Edge sealing equipment for single-side edge sealing of circular hole with edge sealing strip

An edge banding equipment and edge banding technology are applied in the direction of wood processing appliances, household components, etc., which can solve the problems of inability to seal the inner wall of a round hole, unsuitable, and high production cost, and achieve low manufacturing, good use effect, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

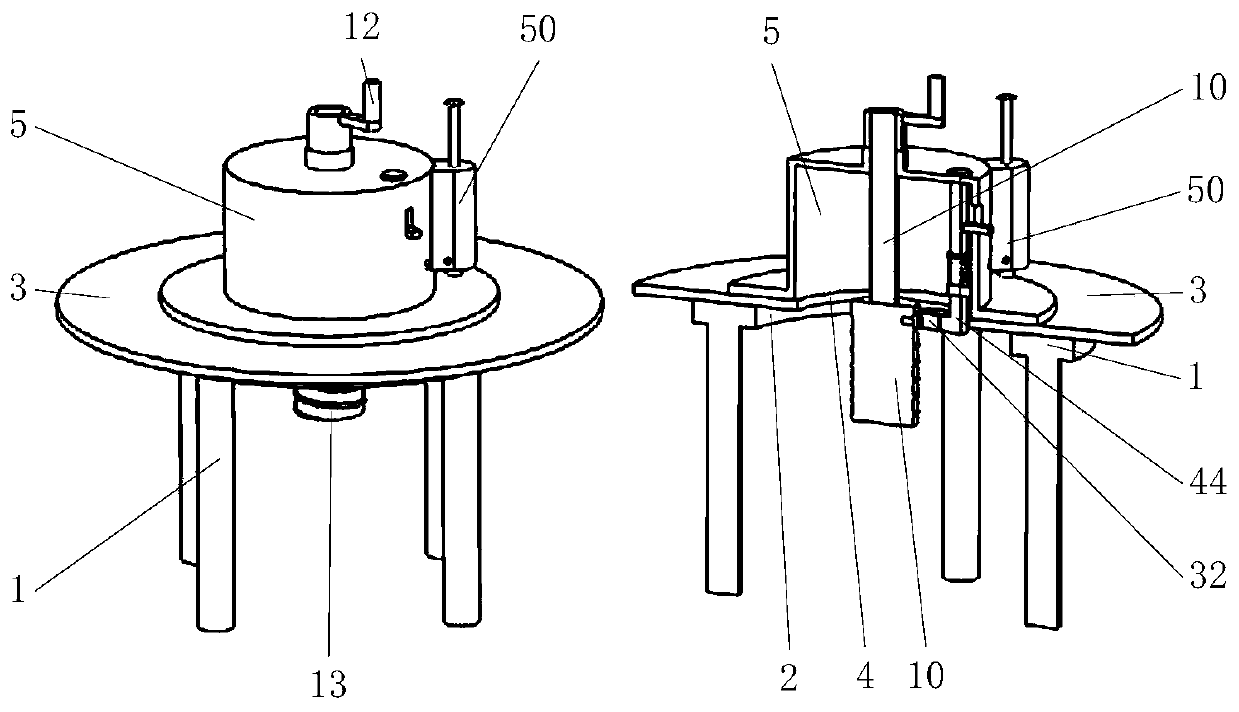

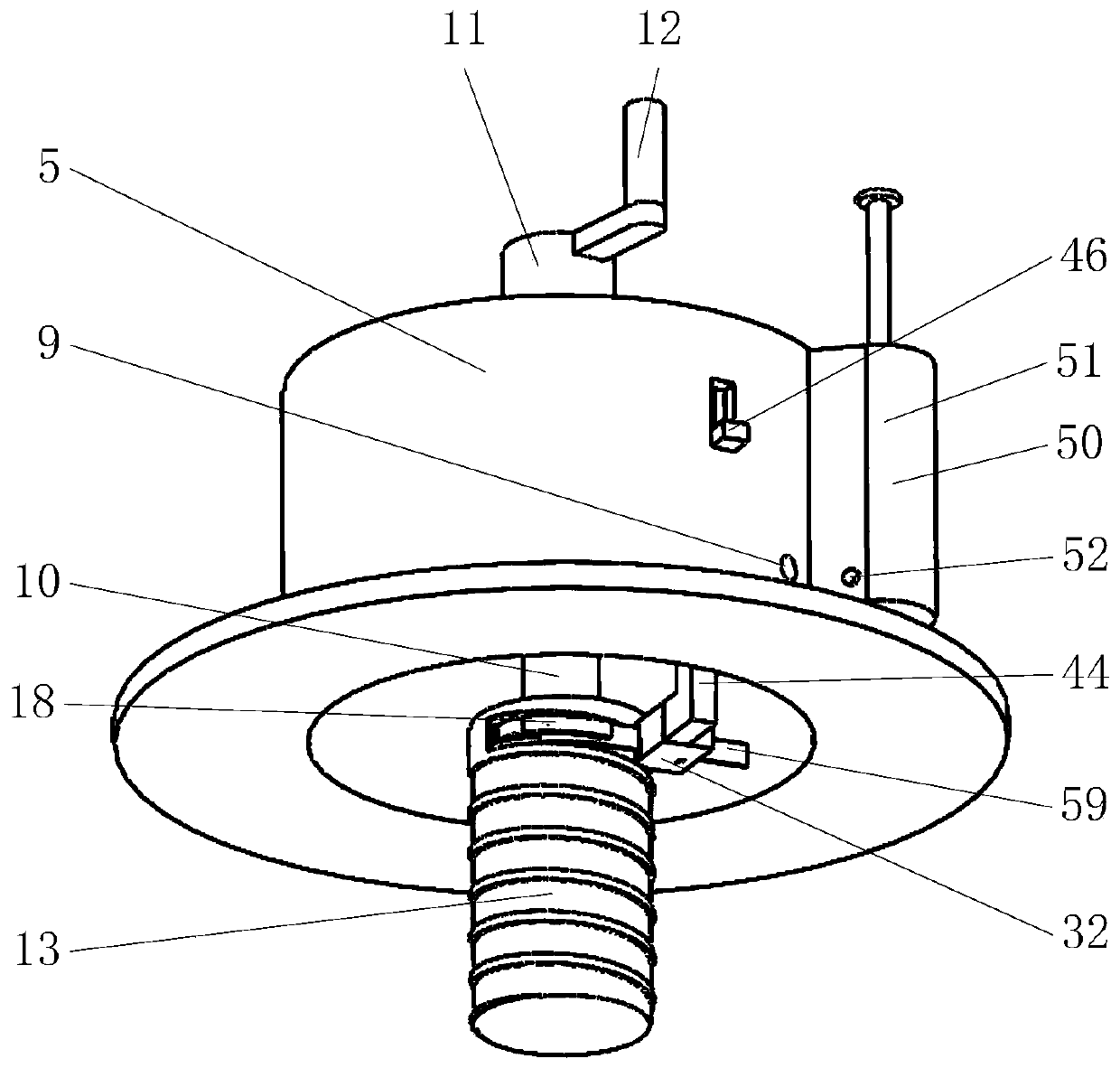

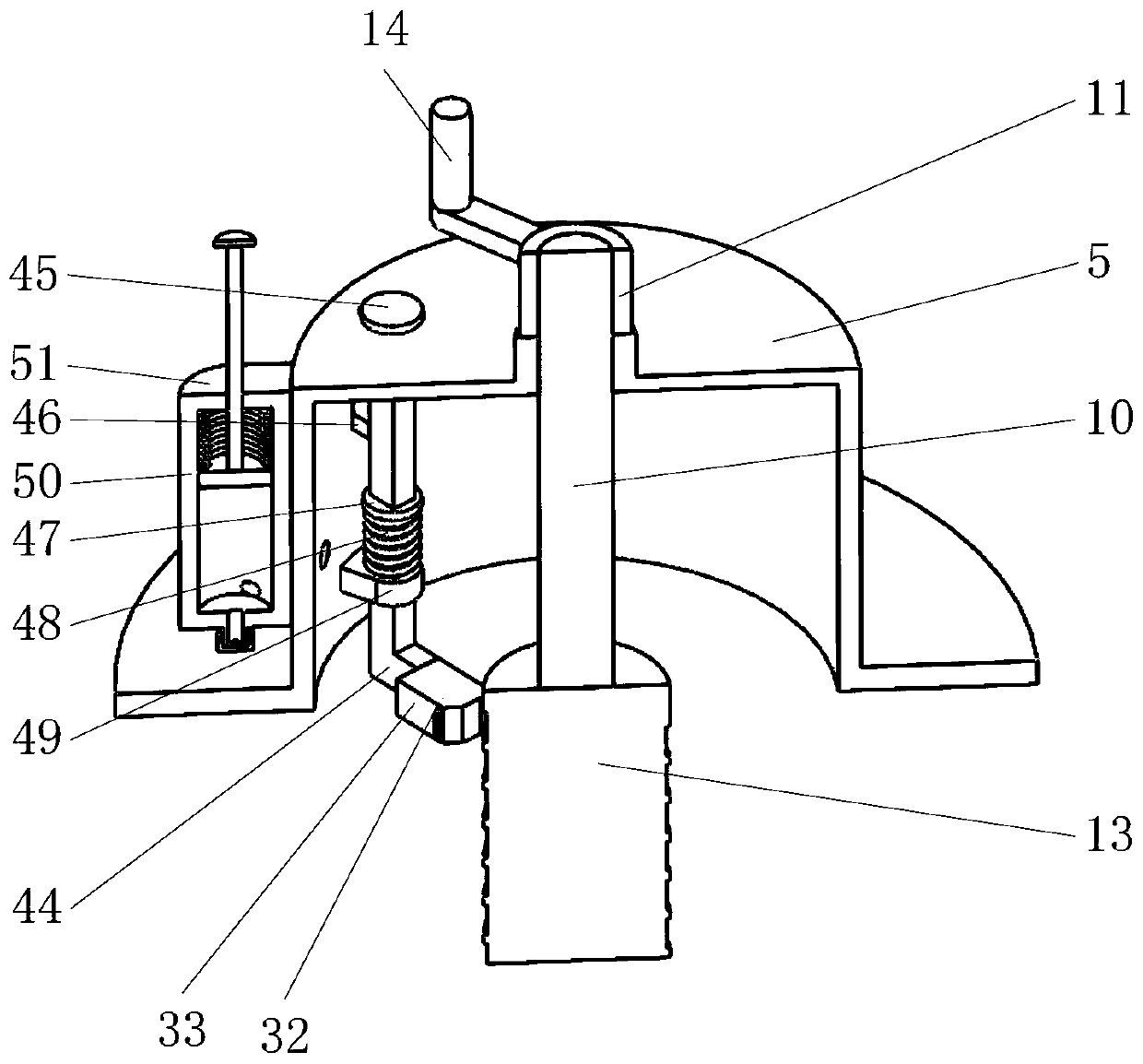

[0036] Such as figure 2 , 3 As shown, it includes a support cylinder 5, a screw rod 10, a cylinder 13, a leaf spring 17, a fixing mechanism 18, a glue application mechanism 32, and a glue injection mechanism 50, wherein as image 3 , 5 , 6, the screw rod 10 that is manually driven to rotate is threadedly matched with the threaded hole 6 at the center of the top cover of the support tube 5, and the lower end of the screw rod 10 is equipped with a column 13 concentric to the central axis; as Image 6 , 7 As shown, there is a helical groove for the helically wound edge strip 59 on the cylindrical surface of the cylinder 13; figure 2 , 3 As shown in , 6, a fixing mechanism 18 for

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap