Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about "Wood working apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

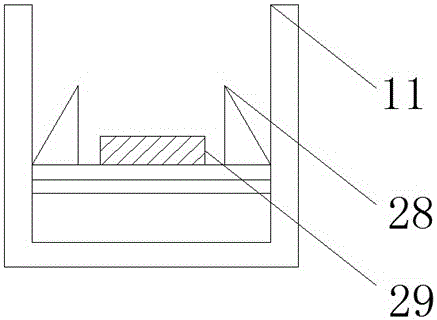

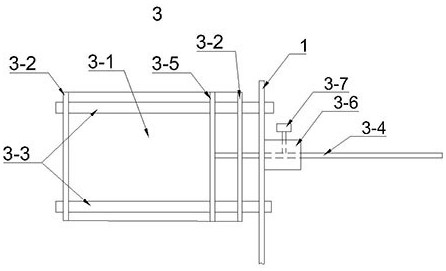

Method and device for flattening bamboo wood

InactiveCN101982306AIncrease profitSmall color differenceWood working apparatusCircular sawMaterials science

Owner:李跃兵

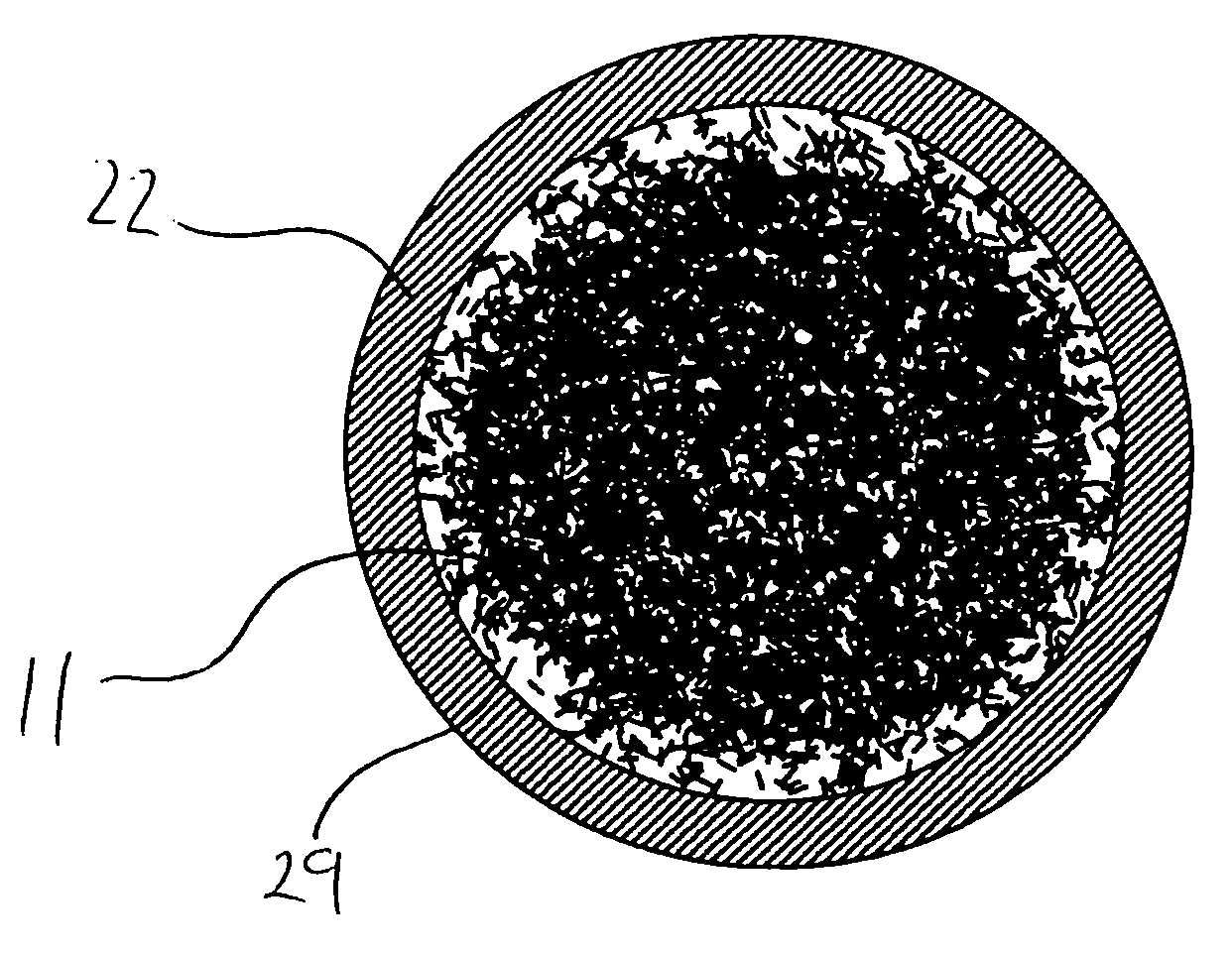

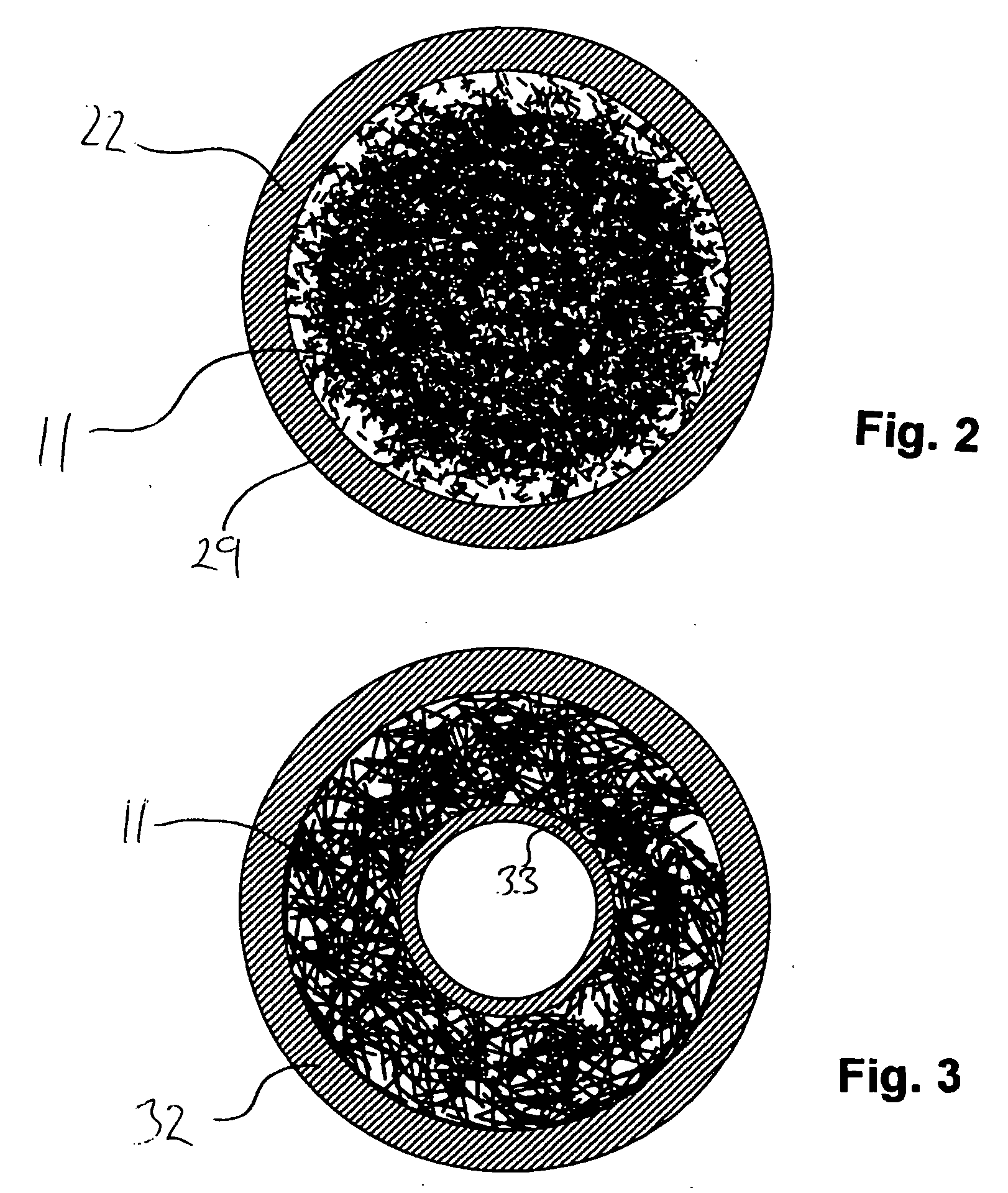

Manufacture of thick preform composites via multiple pre-shaped fabric mat layers

Owner:HONEYWELL INT INC +2

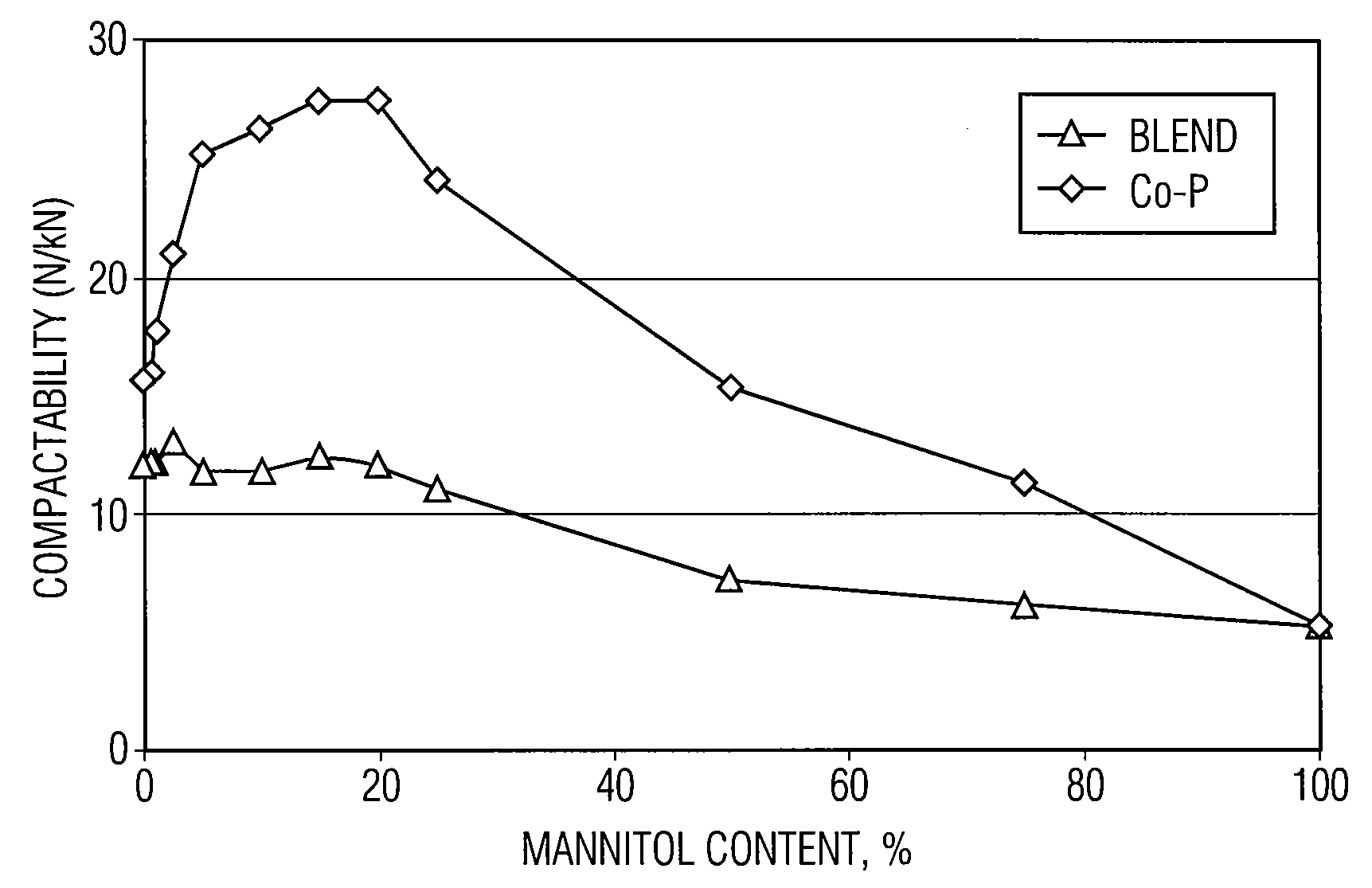

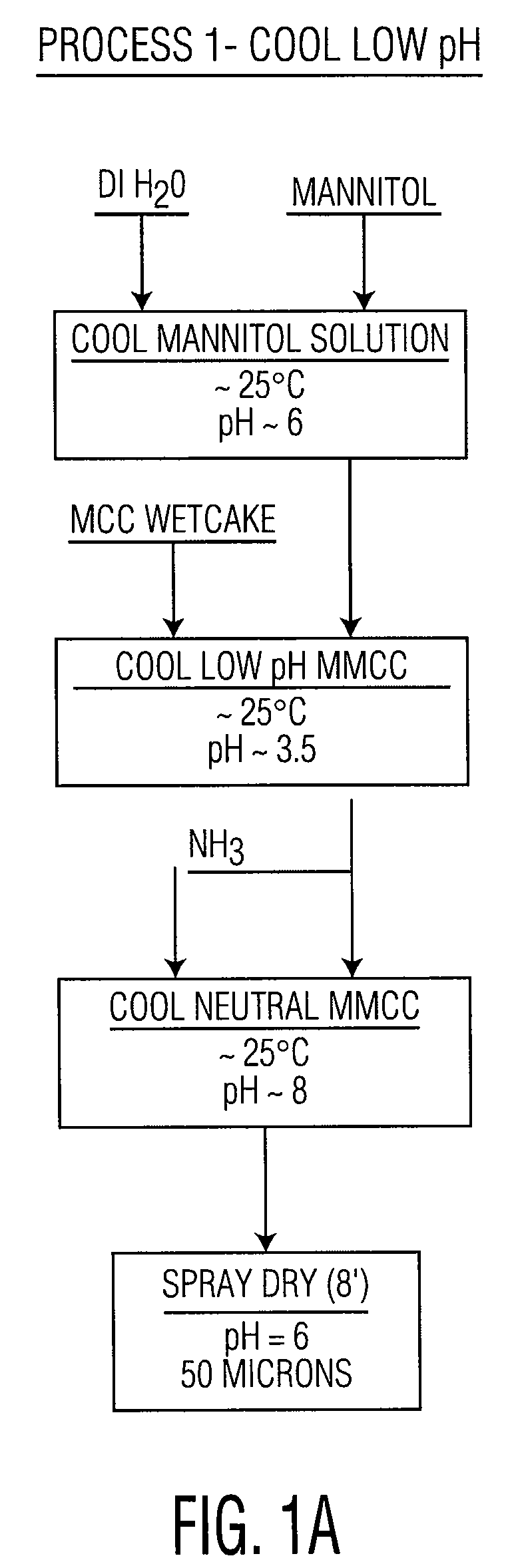

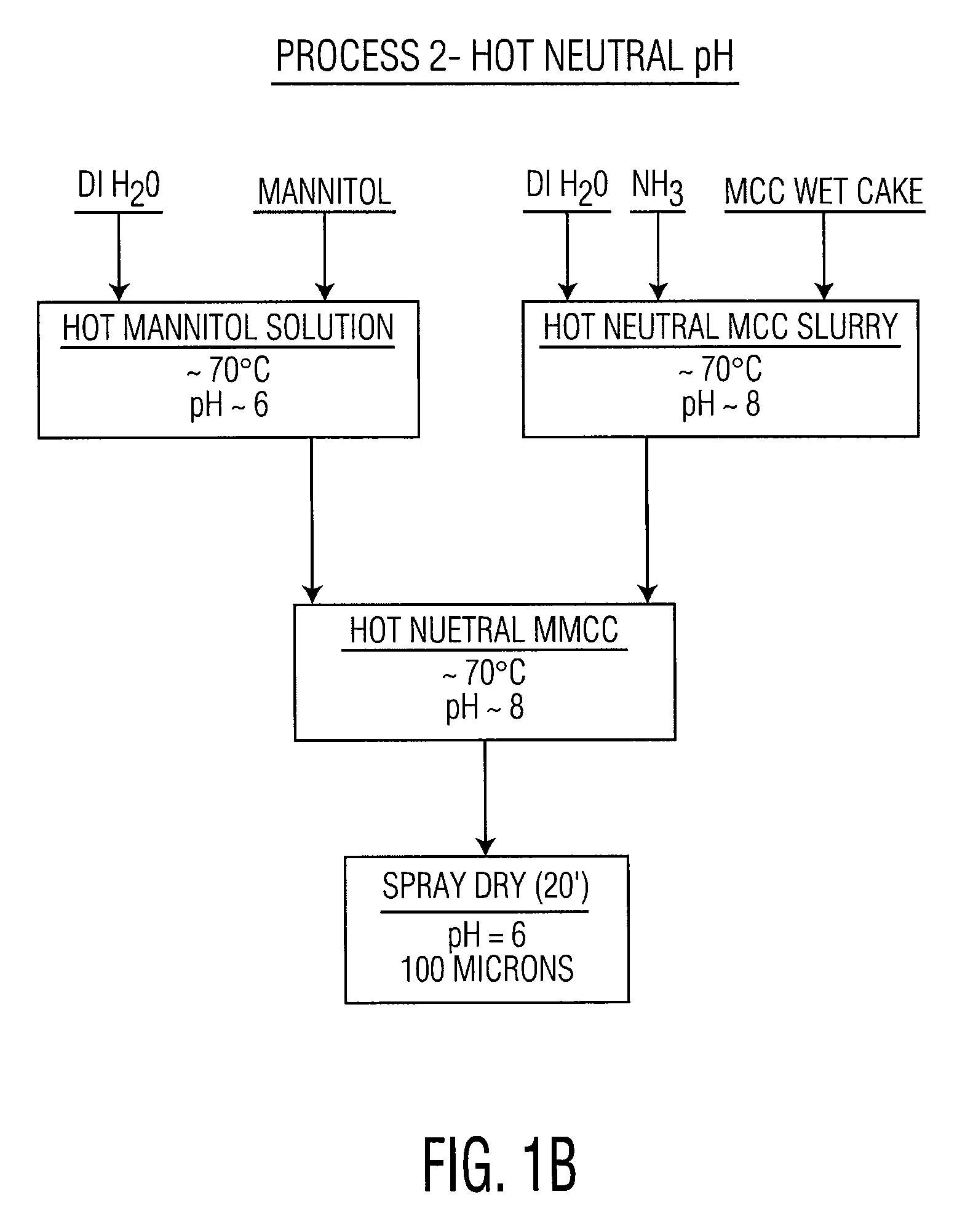

Co-processed microcrystalline cellulose and sugar alcohol as an excipient for tablet formulations

ActiveUS20080131505A1Improve the compaction effectWood working apparatusPill deliveryParticulatesMANNITOL/SORBITOL

Owner:DUPONT NUTRITION USA INC

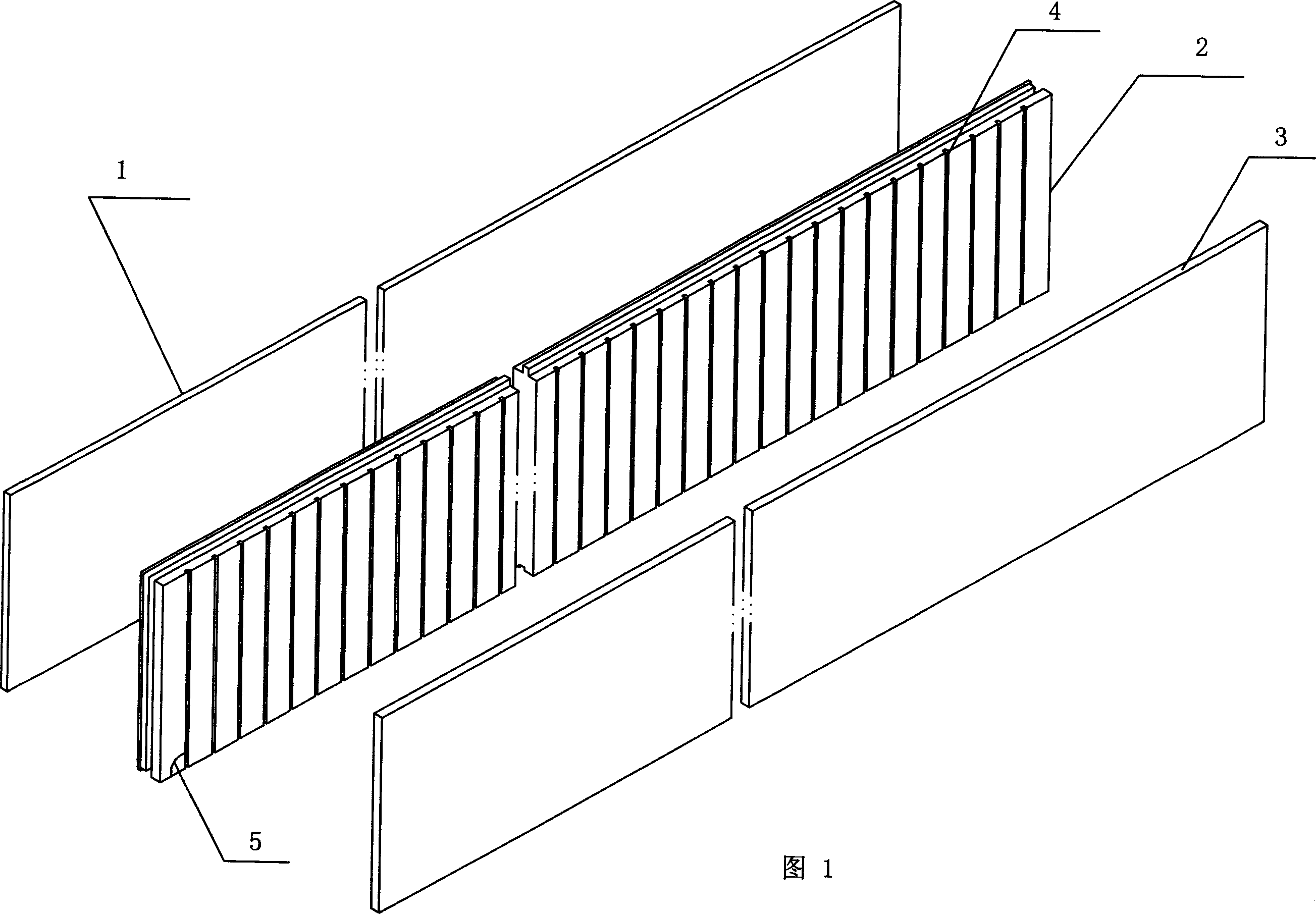

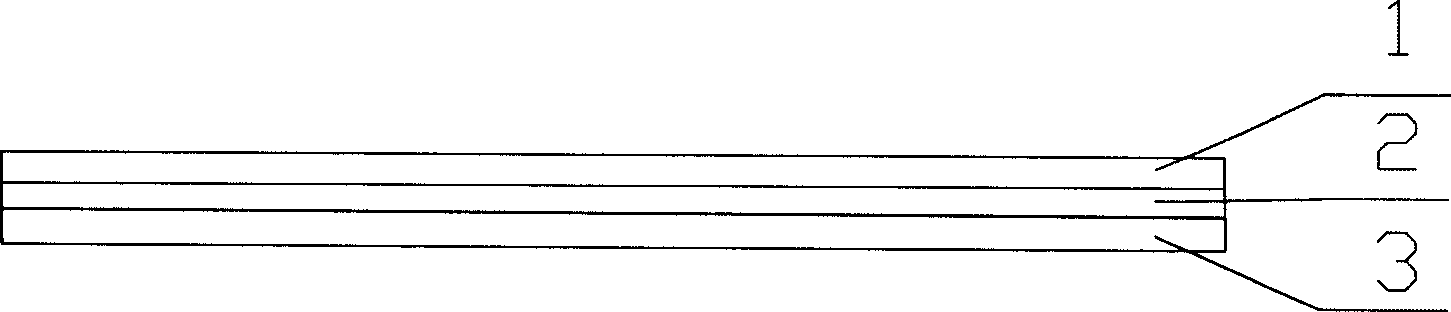

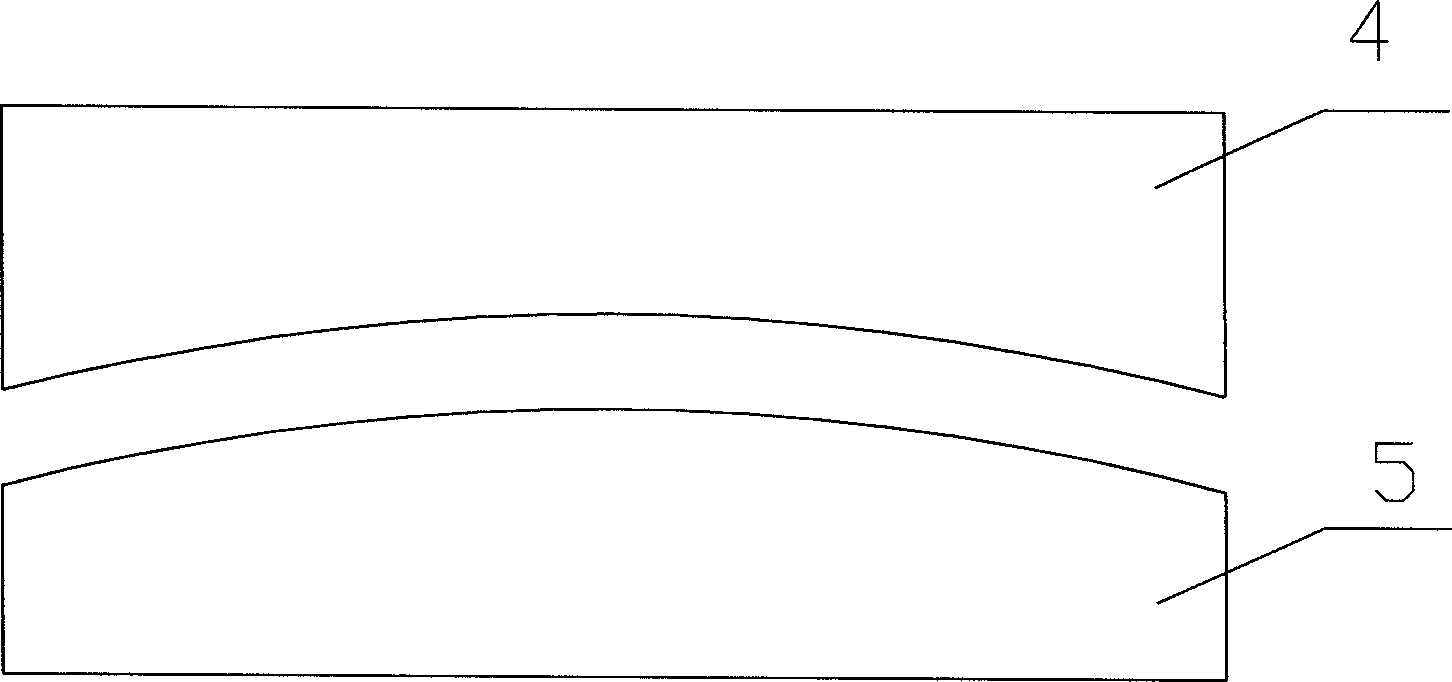

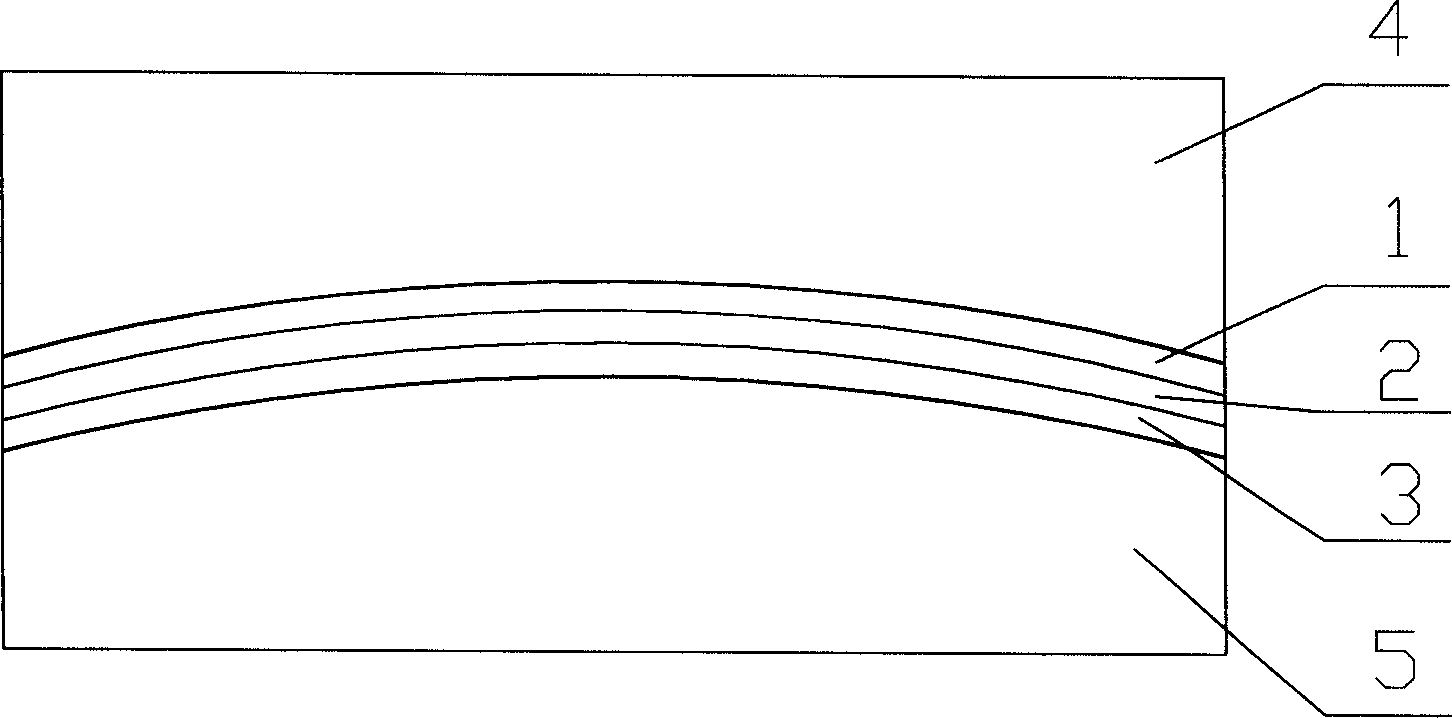

Equalizing three-layered wood compound floor board and mfg. method

InactiveCN100999954AImprove stabilityReduce the chance of crackingWood working apparatusFlooringEngineeringComposite plate

Owner:上海新四合木业有限公司

Fiber mat and process for making same

InactiveUS20060292952A1Improved tensileHigh tear strengthNatural cellulose pulp/paperSpecial paperFiberEngineering

Owner:BUILDING MATERIALS INVESTMENT

Fibreboard from agricultural wastes and a method for manufacturing the same

InactiveUS20120296014A1Low costEasy to usePolyureas/polyurethane adhesivesWood working apparatusPolyolPlant fibre

Owner:UNIVERSITI MALAYA +1

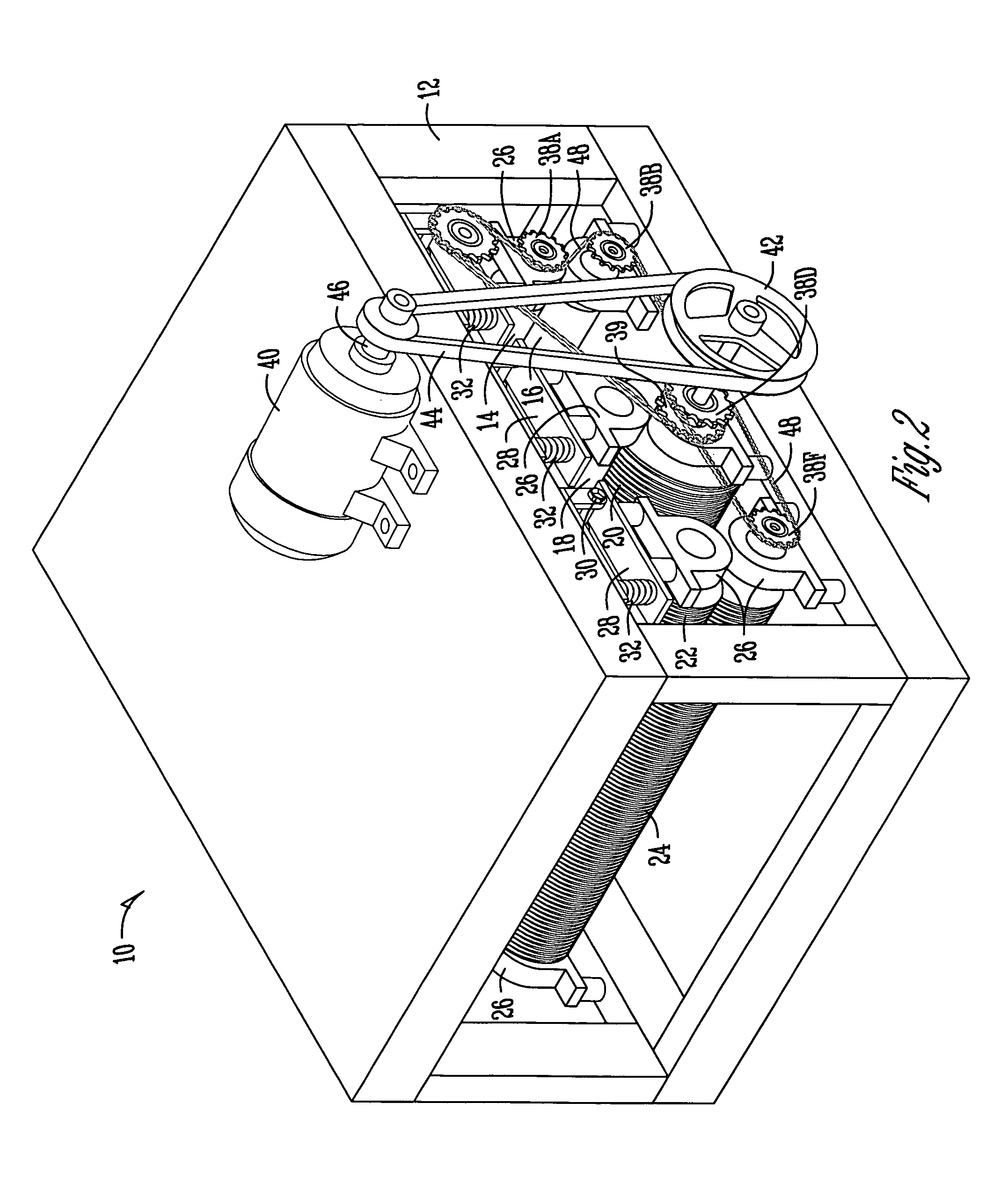

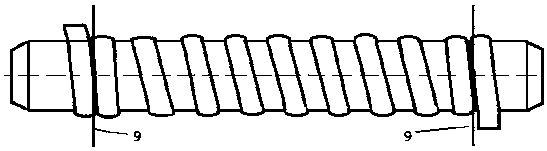

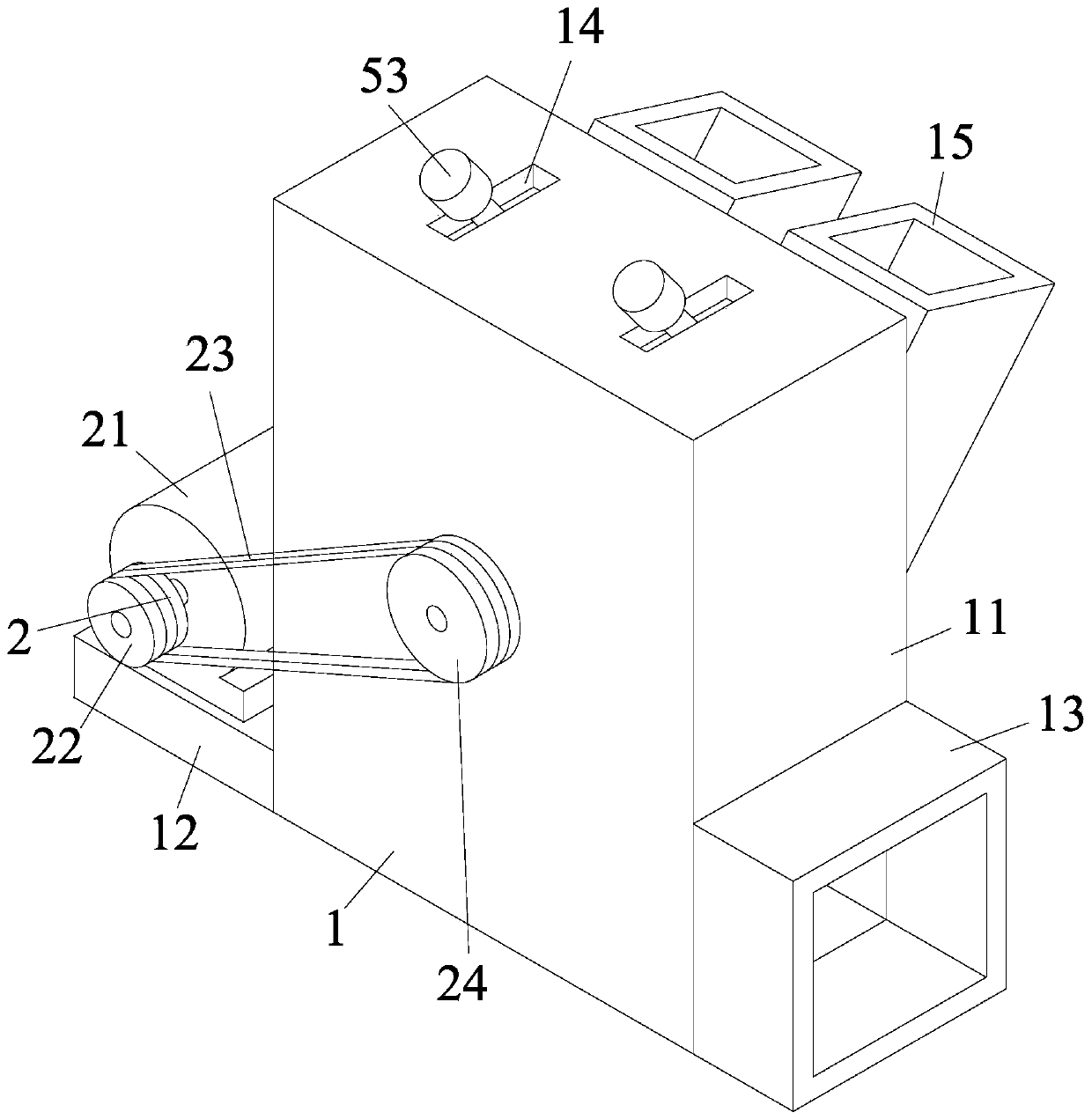

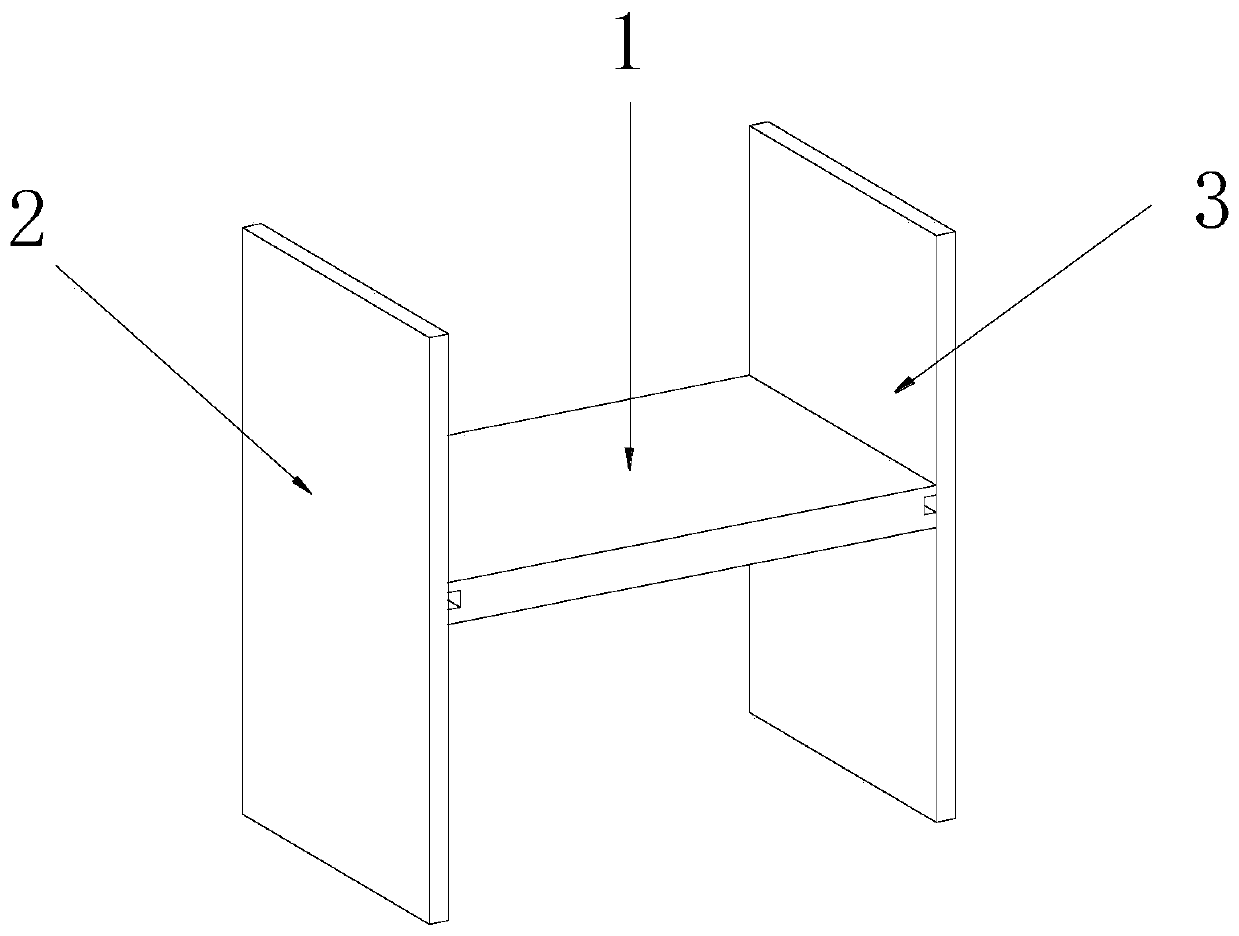

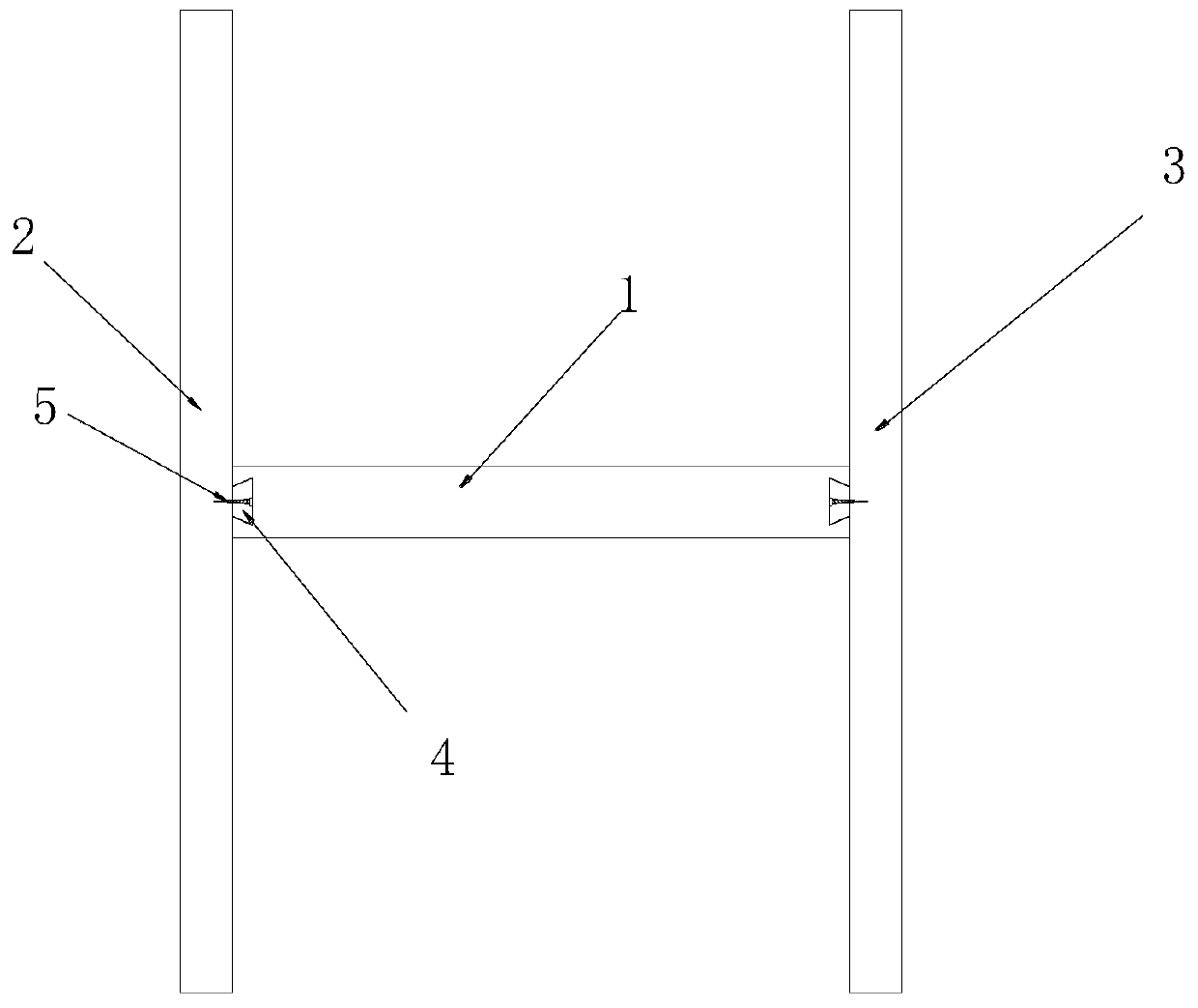

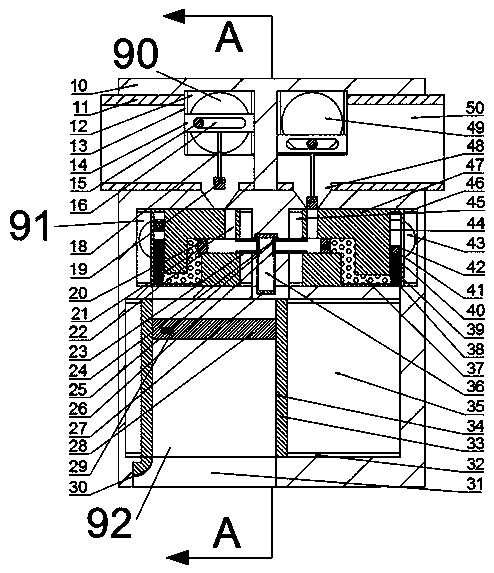

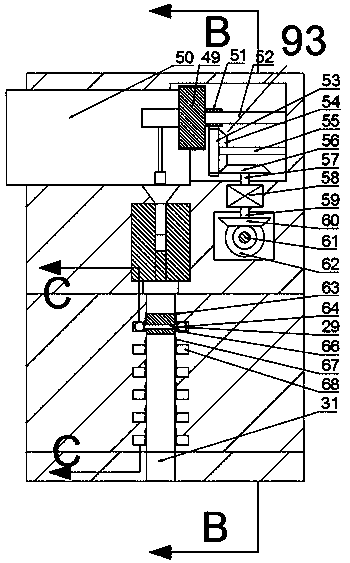

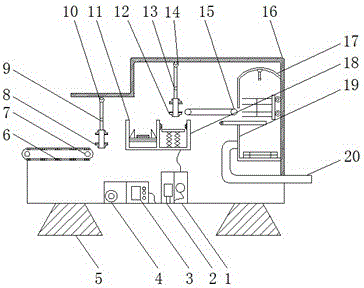

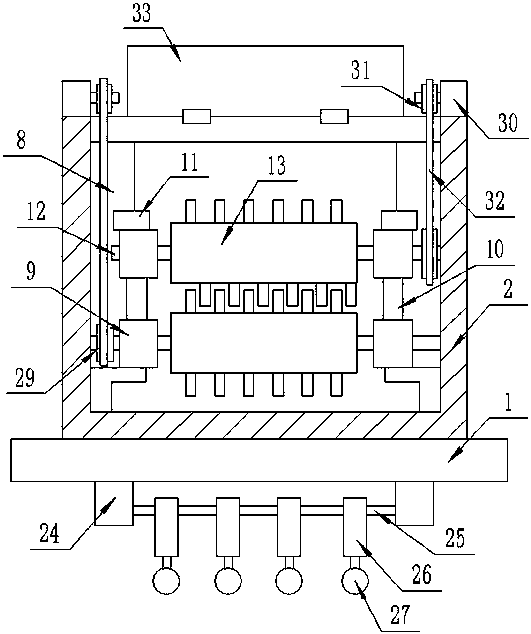

Double layer crusher

ActiveCN104759336AGuaranteed uptimeExtended service lifeWood working apparatusGrain treatmentsEngineeringCrusher

The invention discloses a double layer crusher. A smashing chamber is fixed on a main body of a machine base; a crushing chamber is arranged above the smashing chamber; a feeding opening is formed in the top part of the crushing chamber; a discharging opening is formed in the lower part of the smashing chamber; an rolling cutter rotor assembly is used for smashing wood bars and cutting long bars to small blocks; a centrifugal hammer sheet rotor assembly is used for smashing the small blocks; the inner spaces of the crushing chamber and the smashing chamber are mutually communicated; a screen and a strong magnet device are arranged between the two chambers from up to bottom in sequence. The double layer crusher adopts a unique two-in-one mode; by integrating cutting and smashing functions, the double layer crusher can meet market demands, the cost is lowered and the efficiency is increased.

Owner:SHANDONG YULONG MASCH CO LTD

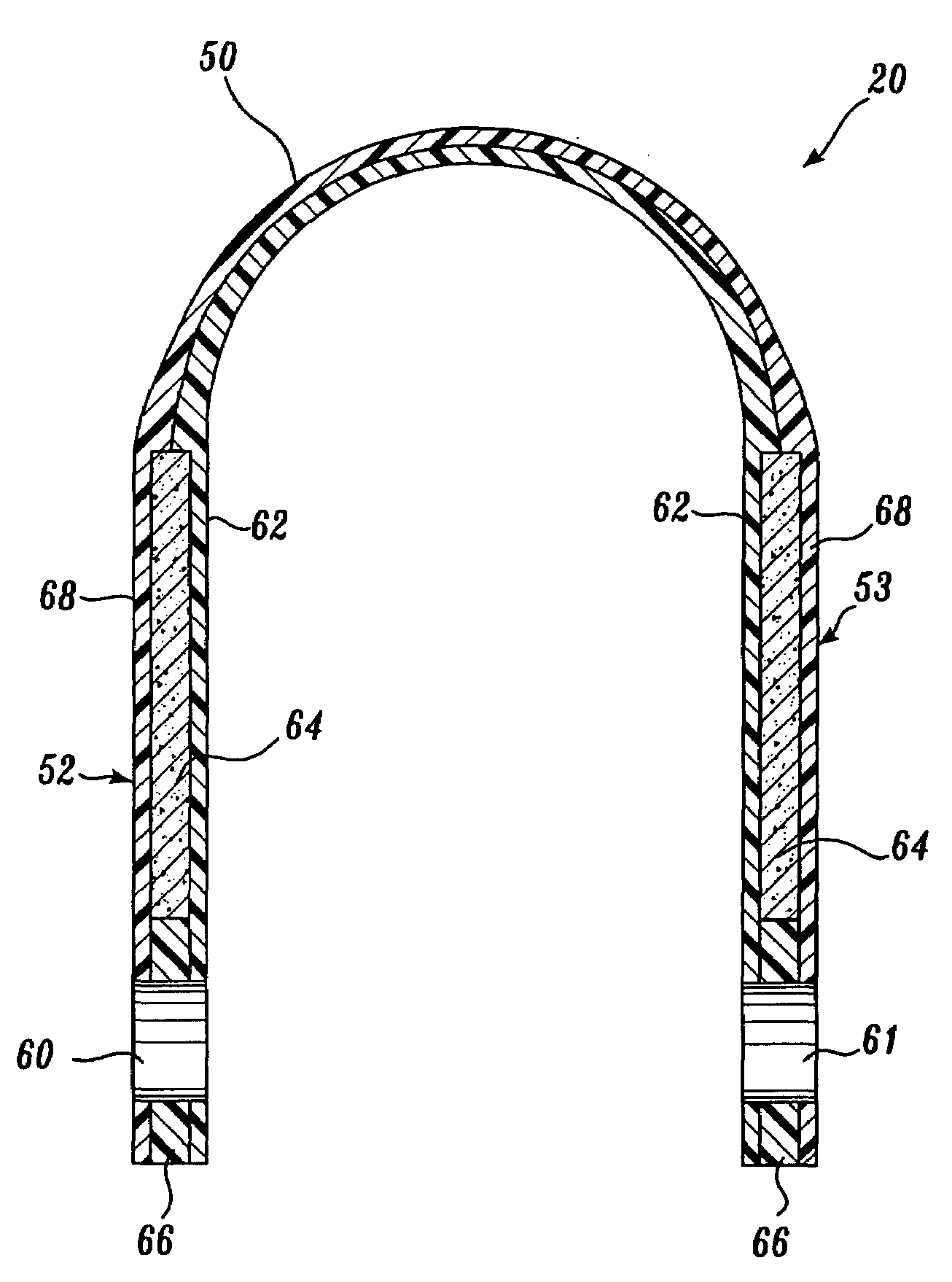

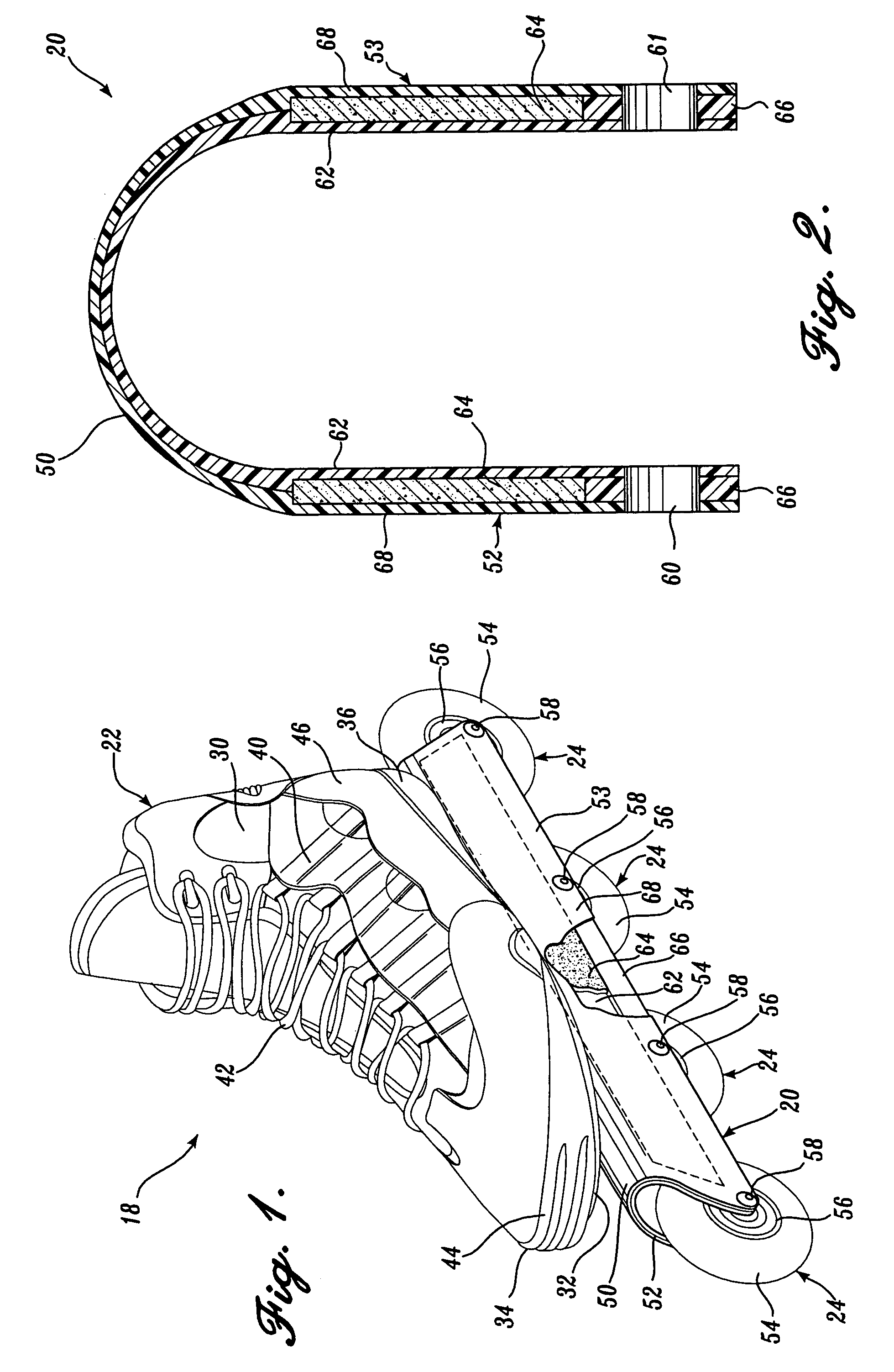

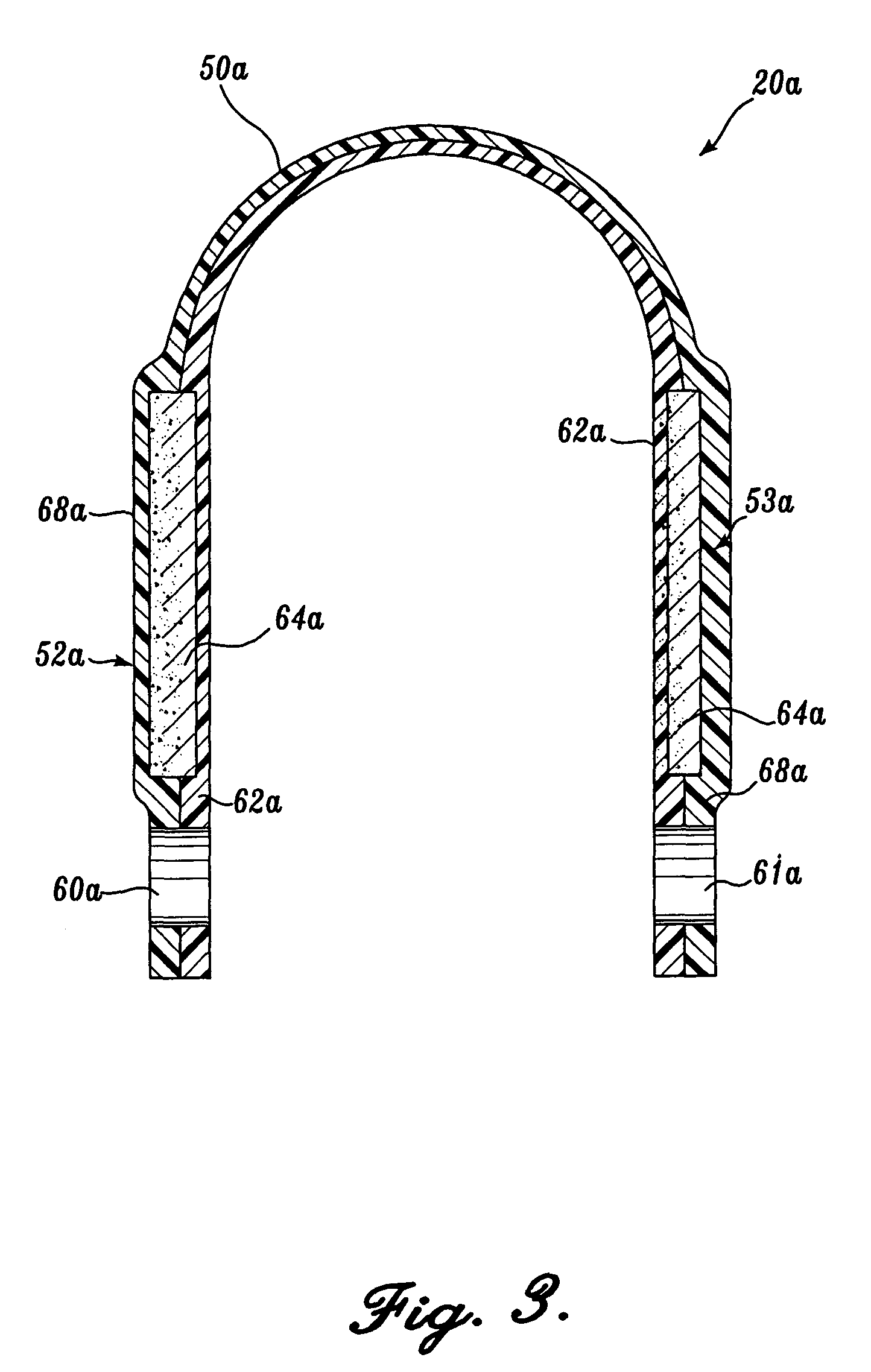

Foam core in-line skate frame

InactiveUS7214337B2Long useful lifeStrength-to-weight ratio can be improvedLaminationWood working apparatusEngineering

Owner:K 2 CORP

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

Machine for conditioning soybean straw

InactiveUS20070044890A1Remove pithIncrease speedCrop conditionersWood working apparatusDrinking strawEngineering

Owner:PREMOMCNE

Antimicrobial lubricant for wood fiber-plastic composites

ActiveUS20050256231A1Prevent rotCoatings with pigmentsNon-macromolecular organic additionSulfateWood fibre

The invention relates to a polymer-cellulosic fiber composition comprising a polymer, a cellulosic fiber, and a quaternary ammonium alkyl salt wherein the latter imparts antimicrobial properties to the composition and functions as a lubricant during the formation of the composition. The quaternary ammonium alkyl salts may be alkyl carboxylate, alkyl sulfate, alkyl sulphonate, alkyl phosphate, or alkyl phosphite. Certain of the salts are new compositions of matter. The method of extruding and the extrudate are also claimed.

Owner:ARXADA LLC

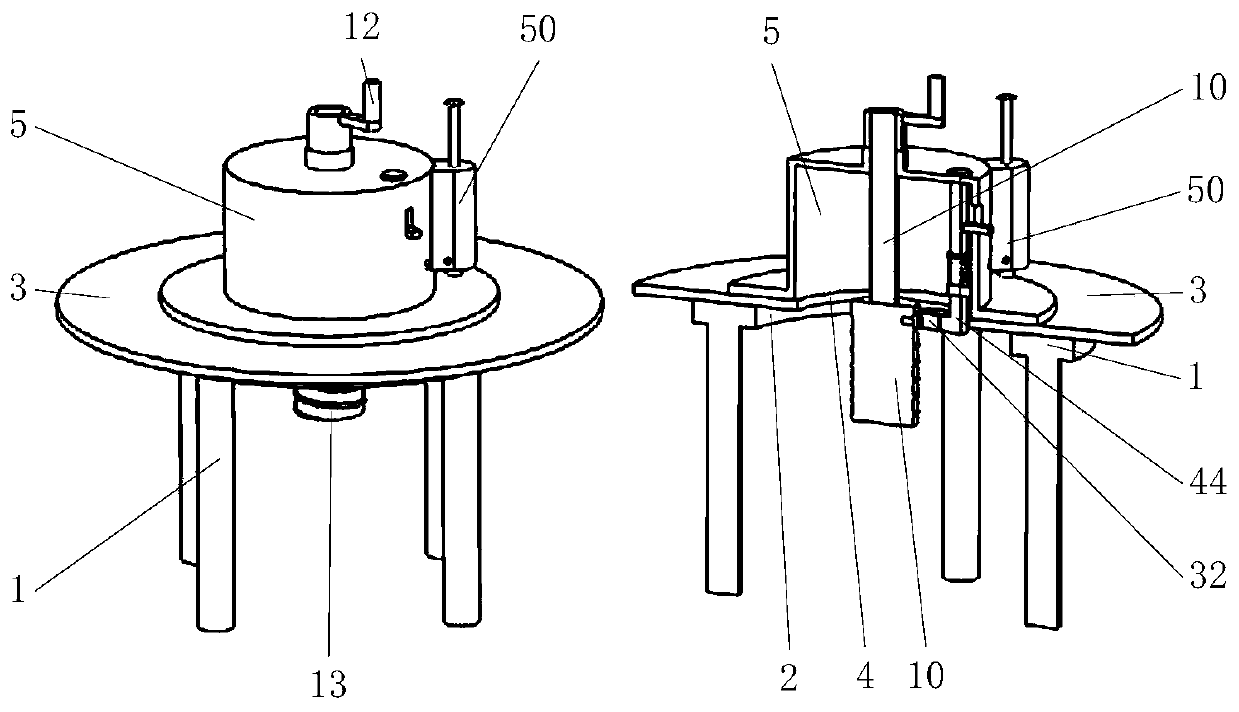

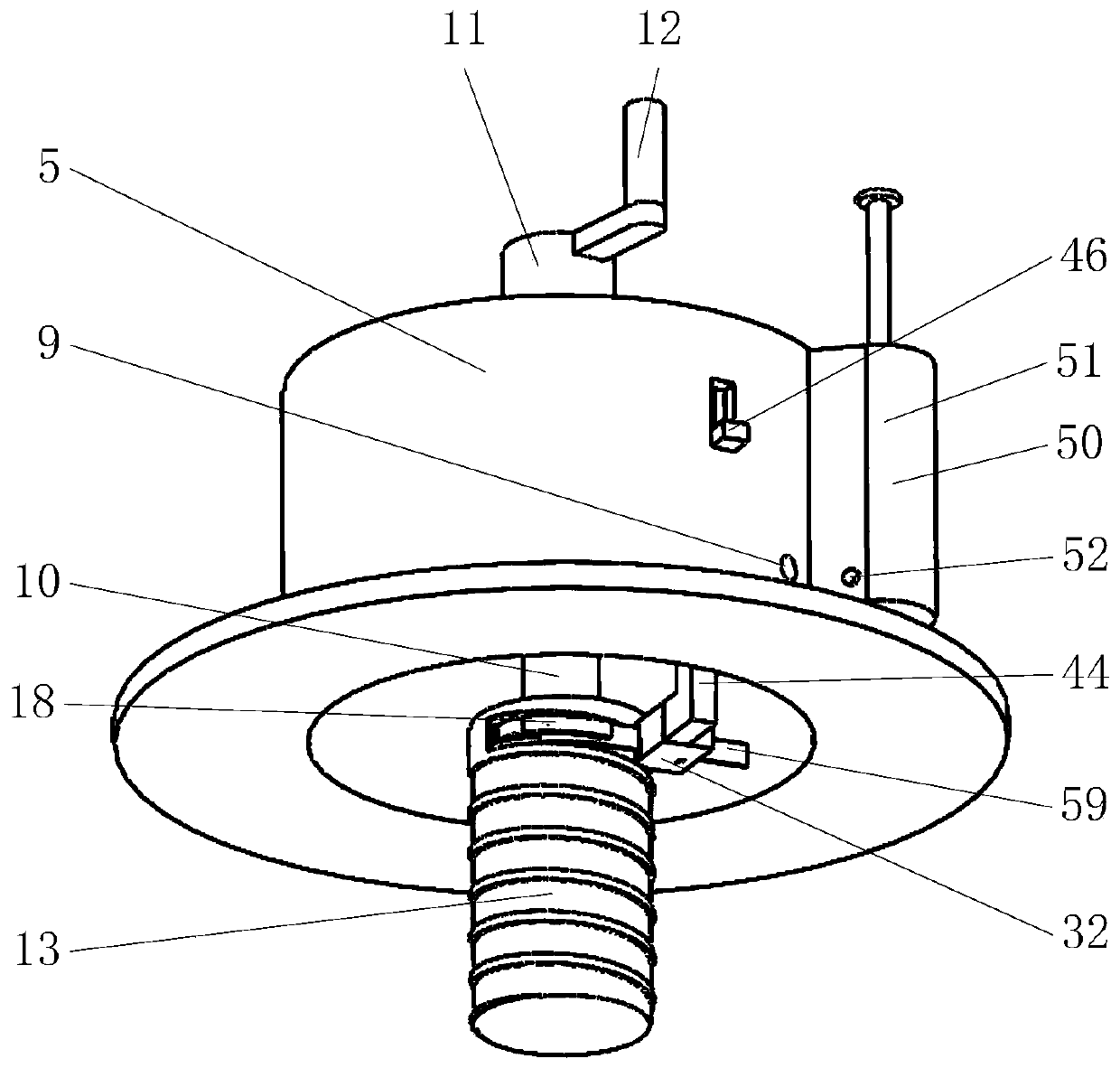

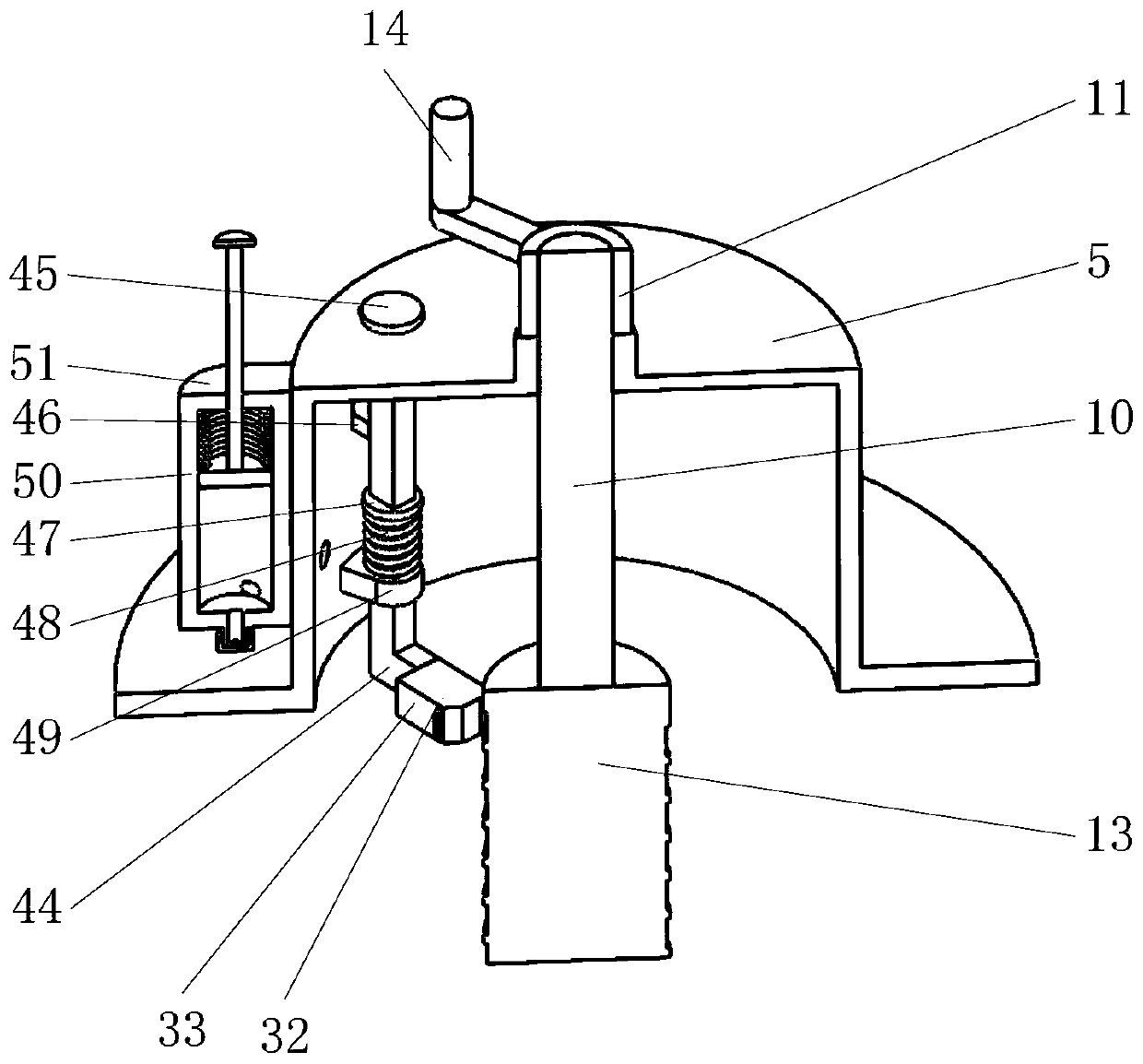

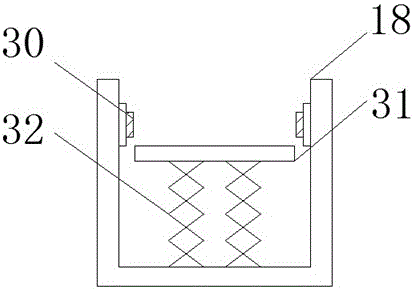

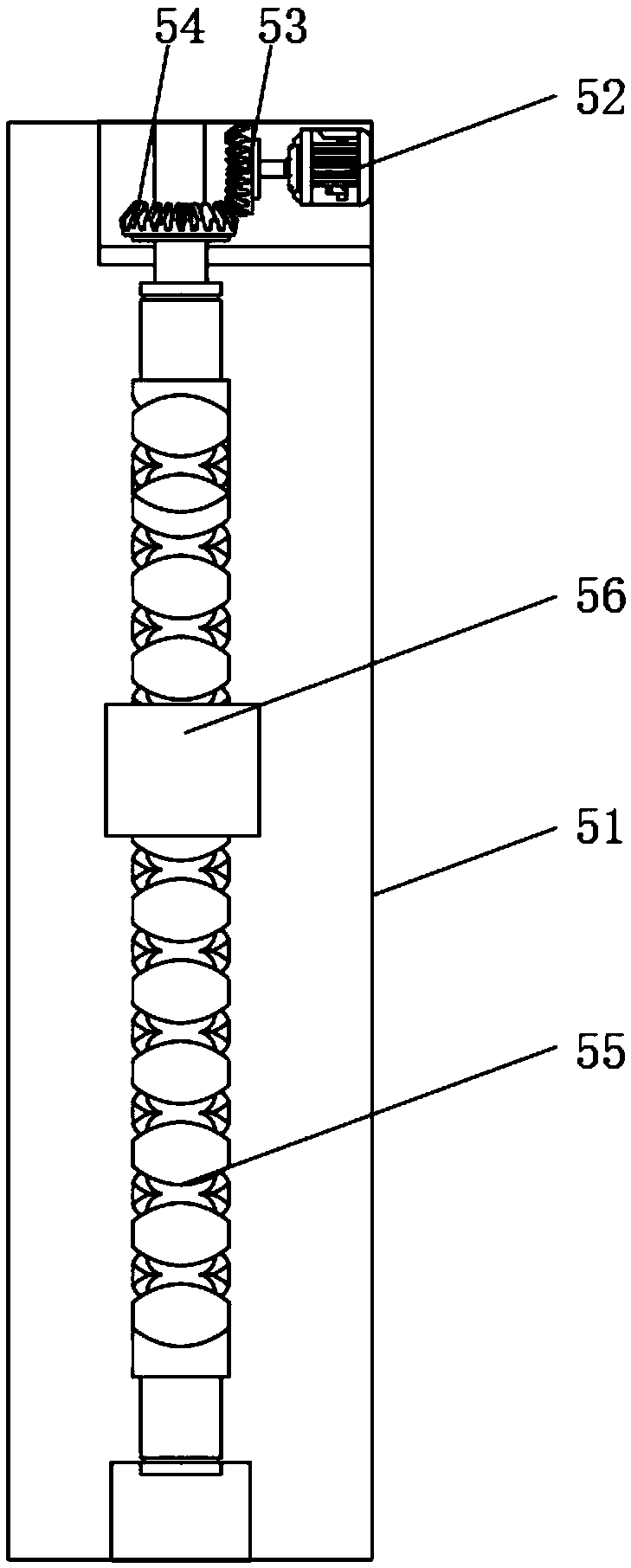

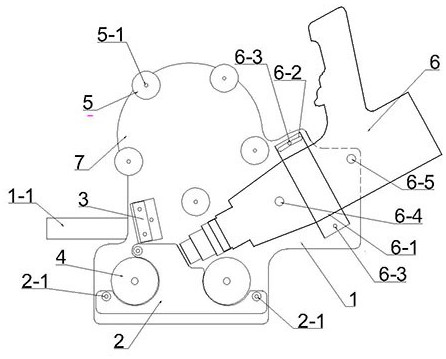

Edge sealing equipment for single-side edge sealing of circular hole with edge sealing strip

ActiveCN110843073AImprove edge banding efficiencyHigh custom production costsWood working apparatusDomestic articlesScrew threadIndustrial engineering

Owner:兰泽(荆门)智能科技有限公司

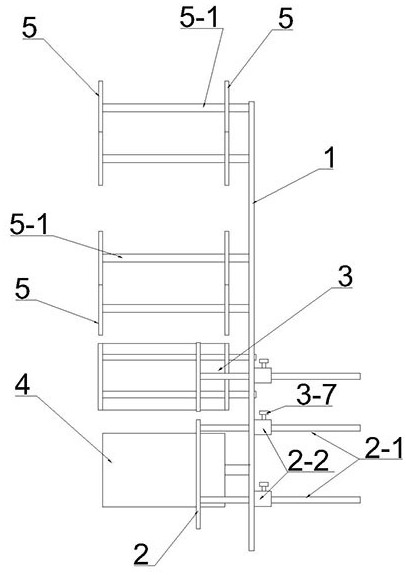

Manufacturing method of bamboo spring bracket and application thereof

InactiveCN109227826AReduce usageReduce production processWood working apparatusCane mechanical workingCarbonizationEngineering

Owner:NANJING FORESTRY UNIV

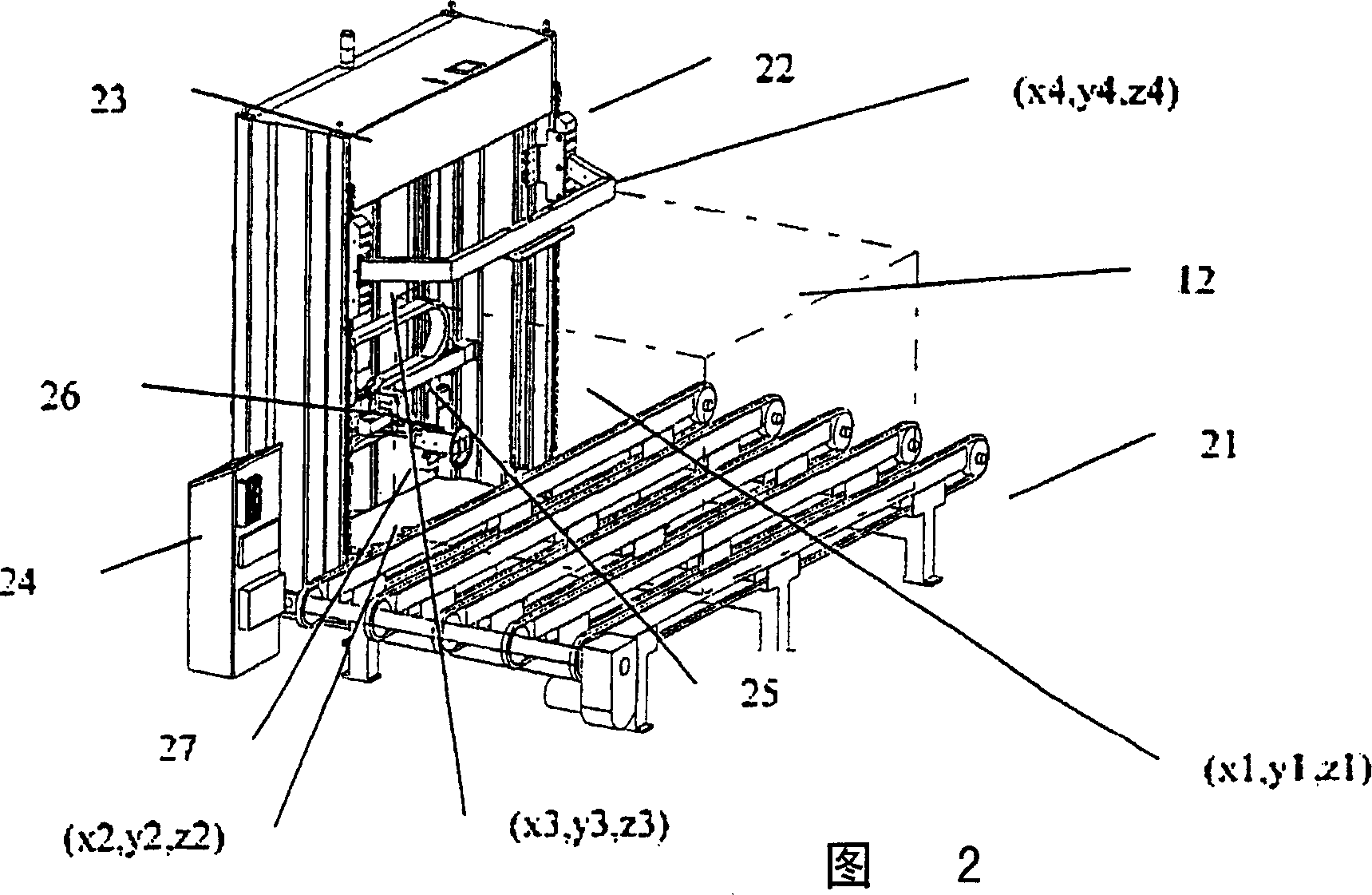

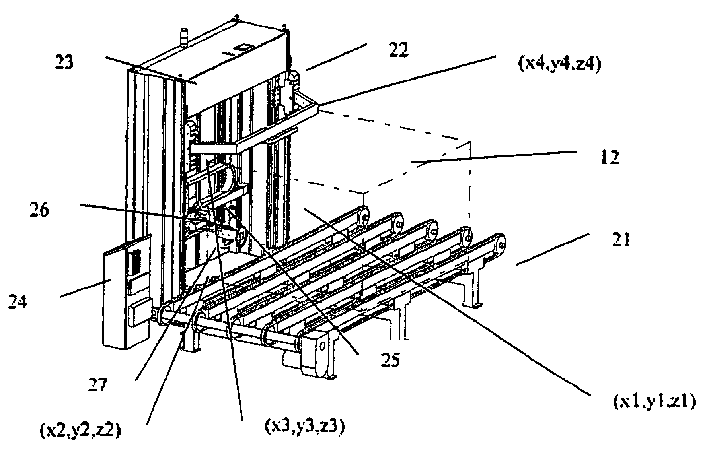

Method and appts. for defining position of edge surface of piled, e.g. boardlike objects

Owner:美特索配电盘有限公司

Method for manufacturing toothpicks through utilizing waste bamboos

InactiveCN110774400AEnsure safetyExtended storage timeGum massageWood working apparatusFiberBiochemical engineering

Owner:YONGDING FUHUA DAILY ACCESSORIES CO LTD

Preparation method of adhesive for making board from straws

Owner:JIANGSU UNIV

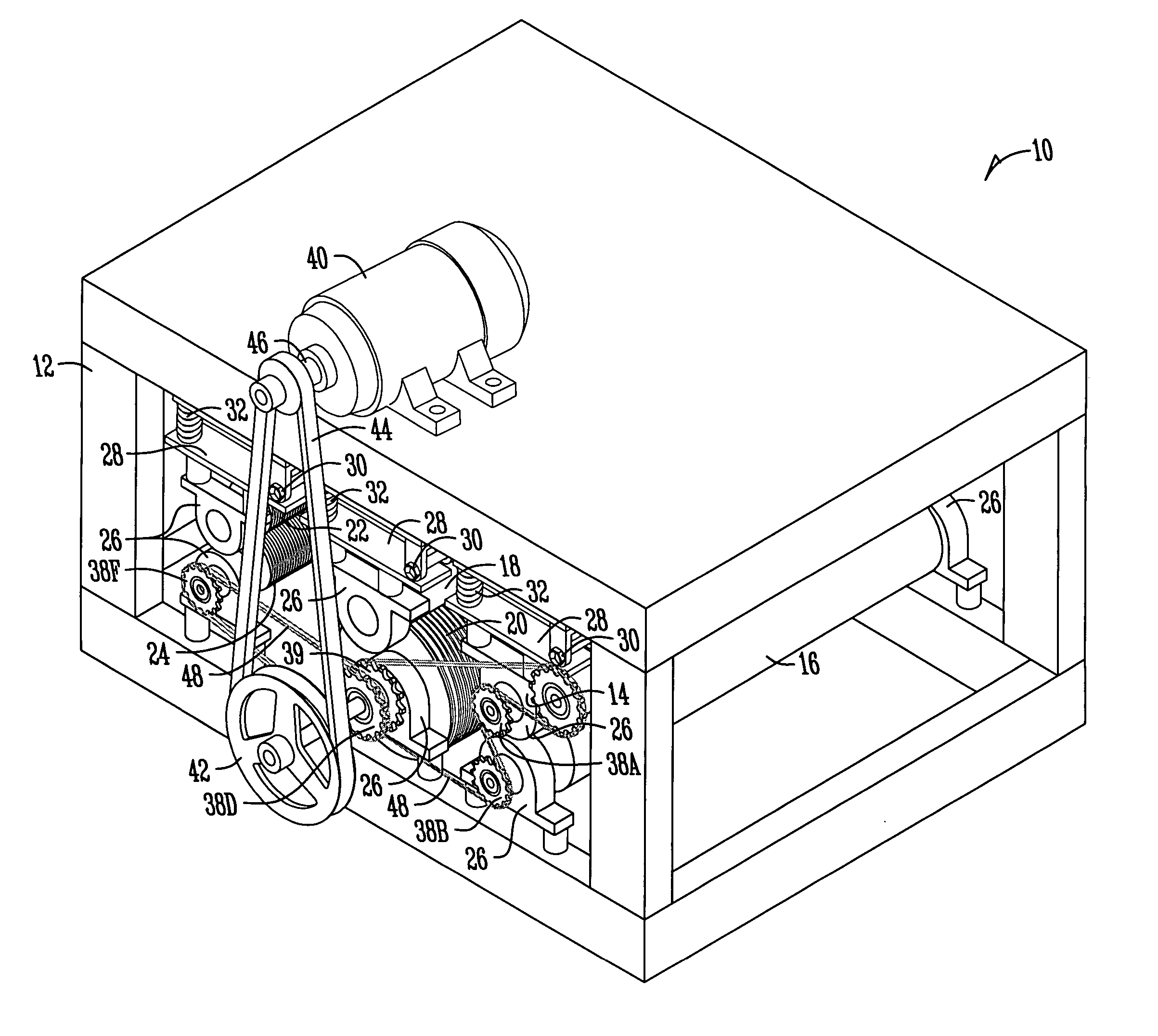

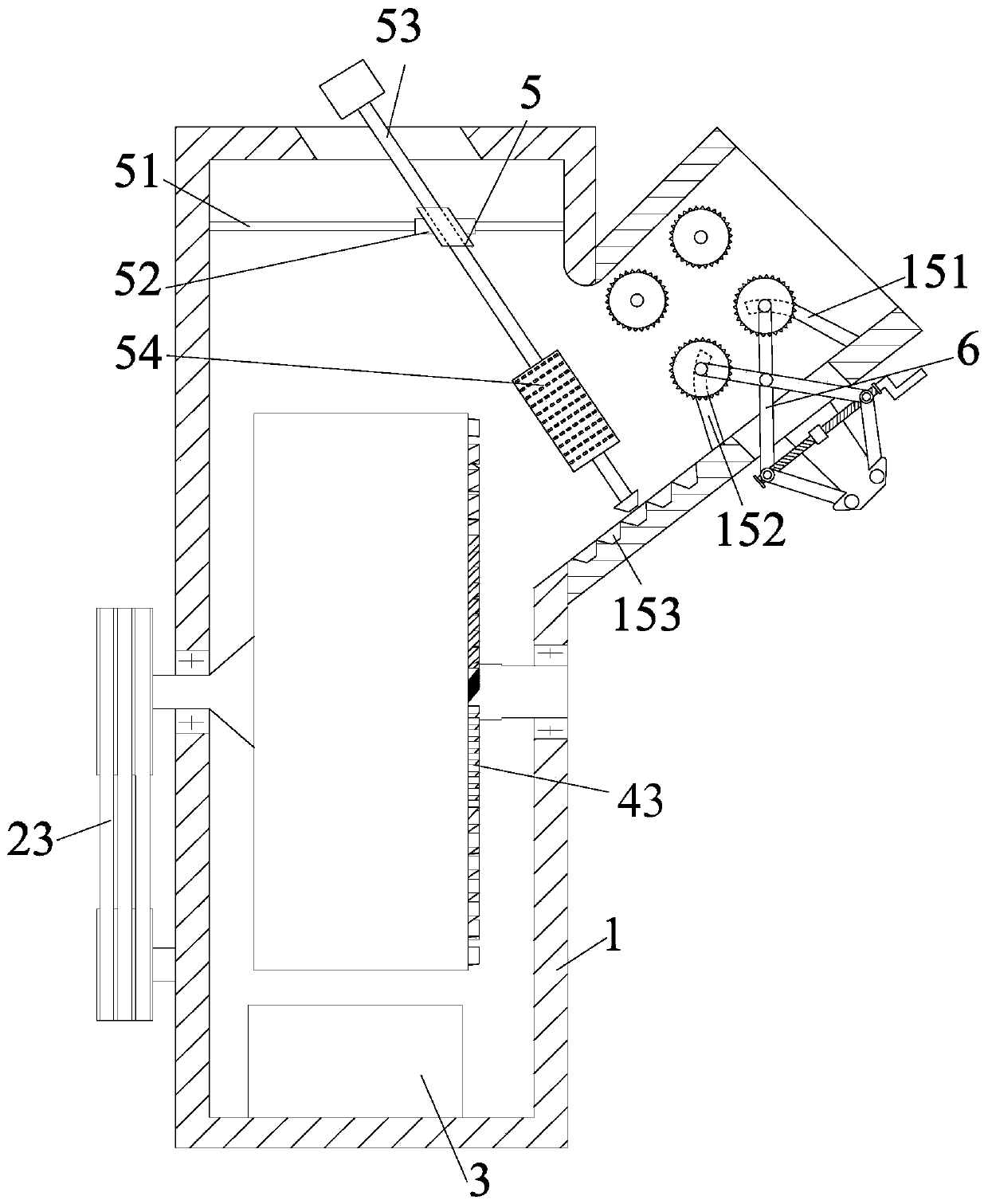

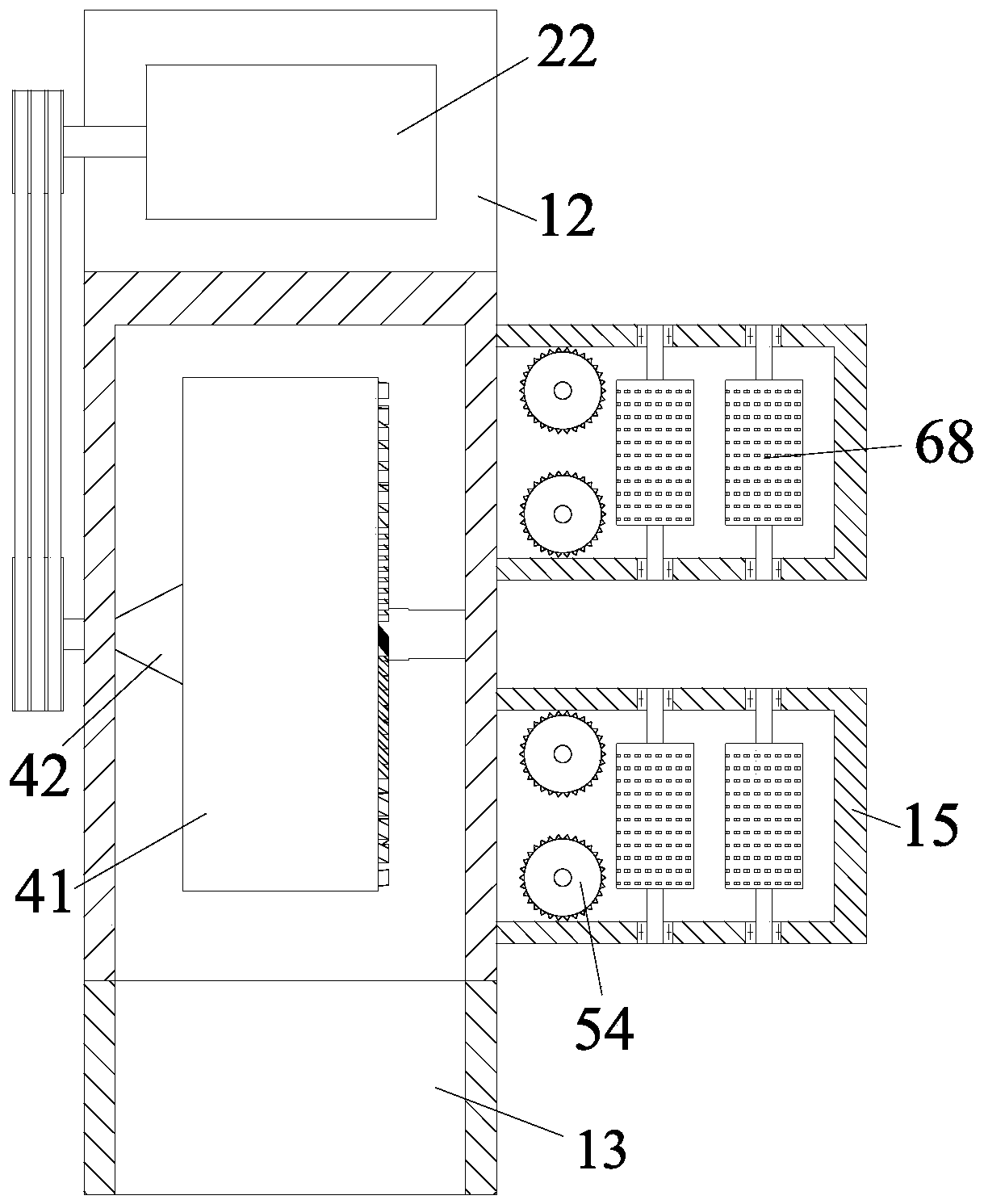

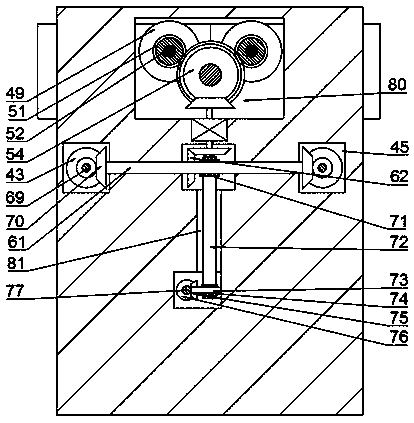

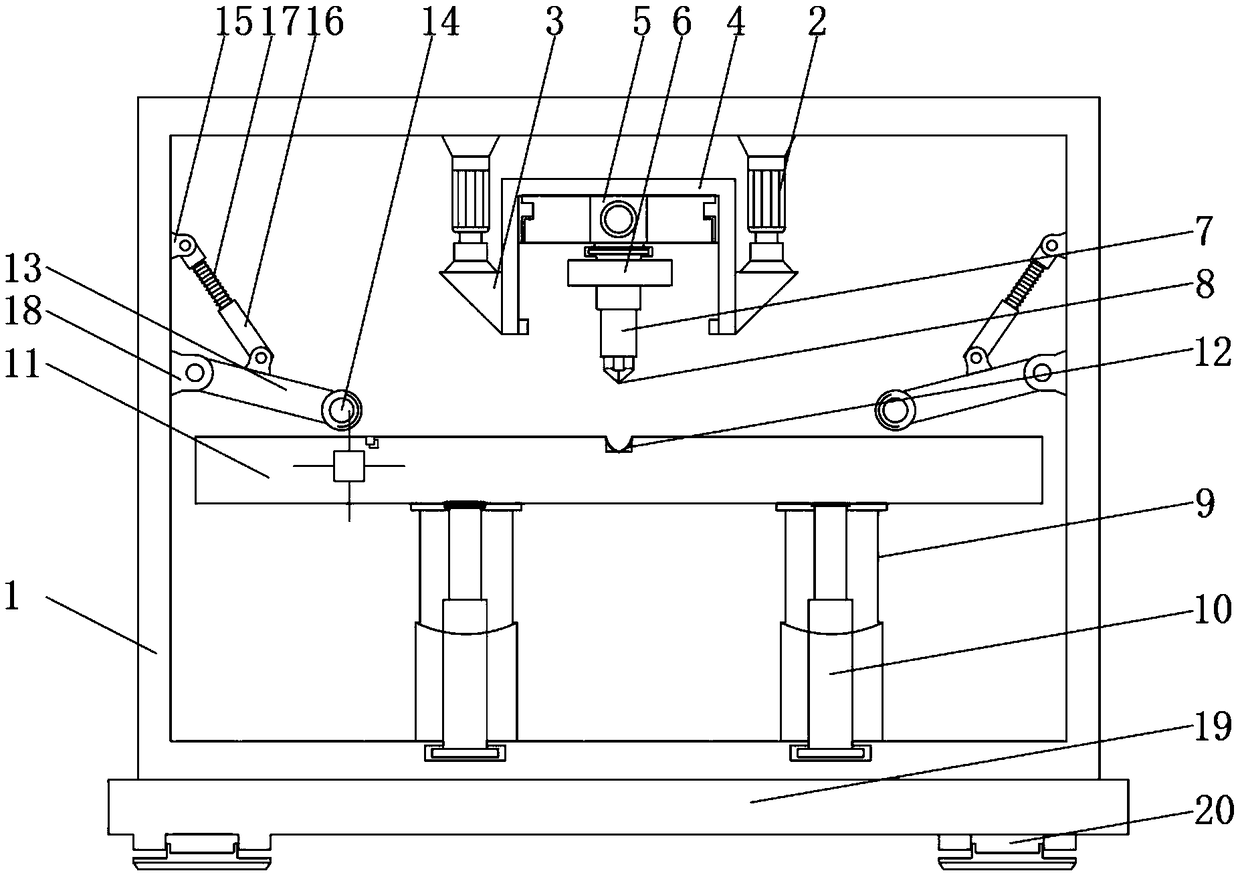

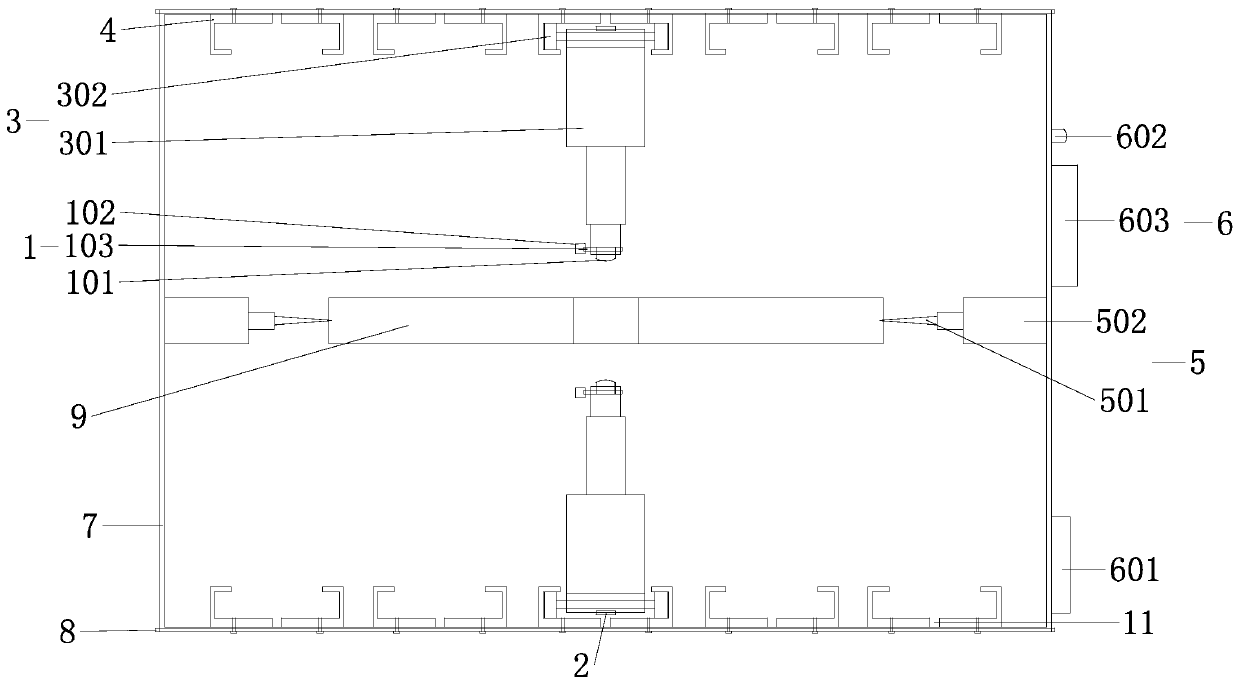

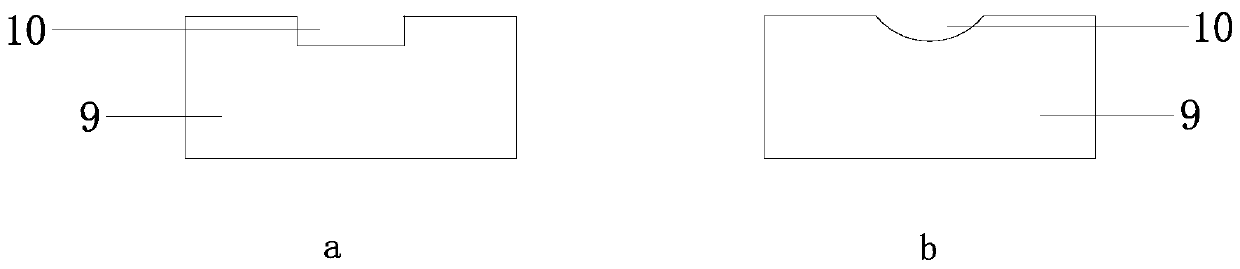

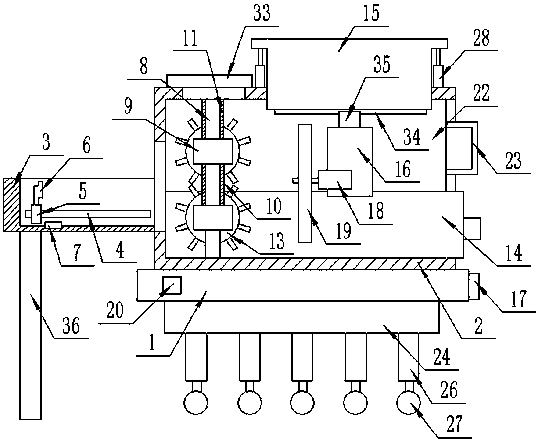

Crushing machine of raw material for preparing wood shaving artificial board

The invention relates to a crushing machine of raw material for preparing a wood shaving artificial board. The machine comprises a box body, a driving device, an air blower, a crushing device, an auxiliary fixing device and a feeding device, wherein the driving device is installed on the front side of the box body, the air blower is installed at the lower end inside the box body, the crushing device is installed in the middle of the box body, the crushing device is located at the upper end of the air blower, the auxiliary fixing device is installed at the upper end of the box body, and the feeding device is installed at the right end of the box body. The crushing machine of the raw material for preparing the wood shaving artificial board can solve the problems that when existing wood shaving machining equipment is used for cutting treatment, the number of cutting tools is small, the cuttings generated through cutting treatment are large in size, the cutting tools are prone to be damaged and are complicated to replace, the wood material is directly cut and machined without limiting and fixing, severe shaking, splashing and even flying are generated in the wood material machining process, so that potential safety hazards and the like are generated in the operation process are solved.

Owner:河北盛奥松木业有限公司

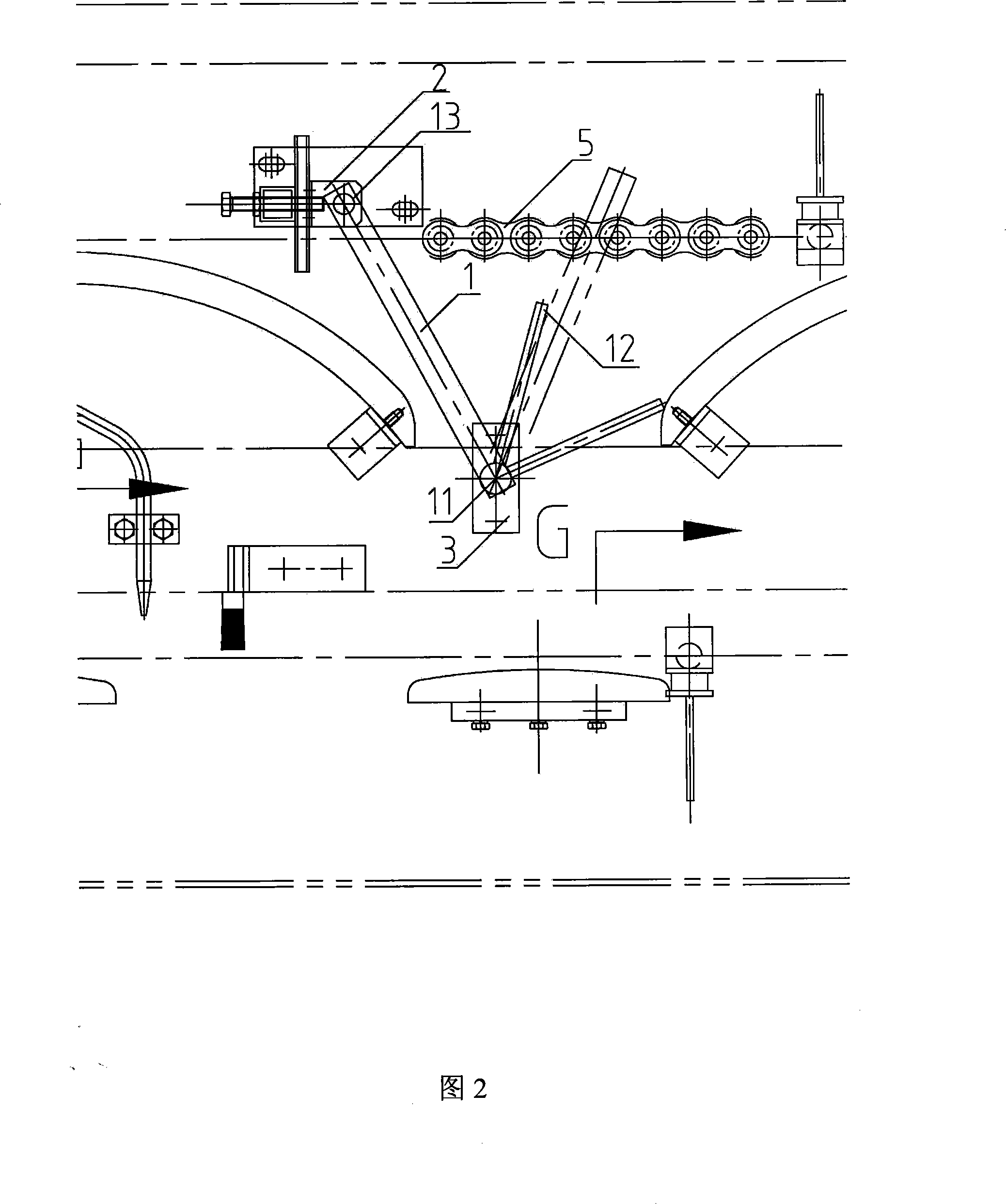

Chain drop detecting mechanism of harrow for paving

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

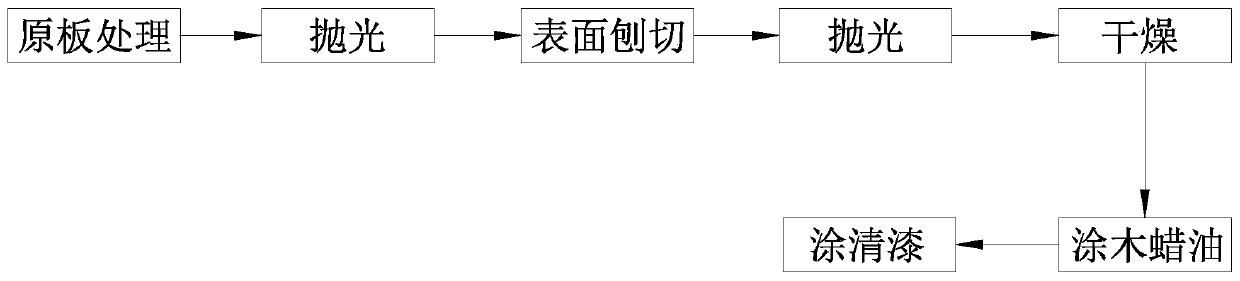

Novel process for cabinet product laminate assembling

InactiveCN110355851AReduce use costShort production processWood working apparatusTransverse planeEngineering

Owner:肇庆市现代筑美家居有限公司

Device for manufacturing powder plasticizing floor

Owner:仙居卡贝环保科技有限公司

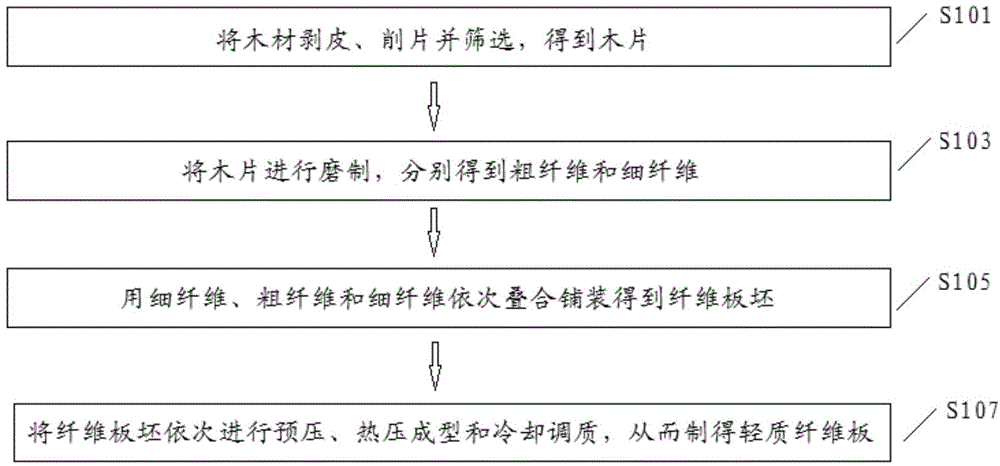

Method for manufacturing light-weight fiberboard

InactiveCN104669394AImprove mechanical propertiesLow densityWood working apparatusFlat articlesFiberSurface layer

Owner:CHINA FOMA GROUP

Bamboo fiber selecting and cutting equipment

InactiveCN108943220APrevent movementReduce workloadWood working apparatusCane mechanical workingHydraulic cylinderFiber

Owner:安吉竹蕾雅竹纤维有限公司

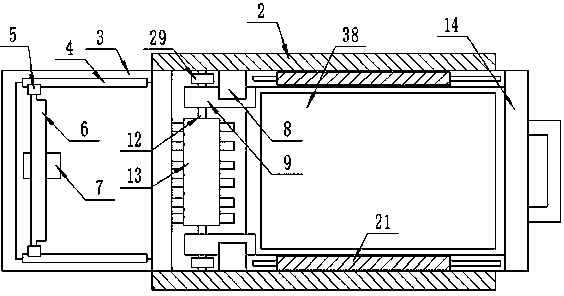

Process and equipment for manufacturing environment-friendly wooden door by utilizing waste resources

ActiveCN112223482ARealize recyclingStir wellWood working apparatusFlat articlesPulp and paper industryIndustrial engineering

The invention provides a process for manufacturing an environment-friendly wooden door by utilizing waste resources. The process comprises the following steps: crushing straw to prepare straw powder,and crushing waste wood to prepare wood chips; crushing the wood chips for the second time and stirring the crushed wood chips uniformly, and then feeding the wood chips into a granulator to prepare wood particles; laying a lower base plate, brushing the surface of the lower base plate with glue for the first time, and uniformly scattering the wood particles on the top surface of the lower base plate; filling the straw powder among the wood particles, then brushing the top surface of the lower base plate with glue for the second time, and compacting the straw powder; brushing the top surface of the lower base plate with glue for the third time, laying an upper base plate and compacting the upper base plate to prepare a wooden door blank; and cutting off the boundary excess materials of thewooden door blank, and bonding the surrounding edge to prepare the environment-friendly wooden door. According to the process, the waste wood is prepared into the wood particles, and then the wood particles are uniformly scattered on the base plates to form a plurality of filling fulcrums, then the straw is prepared into the straw powder, the straw powder is filled among the wood particles to complete internal filling of the environment-friendly wooden door, and the waste resources such as the straw and the waste wood are recycled.

Owner:CHONGQING SHUAIZHIDUN DOOR IND

Intelligent smashing device for wood

Owner:SUZHOU HIGH & SPECIALITY INFORMATION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap