Combined type lock nut for automobile

A locknut and combined technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of inconvenient fixing of positioning pins and poor fixing reliability, and achieve the effect of improving fixing reliability, convenient fixing and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

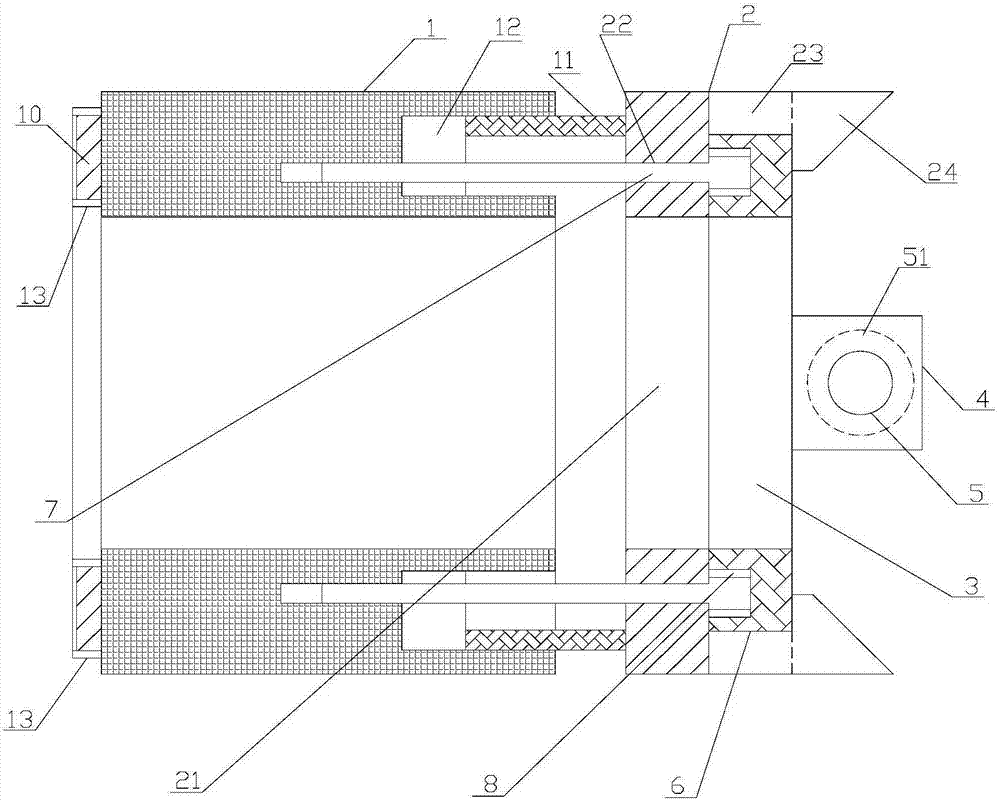

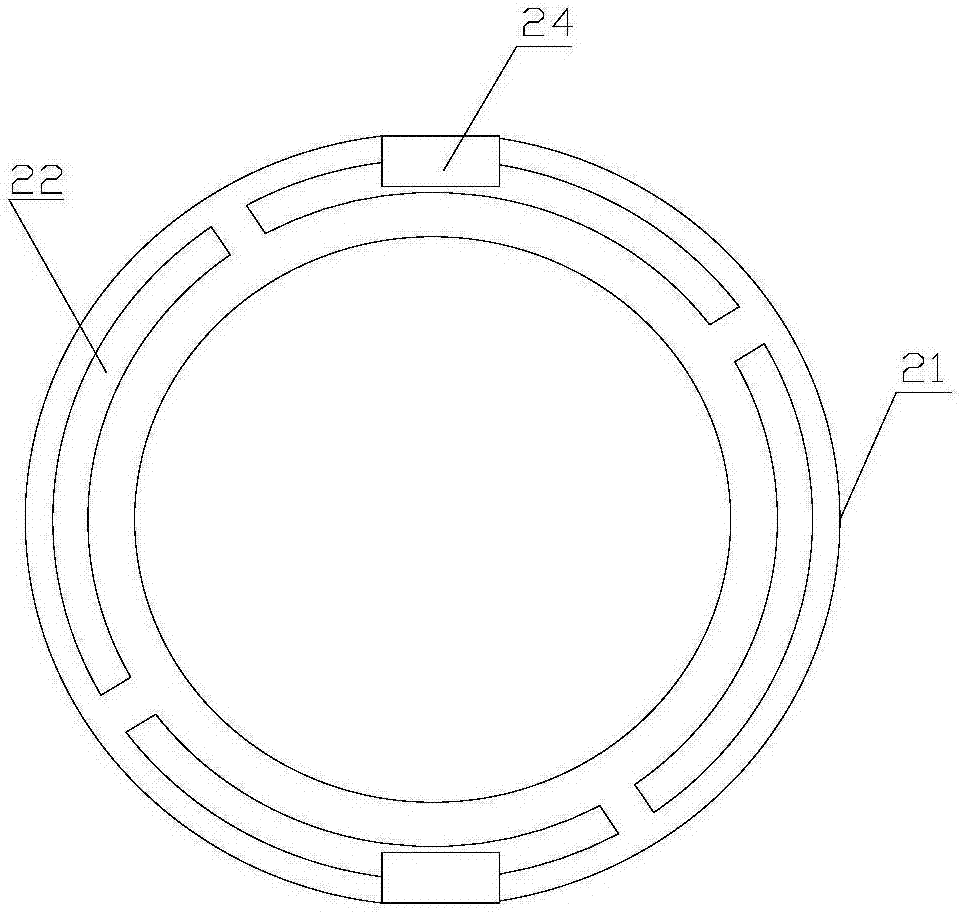

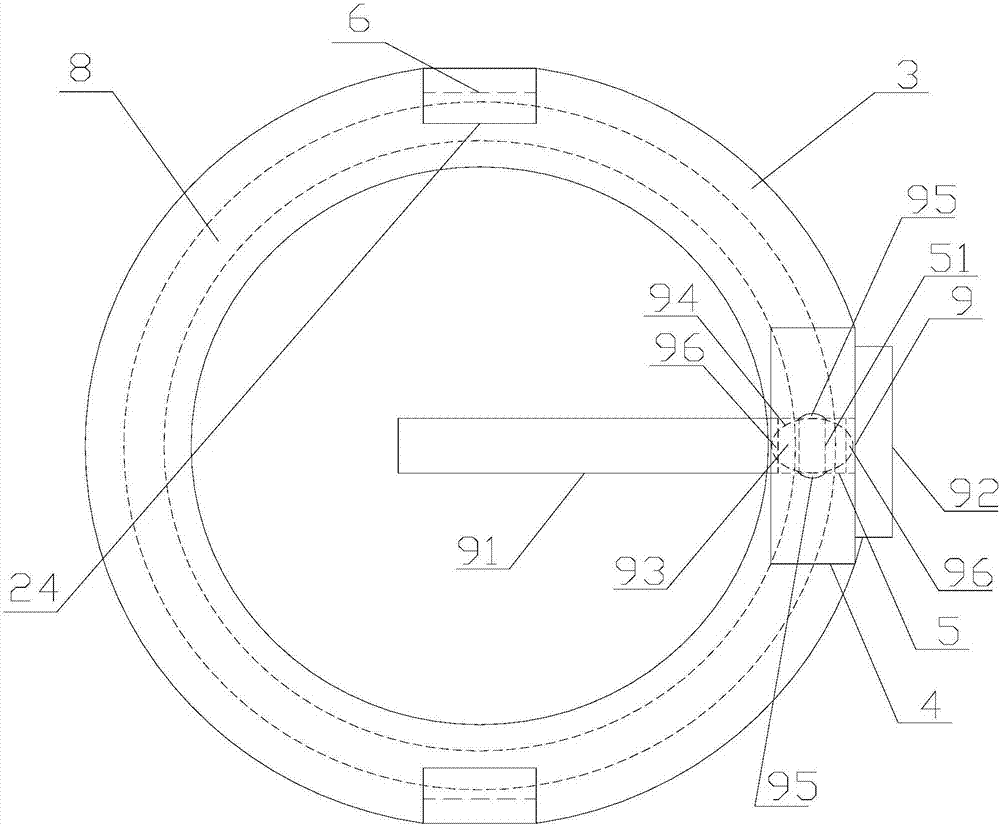

[0018] refer to figure 1 , figure 2 with image 3 , a combined anti-loosening nut for automobiles of the present invention, comprising a nut body 1, a clamping part 2, an annular body 3, a positioning seat 4, a pin hole 5, a positioning pin 9, a support sleeve 11 and a connecting groove 12, the The rear end of nut body 1 is provided with connecting groove 12, and the outer wall of described connecting groove 12 is provided with internal thread, and the outer wall of described support sleeve 11 is provided with the external thread that matches with internal thread, and described support sleeve 11 The rear end supports a clamping part 2, and the clamping part 2 is fixedly connected with the nut body 1 through a bolt 7, and a ring body 3 is fixed on the clamping part 2, and the rear end of the ring body 3 is provided with There is a positioning seat 4, and a pin hole 5 is provided on the positioning seat 4, and a positioning pin 9 is inserted into the pin hole 5, and the clamping

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap