Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

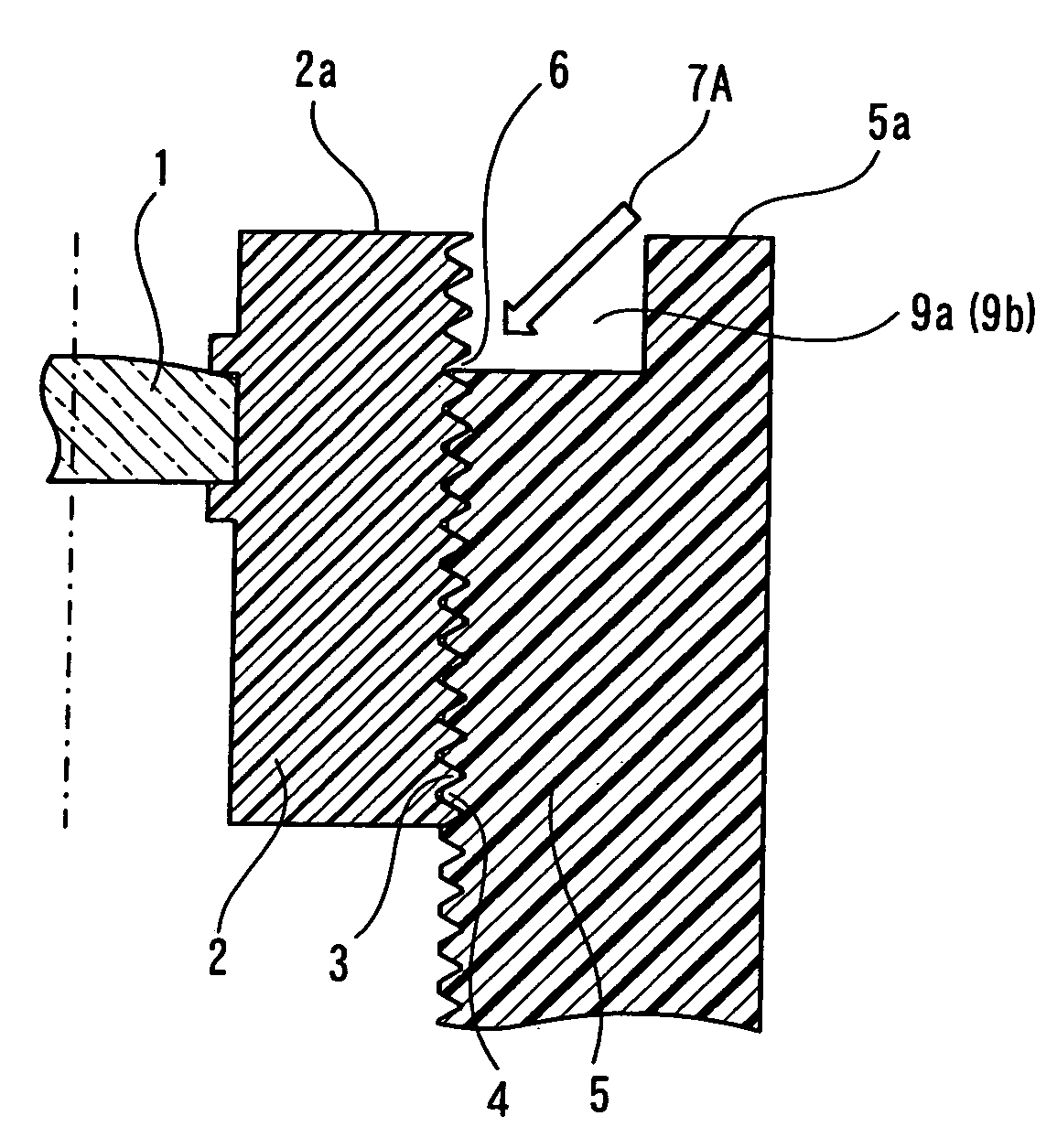

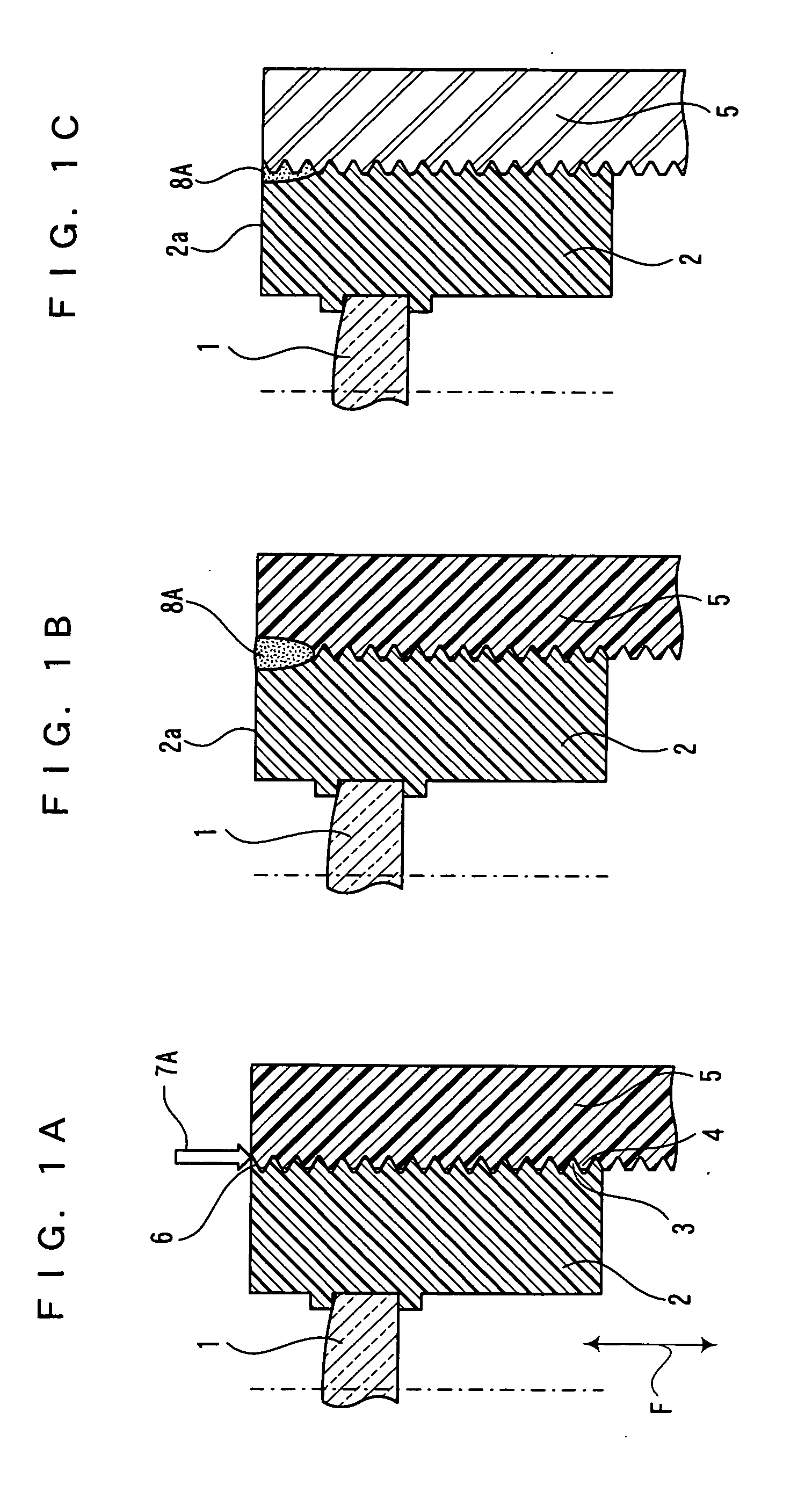

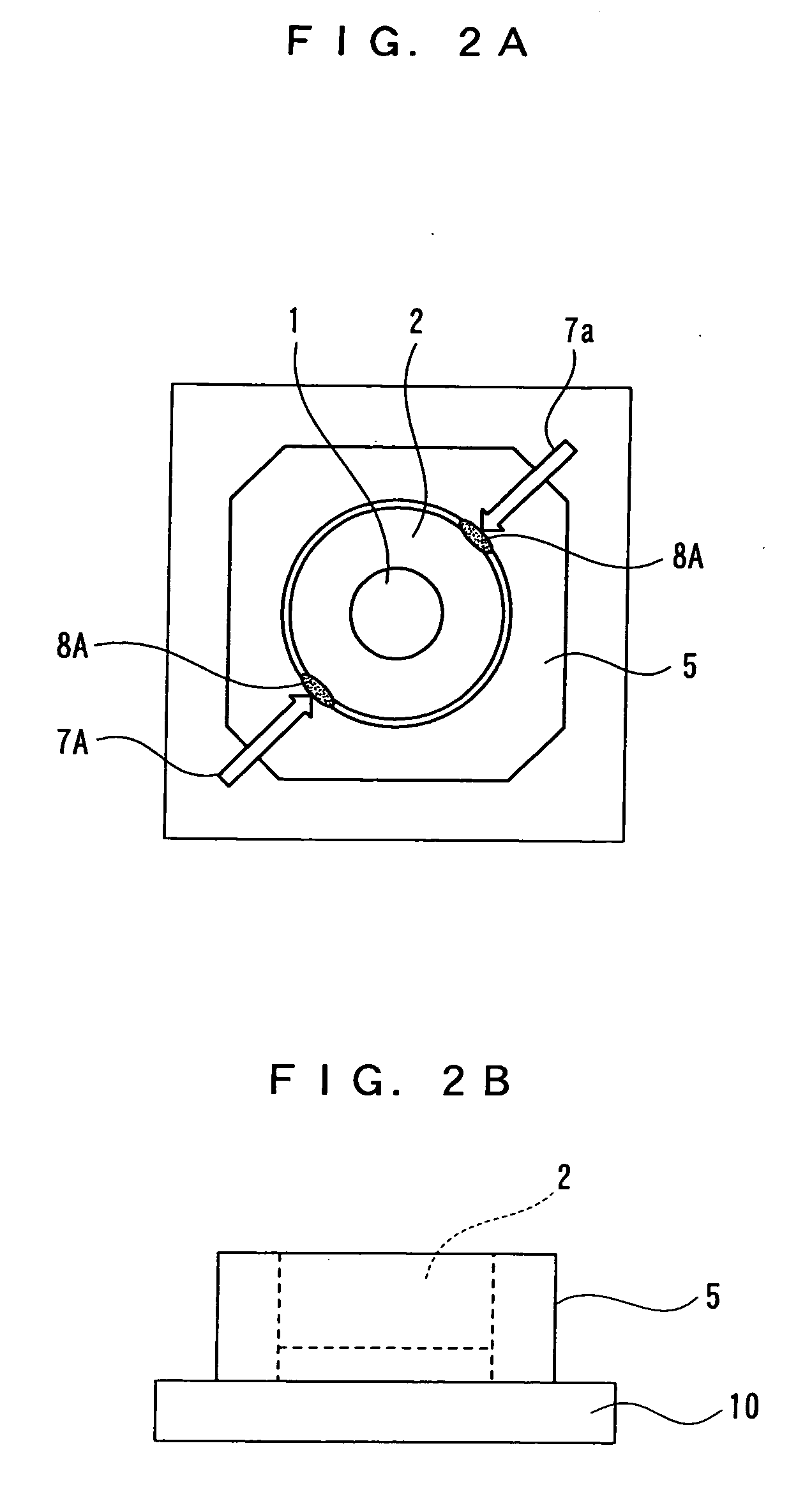

Manufacturing method of optical component and camera module

InactiveUS20060077575A1Slow changeAccurate fixing methodTelevision system detailsOptical articlesCamera moduleOptoelectronics

Owner:PANASONIC CORP

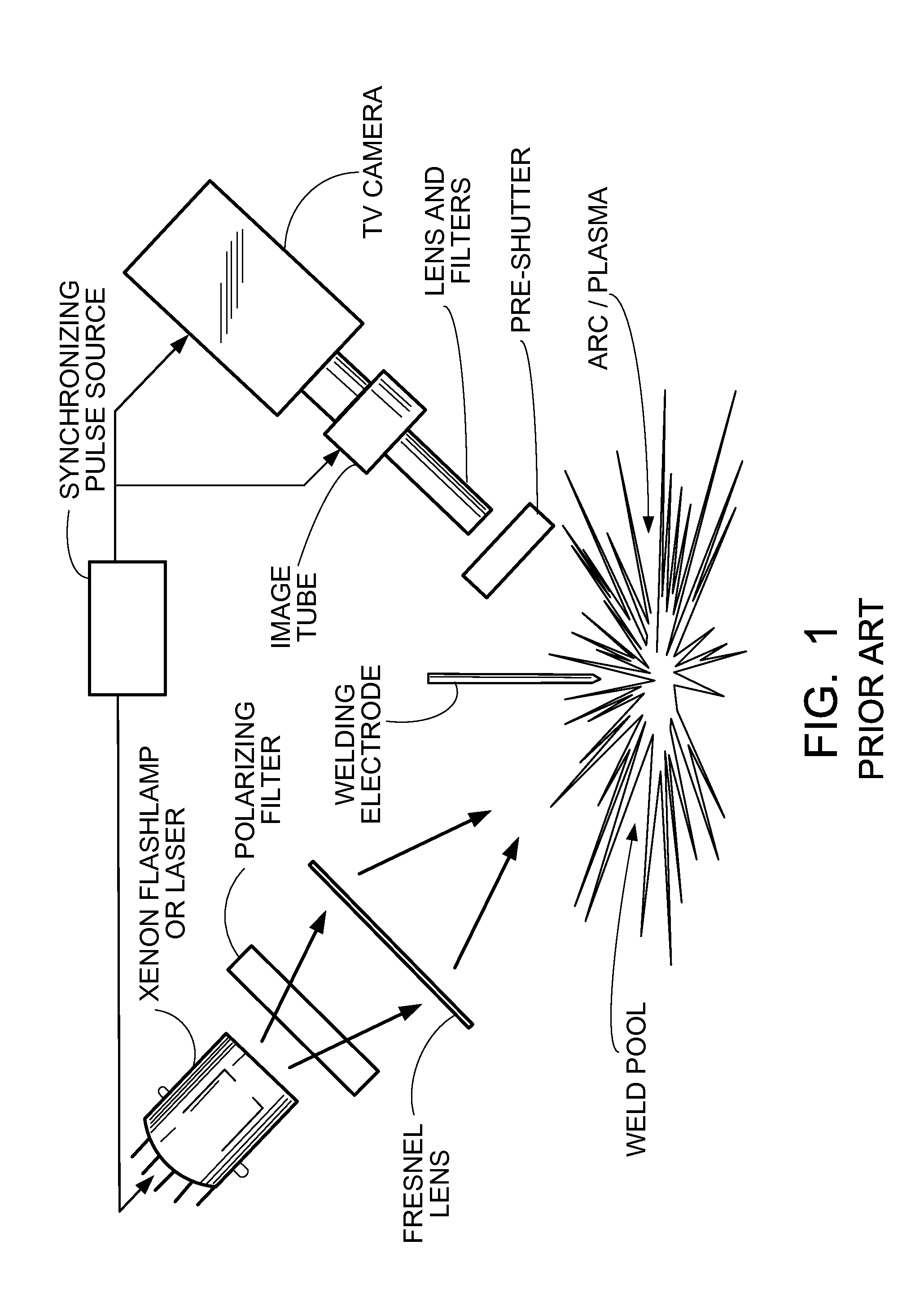

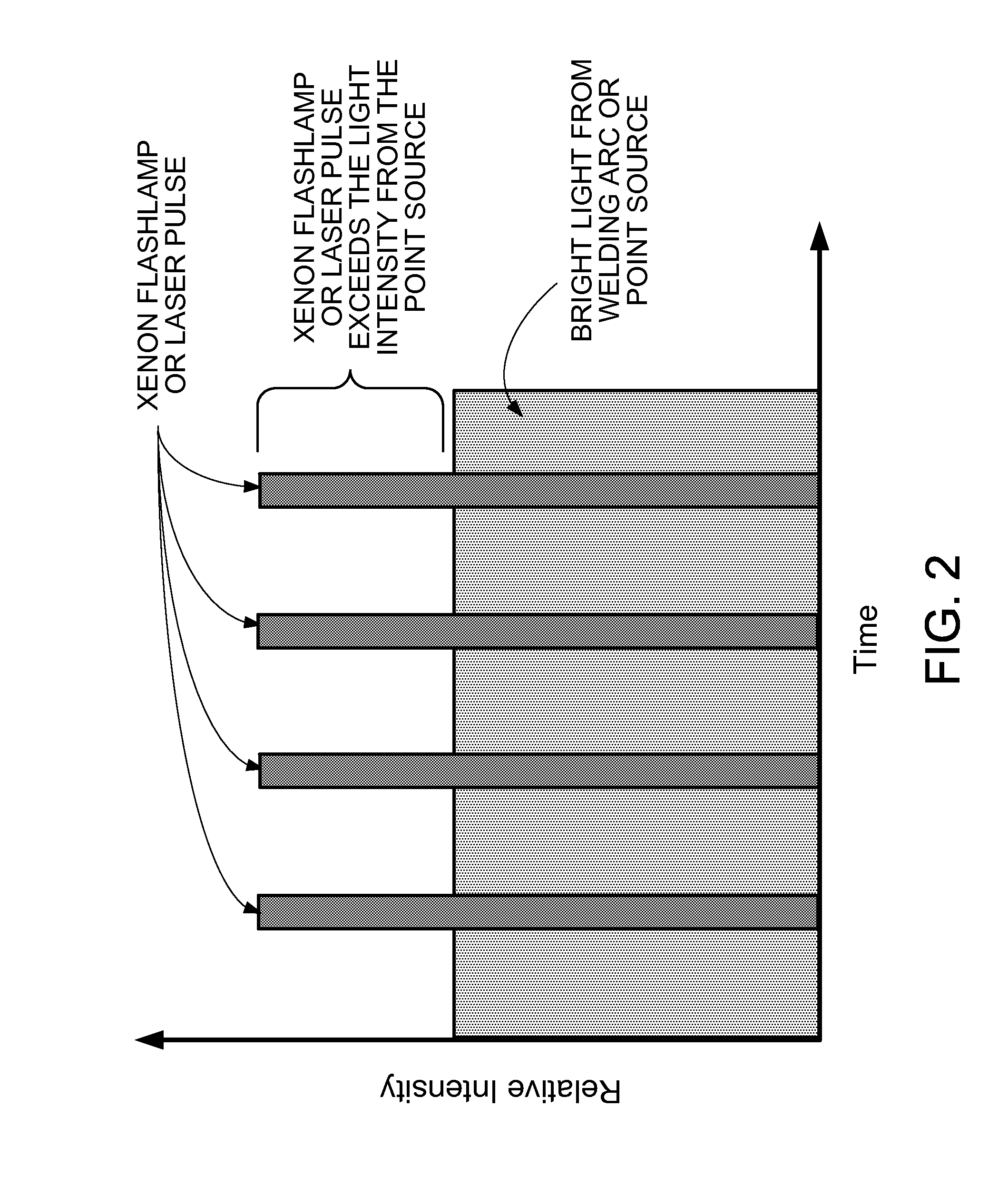

Visual monitoring, or imaging, system and method for using same

Owner:BWXT NUCLEAR OPERATIONS GRP

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

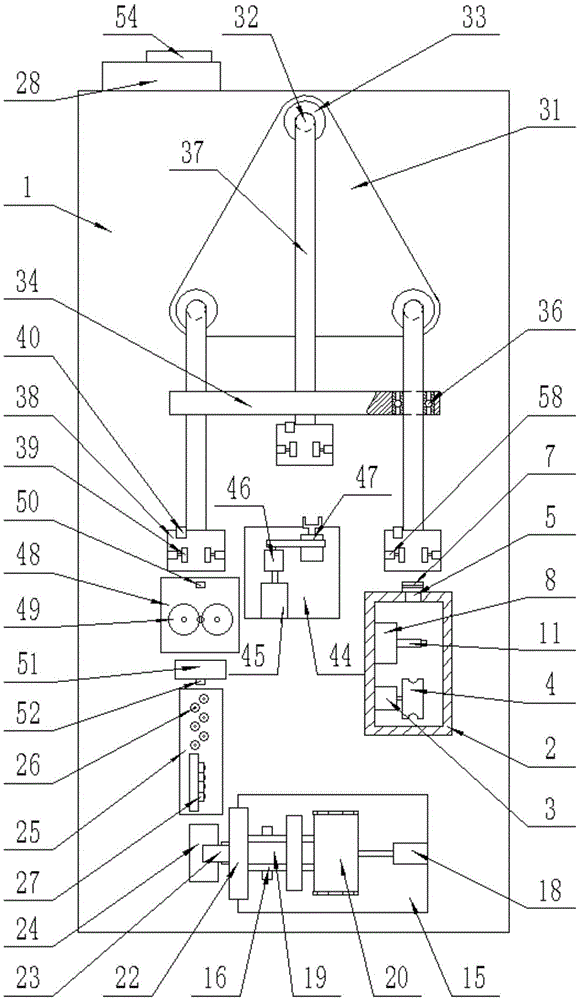

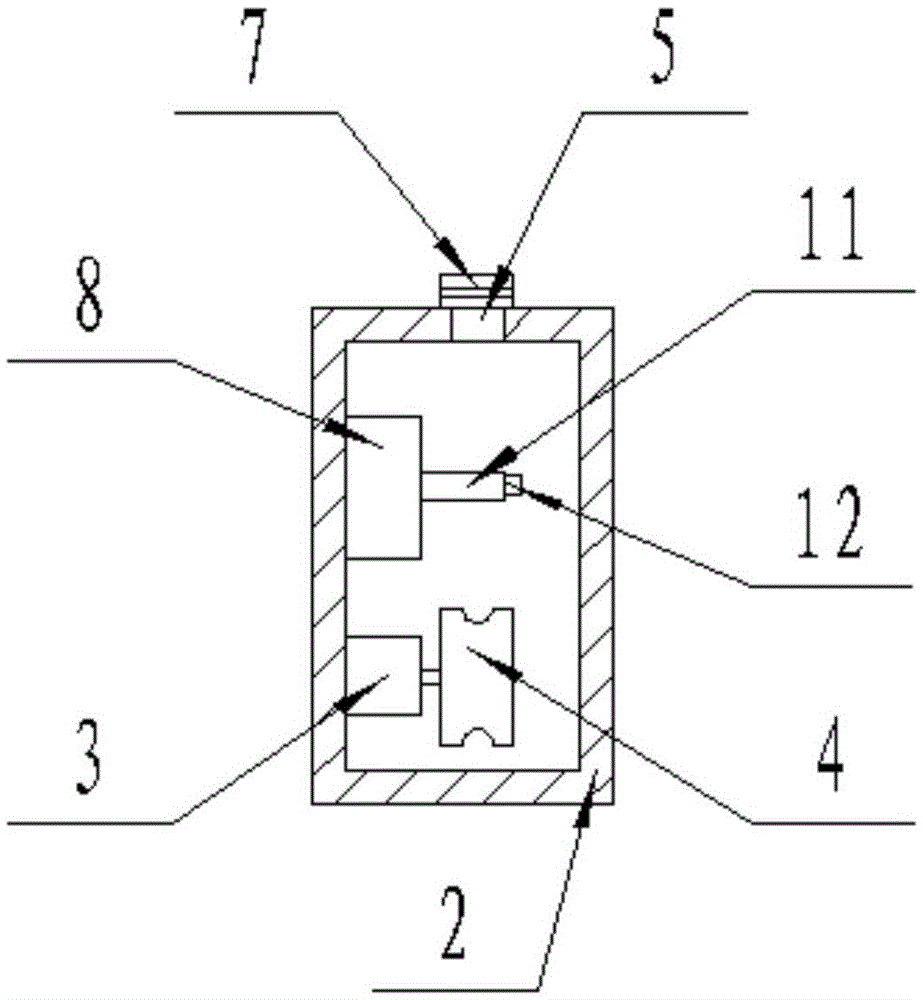

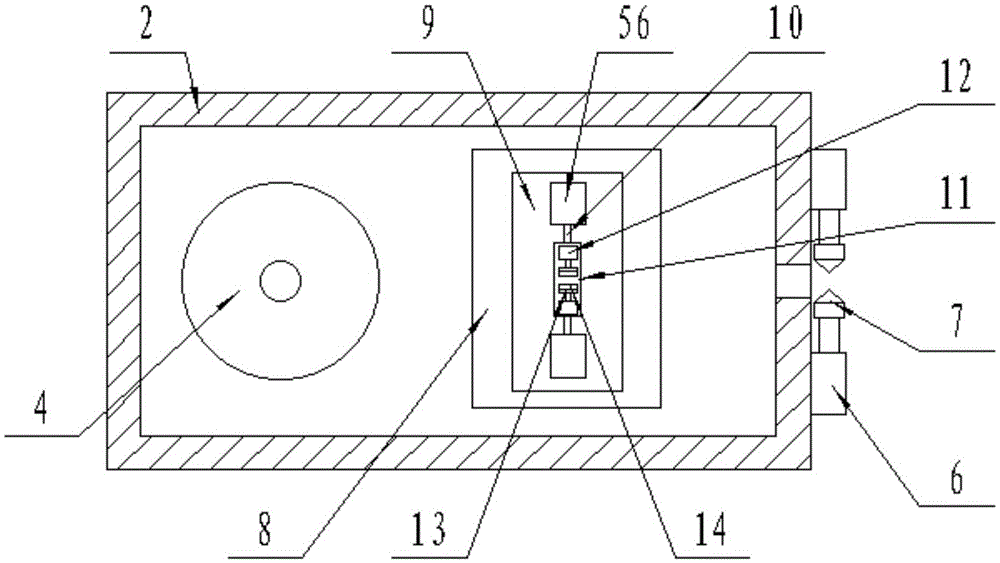

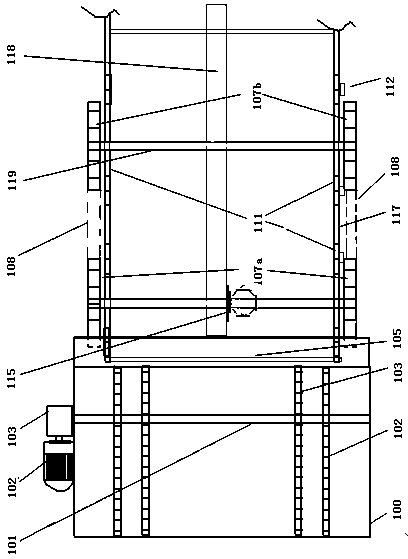

Swing type clamping one-way fuse tube electric wire welding production line

InactiveCN105618637AControllable distanceIncrease productivityLine/current collector detailsProduction lineElectric wire

Owner:徐海慧

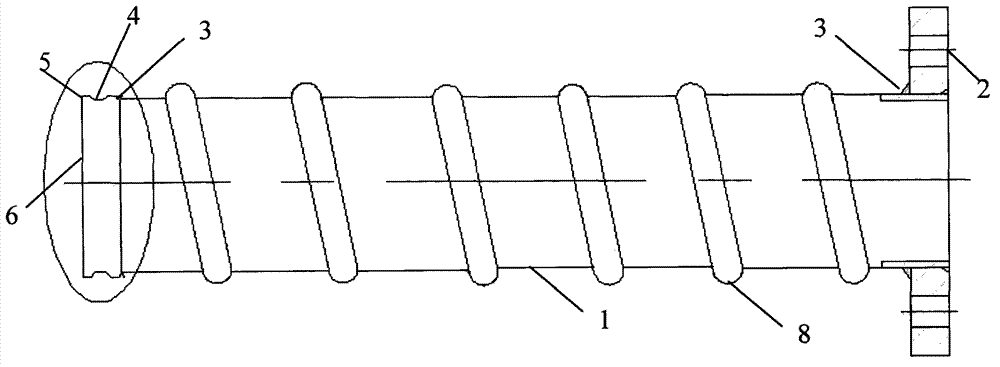

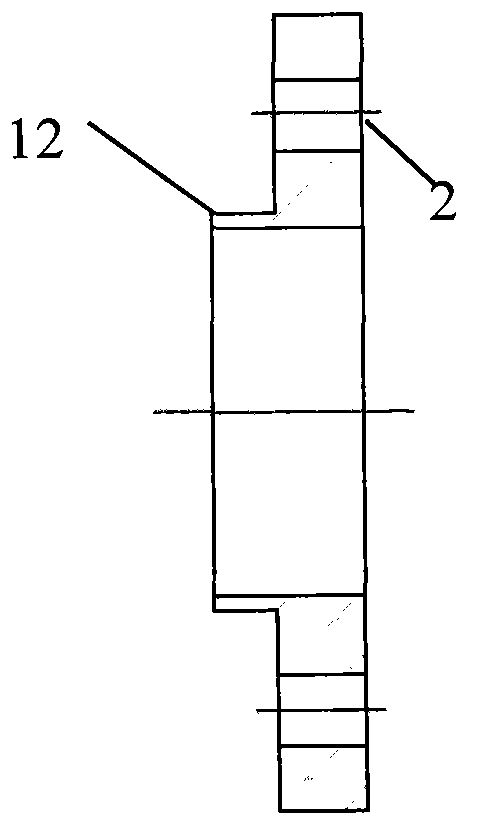

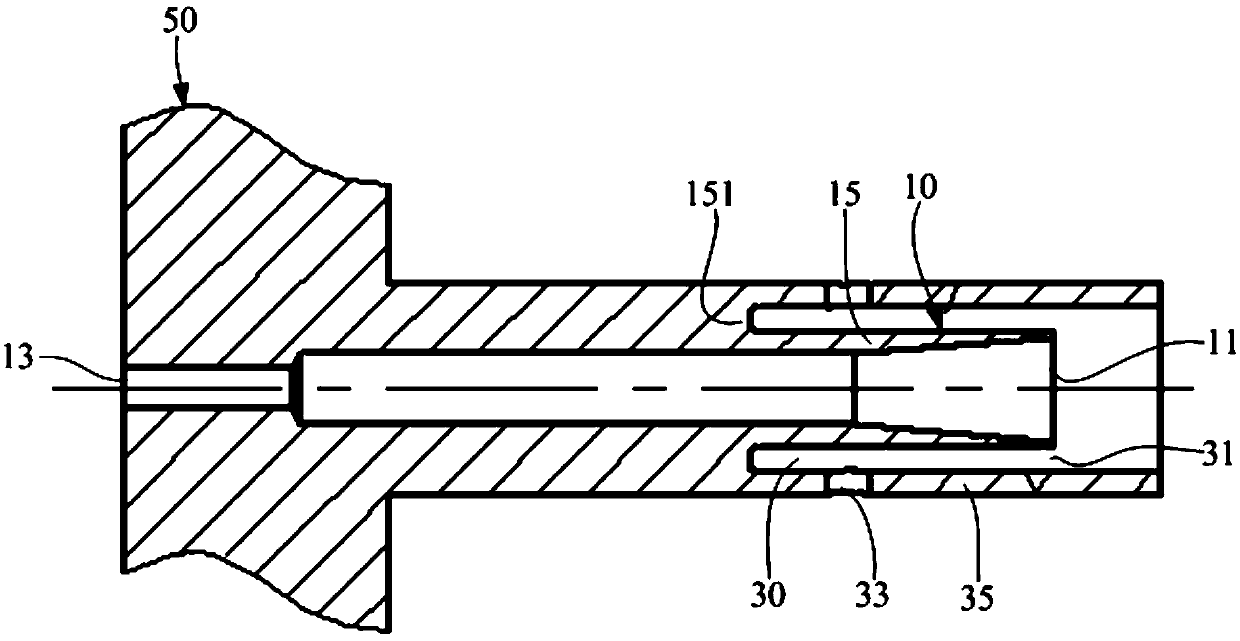

Screw thread welding integral narrow slit type coaxial pulse-tube refrigerator

InactiveCN101298947AImprove uniform distributionImprove the diversion effectCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

The invention discloses a thread weld integral slit type coxial vessle refrigerator, including a compressor, an air line, a fire end flange, a vessle, a cold accumulator, an upper cold head, a lower cold head, a cold end baffle, a copper wire, a first fire end diffuser, a second fire end diffuser, a cold accumulator core plug, a long neck tube and an air reservior, wherein the two ends of the upper cold head have a internal thread with one end welded with the threaded connection of the lower cold head and the other end welded with one end of the cold accumulator after the threaded connection; a round hole is arranged at the center of the upper cold head, and radial slot distributed uniformly are arranged round the round hole; a cold end baffle is arranged in the round hole, and the part of the outside of the cold end baffle is the cold accumulator cold end air applicator part, while the inner part of the cold end baffle is the stacked copper wire and a vessle extending section of the vessle cold end diffuser. The air in the cold accumulator and the vessle communicate with the slot of the upper cold head and the lower cold head by the welding way. The cold head of the invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAOTONG UNIV

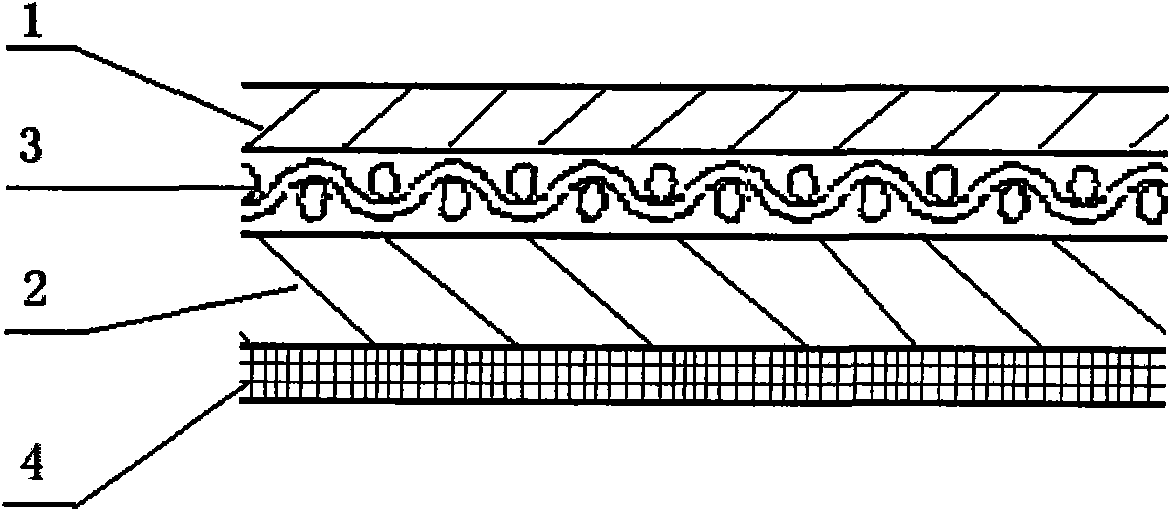

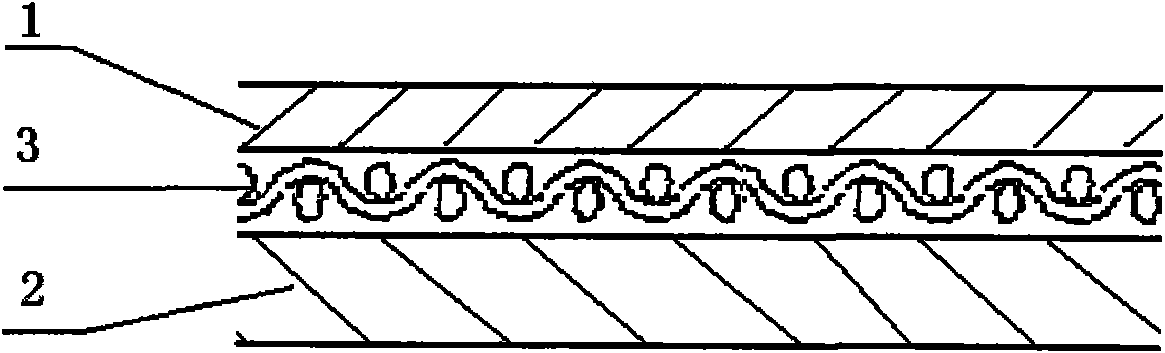

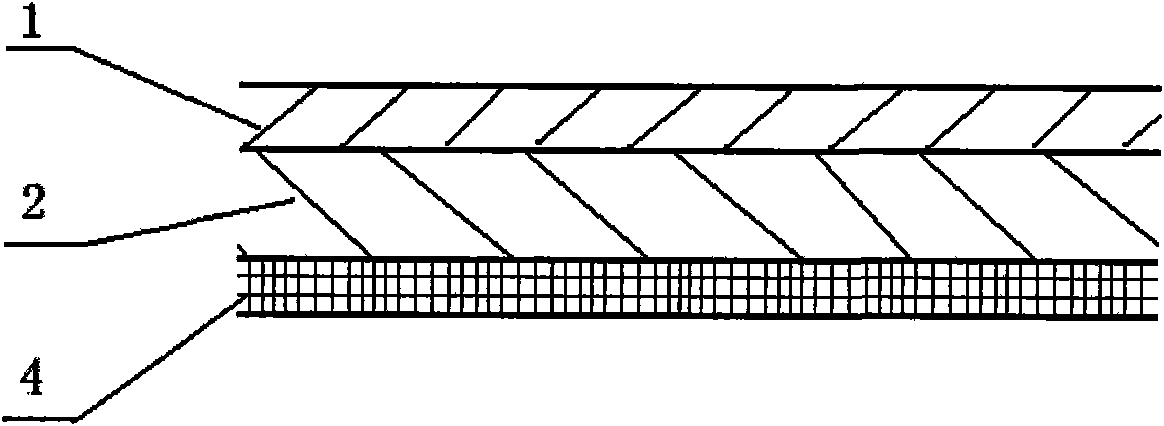

Mineral methane gas drainage pipe and production method thereof

ActiveCN103195988AReduce weightImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationHigh pressureMethane gas

Owner:河北拓安管业有限公司

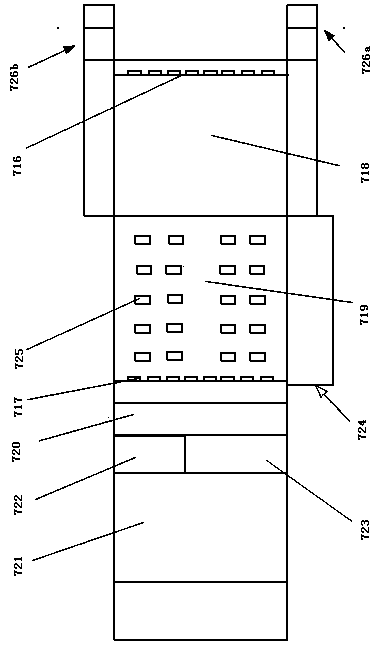

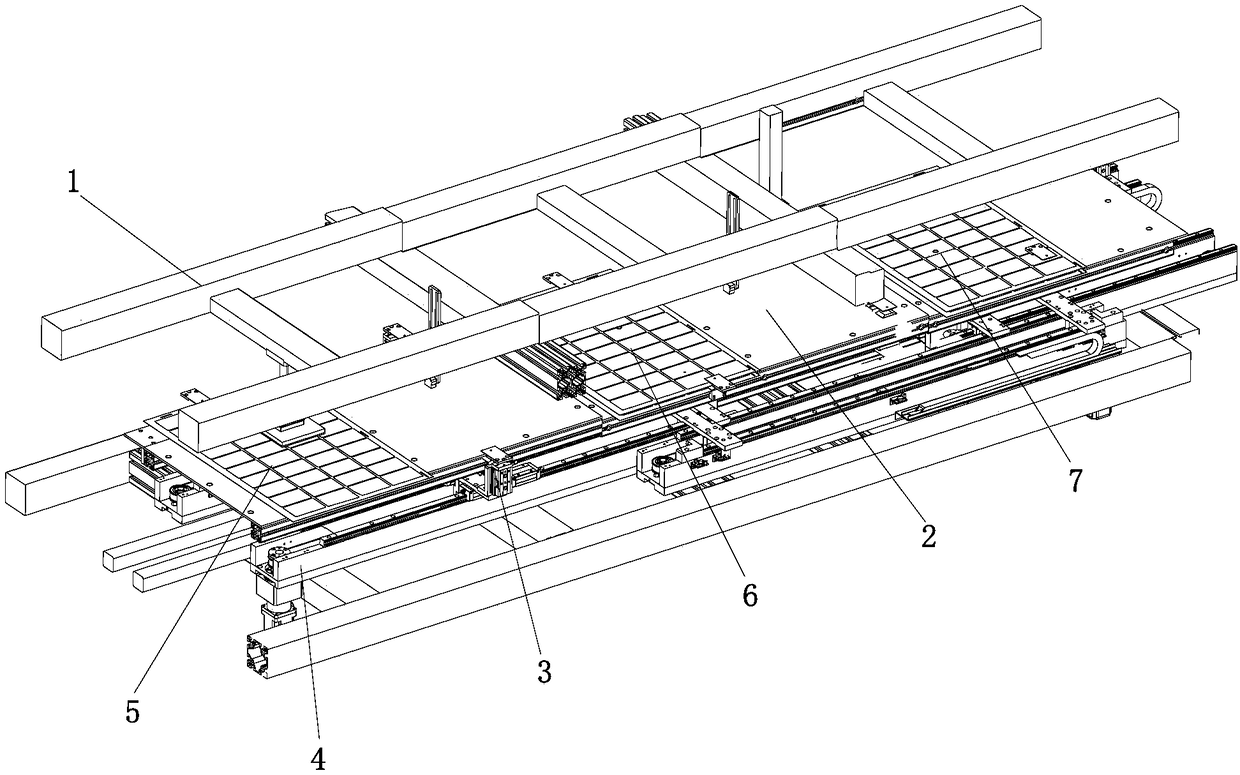

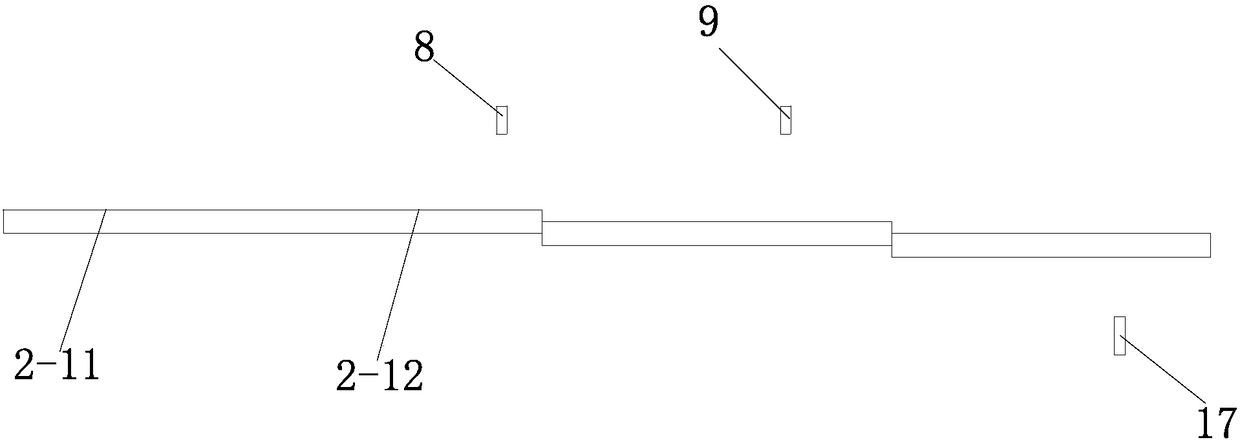

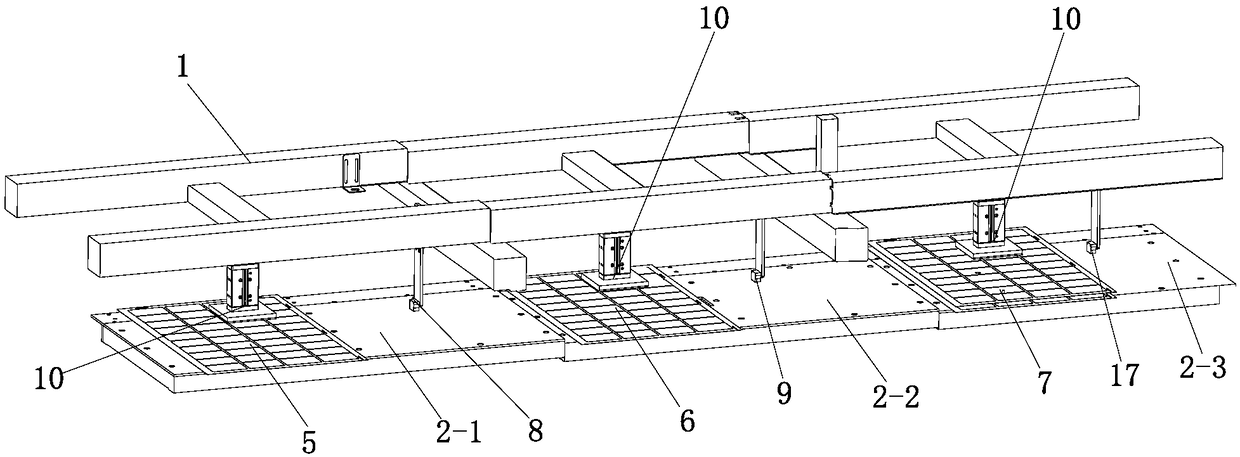

Longitudinal short rib feeding and distributing device and method used during welding of steel bar meshes

ActiveCN110480221APreventing difficulties in the smooth supply of steel barsAccurate transferWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

Owner:河南省鼎鼎实业有限公司

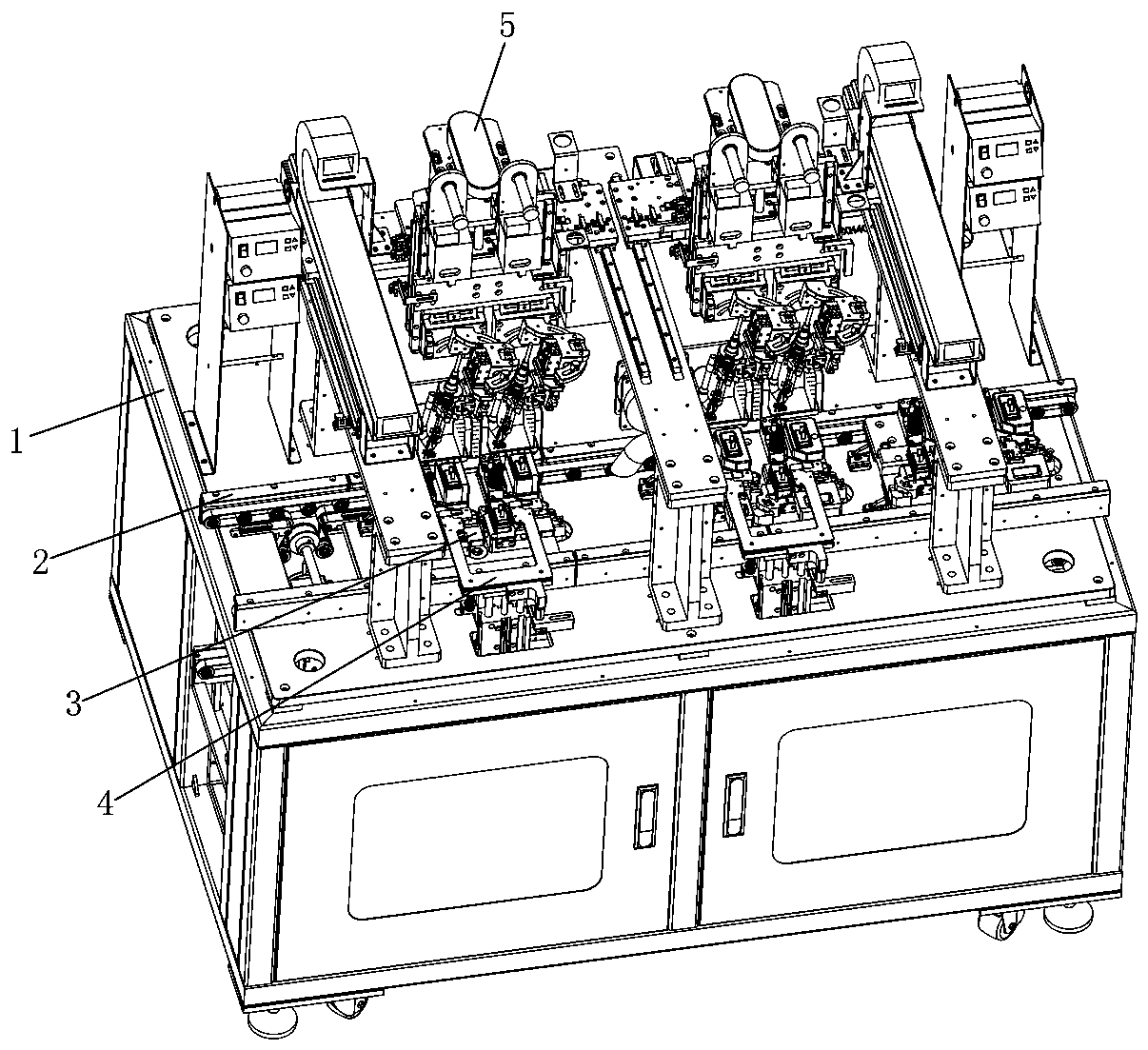

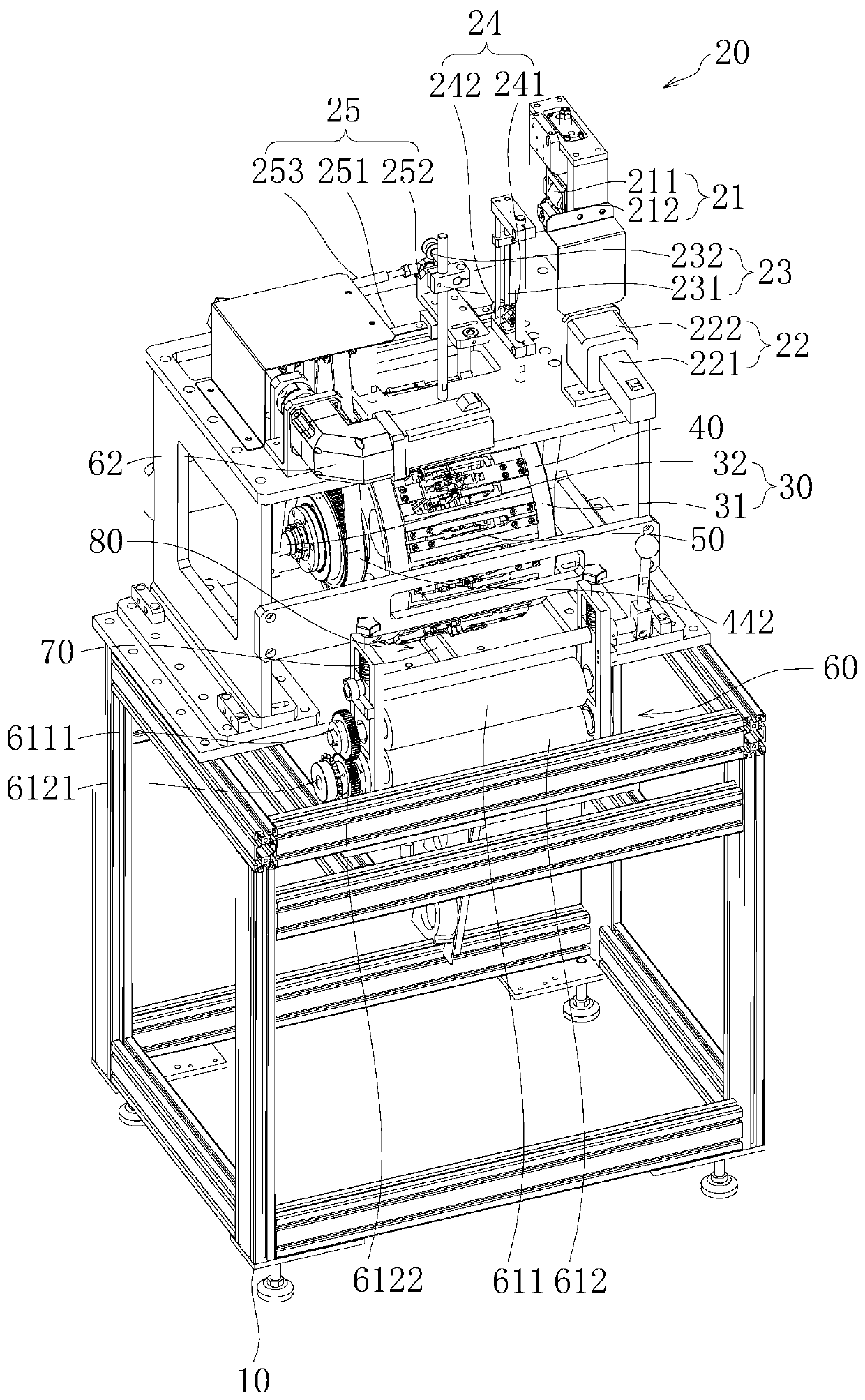

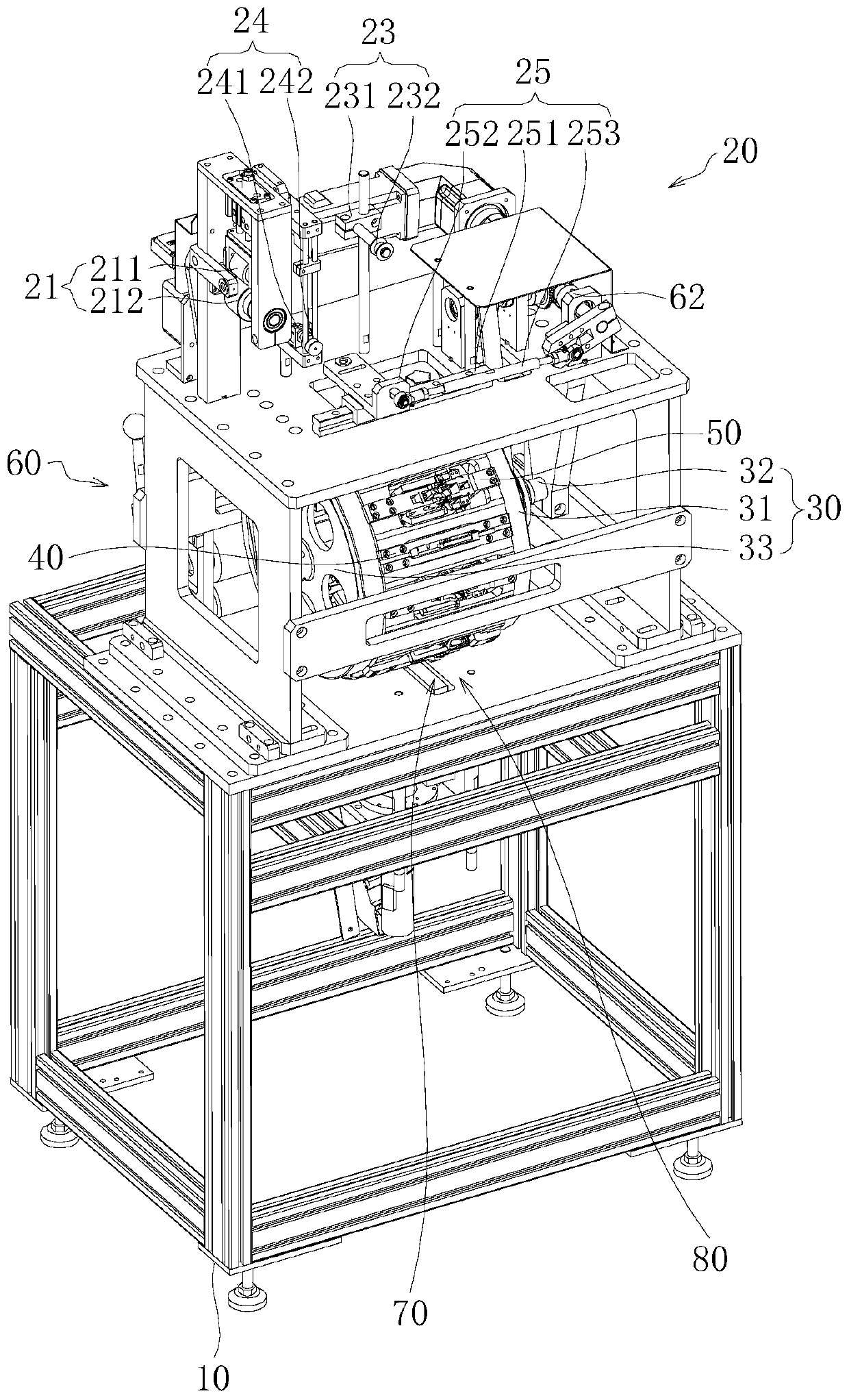

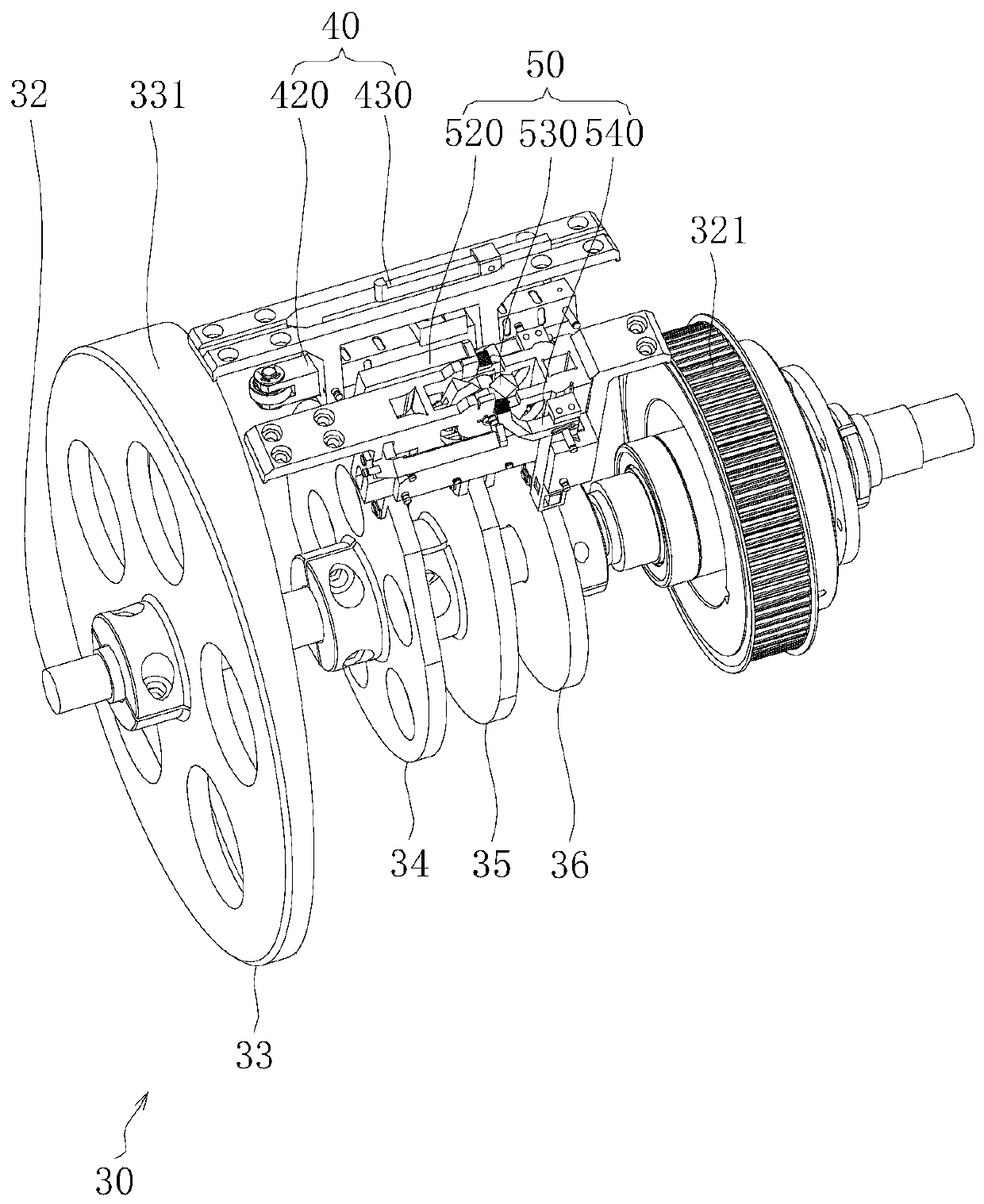

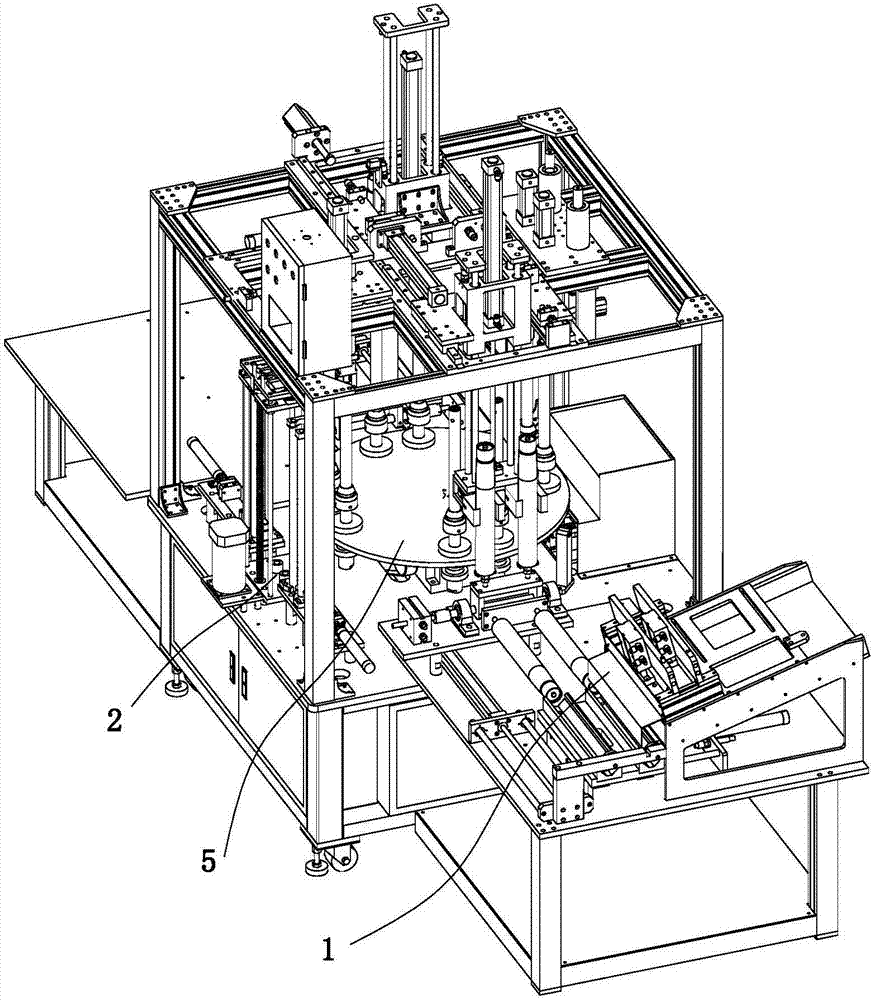

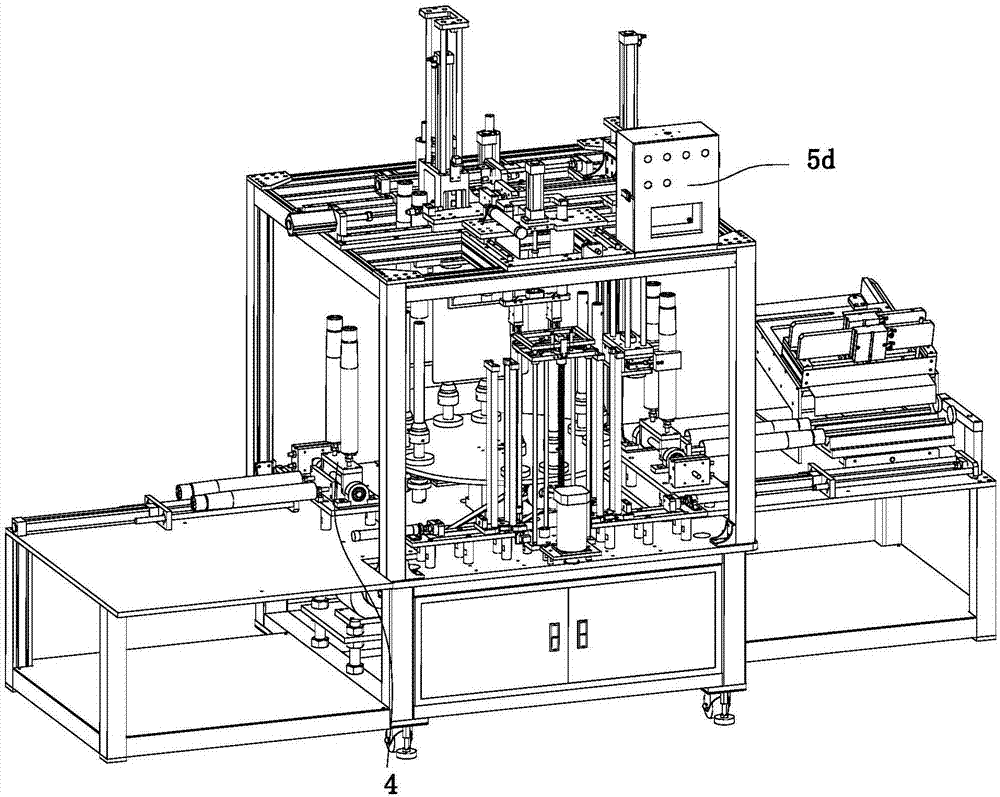

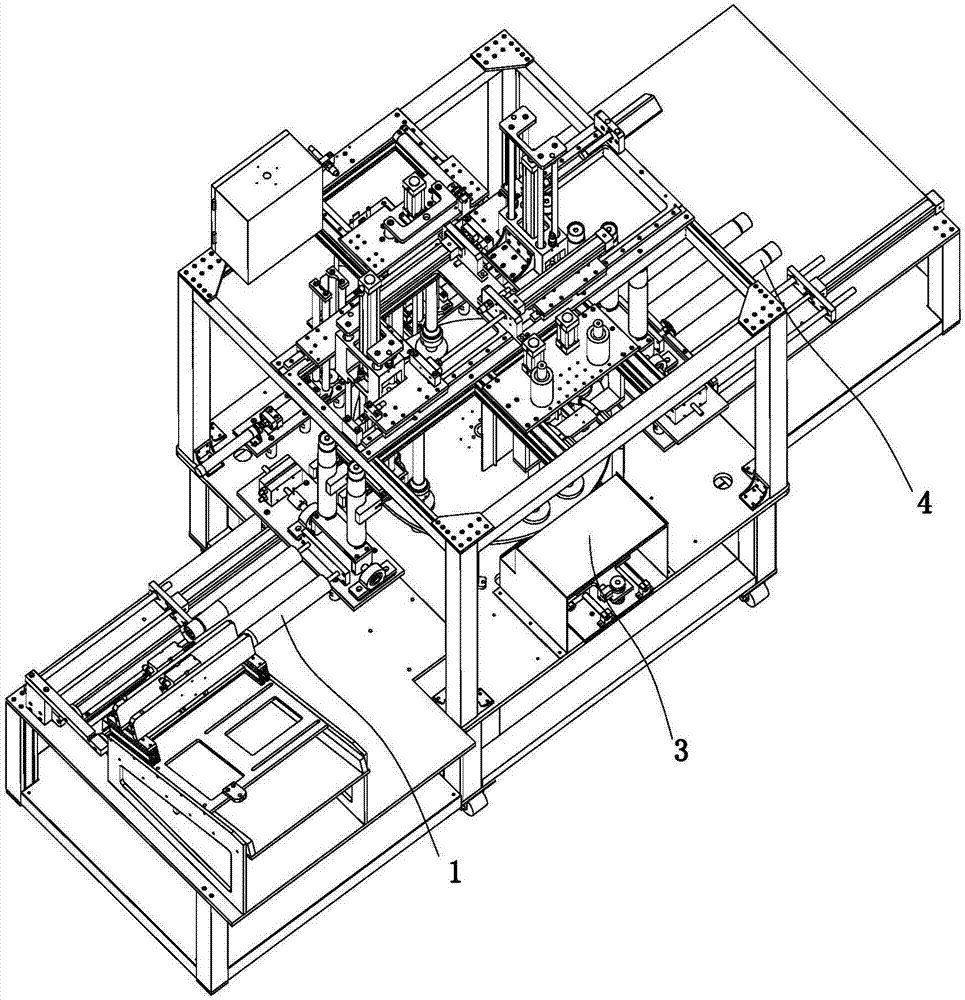

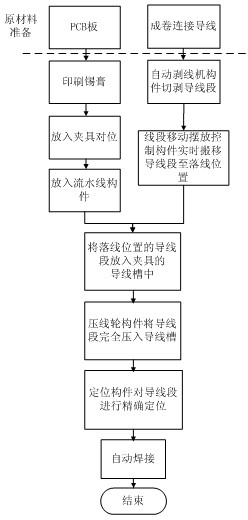

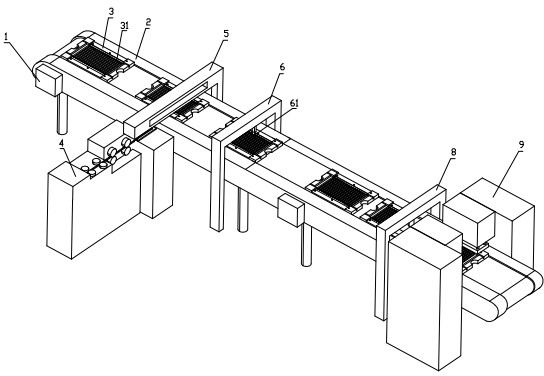

Automatic welder for DC wire of power supply

PendingCN108213645AImprove welding efficiencyPrecision weldingOther manufacturing equipments/toolsSoldering auxillary devicesFine-tuningWelding

The invention discloses an automatic welder for DC wires of a power supply. The automatic welder comprises a conveying pulling body, jigs, a jig positioning mechanism, a pressing mechanism and a welding mechanism, wherein the conveying pulling body is arranged on a rack along a left-right direction; the at least two jigs are arranged on the conveying pulling body; at least two PCBs of the power supply and DC wires of the power supply are placed on the jigs; a welding station is arranged on the side part of the conveying pulling body; the jig positioning mechanism is arranged at the welding station; the pressing mechanism is arranged on the front side of the jig positioning mechanism; the welding mechanism bestrides the upper side of the conveying pulling body and is arranged correspondingto the jig positioning mechanism, and the welding mechanism solders and fixes the connecting parts of the DC wires of the power supply and the PCBs of the power supply; and the jig positioning mechanism loosens the jigs after being soldered. The PCBs and the DC wires which are automatically conveyed and welded are effectively jointed, the PCBs and the DC wires are clamped stably; and the welding mechanism with a flexible fine tuning function achieves precise welding and automatic smoke exhaust and is high in welding efficiency.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Ear band continuous welding machine

Owner:东莞快裕达自动化设备有限公司

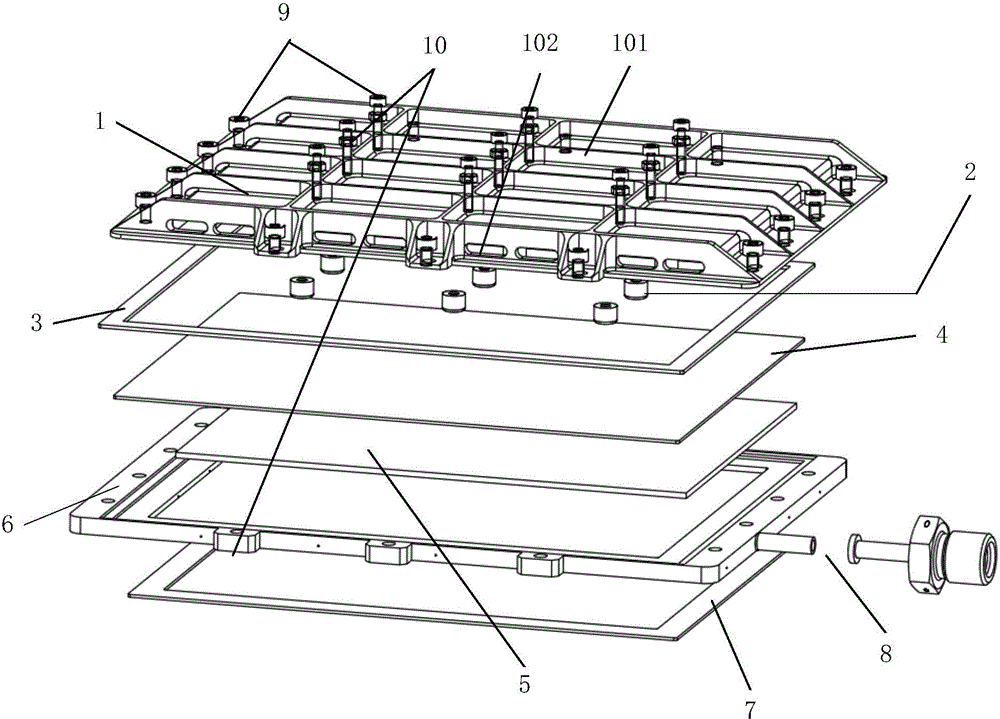

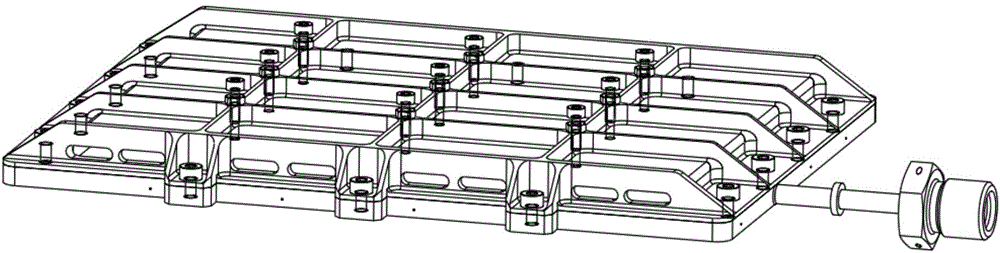

Flat-plate-type water sublimation cold plate for aerospace radiation

ActiveCN104019685AEnsure the uniformity of water supplyConvenience to workIndirect heat exchangersTriple pointEngineering

Owner:BEIJING INST OF SPACECRAFT SYST ENG

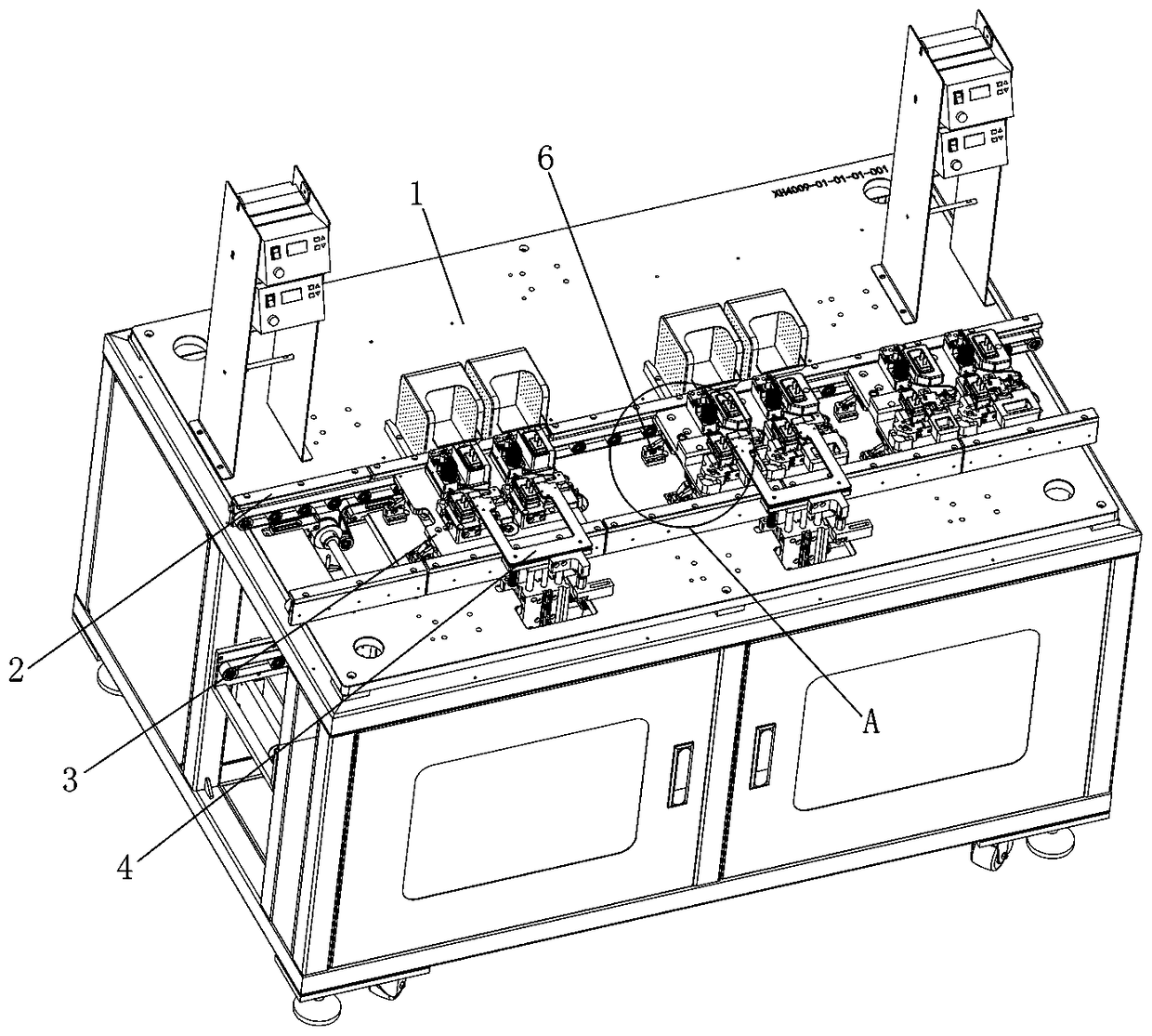

Full-automatic welding machine

ActiveCN107378321APrecise feedingWay accurateWelding/cutting auxillary devicesAuxillary welding devicesVolumetric Mass DensityEngineering

Owner:安徽荣盛精密科技有限责任公司

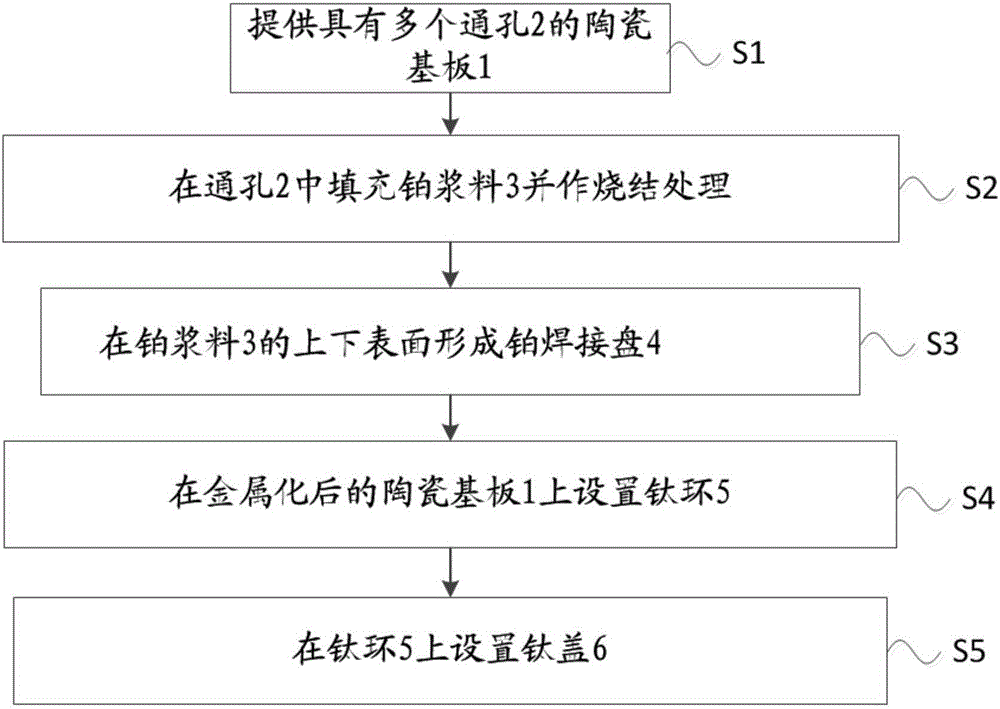

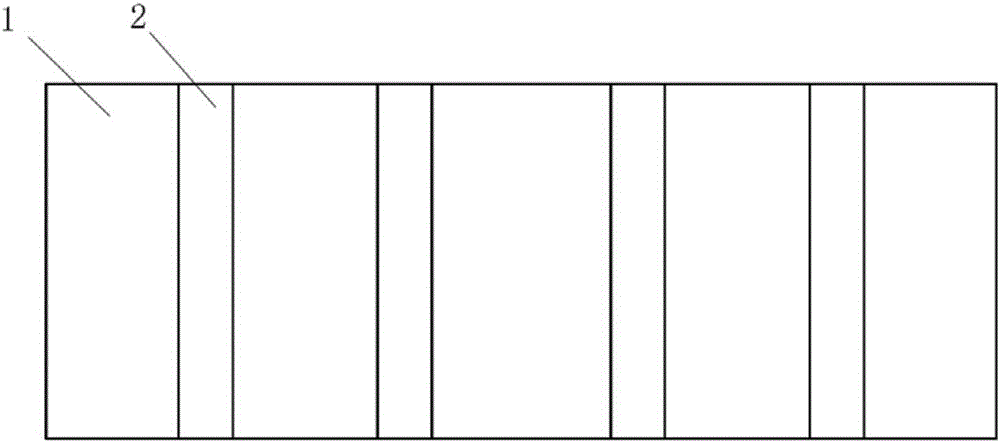

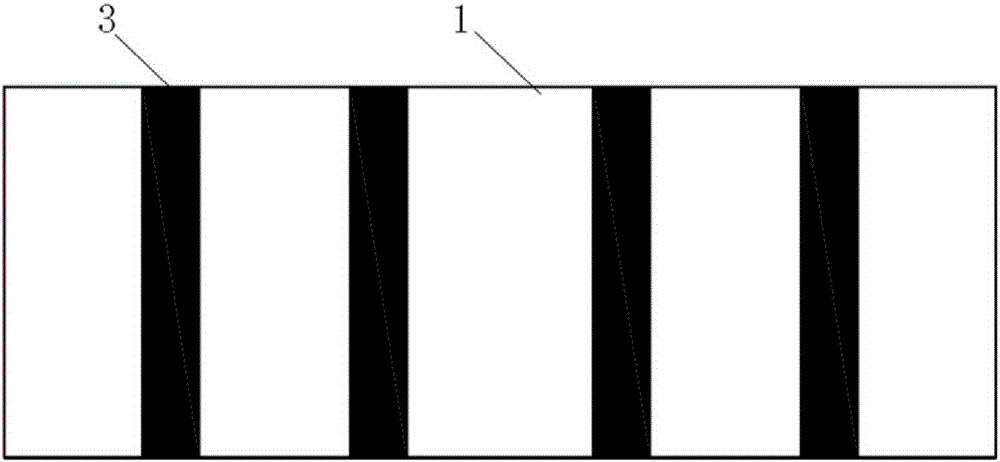

Manufacturing method of implantable artificial retina ceramic packaging body

Owner:深圳市勃望初芯半导体科技有限公司

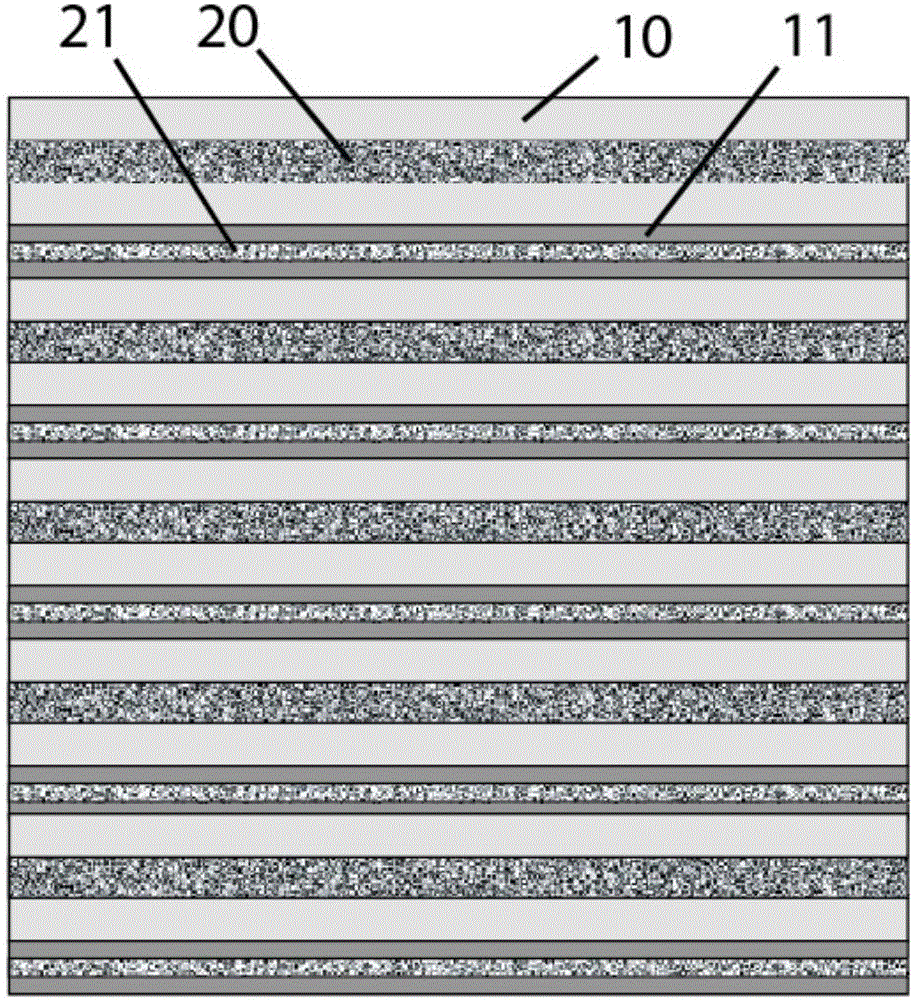

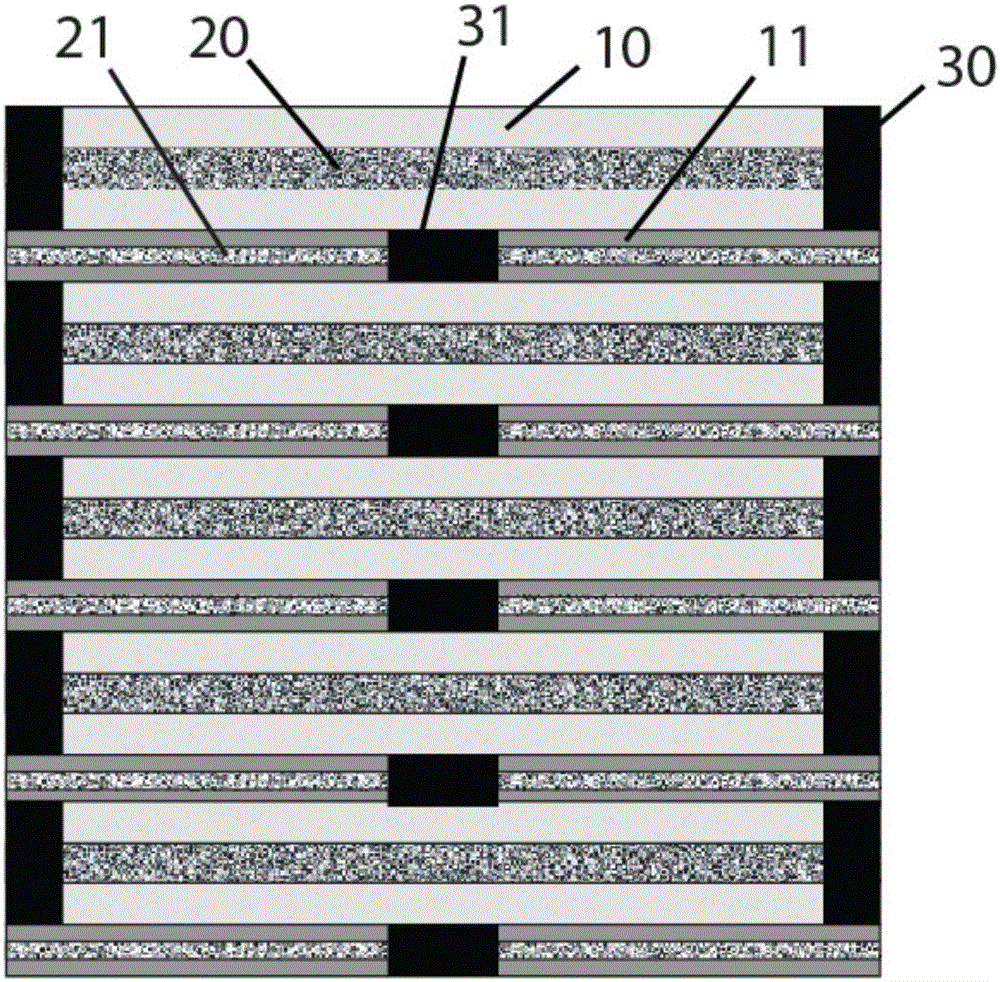

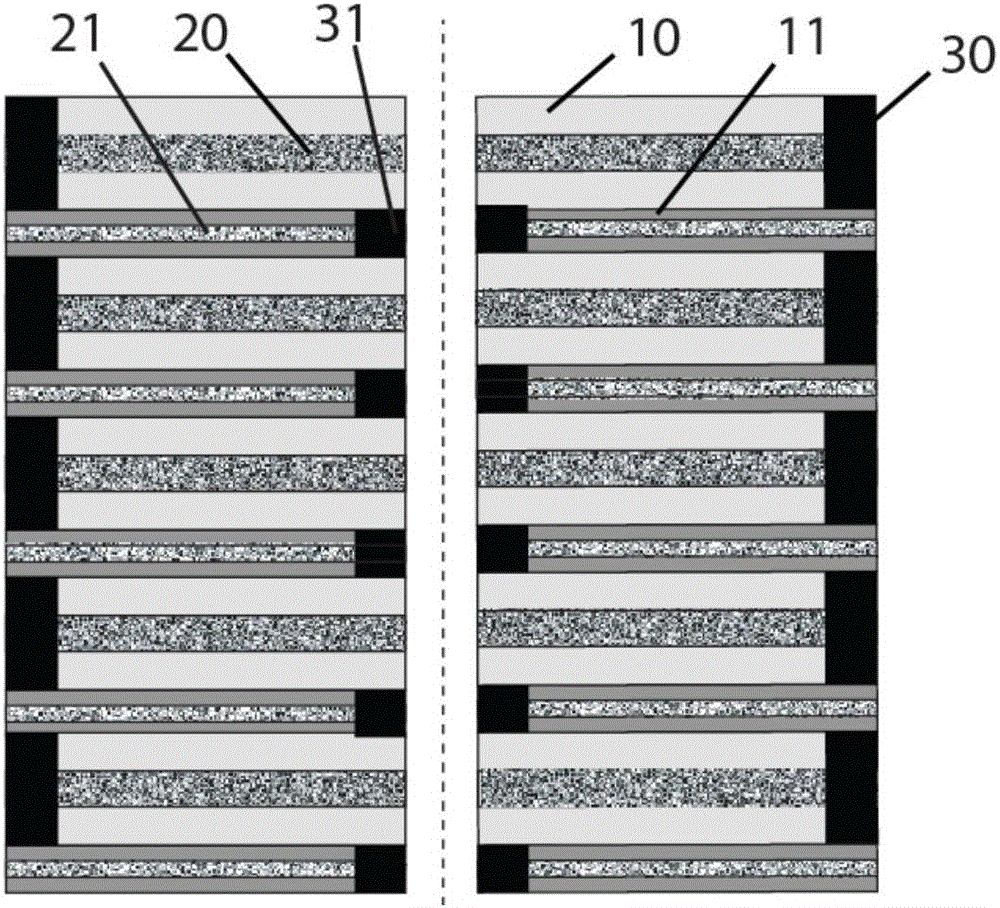

Back contact solar cell string, preparation method thereof, assembly and system

ActiveCN106098831APlay the role of horizontal confluenceImprove fill factorFinal product manufacturePhotovoltaic energy generationFill factorEngineering

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

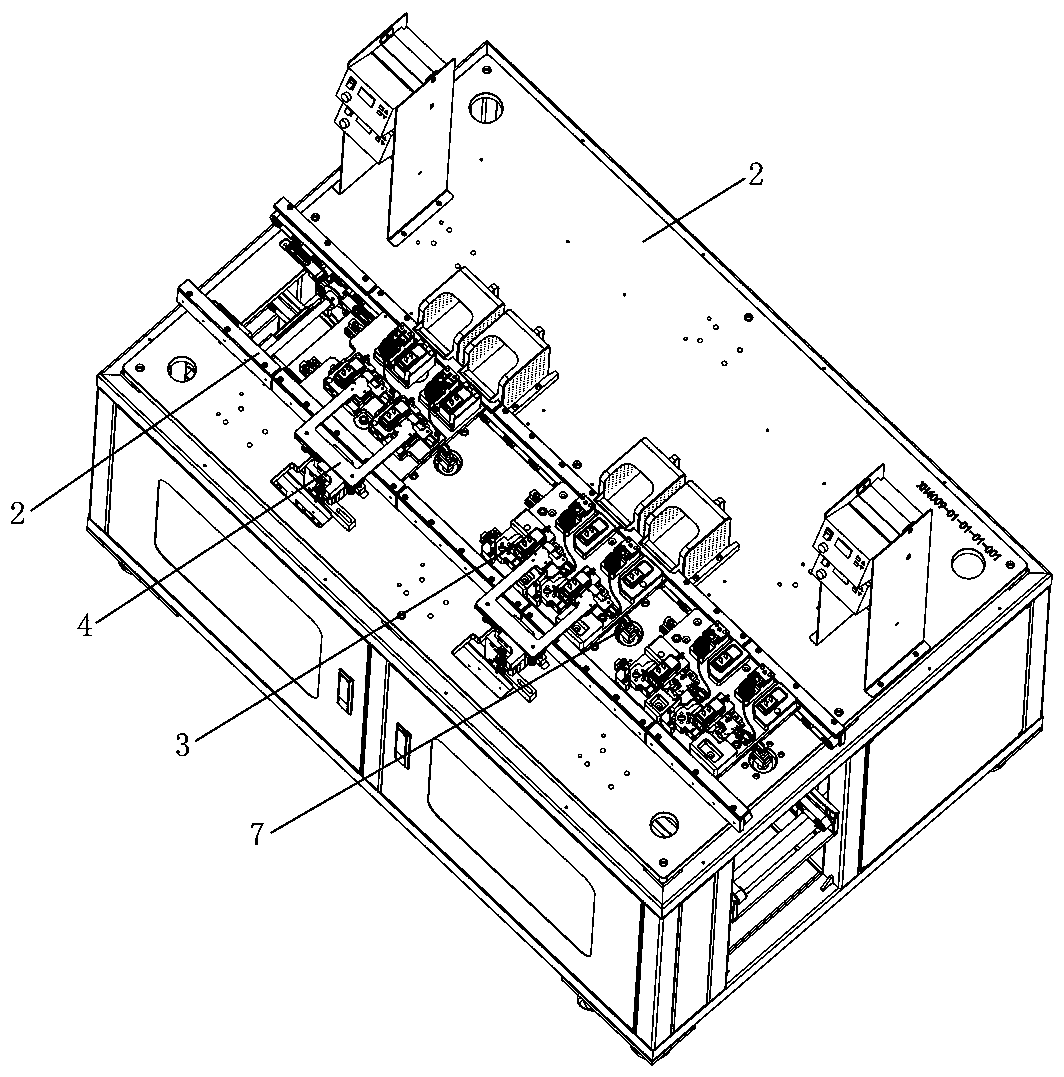

Full-automatic wire bundle machining and assembling equipment

ActiveCN108666841AAutomate operationsReduce manual operationsLine/current collector detailsRubber ringEngineering

Full-automatic wire bundle machining and assembling equipment is characterized in that a wire bundle feeding and cutting mechanism comprises a wire bundle cutting mechanism, a first wire bundle transferring mechanism, a wire bundle coil mechanism, a second wire bundle transferring mechanism, a wire bundle binding mechanism, a wire bundle end positioning mechanism and a third wire bundle transferring mechanism which are sequentially arranged from left to right. A wire bundle end machining and assembling system comprises a plurality of machining stations and a synchronous positioning and transferring mechanism. Each machining station is sequentially provided with a rubber ring sleeving mechanism, a copper ring sleeving mechanism, a peeling mechanism, a pin welding mechanism and a connector riveting and pressing mechanism. The equipment has the advantages that feeding, cutting, winding, binding, rubber ring sleeving, copper ring sleeving, peeling, pin welding, connector riveting and pressing and discharging are completed automatically, automation of the whole process is achieved, manual operation is reduced, the working efficiency is improved, the labor cost is reduced, the working precision is high, and the qualified rate of products is guaranteed.

Owner:ZHEJIANG XIAOYU TECH CO LTD

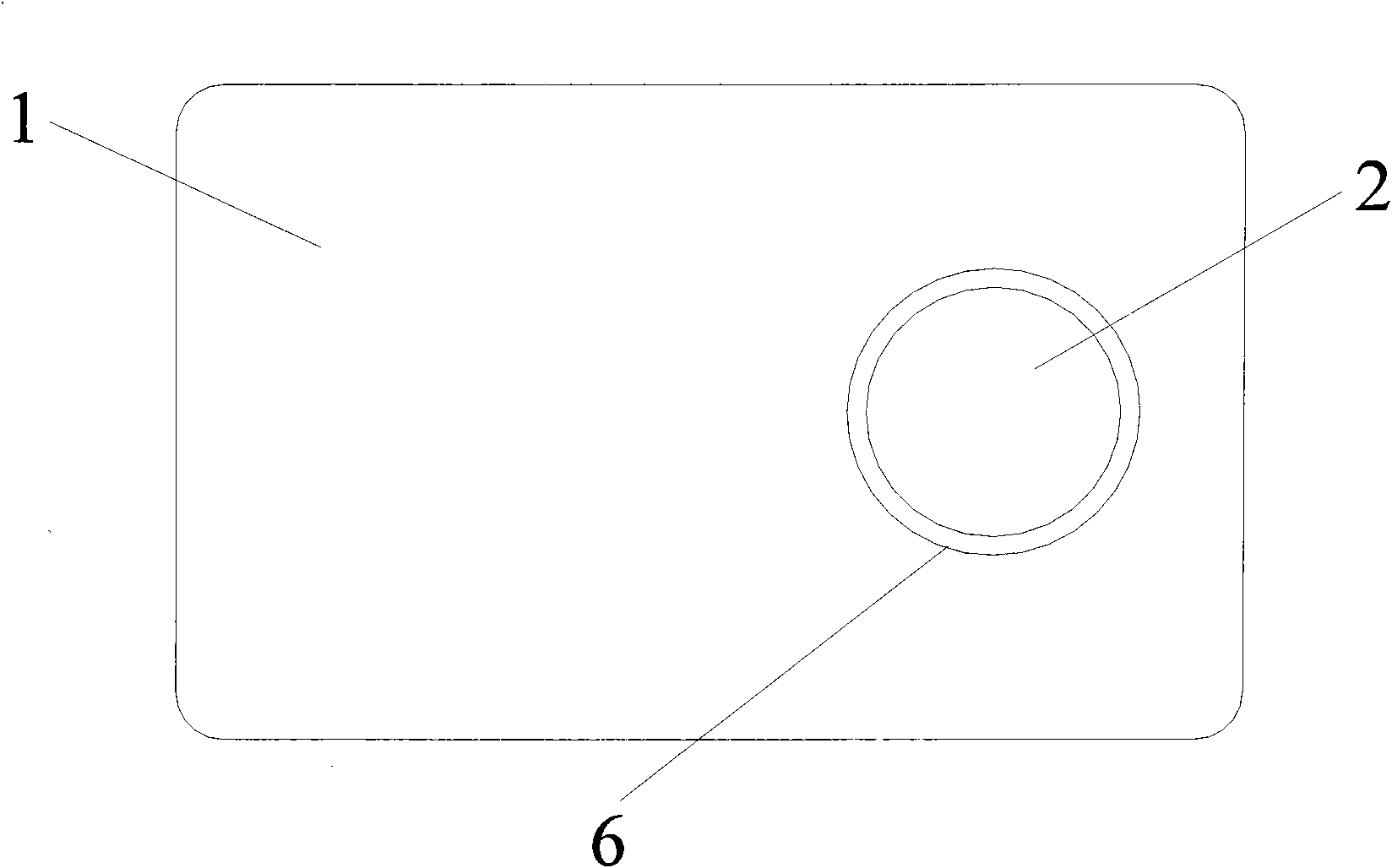

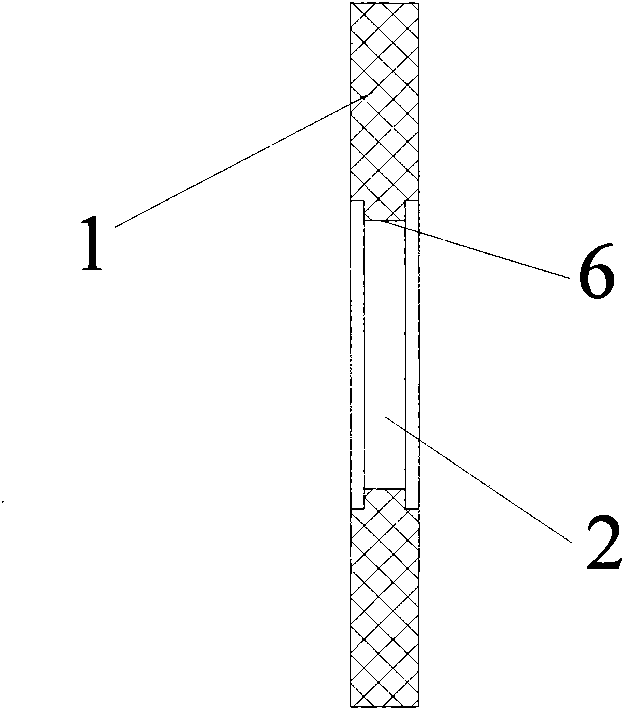

Embedded smart card and manufacturing method thereof

InactiveCN101882232AAvoid discarding defectsReduce maintenance costsRecord carriers used with machinesHot stampingEngineering

Owner:上海卡美循环技术有限公司

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

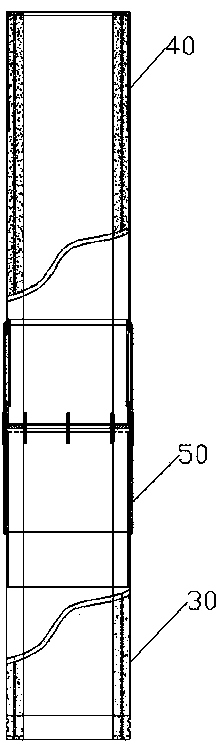

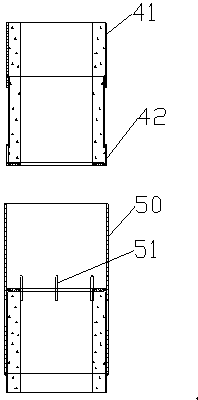

Combined splicing tubular pile and pile splicing method

Owner:国鼎(南通)管桩有限公司

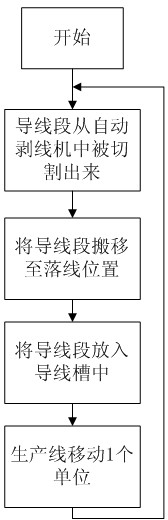

Automatic welding method and system for LED module connecting lead

InactiveCN102570237AFacilitate automatic weldingImprove qualityLine/current collector detailsProduction lineEngineering

Owner:黎明

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce impactAvoid crackingElectric heatingWelding/cutting auxillary devicesFuel tankThermal deformation

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

Welding and radiating turntable

ActiveCN102717214AImprove cooling effectEasy to grasp the rotation angleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringComputer fan

The invention relates to a welding and radiating turntable, which comprises a rotation platform and a platform base plate, wherein the rotation platform is in a disc shape; the center of the rotation platform is connected and fixed with a rotating shaft; the rotating shaft is arranged on the platform base plate; a bearing is arranged between the rotating shaft and the platform base plate; a cross-shaped groove is arranged on the rotation platform; the center of the cross-shaped groove is arranged in the center of the rotation platform; the rotation platform is divided into four equal sectors through the cross-shaped groove; and an air vent is arranged in the central position of each sector. The welding and radiating turntable has the beneficial effects that the bearing is arranged between the rotation platform and the platform base plate, and the position of the platform base plate is fixed, so that the rotation platform can be rotated manually; the cross-shaped groove and the air vents are arranged on the rotation platform, so that the heat of the rotation platform can be radiated conveniently, and particularly, the radiating effect can be further improved through a radiating fan on the platform base plate; and through circumferential scales on the surface of the rotation platform, an operator can grasp the rotation angle conveniently, and can operate flexibly and accurately.

Owner:WUXI UNITE ENERGY TECH CO LTD

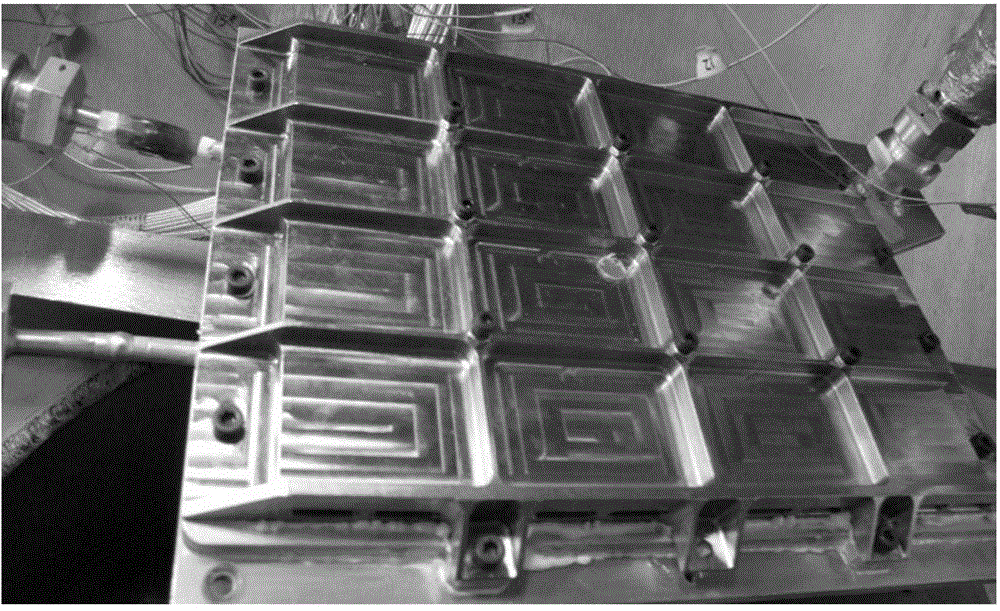

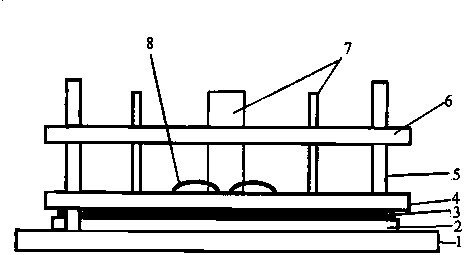

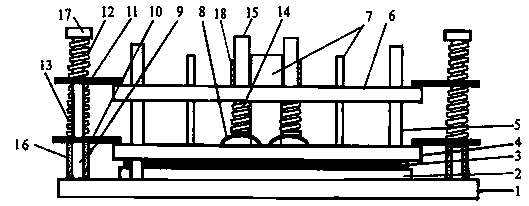

Improved welding mold for welding semiconductor power module

ActiveCN104191063ASimple structural designPractical structural designWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSemiconductor

Owner:XUZHOU HANTONG ELECTRONICS TECH CO LTD

Panel veneer stacking device and method

Owner:GUANGZHOU MINGSEN TECH CO LTD

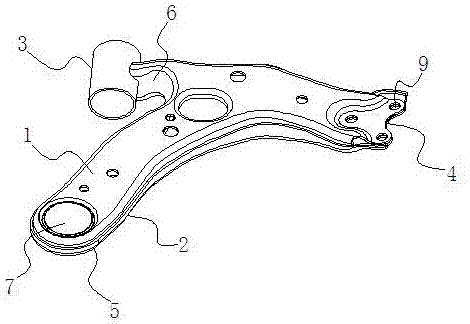

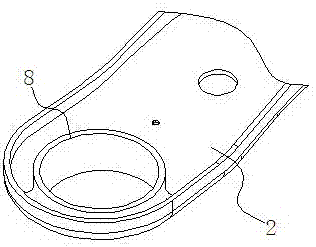

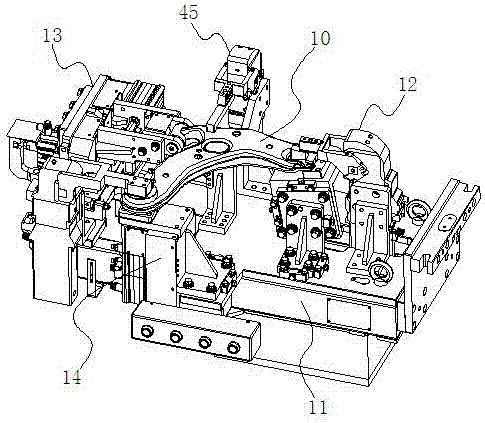

Welding clamping method for automotive suspension control arm

ActiveCN107971676AImprove processing efficiencyGuaranteed machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding clamping method for an automotive suspension control arm. The welding method comprises the steps that a ball head connecting end clamping mechanism, a sleeve connecting end clamping mechanism and a ball head pin mounting end clamping mechanism are arranged on a working platform; before welding, firstly, a top cover and a bottom cover are clamped together through the ball head connecting end clamping mechanism and the ball head pin mounting end clamping mechanism, wherein the top cover and the bottom cover are located at a ball head connecting end and a ball head pin mounting end; then, a sleeve is tightly pressed onto a sleeve connecting end through the sleeve connecting end clamping mechanism; and then, welding is conducted. By means of the welding clamping method, machining precision of the automotive suspension control arm can be guaranteed; the operation is convenient and fast to conduct; and machining efficiency is improved.

Owner:ZHUZHOU KAIFENG IND

Method for testing PCB pad bonding strength

InactiveCN105158154AProtect from thermal shockAvoid adding processesUsing mechanical meansMaterial analysisSolder ballUltimate tensile strength

A disclosed method for testing PCB pad bonding strength comprises the following steps: 1) presetting a solder ball at one end of a test pull pin, and arranging a first soldering-flux wrapping layer on the surface of the solder ball; 2) arranging a second soldering-flux wrapping layer on a PCB sample pad; 3) enabling the test pull pin and the target PCB sample pad to be in vertical centering relationship; 4) enabling the first soldering-flux wrapping layer on the preset solder ball and the second soldering-flux wrapping layer on the pad to be contacted with each other; 5) fusing the preset solder ball on the test pull pin with the target PCB sample pad, so as to form a new welding point; 6) finishing welding between the test pull pin and the target PCB pad; 7) vertically pulling the test pull pin upwards, recording the maximum peeling force and drafting a pull curve; and 8) repeating the steps 1)-7), so as to obtain the pad cratering failure mode, the maximum peeling force and the pull curve of multiple target PCB sample pads and realize evaluation on the PCB pad bonding strength. The method possesses the advantages of concise steps and high operationality, and is relatively beneficial for realizing full-automatic on-line quality detection.

Owner:GUILIN UNIV OF ELECTRONIC TECH

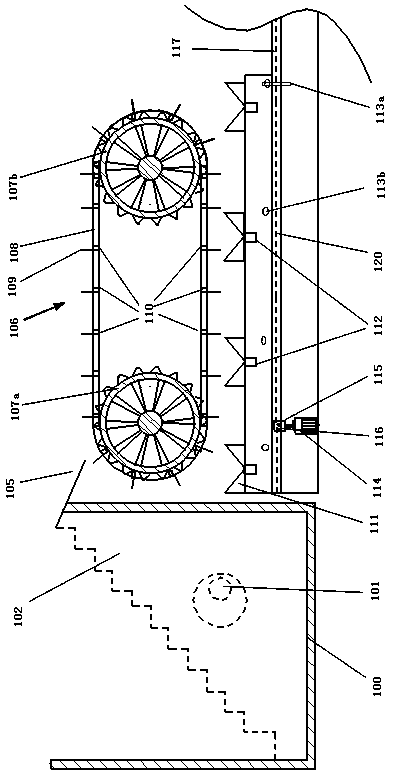

Metal cable connector welding machine

InactiveCN104779508AMeet welding requirementsReasonable designLine/current collector detailsCable/conductor manufactureCopper conductorEngineering

A metal cable connector welding machine comprises a fixed copper conductor (1), a sliding copper conductor (2), bolts (3), push rods (4), slide rods (5), a cable slot I (6), a handle (7), a connecting rod (8), a power regulator (9) and a work bench (10), and is characterized in that the other ends of the slide rods (5) are connected with the handle (7) through the connecting rod (8); ends of two metal cables requiring welding are placed in the cable slot I (6) and a cable slot II (11) respectively and tightened by bolts (3), the handle (7) pushes the slide rods (5) on the push rods (4) through the connecting rod (8), two ends of each cable are contacted and powered on, the cables are molten, and welding is completed. The metal cable connector welding machine is reasonable in design, simple in structure, reliable in action and convenient to operate and can feasibly meet the cable welding requirement, and the product quality is ensured.

Owner:JIANGSU GANGHONG WIRE & CABLE CO LTD

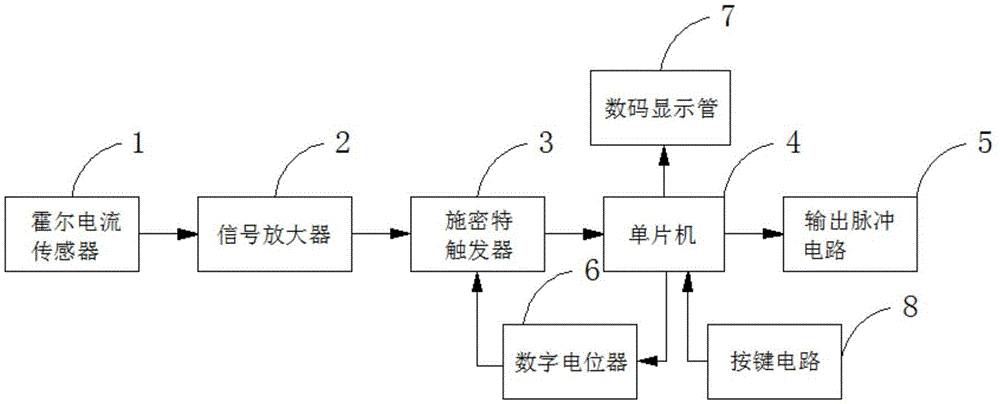

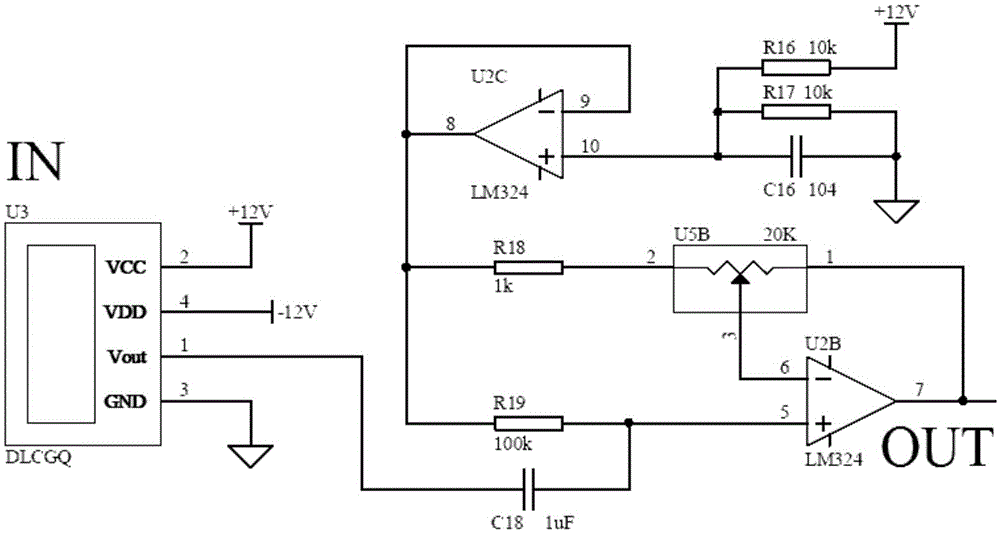

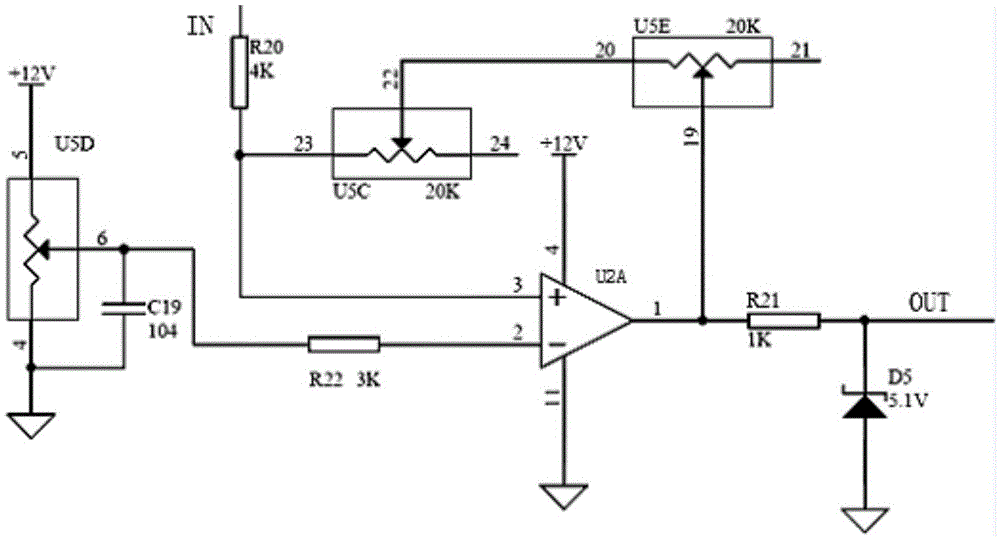

Program controlled trigger and method

InactiveCN105478965AImprove isolationImprove stabilityArc welding apparatusMicrocontrollerCurrent sensor

Owner:GUILIN UNIV OF AEROSPACE TECH

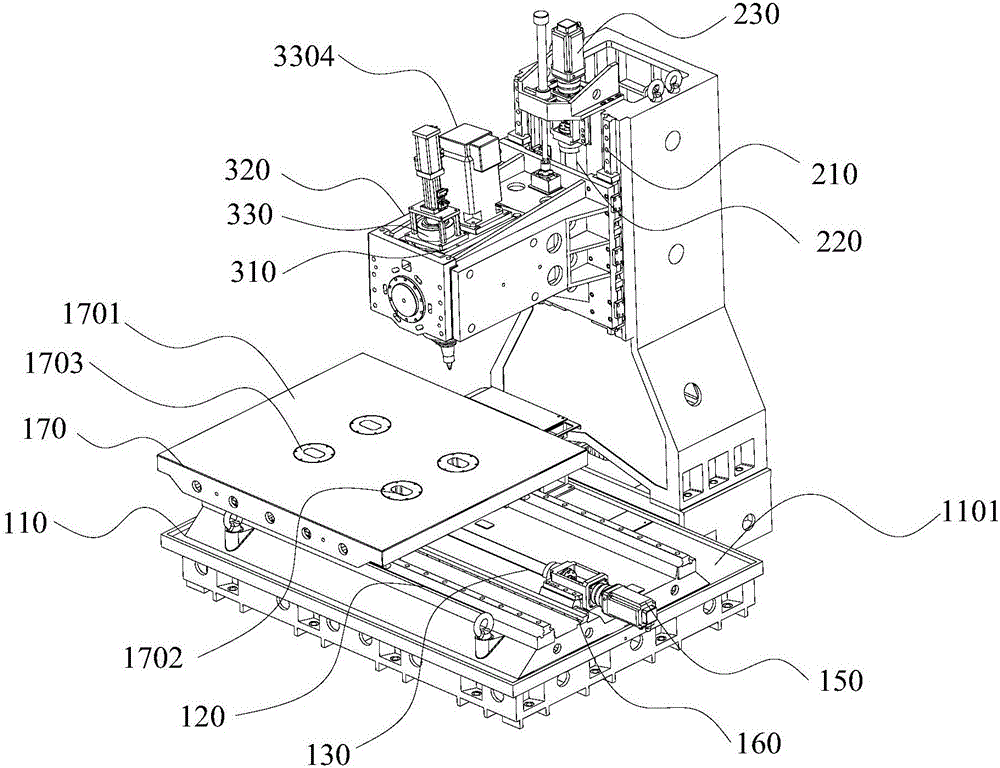

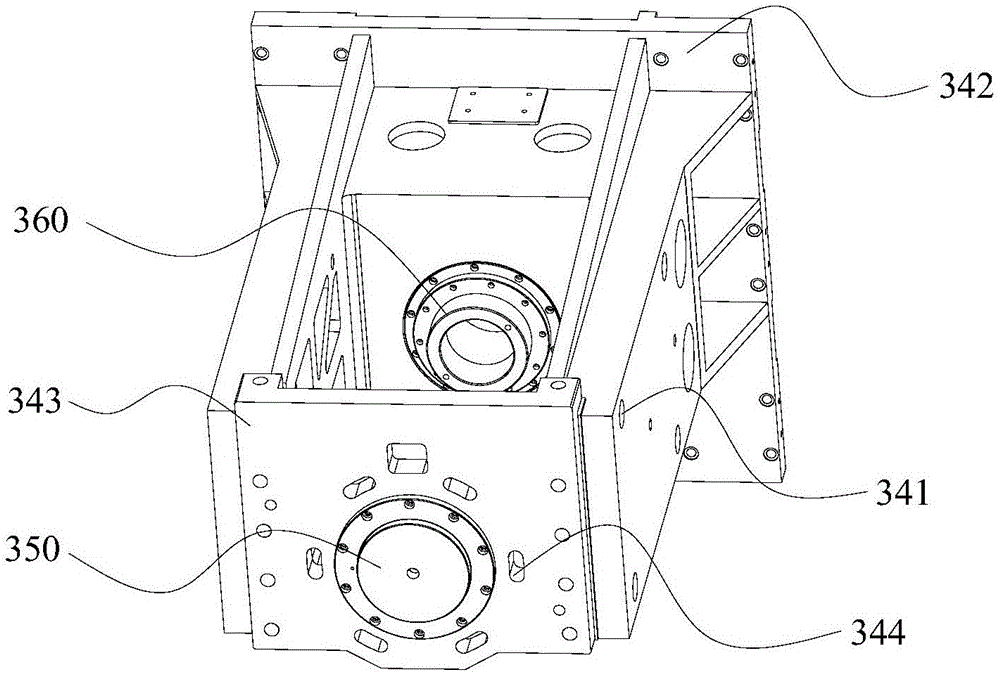

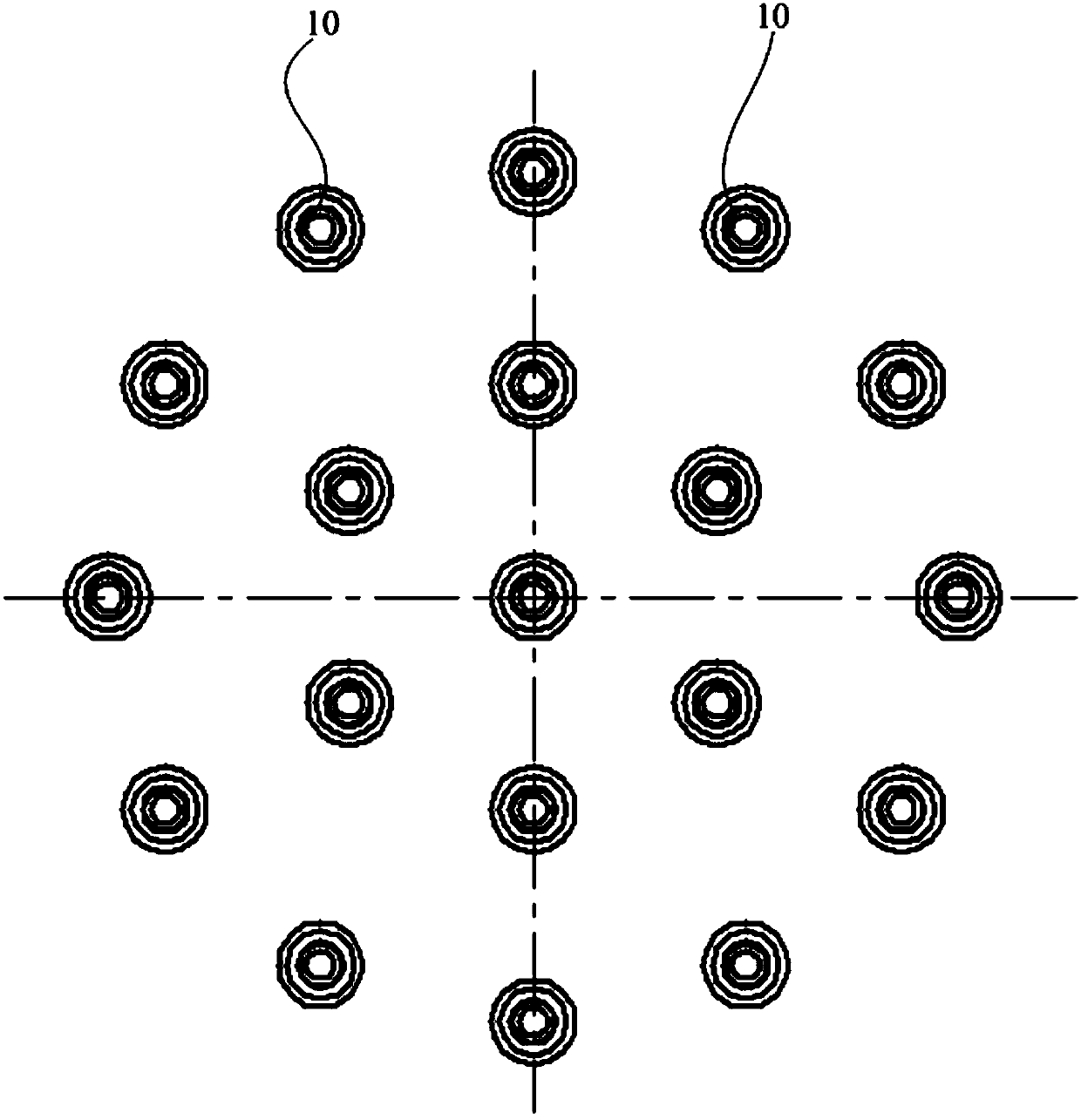

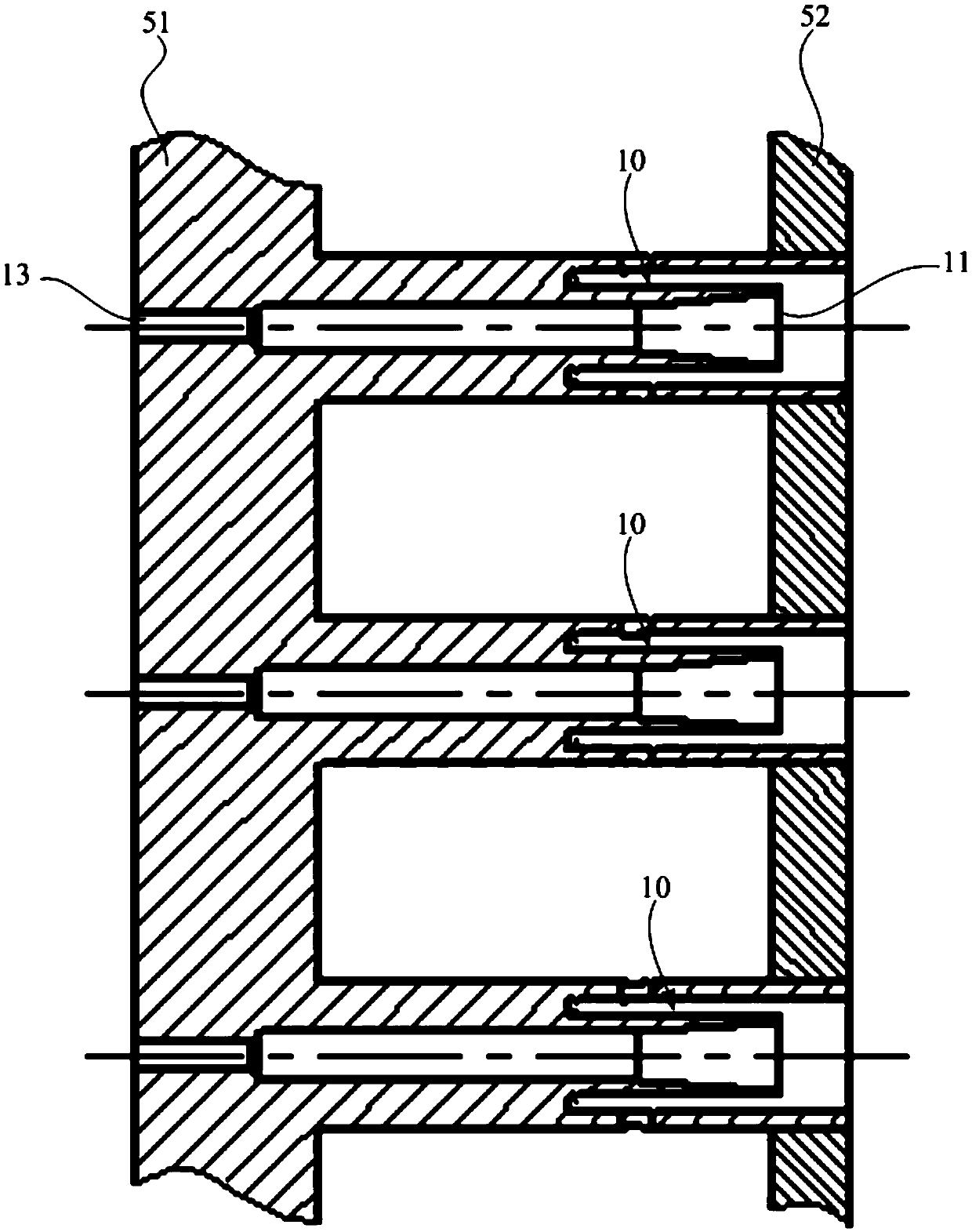

Welding machine and welding apparatus

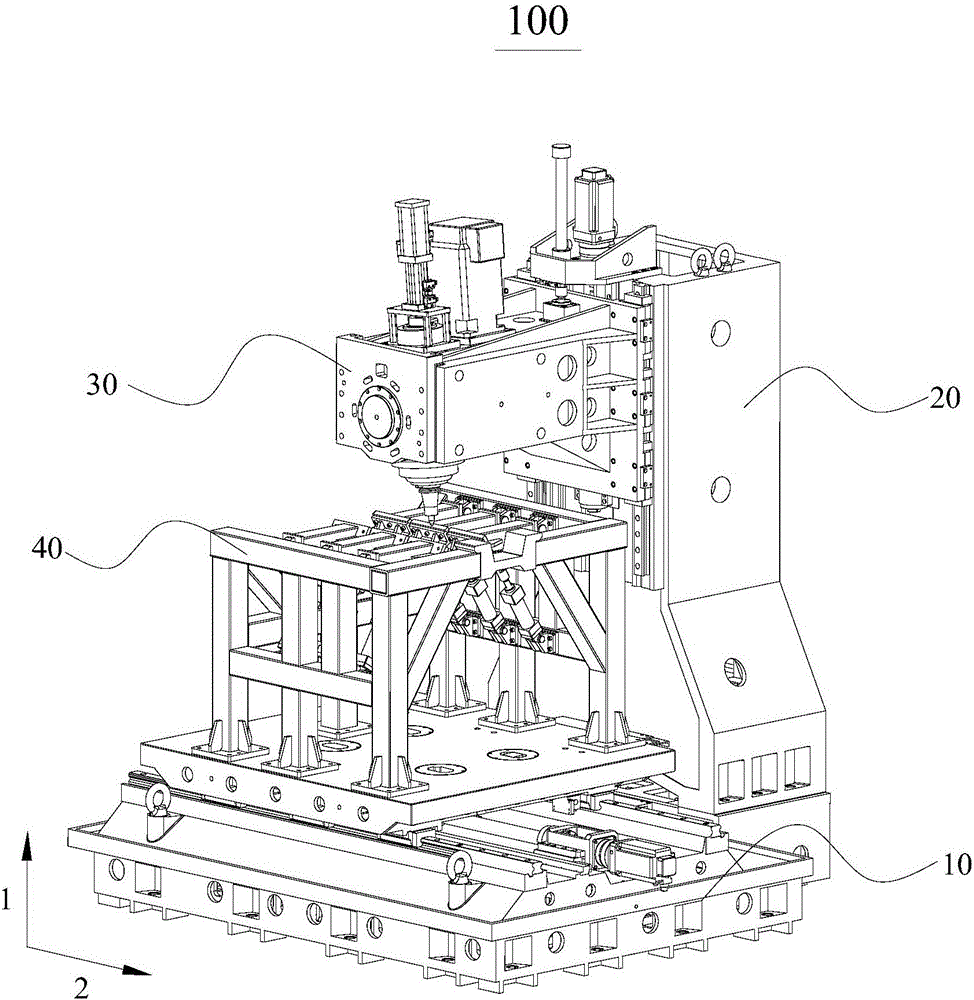

PendingCN106735852AQuality improvementImprove efficiencyNon-electric welding apparatusEngineeringCantilever

Owner:上海驭冉轮毂有限公司

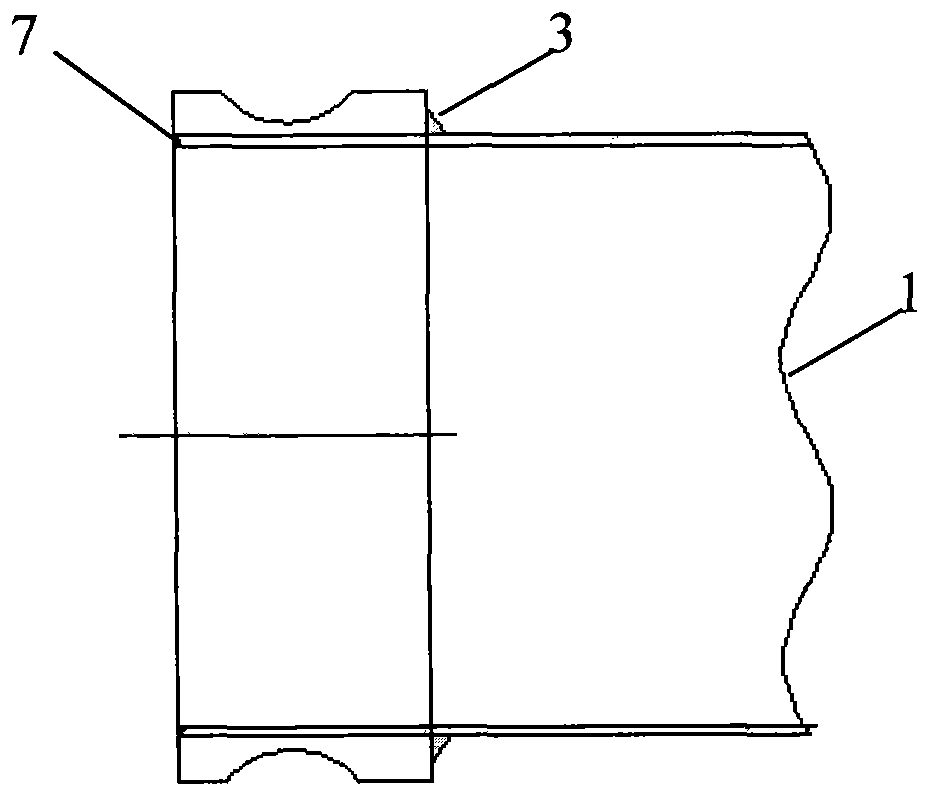

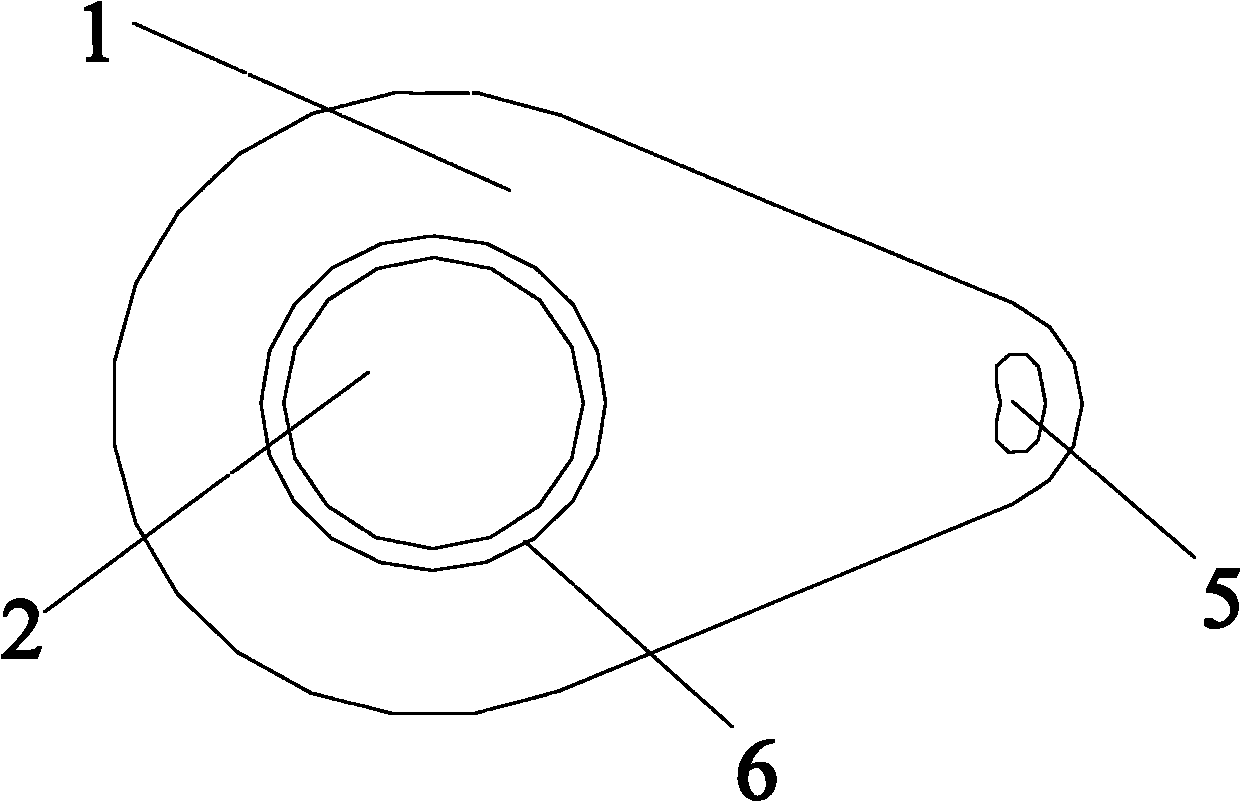

Down-the-hole radial gate with multiple frames and multiple trunnions and two lifting pad eyes

InactiveCN102979063ASmall opening and closing forceReduce capacityBarrages/weirsHydraulic cylinderMultiple frame

The invention discloses a down-the-hole radial gate with multiple frames and multiple trunnions and two lifting pad eyes. The down-the-hole radial gate with the multiple frames and the multiple trunnions and the two lifting pad eyes is characterized in that a multiple frame structure is adopted in the door body structure of a gate (1), and the gate (1) is hinged with a group of trunnions (4) installed on a breast wall (3) of a gate wall (2). The down-the-hole radial gate with the multiple frames and the multiple trunnions and the two lifting pad eyes reduces loads distributed to each main beam and each support arm through the multiple frame structure, shares huge concentrated water pressure of a high water head of a drainage port to the gate through the plurality of trunnions, and the loads distributed to each trunnion are greatly reduced so as to reduce the difficulties of the design, manufacture, welding, transportation and installation of the gate and the casting of the trunnions. The radial gate is provided with the two lifting pad eyes, is operated by adopting a double-cylinder swinging type or a suspension type hydraulic cylinder, the volume of single cylinder hydraulic cylinder is reduced by half so as to reduce the difficulties of the design, manufacture and installation of the hydraulic cylinder. The rotating center of the gate coincides with the circle center of an arc-shaped water-facing surface, and the total water pressure acting on the arc-shaped water-facing surface is enabled to always pass through the rotating center of the trunnions so as to reduce the force of the opening and closing of the gate.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Rocket engine injection structure, injection device, rocket engine and rocket

InactiveCN109653902ASituations to Avoid WeldsReduce the use of weldingRocket engine plantsSpray nozzleInjection device

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Vacuum electron beam welding method of NbTi/Cu superconduction composite sheath

Owner:西部超导材料科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap