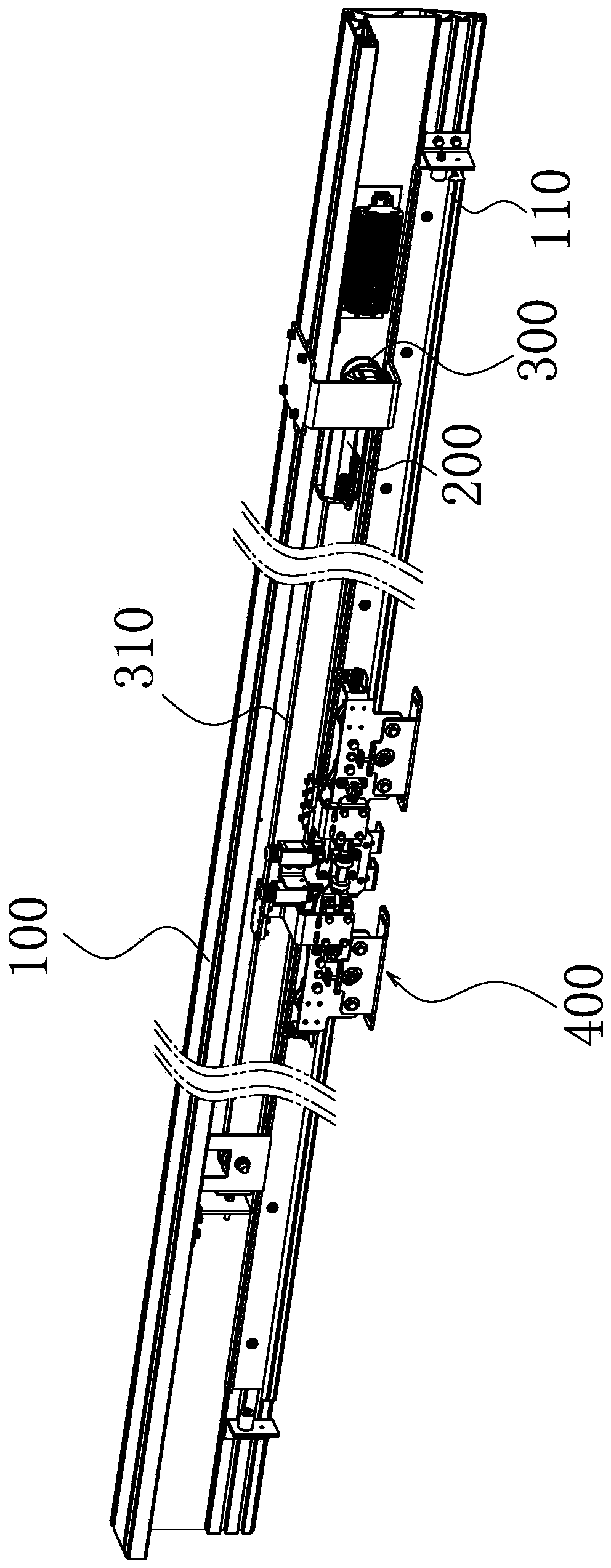

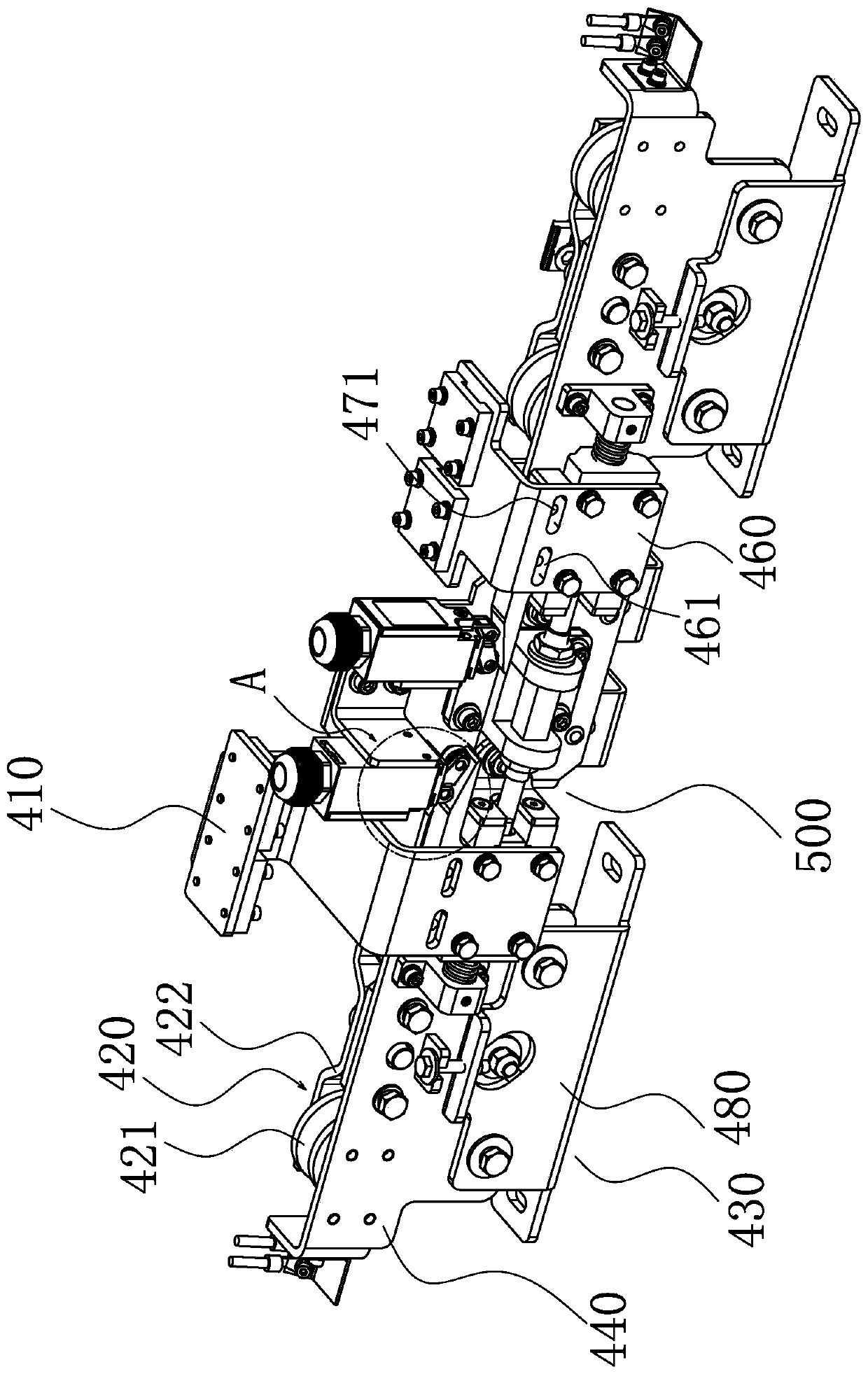

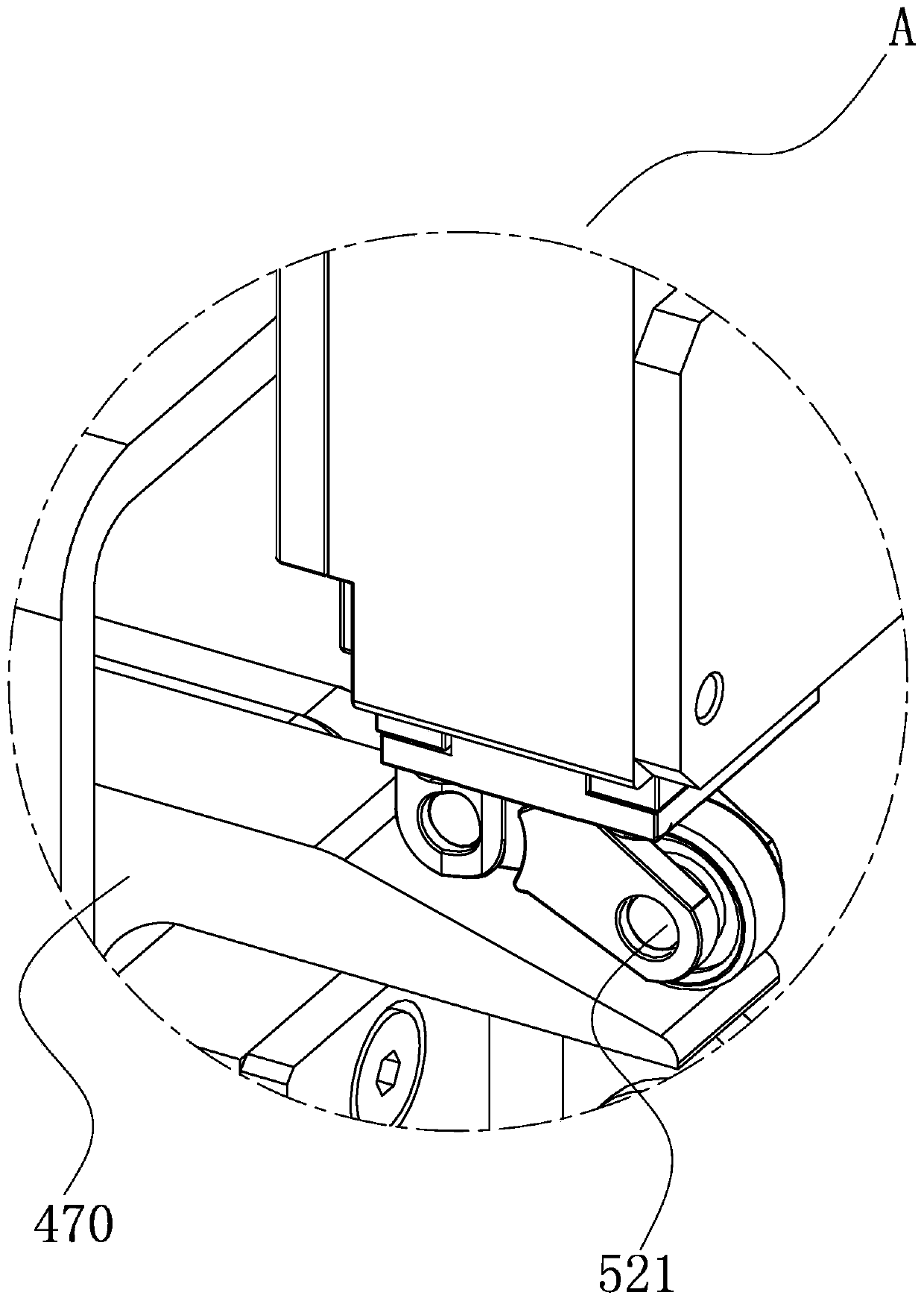

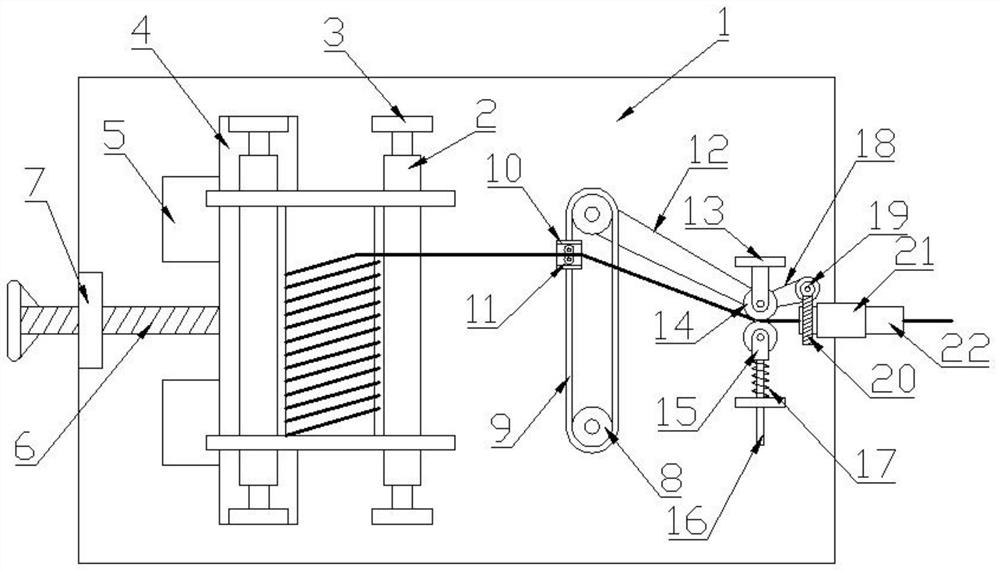

Device for drop test of mobile phone

The invention discloses a device for drop tests of a mobile phone. The device comprises a stand column, a lifting assembly, a control assembly, and a transportation assembly. The stand column is provided with a lifting guide rail. The lifting assembly can slide on the lifting guide rail. Sliding of the lifting assembly on the lifting guide rail is driven by a first wire rope pulley lifting assembly. The lifting assembly comprises a sliding base body, and the sliding base body is rotatably connected with an L-shaped pneumatic finger, and the sliding base body is provided with a rotating assembly. The transportation assembly comprises a feed assembly. The feed assembly comprises a feed sliding rail, and the feed sliding rail is slidably provided with a belt base. The sliding of the belt base on the feed sliding rail is driven by a second wire rope pulley lifting assembly. The belt base is connected with a conveyor belt. A plurality of placing frames are placed on the conveyor belt. The distances between each two adjacent placing frames are equal. Each placing frame is rotatably provided with a clamp. Beneficial effects of the device are that free-fall tests on edges of a mobile phone are realized, and detection efficiency is improved.

Owner:CHONGQING BASICOM SCI & TECH

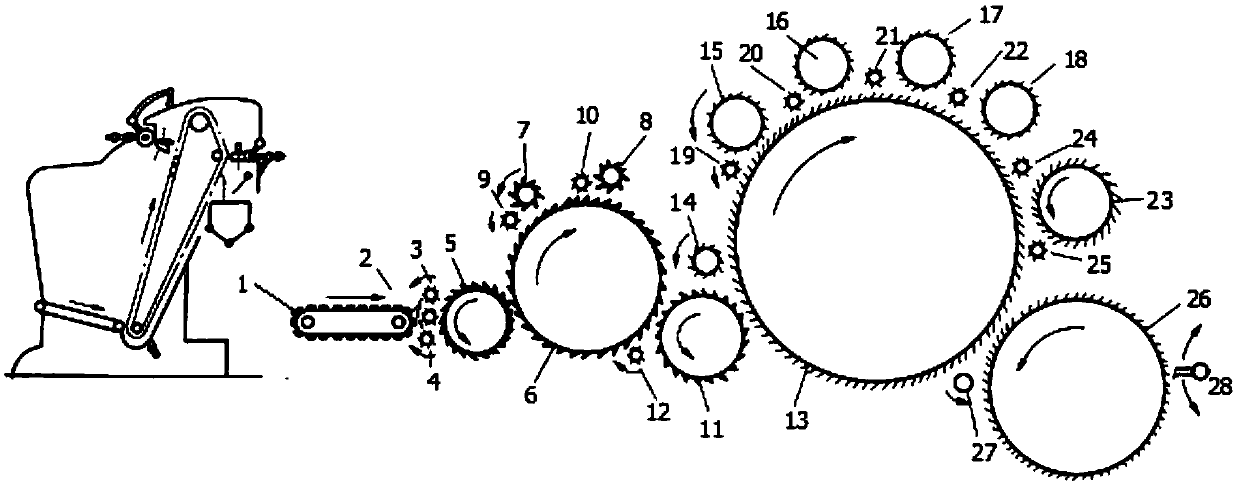

Textile fiber carding machine

InactiveCN105951305AAvoid one-sidednessSort out fullyCarding machinesNon-woven fabricsTextile fiberCarding

Owner:EASTERN LIAONING UNIV

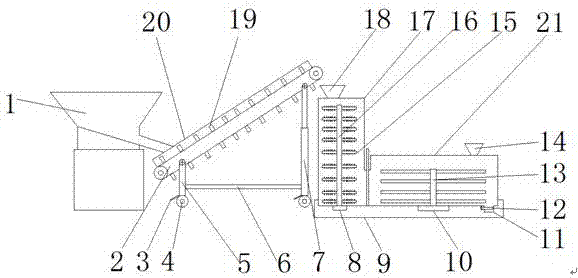

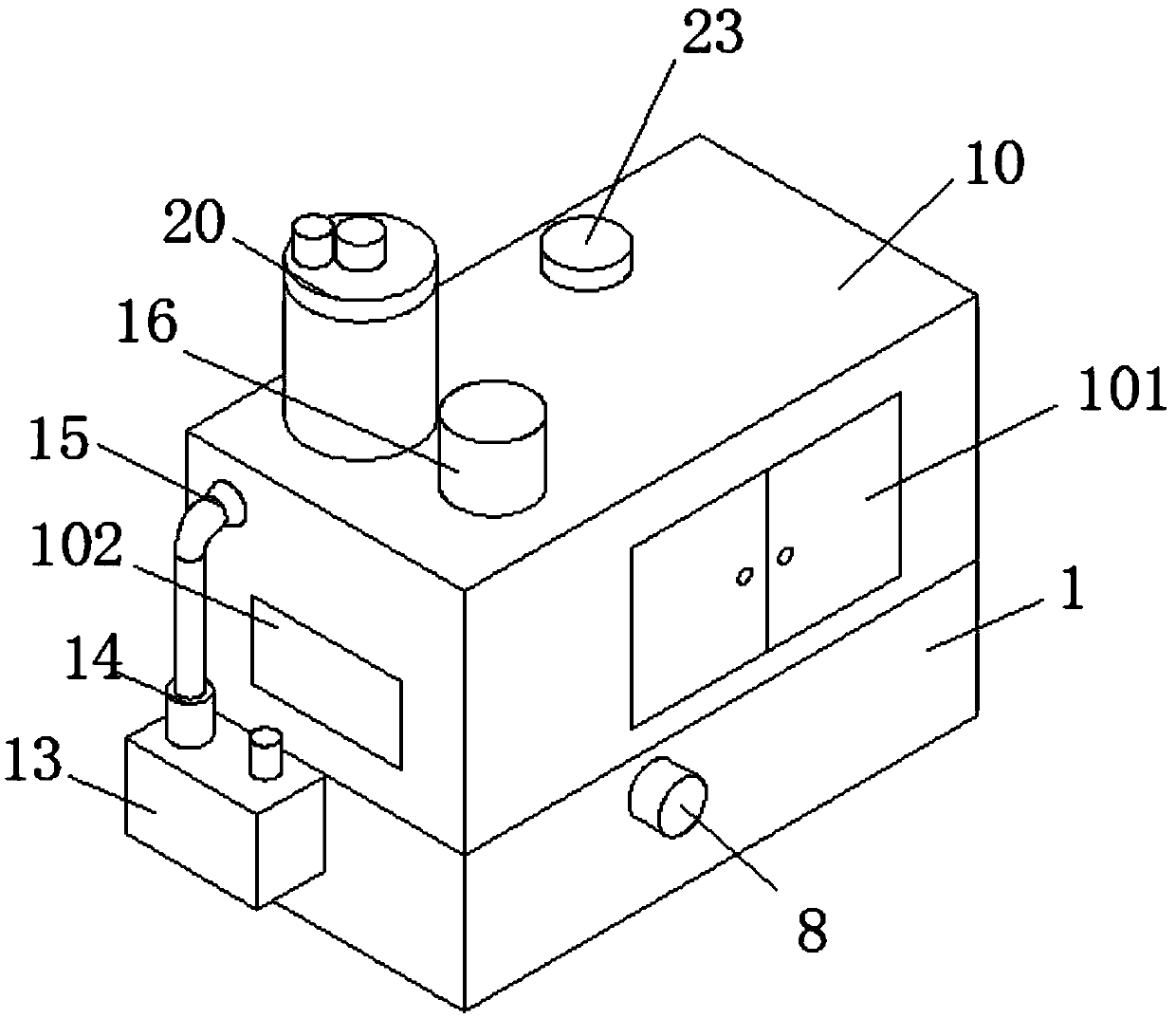

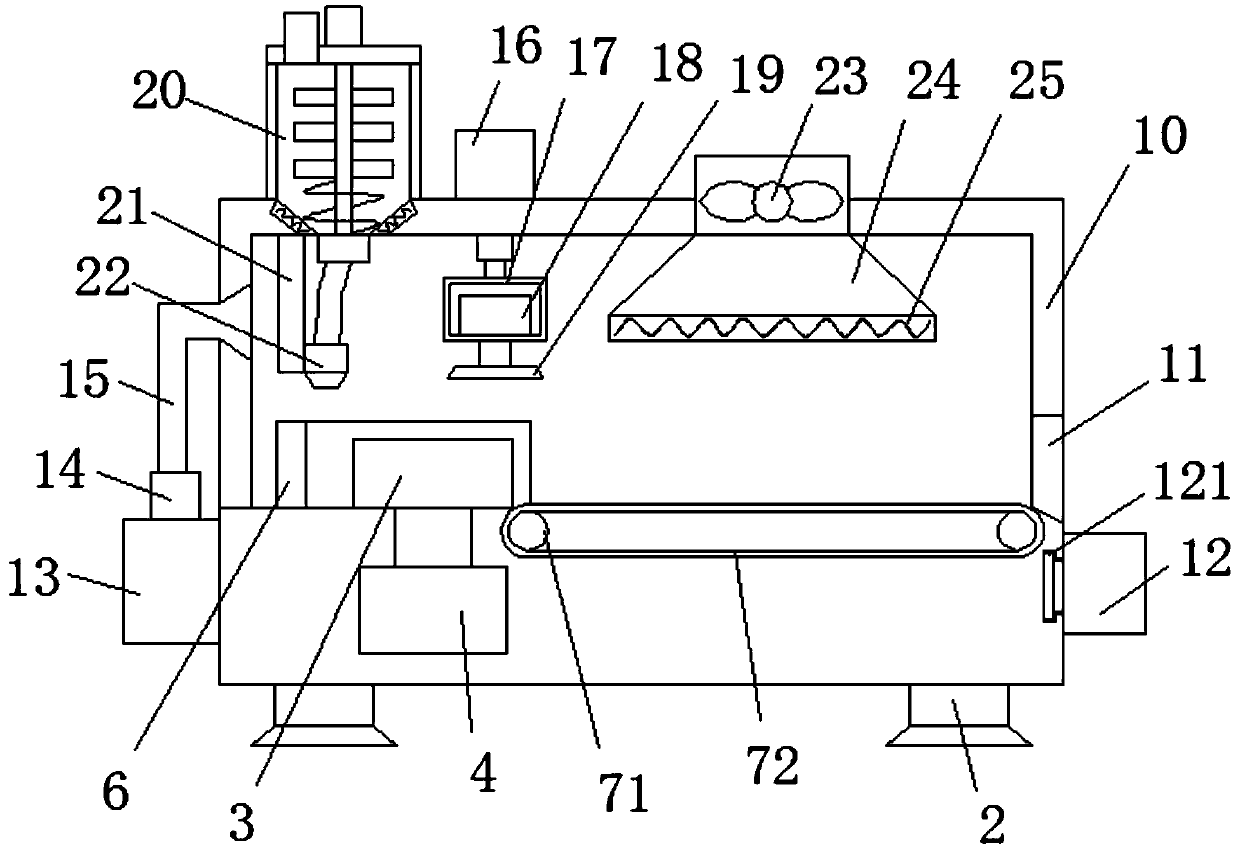

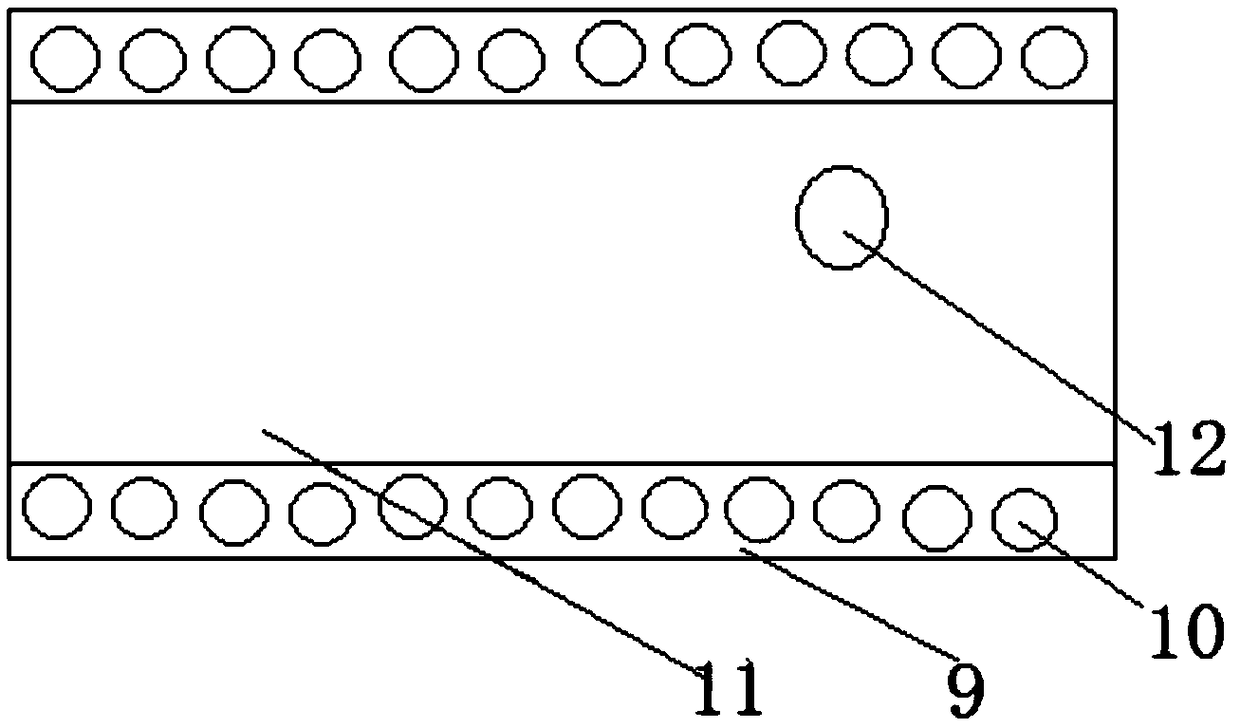

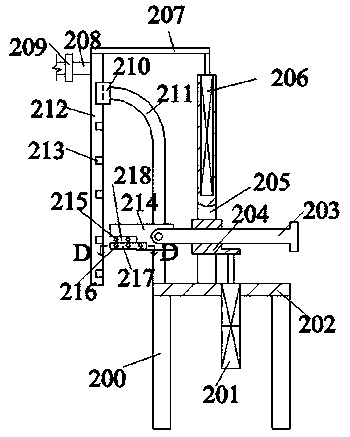

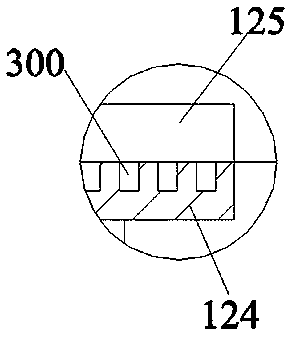

Traditional Chinese medicine tablet filling device

ActiveCN112960201AGuaranteed storage securityGuaranteed sealing performanceCapsThreaded caps applicationSolenoid valveEngineering

The invention relates to the technical field of traditional Chinese medicine processing, in particular to a traditional Chinese medicine tablet filling device which comprises an X-axis conveying mechanism, a filling mechanism, medicine bottles and bottle caps, wherein the filling mechanism and a Z-axis conveying mechanism are installed above the X-axis conveying mechanism; the filling mechanism comprises a first supporting frame, and a tablet tank is fixed to the top end of the first supporting frame; a solenoid valve is fixed to the bottom end of the tablet tank, and the Z-axis conveying mechanism comprises a second supporting box; a second conveyor belt is movably connected to the interior of the second supporting box, and the bottle caps are evenly distributed on the second supporting box; an X-axis driving mechanism is arranged behind the right side of the Z-axis conveying mechanism, and comprises a second supporting frame; and an X-axis sliding table is fixed to the top end of the second supporting frame, and the front end of the X-axis sliding table is slidably connected with a Y-axis driving mechanism. According to the filling device, a screw cap and sealing detection integrated structure is adopted, therefore the sealing detection can be carried out while the caps are sealed, and the storage safety of tablets is ensured.

Owner:YANTAI KANGGUTANG MEDICAL TECH CO LTD

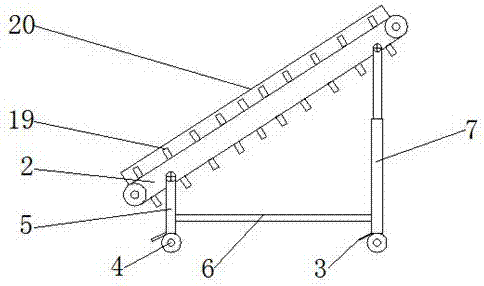

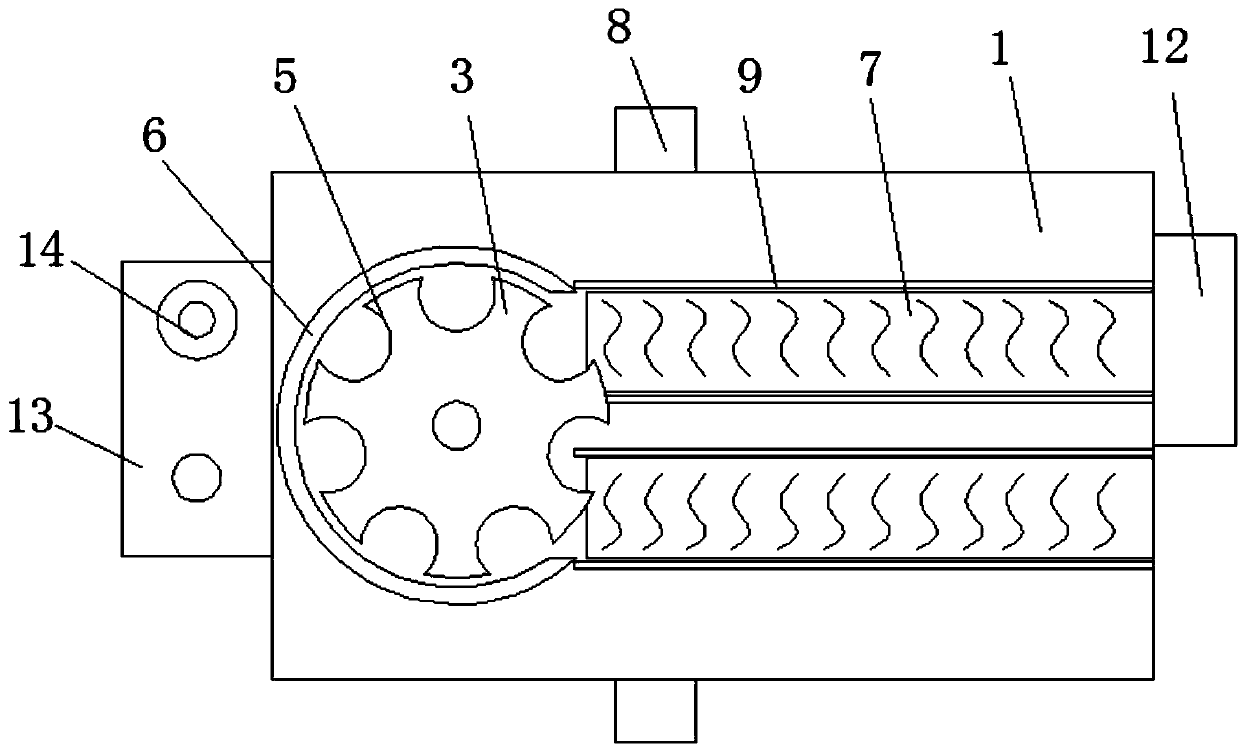

Stalk chopping and mixing feed preparation device

InactiveCN107183766APrevent slippingImprove stabilityFeeding-stuffCuttersHydraulic cylinderSteering wheel

Owner:王文奎

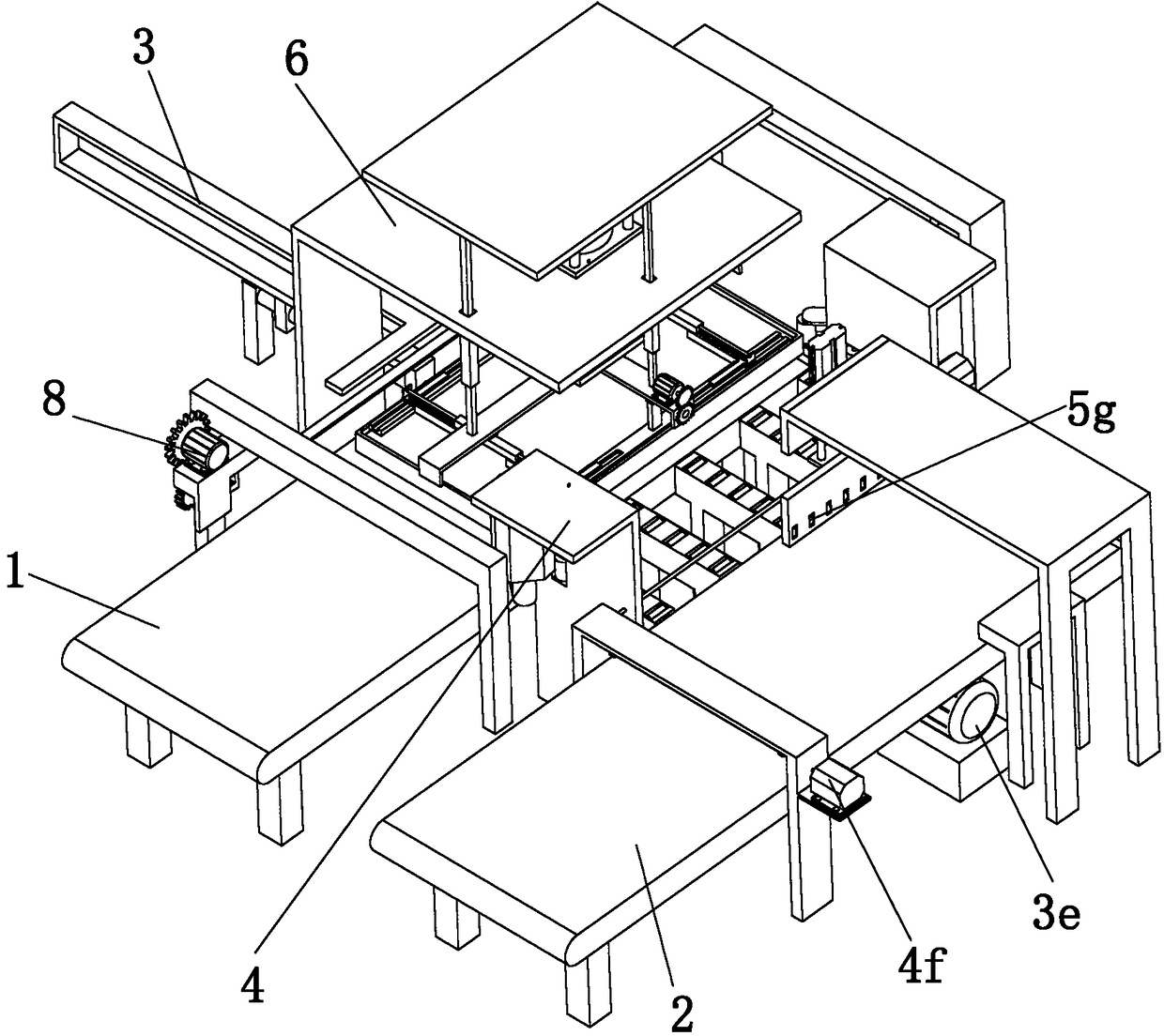

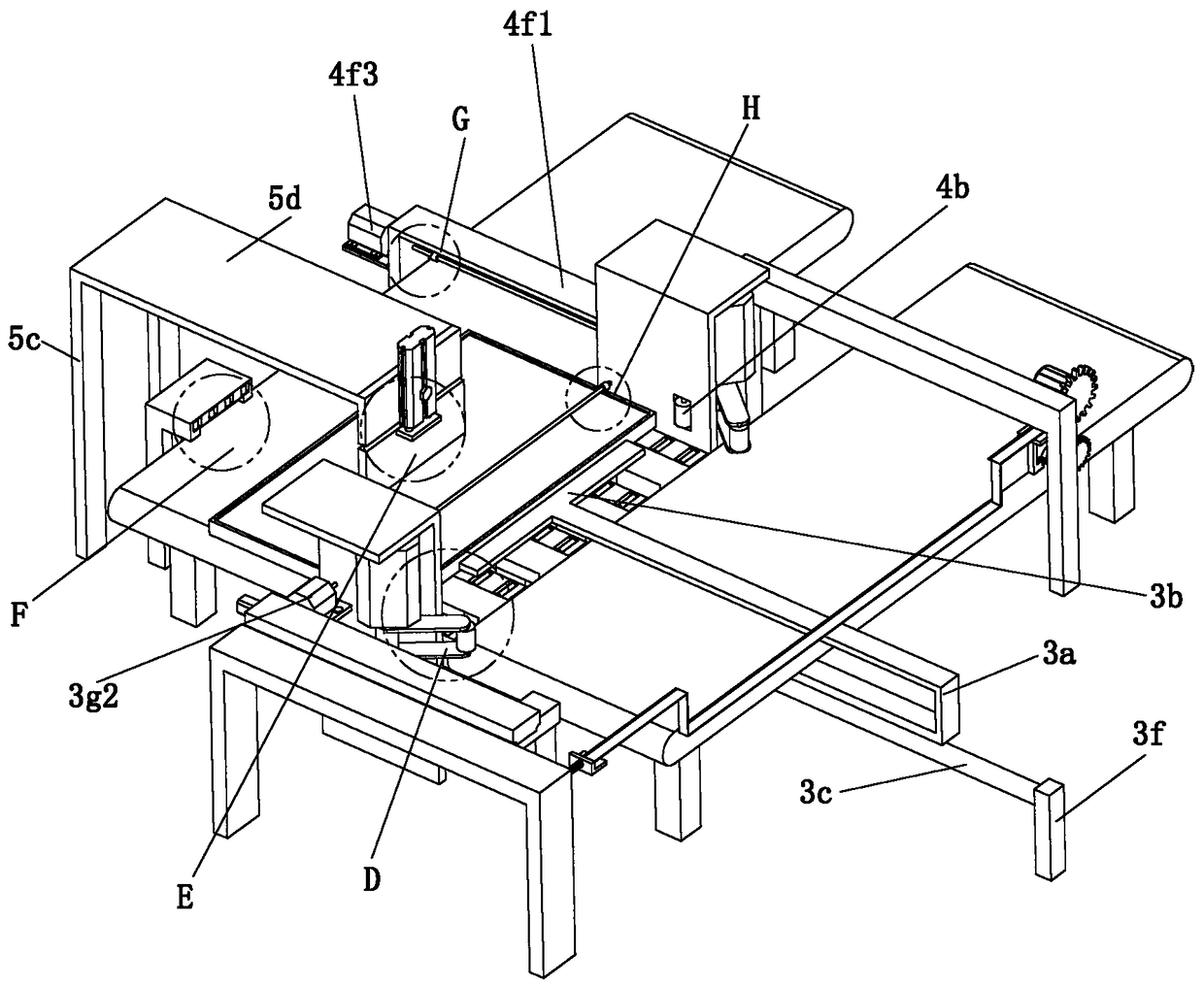

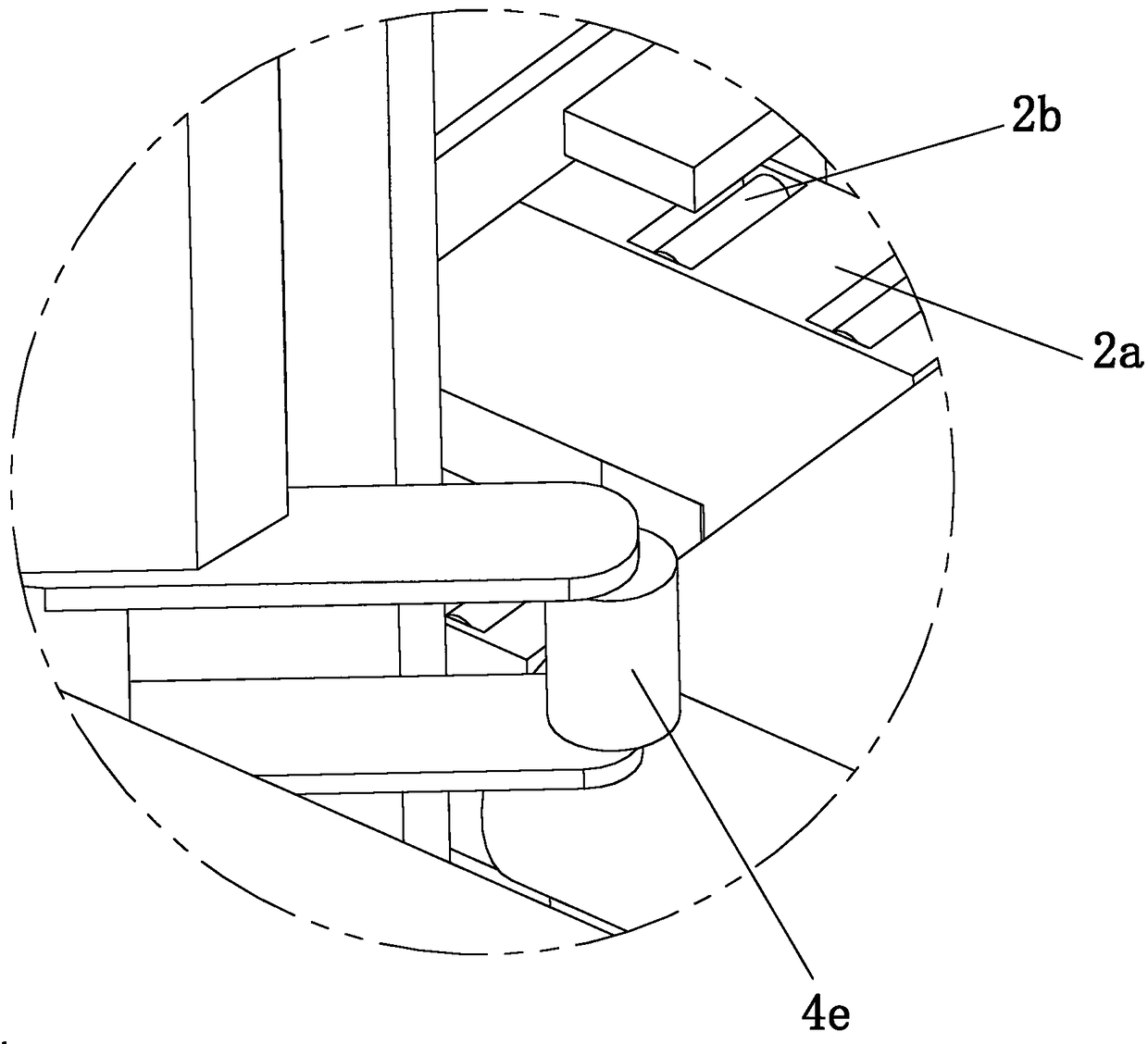

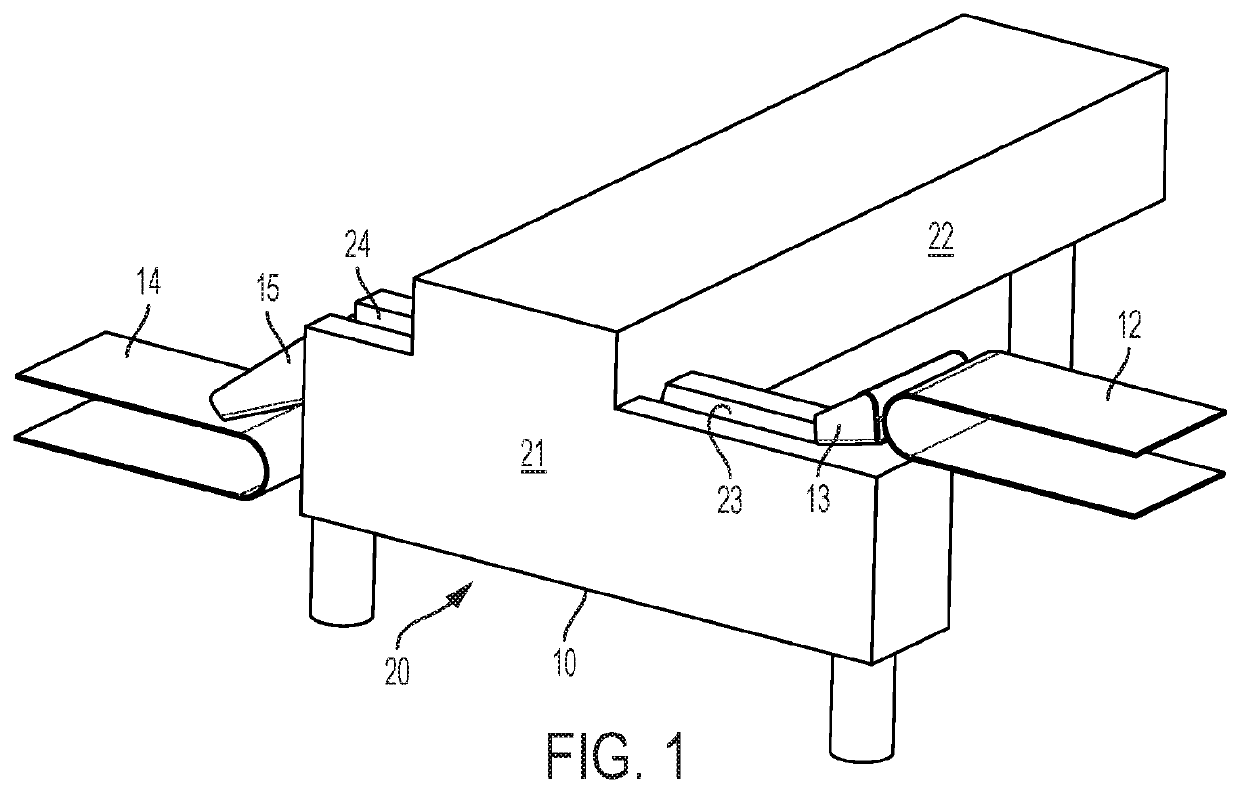

Positioning, cutting and trimming device for edge sealed plank

ActiveCN108748433ASuitable for input requirementsCompact structureProfiling/shaping machinesEngineeringConveyor belt

Owner:HUANGSHAN AOFER FURNITURE

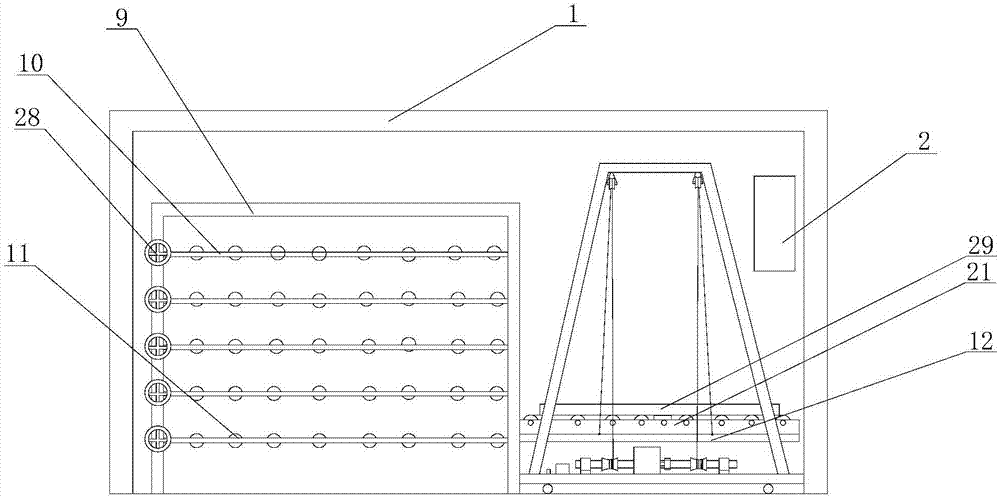

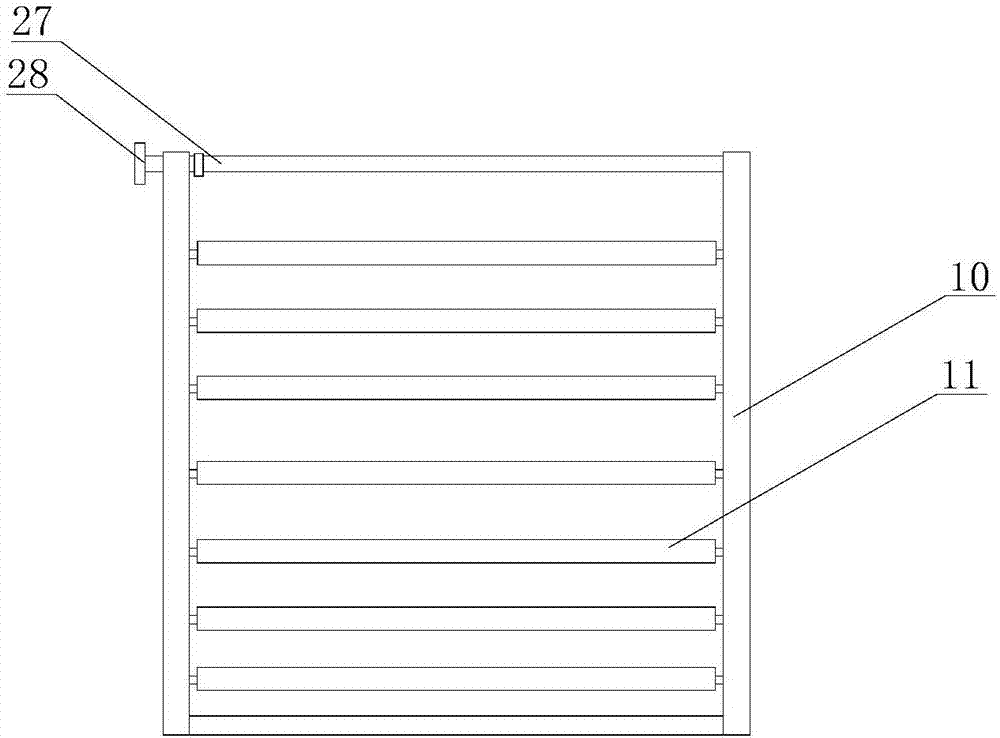

Wood board drying equipment

InactiveCN107976046AImprove drying efficiencyFully contactedDrying gas arrangementsDrying machines with progressive movementsControl systemEngineering

Owner:广西桂林林博士家具有限公司

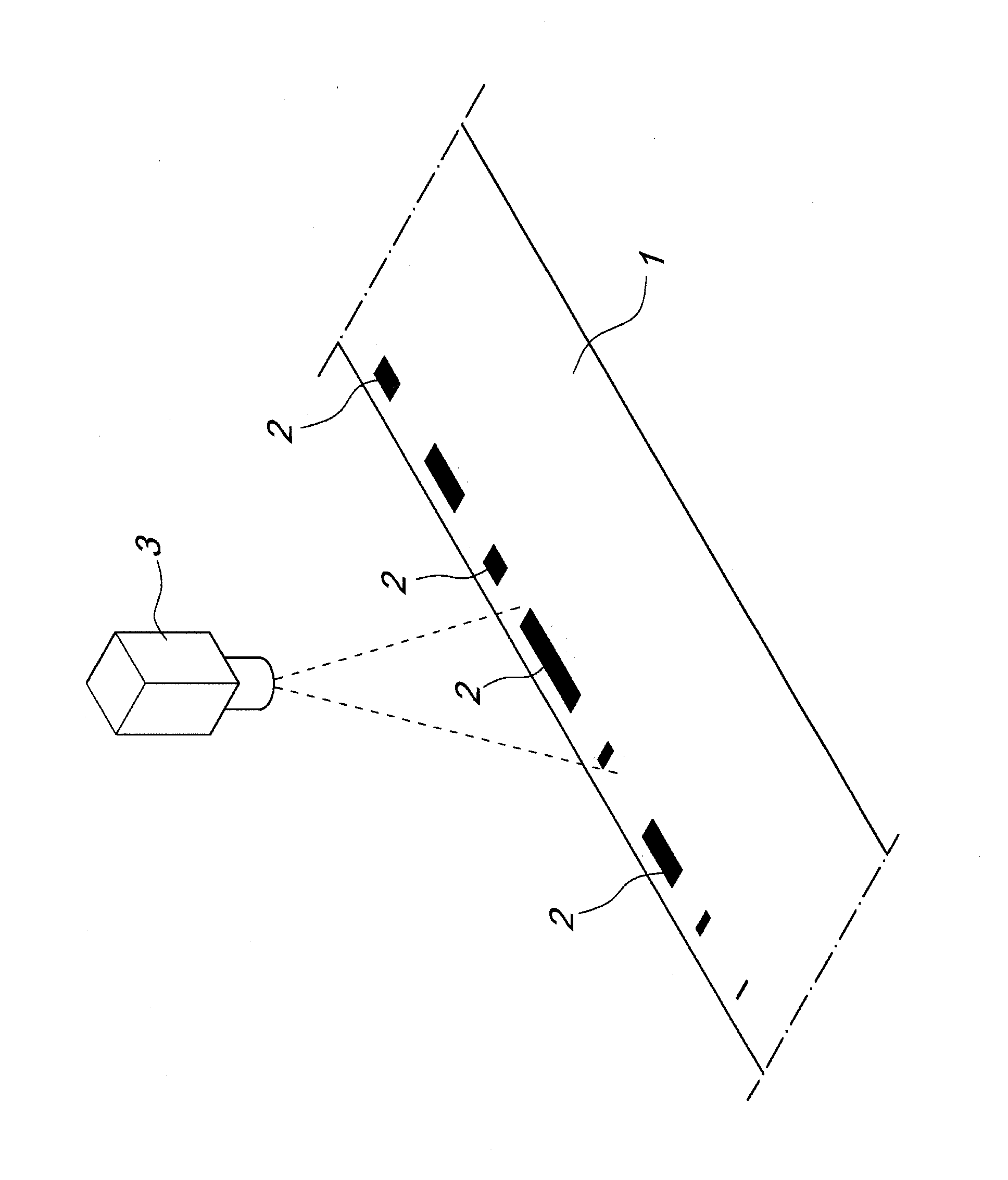

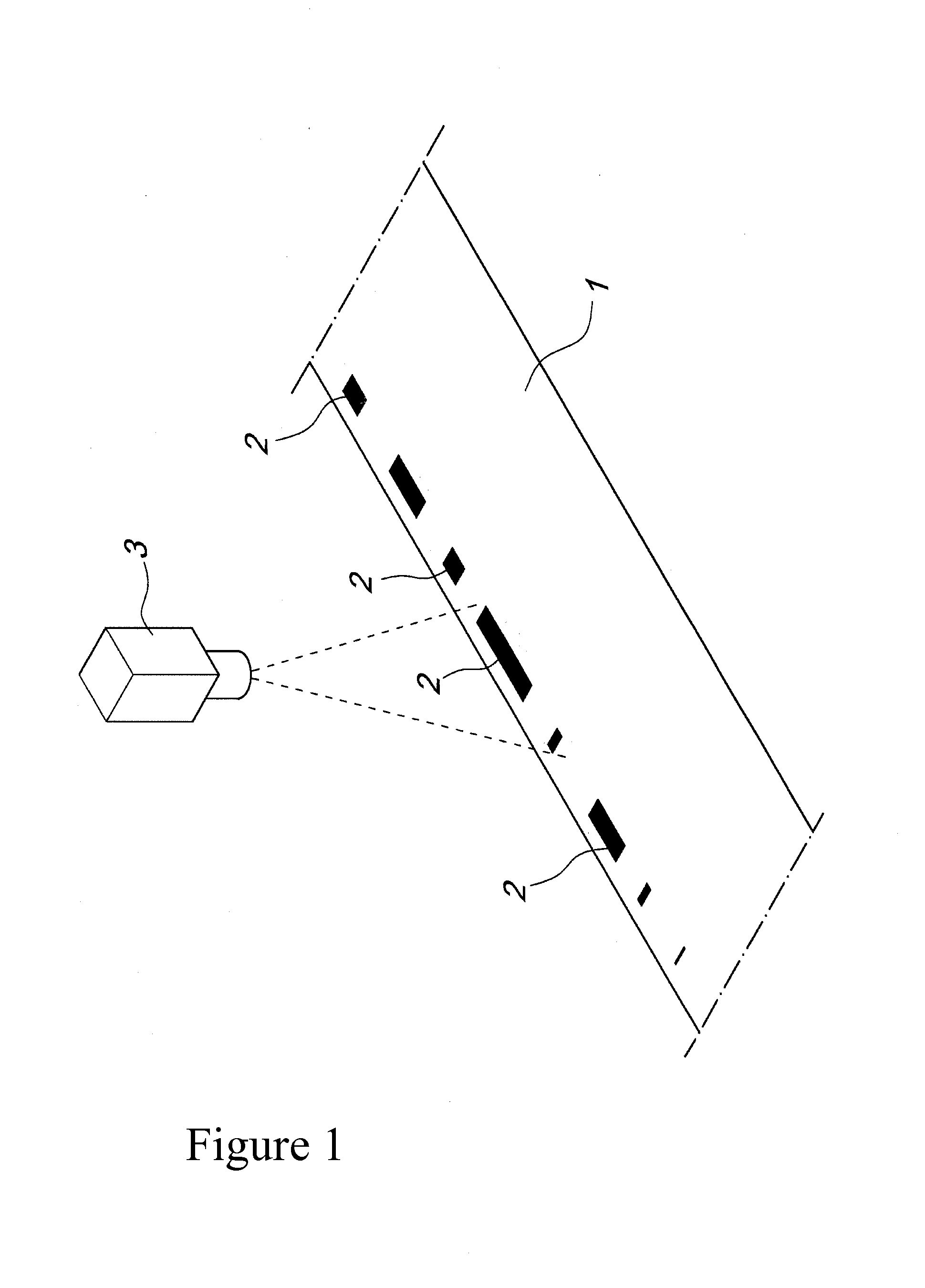

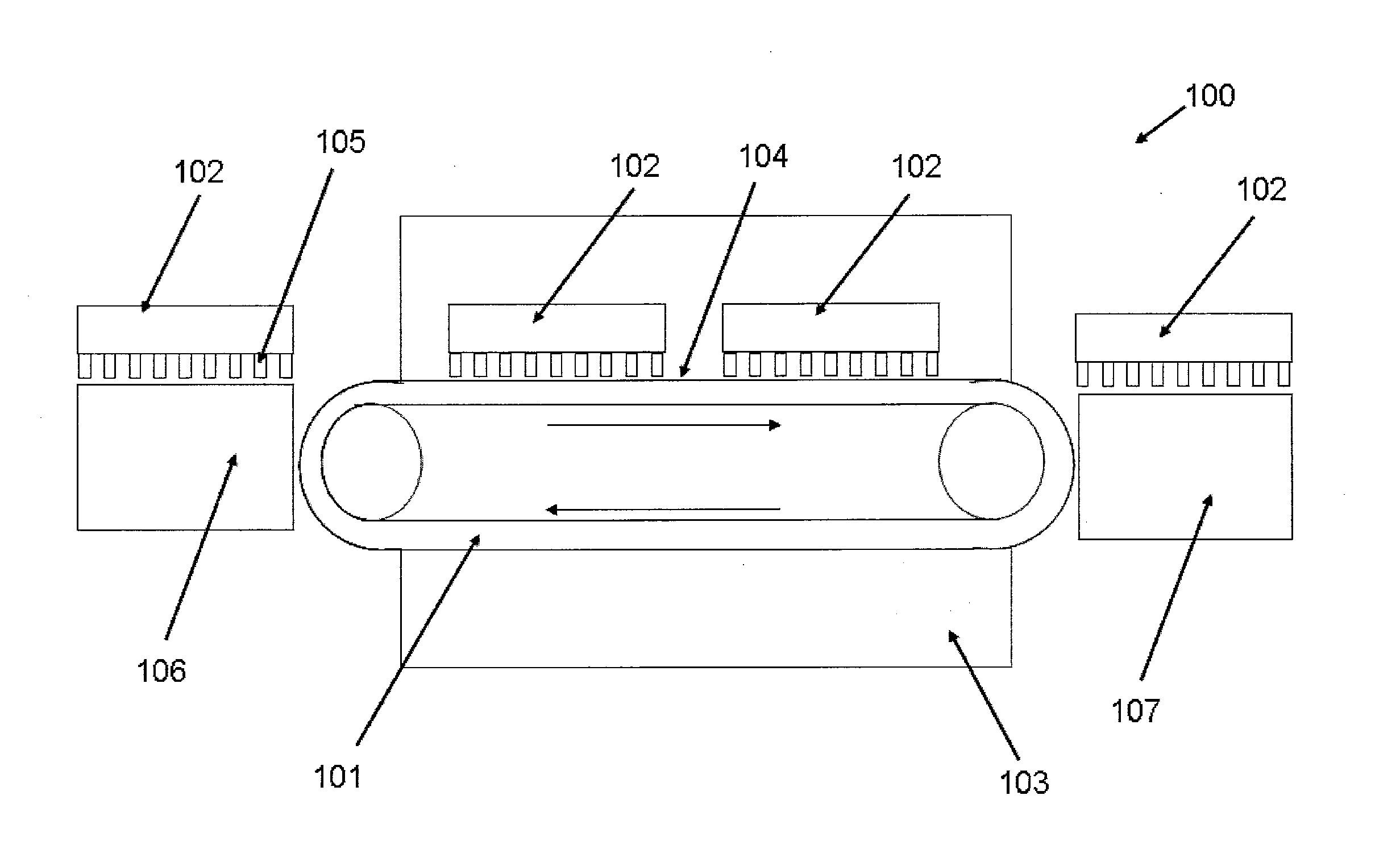

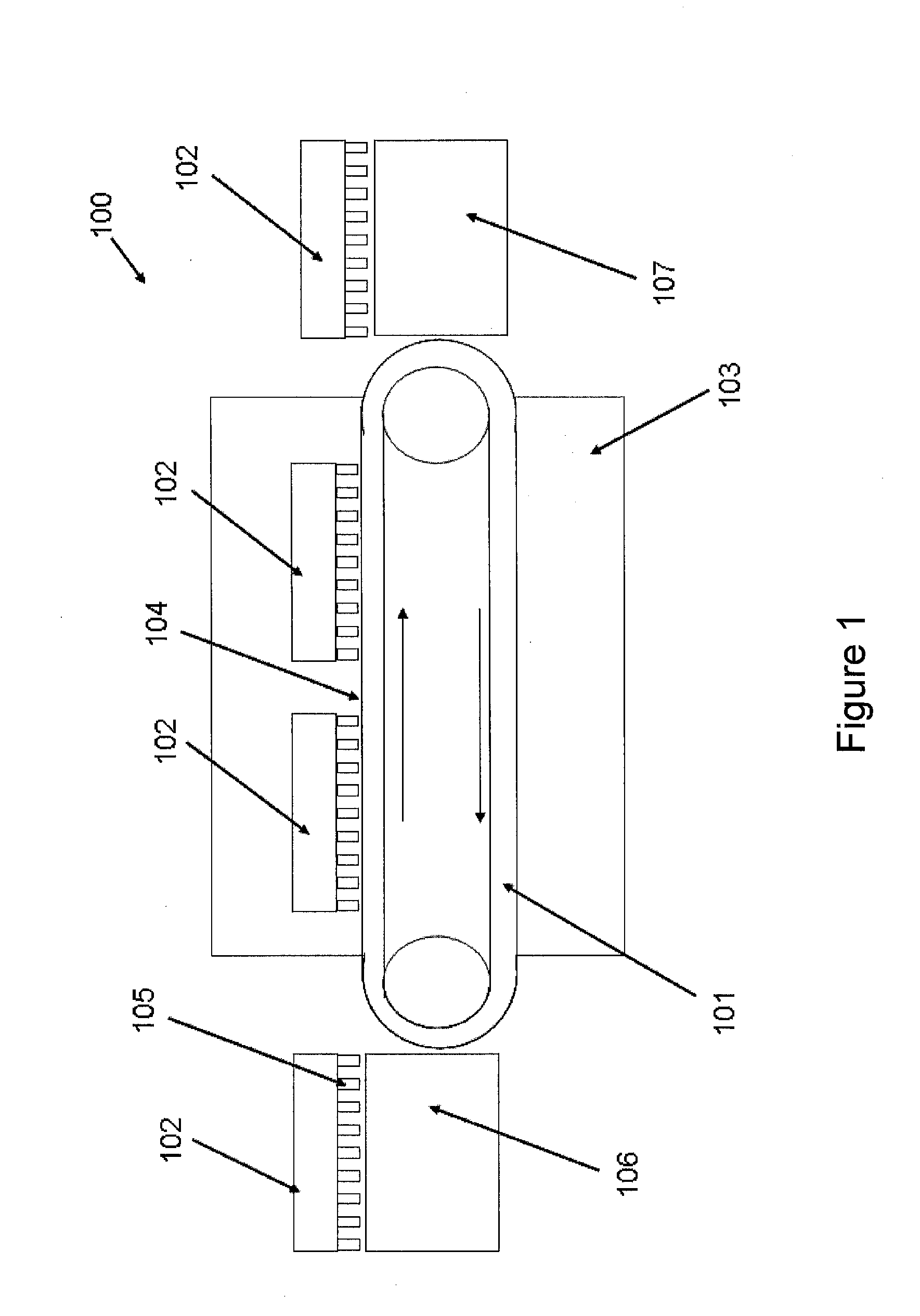

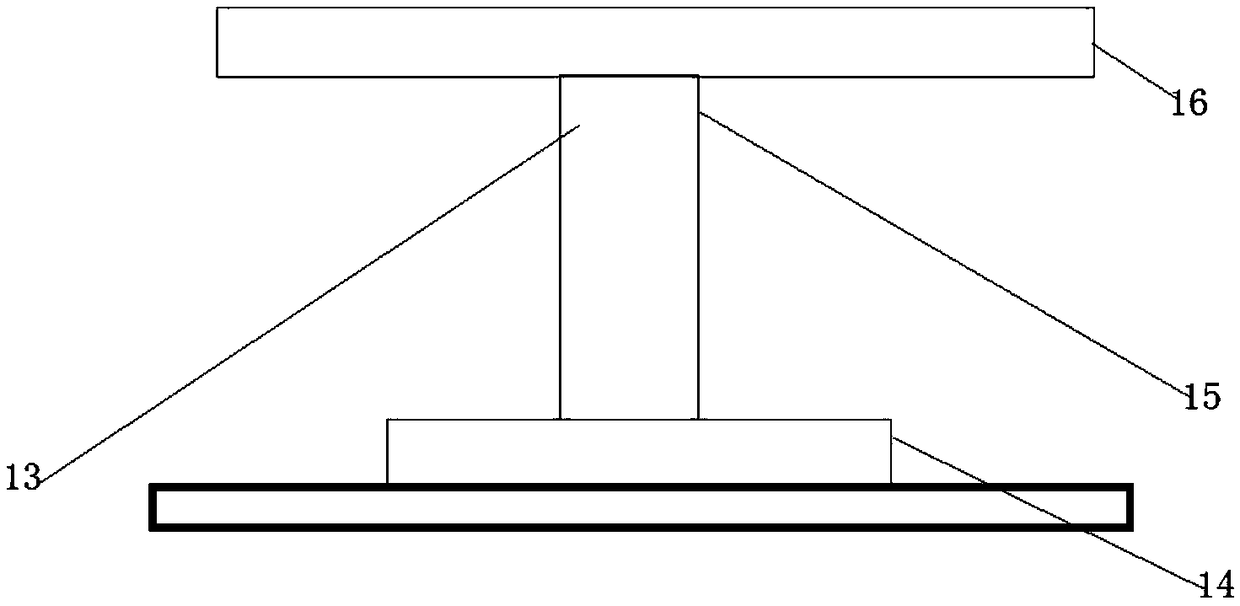

Method and device for detecting the position of a conveyor

ActiveUS20140022562A1Keep full controlConveyorsControl devices for conveyorsEngineeringConveyor belt

Owner:COMELZ SPA

Vegetable noodle production process and microwave drying device thereof

InactiveCN109751838AIncreased versatilityMeet drying needsDrying solid materials with heatDrying chambers/containersMicrowaveWater vapor

Owner:ANHUI QINGSONG FOOD

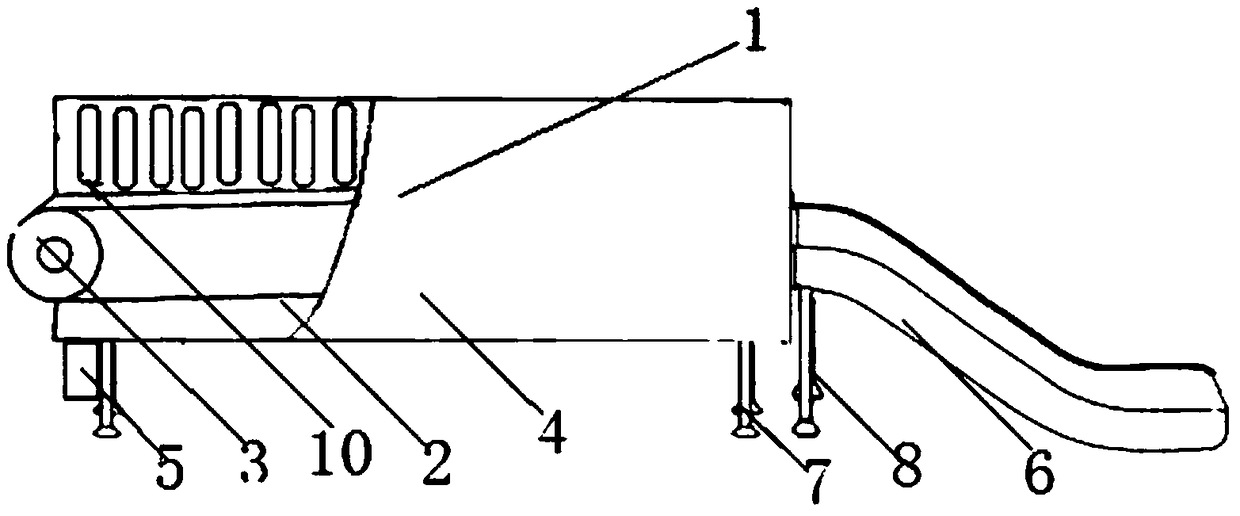

Automatic labeling machine for fruit labeling

InactiveCN111674673ASo as not to damageLabeling lastsLabelling machinesElectric machineConveyor belt

The invention is applicable to the technical field of automation, and provides an automatic labeling machine for fruit labeling. The automatic labeling machine comprises a baseplate, wherein a first roller seat and a second roller seat are arranged on the baseplate; a driven roller and a driving roller are arranged on the first roller seat and the second roller seat respectively; a conveyor belt is wound on the driven roller and the driving roller; a plurality of trays uniformly distributed at intervals are arranged on the conveying belt; a driving component is arranged on a top plate; a supporting rod is arranged on the top plate; a pulling component is arranged on the top plate; a pressing rod is slidably arranged on the top plate; a pressing head is arranged at the bottom end of the pressing rod; and a buffering pressing component is further arranged on the top plate. According to the automatic labeling machine for fruit labeling, a first chain wheel is driven to intermittently rotate through a motor, a fruit is conveyed forwards, meanwhile, the waste paper is wound by a waste paper roller, a label film is wound by a traction roller, the pressing plate is driven to move downwards through an electric telescopic rod, the fruit cannot be damaged under the buffering effect of a spring, and a label can be firmly adhered to the fruit.

Owner:厉佳璇

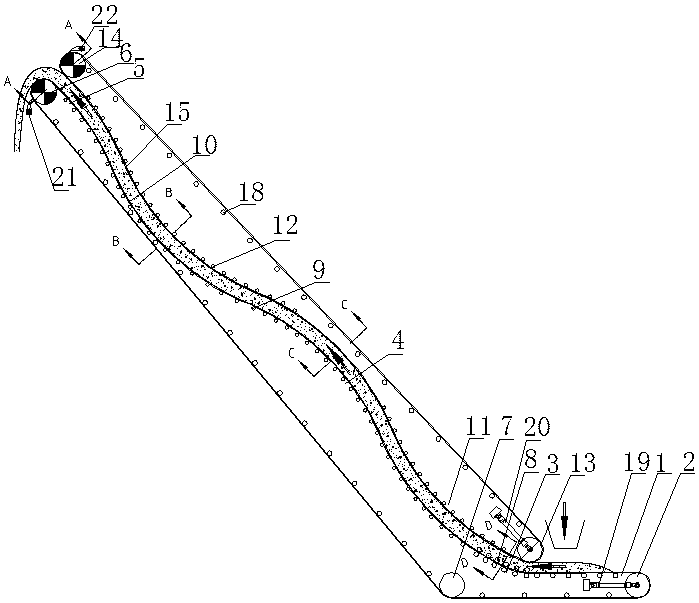

Large-dip-angle belt conveyor

Owner:TIDFORE HEAVY IND

Special adhesive sticker for ethylene propylene diene monomer heat resistance conveyor belt and preparation method of special adhesive sticker

Owner:BAODING HUAYUE RUBBER BELTS

System for producing chocolate-based articles in solidifying form

Owner:IPCO PROCESS SYST BV

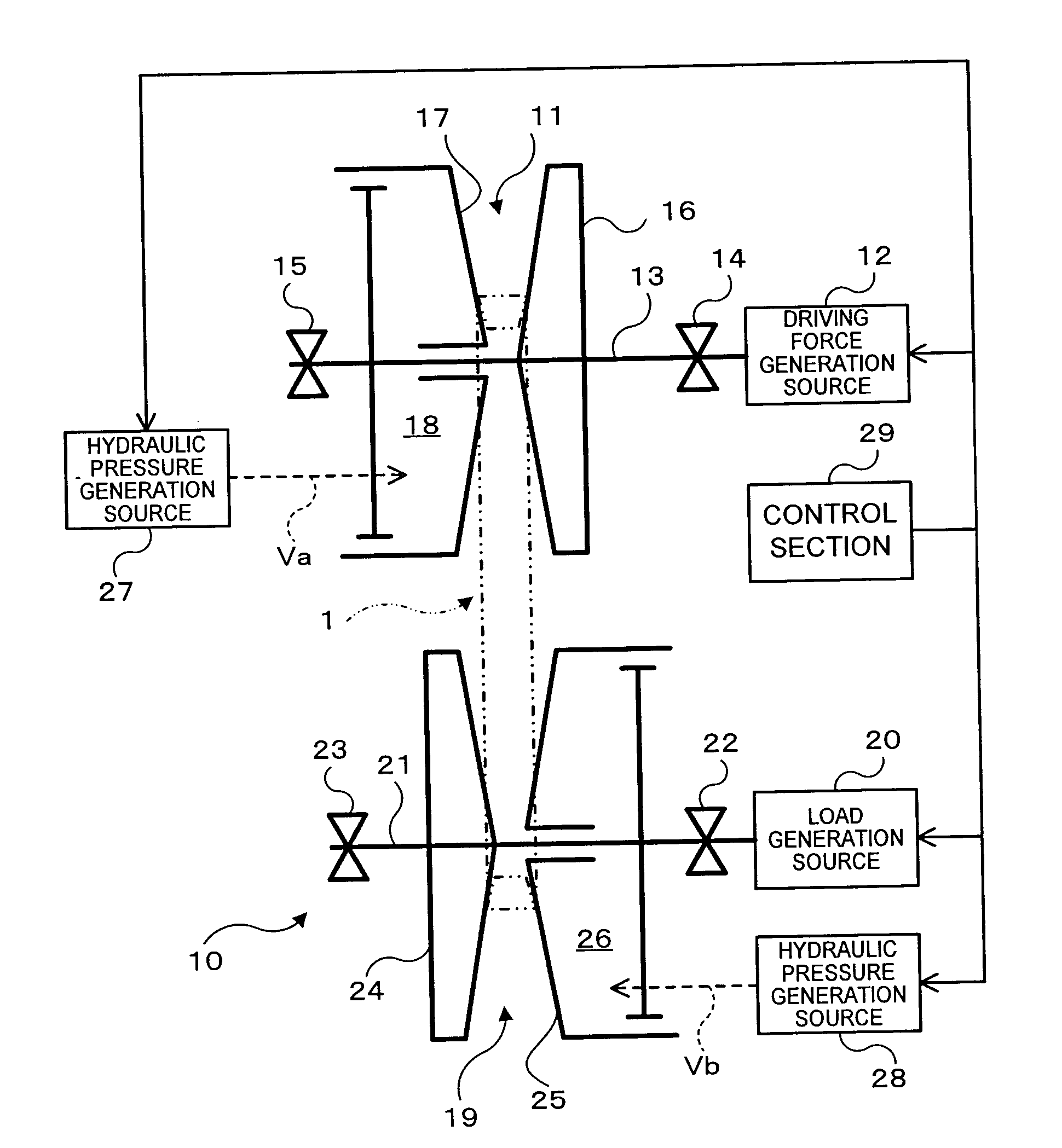

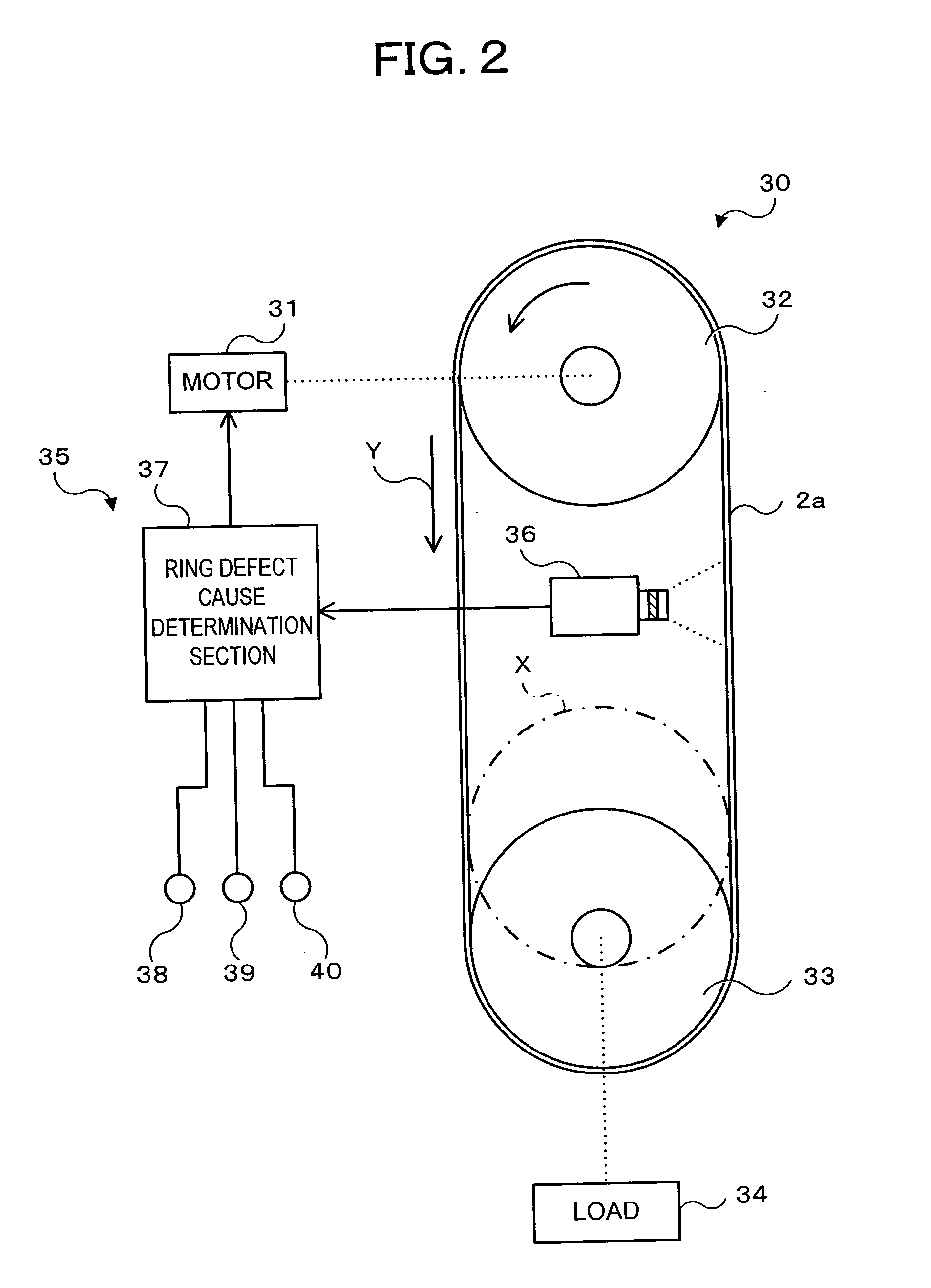

Continuously variable transmission belt inspection method and inspection device thereof

InactiveUS20060037415A1Unnecessary part can be avoidedLow costV-beltsMachine gearing/transmission testingEngineeringMetal powder

Owner:JATCO LTD

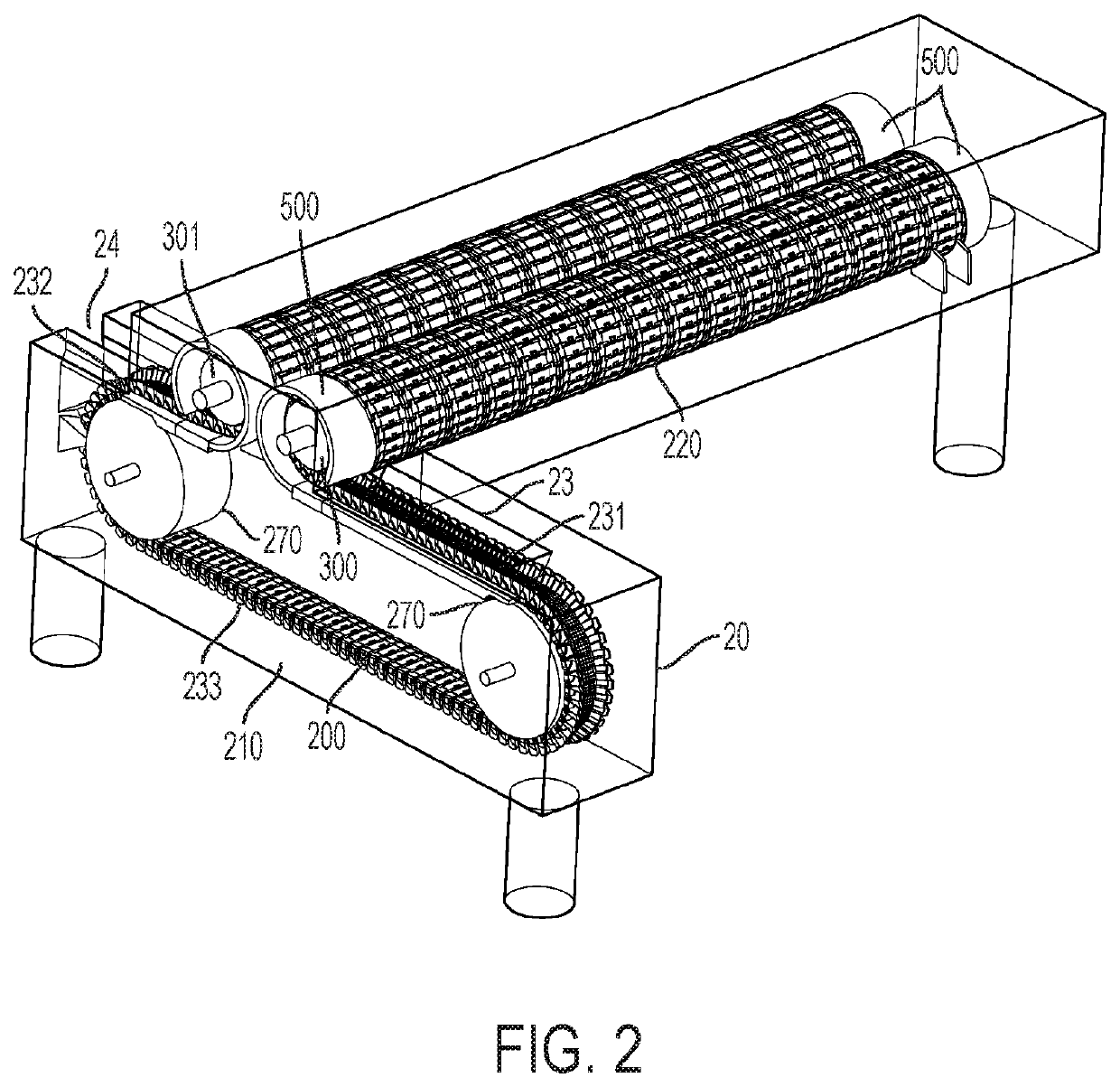

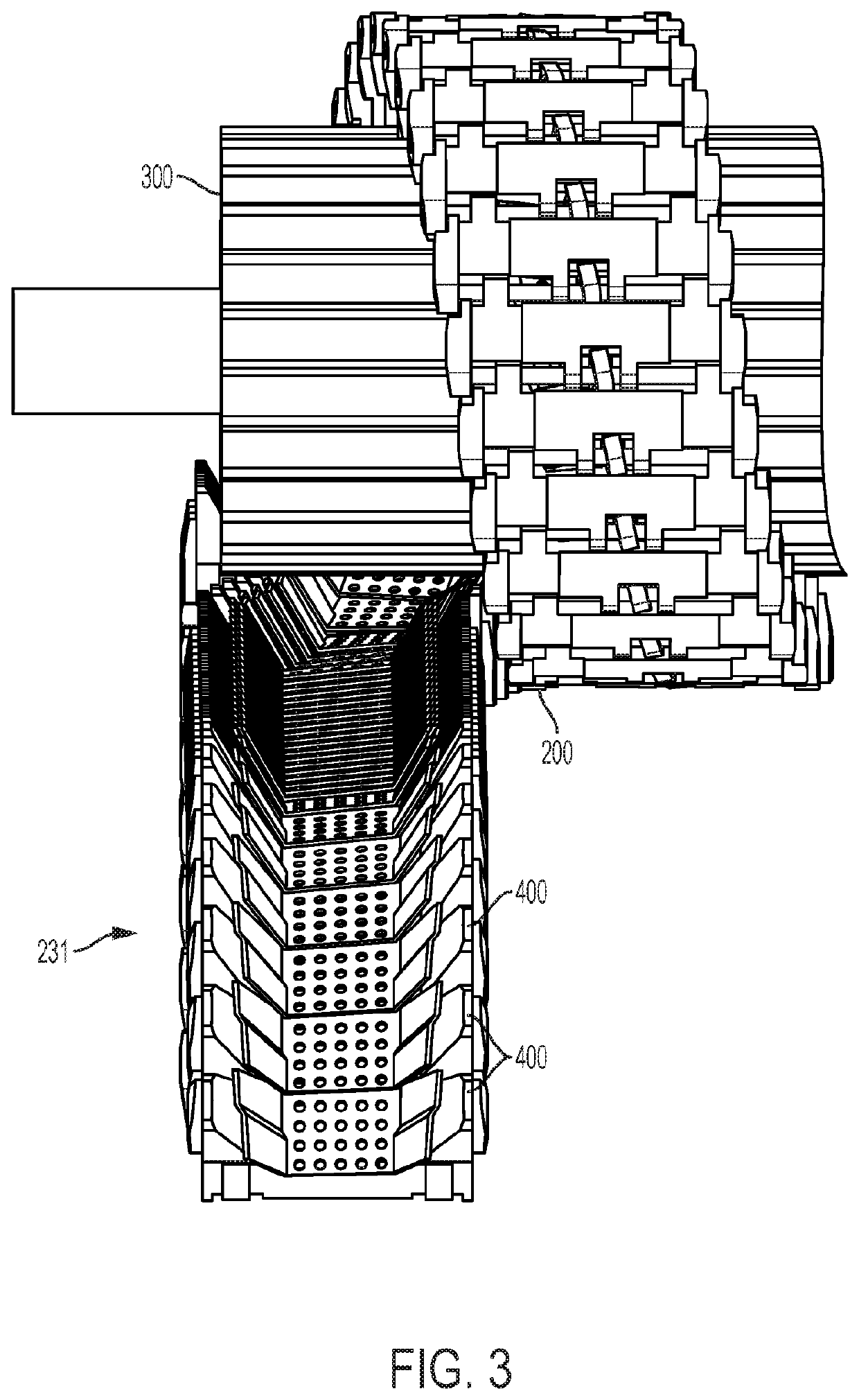

Centrifugal dewatering conveyor system

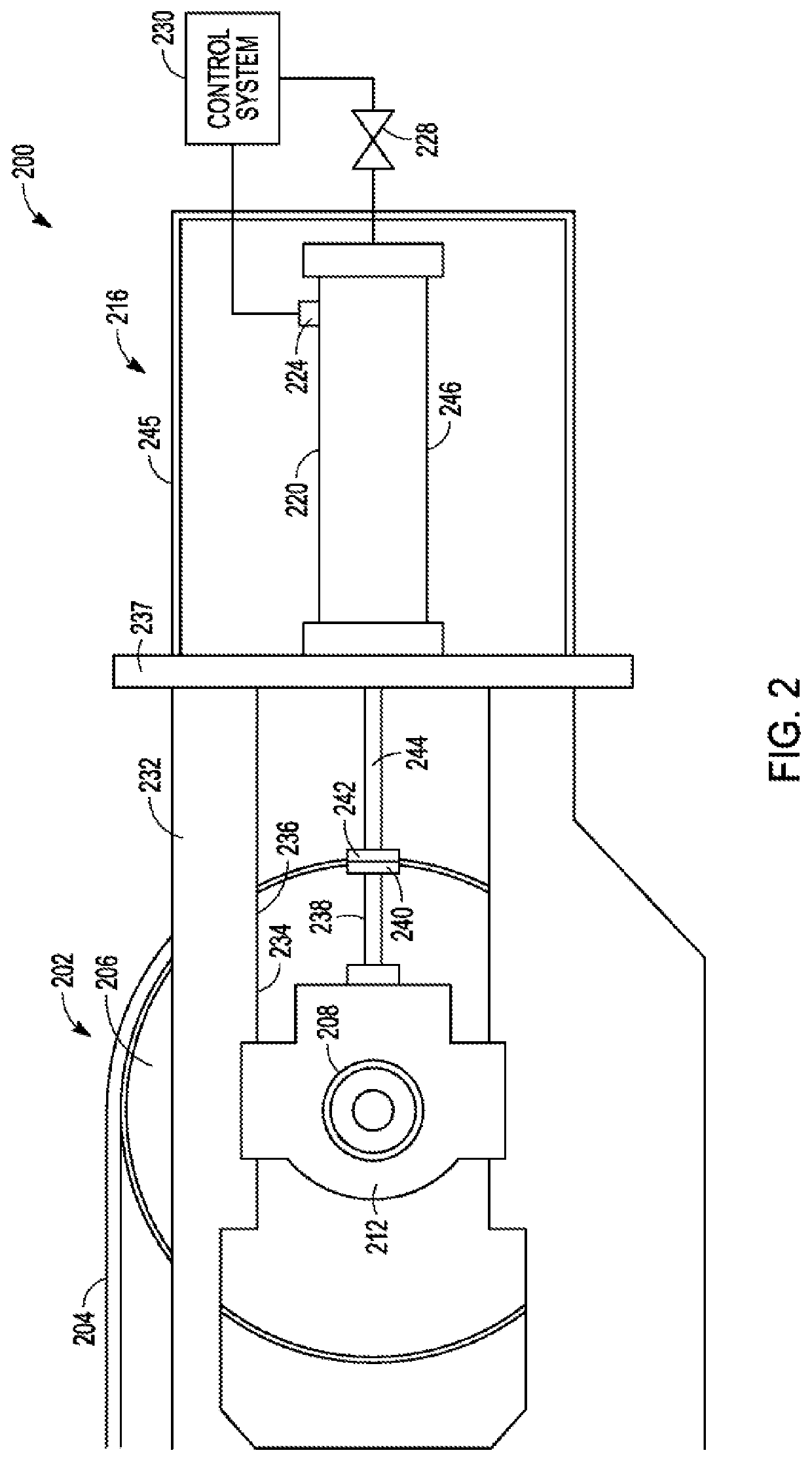

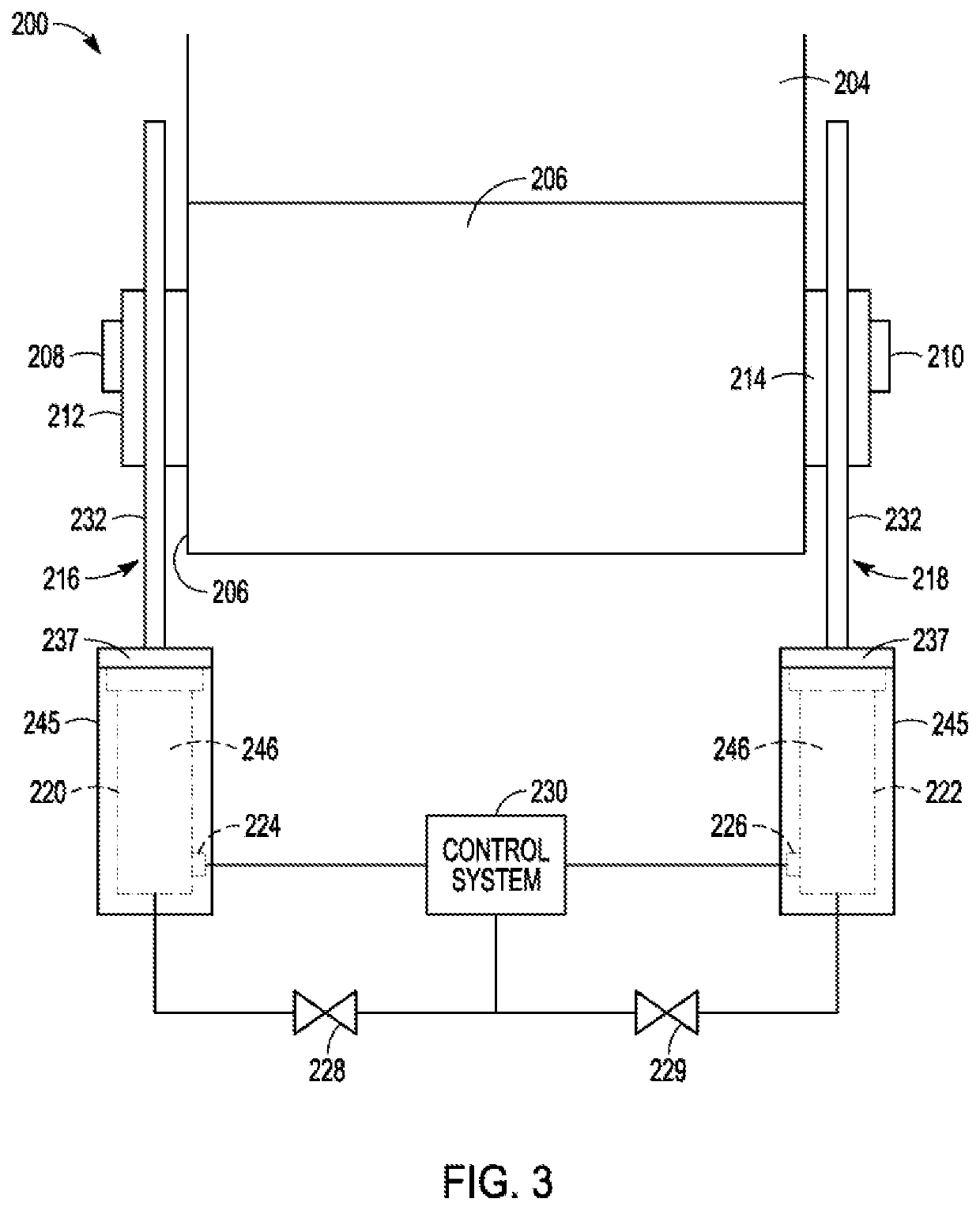

ActiveUS20200062510A1Promote formationConveyorsDrying solid materials without heatEngineeringStructural engineering

Owner:LAITRAM LLC

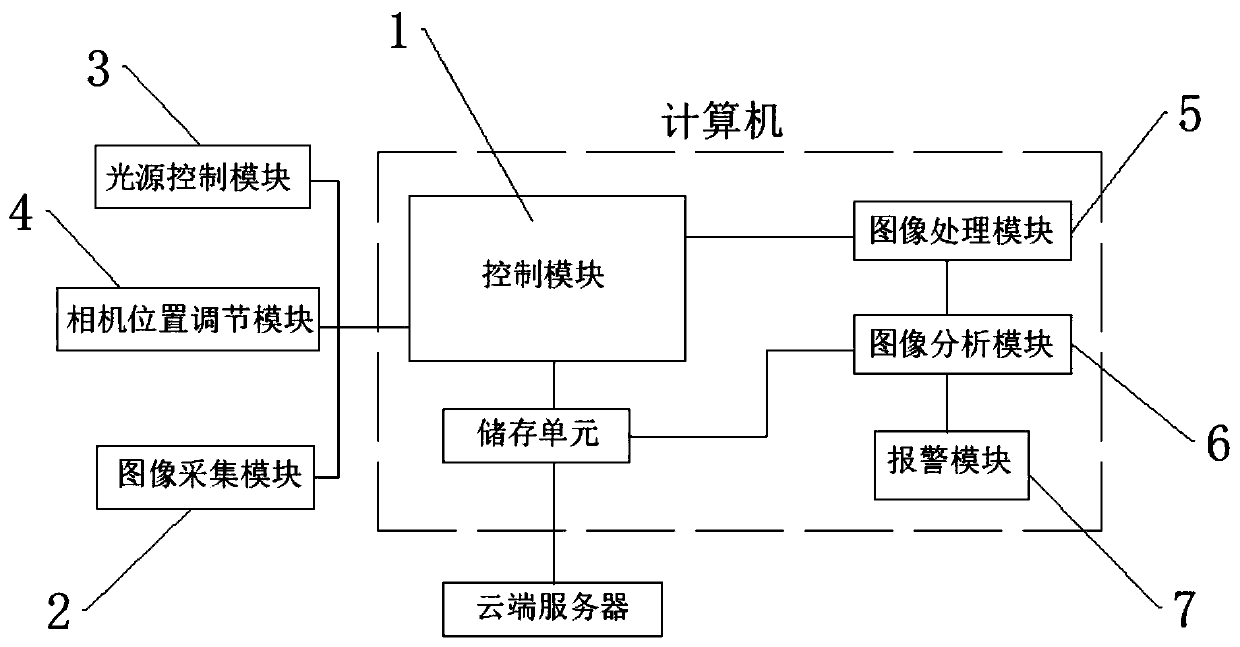

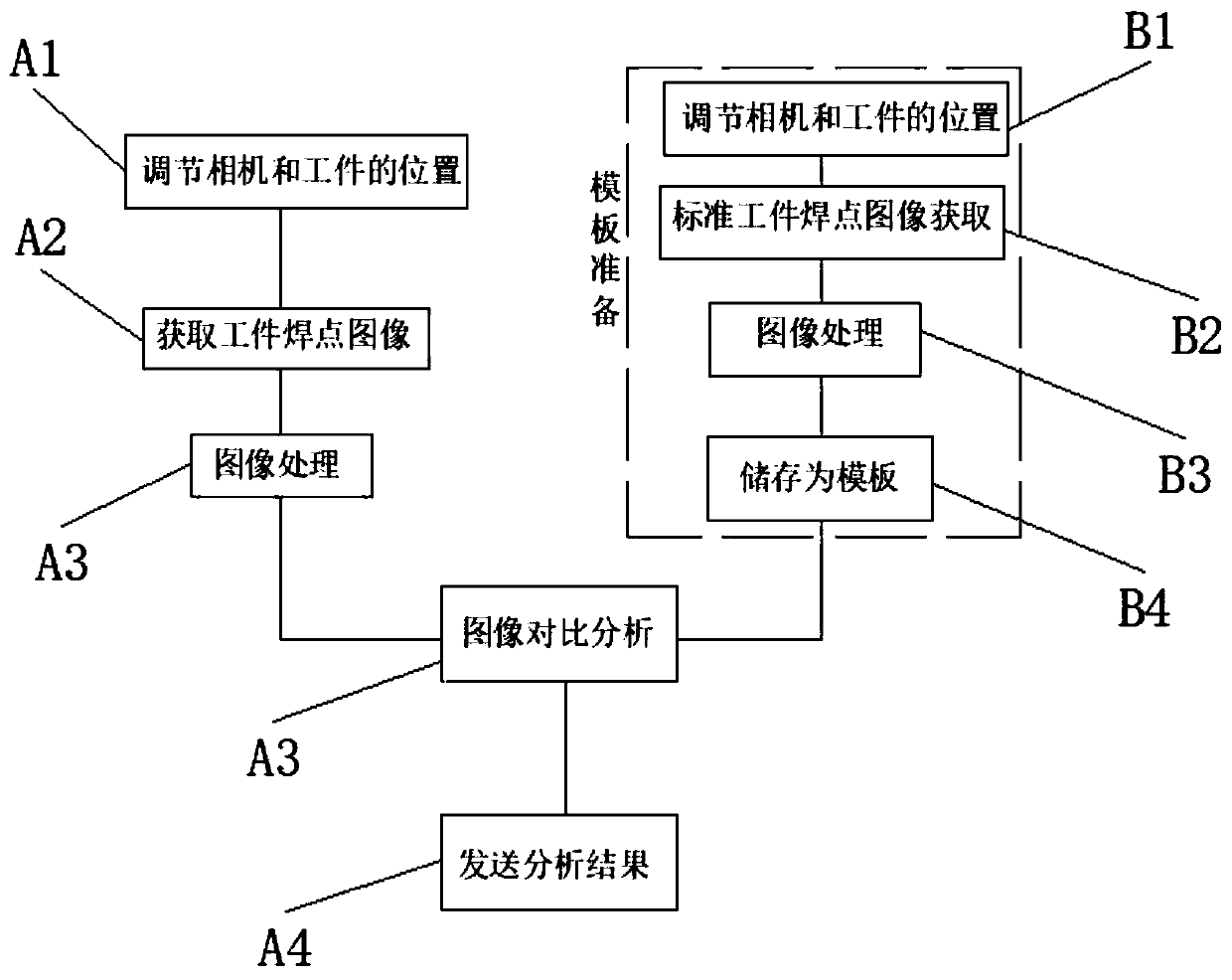

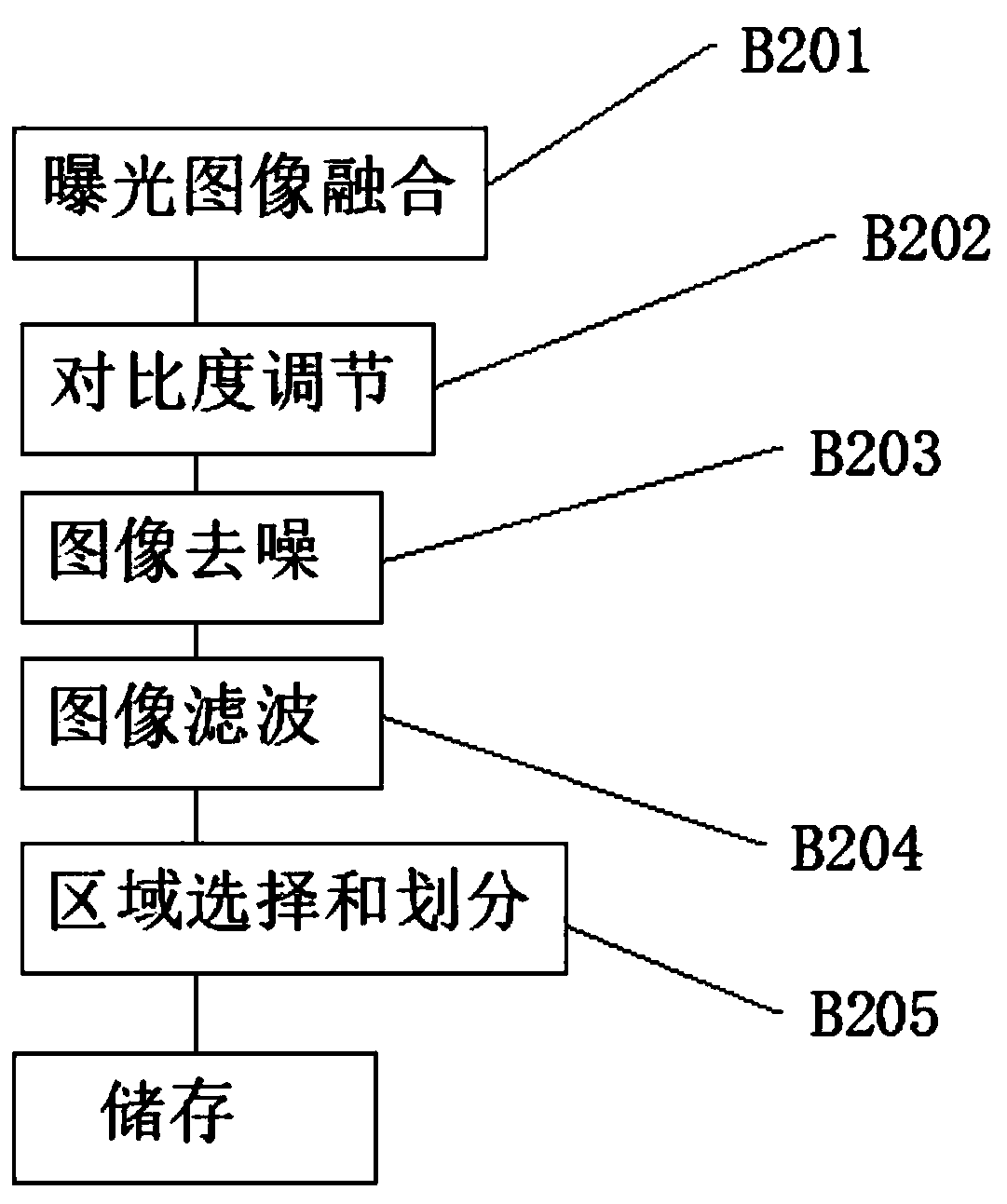

Welding spot appearance detection method based on machine vision

PendingCN111307812AEasy to collectThe analysis result is accurateOptically investigating flaws/contaminationImaging processingMachine vision

Owner:NANCHANG INST OF TECH

Automatic circular metal plate spray coating device

PendingCN111215268AEasy to sendConveying with different conveying directions facilitatesSpray boothsElectric machineSpray coating

Owner:JILIN UNIV

Rotary flexo press with improved paper feeding mechanism

Owner:福建东南艺术纸品股份有限公司

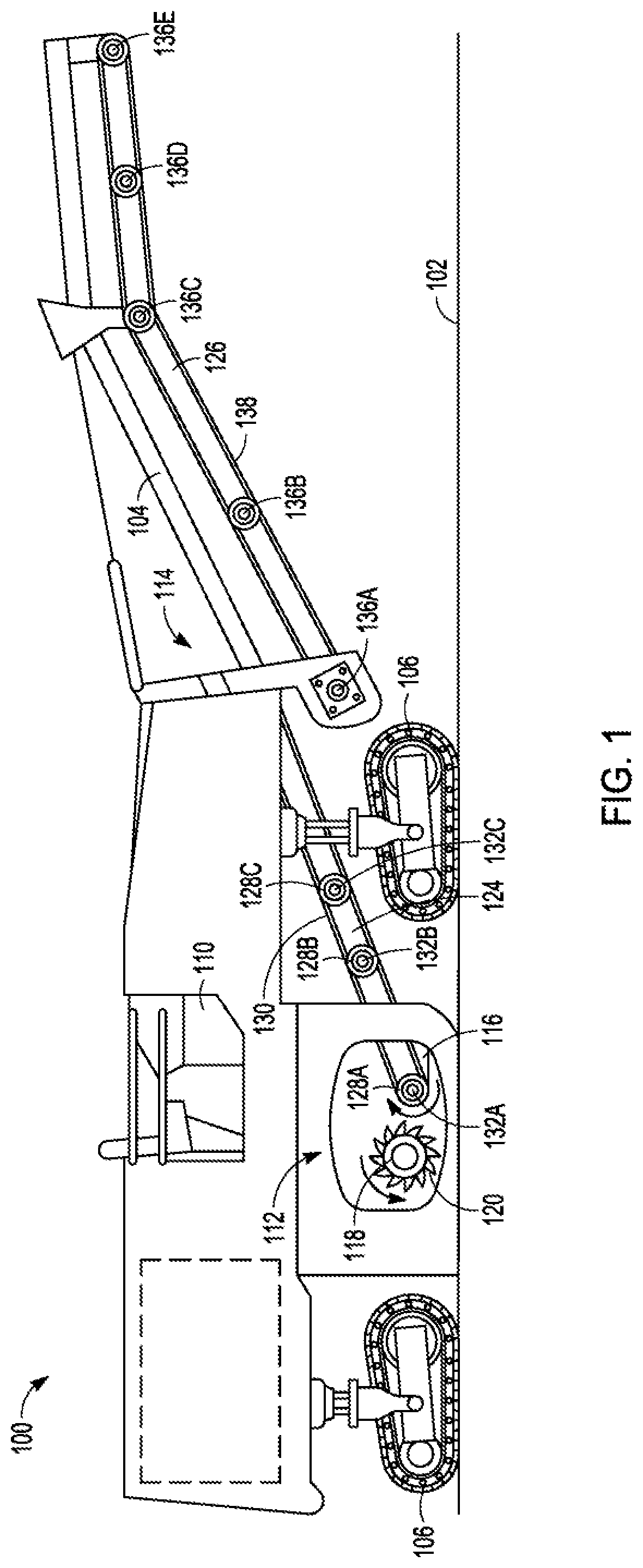

Cold planer with self-adjusting conveyor system

ActiveUS20190367286A1Operating tensionConveyorsControl devices for conveyorsTransmission beltEngineering

Owner:CATERPILLAR PAVING PROD INC

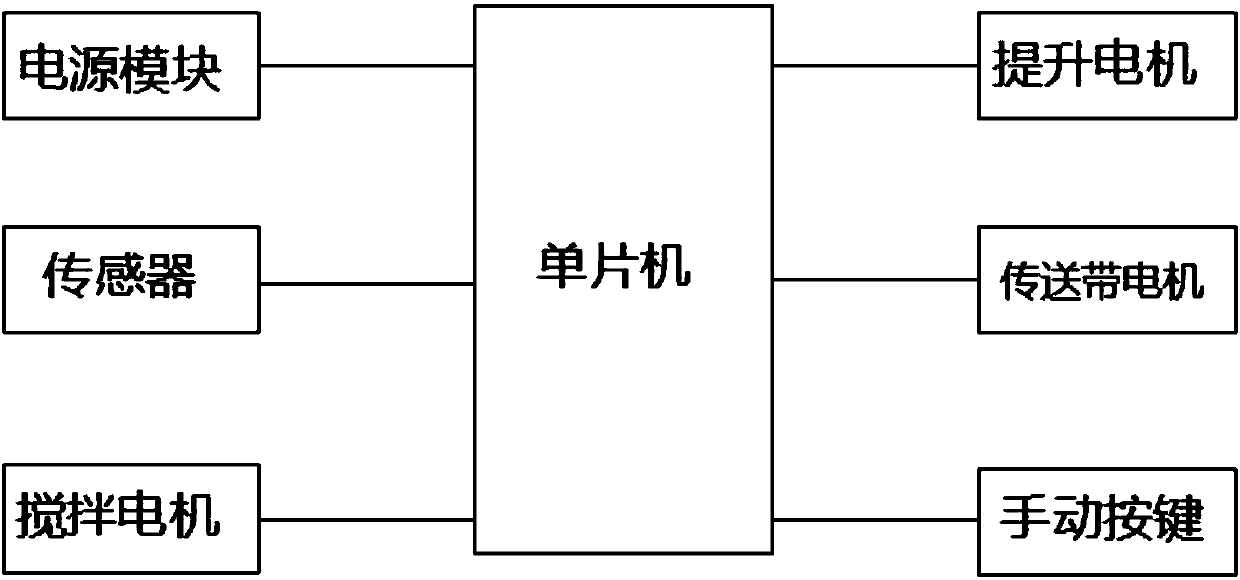

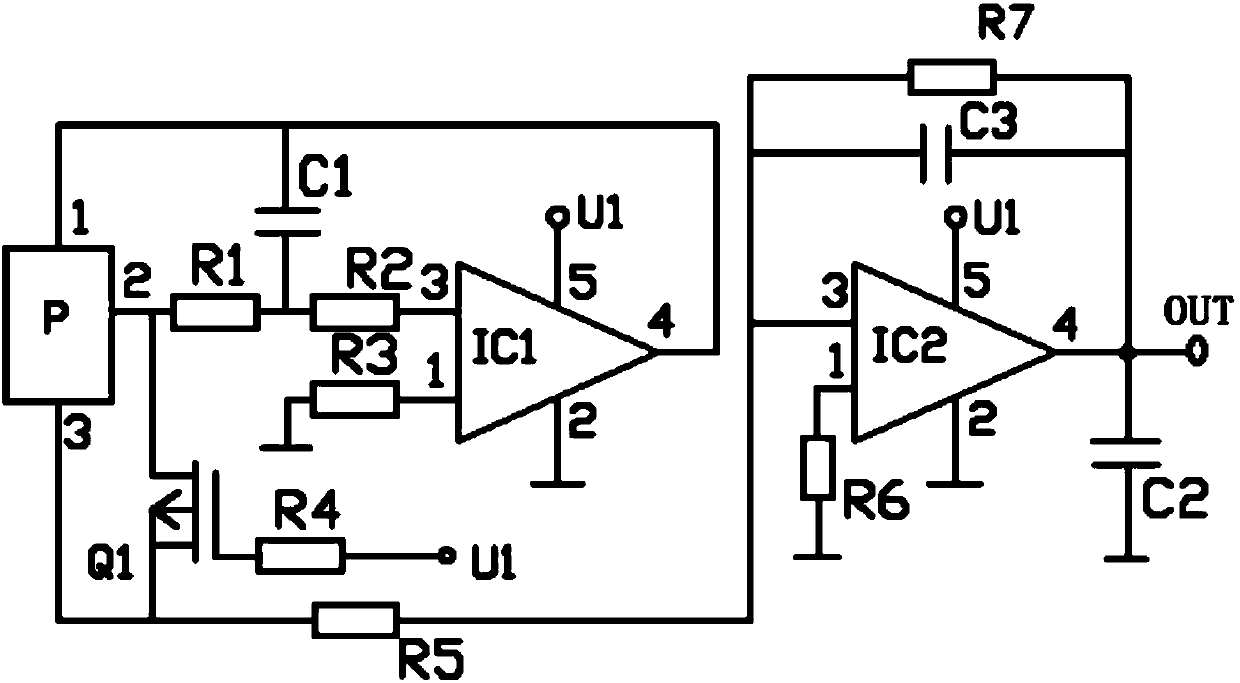

Intelligent marsh gas material reaction box

InactiveCN107674823ABoost auto-excludeRealize intelligent operation controlProgramme controlBioreactor/fermenter combinationsMicrocontrollerEngineering

Owner:HUNAN WANGLONG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Chocolate cutting and counting device

Owner:TIANJIN HEIJINGANG FOOD

Bus umbrella drying system

InactiveCN109059507AEasy to take umbrellaBatteries circuit arrangementsElectric powerHeat conductingConveyor belt

Owner:SHAANXI UNIV OF SCI & TECH

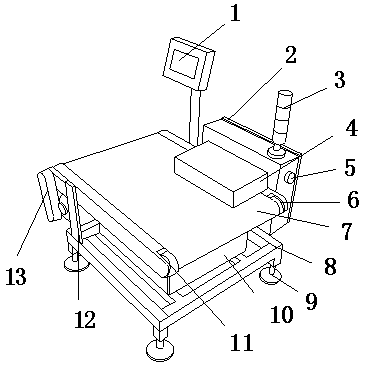

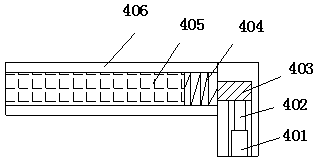

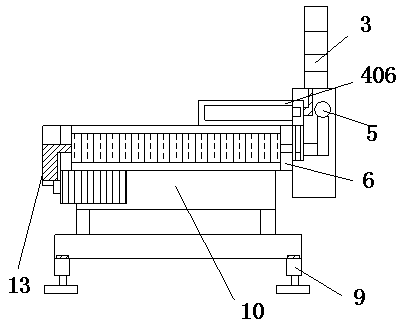

Automatic belt line weighing equipment

InactiveCN107651409AHigh degree of intelligenceReduce work intensityConveyorsControl devices for conveyorsElectricityEngineering

Owner:江苏瑞天建设有限公司

Twisting machine device for tubular product processing

Owner:TIANJIN SHENGFA IND & TRADE

Food detection device

PendingCN113655186AImprove detection efficiencyAdjustable cutting angleConveyorsPreparing sample for investigationAgricultural engineeringDistilled water

Owner:浙江九安检测科技有限公司

A New Method of Preventing Coal Dust Explosion in Underground Coal Mine

InactiveCN102261260AReduce concentrationLower explosion limitDust removalFire preventionSprayerPolyvinyl alcohol

Owner:梁红

Passive door-locking system for safety door

ActiveCN110259272AReduce impactSimple structureNon-mechanical controlsConveyor beltElectrical and Electronics engineering

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

Method and apparatus for tobacco processing using blockchain encryption

InactiveCN109007951AImprove reliabilitySimple structureTobacco preparationTobacco treatmentMotor driveDrive motor

Owner:宁波鄞州台本荣机械设备有限公司

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

Cable take-up and pay-off device for communication engineering

Owner:安徽莱特实业集团有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap